Patents

Literature

358results about How to "Preparation process safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

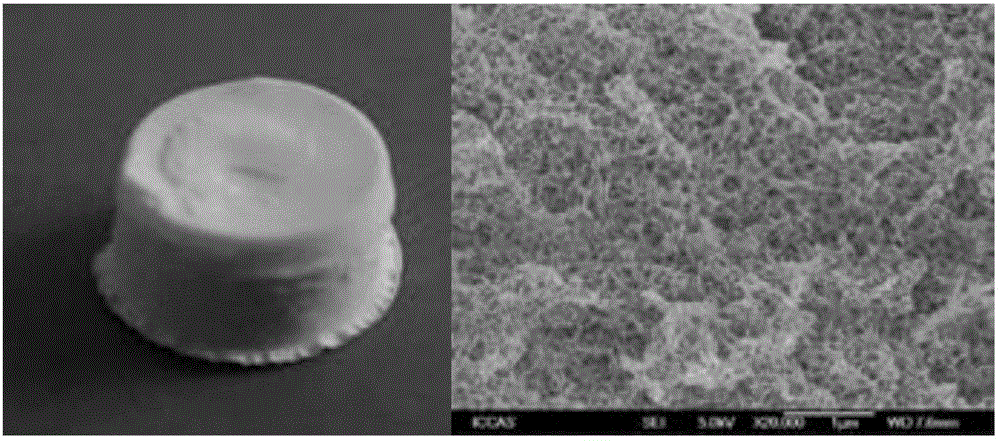

Cellulose aerogel and preparation method for hybrid aerogel thereof

The invention discloses low-cost green cellulose aerogel and a preparation method for hybrid aerogel thereof. The preparation method for the hybrid aerogel of the cellulose aerogel comprises the following steps that cellulose is dissolved into a zinc chloride aqueous solution, centrifugal deaeration is performed, and a uniform and transparent cellulose solution is obtained; the cellulose solution is formed, then the formed cellulose solution is placed into a coagulating bath to be regenerated, in addition, the regenerated cellulose solution is fully washed by use of a solvent, and cellulose solvent gel is obtained; the solvent in the cellulose solvent gel is removed by use of supercritical carbon dioxide drying or freeze drying, and the cellulose aerogel is obtained. Functional filler can be added into the cellulose solution to obtain the hybrid aerogel. By the adoption of different solution forming methods, the cellulose aerogel and the hybrid aerogel thereof in the shapes of sheets, fibers, particles and the like can be prepared. The preparation method is low in cost and is environmentally friendly, and the prepared aerogel is provided with a uniform nano-grade net porous structure.

Owner:INST OF CHEM CHINESE ACAD OF SCI

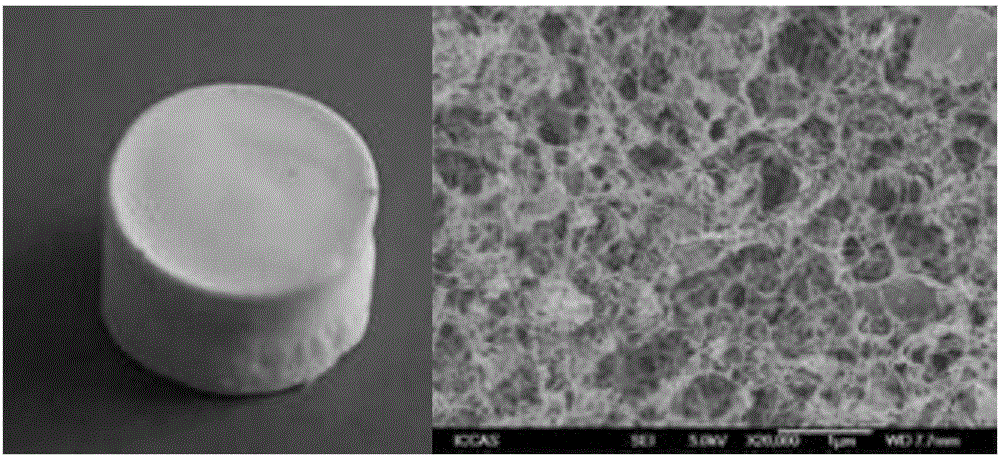

Thermoplastic polyurethane elastomer foam material and preparation method thereof

The invention discloses a thermoplastic polyurethane elastomer foam material, which is prepared from the following raw materials by weight: 80-100 parts of a thermoplastic polyurethane elastomer, 10-40 parts of a filler, 4-7 parts of a foaming agent, 0.6-1.5 parts of a cross-linking agent, 1.0-1.5 parts of a cross-linking assistant, 0.1-1.0 part of a mildew proof antibacterial agent and 1.2-2.0 parts of a lubricant. Adopting the above technical scheme, the invention has the beneficial effects of improving the foam expansion of the thermoplastic polyurethane foam material, expanding the scope of usage of the polyurethane foam material, and realizing compression deformation of a finished product produced from the thermoplastic polyurethane foam at no more than 35%, which is unmatched by an EVA foam material with equivalent foam expansion and similar elasticity. In addition, the foam material improves the performance of existing traditional foam materials, and solves the defects that polyester-type thermoplastic polyurethane elastomer has short service life, easily goes moldy on the product surface and generates mechanical performance loss in the field and damp and hot environment.

