Preparation method of concrete thickener

A thickener and concrete technology, applied in the field of concrete thickener preparation, can solve the problems of low market acceptance rate, increased construction difficulty, slow dissolution speed, etc., achieve simple and convenient operation steps, reduce construction difficulty, and ensure maintenance collapsing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

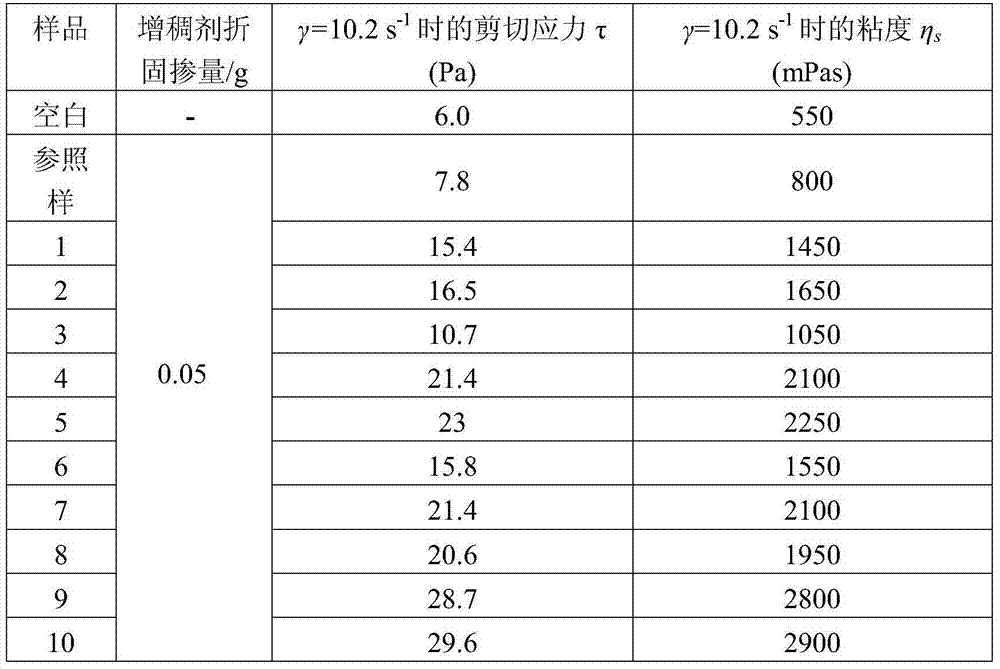

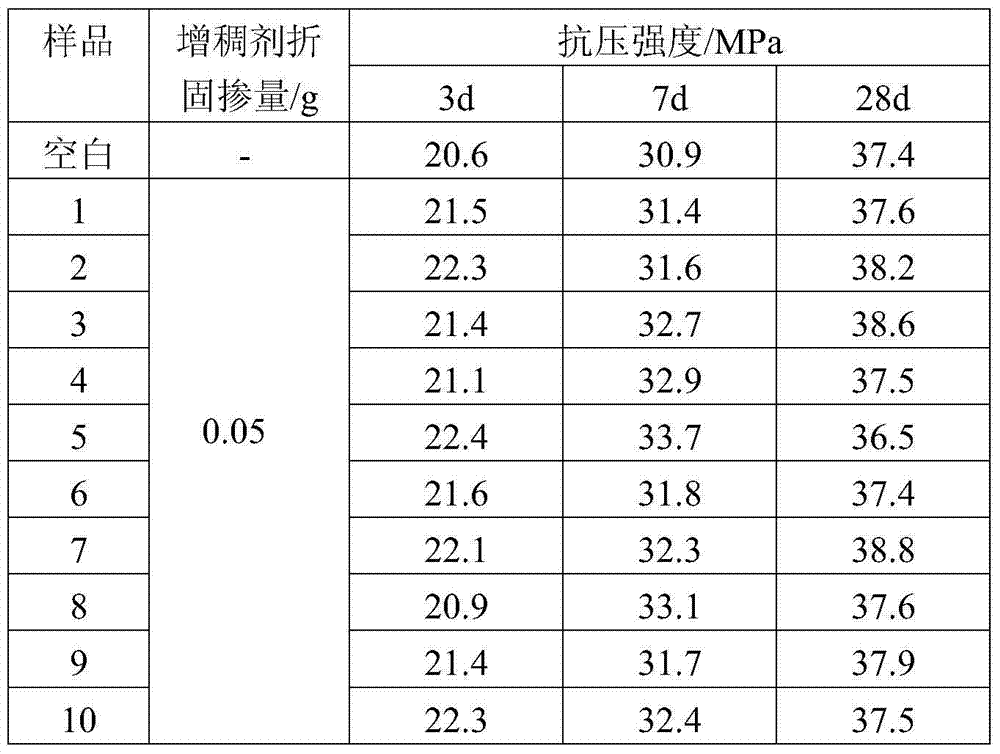

Examples

Embodiment 1

[0023] Add 10g of N-vinyl caprolactam, 20g of hydroxymethyl acrylate and 10g of sodium allyl sulfonate into the reactor and stir evenly, then add dropwise an aqueous solution containing 2g of hydrogen peroxide and 0.3g of sodium ascorbate, keep the temperature at 35°C, and react 3 After one hour, the copolymerization product was obtained; the pH was adjusted to 6 with sodium hydroxide solution, and water was added to obtain a concrete thickener with a concentration of 3 wt%.

Embodiment 2

[0025] Add 10 g of N,N-dimethylacrylamide, 1 g of hydroxyethyl acrylate and 1 g of sodium styrene sulfonate into the reactor, stir evenly, and then dropwise add aqueous solutions containing 0.3 g of ammonium sulfate and 0.1 g of sodium sulfite respectively, keeping After reacting for 4 hours at a temperature of 45° C., a copolymerized product was obtained; the pH was adjusted to 6 with potassium hydroxide solution, and water was added to obtain a concrete thickener with a concentration of 4 wt %.

Embodiment 3

[0027] Add 10g of N,N-diethylacrylamide, 10g of hydroxybutyl acrylate and 5g of sodium vinyl sulfonate into the reactor, stir evenly, then add dropwise the aqueous solution containing 1g of potassium persulfate and 0.6g of sodium bisulfite , keep the temperature at 50° C., and react for 4.5 hours to obtain a copolymerized product; adjust the pH to 7 with sodium hydroxide solution, and add water to obtain a concrete thickener with a concentration of 5 wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com