System for testing comprehensive performance of metal roof

A comprehensive performance testing, metal roofing technology, applied in the testing of machine/structural components, liquid/vacuum measurement for liquid tightness, measuring devices, etc. Problems such as comprehensive inspection of various performances of roofs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

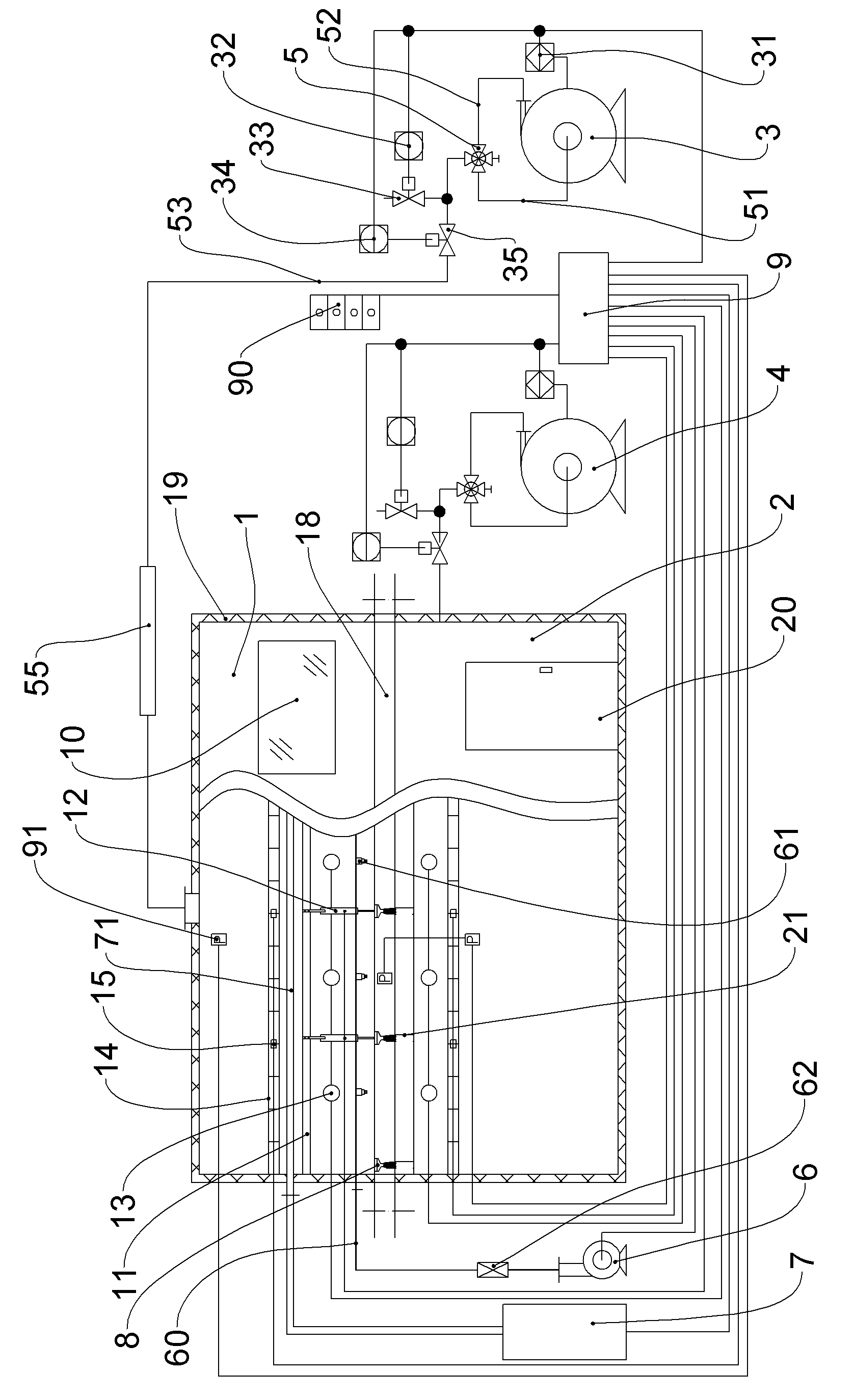

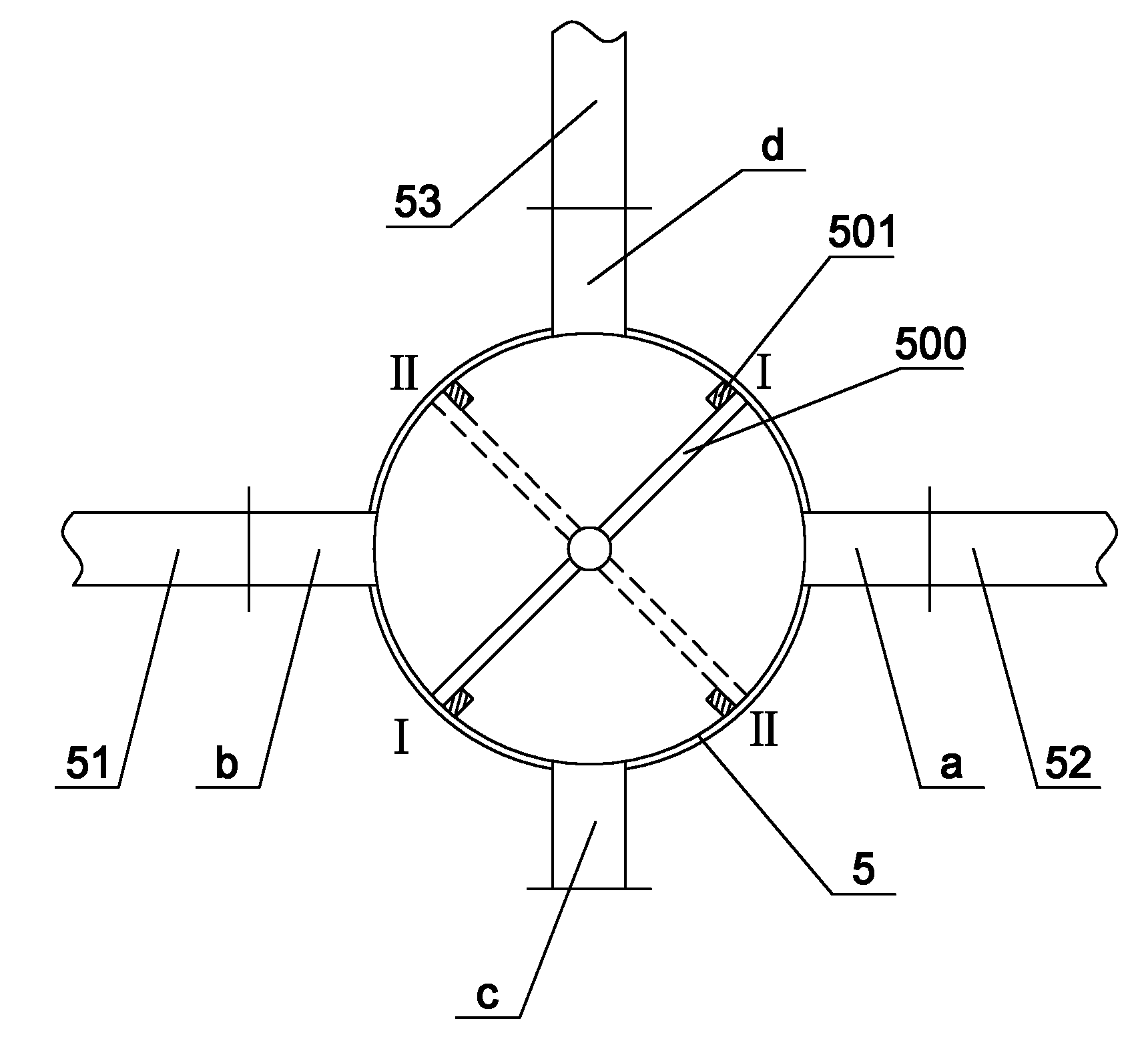

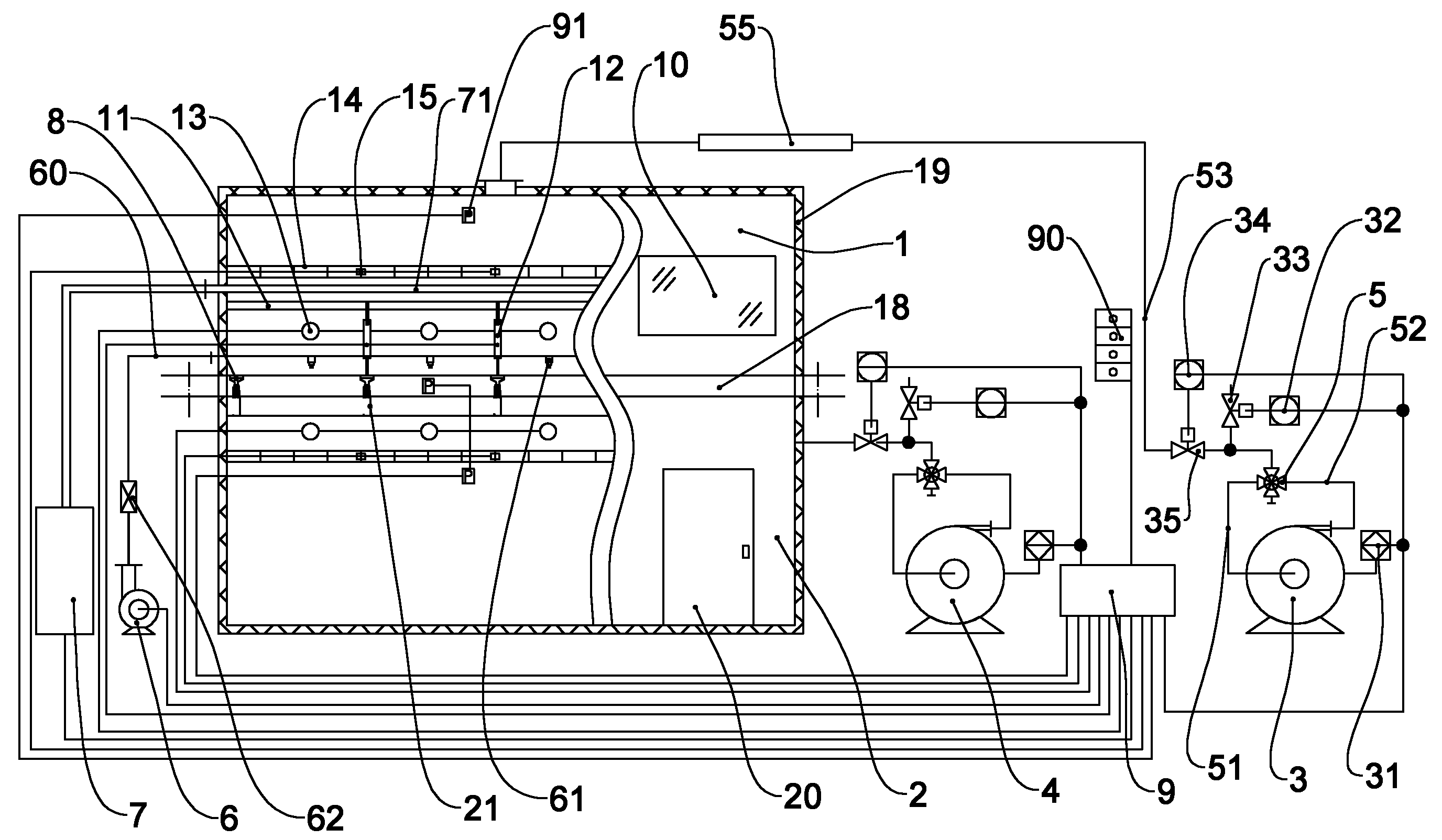

[0021] Such as figure 1 , figure 2As shown, the metal roof comprehensive performance testing system of this embodiment includes an upper box body 1, a lower box body 2, a first air supply and exhaust device, a second air supply and exhaust device, a water pump 6, a refrigerator 7, and an electric control device 9; The top of the lower box 2 is provided with a support 21 for supporting the metal roof test piece 8, and a sealing member 18 is arranged between the upper box 1 and the lower box 2. The upper box 1, the The lower box body 2 forms a closed space with the metal roof test piece 8 respectively, and the wall panels of the upper box body 1 and the lower box body 2 are provided with an insulating layer 19 to reduce heat and cold between the closed space and the outside world. Exchange, maintain the stability of temperature, save energy and test effect is good in the test process, described upper box body 1 is provided with observation window 10, so that observe the compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com