Preparation method of sodium hydroxyethyl sulfonate fatty acid ester

A technology of sodium isethionate and fatty acid ester, which is applied in the fields of sulfonate preparation and organic chemistry, can solve problems such as unsatisfactory foaming performance, unfavorable addition of cleansing powder, and easy blockage of powder feeders, etc., to achieve Strong foaming and hard water resistance, less environmental pollution, and abundant raw material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

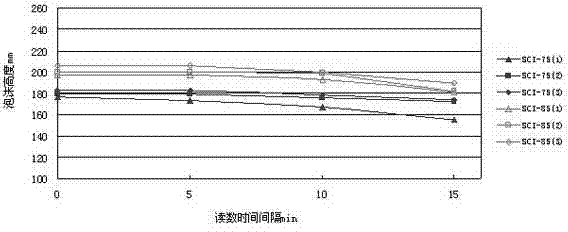

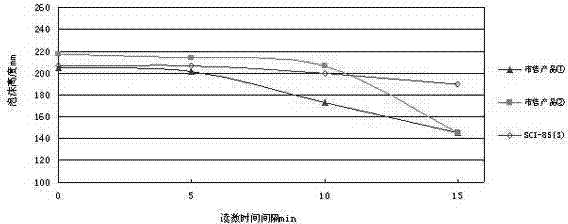

Image

Examples

Embodiment

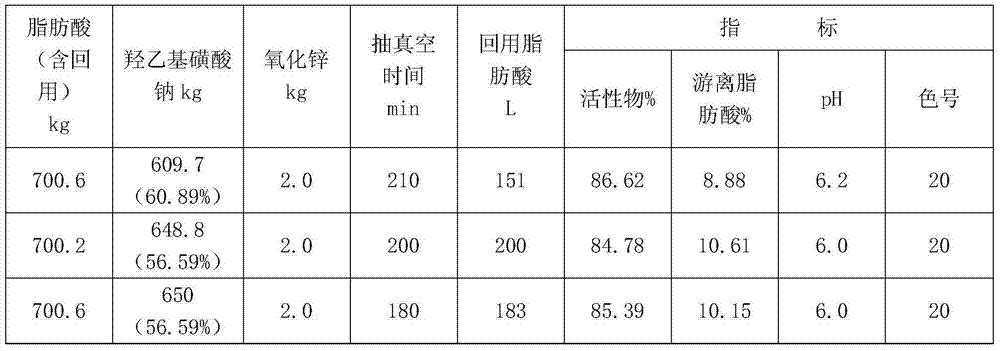

[0027] Weigh the raw materials according to the ratio, sodium isethionate aqueous solution: 614.5kg, coconut oleic acid: 700kg melted in advance, zinc oxide: 2.0kg, put into the reaction kettle in sequence and heat up to 100-160°C for 90 minutes, then heat up to 221°C Start the esterification reaction, the reaction temperature is 240±2°C, the reaction time is maintained for 90 minutes, and then the reaction temperature is raised to 245°C, the total reaction time is 120 minutes, the fatty acid distilled during the esterification is refluxed into the reactor through condensation, and the esterification After the reaction, the vacuuming operation is started, and the vacuuming needs to be carried out slowly to control the foaming on the surface of the material to be stable and uniform. During the vacuuming period, the reactor should not be lower than 232°C. After vacuuming for 1.5 hours, the reactor pressure was -0.095MPa. Continue vacuuming for 3.5 hours. There is no foam on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com