Air-conditioner for vehicle

a technology for air conditioners and vehicles, applied in the field of air conditioners, can solve the problems of not being able to prevent and achieve the effect of reducing the freezing of evaporators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

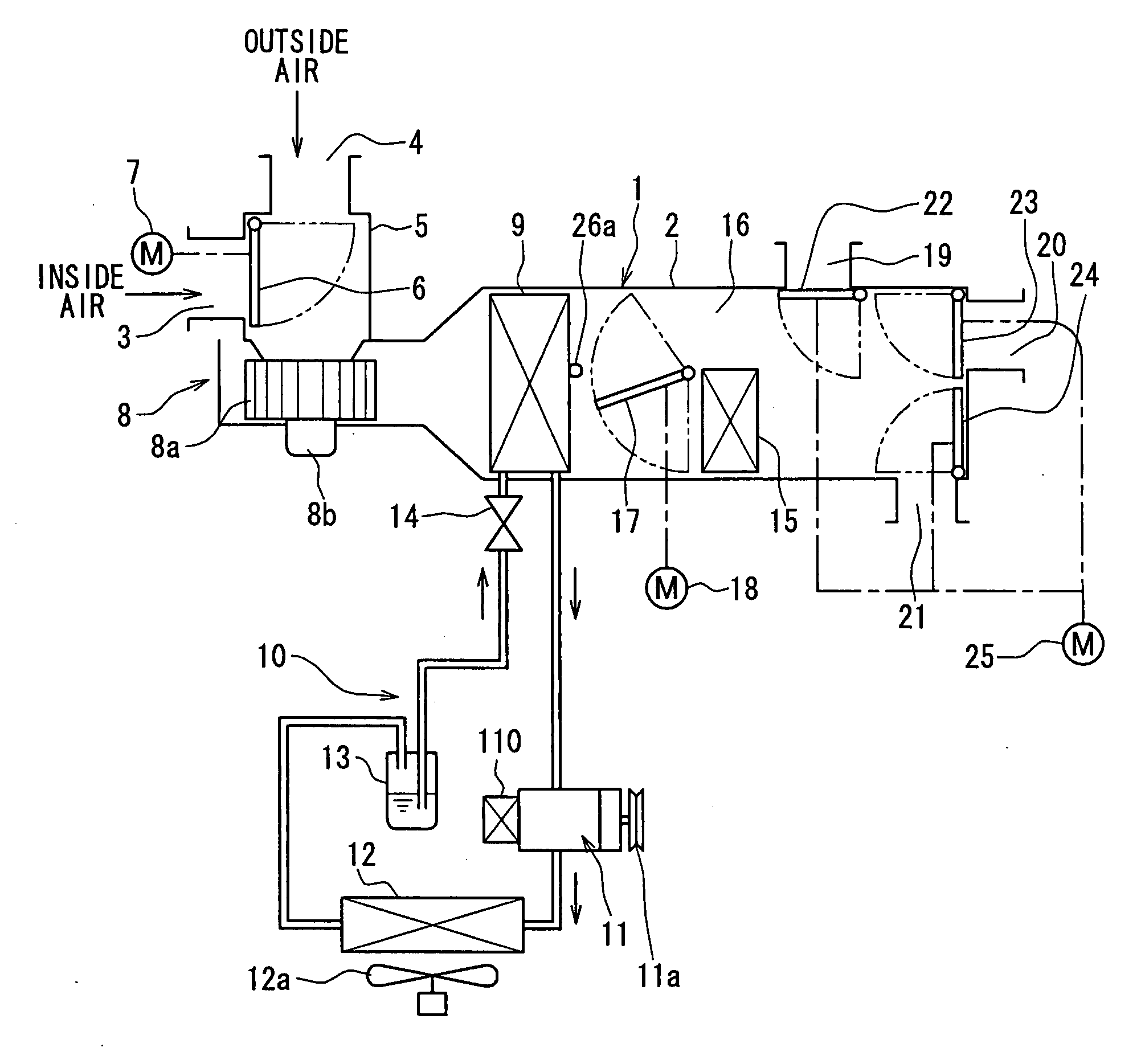

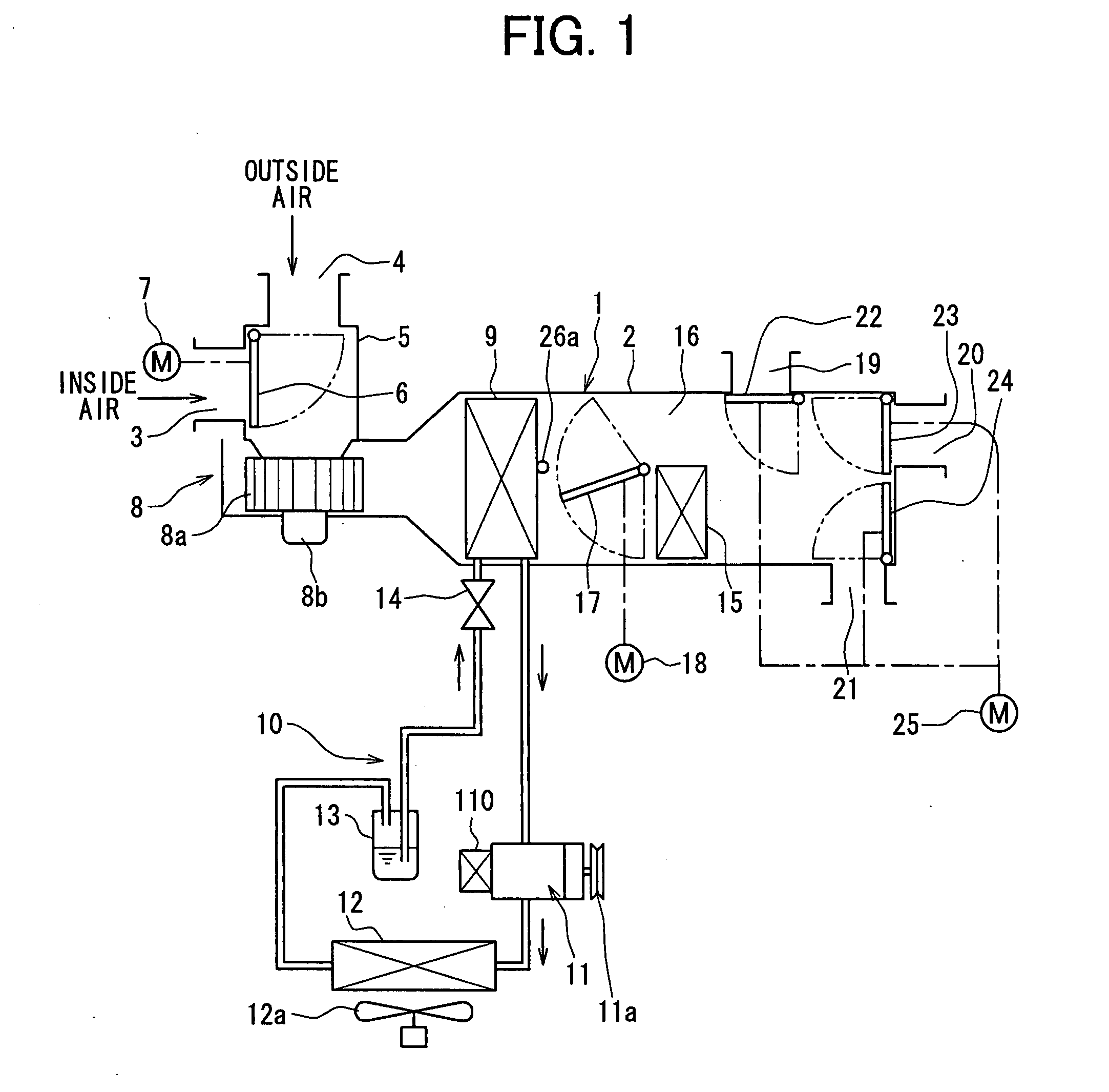

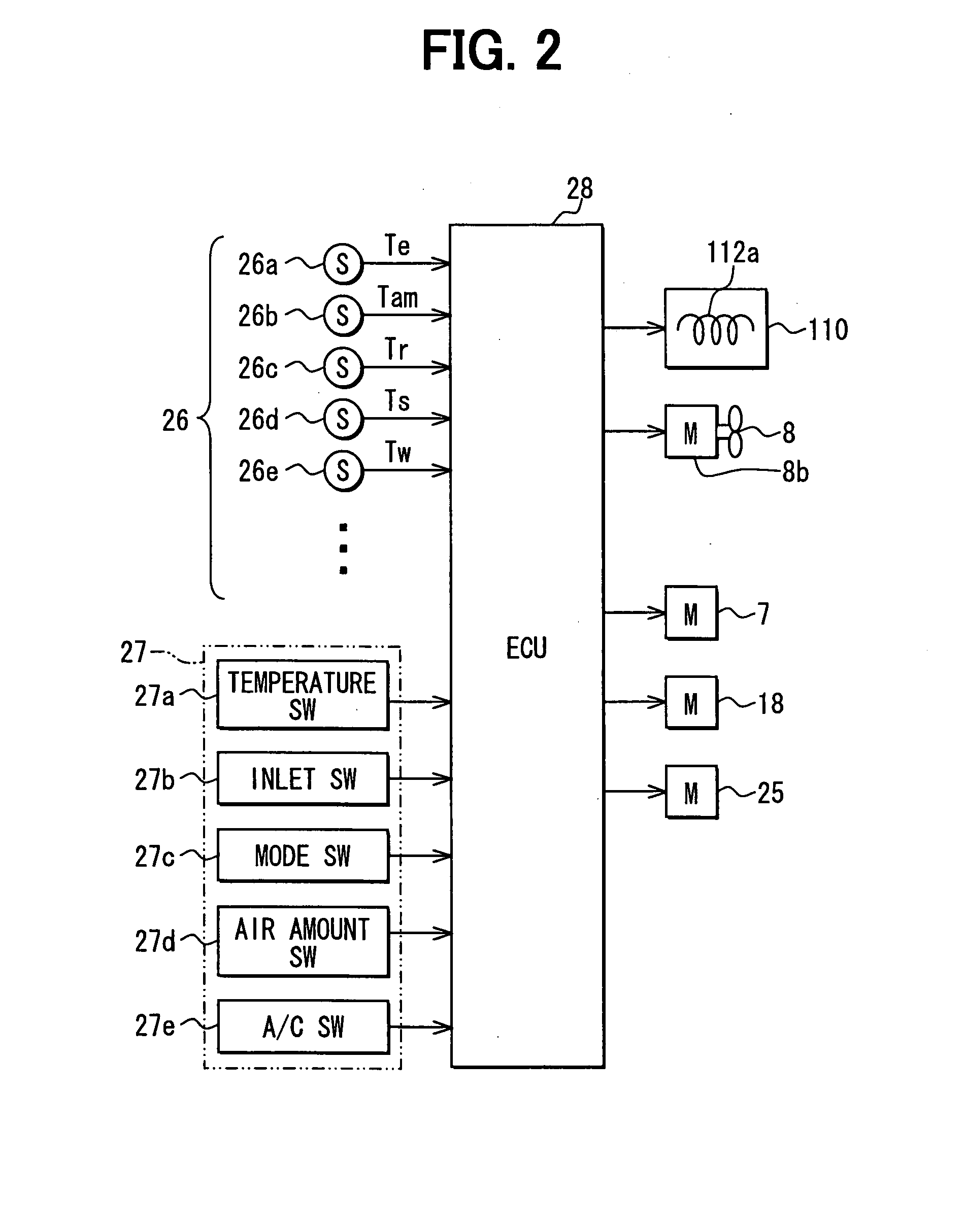

[0030]As shown in FIG. 1, an air-conditioner includes an air-conditioning unit 1 and a refrigeration cycle device 10, and is typically used for a vehicle. An evaporator 9 is disposed in the air-conditioning unit 1. Refrigerant for cooling air sent into a vehicle compartment flows in the evaporator 9 and the refrigeration cycle device 10. When the air-conditioning unit 1 is disposed in an instrument panel at a front part of the vehicle, the air-conditioning unit 1 is used for conditioning air adjacent to a front seat in the vehicle compartment. When the air-conditioning unit 1 is disposed in a trunk or a side-trim at a rear part of the vehicle, the air-conditioning unit 1 is used for conditioning air adjacent to a rear seat in the vehicle compartment.

