Patents

Literature

114 results about "Carnot cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The Carnot cycle is a theoretical ideal thermodynamic cycle proposed by French physicist Sadi Carnot in 1824 and expanded upon by others in the 1830s and 1840s. It provides an upper limit on the efficiency that any classical thermodynamic engine can achieve during the conversion of heat into work, or conversely, the efficiency of a refrigeration system in creating a temperature difference by the application of work to the system. It is not an actual thermodynamic cycle but is a theoretical construct.

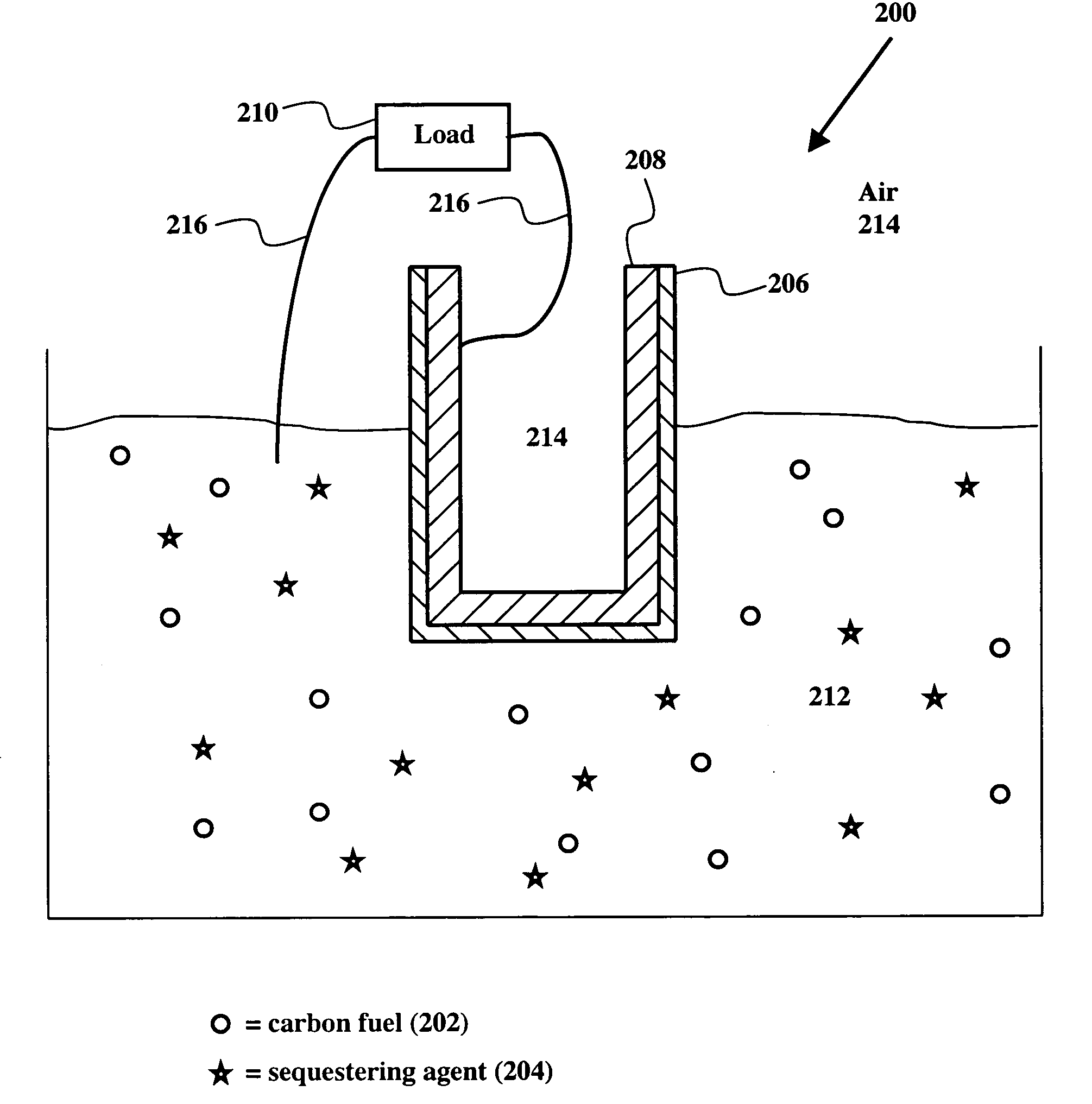

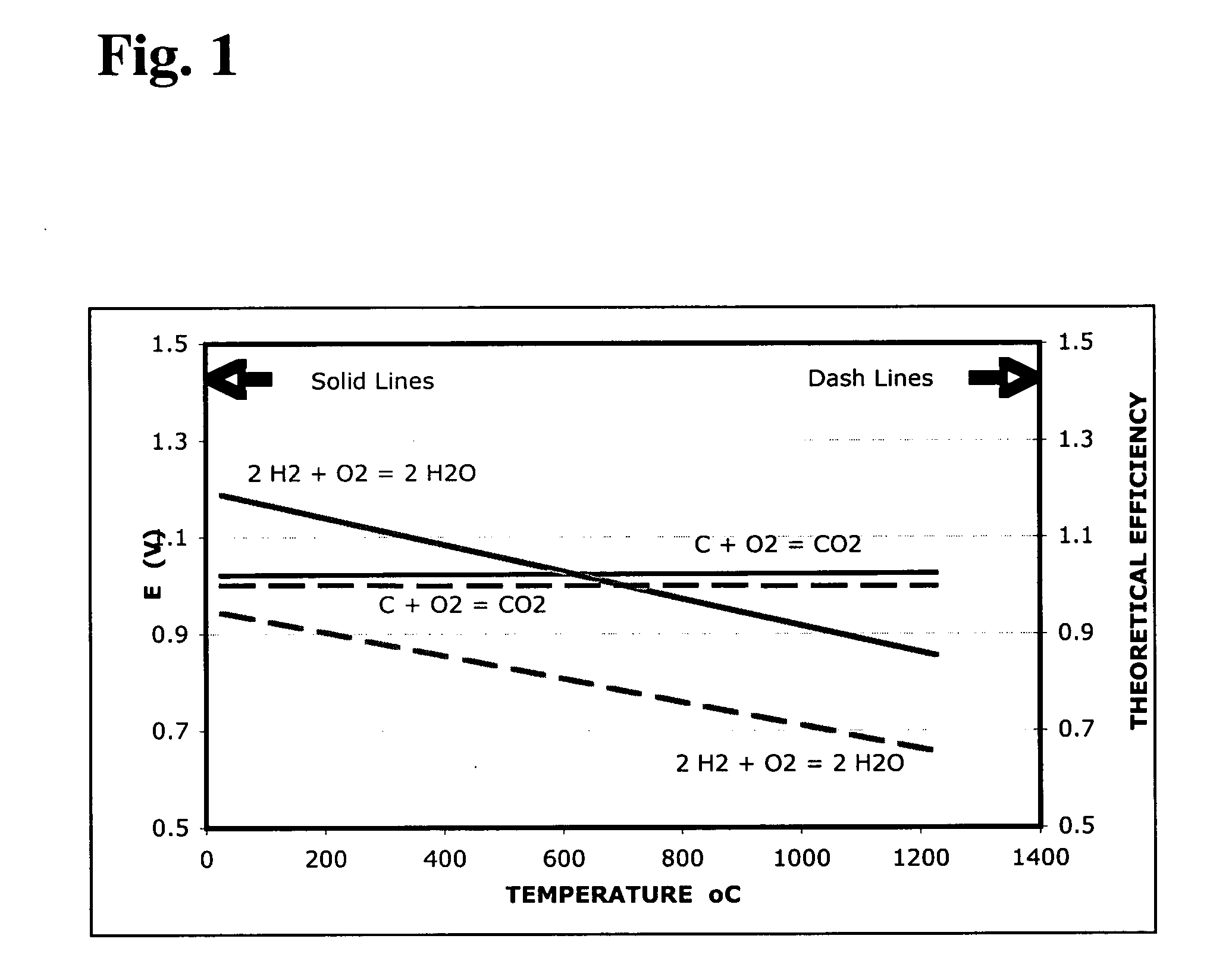

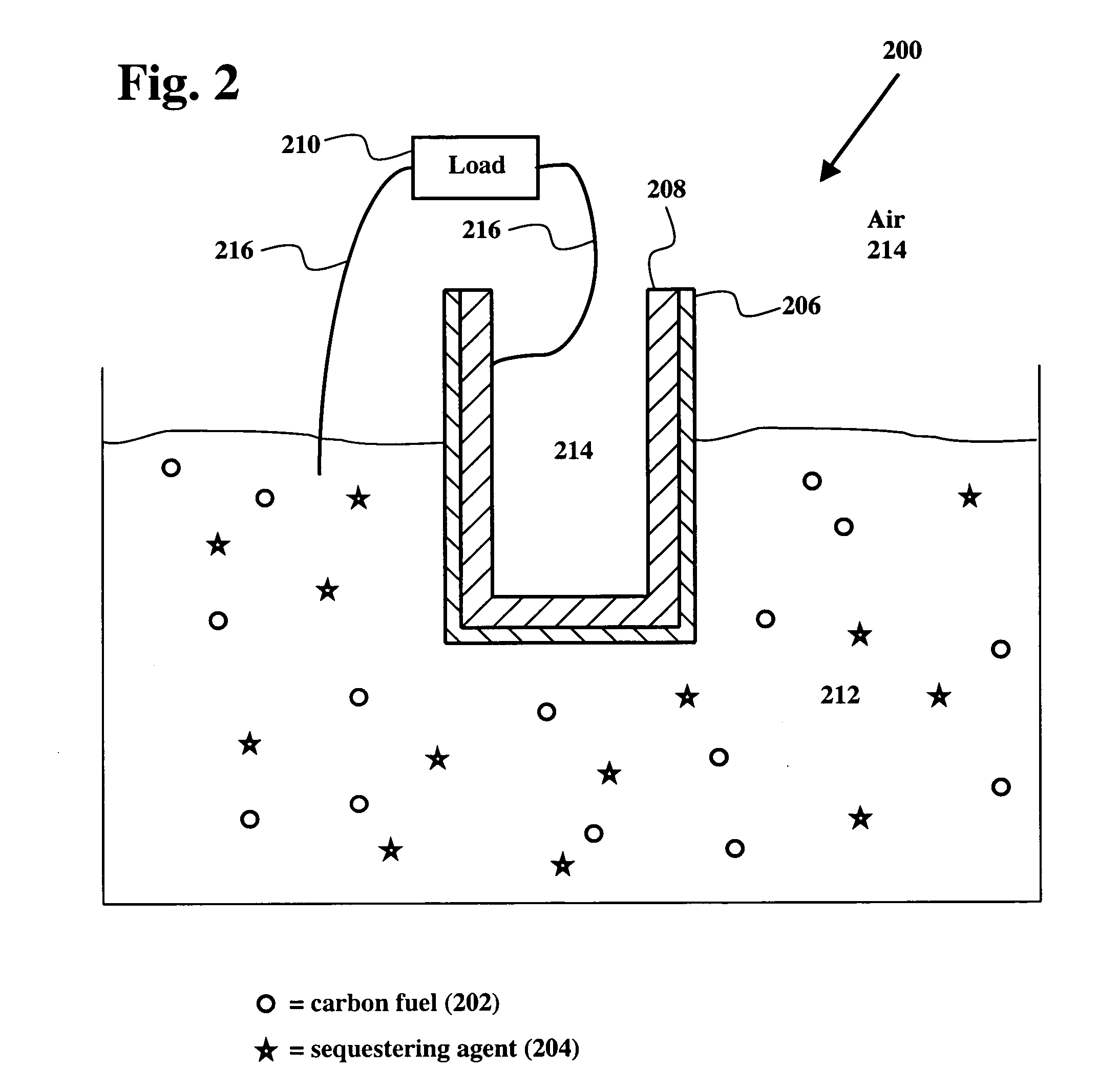

Direct carbon fuel cell with molten anode

This invention discloses a method of converting carbon-containing materials directly to electrical energy without the need for intermediate processing steps. An embodiment comprises the use of a conductive molten medium with dispersed particles of carbon material as the anode in a fuel cell with a solid oxide electrolyte which enables conversion of carbon-containing materials (such as pulverized coal, charcoal, peat, coke, char, petroleum coke, oil sand, tar sand, waste plastics, biomass, and carbon produced by pyrolysis of carbonaceous substance) directly into electrical energy in a single step process. The anode optionally may have a dispersed second solid phase that getters CO2 and SO2 gases that are produced during the anodic reaction. Hence, this invention facilitates near-zero emissions and dramatically reduces the release of environmentally harmful emissions. More importantly, this direct route to electrical energy eliminates Carnot cycle constraints and offers high thermodynamic efficiency.

Owner:DIRECT CARBON TECH

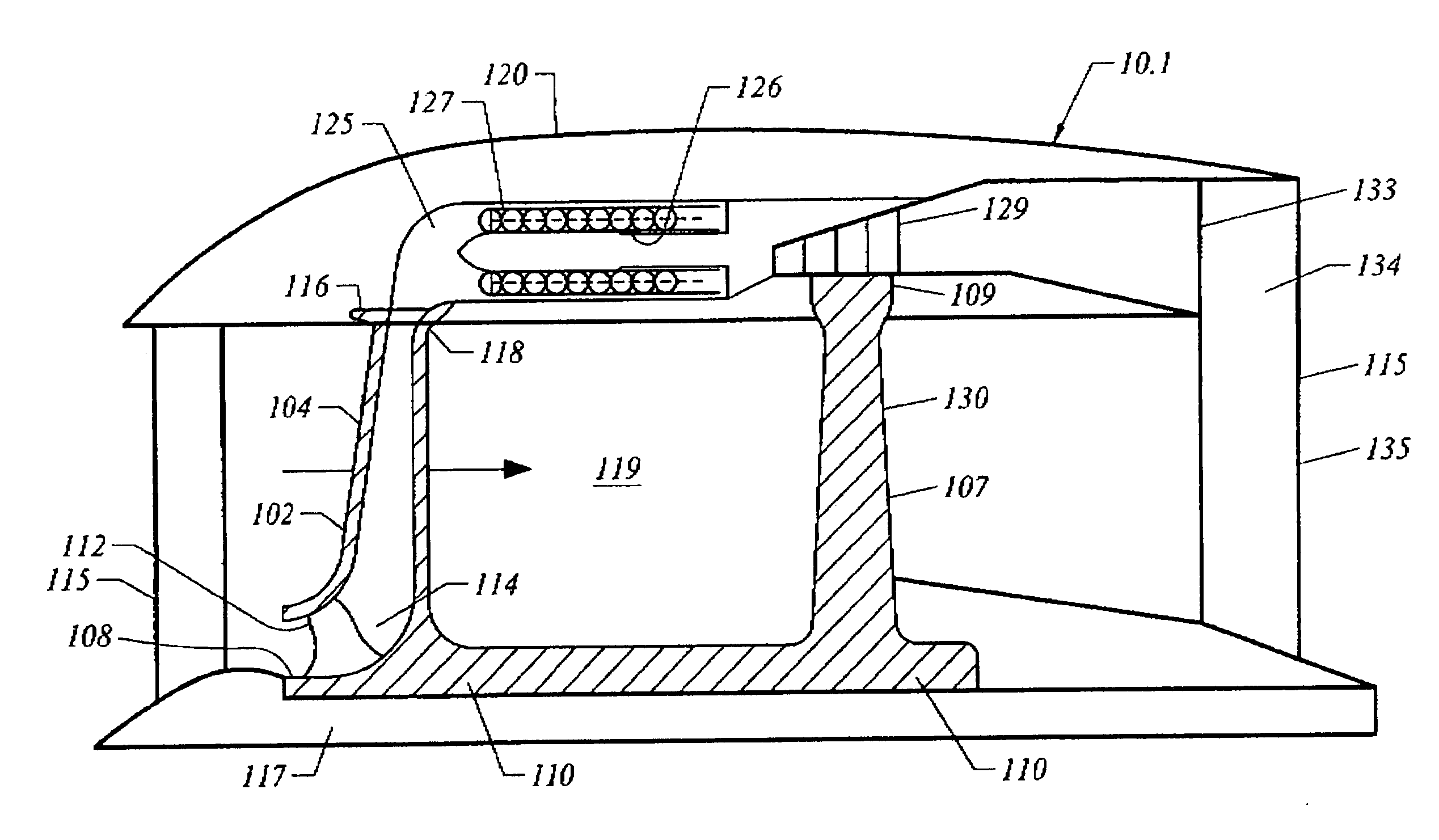

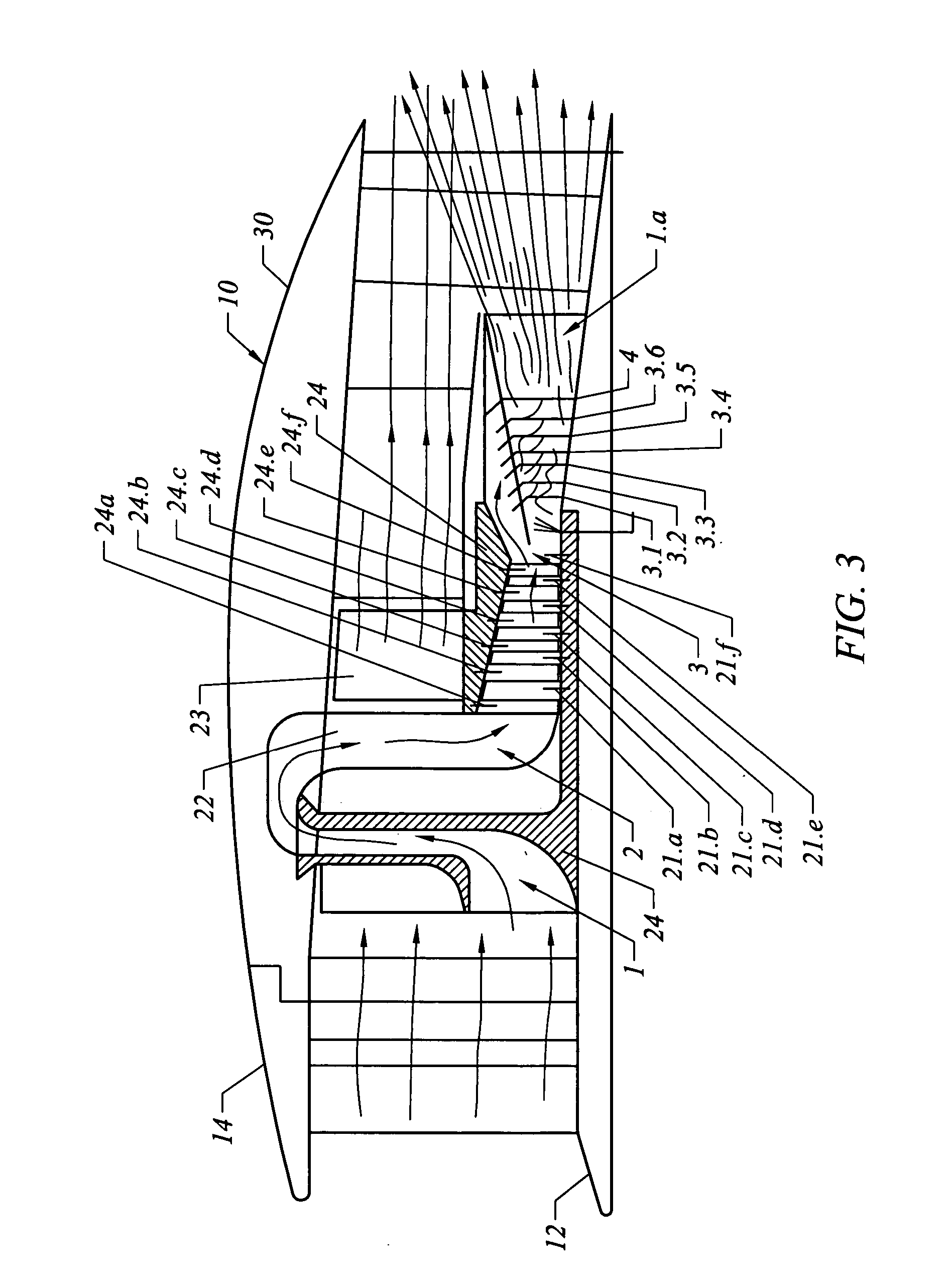

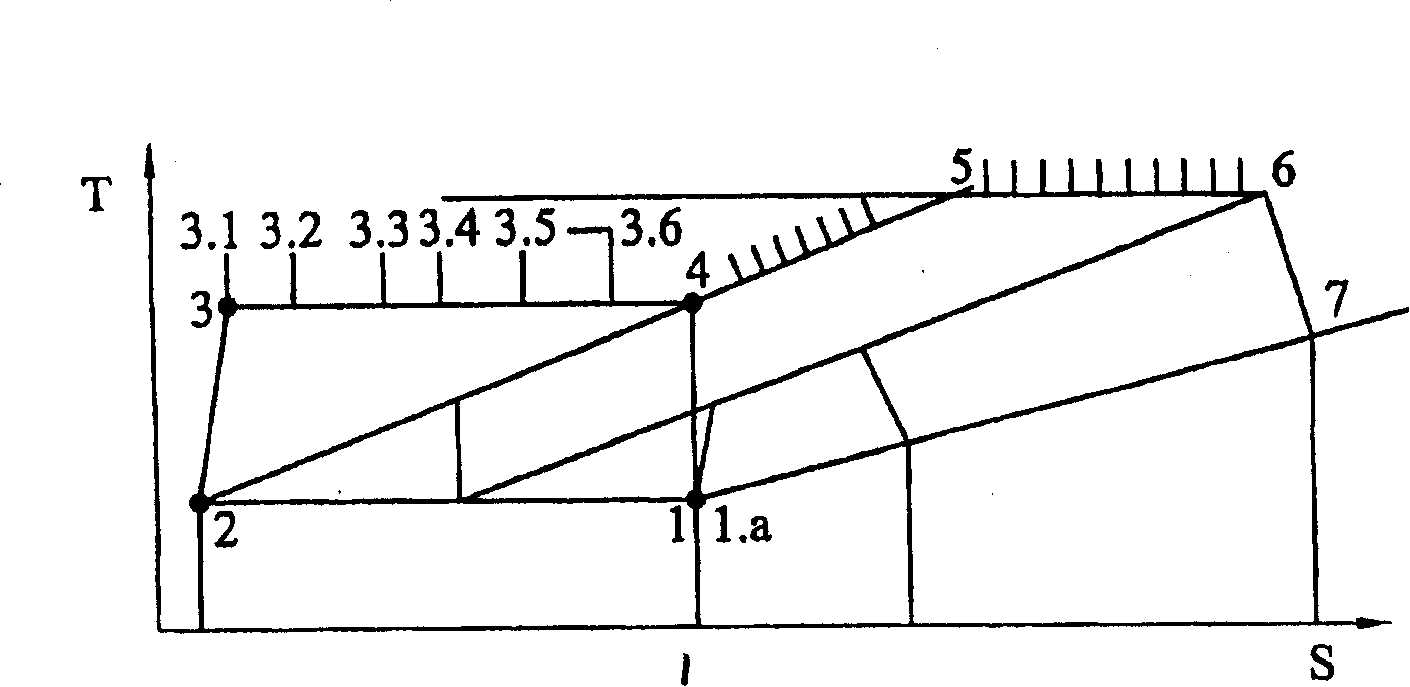

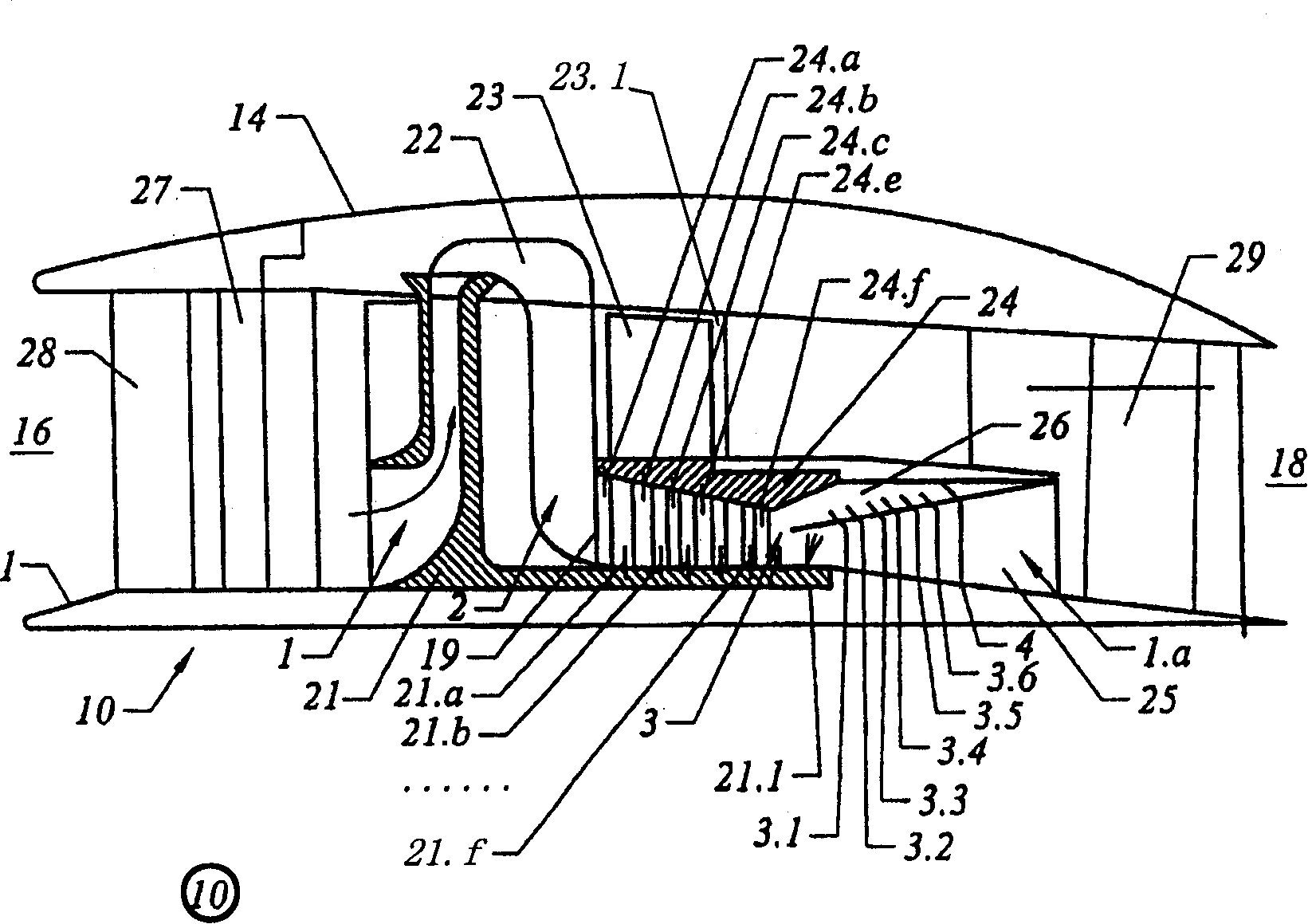

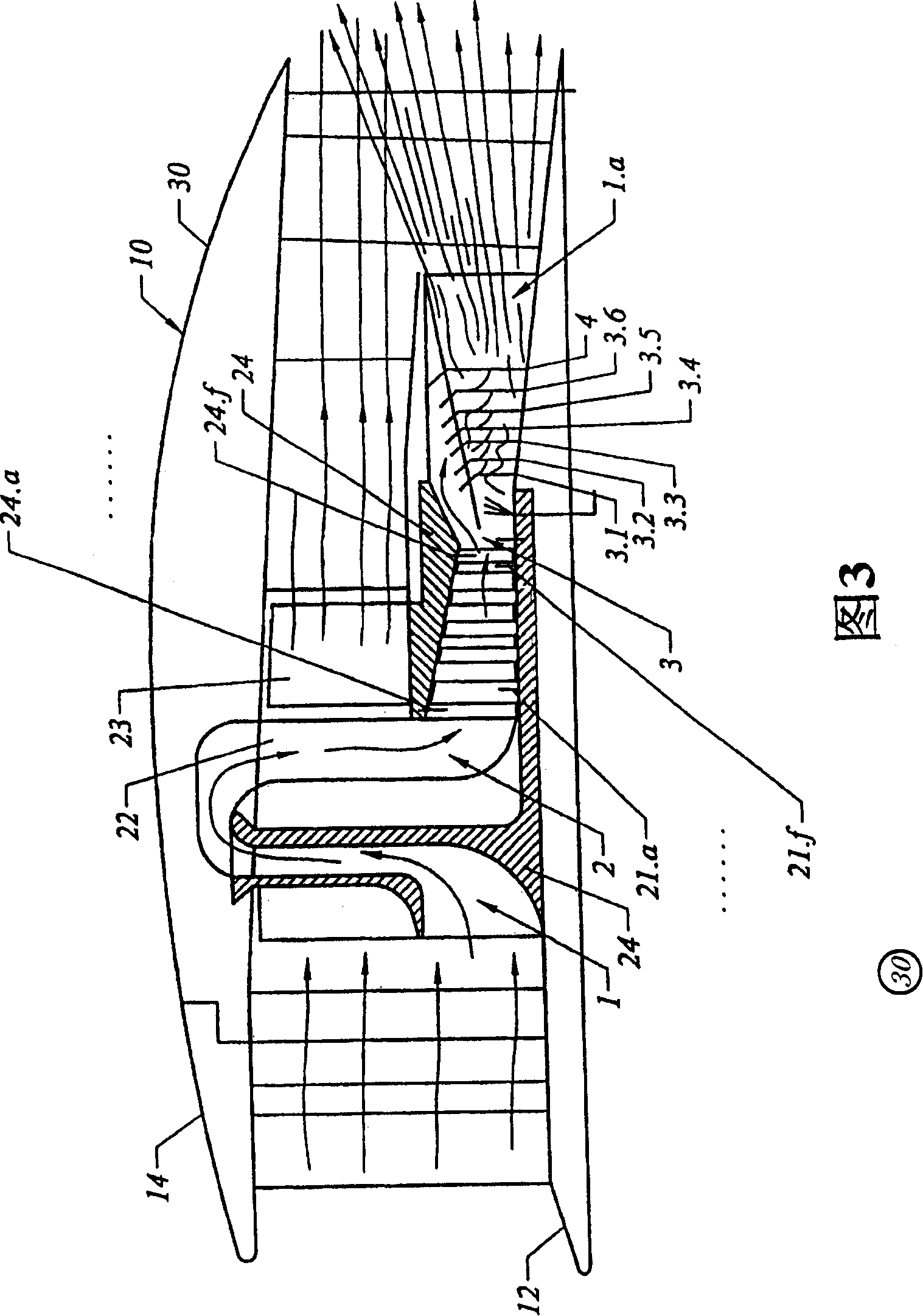

Universal Carnot propulsion systems for turbo rocketry

InactiveUS20060086078A1Maximum efficiencyLarge rangeWorking fluid for enginesGas turbine plantsJet engineCombustion