Owner:泉州三盛橡塑发泡鞋材有限公司

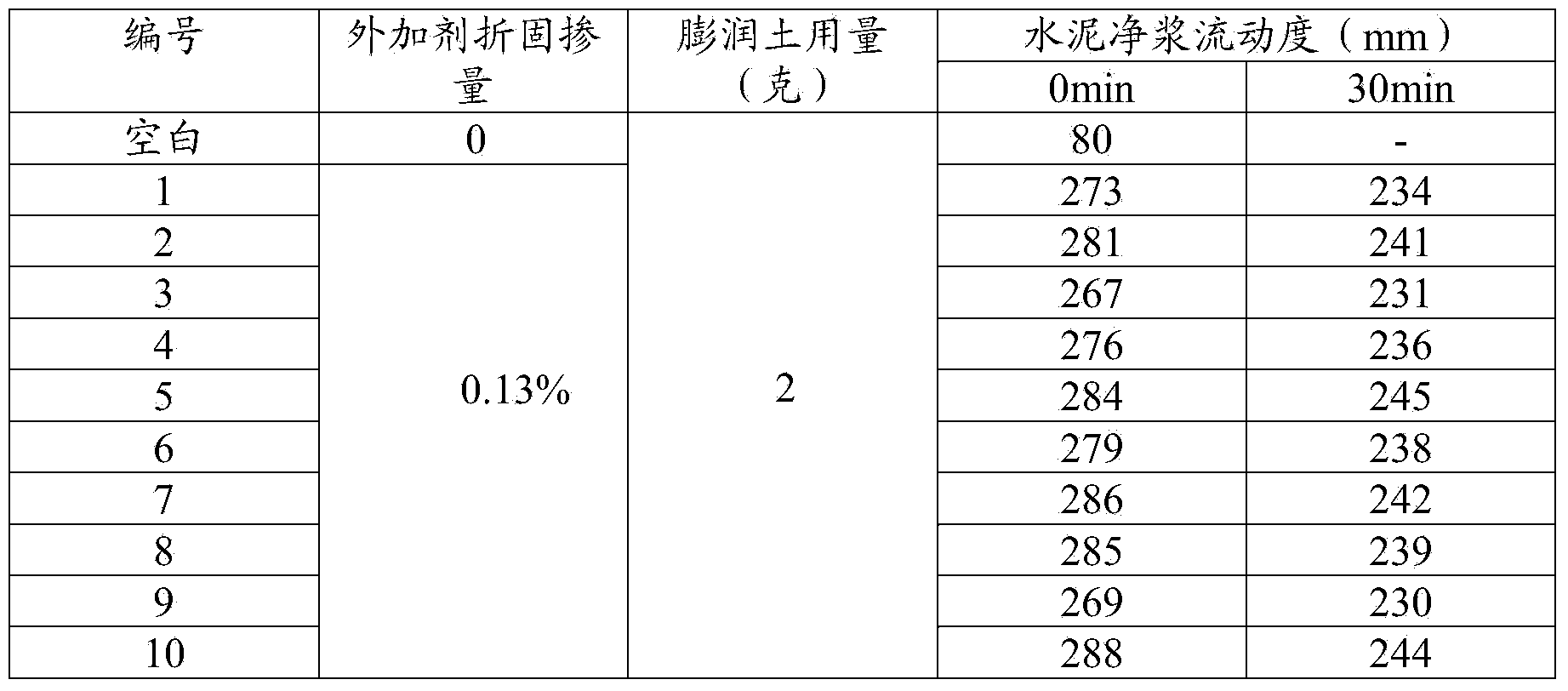

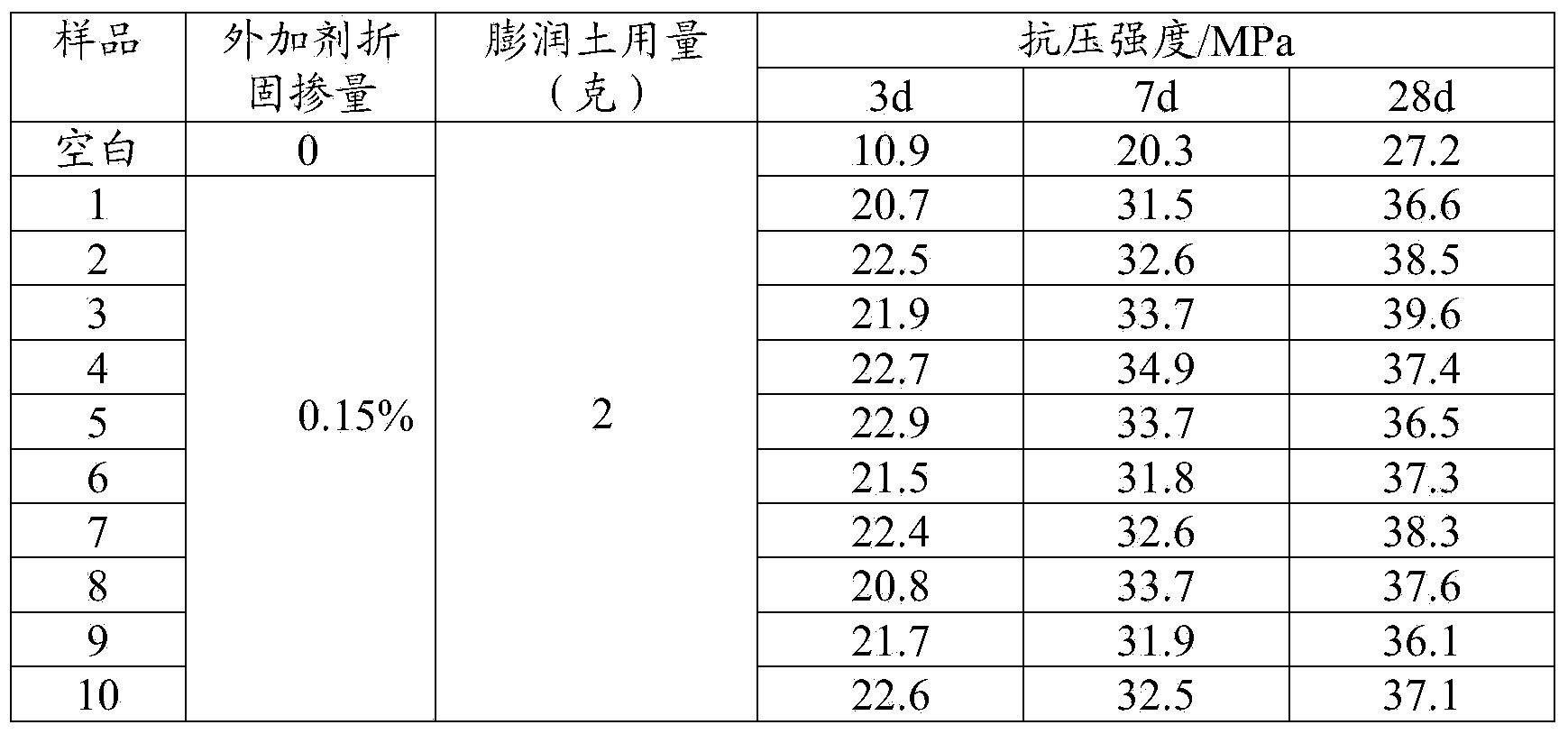

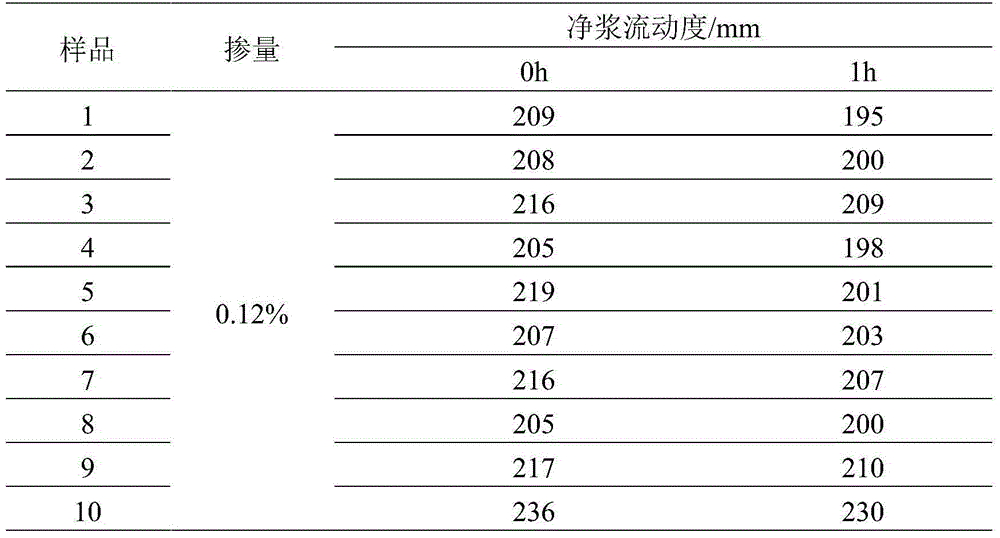

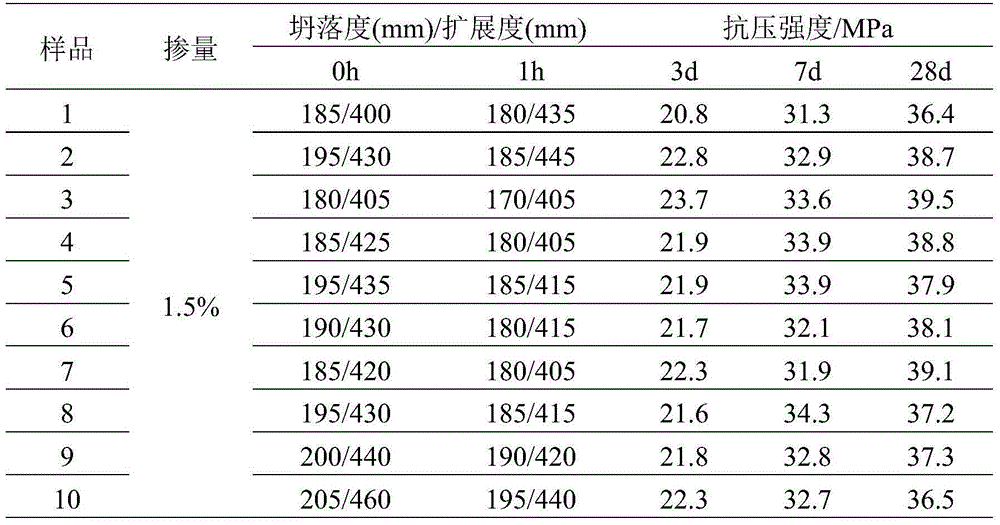

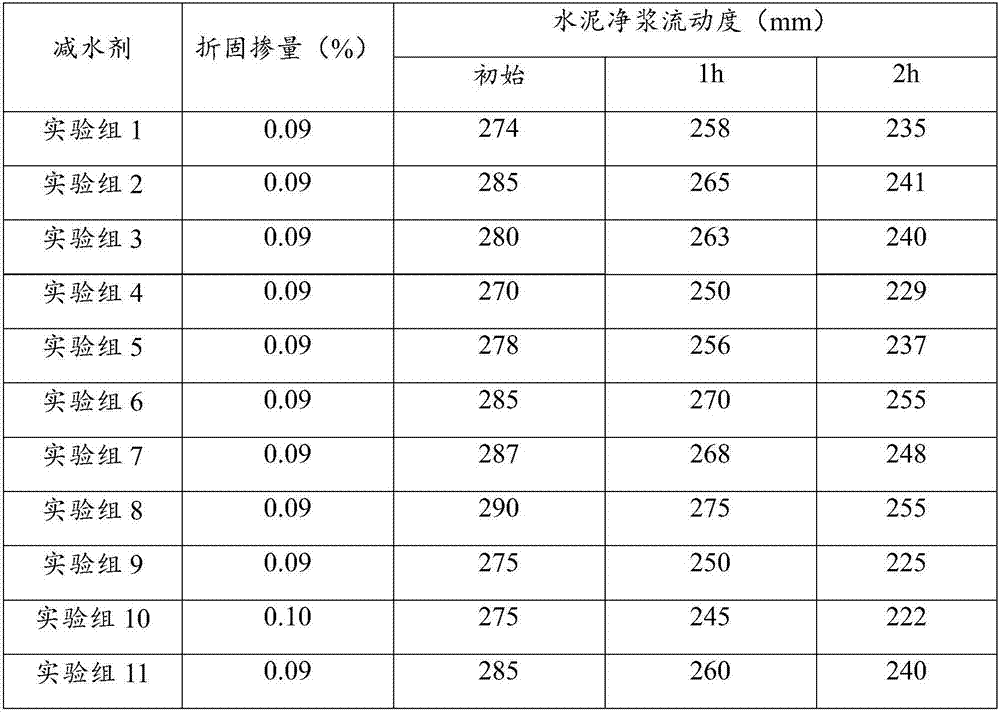

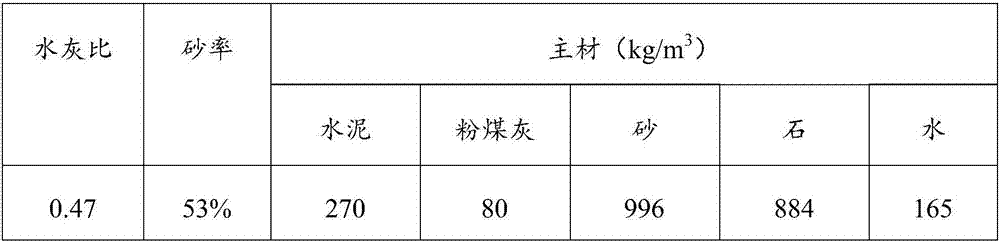

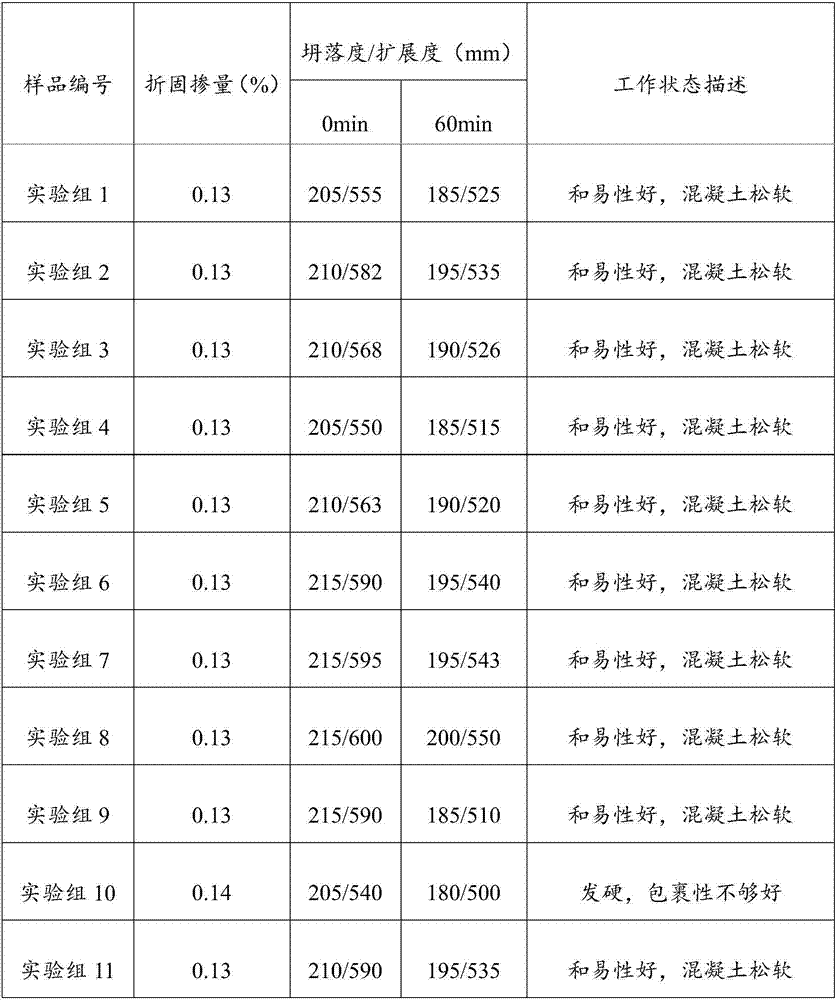

Preparation method of mud-resistant polycarboxylate-type water reducer

The invention relates to a preparation method of a mud-resistant polycarboxylate-type water reducer. The preparation method comprises the following specific steps: stirring an unsaturated small monomer containing an epoxy group, a secondary amine small organic molecule and a small organic molecule containing halogen at certain temperature under the action of a catalyst to obtain a product of quaternary ammonium salt unsaturated small monomer; carrying out water phase free radical polymerization reaction on the quaternary ammonium salt unsaturated small monomer, an unsaturated ester small monomer, an unsaturated sulfoacid small monomer, an unsaturated acid small monomer and an unsaturated polyether large monomer under the combined action of an initiator and a chain transfer agent to obtain a copolymerized product, regulating the pH value after reaction and adding water to obtain the polycarboxylate-type water reducer. The mud-resistant polycarboxylate-type water reducer prepared by the method has the advantages of being simple in reaction, easy to control and low in cost. Besides, adverse effect caused by mud-containing aggregate in the concrete can be avoided, and the problems of insufficient concrete slushing, large slump loss and low strength are solved without increasing the mixing amount of the water reducer.

Owner:JIANGSU CHINA RAILWAY ARIT NEW MATEIRALS CO LTD

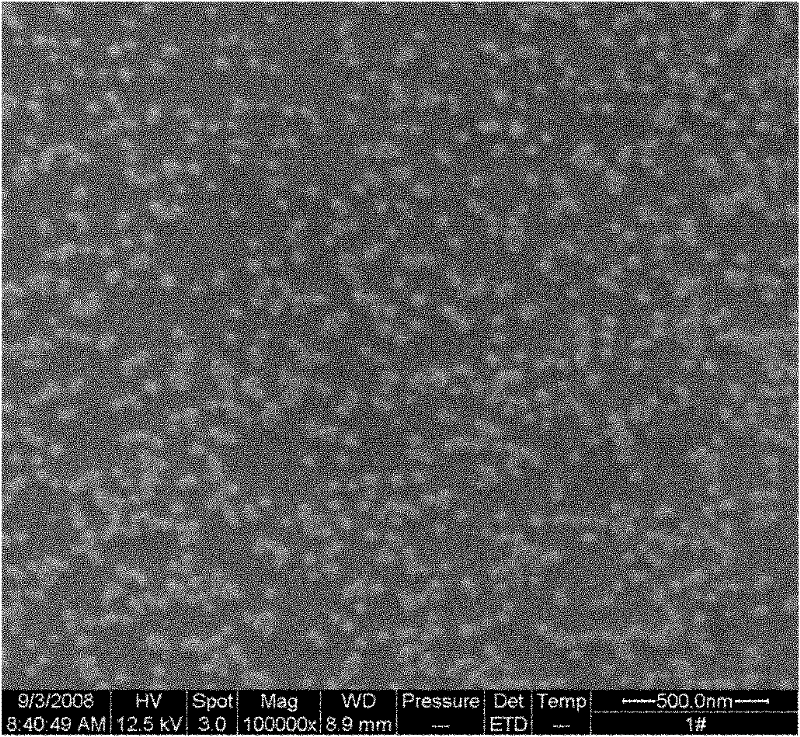

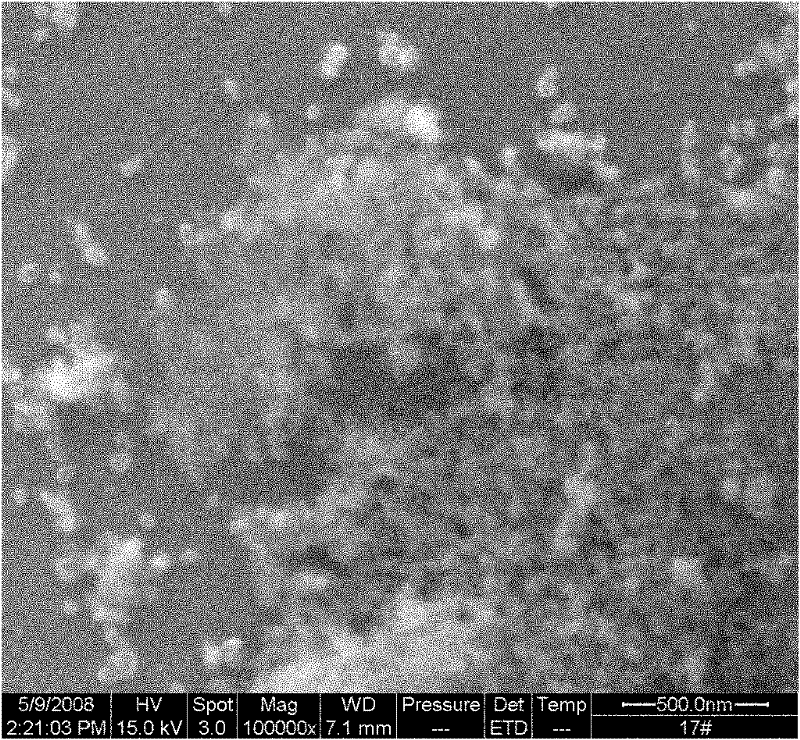

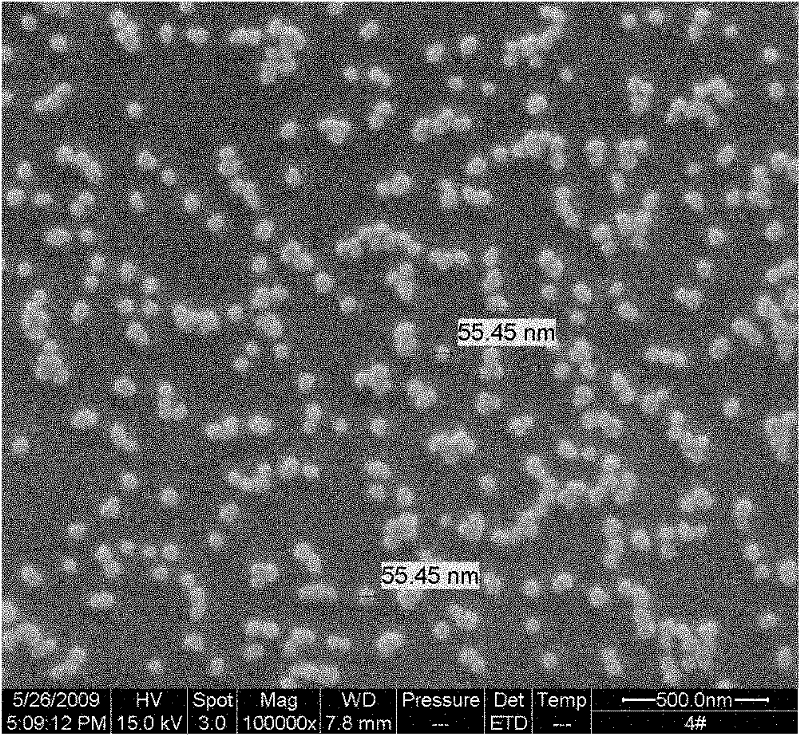

Preparation method for SiO2 sol with high evenness degree

The invention discloses a preparation method for the silica sol with a high evenness degree, belonging to the technical field of electronic manufacturing and SiO2 sol preparation. Under an ultrasonic influence, a silica sol seed solution is prepared and a reaction material is added to the silica sol solution in batches; aqueous solution and metallic silicon powder that serve as basic catalysts are chosen as the reaction material for each batch, and the basic catalyst in each batch is 2-40% of the basic catalyst previously added into the silica sol seed solution, and the metallic silicon powder in each batch is 2-40% of the metallic silicon powder previously added in the silica sol seed solution. After the reaction finishes, the unreacted metallic silicon powder is removed, and the SiO2 sol is produced. The ultrasonic sound adopted for the invention ranges from 20 to 50 kHz. By adopting the invention, production costs can be reduced and product purity is improved. In addition, the method disclosed by the invention has the advantages of safe technical process, simple equipment, and is easy to operate as well as is economic and has high efficiency.

Owner:TSINGHUA UNIV +2

Core-shell type cationic/anionic polyacrylamide profile control oil displacing microsphere and preparation method thereof

The invention discloses a core-shell type cationic / anionic polyacrylamide profile control oil displacing microsphere and a preparation method thereof. The core-shell type cationic / anionic polyacrylamide profile control oil displacing microsphere with a micrometer particle size range is prepared in one pot by adopting a dispersion polymerization method, and the whole preparation process is continuously completed by two steps: firstly synthesizing a core part of a microsphere, and then synthesizing a shell part of the microsphere. The core part of the microsphere consists of water-soluble monomer acrylamide, an ionic monomer I and a crosslinking agent; the shell part of the microsphere consists of water-soluble monomer acrylamide, an ionic monomer II and a crosslinking agent; and the ionic monomer I and the ionic monomer II have opposite charges. The particle size of the core-shell type cationic / anionic polyacrylamide profile control oil displacing microsphere is 1-200mu m. The preparation method is simple in preparation process, the whole preparation process is environmentally friendly and low in cost; and a solvent can be recycled, and the recycling rate is above 80 percent. The core-shell type cationic / anionic polyacrylamide profile control oil displacing microsphere is used as a profile control oil displacing material, and has excellent injectivity and mobility.

Owner:TIANJIN UNIV

Process of preparing high purity chlorogenic acid and flavonid with eucommia leaf

ActiveCN1974527AImprove product qualityHigh content of target ingredientsOrganic compounds purification/separation/stabilisationCarboxylic acid esters separation/purificationChlorogenic acidEthyl acetate

The process of preparing high purity chlorogenic acid and flavonid with eucommia leaf includes the following steps: crushing eucommia leaf and extracting with pH 3-6 alcohol solution of 45 %-55 % concentration; saturation adsorbing the extracted solution with medium polarity JD-1 macroporous resin, and eluting successively with water, 20 %-45 % concentration alcohol solution and 60 %-75 % concentration alcohol solution to obtain crude chlorogenic acid product and flavonid-containing powder separately; eluting the crude chlorogenic acid product in silica gel column with ethyl acetate, acetone, methanol or ethanol, collecting the eluted solution, decompression concentrating, and re-crystallizing the concentrate in acetone or water to obtain refined chlorogenic acid product. The present invention has simple technological process, convenient operation, reuse of the macroporous resin, low comprehensive cost and excellent industrial application foreground.

