Stress loading combination device

A combined device and stress loading technology, which is applied in the direction of measuring devices, using stable tension/pressure to test the strength of materials, instruments, etc., can solve the problems of complex principles, high development costs, and increased research difficulty, so as to reduce test errors, Good test effect and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

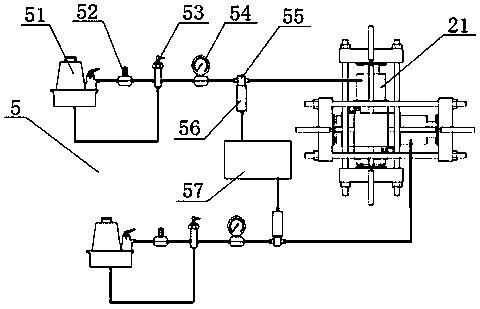

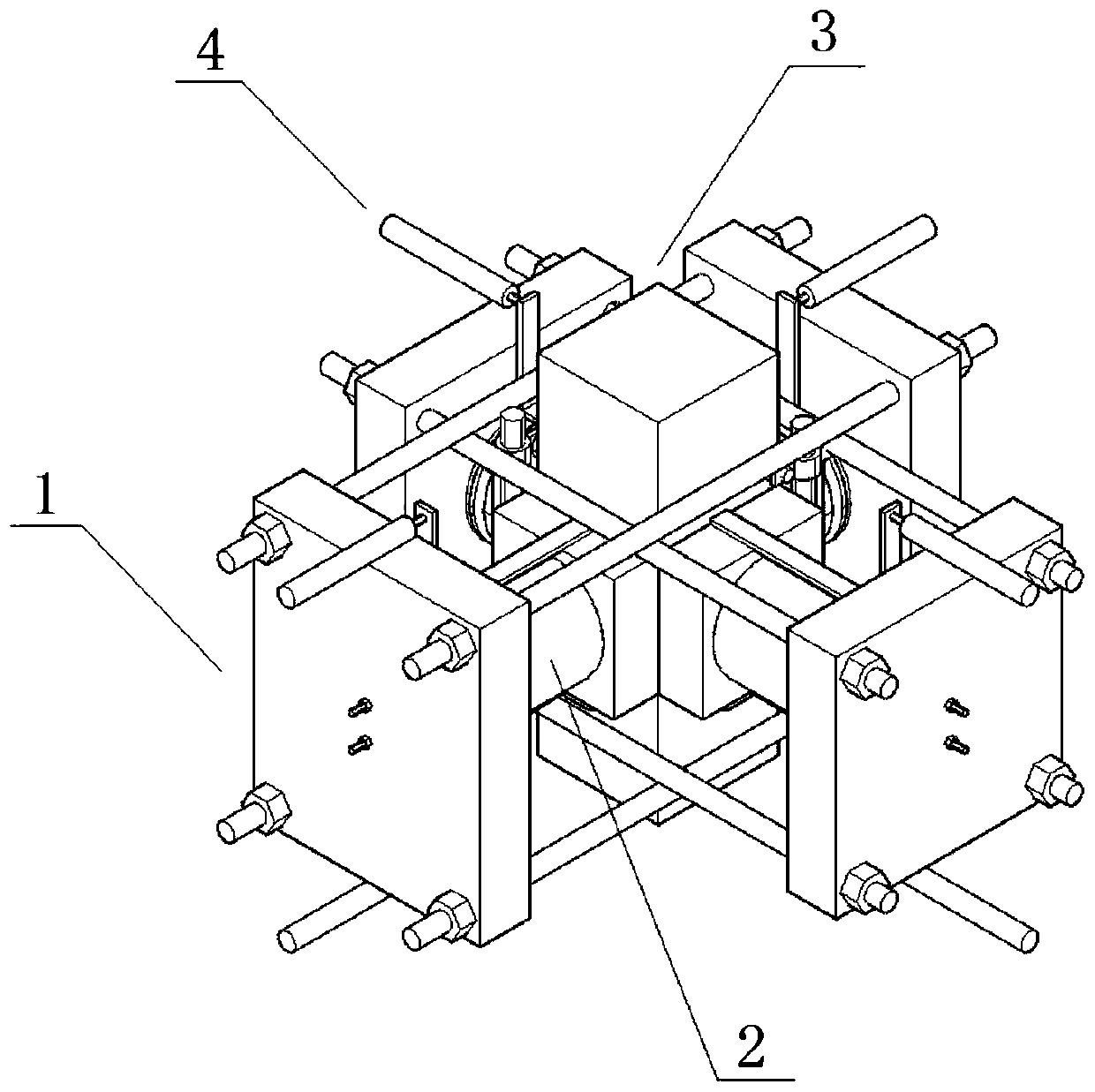

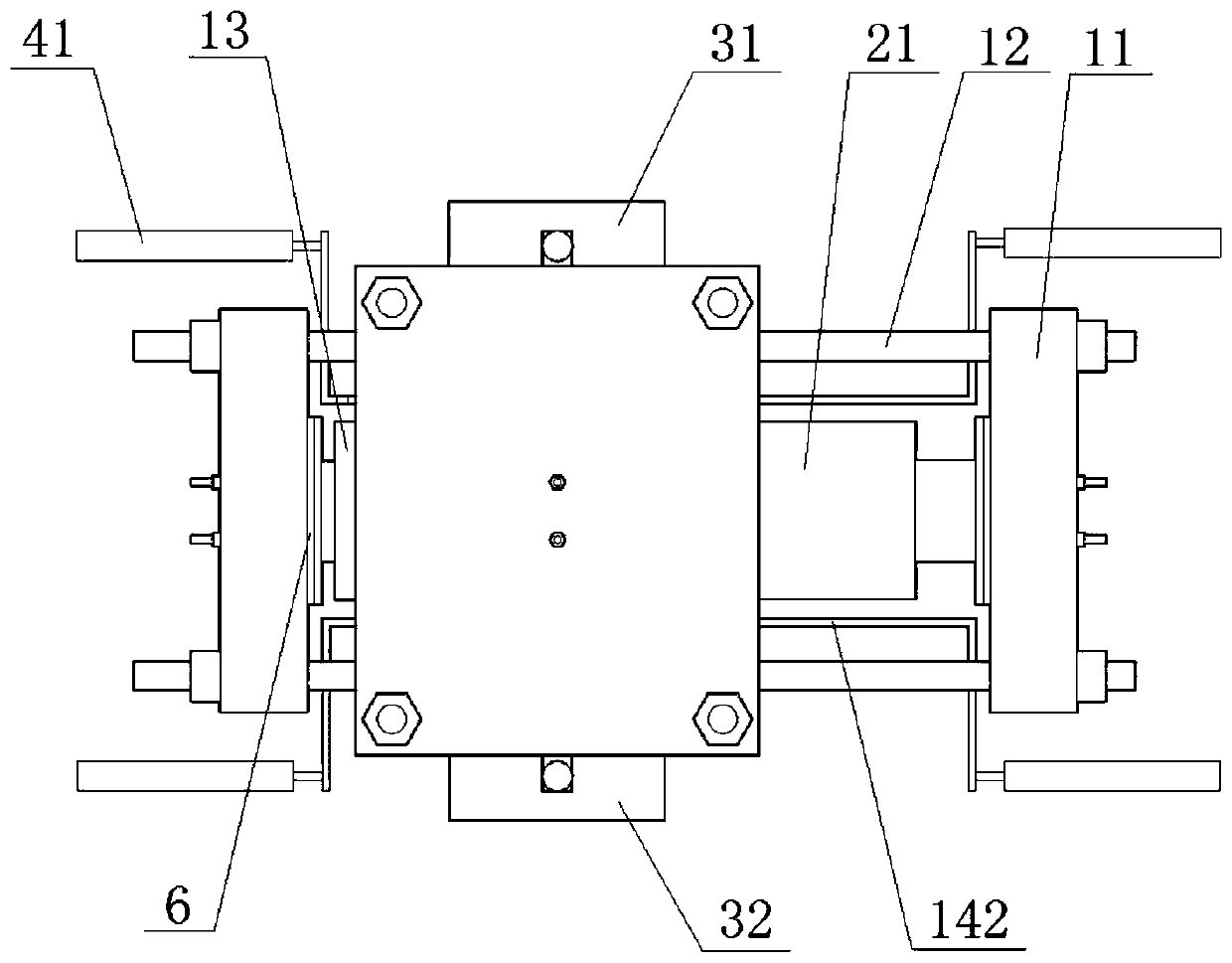

[0033] Such as Figure 1 to Figure 7 Shown is a first embodiment of a stress loading combination device of the present invention, which is used to place on the loading platform of a uniaxial servo press 8 to perform a true triaxial pressure test on a cube specimen 7, and the device includes two mutual The first loading assembly 1 vertically arranged for the circumferential force transmission of the cube test piece 7, and the second loading assembly 3 for the axial force transmission of the cube test piece 7; the first loading assembly 1, the second loading assembly 3 are in close contact with the circumferential surface and the axial surface of the cube specimen 7 respectively; the first loading assembly 1 is connected with the force applying mechanism 2, and the force applying mechanism 2 is connected with the control system 5, the first loading assembly 1 and the second Displacement measuring components 4 are arranged on the loading components 3 .

[0034] The force applyin...

Embodiment 2

[0068] This embodiment is similar to Embodiment 1, the difference is that, as Figure 2 to Figure 4 As shown, in this embodiment, thin sheets for reducing friction are provided between the second pressing plate 141 , the first pressing block 31 , the second pressing block 32 and the cube test piece 7 . The arrangement of thin slices can reduce the friction between the first loading assembly 1 , the second loading assembly 3 and the cube specimen 7 .

[0069] In addition, a gasket 6 for reducing stress concentration is provided between the force applying mechanism 2 , the first pressing plate 13 and the end plate 11 . The arrangement of the gasket 6 can prevent the stress from concentrating on the cube test piece 7 .

[0070] Specifically, as Figure 2 to Figure 5 As shown, the sheet in this embodiment is a polytetrafluoroethylene sheet, and the gasket 6 is a steel gasket.

[0071] In step S2, after the polytetrafluoroethylene sheet is placed on the upper surface of the seco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com