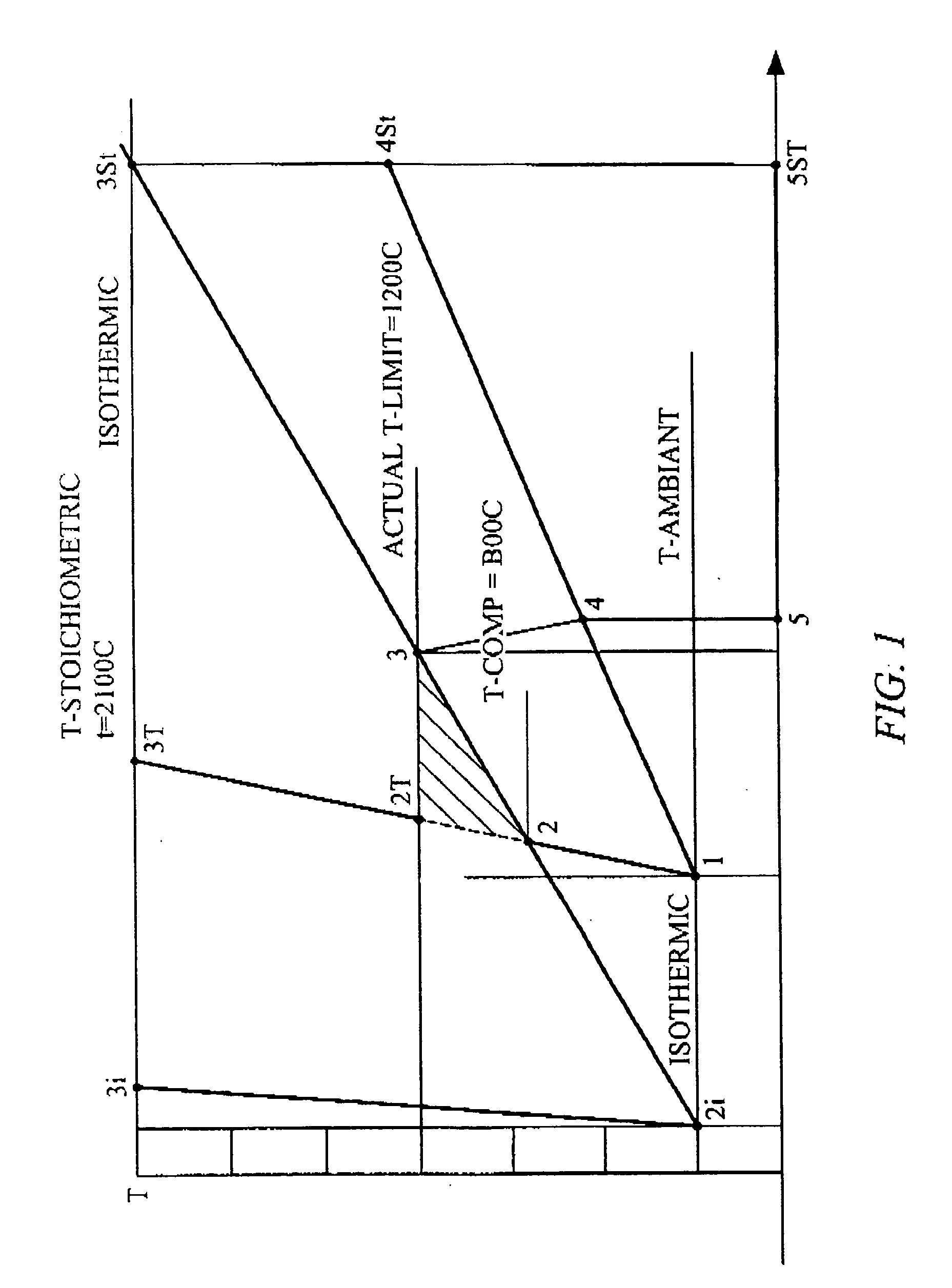

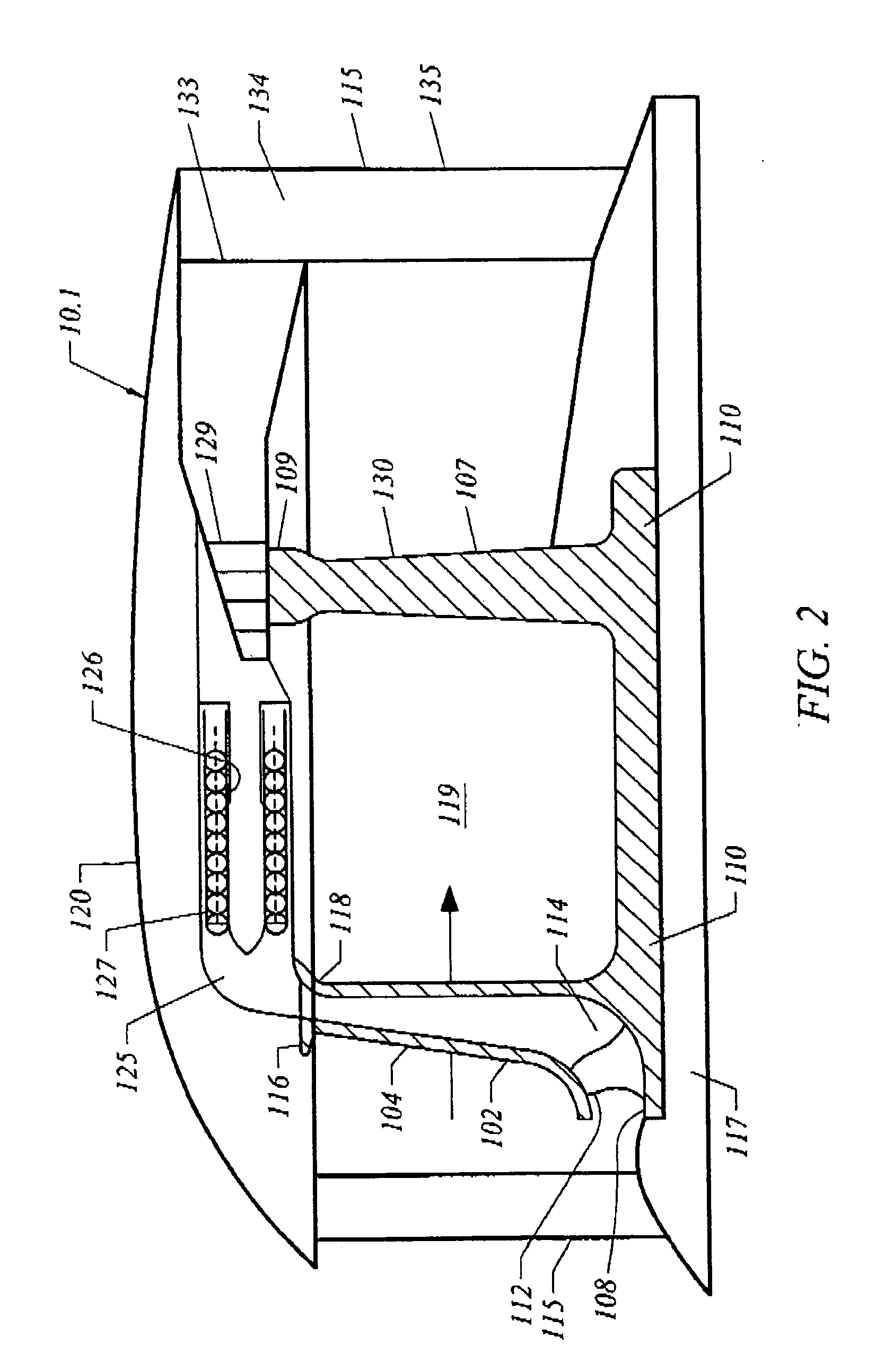

Turbofan jet engines utilizing the Carnot cycle for improved performance with isothermal compression of combustion air and, in part, isothermal expansion of thermally heated air, the engines having a turbofan compressor rotor with hollow fan blades in a core bypass passage through the engine and an annular, peripheral thermal chamber with staged turbine blades in an expansion chamber where heated gases are supplied to multiple stages to maintain peak temperatures.

Owner:PAUL MARIUS A

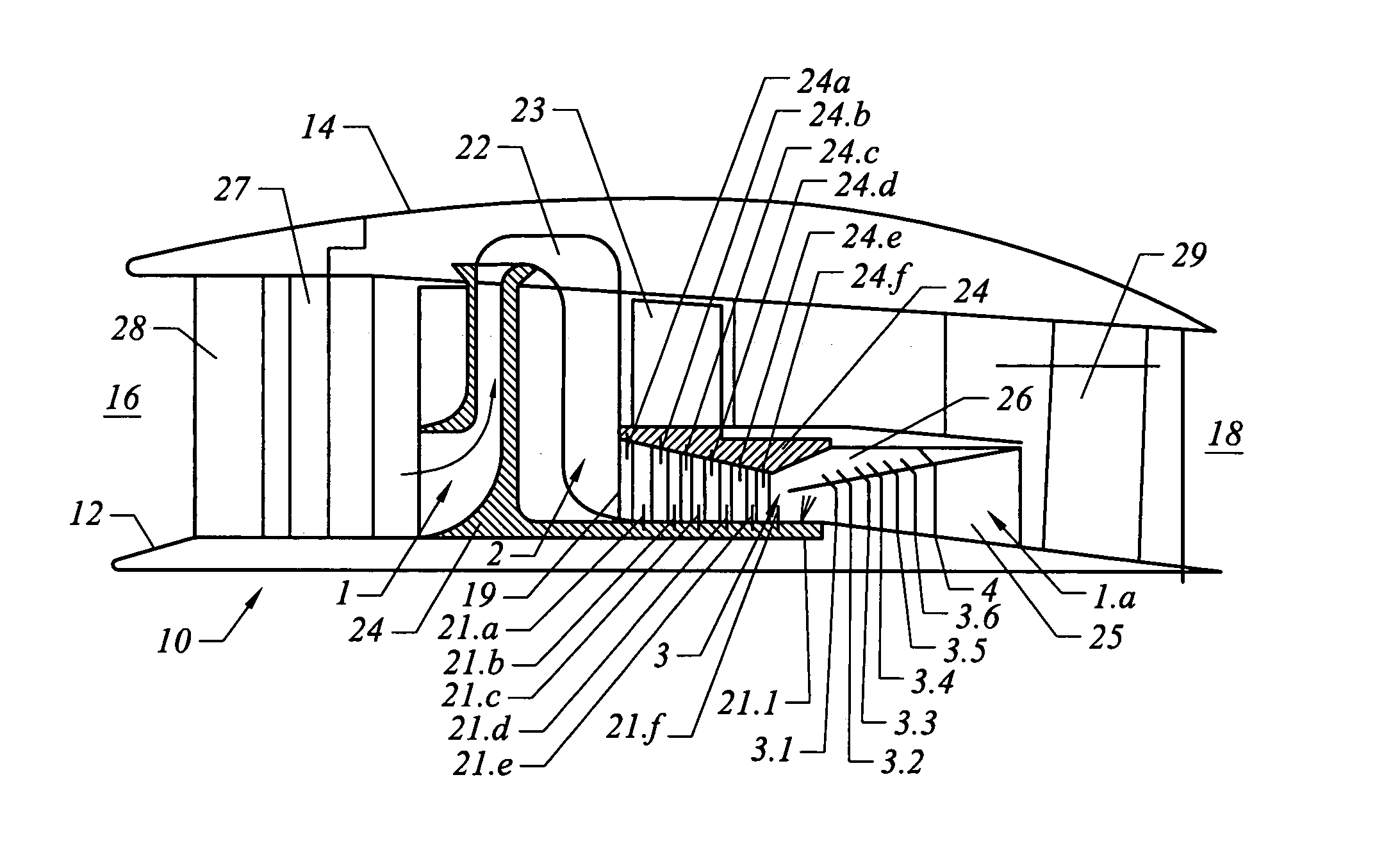

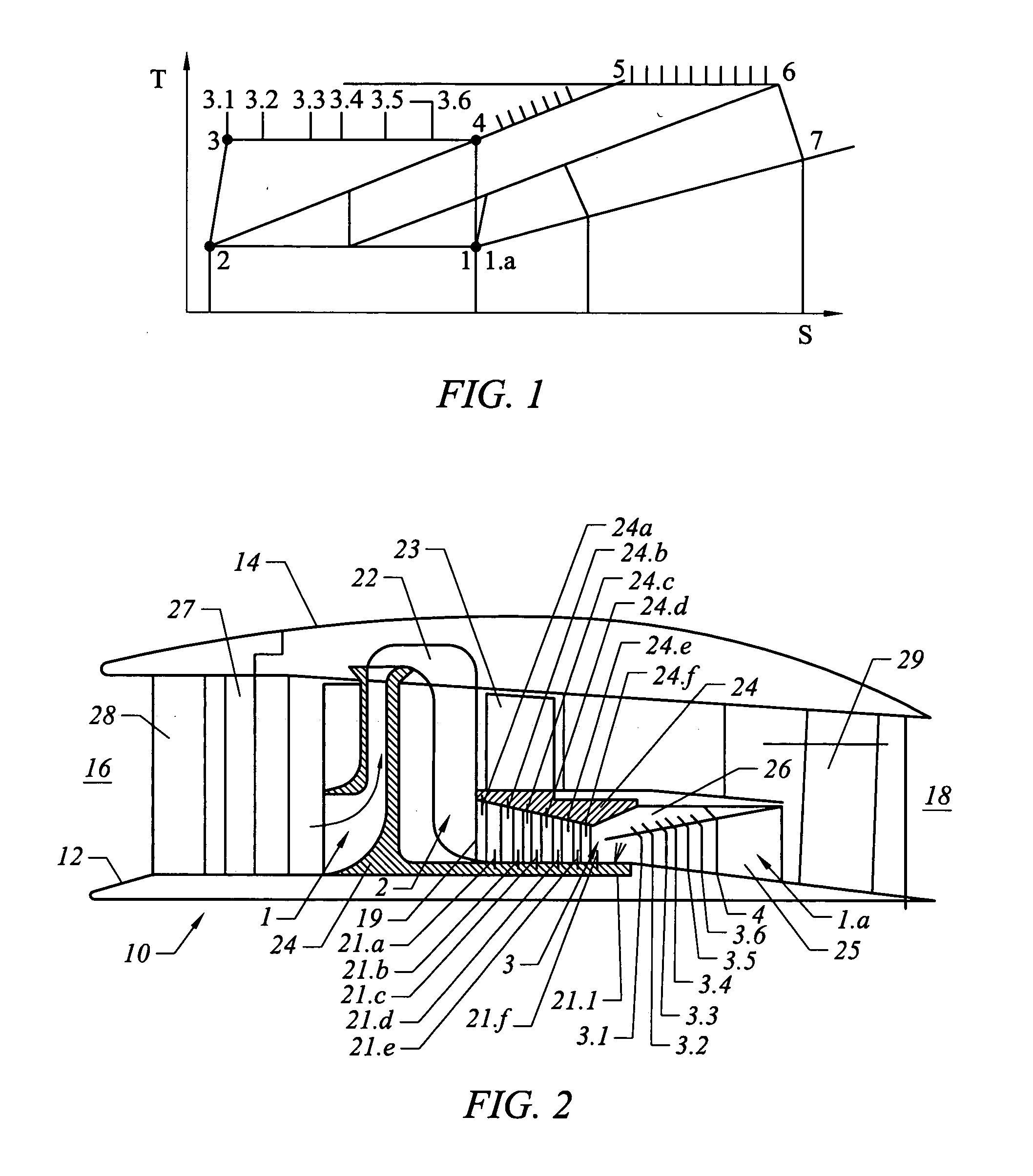

Turbo rocket with real carnot cycle

InactiveUS20050138914A1Improve efficiencyReduce supplyEngine fuctionsBlade accessoriesCombustion chamberCarnot cycle

Engine embodiments primarily designed for aircraft propulsion and power generation incorporating the Carnot cycle for efficient combustion with typical embodiments including air compressors having one or more stages with isothermal compression and including combustion and expansion chambers having in part isothermal expansion before final adiabatic expansion.

Owner:PAUL MARIUS

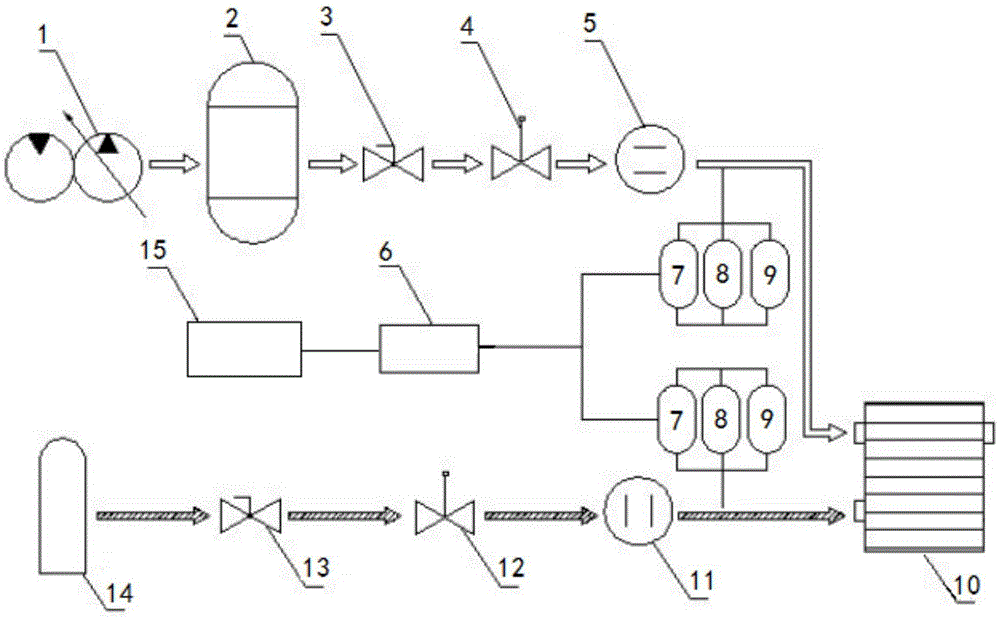

Vehicular fuel battery system and working method thereof

ActiveCN105633435AGuaranteed to workAchieving zero emissionsMotive system fuel cellsElectrochemical responsePower capability

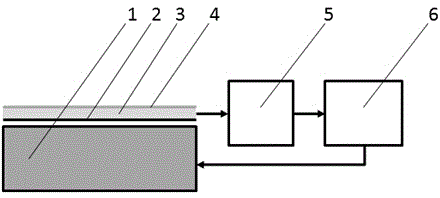

The invention discloses a vehicular fuel battery system, comprising an air compressor (1), an air storage tank (2), an air reducing valve (3), an air control valve (4), an air flow meter (5), a data receiver (6), a detector, a fuel battery (10), a hydrogen flow meter (11), a hydrogen pressure regulating valve (12), a hydrogen reducing valve (13), a hydrogen tank (14) and a comprehensive control device (15), wherein the detector comprises a temperature sensor, a humidity sensor and a pressure sensor. The invention further discloses a working method of the vehicular fuel battery system. Due to adoption of the vehicular fuel battery system and the working method thereof, pure electric drive of a vehicle can be realized, Carnot cycle limitation of internal combustion engine combustion can be overcome, combustion is substituted with electrochemical reaction of fuel; through monitoring the temperature, humidity and pressure of a fuel battery, the internal water management of a fuel battery can be implemented effectively, the use efficiency and power capability of the fuel battery can be improved, various pollutants generated by the fuel battery can be eliminated and zero emission of a vehicle can be realized.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

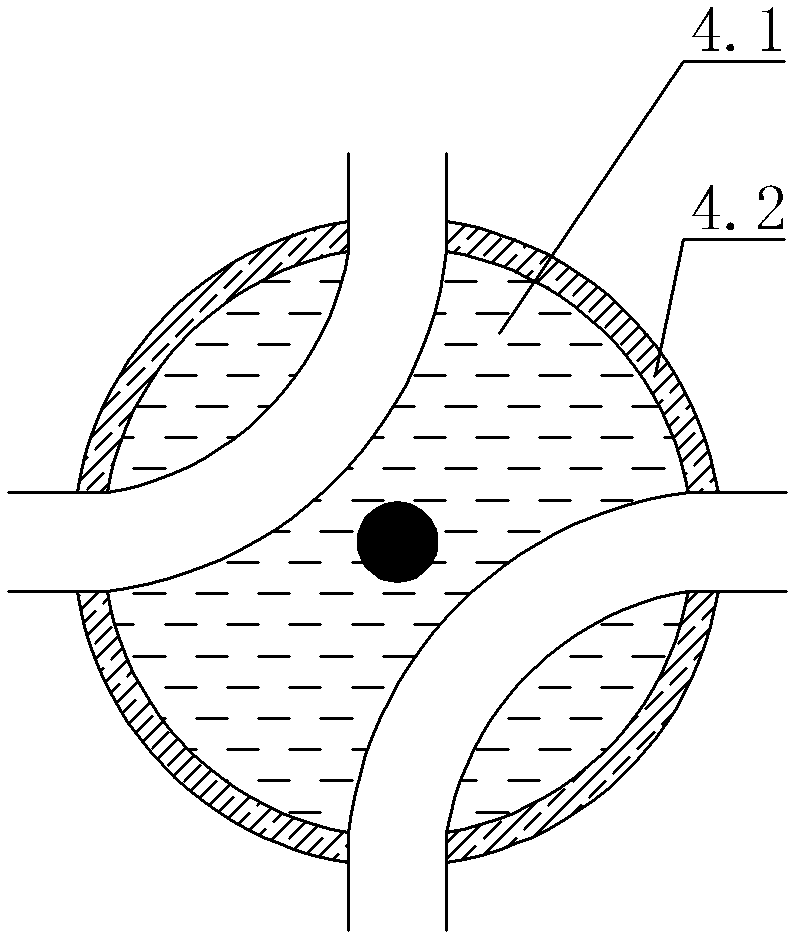

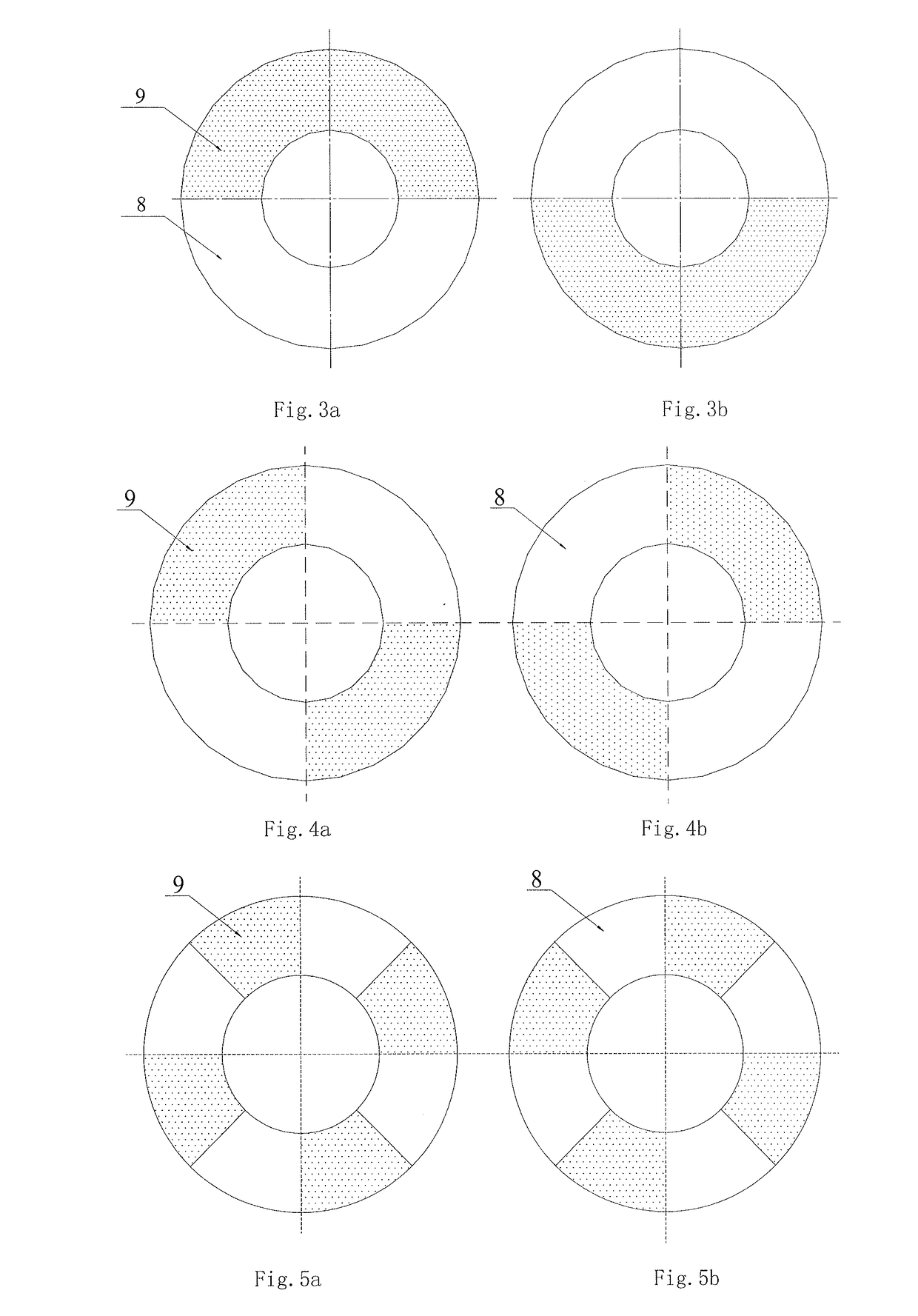

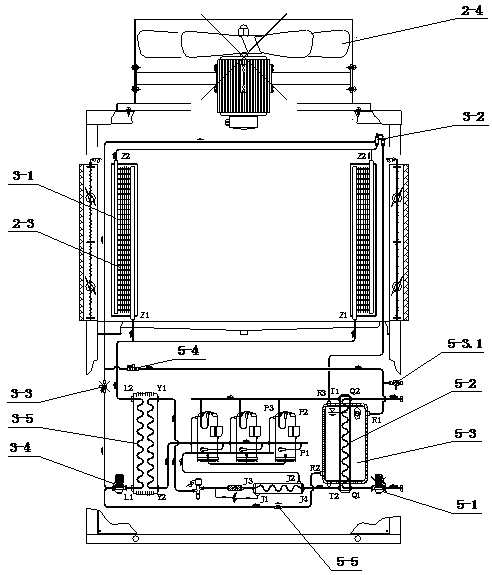

Four-way valve for Carnot cycle system

A four-way valve for a Carnot cycle system comprises a four-way valve body consisting of a valve body and a columnar valve spool. The four-way valve body is connected with an air conditioner through a pipeline, mutually symmetric channels are arranged inside the valve spool and penetrate through the surface of the valve spool, the valve body is provided with more than one through hole corresponding to the channels, and the diameter of each through hole is as same as that of an opening of each channel. A refrigerating state and a heating state are switched only by using a steeping motor for driving the valve spool and the valve body to be in running fit, modes can be switched by means of short-time electrification during running, and the valve can be kept continuing running in the original mode after power is cut off. Besides, the valve spool is hermetically connected with the inner surface of the valve body, so that tightness of the four-way valve is improved, and back flowing is prevented. The shortcomings of complicated structure, difficulty in manufacture, poor reliability and the like of a traditional four-way valve are overcome. The four-way valve has the advantages of simple and reasonable structure, high energy efficiency ratio, high control precision and short staring time, and is convenient for popularization and application.

