Patents

Literature

285 results about "Reaction velocity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

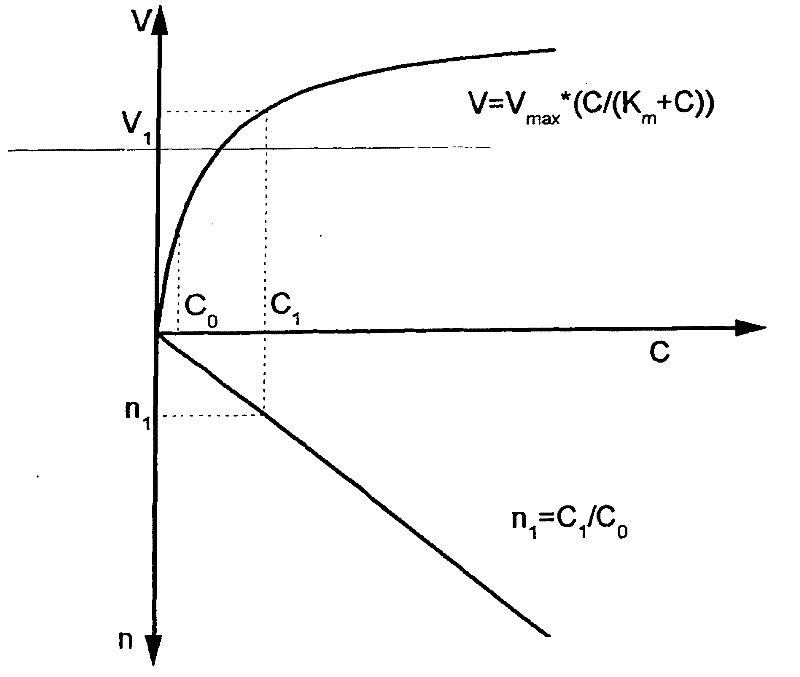

Velocity of reaction is actually the instantaneous rate of reaction. Consider a general reaction: According to the law of mass action, rate of reaction is directly proportional to active mass, hence for the above reaction: This expression is called rate expression and K is called rate constant or velocity constant.

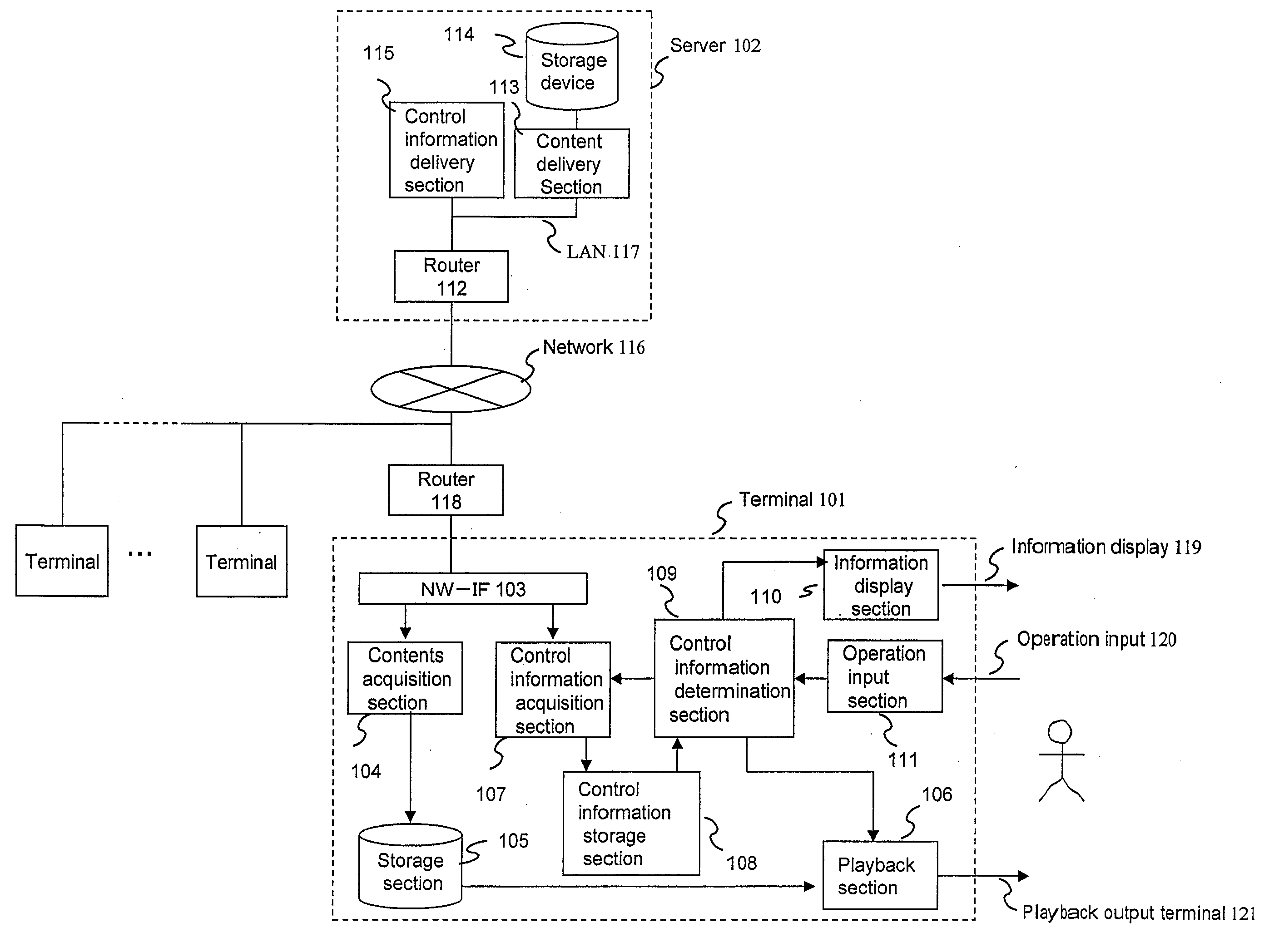

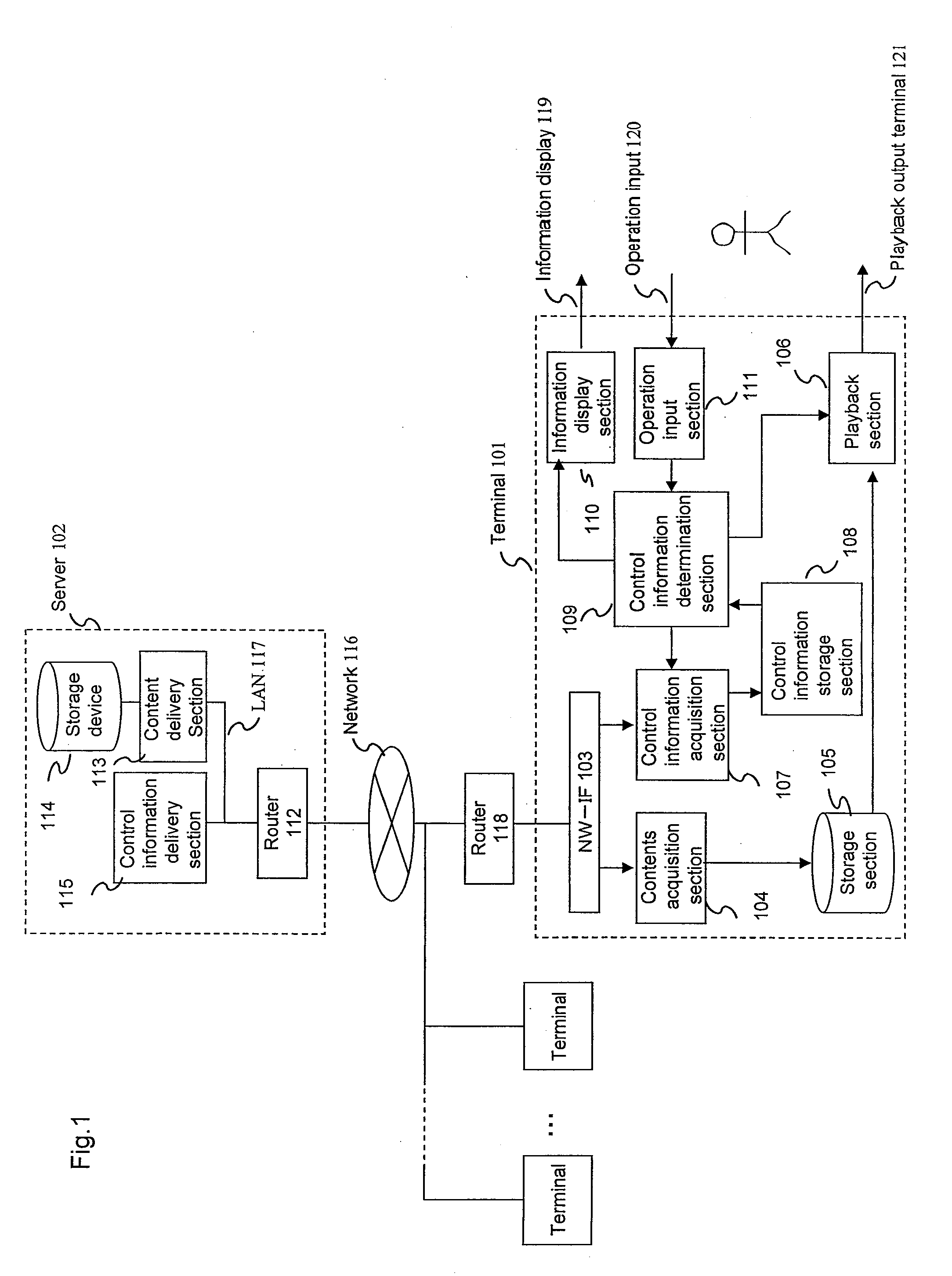

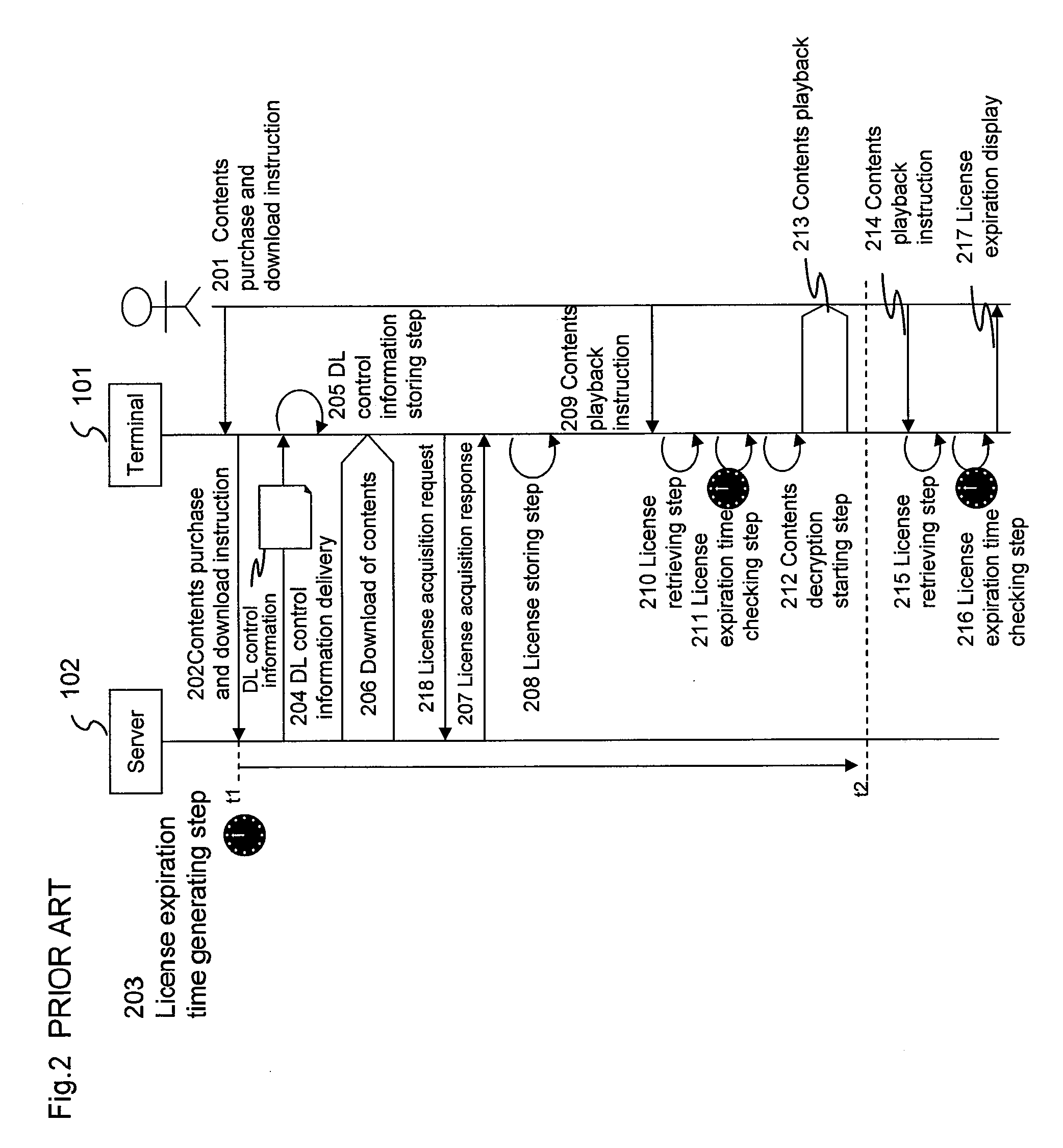

Network audio-video contents playback terminal, server, and system

InactiveUS20100186092A1Stable playbackSimple licensing conditionTelevision system detailsDigital data processing detailsExpiration TimeComputer terminal

Methods to set a viewing and / or listening term are classified into two types, which are a fixed-time-length type to limit time length and a fixed-expiration-time type to limit expiration time. And the timings of license acquisition are classified into two types which are an immediate-acquisition type and a point-of-use type. The type of the timing of license acquisition is written to a meta data which is to be sent to a terminal before initiating download. The terminal determines the timing of license acquisition according to the meta data. When contents are point-of-use type, the terminal doesn't acquire a key and an expiration time information until a time of initiating playback. On the other hand, when contents are immediate-acquisition type, the terminal acquires the key and the expiration time information at any point of time. Since the key is acquired at the early timing such as download completion timing, a reaction velocity in response to a playback instruction can be heighten.

Owner:PANASONIC CORP

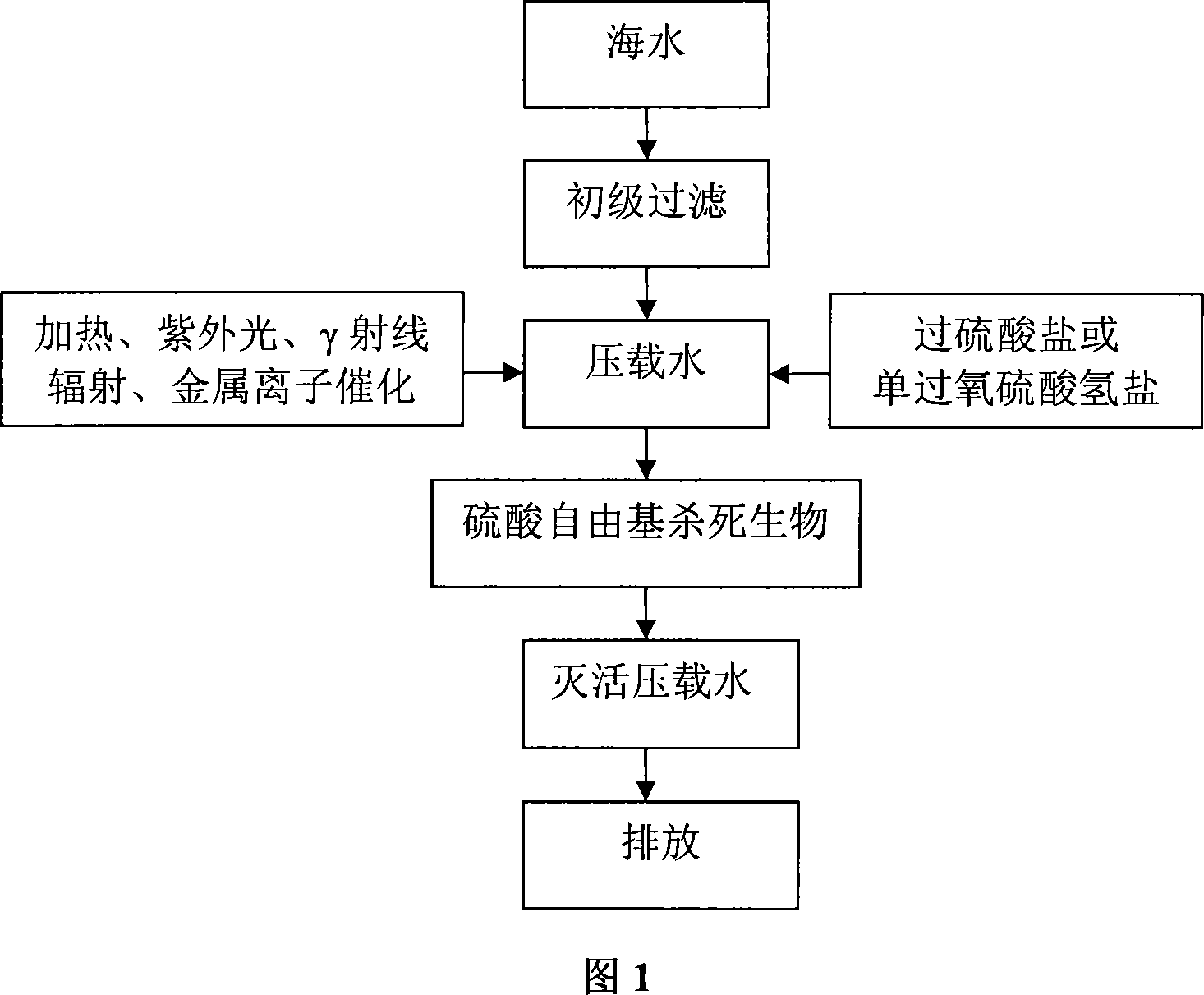

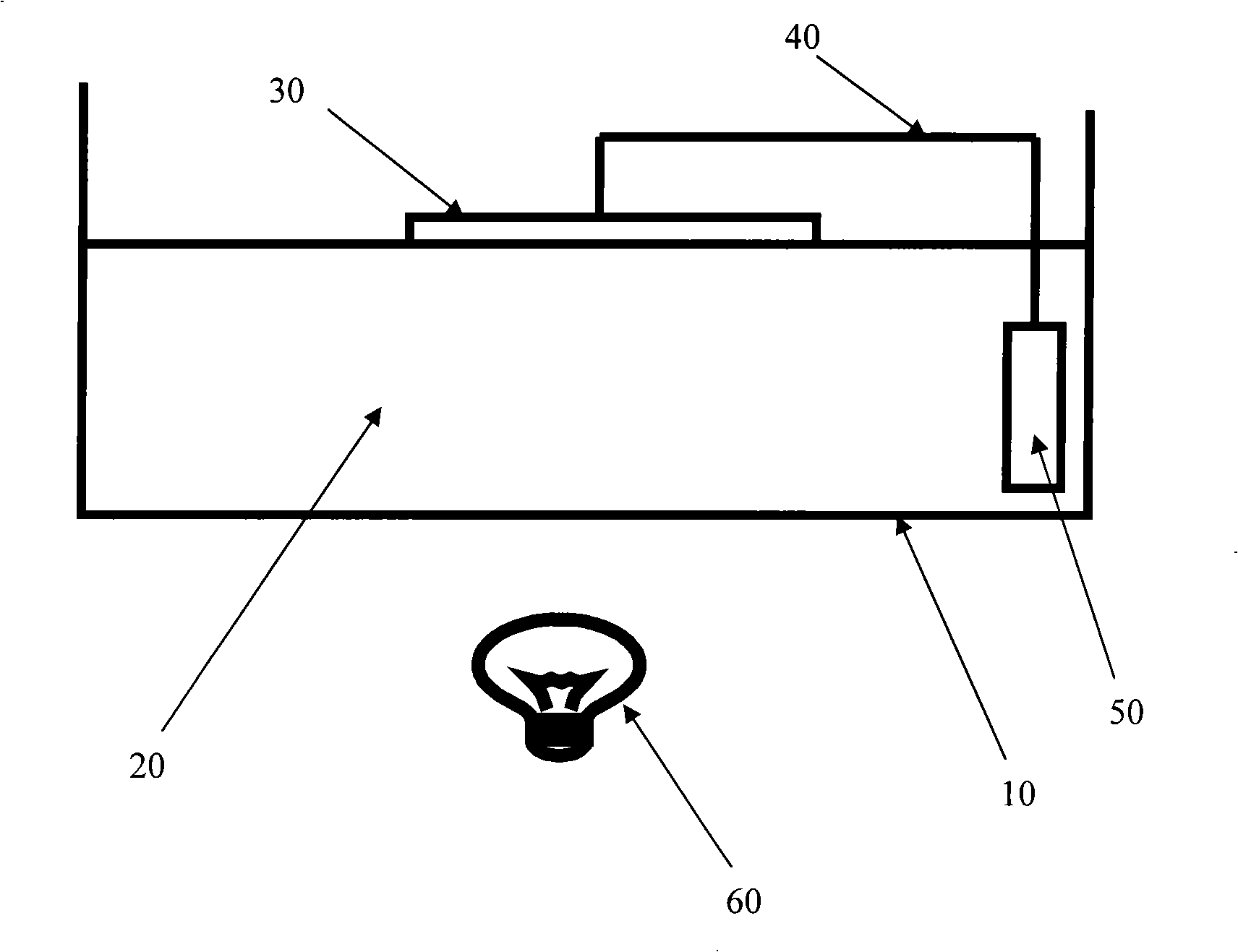

Method for treating ship ballast by high-level oxidation technology based on sulphuric acid free radical

InactiveCN101045573ANo secondary pollutionReduce energy consumptionWater/sewage treatment by irradiationSeawater treatmentHydrogenPersulfate

A process for treating the water-ballast of ship by high-grade oxidizing technique based on free radicals of sulfuric acid in order to kill the microbes in it includes such steps as filtering, adding persulfate or hydrogen monoperoxysulfate salt, generating the free radicals of sulfuric acid by thermo-decompsoing, ultraviolet decomposing, gamma-ray radiation, or metallic ion' s catalytic decomposing, and reaction between said free radicals and water-ballast.

