Patents

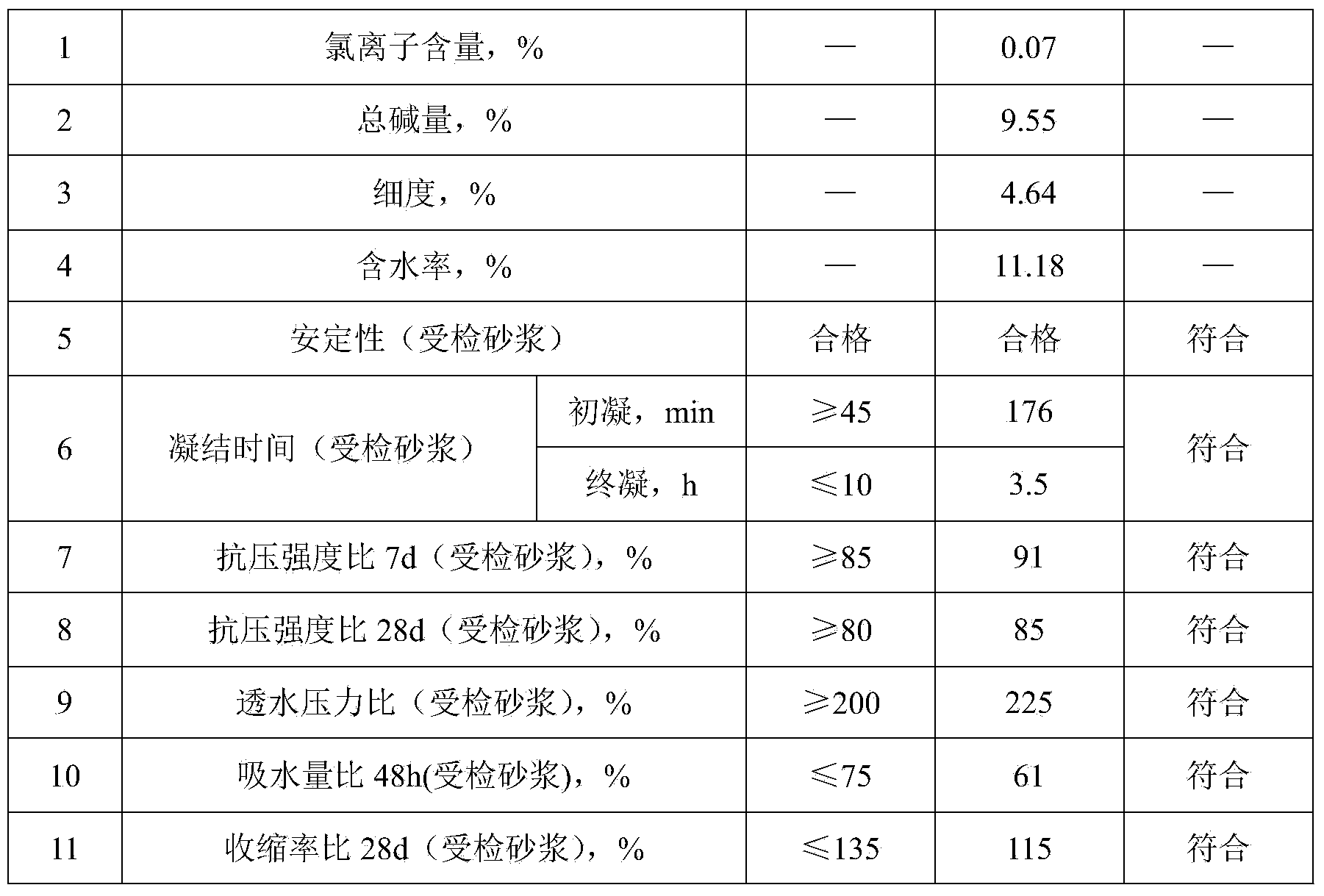

Literature

543 results about "Metal roof" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A metal roof is a roofing system made from metal pieces or tiles characterized by its high resistance, impermeability and longevity. It is a component of the building envelope. Zinc, copper and steel alloys are commonly used.