Owner:MIDEA GRP CO LTD

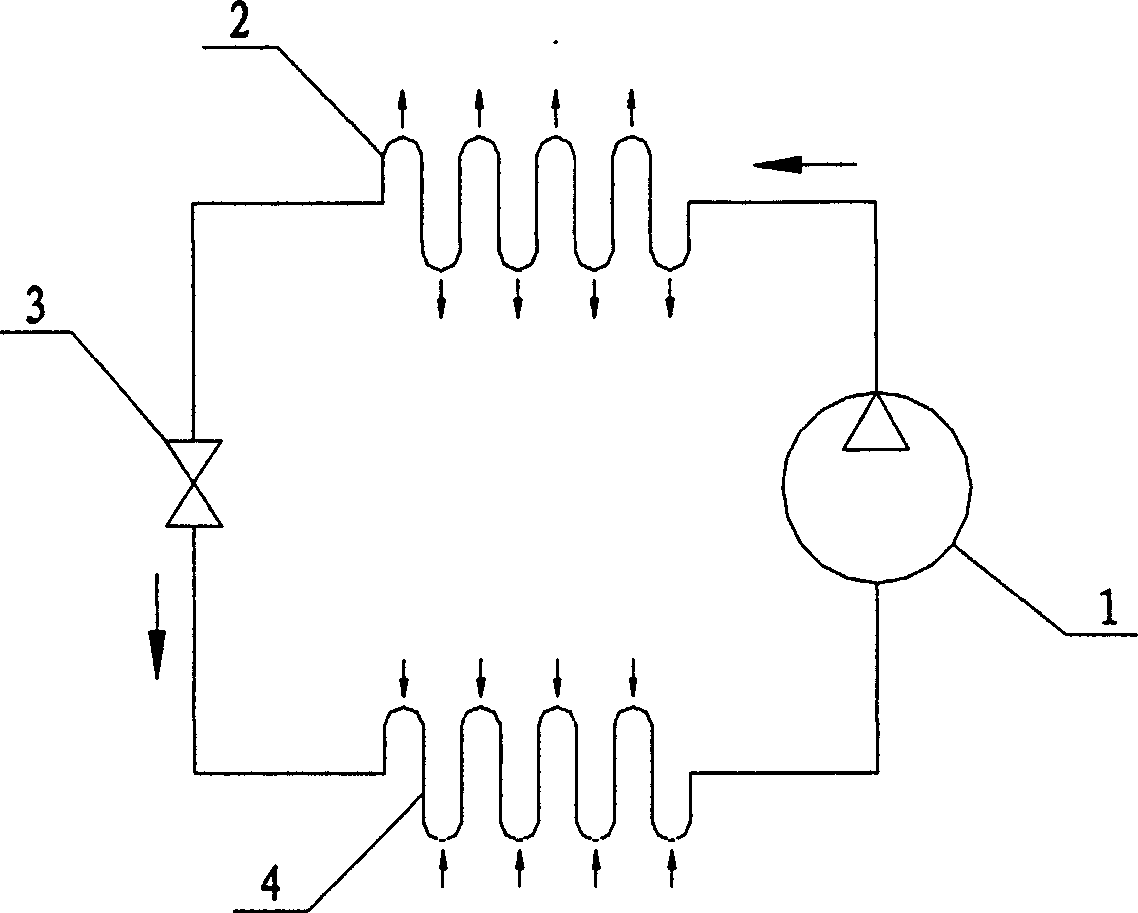

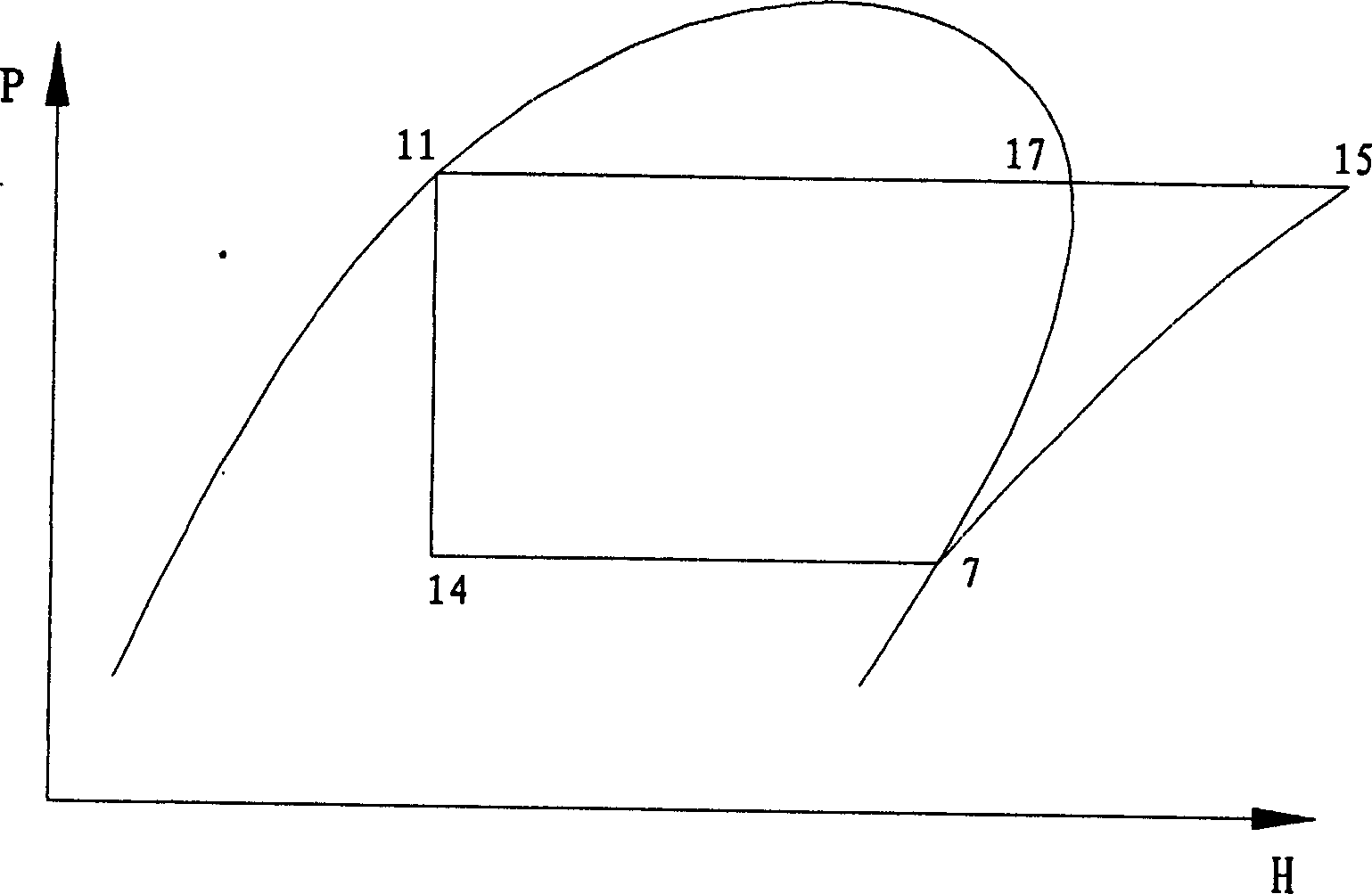

Steam compression type refrigeration cycle device of approximate ideal inverse Carnot cycle efficiency

InactiveCN1683842ALower working fluid temperatureLittle change in thermal perfectionCompression machines with non-reversible cycleCarnot cycleEngineering

The steam compressing refrigeration cycle device includes main cycle system comprising booster pump, condensator, expansion motor, evaporator and compressor connected successively with pipeline to output cold; and secondary cycle system comprising throttle connected across the inlet of the booster pump and the outlet of the condensator as well as the booster pump and the condensator, to further lower the temperature of the work medium in the outlet of the compressor. The expansion motor has its output torque rotating the booster pump and has isoentropic expansion to reduce the entropy of the work medium entering the condensator. The booster pump reduces the operation pressure difference and the power consumption of the compressor. Therefore, the present invention has energy efficiency near ideal inverse Carnot cycle and low hot load one compressor, and may be used widely in refrigeration cycle in air conditioner, refrigerator, etc.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

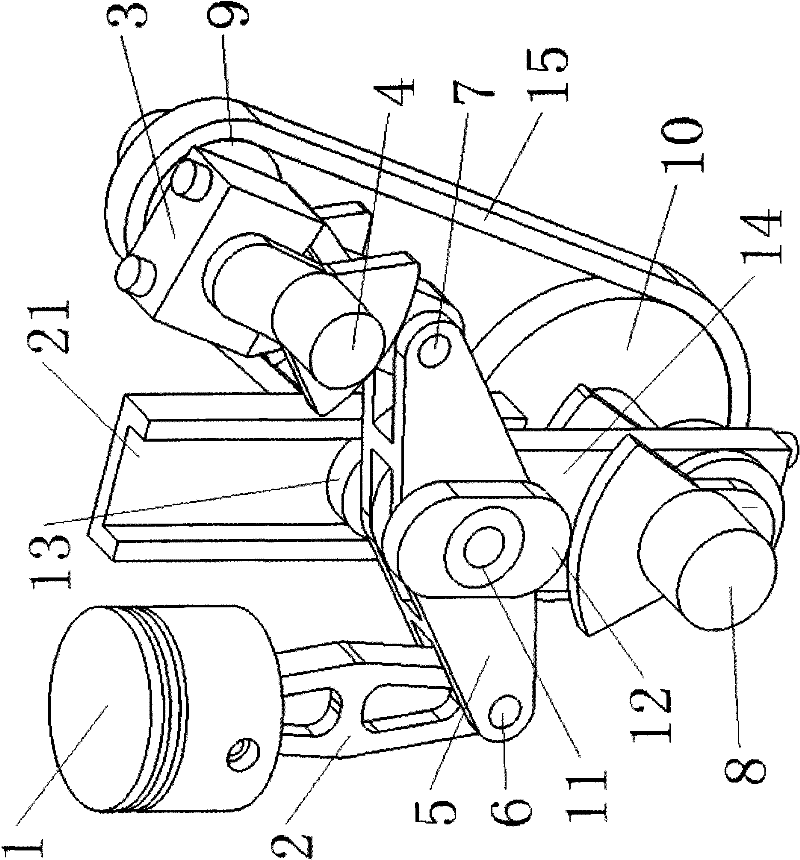

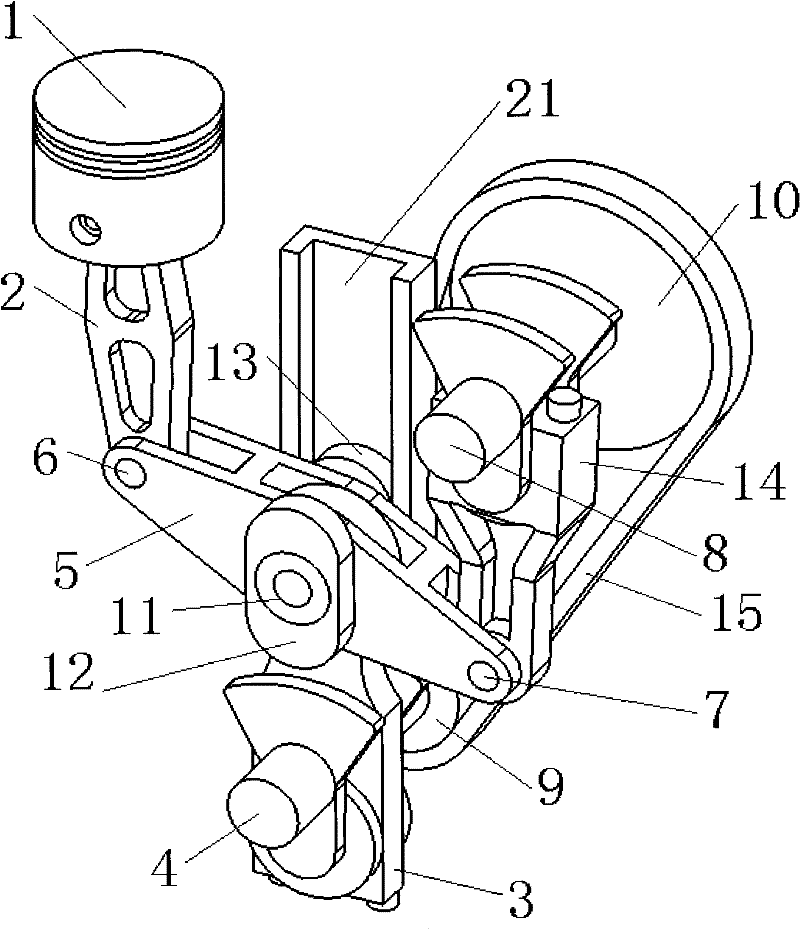

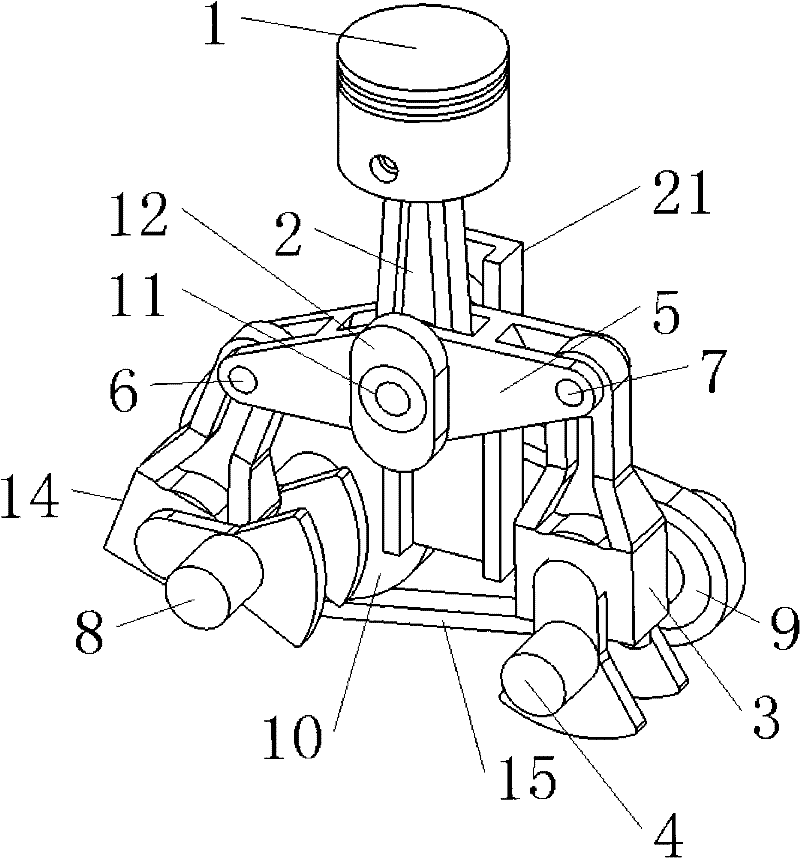

Double-crankshaft-contained variable-compression-ratio Atkinson-cycle internal-combustion engine mechanism

The invention discloses a double-crankshaft-contained variable-compression-ratio Atkinson-cycle internal-combustion engine mechanism, which is an internal-combustion engine technology and is used for improving the usability of an Atkinson-cycle internal-combustion engine and improving the thermal efficiency of the internal-combustion engine to enable the thermal efficiency to be approximate to the highest theoretical efficiency of a Carnot cycle. The mechanism comprises a rocking arm, a second crankshaft, a connecting rod of the second crankshaft, a driving chain, a phase regulator and a derived three-crankshaft Atkinson internal-combustion engine mechanism, wherein the rocking arm is used for connecting a piston connecting rod and a connecting rod of a first crankshaft; the second crankshaft and the connecting rod of the second crankshaft are used for driving the rocking arm to make periodic motion; the driving chain is used for connecting gears on the first crankshaft and the second crankshaft; the gear ratio of the gear for the first crankshaft to the gear for the second crankshaft is 1:2; and the phase regulator is used for regulating the rotary phase relation between the first crankshaft and the second crankshaft. Through the double-crankshaft-contained variable-compression-ratio Atkinson-cycle internal-combustion engine mechanism, the fuel efficiency of a naturally-aspirated internal-combustion engine can be effectively improved, and meanwhile, the double-crankshaft-contained variable-compression-ratio Atkinson-cycle internal-combustion engine mechanism has the actions of additionally regulating the compression ratio and changing the discharging quantity within a small range.