Owner:DALIAN MARITIME UNIVERSITY

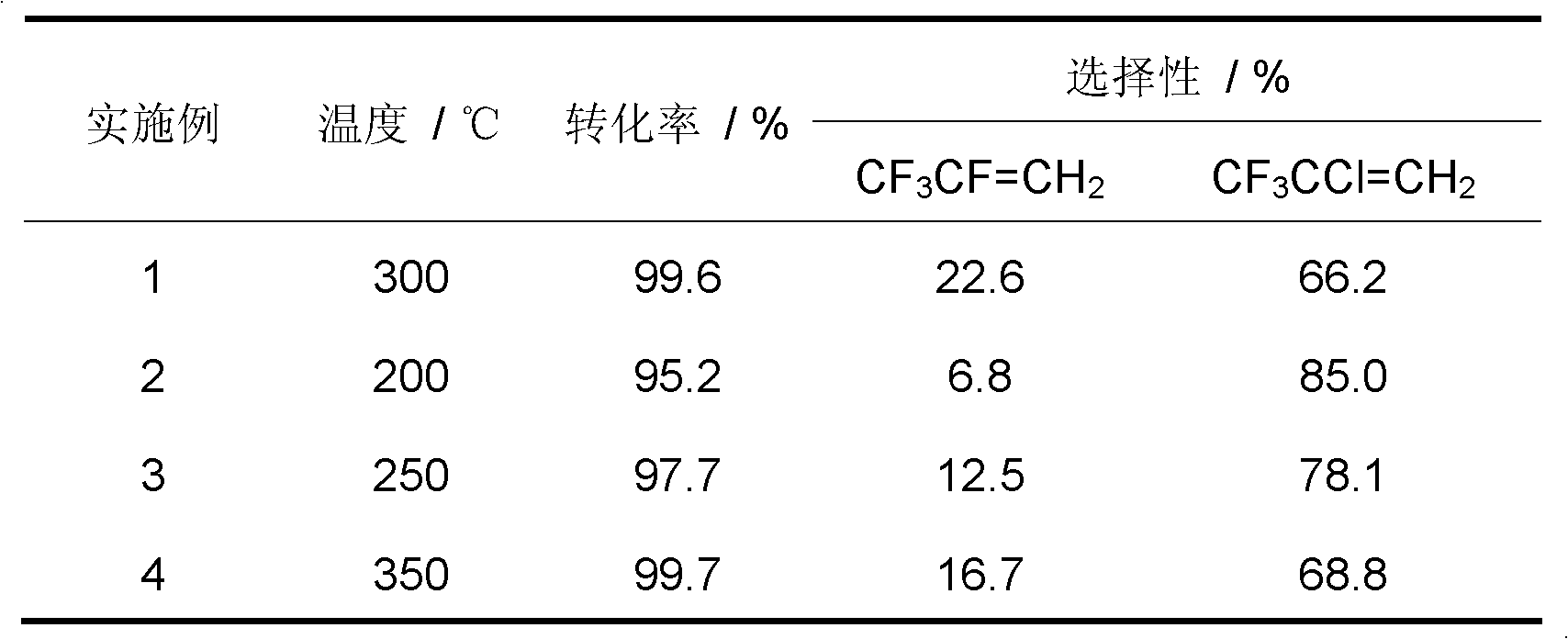

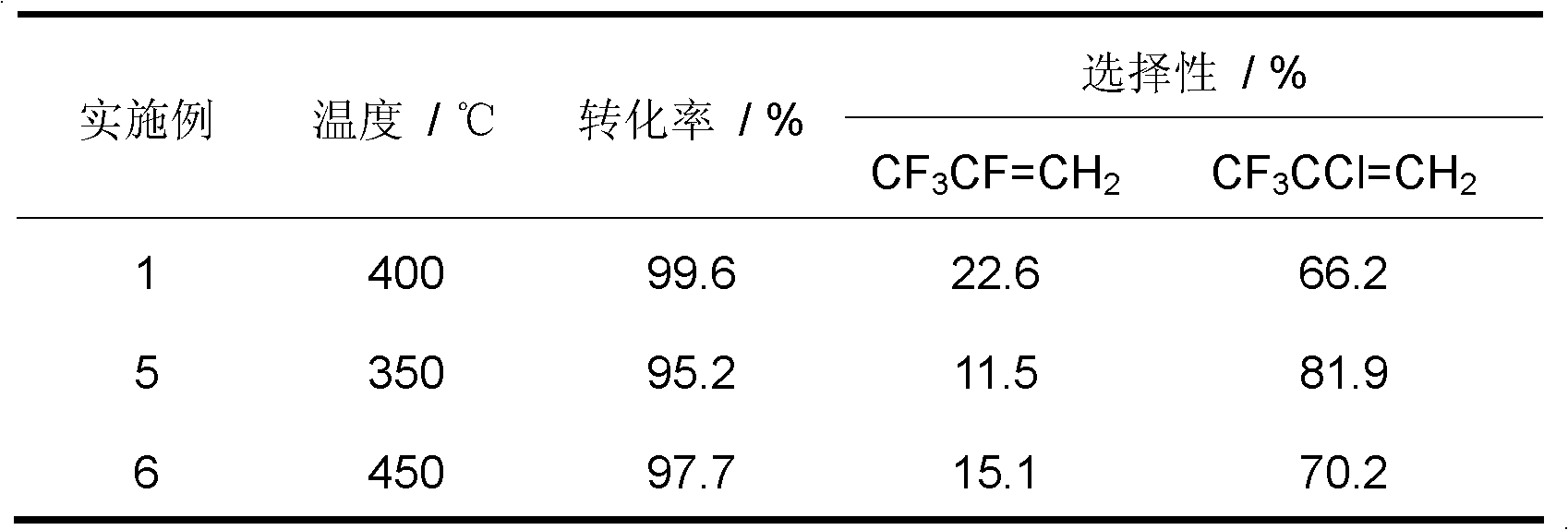

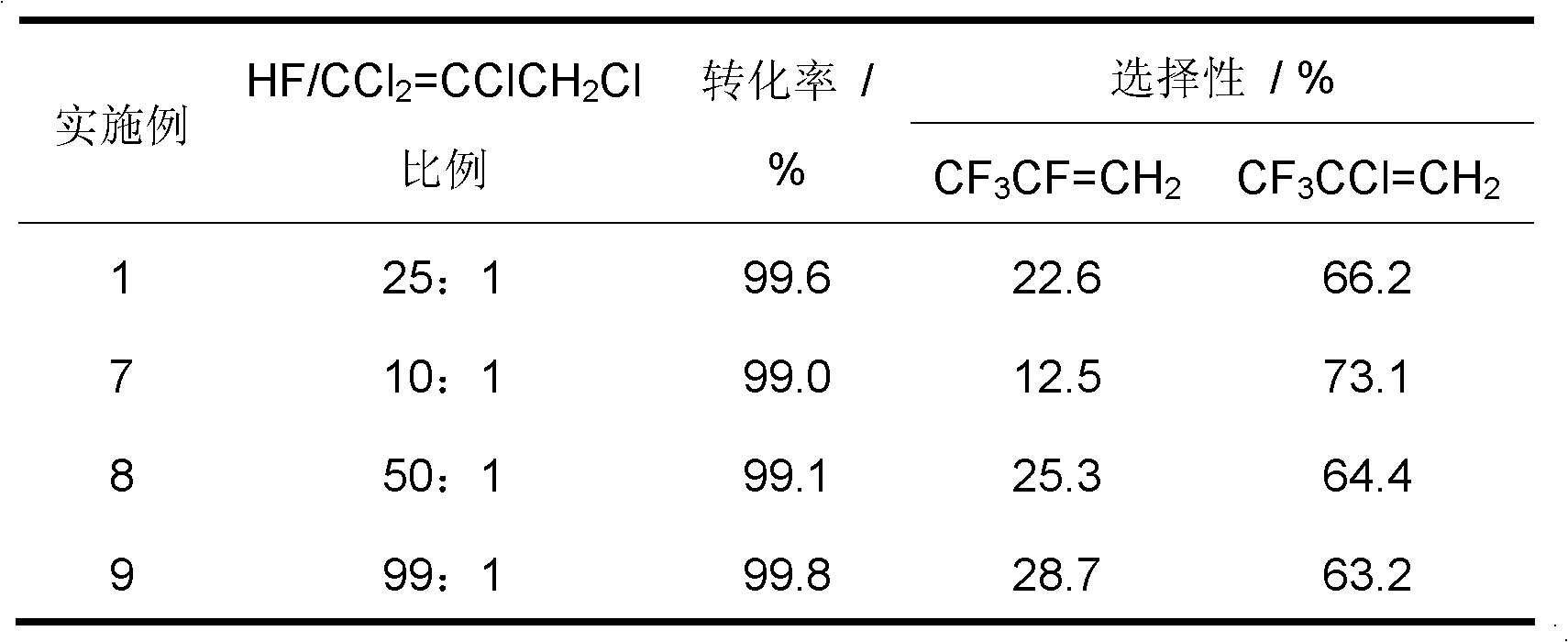

Method for preparing 2,3,3,3-tetrafluoropropene

InactiveCN102351637AMild reaction conditionsSimple processPreparation by hydrogen halide split-offHydrogen fluorideVapor phase

The invention discloses a method for preparing 2,3,3,3-tetrafluoropropene. The method comprises the following steps of: loading Cr2O3 catalyst in a reactor; introducing preheated hydrogen fluoride and 1,1,2,3-tetrafluoropropene gas into the reactor, and performing vapor phase catalytic fluorination to synthesize 2,3,3,3-tetrafluoropropene, wherein a molar ratio of the hydrogen fluoride to the 1,1,2,3-tetrafluoropropene is (10-99):1, the catalyst is equally divided into two sections, the upper-section catalyst in the reaction has the temperature of between 200 and 350DEG C, the lower-section catalyst has the temperature of between 350 and 450DEG C, the reaction velocity is 250-2,000h<-1>, and the reaction pressure is normal pressure; and introducing obtained effluent into a rectifying tower, and performing deacidification and rectification treatment on the 2,3,3,3-tetrafluoropropene to obtain the final product. The method has the advantages of mild reaction conditions, simple process, and optimum distribution of energy and resources.

Owner:ZHEJIANG NORMAL UNIVERSITY

Method for electrochemical depositing solar cell metallic electrode

ActiveCN101257059AAvoid unevennessAvoid damagePhotovoltaic energy generationSemiconductor devicesElectrochemical responseMetallic electrode

Owner:WUXI SUNTECH POWER CO LTD

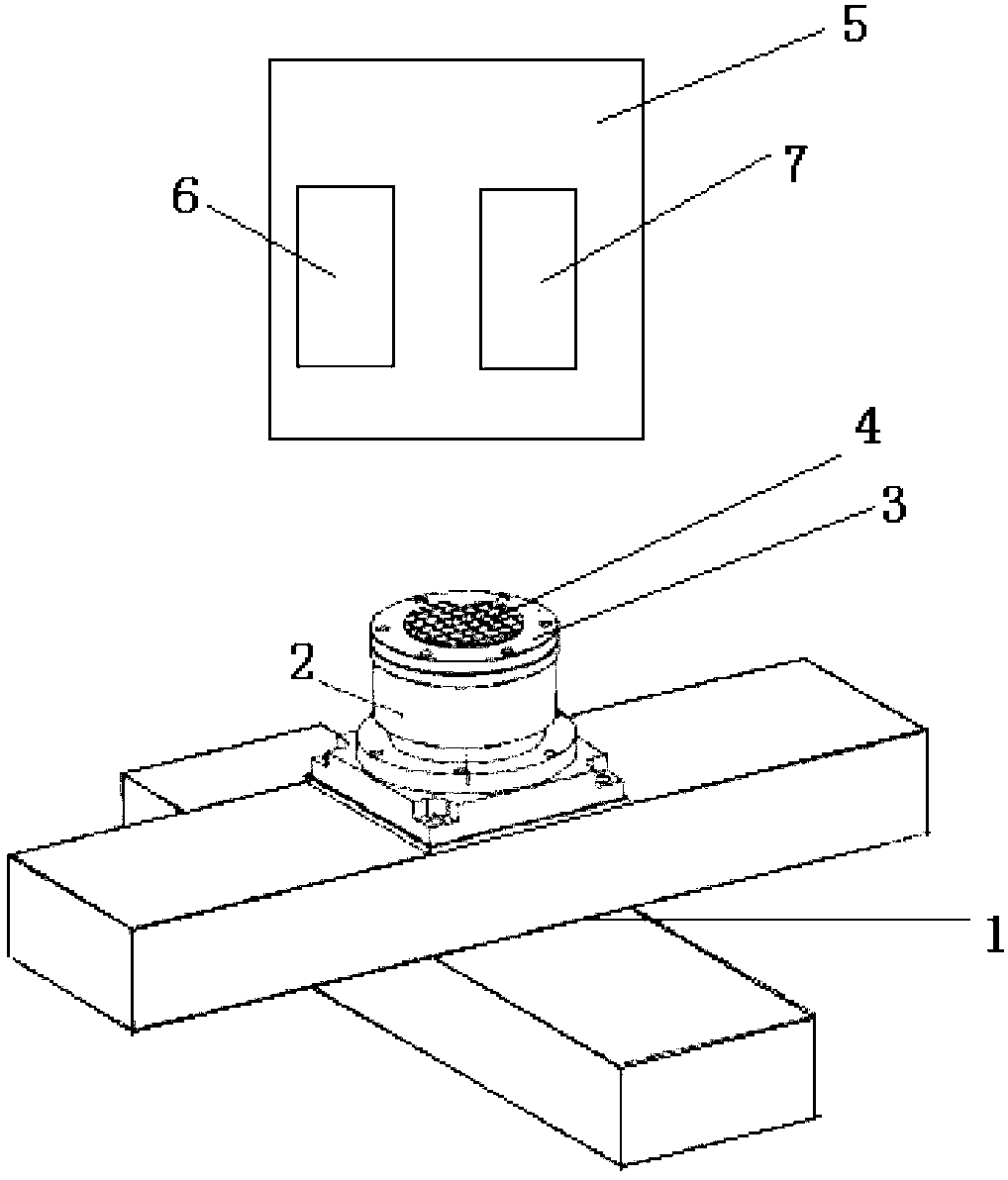

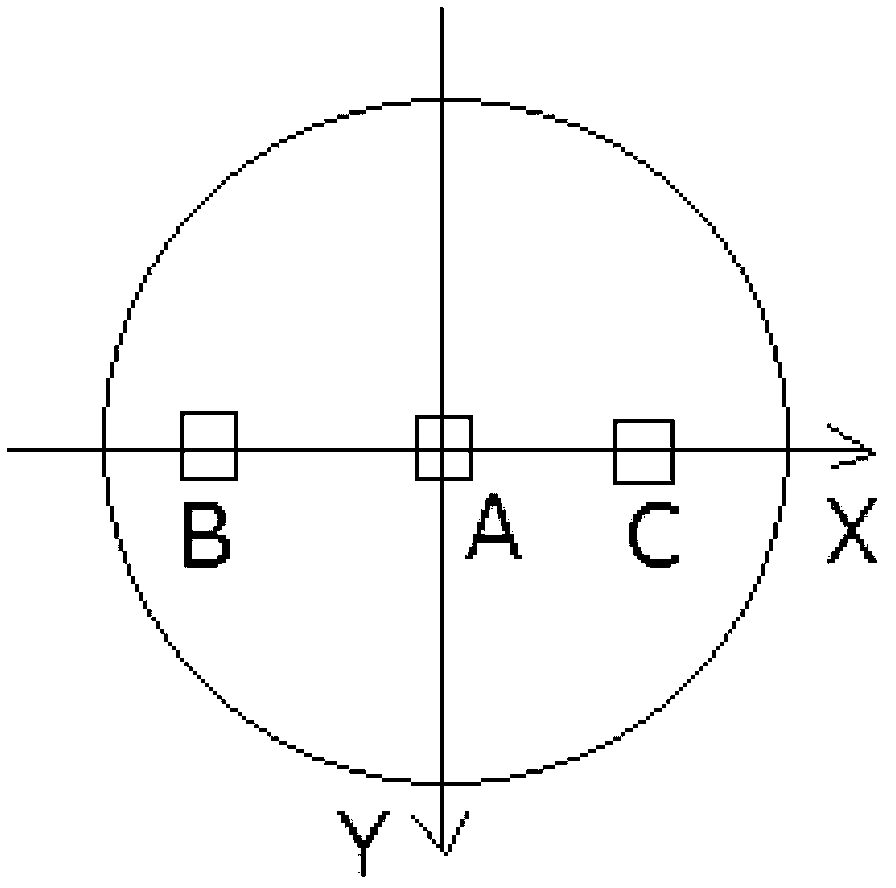

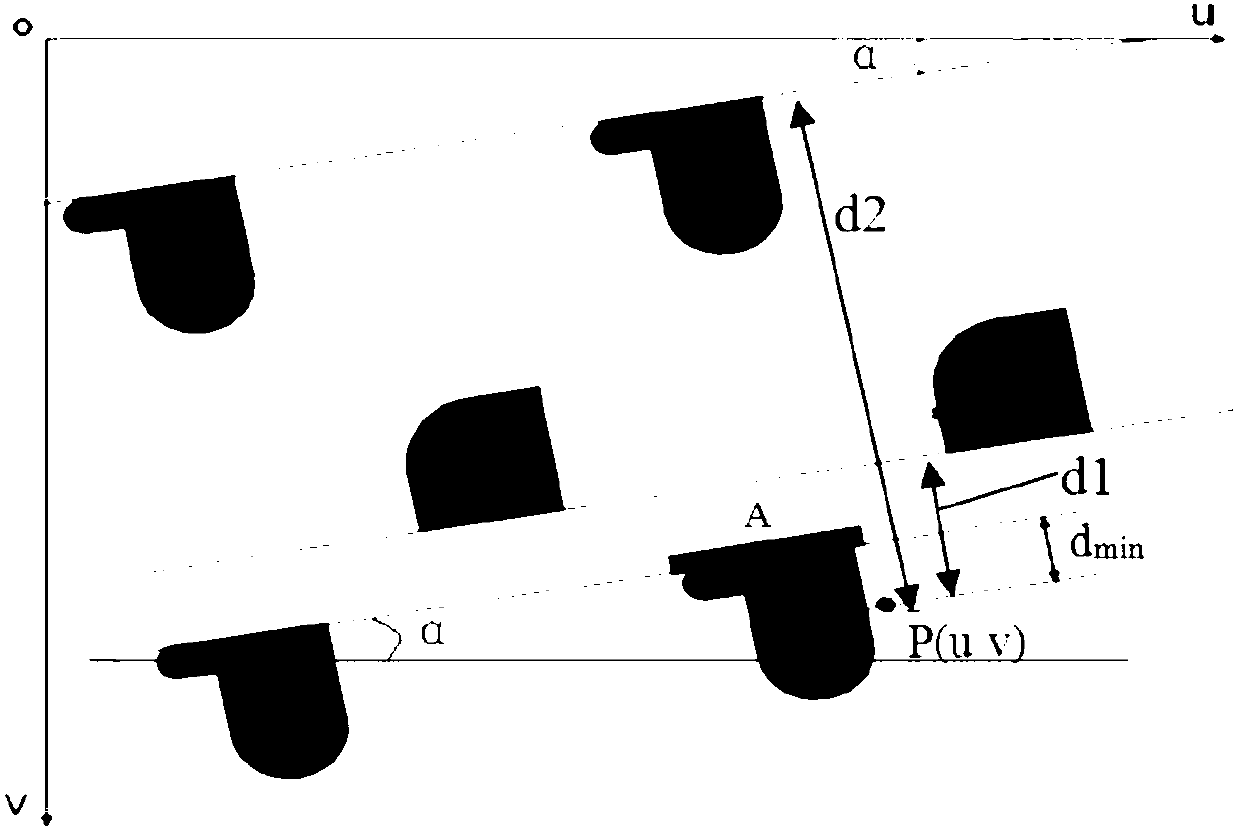

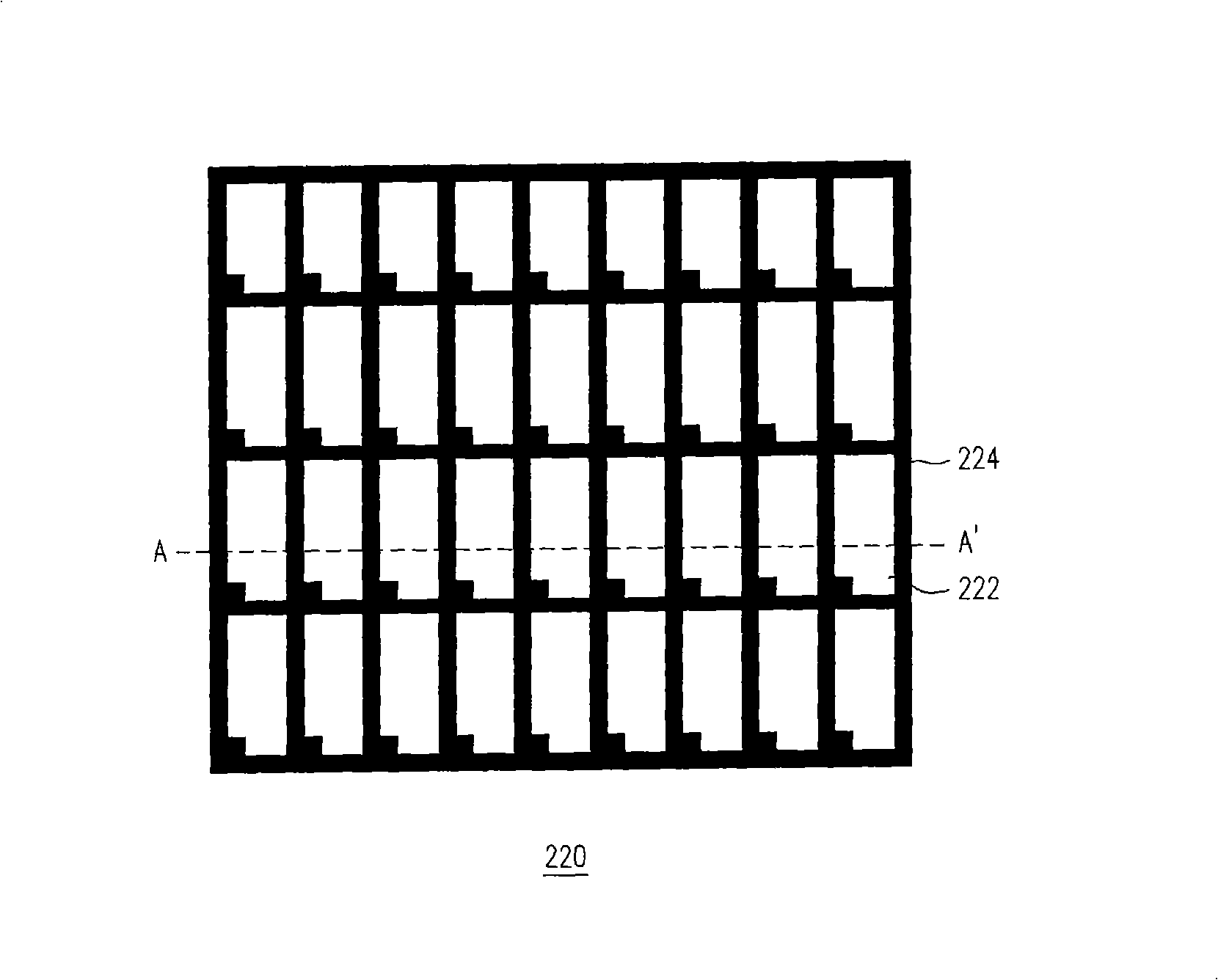

Wafer angular deviation automatic method based on vision

ActiveCN103107121AShorten positioning timeImprove processing efficiencySemiconductor/solid-state device manufacturingNumerical controlReaction rate

The invention discloses a wafer angular deviation automatic method based on vision. The wafer angular deviation automatic method based on vision comprises the following steps: arranging a wafer on an absorptive disk of a four-axis numerical control machine tool platform system; adopting Hough changing to conduct detecting and positioning on images of the wafer shoot by a microcamera of the four-axis numerical control machine tool platform system; shooting an image on an A point of the wafer to determine positions of a feature straight line and a feature point of the wafer, and adjusting positions of the wafer according to an angle formed by the feature straight line and X- axis or Y-axis of the four-axis numerical control machine tool platform system; respectively shooting images on a B point of the wafer and a C point of the wafer again to conduct Hough change detection, checking whether the wafer is accurately positioned by judging whether an incline angle beta of midpoint connecting lines of feature straight lines of the B point of the wafer and the C point of the wafer is zero. The wafer angular deviation automatic method based on vision can accurately positions of the wafer and scribe lines, is high in reliability and rapid in reaction rate, promotes automation and intellectualization of wafer scribing technology, can control valid accuracy to 2 mu, shortens positioning time of the wafer, and improves machining efficiency of the wafer.

