Patents

Literature

778results about How to "Increase heat transfer rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

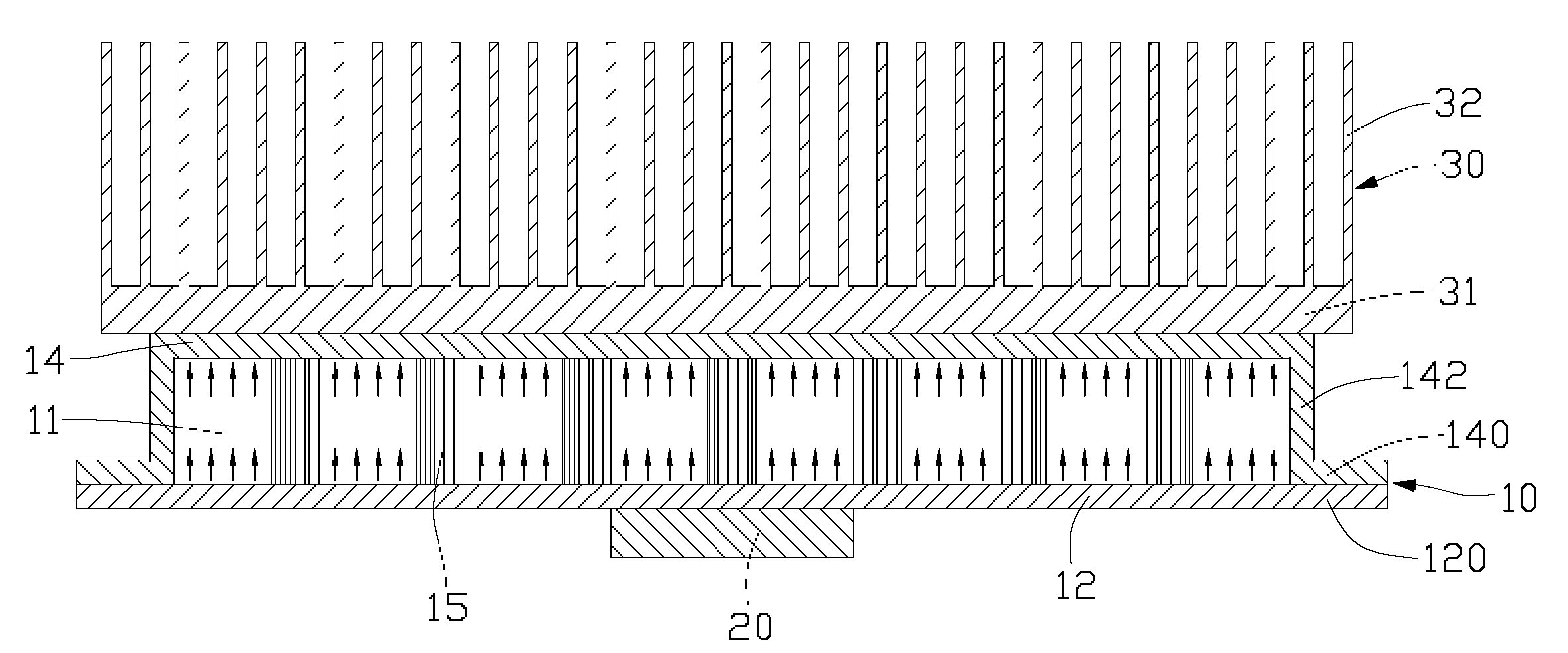

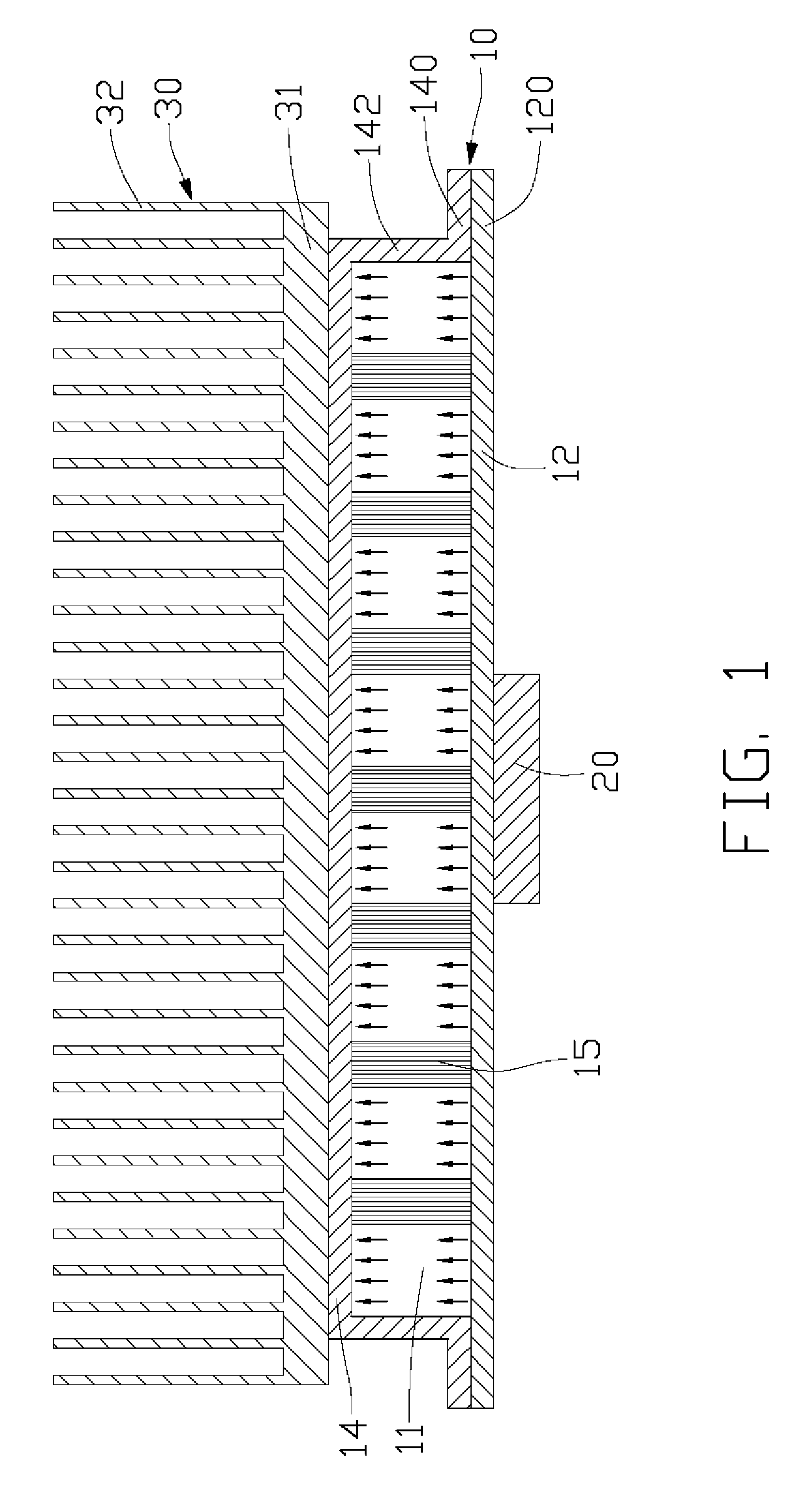

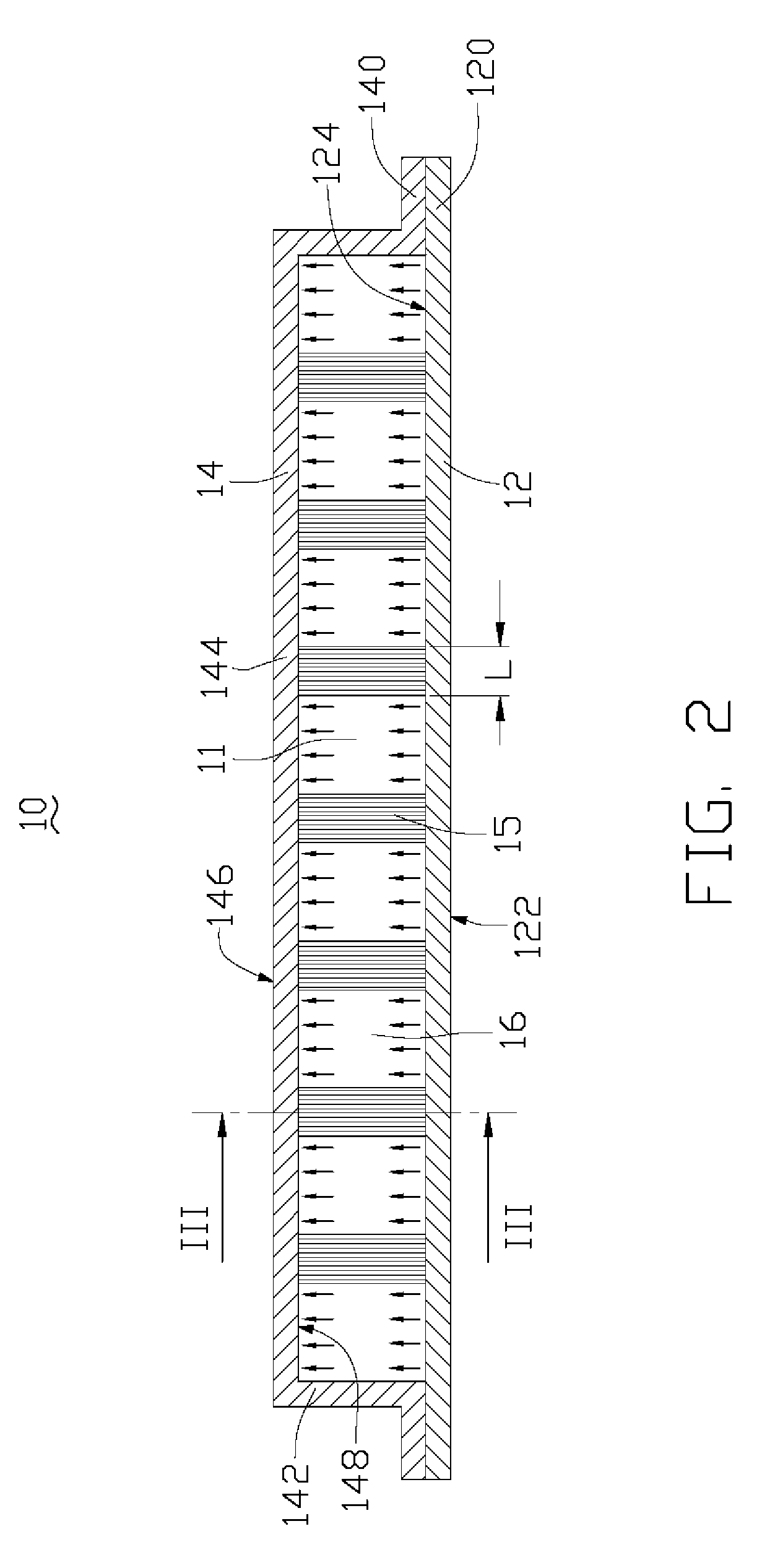

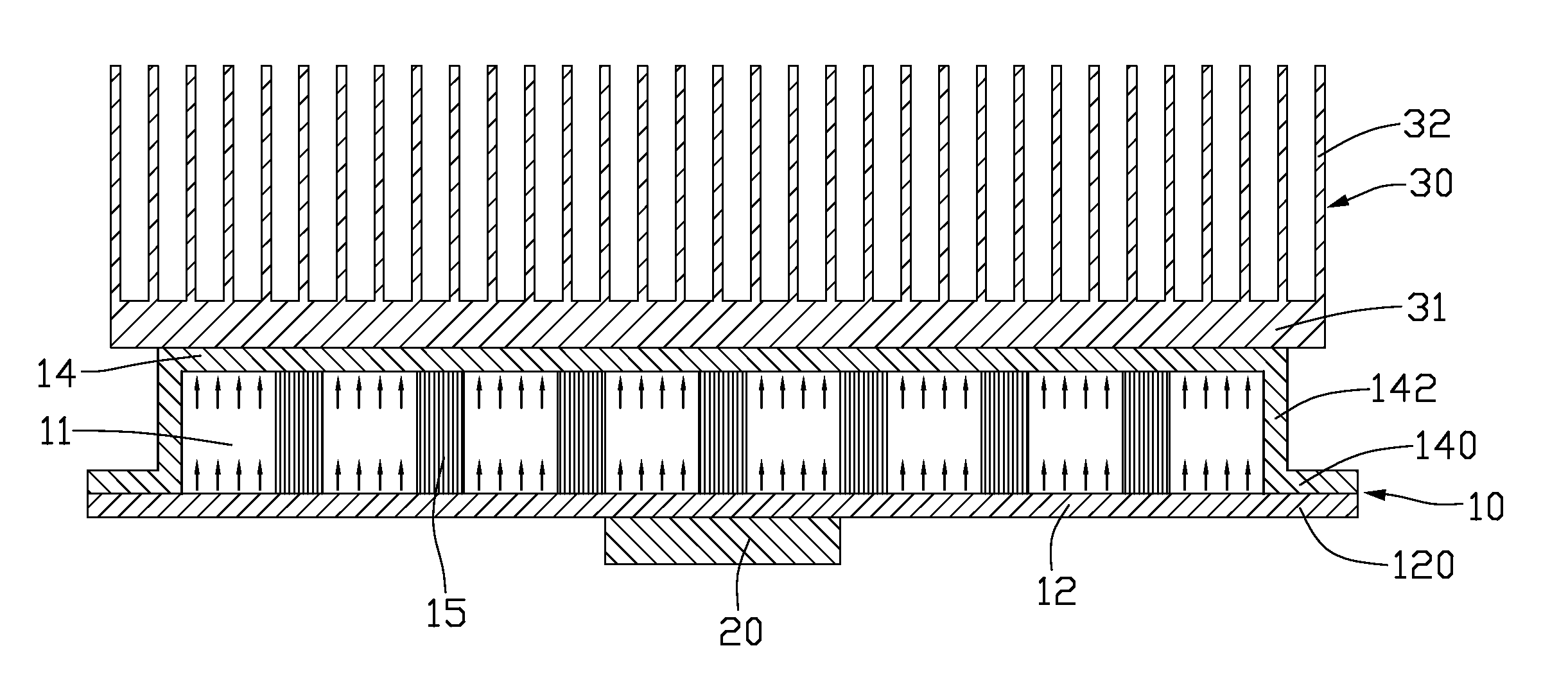

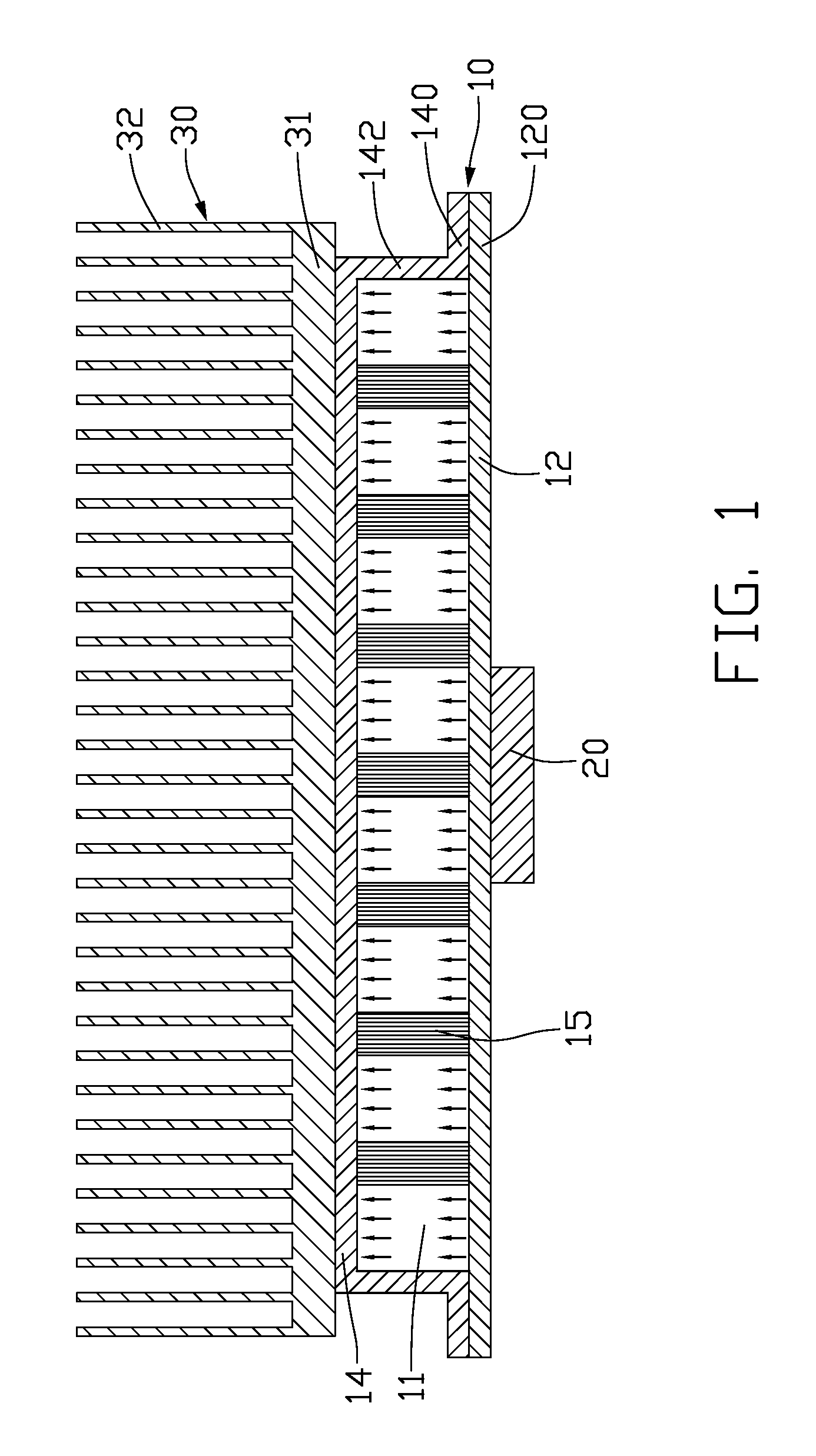

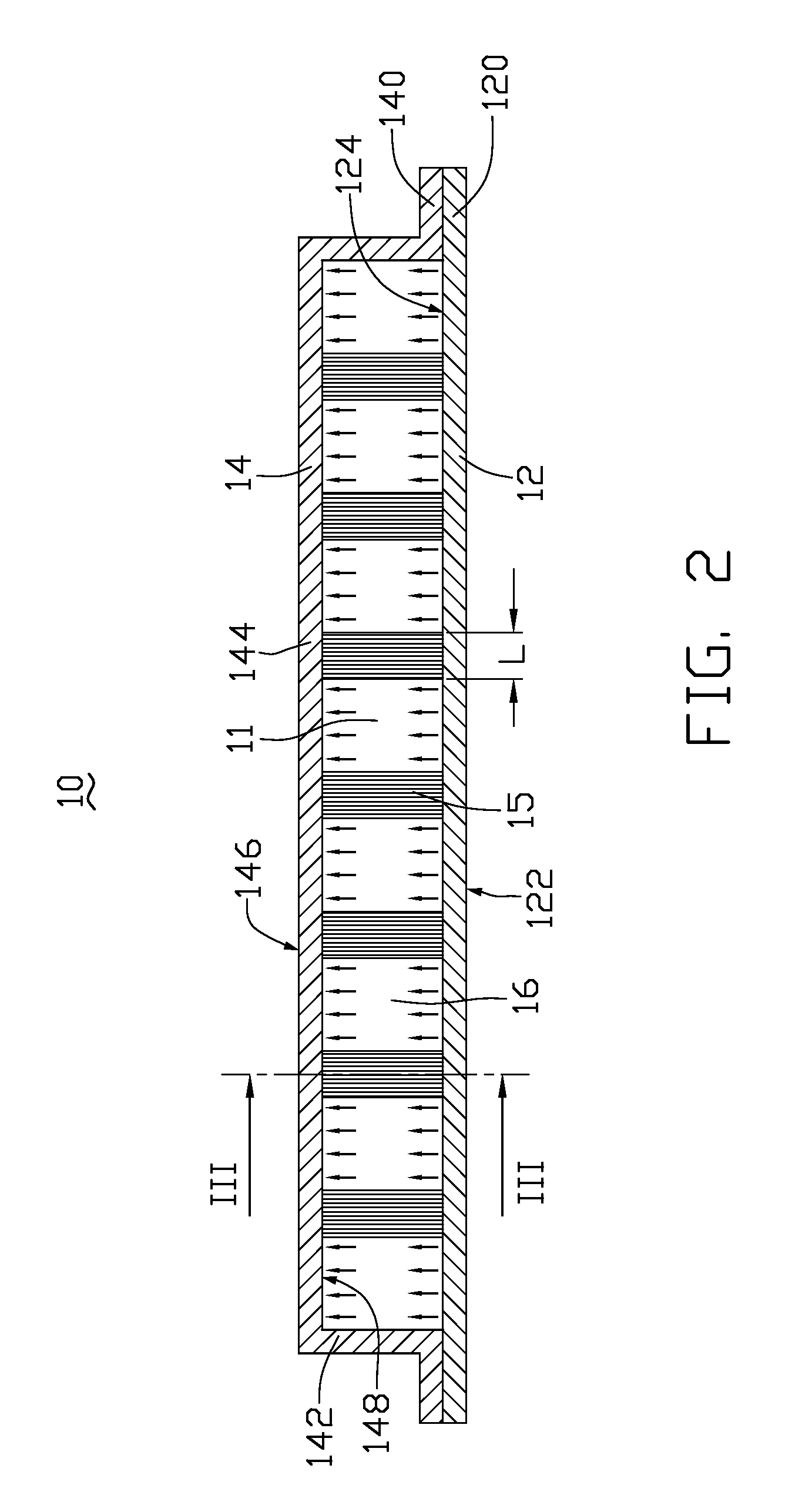

Heat spreader with vapor chamber defined therein

InactiveUS20080174963A1Improve the heating effectDissipate heat generatedSemiconductor/solid-state device detailsSolid-state devicesWorking fluidCarbon nanotube

A heat spreader includes a bottom wall (12) and a cover (14) hermetically connected to the bottom wall. Cooperatively the bottom wall and the cover define a space (11) therebetween for receiving a working fluid therein. A wick structure (15) is received in the space and thermally interconnects the bottom wall and the cover. The wick structure includes at least a carbon nanotube array, which can conduct heat from the bottom wall to the cover and draw condensed liquid of the working fluid from the cover toward the bottom wall.

Owner:HON HAI PRECISION IND CO LTD

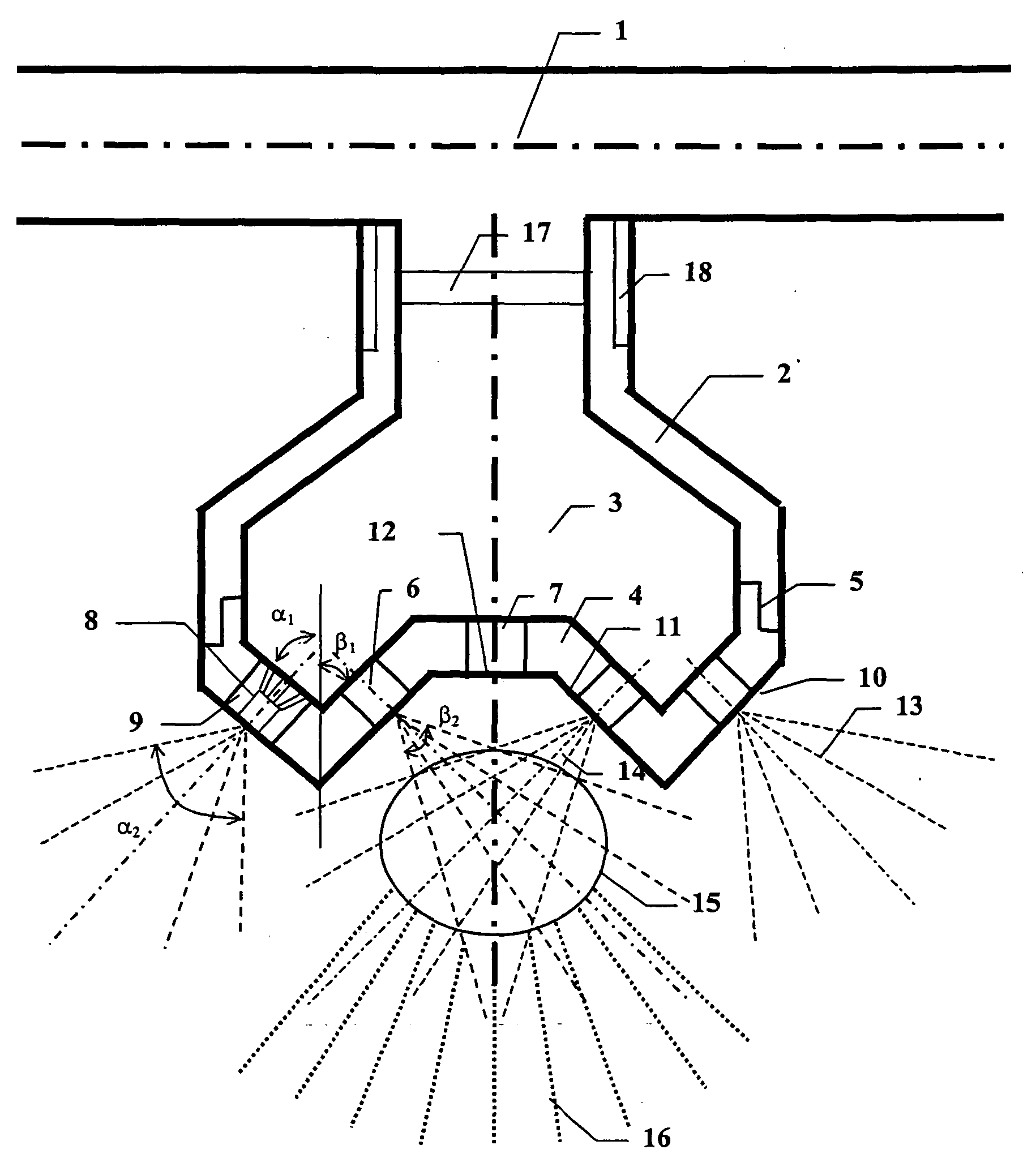

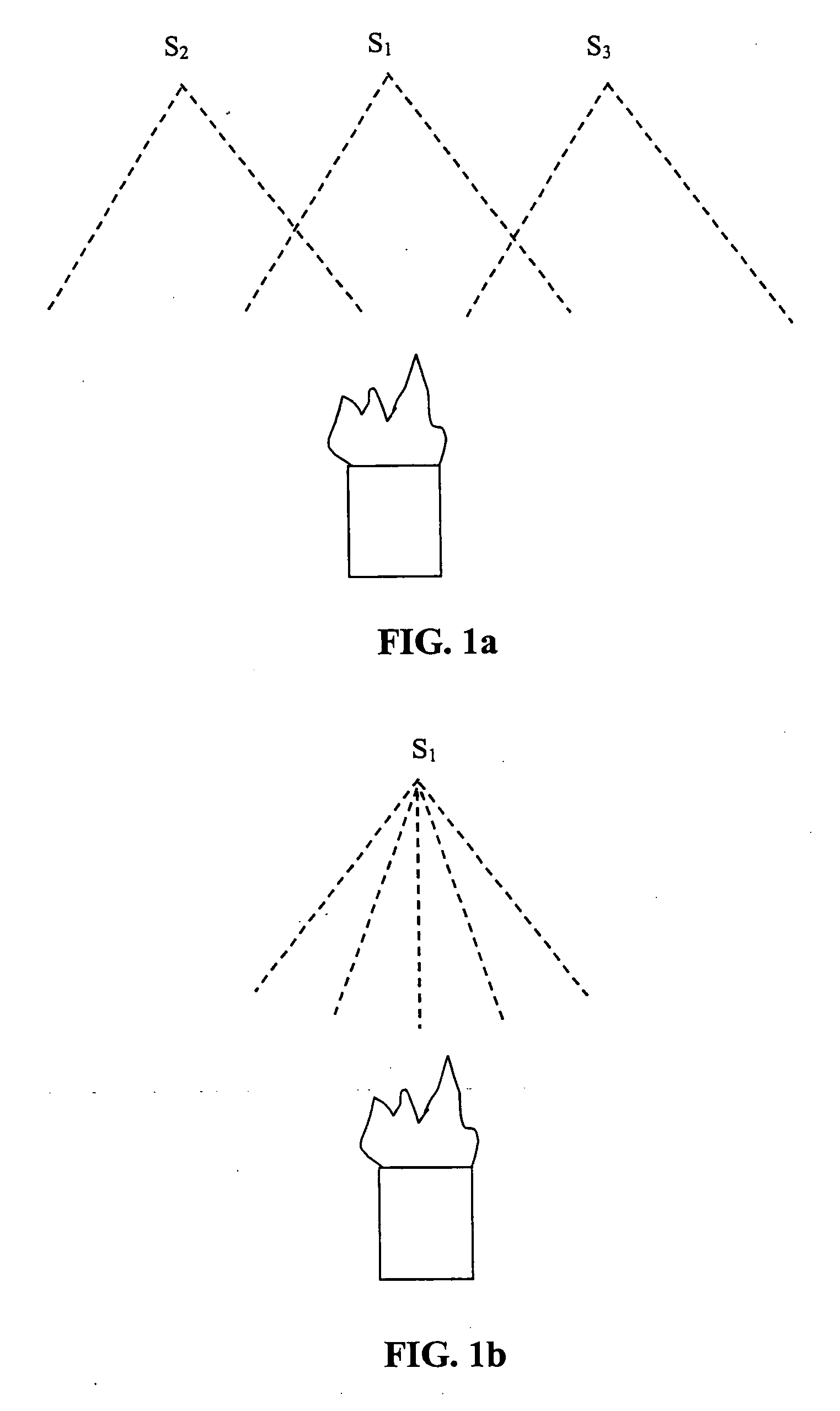

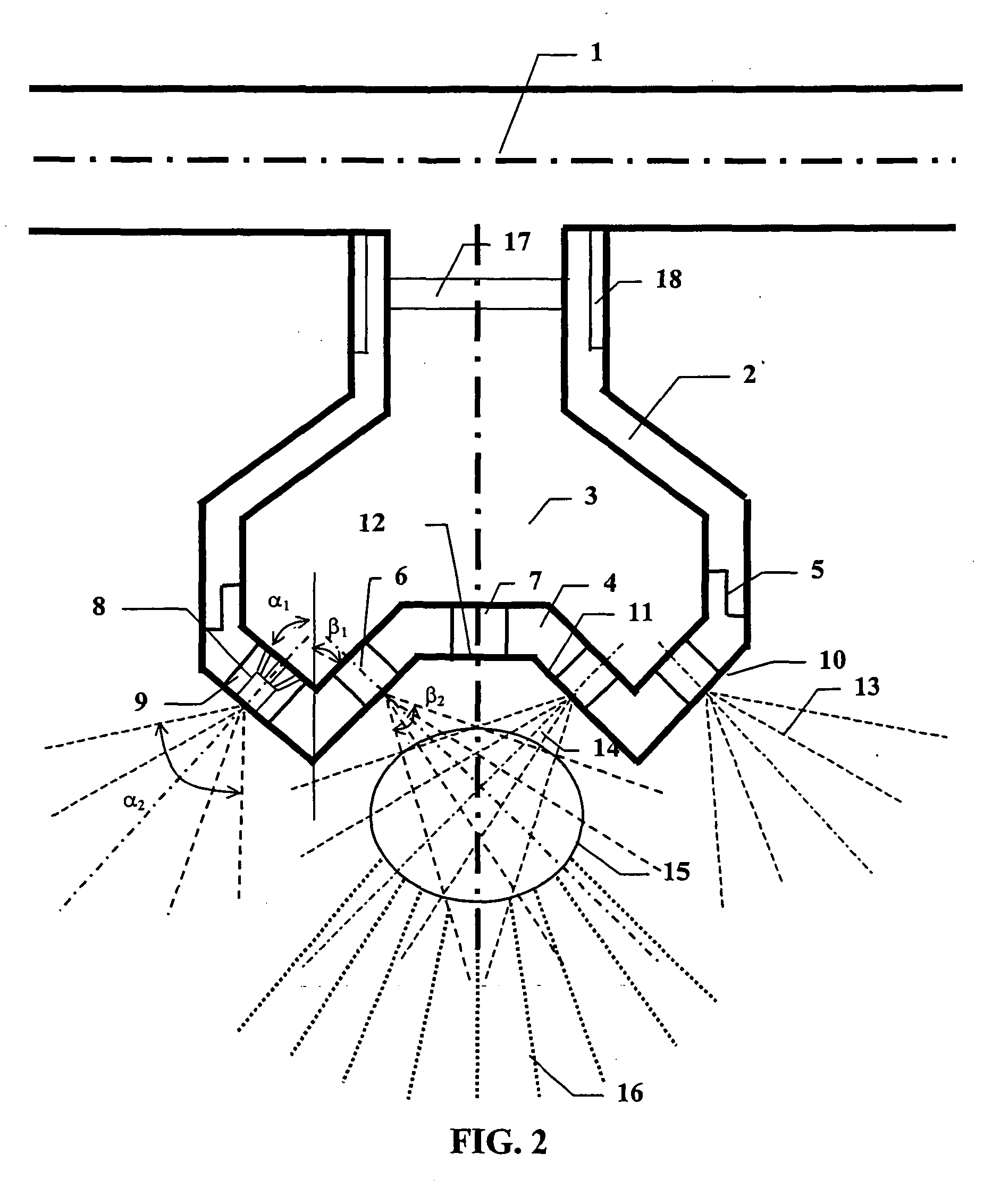

Spray head and nozzle arrangement for fire suppression

InactiveUS20050011652A1Increase heat transfer rateEnhanced inhibitory effectBurnersSpray nozzlesSpray nozzleEngineering

A water spray head for spraying water spray mist in a fire prevention system, includes a water supply duct; a spray head upper body; a fluid chamber; and a “w” shaped bottom, on which at least two rings of nozzles are installed. The water spray head has a body with a “w” shaped bottom, a chamber and two rings of liquid mist nozzles on the slant walls of the “w” shaped bottom. The liquid mist sprays from the nozzles at the inner ring may collide with each other directly or tangentially to form finer liquid droplets and a more uniformly distributed “solid cone” water spray. The water mist formation of the individual nozzle is also designed to be based on the collision of liquid streams from multiple small flow channels in a large flow channel, thereby forming even finer droplets.

