Patents

Literature

40results about How to "Reduce external stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

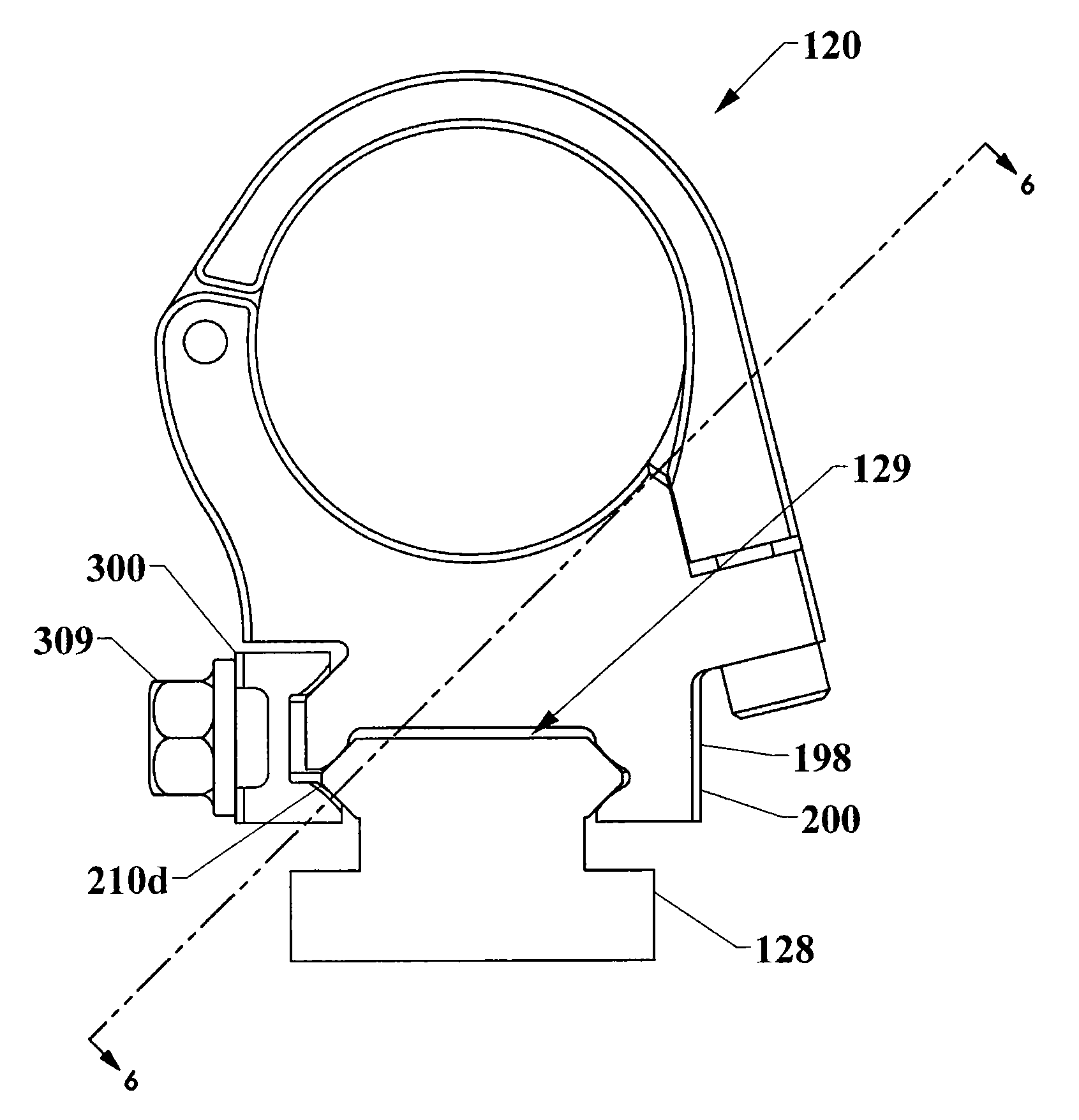

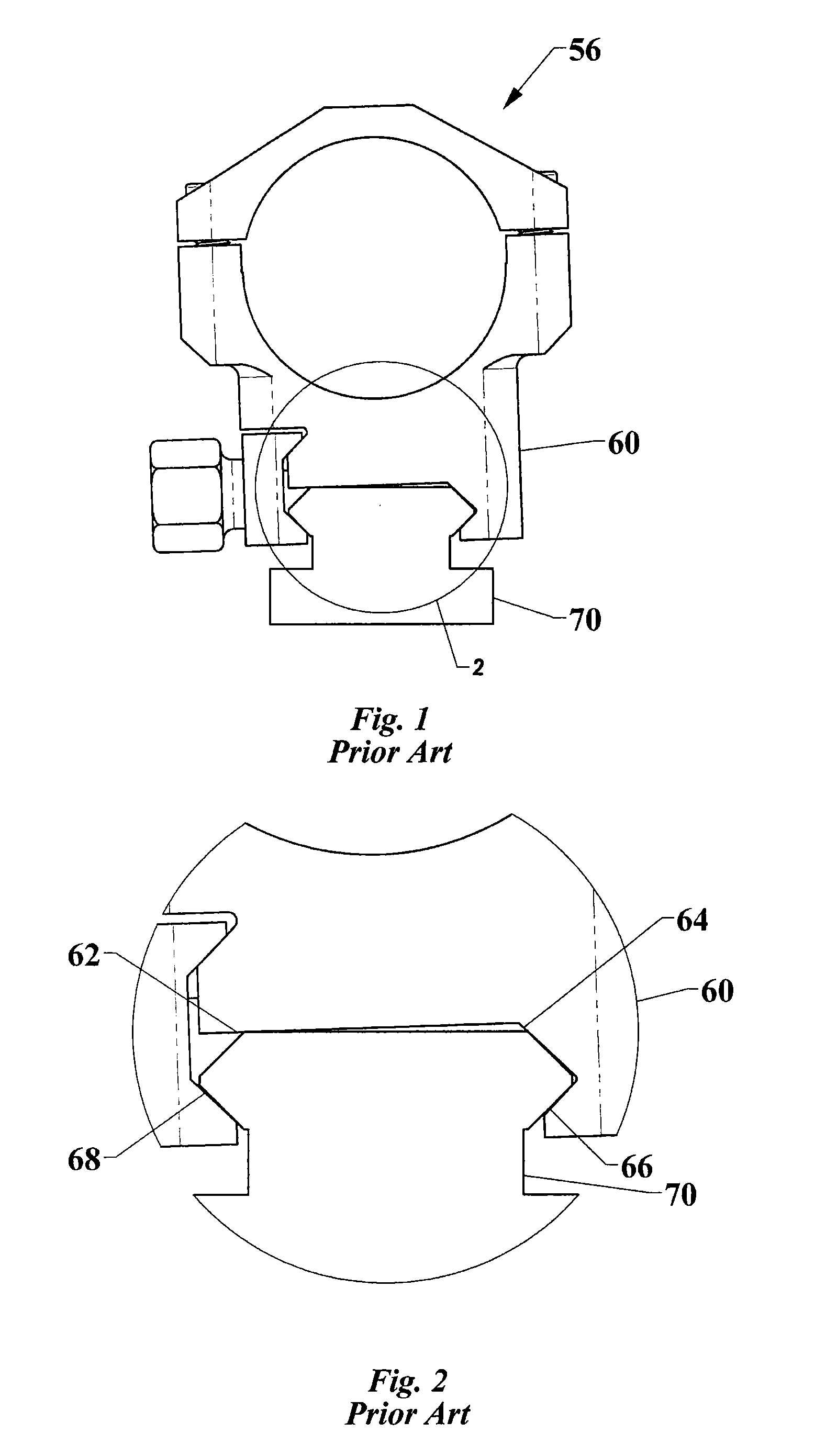

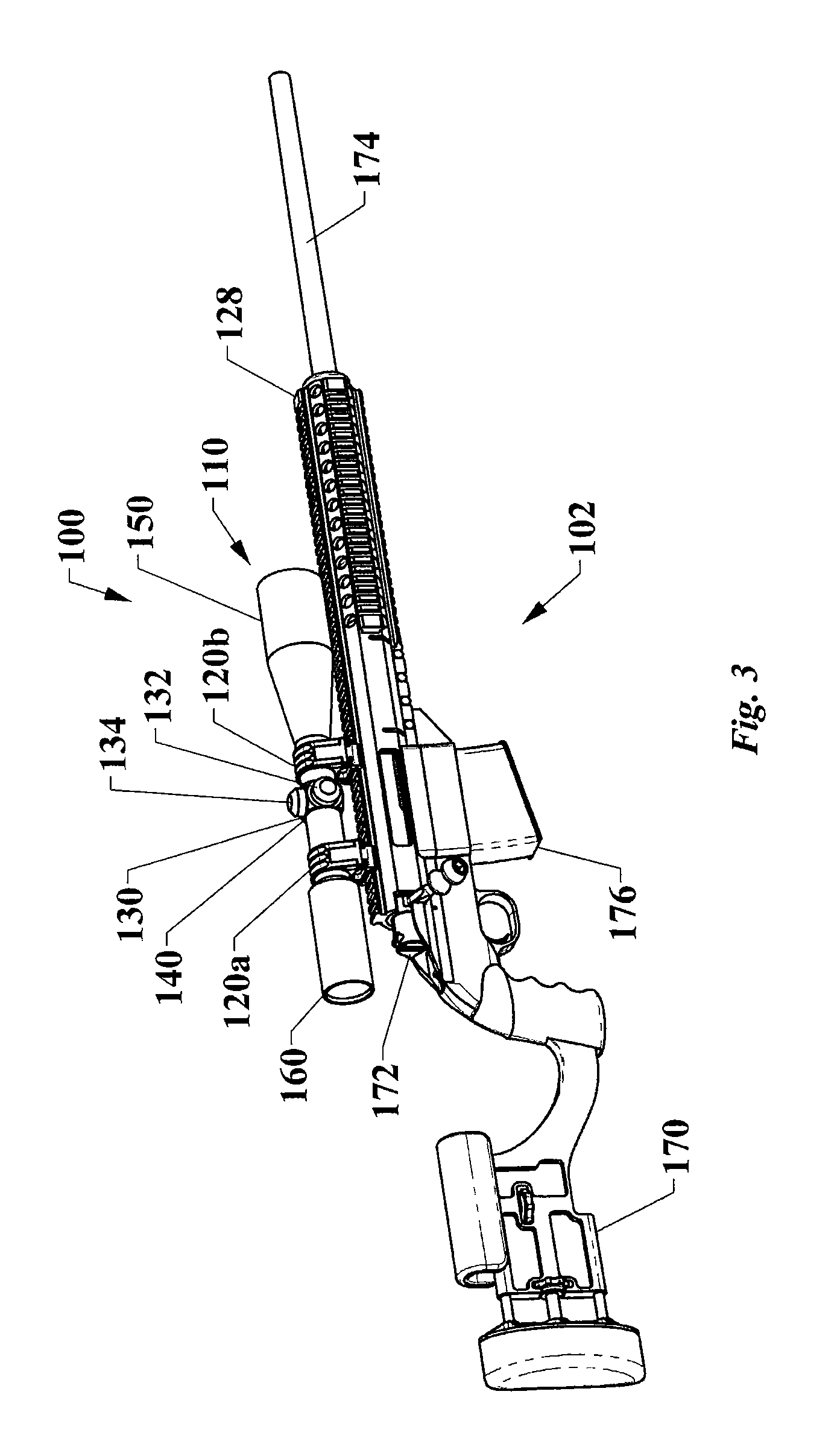

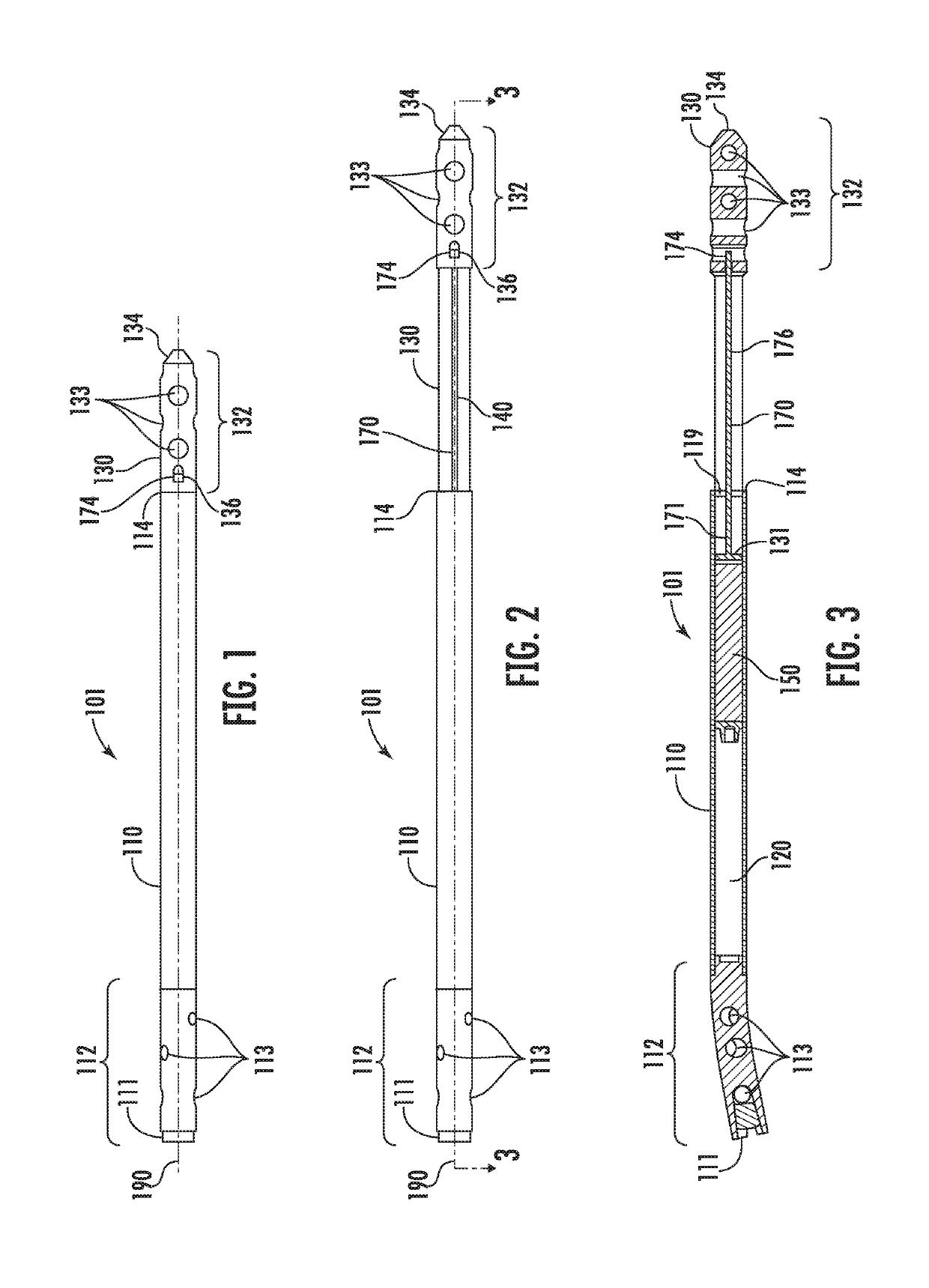

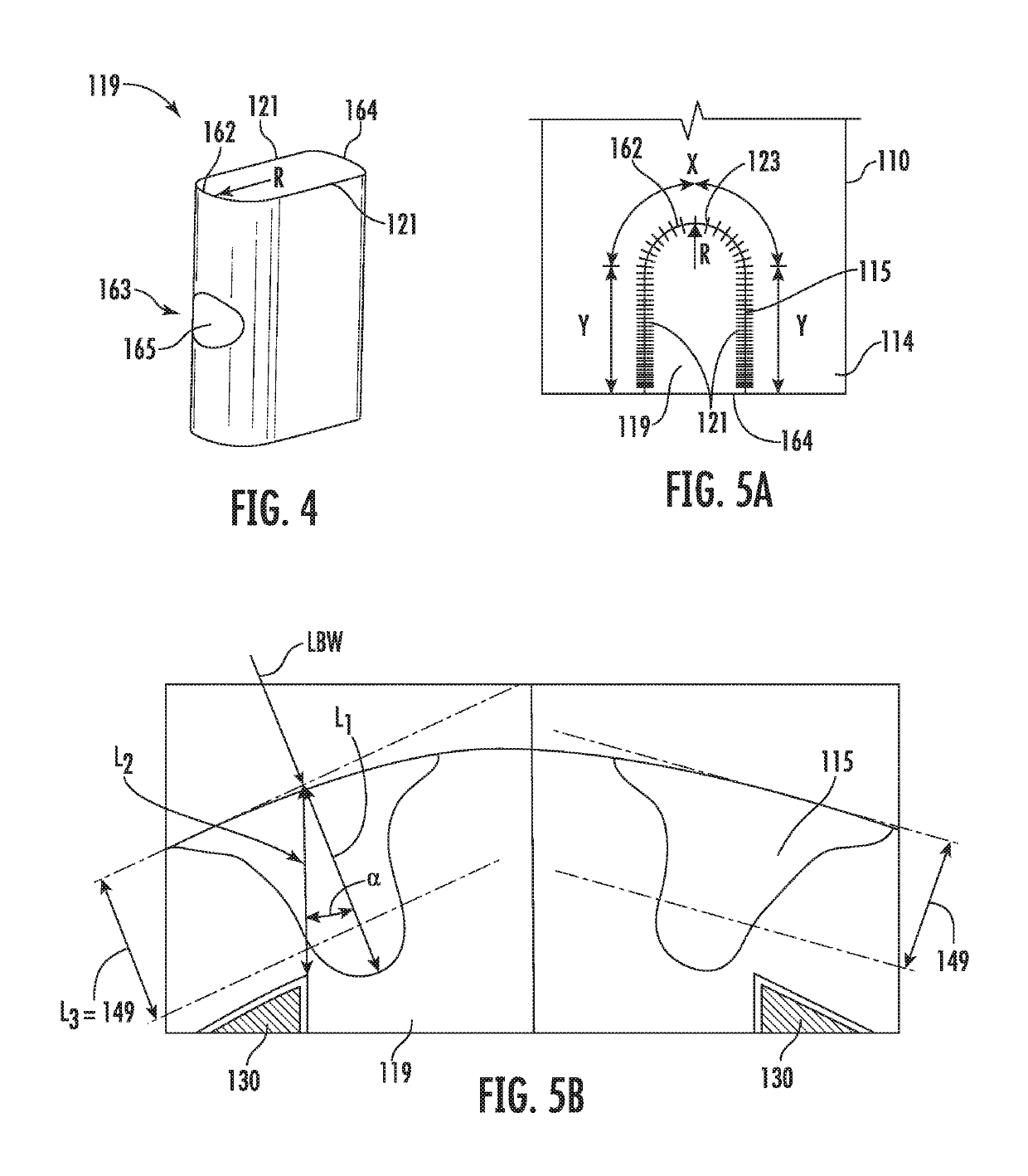

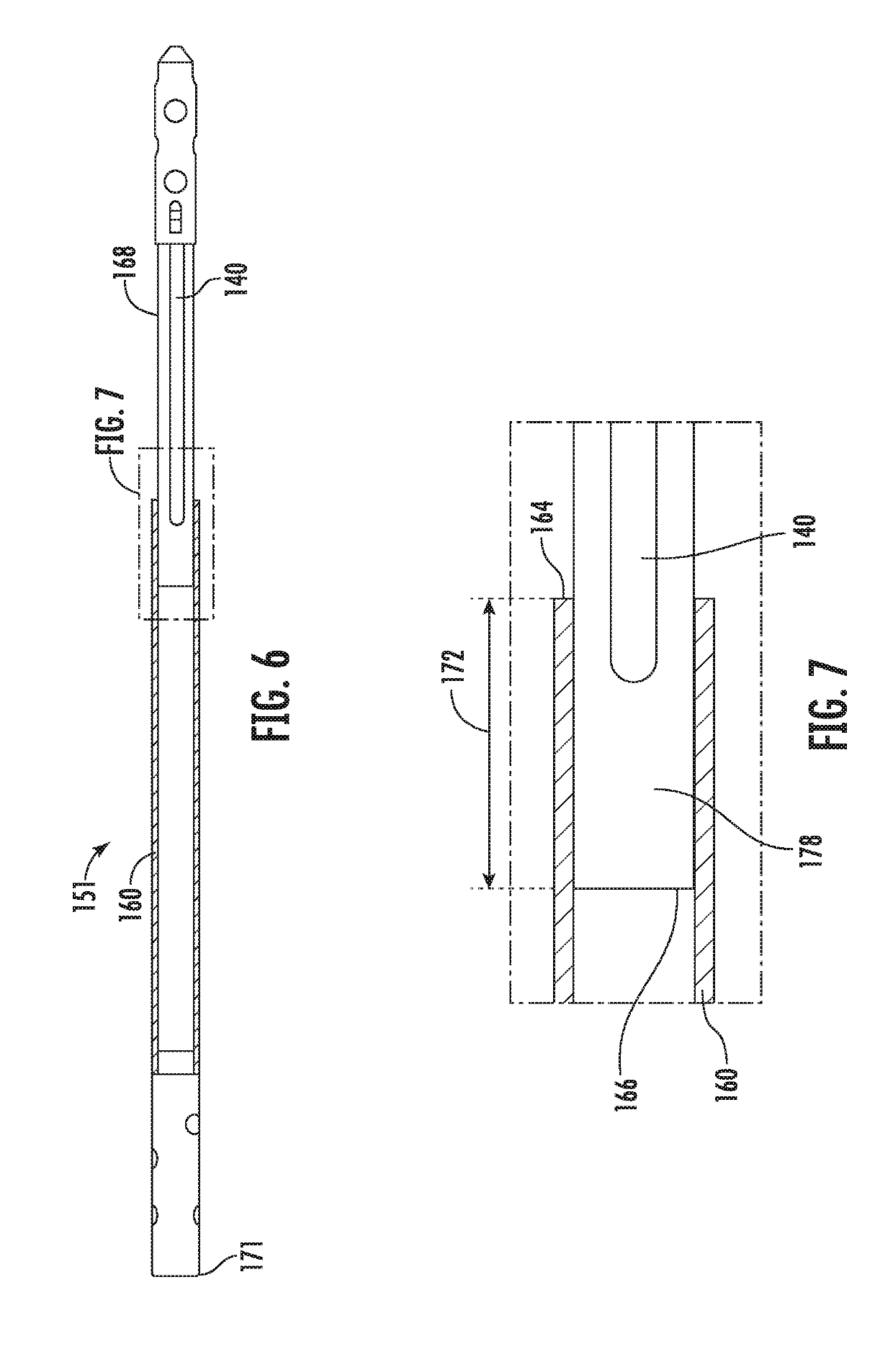

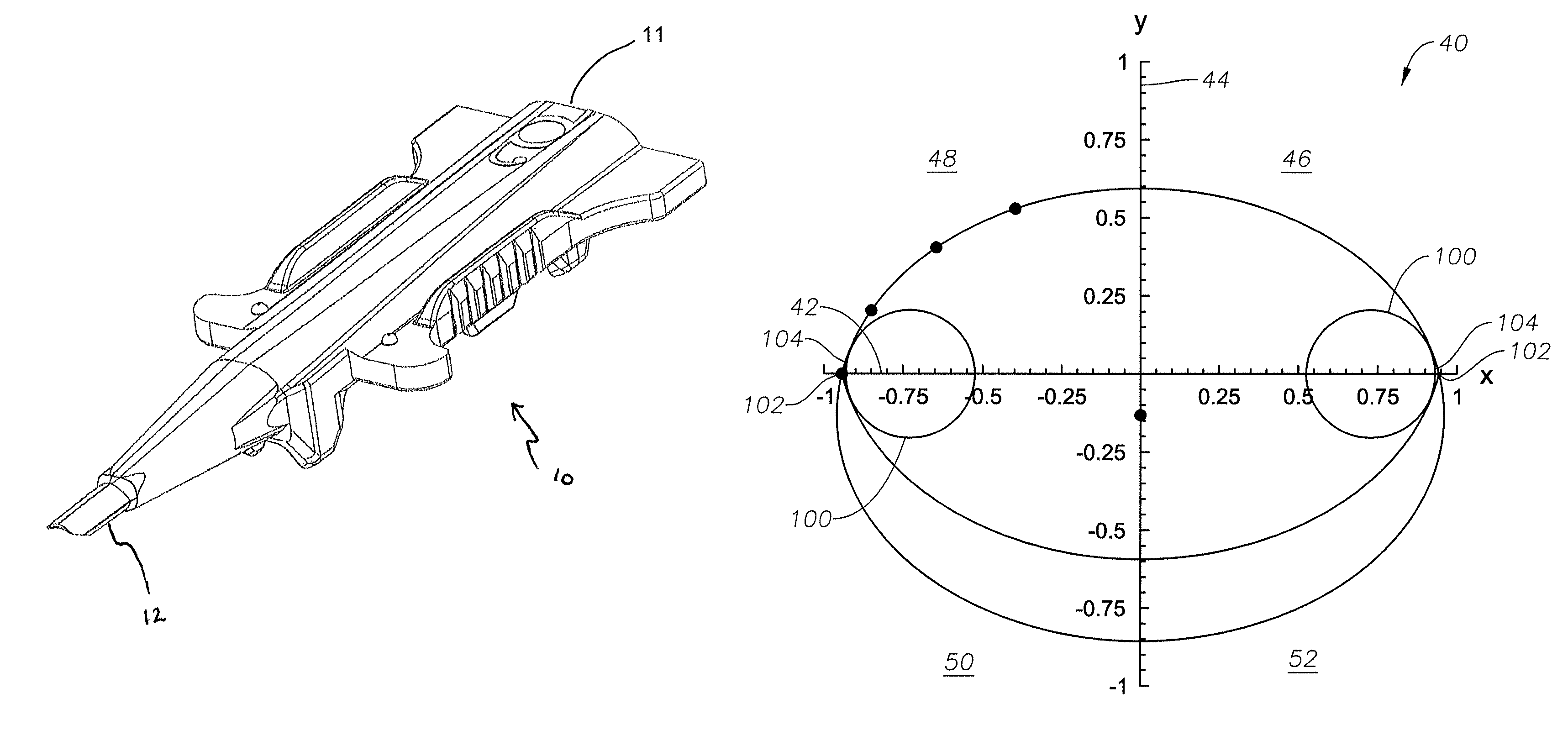

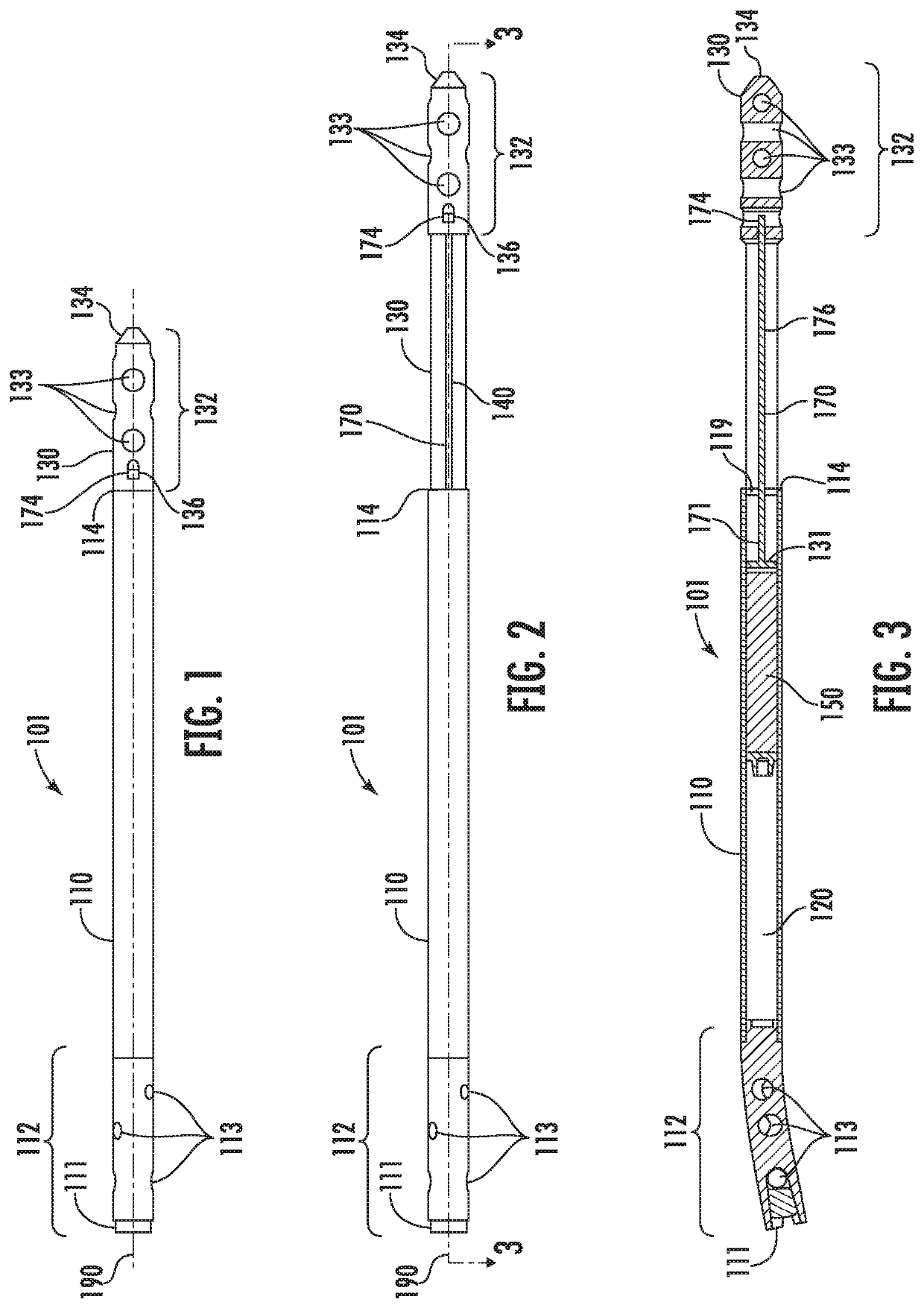

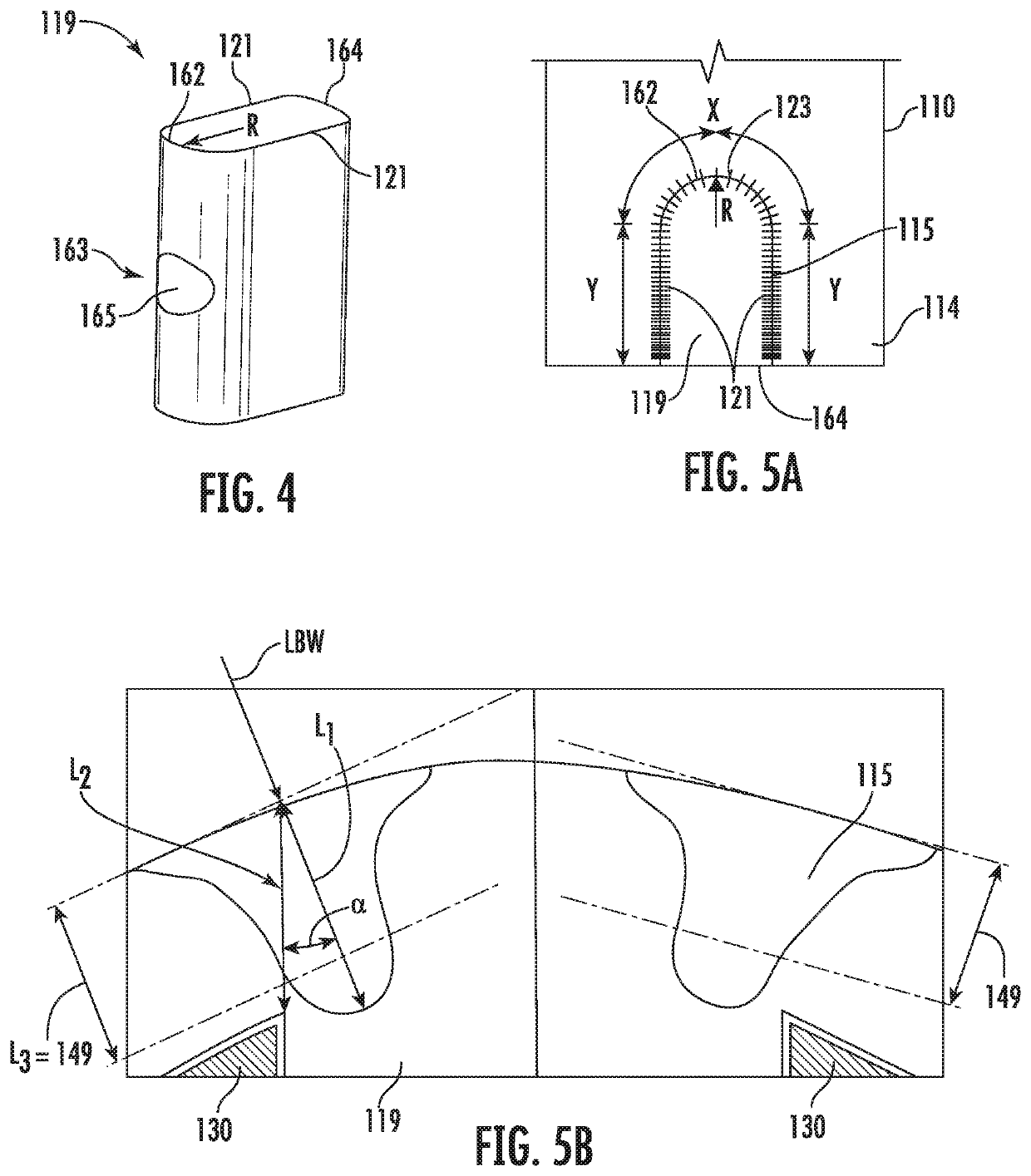

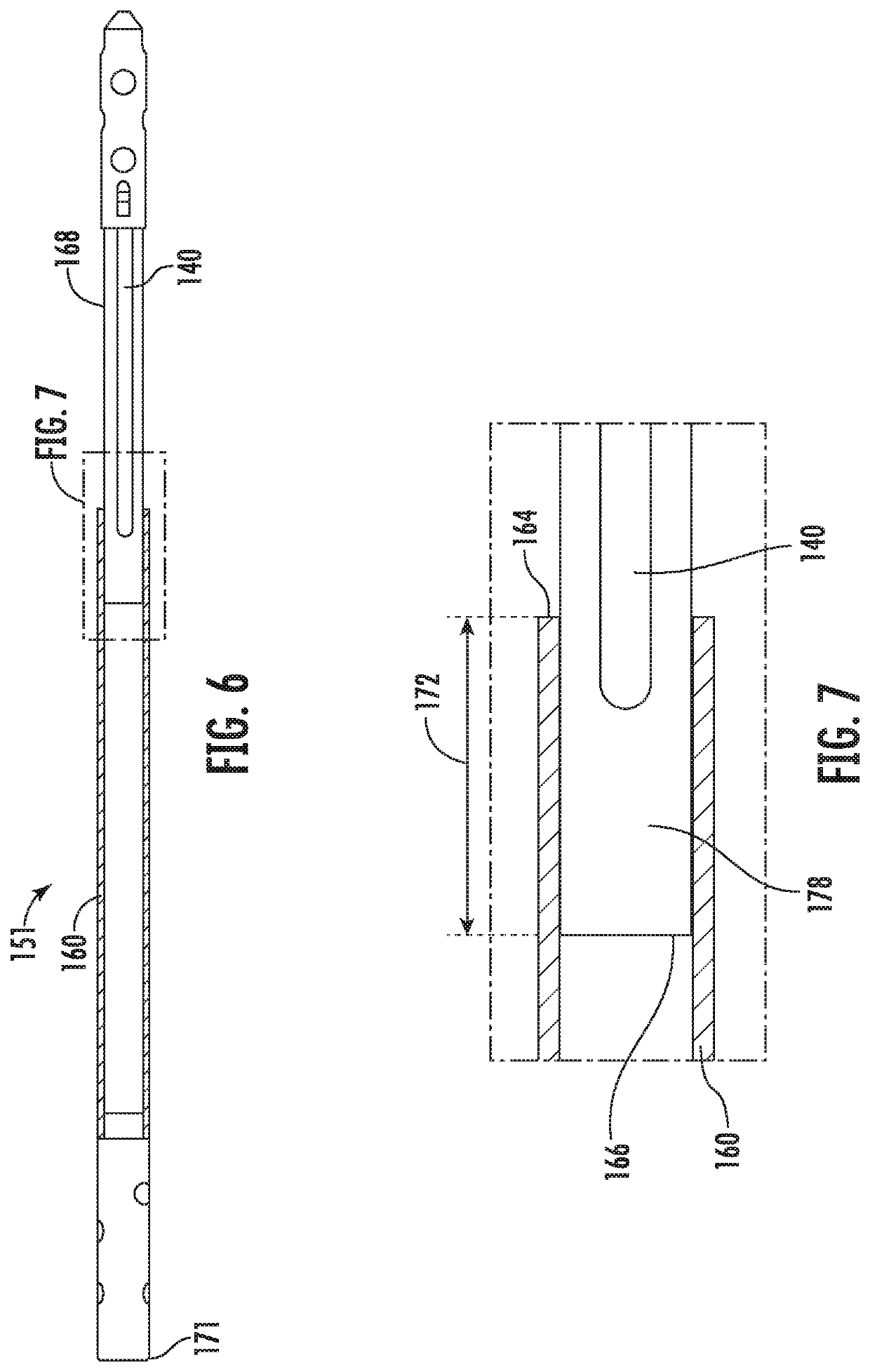

Mounting clamps for coupling scopes to mounting rails of firearms

InactiveUS20110271578A1Minimize and limit and substantially eliminate stress concentrationFlatten outSighting devicesMechanical engineeringInstrumentation

A sighting assembly for a firearm includes a scope and a mounting clamp. The mounting clamp includes a ring cap and a ring base that cooperate to surround and hold the scope. The mounting clamp has a rail clamp that includes a plurality of crowned portions that are configured to physically contact and grip a mounting rail.

Owner:KARAGIAS THEODORE

Film forming composition, process for producing film forming composition, insulating film forming material, process for forming film, and silica-based film

InactiveUS7462678B2Excellent chemical resistance and adhesion and insulating propertyLow dielectric constantPlastic/resin/waxes insulatorsLayered productsSilane compoundsSilanes

A process for producing a film forming composition, the process including hydrolyzing and condensing: (A) at least one silane compound selected from a compound (A-1) shown by the following general formula (1), a compound (A-2) shown by the following general formula (2), and a compound (A-3) shown by the following general formula (3),RaSi(OR1)4-a (1)Si(OR2)4 (2)R3b(R4O)3-bSi—(R7)d—Si(OR5)3-cR6c (3); and(B) a cyclic silane compound shown by the following general formula (4):