Owner:福建省威诺数控有限公司

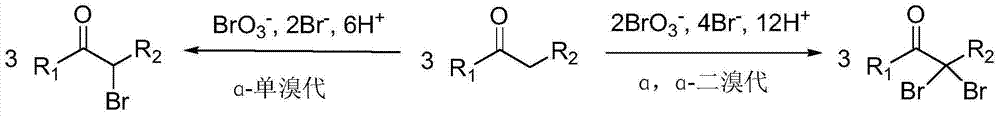

Method for preparing alpha-monobrominated ketone and alpha, alpha-dibrominated ketone compounds by selectively brominating ketone compounds

InactiveCN104119211AIncrease profitHigh selectivity for brominationOrganic compound preparationCarboxylic acid esters preparationKetoneSolvent

The invention discloses a method for preparing alpha-monobrominated ketone and alpha, alpha-dibrominated ketone compounds by selectively brominating ketone compounds. The method comprises the steps of by taking ketone compounds as reactants, taking bromated and metal bromides in the presence of bromic acid or inorganic acid as brominating reagents and taking alcohol as a solvent, selectively brominating the ketone compounds into corresponding alpha-monobrominated ketone. The reaction has effects of high brominating selectivity, gentle reaction condition, high reaction velocity and high yield; the selected brominating reagents are cheap, easily available and low in toxicity; moreover, the method is high in bromine rate which is close to requirements of green chemistry, and therefore, the method is easy for industrial production and has good application prospect.

Owner:HUANGSHAN UNIV

Catalyst for catalytic cracking mixed waste plastic and preparation method thereof

InactiveCN101284235AGood technical effectVersatilityMolecular sieve catalystsLiquid hydrocarbon mixture productionCatalytic pyrolysisCatalytic reforming

The invention discloses a catalyst for manufacturing fuel oil through catalytic pyrolysis of mixed-waste plastics, and a preparation method thereof, and relates to catalytic thermal cracking for manufacturing the fuel oil through waste plastic cracking and a second stage catalyst in thermal cracking catalytic reforming. A first stage catalyst comprises a metallic oxide of 2.0wt percent to 30.0wt percent and carclazyte or montmorillonite of 70.0wt percent to 98.0wt percent; the first stage catalyst is innoxious and cheap, increases the reaction velocity of plastic cracking, reduces the temperature in the scission reaction, improves the selectivity of decomposition products, and is dechlorinated and transformed into innocuous substances. The second stage catalyst is composed of ferric oxide, molybdenum oxide, zinc oxide, cerium oxide, lanthana, nickel oxide or copper oxide, and ZSM-5, MCM-22, USY, REY, Beta or MOR molecular sieves; the second stage catalyst performs the second catalytic pyrolysis and isomerization and the aromatization reversion reactions on pyrolysis gas in the first stage, to increase the distillate rate of pyrolysis gasoline and gas oil. The catalyst and the preparation method thereof have good selectivity, and the raw material does not need classification, washing and drying; the operation is flexible, and the running cost is low; the method is particularly applied to the fuel oil manufacture through the cracking of the mixed-waste plastics in the urban and rural domestic refuse, the composition is complicated; the oil yield of the qualified fuel oil can reach up to more than 70 percent calculated on the basis of the waste plastic.

Owner:TONGJI UNIV

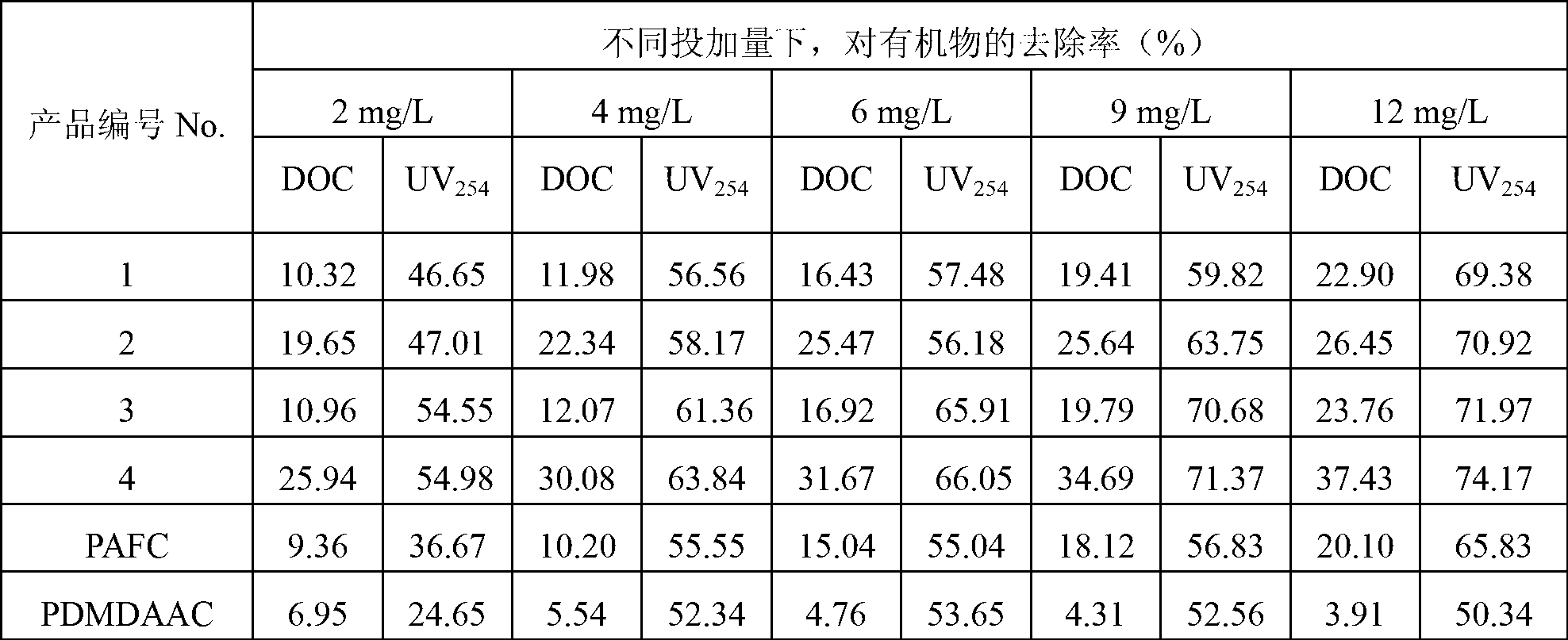

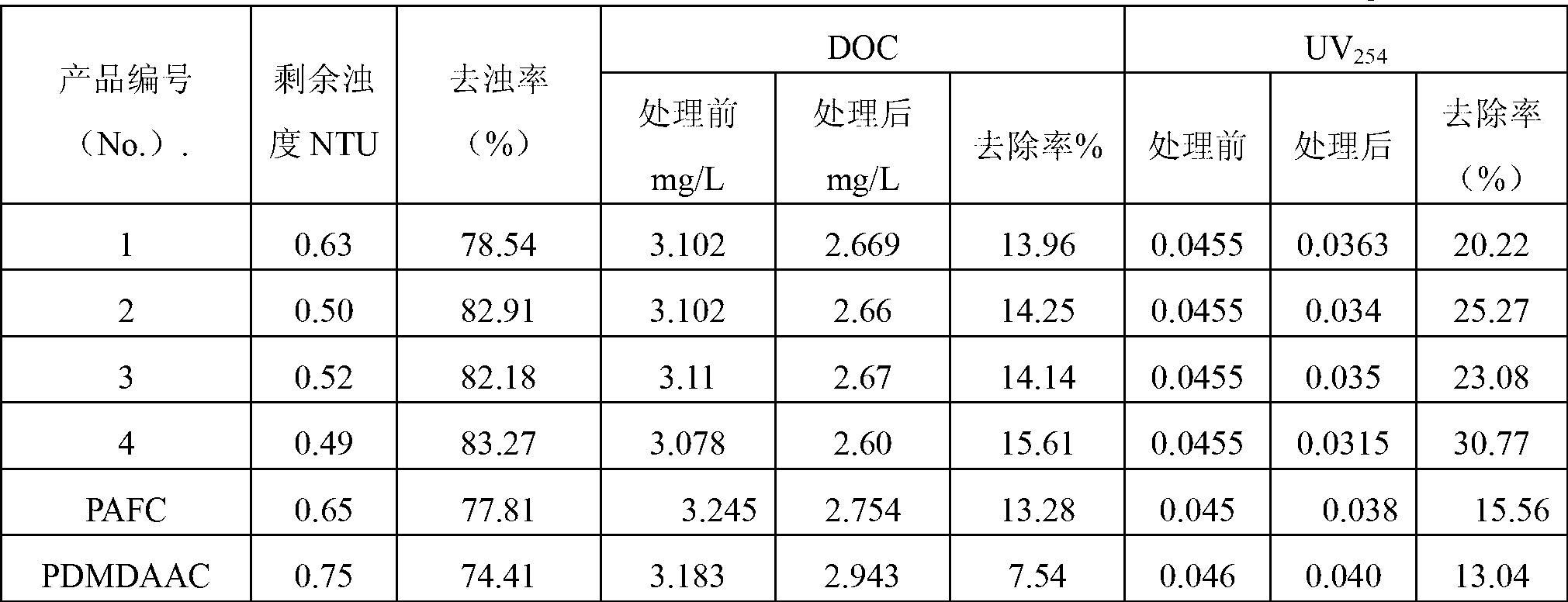

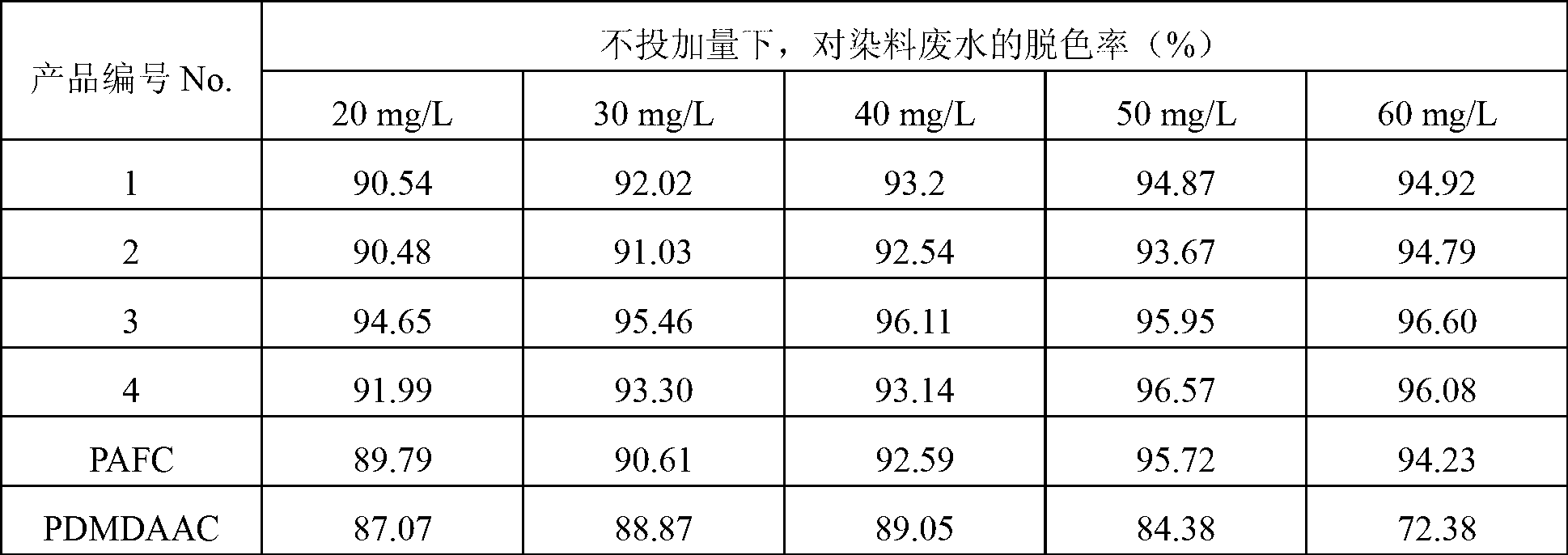

Preparation method of polyaluminum ferric chloride-poly dimethyl diallyl ammonium chloride inorganic/organic composite flocculant

InactiveCN103011359AHigh molecular weightDian ZhongqiangWater/sewage treatment by flocculation/precipitationTextile printerChemical industry

The invention relates to a preparation method of a polyaluminum ferric chloride-poly dimethyl diallyl ammonium chloride (PAFC-PDMDAAC) inorganic / organic composite flocculant. The inorganic / organic composite flocculant is prepared by taking AlCl3.6H2O, FeCl3.6H2O, and PDMDAAC as raw materials and adopting a method of adding PDMDAAC into a PAFC system. The flocculant integrates the advantages of high molecular weight of PDMDAAC, high charge neutrality and adsorption bridging ability, wide application range, good flocculation effect and small generated sludge quantity, and high PAFC reaction velocity, large formed flocculating constituent, high settling velocity, wide applied pH (potential of hydrogen) range, good coagulation effect and the like. The PAFC-PDMDAAC inorganic / organic composite flocculant can be widely applied to the fields of water supply, waste water treatment, papermaking, oil extraction, textile printing and dyeing, mining, daily-use chemical industry and the like, and has a good water treatment effect.

