Systems and methods of additive structure establishment

A technology of additive manufacturing and metal materials, which is applied in the field of additive manufacturing and can solve problems such as long construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

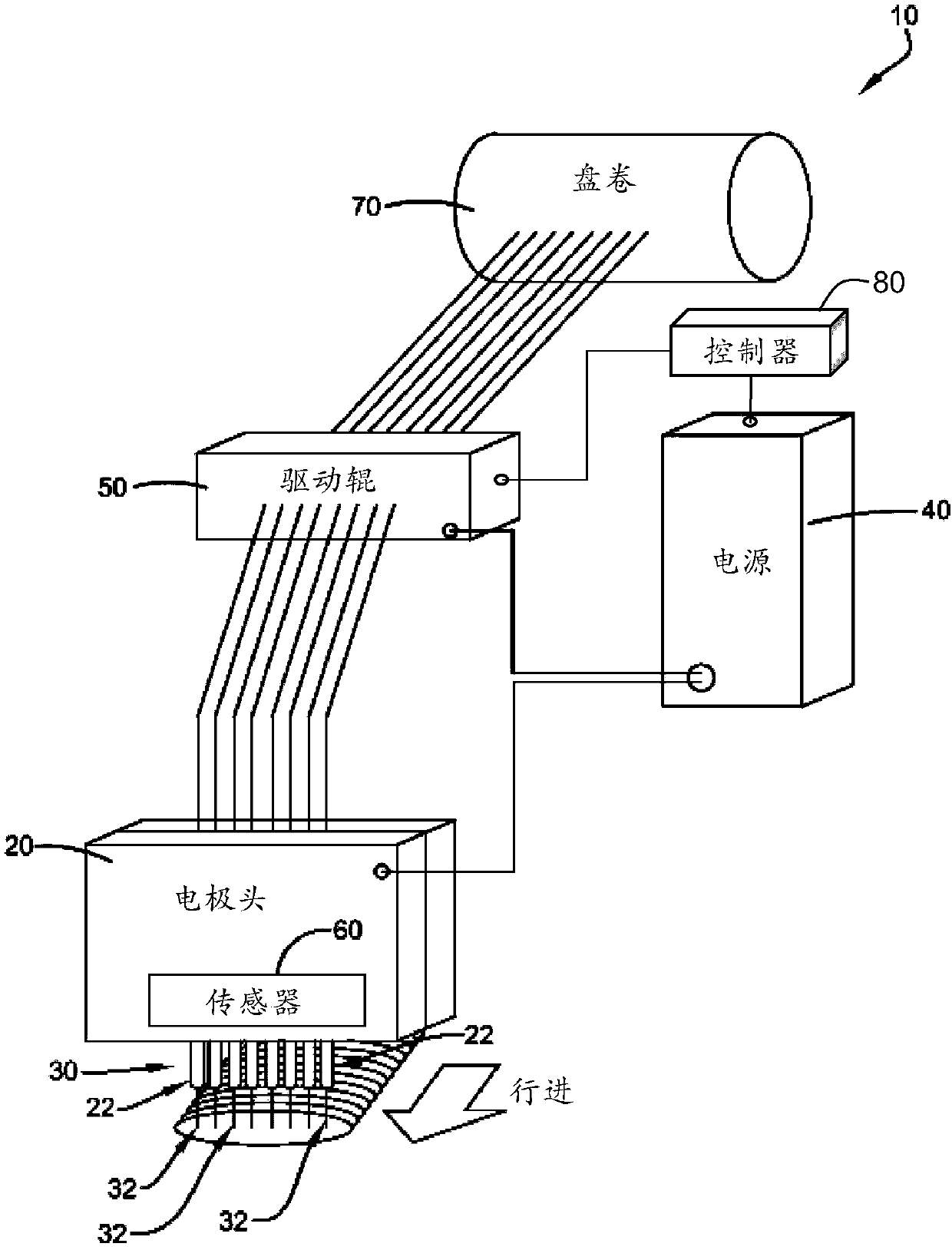

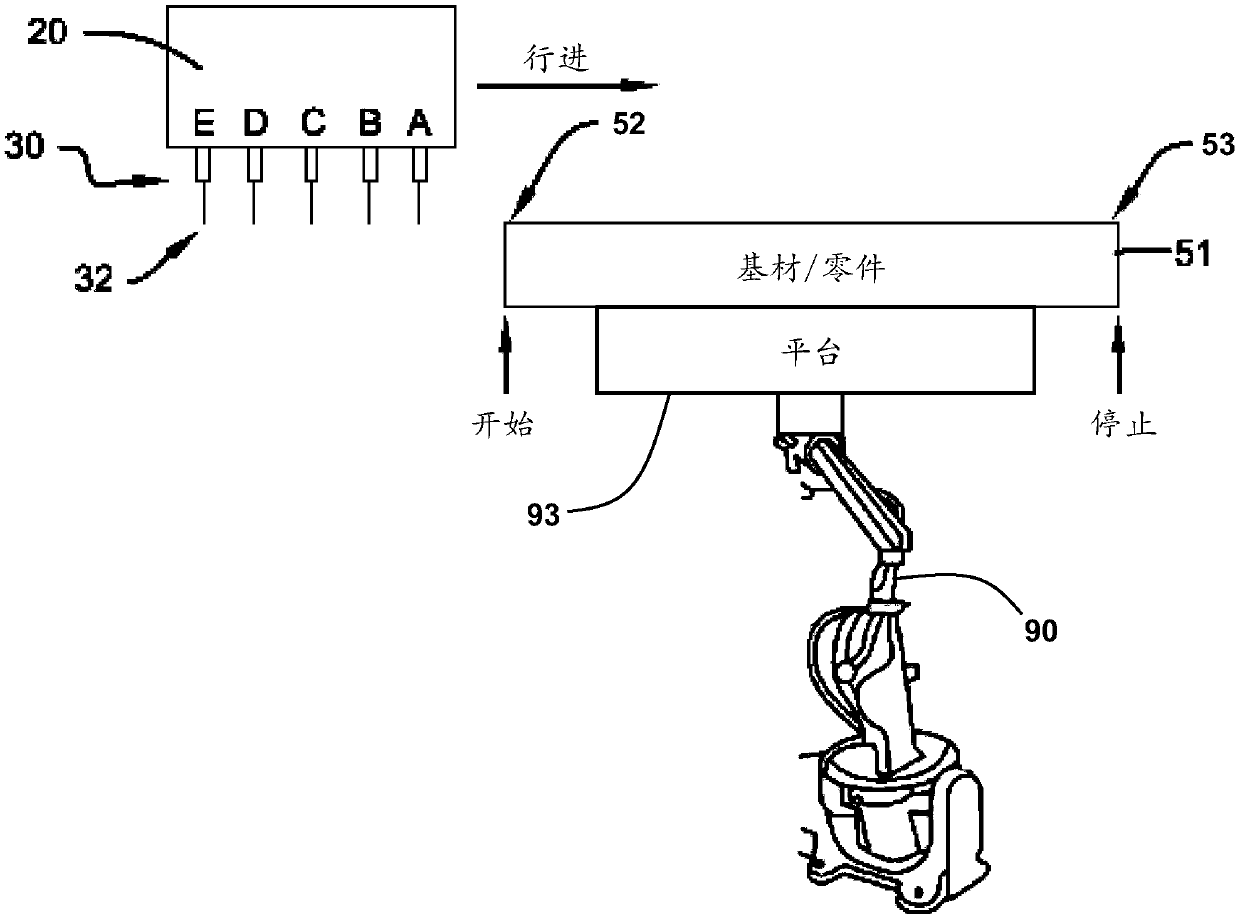

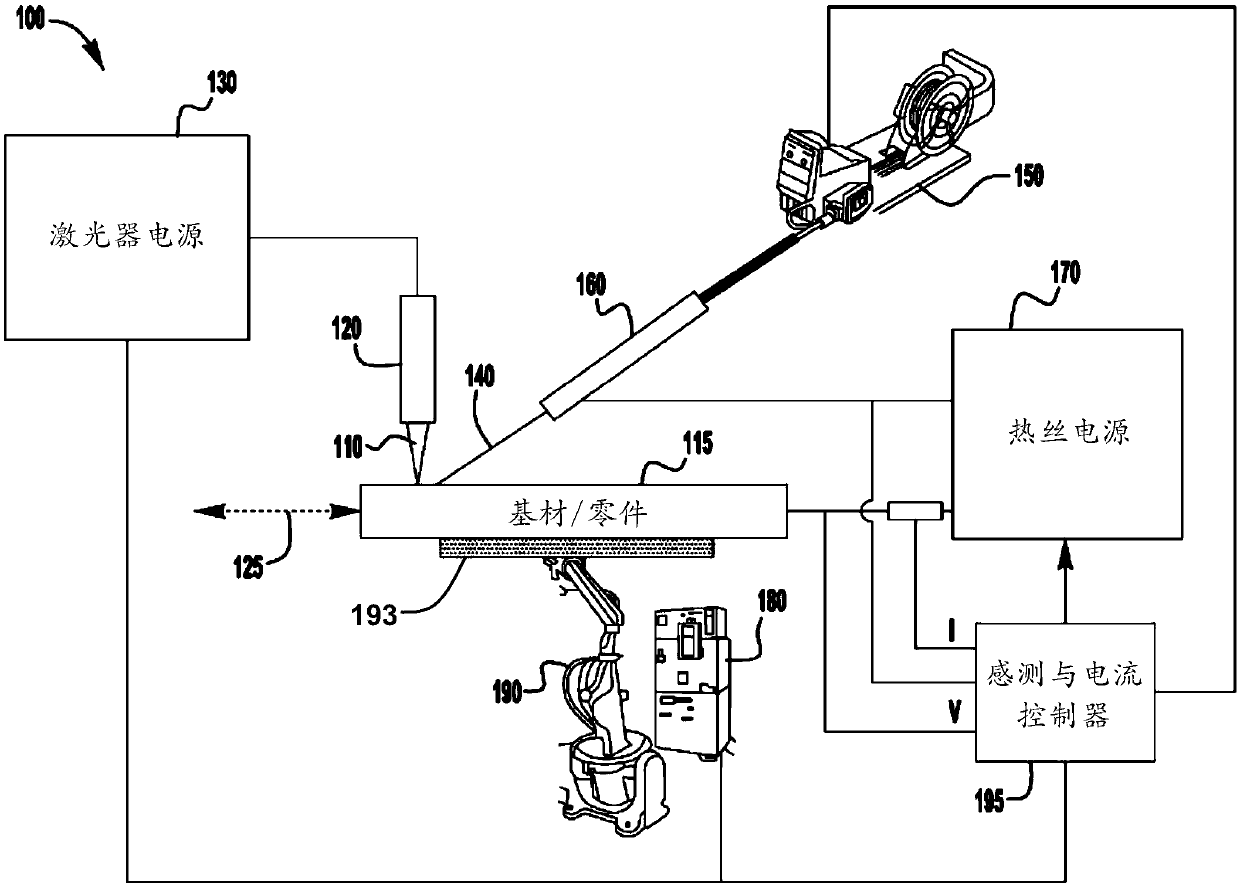

[0031] As is well known, additive manufacturing is a process of depositing material (eg, in multiple layers) onto a substrate / substrate or part in order to create a desired manufactured product. According to one embodiment, a pattern of layers of a three-dimensional (3D) part to be additively manufactured is rendered and stored as digital data. The digital data may eg come from a CAD model or from a scanned part. In some applications, the article may be very complex. However, known methods and systems for additive manufacturing tend to be slow and have limited performance. Embodiments of the present invention address these aspects by providing systems and methods that enable structure building techniques to improve the time and efficiency of additively manufacturing three-dimensional (3D) parts and improve the resulting performance and quality of the parts.

[0032] Embodiments of additive manufacturing systems and methods are disclosed. In one embodiment, an additive manuf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com