Patents

Literature

566results about How to "Improve unevenness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

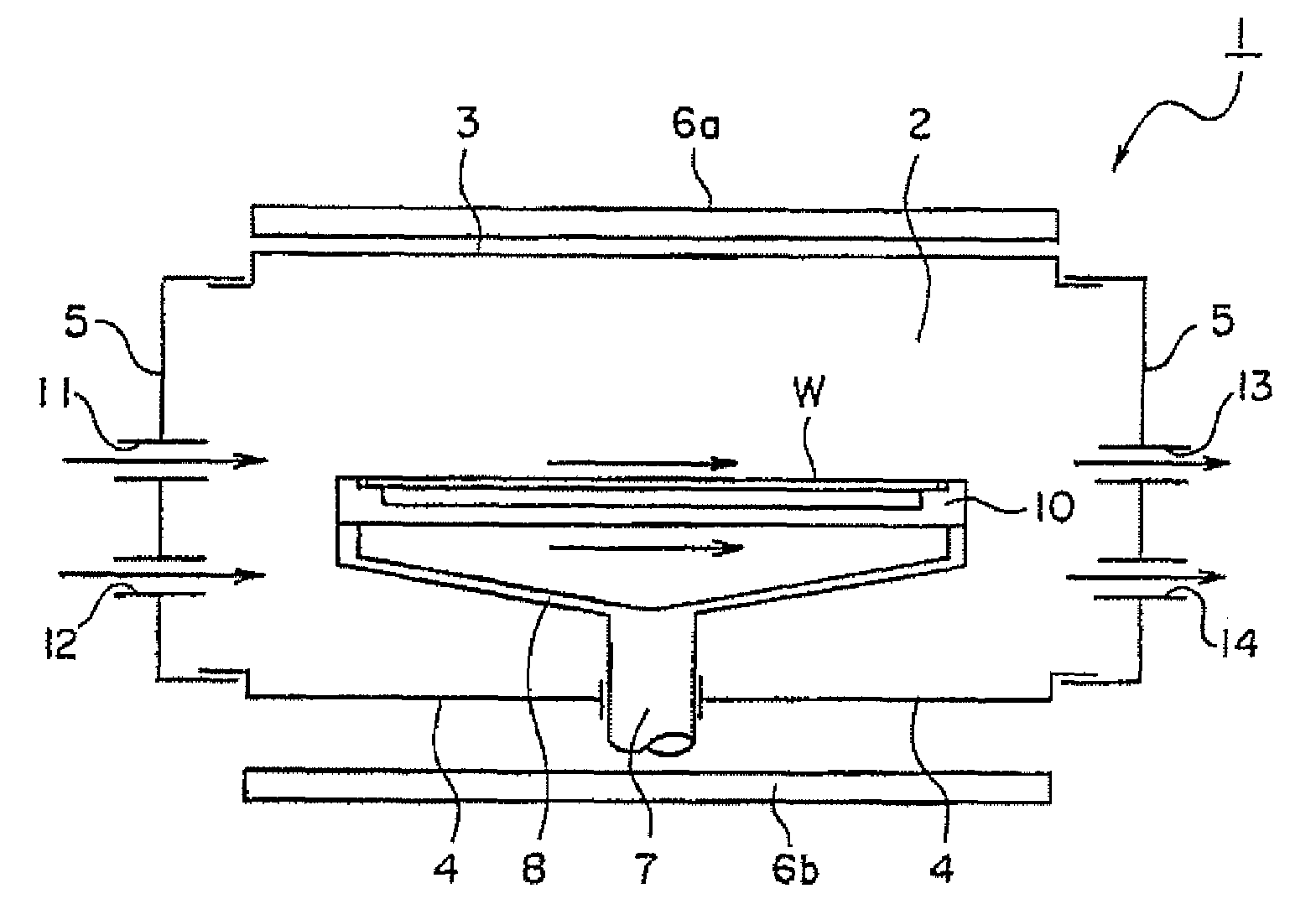

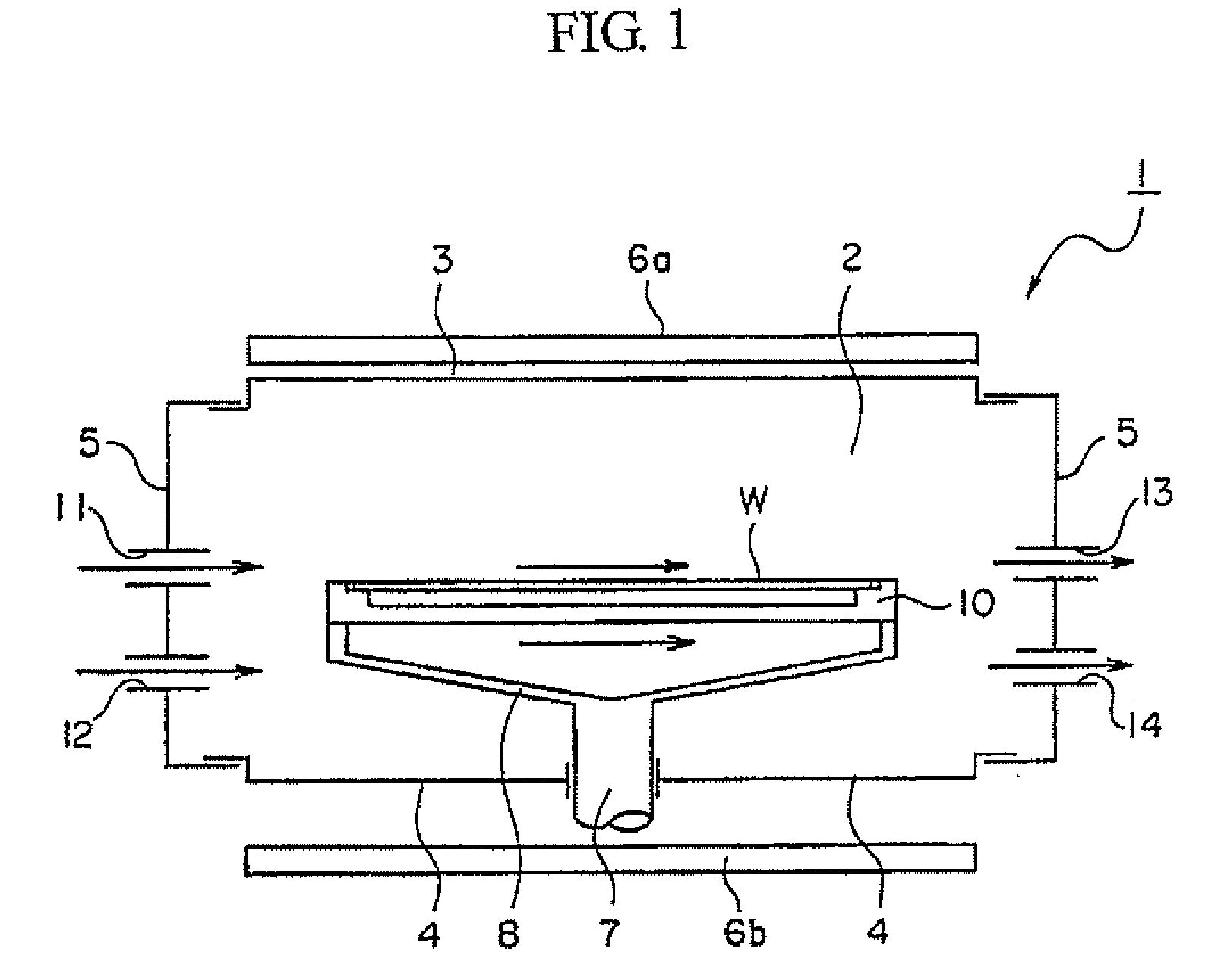

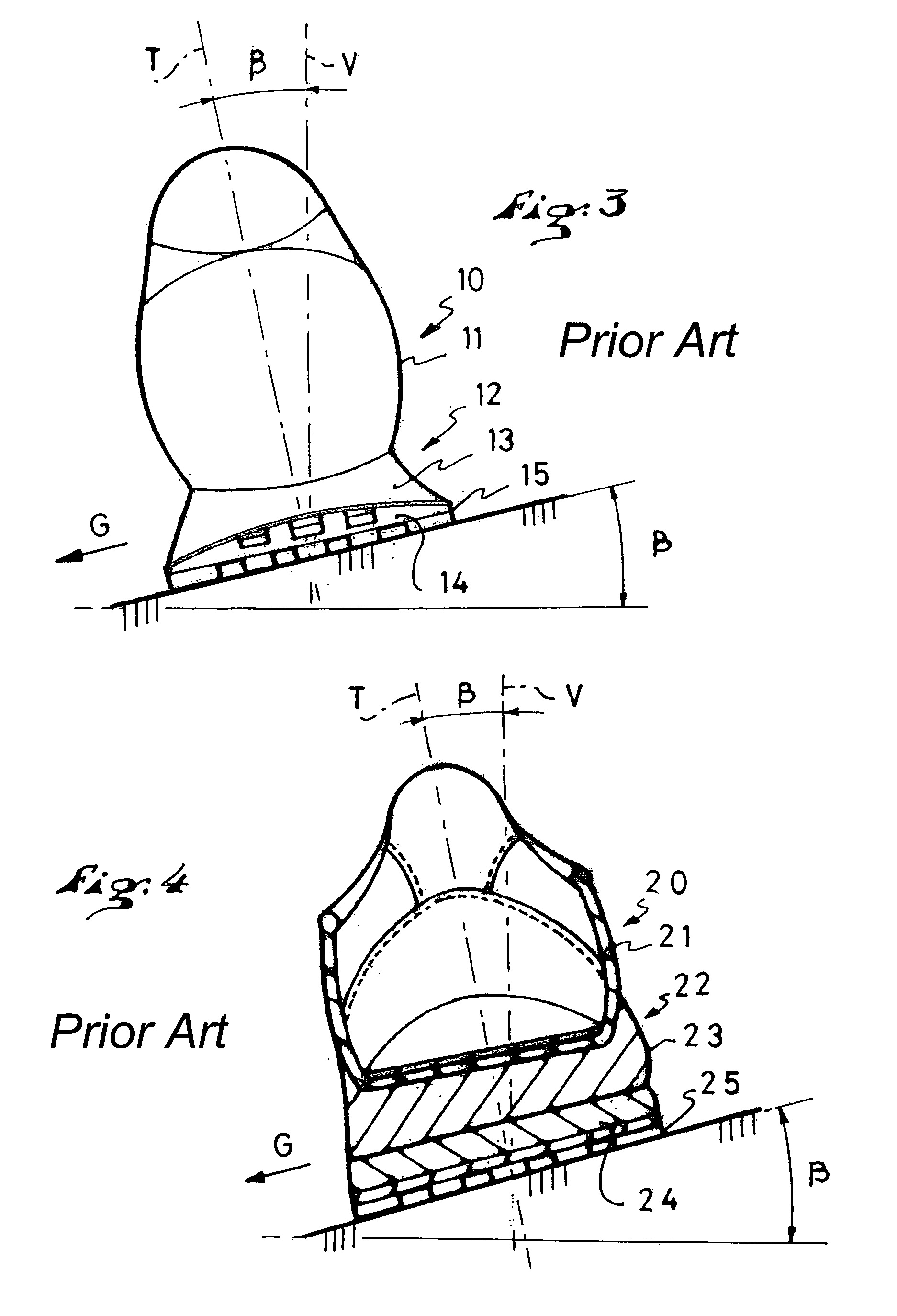

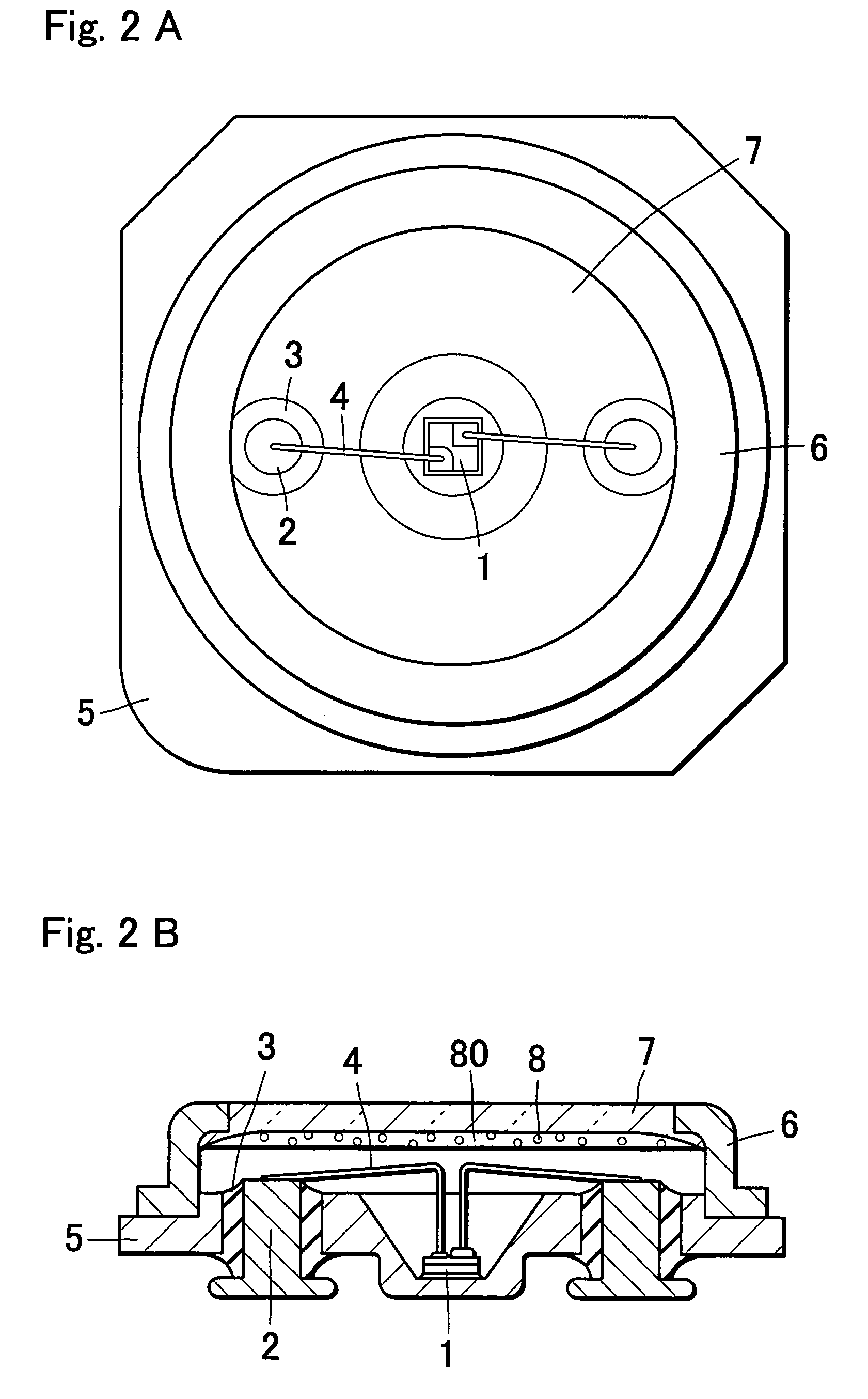

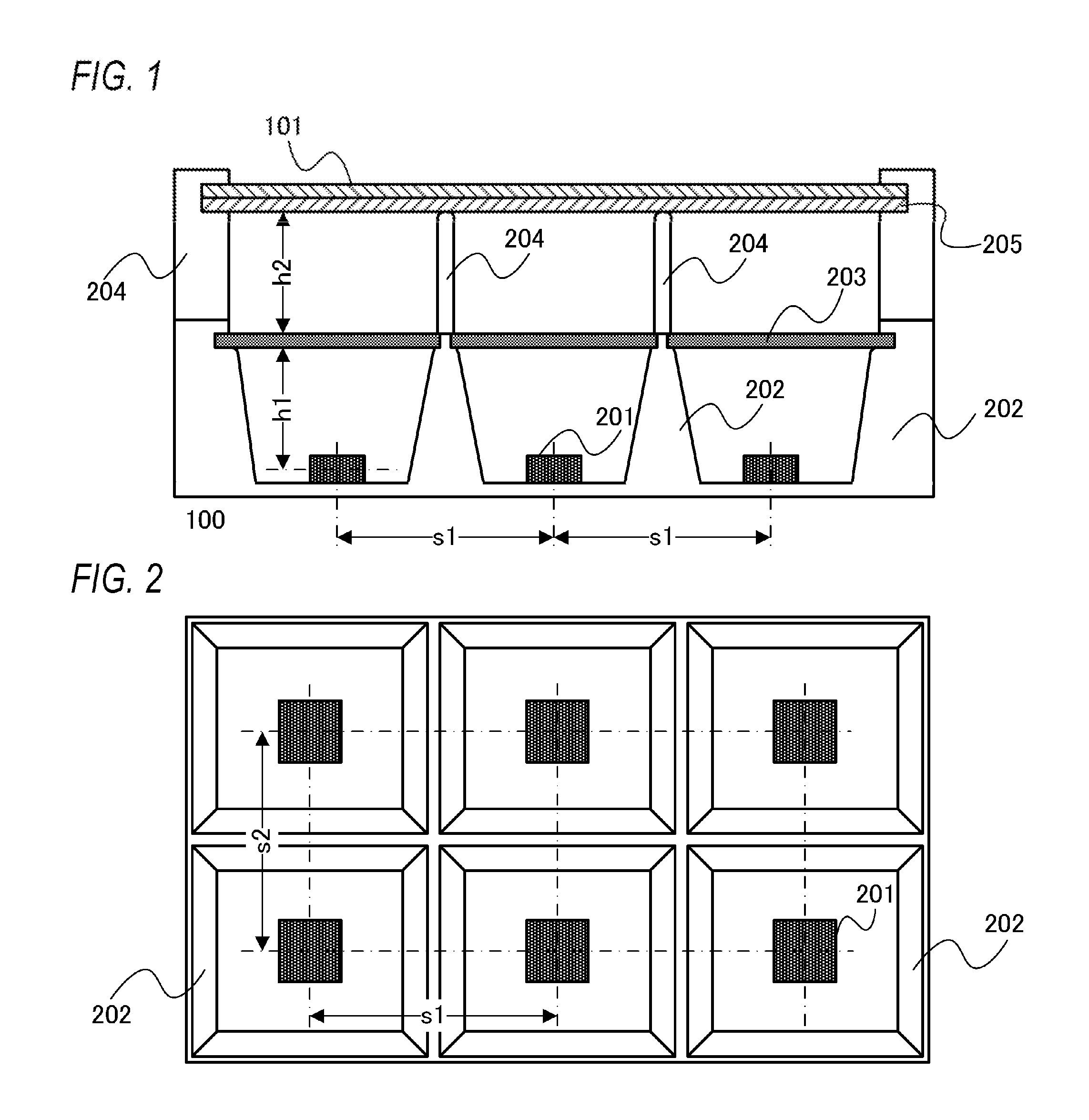

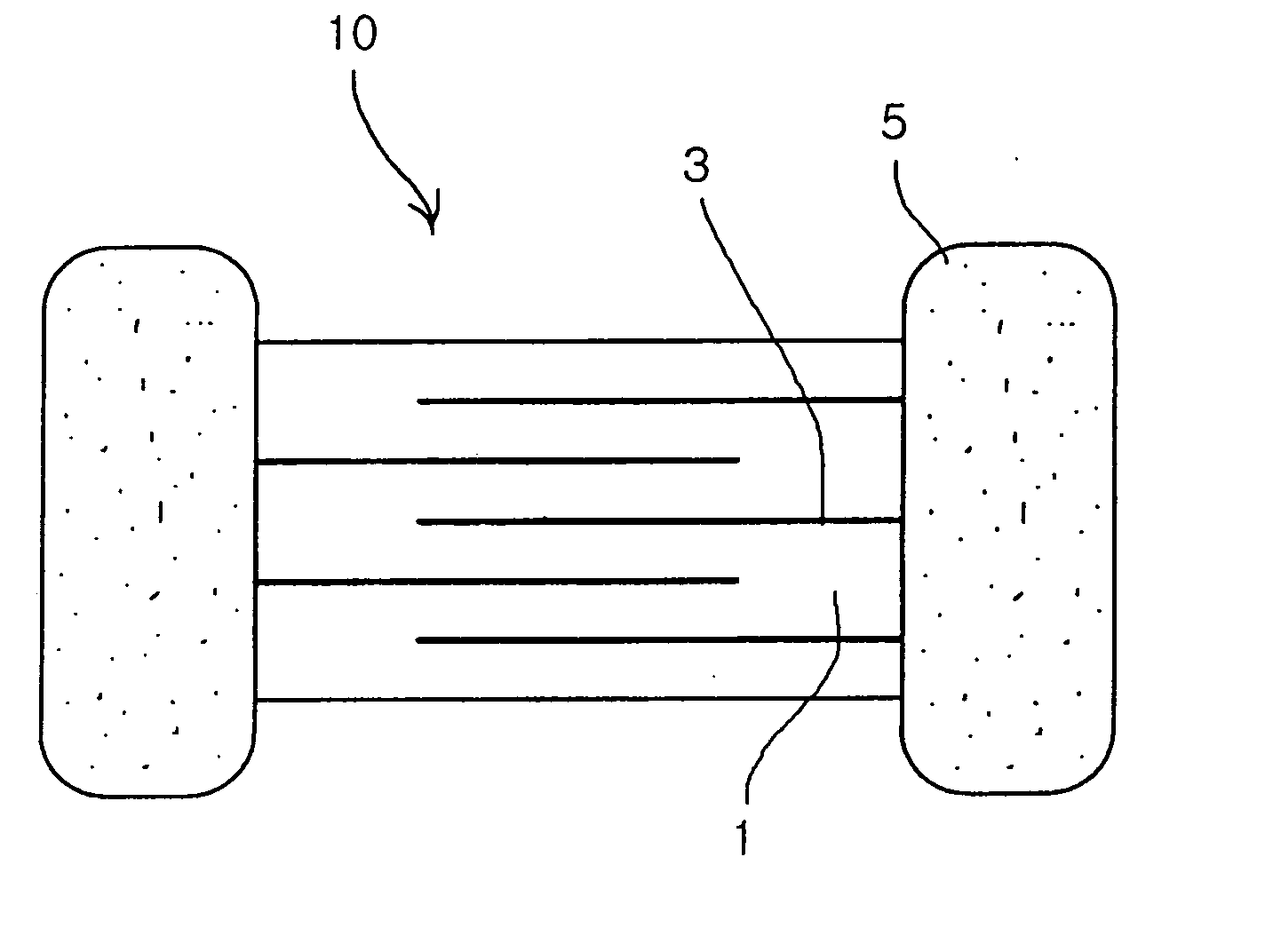

Susceptor For Vapor-Phase Growth Reactor

InactiveUS20080110401A1Avoid radiationPreventing growth unevenness of an epitaxial layerSemiconductor/solid-state device manufacturingFrom chemically reactive gasesSusceptorGas phase

In a susceptor (10) having a wafer pocket (101) for receiving a wafer W at the time of vapor-phase growth, the wafer pocket has at least a first pocket portion (102) for loading an outer circumferential portion of the wafer and a second pocket portion (103) formed to be lower than the first pocket and having a smaller diameter than that of the first pocket portion, and a fluid passage (105) having one end (105a) opening on a vertical wall (103a) of said second pocket portion and the other end (105b) opening on a back surface (104) or a side surface (106) of the susceptor is formed.

Owner:SUMCO CORP

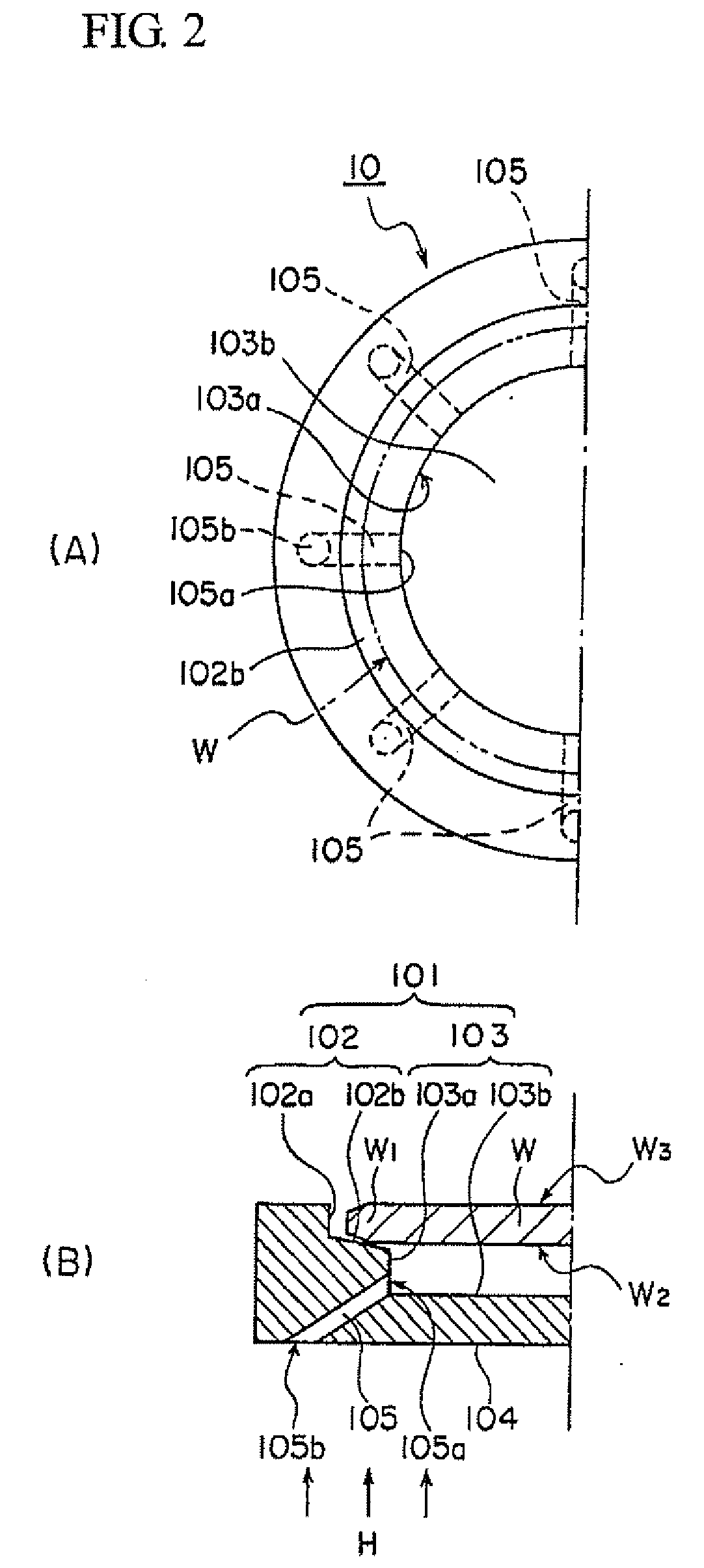

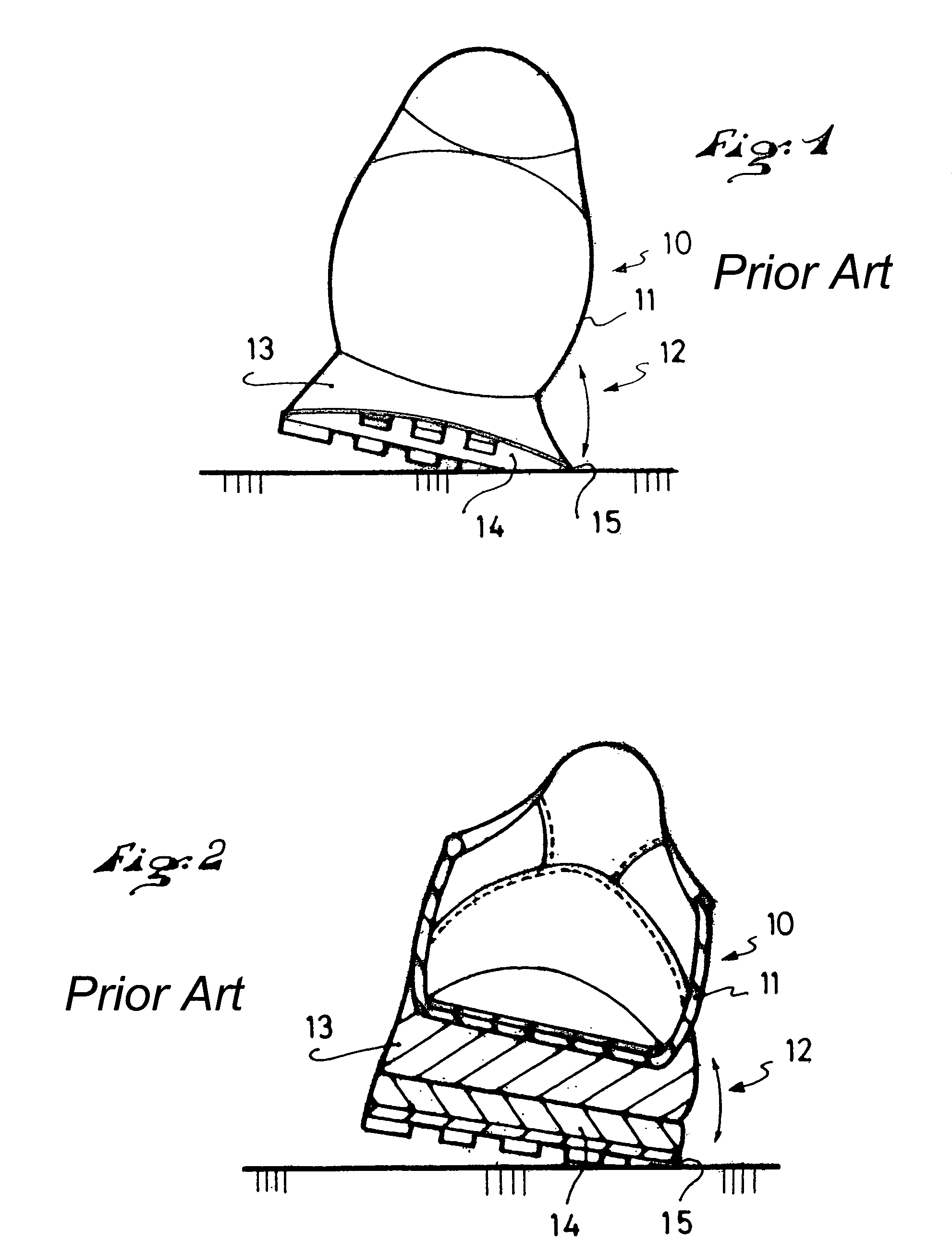

Bottom assembly for an article of footwear

ActiveUS7159339B2Improve gripStrong irregularityCosmetic preparationsSolesEngineeringMechanical engineering

An article of footwear having an upper and an outer bottom assembly, the outer bottom assembly having an outsole and, in the heel zone, an elastically deformable element that is substantially arch-shaped in the transverse direction and extends downward from the lower end of the upper to the medial, lateral edges, respectively, of the outsole.