Owner:朱譞晟

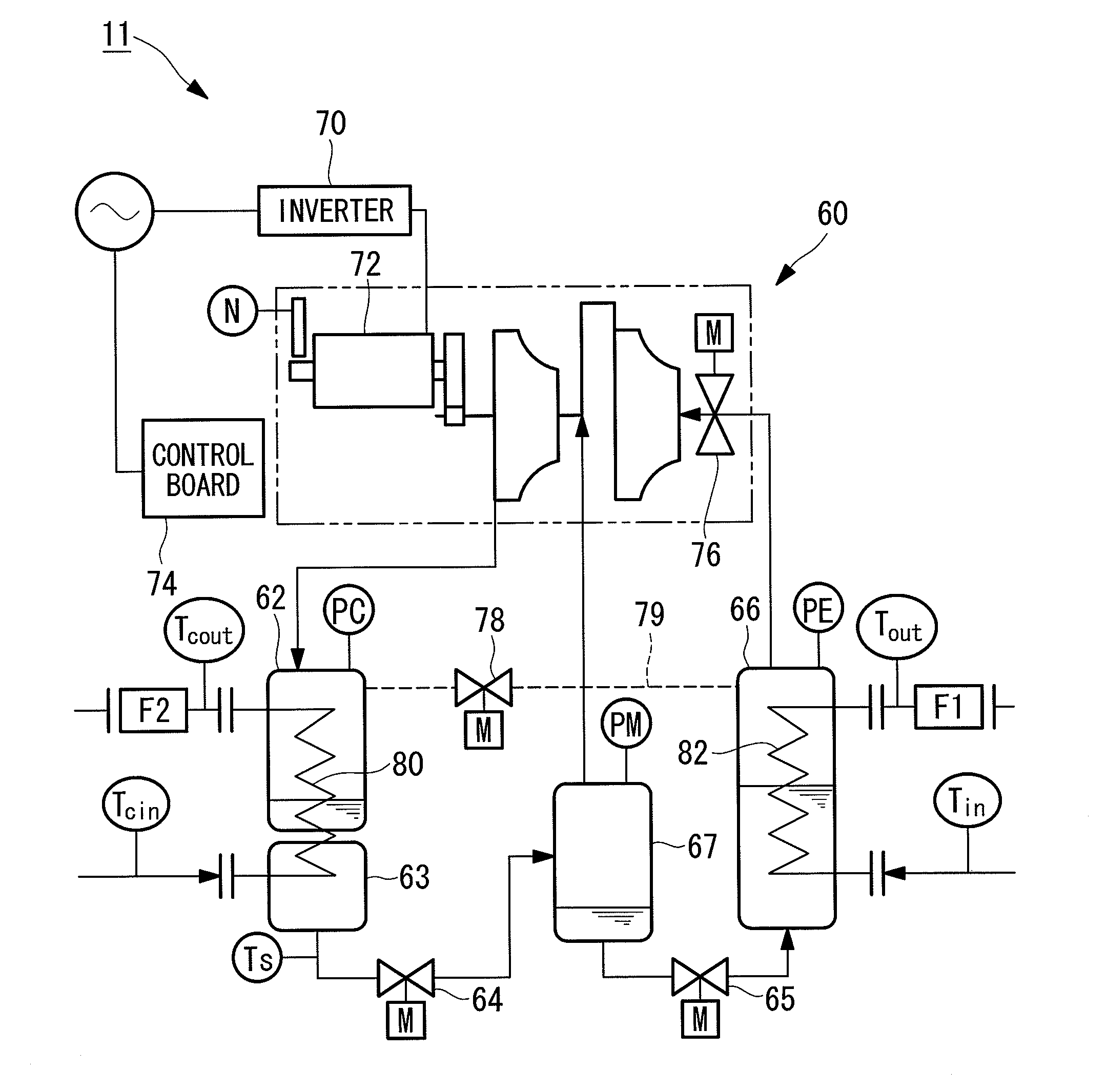

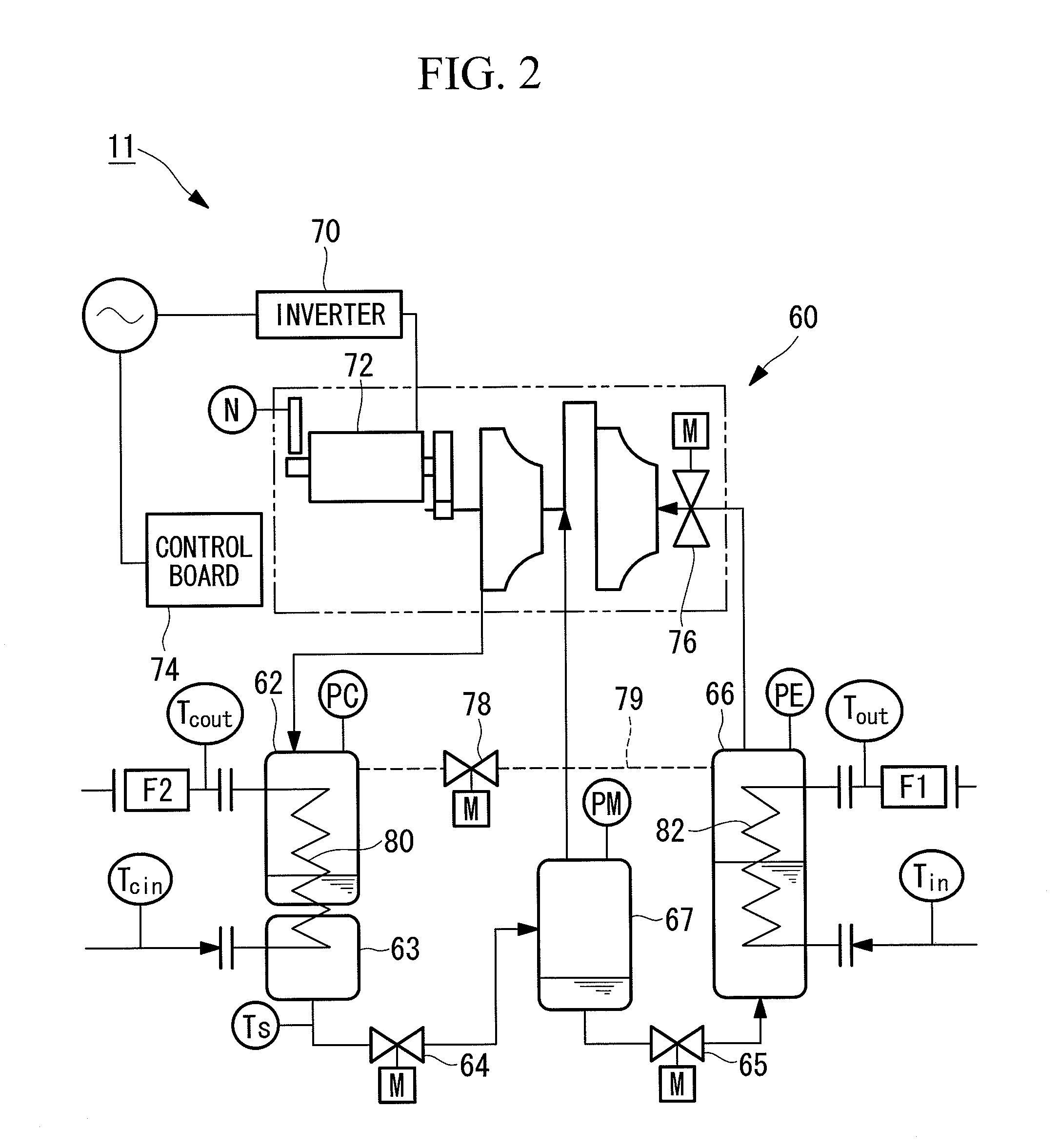

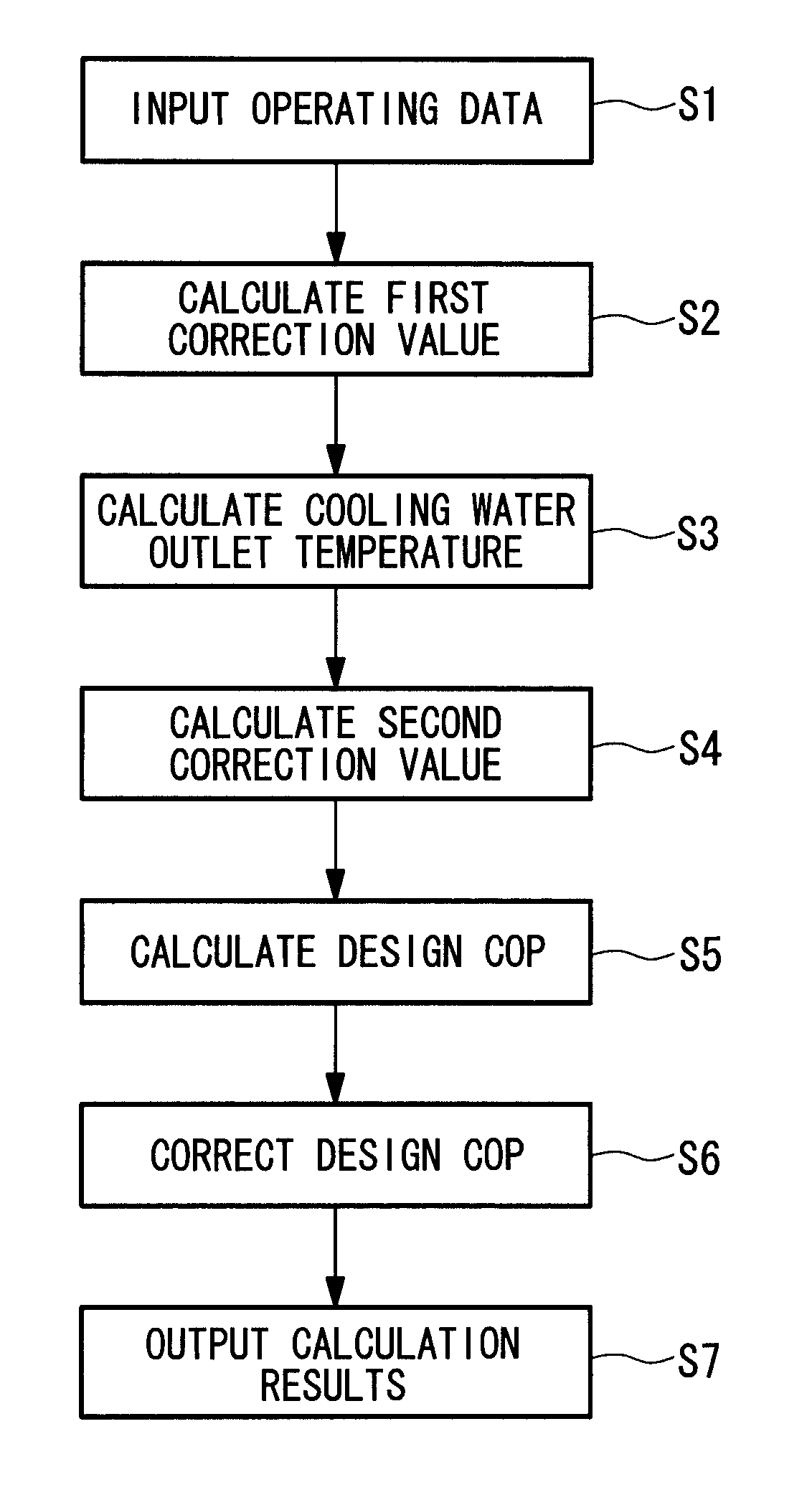

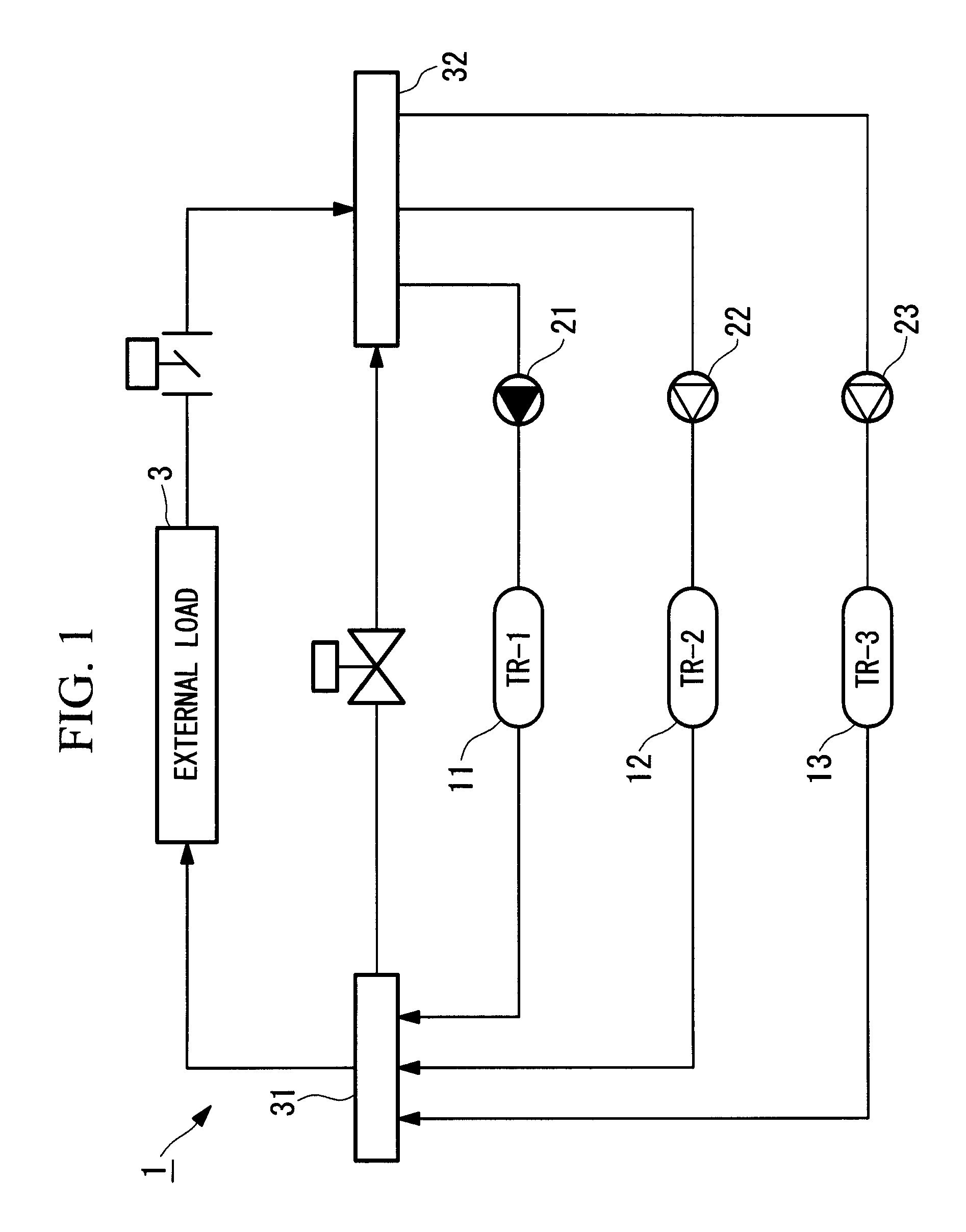

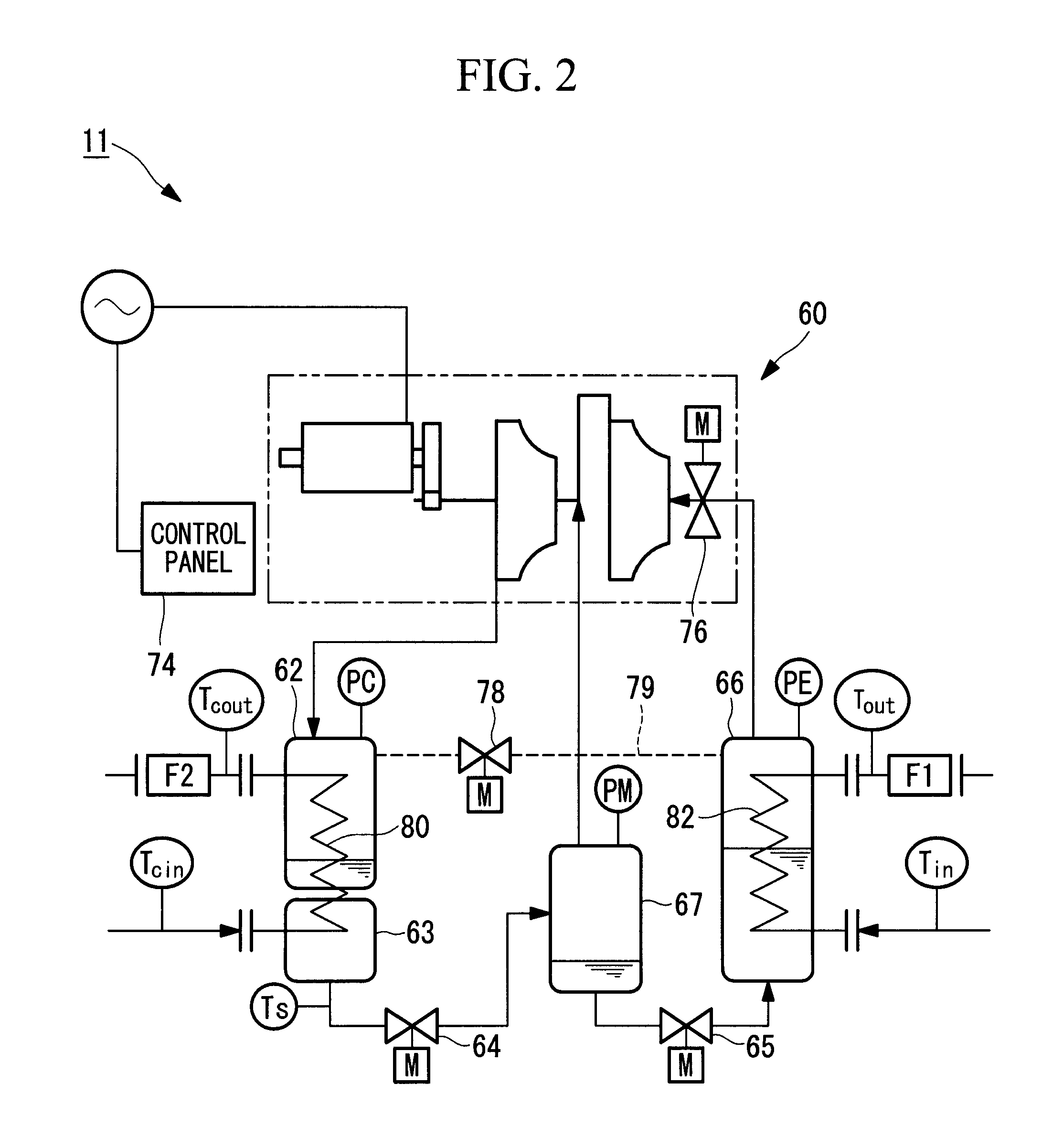

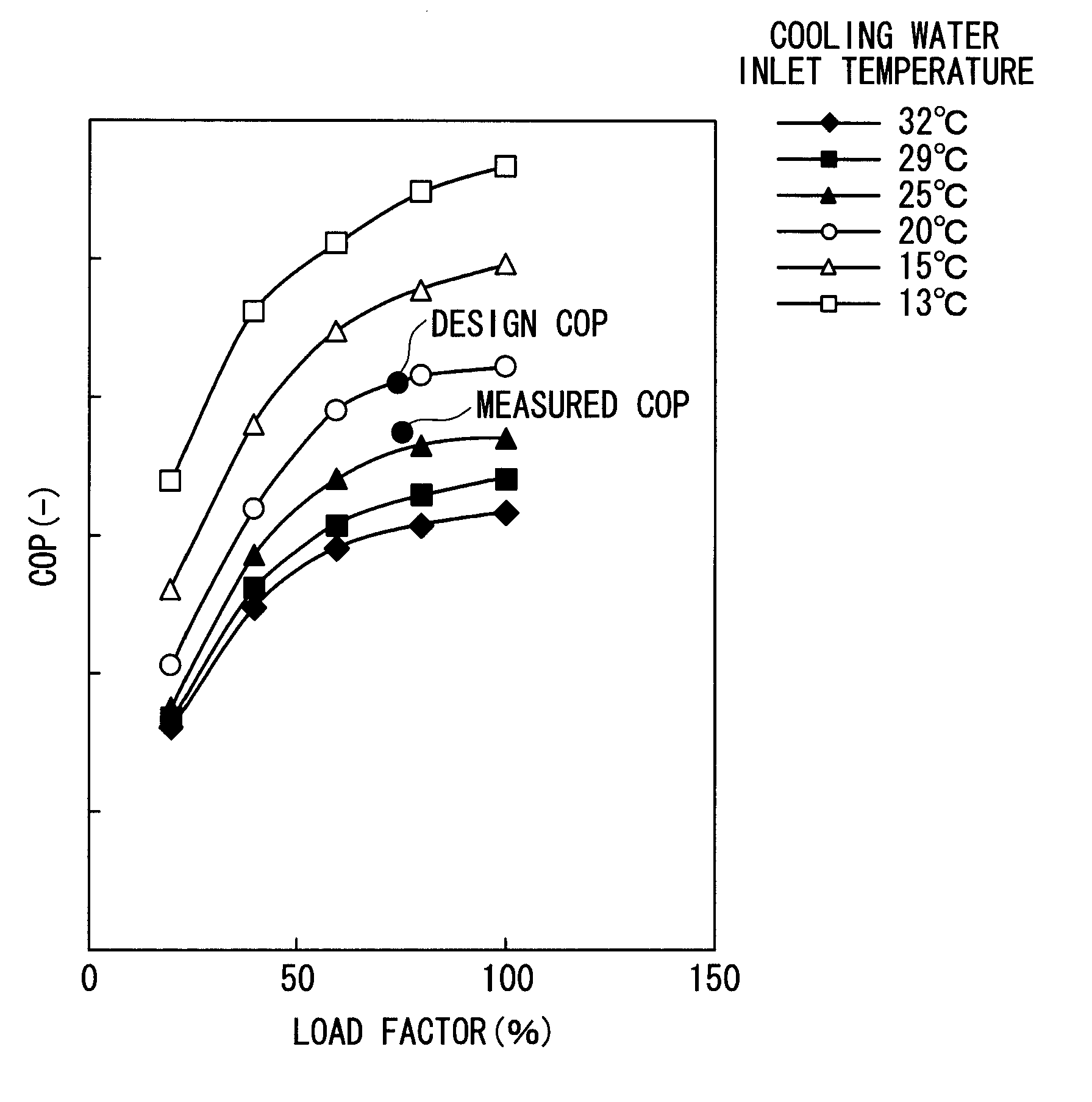

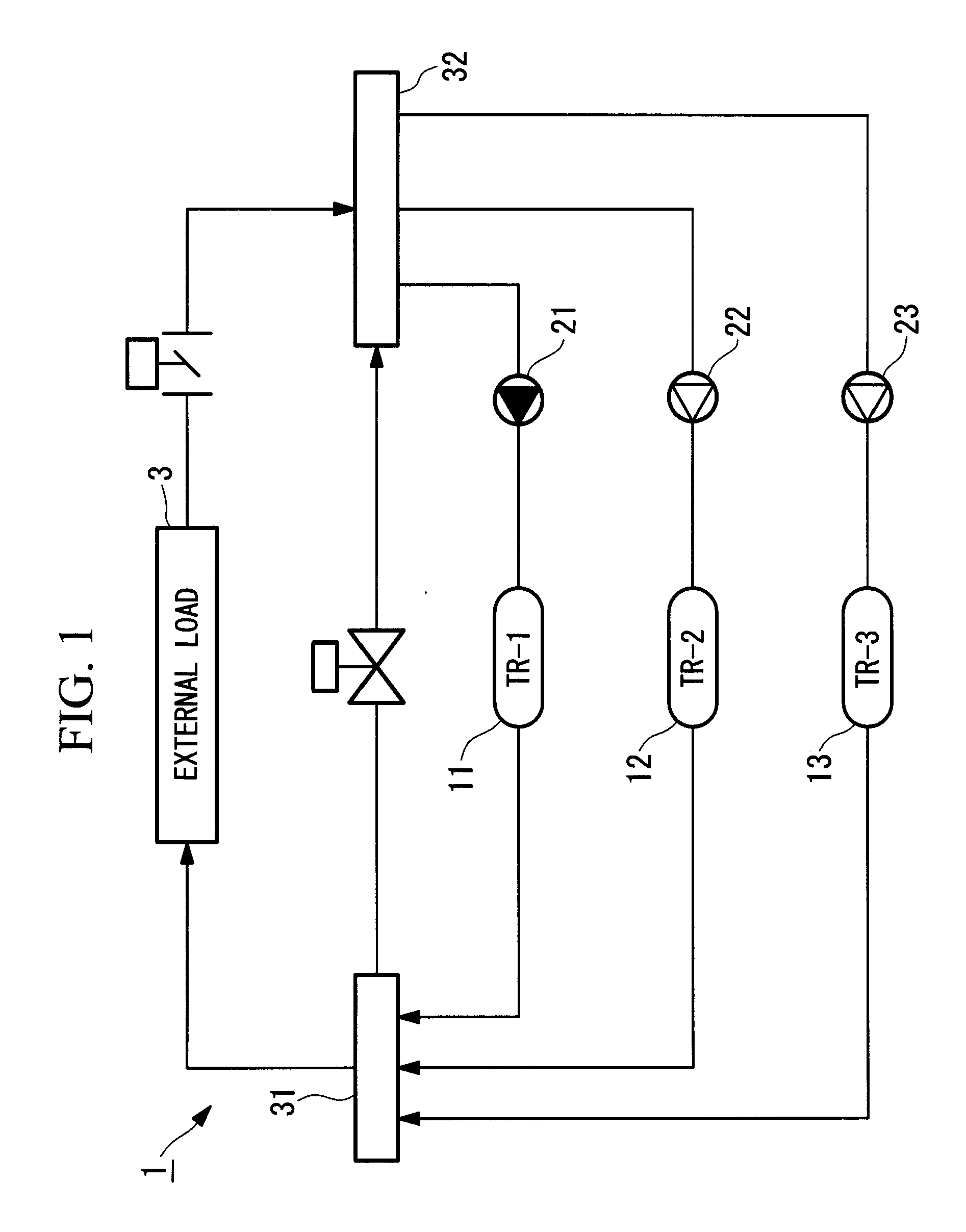

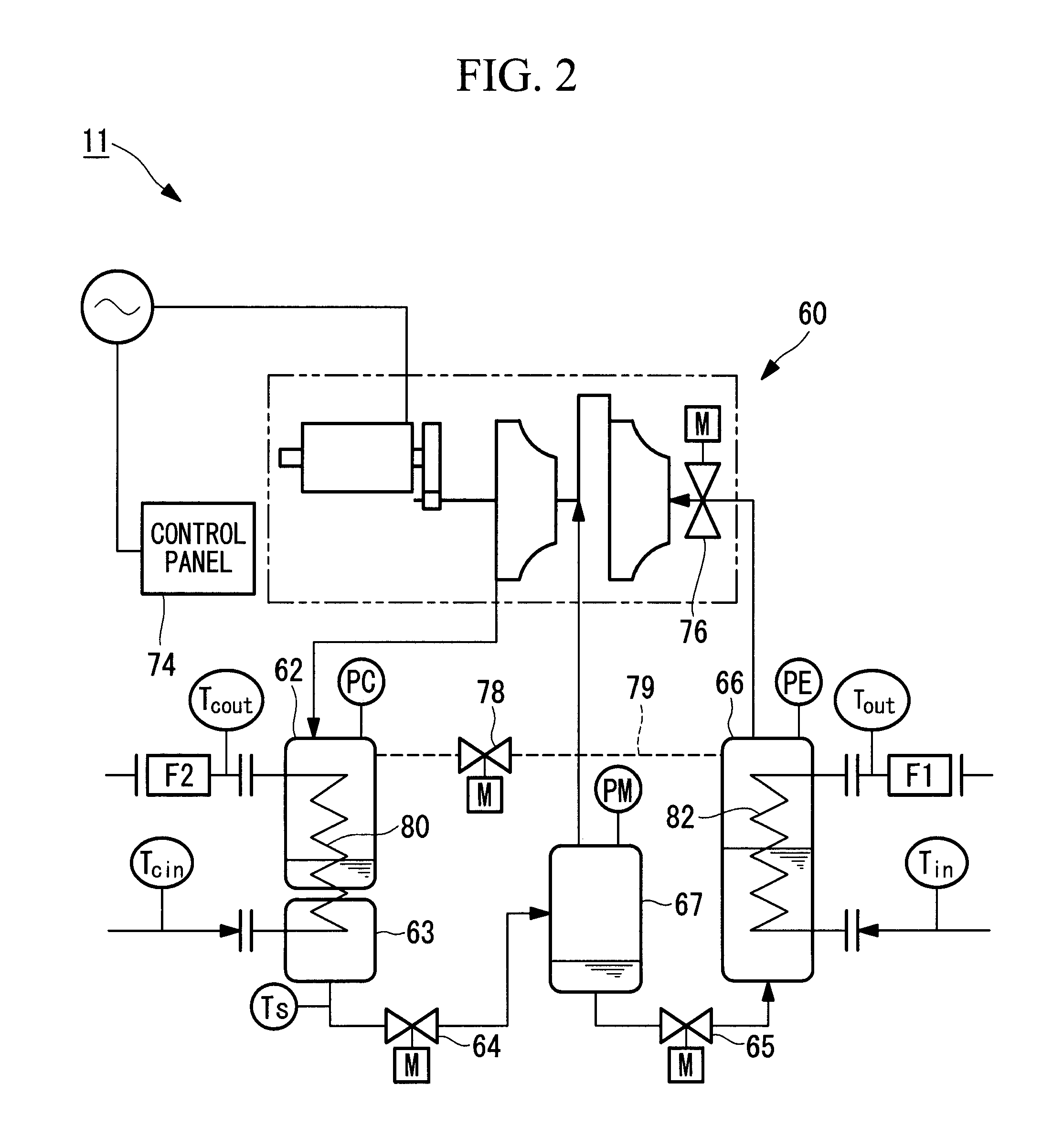

Performance evaluation device for variable-speed centrifugal chiller

ActiveUS20110120162A1Improve accuracyMechanical apparatusCompression machines with non-reversible cycleCentrifugal chillerCurrent load

An object is to sequentially calculate planned COPs. Provided is a performance evaluation device for a variable-speed centrifugal chiller that includes a data acquisition unit that acquires operating data of the variable-speed centrifugal chiller as input data; a storage unit that stores a first arithmetic equation derived on the basis of mechanical characteristics of the chiller and used for calculating a relative load factor that relatively expresses a relationship between a current load factor at a current coolant inlet temperature and a predetermined load factor at a predetermined coolant inlet temperature set as a reference operating point, a second arithmetic equation that expresses a relationship between the relative load factor and a correction coefficient, and a third arithmetic equation used for calculating a planned COP by using the correction coefficient to correct a COP calculation equation derived from a reverse Carnot cycle; and an arithmetic unit that calculates the planned COP under current operating conditions by using the operating data acquired by the data acquisition unit in the first, second, and third arithmetic equations stored in the storage unit.

Owner:MITSUBISHI HEAVY IND LTD

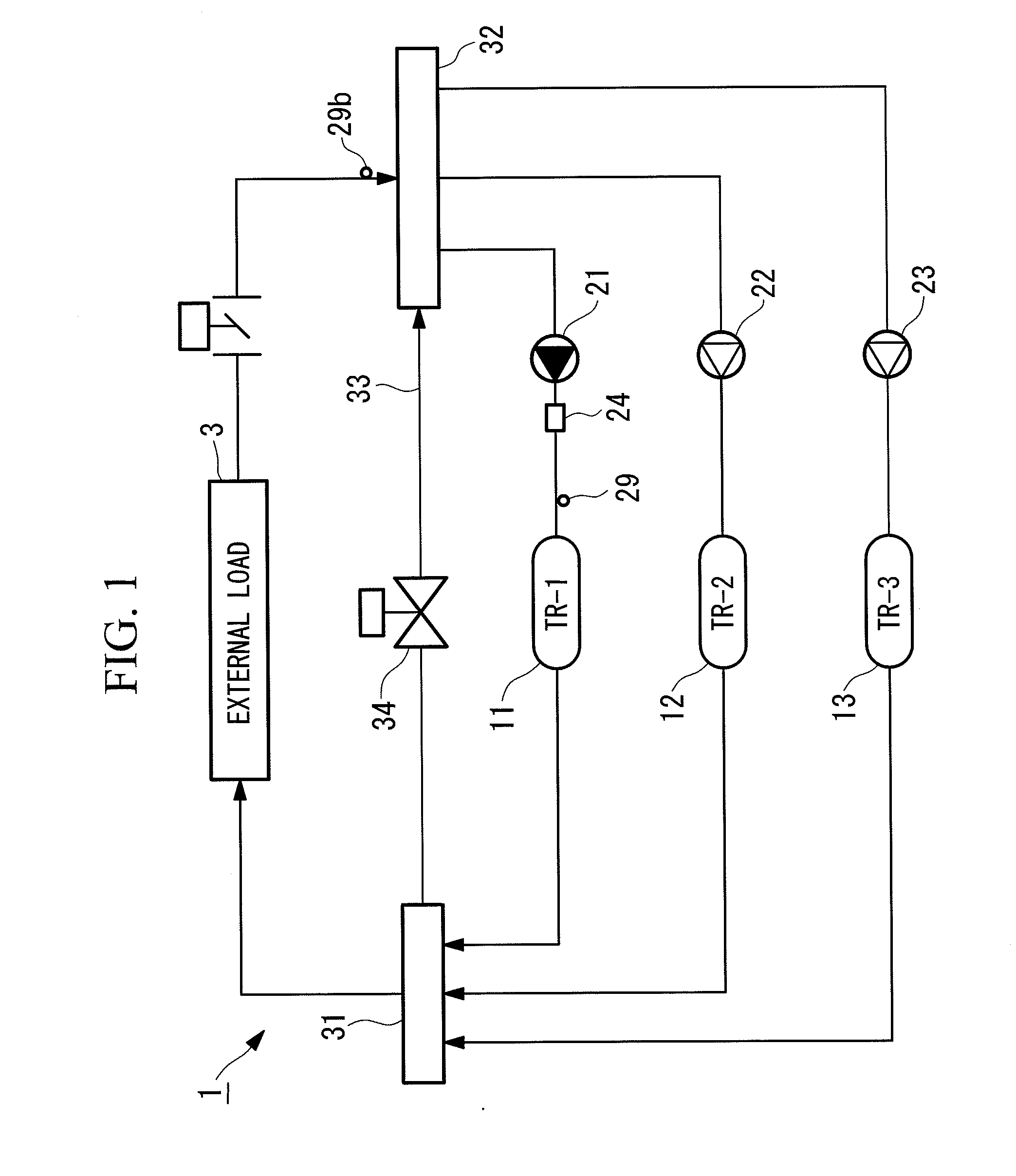

Multipurpose heat pump units

InactiveCN101226019AIncrease profitReduce pollutionFluid heatersHeat pumpsUnderfloor heatingCarnot cycle

The invention discloses a multi-purpose heat pump unit, which configures a heat pump unit providing hot water and floor heating, or configures a two-in-one heat pump unit providing air-conditioning refrigeration and floor heating, or configures a three-in-one heat pump unit which can provide hot water, air-conditioning refrigeration, and floor heating together. The heat pump unit is formed through adding one or two heat exchangers to the heat pump air conditioning unit, and through the carnot circulation or reverse carnot circulation, or through the switch of the control valve, in reverse carnot circulation and conversions between the carnot circulation, and through utilizing the process of heat release and absorption of the high-pressure and high-temperature refrigerant in the compressor. The multi-purpose heat pump unit has advantages of saving equipment investment, improving the efficiency of energy utilization, and reducing the cost and reducing the environmental pollution.

Owner:上海塔格工贸有限公司

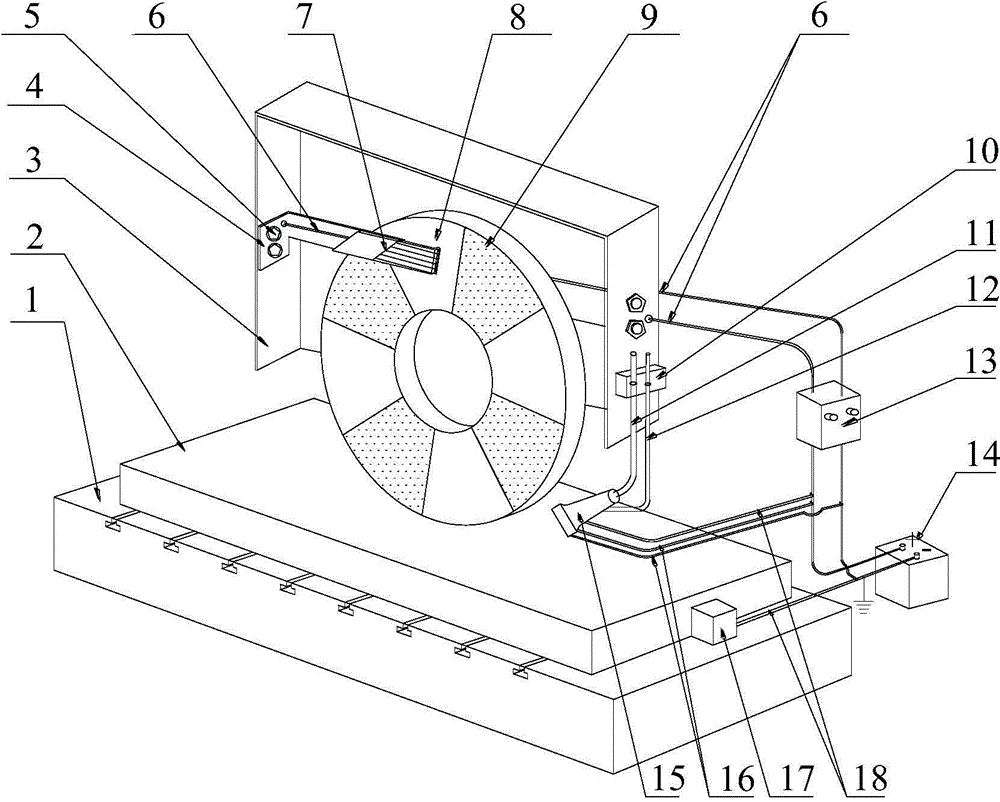

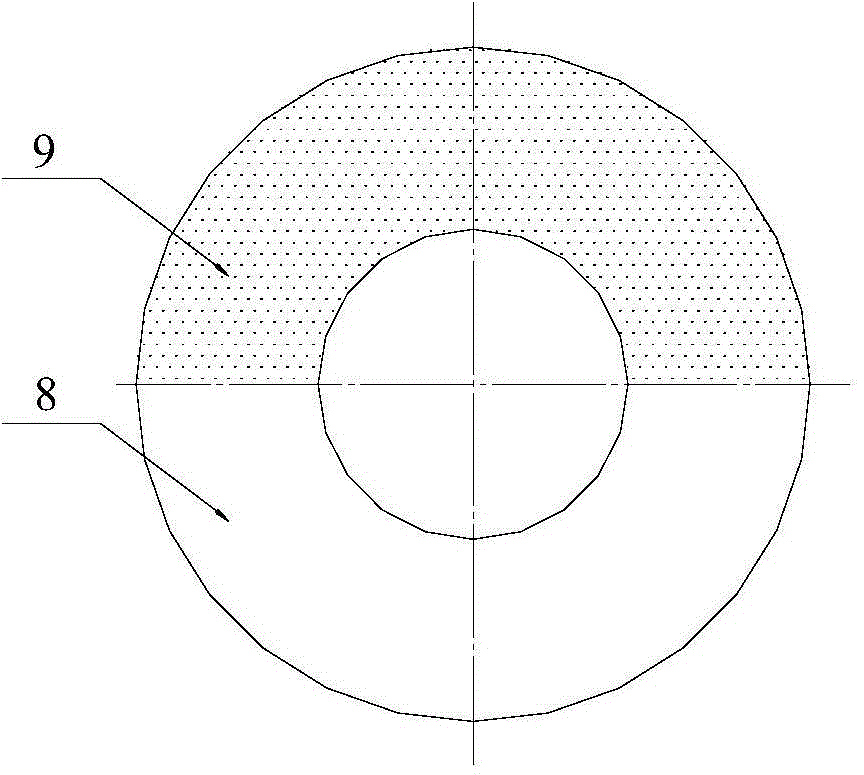

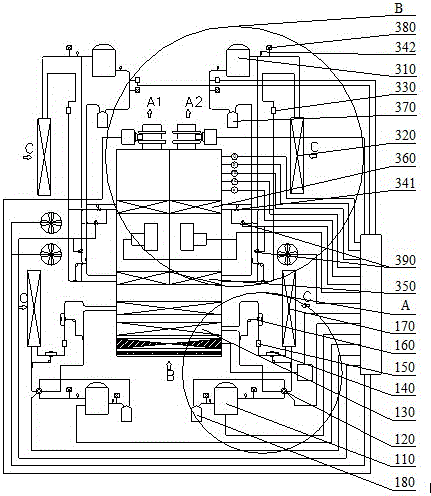

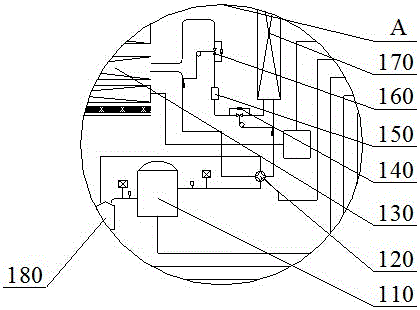

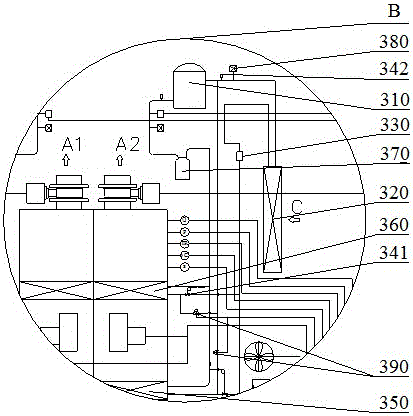

Nano-liquid electrostatic atomization and thermoelectric heat pipe integrated trace lubrication grinding device

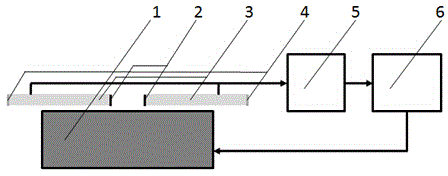

ActiveCN104875116AImprove heat transfer effectImprove cooling effectBonded abrasive wheelsGrinding/polishing safety devicesHigh-voltage direct currentCarnot cycle

The invention discloses a nano-liquid electrostatic atomization and thermoelectric heat pipe integrated trace lubrication grinding device which comprises a grinding wheel with heat pipes and an electrostatic atomization combined spray nozzle in thermoelectric refrigeration and magnetic enhancement electric fields. Thermoelectric film materials cover the surfaces of two sides of the grinding wheel with the heat pipes, and extra electric fields are applied to the outsides of the thermoelectric film materials; a high-voltage direct-current electrostatic generator and a magnetic field forming device are arranged on the outside of the electrostatic atomization combined spray nozzle; the electrostatic atomization combined spray nozzle is connected with a nano-particle liquid supply system and a gas supply system; nano-liquid is subjected to electrostatic atomization and is sprayed to grinding zones by the electrostatic atomization combined spray nozzle, and heat in the grinding zones can be absorbed; the heat can be absorbed by the thermoelectric film materials in the grinding zones under thermoelectric effects, and absorbed heat can be dissipated by the grinding wheel with the heat pipes after the thermoelectric film materials are separated from the grinding zones, so that a Carnot cycle can be formed. The nano-liquid electrostatic atomization and thermoelectric heat pipe integrated trace lubrication grinding device has the advantages that nano-liquid electrostatic atomization and thermoelectric refrigeration and heat pipe refrigeration technologies are integrated with one another, accordingly, a large quantity of grinding heat can be absorbed after the nano-liquid electrostatic atomization and thermoelectric heat pipe integrated trace lubrication grinding device reaches the grinding zones, the grinding temperatures can be reduced, and obvious refrigeration effects can be realized for the grinding zones.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +1

