One-time continuous forming and pouring method for ultralong post-poured fish ridge wall and ultralong fish ridge wall

A fish ridge and super-long technology, which is applied to bridge parts, erection/assembly bridges, bridge materials, etc., can solve the problems of fast watering speed, affecting the durability of the structure, and high sand content, so as to prevent or control temperature cracks and improve water resistance. Crack ability and durability improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The purpose of the present invention is achieved through the following technical solutions:

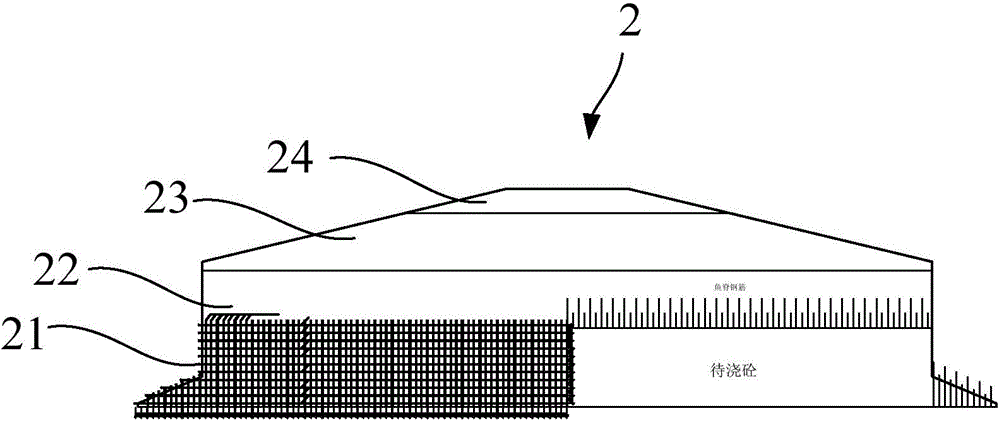

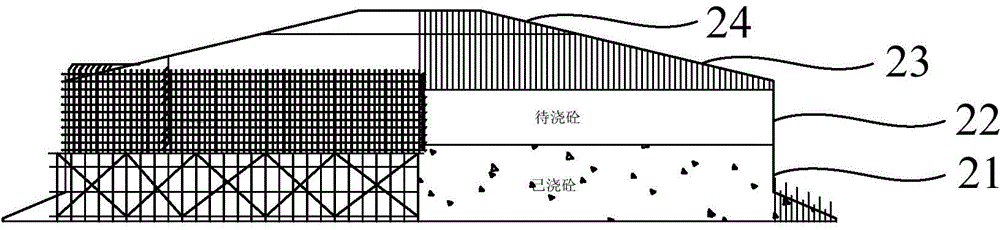

[0041] Such as Figure 1 to Figure 10 Shown, the superlong of the present invention, the one-time continuous forming pouring method of post-watering fish ridge wall, main steps are as follows:

[0042] ①Reserve part of the steel tendons of the box-type bridge deck 1 and stretch them after the concrete pouring of the fish ridge wall; the effect is:

[0043] 1) It can provide part of the pre-compression stress for post-pouring fish ridge wall concrete.

[0044] 2) It can reduce the shrinkage difference with the post-cast fish ridge wall concrete.

[0045] ② Temporary construction steel beams 4 are set in the fish ridge wall;

[0046] It can provide part of the precompressive stress for post-pouring fish ridge wall concrete, and reduce the tensile stress of post-pouring fish ridge wall concrete.

[0047] ③ The steel bars at the junction are appropriately strengthened;

[0048...

Embodiment 2

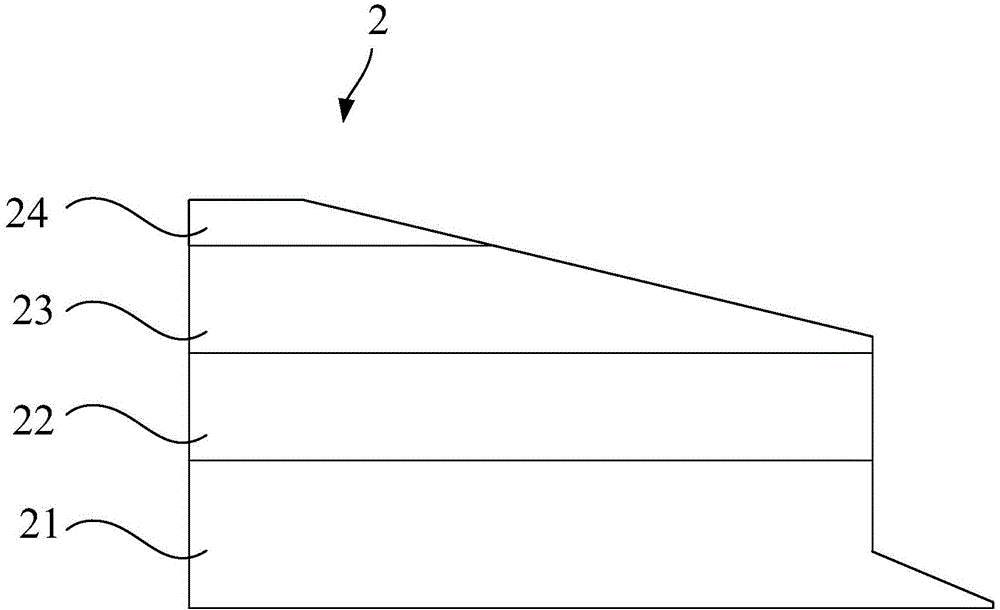

[0085] Based on the one-time continuous molding pouring method of embodiment 1, the present invention also provides a super-long fish ridge wall of a one-time continuous molding structure made by the one-time continuous molding pouring method of the superlong and post-cast fish ridge wall of embodiment 1, The super-long fish ridge wall is made by a one-time forming pouring method of continuous pouring, oblique segmentation, and horizontal layering. Several construction temporary steel beams 4 are arranged in the super long fish ridge wall. The fish ridge wall 2 Anti-crack steel mesh sheet 8 is set at the sudden change of the side section.

[0086] Described anti-cracking reinforced mesh sheet 8 (referring to Figure 10 ) grid spacing is 100mm×100mm.

[0087] By adopting the invention, not only can the anti-cracking ability of the concrete block of the fish ridge wall bear the external constraint stress, the purpose of preventing or controlling temperature cracks can be achiev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com