Electrocatalysis wet-type peroxide oxidizing method for high-effect waste water processing and devices thereof

A technology for treating wastewater and hydrogen peroxide, applied in chemical instruments and methods, water/sewage treatment, water/sewage multi-stage treatment, etc. Achieve the effect of avoiding catalyst loss, simple and easy separation, and good device expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

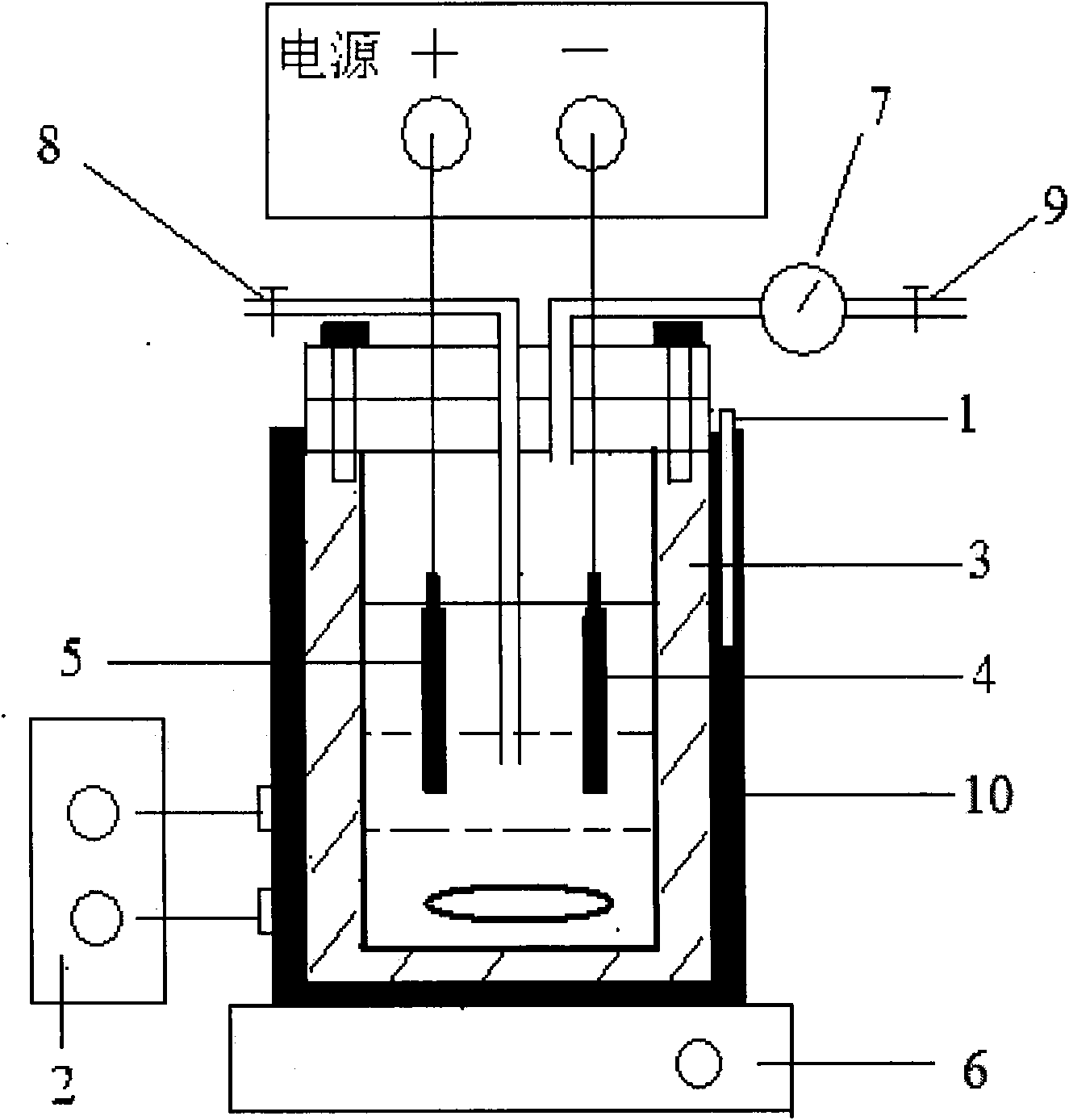

[0023] Embodiment 1: as figure 2 As shown, the device consists of a temperature probe 1, a temperature controller 2, an autoclave 3, a cathode electrode 4, an anode electrode 5, a magnetic stirrer 6, a pressure gauge 7, a liquid phase sampling valve 8, a gas phase sampling valve 9 and a heater 10 components, one end of the cathode electrode 4 and one end of the anode electrode 5 are respectively inserted into the high-pressure reactor 3, and the other end of the cathode electrode 4 and the other end of the anode electrode 5 are respectively connected to the negative and positive poles of the power supply through wires. The wire passes through the top of the autoclave 4, and the outer wall is insulated, so it is still a closed system in design. The high-pressure reaction kettle 3 and the heater 10 are placed on the magnetic stirrer 6 together, the temperature probe 1 is inserted into the heater 10, the side below the heater 10 is connected to the temperature controller 2, and ...