Owner:AGENCY FOR SCI TECH & RES

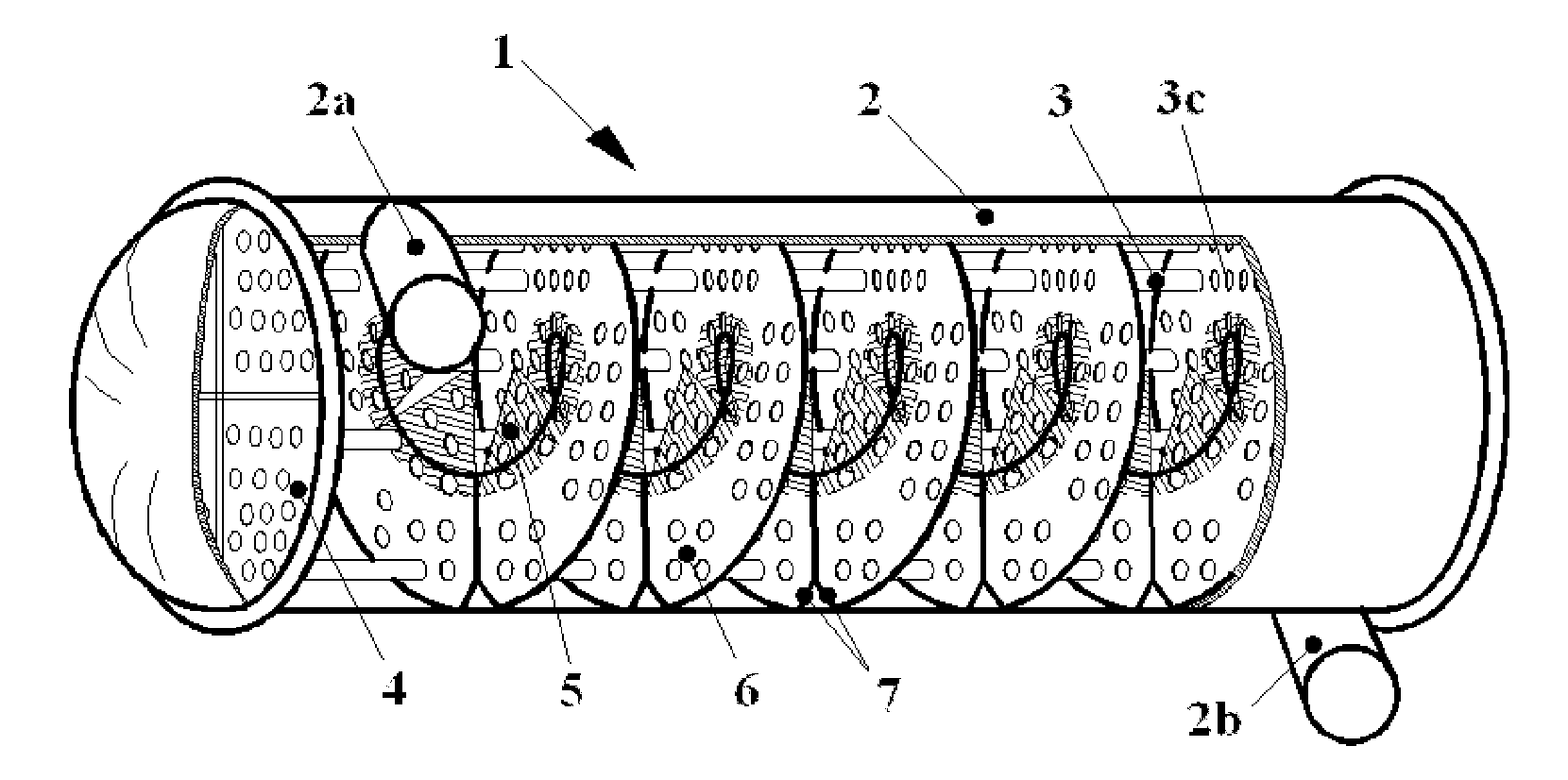

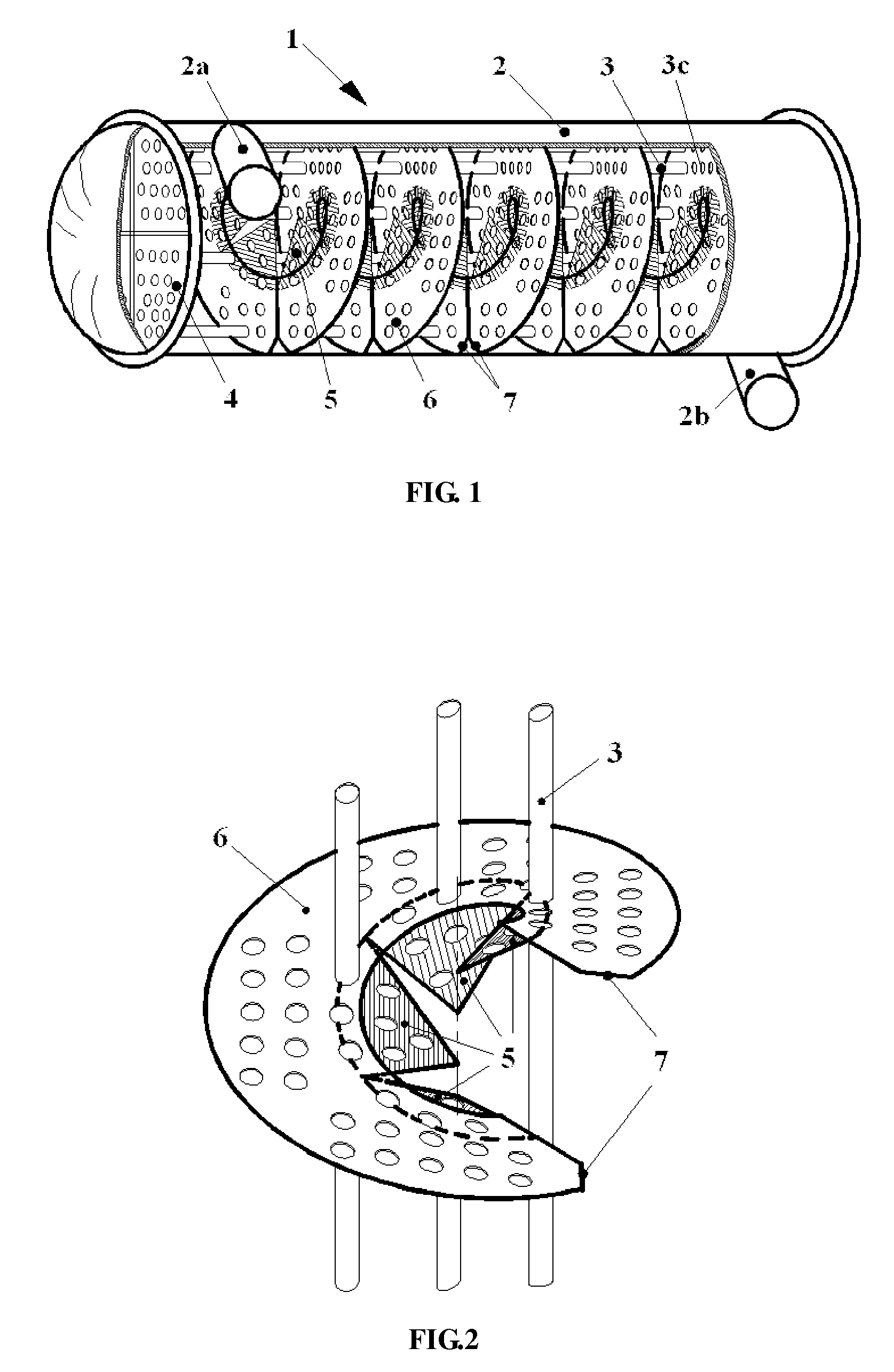

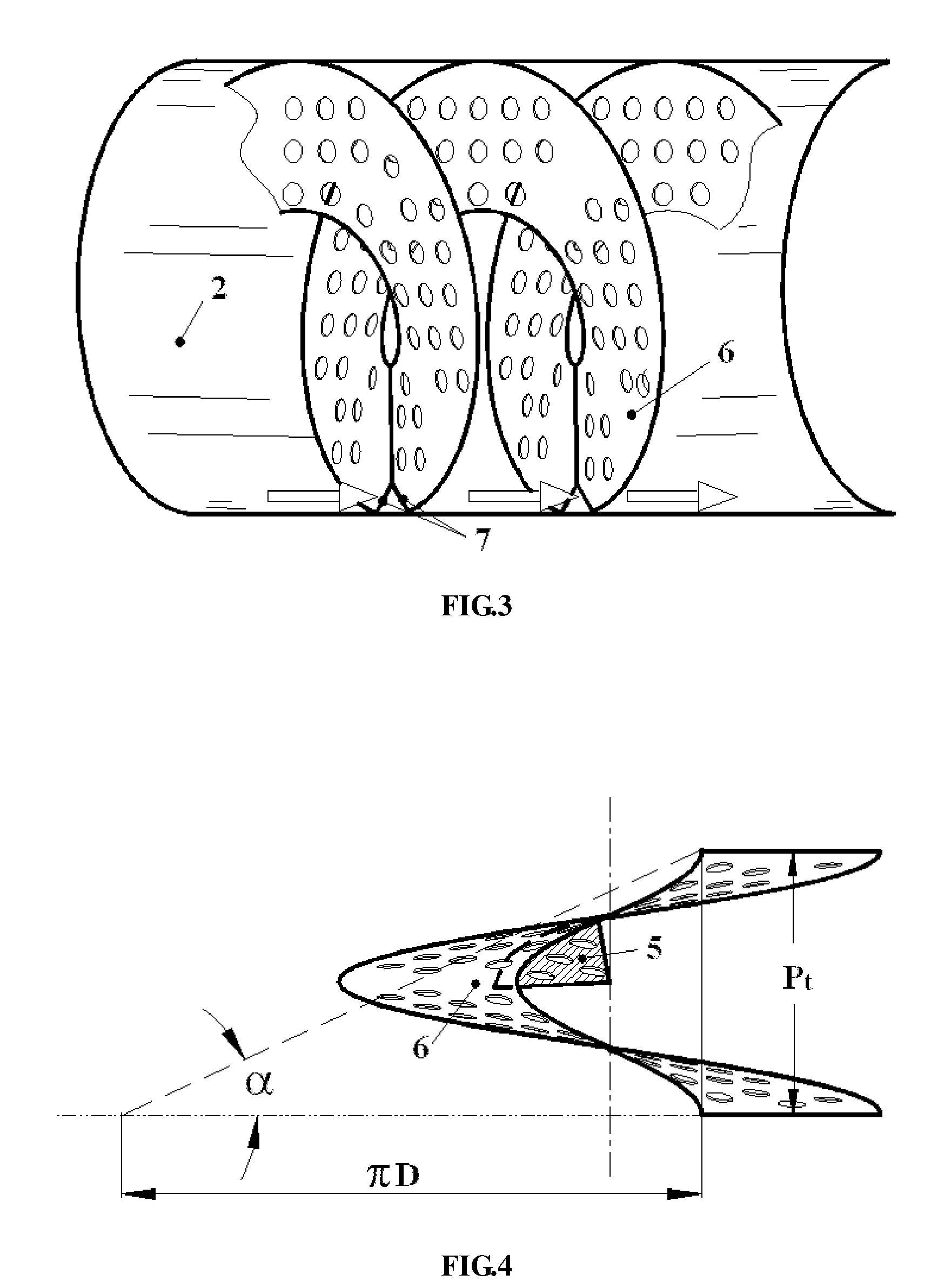

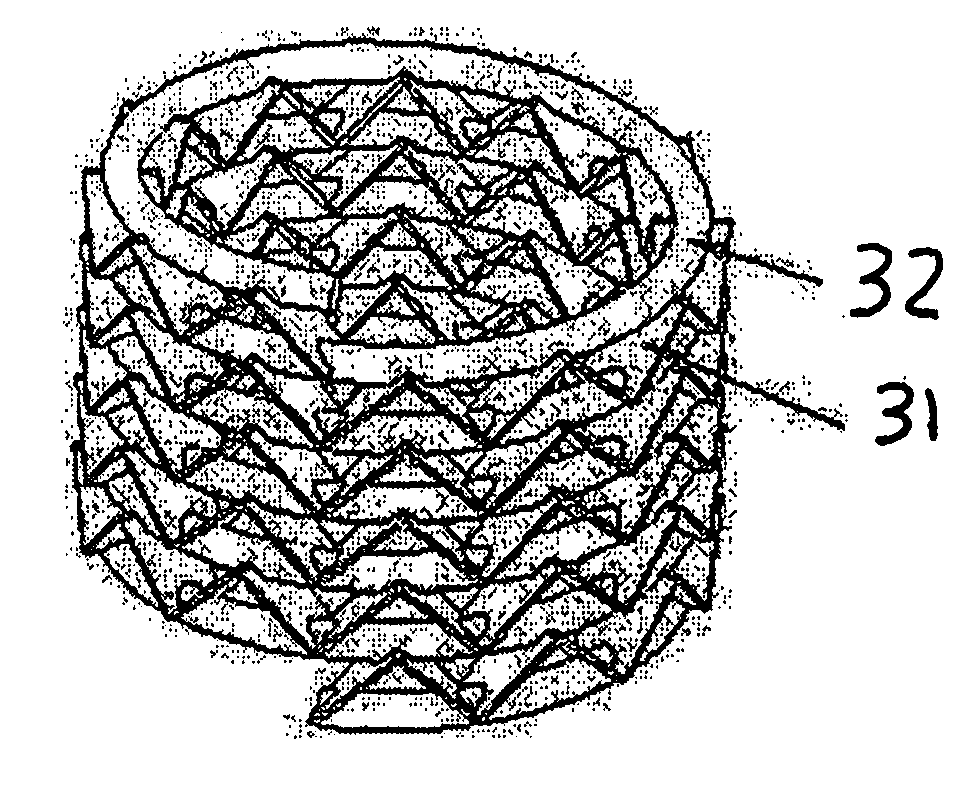

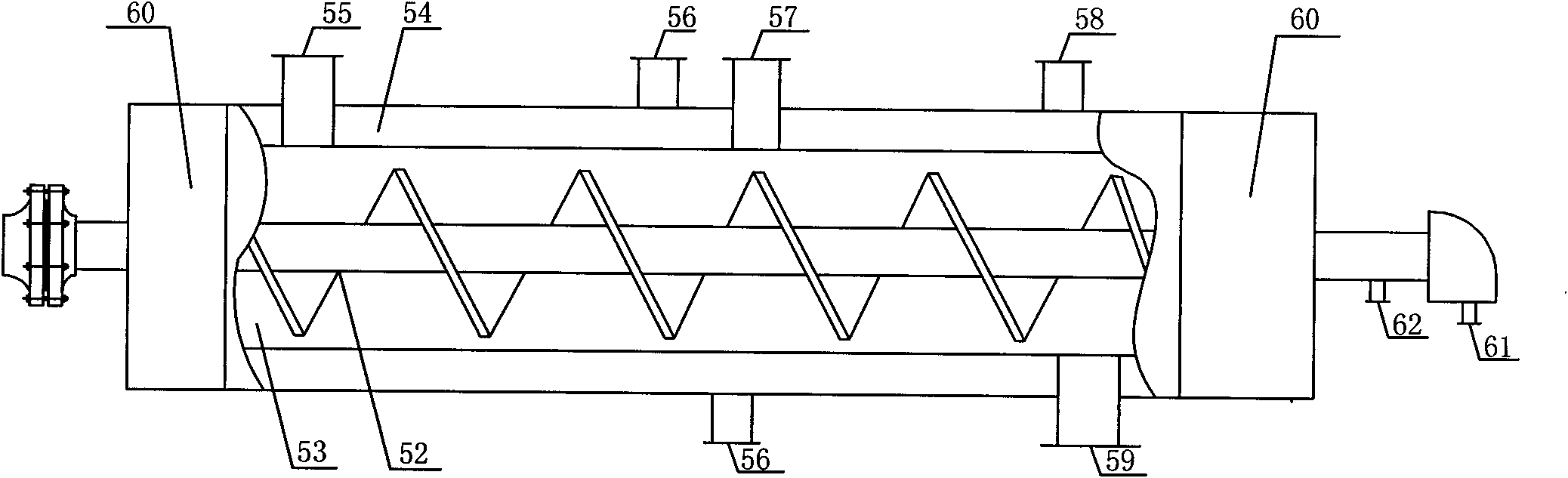

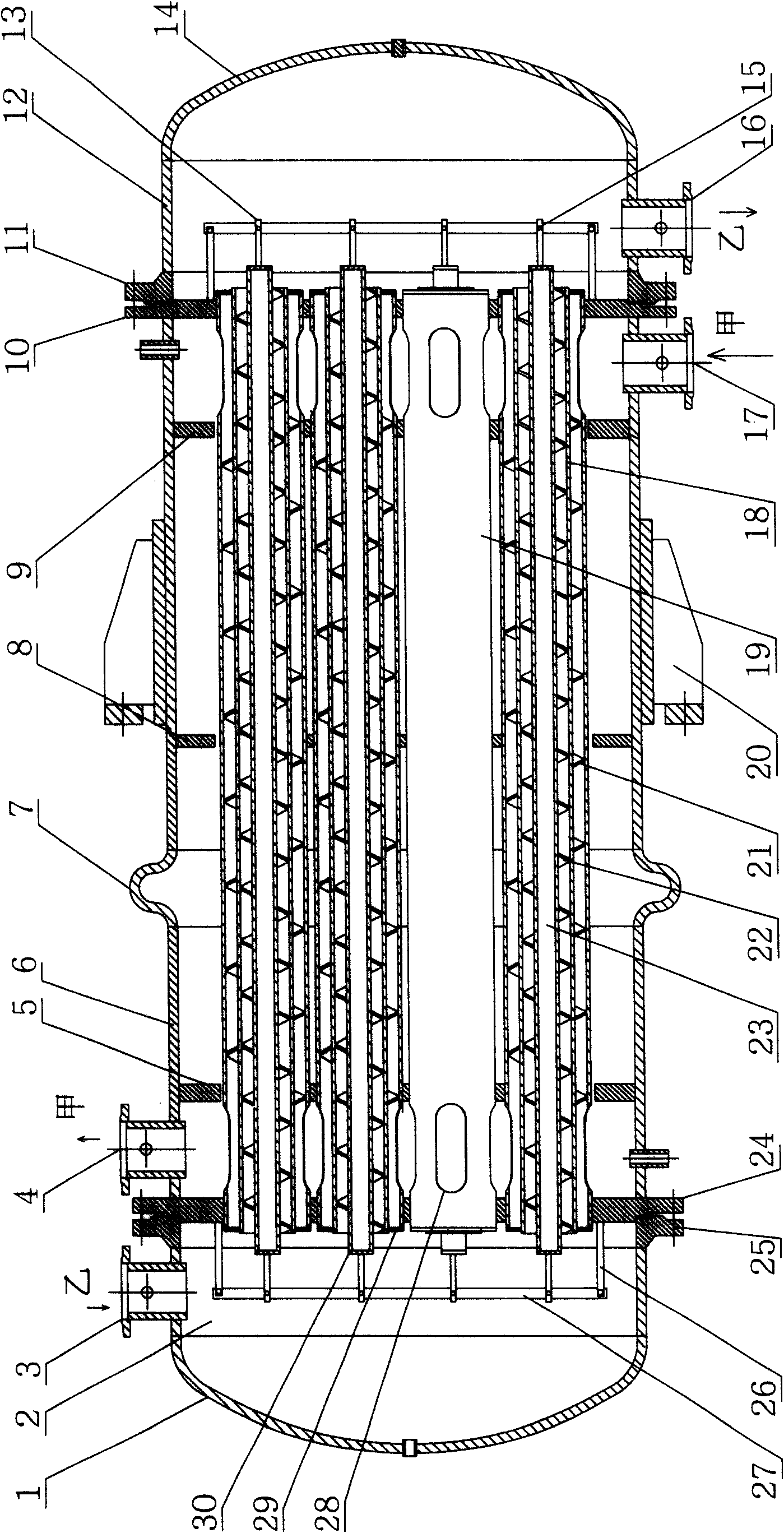

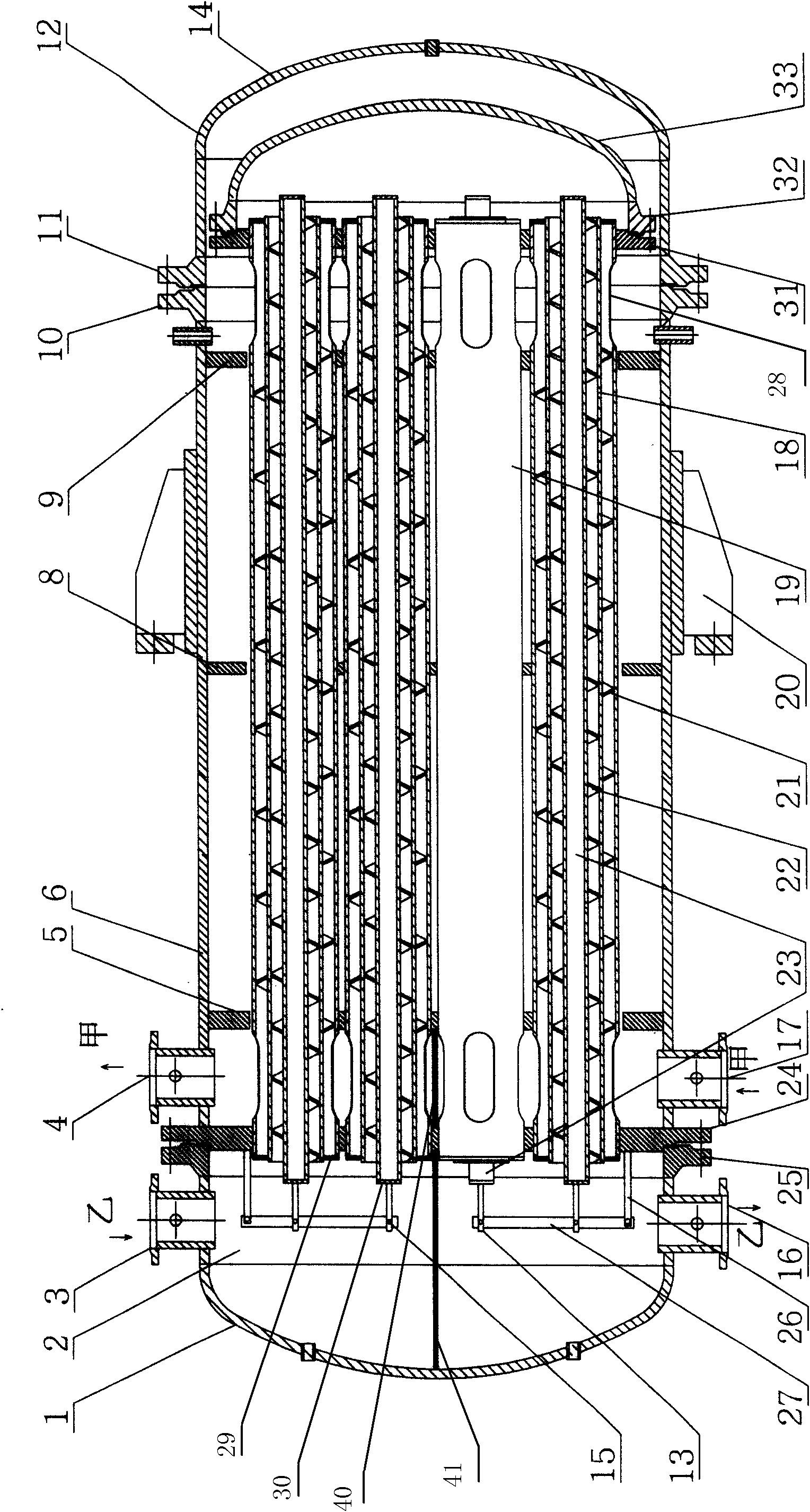

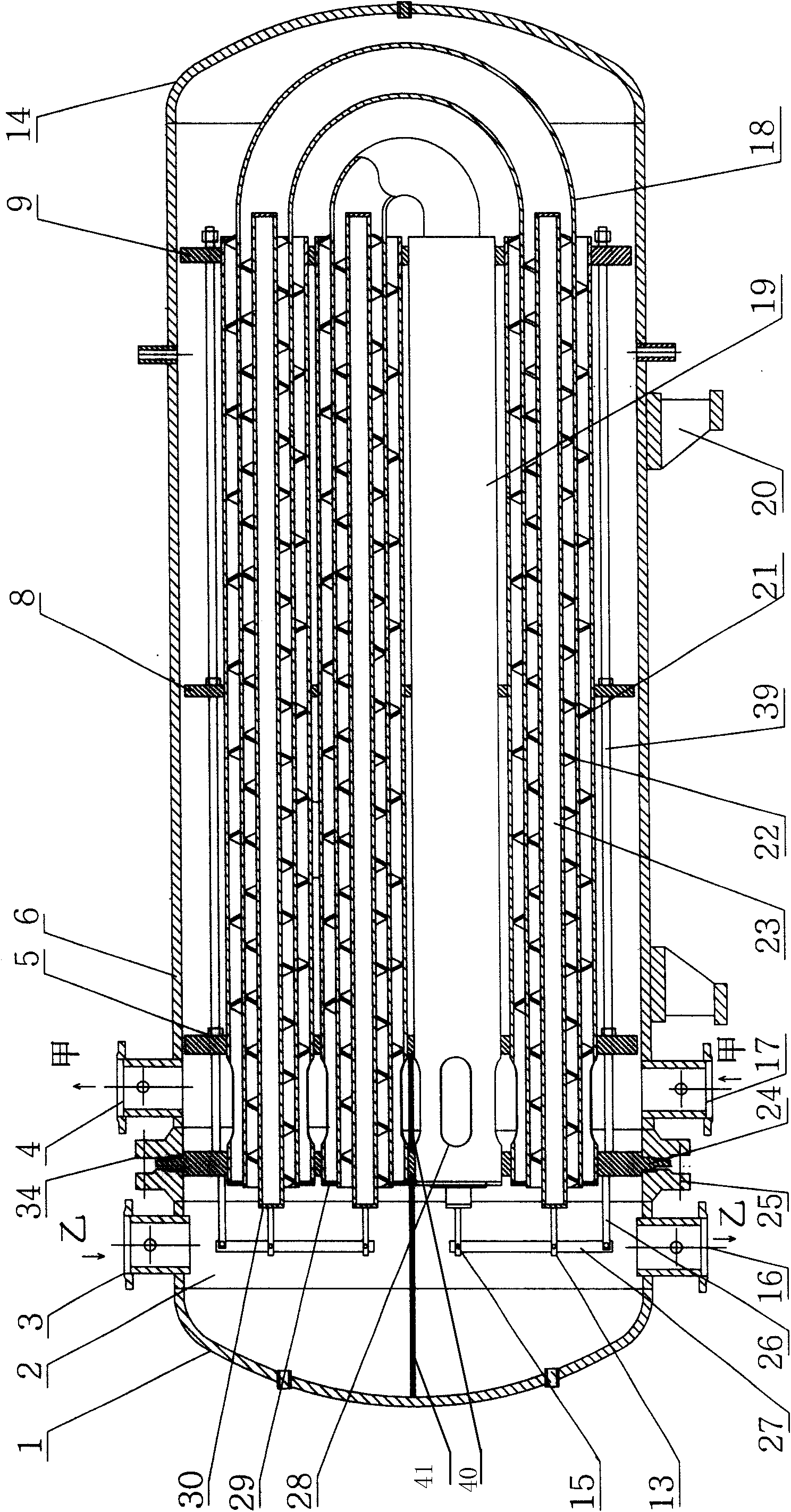

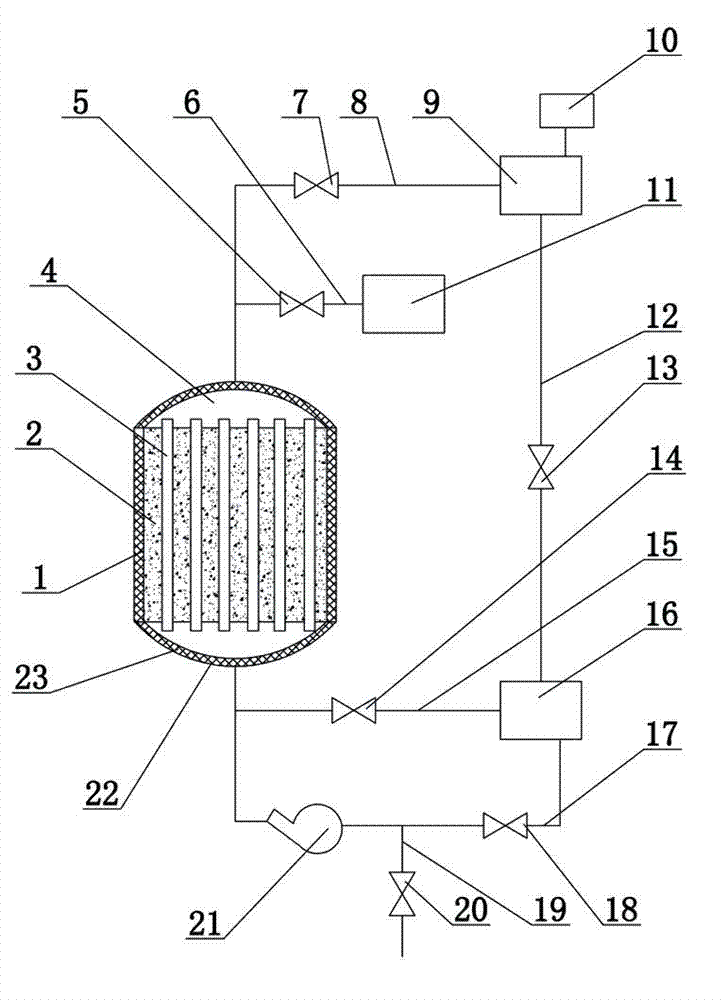

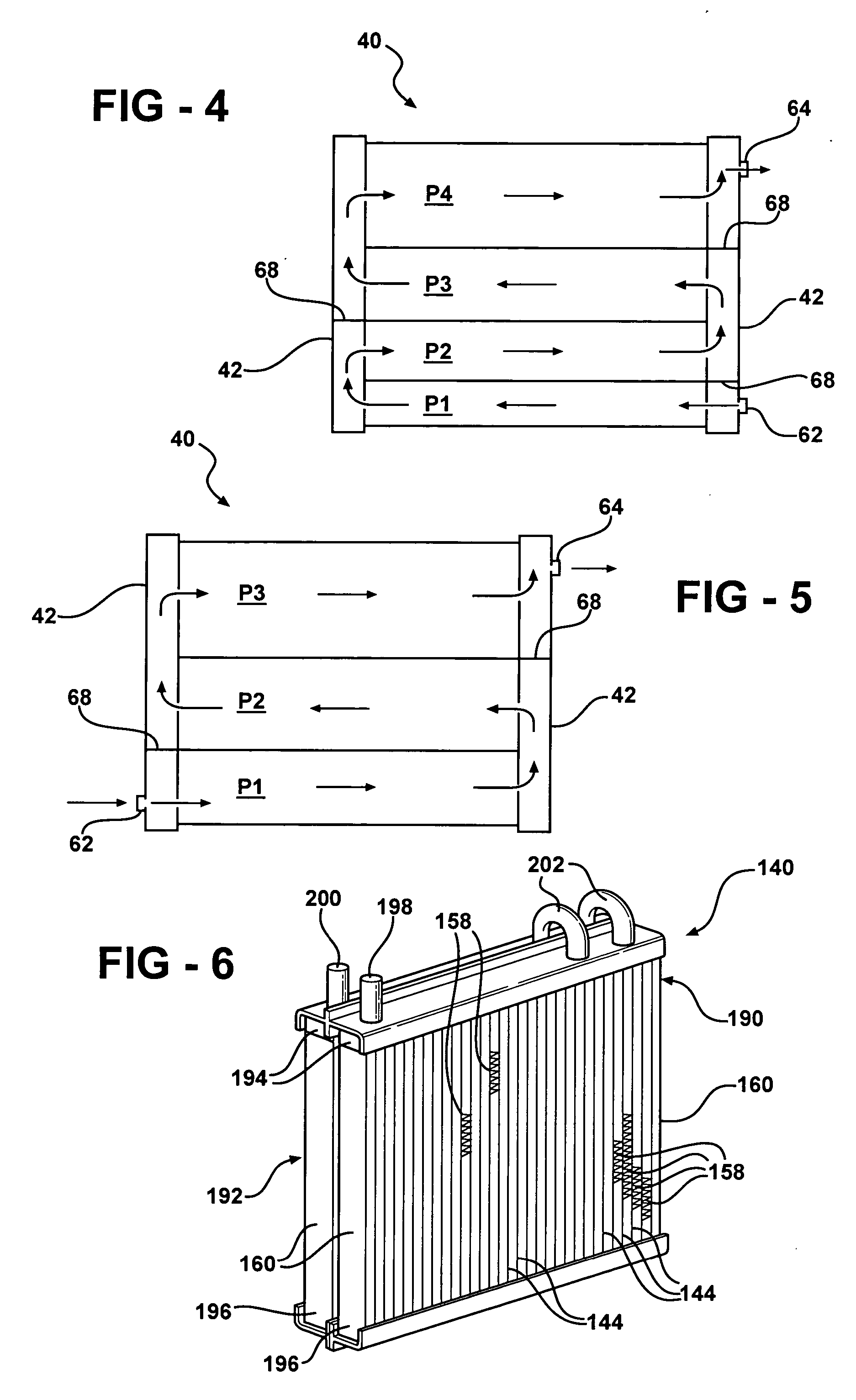

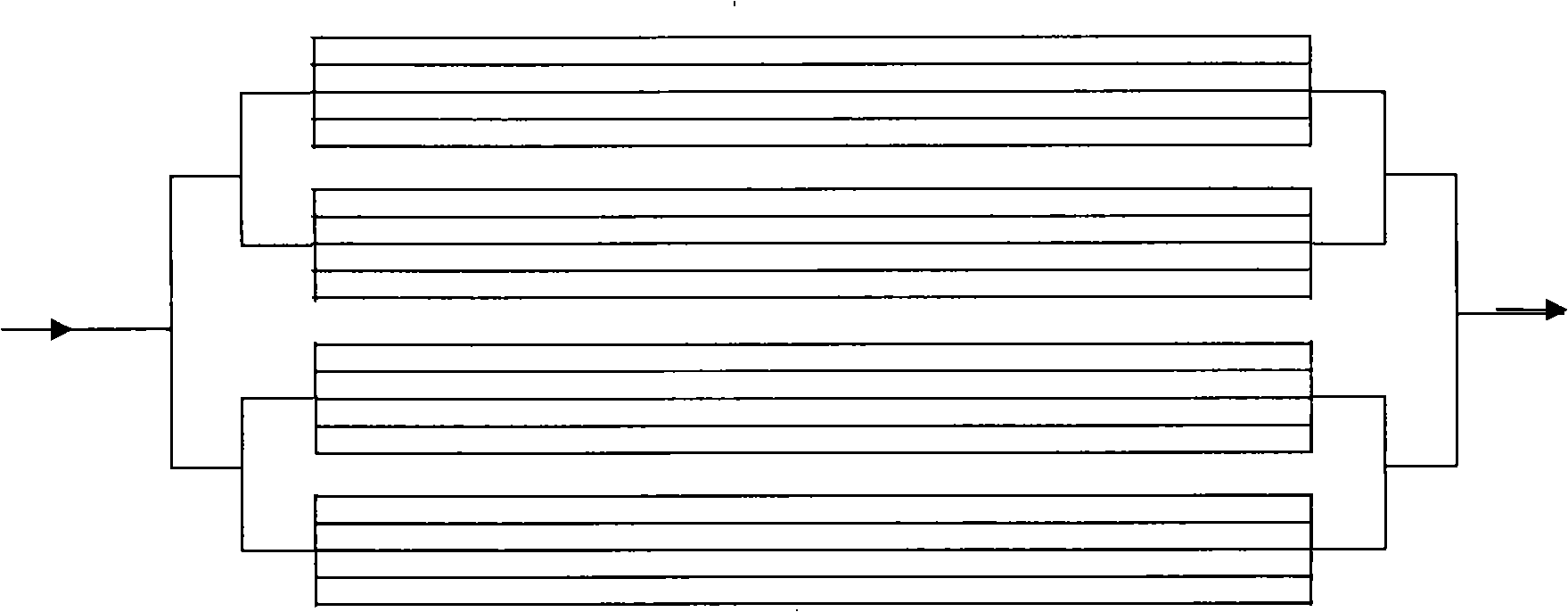

Single shell-pass or multiple shell-pass shell-and-tube heat exchanger with helical baffles

InactiveUS20080190593A1Clean cost be lowerLong service lifeMetal-working apparatusHeat exchanger casingsEngineeringRing doughnut

The present invention provides a single shell-pass shell-and-tube heat exchanger with helical baffles, where within a single pitch, the helical baffles are separated into inner and outer parts along the radial direction of the shell. In the central portion of the inner space of the shell, an inner non-continuous helical form is employed; in other portion outside the central portion, doughnut shaped helical baffles with continuous curved surfaces are arranged to form an outer continuous helical baffle, and the outer helical baffles are arranged to surround the inner helical baffles. Furthermore, the present invention relates to a multiple shell-pass shell-and-tube heat exchanger with helical baffles, in which complete continuous helical baffles are provided in shell-sides other than the inner shell-pass, while non-continuous helical baffles or other flow guide means are employed in the inner shell-pass. The present invention makes flow patterns of fluids on the shell side more desirable, leading to a reduced flow pressure drop, and mitigate fouling, thus the heat transfer rate is improved and the service life of the heat exchanger is increased. The present invention also provides two methods for manufacture of continuous helical baffles, which ensure the concentricity of the tube bundle holes on each continuous helical baffle so as to facilitate installation of heat exchange tube bundles.

