Patents

Literature

56results about "Evacuating shielding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

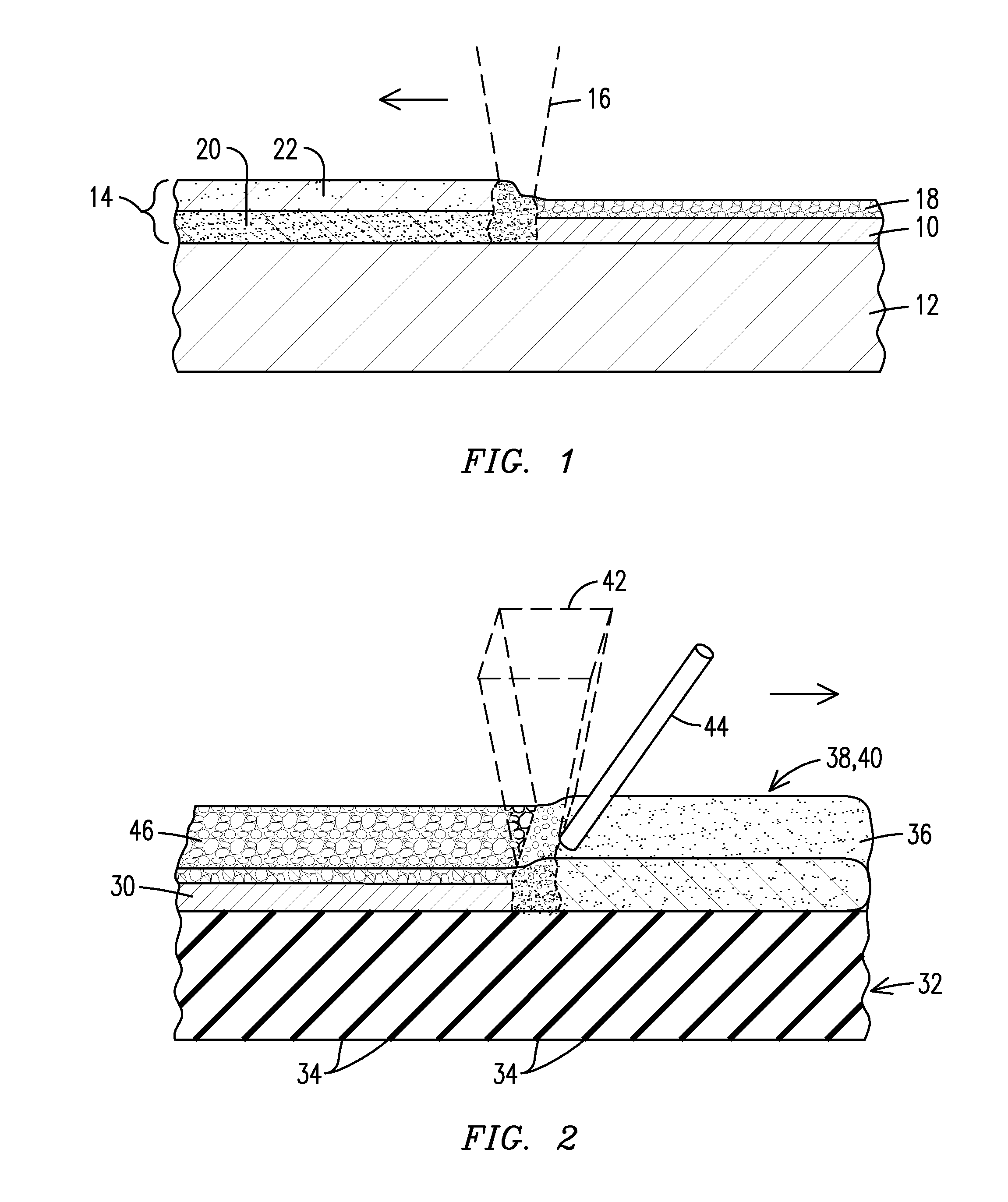

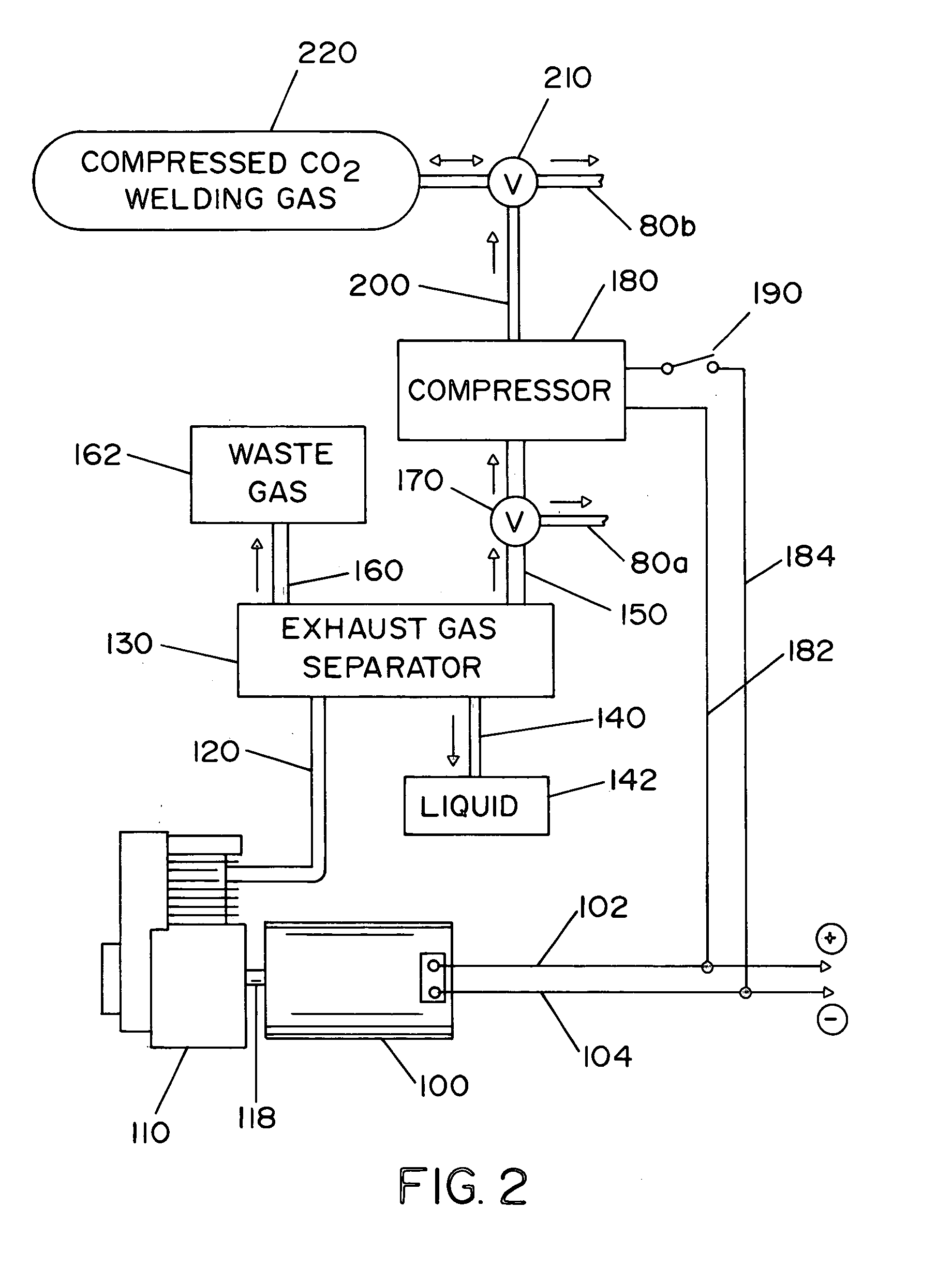

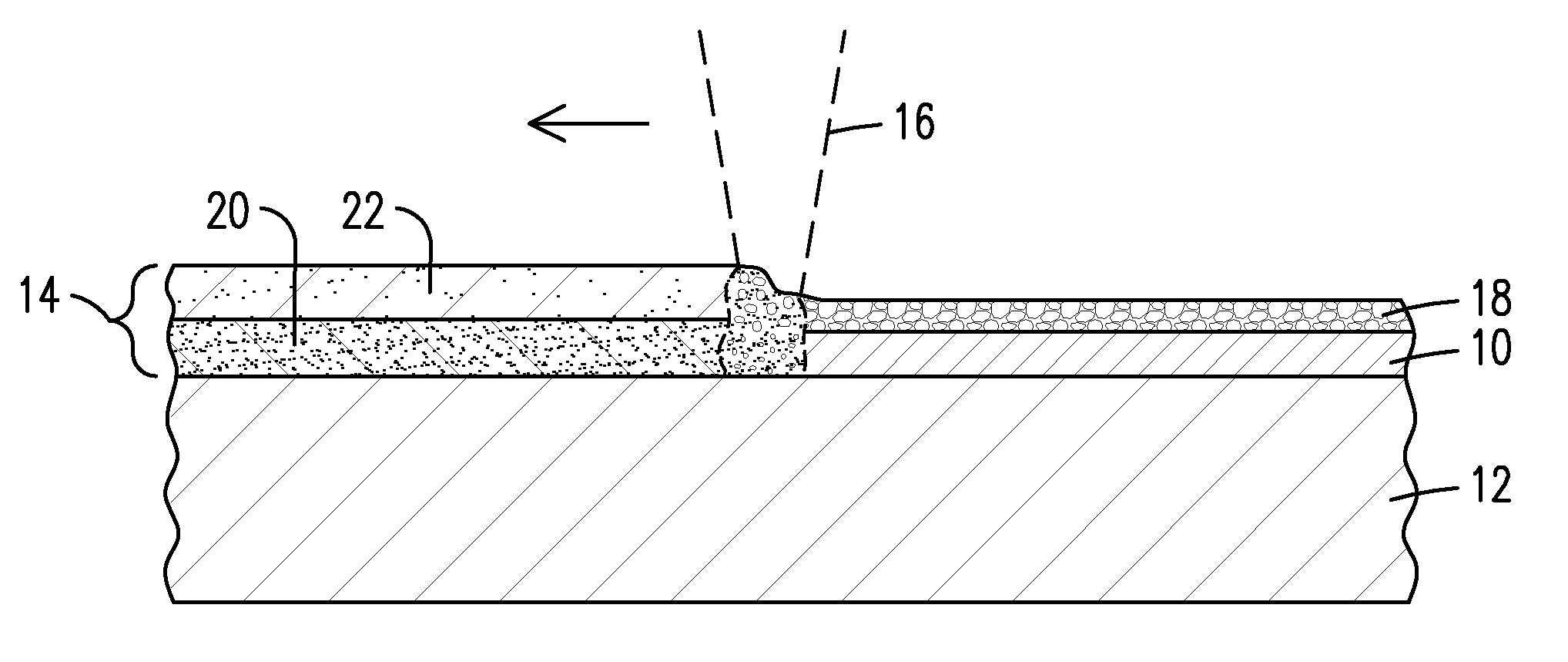

Process for welding

InactiveUS7170032B2Long electrode lifeEvacuating shieldingWelding/cutting media/materialsElastomerShielding gas

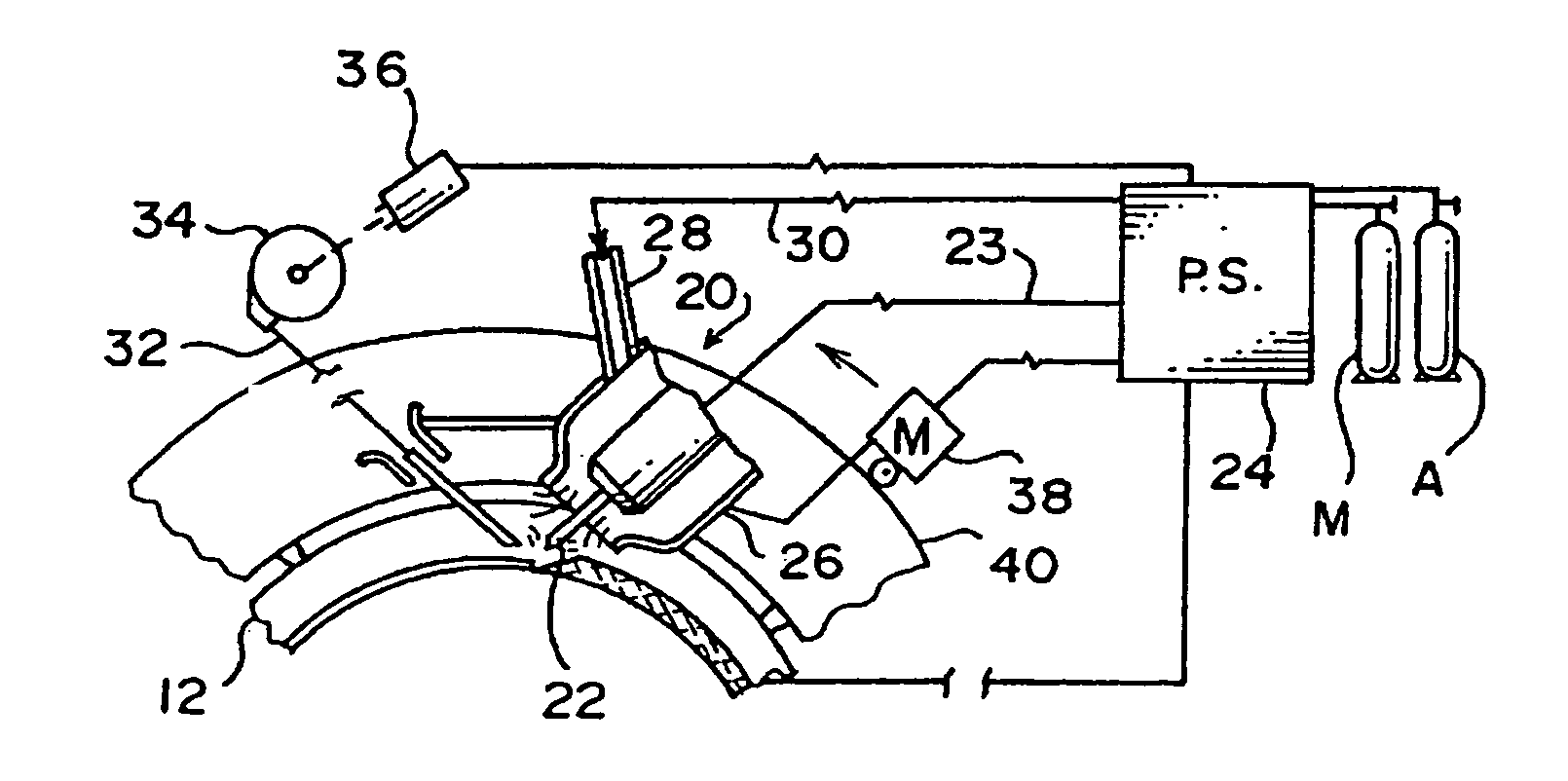

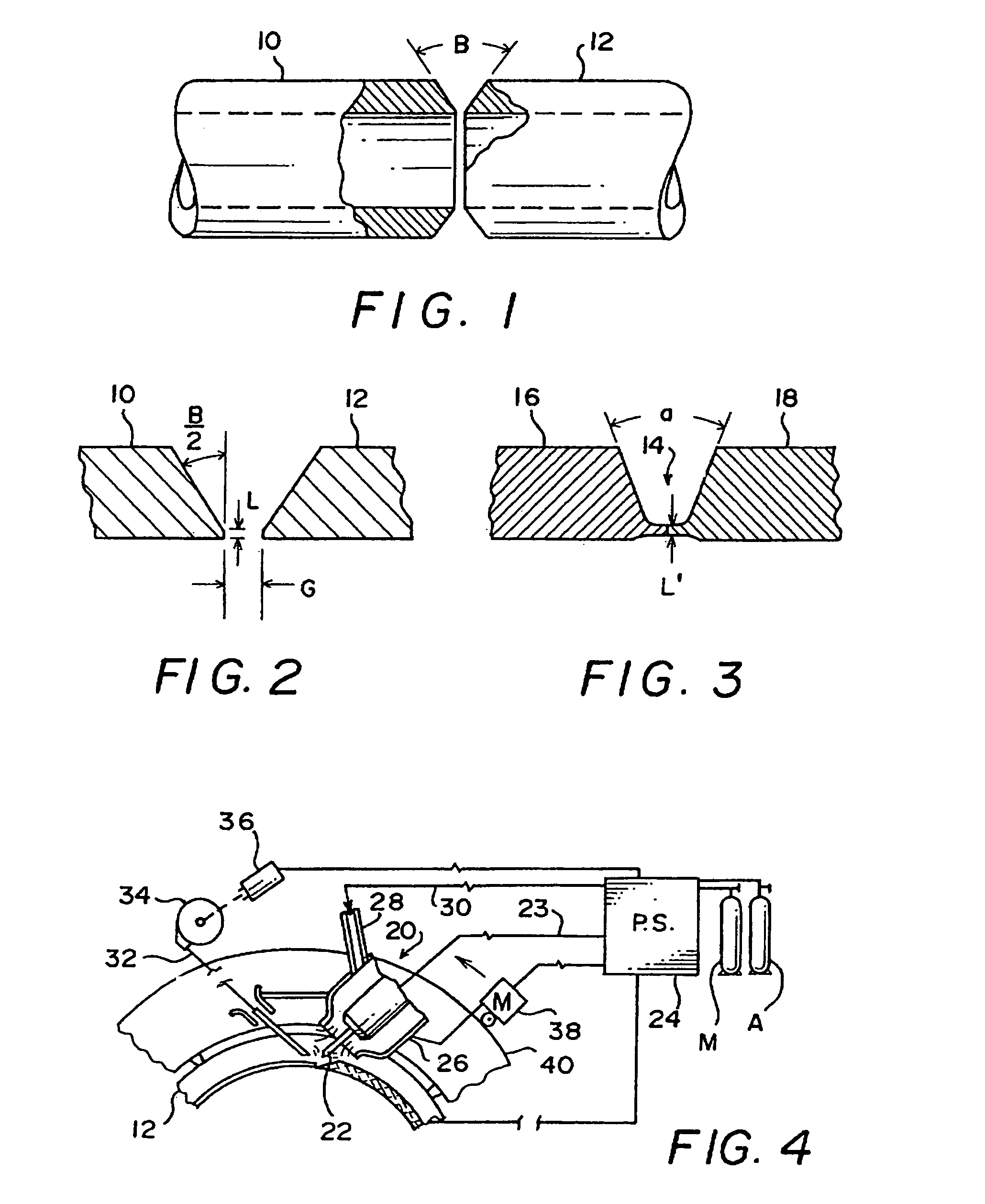

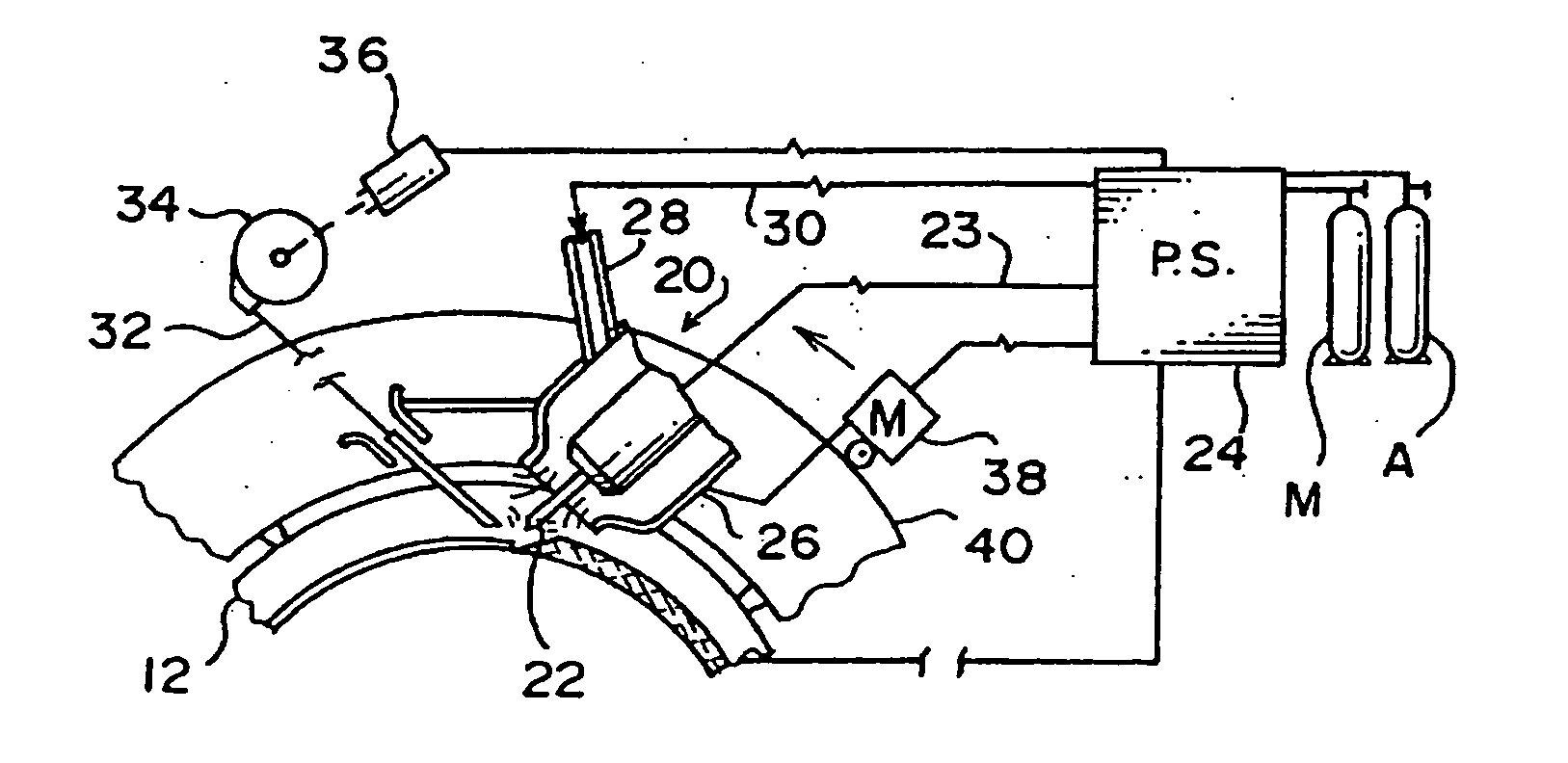

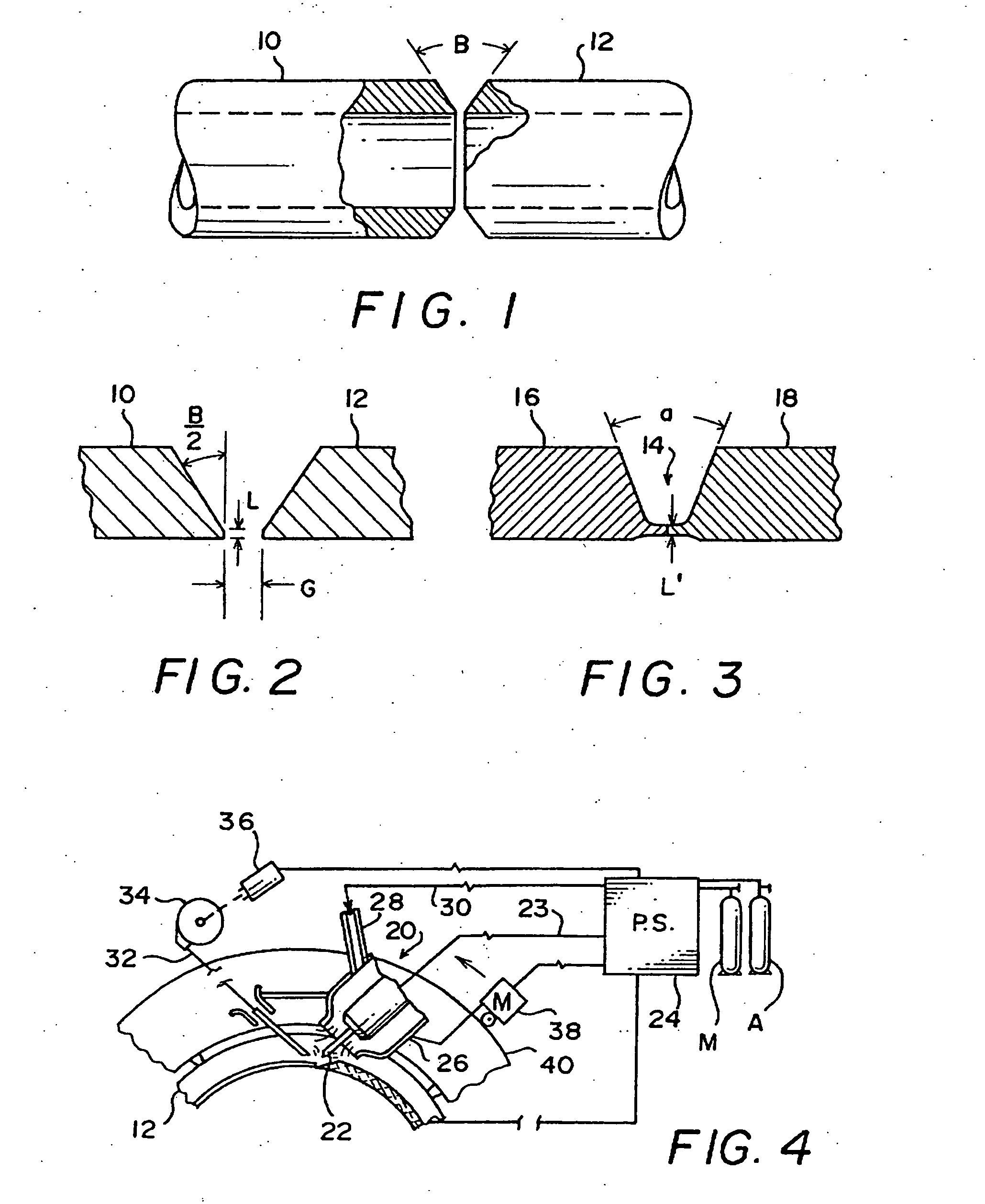

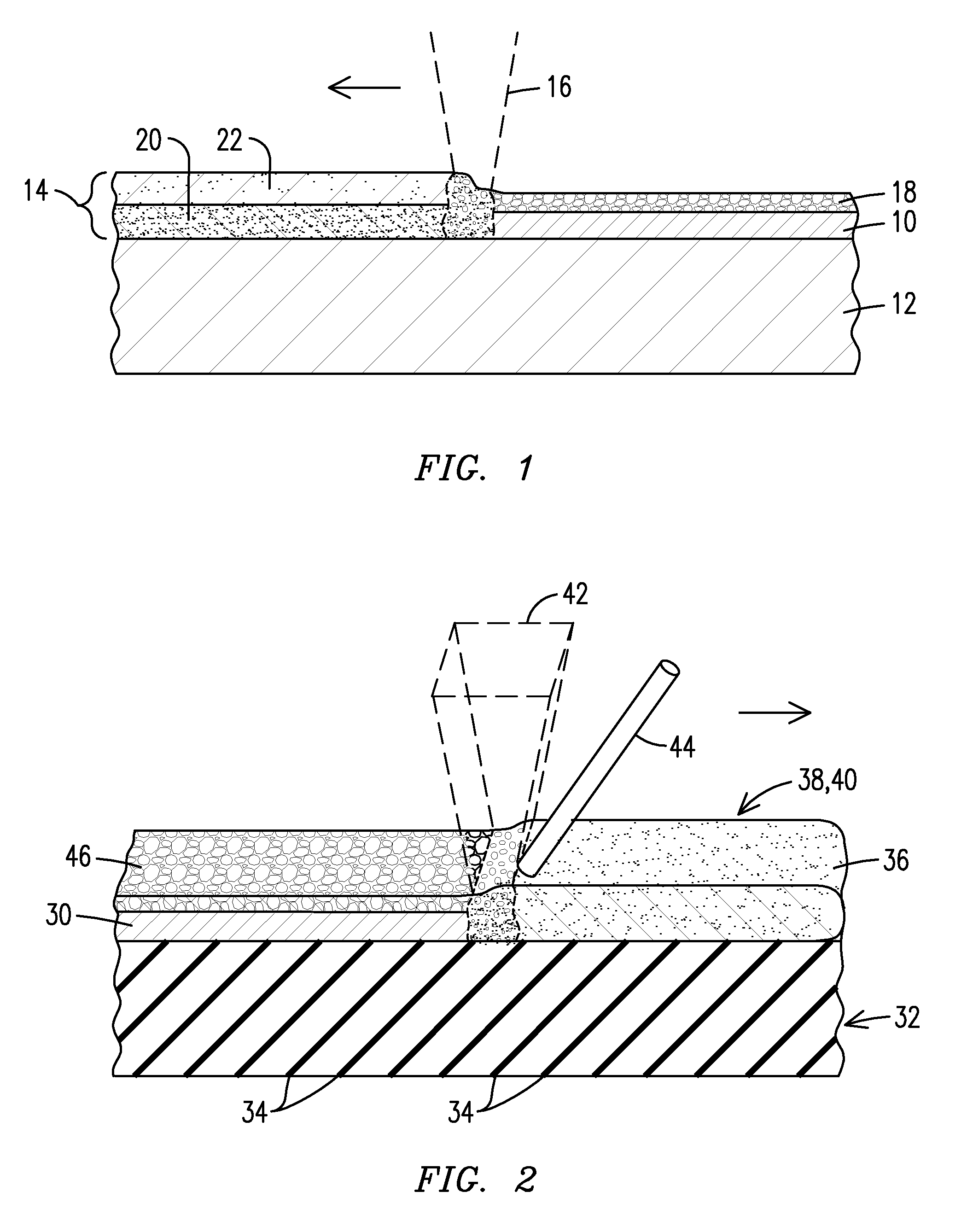

A welding process for non-stainless steel workpieces using GTAW equipment and hydrogen containing shield gas on a first root pass is improved by using a shield gas delivery system comprising hoses or conduits made of elastomeric material having a moisture permeability coefficient of less that 275, preferably less than 100, and using a tungsten electrode composition comprising at least tungsten and lanthanum oxide, and preferably tungsten, lanthanum oxide, yttrium oxide and zirconium oxide. Preventing moisture permeation through the elastomeric hoses delivering hydrogen containing shield gas eliminates expulsion of fused weld metal during second pass filler welding over the root pass weld. Electrode life is enhanced using the tungsten compounds.

Owner:JV IND CO LLC

Process for welding

InactiveUS20050109735A1Long electrode lifeEvacuating shieldingWelding/cutting media/materialsElastomerShielding gas

A welding process for non-stainless steel workpieces using GTAW equipment and hydrogen containing shield gas on a first root pass is improved by using a shield gas delivery system comprising hoses or conduits made of elastomeric material having a moisture permeability coefficient of less that 275, preferably less than 100, and using a tungsten electrode composition comprising at least tungsten and lanthanum oxide, and preferably tungsten, lanthanum oxide, yttrium oxide and zirconium oxide. Preventing moisture permeation through the elastomeric hoses delivering hydrogen containing shield gas eliminates expulsion of fused weld metal during second pass filler welding over the root pass weld. Electrode life is enhanced using the tungsten compounds.

Owner:JV IND CO LLC

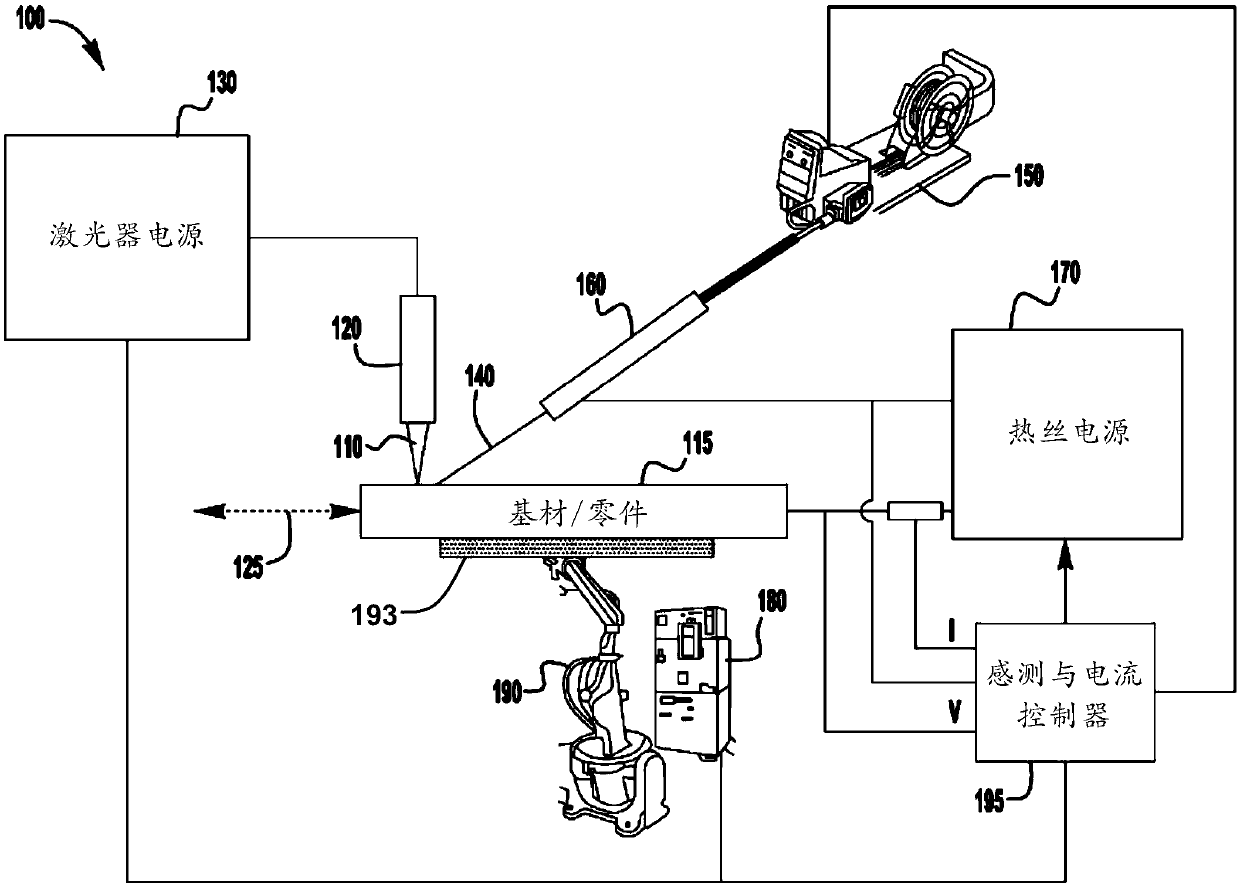

Laser microcladding using powdered flux and metal

A laser microcladding process utilizing powdered flux material (93b). A jet (92) of propellant gas containing powdered alloy material (93a) and the powdered flux material are directed toward a substrate (94). The powdered materials are melted by a laser beam (96) to form a weld pool (98) which separates into a layer of slag (100) covering a layer of clad alloy material (102). The flux material deoxidizes the weld pool and protects the layer of clad alloy material as it cools, thereby allowing the propellant gas to be nitrogen or air rather than an inert gas. In one embodiment, the substrate and alloy materials are superalloys with compositions beyond the traditional zone of weldability.

