Patents

Literature

50results about How to "Lower Wetting Line" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

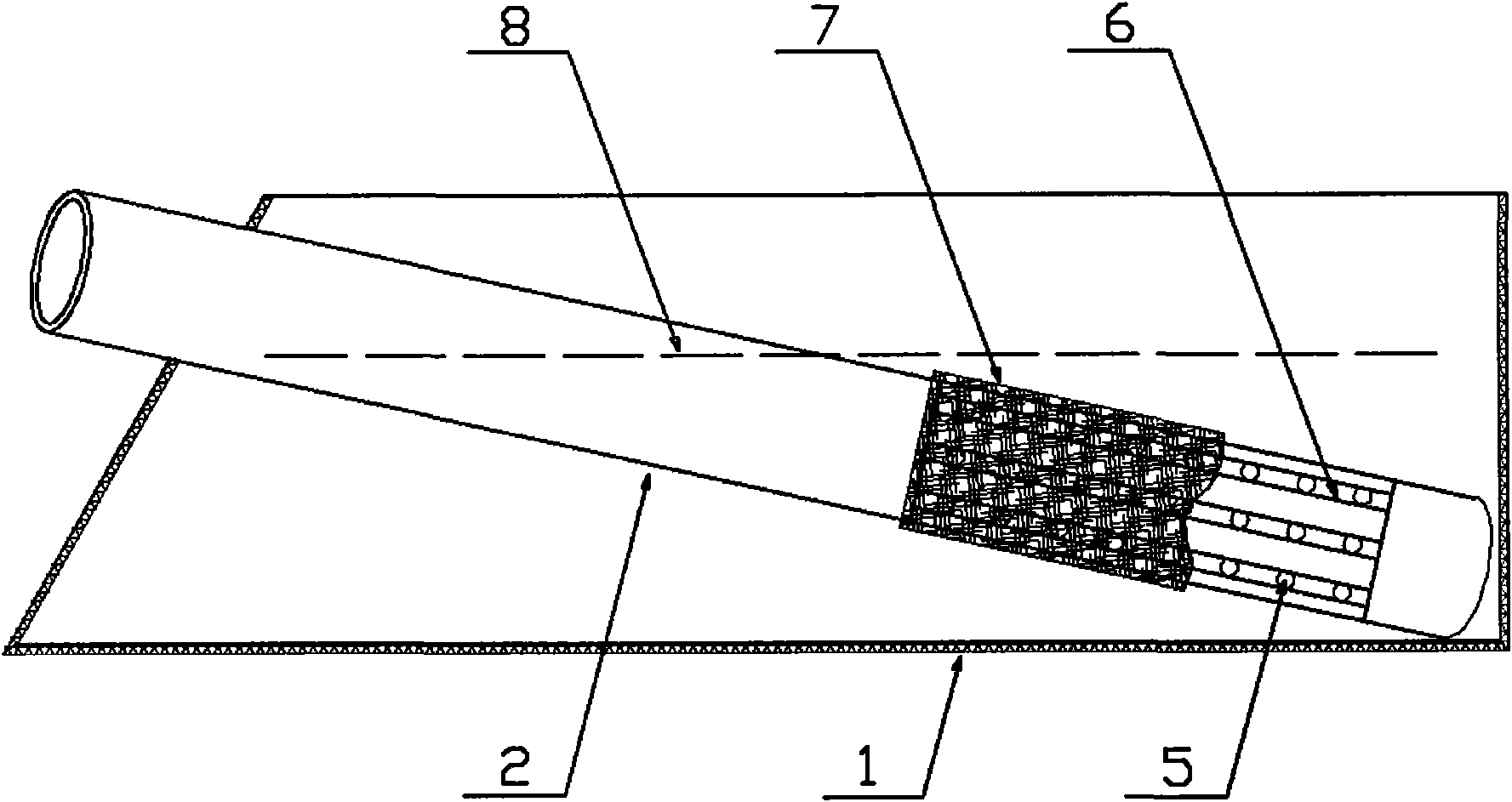

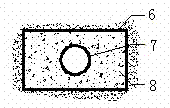

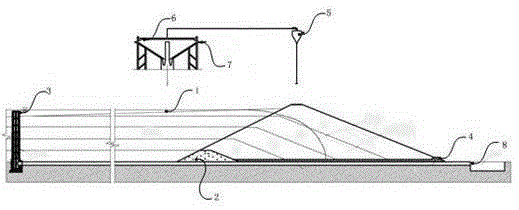

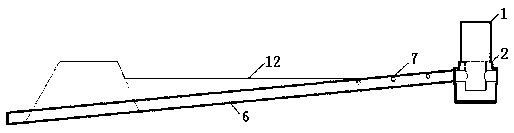

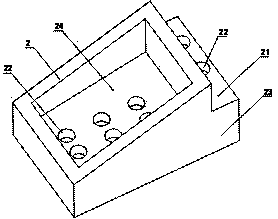

Chemical siltation resisting drainage device for tailing dam

InactiveCN101629417AEnsure normal drainageSmooth drainageExcavationsSoil preservationGeotextileWater seepage

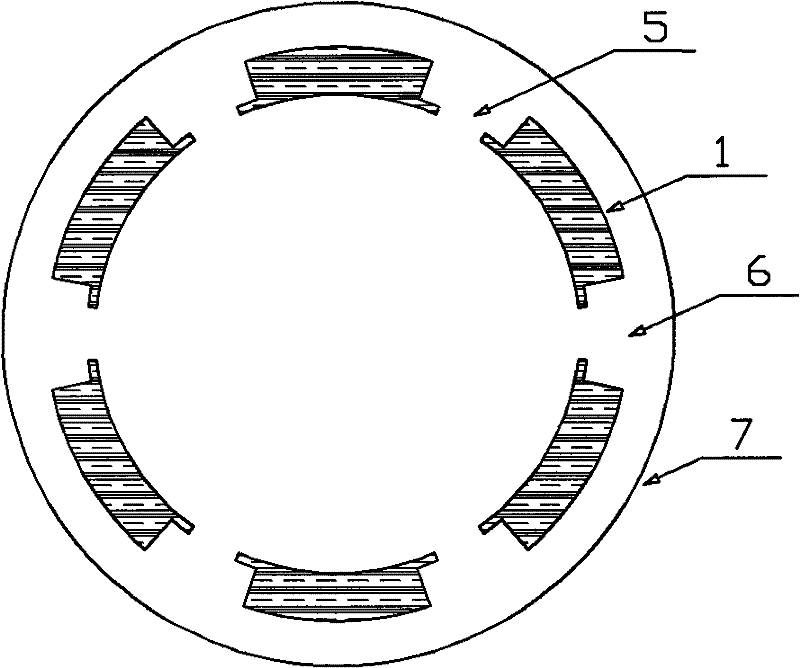

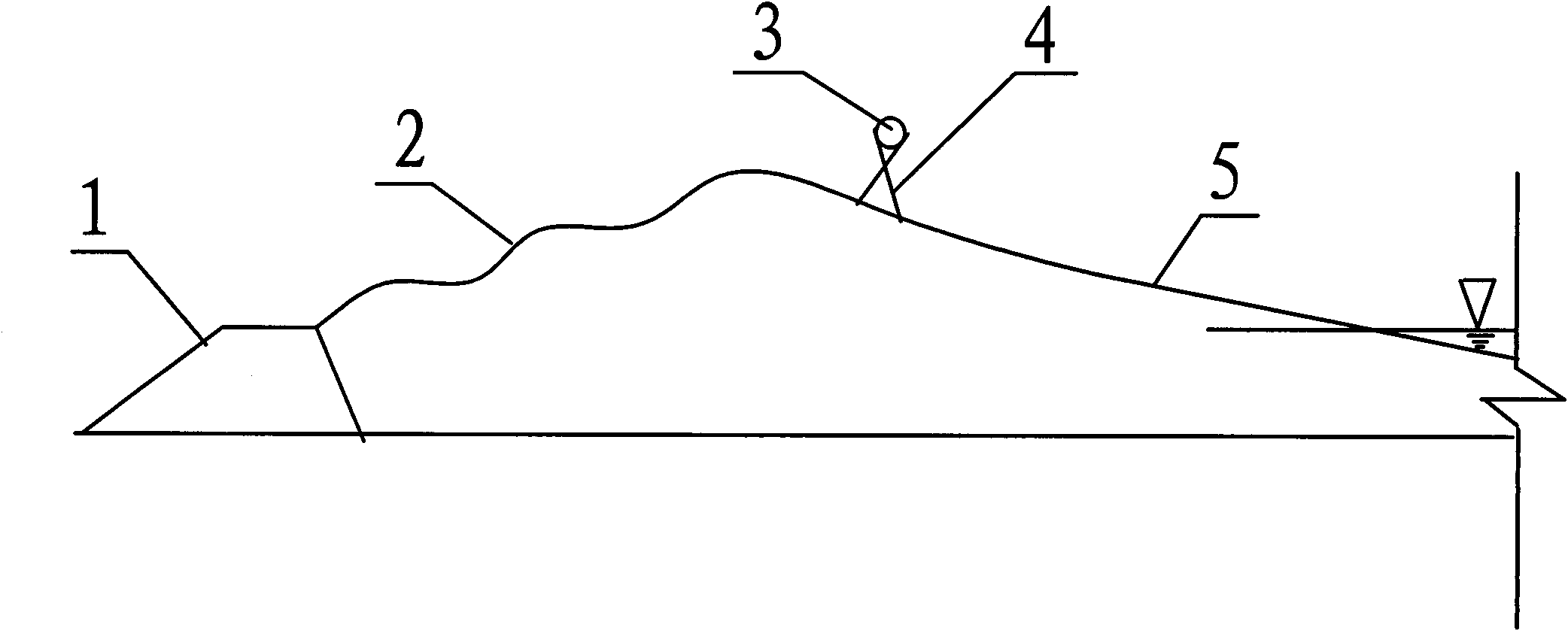

The invention discloses a chemical siltation resisting drainage device for a tailing dam, comprising a drainage pipe, a siltation resisting trough, water seepage holes, water seepage troughs and geotextiles. The invention is characterized in that the drainage pipe is a circular pipe, and the end part of the pipe is provided with the water seepage troughs and the water seepage holes, and the water seepage troughs are tightly wrapped by the geotextiles; the siltation resisting trough is a rectangular box body having no cover, and the front end of the box body is provided with a circular hole having the same pipe diameter as the drainage pipe; the drainage pipe is obliquely arranged in the siltation resisting trough of the box body at an inclination angle so as to prevent the geotextiles from generating chemical siltation and ensure that the dam body can drain normally. The chemical siltation resisting drainage device has the advantages of simple structure, high effectiveness, low cost and convenient use, and ensures that the geotextiles do not alternate between saturation and nonsaturation, thus preventing the geotextiles from generating chemical siltation. By using the chemical siltation resisting drainage device, the drainage capability of the dam is reinforced, thus ensuring smooth drainage, reducing the seepage line of the dam effectively and accordingly lowering the operation risk of the tailing dam.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

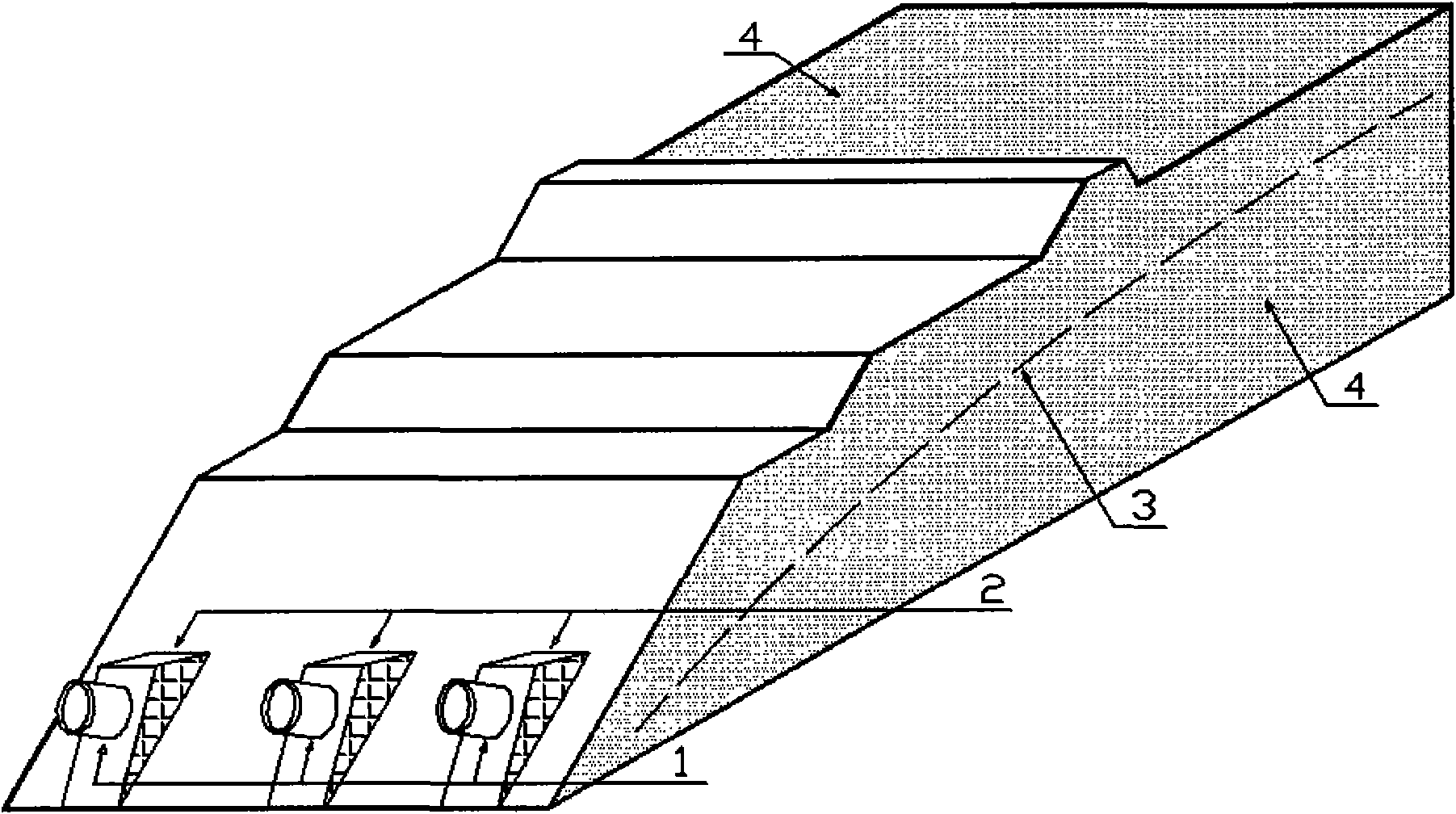

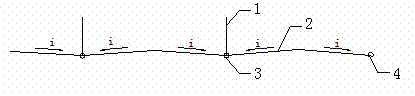

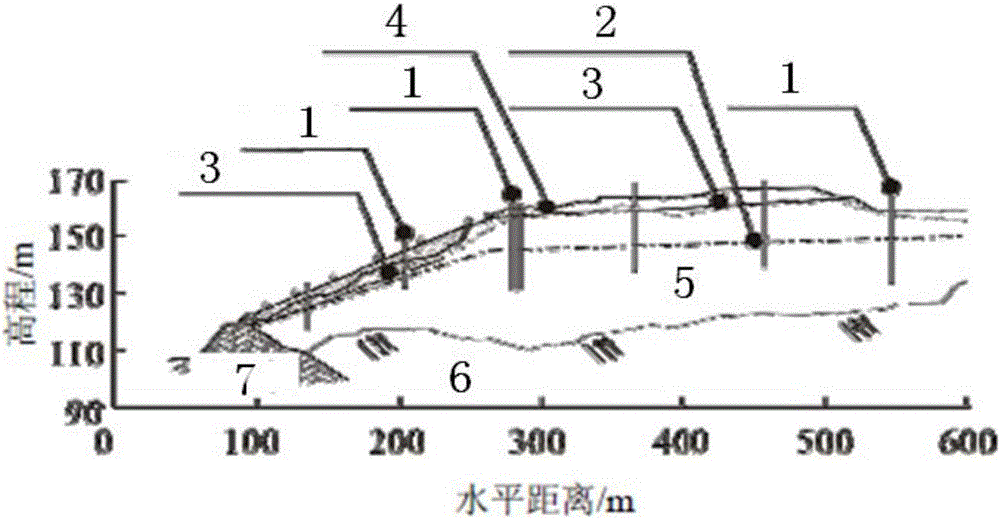

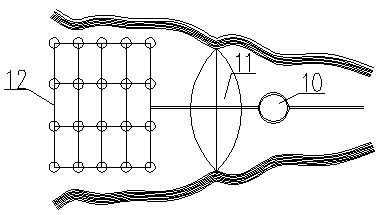

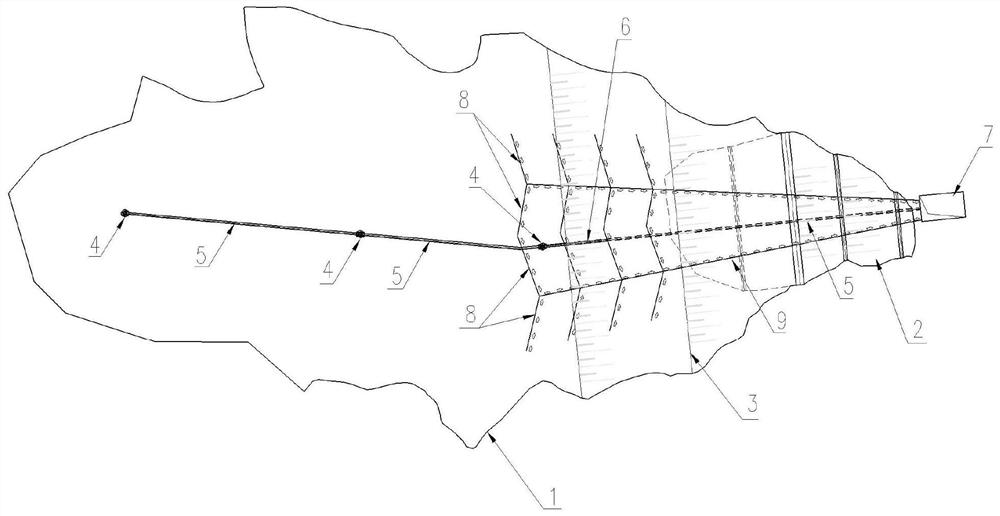

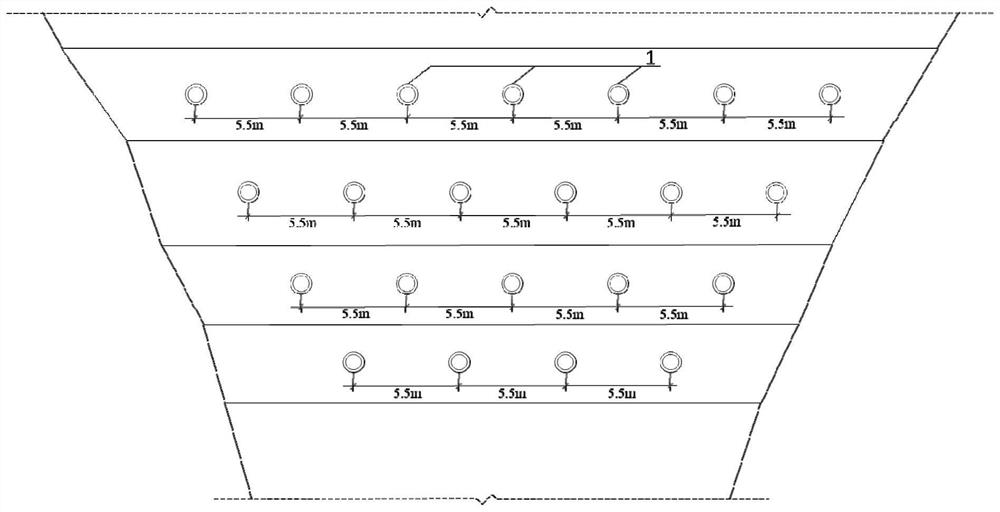

Network type seepage discharging device in transverse direction, longitudinal direction and vertical direction

InactiveCN103615042AGuaranteed operational safetyReduce air resistanceSewage drainingSoil preservationWhole bodyOperation safety

The invention discloses a network type seepage discharging device in the transverse direction, the longitudinal direction and the vertical direction. The network type seepage discharging device comprises vertical seepage collecting bodies, a horizontal transverse seepage collecting body, horizontal longitudinal seepage discharging pipes and a longitudinal flow guiding pipe. A seepage discharging structure of a single node is composed of each vertical seepage collecting body and the corresponding horizontal longitudinal seepage discharging pipe; the horizontal transverse seepage collecting body is connected with the seepage discharging structures of the nodes in the same layer in series, so that a linear seepage discharging structure of each elevation is formed; the linear seepage discharging structures of the elevations are connected in series through the longitudinal flow guiding pipe, so that the network type seepage discharging device is formed in the transverse direction, the longitudinal direction and the vertical direction. According to the network type seepage discharging device in the transverse direction, the longitudinal direction and the vertical direction, seepage discharging is conducted in a combined mode in three directions, a combined type automatically-flowing seepage discharging whole body is formed, the air resistance is small, the seepage permeability is good, washing and dredging are convenient, following maintenance is convenient, the network type seepage discharging device in the transverse direction, the longitudinal direction and the vertical direction is economical, durable, suitable for various solid waste field accumulation bodies of upstream damming and capable of achieving the purpose of effective reduction of an accumulation body seepage line and guaranteeing the operation safety of a dam.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN

Water-saving tailing discharge method

ActiveCN105350498AEmission buildup is easy to controlImprove stabilityVortex flow apparatusSoil drainageTerrainWater saving

The invention belongs to the field of metallurgical mines, and particularly relates to a water-saving tailing discharge method. A place is selected according to the tailing pond address selection principle. A tailing pond, a primary dam, a floodwater drainage system, a seepage drainage system, a tailing conveying system, a tailing classification and condensation system, a water return system and other matched facilities are reasonably arranged according to terrain and geological conditions. The tailing conveying system comprises a section from a dressing plant to a hydrocyclone, a section from the hydrocyclone to a thickener, and a section form the underflow of the thickener to the tailing pond. Pumping or self-flowing conveying can be adopted for the conveying process of each section. The tailing classification and concentration involves the steps that ore pulp coming from the dressing plant is classified through the hydrocyclone; and overflow tailing ore pulp of the hydrocyclone is concentrated through the thickener. The water return system comprises a thickener overflow water return system and a tailing pond water return system. Return water can be conveyed to the mineral processing process to be recycled in a pumping or self-flowing conveying manner. The tailing pond formed through the method is good in anti-seismic property, high in return water utilization rate, low in dam body seepage line, large in anti-slide buckling safety factor, wide in application range and low in operation and management expense.

