High-speed thermal circulation air curtain construction method for tunnel portal

A construction method and thermal cycle technology, applied in the ventilation, heating, space heating and ventilation directions of mines/tunnels, which can solve the problems of freezing tunnel mouths and affecting traffic safety, reduce heat demand and stabilize station temperature. , the effect of driving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

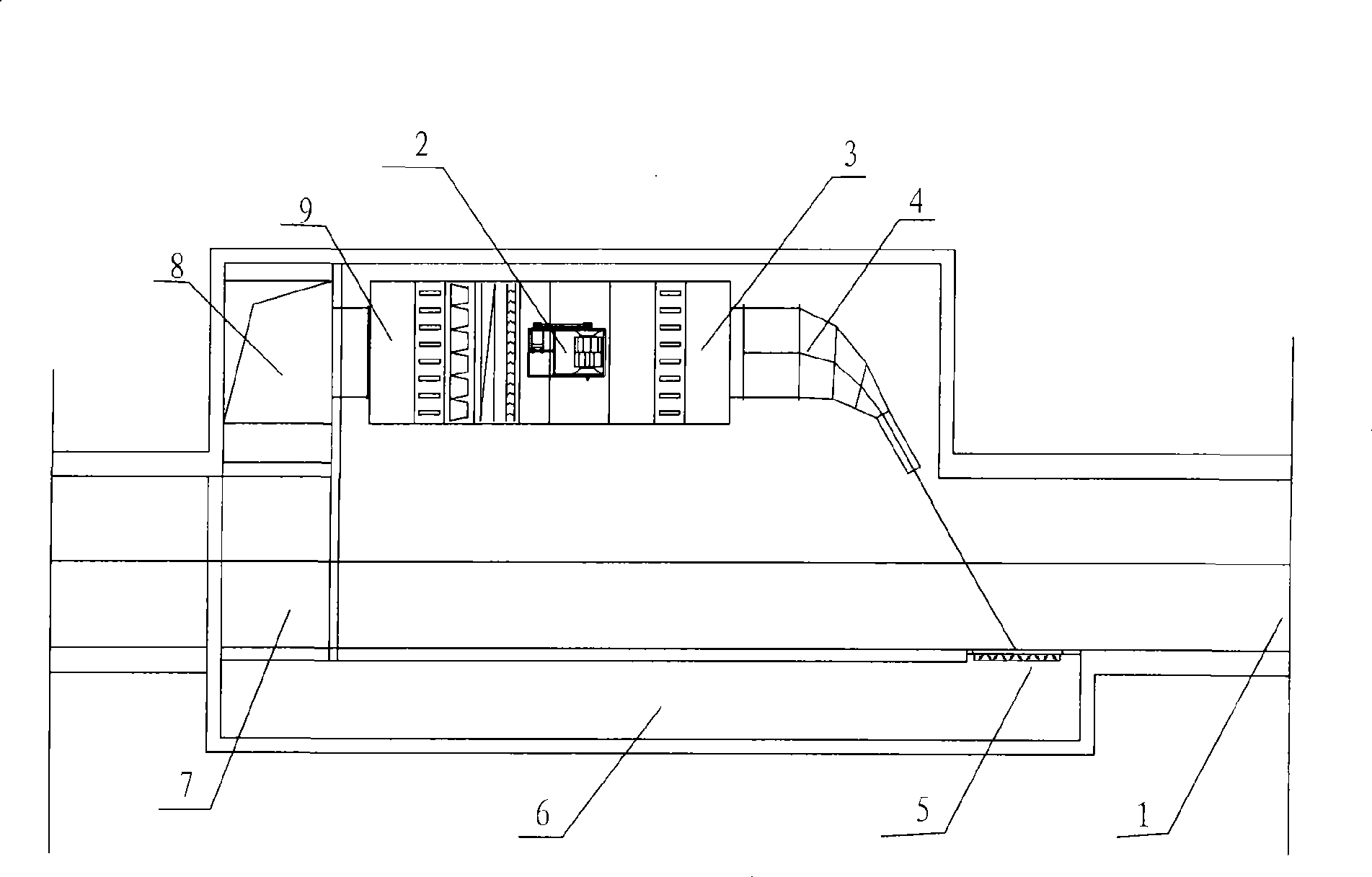

[0016] Example one: such as figure 1 As shown, in this embodiment, a set of air handling units 2 are installed on the side of the tunnel hole 1, and the air heated and pressurized by the air handling units 2 is sprayed out of the hot air curtain at high speed through the air outlet 3 and the high-speed nozzle 4 connected to the air outlet. A circulating air duct 6 is set at the flow direction of the hot air curtain on the other side of the tunnel. The hot air curtain flows back through the circulating air duct 6 and the rail-crossing air duct 7 to the circulation room 8 connected to the air handling unit inlet 9 and then enters the air handling unit 2. Complete the loop of the hot air curtain.

