Patents

Literature

112results about How to "Reduce freezing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

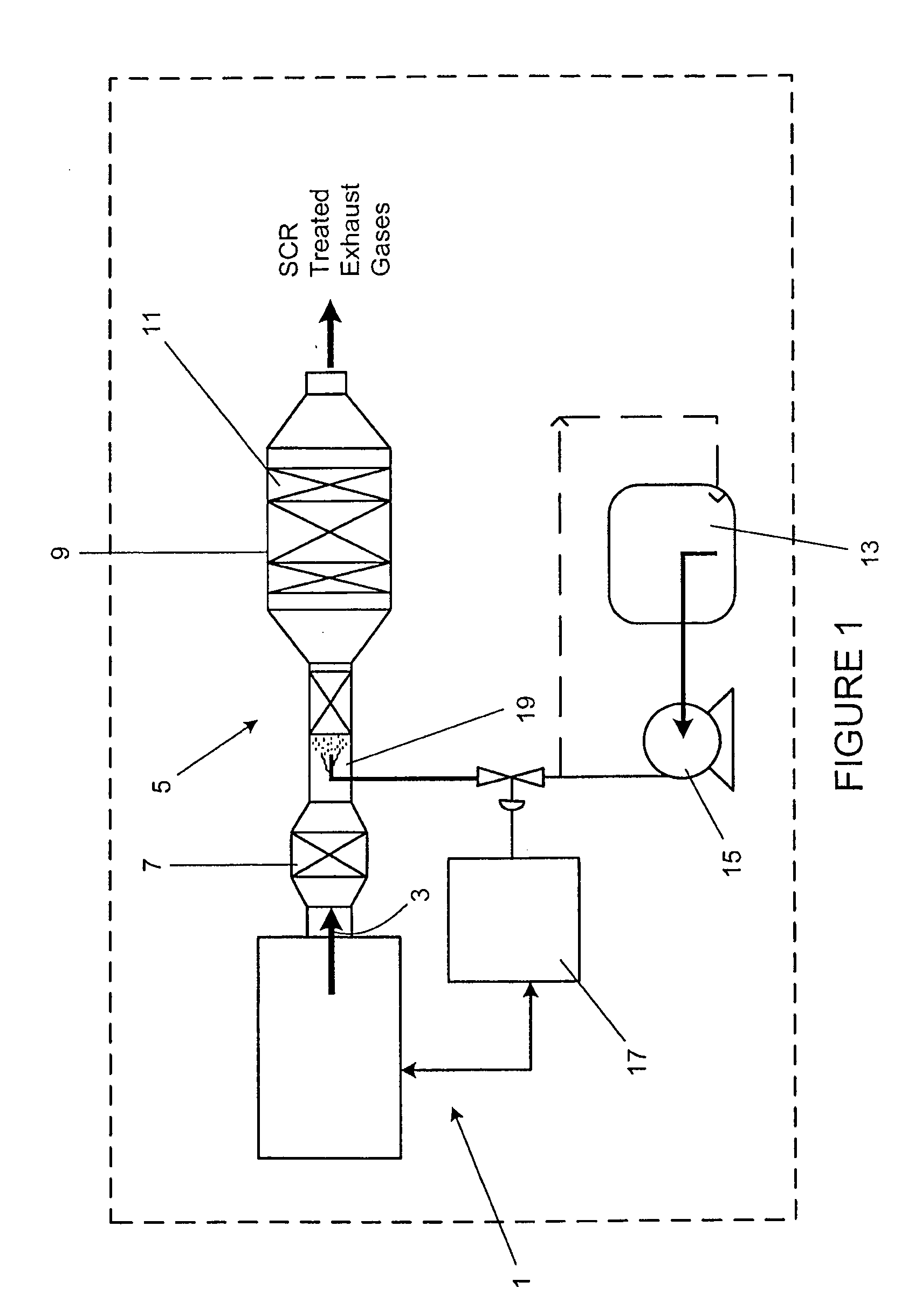

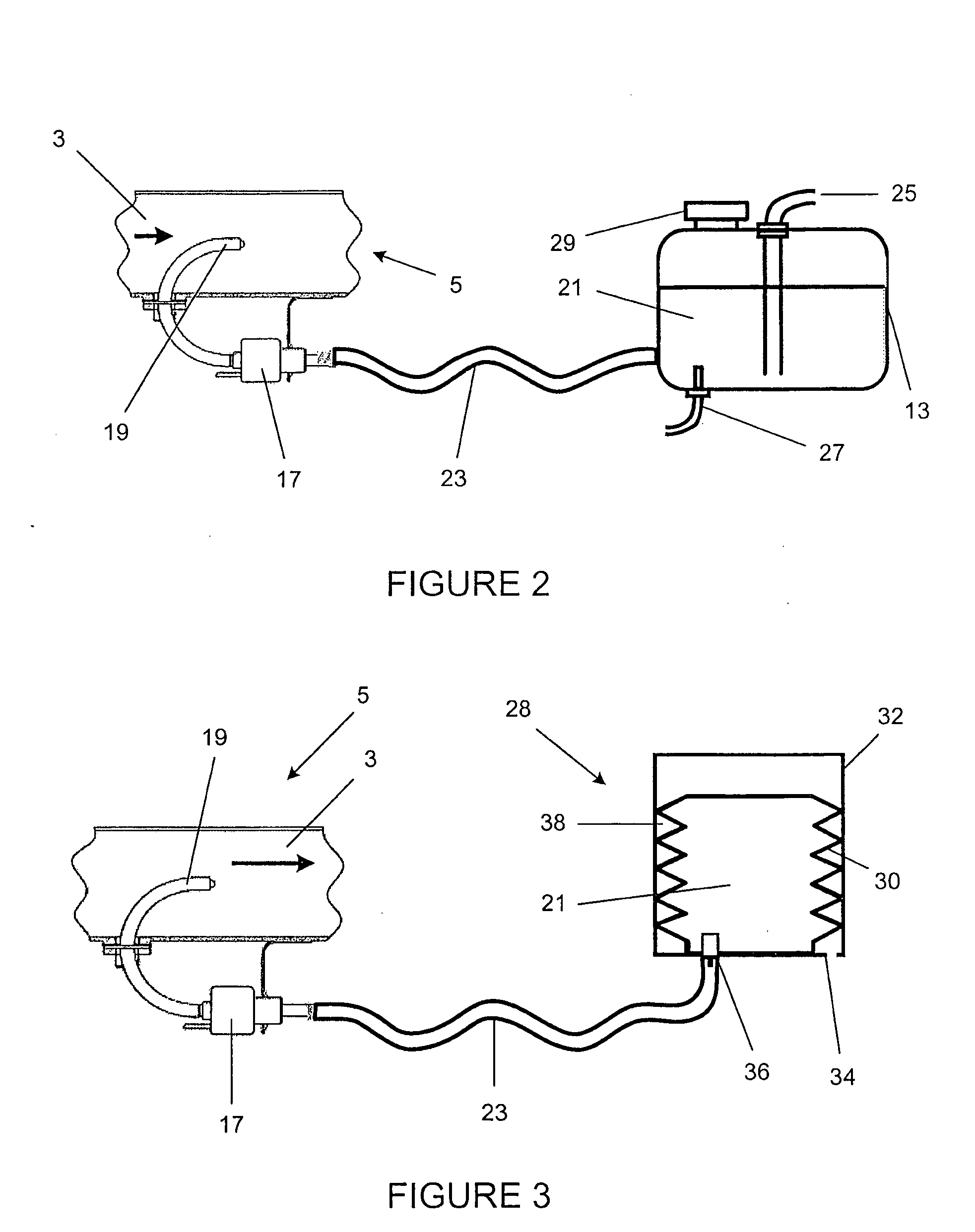

Reservoir for a fluid dosing system

InactiveUS20090013670A1Increase supplyReduce freezingInternal combustion piston enginesExhaust apparatusEngineeringMechanical engineering

Owner:DELPHI TECH INC

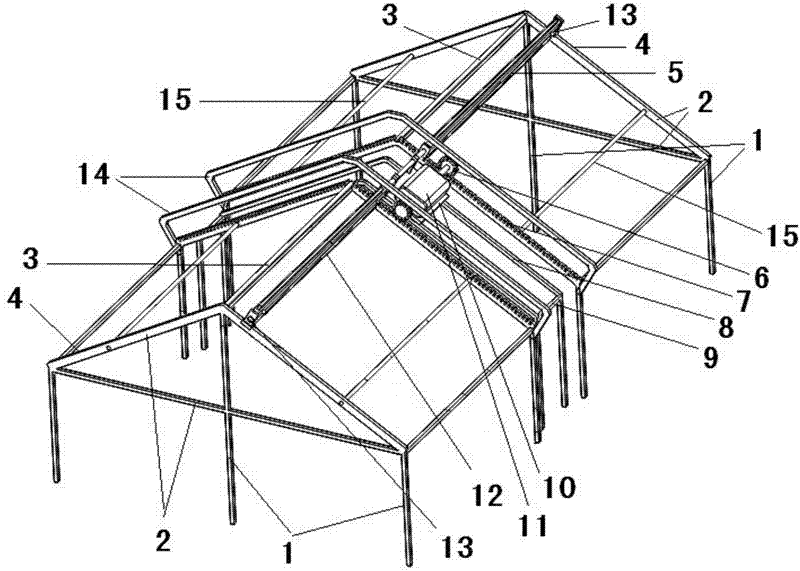

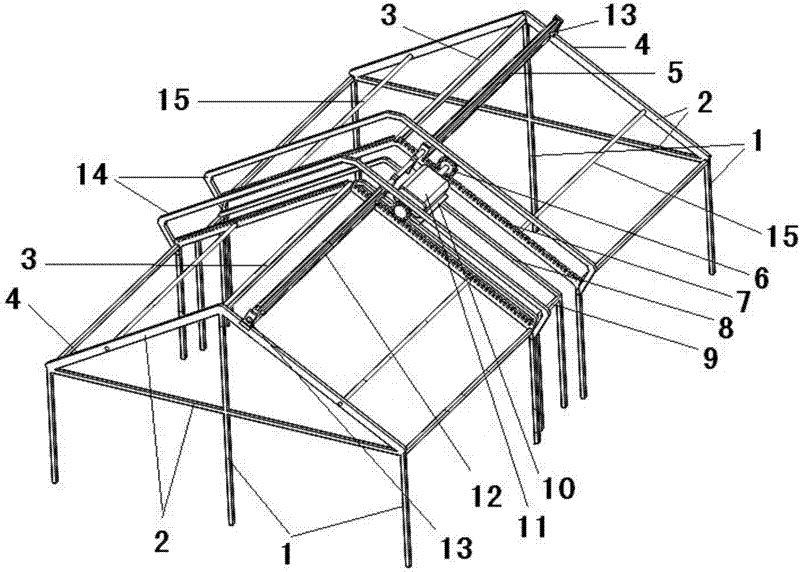

Mechanical scraping and electrical heating combined snow removal greenhouse

ActiveCN102405799AEffective protectionIncrease temperatureClimate change adaptationSnow trapsSnow removalGreenhouse

The invention discloses a mechanical scraping and electrical heating combined snow removal greenhouse. In the greenhouse, a gear guide rail and a platform guide rail are arranged on the cross beam in the middle of the greenhouse, a moving platform is arranged on the platform guide rail, a motor is arranged on a movable platform, and edge guide rails are arranged on the cross beams at the two endsof the greenhouse; driving pinions on the driving shafts on the two sides of the motor are meshed with the gear guide rail, and the driving pinions can move up and down on the gear guide rails; a snow removing plate is arranged at one end of the motor, left and right snow removing plates are formed on the two sides of the snow removing plate and the outer ends of the left and right snow removing plates are embedded in the inner edge rollers of the edge guide rails; a plurality of electric heating tube supporting beams are arranged on a top beam, and waterproof electric heating tubes which areconnected with the power wire through electrical wires are arranged on the surfaces of the electric heating tube supporting beams; and the design heights of the lower ends of the left and right snow removing plates are required to be greater than those of the waterproof electric heating tubes. The mechanical scraping and electrical heating combined snow removal greenhouse has the advantages of effectively removing snow accumulated on the top of the greenhouse, reducing heavy and dangerous snow removing work at night, and allowing planting in greenhouse to be carried out normally on snowy days.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

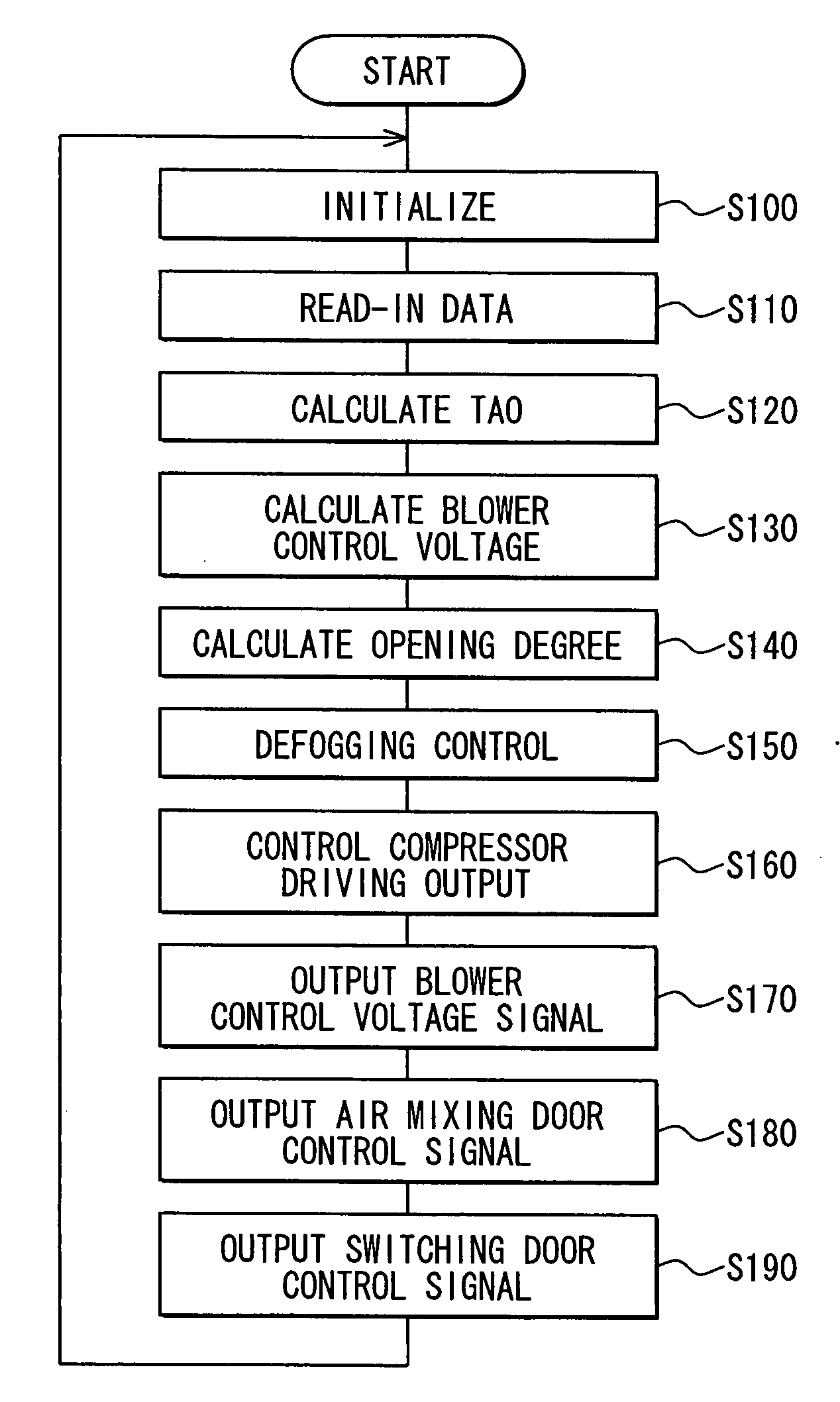

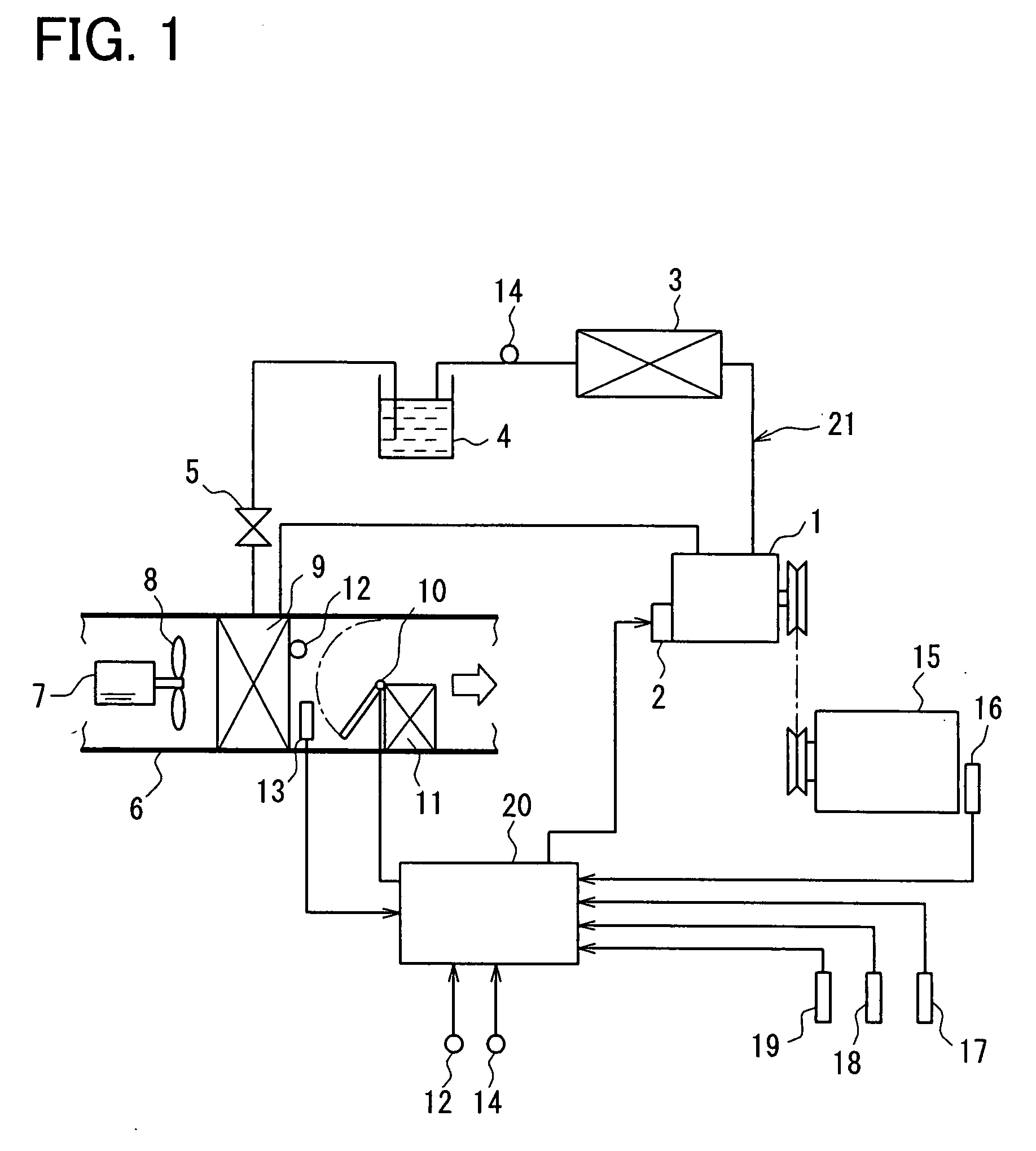

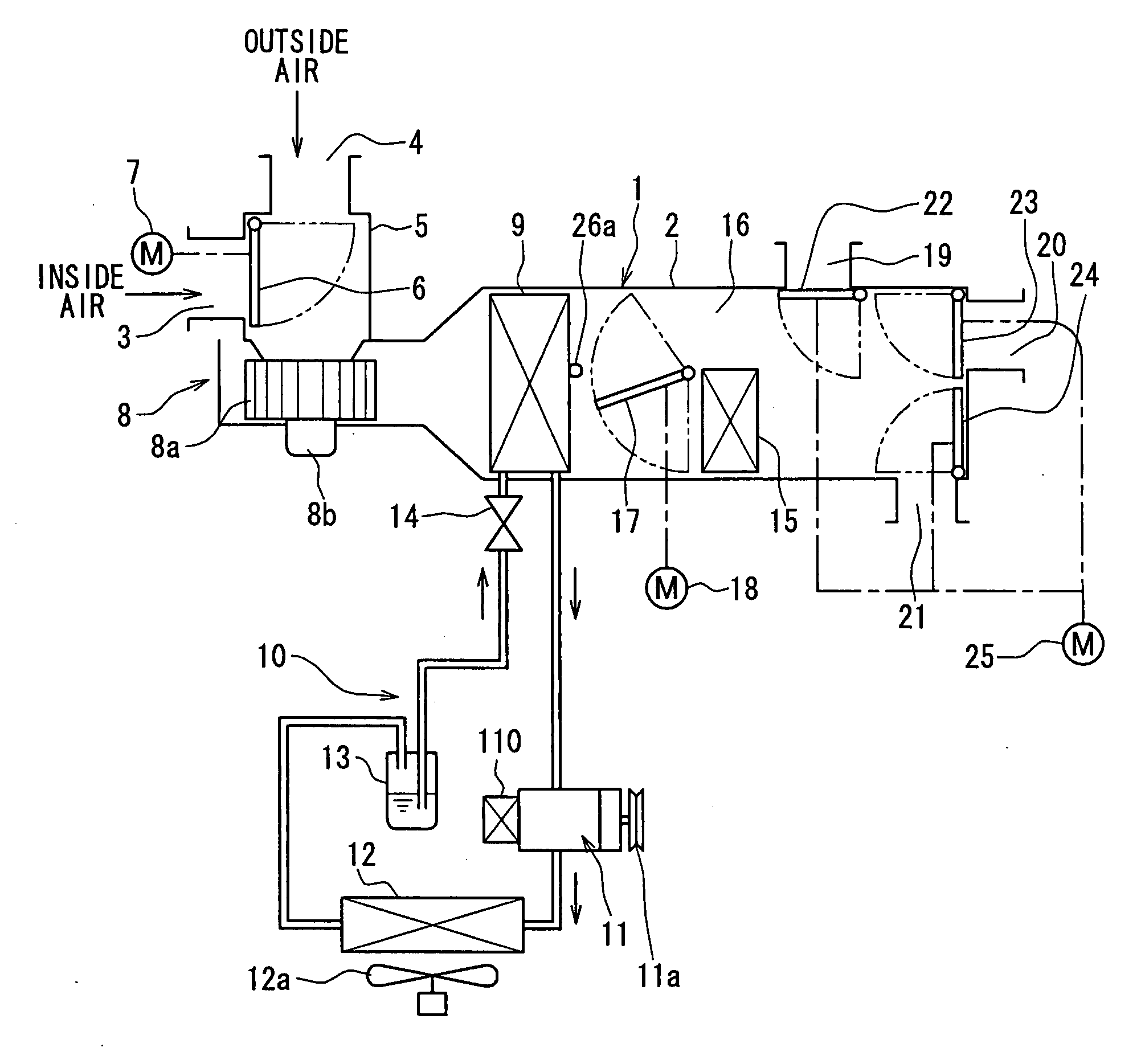

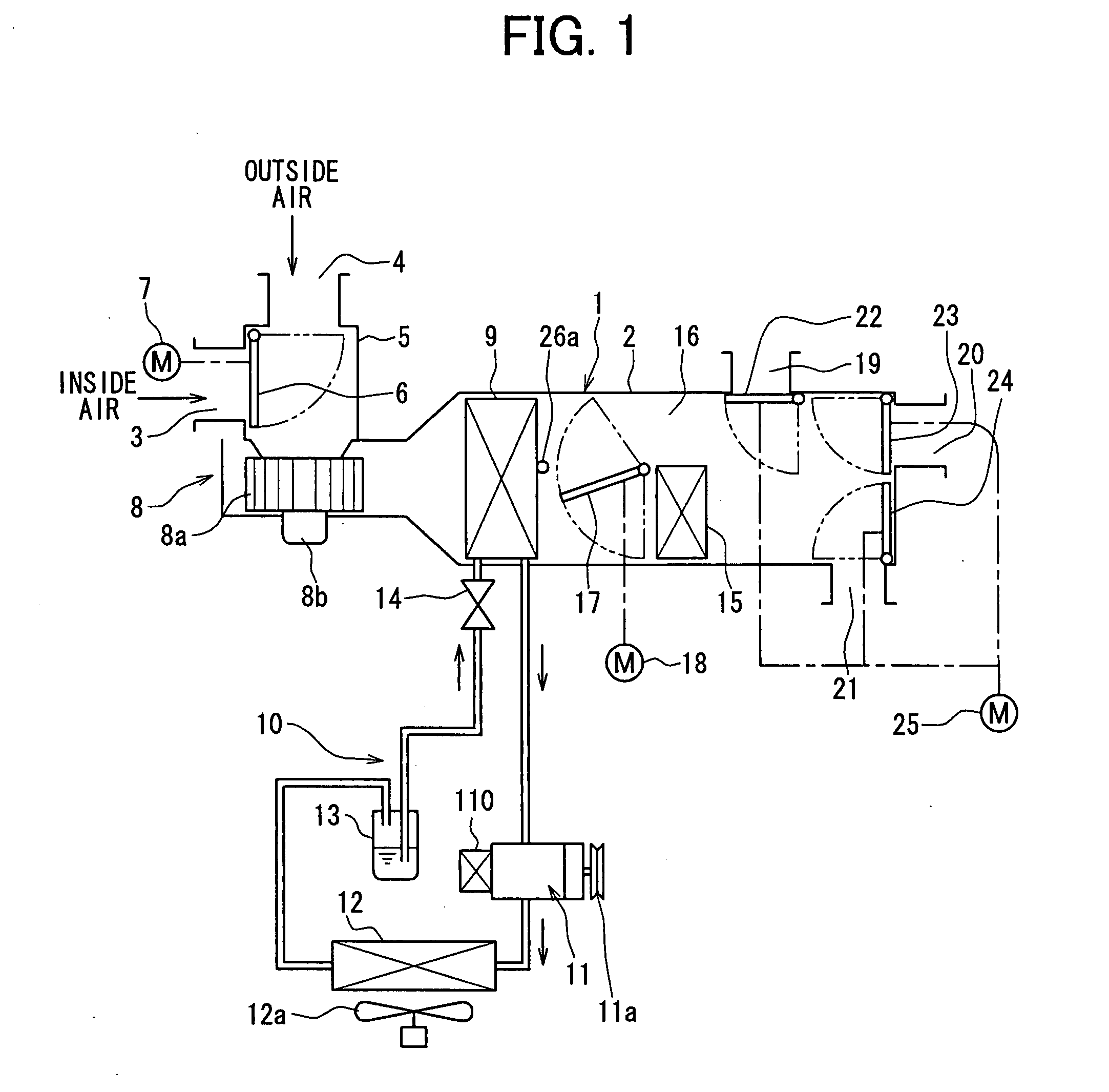

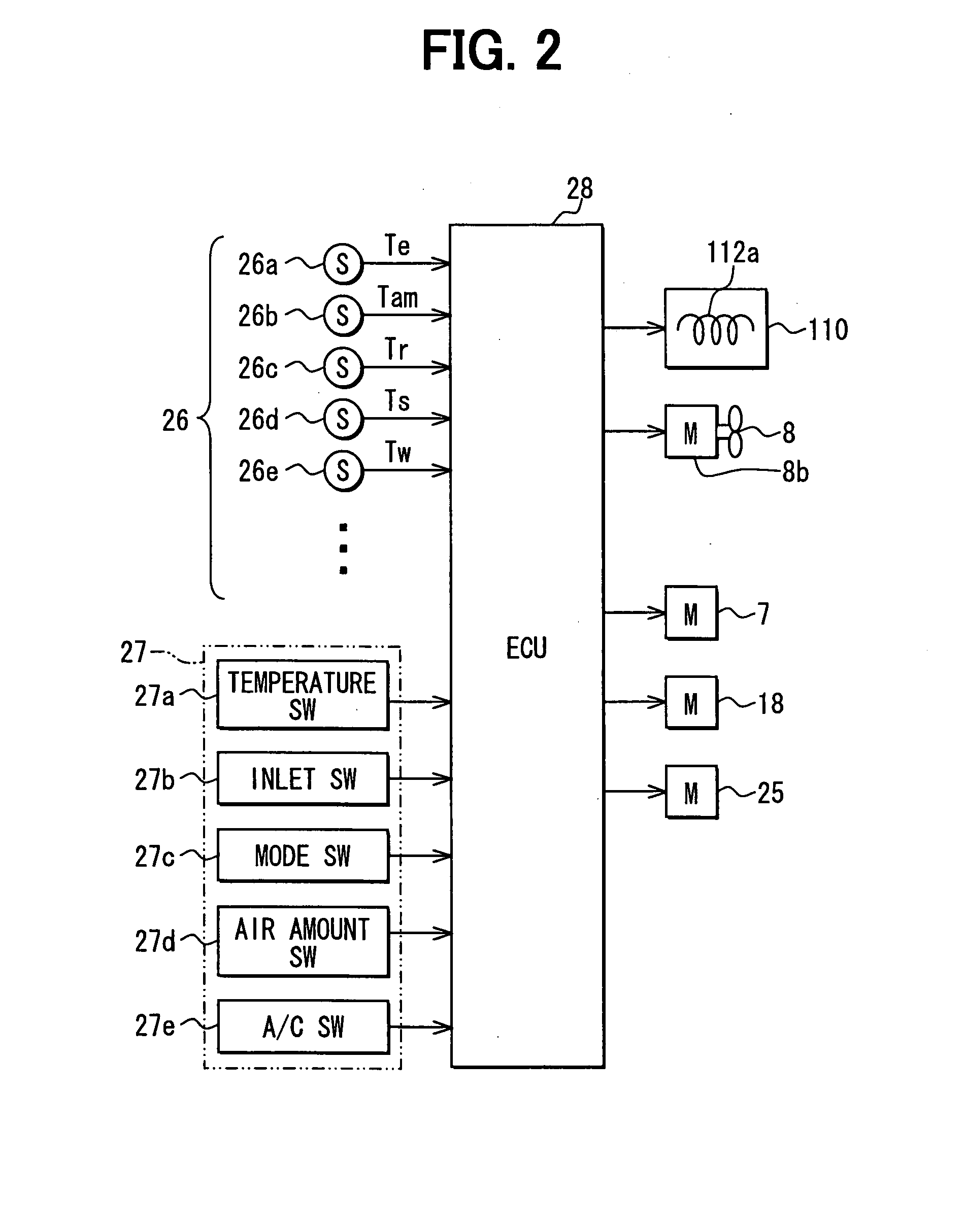

Air conditioning system

ActiveUS20070277544A1Effective capabilityLimit its operationAir-treating devicesCompression machines with non-reversible cycleEngineeringRefrigerant

An air conditioning system for a vehicle has a refrigerant cycle device which has an evaporator and a compressor and in which refrigerant is discharged from the compressor to be evaporated in the evaporator so that air passing the evaporator is cooled to be blown into a passenger compartment of the vehicle. The control unit drives the compressor at a control value which is determined based on at least one of a pressure of the refrigerant in the refrigerant cycle device and an outside-air temperature outside the passenger compartment, when the control unit actuates the compressor.