Owner:SALOMON SA

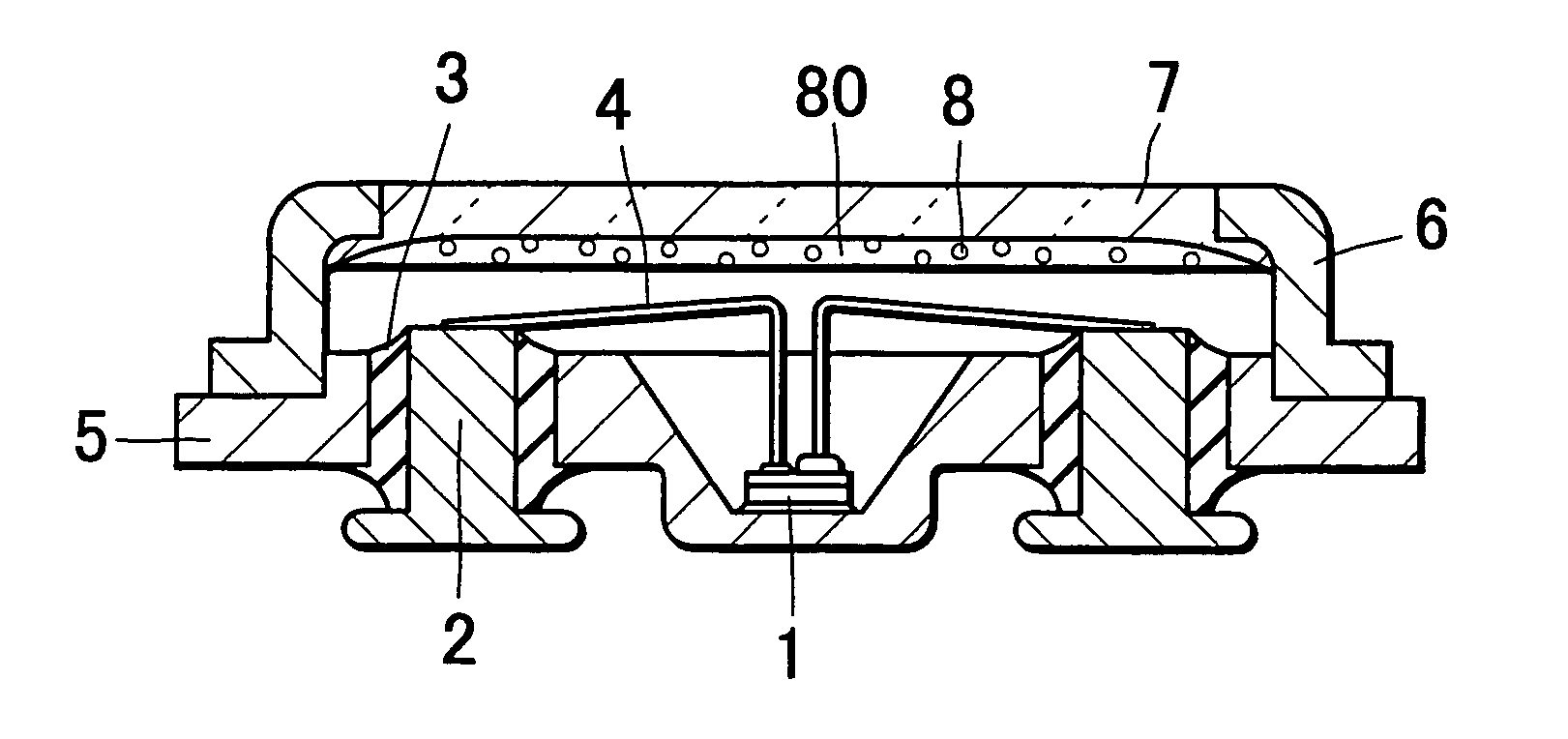

Light emitting device

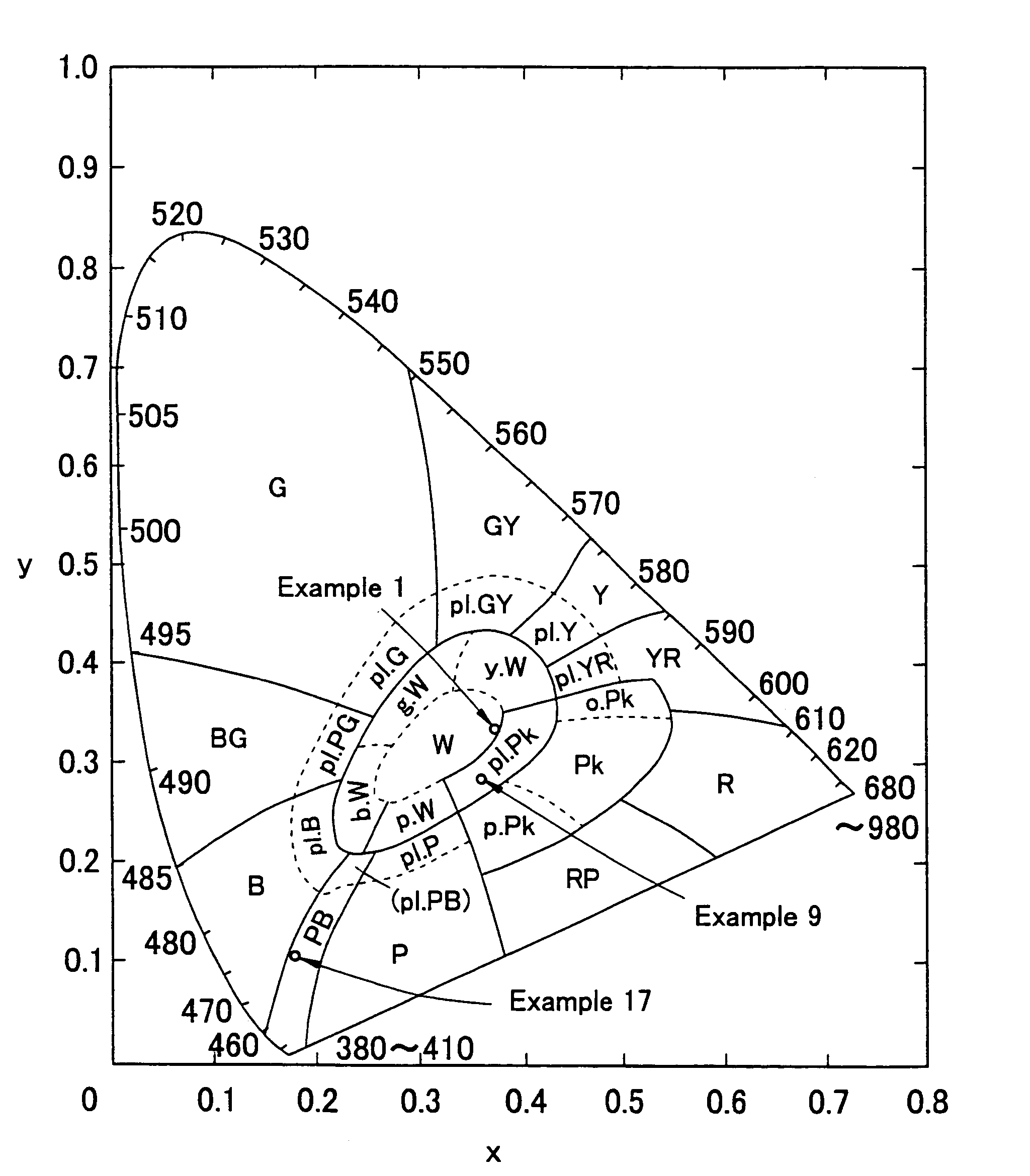

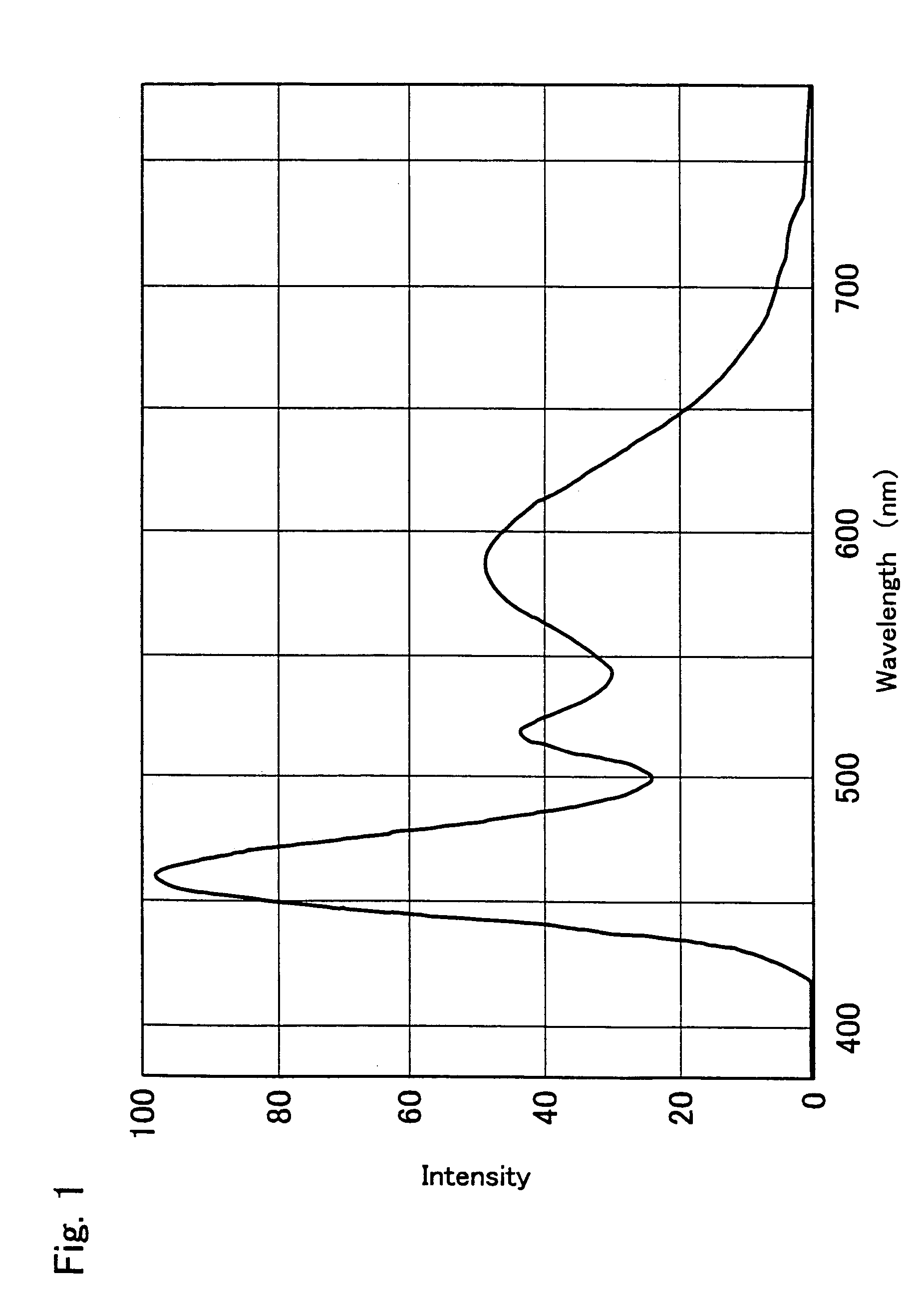

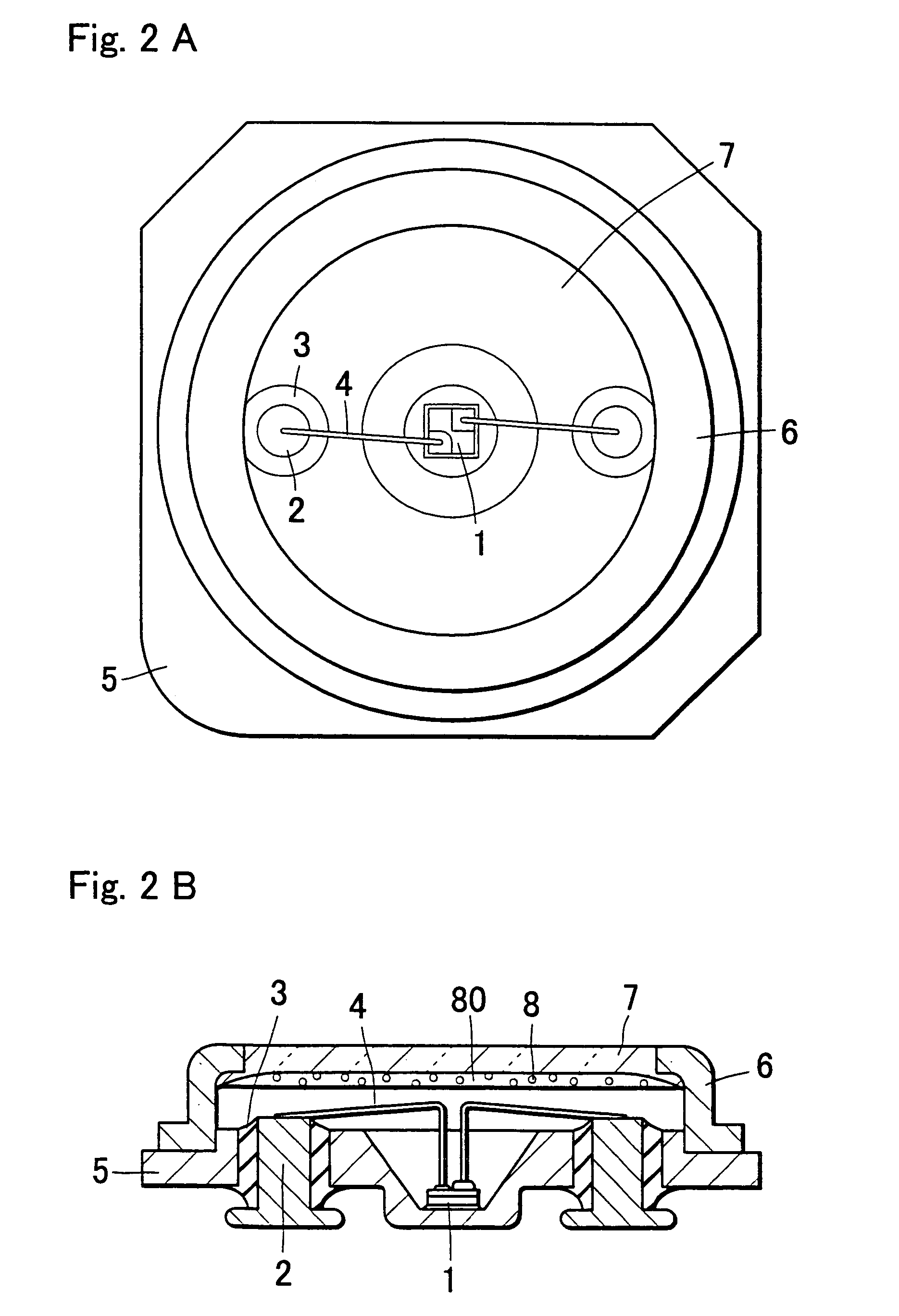

InactiveUS7091656B2Less variation in color toneIncrease brightnessDischarge tube luminescnet screensLamp detailsFluorescenceLength wave

To minimize the variability in the emitted light color and improve the unevenness of color tone, a light emitting device comprises a light emitting element and a fluorescent substance that is excited by the light emitting element, wherein the light emitting element has an emission spectrum in a region from ultraviolet to visible light of short wavelengths, and the fluorescent substance has an emission spectrum that includes two or more emission peaks with at least two peaks of the two or more peaks being in the relation of complementary colors of each other.

Owner:NICHIA CORP

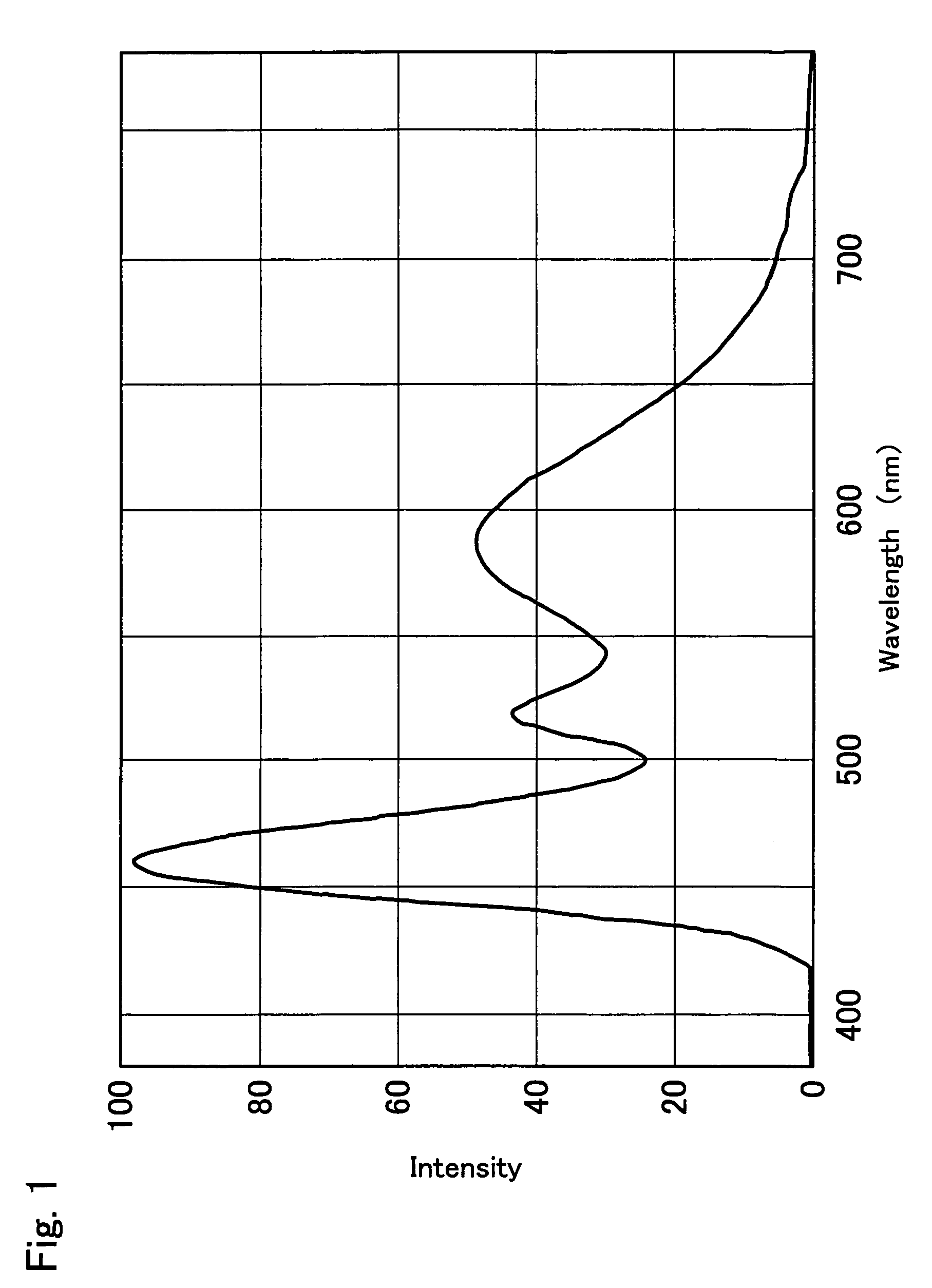

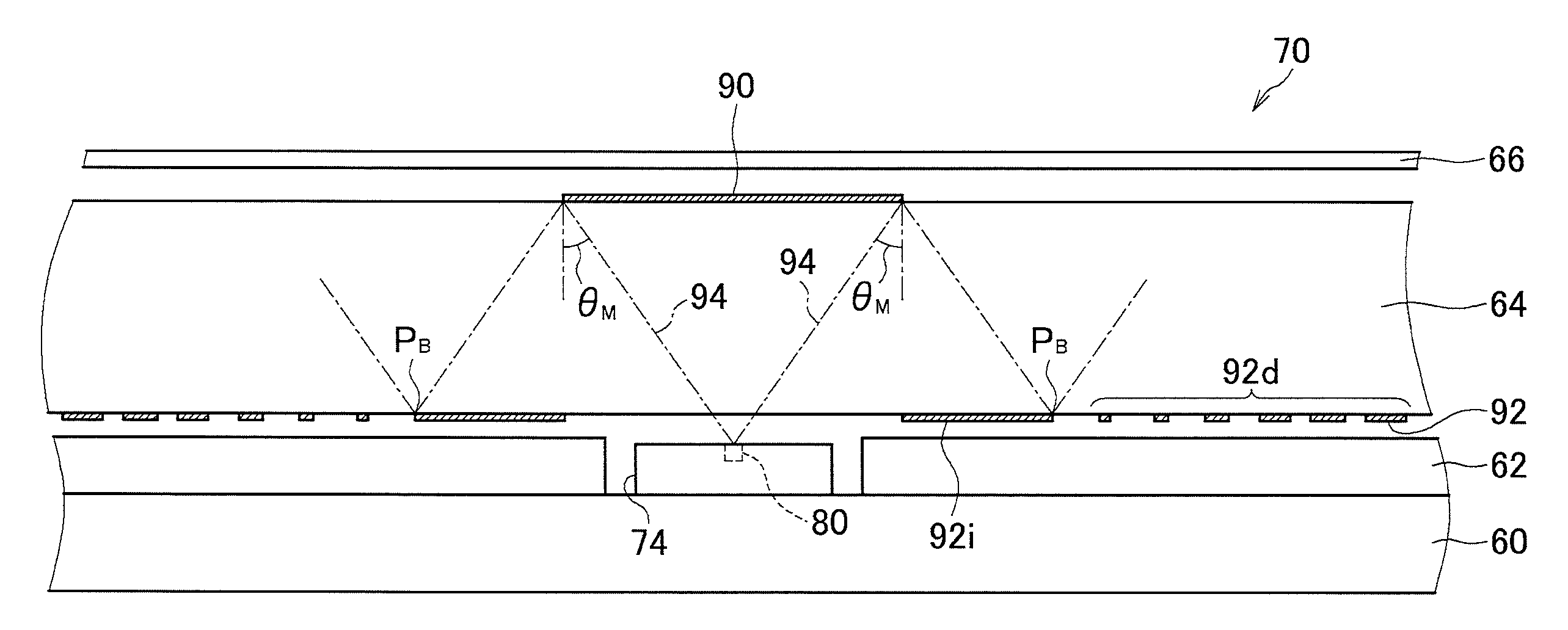

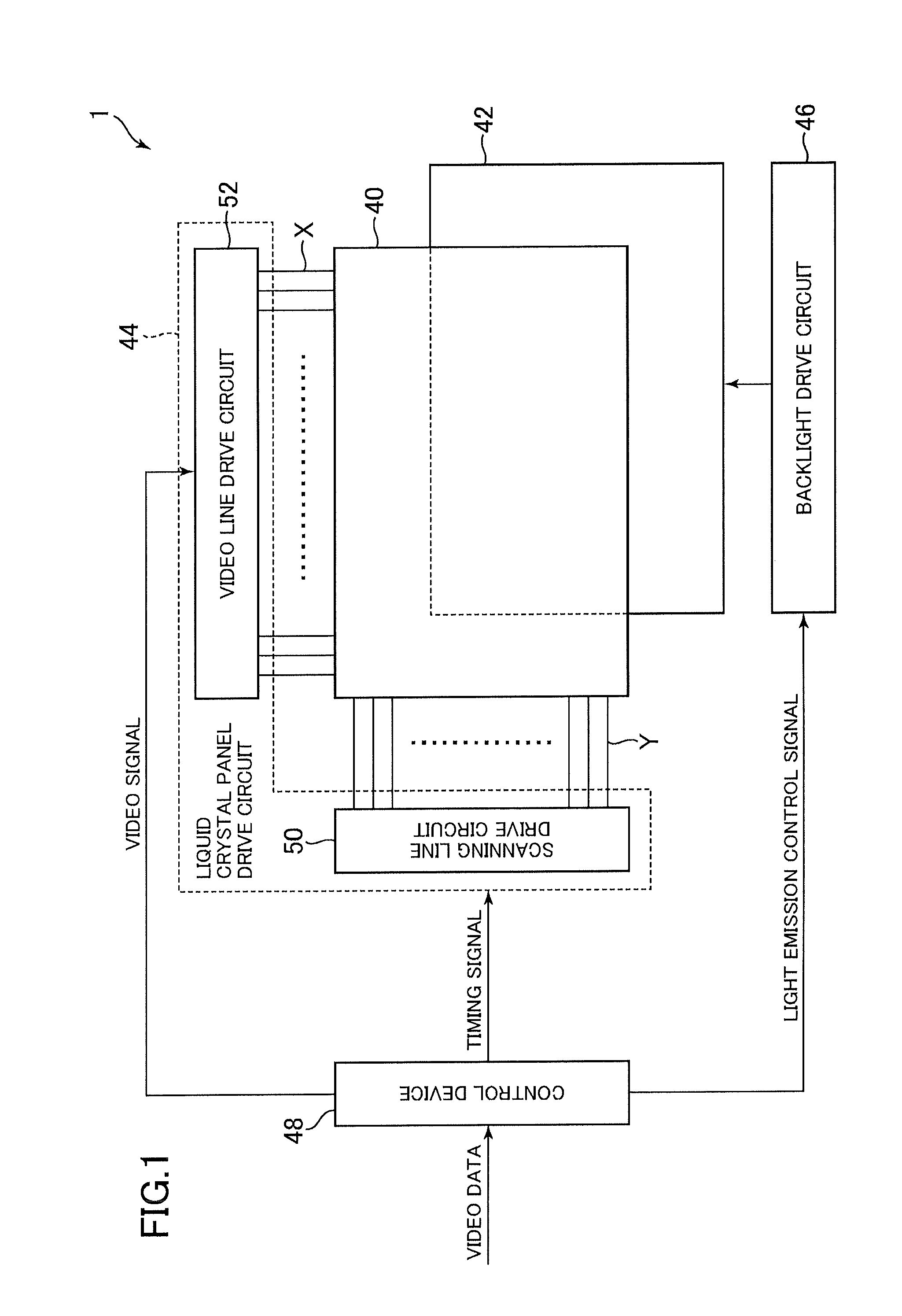

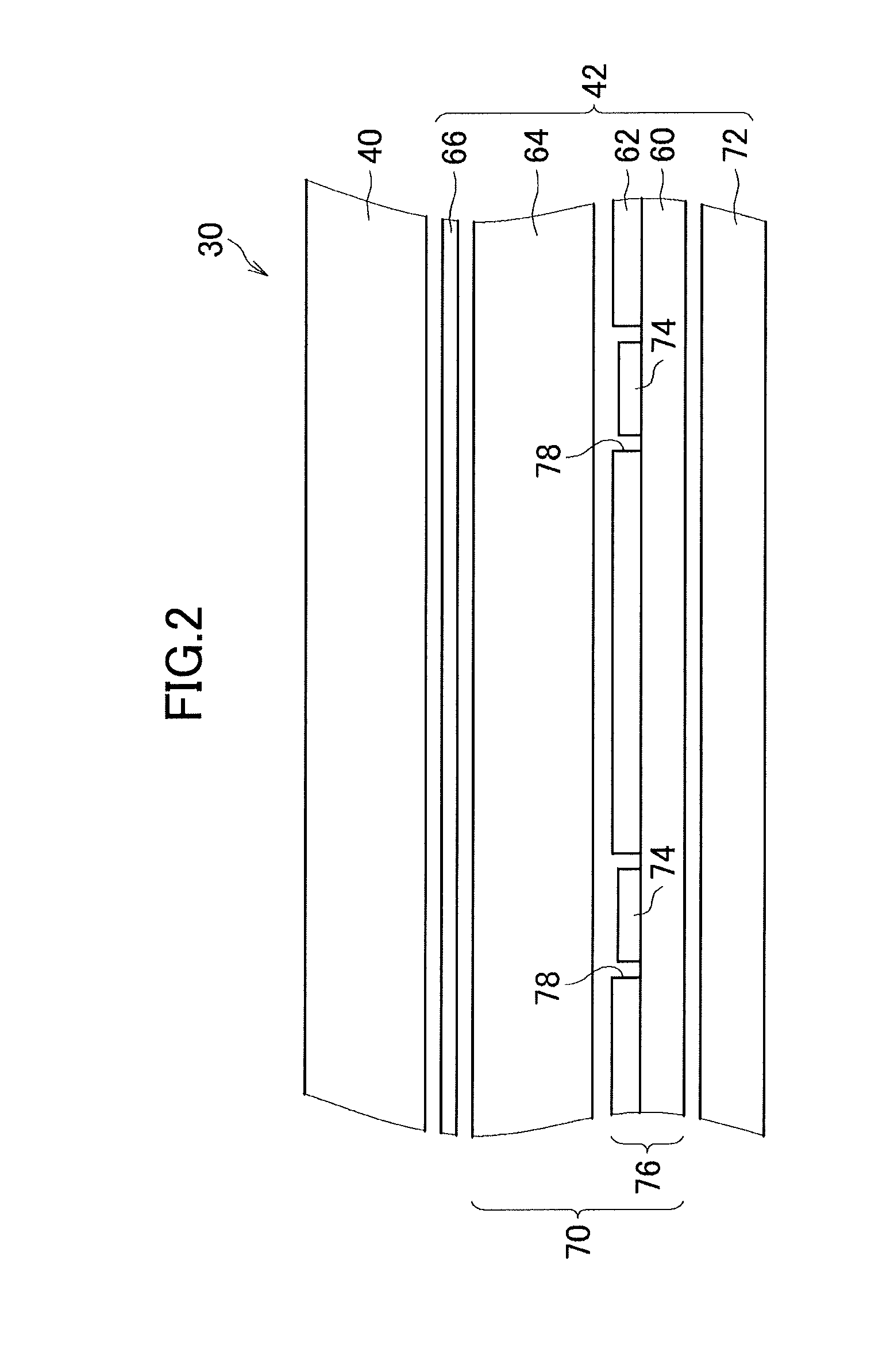

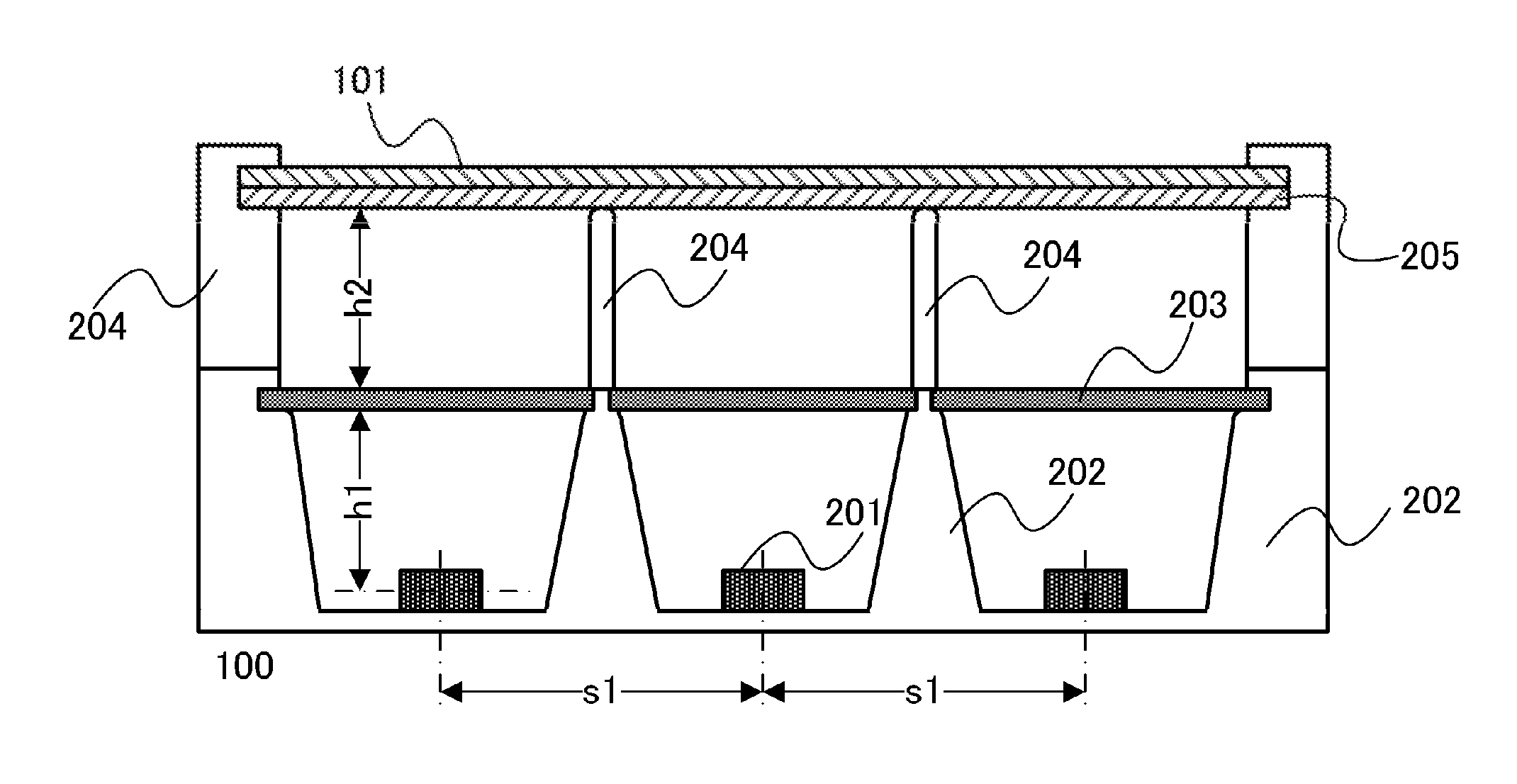

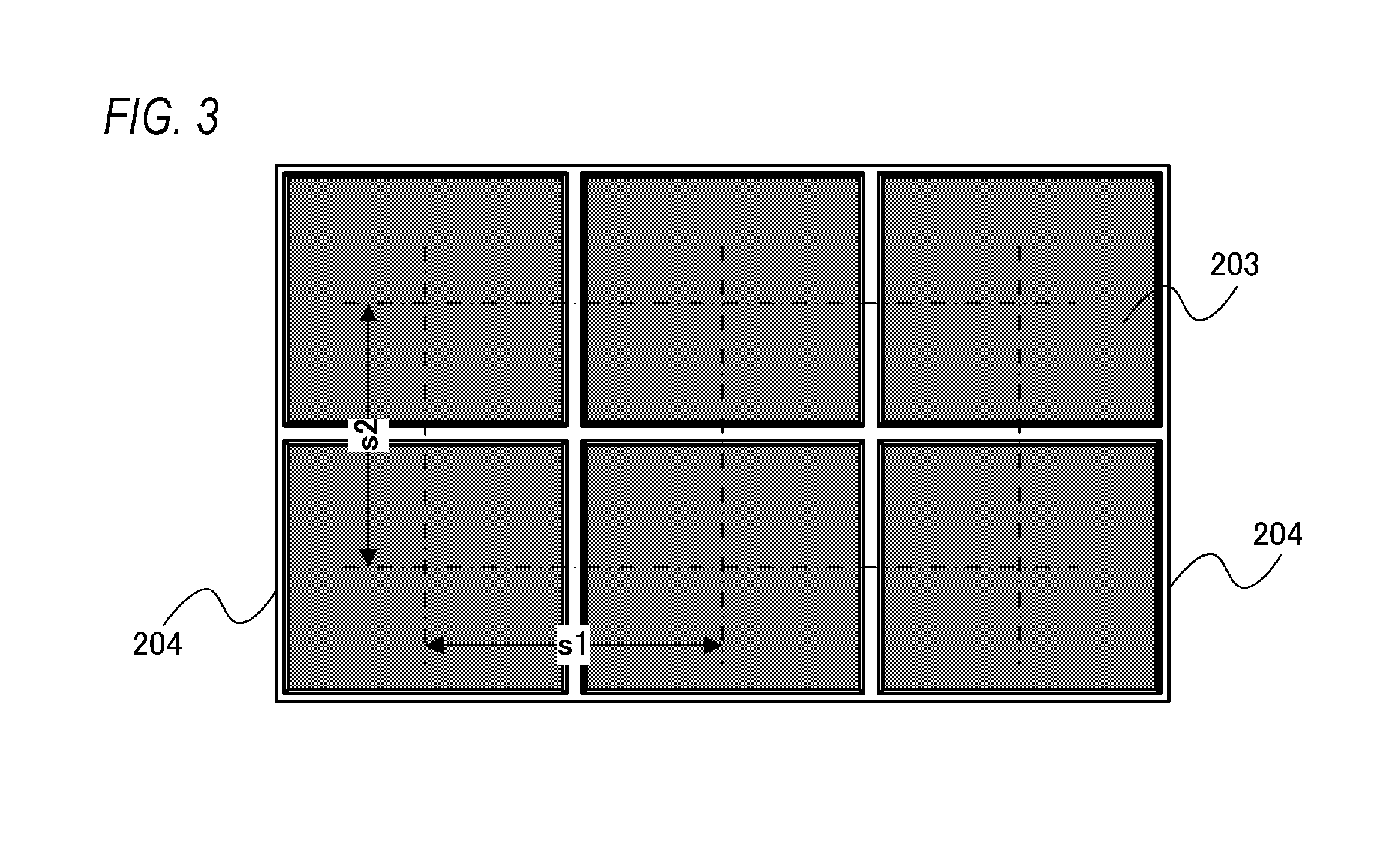

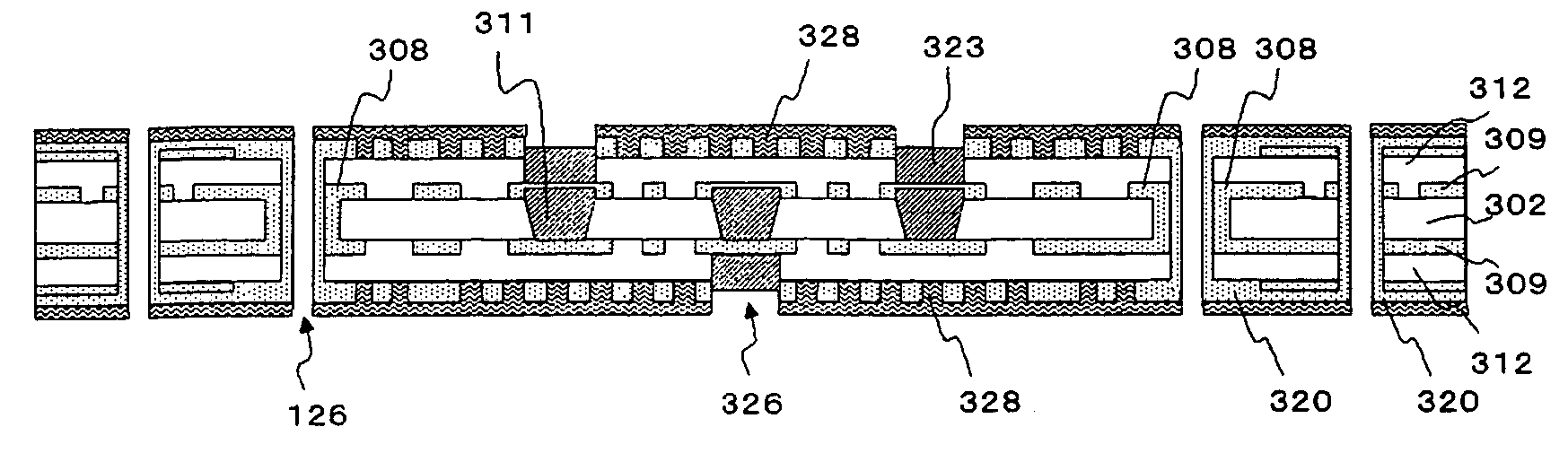

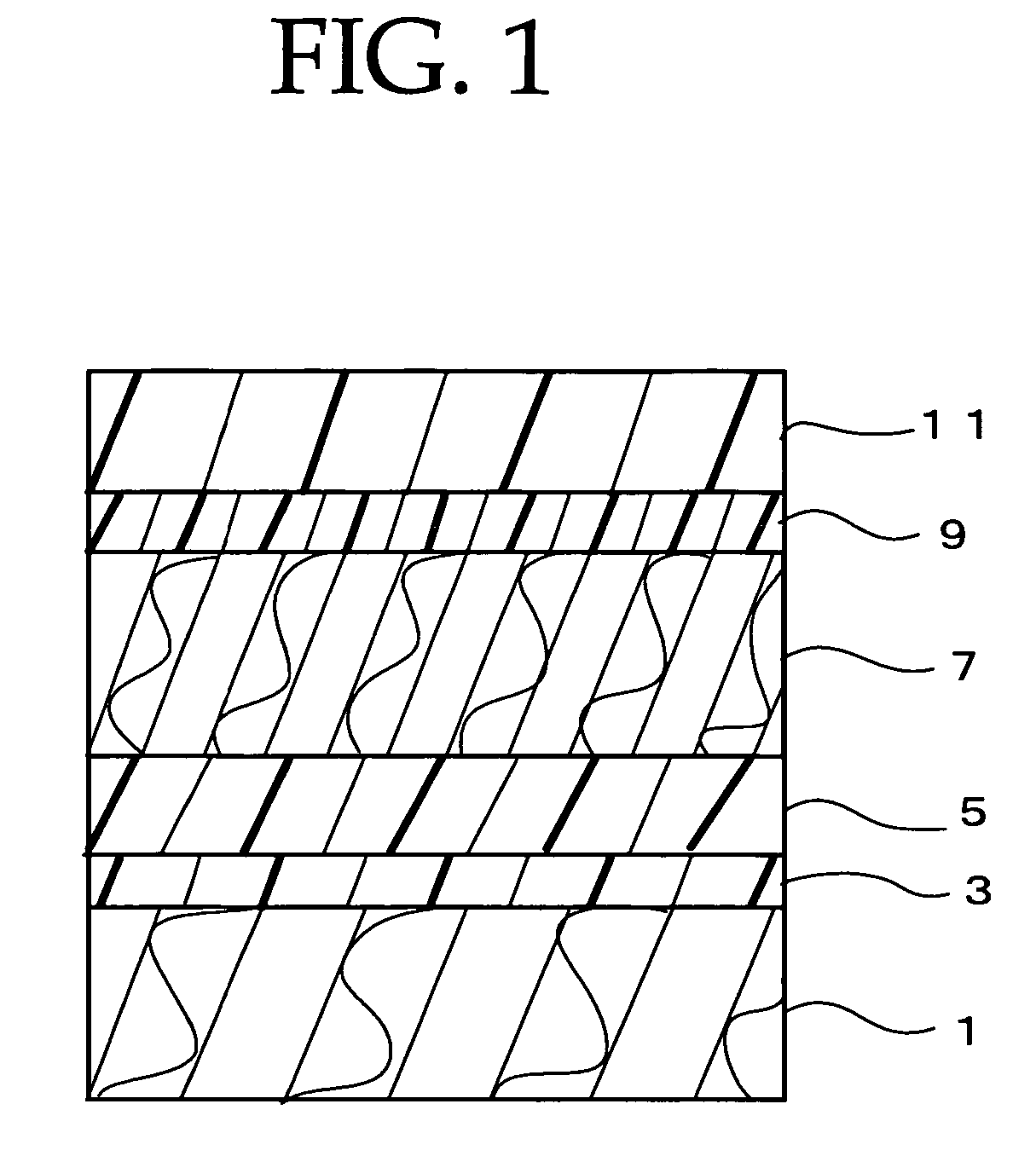

Planar light source device, liquid crystal display device, and television set

InactiveUS20120224111A1Unevenness in intensityImprove unevennessMechanical apparatusTelevision system scanning detailsLiquid-crystal displayEngineering

