Three-phase three-pole amorphous iron-core with support and hoisting structure as well as manufacturing method thereof

A three-phase three-column, amorphous technology, applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of amorphous core transformer capacity limitation, increased coil burden, and heavy core weight. Improve quality, increase capacity, reduce the effect of applied stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Specific embodiments of the present invention are given below in conjunction with the accompanying drawings.

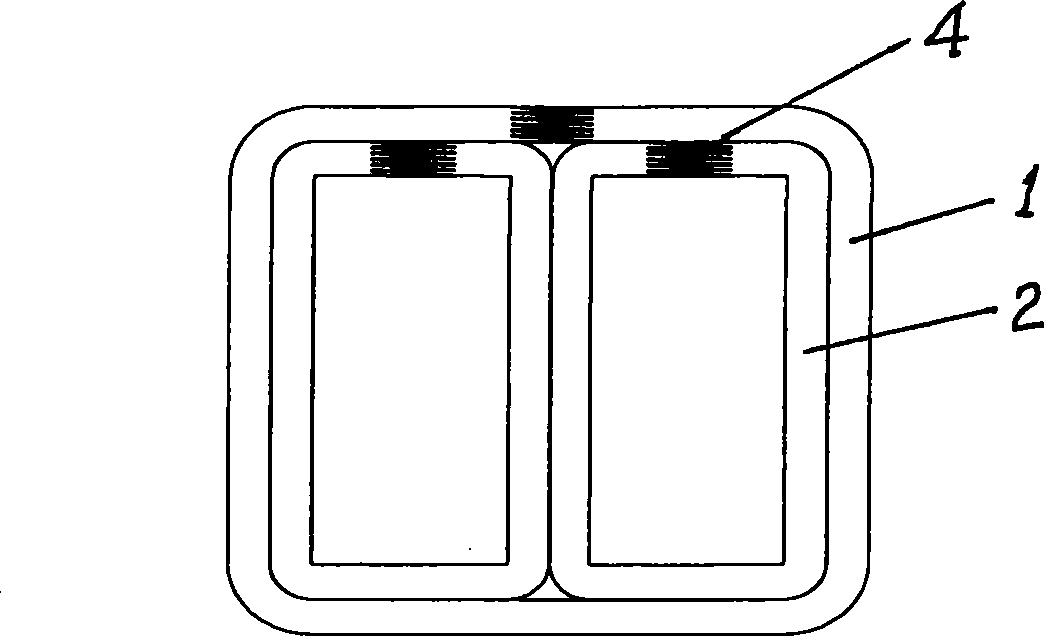

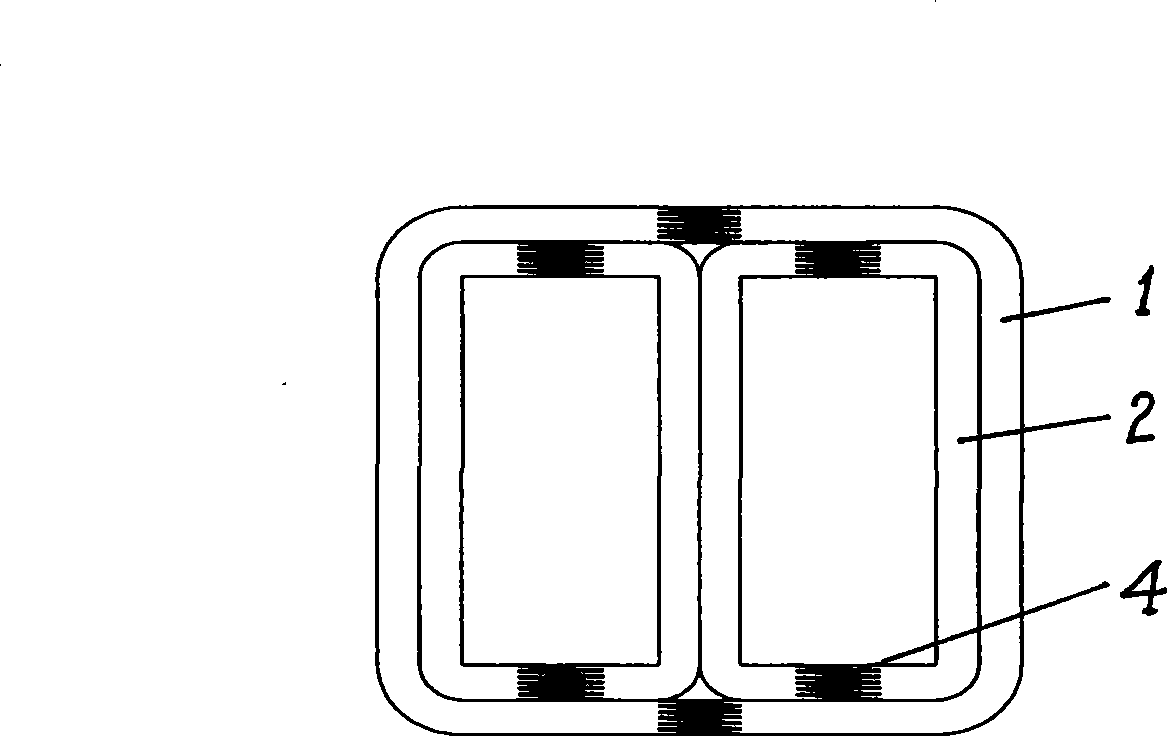

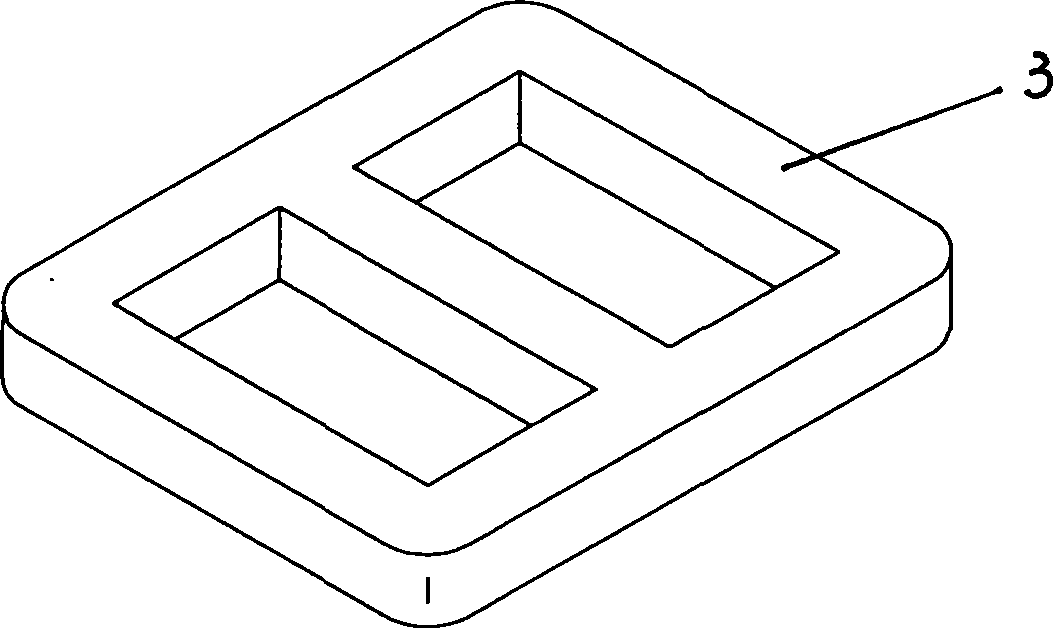

[0036] See attached figure 1 , 2 , 3, 9, 11. The present invention has a three-phase three-pillar amorphous iron core with a supporting and hoisting structure, comprising an amorphous outer iron core 1, an inner iron core 2, an amorphous thin strip cutting joint 4, a resin glue coating 5, and a mountain-shaped support iron plate for the end face 6. The inner layer uses mountain-shaped support iron plate 7, upper clamp 11, lower clamp 12, lifting lug 13, insulating material 14, upper side rail 15 and base 17. The three-phase three-column amorphous iron core is composed of An external capacity 1 and two inner cores 2 are formed. Here, the amorphous core 3 is made of very thin (about 0.025mm) amorphous strips, which are cut, stacked, and then overlapped. The cut-off joint 4 is joined in a lap joint, and the cut-off joint of a single core cycle can be set at one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com