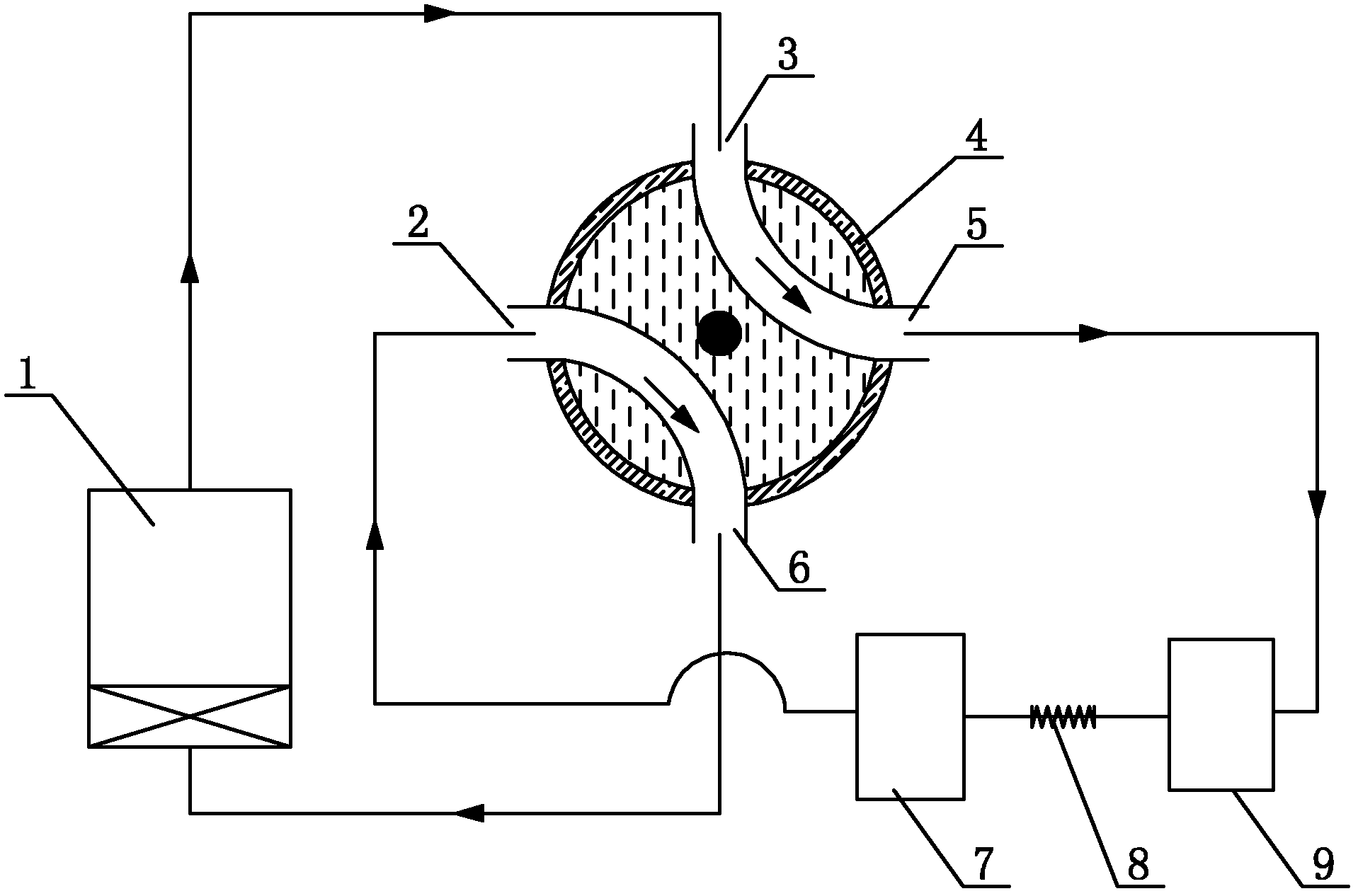

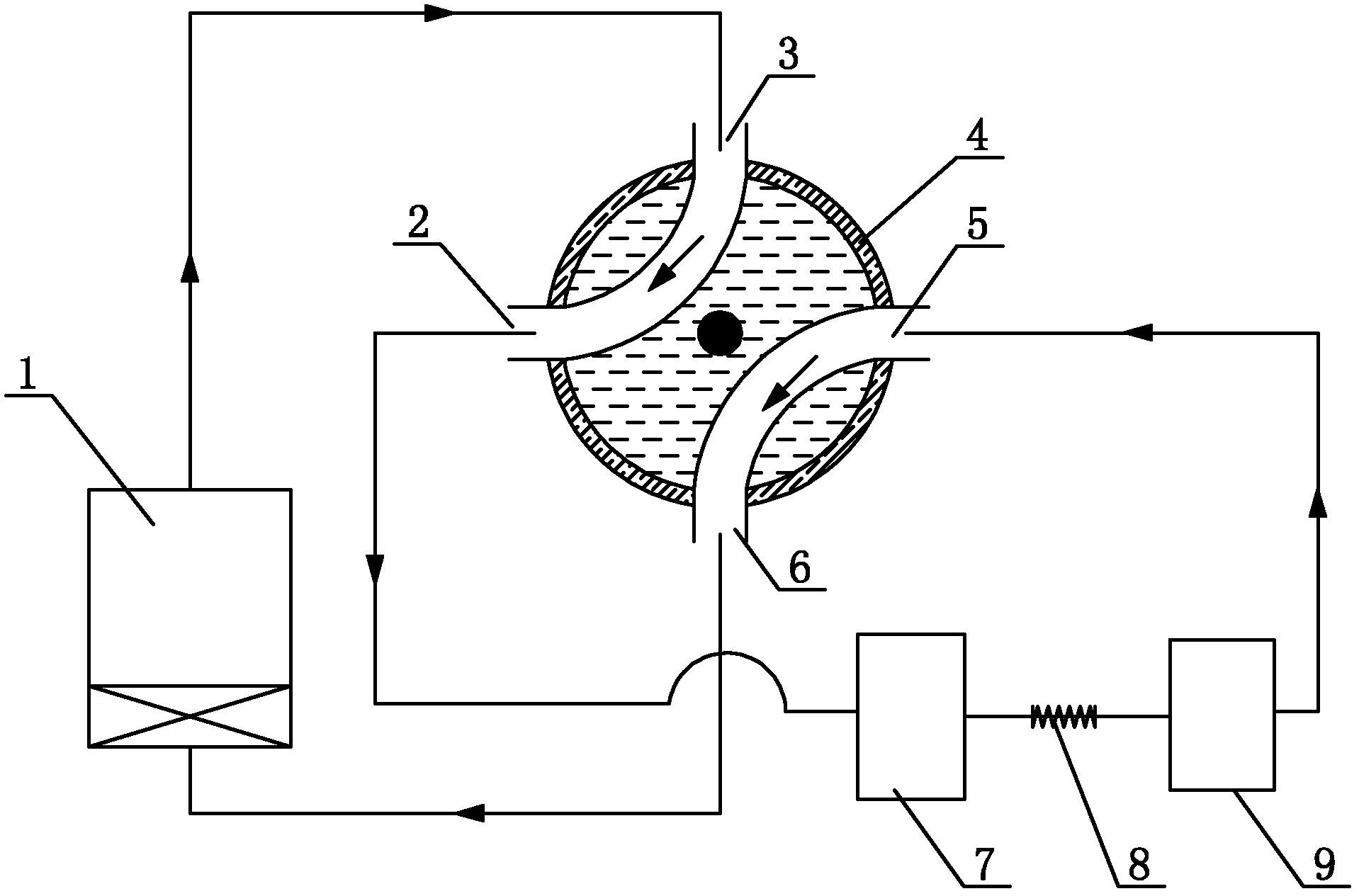

Hybrid engine

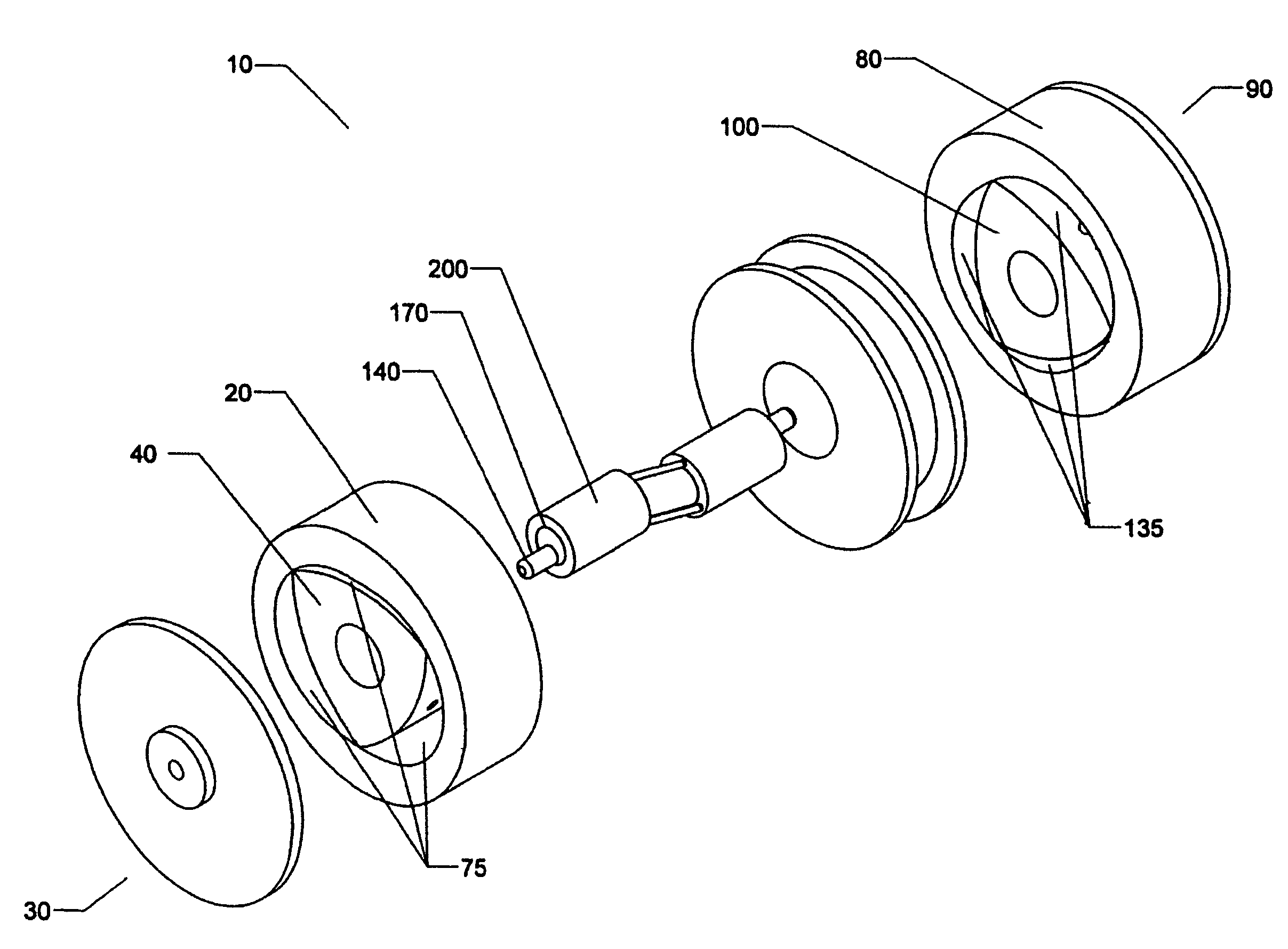

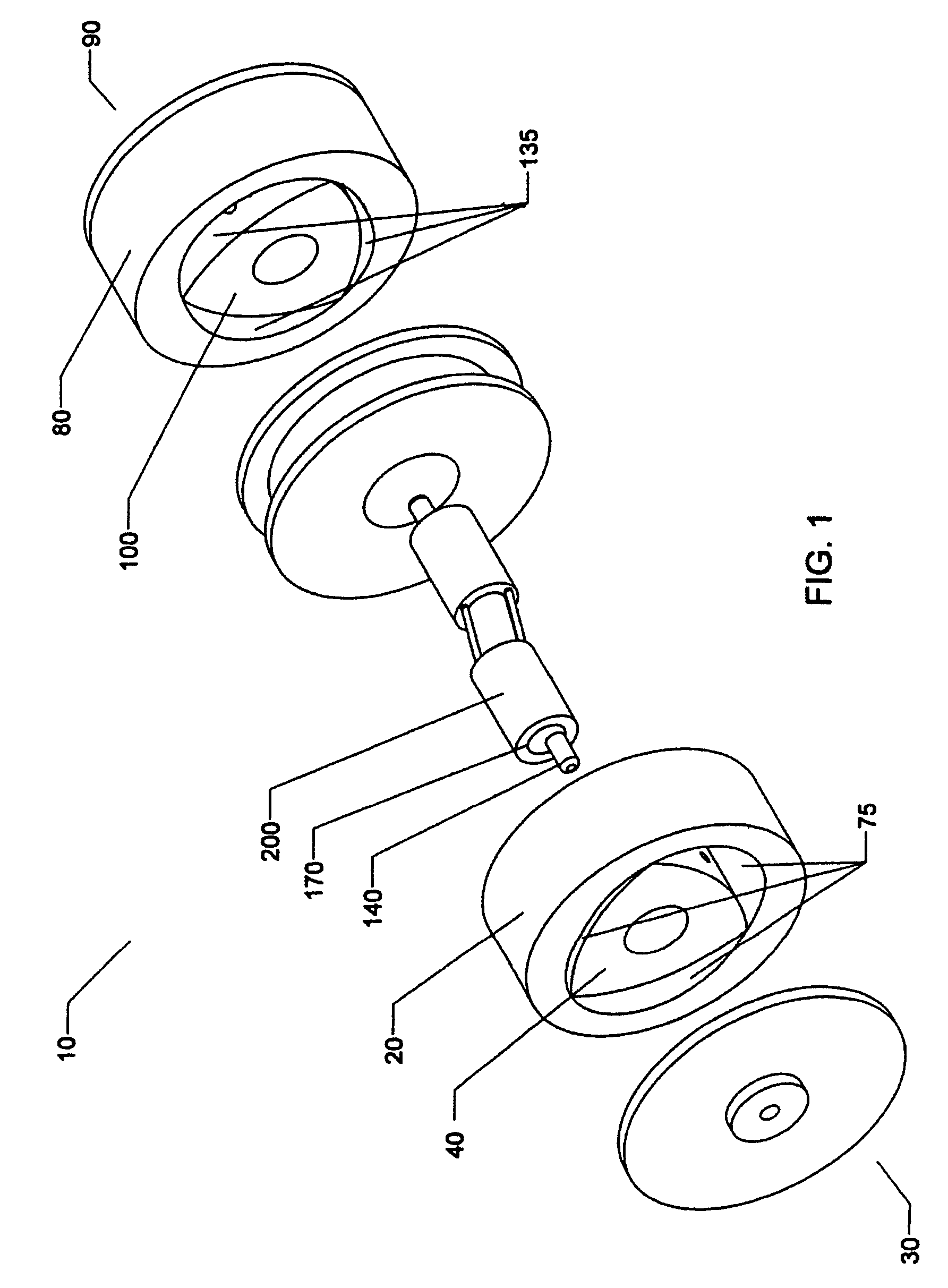

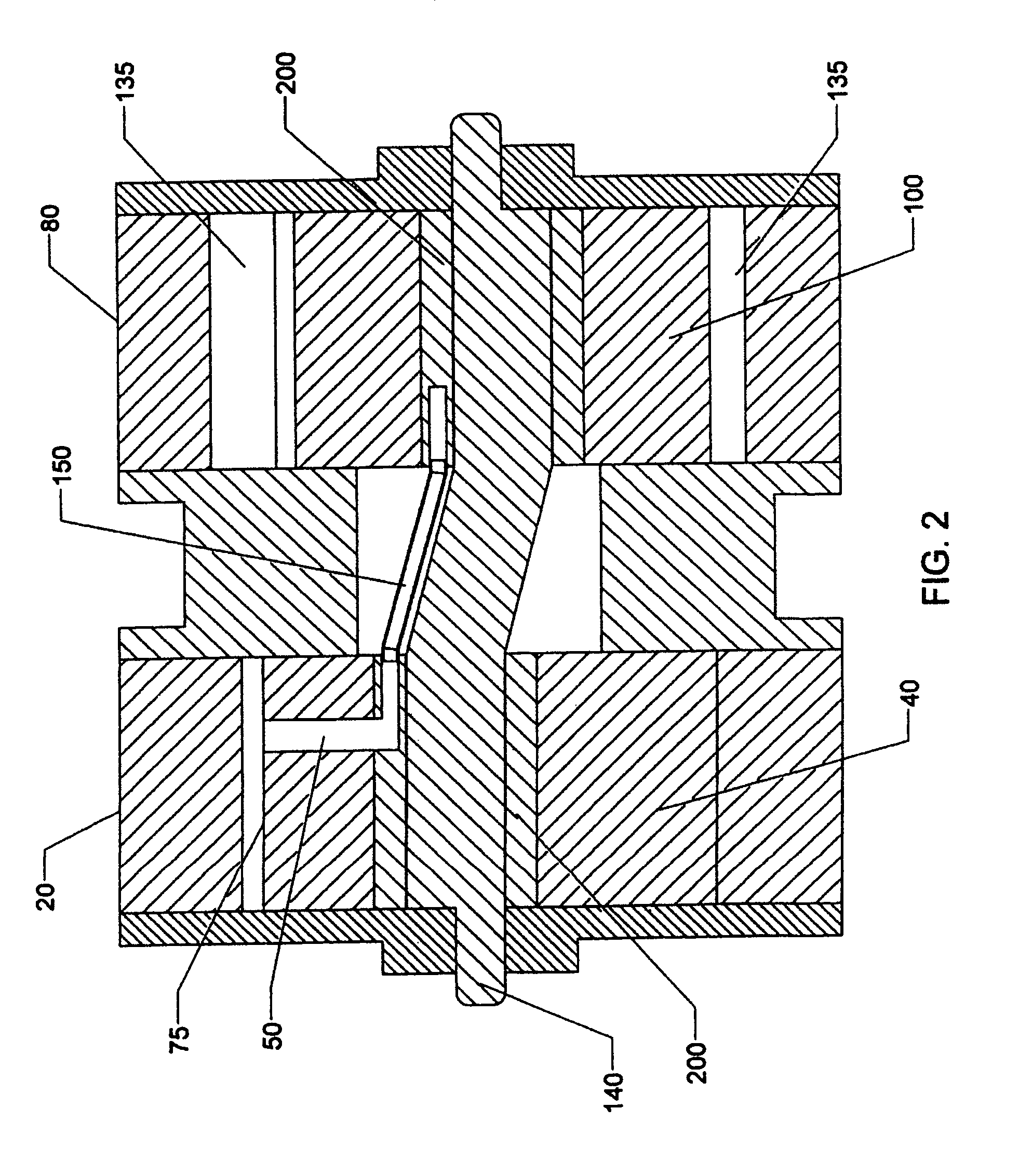

A rotary Wankel-Stirling machine operating upon a compressible working fluid, having a rotary expander having a hot side housing with a heat input interface, a hot side rotor having rotor passages adapted to allow passage of the working fluid between the rotor hub and rotor face, heated chambers formed between the rotor face and the hot side housing, a rotary compressor having a cold side housing with a heat rejection interface, a cold side rotor having rotor passages adapted to allow passage of the working fluid between the rotor hub and rotor face, cooled chambers formed between the rotor face and the cold side housing, a shaft, adapted to rotatably couple the rotor hub of the hot side rotor and the rotor hub of the cold side rotor, the shaft having shaft passages adapted to allow passage of the working fluid between the heated chambers and the cooled chambers, and the working fluid sealed in the machine, wherein the machine operates under the Carnot cycle. The rotary Wankel-Stirling machine may be operated as an engine or a heat pump.

Owner:HERRING JOHN ALEXANDER

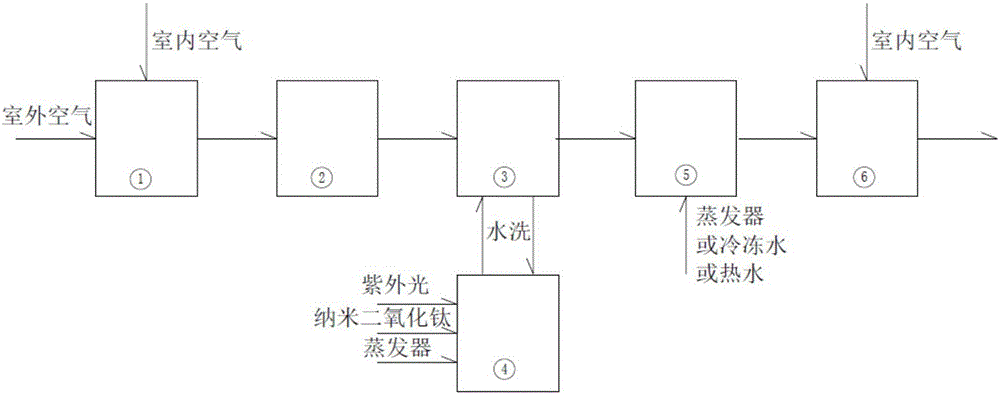

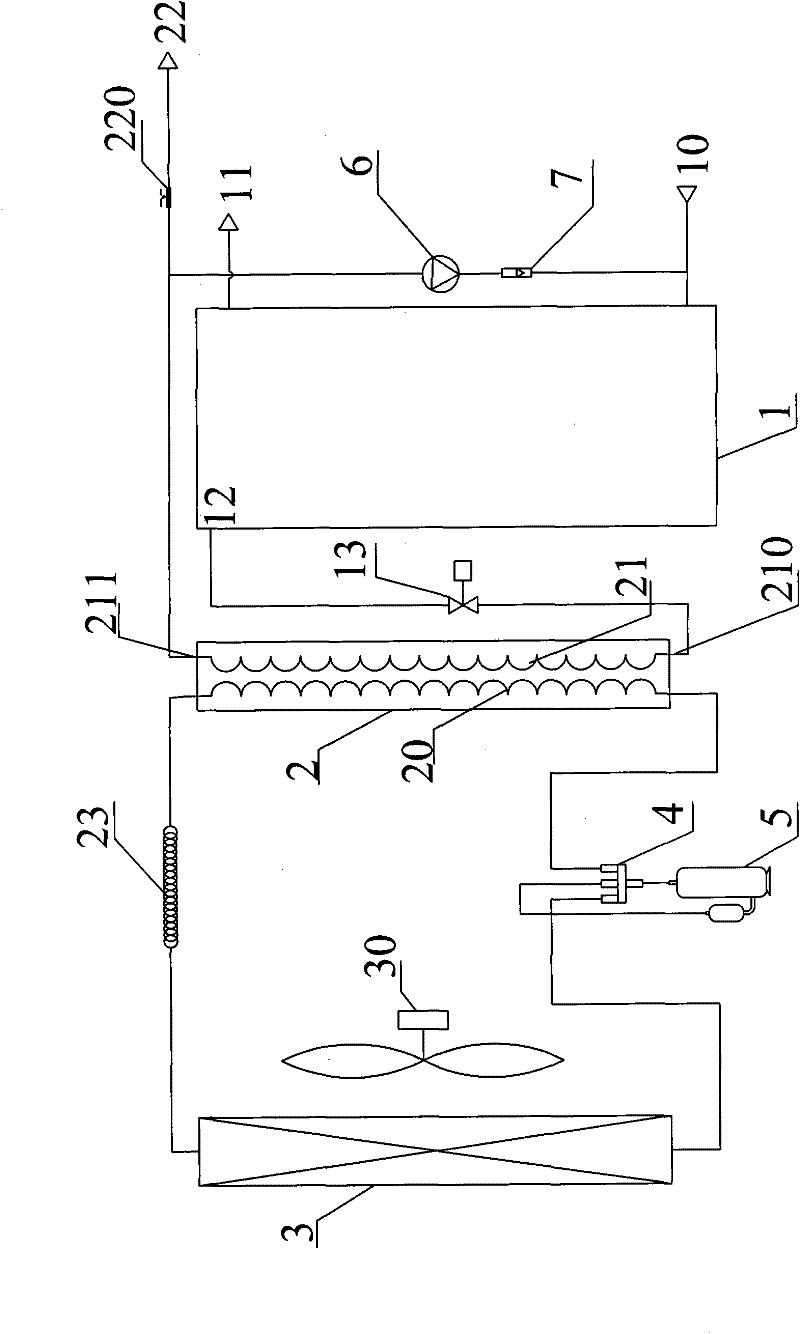

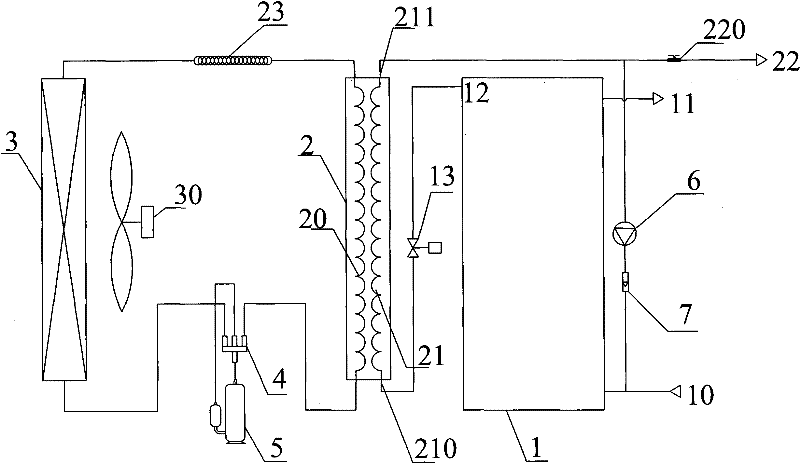

Fresh air system of forest air conditioner

InactiveCN106369675ASolve the four-dimensional spaceEasy to use habitsEnergy recovery in ventilation and heatingMechanical apparatusCarnot cycleFresh air

The invention relates to the field of materials and energy and the field of environment protection. Based on an artificial simulated forest microclimate system, the fresh air system is achieved through Carnot cycle under air conditioner application, and the fresh air system is a mode for replacing fresh air. In severe outdoor air or a closed space, the comfort level of the air conditioner environment meeting the ASHRAE standards is achieved, meanwhile, separate control over temperature and humidity is achieved, air is washed with cold water, pollutants including carbon dioxide, VOC, methanol, peculiar smell, air dust and microorganisms to which the dust is attached in the room are removed, the scheme for removing the pollutants through fresh air ventilation is replaced, and indoor air sterilization is achieved.

Owner:周伟文

Quick water heating device for heat pump

ActiveCN102235746AHeating fastCompatible with modern home useFluid heatersWater storage tankCarnot cycle

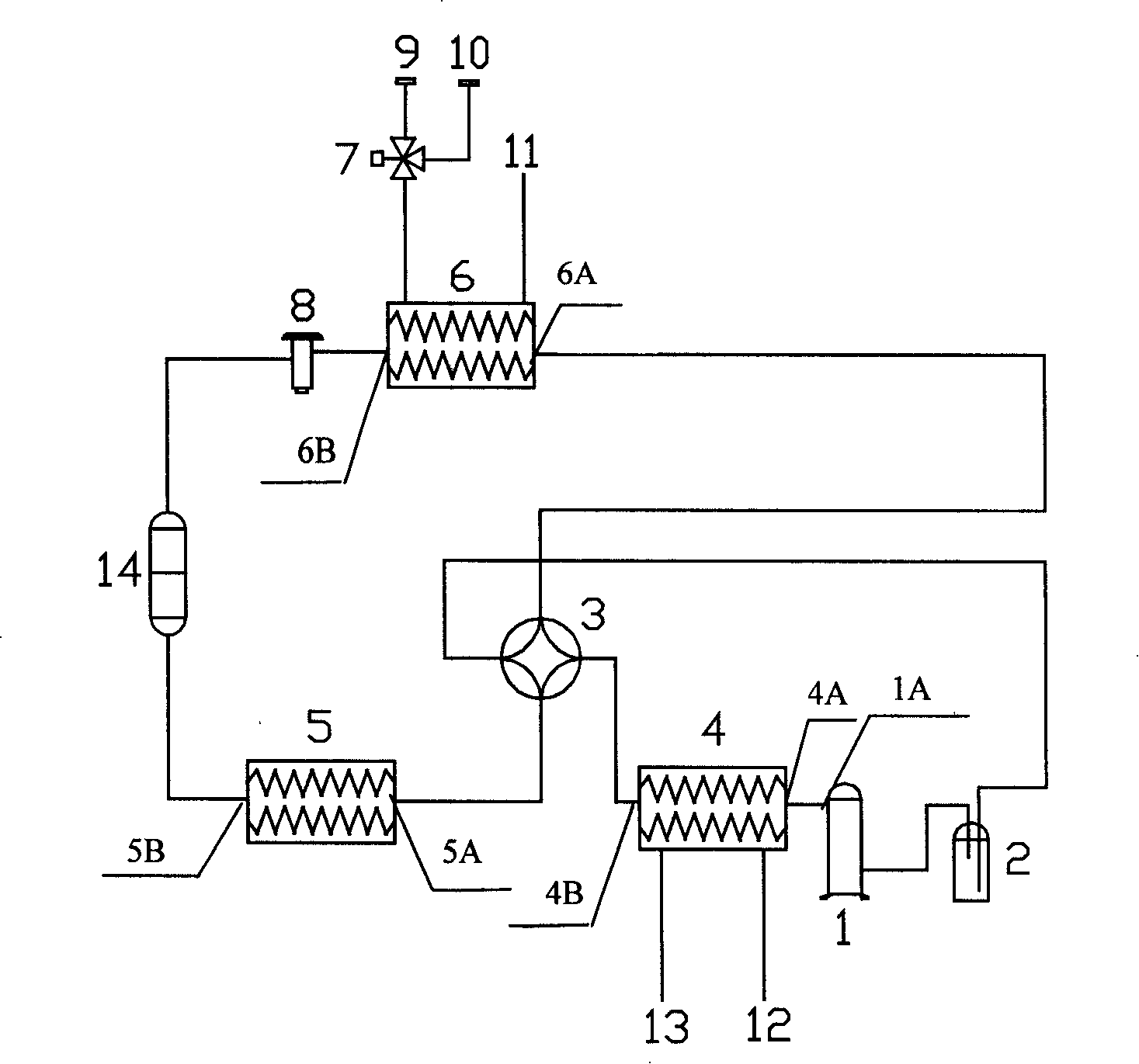

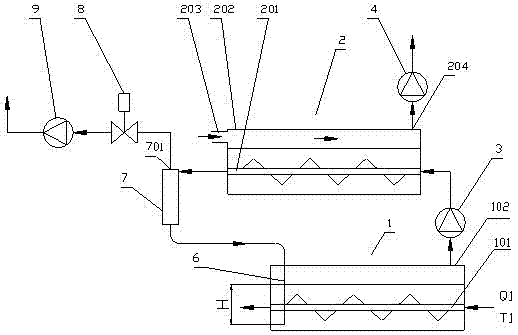

The invention discloses a quick water heating device for a heat pump, which comprises a Carnot cycle system. The quick water heating device for the heat pump further comprises a water storage tank, and a water pipe arranged outside the water storage tank; the bottom of the water storage tank is provided with a water intake; the top of the water storage tank is provided with a circulating water outlet; the circulating water outlet is connected with a water inlet of the water pipe; a water outlet of the water pipe is connected with the water intake of the water storage tank via a circulating water pump and a check valve in sequence; a pipeline between the water outlet of the water pipe and the circulating water pump is provided with a water outlet for bath; and the water pipe is arranged side by side with a refrigerant pipe in the Carnot cycle system to form a heat exchanger. By means of the quick water heating device for the heat pump, disclosed by the invention, the water can be pre-heated and heated quickly, and the service life of the equipment can be prolonged.