In a direct type backlight device of a liquid crystal display device, a light guide plate is used obtain a uniform in-plane distribution of light emission intensity. A reflective sheet (62) having an opening portion is laminated on a front surface of an LED substrate (60), and an LED element (74) is accommodated inside the opening portion. A light guide plate (64) is stacked on the reflective sheet (62). On a front surface of the light guide plate (64), a white reflective film (90) is formed in a non-total reflection region, which is positioned to oppose the LED element (74) and in which an incident angle of light emitted from the LED element (74) to the front surface is smaller than a critical angle. On a rear surface of the light guide plate (64), a pattern made of a white reflective film (92) is formed.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD

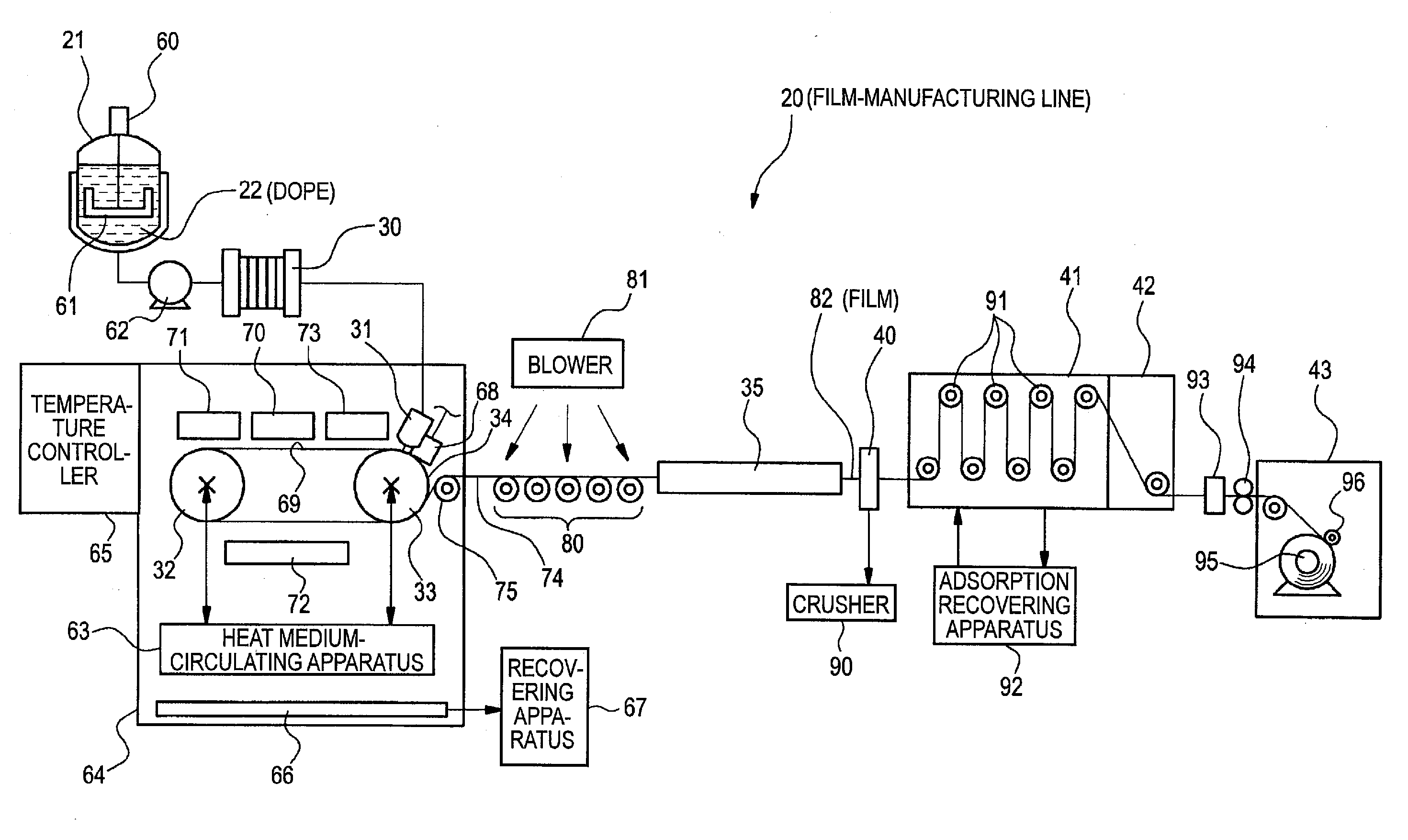

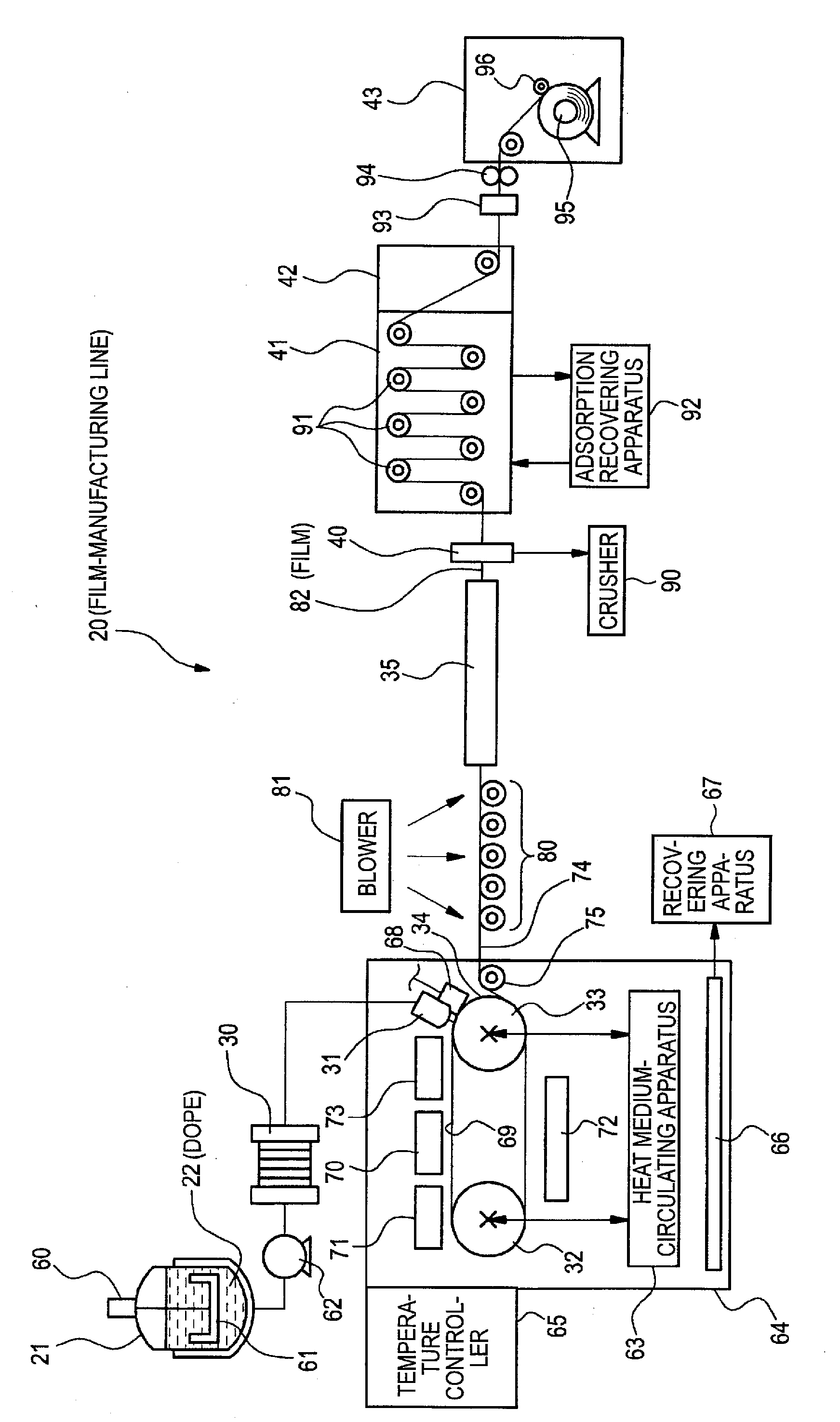

Cellulose acylate film and method for producing the same

A cellulose acylate film showing 10 marks / M2 or less of adhesion marks and having an in-plane retardation value (Re value) of 0 to 200 nm and a retardation value along the thickness direction (Rth value) of 30 to 500 nm. The cellulose acylate film shows favorable optical uniformity and can provide an improved liquid crystal display.

Owner:FUJIFILM CORP

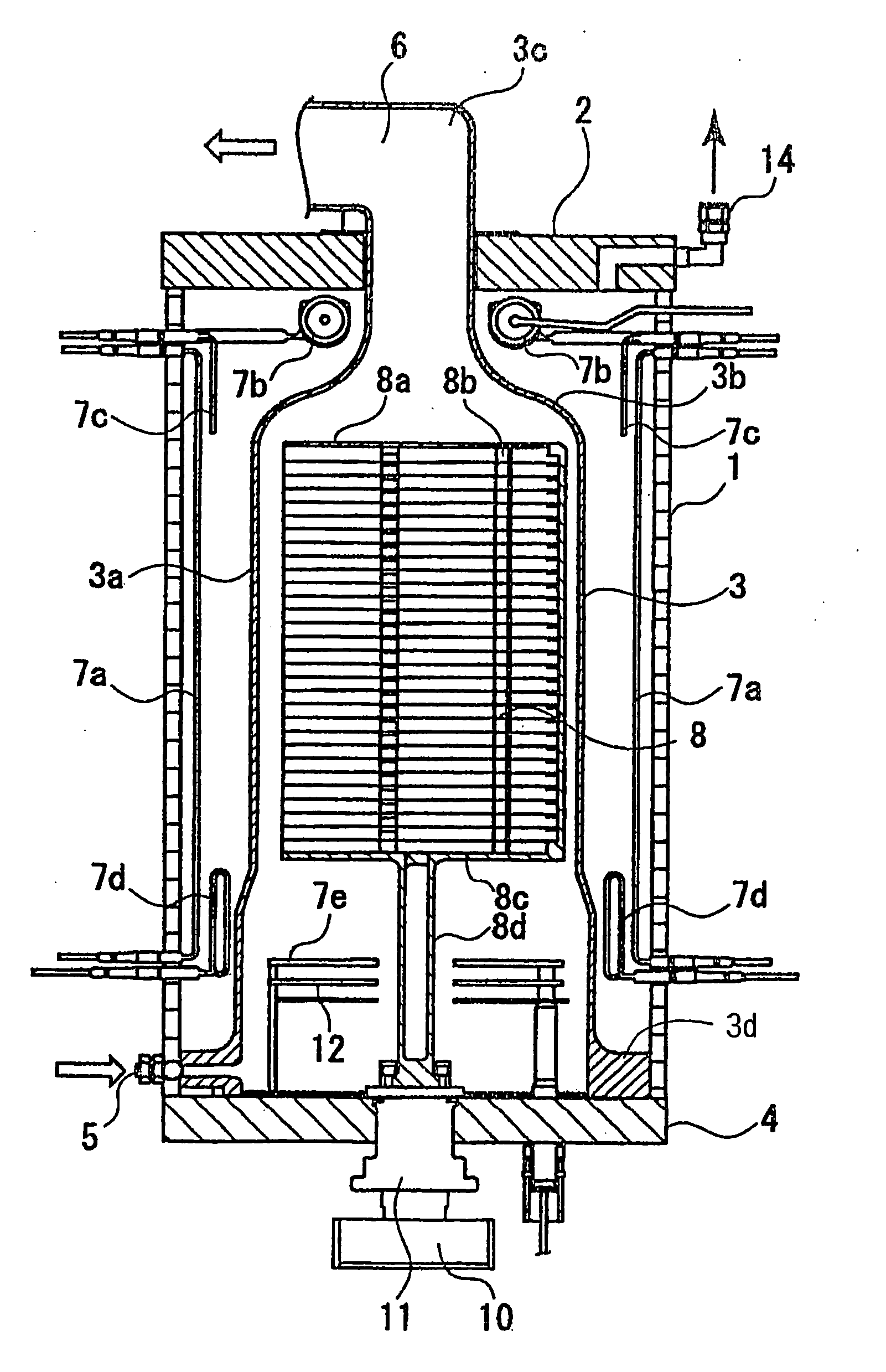

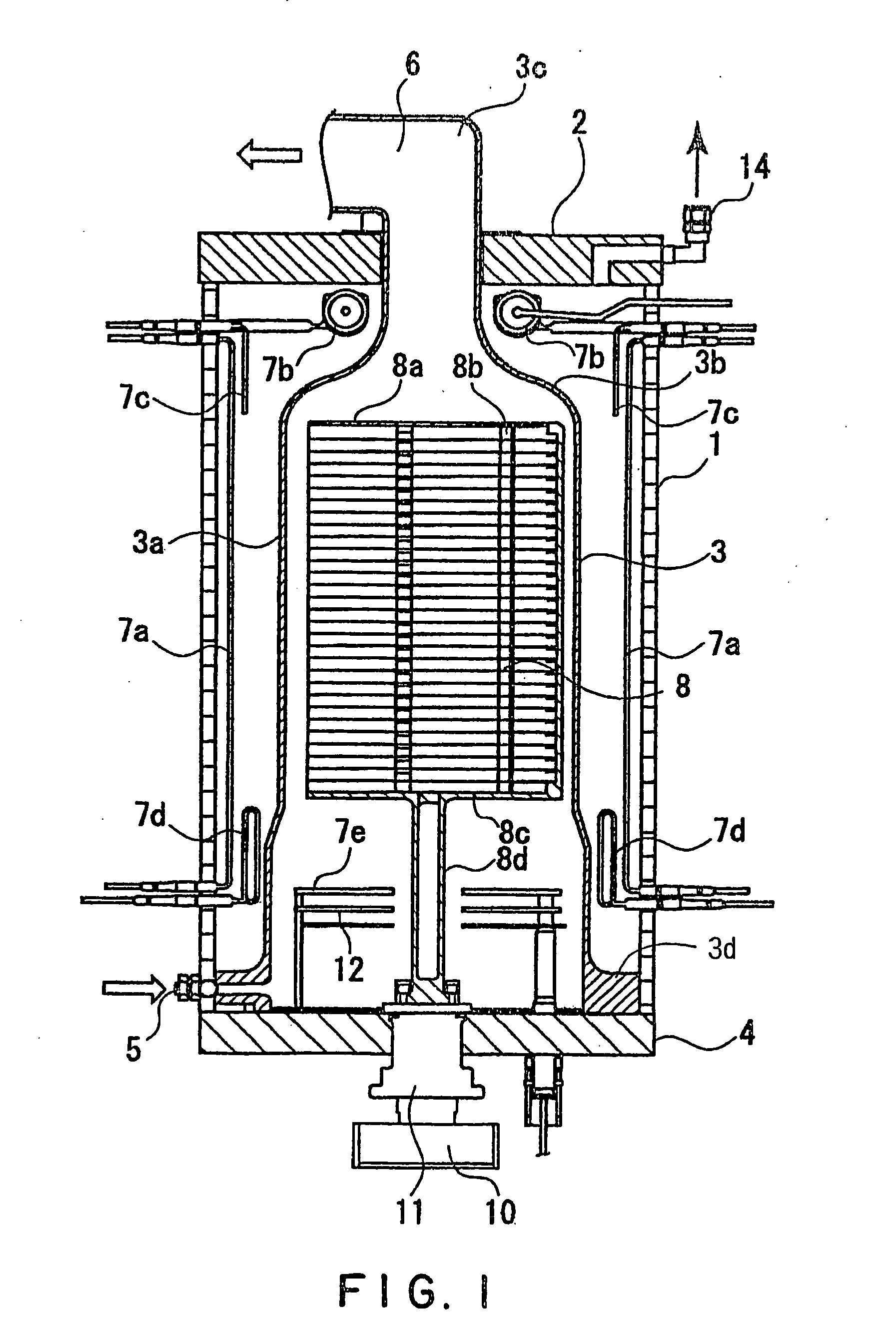

Heat treatment apparatus

ActiveUS20060021582A1Inhibition effectHeating fastMuffle furnacesSemiconductor/solid-state device manufacturingProcess supportEngineering

The present invention is a thermal processing unit including: a heating-furnace body whose upper end has an opening; a reaction tube consisting of a single tube contained in the heating-furnace body; a gas-discharging-unit connecting portion formed at an upper portion of the reaction tube, the gas-discharging-unit connecting portion having a narrow diameter; a substrate-to-be-processed supporting member for supporting a substrate to be processed, contained in the heating-furnace body; and a heating unit for heating the substrate to be processed supported by the substrate-to-be-processed supporting member. The heating unit has: a first heating portion arranged around the reaction tube, a second heating portion arranged around the gas-discharging-unit connecting portion, a third heating portion arranged around an upper portion of the reaction tube, a fourth heating portion arranged around a lower portion of the reaction tube, and a fifth heating portion arranged under the substrate-to-be-processed supporting member.

