Patents

Literature

3081results about How to "Improve heat utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

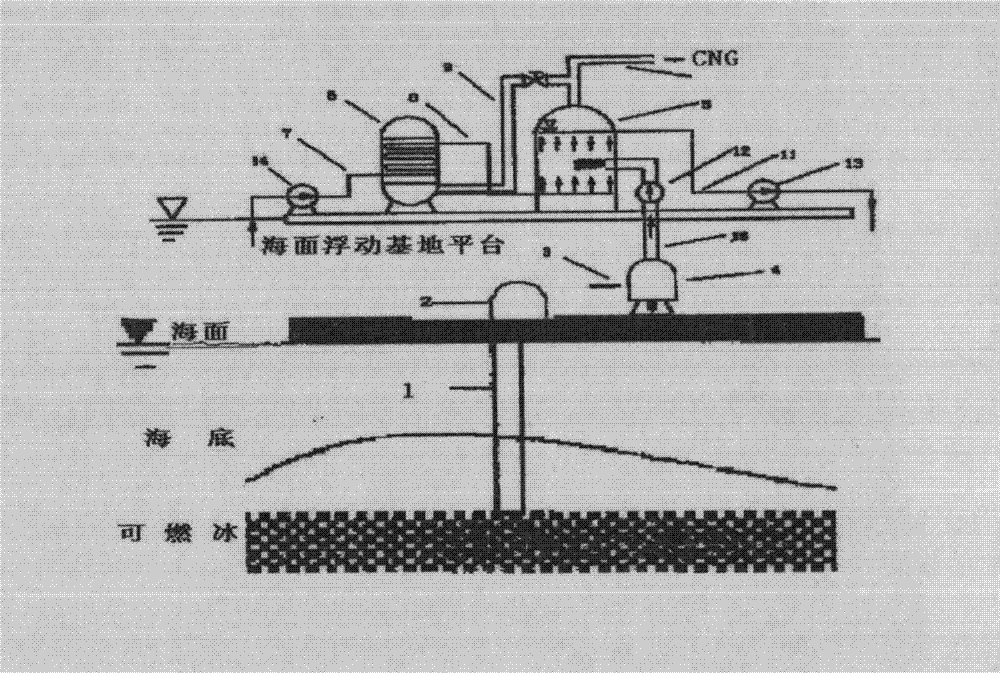

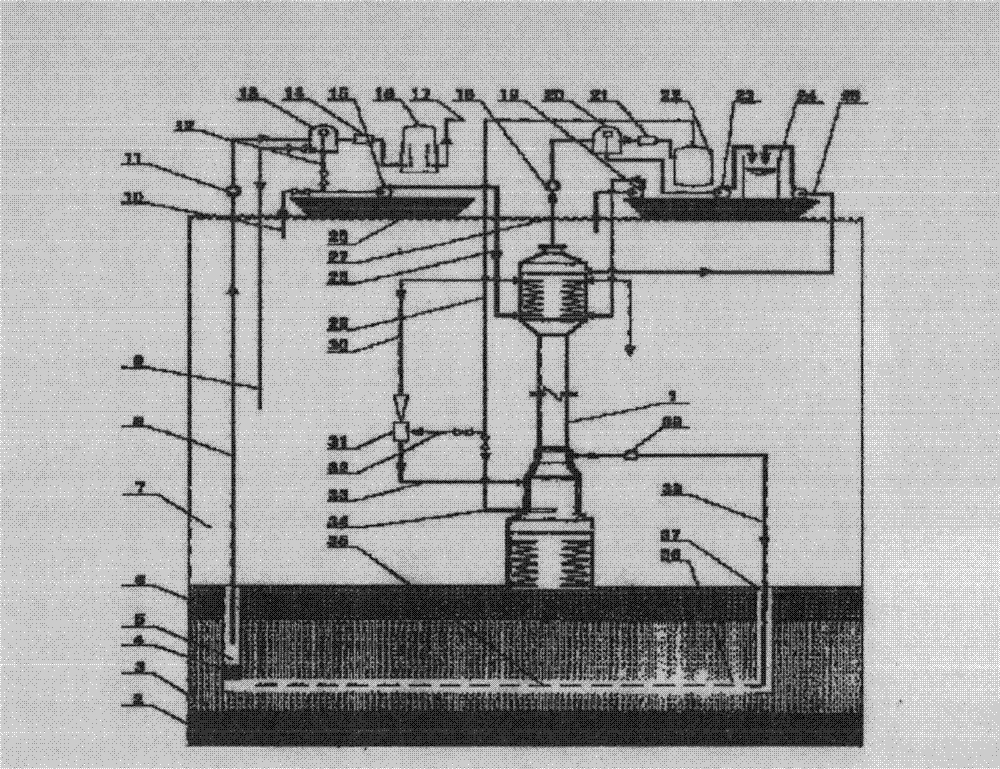

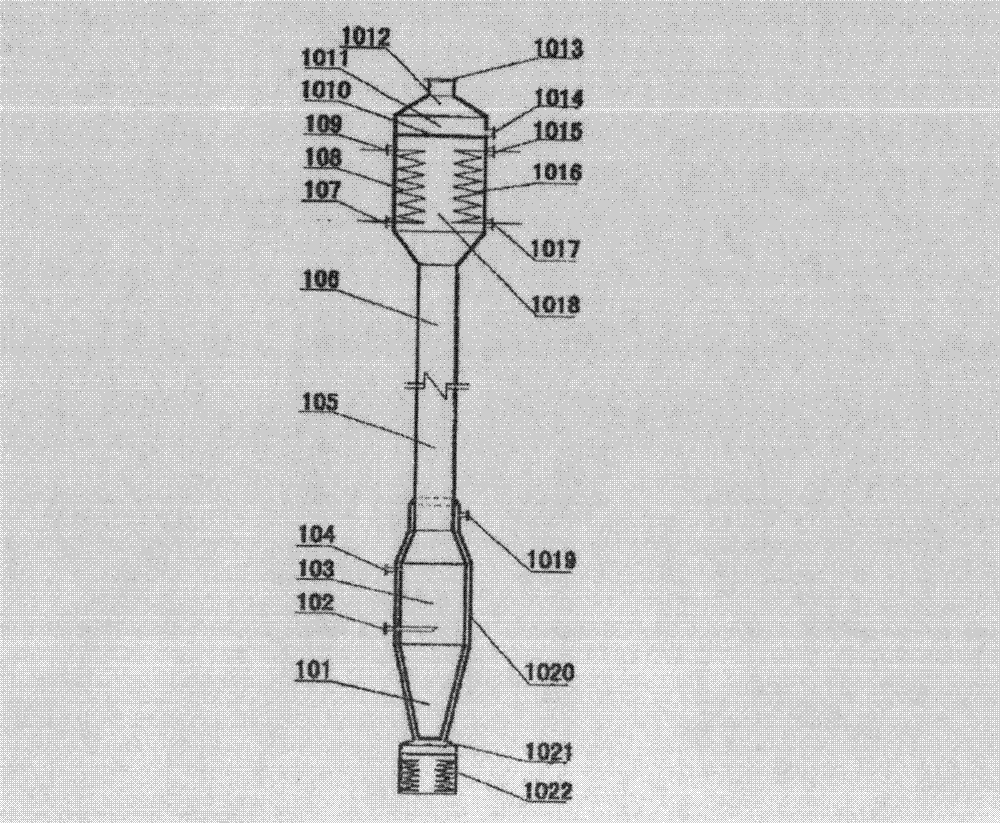

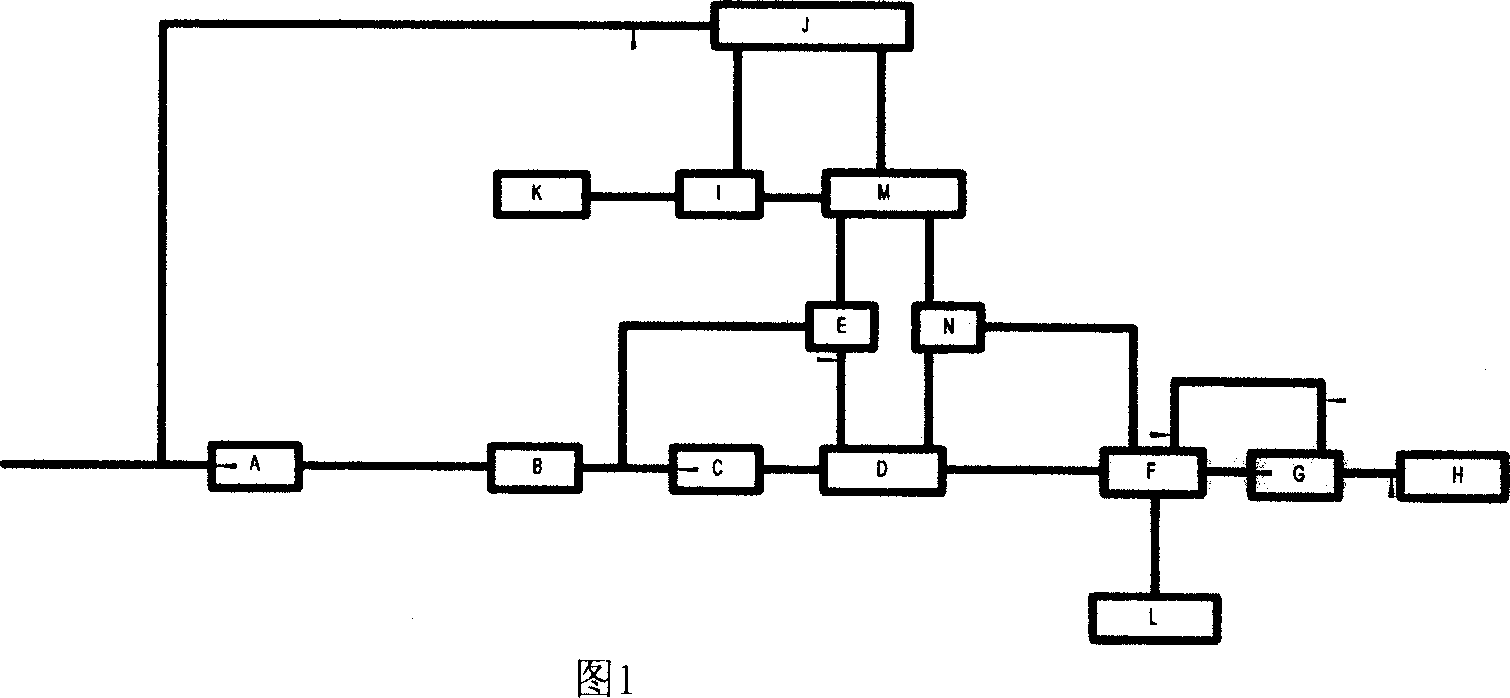

Ocean combustible ice mining device and method

The invention discloses an ocean combustible ice mining method and a mining device adopted by the same. According to the ocean combustible ice mining method, a device for mining combustible ice through heating concentrated saline water is adopted, and heat for heating a combustible ice storage layer is provided by heating the concentrated saline water. The ocean combustible ice mining method is energy-saving and environment-friendly, remarkable in economic benefit, is free from emission and pollution in a mining process, energy-saving and consumption-reducing; and the ocean combustible ice mining device is relatively sample in structure, convenient to use, lower in production cost and convenient for popularization.

Owner:韩中枢

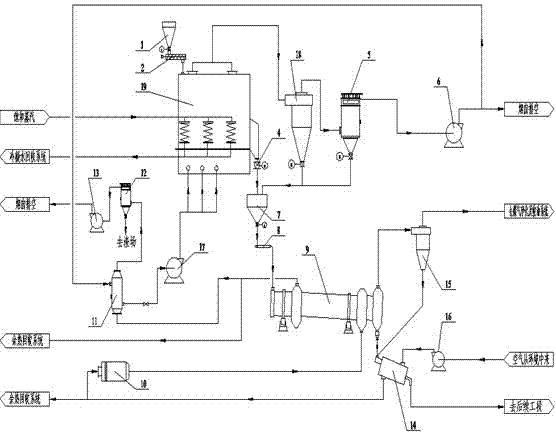

Sludge drying and incinerating treatment process

InactiveCN1931753AAvoid pollutionAvoid harmSludge treatment by oxidationByproduct vaporizationChemical compositionSludge

The present invention relates to environmental protection engineering technology, and is especially sludge drying and incinerating treatment process. The present invention has effective utilization of heat energy, no exhaust of harmful gas and bad smell, no exhaust of dangerous clinker, simple structure and high burning efficiency of the sludge incinerating system, no need of auxiliary fuel and other advantages.

Owner:BEIJING CHINA SCI GENERAL ENERGY & ENVIRONMENT CO LTD

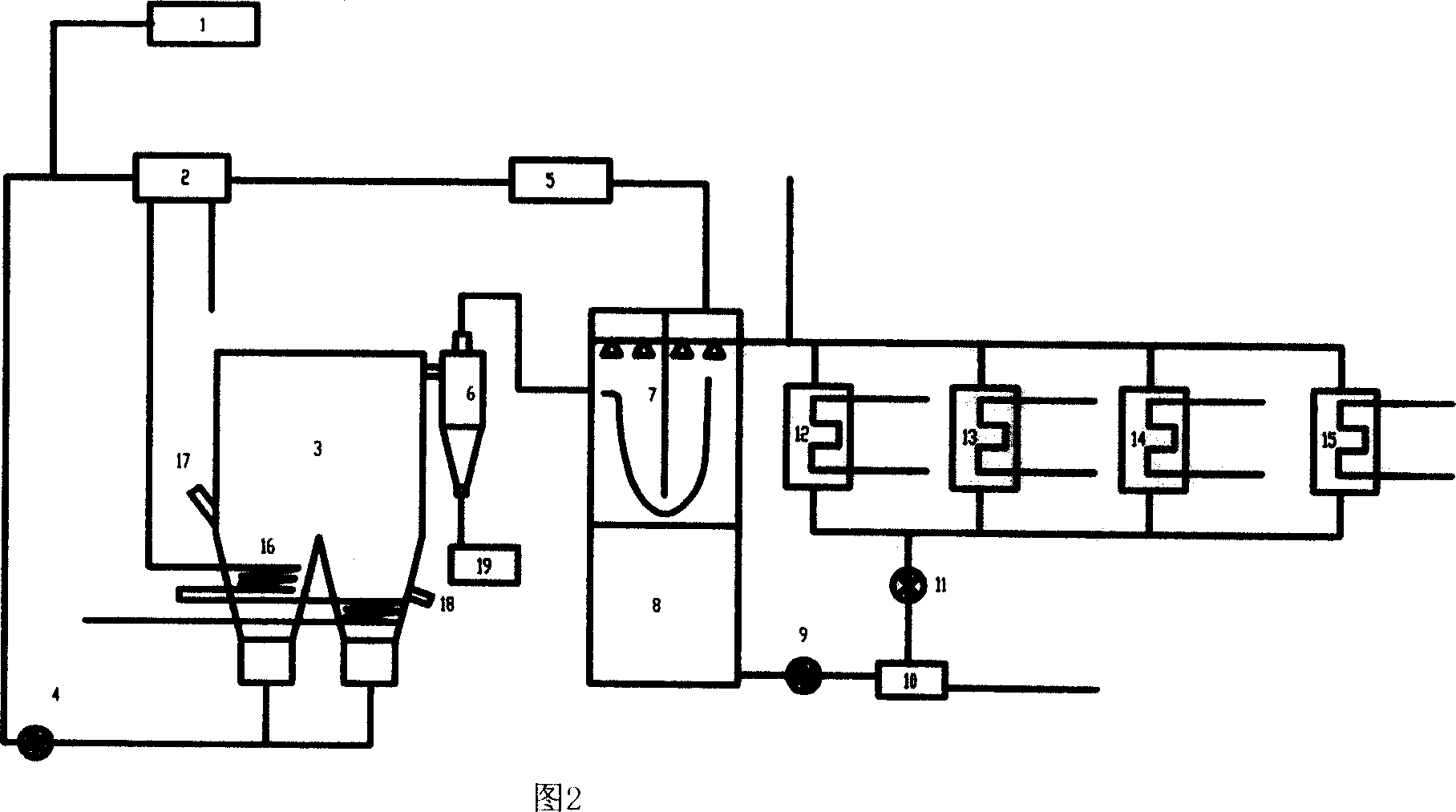

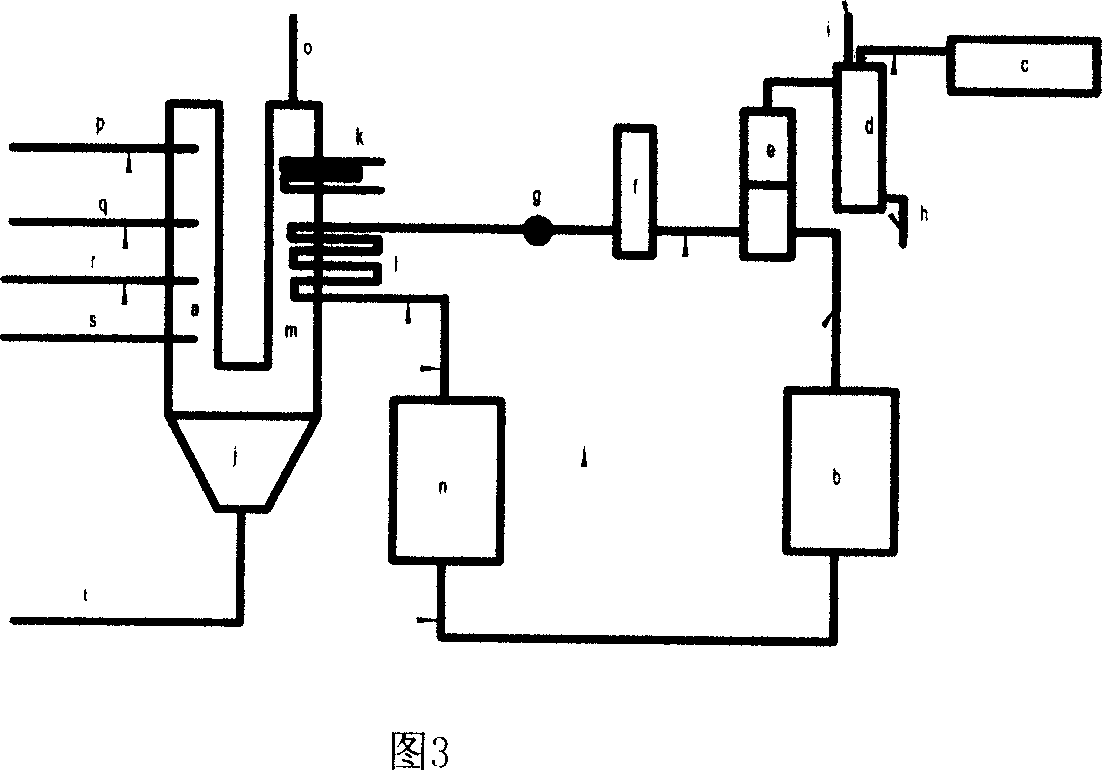

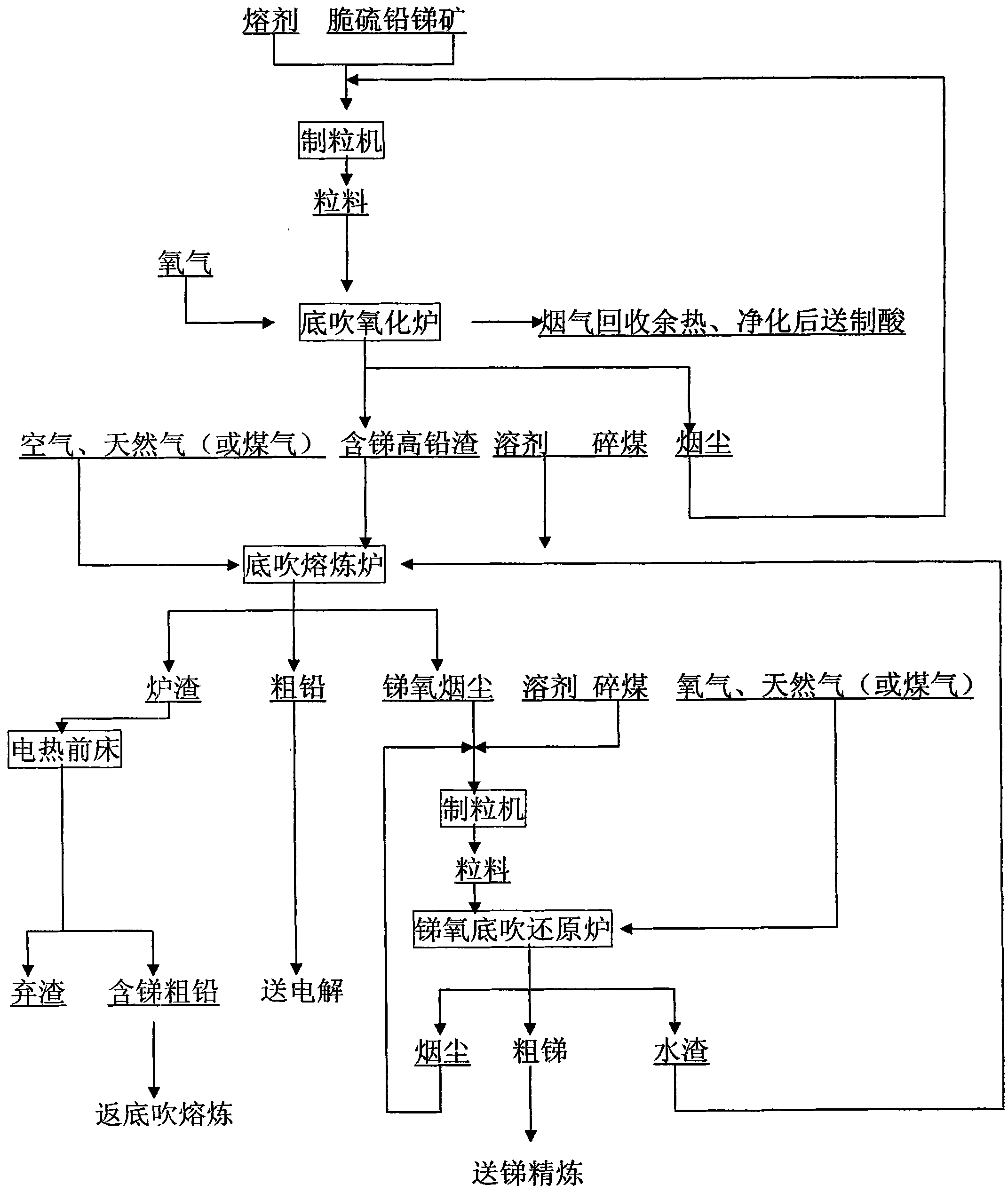

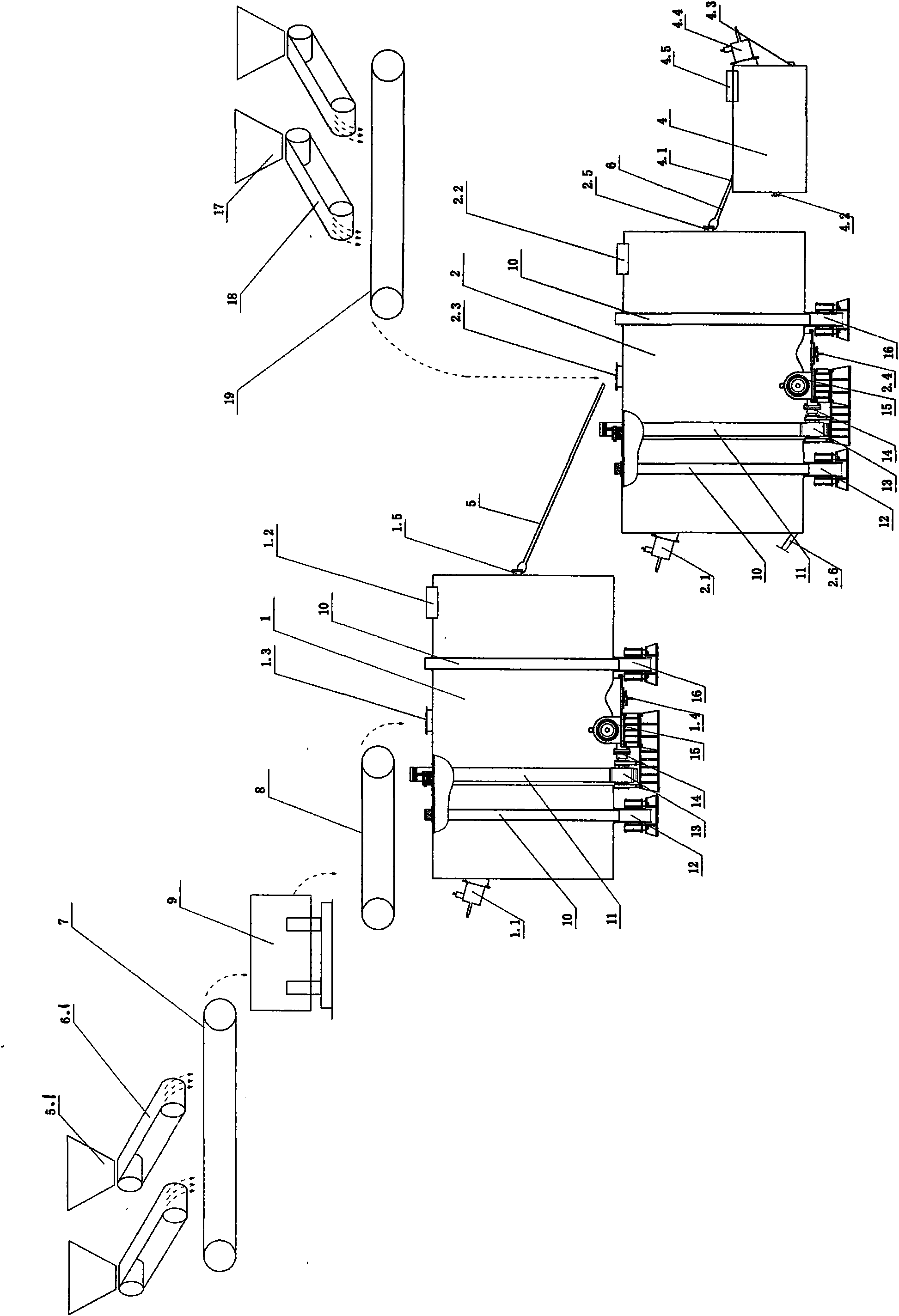

Method and device for smelting jamesonite by bottom-blowing pool

The invention relates to a method and a device for smelting jamesonite by a bottom-blowing pool. The method comprises the following steps of: performing pool smelting, oxidation and desulfurization on the jamesonite by using a bottom-blowing oxidation furnace to produce antimony-containing high-lead slag, a lead-antimony alloy and flue gases suitable for acid preparation; reducing the antimony-containing high-lead slag and blowing the lead-antimony alloy by using a bottom-blowing smelting furnace to produce antimony oxides and lead bullion capable of being used for electrolysis; and reducing the antimony oxides by using a bottom-blowing reduction furnace to produce needle antimony. In the smelting method of the invention, the three bottom-blowing furnaces and an electrically-heated settler are adopted to treat the jamesonite to produce the lead bullion, the needle antimony and the slag; therefore, compared with the prior art, the method has the advantages of short flow, good lead-antimony separation effect, fewer intermediate products, less revert, high resource utilization rate and production continuity; and the bottom-blowing oxidation furnace can realize spontaneous heating balance by sulfide combustion with low energy consumption and high recovery rate and can greatly reduce the cost.