Owner:DENSO CORP

Air-conditioner for vehicle

InactiveUS20070256436A1Reduce freezingDomestic cooling apparatusVehicle heating/cooling devicesEngineeringRefrigeration

An air-conditioner includes a refrigeration cycle device having an evaporator for evaporating refrigerant discharged from a compressor to cool air to be sent into a vehicle compartment. A controller turns on the compressor when a surface temperature of the evaporator or a downstream temperature of air at a downstream side of the evaporator is equal to or larger than a first predetermined value. The controller turns off the compressor when a changing rate of the surface temperature or a changing rate of the downstream temperature is equal to or larger than a second predetermined value. The controller turns on the compressor again when the surface temperature or the downstream temperature becomes equal to or larger than a third predetermined value, which is larger than the first predetermined value.

Owner:DENSO CORP

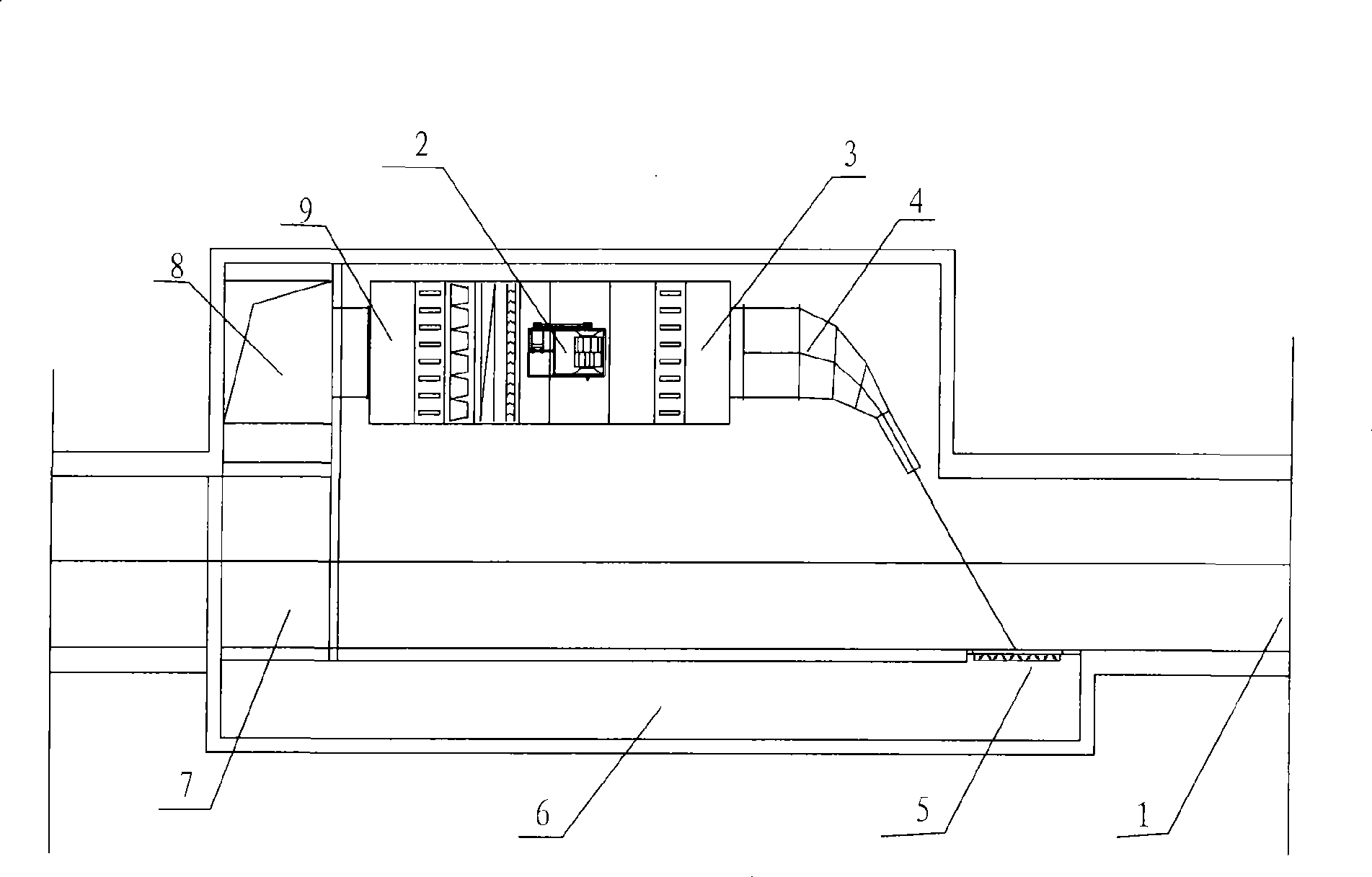

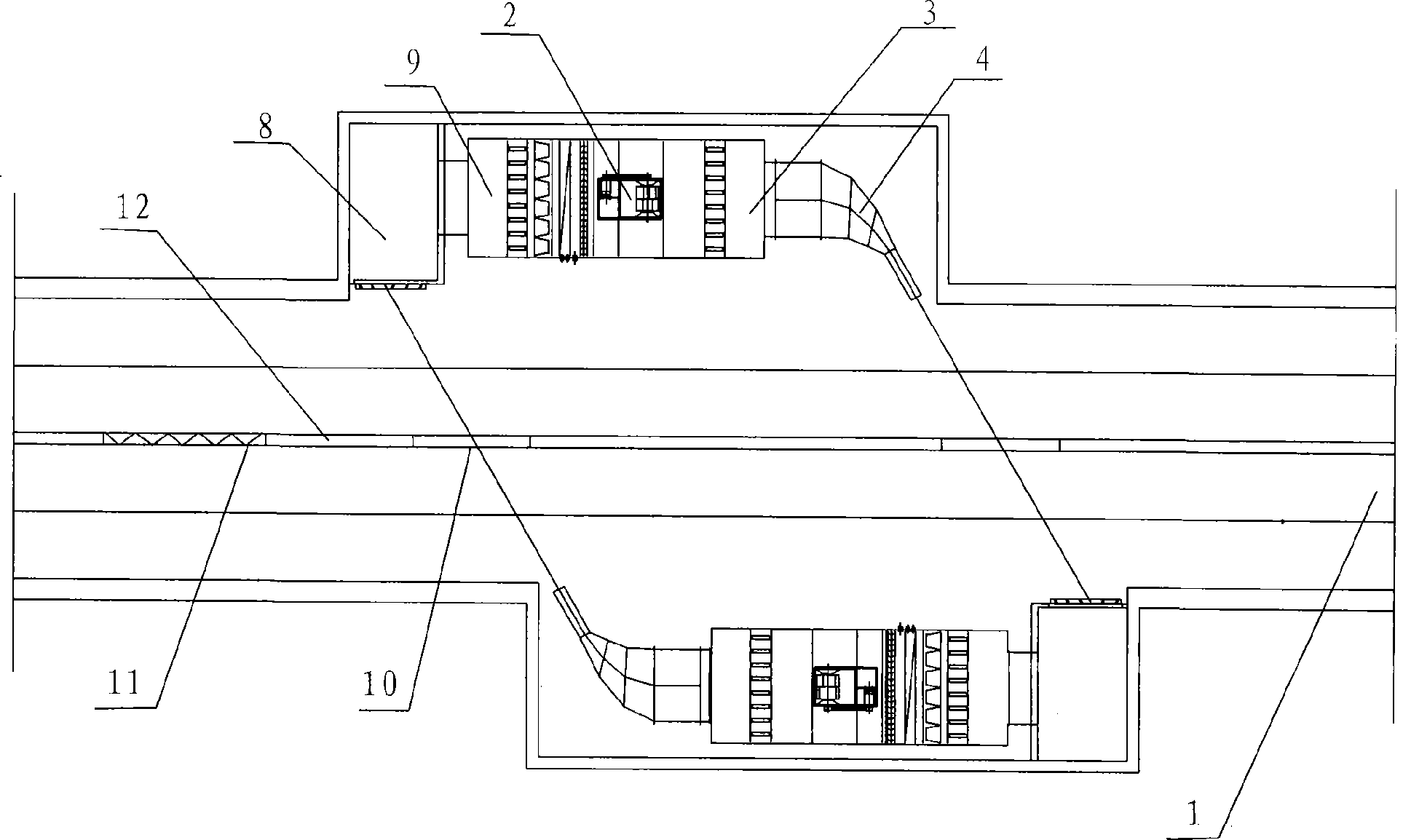

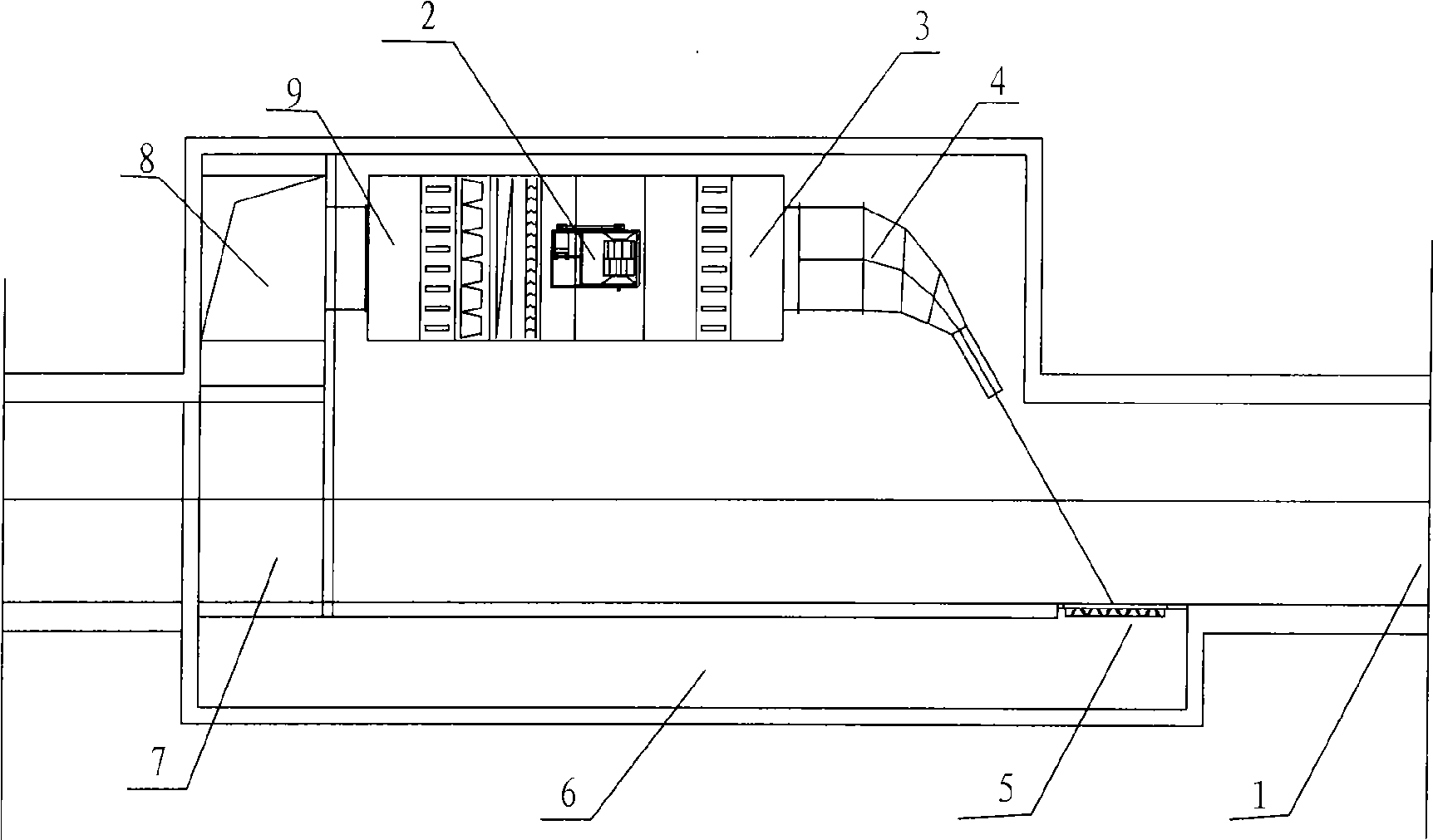

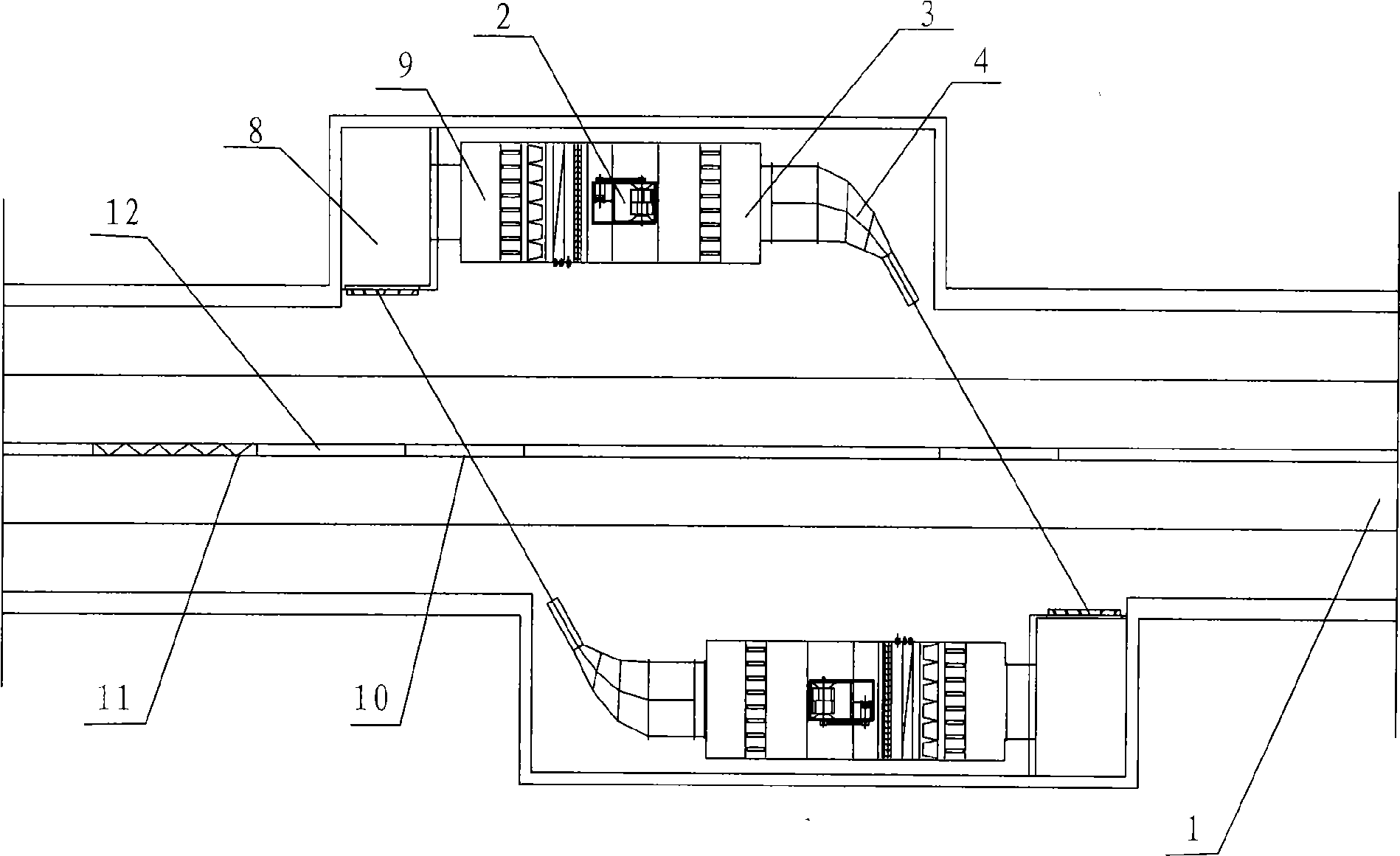

High-speed thermal circulation air curtain construction method for tunnel portal

ActiveCN101463731AReduced caloric needsStable temperatureLighting and heating apparatusTunnel/mines ventillationCold airEngineering

The invention relates to the field of fixed buildings, in particular to a construction method of a tunnel portal high-speed thermal-circulation air curtain applicable to track traffic positive line and access field line portals in high-latitude and high-cold areas. In the method, when a subway underground section is opened to the ground surface, a tunnel portal is provided with a thermal air curtain spouted at a high speed; a thick air curtain is formed at the tunnel portal, preventing sever cold air outside the tunnel from invading and reducing heat exchange; in a parallel-double-portal tunnel, a communicating channel and a circuitous channel are added and arranged in a partition wall of the tunnel, effectively channelizing train piston air; meanwhile, a circulated air channel, a break-of-gauge channel, a circulation chamber, and the like, are arranged to circulate hot air, thus effectively reducing the calorific requirement of an adjacent station, stabilizing the temperature in a station, and reducing the freezing of a hot-cold intersection of the portal and ensuring traffic safety.

Owner:SHANGHAI TUNNEL ENGINEERING RAILWAY TRANSPORTATION DESIGN INSTITUTE

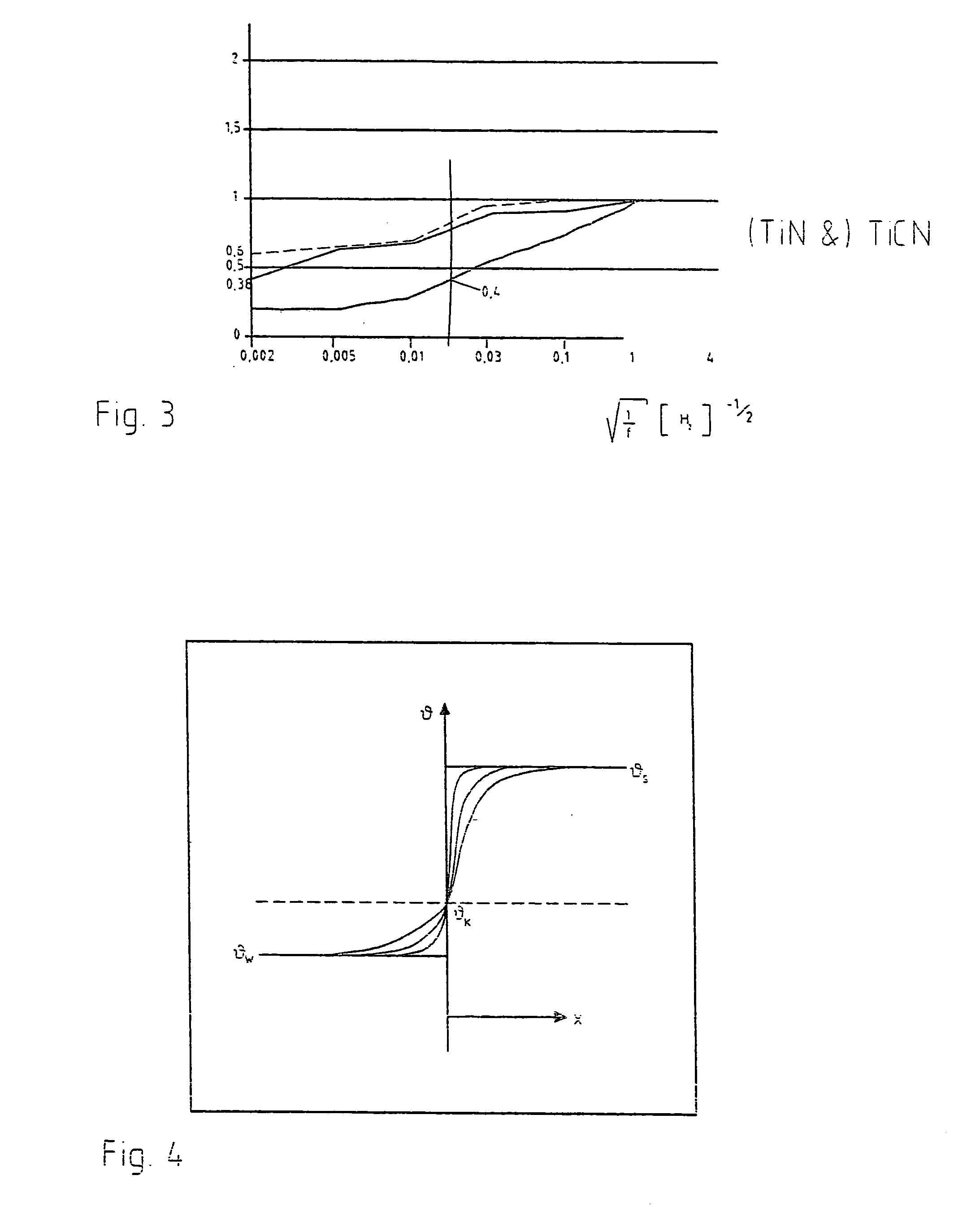

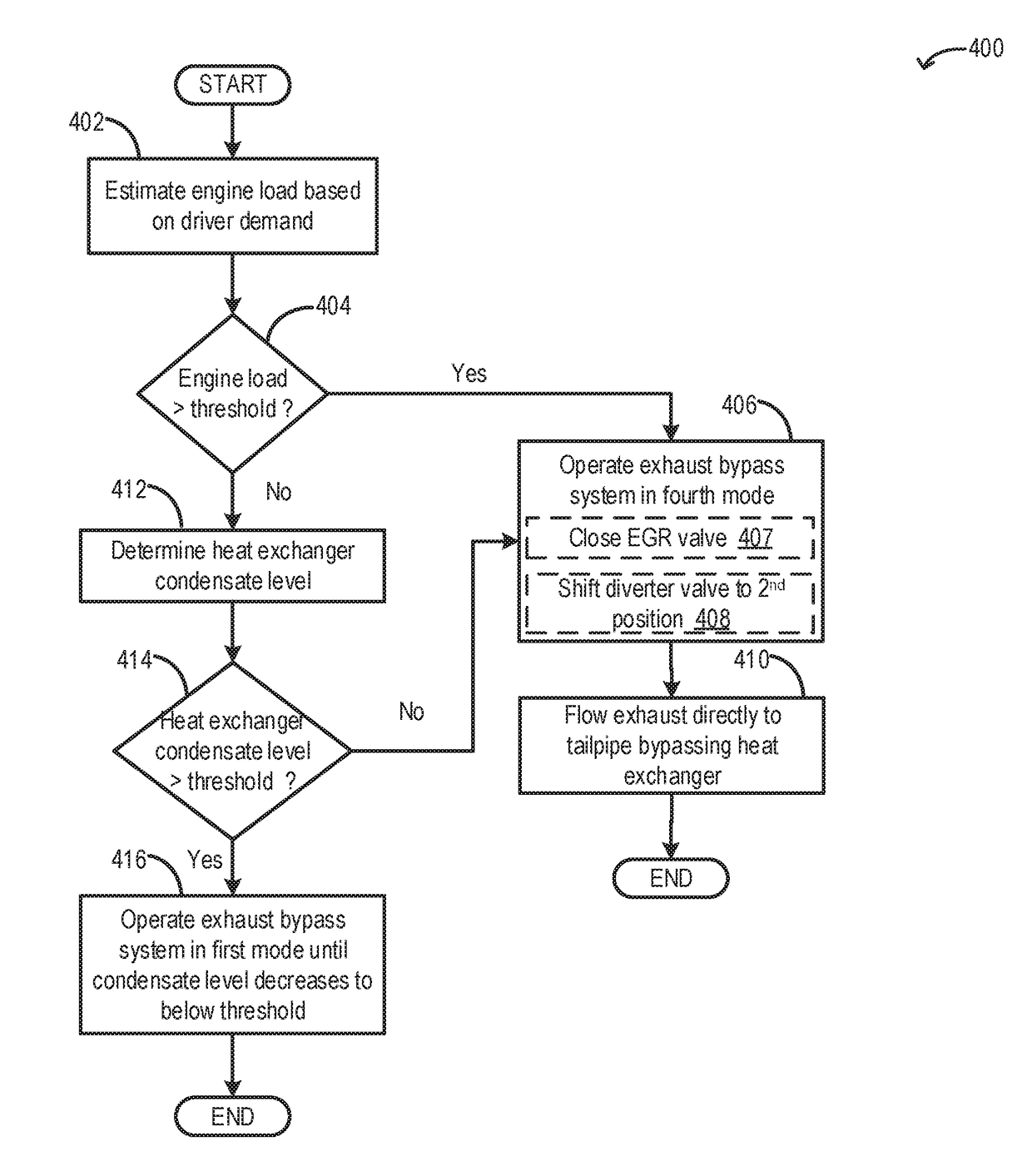

Gloss level adjustment

ActiveUS20050133962A1Highly accurate reproductionAvoid differencesDischarging arrangementMouldsTemperature controlHeat penetration

In a method for injection molding molten materials, especially plastic, in a mold that has a mold surface which comes into contact with the material, at least one coating on the mold surface and a temperature-control means for the mold surface, the mold surface is cooled by the temperature-control means so that the molten material solidifies at the interface with the coating and an injection-molded part can be removed from the form. During this process the molten material is brought into contact with the coating on the mold surface, the thickness of said coating being selected in coordination with the heat penetration coefficient of the coating material such that a specified 60° gloss level and / or color value L is obtained for the injection-molded part.

Owner:OERLIKON SURFACE SOLUTIONS AG PFAFFIKON

Profundity sterilization borehole face high-strength high-performance concrete

InactiveCN101152977AImprove carrying capacityStrong water sealingSolid waste managementChemical admixtureSlag

The present invention discloses a concrete with high strength and high performance for deeply and thickly frozen well wall. The double-doping technology of milled slag as the main mineral doping and different chemical doping is used; the invention is prepared after optimized combination and blending of mixture. The concrete is made by mixing P.0.42.5cement, machine-made sand, limestone rubble, milled rubble, I-level powder coal ash, TK-M intensifier, J851-D early strengthening high-early-strength water reducing agent, JQ-D anti-crack intensifying agent, high-efficiency water reducing agent of liquid polycarboxylic salt, and water. The present invention has the characteristics of the low preparation cost, the simple operation process, the applicability to engineering of the inside of a deeply and thickly frozen and a well wall on the outer layer, and so on.

Owner:盛天宝 +2

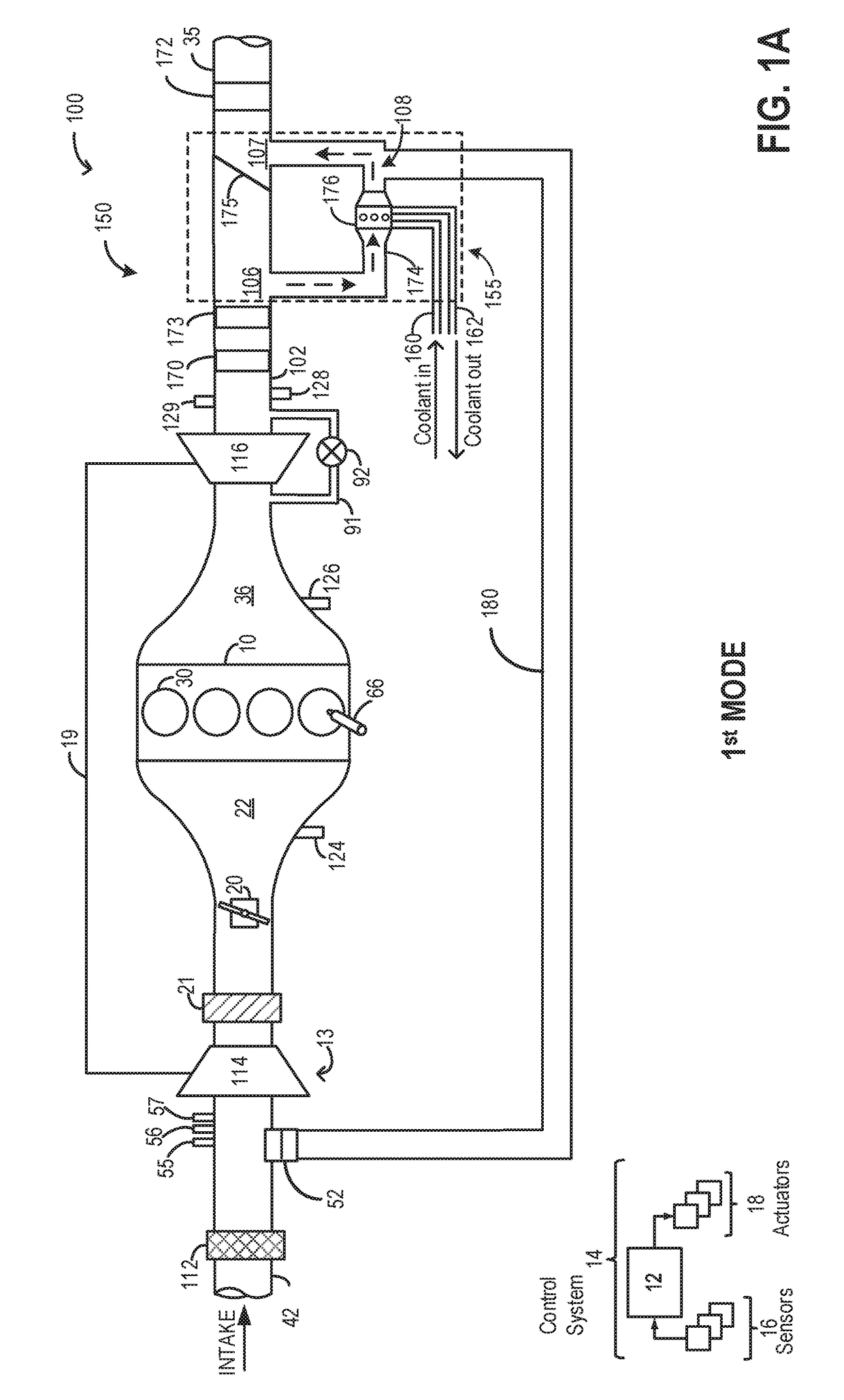

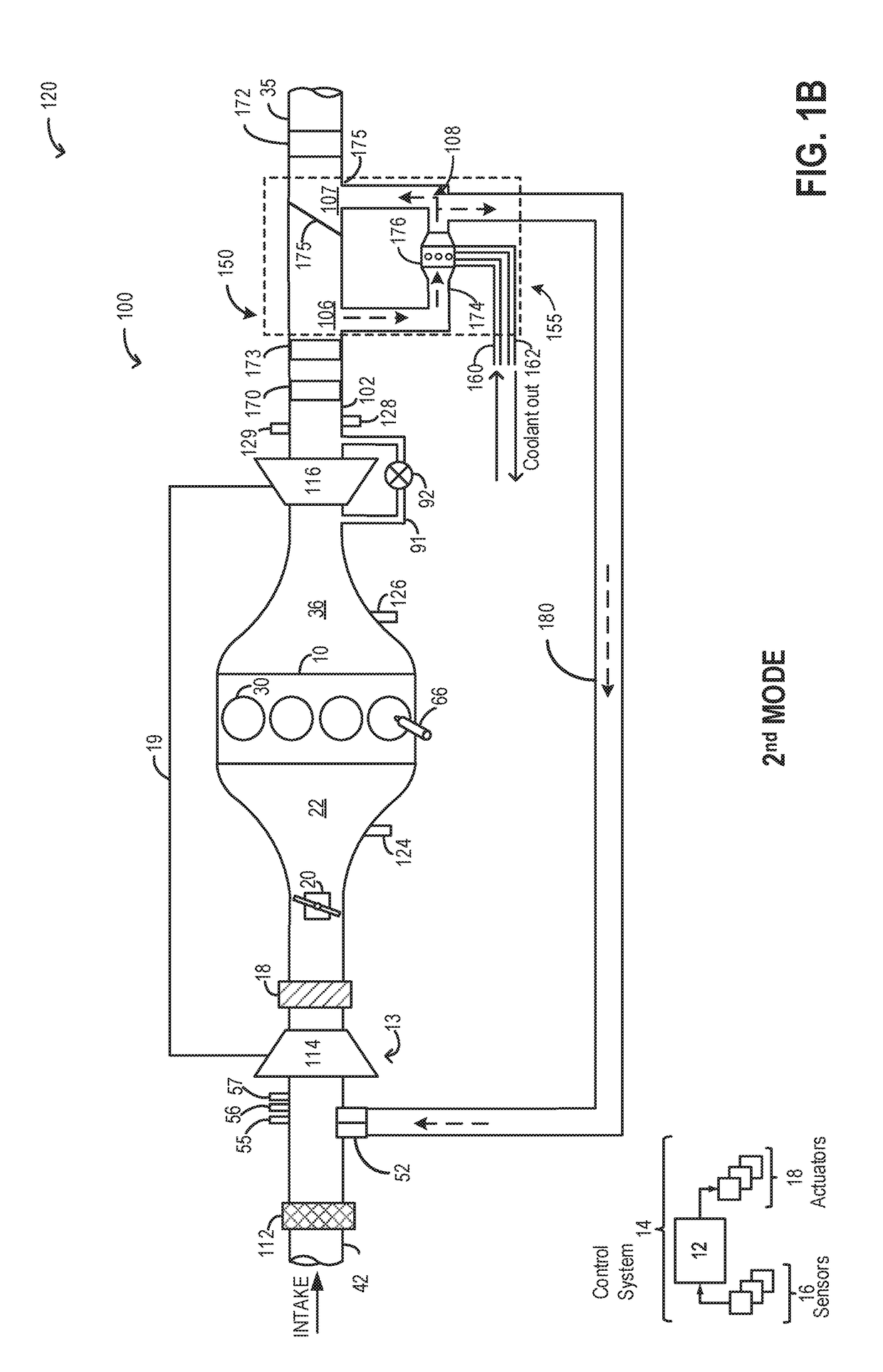

Method and system for exhaust gas recirculation and heat recovery

ActiveUS20180119624A1Reduction of throttle lossImprove knock toleranceLiquid coolingAir-treating devicesExhaust fumesProcess engineering

Methods and systems are provided for exhaust heat recovery and EGR cooling via a single heat exchanger. In one example, a method may include selecting a specific mode of operation of an engine exhaust system with the heat exchanger based on engine operating conditions and an estimated fuel efficacy factor. The fuel efficiency factor may take into account fuel efficacy benefits from EGR and exhaust heat recovery.