Owner:SHANDONG UNIV

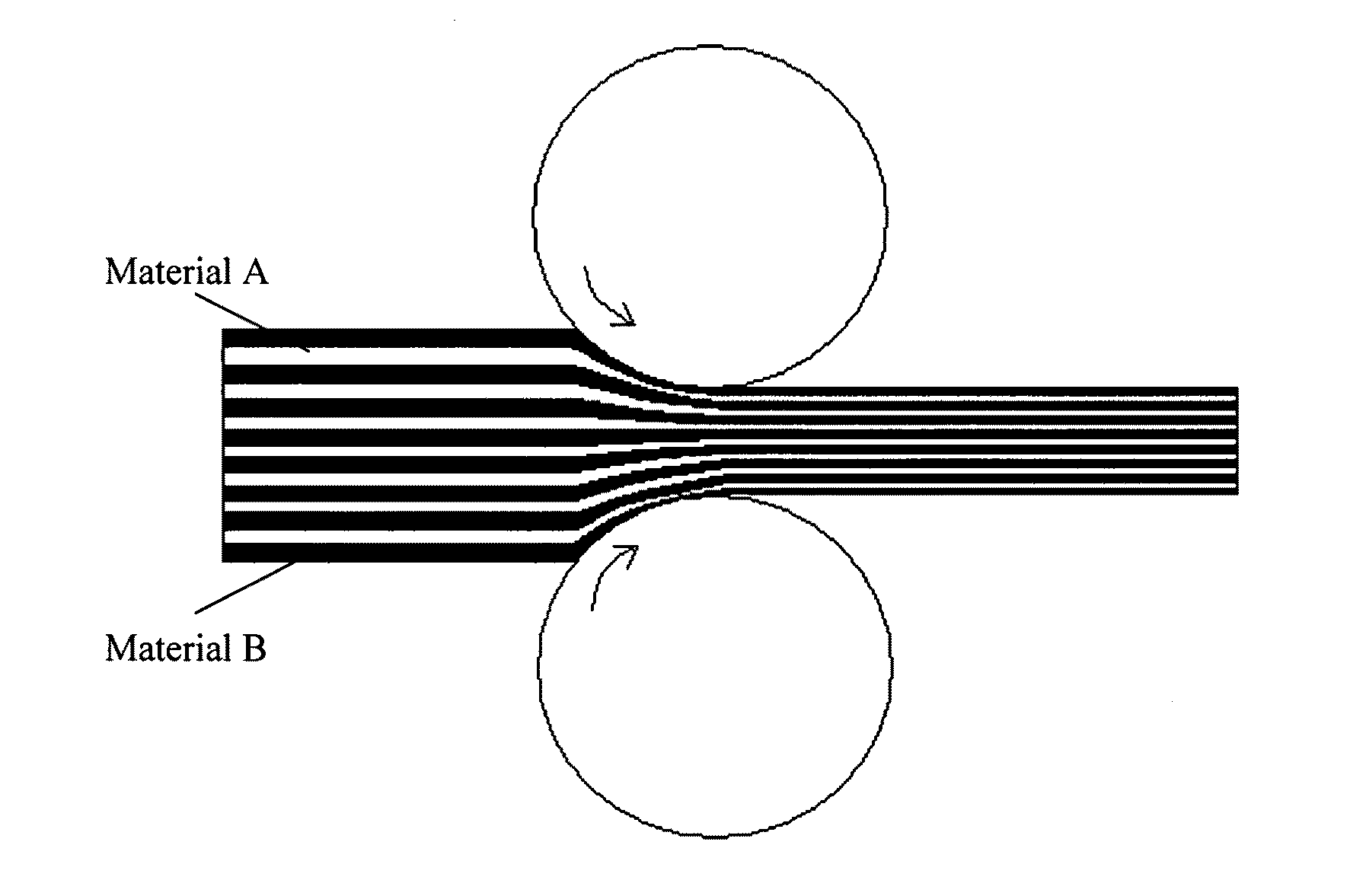

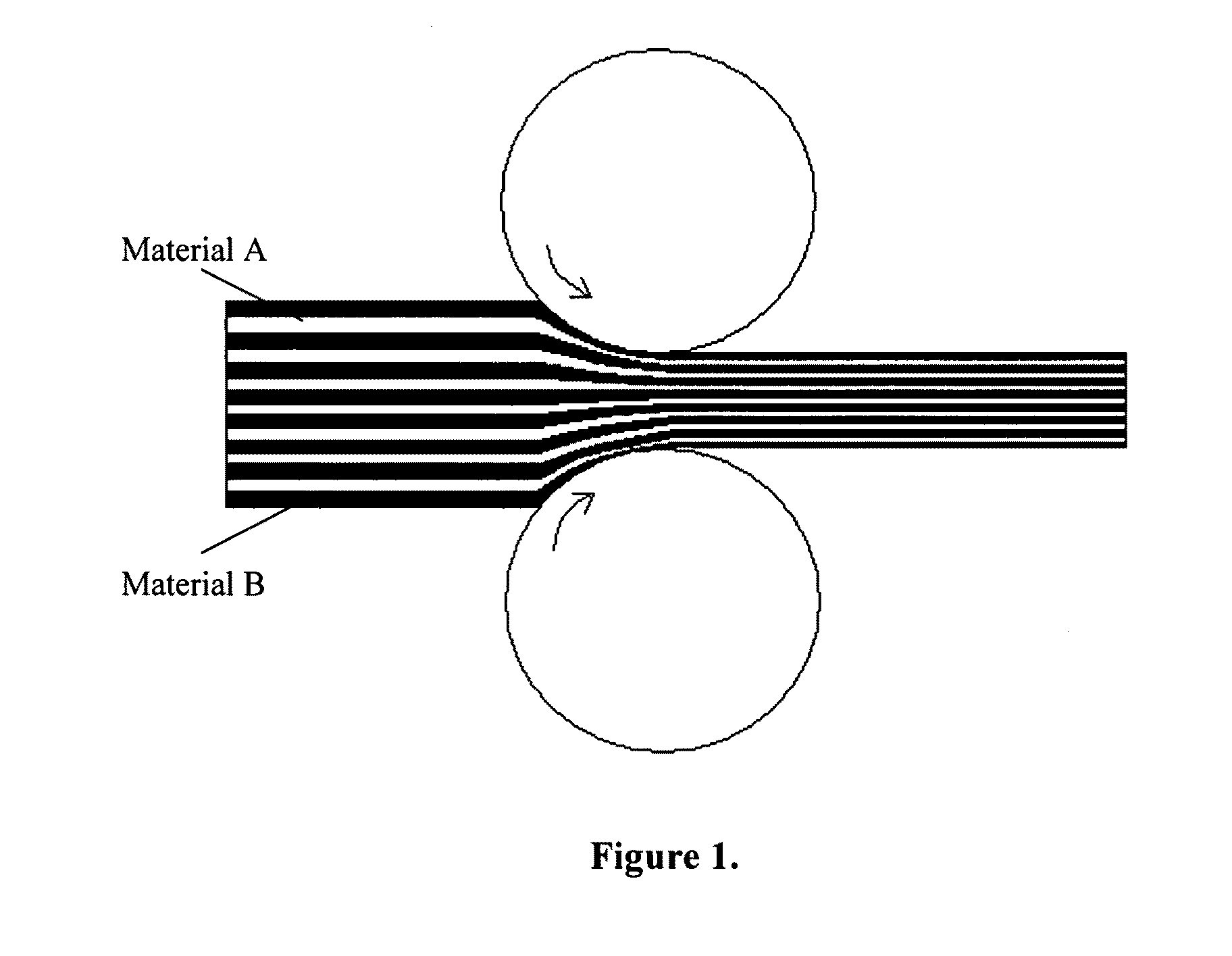

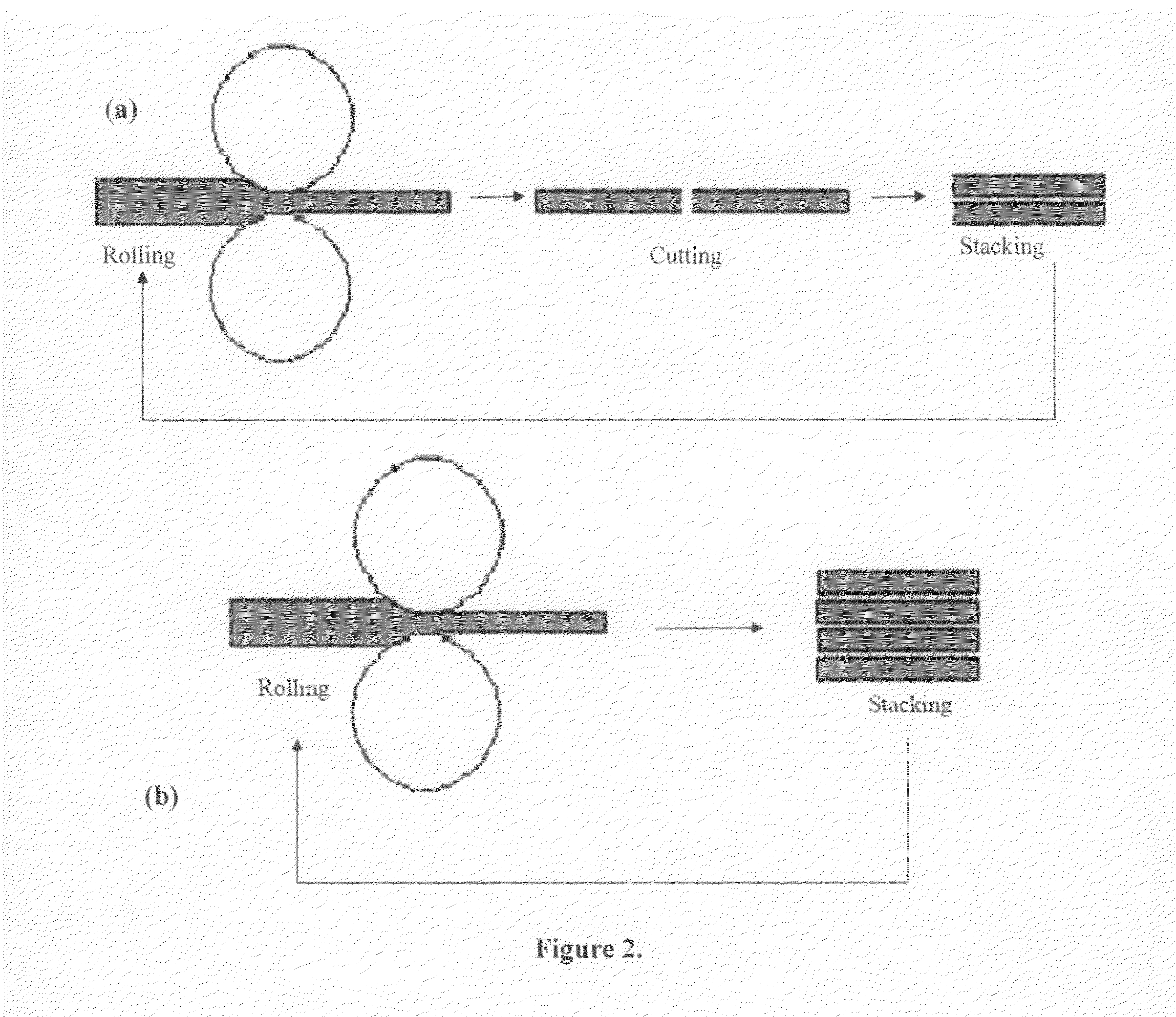

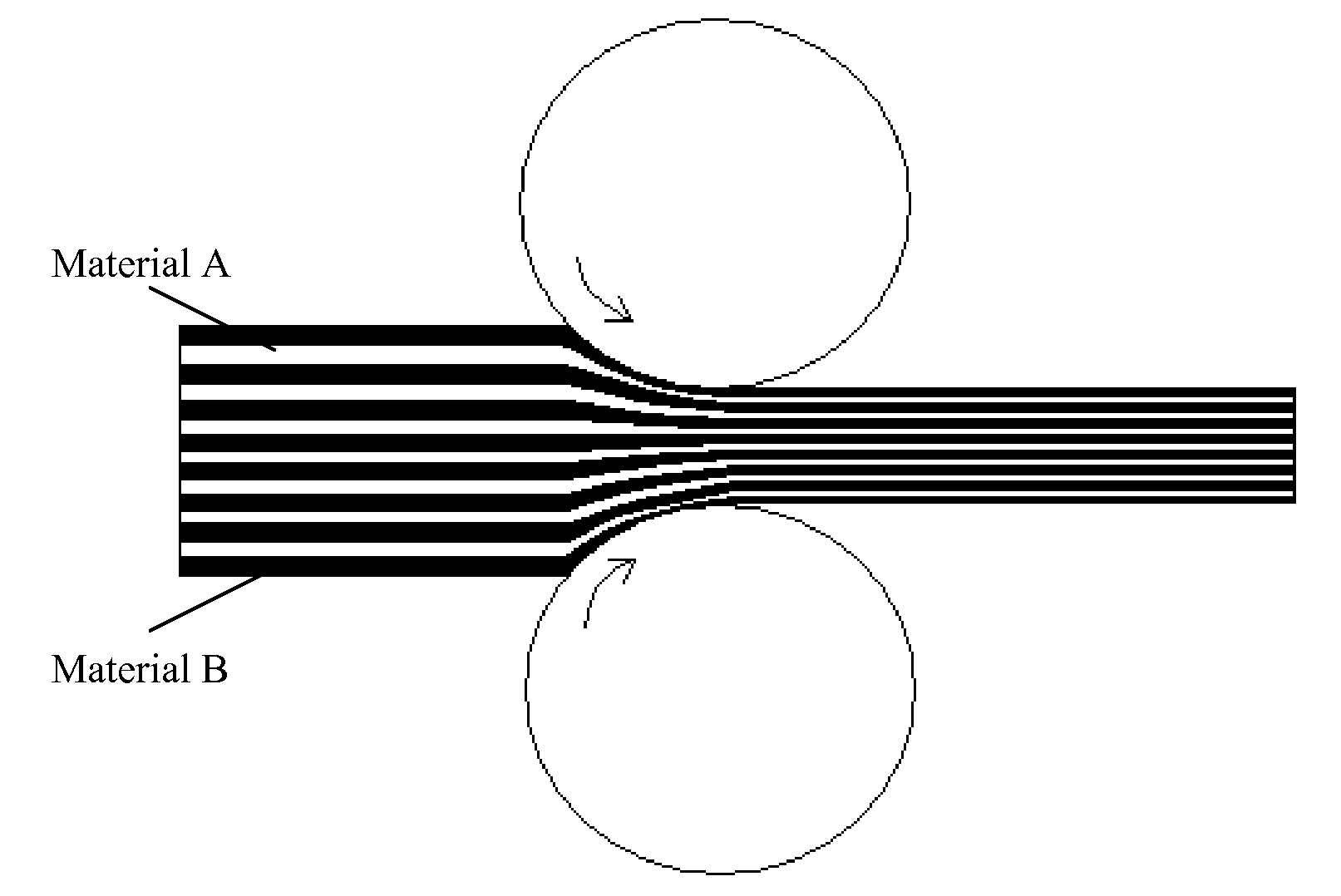

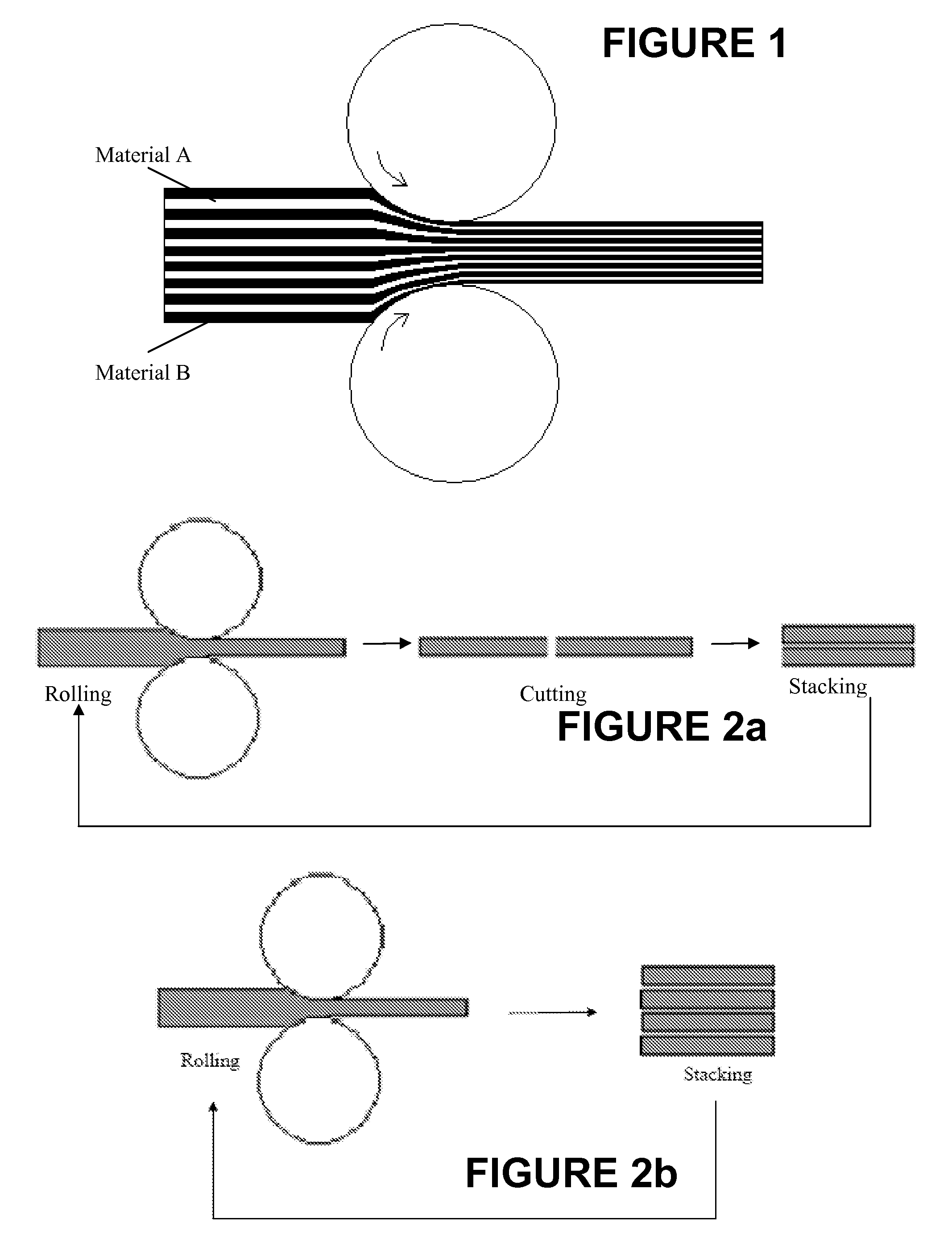

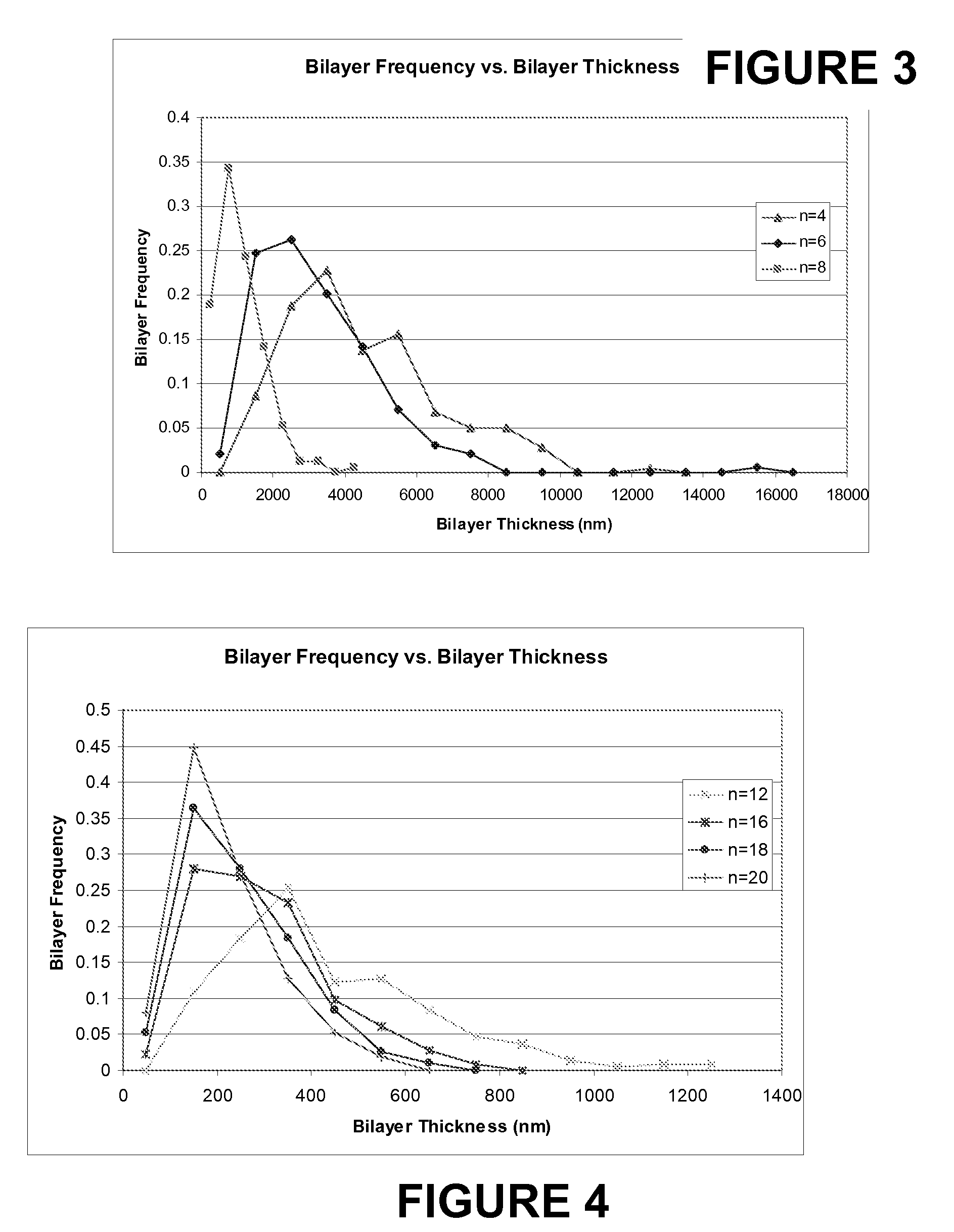

Methods of making reactive composite materials and resulting products

InactiveUS20110027547A1Reduce the cross-sectional areaEliminates tendency of deformedExplosivesThin material handlingMetalMaterials science

Applicants have discovered new composite materials and have developed a variety of new ways of making reactive composite materials (RCMs) and methods of controlling the properties and characteristics of the materials that are pertinent to numerous new or improved applications. This patent application is directed to new and improved ways of making reactive composite materials using mechanical deformation and making such materials with controlled, predictable characteristics. This application is also directed toward useful applications of the resulting materials.In accordance with the invention, RCMs are fabricated by a series of mechanical deformation steps. In the first deformation step, an assembly of reactive layers and / or particles is plastically deformed to reduce its cross sectional area by one-half or more. This severe initial deformation substantially eliminates the tendency of deformed layers to delaminate and eliminates the necessity of using specially cleaned metal layers. Portions of the deformed sheets are stacked or bent into a new assembly, and the new assembly is then deformed. The steps of assembly and deformation are repeated a sufficient number of times that the resulting materials are only locally layered but have relatively uniform reaction velocity and heat generating characteristics predictable by stochastic models derived herein. The resulting product is a controllable, locally layered reactive composite material (LLRCM) that can be fabricated quickly and is useful in a wide variety of applications.

Owner:NANOFOIL CORP

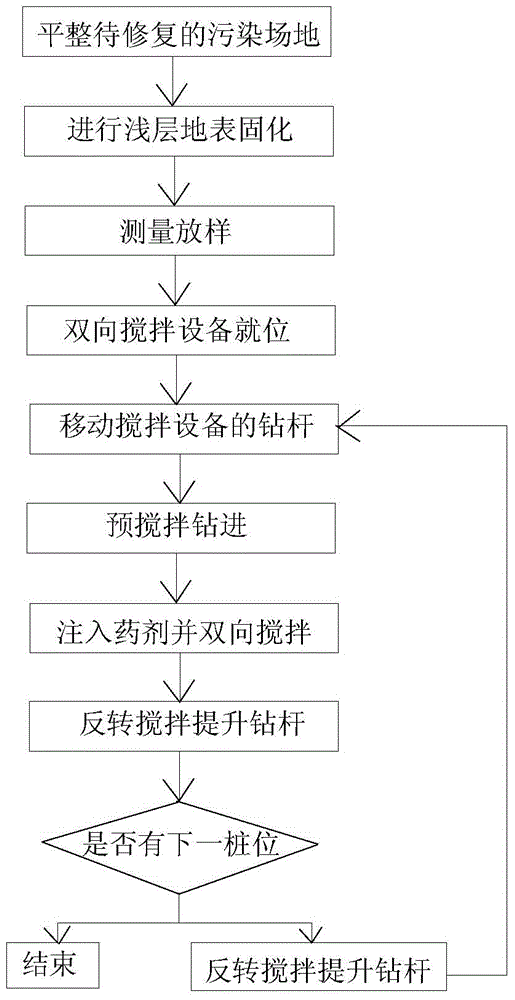

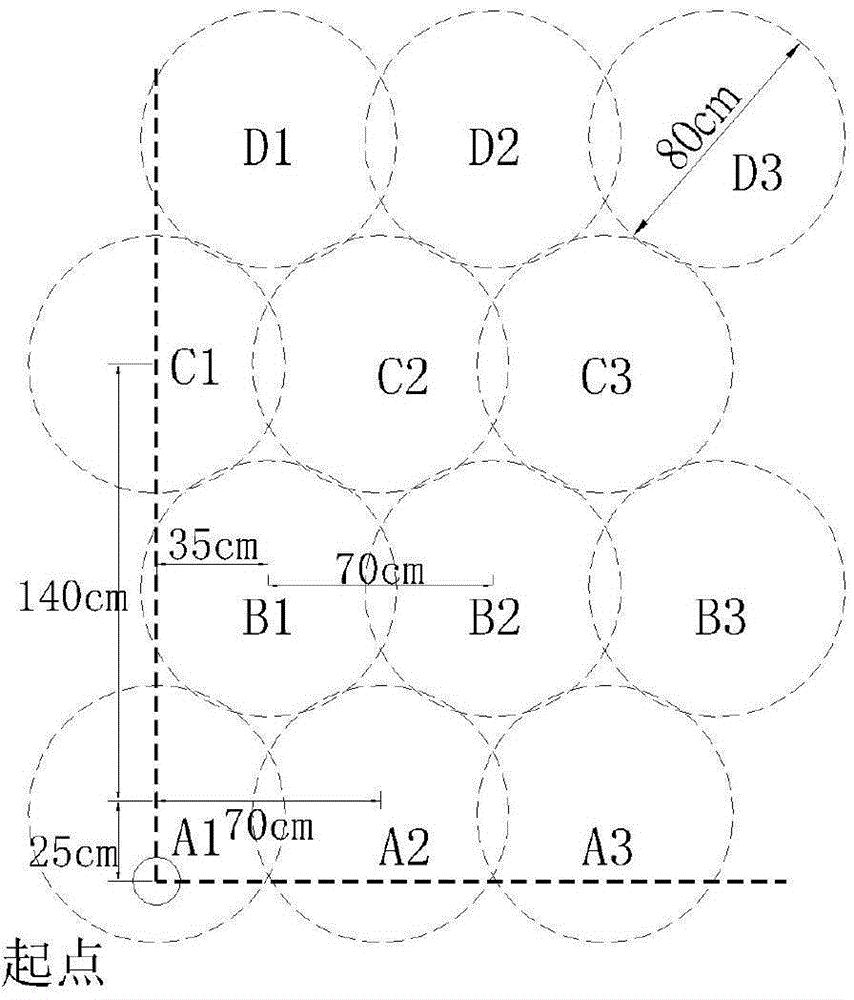

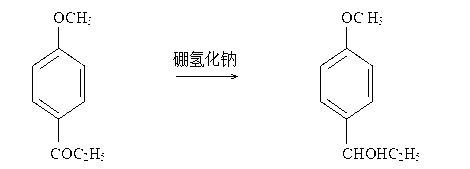

Method for remedying organism contaminated field by using bidirectional stirring injection method

ActiveCN104624629AImprove utilization efficiencyReduce lossesContaminated soil reclamationDrillInjections methods

The invention discloses a method for remedying an organism contaminated field by using a bidirectional stirring injection method. The method comprises the following steps: (1) flattening the contaminated field; (2) performing shallow layer ground hardening; (3) staking out in survey; (4) locating bidirectional stirring equipment in place; (5) moving a drilling rod of the bidirectional stirring equipment; (6) performing pre-stirring drilling; (7) drilling a drill rod, injecting a medicine and stirring bidirectionally, namely, injecting the medicine through an inner tube of a conveying pipeline, injecting a mixed solution of a catalyst and a buffer agent from a pipeline between the inner tube and the outer tube of the conveying pipeline, and mixing and stirring the medicine, the catalyst, the buffer agent and soil at the bottom of the conveying pipeline; (8) lifting up the drill rod through opposite stirring; and (9) moving the drill rod to a next pile site, and repeating the step (5) to (8) until the soil in all pile sites is remedied. By adopting the method, the loss of ground mixed medicines can be reduced, the reaction velocity and the reaction time can be effectively controlled, the problem that grout spills out and turns up from the ground surface can be effectively solved, and the remediation efficiency can be improved.

Owner:SOUTHEAST UNIV +2

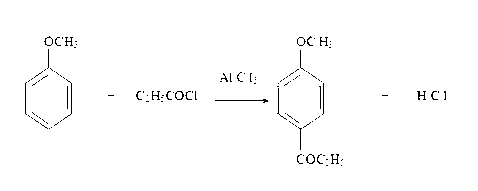

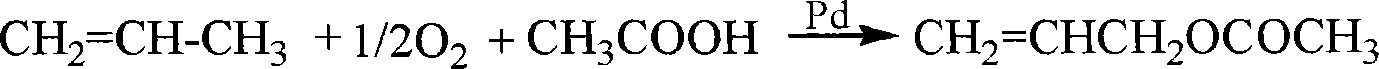

Synthetic method of anethole

InactiveCN103058835AReduce lossesLow costOrganic chemistryOrganic compound preparationSolventSide reaction

The invention discloses a synthetic method of anethole. Anisole and propionyl chloride serve as starting raw materials, are subjected to a friedel-crafts acylation reaction, then are restored through sodium borohydride, and then are catalyzed and dehydrated through organic acid and acid inorganic salt, and finally the anethole is manufactured through rectification. Side reaction is low through the adoption of acylation and reduction, a middle body is not needed to be purified and can be directly put into the next reaction, purification loss and purification cost of the middle body are reduced, yield coefficient is improved, and energy consumption is reduced. A chemical reduction method is utilized to replace a catalytic hydrogenation method, selectivity is high, response speed is fast, side reactions are small in number, and reduction yield coefficient can reach above 98%. Double catalysts are adopted to carry out ordinary pressure low temperature dehydration in dissolvent with a low boiling point, and compared with a negative pressure continuous dehydration method, dehydration time can be shortened by 90%, and the energy consumption is greatly reduced. The total yield coefficient of the method can reach 75%. A product quality index is higher than that of a natural product standard.