Owner:TOKYO ELECTRON LTD

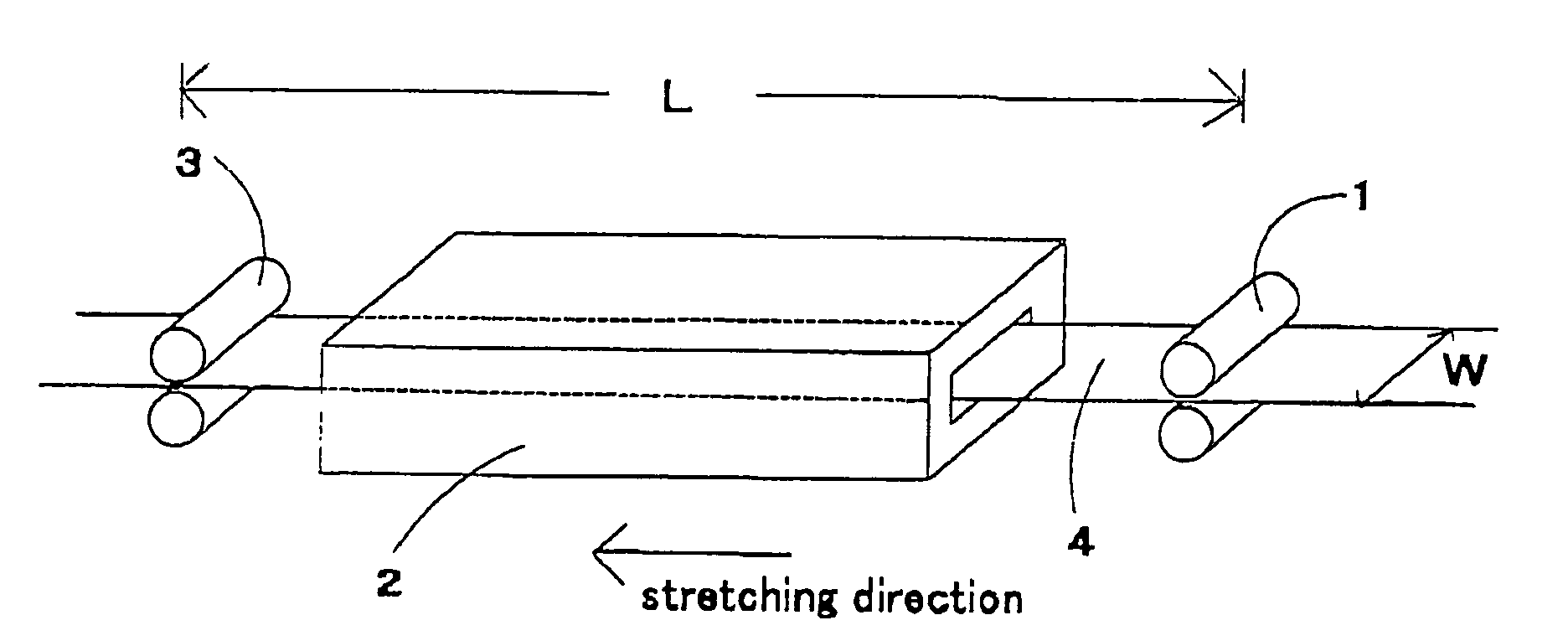

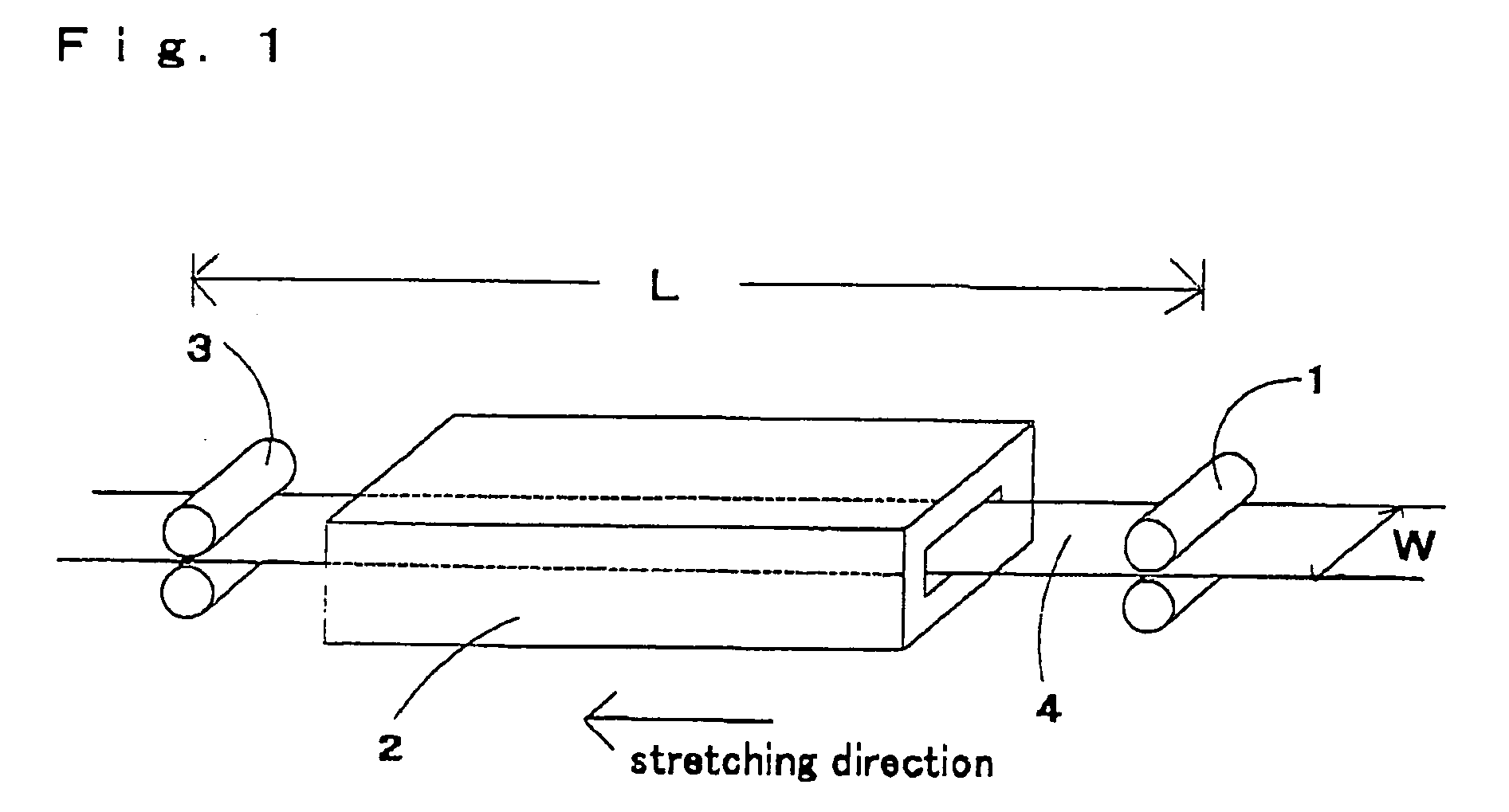

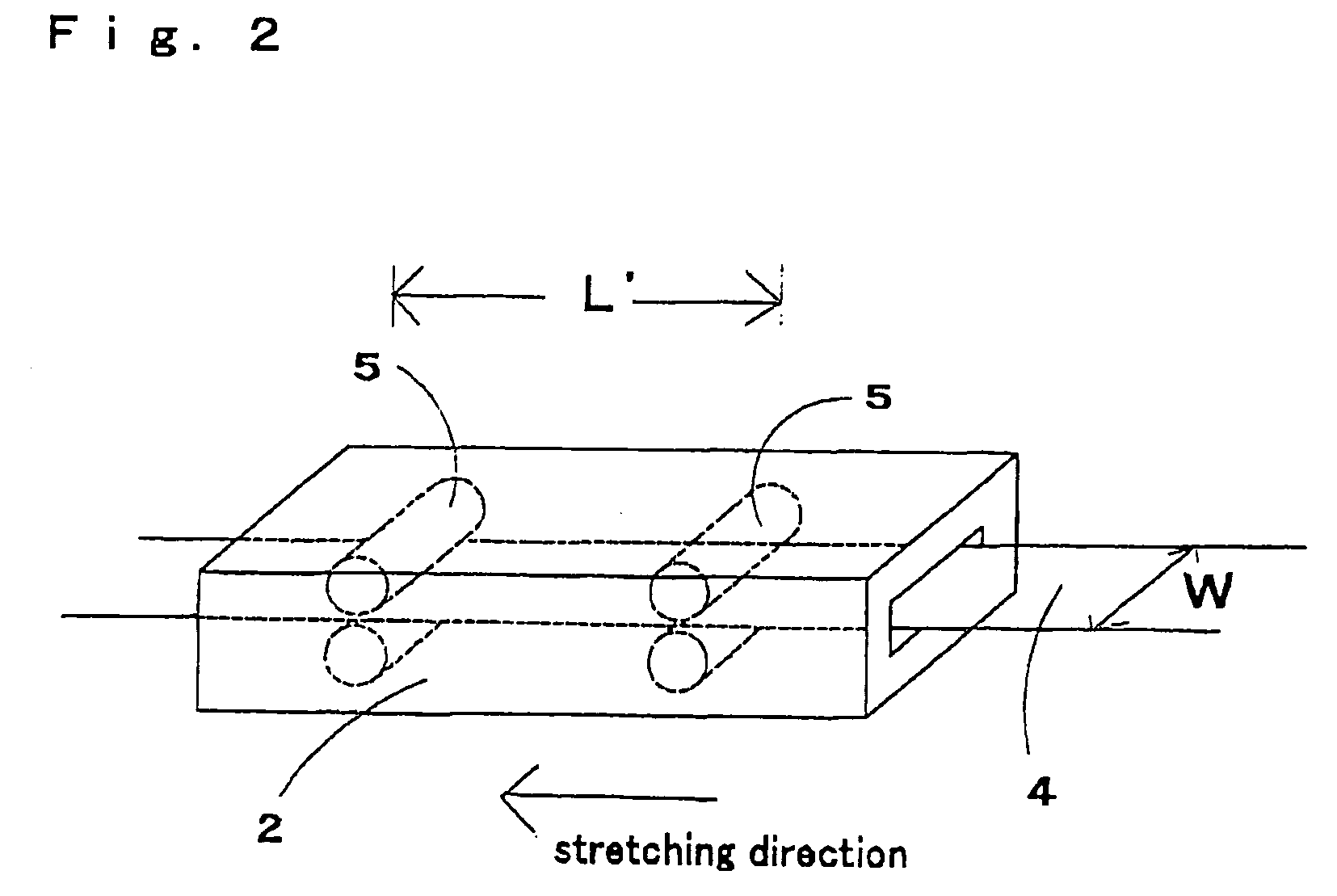

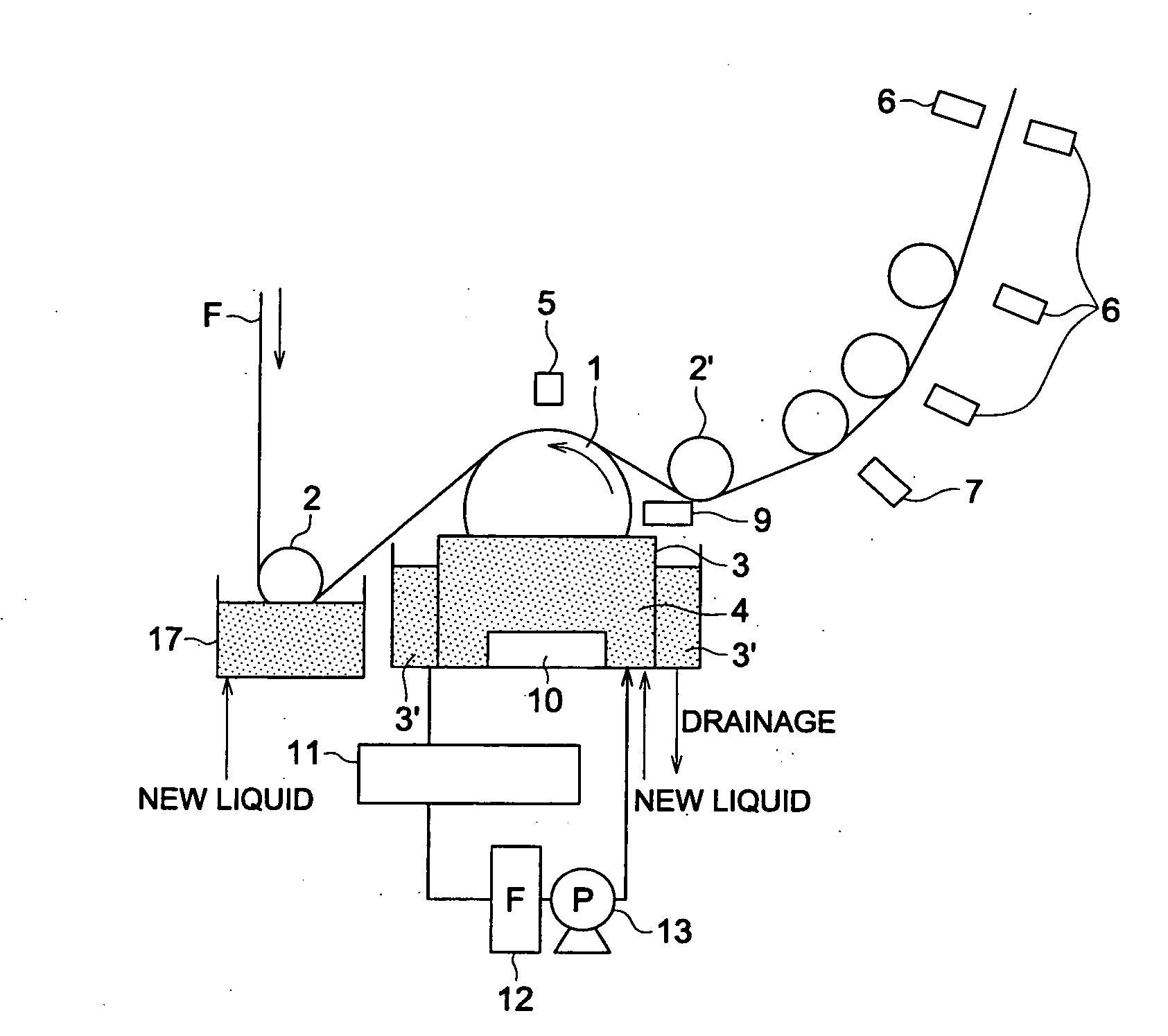

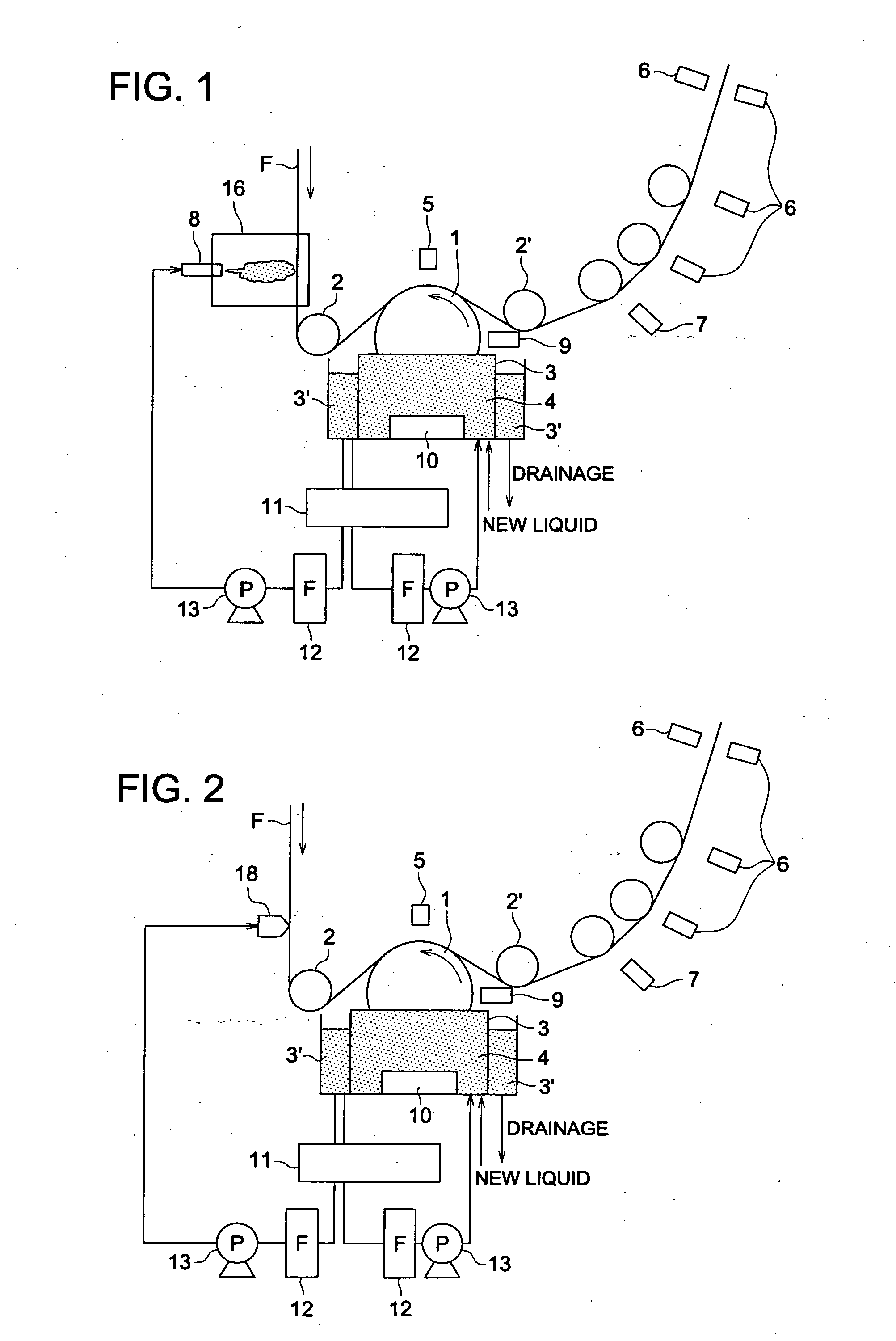

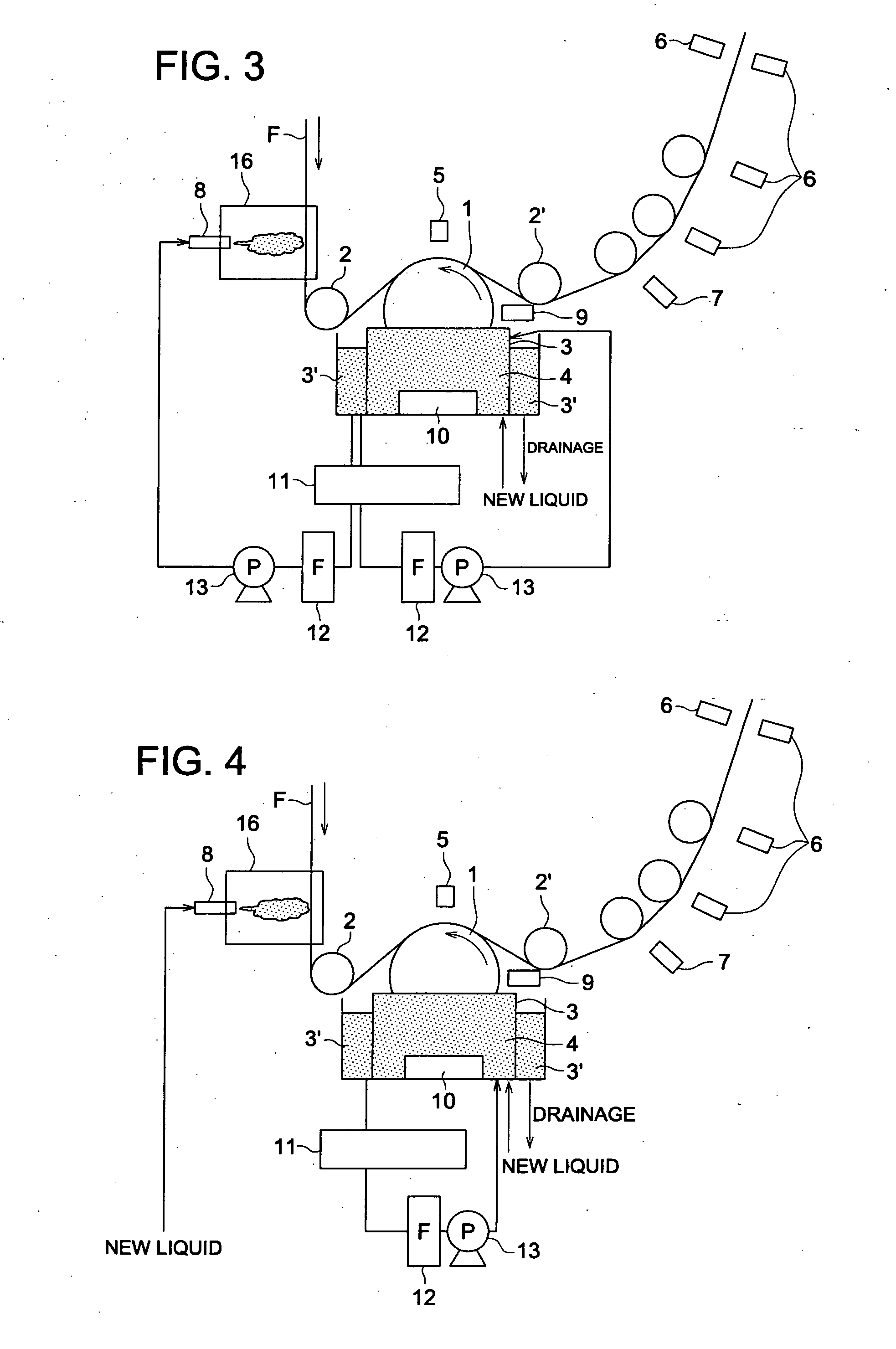

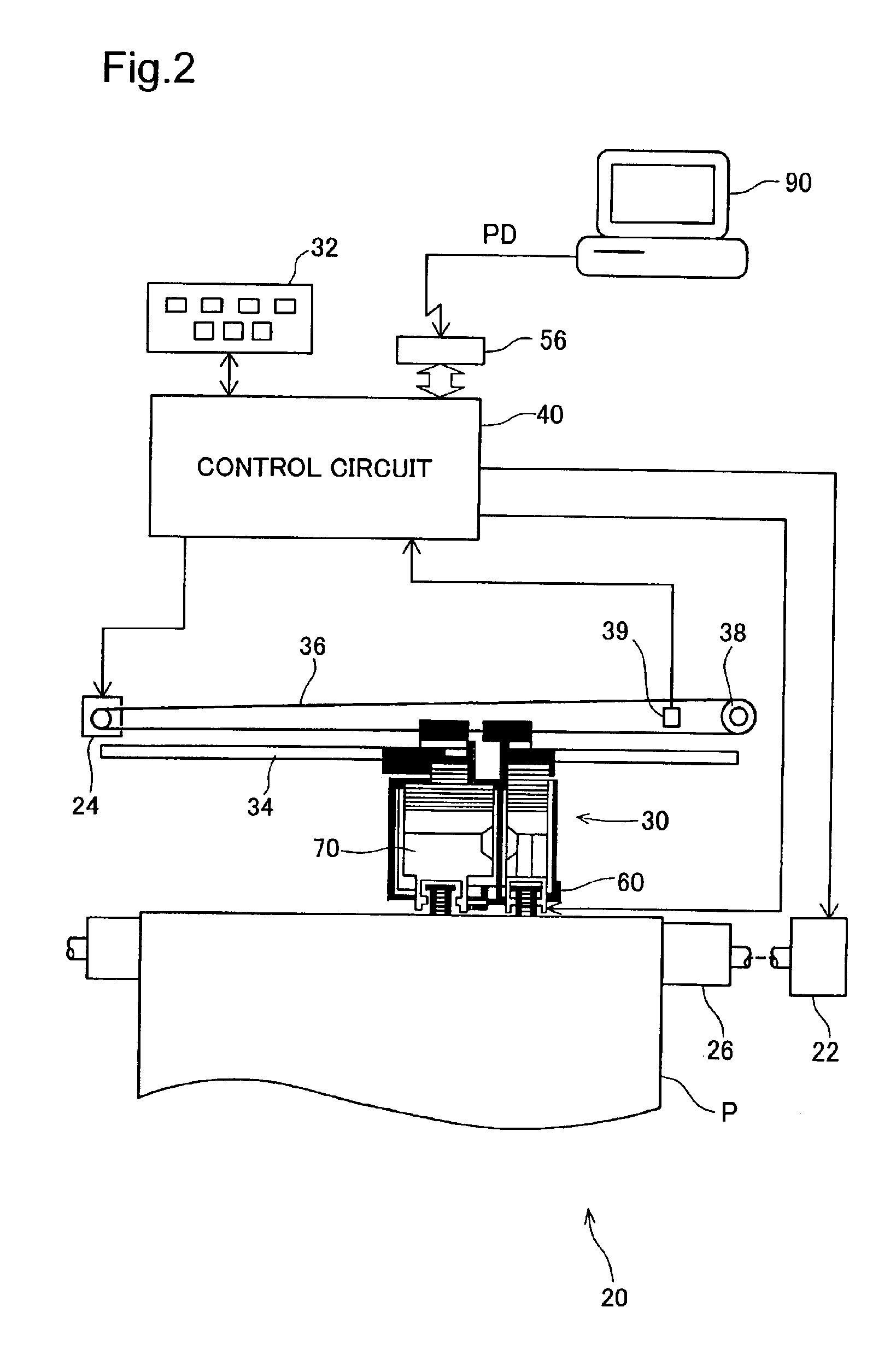

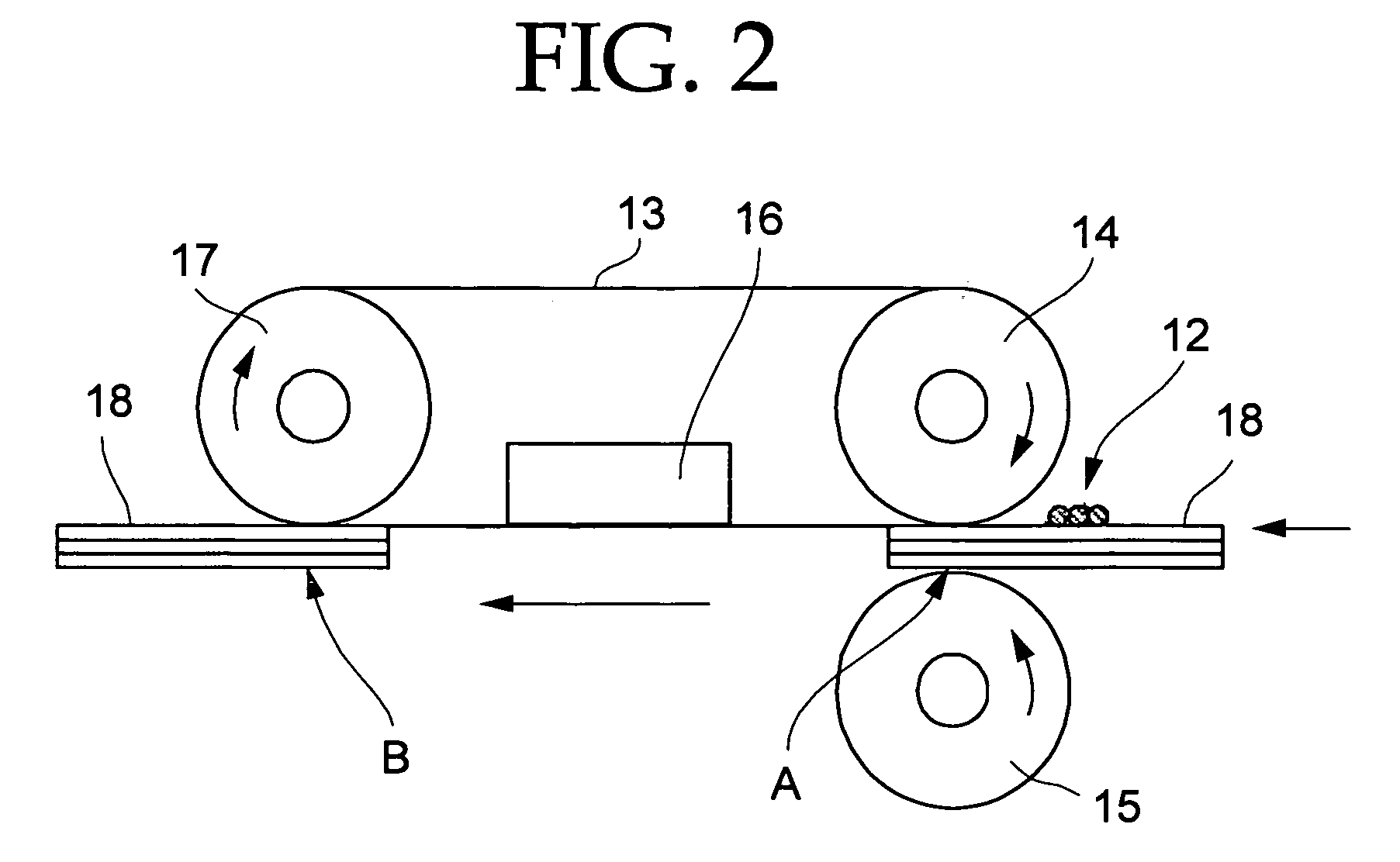

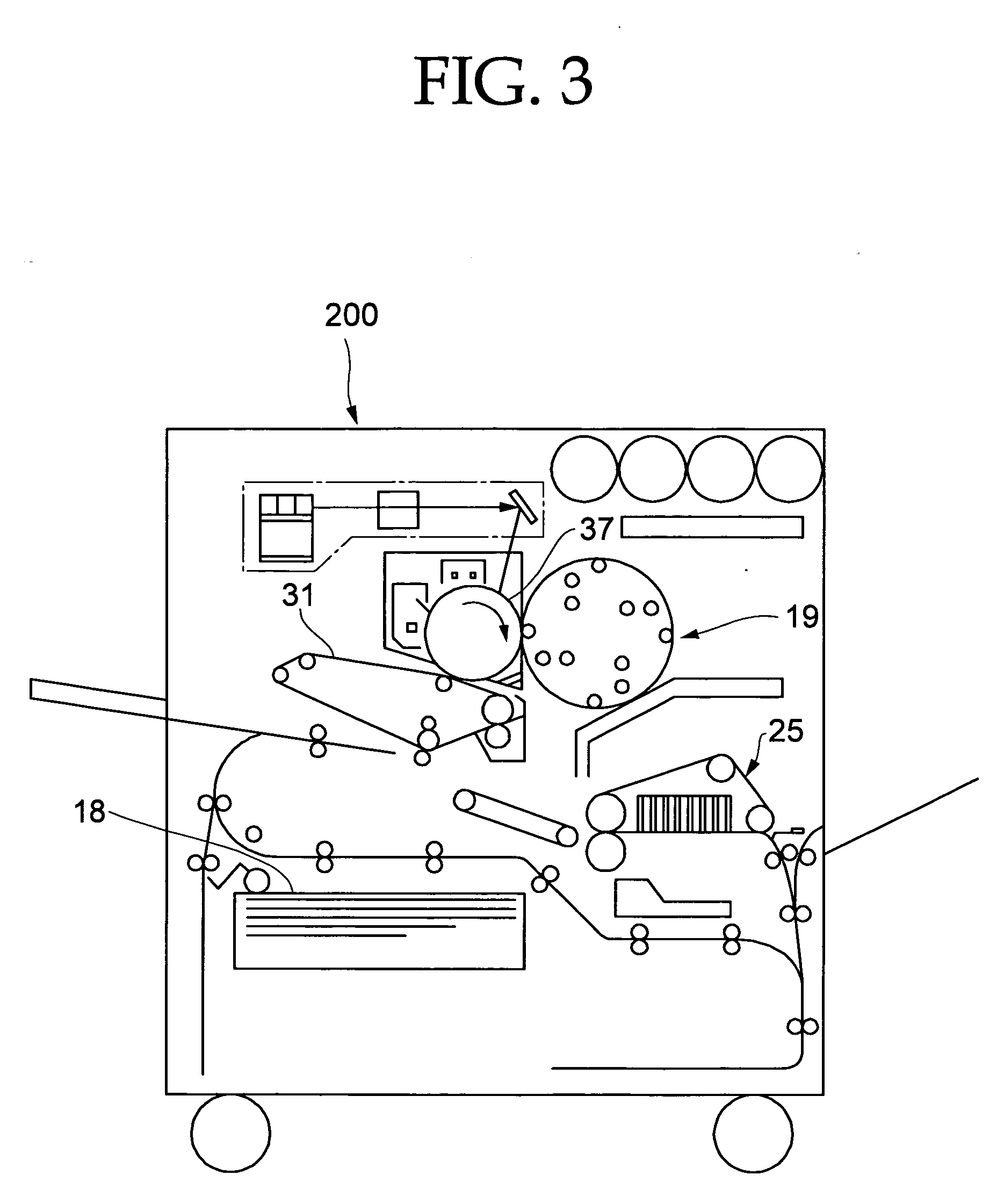

Optical Film Treating Method, Optical Film Treating Apparatus, and Optical Film Producing Method

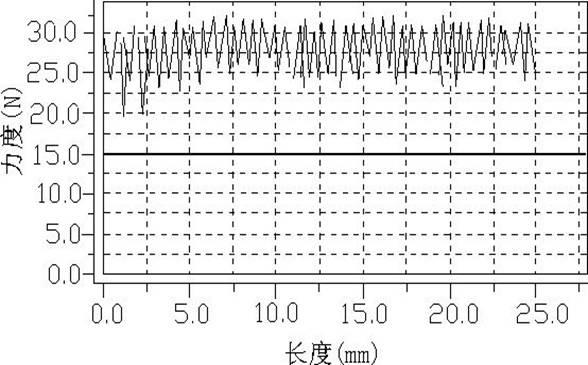

InactiveUS20090232977A1Improve unevennessTransversely streaked unevennessMechanical cleaningPressure cleaningStatic friction coefficientElastomer

A method of optical-film treatment in which coating troubles apt to occur in the formation of a functional layer, e.g., an antireflection layer, on a continuous film by coating fluid application, such as transverse thickness-difference lines, coating streaks, and tailing, are diminished. The method of optical-film treatment comprises wetting with a liquid a continuous film which is being continuously conveyed, continuously rubbing the continuous film with an elastomer, and then removing the liquid from the continuous-film surface, and is characterized in that the surface of the elastomer has a coefficient of static friction of 0.2-0.9.

Owner:KONICA MINOLTA OPTO

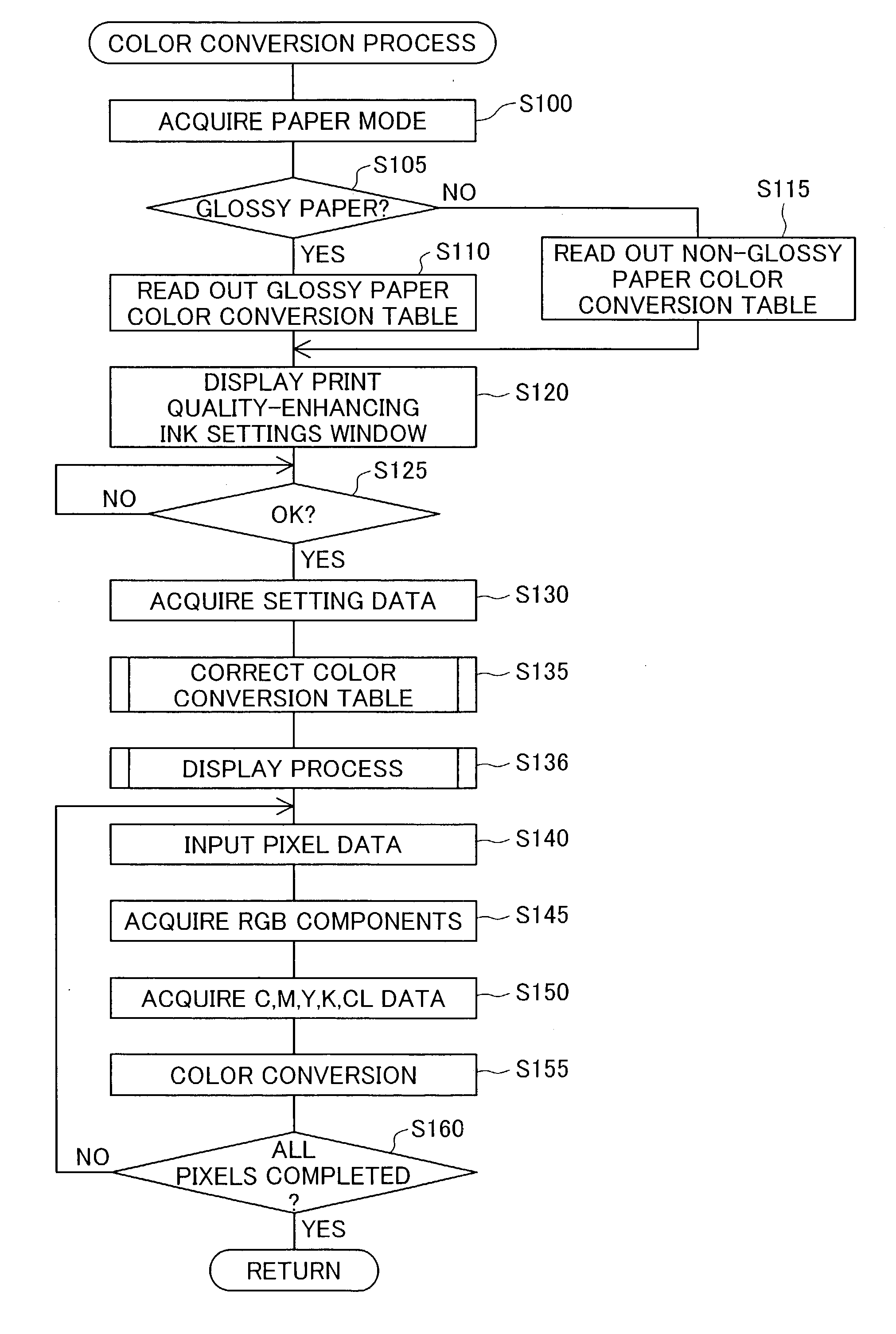

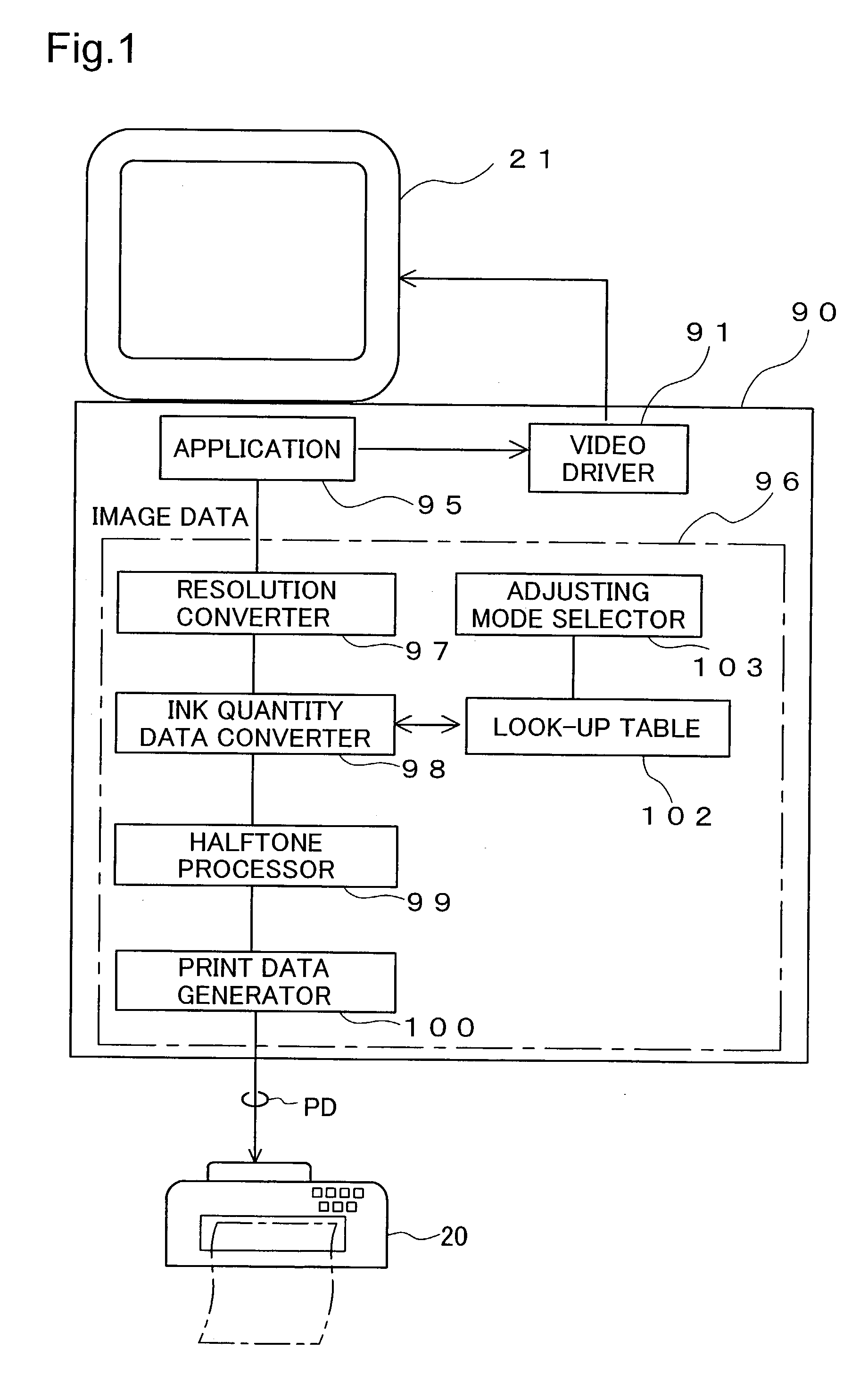

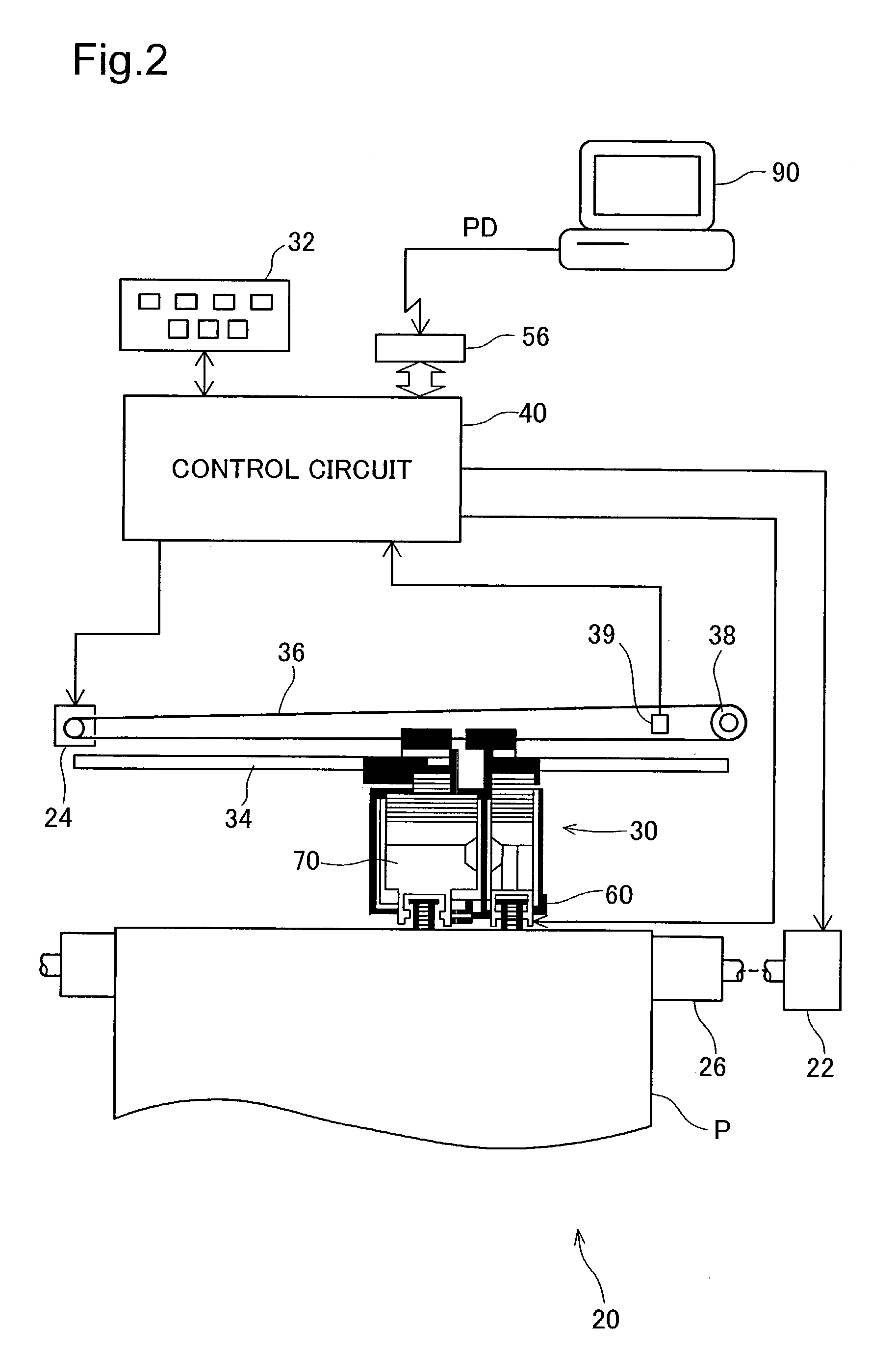

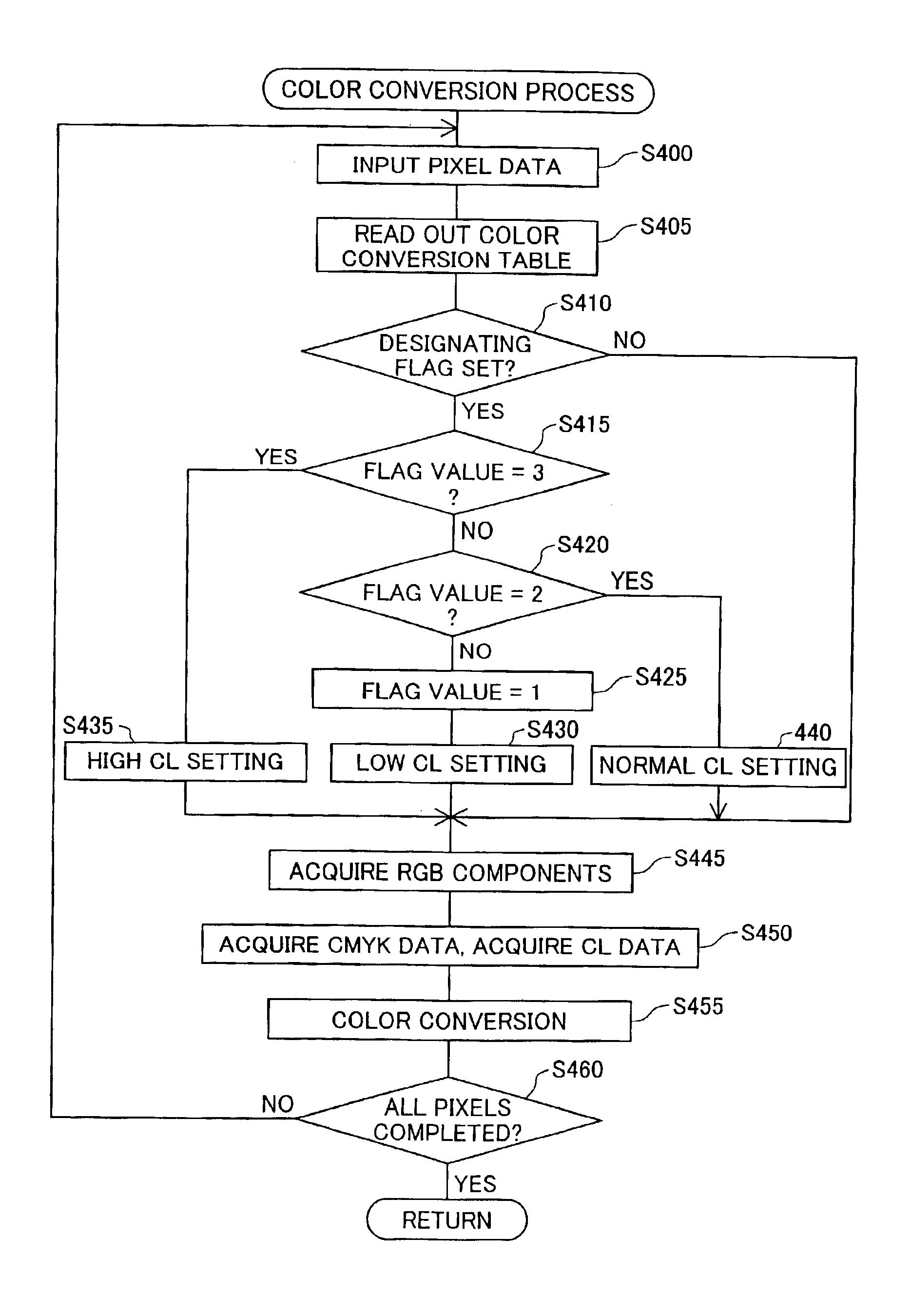

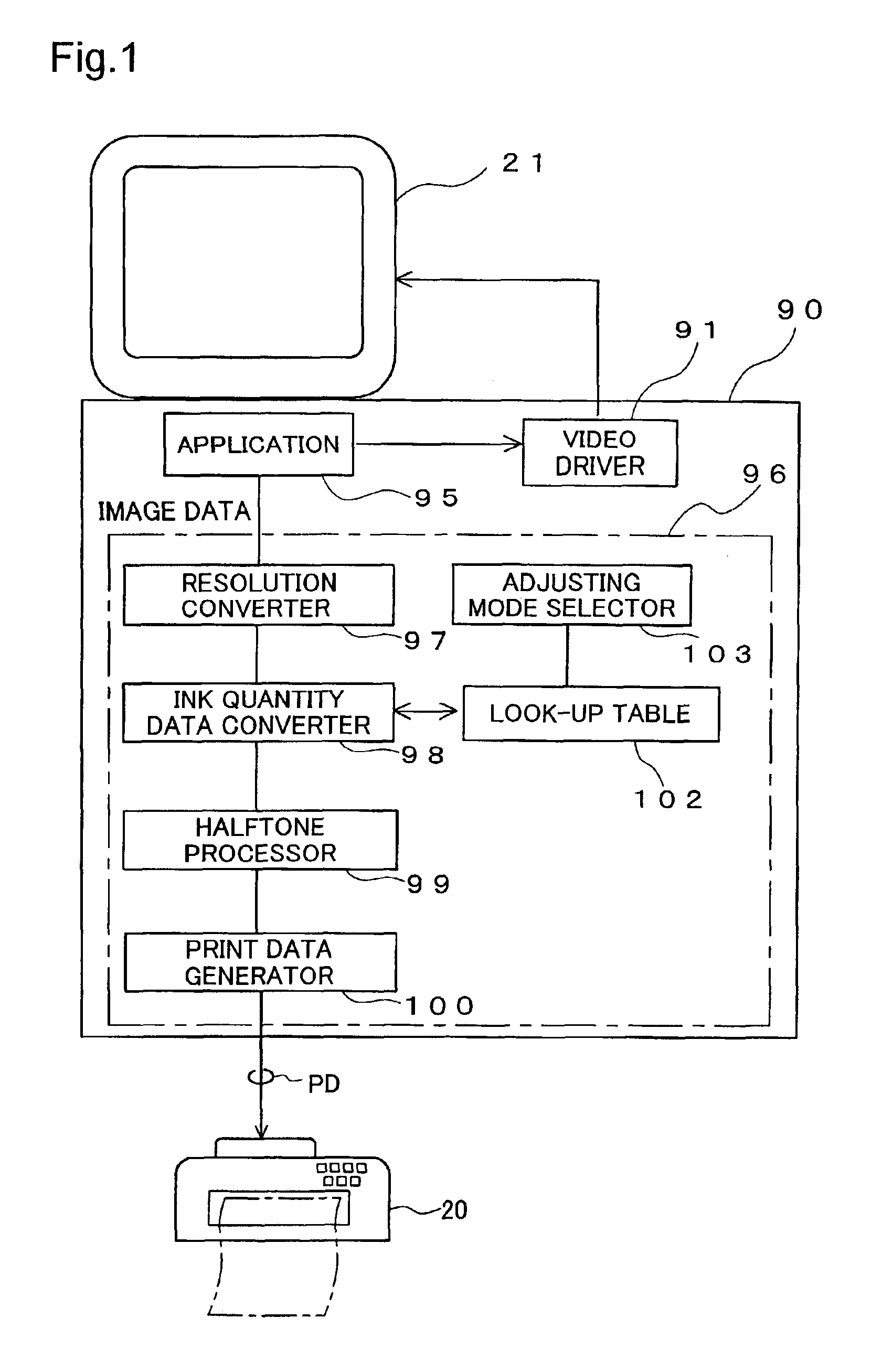

Image printing using print quality enhancing ink

Image quality is improved by adjusting the ejection amount of quality enhancing ink based on the ejection amount of colored ink containing colorant. When a relatively high gross printing medium is used, the quality enhancing ink is ejected in an image area where virtually no colored ink is ejected, thereby improving unevenness in gloss within the print image. When a relatively low gross printing medium is used, on the other hand, the quality enhancing ink is ejected in an image area where the colored ink is ejected on virtually all pixels, thereby improving unevenness in color within the print image. The relationship between the ejection amounts of the quality enhancing ink and the colored ink may be modified by the user.