Owner:XI AN JIAOTONG UNIV

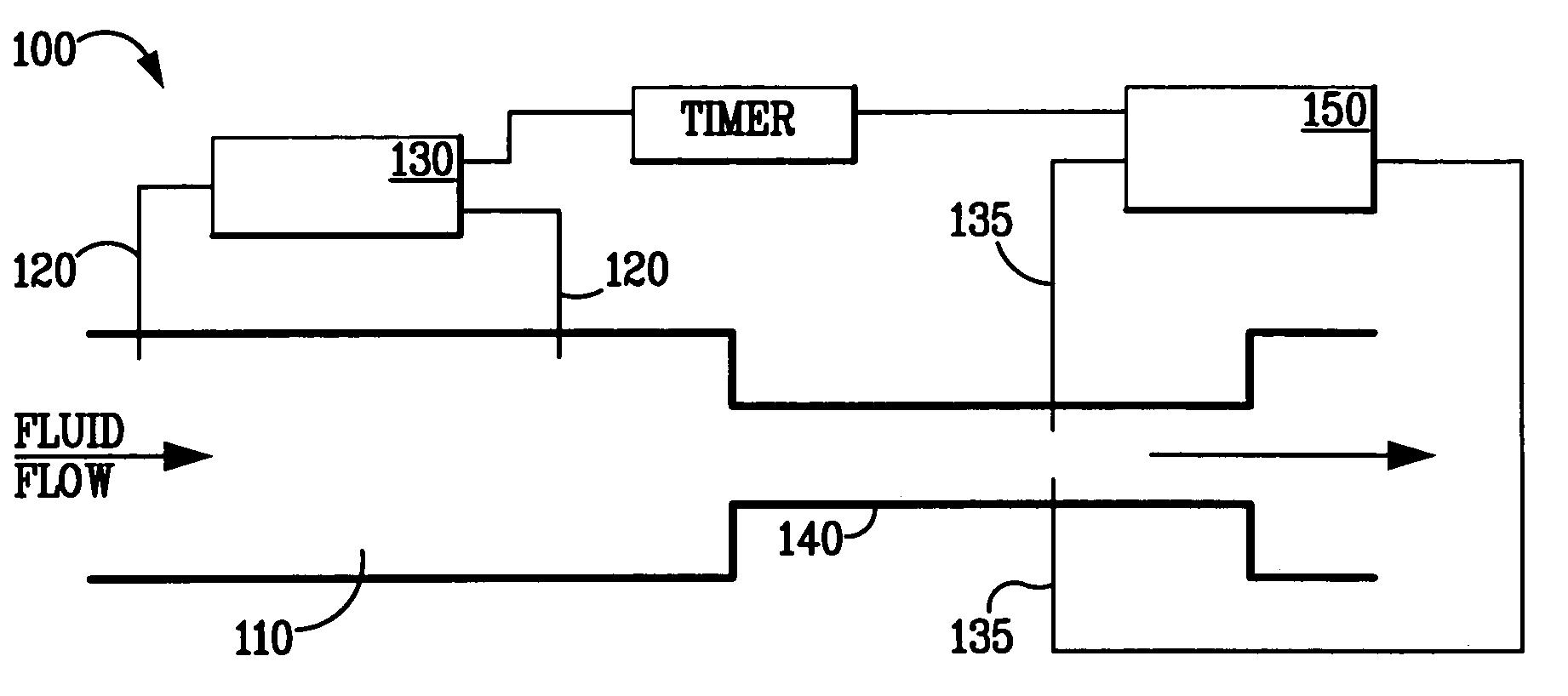

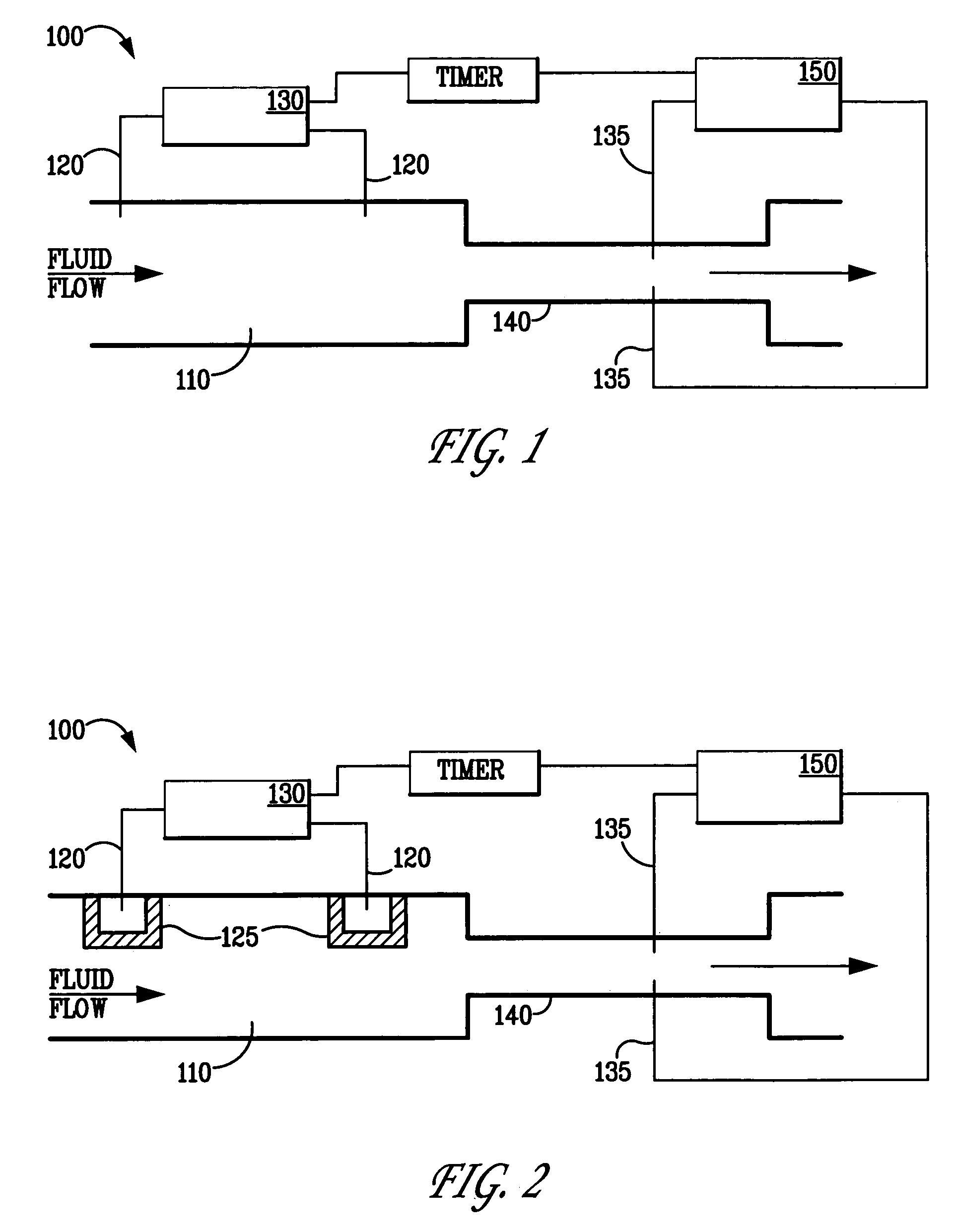

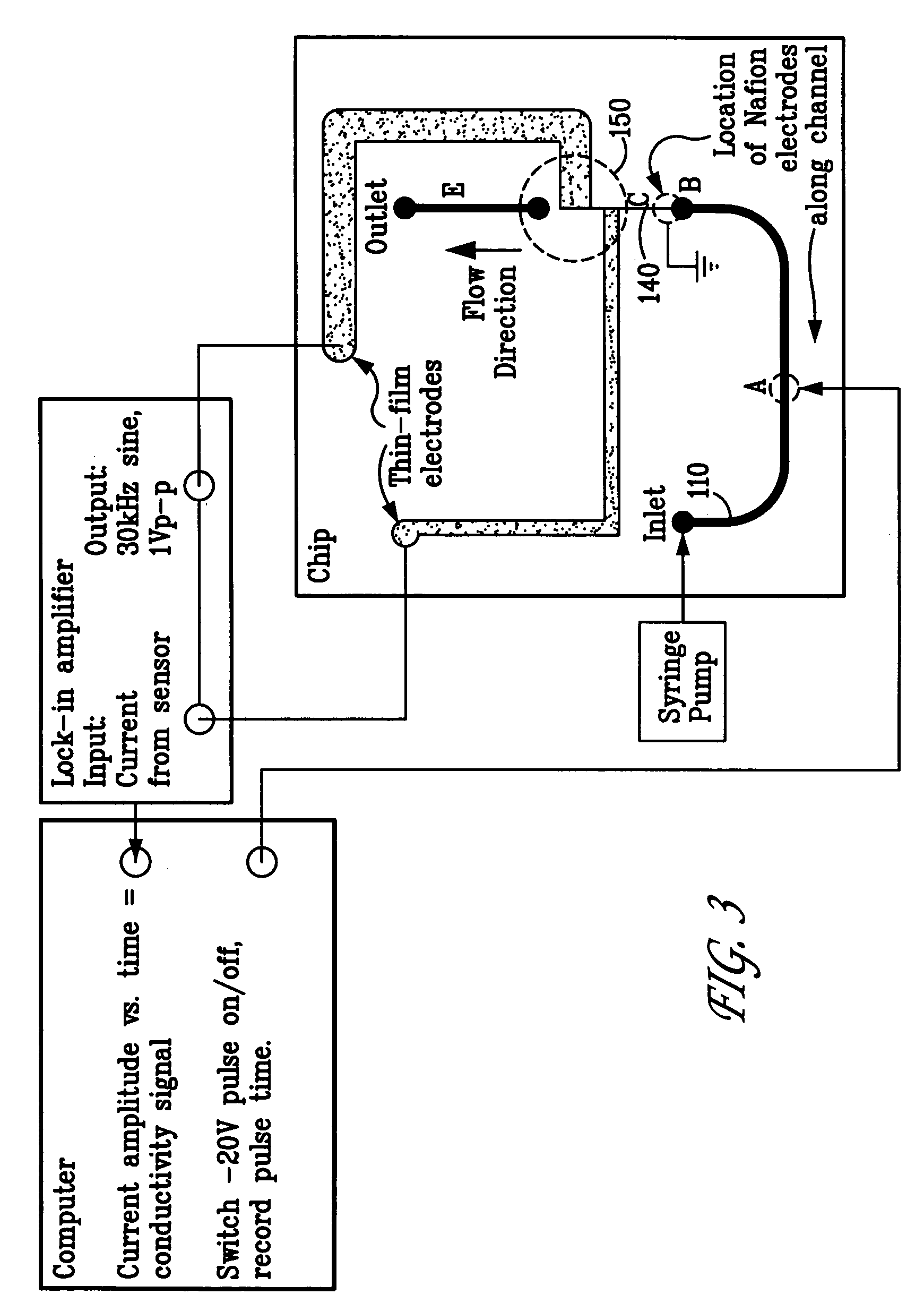

Composition pulse time-of-flight mass flow sensor

InactiveUS7225683B2Increase heat transfer rateHigh sensitivityVolume/mass flow by electromagnetic flowmetersElectrolysisSolvent

Owner:SANDIA NAT LAB

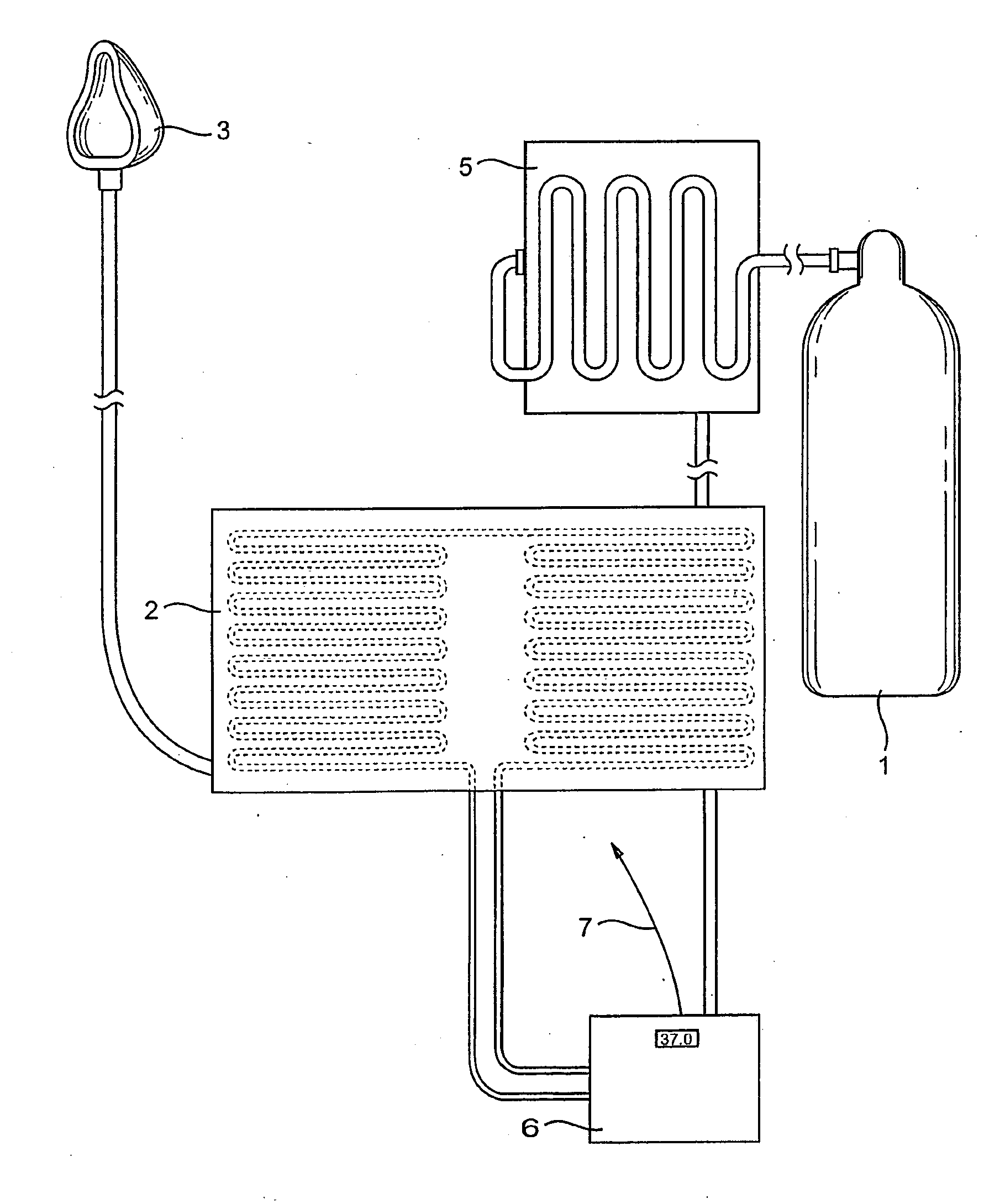

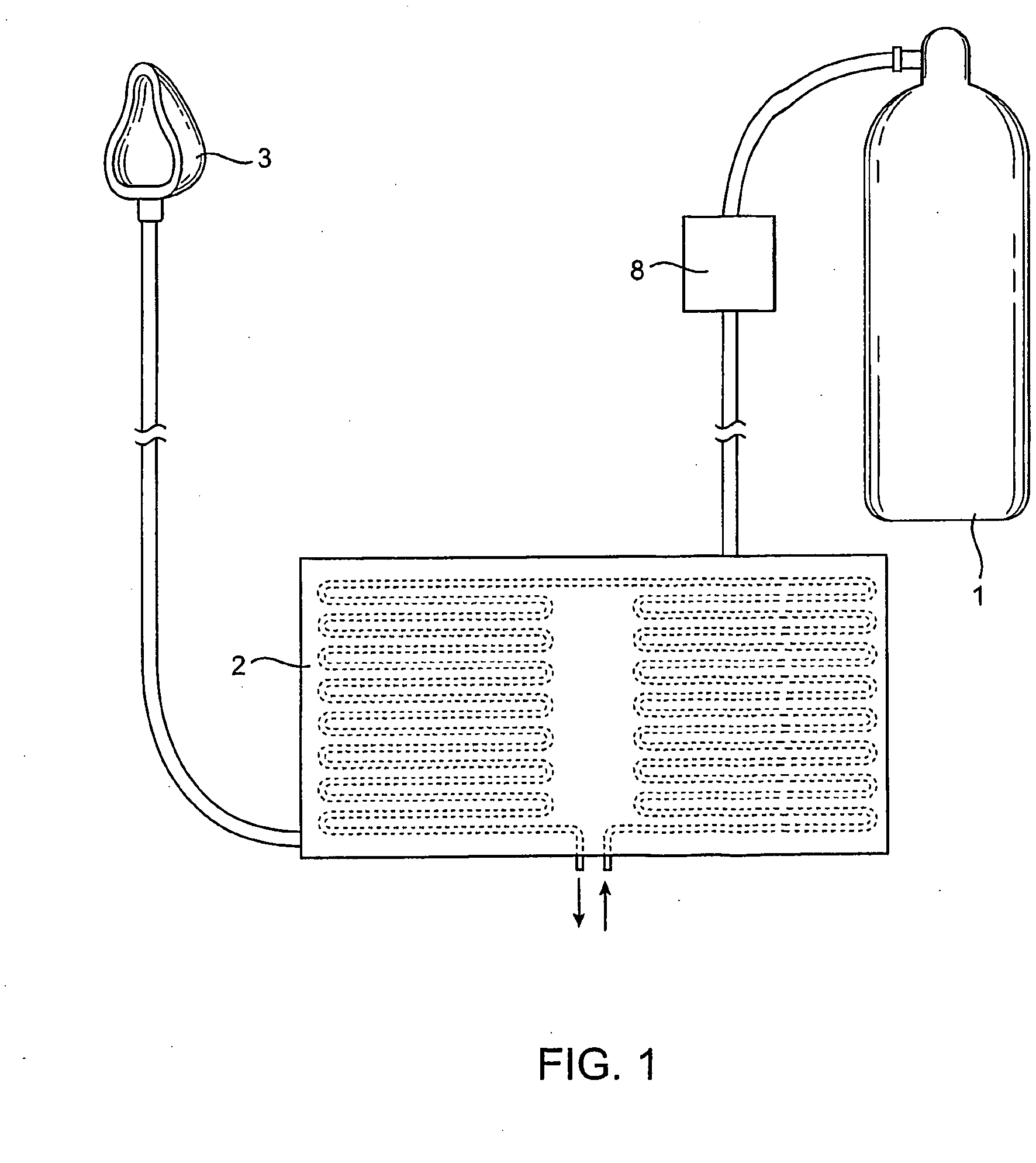

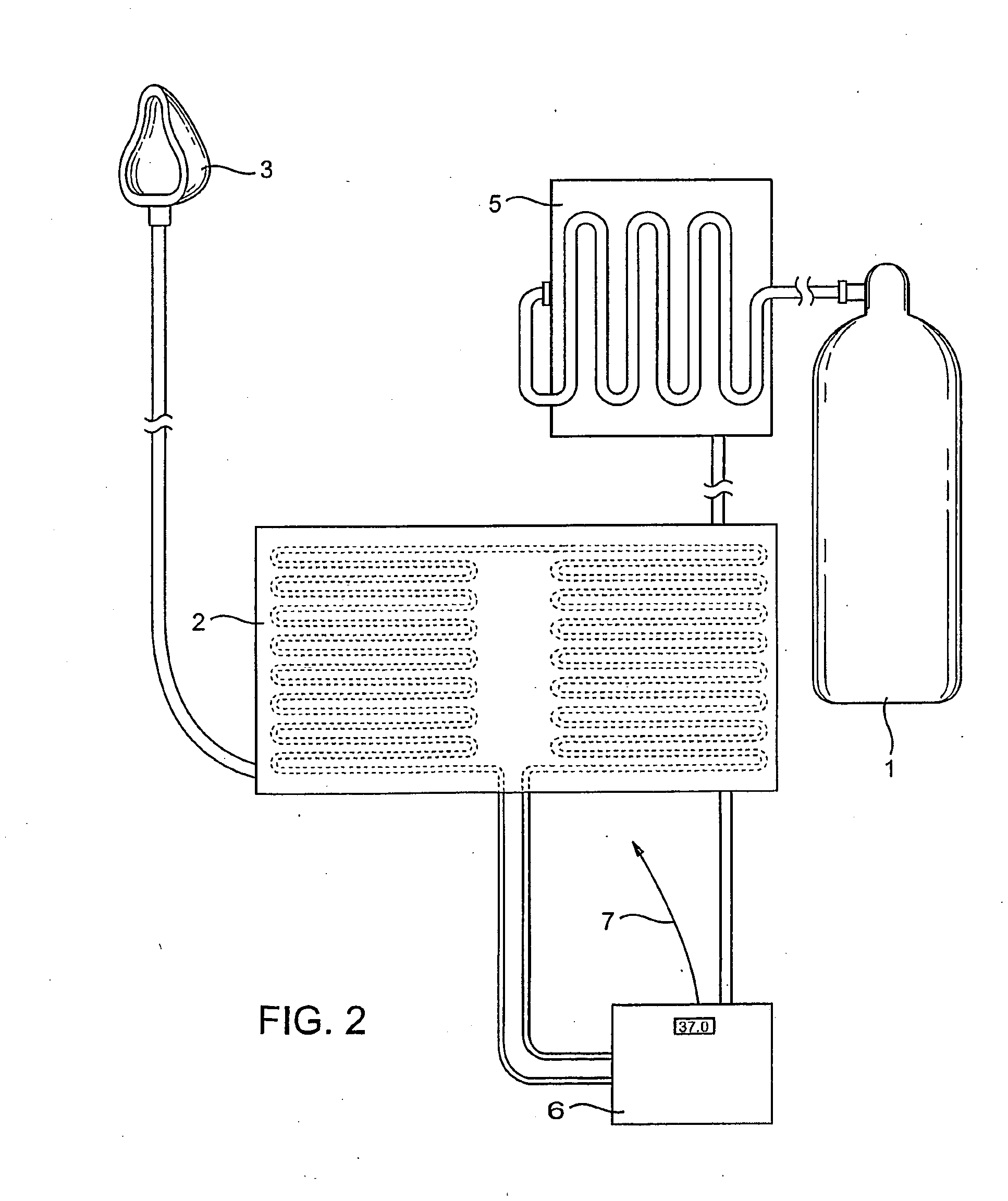

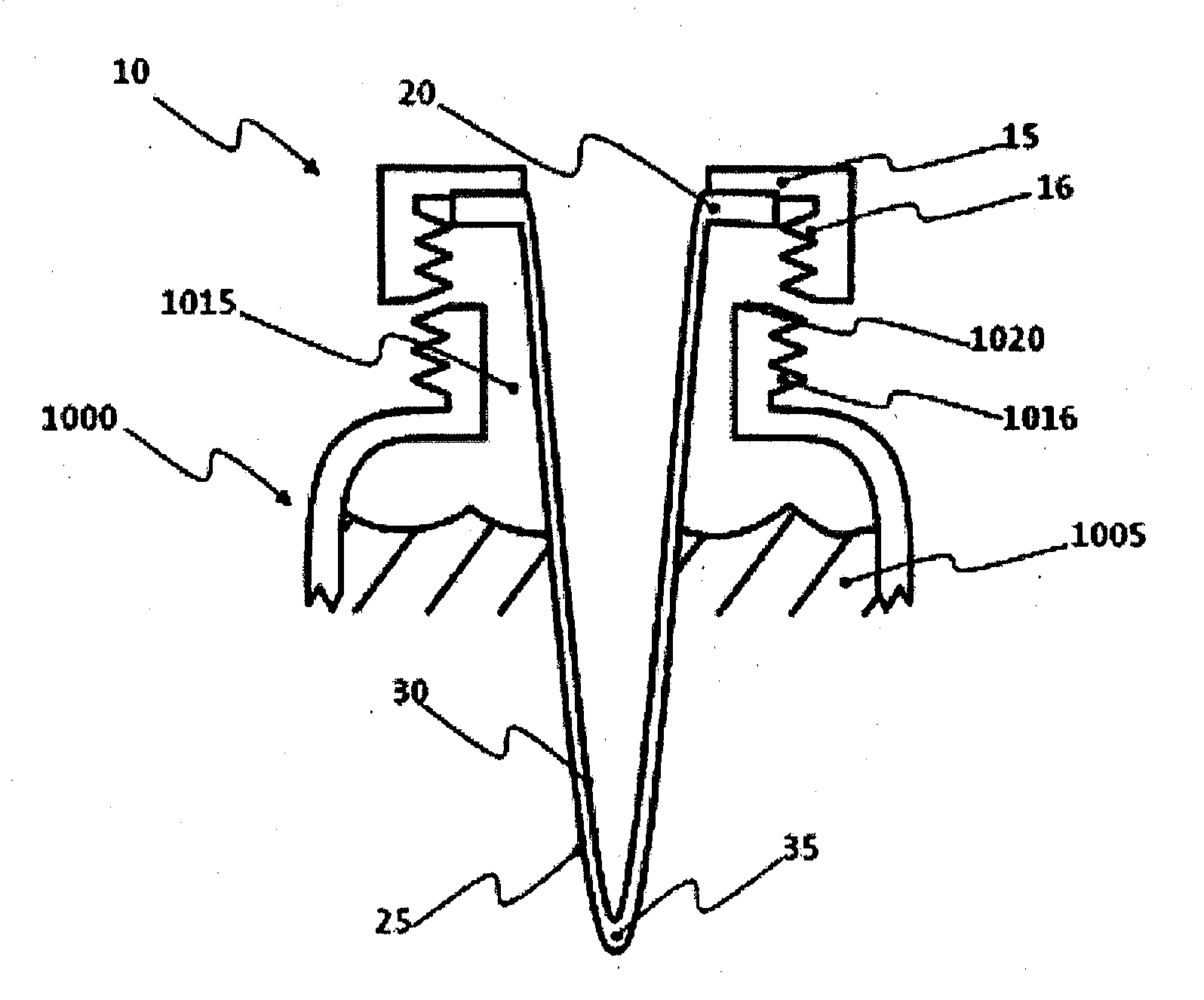

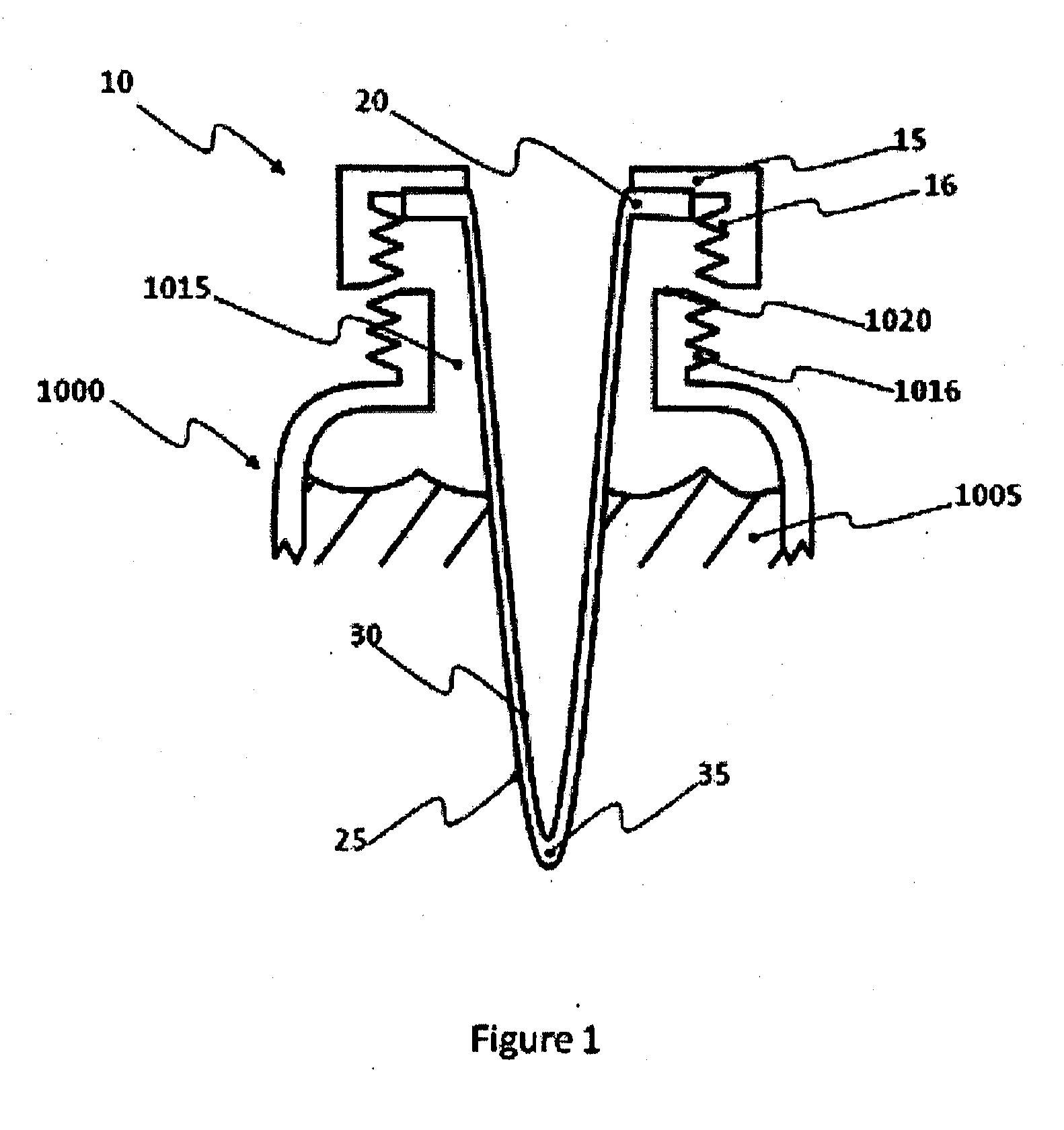

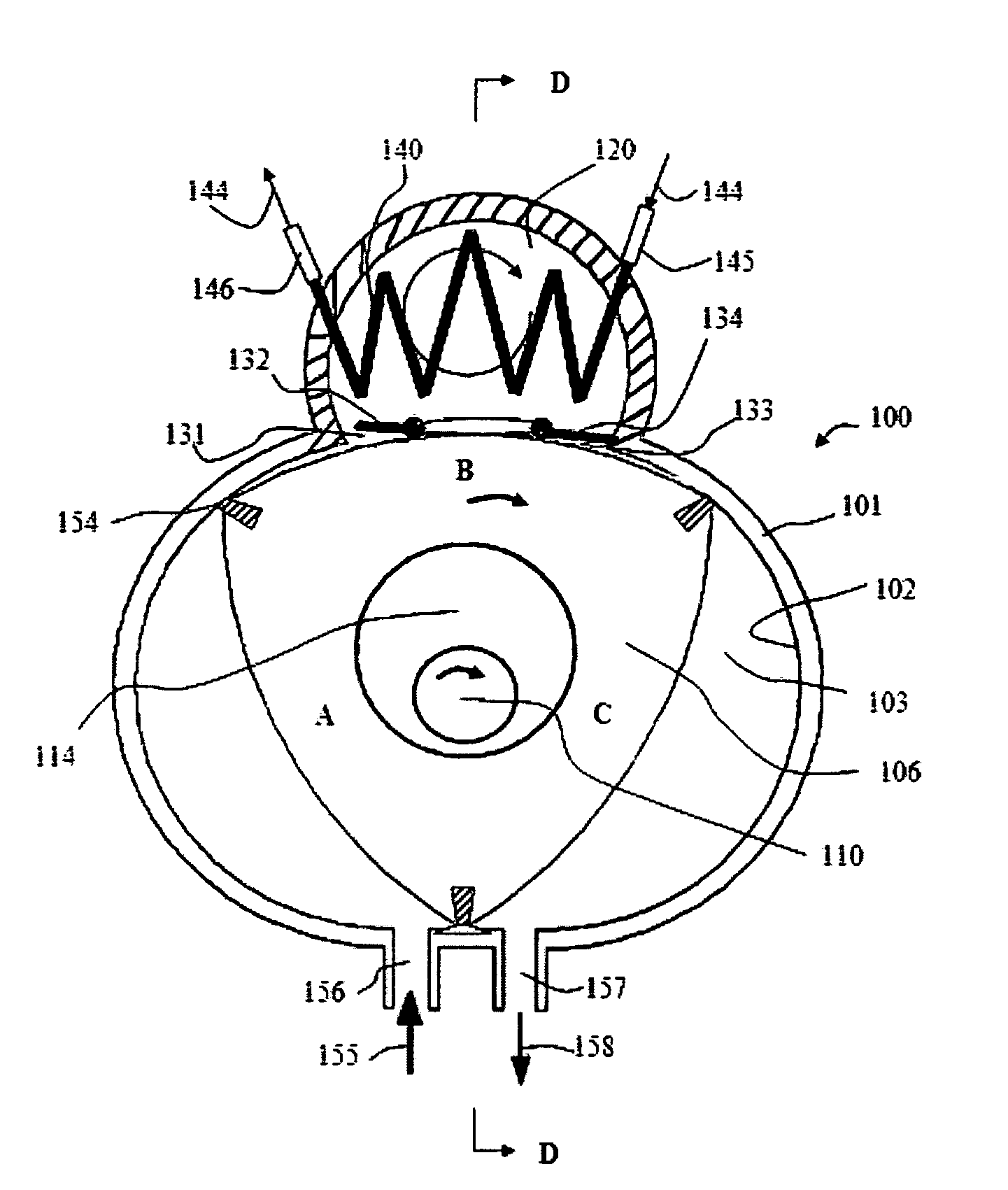

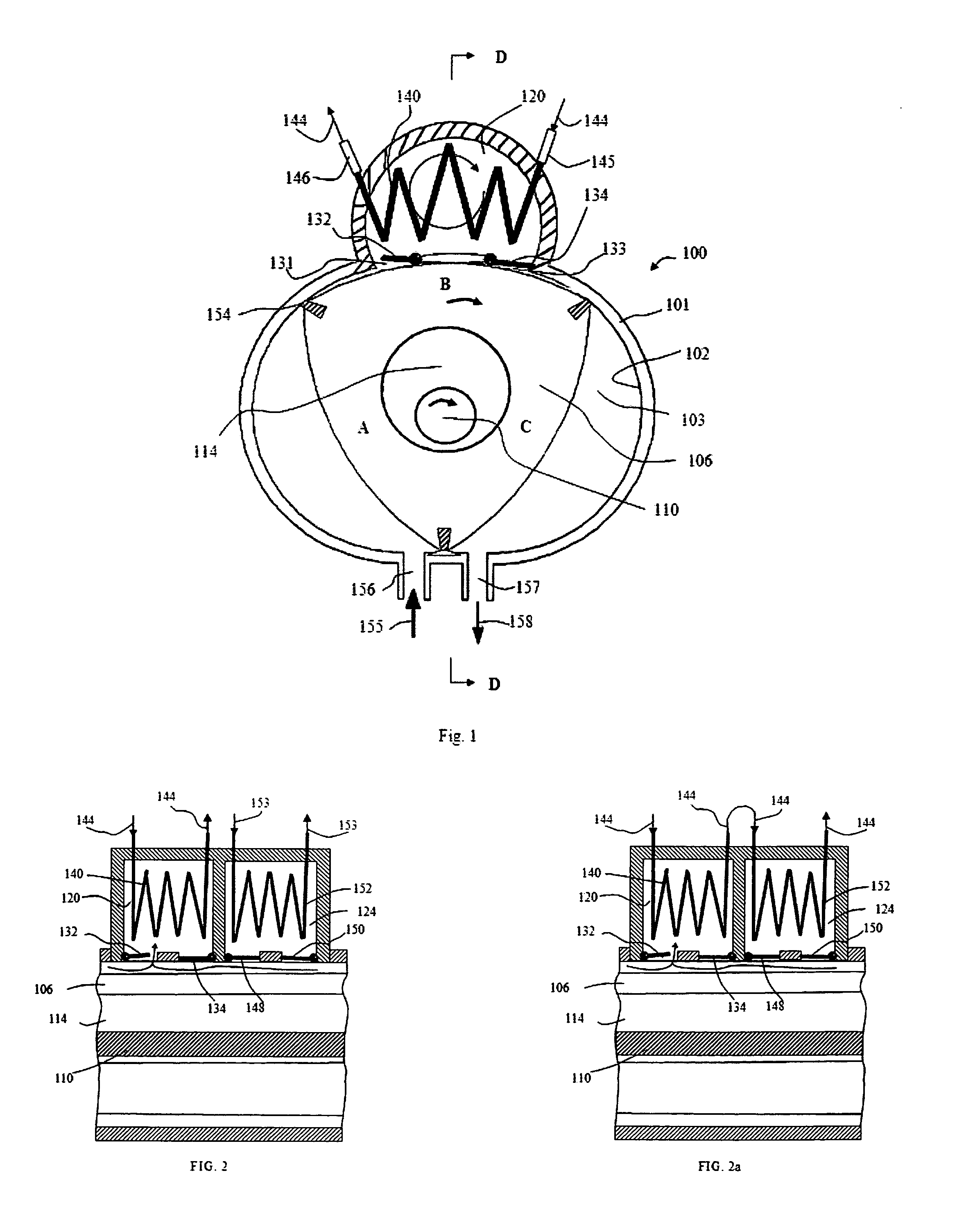

Respiratory System for Inducing Therapeutic Hypothermia

ActiveUS20080262377A1Increase heat transfer rateBurnersNervous disorderTracheal tubeEndotracheal tube

The present invention provides a method and apparatus for controlling a patient's body temperature and in particular for inducing therapeutic hypothermia. Various embodiments of the system are described. The system includes: a source of breathing gas, which may be in the form of a compressed breathing gas mixture; a heat exchanger or other heating and / or cooling device; and a breathing interface, such as a breathing mask or tracheal tube. Optionally, the system may include additional features, such as a mechanical respirator, a nebulizer for introducing medication into the breathing gas, a body temperature probe and a feedback controller. The system can use air or a specialized breathing gas mixture, such as He / O2 or SF / O2 to increase the heat transfer rate. In addition, the system may include an ice particle generator for introducing fine ice particles into the flow of breathing gas to further increase the heat transfer rate.