Owner:HUAIAN WAN BANG SPICE IND CO LTD +1

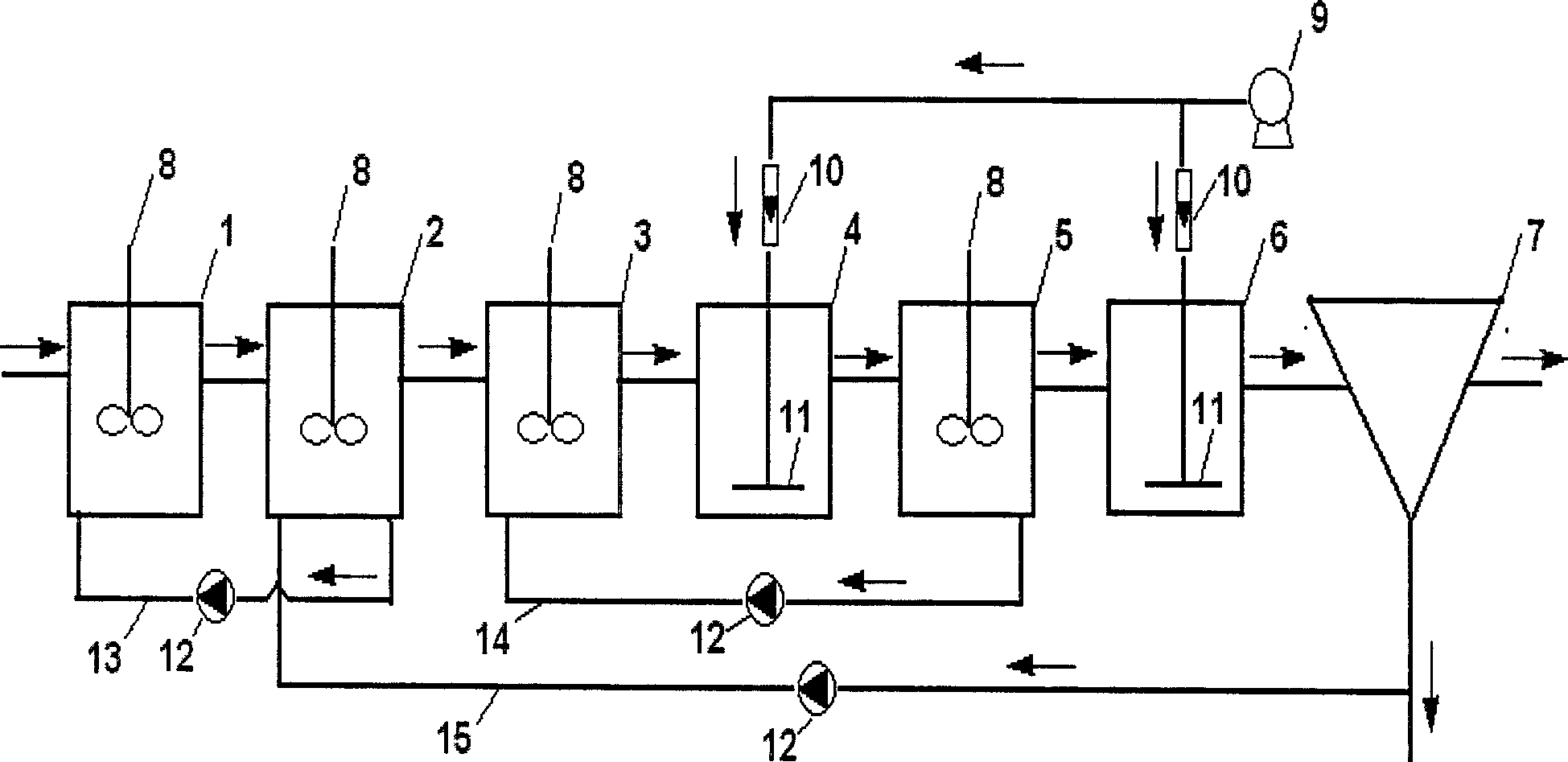

Improved MUCT technology and device

ActiveCN1903744AConducive to survivalImprove environmental conditionsTreatment with aerobic and anaerobic processesWater qualityEngineering

The present invention relates to an improved MUCT process and equipment, belonging to the field of sausage treatment technology. It is characterized by that the aerobic reactor is divided into two stages, between two aerobic reactors a deoxygenation reactor is set,and every aerobic reactor is equipped with an independent gas flow controller. In first aerobic tank it can control low dissolved oxygen to implement short range nitrification and make ammoniac nitrogen be oxidated into nitrite, in second aerobic tank it applies high dissolved oxygen to ensure that the residual nitrite can be oxidated into nitrate. Said equipment also includes a second an aerobic reactor. Besides, said invention also provides the concrete function and action of the deoxygenation reactor and said second anaerobic reactor.

Owner:JIANGSU YULONG ENVIRONMENTAL PROTECTION

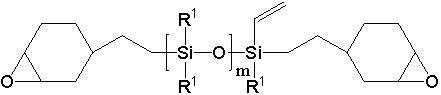

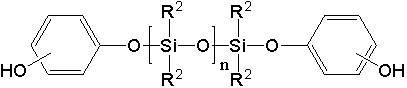

Rapid-curing conductive adhesive composition and method for preparing same

ActiveCN101851478ACompact structureImprove interface bonding performanceEpoxy resin adhesivesElectrically-conducting adhesivesMetal catalystSolvent

The invention relates to a rapid-curing conductive adhesive composition and a method for preparing the same. The composition comprises (A) a silicon-containing epoxy resin, (B) polysiloxane containing phenolic groups, (C) a latent curing accelerator, (D) a metal catalyst, (E) a reaction velocity regulator and (F) a filler, wherein the molecule of the silicon-containing epoxy resin at least comprises one ethylene and two 3,4-epoxy cyclohexyl groups; and the molecule of the polysiloxane at least comprises two oxyphenol groups. When used for electric conduction and / or heat conduction and adhesion of chips or devices in micro-electronics, electronics and optoelectronics industries, the adhesive composition has the advantages of reducing the corrosion of the base material and improving the adhesion and the conductivity, along with no solvent and rapid curing.

Owner:黄文迎 +1

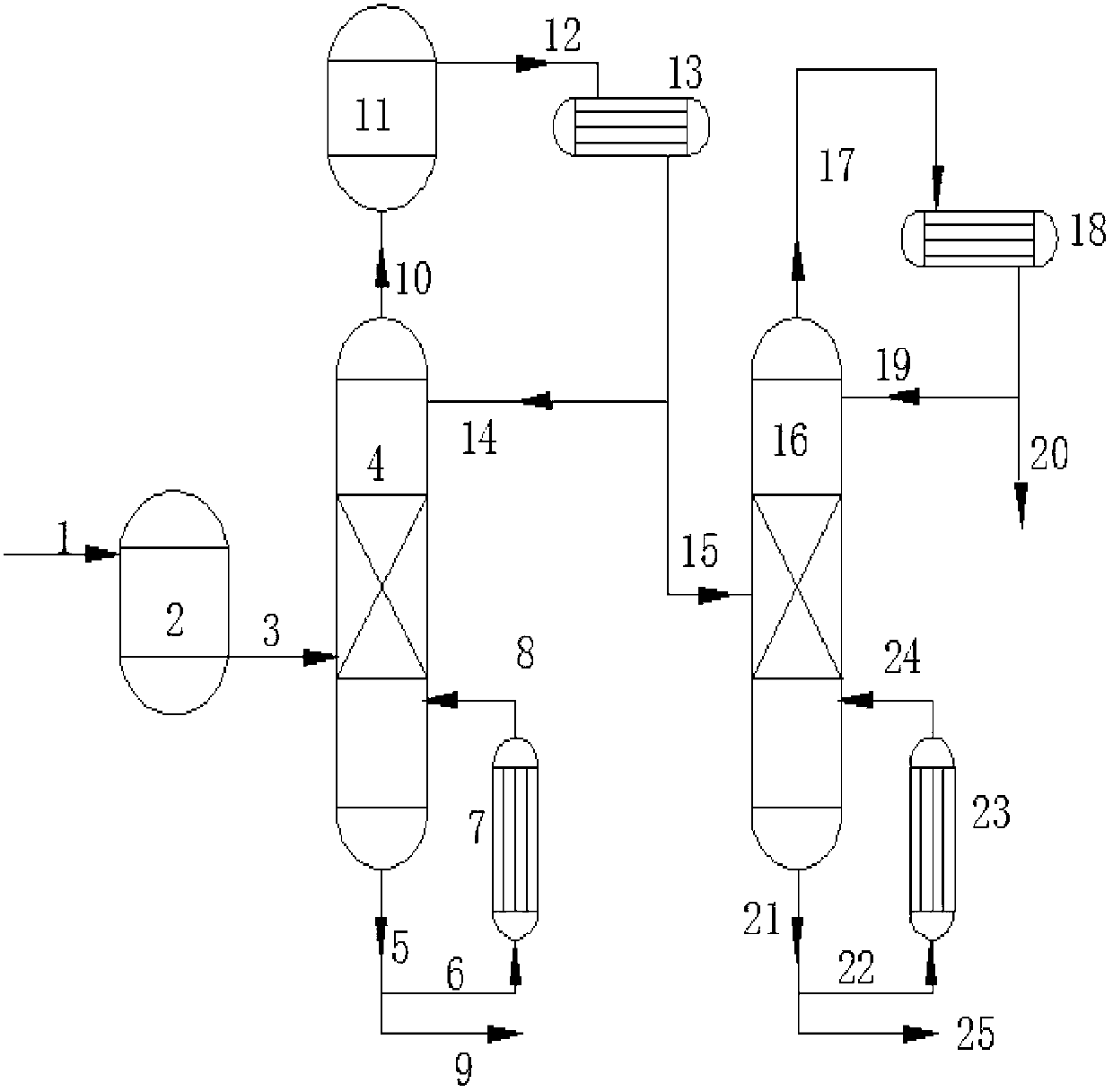

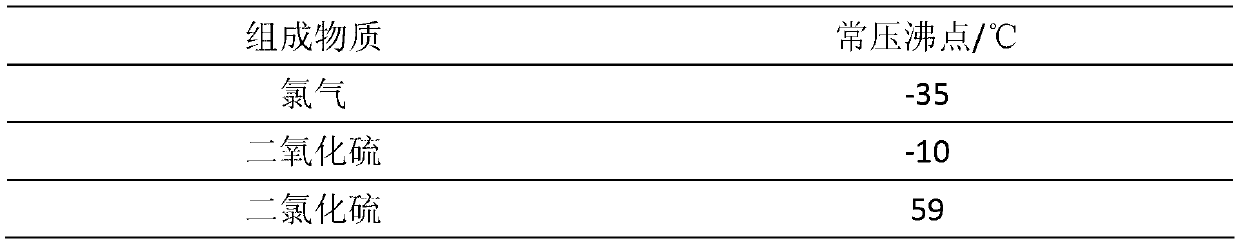

Continuous-pressure-changing rectification method and device for preparing medicine-level sulfoxide chloride

ActiveCN103130197AImprove continuityGuaranteed puritySulfur and halogen compoundsReaction rateDissolution

The invention relates to a continuous-pressure-changing rectification method and a device for preparing medicine-level sulfoxide chloride. With the adoption of the pressure-changing rectification method, an indirect sequence of carrying out heavy component removal and then carrying out light component removal is adopted as a rectification sequence, so that the decomposition of sulfoxide chloride at high temperature is reduced; sulfur is coarsely mixed with raw materials, sulfur is mixed with tower top gas of a heavy component removal tower, and a low-boiling-point substance, namely sulfur dichloride which is hard to remove, is fundamentally converted into a high-boiling-point substance, namely sulfur monochloride which is easy to remove, due to multistep sulfur adding; and a catalyst is added, so that the dissolution rate and reaction rate of the sulfur are accelerated. The heavy component removal tower is subjected to normal-pressure operation; and a light component removal tower is subjected to depressurized operation. The energy consumption of operation is reduced, and the decomposition reaction of the sulfoxide chloride hardly carries out under depressurized conditions, so that the probability that the color and luster of products are polluted by sulfur dichloride is greatly reduced, high-purity and colorless sulfoxide chloride products are produced from tower bottoms, and the content is over 99.9%.

Owner:TIANJIN UNIV

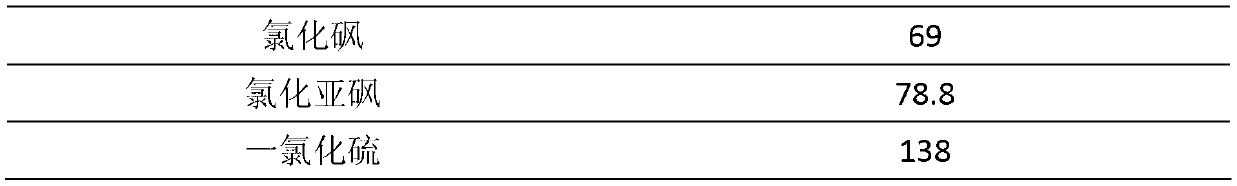

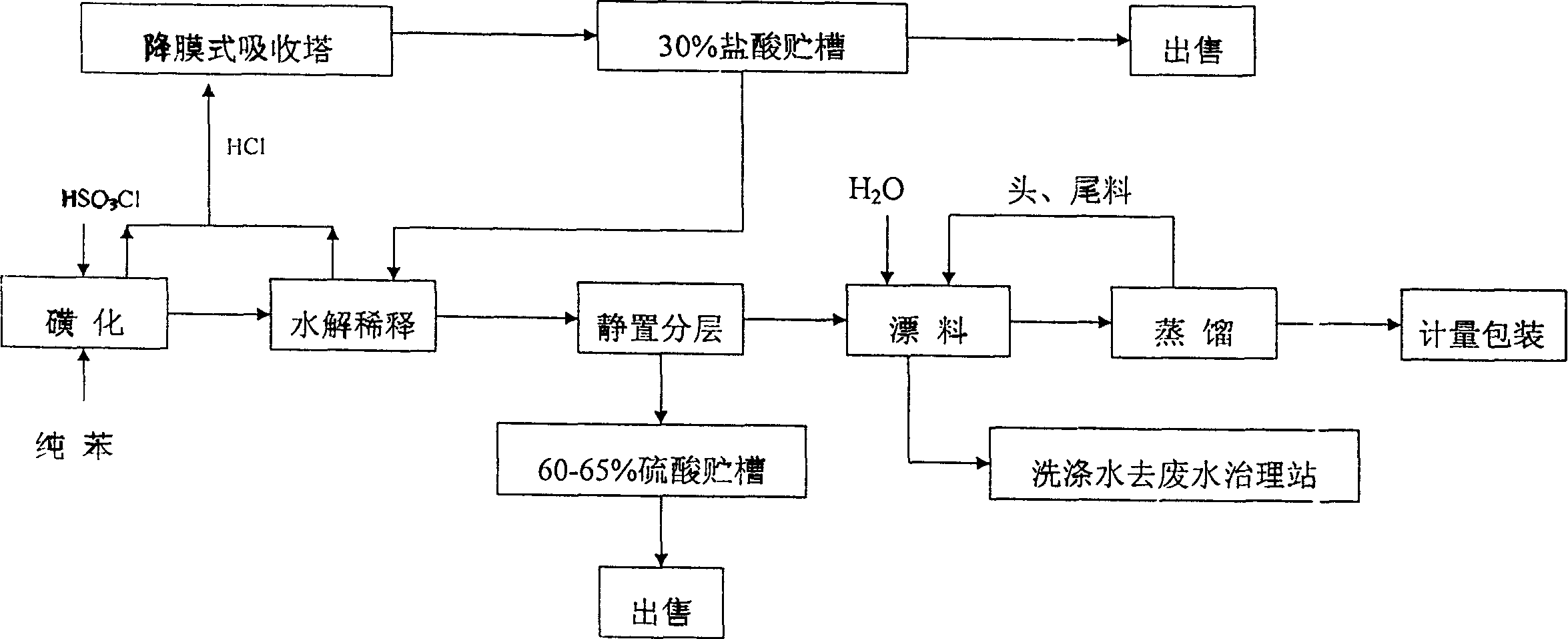

Production technology of phenyl sulfuryl chloride

The present invention provides a production method of benzenesulfonyl chloride. It is characterized by that said invention uses benzene and chlorosulfonic acid as raw material, and makes them undergo the processes of sulfonation reaction, hydrolytic dilution, standing still and layer separation and reduced pressure distillation so as to obtain the invented product. Said invention also provides the concrete steps of every process and its concrete requirements.

Owner:江苏康祥实业集团有限公司

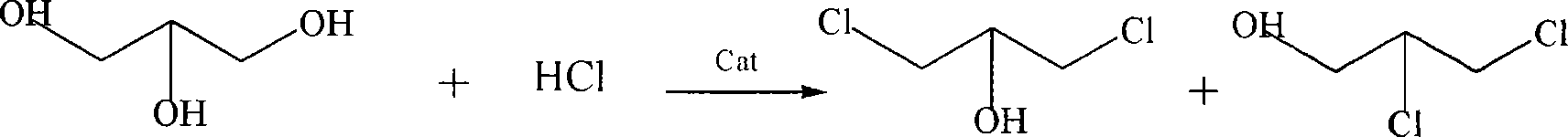

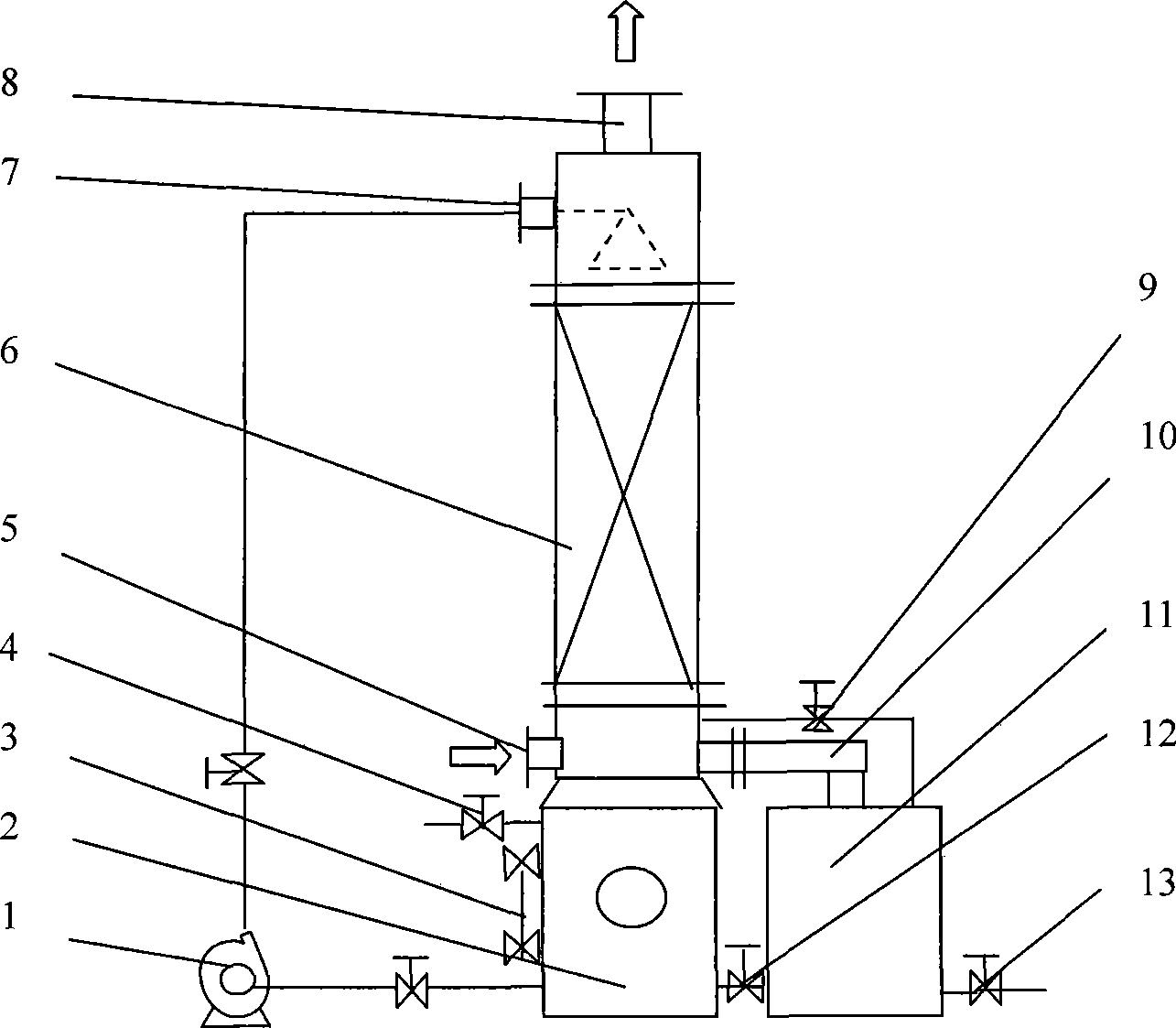

Method for preparing dichloropropanol by glycerol

InactiveCN101182283AImprove conversion rateIncrease reaction ratePreparation by halogen introductionGlycerolCirculating pump

A method of preparing for dichloropropanol from glycerol is that the glycerol and catalyst are added into a spraying type reactor; a liquid circulating pump is used to pump the glycerol and the catalyst our from the spraying type reactor, then the glycerol and the catalyst are sent into the spraying type reactor from the top of the spraying type reactor by the manner of spraying; HCl gas which is absorbed from the lateral part of the spraying type reactor is mixed completely and react with the materials of the glycerol and the catalyst inside the spraying type reactor; at the same time the negative pressure produced by spraying brings a resultant inside the spraying type reactor in the form of an azeotropic matter of water, the dichloropropanol and the HCl; the water and the dichloropropanol in the azeotropic matter are condensed down by a condenser, and the unreacted HCl gas and the complementary HCl gas are sent into the spraying type reactor together for cyclic reaction. The invention has the advantages of the improvement of the reaction velocity and high glycerol transformation rate.

Owner:CHINA RES INST OF DAILY CHEM IND

Method for producing unsaturated polyester resin by utilizing refuse of biatomic acid such as terephthalic acid and catalyst used thereof

The invention discloses a method to use binary ester wastes like P-phthalic acid to prepare unsaturated polyester resin, substituting fully or partly industrial waste residue containing binary acid for the binary acid to produce the unsaturated resin. It adopts stannous oxide, stannous salt or other stannous compound as catalyzer, added in effective quantity of catalyst. It largely reduces production cost and helps protect environment; besides, the new-type catalyzer can accelerate reaction velocity, able to be applied to the production of similar unsaturated resin.