Owner:金建工程设计有限公司

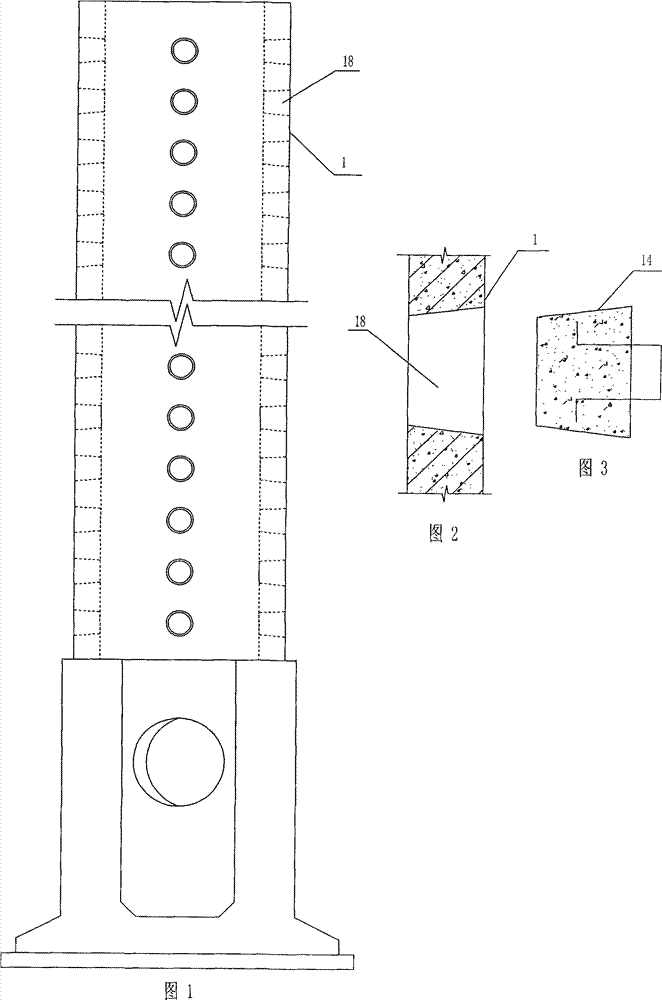

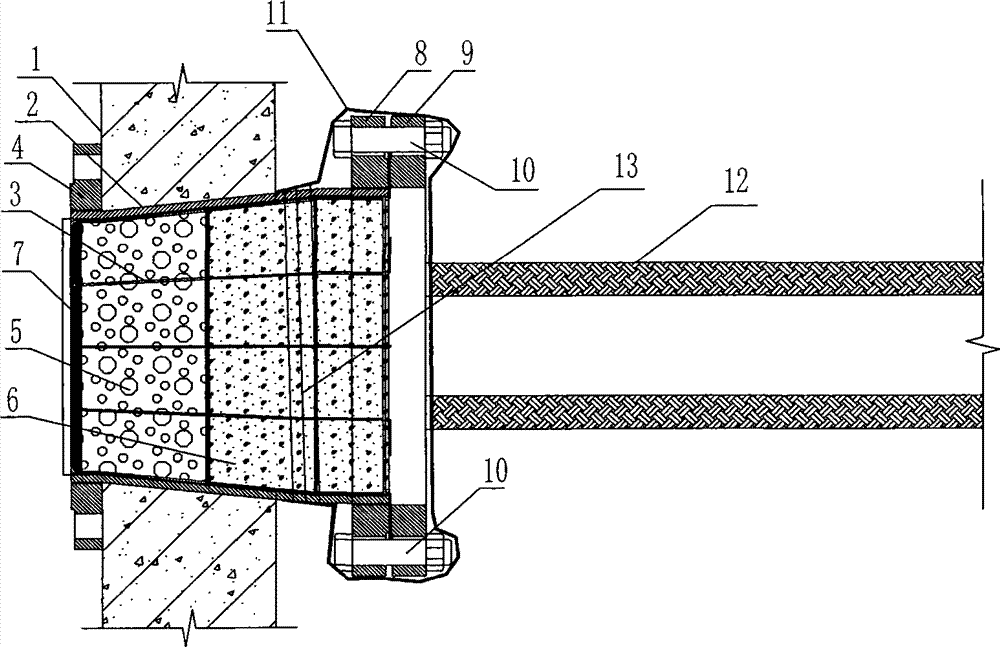

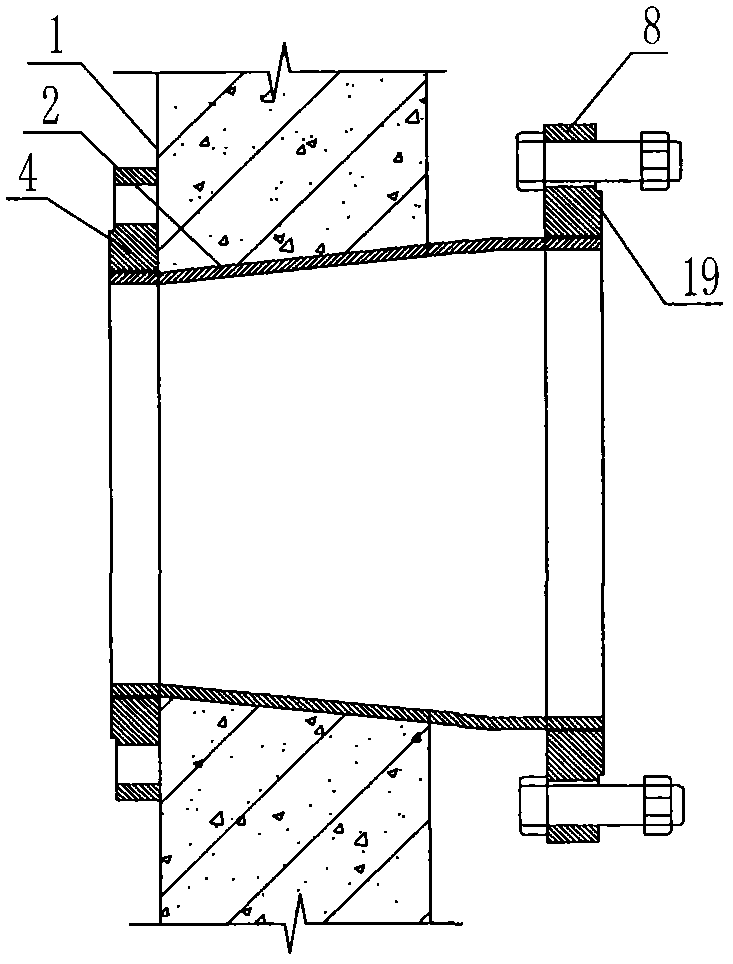

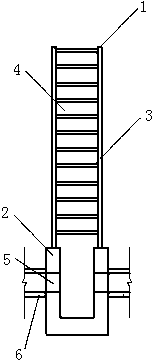

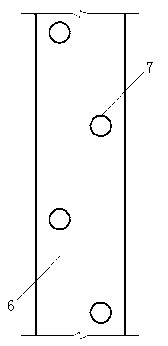

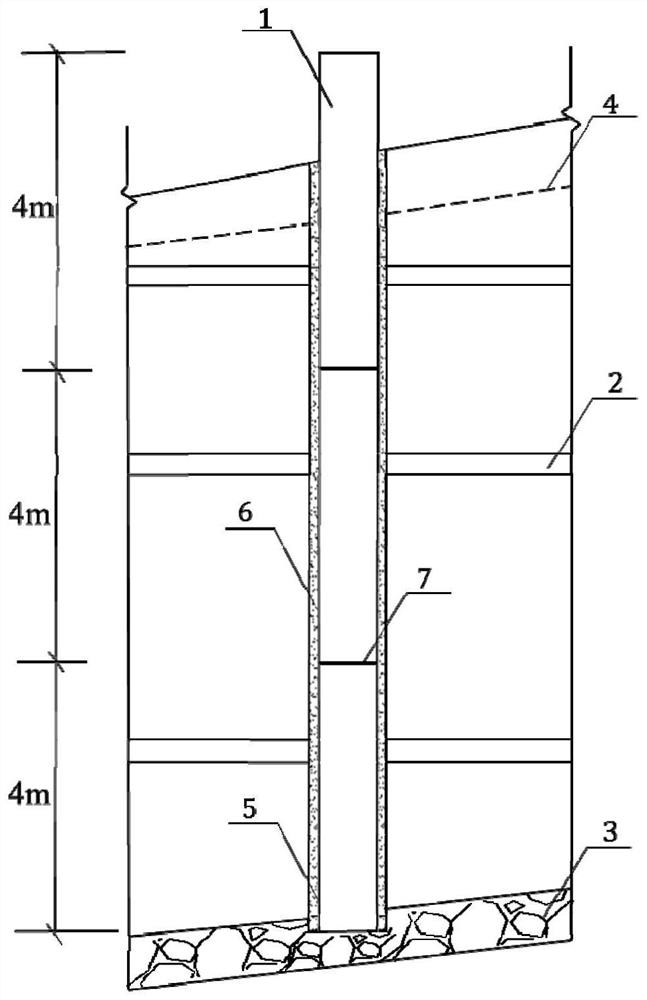

Window-type drainage well and construction method thereof

ActiveCN103924652AStrong combinationGood filtering effectSewerage structuresEnvironmental geologyTextile

The invention discloses a window-type drainage well and a construction method of the window-type drainage well. The window-type drainage well comprises a well casing and a well base. The well casing is provided with a well wall. The well wall is provided with a drainage window. The inner wall of the drainage window is of a circular truncated cone shape. The drainage window is provided with a reducing pipe. The outer wall of the reducing pipe is matched with the inner wall of the drainage window. A cage is arranged in an inner cavity of the reducing pipe and matched with the inner wall of the reducing pipe, the cage is filled with a filtering device, and a first ring flange is arranged on the outer side of the reducing pipe. The first ring flange is connected with a second ring flange, and the second ring flange is connected with a seepage collection device. Or a blind ring flange is fixed on the first ring flange. The construction method of the window-type drainage well comprises the steps of excavating to form a well base foundation, manufacturing the well base, manufacturing the well casing, placing the cage, the filtering plate, coarse sand bags and gravel bags in the reducing pipe, wherein the coarse sand bags and the gravel bags are wrapped in geotechnical cloth, and connecting the first ring flange with the second ring flange or the blind ring flange. According to the window-type drainage well and the construction method of the window-type drainage well, a window can be blocked off, and the window-type drainage well can be further transformed into a seepage collection well; the window-type drainage well is flexible in use and capable of integrating two functions, thereby reducing investments.

