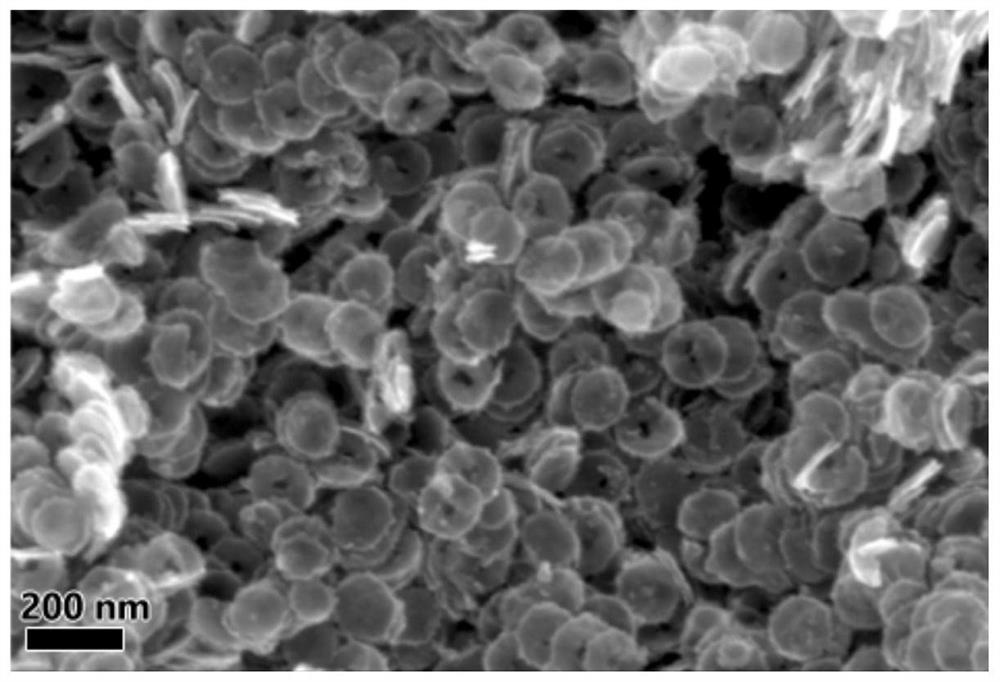

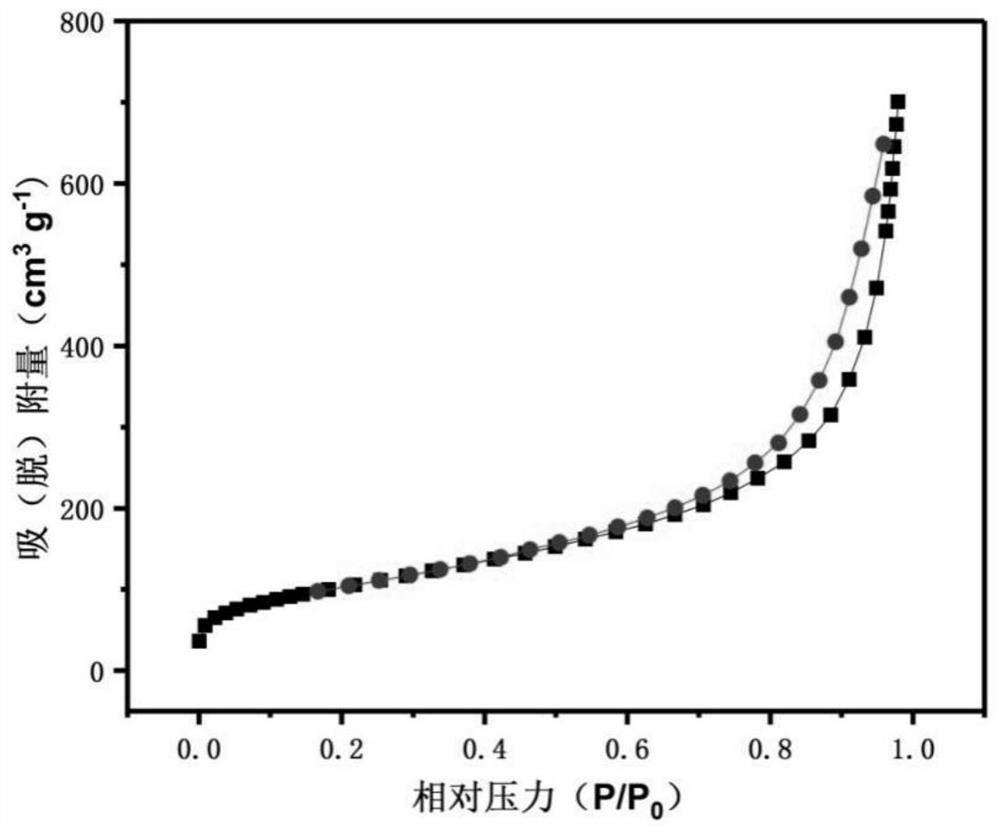

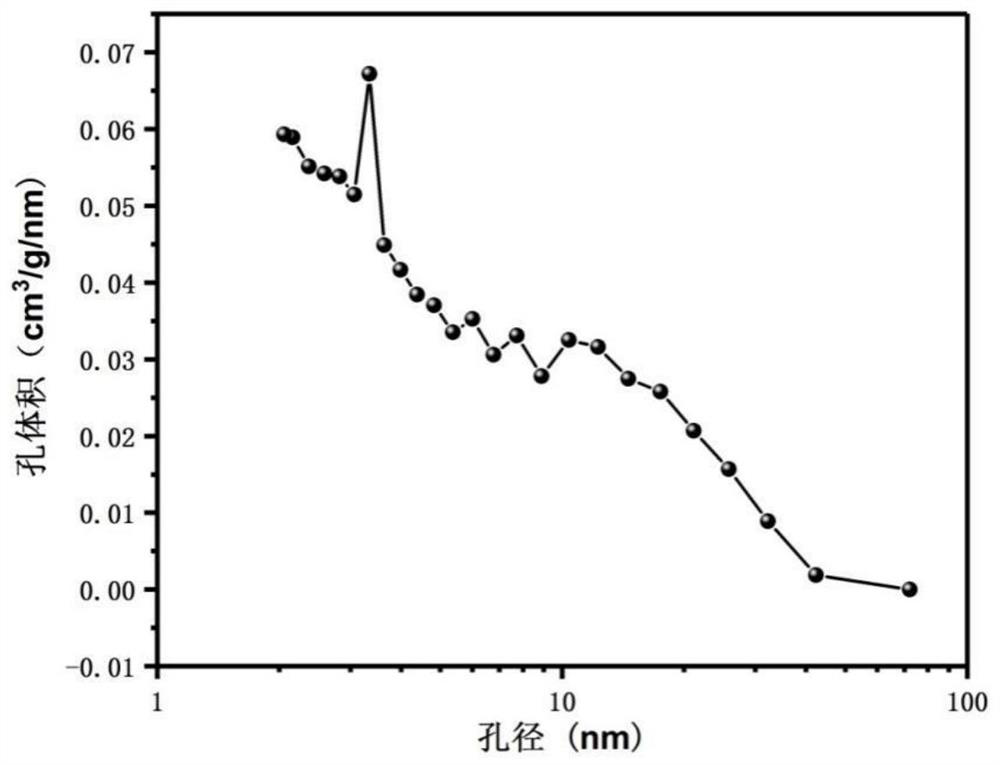

Ultrathin disc-shaped mesoporous carbon material and preparation method and application thereof

A mesoporous carbon, sheet-like technology, applied in the field of fuel cell electrocatalysis, can solve the problem of low economic value, achieve broad application prospects, solve the effects of high cost and good electrocatalytic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This embodiment provides a method for preparing an ultra-thin disc-shaped mesoporous carbon material, wherein the preparation method includes the following steps:

[0045] (1) Add 60 mL of absolute ethanol, 30 mL of deionized water and 10 mL of ammonia water into a 100 mL beaker, stir for 10 min, add 10 mL of TEOS, keep the temperature at 60 ° C, and continue the reaction for 3 h.

[0046] The product was centrifuged and washed three times with absolute ethanol, and then dried at 100°C to obtain spherical silica.

[0047] Spherical silica and waste tire pyrolysis oil are fully mixed at a mass ratio of 3:1; in the present embodiment, the waste tire pyrolysis oil is a heavy fraction of waste tire pyrolysis oil, and the weight fraction of waste tire pyrolysis oil Quality distillates are distillate oils with a temperature greater than 350°C.

[0048] (2) Put the mixture in a corundum porcelain boat, put it into a horizontal furnace and pass in argon gas, raise the temperatur...

Embodiment 2

[0056] This embodiment provides a method for preparing an ultra-thin disc-shaped mesoporous carbon material, wherein the preparation method includes the following steps:

