Patents

Literature

39 results about "Restraint stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

It is a specific type of stress, defined here: " Restraint stress, which is an experimental model for psychosocial stress, is characterized by the activation of the sympathetic nervous system...".

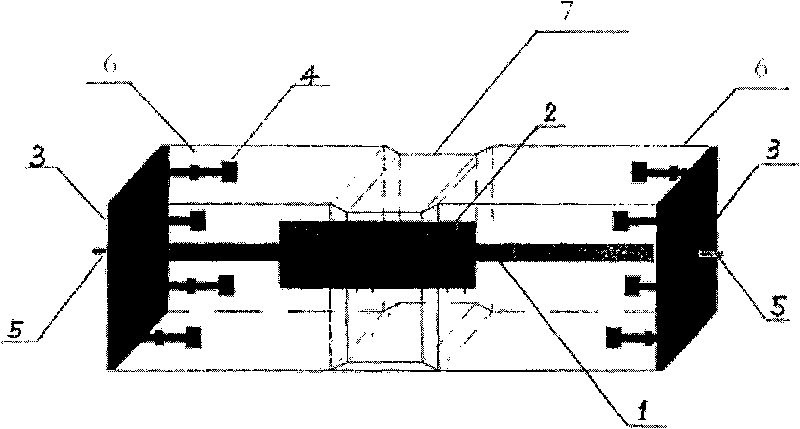

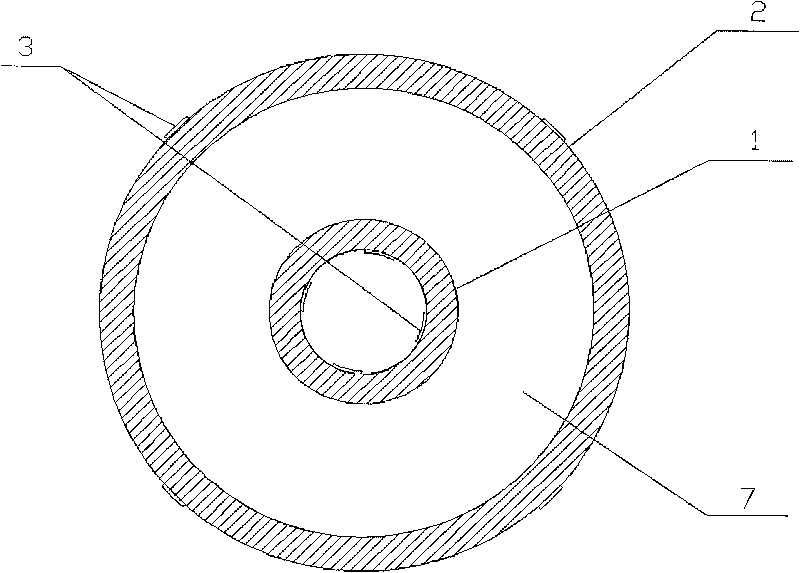

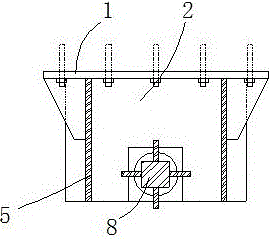

Expansion/shrinkage stress testing device for cement-based material

ActiveCN101738459AEasy to analyzeEasy to compareMaterial testing goodsElectricityStrength of materials

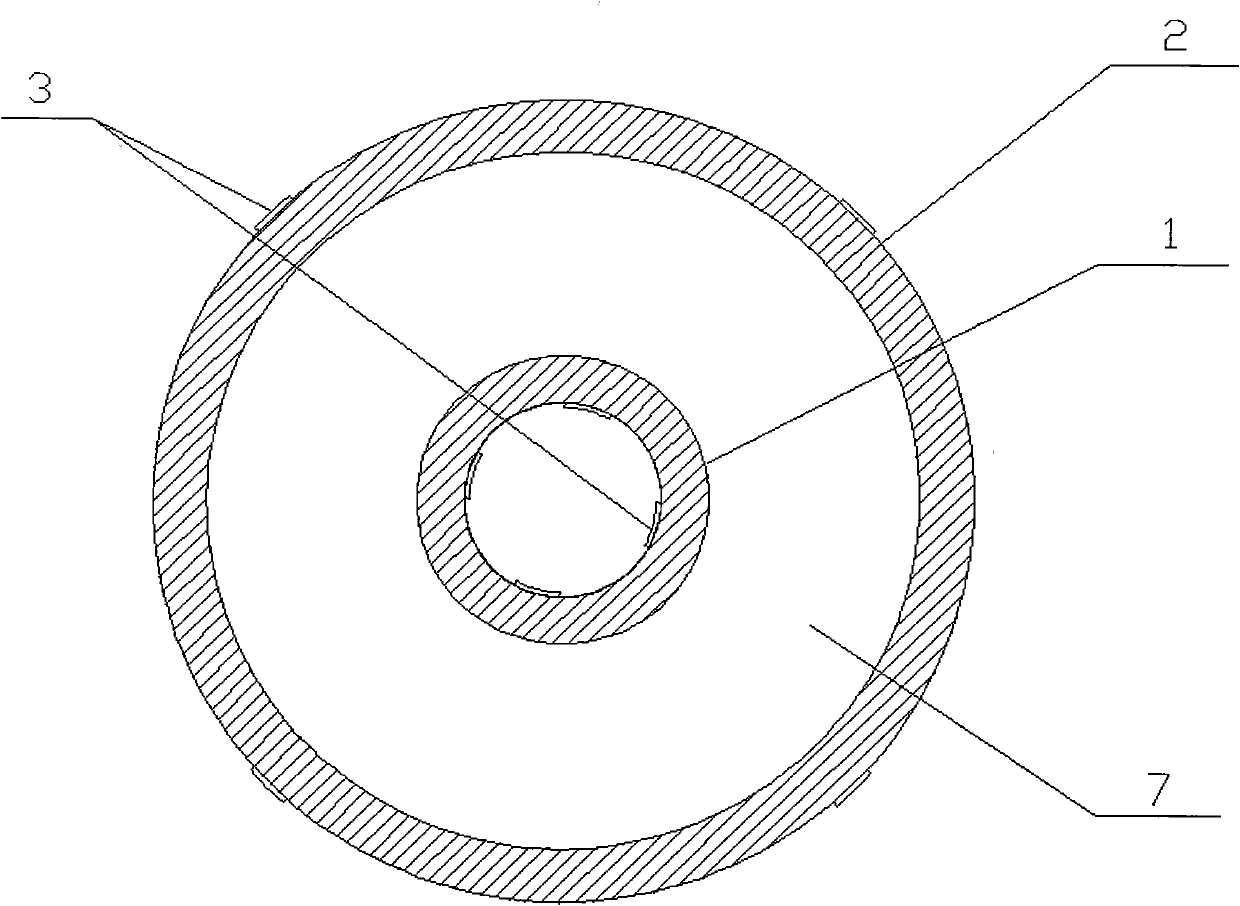

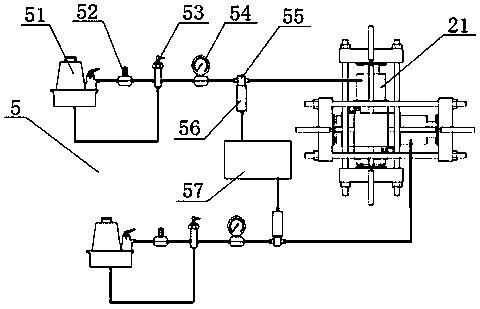

The invention relates to an expansion / shrinkage stress testing device for a cement-based material, which comprises an inner circular ring and an outer circular ring which are coaxial and have the same height, and a stress testing device and a data acquisition device which are electrically interconnected, wherein the inner circular ring and the outer circular ring are made of the same material; and the stress testing device comprises a plurality of test stress plates which are distributed evenly along the circumferential direction on the outer surface of the outer circular ring and the inner surface of the inner circular ring and are electrically connected with the data acquisition device. When the testing device is used, the cement-based material (such as pure slurry, mortar or concrete) is cast between the two rings. The expansion and shrinkage stress can be calculated according to the analysis of material mechanics by measuring the stress. Compared with the prior method, the testing device has the main advantages that: a, the testing device is simple, and simple and convenient to operate; b, the restraint stress is even; and c, the testing of starting self water addition molding can be implemented, the testing process needs no manpower to move the test piece, and continuous and automatic test can be realized.

Owner:JIANGSU SOBUTE NEW MATERIALS

Method for testing expansion/contraction stress of cement-based material

ActiveCN101769916AEasy to analyzeEasy to compareElectrical/magnetic solid deformation measurementMaterial testing goodsElectricityRestraint stress

The invention relates to a method for testing expansion / contraction stress of a cement-based material, which adopts a device for testing the expansion / contraction stress of the cement-based material is adopted. The device comprises inner and outer circular rings which are coaxially arranged and have the same height, and a strain testing device and a data acquisition device which are mutually electrically connected, wherein the materials of the inner and the outer circular rings are the same; the strain testing device comprises a plurality of testing strain gauges; the strain gauges are distributed on the external surface of the outer circular ring and the internal surface of the inner circular ring uniformly along a circumferential direction, and each testing strain gauge is electrically connected with the data acquisition device; the cement-based material is poured between the inner and the outer circular rings, and the strain of the inner and the outer circular rings is tested; and the expansion / contraction stress at a position where the internal radius of the cement-based material is r is calculated according to a formula (I). The method has the advantages that a, the test device is simple, and the operation is simple and convenient; b, restraint stress is uniform; and c, the method can test at the initial stage of watering moulding without moving test specimens, and continuous and automatic test.

Owner:JIANGSU SOBUTE NEW MATERIALS

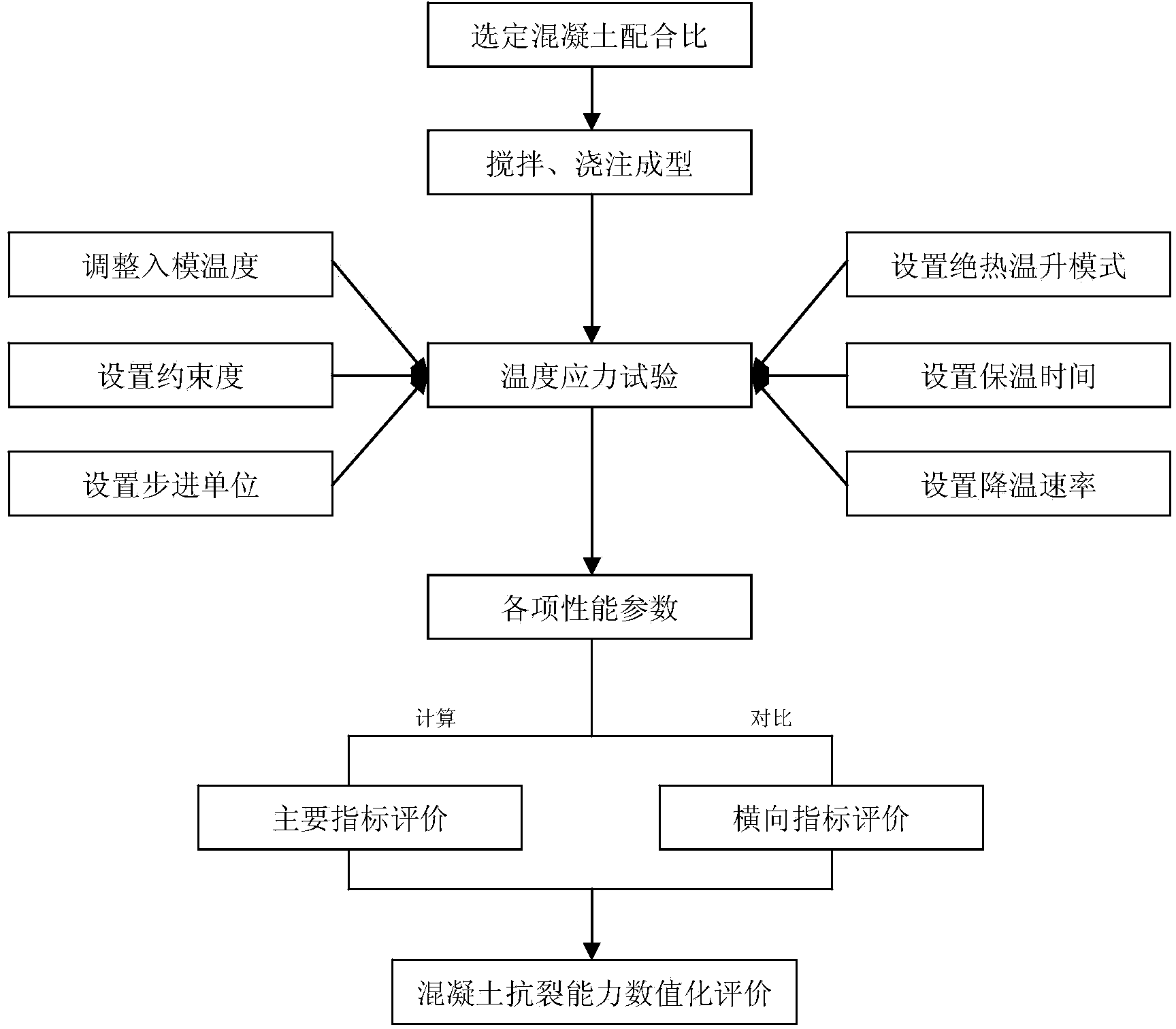

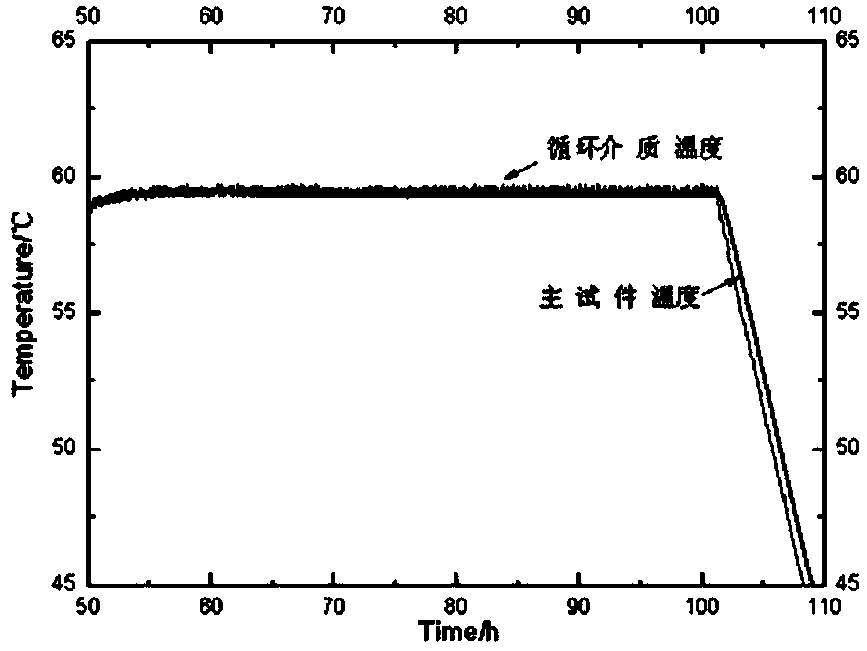

Numeralization evaluation method for crack resistance of concrete

ActiveCN103852384AMaterial strength using tensile/compressive forcesTemperature stressCrack resistance

The invention discloses a numeralization evaluation method for crack resistance of concrete. The numeralization evaluation method comprises the following steps: testing test data of a concrete test piece by using a temperature stress testing machine; calculating a crack-resisting security coefficient Kf and taking the crack-resisting security coefficient Kf as an evaluation criterion of the crack resistance of the concrete; substituting tested cracking stress and room-temperature stress into the calculation in the calculation of the Kf; and when the Kf is more than 1.15, showing that a concrete test piece to be tested has good crack resistance. The evaluation method can be used for rapidly obtaining a testing result, and the temperature sensibility and the restraint stress relaxation performance of the restricted concrete are evaluated by a ratio of the cracking stress to room-temperature stress, so that the cracking resistance of the concrete can be directly evaluated.

