Microorganism and electric field combination reinforcing method for liquefiable foundation

A technology of liquefaction foundation and joint reinforcement, which is used in soil protection, infrastructure engineering, construction, etc., can solve the problems of small construction disturbance, low site requirements, and difficult reinforcement range, so as to improve the resistance to liquefaction and improve unevenness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

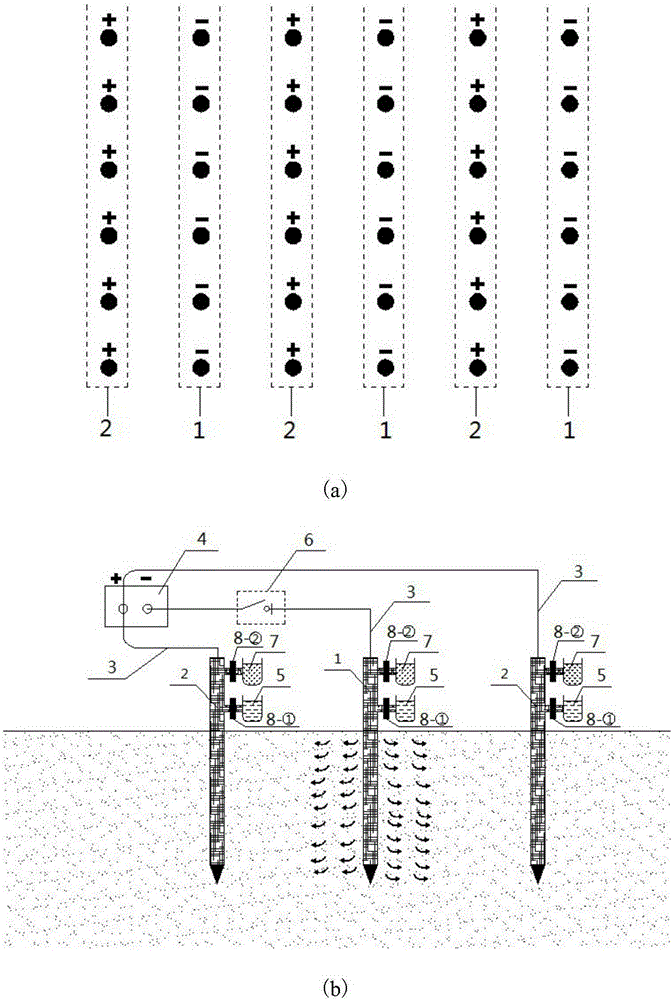

[0028] The plane size of a construction site: 50m in length and 50m in width. According to the data in the engineering survey report, the content of soil particles with a particle size greater than 0.25mm in the site is 76%, which exceeds 50% of the total weight. According to the "Geotechnical Engineering Survey Specification" (GB50021-2001) standards for soil classification, the foundation soil of this site belongs to liquefiable medium sand, and anti-liquefaction treatment measures need to be taken to reinforce the site foundation, and the thickness of the foundation soil layer to be reinforced is 5.0m~5.2m , using the foundation treatment method proposed by the present invention to reinforce the site foundation includes the following steps:

[0029] a. In the foundation to be reinforced, use a drilling rig to drill holes at the location of the holes. The hole distance is 1.0m. Place the grouting pipe a and the grouting pipe b in the hole. The lengths of the grouting pipes a ...

Embodiment 2

[0036] The plane size of a construction site is 120m long and 80m wide. According to the engineering survey report, the soil particles with a particle size greater than 0.1mm in the site are 82%, exceeding 75% of the total weight. According to the "Geotechnical Engineering Survey Specification" (GB50021-2001) standards for soil classification, the foundation soil of this site belongs to liquefiable fine sand, anti-liquefaction treatment measures need to be taken to strengthen the site foundation, the thickness of the foundation soil layer to be reinforced is 4.7m~5.0m , using the foundation treatment method proposed by the present invention to reinforce the site foundation includes the following steps:

[0037] a. In the foundation to be reinforced, use a drilling rig to drill holes at the location of the holes. The hole distance is 1.0m. Put the grouting pipe a and the grouting pipe b in the hole. The lengths of the grouting pipes a and b are both 5.0 m, arranged in rows at i...

Embodiment 3

[0044] In this example, the foundation treatment method proposed by the present invention is used to strengthen the silt foundation with a plane size of 100m in length and 60m in width, and the thickness of the foundation soil layer to be reinforced is 4.51m~4.92m. The method includes the following steps:

[0045] a. In the foundation to be reinforced, use a drilling rig to drill holes at the location of the holes. The hole distance is 0.8m. Put the grouting pipe a and the grouting pipe b in the hole. The lengths of the grouting pipes a and b are both 5.0 m, arranged in columns at intervals, a total of 100 rows and 60 columns of grouting pipes are arranged on the site, the grouting pipe a is connected to the cathode of the DC power supply 4 through the wire 3 as the cathode grouting pipe 1, and the grouting pipe b is connected to the DC The anodes of the power supply 4 are connected as the anode grouting pipe 2, so that the cathode grouting pipe 1 and the anode grouting pipe 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com