Owner:QOOL THERAPEUTICS

Heat spreader with vapor chamber defined therein

InactiveUS7609520B2Improve the heating effectDissipate heat generatedSemiconductor/solid-state device detailsSolid-state devicesWorking fluidCarbon nanotube

Owner:HON HAI PRECISION IND CO LTD

Finned tube for condensation and evaporation

ActiveUS20080196876A1Increase surface areaImprove heat transfer performanceMetal-working apparatusCorrosion preventionEvaporationMechanical engineering

Owner:WIELAND WERKE AG

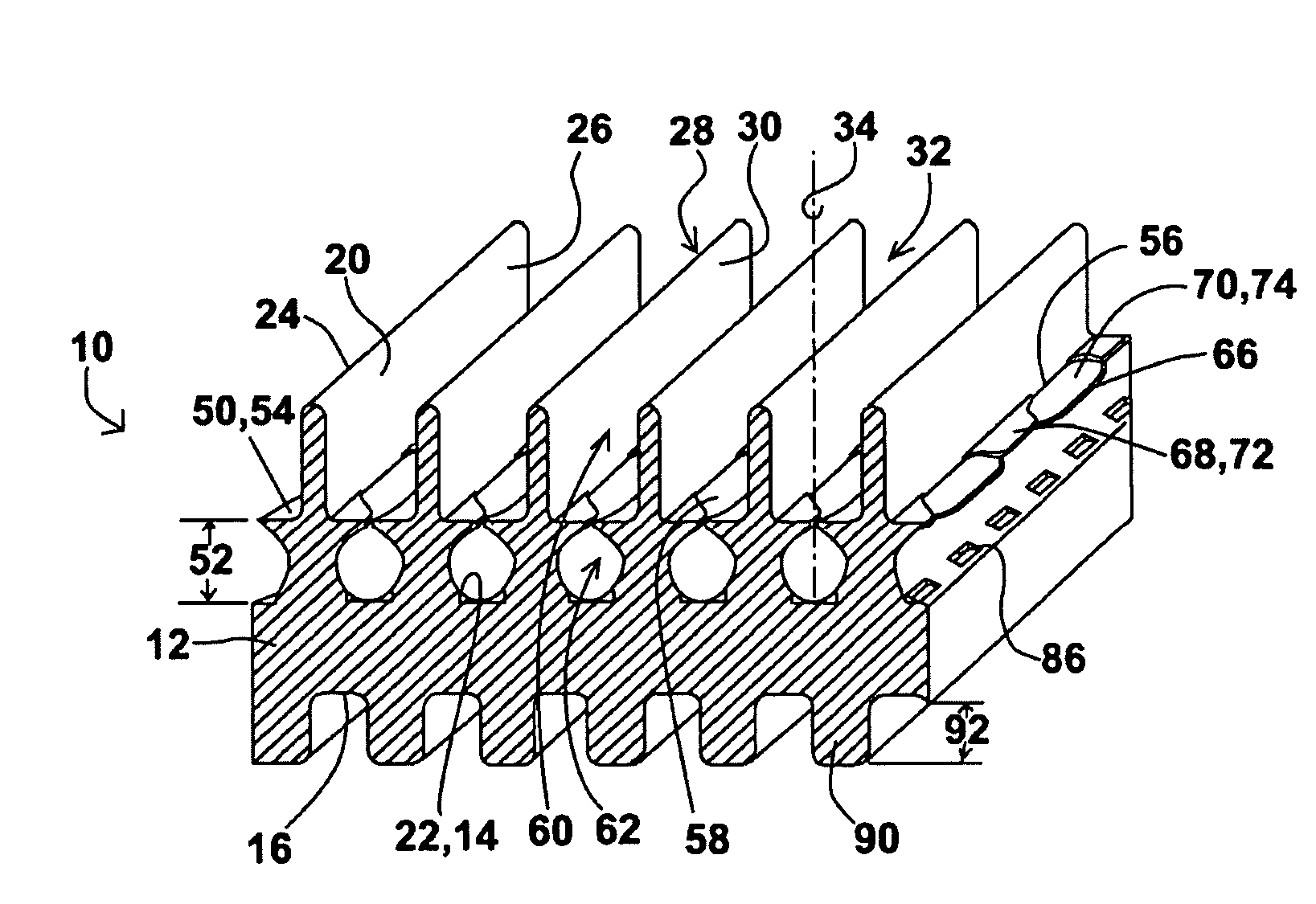

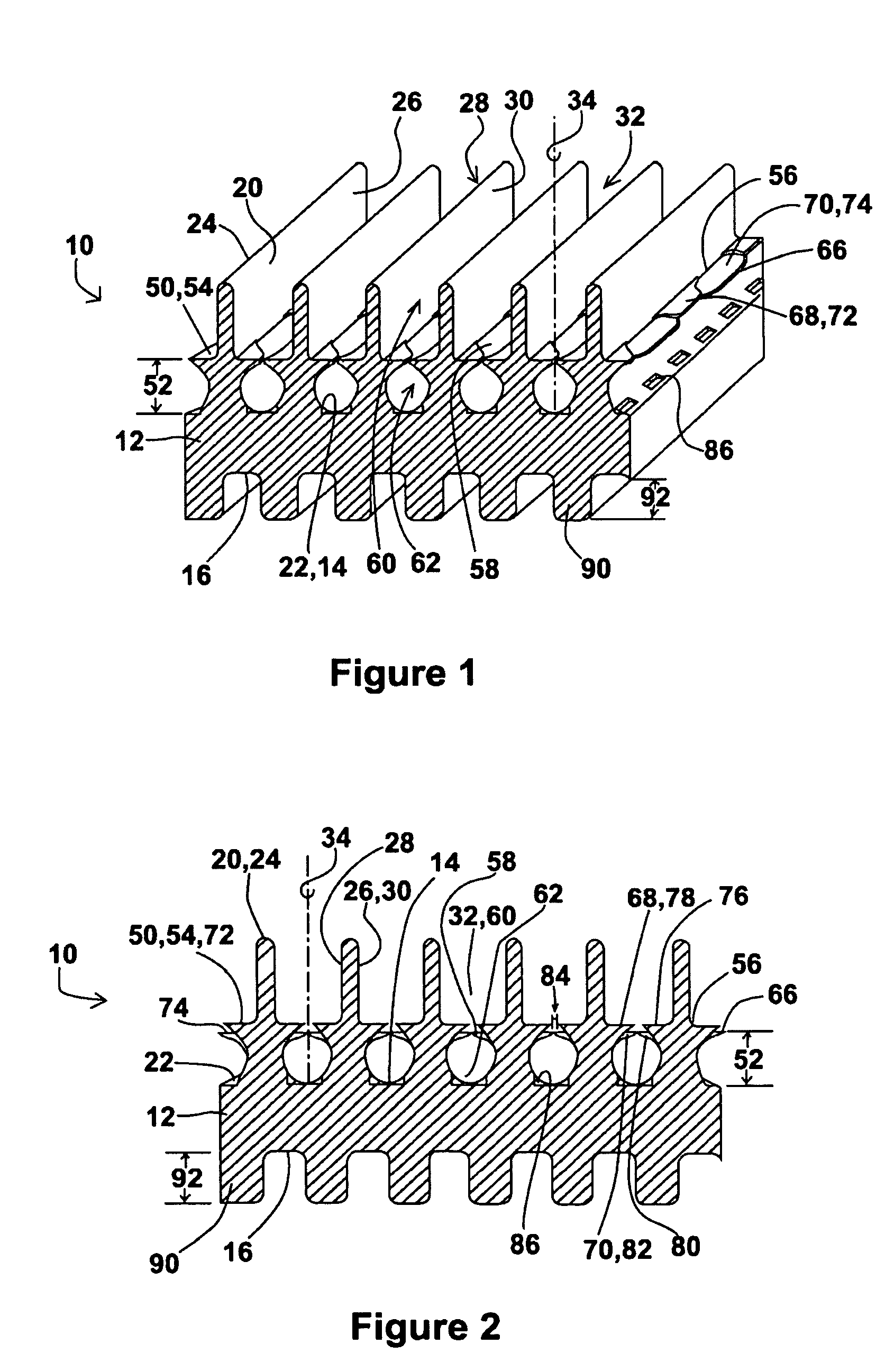

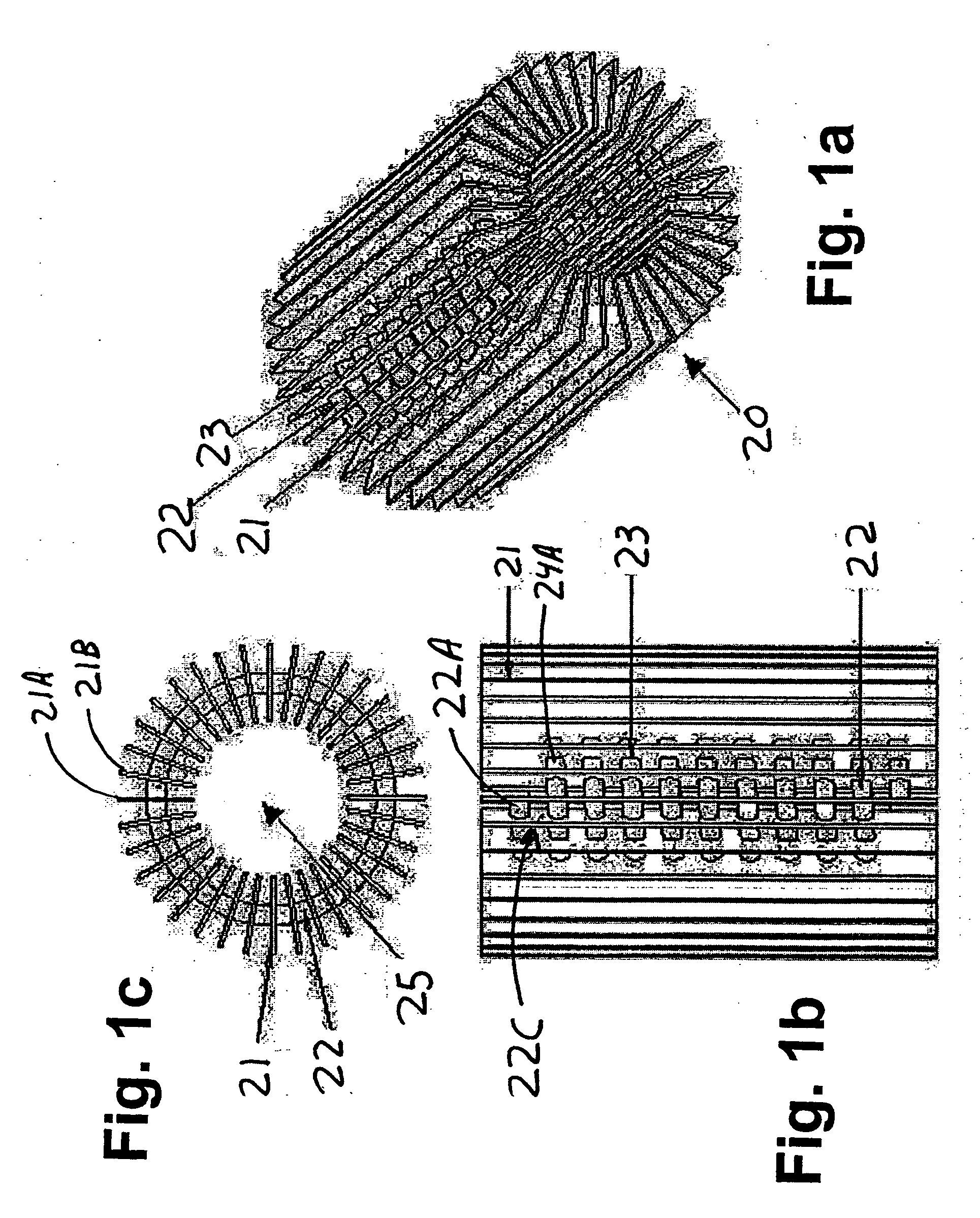

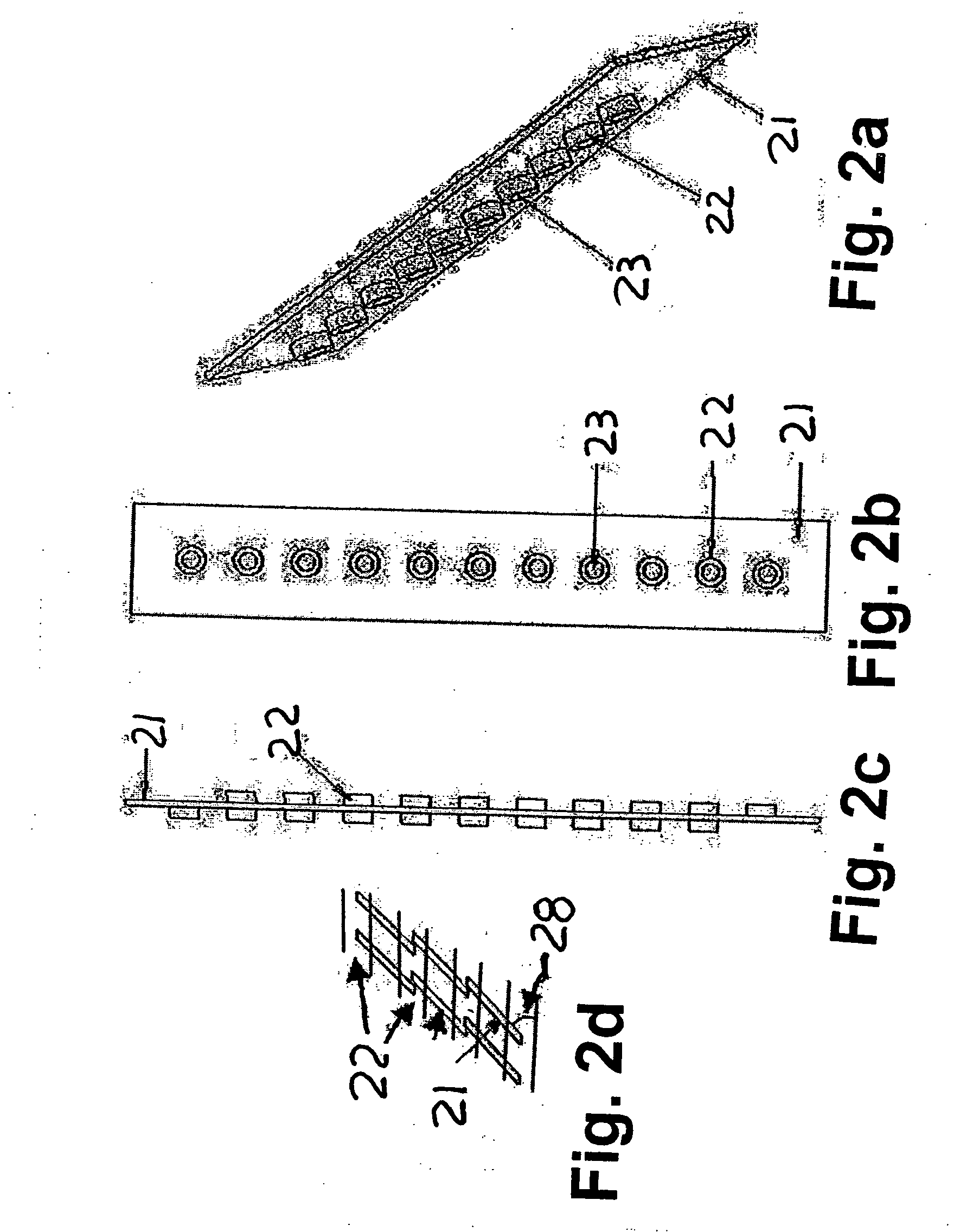

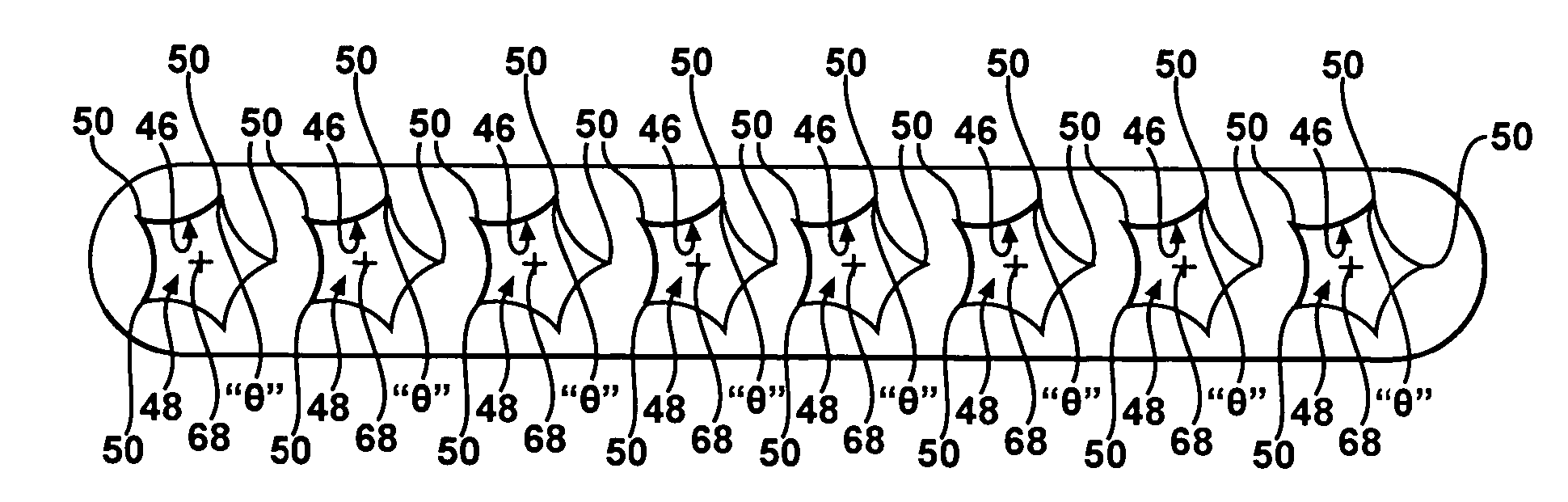

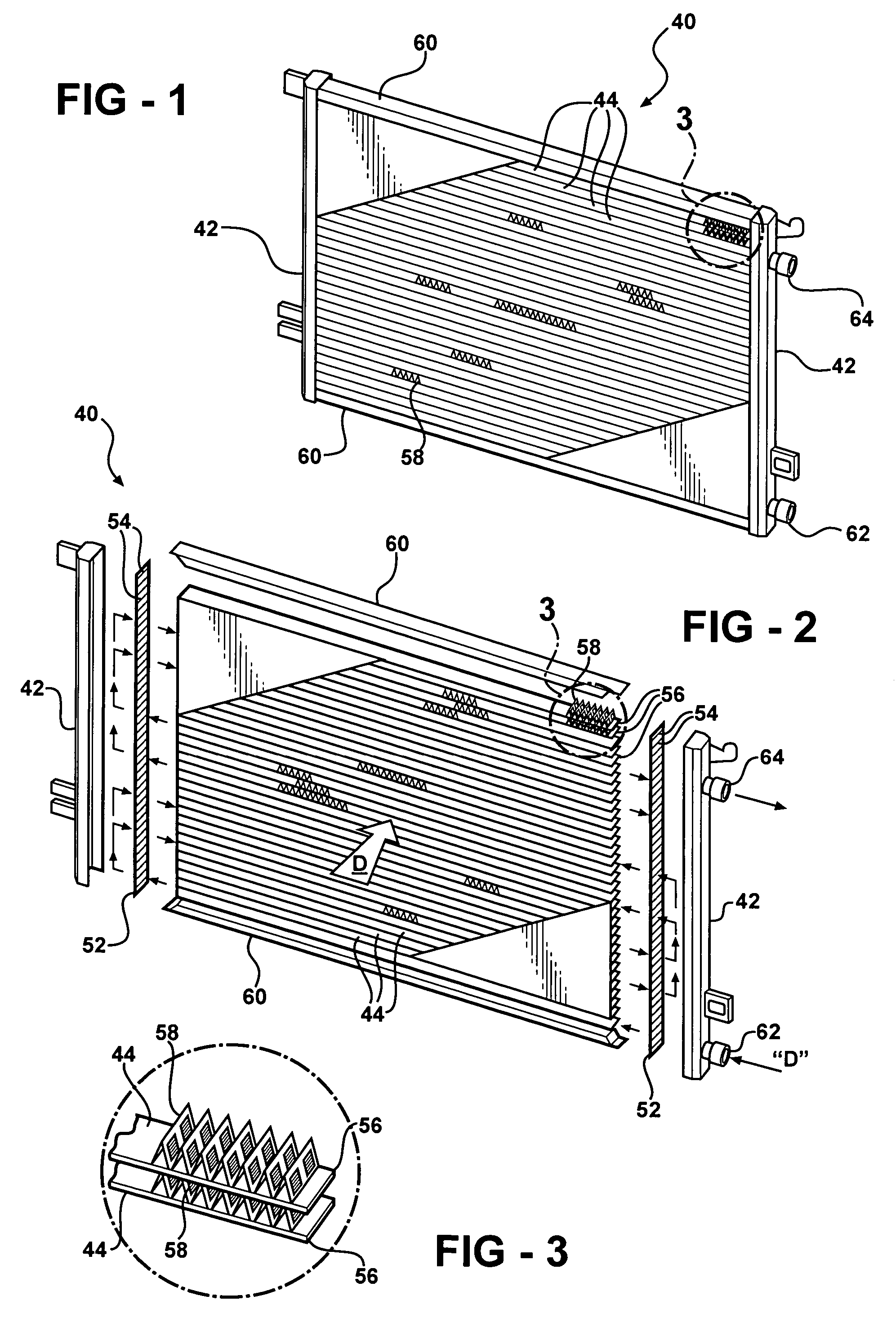

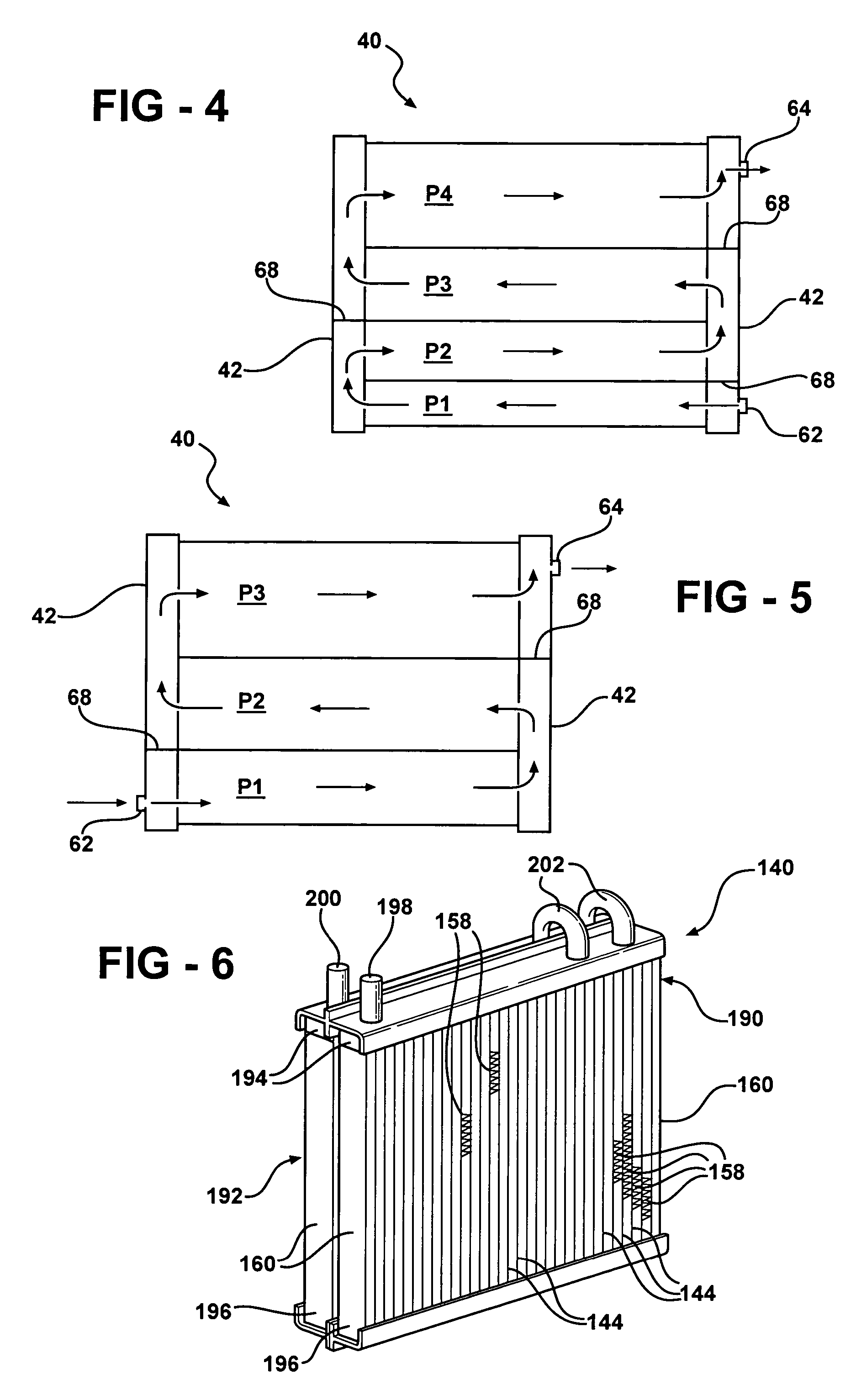

Automotive adsorption heat pump

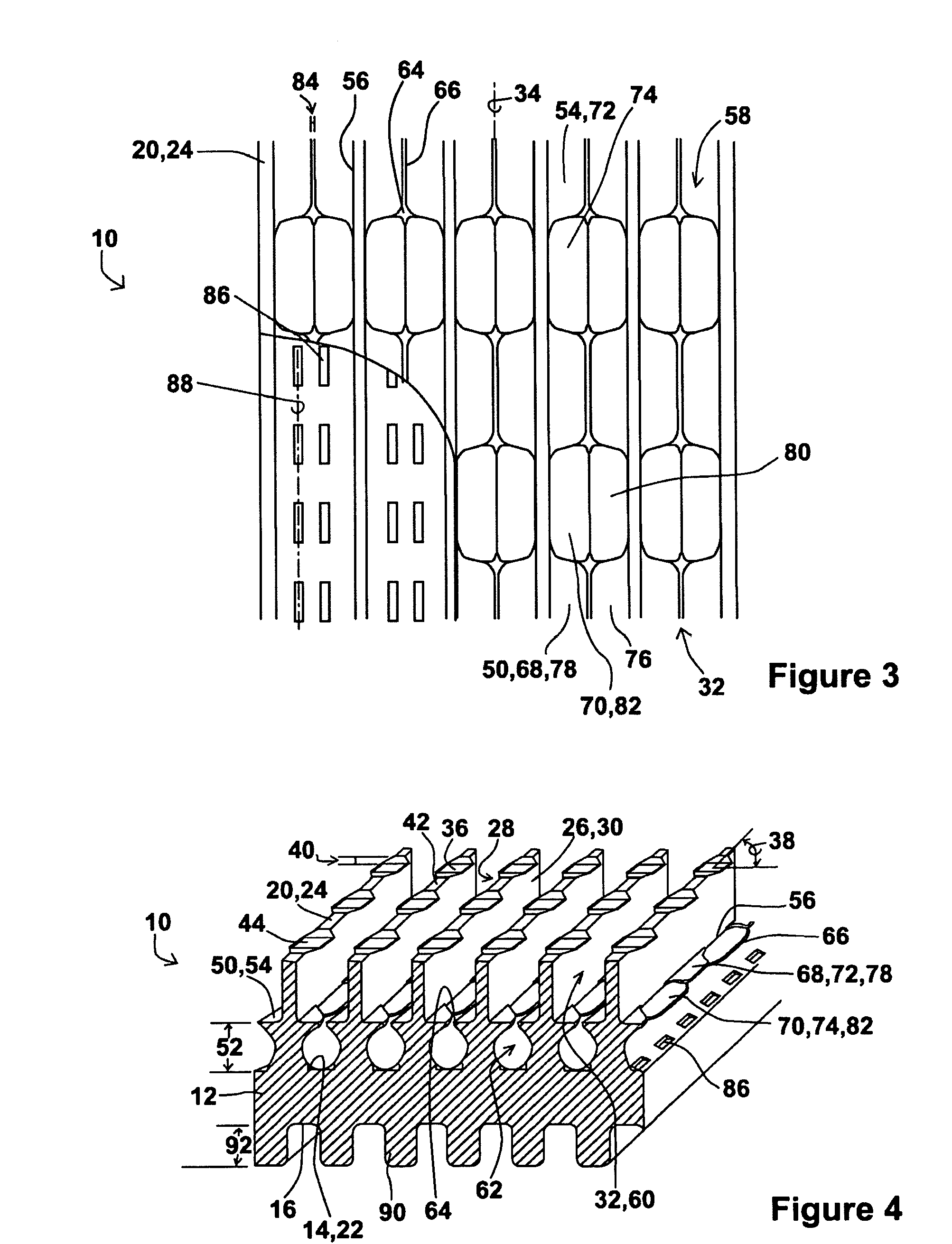

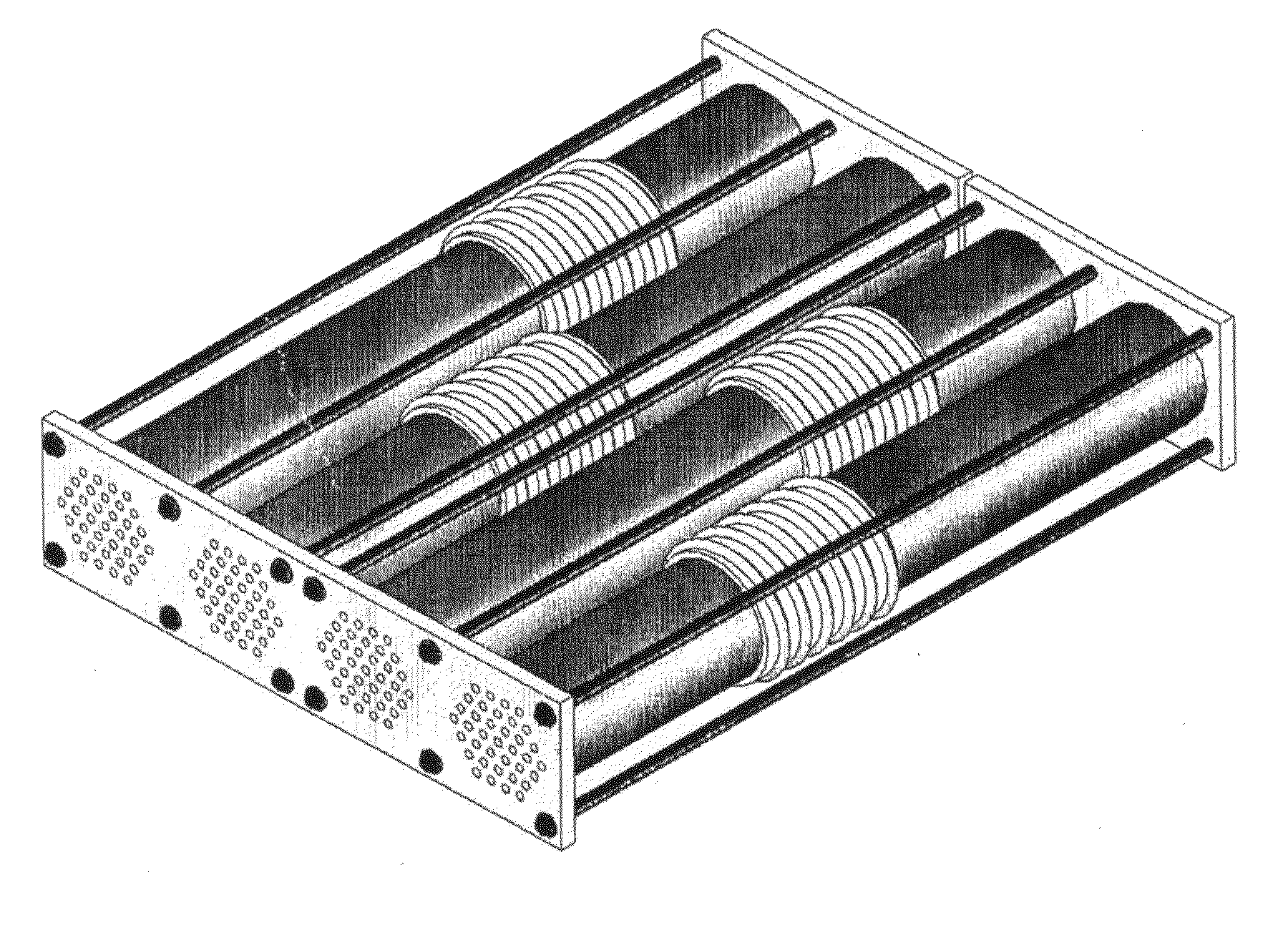

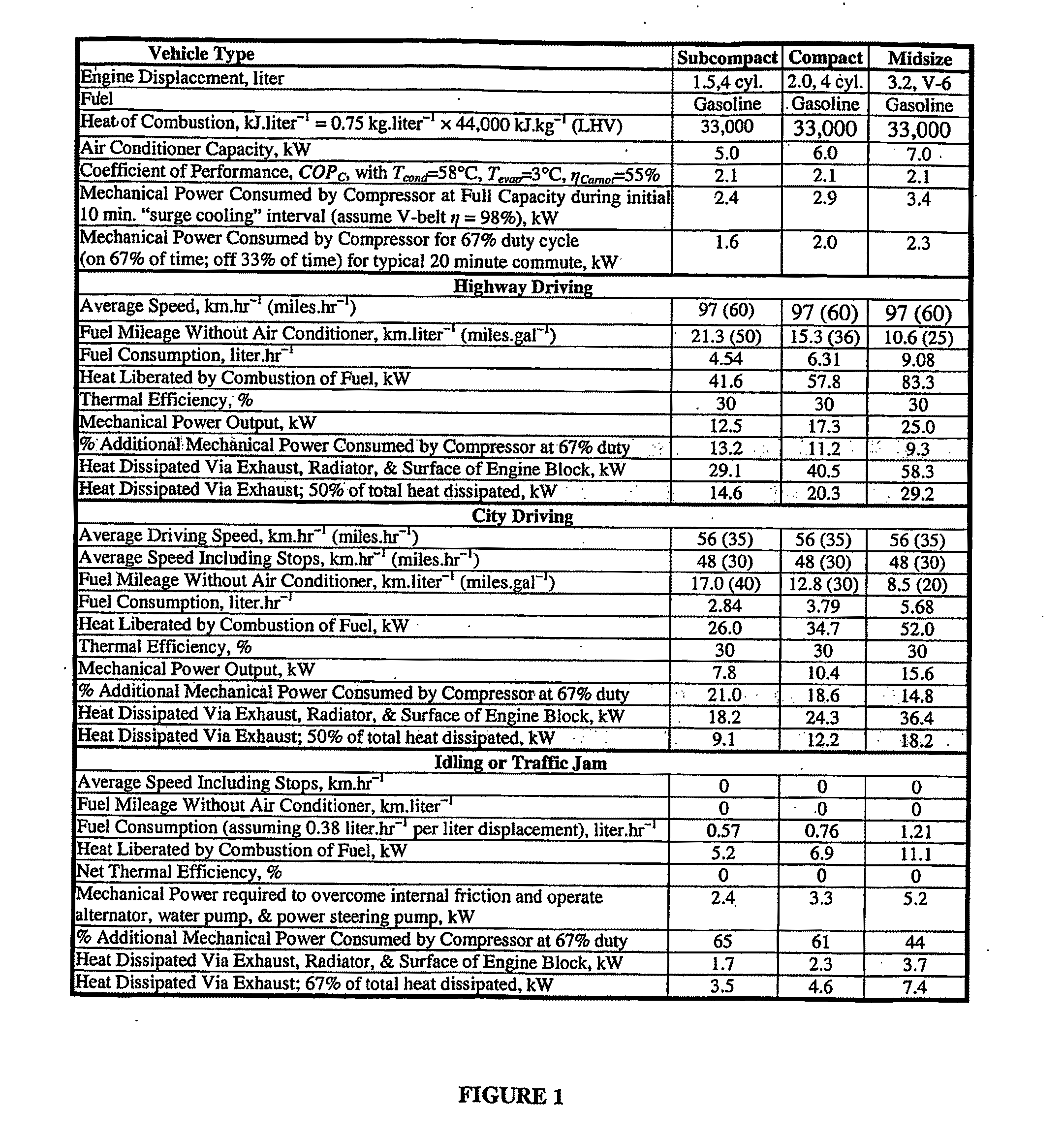

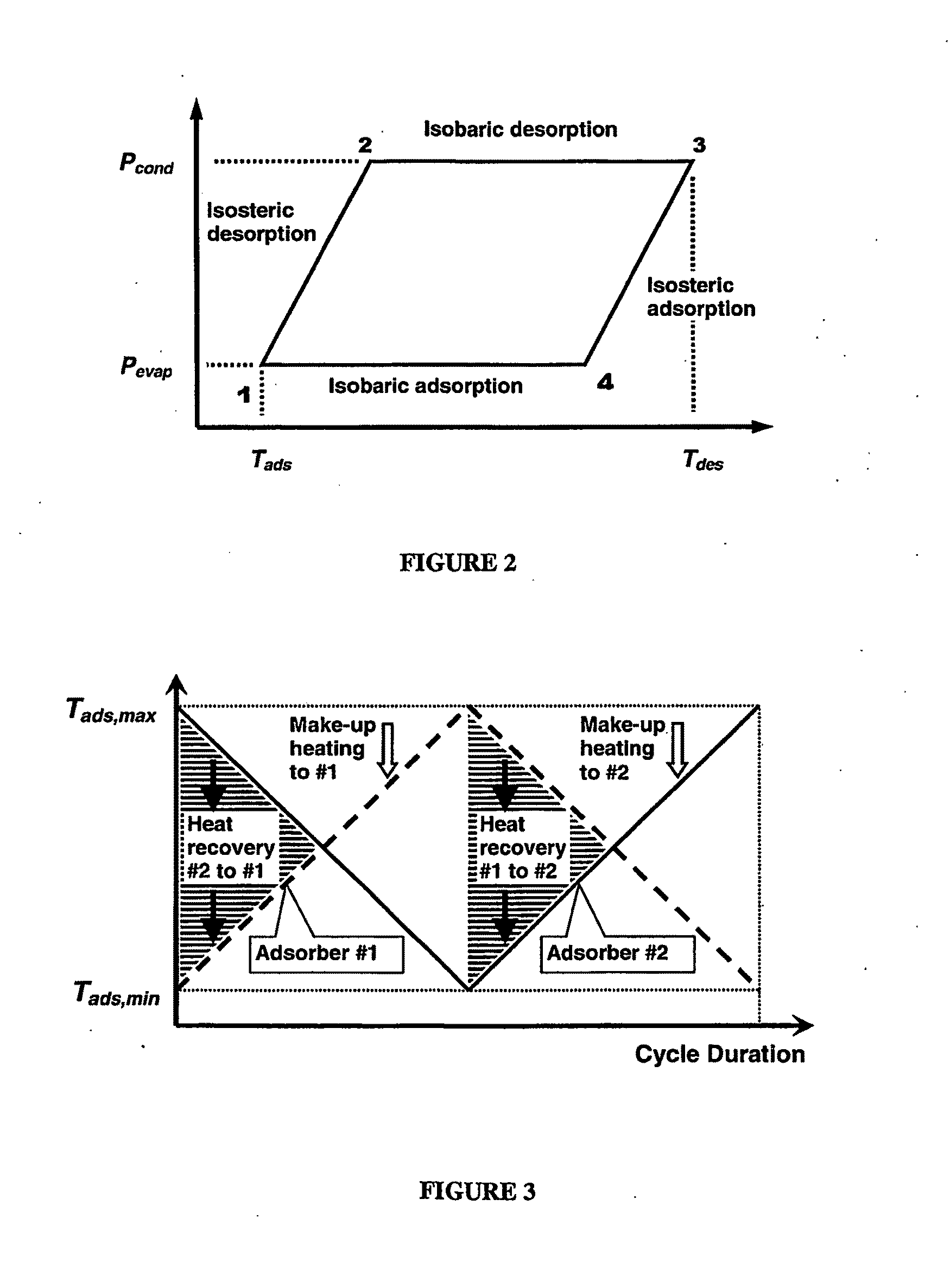

InactiveUS20110005267A1Efficient and reliableLess expensiveClimate change adaptationVehicle heating/cooling devicesSorbentFresh air

An adsorber unit has an outer shell, a plurality of internal tubes extending through the shell for carrying heat transfer fluid, each tube having outwardly projecting fins along its entire length, and a solid adsorbent material in the shell surrounding the tubes such that the fins project into the adsorbent material, the fins being of a material (e.g., metal) of higher thermal conductivity than the adsorbent material. Metal wool loosely packed inside the tubes, or internal radial fins swaged into the tubes, increase internal surface area thereby enhancing convective heat transfer. Metal wool loosely packed between the external fins, or fine wire metal coils lightly squeezed between the external fins, further increase external surface area of the heat exchanger in contact with the adsorbent thereby enhancing contact heat transfer. Performance is enhanced because the external fins and wool or wire coils transport heat more efficiently to all regions of the adsorbent, and permit less non-adsorbent heat exchanger material (e.g., metal) to be used for a given amount of adsorbent. Two or more such units are used in an adsorption heat pump. This design utilizes existing components (e.g., shell-&-tube heat exchanger, internally and externally finned tubing, and metal wool or wire coils) in a novel manner heretofore untried. In one exemplary embodiment, automobile air conditioning, exhaust heat is used to power such an air conditioner. The significant additional power used by the mechanical compressor of an automobile (12%-17% during commuting for subcompact to midsize cars) can be nearly eliminated by powering the air conditioner with otherwise wasted exhaust heat. The adsorbent is heated and cooled by light oil (called Heat Transfer Fluid, HTF) which in turn is heated and cooled by exhaust and fresh air. Such indirect heating and cooling achieves the required efficiency, and allows using phase change material (e.g., wax) to store and therefore fully utilize exhaust heat. A refrigerant reservoir is included which provides immediate cooling after start-up of a cold engine, while the exhaust system and heat pump are still heating up in order to start pumping refrigerant. Eliminating the mechanical compressor increases fuel mileage by 14-18% for midsize, compact, MS and subcompact cars, or 4.6-6.0% annually, given a four-month cooling season.