Owner:JIYUAN YUGUANG NONFERROUS METALLURGY DESIGN & RES INST CO LTD

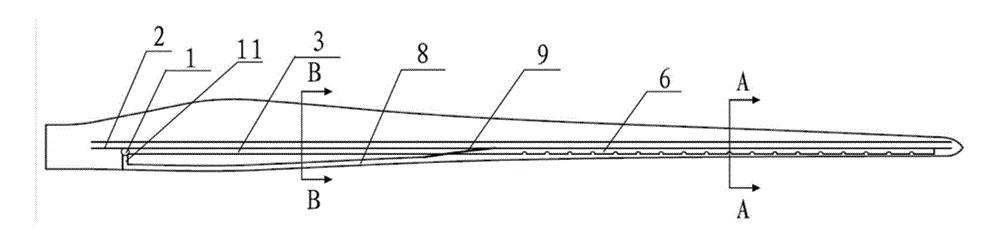

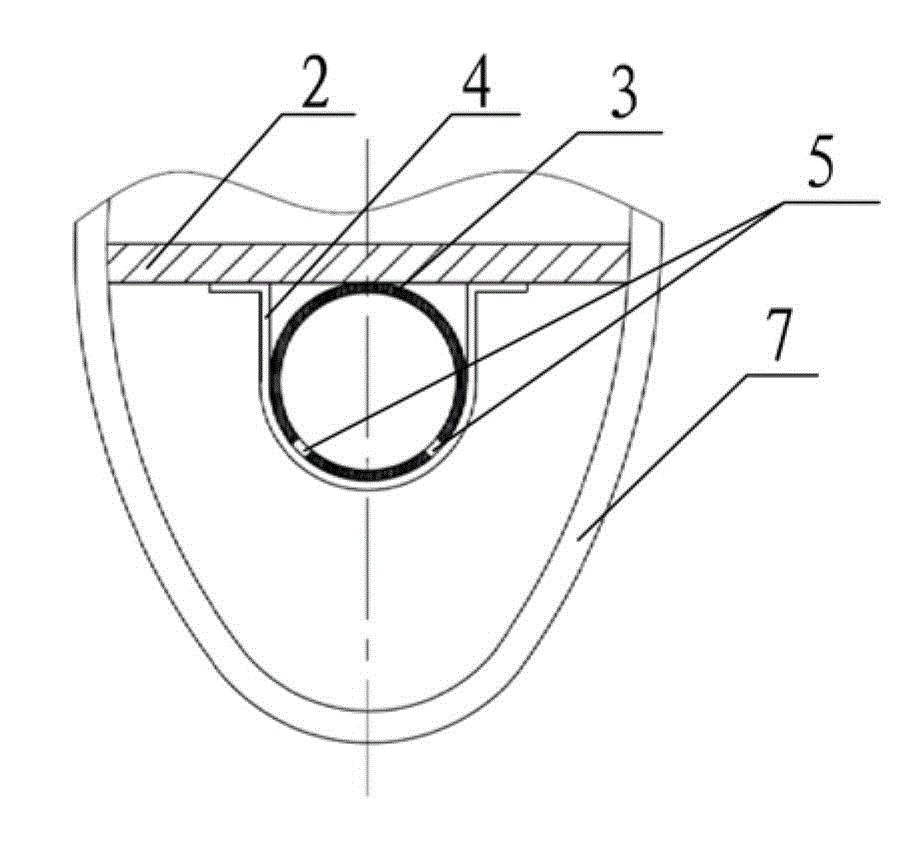

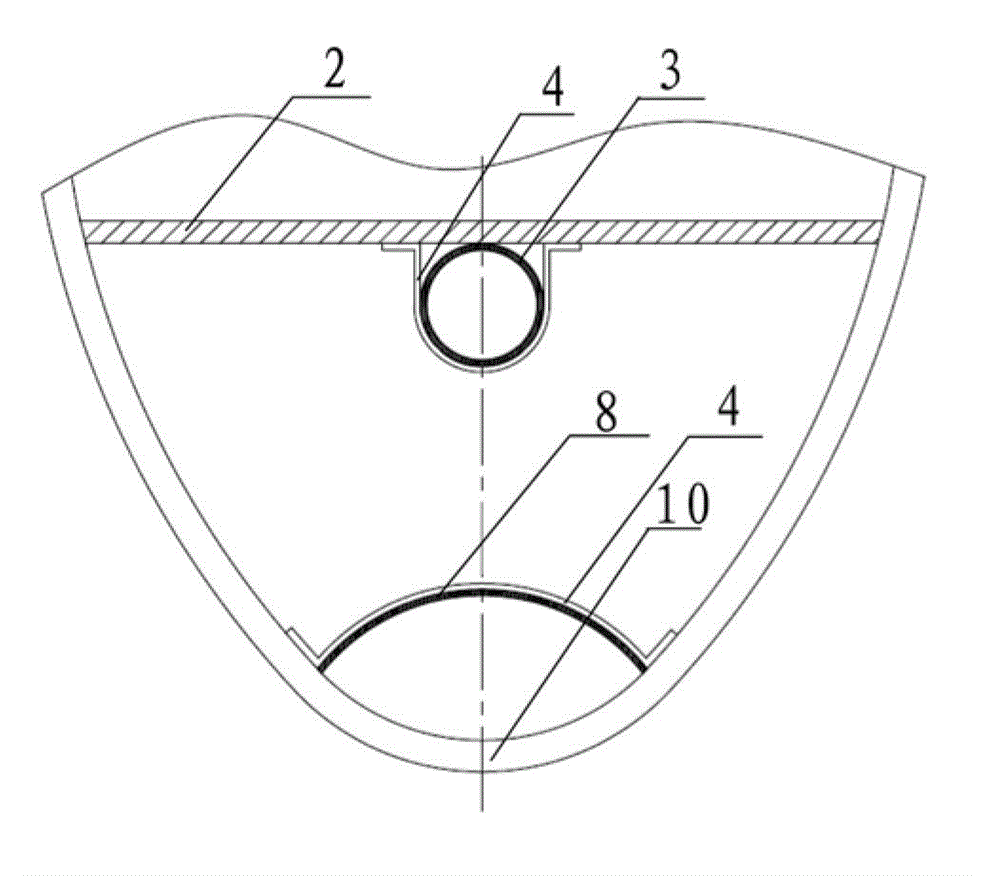

Wind wheel blade with antiicing and deicing functions

ActiveCN102748243ARealize centralized heatingEnables efficient concentrated heating of the blade leading edge shellMachines/enginesWind energy generationThermal energyLeading edge

The invention relates to a wind wheel blade with antiicing and deicing functions, and the wind wheel blade comprises a shell, and a shear web capable of dividing the interior of the shell into a leading edge cavity and a trailing edge cavity, wherein a heating device is arranged in the leading edge cavity and consists of a heating type air blower arranged close to the root of the blade, and an insulating pipeline connected with the air outlet of the heating type air blower; the insulating pipeline is provided with a flute-shaped pipe with a gas orifice at the corresponding sections from the middle of the blade to the blade tip, and the opening direction of the gas orifice faces to the leading edge of the blade; and air flow exhausted by the gas orifice is circulated to the air inlet of the heating type air blower. The wind wheel blade is reasonable in pipe structure form and distribution mode, hot air flow focally heats the leading edge of the blade, especially the blade shell from the middle of the blade to the blade tip, so that the recycling of the hot air flow can be realized, and the utilization rate of heat can be improved.

Owner:GUODIAN UNITED POWER TECH

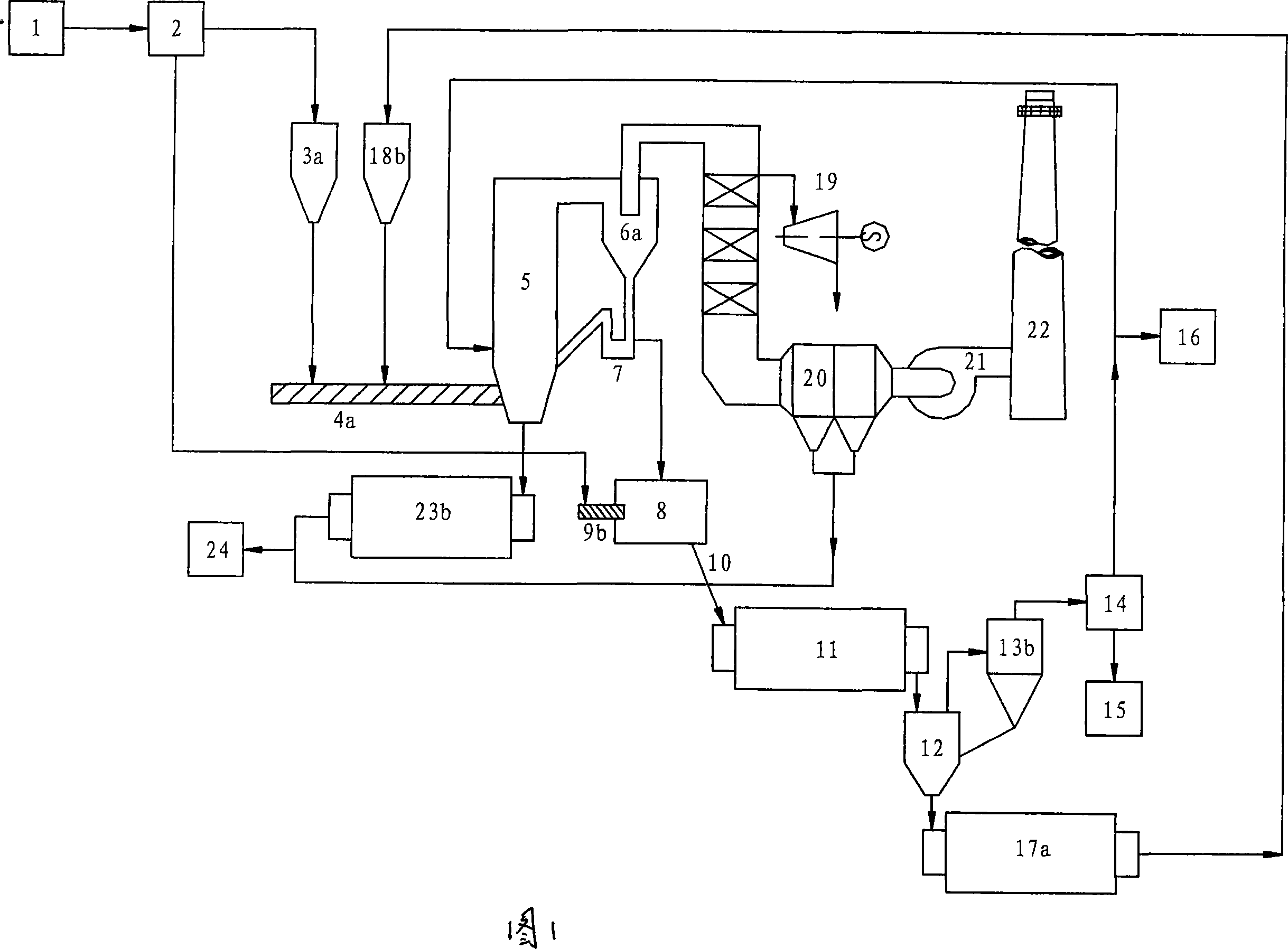

Integral process for oil shale retorting oil refining and coal-char combustion power generation

InactiveCN101117584AGood heat transfer effectImprove heat utilizationInternal combustion piston enginesPowdered engine fuelsHeat carrierCirculating fluidized bed boiler

The present invention discloses an oil shale carbonization oil refining, carbocoal burning electricity generating integrated technology. The present invention is characterized in that green ore oil shale is crushed into 0 to 15mm grains by a crusher, through that circulating fluid bed boiler circulating ash is used as a solid heat carrier, the mixture of the oil shale and the circulating ash is fed into a roller retort to form oil shale oil refining, carbocoal and the oil shale are mixed, fluidized and burned to generate electricity as a whole, separated non-condensation carbonization coal gas is fed into the circulating fluid bed boiler and the both are burned with the carbocoal and the oil shale together or is fed into a gas engine for direct-fired power generation; the carbon content of the clinker after burned on the circulating fluid bed is less than 2 percent, thus no further roasting is necessary, and the present invention can be directly used as building raw material; the thermal value of produced carbonization coal gas which can be directly used as fuel to feed into the boiler for burning is high, the quantity of heat released through burning can be transferred to the water through the heated surface of the boiler, the water is heated into a overheat steam to be used as out-supplied working substance and / or to be fed into a steam turbine for power and electricity generating. The present invention has the advantages that the comprehensive utilization degree is high, the cost is low, the technology is scientific and reasonable, etc.

Owner:NORTHEAST DIANLI UNIVERSITY +1

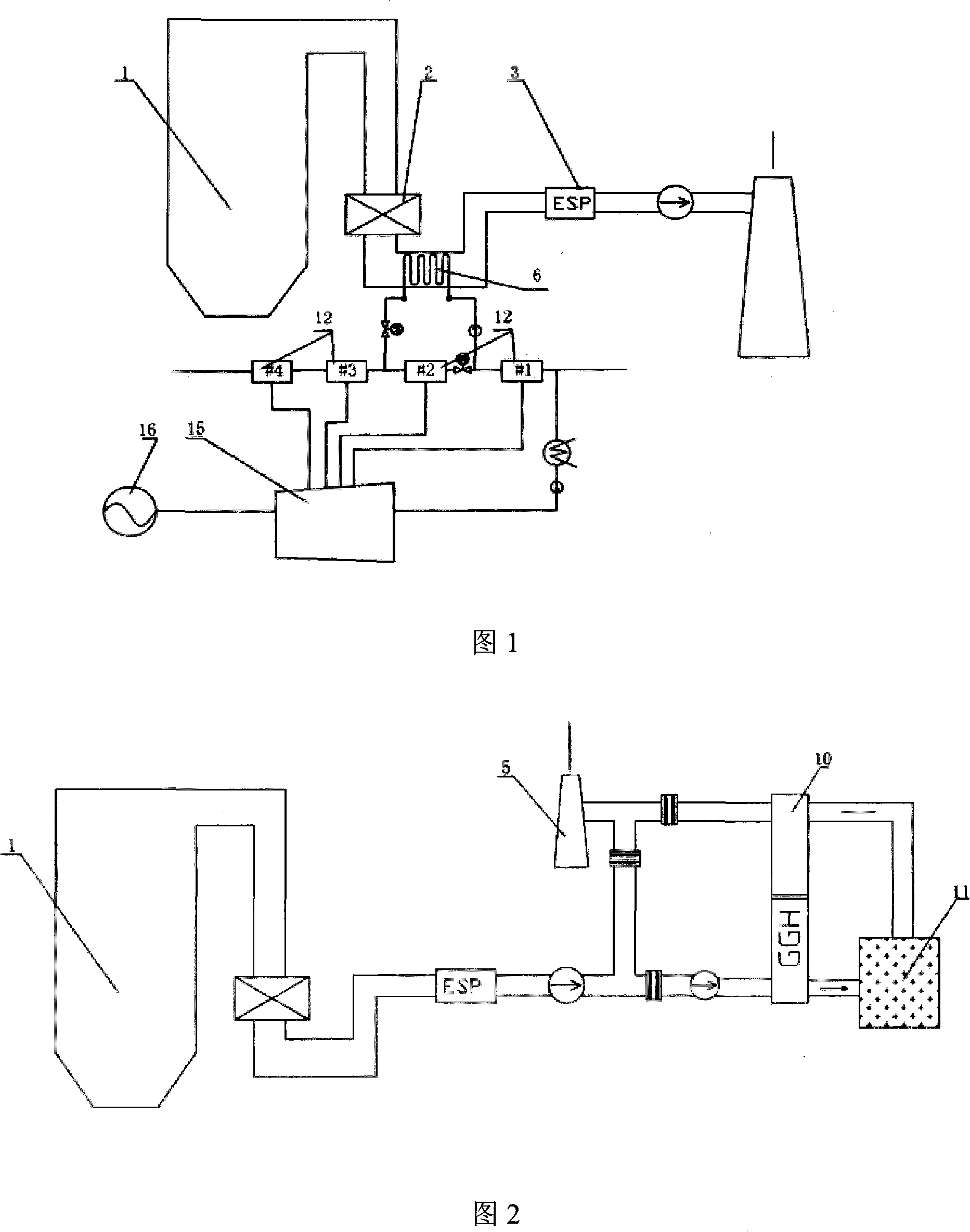

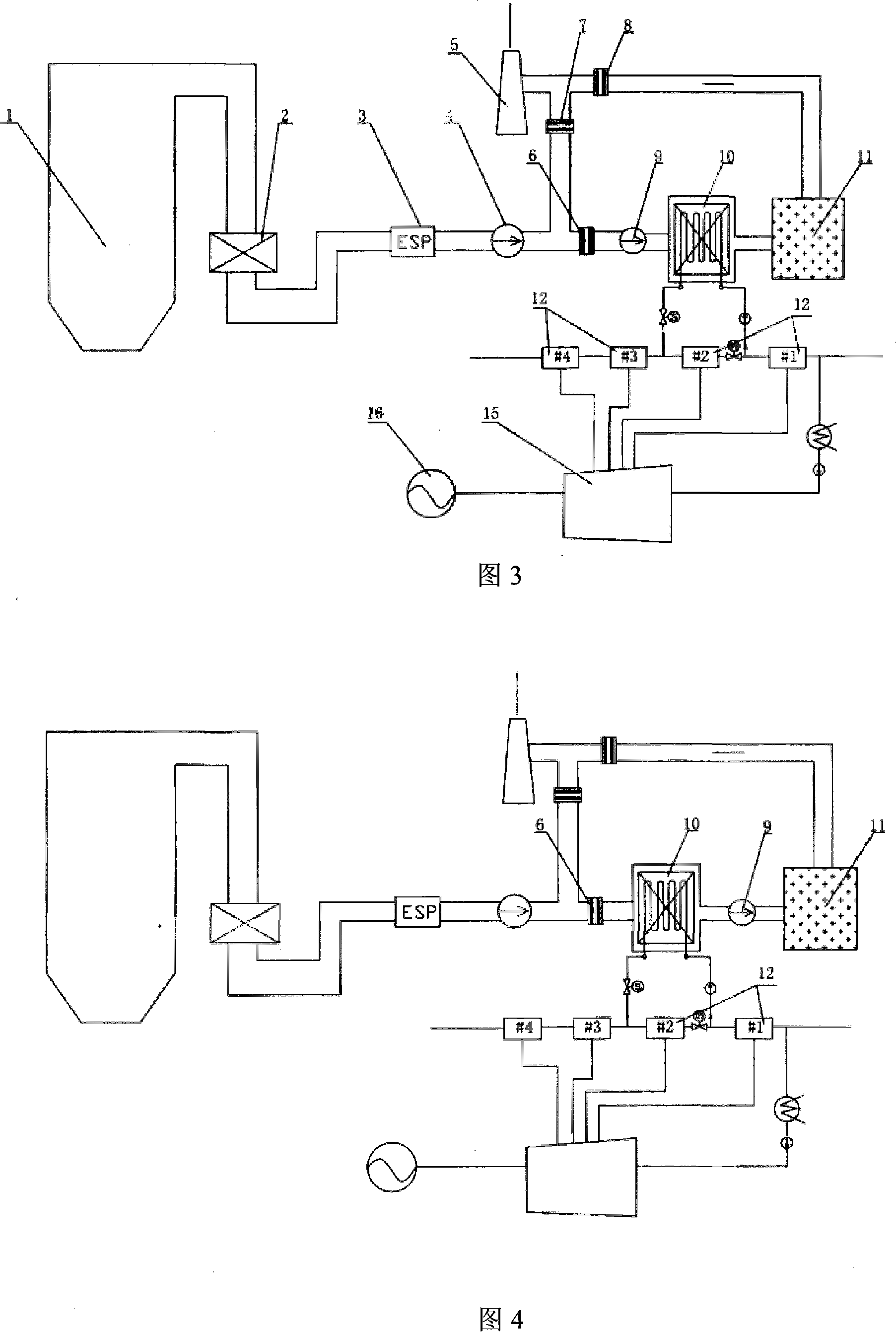

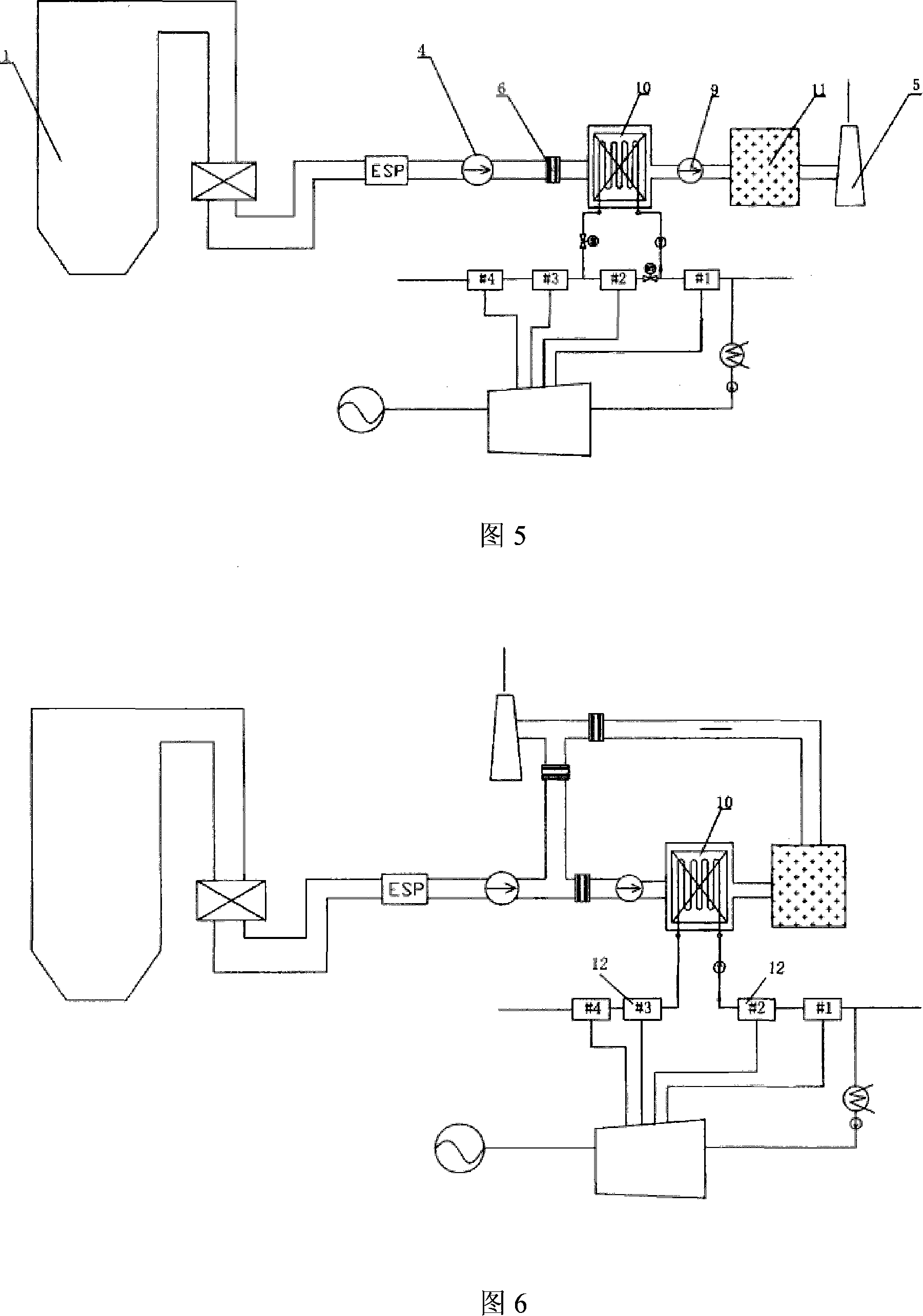

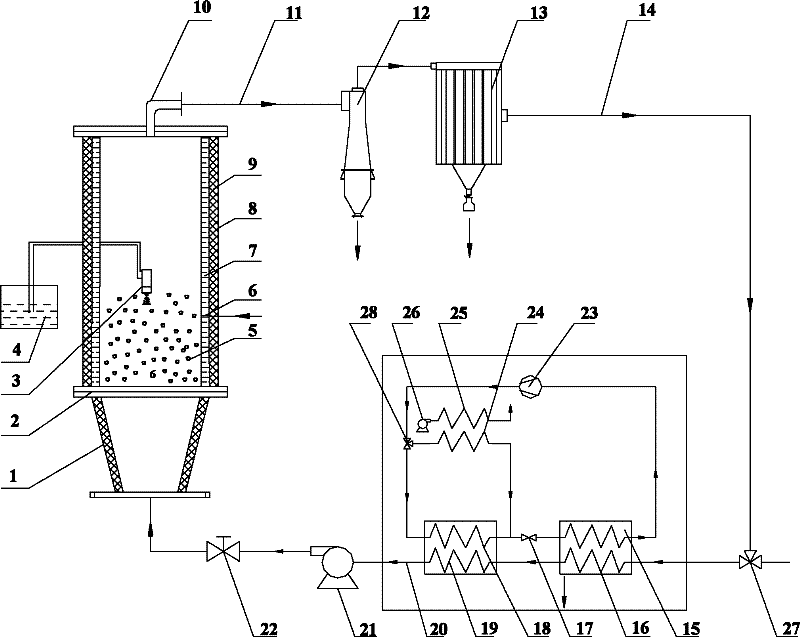

Desulfurize flue gas waste heat recovery system used in fire coal electric generating set

InactiveCN101140072AImprove utilizationOvercoming wear and tearLighting and heating apparatusCombustion technology mitigationThermal energyInlet channel

The invention discloses a desulfurization flue gas waste heat recovery system for a coal-fired generator set, which comprises at least a gas-water heat exchanger for exchanging heat energy between gas state and liquid state, a flue gas inlet channel and a flue gas outlet channel respectively independently communicated with the gas-water heat exchanger, and a condensation water inlet pipeline and a condensation water outlet pipeline; a flue gas inlet of the gas-water heat exchanger is communicated with a rear flue gas channel of a boiler flue gas dust remover in the coal-fired generator set; a flue gas outlet of the gas-water heat exchanger is communicated with the flue gas inlet of a desulfurization absorption tower in a desulfurization system; a condensation water inlet and a condensation water outlet of the gas-water heat exchanger can be in sereies or parallel with at least a first-stage low-pressure heater of a regenerative system. The desulfurization flue gas waste heat recovery system provided in the invention has the advantages of the high waste heat utilization ratio, saving energy and water, the obvious discharge reducing benefit and the high comprehensive utilization degree of abandoned resources.