Owner:FORD GLOBAL TECH LLC

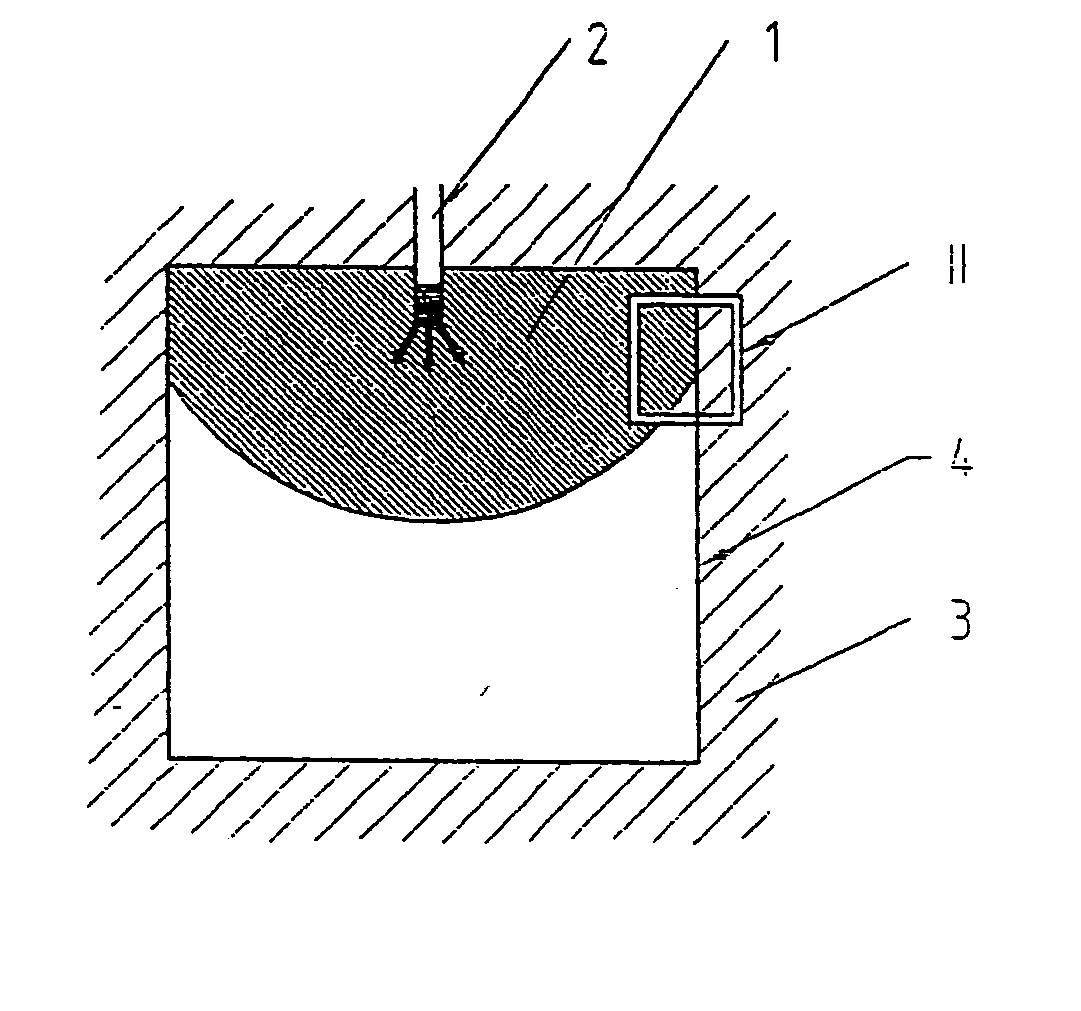

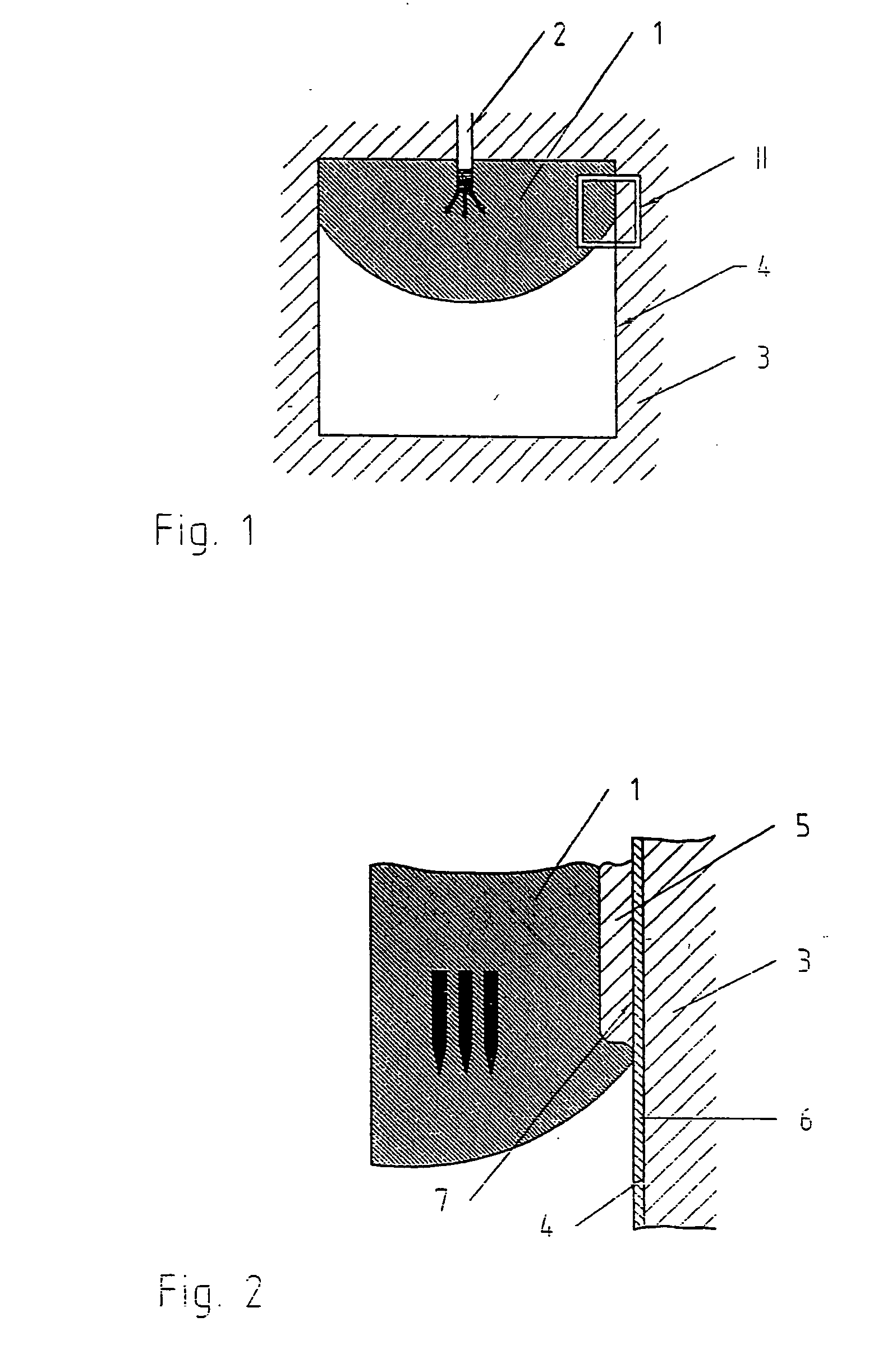

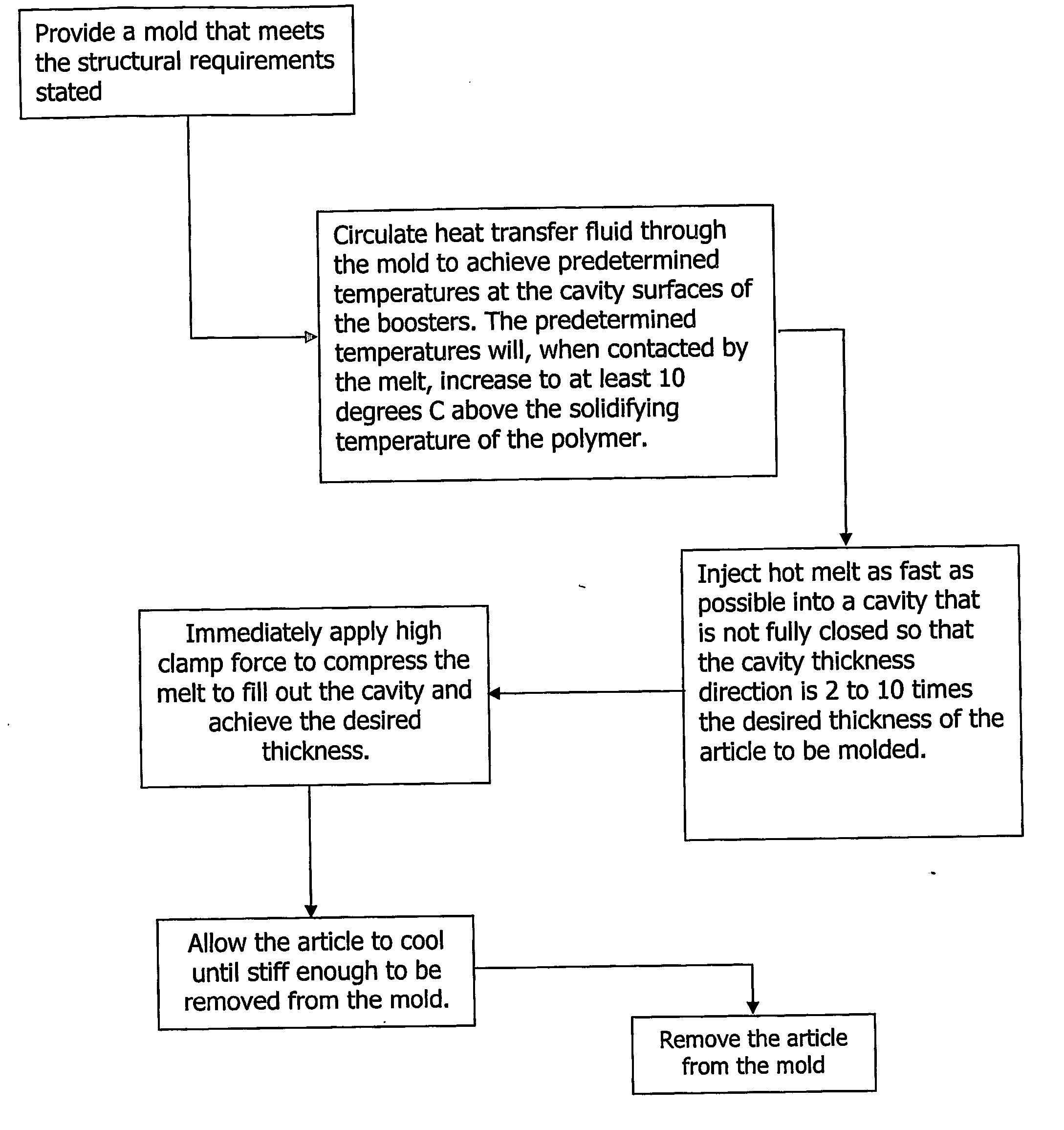

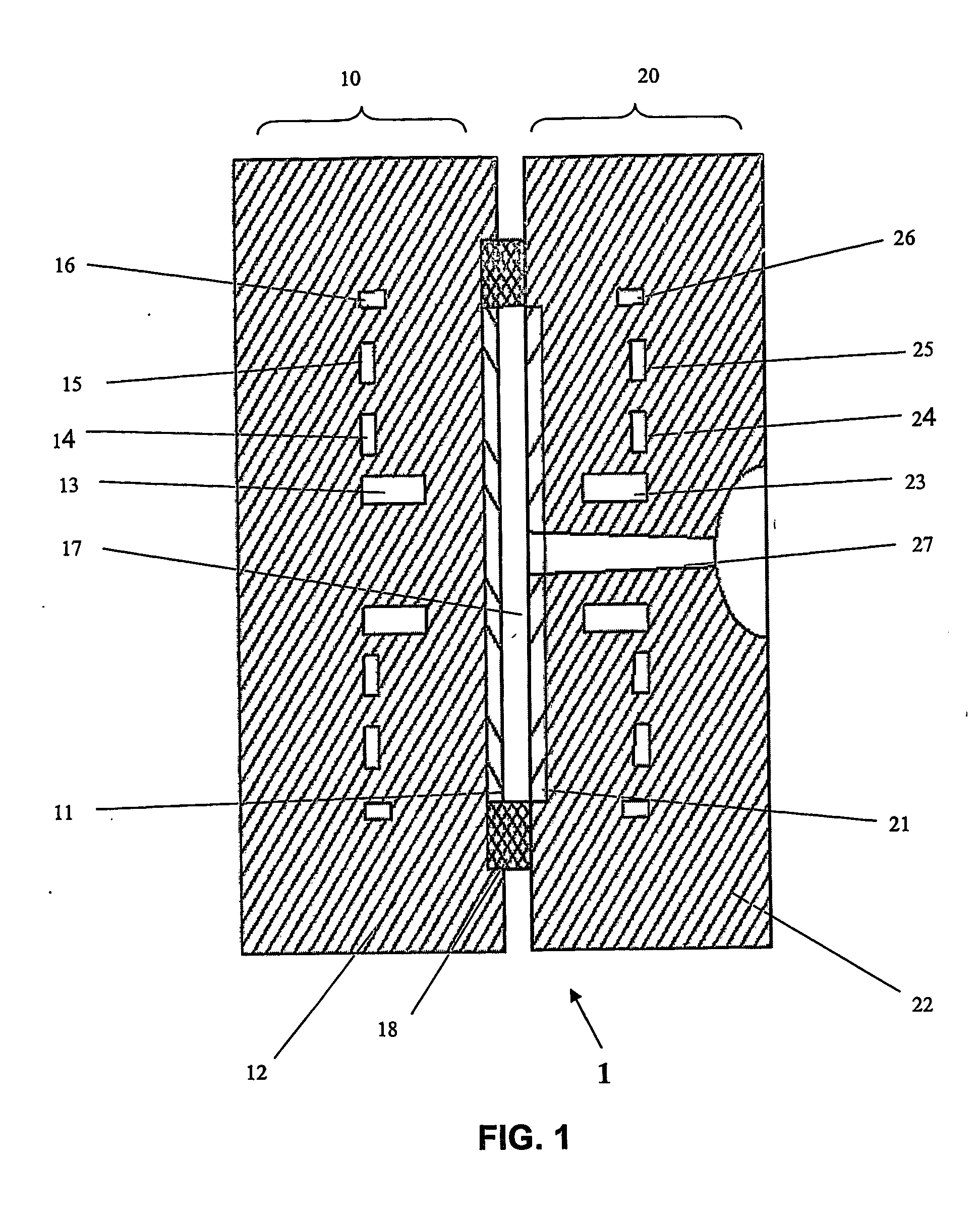

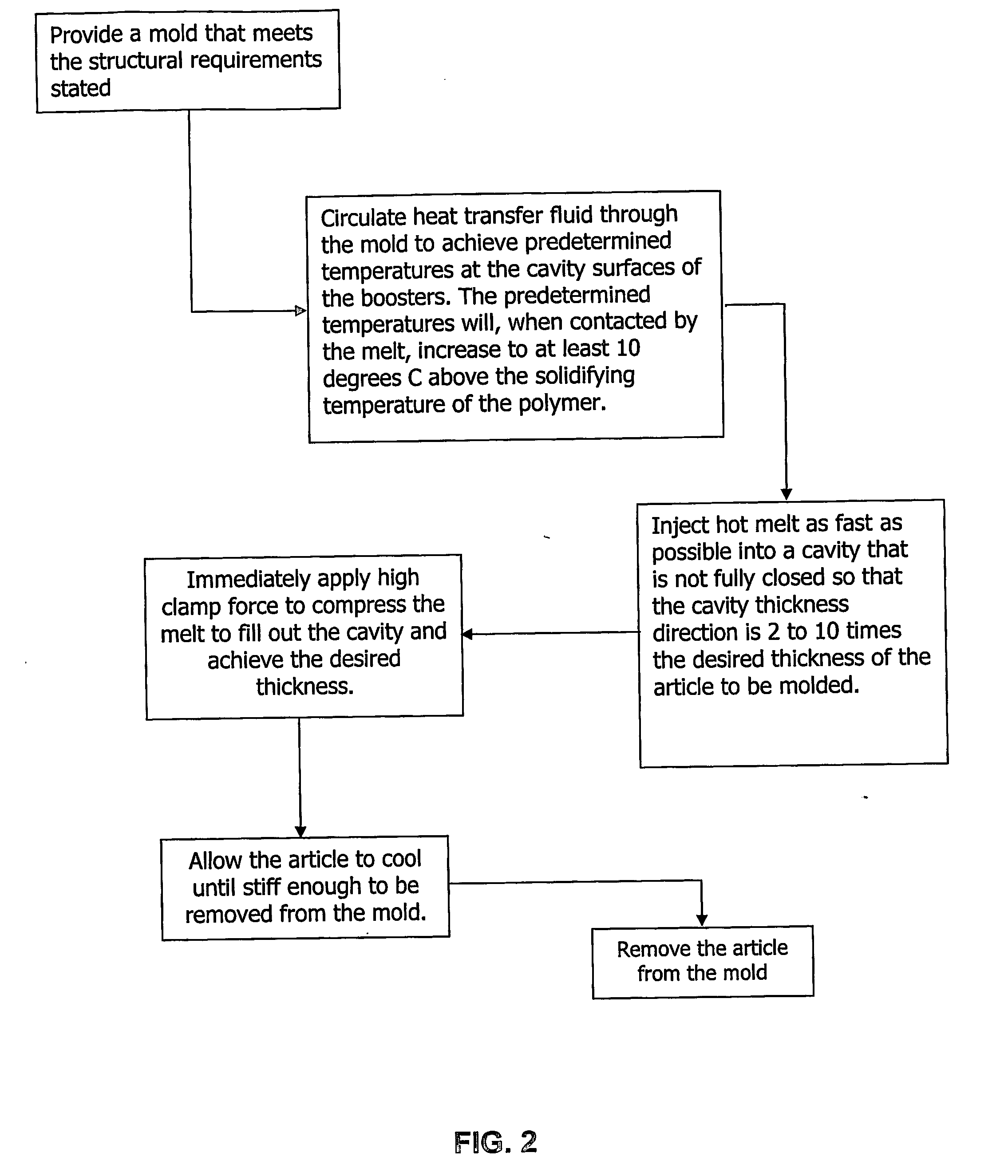

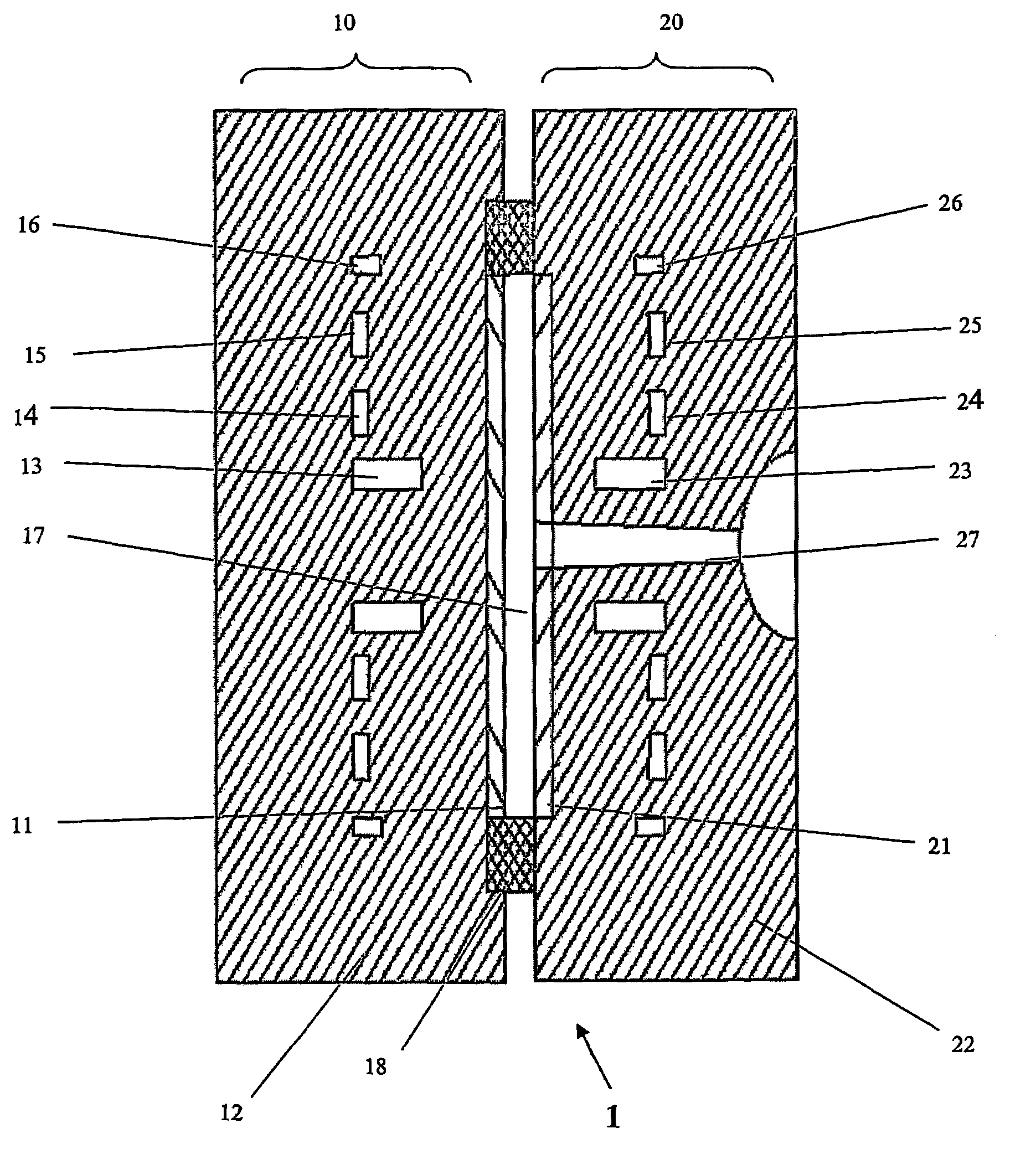

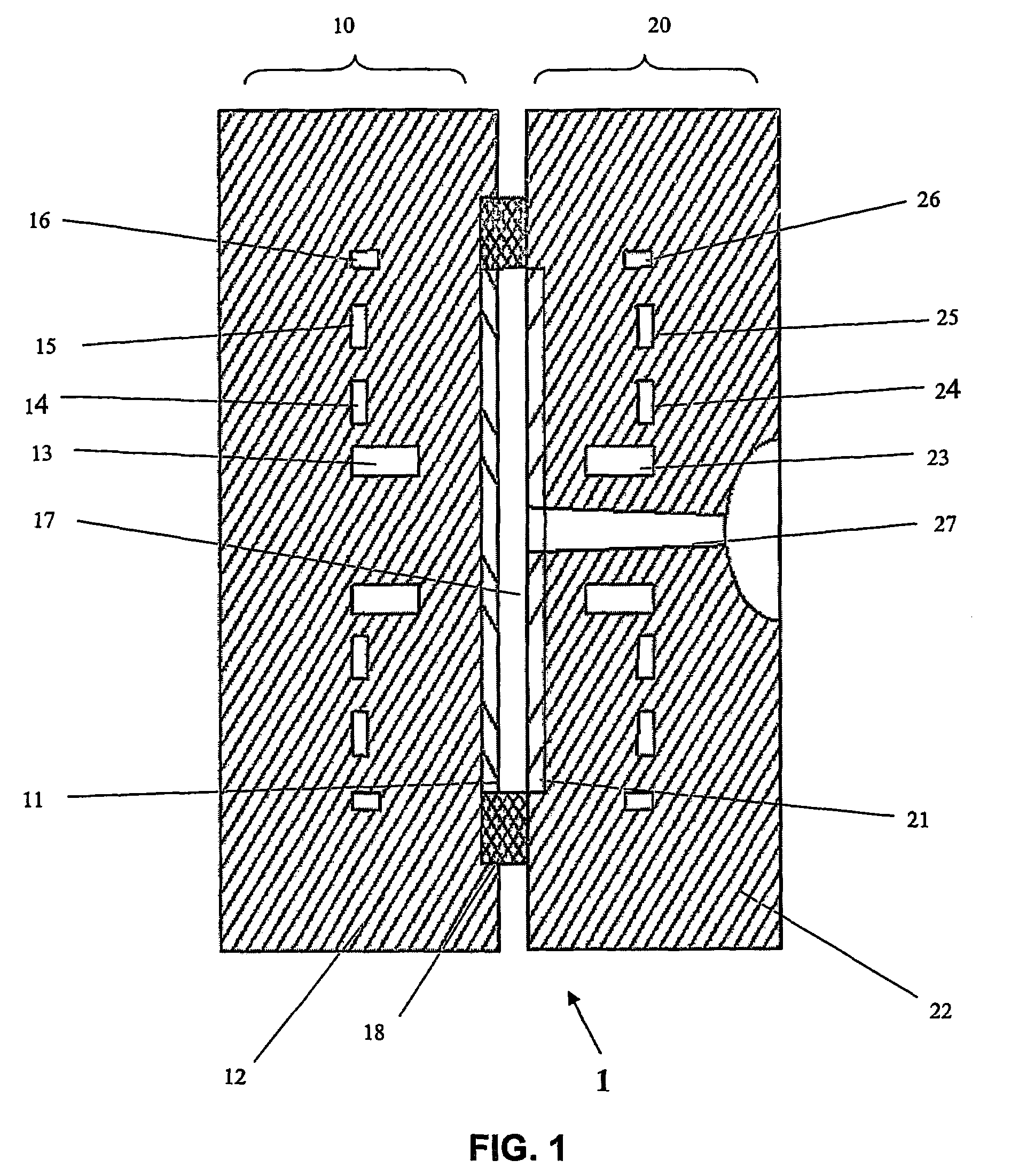

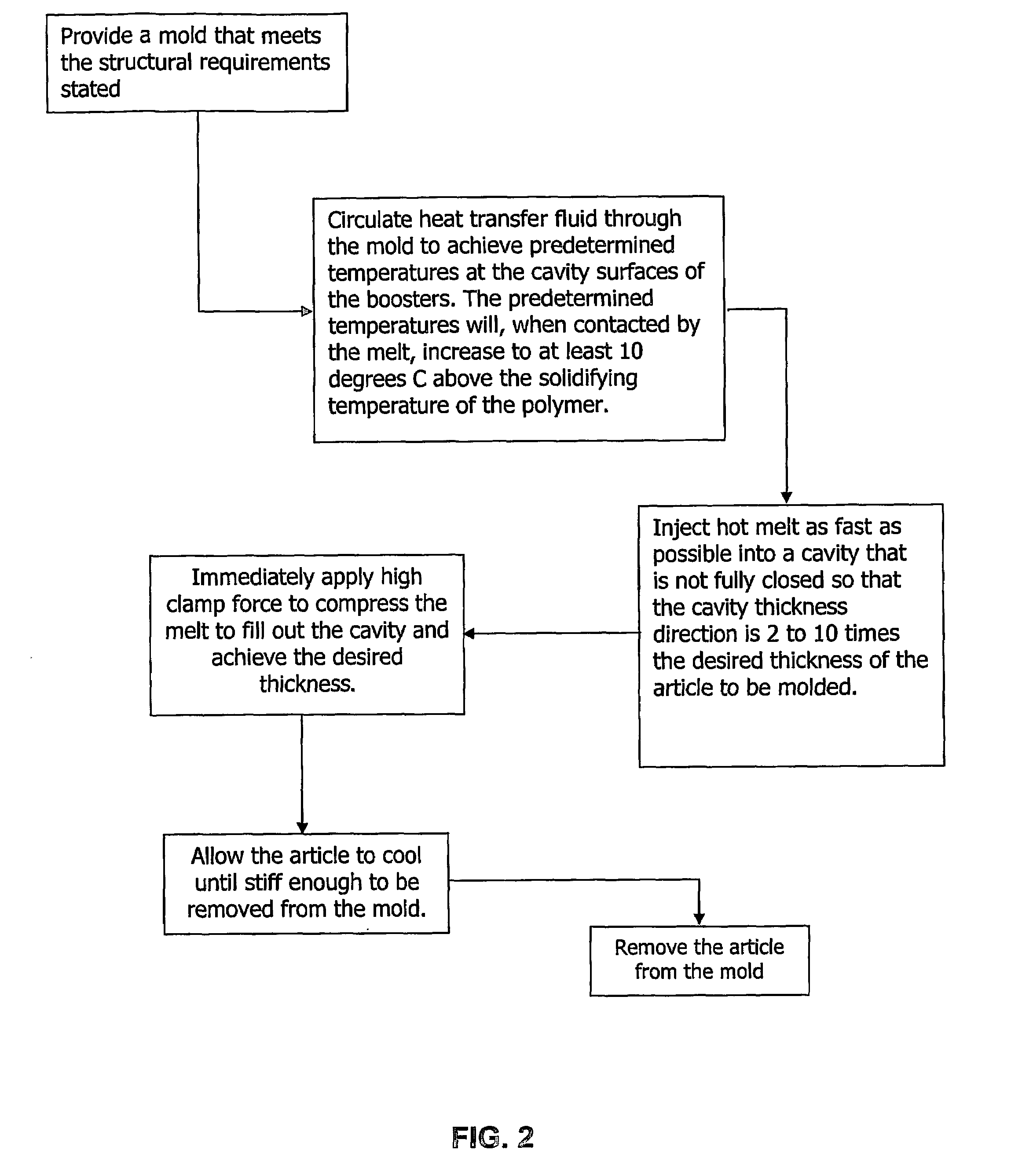

Mold and process for making a very thin wall article

InactiveUS20060170125A1Facilitate material flowIncreasing the thicknessRecord carriersAuxillary shaping apparatusMetallurgyThermal insulation

An injection mold and process are arranged to produce very thin articles, such as data discs. Molten plastic is injected into mold parts forming a thin cavity (17), in a cyclic molding process wherein the mold parts are subjected to a substantially constant temperature stimulus and rise and fall in temperature during injection and cooling of the molten plastic. Temperature boosting thermal insulation layers (11, 21) are placed along at least certain parts of the molding cavity surface. This elevates the temperature of the molted melt material for a time during injection. According to a calculated relationship, this thermal insulation is sized to permit the thin mold cavity to fill before heat transfer to the mold parts solidifies the molding material and blocks further flow. The temperature boosters can be contoured in thickness.

