Black zirconia ceramic and preparation method thereof

A technology of black zirconia and zirconia, applied in the field of ceramics, can solve the problems of increasing energy consumption and preparation cost, environmental hazards, lengthening of mass transfer distance between particles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The invention provides a method for preparing black zirconia ceramics, comprising the following steps:

[0033] (1) Sanding the mixed slurry containing oxide, dispersant and water to obtain primary slurry; the solid content of the mixed slurry is 45% to 55%;

[0034] Described oxide is ferric oxide, cobalt sesquioxide and dichromium sesquioxide;

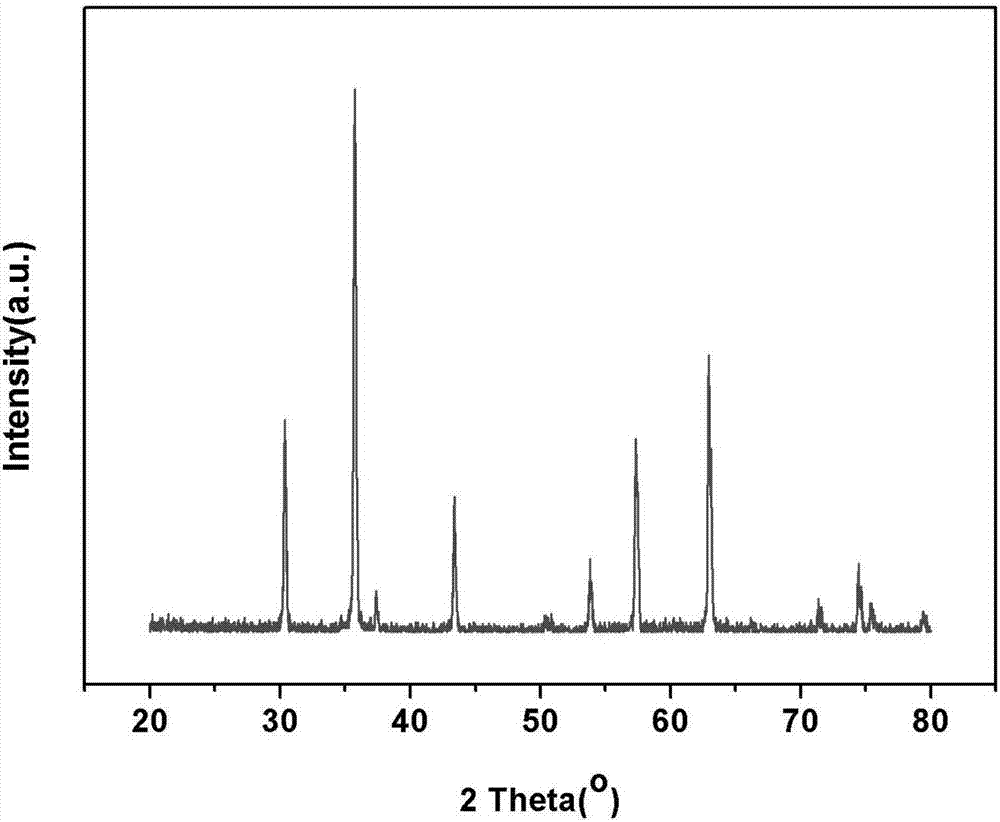

[0035] (2) roasting the primary slurry obtained in the step (1) after drying to obtain the black base material of the iron-chromium-cobalt spinel structure;

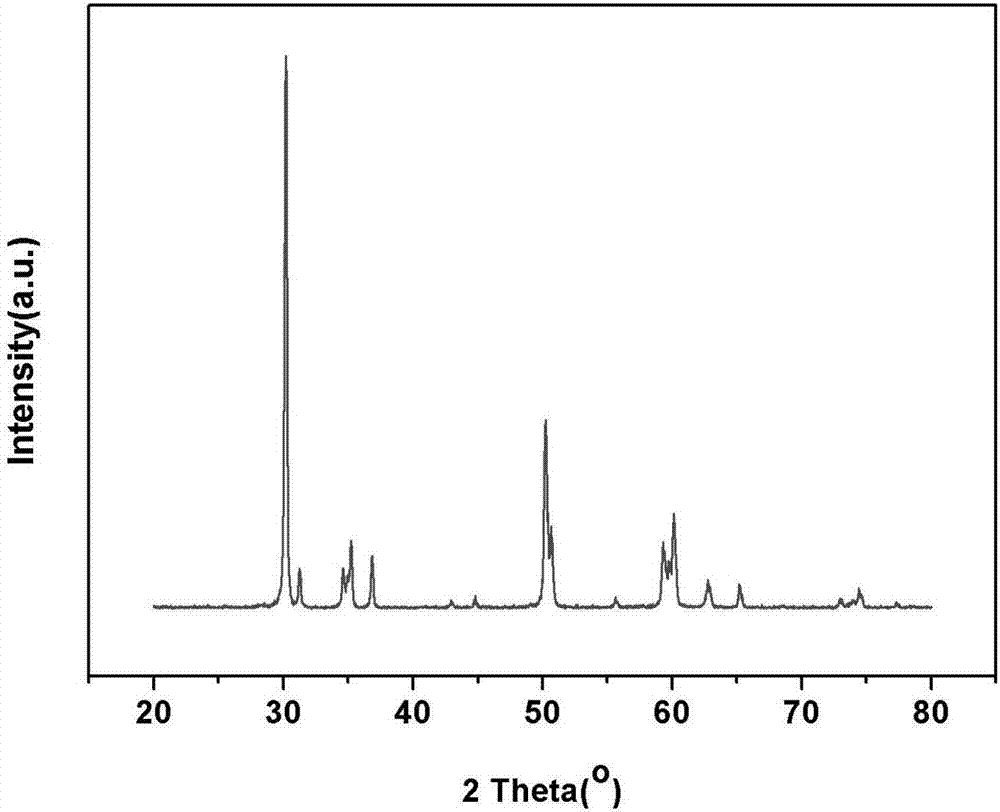

[0036] (3) After mixing the black base material obtained in the step (2) with zirconia, yttrium oxide, dispersant and water, carry out ball milling to obtain a secondary slurry;