Owner:SHANGHAI WAIGAOQIAO NO 3 POWER GENERATION

Method of replacing lime with limestone for slagging and producing steel in oxygen top blown converter

The present invention belongs to the field of steel production, and relates to a method of replacing lime with limestone for slagging and producing steel in an oxygen top blown converter. The invention is characterized in that the limestone is directly added during slagging in the steel production process. The added batch number is increased and the amount of each batch of material is reduced. Namely the lime is added by 1-3 times for slagging formerly, and when the limestone is added for slagging, the limestone is added by 4-8 times. The adding amount of each time, calculated according to the CaO therein, is 1 / 2-1 / 3 of lime added formerly and is for preventing the condensing and incrusting at the metal surface in the furnace in the early period of converting. The adding amount of limestone, calculated according to CaO therein, accounts for 30%-100% of adding amount of lime in the batch. The method of the invention has the main advantages of elimination of lime calcining procedure or reduction of production scale, reduction of cost required for operating the calcining device and reducing the discharged pollution, prevention of heat waste caused by cooling the lime after calcining, low sulfur content in the lime generated in the oxygen top blown converter, and benefit for restraining resulfurization of melted iron in the steel production process.

Owner:UNIV OF SCI & TECH BEIJING

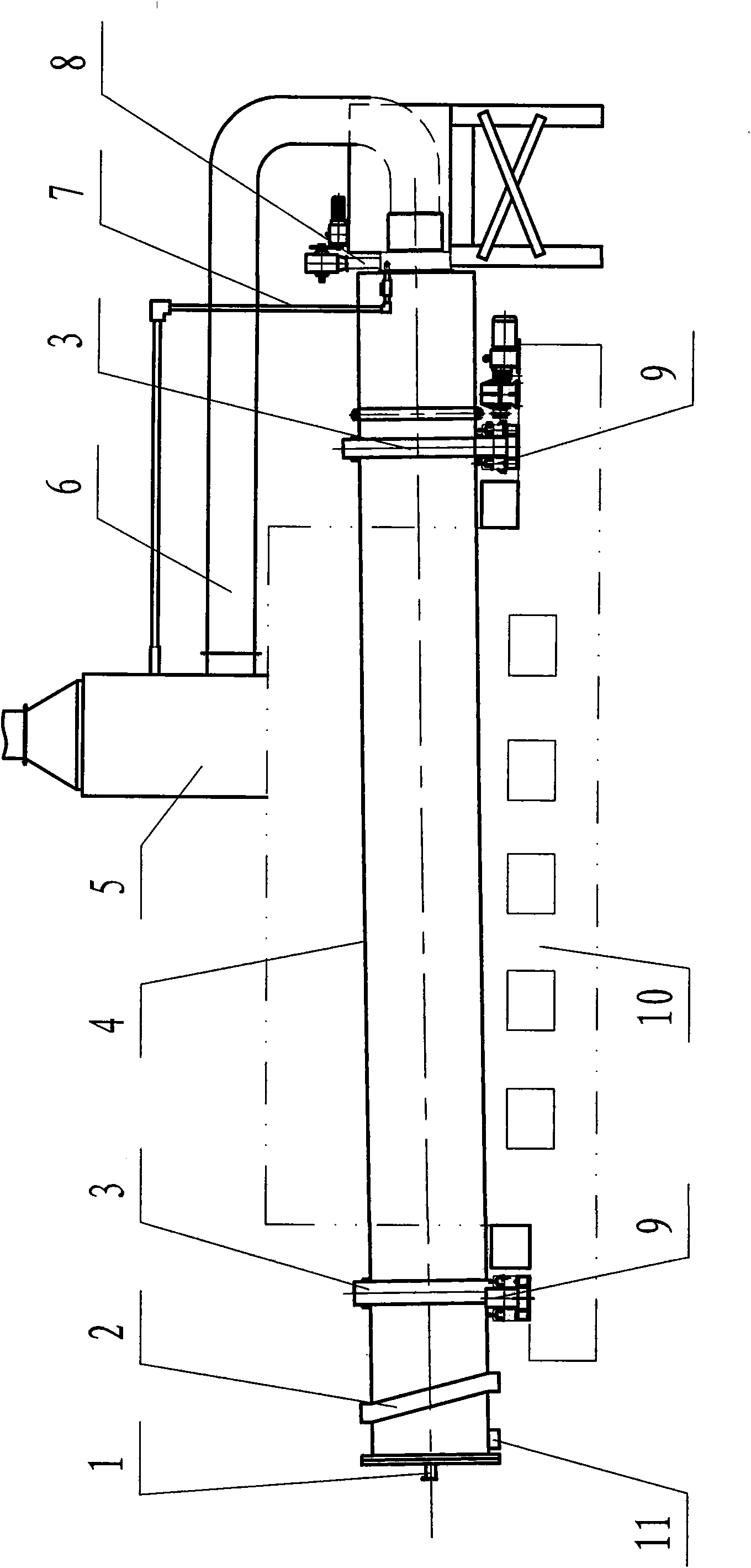

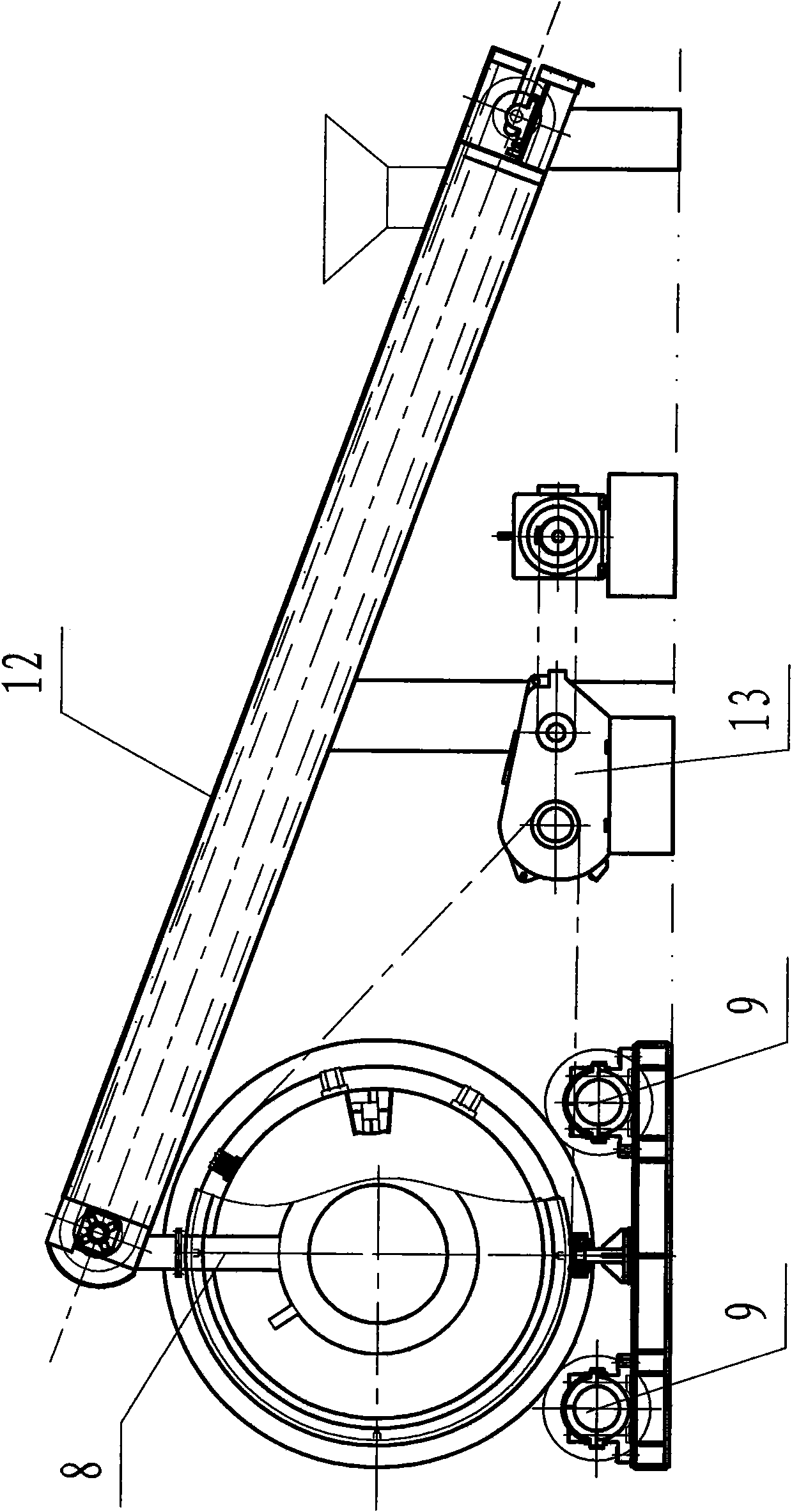

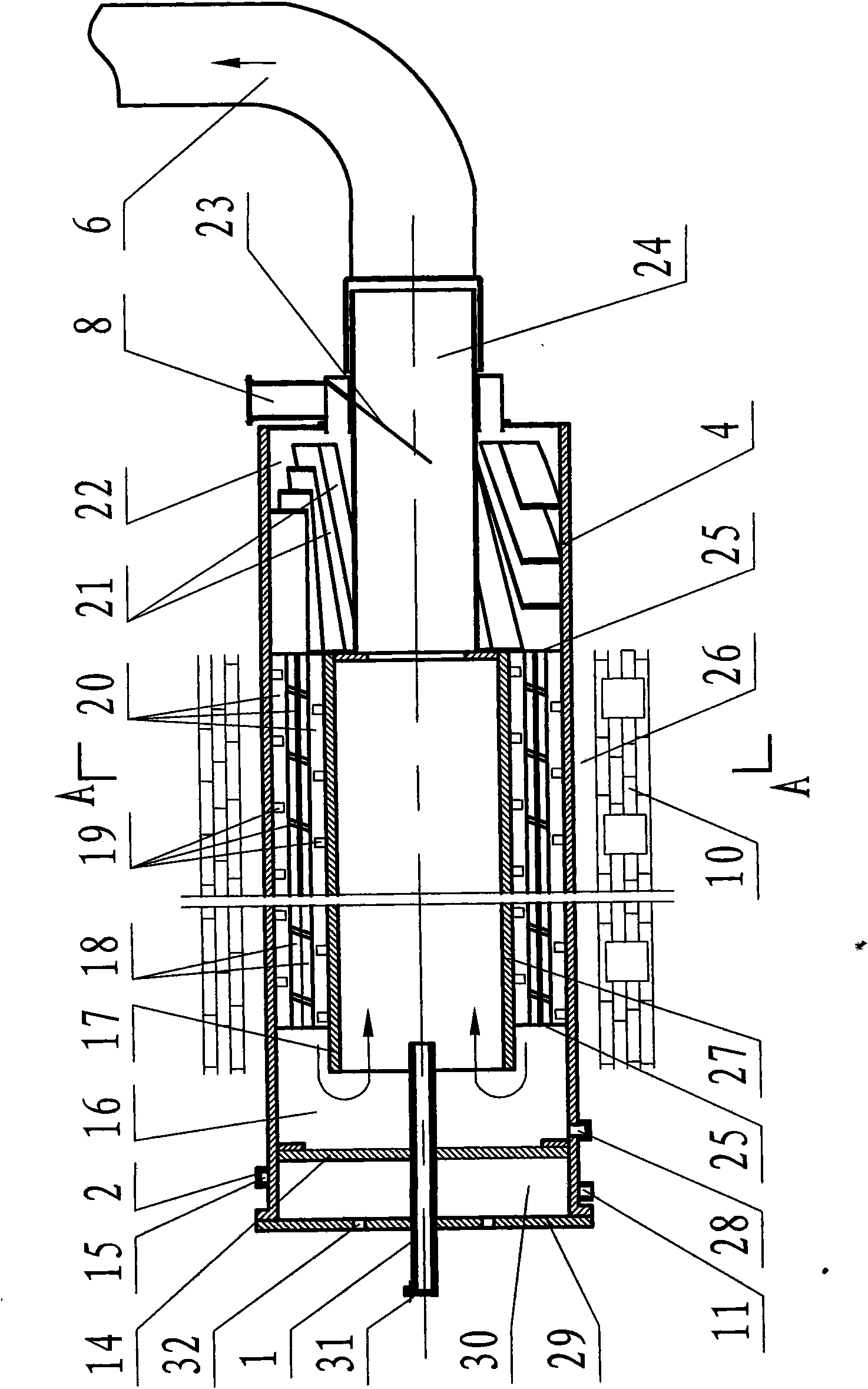

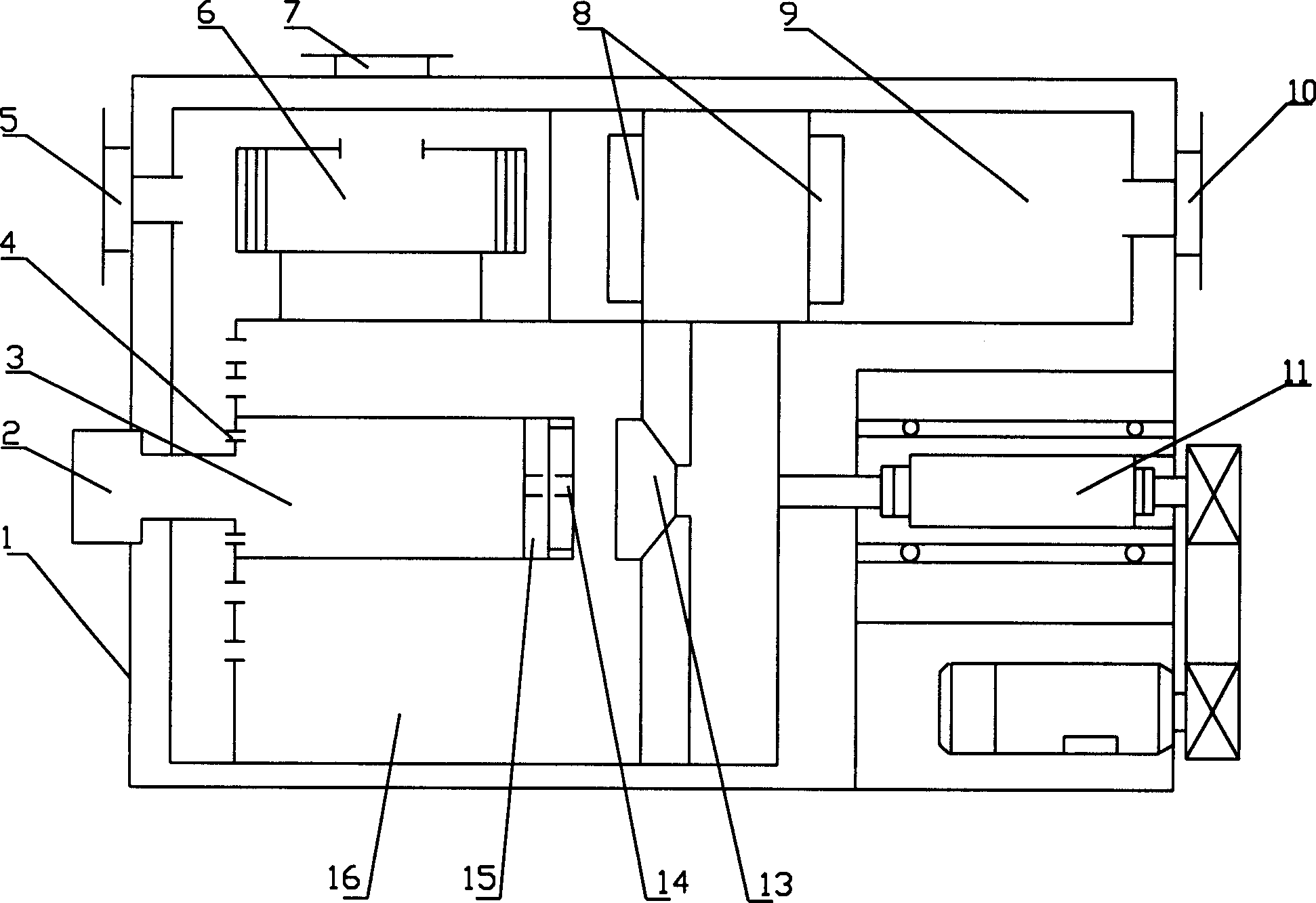

Active carbon horizontal converter

InactiveCN101592439AEvenly heatedImprove the activation effectRotary drum furnacesEngineeringBiological activation

The invention discloses an active carbon horizontal converter in the field of equipment producing active carbon, which comprises a driving mechanism (13), a feed mechanism (12), an outer barrel (4), a gas distributing pipe (1), an exhaust pipe (24), a flue (6), a steam generator (5), and a steam pipe (7), wherein an inner barrel (27) is arranged in the outer barrel (4) and is welded in the outer barrel (4) through a vertical plate (25);at least three independent material channels (18) are formed by the separation of the vertical plate (25) between the outer barrel (4) and the inner barrel (27) ; a shoveling plate is welded in each material channel; and one end of the gas distributing pipe (1) is provided with a gas distributing pipe cover (31), while the other end extends into the inner barrel (27). The active carbon horizontal converter not only can continuously produce the active carbon with a particle size range between 60 meshes and 12 millimeters, but also ensures the bidirectional heating of the inside and outside of materials, thereby having high utilization rate of heat energy and good activation effect, and only needing the activation time for 4 to 5 hours.

Owner:淮北市协力重型机器有限责任公司 +2

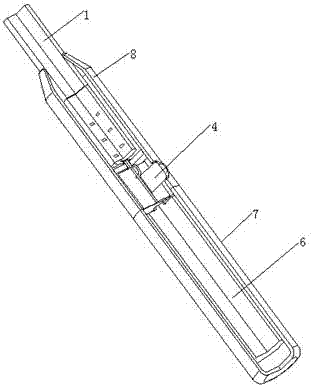

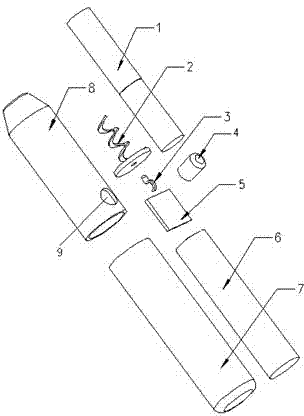

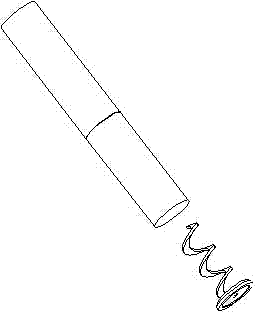

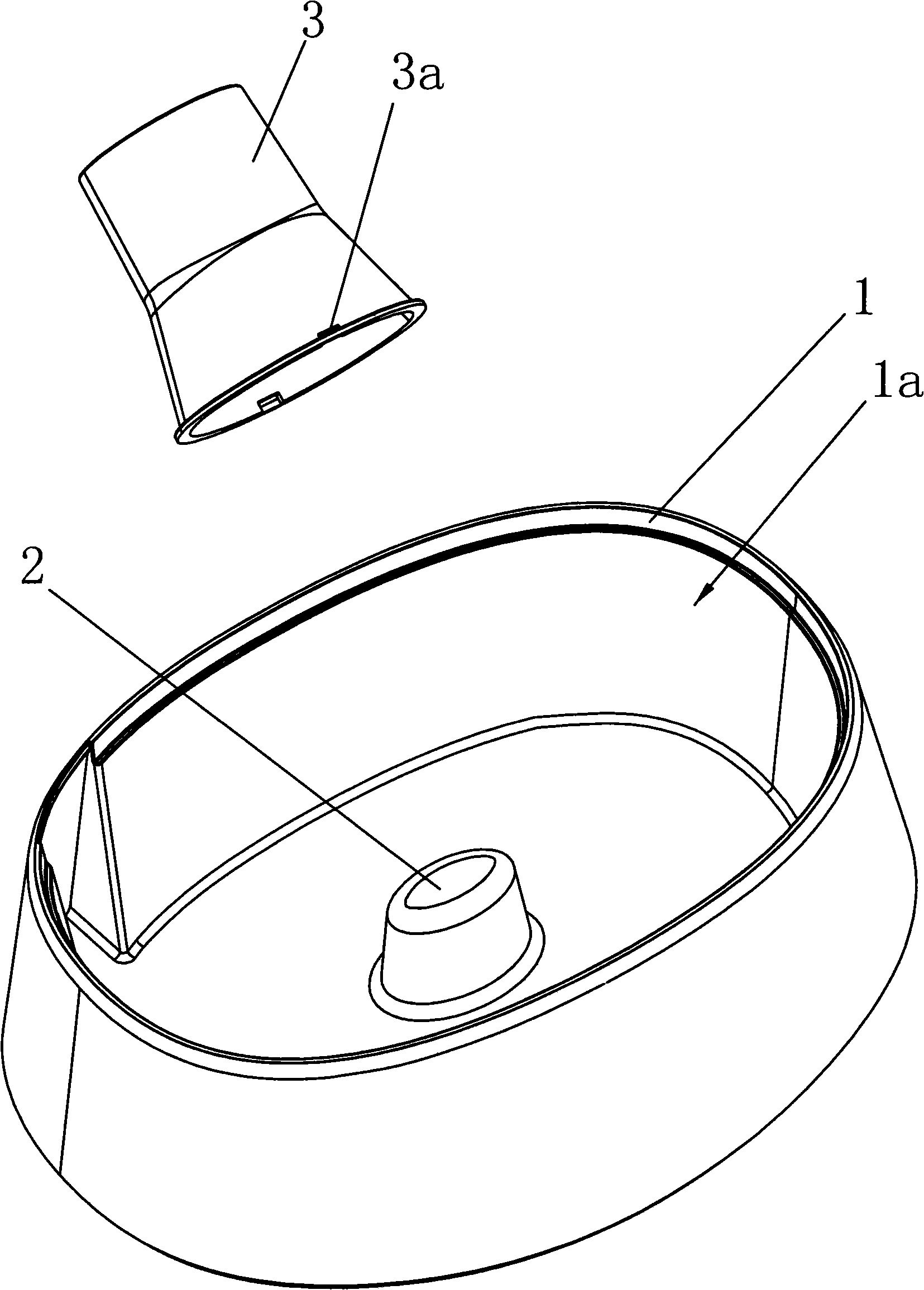

Low-temperature roasted electric heating cigarette, heating body and electric heating cigarette circuit

InactiveCN104489933AIncrease contact areaImprove heat utilizationTobacco devicesOhmic-resistance heating detailsElectric heatingElectricity

The invention discloses a low-temperature roasted electric heating cigarette, a heating body and an electric heating cigarette circuit. The electric heating cigarette comprises a shell and a cover which is matched with the shell, wherein a battery is arranged in the shell; a spiral heating body is fixedly arranged in the shell or the cover; a cavity for accommodating the cigarette is formed in the cover; when the cigarette rotates to enter the cavity, the spiral heating body is screwed into one end of the cigarette to roast the cigarette to produce smoke. The cigarette is uniformly heated and has comfortable smoking mouthfeel; the heat utilization rate is high, the power consumption is low, and the battery life is long; the cleaning is convenient; the carrying is convenient; the economic benefit is high.

