Waterproof crack-resistant foam concrete and manufacture method

A foamed concrete and foam technology, which is applied in ceramic products, applications, household appliances, etc., can solve the problems of foamed concrete having a great impact on durability, reducing the thermal performance and strength of materials, and difficult to overcome the performance of cement materials, etc., and achieve excellent stability. properties, reduced water absorption, high resistance to salt attack and sulfate attack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

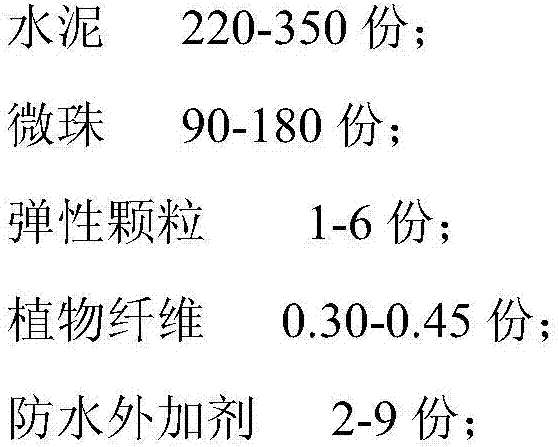

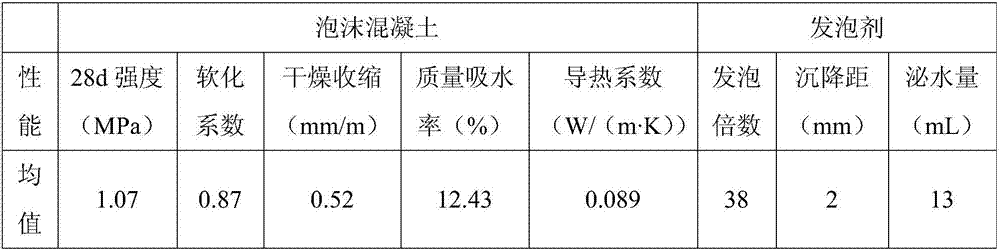

[0037] Cement: 280 parts, ordinary Portland cement, P·O 42.5R grade;

[0038] Microbeads: 150 parts, metakaolin tailings powder;

[0039] Waste rubber powder: 3 parts, fineness is 120 mesh;

[0040] Palm silk: 0.35 parts, the length is 15-25mm;

[0041] Waterproof admixture: 3 parts (60-70 parts of methoxy polyethylene glycol methacrylate polycarboxylate water reducer, 1-3 parts of sodium thiocyanate, 25-30 parts of potassium methyl silicate)

[0042] Foaming agent: (9-13 parts of lauryl dimethyl betaine, 2-3 parts of collagen powder) 16 parts, 78 parts of water, (fatty acid polyethylene glycol ester, hydroxypropyl methylcellulose element) 7 parts.

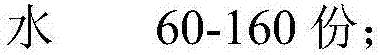

[0043] Prepare foaming agent and 400-grade foamed concrete test blocks according to the above ratio, and measure its performance as follows:

[0044]

Embodiment 2

[0046] Cement: 320 parts, ordinary Portland cement, P·O 42.5R grade;

[0047] Microbeads: 110 parts, 55 parts each of metakaolin tailings powder and waste glass powder;

[0048] Waste rubber powder: 2 parts, fineness is 120 mesh;

[0049] Palm silk: 0.30 parts, the length is 15-25mm;

[0050] Waterproof admixture: 5 parts (methoxy polyethylene glycol methacrylate polycarboxylate water reducer 60-70 parts, sodium thiocyanate 1-3 parts, potassium methyl silicate and polyacrylamide 25-30 parts )

[0051]Foaming agent: (9-13 parts of coconut oil fatty acid diethanolamide, 2-3 parts of microbial protein liquid) 15 parts, 70 parts of water, (propylene oxide-ethylene oxide polyether polyol, hydroxypropyl methyl cellulose) 7 parts.

[0052] Prepare foaming agent and 400-grade foamed concrete test blocks according to the above ratio, and measure its performance as follows:

[0053]

Embodiment 3

[0055] Cement: 285 parts, ordinary Portland cement, P·O 42.5R grade;

[0056] Micro-beads: 90 parts, steel slag fine powder;

[0057] Waste rubber powder: 5 parts, fineness is 130 mesh;

[0058] Palm silk: 0.45 parts, the length is 15-25mm;

[0059] Waterproof admixture: 4 parts (60-70 parts of methoxy polyethylene glycol methacrylate polycarboxylate superplasticizer, 1-3 parts of sodium thiocyanate, 25-30 parts of polymer emulsion)

[0060] Foaming agent: (9-13 parts of dodecyl dimethyl betaine salt and alkyl glycoside quaternary ammonium salt, 2-3 parts of tea saponin) 17 parts,

[0061] 80 parts of water, 8 parts of (silicon resin polyether emulsion, pentaerythritol fatty acid ester).

[0062] Prepare foaming agent and 400-grade foamed concrete test blocks according to the above ratio, and measure its performance as follows:

[0063]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com