Owner:LAMBERT MICHAEL A +1

Finned helicoidal heat exchanger

InactiveUS20070125528A1Additional exchangeHigh densityStationary conduit assembliesStationary tubular conduit assembliesWorking fluidEngineering

Heat exchanger having a plurality of heat transfer tubes arranged substantially in the shape of a helicoidal tube with the individual coils running parallel to one another, and a plurality of fins secured to the external surfaces of the heat transfer tubes and arranged perpendicular to the tube to extend outwardly therefrom. The first working fluid flows inside the heat transfer tubes, and air flows through a passage defined between the adjacent fins and at right angles to the axis of each heat transfer tube. The blower is placed co-axial with the helicoid's axis to further enhance the heat exchange.

Owner:FAKHERI AHMAD

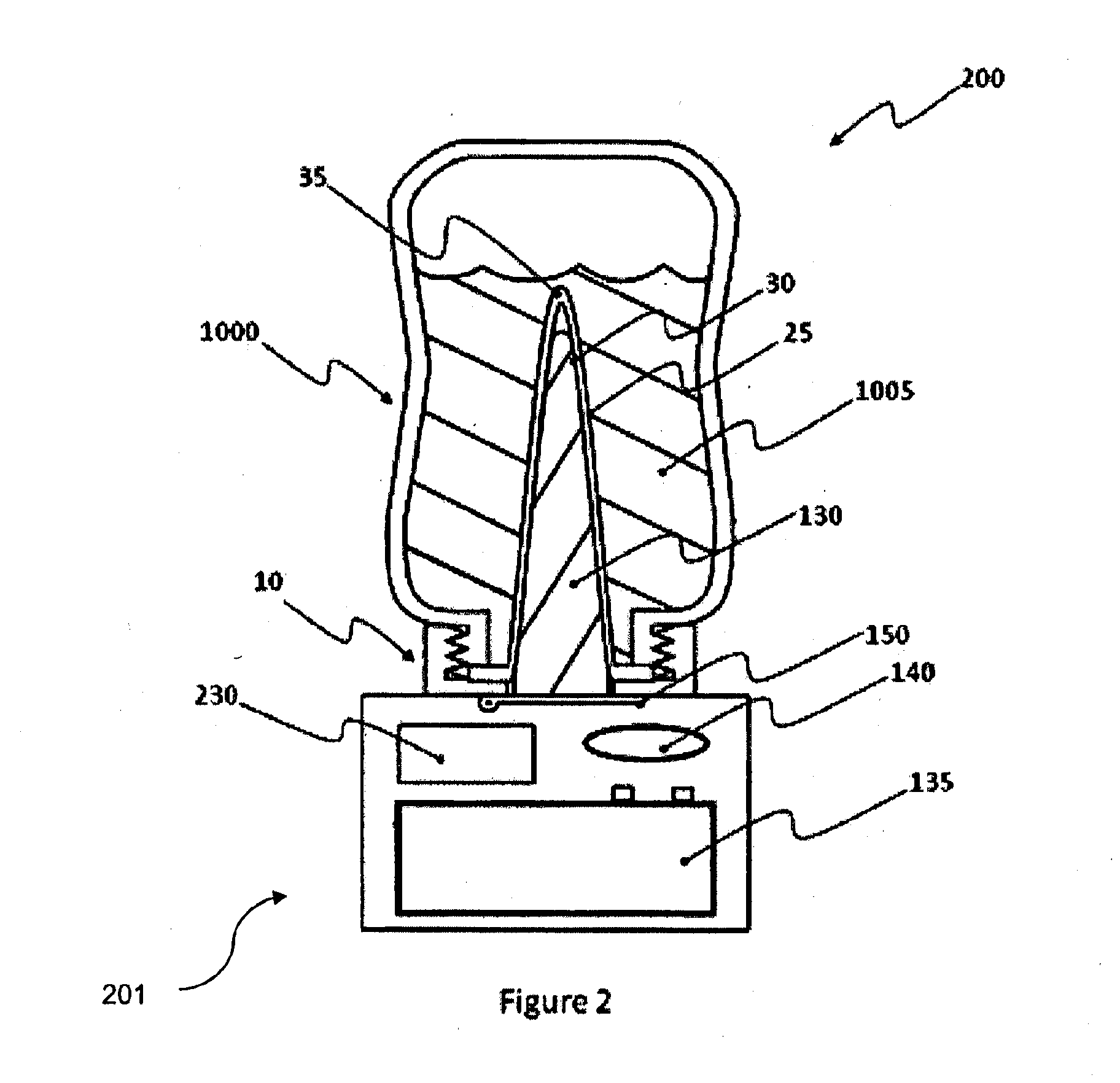

Heat Transfer Apparatus and Container

ActiveUS20130059259A1Increase contactIncrease heat transfer rateFurnace componentsClosure with auxillary devicesTemperature controlEngineering

A container for holding liquid is described. The container defines an inner region inside which liquid is adapted to be held and includes one or more walls for facilitating heating or cooling of the liquid therethrough, the one or more walls being adapted for invagination by a temperature control probe such that the temperature control probe extends into the container without directly contacting contents of the inner region of the container.

Owner:KISMET DESIGN

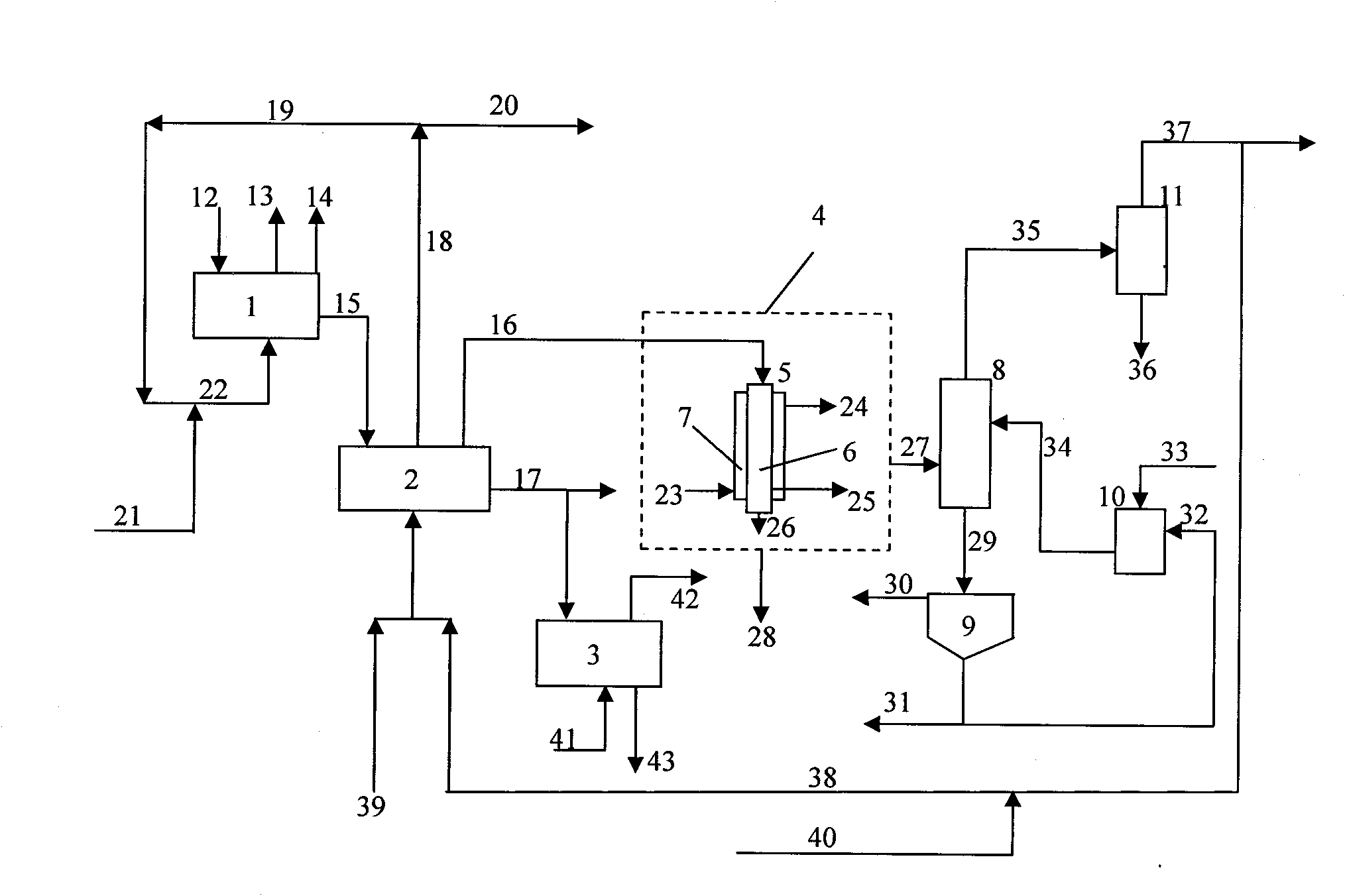

Low-coalification degree pulverized coal pyrolysis method and product prepared through the same

ActiveCN101880540AAlleviate the difficulty of efficient utilizationAlleviate the problem of secondary pyrolysisCoke quenchingSpecial form destructive distillationCoal pyrolysisCoal tar

The invention relates to a low-coalification degree pulverized coal pyrolysis method and a product prepared through the same. The method comprises the following four steps: low-coalification degree pulverized coal pre-drying, low-coalification degree pulverized coal pyrolysis reaction, gas cooling and tar recovery, and hot semi-coke cooling. The method is applicable to heat treatment to low-coalification degree pulverized coal resources so as to obtain high-quality pyrolysis gas and tar products, wherein the gas contains low inert component content, tar contains high light component content and low dust content, and semi-coke products with wide purposes are obtained. The process method is characterized by high comprehensive utilization rate of energy, large amount of treated material, lowdevice investment, easy industrialization realization, environmental friendliness and the like while improving the raw material utilization efficiency.

Owner:XIAN ORIGIN CHEM TECH

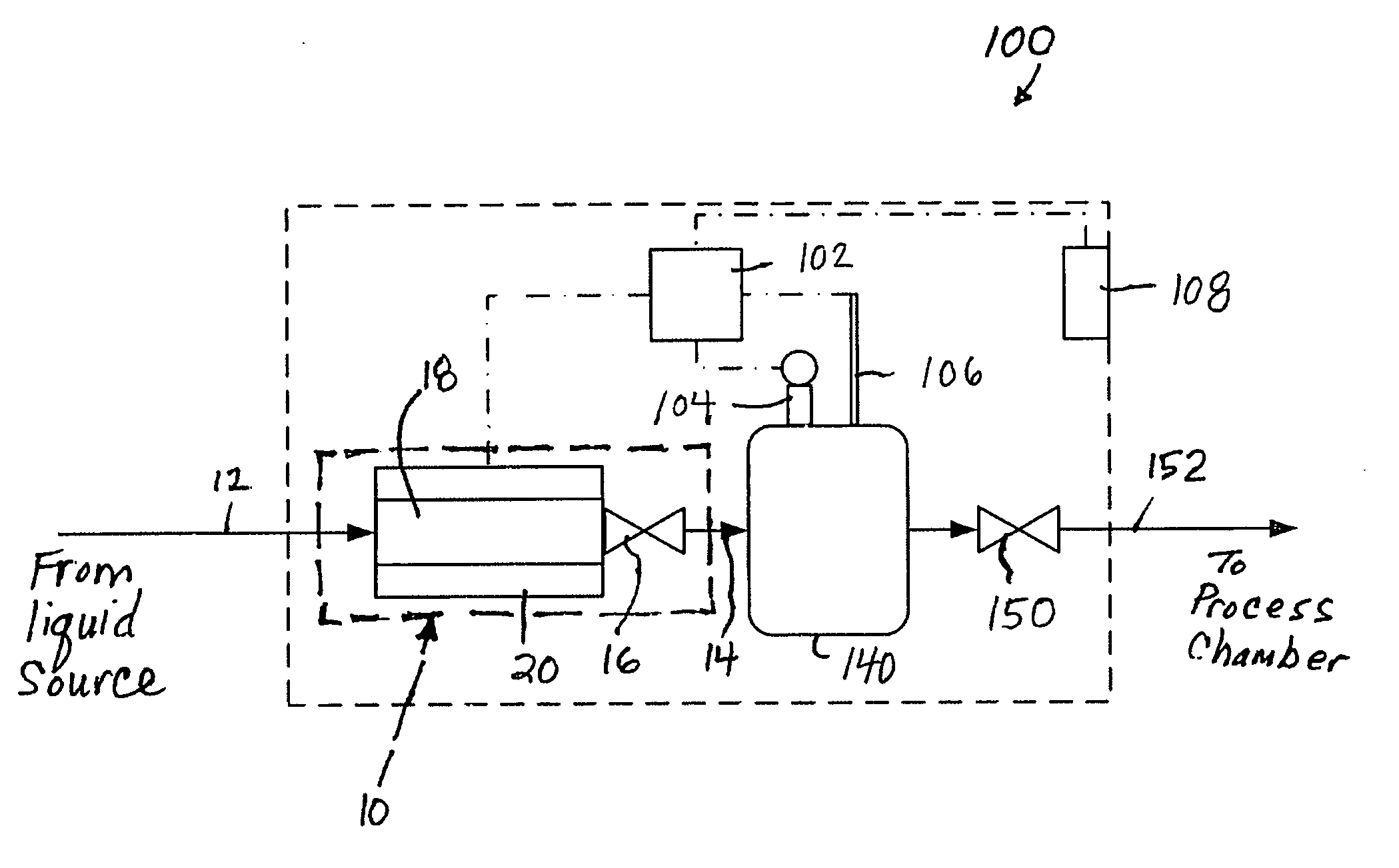

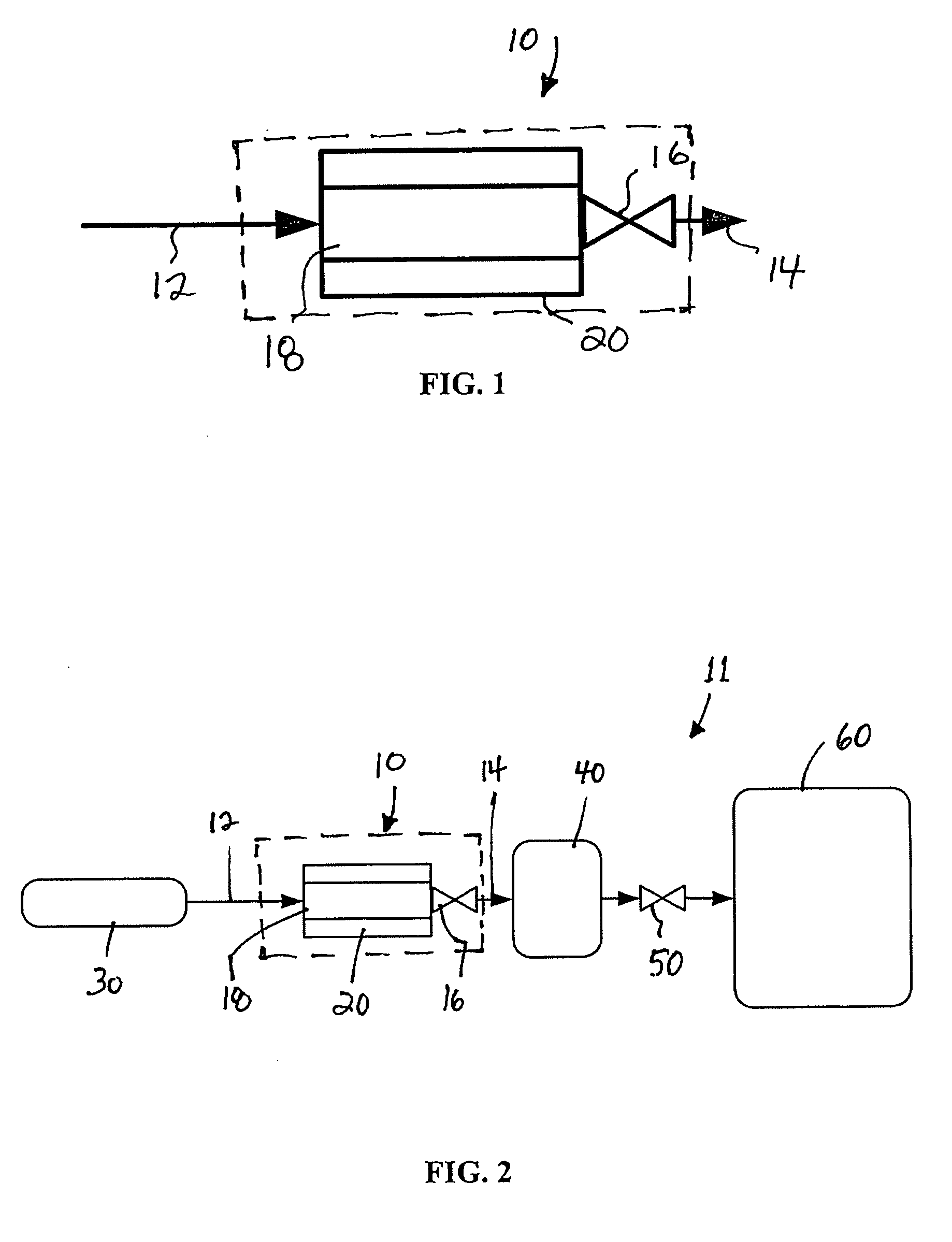

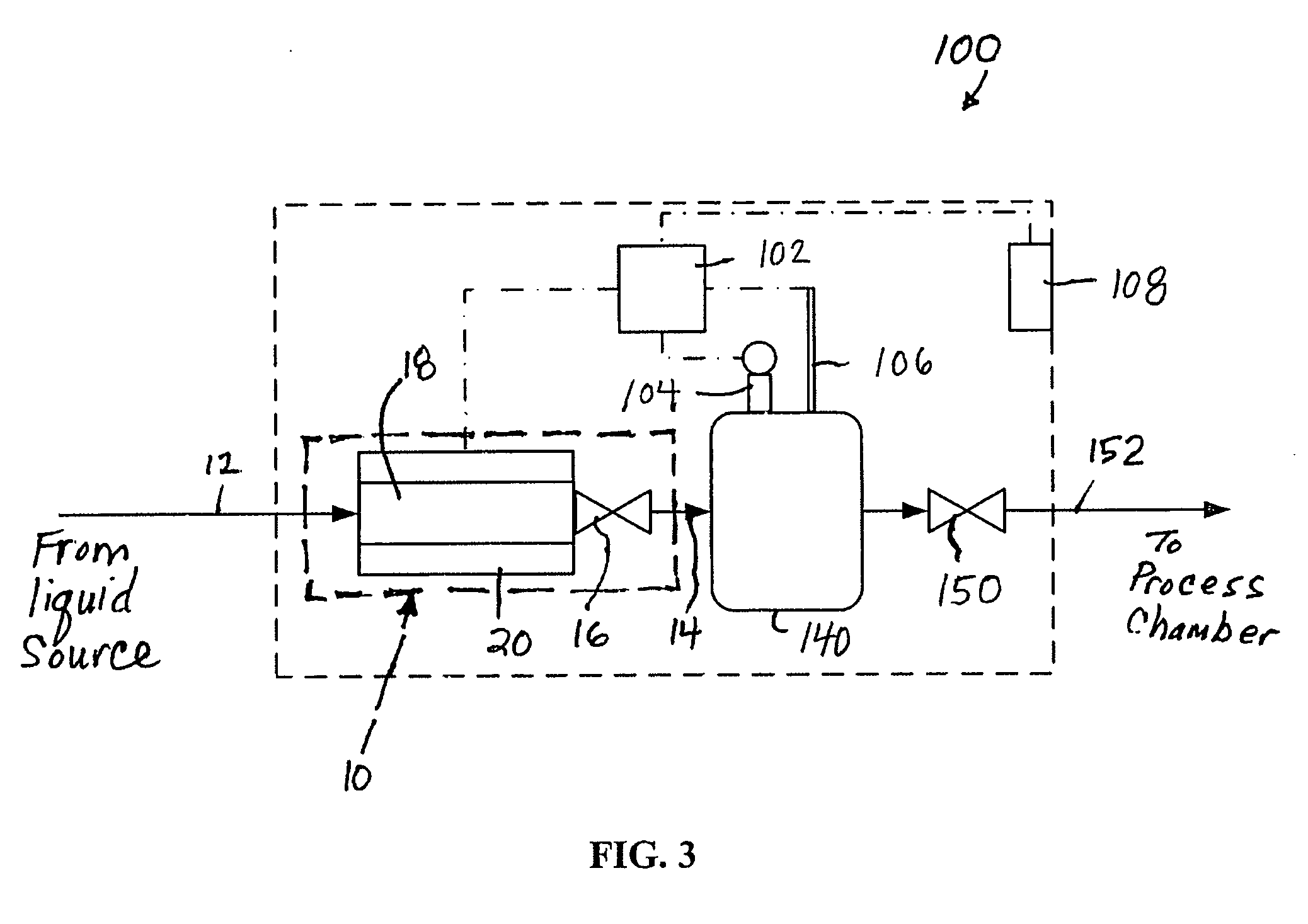

Vaporizer and method of vaporizing a liquid for thin film delivery

InactiveUS20060207503A1Simple designIncrease heat transfer rateBoiling apparatusChemical vapor deposition coatingTransition pressurePorous medium

A vaporizer including an inlet for liquid and an outlet for gas, a gas valve controlling gas flow to the outlet of the vaporizer, and means for heating liquid flowing between the liquid inlet and the gas valve. The vaporizer also includes means for increasing a heat transfer rate of the liquid flowing between the liquid inlet and the gas valve, and for causing a pressure drop in the liquid so that a pressure of the liquid drops below a vapor transition pressure of the liquid upon reaching the gas valve. The pressure drop occurs under isothermal conditions, and the liquid is vaporized on demand only when the valve is opened. The means for increasing a heat transfer rate and for causing a pressure drop can be a plug of porous media.

Owner:MKS INSTR INC

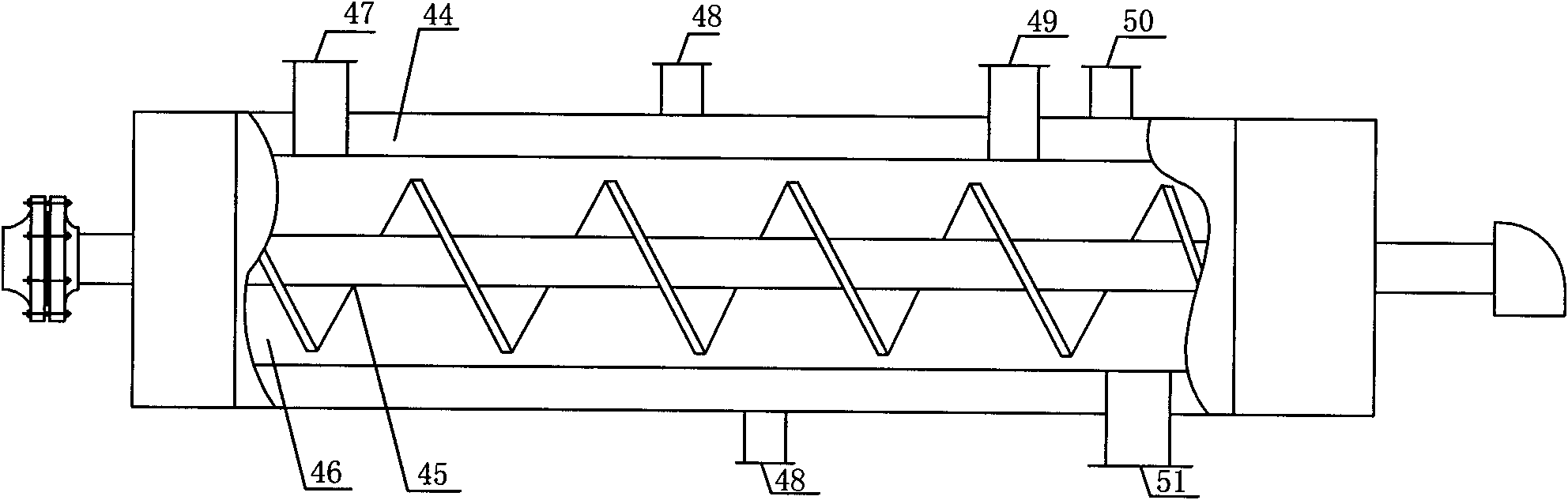

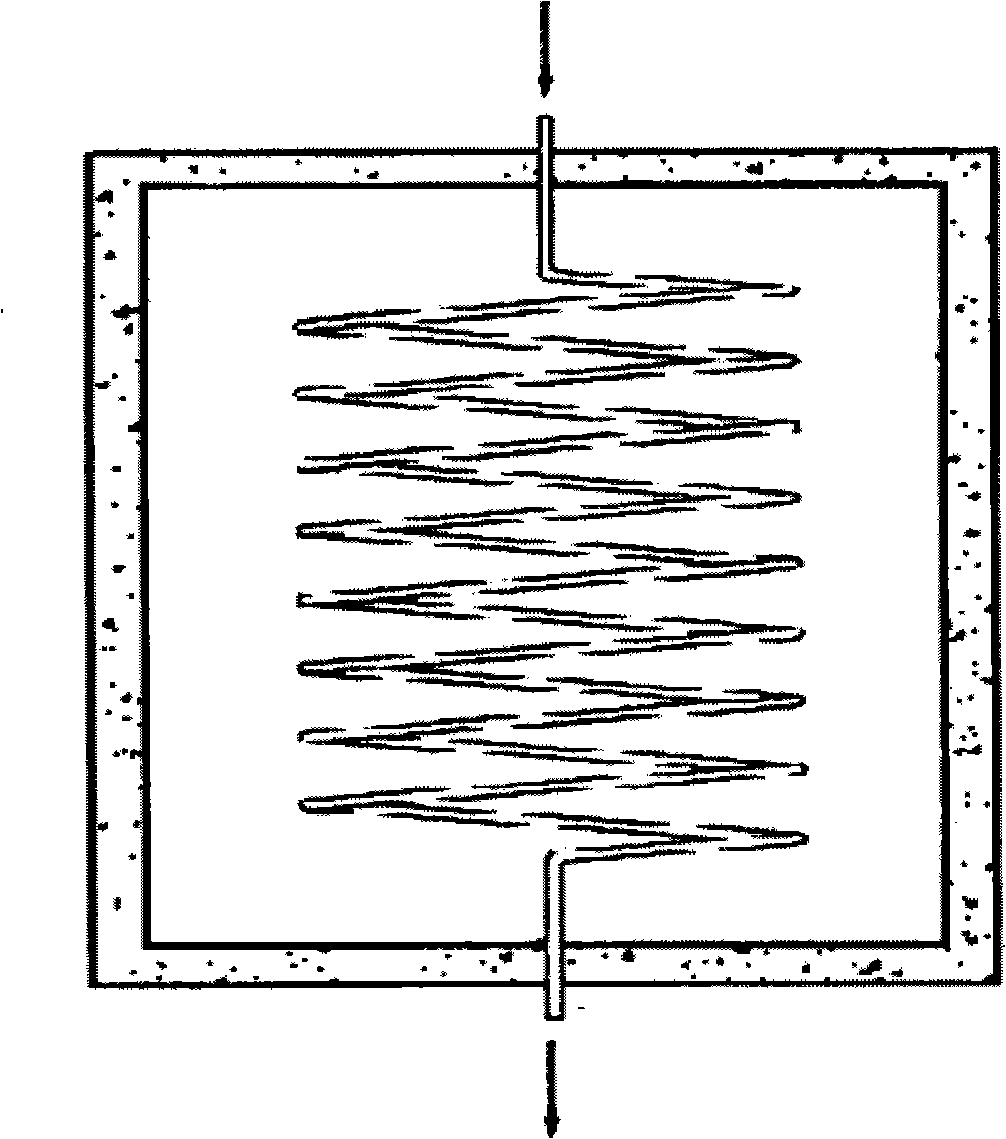

Composite sleeve double-helix heat exchanger

InactiveCN101566437AImprove circulationImprove heat transfer coefficientStationary tubular conduit assembliesViscous flowEngineering

The invention relates to a composite sleeve double-helix heat exchanger. At present, a plate type heat exchanger has high coefficient of heat transfer but can bear lower working pressure; a pipe shelltype heat exchanger is of a pressure-resisting structure but has very low coefficient of heat transfer; and a pipe type heat exchanger is formed by a single heat exchanging pipe or a heat exchange pipe bundle and has low heat transfer rate due to thick viscous flow layer of liquid inside the pipe and poor circulation state due to very low flow rate of liquid outside the pipe. In a double-helix three-sleeve heat exchanging pipe bundle of the composite sleeve double-helix heat exchanger, a middle pipe and a hollow inner pipe form an inner flow passage; inner helical blades are arranged in an annular gap of the middle pipe and the inner pipe; an outer pipe and the middle pipe form an outer flow passage; outer helical blades with opposite handedness with the inner helical blades are arranged in an annular gap of the middle pipe and the outer pipe; and two-phase liquid fast forms an annular lamella in the pipe to flow forwards in a helical scouring way. The structure not only has strong structure, but also can greatly improve the heat-transfer characteristic of the heat exchanger.

Owner:赵文阁

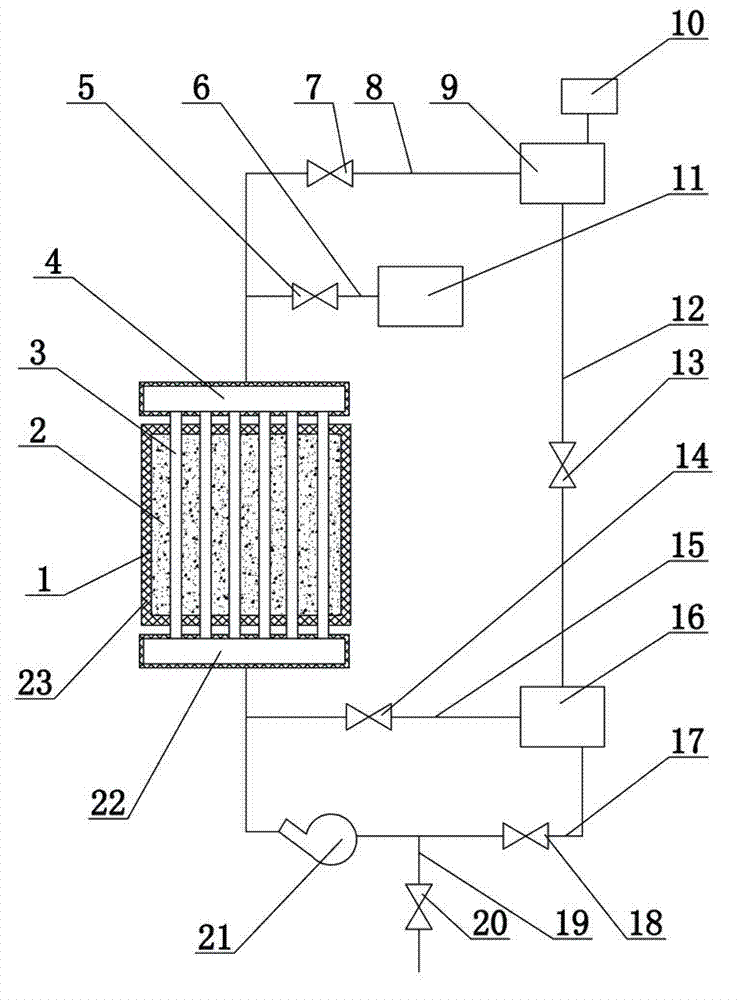

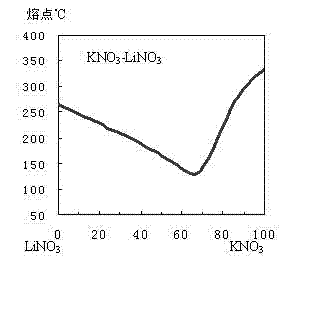

Phase change heat accumulation system for generating steam directly and preparation method of phase change heat accumulation agent

InactiveCN102777874AImprove efficiencyImprove heat transfer coefficientHeat storage plantsChemical industryPorous mediumToxic industrial waste

The invention relates to a phase change heat accumulation system for generating steam directly and a preparation method of a phase change heat accumulation agent. A phase change material is enhanced with graphite foam, and is absorbed in a porous medium of the graphite foam, so that a binary eutectic salt / graphite foam material is prepared and is used as a composite phase change material of a heat accumulation device, the composite phase change material is high in heat conduction coefficient, therefore under the same design condition, the phase change heat accumulation system provided by the invention is applied to systems of a focusing type solar thermal power generation system, an industrial waste heat recovery system and the like, and has the characteristics of high heat transfer efficiency, small volume, low cost and the like. In addition, the phase change heat accumulation system for generating steam directly can flexibly adopt a parallel connection or serial connection mode according to the temperature of high-temperature waste heat steam and the requirement of a steam user; and during serial connection, the binary eutectic salt / graphite foam composite phase change material can be combined in a cascaded manner according to a melting point, thus the efficiency of an energy accumulation system is increased, and the energy can be greatly accumulated.