Owner:金建工程设计有限公司

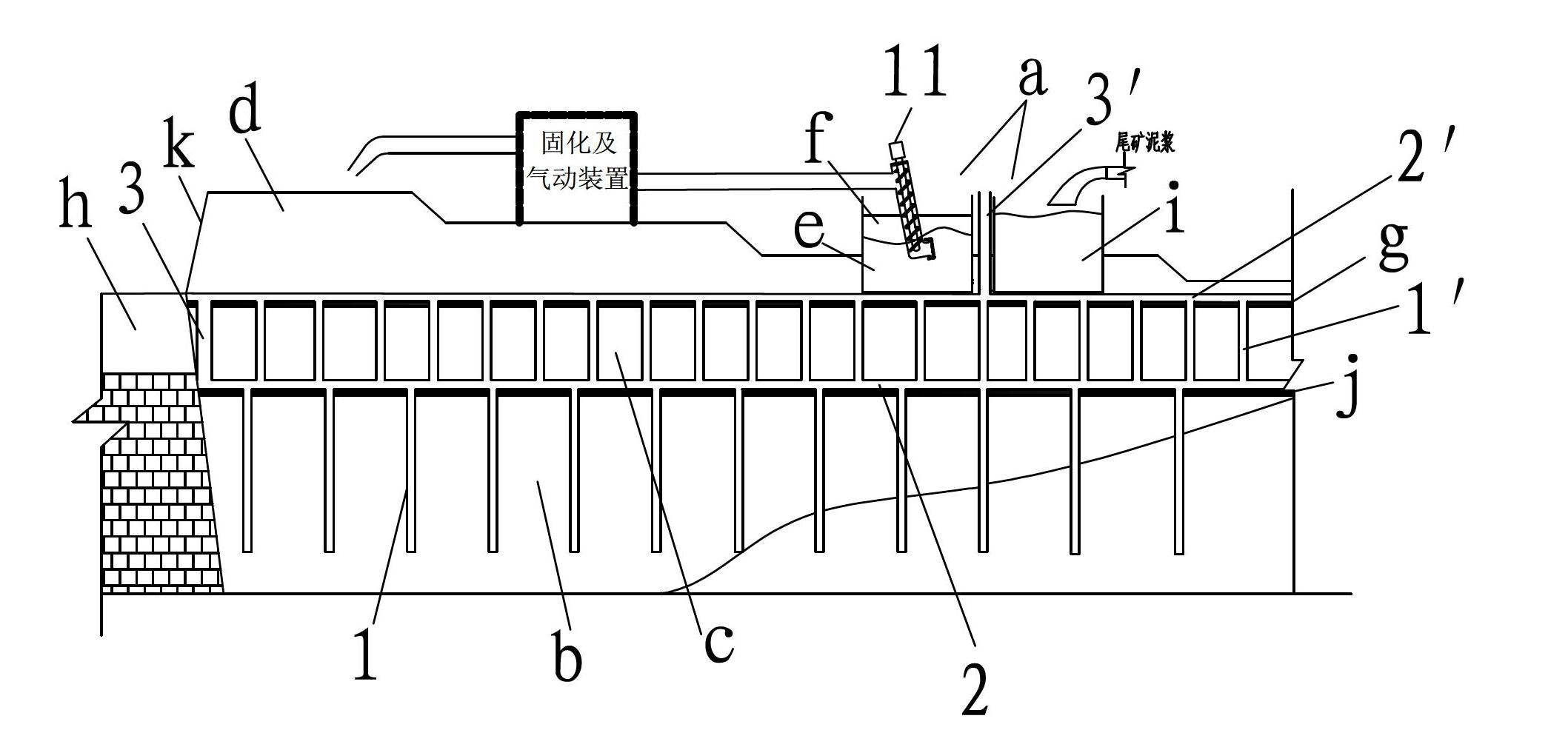

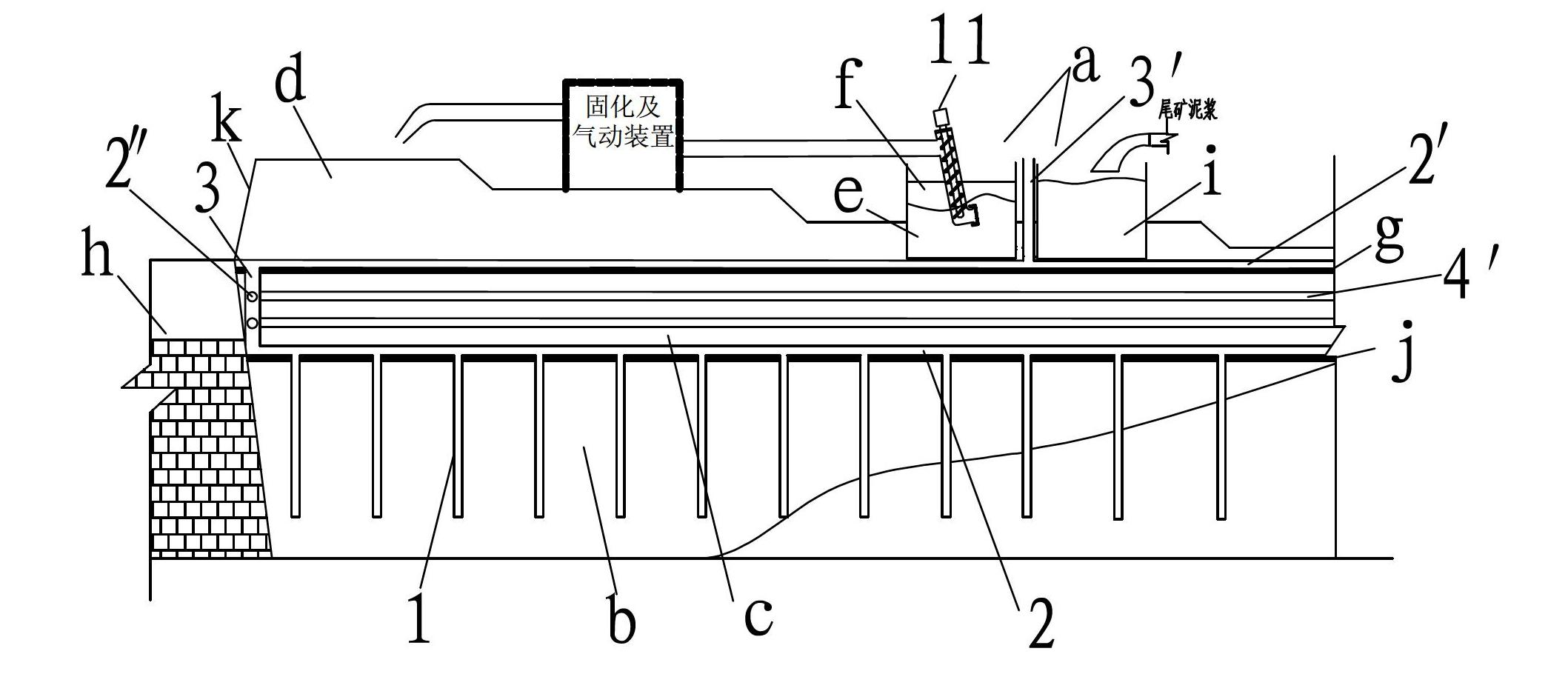

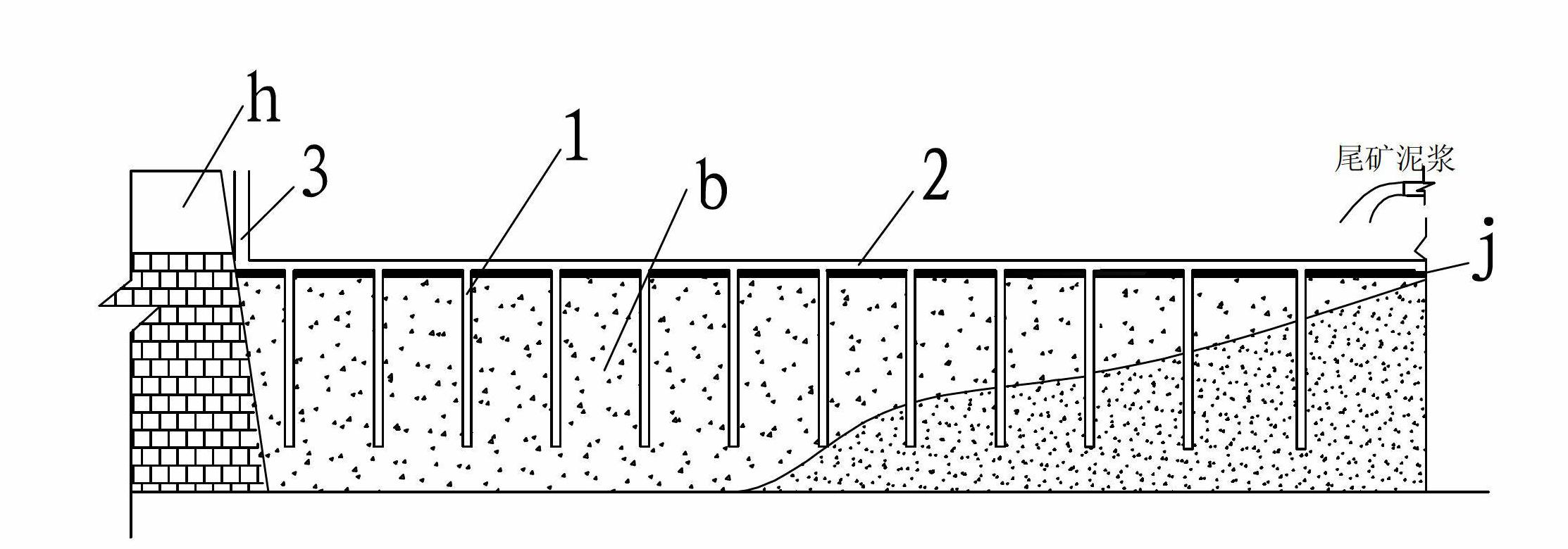

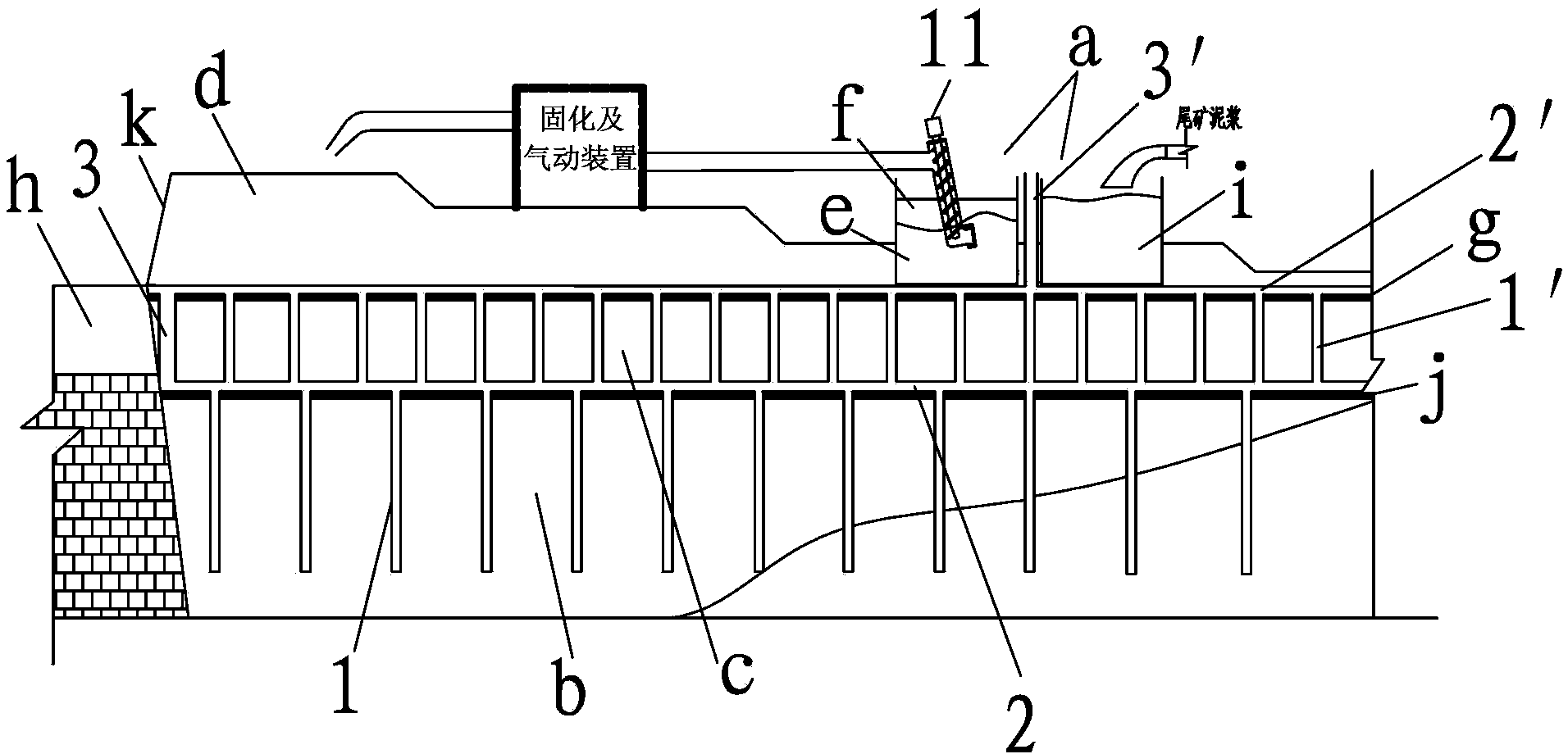

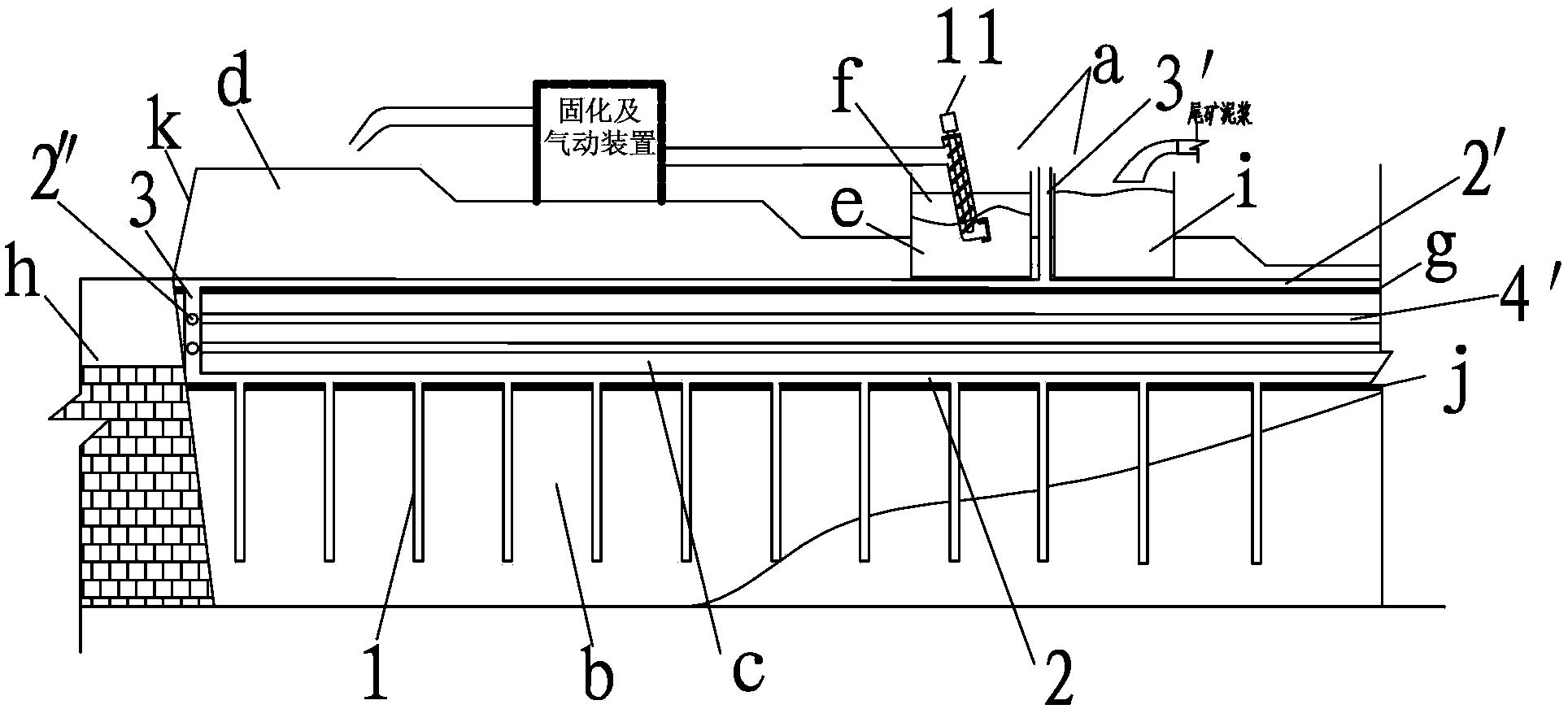

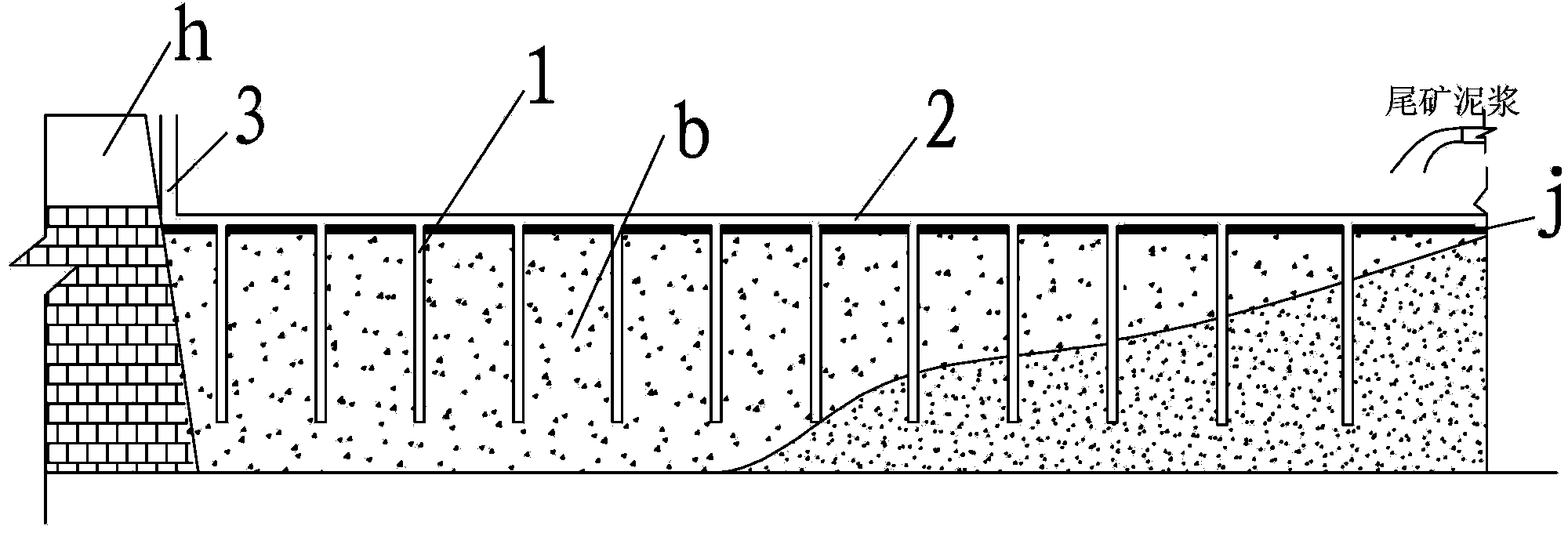

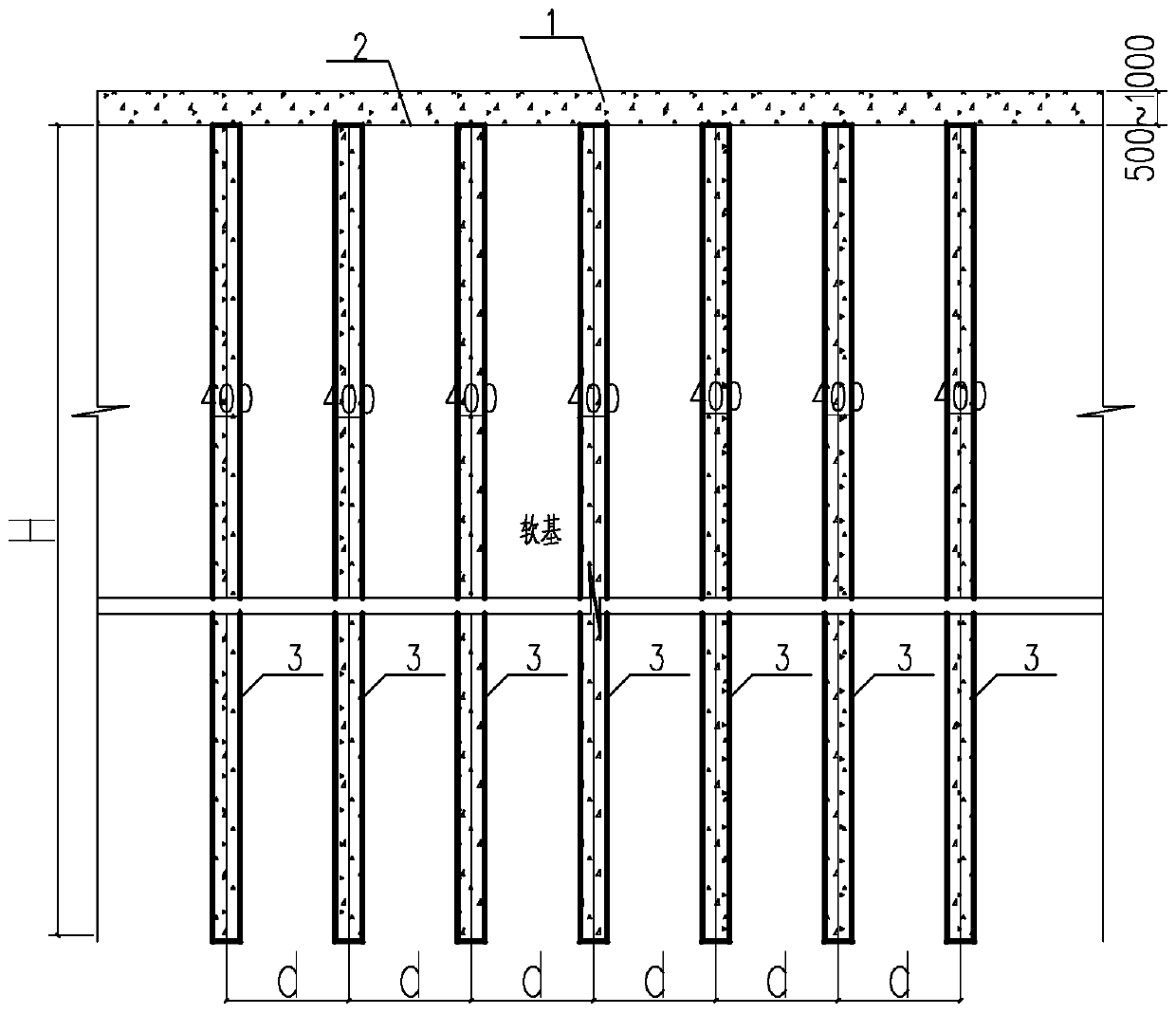

A method for improving in-service tailings pond capacity and a device thereof

The present invention discloses a method for improving an in-service tailings pond capacity and a device thereof, belonging to a field of tailings pond expansion technology. The method and the device are realized through a three-step tailings pond processing: a step of installing a working cushion for a tailings pond with a designed pond capacity and constructing a drainage system for drainage consolidation; a step of increasing the dam body height, discharging new tailings mud into the pond, and installing the working cushion and constructing a drainage system for a second time when the mud reaches the newly-increased dam body height; a last step of conducting consolidation processing on the newly-discharged tailings mud and storing the mud in different areas and on different layers via a paving system. The method for improving the in-service tailings pond capacity and the device thereof substantially reduce horizontal acting force of original tailings mud on an original tailings dam while a saturation line of the tailings dam body is lowered, with safety of the tailing pond improved, void ratio of a tailings soil mass greatly reduced, and the capacity of the tailings tank enhanced. Therefore the service life of the tailings pond is prolonged. The construction device of improving in-service tailings pond capacity has characteristics of easy operation, flexible combination, quick operation, and succinct and efficient construction technology.

Owner:BEIHANG UNIV

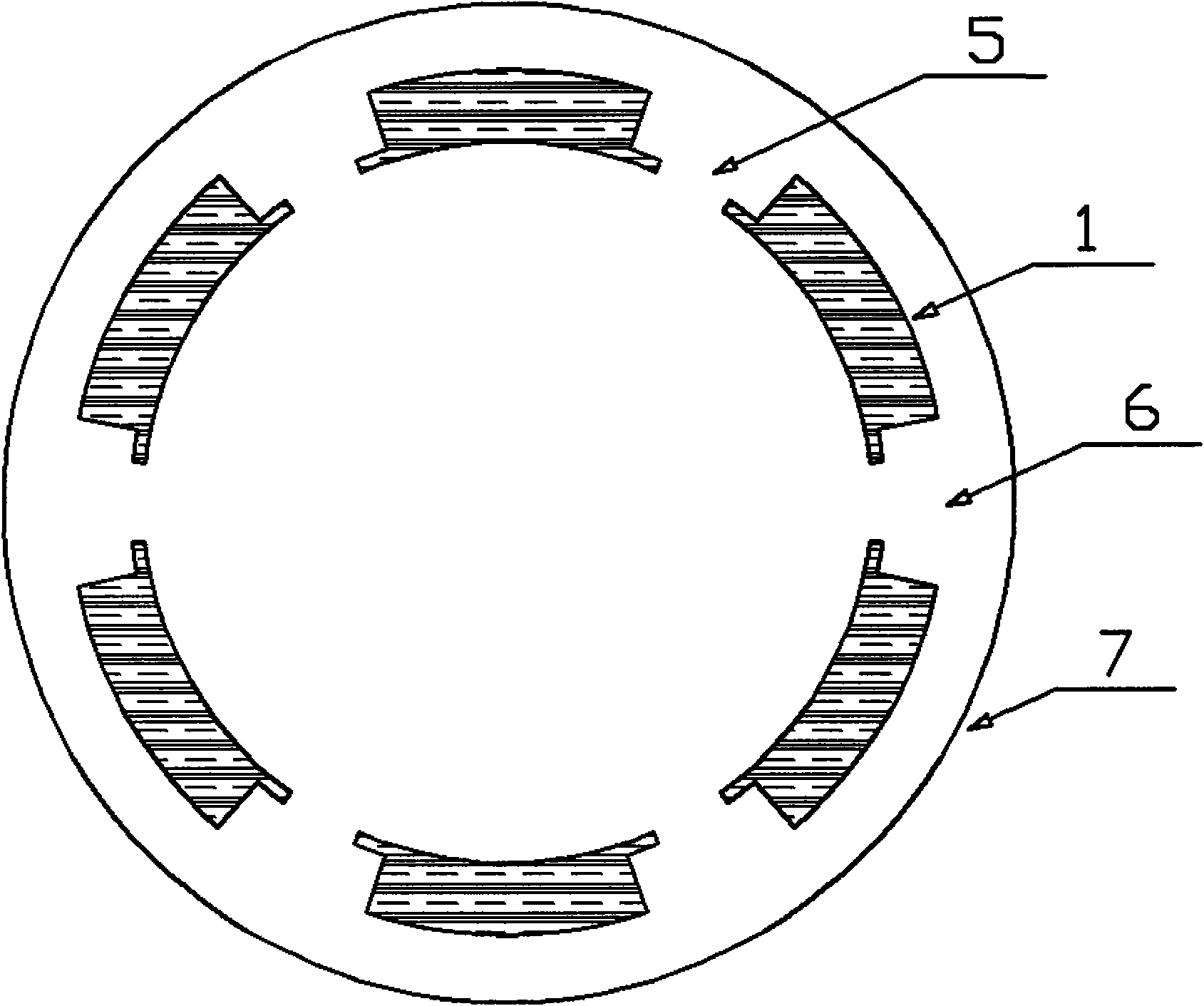

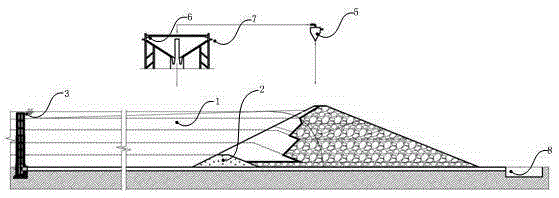

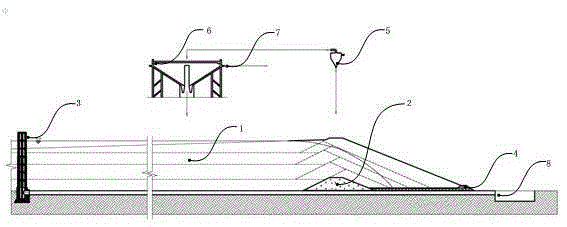

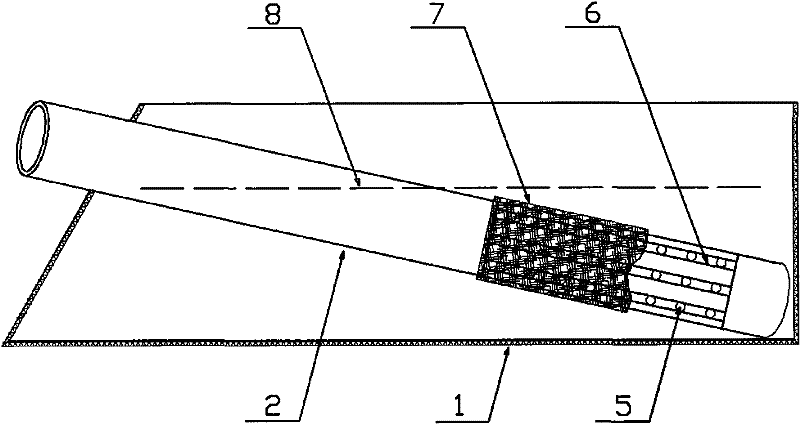

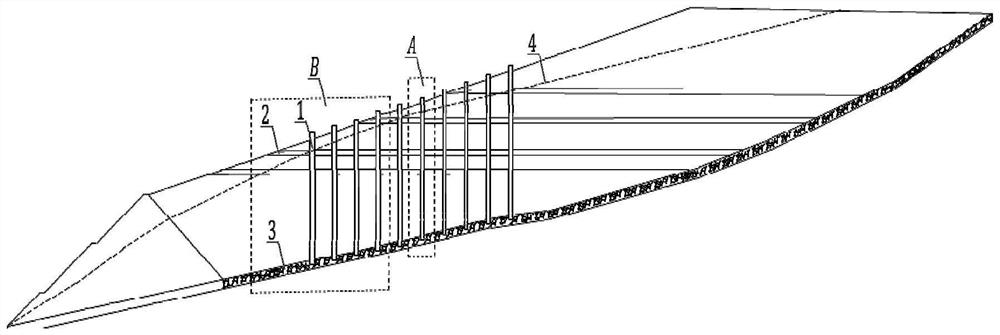

Three-dimensional tailing pond seepage system and seepage method thereof

ActiveCN104213627ASolve drainage problemsLevel of achievementFatty/oily/floating substances removal devicesSewer pipelinesMaintenance managementEngineering

The invention discloses a three-dimensional tailing pond seepage system and a seepage method thereof, and the system and the method are used for solving the problem of common tailing pond seepage effect in the prior art. The three-dimensional tailing pond seepage system comprises a flexible permeable hose vertical to a dam axis and a horizontal drain pipe parallel to the dam axis, wherein the inner end of the flexible permeable hose is communicated with the horizontal drain pipe. The flexible permeable hose, the horizontal drain pipe, a bank slope seepage body and a pond bottom seepage body are utilized for collecting water or separately collecting water, and water in the seepage system is guided out of a dam. The system can be used for cleaning and dredging, can be arranged and built in a tailing pond design stage and constructed in an operating stage, can be used for thoroughly solving the tailing pond seepage problem from the design, construction and operating stages, and is good in seepage effect, convenient in maintenance management, economical and durable.

