Vertical steel bar welding robot in construction site

A technology for welding robots and construction sites, applied in welding equipment, welding accessories, manufacturing tools, etc., can solve the problems of easy fatigue, severe sweating, hard quality and heavy weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

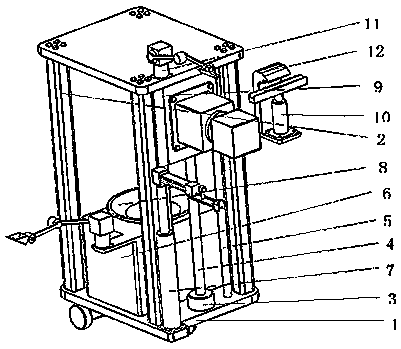

[0017] The invention provides a vertical steel bar welding robot on a construction site. The robot is a welding robot based on electroslag pressure welding, which can replace manual work, thereby reducing labor intensity, improving overall safety, and saving construction costs.

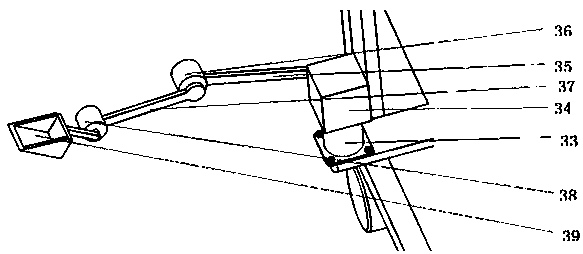

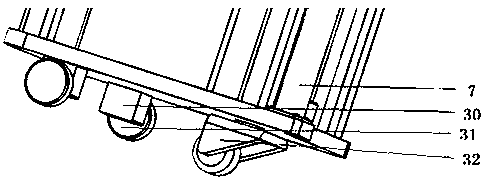

[0018] As an embodiment of the present invention, the present invention provides a vertical reinforcement welding robot on a construction site, including a support frame 1, a support rod 2, a screw motor 3, a transmission screw 4, a slide rod 5, a hydraulic oil tank 6, a hydraulic cylinder 7, Flux holding plate 8, vertical moving plate 9, auxiliary hydraulic cylinder 10, motor one 11, wide hook 12, hydraulic rod fork 13, main motor one 14, main motor two 15, motor two 16, rod one 17, motor three 18 , rod two 19, motor four 20, welding handle wire 21, vertical hydraulic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com