Owner:ZHENGZHOU UNIV

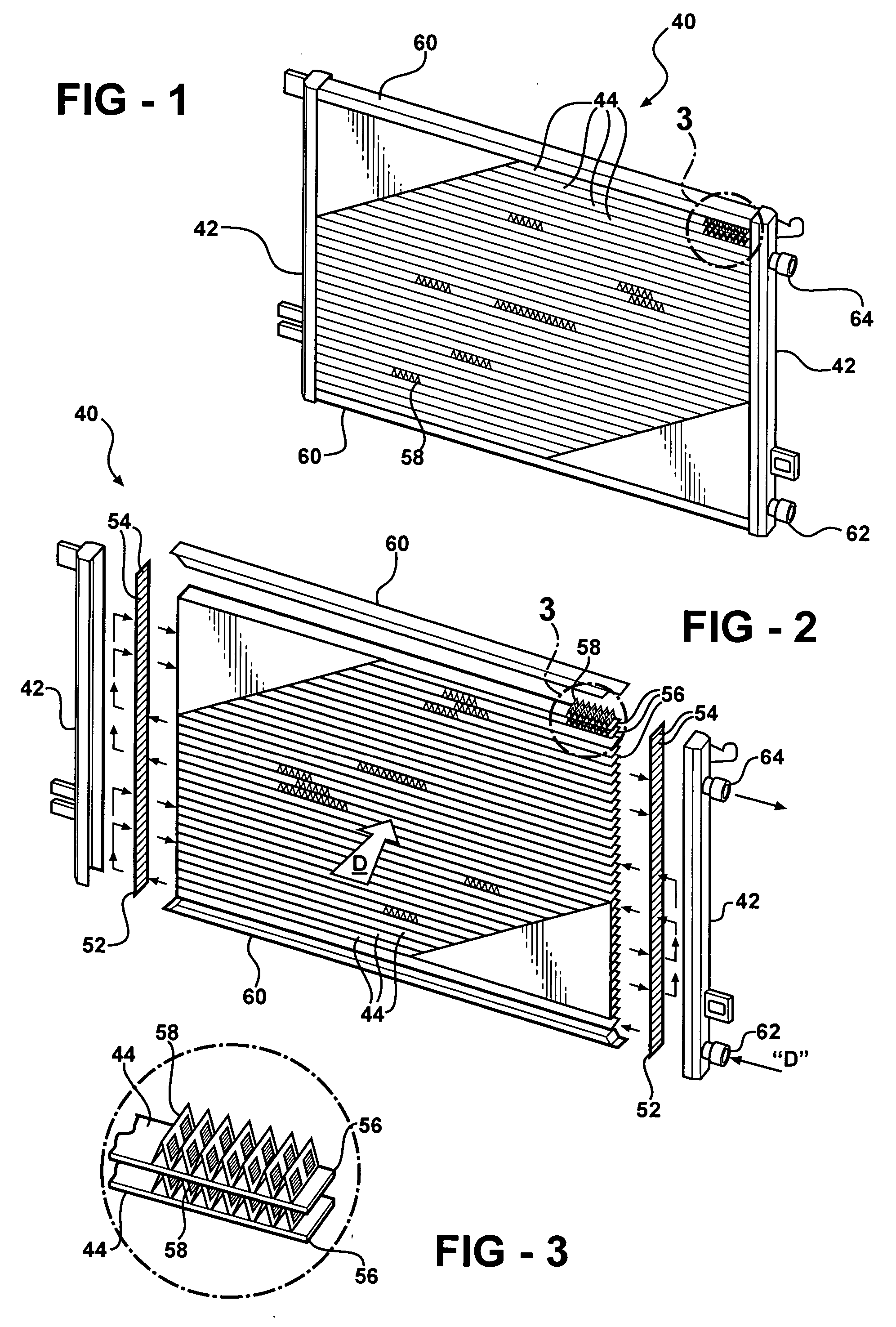

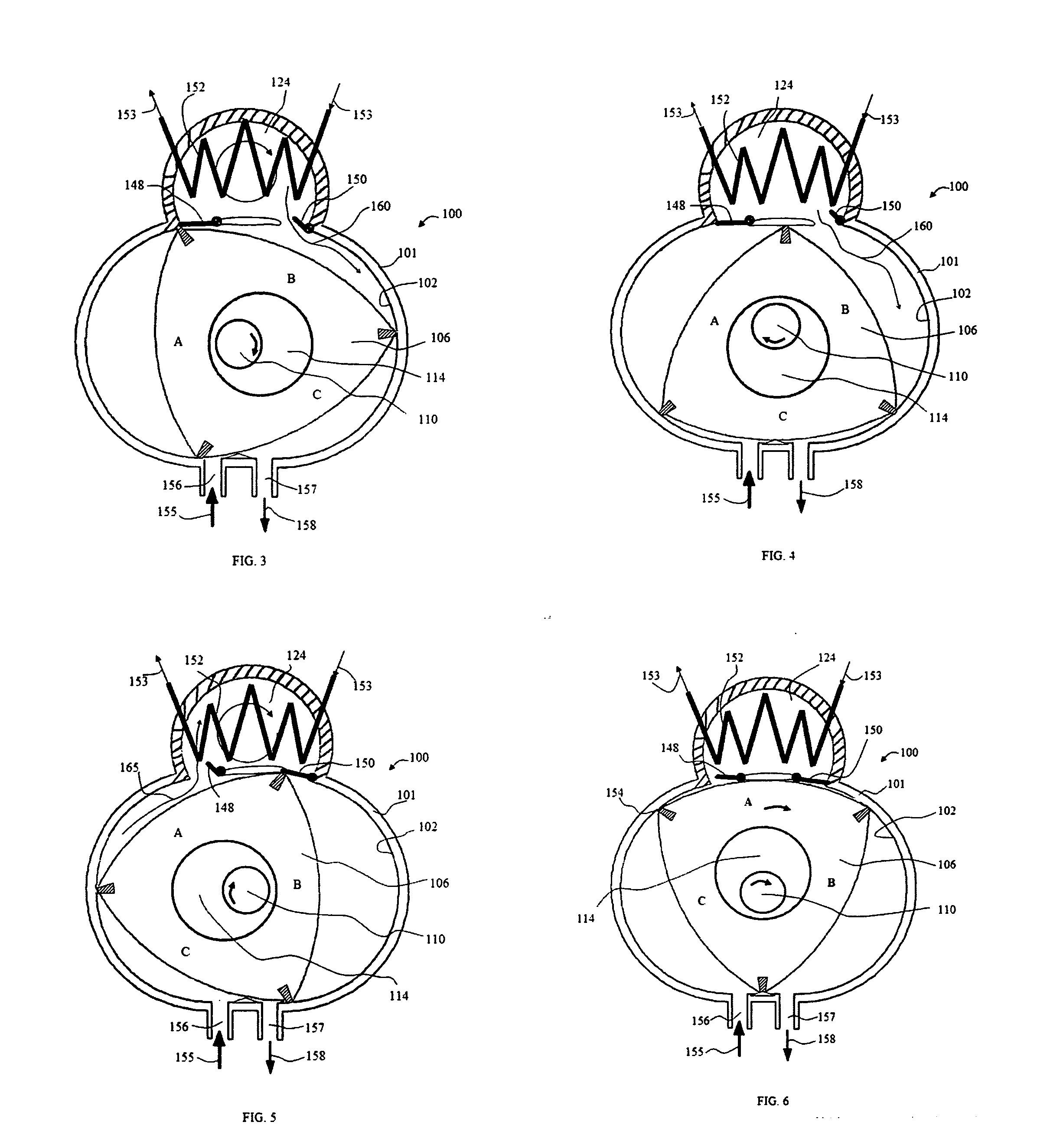

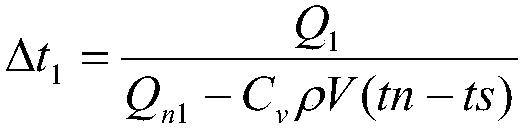

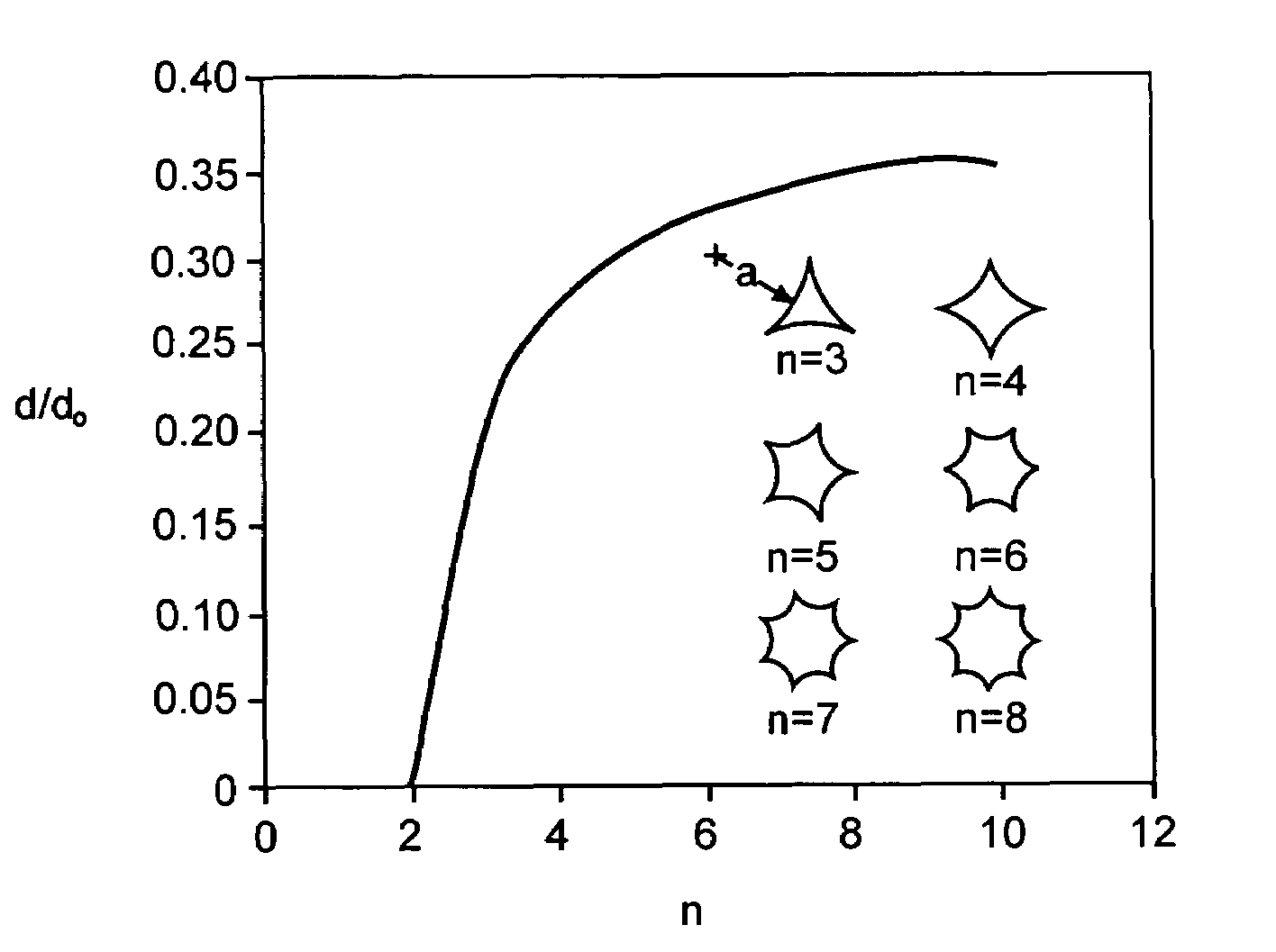

Flat tube evaporator with enhanced refrigerant flow passages

ActiveUS20050274506A1Increase heat transfer rateEnhances nucleate boilingStationary conduit assembliesHeat exchanger casingsEngineeringAir conditioning

A heat exchanger for a heating, ventilating and air conditioning system comprises a plurality of heat exchange tubes extending between a pair of spaced header tanks and arranged in groups of tubes with varying number of tubes in each group to cause a refrigerant to flow in multiple passes in the interior of the tubes across another fluid flowing on the exterior of the tubes. The heat exchange tubes comprise a plurality of flow passages having at least one corner formed by a pair of straight or arcuate sides with an included angle of less than or equal to ninety degrees, more preferably less than or equal to thirty degrees, to promote intense pool boiling within the flow passages. In addition to at least one corner region, the flow passage has a passage-specific optimal hydraulic diameter determined by the relationship between the optimal hydraulic diameter of the passage and the optimal hydraulic diameter of a baseline circular passage.

Owner:MAHLE INT GMBH

Cao heat engine and refrigerator

InactiveUS20100089062A1Increase the number ofExtended durationAuxillary drivesInternal combustion piston enginesThermal energyAir cycle machine

Owner:CAO YIDING

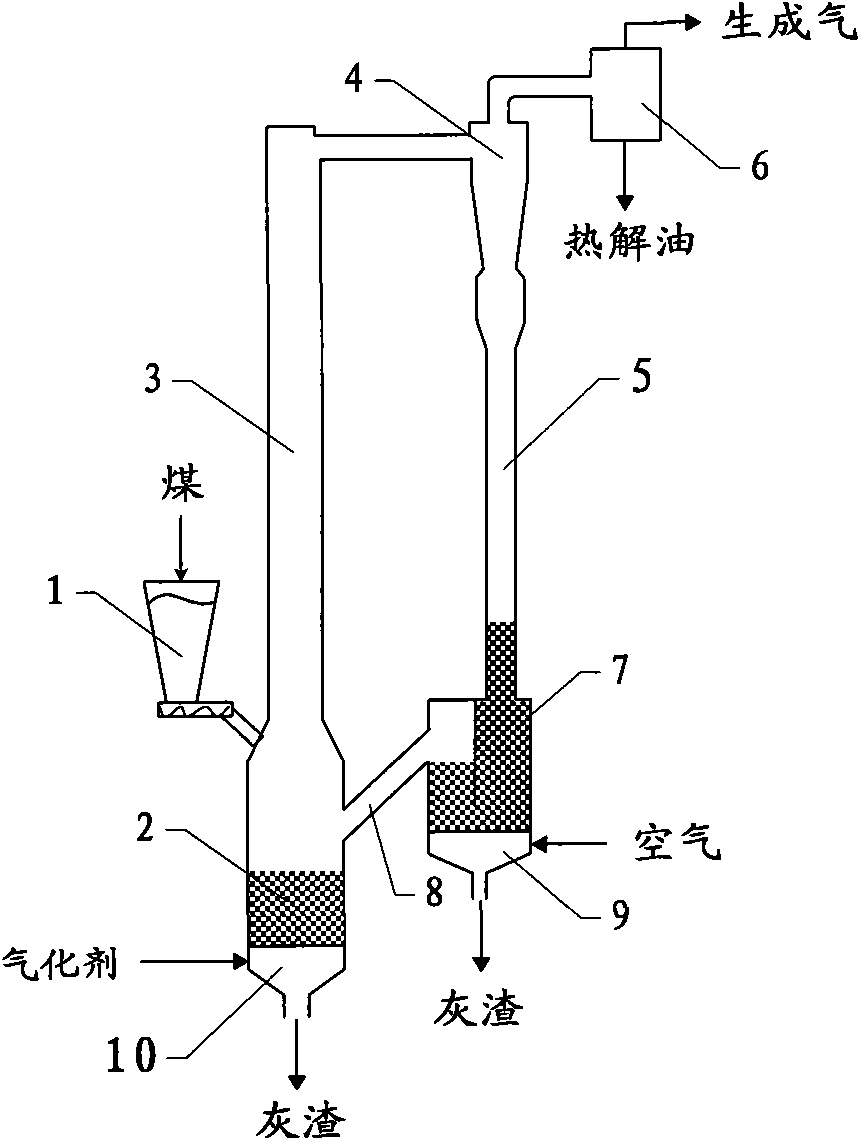

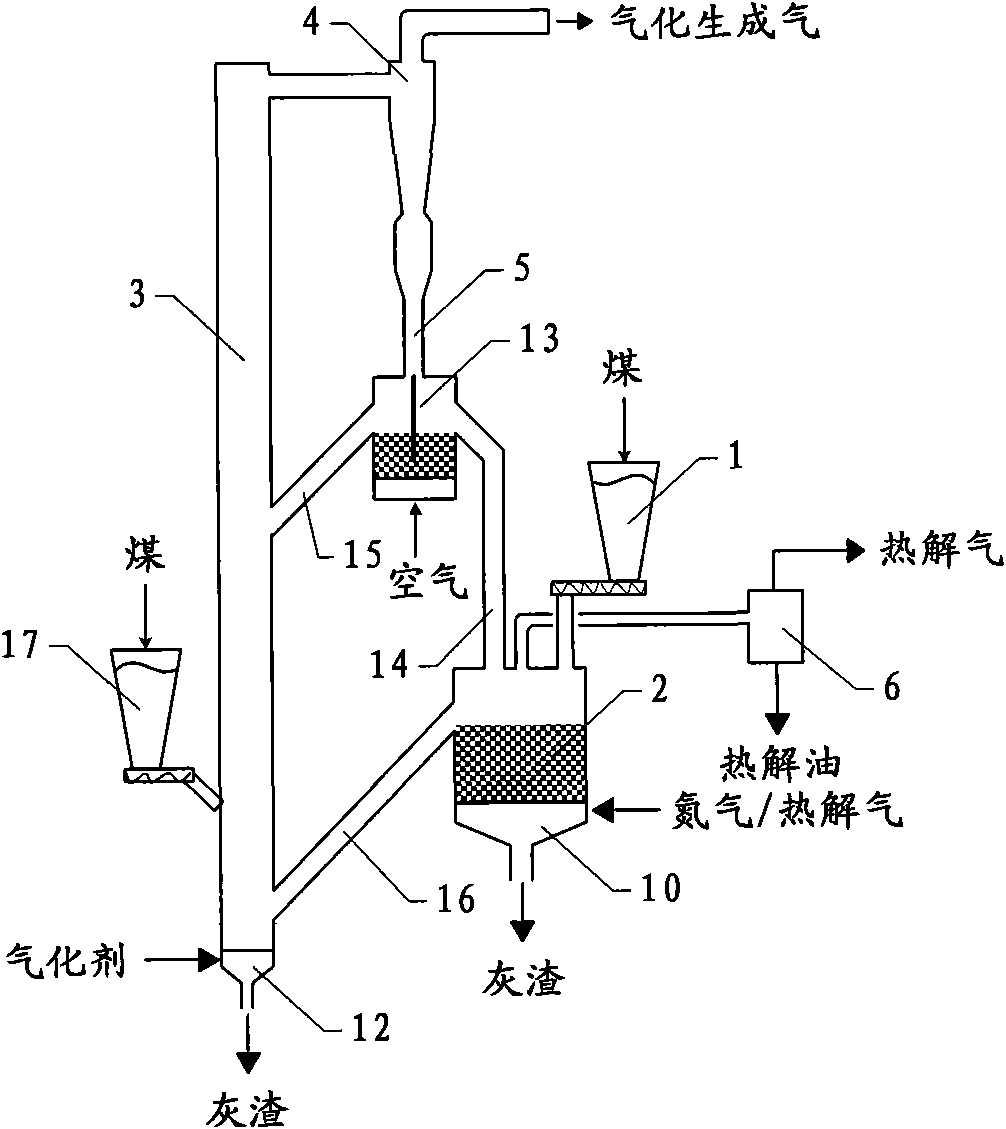

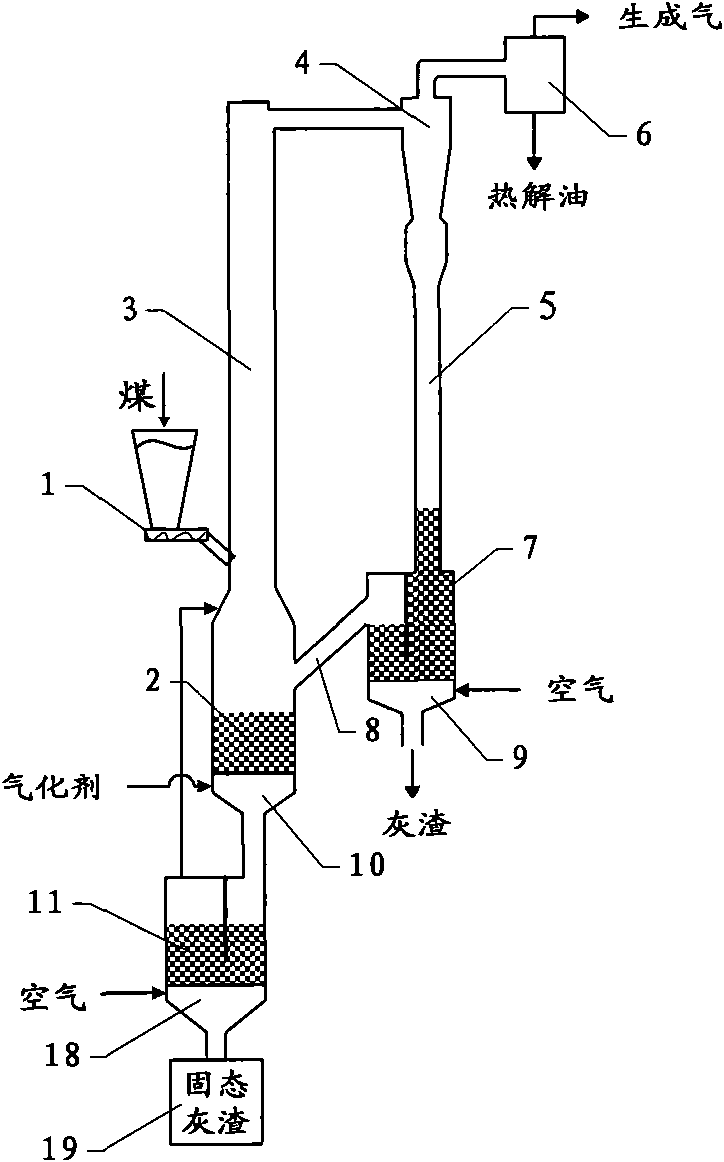

Method and device for utilizing high value through pyrolysis and gasification of coal

ActiveCN101781583ARealize joint productionFast pyrolysisLiquid hydrocarbon mixture productionCombined combustion mitigationOrganic structureFluidized bed

The invention relates to a method and a device for utilizing high value through pyrolysis and gasification of coal. The pyrolysis and gasification processes of the coal are separated in a mode of coupling a dilute phase conveying bed and a dense phase fluidized bed; and the coal is partially or wholly pyrolyzed before gasification, and co-production of pyrolysis gas, gasification generated gas and pyrolysis oil is realized. The dilute phase conveying bed and the dense phase fluidized bed can be coupled in two modes, namely upper-lower coupling and left-right coupling, and are applied to treating the coal in wide particle diameter distribution. High-value organic structures in the coal can be extracted before the gasification of the coal, and the utilization value of the coal is improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

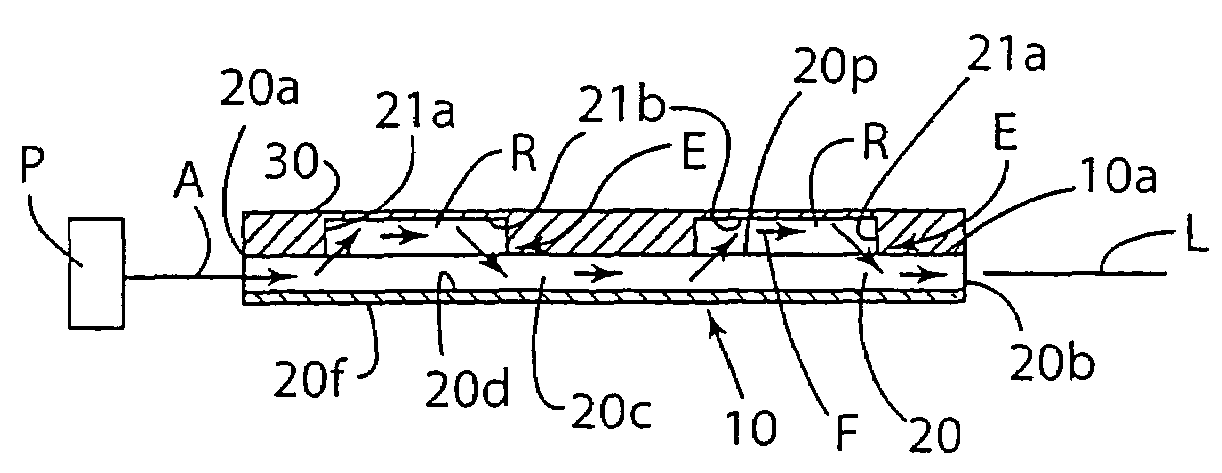

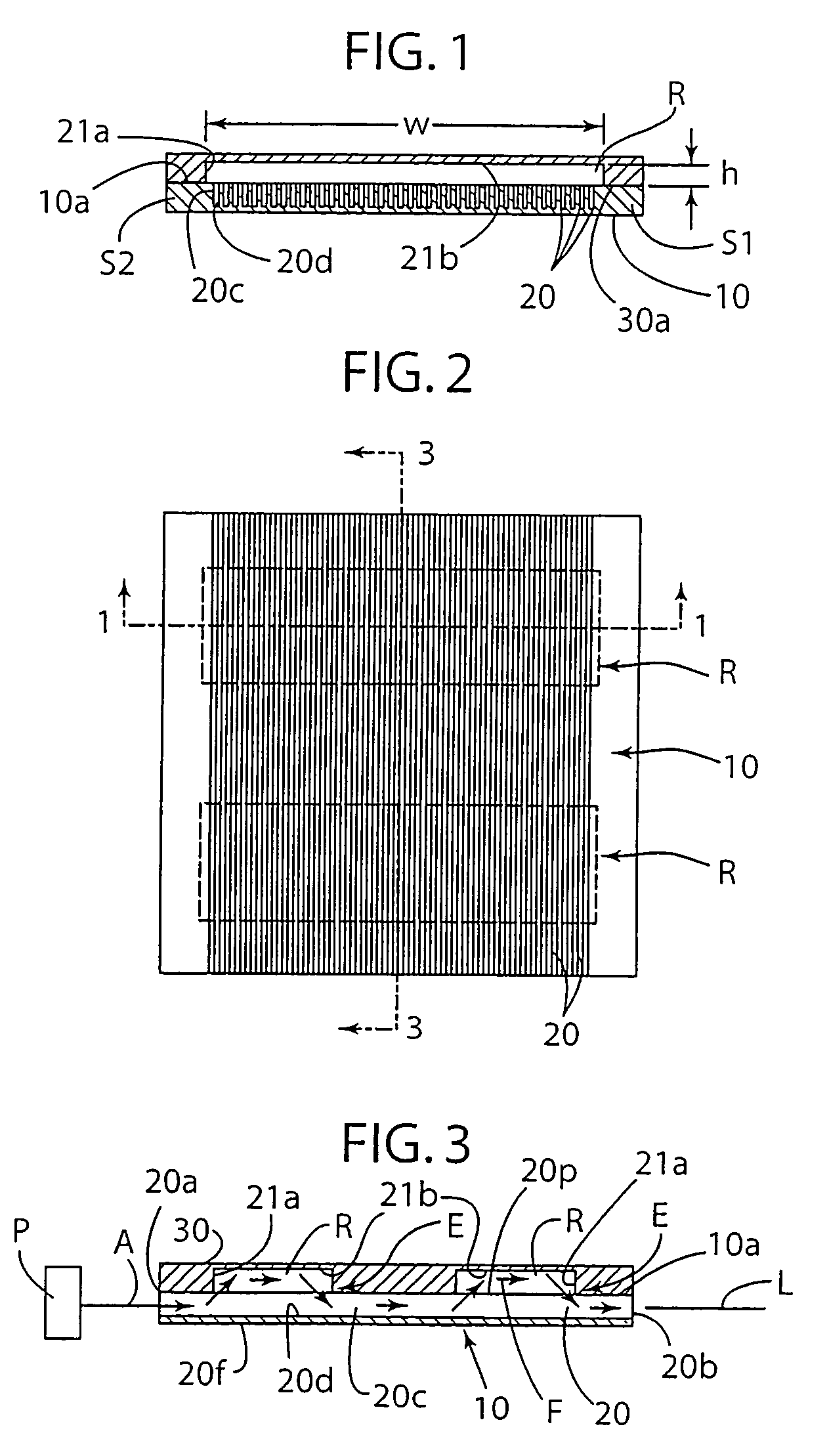

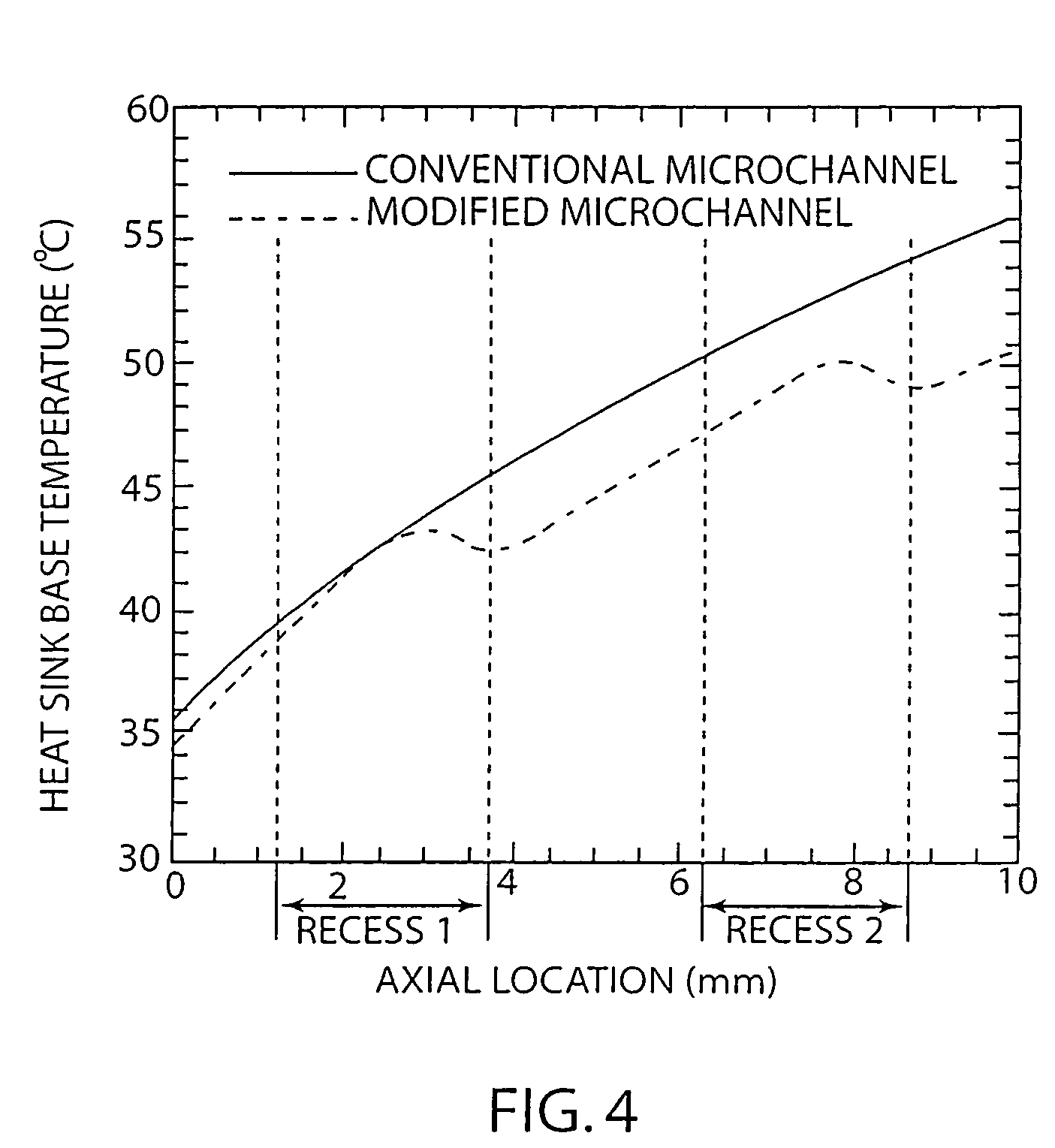

Microchannel heat sink

ActiveUS7277284B2Increase heat removal rateIncrease heat transfer rateSemiconductor/solid-state device detailsSolid-state devicesWorking fluidEngineering

A microchannel heat sink as well as method includes one or more microchannels through which a working fluid flows to remove heat from a heat-generating component, such as a microelectronic chip, and one or more recesses disposed in a surface communicated to the one or more of the microchannel to enhance heat transfer rate of the microchannel heat sink. The recesses can be located in a surface of a cover that closes off the microchannels. The one or more recesses can be located at one or more local hot spot regions to enhance heat transfer rates at the local regions as well as overall heat removal rate of the heat sink.

Owner:PURDUE RES FOUND INC

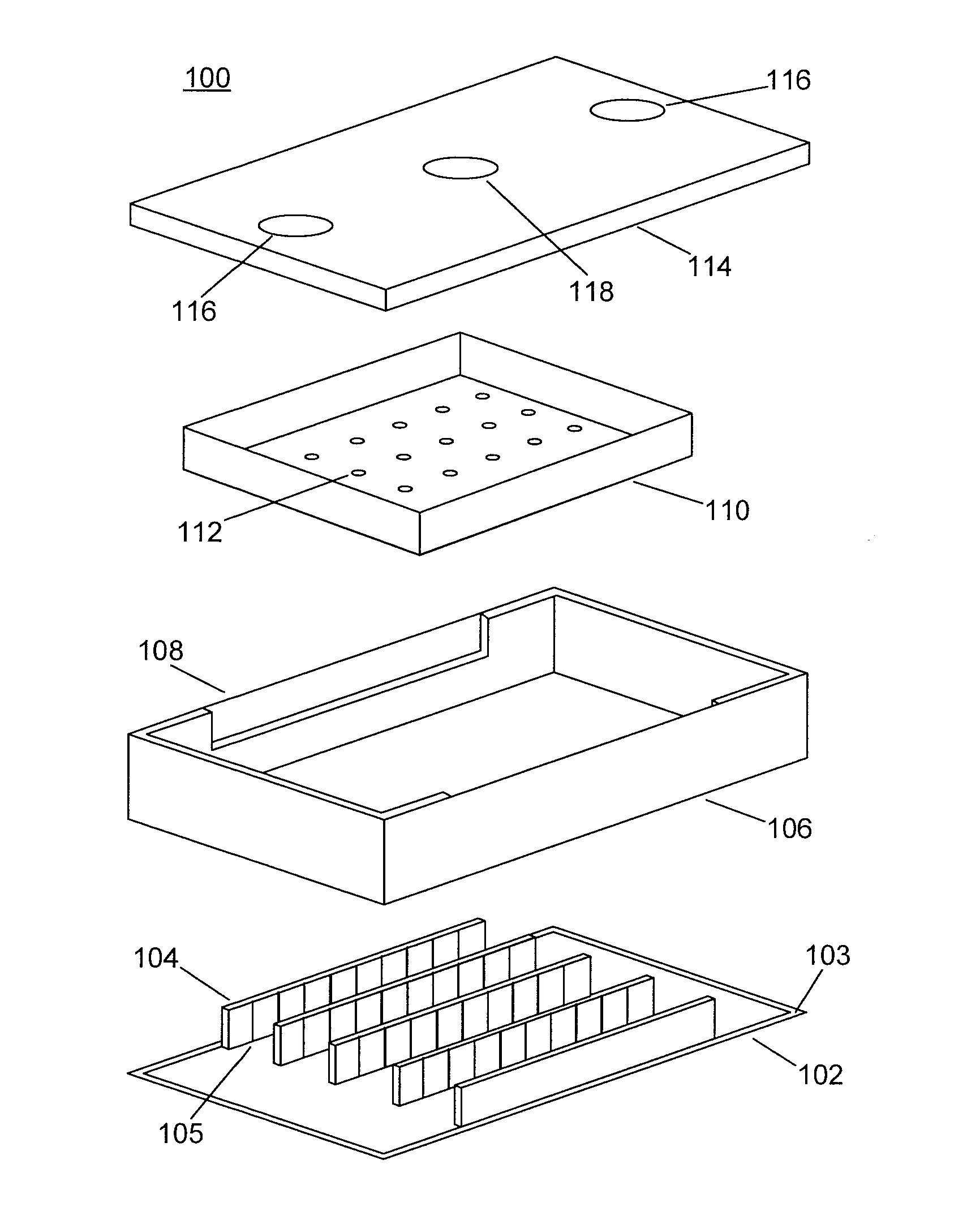

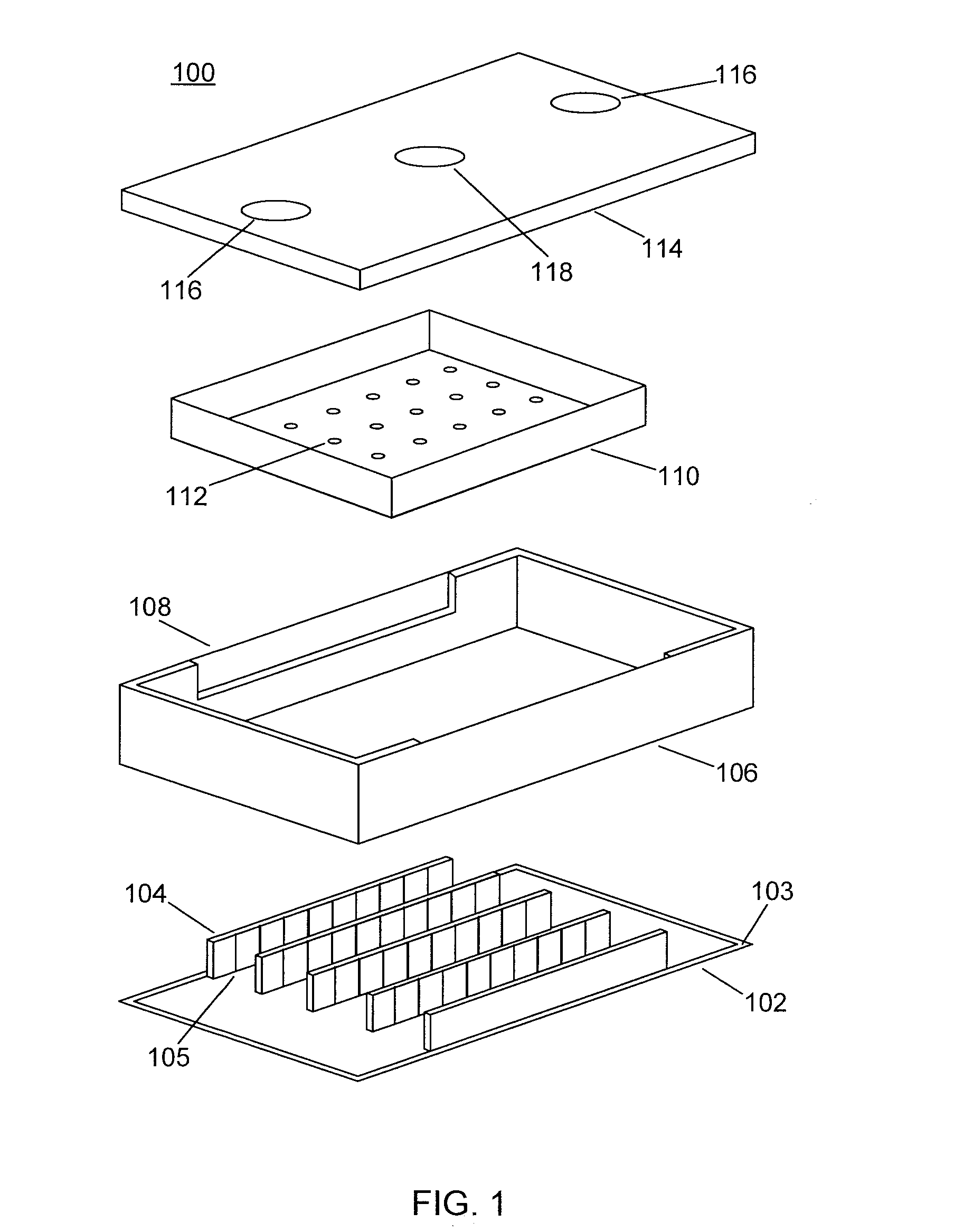

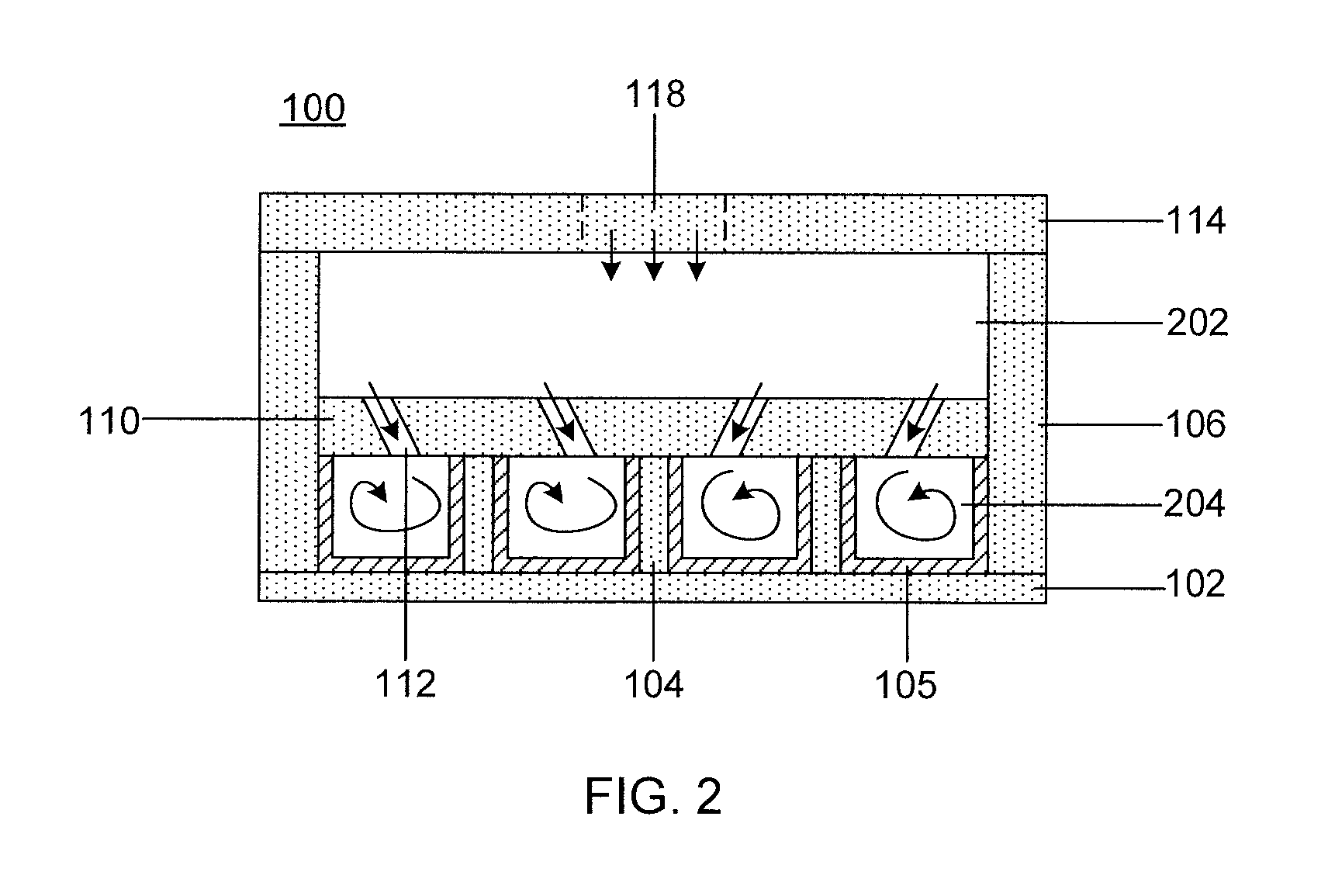

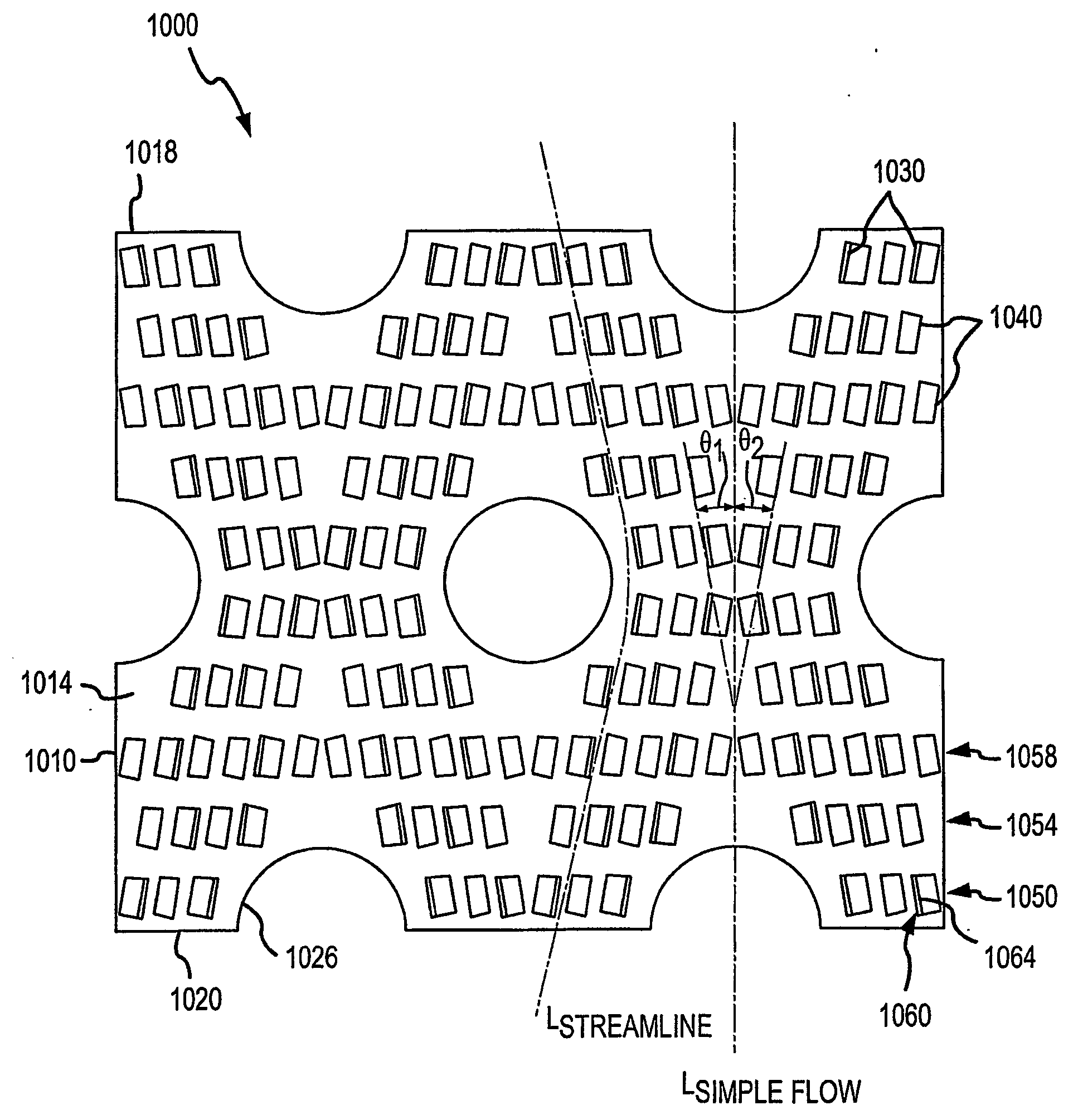

Cold plate with combined inclined impingement and ribbed channels

ActiveUS20130233523A1Increase heat transfer rateSemiconductor/solid-state device detailsSolid-state devicesAngular deviationEngineering

Heat transfer devices and methods for making the same that include a first enclosure having at least one inlet port; a second enclosure having a bottom plate and one or more dividing walls to establish channels, at least one internal surface of each channel having rib structures to create turbulence in a fluid flow; and a jet plate connecting the first enclosure and the second enclosure having impinging jets that convey fluid from the first enclosure to the channels, said impinging jets being set at an angular deviation from normal to cause local acceleration of fluid and to increase a local heat transfer rate.