Owner:CCCC FOURTH HARBOR ENG INST +4

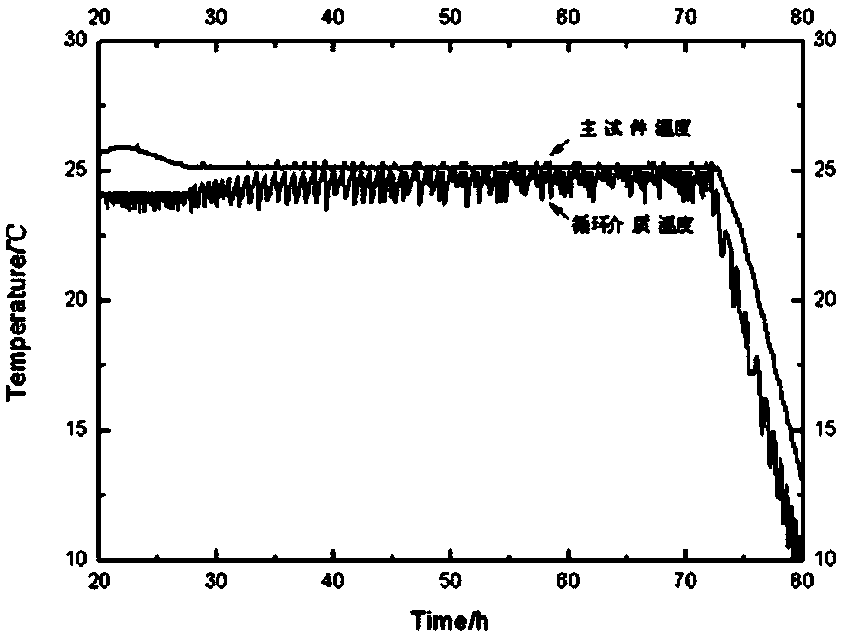

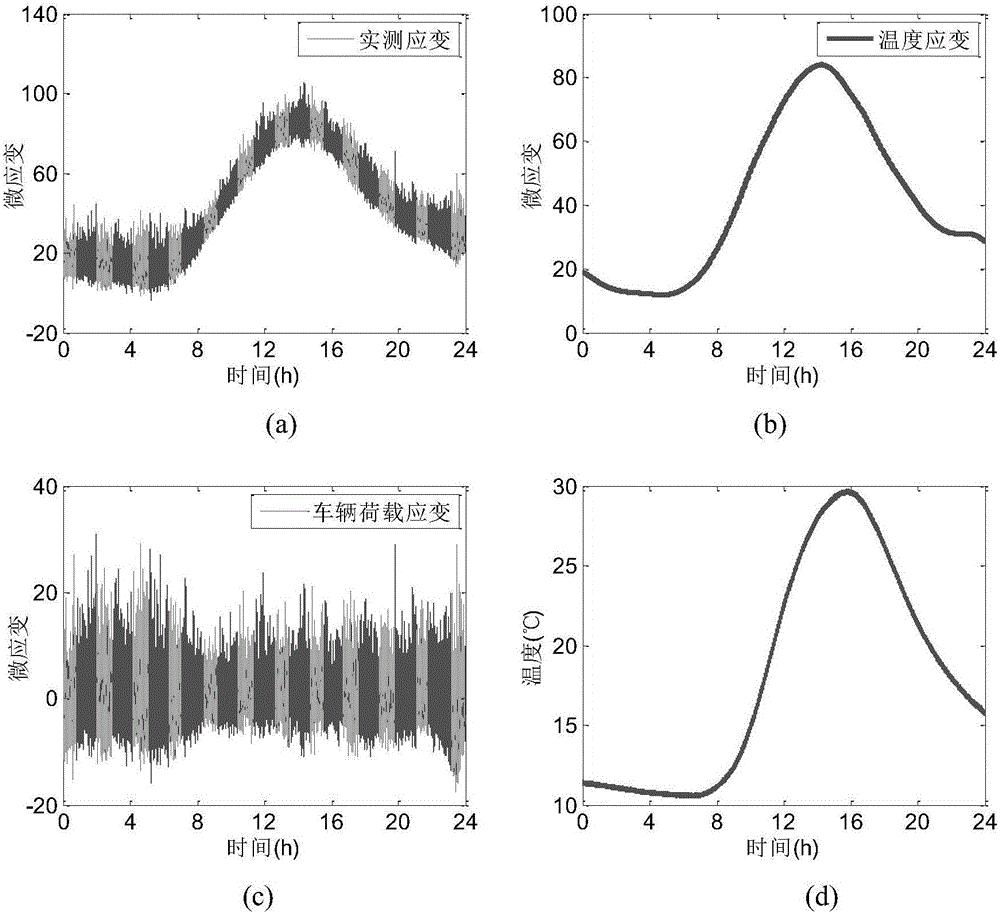

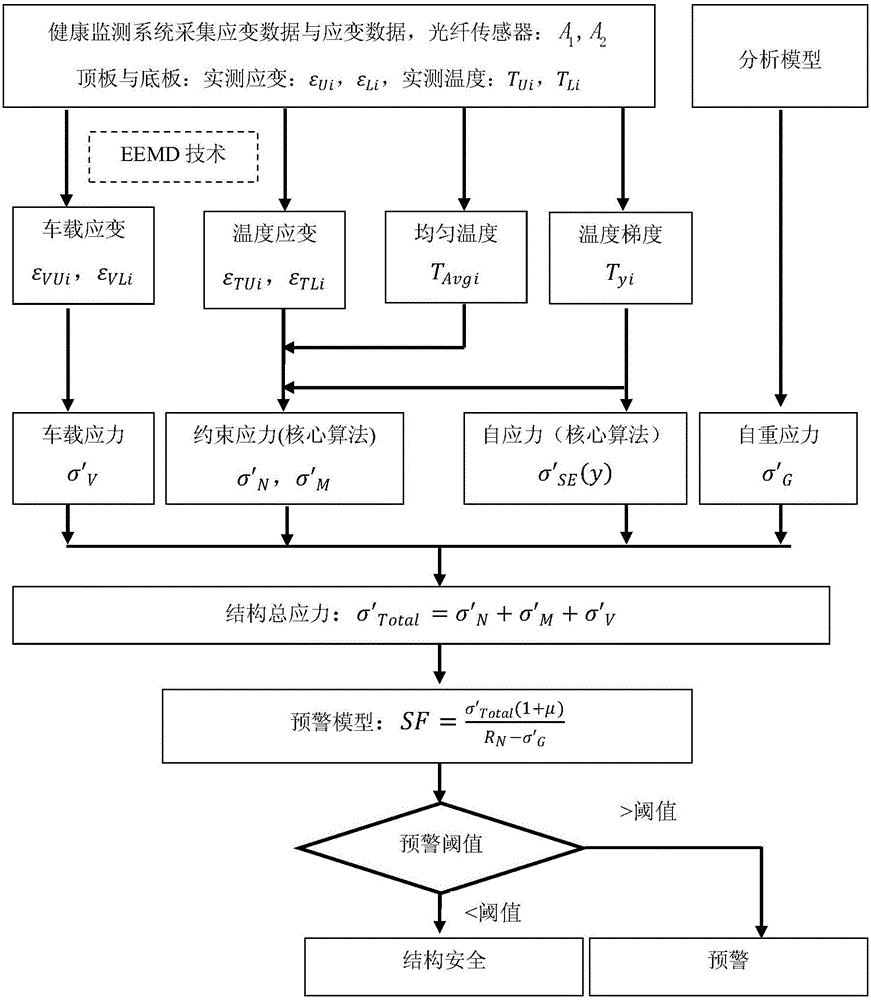

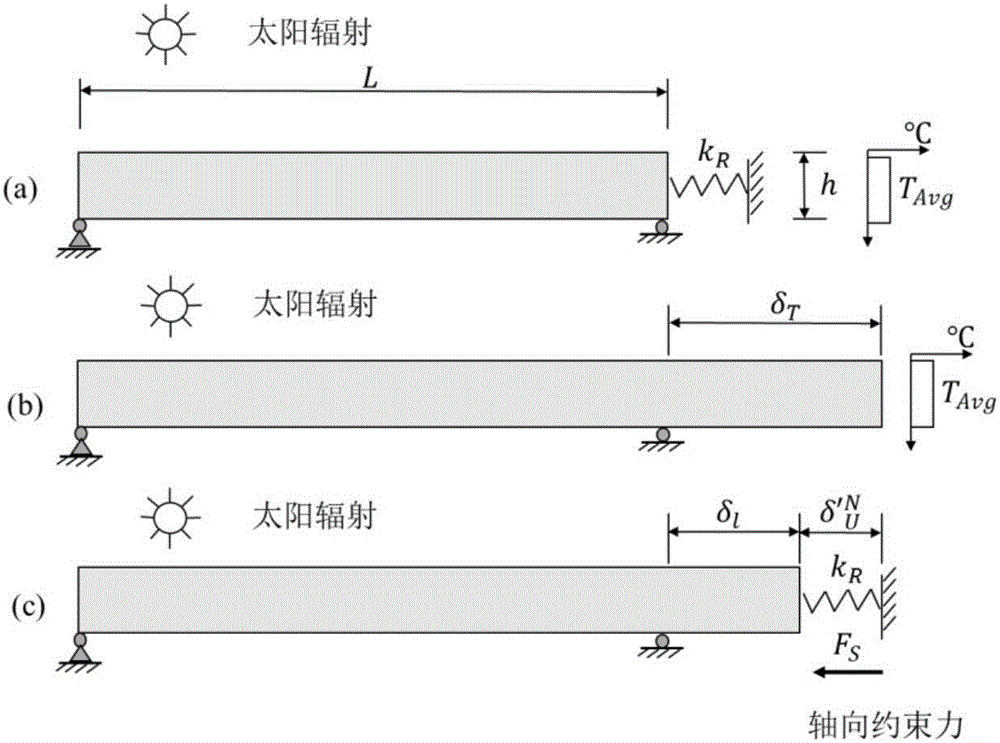

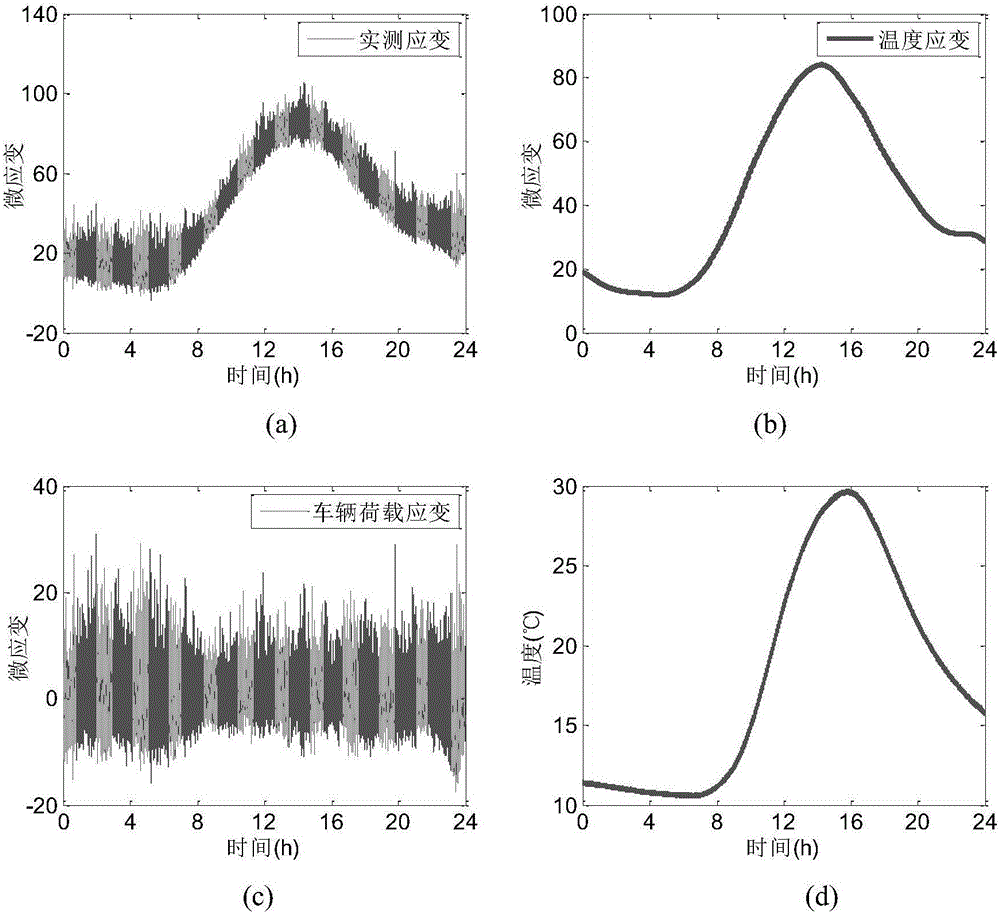

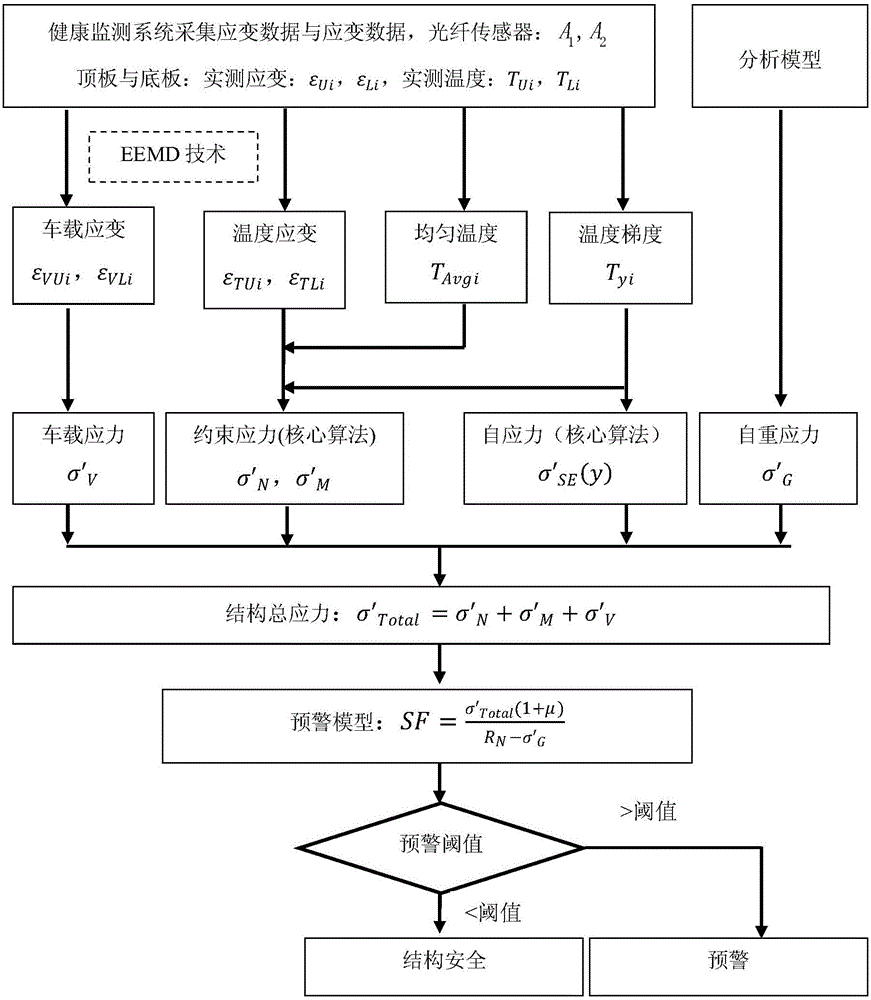

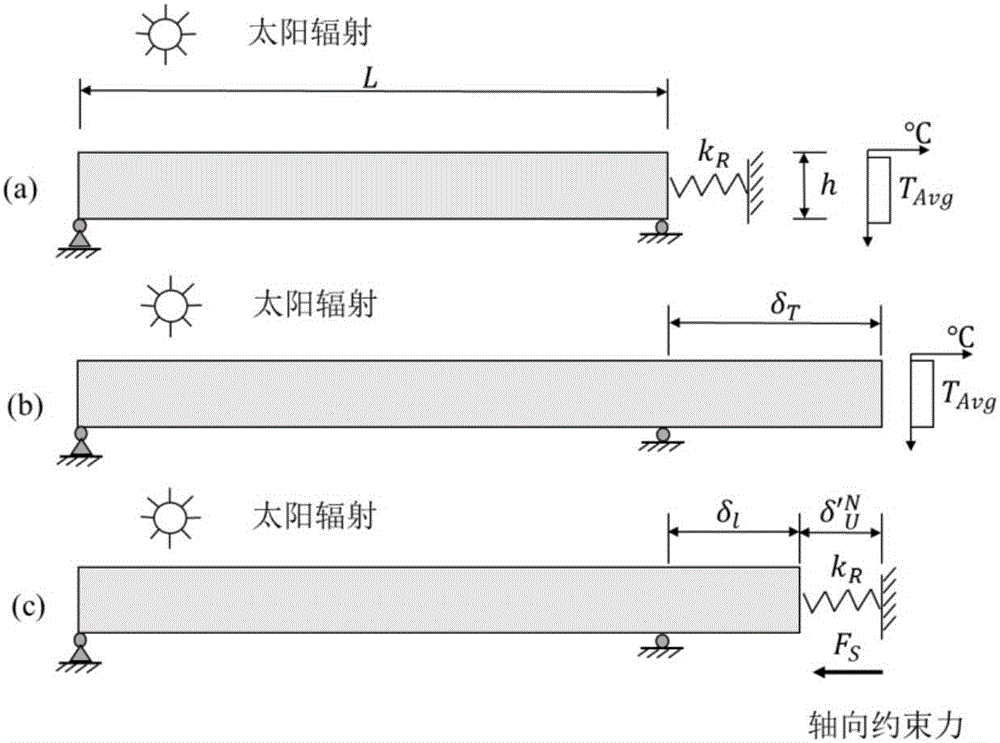

Total stress computing method and safety pre-warning method of large-span steel box girder bridge based on monitored data and temperature stress analysis

ActiveCN106092402AReduce the cost of regular manual inspectionIncrease profitApparatus for force/torque/work measurementTemperature stressElement model

The invention discloses a total stress computing method and safety pre-warning method of a large-span steel box girder bridge based on monitored data and temperature stress analysis. The total stress computing method comprises a step 1 of acquiring the strain and the temperature of the bridge by using a health monitoring system; a step 2 of separating temperature strain from the actually measured strain; a step 3of computing the uniform temperature and gradient temperature on the upper cross section of the steel box girder; a step 4 of computing axial restraint stress; a step 5 of computing bending restraint stress; a step 6 of computing temperature self-stress; a step 7 of acquiring geostatic stress from a finite element model; and a step 8 of computing the total stress of the large-span bridge in operation. Compared with a conventional early warning method, the early warning method is clear in early warning index and clear in mechanical model, takes account of the influence of temperature load on the large-span bridge structure, and is applicable to popularization in engineering field.

Owner:SOUTHEAST UNIV

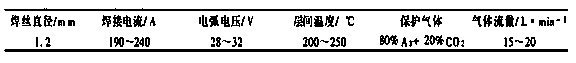

Welding technology of 45 steel and 35 CrMo cast steel

InactiveCN103521887AHigh strengthImprove toughnessArc welding apparatusRestraint stressStress relief

The invention discloses a welding technology of 45 steel and 35 CrMo cast steel. The technology includes the following steps that firstly, preheating is performed, a plate core and a plate piece are placed into an annealing furnace for being preheated to the temperature of 300 DEG C at the temperature rising speed of 40-60 DEG C per hour, heat preservation is performed for one hour, the plate core and the plate piece are taken out of the furnace and assembled, gas is used for continuous heating, and therefore the welding process is constantly kept at the preheating temperature of 200 DEG C and 250 DEG C; secondly, according to a welding manner, an H08Mn2SiA welding wire is adopted, and the argon-rich CO2 gas of 80% of Ar+20% of CO2 is used for protecting welding; thirdly, according to welding parameters, the diameter of the welding wire is 1.2mm, the welding currents are 190-240A, the welding voltage is 28-32V, the interlayer temperature is 200-250 DEG C, and the gas flow is 15-20L / min. Multilayer and multi-bead welding is adopted, welding beads are mutually overlapped, and the width of an overlapped welding joint is no smaller than 1 / 3 that of a welding joint. Meanwhile, each time one layer is welded, an air chipper is used for hammering the welding joint to relieve stress, and after welding, stress relief heat treatment is performed in the furnace. According to the welding technology of the 45 steel and the 35 CrMo cast steel, restraint stress can be greatly reduced, and therefore cracks are effectively prevented.

Owner:洛阳天信矿山机械制造有限公司

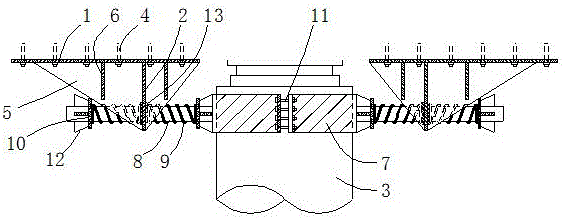

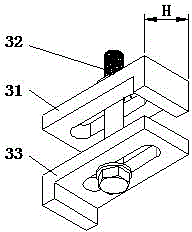

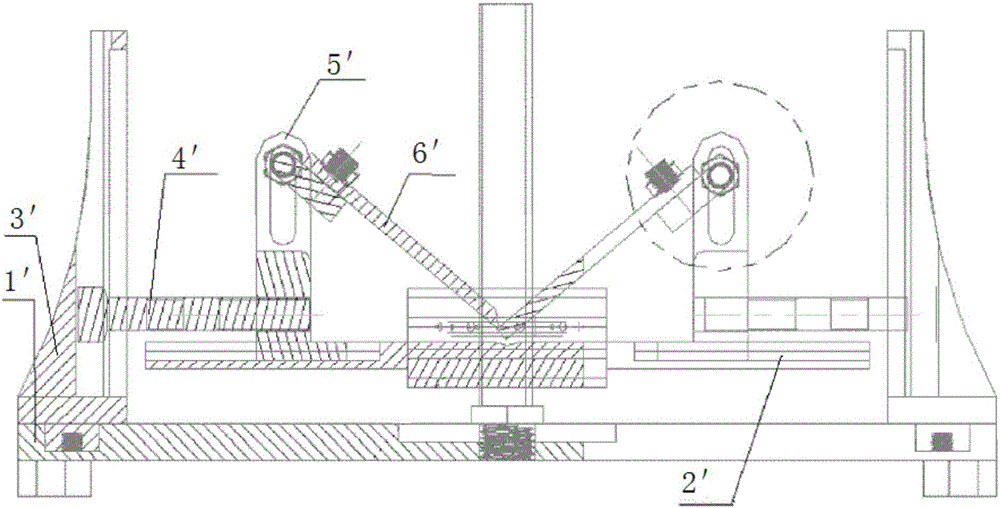

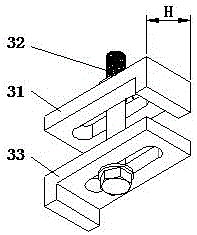

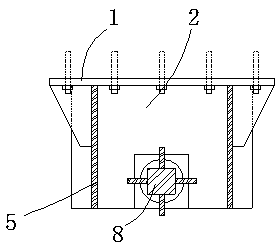

Device for testing cold cracking tendency of welding joint on basis of adjustable rigid restraint and apparition of device

InactiveCN105643131AAvoid stressAvoid Critical ConstraintsWelding apparatusRestraint stressData acquisition

The invention discloses a device for testing cold cracking tendency of a welding joint on the basis of adjustable rigid restraint and an apparition of the device. The device is characterized in that a first support plate and a second support plate are arranged on a base, and guide columns are connected between the first support plate and the second support plate; sliders are arranged on the guide columns, a movable clamp is arranged on the sliders, an oil cylinder is arranged on the base and connected with the sliders, a load sensor is arranged on the second support plate, a fixed clamp is fixedly connected with the second support plate and is opposite to the movable clamp, and each of a first displacement sensor and a second displacement sensor is connected with two samples; the load sensor, the first displacement sensor and the second displacement sensor are collected with a data acquisition card respectively, and the data acquisition card is connected with a controller which is connected with the oil cylinder. External restraint conditions of the welding joint are simulated by the device, and the welding samples keep fixed restraint length in a test process for rigid restraint cracking test, so that the critical restraint stress of steel during cold cracking can be obtained.

Owner:TIANJIN UNIV

Column pier type bridge anti-shifting device and column pier type bridge anti-shifting method

InactiveCN106638273AAvoid offsetReduce harmBridge structural detailsElastic componentRestraint stress

The invention discloses a column pier type bridge anti-shifting device. The column pier type bridge anti-shifting device is characterized by comprising two groups of beam body fixing assemblies which are arranged on left and right sides of the lower surface of a beam body along the width direction, wherein each beam body fixing assembly comprises an anchoring bottom plate, and the anchoring bottom plate is arranged along the width direction of the beam body and is anchored and connected onto the beam body; each anchoring bottom plate is internally provided with a displacement following plate which is vertically arranged downward along the longitudinal direction of the beam body; an elastic component is horizontally arranged between lower sides of the two displacement following plates in the left-right direction; and the elastic component takes a bridge pier below the beam body as the mounting supporting foundation and is mounted on a hoop fixed on the bridge pier. The invention further discloses a column pier type bridge anti-shifting method adopting the device. The column pier type bridge anti-shifting device has the advantages that the structure is simple, the construction is convenient, the horizontal restraining on a beam body of the bridge can be realized very well, the restraint stress can be released and potential safety hazard is reduced.

Owner:YANGTZE NORMAL UNIVERSITY

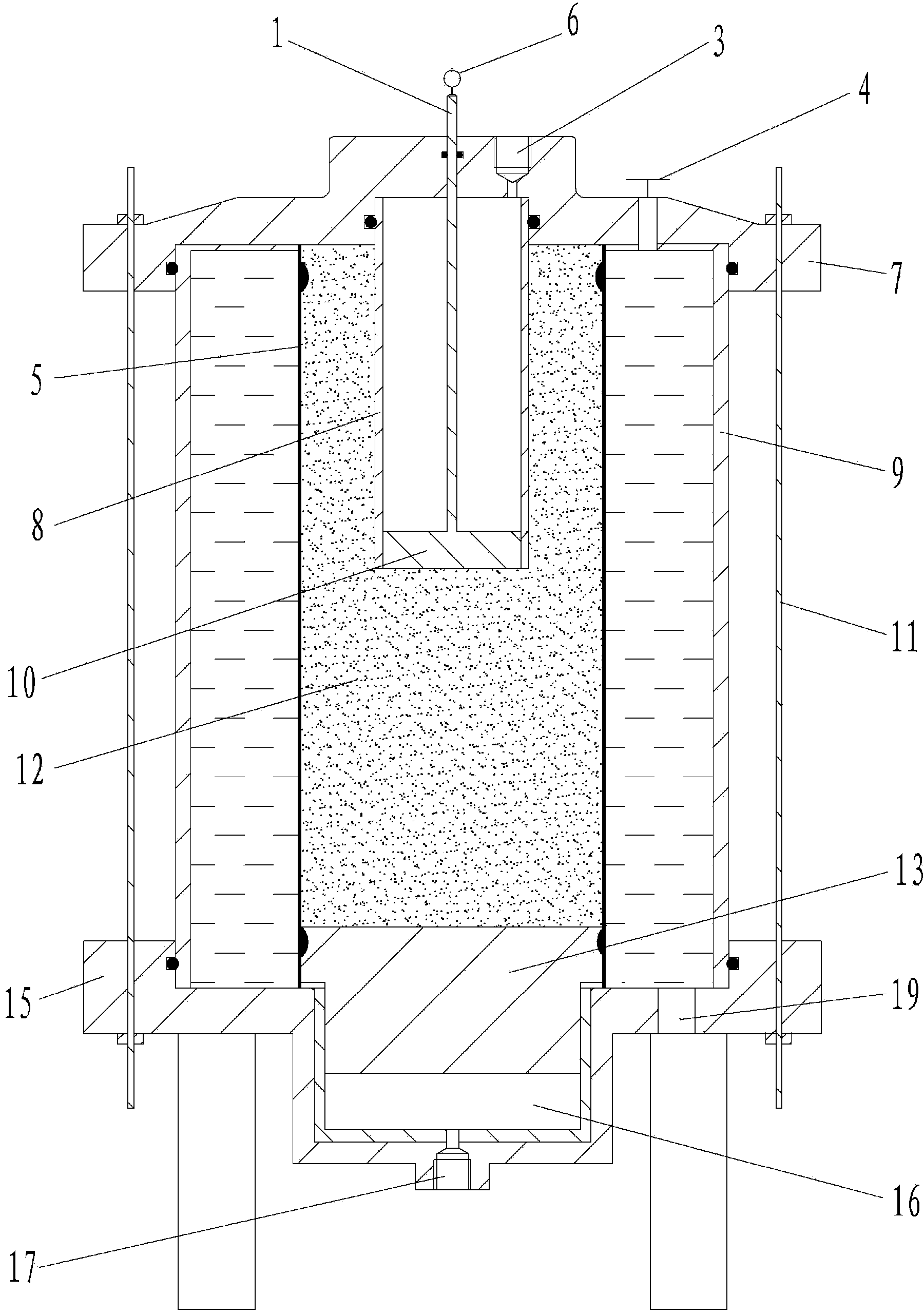

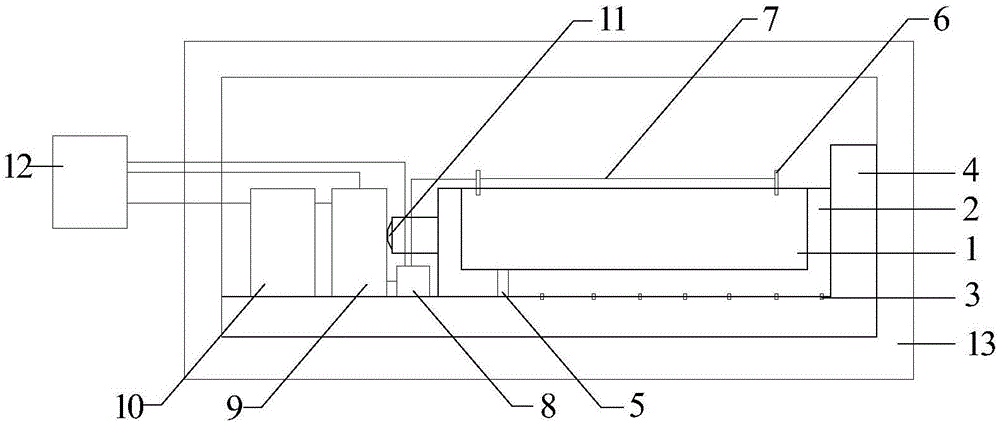

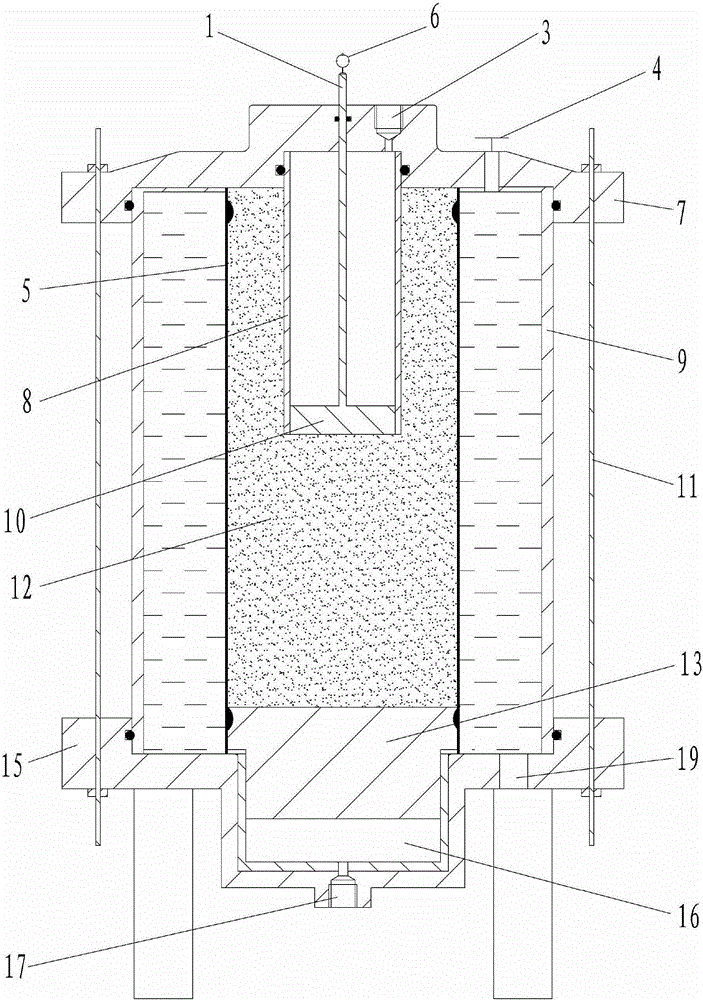

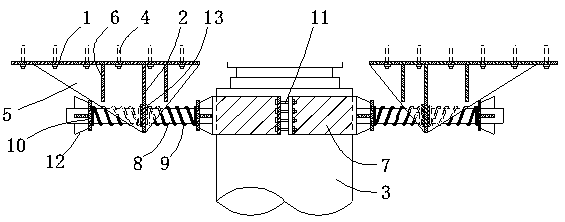

Testing device and testing method for relation between restraint stress and extrusion deformation of tunnel face

ActiveCN104007247AThe test data is accurate and reliableConstruction safetyEarth material testingMechanical solid deformation measurementsExhaust valveRestraint stress

Provided are a testing device and a testing method for a relation between a restraint stress and an extrusion deformation of a tunnel face. A cylindrical pressure chamber is formed by means of a side wall, a top cover and a pedestal in a sealing embedded manner. An oil cylinder is fixed in a groove arranged in a central part of an upper surface of the pedestal. A piston which is in the oil cylinder stretches upwardly into the pressure chamber. An exhaust valve is disposed closed to the side wall on the top cover. An air cylinder barrel, which is smaller than the oil cylinder in diameter, is sealedly embedded on an air cylinder groove arranged in the central part of a bottom surface of the top cover. The air cylinder groove is provided with a vent hole which stretches out through the top cover. A piston in the air cylinder is connected to a displacement measuring rod. An upper end of the displacement measuring rod stretches out from the top cover and is connected to a displacement dial gauge. A water inlet valve is disposed on a position of the pedestal, wherein the position is between an inner chamber of the pressure chamber and the oil cylinder. With the testing device, the relation between the restraint stress and the extrusion deformation of a tunnel face can be accurately tested under different conditions of surrounding rock, thereby providing reliable testing data for design and construction of a tunnel. On the premise of effectively ensuring stabilization of the tunnel face, construction cost is reduced and construction speed is increased.