Owner:SIEMENS ENERGY INC

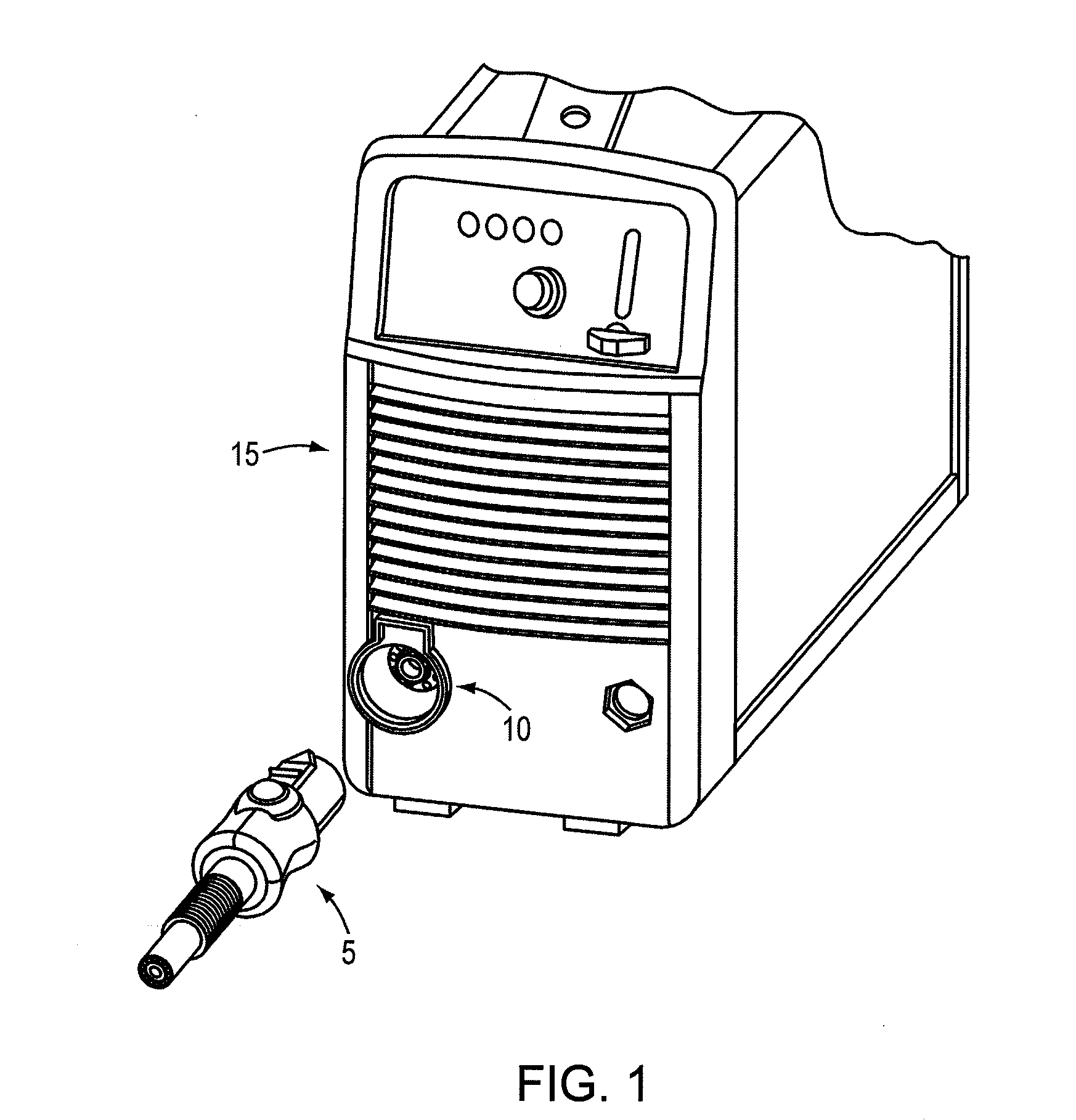

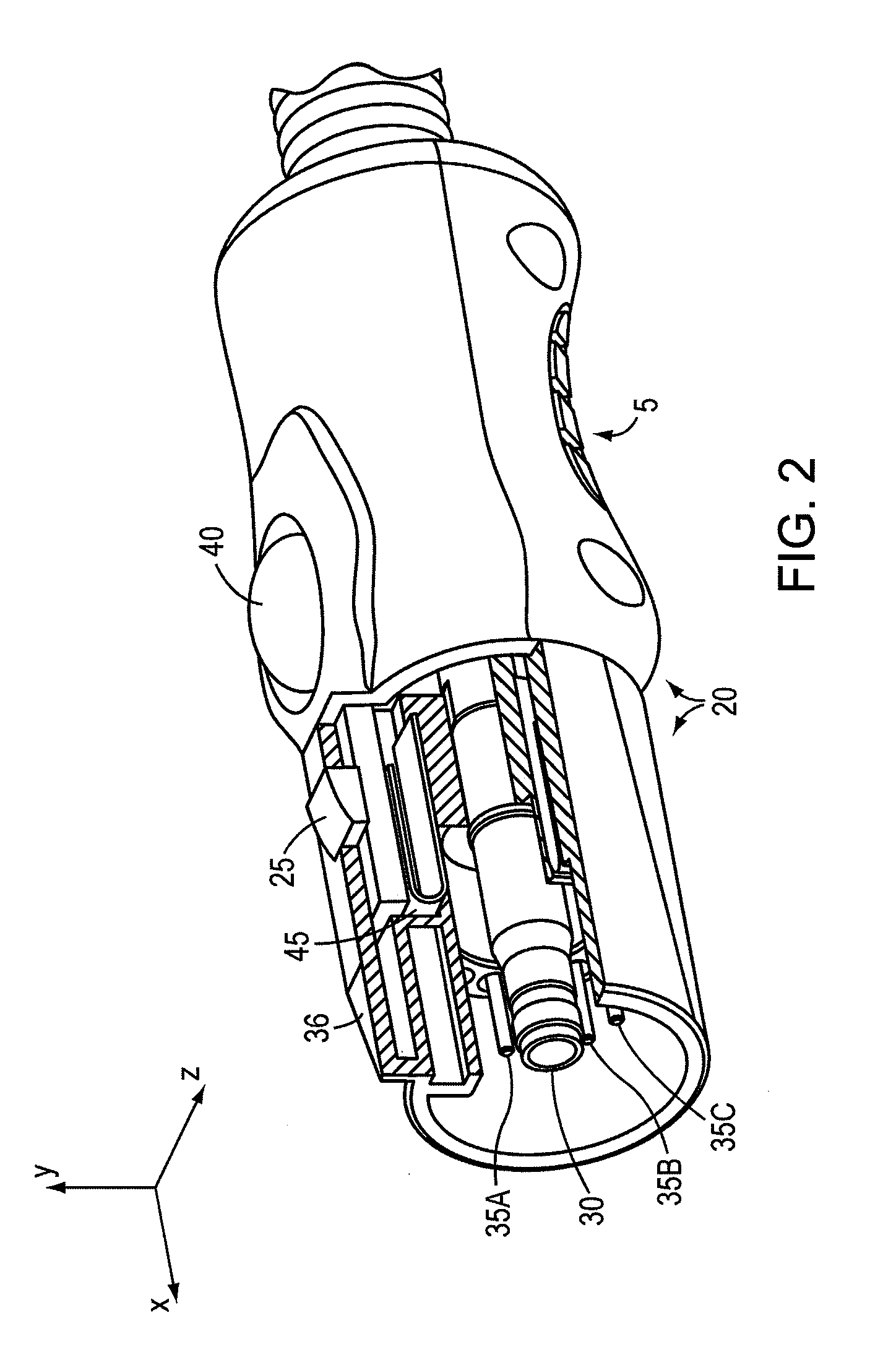

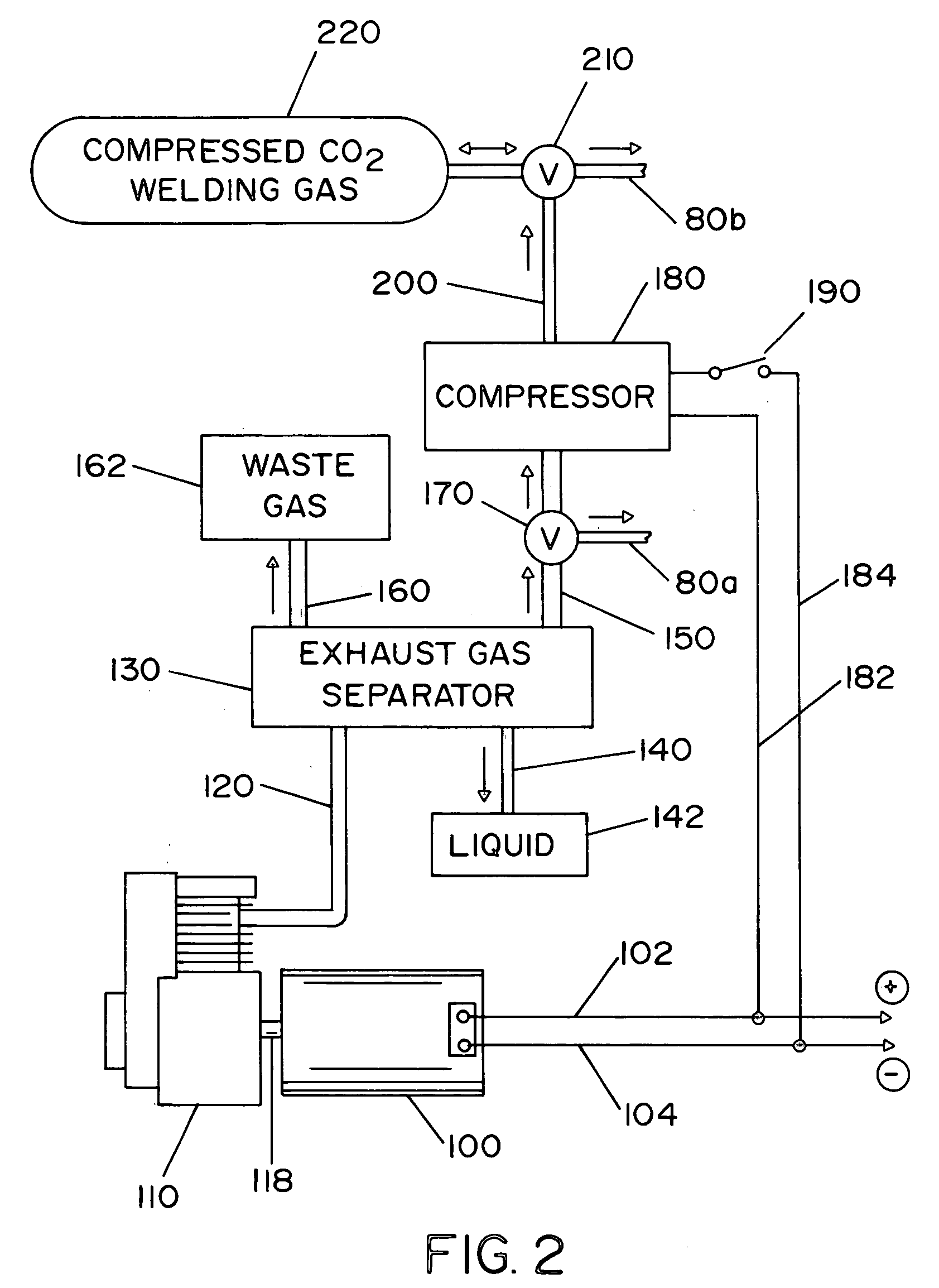

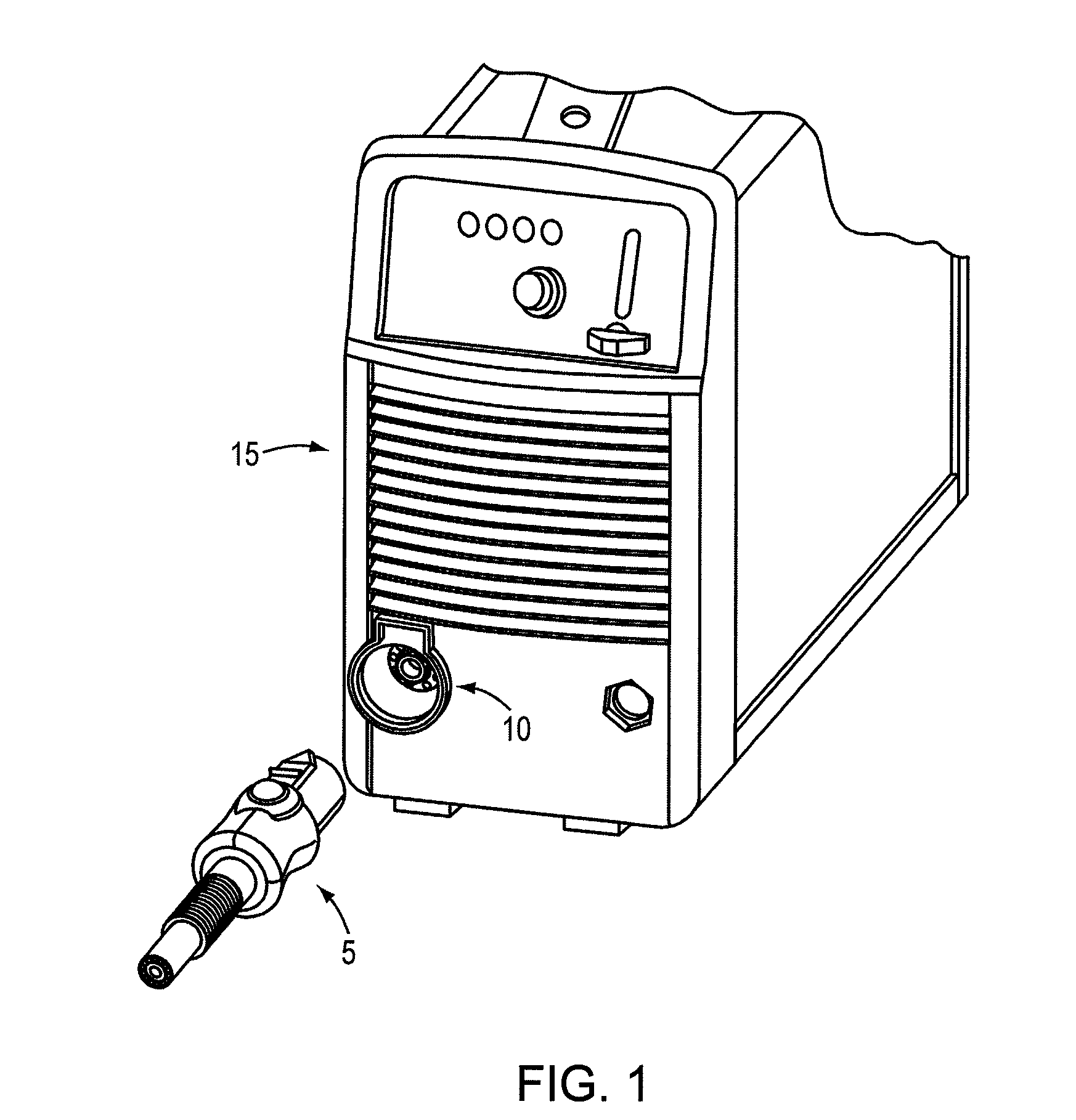

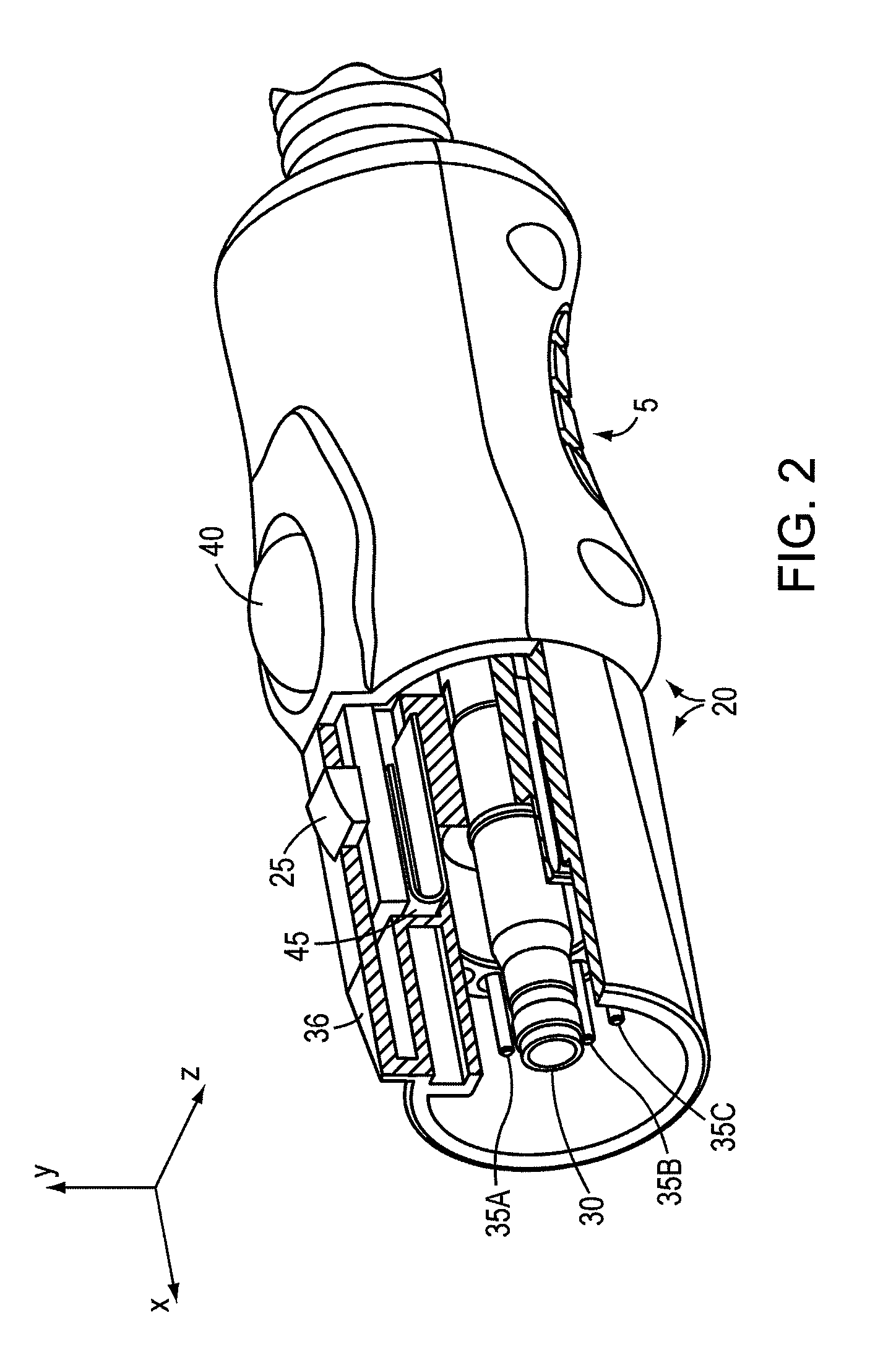

Connector for a Thermal Cutting System or Welding System

ActiveUS20090215302A1Easy alignmentFirmly connectedEvacuating shieldingCoupling device detailsGuide tubeWelding

A connector assembly for a thermal cutting system or welding system can include a housing having a locking device. The locking device can cause, upon application of a translational force, engagement of the connector assembly relative to a stationary receiving mechanism and can cause, upon application of a force on a contact member or a rotational moment on the contact member, disengagement of the locking device relative to the stationary receiving mechanism. The connector assembly can include a conduit disposed in the housing, the conduit carrying a gas to the thermal cutting system or welding system. The connector assembly can include a first current carrying member disposed in the housing, the first current carrying member carrying an operating current to the thermal cutting system or welding system and a second current carrying member disposed in the housing, the second current carrying member carrying a second current.

Owner:HYPERTHERM INC

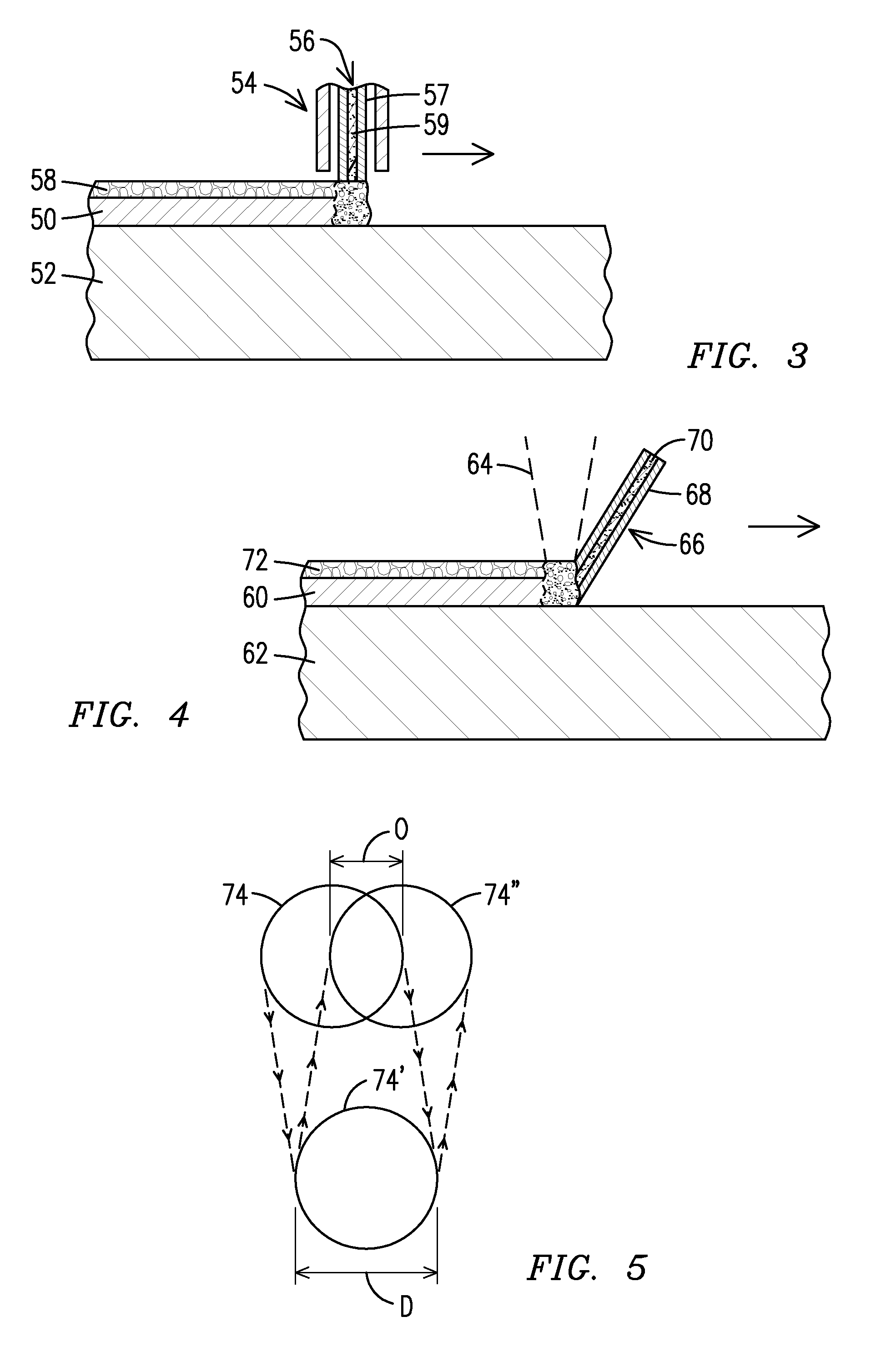

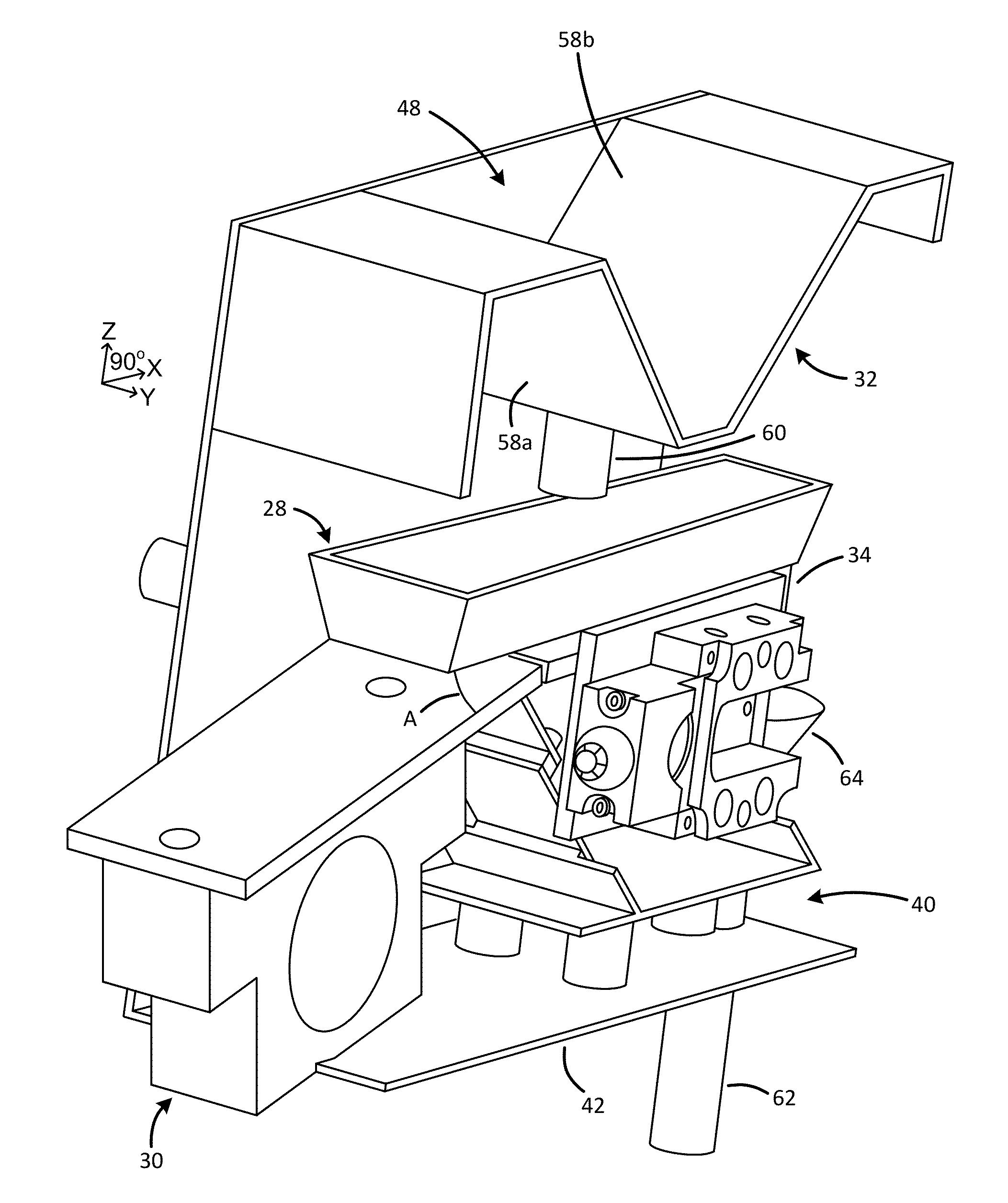

Alloy Depositing Machine And Method Of Depositing An Alloy Onto A Workpiece

A hardfacing machine is used for depositing a hardfacing alloy onto a metallic workpiece. An welding unit includes a wire feed system to supply wire to a welding head. A powder alloy feeding system includes a powder feed nozzle fluidly connected to an alloy powder supply. The welding head and powder feed nozzle move in a travel direction relative to the workpiece. The powder feed nozzle is positioned and oriented to feed a powder stream of alloy powder into a molten pool generated on the workpiece by an electrical arc produced by the welding head at a low temperature location behind the welding head relative to the travel direction. This alloy surfacing strategy limits vaporization of alloy elements by avoiding the high temperature region associated with the electrical arc.

Owner:CATERPILLAR INC

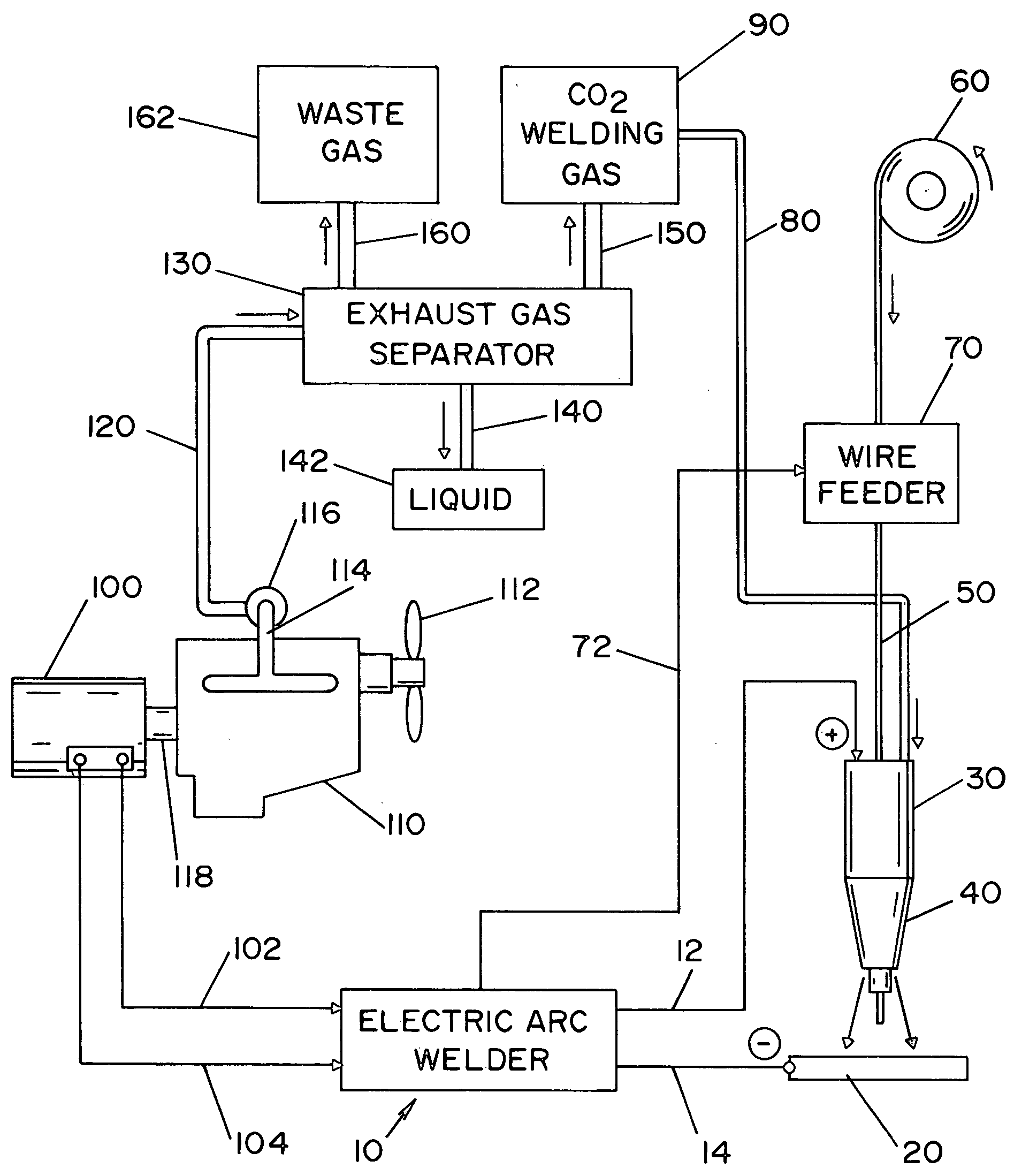

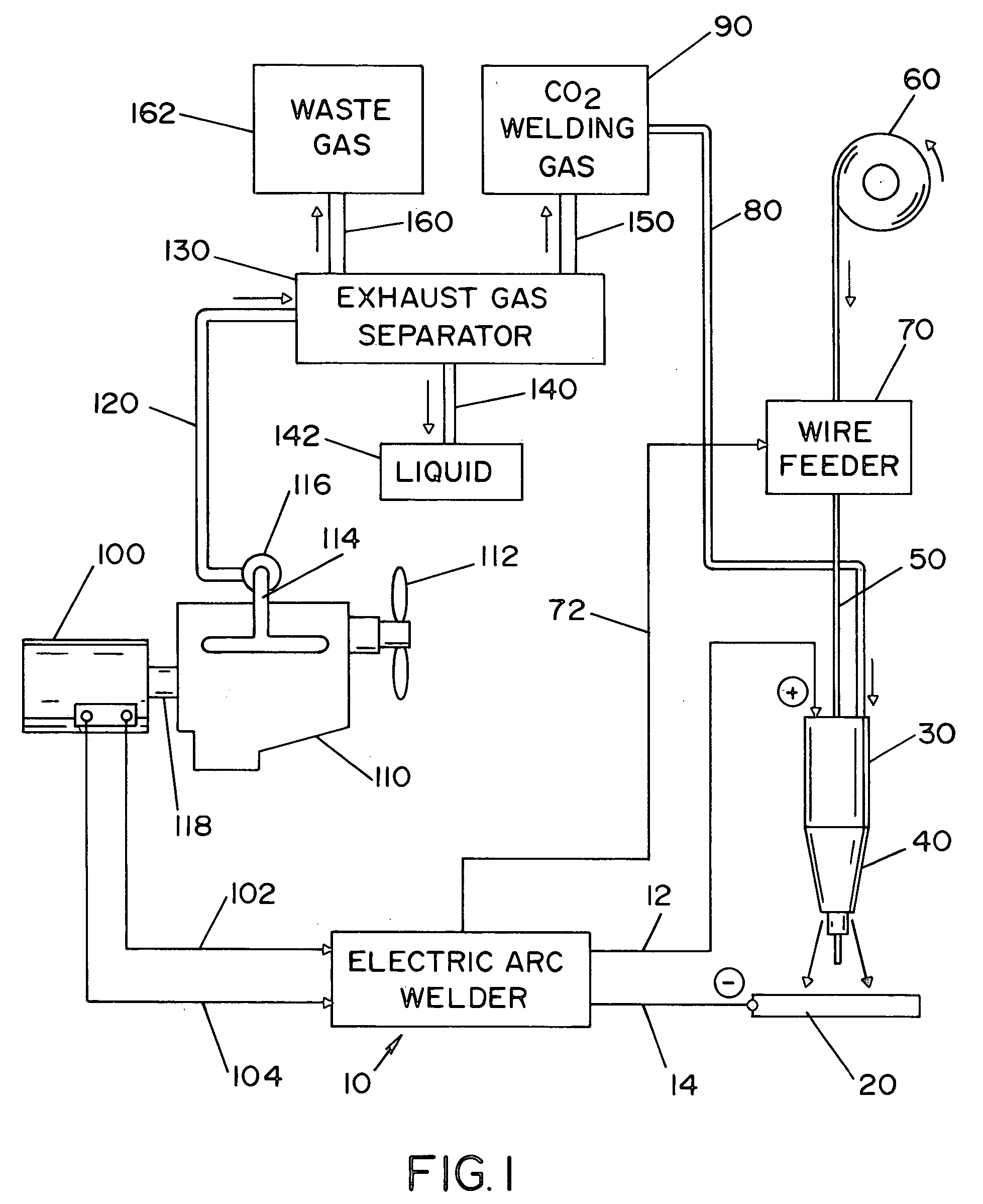

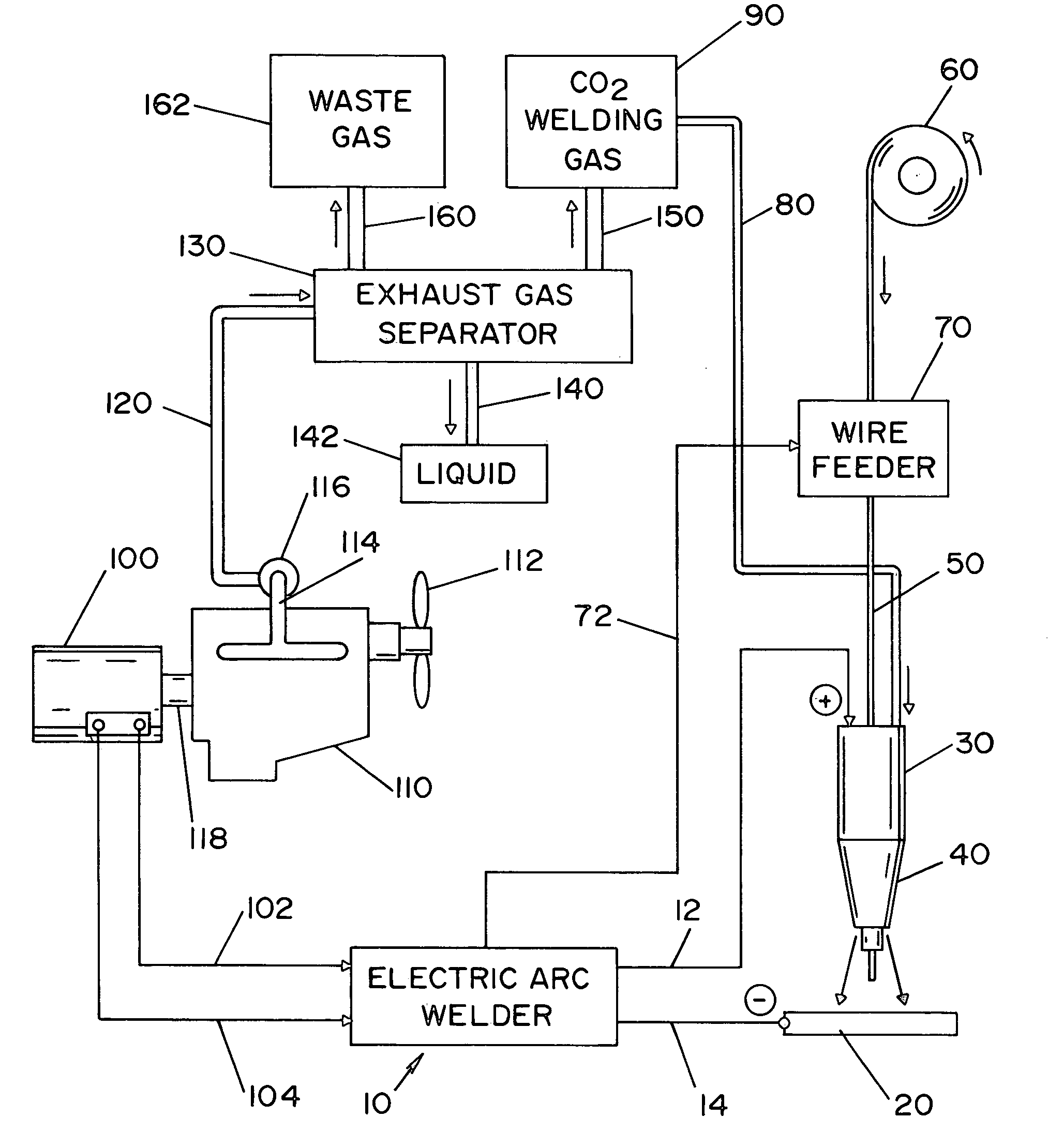

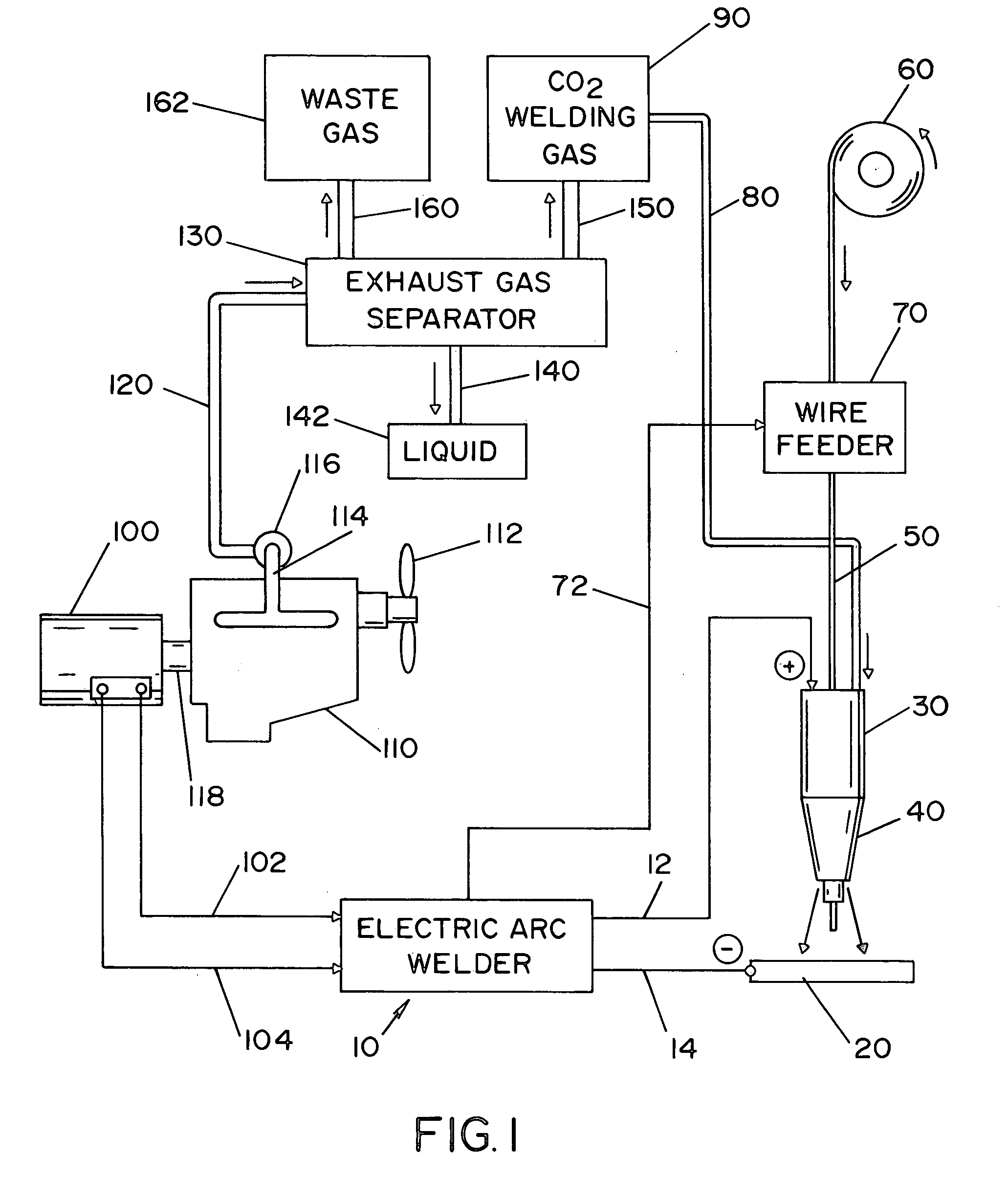

Engine welder with shielding gas generation

InactiveUS20050161450A1Easy to operateEasy to set upEvacuating shieldingElectric discharge heatingShielding gasCarbon Dioxide / Helium

A liquid and gas separator to generate a shielding gas from the exhaust gas of an internal combustion engine. The liquid and gas separator can be a separate portable component or a component that is integrated with the arc welder.