Owner:IBM CORP

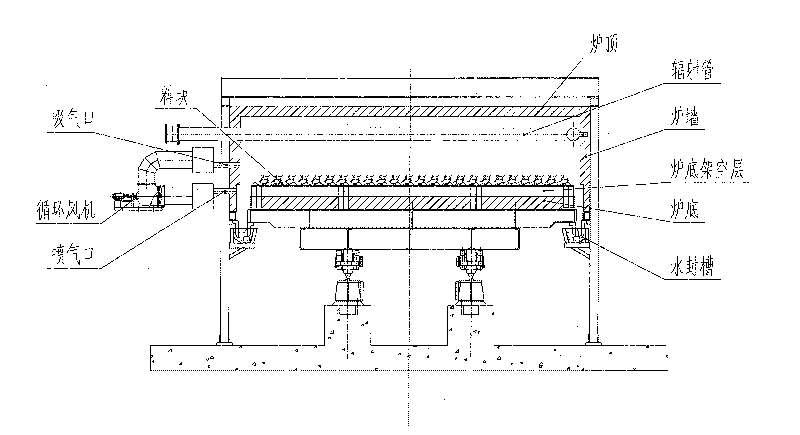

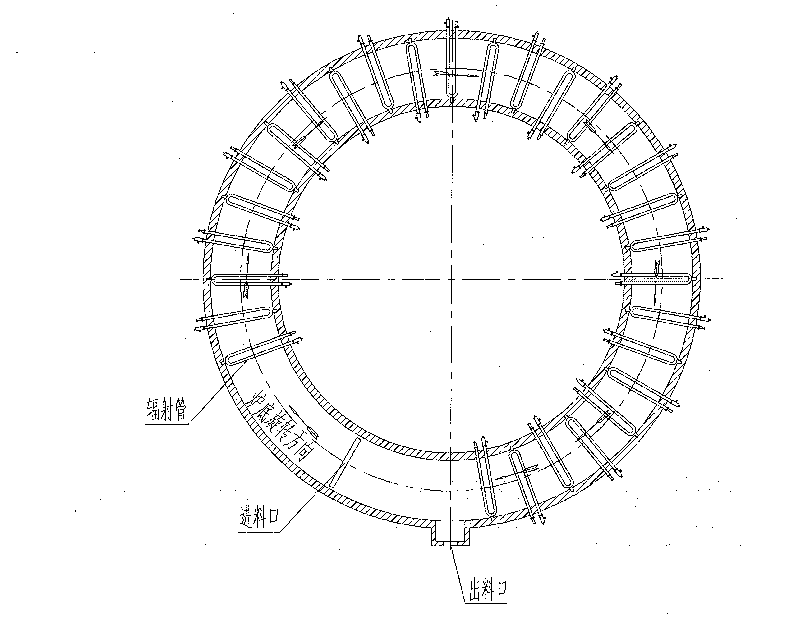

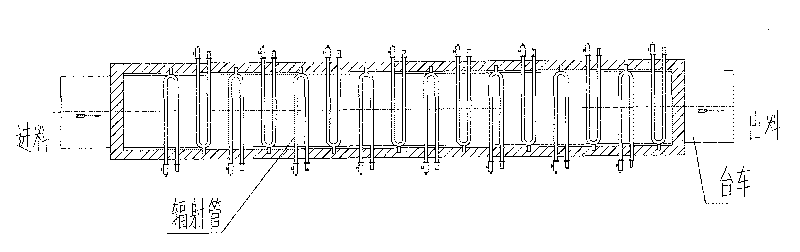

Moving-bed retorting furnace heated comprehensively by radiant tube and circulating airflow

ActiveCN101712878AUnbreakableUniform heating temperatureDirect heating destructive distillationIndirect heating destructive distillationHearthMoving bed

The invention discloses a moving-bed retorting furnace heated comprehensively by a radiant tube and a circulating airflow, comprising a hearth formed by furnace walls, a furnace top and a furnace bottom. The furnace bottom is a circular or through movable furnace bottom; and the upper space of the hearth is provided with a radiant tube heater. By adopting the radiant tube heater to heat, burning products can not be doped in retorting gas, generated retorting oil can keep inherent components, and the retorting gas has high heat value. The furnace bottom is in an overhead layer structure, and afurnace gas-circulating device is arranged between the overhead space and the hearth space above the furnace bottom. The invention has high heat-transferring rate and uniform material-heating temperature and is widely used to retort materials, such as oil shale, coal, lignite, oil sand, plants, and the like.

Owner:SHENWU TECH GRP CO LTD

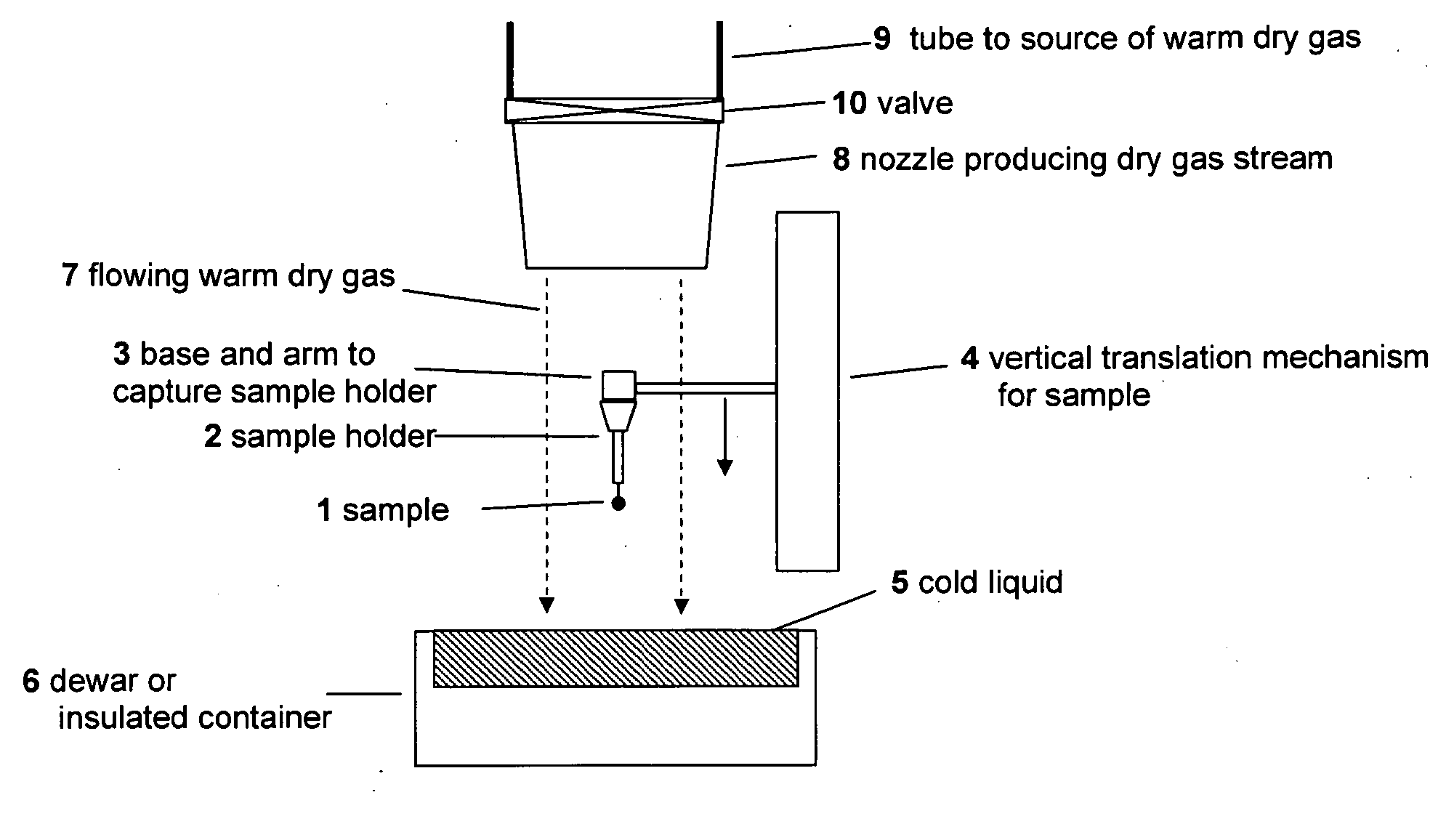

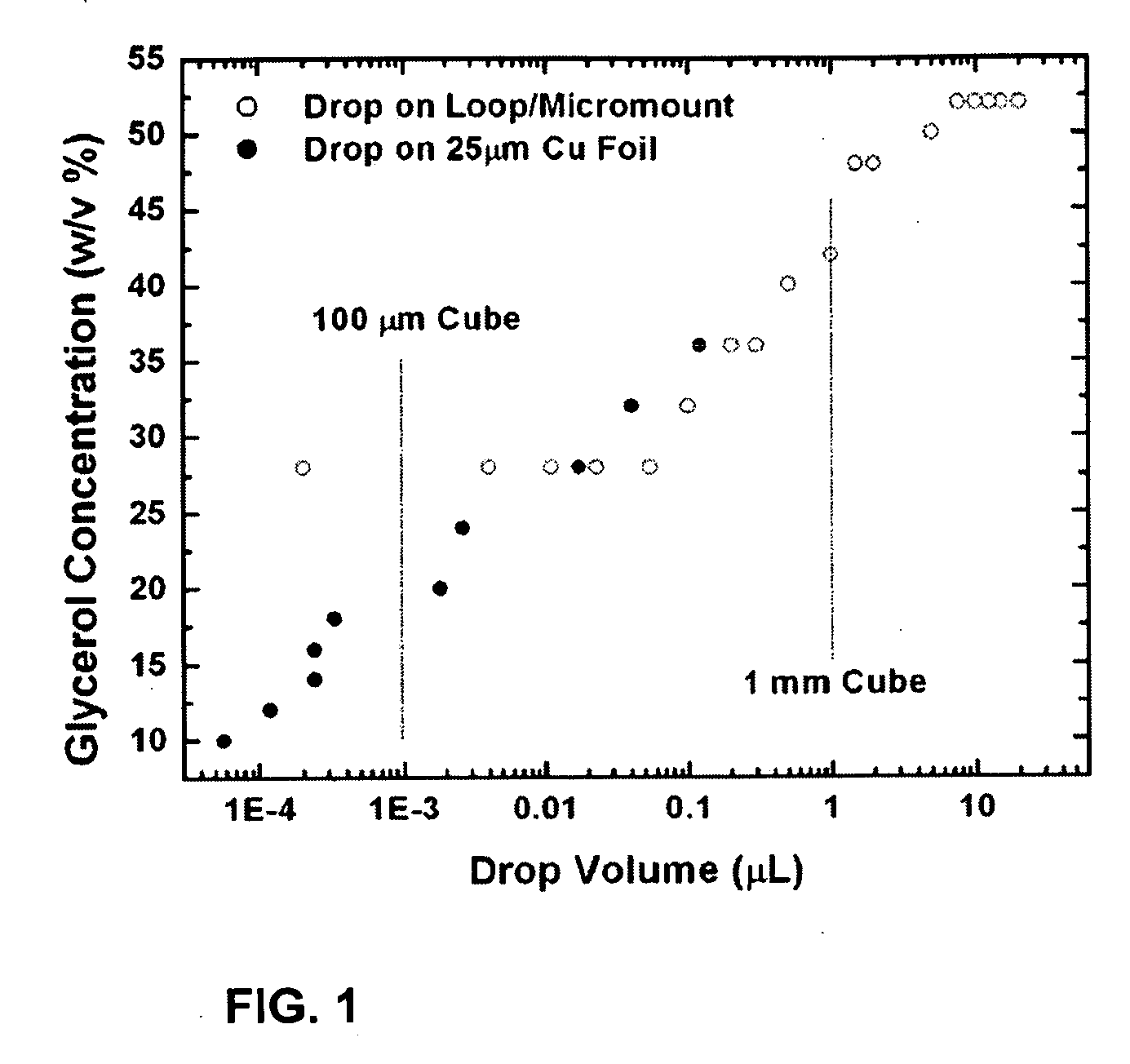

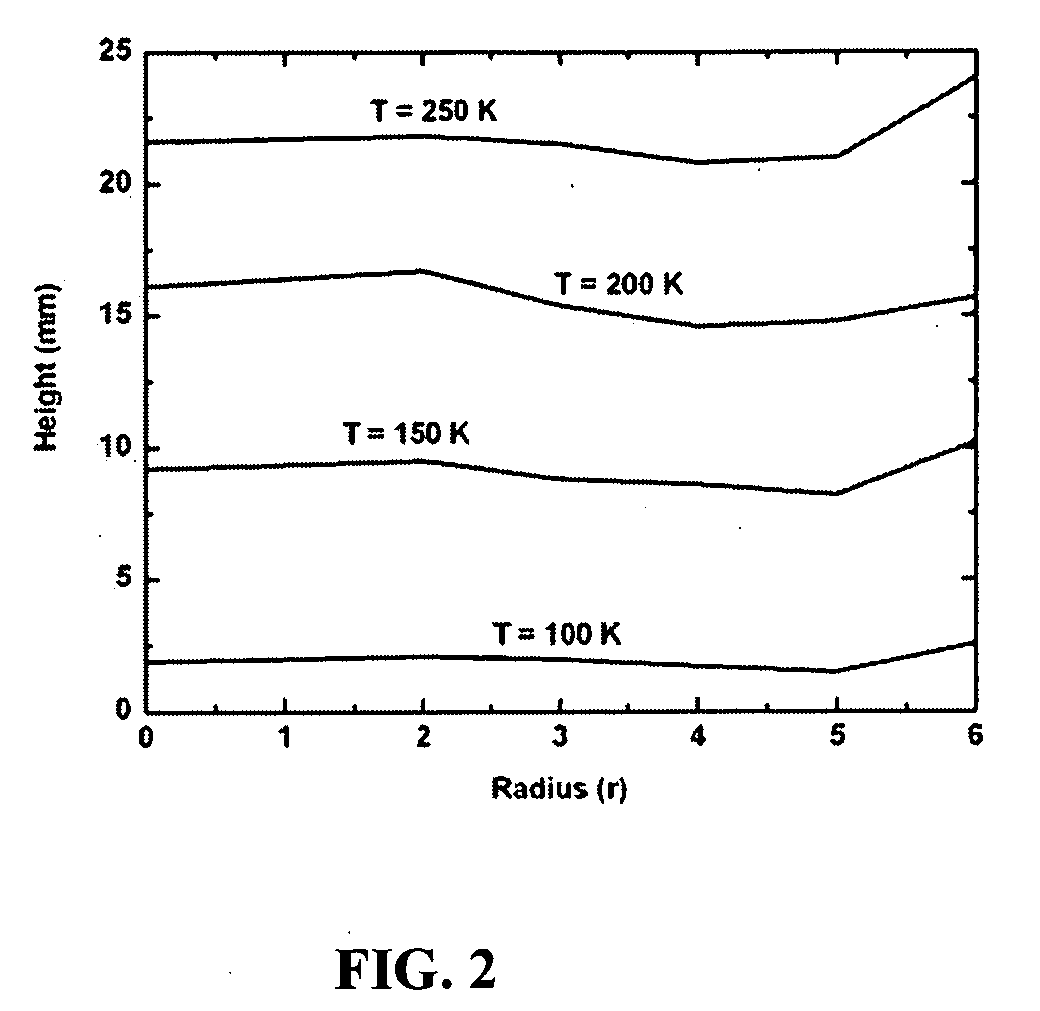

System and method for increased cooling rates in rapid cooling of small biological samples

ActiveUS20090133410A1Reduce condensationReduce freezingPreparing sample for investigationDead animal preservationProcess engineeringLiquid nitrogen

A method and devices for rapid cooling of small biological samples by plunging them in a cryogenic liquid, such as liquid nitrogen, or contacting them with a cryogenic metal surface, reduce or eliminate the cold gas layer that forms above the liquid cryogens or cryogenic surfaces, producing an abrupt transition from ambient (e.g., room) temperature to the cryogen temperature as the sample enters the liquid or contacts the surface. To reduce or eliminate the effects of the cold gas layer, a flow of warm dry gas can be directed along the plunge path, for example. By removing this cold gas layer, cooling times for a 10 micron sample (the size of single cells and the smallest protein crystals now used protein crystallography) will decrease to ˜0.001 s.

Owner:CORNELL RES FOUNDATION INC

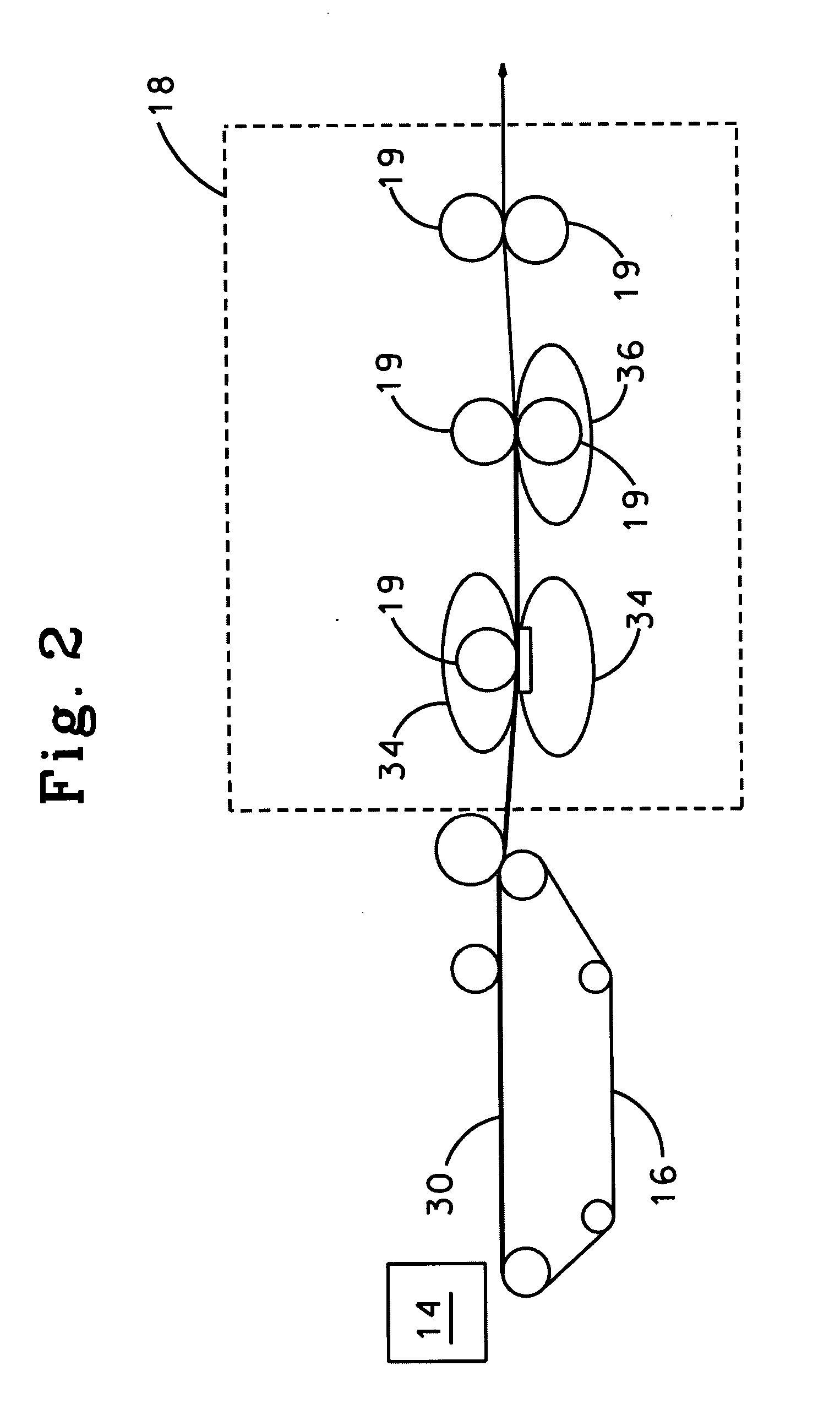

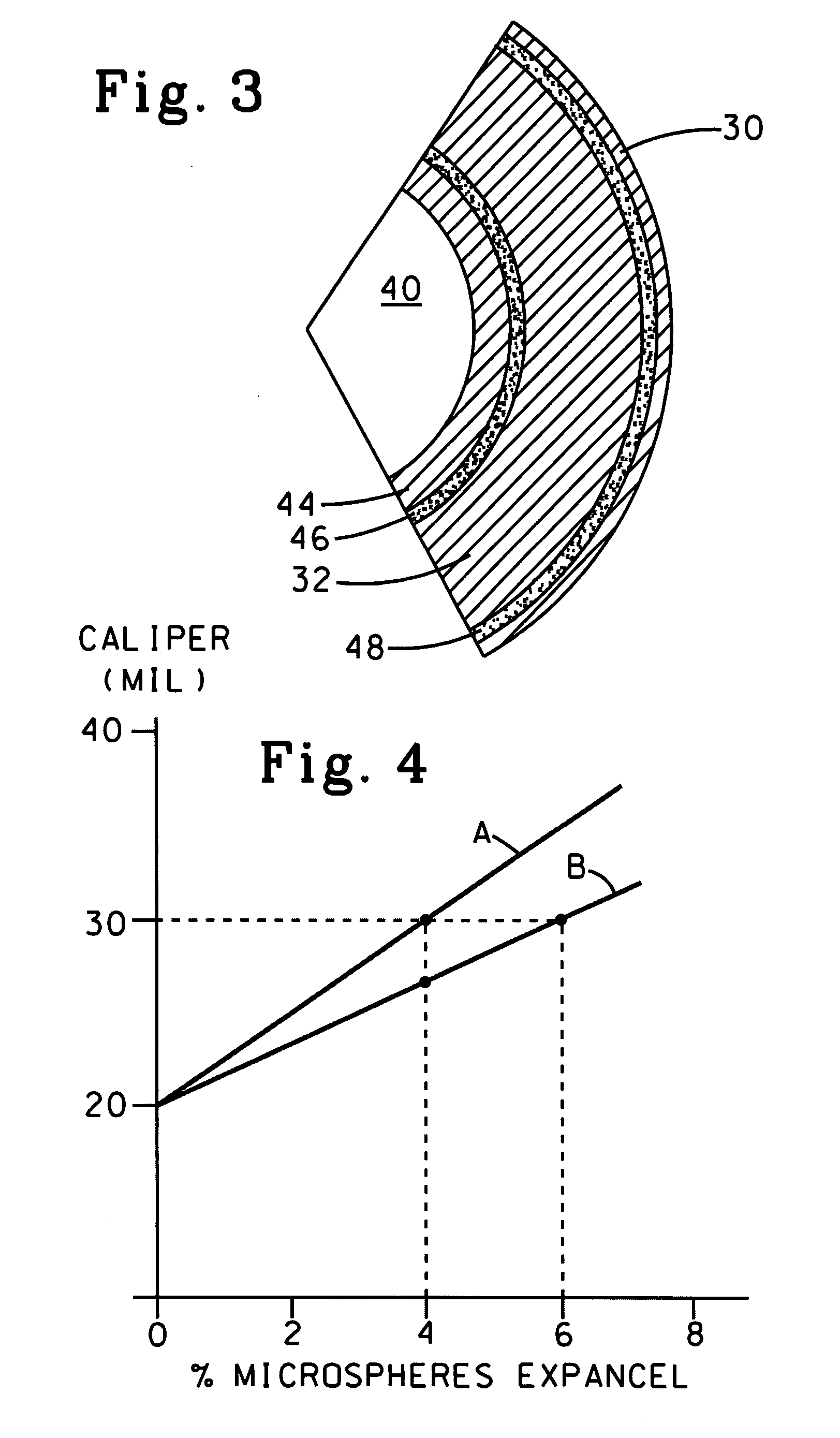

Paperboard material with expanded polymeric microspheres

InactiveUS20070256805A1Improve offset print performanceDecreased print mottle of printedNon-fibrous pulp additionNatural cellulose pulp/paperCoated surfaceMicrosphere

The present invention is related to a paperboard product having a basis weight in a range of 100 to 350 pounds per 3,000 square feet. The paperboard comprises at least one coated surface suitable for printing. The at least one coated surface comprising cellulosic fibers and from about 0.05 to about 0.5 wt. % dry basis expanded synthetic polymer microspheres based on total weight of the of cellulosic fiber dispersed thereof. The coated surface has a Parker smoothness less than about 2.0 and a Hagerty / Sheffield smoothness not less than about 20 Sheffield units.

Owner:INT PAPER CO

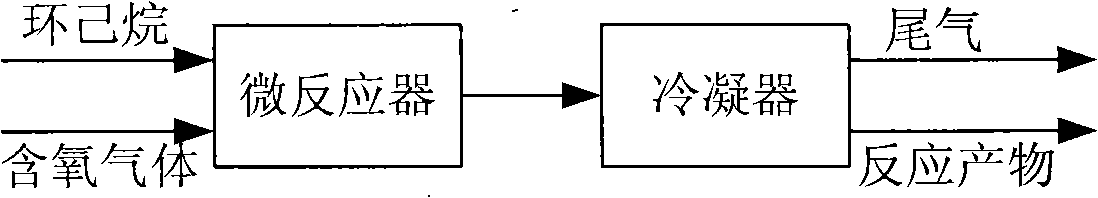

Liquid-phase oxidation method for cyclohexane

ActiveCN101293810AIncreased reaction rate and heat transfer rateIncrease speedOrganic compound preparationPreparation by hydrogenationCyclohexanoneCyclohexanol

A liquid-phase oxidation method of cyclohexane is provided. The oxidation method is characterized in that the method comprises carrying out reaction of molecular oxygen-containing gas and cyclohexane at a mole ratio of (0.1-10):1 in a micro-reactor under 0.8-2.5MPa at 145-200 DEG C for 0.5-30min. The micro-reactor is a micro-channel reactor or a micro-tube reactor. The method ensures safety and enhances heat transfer, and can remarkably improve the oxidizing reaction speed of cyclohexane and the total selectivity of cyclohexanone, cyclohexanol and cyclohexyl hydrogen peroxide.

Owner:CHINA PETROLEUM & CHEM CORP +1

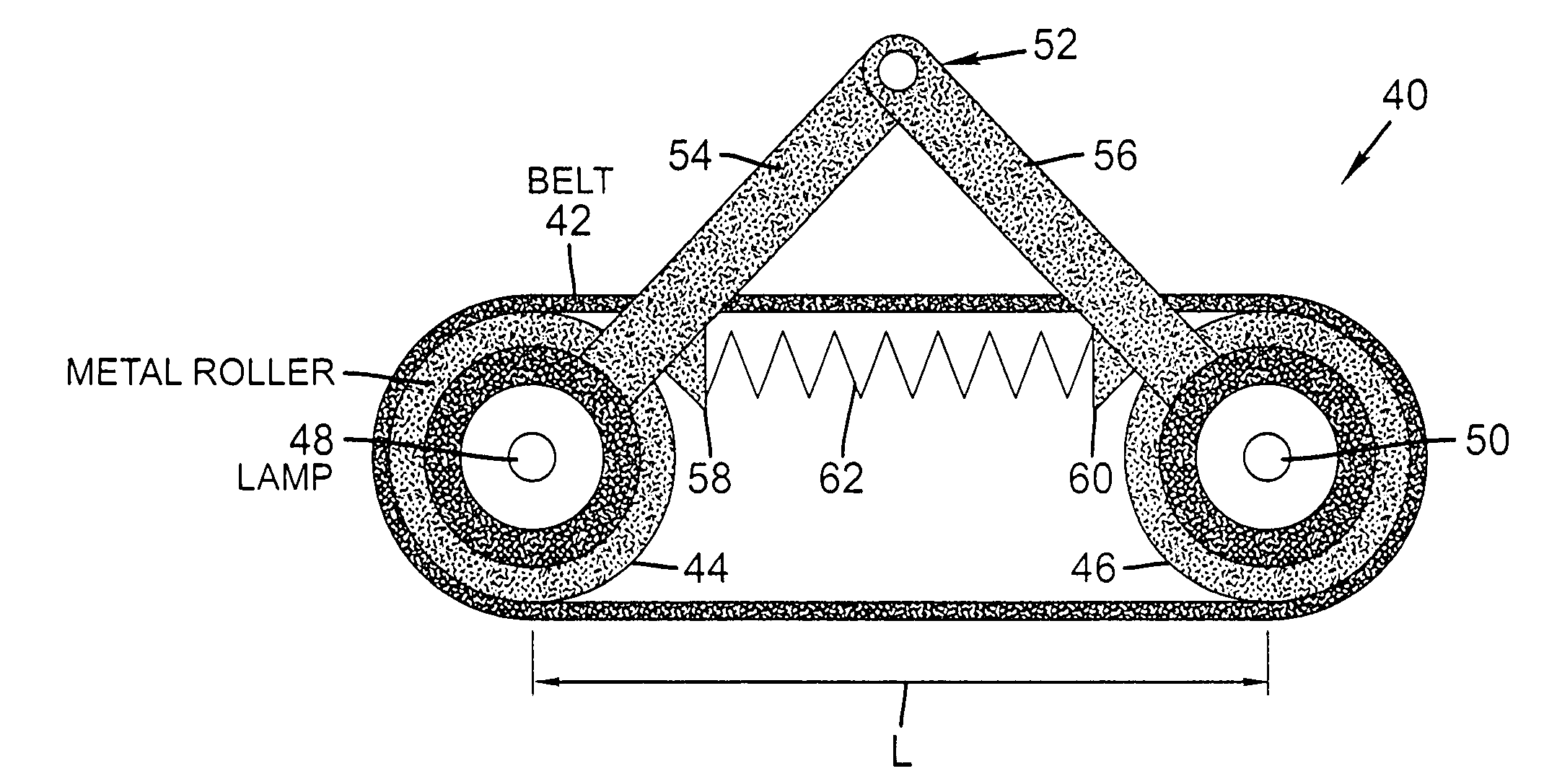

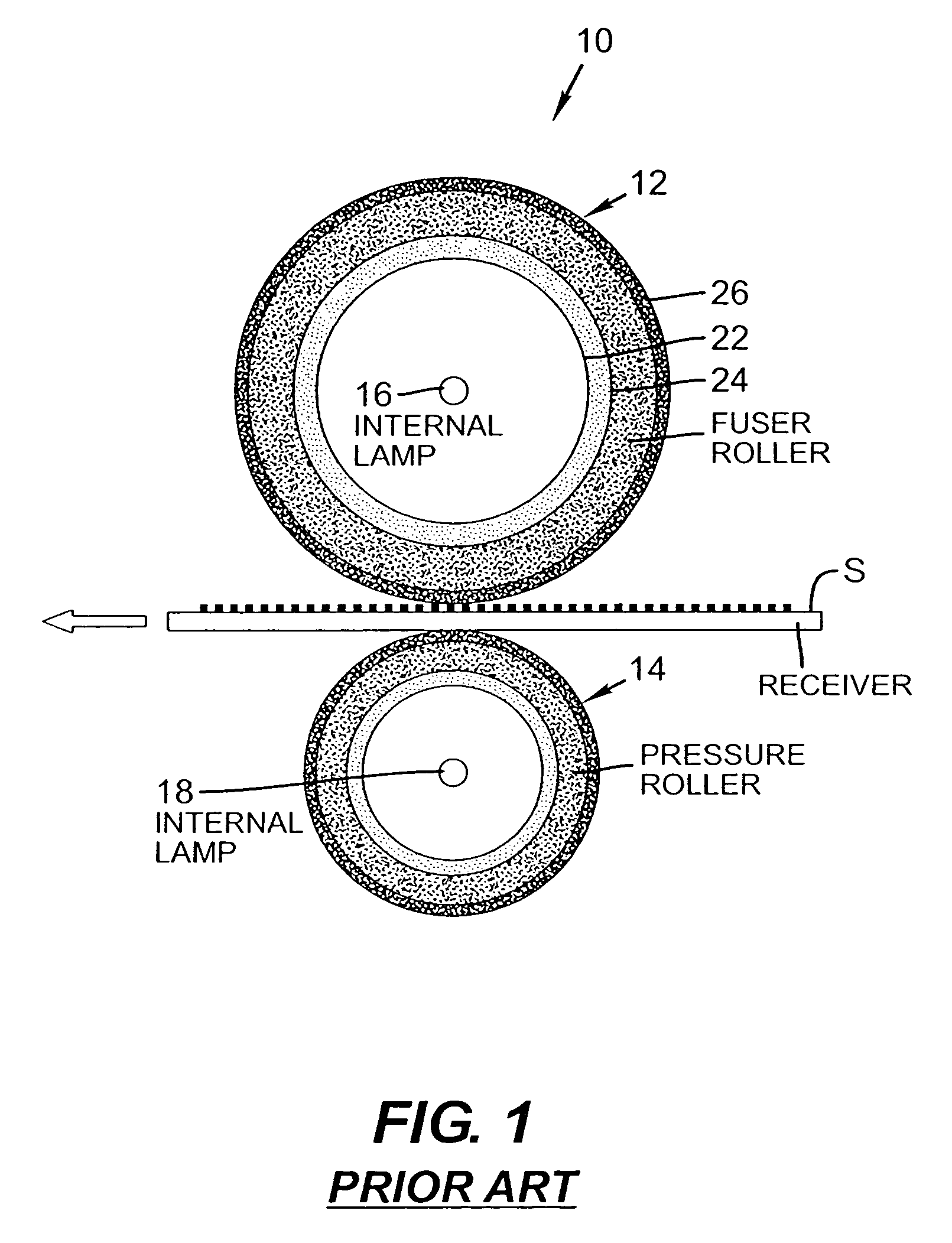

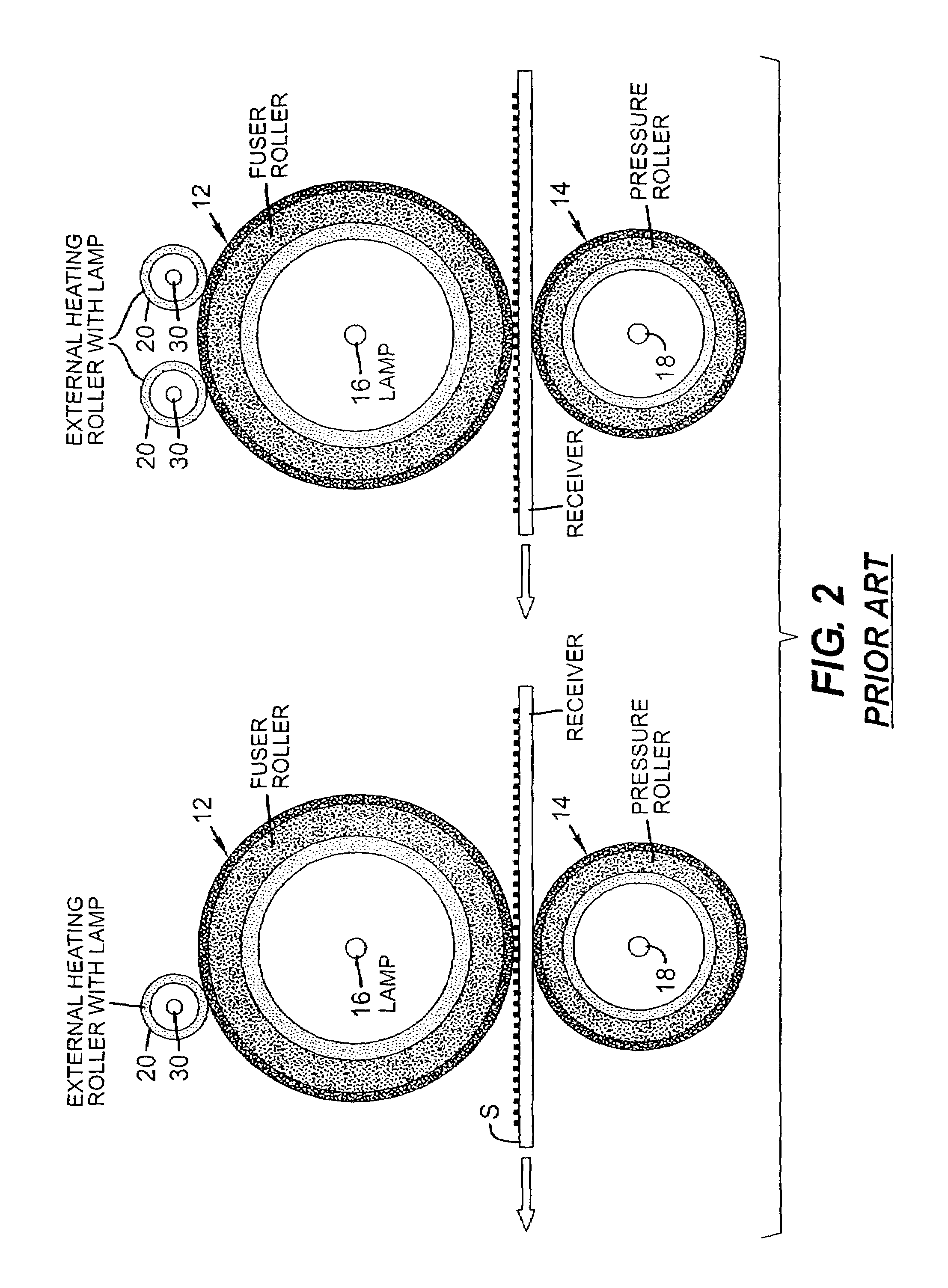

Variable power fuser external heater

ActiveUS7194233B2Reduce the applied forceIncrease heat transfer rateElectrographic process apparatusEngineeringElectrical and Electronics engineering

An external heater for a fuser assembly for a reproduction apparatus. The fuser assembly includes a fuser member for fusing a marking particle image to a receiver member. The external heater has a heat transfer surface adapted to be selectively engaged with the fuser member, and a device for heating said heat transfer surface. A mechanism is provided for engaging a variable portion of the heat transfer surface with the fuser member to selectively change the amount of heat transferred from the heating device to the fuser member through the heat transfer surface.