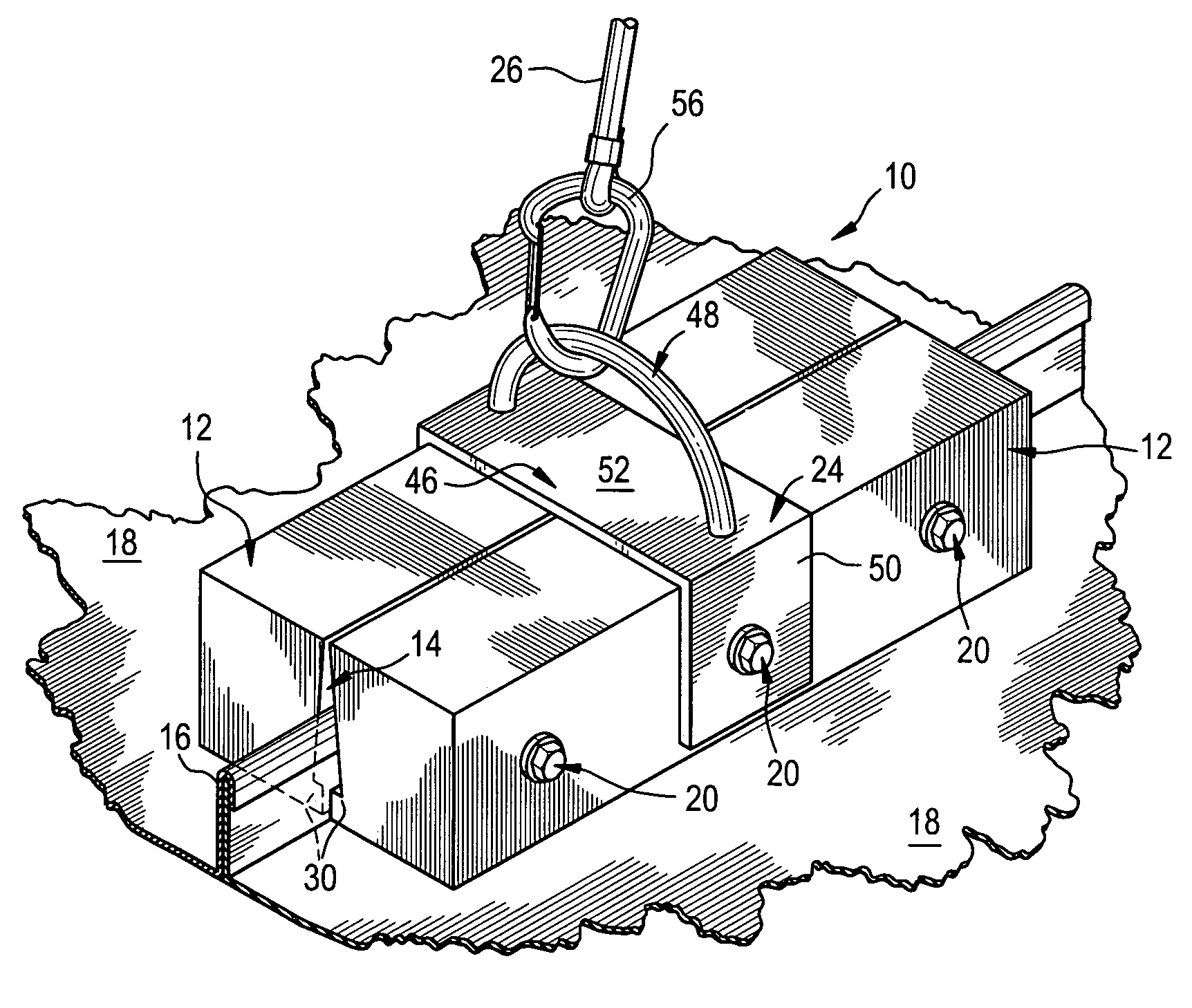

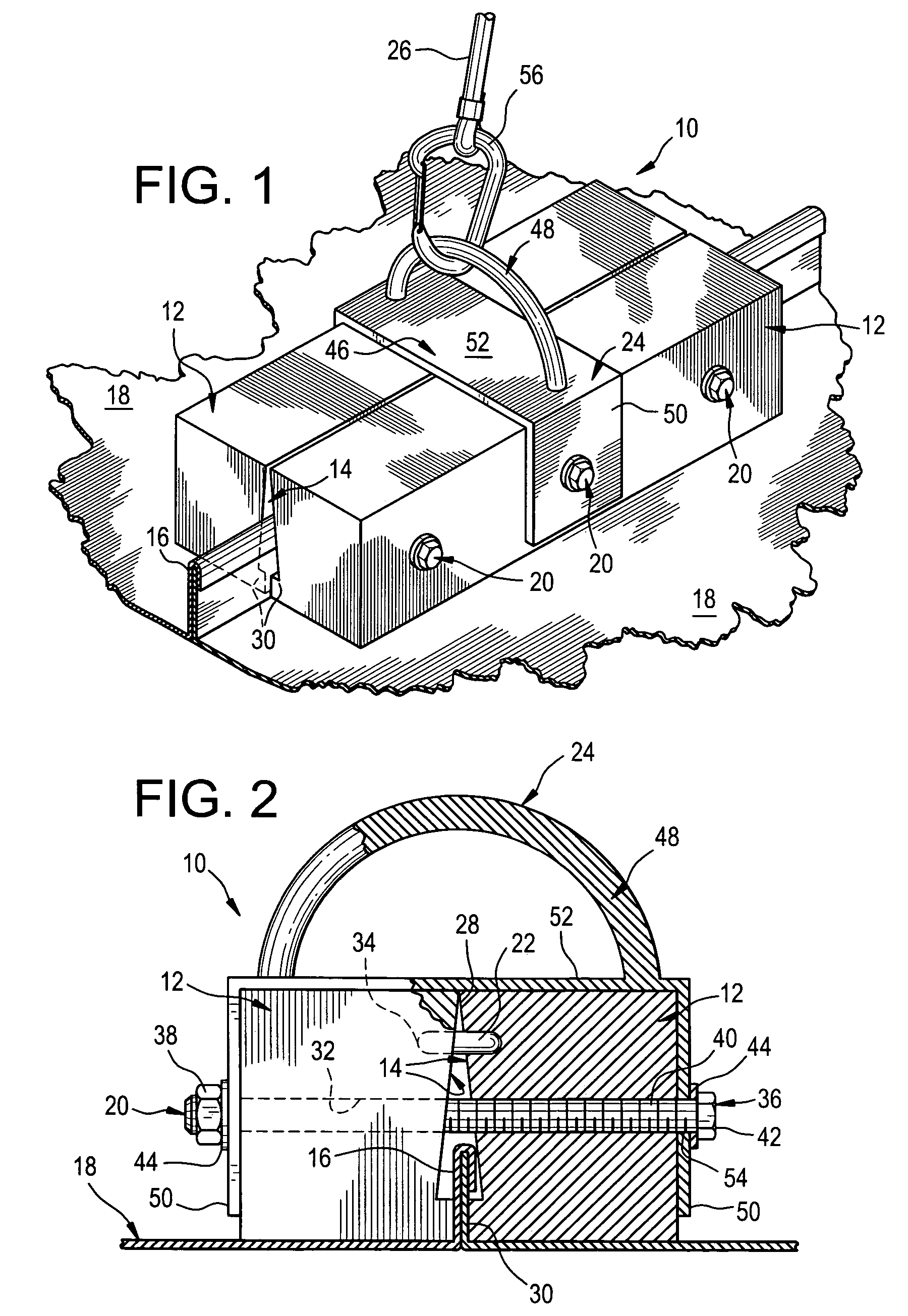

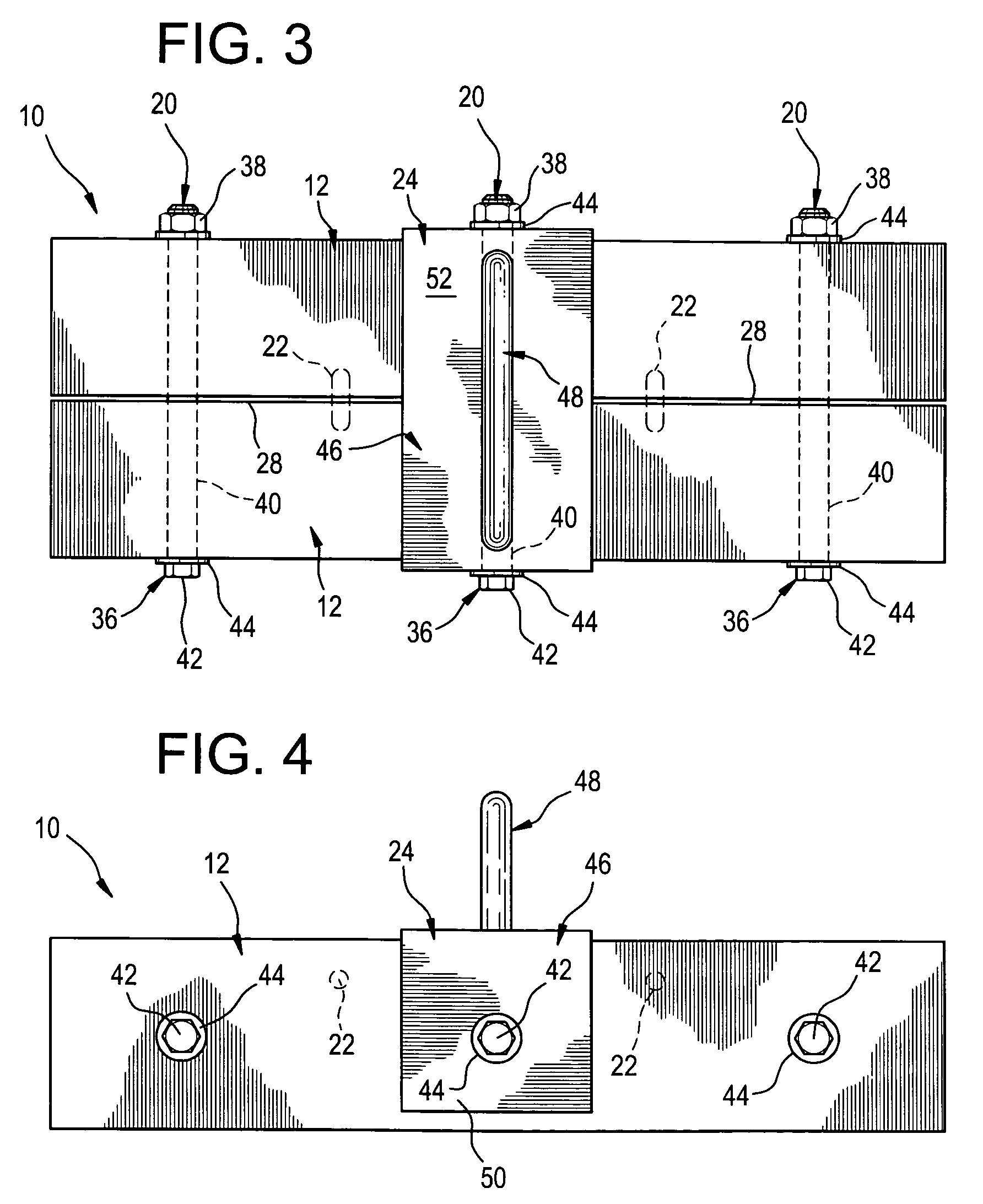

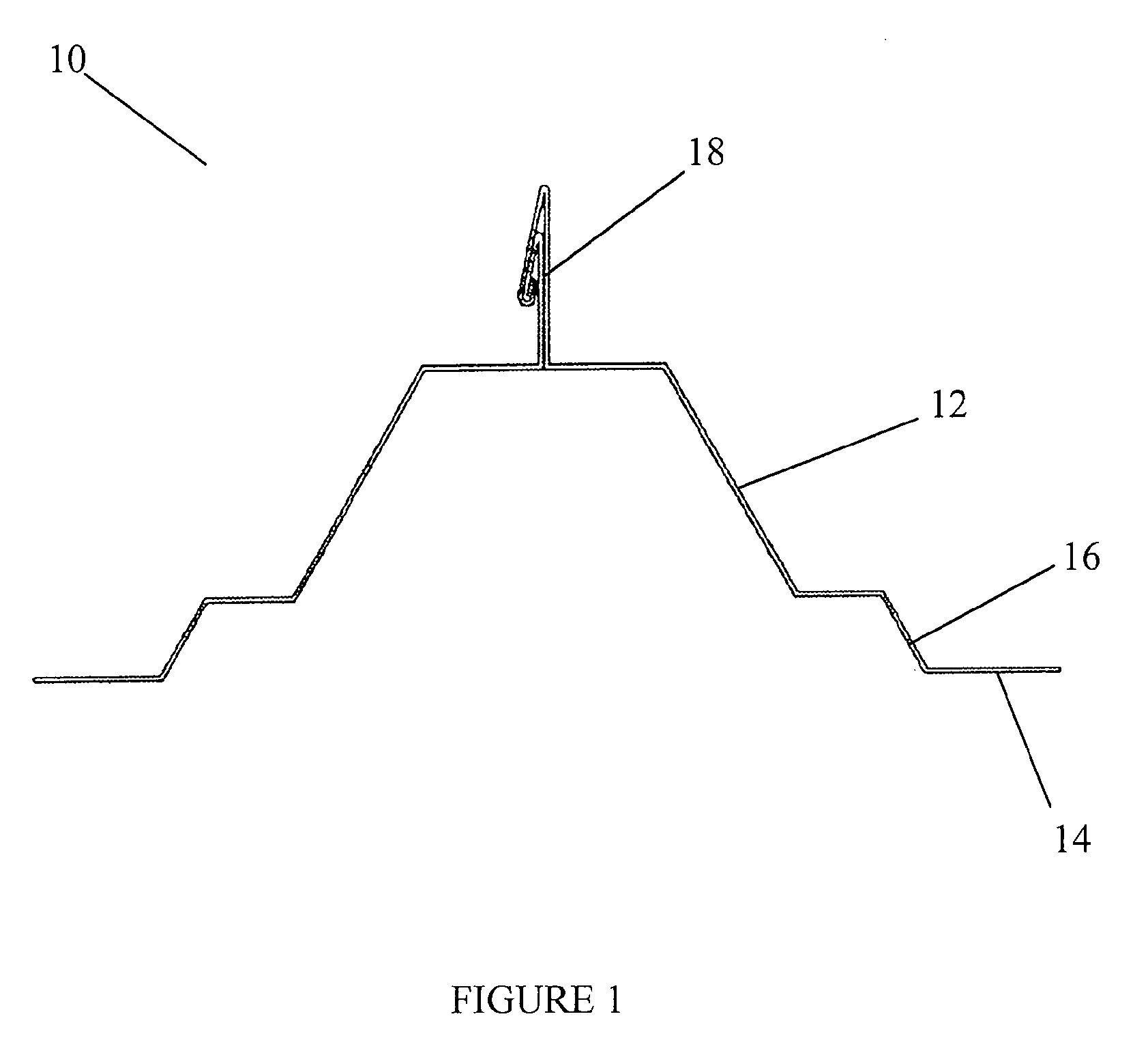

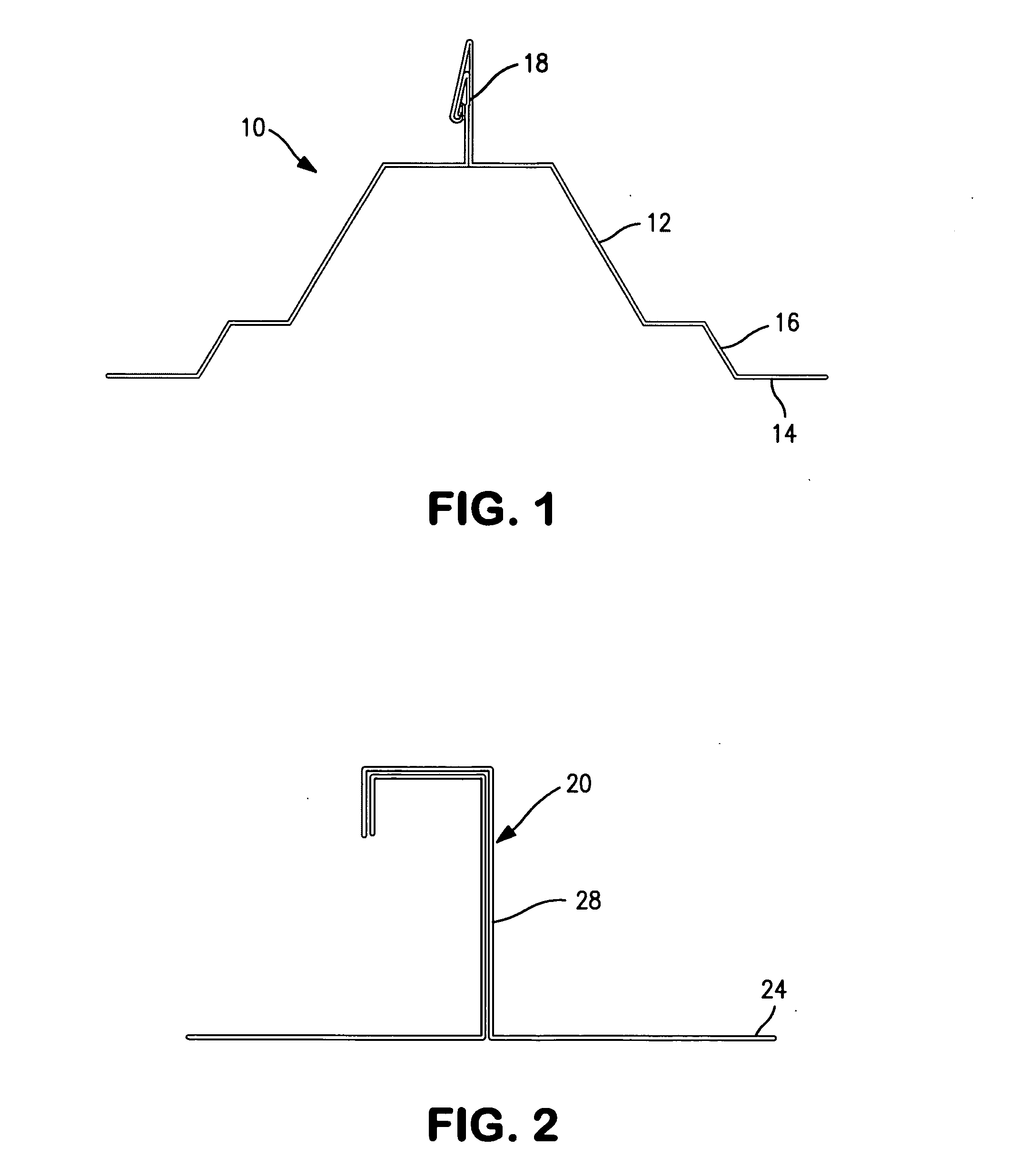

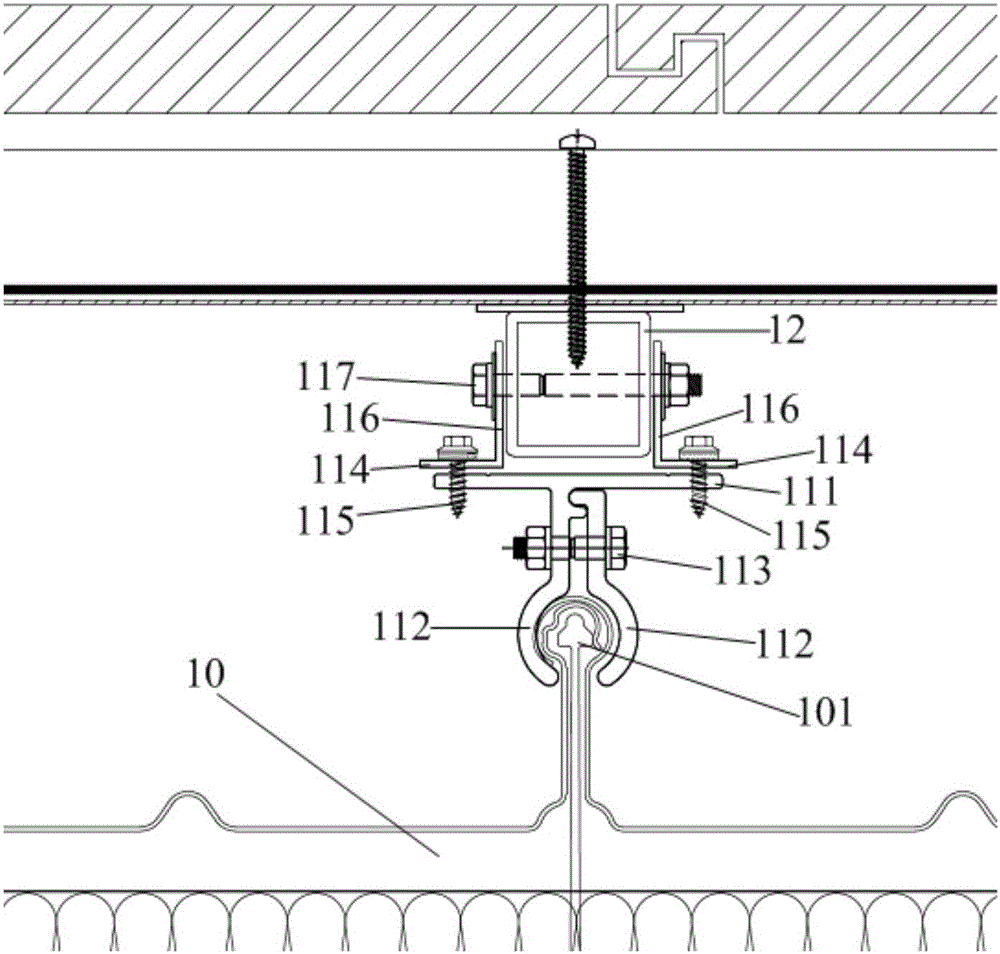

Roof anchor

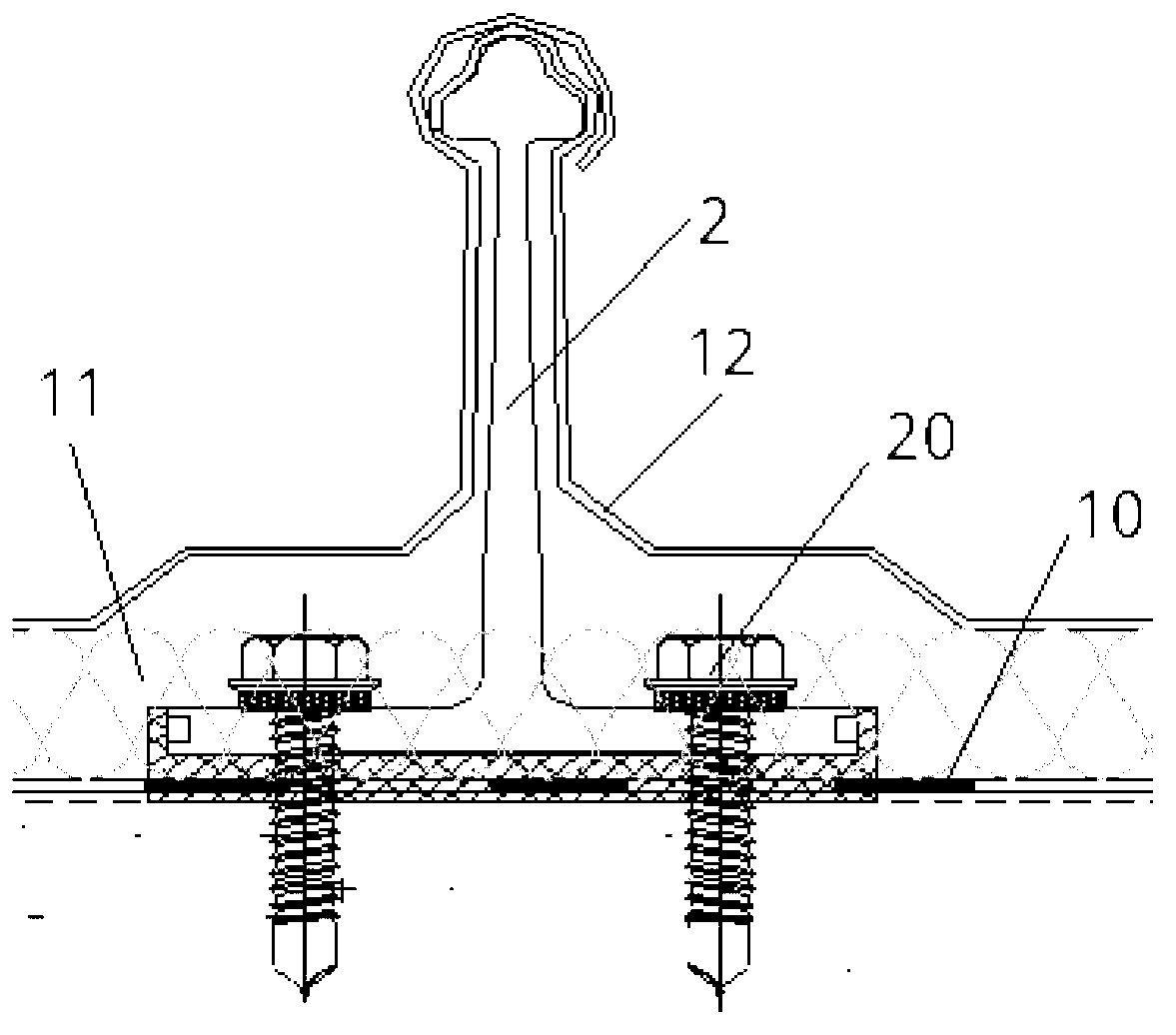

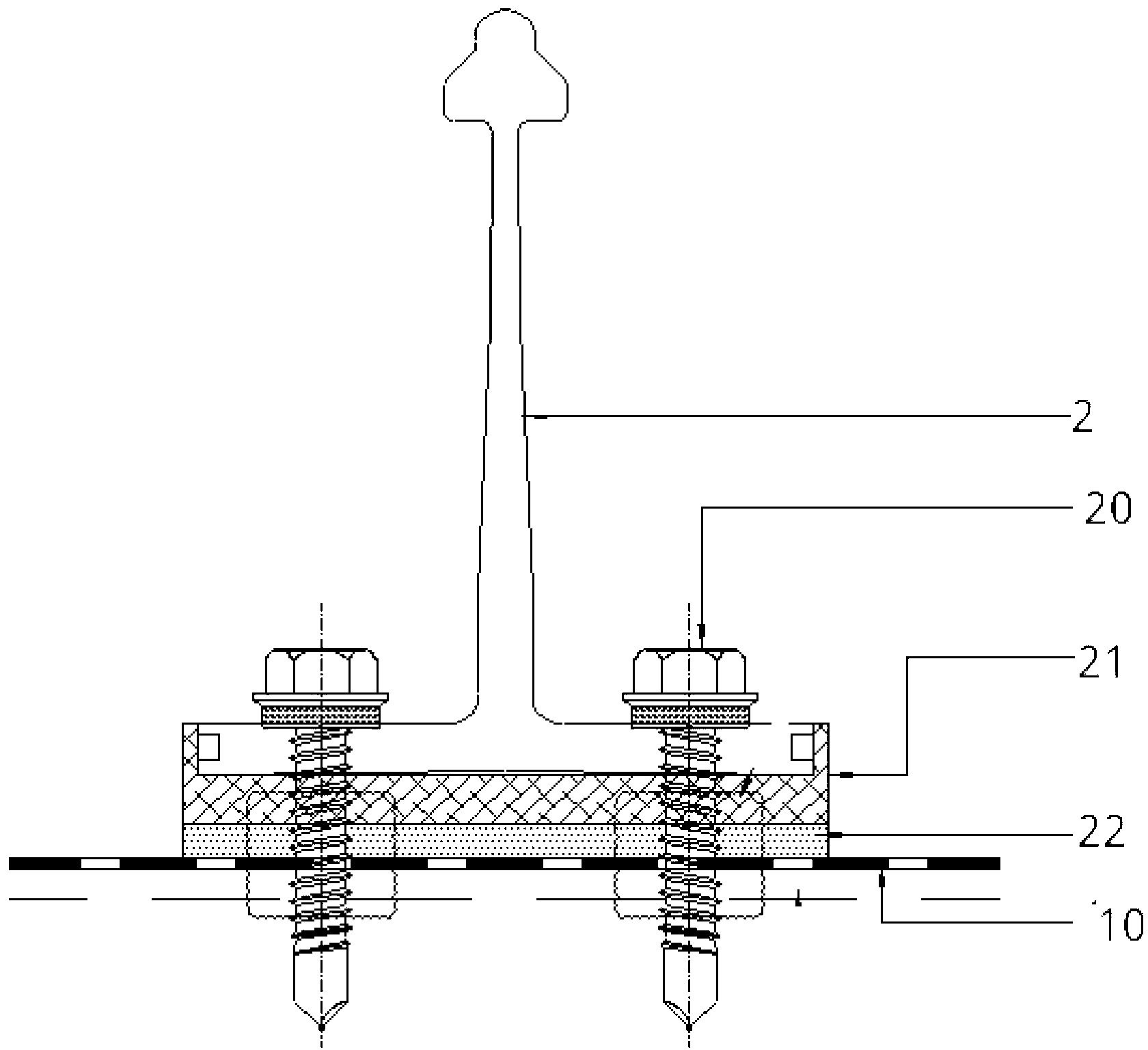

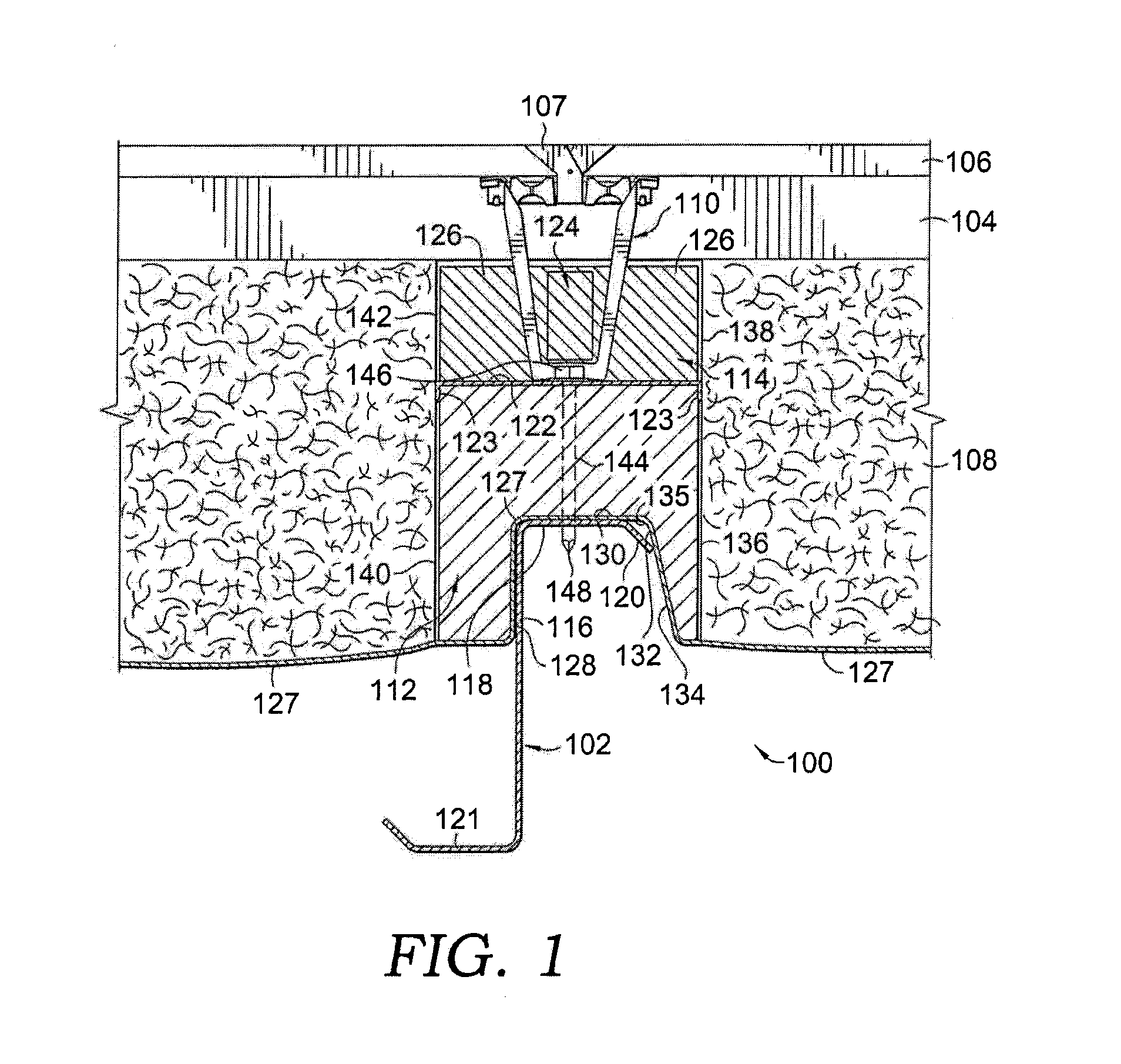

ActiveUS7240770B2Easy to installReduce manufacturing costCandle holdersSafety beltsEngineeringMetal roof

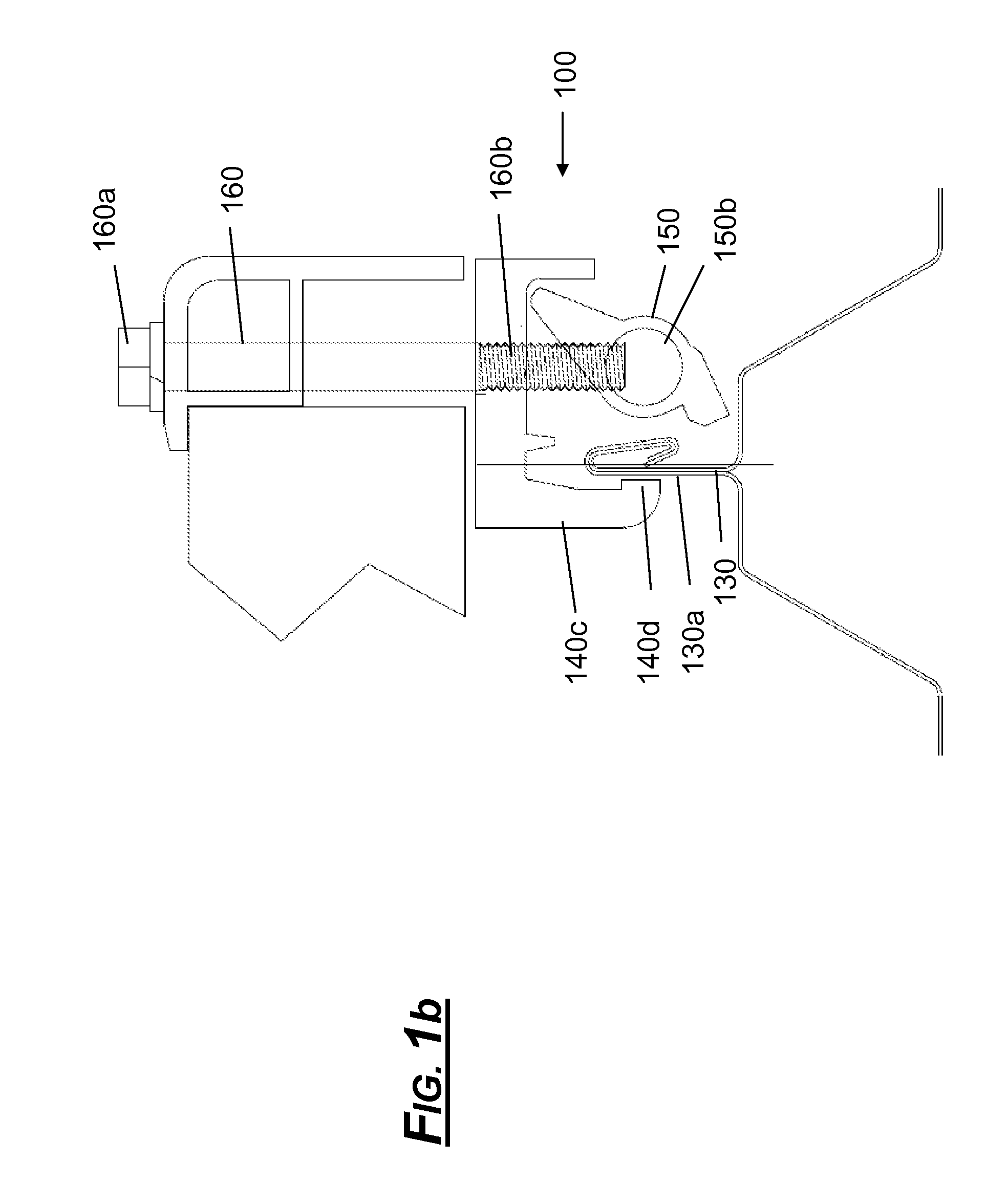

A roof anchor including a pair of blocks positioned side-by-side. The blocks have adjacent, inner surfaces with notches cut therefrom for receiving a standing seam of a metal roof. The blocks also have outer surfaces remote from the inner surfaces. A bracket is positioned over the pair of blocks. The bracket includes a base portion having a pair of legs, each being positioned adjacent a respective one of the outer surfaces of the blocks, and a crosspiece, positioned adjacent the tops of the blocks, joining the legs together. A loop portion is affixed to the base portion for securement of a workman's safety lanyard. A threaded fastener penetrates the pair of blocks and the pair of legs for: fastening the pair of blocks together, securing the bracket to the pair of blocks, and clamping the pair of blocks upon a standing seam of a metal roof.