Owner:杭州康泉热水器有限公司

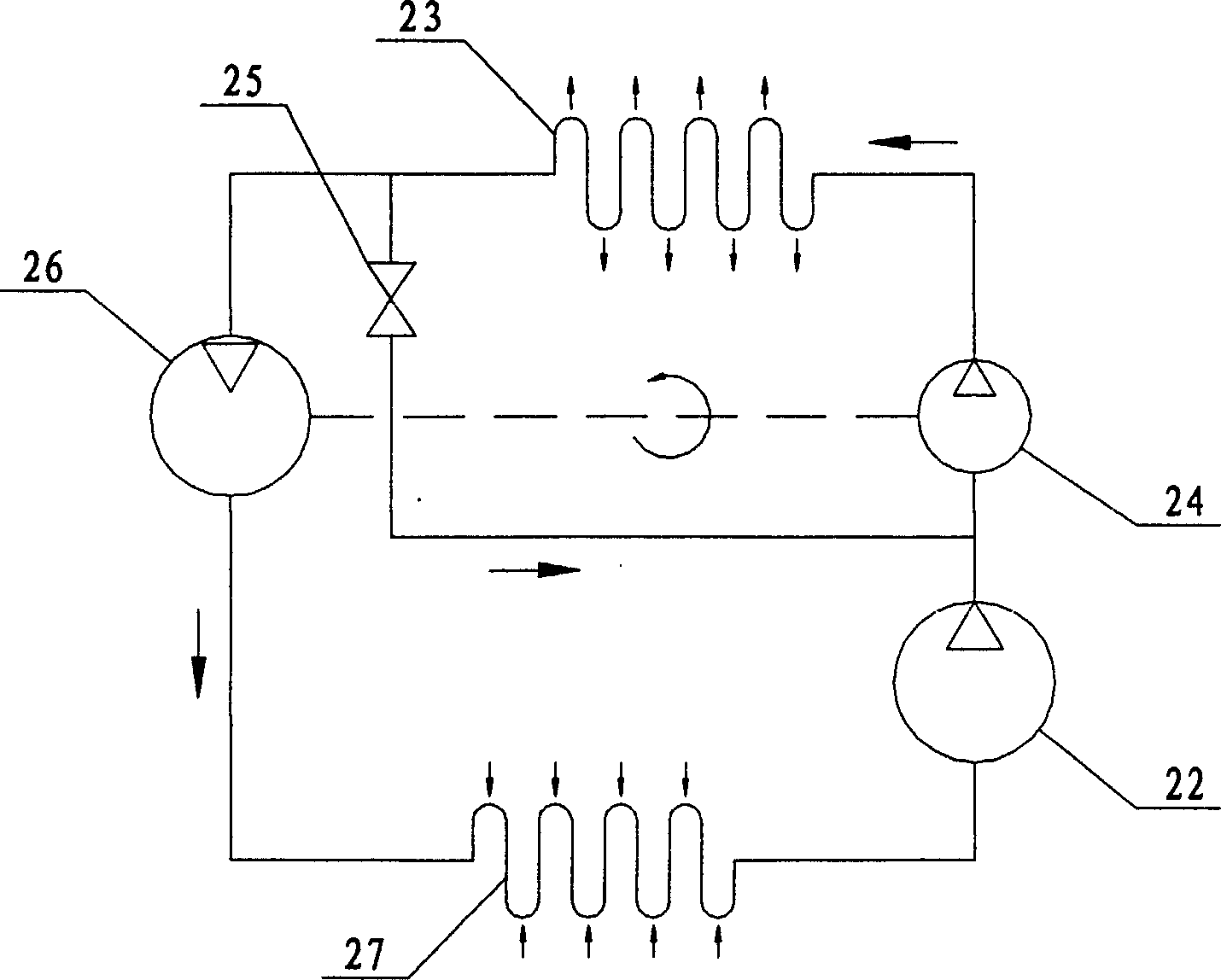

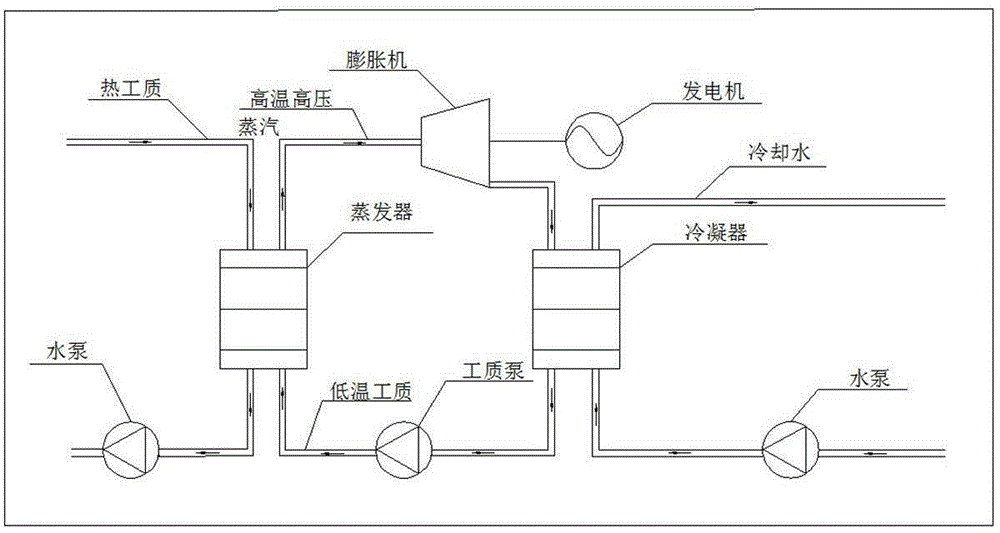

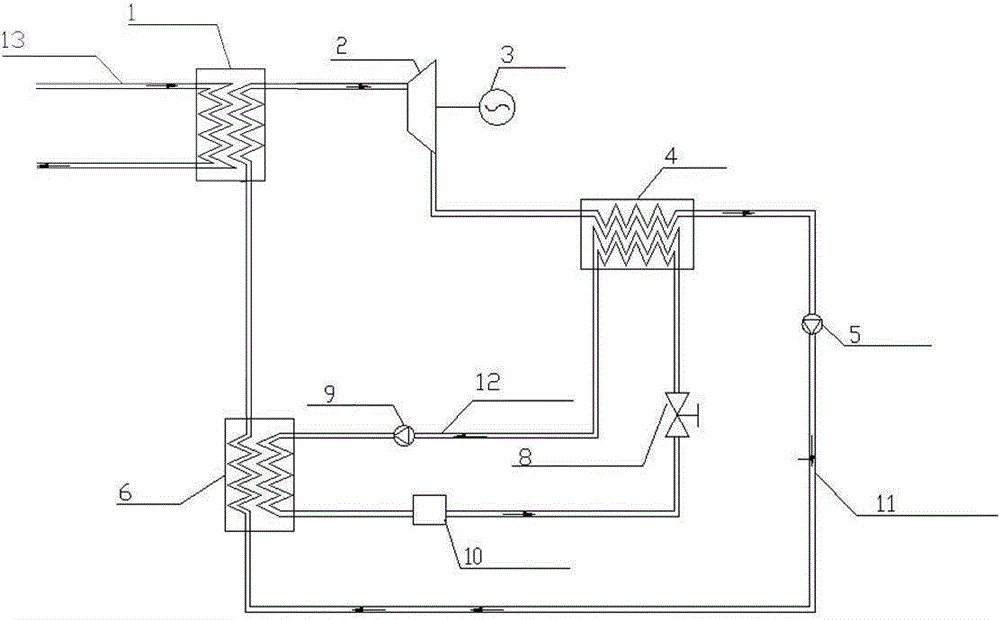

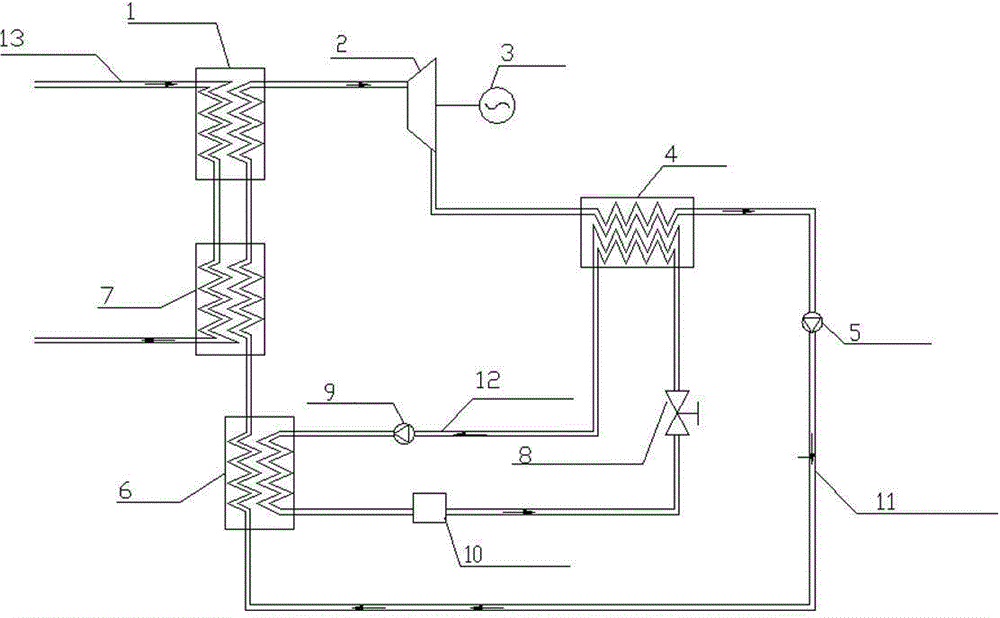

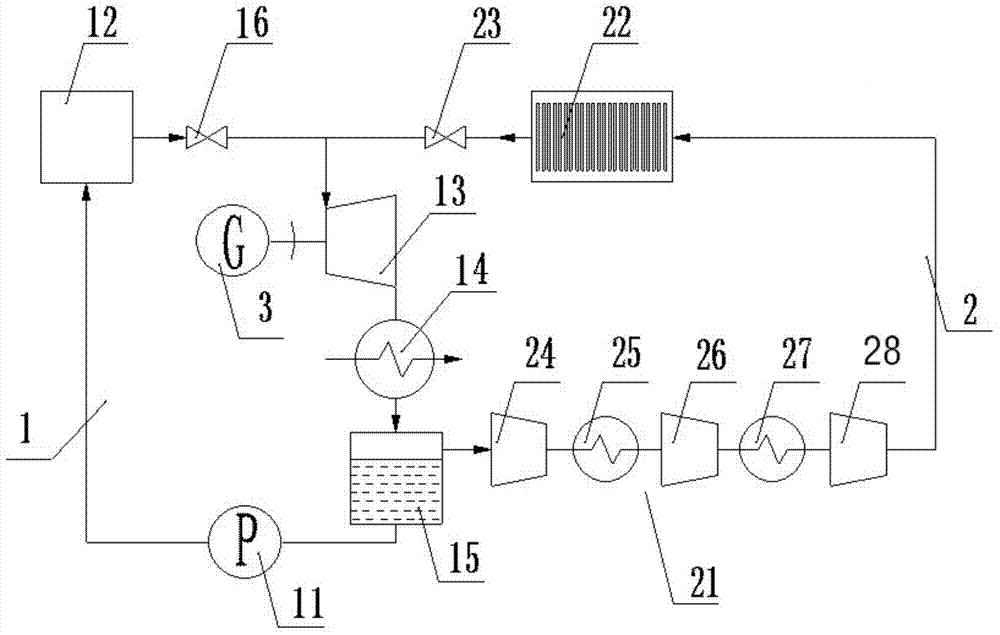

Rankine cycle power generation system capable of realizing efficient utilization of heat energy

InactiveCN104481619AImprove effective useImprove heat utilizationEnergy industrySteam engine plantsCarnot cycleThermoelectric conversion

The invention belongs to the field of energy source application and mainly relates to a Rankine cycle power generation system capable of realizing efficient utilization of heat energy. The system is the Rankine cycle power generation system with a reversible Carnot cycle subsystem, namely a heat regenerator is additionally arranged between a Rankine cycle working medium pump and a steam generator, and one reversible Carnot cycle system is composed of the Rankine cycle power generation system, the heat regenerator, a compressor, an expansion valve and a condenser by a heat regeneration medium and a pipeline; the reversible Carnot cycle system has the function of conveying a lot of the heat energy, which is brought away by a cooling medium in the condenser, is discharged and is absorbed by the system in a current Rankine cycle, back to the working medium of the Rankine cycle by the heat regeneration medium, so that the thermoelectric conversion rate is extremely improved.

Owner:辽宁中联能源科技有限公司

Temperature different generator

InactiveCN102684560ALarge temperature differenceIncrease pressure differenceGenerators/motorsCarnot cycleLithium bromide

The invention provides a temperature different generator which is composed of a heat source and a power generating unit, wherein the generator is formed by a Carnot cycling machine, a lithium bromide set, a generator and a booster pump, wherein the Carnot cycling machine is formed by four parts including a blade, a heat radiator, a throttling unit and an evaporator; and the lithium bromide set is formed by a generator, a condenser, an evaporator, an absorber, a heat exchanger, a circulating pump and the like. The temperature different generator has the beneficial effects that the combined lithium bromide set can expand a low-grade heat source temperature difference at 60-150 DEG C to 100-240 DEG C, and a temperature difference between the heat radiator and the evaporator of the Carnot cycling machine is enlarged, so that a pressure difference of the blade is expanded; and finally, the power generation efficiency is improved to 25-35%, and the temperature different generator can be used for a thermal power plant or other boilers to carry out residual heat power generation and solar power generation.

Owner:杨贻方

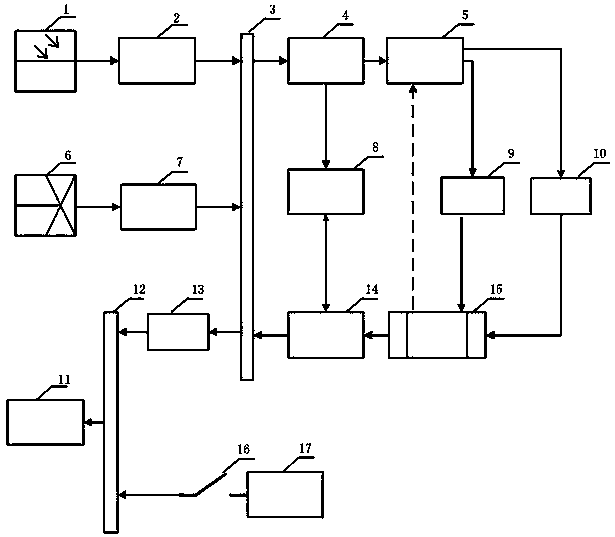

Multi-energy complemented hybrid power generation system of wind, light and proton exchange membrane fuel battery, and method

PendingCN110266040AImprove utilization efficiencyBatteries circuit arrangementsSingle network parallel feeding arrangementsElectrochemical responseLight energy

The invention discloses a multi-energy complemented hybrid power generation system of a wind, light and proton exchange membrane fuel battery, and a method. A power generation proportion of solar energy and wind power is continuously increased; a situation of wind and light abandoning is very rigorous; the reliability, a performance index and a life cycle of a proton exchange membrane fuel battery are greatly improved along with technical breakthrough; and a commercial operation stage is entered. Abandoned wind and abandoned light energy sources are comprehensively utilized by the proton exchange membrane fuel battery; water is electrolyzed by surplus power generated by a photovoltaic array and a wind power generator to generate hydrogen and oxygen; an electrochemical reaction is performed in the proton exchange membrane fuel battery; chemical energy of fuel is directly converted into electric energy; heat engine carnot cycling is not required; a reaction product is the water; and the clean and environment-friendly multi-energy complemented hybrid power generation system of the wind, light and proton exchange membrane fuel battery is formed.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Minimal quantity lubrication grinding device integrating nanofluid electrostatic atomization with electrocaloric heat pipe

InactiveUS20170120419A1Reduce the temperatureImprove machine qualityMachines using electric/magnetic effectsGrinding/polishing safety devicesCarnot cycleEngineering

A minimal quantity lubrication grinding device including: heat pipe grinding wheel covered with electrocaloric film material on both side surfaces, wherein external electric field is applied to outside of the electrocaloric film material; and electrostatic atomization combined nozzle provided with high-voltage DC electrostatic generator and magnetic field forming device at the outside and in an electrocaloric refrigeration and magnetically enhanced electric field; electrostatic atomization combined nozzle is respectively connected with nanoparticle liquid and gas supply system; and nanofluid is electrostatically atomized by electrostatic atomization combined nozzle and is jet to grinding area to absorb heat of grinding area; electrocaloric film material absorbs heat in grinding area through electrocaloric effect and disperses absorbed heat through heat pipe grinding wheel after leaving grinding area to form a Carnot cycle. Nanofluid electrostatic atomization is integrated with electrocaloric refrigeration and heat pipe.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

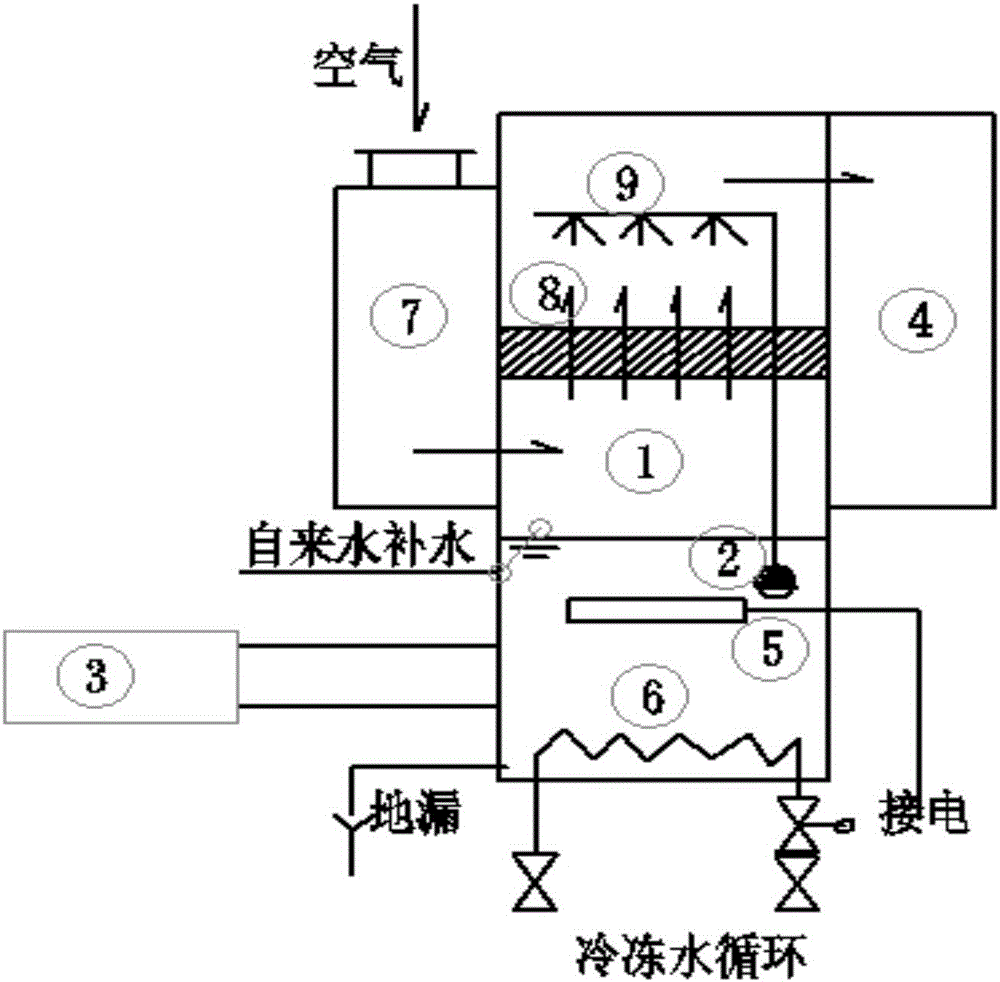

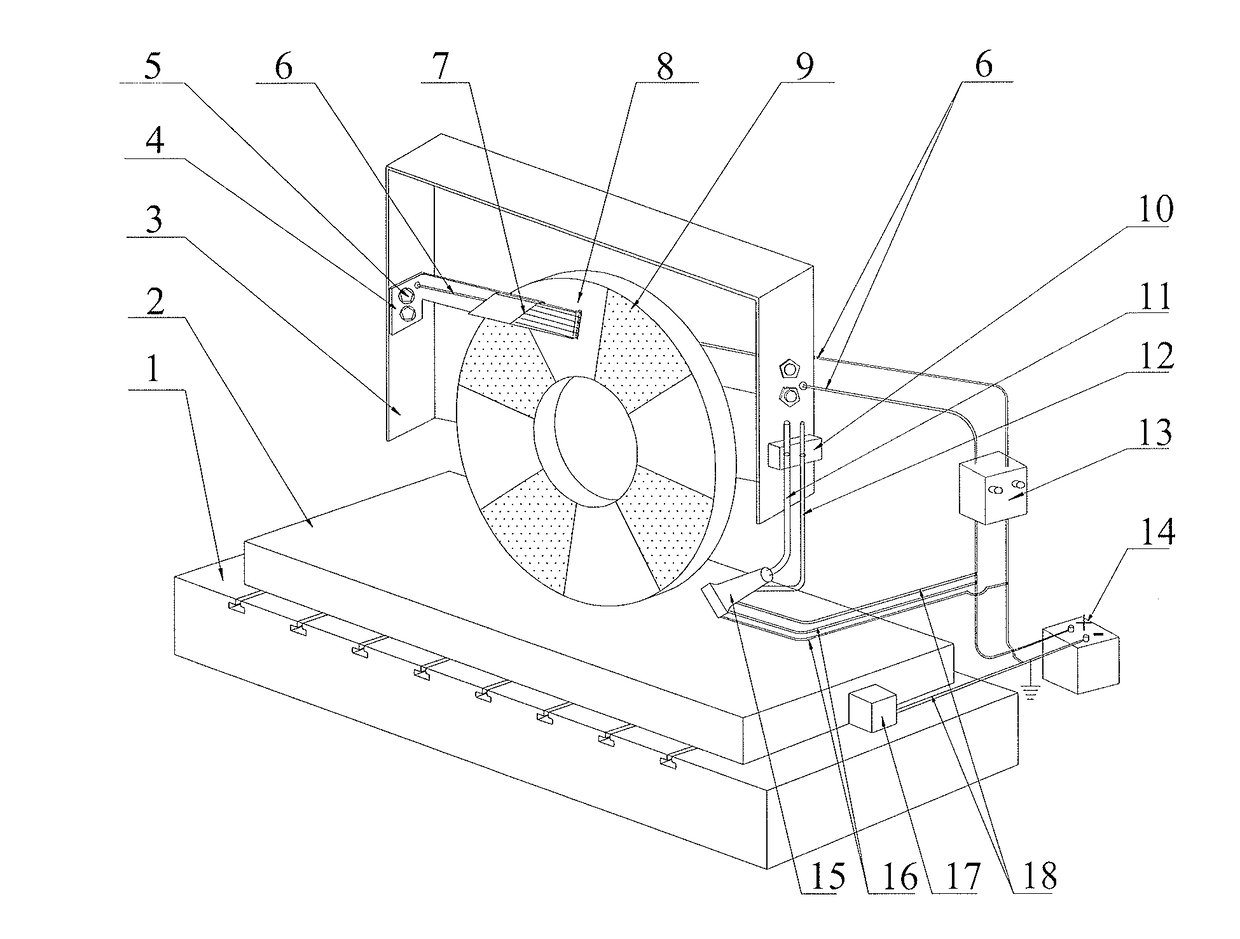

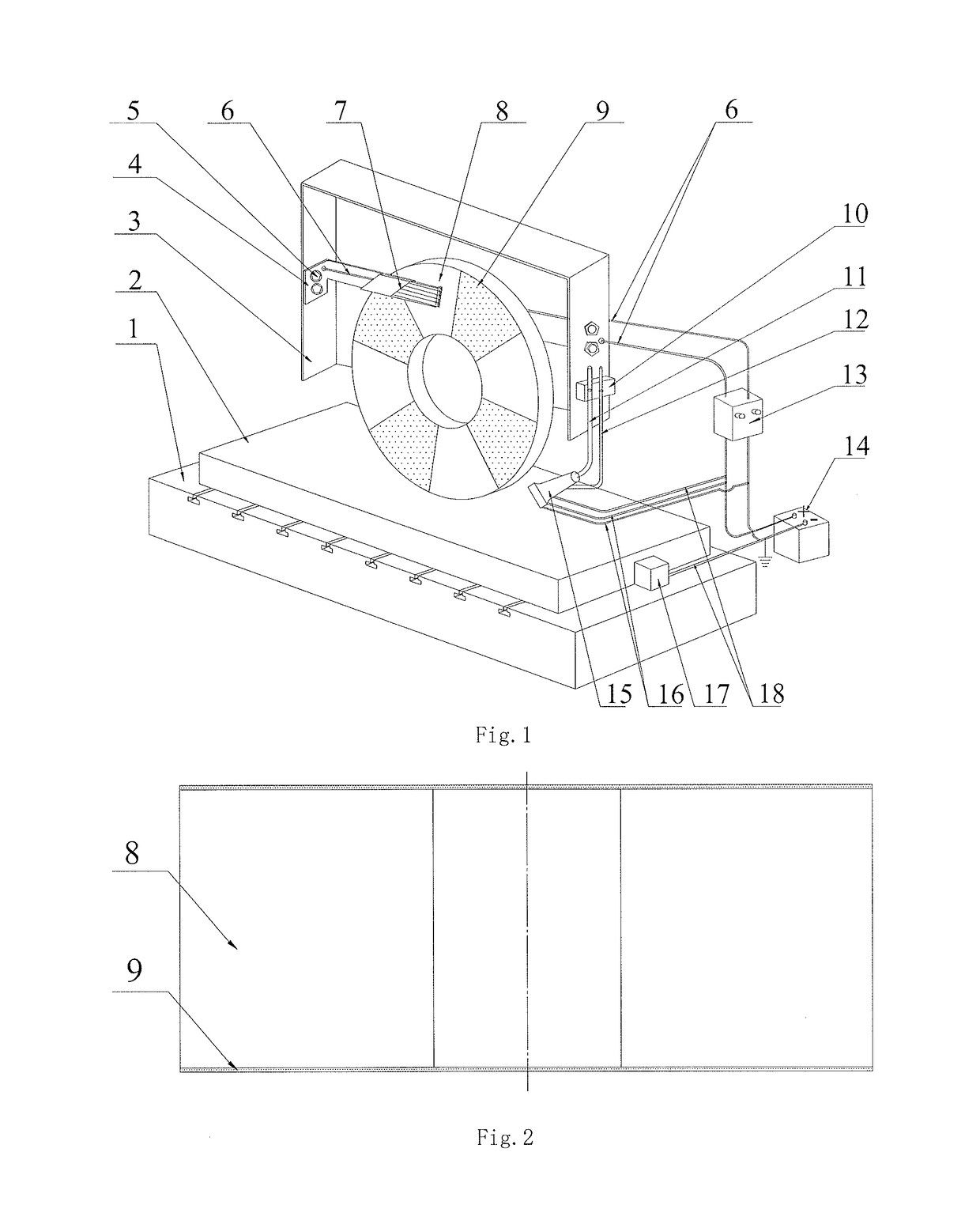

Solar energy secondary heat-source tower heat pump integrated device

ActiveCN101858627ANo pollution in the processReduce operating energy consumptionSemi-permeable membranesHeat pumpsEvaporationCogeneration

