Foaming agent for CO2 oil displacement system and preparation method thereof

A technology of foaming agent and system, which is applied in the field of foaming agent and its preparation in CO2 flooding system, and can solve the problems of unstable foam, unsatisfactory, and incapable of large-dose use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

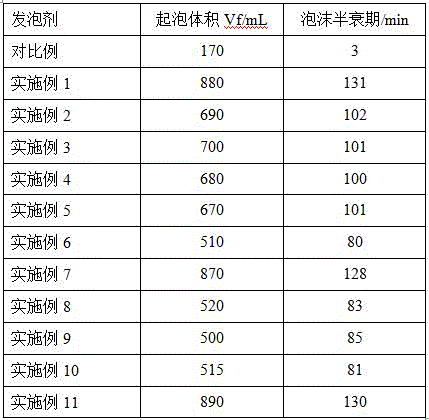

Examples

Embodiment 1

[0031] one for CO 2 The foaming agent of the oil displacement system is composed of the following components by weight: dodecyl hydroxypropyl phosphate betaine 0.2g, surfactant C with star molecular structure 12 h 25 N[CH 2 CH 2 CONHCH 2 CH 2 NH(CH 2 CH 2 CONHCH 2 CH 2 NH 2 ) 2 ] 2 0.1 g, 100 g of water.

[0032] Wherein, the surfactant with star-shaped molecular structure is prepared by the following method:

[0033] (1) Add 14.24 mmol of dodecylamine C 12 h 25 NH 2 Dissolve in 30mL of methanol to form a methanol solution of dodecylamine, add 0.24mol of methyl acrylate dropwise to the methanol solution of dodecylamine, stir at room temperature for 24h, and then rotate at 60°C for 1.5 h, get C 12 h 25 N(CH 2 CH 2 COOCH 3 ) 2 , is light yellow viscous liquid;

[0034] (2) Weigh 7.12mmol of product C from step (1) 12 h 25 N(CH 2 CH 2 COOCH 3 ) 2 , dissolved in 15mL of methanol, under ice bath, dropwise added 0.30mol ethylenediamine, after the dropwis...

Embodiment 2

[0039] one for CO 2 The foaming agent of the oil displacement system is composed of the following components by weight: dodecyl hydroxypropyl phosphate betaine 0.05g, surfactant C with star molecular structure 12 h 25 N[CH 2 CH 2 CONHCH 2 CH 2 NH(CH 2 CH 2 CONHCH 2 CH 2 NH 2 ) 2 ] 2 0.05 g, water 95 g.

[0040] Wherein, the surfactant with star-shaped molecular structure is prepared by the following method:

[0041] (1) Add 16mmol of dodecylamine C 12 h 25 NH 2 Dissolve in 35mL of methanol to form a methanol solution of dodecylamine, add 0.24mol of methyl acrylate dropwise to the methanol solution of dodecylamine, stir at room temperature for 24h, and then at 60°C, rotary evaporate for 0.5 h, get C 12 h 25 N(CH 2 CH 2 COOCH 3 ) 2 , is light yellow viscous liquid;

[0042] (2) Weigh 7.5mmol of product C from step (1) 12 h 25 N(CH 2 CH 2 COOCH 3 ) 2 , dissolved in 20mL of methanol, under an ice bath, dropwise added 0.30mol ethylenediamine, after the ...

Embodiment 3

[0047] one for CO 2 The foaming agent of the oil displacement system is composed of the following components by weight: 0.4 g of dodecyl hydroxypropyl phosphate betaine, surfactant C with star molecular structure 18 h 37 N[CH 2 CH 2 CONHCH 2 CH 2 NH(CH 2 CH 2 CONHCH 2 CH 2 NH 2 ) 2 ] 2 0.5 g, water 100 g.

[0048] Wherein, the surfactant with star-shaped molecular structure is prepared by the following method:

[0049] (1) 13.33 mmol of octadecylamine C 18 h 37 NH 2 Dissolve in 30mL of methanol to form a methanol solution of octadecylamine, weigh 0.24mol of methyl acrylate and add it dropwise to the methanol solution of octadecylamine, stir at room temperature for 24h, and then rotary evaporate at 60°C for 3h , get C 18 h 37 N (CH 2 CH 2 COOCH 3 ) 2 , is light yellow viscous liquid;

[0050] (2) Weigh 6.82mmol of product C from step (1) 18 h 37 N (CH 2 CH 2 COOCH 3 ) 2 , dissolved in 15mL of methanol, under ice bath, dropwise added 0.30mol ethylene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com