Owner:JSR CORPORATIOON

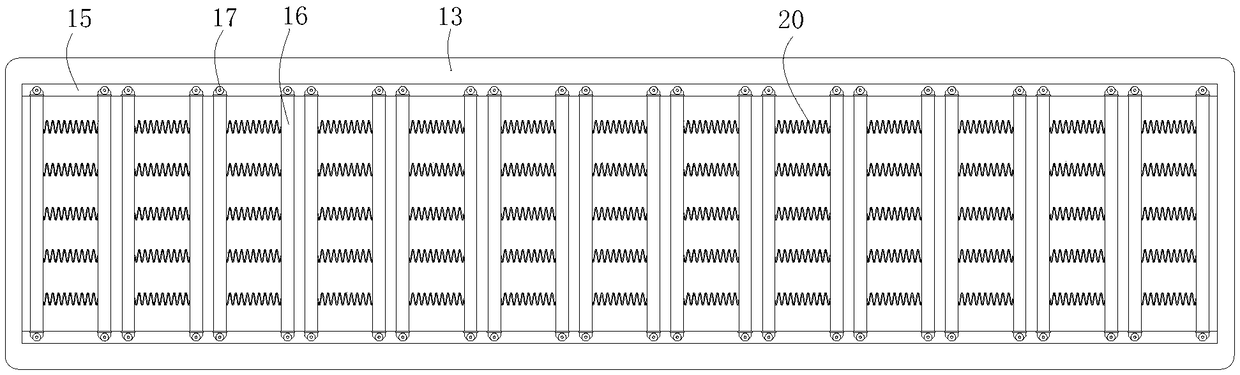

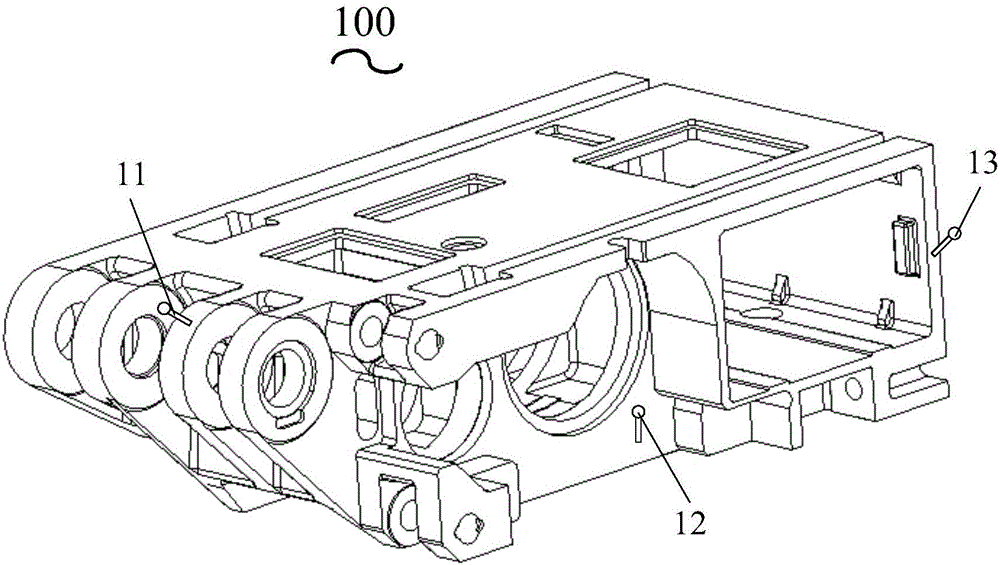

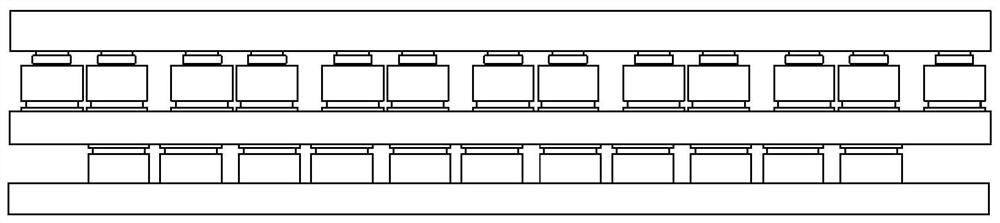

New energy power generation equipment fitting transportation device

InactiveCN108945727ASolve problems that cannot be effectively protectedImprove applicabilityContainers to prevent mechanical damageRigid containersNew energyEngineering

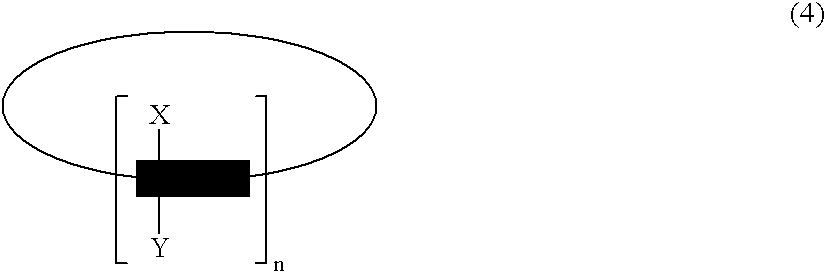

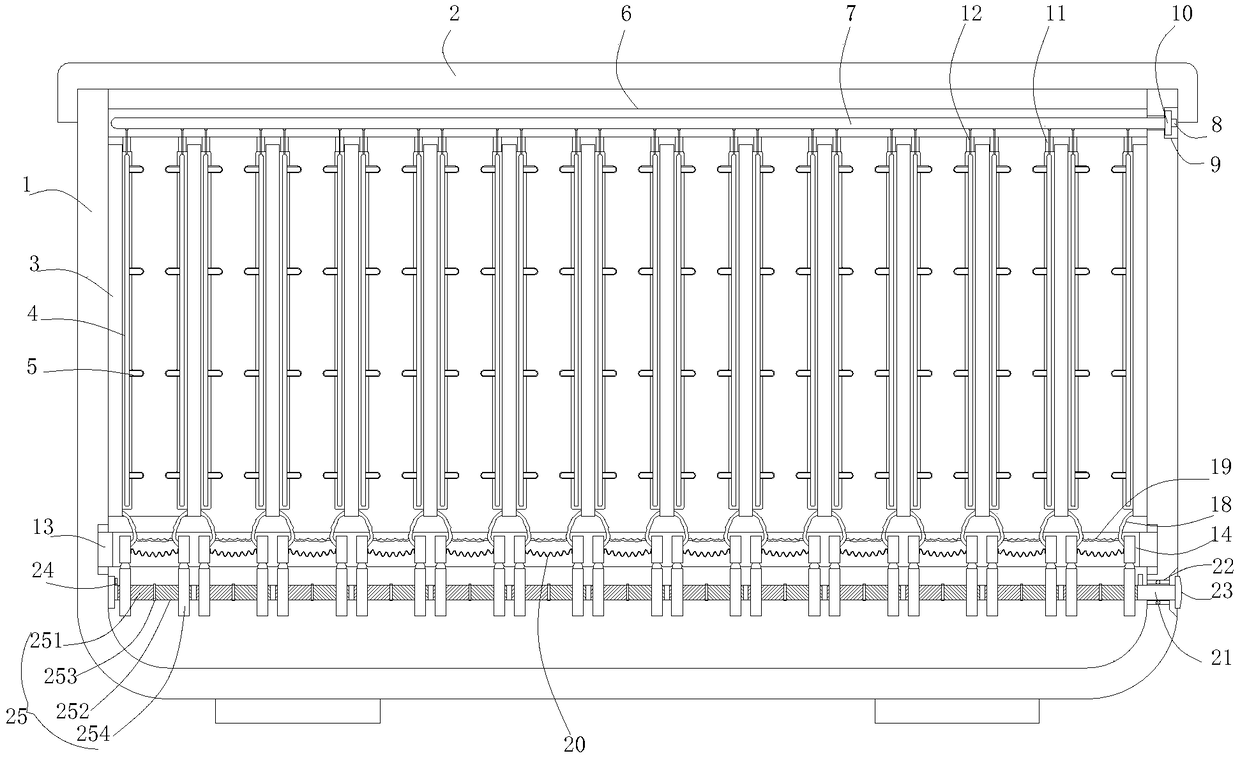

The invention relates to the technical field related to new energy, and discloses a new energy power generation equipment fitting transportation device. The new energy power generation equipment fitting transportation device comprises a box body, a box cover, fourteen vertical separation plates, twenty-six airbag layers, multiple airbag projections, a transverse mounting groove, a transverse multi-way pipe, an air guide joint, an embedding groove, a switch valve, twenty-six vertical guide grooves, twenty-six vertical air guide pipes, a mounting plate, a guide groove, two guide chutes, twenty-six mounting slide plates, fifty-two movable rollers, twenty-six lateral extension rubber layers, thirteen transverse extension rubber layers, thirteen sets of arc springs, a polish rod, an inner bearing, a starlike handle, two limiting blocks and thirteen thread set mechanisms; the box cover is positioned above the box body; and the fourteen vertical separation plates are distributed between the front and back side inner walls of the box body at equal intervals. The new energy power generation equipment fitting transportation device realizes multiple times of counteraction and buffering of stress transferred by photovoltaic panels, effectively protects the bottoms of the photovoltaic panels, and improves the applicability.