Owner:GUANGZHOU HANFANG PHARMA

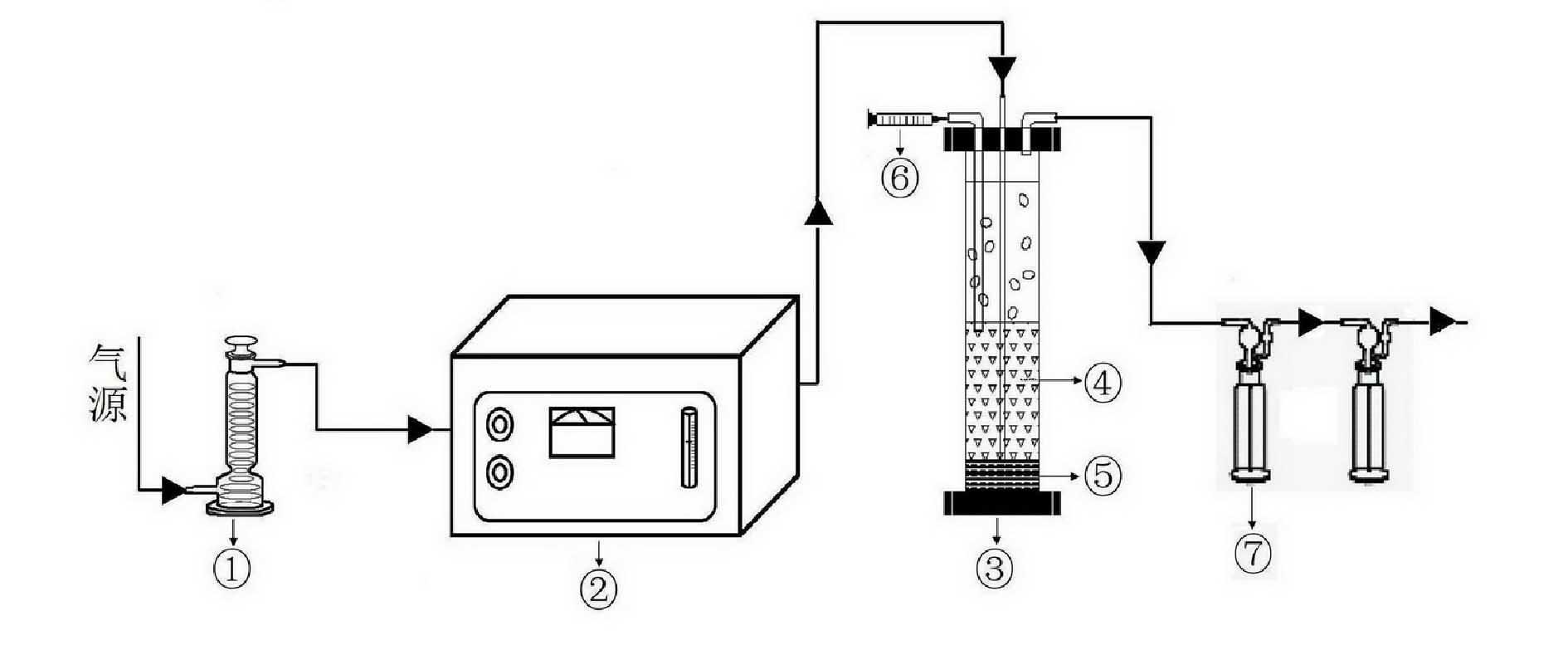

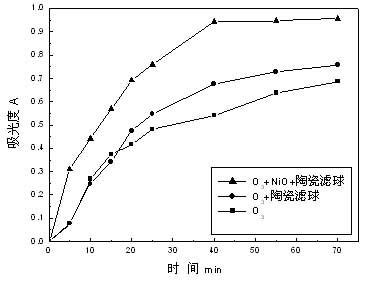

Preparation method of load-type metallic oxide ozone catalytic oxidation catalyst

InactiveCN102626629AHigh catalytic activityIncreased rate of catalytic degradationWater contaminantsMetal/metal-oxides/metal-hydroxide catalystsPtru catalystCatalytic oxidation

The invention relates to a preparation method of a catalyst, in particular to a preparation method of a load-type metallic oxide ozone catalytic oxidation catalyst, which is characterized by comprising the following steps of (1) selecting ceramic filter bulbs to serve as a carrier, washing through deionized water, soaking for 24h by using diluted hydrochloric acid, and washing through the deionized water to effluent neuter for stoving; (2) dipping for 24h in nickel nitrate solution with the concentration of 0.1-1.0mol / L and drying; (3) roasting for 5h in a muffle furnace at 500 DEG C to obtain roasting objects; and (4) washing through the deionized water and stoving to obtain the load-type metallic oxide ozone catalytic oxidation catalyst. The preparation method is simple, low in cost, capable of greatly improving oxidation rate and efficiency of ozone on organic pollutant, good in product stability and capable of repeatedly using, and having important significant on application and dissemination of catalytic ozonation techniques.

Owner:WUHAN UNIV OF TECH

Preparation method of novel polycarboxylic acid type water-reducer

The invention discloses a preparation method of a novel polycarboxylic acid type water-reducer. The novel polycarboxylic acid type water-reducer is prepared by the following steps: 1) a unsaturated acid monomer and an amine unsaturated monomer react under the action of a chain transfer agent, an initiator and a reducing agent to obtain a copolymer containing an amino group; 2) excessive diisocyanate is dropwise added into methoxy polyethylene glycol to react under the action of a catalyst so as to obtain methoxypolyethylene glycol mono-isocyanate; 3) the copolymer containing the amino group is added into the methoxypolyethylene glycol mono-isocyanate to react and then pH value is adjusted so as to obtain a novel polycarboxylic acid water-reducer. According to the method, product performance is adjusted by controlling molecular structure / molecular weight of the amine copolymer and molecular weight of methoxy polyethylene glycol. Reactions are fast and efficiency is high. In addition, no organic solvent is used; the water-reducer is nontoxic and pollution-free; and operation is simple. The polycarboxylic acid type water-reducer prepared by the method is a functional polycarboxylic acid type high-efficiency water-reducer, and product performance is stable.

Owner:JIANGSU CHINA RAILWAY ARIT NEW MATEIRALS CO LTD

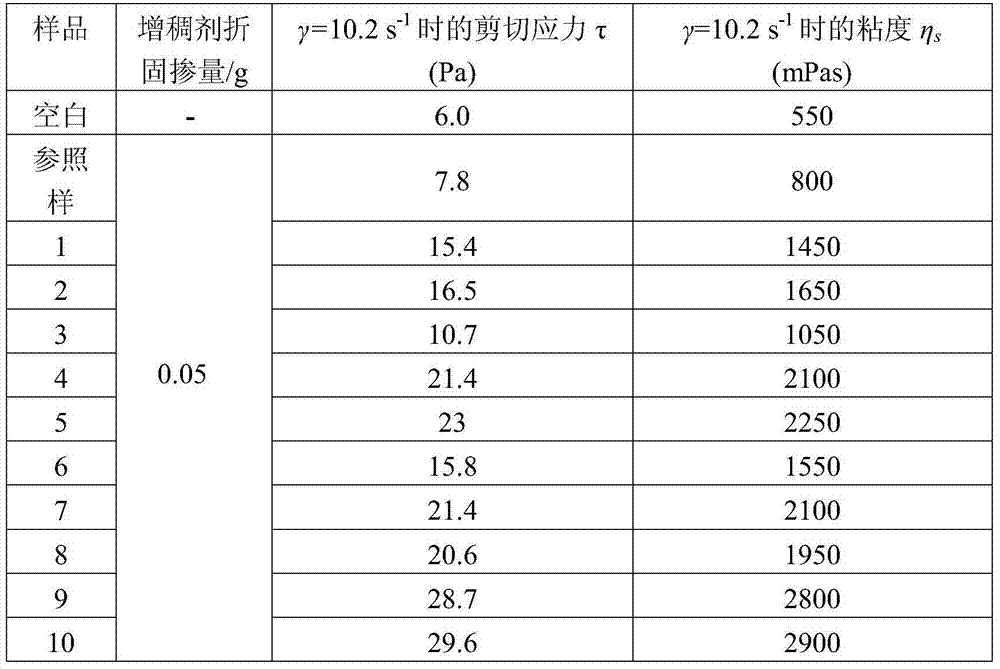

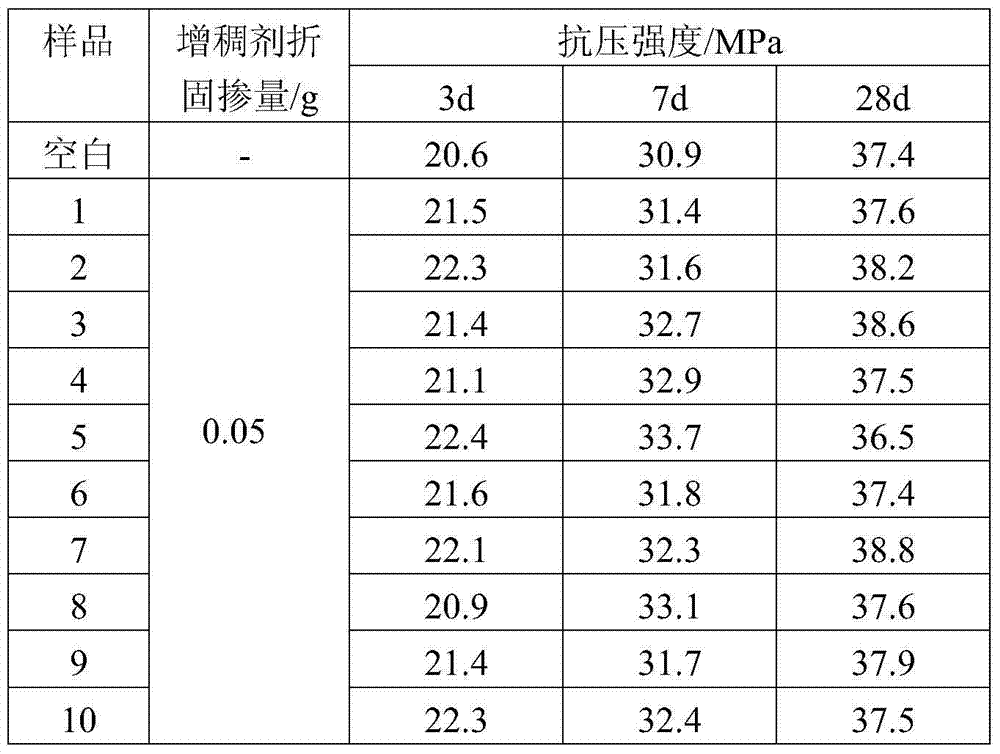

Preparation method of concrete thickener

The invention discloses a preparation method of a concrete thickener. The preparation method of the concrete thickener comprises subjecting small unsaturated amide monomers, small unsaturated hydroxyl-ester monomers and small unsaturated sulfoacid monomers to aqueous phase radical polymerization under the combined action of a redox system composed of initiating agent and reducing agent to obtain polymerized products; adjusting the PH of the polymerized products to be 6-7; adding water into the polymerized water to obtain the concrete thickener at a concentration of 3-10wt%. According to the preparation method of the concrete thickener, the product performance can be adjusted by controlling the molecular weight of the polymerized products, so that high reaction velocity can be obtained, organic solvent can be omitted, and being non-toxic and pollution-free and simple in operation can be achieved. The concrete thickener prepared through the method can avoid segregation under the premise of achieving high water retention, thereby guaranteeing the slump resisting performance of concrete and achieving stable product performance.

Owner:JIANGSU CHINA RAILWAY ARIT NEW MATEIRALS CO LTD

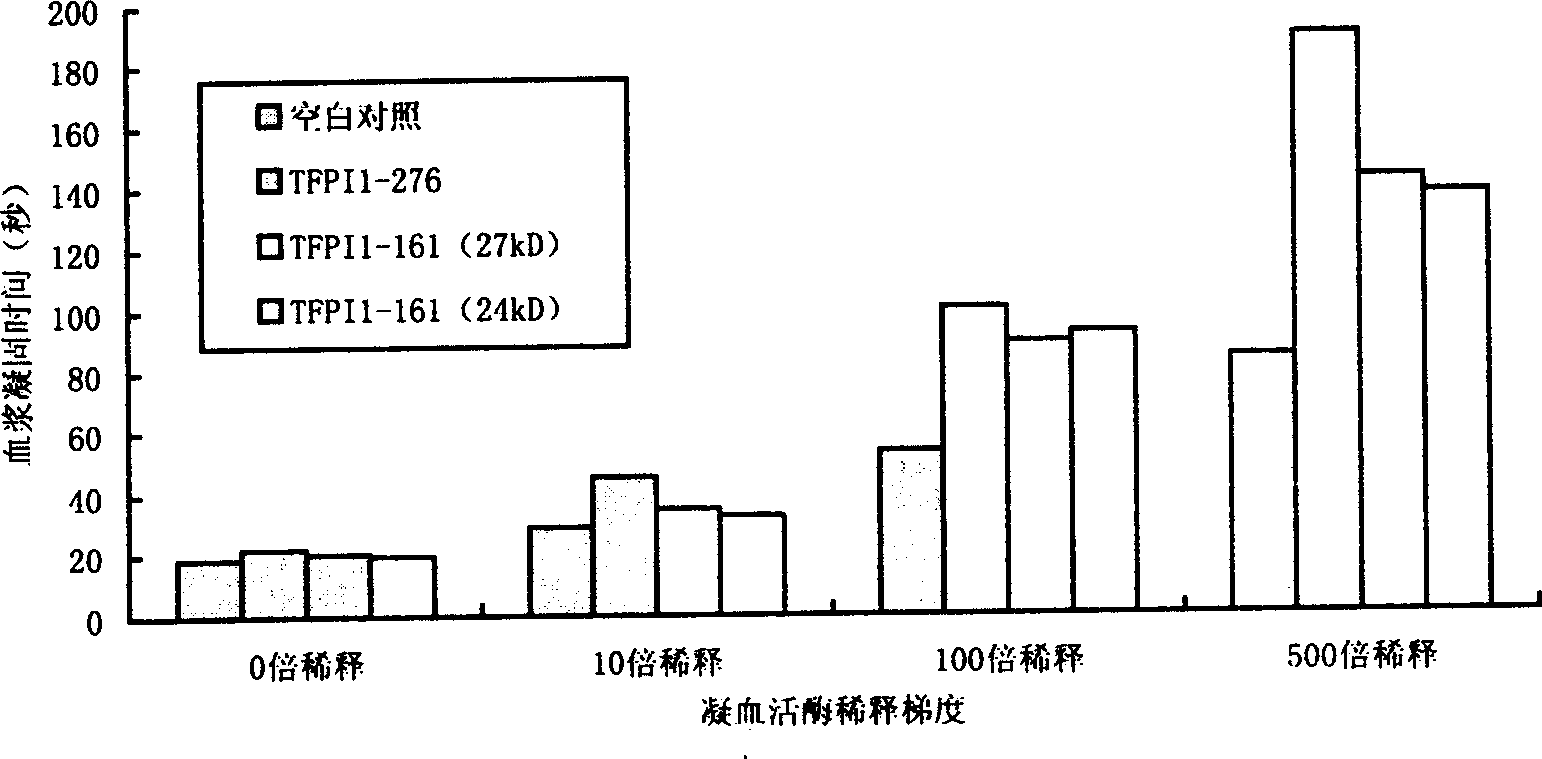

Long-acting reconbinant tissue factor channel inhibitor and preparing method thereof

InactiveCN1528894AExtended half-lifeHighly effective anticoagulantFermentationVector-based foreign material introductionBiotechnologyInclusion bodies

The invention belongs to biology technology field, which concretely refers to controlled release tissue factor path inhibitor (LTFPI) and the manufacturing method, and the application. The invention analyzes and experiments the biology information science and structure molecular biology science of tissue factor path inhibitor (TFPI) and its acceptor low density lipoprotein acceptor correspondent protein (LRP), it ascertains the part where the TFPI carboxy end combines with LRP and is eliminated. It designs TFPI carboxy end mutant, which is recombined with primary nucleus or eukarya expressing carrier after constructing LTFPI gene through PCR location, it converts bacillus coli or bici yeast, sifts the high expression project fungus. The primary project fungus are yeasted and expanded, crushed, then they are centrifugated and collects the inclusion body, purifies the LTFPI through molecular sift and ion interchanging two-step method; the eukarya project fungus are carried on with two-step purifying directly. The half-life are prolonged, it has good pour-depressant function.