Owner:LANZHOU ENG & RES INST OF NONFERROUS METALLURGY +1

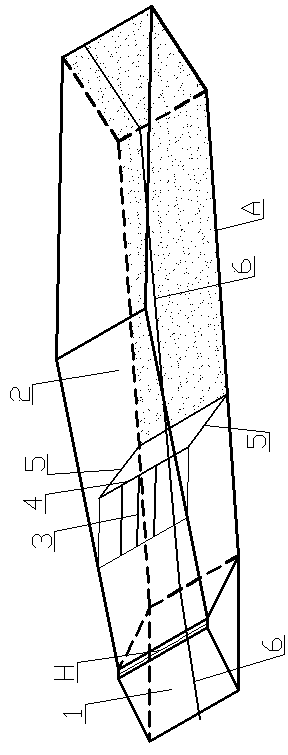

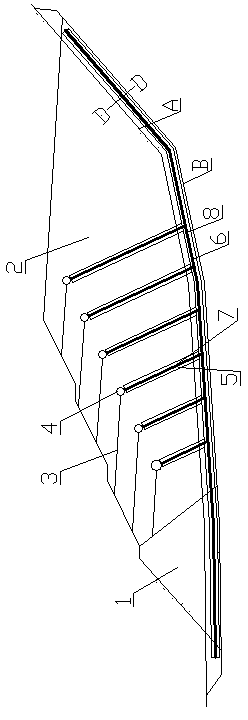

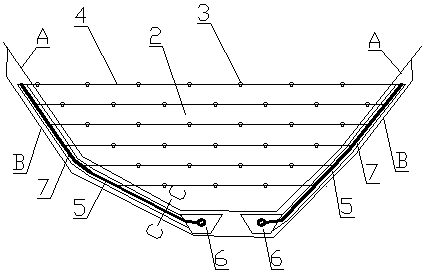

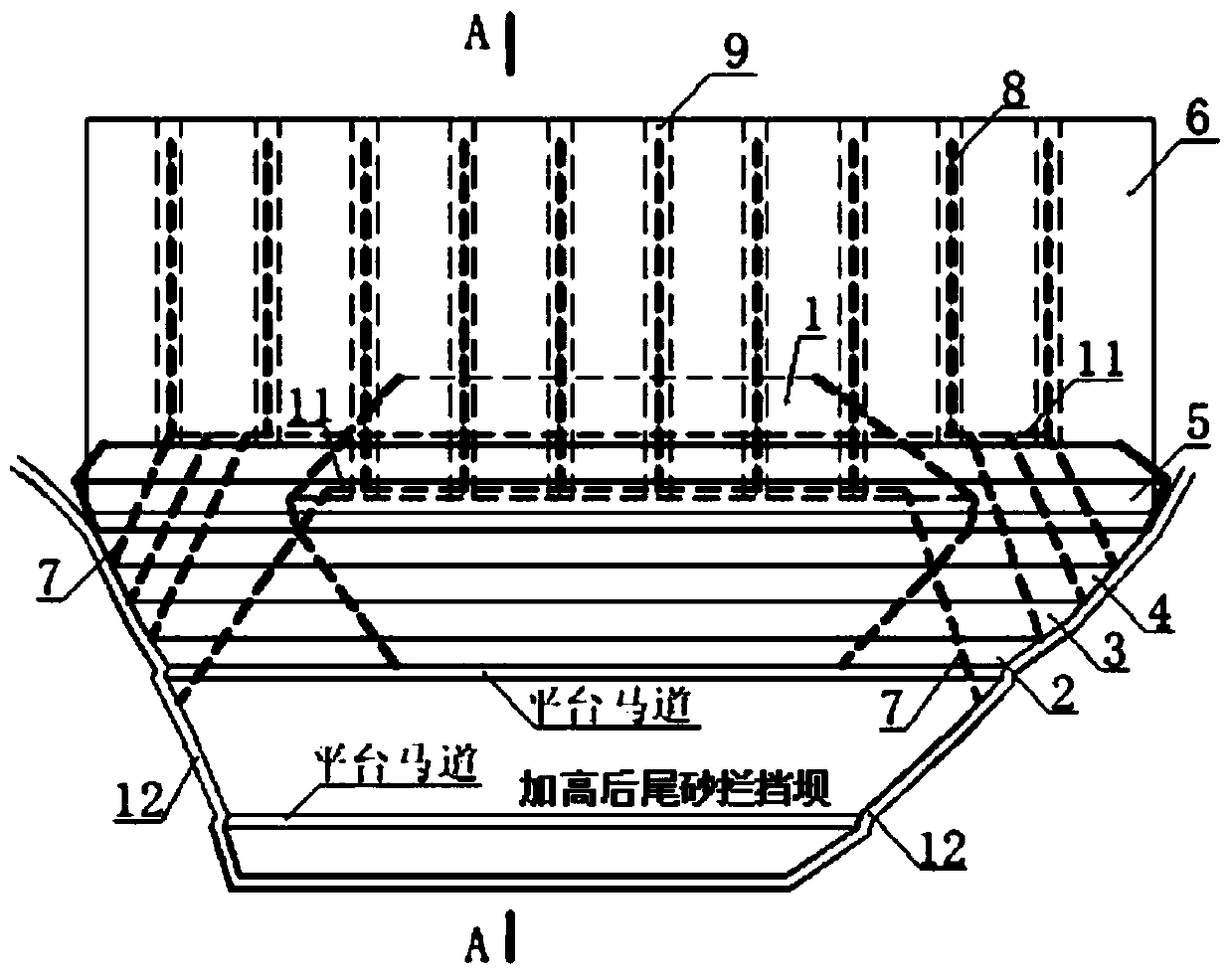

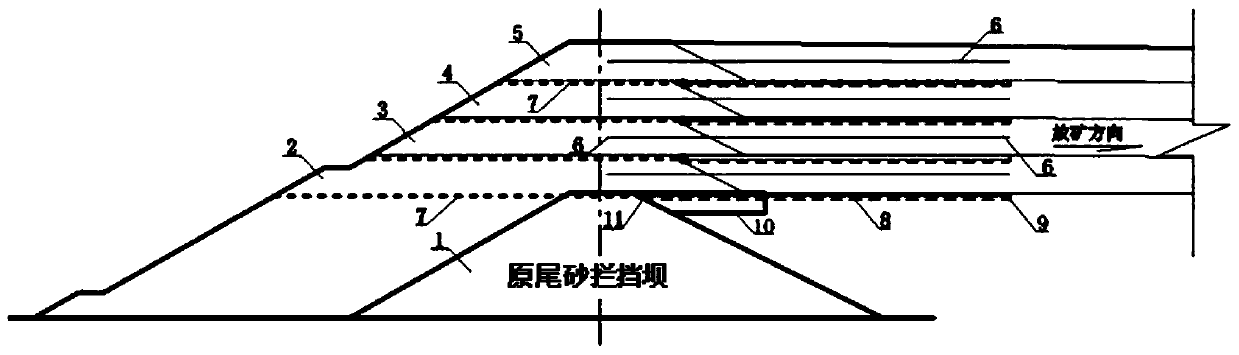

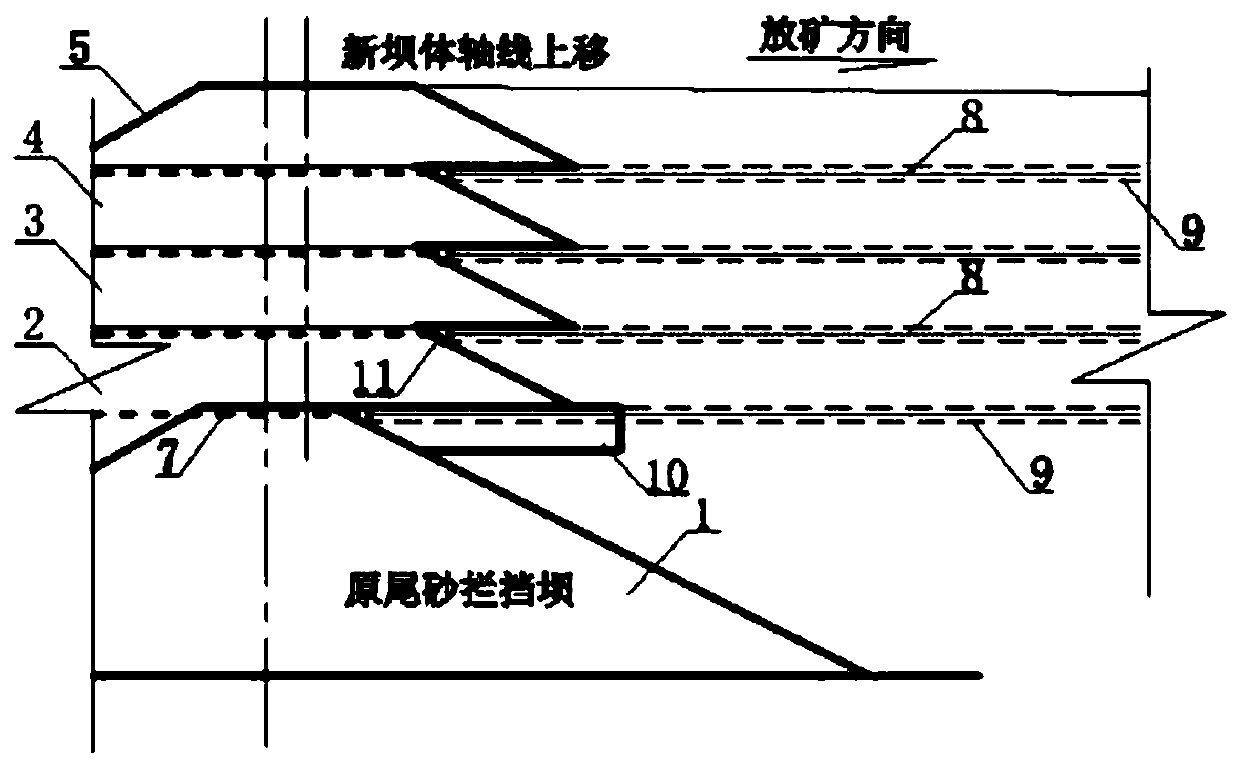

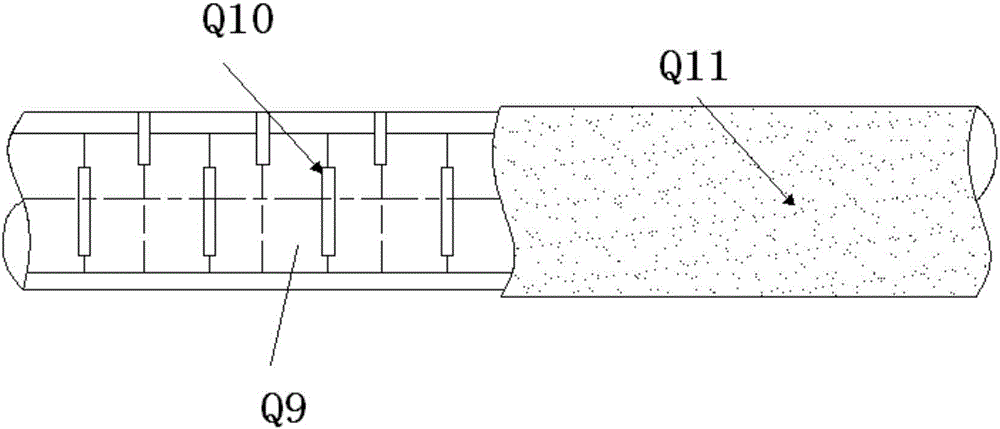

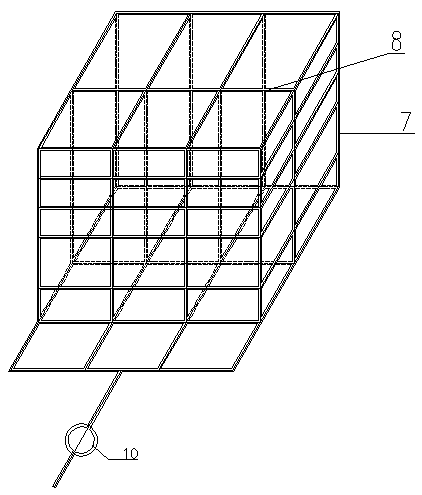

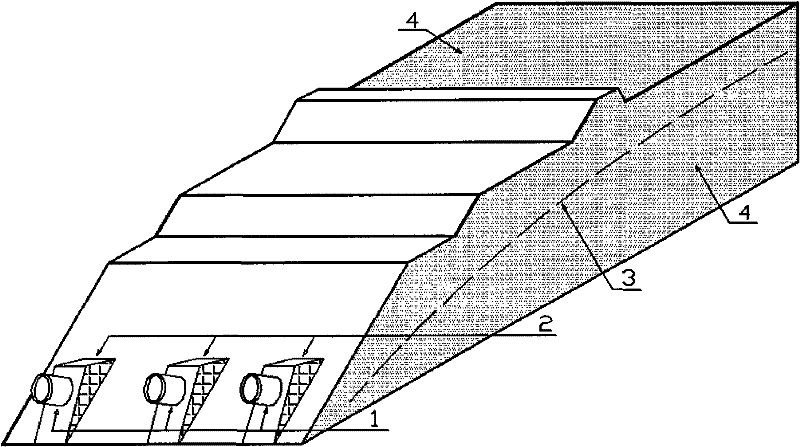

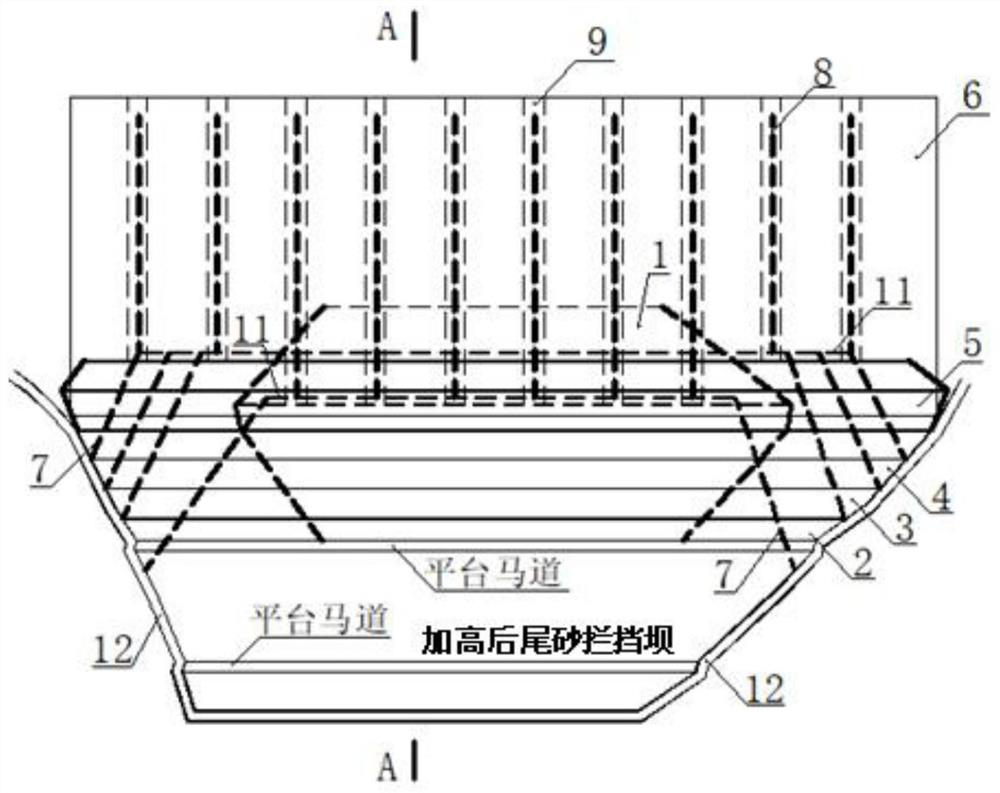

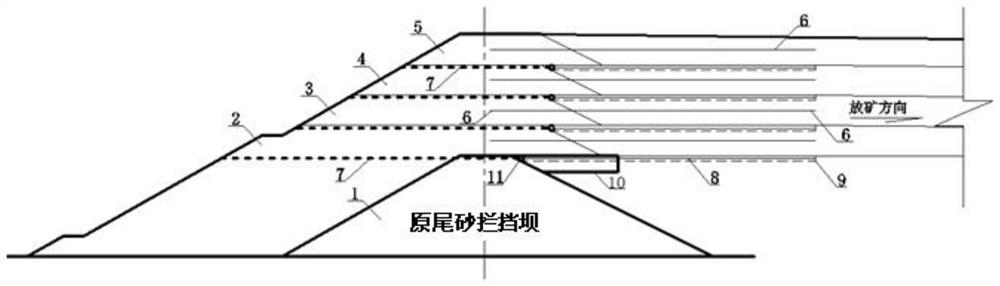

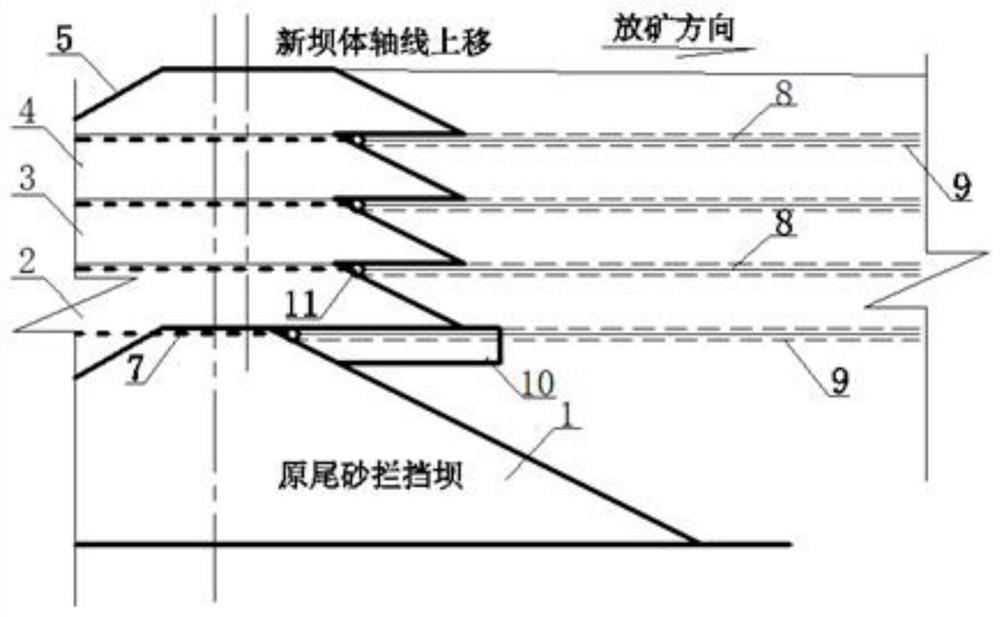

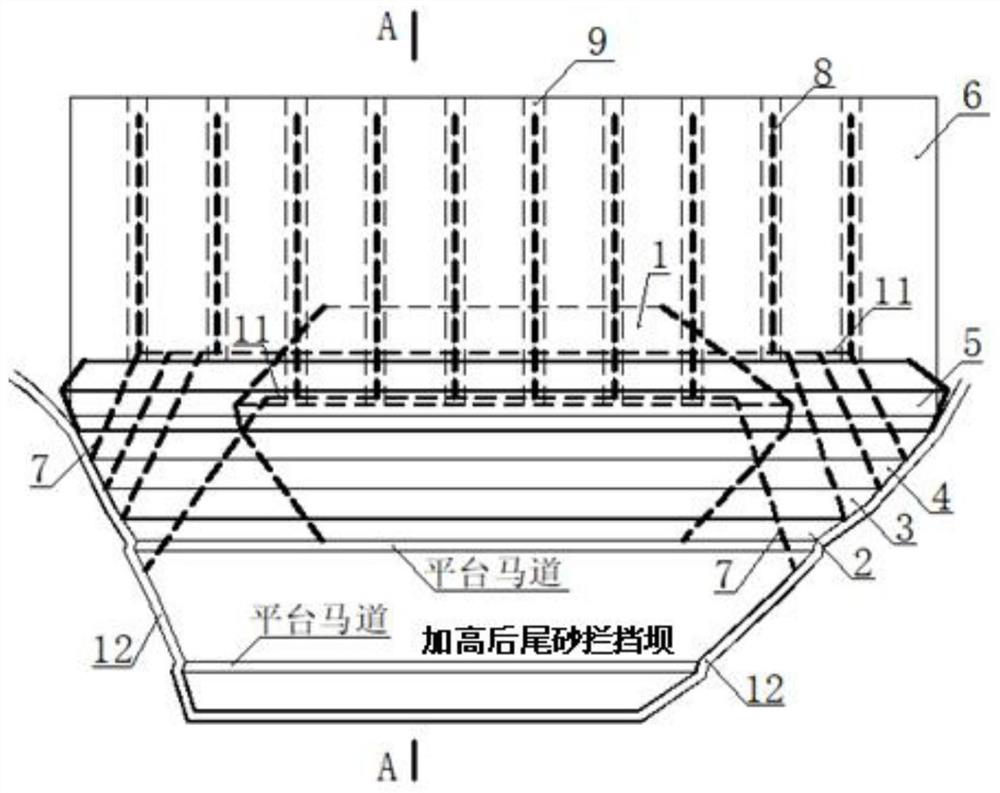

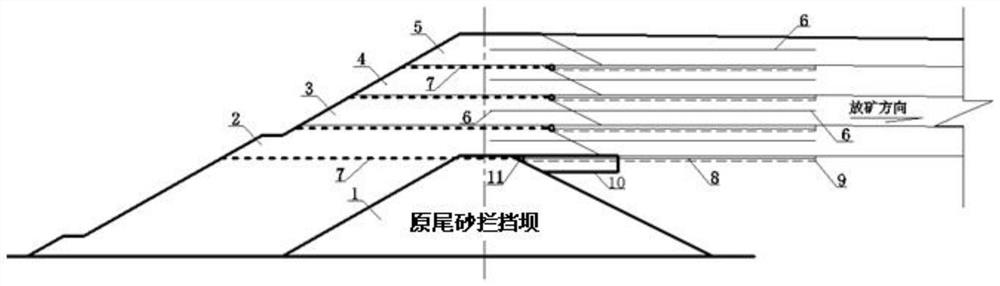

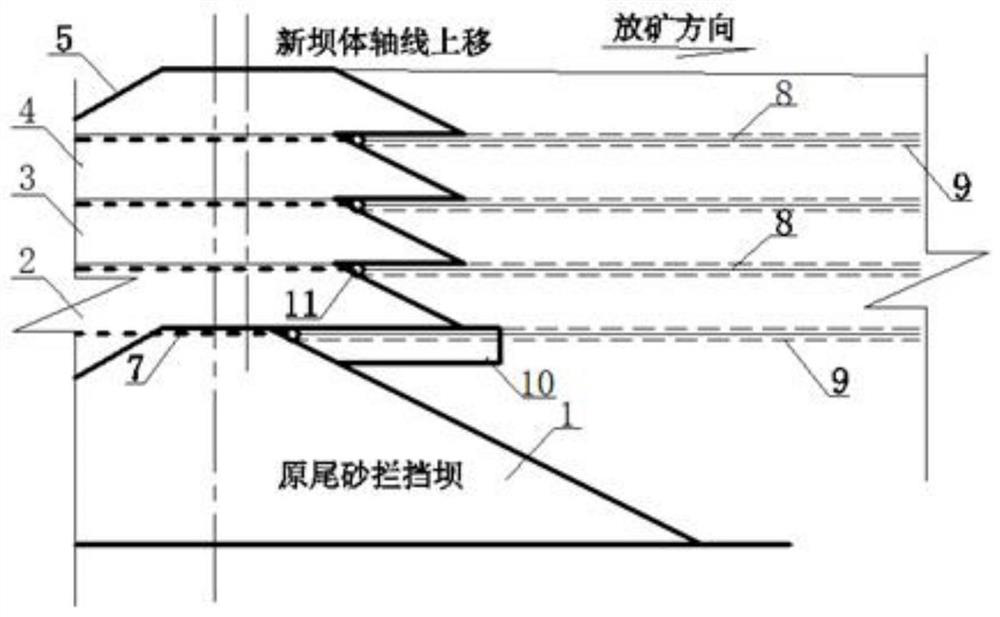

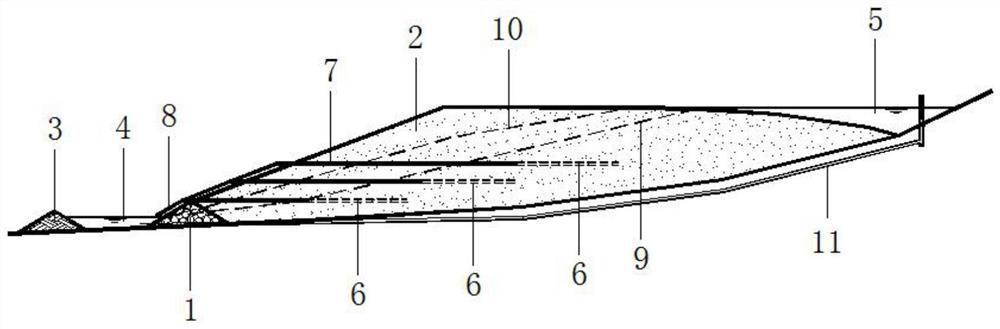

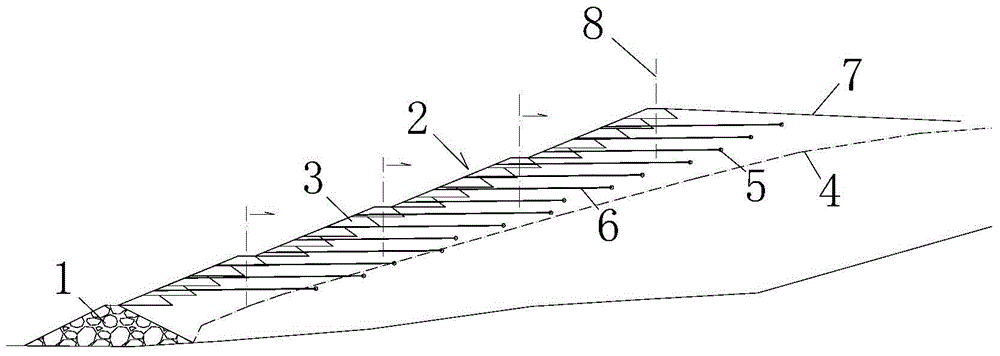

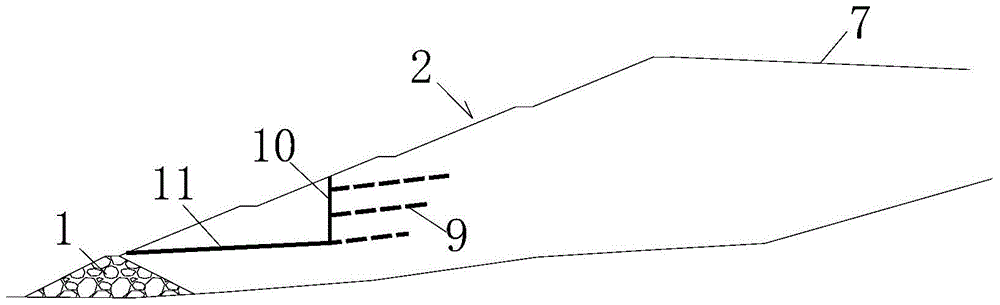

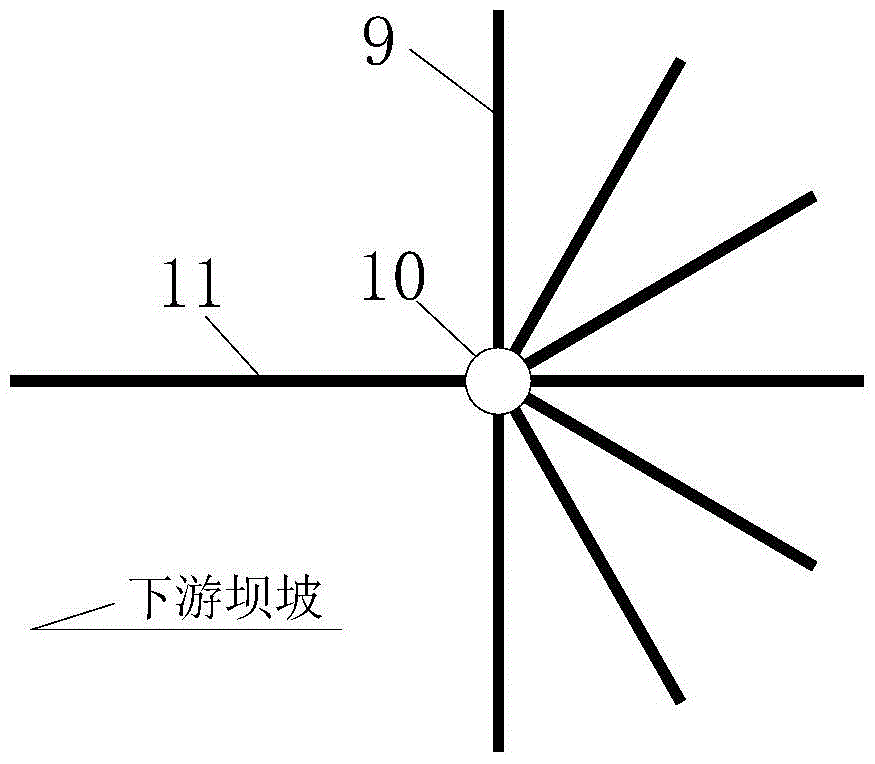

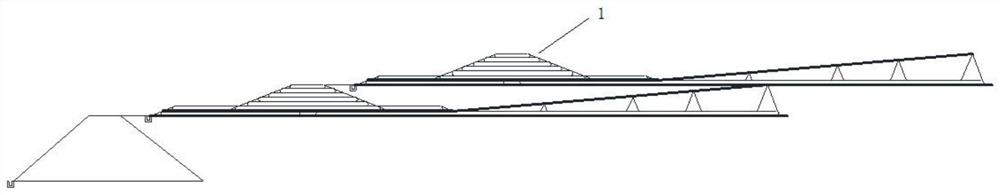

Superfine particle tailing reservoir heightening and capacity expanding stacking-discharging structure capable of achieving one-time dam building by adopting center line method

ActiveCN111305210AIncrease storage capacityExtend production service lifeEarth-fill damsRock-fill damsWaste dumpAbutment

The invention discloses a superfine particle tailing reservoir heightening and capacity expanding stacking-discharging structure capable of achieving one-time dam building by adopting a center line method. The structure is formed by combining an original tailing blocking dam (1), a dam abutment flood intercepting trench (12), a first-stage heightening dam body (2), a second-stage heightening dam body (3), a third-stage heightening dam body (4),..., and an nth-stage heightening dam body; a row of medium-coarse tailing drainage blind drains (9) which are parallel to one another and perpendicularto the axis of the corresponding dam body are constructed in the portion on the top layer of each stage of heightening dam body; draining communication pipes (7) and underground water collecting pipes (11) are laid; drainage floral tubes (8) are buried in the medium-coarse sand drainage blind drains (9); and layers of high-strength anti-corrosion geogrid (6) are laid every 0.5-1.0 m of verticalinterval. According to the invention, solidification of fine particle tailings is accelerated, the mechanical strength index of the fine particle tailings is improved and increased, thus, the capacityof a tailing reservoir is remarkably increased, the production service life is prolonged, and meanwhile, the problems that the capacity of parts of waste dumps are not enough, and mining waste rock is stacked are solved.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

Tailings pond flood drainage system for draining in advance efficiently and prolonging clarification distance

InactiveCN103541330AAdd clarification effect purposeIncrease clarification distanceDamsClimate change adaptationTailingsWater resource management

The invention discloses a tailings pond flood drainage system for draining in advance efficiently and prolonging a clarification distance. The tailings pond flood drainage system comprises a draining well and a flood drainage pipe, wherein the draining well comprises a well base, a headframe and an arched cover plate, the well base is provided with a casing pipe, a water inlet is formed in the headframe, the casing pipe is connected to the flood drainage pipe, a water inlet hole is formed in the top part of the flood drainage pipe, and non-woven geotechnical cloth wrapped concrete plug is used for blocking, so that inflow elevation of the water inlet hole of the flood drainage pipe is improved. The flood drainage system has the advantages as follows: 1) water drainage can be done in advance through a prepared hole of the flood drainage pipe based on a demand in the early period of the operation of the tailings pond, so that the purpose of accelerating solidification of tailings of a fill dam is realized; 2) water drainage can be done through the prepared hole of the flood drainage pipe based on a demand in the middle and later periods of the operation of the tailings pond, so that the purpose of prolonging the clarification distance of drained water outside the tailings pond, improving the clarification effects and reducing the environmental pollution is realized; 3) the blocking construction of the prepared hole of the flood drainage pipe is convenient, fast and economic.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN

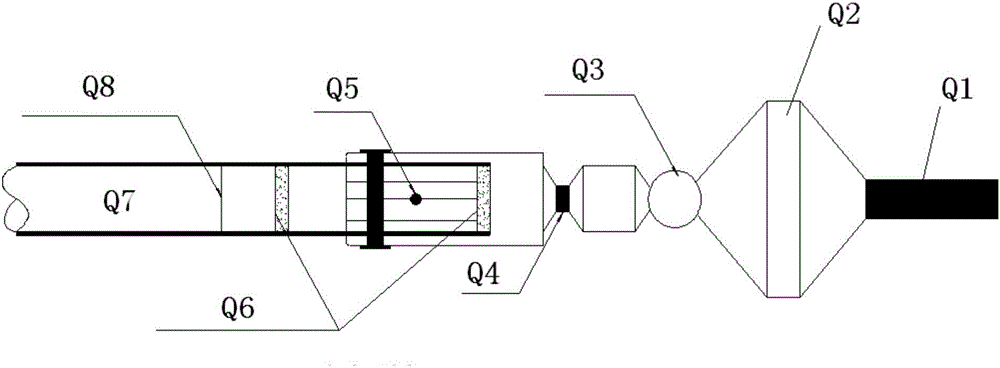

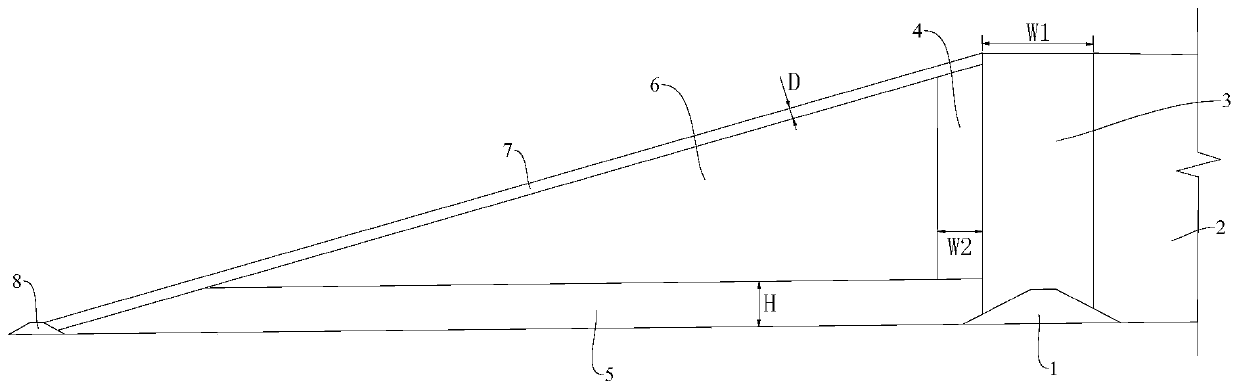

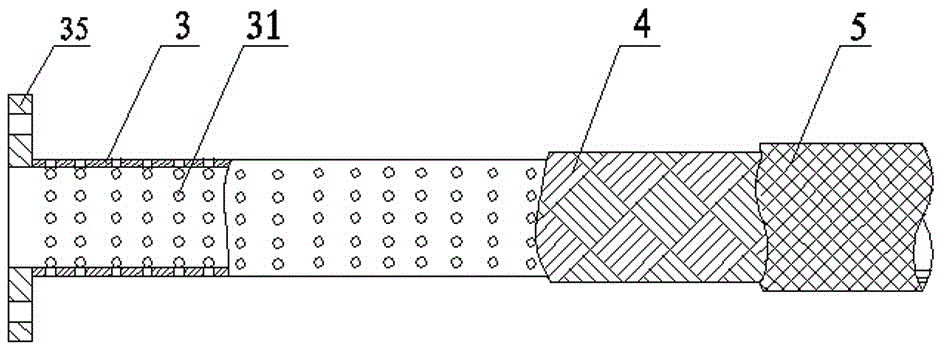

Method for applying horizontal directional drilling to refuse landfill leachate drainage

InactiveCN106436776AGood for drainage and consolidationLower Wetting LineProtective foundationEnvironmental engineeringLeachate