Owner:NEC CORP +1

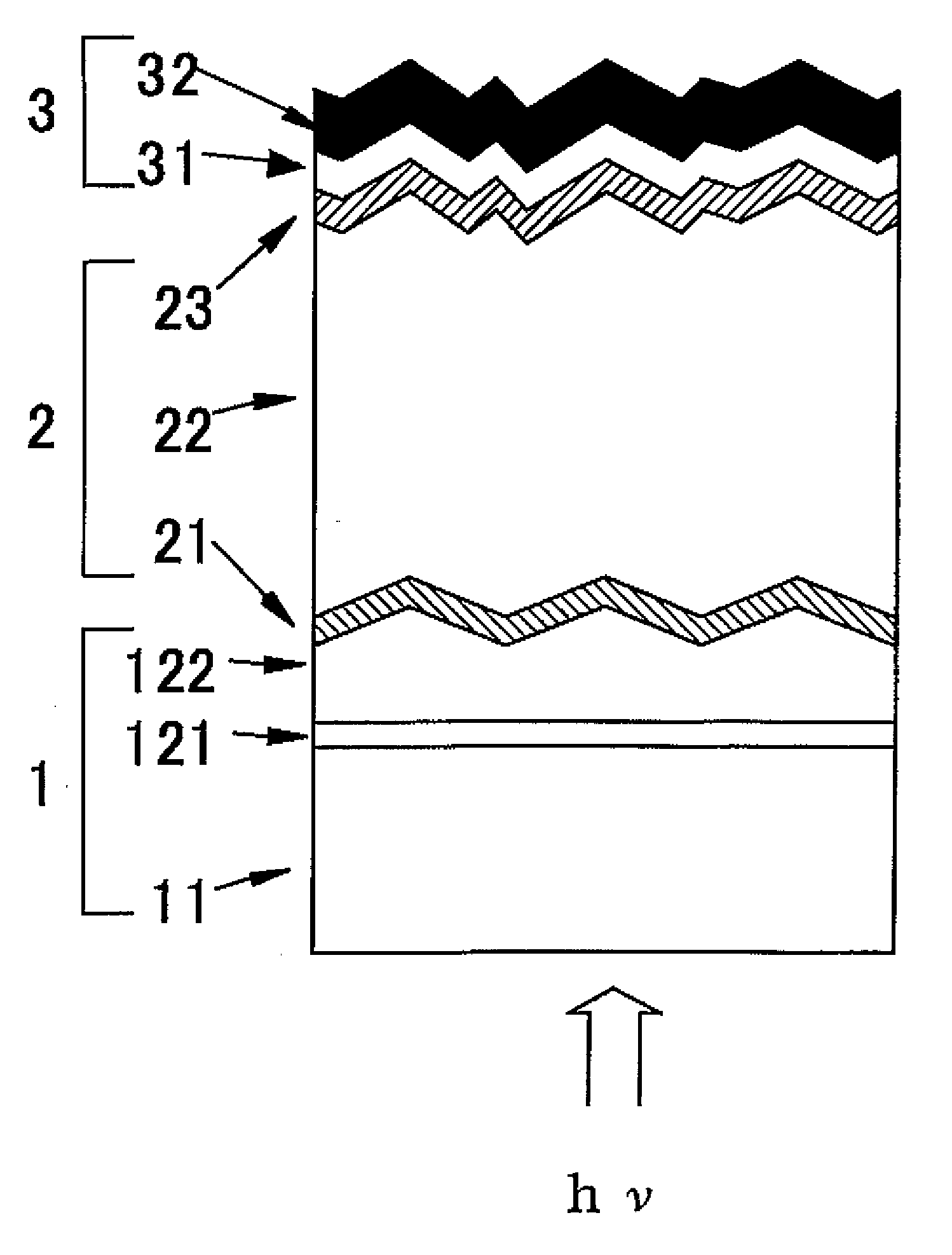

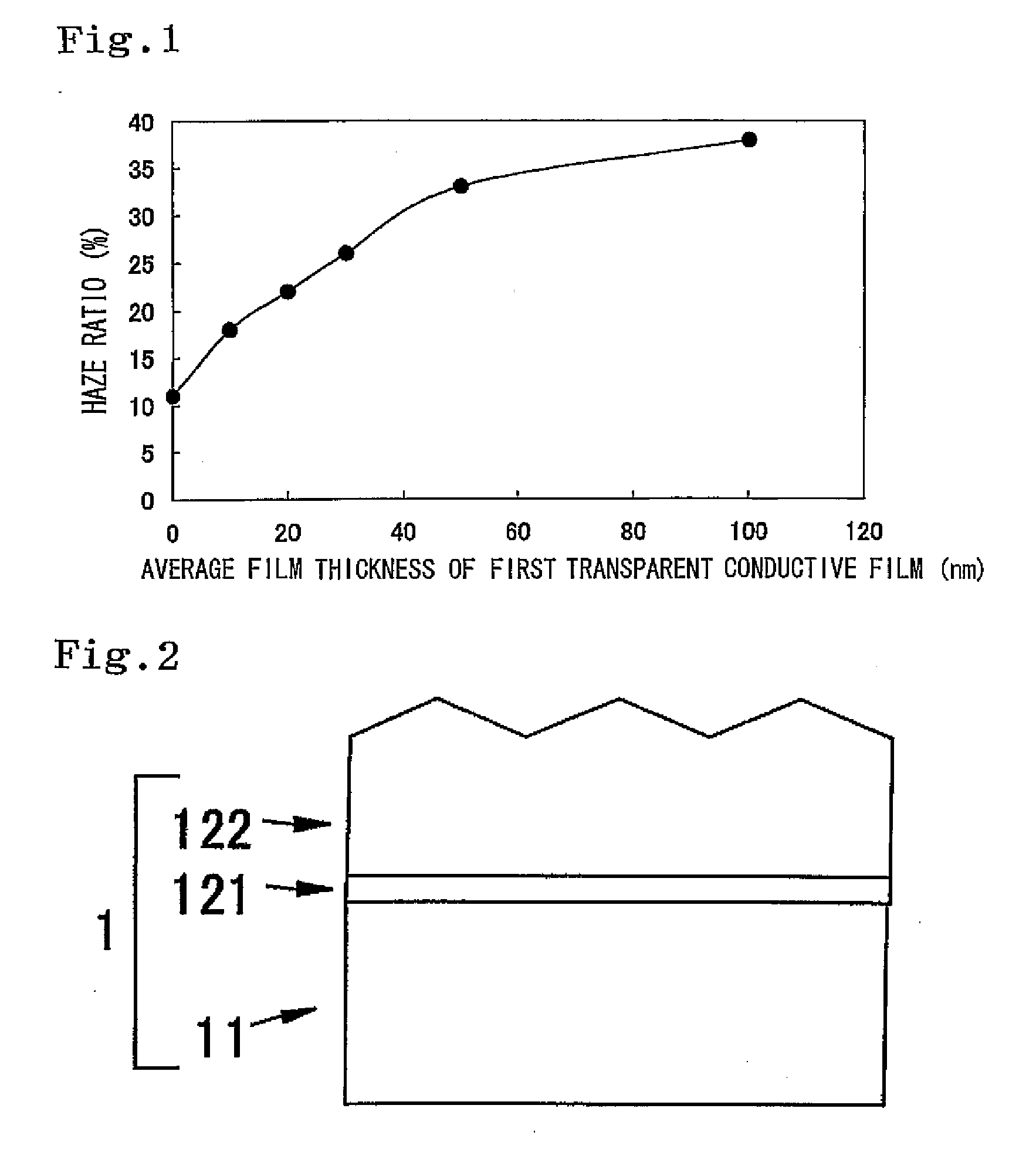

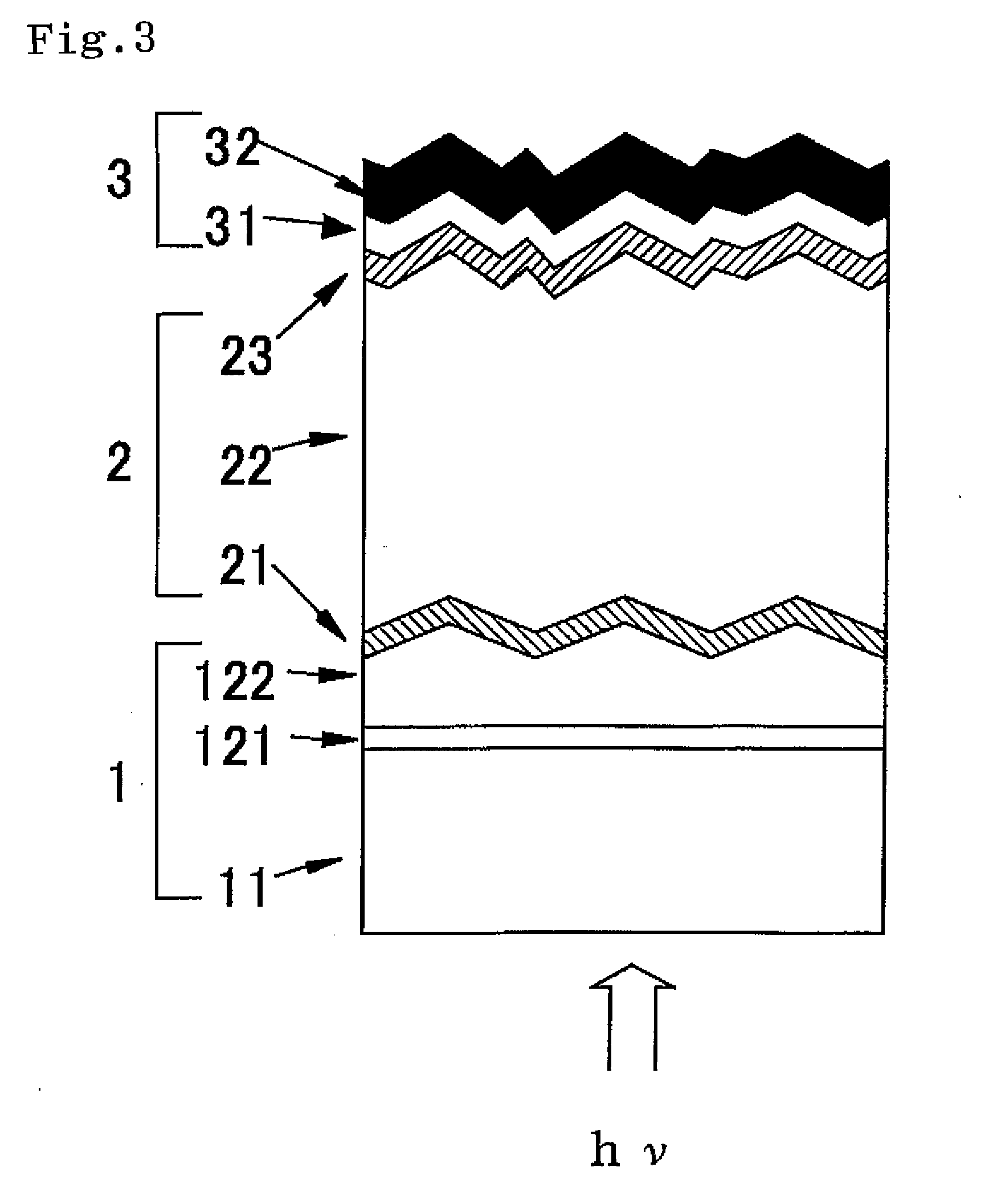

Substrate Provided with Transparent Conductive Film for Photoelectric Conversion Device, Method for Manufacturing the Substrate, and Photoelectric Conversion Device Using the Substrate

InactiveUS20100024862A1Improve unevennessImprove performancePV power plantsSemiconductor/solid-state device detailsElectrically conductiveOxide

Provided in this invention is a low-cost substrate provided with a transparent conductive film for photoelectric conversion device, which can improve performance of the photoelectric conversion device by enhanced light confinement effect achieved with effectively increased surface unevenness of the substrate. A method for manufacturing said substrate and a photoelectric conversion device using said substrate which can show improved performance are also provided. The substrate provided with the transparent conductive film for the photoelectric conversion device comprises a transparent insulating substrate and a transparent electrode layer containing at least zinc oxide deposited on the transparent insulating substrate, wherein the transparent electrode layer is composed of a double layer structure wherein first and second transparent conductive films are deposited in this order from a substrate side. The transparent conductive film has an average film thickness of 10-500 nm, and the second transparent conductive film has an average film thickness of 300-1,500 nm. The average film thickness of the second transparent conductive film is larger than that of the first transparent conductive film, and an average height difference of the unevenness on the surface of the second transparent conductive film is 10-300 nm, which is larger than that of the first transparent conductive film.

Owner:KANEKA CORP

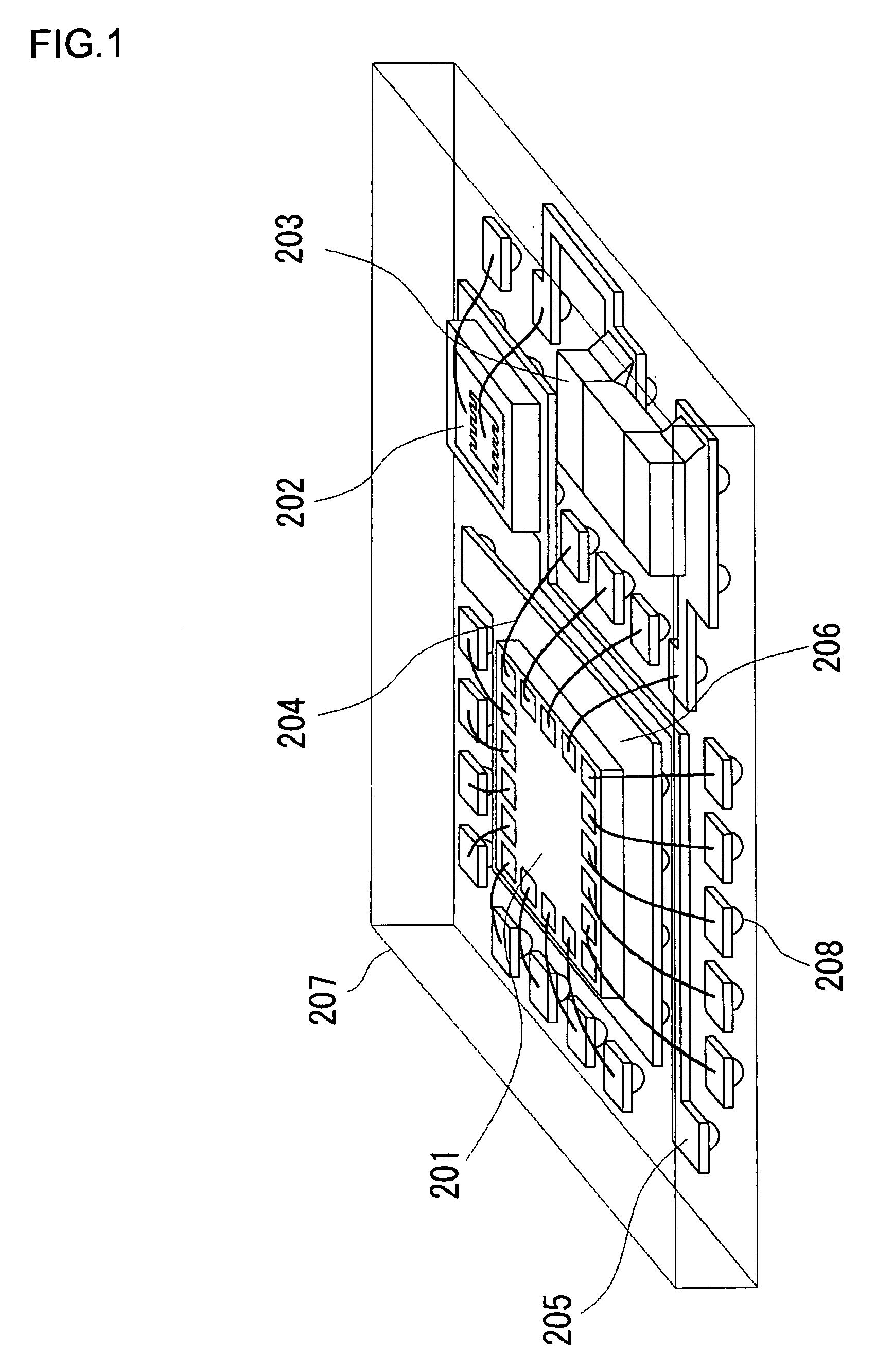

Light source apparatus and image display apparatus

ActiveUS20150300576A1Good colorImprove unevennessNon-electric lightingPoint-like light sourceOptoelectronicsLight source

A light source apparatus includes: a plurality of light sources provided, respectively, in a plurality of first divided regions; a first suppressing member that suppresses, for each of the plurality of first divided regions, spreading of light emitted from a light source provided in the first divided region; a conversion member that converts the color of the light emitted from the light sources and emits light of the converted color; and a diffusing member that is provided on a side closer to the emission surface than the conversion member so as to diffuse the light emitted from the conversion member, wherein the diffusing member is apart from the conversion member by a predetermined distance.

Owner:CANON KK

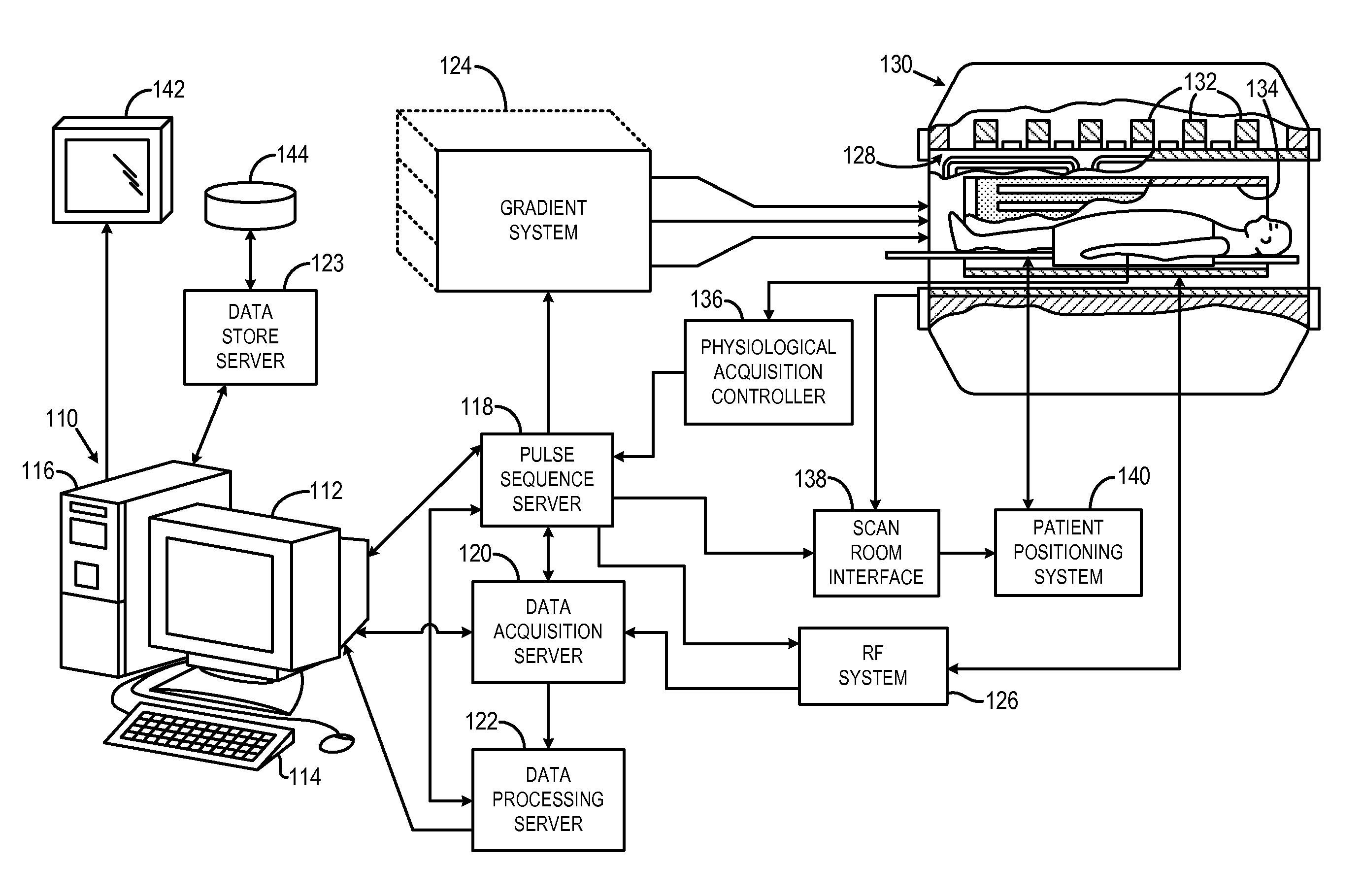

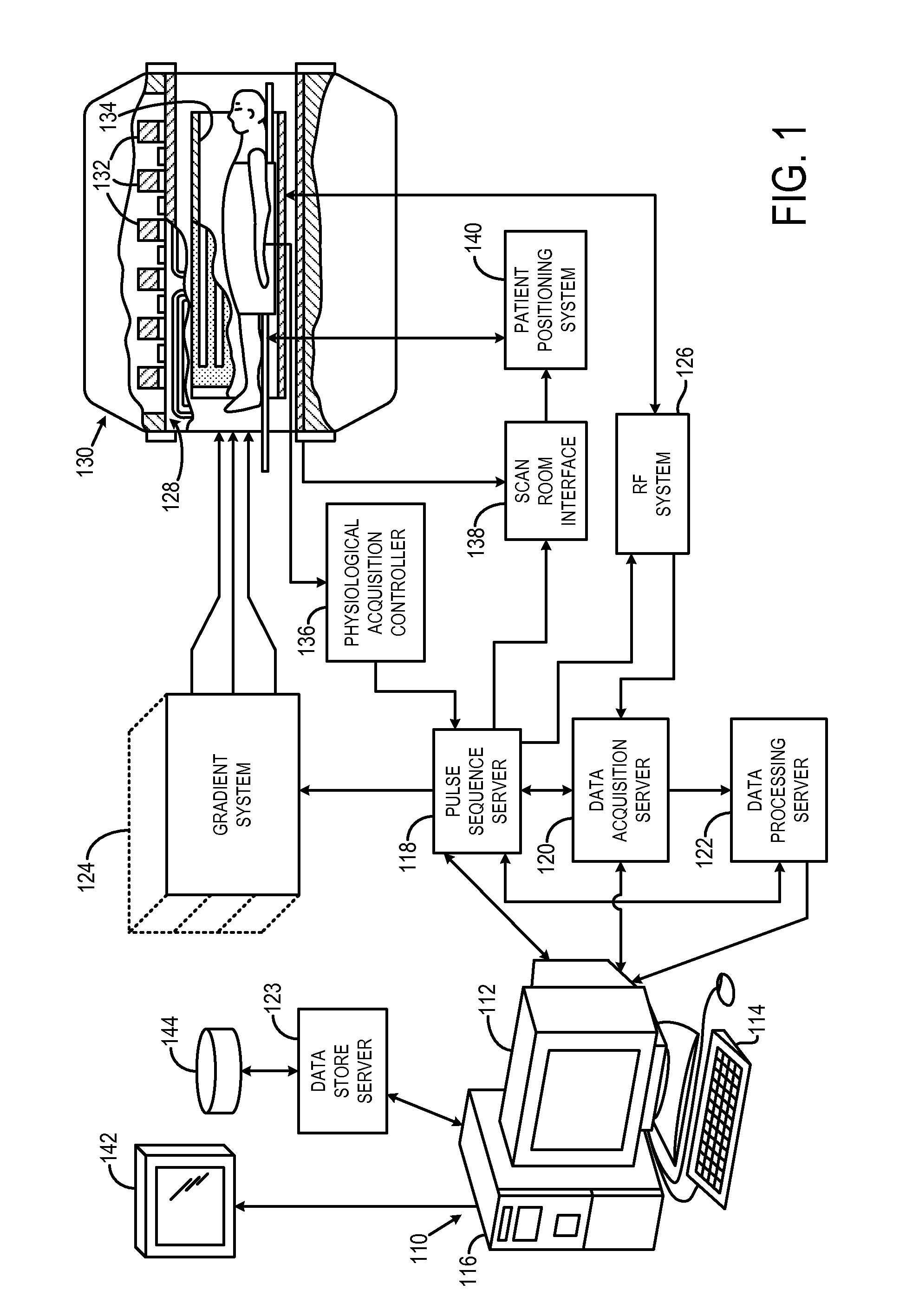

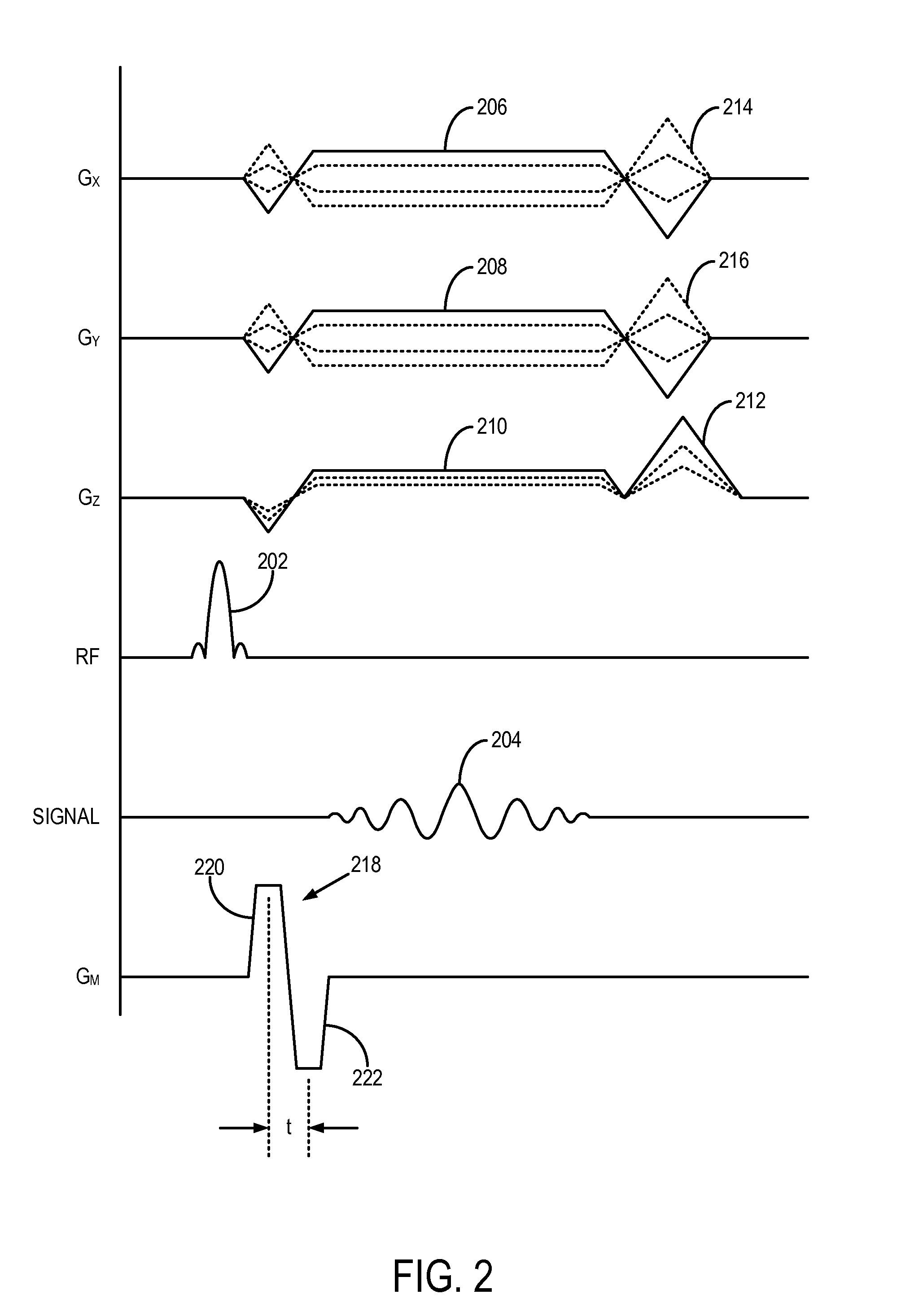

Method for magnitude constrained phase contrast magnetic resonance imaging

ActiveUS20100085052A1Reduce the impactFew measurementMeasurements using NMR imaging systemsElectric/magnetic detectionChemical shift imagingComputer science

A method for magnitude constrained phase contrast magnetic resonance imaging (MRI) is provided. The method utilizes an assumption that the image magnitude is shared across a series of images reconstructed from a set of phase contrast enhanced k-space data. In this manner, one common magnitude image and a plurality of phase images are reconstructed substantially contemporaneously from the acquired image data. The method is further applicable to other phase contrast MRI methods, such as phase contract velocimetry. Moreover, simultaneous phase contrast velocimetry and chemical shift imaging, in which water and fat signal separation is achieved, is provided.

