Methods of making reactive composite materials and resulting products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063]This description is divided into two parts: Part I describes reactive composite materials and their fabrication in accordance with the invention; and Part II describes the beneficial features and characteristics of the resulting products in relation to fabrication parameters.

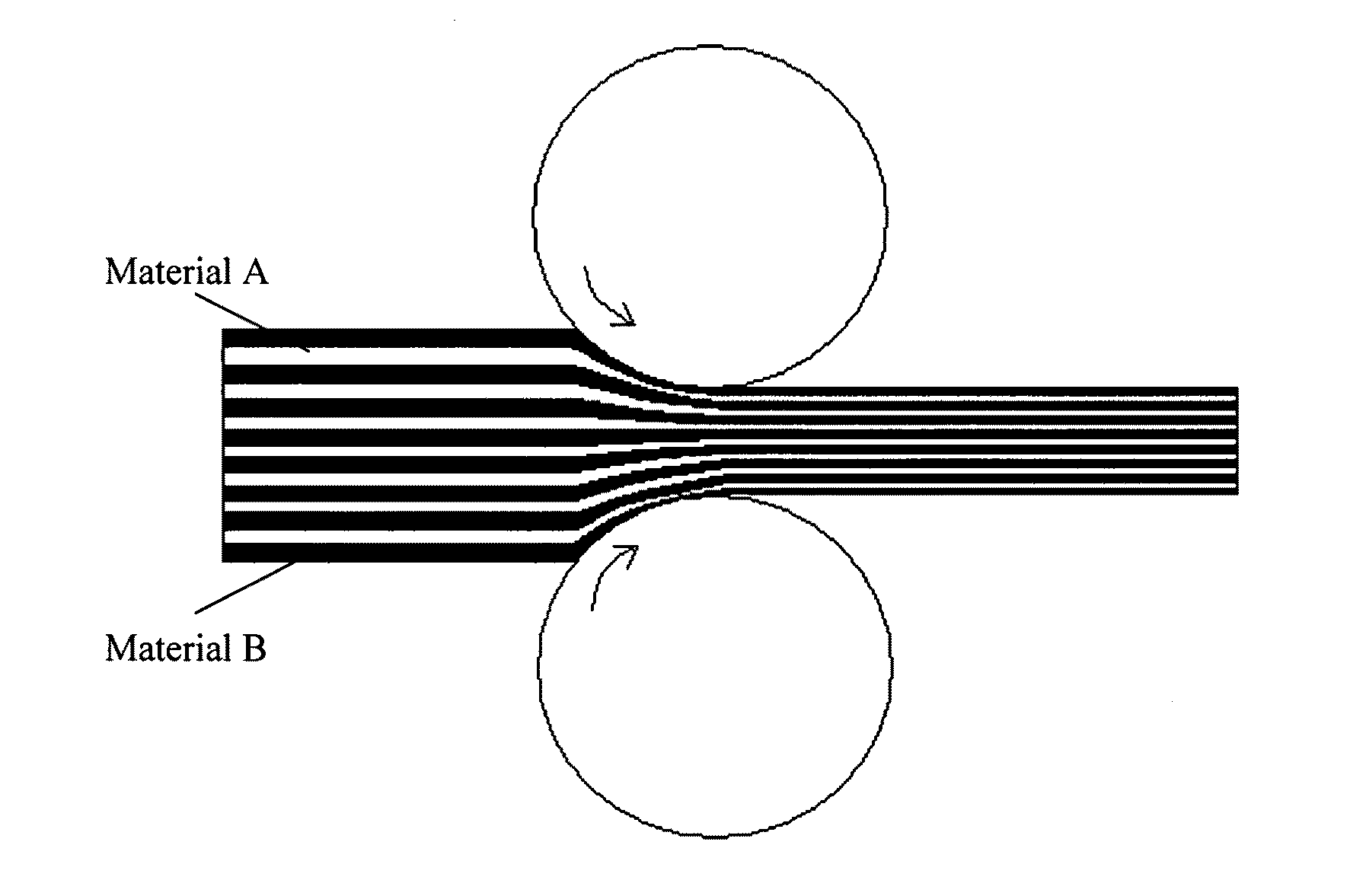