Owner:SOUTHWEST JIAOTONG UNIV

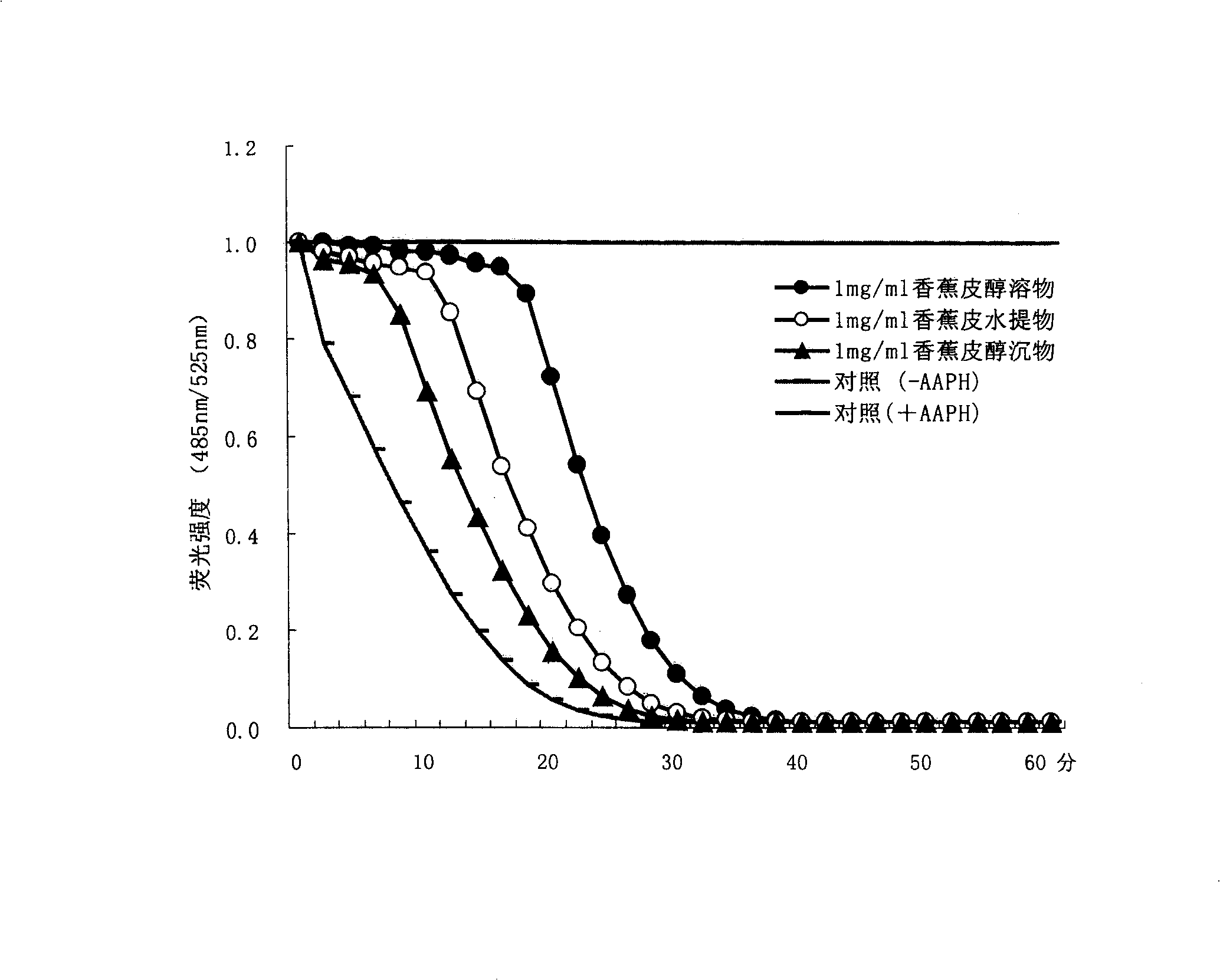

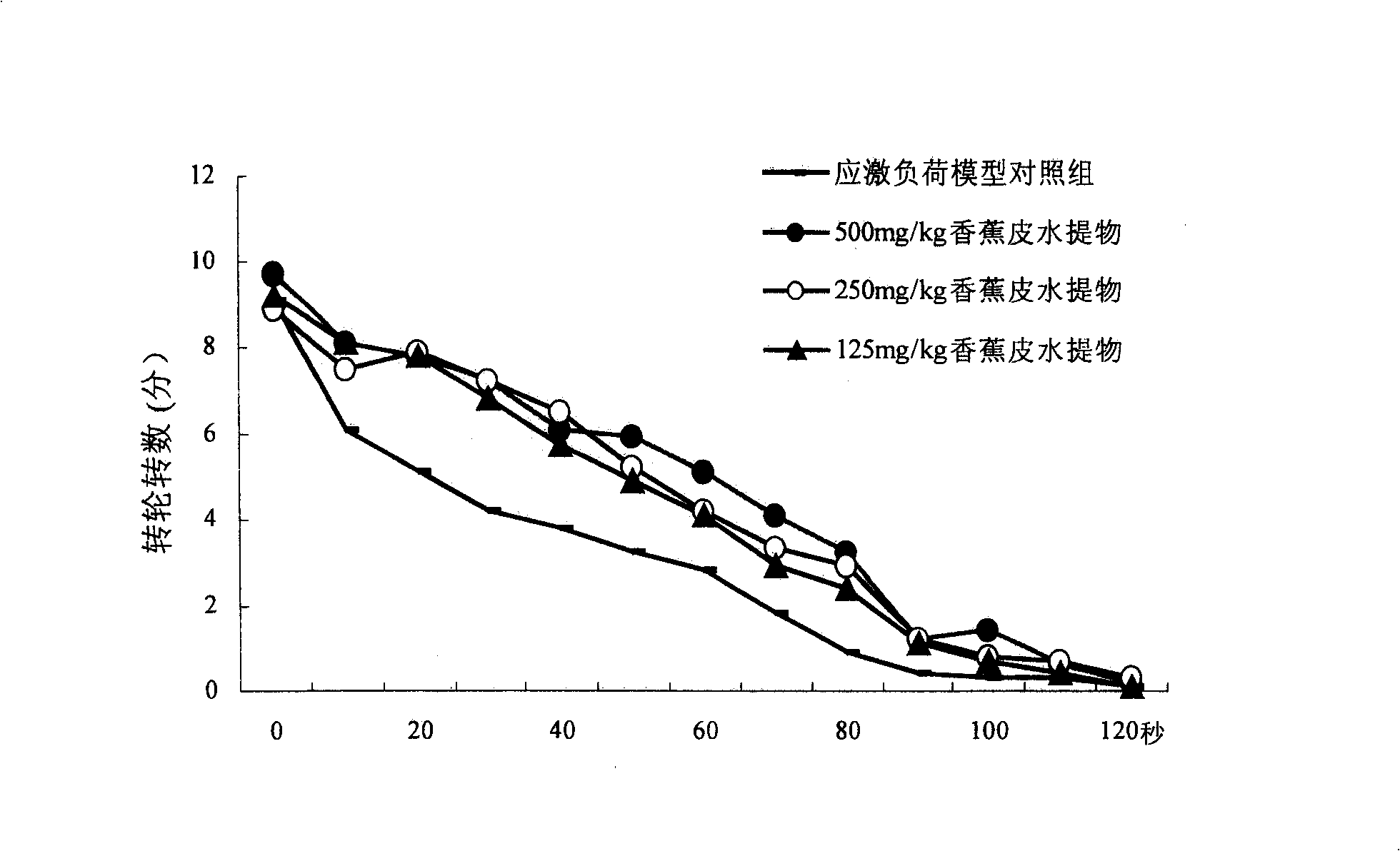

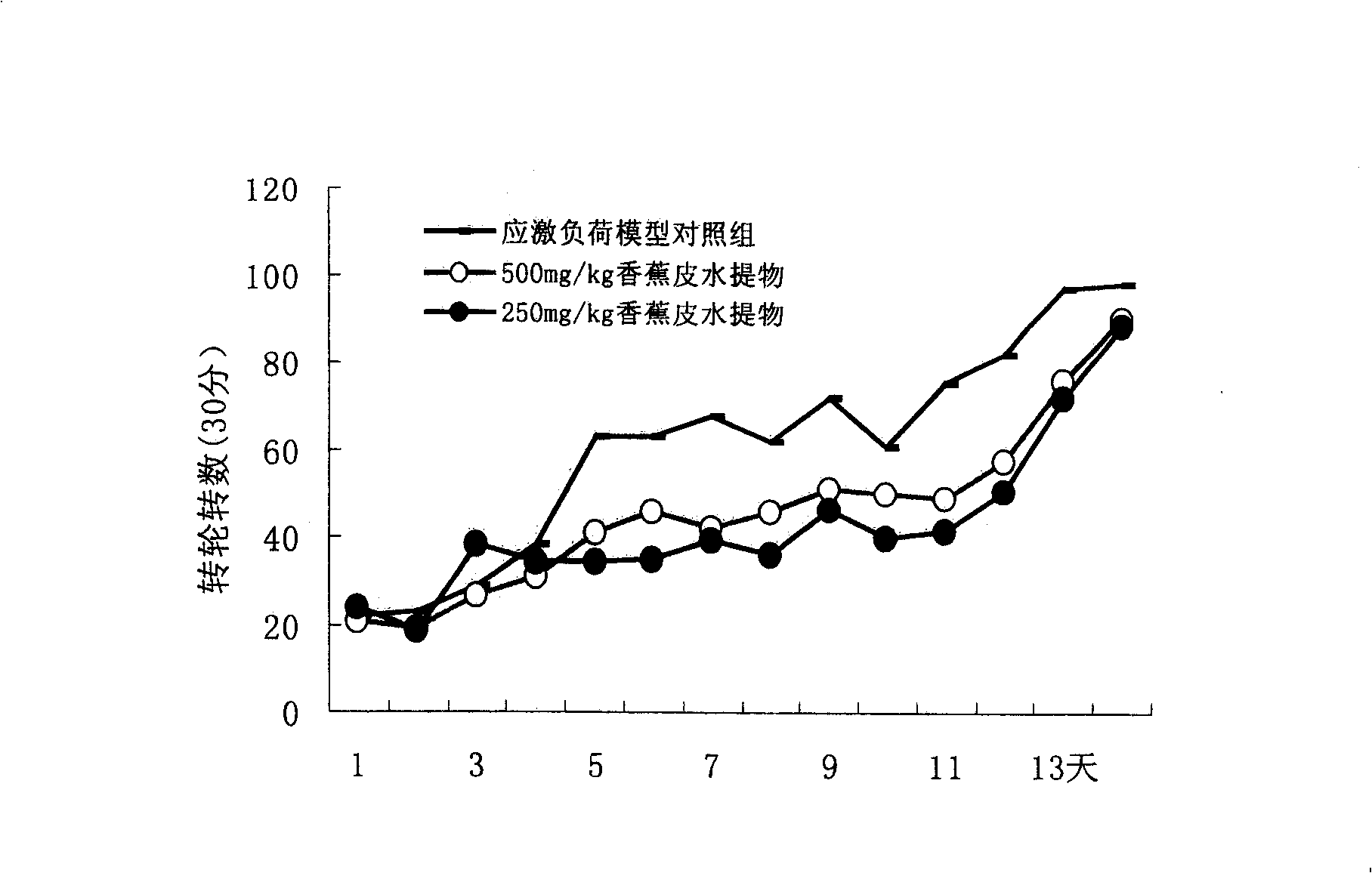

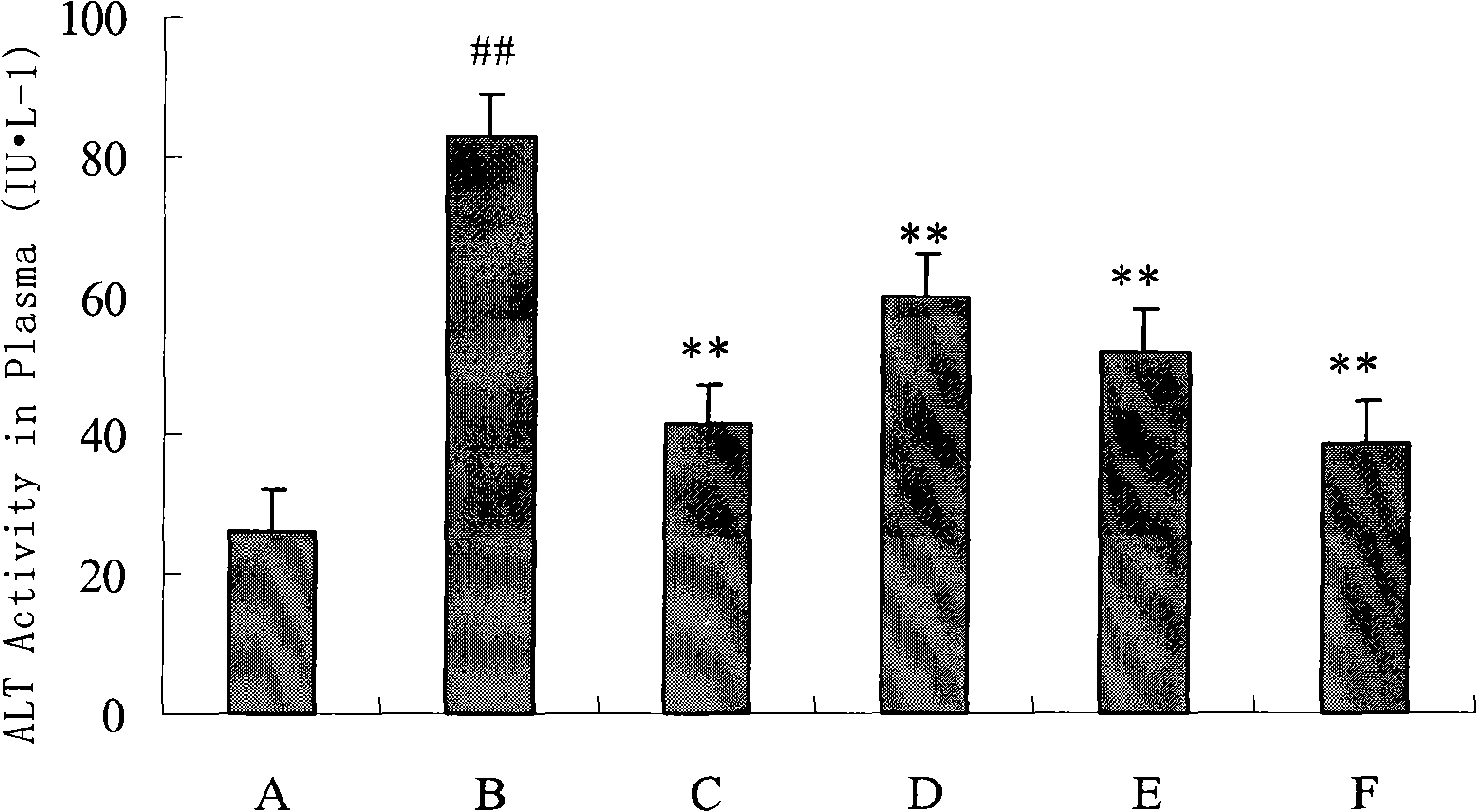

New anti-stress and tidepressant purpose of banana tegument extract

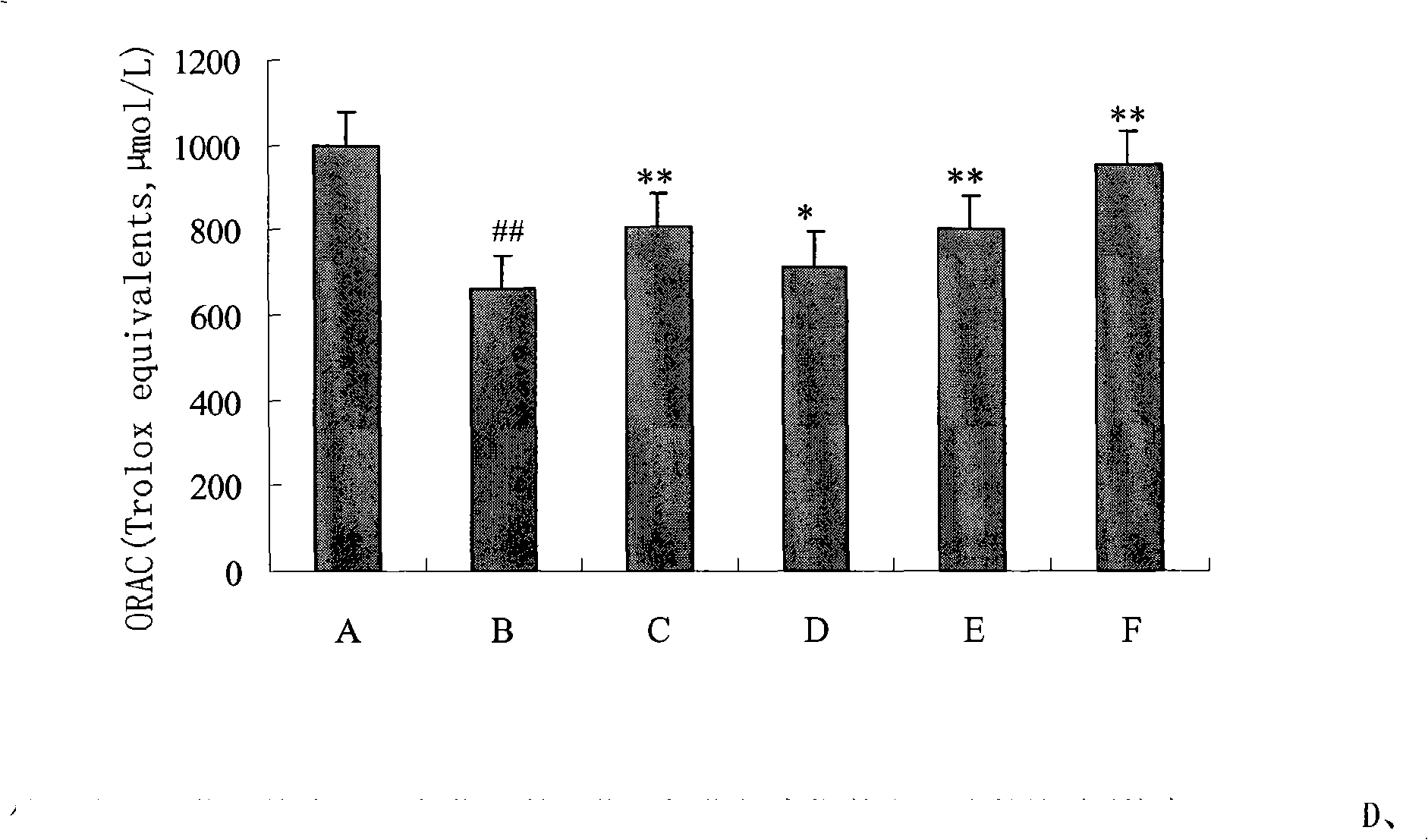

InactiveCN101244160ARelieve and improve fatigueRelieve and improve liver damageNervous disorderDigestive systemFood additiveAnti stress

The invention relates to a medicine, a healthy food and a food additive, which adopt the extract of banana skin as raw material and is used for preparing anti-stress and antidepressant medicines and medicines for alleviating and improving the adverse reactions of hepatic injury caused by stress load. The medicine is based on that the extract of banana skin has regulation effect on the restraint stress mice plasma, anti-oxidation capacity of liver and the content of malon dialdehyde (MDA) in liver, and has significant effect on the improvement effect of increase of pyruvic transaminase of restraint stress mice plasma and on the in vitro anti-oxidation experiment. The usage amount of the extraction of banana skin in various finished products of medicine, healthy food and food additive can be 0.01 to 100% in weight ratio due to high safety and exact biological activity.