Owner:CHINA TOBACCO HUNAN INDAL CORP

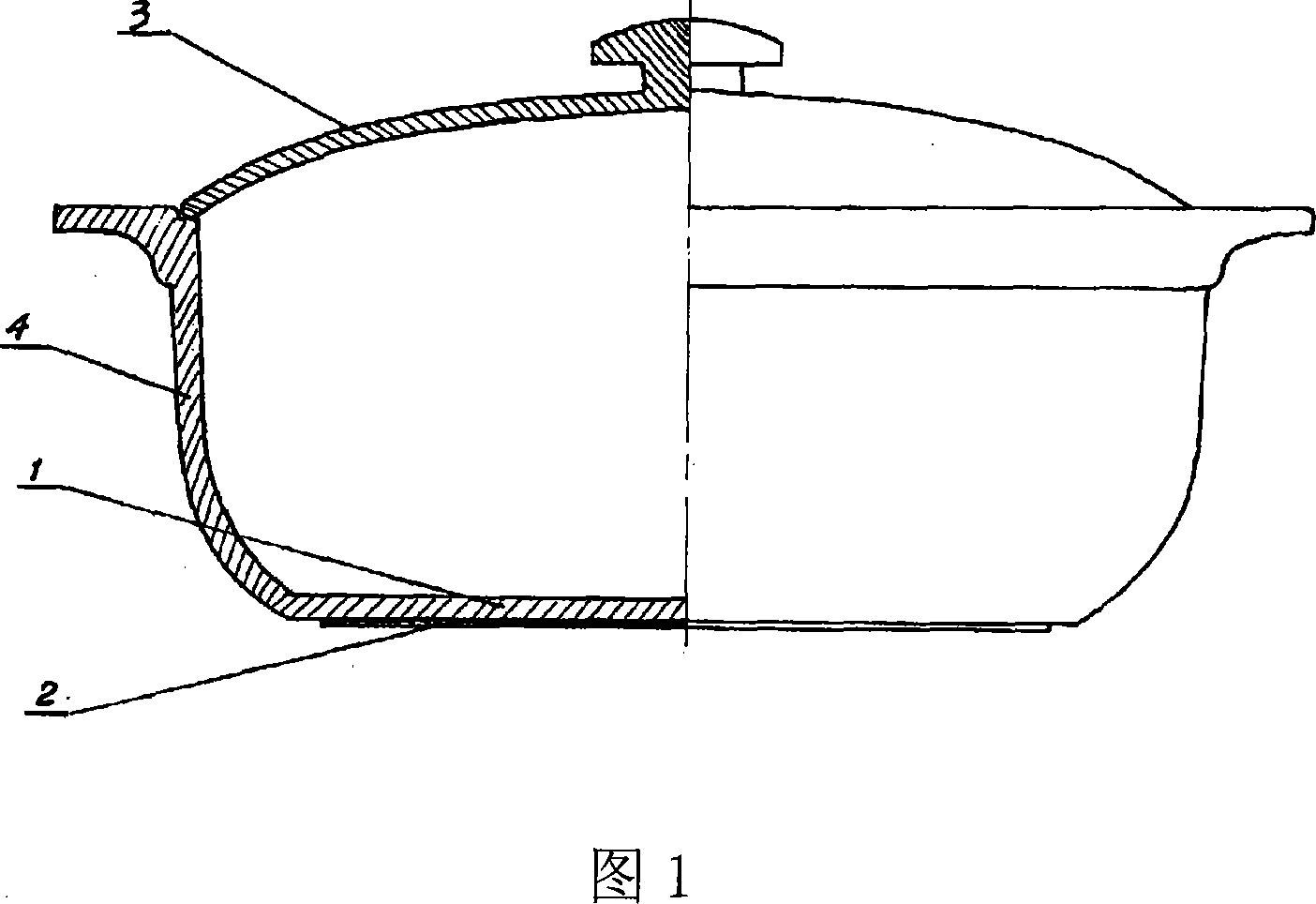

High heat-resisting ceramic cooking cook ware suitable for electromagnetic induction furnace

InactiveCN101077274ADeliciousImprove heat utilizationCooking-vessel materialsLithiumThermal stability

The present invention discloses one kind of high temperature resistant ceramic cooker suitable for use in electromagnetic induction furnace. The high temperature resistant ceramic cooker is produced with the main materials, including lithium-containing mineral material, quartz, kaolin, etc, and through grinding, mixing, forming, drying, glazing and high temperature baking to obtain the ceramic body; coating far infrared radiation layer, electromagnetically inducing eddy flow heating layer and far infrared reflecting layer to the bottom of the ceramic body; and roasting. It has high heat stability, no cracking even in no-water cooking state, high heat utilization rate and long service life. It is especially suitable for cooking in electromagnetic induction furnace.

Owner:JINGDEZHEN CERAMIC INSTITUTE

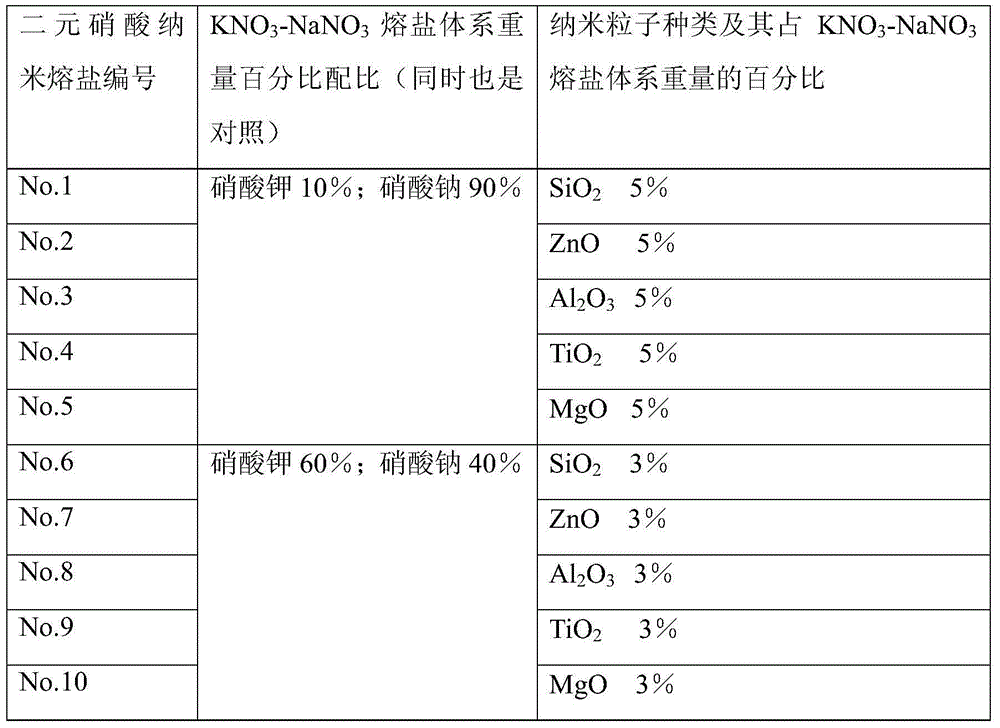

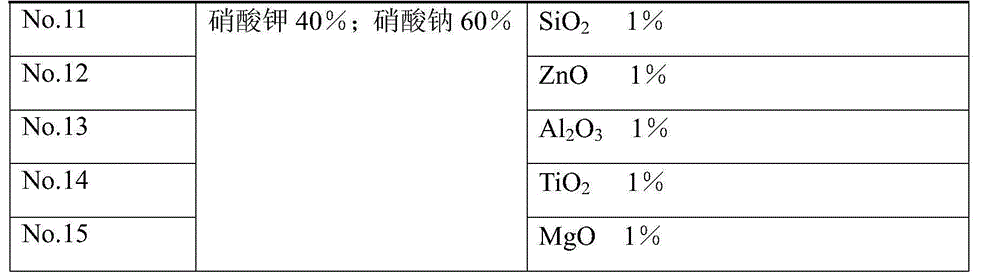

Nanometer molten binary nitrate heat-transfer heat-storage medium and preparation method thereof

ActiveCN103911121AImprove thermal conductivityImprove thermal stabilityFrom solar energySolar heat devicesMolten saltHeat stability

The invention relates to a nanometer molten binary nitrate heat-transfer heat-storage medium and a preparation method thereof and belongs to the field of solar photo-thermal electricity generation. The nanometer molten binary nitrate heat-transfer heat-storage medium is characterized in that nano-particles are dispersed in a KNO3-NaNO3 and KNO3-NaNO2 solid-liquid phase-change molten binary nitrate system at a high temperature so that the nanometer molten binary nitrate heat-transfer heat-storage medium is compounded, and the nano-particles comprise SiO2, ZnO, Al2O3, TiO2, CaO and / or MgO nanoparticles. The nanometer molten binary nitrate heat-transfer heat-storage medium solves the problem that the existing nanometer molten binary nitrate system has a low heat conductivity coefficient, poor heat stability and a narrow use temperature scope and can be widely used in the technical field of solar photo-thermal electricity generation.

Owner:QINGHAI ENESOON NEW MATERIAL TECH & SCI CO LTD

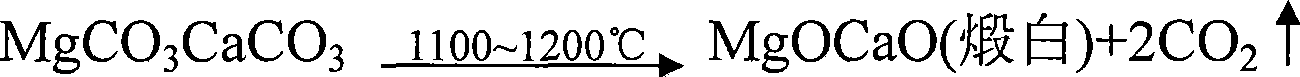

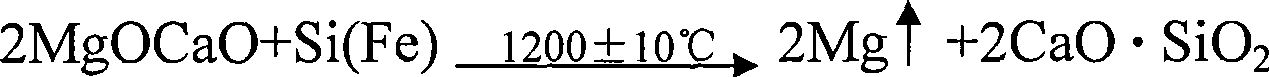

Process for smelting magnesium by microwave heating Pidgeon process

The invention discloses a magnesium reduction process through a micro-wave heating silicothermic method; the process comprises the following steps: 1. dolomite calcinations: the dolomite is heated to 1100 DEG C to 1200 DEG C and becomes calcined dolomite; 2. the calcined dolomite, silicon nitride powder and fluorite powder are weighed, mixed, milled and then pressed into a ball which meets technological requirements; 3. the ball is put into a closed non-metal reduction tank of a micro-wave heating oven to be heated under 1000 DEG C to 1200 DEG C, so that the magnesium compound in the ball reacts with the silicon nitride powder; 4. the vacuum degree of the closed non-metal reduction tank is kept to be 13.3Pa or higher for 4h to 6h; magnesium vapor is condensed in a condenser and becomes crude magnesium; 5. the crude magnesium is heated, melted and refined by solvent, to obtain refined magnesium; 6. acid washing and the like. The method evenly and quickly heats in the principle of micro-wave heating with high heating efficiency, is easy to be controlled, saves production cost, is safe, environment protective and harmless.

Owner:重庆科健冶金材料有限公司

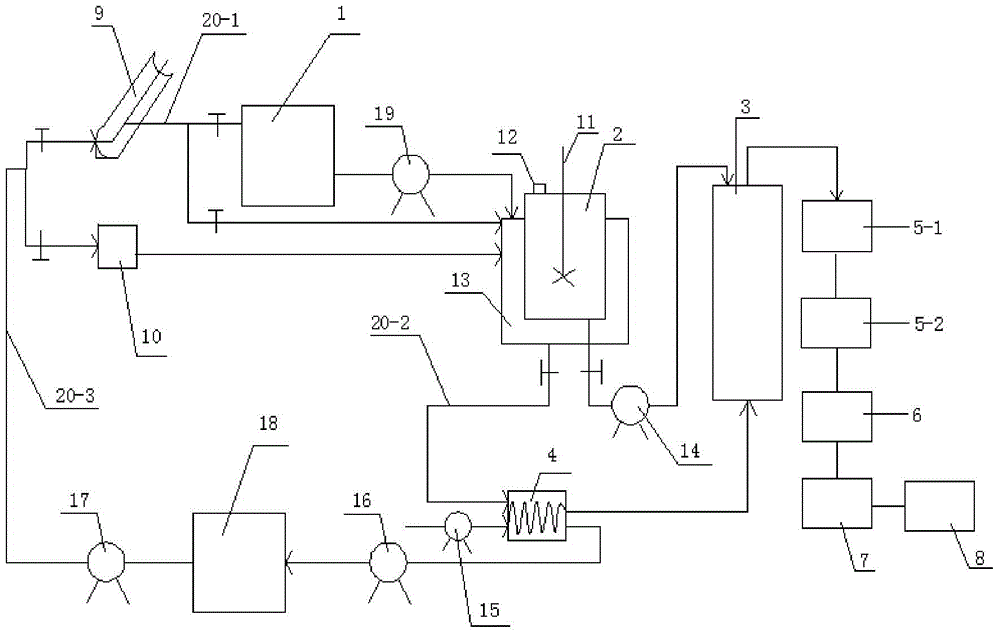

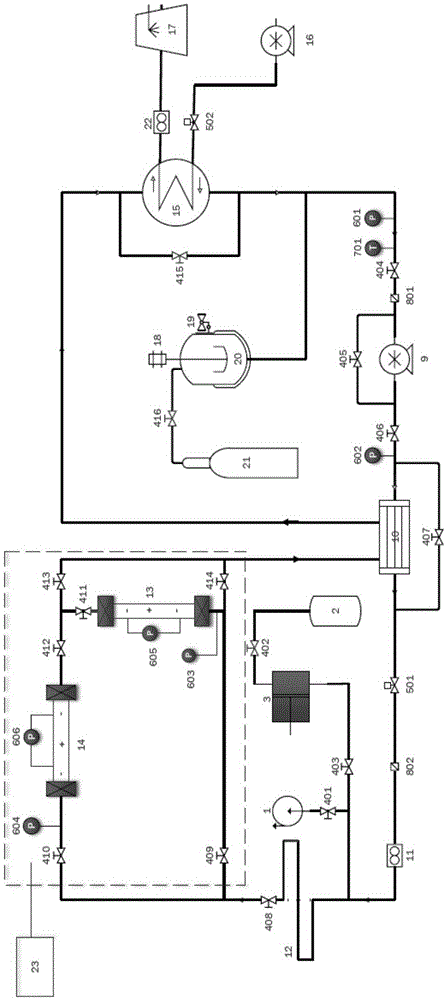

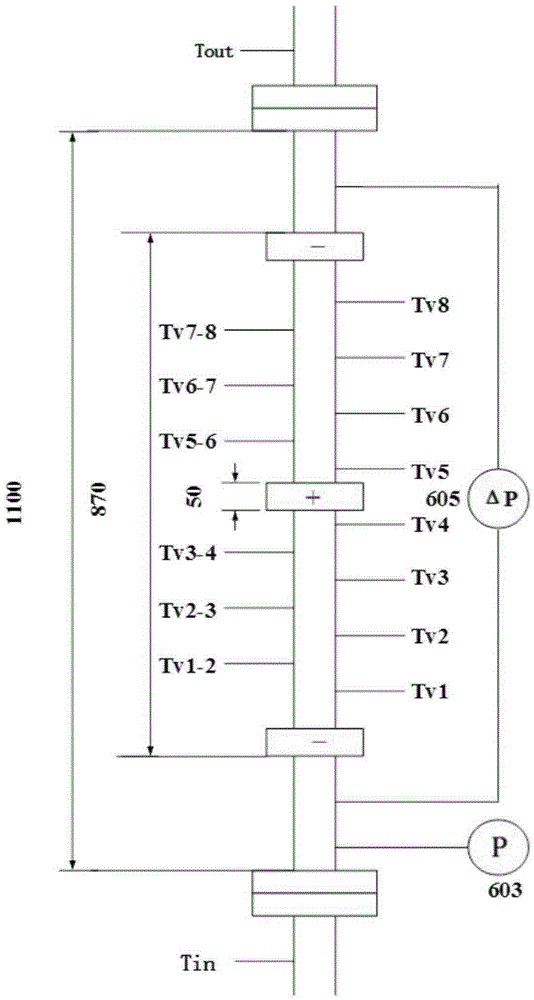

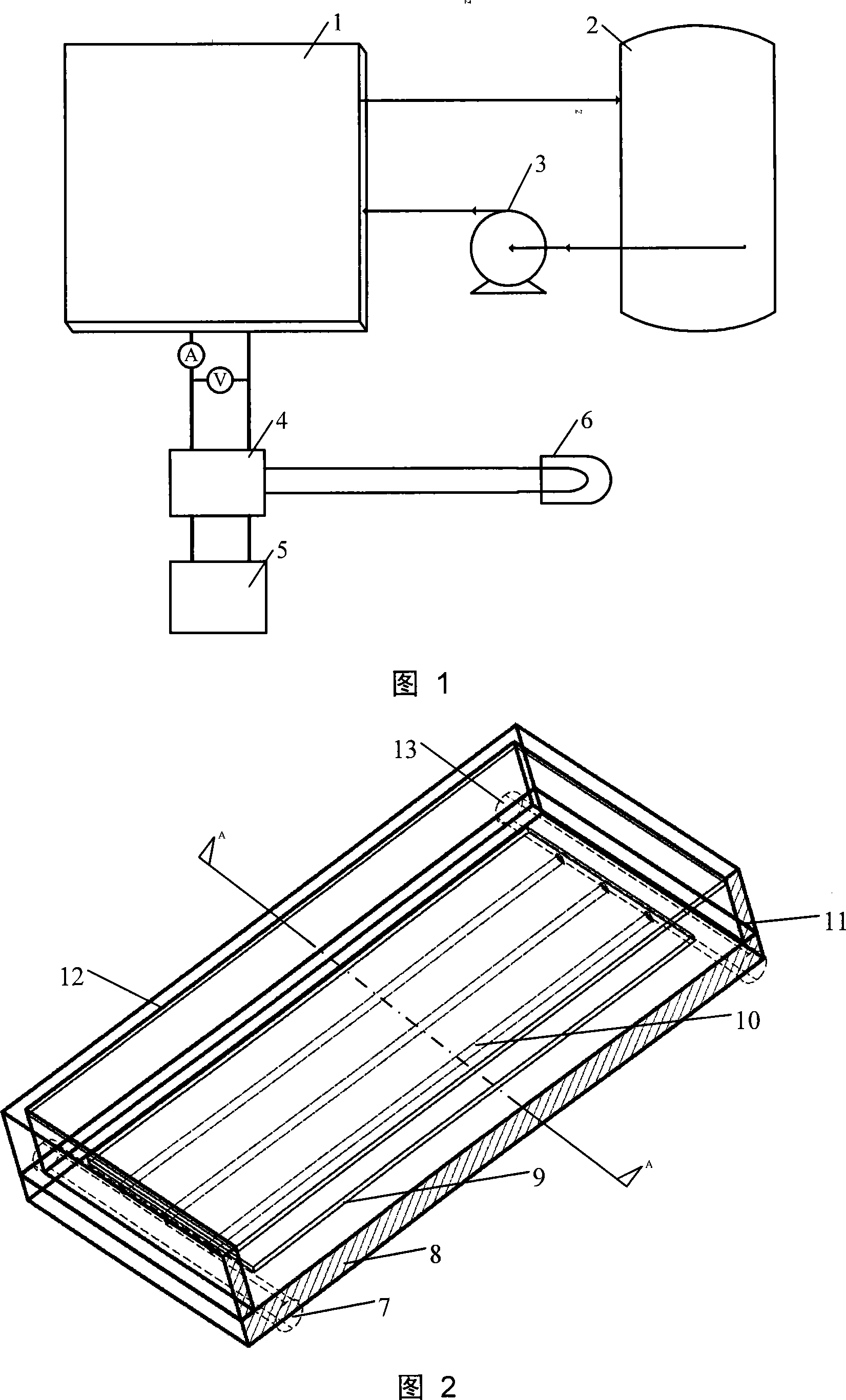

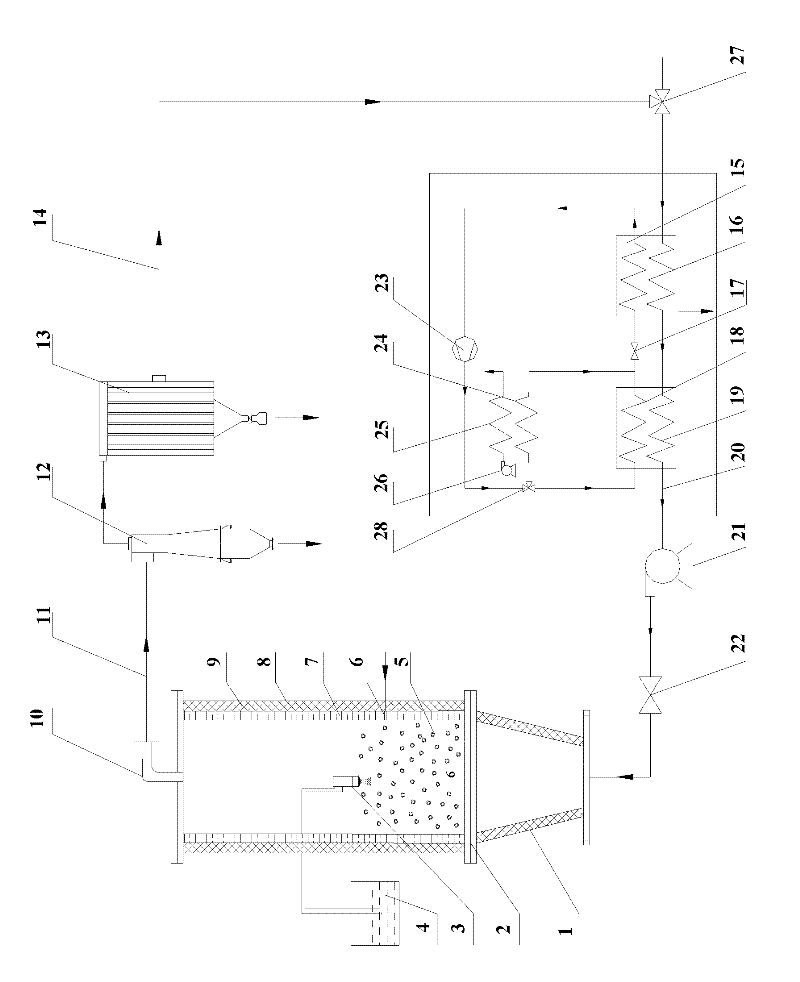

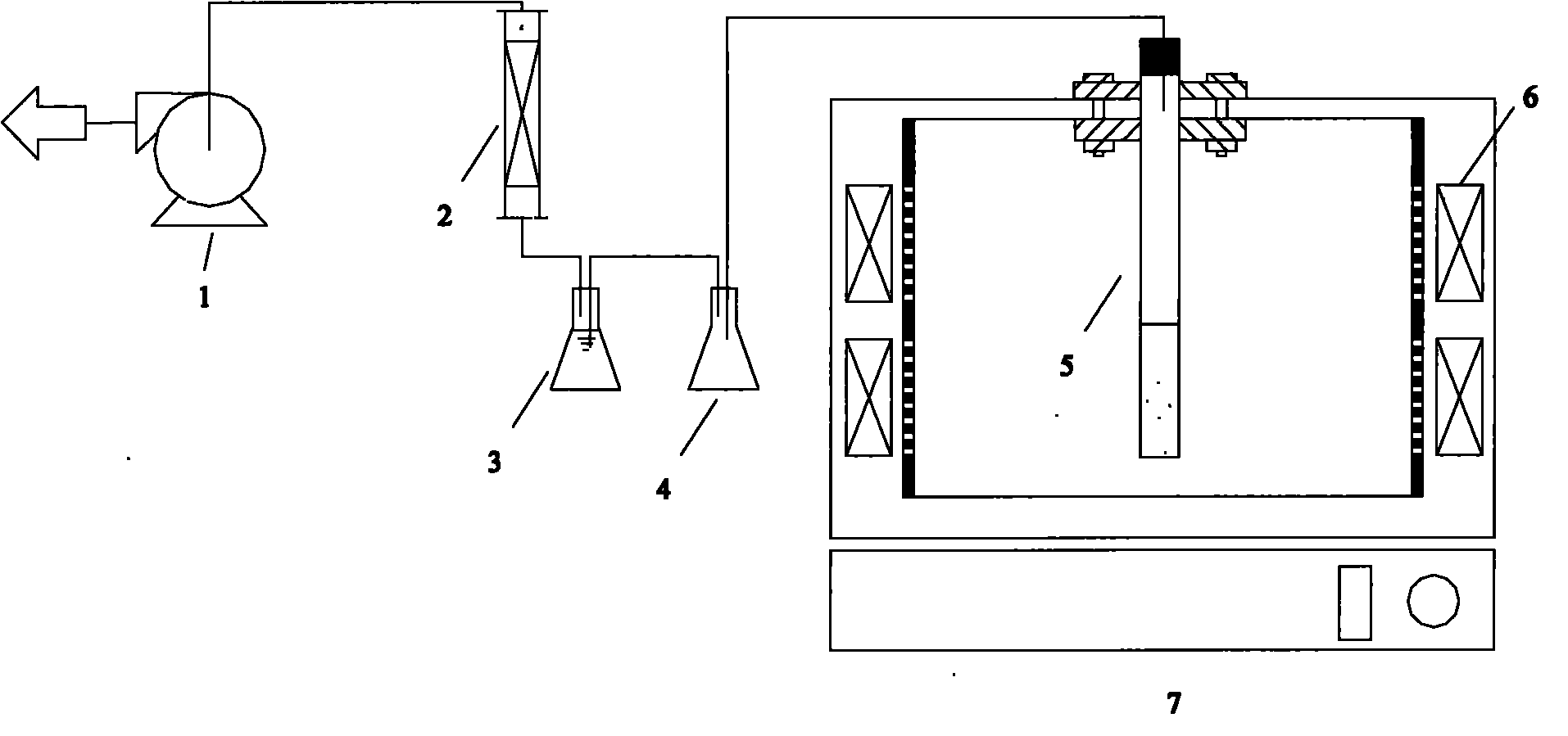

Supercritical Freon heat exchange experiment system and experiment method thereof

ActiveCN105301047AVersatileSimple and reliable structureMaterial heat developmentEngineeringHigh pressure

The invention discloses a supercritical Freon heat exchange experiment system and an experiment method thereof. The system comprises a vacuum and Freon injection module consisting of a vacuum pump, a coolant tank, a coolant recycling and injection machine, a valve and a pipeline connected to a main loop, a circulating module consisting of a shield pump and a closed type loop pipeline, a heat return module consisting of a heat regenerator and a bypass pipeline, a preheating module consisting of a snake-shaped preheating section and a direct current power supply, an experiment module consisting of an experiment section and a relevant valve, and a pressure adjustment module consisting of a high-pressure nitrogen bottle, a pressure stabilizer, a safety valve and a pressure reduction valve, wherein Freon flows into the experiment section after being subjected to heat regeneration and preheated from the outlet of the shield pump, and then finally returns to the inlet of the shield pump after being cooled by a condenser, thus forming a closed circulation. The invention further provides an experiment method of the system. The system can bear a higher-temperature working condition and a higher-pressure working condition, ensure that the Freon can run cyclically under a supercritical state, and also easily, conveniently and quickly adjust system parameters.

