Preparation method of mud-resistant polycarboxylate-type water reducer

A technology of polycarboxylate and water reducer, which is applied in the field of polycarboxylate water reducer for cement concrete, which can solve the problem of poor adaptability between polycarboxylate water reducer and inferior mud-containing sand and gravel, and the difficulty in obtaining the quality of concrete raw materials Better guarantee, poor workability of concrete mixture and other problems, to achieve the effect of solving the problem of mud content, simple and convenient operation steps, and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

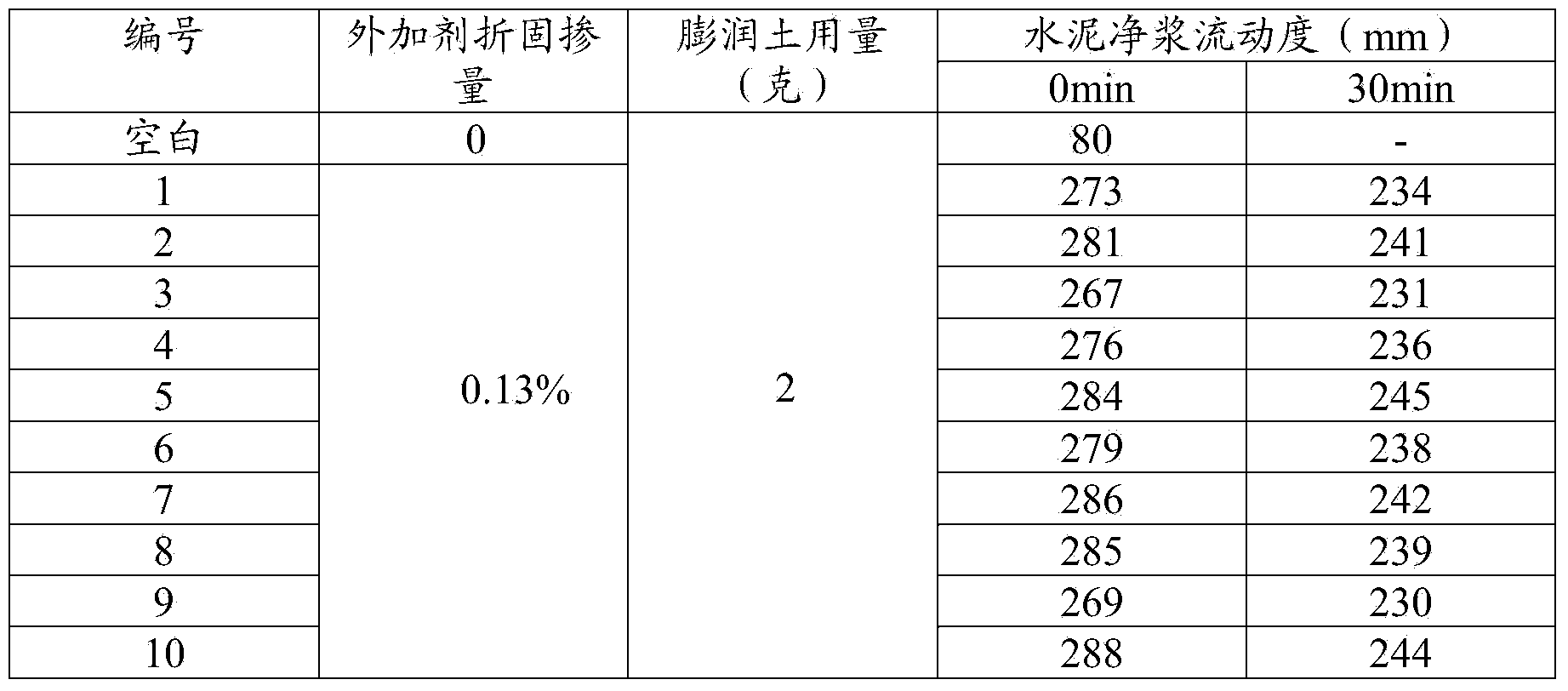

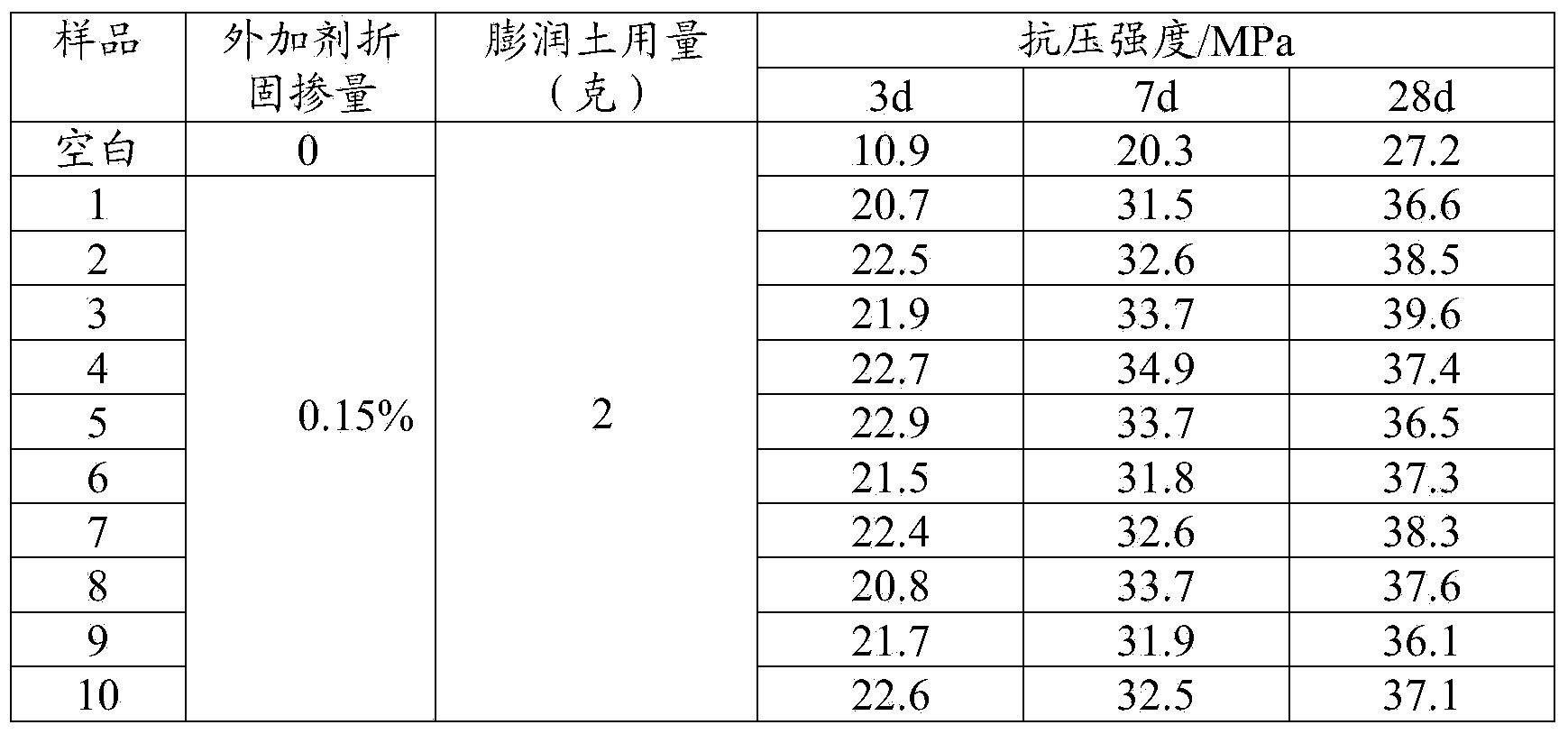

Examples

Embodiment 1

[0026] Step 1) Preparation of quaternary ammonium salt unsaturated small monomers: 142g (1mol) glycidyl methacrylate, 38.25g (0.85mol) dimethylamine, 80.75g (0.85mol) methyl bromide at 5°C catalyst 0.03mol Al(OTf) 3 Under the action of stirring for 72h, the product quaternary ammonium salt unsaturated small monomer was obtained;

[0027] 2) Preparation of anti-mud type water reducer: 20 g of quaternary ammonium salt unsaturated small monomers, 2 g of methyl acrylate, 30 g of sodium allyl sulfonate and allyl polyethylene glycol (M n = 300g / mol) 300g was first added to the reactor and stirred evenly, then 0.61g hydrogen peroxide and 0.56g mercaptopropionic acid aqueous solution were added dropwise respectively, and the temperature was kept at 35°C, and after 3 hours of reaction, the copolymerization product was obtained; pH was adjusted with sodium hydroxide solution Step 6, adding water to obtain a polycarboxylic acid-based superplasticizer with a concentration of 5 wt%.

Embodiment 2