Owner:苏州波粒新能源科技有限公司

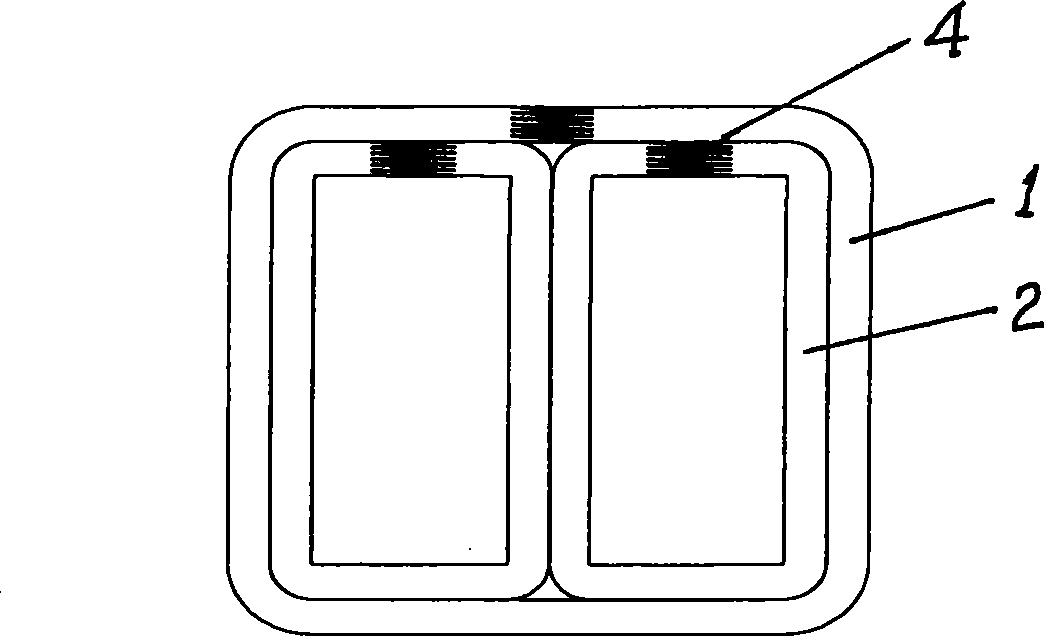

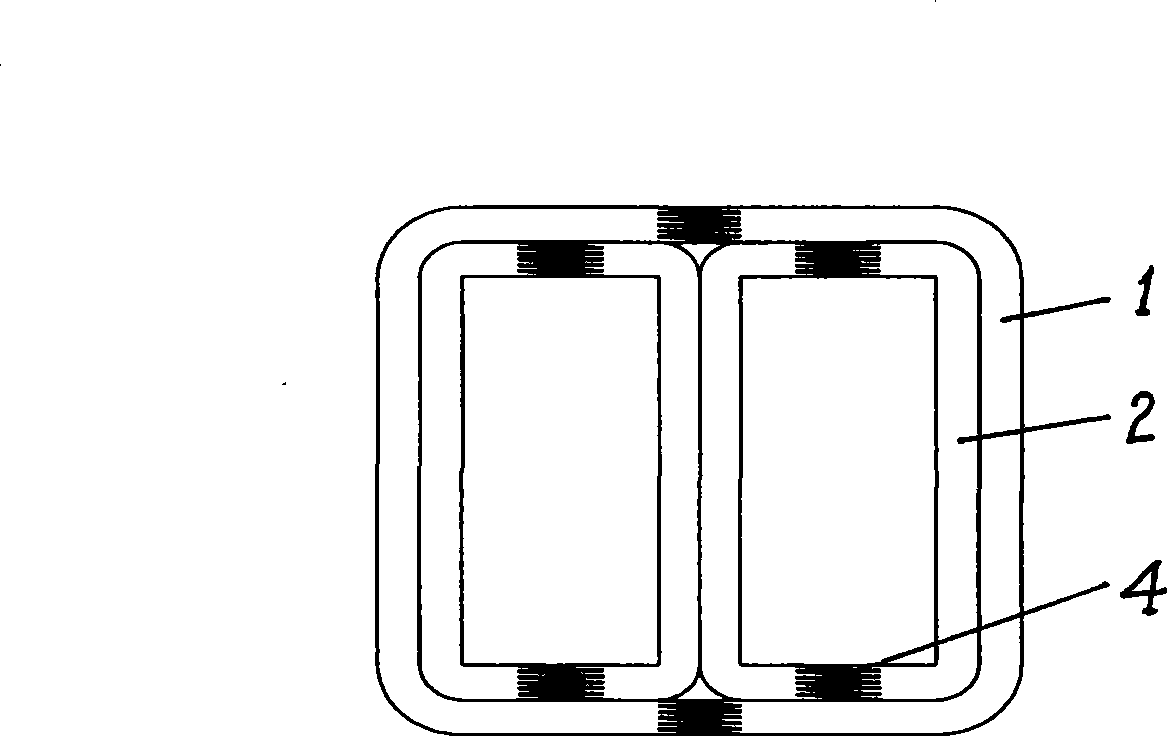

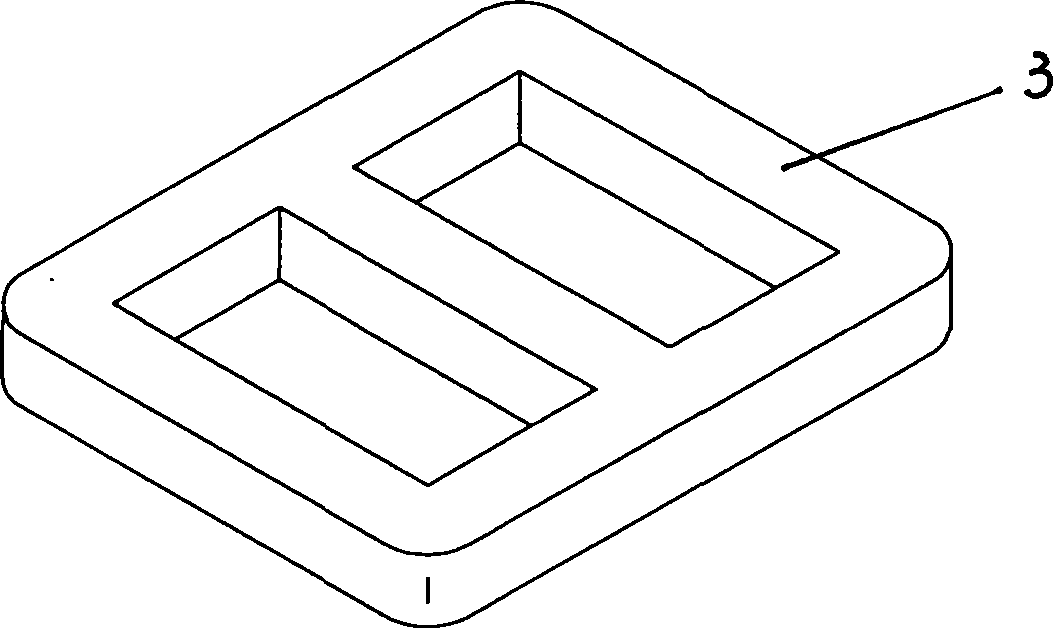

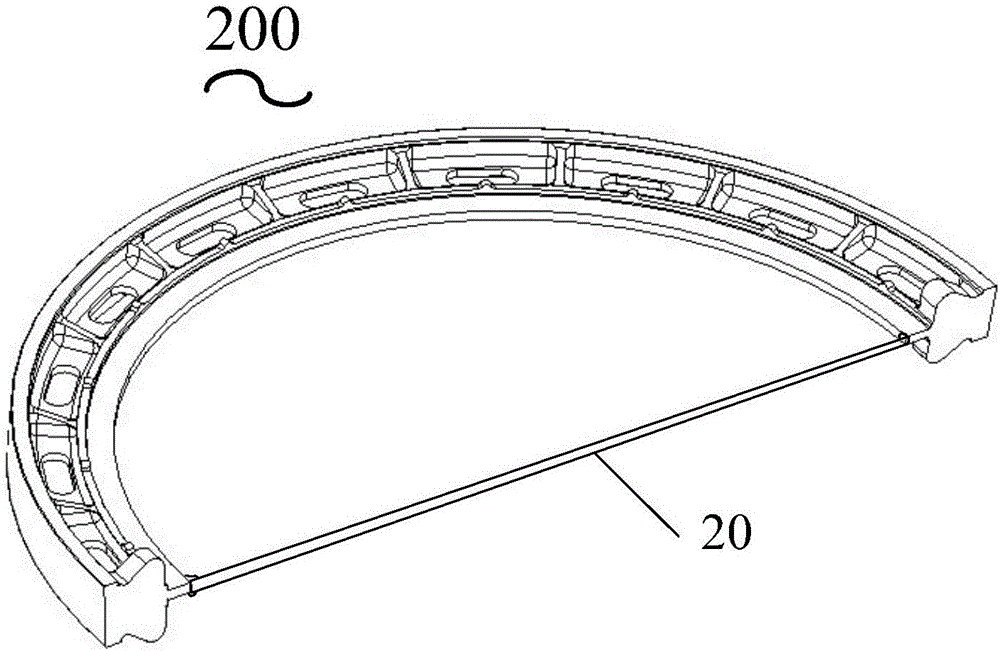

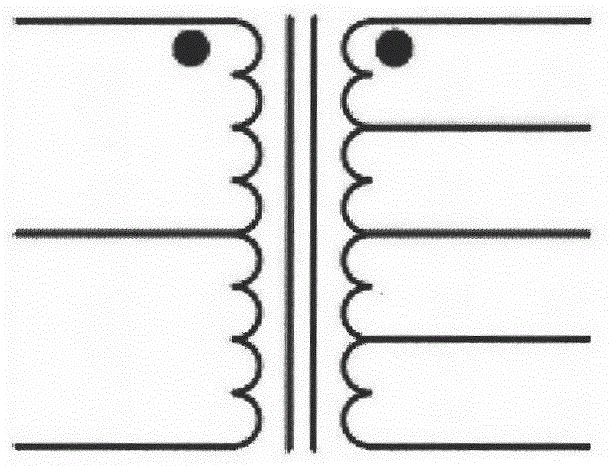

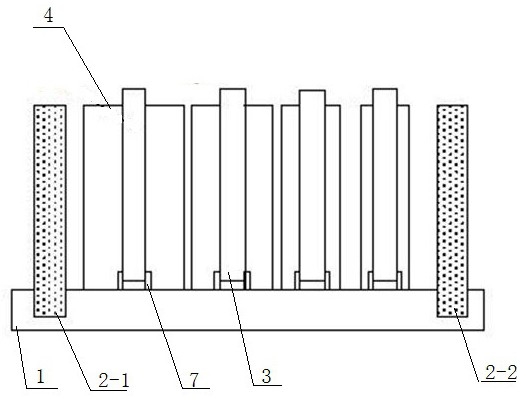

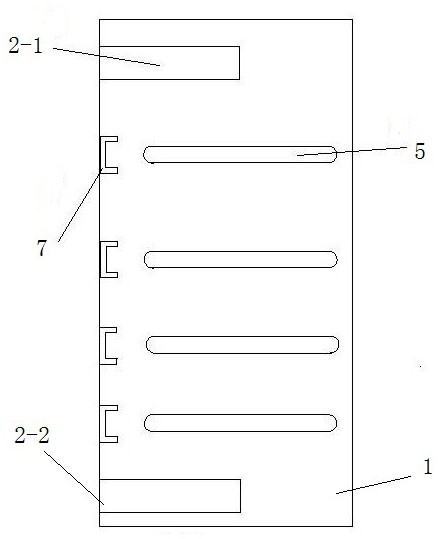

Three-phase three-pole amorphous iron-core with support and hoisting structure as well as manufacturing method thereof

InactiveCN101436459AIncrease lossImprove noiseTransformers/inductances magnetic coresInductances/transformers/magnets manufactureManufacturing technologyTransformer

The invention relates to the technical field of transformer manufacture, in particular to a three-phase three-column non-crystalline iron core with a support and a lifting structure, and a method for manufacturing the same. The three-phase three-column non-crystalline iron core comprises a non-crystalline iron core, a non-crystalline thin strip cut joint opening, a resin rubber coating, an insulating material, a supporting iron plate, an upper clamp and a lower clamp, a lifting lug, a pedestal and the like, wherein the non-crystalline iron core consists of an outer iron core and two inner iron cores; the end face and the inner layer of the iron core are agglutinated with the orographic supporting iron plate through a resin adhesive; the outside of the iron core agglutinated with the supporting iron plate is tightened by the upper clamp and the lower clamp; and the upper clamp is provided with the lifting lug, while the lower clamp is arranged with the pedestal. With the supporting iron plate, the non-crystalline iron core can be supported without depending on coils, and with the clamps, the iron core is fastened into a whole. The non-crystalline iron core is convenient to erect and lift, improves the assemblies of the iron core and the coils, reduces applied stress, improves the loss and the noise of the iron core, and upgrades the quality of a non-crystalline transformer, thus the manufacture of a large-capacity non-crystalline iron core transformer is practicable.

Owner:TATUNG (SHANGHAI) CO LTD

Deformation-prevention heat treatment method for large thin-wall steel casting

InactiveCN106048186AReduce external stressReduce thermal stressFurnace typesHeat treatment process controlThick wallHeat stress

Disclosed is a deformation-prevention heat treatment method for a large thin-wall steel casting. The method comprises the steps of arranging a lifting and transporting tray, arranging a steel casting supporting pad, arranging external connection temperature measuring devices, and carrying out heat treatment and quenching. In the step of arranging the external connection temperature measuring devices, the three external connection temperature measuring devices are arranged at the thickest wall, the thinnest wall and the middle portion of the steel casting and are used for monitoring the temperature of the thickest wall, the thinnest wall and the middle portion of the steel casting; and through arrangement of the lifting and transporting tray and deformation-prevention tie bars, the heat treatment temperature is precisely controlled, quenching media are changed to reduce external stress, heat stress and structural stress borne by the steel casting, and finally, it is ensured that after heat treatment and quenching of the steel casting, the casting does not deform.

Owner:KOCEL STEEL

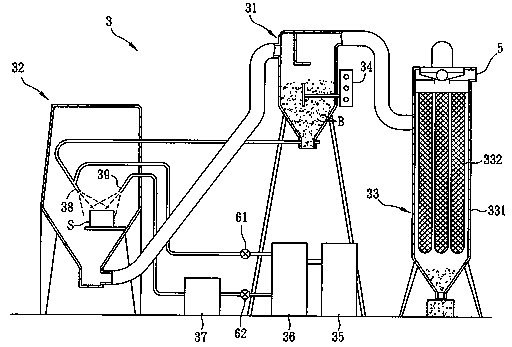

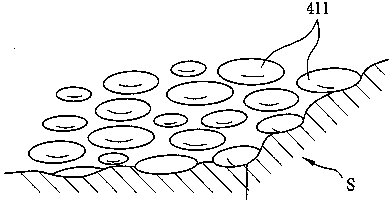

Metal surface lubrication method

InactiveCN103465172AHigh hardnessImprove self-lubricityAbrasive machine appurtenancesHardnessHigh pressure

The invention discloses a metal surface lubrication method. The metal surface lubrication method comprises the steps of preparing materials, preheating, converting gases, spraying and recycling. During the spraying process, true-ball-shaped roll balls and a solid lubricating agent are pushed by high-pressure inert gases, and to-be-processed elements are sprayed and impacted by utilizing the mixed grinding roll balls and the solid lubricating agent; a plurality of micro holes formed by impact of ball-shaped particles are formed in the surfaces of the to-be-processed elements, so that tissues of the surfaces of the to-be-processed elements are compressed to be tiny so as to lead to external stress reduction; while the surfaces of the to-be-processed elements are high in hardness because of the tough tissues formed by impact; meanwhile the self-lubrication property of the to-be-processed elements is improved as the solid lubricating agents are attached to the surfaces of the to-be-processed elements.

Owner:ZHANGJIAGANG JINFENG RUNERFA HARDWARE PLASTIC FACTORY

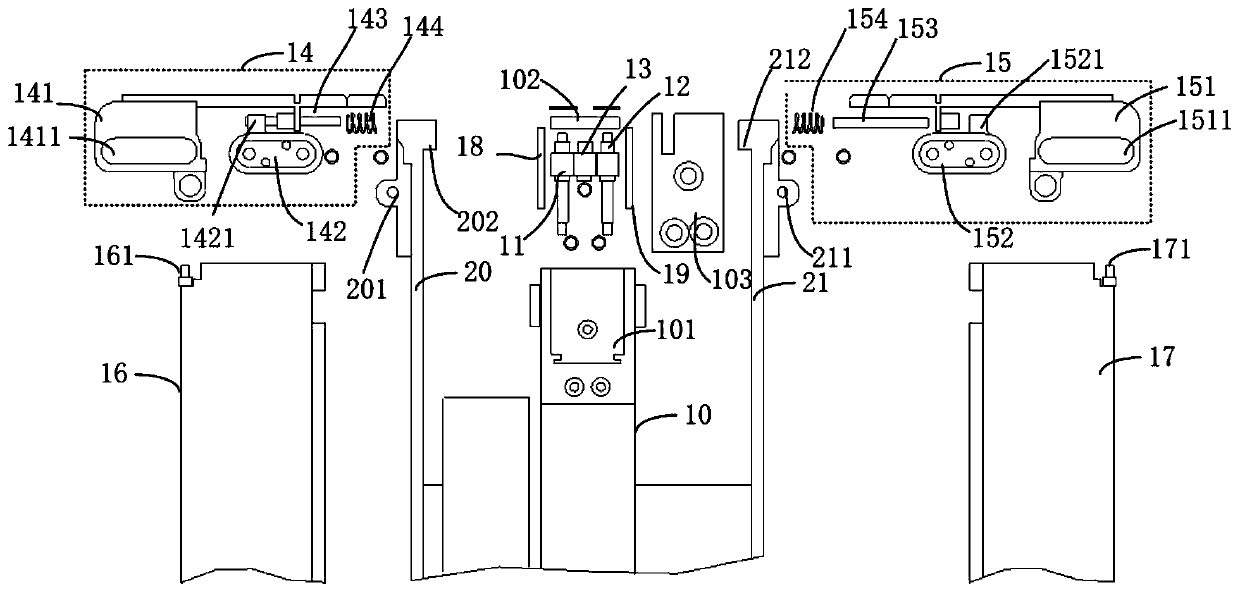

Implantable bone adjustment devices

A bone adjustment device such as, for example, an intramedullary lengthening nail may include a first or outer body portion having a notch, a second or inner body portion, a threaded shaft coupled to the first body portion to rotate relative thereto, an inner magnet received by the first body portion and coupled to the threaded shaft for rotation therewith, and a threaded block positioned in the notch, the threaded block having internal threads, the threaded shaft passing through the threaded block and threadedly engaging with the internal threads. Various reconfiguration assembly embodiments include welding the threaded block to the first body portion, the notch being located a distance from the distal end of the first body portion, an overlapping arrangement between the first body portion and the second body portion, and a collar positioned over the first body portion.

Owner:SMITH & NEPHEW INC

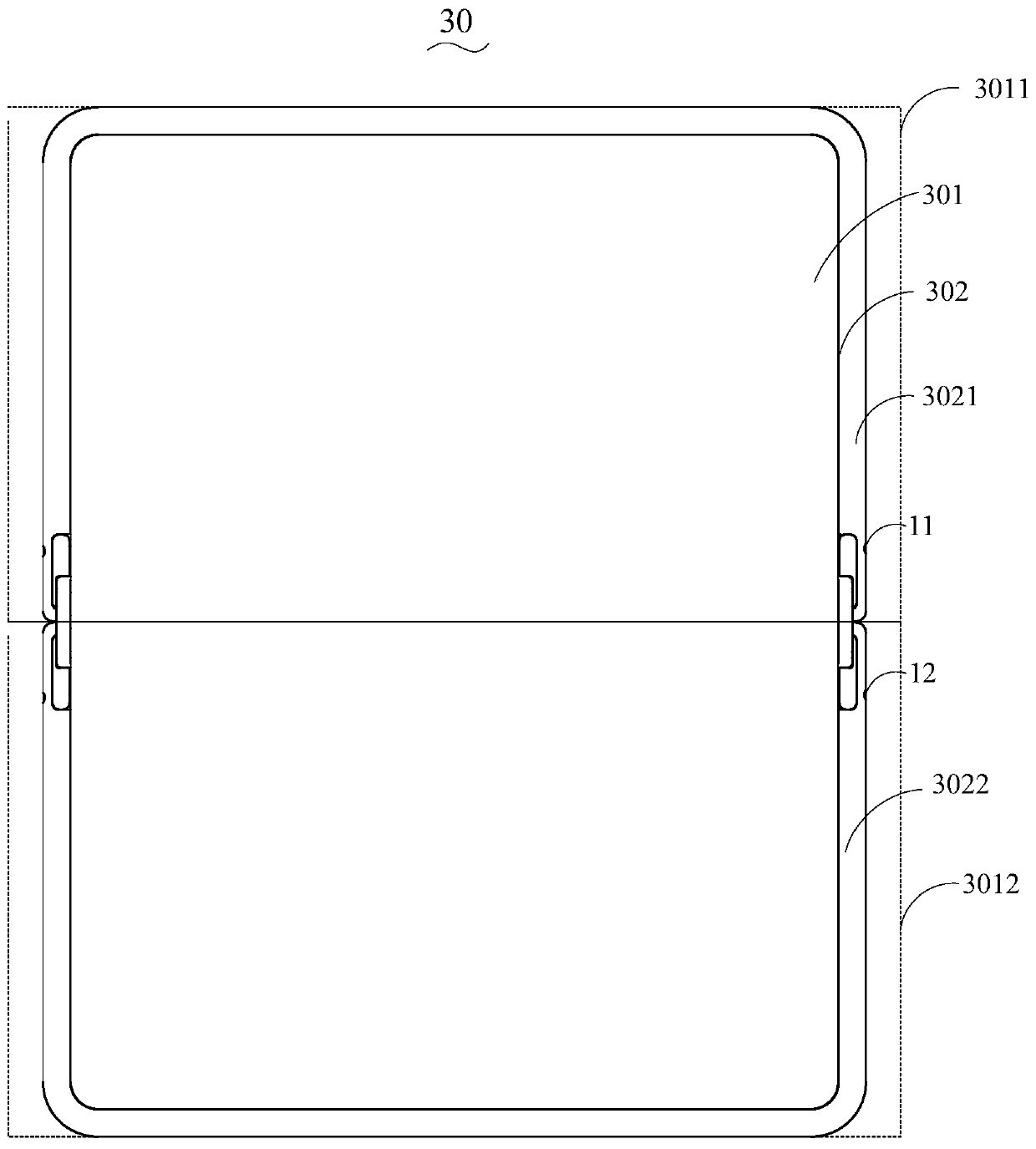

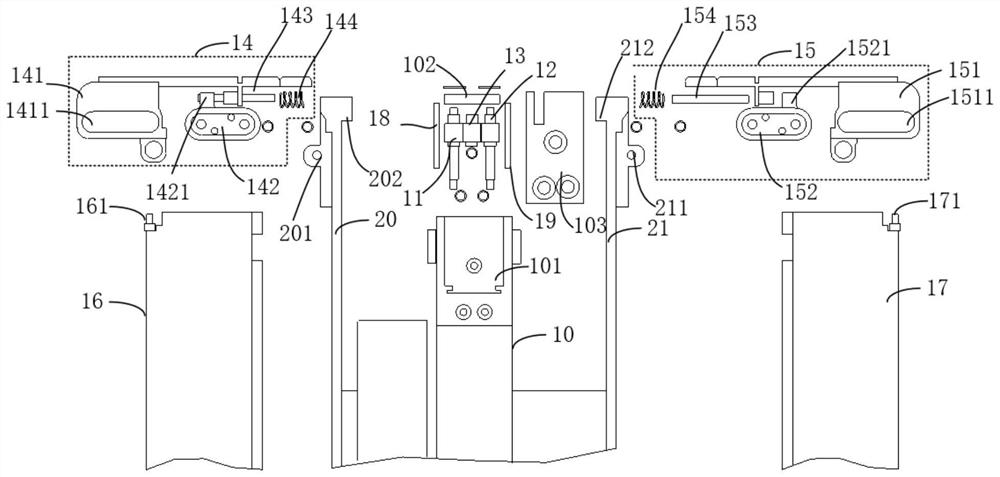

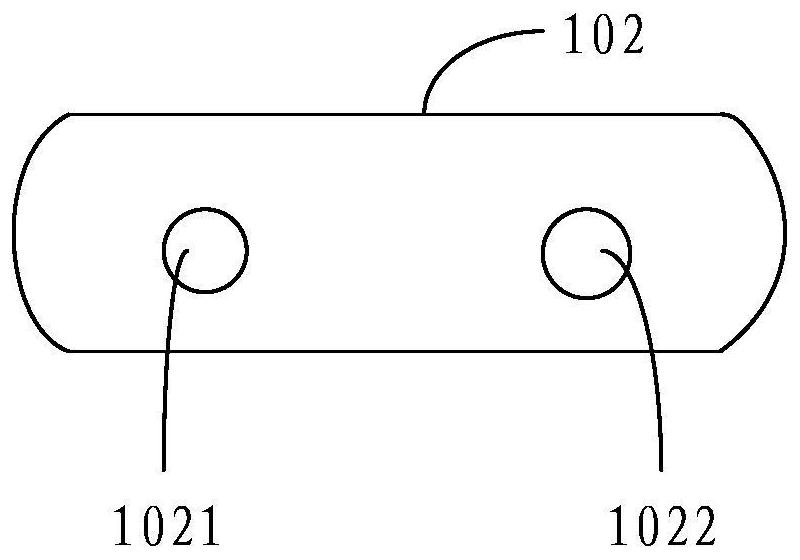

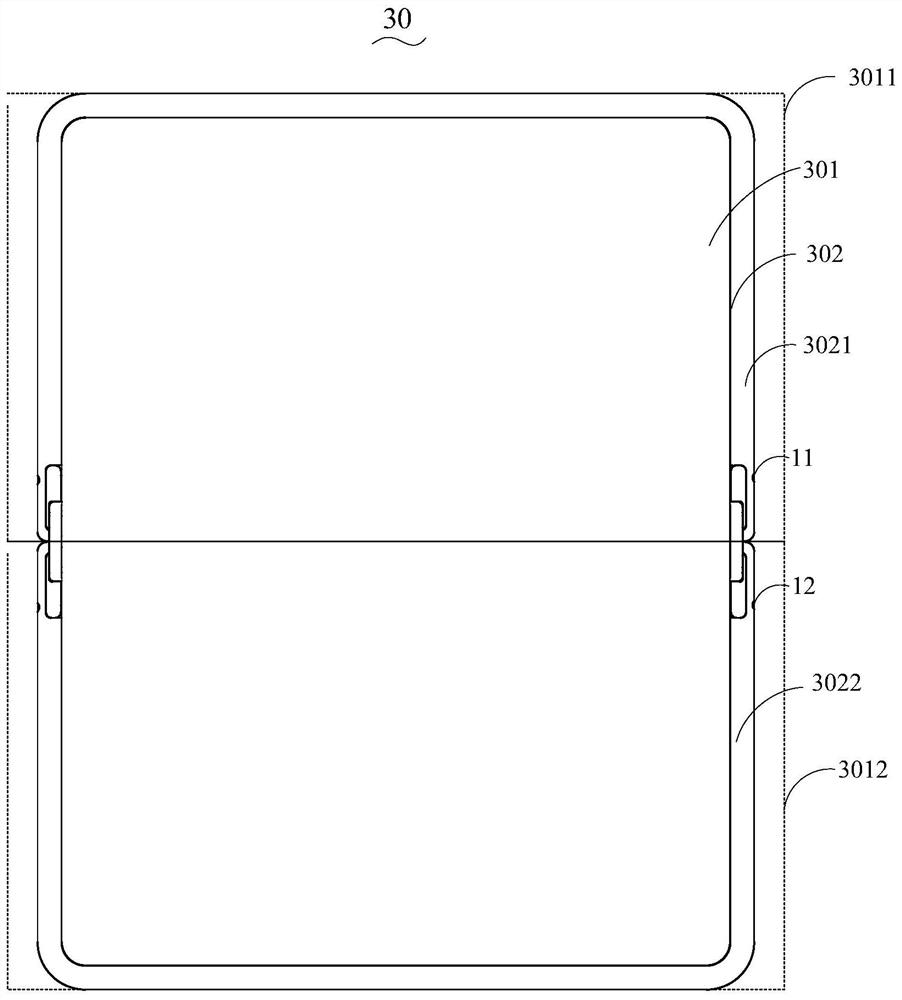

Rotating shaft mechanism and electronic device

ActiveCN110958338AImprove reliabilityExtended service lifeTelephone set constructionsEngineeringStructural engineering

The invention discloses a rotating shaft mechanism and an electronic device. The rotating shaft mechanism is applied to the foldable electronic device. According to the embodiment of the invention, the first screen part and the second screen part of the electronic device do opposite motion through the rotating shaft mechanism, so that the screen is in an unfolded state. The rotating shaft mechanism retracts inwards relative to the shell of the electronic device so as to reduce the external stress of the shell on the screen when the screen is unfolded, so that the screen is protected from beingdamaged, the reliability of the electronic device is enhanced, and the service life is prolonged.