Owner:XI AN JIAOTONG UNIV

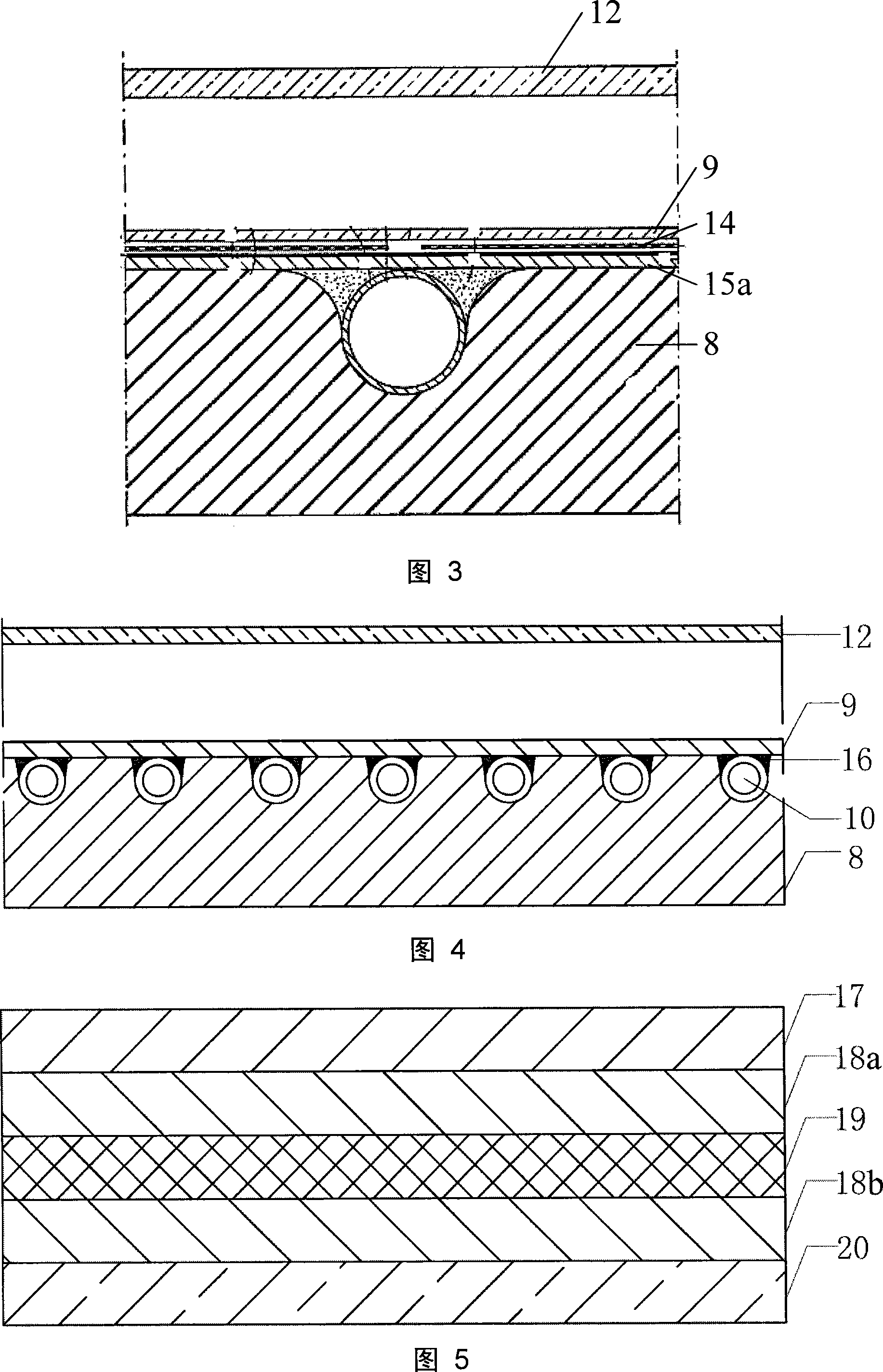

Solar photovoltaic/photothermal combined apparatus

InactiveCN101022138AIncrease the heat exchange areaReduce thermal resistanceSolar heating energySolar heat devicesGlass coverInsulation layer

This invention relates to a photovoltage / photoheat coupled device including a solar cell, a glass cover plate set on the cell, a heat-collecting tube under the cell and a back sealed insulation material, in which, this invention sets a heat-collecting copper plate sprayed with a light absorption layer under the lower conglutinated insulation layer of the cell to replace the opaque back sealing film of a cell, besides, tin-lead or laser continuous welding is used in the connection part between the heat-collecting copper plate and the heat-collection tube to reduce heat resistance between them.

Owner:TSINGHUA UNIV

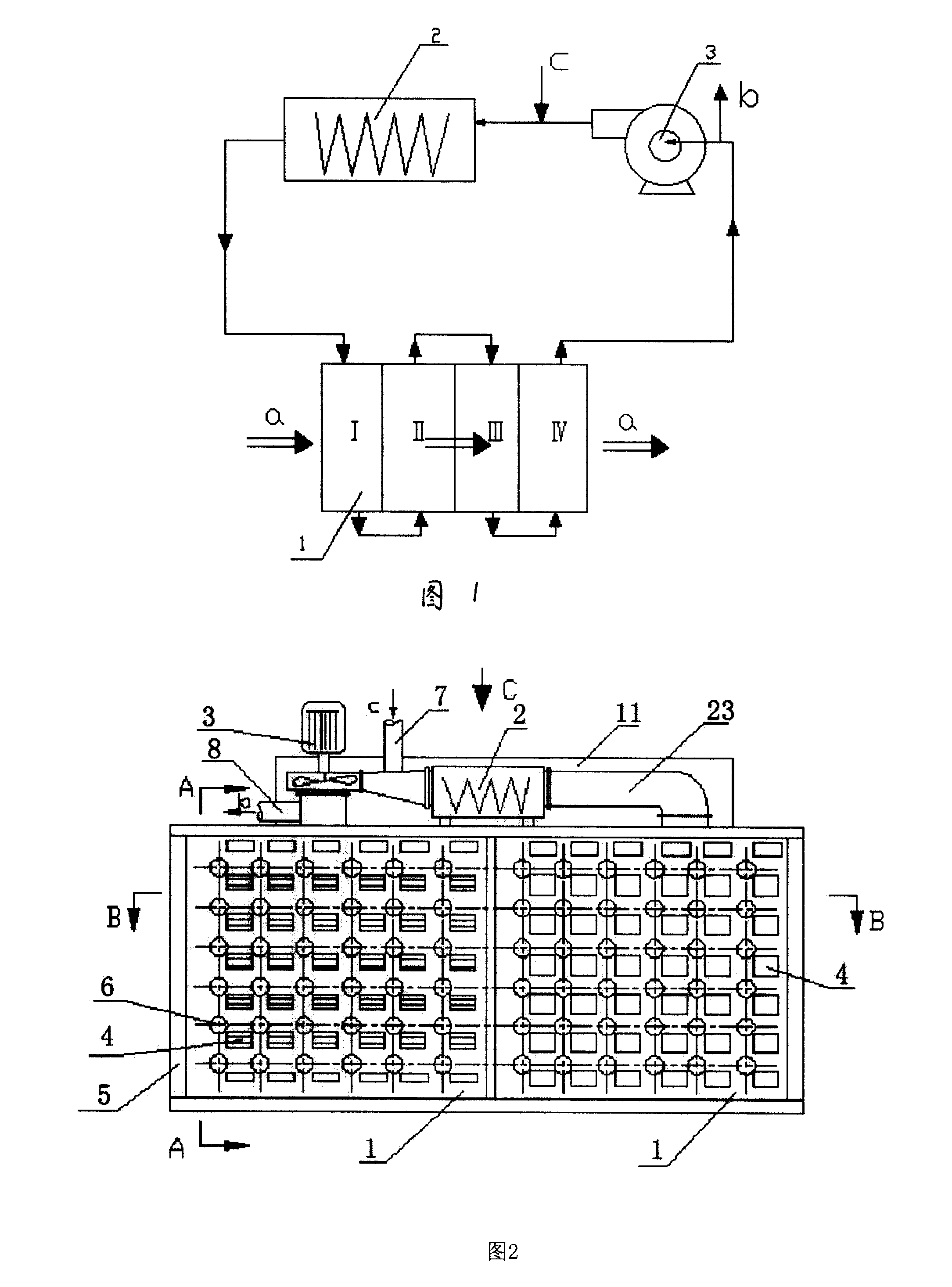

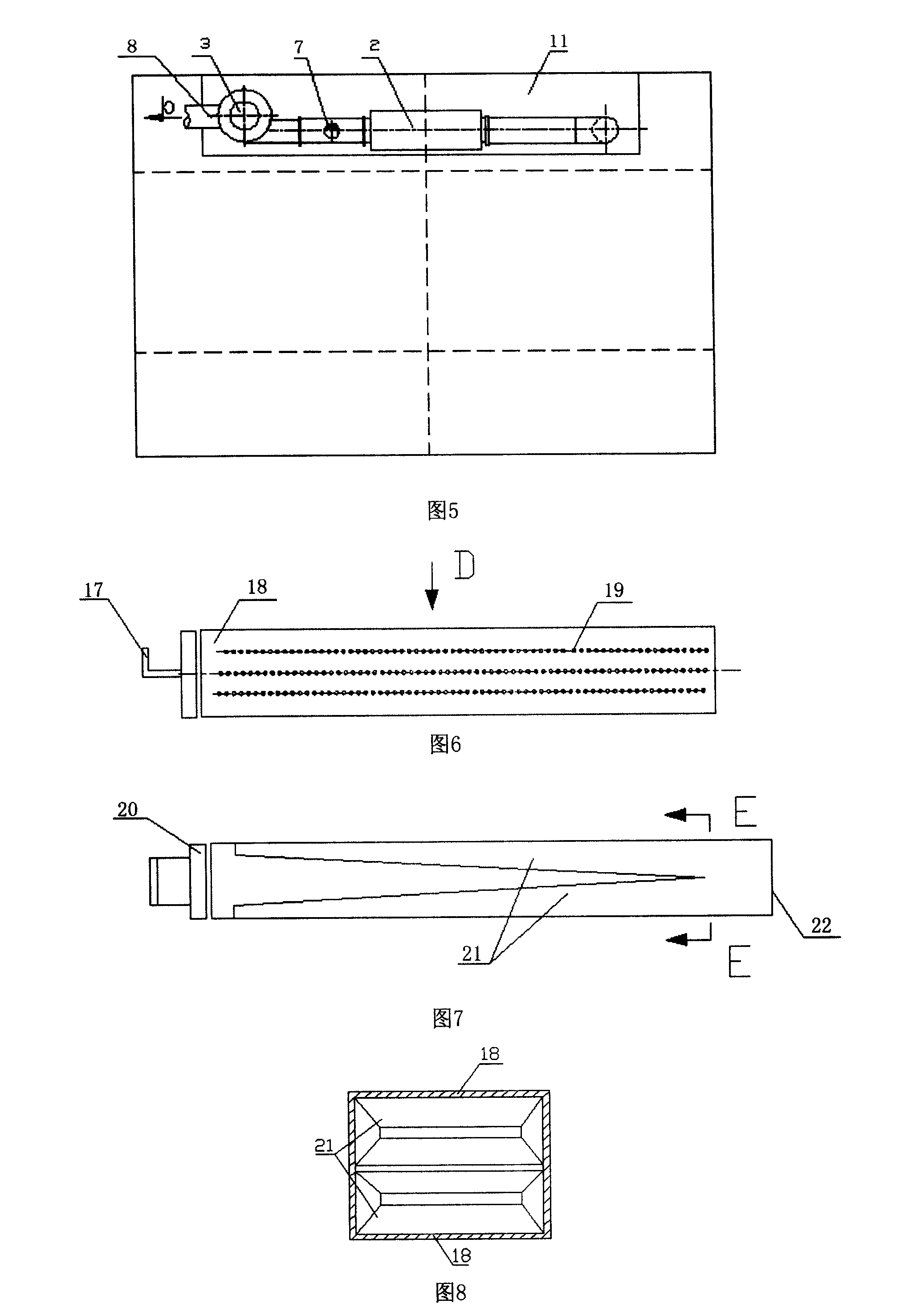

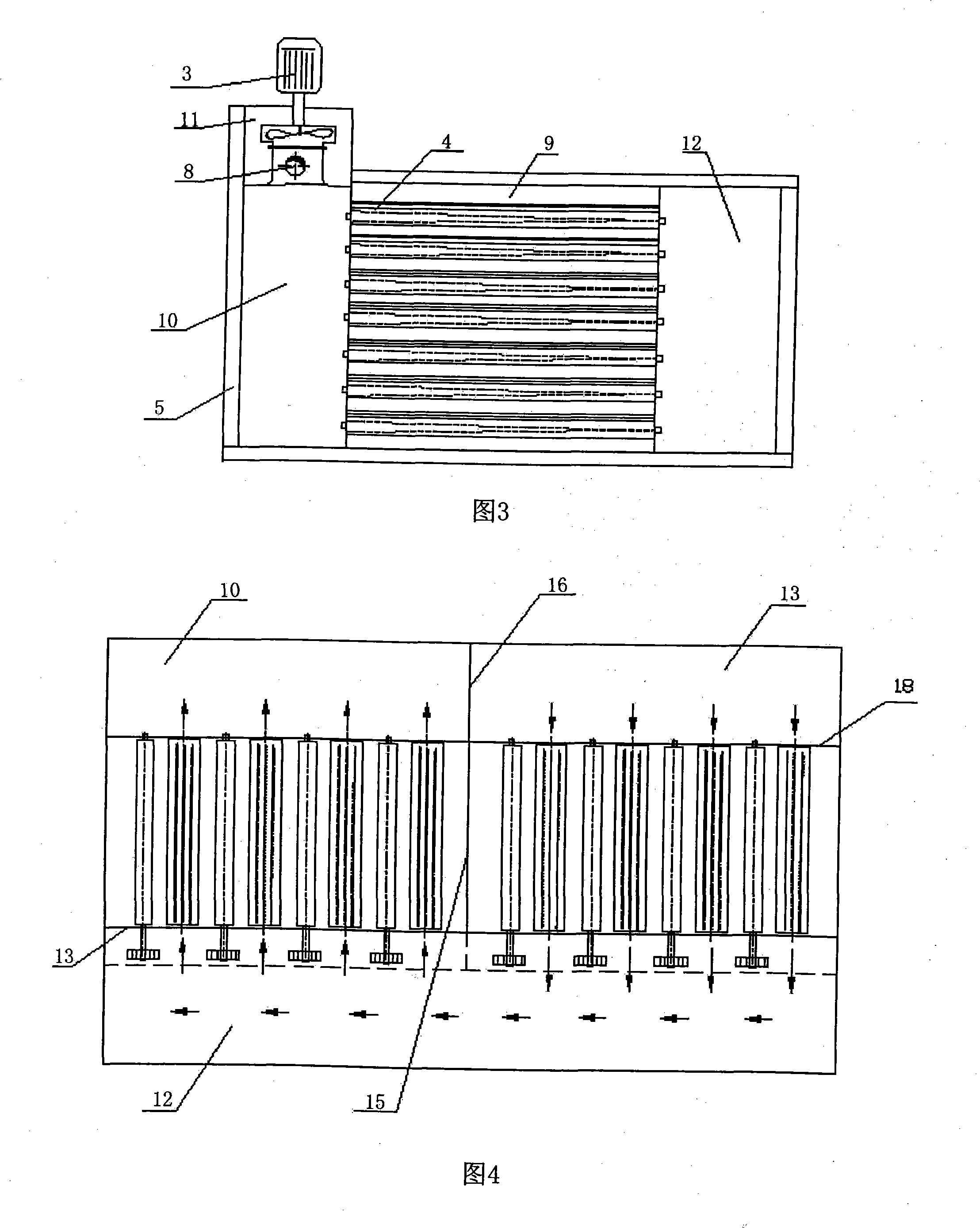

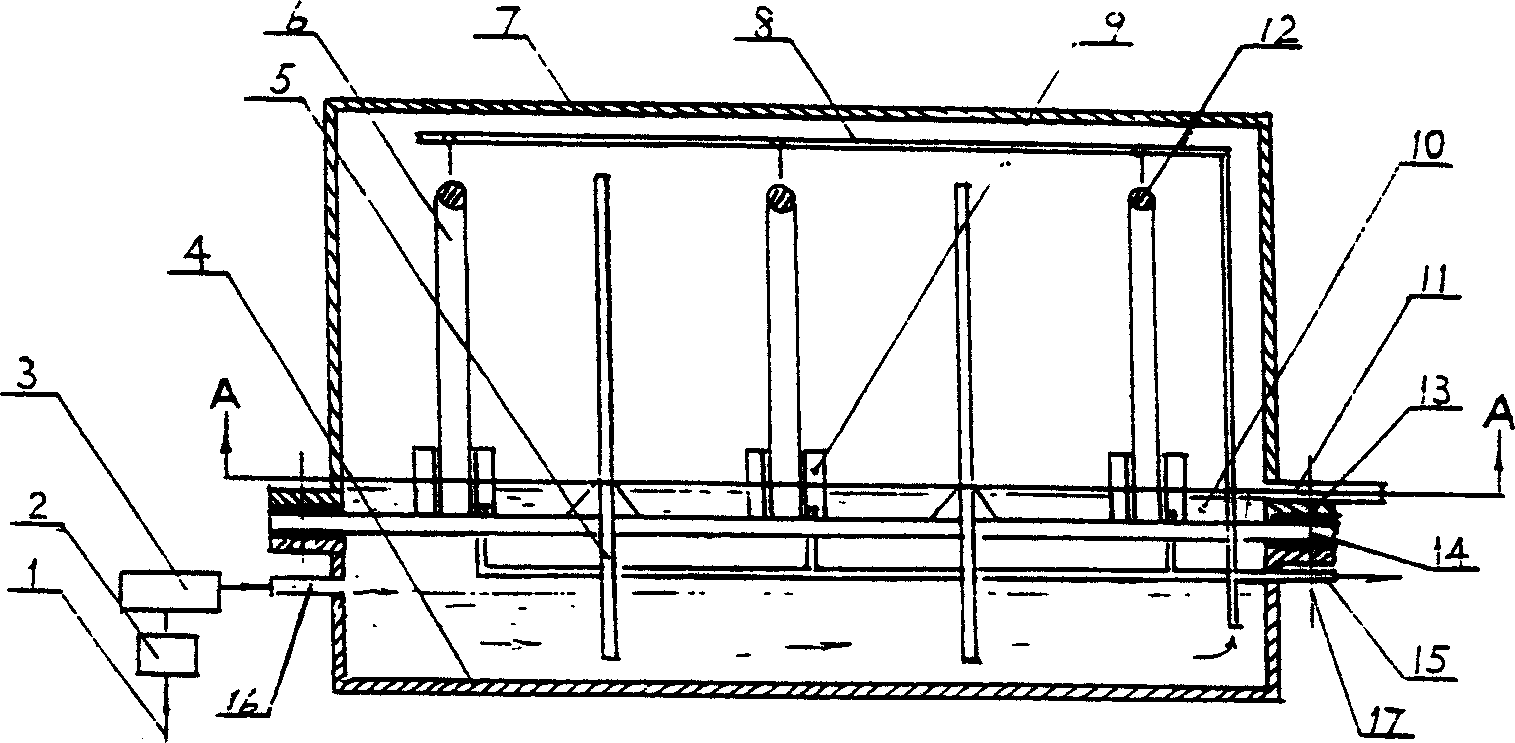

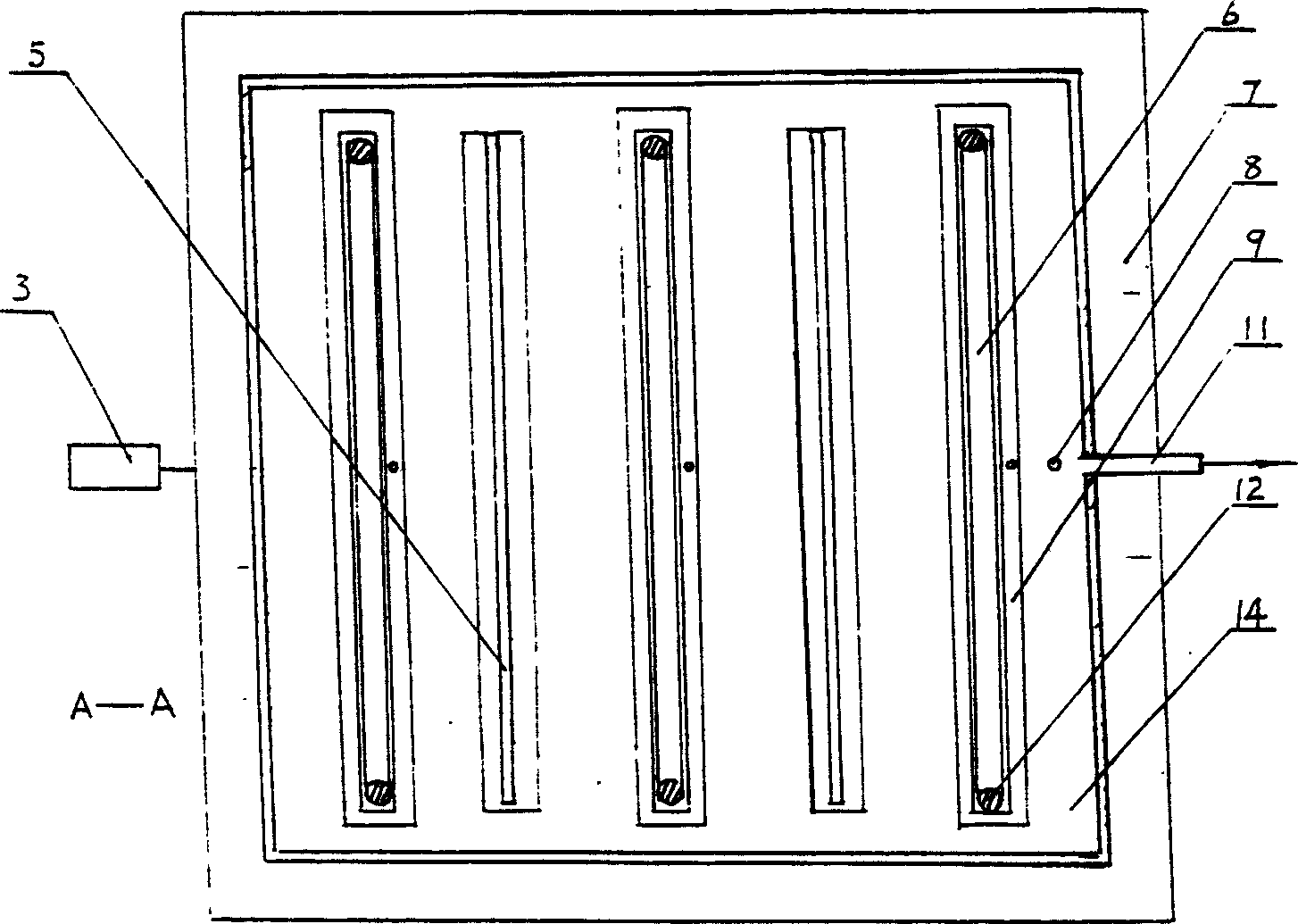

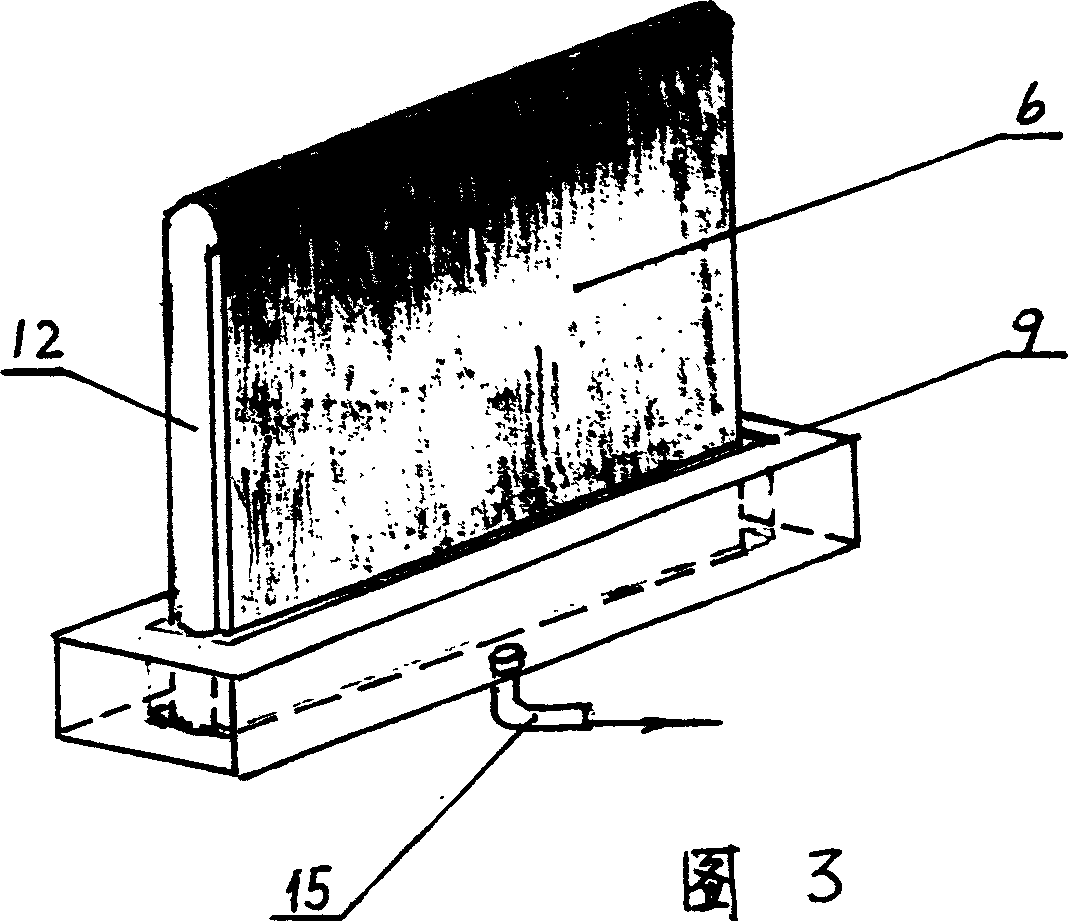

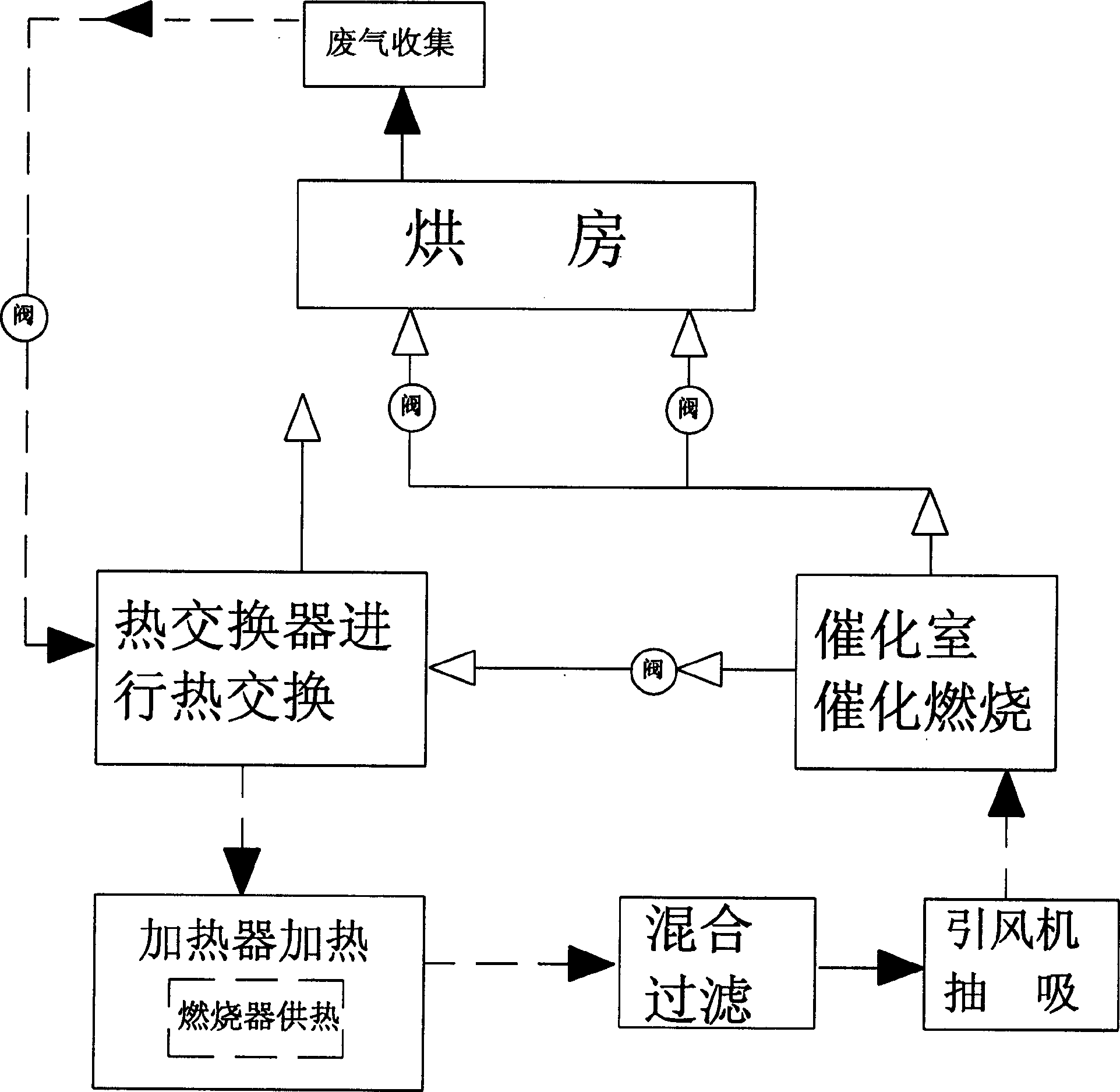

Multi- flow path transverse circulation gypsum board drying apparatus and its drying method

ActiveCN101236047AUniform drying effectEliminate flow resistance lossDrying solid materials with heatDrying gas arrangementsGypsumAirflow

The invention relates to multi-paths horizontal circulation drying device for plasterboards and a drying method thereof, and the drying device is formed by a roller conveyer with the closed inner portion provided with one layer, multi-layers in most cases, and an air circulating device, wherein the roller conveyer is disposed in a main passage, two sides of which are provided with auxiliary passages, the upper portion of the auxiliary passage on one side is provided with an overhead passage, and a circulating fan and a heating device are arranged inside the overhead passage. The drying device is divided into a plurality of areas in the direction of material delivery, each area can be divided into 2-4 segments, each segment is provided with a plurality of air supply blowing pipes, and the main passages of each segment are provide with air flow resistant separators. Hot air as drying medium flows reversely at the first and second segments or the third and the fourth segments via the air supply blowing pipes, and reciprocates and circulates within the plate drying area by horizontal double-paths or multi-paths, thereby forming the intrinsic inherent condition which guarantees moisture on the two sides of the dried plate to be uniformly evaporated, simultaneously the multi-paths horizontal circulation drying device has the advantages of flow resistance consumption reduction, exhaust temperature reduction, increasing energy efficiency and construction cost reduction.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

Landing solar energy capillary evaporating seawater desalting apparatus

InactiveCN1583583AIncrease evaporative loadStrong ability to absorb sunlightGeneral water supply conservationWater/sewage treatmentWater desalinationSaline water

A land-type solar seawater desalinating apparatus with capillary evaporation function is composed of seawater tube, seawater pump, seaweed removing unit, fresh water condensing plate and its cooling trough, capillary evaporator, sealed transparent casing, seawater distributing tube, concentrated saline collector, fresh water collector, etc.