The invention discloses a method for applying horizontal directional drilling to refuse landfill leachate drainage. The method comprises the steps that a drill hole of K meters is drilled in the part, in a preset low-point position of a side slope of a refuse dam, of a refuse dump body by a horizontal directional drilling rig, a leachate guiding pipe is carried by a drill bit of the horizontal directional drilling rig to enter the drill hole and enter the refuse dump body along with the drill bit, and finally a leachate drainage channel is formed; and the pipe body, located within the range from the front end to the position away from the front end of the leachate guiding pipe by S meters, of the leachate guiding pipe is of a floral pipe structure wrapped with geotextile, grooves are formed in the two sides and the top of the floral pipe structure at intervals, wherein S is smaller than K. According to the method for applying horizontal directional drilling to refuse landfill leachate drainage, the horizontal directional drilling technology is introduced into the field of refuse landfill leachate drainage and combined with the refuse landfill leachate drainage technical characteristics, so that an artesian leachate drainage facility is formed, the phreatic line is effectively lowered, and drainage consolidation of stockpiling refuse is facilitated; and the method has the advantage of being easy and convenient to construct, low in manufacturing cost and the like.

Owner:上海胜义环境科技有限公司

Damming method of tailing subdam

InactiveCN103628488AOvercome the Prejudice Not to Build Dams DirectlyEnsure safetyEmbankmentsEngineeringTailings

The invention relates to a damming method of a tailing subdam and belongs to the technical field of mine dam construction. The damming method comprises the steps: firstly, designing the slope of a tailing fill dam and the height of the subdam by adopting a conventional method, and designing the positions and the quantity of draining well pillars according to seepage and stability calculation; when tailings are piled up to the elevation of the top of a starter dam, performing paying-off location on the subdam and determining the mounting starting point position of the subdam which is composed of prefabricated parts; mounting the prefabricated parts by an all-stretcher bonding method; next, backfilling soil in the chamber of the prefabricated parts; when the elevation of the subdam reaches the predetermined elevation of each draining well pillar, nesting the prefabricated part in the corresponding position to the draining well pillar until the subdams in a whole tailing piling storage area are completely built. The damming method provided by the invention avoids the problems of heavy sand blowing of fine-particle tailings and unsmooth drainage in a dam body, and is advantageous for effectively reducing the seepage line; furthermore, the safety of a tailing warehouse is ensured; as a result, the prejudice that the fine-particle tailings are not suitable for direct damming in the prior art is overcome; at the same time, the damming method of the tailing subdam is simple, convenient, quick, stable and safe, and also capable of beautifying the environment.

Owner:YUNNAN AGRICULTURAL UNIVERSITY

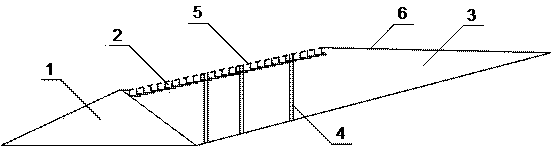

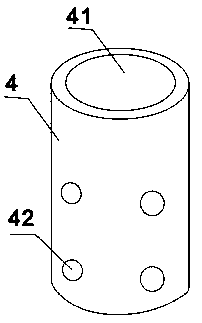

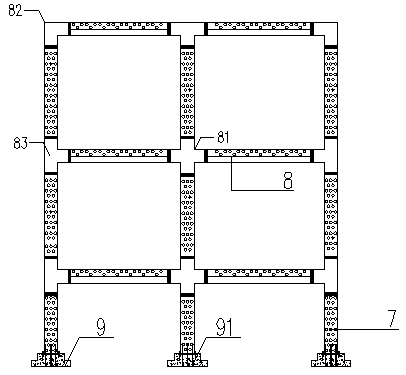

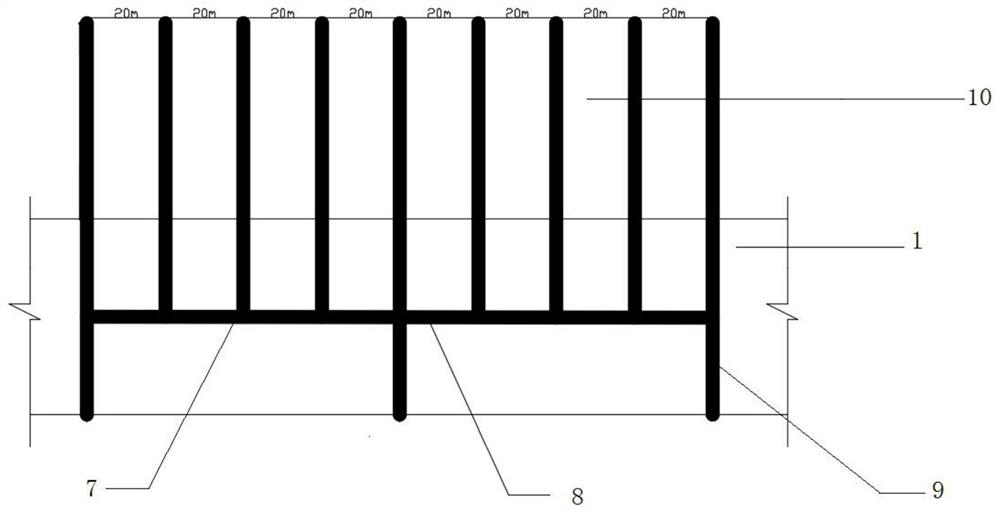

Framework type seepage drainage system and method

PendingCN108914879ALower Wetting LineEnsure safety and stabilityDamsClimate change adaptationSewageWater seepage

The invention discloses a framework type seepage drainage system and a method, and belongs to the field of sewage drainage in a tailing pond, which aims at solving the problem of difficulty in drainage of tailing water in the tailing pond. The framework type seepage drainage system is characterized in that a framework seepage drainage body is arranged in the tailing pond, and is formed by connecting a column type seepage drainage pipe on the vertical direction and a beam type seepage drainage on the horizontal direction through a connector; seepage drainage holes are uniformly distributed in the column type seepage drainage pipe, and water seepage holes are uniformly distributed in the upper half part of the beam type seepage drainage pipe; a geotechnical cloth is coated at the outer sideof the beam type seepage drainage pipe. The framework type seepage drainage system has the advantages that the occurrence of dam collapse accidents is prevented, the safety of lives, properties and existing facilities at the downstream zone is guaranteed, and the serious environmental pollution is prevented.

Owner:LANZHOU ENG & RES INST OF NONFERROUS METALLURGY

Midline type tailing dam

PendingCN110318404AImprove intrinsic safetyLower Wetting LineEmbankmentsTailings damMining engineering

The invention discloses a midline type tailing dam which comprises an initial-stage dam and a tailing stacking dam, wherein the tailing stacking dam comprises a first stacking area, a second stackingarea, a third stacking area, a fourth stacking area and a fifth stacking area; the first stacking area is formed through stacking fine-grain tailings graded by a hydrocyclone; each of the second stacking area, the third stacking area, the fourth stacking area and the fifth stacking area is formed through stacking coarse-grain tailings graded by the hydrocyclone; and the tailings permeability coefficient of the third stacking area and the fourth stacking area is greater than that of the fifth stacking area, and the tailings permeability coefficient of the fifth stacking area is greater than that of the second stacking area. According to the midline type tailing dam, the midline type tailing dam is divided into different areas, and the corresponding tailings permeability coefficient is controlled according to the characteristic of each area, so that different areas can better play the respective roles, the dam body seepage line is lowered, and the dam body stability is improved to further improve the essential safety of the midline type tailing dam.