Owner:THERMAL WAYE MOLDING

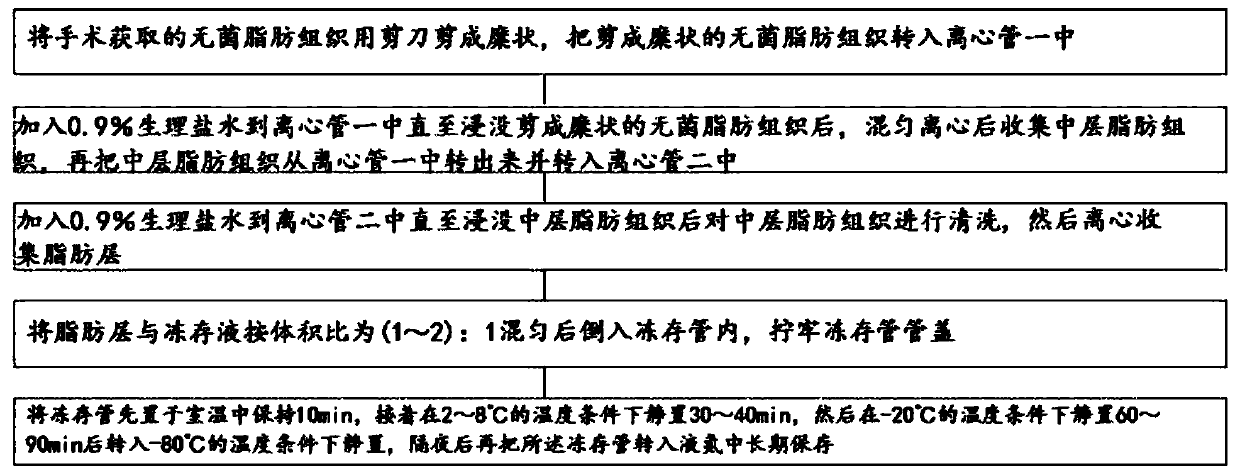

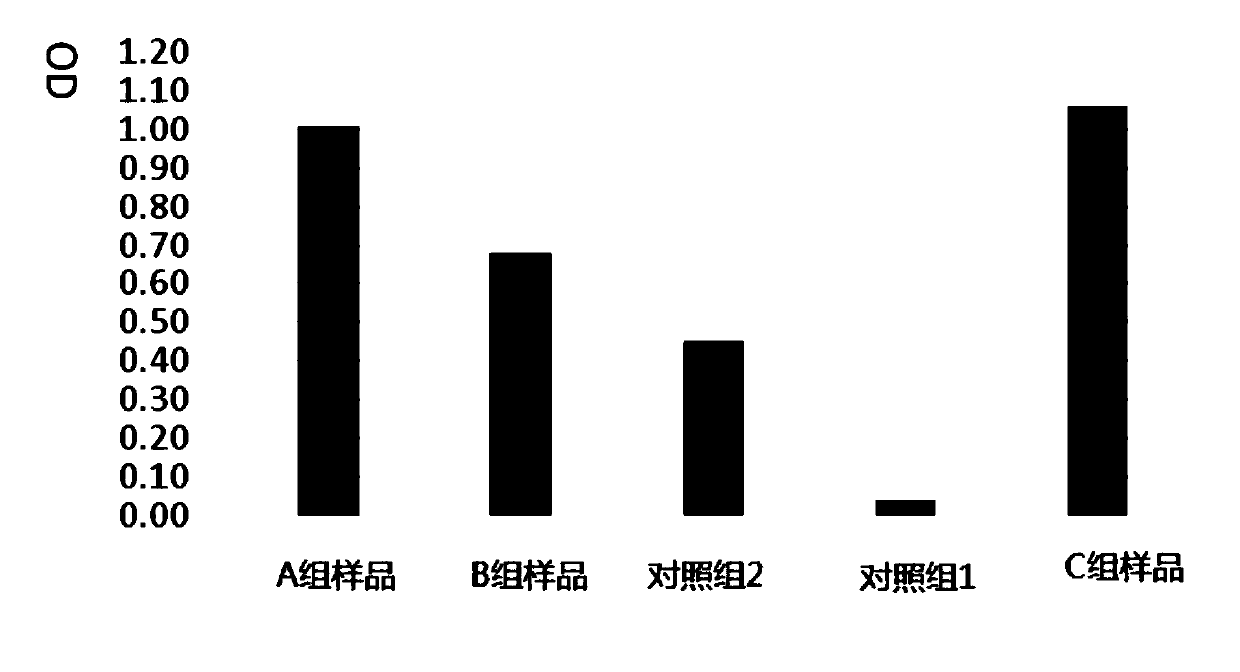

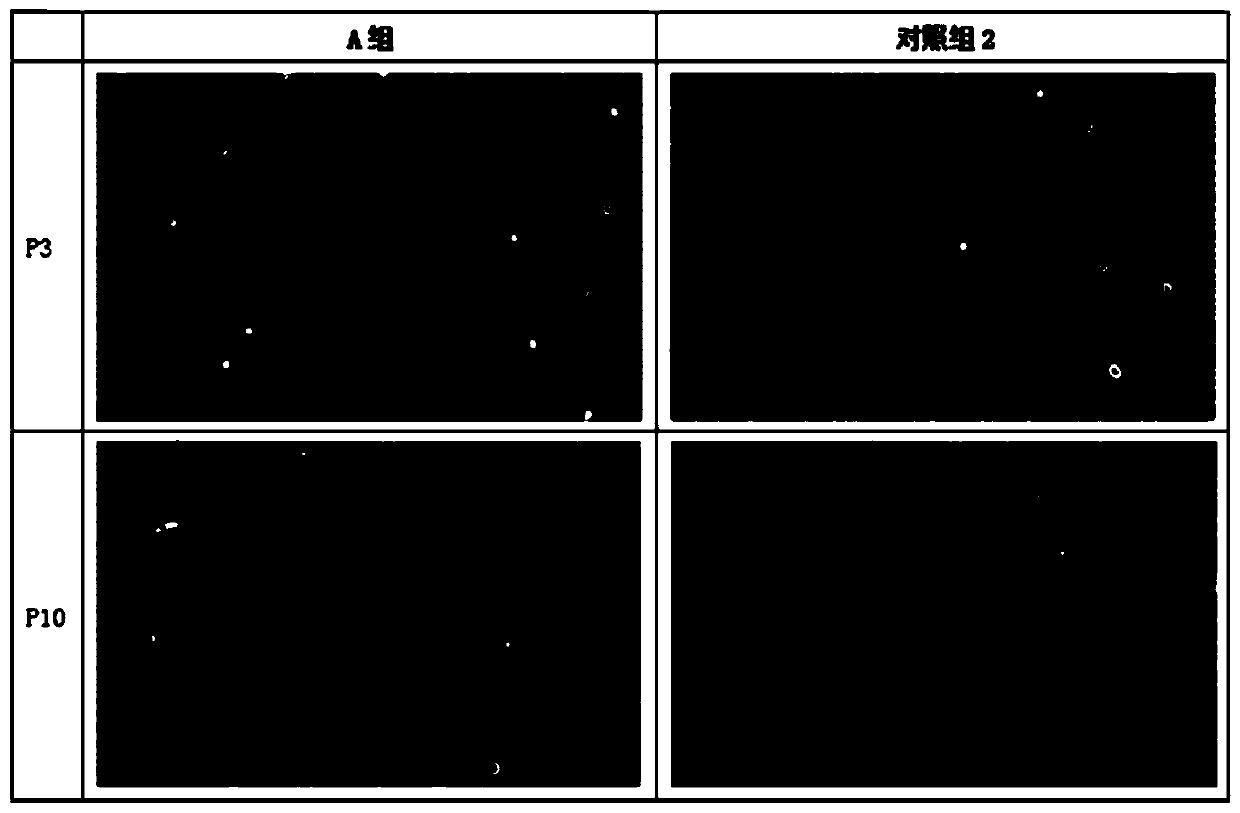

Adipose tissue cryopreservation liquid at clinical application level and cryopreservation method

Adipose tissue cryopreservation liquid at a clinical application level and a cryopreservation method. The adipose tissue cryopreservation liquid at the clinical application level comprises 15-50-mmol / L saccharose, 15-50-mmol / L mannitol injection, 1-5-mmol / L glucose injection, 1-3-mol / L adenosine injection, 0.5-5-mmol / L reduced glutathione, 1-4.5-mol / L trehalose and 0.1-1-mmol / L EDTA-2Na; and the components are mixed to form mixed liquid, and the mixed liquid is the adipose tissue cryopreservation liquid at the clinical application level. By means of the adipose tissue cryopreservation liquid,in combination with the cryopreservation method thereof, at the clinical application level, the defect of adverse reaction due to 2-[4-(2-hydroxyethyl)piperazin-1-yl]ethanesulfonic acid (HEPES), phenol red, DMSO, animal serum, blood platelet extracts and the like which are used in the prior art is effectively overcome.

Owner:陕西医赛尔生物科技有限公司

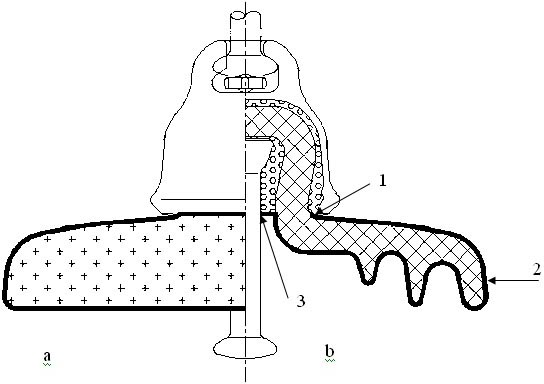

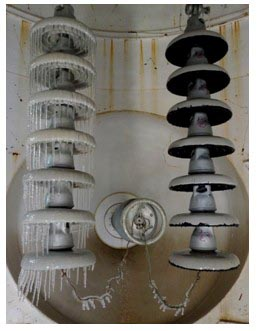

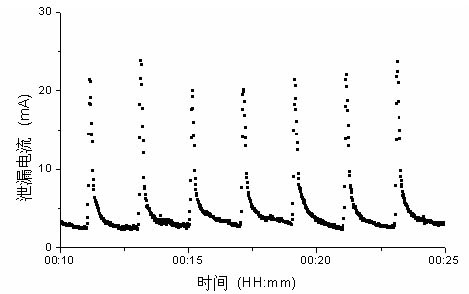

Insulator and transmission line

ActiveCN102511065AWith self-shutdown effectIncrease surface temperatureRubber insulatorsPower cables for overhead applicationConductive coatingEngineering

The present invention discloses an insulator comprising an insulation surface, wherein one part of the insulation surface is coated with conductive coating having special resistivity,the conducting coating area of the special resistivity and the uncondutive coating area are arranged in a discontinuous conduting channel between an upper armour clamp and a lower armour clamp of the insulator under a dry environment,and the conductive coating area of the special resistivity makes the leakage current value caused on the insulation surface reach to the temperature for preventing ice coating under ice coating weather conditions. The utility model also discloses a transmission device using the insulator. under the ice coating weather conditions, the conductive coating can improve the leakage current value of the surface of the insulator so as to prevent ice coating.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV +1

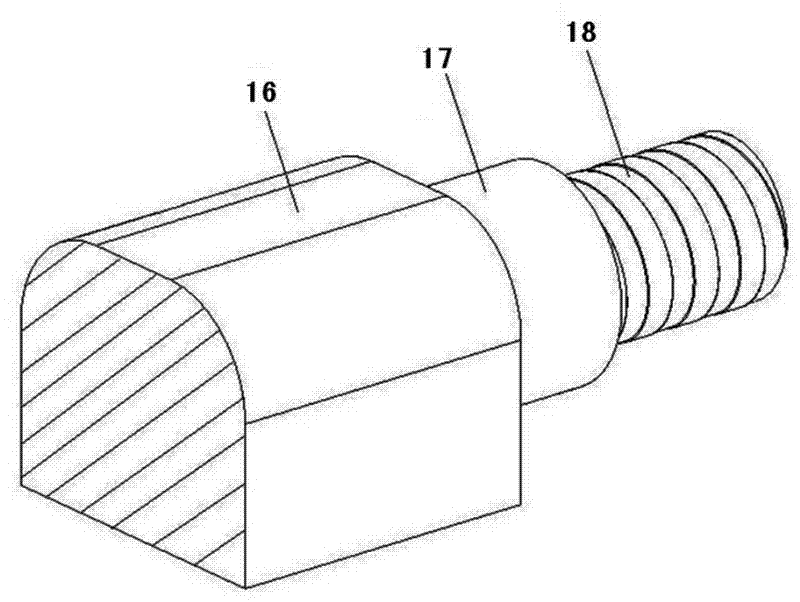

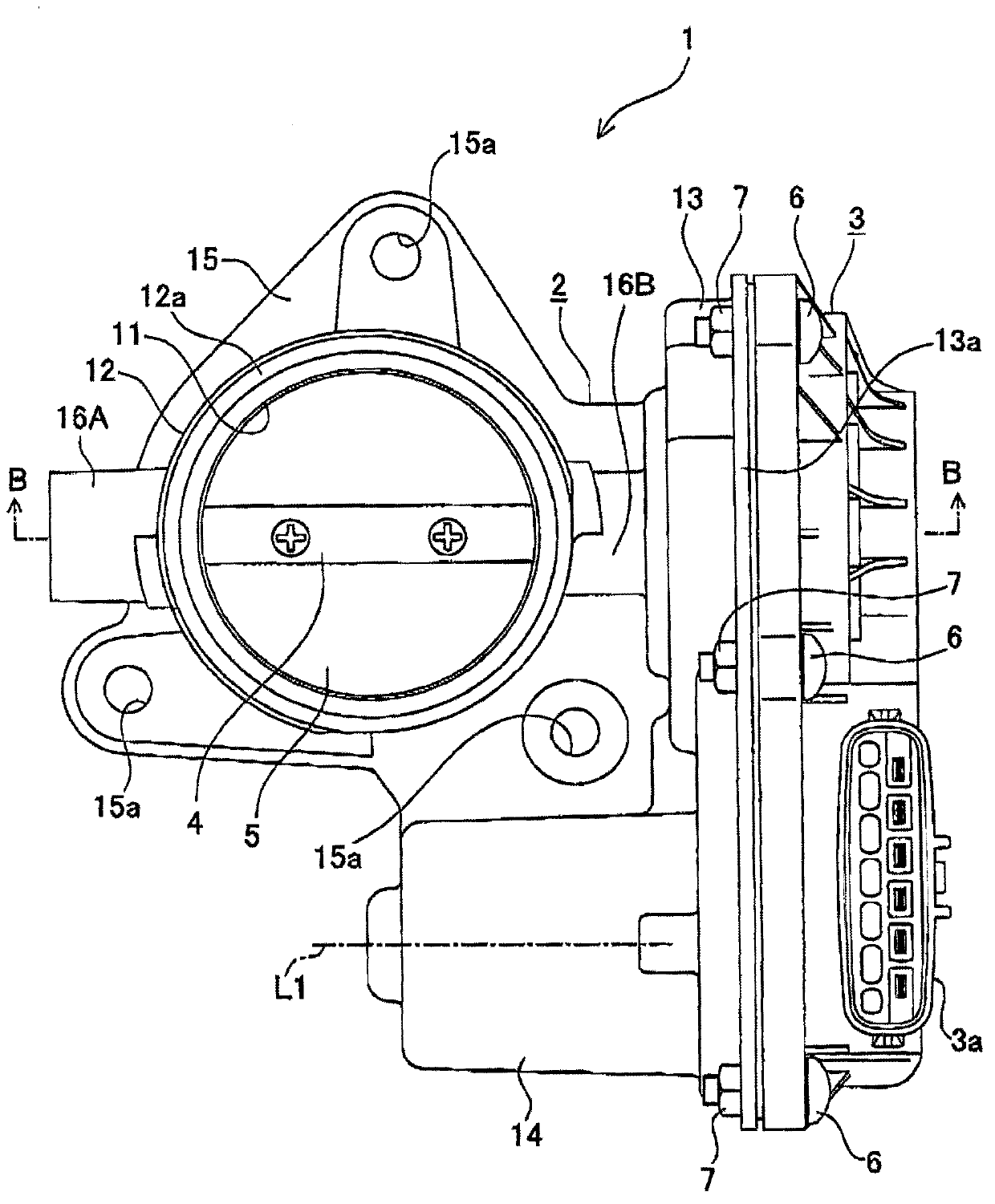

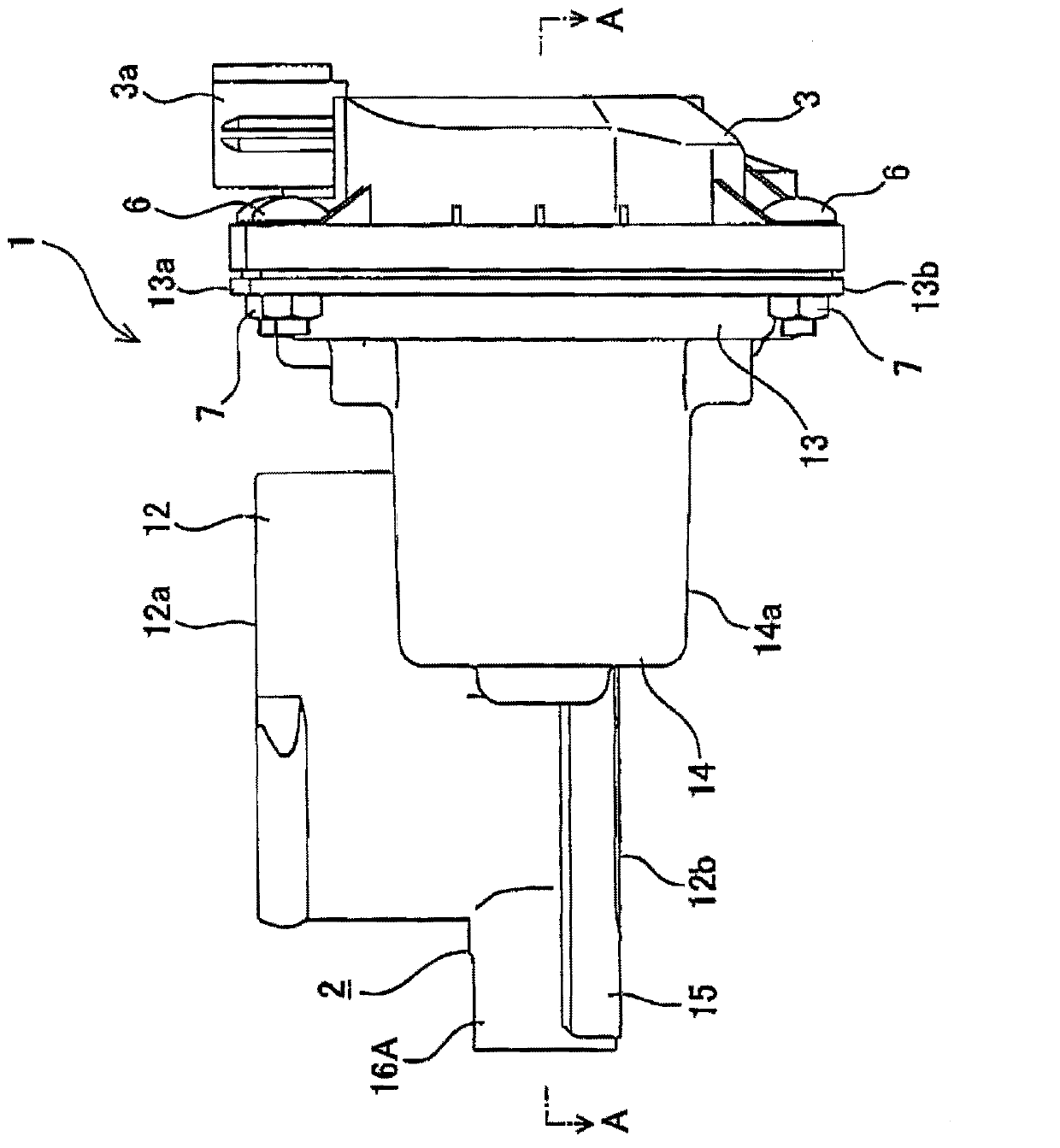

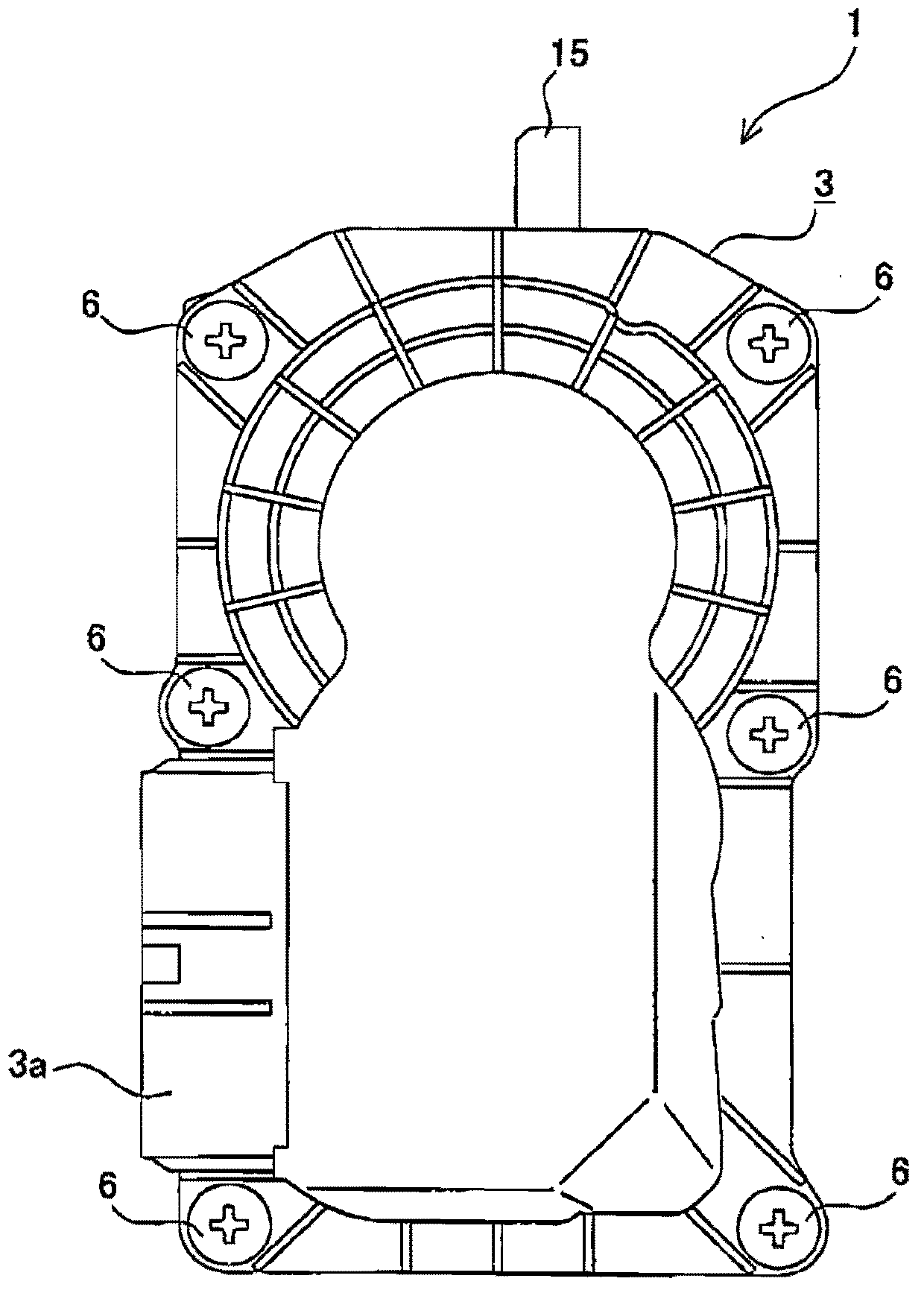

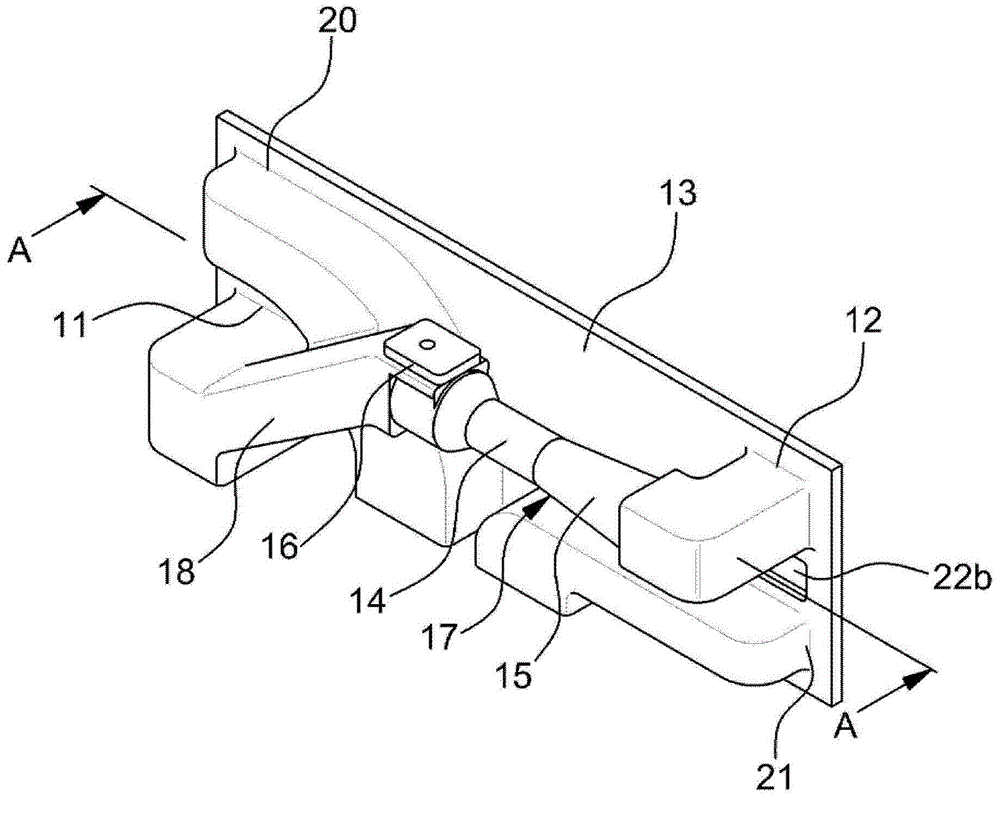

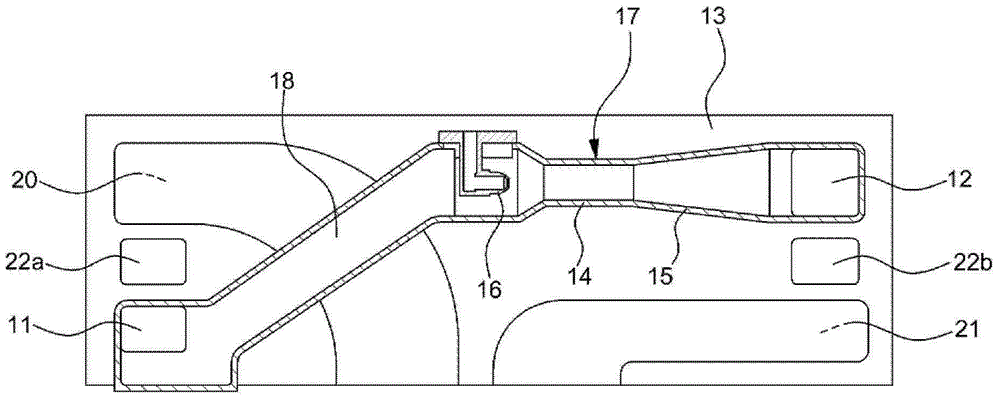

Throttle valve device

InactiveCN103104352AImprove disengagementGuaranteed detection accuracyEngine controllersMachines/enginesControl theoryShuttle valve

The invention provides a throttle valve device, which can improve removing performance of freezing between a valve core and a hole inner wall of a throttle valve. The throttle valve device is characterized in that, a throttle valve shaft (4) is made to rotate via use of a motor, etc. An opening degree, which is decided by a throttle valve core (5), of a hole (11) is changed, and air inlet flow of the hole is adjusted. The throttle valve shaft is supported to be rotatable by a pair of sliding bearings (21A, 21B) disposed corresponding to two end parts of the throttle valve shaft. Two bearings are disposed at a throttle valve body (2) or a throttle valve pipe (12) in a mode that the throttle valve shaft is adjacent to a downstream side end (11b) of the hole. When the throttle valve core becomes a closed state of almost completely closing the hole, the throttle valve core is configured to form a specified closed angle (theta 1) with the radial direction of the hole, one end part (5a) of the throttle valve is adjacent to a downstream side end of the hole. When the throttle valve core starts to open the hole, one end part (5a) of the throttle valve is immediately exposed.