Owner:周梦然

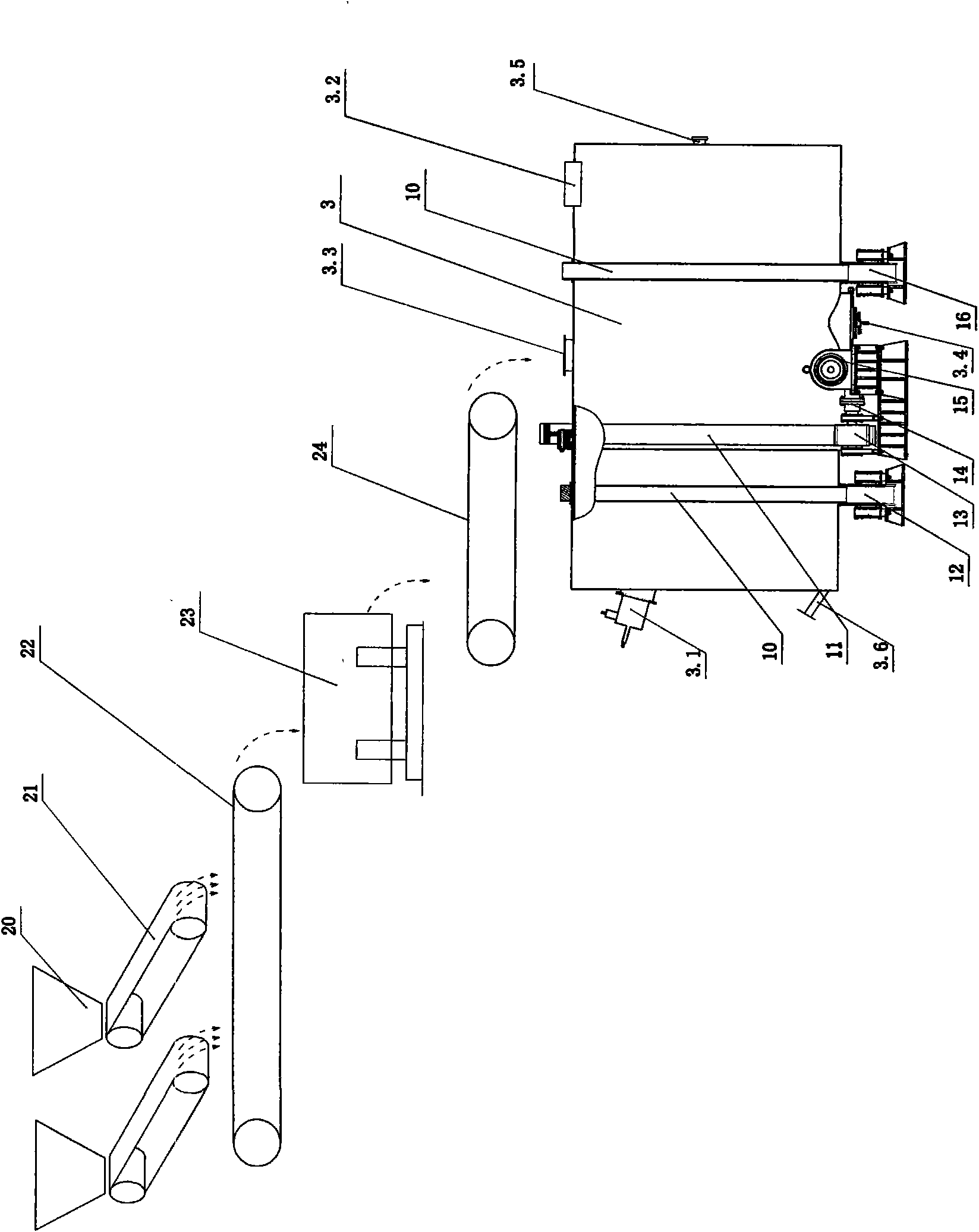

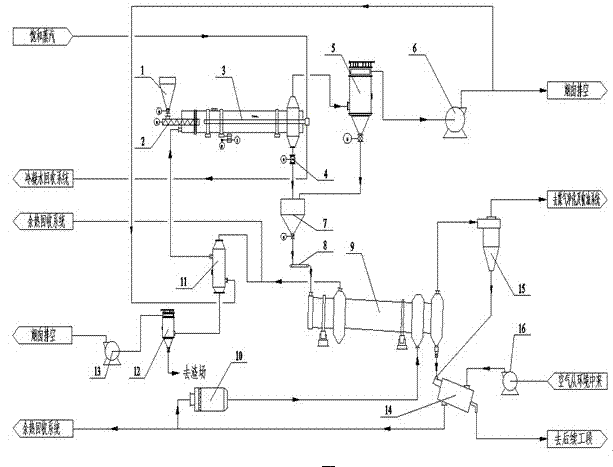

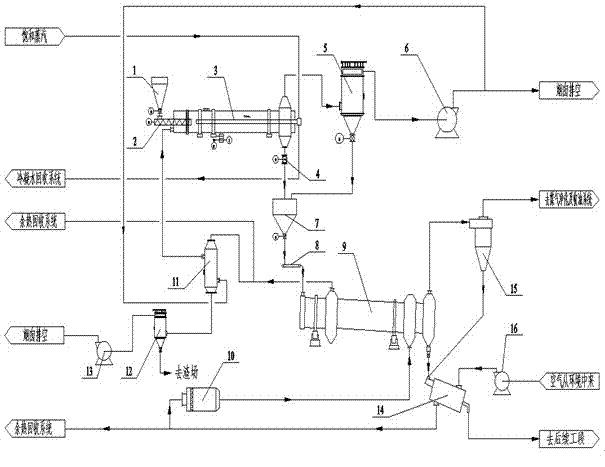

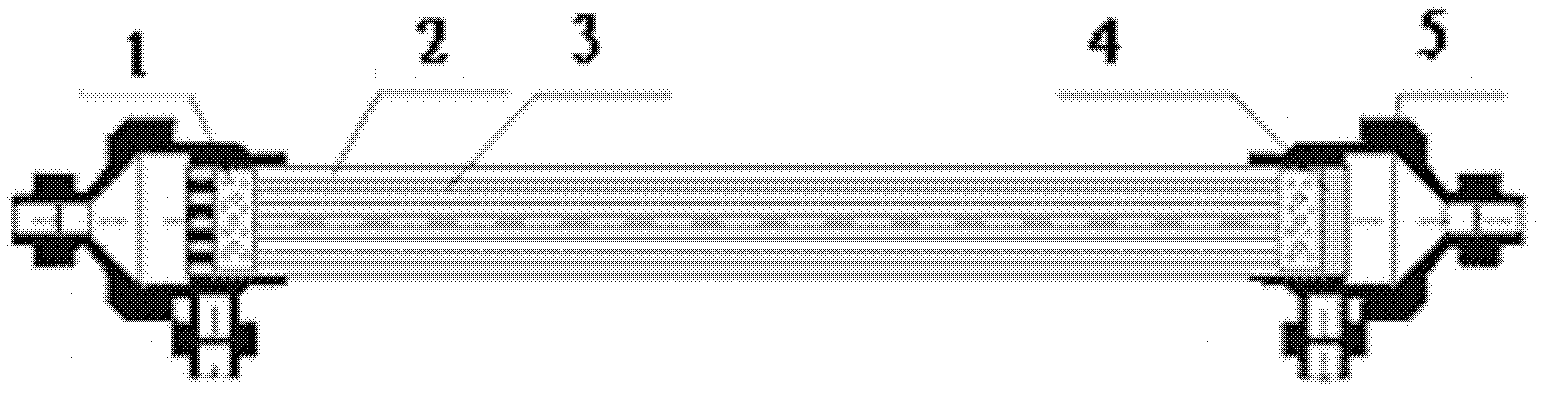

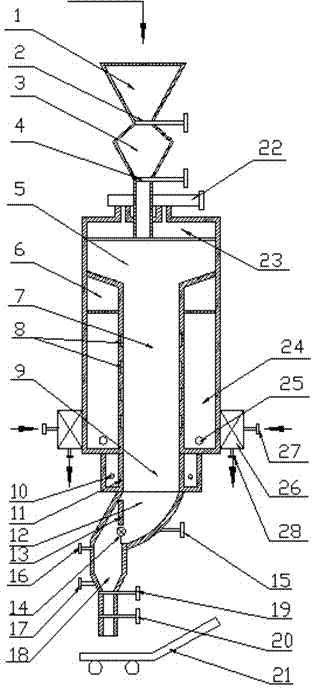

Drying and dry distillation combined quality improving process and system for low rank coal

The invention discloses a drying and dry distillation combined quality improving process and a drying and dry distillation combined quality improving system for low rank coal, which are used for overcoming the defects existing in the prior art and are particularly suitable for drying and dry distillation combined quality improvement of brown coal with high water content or other low rank coal such as long flame coal, non-caking coal or weakly caking coal, gas coal and the like. In the process, a combined quality improving method in which a steam revolving drier for drying and a multi-pipe revolving low-temperature dry distiller for dry distillation are provided is adopted, so that the problems of large coking wastewater handling capacity, large coal gas handling capacity and the like existing in a pure dry distillation process are solved. The drying and multi-pipe revolving low-temperature dry distillation combined quality improving process provided by the invention has the advantages of high energy utilization ratio, safe and stable systems, small dry distillation gas handling capacity, small coking wastewater handling capacity, high tar yield, high coal gas heat value and the like.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

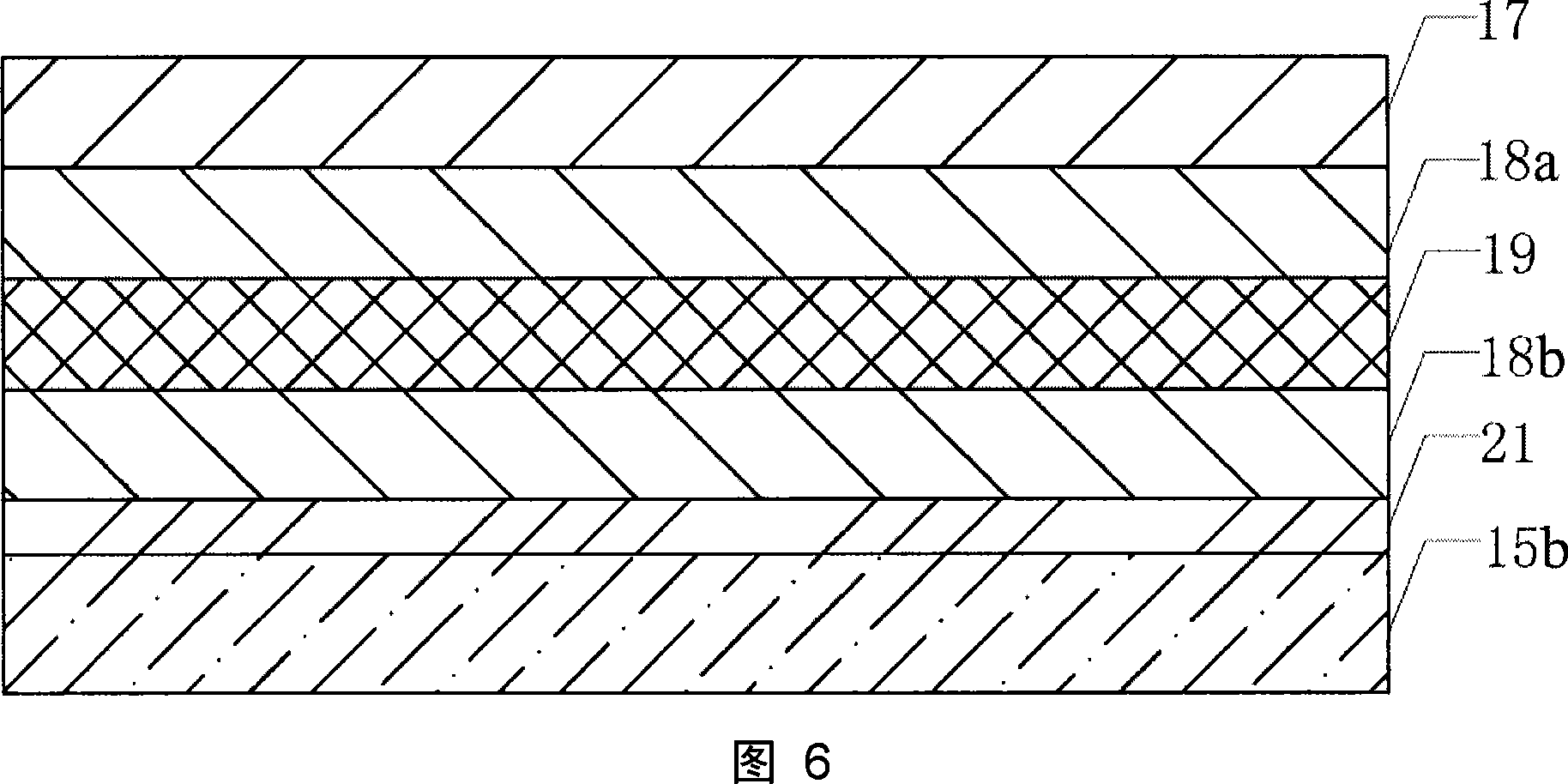

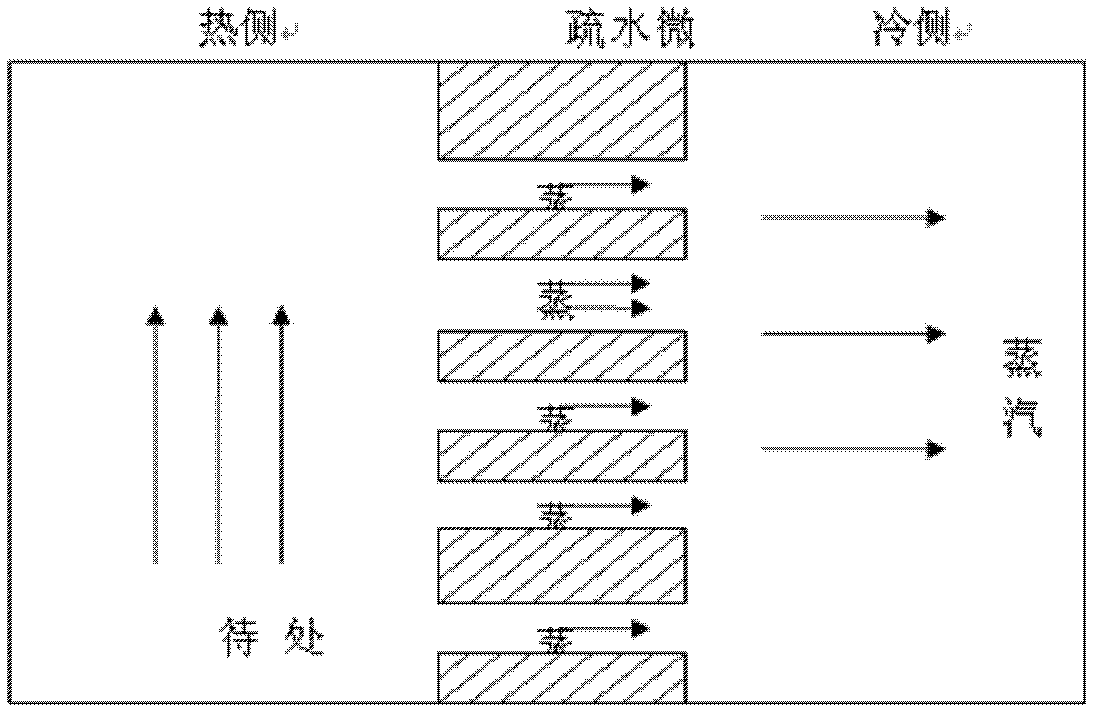

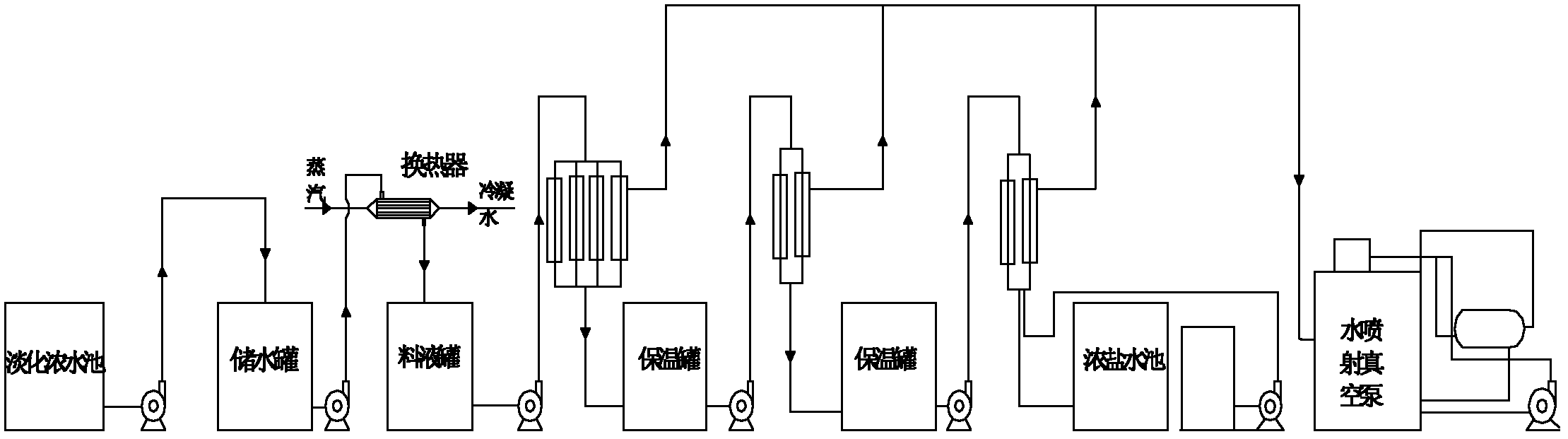

Multi-stage series membrane distillation strong brine desalting method and device

InactiveCN102491577AImprove heat utilizationSave heatSeawater treatmentMultistage water/sewage treatmentChemistryInlet temperature

The invention relates to a method for treating strong brine by using multi-stage series membrane distillation. The method comprises three steps of: preheating before performing strong brine membrane distillation, performing membrane distillation and condensing distilled steam to obtain desalted water, and is characterized in that: during membrane distillation, 3 to 5 stages of membrane distillation units are adopted; a membrane component (a membrane area) of each stage of the membrane distillation unit is different according to an operating scale; and the membrane components are connected in series with one another. In the multi-stage membrane distillation unit mode for treating the strong brine, the strong brine distilled by the previous stage is directly used as material inlet liquid in the next stage; as the whole process is continuous, the temperature required by the process is low; the temperature of the strong brine of the previous stage of the membrane distillation unit meets the requirement on the water inlet temperature of the next stage of the membrane distillation, so that heat sources required by the later stages of membrane distillation are saved, and the heat utilization rate during membrane distillation is increased; the heat sources for heat exchange can be low-level heat sources, such as raw stream, solar energy, terrestrial heat, factory waste heat and the like, so that energy can be saved effectively; and the comprehensive cost of the membrane distillation method for treating the liquid is reduced.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

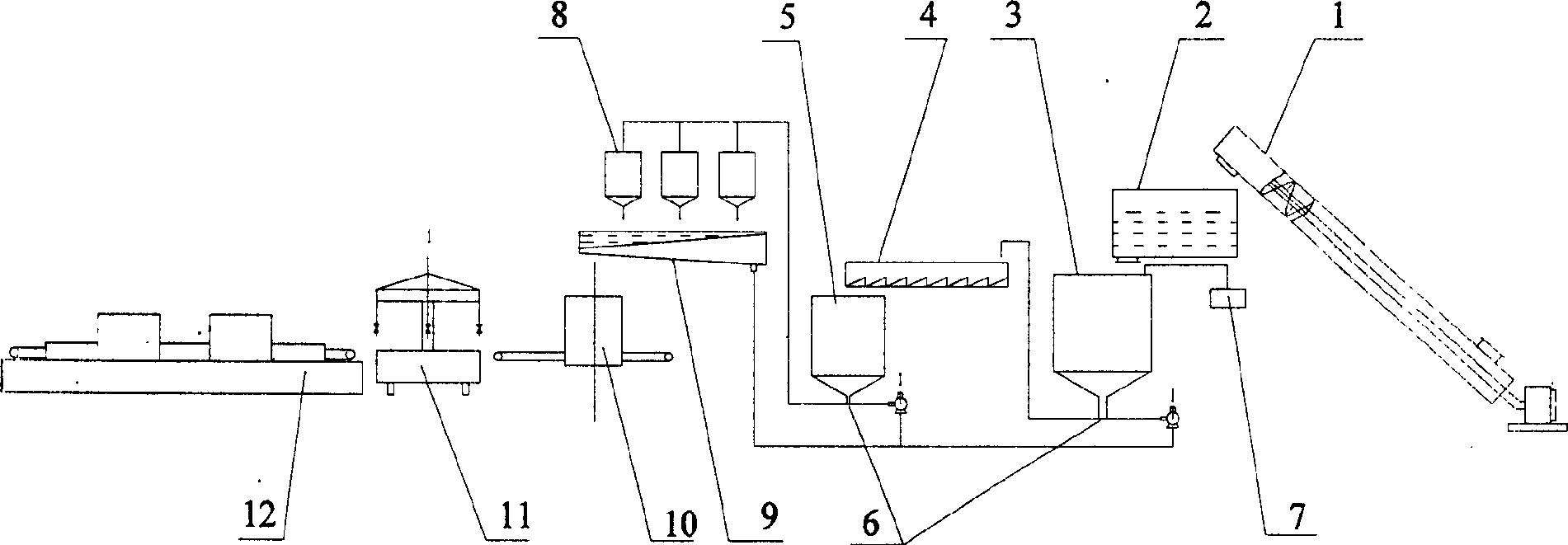

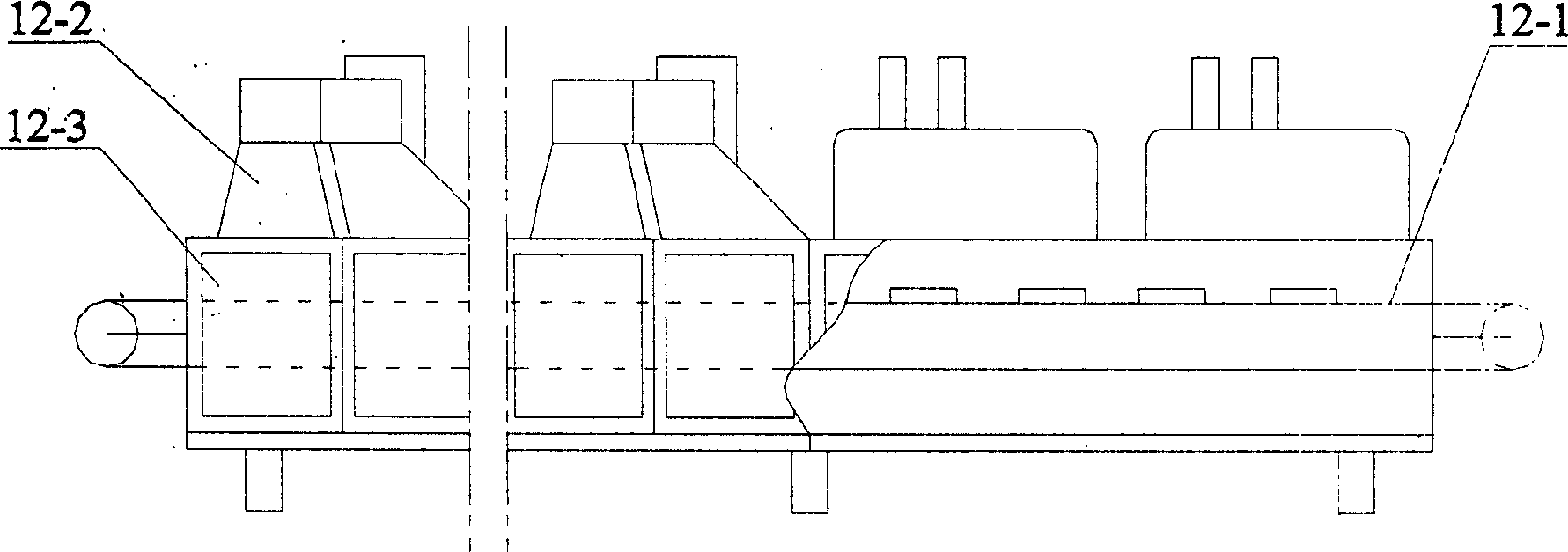

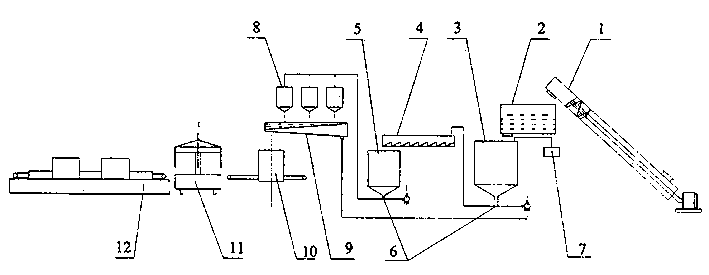

Method and device for continuously cooking rice

A technology for continuously cooking rice includes such steps as washing rice, immersing, quantitatively loading in boxes, microwave cooking and outputting rice in boxes. Its apparatus is composed of screw conveyer, high-position rice tank, rice washer, redox washer, jet-type sprayer, step impurities remover, rice immersing container, oblique rich dropper, quantitative loaders of rice and water, and continuous microwave cooker. Its advantages are high speed, high utilization rate of heat energy, and high productivity.