Owner:海菲尔(辽宁)生物科技有限公司

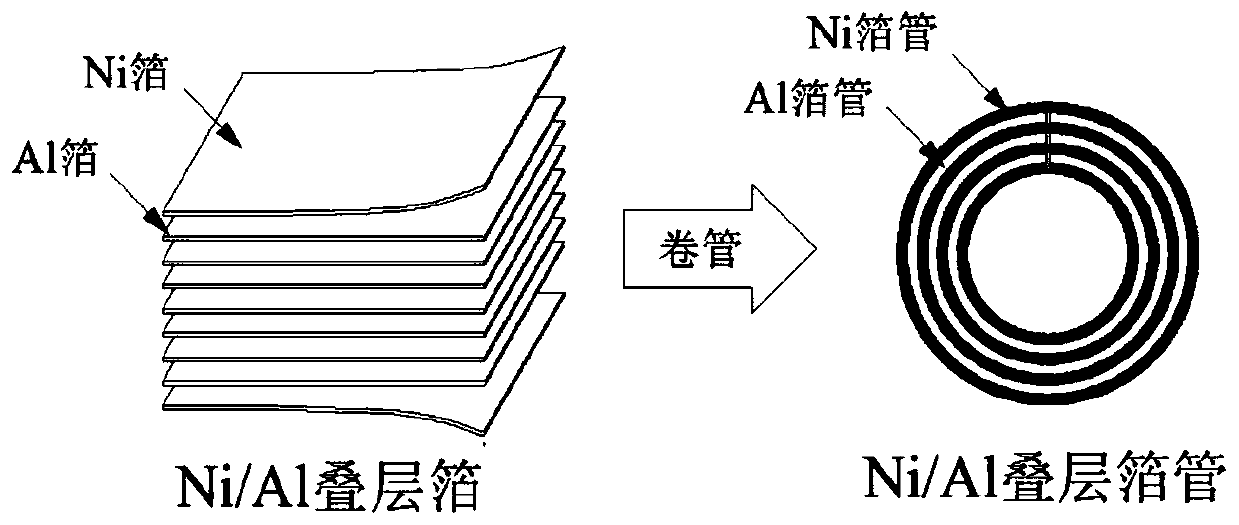

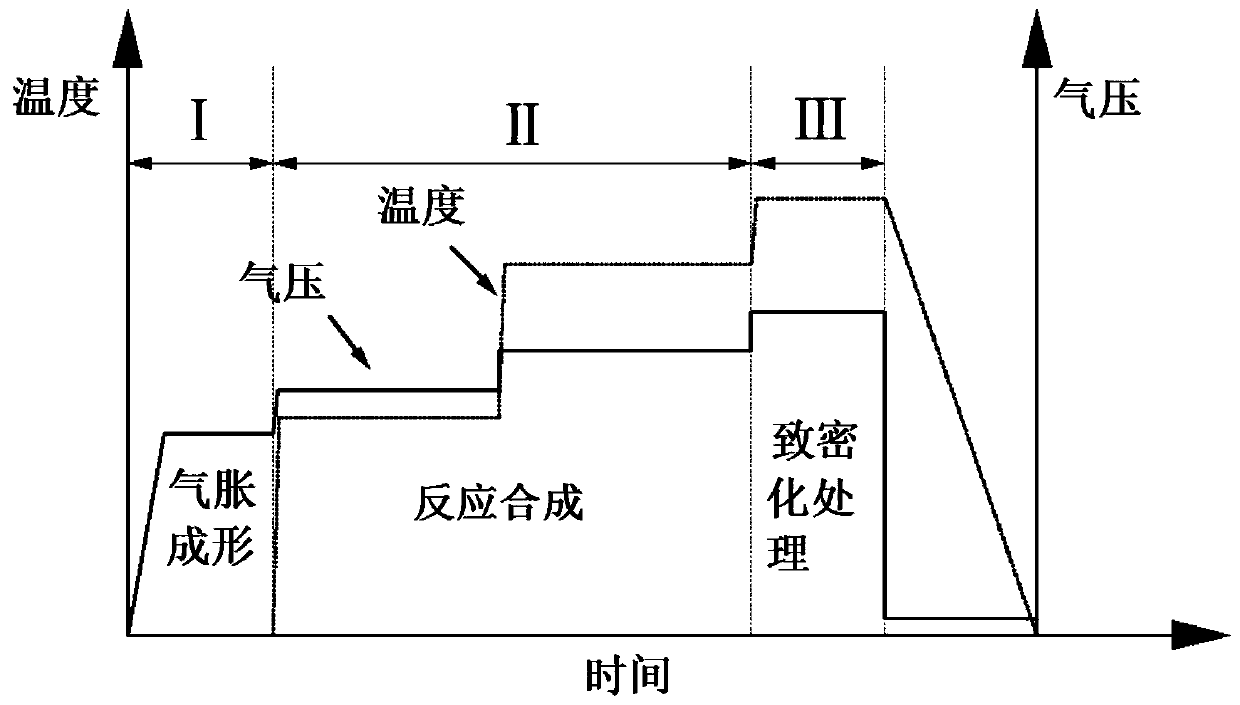

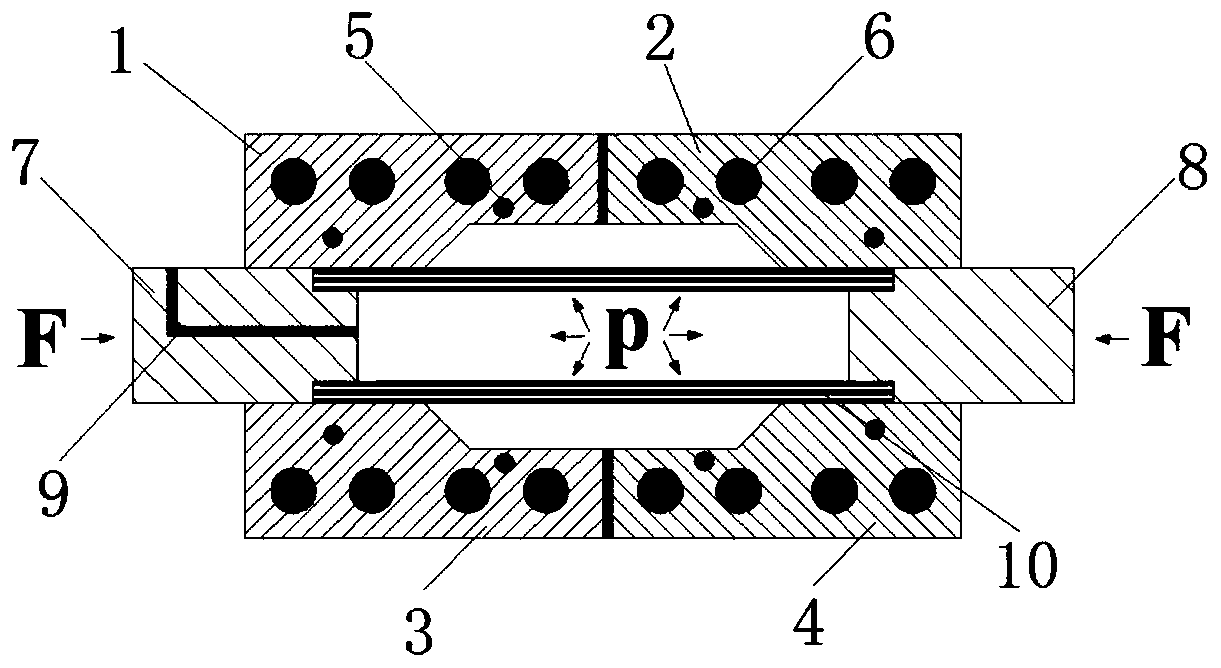

NiAl alloy thin-walled pipe fitting forming and controlling performance integrated method

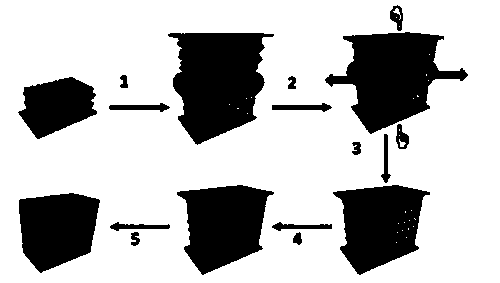

ActiveCN110142332AHigh controllability of specifications and ingredientsPreparation process safetyShaping toolsRigid pipesThin walledNial

The invention provides an NiAl alloy thin-walled pipe fitting forming and controlling performance integrated method and belongs to the technical field of precise forming of intermetallic compound thin-walled pipe fittings. The NiAl alloy thin-walled pipe fitting forming and controlling performance integrated method comprises the following steps that Ni foils and Al foils are alternately laminatedand coiled to obtain an Ni / Al foil an ag / l laminated foil tube; and the Ni / Al laminated foil tube is subjected to plastic forming, reaction synthesis and densification treatments in an air expansion forming die to obtain the NiAl alloy thin-walled pipe fitting. The NiAl alloy thin-walled pipe fitting forming and controlling performance integrated method solves the problems of difficulty in controlof material flowing and tissue performance and complex procedures of existing NiAl alloy slab preparation and the thin-walled pipe fitting formed with a slab. Data of the embodiment of the inventionshows that the NiAl alloy thin-walled pipe fitting obtained by the method is high in forming rate and size precision, uniform in component distributed, good in compactness and non-defective in surface.

Owner:DALIAN UNIV OF TECH

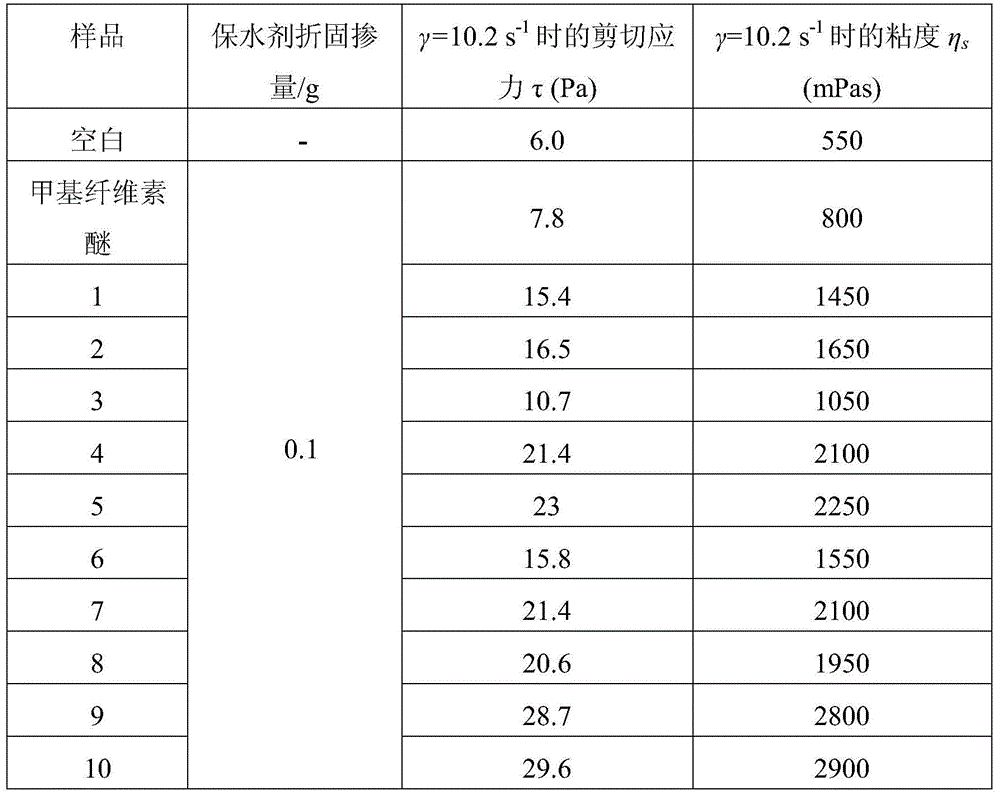

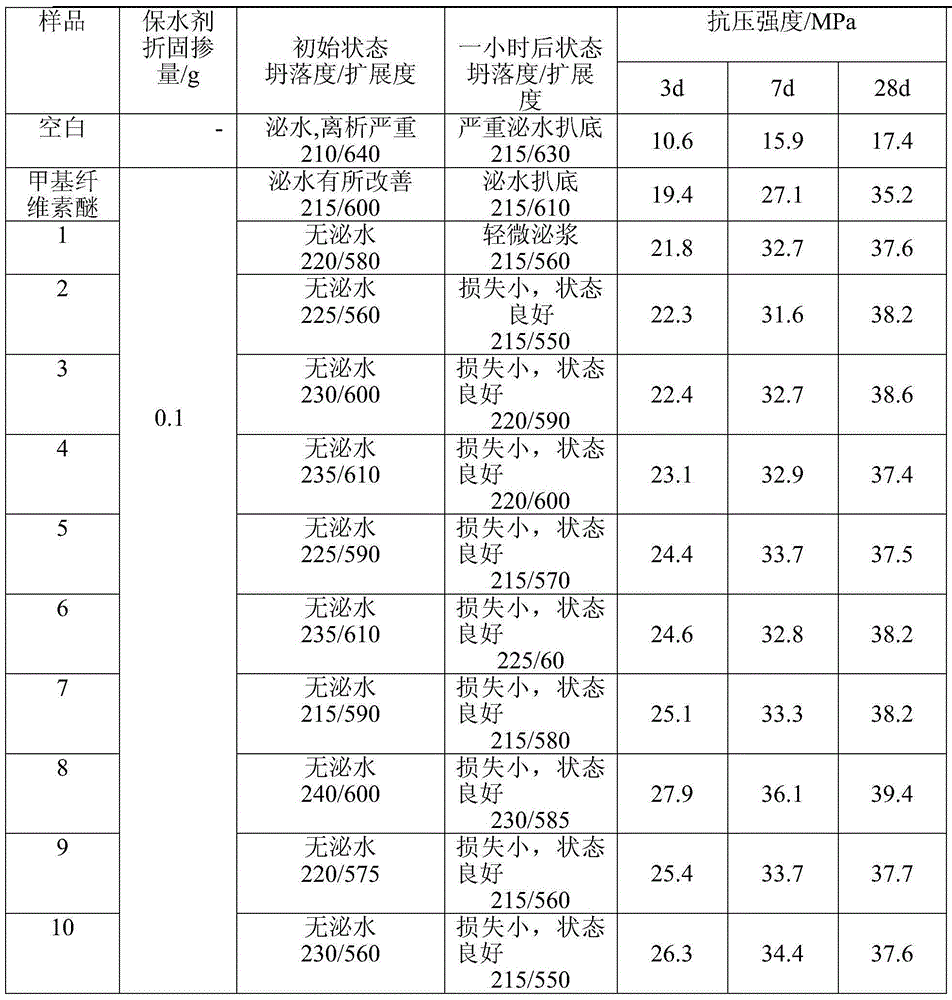

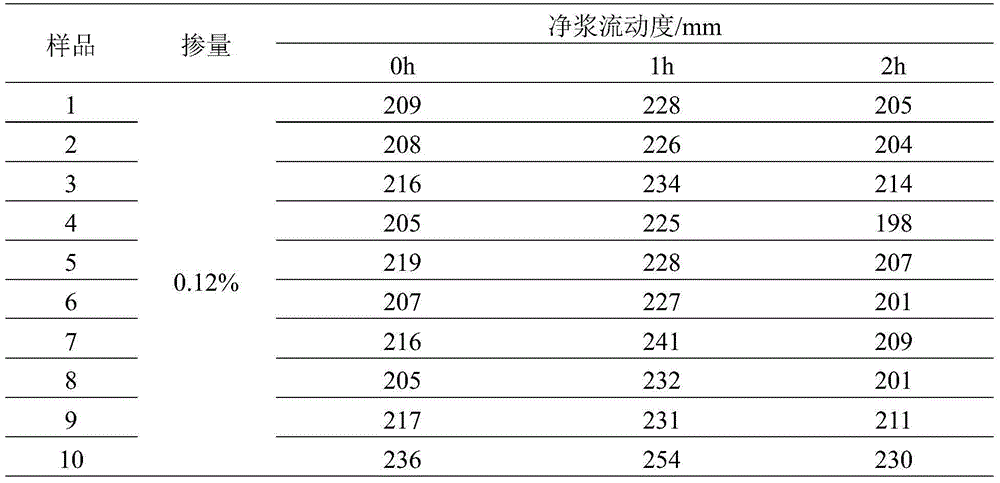

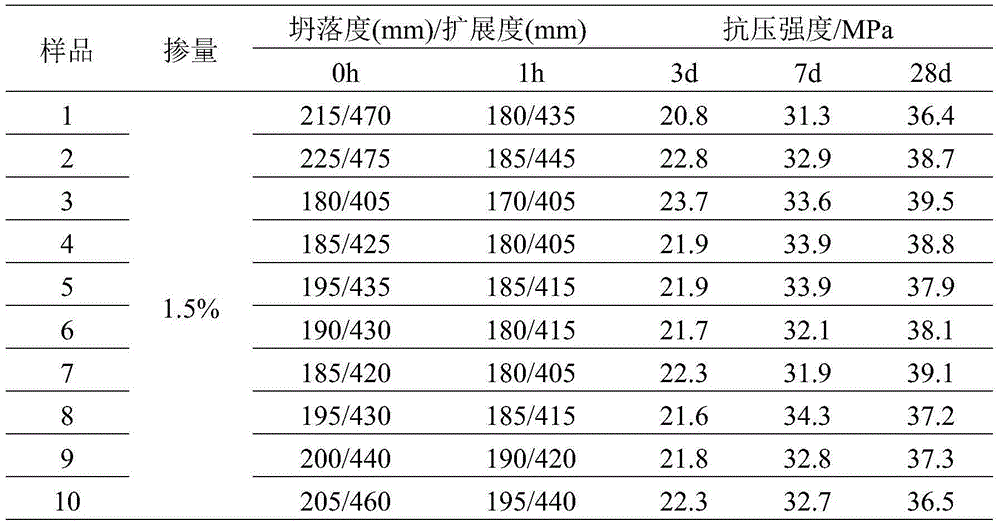

Preparation method of water retaining agent

InactiveCN104628968AAddressing Adaptive IssuesSolve the problem of adaptability, especially the large mud content of sand and gravelAcid waterOrganic solvent

The invention discloses a preparation method of a water retaining agent. The preparation method comprises the following steps: carrying out an aqueous phase radical polymerization reaction on unsaturated amide micro-monomers, unsaturated sulphonic acid micro-monomers and unsaturated polyether macromers or unsaturated ester macromonomers under the coaction of an oxidation-reduction system composed of an initiator and a reducing agent to obtain a copolymerization product, regulating the pH value to 6-7 after the reaction, and adding water to obtain the water retaining agent with mass concentration of 1-60%. The preparation method disclosed by the invention is used for adjusting the product properties by controlling the monomer proportion, the temperature and the dosage of the initiator and the reducing agent, the reaction speed is high, the efficiency is high, no organic solvent is used, no toxin or pollution is generated, and the operation is simple. The unsaturated macromonomers are introduced into the prepared concrete / mortar water retaining agent to ensure excellent water retaining property and obviously perfect such stirring states of the concrete / mortar as bleeding / separation and the like without generating such adverse effects as strength and the like, meanwhile, the water retaining agent can be compounded with a polycarboxylic acid water reducing agent at any proportion to ensure good intermiscibility. The product performance is stable.