Owner:冯锦和

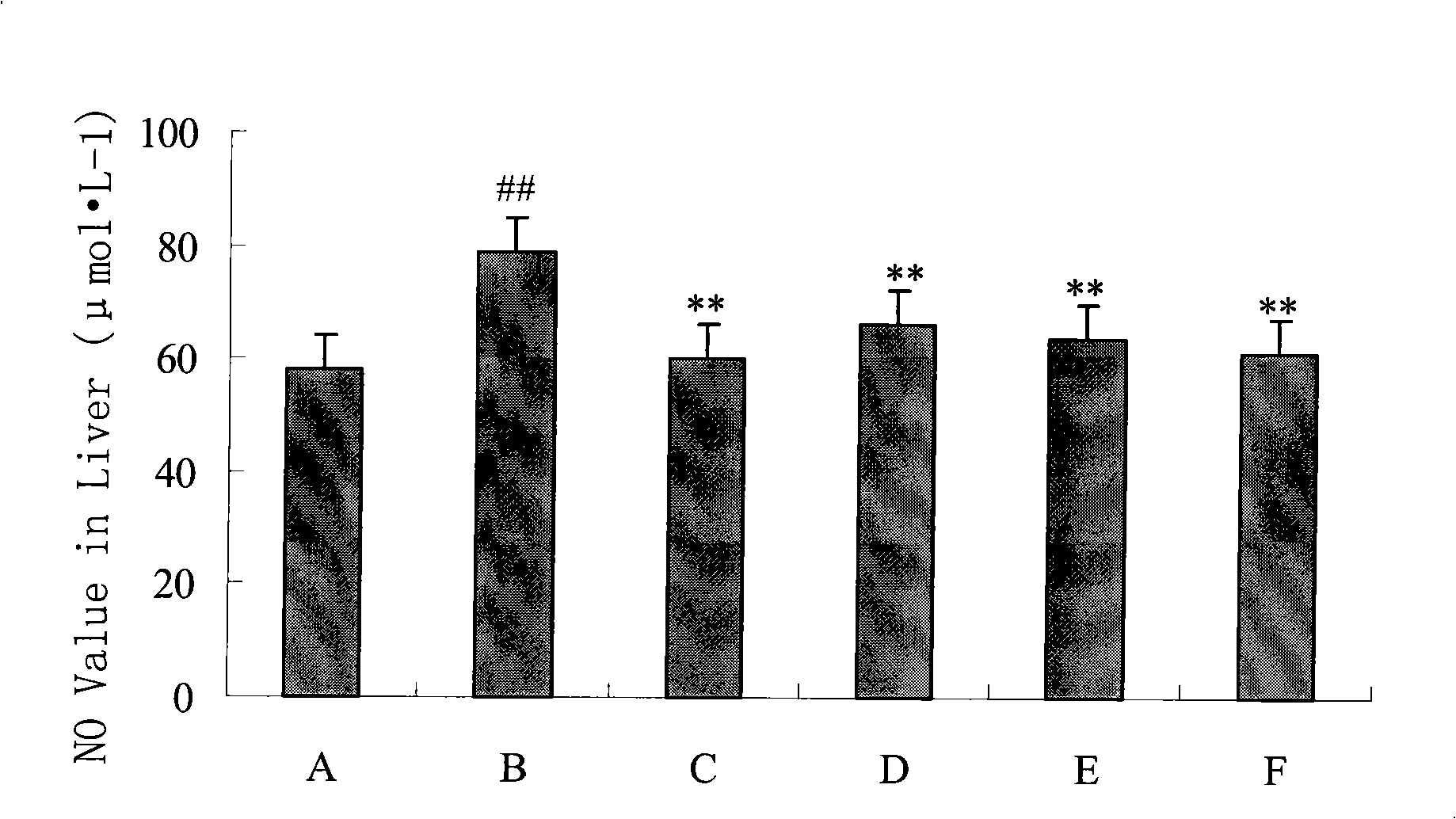

Novel use of bamboo shell extract

The purpose of the invention is to provide medicine, healthy food and food additive with bamboo shoot shell or bamboo shoot shell extract as raw materials and used for oxidation resistance, stress resistance and improving all clinical symptoms produced by stress load or physical or mental fatigue. Definitely, the invention provides medicine, healthy food and food additive which can improve the physical and mental fatigue of the organism and liver functions, can be taken for a long time, is safe without toxin and side effect and the components thereof based on the bamboo shoot shell extract with restraint stress load ALT, blood serum and liver oxidation resistance capability index, liver-nitrogen oxide, etc., as indexes. In addition, the invention provides the medicine, healthy food, food additive and the components thereof which prove that the oxidation resistance embodied by the bamboo shoot shell and the bamboo shoot shell extract can be used to improve and mitigate all the clinical symptoms because of the oxidation and the stress produced by physical and mental fatigue.

Owner:东莞市竟恒流通研究所

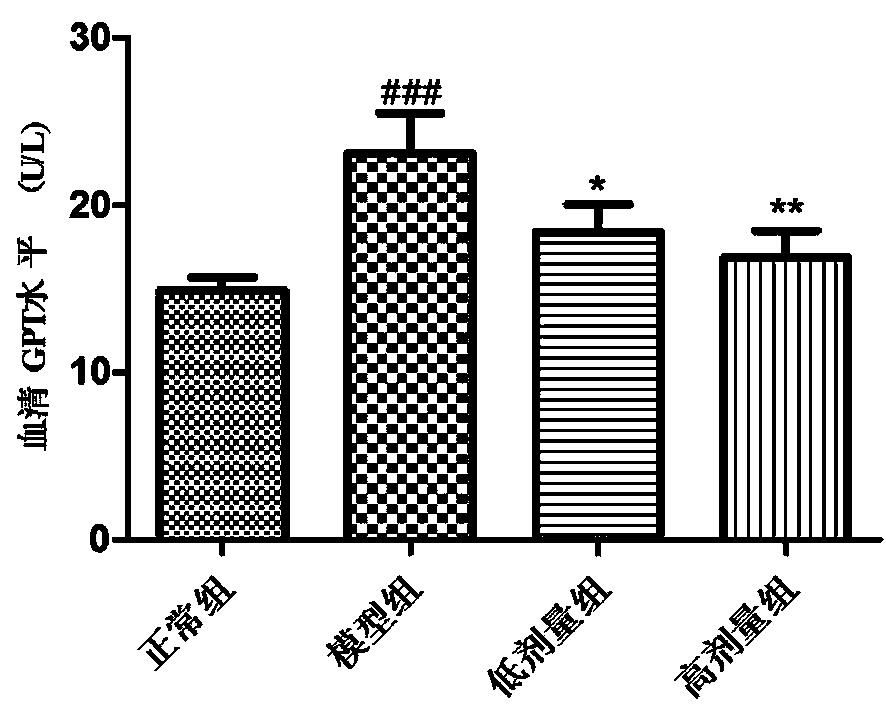

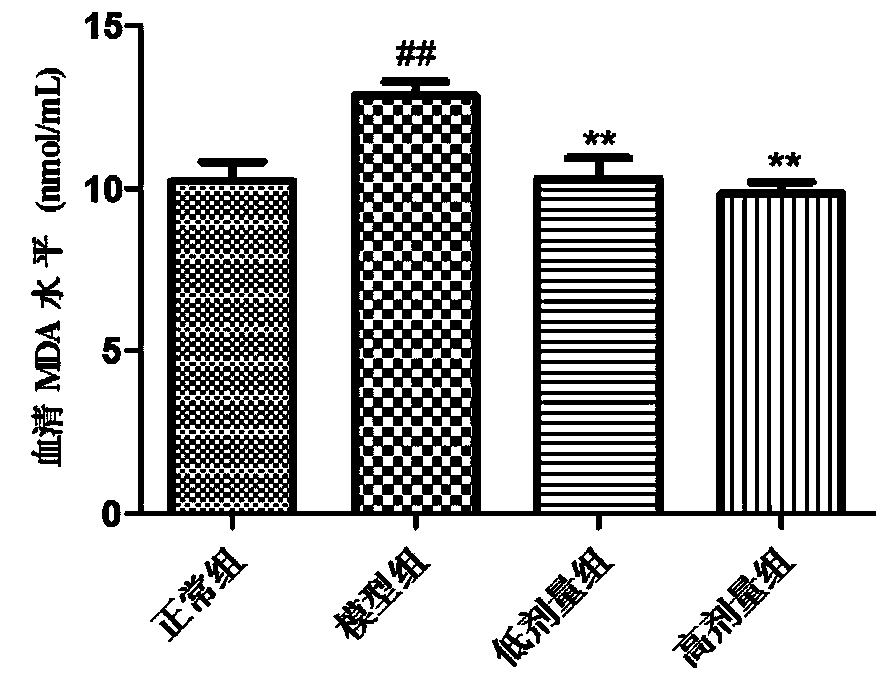

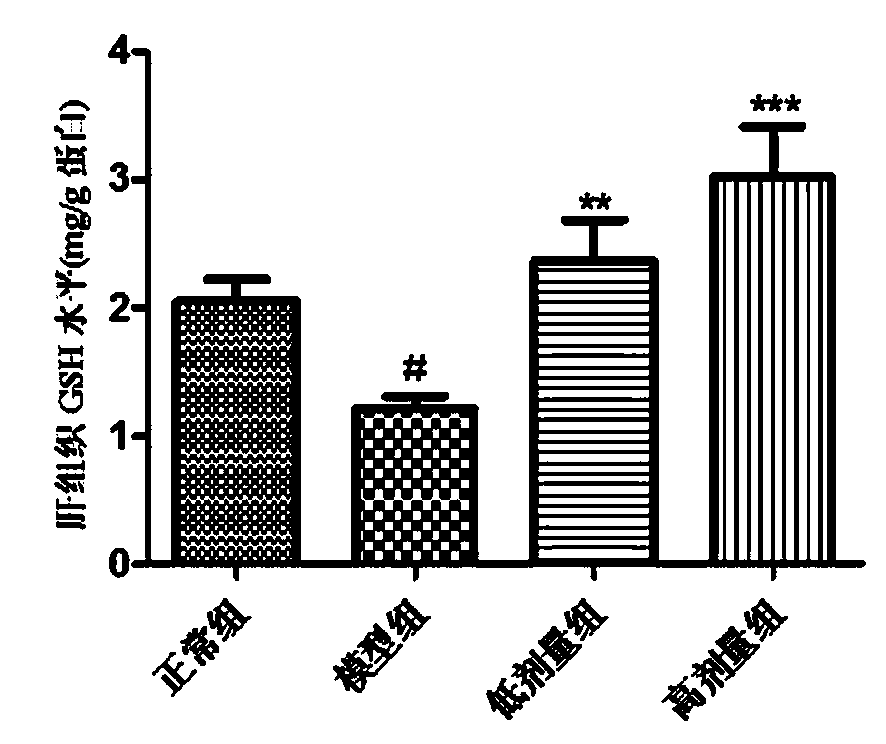

Applications of black rice anthocyanin extract in preparing medicament for protecting restraint stress-induced liver injury

InactiveCN103405674ALower levelImprove the level ofDigestive systemPlant ingredientsReactive oxygen radicalsMedicine

The invention discloses applications of black rice anthocyanin extract in preparing medicament for protecting restraint stress-induced liver injury. The related research shows that the black rice anthocyanin extract achieves the function of obviously balancing the reactive oxygen species in the body, is capable of reducing the GPT (Glutamic Pyruvic Transaminase), MDA (Methylene Dioxyamphetamine) and XOD (Xanthine Oxidase) levels of the organism under the pathological condition, and improving the GSH (glutathione) level of antioxidant substance in the body, and can be used for preparing the medicament for protecting restraint stress-induced liver injury.

Owner:SUZHOU UNIV

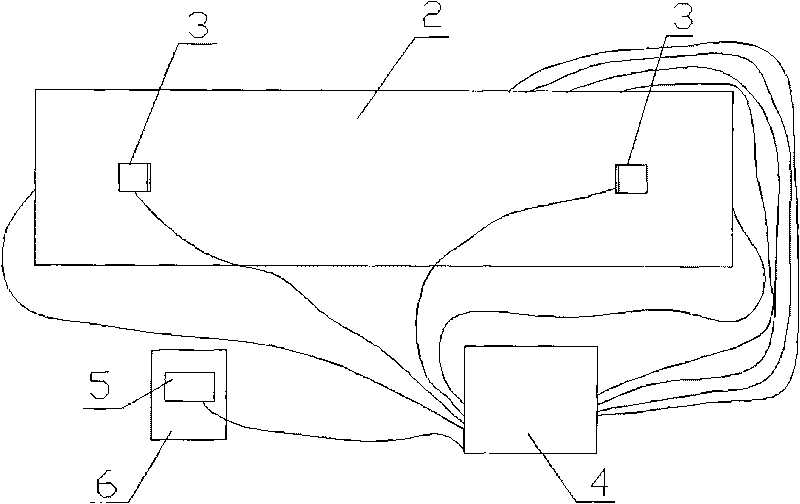

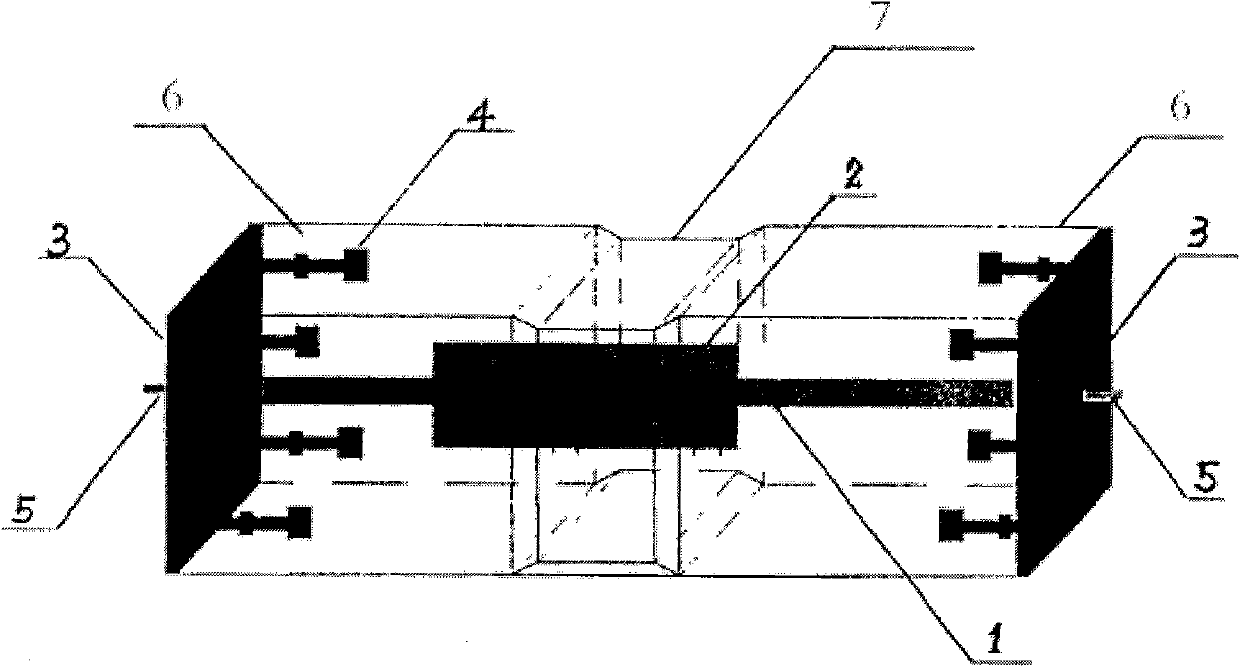

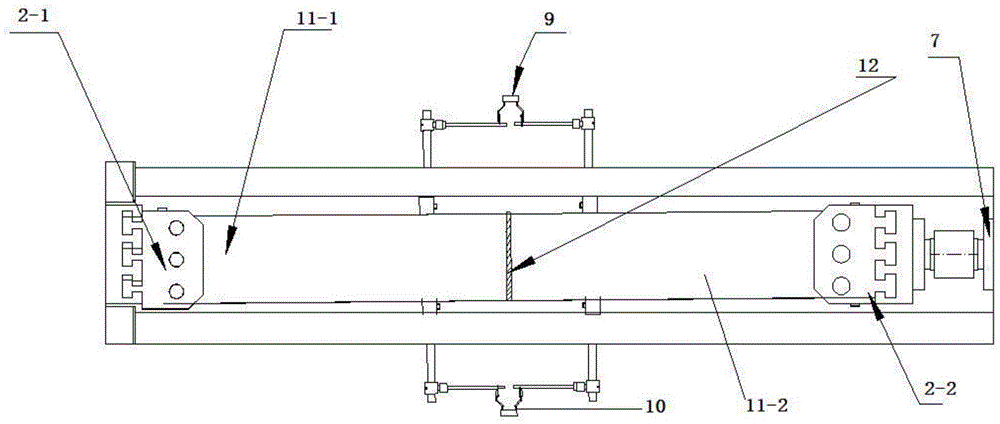

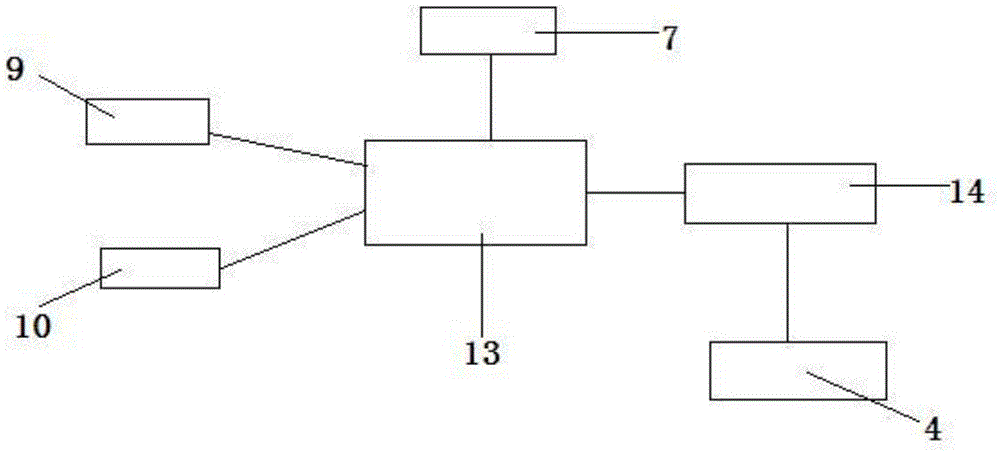

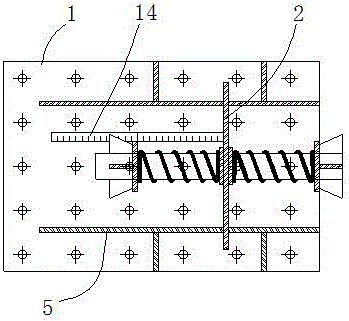

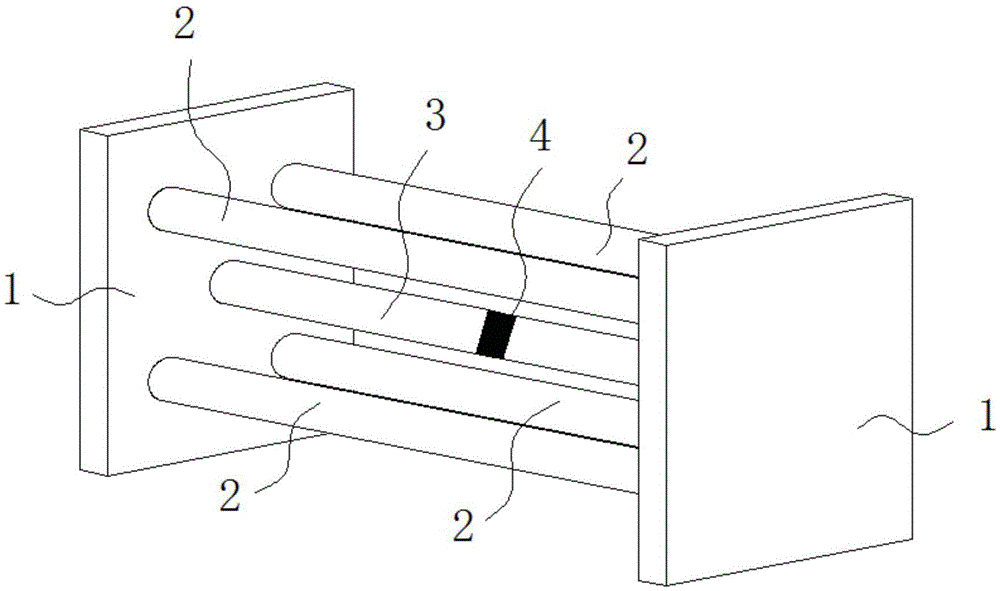

Oil-gas pipeline restraint simulator and testing method thereof

ActiveCN105643135AImplement restraint simulation testingHigh degree of restraintMetal working apparatusWelding apparatusPipe fittingRestraint stress

The invention provides an oil-gas pipeline restraint simulator and a testing method thereof. The oil-gas pipeline restraint simulator comprises a first fixing plate, a second fixing plate, a rigidity restraint support, a first sample pipe fitting, and a second sample fitting, wherein the first fixing plate and the second fixing plate are oppositely arranged, the rigidity restraint support, the first sample fitting and the second sample fitting are arranged between the first fixing plate and the second fixing plate. The testing method includes setting the rigidity restraint support, welding the sample pipe fittings, cutting the testing sections, and testing data. As shape and size of the sample pipe fittings can be tested according to the full size of the oil-gas pipeline in actual operation, size is free of limit, and through the simple pipe fitting welding structure, restraint simulation testing of the oil-gas pipeline can be realized. The oil-gas pipeline restraint simulator can simulate high restraint and restraint stress and is wider in application range and more accurate in testing.