[0017] Among them, the wind speed of the hot air curtain sprayed by the high-speed nozzle 1 must not be less than 20 m / s, in order to eject a high-speed airflow with a certain thickness, and form a thick hot air curtain at the mouth of the tunnel to block the intrusion of external cold wi...

Embodiment 2

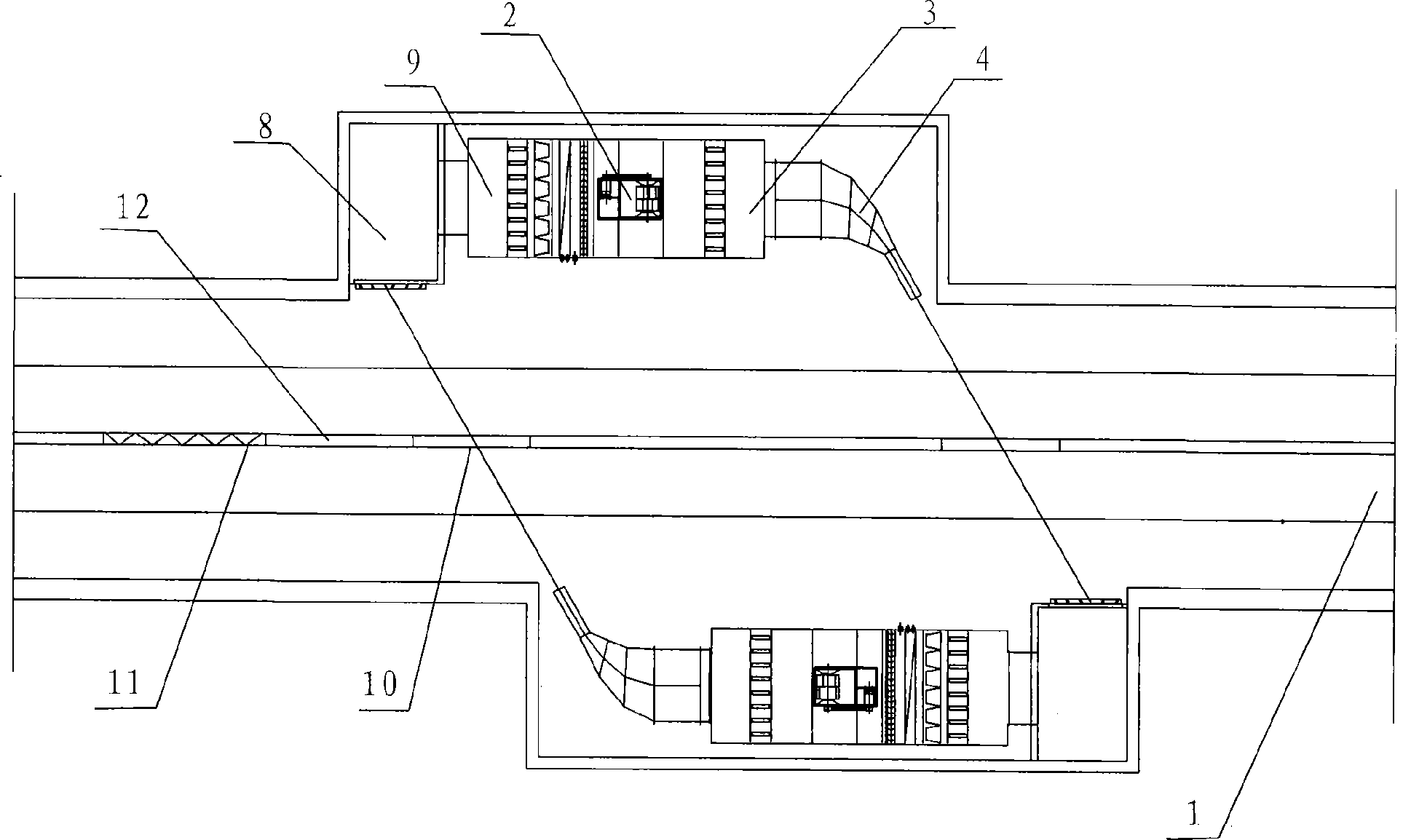

[0019] Embodiment two: such as figure 2 As shown, in this embodiment, a set of air handling units 2, high-speed nozzles 4, and circulation chamber 8 are installed on both sides of the tunnel. Two hot air curtains are generated at the tunnel entrance, and the hot air curtain generated on one side is blown to the other side. The circulation room 8 forms a circulating hot air curtain. The wind speed of the hot air curtain sprayed by the high-speed nozzle 4 must also not be less than 20 m / s, and the installation angle of the high-speed nozzle 4 must ensure that the hot air curtain flows to the flow chamber 8 on the other side.

[0020] In the case of a parallel Shuangdong tunnel running in two lines, a passage 10 is provided on the tunnel isolation wall 12 through which the hot air curtain flows, and a fire shutter can be installed on the passage 10. A bypass air duct 11 is provided on the isolation wall 12 of the parallel Shuangdong tunnel.

[0021] The invention has been applied in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com