Owner:CHINA ENFI ENGINEERING CORPORATION

Chemical siltation resisting drainage device for tailing dam

InactiveCN101629417BPrevent chemical foulingEnsure normal drainageExcavationsSoil preservationTailings damEngineering

The invention discloses a chemical siltation resisting drainage device for a tailing dam, comprising a drainage pipe, a siltation resisting trough, water seepage holes, water seepage troughs and geotextiles. The invention is characterized in that the drainage pipe is a circular pipe, and the end part of the pipe is provided with the water seepage troughs and the water seepage holes, and the waterseepage troughs are tightly wrapped by the geotextiles; the siltation resisting trough is a rectangular box body having no cover, and the front end of the box body is provided with a circular hole having the same pipe diameter as the drainage pipe; the drainage pipe is obliquely arranged in the siltation resisting trough of the box body at an inclination angle so as to prevent the geotextiles from generating chemical siltation and ensure that the dam body can drain normally. The chemical siltation resisting drainage device has the advantages of simple structure, high effectiveness, low cost and convenient use, and ensures that the geotextiles do not alternate between saturation and nonsaturation, thus preventing the geotextiles from generating chemical siltation. By using the chemical siltation resisting drainage device, the drainage capability of the dam is reinforced, thus ensuring smooth drainage, reducing the seepage line of the dam effectively and accordingly lowering the operation risk of the tailing dam.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

Tubular microporous tailing damming method

The invention relates to a tubular microporous tailing damming method which comprises the following steps of: manufacturing an ore drawing tube: by using a middle and small diameter tube as the ore drawing tube, discontinuously drilling to evenly distribute ore drawing holes on the lower side of the ore drawing tube in the opposite directions; installing an ore drawing tube support: arranging the ore drawing tube on a dry inner-store beach, wherein the ore drawing tube support is installed by a preset distance and fixed on the dry inner-store beach; installing the ore drawing tube support: installing and fixing the manufactured ore drawing tube on the ore drawing tube support; adjusting the ore drawing holes: opening and clogging the ore drawing holes as required during ore drawing; and damming: depositing tailings to form high-strength sub dams connected with the initial dam during ore drawing. The invention has the characteristics of large dry beach slope ratio, large particle size of tailing deposited in front of the dam, high strength, good water drainage effect, low dam body seepage line, long effective dry beach, huge safe freeboard and good safety, and the method is applicable to ore drawing damming of middle and small tailing stores.

Owner:中冶沈勘工程技术有限公司

System combining bottom seepage drainage and flood drainage facilities

InactiveCN112982318AShorten the timeAccelerated drainage consolidationBarrages/weirsSewerage structuresTube drainageEnvironmental engineering

The invention discloses a system combining bottom seepage drainage and flood drainage facilities. The system comprises the flood drainage facilities and the seepage drainage facilities; the seepage drainage facilities comprise seepage collection facilities and seepage guide pipes; the flood drainage facilities comprise one or more of a drainage well, a drainage culvert pipe and a drainage chute; the seepage collection facilities comprise seepage collection pipes; and the seepage collection pipes communicate with the flood drainage facilities through the seepage guide pipes, and seepage water collected by the seepage collection facilities is guided into the flood drainage facilities. By means of the method, the use number of the seepage guide pipes can be reduced, the seepage path length of the seepage drainage facilities is reduced, drainage of the seepage water is accelerated, the seepage line is reduced, and the seepage drainage effect is enhanced; and meanwhile, due to the improvement of the seepage drainage effect, the external water pressure around the flood drainage facilities can be reduced, the external load of the flood drainage facilities is reduced, and the stability of flood drainage structures is improved. The method can be widely suitable for arrangement of the seepage drainage and flood drainage facilities of various tailing ponds and is also suitable for red mud storage yards, refuse dump landfills and refuse dumps.

Owner:金建工程设计有限公司

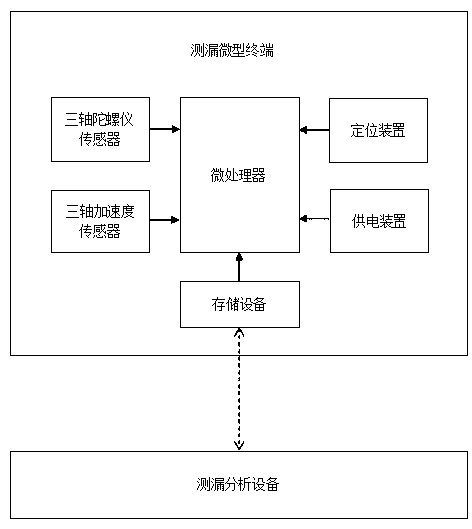

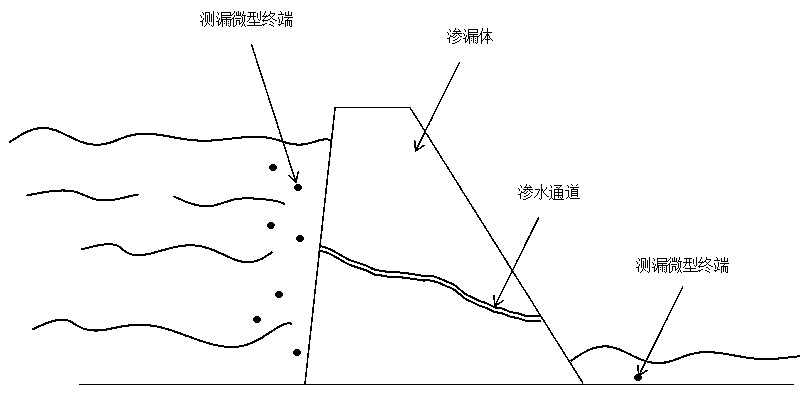

Leakage channel detection system and method based on motion trail analysis

ActiveCN111537156AImprove stabilityLower Wetting LineDetection of fluid at leakage pointNavigation by speed/acceleration measurementsEngineeringWater level

The invention discloses a leakage channel detection system and method based on motion trail analysis. The system comprises a plurality of leakage detection micro terminals and leakage detection analysis equipment, wherein the leakage detection micro terminal comprises a leakage detection shell and a space motion trail recording module fixedly arranged in the leakage detection shell, the leakage detection micro terminal is thrown to a high water level side, flows through a leakage channel in a leakage body, and reaches a low water level side, and the motion trail parameters stored in the microleakage detection terminal are collected through the leakage detection analysis equipment. According to the invention, the leakage detection micro terminals are used for collecting the space motion trail from the high water level side to the low water level side through the leakage channel of the leakage body, and the space motion trail analysis is carried out through the leakage detection analysis equipment, so that information such as the inlet position, the outlet position, the leakage track and the like of the leakage channel of the leakage body is obtained, and a basis is provided for formulating leakage treatment measures of the leakage body; and the system is clear in scheme principle, simple to operate, accurate in test and applicable to concentrated leakage channel detection and analysis of most common leakage bodies such as dams, embankments and the like.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

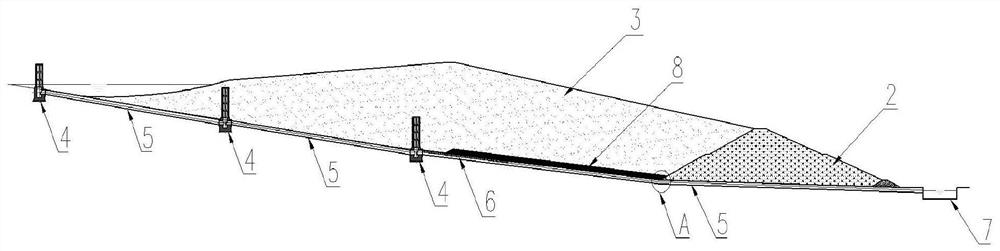

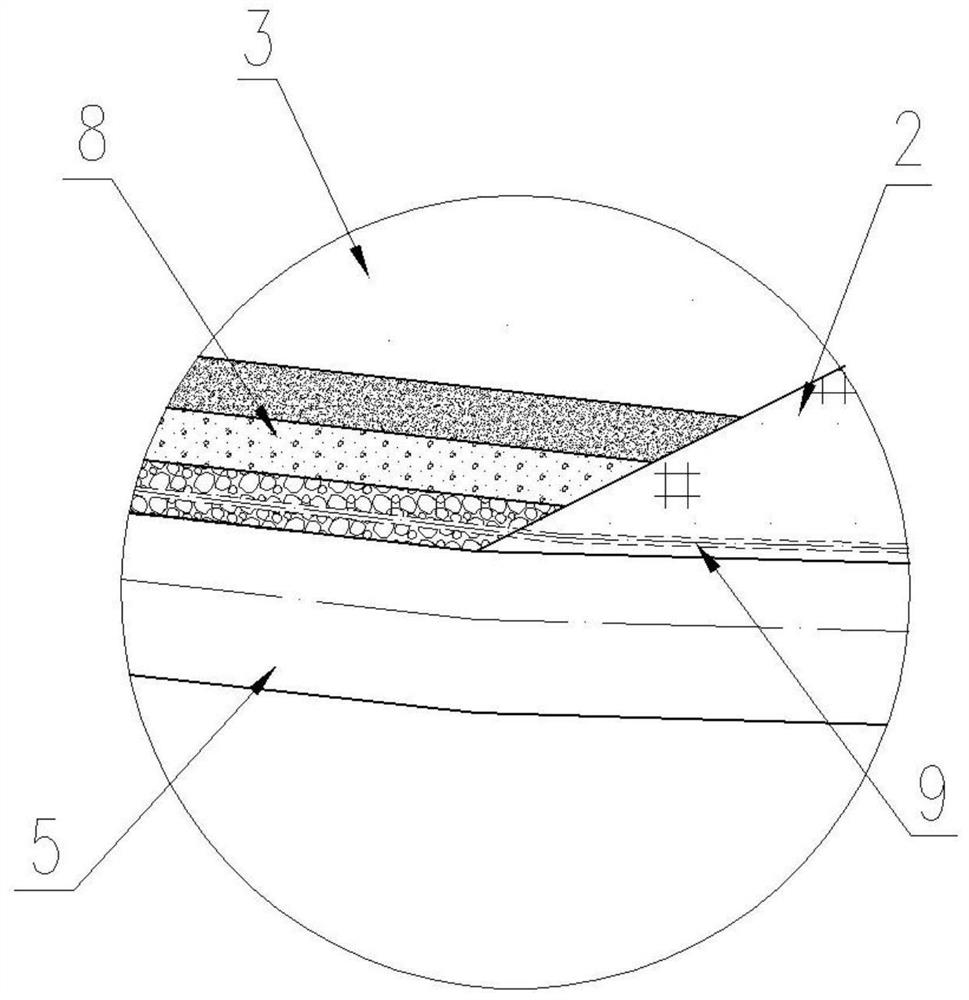

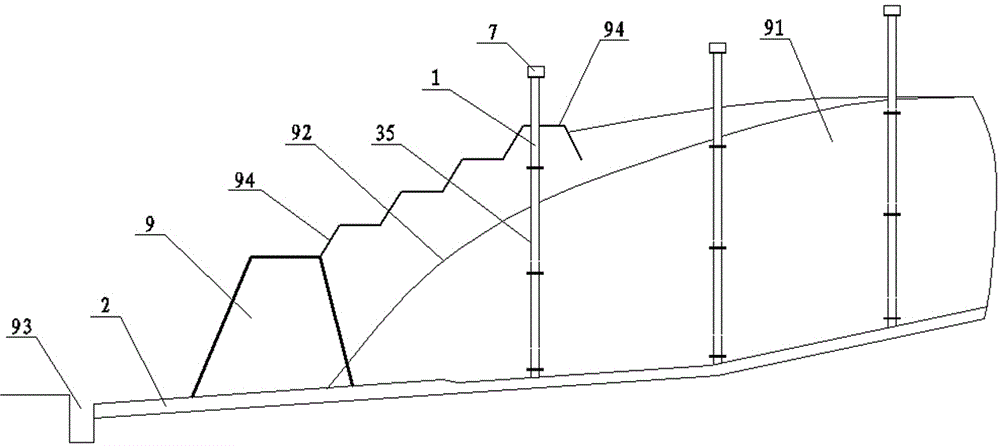

A method of heightening and expanding the volume of ultra-fine tailings reservoir with one-time dam construction using the center line method

ActiveCN111305211BIncrease storage capacityExtend production service lifeSewer pipelinesBulkheads/pilesDitchGeogrid

The invention discloses a method for heightening and expanding the capacity of an ultra-fine tailings reservoir for one-time construction of the dam by adopting the center line method, adopting a staged construction method for heightening and expanding the capacity, and successively stacking the first level of heightening dam body (2), The second-level heightening dam body (3), the third-level heightening dam body (4) ..., construct a row of medium-coarse sand seepage drainage of the level parallel to each other and perpendicular to the axis of the dam body on the top floor of each level of heightening dam body For the blind ditch (9), lay drainage connecting pipes (7) and groundwater collection pipes (11), and bury seepage flower pipes (8) in the medium-coarse sand drainage blind ditch (9) of this level, with a vertical interval of 0.5m~ A layer of high-strength corrosion-resistant geogrid (6) is fully paved at a height of 1.0m. The method of the invention accelerates the consolidation of fine-grained tailings, improves and increases the mechanical strength index of fine-grained tailings, significantly increases the storage capacity of tailings storage, prolongs the service life of production, and relieves the pressure of enterprises to discharge tailings. , At the same time, it also solves the problem of insufficient capacity of some dumps and the accumulation of mining waste rocks.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES CO LTD +1

Heightened and expanded stacking structure of ultra-fine tailings reservoir with one-time construction of dam by midline method

ActiveCN111305210BIncrease storage capacityExtend production service lifeEarth-fill damsRock-fill damsMining engineeringDrainage tubes

Owner:SINOSTEEL MAANSHAN INST OF MINING RES CO LTD

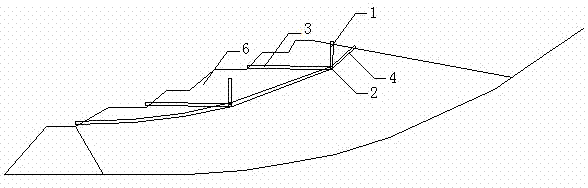

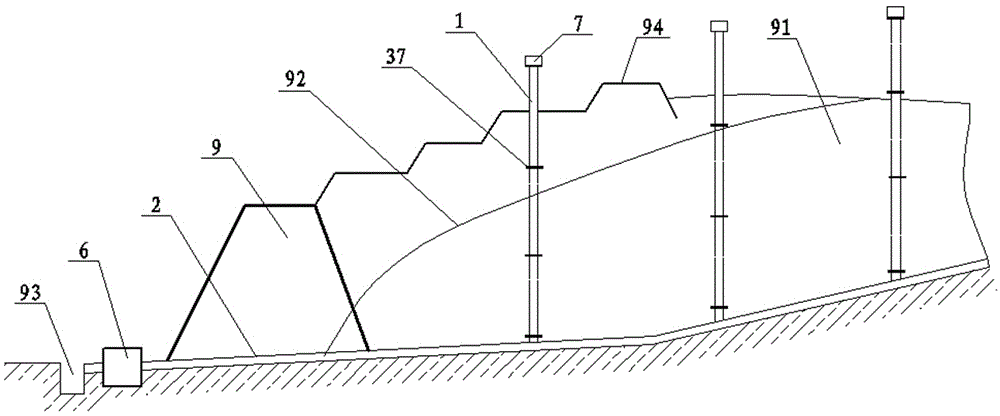

A method for regulating backwater in a phosphogypsum reservoir

ActiveCN108797652BMaximum dischargeAdjust storage water volumeSewerage structuresProtective foundationEnvironmental engineeringHydrology

The invention discloses an ardealite storehouse water return adjustment method. A first layer of plastic leakage discharge blind pipes (6) is arranged at the bottom of an ardealite fill dam (2) and the upper part of an impermeable layer toward the inside of a storehouse; after the stockpiling height of ardealite exceeds the dam top of an initial-stage dam (1), a layer of plastic leakage dischargeblind pipes (6) is arranged toward the inside of the storehouse when the stockpiling height rises per 8-12 m; the plastic leakage discharge blind pipes (6) are connected with horizontal drainage pipes(7) and extend to a dam slope surface; and a dam slope drainage pipe (8) is arranged on slope surfaces of outer slopes of the initial-stage dam (1) and the ardealite fill dam (2). In the dry season,the flow of a valve mounted at an outlet of the dam slope drainage pipe (8) is adjusted to be large, so that a water level in the ardealite fill dam (2) falls to a low water line (9); and in the rainyseason, the flow of the valve mounted at the outlet of the dam slope drainage pipe (8) is adjusted to be small, so that the water level in the ardealite fill dam gradually rises to a high water line(10). By employing the characteristics of high void ratio and permeability of the ardealite and controlling the seepage discharge, the function of water return adjustment is realized.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