Owner:GUANGDONG DAPENG LNG COMPANY

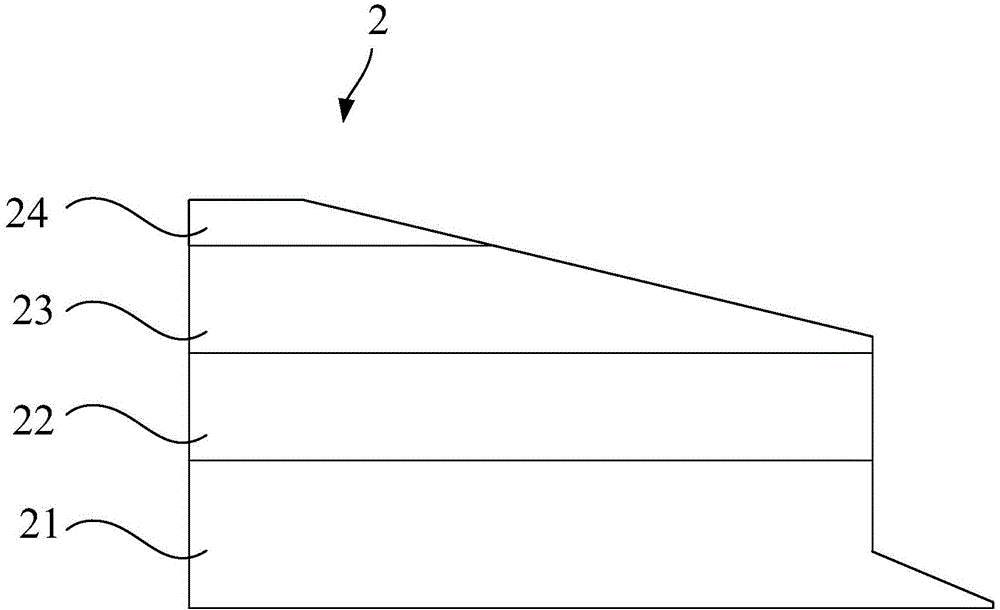

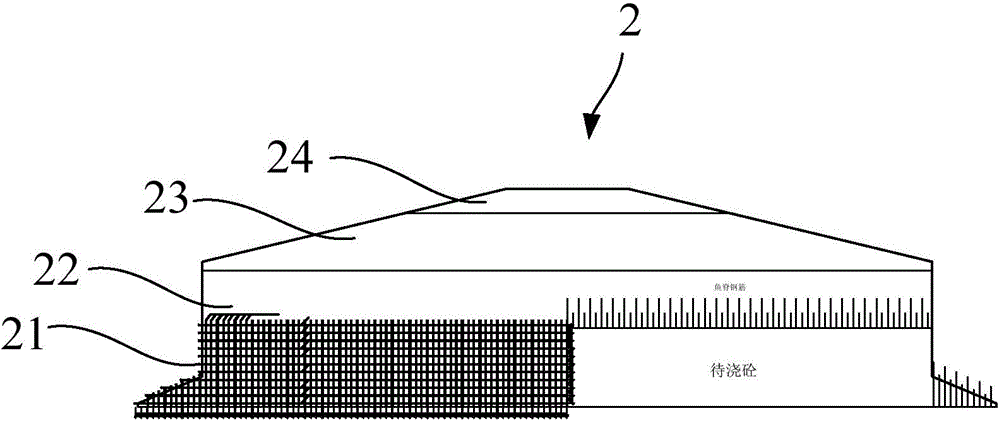

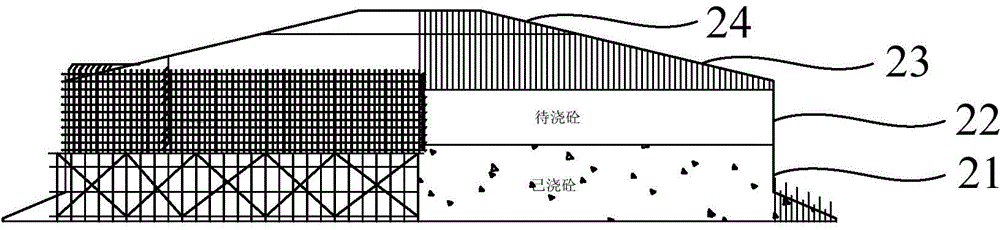

One-time continuous forming and pouring method for ultralong post-poured fish ridge wall and ultralong fish ridge wall

ActiveCN104652280AImprove crack resistanceIncreased durabilityBridge structural detailsBridge erection/assemblyCrack resistanceSlag

The invention discloses a one-time continuous forming and pouring method for an ultralong post-poured fish ridge wall and an ultralong fish ridge wall. The method comprises the following steps of arranging an anti-cracking steel bar mesh at an abrupt change position on the section of the side surface of the fish ridge wall, and performing layered casting on the fish ridge wall by concrete, further comprises the steps of S1, retaining part of box type bridge panel steel strand, and tensioning the box type bridge panel steel strand after the first layer of concrete of the fish ridge wall is cast; S2, arranging a temporary construction steel strand in the fish ridge wall; S3, reinforcing the side surface of the concrete at the combined position of the fish ridge wall during layered casting; S4, doping a proper amount of superfine slag powder and coal ash into the concrete for casting the fish ridge wall; S5, carrying out once continuous pouring by a slantways segmenting and horizontal layering method. According to the method, the cracking resistance of a concrete block body of the fish ridge wall under external restraint stress can be enhanced, and the aim of preventing or controlling temperature cracks is fulfilled.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

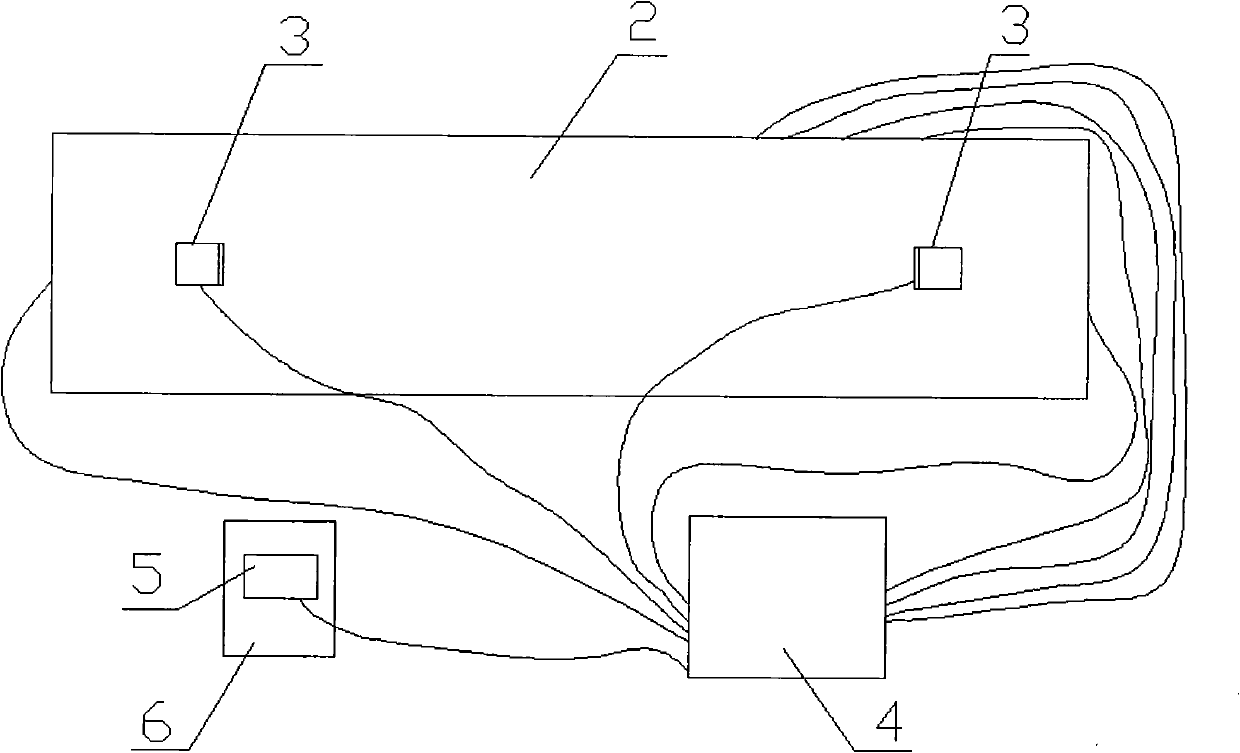

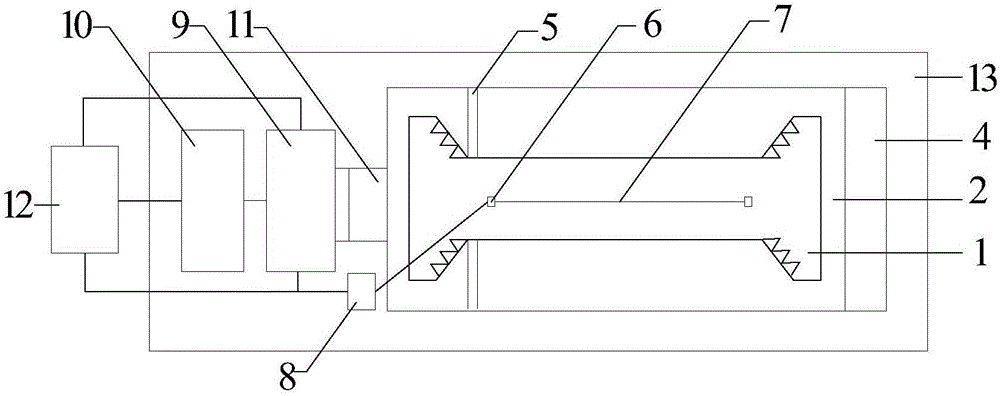

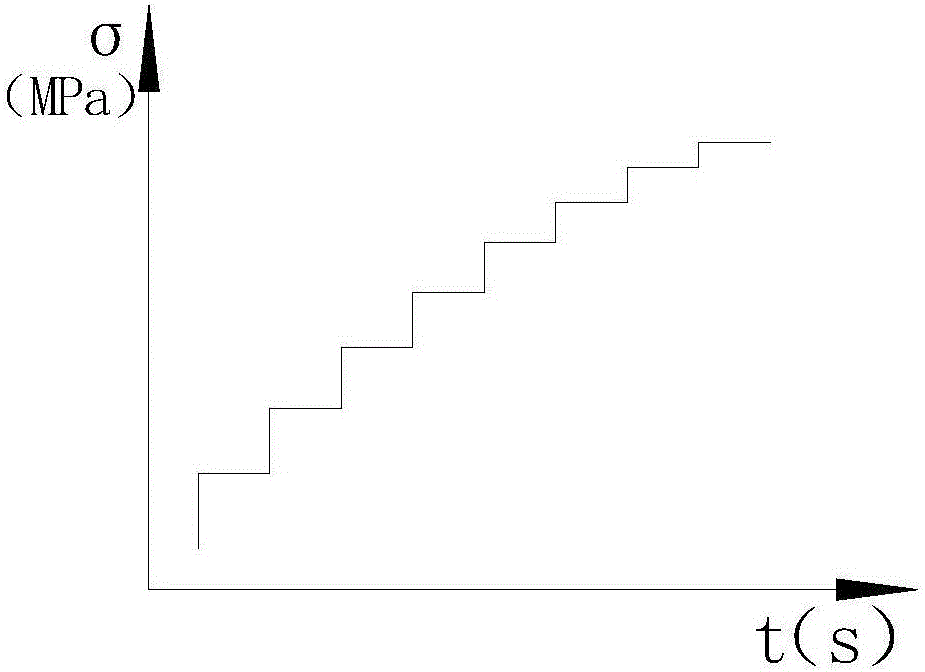

Test device and method for axial full restraint stress

The invention discloses a test device and method for axial full restraint stress. The test device for axial full restraint stress comprises a restraint frame, a displacement sensing system, a restraint test piece, a load sensor, an actuator and an environmental cabinet. The restraint frame, the displacement sensing system, the restraint test piece, the load sensor and the actuator are all located in the environmental cabinet, the restraint frame is composed of a test piece template, a base plate and a spherical hinge, the test piece template comprises a fixed template and a moving template, the fixed template is fixed on the base plate, the actuator is fixed on the base plate, an execution end of the actuator is connected to the moving template through the load sensor, and the spherical hinge is arranged on the end of the moving template. Compared with the prior art, the test device for the axial full restraint stress is simple in structure, high in test precision and simple in test method. The device can achieve a 100% restraining degree of a test piece, and can control the temperature of a test piece through the environmental cabinet. The device is applicable to measurement of early phase restraint stress of concrete in a scientific research and construction site, and has a wide market application prospect.

Owner:HOHAI UNIV

Technology for reducing cold crack sensibility of X80 pipeline steel welding

InactiveCN103586569ADiffusion and spilloverReduce the degree of hardeningArc welding apparatusFurnace typesCrack resistanceHeat-affected zone

The invention relates to the technical field of pipeline welding, in particular to a technology for reducing cold crack sensibility of X80 pipeline steel welding. The technology includes the steps of preheating, welding and heat treatment after the welding. A high preheating temperature is adopted for slowing down cooling speed after the welding, which helps diffusible hydrogen in weld joint metal to escape, meanwhile, the quench hardening degree of weld joints and heat affected areas is reduced, and the crack resistance of a welded splice is improved. The heat treatment is performed at once after the welding, high-temperature heating is performed, then slow cooling is performed, and heat preservation is performed so that residual stress after the welding can be eliminated, and the residual hydrogen is prompted to diffuse and escape. Therefore, cold cracks caused by restraint stress and the quench hardening structure can be reduced.

Owner:HOHAI UNIV CHANGZHOU

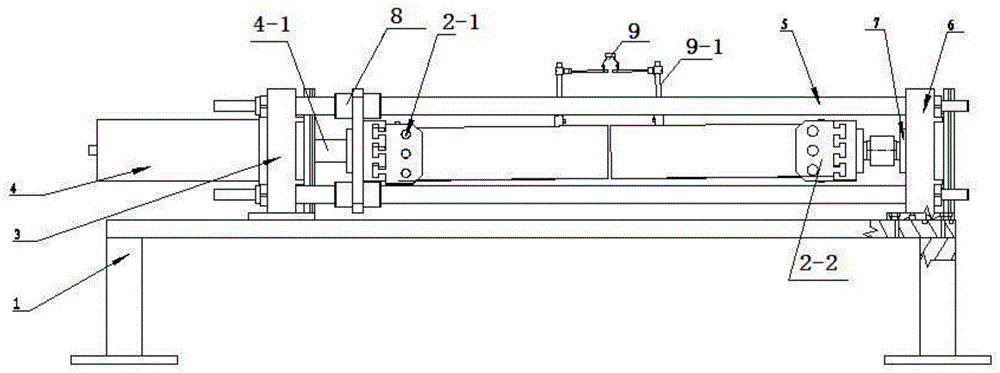

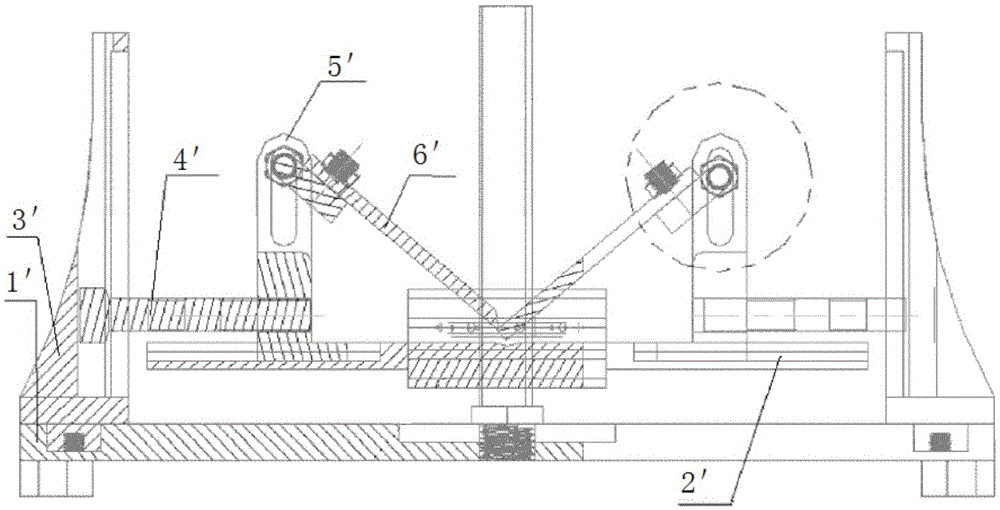

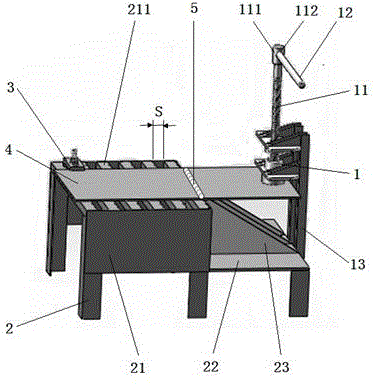

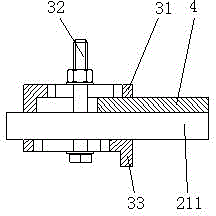

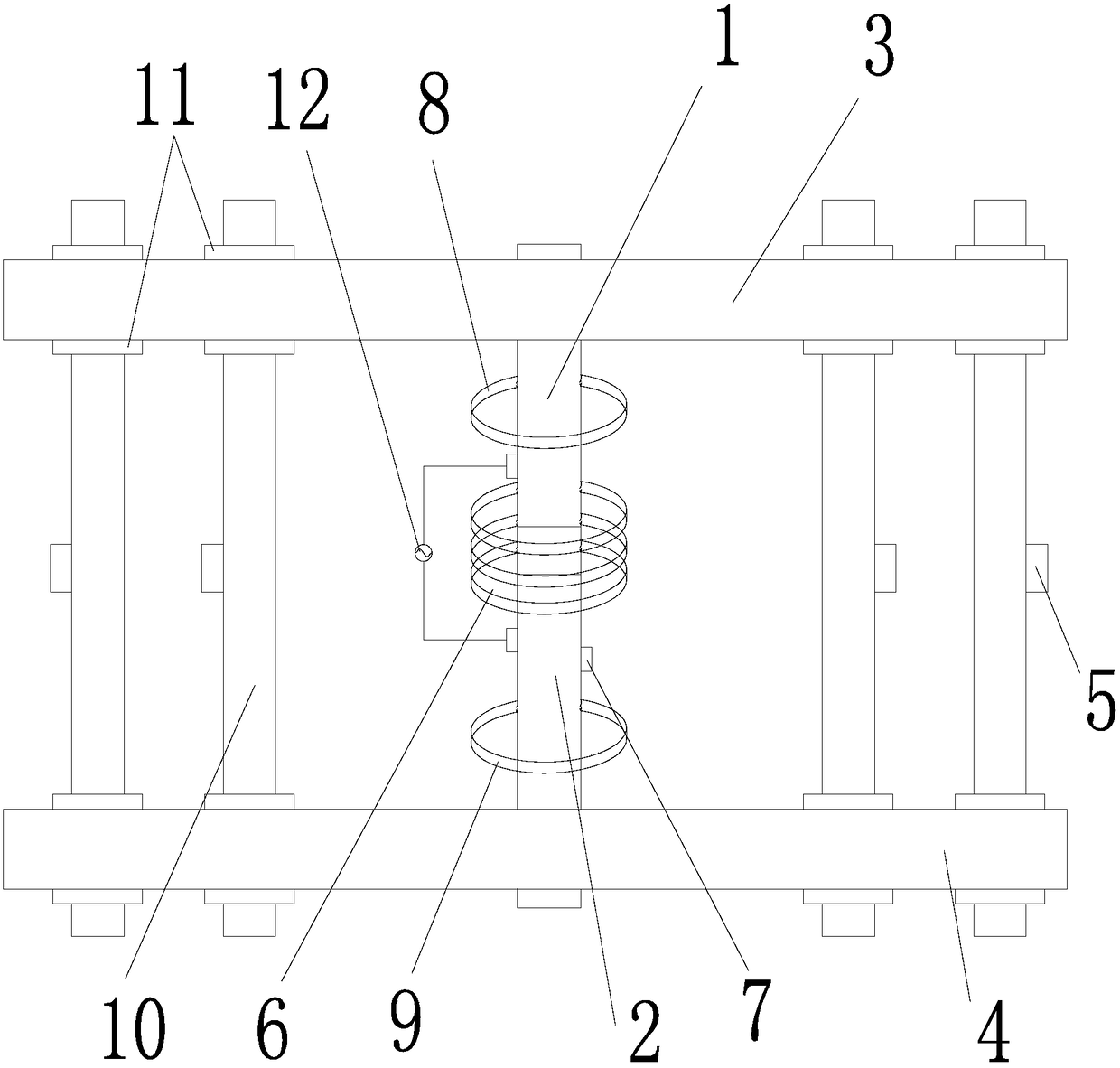

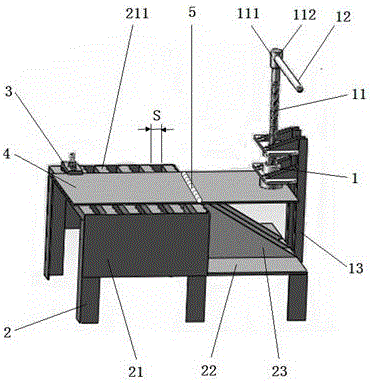

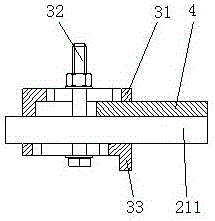

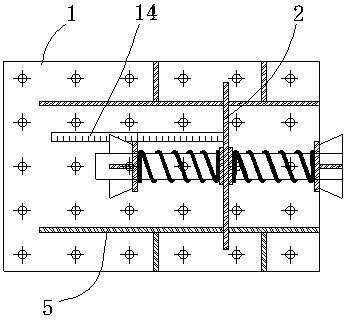

Adjustable welding restraint stress testing device

ActiveCN104880364ASo as not to damageGuaranteed StrengthStrength propertiesRestraint stressEngineering

The invention discloses an adjustable welding restraint stress testing device. The adjustable welding restraint stress testing device comprises a force application unit, a fixture unit and a body unit, the fixture unit is arranged between two transverse rods on the body unit, the force application unit is corresponding to a weld element on the body unit, and pressure is applied to the weld element through an adjustable screw rod; the fixture unit comprises an upper press plate, a bolt and a lower press plate, and the weld element passes through the upper press plate and lower press plate to fix on the body unit in a compression mode through the bolt. The adjustable welding restraint stress testing device is capable of quickly and conveniently measuring the critical restraint degree and critical restraint stress of the cold crack of a weld assembly so as to provide a scientific basis for formulating reasonable welding parameters and technology conditions; the adjustable welding restraint stress testing device is convenient to use, scientific and reasonable in structure, simple in production technique, low in manufacturing cost and easy to popularize; the adjustable welding restraint stress testing device can be broadly used for the welding restraint degree evaluation test for different kinds of steels.