Embodiment 2

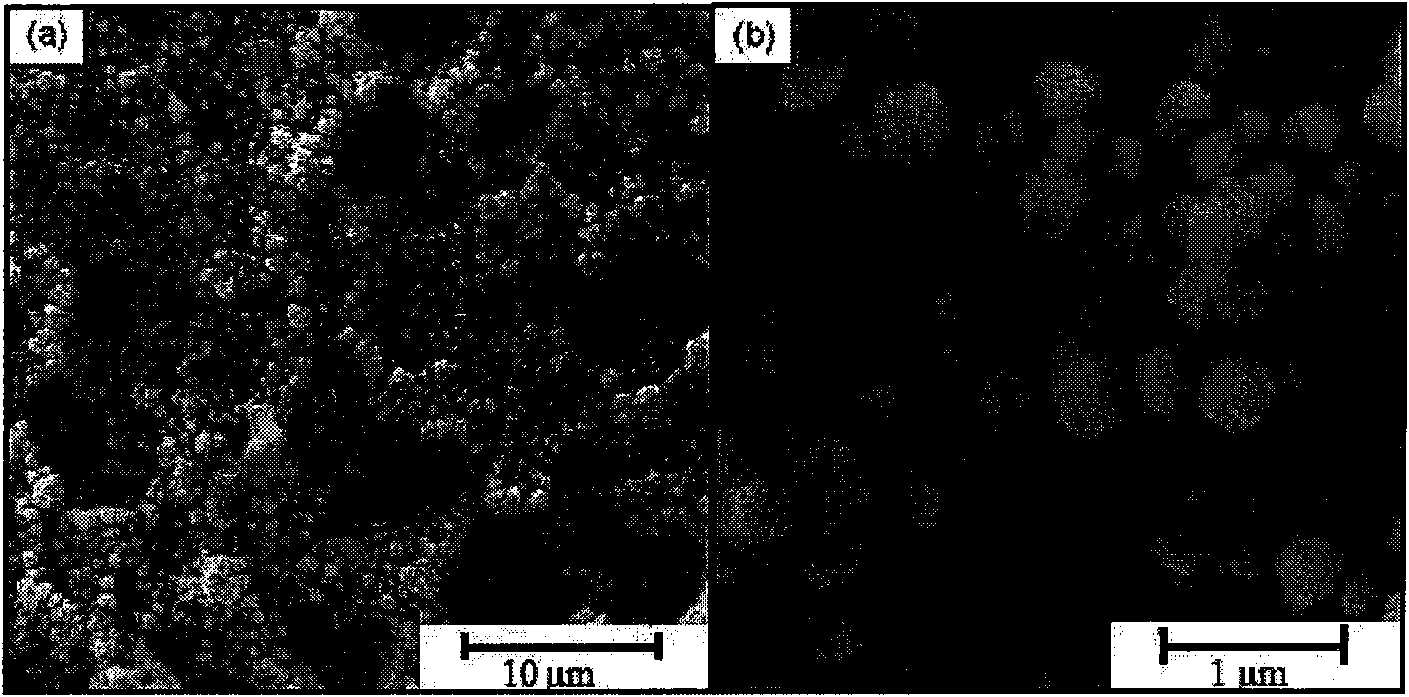

[0024] Embodiment 2: process 2,4-dichlorophenoxyacetic acid waste water

[0025] The titanium plate loaded with nano-platinum particle electrocatalyst is used as the anode electrode 5, and the pure titanium plate is used as the cathode electrode 4. The areas of the cathode electrode 4 and the anode electrode 5 are both 11.6 cm 2 , The electrode spacing is 2cm. The concentration of simulated wastewater 2,4-dichlorophenoxyacetic acid is 100mg / L, and the supporting electrolyte is 0.05mol / L Na 2 SO 4 , the treatment volume is 0.45L. The reactor was filled with N 2 To 0.5MPa, hydrogen peroxide concentration 0.2mol / L. When using the electrocatalytic wet hydrogen peroxide oxidation method, a certain voltage is applied to the cathode and anode, so that the current density of the titanium plate loaded with nano-platinum particle electrocatalyst is 5mA / cm 2 . Nano-platinum catalyzed wet hydrogen peroxide oxidation was used as a comparative test to compare the effects. The removal...

Embodiment 3

[0027] Embodiment 3: process methyl orange wastewater

[0028] The titanium plate loaded with nano-platinum particle electrocatalyst is used as the anode, and the pure titanium plate is used as the cathode, and the electrode area is 8cm 2 , the distance between the electrodes is 2cm, the concentration of methyl orange in the simulated wastewater is 100mg / L, and the supporting electrolyte is 0.05mol / LNa 2 SO 4 , the treatment volume is 0.28L. The reactor was filled with N 2 To 0.3MPa, hydrogen peroxide concentration 0.1mol / L. When using the electrocatalytic wet hydrogen peroxide oxidation method, a certain voltage is applied to the cathode and anode, so that the current density of the titanium plate loaded with nano-platinum particle electrocatalyst is 5mA / cm 2 . Nano-platinum catalyzed wet hydrogen peroxide oxidation was used as a comparative test to compare the effects. The removal rate of TOC also showed that the mineralization rate of methyl orange by electrocatalytic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com