Construction Method of Isolation Layer of Concrete Face Rockfill Dam

A technology for concrete panels and construction methods, applied in dams, barrages, infrastructure projects, etc., can solve problems such as damage to the waterproofing and separation lubrication of the separation layer, a large number of construction equipment, and complex construction processes, and achieve fast and efficient construction. The method is simple and the effect of improving the anti-seepage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

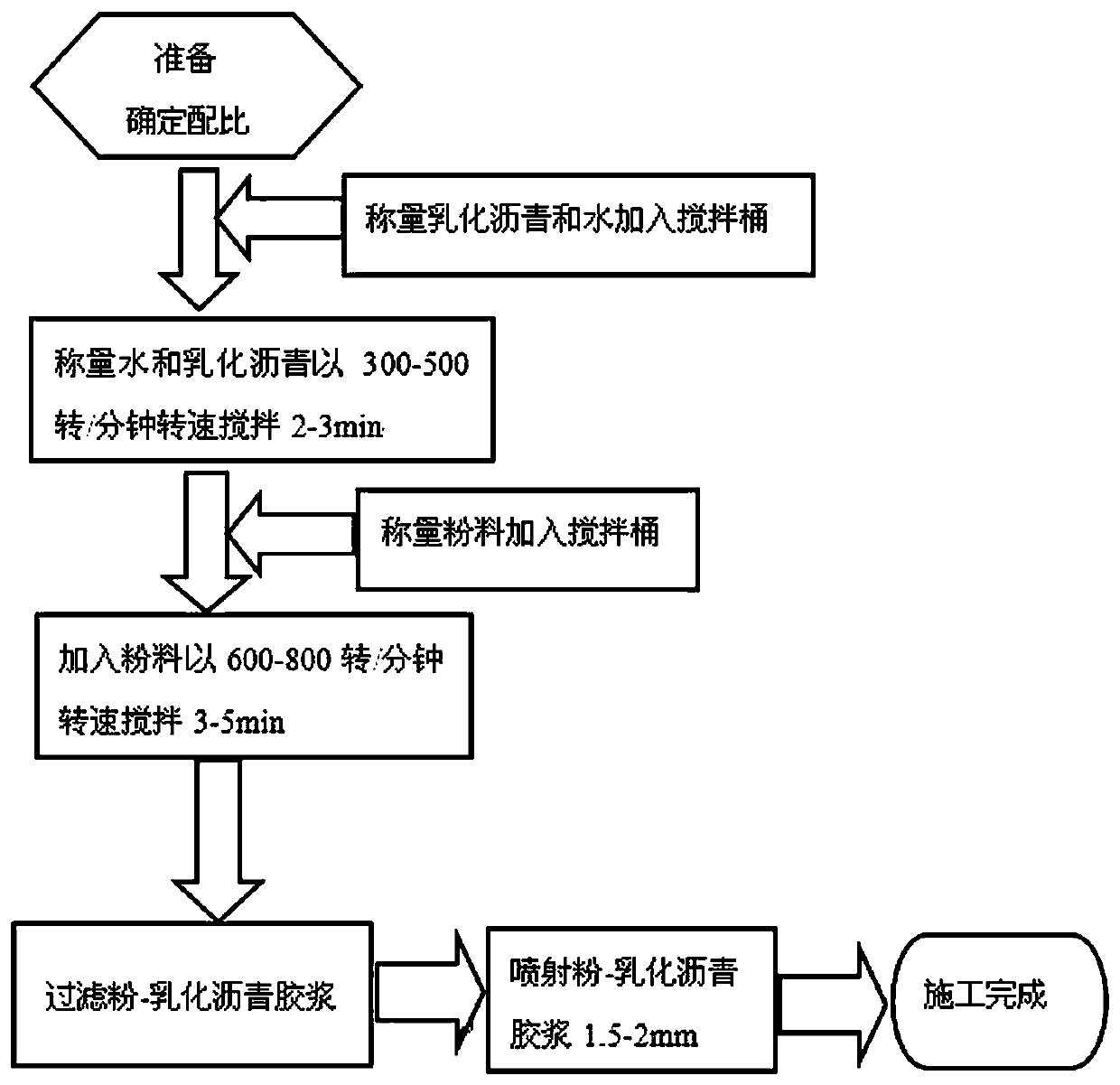

[0021] see figure 1 , the construction method of the isolation layer of the concrete face rockfill dam of the present embodiment 1 comprises the following steps:

[0022] (1) According to emulsified asphalt 150kg, water 120kg, cement 300kg ingredients:

[0023] (2) When the natural environment temperature is 28°C and the water temperature is 15°C, weigh 150kg of emulsified asphalt and 120kg of water according to the formula ratio and put them into the mixing tank, stir at 300-500 rpm for 2-3 minutes to mix the emulsified asphalt and water Uniform;

[0024] (3) Slowly add 300kg of cement into the emulsified asphalt and water mixture material that is well stirred in step (1) according to the formula ratio, and stir at 600-800 rpm for 3-5 minutes to make it fully mixed to form powder - emulsified asphalt mortar;

[0025] (4) Filter the fully mixed powder-emulsified asphalt mortar in step ((3) to remove the mortar residue, and keep stirring at a speed of 300-500 rpm to prevent ...

