High-speed thermal circulation air curtain apparatus for tunnel portals

A technology of thermal circulation and circulating air duct, applied in the field of fixed buildings, can solve problems such as energy waste affecting driving safety, and achieve the effects of reducing freezing phenomenon, driving safety, and reducing heat demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

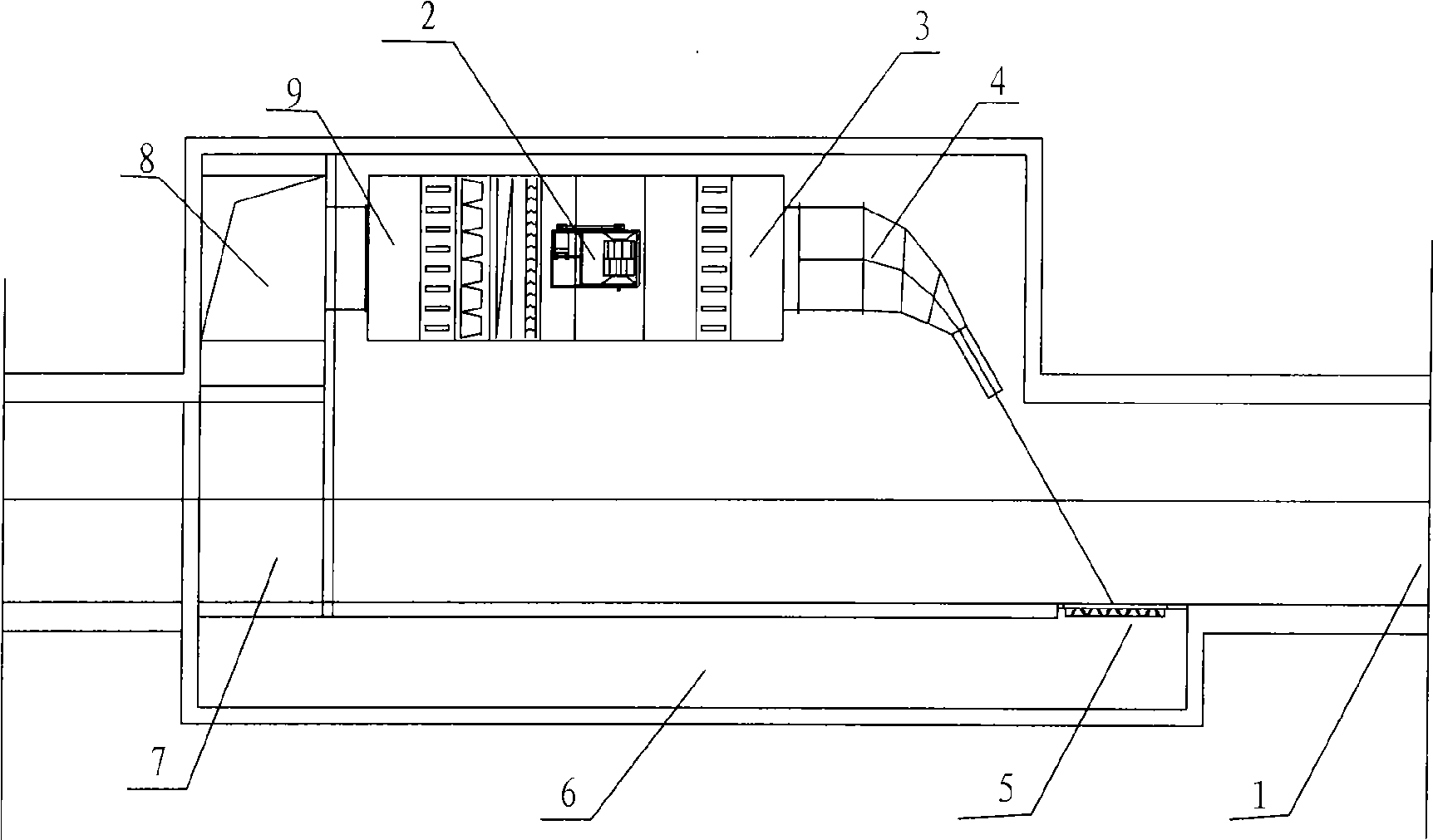

[0014] Embodiment one: if figure 1 As shown, this embodiment includes a tunnel entrance 1, an air handling unit 2, an air handling unit outlet 3, a high-speed nozzle 4, a circulating air duct inlet 5, a circulating air duct 6, a rail passing air duct 7, a circulation chamber 8, an air Air inlet 9 of the processing unit. A set of air handling unit 2 is installed on the side of the tunnel entrance 1 near the station. The air heated and pressurized by the air handling unit sprays out the hot air curtain at high speed through the air outlet 3 and the high-speed nozzle 4 connected to the air outlet. On the other side of the tunnel The circulation air duct 6 is set at the flow direction of the hot air curtain, and the hot air curtain flows back to the circulation chamber 8 connected to the air inlet 9 of the air handling unit through the circulation air duct 6 and the rail passage 7 in turn, and then enters the air handling unit to complete the circulation of the hot air curtain . ...