Owner:AISAN IND CO LTD

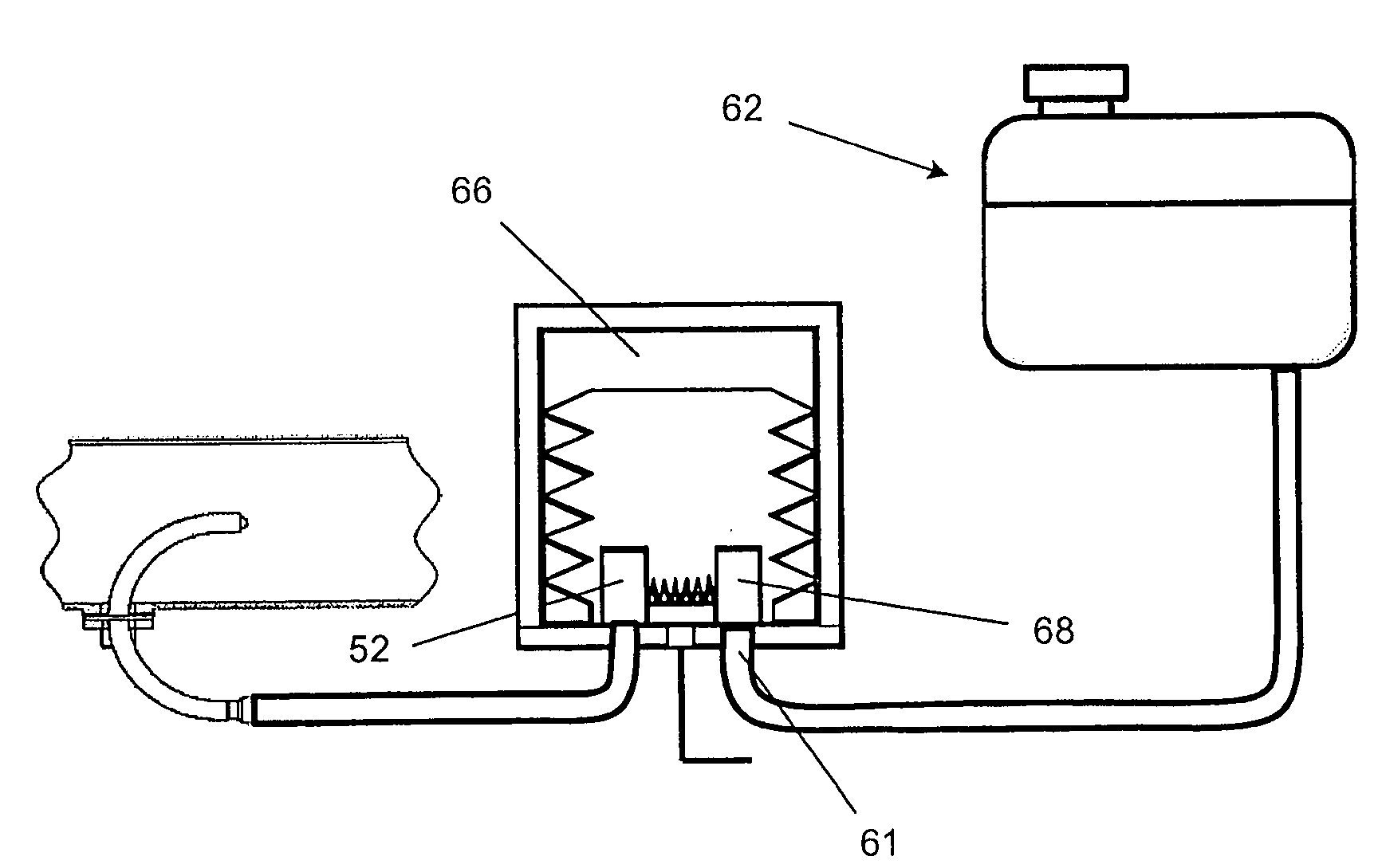

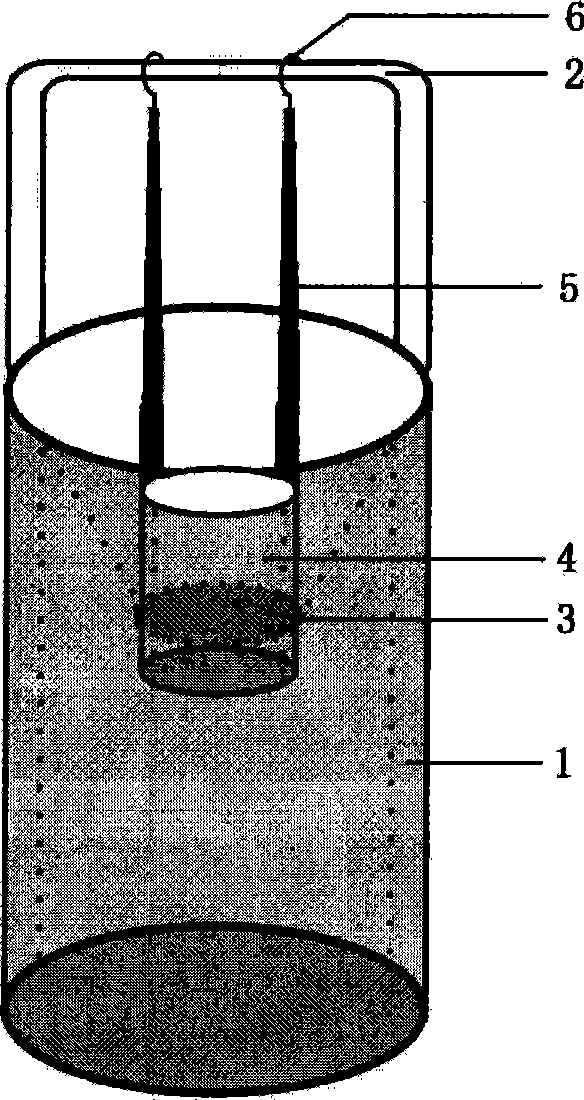

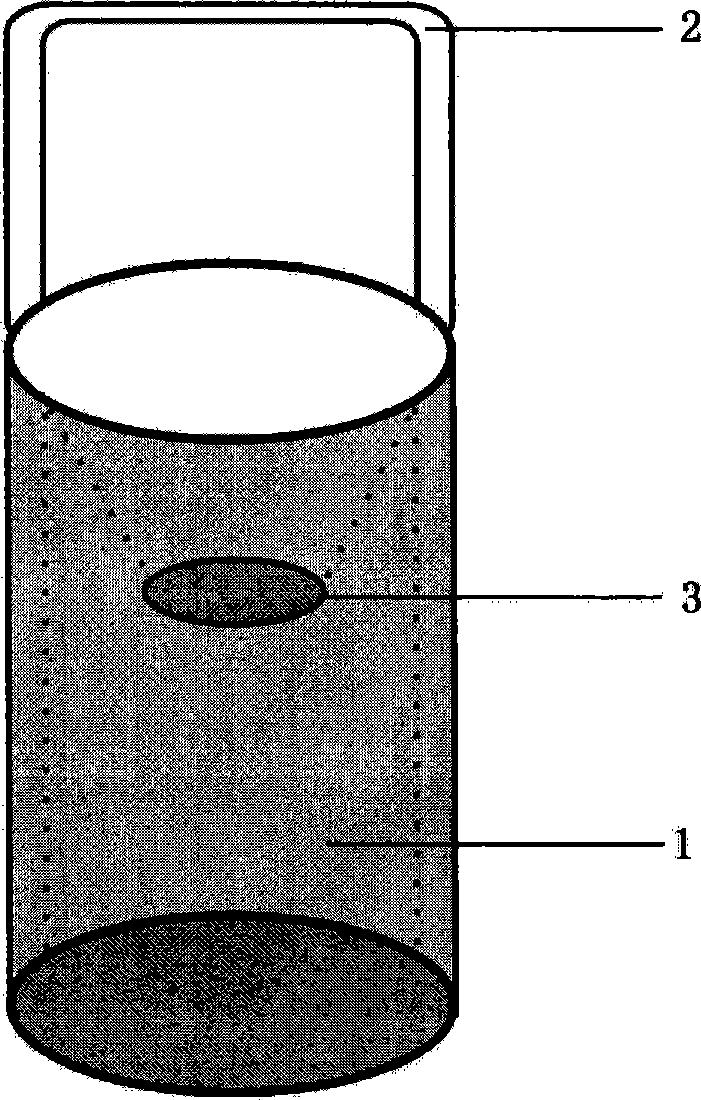

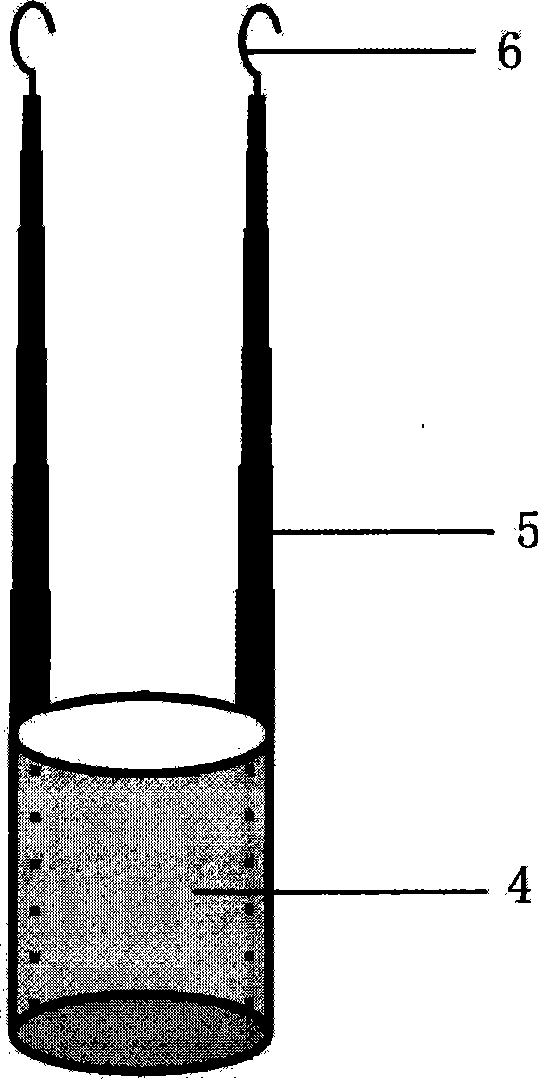

Multifunction organization embedding and refrigerating plant

InactiveCN101451928AReduce volatilityEasy to carryLighting and heating apparatusWithdrawing sample devicesFrozen tissueEmbryo

This invention is a tissue embed-freeze apparatus for frozen tissue section used for life science experiment and medical pathological tissue examination, comprised of a multifunctional liquid nitrogen storage thermostatic bottle and an adjustable suspending water tank. The multifunctional liquid nitrogen storage thermostatic bottle is internally designed with a conical baffle for the adjustable suspending water tank to enter, used for freezing the embedded tissue and reducing volatilization of liquid nitrogen therein. The adjustable suspending water tank is disposed with two freely operable pull rods on two sides thereof, in order to adjust immerging depth and position of the water tank into the liquid nitrogen in the thermostatic bottle within 0 to 30cm according to actual need. With utilization, this invention can rapidly and conveniently carry out high quality freezing process can be carried out on embedded tissue and embryo as a special tissue embed-freeze apparatus, especially suitable for life science, pathology and anatomy, etc., which simultaneously bring new improvement for existing tissue embed-freeze module.

Owner:INST OF ANIMAL SCI OF CHINESE ACAD OF AGRI SCI

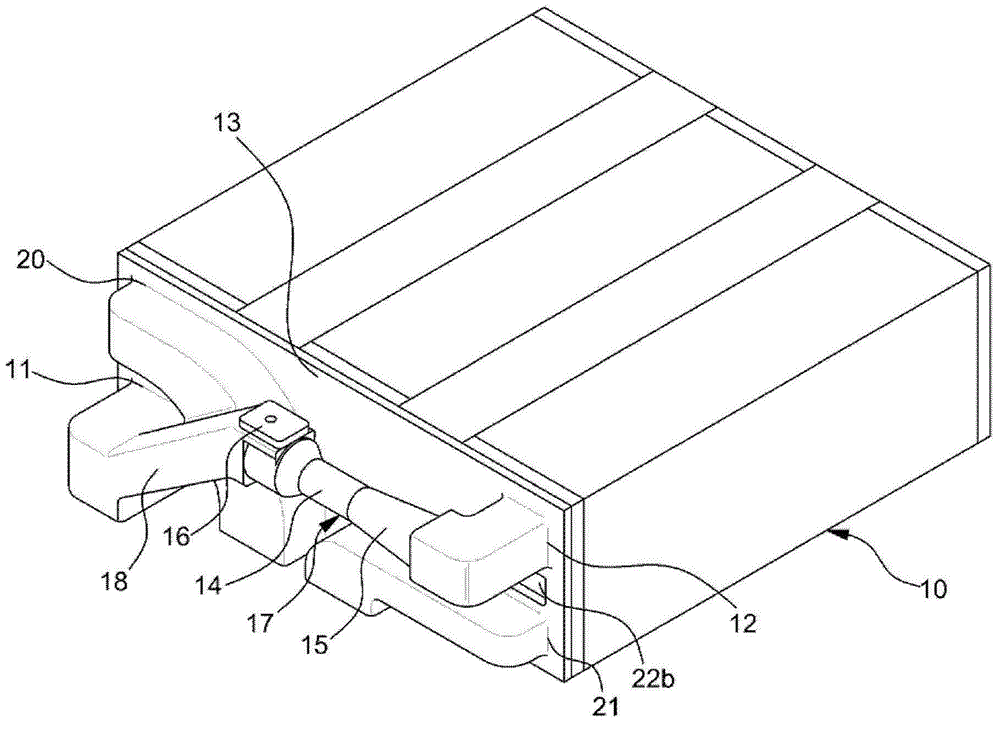

Mold and process for making a very thin wall article

InactiveUS7279122B2Reduce freezingConstrict dimensionRecord carriersAuxillary shaping apparatusShell moldingThermal insulation

An injection mold and process are arranged to produce very thin articles, such as data discs. Molten plastic is injected into mold parts forming a thin cavity (17), in a cyclic molding process wherein the mold parts are subjected to a substantially constant temperature stimulus and rise and fall in temperature during injection and cooling of the molten plastic. Temperature boosting thermal insulation layers (11, 21) are placed along at least certain parts of the molding cavity surface. This elevates the temperature of the molted melt material for a time during injection. According to a calculated relationship, this thermal insulation is sized to permit the thin mold cavity to fill before heat transfer to the mold parts solidifies the molding material and blocks further flow. The temperature boosters can be contoured in thickness.

Owner:THERMAL WAYE MOLDING

Construction method of large-volume concrete in severe cold areas

InactiveCN108999405AEnsure mixing qualityReduce freezingBuilding material handlingElectric heatingCold area

The invention discloses a construction method of large-volume concrete in severe cold areas, which comprises the steps of 1, mix proportion design of concrete raw materials; 2, heat preservation storage of the concrete raw materials, wherein the step further comprises the sub-steps of 2.1, heat preservation storage of gravel aggregates, and 2.2, storage and heating of water by adopting an electricheating water tank; 3, mixing of the concrete raw materials; 4, concrete transportation; 5, concrete pouring; and 6, concrete maintenance. According to the construction method of large-volume concrete in the severe cold areas, heat preservation can be performed on the concrete forming process through setting the measures of performing heat preservation on the concrete raw materials, performing heat preservation on the raw material mixing process, performing heat preservation on concrete transportation and pouring and performing heat preservation on concrete maintenance, thereby ensuring the mixing quality, the pouring quality and the forming quality of the concrete.

Owner:CHINA HYDROPOWER ELEVENTH ENG BUREAU ZHENGZHOU CO LTD +1

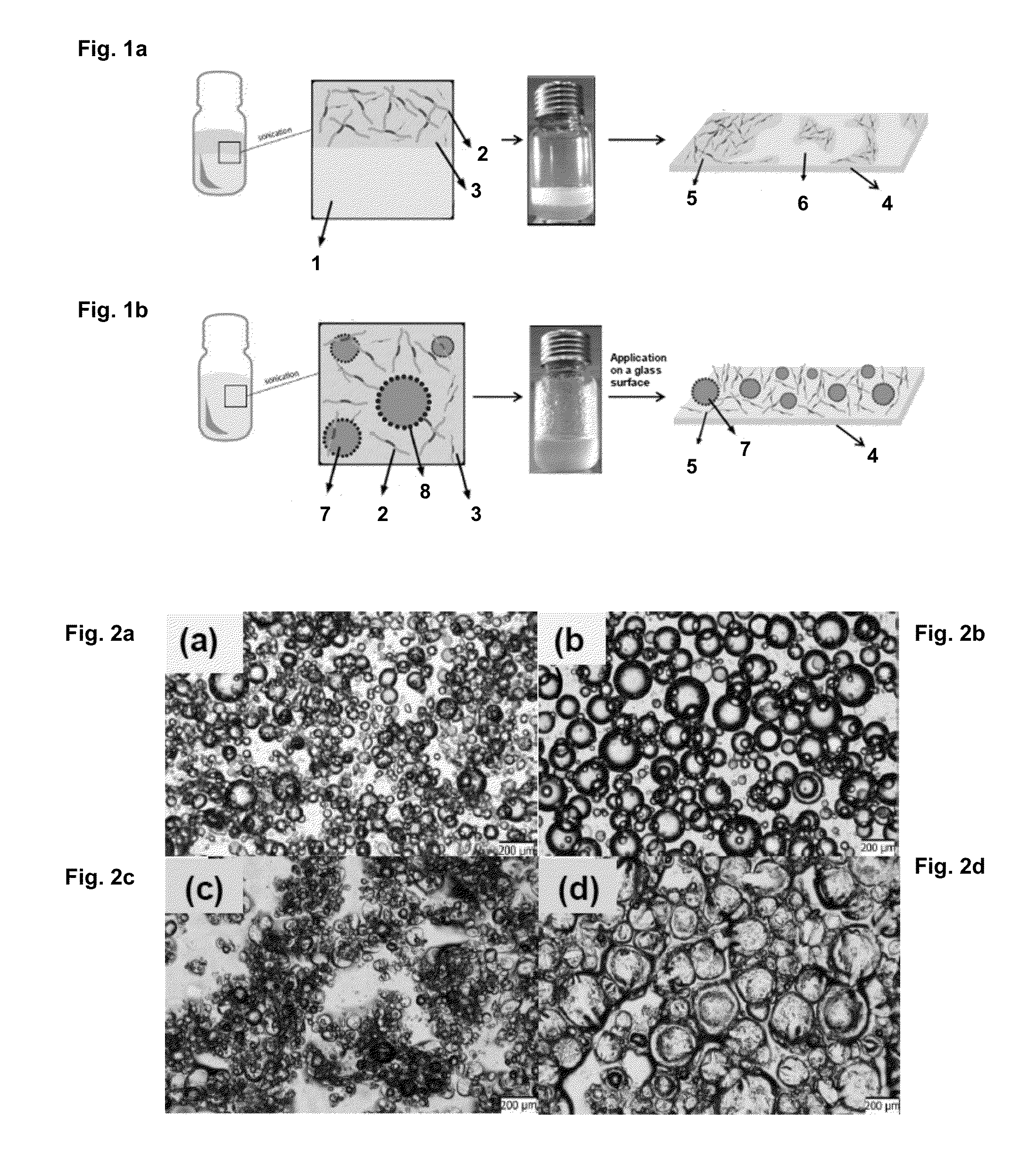

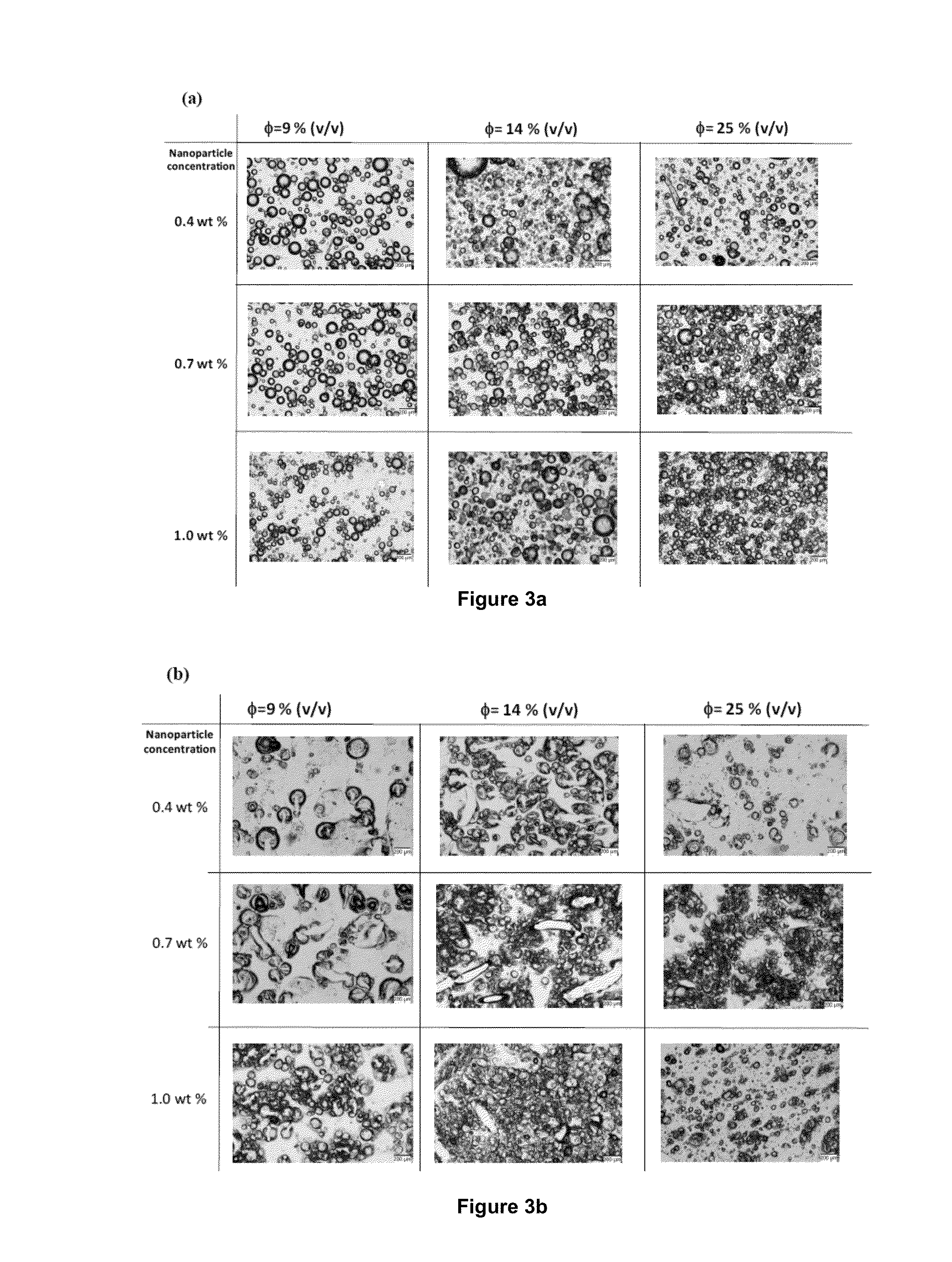

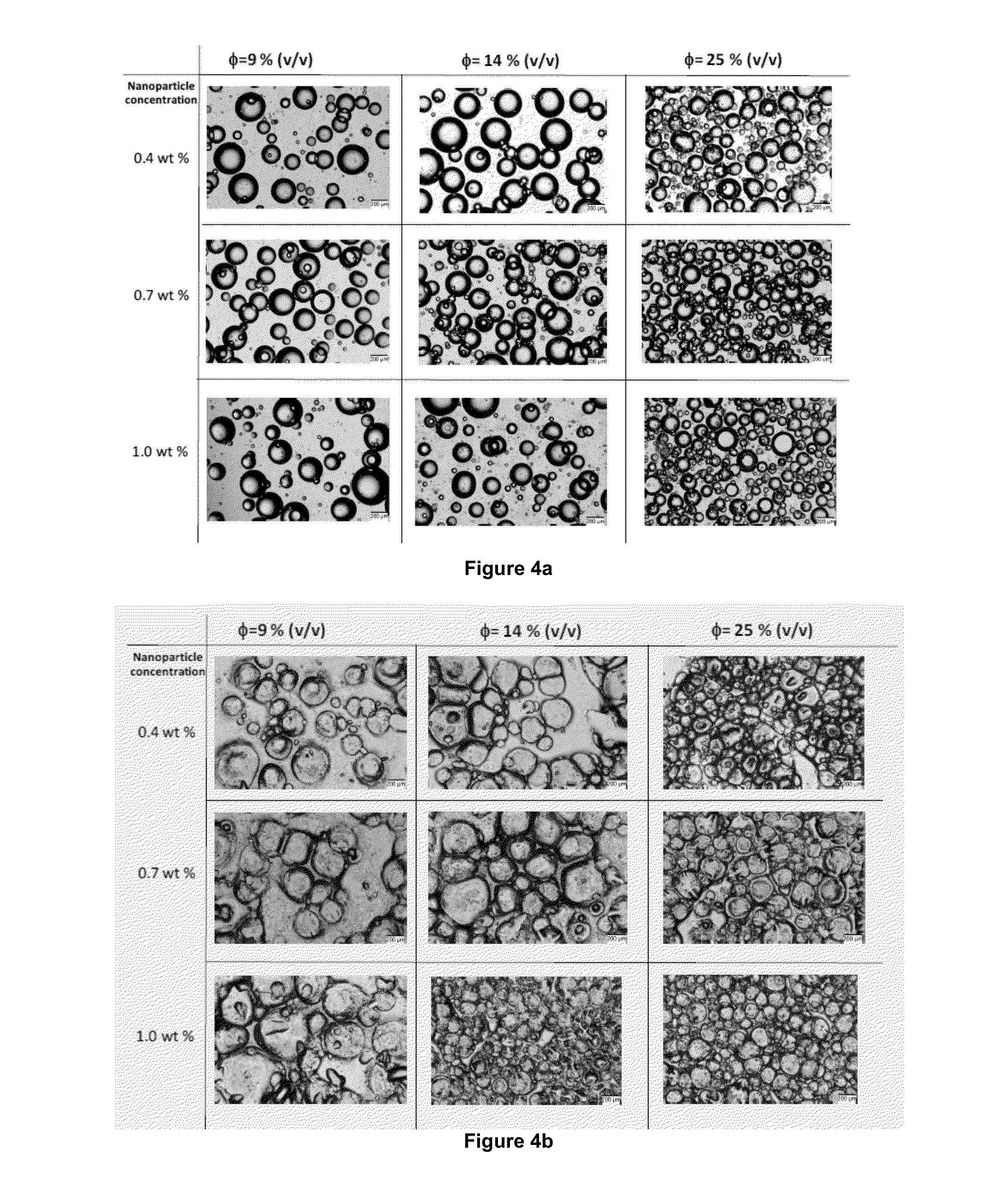

Nanoparticle and gelation stabilized functional composites of an ionic salt in a hydrophobic polymer matrix

ActiveUS20160244630A1Enhanced mechanical strength and viscoelastic behaviorControl releaseSemi-permeable membranesOther chemical processesIonDispersed media

A controlled released composite membrane comprising hydrophobic styrene-butadienestyrene block copolymer as hydrophobic continuous medium and hydrophilic functional agents incorporated within silica nanoparticles as hydrophilic dispersed medium and a preparation process of said membrane are described.