Owner:JIANGSU CHINA RAILWAY ARIT NEW MATEIRALS CO LTD

Preparation method of amine-ester slow-setting polycarboxylic acid type water-reducer

The invention discloses a preparation method of an amine-ester slow-setting polycarboxylic acid type water-reducer. The preparation method comprises the following concrete steps: 1) a unsaturated acid monomer and a hydroxyl-containing unsaturated monomer are subjected to a normal temperature oxidation-reduction free radical polymerization reaction under the action of an initiator, a reducing agent and a chain transfer agent to obtain a hydroxyl-containing copolymerization product; 2) excessive diisocyanate is added into methoxypolyethylene glycol to react under the action of a catalyst so as to obtain methoxypolyethylene glycol monoisocyanate; and 3) the hydroxyl-containing copolymerization product obtained in the step 1) is added into the methoxypolyethylene glycol monoisocyanate obtained in the step 2) to react, and then pH value is adjusted by alkali neutralization so as to obtain the amine-ester slow-setting polycarboxylic acid type water-reducer. According to the method, product performance is adjusted by controlling molecular structure / molecular weight of the hydroxyl-containing copolymerization product and molecular weight of methoxy polyethylene glycol / type of diisocyanate. Reaction efficiency is greatly raised, and reaction time is shortened. In addition, no organic solvent is used; the water-reducer is nontoxic and pollution-free; and operation is simple. The product performance is stable.

Owner:JIANGSU CHINA RAILWAY ARIT NEW MATEIRALS CO LTD

Red-light fluorescent powder with narrow band and preparation method of red-light fluorescent powder

ActiveCN105505384AHigh color purityHigh color rendering indexLuminescent compositionsSolid-stateNarrow band

The invention provides red-light fluorescent powder with a narrow band and a preparation method of the red-light fluorescent powder. The general chemical formula of the red-light fluorescent powder with the narrow band is AnB(1-x)MnxF6, wherein A is at least one of Na, K, Ba and Zn, B is at least one of Ti, Si, Ge and Gd, n is larger than or equal to 1 and smaller than or equal to 2, and x is larger than 0 and smaller than or equal to 2. The inner quantum efficiency of the AnB(1-x)MnxF6 fluorescent powder can reach 90%, and the red-light fluorescent powder with the narrow band has extremely narrow half-peak breadth and has very large development space in the backlight field. According to the preparation method of the red-light fluorescent powder with the narrow band, a high-temperature solid-state method is adopted for preparation, hydrofluoric acid with high concentration is effectively avoided, harm to a human body and the environment is avoided, and meanwhile, the high-temperature solid-state method for preparation is more suitable for large-scale industrial production.

Owner:HEBEI LIFU CHEM TECH

Preparation method of rear-earth magnesium alloy product

The invention relates to a preparation method of a rear-earth magnesium alloy product. The preparation method comprises the following steps of: placing dehydrated rear-earth chlorate in a melting electrolysis device; adding dehydrated magnesium chloride, potassium chloride and titanium dichloride for dispersing, mixing and carrying out melting electrolysis, so that rear-earth magnesium intermediate alloy is generated by co-electrodeposition of rear-earth ion and magnesium ion at a negative electrode; burdening and mixing the rear-earth magnesium intermediate alloy and the metal magnesium in a smelting device, wherein a molar ratio of the rear-earth metal to the magnesium is (0.1-1.0):100; heating up the rear-earth magnesium alloy mixture for melting, immersing the smelting agent inside the melt and stirring, increasing the temperature to 780 DEG C and stewing for 20 minutes for dividing the melt into an upper layer, a middle layer and a lower layer, wherein the middle melt layer is used as the rear-earth magnesium alloy melt; casting after pre-cooling, cooling and forming, and carrying out surface treatment after carrying out mechanical processing and thermal processing, so that a compact proactive film layer is covered on the surface of the rear-earth magnesium alloy product. The preparation method of the rear-earth magnesium alloy product is high in preparation efficiency, safe and reliable in process, environment-friendly and low in energy consumption.

Owner:YANGZHOU FENG MING METAL PROD

Sole material and preparation method thereof

The invention discloses a sole material. The sole material is characterized in that the sole material is prepared from 50-150 parts of TPU, 10-50 parts of PVC, 10-30 parts of a plasticizer, 3-6 parts of a stabilizer, 2-20 parts of a compatilizer, 0-1 part of a crosslinking agent, 0-50 parts of a filler, and 0-1 part of a lubricant, wherein the compatilizer is one of chlorinated polyethylene and ethylene-vinyl acetate grafted maleic anhydride. According to the invention, after adopting above technical scheme, the compatibility of a blend of the TPU and the PVC is improved, so a problem of bad compatibility of blends treating the TPU as a primary material and the PVC as an auxiliary material in the prior art is solved, thereby the utilization of excellent characteristics of the TPU and the PVC makes the sole material of the invention have the advantages of good wear resistance and low production cost.

Owner:QUANZHOU XINTAI SHOES MATERIAL

Preparation method of water dispersible granule medicinal fertilizer

The invention discloses a preparation method of a water dispersible granule medicinal fertilizer, which comprises the following steps of: firstly preparing fillers, sterilizing agents, compound activating agents, micro element fertilizers and a compound assistant which are required for preparing the medicinal fertilizers according to component proportion of different medicinal fertilizers, wherein the sterilizing agents contain liquid raw materials; then, taking a part of fillers for adsorbing the liquid raw materials, adding rest of other components and uniformly mixing to obtain a raw material mixture; carrying out air current pulverization on the raw material mixture to be below 15 microns to obtain wettable powder; controlling the granularity D98 to be less than or equal to 15 microns and the suspension ratio to be over 80 percent; taking water-borne binder solutions and mixing the water-borne binder solutions with the wettable powder, and obtaining an intermediate product through squeezing granulation-drying or boiling granulation; and finally, screening to obtain the water dispersible granule medicinal fertilizer product with the required grain size. The preparation process has the advantages of environmental friendliness, security, low cost, capability of guaranteeing product quality and the like.

Owner:湖南大方农化股份有限公司

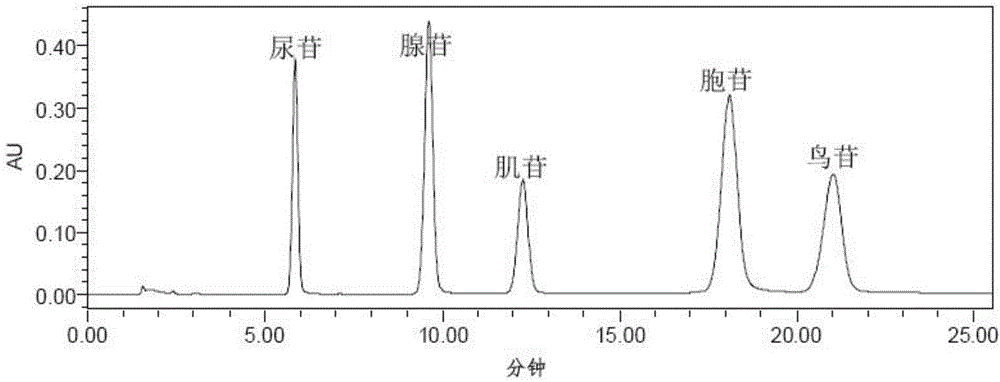

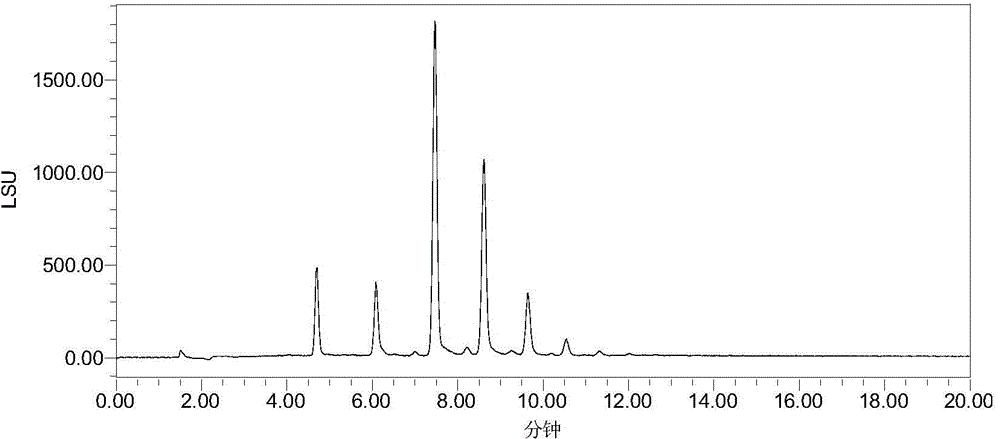

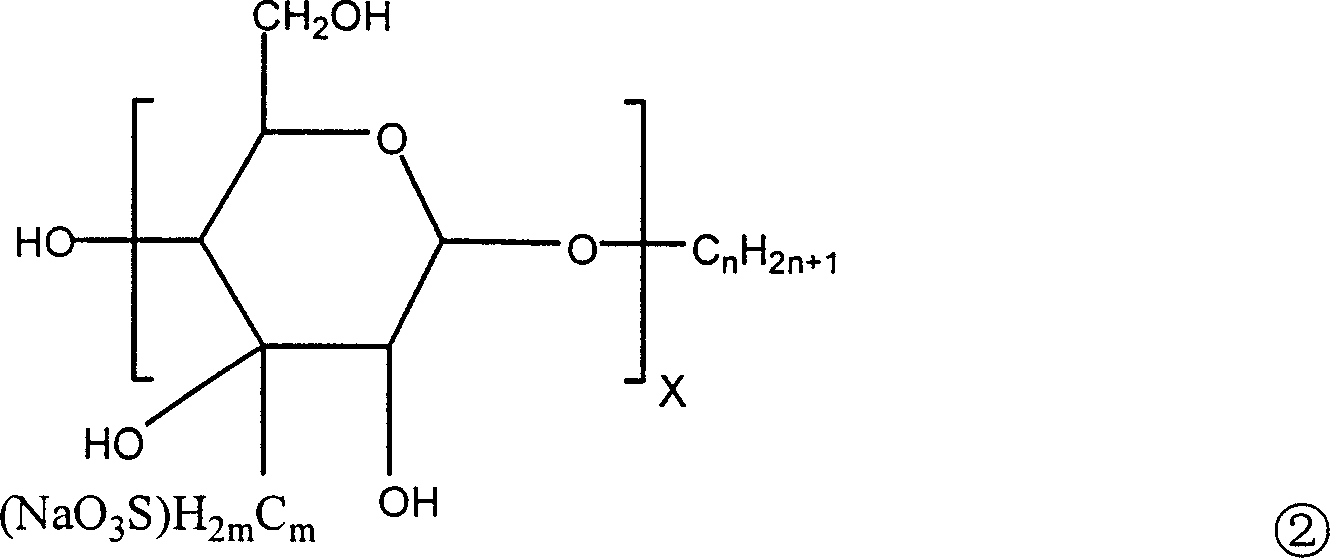

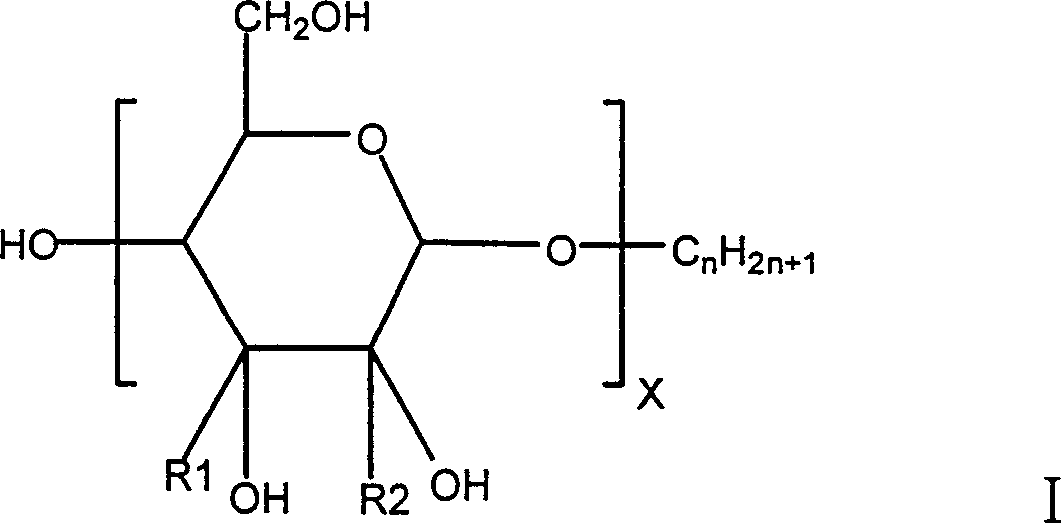

Preparation method of liquid chromatographic stationary phrase and glycosyl-bonded stationary phrase

InactiveCN105749887ANovel structureImprove hydrophilicityOther chemical processesChromatographic separationChemical reaction

The invention relates to a liquid chromatographic stationary phrase, specifically to a preparation method of a liquid chromatographic stationary phrase and a glycosyl-bonded stationary phrase. A glycosyl-bonded silica gel stationary phase is prepared through a sulfydryl-alkene click chemical reaction free of heavy-metal catalysis. According to the method, sulfydryl groups are introduced on the surface of silica gel to prepare a sulfydryl silica gel intermediate; and through an addition reaction of sulfydryl groups and alkenyl groups, alkenyl saccharide molecules are bonded to the surface of silica gel. The method is free of heavy-metal catalysis, and therefore, the final product is free of heavy-metal residues, and adverse effects of heavy metals on performance of the product can be totally avoided. The preparation method is simple and reliable in process, mild in reaction condition, quite easy for massive preparation, and wide in application range. The glycosyl-bonded stationary phrase can be used as a separating material for hydrophilic interaction liquid chromatography, and is widely applied to selective separation of polar compounds, such as oligosaccharide, glycopeptide, glycoprotein, polypeptide, and nucleoside.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Superhydrophobic polyvinylidene fluoride (PVDF) aerogel material and preparation method thereof

InactiveCN108192129AAvoid acid/base catalyzed hydrolysis-polymerization processNo chemical reactionPorosityOrganic solvent

The invention relates to a superhydrophobic PVDF aerogel material. The superhydrophobic PVDF aerogel material is characterized in that the material is a white opaque blocky material with a density of0.075-0.198 g / cm<3>, a porosity of 89-95.8%, a specific surface area of 256-343 m<2> / g, a water contact angle of 153-158 degrees and a thermal conductivity of 0.03531-0.04463 W / (m.K); and the materialhas a hierarchical pore structure, wherein the sizes of nanopores are in a range of 3-100 nm, and the sizes of micropores are in a range of 0.5 to 5 [mu]m. A PVDF aerogel is prepared by using a physical sol-gel process based on a phase inversion method. A preparation method for the PVDF aerogel comprises the following steps: subjecting PVDF powder and an additive to dissolving and uniform mixingin an organic solvent at a certain temperature; then adding deionized water and allowing PVDF to undergo phase inversion so as to form a PVDF gel; and subjecting the PVDF gel to solvent replacement and drying successively to prepare the PVDF aerogel. A novel preparation method is adopted in the invention to prepare the novel superhydrophobic PVDF aerogel material, and the method is simple in process and easy to realize industrial production; and the prepared PVDF aerogel material has low thermal conductivity and is a heat insulation material applicable to low-temperature humid environments.