Owner:HUNAN UNIV OF SCI & TECH

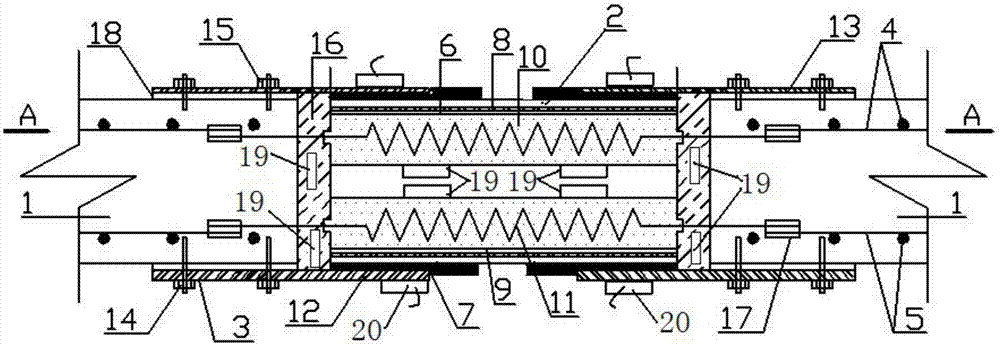

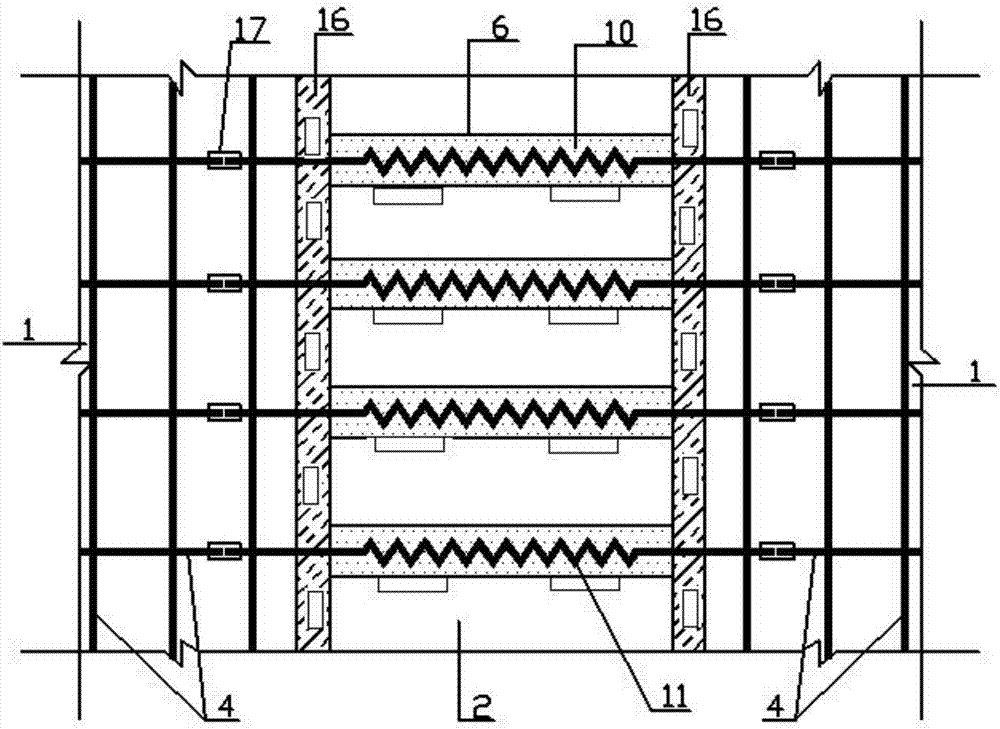

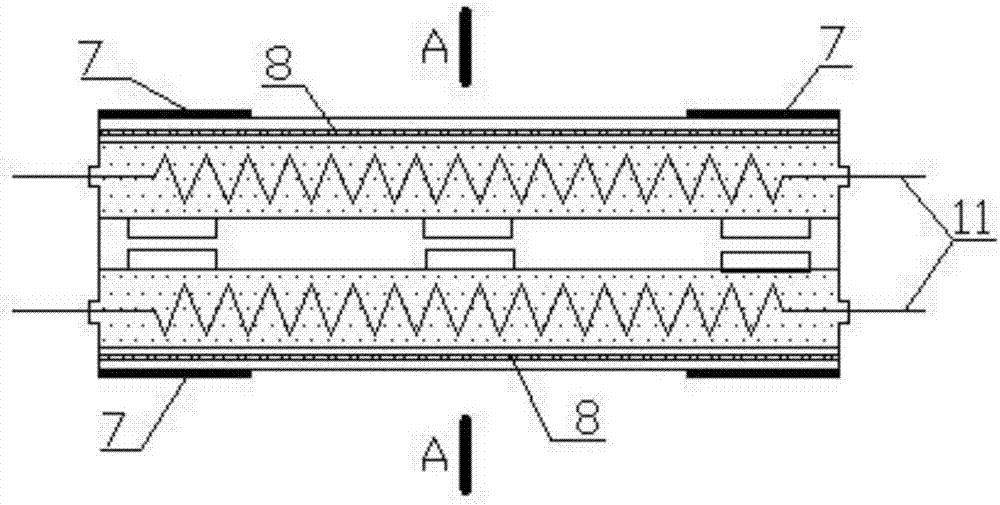

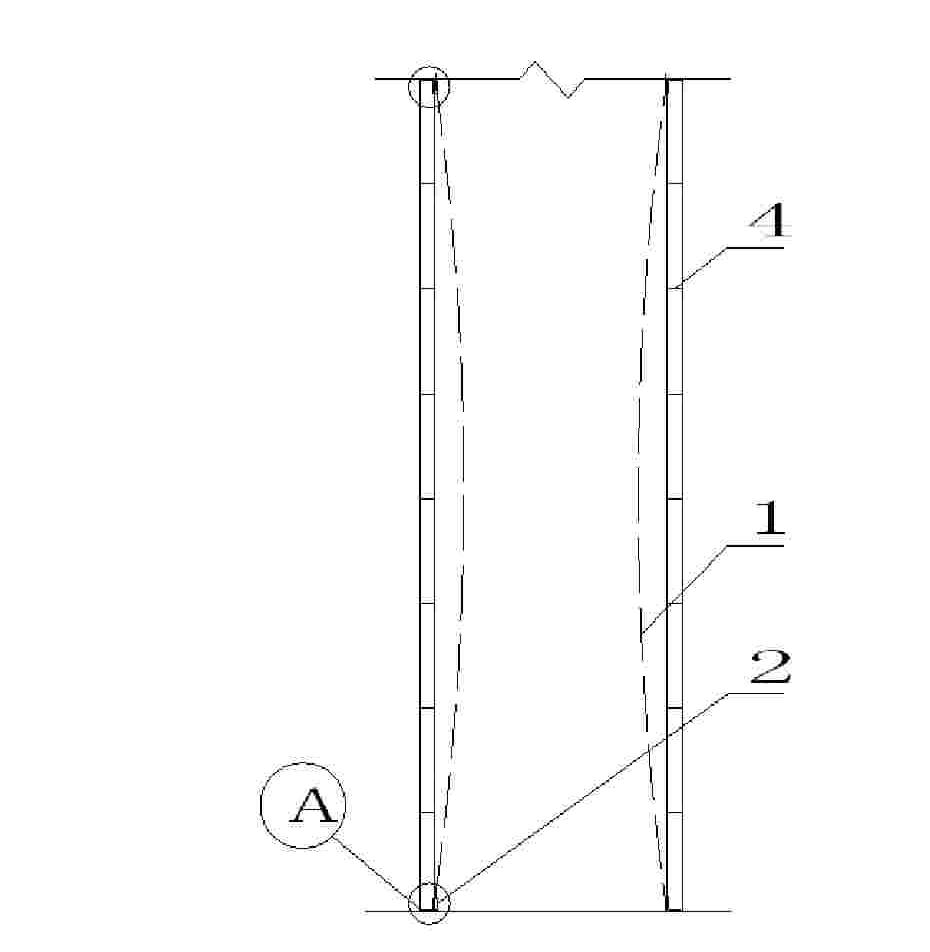

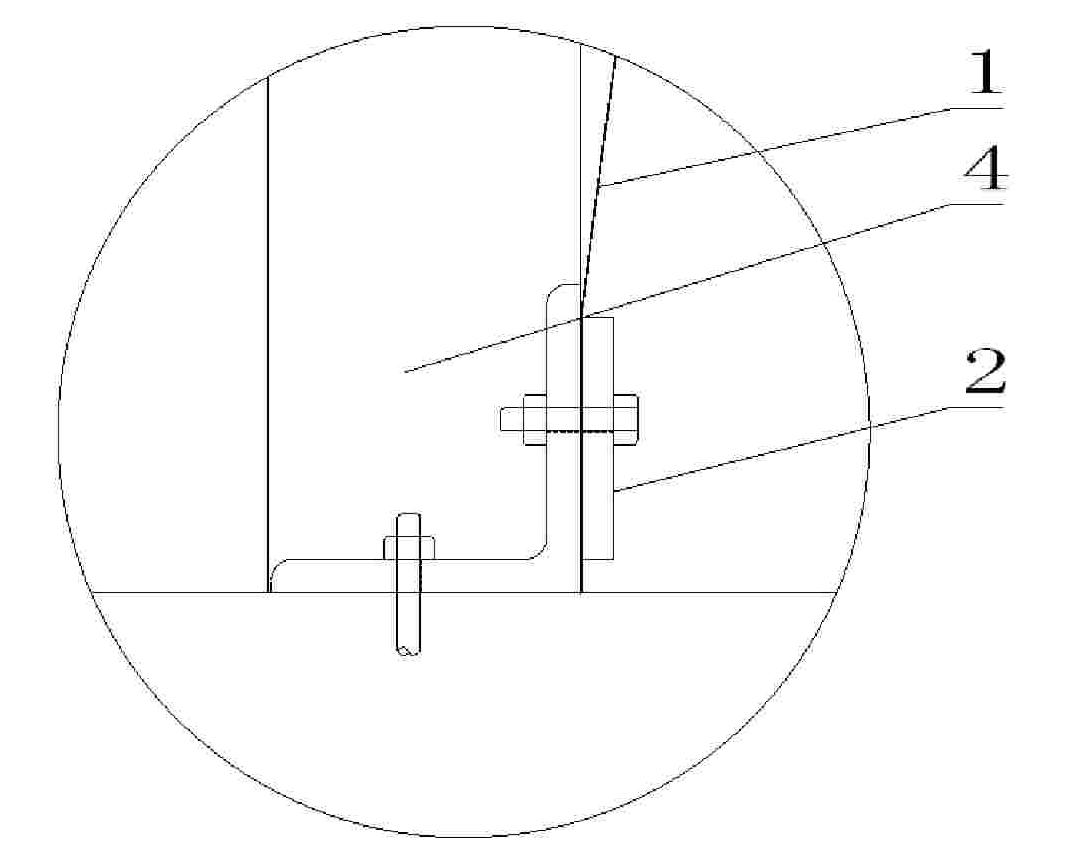

Controllable device capable of releasing stress generated by temperature and contraction of overlong concrete structure and construction method

InactiveCN107268856AFriction-resistantExtend your lifeFloorsBuilding reinforcementsRestraint stressStress strength

The invention discloses a controllable device capable of releasing stress generated by temperature and contraction of an overlong concrete structure. The controllable device comprises concrete main body floor plates (1) on the two sides and a concrete connecting plate (2); steel plate anti-shearing connecting pieces (3) are additionally arranged on the end portions of the upper ends and the lower ends of the concrete main body floor plates (1); and meanwhile, a plurality of movable temperature sensors (20) are arranged on the outermost sides of the concrete connecting plate (2) and the steel plate anti-shearing connecting pieces (3) so as to monitor the temperature transmitted from translation layers (7) to the concrete connecting plate (2) and the steel plate anti-shearing connecting pieces (3) in real time. Under the effect that horizontal beam plate components are not influenced to transmit bending moment and shearing force, the controllable device can not only release partial axial deformation of the horizontal components to achieve the purpose of reducing restraint stress generated by temperature and contraction deformation of the overlong concrete structure, but also monitor the stress strength and the temperature range in real time, so that control over the whole process is achieved; and the controllable device is suitable for overlong concrete structures and jointed structures.

Owner:XUZHOU NORMAL UNIVERSITY

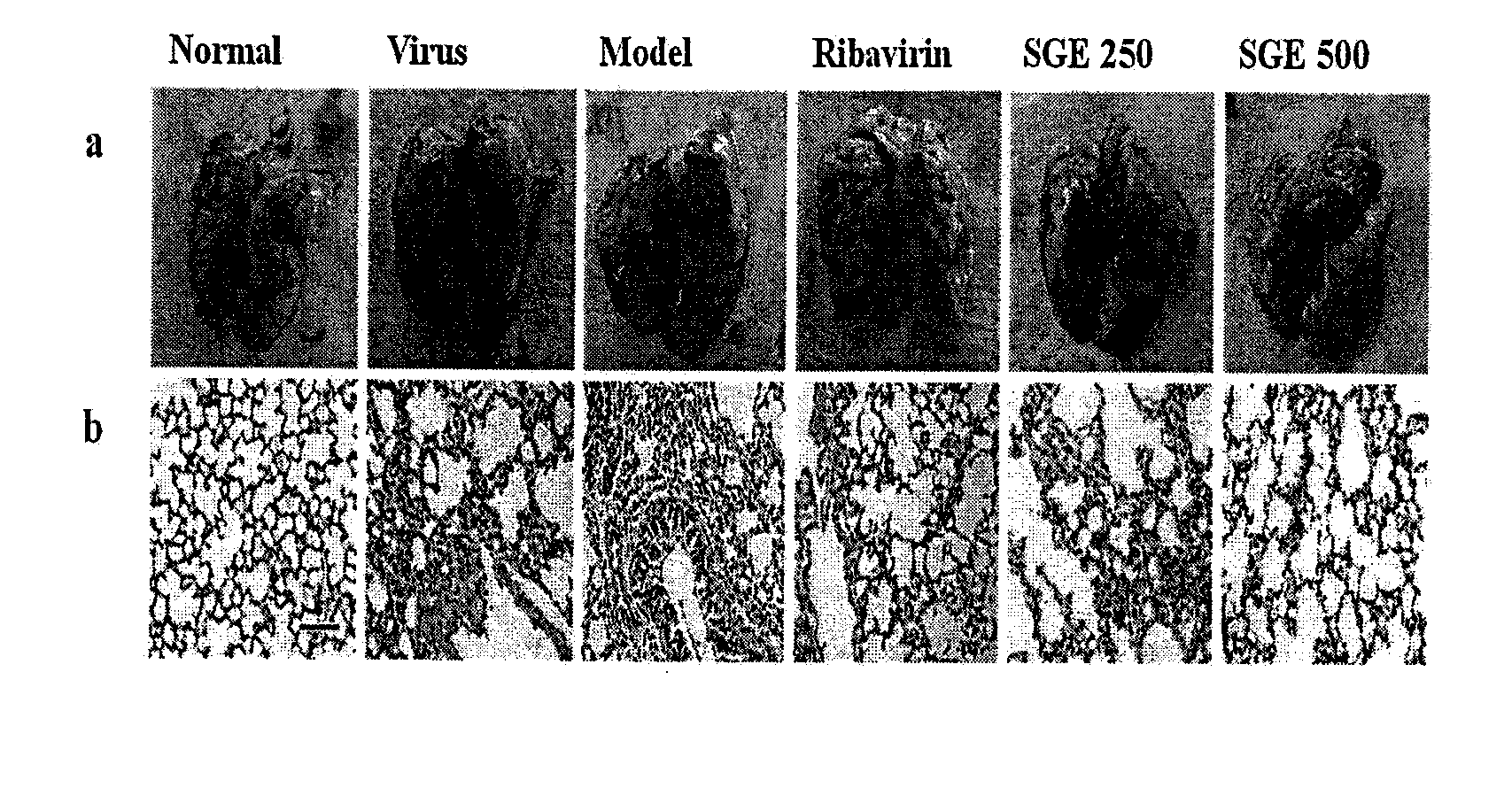

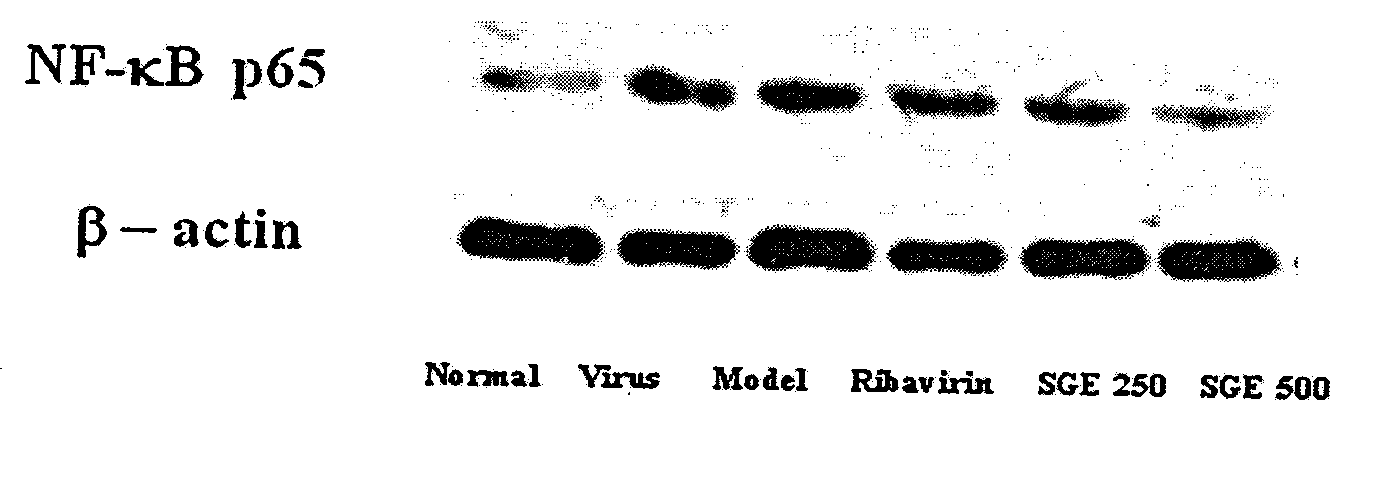

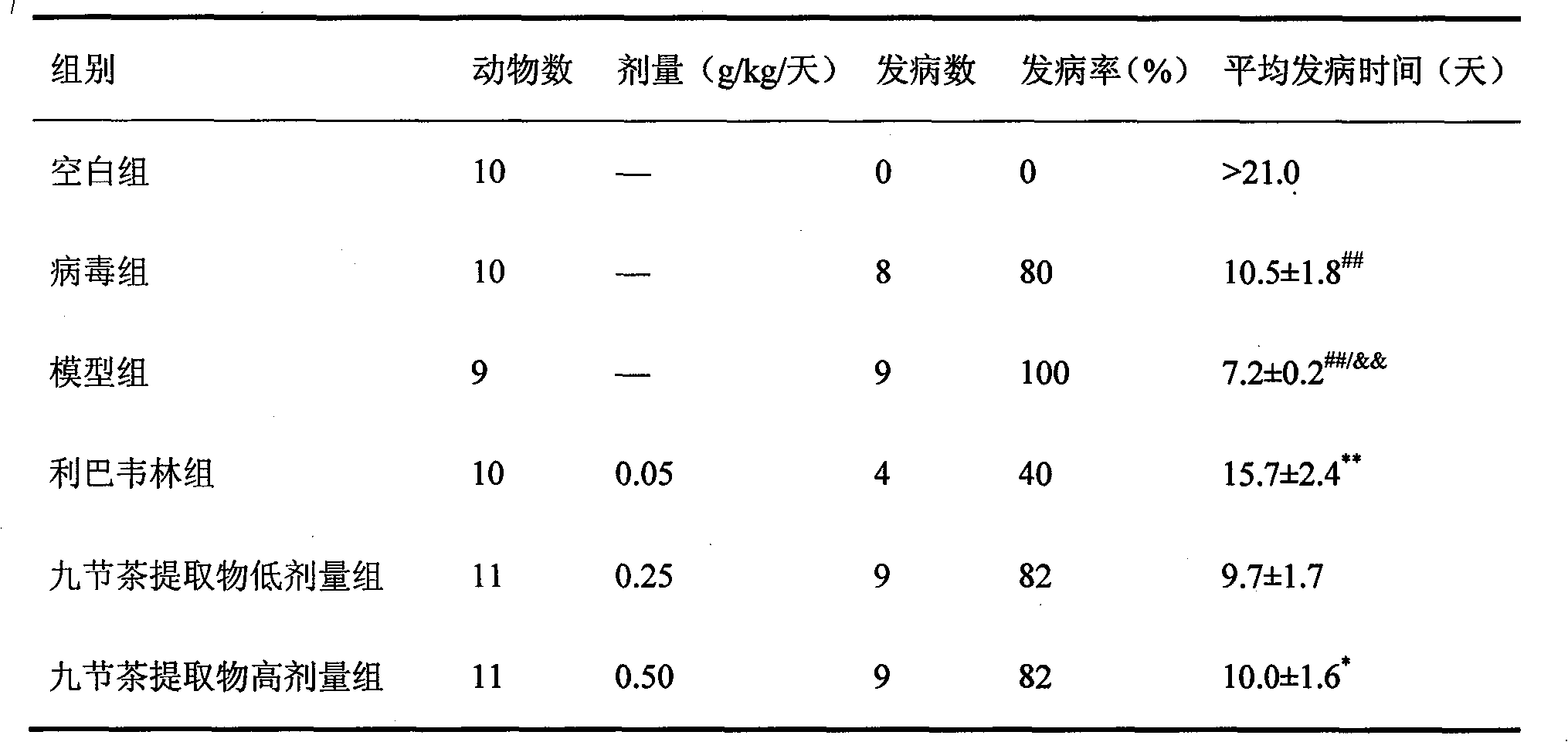

Application of glabrous sarcandra glabrous herb extract in reducing susceptibility of influenza virus

ActiveCN102793731BReduce morbidityReduce mortalityAntiviralsRespiratory disorderInflammatory factorsInfluenza A (H1N1) virus

The invention provides novel application of a glabrous sarcandra glabrous herb extract, belongs to the field of medicines, and provides an active extract of a medicinal material glabrous sarcandra glabrous herb through water extraction, alcohol precipitate and drying. 100g of the extract comprise 5 to 20g of tannin, and 0.02 to 1g of isofraxidin. The extract is confirmed and proved due to the effect that the incidence rate and death rate of a low influenza A H1N1 virus FM1 strain infected restraint stress loaded mouse can be reduced based on the glabrous sarcandra glabrous herb extract, and the lung tissue viral load of an influenza virus loaded mouse and inflammatory factor effects can be remarkably reduced by the extract. The glabrous sarcandra glabrous herb extract can be used for preparing medicaments applied to susceptibility of a human body to the influenza virus, relieving pneumonia and other respiratory inflammations due to secondary of body susceptible virus, pulmonary dysfunction and other clinical symptoms, and can be used for particularly effectively preventing, reducing or treating various clinical symptoms caused by virus injection occurring in an influenza virus susceptible body.

Owner:GUANGZHOU BAIYUNSHAN JINGXIUTANG PHARM CO LTD

Welded component postwelding heat treatment process

InactiveCN105714096ASimple heat treatment processGood welding performanceFurnace typesHeat treatment furnacesRestraint stressSize change

The invention discloses a welded component postwelding heat treatment process including the following steps: 1) postwelding heat treatment is required to preferably adopt a method of heating in a furnace, and the heat treatment furnace is required to meet relevant provisions of GB9452; and under a condition of accumulation of the corresponding relationship value of the furnace temperature and heated components, the temperature of the furnace is generally allowed to calculate the temperature of the heated components during furnace internal heat treatment; 2) the heated components are required to be neatly placed in an effective heating area in the furnace, the furnace internal heat is guaranteed to be evenly circulated, and during flame furnace internal heat treatment, flame is required to be avoided from directly spraying onto the workpieces; and 3) for preventing generation of the restraint stress and deformation, a support of the heated components is required to be reasonably placed, and necessary supporting and other tools are required to be additionally added on large thin-wall members and components with great structure and geometry size changes so as to increase the stiffness and balancing stability. The technical problem to be solved comprises that provided is the welded component postwelding heat treatment process; the heat treatment process is simple in method and can make a welding effect better and more stable.