Owner:SOUTH CHINA UNIV OF TECH

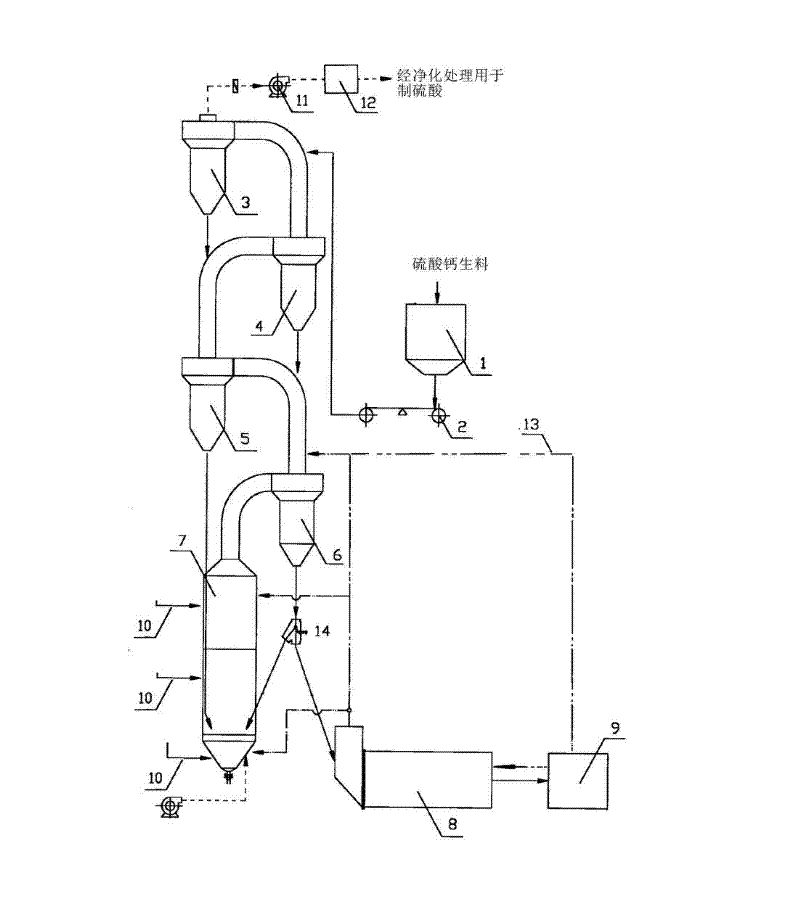

Method for producing sulfur dioxide from calcium sulfate and sulfur

ActiveCN102502524AQuick responseImprove heat utilizationChemical industrySulfur compoundsClinker (cement)Sulfur dioxide

The invention provides a method for producing sulfur dioxide from calcium sulfate and sulfur and relates to a chemical production process for producing sulfuric acid and cement clinker by adopting calcium sulfate. The method comprises the following steps: a, drying wet calcium sulfate into semi-hydrated gypsum, mixing other correction raw materials into the semi-hydrated gypsum to prepare a raw material, adding the raw material into a material preheating system consisting of multiple stages of cyclone preheaters, preheating, and then feeding into a reduction furnace; b, spraying liquid sulfur into the reduction furnace; c, controlling the content of oxygen in the reduction furnace to be less than 1.5%, and reducing calcium sulfate to generate calcium sulfide; and d, controlling the molar ratio of calcium sulfide generated in the step c to unreacted calcium sulfate to be (1:2)-(9:1), feeding a mixture of calcium sulfide and unreacted calcium sulfate into a rotary kiln and then reacting at oxidation atmosphere at the temperature of 900-1450 DEG C so as to obtain SO2 and the cement clinker. The method is rapid in reaction speed (the reaction time is only few seconds under fluidization), high in heat utilization rate, simple in process, and easily controllable in reaction condition.

Owner:YUNNAN YUNTIANHUA

Method for extracting nickel or cobalt from nickel ore with chloridizing roasting-leaching method

InactiveCN101550491ALow heating temperatureImprove heat utilizationProcess efficiency improvementExhaust gasNon-ferrous metal

The present invention relates to a technique for extracting non-ferrous metal, and specifically to a method for extracting nickel or cobalt from nickel ore with chloridizing roasting-leaching method. The aim of the invention is to settle the technical problem for extracting nickel or cobalt from nickel ore. The method of the invention comprises the following steps: grinding the dried powder of nickel ore, mixing the nickel ore with ammonium chloride, then putting the mixed compound into a sealed kiln for calcining, directly leaching the roasted product, adjusting the pH value of leaching liquid with the ammonia water recycled from end gas in the kiln, and controlling the pH value to 6.5-7.5 for recycling the nickel or cobalt. The grade of nickel or cobalt concentrate recycled by deposition according to the invention is high and can obtain more than 30% of nickel content. The subsequent processing and utilizing are facilitated. No exhaust gas or wastewater is discharged in the industrial process. The requirement of green production is satisfied.

Owner:谢永巨 +2

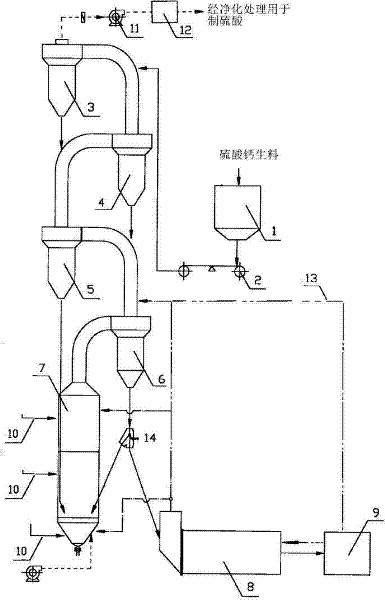

Drying room exhaust gas purification and energy recovery system and apparatus

InactiveCN1546211AHigh purification rateImprove purification rateDispersed particle separationProduct gasProcess engineering

The invention discloses a system and device for drying room waste gas processing and energy reclaiming, it uses circular system to combine heat conversion, heating and catalyzing combustion together, which includes: (1) the waste gas discharged form the drying room is preheated in the heat converter; (2) the preheated gas is heated in the heating room; (3) the waste gas is filtered and extracted into the catalyst room to be carried on catalyzing combustion; (4) the purified gas provides heat in the drying room; the residue gas enters the heat converter and provides heat for the waste gas and then they are discharged off. The structure is compact, the space if small, the assembly is convenient; the heat energy utilization efficiency is high.

Owner:杭州天人环保设备有限公司

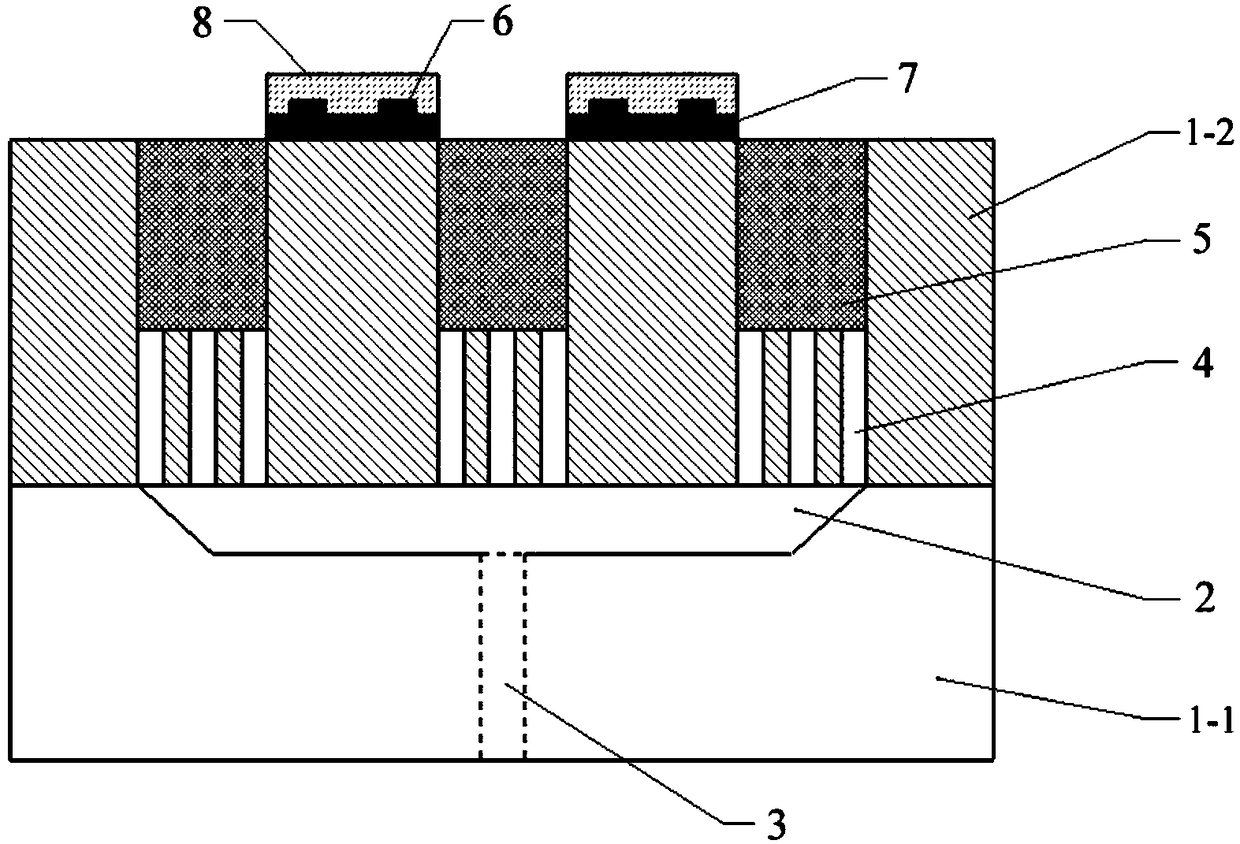

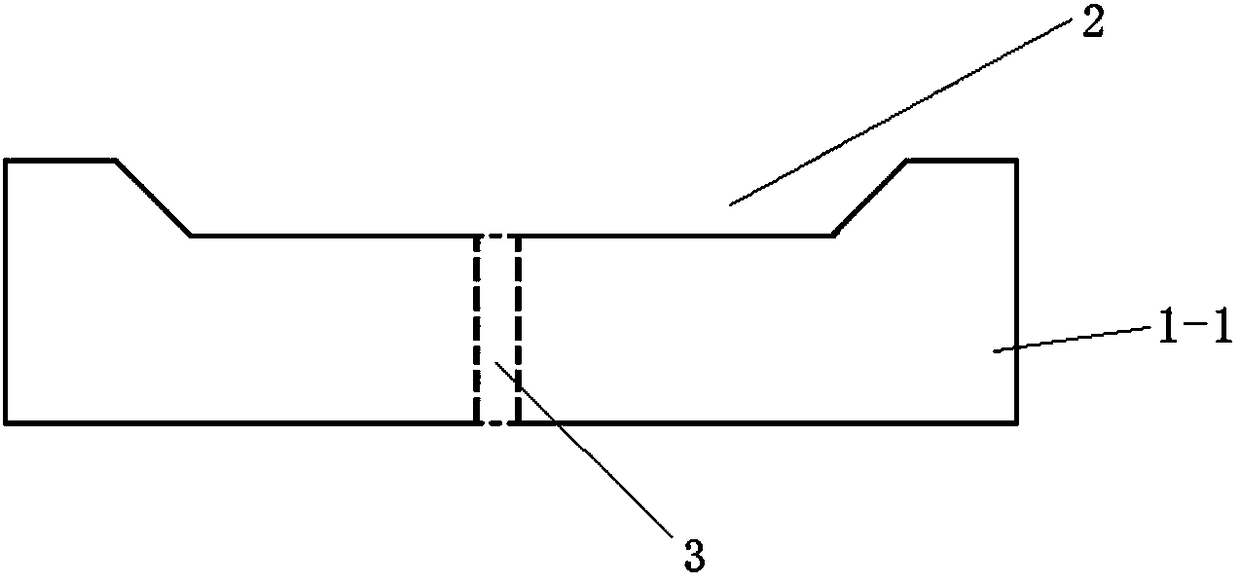

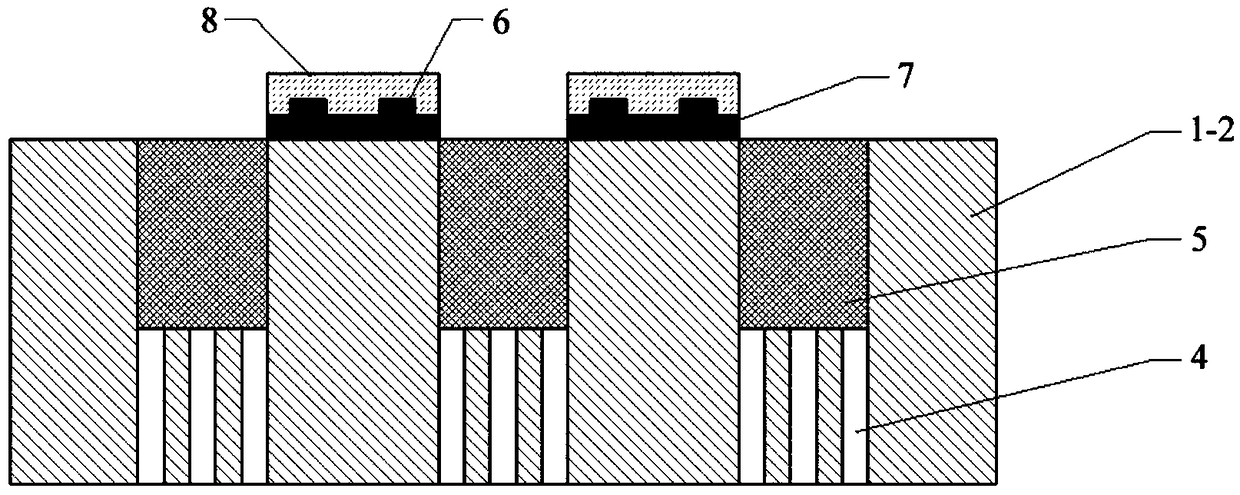

An MEMS heating chip integrating multiple Pt temperature sensors and a manufacture method therefor

ActiveCN108158039ASolution to short lifeWork reliablyTobacco devicesOhmic-resistance heatingElectrical resistance and conductanceEngineering

The invention provides an MEMS heating chip integrating multiple Pt thin film resistor temperature sensors. The MEMS heating chip comprises a first substrate (1-1) and a second substrate (1-2). The front side of the first substrate is provided with a concave micro-cavity body (2); a micro-through hole (3) penetrating through the first substrate (1-1) is formed in the micro-cavity body (2); the back side of the second substrate (1-2) is provided with a micro-channel array (4) perpendicular to the back side thereof; the central area of the front side is provided with a multi-hole structure (5) perpendicular to the front side thereof; the micro-channel array (4) communicates with the multi-hole structure (5); the surface of the front side of the second substrate is provided with a plurality of Pt thin film resistor temperature sensors (6); the front side of the first substrate (1-1) and the back side of the second substrate (1-2) are bonded together. The invention also provides a manufacture method for the heating chip. The temperature of the heating chip can be measured in real time and the problem of inaccurate temperature measurement can be effectively avoided.

Owner:CHINA TOBACCO YUNNAN IND

Equipment and method for carrying out spray freezing and drying on inert particles

ActiveCN102226629AFreezing helpsIncrease heat transfer rateDrying solid materials with heatHearth type furnacesFreeze-dryingSpray coating

The invention relates to equipment for carrying out spray freezing and drying on inert particles, comprising a fluidizing system, an atomizing system, a freezing system and a heat exchange system, wherein the heat exchange system is connected to the fluidizing system by virtue of a gas pipeline. The invention also relates to a method for carrying out spray freezing and drying on the inert particles, comprising the following steps of: (1) adding an inert particle group; (2) introducing a refrigerant; (3) introducing low-temperature low-humidity fluidizing gas; (4) freezing and spray coating; (5) freezing and drying; and (6) separating powder. The equipment and process for carrying out spray freezing and drying on inert particles in the invention couple processes such as fluidizing, cold spray coating, drying and separating, thus atomizing, freezing, drying and separating can be completed in one equipment, enclosed action and continuous operation are realized, no pollution is produced to the environment, dried feed liquid foods and medicines can be dried into powder finished products in one step, and no secondary processing is required; and besides, the structure is simple, the operation is convenient, and the manufacturing cost of equipment is reduced.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

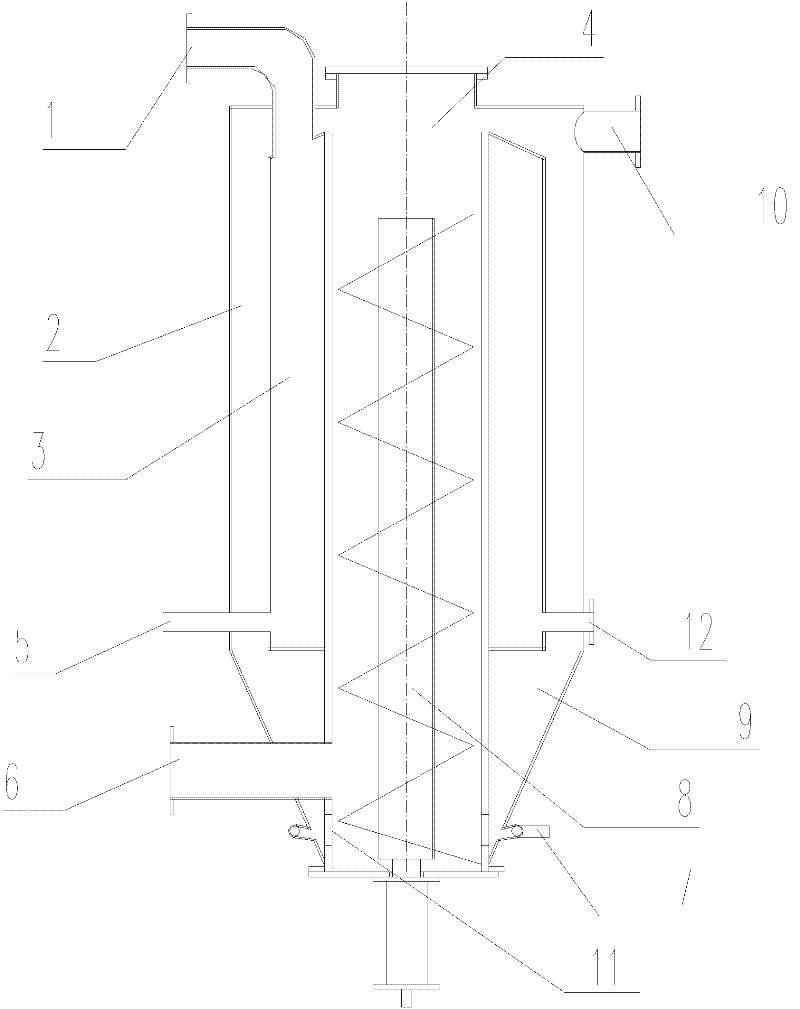

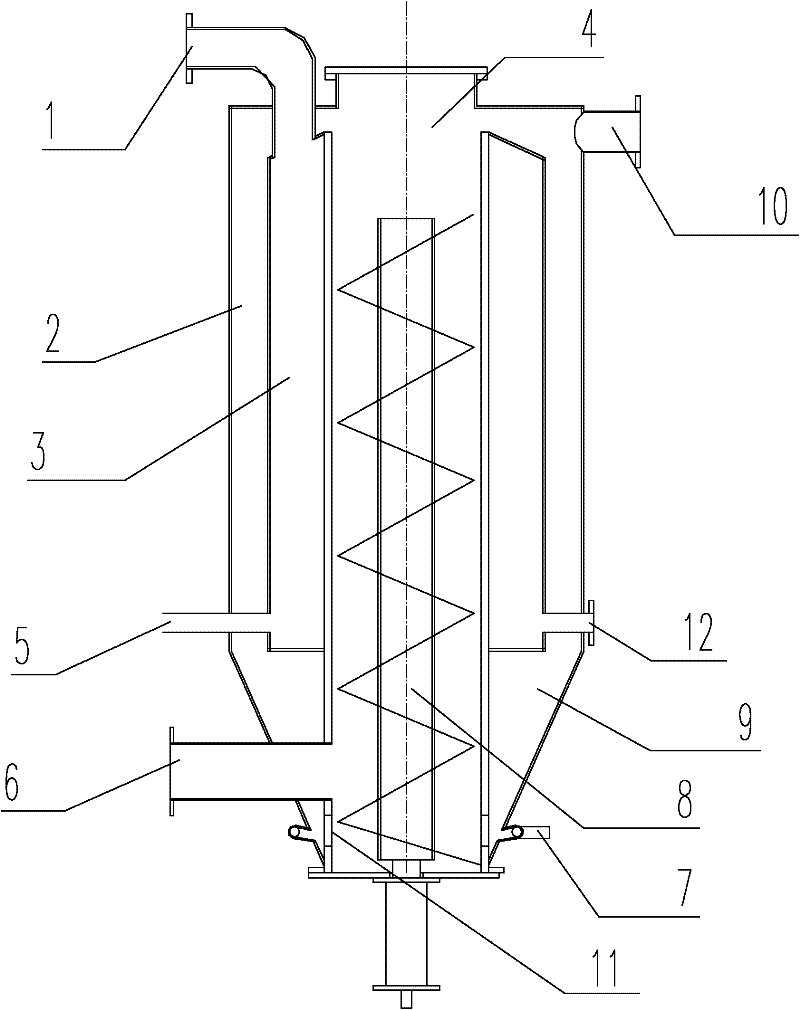

Internal circulation external heating type gasification device

ActiveCN102260536AReduce heat lossExtended stayGranular/pulverulent flues gasificationWater vaporResidual carbon

The invention discloses an internal circulation external heating type gasification device. The device comprises a central gasification chamber, an annular heating chamber, a peripheral gasification chamber, a residual carbon reflux chamber and the like. Biomass micron fuel enters the annular heating chamber and is efficiently burned, so that the required heat is provided for the central gasification chamber, the peripheral gasification chamber and the residual carbon reflux chamber. Cracking and gasification raw materials absorb the heat in the down-up movement process of the central gasification chamber to be cracked and gasified, and an initial cracking product then enters the peripheral gasification chamber and is further gasified; and residual carbon refluxes through the residual carbon reflux chamber and enters the central gasification chamber to carry out a water gas reaction with water vapor, so that medium-calorific-value gas of which the content of CO and the content of H2 are equal and CO and H2 account for about 80 percent of the total amount is obtained. In the device, an internal circulation external heating mode is used for gasification; and the device has the advantages of high heat utilization rate, heat transfer efficiency and gasification efficiency and the like, and the calorific value of gas is high. The internal circulation external heating type gasification device can be widely applied to the preparation of the gas by cracking and gasifying municipal organic refuse, agricultural and forest residues and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