Owner:NANJING TECH UNIV

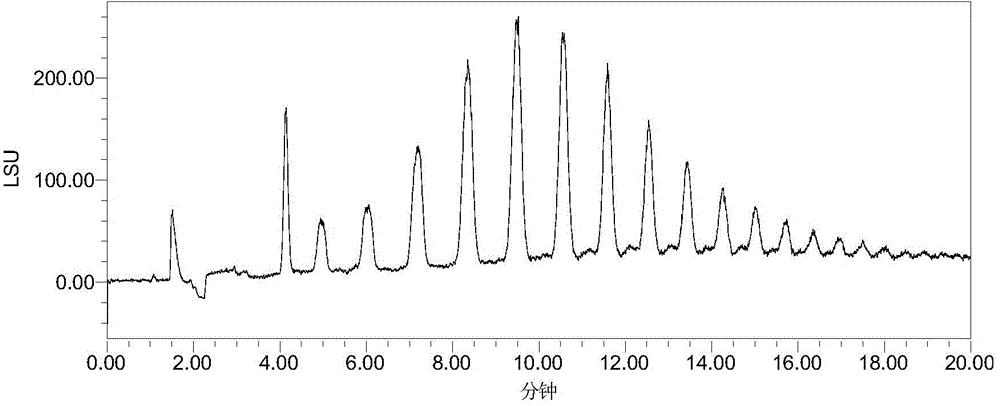

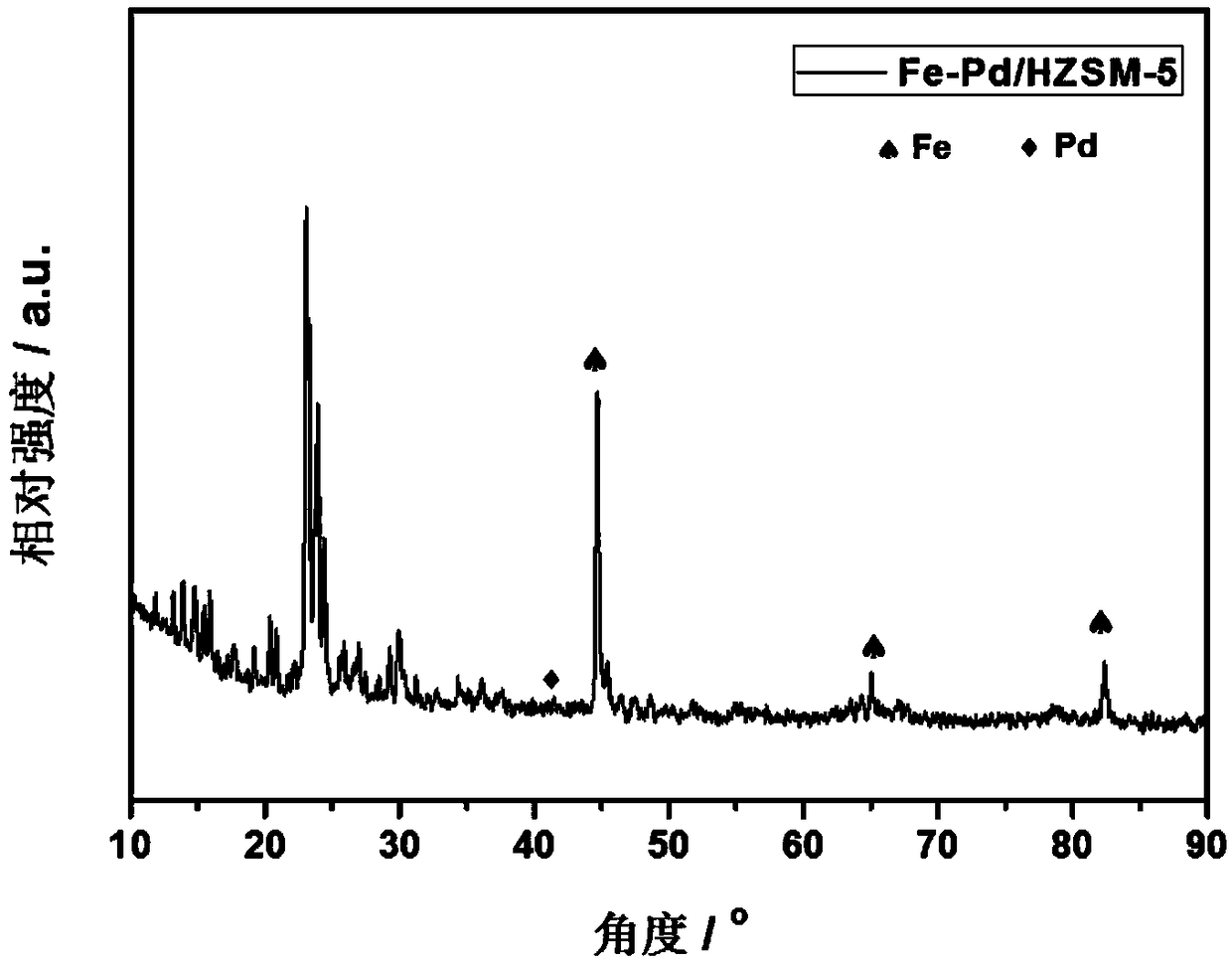

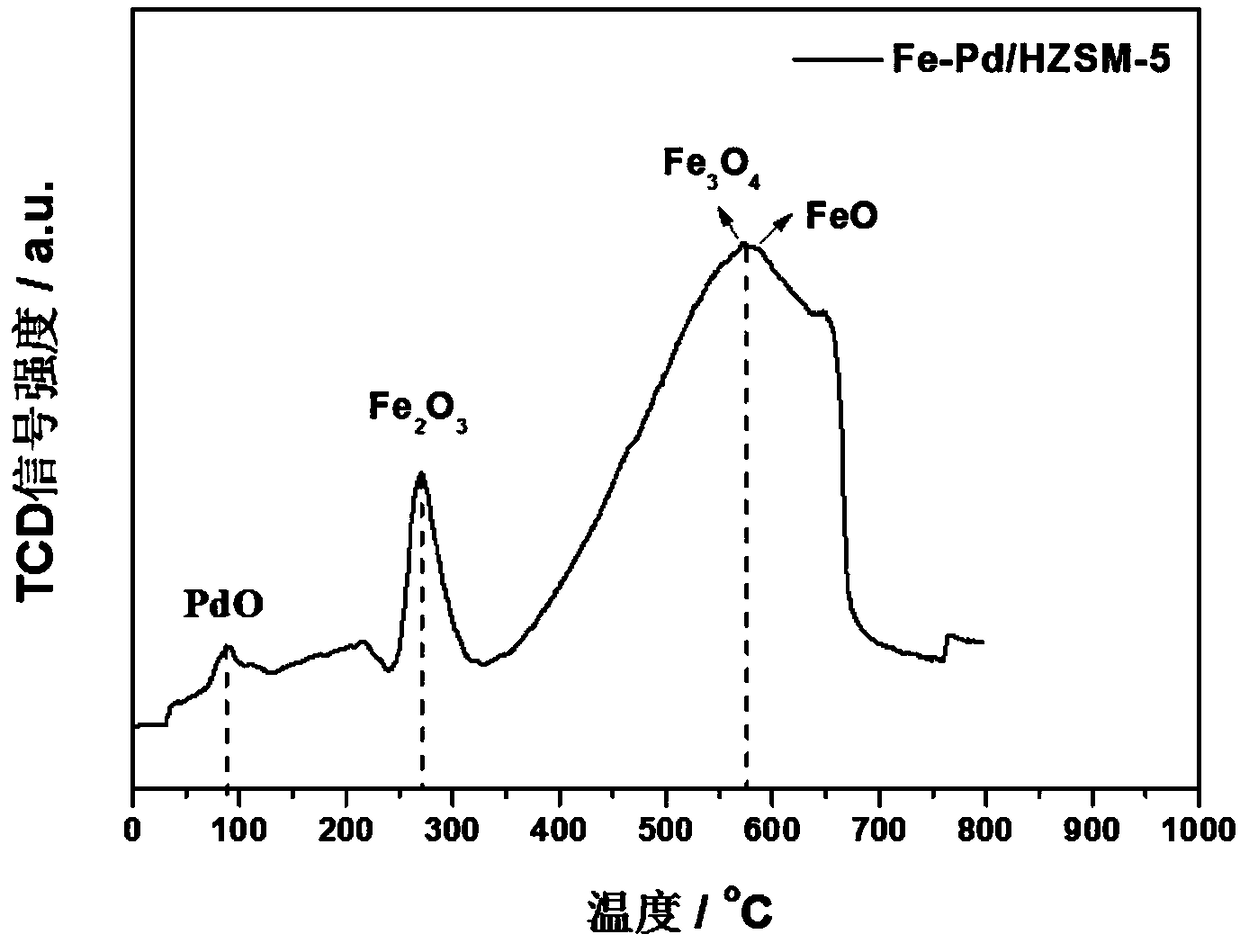

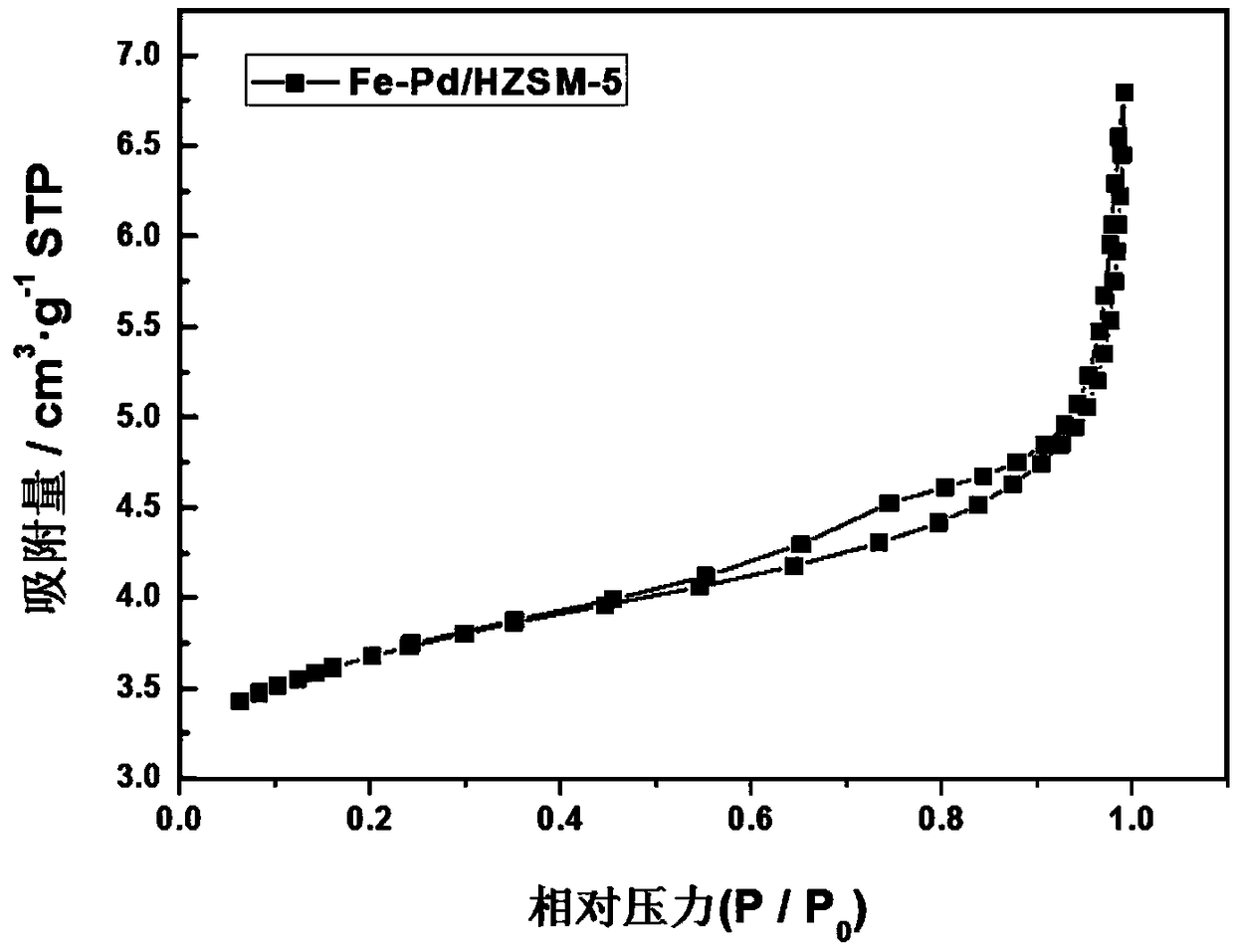

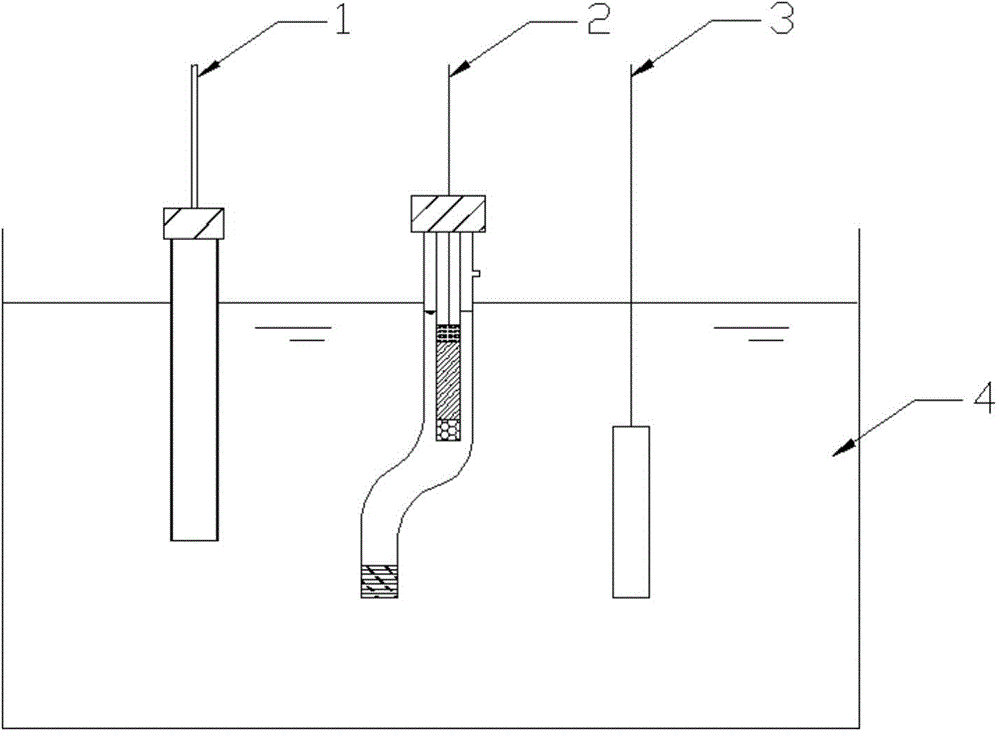

HZSM-5 supported Fe-Pd bimetallic catalyst for lignin hydrogenation and depolymerization and preparation method thereof

ActiveCN109289903AHigh activityGood dispersionMolecular sieve catalystsLiquid hydrocarbon mixture productionDepolymerizationCalcination

The invention belongs to the technical field of catalysts, and discloses a HZSM-5 supported Fe-Pd bimetallic catalyst for lignin hydrogenation and depolymerization and a preparation method thereof. The preparation method of the invention uses an iron source and a palladium source as raw materials, the materials are dispersed on the surface of a HZSM-5 molecular sieve by an impregnation method, andthe catalyst is prepared by high-temperature calcination and hydrogen reduction. The method of the invention simultaneously loads Fe and Pd onto a carrier to realize the reduction of elemental iron,the Fe promotes the high dispersion of Pd, and improves the catalytic efficiency and the catalytic selectivity; a molecular sieve HZSM-5 is used as the carrier to improve the dispersibility and activecatalytic sites of the active metal, and the catalytic activity can be improved, the obtained HZSM-5 supported Fe-Pd bimetallic catalyst for lignin hydrogenation and depolymerization is applied to catalytic hydrogenation and depolymerization of lignin, the conversion rate of lignin hydrogenolysis is 98.1wt%, the yield of bio-oil is 78.5 wt%, and the yield of a monophenol compound is as high as 27.9wt%.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method for anode material of red phosphorous cladding carbon nano tube composite ion battery

InactiveCN105098154AThe ratio is easy to controlSimple preparation processCell electrodesHigh ratePhosphate

The invention belongs to the field of a nano functional material and a new energy source, and relates to a preparation method for an anode material of a red phosphorous cladding carbon nano tube composite ion battery. The preparation method comprises the following steps of: mixing pretreated red phosphorous powder and a carbon nano tube according to a certain quality proportion; preparing to a uniform serous liquid with an appropriate amount of a grinding agent and transferring the uniform serous liquid to a ball grinding tank; carrying out anaerobic wet high-energy ball grinding, and thereby obtaining the anode material of the red phosphate cladding carbon nano tube ion battery, wherein effective ball grinding time is 2 to 6 hours. The core of the invention is that the simple and high-efficiency anaerobic wet high-energy ball grinding is adopted to further prepare the anode material of the red phosphate cladding carbon nano tube ion battery; red phosphate is uniformly coated on the surface of the carbon nano tube, a particular conductive network in the composite material is built by means of the carbon nano tube, the contact area of the red phosphate and the carbon nano tube is increased, and thus, the anode material of the composite ion battery has the advantages of high specific capacity, high rate performance and stable circularity; and moreover, the process is simple, the preparation quantity is large, and industrial production is easy to achieve.