Owner:CONSTR SPECIALTY ANCHORS

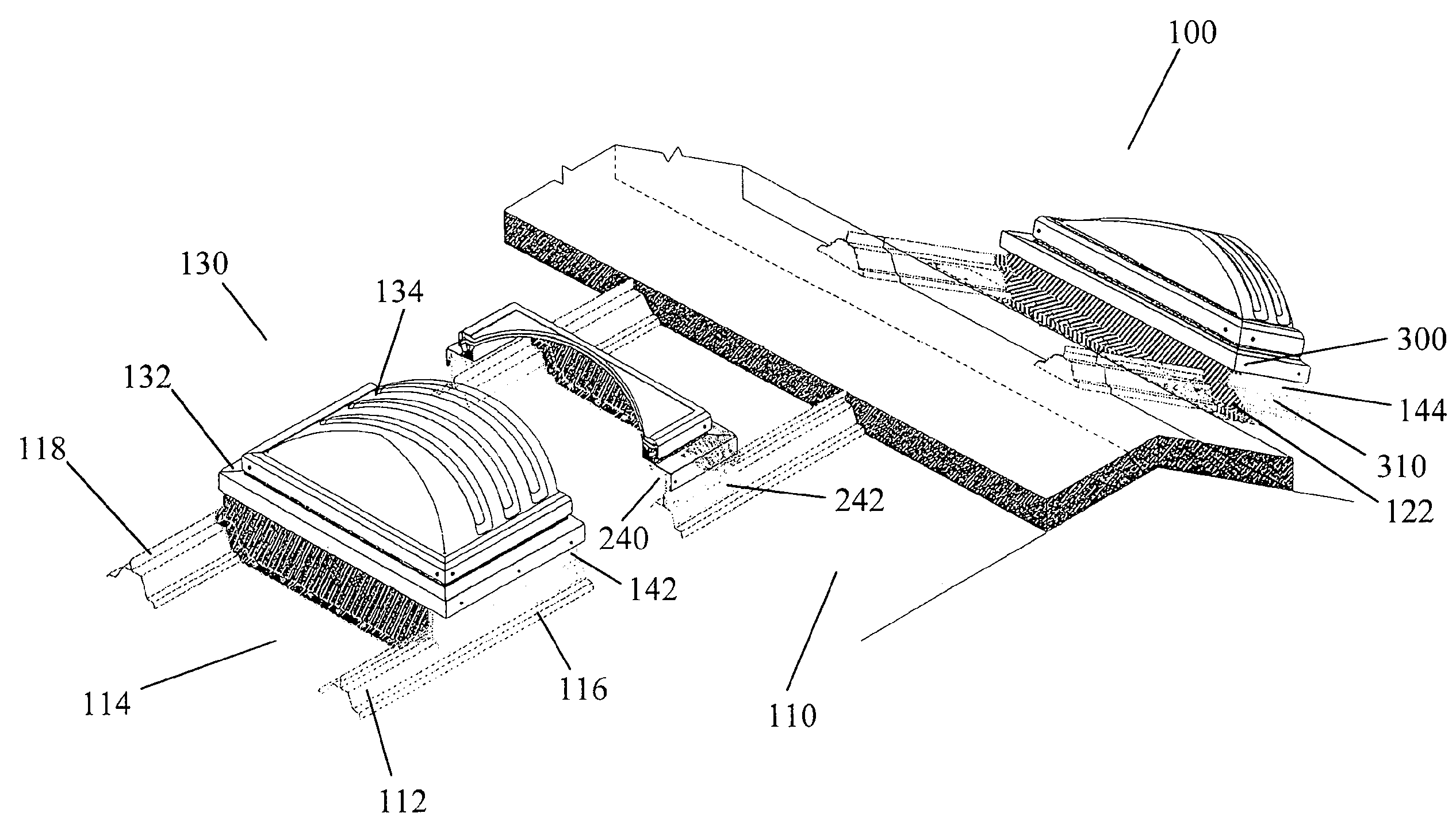

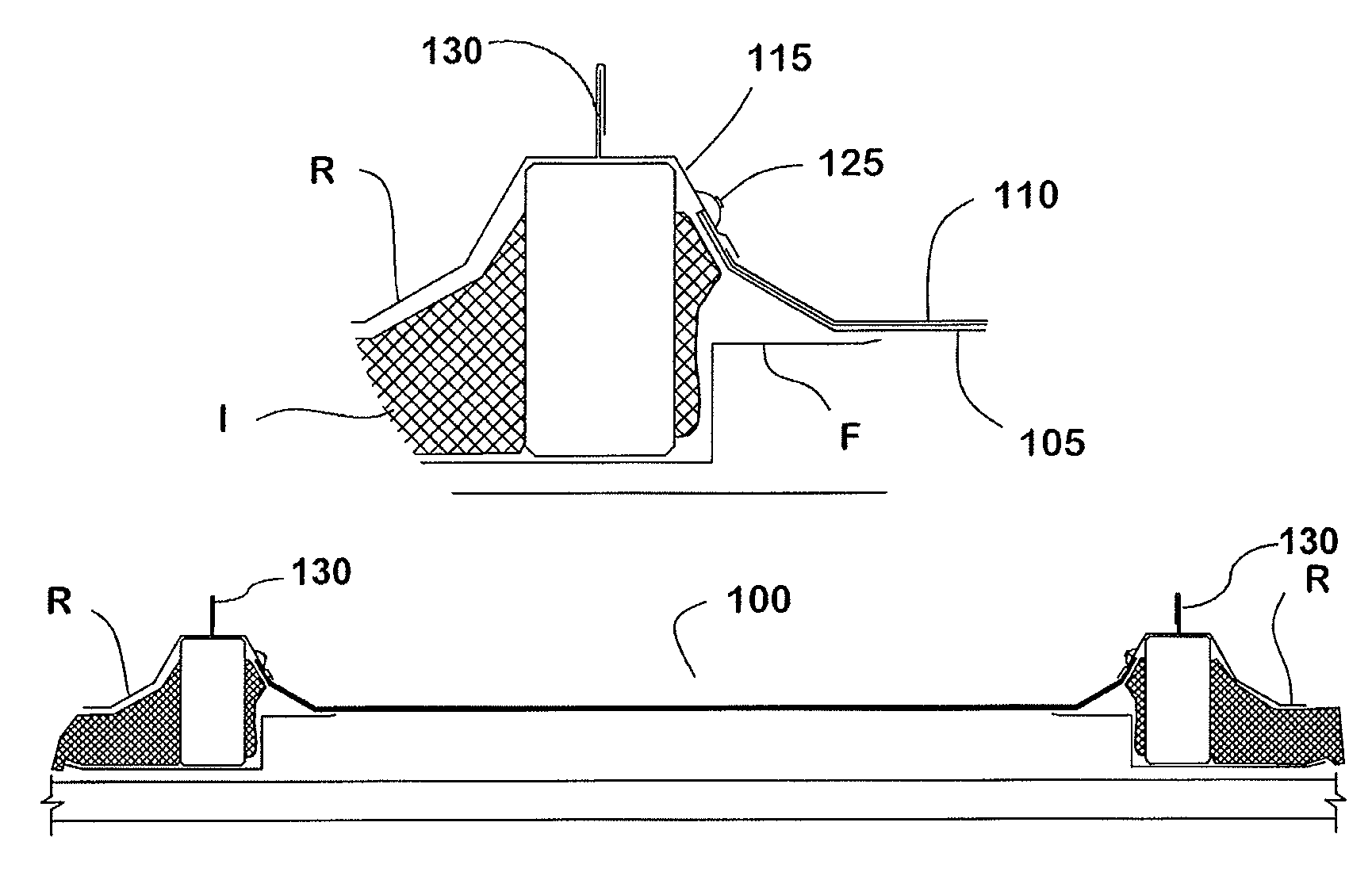

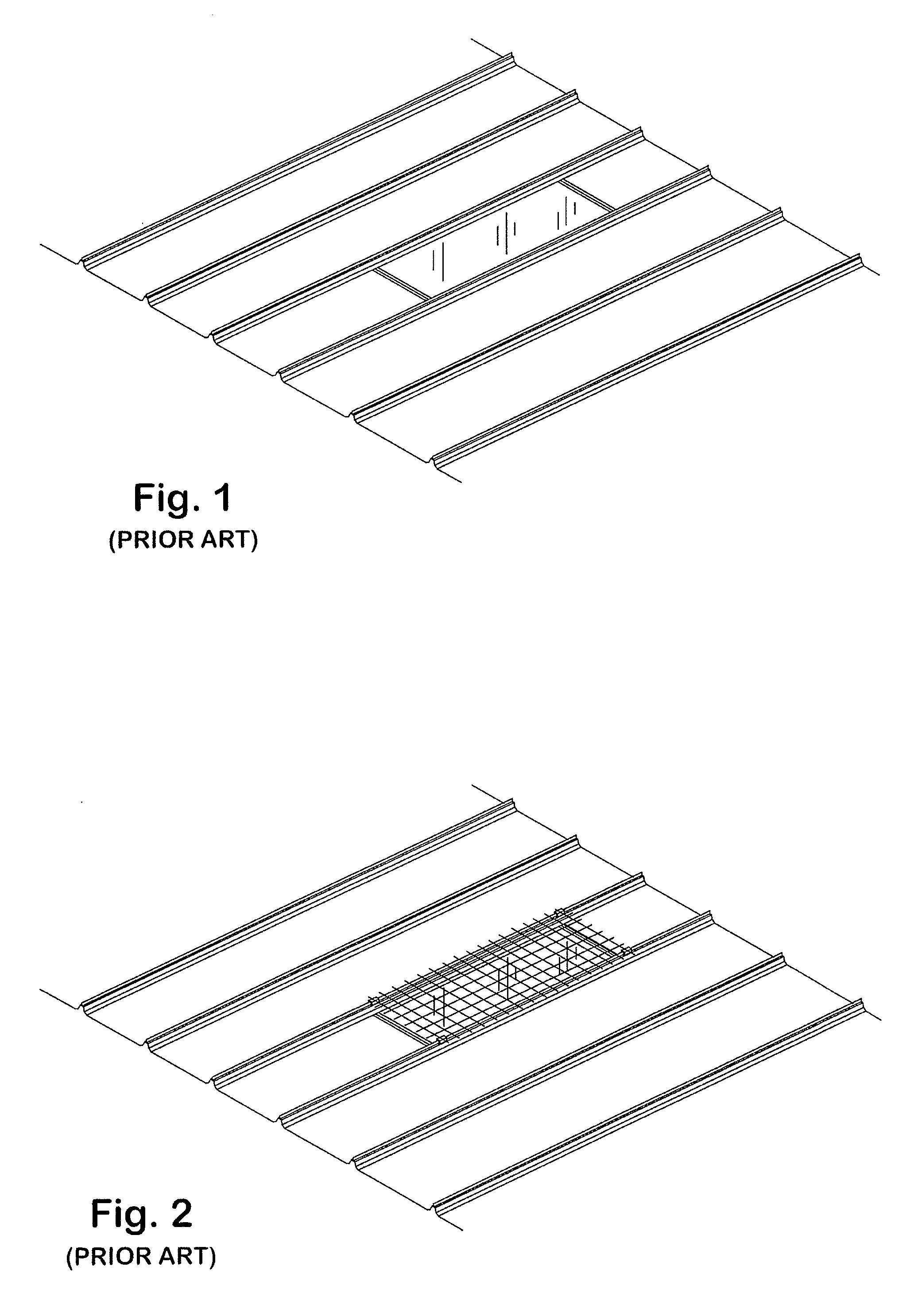

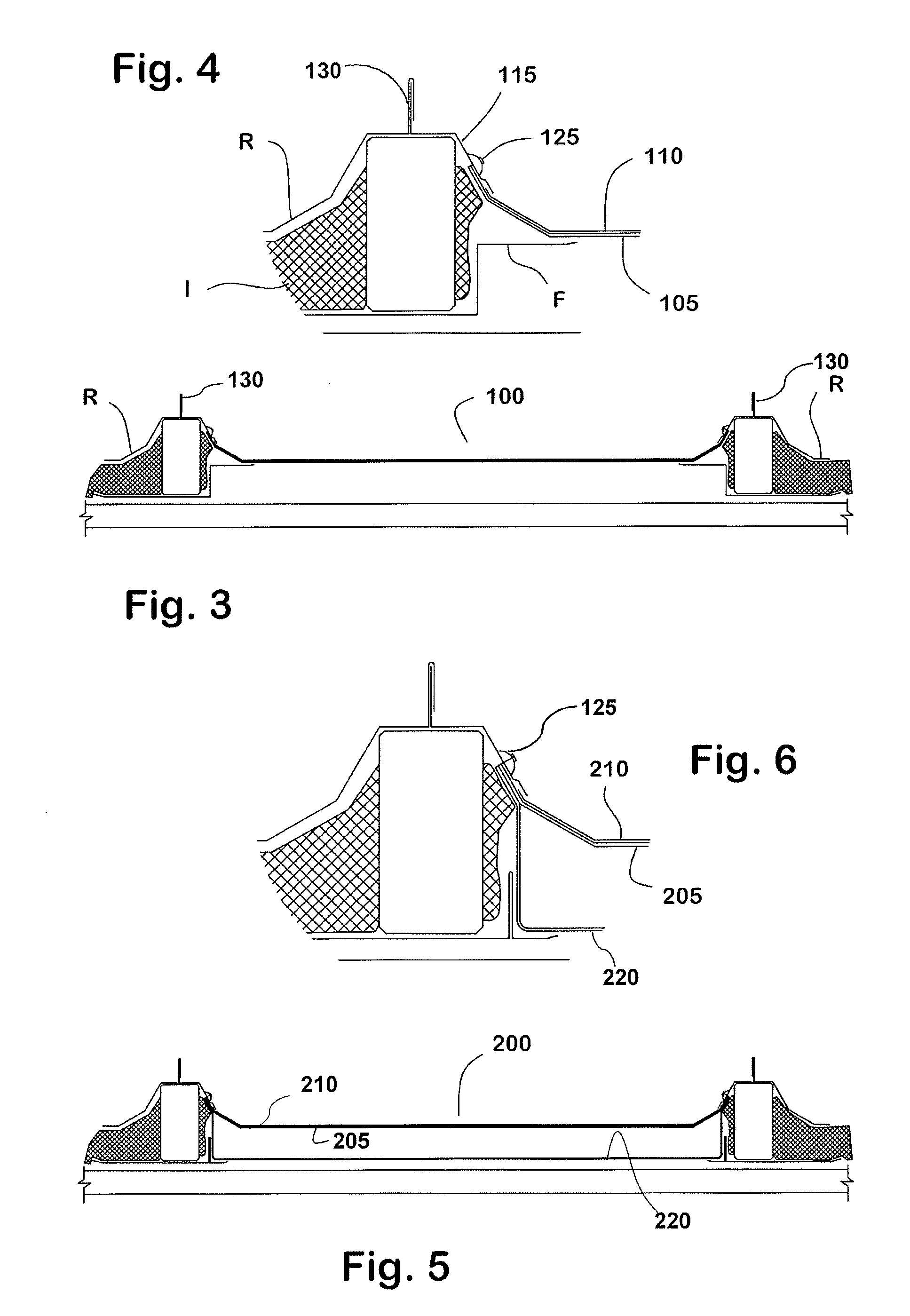

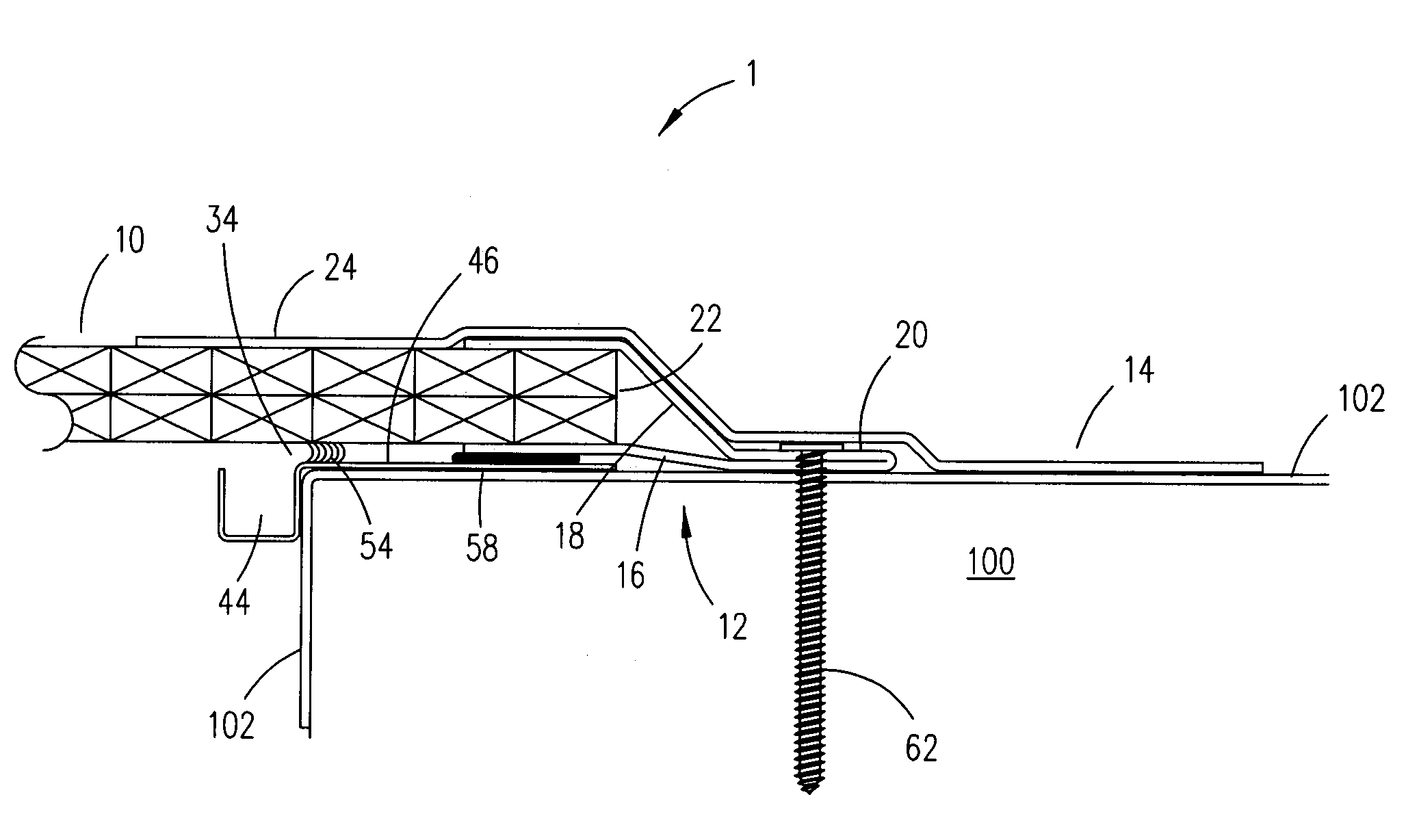

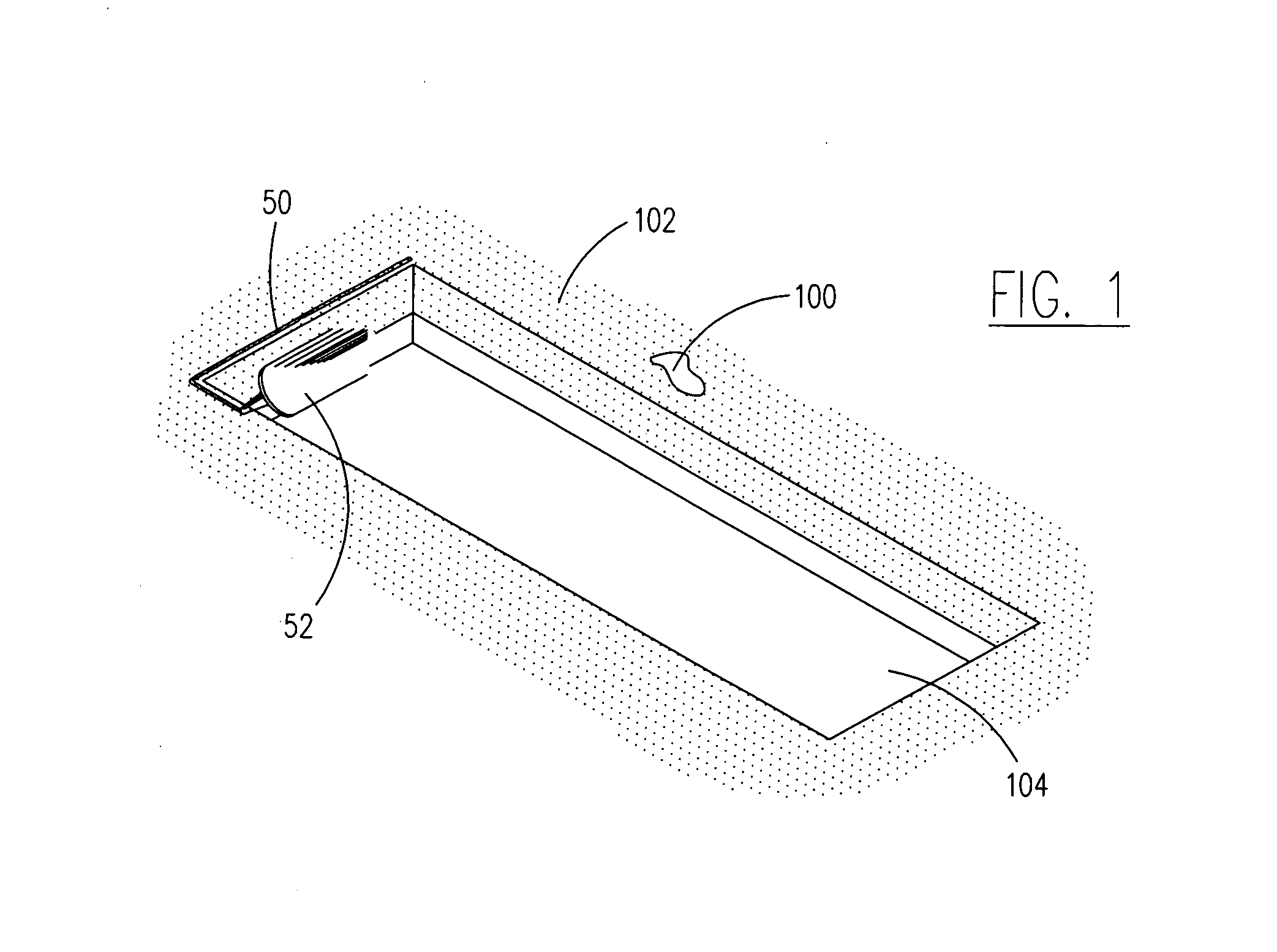

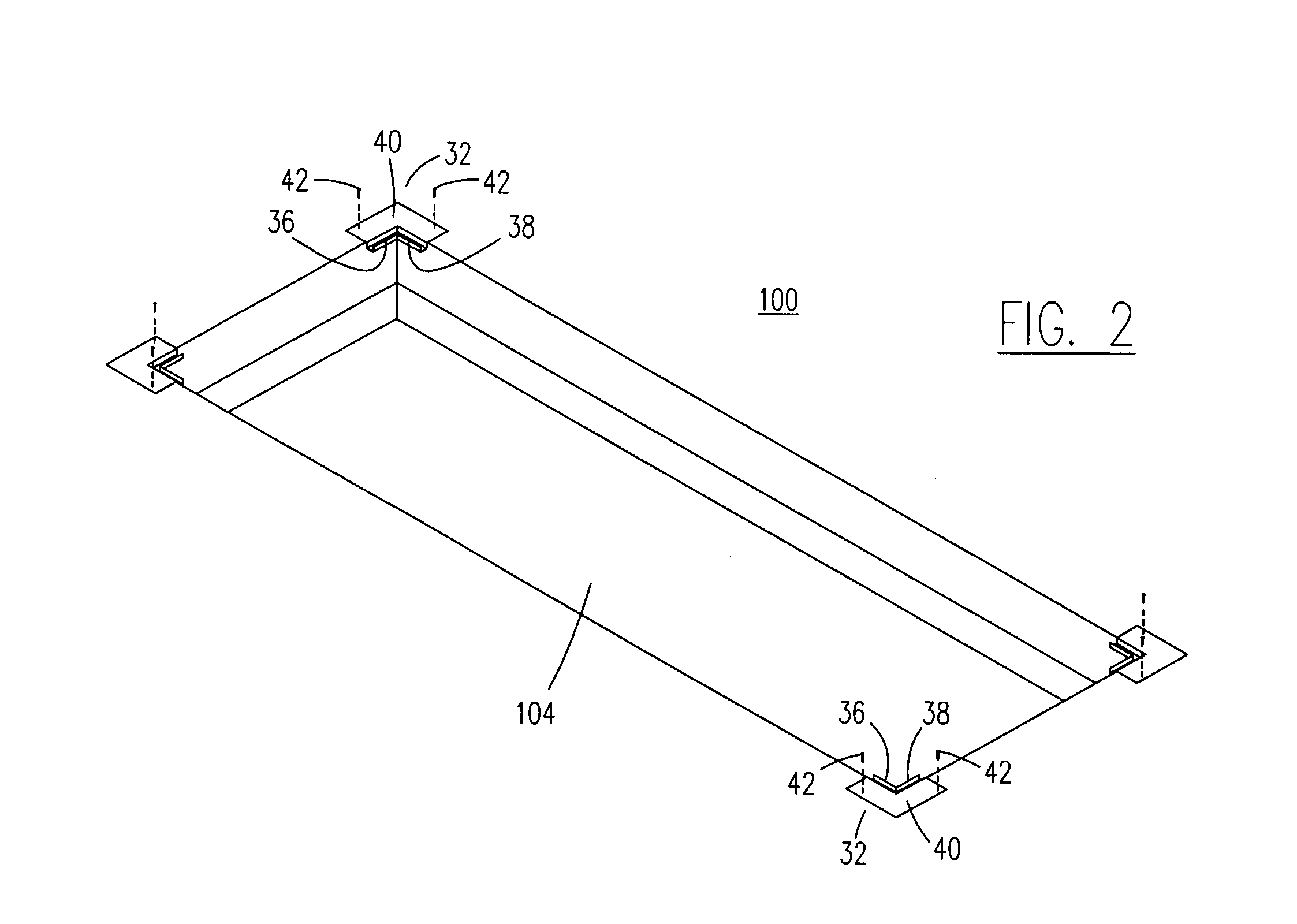

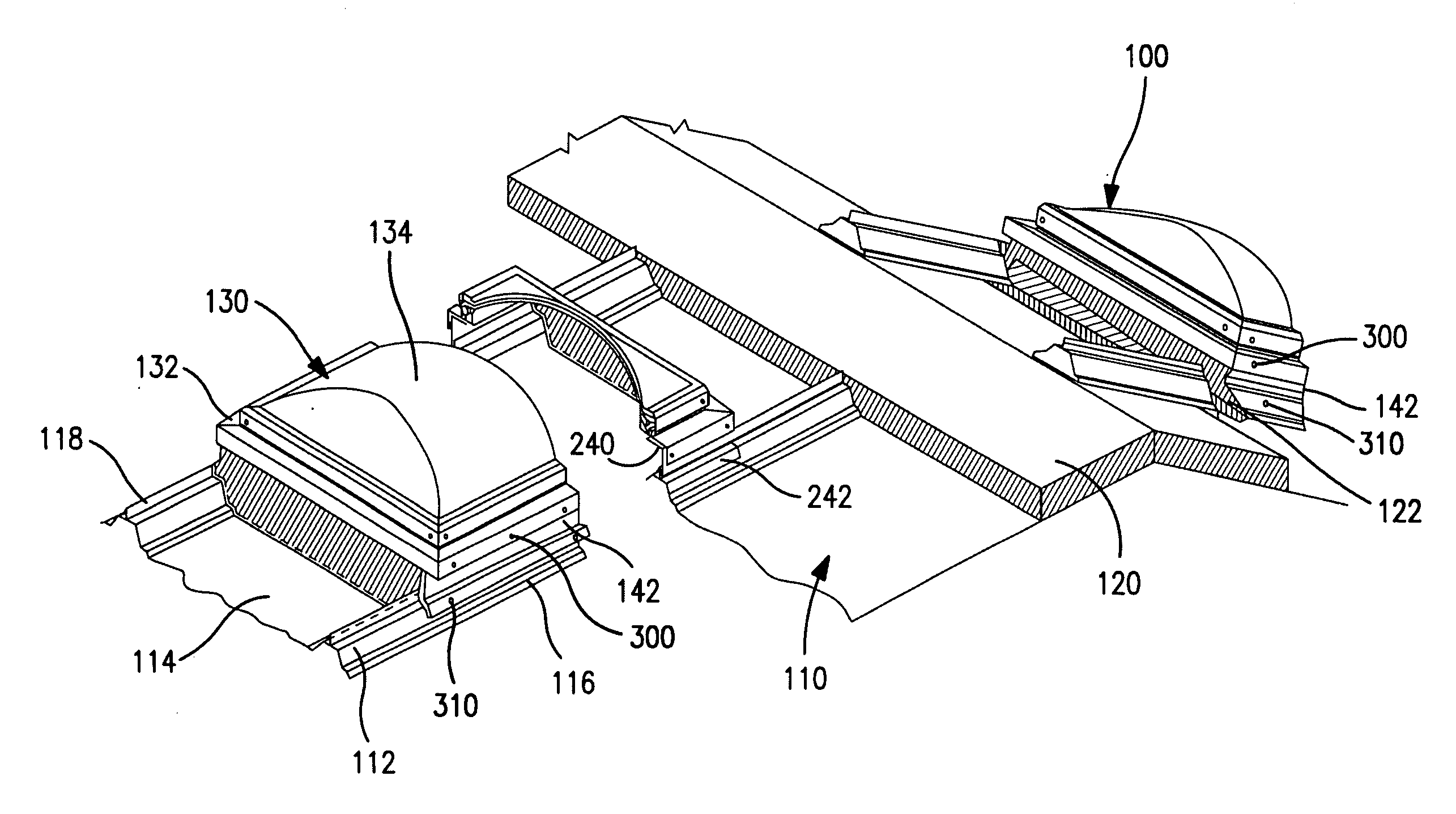

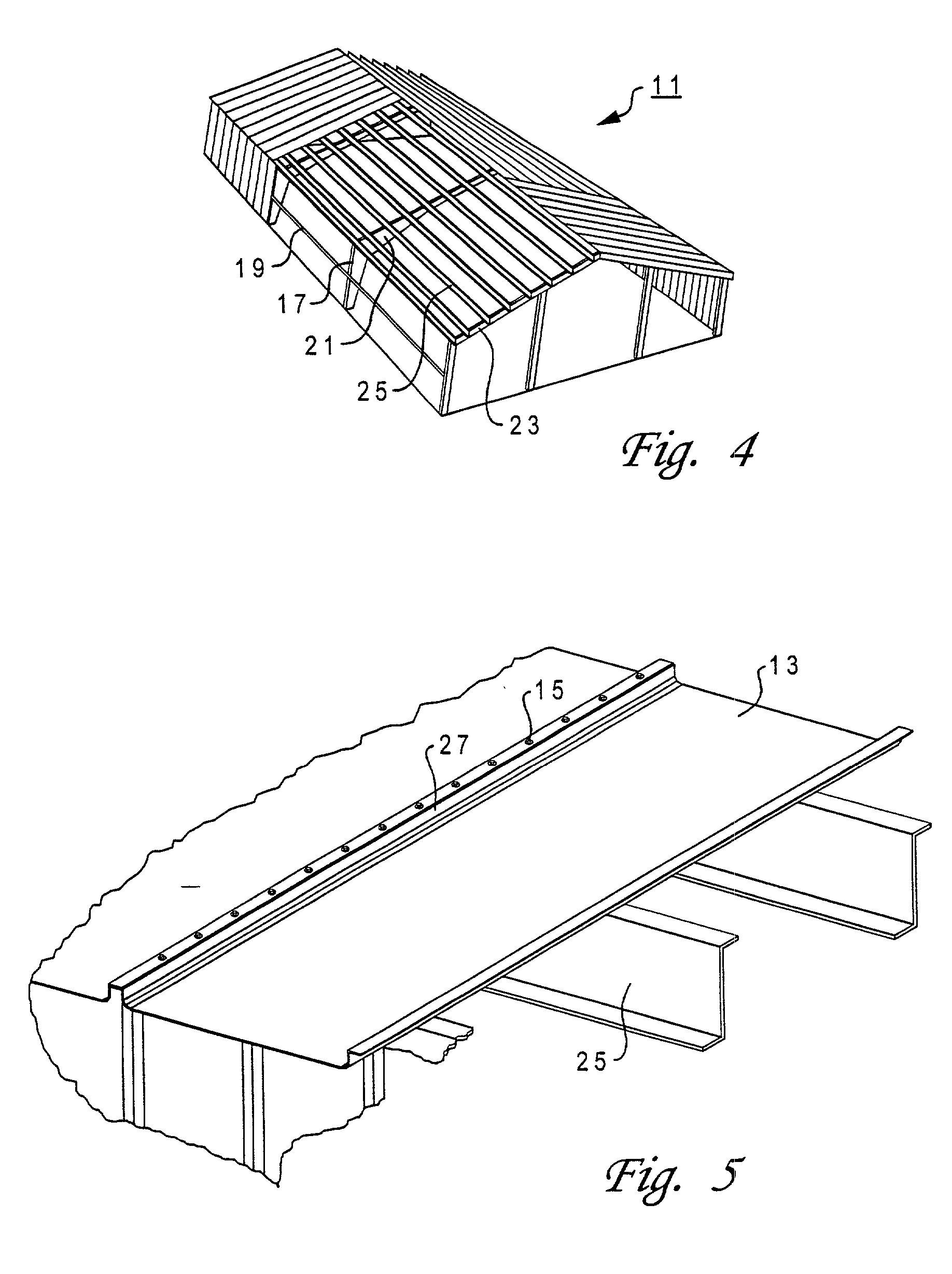

Curbless multiple skylight and smoke vent system

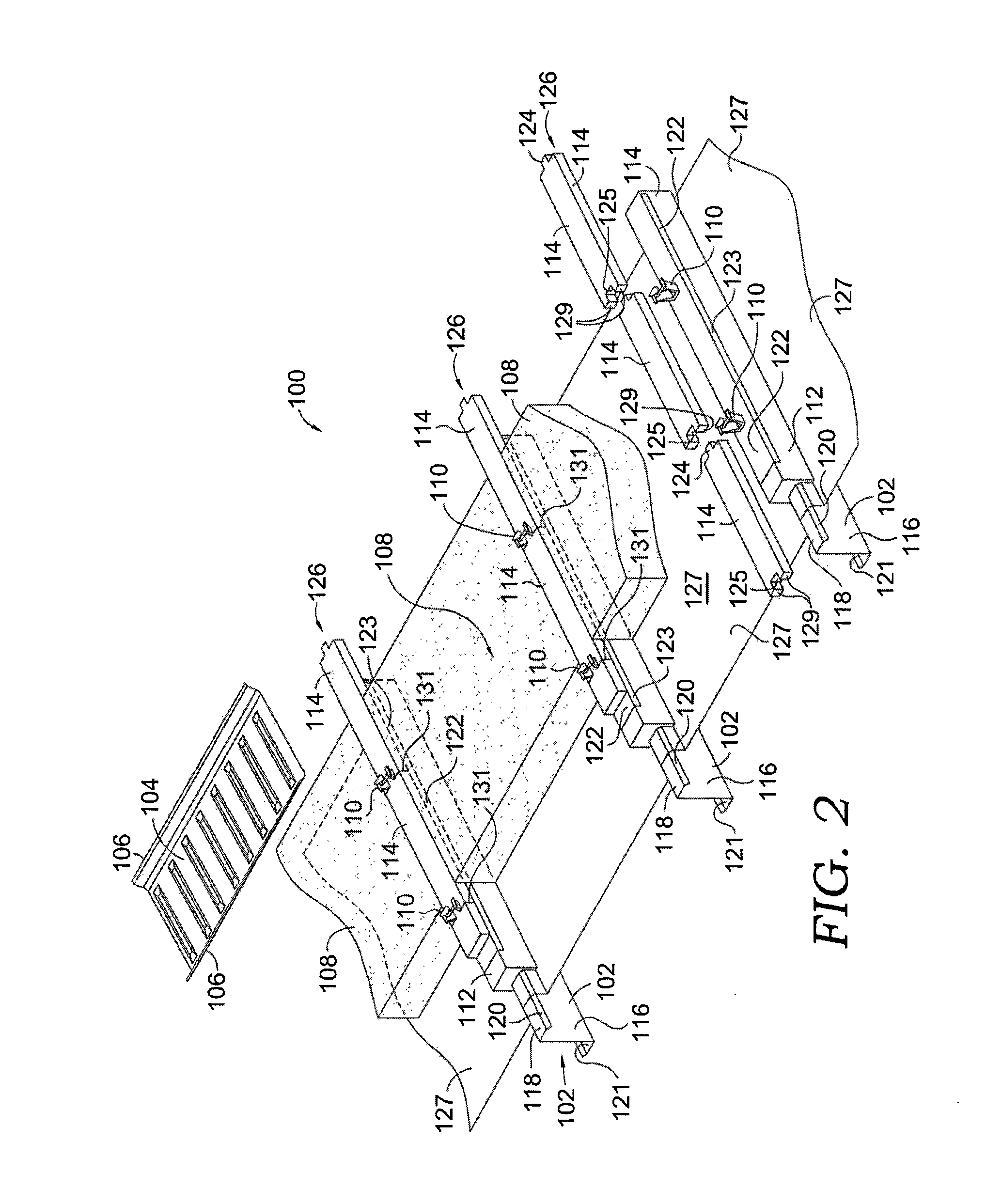

InactiveUS20100162643A1Prevent buildupEffective expansionBuilding roofsRoof covering using slabs/sheetsSkylightEngineering

The invention provides a system for installing a roof penetrating structure to a metal roof, the system comprising: a) a rail and closure structure adapted to be supported by adjacent rib elevations of said roof; b) a skylight adapted to be supported on the rail and closure