Owner:陈少岳 +3

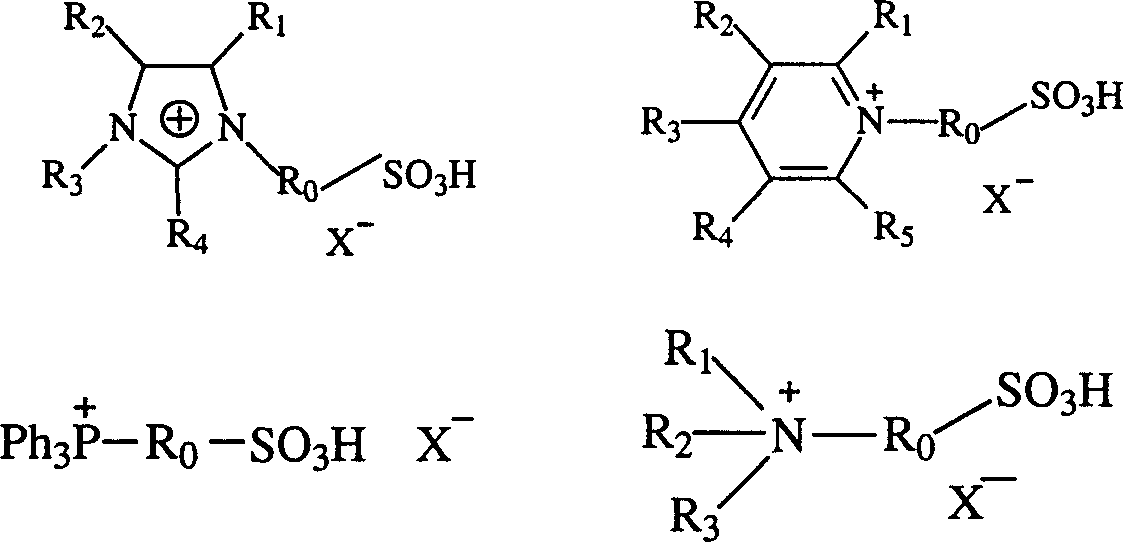

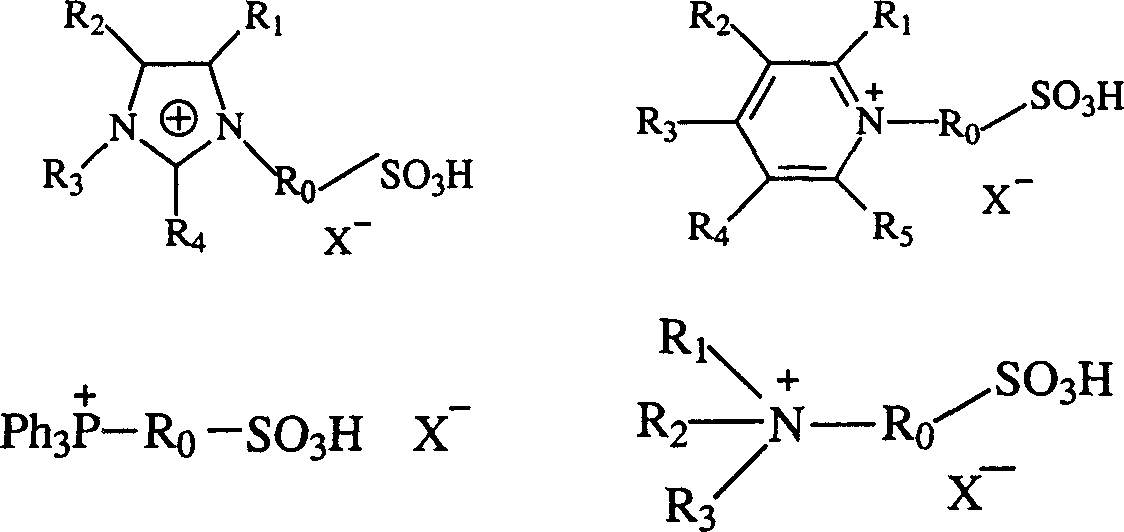

Method for preparing bio- diesel oil

InactiveCN1737086AImprove stabilityNot easy to hydrolyzeBiofuelsLiquid hydrocarbon mixture productionAlcoholBiodiesel

The invention relates to a method for preparing bio- diesel, wherein ionic liquid is used as the catalyst, the reaction temperature is 20-300 deg. C, the reaction pressure is 0.1-2 MPa, the mol ratio of biological grease and short chain alcohols is between 1:30-1:1, the mol ratio of biological grease and ionic liquid catalyst is between 300:1-1:1.

Owner:TSINGHUA UNIV

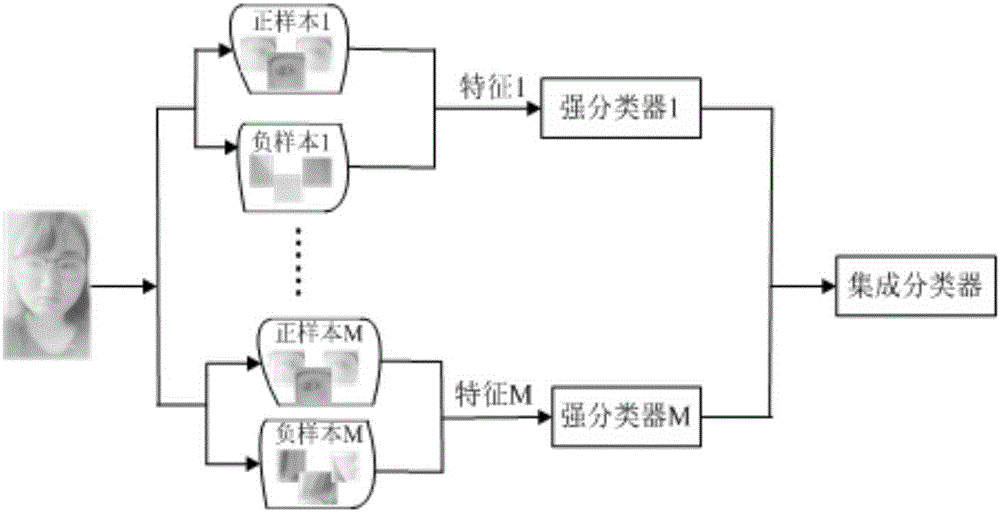

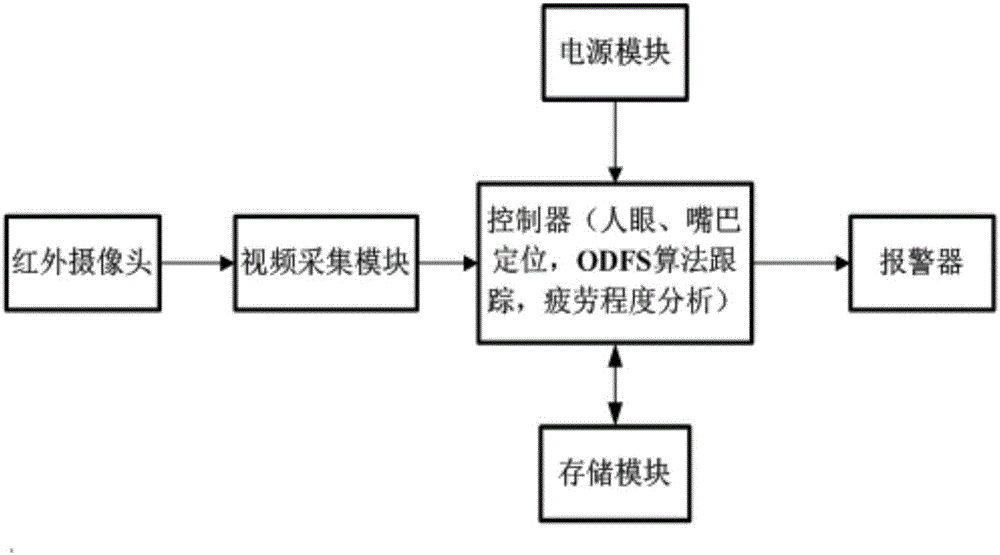

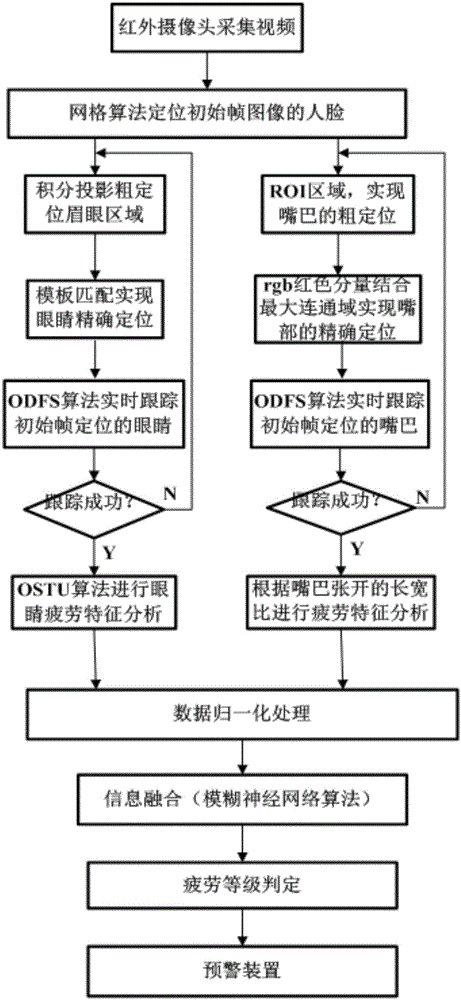

Real time driver fatigue warning system based on multi-source information fusion

ActiveCN106682603AEliminate distractionsImprove robustnessCharacter and pattern recognitionWireless transmissionHistogram equalization

A real time driver fatigue warning system based on multi-source information fusion. Through the real-time acquisition of the driver's facial image from the infrared camera, median filtering of the face image and histogram equalization preprocessing are carried out. After the localization of the initial frame of human eye, the initial frame of the mouth is positioned, and then the real-time tracking is carried out. The OSTU algorithm was used to analyze the state of the eyes and mouth, and the state of the eyes and mouth was analyzed. Finally, the alarm system was activated by wireless transmission equipment when it is necessary according to the different levels of fatigue. The invention has the advantages of small overall operation amount, fast transmission rate, high detection precision and fast response speed, and has the advantages of more practicality and wider application range.

Owner:SHAANXI UNIV OF SCI & TECH

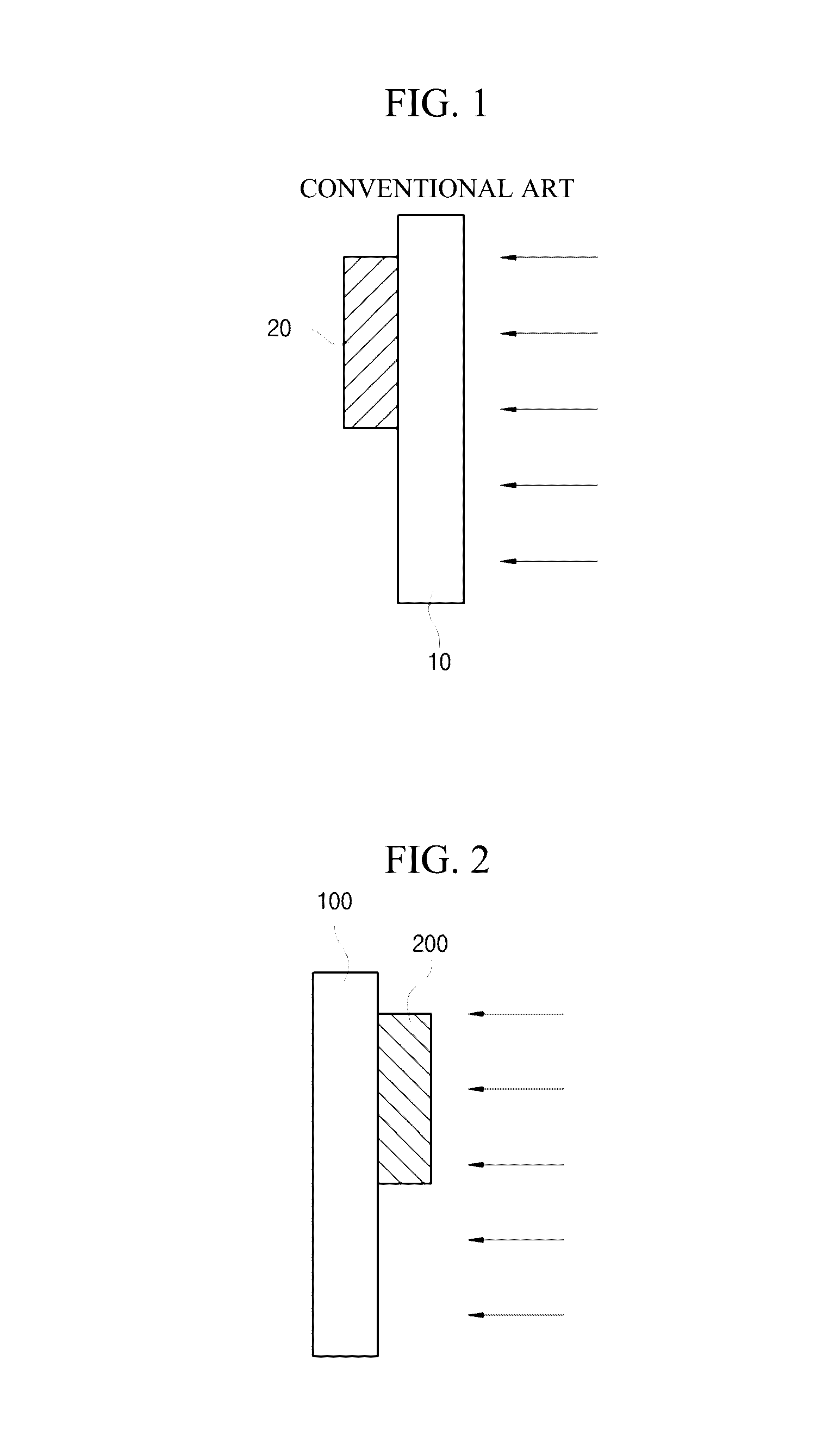

Display room mirror

ActiveUS9499103B2Improving contrast and reaction velocityReduce thickness and weightNon-linear opticsOptical viewingEngineeringLight-emitting diode

Provided is a display room mirror, including a room mirror disposed in an inner part of a vehicle to detect a rear situation of the vehicle; and an organic light emitting diode (OLED) panel formed in a part or an entire part of a front surface of the room mirror, thereby improving a contrast and a reaction velocity and reducing a thickness and a weight of the room mirror.

Owner:LG INNOTEK CO LTD

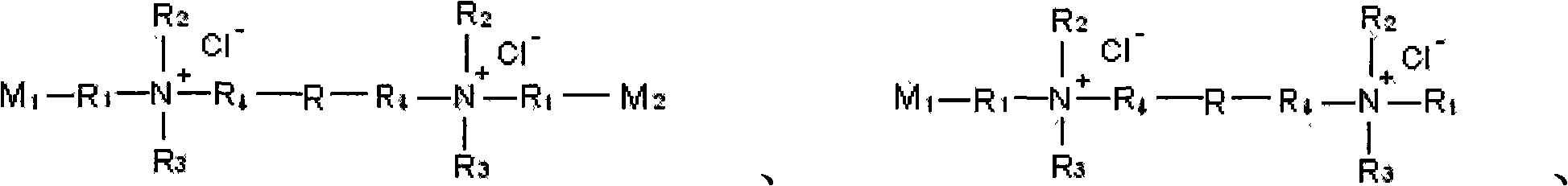

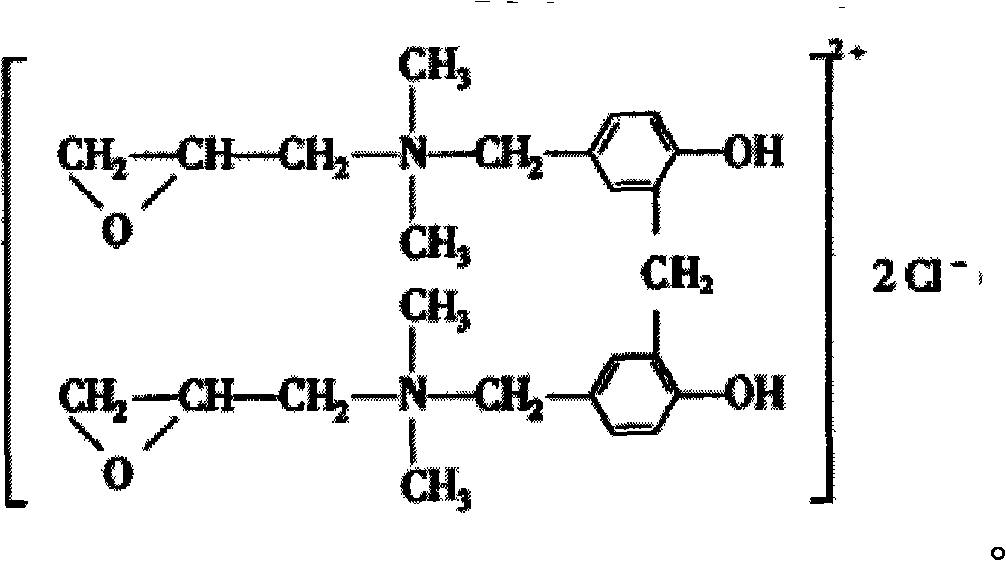

Method for improving cationized modification evenness of cotton fabrics

The invention belongs to the technical field of dyeing and finishing, relating to a method for improving the cationized modification evenness of cotton fabrics. The method comprises the following steps: (1) preparing modified solution by utilizing modifier containing reactive groups and cationic groups, placing the cotton fabrics in the modified solution, heating the solution to the temperature of between 85 and 95 DEG C, and preserving the temperature for 20 to 30 minutes; and (2) cooling the mixture system obtained in the step (1) to the temperature of between 30 and 40 DEG C, adding caustic soda in the mixture system to ensure that the concentration of the mixture system in the solution reaches 0.5 to 1g / L, reacting for 20 to 30 minutes, and taking out and washing the cotton fabrics with water. The double-temperature modification process ensures that the cationic modifier is diffused and homogenized in the high-temperature neutral condition, and reacts and combines with the cotton fibers in the low-temperature strong alkali condition, thus reducing modifying unevenness caused by hydrolysis loss and excessive reaction velocity of the modifier in the high-temperature alkali condition, or reducing the problem of poor modifying evenness and penetration of the modifier in the low temperature condition.

Owner:HUZHOU ZHILI CHILDRENS CLOTHING DEV

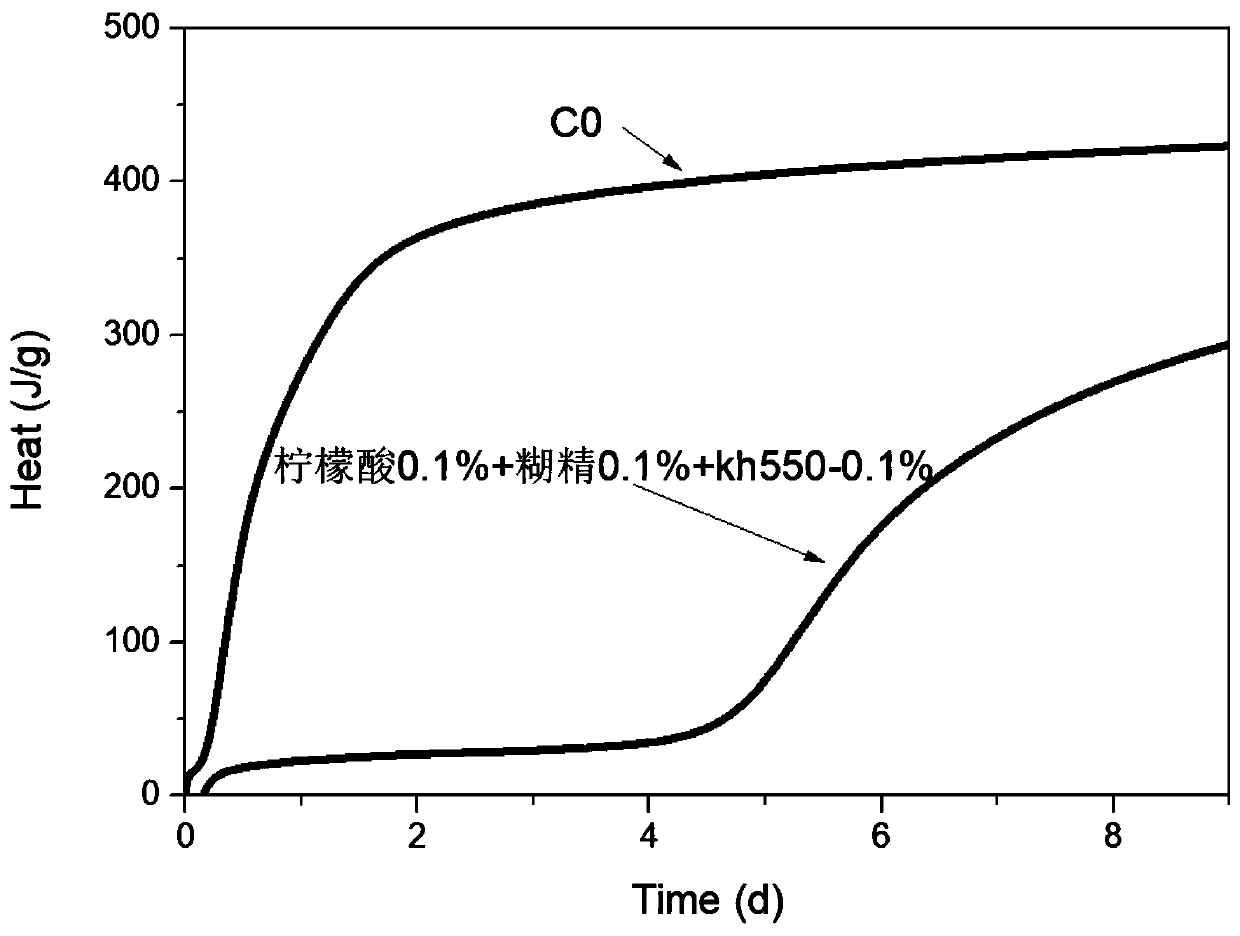

Composite and adjustable hydration heat cement-based material and application thereof

ActiveCN109776022ASlow down the rate of hydration reactionsAvoid concentrated releaseHydration reactionTemperature stress

The invention discloses a composite and adjustable hydration heat cement-based material and application of the material in reducing the speed of a cement hydration reaction. The composite and adjustable hydration heat cement-based material comprises a cross-linking agent, organic acid and organic starch-base macromolecule matter. The composite and adjustable hydration heat cement-based material issimple in preparation technology, low in cost and capable of adjusting the cement hydration rate by stages, and compared with the prior art, great improvement is achieved, and the maximum peak valueof the heat release rate of cement hydration can be reduced. The amount of released heat in the cement hydration process can be further reduced, the phenomenon that cracking of mass concrete is causedby temperature stress is effectively reduced, and the durability and safety of a mass concrete member are improved.