Embodiment 2

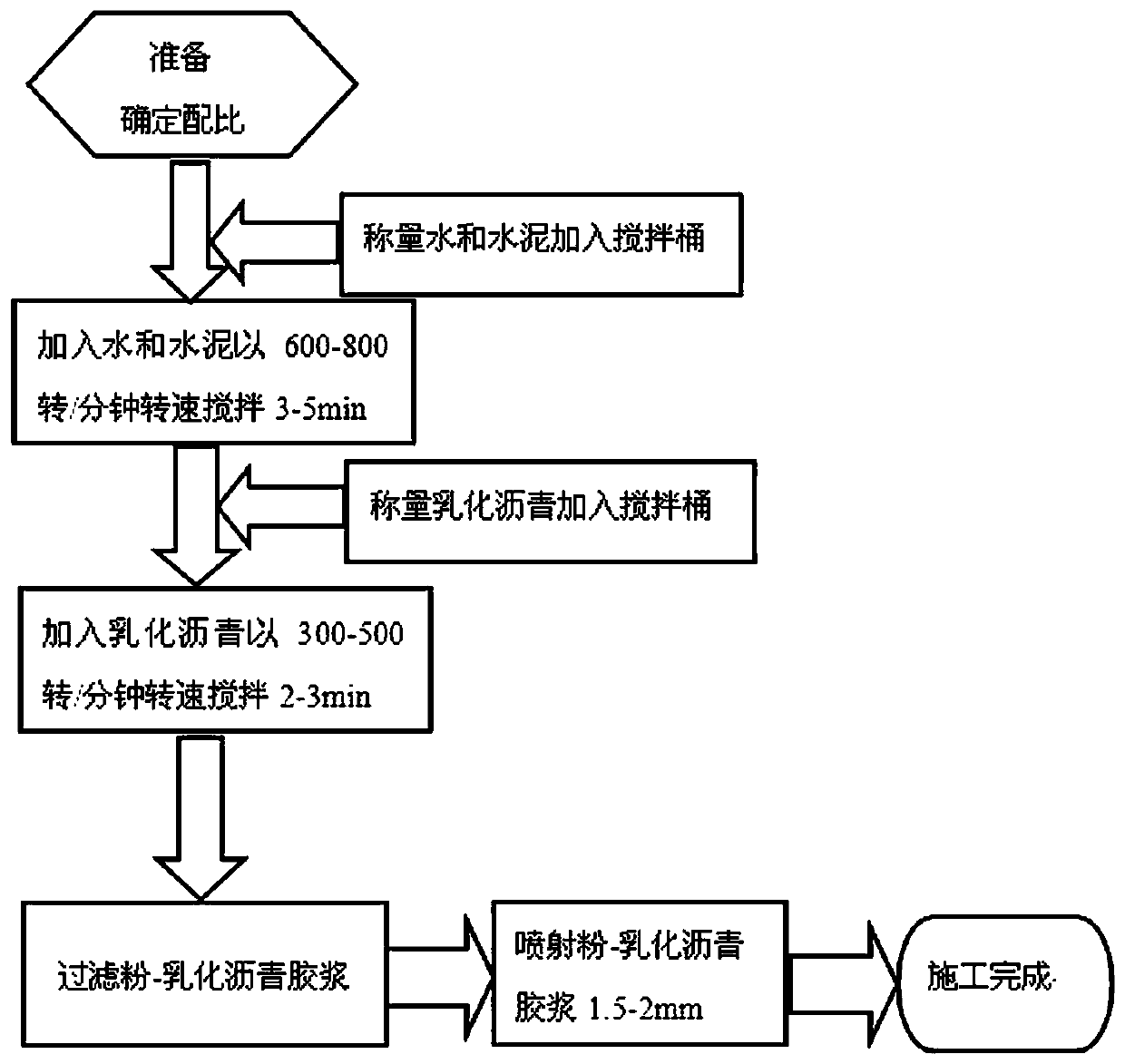

[0028] see figure 2 , the present embodiment 2 is basically the same as embodiment 1. The difference is that in step (2), put 120kg of water and 300kg of cement into the mixing bucket in turn, and stir for 3-5 minutes at a speed of 600-800 rpm to mix the cement and water evenly; in step (3), the emulsified asphalt Add it to the well-stirred cement and water mixture in step (2), and stir at a speed of 300-500 rpm for 2-3 minutes to make it fully mixed to form a powder-emulsified asphalt mortar.

[0029] The construction method of the isolation layer of the concrete face rockfill dam of the present invention is preferably spraying 1.5-2 mm at a time. If the thickness is required to be greater than 2mm, the second injection should be carried out before the first asphalt is not demulsified and the cement is not initially set.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com