TIG wire feeding pen

A wire pen and wire feeding technology, applied in welding equipment, welding accessories, arc welding equipment and other directions, can solve the problems of poor uniformity and stability of manual wire feeding, inconvenient portability and maintenance, large volume and quality, etc. Uniformity and instability issues, improved weld formation and quality, easy and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to better understand the purpose, technical solutions and advantages of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to explain the present invention, and are not intended to limit the present invention.

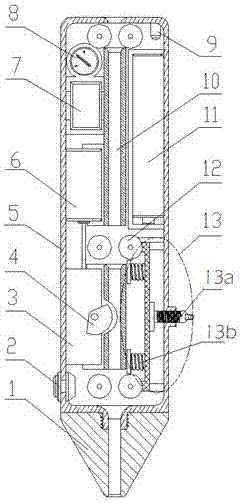

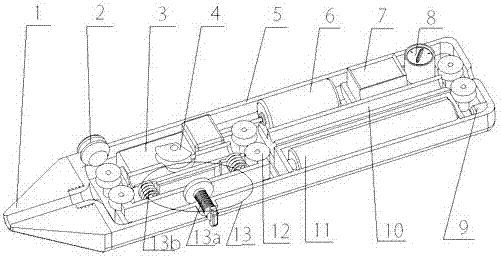

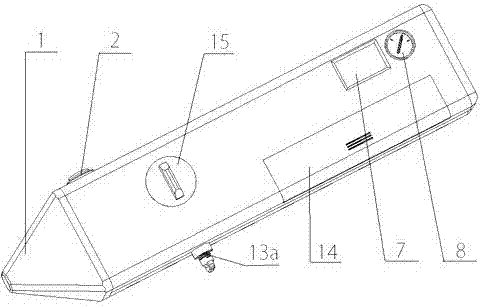

[0019] See attached Figure 1 ~ Figure 4 , a TIG welding wire feeding pen, the wire feeding channel is formed by six guide wheels 12, a welding wire conduit 10, the wire outlet hole of the heat sink tip 1 and the wire inlet hole at the rear end of the pen housing 5. The wire feeding wheel 4, the speed reducer 3 are connected with the micro motor 6 to provide power for the wire feeding. The micro motor 6, the electricity display 7, the governor 8, the charging interface 9 and the rechargeable battery 11 are connected by wires to form a power supply system. The pressure regulating valve 13a and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com