Owner:TIANJIN POLYTECHNIC UNIV

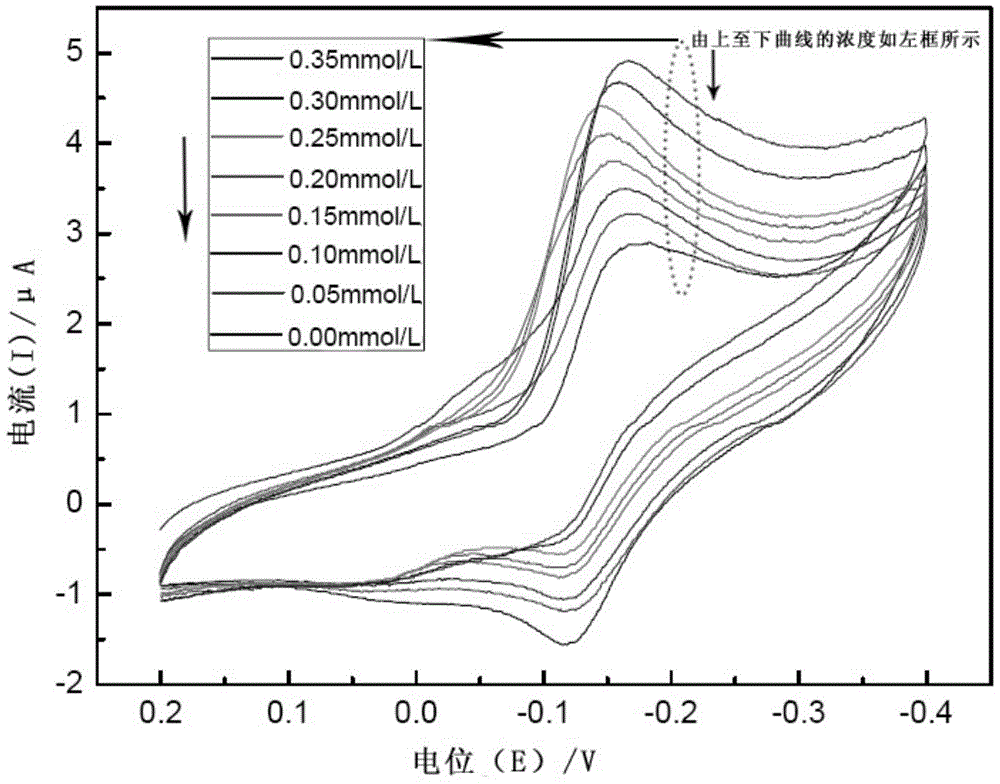

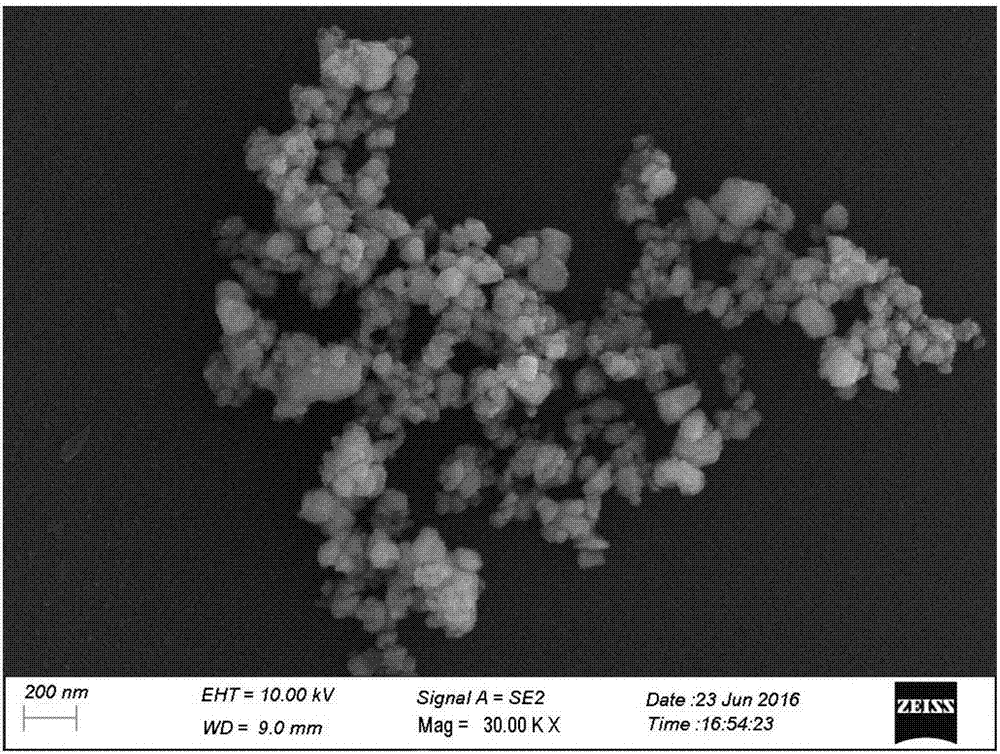

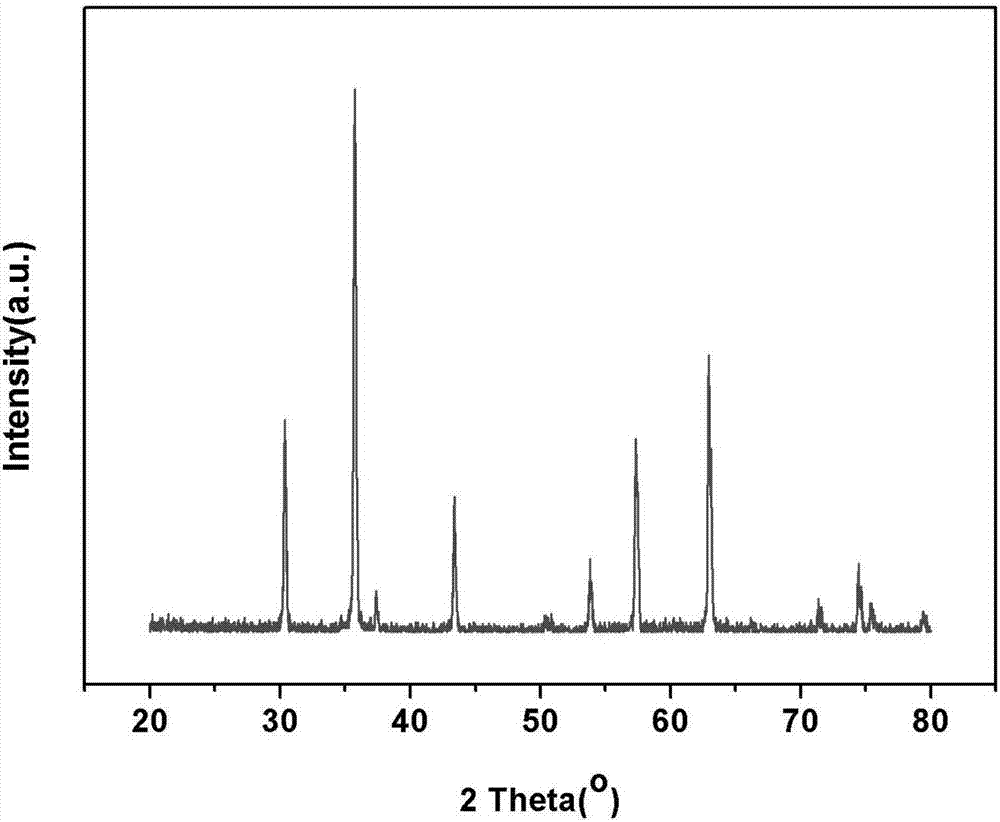

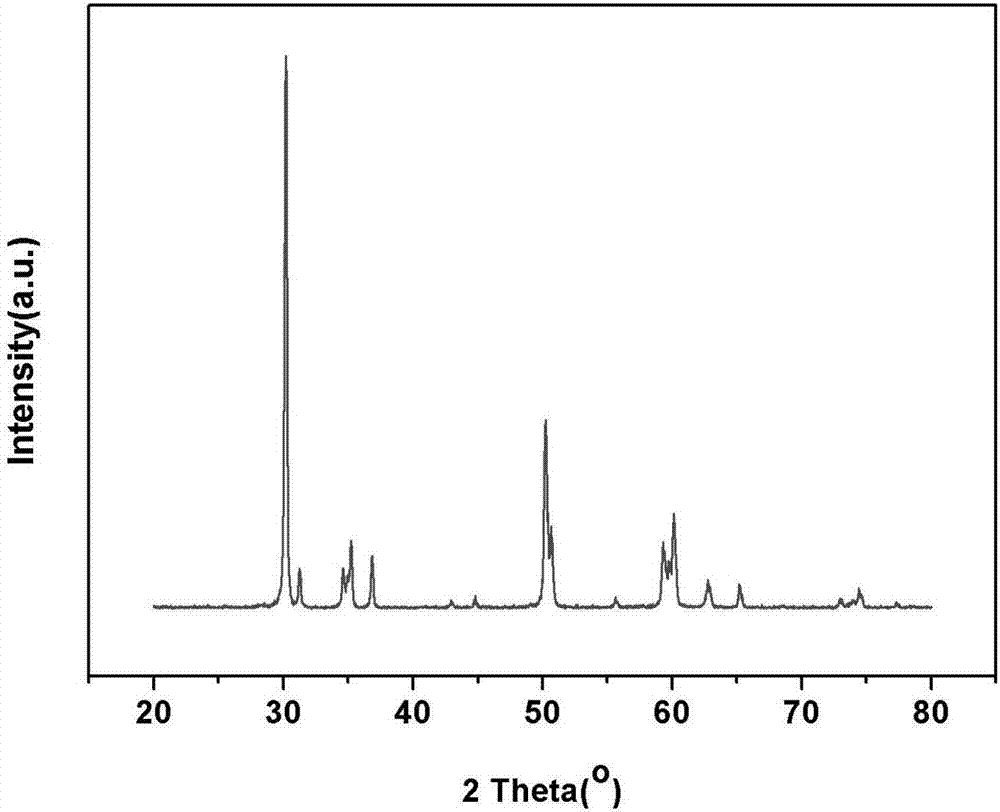

Enzyme biosensor for detecting cholesterol as well as preparation method and application of biosensor

InactiveCN103954660AFacilitates electron transferExcellent electron transfer abilityMaterial electrochemical variablesElectrochemical biosensorEnzyme membrane

The invention belongs to the technical field of electrochemical biosensors and particularly relates to an enzyme biosensor for detecting cholesterol as well as a preparation method and an application of the biosensor. The enzyme biosensor adopts a classical three-electrode system, wherein a specific matter recognizing enzyme membrane is solidified on a working electrode and mainly formed by mixing graphene, thionine, cholesterol oxidase, horse radish peroxidase and chitosan. The preparation method of the enzyme biosensor comprises the following steps: firstly uniformly mixing a thionine solution, a chitosan solution of the graphene, a horse radish peroxidase solution and a cholesterol oxidase solution, dripping onto the processed working electrode, forming the three-electrode system together with a reference electrode and a counter electrode to obtain the enzyme biosensor. The enzyme biosensor disclosed by the invention has the advantages of economical efficiency, simplicity, rapidness, sensitivity and the like, is simple in preparation and can be used for the quantitative determination of the cholesterol.

Owner:SOUTH CHINA UNIV OF TECH

Black zirconia ceramic and preparation method thereof

The invention provides black zirconia ceramic and a preparation method thereof. The preparation method comprises the steps of sanding mixed slurry containing oxide, a dispersing agent and water, which has the solid content of 45 to 55%, to obtain primary slurry; then drying the obtained primary slurry, roasting the dried primary slurry to obtain a black base material of an iron-chromium-cobalt spinel structure, sanding ball-milled secondary slurry containing the black base material, zirconium oxide, yttrium oxide, dispersing agent and water, which has the solid content of 55 to 65%, to obtain third-level slurry with material particle size not higher than 100nm; then mixing the three levels of slurry with binder and granulating, shaping, removing binder and roasting to obtain the black zirconia ceramic. The preparation method disclosed by the invention utilizes a sanding technology to finally refine the material particle size smaller than 100nm, so that the defects that a traditional solid-phase method has long mass transfer distance among particles and overhigh reaction temperature are overcome, decomposition and volatilization of the black base material are effectively inhibited, and further the stability of the black base material and color evenness of ceramic are improved.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

A solid polycarboxylic acid water reducer and a preparing method thereof

InactiveCN106866894AImprove performanceWater-reducing and slump-preserving performance is comparableAcid waterDouble bond

The invention relates to the technical field of concrete admixtures, and provides a solid polycarboxylic acid water reducer and a preparing method thereof. The water reducer is mainly prepared from an unsaturated polyoxyethylene ether macromonomer, an unsaturated double-bond carboxylic acid type low-molecular-weight monomer, an initiating oxidant, an initiating reductant and a chain transferring agent according to a mass ratio of 400:(45-55):(3-10):(0.6-2.5):(2-3) at 40-50 DEG C. Water reduction and slump loss resistant properties of the water reducer are equivalent to those of traditional liquid polycarboxylic acid water reducers. The method includes adding the unsaturated double-bond carboxylic acid type low-molecular-weight monomer, the initiating oxidant, the initiating reductant and the chain transferring agent into the melt unsaturated polyoxyethylene ether macromonomer, and performing polymerization at 40-50 DEG C. The synthetic temperature of the method is relatively low, energy consumption is low and a preparing cost is low.

Owner:重庆石博士新材料有限公司

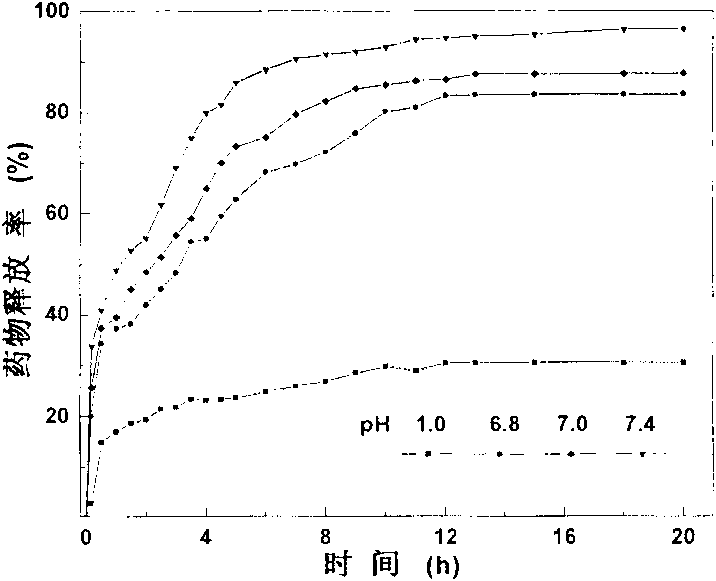

Alginic acid inorganic nanometer composite gel microspheres and preparation method

InactiveCN101612128APreparation process safetyIncrease sustained releasePharmaceutical non-active ingredientsGranular deliveryPolypropyleneCarbon nanotube

The invention relates alginic acid inorganic nanometer composite gel microspheres and a preparation method; the gel microspheres comprise the following components by weight percent: 1-7% of alginate, 0.5-10% of carbon nanotubes, 1-50% of triblock surfactant polyethylene oxide-polypropylene oxide-polyethylene oxide and the balance water. The production process of the gel microspheres is safe, simple and effective and accords with the requirements of environmental protection. The alginic acid carbon nanotubes composite gel microspheres which is prepared by the preparation method of the invention and is introduced with carbon nanotubes can relieve the swelling speed of the complexed alginic acid microspheres, can be used as a carrier to combine with drugs, proteins, enzymes and other biological products and can be used as a drug carrier owning to the pH sensitivity of the composite gel microspheres.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH +1

