Avalanche energy tester of power MOSFET device

A tester and device technology, applied in the field of power MOSFET device avalanche energy tester, can solve problems such as the inability to provide high instantaneous current power MOSFET avalanche energy test, and achieve the effect of improving test ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

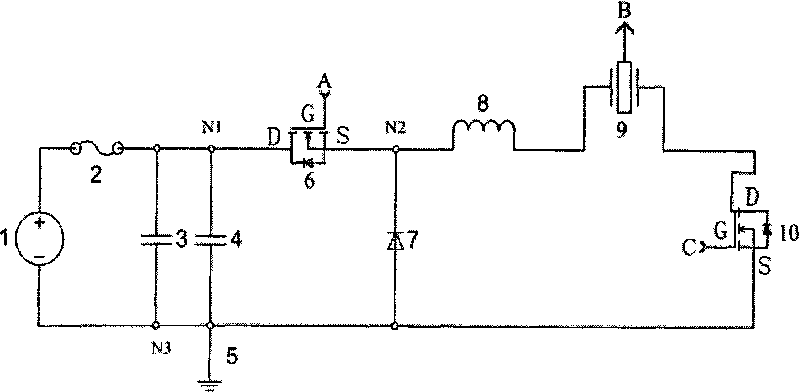

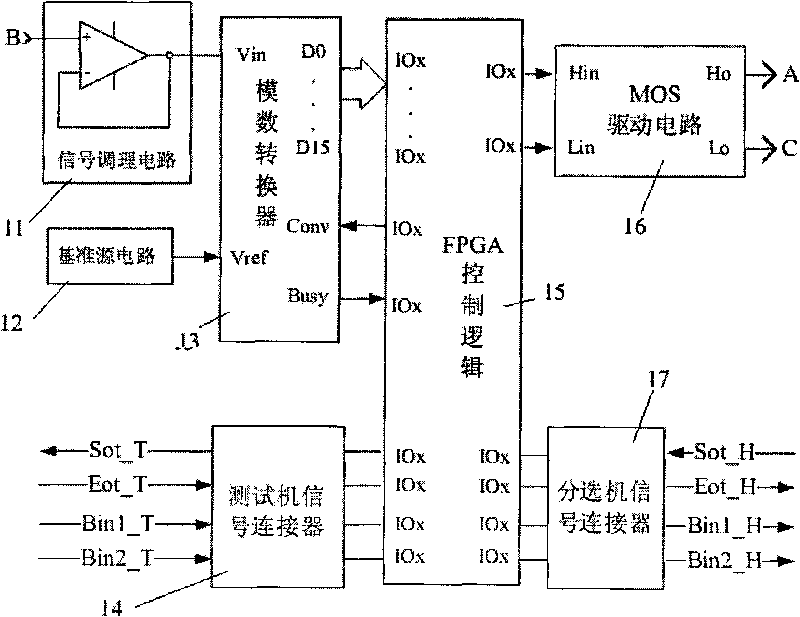

[0022] The power MOSFET device avalanche energy tester of the present invention comprises a front-end avalanche test circuit and a back-end avalanche current sampling circuit.

[0023] like figure 1 As shown, the hardware structure of the front-end avalanche test circuit is: including a 0-50V adjustable DC power supply 1, the positive pole of the adjustable DC power supply 1 is connected to the 1A fuse 2; the other end of the fuse 2 is connected to the MOSFET device 6 (selected model is The drain of IXFX140N30P) is connected; the source of MOSFET device 6 is connected with one end of inductor 8; the other end of inductor 8 is connected with the current input end of current inductor 9; the current output end of current inductor 9 is connected with MOSFET device 10 to be tested The drain of the MOSFET device 10 to be tested is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com