Owner:SOUTHEAST UNIV

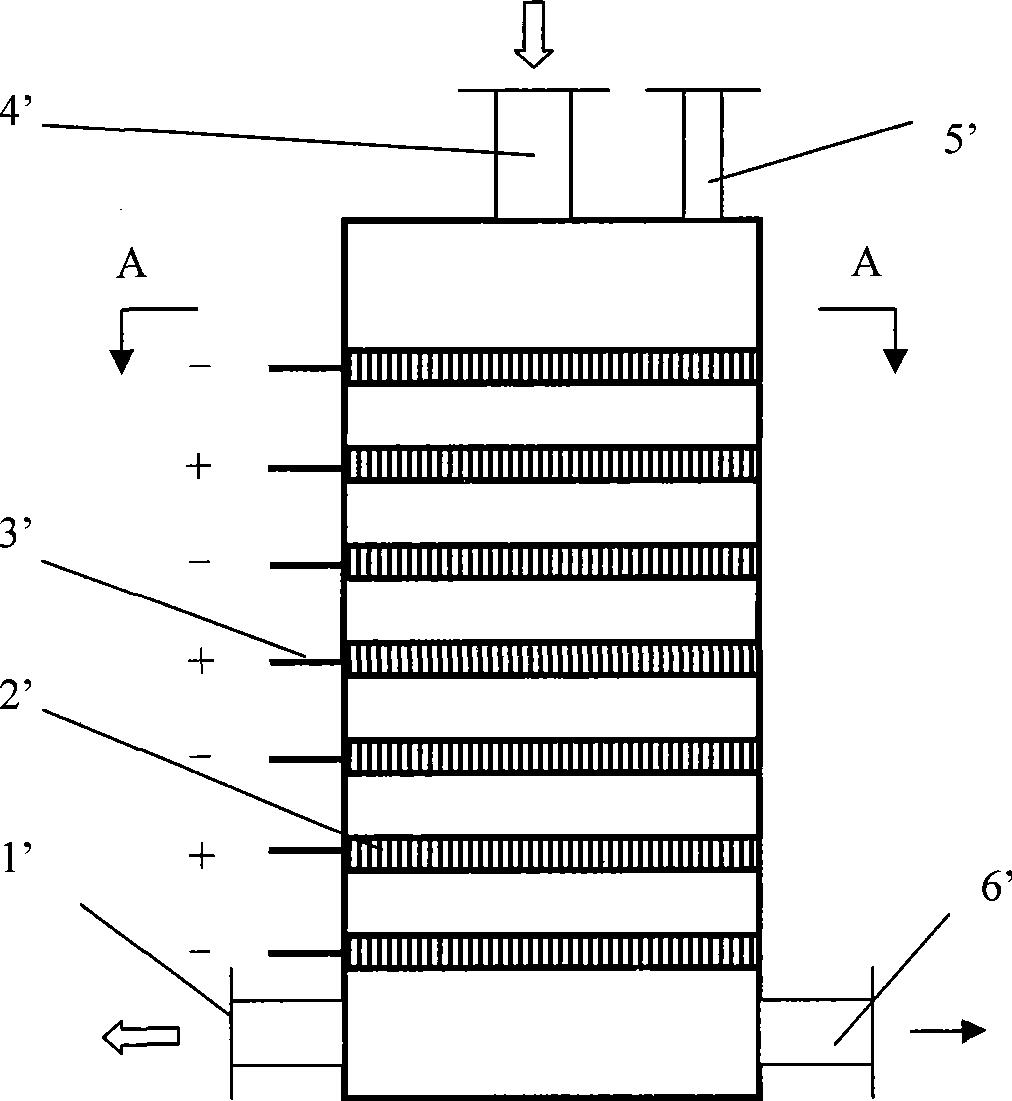

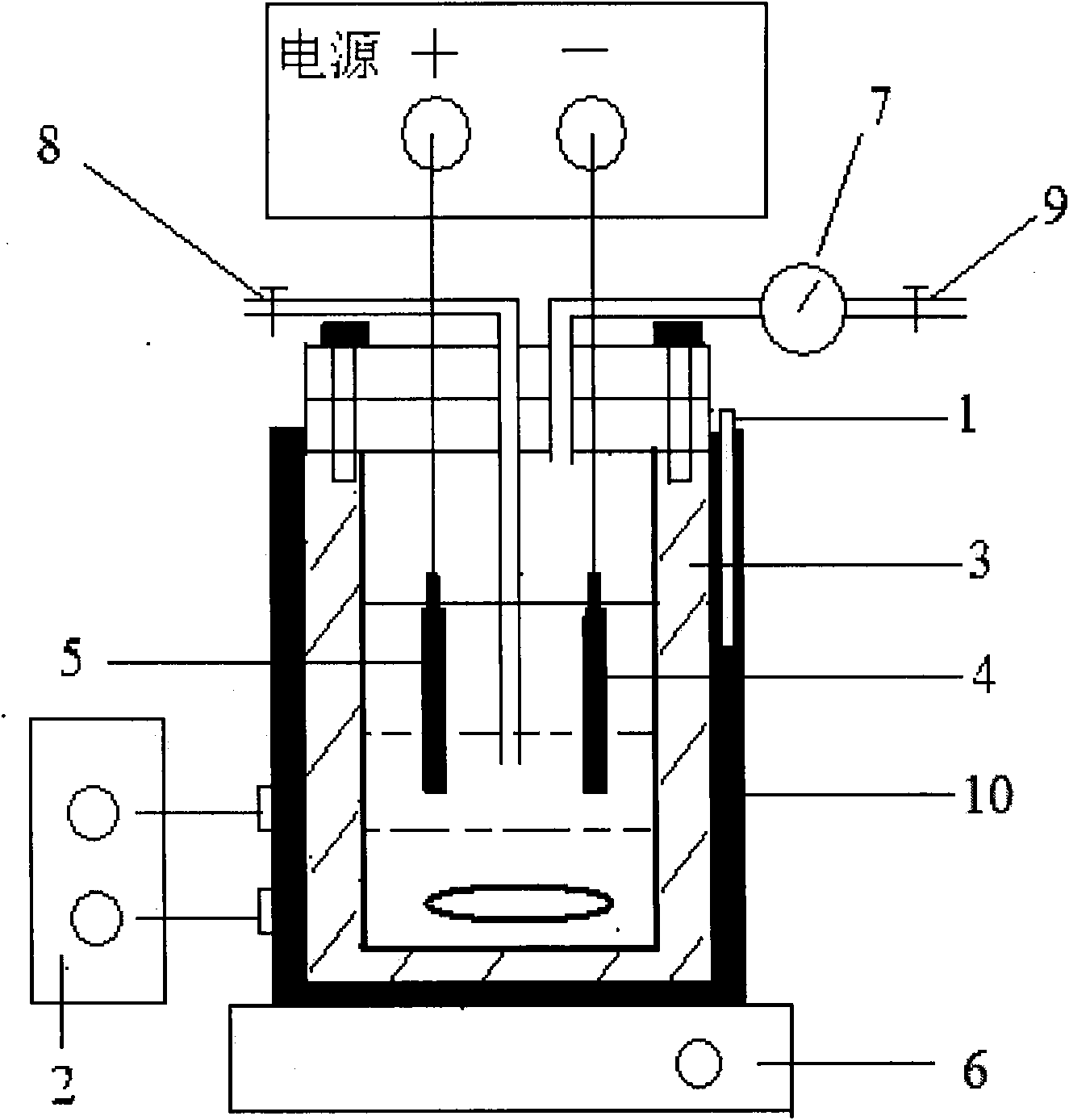

Method for absorption treatment of noxious exhaust gas by electrochemistry method

InactiveCN101474527AImprove removal efficiencyQuick responseGas treatmentDispersed particle separationElectrochemical responseSolubility

The invention relates to a method for absorbing and treating harmful waste gases by an electrochemical process. Gases containing the harmful waste gases to be treated are led into an adsorption tower; wherein, the harmful gases are absorbed by absorption liquid and become a resulting absorbent product. The purified gas is discharged from a gas discharging port. The absorption liquid containing the resulting absorbent product enters into an electrochemistry reactor. The resulting absorbent product are reacted chemically in the electrochemistry reactor and converted into materials with the chemical stability so that the absorption liquid is regenerated. The absorption liquid is of acid aqueous solution or acid and salt blending aqueous solution. The method causes that the electrochemistry oxidation reaction is carried out on the absorbed noxious substance in the sour environment; the reaction velocity is greatly increased. The method is especially suitable for the reaction absorption treatment of harmful waste gases such as hydrocarbon with bad water-solubility, organic matters containing halogen, sulfur or nitrogen elements, waste gas in a sewage plant and ammonia, etc.

Owner:黄立维

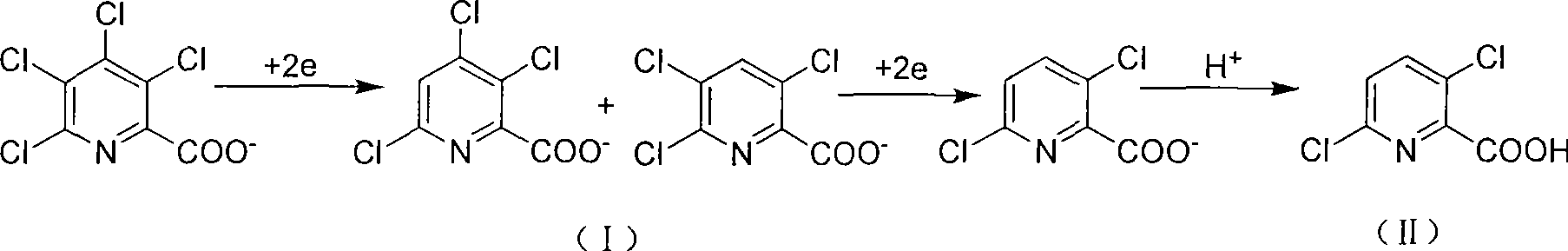

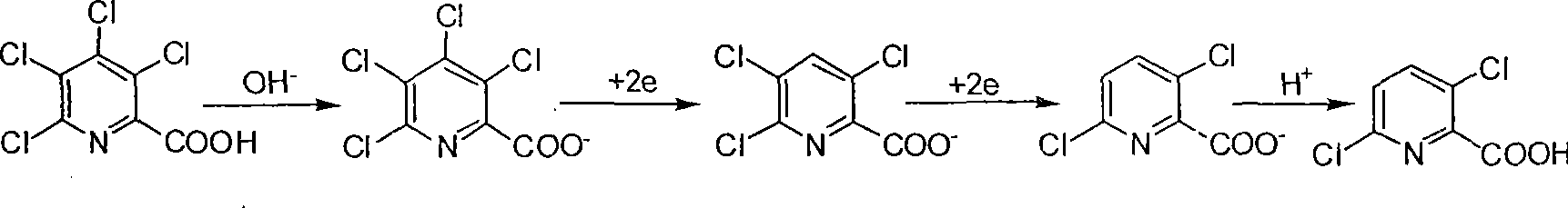

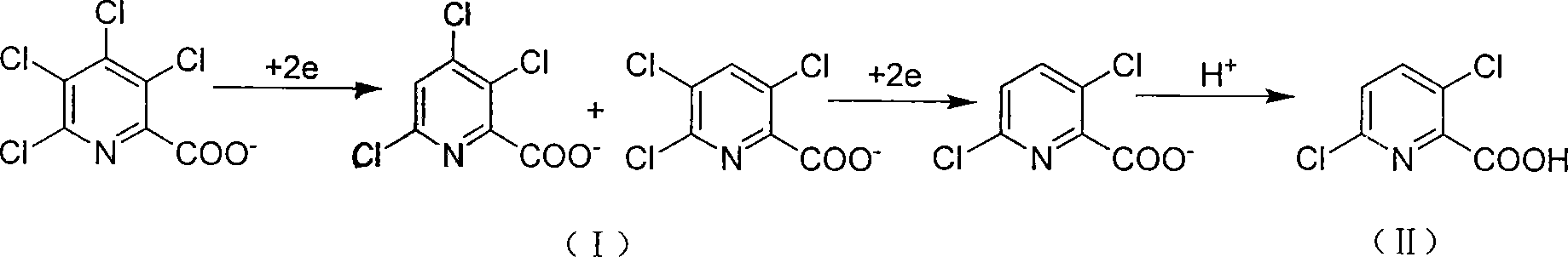

Electrolytic synthesis method for 3,6-dichloropicolinic acid

ActiveCN101235512AReduce dosageIncrease temperatureOrganic chemistryElectrolysis componentsElectrolysisSynthesis methods

An electrolytic synthesis method of 3,6-matrigon takes alkaline aqueous solution as the reacting medium, which comprises the following step: dissolving 3,4,5,6-tetrachloropicolinic acid or the salt of the 3,4,5,6-tetrachloropicolinic acid in the alkaline aqueous solution, proceeding the electrolytic reducing reaction, obtaining target compound (II) after the electrolytic reaction and the acidification, wherein, firstly, proceeding the electrolytic reaction in the alkaline aqueous solution system with pH value 8.5-11, secondly, continuingly completing the electrolytic reaction under condition of the alkaline range is between pH value 13 and pH value 13.5 after obtaining trichloropyridine formate intermediate compound (I). The method has the advantages of easy operation, safety, friendly to the environment, the reaction temperature of the first stage can reach over 80 DEG C, the dissolvability of the reactant is efficiently improved, the reaction velocity is quickened, the batch output of the products is increased, and the spurging and the hydroxylating secondary reaction are efficiently avoided.

Owner:LIER CHEM CO LTD

Method Of Making Reactive Composite Materials and Resulting Products

InactiveUS20090178741A1Large-scale and cost-effective mechanical formationEliminates tendency of deformedExplosive working-up apparatusEngineeringMechanical engineering

Novel reactive composite materials and associated methods for making the same which are pertinent to numerous new or improved applications. The method for making the reactive composite materials utilizes mechanical deformation to manufacture such materials with controlled, predictable characteristics. In the first deformation step, an assembly of reactive layers and / or particles is plastically deformed to reduce its cross sectional area by one-half or more. Portions of the deformed sheets are stacked or bent into a new assembly, and the new assembly is then deformed. The steps of assembly and deformation are repeated a sufficient number of times that the resulting materials are only locally layered but have relatively uniform reaction velocity and heat generating characteristics predictable by stochastic models derived herein.

Owner:NANOFOIL CORP

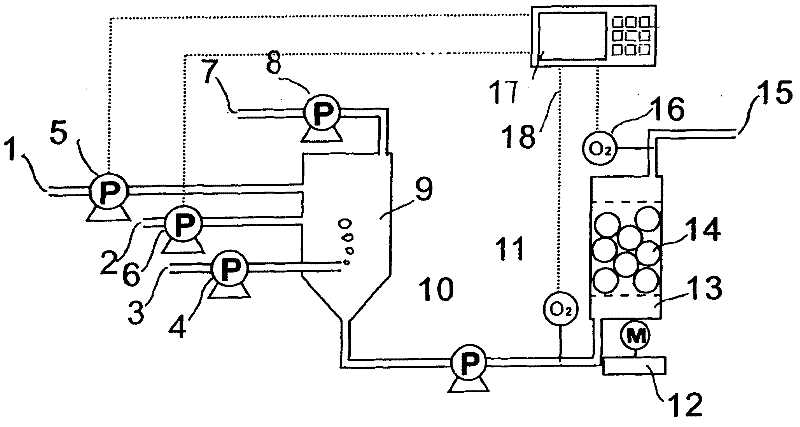

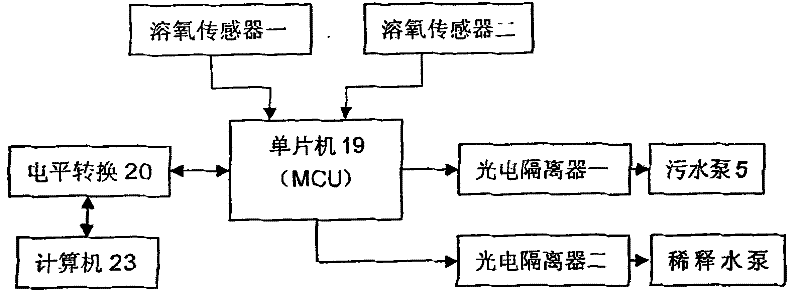

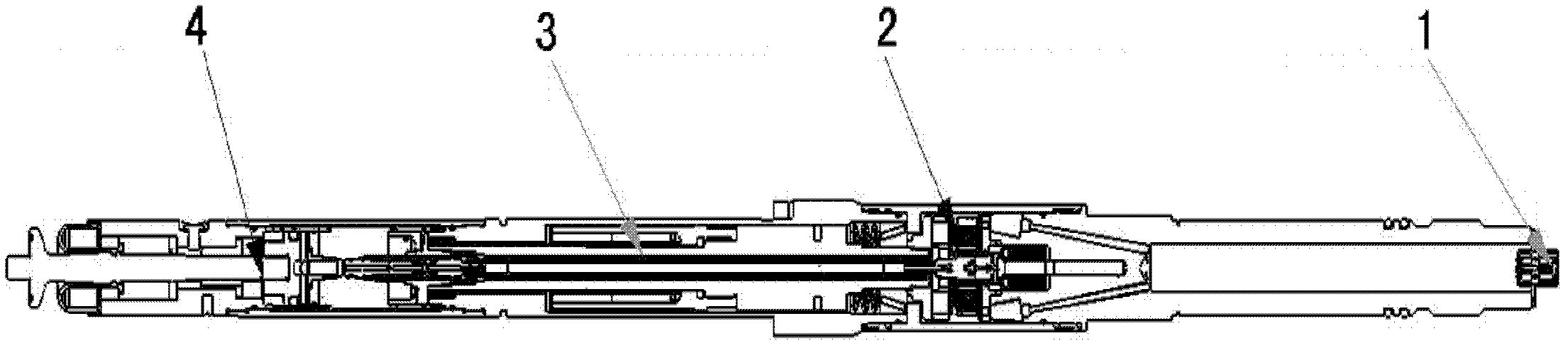

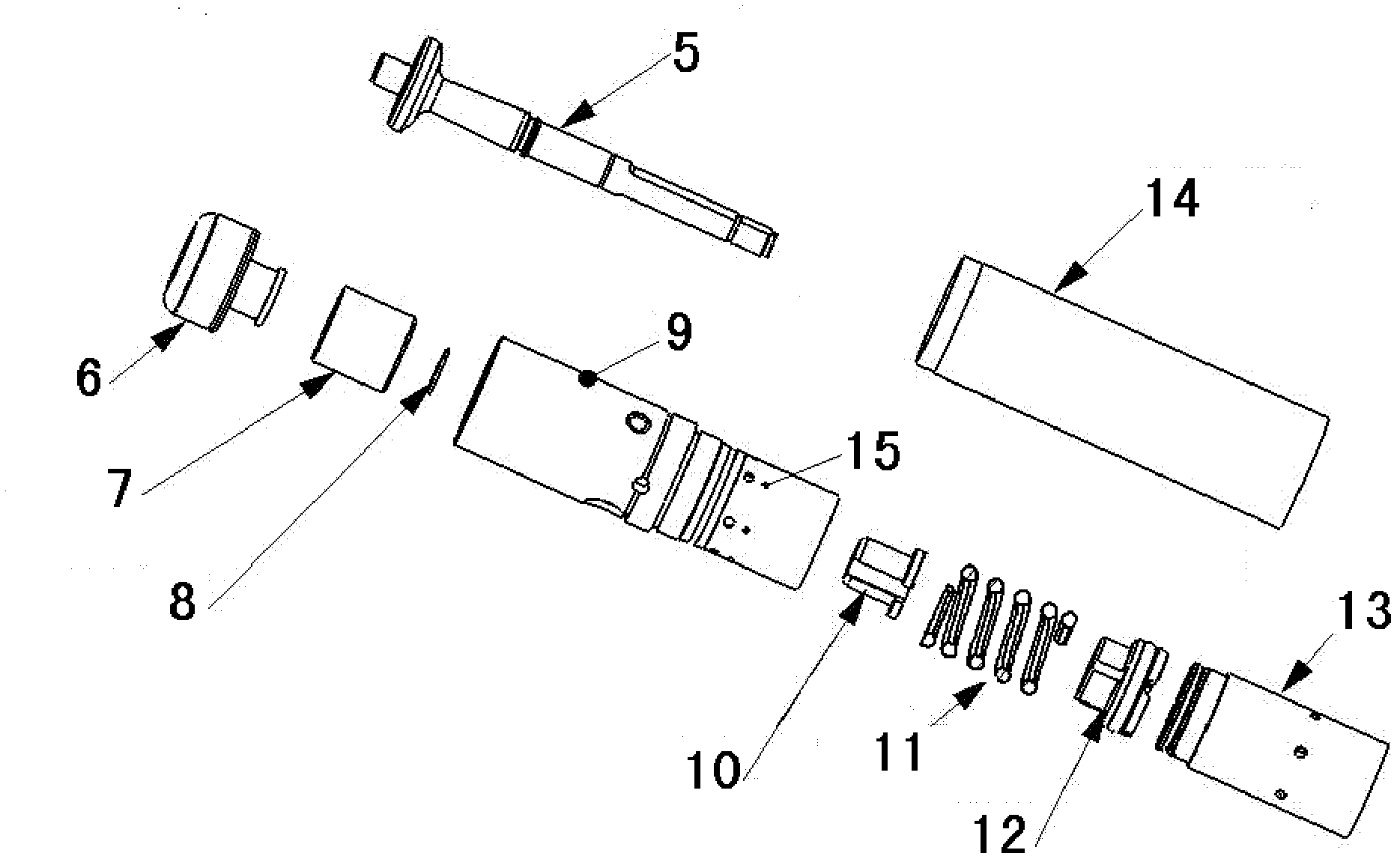

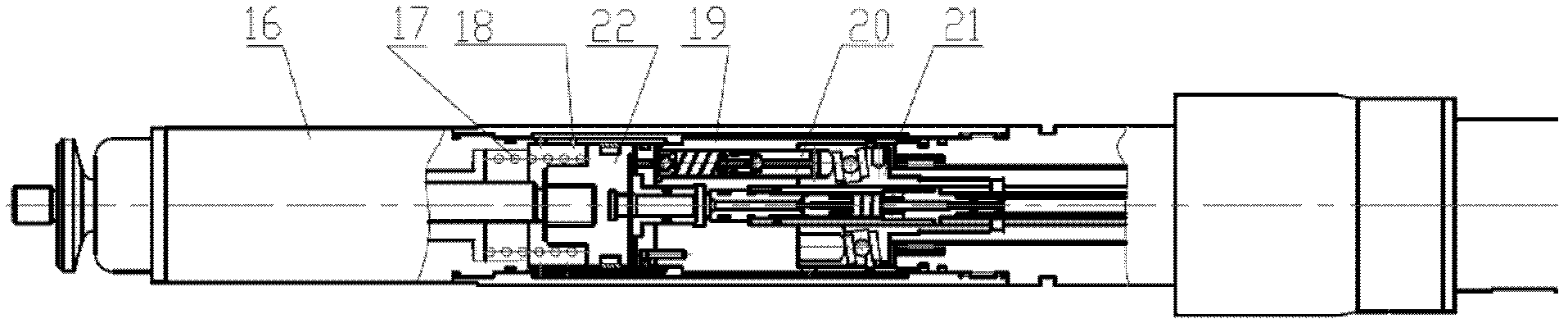

Biochemical oxygen demand bod on-line measuring instrument and its detection method

InactiveCN102288653ADensity Type LimitsNo need to replaceMaterial electrochemical variablesMeasuring instrumentAir pump

The invention relates to a biochemical oxygen demand BOD online measuring instrument and a detection method thereof. The sewage pump, dilution water pump, air pump and buffer pump are connected to the aeration tank, the aeration tank is connected to the reactor, the reactor is connected to the controller, the connecting pipe and the connecting wire are equipped with dissolved oxygen electrodes, and the controller is connected to the sewage pump, dilution water pump. When the sewage to be tested passes through the sewage pump, the dilution water passes through the dilution water pump, and the air is pumped to the aeration tank through the air pump to aerate and reach dissolved oxygen saturation, after passing through the porous ceramic of the reactor, measure the change of dissolved oxygen concentration before and after passing through the porous ceramic material . The dissolved oxygen concentration of the effluent sewage after the reaction is continuously monitored by the dissolved oxygen sensor. The controller controls the input flow rate of the sample to keep the change of the dissolved oxygen concentration constant, and calculates the BOD value according to the flow rate of the sample to be tested under the condition that the dissolved oxygen concentration reaches the same constant value after the reaction and the input flow rate of the standard sample. The measurement process of the present invention is fully automated, can monitor continuously in real time, and display the dynamic BOD value of the water body at any time.