[0031]The air-conditioning unit 1 has a case 2, and the case 2 has an air passage, through which air is sent toward an occupant in the vehicle compartment. An intake air switching box 5 is disposed at an upstream part of the air passage,...

second embodiment

[0066]A control of the compressor 11 in a second embodiment will be described with reference to FIGS. 7 and 8. When the air-conditioning switch 27e is turned on, the ECU 28 performs a subroutine A shown in FIG. 8 (S150 in FIG. 7).

[0067]As shown in FIG. 8, in the subroutine A, the ECU 28 performs a treatment for detecting a revolution number Ne(rpm) of the vehicle engine (S151). Next, when the detected revolution number Ne is equal to or larger than a predetermined value N1, the ECU 28 applies the detected revolution number Ne into a control characteristic map of S152, and calculates an evaporator surface temperature TEOA. The predetermined value N1 is a revolution number capable of causing the freezing of the evaporator 9, because the compressor 11 has a high capacity for compressing refrigerant. The predetermined value N1 is determined based on experiments, and memorized in the ECU 28 in advance.

[0068]When the detected revolution number Ne is between N1 and N2, the evaporator surfa...

third embodiment

[0077]A control of the compressor 11 in a third embodiment will be described with reference to FIGS. 9 and 10. When the air-conditioning switch 27e is turned on, the ECU 28 performs a subroutine B shown in FIG. 10 (S154 in FIG. 9).

[0078]As shown in FIG. 10, in the subroutine B, the ECU 28 performs a treatment for detecting an outside air temperature TAM(° C.) through the outside air temperature sensor 26b (S155). Next, when the detected outside air temperature TAM is equal to or smaller than a predetermined value T2, the ECU 28 applies the detected outside air temperature TAM into a control characteristic map of S156, and calculates an evaporator surface temperature TEOB. The predetermined value T2 is an outside air temperature capable of causing the freezing of the evaporator 9, because the condenser 12 has a high cooling capacity. The predetermined value T2 is determined based on experiments, and memorized in the ECU 28 in advance.

[0079]When the detected outside air temperature TA...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com