[0029] Step 1) Preparation of quaternary ammonium salt unsaturated small monomers: 142g (1mol) glycidyl methacrylate, 69.35g (0.95mol) diethylamine, 109g (1mol) ethyl bromide at 10°C catalyst 0.05mol Sc(OTf) 3 Under the action of stirring for 50h, the product quaternary ammonium salt unsaturated small monomer is obtained;

[0030] 2) Preparation of anti-sludge water-reducing agent: 30 g of quaternary ammonium salt unsaturated small monomer, 40 g of n-propyl acrylate, 20 g of sodium acrylate and methallyl polyethylene glycol (M n = 800g / mol) 360g was first added to the reactor, stirred evenly, then added dropwise 0.9g of ammonium persulfate and 3g of 2-mercaptopropionic acid aqueous solution respectively, kept the temperature at 45°C, and reacted for 4 hours to obtain the copolymerization product; The potassium solution was adjusted to pH 6, and water was added to obtain a polycarboxylic acid-based high-performance water reducer with a concentration of 15 wt%.

Embodiment 3

[0032] Step 1) Preparation of quaternary ammonium salt unsaturated small monomer: 127g (1mol) glycidyl acrylate, 95.95g (0.95mol) dipropylamine, 123g (1mol) bromopropane at 15°C catalyst 0.04mol Al(OTf) 3 Under the action of stirring for 48h, the product quaternary ammonium salt unsaturated small monomer was obtained;

[0033] 2) Preparation of anti-mud type water reducing agent: 10 g of quaternary ammonium salt unsaturated small monomer, 40 g of n-butyl acrylate, 30 g of sodium vinylbenzene sulfonate and 3-methyl-3-butene-1-polymer Ethylene Glycol (M n =1000g / mol) 300g was firstly added to the reactor, stirred evenly, then dripped with potassium persulfate 0.5g and 0.1g 3-mercaptopropionic acid aqueous solution respectively, kept the temperature at 50°C, and reacted for 4.5 hours to obtain a copolymerization product; The sodium oxide solution was adjusted to pH 7, and water was added to obtain a polycarboxylic acid-based high-performance water reducer with a concentration of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com