structure; and c) a support member for sealing a cut away portion of the rib structure to divert water away from the rail and closure structure.

Owner:ABL IP HLDG +1

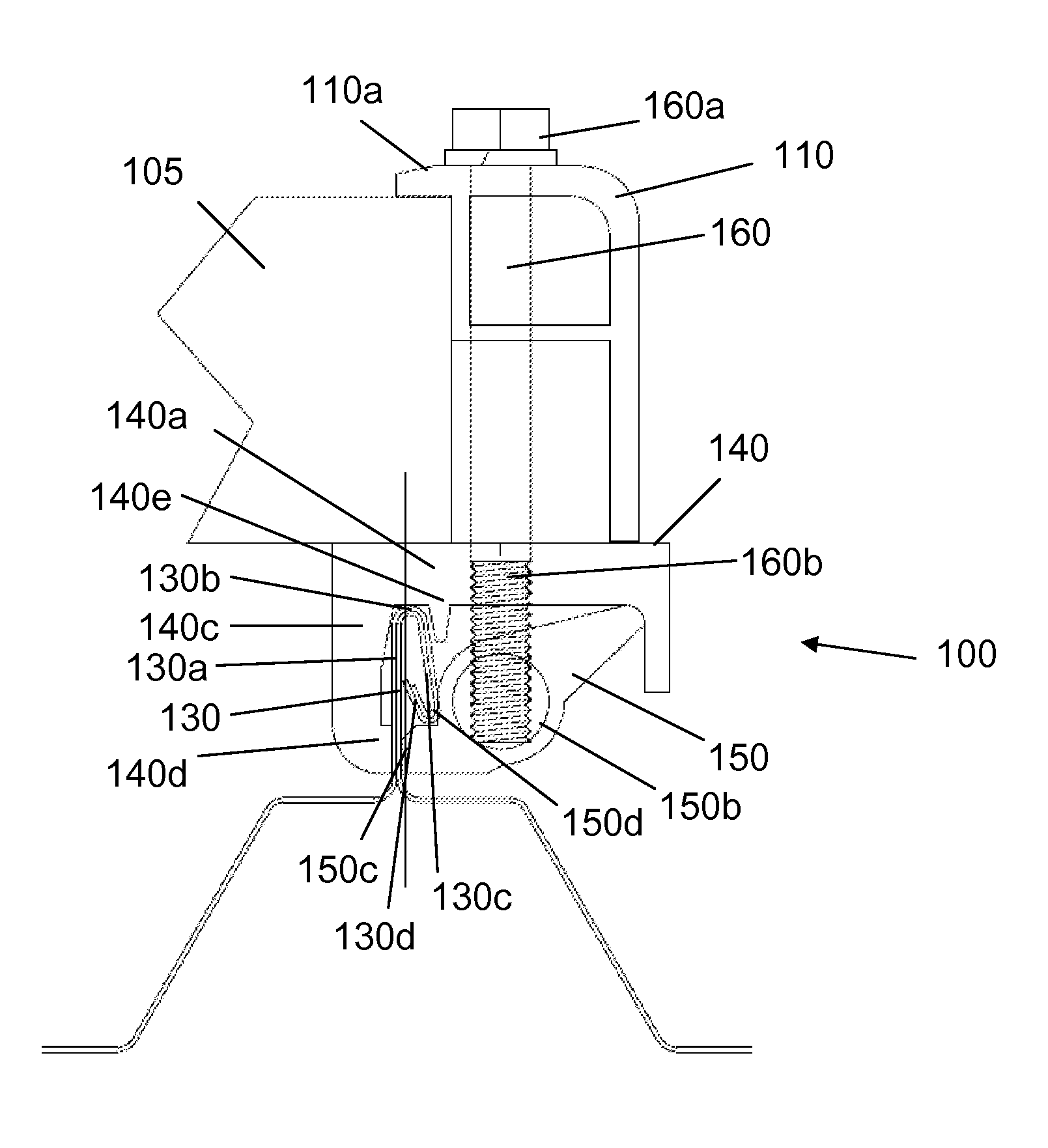

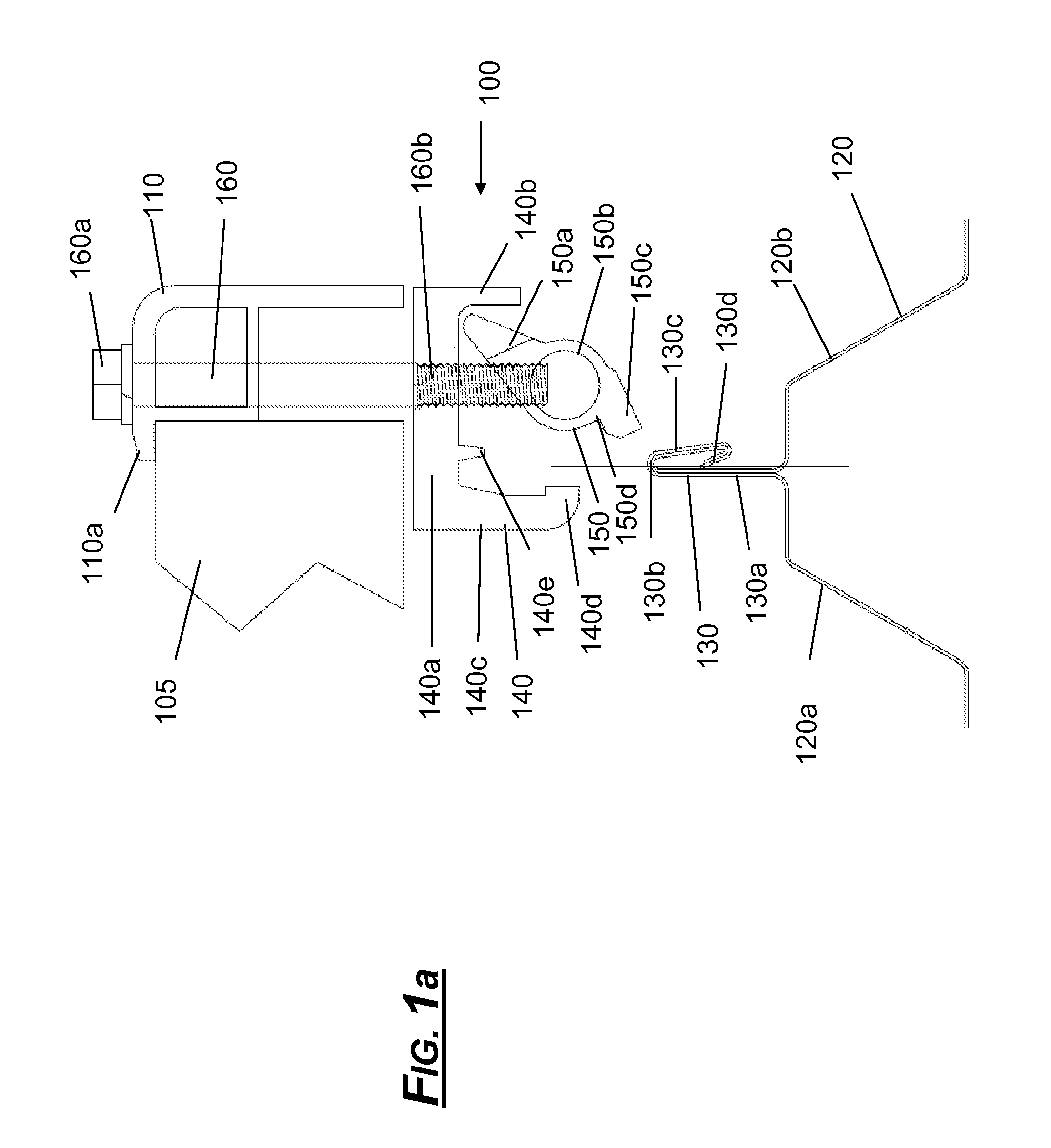

Camming clamp for roof seam

A clamp described herein can secure a solar cell array to a seam of a standing seam metal roof. The clamp has a cam that is rotated by the tightening of a bolt to cause the cam to engage the seam. The clamp also has a receiver for receiving the seam and the rotated cam. By installing the clamp on the seam, the solar cell array can be secured to the standing seam metal roof without drilling into the roof. Because no screws are required to be drilled into the rooftop, the damage to the rooftop is substantially reduced. Also, by reversing the process described above, the clamp can be uninstalled in a similar fashion.