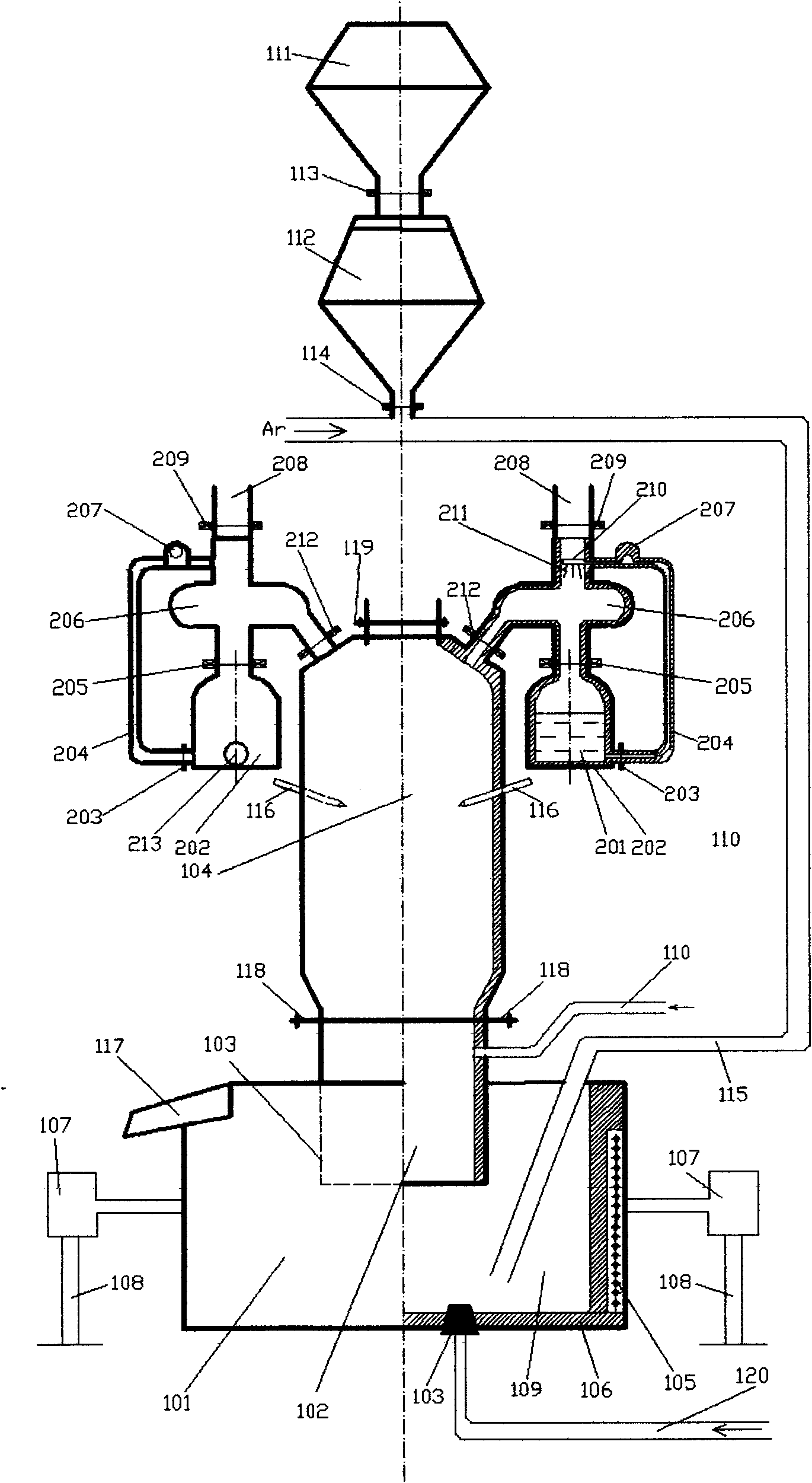

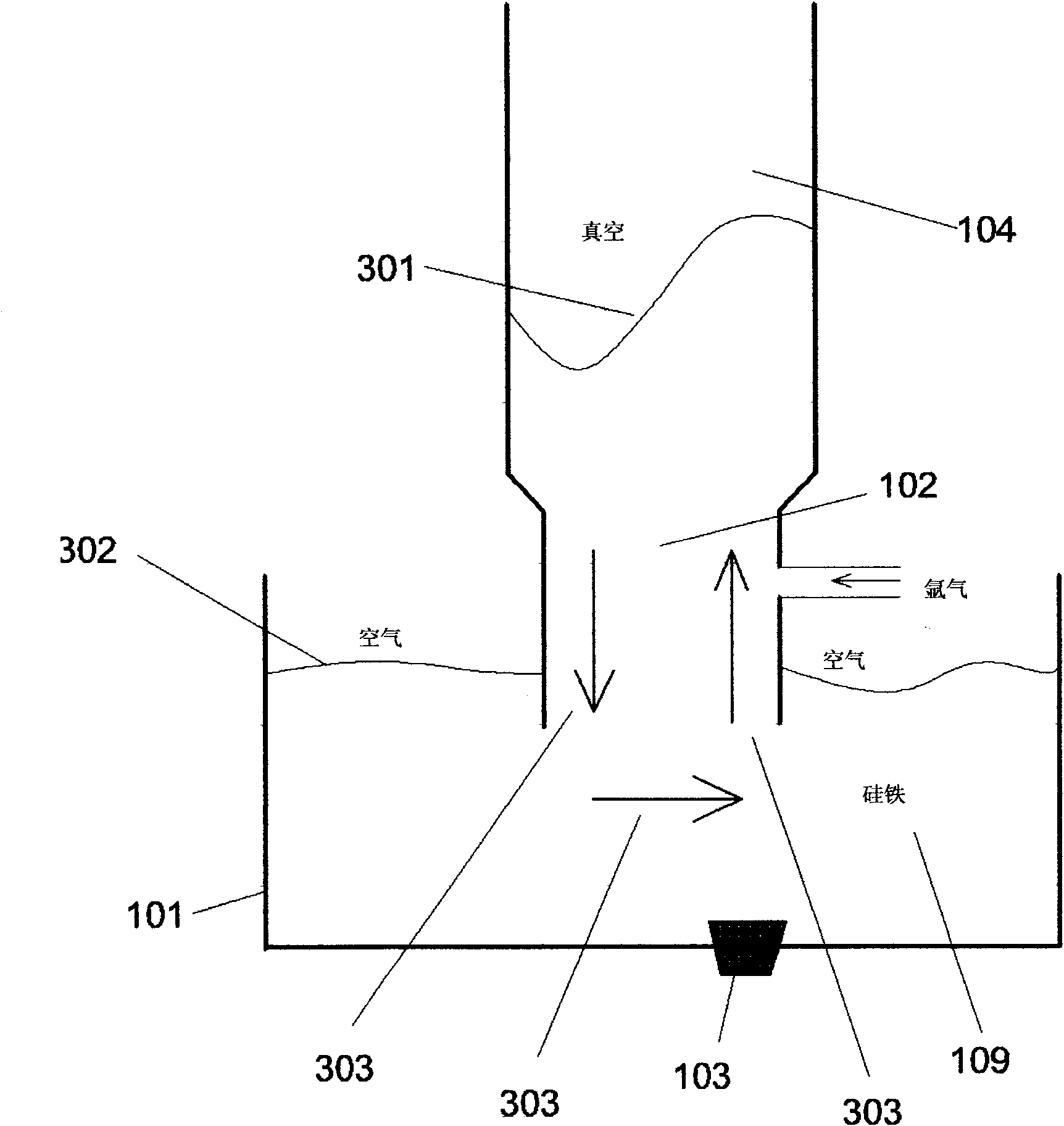

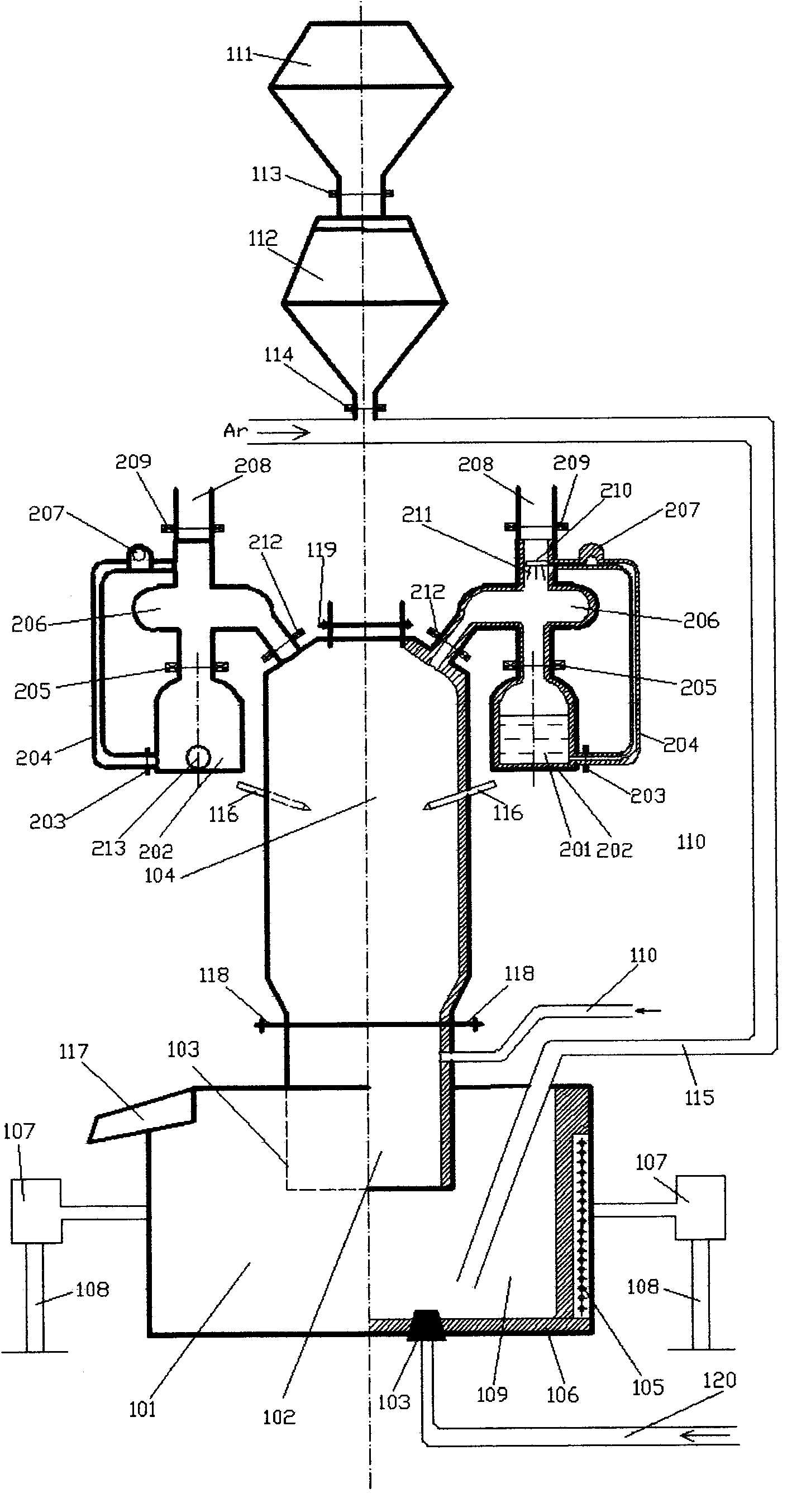

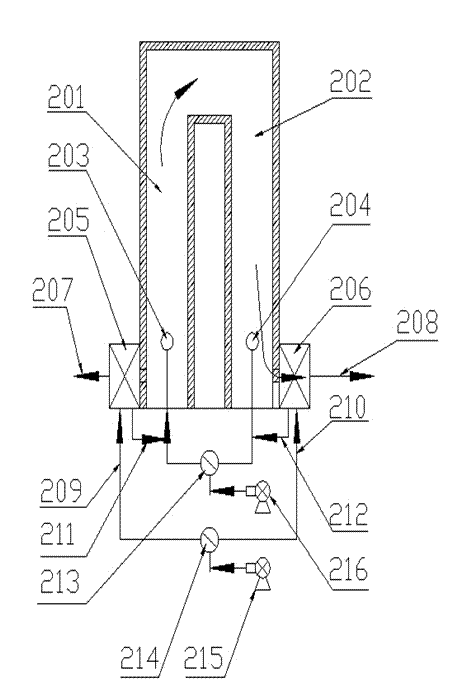

Single-dip pipe silicon iron bath vacuum circulated magnesium-smelting device and method

The invention discloses single-dip pipe silicon iron bath vacuum circulated magnesium-smelting device and method. The device comprises an induction furnace (101), a vacuum reaction chamber (104), a single dip pipe (102) and an argon blowing pipe (110) with a side wall communicated with guided flows; and besides, the device also comprises a magnesium steam condenser (206), a magnesium liquid spray thrower (210), a magnesium liquid storer (202) and magnesium mining powder conveying and spraying devices (111)-(115), wherein the magnesium steam condenser (206), the magnesium liquid spray thrower (210) and the magnesium liquid storer (202) are communicated. The method comprises the following steps of: preparing silicon iron liquid with the silicon content of 30%-65% and the temperature of 1,350-1,600 DEG C, making the mixtures of the silicon iron liquid and magnesium mining powder blown into the silicon iron liquid annularly flow between a vacuum reaction device and the induction furnace at the vacuum degree of 350 Pa-10,000 Pa for reaction to generate magnesium steam, carrying out condensation and magnesium liquid spraying to the magnesium steam to generate magnesium liquid, making the magnesium liquid flow into a storing device, and then pouring magnesium ingots. The device has the advantages of energy saving, low consumption, high productivity and the like.

Owner:杭州吉幔铁氢能科技有限公司

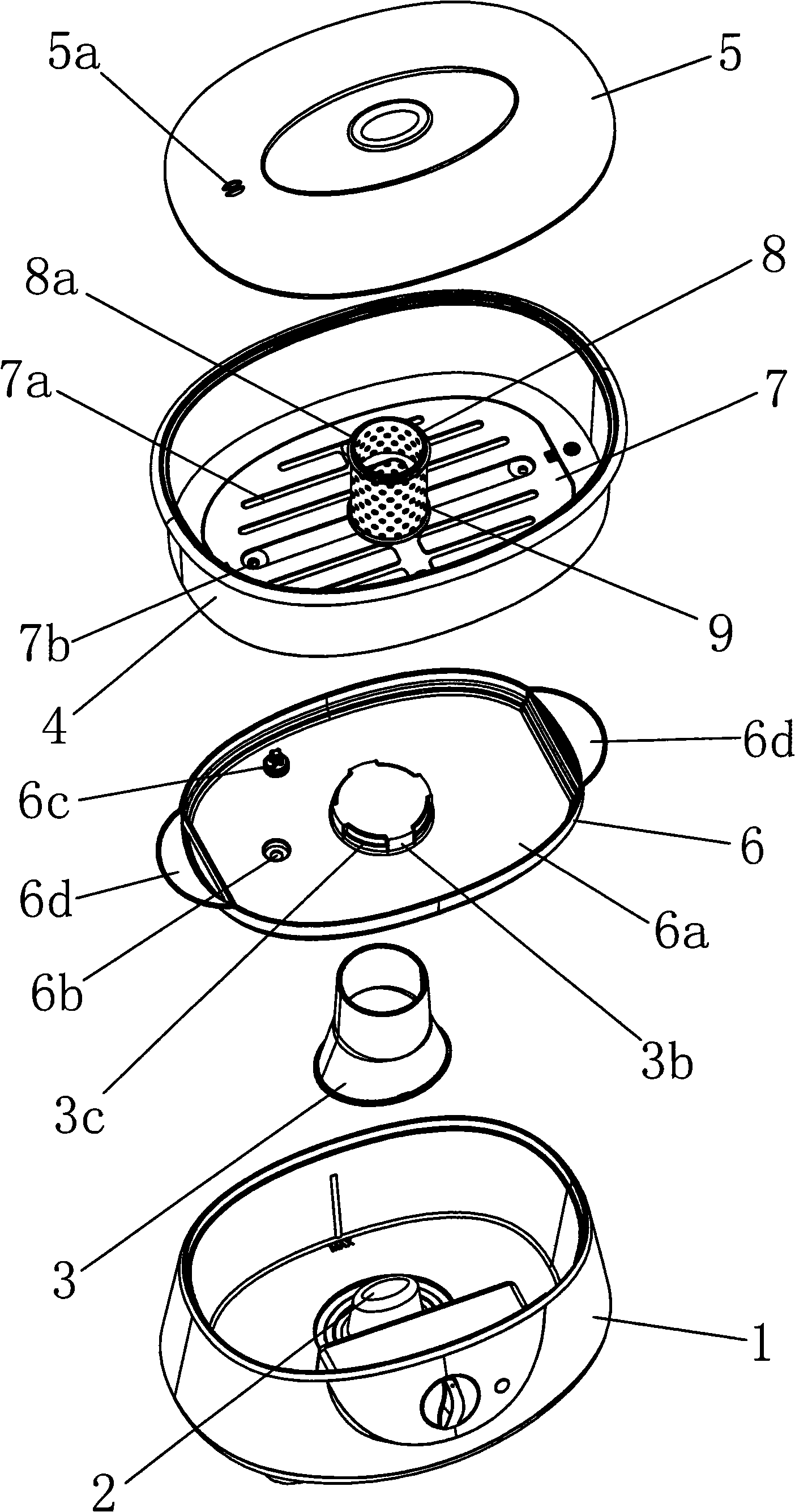

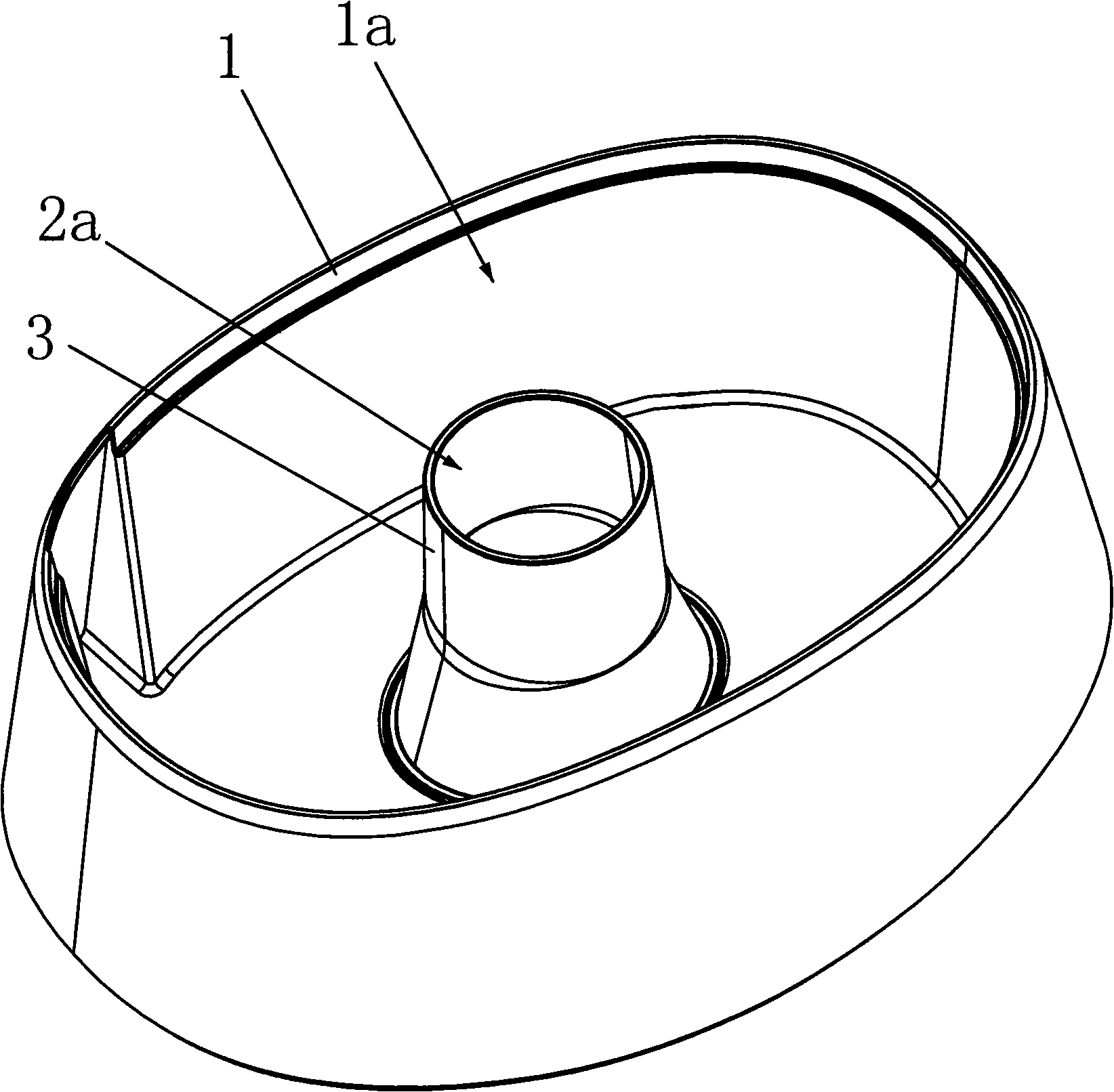

Energy-saving consumption-reducing electric steamer

InactiveCN101357039AOccurs continuouslyImprove heating efficiencySteam cooking vesselsWater savingThermal energy

The invention relates to the field of electric steam cooker, in particular to an electric steam cooker which can save the energy and reduce the dissipation. The electric steam cooker comprises a water storing vessel, a steaming layer and a top cover; the electric steam cooker is internally provided with a steam quick generation device, a non-mixed flour device, and a usable water circulation device; the water storing vessel, a separation cover and a heating body which is enclosed inside the separation cover form the steam quick generation device; the steam quick generation device can continuously and quickly generate the steam, has high heating efficiency, high utilization ratio of the heat energy and low energy dissipation; the separation layer and a steam guiding column form the non-mixed flour device; when various foods are steamed and cooked in a disposable way, mixed flour phenomena is not generated inside all steaming layers, thus enlarging the application range of the electric steam cooker; the top cover, the steaming layer, a water collecting layer and the water storing vessel form the usable water circulation device; the usable water circulation device recycles and reuses the condensed water, thus achieving the objects of saving the water and the energy and reducing the energy dissipation.

Owner:GUANGDONG LUBY ELECTRONICS

Biomass particle fuel

InactiveCN101955830AAvoid or reduce flowHigh calorific valueBiofuelsSolid fuelsEngineeringAnthracite

The invention discloses a biomass particle fuel. The biomass particle fuel comprises the following components in percentage by weight: 50 to 60 percent of plant straw, 2 to 5 percent of anthracite, 15 to 20 percent of coal slime, 2 to 5 percent of yellow mud, 2 to 5 percent of waste grease, 8 to 12 percent of food wastes, 8 to 12 percent of water and 10 to 15 percent of large animal manure. The fuel has the characteristics that: firstly, heat value is increased remarkably and unit heat value is up to 5,000 kilocalories; secondly, burning point is lowered greatly; thirdly, due to the addition of supporting materials such as the yellow mud and the like, air permeability is improved and heat utilization ratio is increased; fourthly, combustion time can be prolonged from 1.5 hours of a pure biomass fuel on average to over 3 hours; fifthly, a large number of food wastes are consumed, so that drainage oil and garbage pigs are reduced and prevented from being sold on the market; and sixthly, the pollution of the large animal manure on the environment is reduced.

Owner:王德明

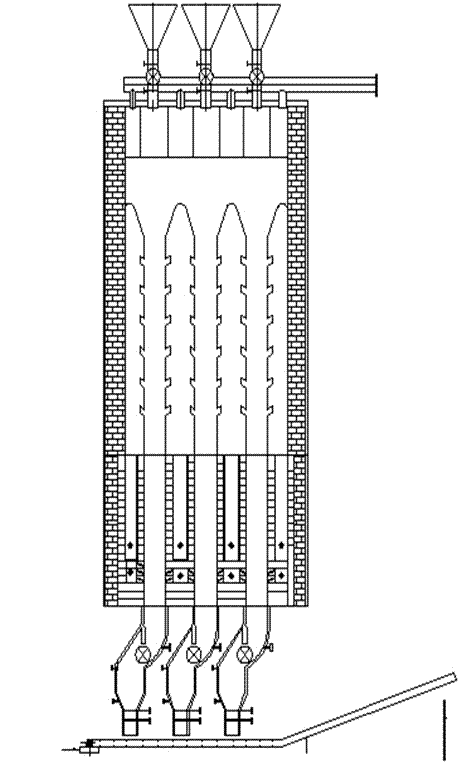

HY type dry distillation furnace

ActiveCN103923676ASolve the problem of low utilization efficiencyImprove utilization efficiencyIndirect and direct heating destructive distillationEnergy inputCombustion chamberHeat carrier

The invention discloses an HY type dry distillation furnace which is characterized by comprising a plurality of dry distillation subunits, wherein each dry distillation subunit comprises a charging device, an oil gas discharge device, a dry distillation device, a heating device and a coke discharge device; materials are subjected to dry distillation by using a combined radiation heat exchange and convection heat exchange mode in the furnace; gas generated in a dry distillation process is used as a dry distillation heat source, and the dry distillation heat can be self-balanced; the materials are directly heated by virtue of radiation of a furnace wall of a combustion chamber, and a heat carrier does not need to be subjected to secondary heating and long-distance conveying; a dry distillation gas outputting device is arranged in the furnace, so that the gas in the furnace flows smoothly; coke is discharged by a dry method. The dry distillation furnace is high in heat utilization efficiency, low in outlet gas quantity, low in water consumption, high in oil yield and large in daily treatment capacity capable of being more than 6,000 tons, and is suitable for low and medium-temperature dry distillation of the materials such as oil sand, oil shale, coal and the like, and suitable for oil refining and dry distillation of large particle materials and small particle materials of less than 15mm.

Owner:辽宁智越建设有限公司

Method for preparing activated carbons by using plastics of recycled waste circuit boards as raw material

InactiveCN101948110AImprove heat utilizationReduce heat lossSolid waste disposalElectronic waste recyclingRecovery methodActivated carbon

The invention discloses a method for recycling the plastics of waste circuit boards, which comprises the following steps: preparing activated carbons by using the plastics of screened waste circuit boards as a raw material through the methods of chemical activation and microwave heating; then soaking the obtained activated carbons in drug with certain concentration for twenty-four hours, wherein the volume ratio of the plastic powder of the waste circuit boards to the drug is 1:3; activating by putting the activated carbons in a micro-wave oven for radioactivation; carrying out acid-washing on the activated carbons subjected to radioactivation by hydrochloric acid solution with 1:9 in volume ratio so as to remove ashes; rinsing the activated carbons subjected to acid-washing by water so as to regulate the pH value of the activated carbon to be 7; finally, putting the activated carbons in a drying oven, and then crushing the dried activated carbons so as to obtain the finished activated carbon product. The iodine sorption value of the prepared activated carbon product is 404.8 mg / g, the methylene blue sorption value thereof is 47.2 mg / g, and the yield is 38.1 percent. By using the method of the invention, the plastics of waste circuit boards are prepared into activated carbons by using the methods of chemical activation and microwave heating, and the adsorption property of the prepared activated carbon is similar to that of general industrial activated carbons, therefore, the method of the invention is also a new better way for recycling the plastics of waste circuit boards.

Owner:KUNMING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com