[0057] (1) Add 60 mL of absolute ethanol, 30 mL of deionized water and 10 mL of ammonia water into a 100 mL beaker, stir for 10 min, add 10 mL of TEOS, keep the temperature at 60 ° C, and continue the reaction for 3 h.

[0058] The product was centrifuged and washed three times with absolute ethanol, and then dried at 100°C to obtain spherical silica.

[0059] Spherical silica and waste tire pyrolysis oil are fully mixed in a mass ratio of 2:1; in the present embodiment, the waste tire pyrolysis oil is a heavy fraction of waste tire pyrolysis oil, and the weight Quality distillates are distillate oils with a temperature greater than 350°C.

[0060] (2) Put the mixture in a corundum porcelain boat, then put it into a horizontal furnace and pass in argon gas, raise the temperature in the horizontal furnace to...

Embodiment 3

[0063] This embodiment provides a method for preparing an ultra-thin disc-shaped mesoporous carbon material, wherein the preparation method includes the following steps:

[0064] (1) Add 60 mL of absolute ethanol, 30 mL of deionized water and 10 mL of ammonia water into a 100 mL beaker, stir for 10 min, add 10 mL of TEOS, keep the temperature at 60 ° C, and continue the reaction for 3 h.

[0065] The product was centrifuged and washed three times with absolute ethanol, and then dried at 100°C to obtain spherical silica.

[0066] Spherical silica and waste tire pyrolysis oil are fully mixed in a mass ratio of 4:1; in the present embodiment, the waste tire pyrolysis oil is a heavy fraction of waste tire pyrolysis oil, and the weight Quality distillates are distillate oils with a temperature greater than 350°C.

[0067] (2) Put the mixture in a corundum porcelain boat, then put it into a horizontal furnace and pass in argon gas, raise the temperature in the horizontal furnace to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com