Owner:COMML COPY INNOVATIONS INC

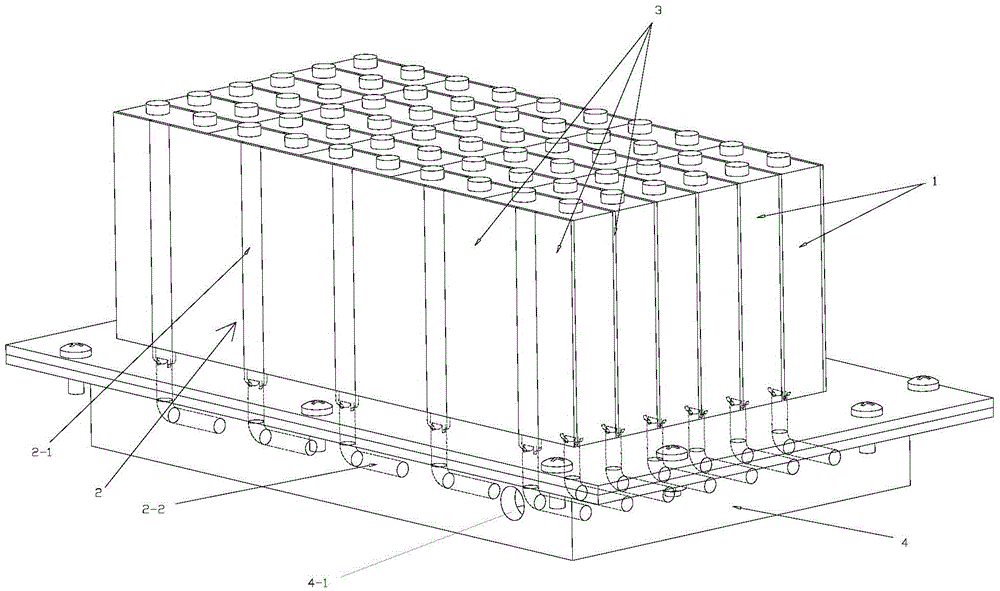

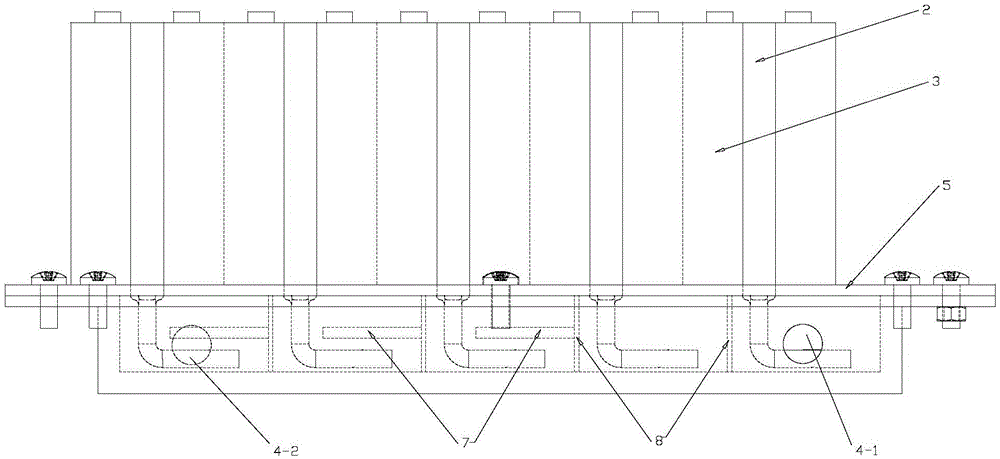

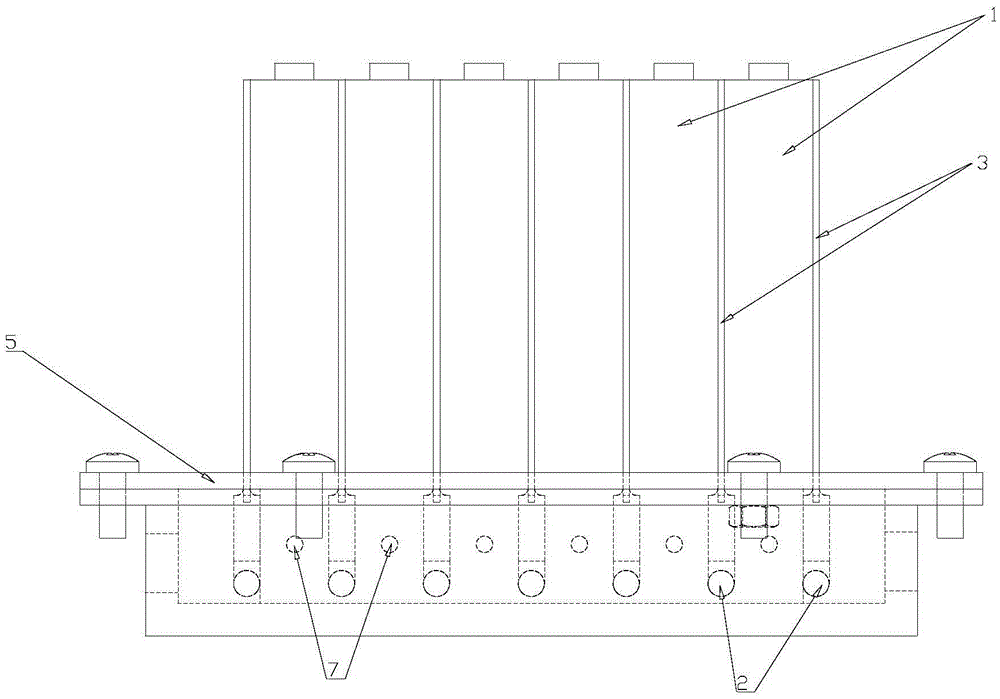

Power battery composite heat management system and method thereof

ActiveCN105633509AImprove thermal conductivityReduce weightSecondary cellsPower batteryHeat management

The invention discloses a power battery composite heat management system and a method thereof. The power battery composite heat management system comprises a water tank filled with a circulating fluid, a circulating pump, a sealing cover plate of the water tank, and a battery pack array which is fixedly mounted above the sealing cover plate and is composed of a plurality of battery cells, wherein a temperature equalizing plate and a heat pipe are adhered onto the surface of each battery cell respectively, and cooing sections of the heat pipes pass through the sealing cover plate to be arranged in the circulating fluid in the water tank; a circulating fluid inlet is formed in one side end of the water tank, a circulating fluid outlet is formed in the other side end of the water tank, and a circulating fluid turbulent flow structure is arranged inside the water tank, so that the circulating fluid flows into the circulating fluid outlet from the circulating fluid inlet of the water tank in a curve flowing manner. The system and the method thereof can solve the technical problems such as heat dissipation, battery pack temperature difference reduction, battery preheating and heat cyclic utilization under different working conditions of batteries; and meanwhile, the system is compact and simple in structure and convenient in installation and maintenance, accords with the development tendency of battery heat management systems and electric automobiles, and has good application prospects.

Owner:SOUTH CHINA UNIV OF TECH

Graphene composite modified high-strength polyethylene fiber and preparation method thereof

InactiveCN104762683AEasy to prepareExcellent performanceWet spinning methodsMonocomponent polyolefin artificial filamentUltra-high-molecular-weight polyethyleneFiber

The invention discloses graphene composite modified high-strength polyethylene fiber and a preparation method thereof. The graphene composite modified high-strength polyethylene fiber comprises UHMWPE (ultra-high molecular weight polyethylene) and graphene, wherein calculated by weight percentage, UHMWPE accounts for 98%-99.8%, and graphene accounts for 0.2%-2%; the molecular weight of UHMWPE is 2.4 million-2.6 million; and the particle size of graphene is 0.5-1.5um, and the particle size is 0.33-0.35nm. The preparation method disclosed by the invention is simple and convenient, and excellent performances are realized. Graphene is mixed into a white oil solution of UHMWPE by a method of adding a stock solution, uniform stirring is performed, and then the graphene modified high-strength polyethylene fiber is further prepared by spinning by a wet spinning method, so that the performances are effectively improved.

Owner:YANAN BICON PHARMACEUTICAL LISTED COMPANY

Heat exchanger fin, heat exchanger, condensers, and evaporators

InactiveUS20070051502A1Increase heat transfer rateAvoid it happening againEvaporators/condensersMetal-working apparatusEngineeringLouver

A heat exchanger fin, capable of improving heat transfer rate while preventing generation of heat bypass flow, such as a louver fin provided with a plurality louvers arranged at certain intervals in the introduction direction of air. The louvers are formed by cutting and bending the heat exchanger fin so that the air is passed while being guided by the louvers. The plurality of louvers include louvers different in louver width, the louver width being defined by a length of the louver along which the heat medium passes. Wider louvers and narrower louvers can be arranged alternatively.

Owner:SHOWA DENKO KK

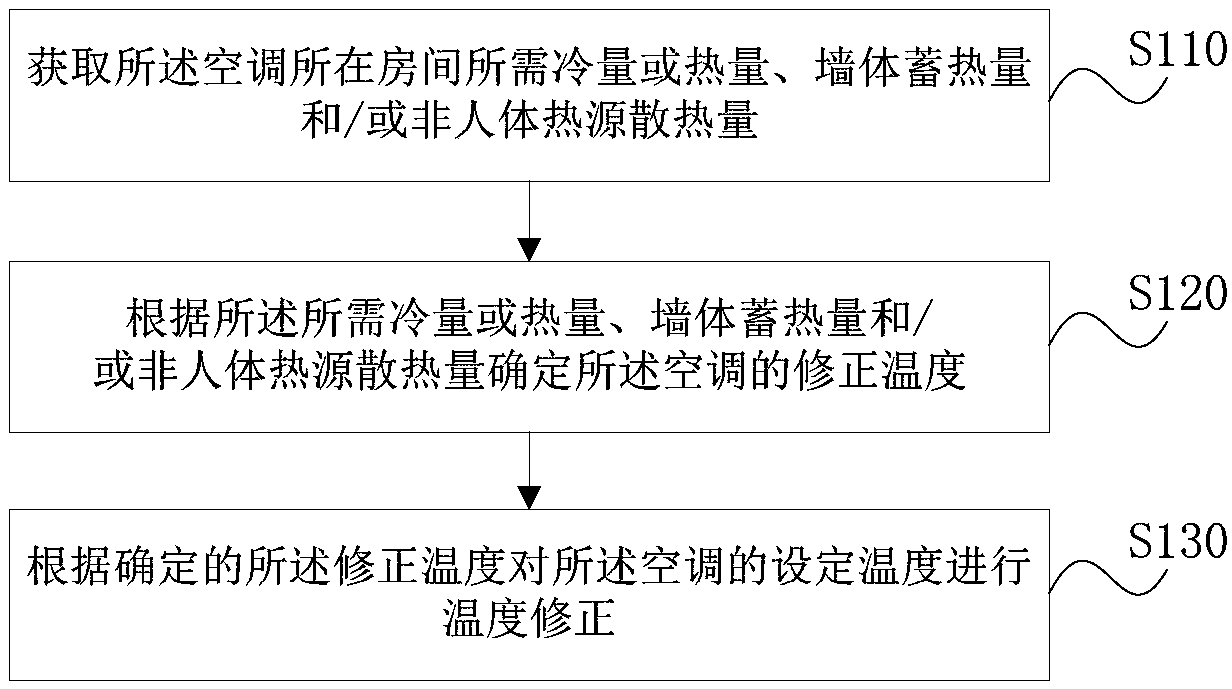

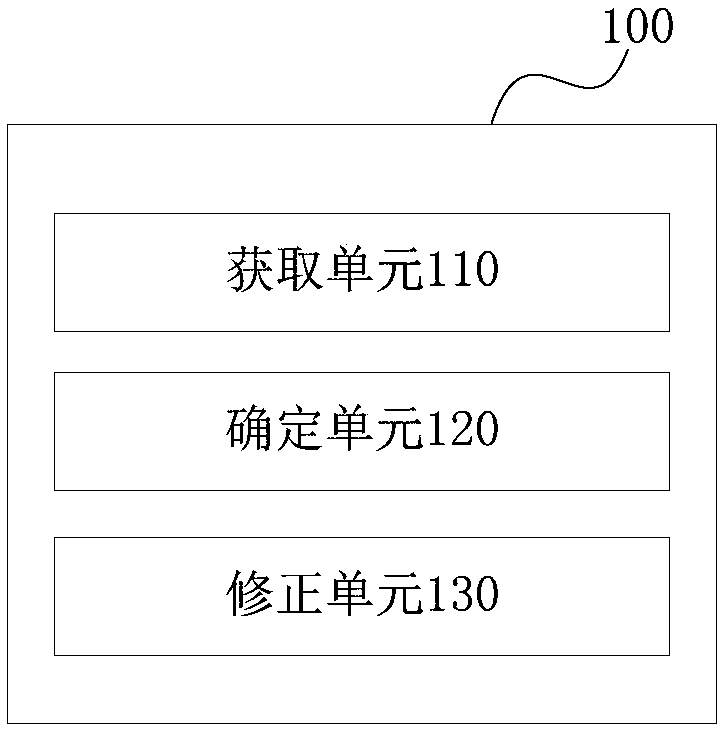

Temperature correction method, device, storage medium of air conditioner and air conditioner

ActiveCN108679788AGuaranteed comfort requirementsPrecise temperature controlMechanical apparatusTemperature controlEngineering

The invention provides a temperature correction method, device, storage medium of an air conditioner and an air conditioner. The method comprises following steps: obtaining a required cooling quantityor heat quantity, wall heat storage capacity, and / or non-human body heat source heat dissipation capacity in a room where the air conditioner is located; determining the corrected temperature of theair conditioner according to the required cooling quantity or heat quantity, wall heat storage capacity, and / or non-human body heat source heat dissipation capacity; performing temperature correctionof the set temperature of the air conditioner according to the determined corrected temperature. The solution provided by the invention can realize the temperature control of the air conditioner and respond to the fluctuation of the external temperature in time, and can perform temperature compensation according to the need, so that the temperature control of the air conditioner is more precise, and the user is provided with a more comfortable indoor environment.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Flat tube evaporator with enhanced refrigerant flow passages

ActiveUS7080683B2Increase heat transfer rateEnhances nucleate boilingStationary conduit assembliesHeat exchanger casingsEngineeringAir conditioning

A heat exchanger for a heating, ventilating and air conditioning system comprises a plurality of heat exchange tubes extending between a pair of spaced header tanks and arranged in groups of tubes with varying number of tubes in each group to cause a refrigerant to flow in multiple passes in the interior of the tubes across another fluid flowing on the exterior of the tubes. The heat exchange tubes comprise a plurality of flow passages having at least one corner formed by a pair of straight or arcuate sides with an included angle of less than or equal to ninety degrees, more preferably less than or equal to thirty degrees, to promote intense pool boiling within the flow passages. In addition to at least one corner region, the flow passage has a passage-specific optimal hydraulic diameter determined by the relationship between the optimal hydraulic diameter of the passage and the optimal hydraulic diameter of a baseline circular passage.

Owner:MAHLE INT GMBH

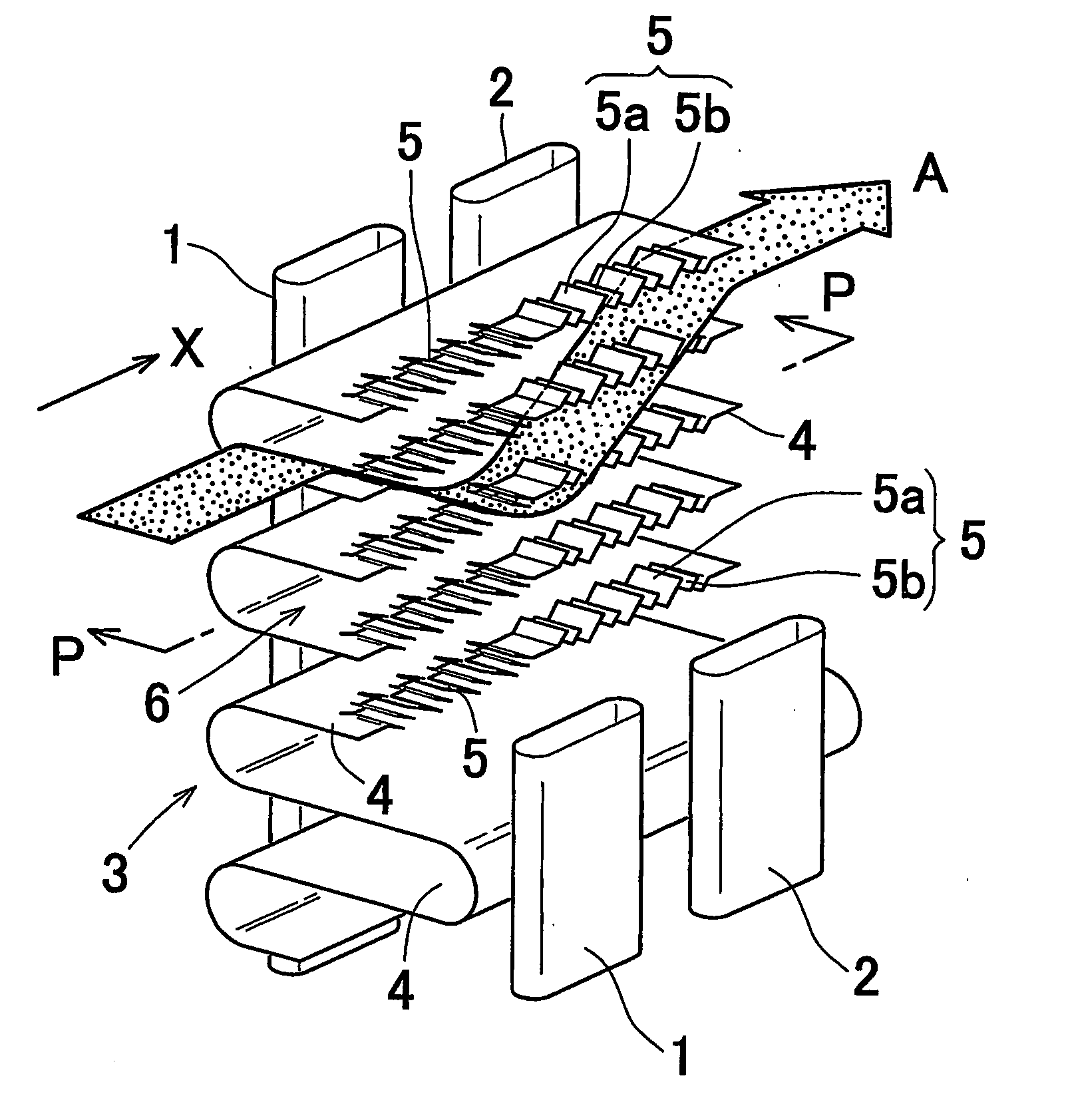

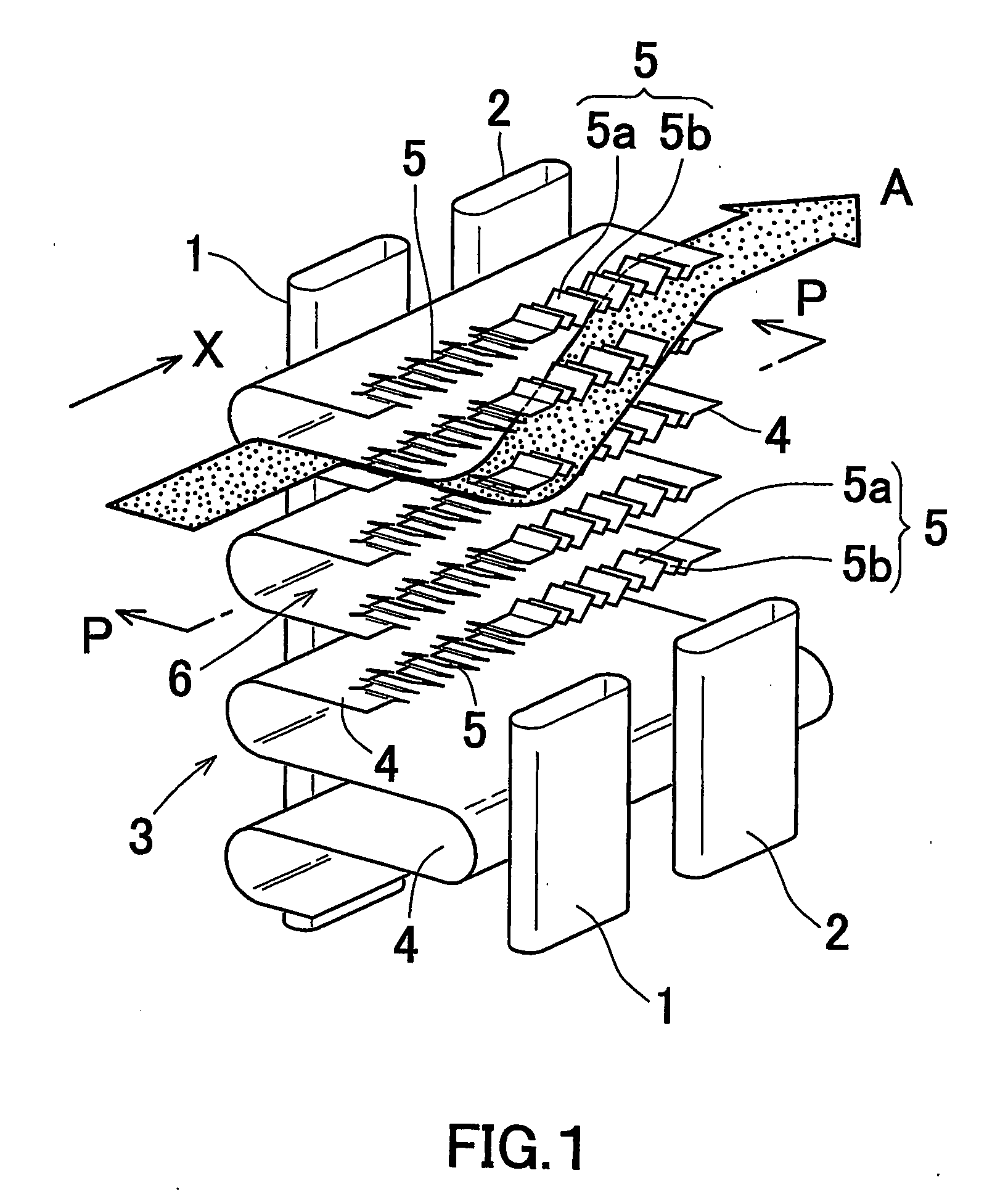

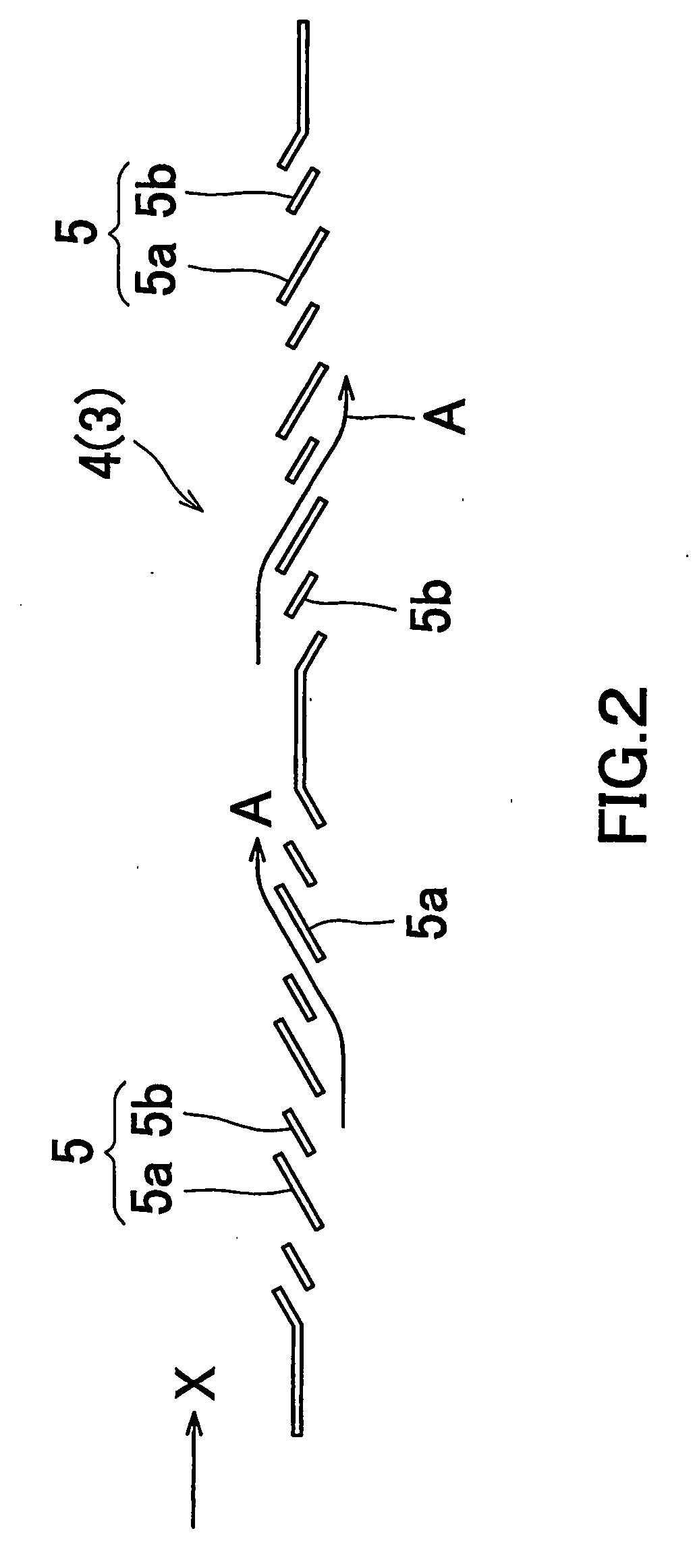

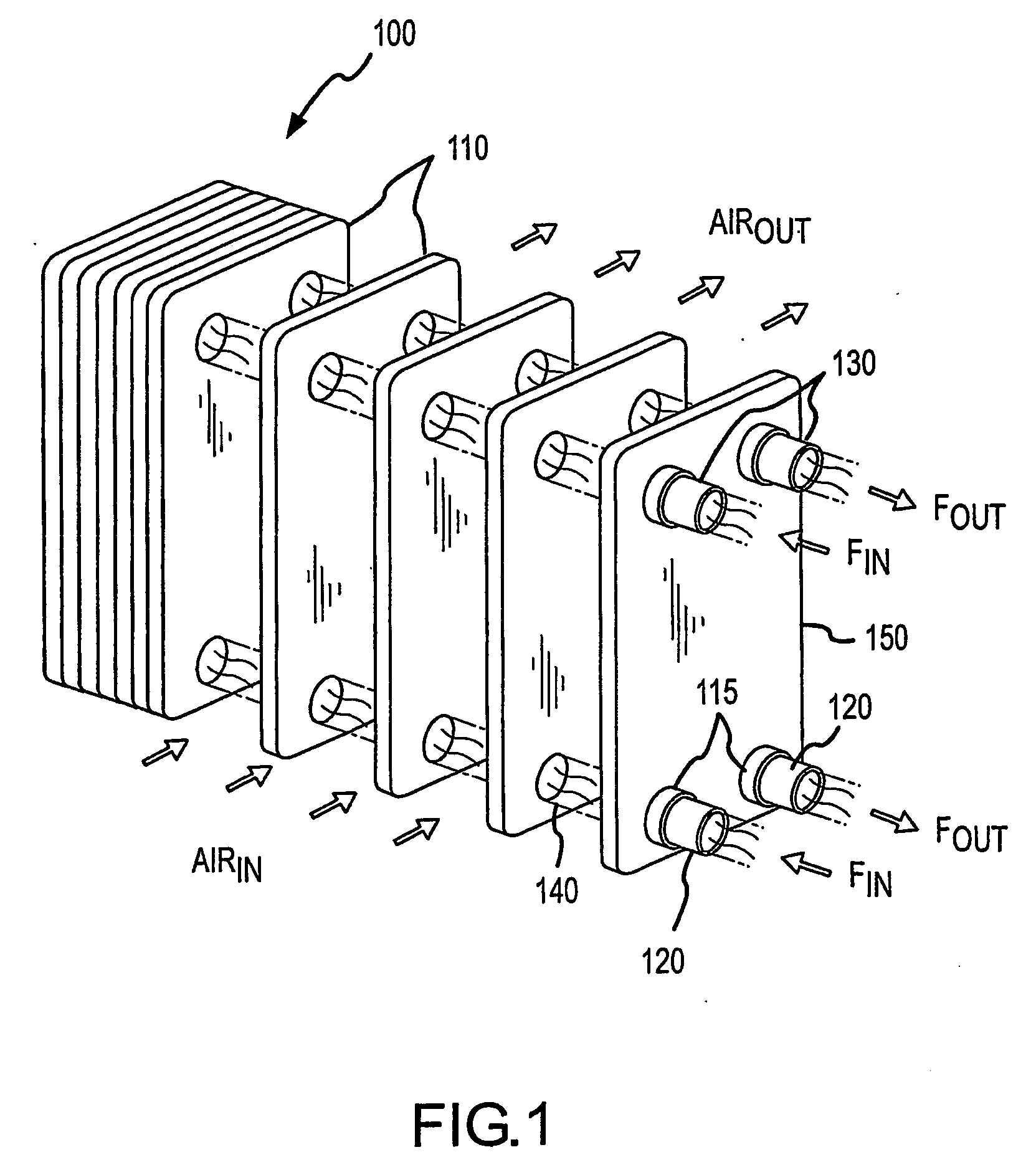

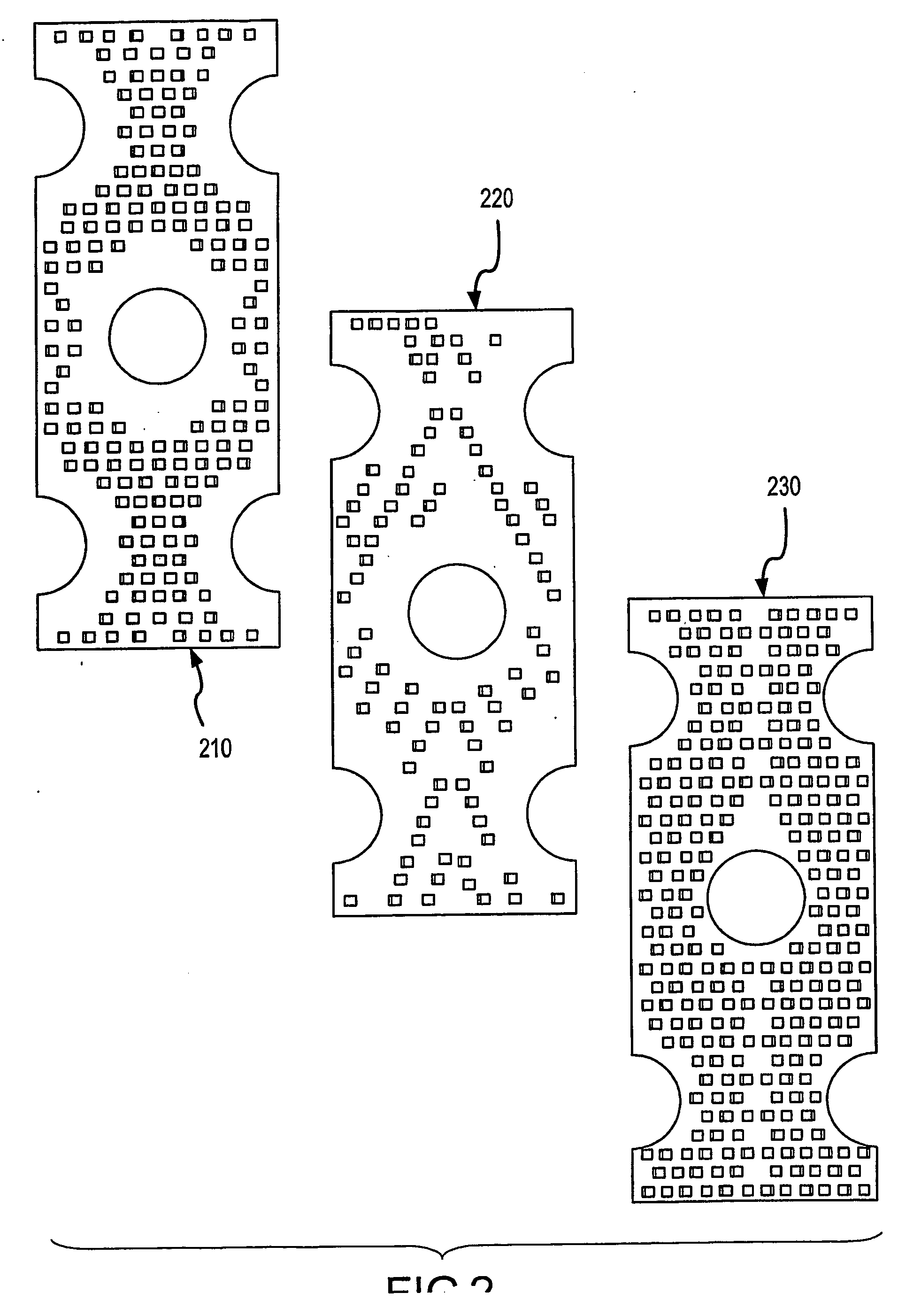

Tabbed transfer fins for air-cooled heat exchanger

InactiveUS20060169019A1Increase heat transfer rateMinimizing creationSpacing meansMechanical apparatusEngineeringHeat exchanger

Heat transfer fins (110), and heat exchangers (100) incorporating such fins (110), enhancing heat transfer with acceptable pressure drop increase. The fins (110) include tabs or secondary fins bent upward and downward from the fin body at a selected bend angle. All or a majority of the tabs are aligned with a simple flow path or with local flow paths for cooling air adjacent the fins (110) to minimize turbulence and pressure drop. The tabs are planar and generally aligned parallel to the simple flow path or local flow paths and are arranged so as to serve as a plurality of sites for starting new boundary layers by offsetting the tabs such that downstream tabs are not shadowed by upstream tabs. The tabs have a height sufficiently large to extend the tabs out into boundary layers on the fin (110). The tabs provide more uniform flow over fins (110) and shrink wake size behind tubes (120).

Owner:ALLIANCE FOR SUSTAINABLE ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com