Owner:TURKIYE PETROL RAFINERILERI ANONIM SIRKETI TUPRAS +1

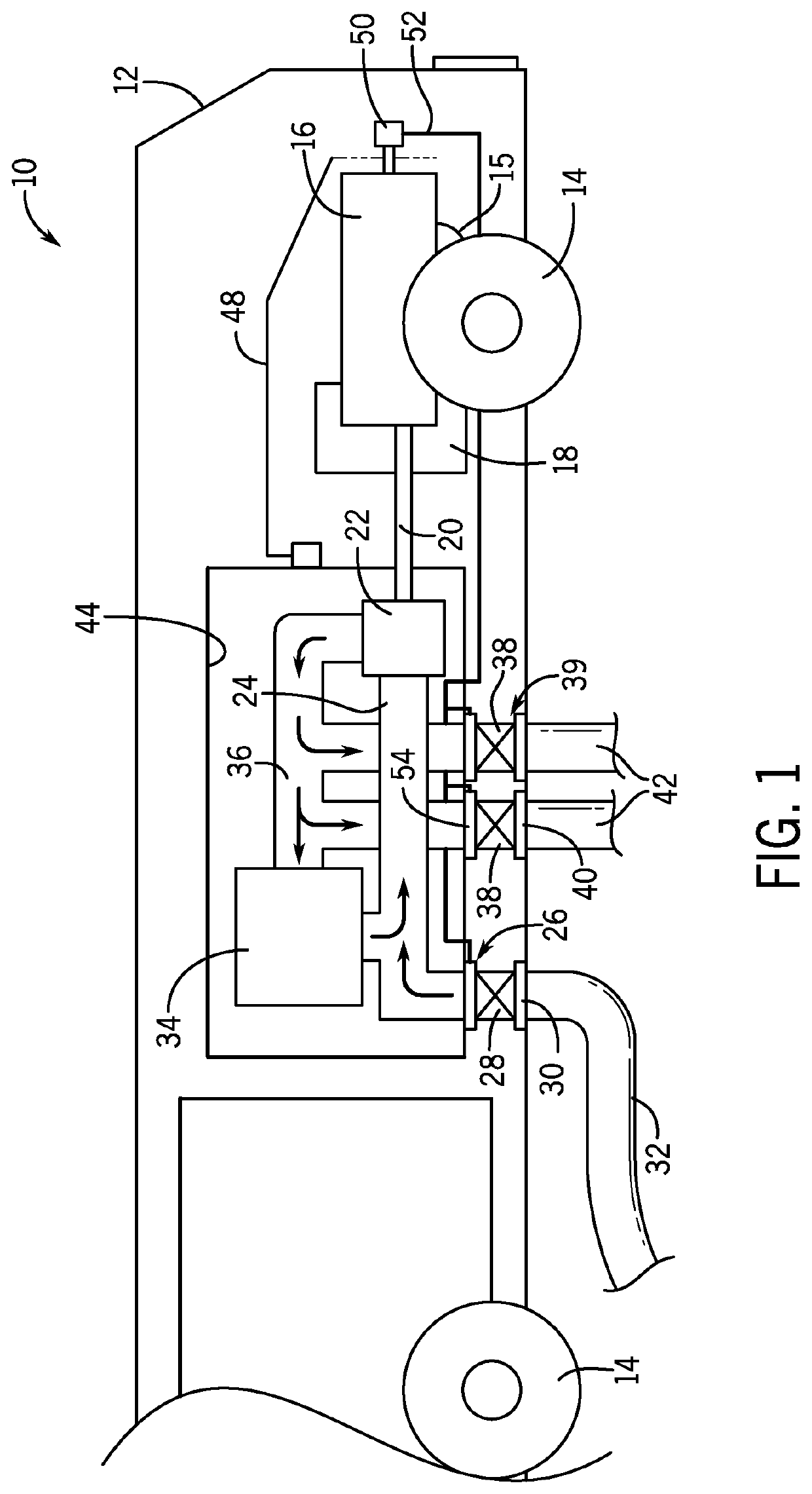

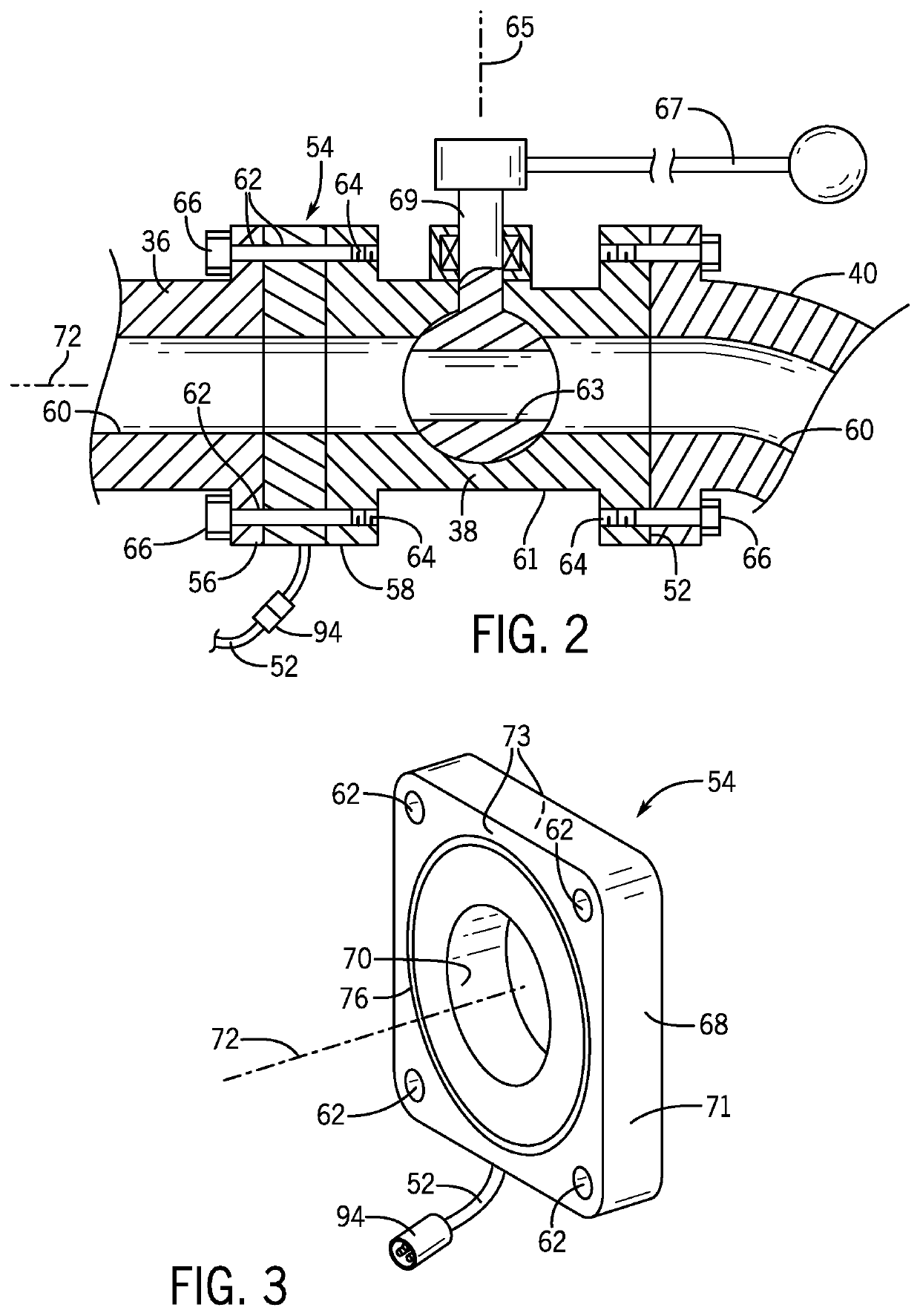

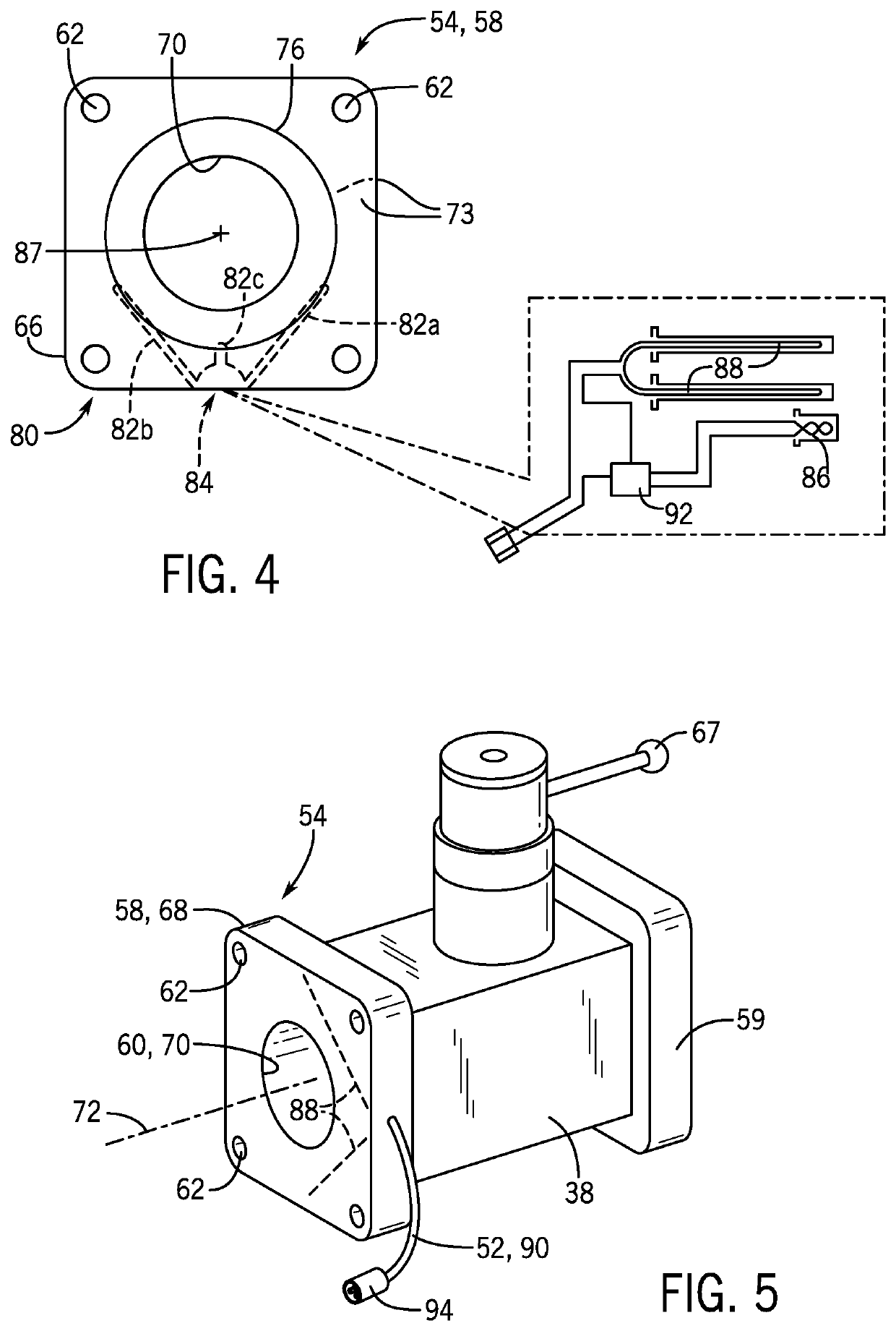

Water valve heater for firetrucks and the like

ActiveUS20200224789A1Reduce freezingAmple roomAuxillary drivesPlug valvesThermodynamicsThermal water

Owner:WISYS TECH FOUND

Fuel cell stack manifold with ejector function

ActiveCN104810532AReduce manufacturing costSimplify the manufacturing processFinal product manufactureFuel cell detailsEngineeringHydrogen supply

A fuel cell stack manifold having an ejector function of which the manufacturing cost and the weight can be reduced by optimizing hydrogen supply and recirculation channels and removing other members. hardware without a separate ejector structure for additionally attaching an ejector, of which the productivity can be improved by removing from an ejector assembly process. The fuel cell system minimizes joints through which hydrogen may leak, by implementing a new structure of a manifold added with an ejector function by integrally forming / manufacturing a stack manifold having a venturi and diffuser structure and adding a nozzle thereto.

Owner:HYUNDAI MOTOR CO LTD

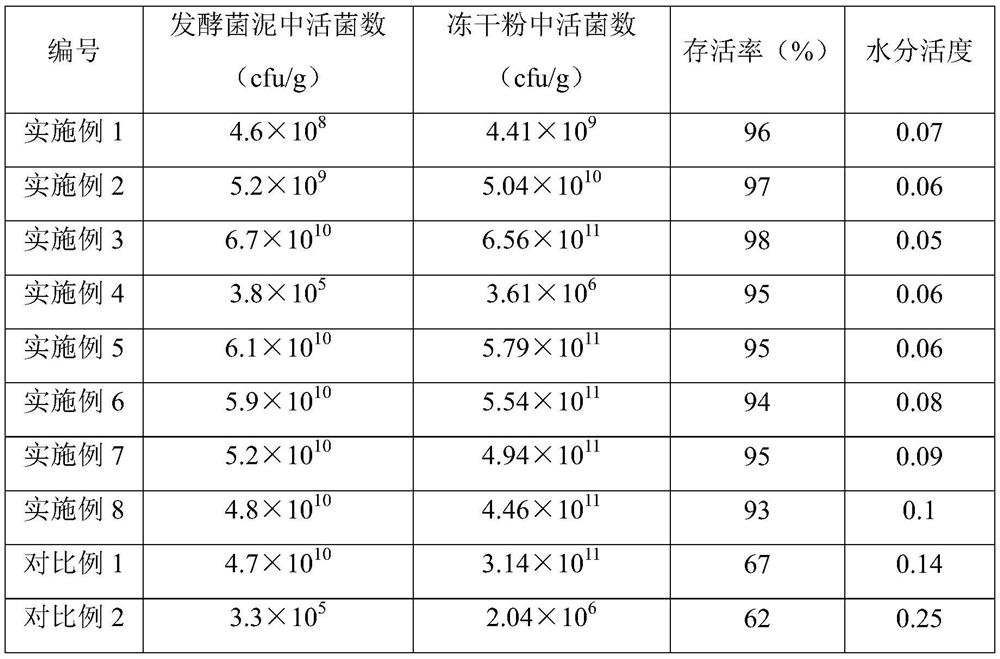

Probiotics freeze-dried powder as well as preparation method and application thereof

ActiveCN112553128AImprove survival rateAvoid damageMilk preparationBacteriaBiotechnologyProbiotic bacteria

The invention relates to a probiotic production process, and discloses probiotic freeze-dried powder as well as a preparation method and application thereof. The preparation method of the probiotic freeze-dried powder comprises the following steps of (1) providing a mixture of probiotic-containing fermented bacterial sludge, a protective agent and a moisture activity regulator; and (2) spraying arefrigerating medium to the mixture to freeze the mixture, and carrying out vacuum drying. According to the preparation method, a mode of spraying the refrigerating medium to the probiotic bacterial sludge is adopted so that probiotic bacterial cells can be quickly frozen, the inactivation of protein and enzyme is reduced, ice crystals generated in the freezing process of probiotics are fine, thedamage to cell structures is avoided, and the survival rate of the probiotics in the freezing process is increased.

Owner:瞿瀚鹏

Environmental-friendly fulvic acid compound snow-melting agent

The invention relates to an environmental-friendly fulvic acid compound snow-melting agent and belongs to the technical field of materials for roads. The environmental-friendly fulvic acid compound snow-melting agent is prepared by the following steps: by taking lignite as a raw material, crushing the lignite and pre-oxidizing and degrading the lignite with hydrogen peroxide; then combining the lignite with glacial acetic acid; under microwave irradiation, further oxidizing and degrading the lignite to extract fulvic acid; generating more functional groups such as carboxylic acid, alcohol, amine and ester capable of reducing the freezing point; then performing purification and performing a reaction with carbide slag and magnesium oxide and the like to generate fulvic acid / calcium acetate magnesium; and finally, compounding with ammonium chloride to prepare the environmental-friendly fulvic acid compound snow-melting agent. The environmental-friendly fulvic acid compound snow-melting agent prepared by the invention is good in snow-melting effect and small in damage to vegetables, meets the environmental-friendly requirements, is rich in nutritional elements needed by plants to facilitate nutrient adsorption of the vegetables, and has a wide application prospect.

