Preparation method of polyaluminum ferric chloride-poly dimethyl diallyl ammonium chloride inorganic/organic composite flocculant

A technology of dimethyl diallyl ammonium chloride and polyaluminum ferric chloride, which is applied in the chemical field, can solve problems such as differences in molecular weight and particle size flocculation and bridging ability, and achieve good flocculation effect, wide application range, and reaction fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

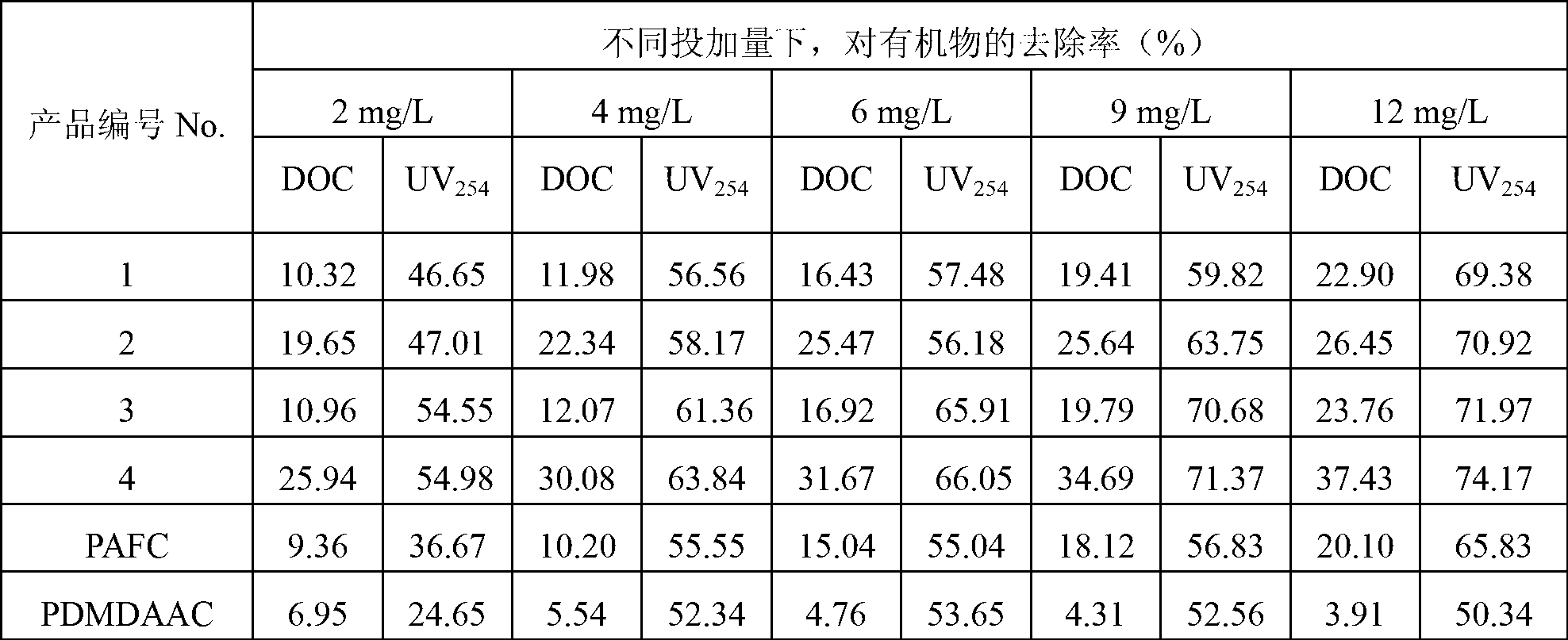

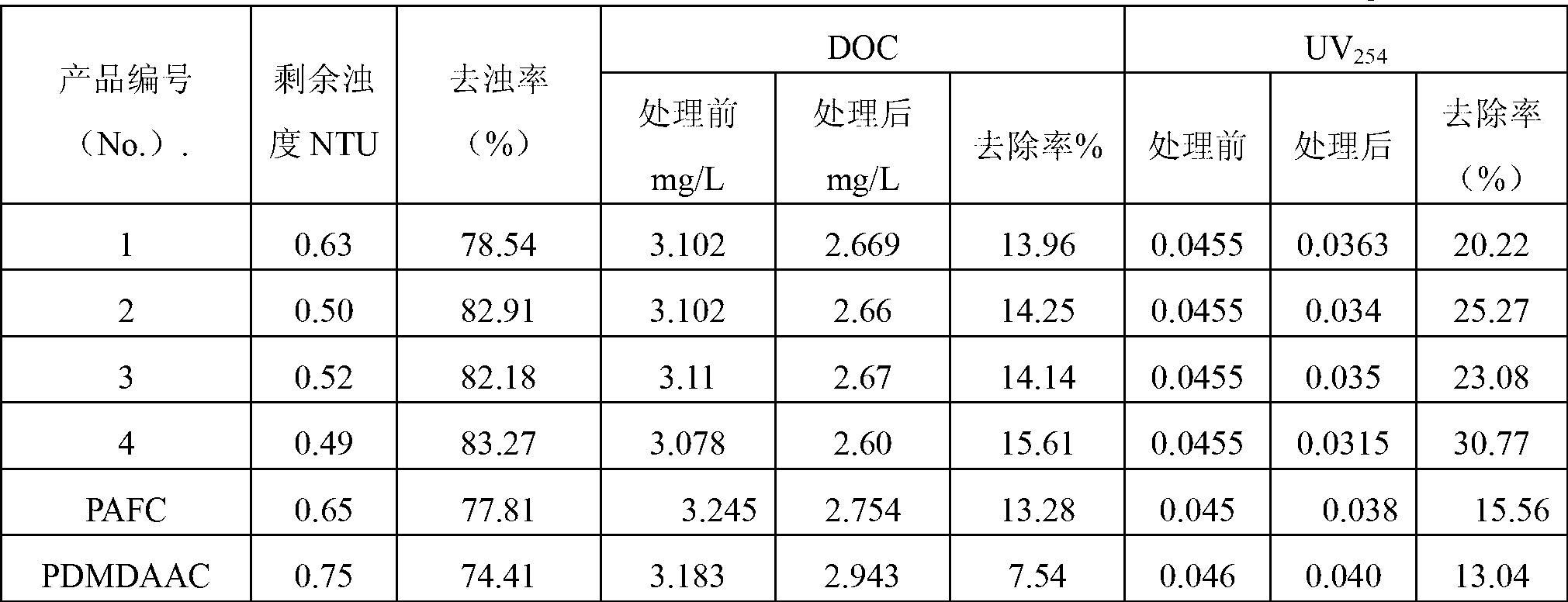

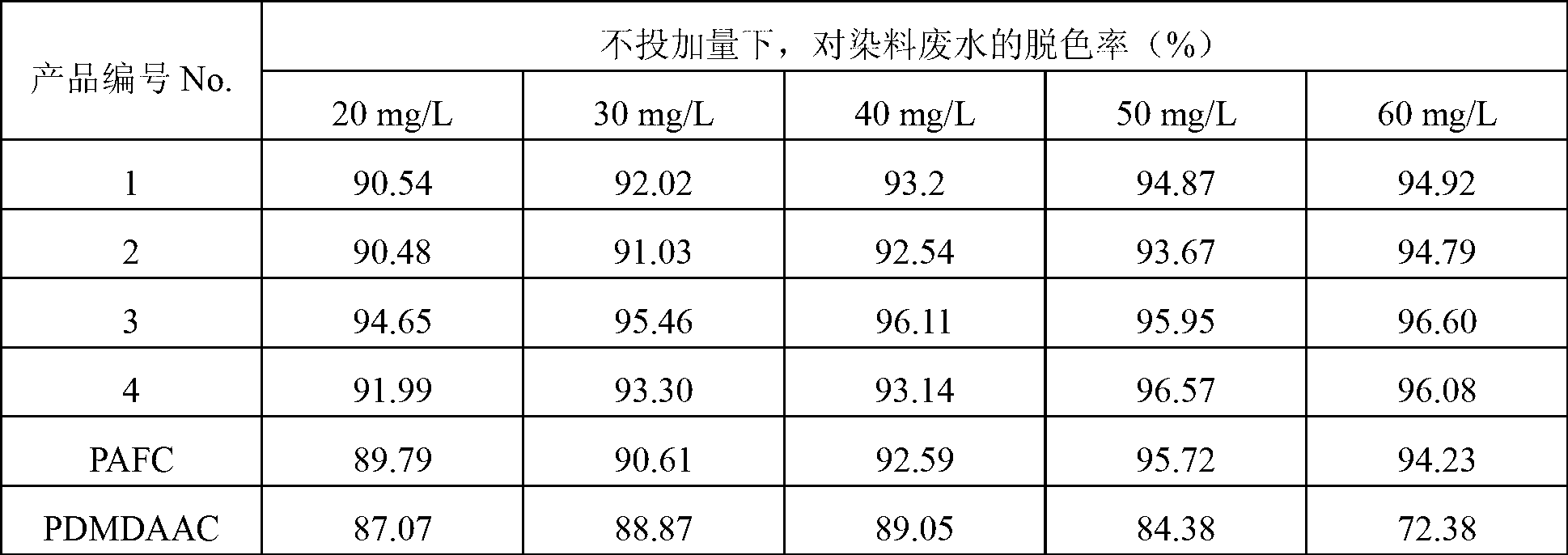

Embodiment 1

[0019] Take a certain amount of AlCl 3 ·6H 2 O and FeCl 3 ·6H 2 O solid is placed in a beaker, prepared as a solution, and Na is added under the condition of stirring 2 CO 3 The liquid adjusts the degree of alkalinity to 51%, in which Fe 2 o 3 、Al 2 o 3 Concentrations were 6.48%, 10.32%, adding Na 2 HPO 4 12H 2 O stabilizer with AlCl 3 ·6H 2 O and FeCl 3 ·6H 2 The mass percentage of the stabilizer based on the total amount of O is 10.7%, and a polyaluminum ferric chloride solution (PAFC) is obtained. Take PAFC and PDMDAAC products at a mass ratio of 20:1, stir and react at room temperature for 4 hours to prepare an inorganic-organic composite flocculant PAFC-PDMDAAC, and the obtained product is represented by No.1.