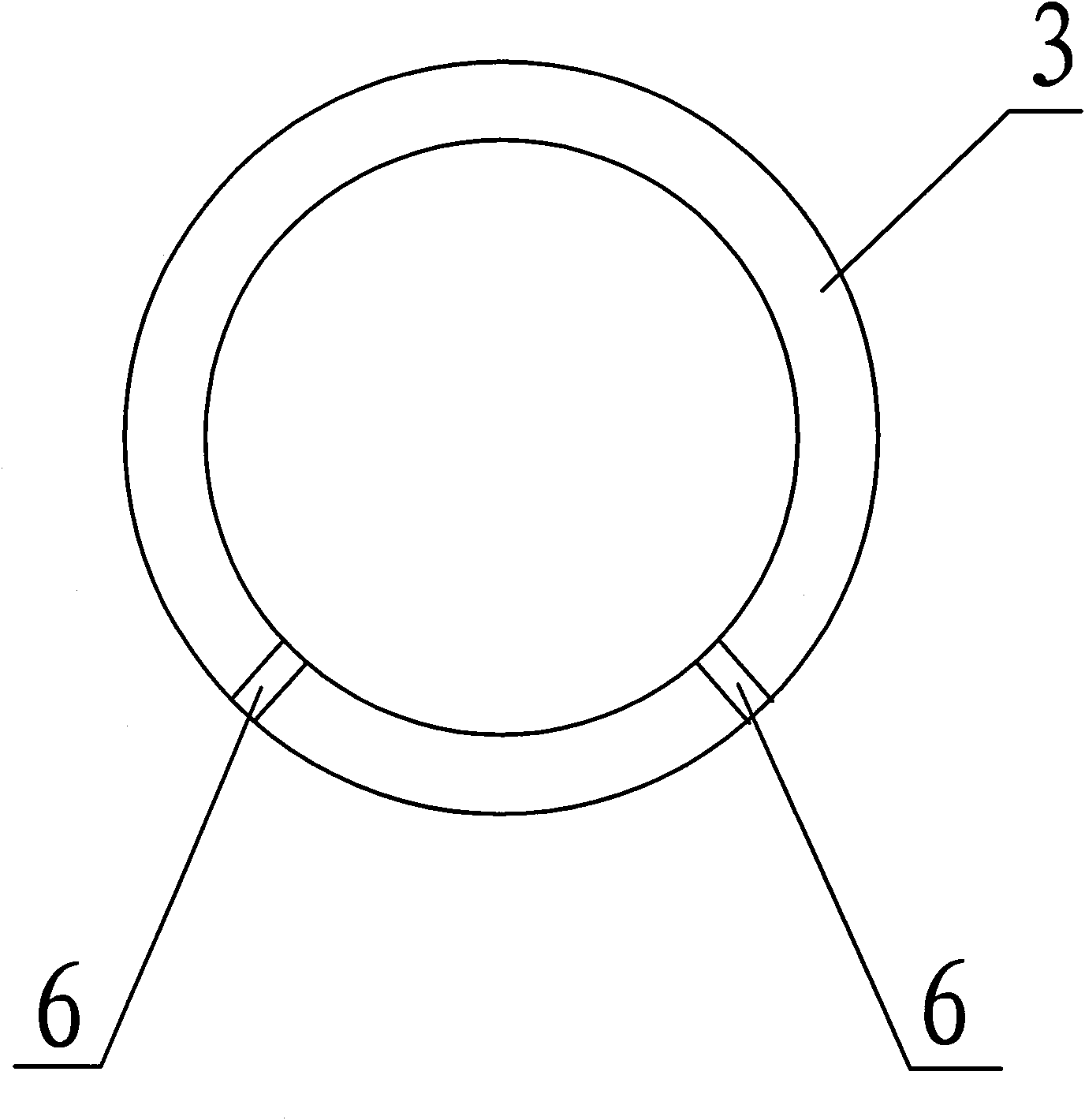

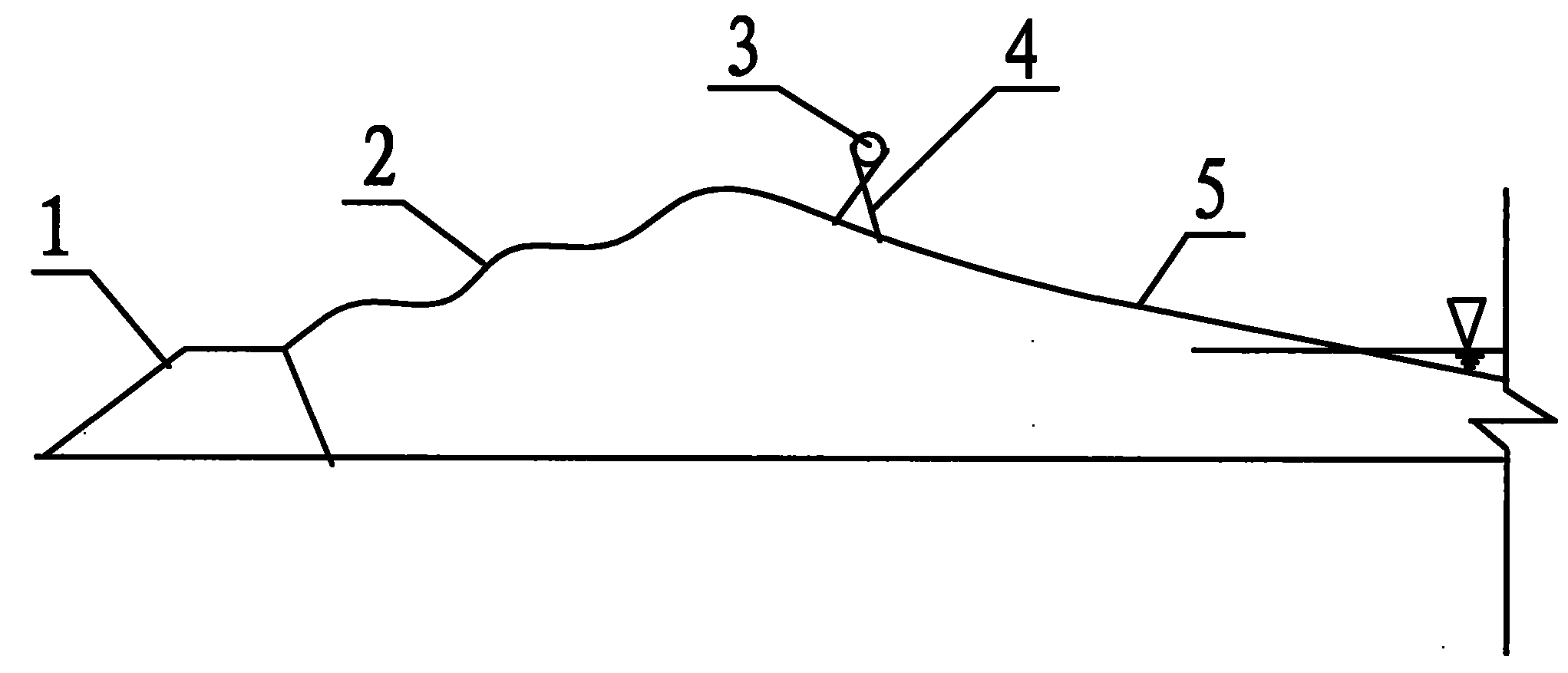

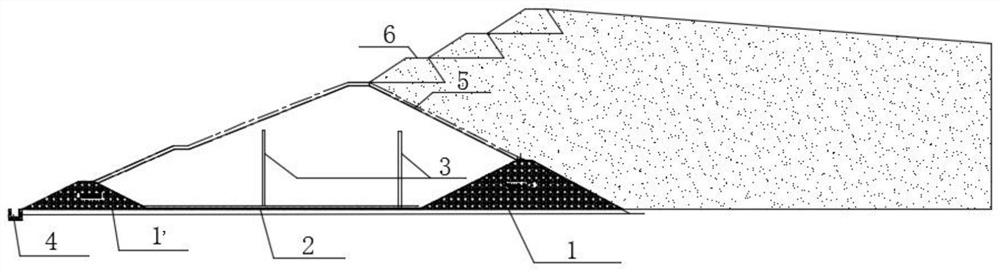

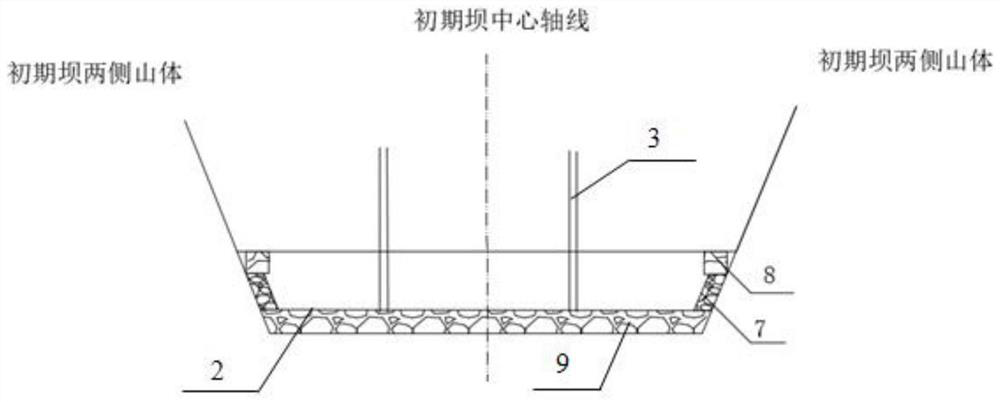

A cohesive soil primary dam structure for upstream tailings pond

The invention discloses a cohesive soil primary dam structure used for an upstream tailings pond. Firstly, an anti-seepage layer at the bottom of the primary dam body is laid on the bottom of the primary dam body, and an upstream seepage drainage edge of the primary dam is respectively arranged on the upper and lower reaches of the primary dam. body (1), the seepage prism (1') downstream of the initial dam, and the initial dam seepage mattress (2) is laid on the anti-seepage layer at the bottom of the initial dam body, and the lower end of the vertical seepage blind ditch pipe (3) is connected to the The initial dam drainage mattress (2) is connected; the oblique drainage blind ditch is pre-buried at the contact position between the initial dam and the mountain, and the horizontal drainage blind ditch is pre-buried at the contact position between the initial dam and the mountain; the initial dam is piled up layer by layer from bottom to top , and layer-by-layer compaction, the anti-seepage slope protection layer (5) is constructed on the upstream slope of the initial dam. The oblique drainage blind ditch, the horizontal drainage blind ditch, the upstream seepage drainage prism of the initial dam, the downstream seepage drainage prism of the initial dam, the vertical seepage drainage blind ditch pipe and the initial dam seepage drainage mattress of the present invention jointly constitute a combined seepage drainage system, can effectively reduce the dam body infiltration line.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +1

A high-efficiency vertical seepage drainage device for tailings pond

ActiveCN103590430BLower Wetting LineEnsure safetyProtective foundationTailings damMechanical engineering

Owner:KUNMING IRON & STEEL HLDG CO LTD

Method for reducing wetted surface of dam slope of mud-containing interlayer tailing dam

According to the method for reducing the wetted surface of the dam slope of the mud-containing interlayer tailing dam, the drill holes are vertically formed in the dam body, penetrate through the mud interlayer and extend to the drainage lens body at the bottom of the dam body, and the non-fine concrete water permeable pipes are installed and wrapped with the anti-corrosion inverted filter geotechnical cloth to prevent the water permeable holes from being blocked; the non-fine concrete permeable pipe penetrating through the mud interlayer can quickly drain water in the mud interlayer to the bottom of the dam body, and the water is discharged into a confluence area under the dam through the drainage lens body. Water in the mud interlayer can rapidly infiltrate downwards through the non-fine concrete permeable pipe, so that the infiltration line of the dam body is effectively reduced, and the stability of the dam body is improved.

Owner:XIAN UNIV OF TECH

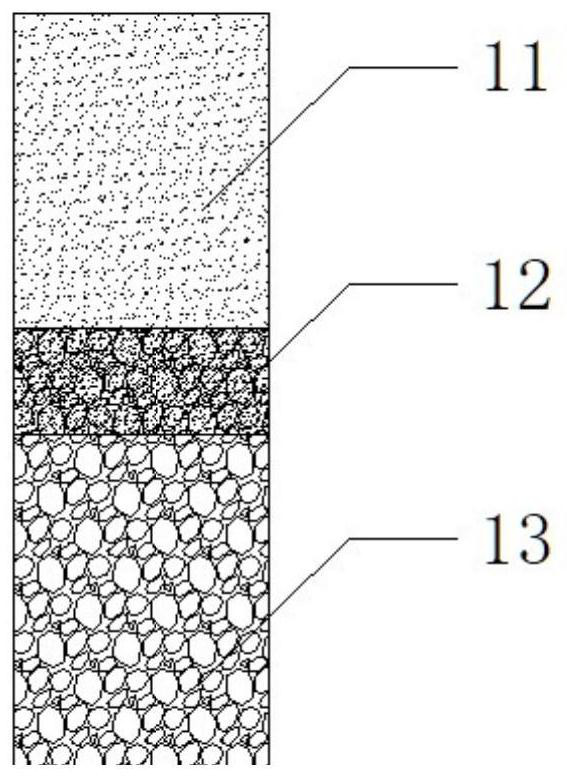

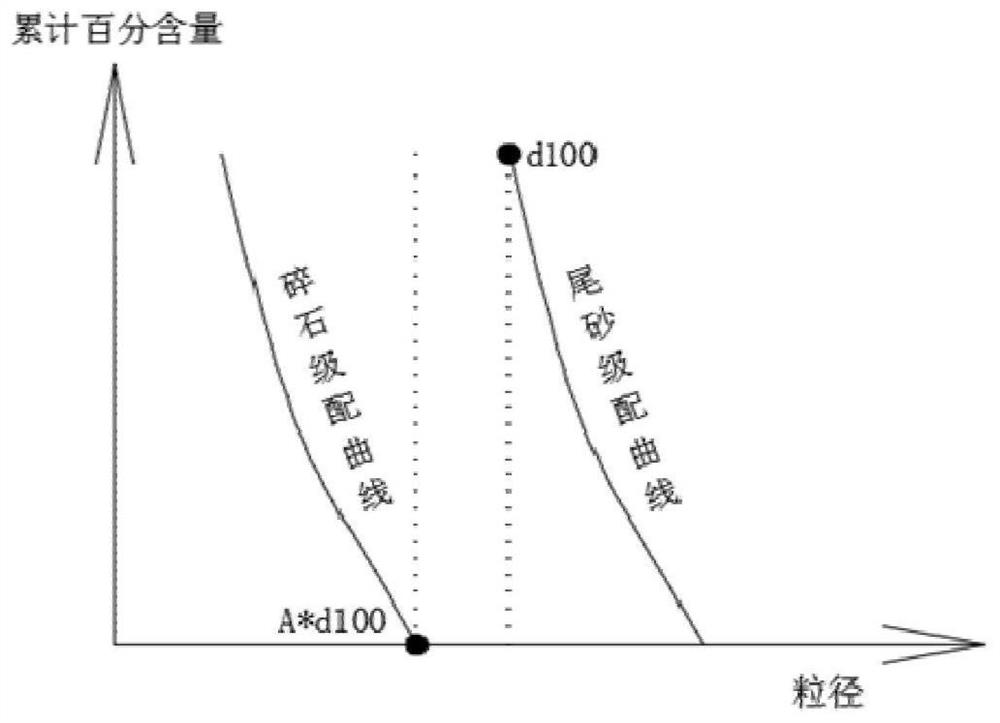

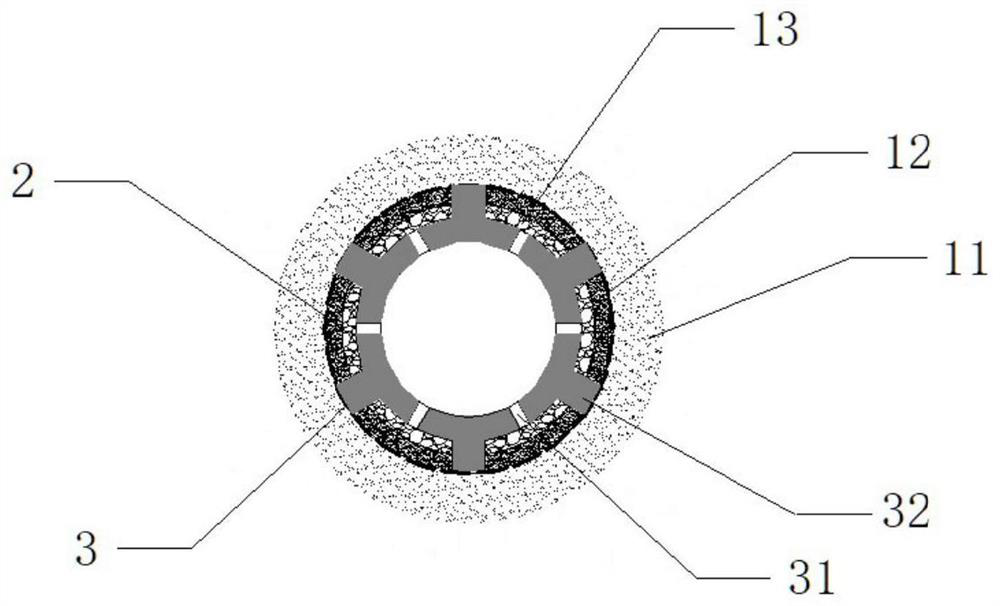

Tailings reverse filter material, preparation method and application, seepage structure and application of reverse filter material

ActiveCN113171652BAccelerated consolidationLower Wetting LineFiltration circuitsBulkheads/pilesSoil scienceTailings dam

The invention provides a tailings reverse filter material, a preparation method and its application, a reverse filter material drainage structure and its application, and specifically relates to the technical field of tailings treatment. The tailings anti-filtration material includes stacked gravel layers, gravel tailing sand joint transition layer and tailing sand layer; the gravel tailing sand joint transition layer includes gravel and tailing sand, and the tailing sand is filled between adjacent gravels gap. The seepage drainage structure of the reverse filter material includes the seepage drainage pipe and the gravel layer arranged in sequence outside the drainage pipe wall, the gravel tailing sand combined transition layer and tailing sand layer, and a filter screen, which is sleeved on the Outside the seepage drainage pipe, it is arranged between the gravel tailings joint transition layer and the tailings layer. Drainage holes and partitions are arranged around the seepage pipe. The tailings reverse filter material and reverse filter material drainage structure provided by this application can accelerate the discharge of water in the tailings, prevent silting, improve the degree of consolidation of the tailings, reduce the infiltration line during the accumulation of the tailings, and ensure that the tailings The bearing capacity and shear strength of the dam improve the safety of the tailings dam.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

A reverse seepage drainage system suitable for upstream tailings pond and upstream tailings pond