Owner:张大鸣

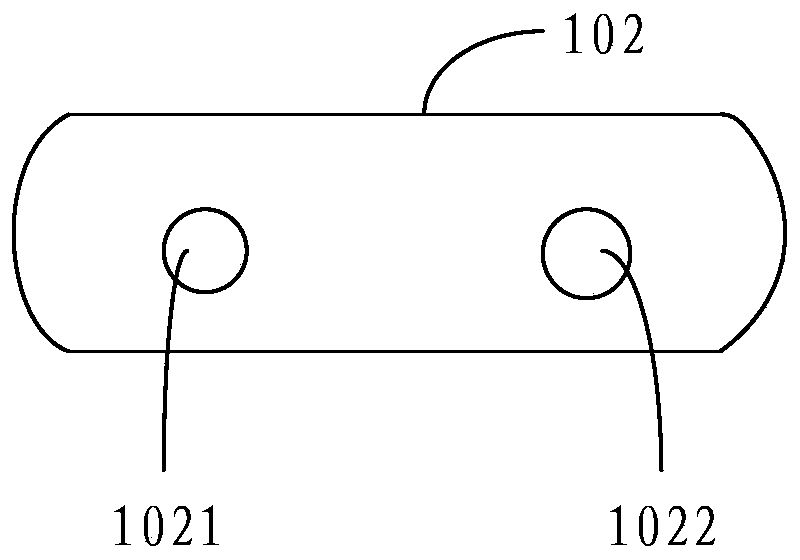

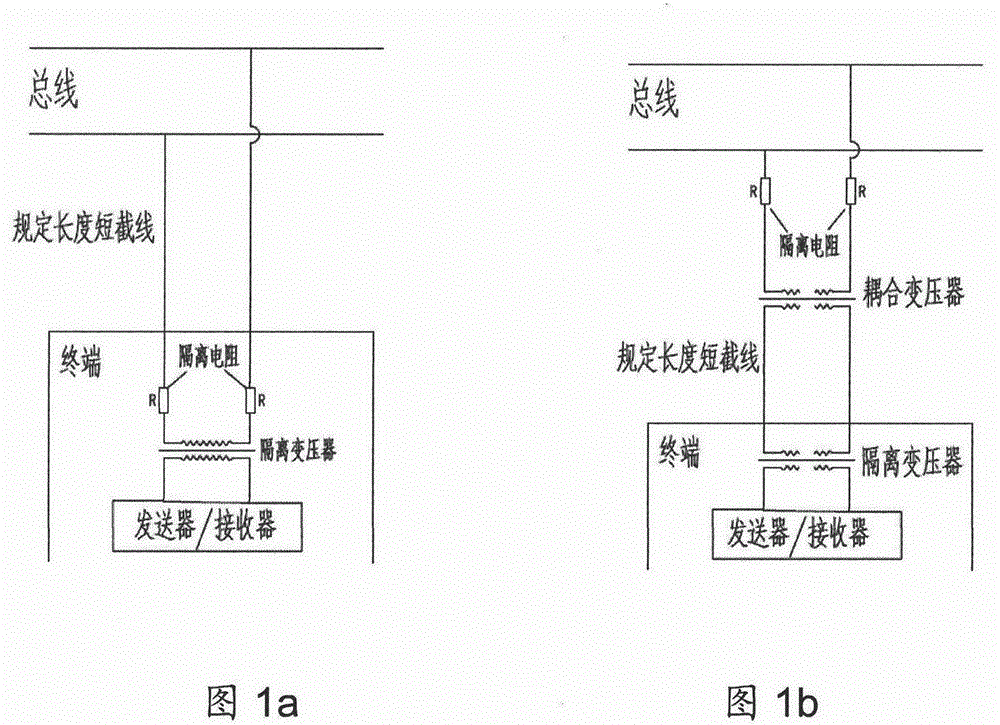

An isolation transformer with environment-resistant metal full potting structure

ActiveCN103050248BImprove mechanical environmental performanceHigh mechanical strengthTransformers/inductances coils/windings/connectionsMetallic enclosureEngineering

The invention relates to a weather-proof isolation transformer with a metal full filling and sealing structure. The isolation transformer comprises a metal shell, a transformer coil, a bottom plate, a glue filling wall and an extraction rod. The extraction rod penetrates through the bottom plate to be fixed onto the bottom plate, one end of the extraction rod is connected with the transformer coil, the other end of the extraction rod is connected with an external device, the glue filling wall is fixedly connected to the edge of the bottom plate to form a filling and sealing space on the bottom plate, the filling and sealing space is filled with filling and sealing glue to fix the transformer coil, an opening at one end of the metal shell is sleeved on the glue filling wall, and an opening end of the metal shell is fixedly connected with the bottom plate to achieve a function of integral sealing. The isolation transformer has the advantages of high mechanical strength, more outstanding weatherproof performance, longer storage and service life, more excellent space adaptability and high electromagnetic compatibility.

Owner:CHINA AEROSPACE TIMES ELECTRONICS CORP

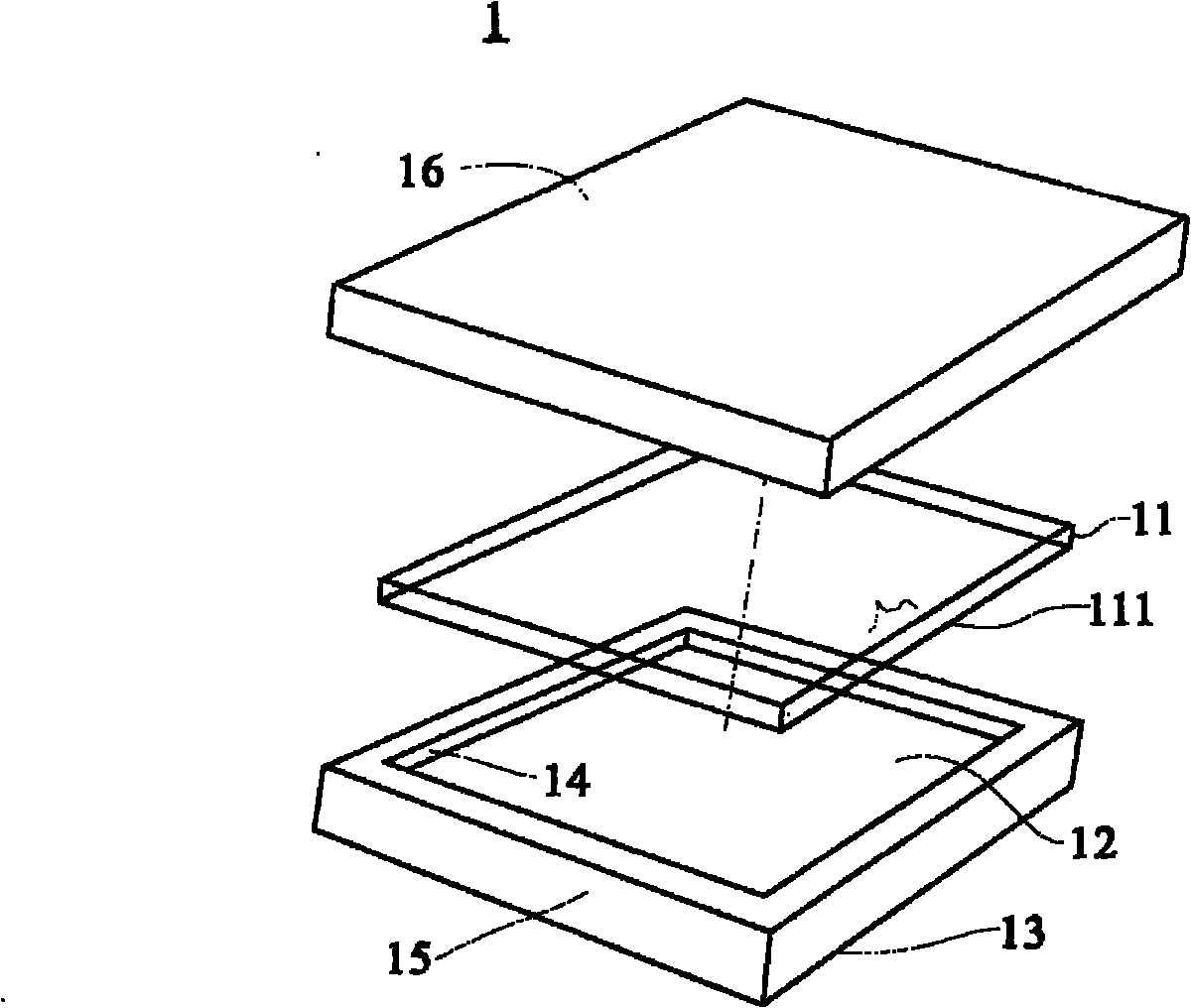

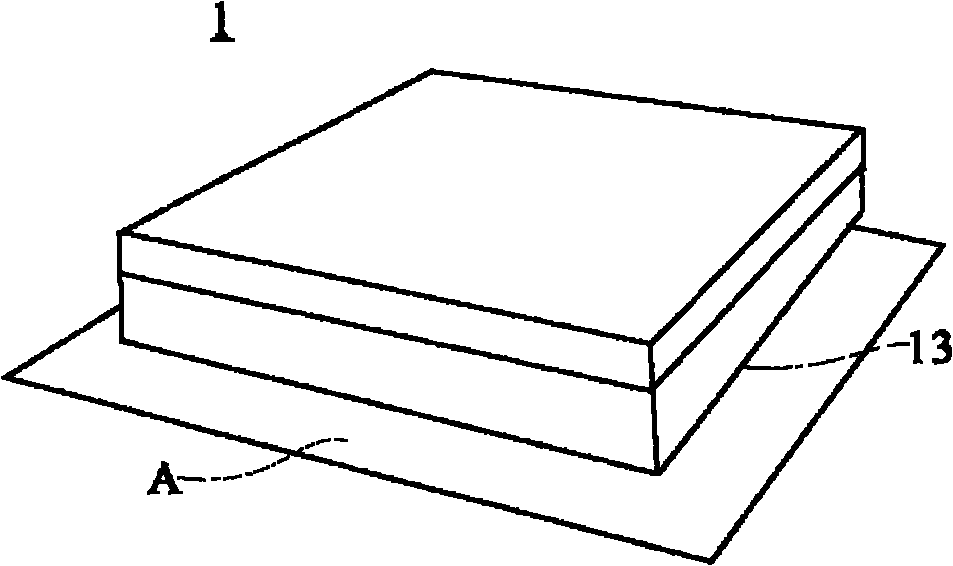

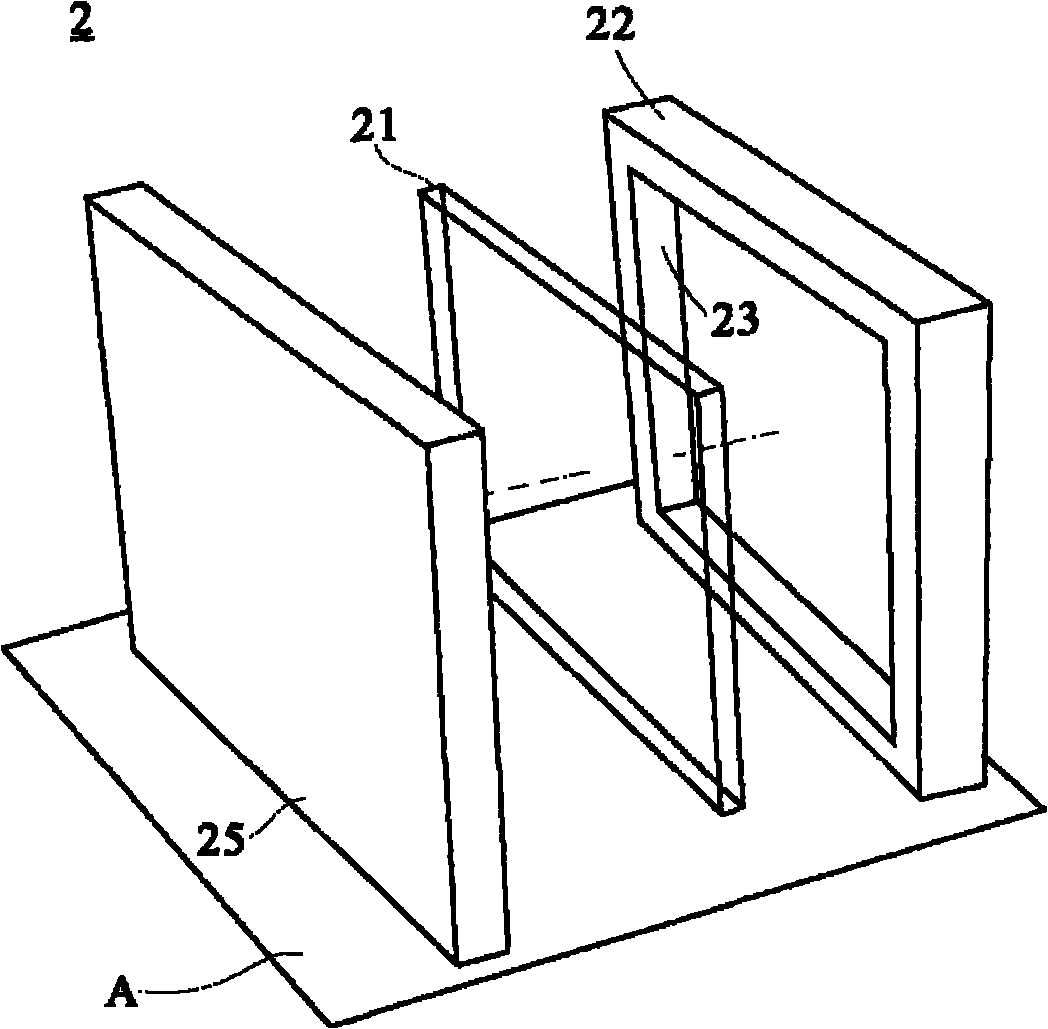

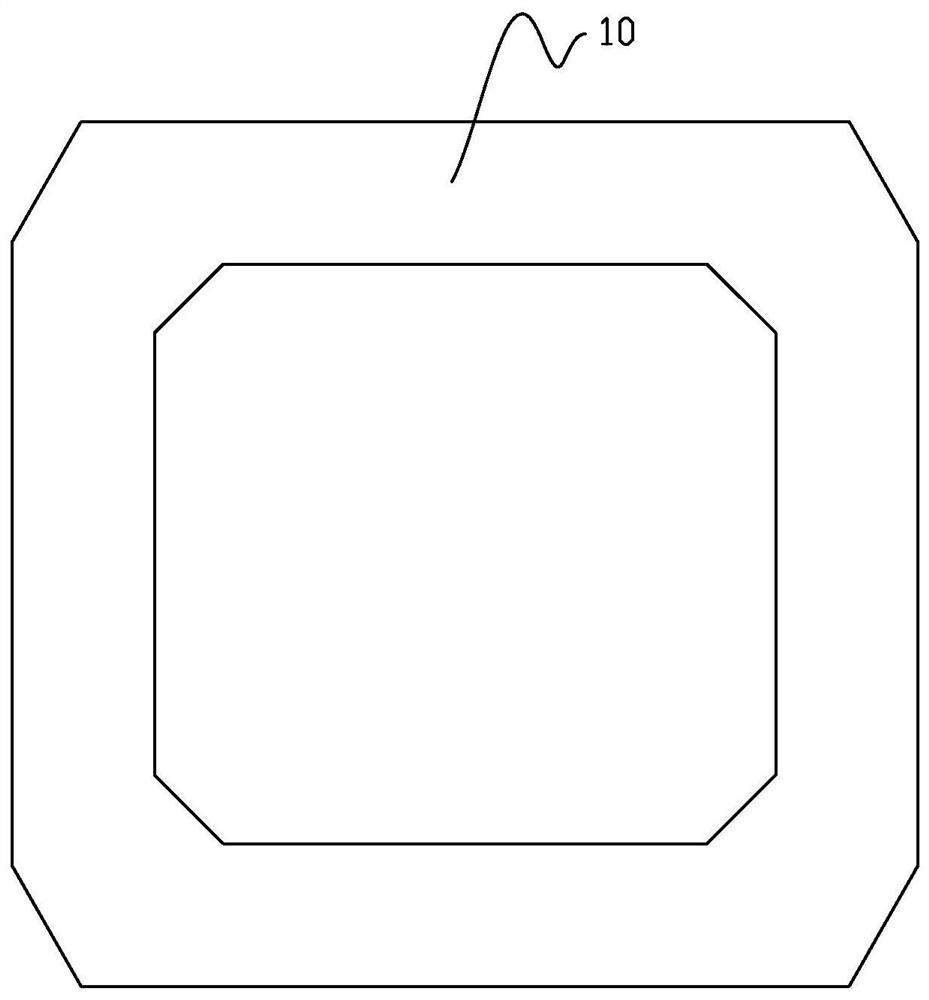

Box body, guide carrier for guiding the position of box body and position guiding method

InactiveCN102050280AEffective protectionReduce external stressDamagable goods packagingGlass productionEngineeringMechanical engineering

The invention provides a box body, a guide carrier for guiding the position of the box body and a position guiding method.The box body comprises four outer side walls and four inner side walls.The inner side walls are adjacent to each other to define an accommodation space for accommodating at least one substrate.The extending direction of each of the outer side walls is at an angle with the extending direction of the corresponding inner side wall.The position guiding carrier comprises a support base and a rotary platform.The support base is equipped with a pre-set reference face.The box body can be rotated from a first position on the rotary platform to a second position, so that the inner side walls of the box body are parallel to the pre-set reference face.

Owner:孙月卫

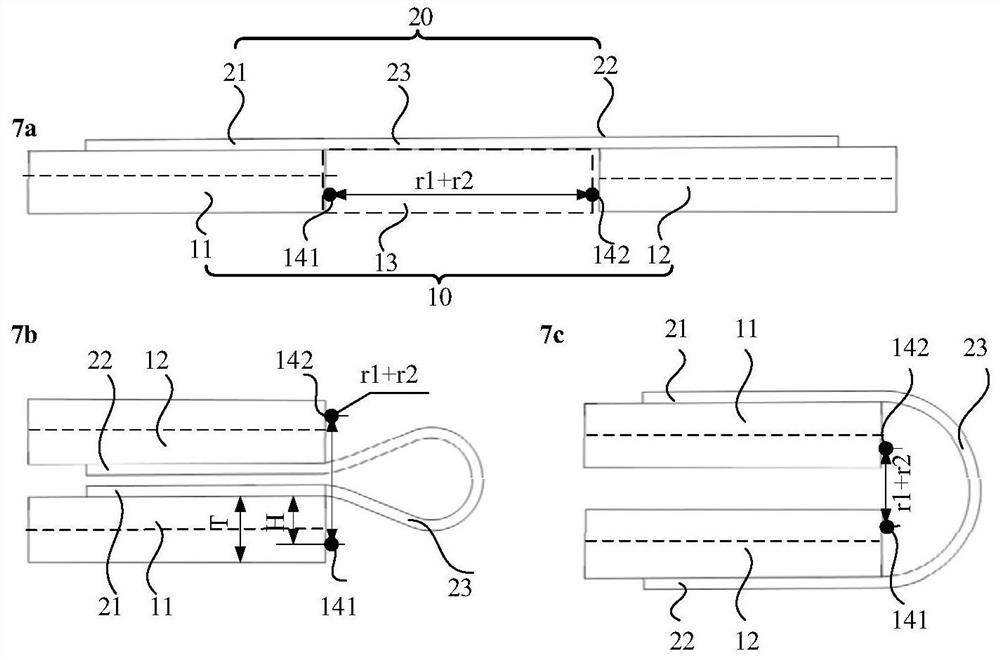

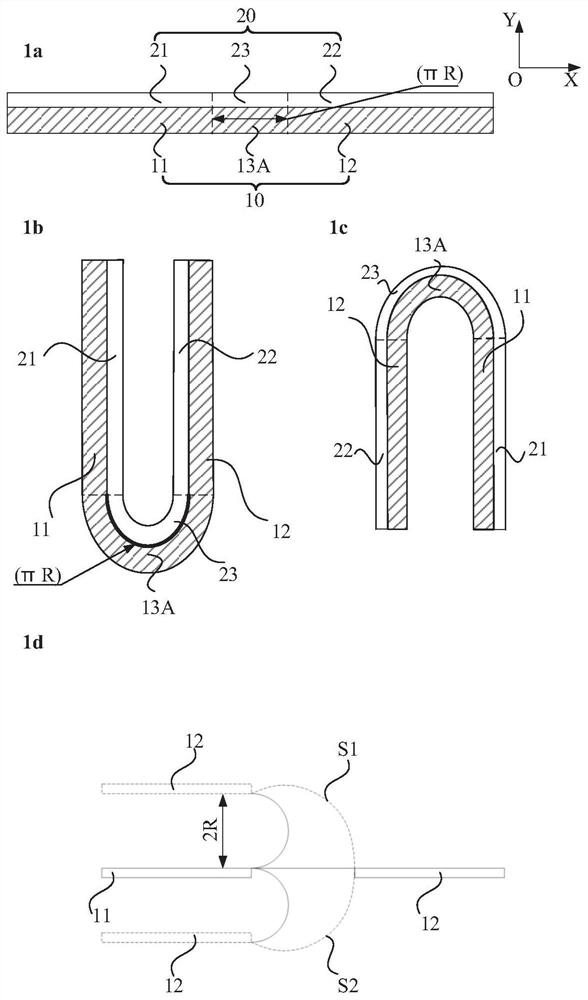

Bending structure, display device and bending jig

The invention discloses a bending structure, a display device and a bending jig. The bending structure comprises a first rotatable supporting plate and a second rotatable supporting plate, wherein thefirst rotatable supporting plate and the second rotatable supporting plate are rotationally connected, and the relative rotation angle between the first rotatable supporting plate and the second rotatable supporting plate is larger than or equal to 0 degree and smaller than or equal to 360 degrees; the spacing area is located between the first rotatable supporting plate and the second rotatable supporting plate; the first rotatable supporting plate is used for supporting a first non-bending area of a to-be-bent part, the second rotatable supporting plate is used for supporting a second non-bending area of the to-be-bent part, and in the flattening state, the projection of the bending area of the to-be-bent part on the bending structure covers the interval area; wherein the bending area ofthe part to be bent is located between the first non-bending area and the second non-bending area. According to the bending structure, the thickness of the bent structure in the infolding limit stateis reduced.

