Preparation method of water retaining agent

The technology of a water-retaining agent and an initiator is applied in the field of preparation of concrete/mortar water-retaining agent, which can solve the problems of slump loss of concrete mixture, limited supply of river sand, and high mud content, so as to increase slump retention and water retention. performance, improved bleeding/segregation, simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

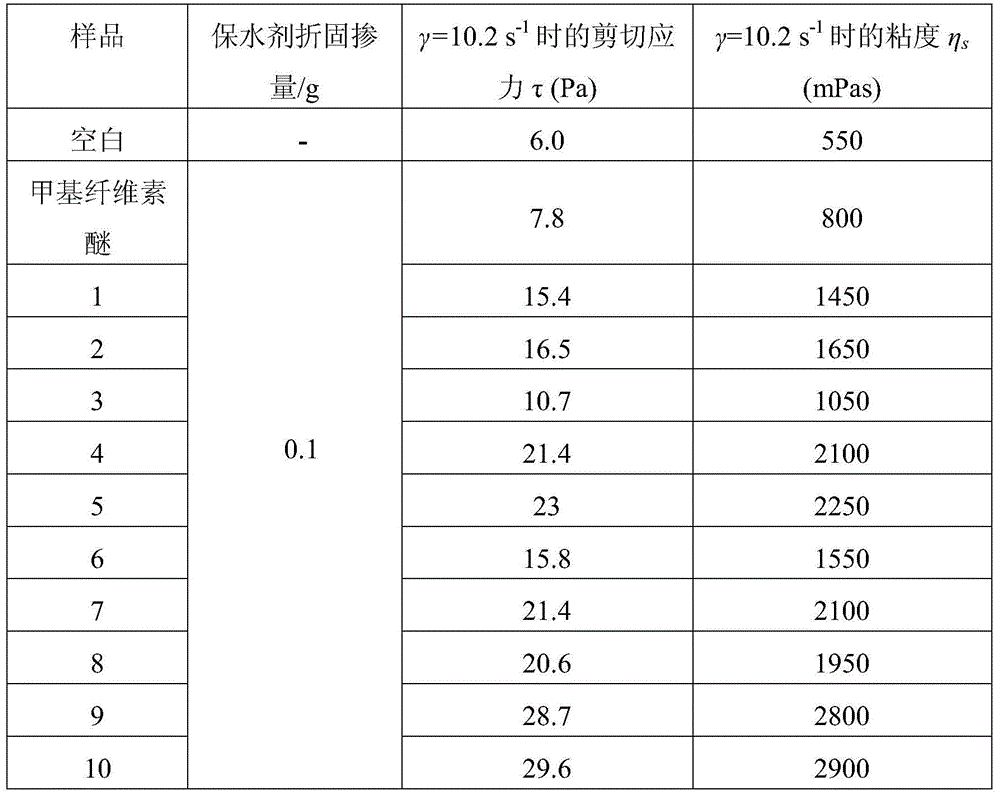

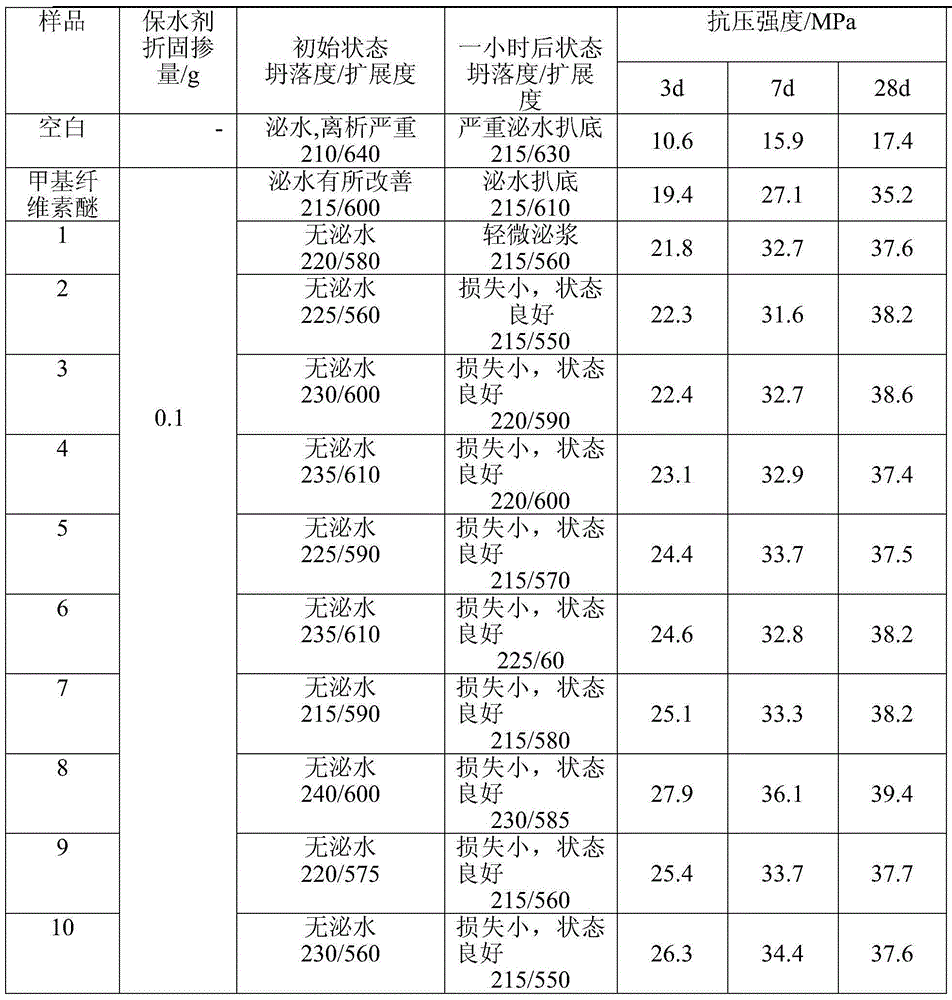

Examples

Embodiment 1

[0026] Acrylamide 10g, allyl sodium sulfonate 3g and allyl polyethylene glycol (M n =300) 100g is added in the reactor and stirred evenly, then drips the aqueous solution that contains 2g hydrogen peroxide and 0.1g sodium ascorbate respectively, keeps temperature 45 ℃, after reacting for 3 hours, obtains copolymerization product; Regulate pH to 6 with sodium hydroxide solution, Add water to obtain a concrete / mortar water retaining agent with a concentration of 1wt%.

Embodiment 2

[0028] Mix 10 g of N,N-dimethylacrylamide, 1 g of sodium styrene sulfonate and methallyl polyethylene glycol (M n =800) 50g was added in the reactor, stirred evenly, then added dropwise the aqueous solution containing ammonium sulfate 0.3g and 0.1g sodium sulfite respectively, kept the temperature at 55°C, and reacted for 4 hours to obtain the copolymerization product; adjust the pH with potassium hydroxide solution To 6, add water to obtain a concrete / mortar water retaining agent with a concentration of 10wt%.

Embodiment 3

[0030] N,N-diethylacrylamide 10g, sodium vinylsulfonate 2g and 3-methyl-3-butene-1-polyethylene glycol (M n =1200) 80g was added in the reactor, stirred evenly, then dripped the aqueous solution containing potassium persulfate 1g and 0.6g sodium bisulfite respectively, kept the temperature at 50°C, and reacted for 4.5 hours to obtain the copolymer product; Adjust the pH to 7, add water to obtain a concrete / mortar water retaining agent with a concentration of 45wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com