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

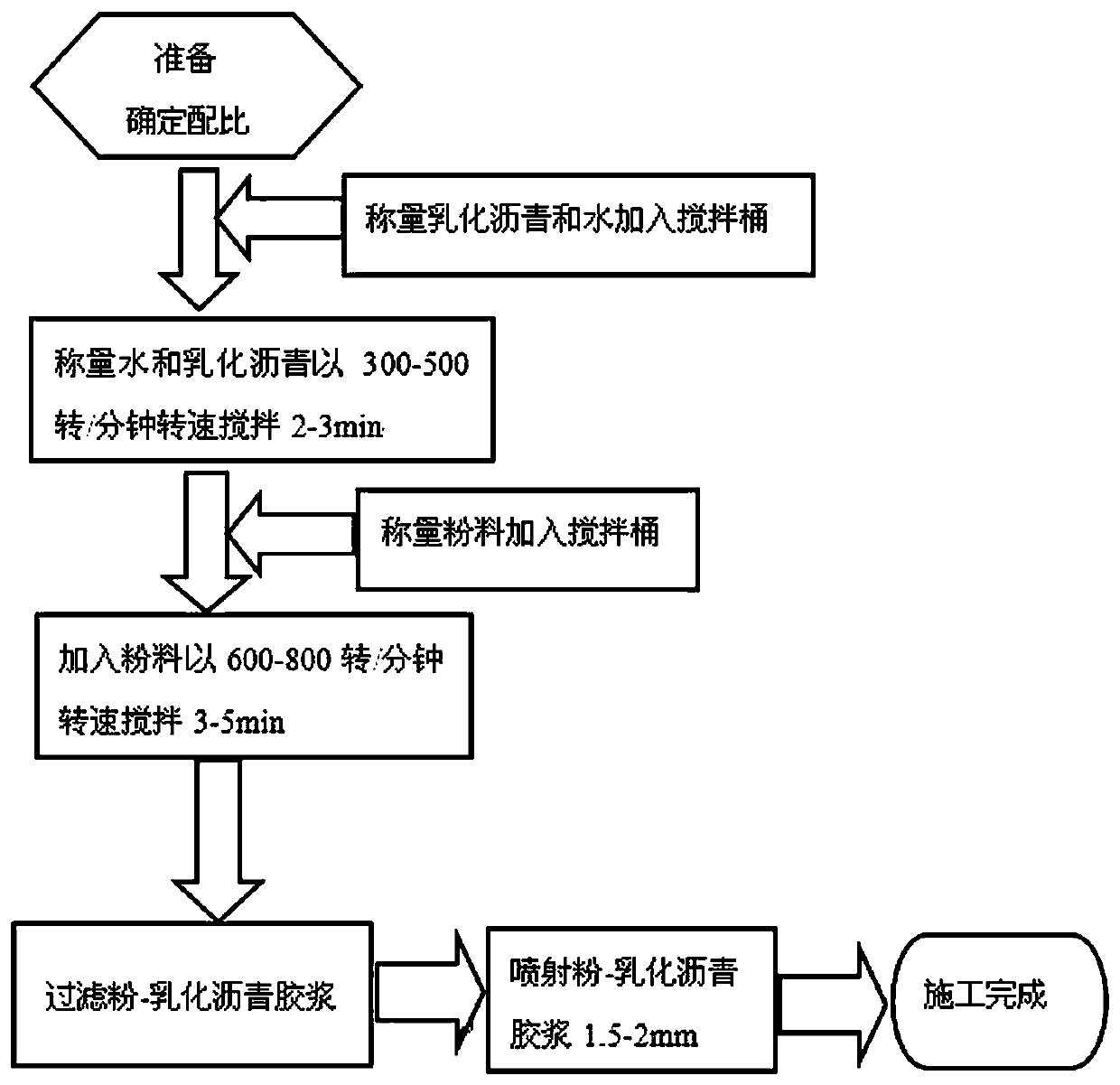

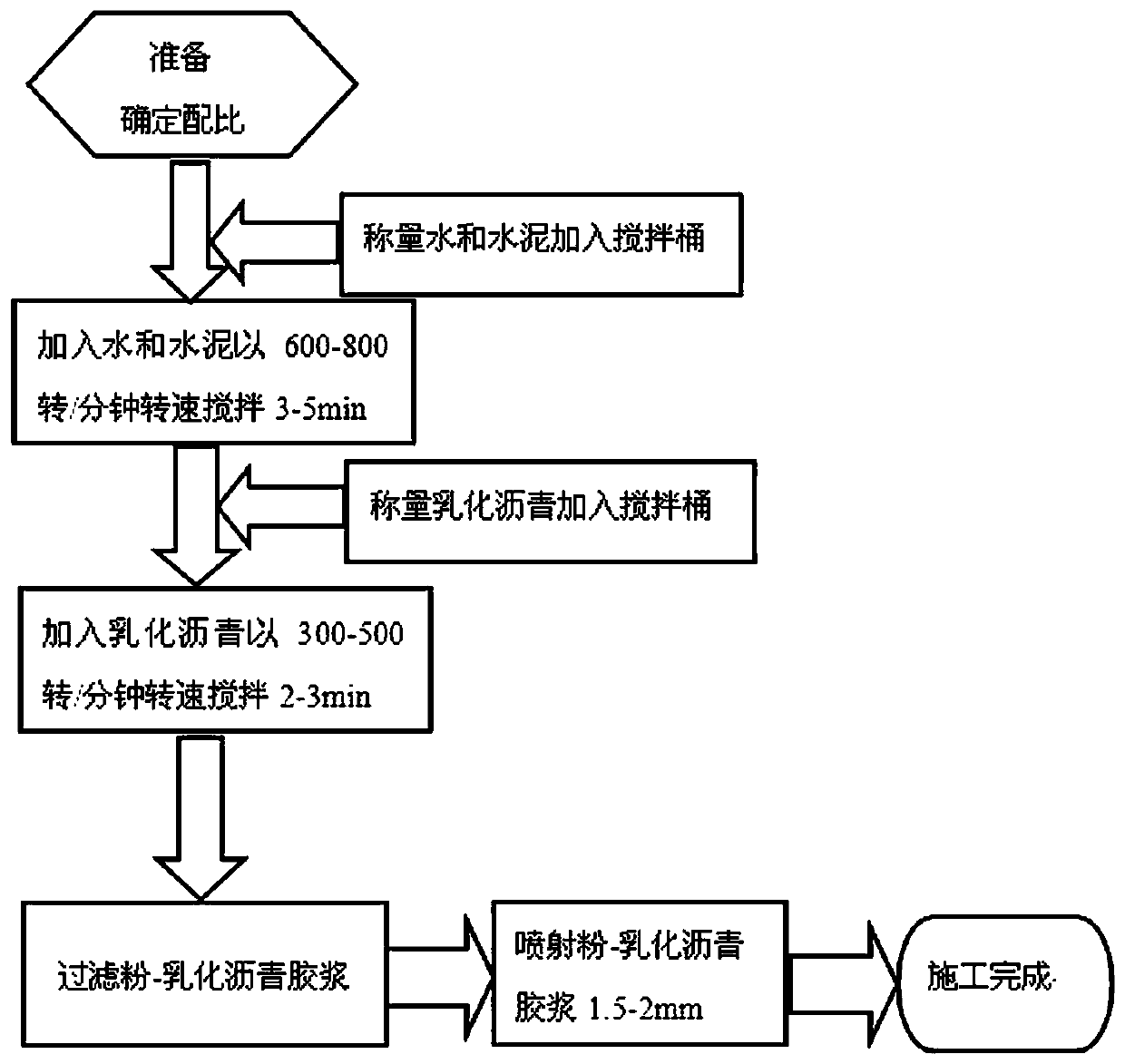

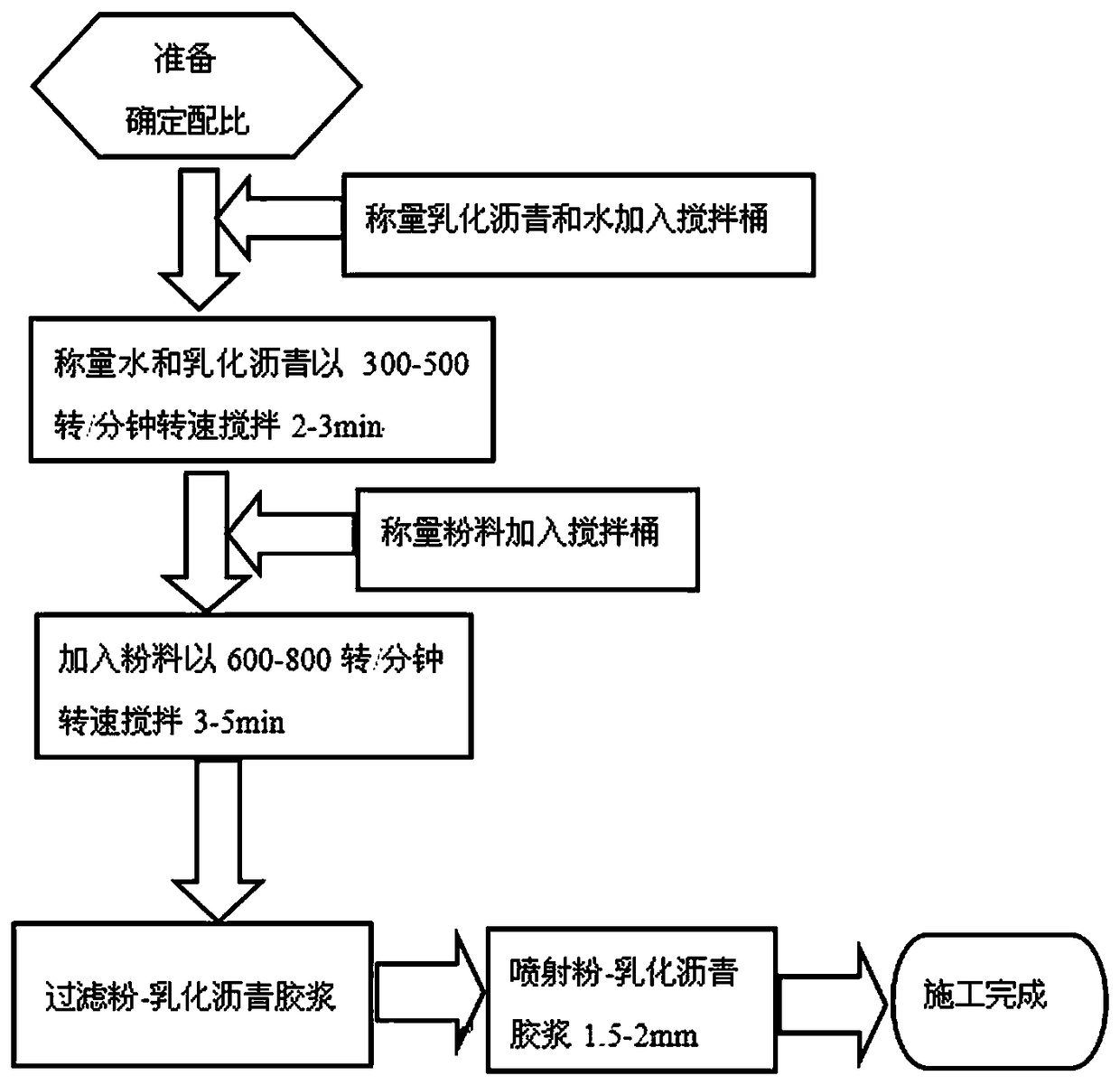

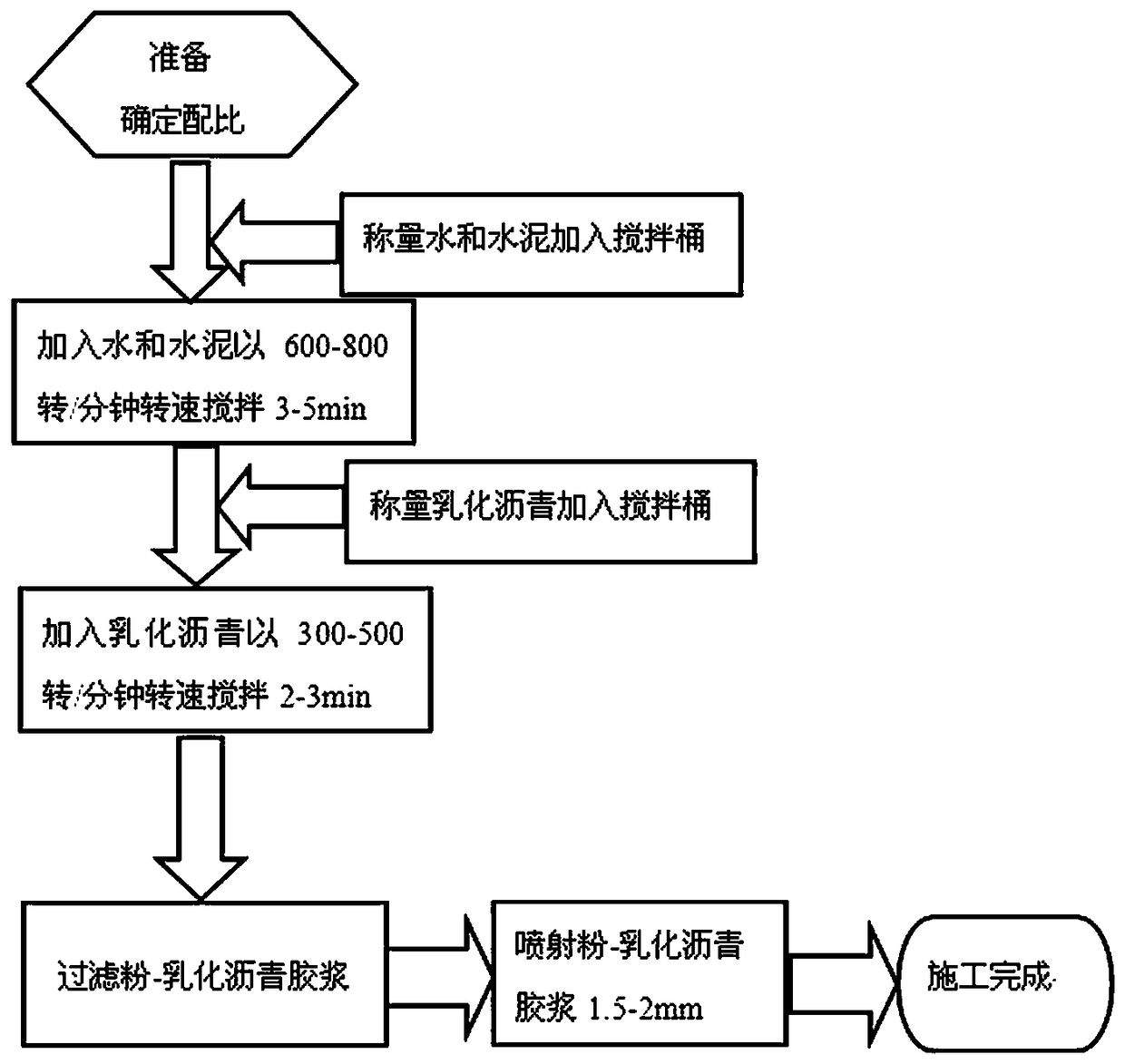

Construction Method of Isolation Layer of Concrete Face Rockfill Dam

ActiveCN108978594BImprove performanceReduce external stressFoundation engineeringEarth-fill damsArchitectural engineeringBitumen emulsion

The invention provides a concrete face rockfill dam isolating layer construction method. The concrete face rockfill dam isolating layer construction method comprises the following steps of: (1) preparing powder-emulsified asphalt mortar on the scene; (2) filtering the powder-emulsified asphalt mortar to remove glue residues for later application, continuously stirring, and storing for 1.5 hours after stirring; and (3) conveying the powder-emulsified asphalt mortar to a working face through a conveying hose, spraying the powder-emulsified asphalt mortar onto a protective surface through a spraygun at the working pressure of 0.8-1.2MPa to form a semi-rigid isolating layer, and separating the protective surface from a concrete face by the semi-rigid isolating layer which has the effects of lubrication and seepage control. The face rockfill dam upstream protective surface isolating layer construction method is simplified; and the concrete face rockfill dam isolating layer construction method improves the gluing quality of the isolating layer and the protective surface, has a good effect of separating different layers and reduces the restraint stress of the face and the generation of concrete face cracks.

Owner:GEZHOUBA GRP NO 2 ENG

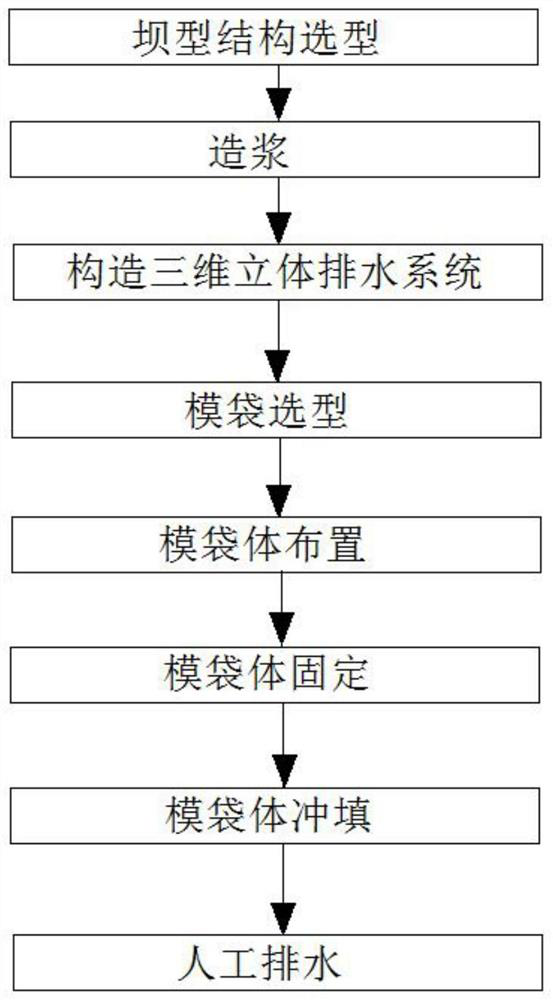

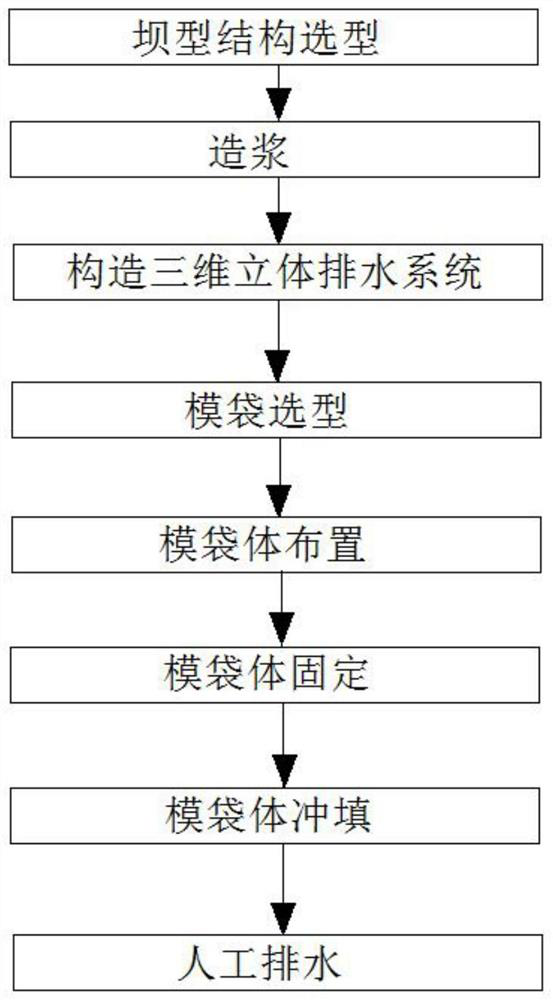

Full tailing slurry filling mold bag solidified body dam stacking process

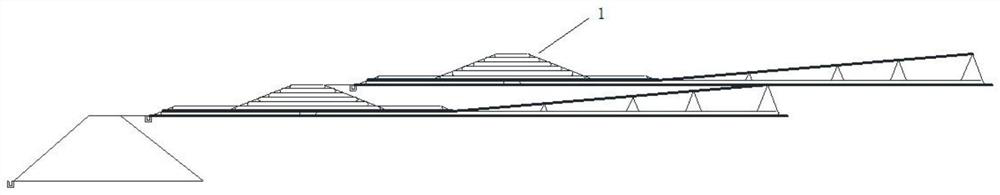

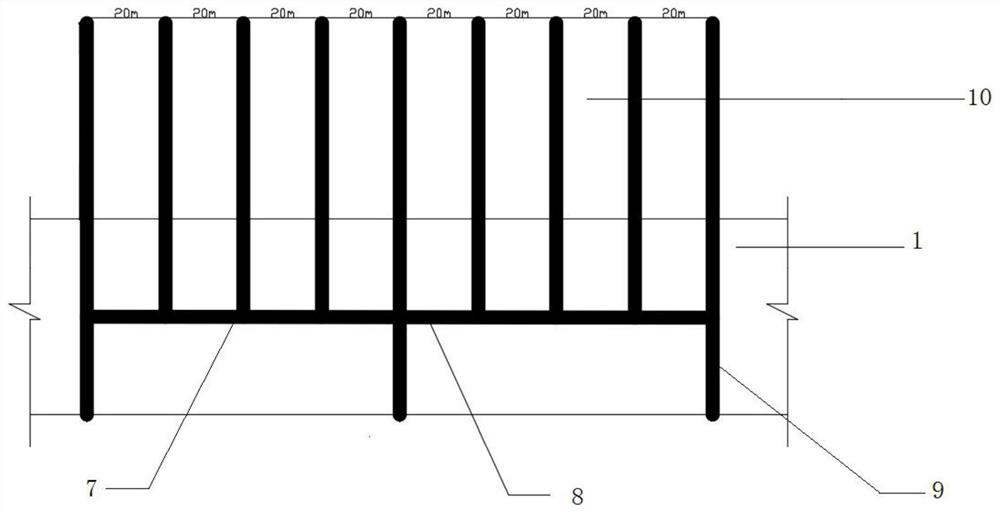

ActiveCN113006092ADrain fastImprove securityEmbankmentsSoil preservationPhysical chemistryEngineering

The invention discloses a full tailing slurry filling mold bag solidified body dam stacking process, and relates to the technical field of mold bag dam stacking. The full tailing slurry filling mold bag solidified body dam stacking process comprises the steps of dam type structure type selection, slurry making, three-dimensional drainage system construction, mold bag type selection, mold bag body arrangement, mold bag body fixation, mold bag body filling, manual drainage and the like. The full tailing slurry filling mold bag solidified body dam stacking process used as a novel technology for achieving tailing pond full tailing slurry dam stacking is an iteration and innovation of an existing mold bag damming mode, the damming process is simple and convenient, the mode is fast, the formed dam body is low in infiltration line, and the dam body is high in stability and safety. In addition, tailings particles of -200 meshes to -400 meshes can be stockpiled and treated through the formed filling mold bag solidification dam body, a three-dimensional drainage system is formed in the dam body through staggered and staggered-layer arrangement of the mold bag solidification bodies, rapid drainage of the mold bag solidification bodies can be achieved, and practicability is high.

Owner:江苏驰凯科技工程有限公司 +1

A dam-filling process of full tailings slurry flushing and filling mold bags with solidified body

The invention discloses a dam-filling process of full tailings slurry filling mold bags and solidified bodies, and relates to the technical field of mold bag dam stacking, including dam structure selection, slurry making, three-dimensional three-dimensional drainage system construction, mold bag selection, and mold bag body Layout, mold bag body fixing, mold bag body filling, artificial drainage and other processes, this process, as a new technology to realize tailings slurry dams in tailings ponds, is an iteration and innovation of the previous mold bag dam building methods, not only the dam building process The method is simple and fast, and the formed dam body has a low infiltration line, high dam body stability, and high safety. In addition, the solidified dam body formed by the present invention can store and process -200 to -400 mesh tailings particles, and the dam body has a three-dimensional drainage system formed by dislocation and staggered arrangement of the solidified body of the mold bag, which is beneficial to Realize rapid drainage of mold bag solidified body, strong practicability.

Owner:江苏驰凯科技工程有限公司 +1

Concrete face rockfill dam isolating layer construction method

ActiveCN108978594AImprove performanceReduce external stressFoundation engineeringEarth-fill damsWorking pressureRestraint stress

The invention provides a concrete face rockfill dam isolating layer construction method. The concrete face rockfill dam isolating layer construction method comprises the following steps of: (1) preparing powder-emulsified asphalt mortar on the scene; (2) filtering the powder-emulsified asphalt mortar to remove glue residues for later application, continuously stirring, and storing for 1.5 hours after stirring; and (3) conveying the powder-emulsified asphalt mortar to a working face through a conveying hose, spraying the powder-emulsified asphalt mortar onto a protective surface through a spraygun at the working pressure of 0.8-1.2MPa to form a semi-rigid isolating layer, and separating the protective surface from a concrete face by the semi-rigid isolating layer which has the effects of lubrication and seepage control. The face rockfill dam upstream protective surface isolating layer construction method is simplified; and the concrete face rockfill dam isolating layer construction method improves the gluing quality of the isolating layer and the protective surface, has a good effect of separating different layers and reduces the restraint stress of the face and the generation of concrete face cracks.

Owner:GEZHOUBA GRP NO 2 ENG

A method for improving in-service tailings pond capacity and a device thereof

The present invention discloses a method for improving an in-service tailings pond capacity and a device thereof, belonging to a field of tailings pond expansion technology. The method and the device are realized through a three-step tailings pond processing: a step of installing a working cushion for a tailings pond with a designed pond capacity and constructing a drainage system for drainage consolidation; a step of increasing the dam body height, discharging new tailings mud into the pond, and installing the working cushion and constructing a drainage system for a second time when the mud reaches the newly-increased dam body height; a last step of conducting consolidation processing on the newly-discharged tailings mud and storing the mud in different areas and on different layers via a paving system. The method for improving the in-service tailings pond capacity and the device thereof substantially reduce horizontal acting force of original tailings mud on an original tailings dam while a saturation line of the tailings dam body is lowered, with safety of the tailing pond improved, void ratio of a tailings soil mass greatly reduced, and the capacity of the tailings tank enhanced. Therefore the service life of the tailings pond is prolonged. The construction device of improving in-service tailings pond capacity has characteristics of easy operation, flexible combination, quick operation, and succinct and efficient construction technology.

Owner:BEIHANG UNIV

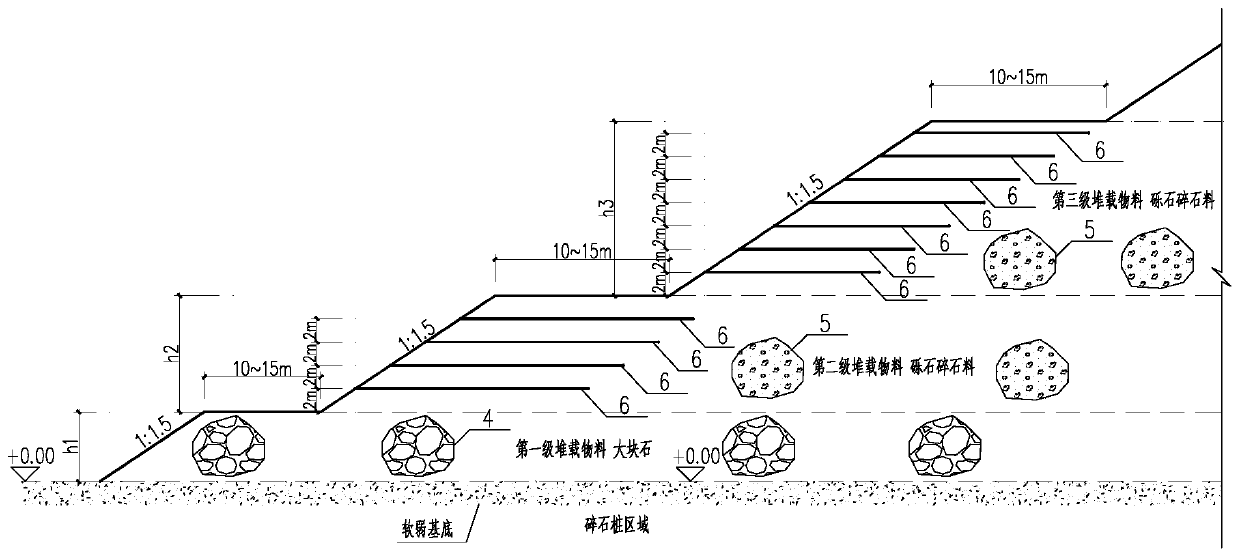

Reinforcing and surcharge structure used for preventing deep soft foundation dump against floor heave and instability

InactiveCN111519600AHigh consolidation strengthEnhanced drain consolidation effectGeotextilesSoil preservationSoil scienceSoil mechanics

The invention discloses a reinforcing and surcharge structure used for preventing a deep soft foundation dump against floor heave and instability. The reinforcing and surcharge structure used for preventing the deep soft foundation dump against floor heave and instability is composed of a vertical-horizontal consolidated drainage system and a hierarchical surcharge preloading and counter pressingsystem. The vertical-horizontal consolidated drainage system is jointly composed of gravel piles (3), geotextile (2) and a gravel cushion layer (1). The hierarchical surcharge preloading and counterpressing system is located on the upper part of the deep soft foundation gravel pile vertical-horizontal consolidated drainage system and adopts large stone blocks, gravel and or broken stone materials to conduct graded surcharge preloading. According to the reinforcing and surcharge structure used for preventing the deep soft foundation dump against floor heave and instability, an effective drainage channel can be provided for saturated silts and other fine particle materials scoured on the downstream side of the dump, the internal drainage time of the soft foundation is shortened, consolidation of the saturated soft foundation is accelerated, the rock-soil mechanics index and bearing capacity of the base soft foundation are improved, the stability of the bearing capacity of the soft foundation in the surcharge preloading process is effectively improved and controlled, the internal floor heave is prevented, and settlement due to uneven inner stress is prevented.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com