Coaxial in-arc wire feeding and out-arc powder feeding TIG electric arc additive manufacturing device

An additive manufacturing and powder feeding technology, applied in the field of arc additive manufacturing, can solve the problems of increased manufacturing cost, difficult to manufacture wire, difficult to manufacture parts with high alloy content, etc., to achieve constant process conditions and ensure molding. The effect of quality, isolation against damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

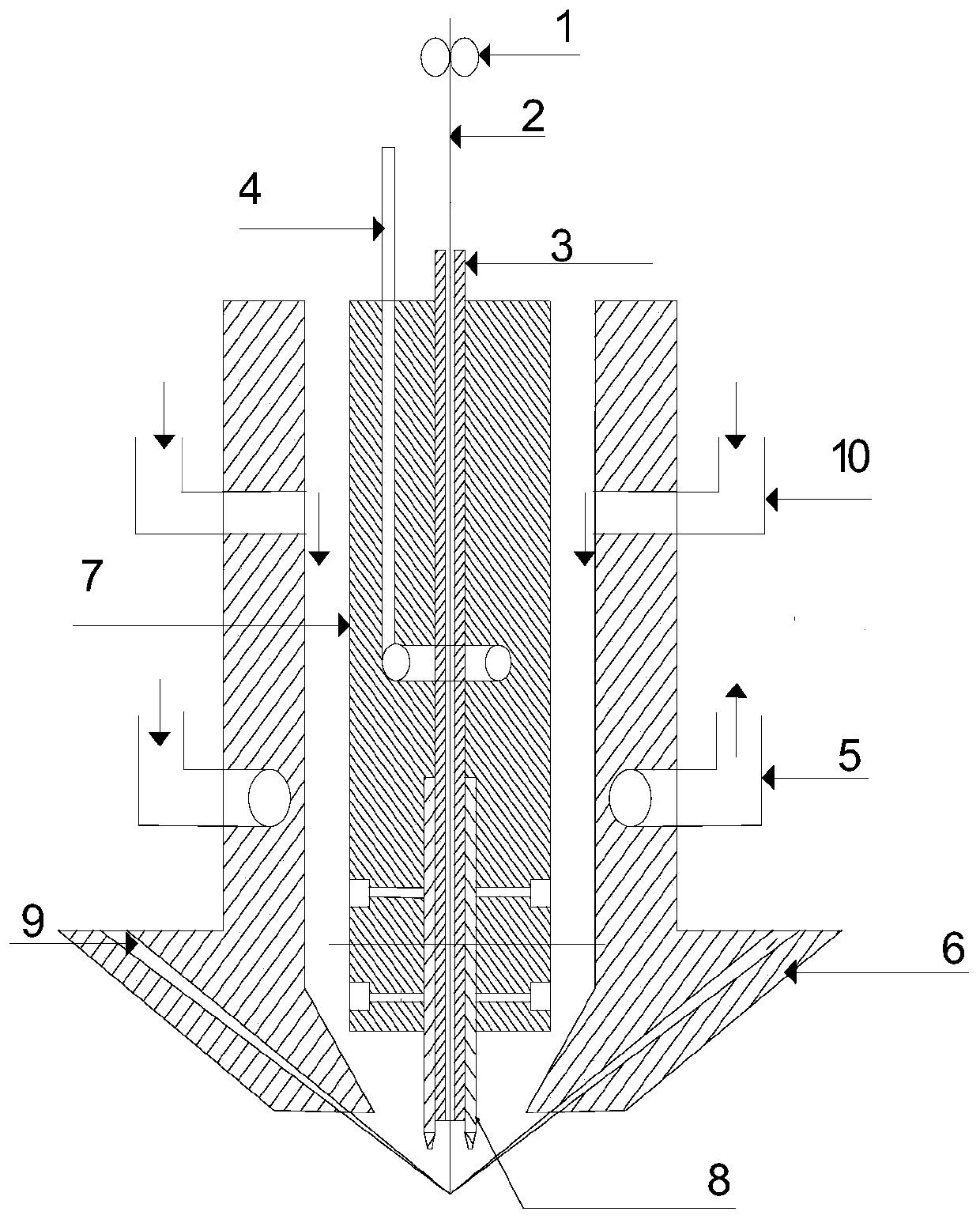

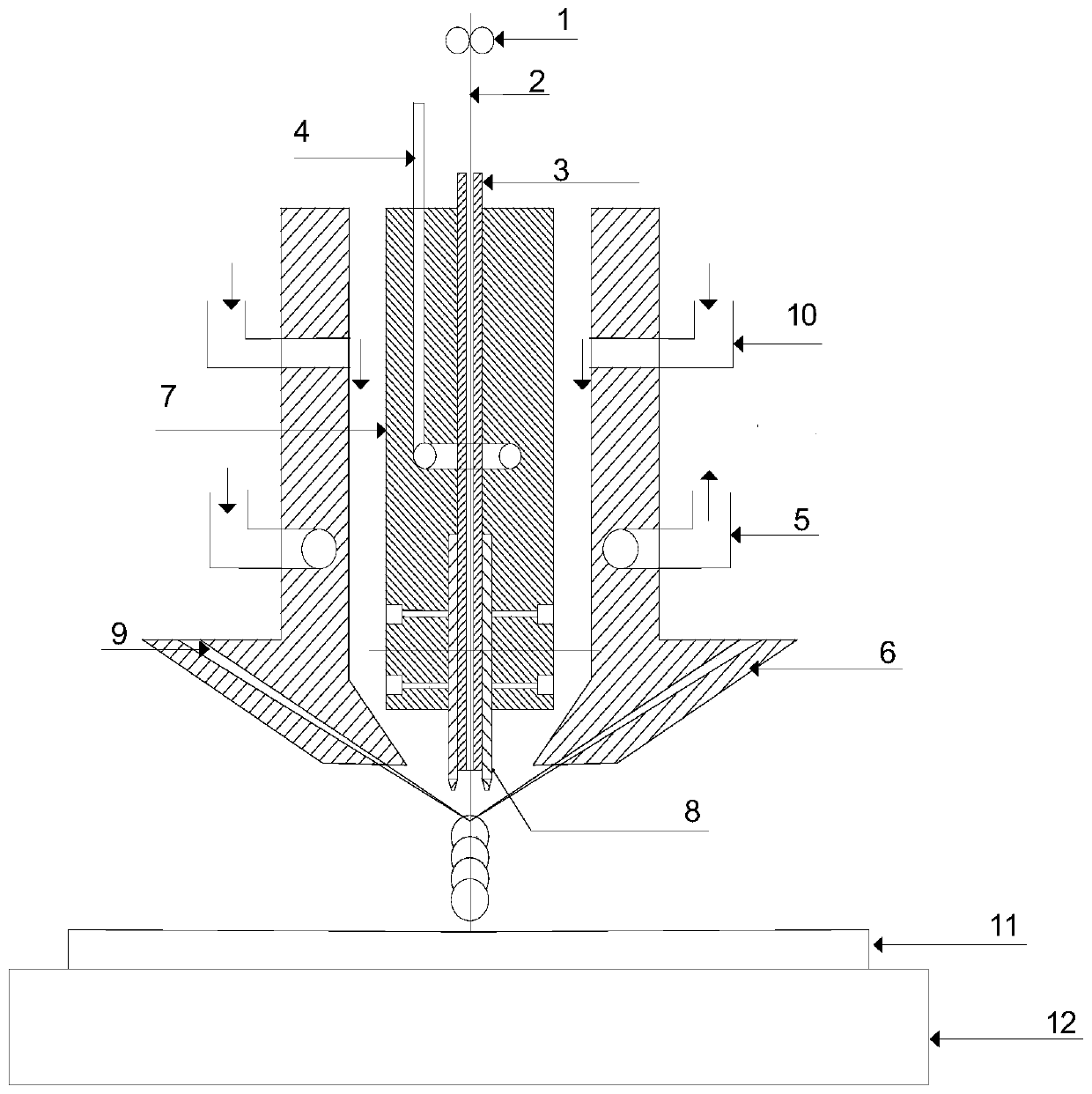

[0050] A coaxial arc wire feeding and arc powder feeding TIG arc additive manufacturing device, the device includes SiO 2 Glass tube 3, four-way powder feeding nozzle 6, tungsten copper cooling body 7, half-split hollow tungsten electrode 8 and four-way powder feeding channel 9;

[0051] SiO 2 The glass tube 3 passes through the tungsten copper cooling body 7, the tungsten copper cooling body 7 is arranged in the four-way powder feeding nozzle 6, and the four-way powder feeding channel 9 is arranged at the bottom of the four-way powder feeding nozzle 6 (that is, as figure 2 at the frustum of the bottom shown);

[0052] The upper end of the half-split hollow tungsten pole 8 extends into the copper tungsten cooling body 7, SiO 2 The lower end of the glass tube 3 extends into the half-cracked hollow tungsten electrode 8;

[0053] SiO 2 The glass tube 3, the half-split hollow tungsten electrode 8 and the four-way powder feeding nozzle 6 adopt a coaxial design.

[0054] The h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com