Owner:HEFEI VISIONOX TECH CO LTD

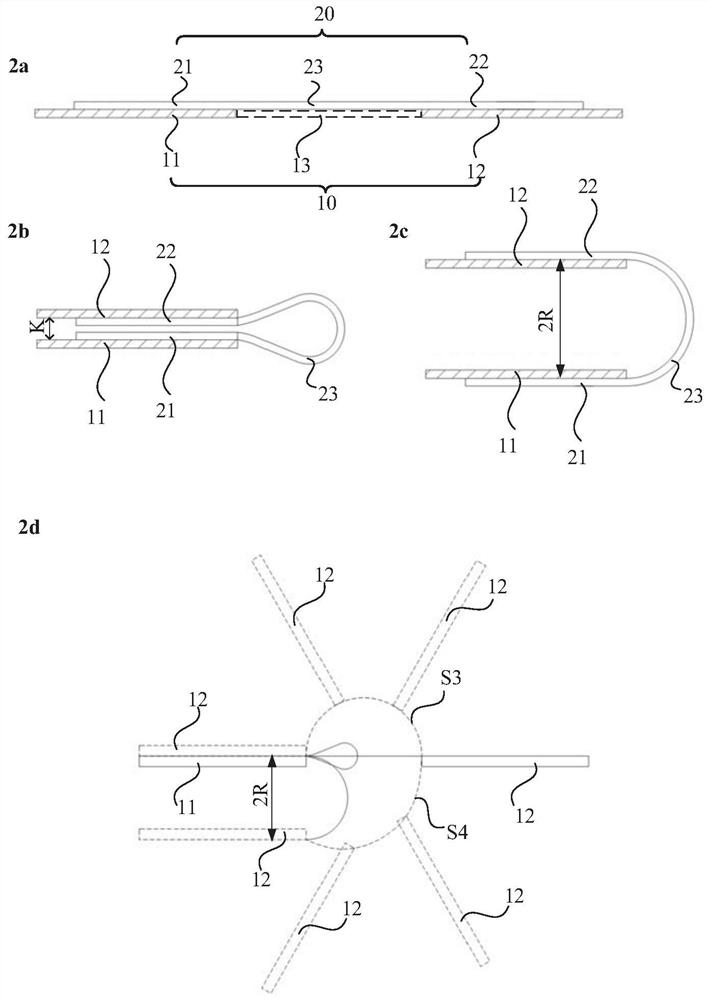

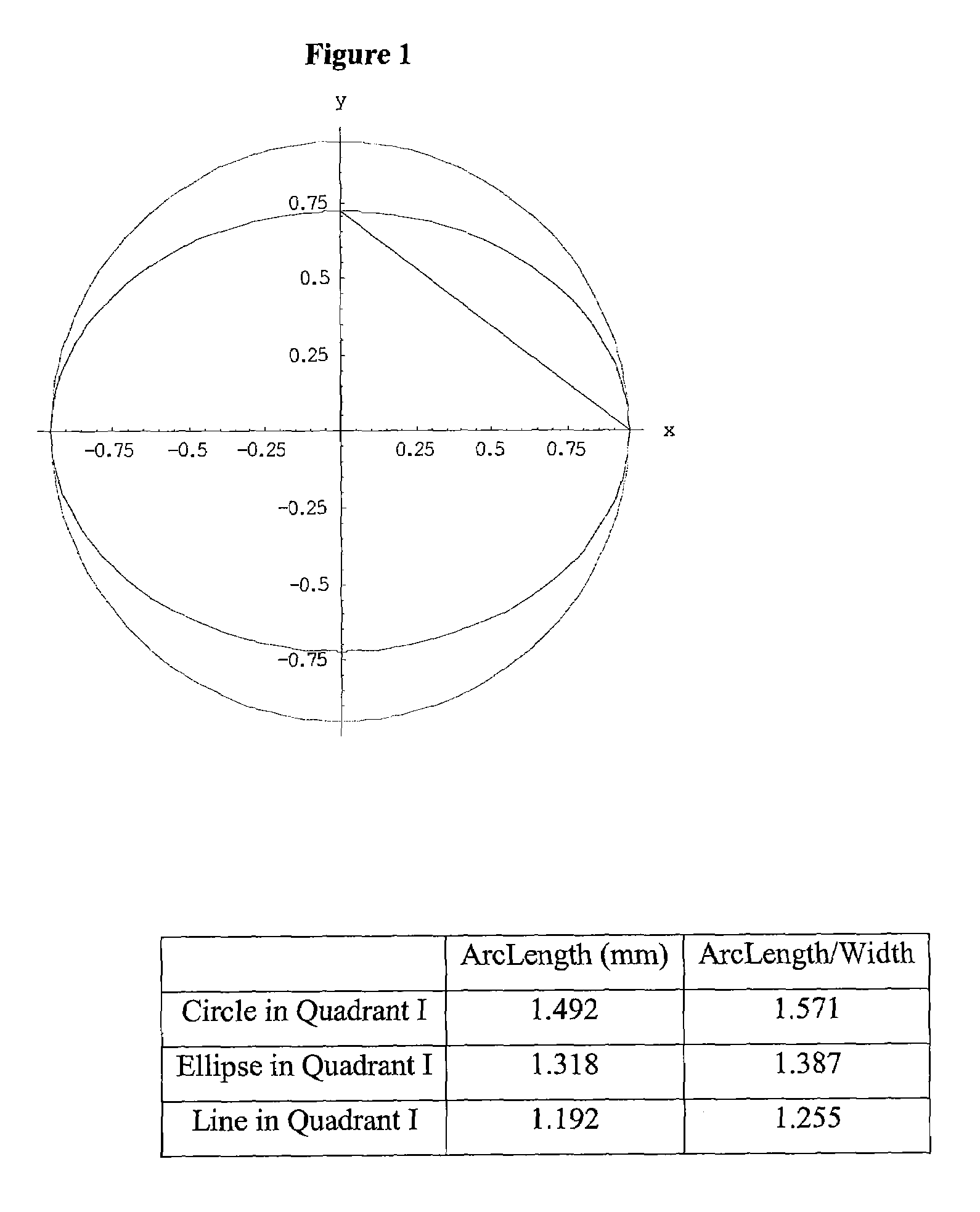

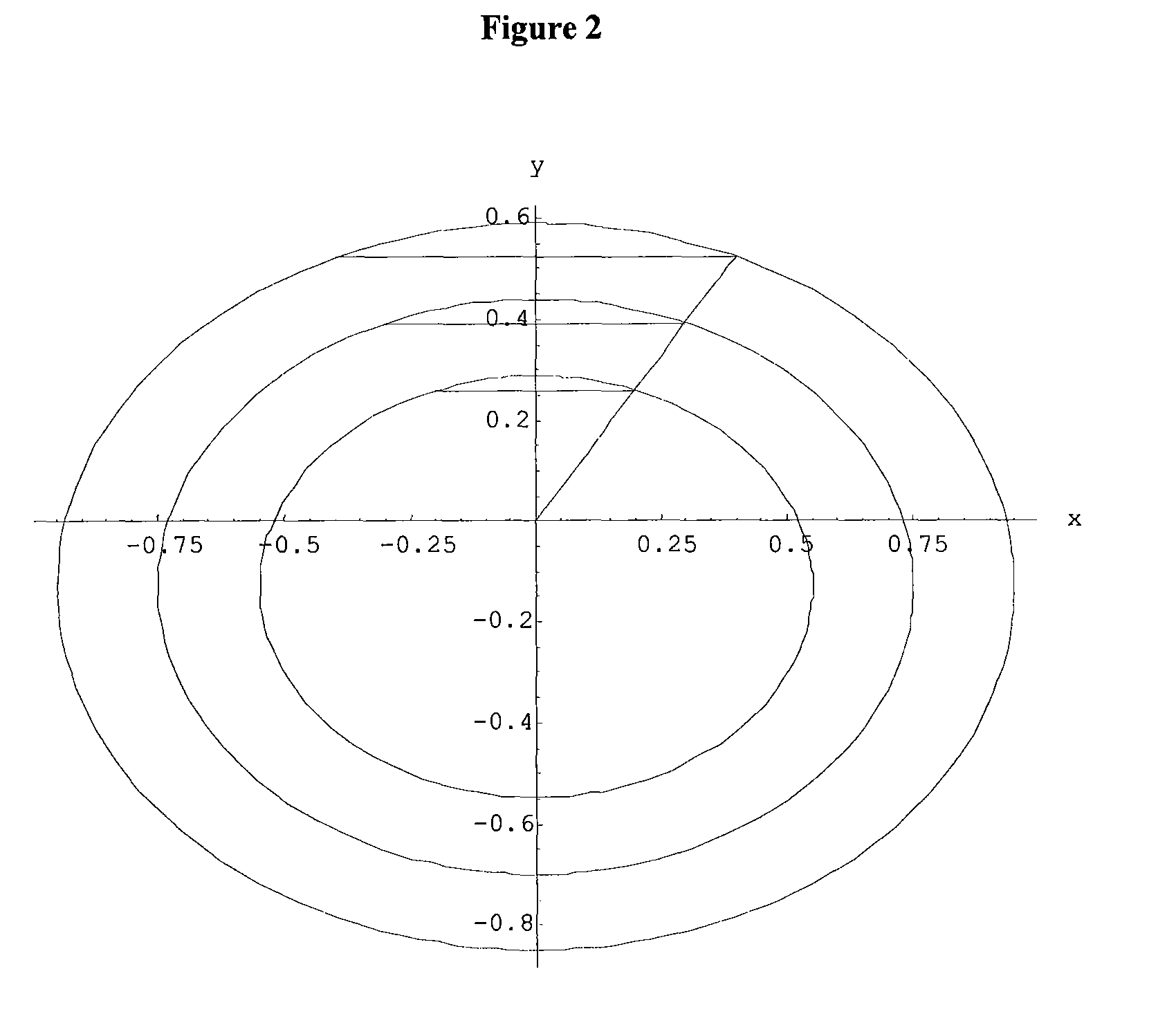

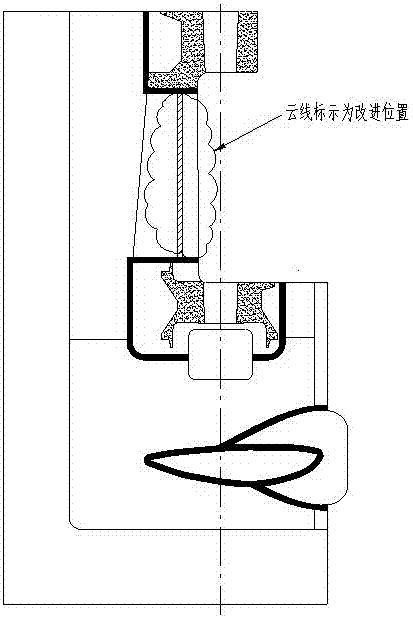

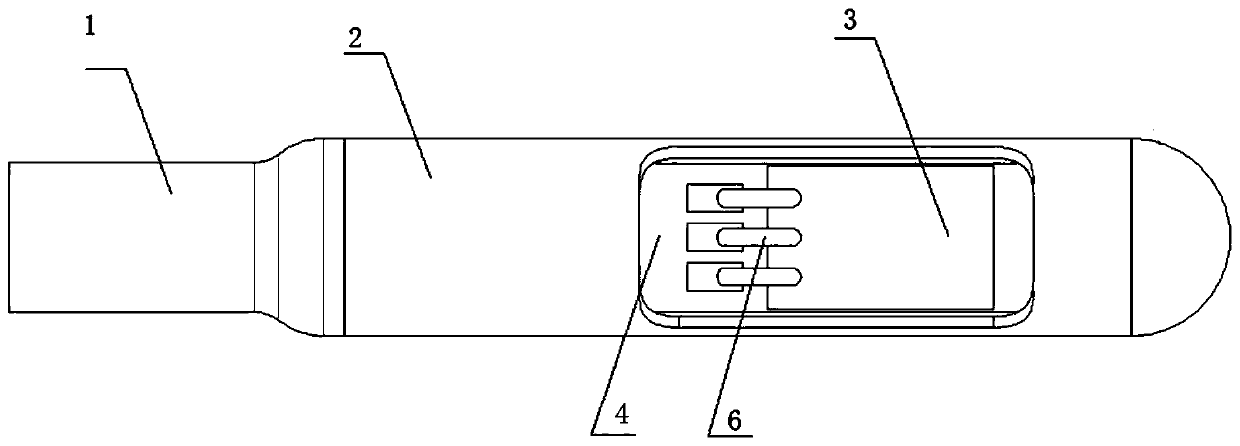

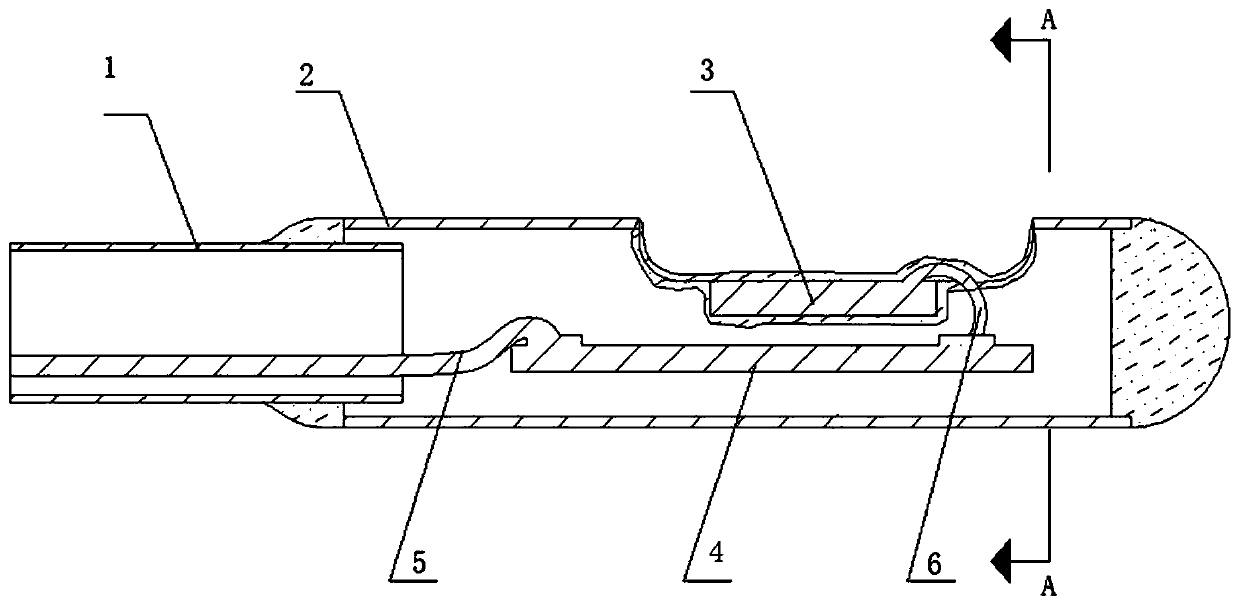

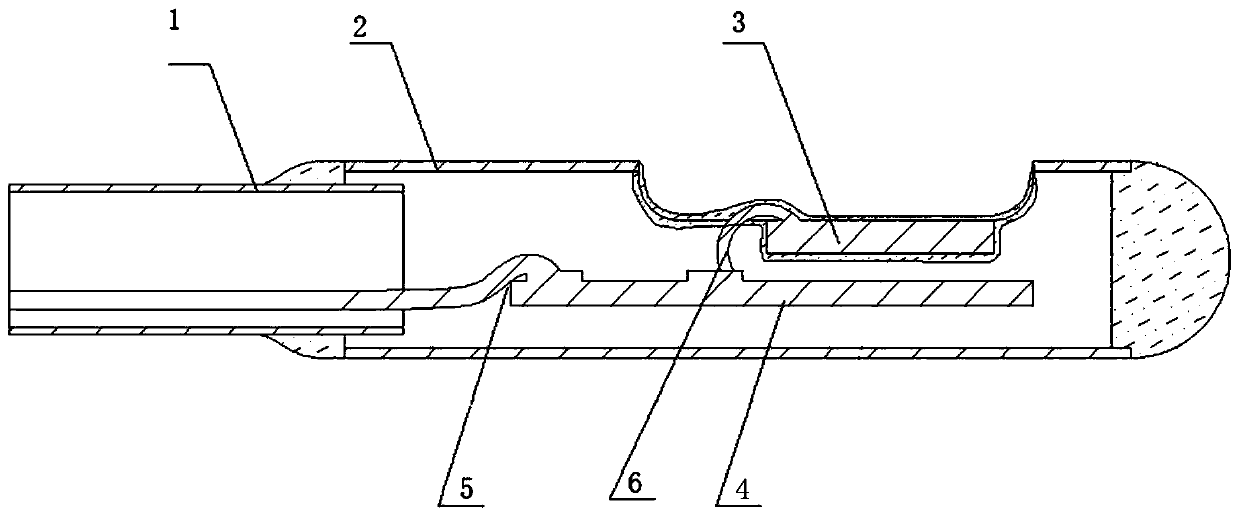

Lens delivery system cartridge

ActiveUS8894664B2Reduce external stressReduce the possibilityEye treatmentIntraocular lensEngineeringIncision wound

A cartridge for an IOL delivery system that has an injector tip geometry designed to reduce stresses at the incision wound edges generated during insertion of an IOL into an eye is disclosed. The injector tip geometry includes a tubular nozzle having a modified elliptical cross section. The injector tip geometry reduces stresses generated reduce the likelihood of tearing or overstretching the wound during cartridge tip insertion and residence time in the wound while the lens is being delivered into the eye.

Owner:ALCON INC

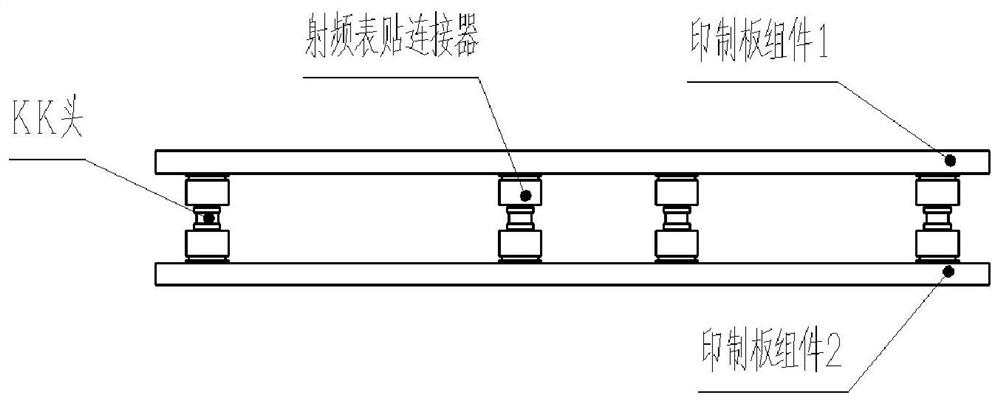

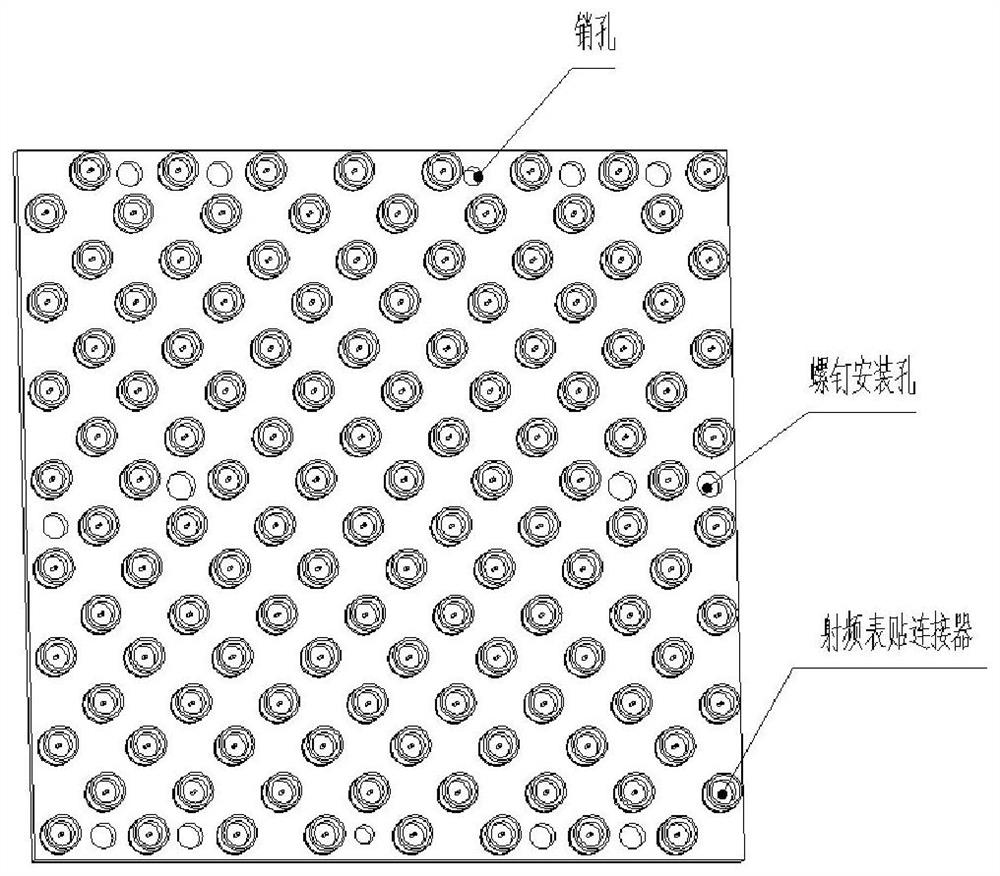

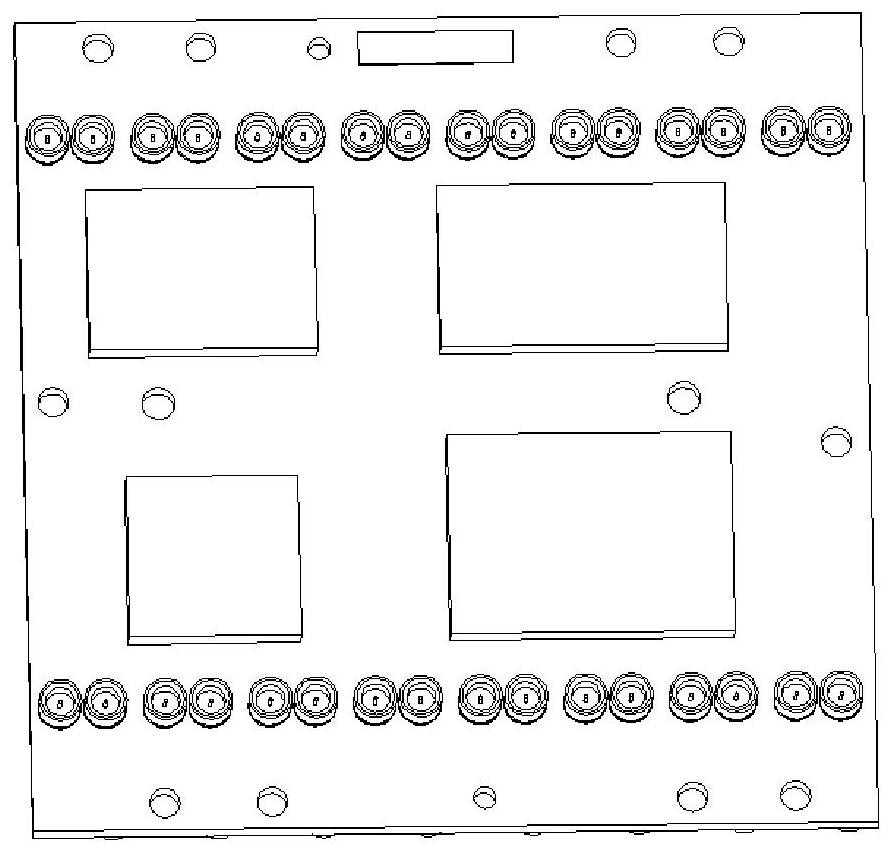

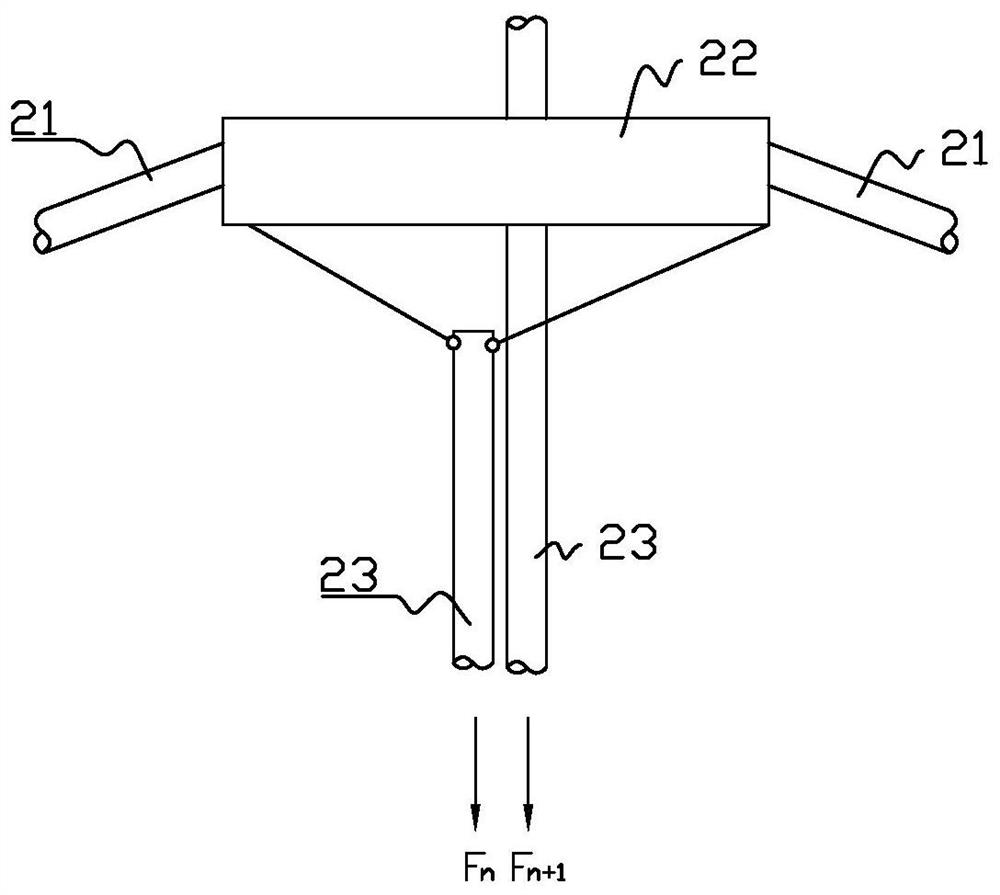

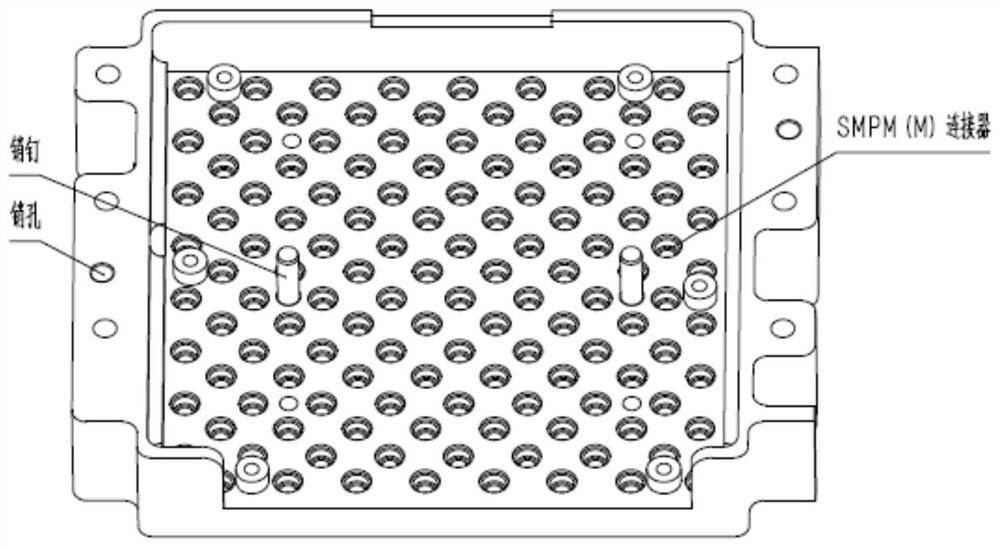

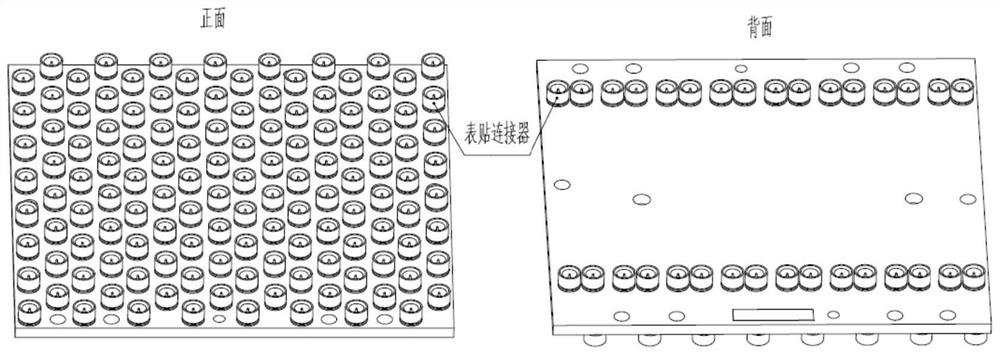

Welding device and welding method for printed board assembly based on inter-board vertical interconnection

