Test device and method for axial full restraint stress

A fully restrained, test device technology, applied in the direction of measuring devices, material inspection products, instruments, etc., can solve the problems of poor sensitivity, long test cycle, small constraints, etc., to achieve increased anchoring performance, strong adjustability, and easy maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

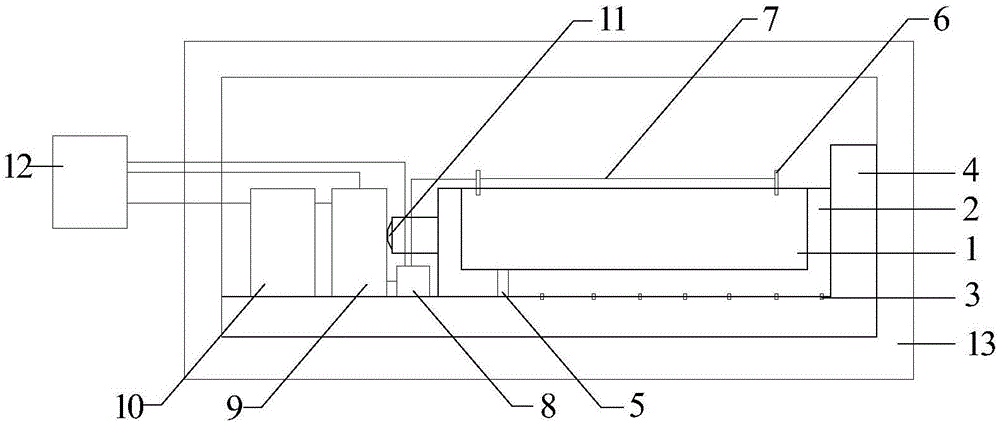

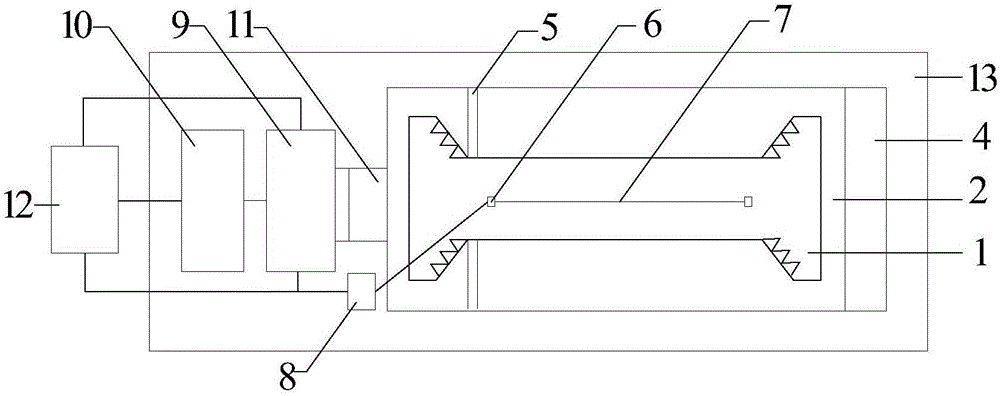

[0025] Below in conjunction with accompanying drawing, the present invention will be further described:

[0026] A test device for axially fully constrained stress includes a constrained frame, a high-precision displacement sensing system, a polytetrafluoroethylene plate 5, a load sensor 9, an actuator 10, a computer 12, an environmental chamber 13 and a constrained specimen 1. The constraining frame is composed of specimen template 2, bolts 3, bottom plate 4 and spherical hinge 11. The high-precision displacement sensing system is composed of a displacement sensor 8 , an embedded part 6 and a transmission wire 7 . The sample template 2 and the bottom plate 3 are connected together by bolts 3, and the sample template 2 is fixed on the horizontal frame.

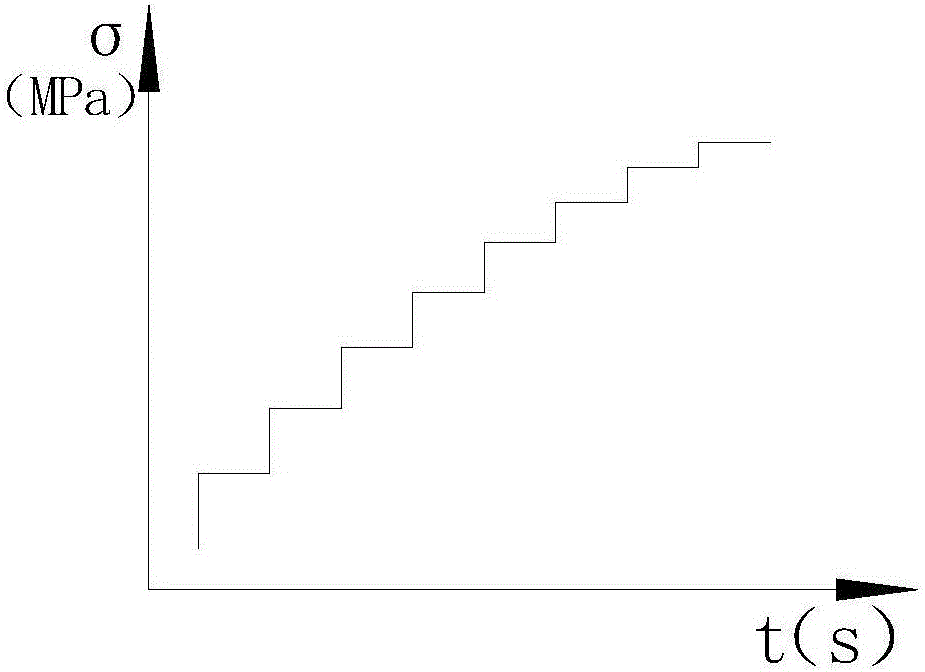

[0027] Such as figure 1 As shown, one end of the constraint specimen 1 is fixed, the other end can move freely, and the polytetrafluoroethylene plate 5 can be freely stretched. The embedded parts 6 are inserted into both en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com