[0037] The solid content of the secondary slurry is 55% to 65%;

[0038] (4) Sanding the secondary slurry obtained in the step (3) to obtain a tertiary slurry;

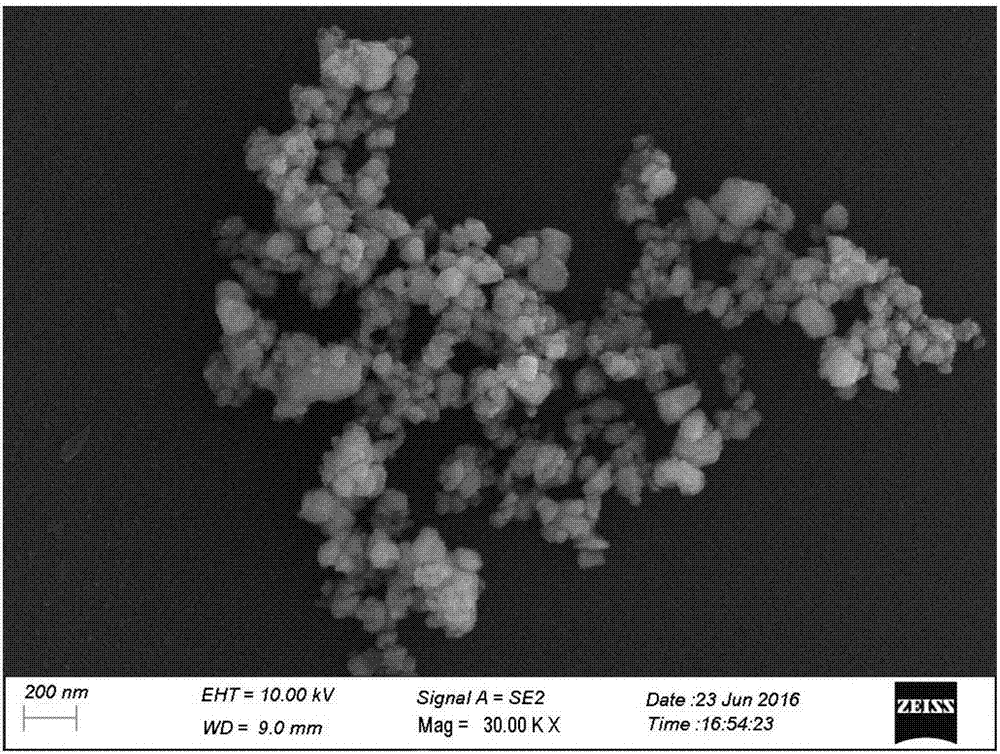

[0039] The particle size of the material in the tertiary slurry is not higher than 100nm;

[0040] (5) Mix the tertiary slurry ob...

Embodiment 1

[0065] Calculate with the total mass of ferric oxide, cobalt trioxide and dichromium trioxide as 1000 parts, accurately weigh 500 parts of ferric oxide, 250 parts of dicobalt trioxide, and 250 parts of dichromium trioxide, and disperse The agent polymethacrylic acid ammonium and polyethylene glycol are 1.5 parts each, add deionized water, adjust the solid content of the slurry to 45%, and pass the material through a sand mill for 2 hours, and the grinding body is a particle size of 0.6 ~ 0.8mm. Zirconia beads, the sanding speed is 800r / min; the particle size of the sanded material is lower than 100nm.

[0066] Spray and dry the sanded slurry, adjust the atomization frequency to 35Hz, the air inlet temperature to 240°C, and the air outlet temperature to 85°C, and sinter the dry powder at 1300°C for 3 hours to form a stable spinel structure Black base.

[0067] Based on the total mass of iron-chromium-cobalt spinel structure black base material, zirconia and yttrium oxide as 10...

Embodiment 2

[0072] Calculate with the total mass of ferric oxide, cobalt sesquioxide and dichromium trioxide as 1000 parts, accurately weigh 400 parts of ferric oxide, 300 parts of dicobalt seoxide, and 300 parts of dichromium trioxide, and disperse The agent ammonium polyacrylate is 2 parts, add deionized water, adjust the solid content of the slurry to 45%, and grind the material for 2 hours through a sand mill. The grinding body is zirconia beads with a particle size of 0.6 to 0.8 mm. 800r / min; the particle size of the sand-milled material is lower than 100nm.

[0073] Spray and dry the sanded slurry, adjust the atomization frequency to 35Hz, the air inlet temperature to 240°C, and the air outlet temperature to 85°C, and sinter the dry powder at 1300°C for 3 hours to form a stable spinel structure Black base.

[0074] Based on the total mass of iron-chromium-cobalt spinel structure black base material, zirconia and yttrium oxide as 1000 parts, accurately weigh 50 parts of iron-chromiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com