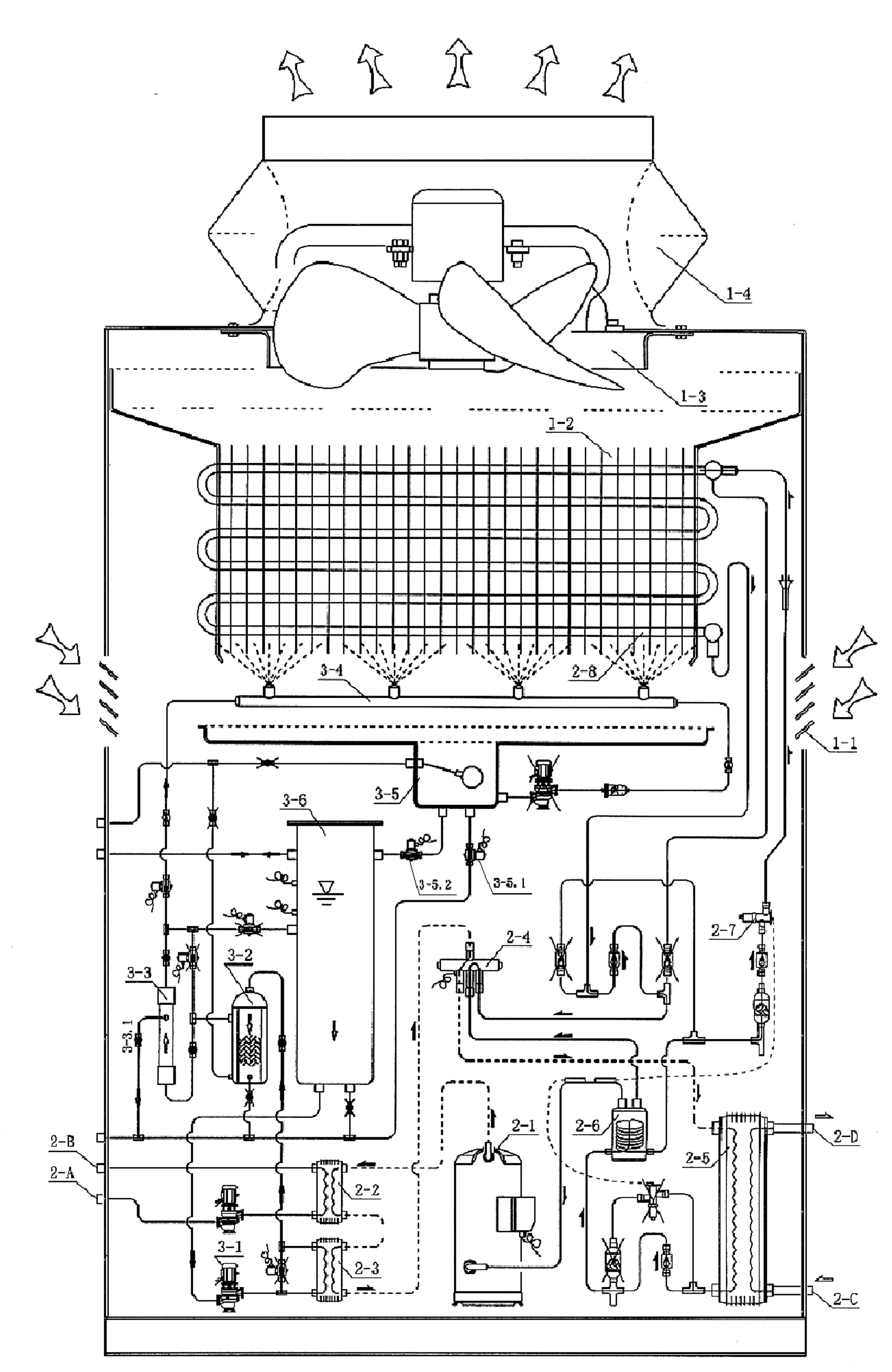

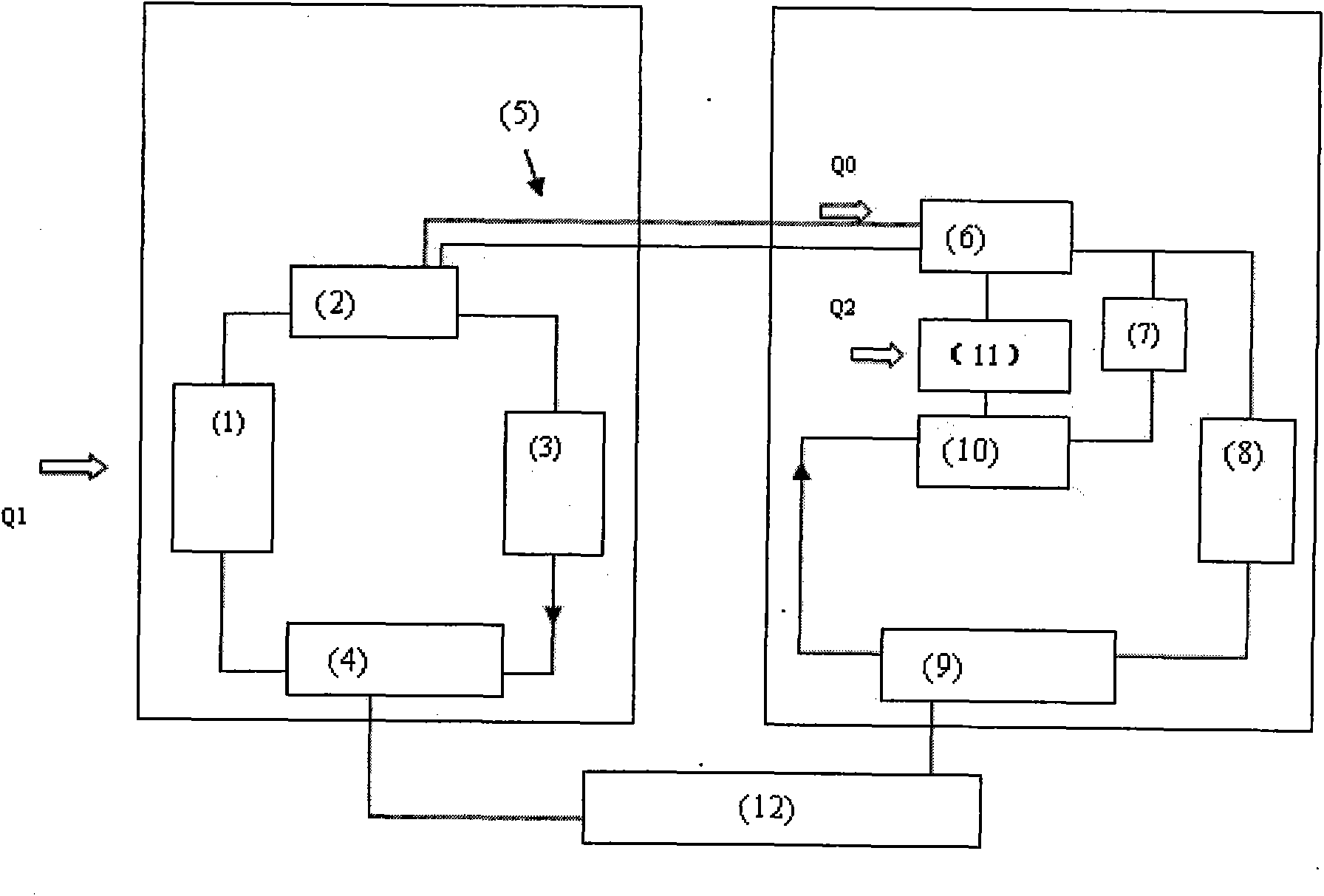

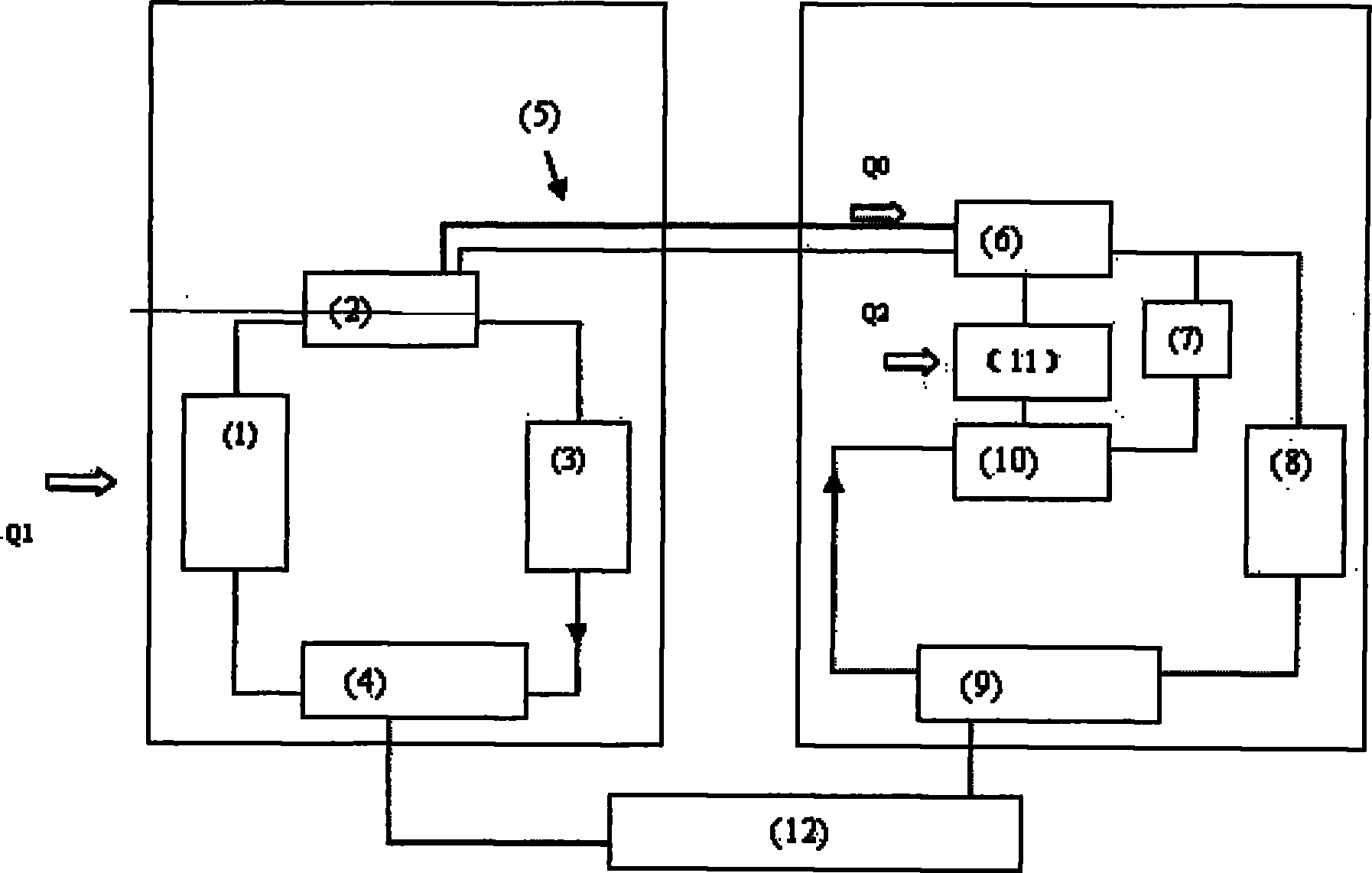

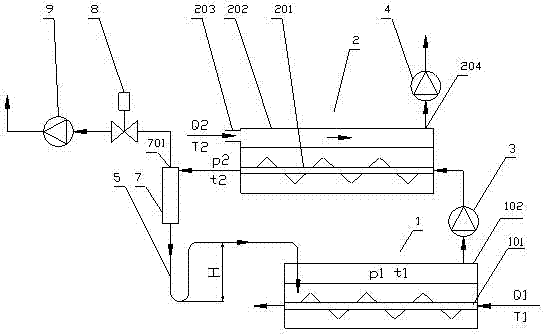

The invention discloses a solar energy secondary heat-source tower heat pump integrated device. The integrated device consists of a close-type working medium cold- and heat-source tower, a heat pump reverse Carnot cycle system, and a humid heat-source condensation water separator. The device is particularly suitable for household air conditioners under high-temperature and high-humidity environment in summer and under low-temperature and high-humidity environment in winter; and the device is a high-efficiency negative pressure evaporation water chiller in summer and is an effective frost-less air-source heat pump in winter so as to realize energy supply for heat transmission of small temperature difference from air, and triple cogeneration of hot air-conditioning, cold air-conditioning and hot water without boilers, electric auxiliary terminals or carbon emission, of the household air conditioners.

Owner:长沙东尤工程设备有限公司

Centrifugal chiller performance evaluation system

ActiveUS8812263B2Improve versatilityCompression machines with non-reversible cycleEvaporators/condensersCentrifugal chillerOperating point

Design COP is iteratively computed. Provided is a centrifugal chiller performance evaluation system including a data acquisition section for acquiring operating data from a centrifugal chiller as input data; a storage section storing a design COP estimation formula obtained by adding correction values corresponding to losses occurring in an actual environment to a computational formula for ideal actual-machine COP expressed using COP characteristics of a reverse Carnot cycle; and a computing section for estimating a design COP at a current operating point using the operating data acquired by the data acquisition section and the design COP estimation formula stored in the storage section. The correction values include a first correction value calculated from a first computational formula including the load factor of the centrifugal chiller as a variable and a second correction value calculated from a second computational formula including a difference between cooling water outlet temperature and chilled water outlet temperature as a variable. The second correction value contains an offset from the first correction value depending on cooling water inlet temperature.

Owner:MITSUBISHI HEAVY IND LTD

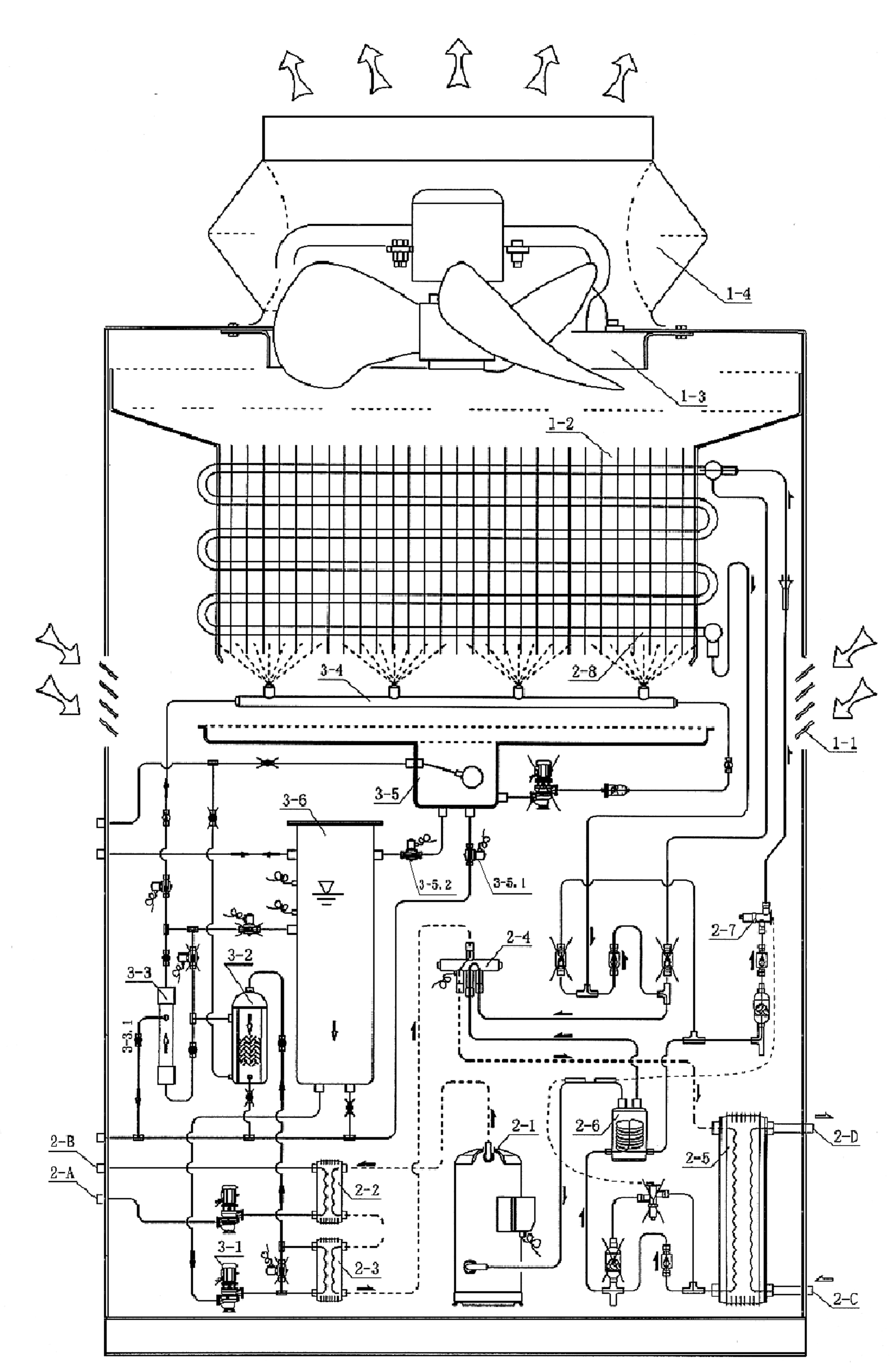

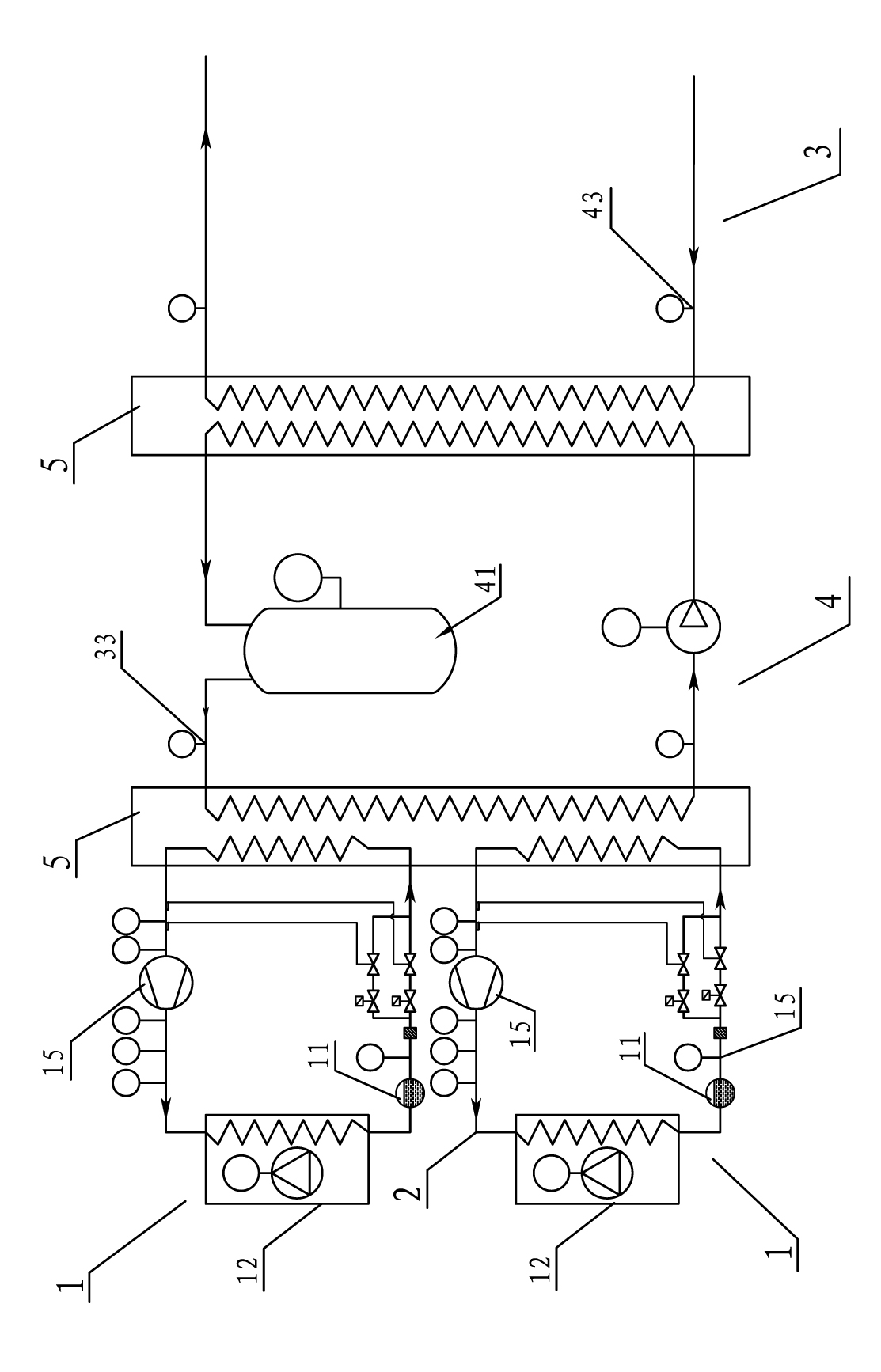

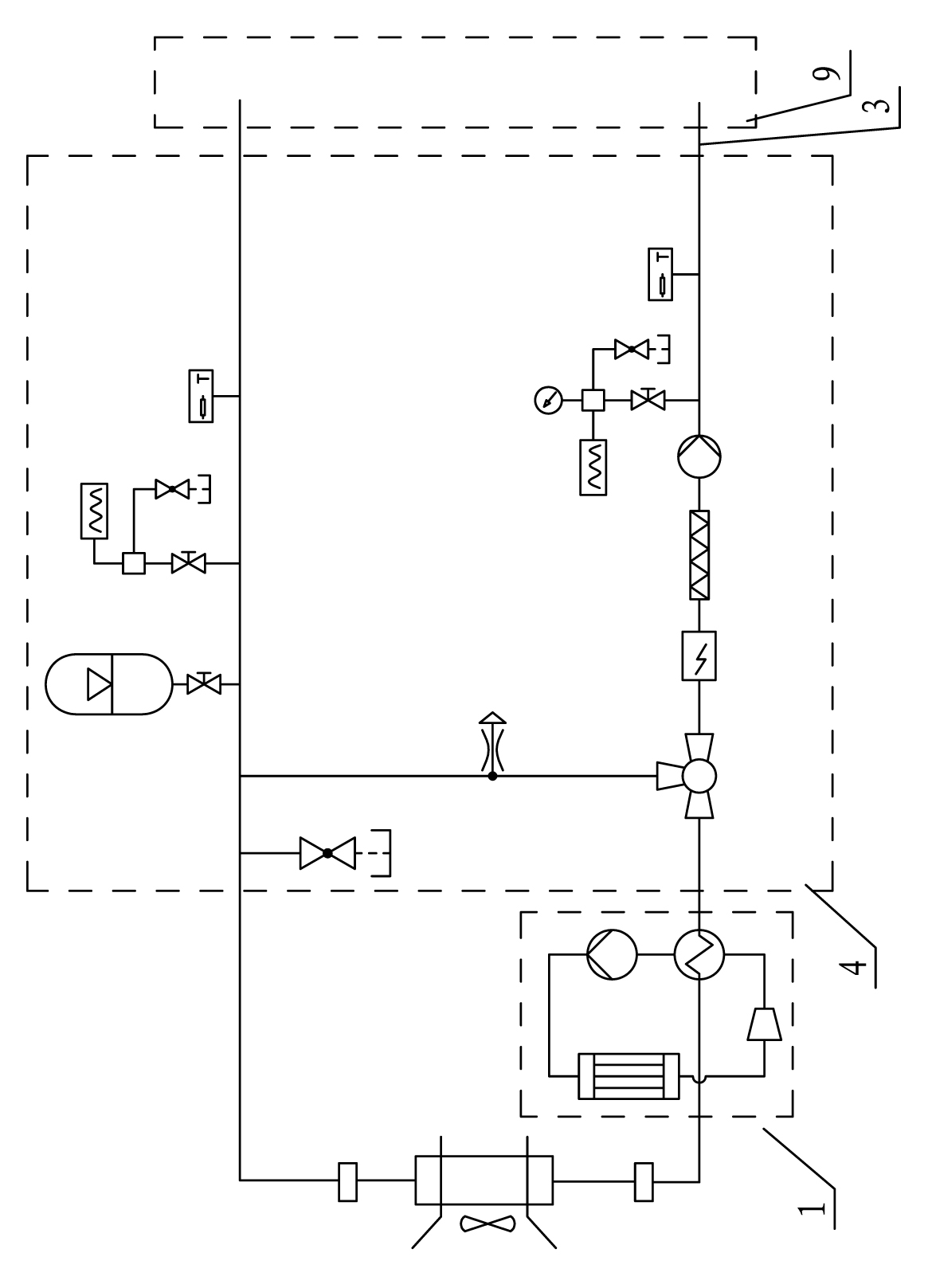

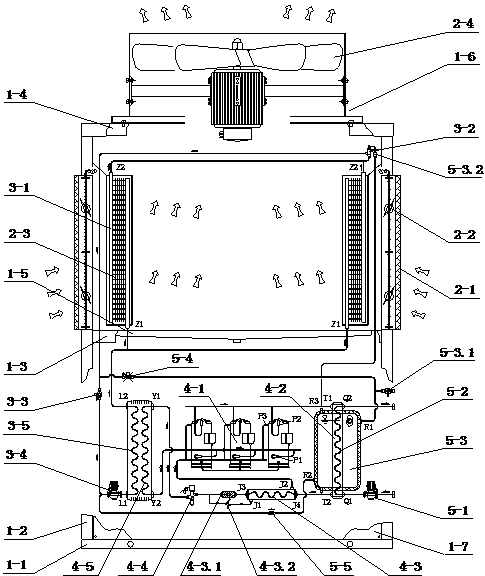

Cooling method of pure water circulation system for wind generation and cooling system implementing method

InactiveCN102062061AImprove adaptabilityGuaranteed purityWind energy generationCooling/ventilation/heating modificationsTemperature controlCarnot cycle

The invention discloses a cooling method of a pure water circulation system for wind generation and a cooling system implementing the method. In the cooling method, an assistant water circulation system is adopted as an intermediate medium to carry out the heat of the pure water circulation system and forcibly cool the heat; and the cooling system is designed for implementing the method, comprises a pure water circulation system and a reverse Carnot cycle cooler system, and performs indirect temperature control and refrigeration on the pure water circulation system by taking the assistant water circulation system as the intermediate heat transfer medium. In the cooling method disclosed by the invention, the adaptability of the wind generation system is remarkably extended and the method is applicable to various wind generation occasions; and the cooling system has the advantages of compact structure and low cost, can forcibly cool the circulating water without condensation in the case of relatively low temperature difference between water and environment, and is used for cooling the circulating water in wind generation.

Owner:GUANGZHOU GOALAND ENERGY CONSERVATION TECH

Closed nano-fluid haze absorption heating machine

ActiveCN104180440AFacilitated DiffusionImprove air qualityLighting and heating apparatusElectrostatic separationAir cycleThermal energy

The invention discloses a closed nano-fluid haze absorption heating machine which comprises a purifying and heating integrated machine frame structure, a static haze absorption freezing and defogging system, a wet-cold heat source absorption circulating system, a Carnot cycle low-temperature increasing system and a sleeve energy storage heating and haze removing system. The closed nano-fluid haze absorption heating machine is characterized in that wet-cold heat source air with haze is driven to enter the static haze absorption freezing and defogging system in a circulating manner, the haze is removed, sterilization and dehumidification are realized, a wet-cold heat source with the haze is taken by the wet-cold heat source absorption circulating system and improved into high-temperature heat energy, small boiler heating is replaced and the periodic internal hot fluid frost haze removing process for more than 12 hours under the condition of environmental negative temperature is realized by the sleeve energy storage heating and haze removing system, and the closed nano-fluid haze absorption heating machine is economical and environmentally friendly, replaces fossil energy, decreases haze condensation nucleuses and is widely applicable to pollution-free heating for Chinese small and medium towns.

Owner:森创中汇(北京)热电科技有限公司

Turbo rocket with real Carnot cycle

Owner:马里厄斯・A・保罗

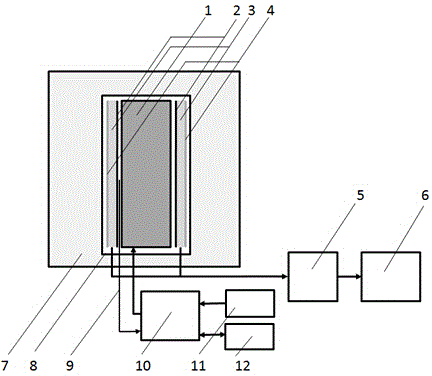

Heat pump temperature adjusting system, heat pump type airplane ground air conditioning unit and temperature adjusting control method

ActiveCN106742038AImprove energy efficiency ratioMechanical apparatusHeat pumpsAtmospheric airCarnot cycle

The invention discloses a heat pump temperature adjusting system, a heat pump type airplane ground air conditioning unit and a temperature adjusting control method. The heat pump temperature adjusting system comprises a first compressor, a four-way reversing valve, a first use side heat exchanger, a drying filter, a first thermostatic expansion valve, a first cold and heat source side heat exchanger, a four-way reversing valve and a first gas-liquid separator which are sequentially and cyclically arranged. A heat pump temperature adjusting mode can be adopted for the heat pump temperature adjusting system, a reverse Carnot cycle is utilized, through a small amount of high-grade electric energy input, low-grade heat energy in atmosphere is transferred into use side air, the energy efficiency ratio is greatly increased, the energy efficiency ratio of the system can reach up to 3.0 to 3.5, energy consumption is reduced to 14%-16% of electric heating energy consumption, and a large amount of energy is saved.