ActiveCN113305385AGuaranteed success rateGuarantee the quality of signal transmissionPrinted circuit assemblingSoldering apparatusSoldering processWelding process

The invention relates to the technical field of electronic equipment, and discloses a welding device and welding method for a printed board assembly based on inter-board vertical interconnection. The welding device comprises a positioning plate, a supporting plate, pins and screws, wherein the positioning plate is arranged above a printed board, the supporting plate is arranged below the printed board, the positioning plate, the supporting plate and the printed board are positioned through the pins, and the positioning plate, the supporting plate and the printed board are fixed together through the screws. According to the welding device and welding method, the welding device is adopted to mount and position a surface-mounted connector on the printed board assembly, the buckling deformation of the printed board in the welding process is controlled, accurate positioning and reliable welding of the surface-mounted connector based on inter-board vertical interconnection are realized, the problems of the position offset of the surface-mounted connector on the printed board assembly, the inclination and flotation of the connector and the buckling deformation of the printed board can be solved, and therefore the realizability and reliability of inter-board vertical interconnection are improved.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

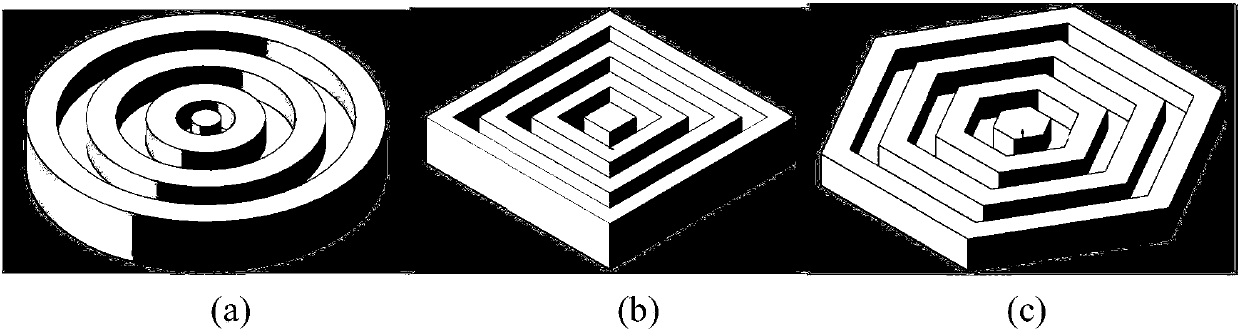

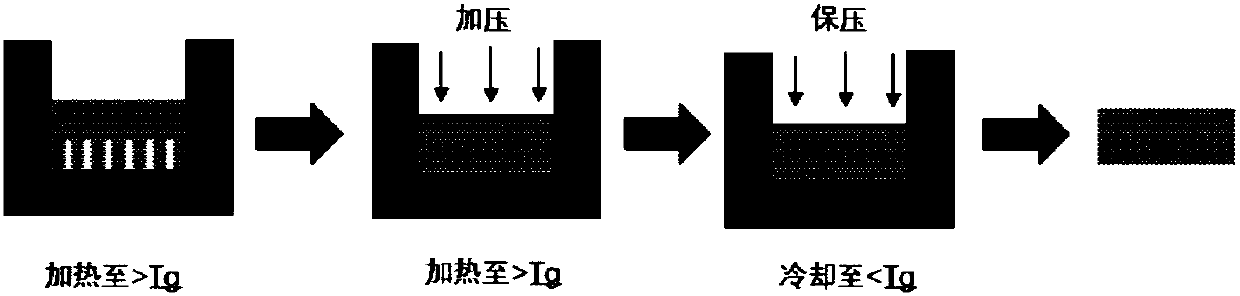

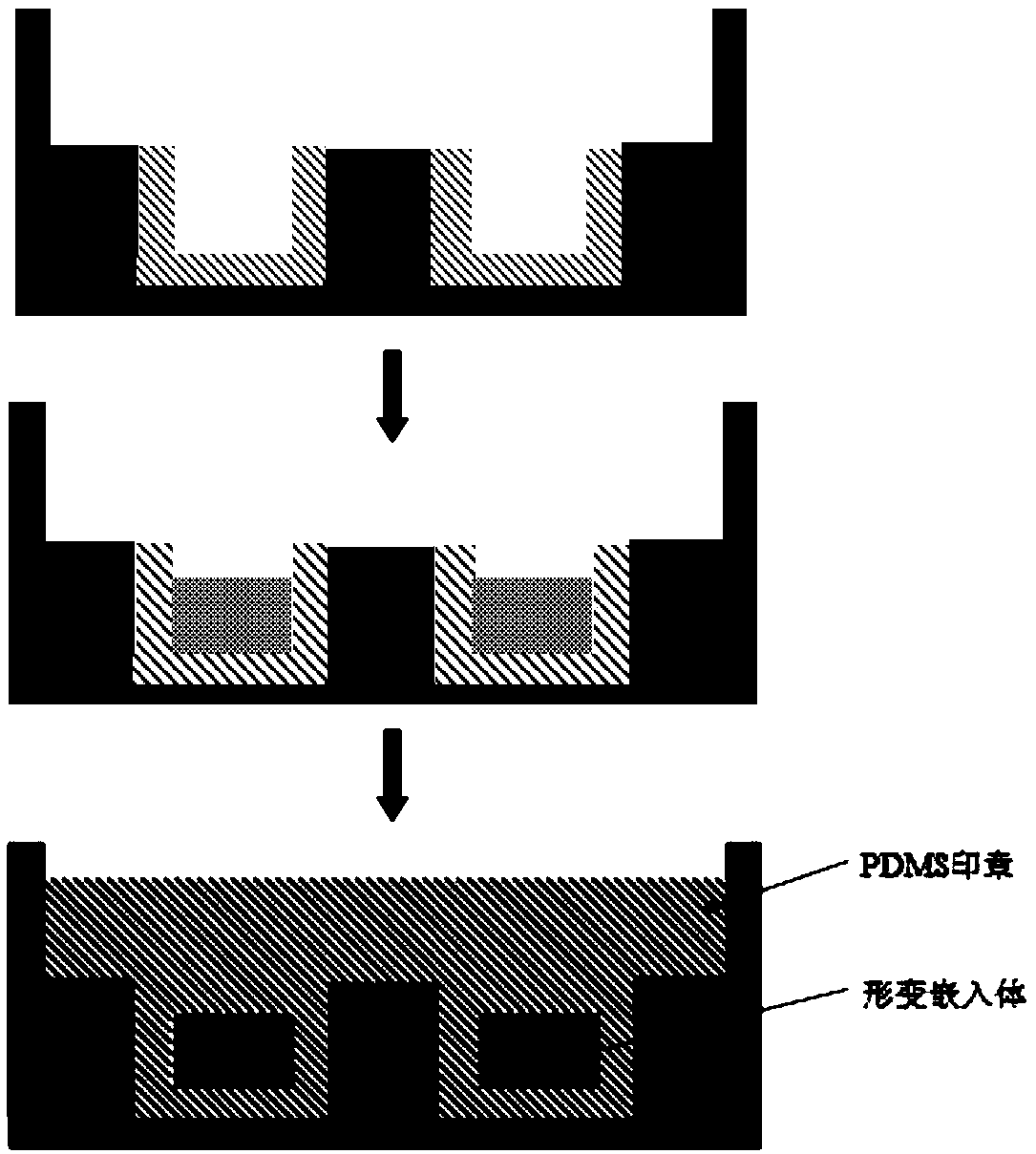

Quantum dot transfer printing method

ActiveCN109927431AImprove deformation uniformityReduce contact areaOther printing apparatusQuantum dotQuantum

The invention belongs to the technical field of quantum dots, and particularly relates to a quantum dot transfer printing method. The quantum dot transfer printing method comprises the following stepsthat a seal is provided, a deformation embedded body is arranged on a seal surface protruding part of the seal, and the deformation embedded body is obtained in the mode that an initial embedded bodymanufactured by materials containing shape memory polymers are deformed; a quantum dot initial film arranged on the surface of a donor substrate is provided, and the initial film is subjected to transfer printing onto the seal surface, provided with the deformation embedded body, of the seal to form a quantum dot patterned film layer; the seal with the quantum dot pattern film layer subjected totransfer printing makes contact with a target substrate, the deformation embedded body is restored to the initial embedded body, and thus the quantum dot pattern film layer is subjected to transfer printing onto the target substrate. According to the quantum dot transfer printing method, part of pattern residues finally caused by nonuniform stress restoring is reduced, the integrity of transfer printing of the quantum dot pattern film layer is improved, and externally-applied stress required by repeated using of the seal is reduced.

Owner:TCL CORPORATION

Implantable bone adjustment devices

Owner:SMITH & NEPHEW INC

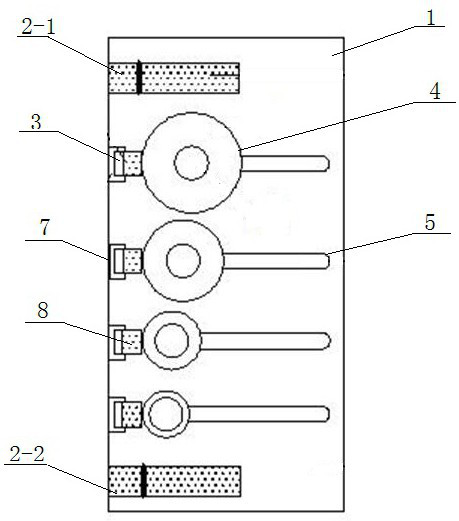

Fiber winding auxiliary tool for optical fiber macrobend loss test, and application method

PendingCN112378622AImprove work efficiencyMeet testing needsTesting fibre optics/optical waveguide devicesFiberEngineering

The invention provides a fiber winding auxiliary tool for an optical fiber macrobend loss test. The fiber winding auxiliary tool comprises a chassis, an optical fiber guide assembly, a fiber winding assembly and optical fiber clamping components, wherein the fiber winding assembly comprises a plurality of fiber winding circular shafts with different diameters, the fiber winding circular shafts arevertically arranged on the chassis, each optical fiber clamping component corresponds to one fiber winding circular shaft, the optical fiber clamping component comprises a mounting shaft, a clampingpressing rod and a sponge strip, the sponge strip can be driven by the clamping pressing rod to rotate towards the fiber winding circular shaft and is in close contact with the fiber winding circularshaft, an optical fiber is introduced into the device through the optical fiber guiding assembly, optical fiber rings with different diameters are formed through surrounding of the optical fiber winding circular shafts with different diameters, and the optical fiber clamping components play a role in clamping the wound optical fiber rings. The invention further provides an application method of the device. According to the invention, the device can rapidly complete the winding work of various optical fibers, is small in size, can be fixed to various testing instruments for use, effectively improves the testing efficiency of optical fiber macrobend loss testing, and improves the stability of a testing result.

Owner:TONGDING INTERCONNECTION INFORMATION CO LTD

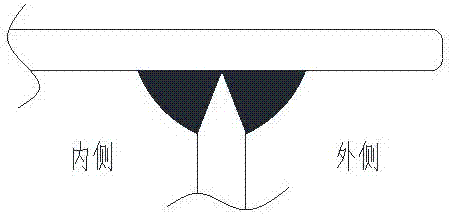

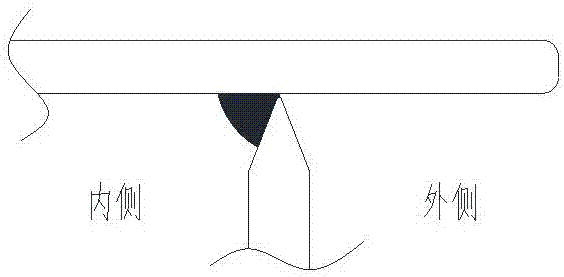

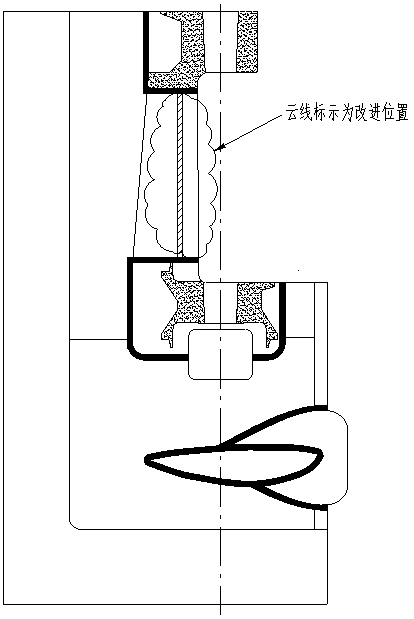

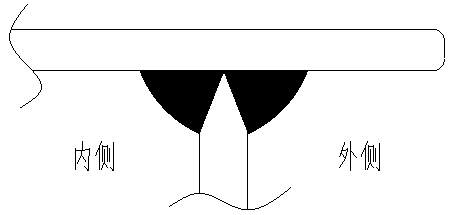

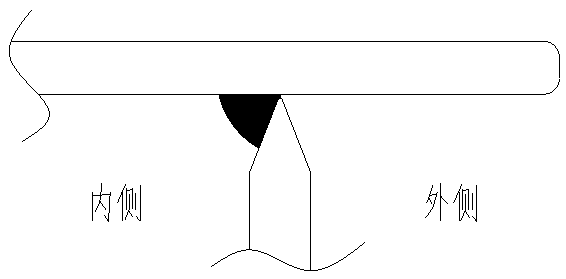

Ship thick-plate welding technology

ActiveCN107052516ALess difficult for welders to operateReduce external stressArc welding apparatusThick plateMarine engineering

The invention discloses a ship thick-plate welding technology. The ship thick-plate welding technology comprises the following steps that flat welding and balanced welding are adopted for ship thick plates; welding is conducted on a small part of the inner sides of the ship thick plates, and then balanced welding is conducted on the outer sides of the ship thick plates; welding is conducted on one part of the inner sides of the ship thick plates again, and carbon arc air gouging is conducted on the outer sides of the ship thick plates, wherein carbon arc air gouging is used for back chipping and beveling, and each air-gouged bevel needs to range from 50 degrees to 60 degrees; balanced welding is conducted on the outer sides of the ship thick plates and the inner sides of the ship thick plates after the outer sides of the ship thick plates are subjected to carbon arc air gouging, preheating is conducted firstly, the first layer is filled with metal, welding feet need to be small, and short-arc welding is adopted; temperature is measured through a point temperature gun before second welding is conducted; the inner sides of the ship thick plates are completely welded, wherein when the inner side is welded with one layer, the symmetrical outer side also needs to be welded with one layer, and the interlayer temperature is smaller than 100 DEG C or smaller than 250 DEG C; and the outer sides are completely welded, wherein after the last part of each inner side is completely welded, the corresponding outer side also needs to be completely welded, and the temperature is kept between 300 DEG C and 400 DEG C. Flat welding is adopted by the ship thick plates, the operation difficulty of flat welding positions is small for a welder, outer side stress can be better reduced by means of steel plate preheating and double-face balanced welding, and therefore the crack defect is effectively avoided.

Owner:南通远洋船舶配套有限公司

Metal piece anti-deformation heat treatment process

InactiveCN107746912AImprove compactnessReduce external stressQuenching agentsAcid washingCopper oxide

The invention discloses a heat treatment process for anti-deformation of metal parts, which comprises the following process steps: (1) pickling treatment of metal parts in 15% hydrochloric acid solution, ultrasonic treatment in the later stage of treatment, and finally washing with pure water, blowing Dry; (2) Metal parts are coated with a protective layer, and the components in the protective layer are proportioned according to the following parts by weight: 45 parts of glass frit, 2 parts of iron oxide, 5 parts of chromium oxide, 8 parts of copper oxide, and 2 parts of aluminum oxide , 6 parts of acrylic acid, 15 parts of polyvinyl acetate emulsion, 15 parts of ethanol solution; (3) Heating by laser flame spraying, heating to a temperature of 860 ° C, and continuing heating for 12 minutes; (4) Cooling metal parts, the temperature is cooled to 120 ° C , the cooling medium is a polyalkylene glycol polymer aqueous solution with a concentration of 14%. The invention can prevent the deformation of the metal parts and ensure the quality of the metal parts.

Owner:湖州正德轻工机械有限公司

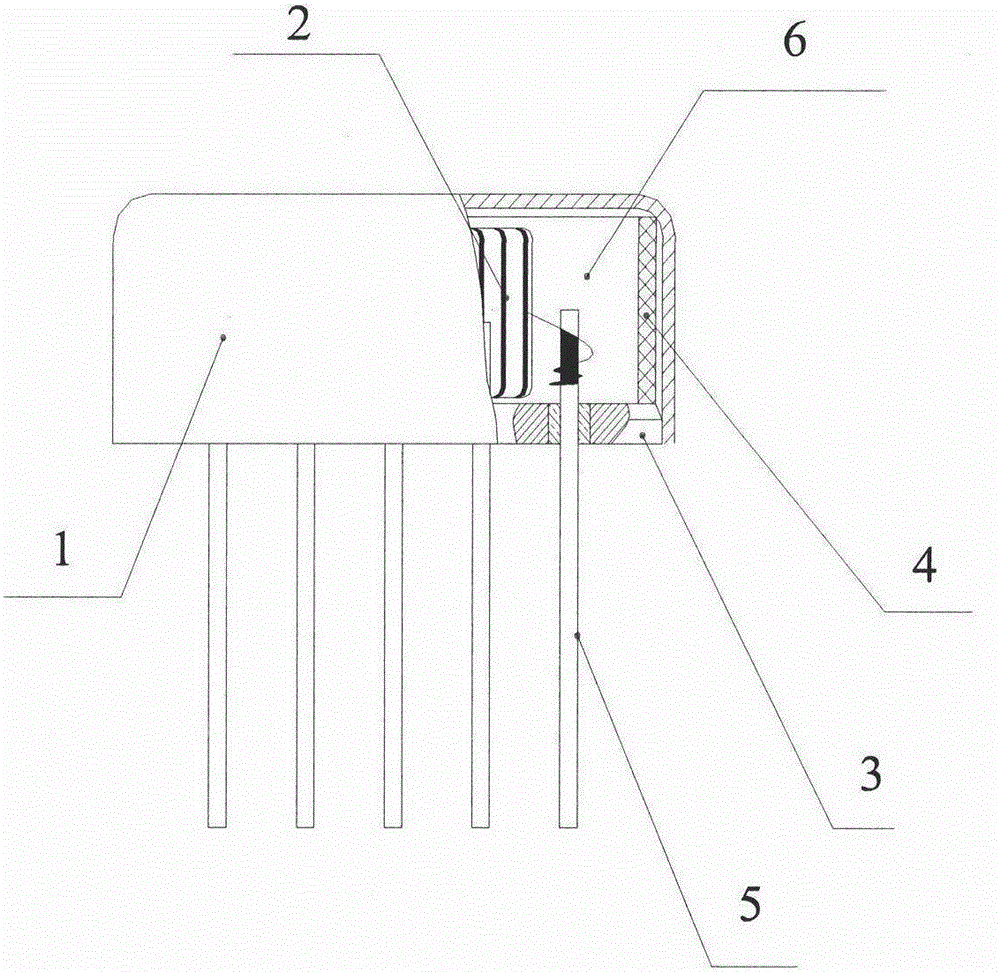

Probe package structure of human body pressure measuring sensor

PendingCN110279409AReduce external stressPlay a protective effectCatheterIntracranial pressure measurementMinimum timeEngineering

The invention discloses a probe package structure of a human body pressure measuring sensor. The probe package structure comprises a wire, a protection tube, a micro PCB (printed circuit board), a pressure chip and a transition wire, wherein the wire is powered on by the pressure chip and is used for signal transmission; the protection tube is provided with a groove, one end of the protection tube is in sealing communication with a plastic conduit, and the other end is a closed end; the micro PCB is placed in the groove, and a signal output end of the micro PCB is connected with the wire; the pressure chip is placed in the groove, and a sensing surface of the pressure chip is perpendicular to the opening direction of the groove; the transition wire is connected with the pressure chip and the micro PCB; a gap between the pressure chip and the protection tube is filled with protective glue; the surface of the pressure chip is filled with the protective glue; and a low stress medium is filled between the pressure chip and the micro PCB. The chip in the invention is minimally subjected to external stress, thereby ensuring minimum fluctuation of the output value of a packaged sensor and minimum time drift, avoiding the risk of short circuit, improving the stability of test value of the pressure chip, and thus effectively improving the accuracy of pressure monitoring.