Owner:WISCONSIN ALUMNI RES FOUND

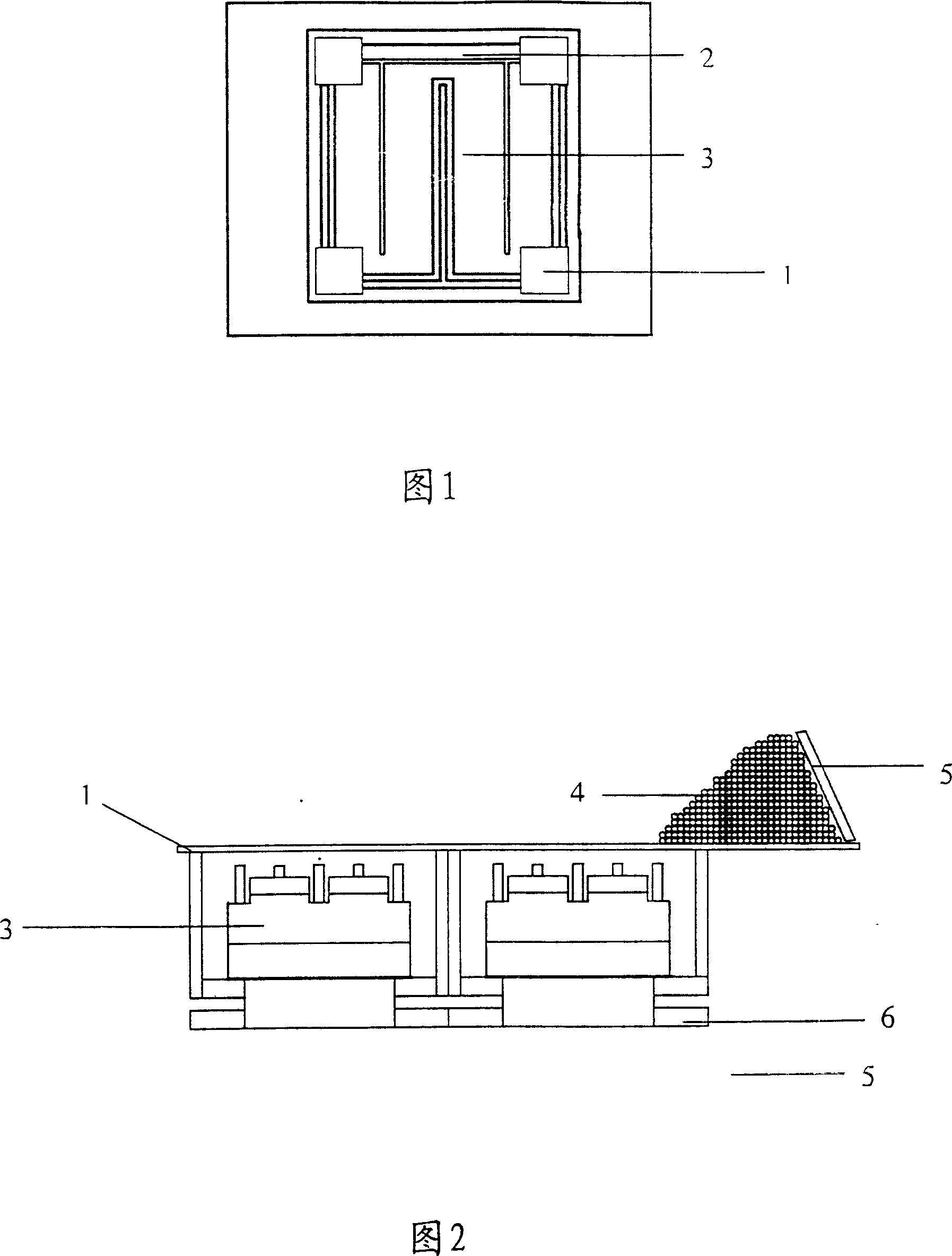

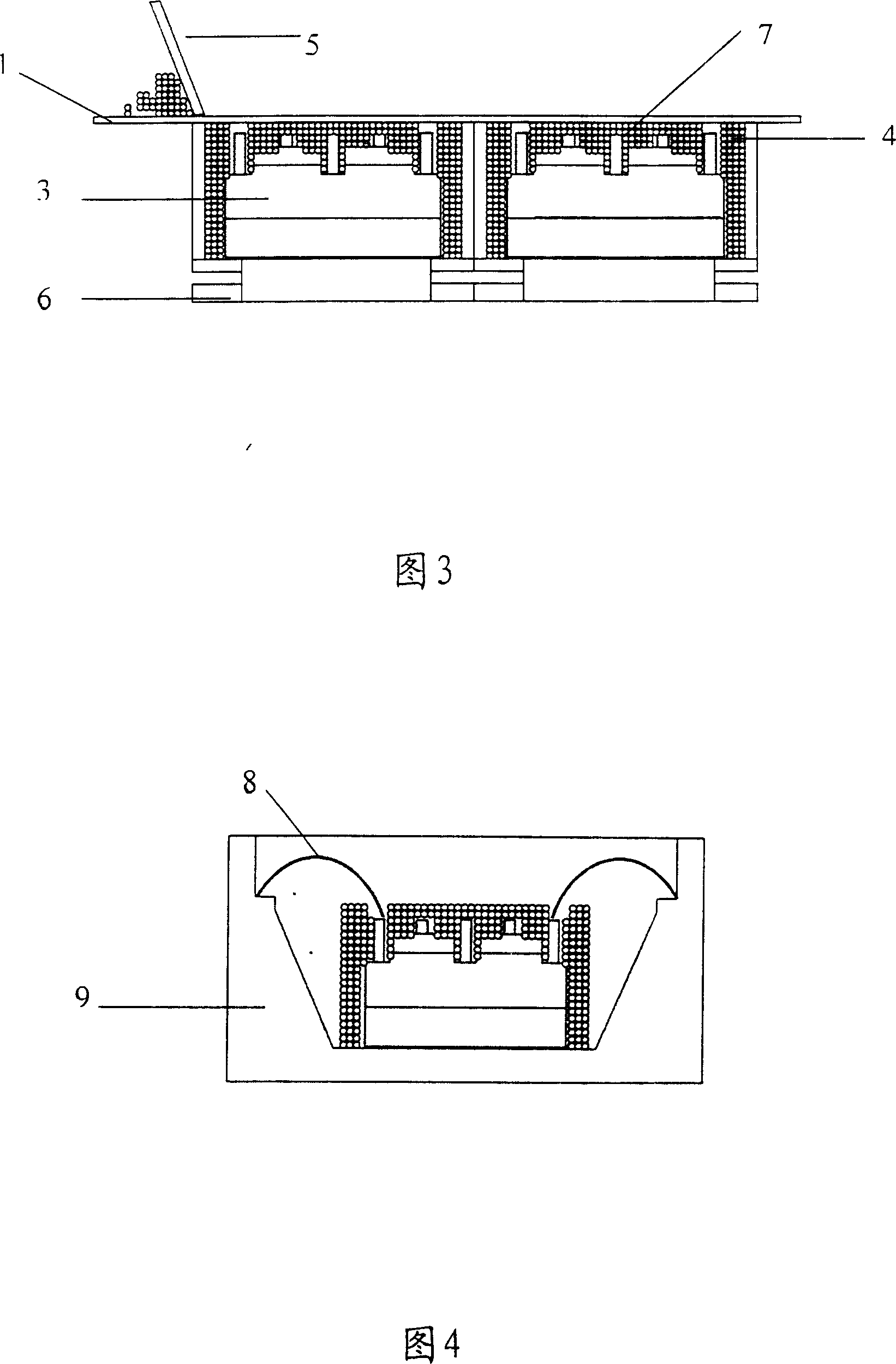

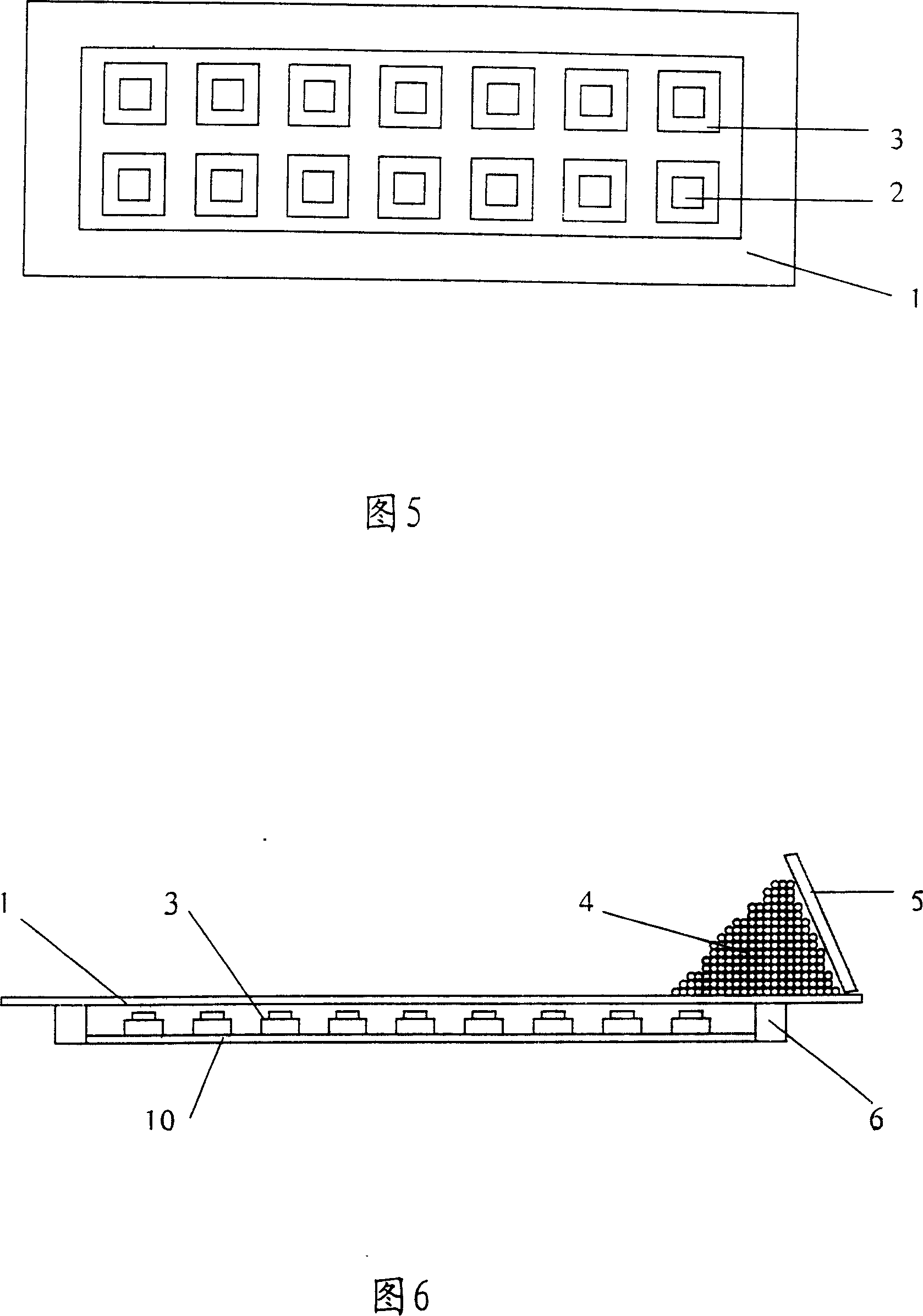

LED chip surface fluorescent powder layer coating method

InactiveCN101099964AImprove uniformityImprove unevennessLiquid surface applicatorsCoatingsScreen printingFluorescence

The present invention is process of painting fluorescent powder layer to the surface of LED chip. The fluorescent powder is first mixture with glue to form homogeneous fluorescent glue, and the fluorescent glue is then painted to the front side and lateral sides of the LED chip homogeneously by means of simple screen printing process. Painting fluorescent powder layer to the surface of LED chip can convert the fluorescent emitting wavelength of the LED and makes it possible to produce LED devices of different colors.

Owner:INTEX OPTOELECTRONICS XIAMEN CO LTD

Fabrication method for functional surface

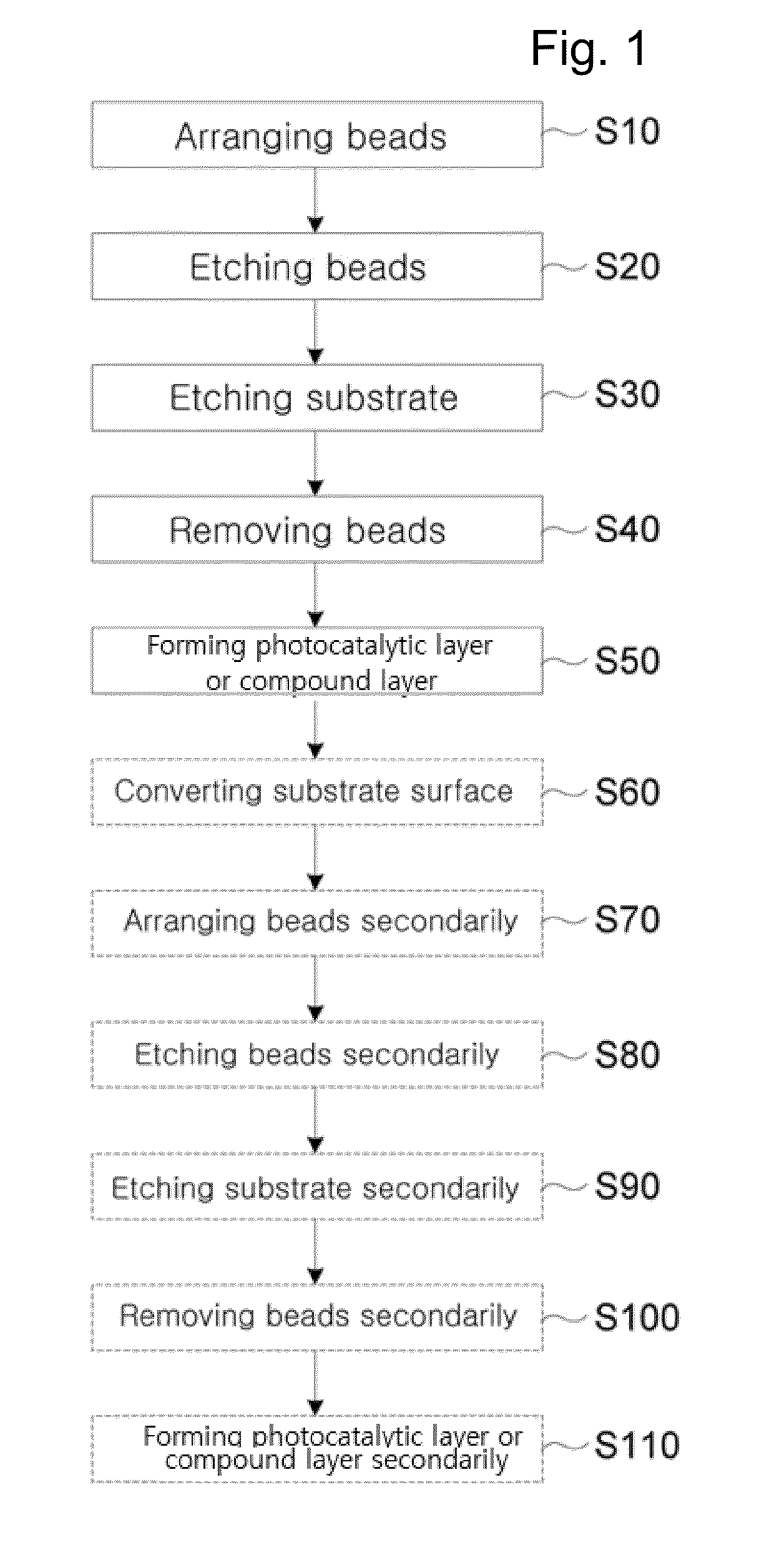

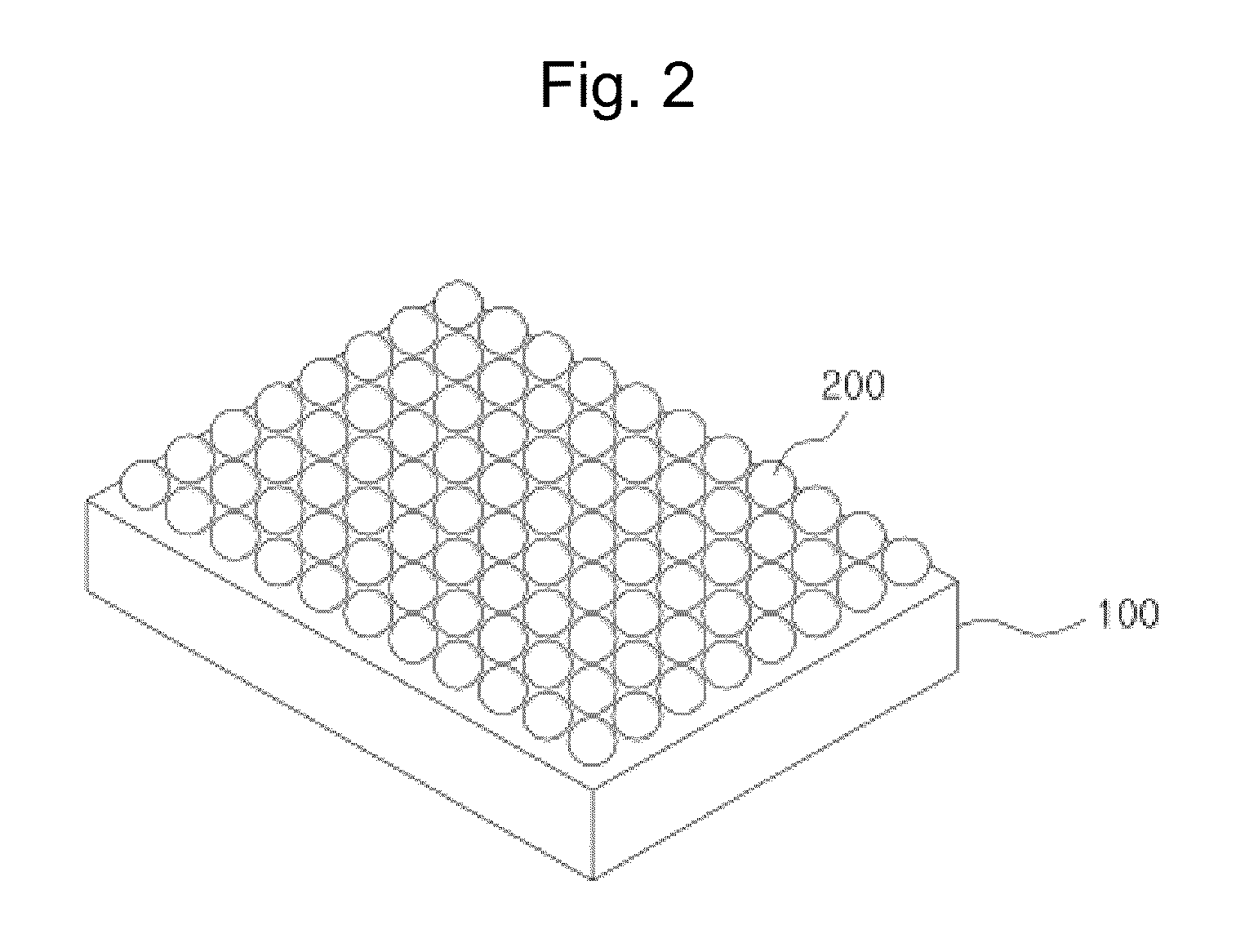

ActiveUS20110028305A1Short timeGood physical stabilityMaterial nanotechnologyCatalyst protectionOptoelectronicsSurface tension

Provided is a fabrication method for a functional surface that has self-cleaning ability and superhydrophilic anti-reflective property, which includes a) arranging a plurality of beads having a sphere shape on a surface of a transparent substrate; b) forming a predetermined inter-bead gap by etching the plurality of beads; c) forming a surface unevenness on the surface of the substrate by etching the substrate using the plurality of the beads having the predetermined gap as an etching mask; d) removing the plurality of the beads from the surface of the substrate; and e) forming a photocatalytic layer or a compound layer having a surface tension of 18 to 28 N / m on the surface of the substrate formed with the surface unevenness.

Owner:KOREA INST OF MASCH & MATERIALS

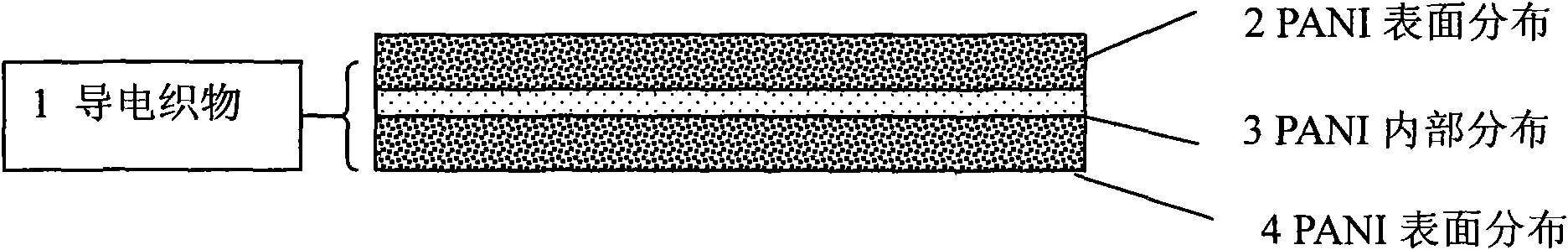

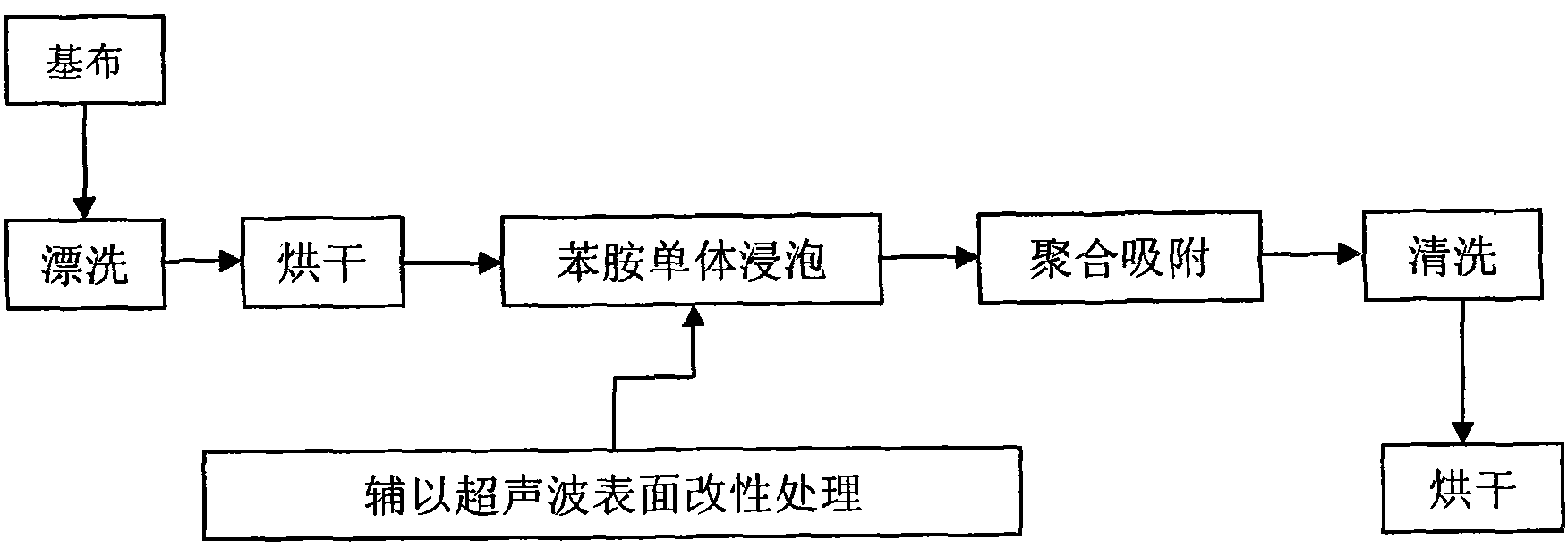

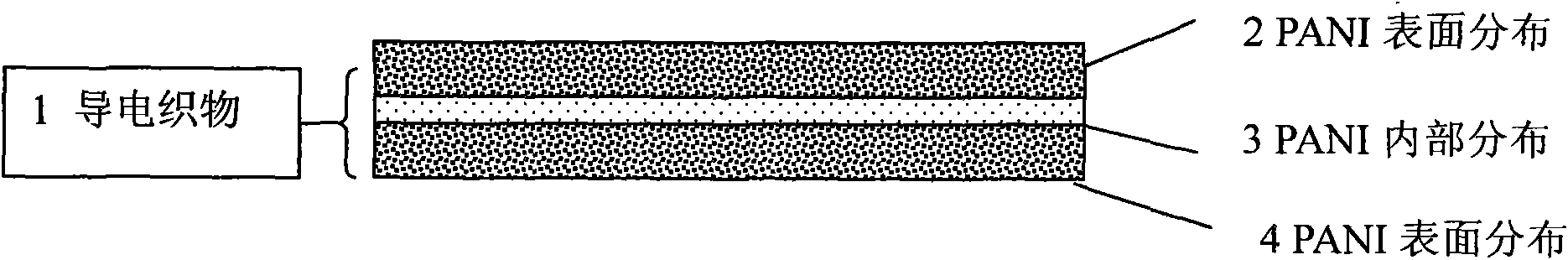

Novel method for preparing polyaniline composite conductive fabric

InactiveCN102337679AAutomatic elimination of influenceAccurate measurementPhysical treatmentFiberConductive polymer

The invention relates to a novel method for preparing a polyaniline composite conductive fabric. The novel method for preparing a polyaniline composite conductive fabric is characterized in that a conductive fabric with good conductive properties is prepared from a chemical fiber fabric as a matrix material and polyaniline as a conductive material through an in-situ polymerization method (also known as an in-situ adsorption polymerization method). The novel method for preparing a polyaniline composite conductive fabric adopts an ultrasonic dipping treatment process as an auxiliary process of a base fabric dipping process adopting aniline. Therefore, the novel method for preparing a polyaniline composite conductive fabric has good surface modification effects on a base fabric, is beneficial for depositing a conductive material on fiber surfaces of the base fabric in polymerization and enabling the conductive material to permeate into fibers of the base fabric, and improves conductivity and conductive stability. A conductive fabric prepared by the novel method has high conductivity and good environmental stability, is easy for synthesis, and keeps physical and mechanical properties belonging to fabrics on the basis of acquirement of conductive properties, wherein surface resistance R of the conductive fabric is reduced to a value of 1 to 5 kilo-ohm.

Owner:WUYI UNIV

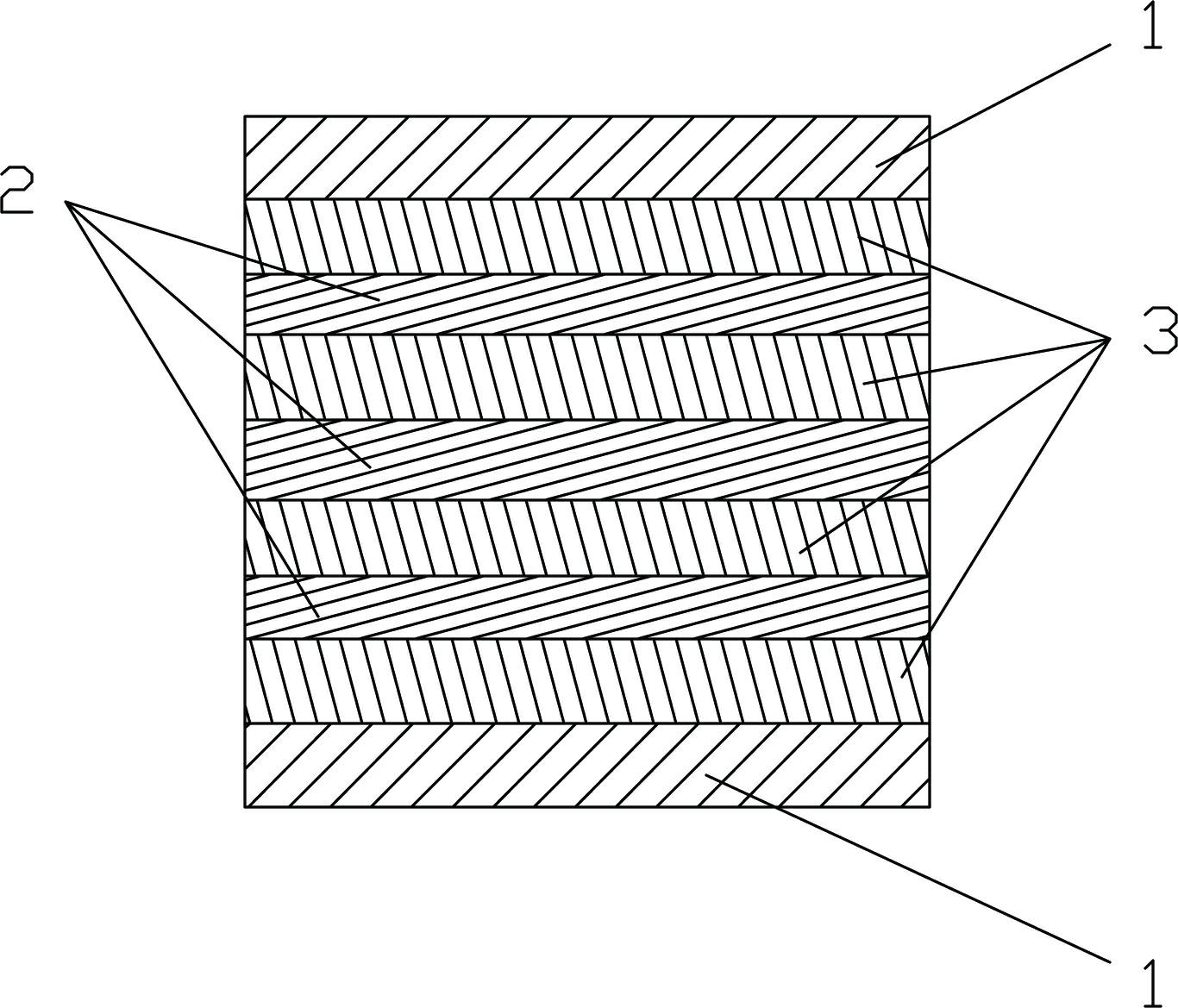

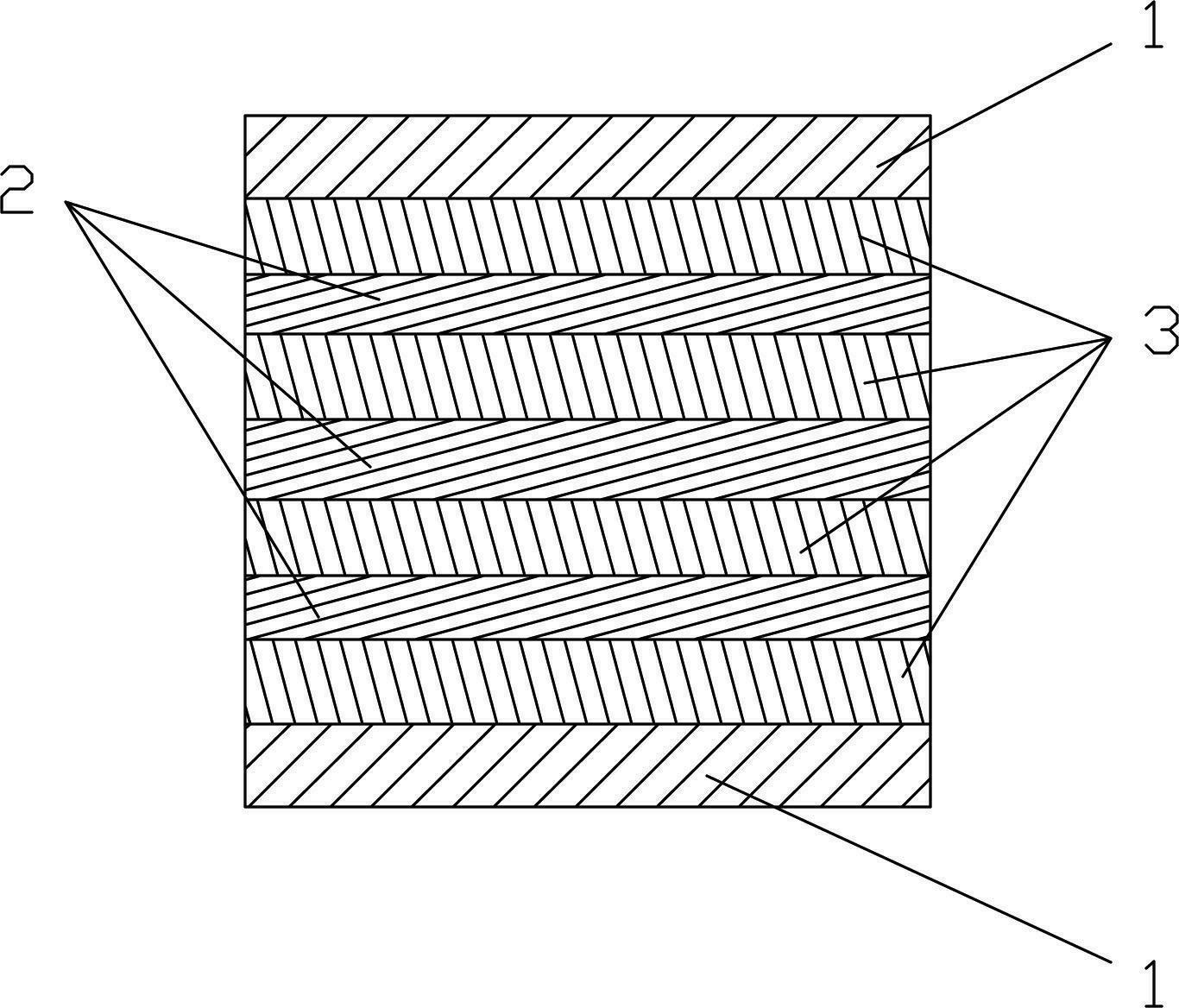

Method for manufacturing ceramic filled polytetrafluoroethylene glass fiber copper-clad substrate

InactiveCN102555349AHigh peel strengthGood electrical conductivityGlass/slag layered productsMetal layered productsFiberGlass fiber

The invention discloses a method for manufacturing a ceramic filled polytetrafluoroethylene glass fiber copper-clad substrate. The method sequentially comprises the following processes of: 1) preparing a polytetrafluoroethylene solution; 2) stirring the prepared polytetrafluoroethylene solution, ceramic powder and a dispersing agent with high-speed stirring equipment to form a solvent; 3) immersing a glass fiber fabric in the solvent to form an impregnated fabric; and 4) sequentially paving a pure polytetrafluoroethylene thin film and the impregnated fabric between copper foil layers, wherein the copper foil layers are connected with the pure polytetrafluoroethylene thin film. According to the method, the ceramic powder, the polytetrafluoroethylene solution and the dispersing agent are mixed and blended together to form common excellent waveguide medium substrates with low dielectric loss and different dielectric constants. The high conductivity of copper foils can be greatly improved through the ceramic filled copper-clad substrate, the copper-clad substrate also has high heat conductivity, and the stripping strength of the substrate can be greatly improved.

Owner:珠海国能复合材料科技有限公司

Light emitting device

InactiveUS7247257B2Minimizes variabilityImprove unevennessDischarge tube luminescnet screensElectroluminescent light sourcesFluorescenceLength wave

To minimize the variability in the emitted light color and improve the unevenness of color tone, a light emitting device comprises a light emitting element and a fluorescent substance that is excited by the light emitting element, wherein the light emitting element has an emission spectrum in a region from ultraviolet to visible light of short wavelengths, and the fluorescent substance has an emission spectrum that includes two or more emission peaks with at least two peaks of the two or more peaks being in the relation of complementary colors of each other.

Owner:NICHIA CORP

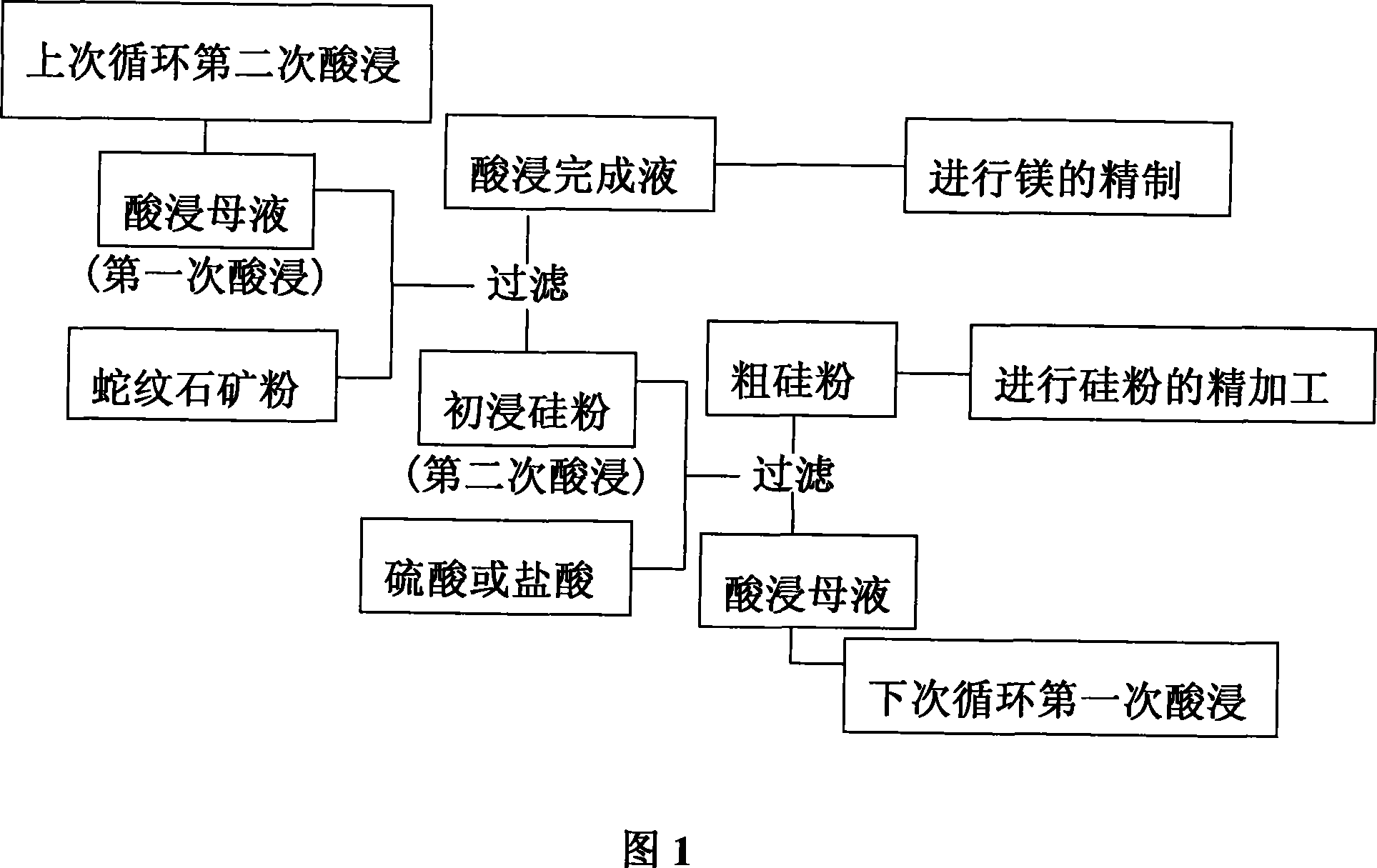

Acid picking method for extracting mineral from serpentine

InactiveCN101235441AHigh development valueRealize large-scale industrial productionSilicon oxidesProcess efficiency improvementSlagSilicon dioxide

A method for abstracting minerals from serendipities belongs to the technical field for abstracting metal compounds from ores or ore concentrates through a wet method. The steps of the method are based on a conventional method for using an acid leaching method to abstract magnesium and silicon from the serendipities and compound alternative and circulating acid leaching is carried out for the serendipities, namely the serendipities is acid-leached. The method comprises: processing after dividing the acid leaching into acid leaching solution and acid leaching slag according to leaching targets and adding acid leaching additive which contains fluorine to intensify acid-leaching reaction, thereby, the extraction rate of the magnesium from the serendipities can be increased to more than 99%, and simultaneously the purity of silicon dioxide in filter residue is increased to more than 90%, and repeated reuses of pickle liquor and cleaning mixture in the whole acid leaching process are realized through circulating and alternative acid leaching. The whole technical process does not produce discard solution, waste residue and other contaminants completely, the cost of production is lowered, and the developing value of the serendipities is increased.

Owner:福建省盛龙化工有限公司

Optical film and method for manufacturing the same

ActiveUS20110157524A1Control generationIncrease contrastImpression capsPolarising elementsCelluloseAcrylic resin

An optical film is provided and includes a cellulose ester and an acrylic resin. The mass ratio of the cellulose ester to the acrylic resin is 70 / 30 to 5 / 95, the total haze value of the optical film is 0.80 or less, the internal haze value of the optical film is 0.01 to 0.28, and the modulus of elasticity in the transverse direction of the optical film is 2,700 to 7,000 MPa.