Owner:LINCOLN GLOBAL INC

Connector for a thermal cutting system or welding system

A connector assembly for a thermal cutting system or welding system can include a housing having a locking device. The locking device can cause, upon application of a translational force, engagement of the connector assembly relative to a stationary receiving mechanism and can cause, upon application of a force on a contact member or a rotational moment on the contact member, disengagement of the locking device relative to the stationary receiving mechanism. The connector assembly can include a conduit disposed in the housing, the conduit carrying a gas to the thermal cutting system or welding system. The connector assembly can include a first current carrying member disposed in the housing, the first current carrying member carrying an operating current to the thermal cutting system or welding system and a second current carrying member disposed in the housing, the second current carrying member carrying a second current.

Owner:HYPERTHERM INC

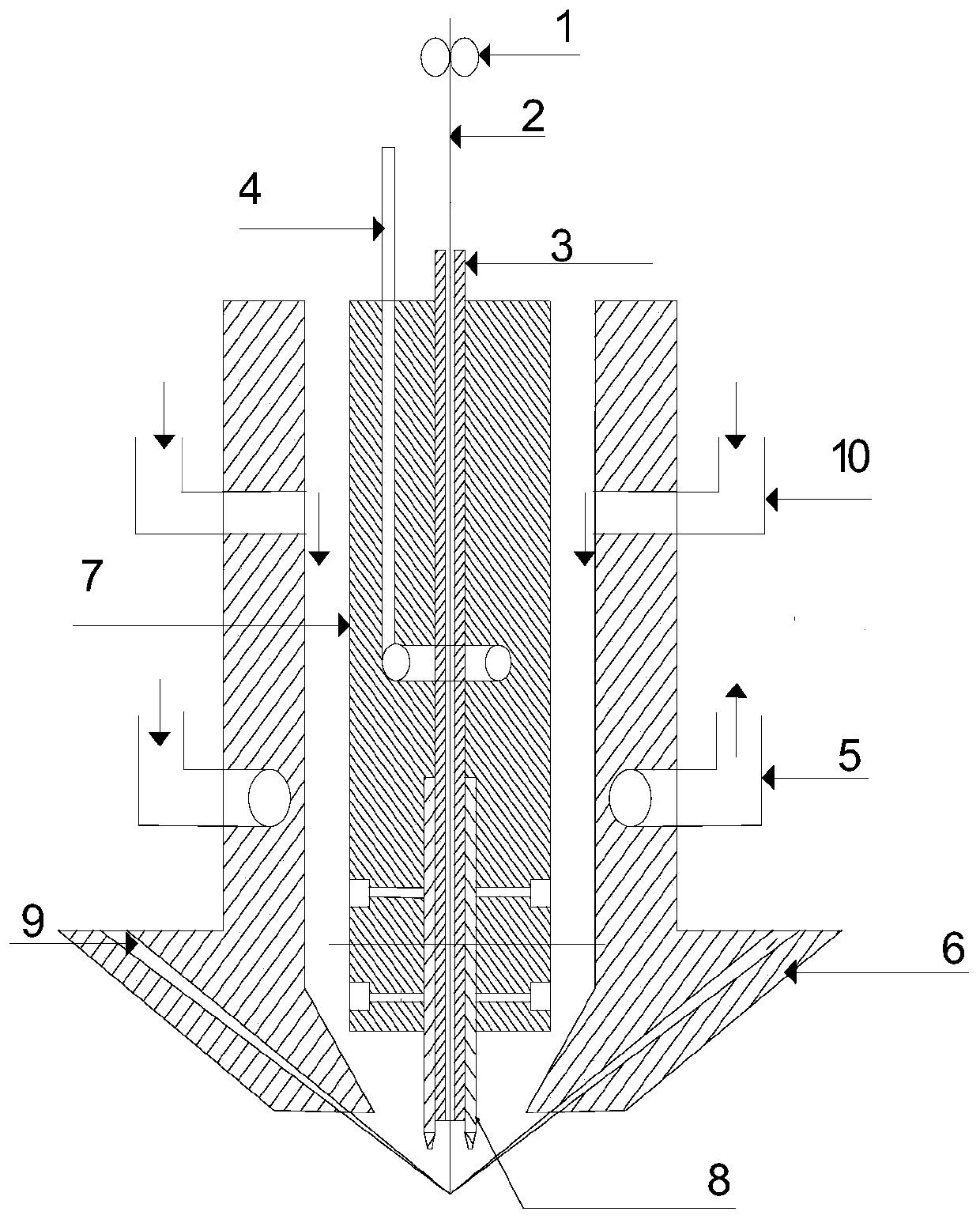

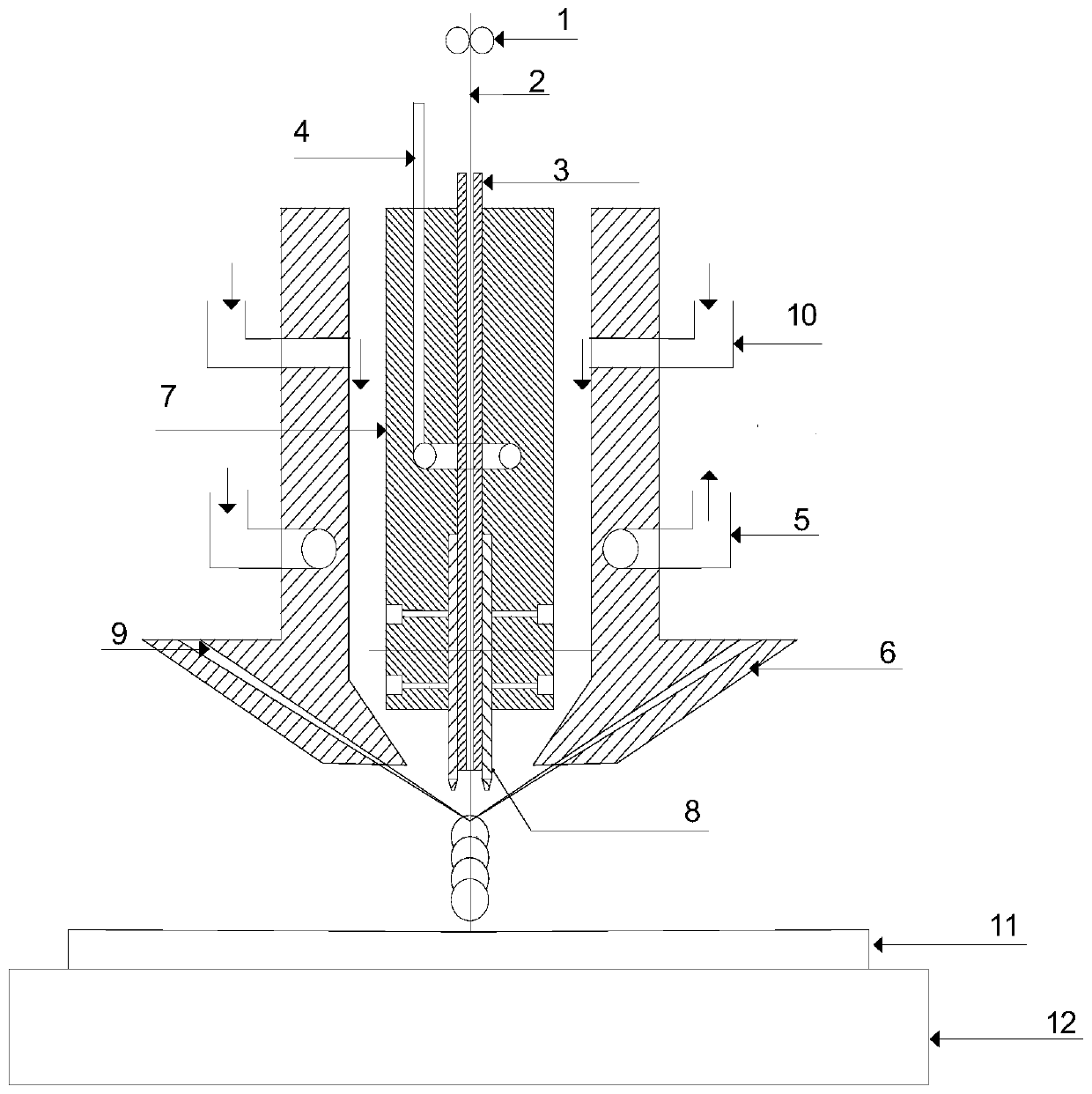

Coaxial in-arc wire feeding and out-arc powder feeding TIG electric arc additive manufacturing device

InactiveCN111266702AGuaranteed to be constantAdjustable wire feed speedEvacuating shieldingMetallurgySpray nozzle

The invention relates to a coaxial in-arc wire feeding and out-arc powder feeding TIG electric arc additive manufacturing device. The device comprises a SiO2 glass tube, four powder feeding spray nozzles, a tungsten electrode red copper cooling body, a half-cracking hollow tungsten electrode and four powder feeding channels. Four types of alloy powder with different components can be supplied at most through the four powder feeding channels and the powder feeding quantity of each powder feeding channel is adjustable, and additive manufacturing of a functional gradient structure material part is achieved easily, so that material, structure and service performance of the additive manufacturing part are matched optimally.

Owner:SHENYANG POLYTECHNIC UNIV

Engine welder with shielding gas generation

InactiveUS6924460B1Quality improvementReduce stepsEvacuating shieldingElectric discharge heatingExternal combustion engineShielding gas

A liquid and gas separator to generate a shielding gas from the exhaust gas of an internal combustion engine. The liquid and gas separator can be a separate portable component or a component that is integrated with the arc welder.

Owner:LINCOLN GLOBAL INC

Laser microcladding using powdered flux and metal

A laser microcladding process utilizing powdered flux material (93b). A jet (92) of propellant gas containing powdered alloy material (93a) and the powdered flux material are directed toward a substrate (94). The powdered materials are melted by a laser beam (96) to form a weld pool (98) which separates into a layer of slag (100) covering a layer of clad alloy material (102). The flux material deoxidizes the weld pool and protects the layer of clad alloy material as it cools, thereby allowing the propellant gas to be nitrogen or air rather than an inert gas. In one embodiment, the substrate and alloy materials are superalloys with compositions beyond the traditional zone of weldability.