Owner:GUANGDONG SHENLING ENVIRONMENT SYST CO LTD

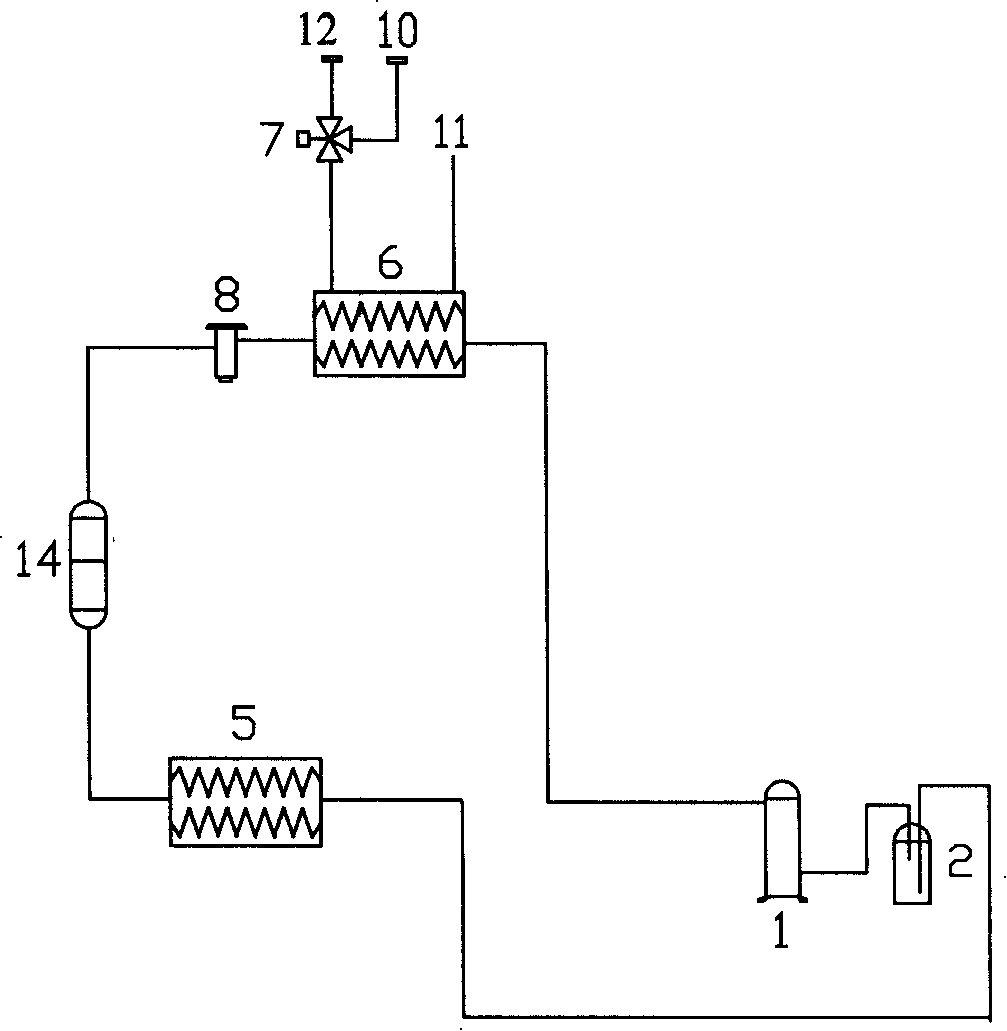

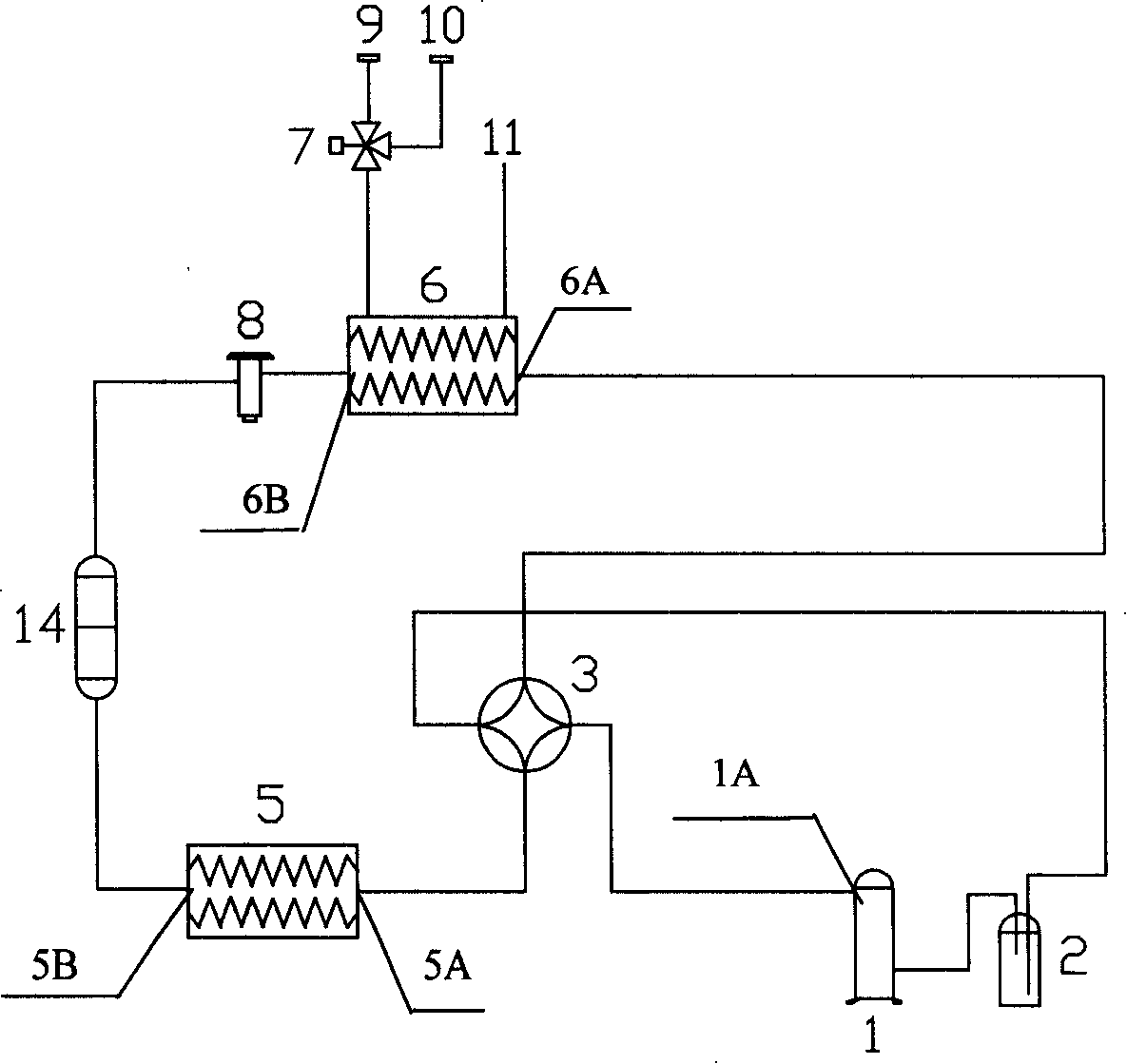

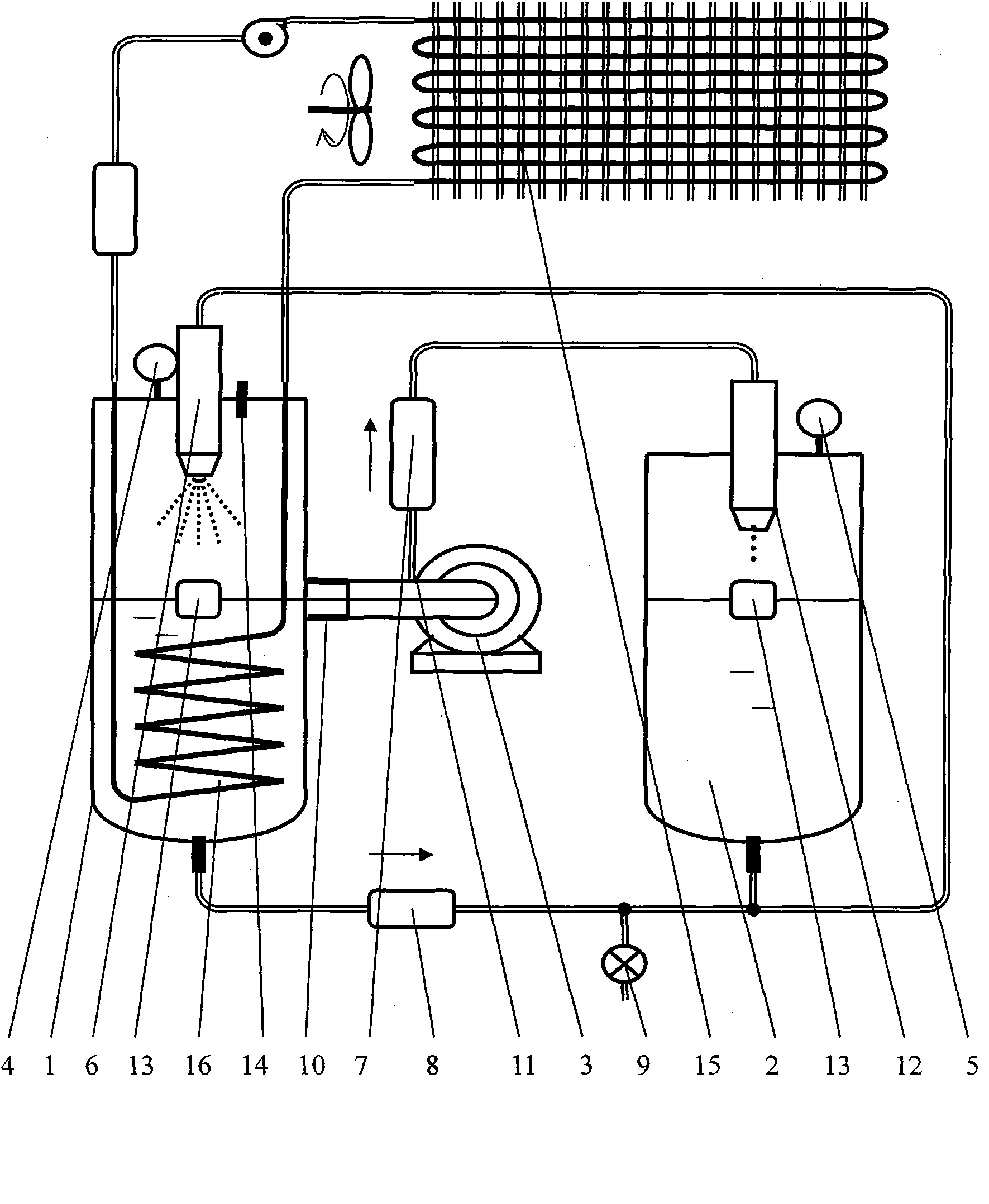

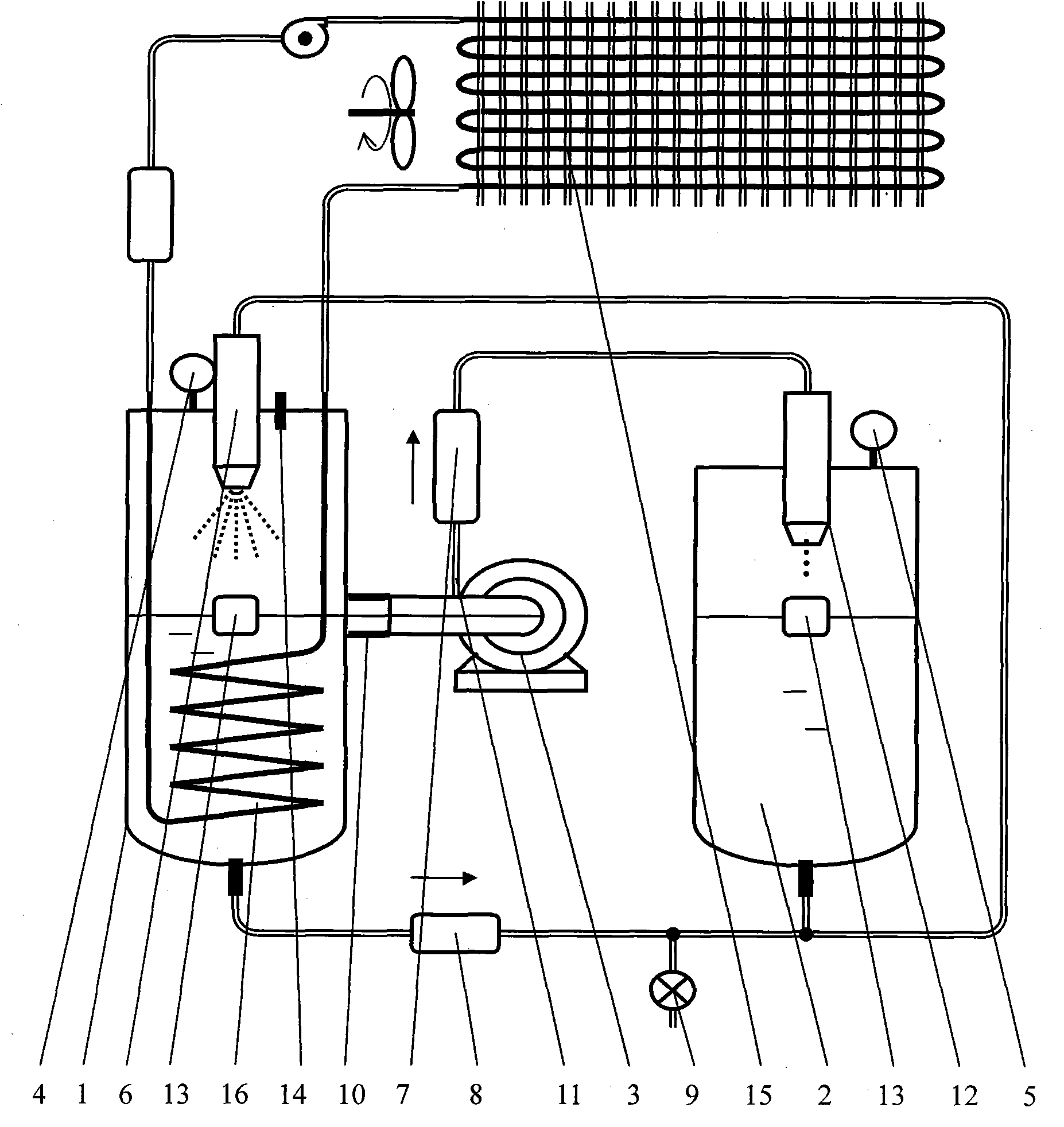

YXY type vacuum pressurized injection and vacuum evaporation refrigerating device

InactiveCN102313396ATake advantage ofObvious superiorityAir conditioning systemsRefrigeration machinesLiquid stateCarnot cycle

The invention relates to a YXY type vacuum pressurized injection and vacuum evaporation refrigerating device. The device consists of an evaporating tank, a storage tank, a rotary vane vacuum / pressurized injection pump or a self-suction injection pump, a vacuum meter, a pressure gauge, an injector, a check valve and a liquid discharging valve which are connected in series sequentially. The device is characterized in that: the liquid level in the evaporating tank and the liquid level in the storage tank are at the same horizontal position; and the rotary vane vacuum / pressurized injection pump simultaneously sucks a vaporous refrigerant and a liquid refrigerant from the input end of the rotary vane vacuum / pressurized injection pump. The device has the advantage of opening a new world for more widely using a Carnot cycle theory. Technical measures of vacuum and pressurized injection and evaporation refrigeration are taken by using the high-vacuum self-suction vaporous / liquid mixed injection pump. Only 1.6 to 2 atmospheric pressure of refrigerants is only required, and the liquid flow rate is only 0.2kg / second although the gas flow is up to 4 liters / second, so that a motor with the power of 1,200 watts is required only. An embodiment of the invention is given by combining attached figures.

Owner:江苏凯天机电制造有限公司

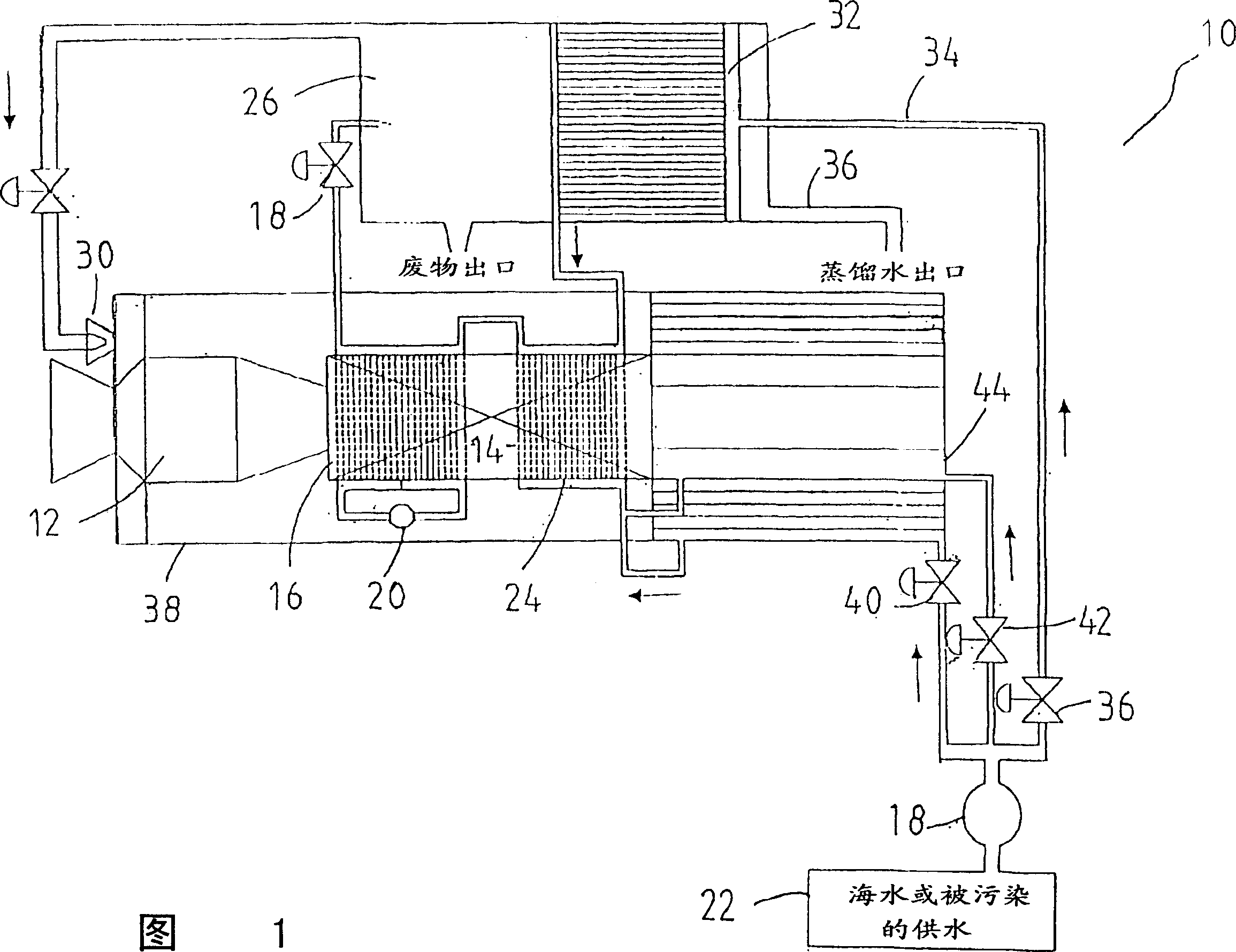

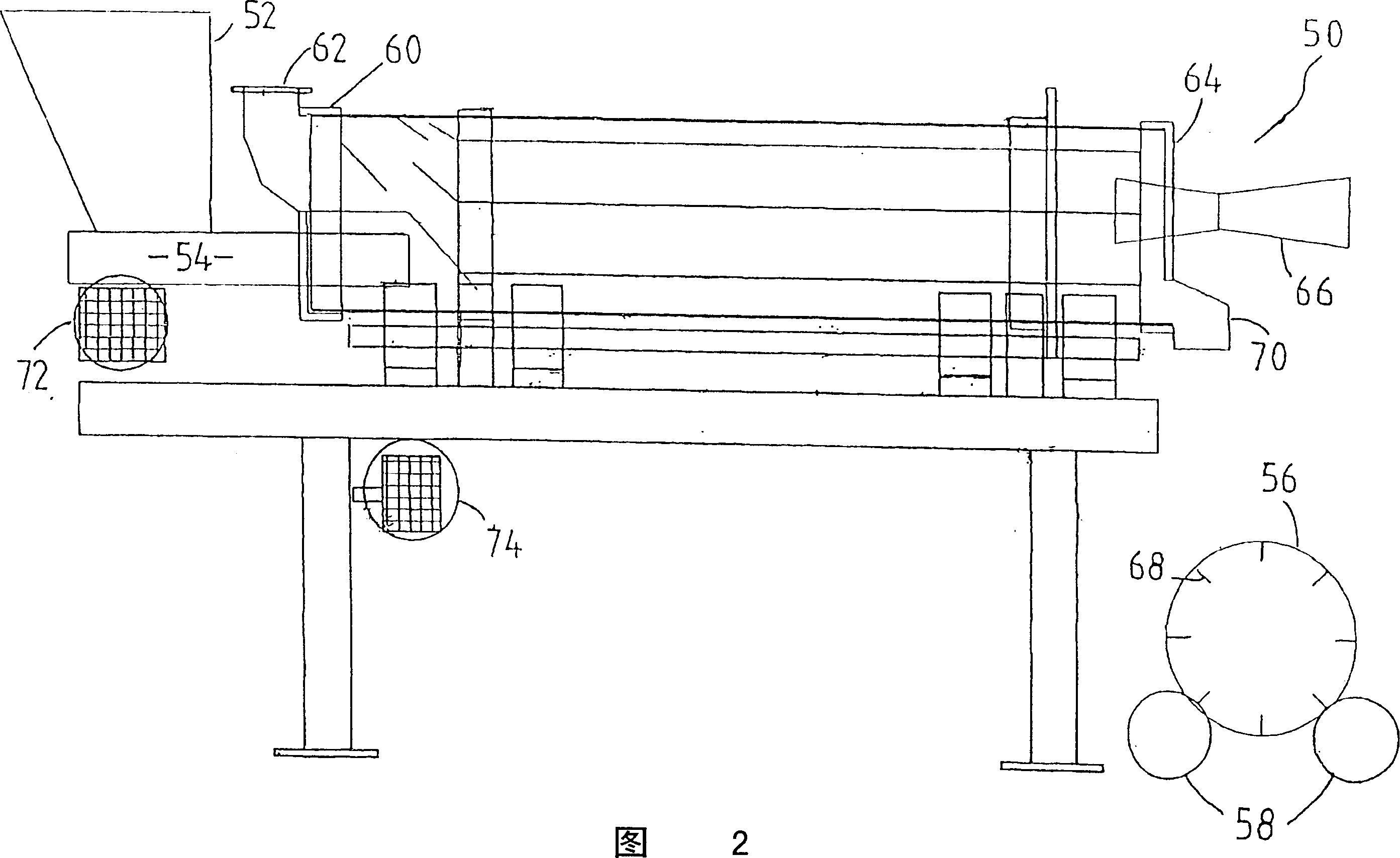

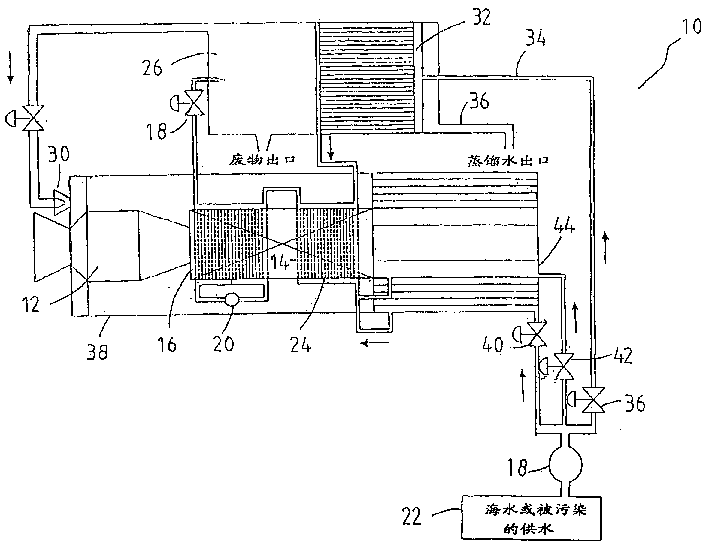

Water distillation system

A distillation system is provided for recovering water from sea water and other polluted water source. The system has a heat engine embodying Carnot cycle and a Rankine cycle formed by heat exchangers, flash evaporator and condenser. Burnt gases from the engine such as a jet engine no longer fit for flying are directed into a duct where the exchangers are located. Sea water is pumped into the heat exchanger for preheating by residue heat in the duct and then into the exchanger for further heating. A recirculating pump raises water pressure in the exchanger for increasing boiling point to about 165° C. The heated water is fed into the evaporator where it changes into vapour and condensed into water by the condenser. The jet air stream is used to create Venturi effect for maintaining sub-atmospheric pressure in the evaporator. Any solid left in the evaporator is removed by a transfer mechanism.

Owner:AQUA DYNE

High-efficient refrigerating air-conditioner

InactiveCN102679476AReduce energy consumptionAir conditioning systemsRefrigeration machinesLithium bromideCarnot cycle

The invention provides a high-efficient refrigerating air-conditioner and relates to the aspect of the improvement for the energy consumption of a traditional refrigerating air-conditioner. By adopting the high-efficient refrigerating air-conditioner, the energy waste of the traditional refrigerating air-conditioner during a working process of a condenser is eliminated and the heat at one end of the condenser of the traditional refrigerating air-conditioner is utilized to refrigerate again. A double unit composed of a Carnot cycle unit and a lithium bromide unit is adopted; the condenser of the Carnot cycle unit is coupled with a generator of the lithium bromide unit in a linking or other combining mode, so that the heat of the condenser is transferred to the generator for driving the lithium bromide unit to run; the defect of the traditional air-conditioner that heat is radiated and wasted at one end of the condenser is overcome; the heat energy is utilized to refrigerate, so that the refrigerating efficiency is increased; the coefficient of performance (COP) reaches or exceeds 8.5; energy is saved and heat island effect is relieved; and the high-efficient refrigerating air-conditioner is suitable for air refrigeration of big, medium / small-size leisure and recreation places and offices.

Owner:杨贻方

Refrigeration system with low energy consumption and using method thereof

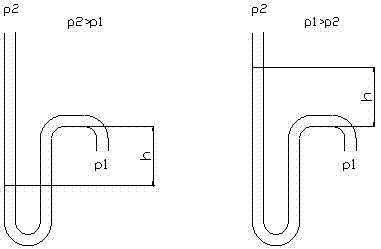

ActiveCN102353169AActs as an expansion valveNo energy consumptionEvaporators/condensersCompression machines with reversible cycleCarnot cycleEngineering

The invention relates to a refrigeration system. The refrigeration system comprises an evaporator, a condenser, a compressor and a U-shaped tube or a straight tube, wherein the mounting position of the condenser is higher than that of the evaporator; and the height H of the U-shaped tube or the depth H that the straight tube is inserted below the liquid level of a refrigerant in the evaporator accords with a formula of rho gH>p2-p1, wherein rho is the density of the refrigerant. For a condition that indoor temperature T1 is lower than outdoor temperature T2, the refrigeration system adopts Carnot reverse cycle; and for a condition that the indoor temperature T1 is higher than the outdoor temperature T2, the refrigeration system adopts Carnot cycle, p2<p1, at the moment, refrigerant steam pushes the compressor to idle, and the refrigerant in the U-shaped tube or the straight pipe completes constant entropy compression by means of self gravity without energy consumption, so that the energy consumption of the system is extremely low. The refrigeration system can use other liquid with the boiling point between 20 and 100 DEG C, such as methanol, ethanol and the like as the refrigerant.

Owner:卓卫民

Centrifugal chiller performance evaluation system

ActiveUS20120029889A1Improve versatilityCompression machines with non-reversible cycleEvaporators/condensersCentrifugal chillerOperating point

Design COP is iteratively computed. Provided is a centrifugal chiller performance evaluation system including a data acquisition section for acquiring operating data from a centrifugal chiller as input data; a storage section storing a design COP estimation formula obtained by adding correction values corresponding to losses occurring in an actual environment to a computational formula for ideal actual-machine COP expressed using COP characteristics of a reverse Carnot cycle; and a computing section for estimating a design COP at a current operating point using the operating data acquired by the data acquisition section and the design COP estimation formula stored in the storage section. The correction values include a first correction value calculated from a first computational formula including the load factor of the centrifugal chiller as a variable and a second correction value calculated from a second computational formula including a difference between cooling water outlet temperature and chilled water outlet temperature as a variable. The second correction value contains an offset from the first correction value depending on cooling water inlet temperature.

Owner:MITSUBISHI HEAVY IND LTD

Method for cooling heating element and recovering energy of heating element

InactiveCN104410141AExtend battery lifeBatteries circuit arrangementsElectric powerThermal energyThermoelectric materials

The invention relates to a method for cooling a heating element and recovering the energy of the heating element. According to the method, a thermoelectric material or a thermoelectric device on the surface of the heating element is used as a working substance, the temperature difference of the heating element and the environment is used to generate power and do work, the heat is absorbed from the heating element and is released to the surrounding environment through Carnot cycle, a voltage stabilizing module is connected to charge a power supply, so that the purposes of reducing the temperature of the heating element and recovering the energy of the heating element are fulfilled. The heating element is actively cooled without consuming electric power, the heat energy is converted to the electric power to charge the power supply in the cooling process, and the energy is recovered.

Owner:SUN YAT SEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com