Owner:成都拓蓝精创医学技术有限公司

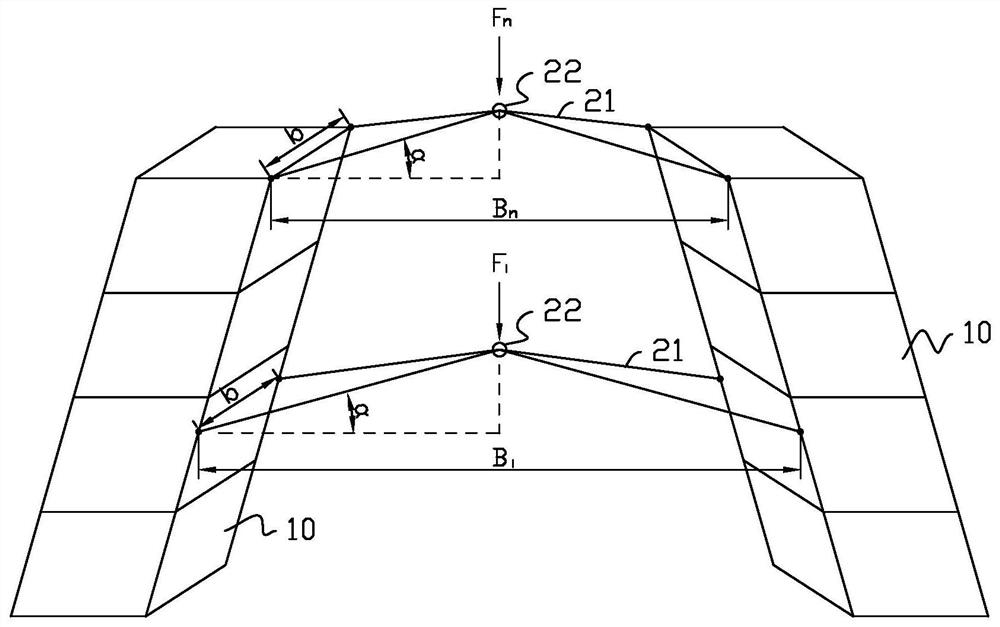

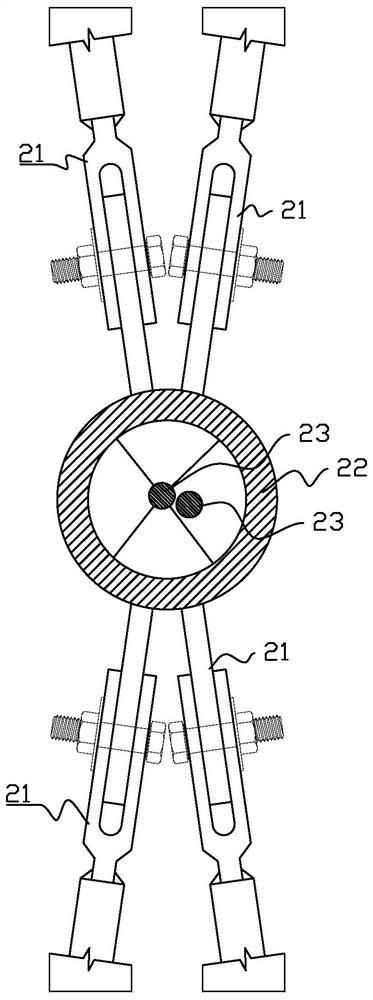

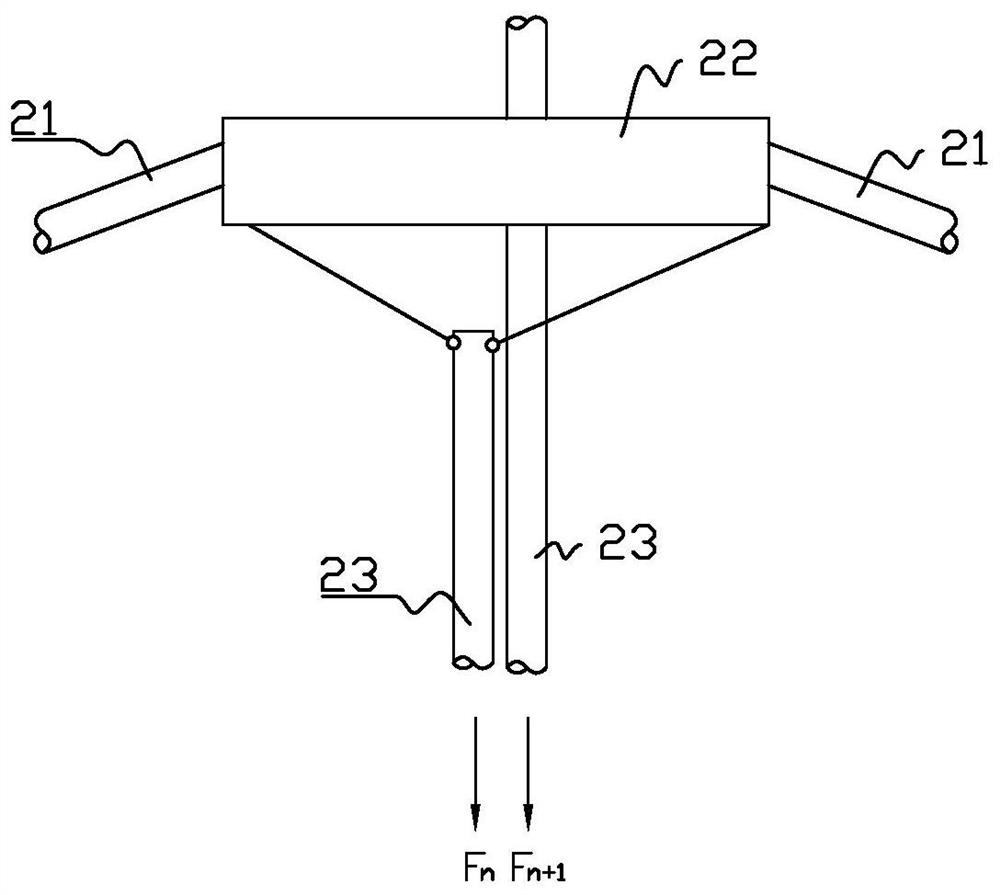

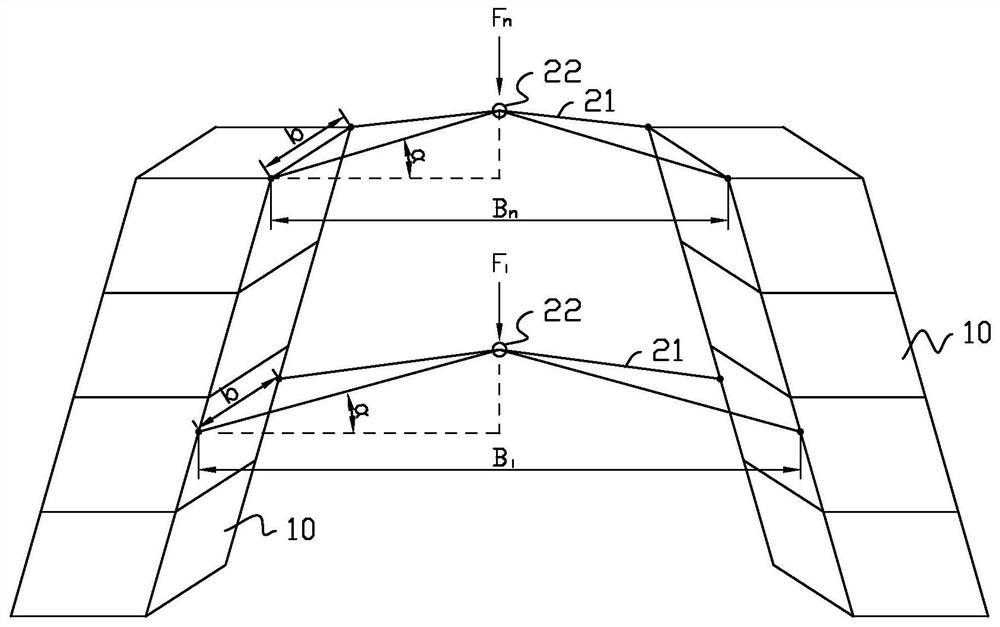

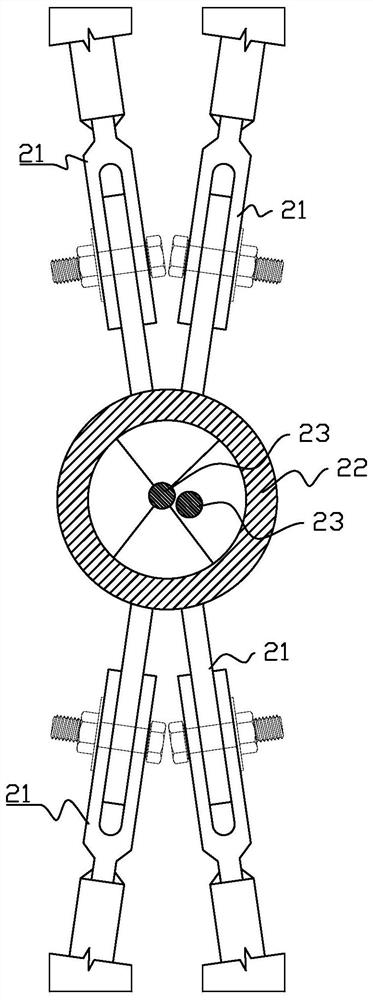

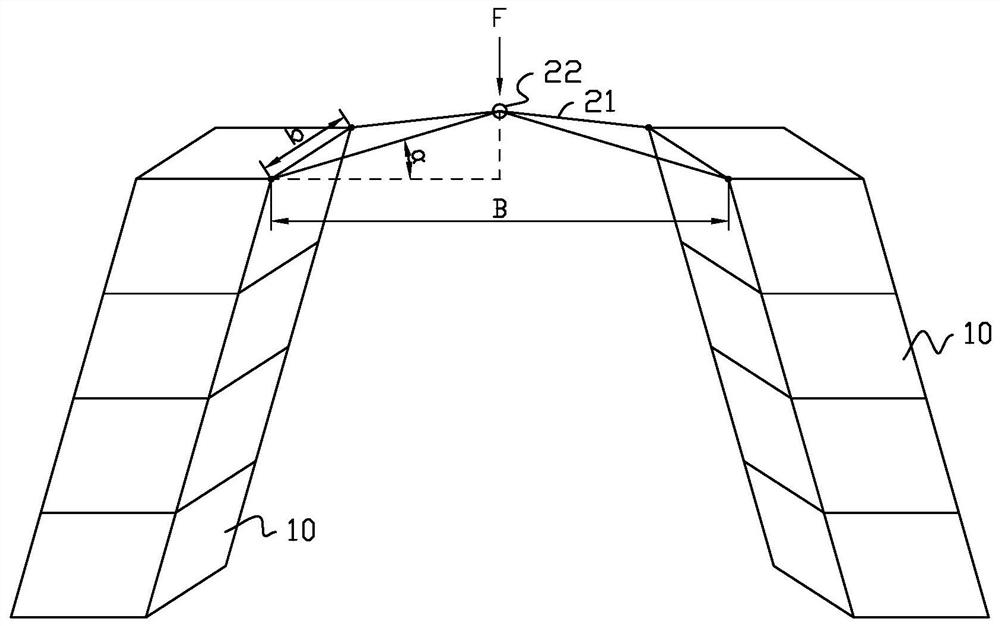

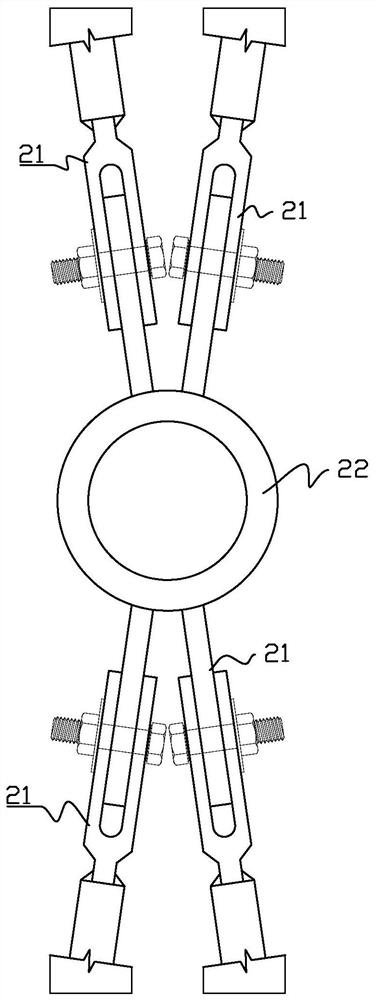

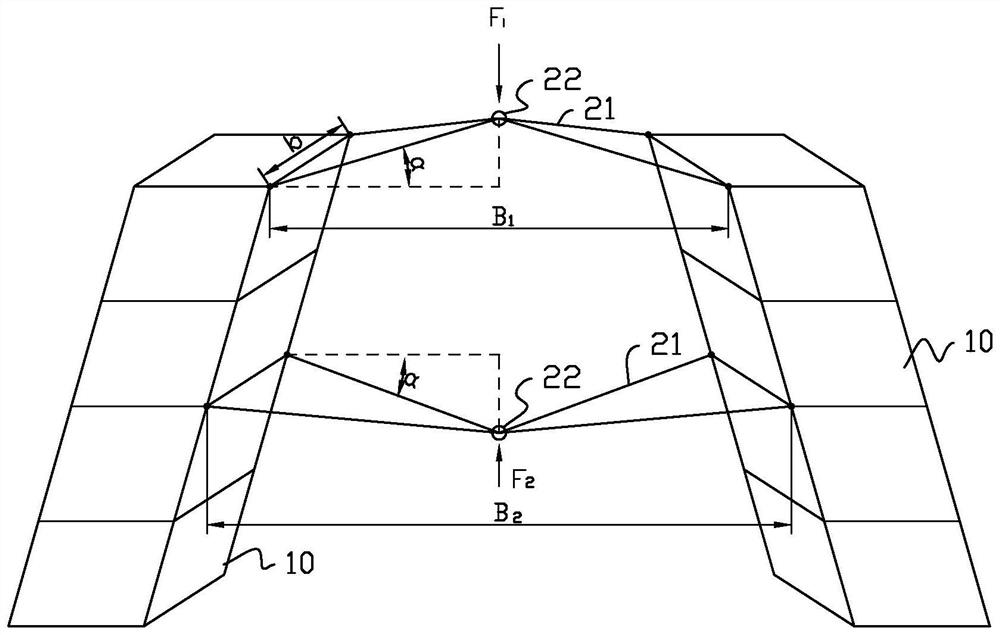

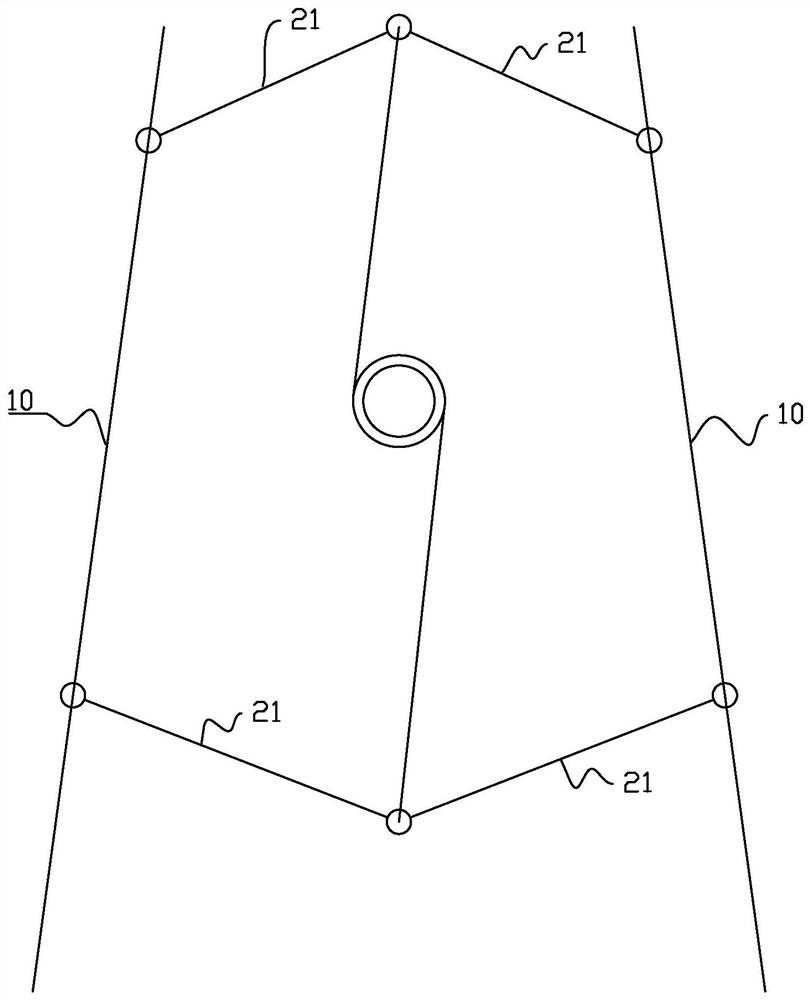

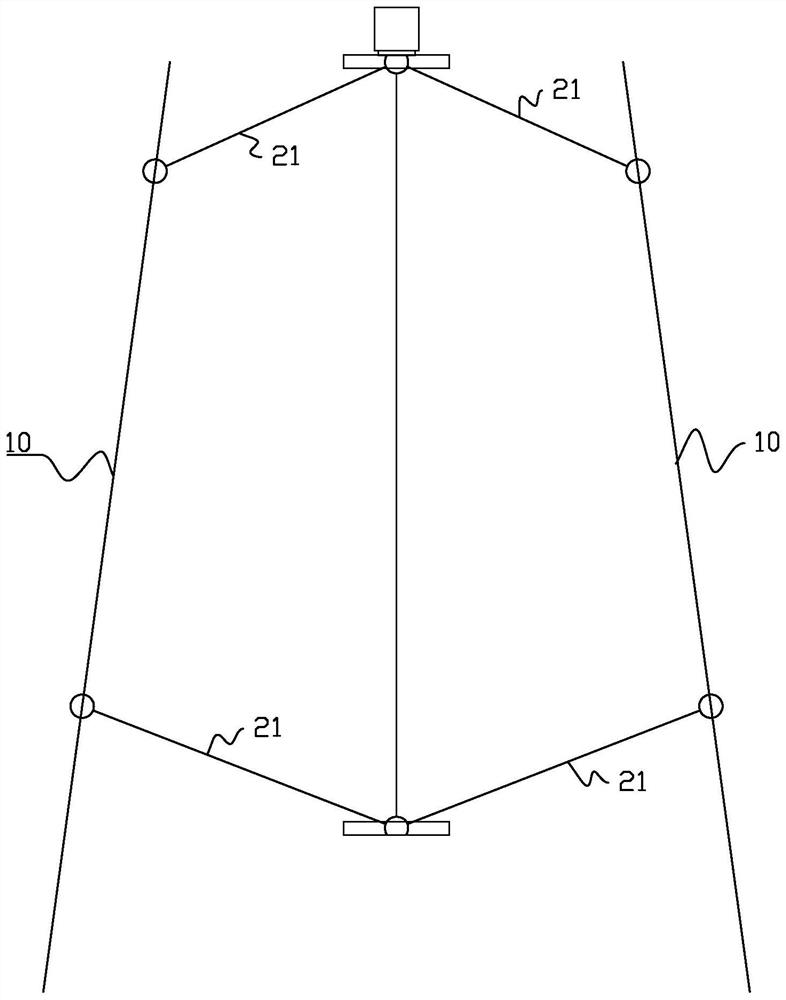

Diagonal bracing device and installation structure for construction of bridge pylons and columns

ActiveCN113356058BImprove construction qualityReduce external stressBridge structural detailsBridge erection/assemblySocial benefitsArchitectural engineering

The invention relates to the field of bridge tower construction, and discloses a diagonal brace device and an installation structure for bridge tower column construction, including making the diagonal brace device, gradually constructing the bridge tower column and installing the diagonal brace device on two bridges during the construction process. Between the pylons, tension is finally applied to the diagonal bracing device so that the cross bridge supports the two pylons. The present invention adopts the form of multiple triangular pyramid diagonal braces, and applies downward vertical force on the top of the diagonal braces, so as to decompose the horizontal thrust of multiple transverse bridges and act on the bridge tower column, thereby reducing the self-weight and construction load. Tensile strain on the outer side of the bottom of the bridge tower column and the outer side of the bridge tower column at the first diagonal brace. The method of applying vertical force by the diagonal bracing device is relatively simple, the internal force is adjustable and the efficiency is high; under the same support effect requirements, the diagonal bracing device can significantly reduce the number of temporary horizontal braces, and the cross section of the diagonal bracing member is more horizontal than the traditional multi-layer The cross brace has the advantages of small cross-section, light weight, and convenient construction, and has significant engineering significance and economic and social benefits.

Owner:GUANGXI UNIV +2

Inclined strut device for bridge tower column construction and mounting structure

ActiveCN113356058AImprove construction qualityReduce external stressBridge structural detailsBridge erection/assemblySelf weightVertical force

The invention relates to the field of bridge tower construction, and discloses an inclined strut device for bridge tower column construction and a mounting structure. The device is characterized in that the the inclined strut device is manufactured, bridge tower columns are constructed step by step, the inclined strut device is mounted between the two tower columns in the construction process, and finally tension force is applied to the inclined strut device, so that the two tower columns are supported in the transverse bridge direction. A plurality of triangular cone inclined struts are adopted, and downward vertical force is applied to the top end of the inclined strut device, so that a plurality of horizontal thrusts in the transverse bridge direction are decomposed to act on the bridge tower columns, and tension strain generated by self weight and construction load on the outer sides of the bottoms of the bridge tower columns and the outer sides of the bridge tower columns at the first inclined strut is reduced. The method for applying the vertical force by the inclined strut device is simple, the internal force is adjustable, and the efficiency is high; under the requirement of the same supporting effect, the inclined strut device can remarkably reduce the number of temporary horizontal cross braces, compared with a traditional multi-channel horizontal cross brace, the cross section of a inclined strut component has the advantages of being small in cross section, light in weight, convenient and fast to construct and the like, and the inclined strut device has remarkable engineering significance and economic and social benefits.

Owner:GUANGXI UNIV +2

A Blind Insertion Structure of Vertical Interconnection between Boards and Its Realization Method

ActiveCN113286425BControl WarpageReduce external stressPrinted circuit assemblingPrinted circuit non-printed electric components associationSurface mountingStructural engineering

