Pipeline laying construction method combining non-excavation jacking and liquid nitrogen horizontal freezing excavation laying

A trenchless, combined technology, applied in pipeline laying and maintenance, mechanical equipment, pipes/pipe joints/fittings, etc., can solve problems such as ground subsidence, traffic interruption, building collapse, urban traffic building hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

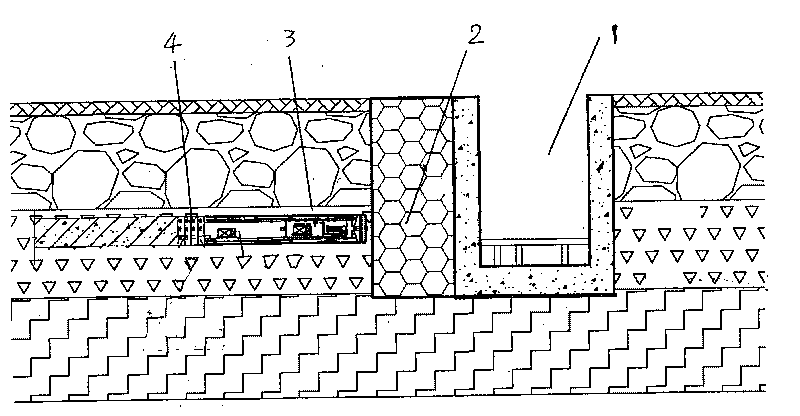

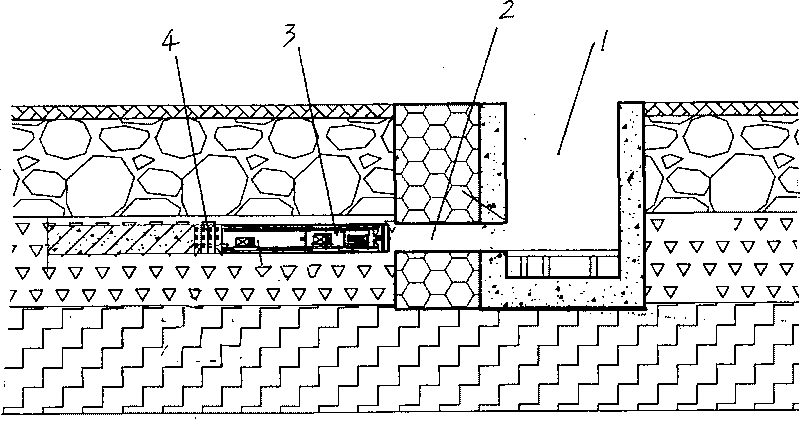

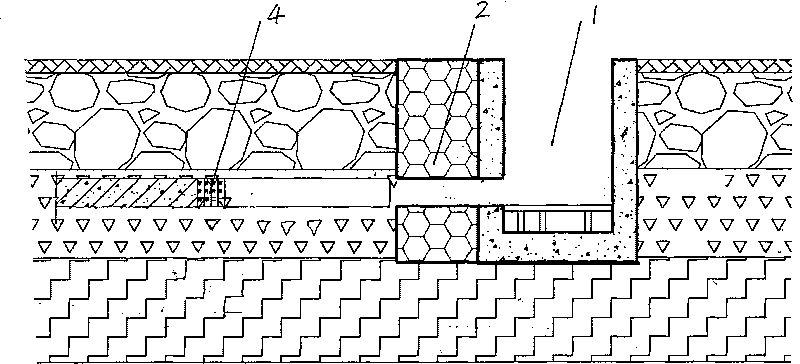

[0008] Liquid nitrogen horizontal freezing reinforcement is carried out in the entry area 2 of the receiving well 1, and a consolidation area with a certain soil layer strength is formed in the entry area 2. When the pipe jacking machine 3 constructed by the trenchless jacking technology reaches the area near the receiving well 1, Excavate the soil body horizontally in the consolidated hole entry area 2, and excavate and lay pipe joints 4, which are combined with pipe joints jacked by trenchless jacking technology to form underground pipelines.

[0009] During implementation, when the usual reinforcement method in the receiving well area combined with the water stop device cannot effectively prevent water and soil loss in the sandy soil layer, liquid nitrogen horizontal freezing reinforcement can be used in the receiving well area, so that the incoming water can be rapidly made The hole area develops a certain strength, creating a consolidated area, thereby preventing soil eros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com