Owner:陈威

Positive pulse device for slurry under shaft

ActiveCN102536217AChange the return reaction speedShorten the round trip distanceSurveyTrip distanceSlant angle

The invention discloses a positive pulse device for high-speed slurry under a shaft. The positive pulse device comprises an output terminal, a valve body and generator assembly, an intermediate bearing bush and top assembly which are connected sequentially, wherein the top assembly comprises a piston and a spring which are arranged in a shell on the top and a plunger pump and a tilting tray which are arranged at the upper end of the intermediate bearing bush; the plunger pump comprises a plunger pump shell and a plunger positioned in the plunger pump shell; an oil drainage hole is formed in the shell on the top and is positioned on the end part below the shell on the top; and a return spring is arranged between the shell on the top and the piston. In order to overcome the defect of slow data transmission of the conventional pulser, according to the positive pulse device, parts such as the oil drainage hole, the plunger, the tilting tray and the like are improved, namely a slant angle of the tilting tray is improved, the round-trip distance of the piston is shortened, the speed of pulses is improved, and the return spring is arranged between the piston and the pump additionally to change the response speed of the return stroke of the pulser, so that the response speed of the pulser is improved, and the data transmission speed of high-speed pulse interval data formats is ensured.

Owner:GOALTECH

Electrocatalysis wet-type peroxide oxidizing method for high-effect waste water processing and devices thereof

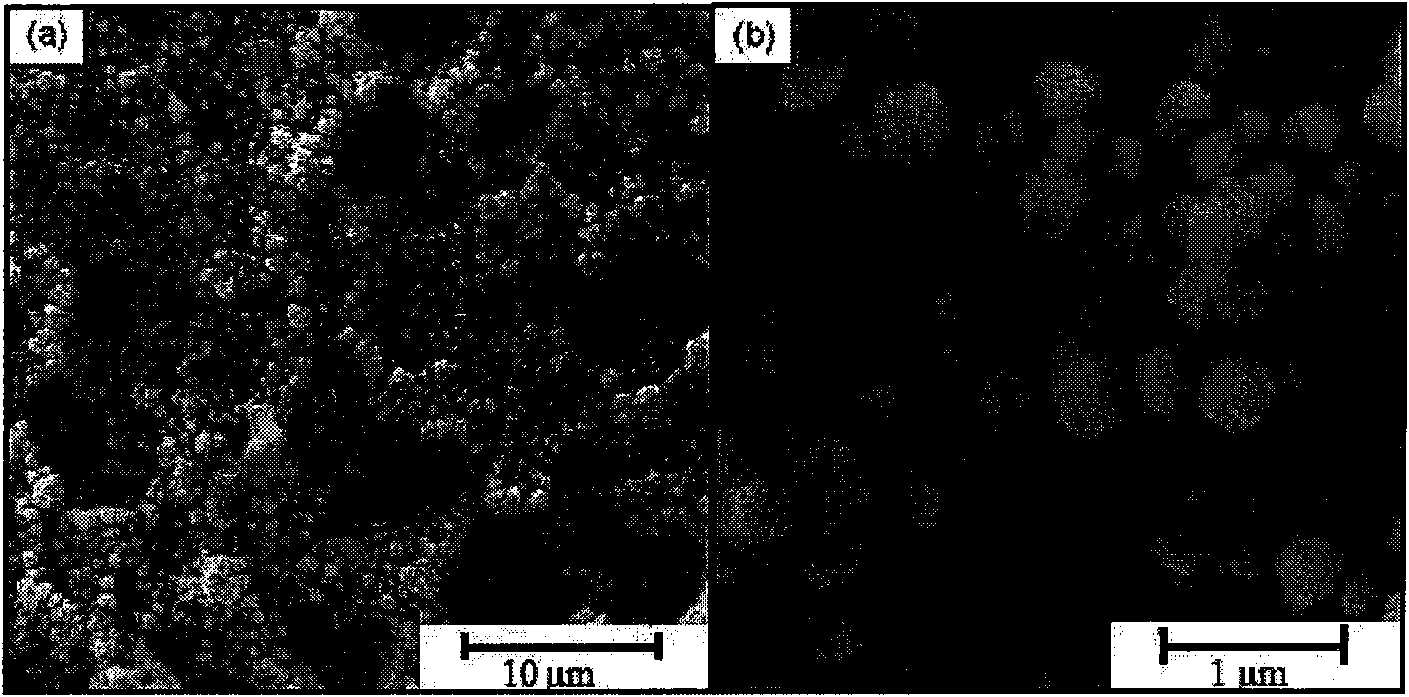

InactiveCN101671088ATake full advantage of electrocatalytic propertiesGood electrocatalytic propertiesMultistage water/sewage treatmentWater/sewage treatment by heatingTin dioxideGas phase

The invention relates to an electrocatalysis wet-type peroxide oxidizing method for high-effect waste water processing and devices thereof. Devices used for the method comprise a high-pressure reaction kettle, a heater, a temperature controller, a magnetic stirrer, a pressure meter, a liquid-phase sampling valve, a gas-phase sampling valve, a replaceable anode electrode and a replaceable cathode electrode. The invention uses a nanometer platinum electrode as an electrocatalyst of wet-type catalysis oxidization to be applied in the organic pollutant of difficult biochemical degradation. Compared with the common catalysis wet-type peroxide method of a nanometer platinum catalyst, the invention accelerates the oxidizing reaction velocity and the mineralizing velocity of the organic pollutant,and reduces the oxidizing and activating energy of the primary reacting substance. Under the condition of same time and different temperatures, the removal rate of TOC in 2, 4-dichlorphenoxyacetic acid is increased by 80 to 93 percent. The anode of the device used by the method can be a replaceable anode, and flat plate electrodes in common use such as a boron-mixed diamond membrane electrode, alead dioxide electrode, a tin dioxide electrode and the like can be applied in the method of waste water processing. The technology has simple operation, and has good processing effect on organic waste water, and wide application prospect and developing potential.

Owner:TONGJI UNIV

Method for hydrocarbon raw material steam thermal cracking

InactiveCN107814675ASpeed up the cracking reaction rateImprove unit time processing capacityHydrocarbon by hydrocarbon crackingPolyolefinPolyamide

The invention relates to a method for hydrocarbon raw material steam thermal cracking. According to the method, one or more tree-like branched polymers are adopted as active aids to be put into a cracking raw material and cracked simultaneously or cracked in sequence in the thermal cracking process, and cracking of a hydrocarbon raw material is initialized and induced, so that the reaction velocity is increased, the reaction temperature is reduced, and product distribution can be regulated and controlled. The tree-like branched polymers used in the method comprise polyolefin, poly(ether-ester), polyether, polyamide, polyurethane, polysilane and the like, and the addition amount of the polymers is within 0.001-10%.

Owner:ZHEJIANG UNIV

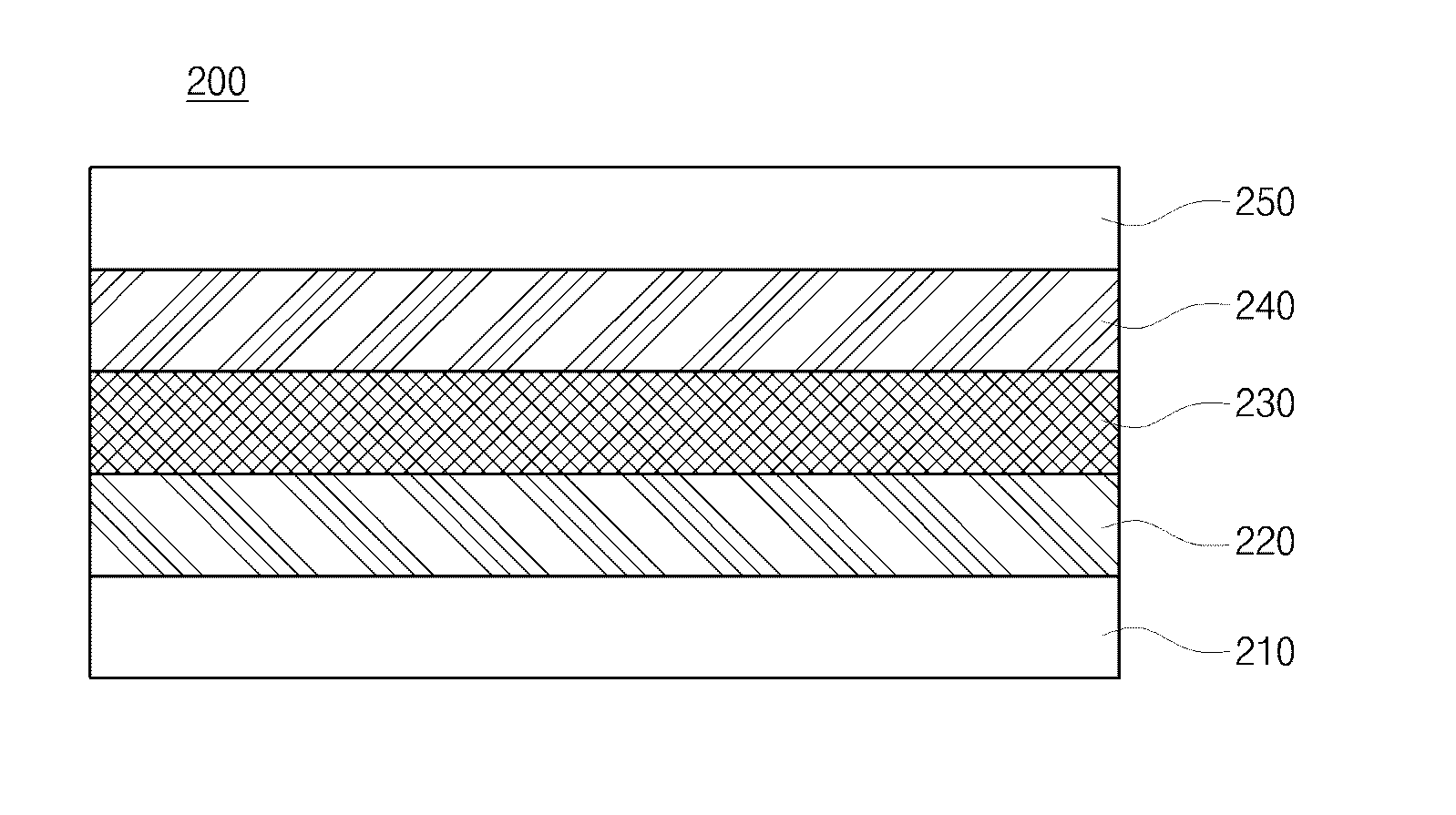

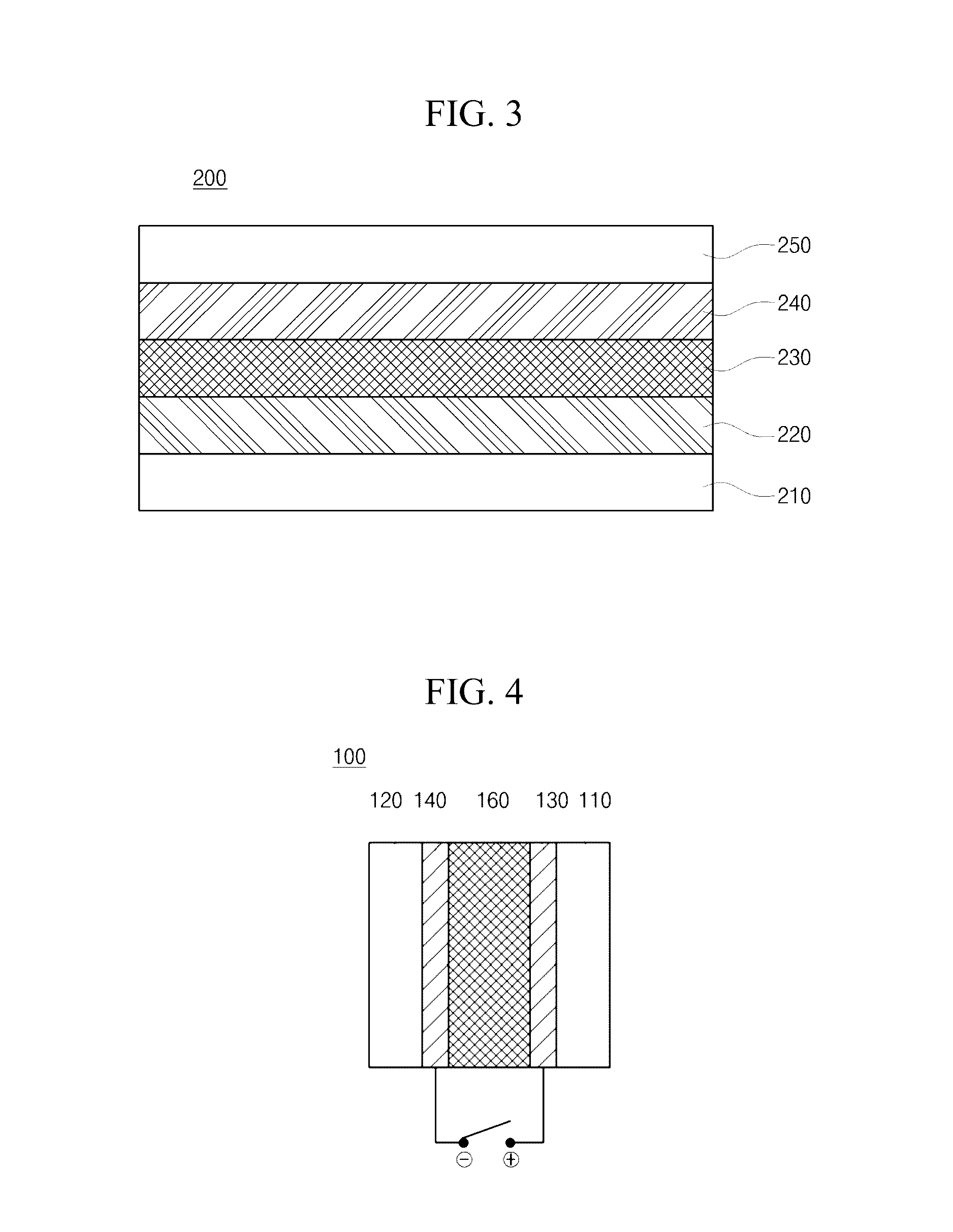

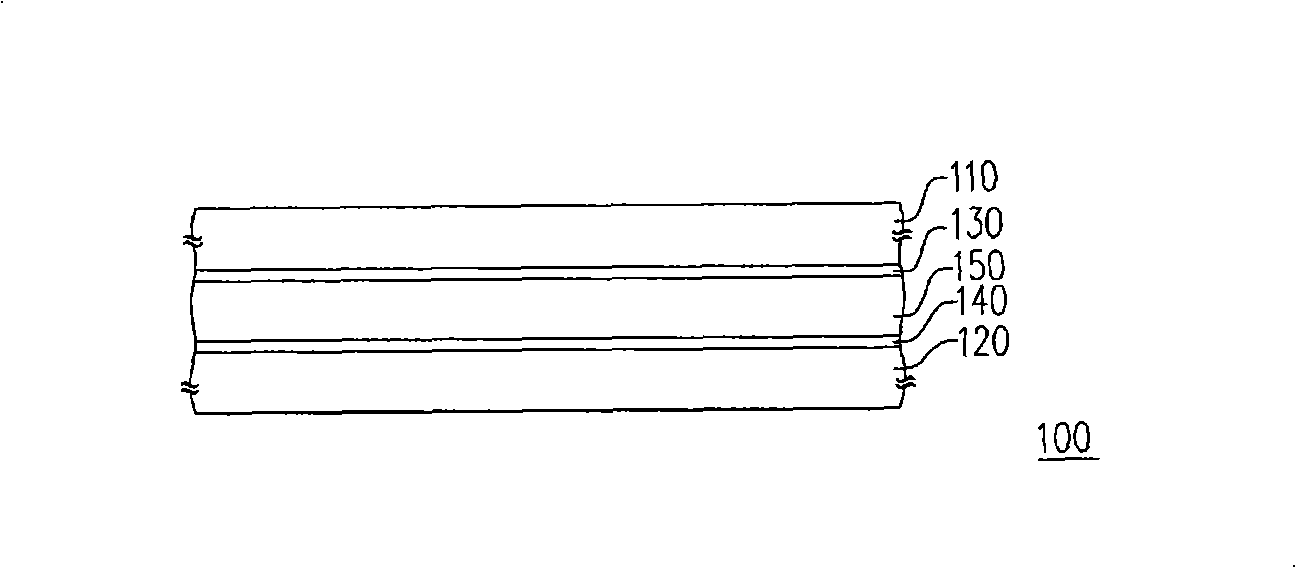

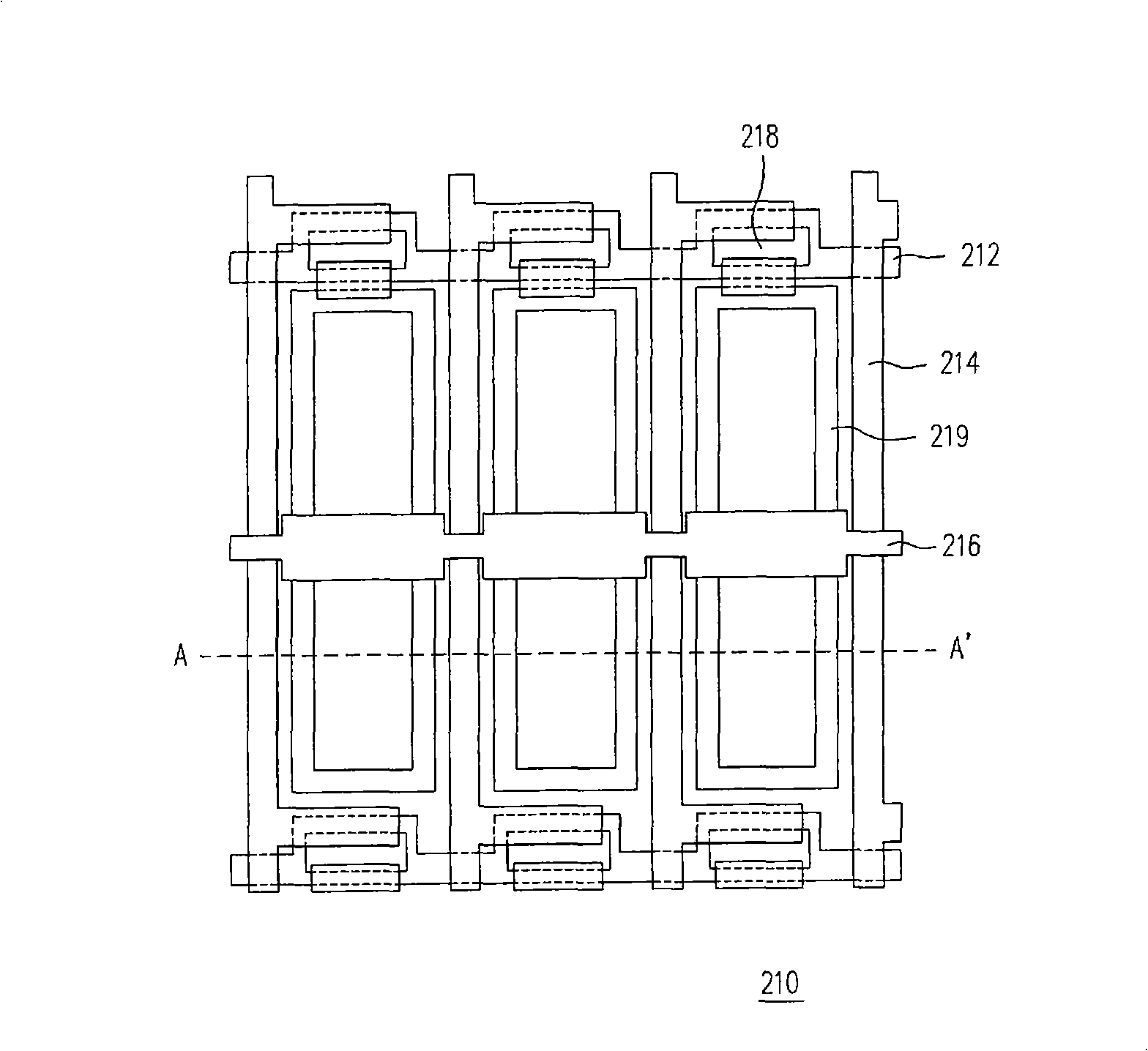

Lcd device and its manufacture method

InactiveCN101285967AStrong anchoring forceImprove stabilityNon-linear opticsReaction velocityLiquid crystal molecule

The invention relates to a liquid crystal device and a method for manufacturing the same. The liquid crystal display device comprises a substrate, a subtend substrate, a liquid crystal layer, a non-contacting alignment layer and a liquid crystal stable layer. The liquid crystal layer is provided with at least one liquid crystal molecule; the liquid crystal layer is arranged between the substrate and the subtend substrate; the non-contacting alignment layer is arranged between the substrate and the liquid crystal layer and / or between the subtend substrate and the liquid crystal layer; and the liquid crystal stable layer is arranged between the liquid crystal layer and the non-contacting alignment layer. The liquid crystal display device simultaneously combines the non-contacting alignment layer and the liquid crystal stable layer, thereby having the characteristics of providing good and stable alignment effect for the liquid crystal molecule and contributing to simultaneously improving reaction velocity and wide view angle of the liquid crystal molecule and so on.

Owner:INNOLUX CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com