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

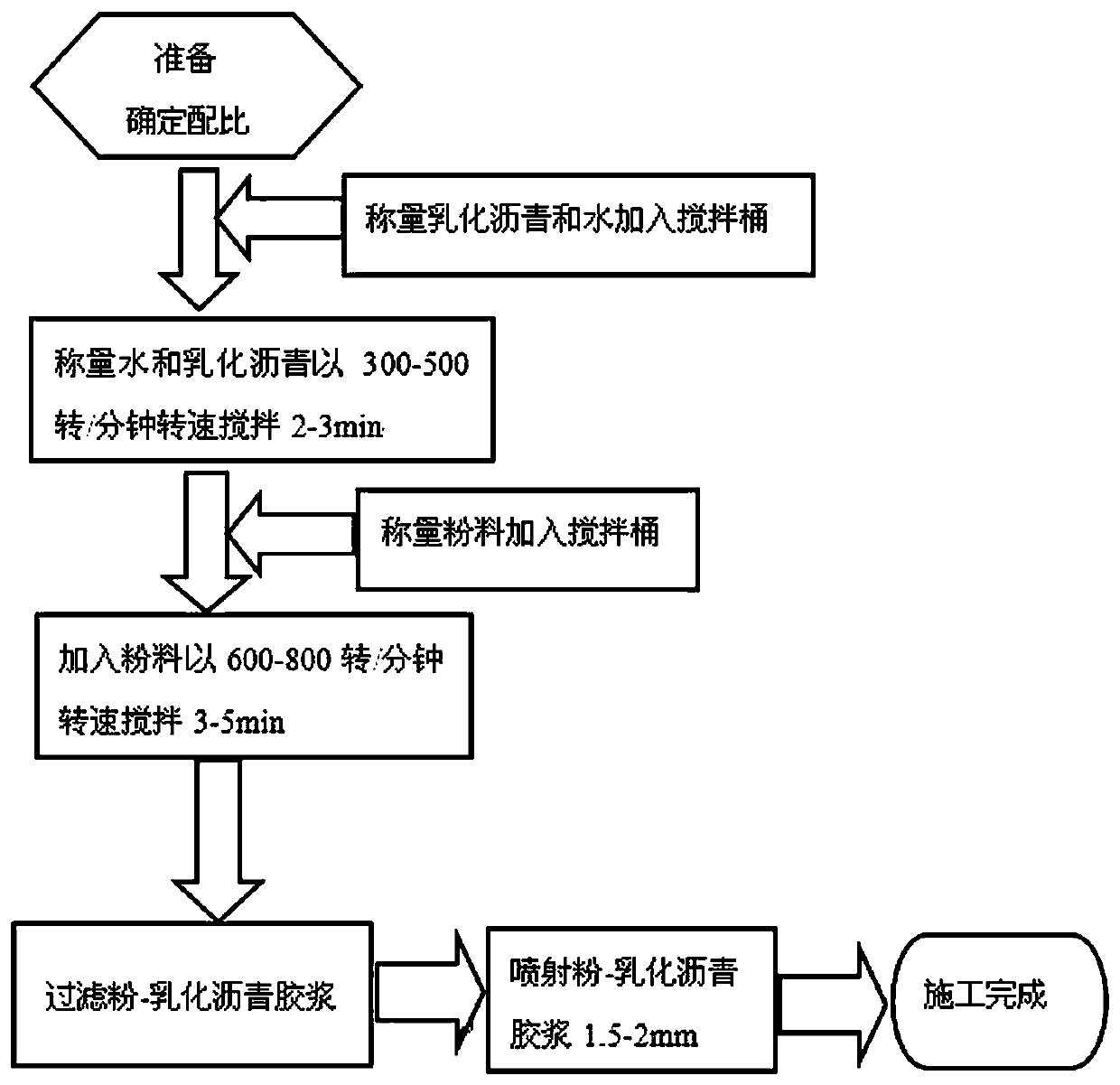

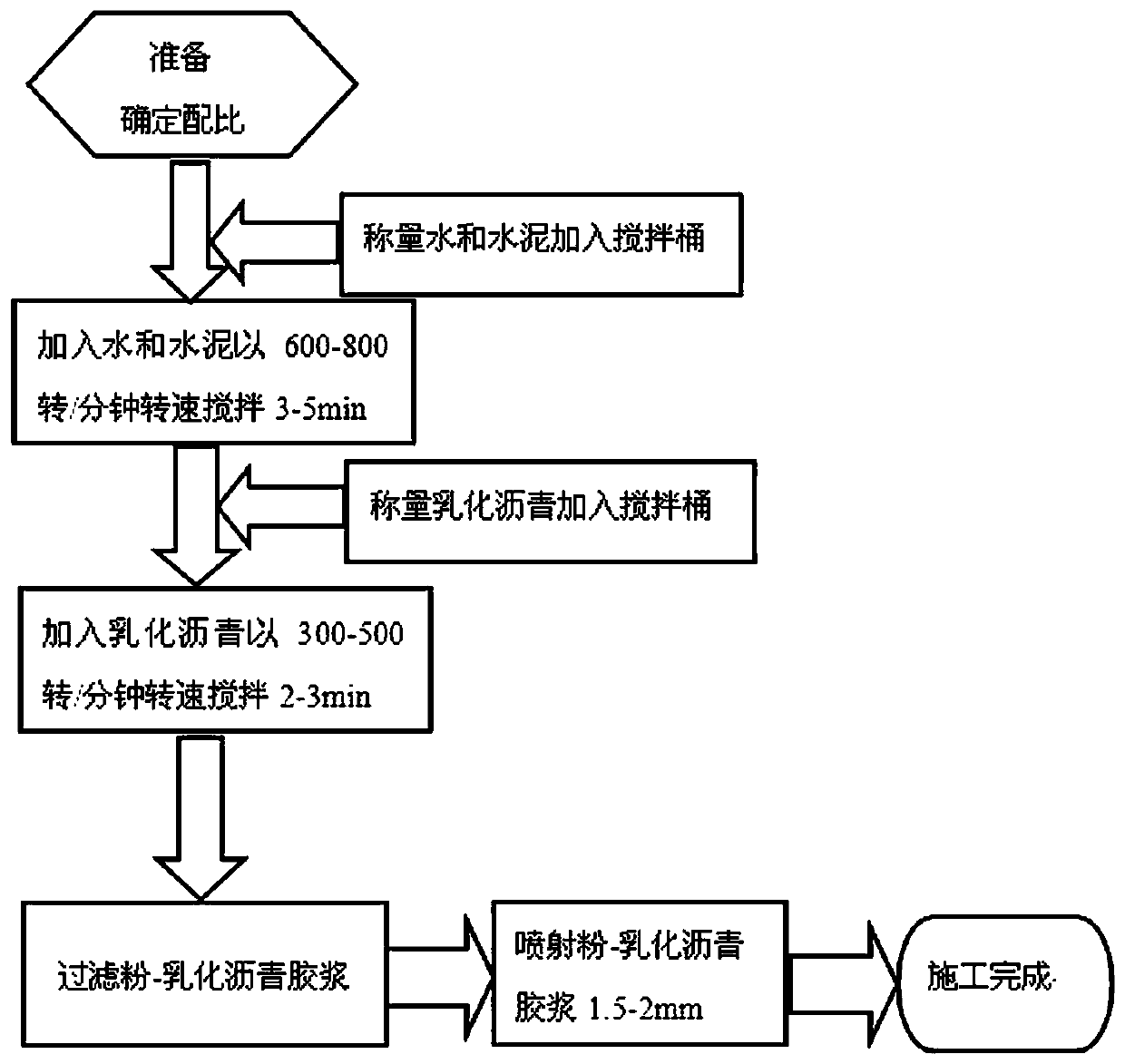

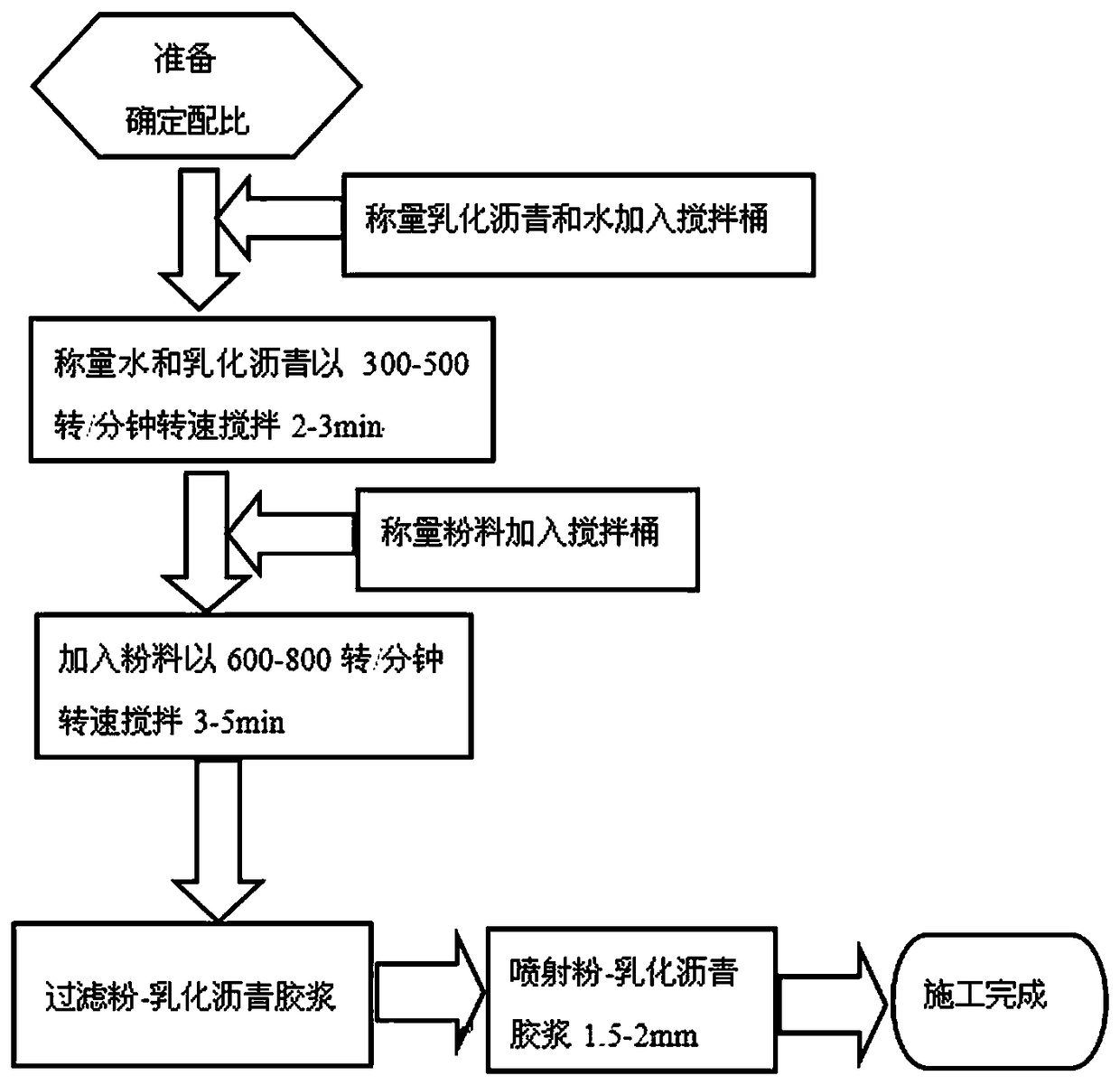

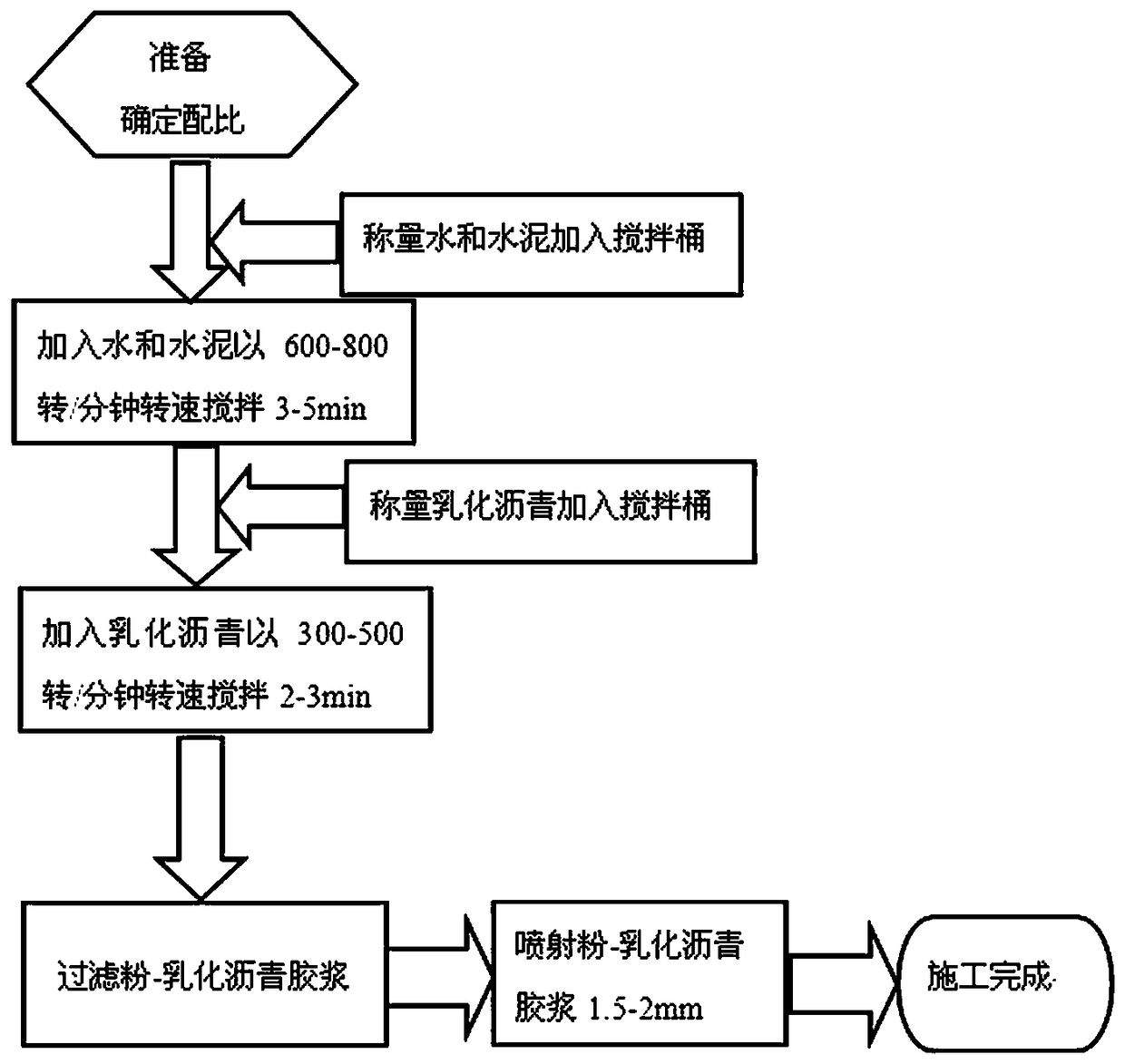

Construction Method of Isolation Layer of Concrete Face Rockfill Dam

ActiveCN108978594BImprove performanceReduce external stressFoundation engineeringEarth-fill damsArchitectural engineeringBitumen emulsion

The invention provides a concrete face rockfill dam isolating layer construction method. The concrete face rockfill dam isolating layer construction method comprises the following steps of: (1) preparing powder-emulsified asphalt mortar on the scene; (2) filtering the powder-emulsified asphalt mortar to remove glue residues for later application, continuously stirring, and storing for 1.5 hours after stirring; and (3) conveying the powder-emulsified asphalt mortar to a working face through a conveying hose, spraying the powder-emulsified asphalt mortar onto a protective surface through a spraygun at the working pressure of 0.8-1.2MPa to form a semi-rigid isolating layer, and separating the protective surface from a concrete face by the semi-rigid isolating layer which has the effects of lubrication and seepage control. The face rockfill dam upstream protective surface isolating layer construction method is simplified; and the concrete face rockfill dam isolating layer construction method improves the gluing quality of the isolating layer and the protective surface, has a good effect of separating different layers and reduces the restraint stress of the face and the generation of concrete face cracks.

Owner:GEZHOUBA GRP NO 2 ENG

Concrete face rockfill dam isolating layer construction method

ActiveCN108978594AImprove performanceReduce external stressFoundation engineeringEarth-fill damsWorking pressureRestraint stress

The invention provides a concrete face rockfill dam isolating layer construction method. The concrete face rockfill dam isolating layer construction method comprises the following steps of: (1) preparing powder-emulsified asphalt mortar on the scene; (2) filtering the powder-emulsified asphalt mortar to remove glue residues for later application, continuously stirring, and storing for 1.5 hours after stirring; and (3) conveying the powder-emulsified asphalt mortar to a working face through a conveying hose, spraying the powder-emulsified asphalt mortar onto a protective surface through a spraygun at the working pressure of 0.8-1.2MPa to form a semi-rigid isolating layer, and separating the protective surface from a concrete face by the semi-rigid isolating layer which has the effects of lubrication and seepage control. The face rockfill dam upstream protective surface isolating layer construction method is simplified; and the concrete face rockfill dam isolating layer construction method improves the gluing quality of the isolating layer and the protective surface, has a good effect of separating different layers and reduces the restraint stress of the face and the generation of concrete face cracks.

Owner:GEZHOUBA GRP NO 2 ENG

Construction method of temporary single diagonal bracing bridge tower

PendingCN113322812AImprove construction qualitySave time and costBridge structural detailsBridge erection/assemblySelf weightVertical force

The invention belongs to the field of bridge tower construction and discloses a construction method of a temporary single diagonal bracing bridge tower. The construction method comprises the following steps of: manufacturing a diagonal bracing device; gradually constructing a bridge tower; installing the diagonal bracing device between two tower columns in the construction process; and applying tension force to the diagonal bracing device so as to support the two tower columns in the transverse bridge direction. A traditional horizontal support construction method is improved; a triangular cone diagonal bracing mode is adopted, and the principle is that downward vertical force is applied to the top end of the diagonal bracing device, so that horizontal thrust in the transverse bridge direction is decomposed to act on the tower columns, and the outer side tensile strain of the bottoms of the tower columns of the bridge tower generated by self weight and construction loads is reduced. The method for applying the vertical force by a temporary device is simple, the internal force is adjustable, and the efficiency is high; under the requirement of the same supporting effect, the single temporary diagonal bracing can remarkably replace multiple groups of horizontal cross struts; the diagonal bracing is simple in structure;the diagonal bracing component is smaller in cross section than that of a traditional horizontal cross strut,lighter in weight and is convenient and fast in construction and has remarkable engineering significance and economic and social benefits.

Owner:中国铁路南宁局集团有限公司南宁铁路工程建设指挥部 +2

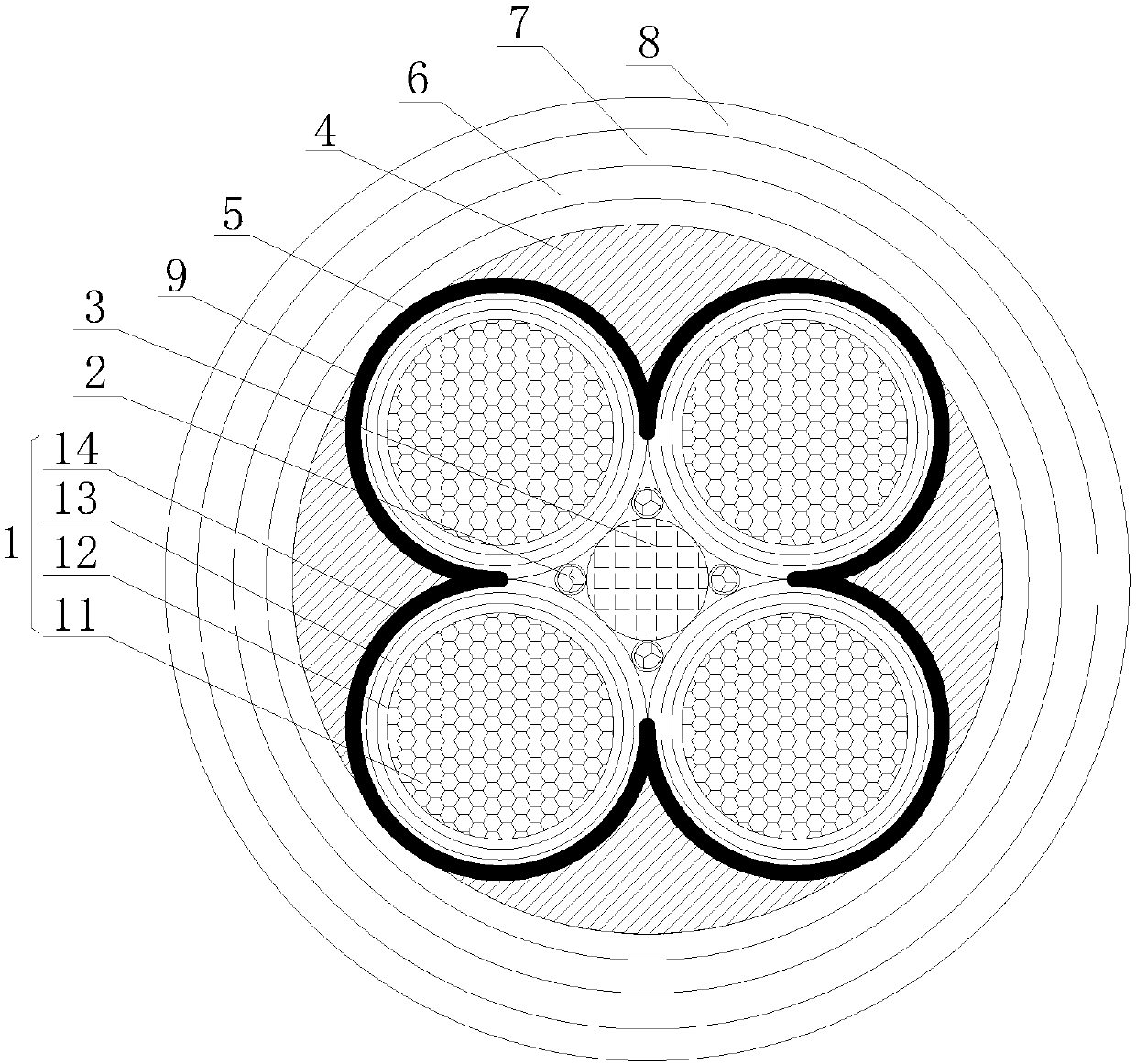

High temperature resistant and flame resistant power cable

InactiveCN107871554ARegular structureTake advantage ofInsulated cablesPower cablesPower cableCarrying capacity

The invention relates to a high temperature resistant flame retardant power cable, comprising a cable core, a total wrapping layer, an outer refractory material layer, an armor layer and an outer sheath; the cable core includes a flame retardant sleeve and four wires; the flame retardant sleeve It includes four flame retardant parts, which are connected end to end in sequence, and an outer elastic part is arranged between any two adjacent flame retardant parts, and the outer elastic part has an outer arc surface and two inner arc surfaces , the outer arc surfaces of the outer elastic parts cooperate with each other so that the cable core has a circular cross-section, and the inner arc surfaces of the outer elastic parts respectively abut against the outer arc surfaces of the two flame retardant parts; the wires abut against the On the inner arc surface of the flame retardant, the central connection line of the four wires is a square, and an inner elastic piece is arranged between the four wires, and the inner elastic piece is circumscribed with the wire, and there is an inner elastic piece between the four wires and the inner elastic piece. Tensile core, the tensile core is wrapped around the inner elastic. The invention has excellent high temperature resistance and flame retardancy, large carrying capacity and high safety.

Owner:天津市威武科技有限公司

Opposite-pulling combination device of bridge tower inclined support and construction method

ActiveCN113338163AReduce external stressSimple methodBridge structural detailsBridge erection/assemblyTensile strainSocial benefits

The invention relates to the field of bridge tower construction, and particularly discloses an opposite-pulling combination device of a bridge tower inclined support and a construction method, the opposite-pulling combination device comprises at least one pair of inclined supporting devices and a force application device, and the pair of inclined supporting devices are arranged at different heights between tower columns of a bridge tower. A plurality of triangular cone inclined struts are adopted, and downward vertical force is applied to the top ends of the inclined supporting pieces, so that a plurality of horizontal thrust in the transverse bridge direction is decomposed to act on the tower column, and tensile strain generated by self weight and construction load on the outer side of the bottom of the tower column of the bridge tower and the outer side of the tower column of the bridge tower at the first inclined strut is reduced. The method for applying the vertical force by the inclined supporting piece is simple, the internal force is adjustable, and the efficiency is high; under the requirement of the same supporting effect, the temporary multi-diagonal supporting piece can remarkably reduce the number of temporary horizontal cross braces, the cross section of a diagonal supporting component has the advantages of being small in internal force, small in cross section, light in weight, convenient and fast to construct and the like compared with a traditional multi-horizontal cross brace, and the opposite-pulling combination device of a bridge tower inclined support has remarkable engineering significance and economic and social benefits.

Owner:广西北投交通养护科技集团有限公司 +2

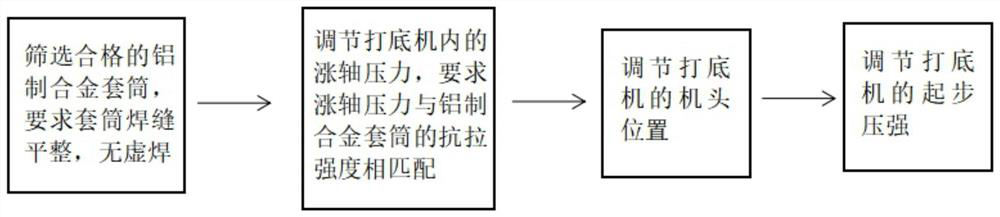

Method for reducing grooves during bottoming of aluminum alloy sleeve

The invention discloses a method for reducing grooves during bottoming of an aluminum alloy sleeve. The method has the following advantages: (1) the pressure of an expansion shaft is matched with the tensile strength of the aluminum alloy sleeve, on one hand, slipping between the expansion shaft and the aluminum alloy sleeve can be avoided, and on the other hand, the external pressure of the pressure of the expansion shaft on the aluminum alloy sleeve can be reduced; and (2) the starting pressure intensity is adjusted, so that the stress release on the aluminum alloy sleeve can be effectively buffered, and the phenomenon that grooves are formed in the surface of the aluminum alloy sleeve due to the fact that the stress release rate is too high is avoided.

Owner:INNER MONGOLIA LIANSHENG NEW ENERGY MATERIALS CO LTD

Shaft mechanism and electronic device

ActiveCN110958338BImprove reliabilityExtended service lifeTelephone set constructionsStructural engineeringMechanical engineering

The application discloses a rotating shaft mechanism and an electronic device. The hinge mechanism is applied to foldable electronic devices. The first screen part and the second screen part of the electronic device in the embodiment of the present application move in opposite directions through the rotating shaft mechanism so that the screen is in the unfolded state, and the rotating shaft mechanism is retracted relative to the housing of the electronic device to reduce the screen when it is unfolded. When subjected to external stress of the casing, the screen is protected from damage, thereby enhancing the reliability of the electronic device and prolonging the service life.

Owner:张大鸣

Ship thick plate welding process

ActiveCN107052516BLess difficult for welders to operateReduce external stressArc welding apparatusThick plateSheet steel

The invention discloses a ship thick-plate welding technology. The ship thick-plate welding technology comprises the following steps that flat welding and balanced welding are adopted for ship thick plates; welding is conducted on a small part of the inner sides of the ship thick plates, and then balanced welding is conducted on the outer sides of the ship thick plates; welding is conducted on one part of the inner sides of the ship thick plates again, and carbon arc air gouging is conducted on the outer sides of the ship thick plates, wherein carbon arc air gouging is used for back chipping and beveling, and each air-gouged bevel needs to range from 50 degrees to 60 degrees; balanced welding is conducted on the outer sides of the ship thick plates and the inner sides of the ship thick plates after the outer sides of the ship thick plates are subjected to carbon arc air gouging, preheating is conducted firstly, the first layer is filled with metal, welding feet need to be small, and short-arc welding is adopted; temperature is measured through a point temperature gun before second welding is conducted; the inner sides of the ship thick plates are completely welded, wherein when the inner side is welded with one layer, the symmetrical outer side also needs to be welded with one layer, and the interlayer temperature is smaller than 100 DEG C or smaller than 250 DEG C; and the outer sides are completely welded, wherein after the last part of each inner side is completely welded, the corresponding outer side also needs to be completely welded, and the temperature is kept between 300 DEG C and 400 DEG C. Flat welding is adopted by the ship thick plates, the operation difficulty of flat welding positions is small for a welder, outer side stress can be better reduced by means of steel plate preheating and double-face balanced welding, and therefore the crack defect is effectively avoided.

Owner:南通远洋船舶配套有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com