Owner:SUNRUN SOUTH LLC

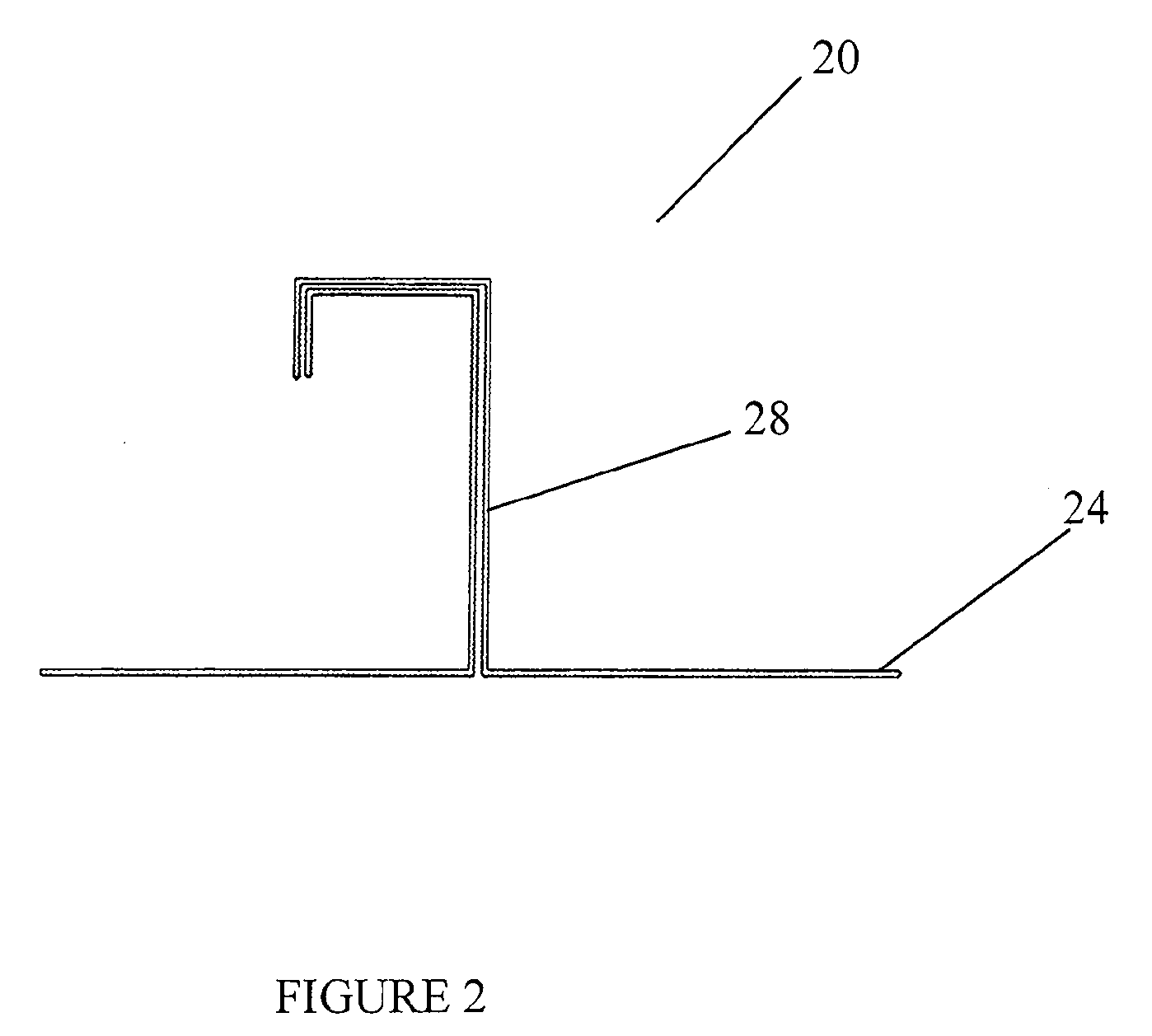

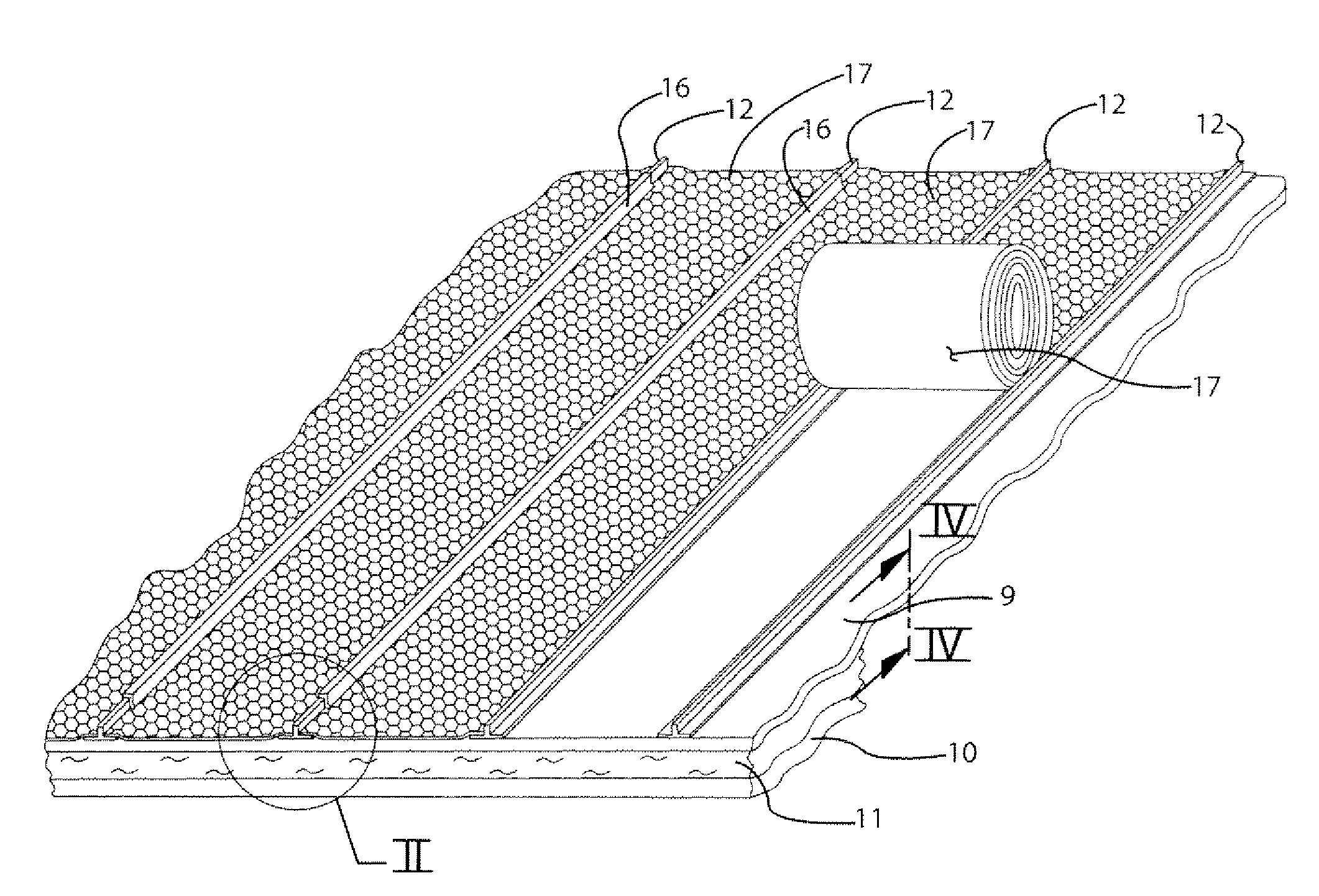

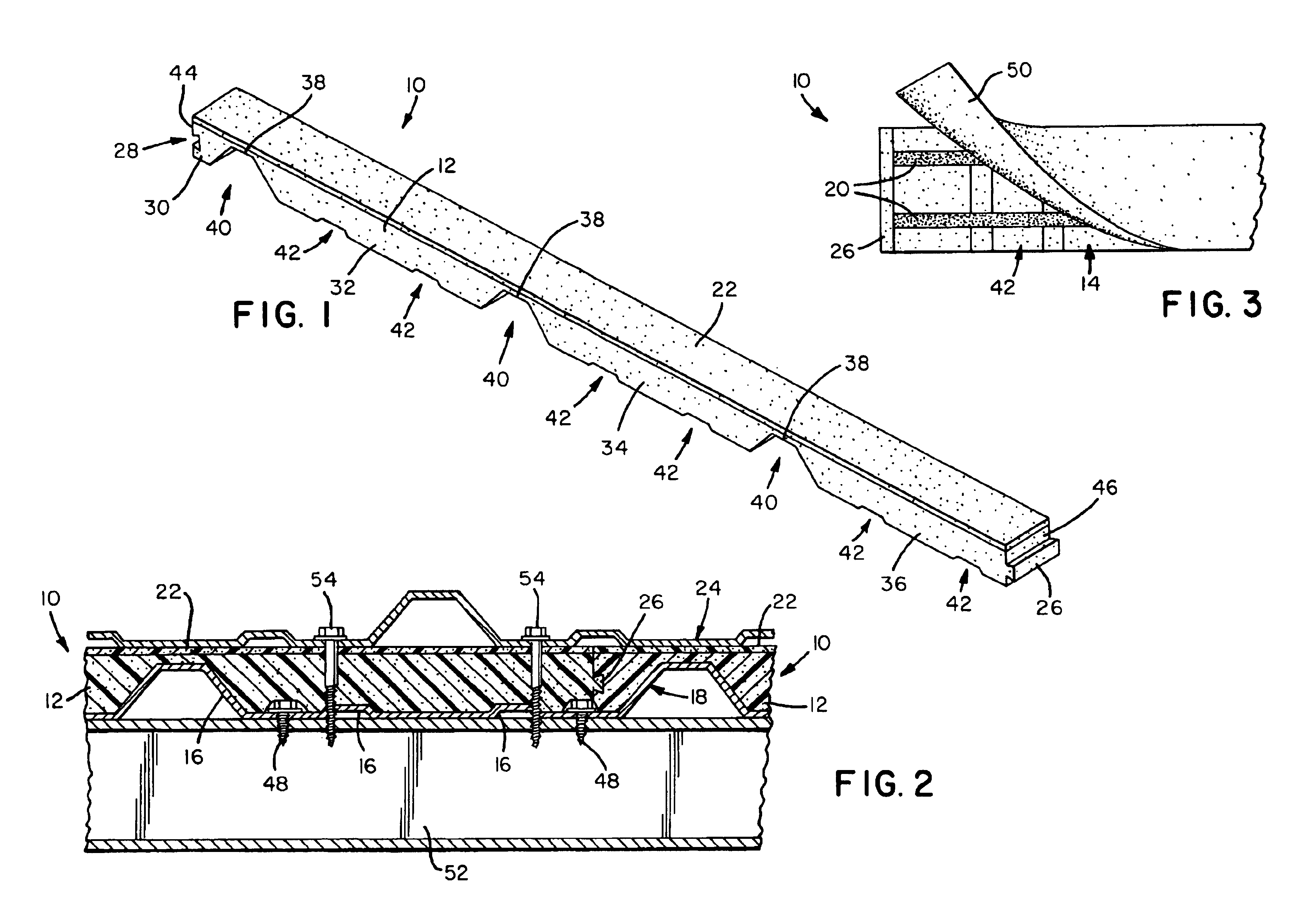

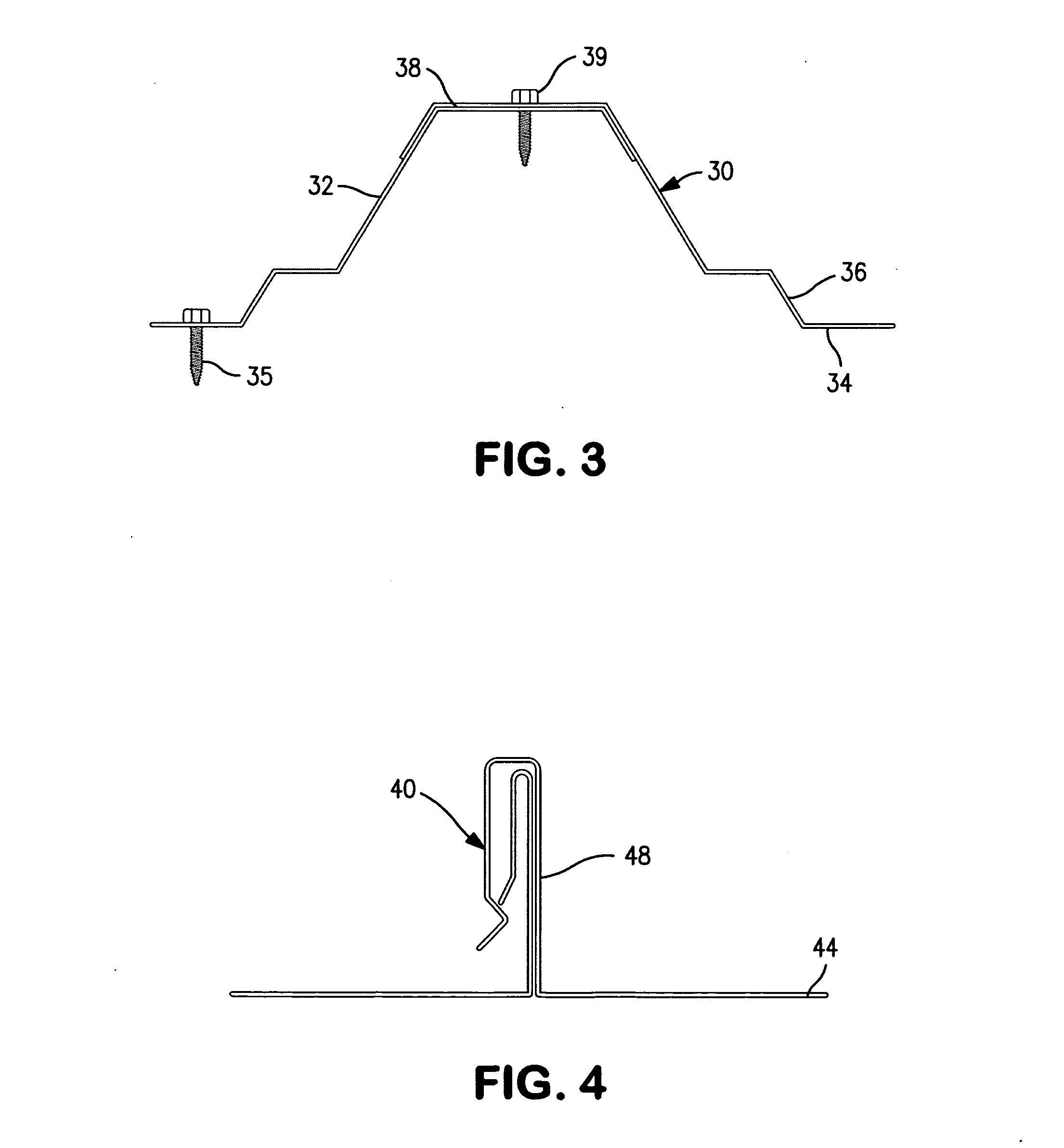

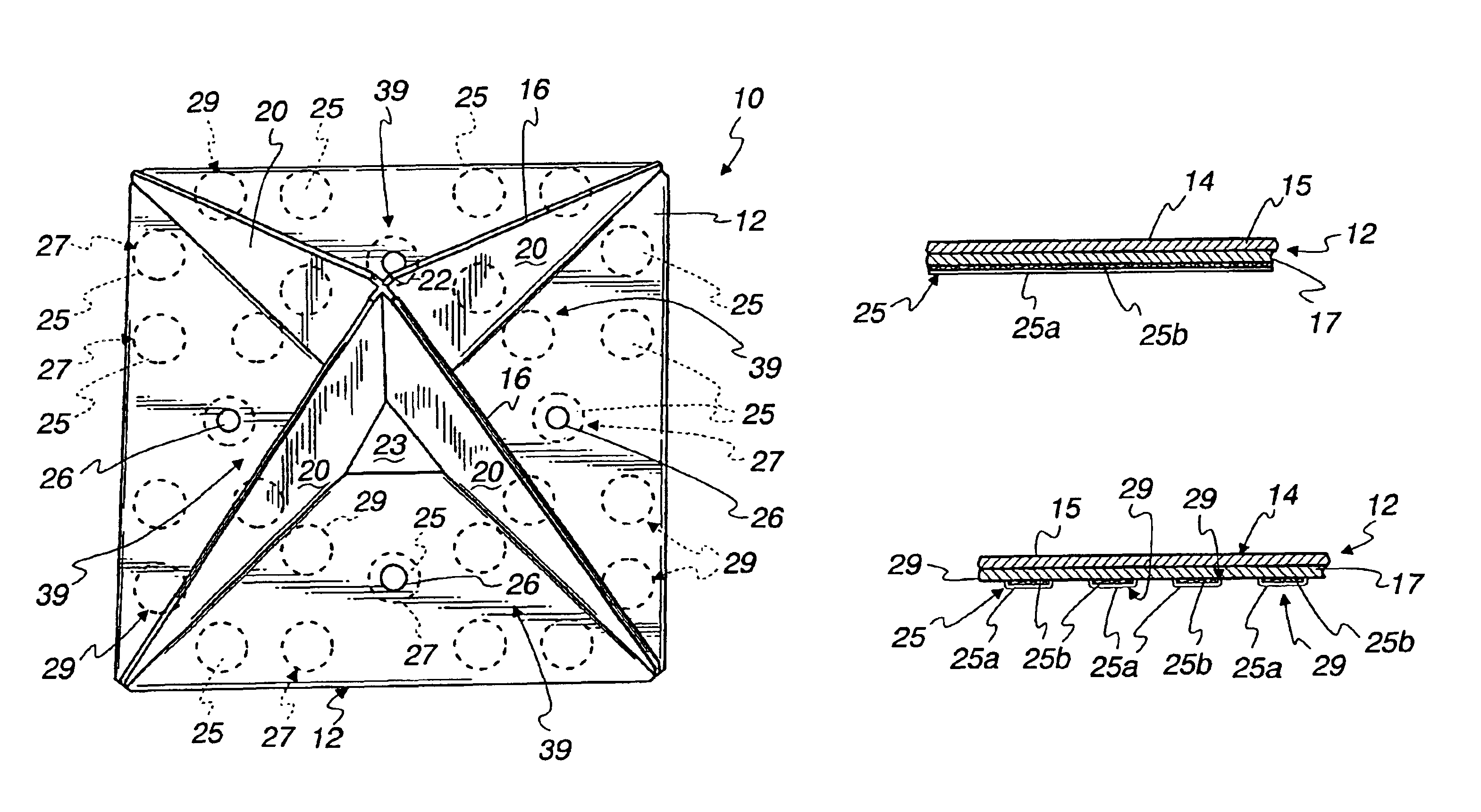

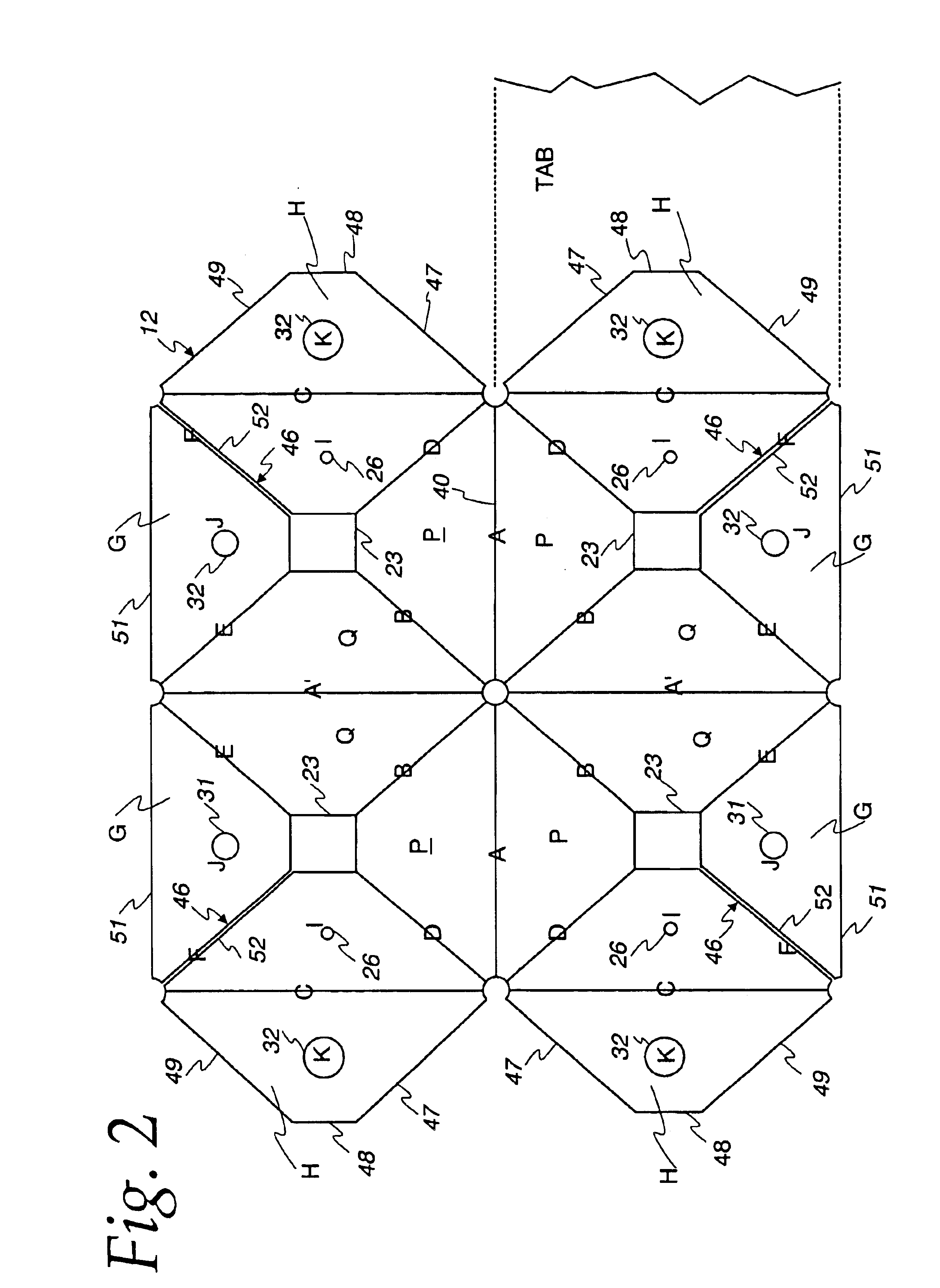

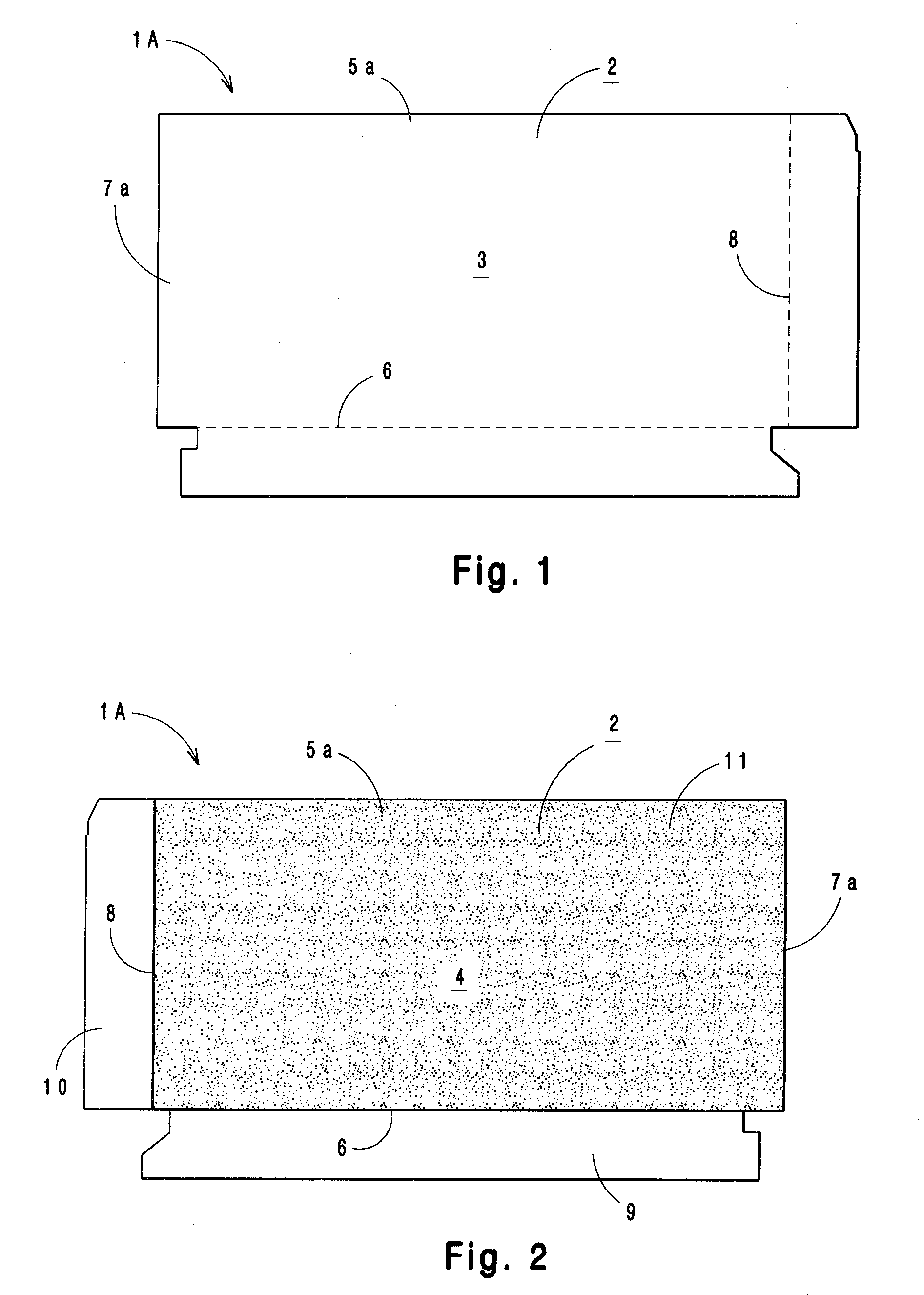

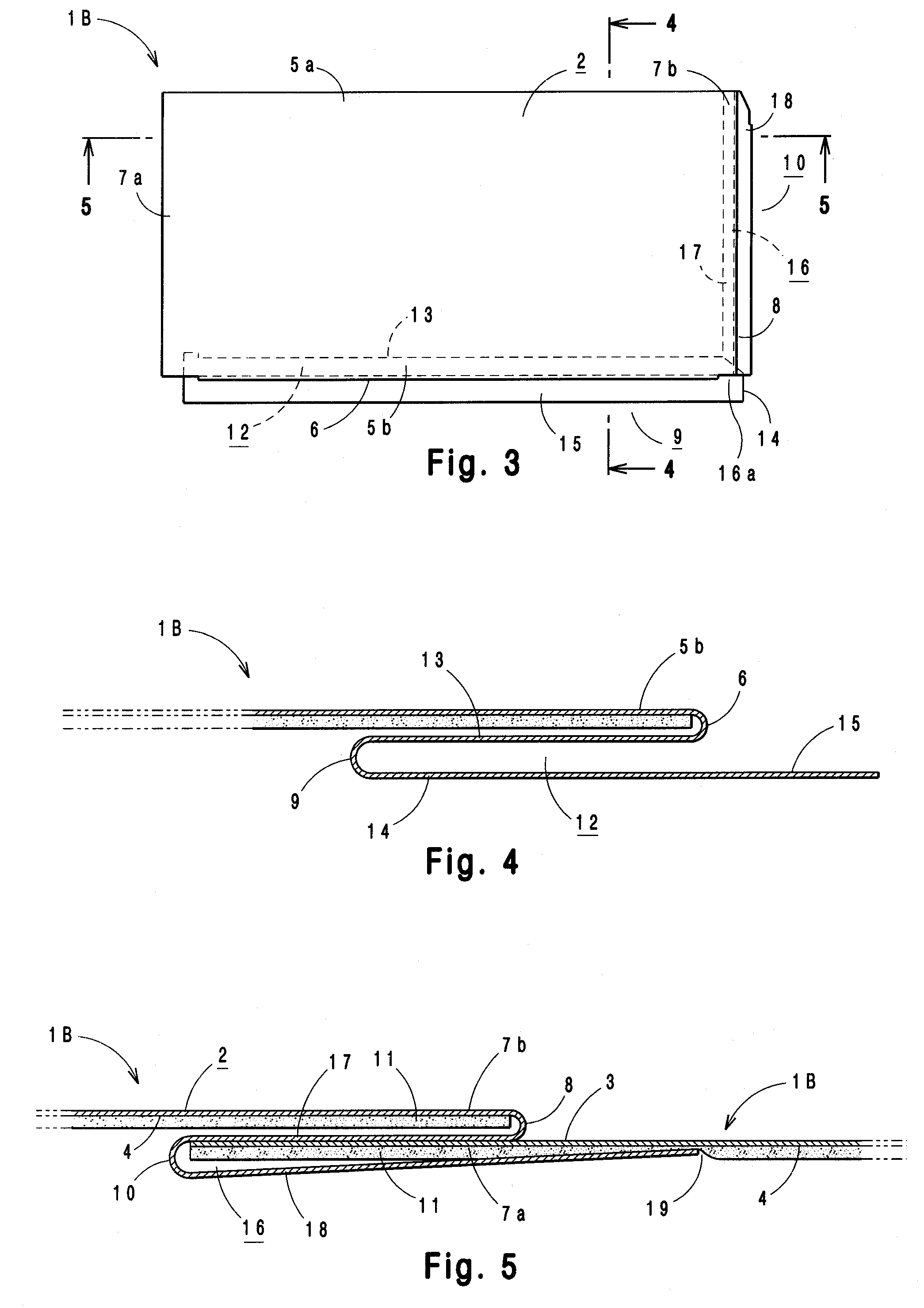

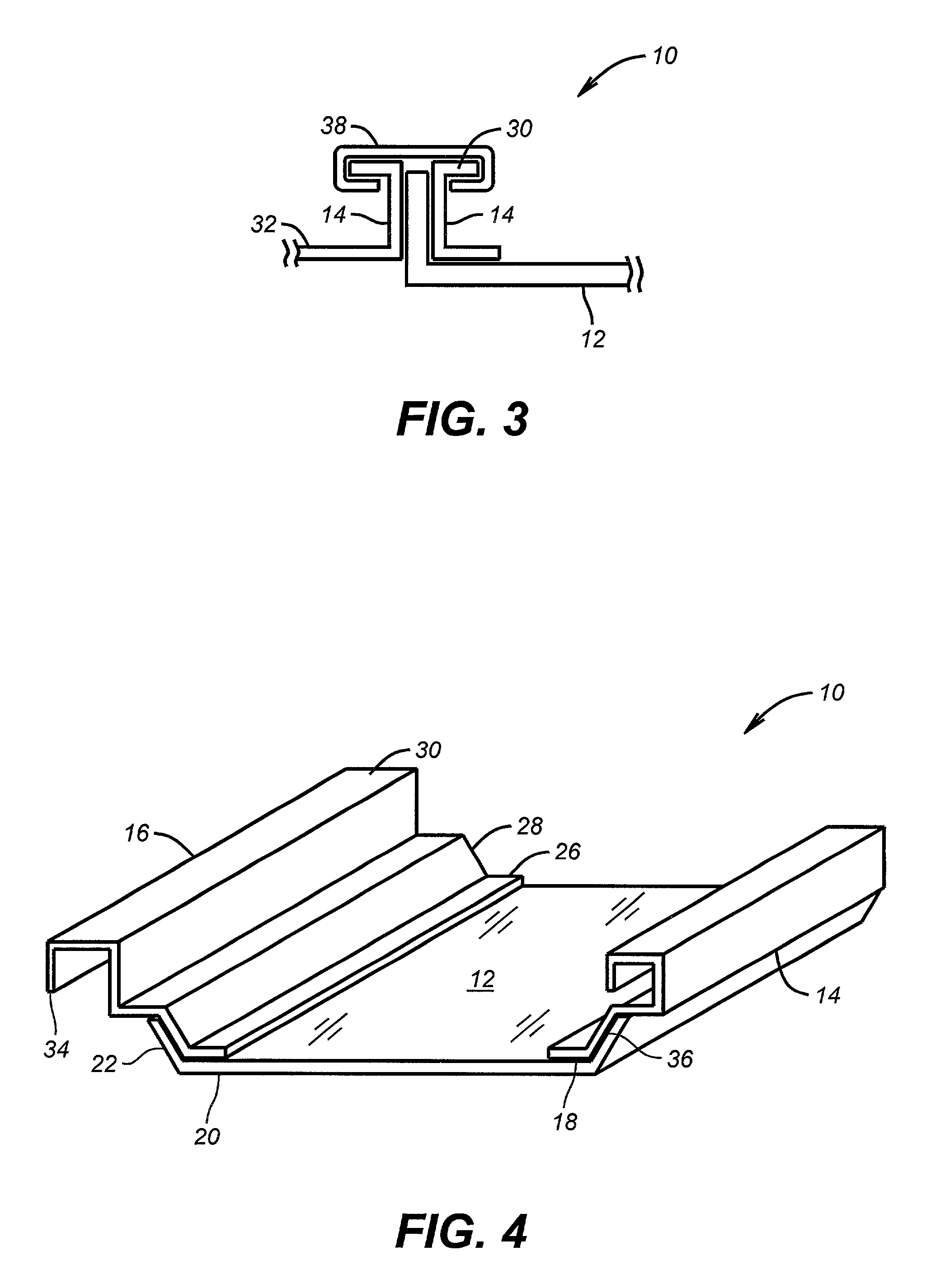

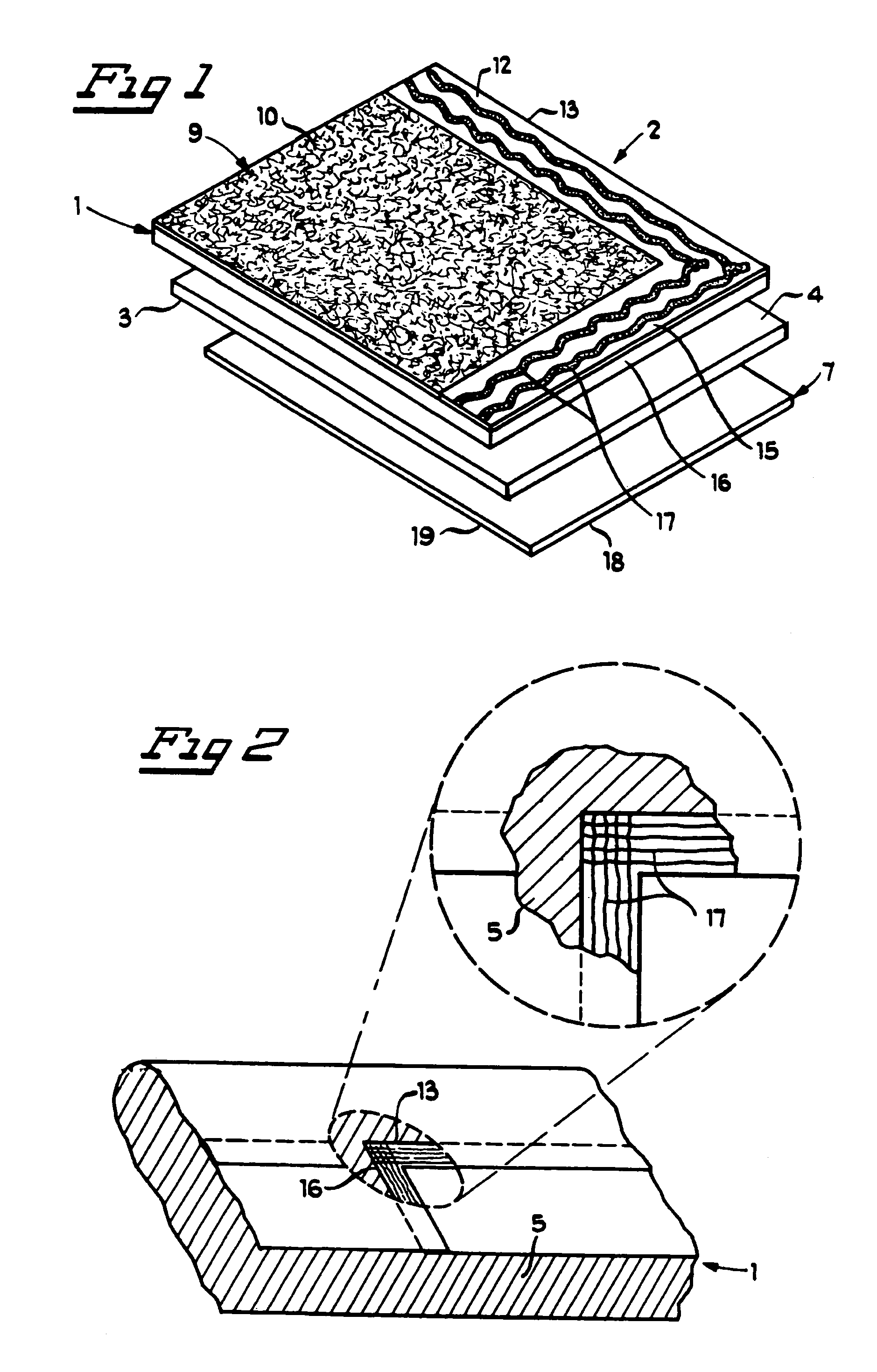

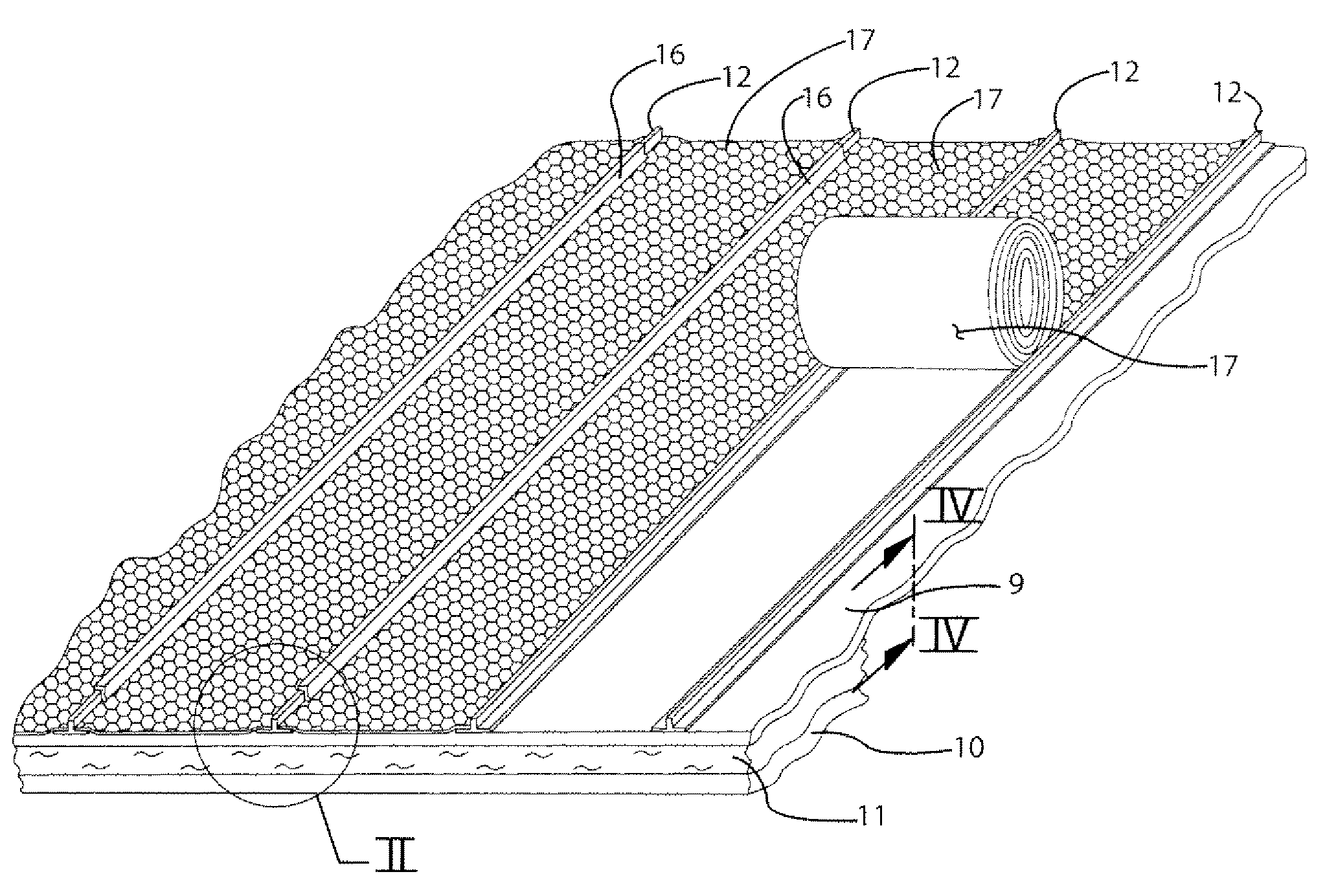

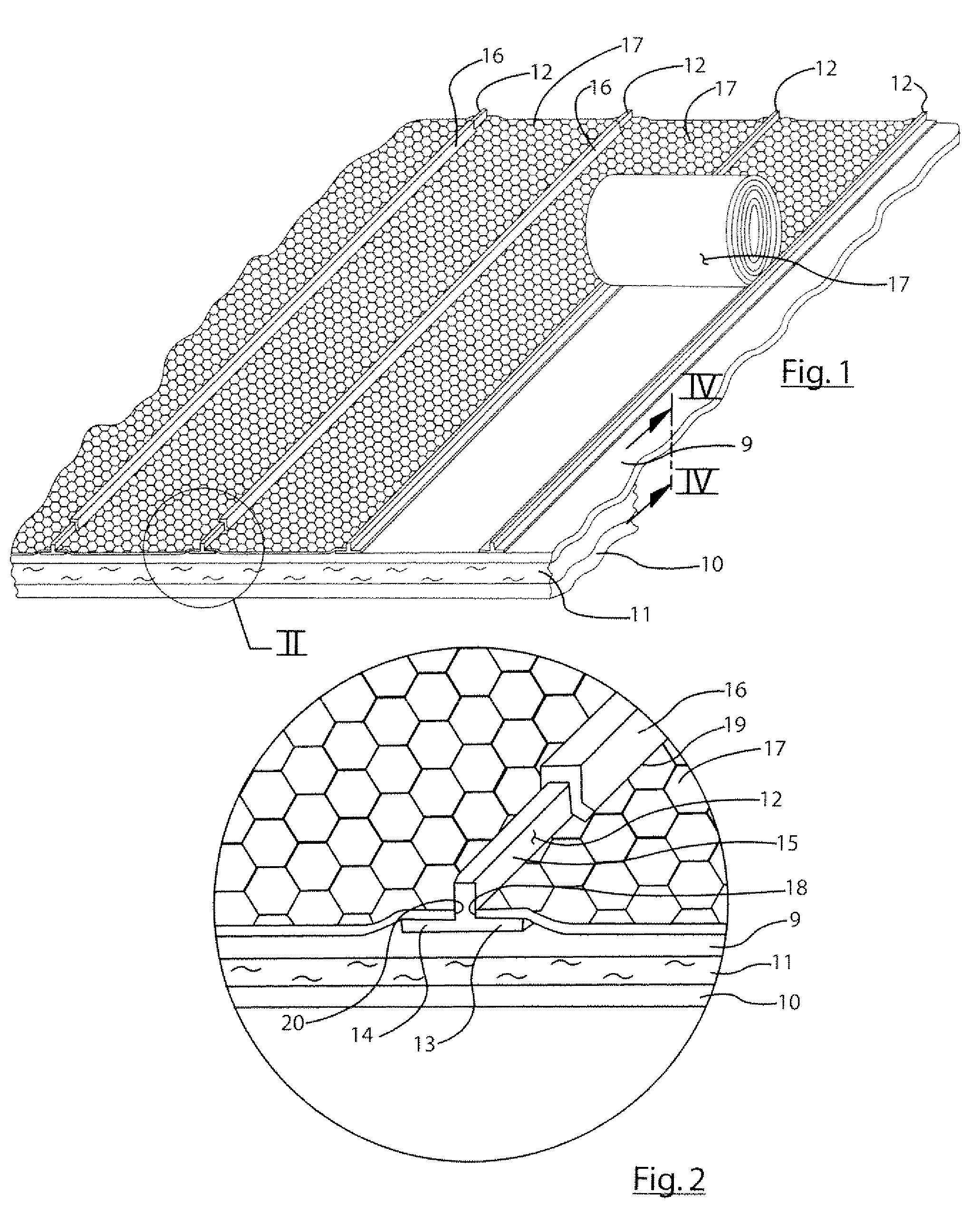

Roof membrane and roof system using the membrane to simulate a standing seam metal roof

A roof membrane is disclosed, for use in simulating a standing seam metal roof when applied to a roof surface and a roof system is also provided, that employs the roof membrane, disposed between longitudinal, but spaced-apart, generally parallel roof battens. Underlayments of various constructions are also provided, beneath the membrane, as an option. Caps are provided for upstanding legs of the roof battens.

Owner:CERTAINTEED CORP

Safety Reinforced Light Transmitting Panel Assembly

A light-transmitting roof panel assembly, having the same shape as adjoining metal roof panels in a standing seam metal roof, includes an outer transparent panel made of a polymeric material and an inner reinforcing panel made of perforated metal. The inner and outer panels nest together and lie flush with the roof. Crimpable side corrugation pieces are attached to the reinforcing panel so that the assembly can be connected to neighboring roof panels by seaming.

Owner:BLUESCOPE BUILDINGS NORTH AMERICA

Spacer for retrofitting corrugated metal roofs

InactiveUS6944997B2Minimize likelihood of damageEasy to installRoof covering using slabs/sheetsCeilingsHigh densityEngineering