Owner:FUJIFILM CORP

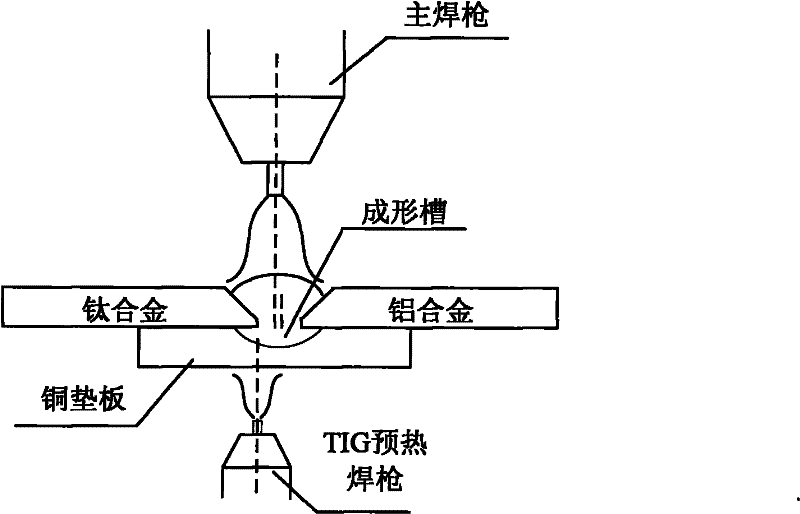

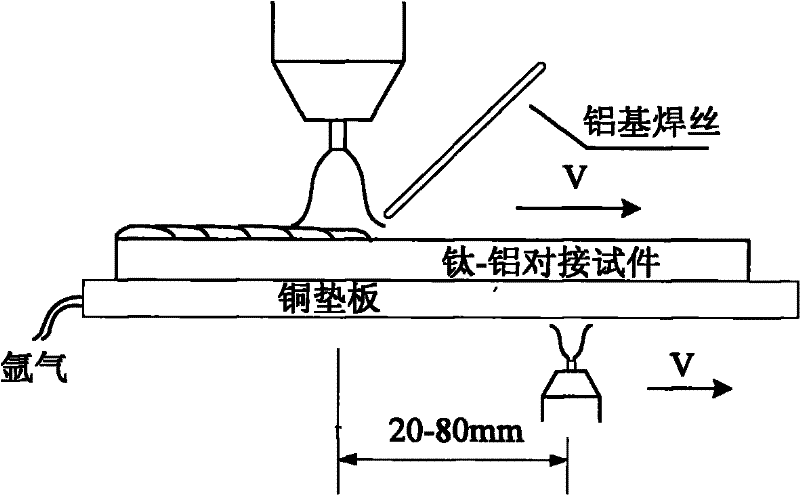

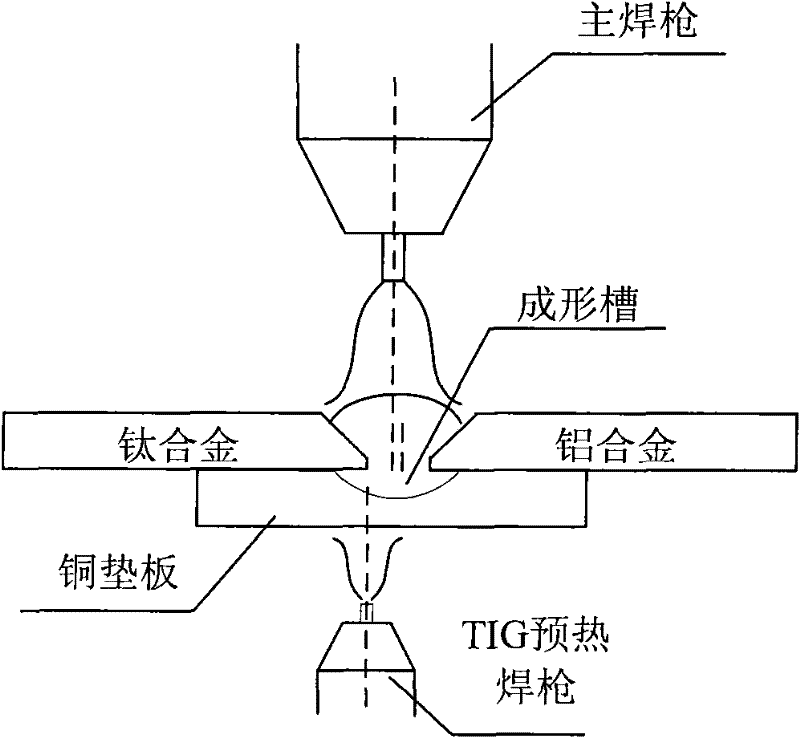

Arc welding-brazing method for titanium-aluminum dissimilar alloy TIG (tungsten inert gas) arc preheating

The invention provides an arc welding-brazing method for titanium-aluminum dissimilar alloy TIG (tungsten inert gas) arc preheating. A TIG preheating welding gun is introduced to common arc welding, a titanium-aluminum connector is locally preheated by heating a copper backing plate with a TIG preheating arc, V-shaped grooves with truncated edges are processed on two sides of each of a titanium alloy plate and an aluminum alloy plate, the copper backing plate is additionally padded at the butt joint of the connector, the TIG arc is used for heating the back of the copper backing plate, areas close to the titanium-aluminum connector are preheated by means of heat conduction of the copper backing plate, and uniform movement of the TIG preheating arc and a main arc is ensured during welding. The arc is used as a heating source, the requirement on cleaning the surface of a workpiece can be lowered by the aid of a cathode atomizing function of the arc, growth of intermetallic compounds of titanium-aluminum brazing interfaces can be hindered by the aid of an electromagnetic stirring function of the arc, appearance and distribution of the intermetallic compounds are improved, a high-strength titanium-aluminum welding connector can be formed, the equipment cost is low, practicability is high, and the arc welding-brazing method is convenient in popularization and application.

Owner:HARBIN INST OF TECH

Image printing using print quality enhancing ink

InactiveUS6863374B2Improve image qualityEnhance the imagePrintingImaging qualityPulp and paper industry

Image quality is improved by adjusting the ejection amount of quality enhancing ink based on the ejection amount of colored ink containing colorant. When a relatively high gross printing medium is used, the quality enhancing ink is ejected in an image area where virtually no colored ink is ejected, thereby improving unevenness in gloss within the print image. When a relatively low gross printing medium is used, on the other hand, the quality enhancing ink is ejected in an image area where the colored ink is ejected on virtually all pixels, thereby improving unevenness in color within the print image. The relationship between the ejection amounts of the quality enhancing ink and the colored ink may be modified by the user.

Owner:NEC CORP +1

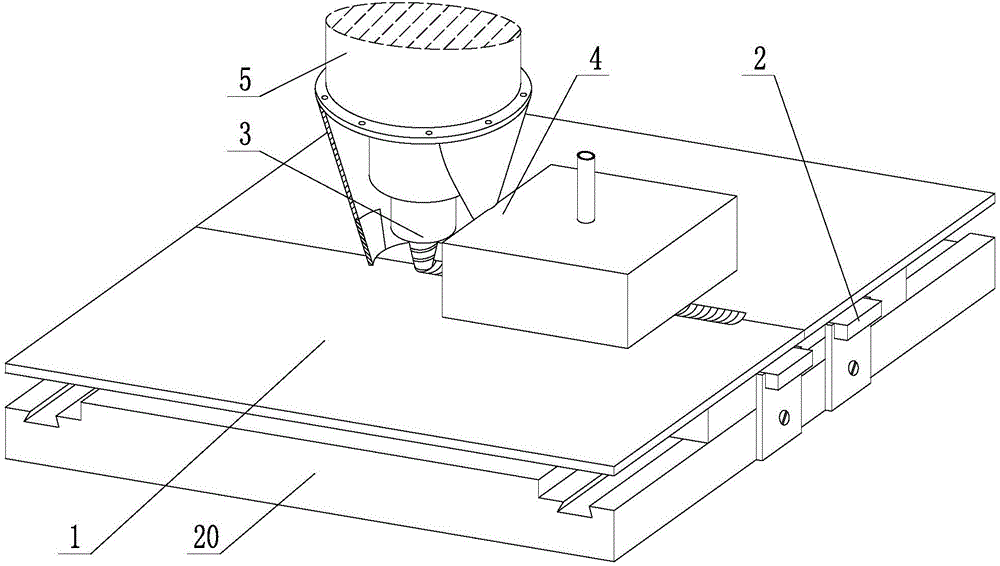

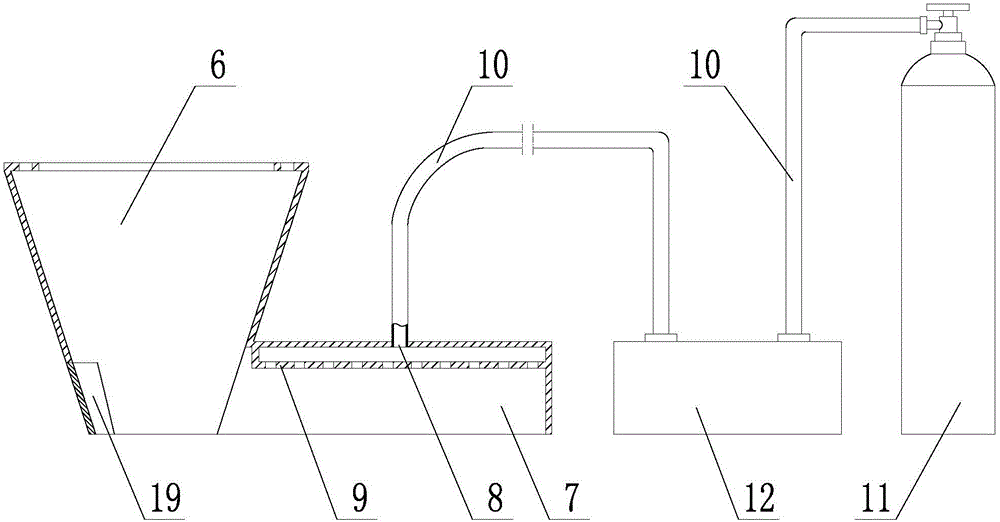

Friction stir welding process for combining back surface heating with frontal surface chilling

ActiveCN106271025AReduce temperature gradientImprove unevennessNon-electric welding apparatusCarbon Dioxide / HeliumShielding gas

The invention discloses a friction stir welding process for combining back surface heating with frontal surface chilling. The friction stir welding process comprises the following steps: a workpiece to be welded is fixedly clamped; heaters are arranged on two sides of a welding line area; a chilling shielding gas protective cover for moving along with a stirring head is arranged on the outer side of the stirring head; the heaters are started to heat the back surface of the workpiece to be welded, so that the temperature of the upper surface of the workpiece to be welded is not higher than 250 DEG C; the chilling shielding gas protective cover is filled with the chilling shielding gas, and the covering range includes the welding line area and the upper surface area of the workpiece to be welded rightly above the heaters; friction stir welding equipment is started, and the rotating stirring head is controlled to insert in the workpiece to be welded; the shaft shoulder end surface of the stirring head is continuously pressed down by a section of distance, and the stirring head is stopped until a set inserting depth is reached; the stirring head is controlled to continuously rotate by a period of time under the set inserting depth, so that the welding line area of the workpiece to be welded is fully preheated to reach an excellent plastic state; and the stirring head is controlled to finish the welding work of the welding line area at a set welding speed.

Owner:SHENYANG AEROSPACE UNIVERSITY

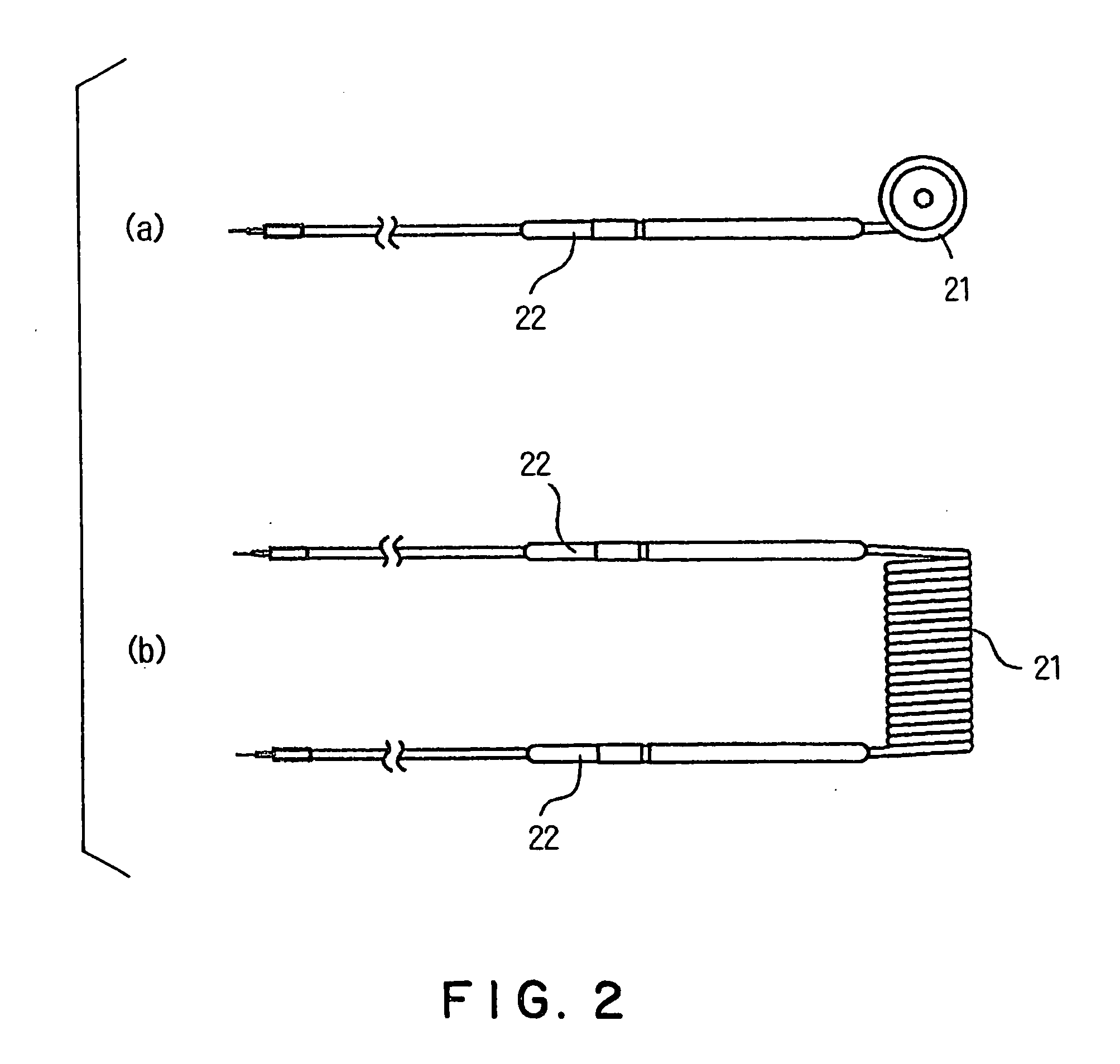

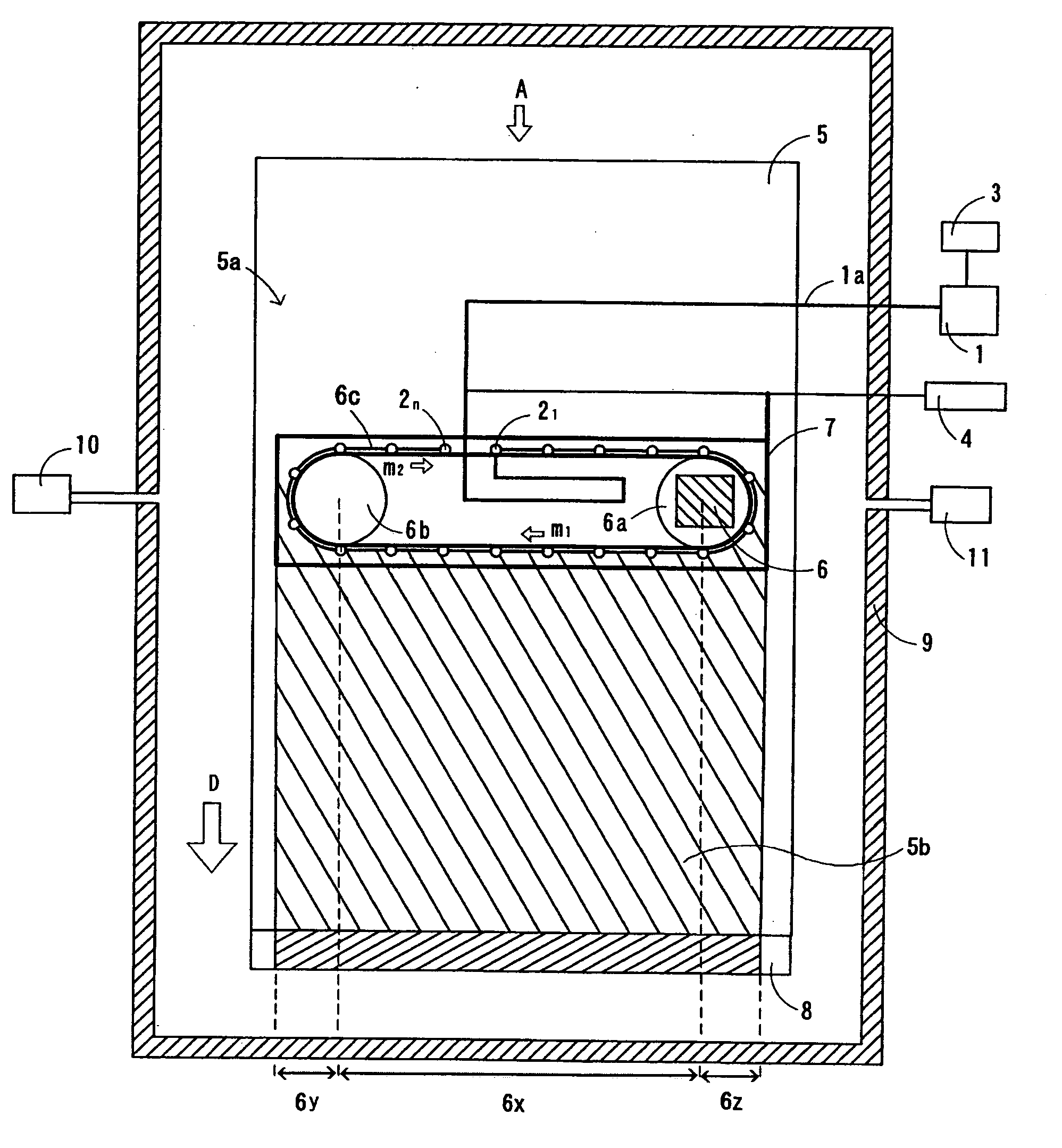

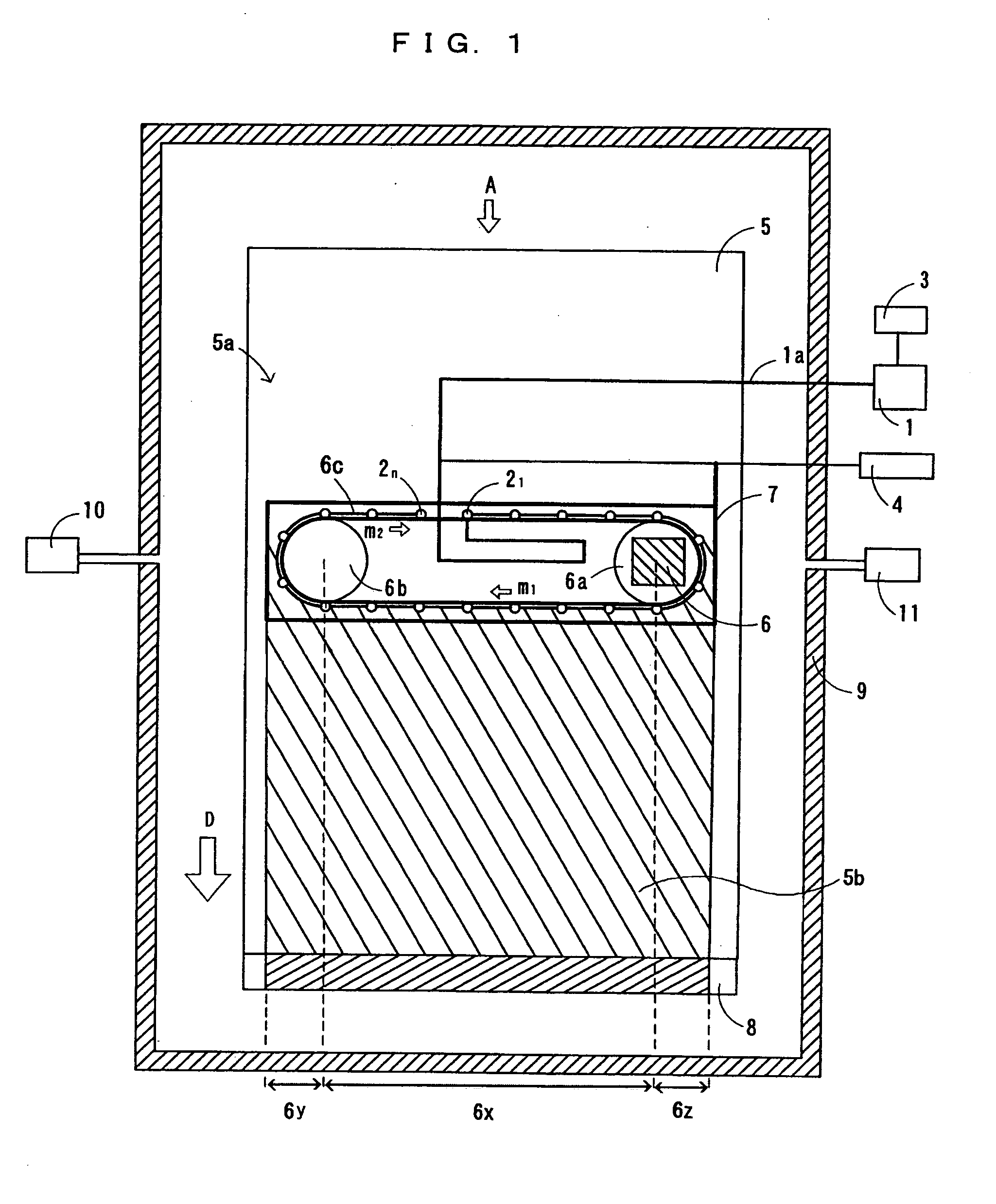

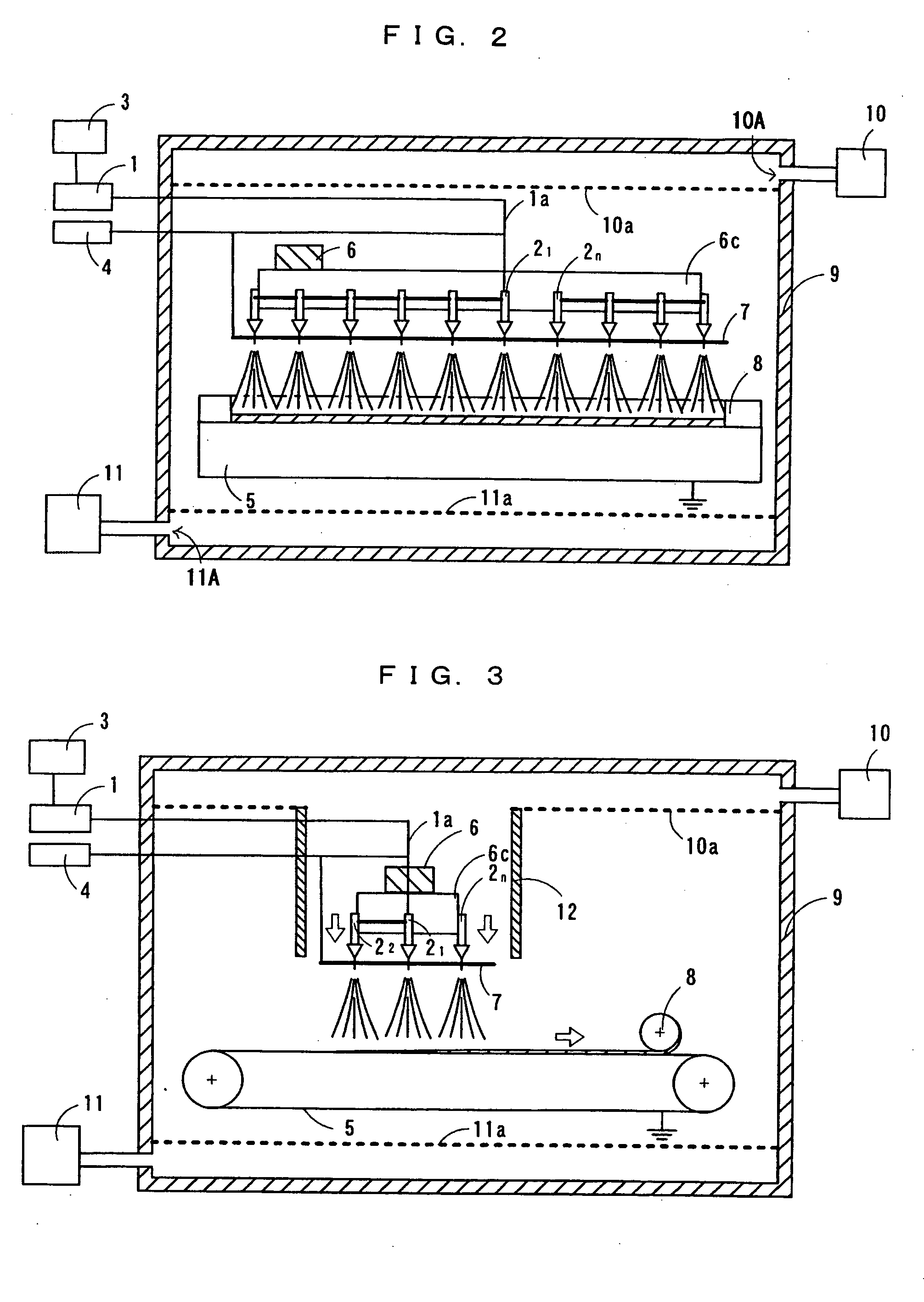

Method and apparatus of producing fibrous aggregate

InactiveUS20060060999A1Guaranteed smooth productionUniform mechanical strengthFilament/thread formingAuxillary shaping apparatusLinear motionEngineering

A method of producing fibrous aggregate, comprising: a supplying and discharging step in which a fiberizable liquid is supplied from a means for storing a fiberizable liquid to a means for discharging a fiberizable liquid via a supplying pipe, and the fiberizable liquid is discharged from the discharging means; and a fibers-collecting step in which fibers drawn and fiberized by applying an electrical field to the discharged fiberizable liquid are accumulated directly on a collecting surface of a collector while the collecting surface is unidirectionally conveyed to form the fibrous aggregate; wherein the discharging means is carried on a support capable of moving along an endless track capable of rotationally travelling between a pair of rotating shafts, and the fiberizable liquid is discharged from the discharging means while the support is revolved at a constant velocity under the condition that a moving direction of a linear motion area in the endless track conforms to a width direction of the collecting surface is disclosed.

Owner:NIPPON BAIRIIN

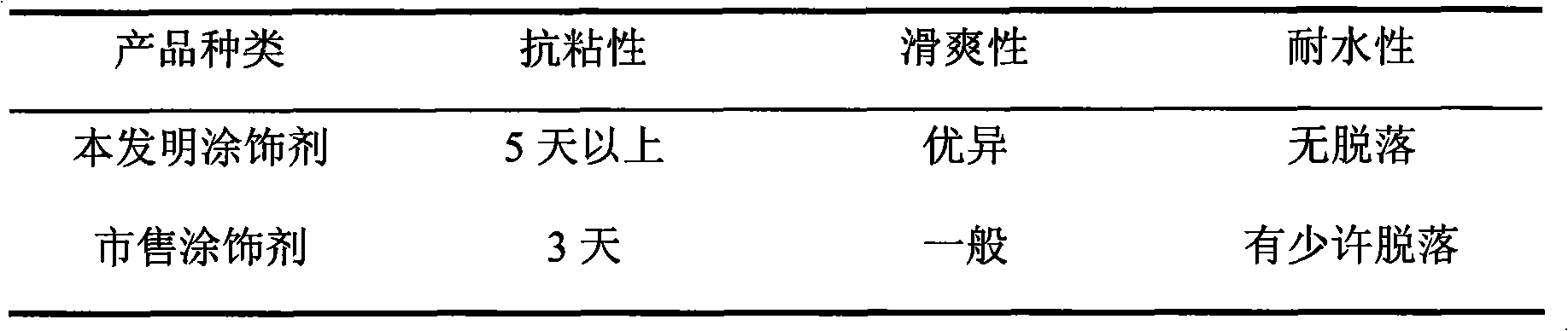

Organosilicon-modified acrylate emulsion and preparation method of coating agent for powder-free gloves

InactiveCN101575398ALow costImprove unevennessAntifouling/underwater paintsPaints with biocidesEmulsionSolid content

The invention relates to an organosilicon-modified acrylate emulsion and a preparation method of a coating agent for powder-free gloves. The preparation method comprises the following steps of: preparing the organosilicone-modified acrylate emulsion; adding the organosilicon-modified acrylate emulsion into a stirred tank; adding a wetting agent for base materials, a germicide and deionized water under constant mixing; then adding a foam killer, a thickening agent, a pH value conditioner after evenly mixing; and discharging after evenly mixing. The solid content of the coating agent of the organosilicon-modified acrylate emulsion is between 10% and 30%; the surface tension is not more than 35mN / m; and the viscosity is between 100 mPa.s and 1000mPa.s; and the pH value is between 7 and 9. The coating agent is diluted with the deionized water according to a rate of 1:19, is leached by a hand model coated with a disposable glove and then is dried at the temperature between 100 DEG C and 150 DEG C. Finally the powder-free gloves processed by the coating agent are formed after demolding.