Owner:SIEMENS ENERGY INC

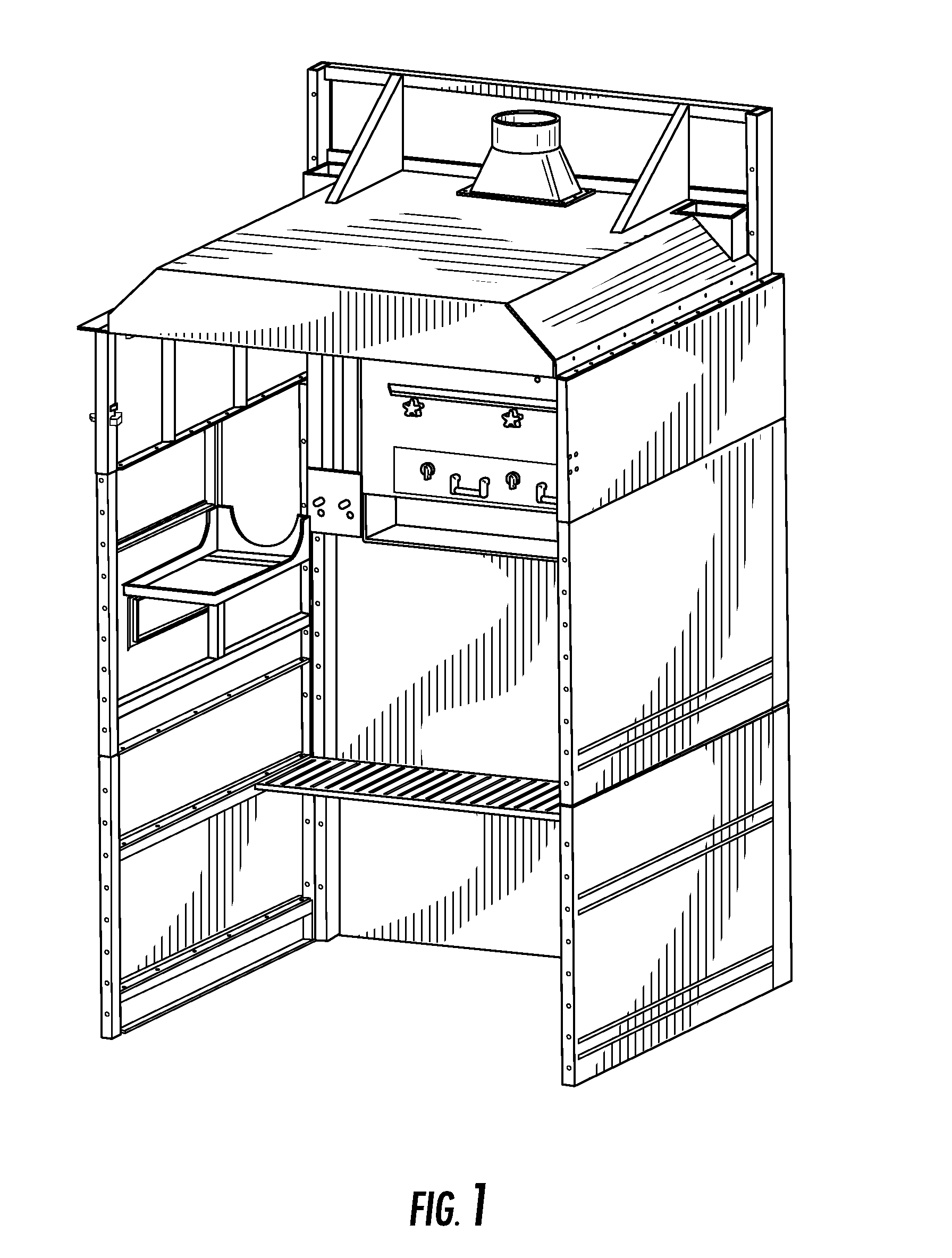

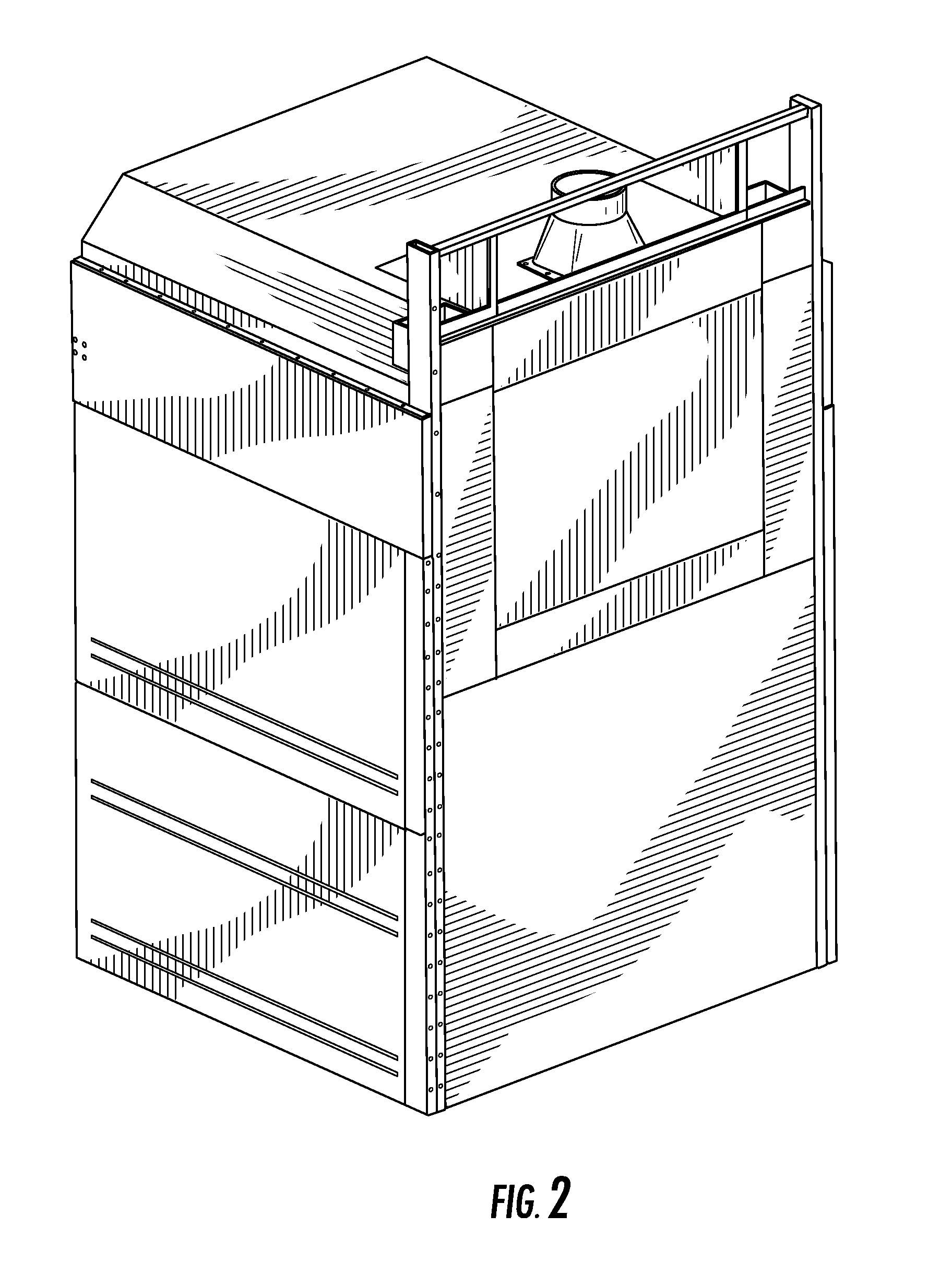

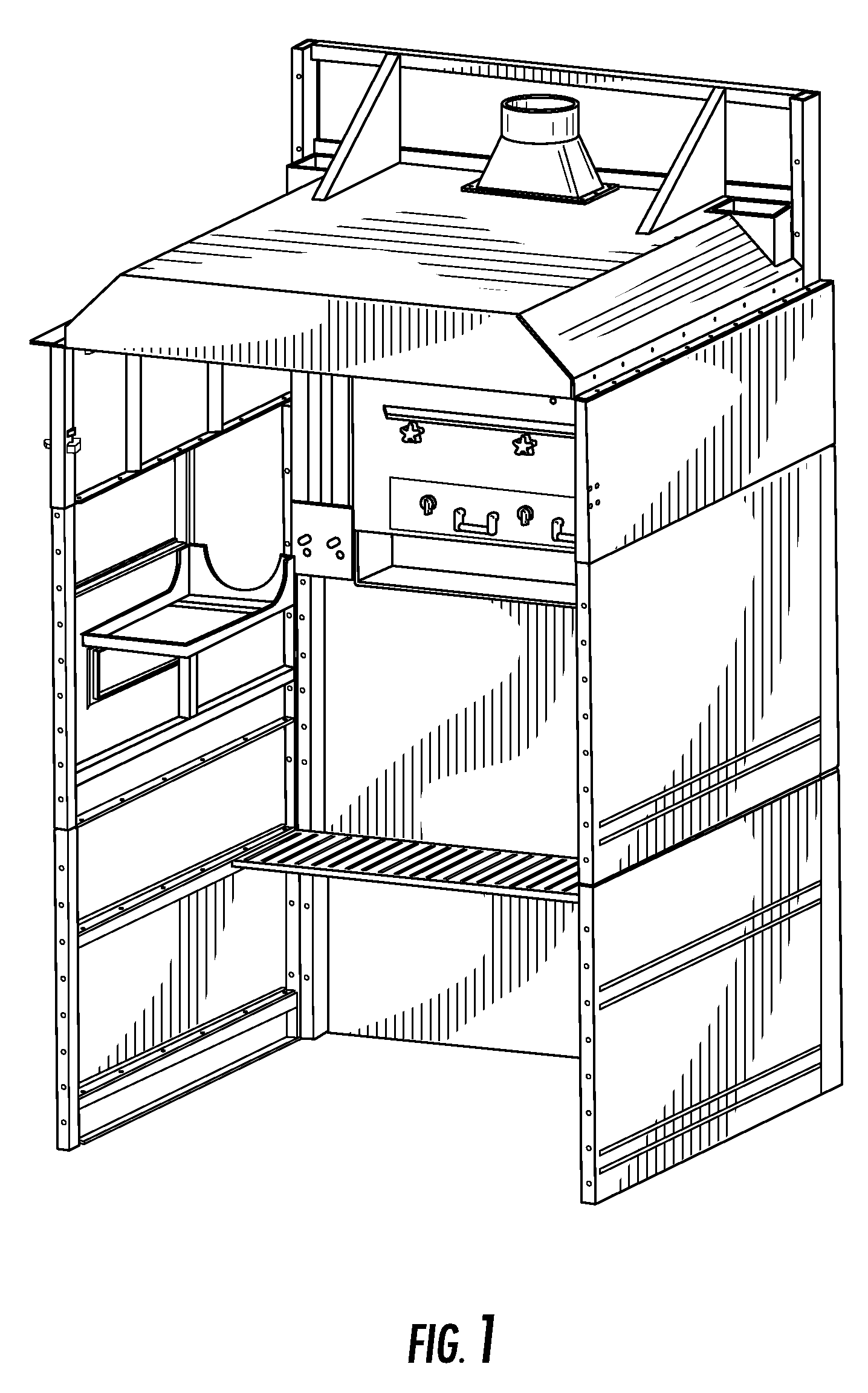

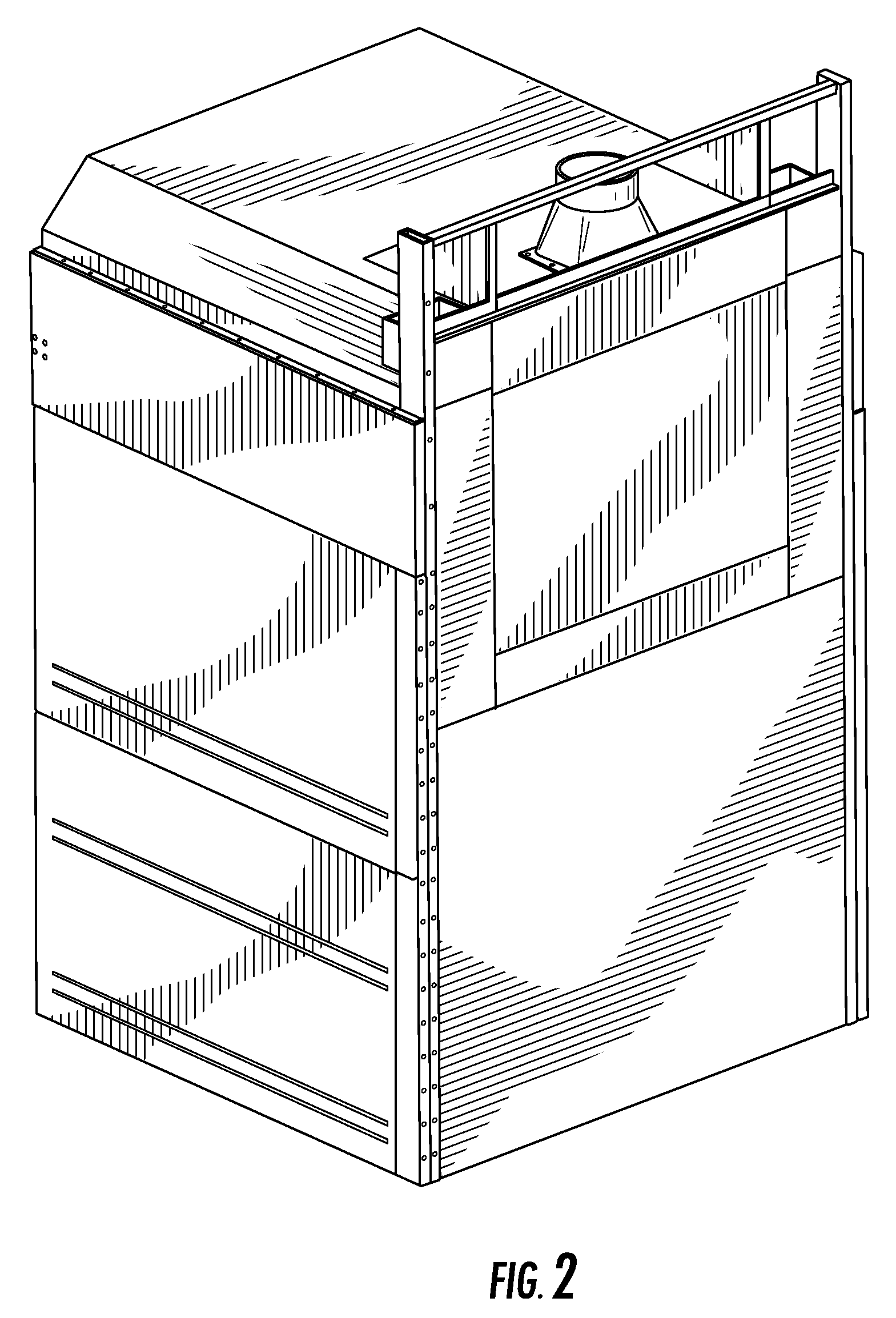

Welding booth

Owner:AVANI ENVIRONMENTAL INTL INC

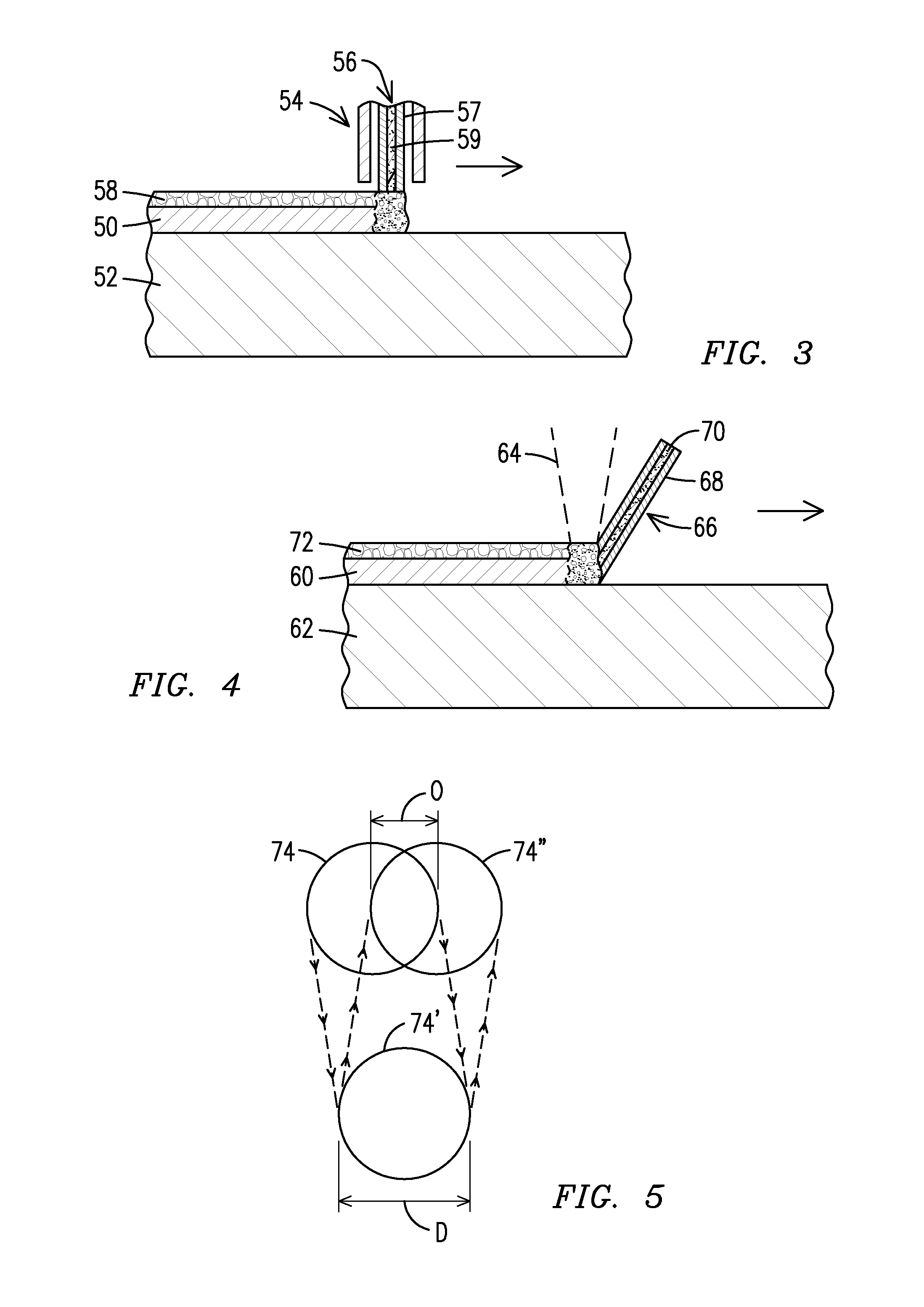

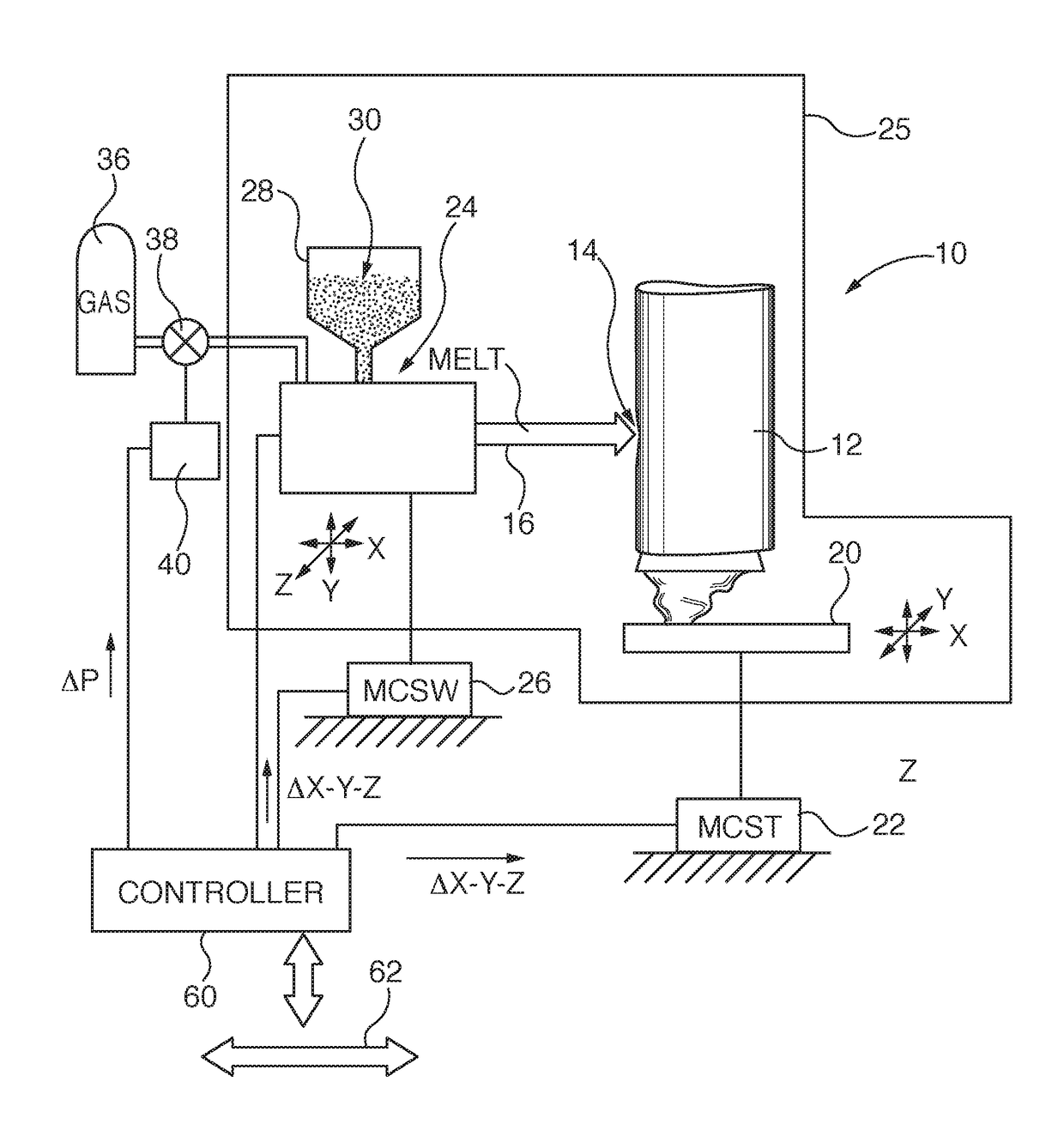

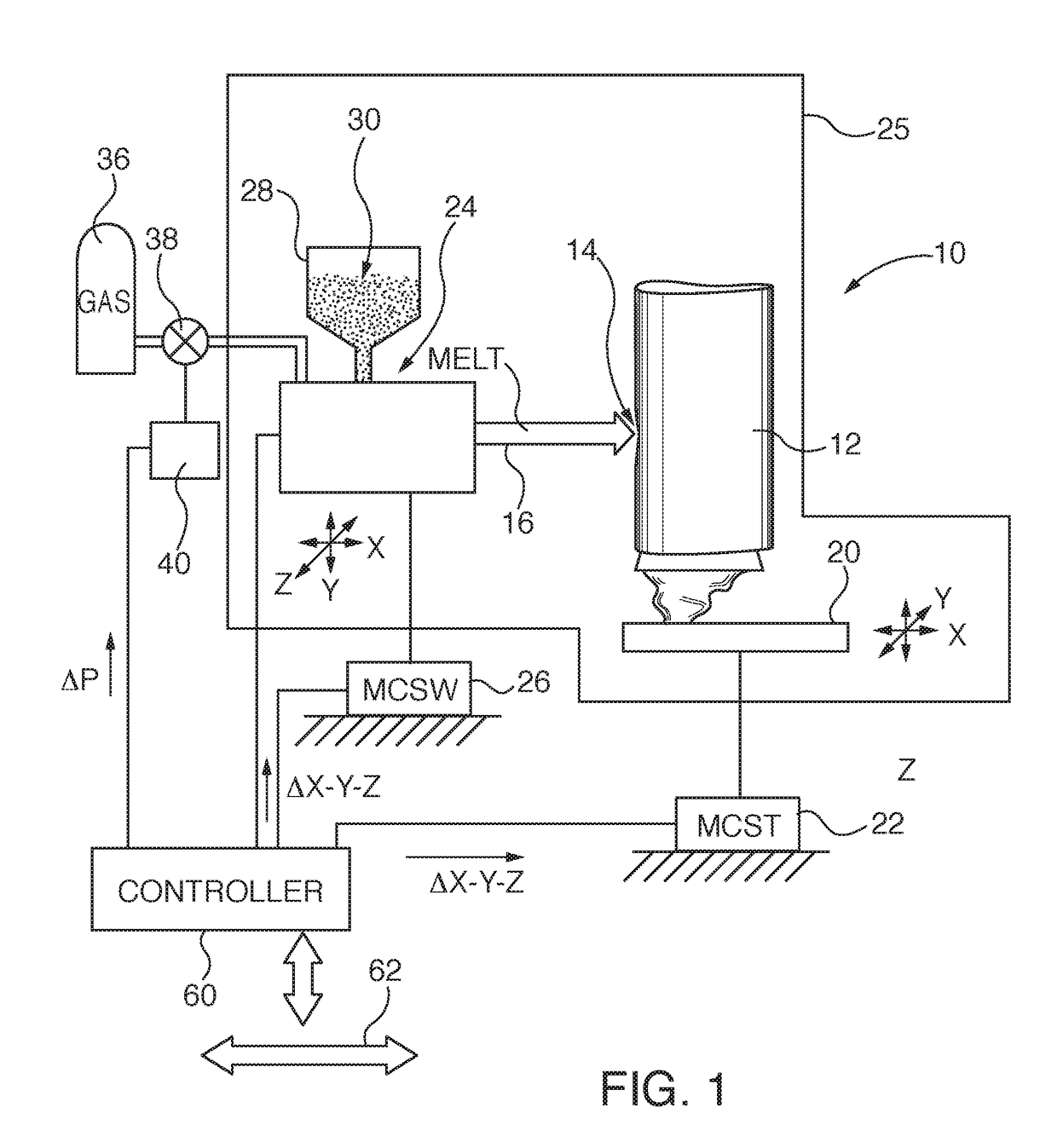

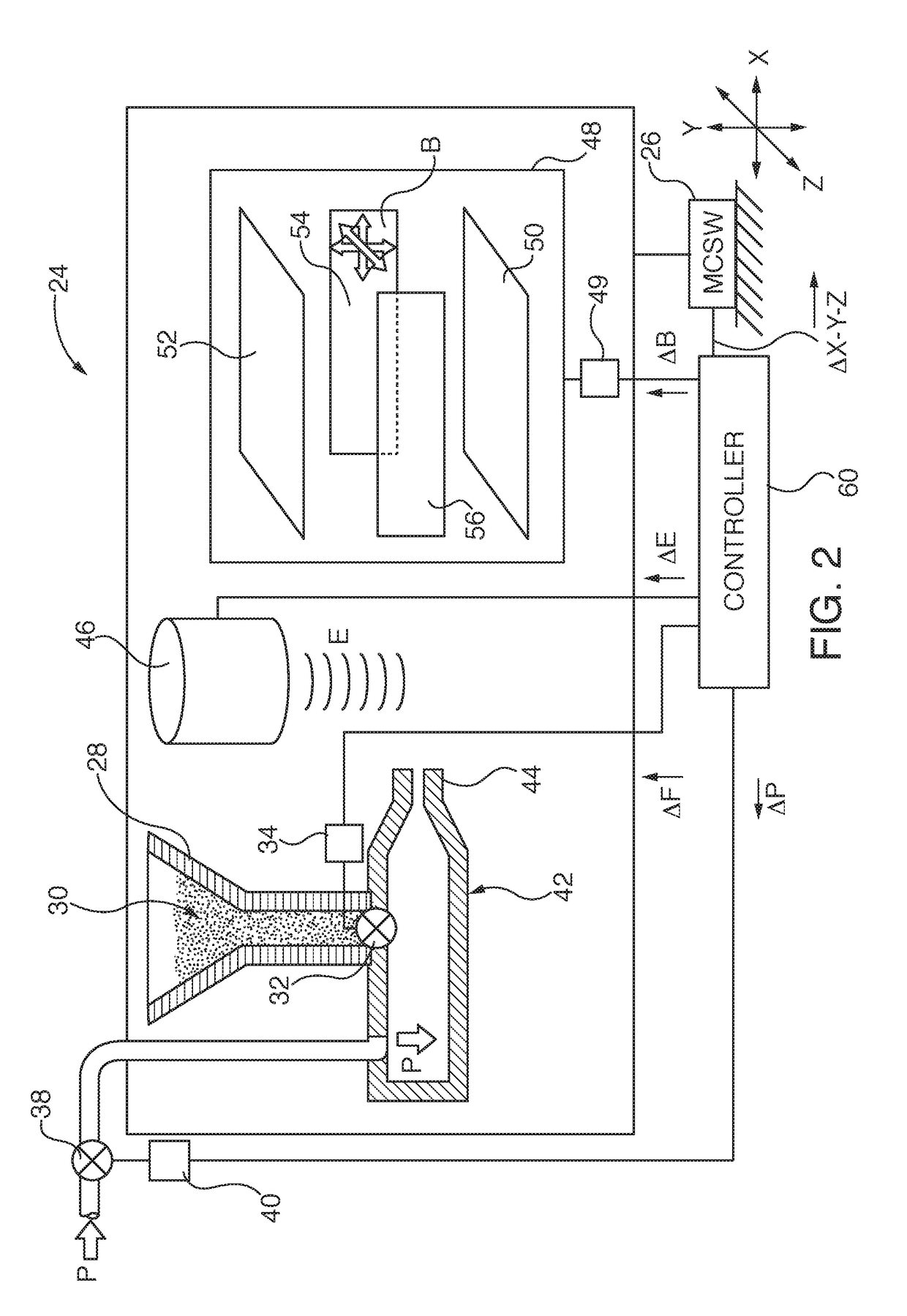

Method and apparatus for levitation additive welding of superalloy components

InactiveUS20170252876A1Accurate layeringAdd dimensionTurbinesEvacuating shieldingLevitationRelative motion

Superalloy components for turbine engines are additively welded by propelling a stream of powdered filler, which includes superalloy powder filler, through a nozzle at a powder stream mass flow rate, with pressurized gas. The powdered filler stream is melted and agglomerated into a continuous melt stream with a laser or arc heating source located downstream of the nozzle. The melt stream is levitated within a magnetic field generated by at least one electromagnet coil that is oriented downstream of the heating source, and directed onto the superalloy component, by relative motion between the melt stream and the superalloy component.

Owner:SIEMENS ENERGY INC

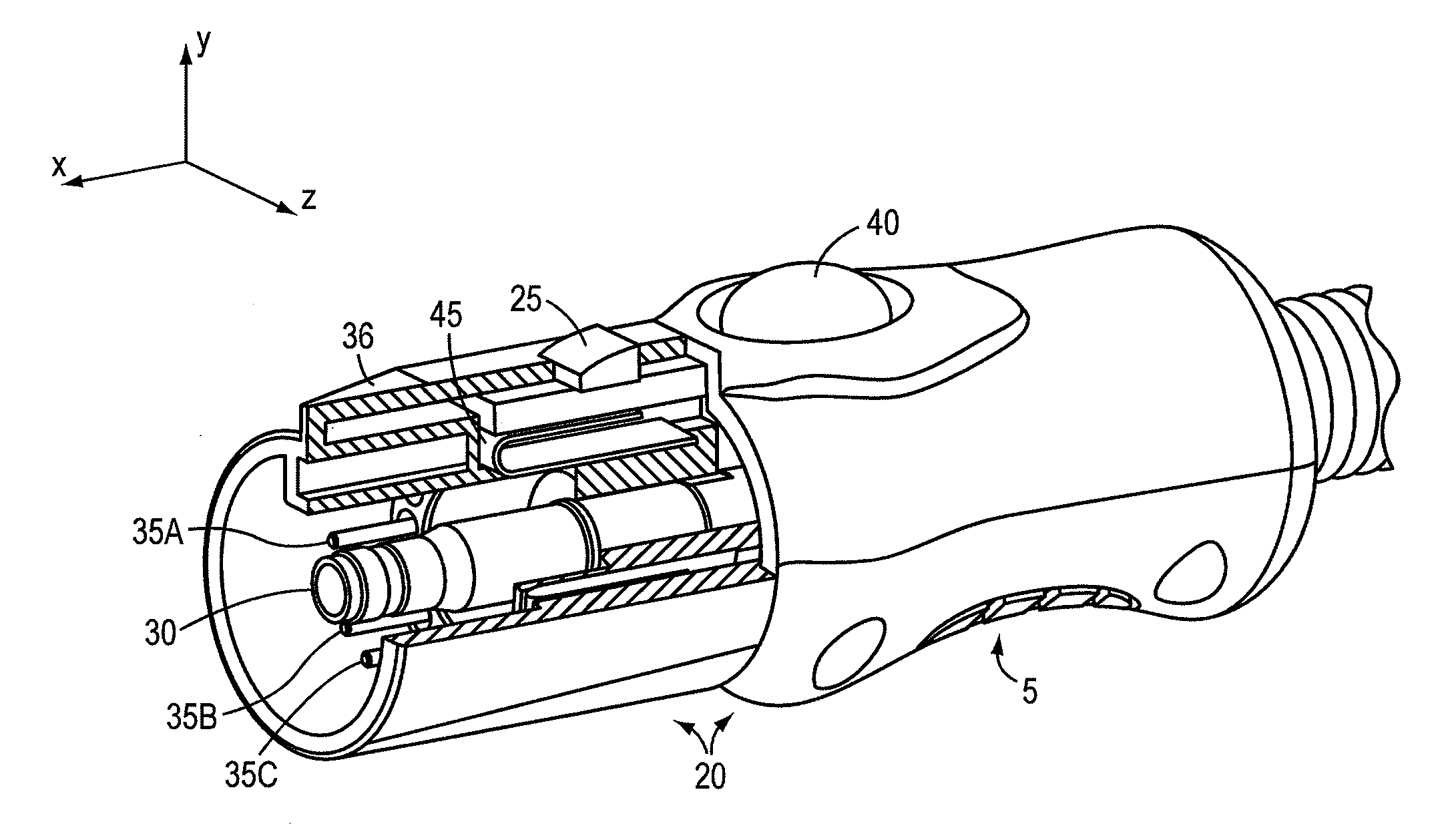

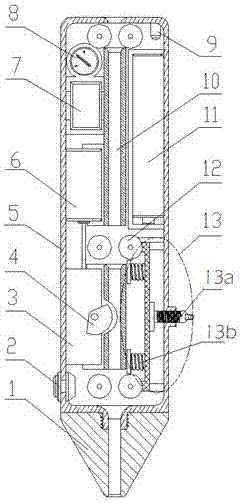

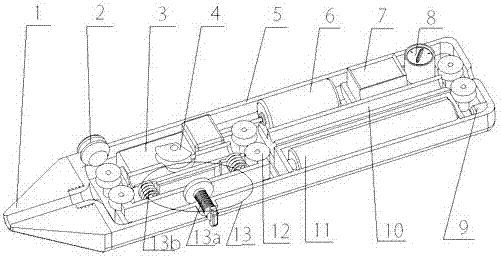

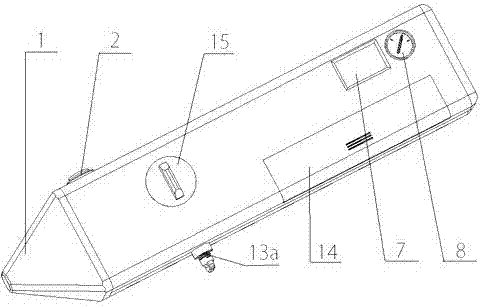

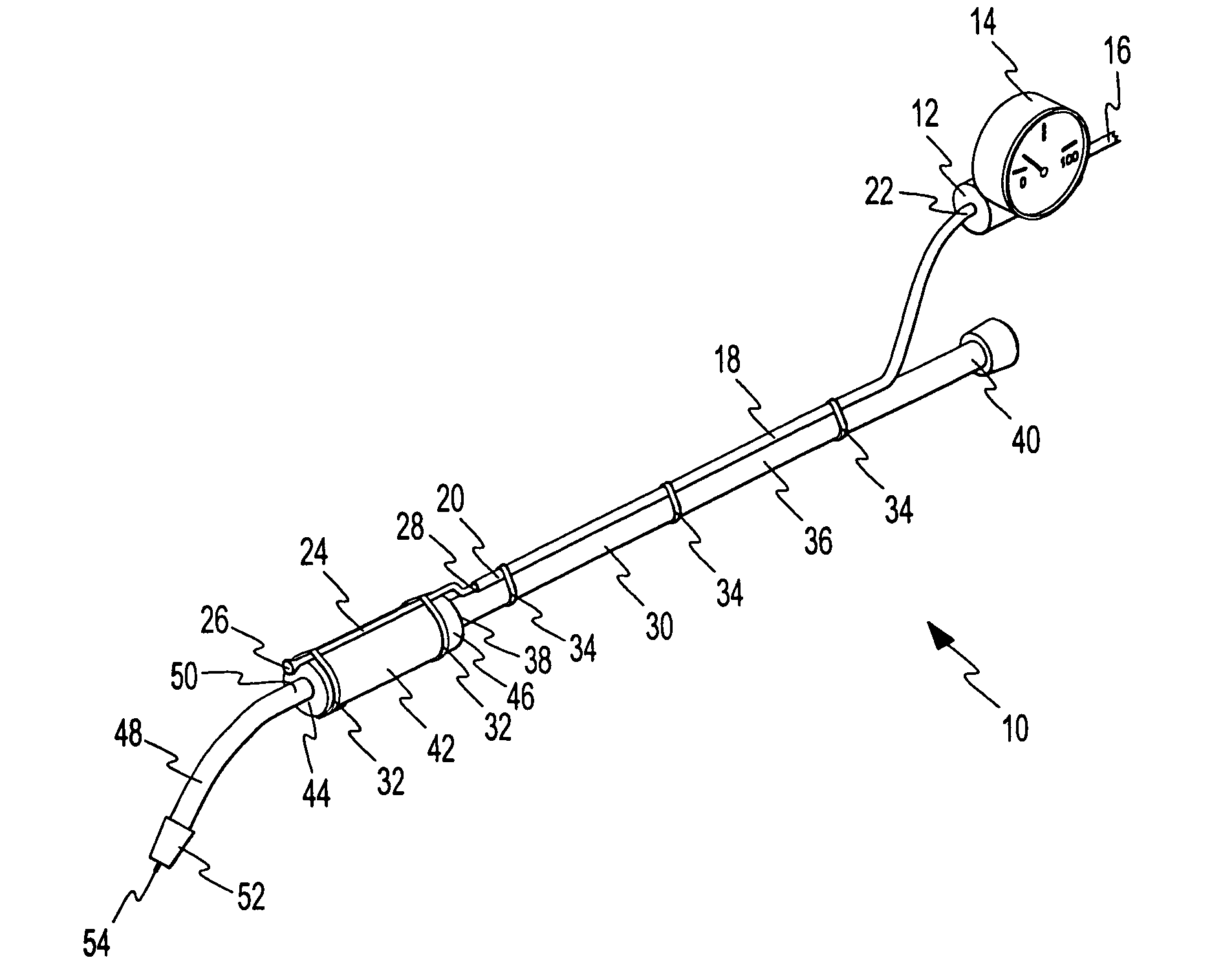

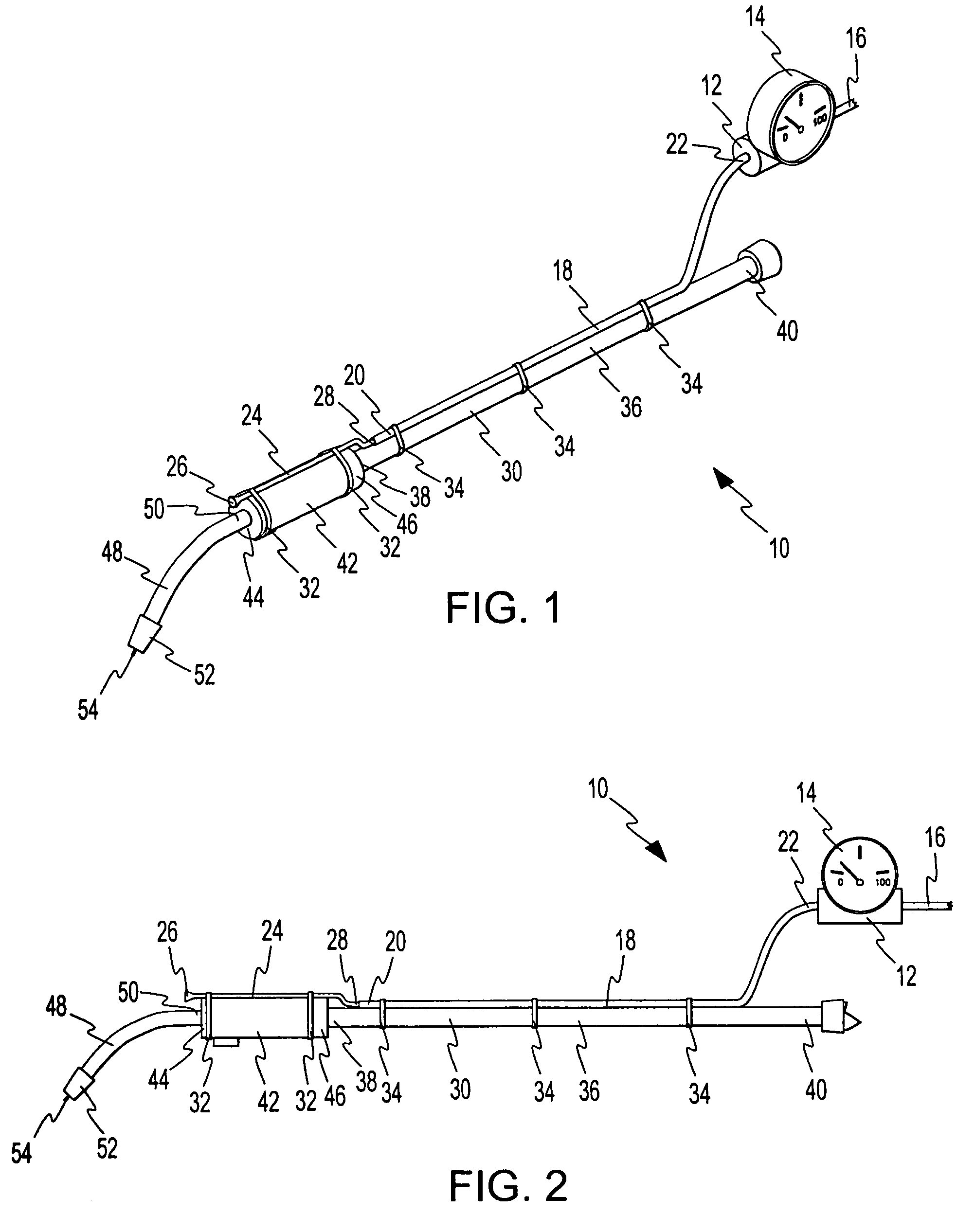

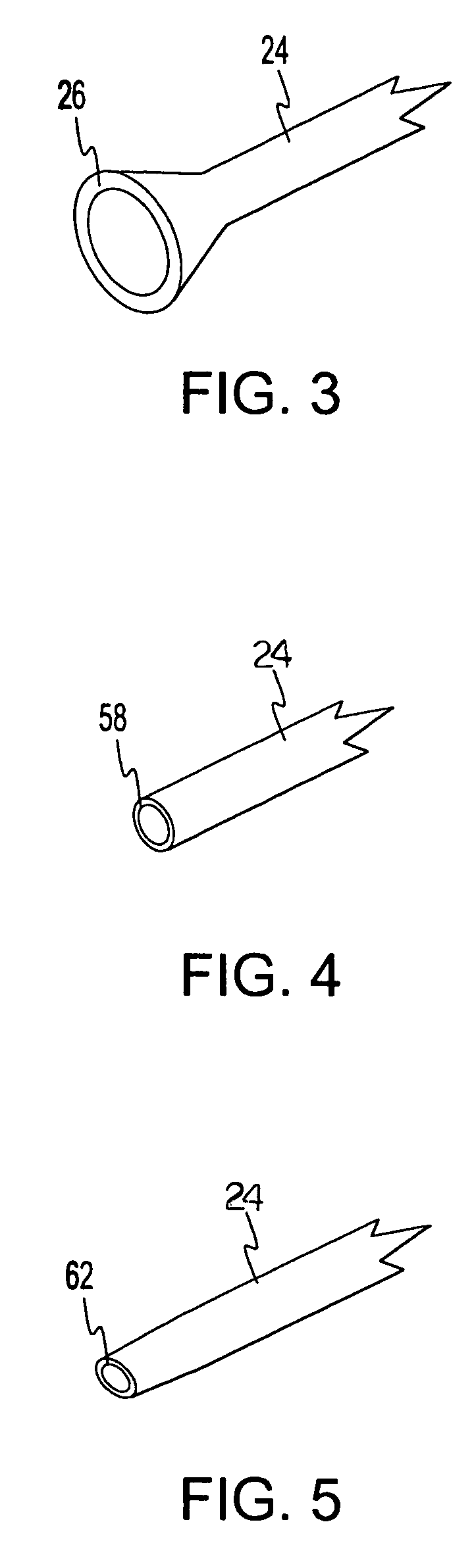

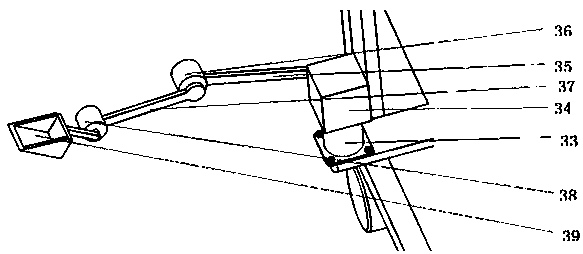

TIG wire feeding pen

ActiveCN107511568AReduce labor intensityEasy and flexible operationEvacuating shieldingElectrical batteryElectric machine

A TIG wire feeding pen comprises a heat dissipation pen point, a wire feeding switch, a speed reducer, a wire feeding wheel, a pen shell, a mini type shell, an electric quantity display, a speed regulator, a charging interface, a welding wire guide pipe, a chargeable battery, guide wheels, a pressure adjuster, a battery replacing window and a wire feeding wheel replacing window. The mini type motor and the speed reducer are connected with the wire feeding wheel and provide power for wire feeding, and continuous or different-step-size stepping wire feeding is achieved by replacing circular or different-arc-length fan-shaped wire feeding wheels. The pressure adjuster is used for adjusting the pressure of the guide wheels, and welding wires different in diameter are conveyed out. The wire feeding speed is adjusted through the speed regulator, wire feeding is controlled through the wire feeding switch, and the electric quantity display monitors the residual electric quantity. The heat dissipation pen point is made of a material good in heat conduction coefficient, and welding wire heat dissipation is facilitated. The TIG wire feeding pen is convenient to carry, the labor intensity of workers is relieved, the problem about stability, consistency and accuracy of TIG manual wire feeding is solved, and the welding line formability and production efficiency are improved.

