Device for testing cold cracking tendency of welding joint on basis of adjustable rigid restraint and apparition of device

A technology for welding joints and test devices, applied in welding equipment, metal processing equipment, manufacturing tools, etc., to achieve the effect of increasing the probability of thermal cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

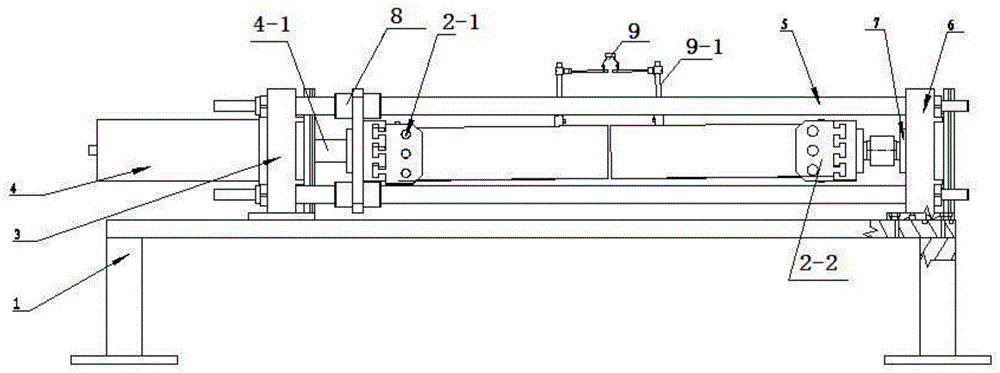

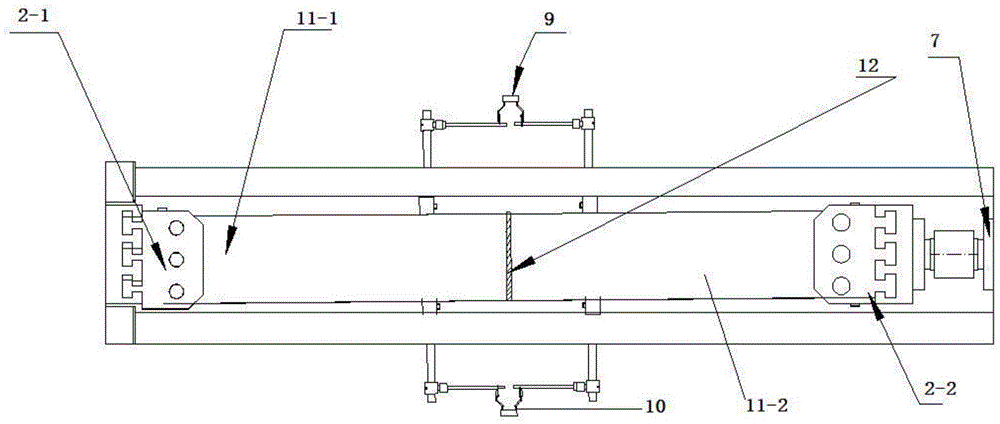

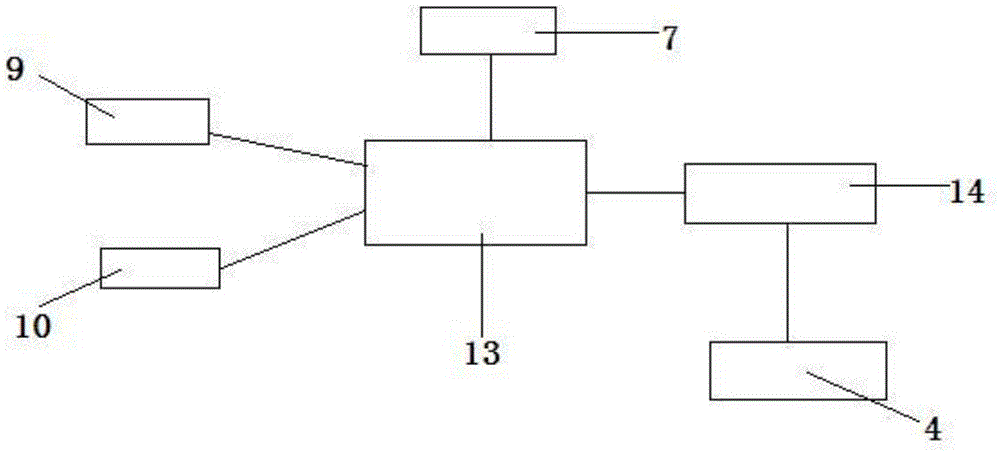

[0021] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0022] As shown in the accompanying drawings, a welded joint cold cracking tendency test device based on adjustable rigid restraint of the present invention includes a base, a moving fixture, a fixed fixture, a first support plate, an oil cylinder, a guide column, a second support plate, and a load A sensor, a slider, a first displacement sensor and a second displacement sensor, wherein:

[0023] A first support plate and a second support plate are arranged on the base, and a guide column arranged along the horizontal direction is connected between the first support plate and the second support plate; a slide block is provided on the guide column, and can be carried out along the guide column. To move, a moving fixture is set on the slider, and the slider moves along the guide column; an oil cylinder is set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com