Owner:天津碧海蓝天水性高分子材料有限公司

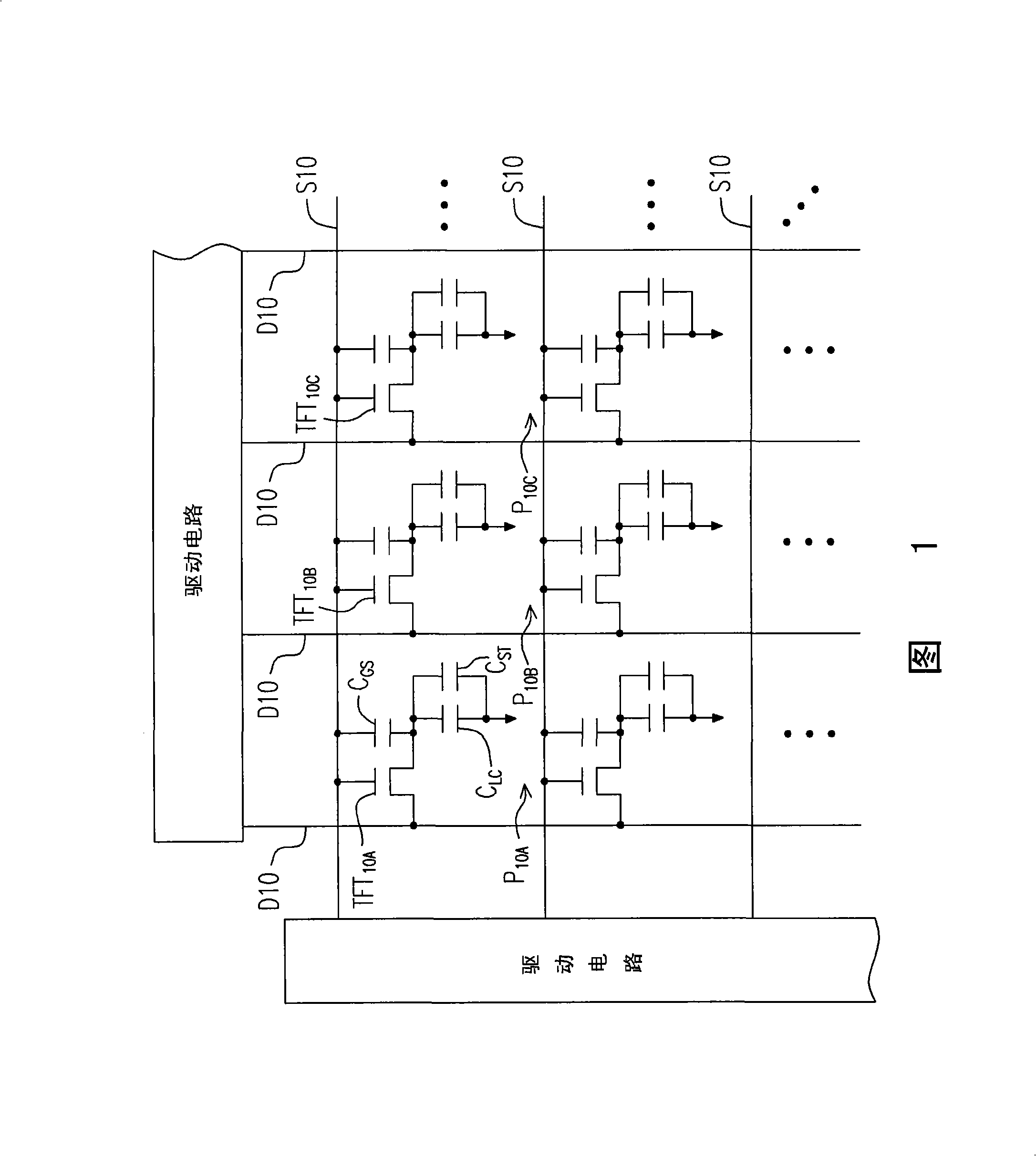

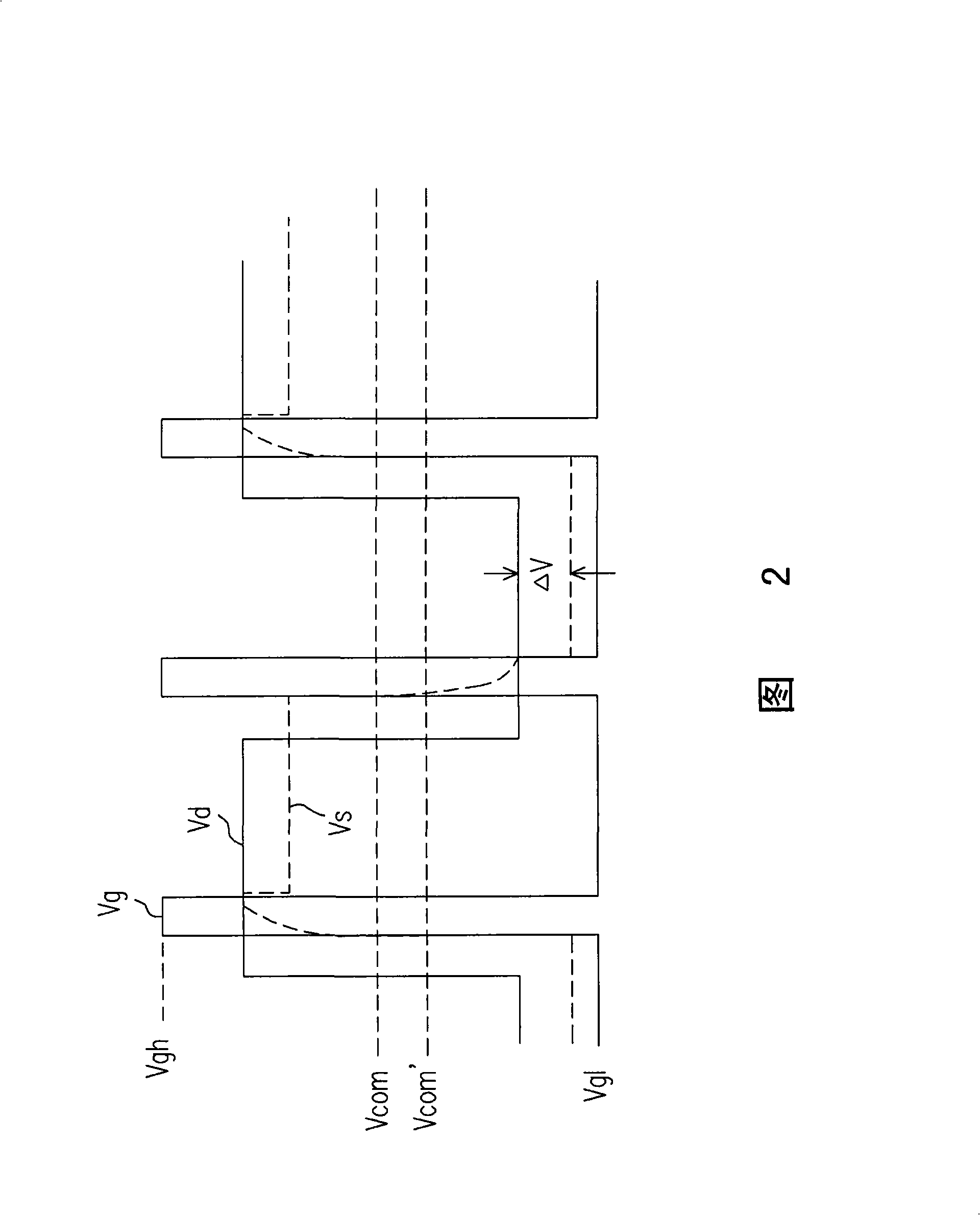

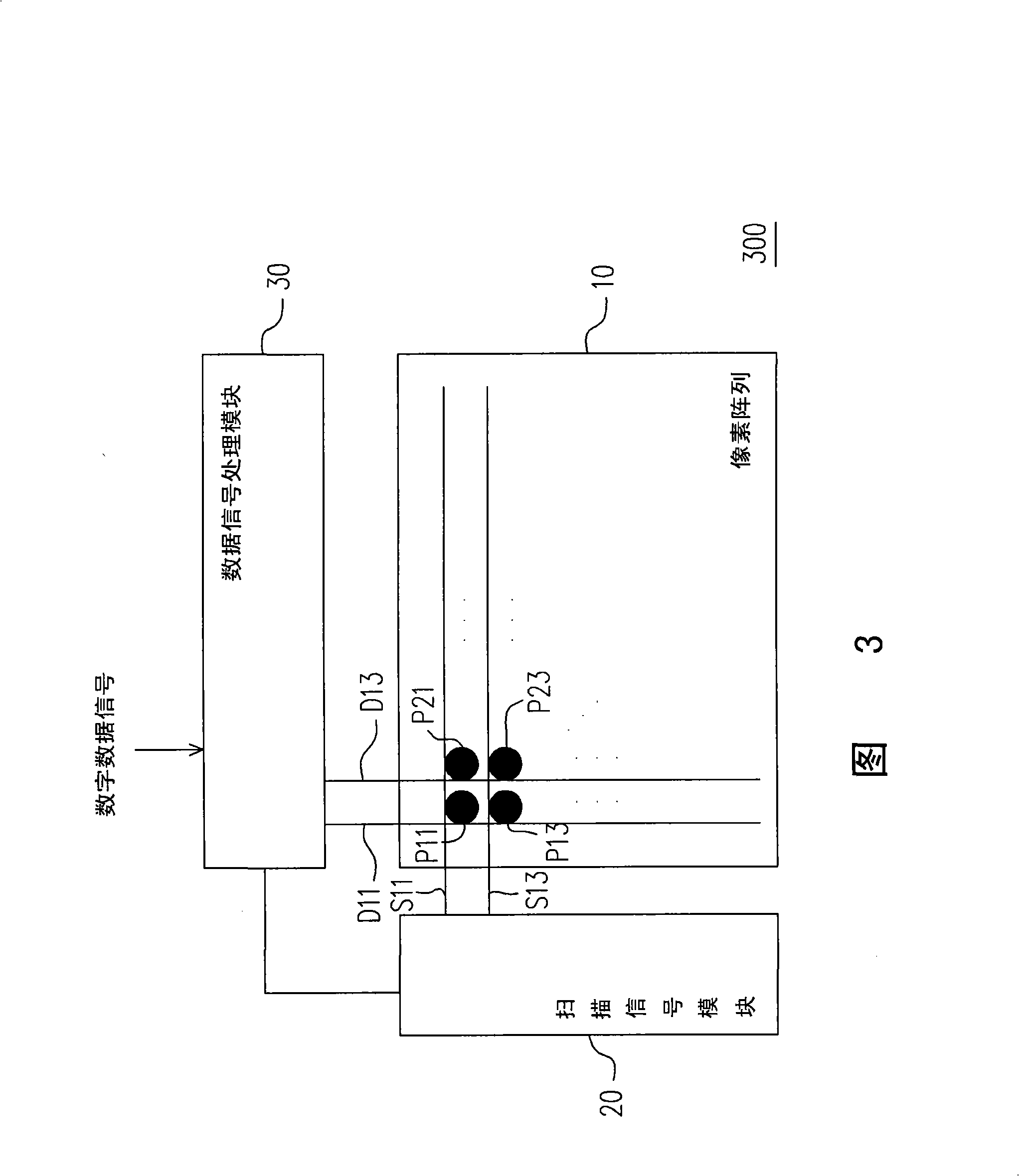

LCD device

InactiveCN101320179AImprove unevennessStatic indicating devicesNon-linear opticsDigital dataLiquid-crystal display

The present invention discloses a liquid crystal display device which comprises a pixel array, a plurality of scanning beams, a plurality of data wires, a scanning signal module and a data signal processing module; wherein, the pixel array comprises a plurality of pixels; the scanning signal module conveys scanning signals to the pixels by scanning beams; the data signal processing module is coupled with the data wires for compensating and transforming received data signals to produce simulative voltage signals and for compensating positive voltage to the simulative voltage signals which are conveyed to the pixels through the data wires. The positive voltage compensation is reduced as the distance between each pixel and the input ends of the scanning wires is increased, so the problem of the uneven picture is solved.

Owner:INNOLUX CORP

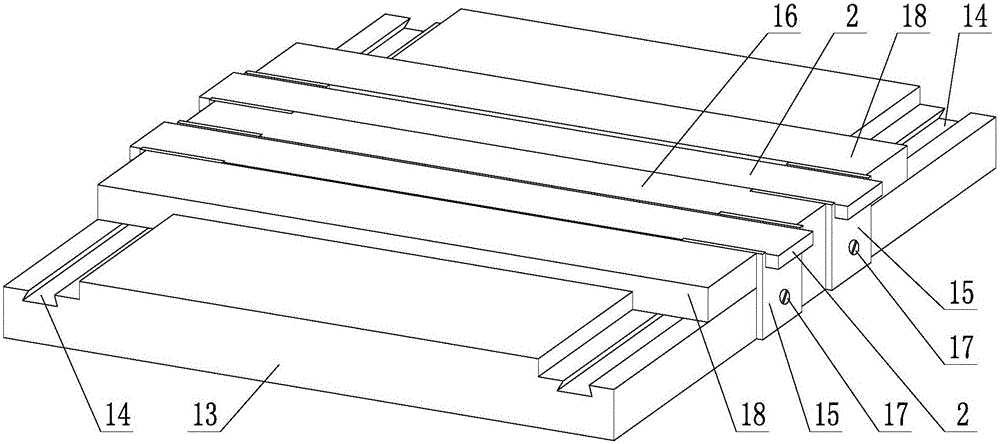

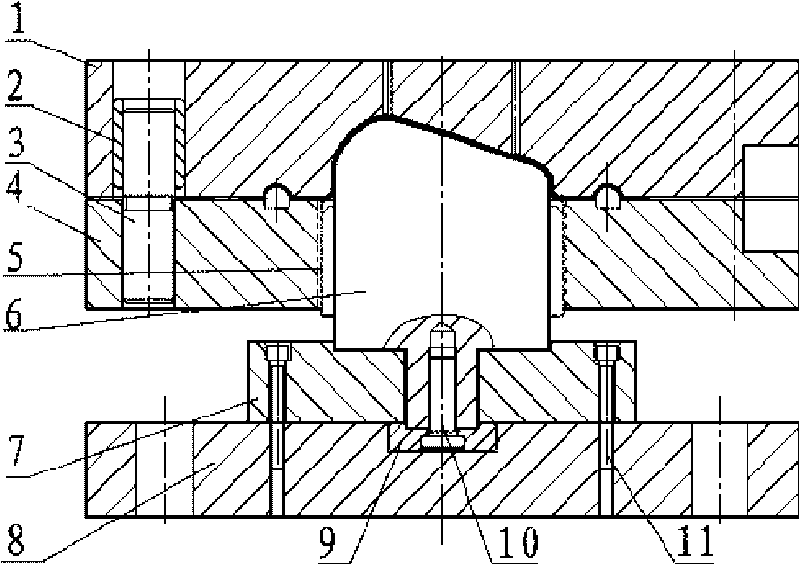

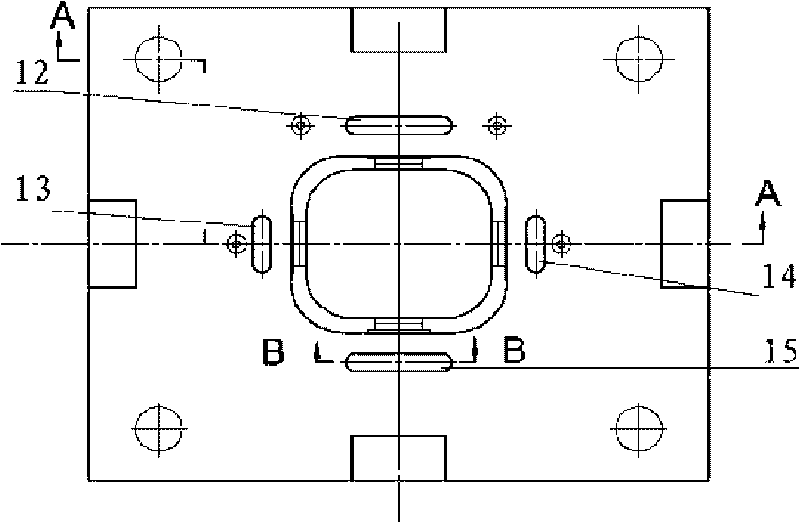

Punching die based on uneven resistance of deep-drawing rib

InactiveCN101700548ASpeed up the flowImprove the quality of stretch formingShaping toolsPunchingDeep drawing

The invention discloses a punching die based on uneven resistance of a deep-drawing rib, belonging to the technical field of metal plasticty machining. The punching die comprises a convex die, a concave die, a blank holder, a convex die base plate, a lower die plate, a guide post, a guide sleeve, a guide plate and a convex die gasket, wherein the convex die and the convex die base plate are fixedly connected with each other, the convex die base plate is fixedly arranged on the lower die plate, the lower die plate is connected with a downwardly-arranged motion mechanism of a pressure machine, the blank holder is connected with the pressure machine, the guide plate is arranged in the blank holder and contacted with the convex die, the guide post and the guide sleeve are respectively arranged in the blank holder and the concave die, and the positions of the guide post and the guide sleeve are matched with each other, the concave die is fixedly connected with an upper slider of the pressure machine, and two sides corresponding to the positions of the convex die are respectively provided with two deep-drawing ribs with variable resistance and two corresponding lower grooves on a material pressing surface of the blank holder. By adopting the invention, the flow evenness of metals of a flange part and a side wall part of box-shaped components with inclined bottom surfaces is remarkably improved, and local crushing or wrinkling conditions caused by even increase or even decrease of the resistance of the deep-drawing ribs are avoided.

Owner:SHANGHAI JIAO TONG UNIV +1

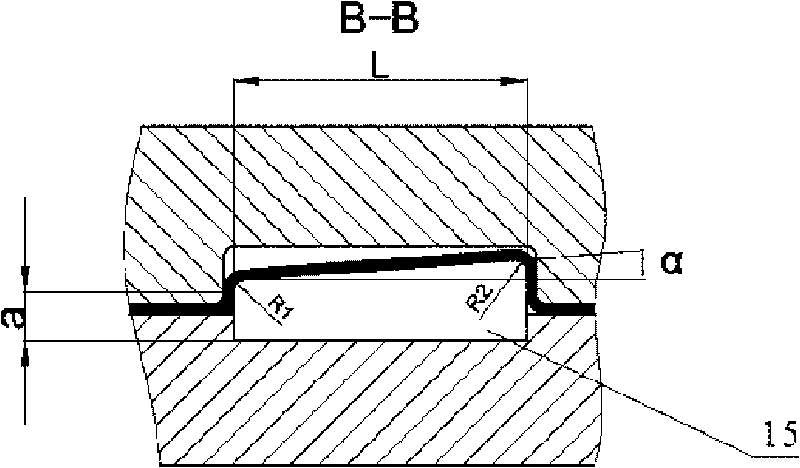

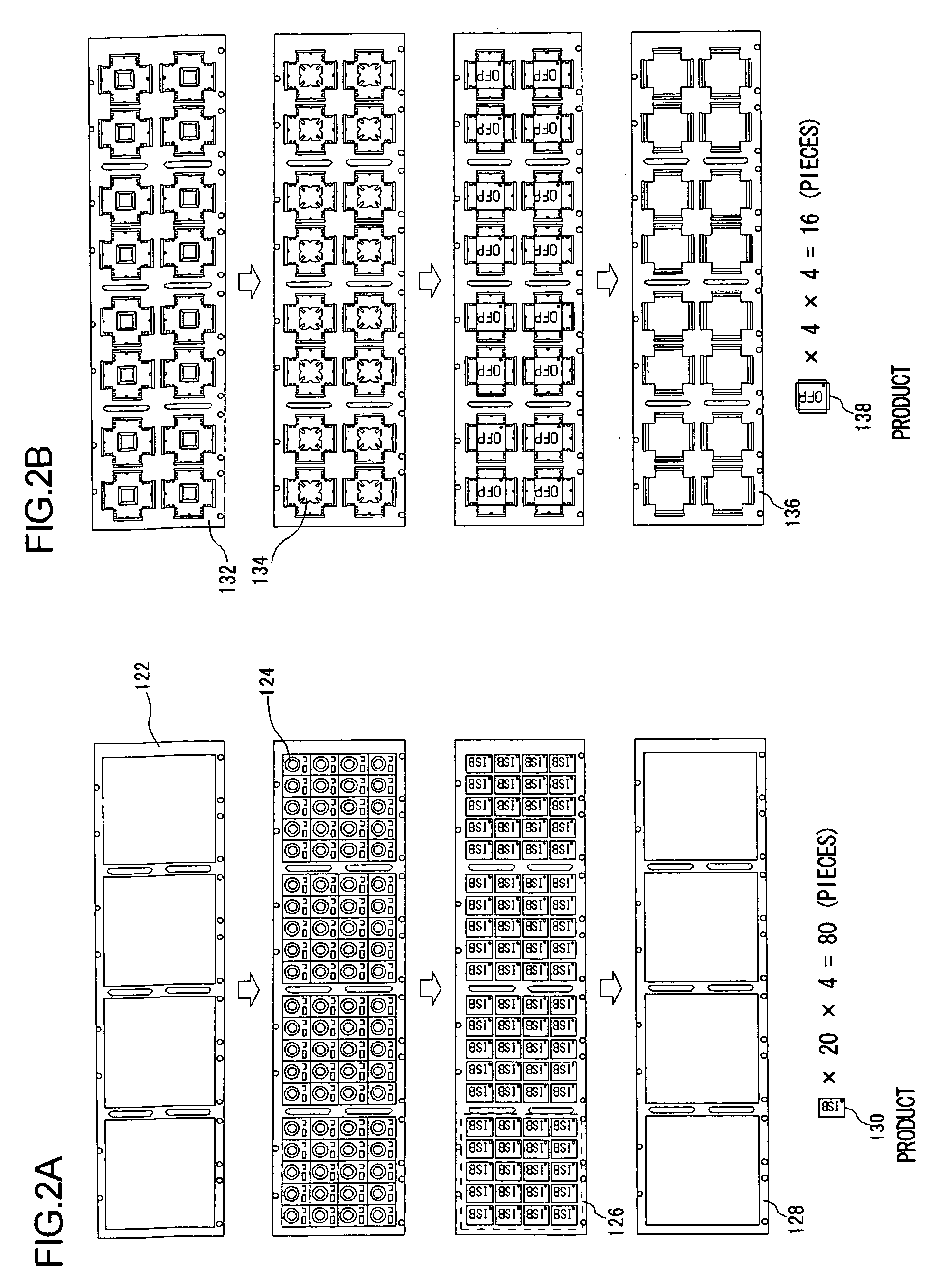

Device mounting board and semiconductor apparatus using device mounting board

InactiveUS20050218480A1Excellent reliability and heat-resistant propertyEasy maintenanceSemiconductor/solid-state device detailsSolid-state devicesResistSemiconductor

The device mounting board according to the first embodiment has the structure in which an dielectric resin film and a photoimageable solder resist film are sequentially laminated on an upper surface of a base material. The device mounting board also has the structure in which the dielectric resin film and the photoimageable solder resist film are sequentially laminated on a lower surface of the base material. The photoimageable solder resist film contains the cardo type polymer.

Owner:SANYO ELECTRIC CO LTD

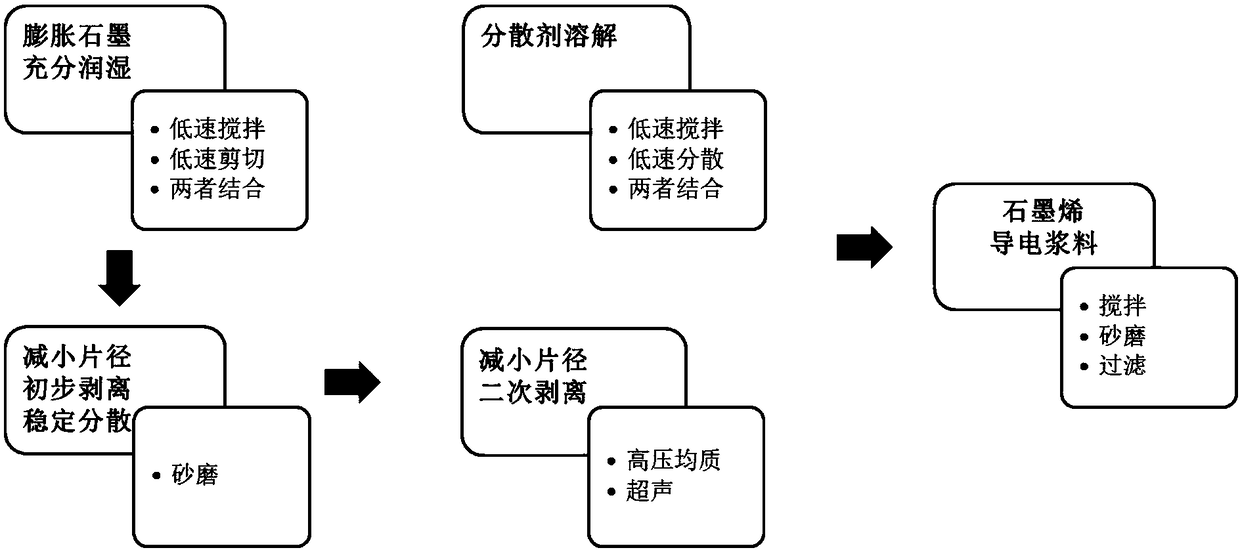

Method and device for massively producing graphene conductive slurry and prepared graphene conductive slurry

ActiveCN108630338AExcellent physical and chemical propertiesEvenly dispersedNon-conductive material with dispersed conductive materialCable/conductor manufactureHigh concentrationGraphite

The invention provides a method and a device for massively producing a graphene conductive slurry and a prepared graphene conductive slurry. The method comprises the following steps of a) mixing graphite and a solvent, carrying out at least one low-speed mixing processing or / and low-speed shearing processing and acquiring a graphite dispersion liquid; b) carrying out at least one sanding processing on the graphite dispersion liquid and acquiring a preliminary stripped graphene dispersion liquid; c) carrying out at least one high pressure homogenization processing or / and ultrasonic processing on the preliminary stripped graphene dispersion liquid, and acquiring a single layer or a small layer of graphene dispersion liquid; d) dissolving a dispersing agent in a solvent to obtain a dispersantsolution; and e) mixing the single layer or the small layer of graphene dispersion liquid and the dispersant solution, carrying out at least one sanding processing, and acquiring the graphene conductive slurry. By using the method, under the condition of environmental protection, the stable and uniformly-dispersed graphene conductive slurry with a high concentration is acquired. And the device issuitable for the continuous automatic production of the high-concentration and high-stability graphene conductive slurry.

Owner:北京地泽科技有限公司

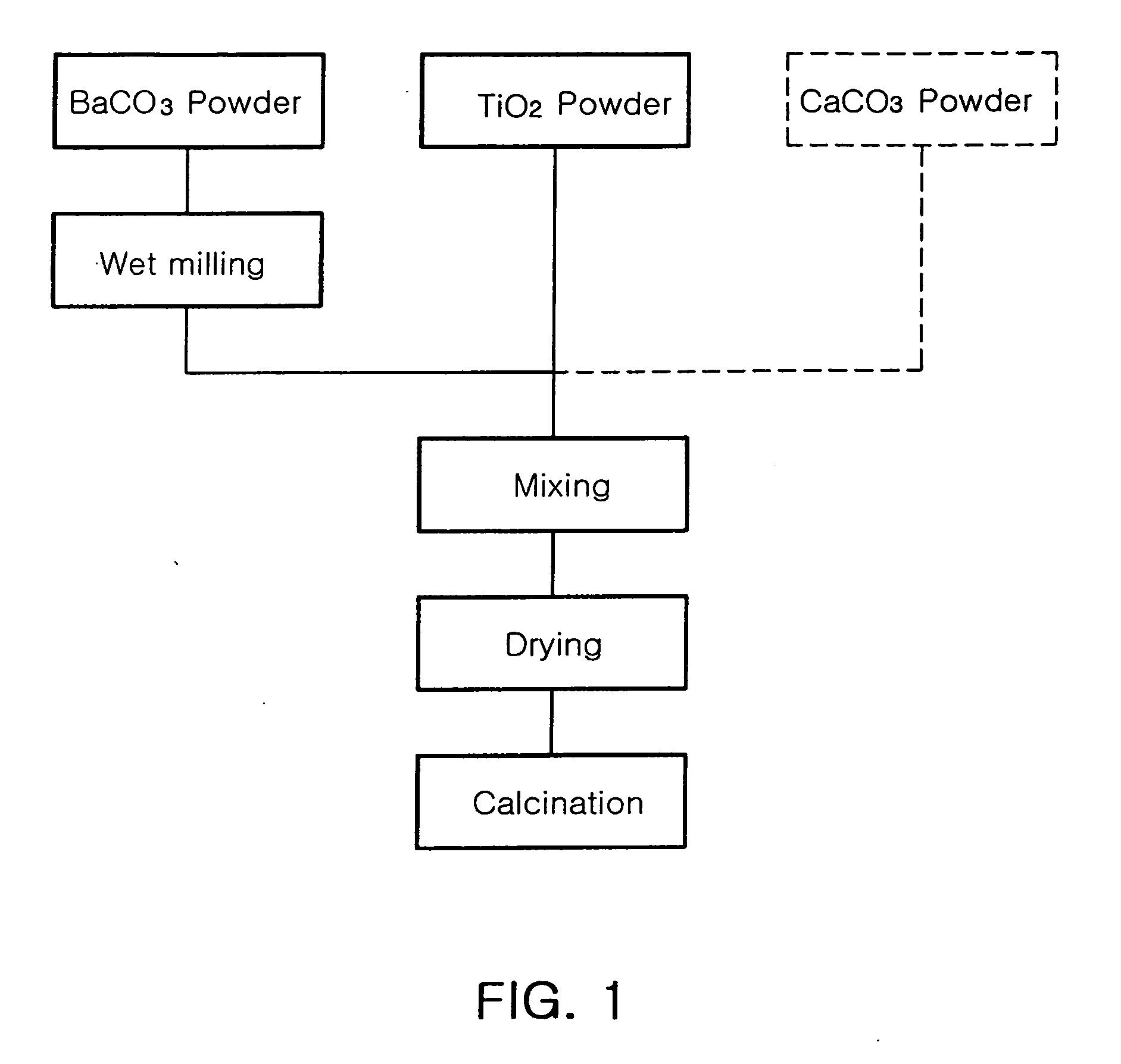

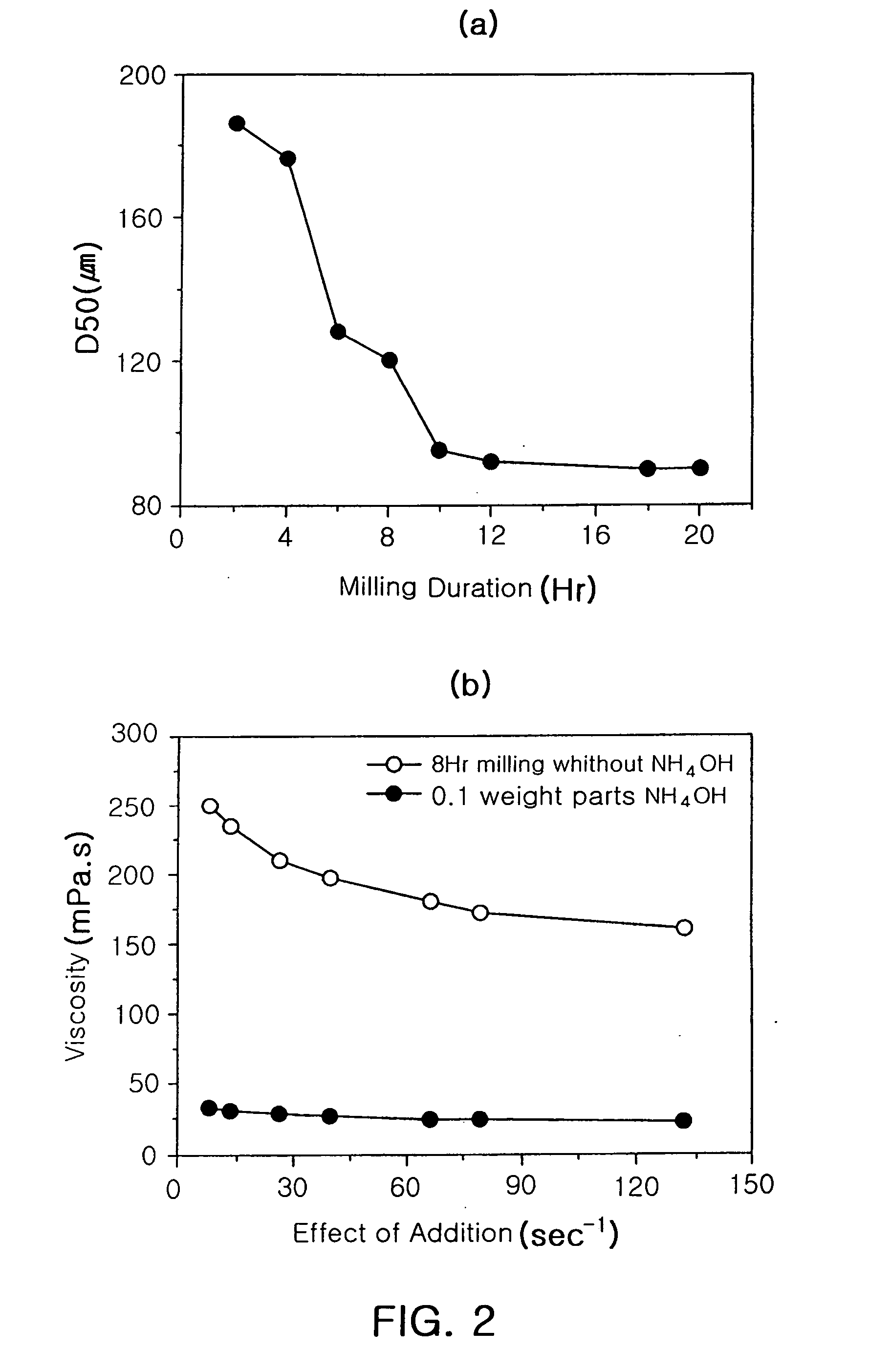

Method for manufacturing dielectric ceramic powder, and multilayer ceramic capacitor obtained by using the ceramic powder

InactiveUS20060221550A1High tetragonal crystalinityUniform particle size distributionAlkaline earth titanatesMaterial nanotechnologyTitanium dioxideMaterials science

The invention relates to a method for manufacturing dielectric ceramic powder and a multilayer ceramic capacitor using the ceramic powder. According to the invention, BaCO3 powder is dispersed into a solution of solvent and dispersant to prepare BaCO3 slurry and then the resultant BaCO3 slurry is wet-milled. Also, TiO2 powder slurry is mixed into the wet-milled BaCO3 slurry to form mixed slurry and then the mixed slurry is dried into mixed powder. Finally, the dried mixed powder is calcined to produce BaTiO3 powder.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Image-recording label sheet and process for image forming

InactiveUS20050181946A1Excellent adhesion resistanceSuppress stressStampsAblative recordingCrazingImage formation

The object of the present invention is to provide an image-recording label sheet in which between an image-recording layer and a base, an intermediate layer suppressing the stress is disposed and when the label sheet is adhesive-bonded to a medium having a curved or uneven surface in which an image is transferred from the label sheet, the crazing in the label sheet can be prevented, and which is excellent in adhesion resistance and is preferred for the electrophotography; and a method for forming an image using the image-recording label sheet. For the object, the present invention provides an image-recording label sheet comprising a separator, and at least a peeling treating layer, an adhesive layer, a base, an intermediate layer, and an image-recording layer which are disposed on the separator in this order, wherein every one of the image-recording layer, the intermediate layer and the adhesive layer comprises a thermoplastic resin and the glass transition temperature (Tg1) of the thermoplastic resin in the image-recording layer, the glass transition temperature (Tg 2) of the thermoplastic resin in the intermediate layer and the glass transition temperature (Tg 3) of the thermoplastic resin in the adhesive layer satisfy the inequality: Tg 1>Tg 2>Tg 3.

Owner:FUJIFILM HLDG CORP

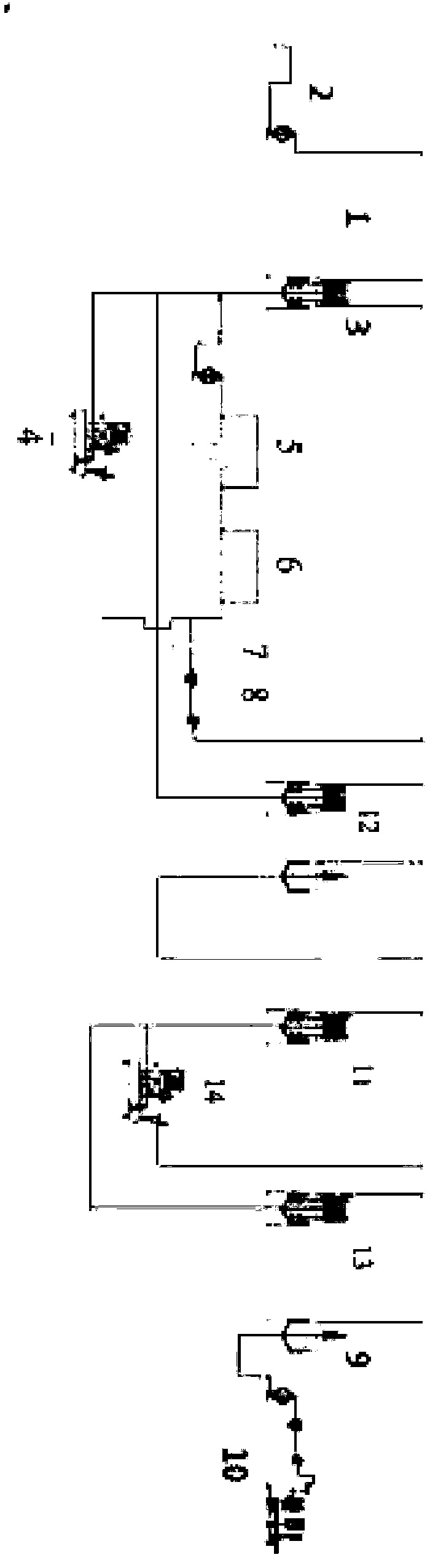

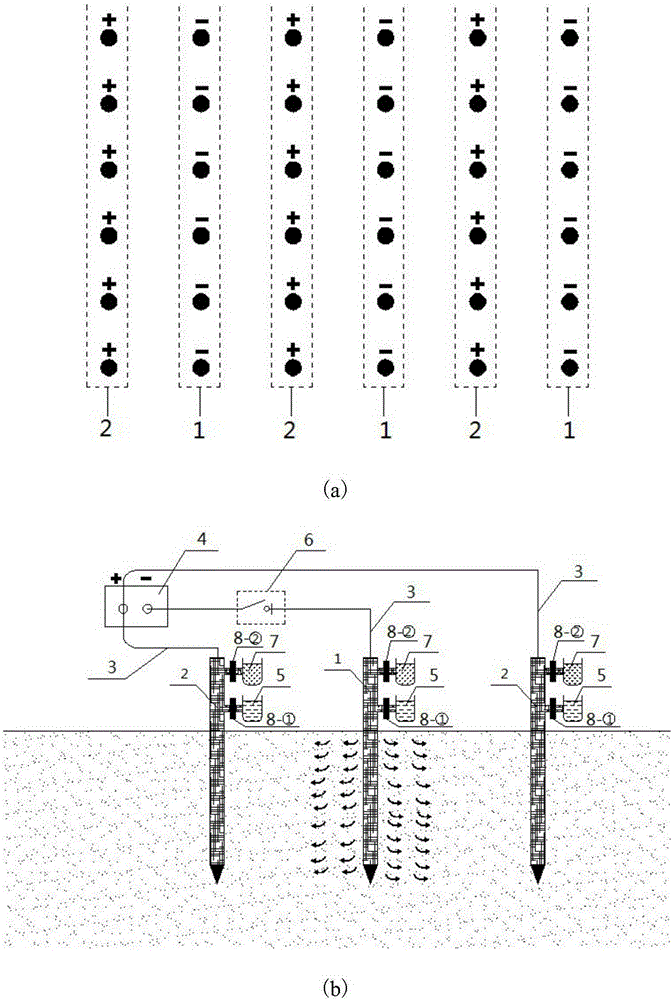

Microorganism and electric field combination reinforcing method for liquefiable foundation

InactiveCN105220681AImprove resistance to liquefactionImprove unevennessSoil preservationSewage treatmentDirect current

A microorganism and electric field combination reinforcing method for a liquefiable foundation comprises the following steps of a, drilling holes in the foundation to be reinforced, arranging grouting pipes a and b in rows and at intervals, and connecting the grouting pipes a with a cathode of a direct current power supply 4 into cathode grouting pipes 1 and connecting the grouting pipes b with an anode of the direct current power supply 4 into anode grouting pipes 2 through conducting wires 3; b, opening a first valve 8, and injecting a urease-producing microorganism solution 5 into the stratum through the cathode grouting pipes 1; c, when grouting begins, closing a switch 6 of the direct current power supply 4, forming a direct current electric field in a region between the cathode and anode grouting pipes, and after the action of the electric field finishes, closing the first valve 8; d, opening a second valve 8, injecting a cement solution 7 into the stratum through the cathode grouting pipes 1, closing the second valve 8, and standing for 8-12h; and e, exchanging the cathode and the anode which are connected with the grouting pipes a, repeating the steps b to d to carry out a new round of reinforcing on the foundation, pulling out all the grouting pipes after grouting is carried out on the place for required times, and pumping underground water to carry out sewage treatment.

Owner:NANJING FORESTRY UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com