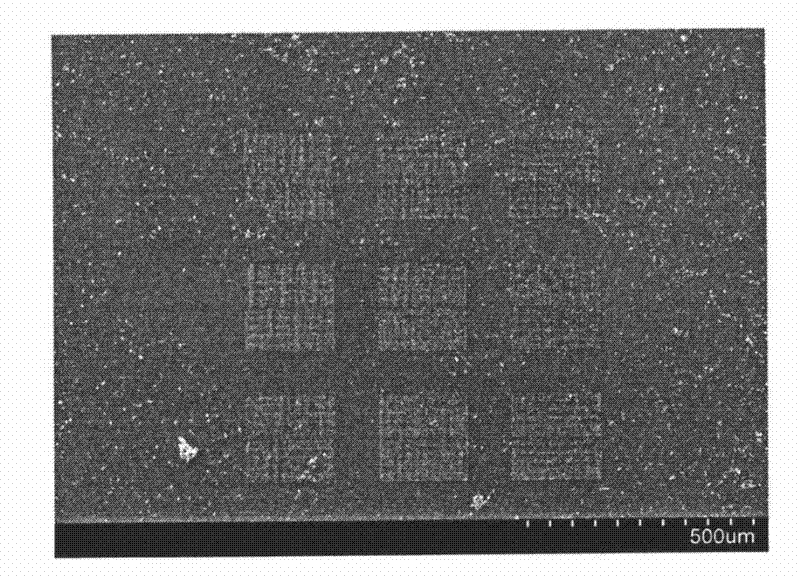

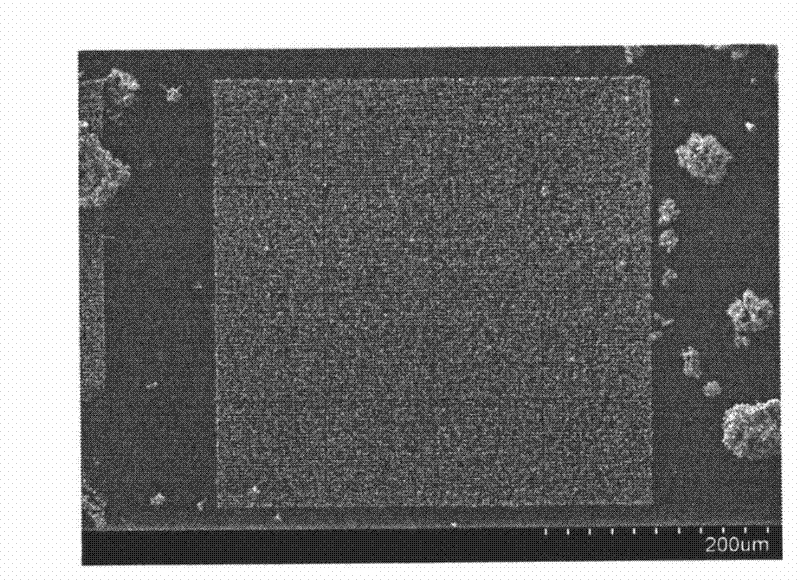

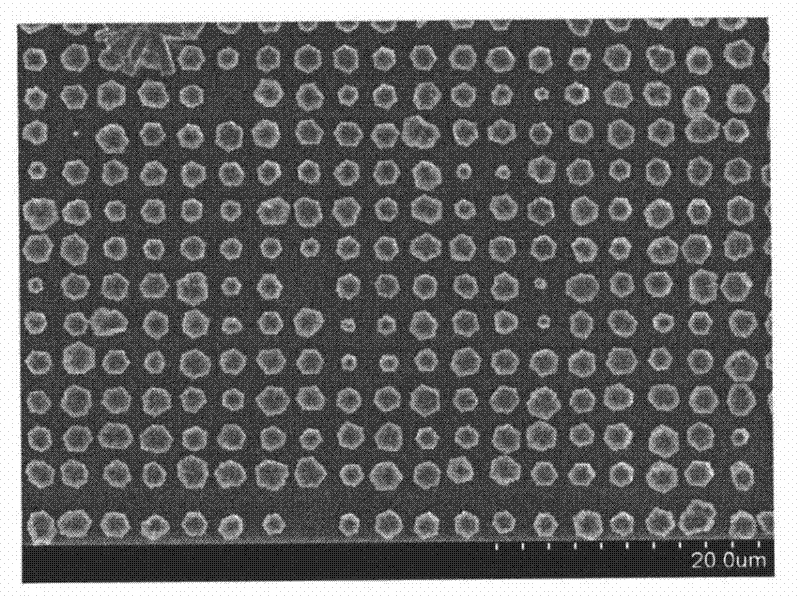

Zinc oxide micro-nano array and preparation method thereof

InactiveCN102476823ASimple preparation processStrong maneuverabilityZinc oxides/hydroxidesNanotechnologyOxideNitrogen gas

The invention provides a zinc oxide micro-nano array and a preparation method thereof. The method includes steps that firstly, water solution containing Zn(NO3)26H2O and (CH2)6N4 is prepared; secondly, a substrate is prepared, metal zinc is arranged on the surface of a silicon wafer by means of thermal evaporation while oxygen is fed, a zinc oxide film is formed by means of reaction, or a zinc oxide film is formed by means of evaporation by a magnetic sputtering method, after the substrate is cooled, photoresist is sprayed on the film, local electron beam lithography is carried out on the photoresist, and a channel array is obtained; and thirdly, the substrate prepared in the second step is soaked in precursor solution prepared in the first step for 1 hour to 12 hours, and then is taken out and dried by nitrogen after being cleaned, and a zinc oxide array is formed. By controlling reaction conditions, controllable regulation of the diameter of a single zinc oxide line on a zinc oxide nano harness aggregate can be realized.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

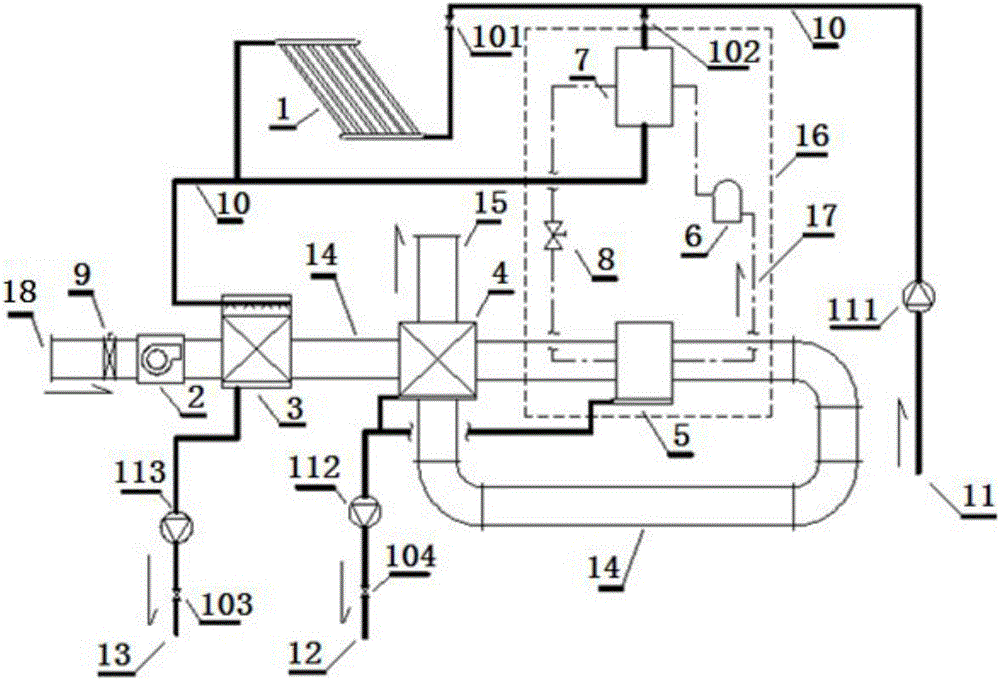

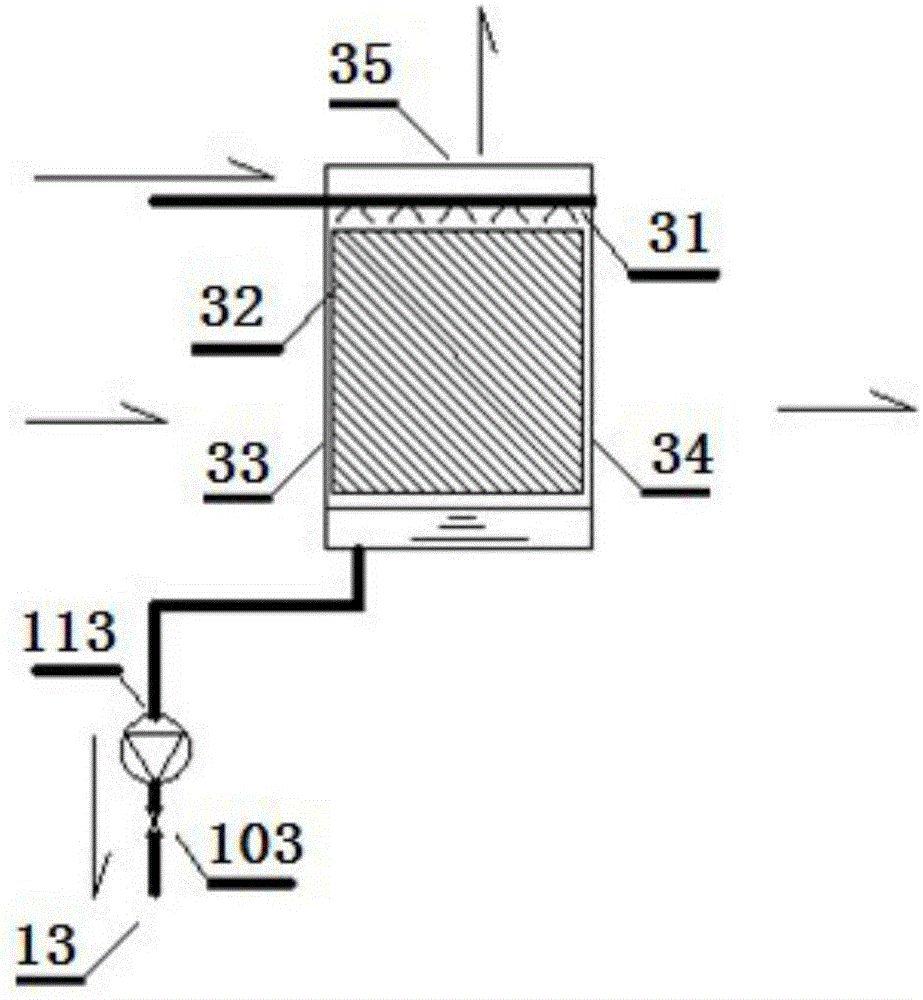

Seawater desalination system adopting combined operation of solar collector and seawater-source heat pump

ActiveCN105152247ALow costEnergy saving and environmental protectionHeat pumpsGeneral water supply conservationWater sourceEnergy recovery

The invention discloses a seawater desalination system adopting combined operation of a solar collector and a seawater-source heat pump. The system comprises the solar collector and a seawater-source heat pump unit, wherein the seawater-source heat pump unit comprises a seawater-source heat pump evaporator, a seawater-source heat pump compressor, a seawater-source heat pump condenser and a seawater-source heat pump electronic expansion valve. The seawater desalination system has the advantages of small overall size, simple structure, portability, convenience in transportation and initial cost saving; solar energy as a rich renewable energy source in a sea island is used, energy saving and environmental protection are realized, and the cost is low; fresh water can be prepared through a simple physical process, low requirements are needed for seawater pretreatment, a fresh water preparation process is safe and reliable, and the service life is long; an air-air heat exchanger is taken as an energy recovery device, energy waste can be avoided, and the energy utilization rate can be increased; when residents on the sea island adopt the seawater-source heat pump as a building cooling and heating source, and the system shares the seawater-source heat pump, so that the initial cost is saved again.

Owner:TIANJIN UNIV

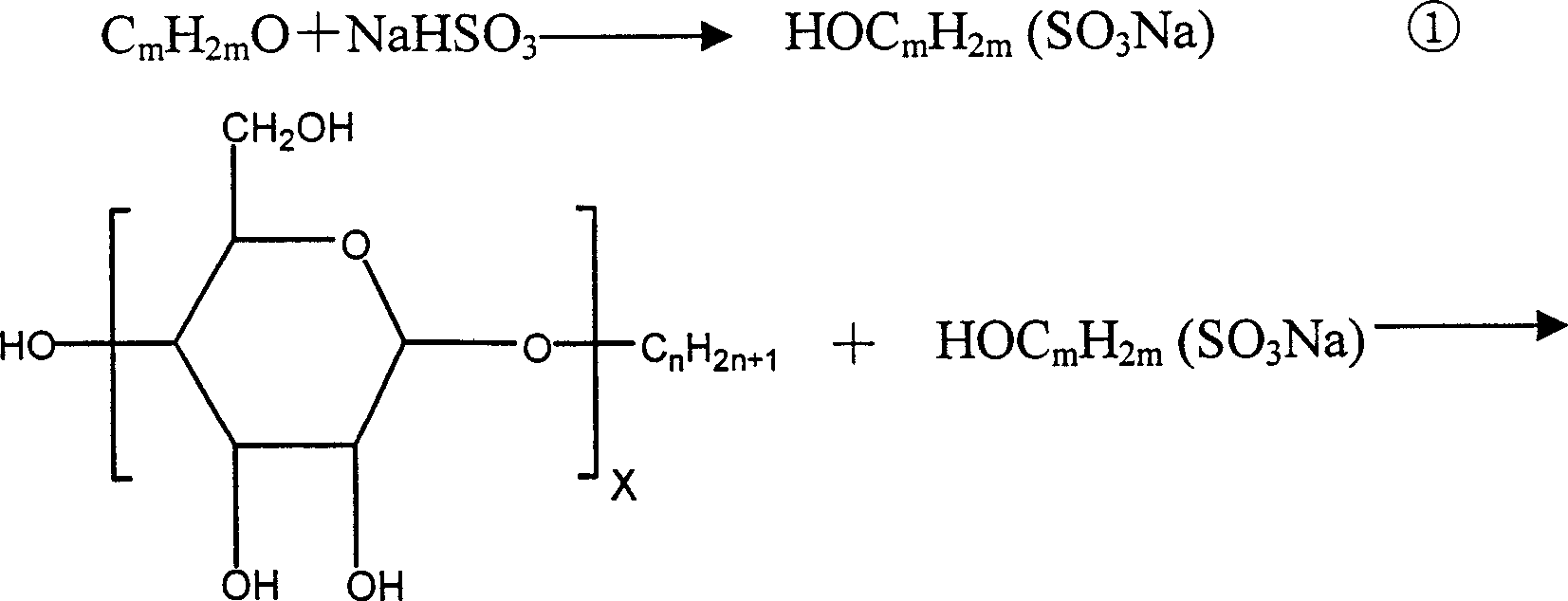

Low foamability drilling fluid and its preparation method

The invention relates to low-foamability drilling fluid as modified auxiliary agent composed of slurry and modified alkyl glycoside, wherein, the volume of modified auxiliary agent is 1-50% of slurry, and prepared by: mixing starch and low-carbon alcohol for glycosidation with catalyst to obtain material contained with low-carbon alkyl glycoside; adding sulphonating agent and aldehyde for further reaction at (50-100)+ / -5Deg to obtain the final product. The product has better adsorption, action ability with bentonite, and viscosity reduction ability, and fits to middle-deep well or ultradeep well.

Owner:CHINA PETROLEUM & CHEM CORP +1

Demercuration catalyst taking metal organic framework as carrier and preparation method thereof

InactiveCN107812541ALarge specific surface areaImprove mercury removal efficiencyGas treatmentOrganic-compounds/hydrides/coordination-complexes catalystsMetal-organic frameworkNitrogen gas

The invention discloses a preparation method of a demercuration catalyst taking a metal organic framework as a carrier and belongs to the technical field of catalysts. According to the invention, trimesic acid is dissolved in an organic solvent to obtain a mixed solution A, transition metal salt is dissolved in deionized water to obtain a transition metal salt solution B, an active component and an assisting carrier salt are dissolved in the deionized water to obtain an active component aqueous solution C; adding the mixed solution A to the transition metal salt solution B for uniformly mixingwhile stirring at the temperature of 30-60 DEG C, introducing nitrogen, and then reacting for 1-3h under ultrasonic conditions; adding the active component aqueous solution C to the reaction solution, heating to 120-150 DEG C and performing thermostatic reaction for 12-36h, and cooling; and filtering, washing, drying, grinding, tabletting and sieving the reaction product to obtain the demercuration catalyst taking a metal organic framework as a carrier. The catalyst provided by the invention has relatively high adsorbing efficiency and adsorbing time.

Owner:KUNMING UNIV OF SCI & TECH

Preparation method of polyimide film

The invention discloses a preparation method of a polyimide film. The preparation method mainly comprises the following steps: preparing a template, preparing a polyamide acid solution, preparing a porous polyamide film, and preparing the polyimide film of which the surface is compact. The preparation method provided by the invention is safe in the whole technological process, no expensive equipment is needed, the operation procedures are simple, the composition of a product is easy to control, the prepared polyimide film is smooth in surface, ultralow in dielectric constant, and controllable in aperture size, and has an excellent mechanical property, and pores are orderly distributed on the polyimide film.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com