Owner:CHONGQING YONGLIN MACHINERY EQUIP

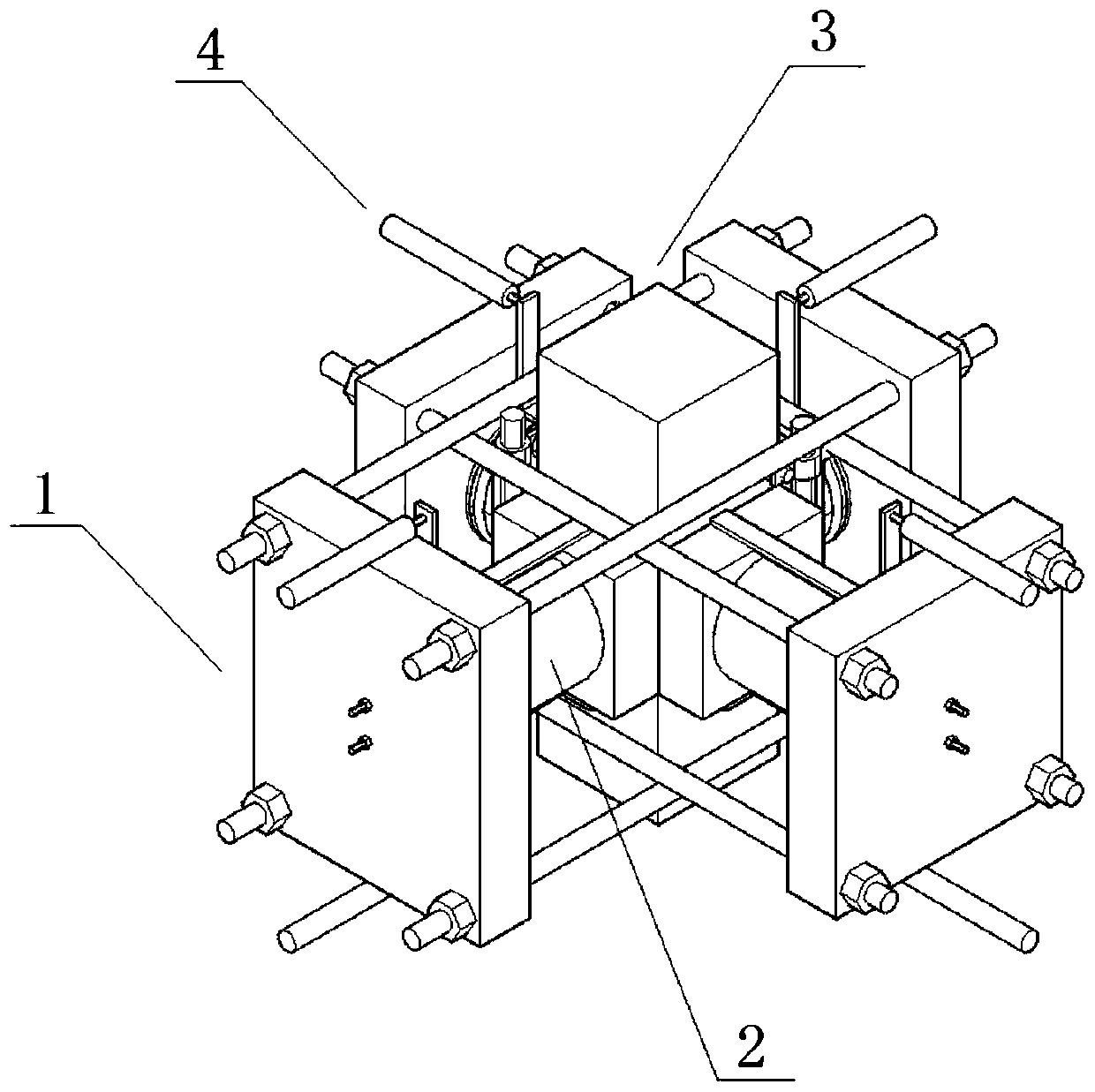

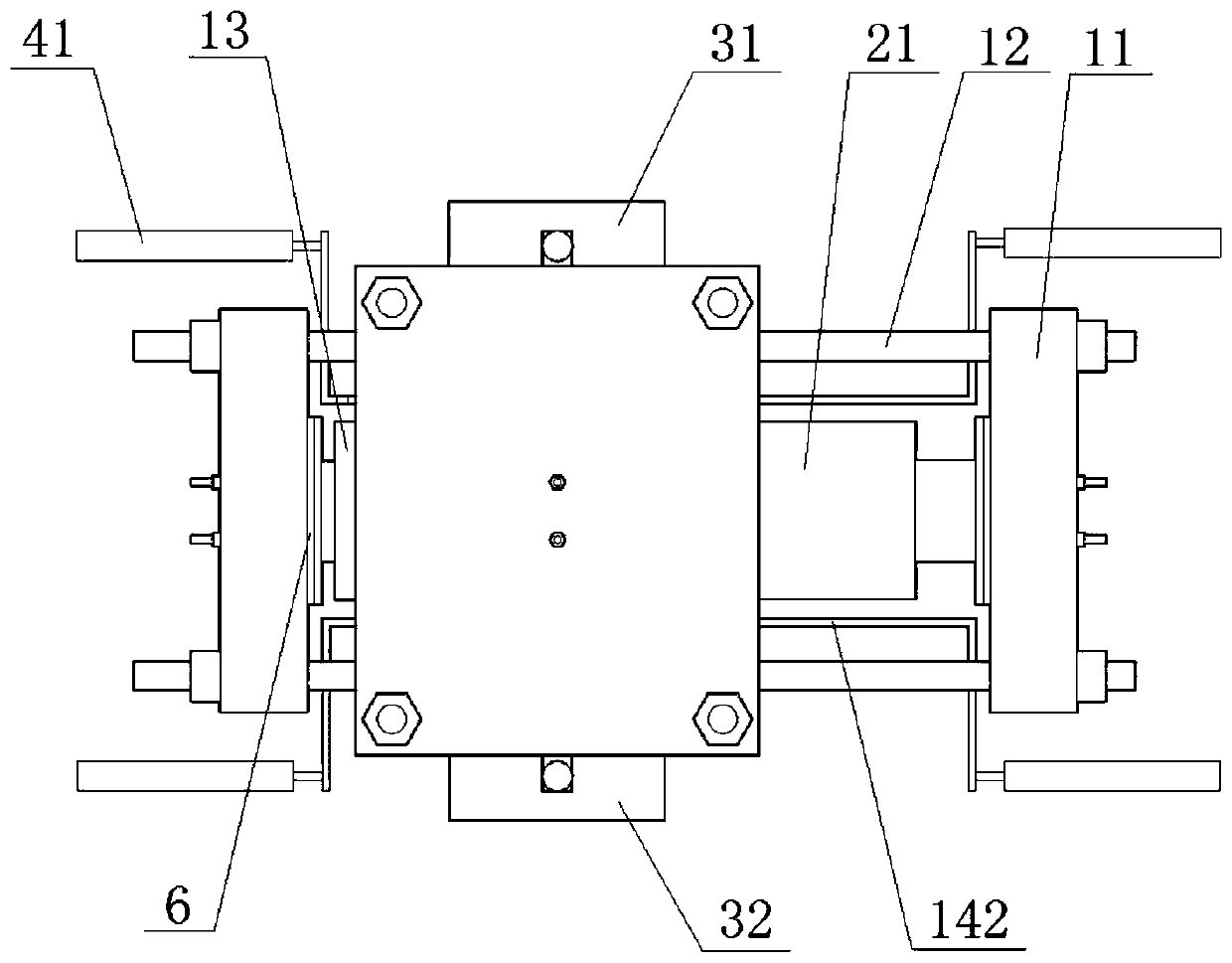

Stress loading combination device

PendingCN110514523AThe test effect is goodEven by forceMaterial strength using tensile/compressive forcesControl systemRestraint stress

The invention relates to the technical field of building material test equipment, in particular to a stress loading combination device. The device is used for being placed on a loading platform of a uniaxial servo press to perform a true triaxial pressure test on a cubic test piece. The device comprises two groups of first loading components and second loading components, wherein the first loadingcomponents are arranged perpendicular to each other and are used for transmitting force in a circumferential direction of the cubic test piece, and the second loading components are used for transmitting force in an axial direction of the cubic test piece; the first loading components and the second loading components make close contact with a circumferential surface and an axial surface of the cubic test piece respectively; and a force application mechanism is connected to each first loading component, a control system is connected to each force application mechanism, and displacement measurement components are arranged on the first loading components and the second loading components respectively. Through the device, restraint stress can be precisely controlled, manufacturing cost is low, operation is easy, and the application range is wide.

Owner:GUANGDONG UNIV OF TECH

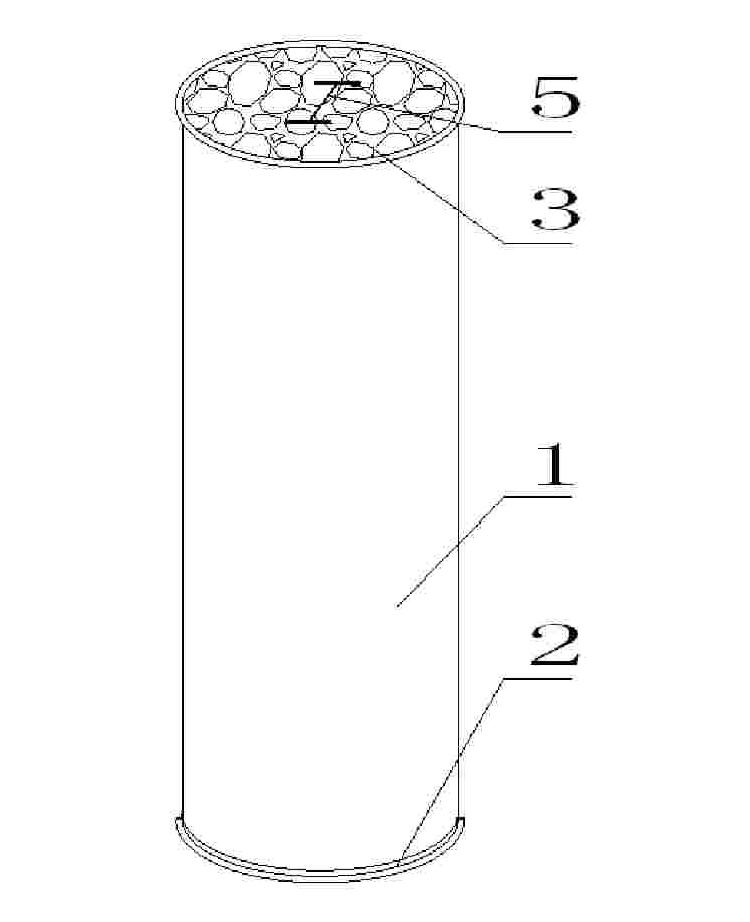

Pre-stress fibre restriction concrete member and construction method thereof

InactiveCN101318352BImprove bearing capacityImprove ductilityCeramic shaping apparatusFiberReinforced concrete

Owner:贵州建工集团第四建筑工程有限责任公司

An oil and gas pipeline restraint simulation device and its testing method

ActiveCN105643135BImplement restraint simulation testingTest accurateMetal working apparatusWelding apparatusPipe fittingRestraint stress

The invention provides an oil-gas pipeline restraint simulator and a testing method thereof. The oil-gas pipeline restraint simulator comprises a first fixing plate, a second fixing plate, a rigidity restraint support, a first sample pipe fitting, and a second sample fitting, wherein the first fixing plate and the second fixing plate are oppositely arranged, the rigidity restraint support, the first sample fitting and the second sample fitting are arranged between the first fixing plate and the second fixing plate. The testing method includes setting the rigidity restraint support, welding the sample pipe fittings, cutting the testing sections, and testing data. As shape and size of the sample pipe fittings can be tested according to the full size of the oil-gas pipeline in actual operation, size is free of limit, and through the simple pipe fitting welding structure, restraint simulation testing of the oil-gas pipeline can be realized. The oil-gas pipeline restraint simulator can simulate high restraint and restraint stress and is wider in application range and more accurate in testing.

Owner:GUANGDONG DAPENG LNG COMPANY

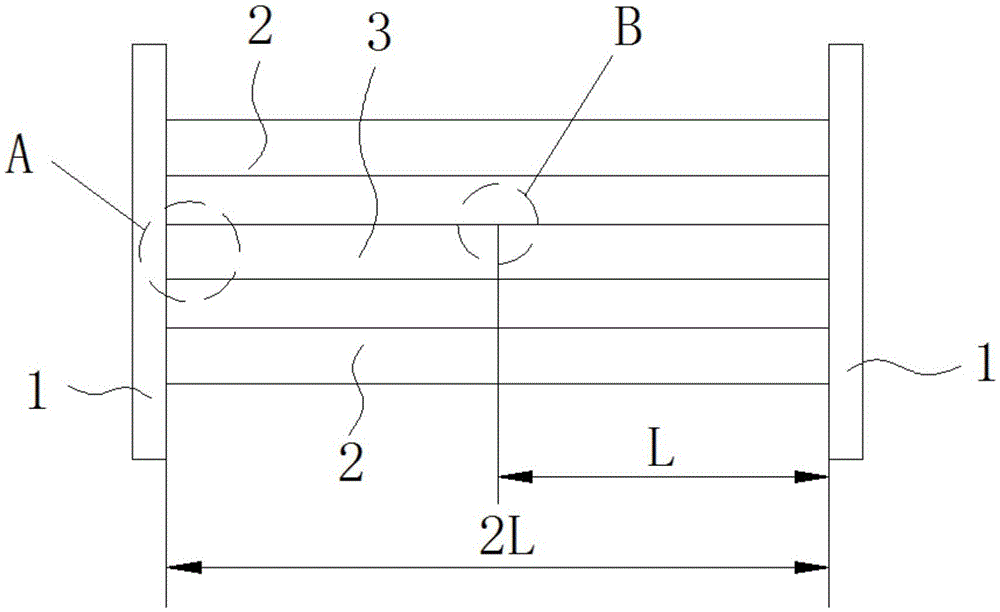

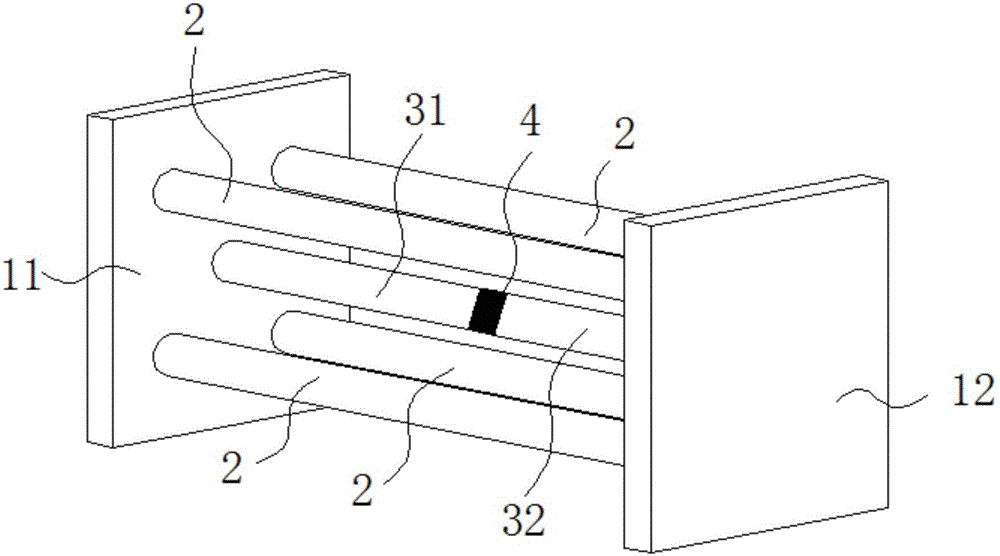

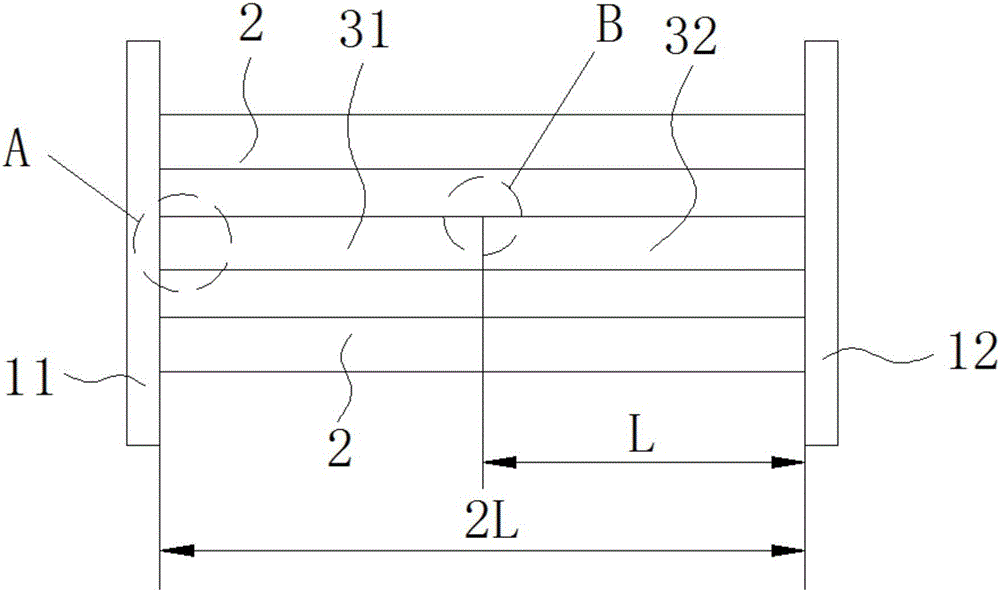

Apparatus and method for testing welding restraint stress

ActiveCN109141705AReaction force controlReduce sizeApparatus for force/torque/work measurementStress measuresRestraint stress

The invention discloses an apparatus for testing welding restraint stress. The apparatus comprises a first supporting member, a second supporting member, a stress bearing assembly, and a stress measuring assembly; a first welding sample is connected to the symmetry center of the first supporting member; a second welding sample is connected to the symmetry center of the second supporting member; the portions to be welded of the first welding sample and the second welding sample are close to each other; the stress bearing assembly is connected between the first supporting member and the second supporting member in a stress-adjustable manner so as to deform correspondingly when bearing the welding restrain stress; and the stress bearing assembly is symmetrically disposed with respect to the symmetry centers of the first supporting member and the second supporting member; and the stress measuring assembly is connected to the stress bearing assembly and is used for outputting the welding restraint stress borne by the stress bearing assembly. The present invention also discloses a method for testing weld restraint stress. With the apparatus and method for testing welding restraint stressof the invention adopted, the welding restraint stress borne by the welding samples can be accurately acquired during a welding process, and the magnitude of the welding restraint stress borne by thewelding samples can be controlled.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

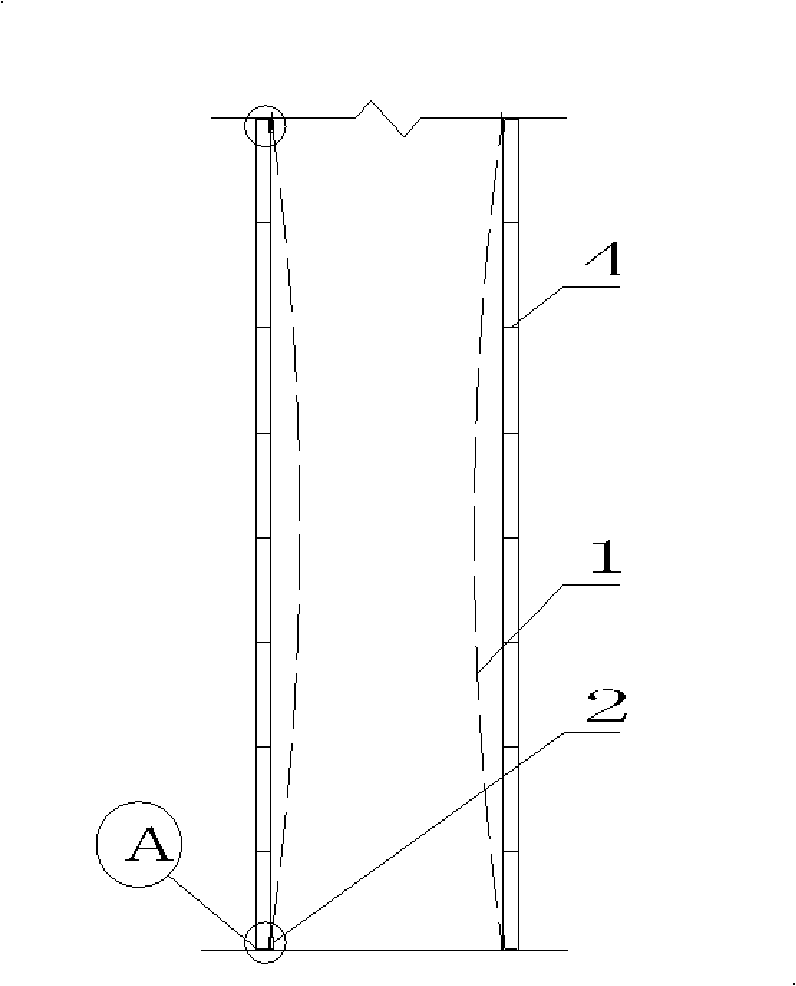

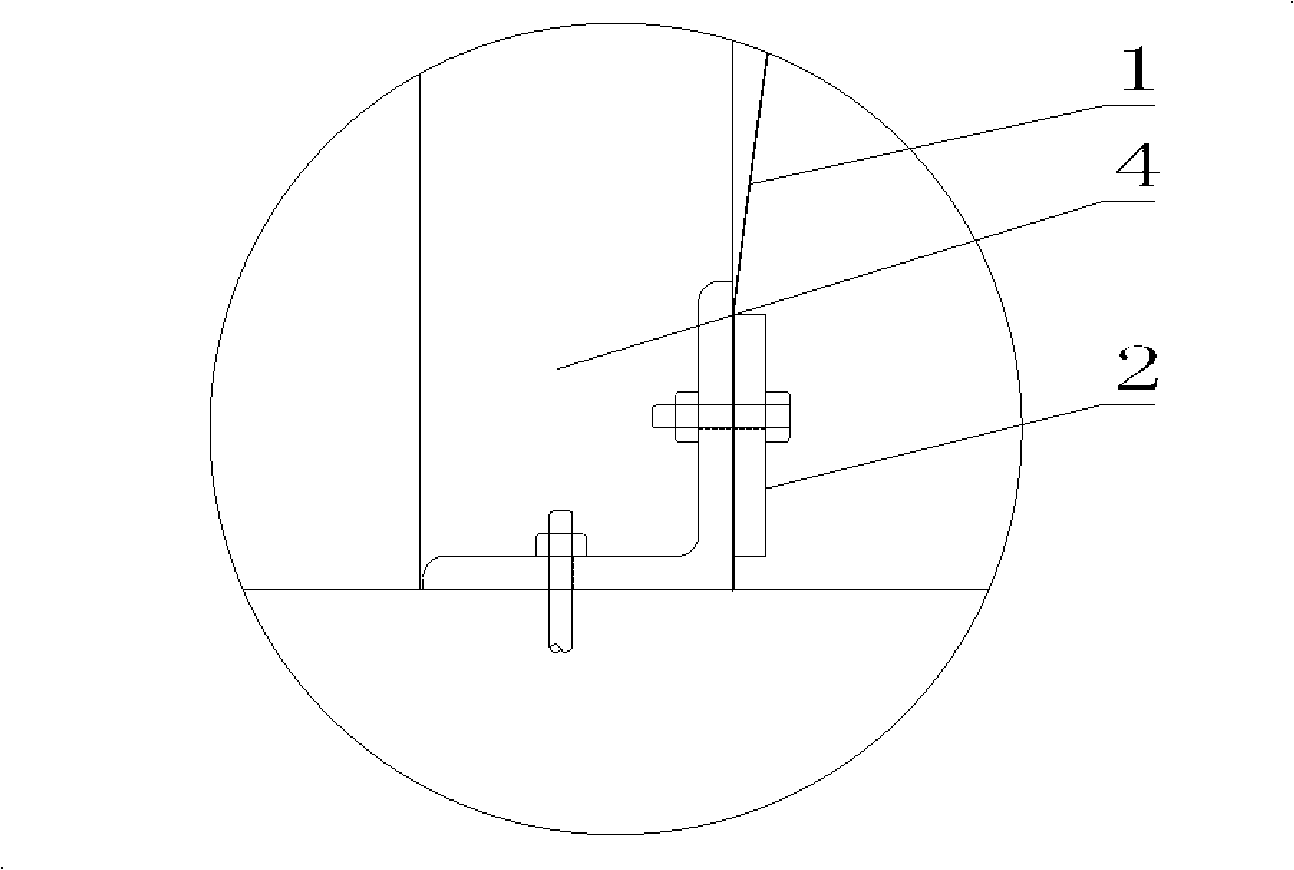

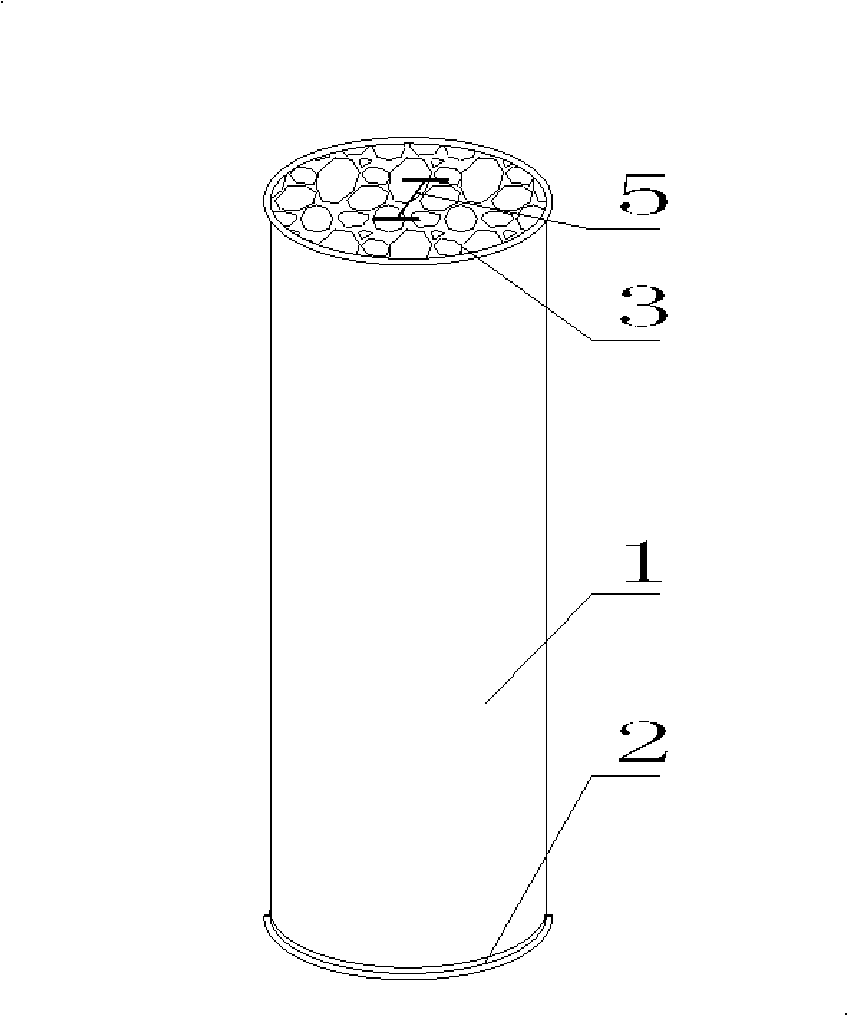

Pre-stress fibre restriction concrete member and construction method thereof

InactiveCN101318352AImprove bearing capacityImprove ductilityCeramic shaping apparatusFiberReinforced concrete

The invention discloses a construction method for prestressed fiber restraining concrete members. In the process of manufacturing concrete members, fiber cloth is made into a cylinder at first, and then the concrete added with expansive agent is poured into the fiber cloth cylinder. The fiber cloth cylinder is propped to open by the extrusion force which is resulted from a concrete self-weight and vibration process, and the fiber cloth cylinder prevents the concrete from expanding in a reverse direction, which leads the fiber cloth cylinder to produce restraint stress to the concrete; in a concrete solidification process, the concrete continues expanding under the action of the expansive agent, which leads the fiber cloth produce restraint stress for a second time; in such a method, the prestressed fiber restraining concrete members are made. The creativity of the invention lies in that owing to adopting a structure of prestressed fiber restraining concrete members, the bearing capacity and ductility of concrete members are greatly raised; owing to adopting nonmetallic material as prestressed material, the structural cost is greatly reduced; besides, protective layers which are necessary for reinforced concrete members are saved and the problem of durability is solved once and for all.