Owner:VERKAMP MARK J

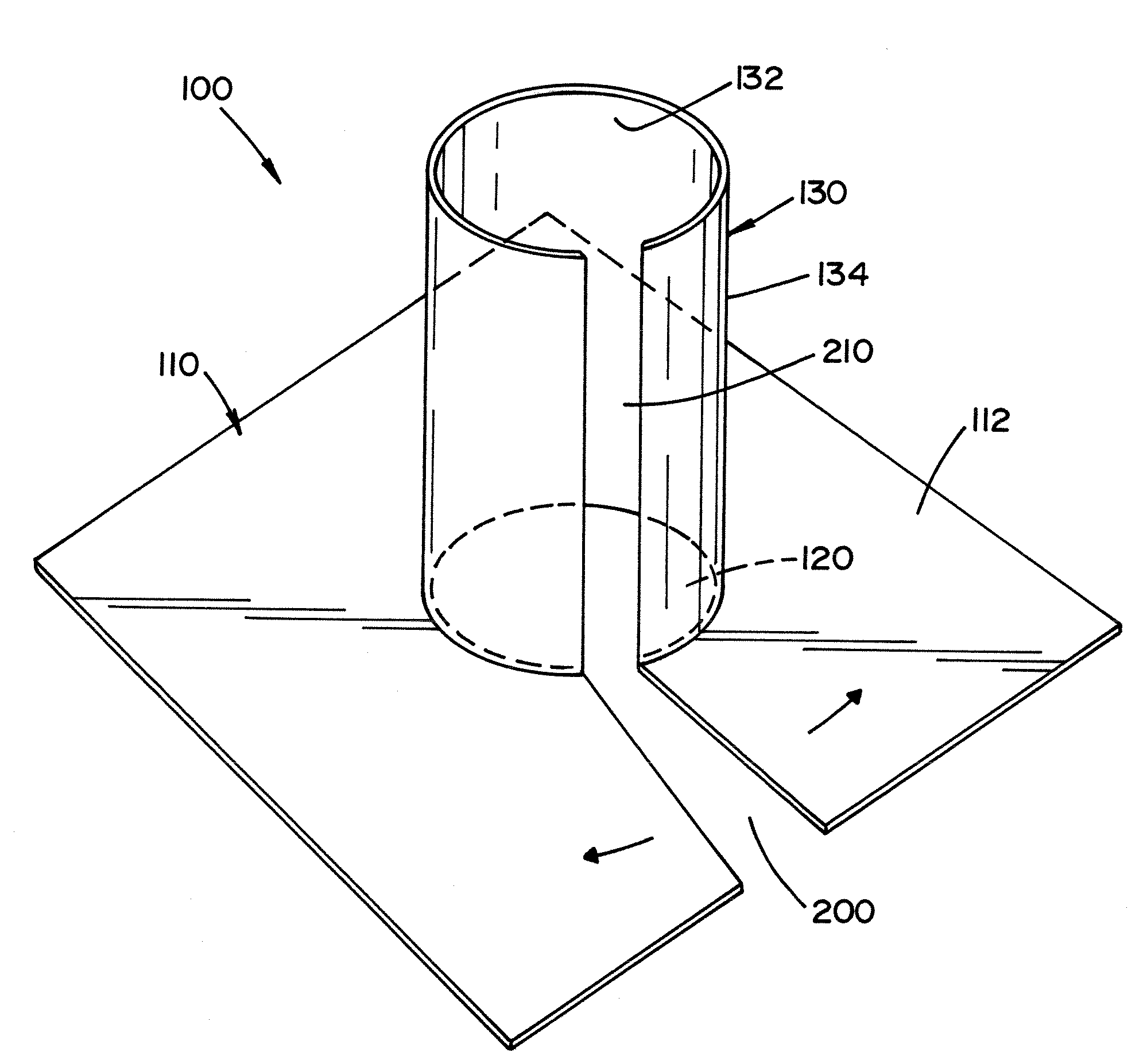

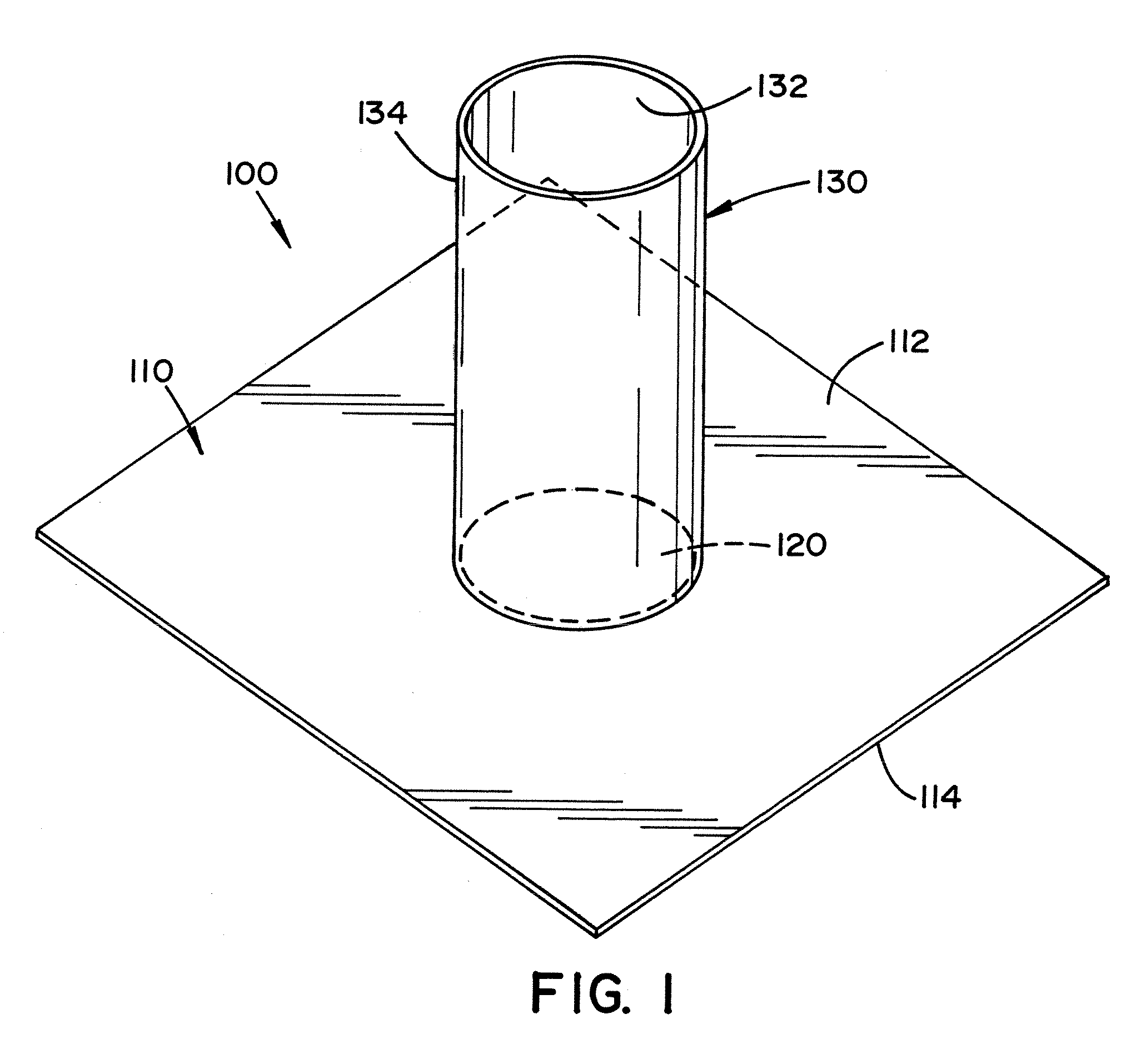

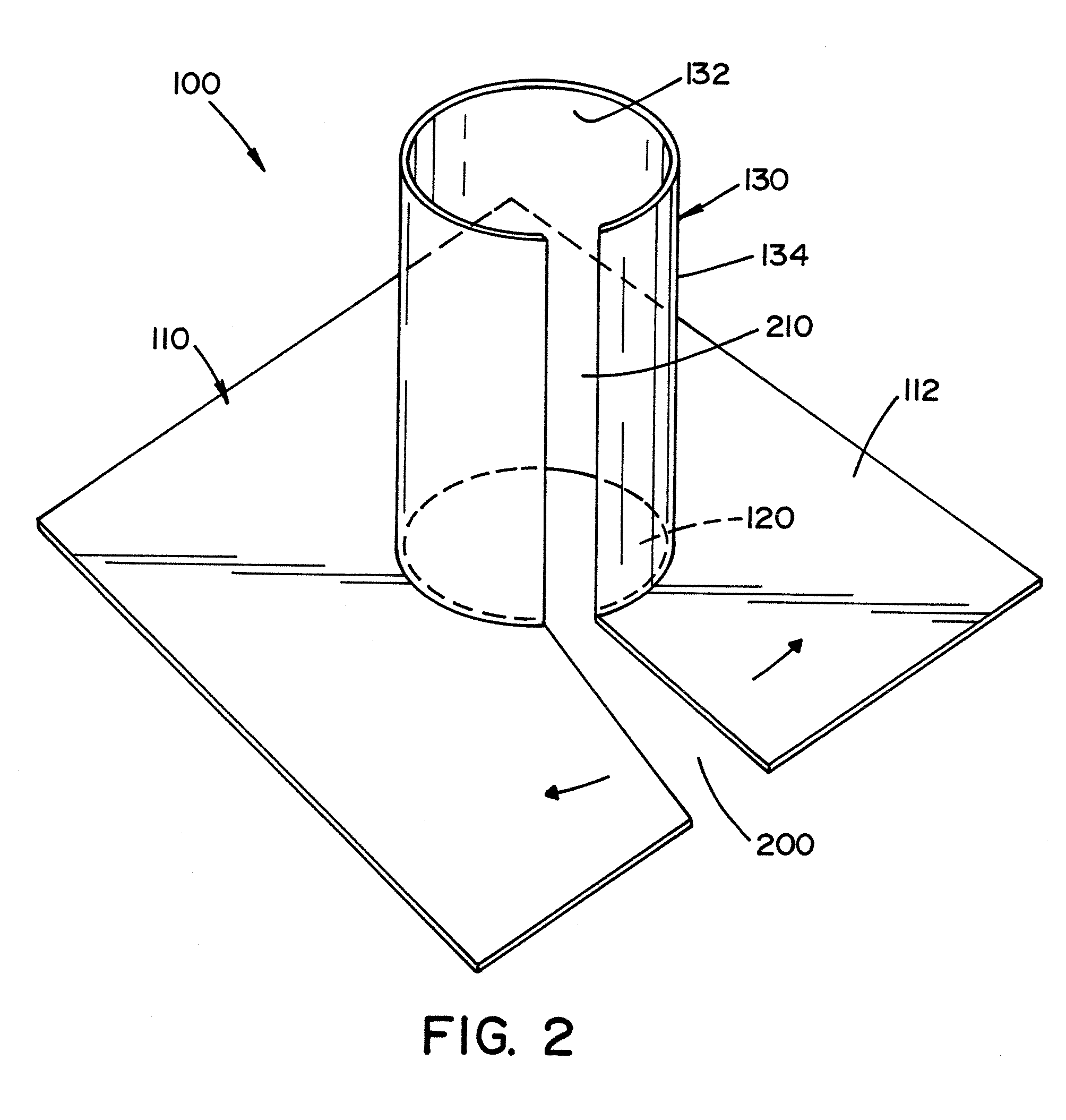

Zinc flashing for roof penetrations

An improved zinc flashing system for use with metal and non-metal roof systems. The improved zinc flashing system includes a base plate that includes an aperture and vertical tube that is attached to the base plate. The vertical tube form extends upwardly from the upper surface of the base plate or downwardly from the bottom surface of the base plate. The zinc flashing system is designed to form a water-tight seal about a roof penetration and / or a roof drain. A protective layer can be used to inhibit or prevent contact of the zinc material of the zinc flashing with a roofing structure. The protective layer can be connected and / or coated to the zinc flashing.

Owner:GARLAND INDS

Metal roof retrofit skylight

InactiveUS7937900B1Efficient replacementEasy to replaceRoof covering using slabs/sheetsBuilding roofsEngineeringMembrane roofing

A metal roof retrofit skylight preferably includes a glazing pane, a pane retention frame and at least one self-stick sealing sheet. The pane retention frame preferably includes a bottom leg and a top leg. One end of the bottom and top legs preferably form a fastening flange. The other end of the top is offset from the bottom leg to form a pane space that is sized to receive a thickness of the glazing pane. Each self-stick sealing sheet includes a sealing sheet and release paper. The sealing sheet is applied over a portion of the glazing pane and a membrane roofing material to provide a seal between the membrane roofing material and the glazing pane. An optional condensation collector is installed in a skylight opening in the metal roof. The metal roof retrofit skylight is attached to the metal roof around a perimeter of the skylight opening.

Owner:GAFFNEY STEVEN M MR

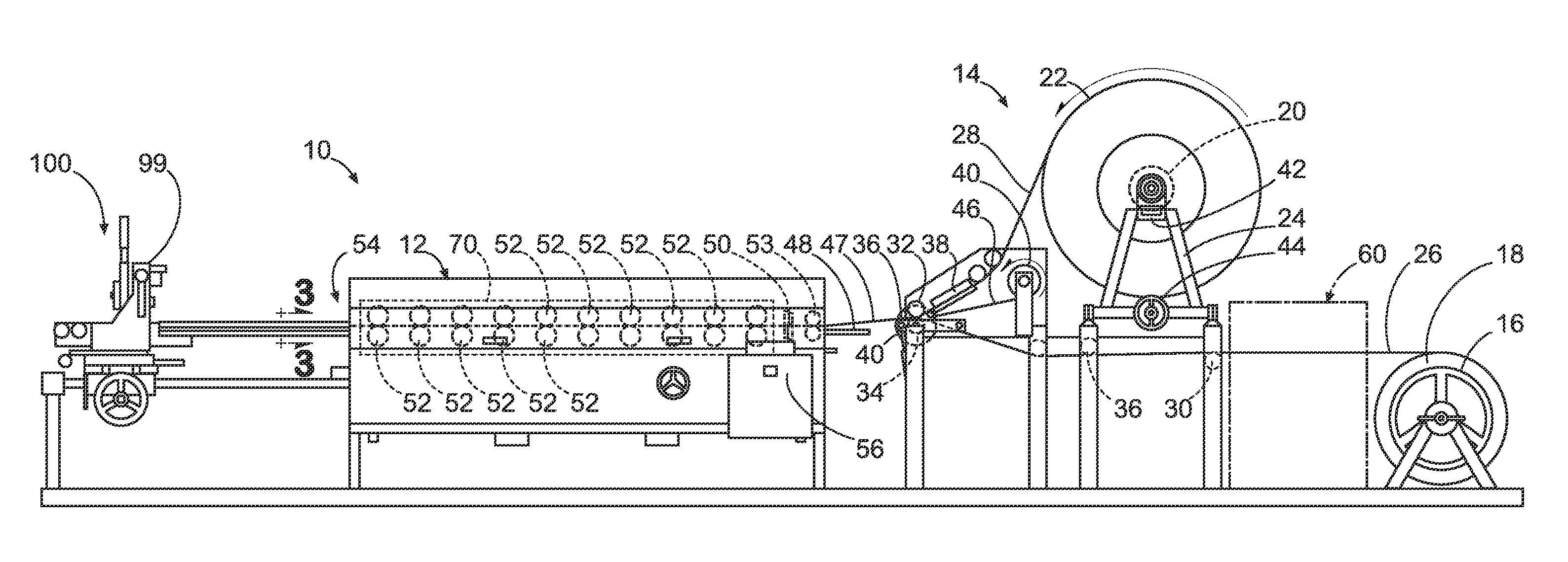

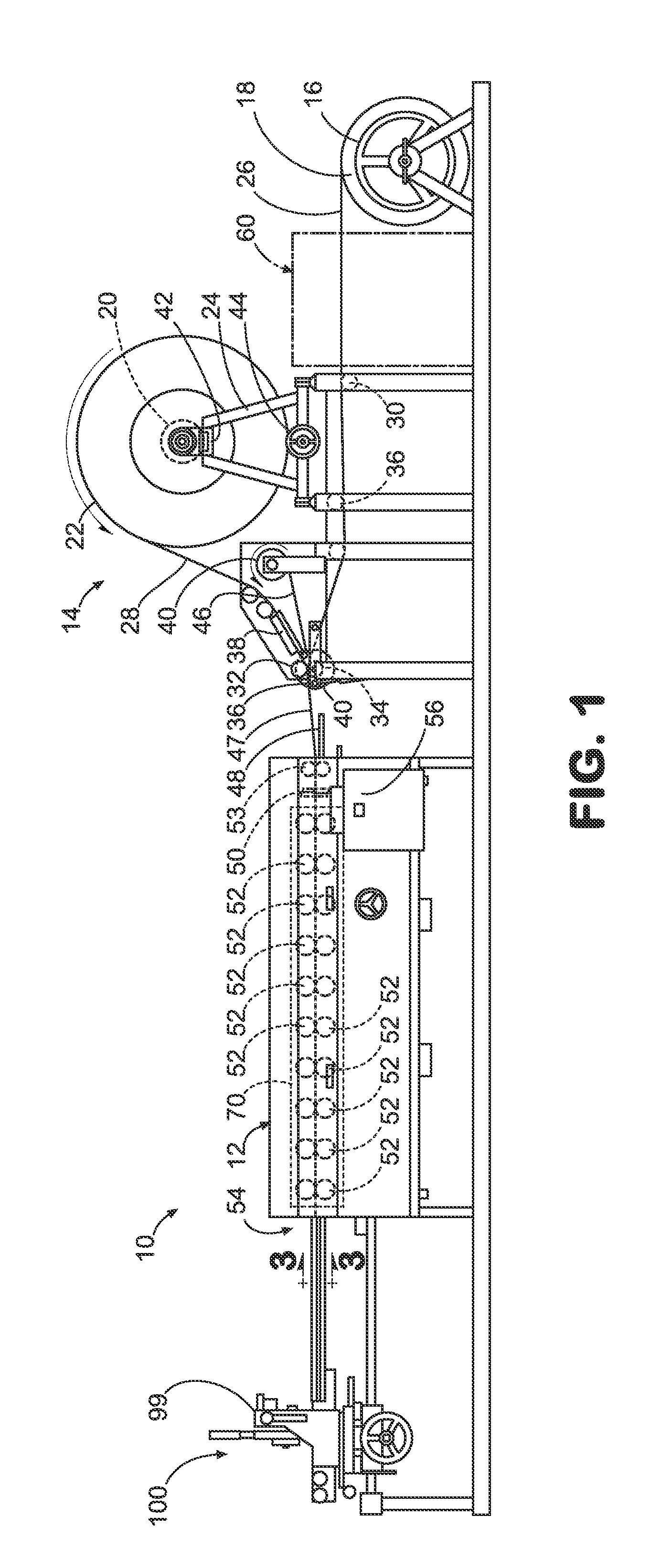

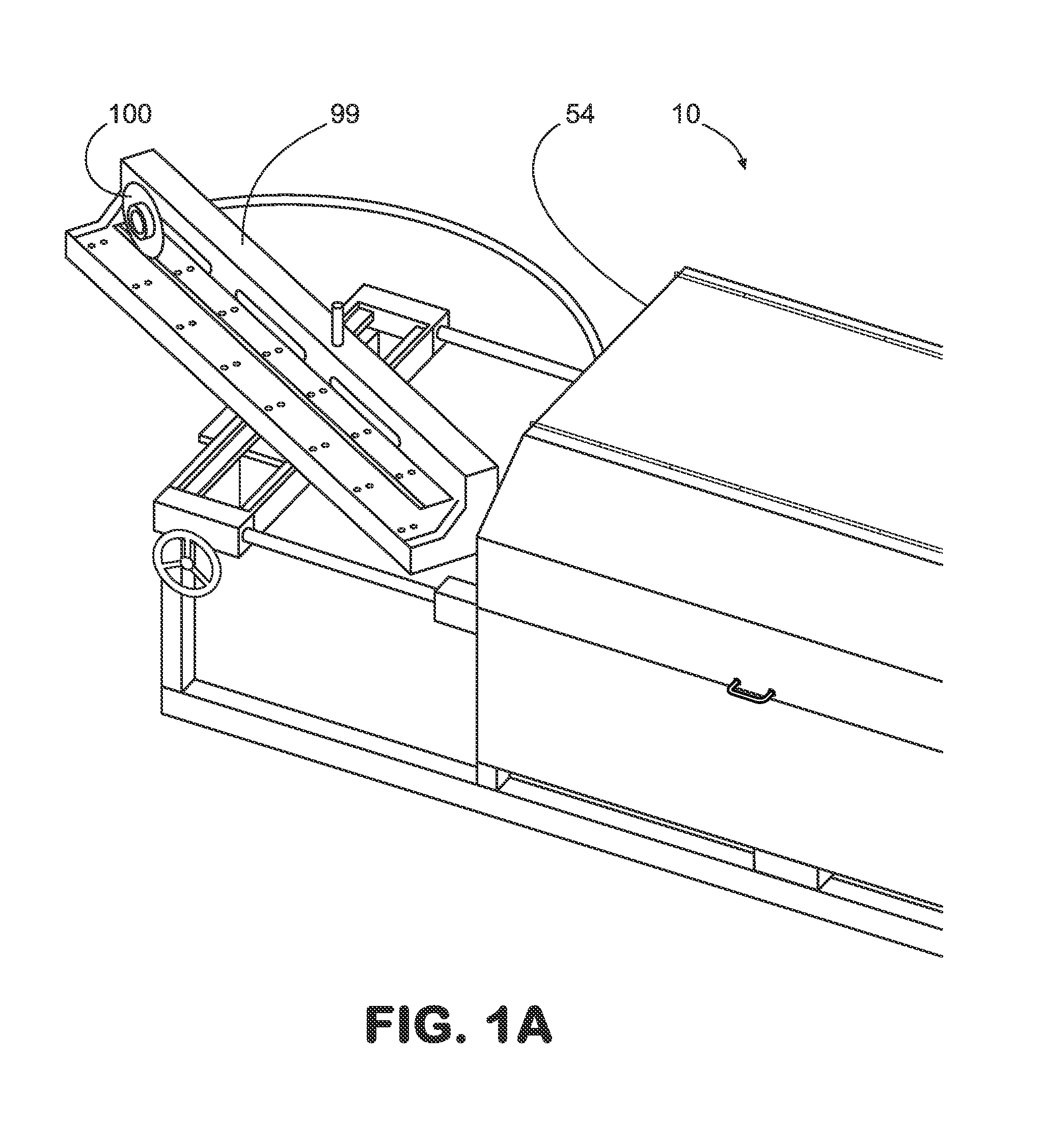

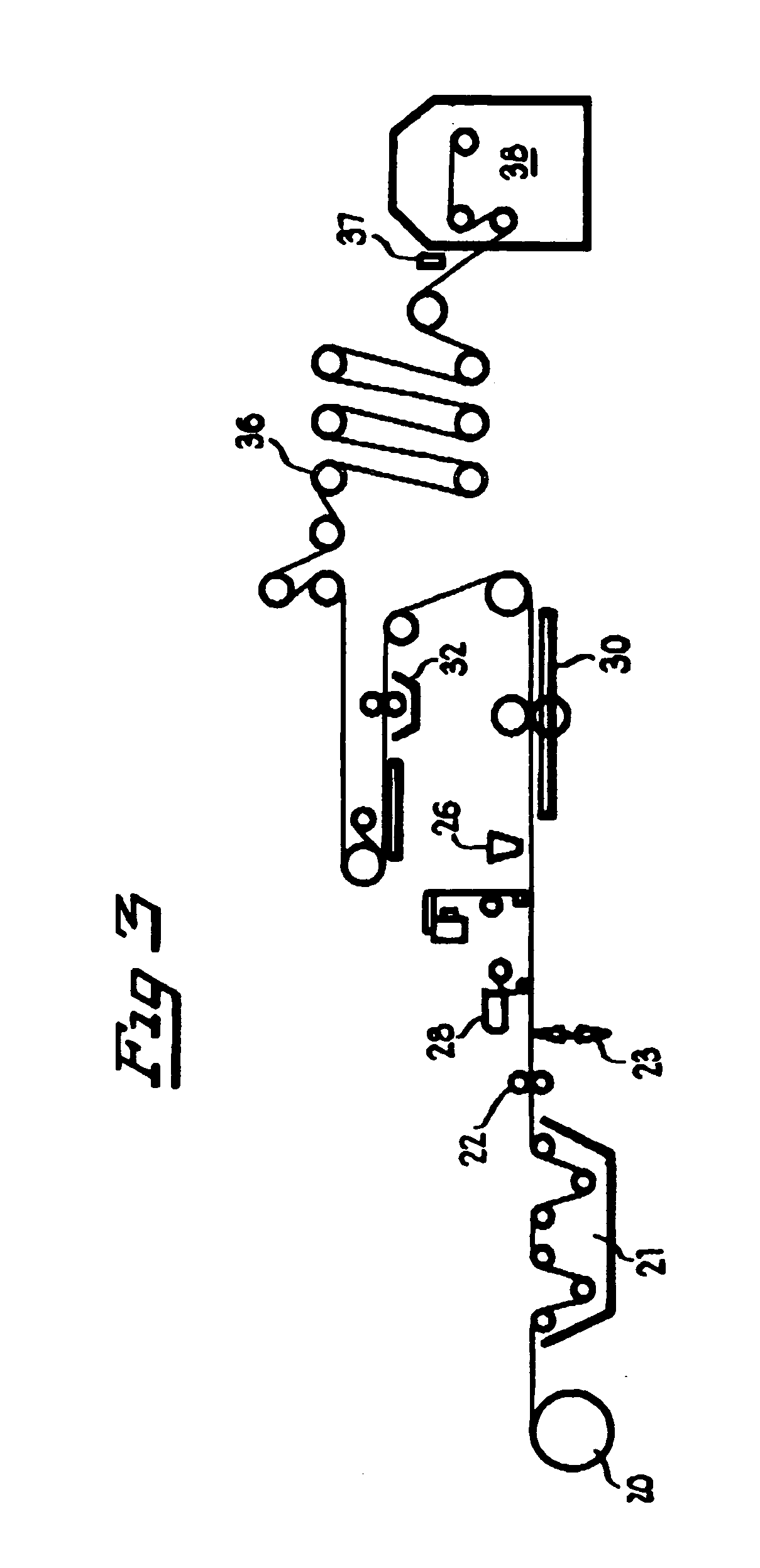

Probrammable Rollfromer for Combining an Architectural Sheet with a Solar Panel and Method

A programmable machine and method for adhering a flexible photovoltaic film panel onto metal supplied from a roll for forming a combination solar and roof panel is provided. The voltaic film panels and metal to which is adhered are supplied on rolls which are fed from reels. The rollformer can form male and female edges on the metal which are necessary for a metal roof. The angle at which the exit cutter can cut is calculated by the programmable computer. A measuring device for measuring the roofing and transferring the data to the programmable machine or the placement of the solar film panels and the cutting of the panels is also provided,

Owner:METALFORMING

Roof penetrating closure structures and systems

The invention provides an environment-accessing structure for providing environmental access to the interior of a building through an aperture in the roof. The environment-accessing structure can provide natural day-lighting by use of a skylight lens as the closure member, or a smoke vent which can be opened and closed. Such smoke vent can be transparent or translucent to natural sunlight, or can be opaque. Such environment-accessing structure is installed in an aperture in a metal roof. The system limits opportunity for water leakage from the outside environment. The environment-accessing structure includes a rail and closure structure adapted to be supported by adjacent rib elevations of adjacent roof panels, a closure panel adapted to be supported on the rail and closure structure, and a diverter which seals a cut away portion of the rib structure and diverts water laterally away from the rail and closure structure.