Owner:NANCHANG UNIV

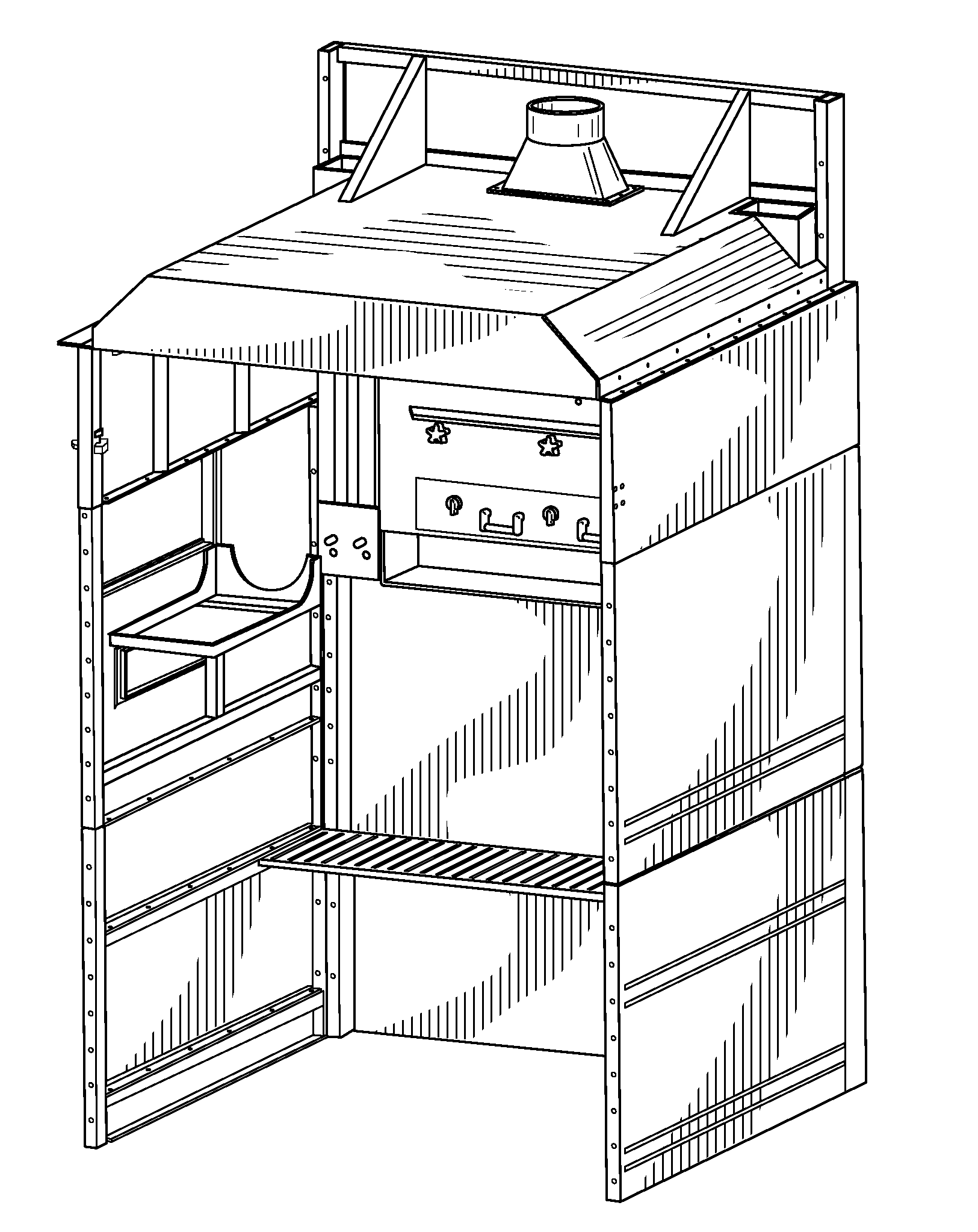

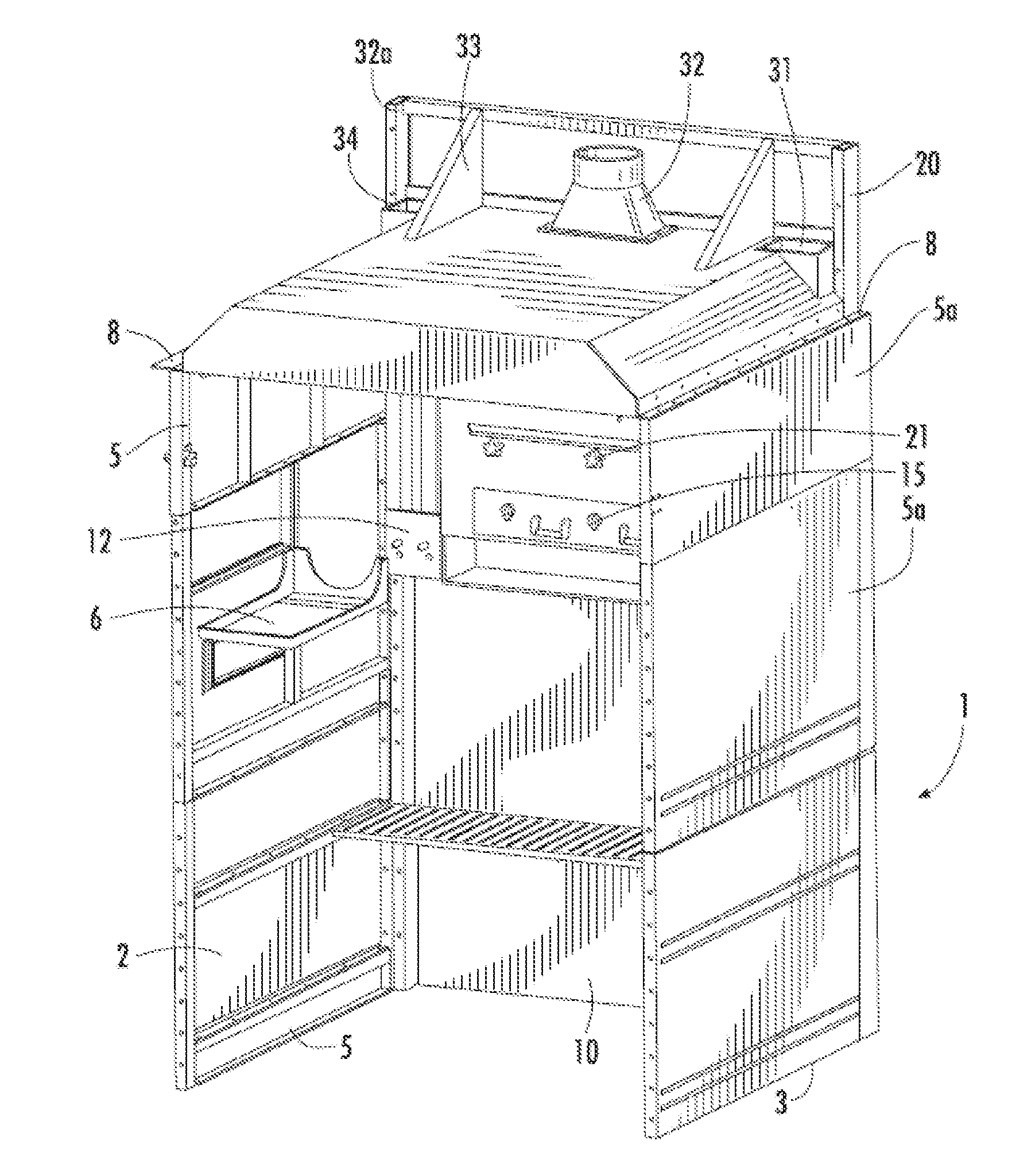

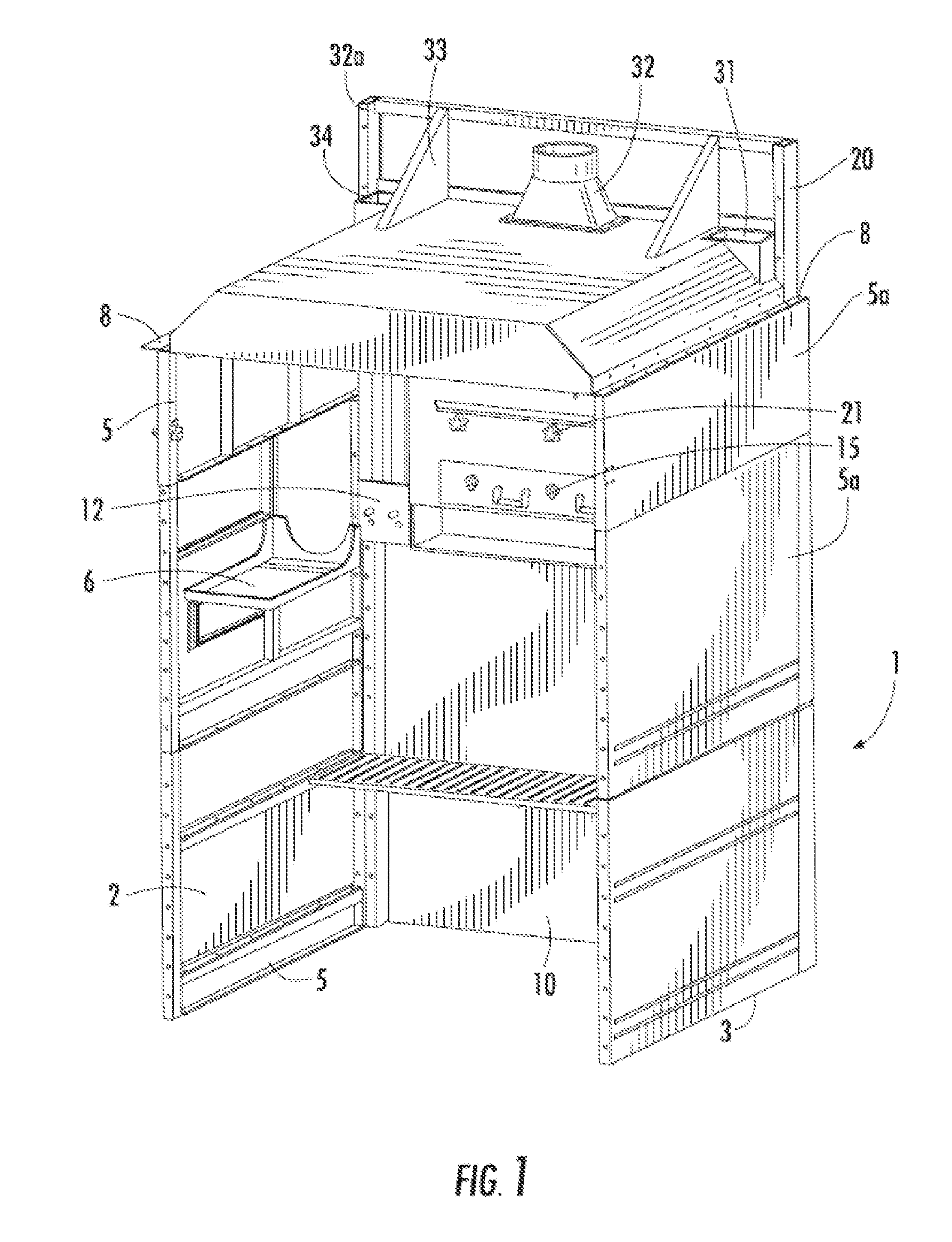

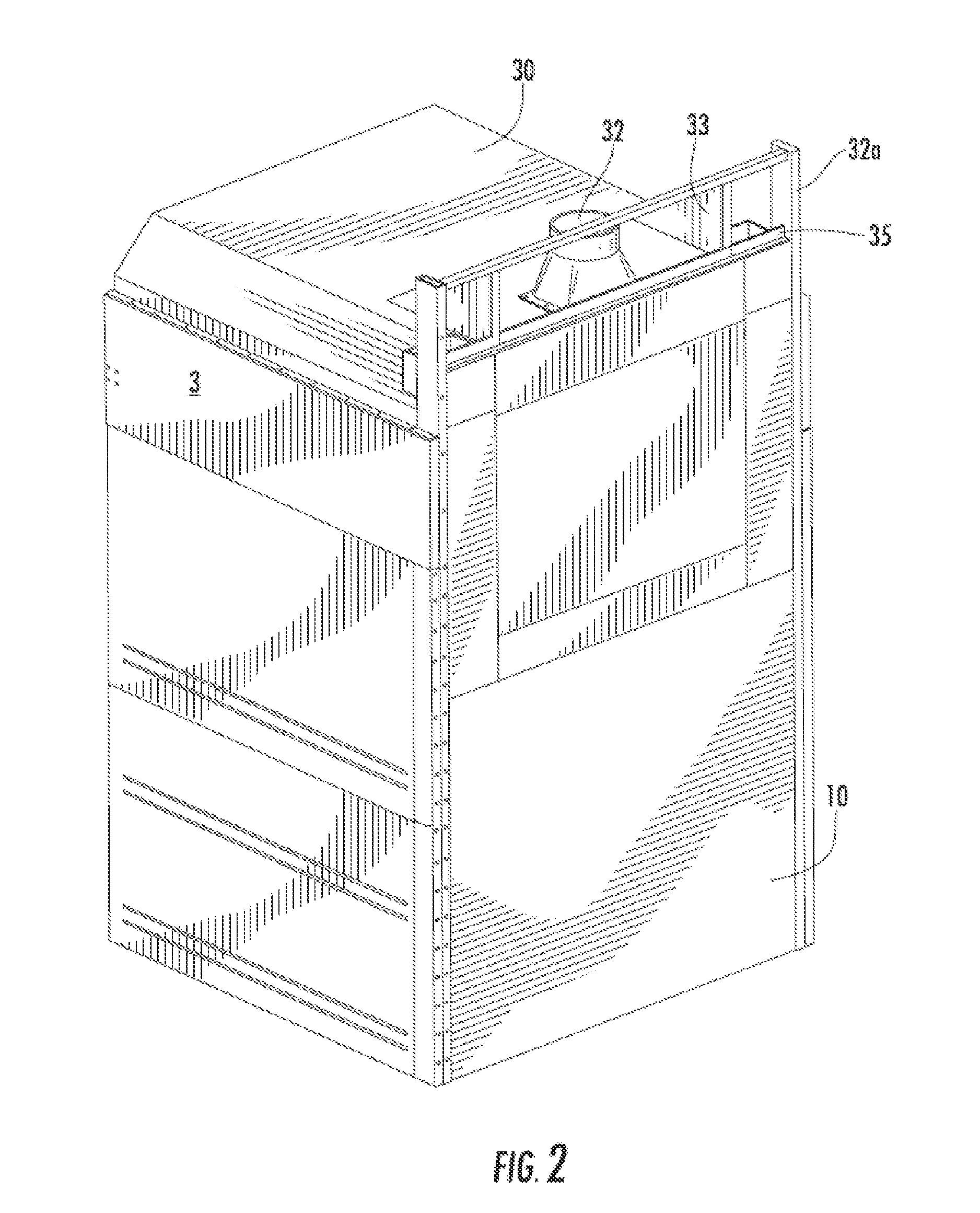

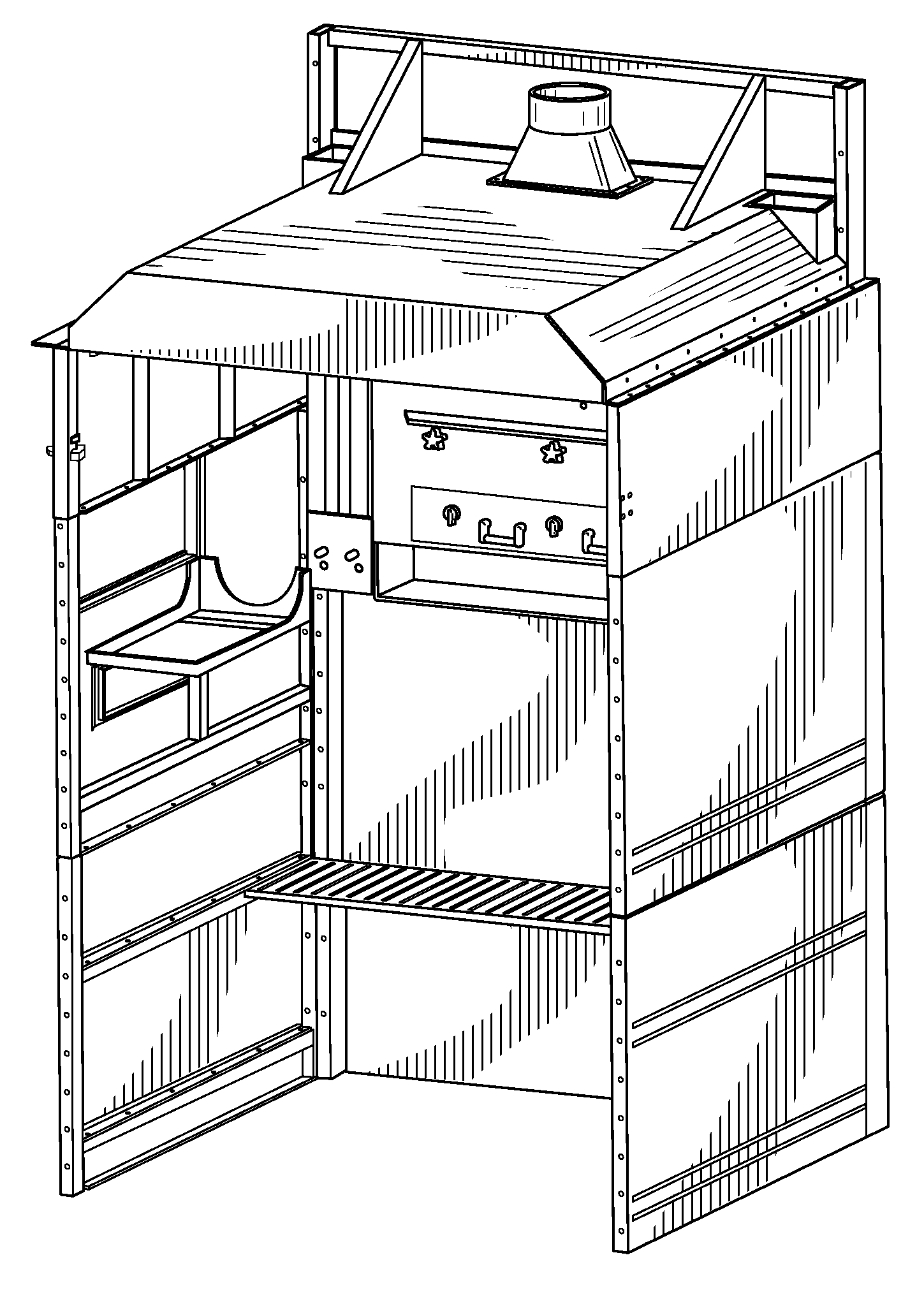

Welding booth

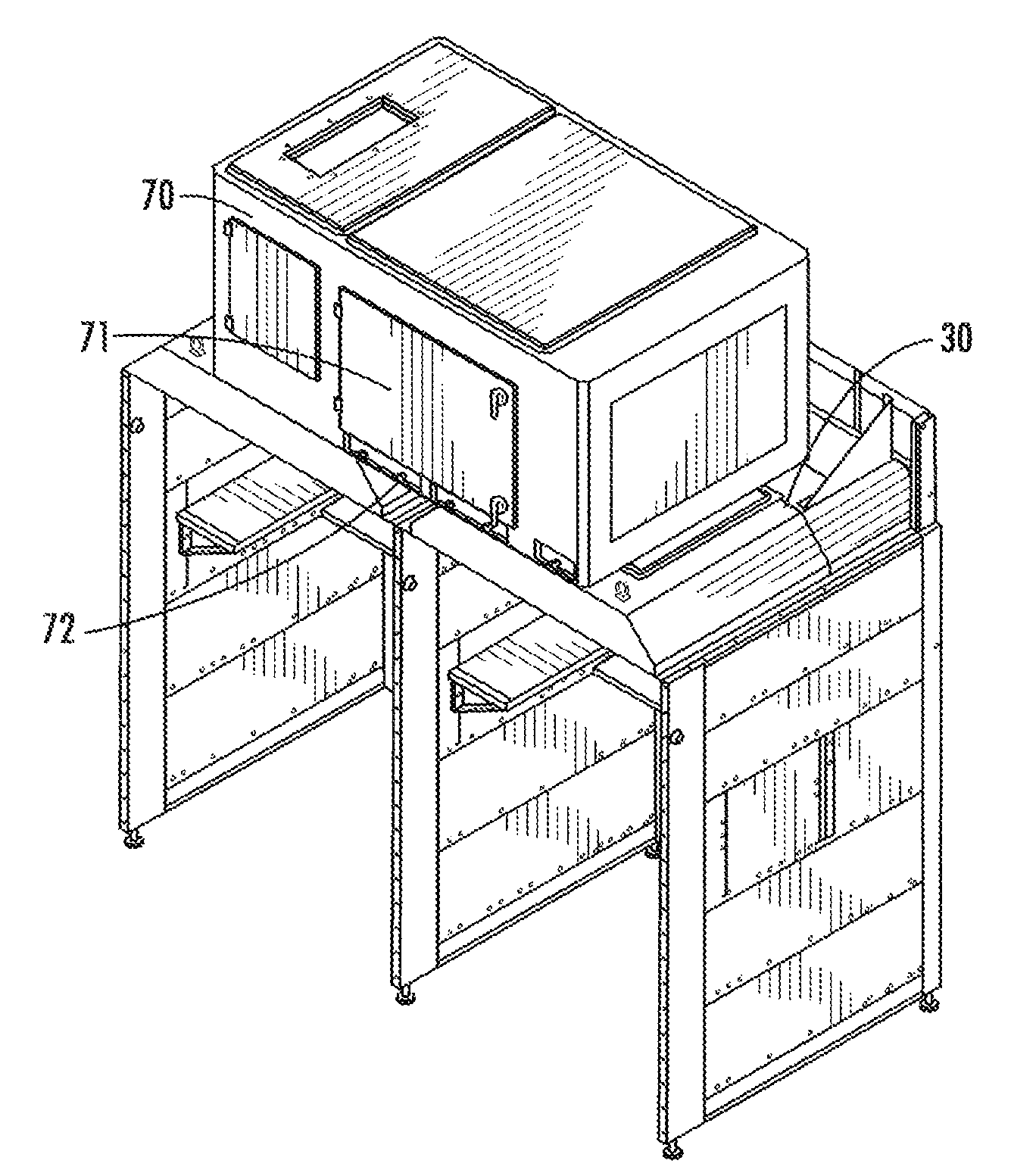

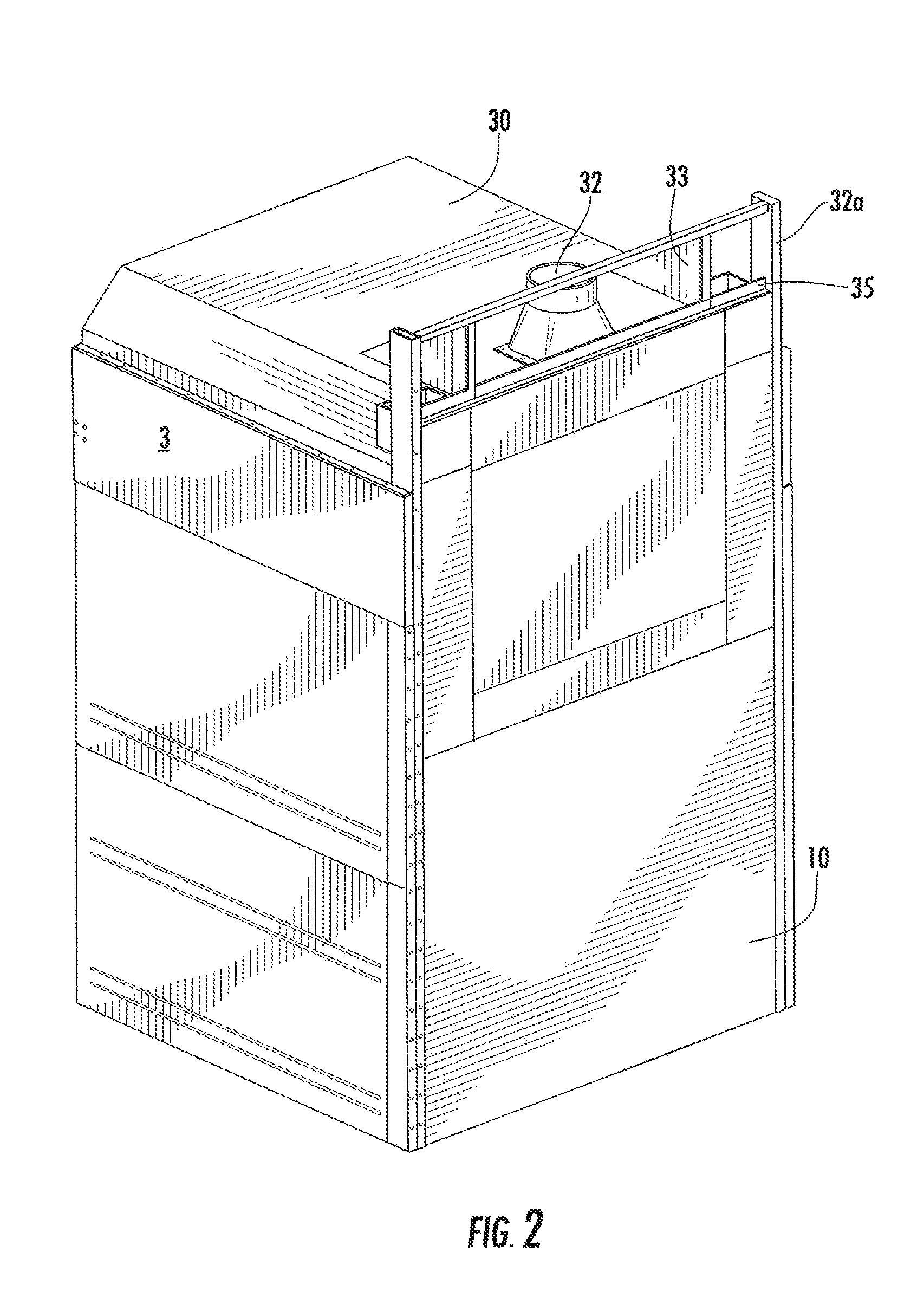

InactiveUS20120270489A1Reduce spacingCombination devicesDomestic stoves or rangesEngineeringSmall foot

The present invention relates to a welding booth that has a small foot print and can be joined to other booths for maximization of floor space use.

Owner:AVANI ENVIRONMENTAL INTL INC

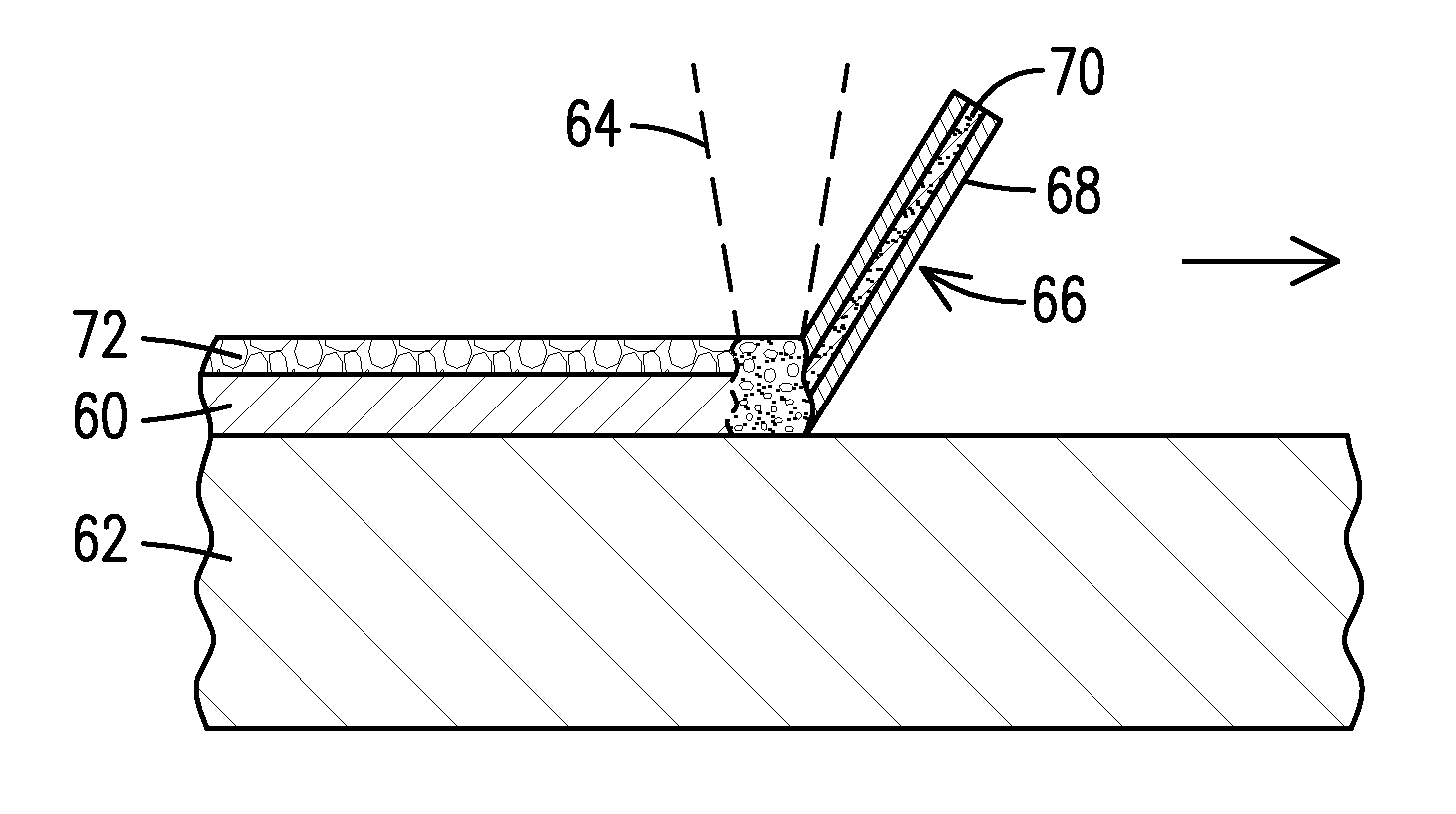

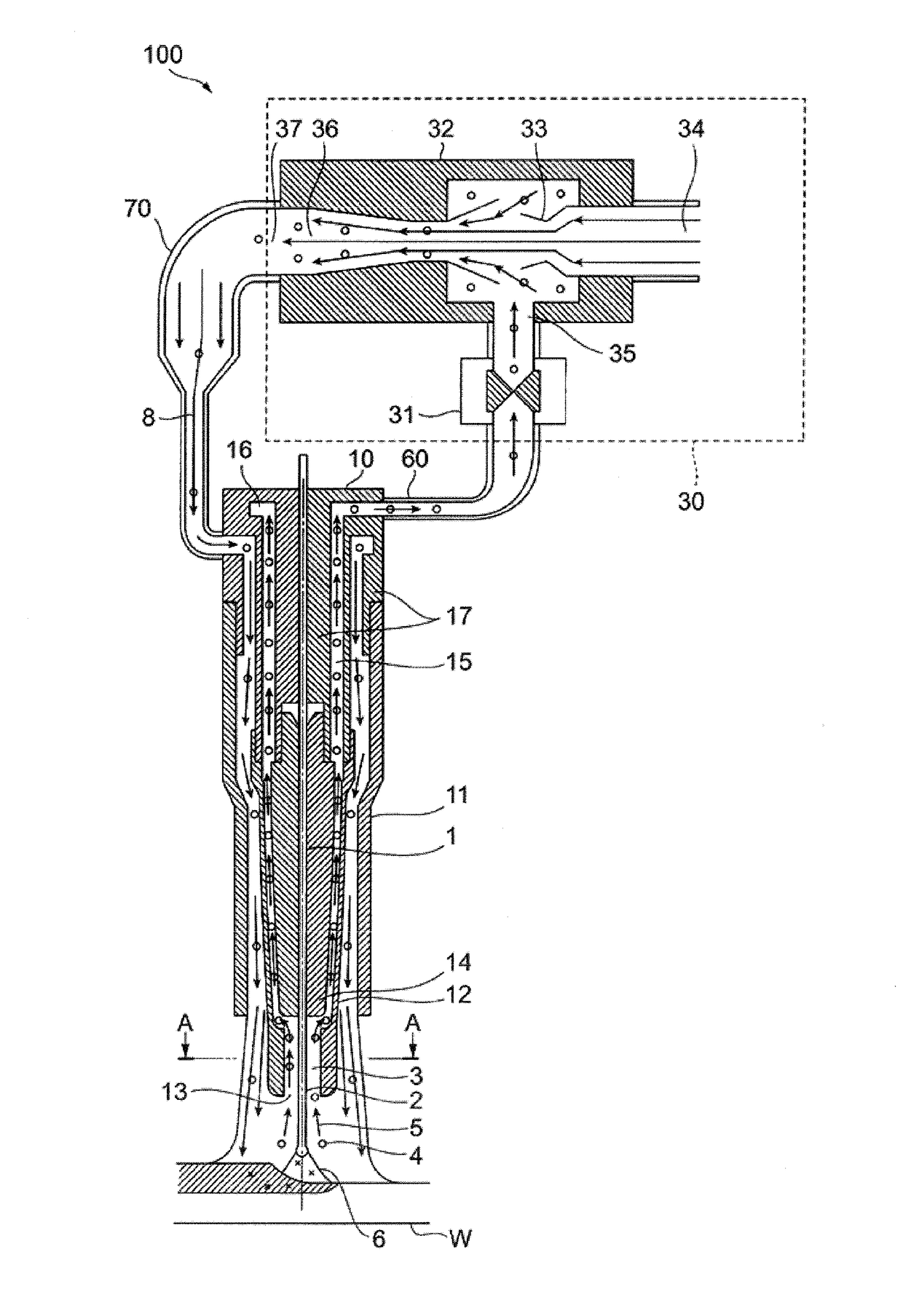

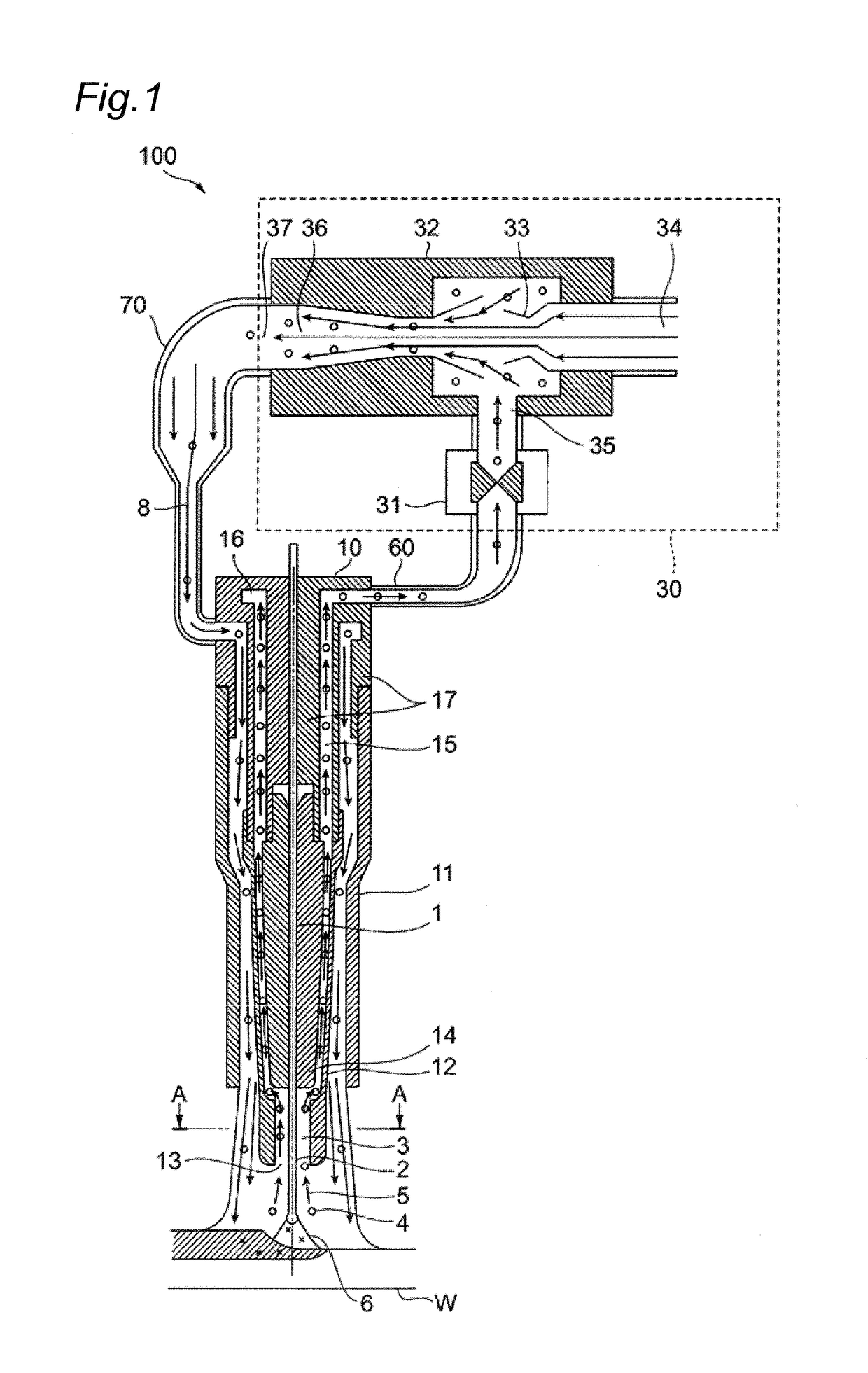

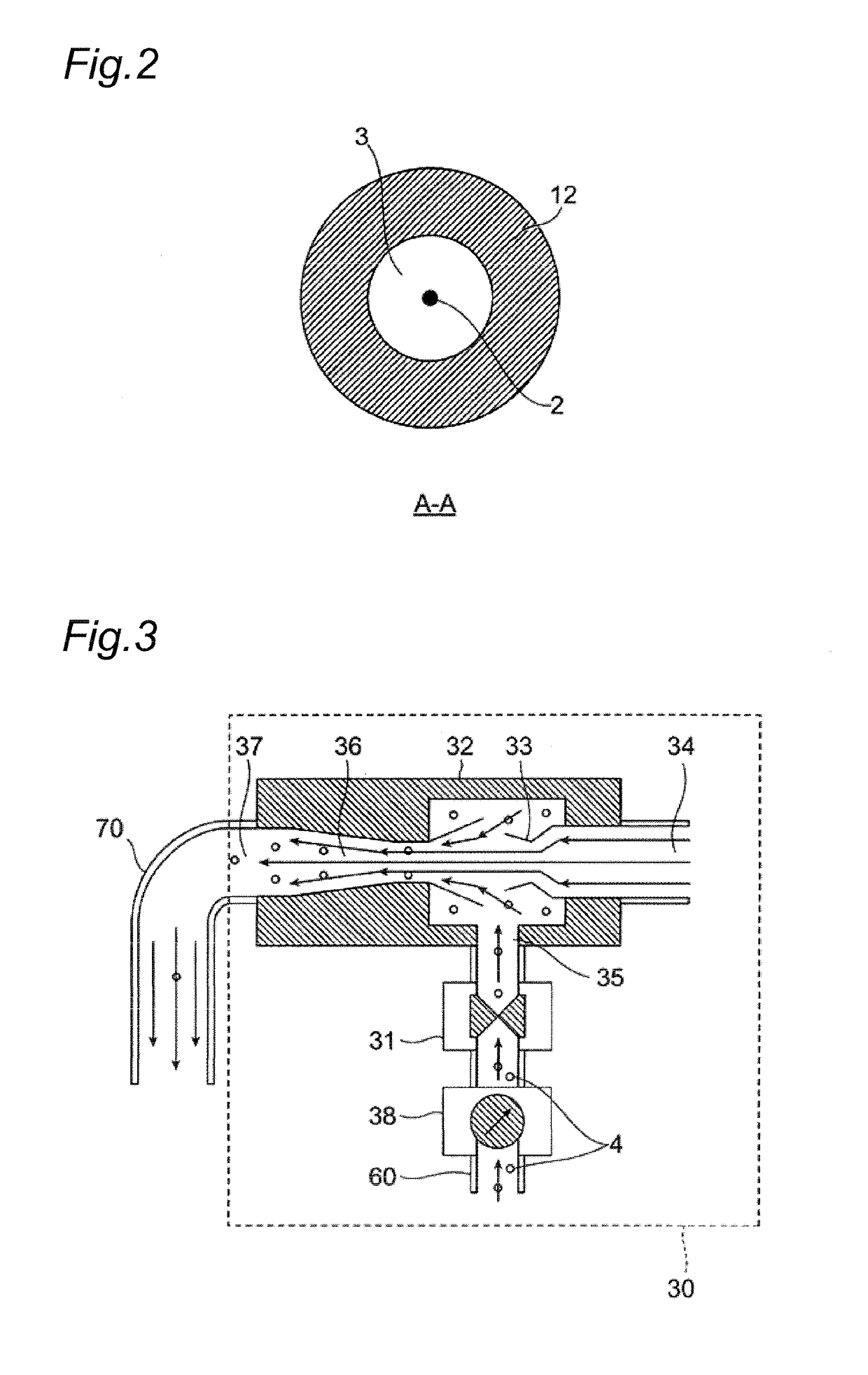

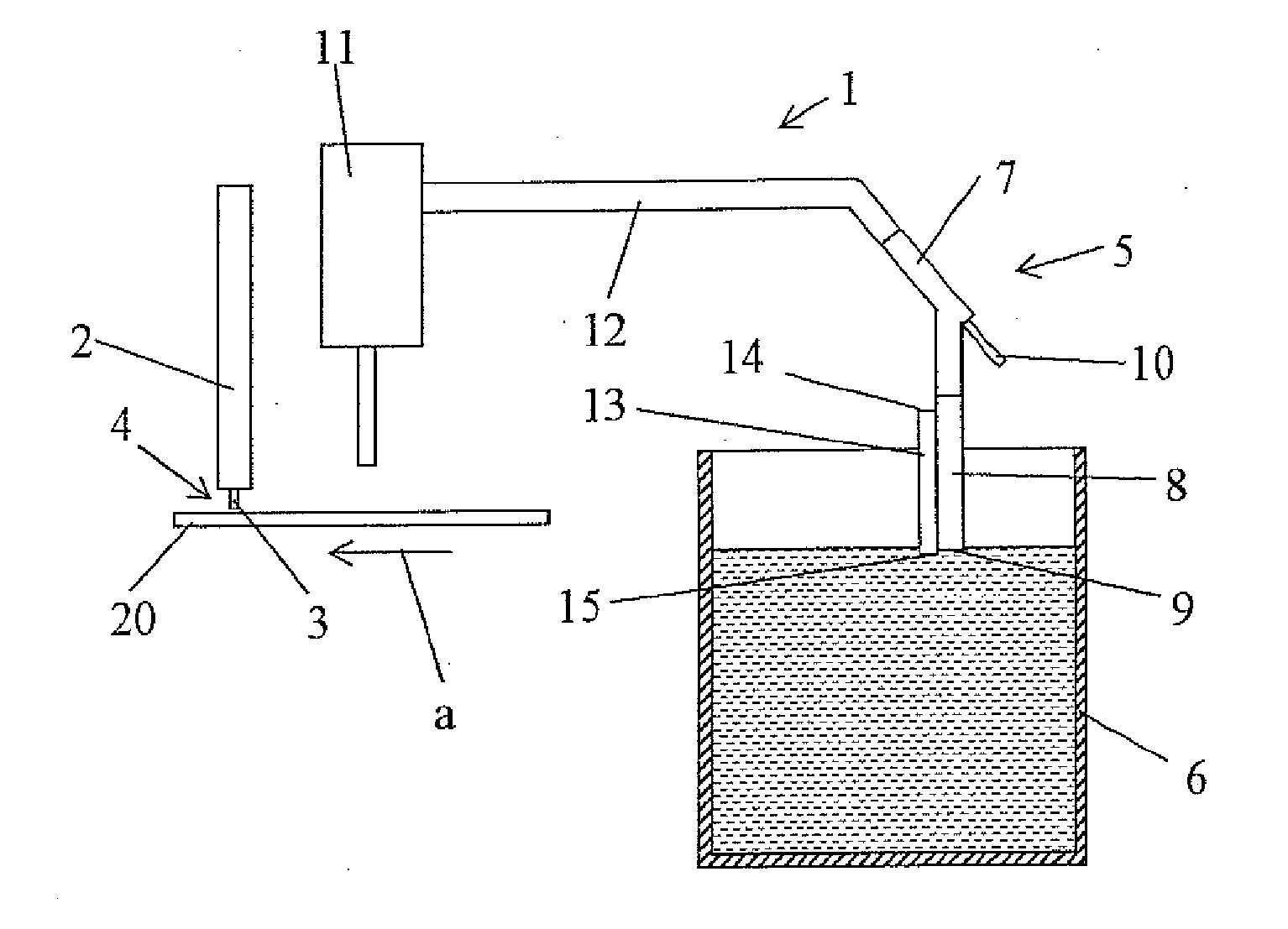

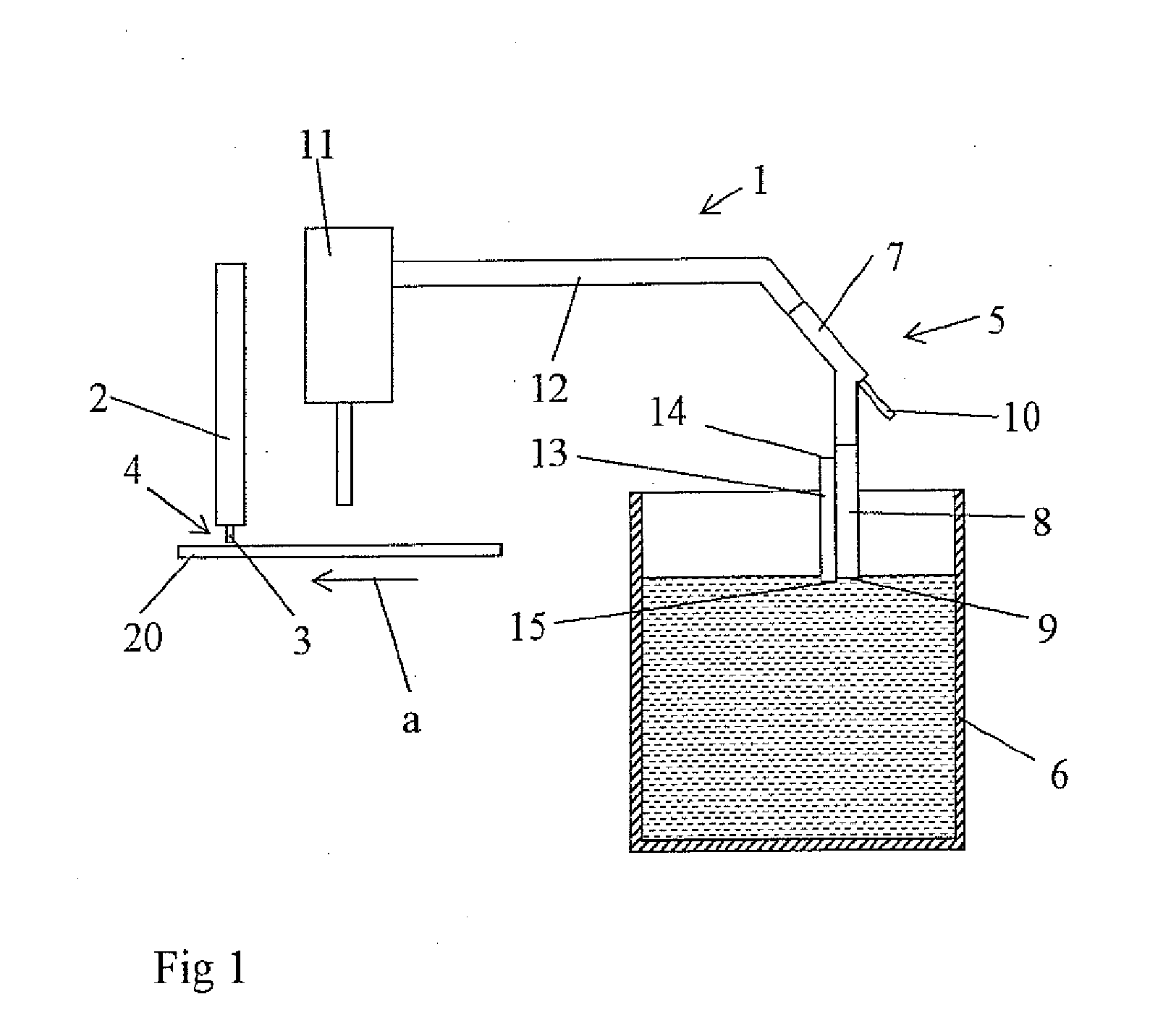

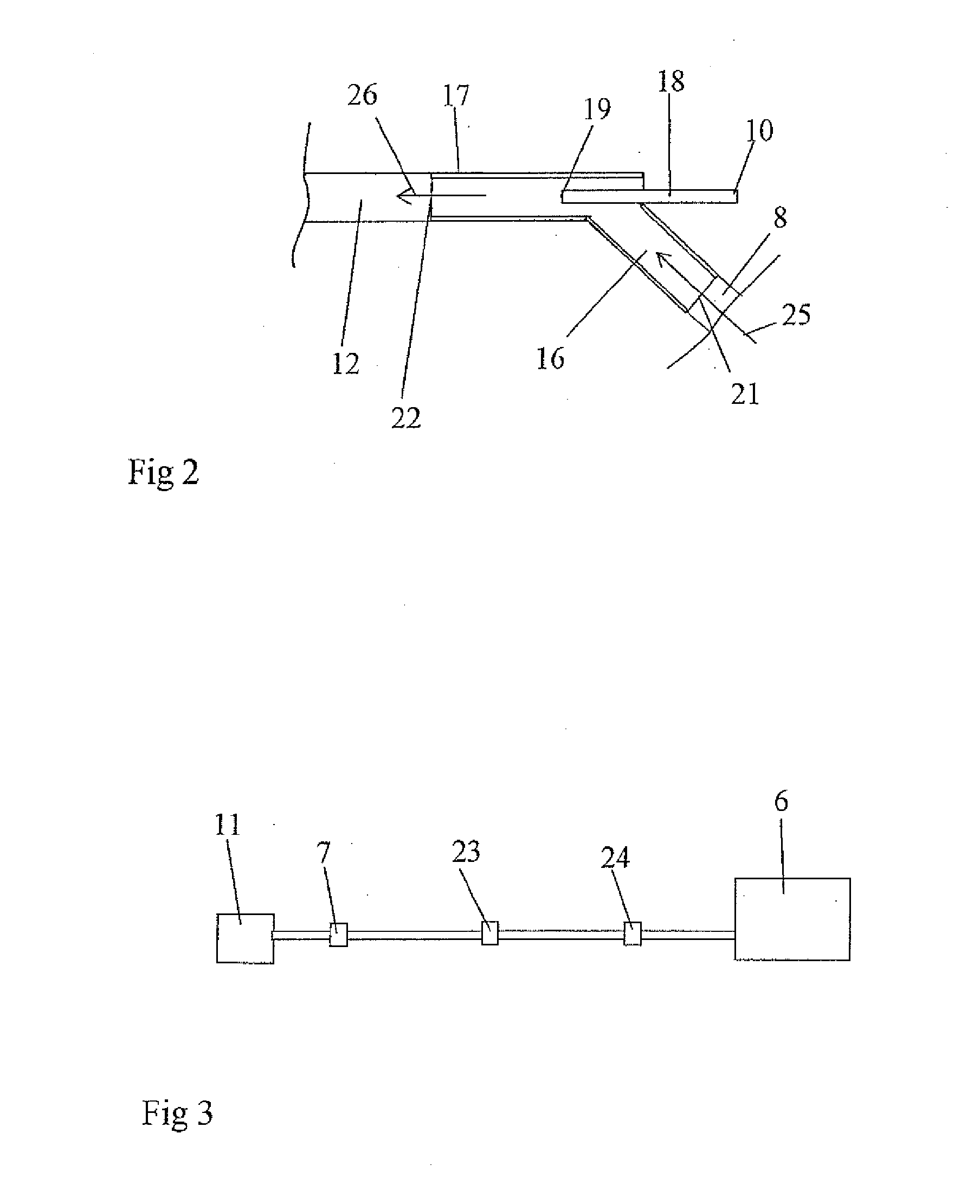

Welding device and welding method

ActiveUS20180015561A1Reduce the amount requiredSupport devices with shieldingEvacuating shieldingCarbon Dioxide / HeliumShielding gas

A welding system includes a welding torch that welds a workpiece by using a wire, a suction device that sucks shielding gas, and a sucked shielding gas supply path for allowing the sucked shielding gas to flow, wherein the welding torch includes a contact chip that guides the wire, a shielding gas supply nozzle that supplies the shielding gas to a weld zone, and a suction nozzle that surrounds a periphery of the wire protruding from the contact chip, and is opened toward a tip of the wire to suck the shielding gas.

