Improved MUCT technology and device

A technology of a process device and a stirring device, applied in the field of biological sewage treatment, can solve the problems of increased water treatment cost and low reaction speed, and achieve the effects of preventing further harm, high nitrous acid accumulation rate, and maintaining nitrous acid accumulation rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

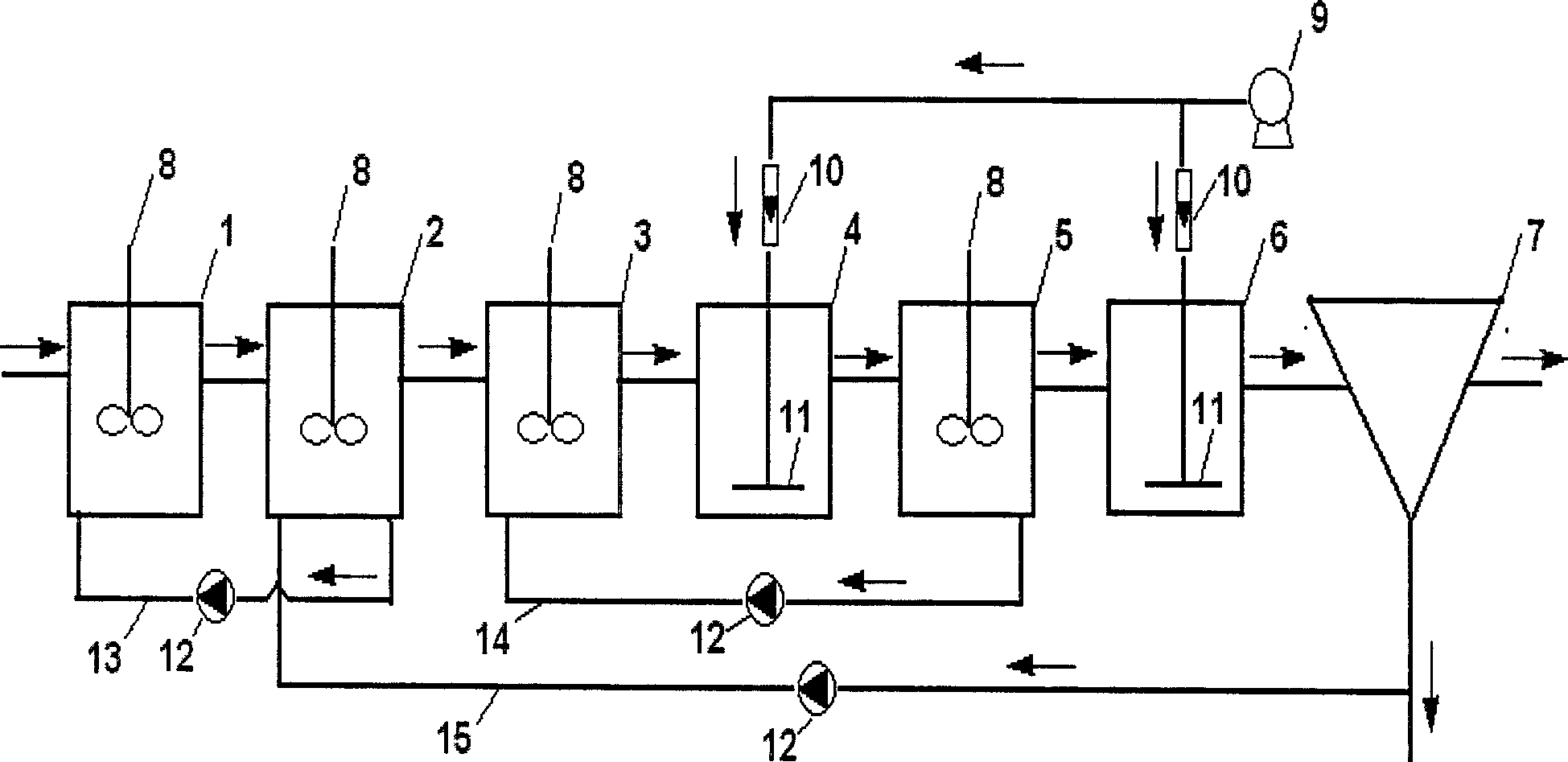

[0037] The improved MUCT process operation steps refer to the appendix figure 1 . This process method is based on the order of phosphorus removal and nitrification reactions in the traditional MUCT nitrogen and phosphorus removal system, and controls the nitrosation and nitrification that occur sequentially in the aerobic nitrification process in two reactors, forming a two-stage process. Aerobic nitrification process. In order to prevent the influence of dissolved oxygen on anoxic phosphorus uptake, a deoxygenation reactor is set up after the first aerobic reactor, and the dissolved oxygen in the reflux liquid is reduced to the minimum. At the same time, the reflux of the aerobic nitrification liquid originates from the deoxygenation reactor. The device adopted in the technical solution of the invention is a denitrification phosphorus removal process device capable of simultaneously realizing short-range nitrification and using nitrite as an electron acceptor.

[0038] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com