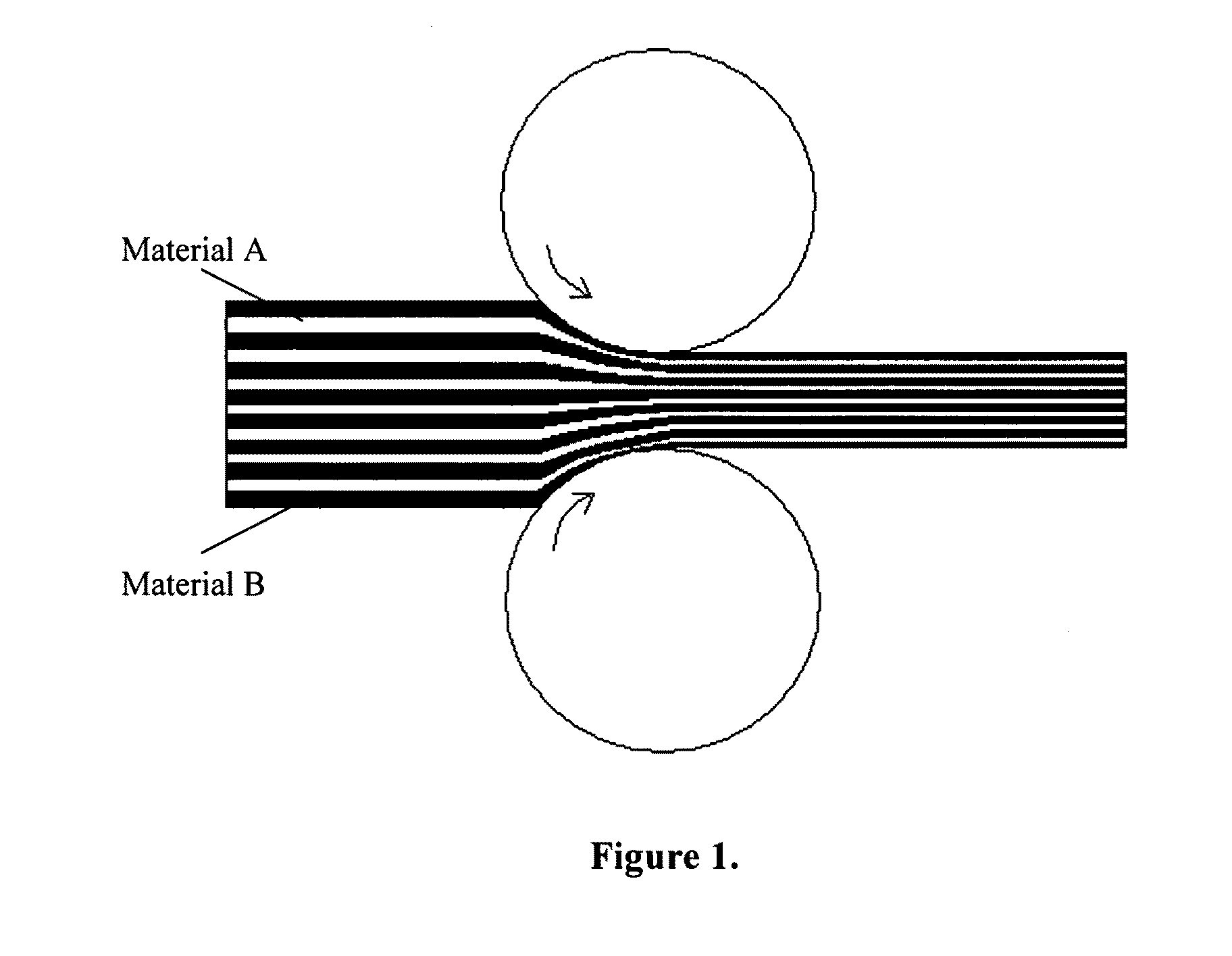

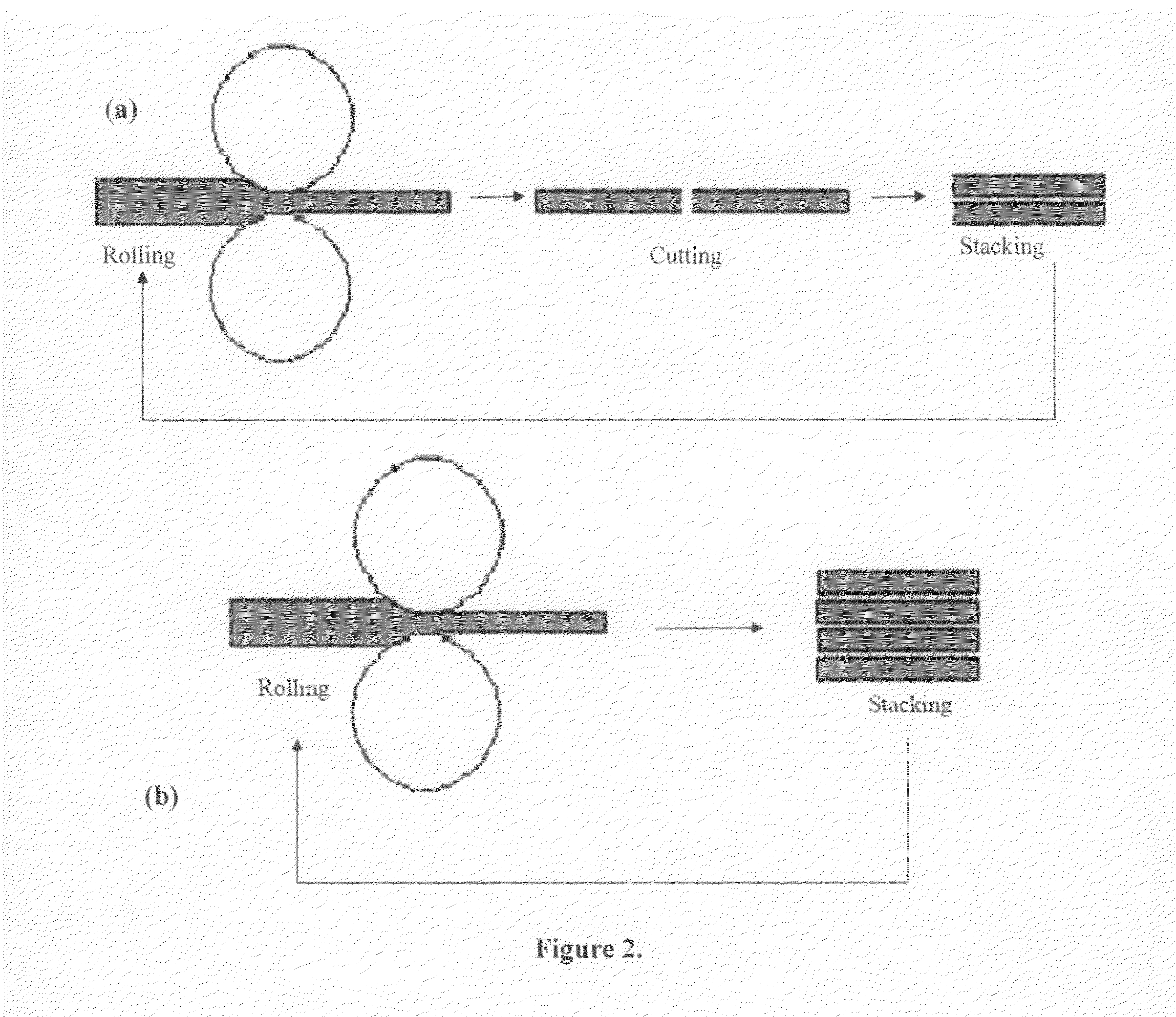

[0064]I. Methods of Fabricating Reactive Composite Materials

[0065]Recent developments in reactive multilayer technology have shown that it is possible to carefully control both the heat of the reaction as well as the reaction velocity, and have also provided alternative means for fabricating nanostructured multilayers. For instance, it has been demonstrated that the velocities, heats, and temperatures of the reactions can be controlled in uniformly layered RCMs by varying the thicknesses of the alternating layers1,2. It has also been shown that the heats of reaction can be controlled by modifying the multilayer composition, or by low-temperature annealing of the reactive multilayers after their fabrication...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com