Owner:KOBE STEEL LTD

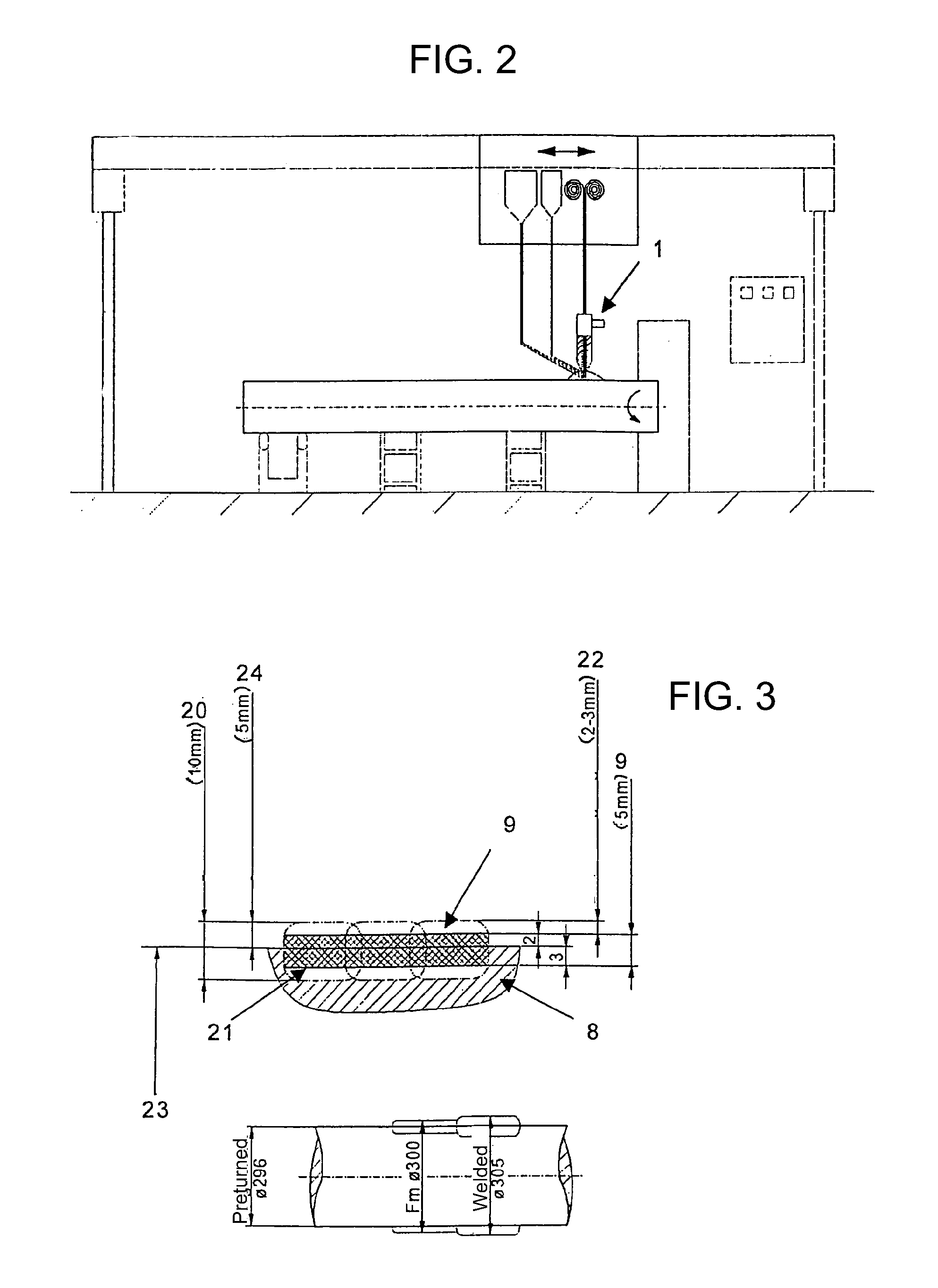

Method of welding a wear layer onto a parent material using a plurality of flux-cored wire electrodes, metal powder and welding powder

A method of welding a wear layer onto a parent material, wherein a welding current is applied to a first wire electrode and to at least one second wire electrode. The first wire electrode and at least one second wire electrode are continuously fed to the parent material for producing a common weld pool. Metal powder and welding powder are fed to the weld pool. The wire electrodes are flux-cored wire electrodes, having a core and a covered electrode. The flux-cored wire electrodes have a higher alloy than a weld deposit analysis of the wear layer to be welded on the parent material. The covered electrode of the flux-cored wire electrodes includes an alloy, which has magnetization properties suitable for adhesion of the metal powder.

Owner:GUSTAV WIEGARD MASCHFAB GMBH & CO KG

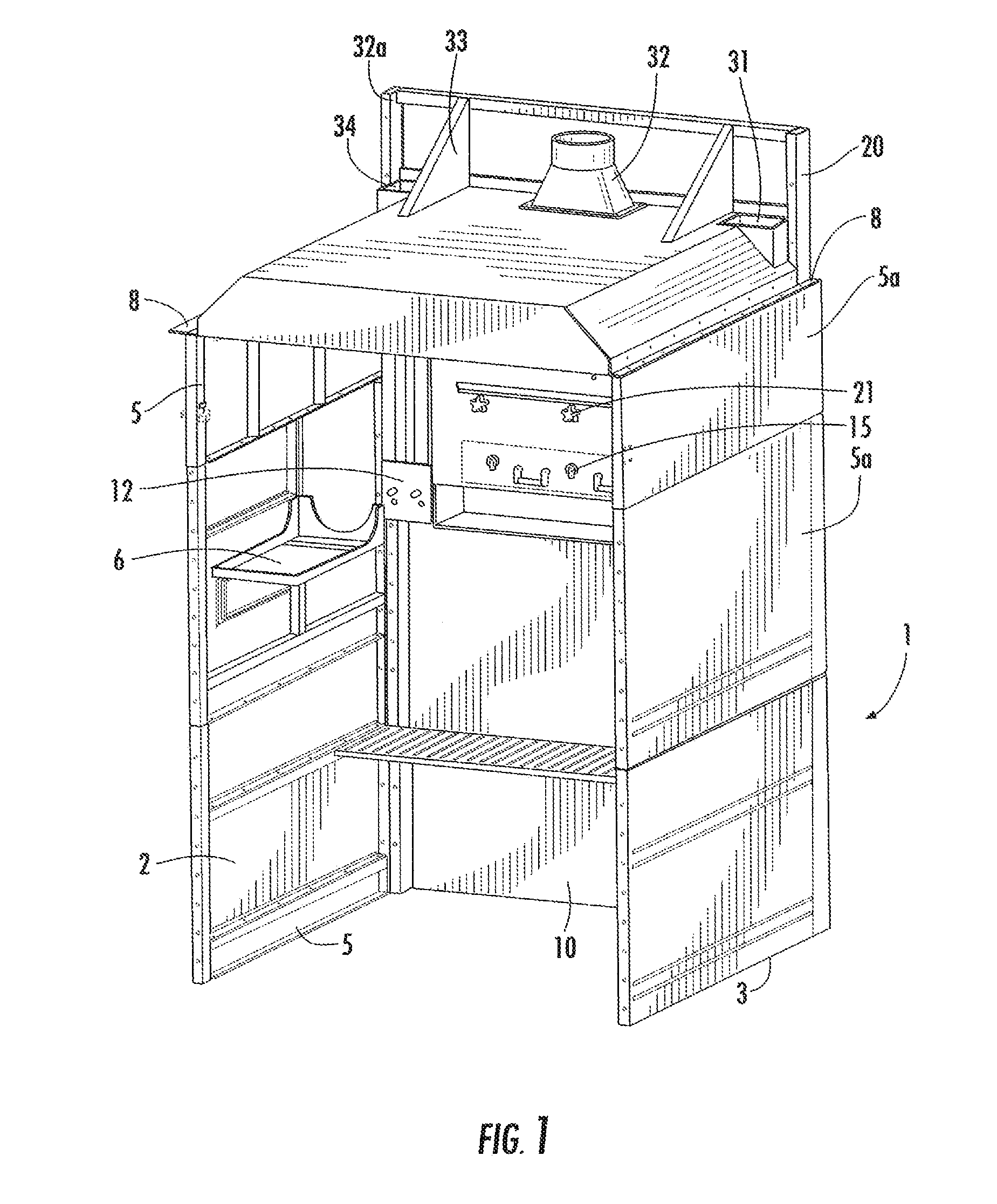

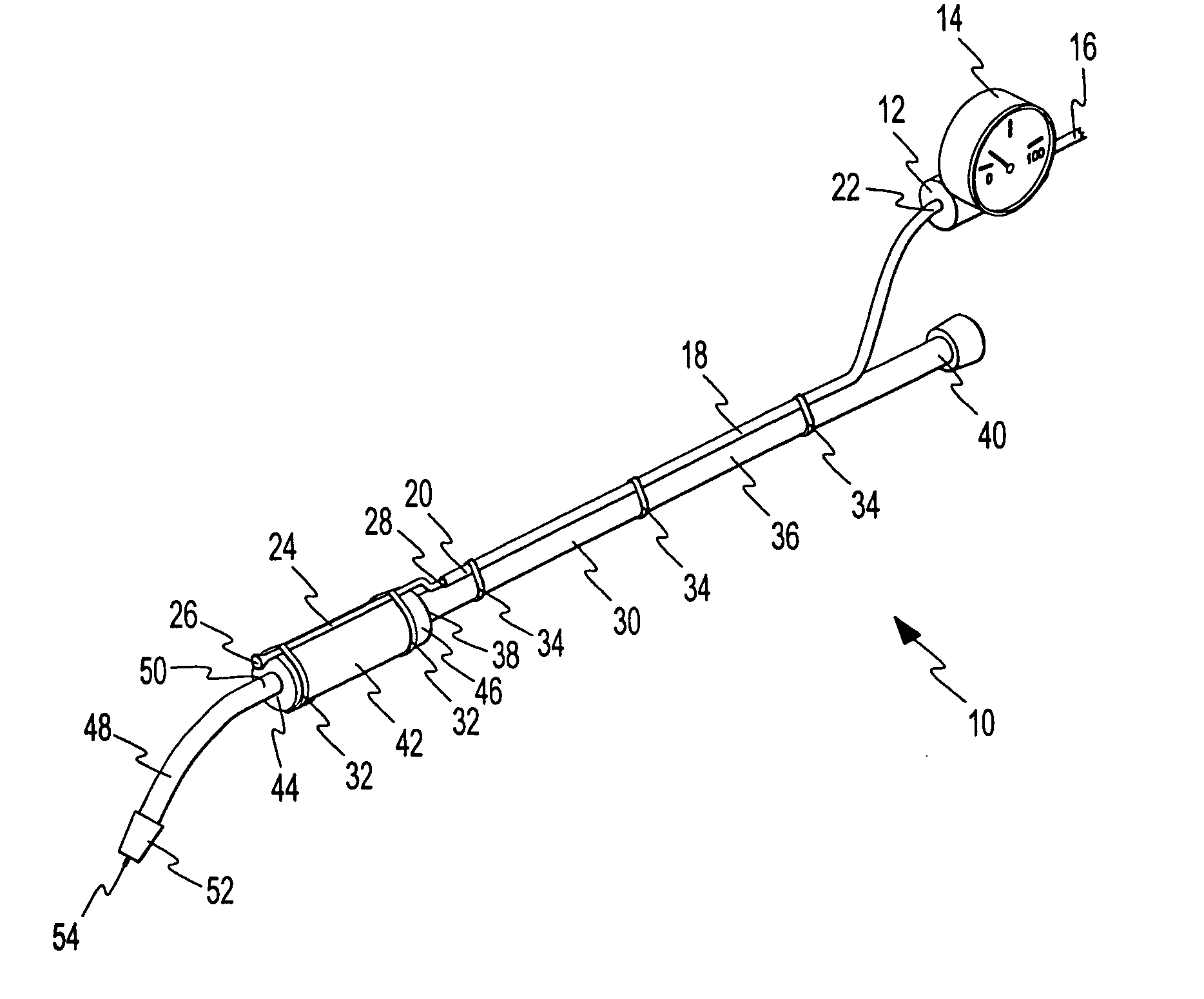

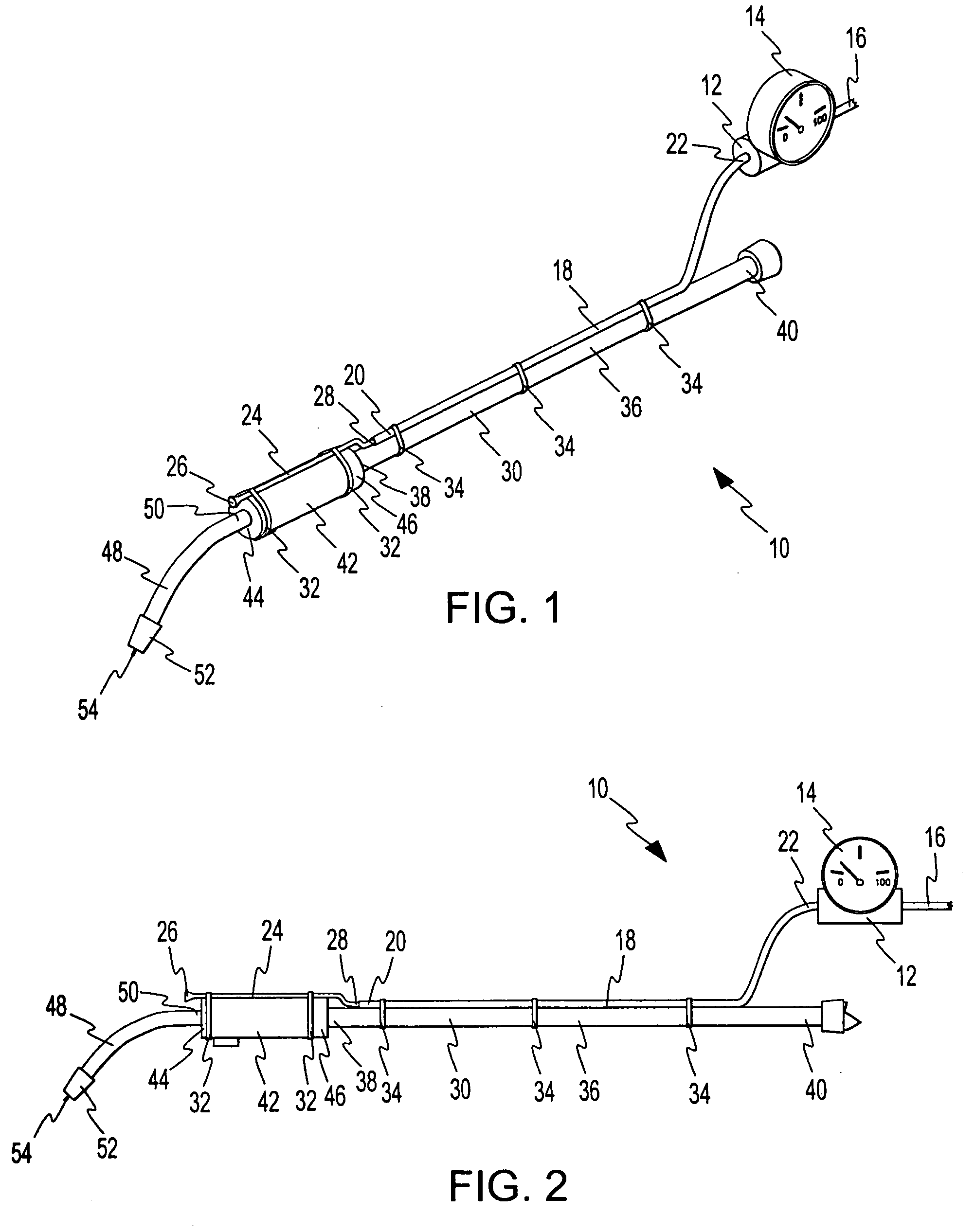

Less smoke fume-dispersing device for welding operations

A fume-dispersing device and welder combination for removing unwanted gases from a welding work area comprises a welder including a grip portion having an axis, and a welding tip extending in an axial direction from said grip portion and providing a distal welding end that affects a welding operation; and a fume-dispersing device including a fume dispersion tube recessed axially from said distal end of said welding tip and providing an open end. A method is provided employing such a device.

