Double-crankshaft-contained variable-compression-ratio Atkinson-cycle internal-combustion engine mechanism

A technology of internal combustion engine and double crankshaft, applied in the field of variable compression ratio Atkinson cycle internal combustion engine mechanism, which can solve the problems of high complexity, cumbersome manufacturing process and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Three exemplary embodiments of the present invention are described in detail below.

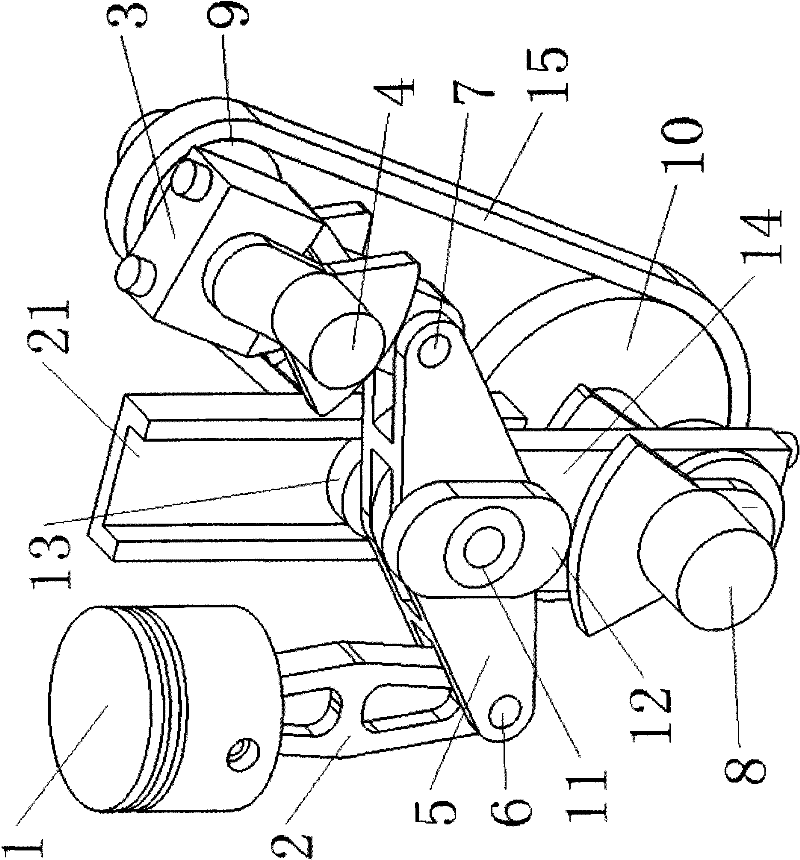

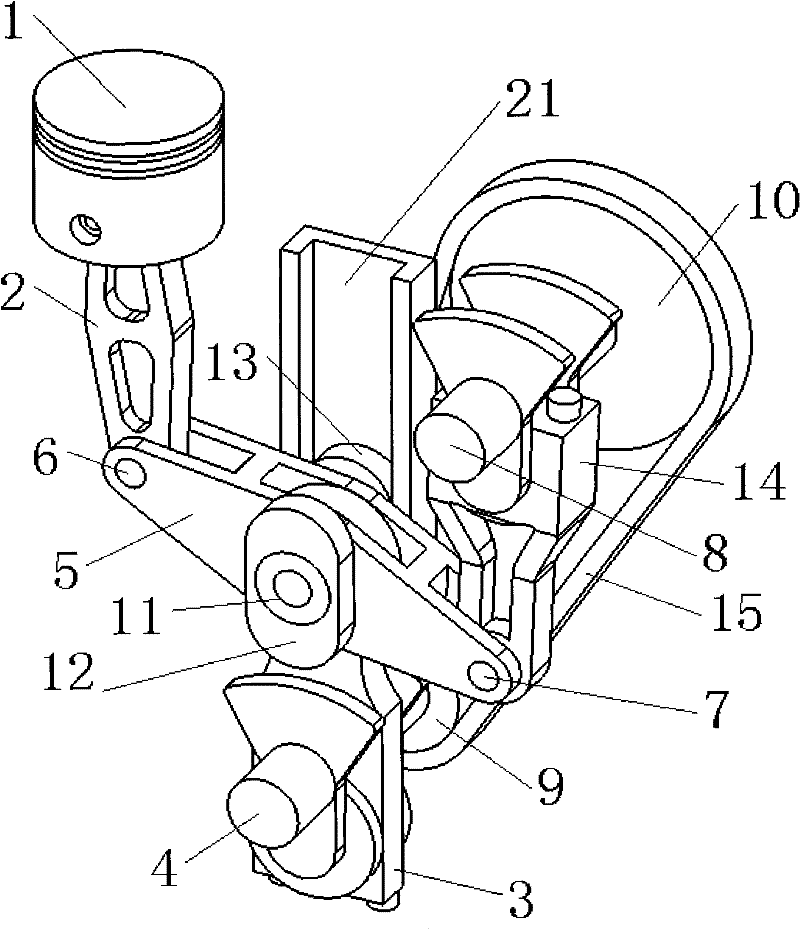

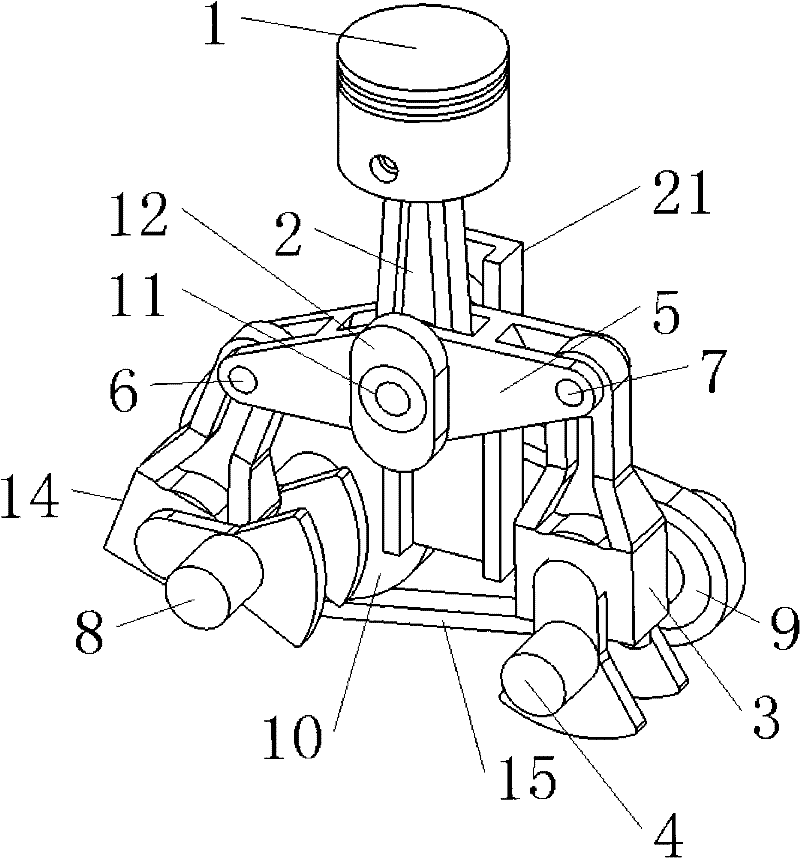

[0013] figure 1 is a schematic diagram showing a structural diagram of the first embodiment. The piston 1 is connected to one end of the rocker arm 5 through the piston connecting rod 2 and the shaft 6; the first crankshaft 4 is connected to the other end of the rocker arm 5 through the connecting rod 3 and the shaft 7; the fulcrum of the rocker arm 5 in the middle is connected by the fulcrum shaft 11 The connecting rod 14 of the second crankshaft 8 is also connected with two elliptical fulcrum pads 12 and 13 on both sides of the rocking arm 5; the fulcrum pad 13 is installed in the vertical straight groove 21, and the fulcrum pad The block 12 is in the opposite groove (not shown), and can only move up and down in a straight line; the gear 9 is installed on the first crankshaft 4, and the gear 10 is installed on the second crankshaft 8, and the two are connected by a chain 15, so The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com