Owner:贵州建工集团第四建筑工程有限责任公司

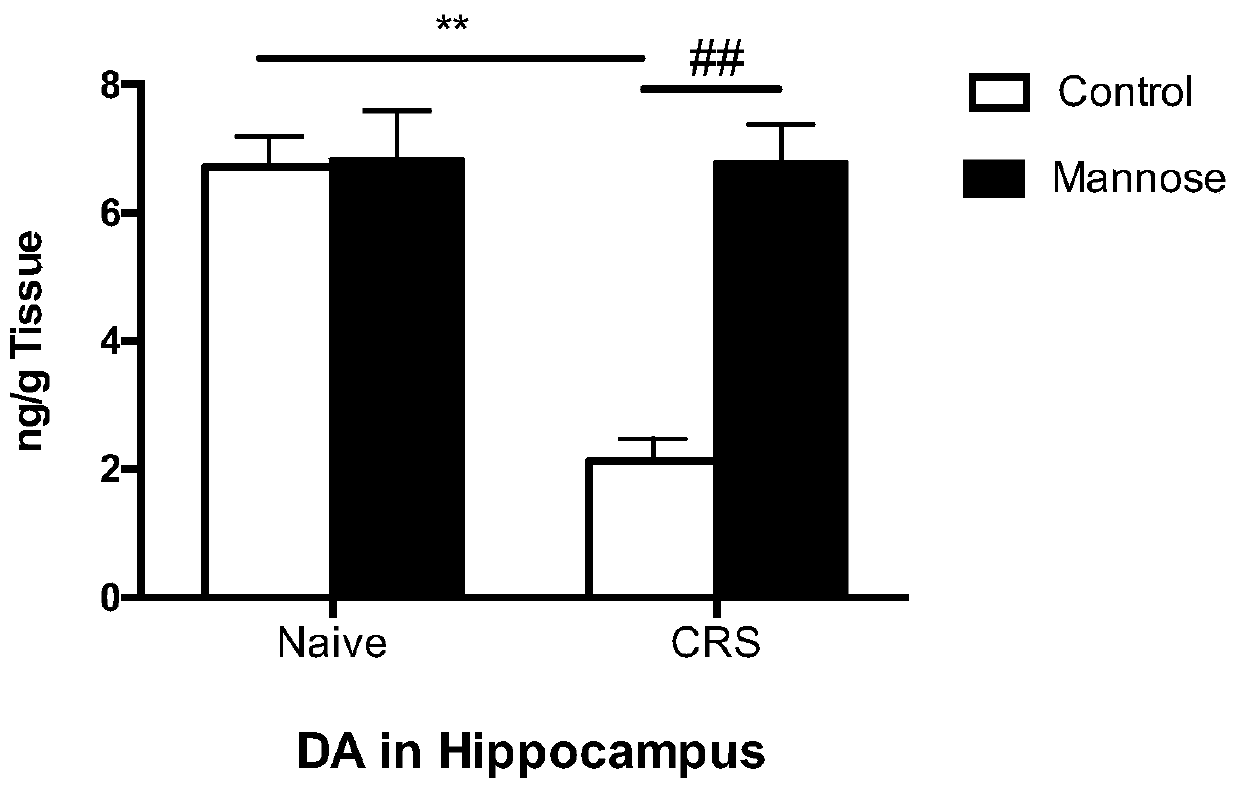

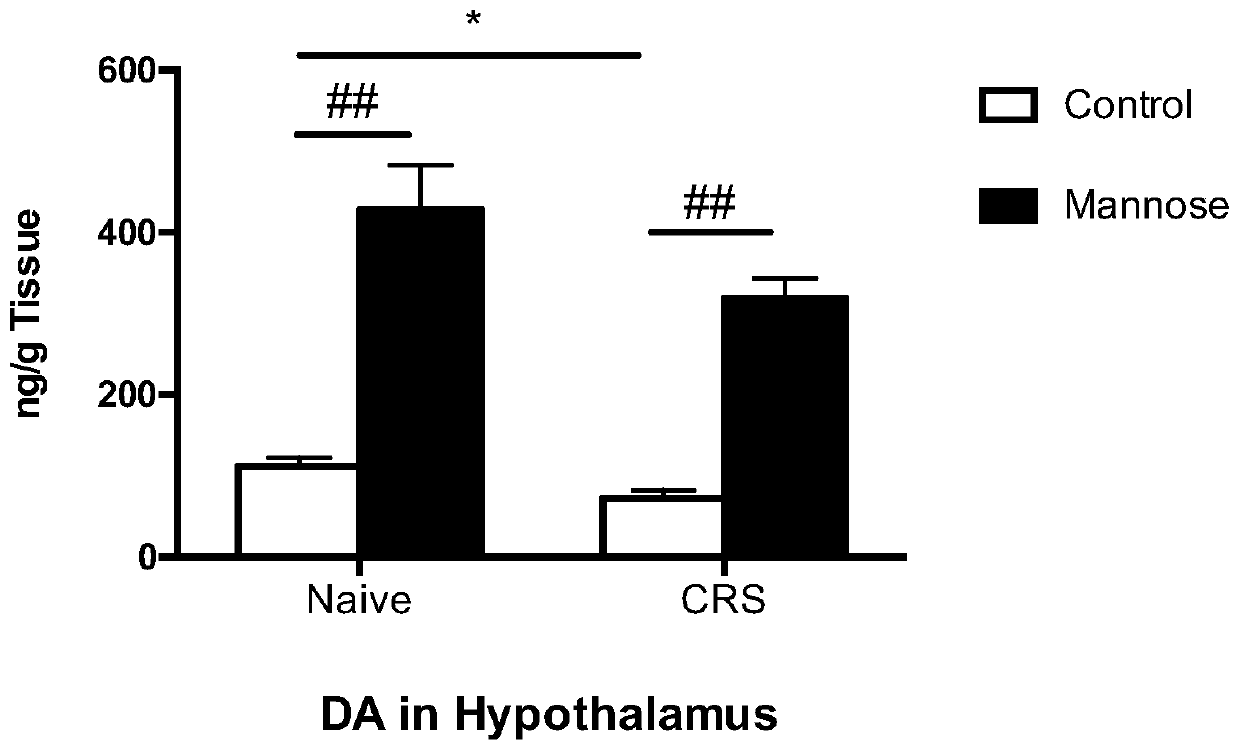

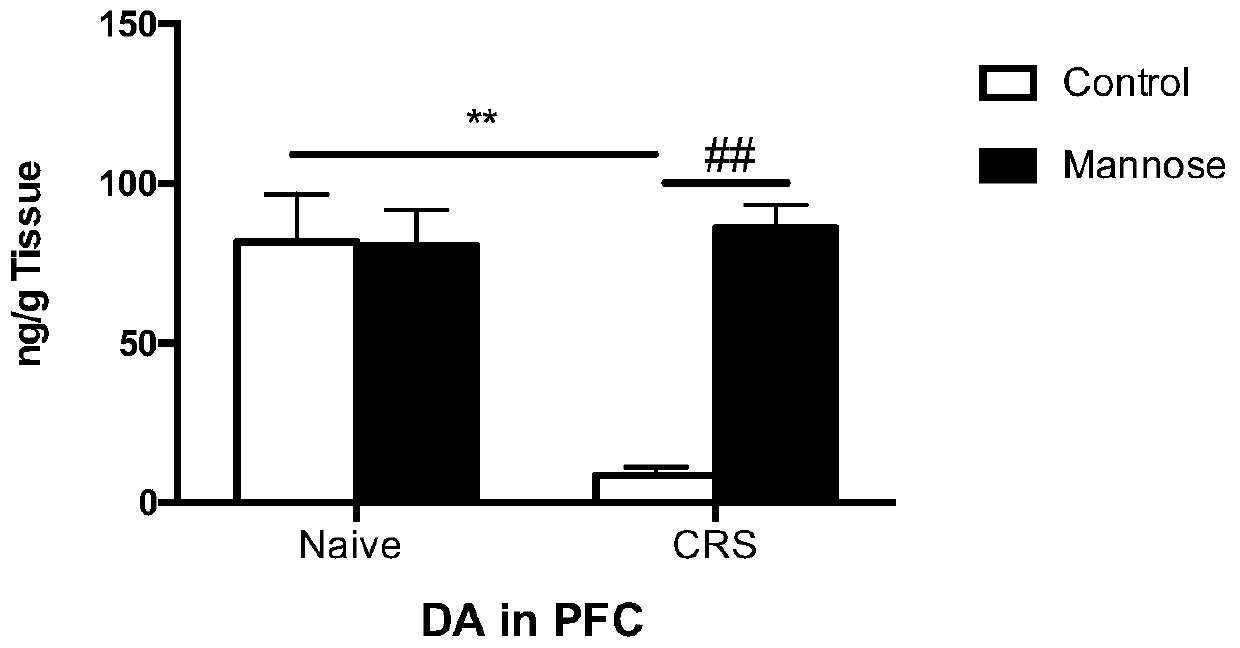

Application of D-mannose in preparation of product for resisting dopamine reduction and/or improving dopamine level

InactiveCN109820862AImpaired resistanceImprove the level ofOrganic active ingredientsNervous disorderMedicineDopaminergic

The invention relates to application of D-mannose in preparation of a product for resisting dopamine reduction and / or improving the dopamine level. A chronic restraint stress model is utilized to damage mouse dopaminergic neurons ((as described in the description) no restraint stress, CRS chronic restraint stress) and find that D-mannose is resistant resist reduction of mice hippocampus, hypothalamic and prefrontal dopamine, so that dopaminergic neuron loss can be resisted, the degradation of dopamine in the hypothalamus (MAO-B) can be restrained, the dopamine level is increased, and the dopaminergic neuron functions are restored.

Owner:SHANDONG UNIV

Total stress calculation method and safety warning method of long-span steel box girder bridge based on monitoring data and temperature stress analysis

ActiveCN106092402BReduce the cost of regular manual inspectionIncrease profitApparatus for force/torque/work measurementTemperature stressElement model

The invention discloses a total stress computing method and safety pre-warning method of a large-span steel box girder bridge based on monitored data and temperature stress analysis. The total stress computing method comprises a step 1 of acquiring the strain and the temperature of the bridge by using a health monitoring system; a step 2 of separating temperature strain from the actually measured strain; a step 3of computing the uniform temperature and gradient temperature on the upper cross section of the steel box girder; a step 4 of computing axial restraint stress; a step 5 of computing bending restraint stress; a step 6 of computing temperature self-stress; a step 7 of acquiring geostatic stress from a finite element model; and a step 8 of computing the total stress of the large-span bridge in operation. Compared with a conventional early warning method, the early warning method is clear in early warning index and clear in mechanical model, takes account of the influence of temperature load on the large-span bridge structure, and is applicable to popularization in engineering field.

Owner:SOUTHEAST UNIV

An adjustable welding restraint stress test device

ActiveCN104880364BSo as not to damageGuaranteed StrengthStrength propertiesRestraint stressEngineering

Owner:HUNAN UNIV OF SCI & TECH

Experimental device and test method for the relationship between constraint pressure and extrusion deformation of tunnel face

ActiveCN104007247BThe test data is accurate and reliableConstruction safetyEarth material testingMechanical solid deformation measurementsExhaust valveInlet valve

Provided are a testing device and a testing method for a relation between a restraint stress and an extrusion deformation of a tunnel face. A cylindrical pressure chamber is formed by means of a side wall, a top cover and a pedestal in a sealing embedded manner. An oil cylinder is fixed in a groove arranged in a central part of an upper surface of the pedestal. A piston which is in the oil cylinder stretches upwardly into the pressure chamber. An exhaust valve is disposed closed to the side wall on the top cover. An air cylinder barrel, which is smaller than the oil cylinder in diameter, is sealedly embedded on an air cylinder groove arranged in the central part of a bottom surface of the top cover. The air cylinder groove is provided with a vent hole which stretches out through the top cover. A piston in the air cylinder is connected to a displacement measuring rod. An upper end of the displacement measuring rod stretches out from the top cover and is connected to a displacement dial gauge. A water inlet valve is disposed on a position of the pedestal, wherein the position is between an inner chamber of the pressure chamber and the oil cylinder. With the testing device, the relation between the restraint stress and the extrusion deformation of a tunnel face can be accurately tested under different conditions of surrounding rock, thereby providing reliable testing data for design and construction of a tunnel. On the premise of effectively ensuring stabilization of the tunnel face, construction cost is reduced and construction speed is increased.

Owner:SOUTHWEST JIAOTONG UNIV

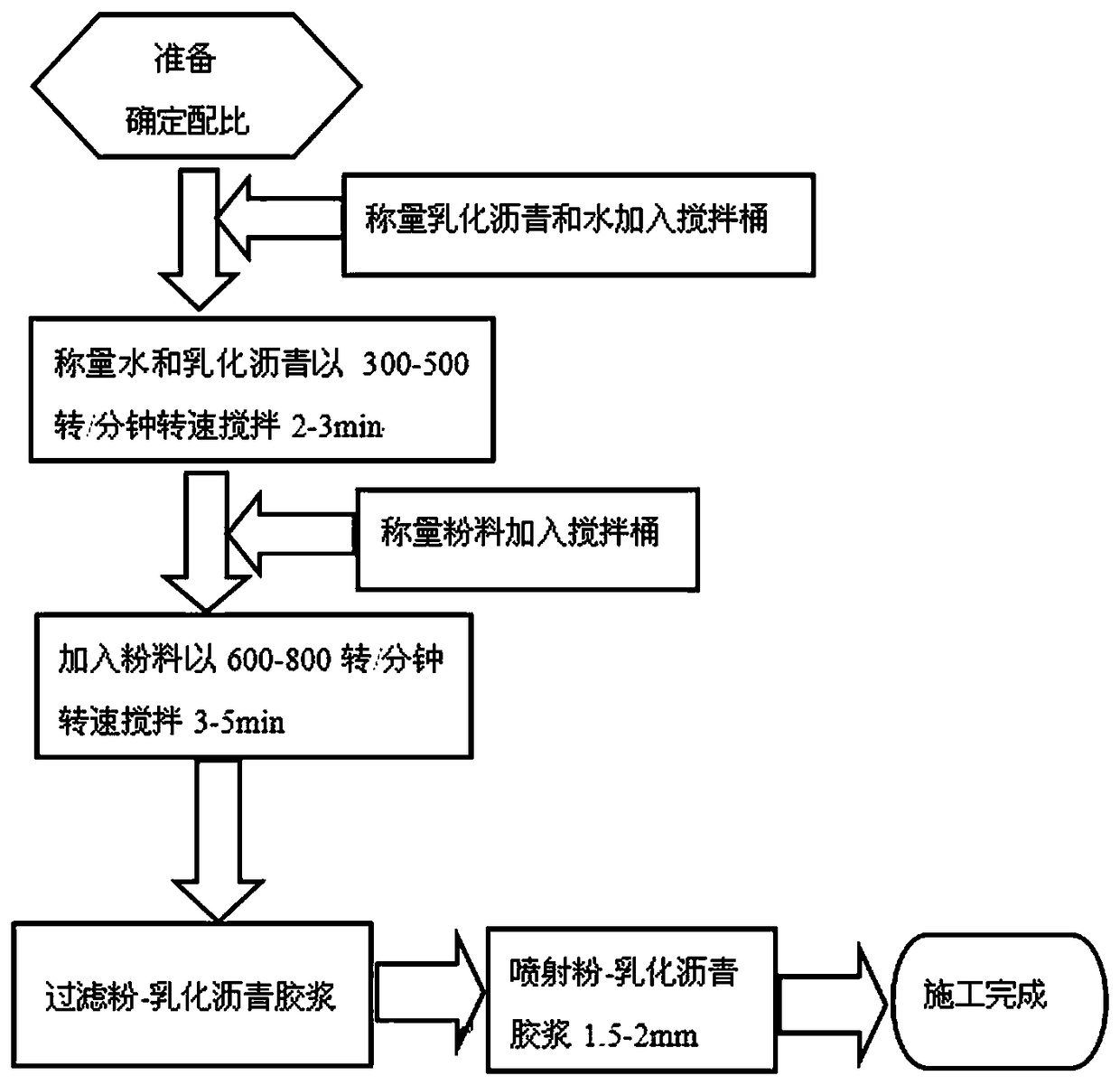

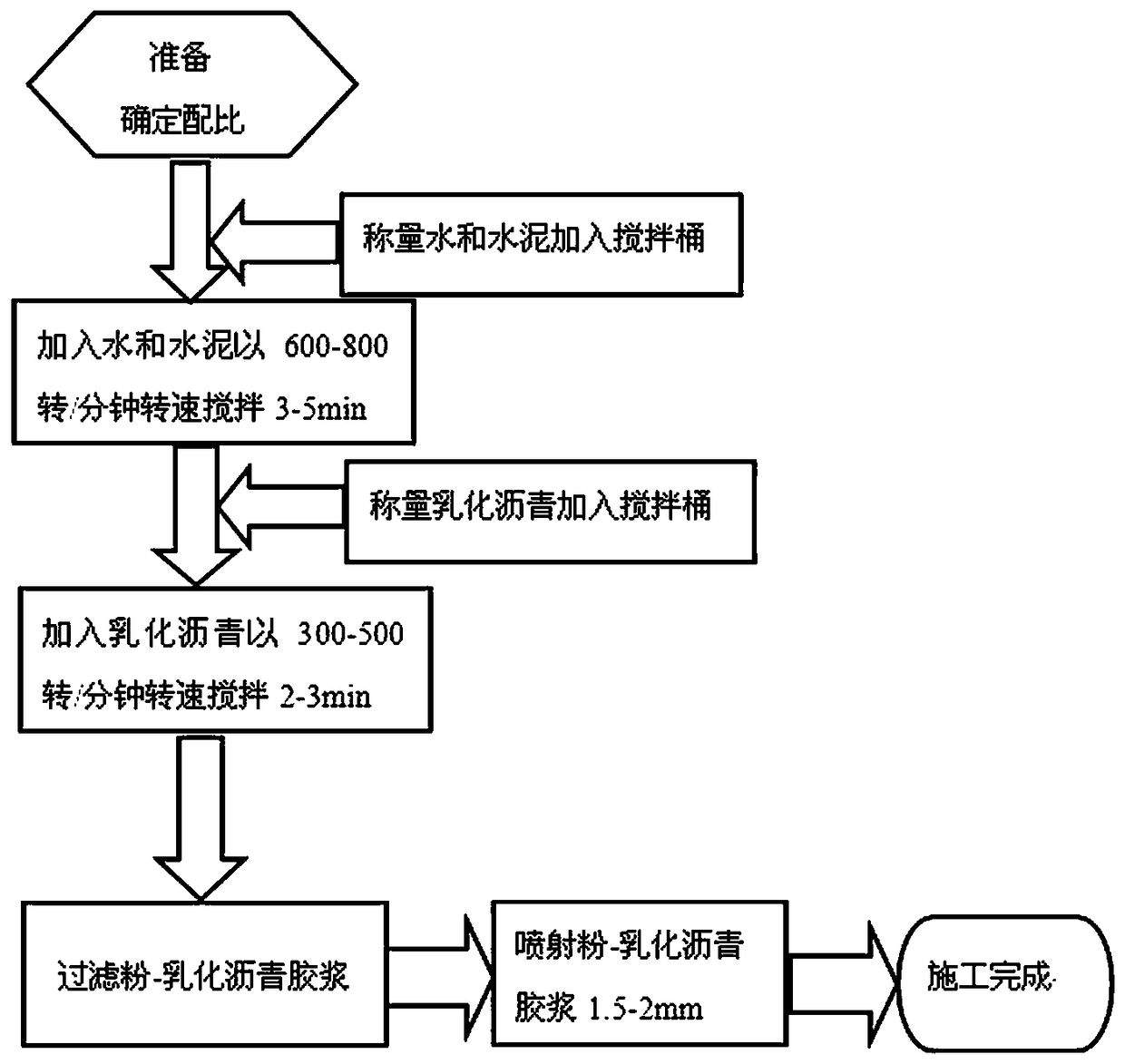

Concrete face rockfill dam isolating layer construction method

ActiveCN108978594AImprove performanceReduce external stressFoundation engineeringEarth-fill damsWorking pressureRestraint stress

The invention provides a concrete face rockfill dam isolating layer construction method. The concrete face rockfill dam isolating layer construction method comprises the following steps of: (1) preparing powder-emulsified asphalt mortar on the scene; (2) filtering the powder-emulsified asphalt mortar to remove glue residues for later application, continuously stirring, and storing for 1.5 hours after stirring; and (3) conveying the powder-emulsified asphalt mortar to a working face through a conveying hose, spraying the powder-emulsified asphalt mortar onto a protective surface through a spraygun at the working pressure of 0.8-1.2MPa to form a semi-rigid isolating layer, and separating the protective surface from a concrete face by the semi-rigid isolating layer which has the effects of lubrication and seepage control. The face rockfill dam upstream protective surface isolating layer construction method is simplified; and the concrete face rockfill dam isolating layer construction method improves the gluing quality of the isolating layer and the protective surface, has a good effect of separating different layers and reduces the restraint stress of the face and the generation of concrete face cracks.

Owner:GEZHOUBA GRP NO 2 ENG

An anti-deviation device and anti-deviation method for a column-pier bridge

InactiveCN106638273BAvoid offsetReduce harmBridge structural detailsElastic componentRestraint stress

The invention discloses a column pier type bridge anti-shifting device. The column pier type bridge anti-shifting device is characterized by comprising two groups of beam body fixing assemblies which are arranged on left and right sides of the lower surface of a beam body along the width direction, wherein each beam body fixing assembly comprises an anchoring bottom plate, and the anchoring bottom plate is arranged along the width direction of the beam body and is anchored and connected onto the beam body; each anchoring bottom plate is internally provided with a displacement following plate which is vertically arranged downward along the longitudinal direction of the beam body; an elastic component is horizontally arranged between lower sides of the two displacement following plates in the left-right direction; and the elastic component takes a bridge pier below the beam body as the mounting supporting foundation and is mounted on a hoop fixed on the bridge pier. The invention further discloses a column pier type bridge anti-shifting method adopting the device. The column pier type bridge anti-shifting device has the advantages that the structure is simple, the construction is convenient, the horizontal restraining on a beam body of the bridge can be realized very well, the restraint stress can be released and potential safety hazard is reduced.

Owner:YANGTZE NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com