Owner:DEAN CHAD J

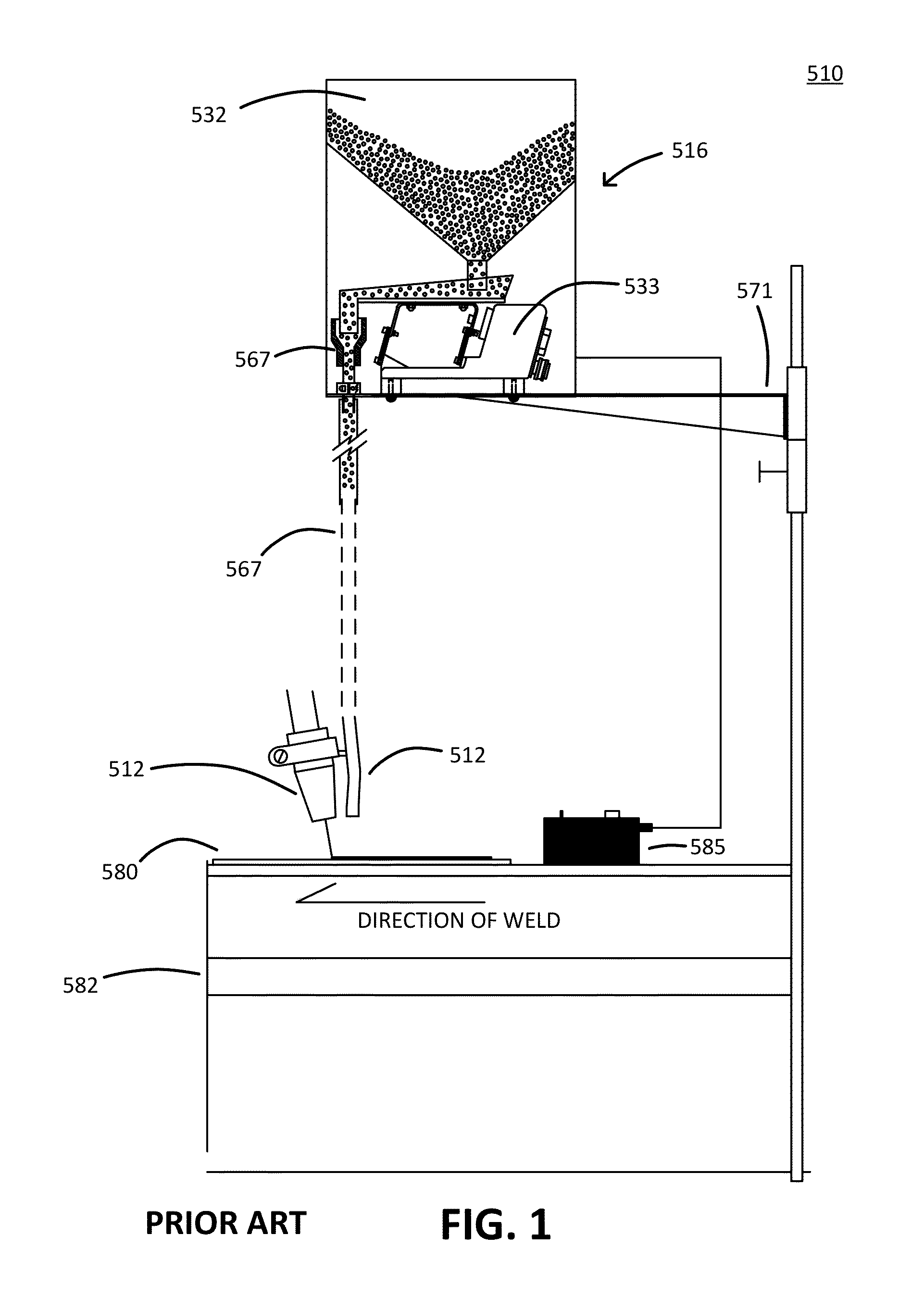

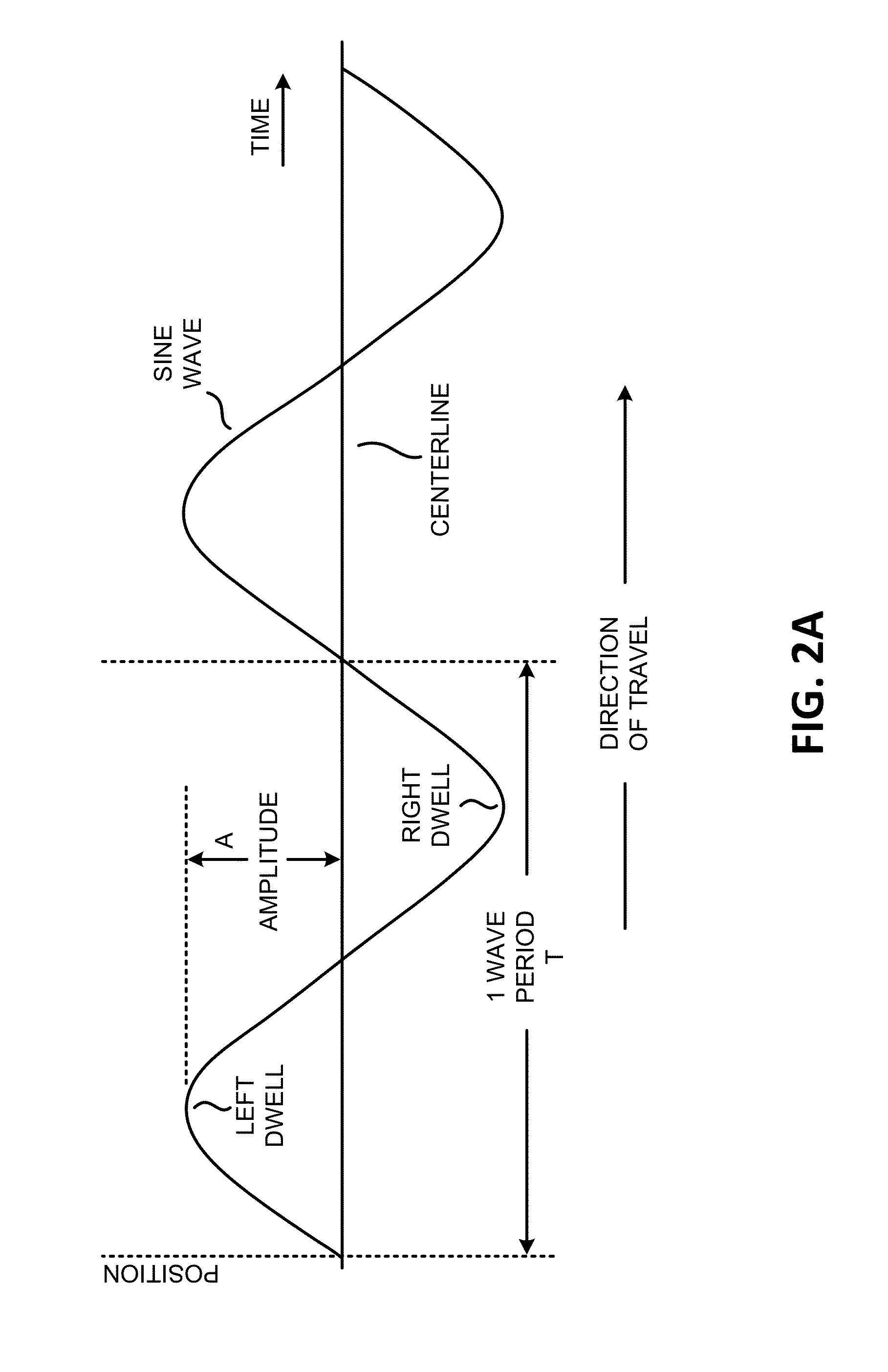

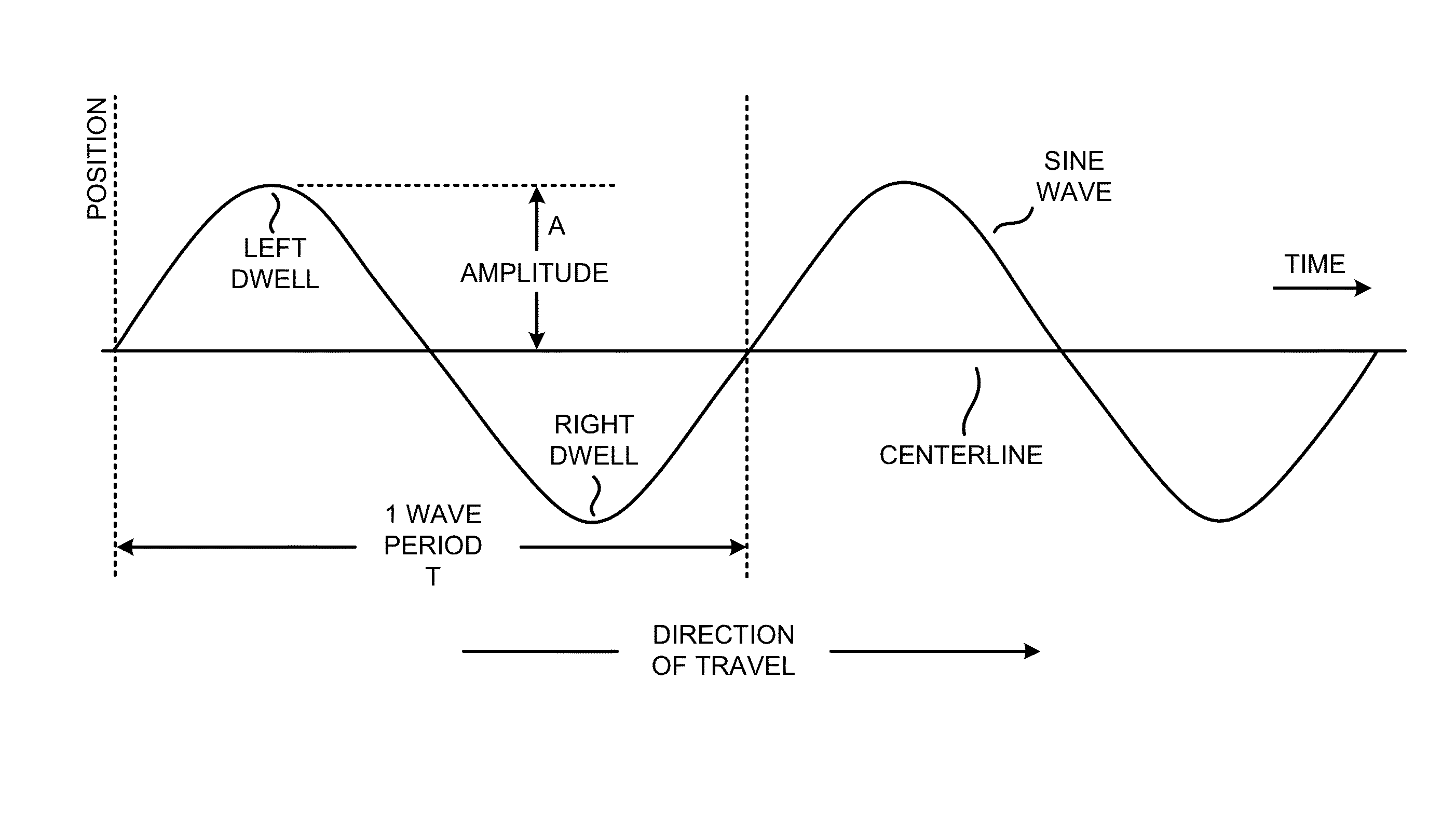

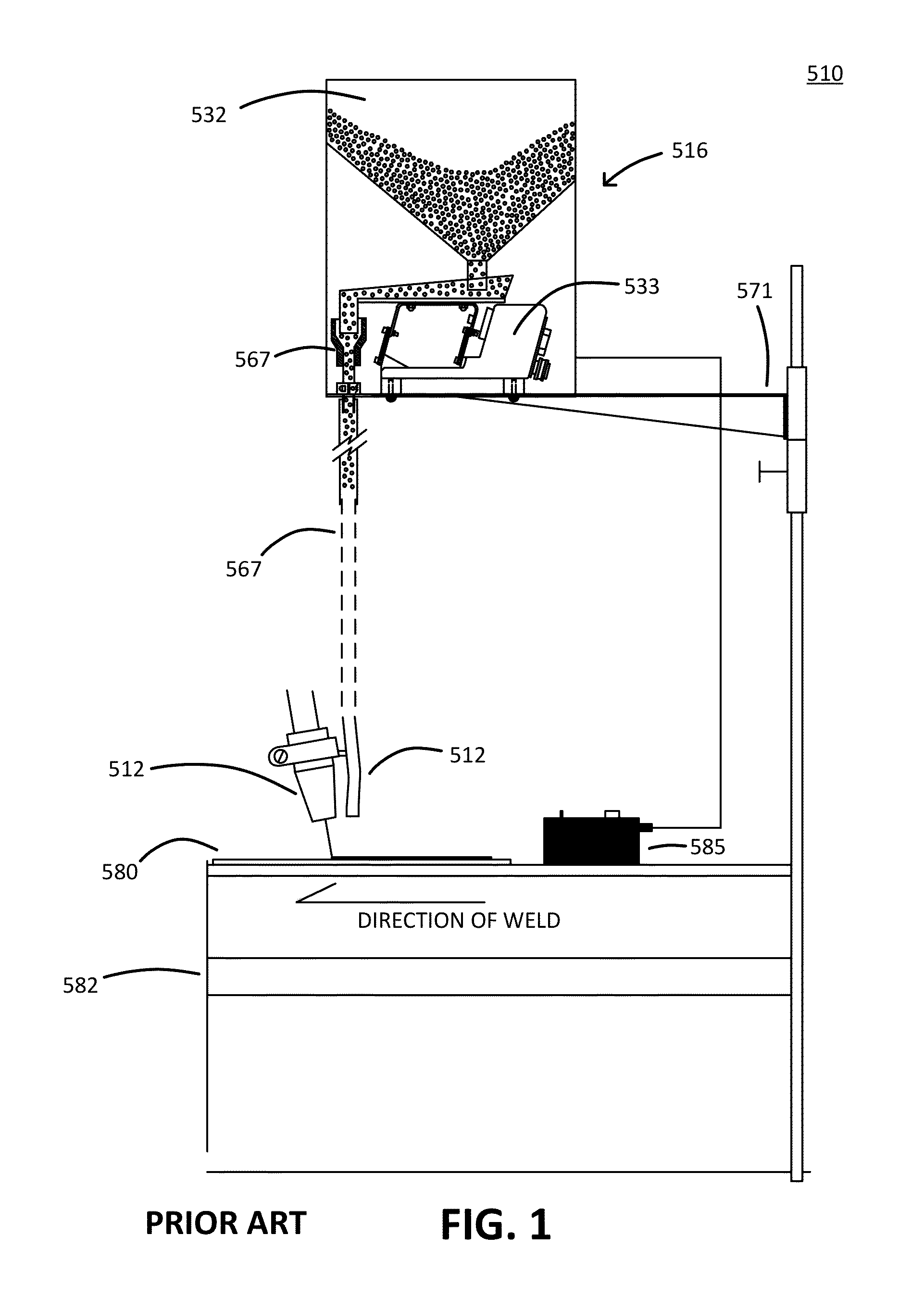

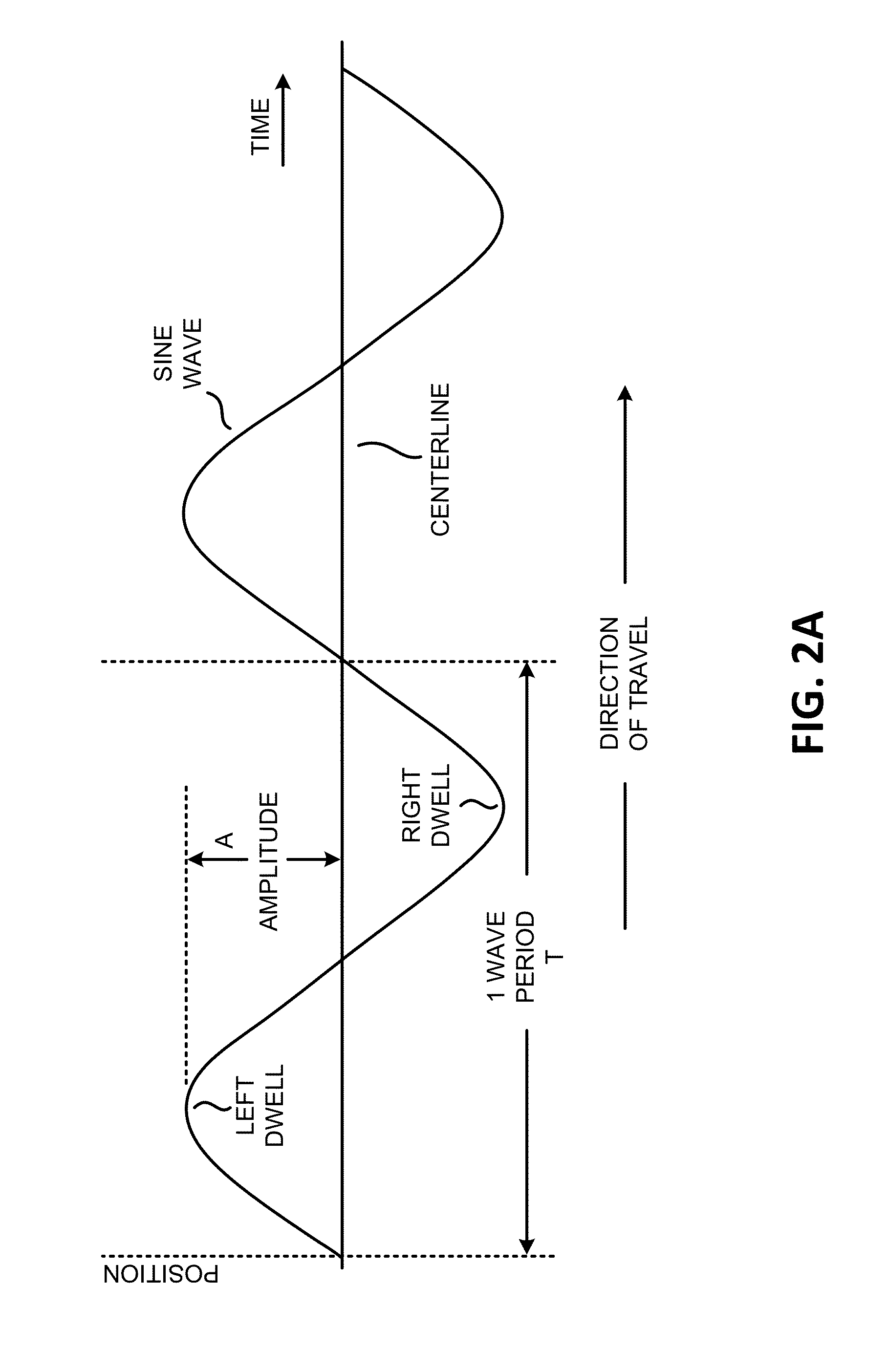

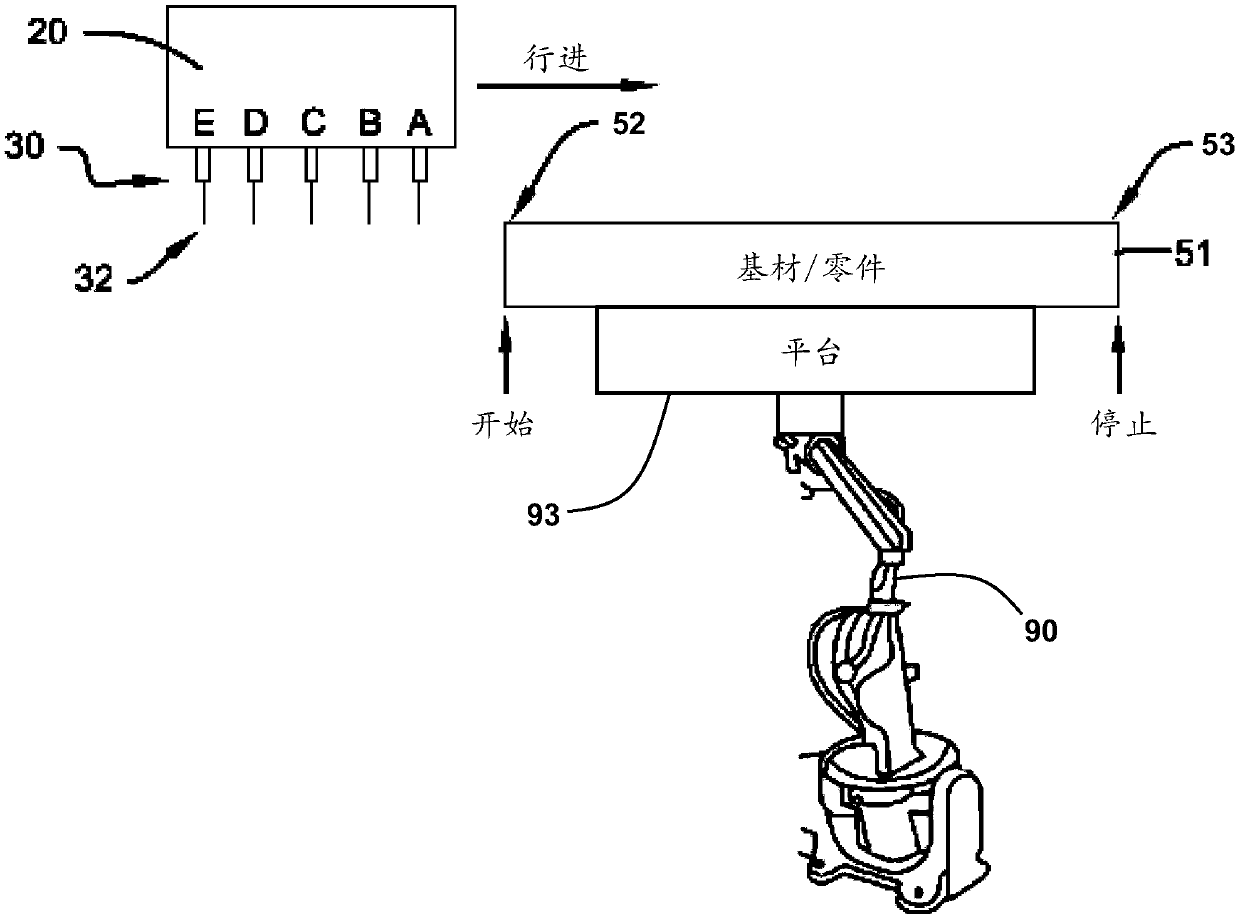

Automatic system for abrasive hardfacing

ActiveUS20150266124A1Optimal for incorporationOpportunities decreaseEvacuating shieldingParticulatesEngineering

Arc welding systems, apparatus and methods are for hardfacing are provided, including particle feeding apparatus. In one aspect the workpiece is moved in an oscillatory fashion while keeping the welding torch and the particulate delivery system stationary during at least a portion of welding pass. The welding torch and particulate delivery system may also be moved in a non-oscillatory fashion. Process speeds of about 18-30 in / min can be obtained with carbide incorporation of greater than 30% and uniform distribution.

Owner:VERMEER MFG CO

Automatic system for abrasive hardfacing

ActiveUS9321117B2Optimal for incorporationOpportunities decreaseEvacuating shieldingParticulatesEngineering

Arc welding systems, apparatus and methods are for hardfacing are provided, including particle feeding apparatus. In one aspect the workpiece is moved in an oscillatory fashion while keeping the welding torch and the particulate delivery system stationary during at least a portion of welding pass. The welding torch and particulate delivery system may also be moved in a non-oscillatory fashion. Process speeds of about 18-30 in / min can be obtained with carbide incorporation of greater than 30% and uniform distribution.

Owner:VERMEER MFG CO

Welding booth

ActiveUS20100258546A1Reduce spacingDomestic stoves or rangesEvacuating shieldingEngineeringSmall foot

The present invention relates to a welding booth that has a small foot print and can be joined to other booths for maximization of floor space use.

Owner:AVANI ENVIRONMENTAL INTL INC

Systems and methods of additive structure establishment

Embodiments of systems and methods of additive manufacturing are disclosed. In one embodiment, a metal deposition device (MDD) is configured to deposit a metal material during an additive manufacturing process. A controller is operatively coupled to the MDD and is configured to command the MDD to deposit the metal material on a base to form a contour of a part. The controller is configured to command the MDD to deposit the metal material on the base to form an infill pattern within a region outlined by the contour. The infill pattern is a wave shape having a wavelength. The controller is configured to command the metal deposition device to fuse the infill pattern to the metal contour at crossover points, where the infill pattern meets the contour, by applying energy at the crossover pointsand reducing a deposition rate of the metal material at the crossover points to prevent distorting the contour.

Owner:LINCOLN GLOBAL INC

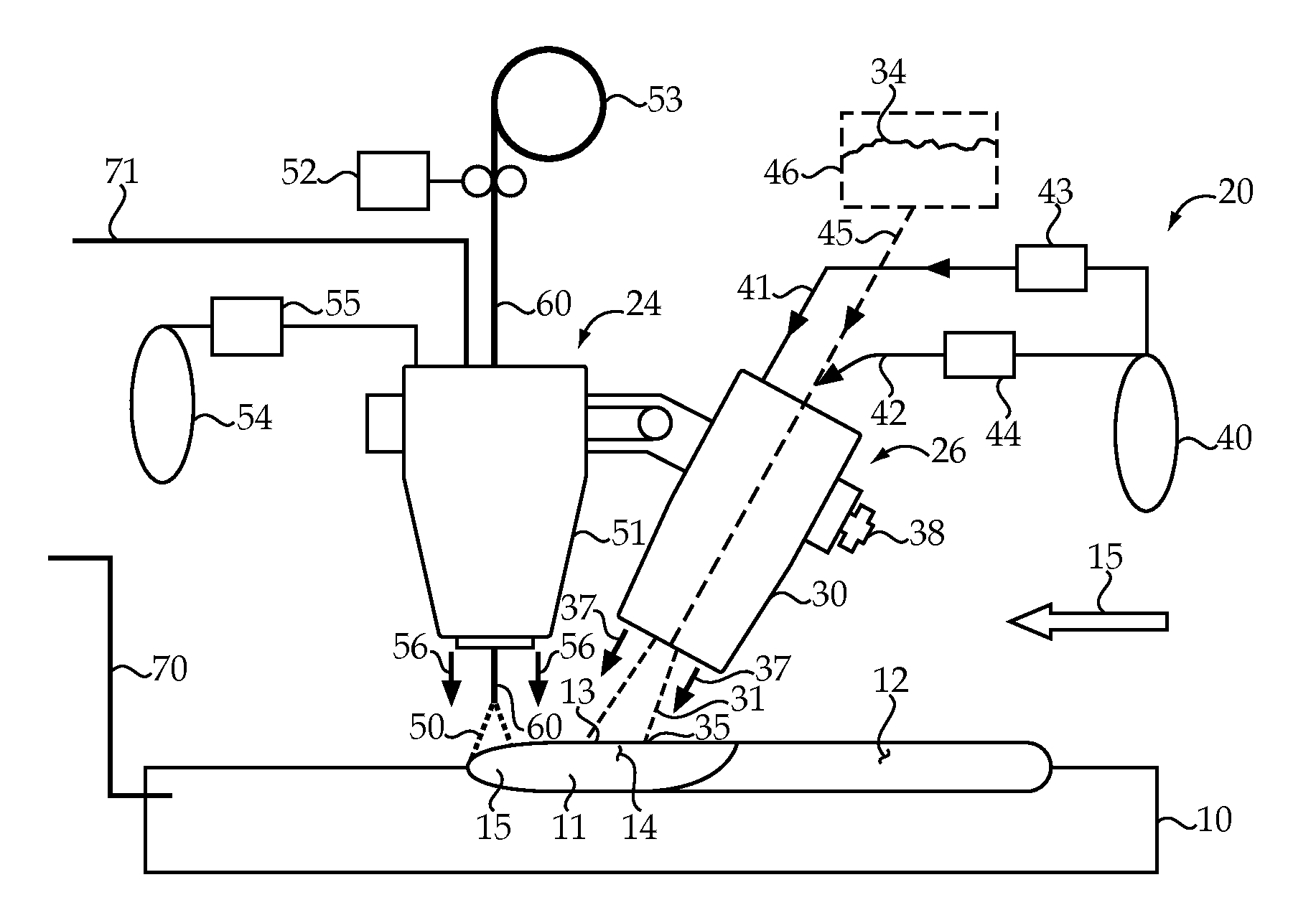

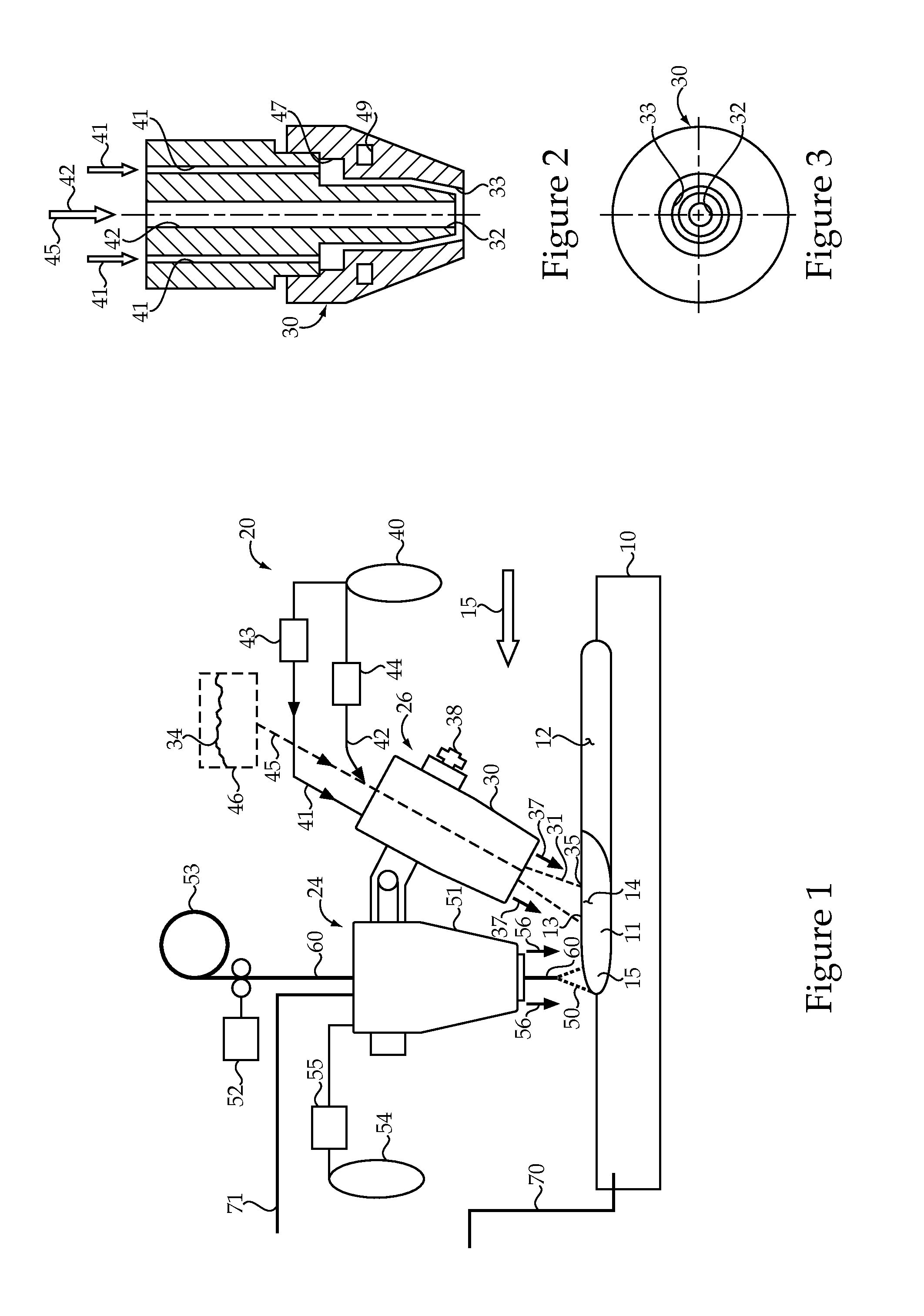

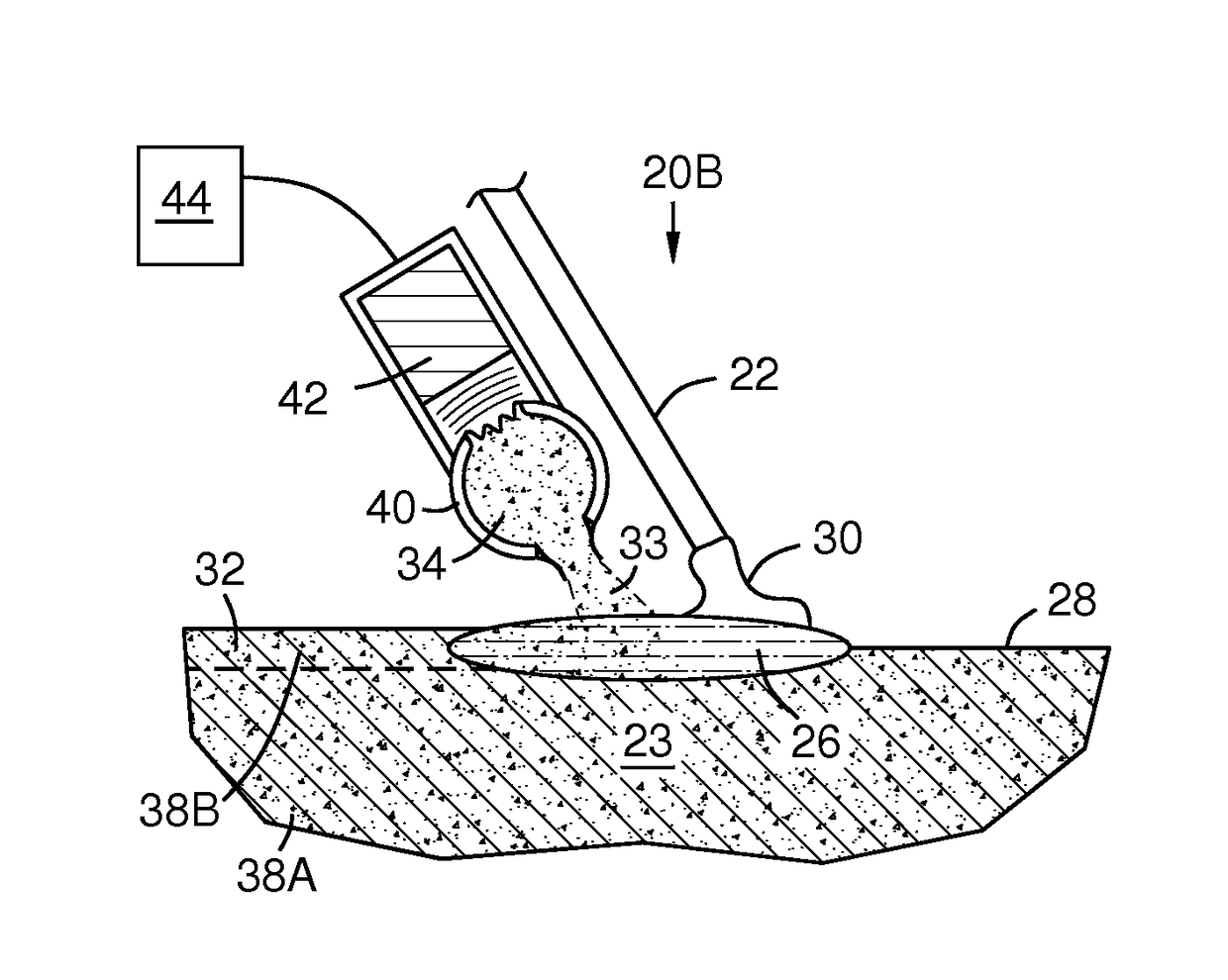

Formation and repair of oxide dispersion strengthened alloys by alloy melting with oxide injection

ActiveUS20170080508A1Evacuating shieldingMetallic material coating processesMetal alloyOxide dispersion-strengthened alloy

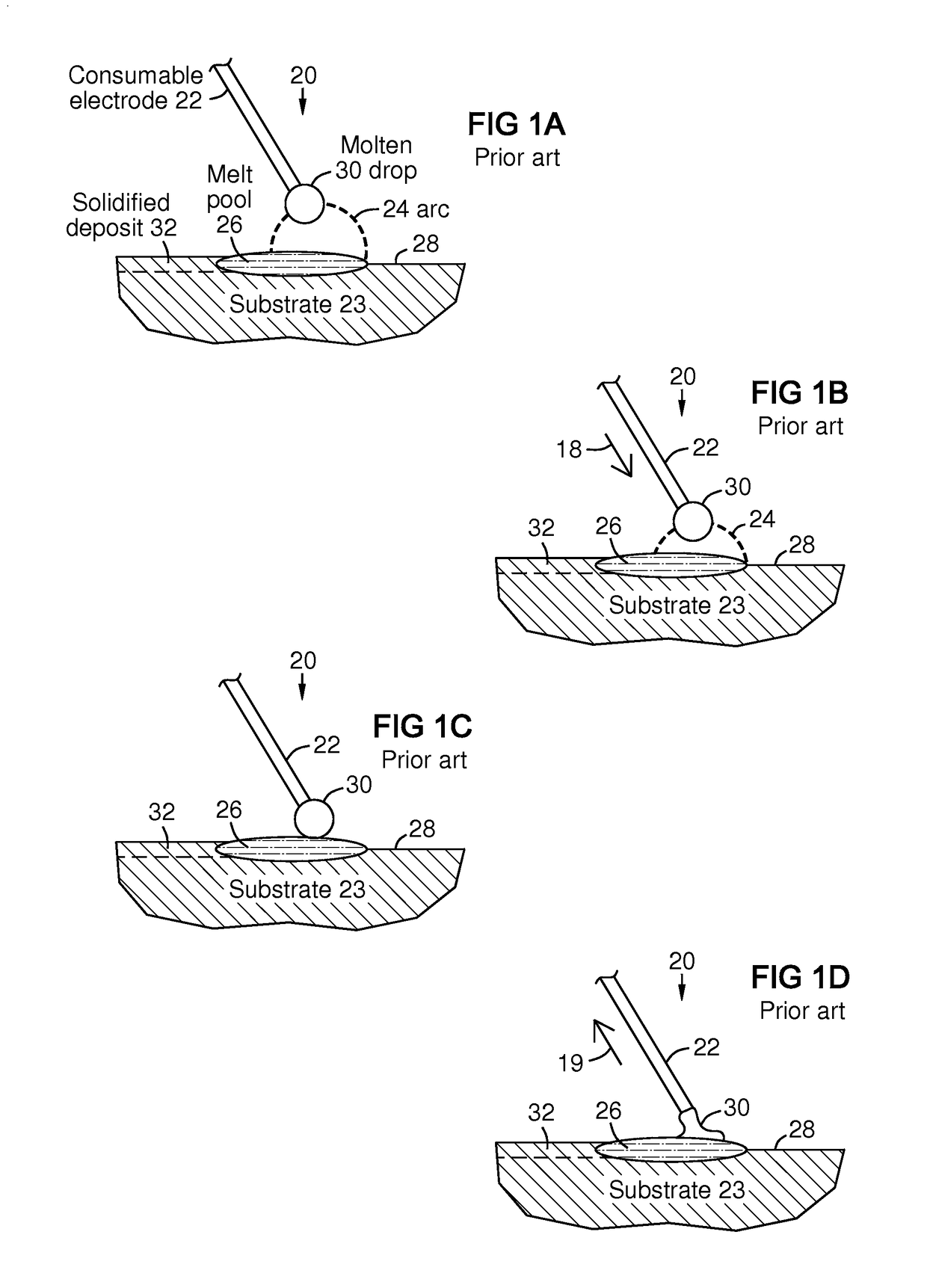

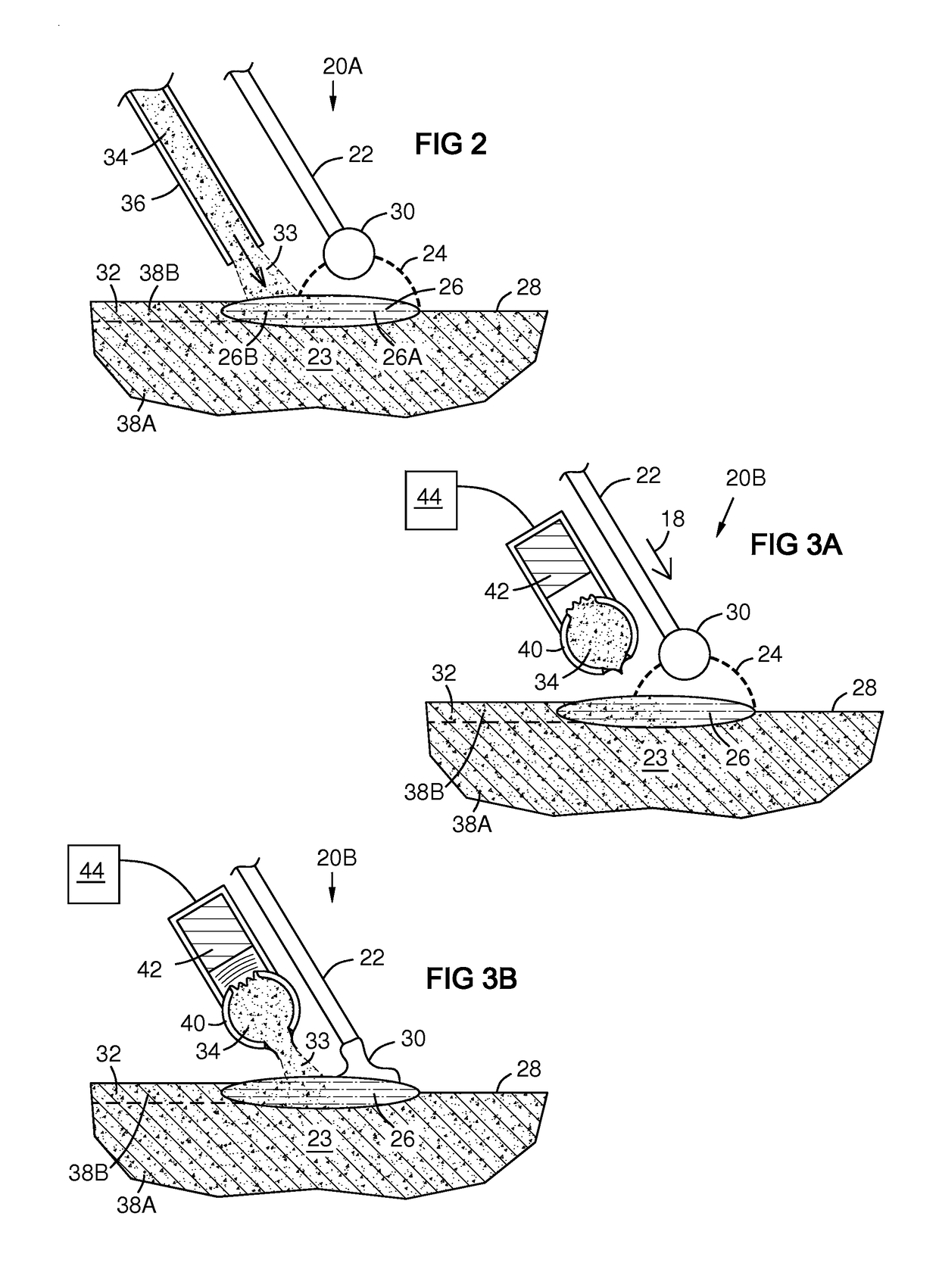

Melting energy exemplified by an arc (24) is delivered to a metal alloy material (22, 23), forming a melt pool (26). A metal oxide material (34) is delivered (33) to the melt pool and dispersed therein. The melting energy and oxide deliveries are controlled (44) to melt the alloy material, but not to melt at least most of the metal oxide material. The deliveries may be controlled so that the melting energy does not intercept the metal oxide delivery. The melting energy may be controlled to create a temperature of the melt pool that does not reach the melting point of the metal oxide. Deliveries of the melting energy and the oxide may alternate so they do not overlap in time. A cold metal transfer apparatus (22) and process (18, 19, 20) may be used for example in combination with an oxide particle pulse delivery device (42, 46).

Owner:SIEMENS ENERGY INC

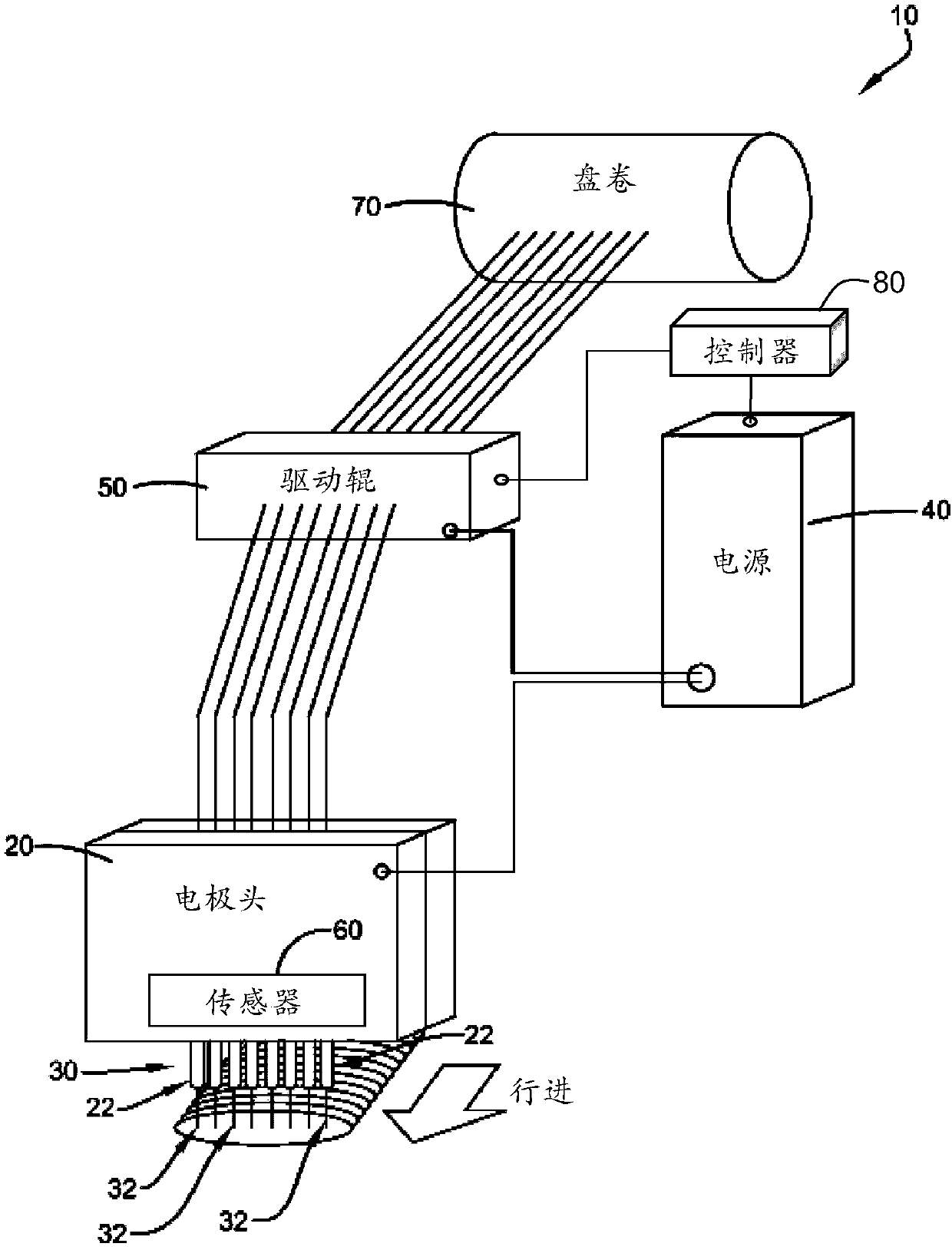

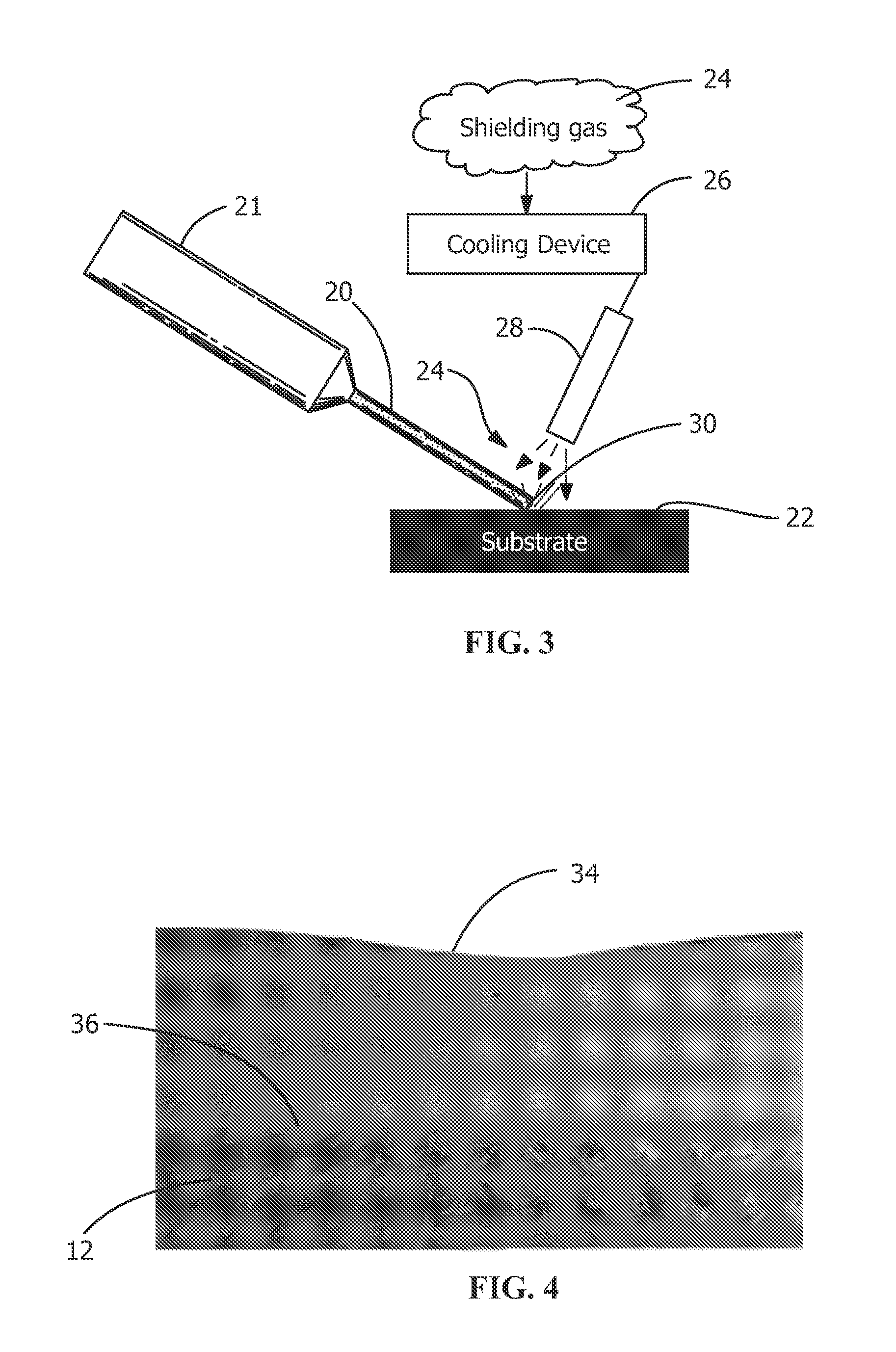

Electrospark deposition system for repair of gas turbine

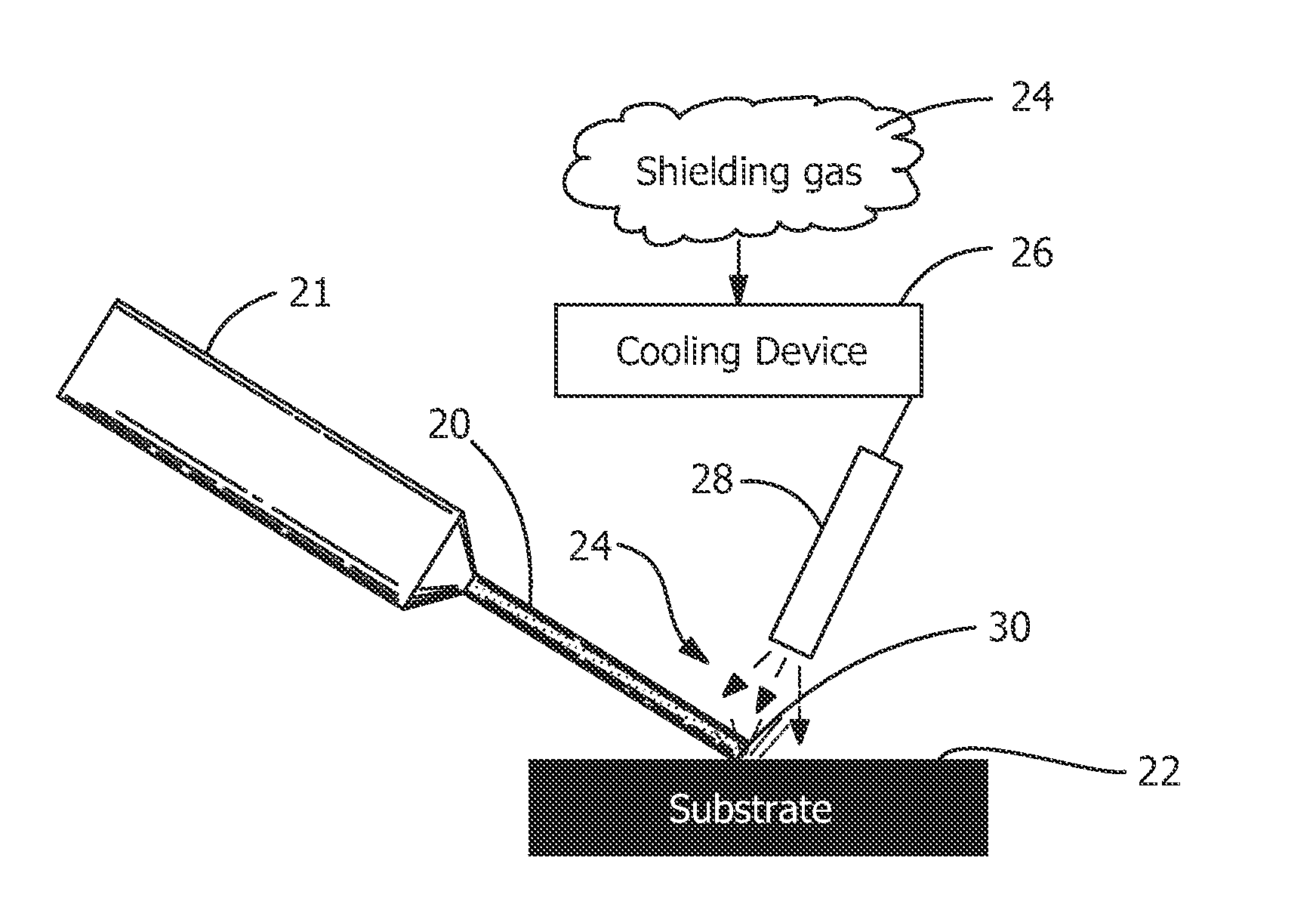

InactiveUS20160008908A1Reduce the temperatureContinuous operationTurbinesSupport devices with shieldingShielding gasEngineering

A system and method for repairing a metal substrate includes an electrospark device and an electrode removably supported in the electrode holder. The electrospark device applies a coating of a material when placed into contact with the metal substrate. A cooling device to lowers the temperature of shielding gas flow below an ambient temperature. A conduit is arranged to direct a flow of the shielding gas to the interface of the electrode and the substrate to cool the area of the substrate receiving the coating.