Embodiment 2

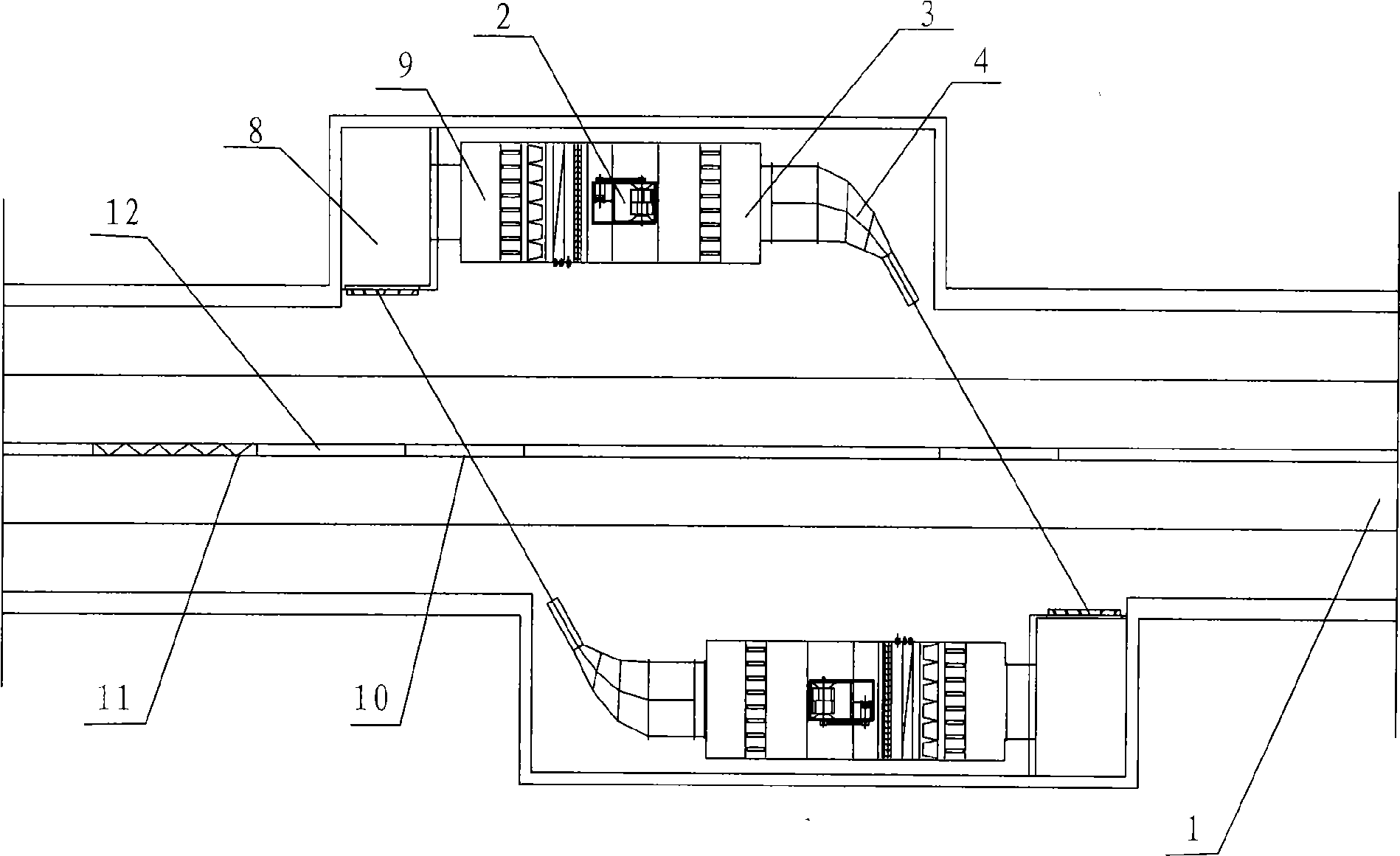

[0017] Embodiment two: if figure 2 As shown, this embodiment includes a tunnel entrance 1, an air handling unit 2, an air handling unit air outlet 3, a high-speed nozzle 4, a circulation chamber 8, an air handling unit air inlet 9, a channel 10, a circuitous air duct 11, and a tunnel partition wall 12. A group of air handling units 2, high-speed nozzles 4 and circulation chamber 8 are installed on both sides of the tunnel, and two hot air curtains are generated at the tunnel entrance 1, and the hot air curtain generated on one side is blown to the circulation chamber on the other side to form a circulating hot air screen. The wind speed of the hot air curtain ejected from the high-speed nozzle 4 must also be no less than 20 m / s, and the installation angle of the high-speed nozzle 4 must ensure that the hot air curtain flows to the circulation chamber on the other side.

[0018] When it is a parallel double-hole tunnel running on two lines, a channel 10 is provided on the tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com