Equipment and method for carrying out spray freezing and drying on inert particles

A spray freeze-drying, inert particle technology, applied in the direction of drying solid materials, lighting and heating equipment, heating to dry solid materials, etc., can solve the problems of increasing condenser load, poor process continuity, and conventional fluidization difficulties. The effect of increasing the drying rate, increasing the contact area, and accelerating the rate of heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

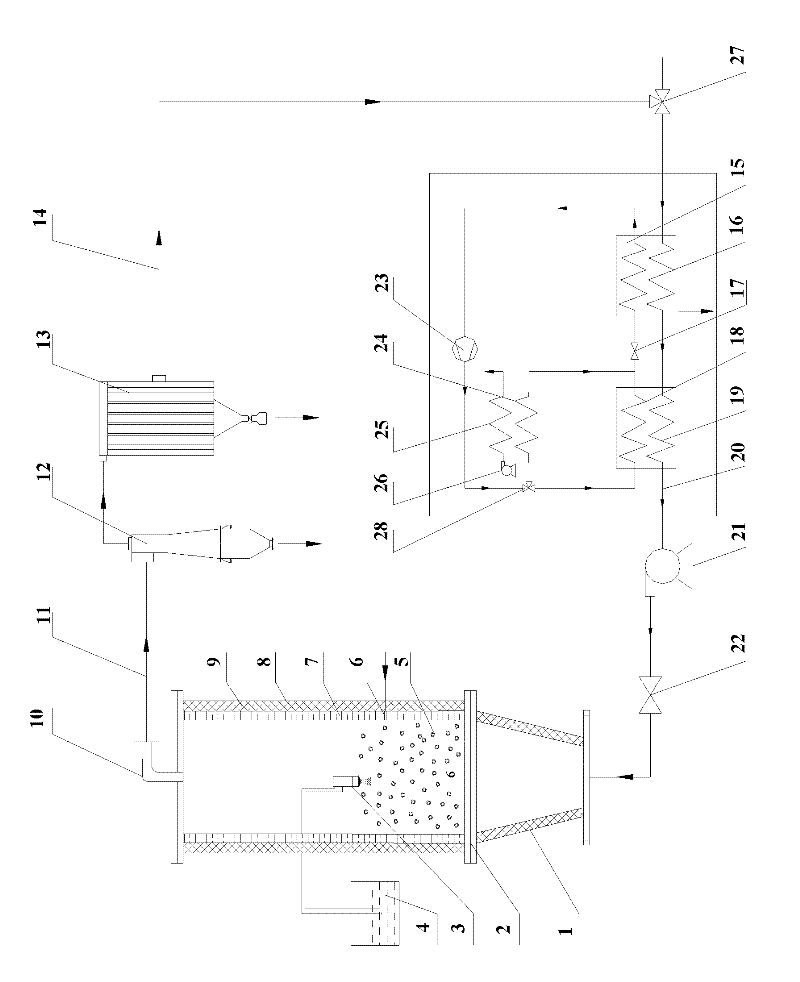

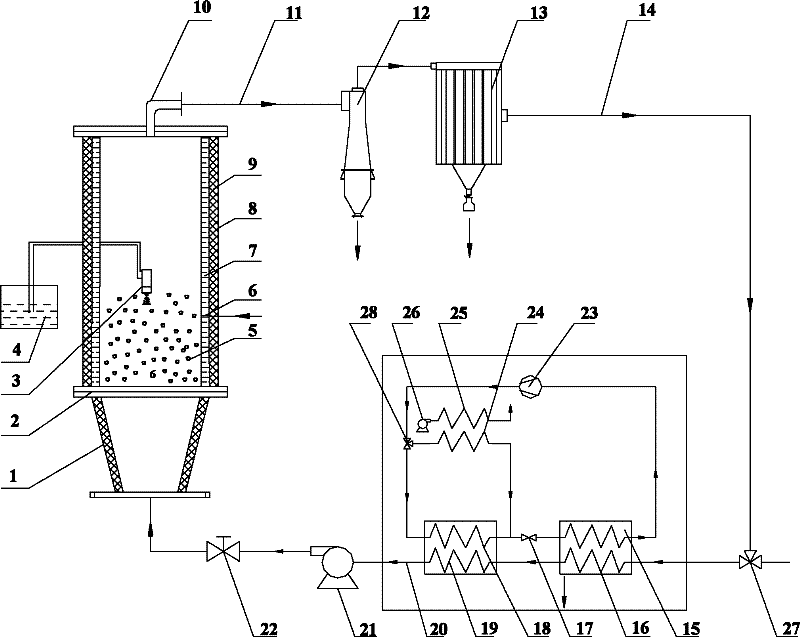

[0034] An inert particle spray freeze-drying device includes a fluidization system, an atomization system, a refrigeration system and a heat exchange system.

[0035] The fluidization system includes a fluidized bed, a fan 21 and regulating valves 22 and 27. The fluidized bed is composed of a bed 9, an air chamber 1, and a gas distribution plate 2. A gas outlet 10 is arranged on the top of the bed of the fluidized bed, and a gas inlet is arranged at the bottom of the air chamber. The atomization system includes a feed liquid storage tank 4 and an atomizer 3, and the atomizer is installed inside the bed of the fluidized bed. The atomizer is a pressure atomizer or an air flow atomizer. The particle size of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com