Owner:GENERAL ELECTRIC CO

Less smoke fume-dispersing device for welding operations

A fume-dispersing device and welder combination for removing unwanted gases from a welding work area comprises a welder including a grip portion having an axis, and a welding tip extending in an axial direction from said grip portion and providing a distal welding end that affects a welding operation; and a fume-dispersing device including a fume dispersion tube recessed axially from said distal end of said welding tip and providing an open end. A method is provided employing such a device.

Owner:DEAN CHAD J

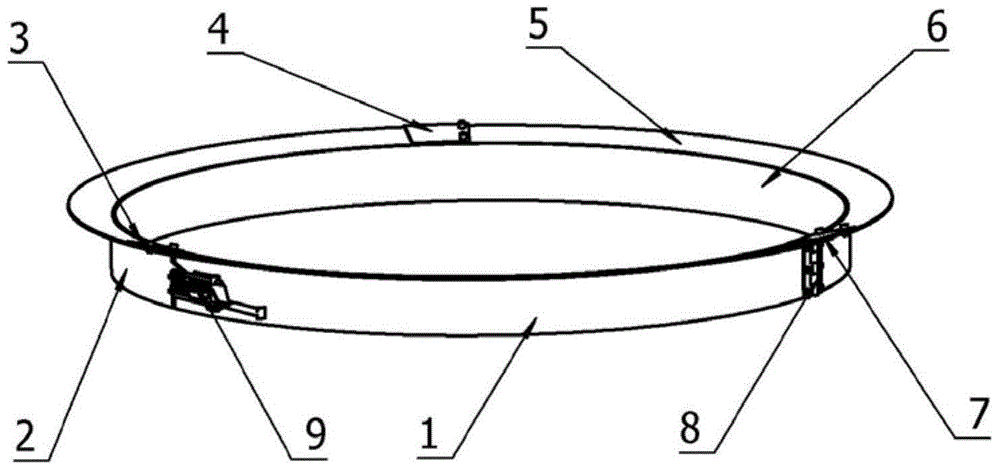

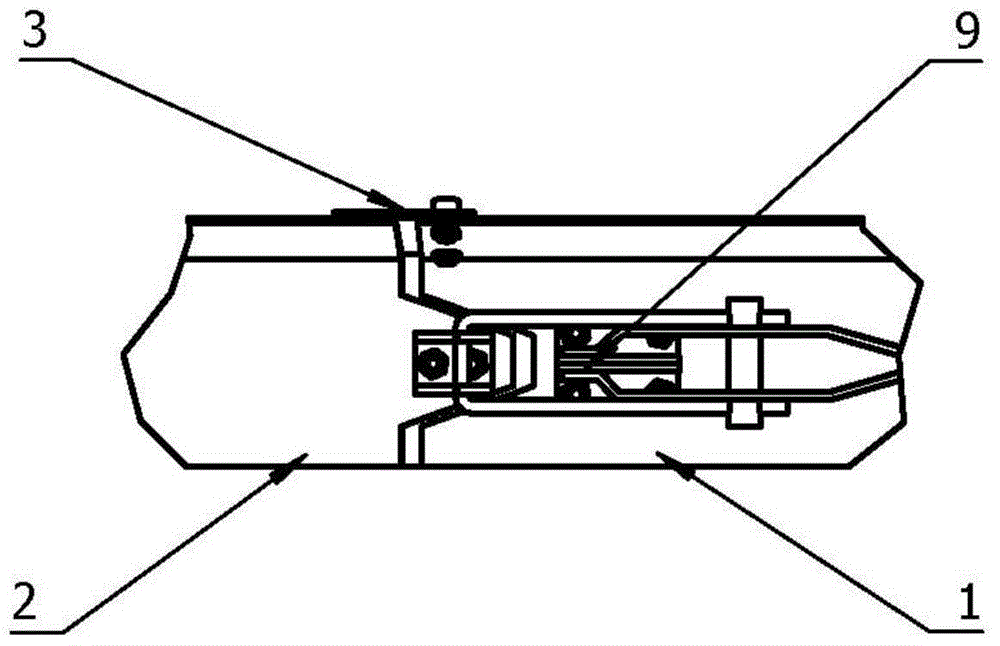

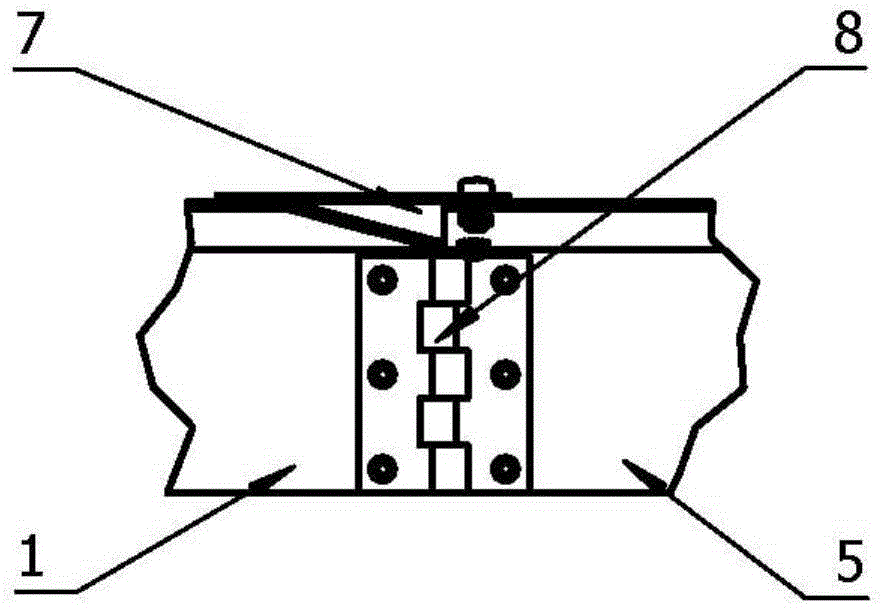

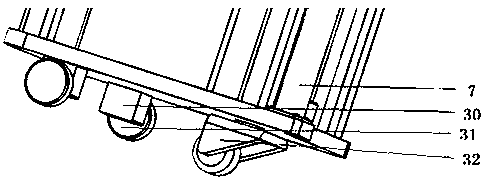

Soldering flux bracket for pile pipe submerged-arc soldering

ActiveCN104439659AImprove the level of automation technologyImprove welding qualityEvacuating shieldingMetal working apparatusEngineeringSoldering

The invention discloses a soldering flux bracket for pile pipe submerged-arc soldering, and belongs to the technical field of soldering. The soldering flux bracket for pile pipe submerged-arc soldering comprises a first arc ring, a lock catch, a second arc ring, a first hinged piece, a second hinged piece and a third arc ring, wherein the first arc ring is in contact with a pile pipe, the lock catch is connected with the first arc ring, the second arc ring is connected with the first arc ring through the lock catch, the first arc ring is in contact with the pile pipe, the first hinged piece is connected with the first arc ring, the second hinged piece is connected with the second arc ring, one end of the third arc ring is connected with the first arc ring through the first hinged piece, the other end of the third arc ring is connected with the second arc ring through the second hinged piece, and an annular structure is defined by the first arc ring, the second arc ring and the third arc ring and clamped on the pile pipe. By means of the soldering flux bracket for pile pipe submerged-arc soldering, the submerged-arc soldering technology is smoothly applied to soldering operation of the pile pipe.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

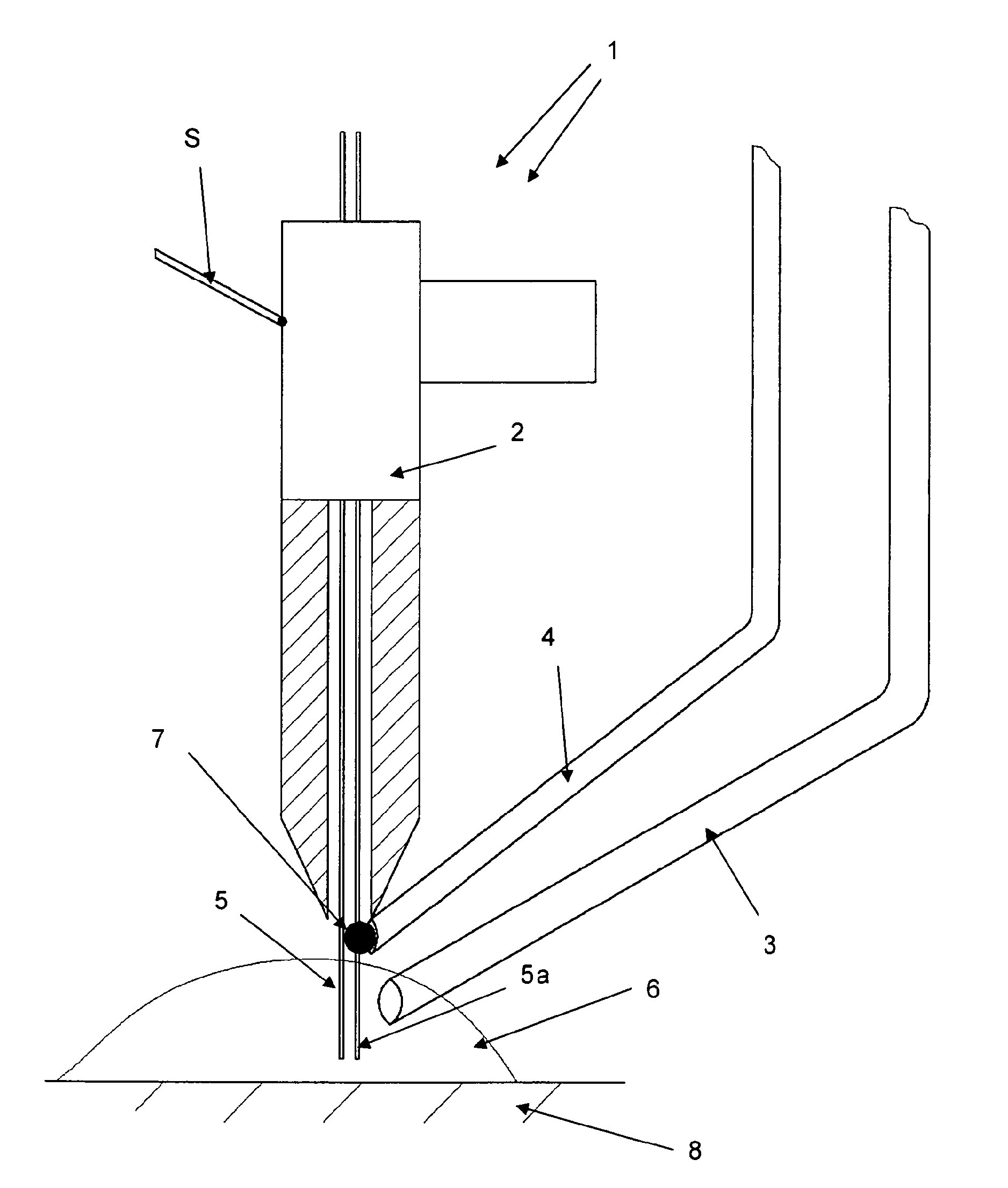

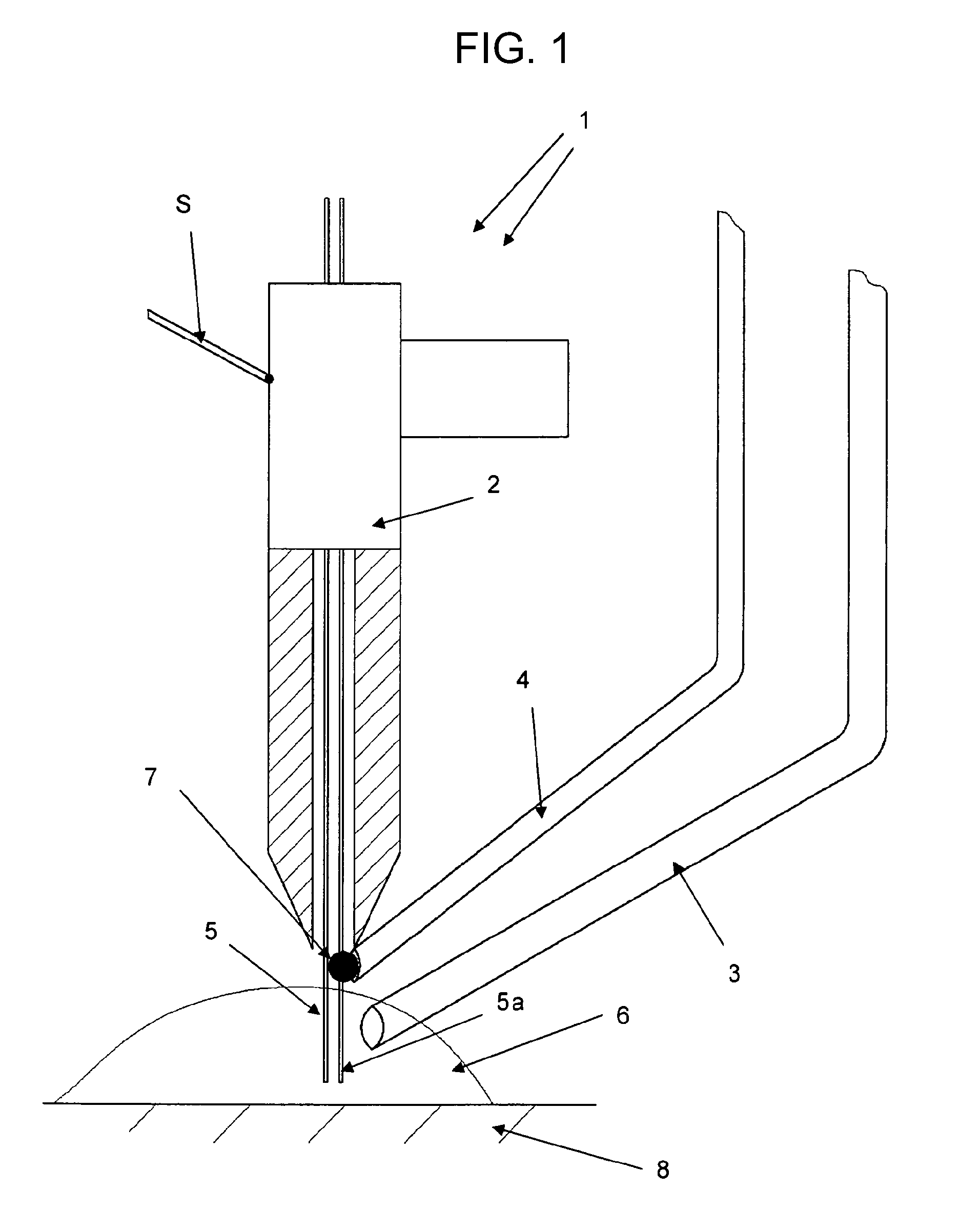

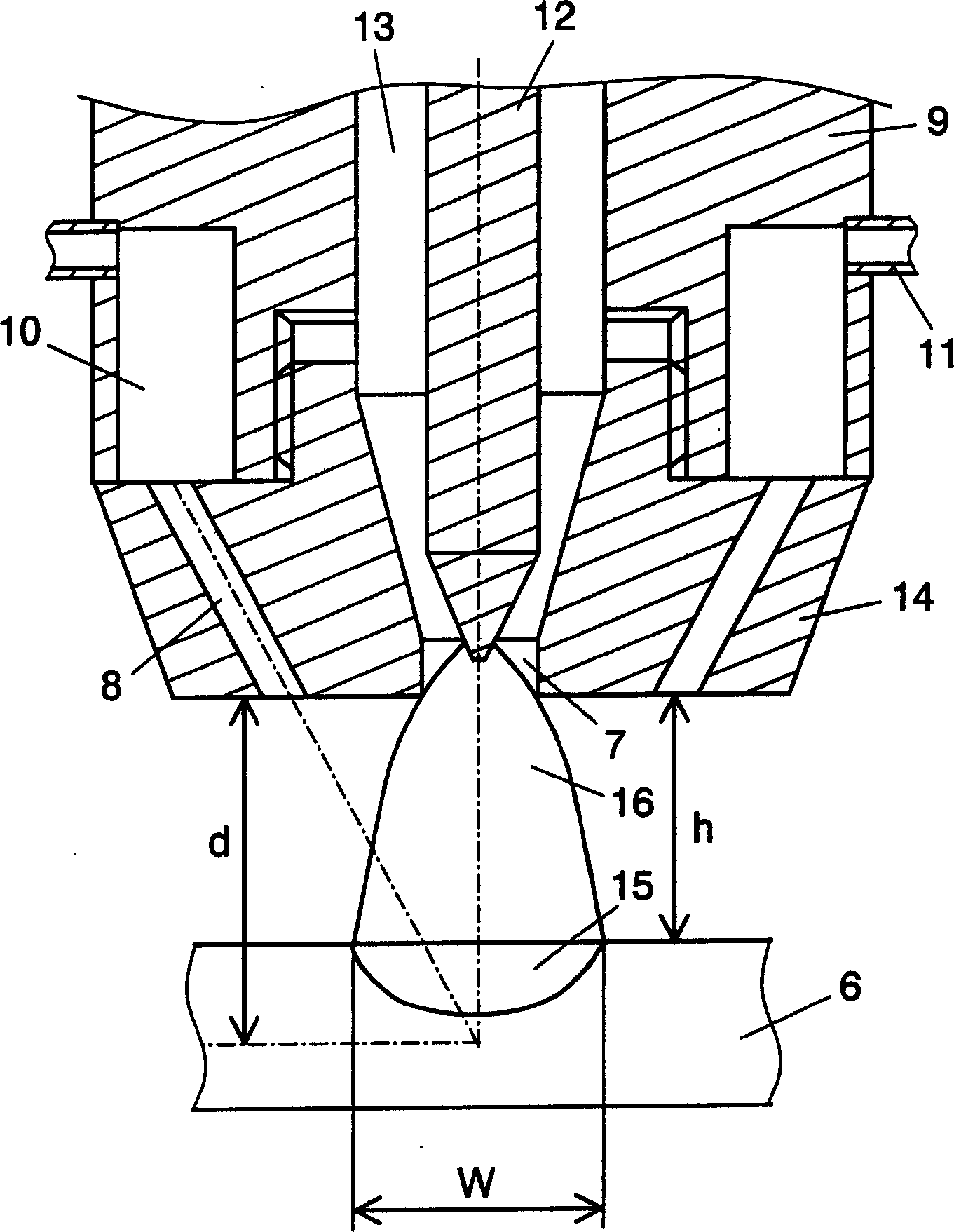

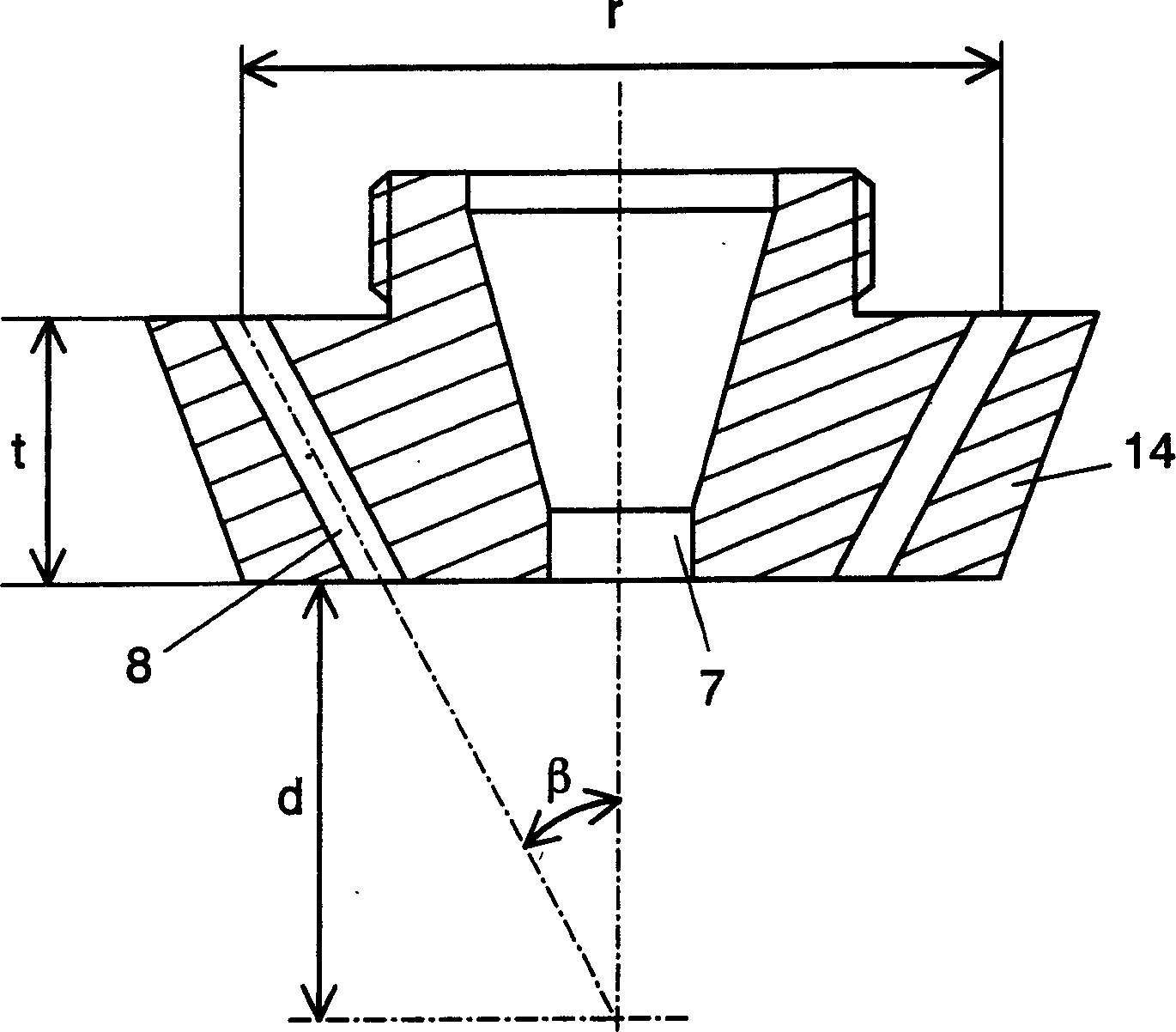

Powder plasma welding device and welding method

A plasma powder welding device in this invention comprises a powder having an identical kind of main component as that of a work piece, a feeder feeding the powder to the work piece, a welding torch generating a plasma between itself and the work piece for focusing the powder fed by the feeder on the work piece and transferring the powder to the work piece, and a power source supplying an electric power to the welding torch, wherein a distance from the welding torch to a focal point to which the powder is focused is set nearly equal to or more than the height of the torch.

Owner:PANASONIC CORP

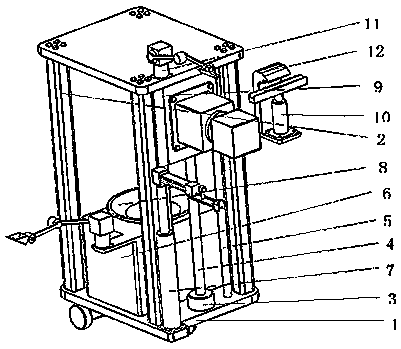

Vertical steel bar welding robot in construction site

The invention relates to a vertical steel bar welding robot in a construction site. A hydraulic oil tank is arranged on a bottom plate of a support frame, and a flux containing plate is arranged on the hydraulic oil tank; a screw motor is embedded in one side of the bottom plate of the support frame and fixedly connected with one end of a transmission screw; a hydraulic cylinder is arranged on thebottom plate of the support frame; a vertical moving plate is in threaded connection with the transmission screw; a main motor I is fixed on the vertical moving plate, a shell of a main motor II is fixedly connected with the main motor I, the root of a wide hook is fixedly connected with the main motor II, and an auxiliary hydraulic cylinder is fixed on the wide hook; a welding wire is fixed on atop plate of the support frame through a mechanical arm I; the hydraulic cylinder is matched with a vertical hydraulic rod by a moving pair, the vertical hydraulic rod controls work of a pair of semi-circular drums through a mechanical arm II, a digging tool is installed on an extension plate at one corner of the hydraulic oil tank through a mechanical arm III, and a wheel driving mechanism is arranged at the bottom of the bottom plate of the support frame. The welding robot is based on electroslag pressure welding and can replace manual operation, thereby reducing labor intensity, improvingoverall safety and saving construction cost.

Owner:南通欧创自动化工程有限公司

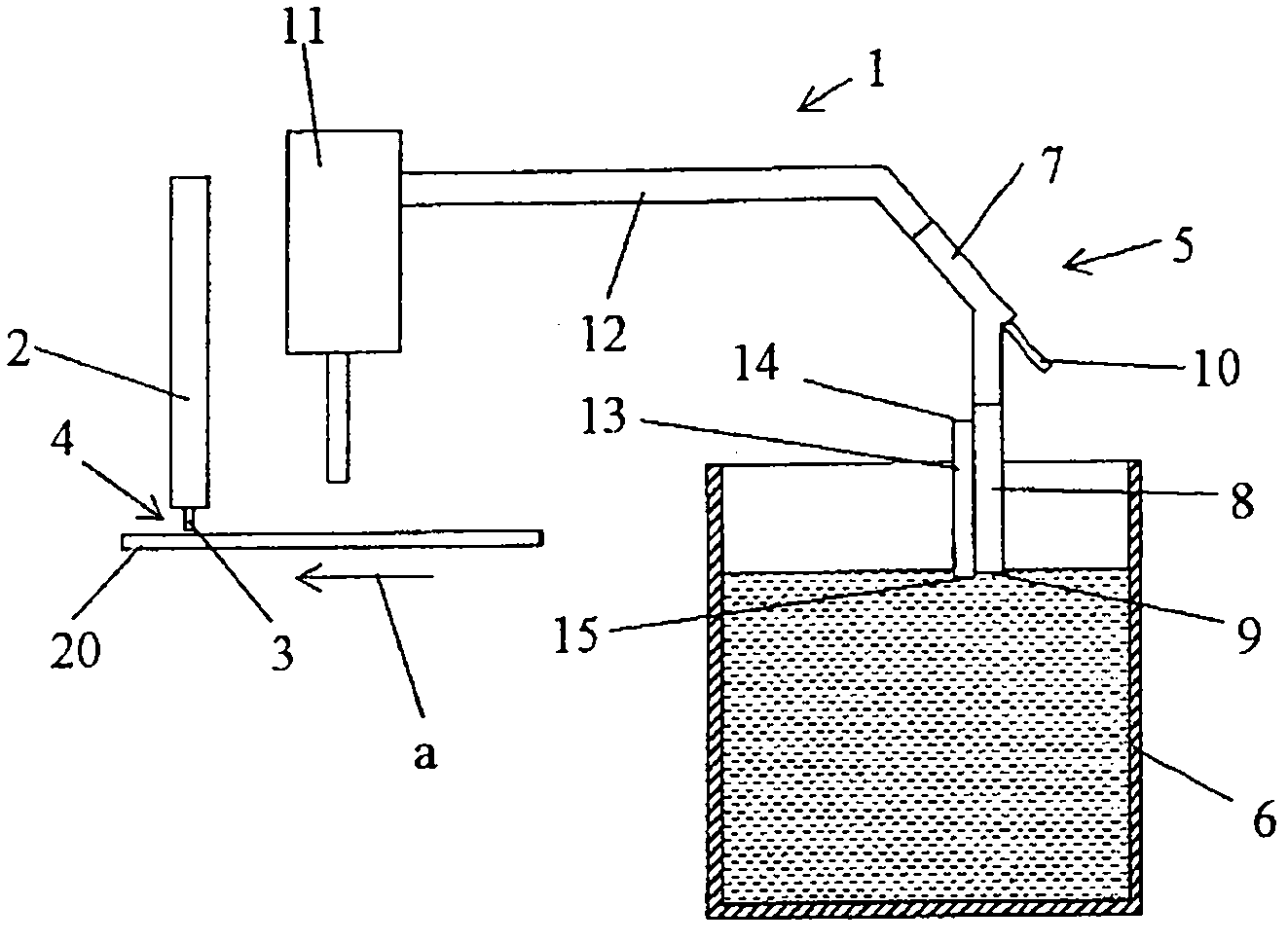

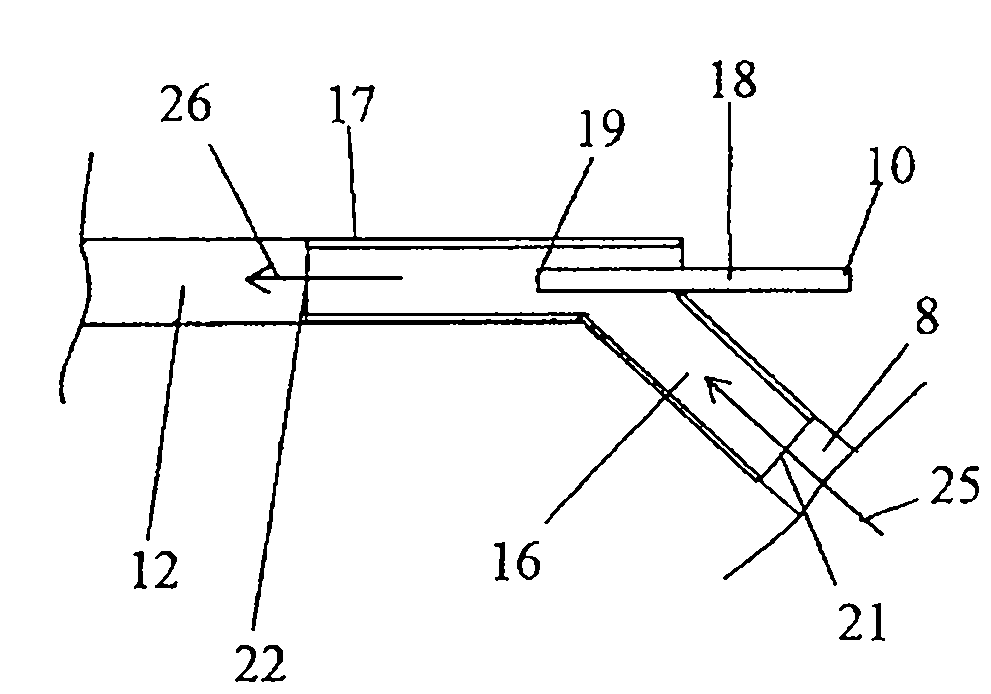

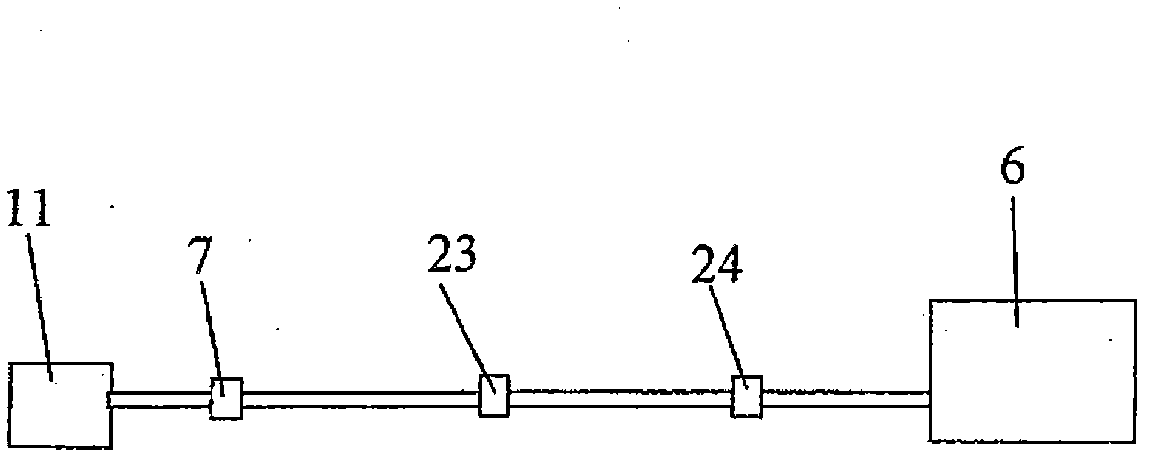

Device for handling powder for a welding appatarus

A welding device (1) for powder welding is described, which comprises a welding head (2) for transportation of at least one welding electrode (3) to a welding area (4), and a powder transportation device (5) for transportation of powder from a container (6) to the welding area (4). The powder transportation device (5) comprises at least a first pipe (8) which at a first end has an opening (9) which is arranged to be placed in the container (6) in order to transport fluxing agent from the container (6). The powder transportation device (5) comprises at least a first ejector (7) which is connected to the second end of the first pipe (8) and which is arranged to transport powder from the container (6) via the first pipe (8) using pressurized gas.

Owner:ESAB AB

Device for handling powder for a welding apparatus

A welding device for powder welding is described, which comprises a welding head for transportation of at least one welding electrode to a welding area, and a powder transportation device for transportation of powder from a container to the welding area. The powder transportation device comprises at least a first pipe which at a first end has an opening which is arranged to be placed in the container in order to transport fluxing agent from the container. The powder transportation device comprises at least a first ejector which is connected to the second end of the first pipe and which is arranged to transport powder from the container via the first pipe using pressurized gas.

Owner:ESAB AB

Welding booth

The present invention relates to a welding booth that has a small foot print and can be joined to other booths for maximization of floor space use.

Owner:AVANI ENVIRONMENTAL INTL INC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com