Owner:常州杰轩纺织科技有限公司

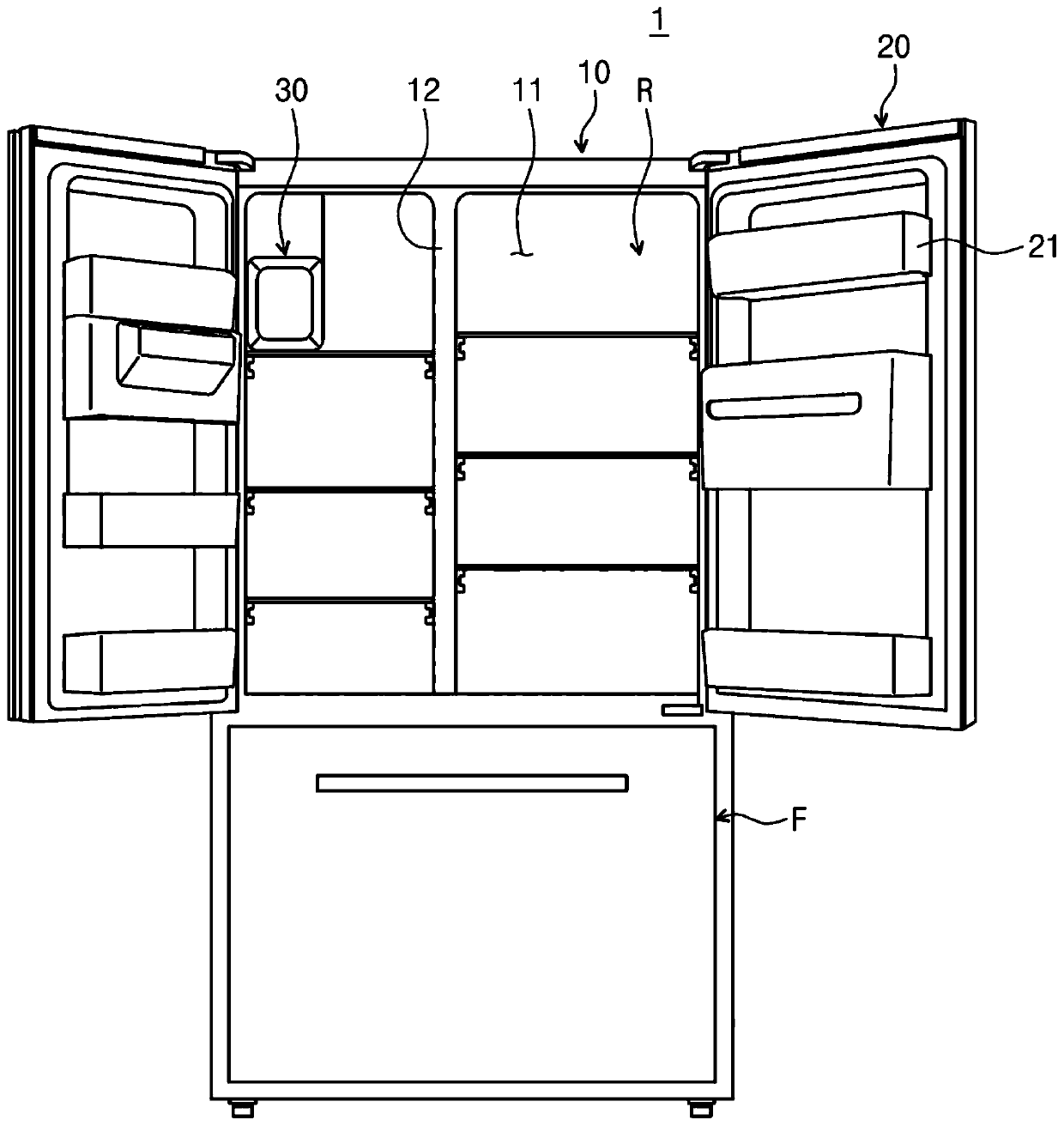

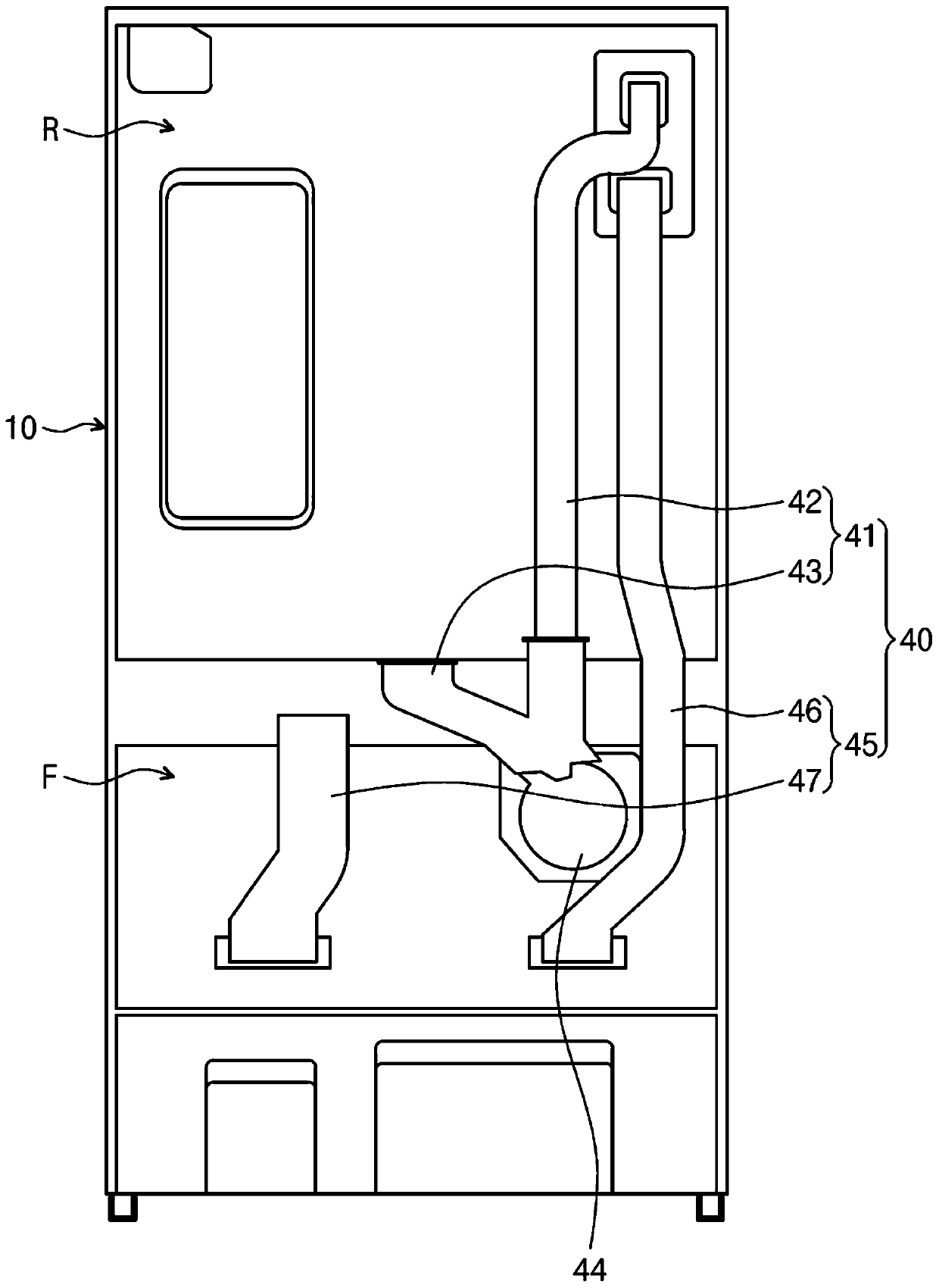

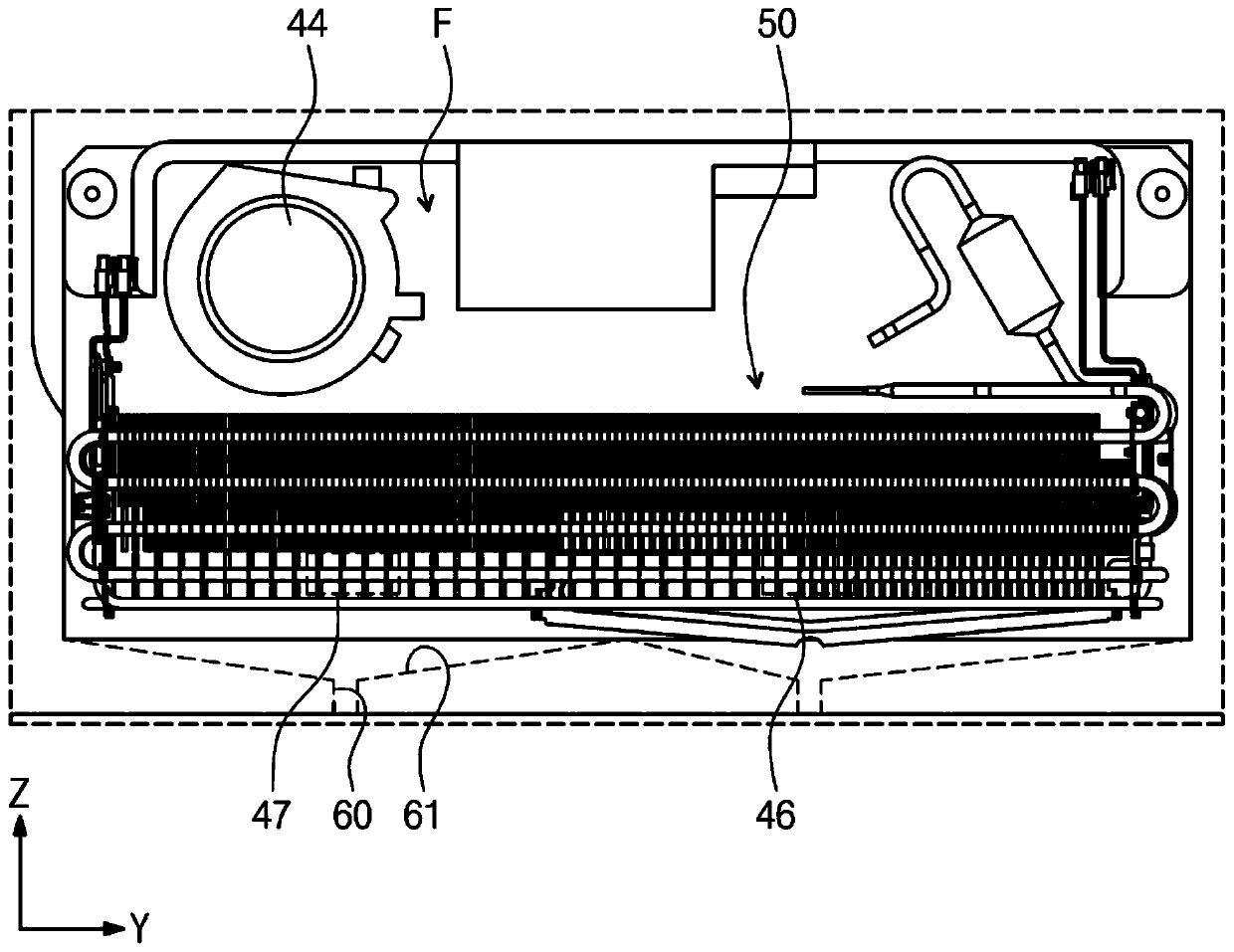

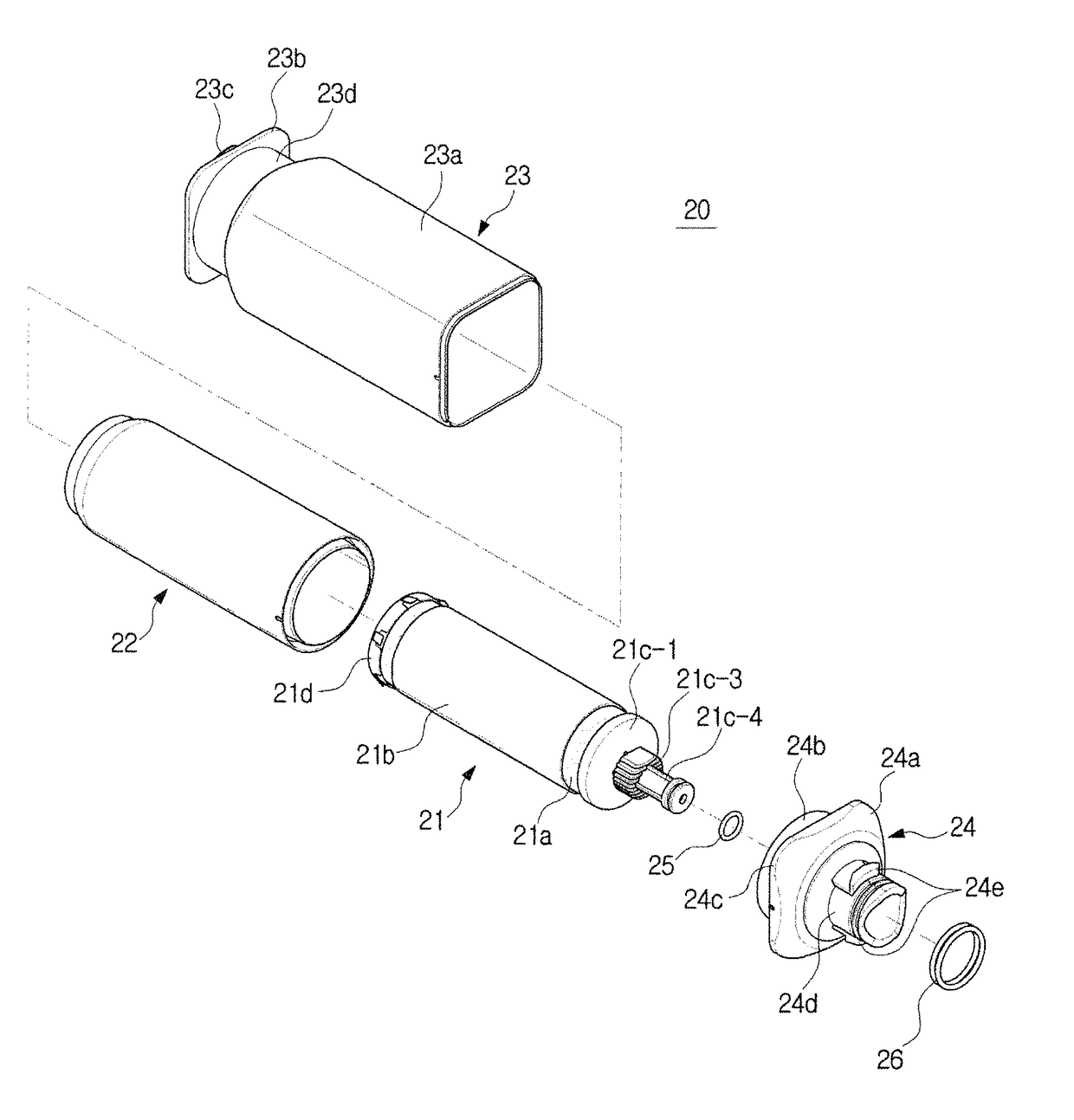

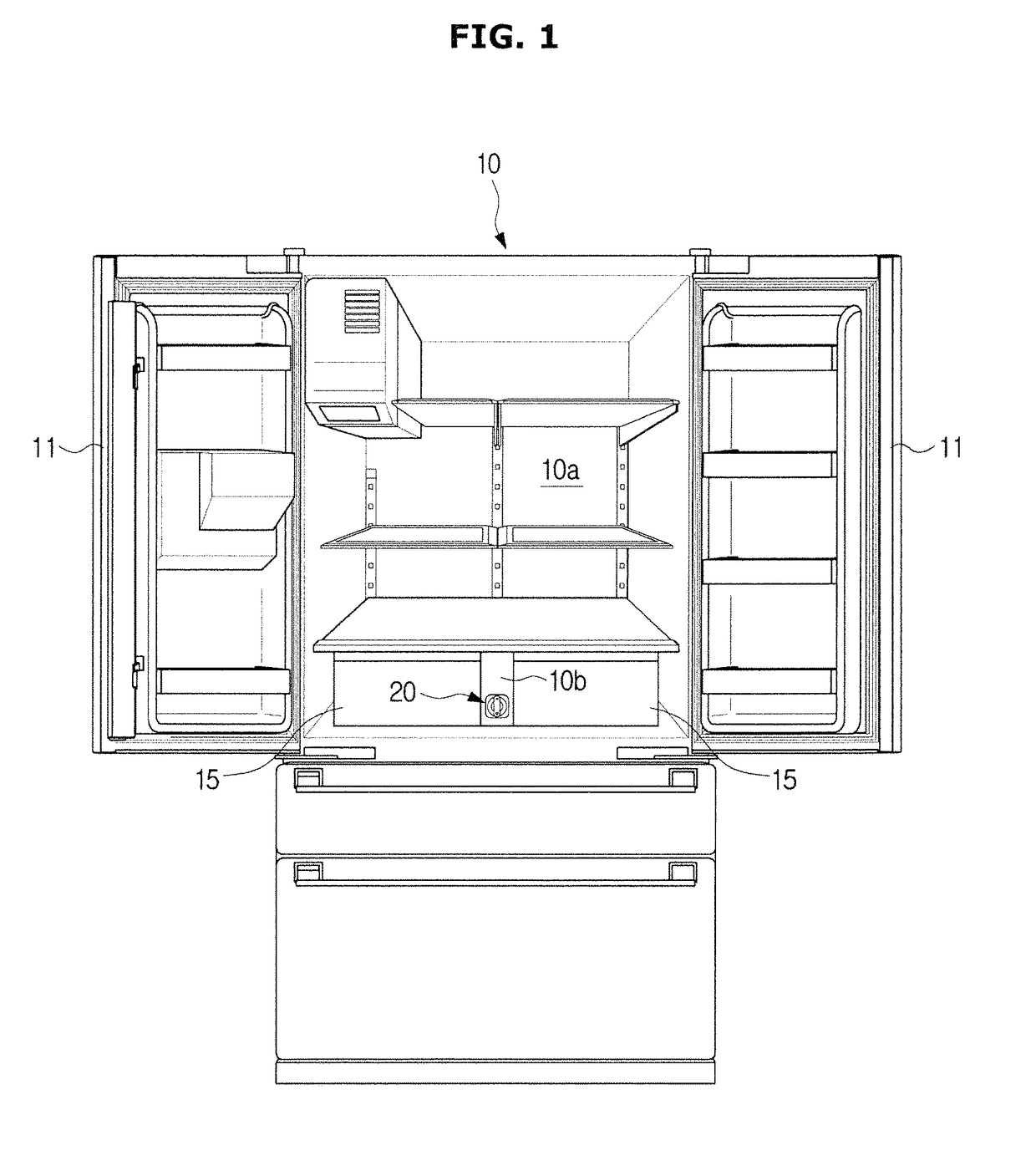

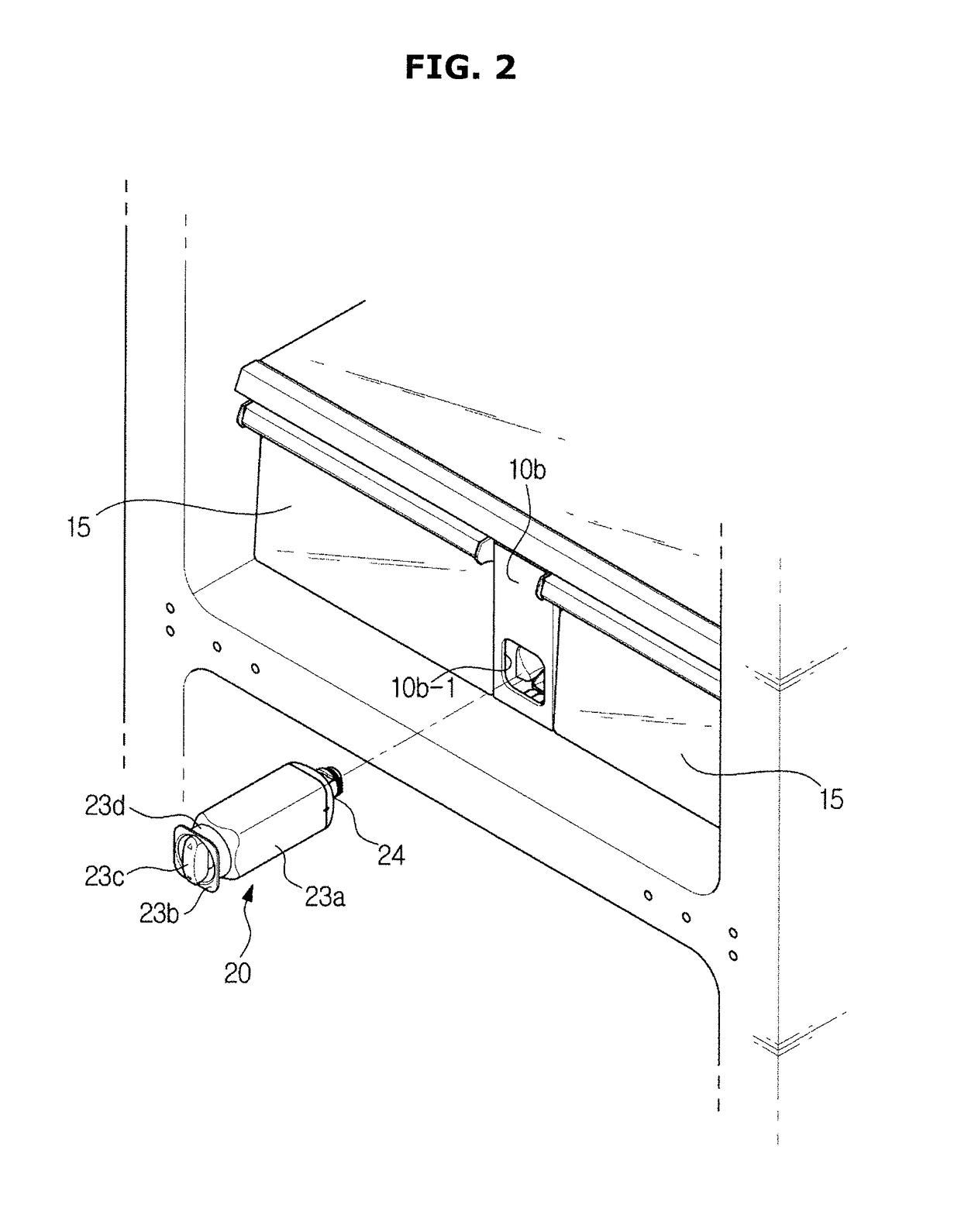

Evaporator unit and refrigerator having same

ActiveCN110411070AReduce freezingAvoid direct contactDomestic refrigeratorsEvaporators/condensersEvaporationEngineering

The invention relates to an evaporation unit and a refrigerator having the same. According to the embodiment of the invention, the refrigerator includes a main body having a storage room therein; a door on the main body, configured to open and close the storage room; and an evaporation unit at one side of the storage room. The evaporation unit includes an evaporator configured to cool air by exchanging heat between a refrigerant in the evaporator and the air; and a partition in the evaporator, configured to partition the evaporator into two areas.

Owner:DAEWOO ELECTRONICS CO LTD

Water purifying filter

ActiveUS20180015400A1Reduce freezingReduce harmLighting and heating apparatusTreatment involving filtrationWaste managementHeat transfer

A water purifying filter has a cylindrical inner housing to receive a filter therein, and an outer housing to receive the inner housing. The inner housing and the outer housing are spaced apart from each other to form an insulation space configured to suppress heat transfer and to reduce the filter freezing inside the inner housing.

Owner:SAMSUNG ELECTRONICS CO LTD

Elastic graphene aerogel and preparation method and application thereof

ActiveCN110327851AImprove hydrophobicityReduce freezingFatty/oily/floating substances removal devicesOther chemical processesFoaming agentCvd graphene

The invention discloses an elastic graphene aerogel and a preparation method and application thereof. The preparation method comprises the following steps: (1) dispersing graphene oxide and a reducingagent in water to obtain a graphene oxide dispersion liquid; (2) mixing a foaming agent and the graphene oxide dispersion liquid, and foaming to obtain a mixed liquid; (3) reacting the mixed solutionat 70-90 DEG C for 2-12h, and then cooling to 15-35 DEG C to obtain graphene hydrogel; (4) soaking the graphene hydrogel in an ammonia water solution to obtain the soaked graphene hydrogel; (5) freezing the soaked graphene hydrogel at-55 to-10 DEG C, then raising the temperature to 15 to 35 DEG C, and drying at normal pressure to obtain the elastic graphene aerogel. The method can obtain the elastic graphene aerogel with higher mechanical performance and adsorption performance.

Owner:城康材料技术有限公司

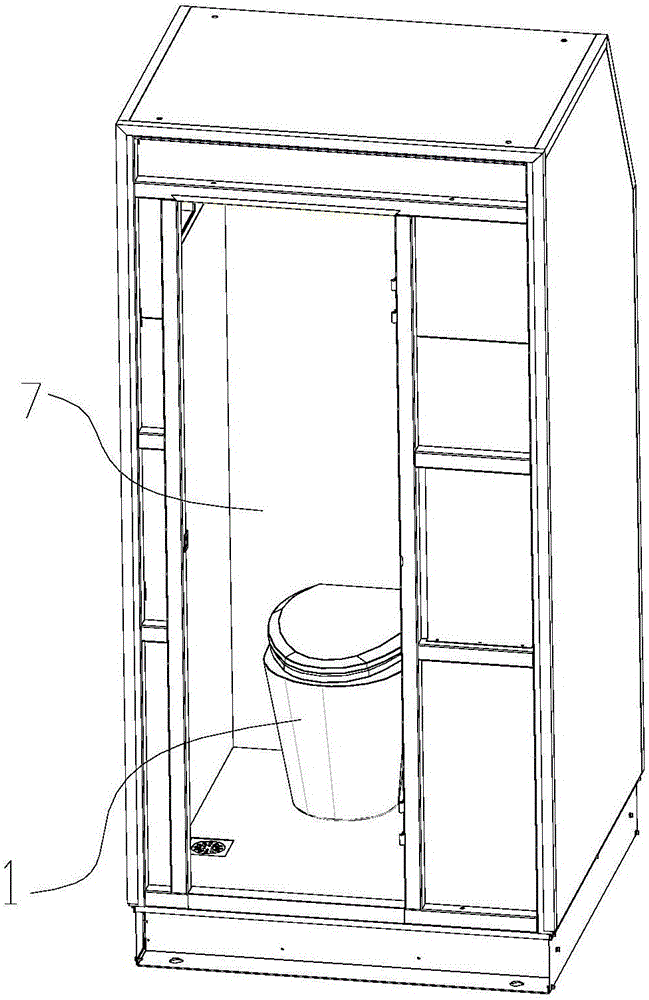

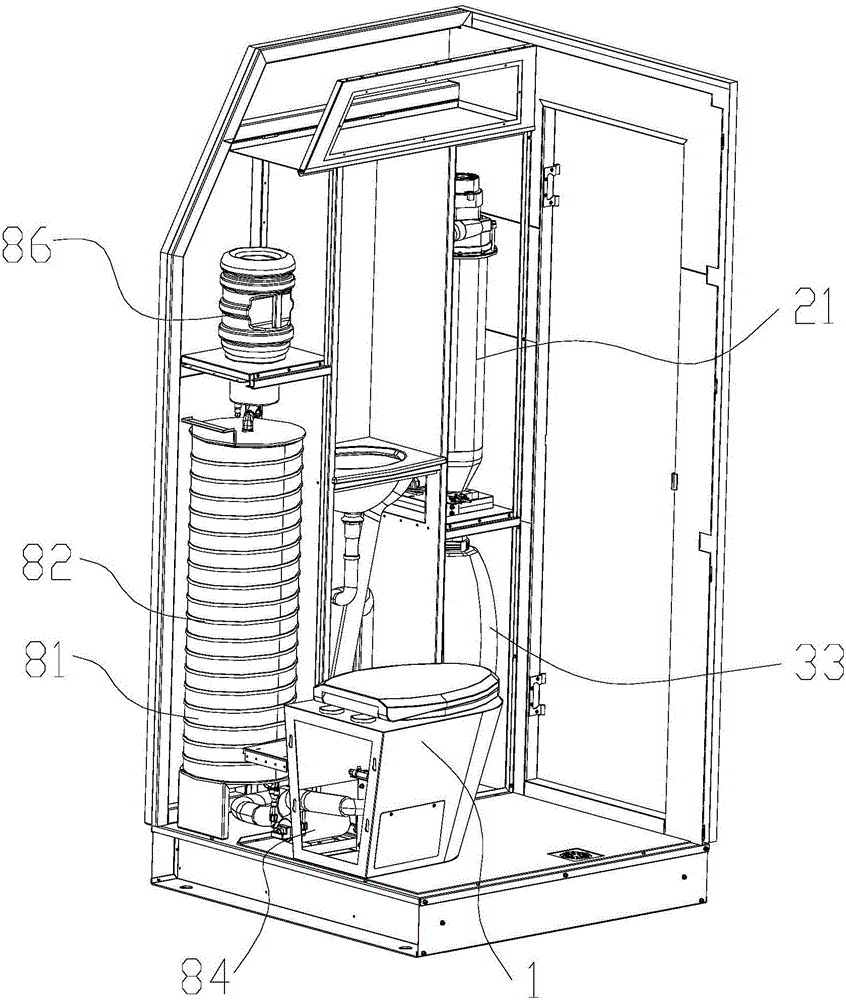

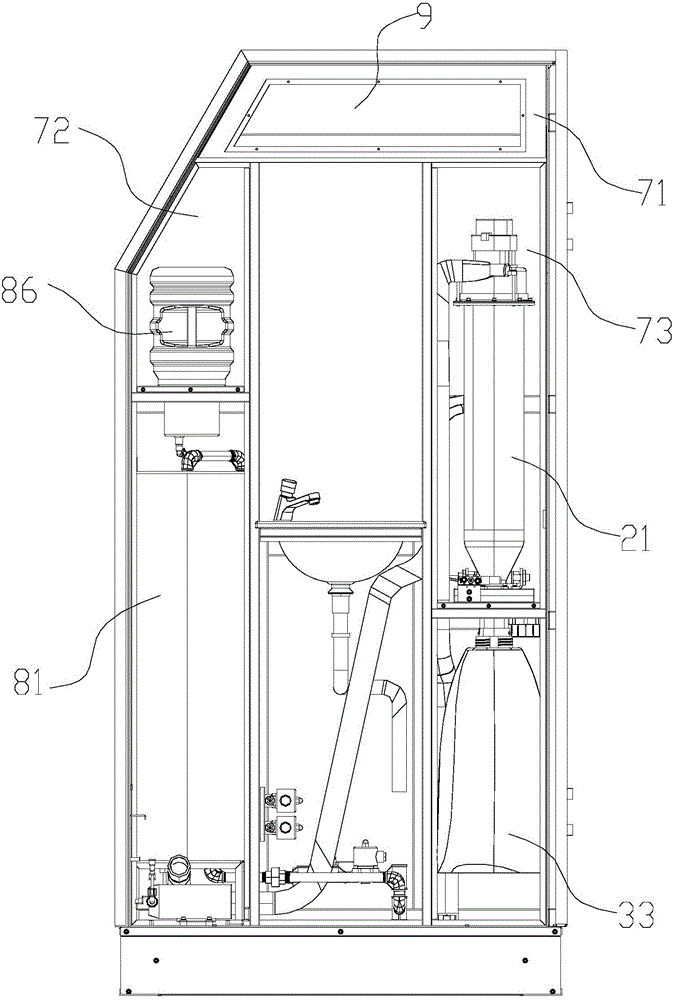

Toilet with automatic dirt collecting function

The invention discloses a toilet with an automatic dirt collecting function.The toilet comprises a chamber, a toilet bowl located in the chamber, a flushing system for flushing the interior of the toilet bowl, a suction mechanism, a dirt collecting assembly and a first valve.The suction mechanism comprises a gas-liquid separation box, a vacuumizing device and a dirt inflow pipe.The gas-liquid separation box comprises a box body and a conical net, a vacuum connector is arranged on the top of the box body, a dirt inflow opening is formed in one side of the box body, a dirt outlet is formed in the bottom of the box body, the conical net is fixedly arranged in the box body and located above the dirt inlet, and the external diameter of the conical net is gradually reduced from top to bottom.The dirt collecting assembly comprises a dirt discharge pipe and a dirt collecting bag, the upper end of the dirt discharge pipe is used for being communicated with the dirt outlet, the dirt collecting bag is detachably installed at the lower end of the dirt discharge pipe, and the interior of the dirt collecting bag is communicated with the lower end of the dirt discharge pipe.The first valve is installed between the dirt discharge pipe and the dirt outlet and used for controlling communication or isolation of the dirt discharge pipe and the dirt outlet.Dirt of the toilet bowl can be automatically collected, and an anti-freezing effect can be achieved.

Owner:BEIJING HUASHENGLUTAI TECH CO LTD

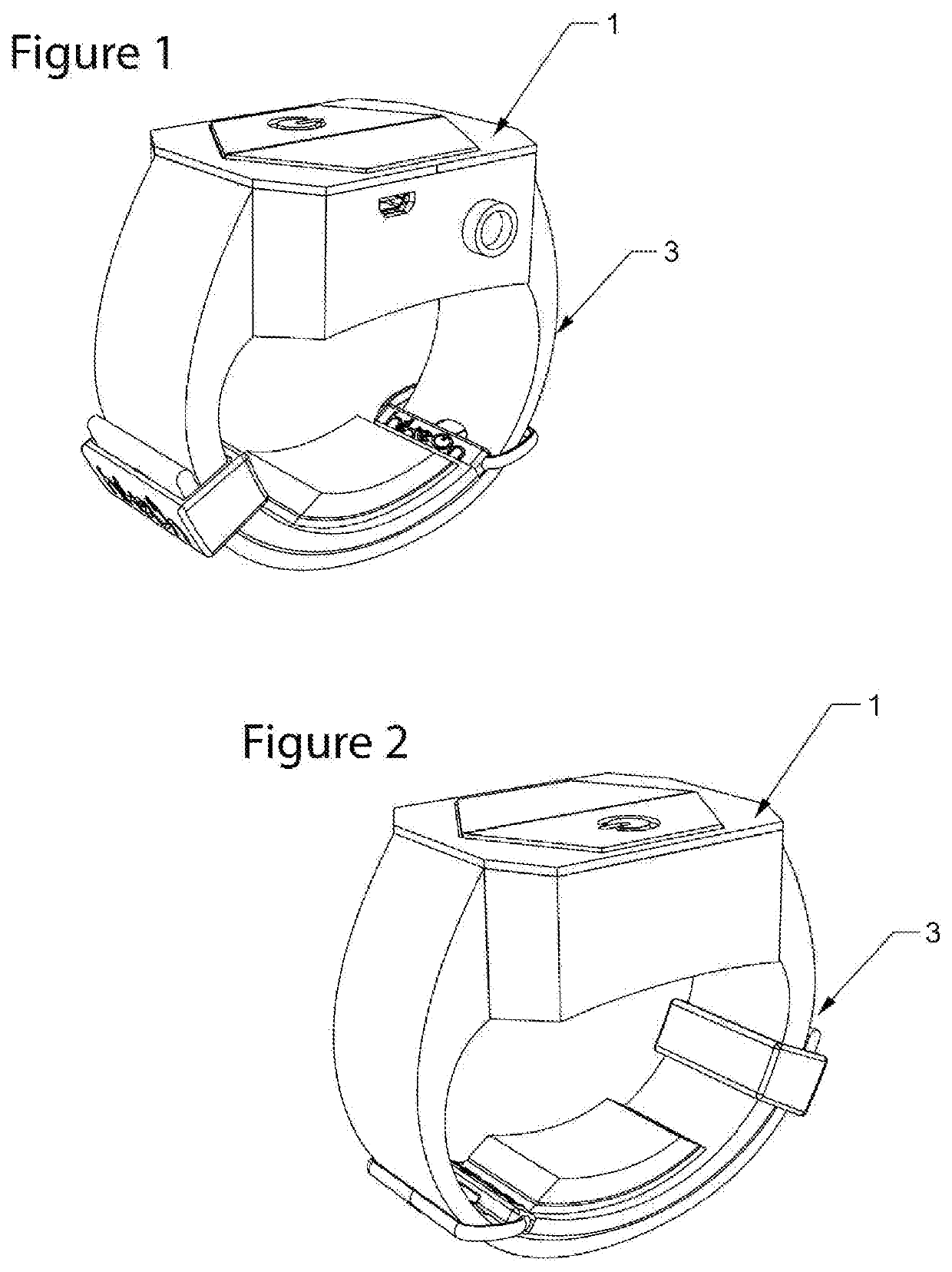

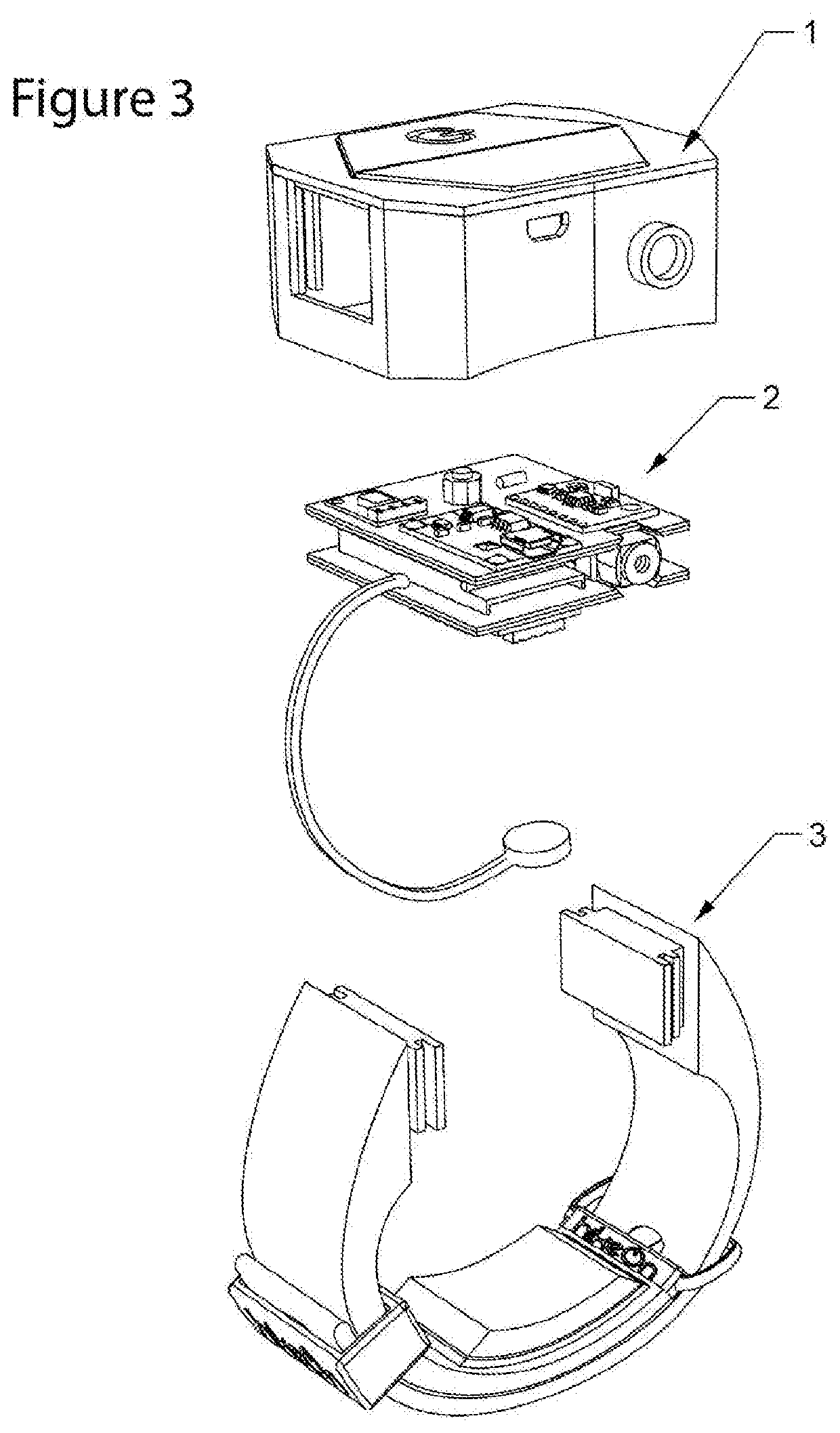

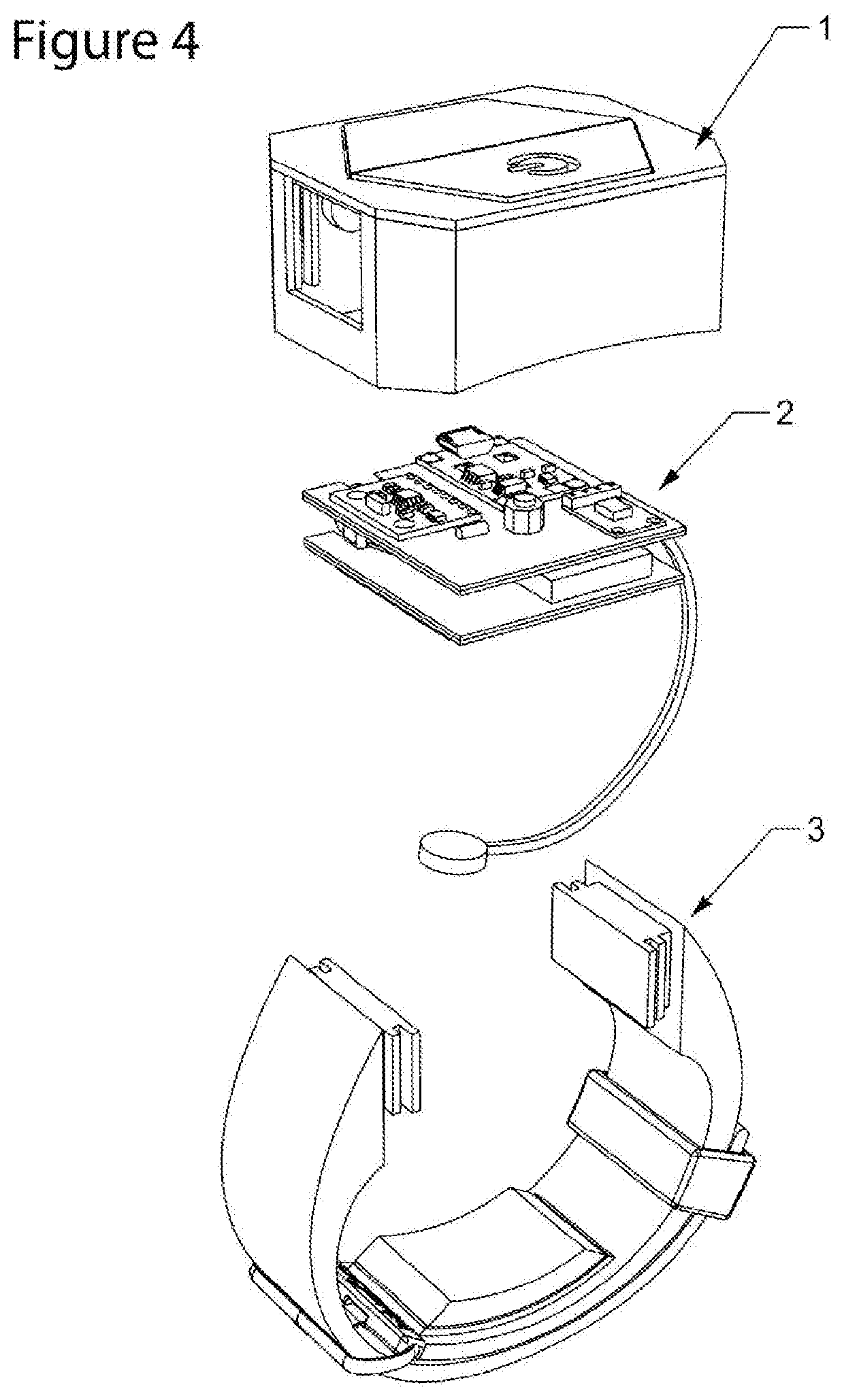

Sensorial electronic device for the rehabilitation of patients with parkinson's disease

ActiveUS20200188210A1Reduce freezingImprove postureChiropractic devicesVibration massageElectric machineHand held

This invention refers to a device that reduces and counteracts human motor symptoms (tremor in the upper limbs, muscular stiffness, bradykinesia or slowness in movements, postural disruptions, Parkinsonian walking and freezing in the walking) caused by Parkinson's disease. The device produces vibration by means of a micro-motor that can be modulated in time, speed and power. A laser diode generates a light that is projected in the ground in the form of a horizontal line, a Bluetooth module communicates this device with different intelligent electronic devices and with applications. These components are powered by a rechargeable handheld power source. The components are powered by a rechargeable handheld electric energy source.