[0020] Inorganic-organic composite flocculant PAFC-PDMDAAC, the appearance is reddish-brown liquid, containing Fe 2 o 3 、Al 2 o 3 The weight percentages are 5.14% and 8.19%, respectively, the mass percentage of PDMDAAC (solid content is 40.6%) i...

Embodiment 2

[0022] Take a certain amount of AlCl 3 ·6H 2 O and FeCl 3 ·6H 2 O solid is placed in a beaker, prepared as a solution, and Na is added under the condition of stirring 2 CO 3 solution to adjust the alkalinity to 50%, in which Fe 2 o 3 、Al 2 o 3 Concentrations were 6.48%, 10.32%, adding Na 2 HPO 4 12H 2 O stabilizer (its mass percentage is 10.8%, with AlCl 3 ·6H 2 O and FeCl 3 ·6H 2 O total amount), to obtain polyaluminum ferric chloride solution (PAFC product). Mix PAFC and PDMDAAC at a mass ratio of 10:1, stir and react at room temperature for 5 hours to prepare an inorganic-organic composite flocculant PAFC-PDMDAAC, and the obtained product is represented by No.2.

[0023] Inorganic-organic composite flocculant PAFC-PDMDAAC, the appearance is reddish-brown liquid, containing Fe 2 o 3 、Al 2 o 3The weight percentages are 5.06% and 8.07%, respectively, the weight percentage of PDMDAAC (40.6% solid content) is 1.92%, the density (20°C) is 1.28, and the degree o...

Embodiment 3

[0025] Take a certain amount of AlCl 3 ·6H 2 O and FeCl 3 ·6H 2 O solid is placed in a beaker, prepared as a solution, and Na is added under the condition of stirring 2 CO 3 The solution adjusts the degree of alkalinity to 61%, of which Fe 2 o 3 、Al 2 o 3 Concentrations were 6.5%, 10.4%, adding Na 2 HPO 4 12H 2 O stabilizer (its mass percentage is 10.7%, with AlCl 3 ·6H 2 O and FeCl 3 ·6H 2 O total amount), the polyaluminum ferric chloride solution (PAFC) was obtained. Mix PAFC and PDMDAAC at a mass ratio of 20:1, stir and react at room temperature for 5 hours to prepare an inorganic-organic composite flocculant PAFC-PDMDAAC, and the obtained product is represented by No.3.

[0026] Inorganic-organic composite flocculant PAFC-PDMDAAC, the appearance is reddish-brown liquid, containing Fe 2 o 3 、Al 2 o 3 The weight percentages are 5.24% and 8.39%, respectively, the weight percentage of PDMDAAC (40.6% solid content) is 0.99%, the density (20°C) is 1.24, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com