Owner:N TECS LABS SA DE CV

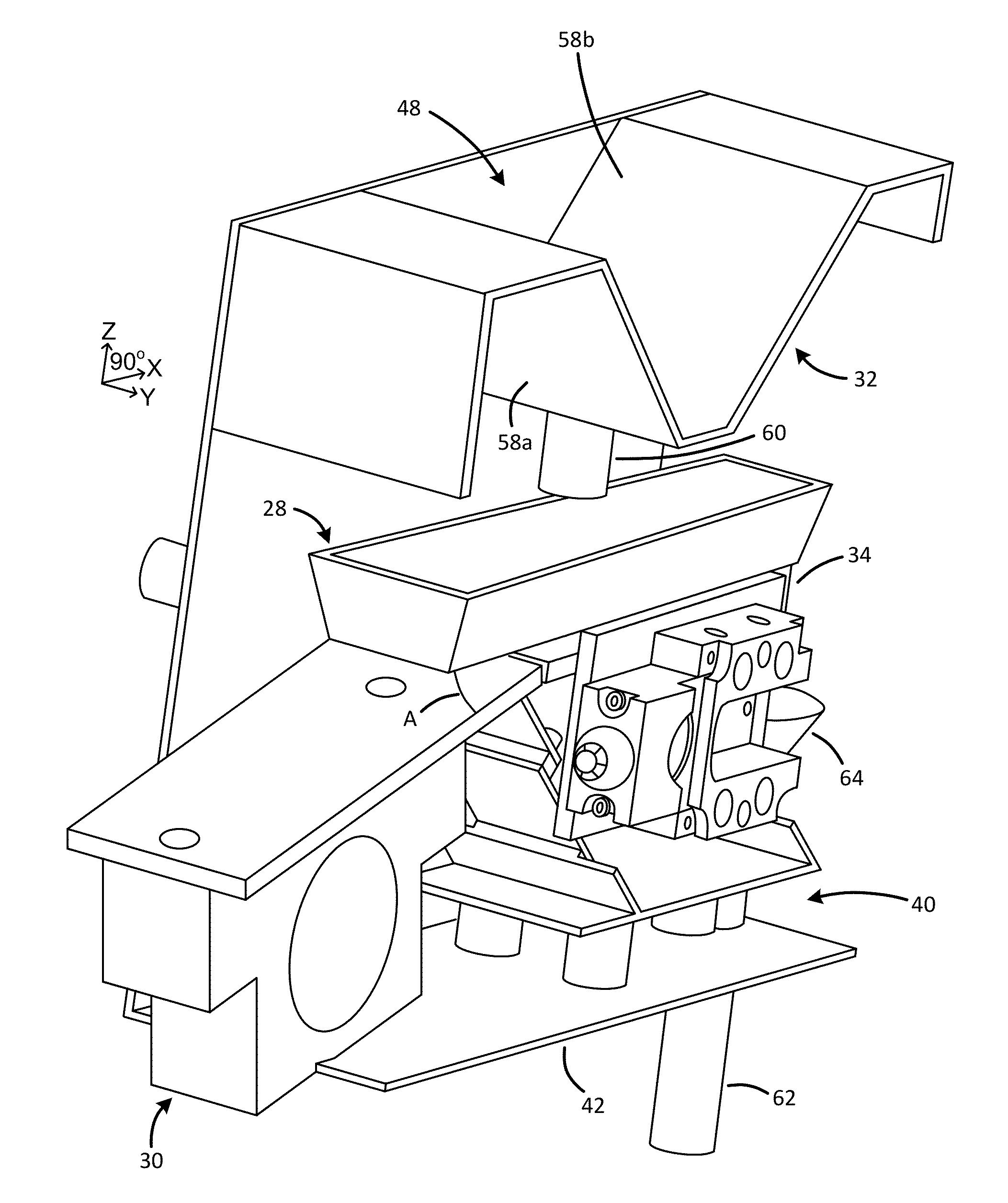

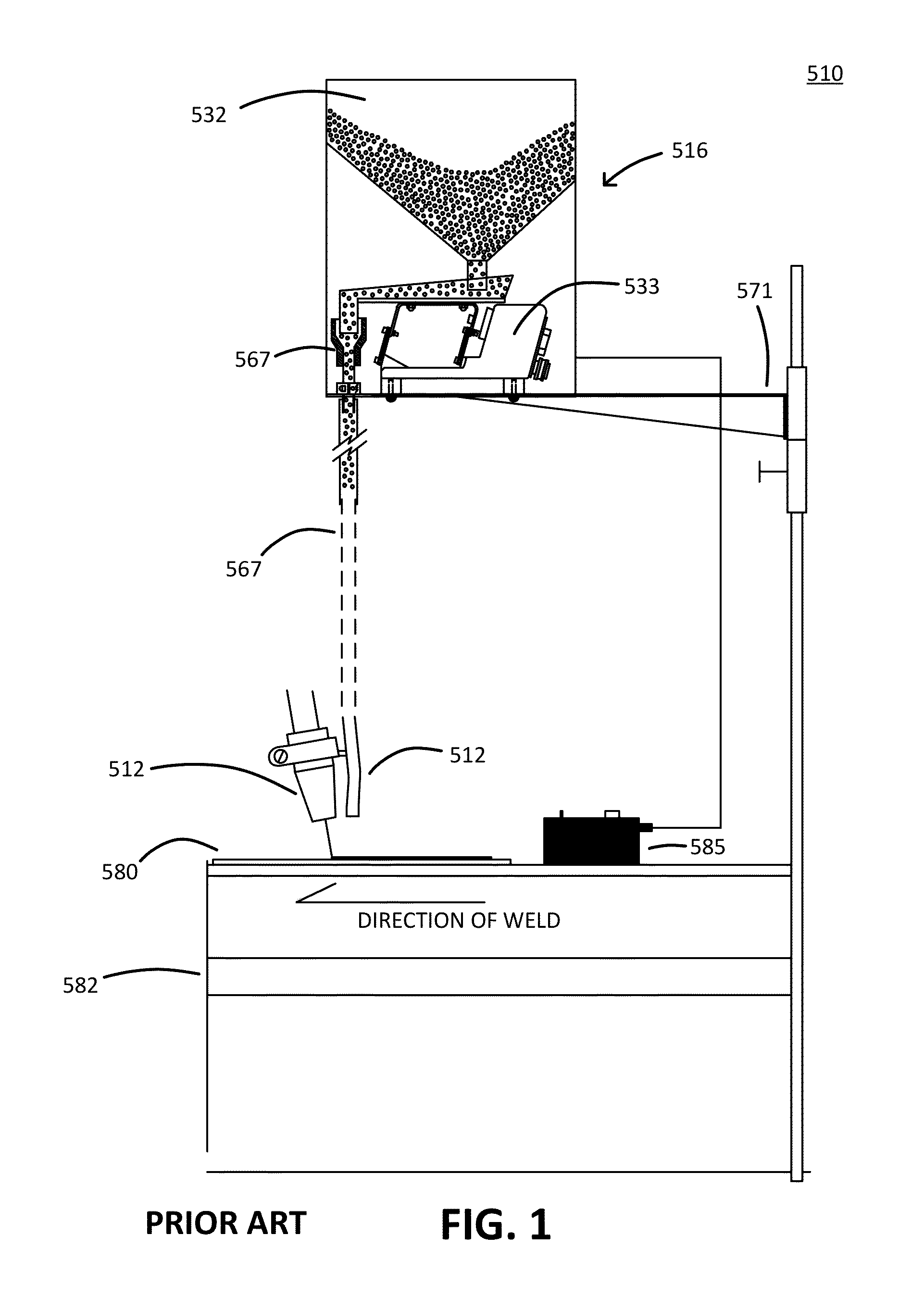

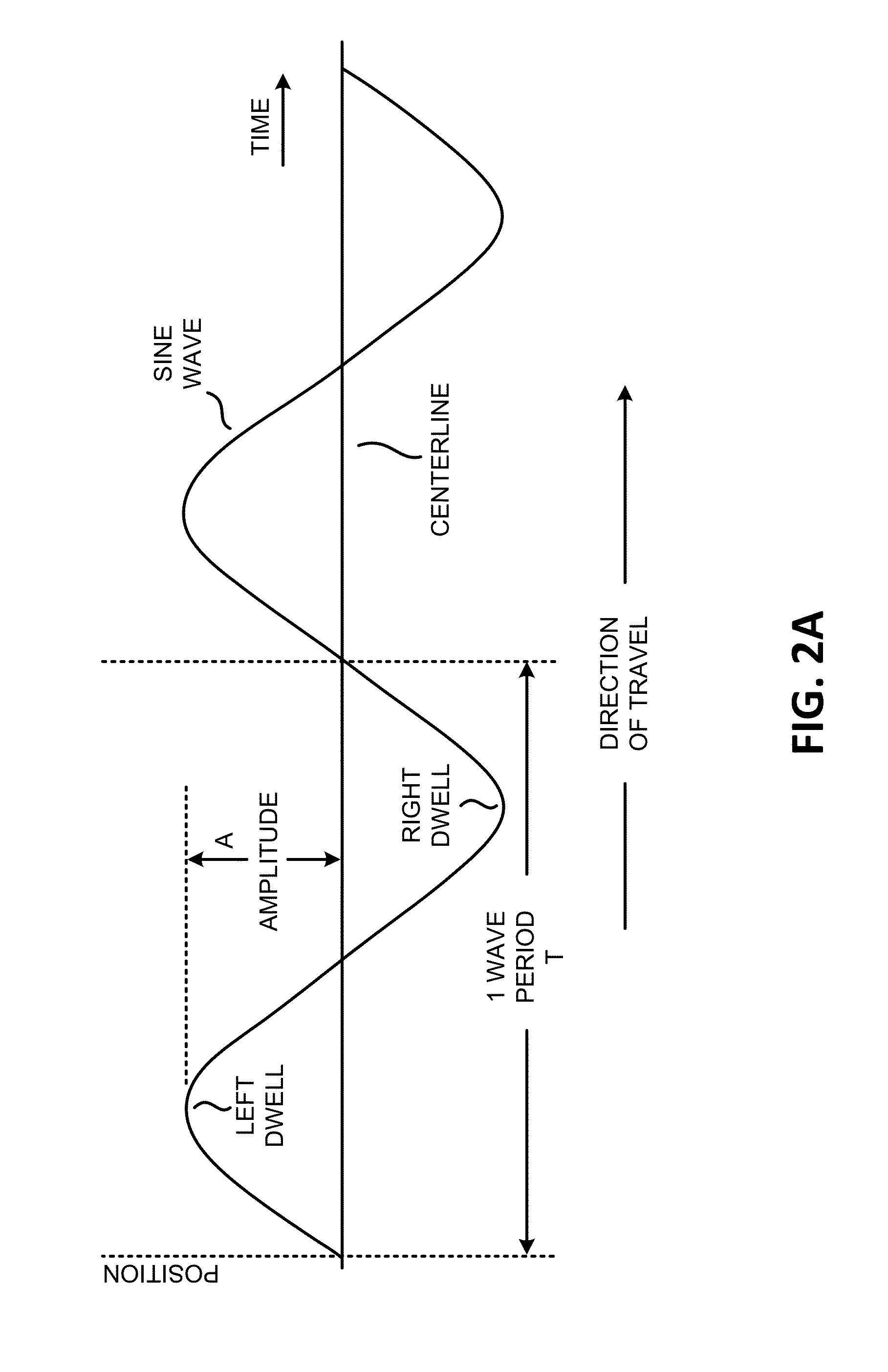

Automatic system for abrasive hardfacing

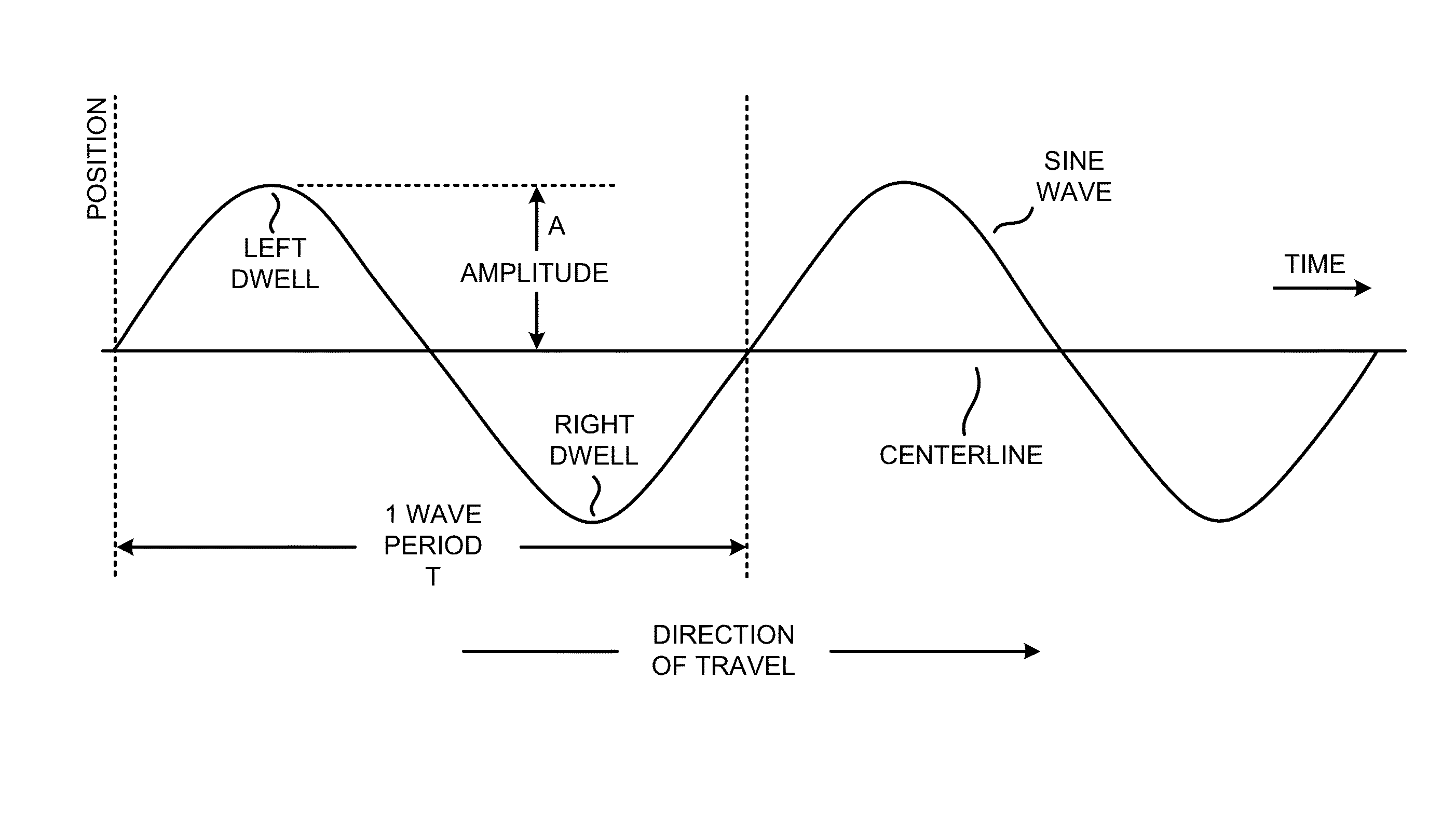

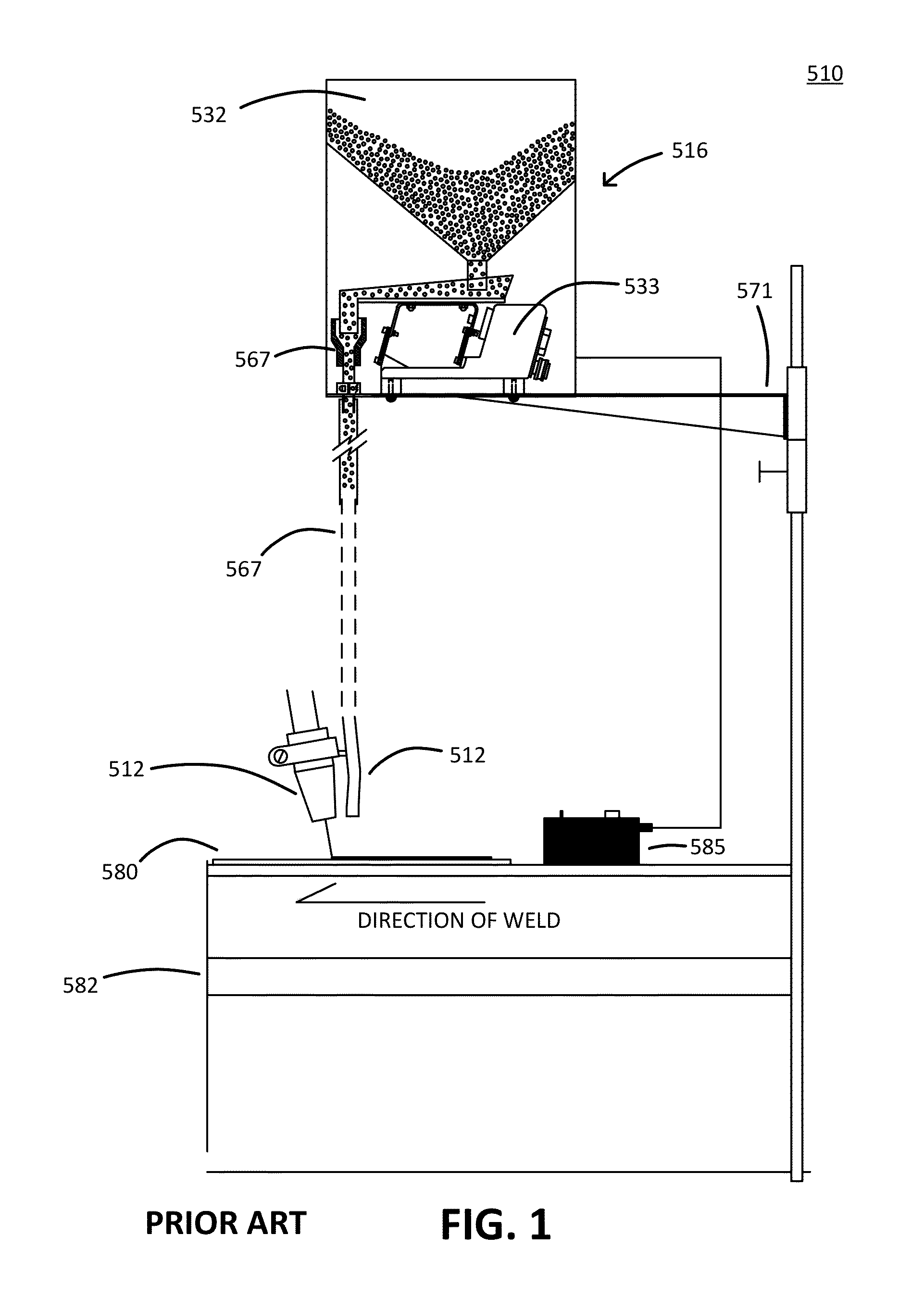

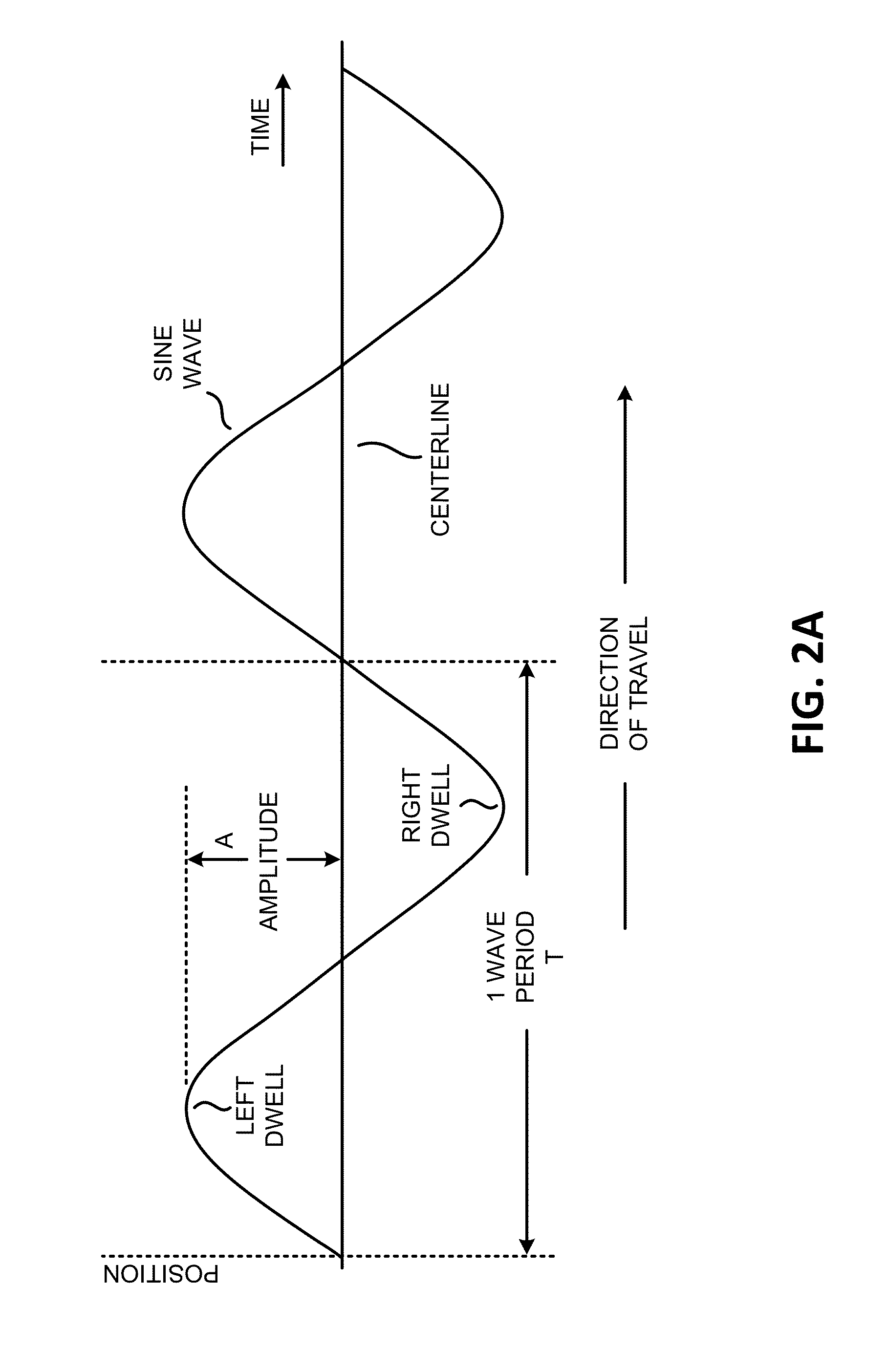

ActiveUS20150266124A1Optimal for incorporationOpportunities decreaseEvacuating shieldingParticulatesEngineering

Arc welding systems, apparatus and methods are for hardfacing are provided, including particle feeding apparatus. In one aspect the workpiece is moved in an oscillatory fashion while keeping the welding torch and the particulate delivery system stationary during at least a portion of welding pass. The welding torch and particulate delivery system may also be moved in a non-oscillatory fashion. Process speeds of about 18-30 in / min can be obtained with carbide incorporation of greater than 30% and uniform distribution.

Owner:VERMEER MFG CO

Automatic system for abrasive hardfacing

ActiveUS9321117B2Optimal for incorporationOpportunities decreaseEvacuating shieldingParticulatesEngineering

Arc welding systems, apparatus and methods are for hardfacing are provided, including particle feeding apparatus. In one aspect the workpiece is moved in an oscillatory fashion while keeping the welding torch and the particulate delivery system stationary during at least a portion of welding pass. The welding torch and particulate delivery system may also be moved in a non-oscillatory fashion. Process speeds of about 18-30 in / min can be obtained with carbide incorporation of greater than 30% and uniform distribution.

Owner:VERMEER MFG CO

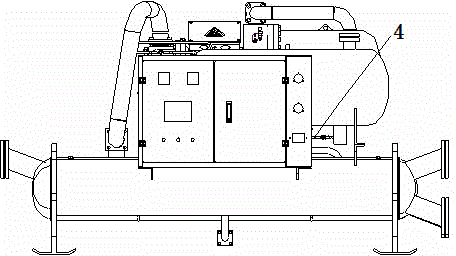

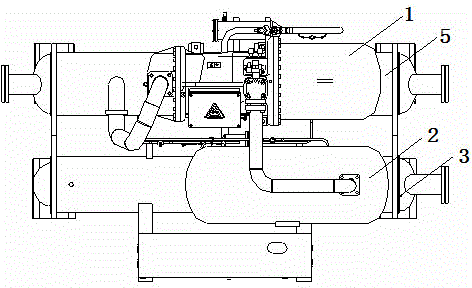

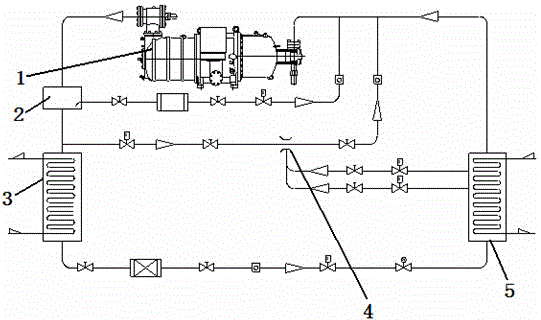

Water source heat pump unit system for low temperature water source

InactiveCN104676978AReduce freezingPrevent freezingHeat pumpsEvaporators/condensersWater source heat pumpWater source

The invention relates to an air conditioning unit device, in particular to a water source heat pump unit system for a low temperature water source. The system comprises a compressor, an oil separator, a condenser, a oil return injecting device and an evaporator; the evaporator is in a falling film type structure, a liquid distributor is arranged in the upper portion of the evaporator, the top of the evaporator is provided with a liquid incoming pipe, the port of the liquid incoming pipe contacts with the surface of the liquid distributor, the top of the evaporator is provided with an exhaust pipe, the bottom of the evaporator is provided with a discharge pipe, and heat exchange pipe beams are arranged below the liquid distributor. According to the system, water is distributed to the surface of the heat exchange pipes evenly through the liquid distributor, the heat exchange effect is fine, the refrigerant can be evaporated fully, the refrigerant storage amount is reduced, and the heat exchange pipes are prevented from freezing; meanwhile, since the level of the evaporator is low, the mixing ratio of lubrication oil is decreased, the lubrication oil can be injected to the compressor through the oil return injecting device, and the fine oil returning effect is achieved.

Owner:SHANDONG YUGIA FUERDA AIR CONDITIONER EQUIP

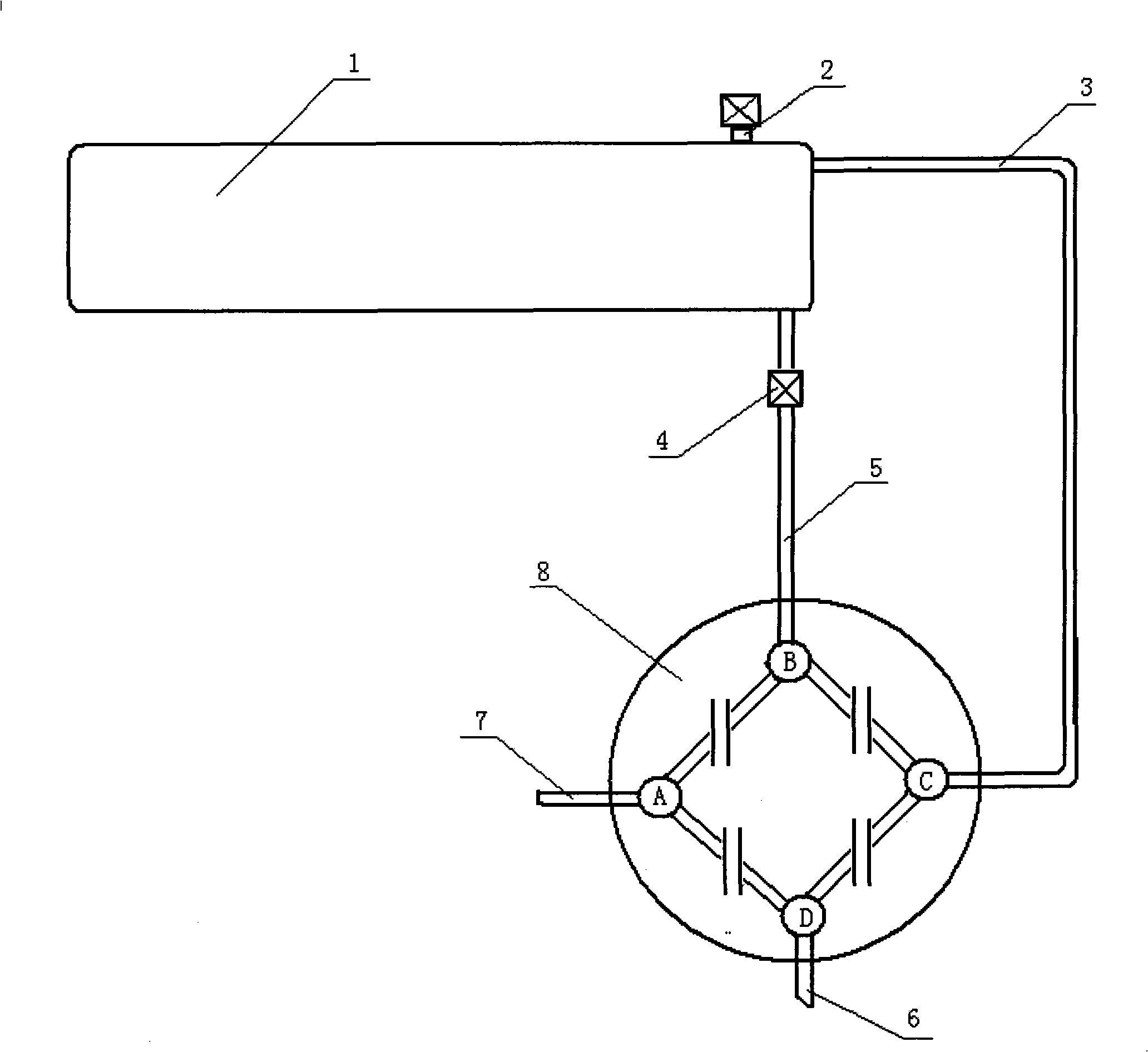

High-speed thermal circulation air curtain apparatus for tunnel portals

ActiveCN101476474AReduced caloric needsStable temperatureLighting and heating apparatusTunnel/mines ventillationCold airEngineering

The invention relates to fixed buildings, in particular to a tunnel portal high speed heat cycle wind curtain device which is suitable for track traffic main lines of high latitude and cold areas and inlet and outlet line portals. The device is provided with a hot air curtain which is injected at a high speed at the tunnel portal and forms a thick air curtain wall at the tunnel portal so as to stop the intrusion of severe cold air outside a tunnel, and reduce heat exchange. When the tunnel is a parallel double-portal tunnel, a communication channel and a bypass channel are added in the tunnel partition wall so as to effectively lead the piston wind of a train. At the same time, a cycle wind channel, a track passing channel, a ventilation chamber, and the like are arranged so as to achieve the cycle of hot air, effectively reduce heat requirements of adjacent stations, stabilize the station temperature, and reduce freezing phenomenon generated by cold and heat intersection of the portal, thereby making traffic safe.

Owner:SHANGHAI TUNNEL ENGINEERING RAILWAY TRANSPORTATION DESIGN INSTITUTE

Bearing solar water heater pressure relief and emptying system

InactiveCN101261048AReduce installation costsEasy to useSolar heat devicesMultiple way valvesSolar waterWater pipe

The invention provides a pressure relief emptying system for a bearing solar water heater, consisting of a water tank, an upper water pipe, a lower water pipe, a multidirectional control valve, a non-return valve, a negative pressure valve and a water faucet, wherein, the multidirectional control valve is connected between the water faucet and the upper water pipe and between a water outlet pipe and a running water pipe and is provided with four interfaces which are respectively connected with the running water pipe, the upper water pipe, the lower water pipe and the water faucet; the upper water pipe and the lower water pipe are respectively connected with a water inlet and a water outlet of the water tank of the solar water heater; the non-return valve is arranged on the upper water pipe; and the negative pressure valve is arranged on the water tank. The multidirectional control valve has the emptying function, and water feeding, water discharging and water emptying are completed by utilization of the multidirectional control valve, thereby the pressure relief emptying system for the bearing solar water heater reduces consumption of water pipes, joints and so on, reduces the assembly cost and the conditions of freezing and plugging and cold water exhaustion, realizes the water emptying of the lower water pipe and is more convenient to use.

Owner:山东天丰太阳能制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com