Owner:T&M INVENTIONS

Metal snow guard

InactiveUS6922948B2Prevent overheating and underheatingRuining appearanceRoof covering using slabs/sheetsRoof covering using tiles/slatesRough surfaceWire mesh

A metal snow guard is provided with a solid layer of soldering material on its base to be heated and melted with application of heat to the upper side of the snow guard to solder the base to an underlying metal roof. The preferred soldering material comprises an interior layer of solder and an outer layer of flux. In one form, the soldering material is in the form of spaced spots or projections providing a rough surface on the underside of the snow guard with the projections melting and spreading laterally into uneven surfaces where the roof or the base of the snow guard is not flat. The amount of solder and / or flux in the solid layer is limited so that the solder and / or flux does not flow outwardly from the snow guard and run down the metal roof thereby damaging or marring the metal roof surface. The preferred snow guards are formed of sheet metal of relatively few pieces and which are folded and joined together in an inexpensive manner. Preferably, the projections of soldering material are formed by forcing a paste of solder and flux through spaced holes in a plate or screen onto the base and then applying heat to melt the past and form a crust of flux on the outside of the projections which are mainly then comprised of solder. The outer crust layer of flux should protect the inner solder from oxidizing.

Owner:SNO GEM

Organic-inorganic composite nanometer heat-insulating fire-retardant coating and preparation method thereof

ActiveCN104177965AImprove adhesionImprove anti-corrosion performanceFireproof paintsEpoxy resin coatingsEpoxyOrganic film

The invention discloses an organic-inorganic composite nanometer heat-insulating fire-retardant coating and a preparation method thereof. The organic-inorganic composite nanometer heat-insulating fire-retardant coating is prepared by mixing organic film-forming substance acrylic ester emulsions or styrene-acrylate emulsions, epoxide resin, organic intumescent fire-retardant system pentaerythritol, melamine and ammonium polyphosphate with inorganic fire retardant nanometer aluminum hydroxide, nanometer magnesium hydroxide, filler nanometer titanium dioxide, ceramic hollow microspheres, glass hollow microspheres and a part of auxiliary agents. The organic-inorganic composite nanometer heat-insulating fire-retardant coating disclosed by the invention not only has excellent facing property and fire-retardant property, but also achieves reflection effect on solar radiation and certain heat-insulating and heat-preserving property on a substrate, also has good adhesivity, mechanical property and hydrophobic effect, can be formed through spray coating or brush coating before being solidified, and is a novel water-based multifunctional fire-retardant material. The organic-inorganic composite nanometer heat-insulating fire-retardant coating disclosed by the invention can not only be used as a general building wall body fire-retardant coating, but also be suitable for the fire prevention of building and ornament materials, heat-insulating materials, steel structure supports, beam columns, metal roofs and the like.

Owner:山西省建筑科学研究院集团有限公司

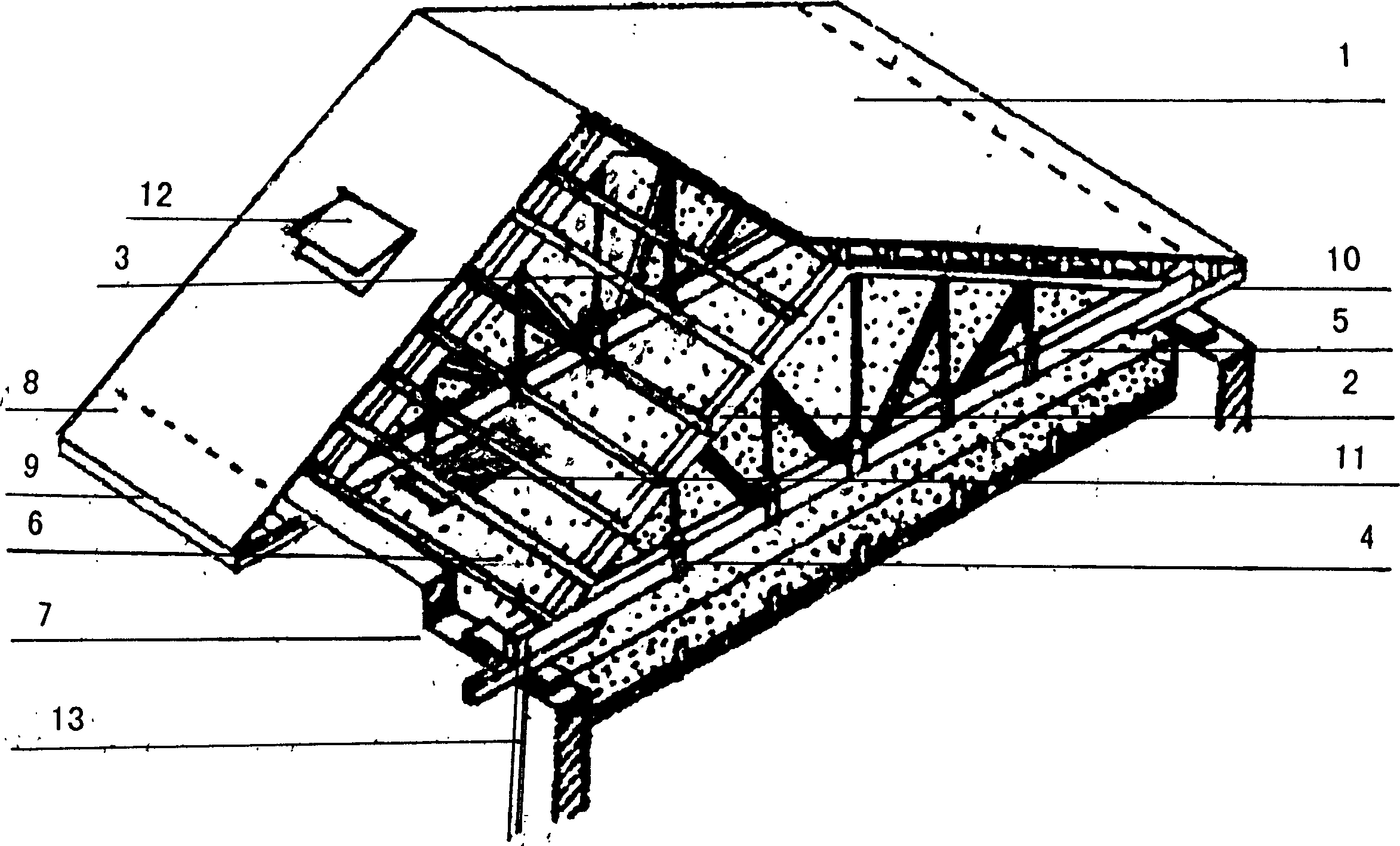

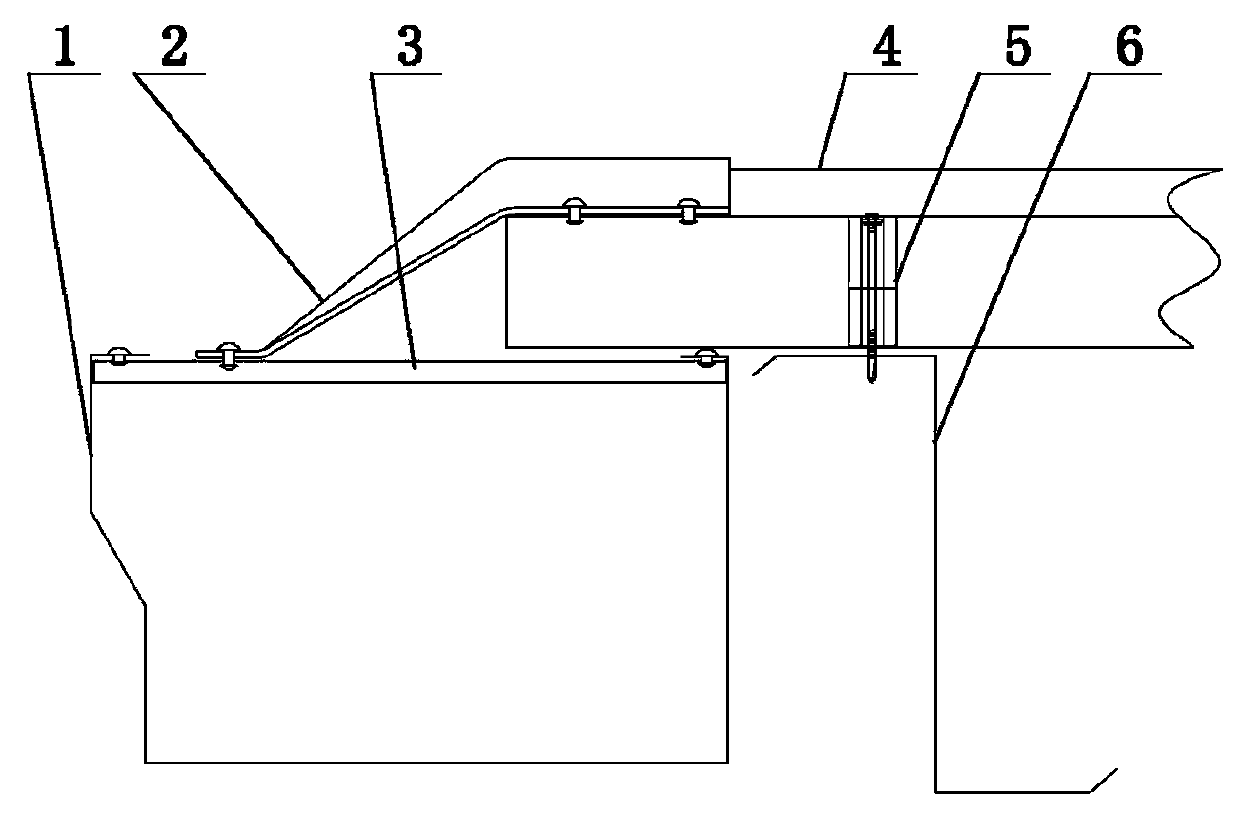

Water-proof heat insulation metal roof

InactiveCN1425836APollution impactExtended service lifeBuilding roofsRoof covering using tiles/slatesEngineeringMetal

The waterproof heat insulating metal roof consists of metal tiles, roof frame, roof surface frame, containing parts and horizontal crossbeam, and is constructed on structure and apart from the top layer ceiling. The metal tile may be corrugated tile, flat tile or composite tile; and there is one lightning arrester earthing wire. The waterproof heat insulating metal roof can play the roles of preventing water and isoalting heat, and has very long service life, over 25 years, without need of maintenance. In addition, the used roof material may be recovered and has no environmental pollution.

Owner:林渝茂

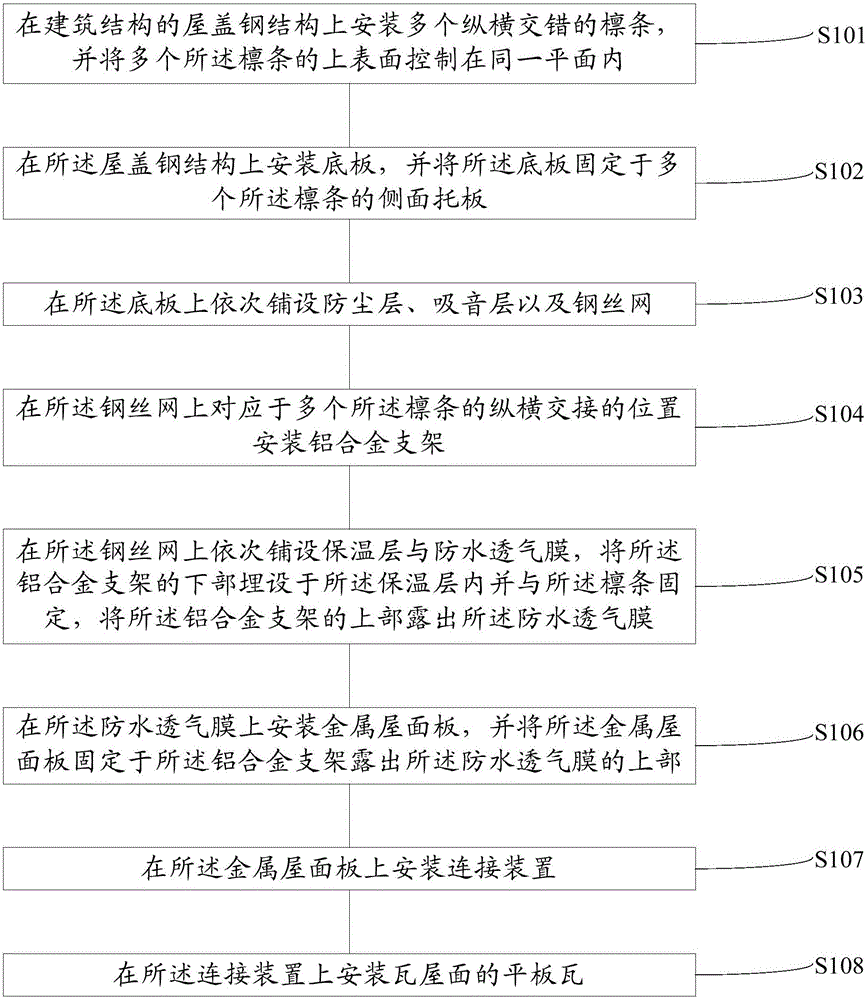

Metal roof plate and plane tile combined roof system and construction method thereof

ActiveCN105908910ASolve the problem of whether the connection is reliableSolve hidden dangers of waterproofingRoof covering insulationsInsulation layerAlloy

The invention discloses a metal roof plate and plane tile combined roof system and a construction method thereof. The method comprises the following steps that a plurality of longitudinally and transversely staggered purlines are arranged on a roof steel structure of a building structure, and the upper surfaces of the plurality of purlines are controlled in the same plane; a bottom plate is arranged on the roof steel structure, and is fixed on a side surface support plate of the plurality of purlines; a dustproof layer, a sound absorbing layer and a steel wire net are sequentially paved on the bottom plate; an aluminum alloy support frame is arranged in a position, corresponding to the longitudinally and transversely connected position, on the steel wire net; a heat insulation layer and a waterproof ventilated membrane are sequentially laid on the steel wire net; the lower part of the aluminum alloy support frame is embedded in the heat insulation layer and is fixed with the purlines; the upper part of the aluminum alloy support frame is exposed out of the waterproof ventilated membrane; a metal roof plate is arranged on the waterproof ventilated membrane, and is fixed at the upper part, exposed out of the waterproof ventilated membrane, of the aluminum alloy support frame; a connecting device is arranged on the metal roof plate; and plane tiles of a tiled roof are arranged on the connecting device.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

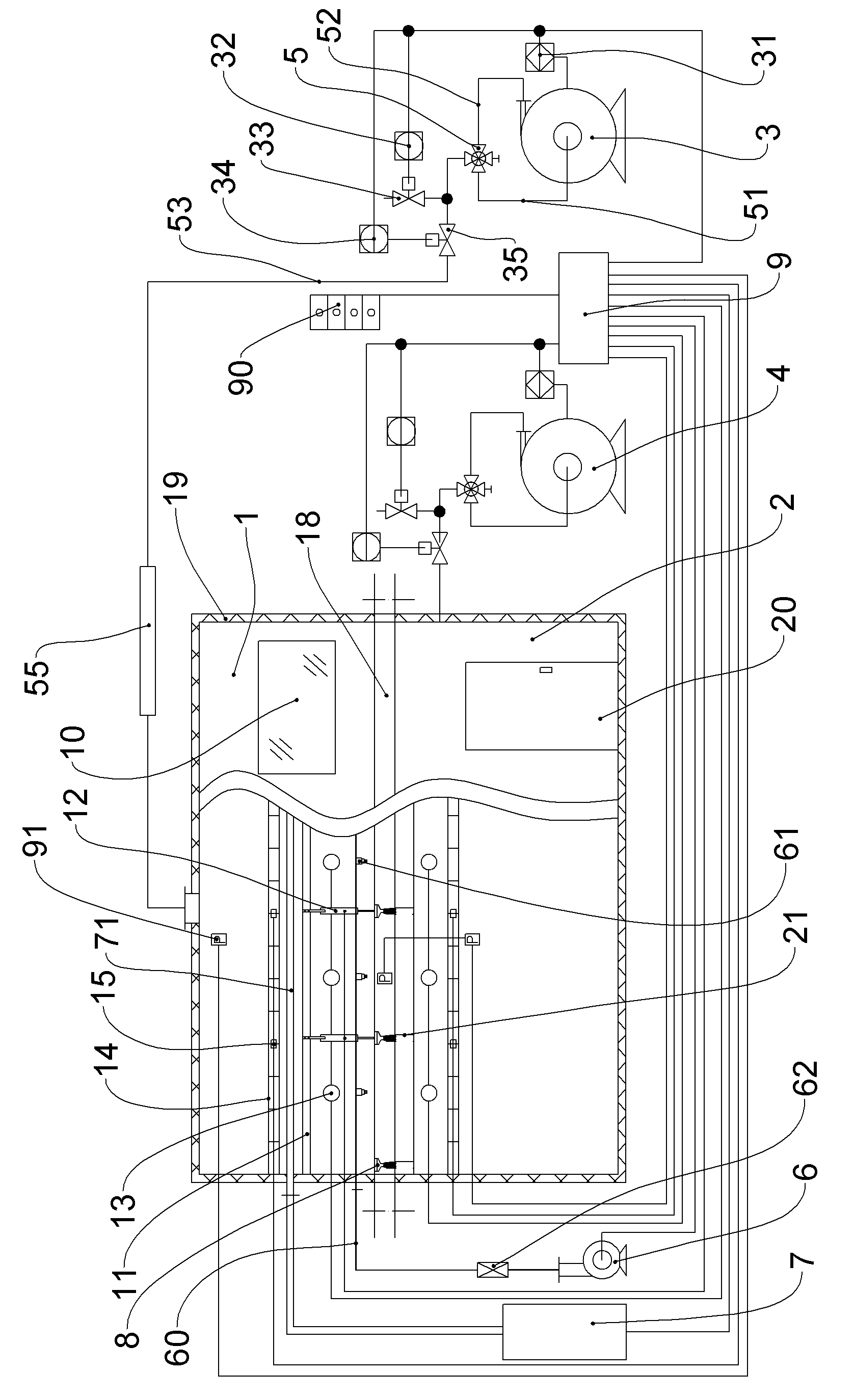

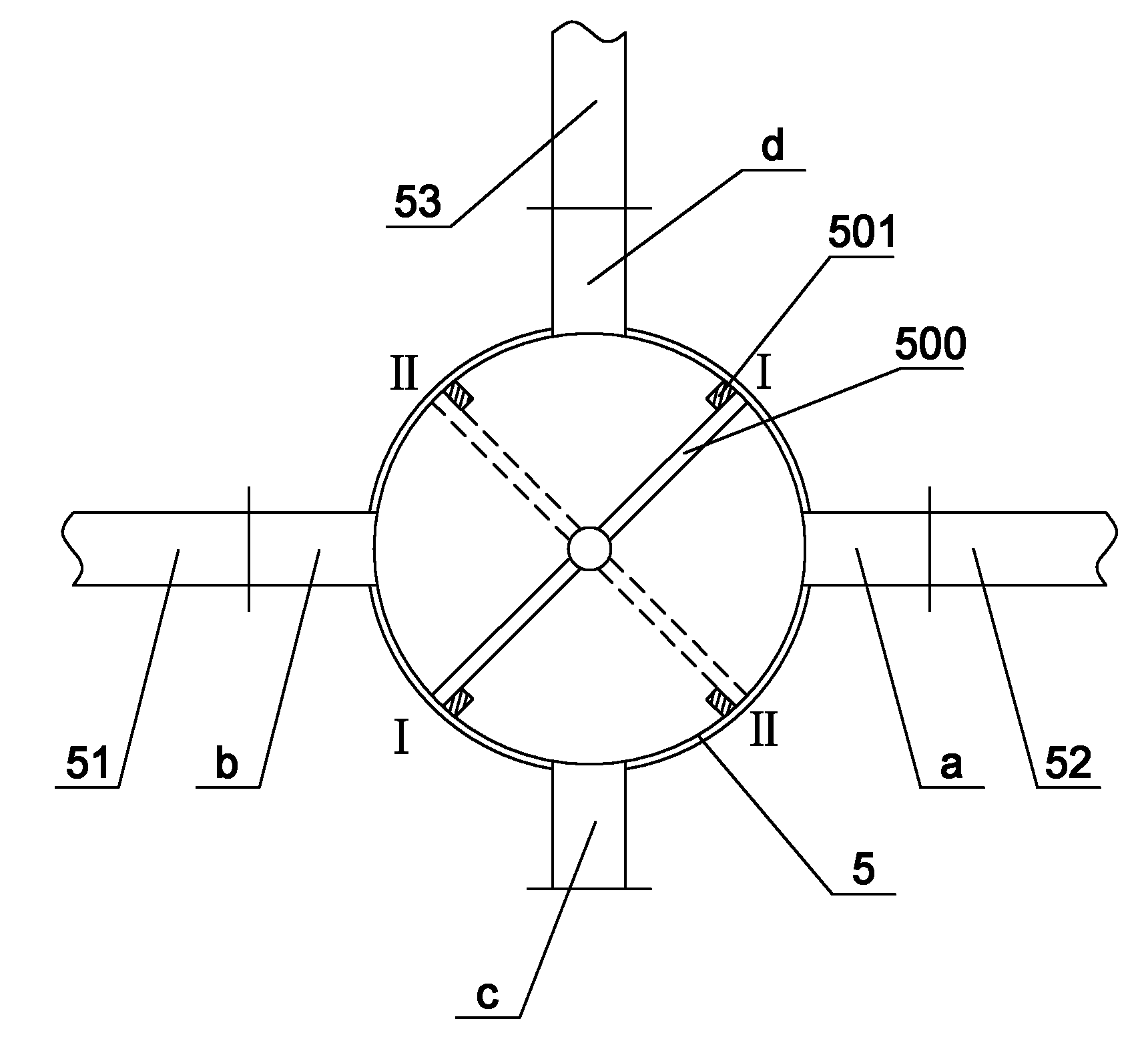

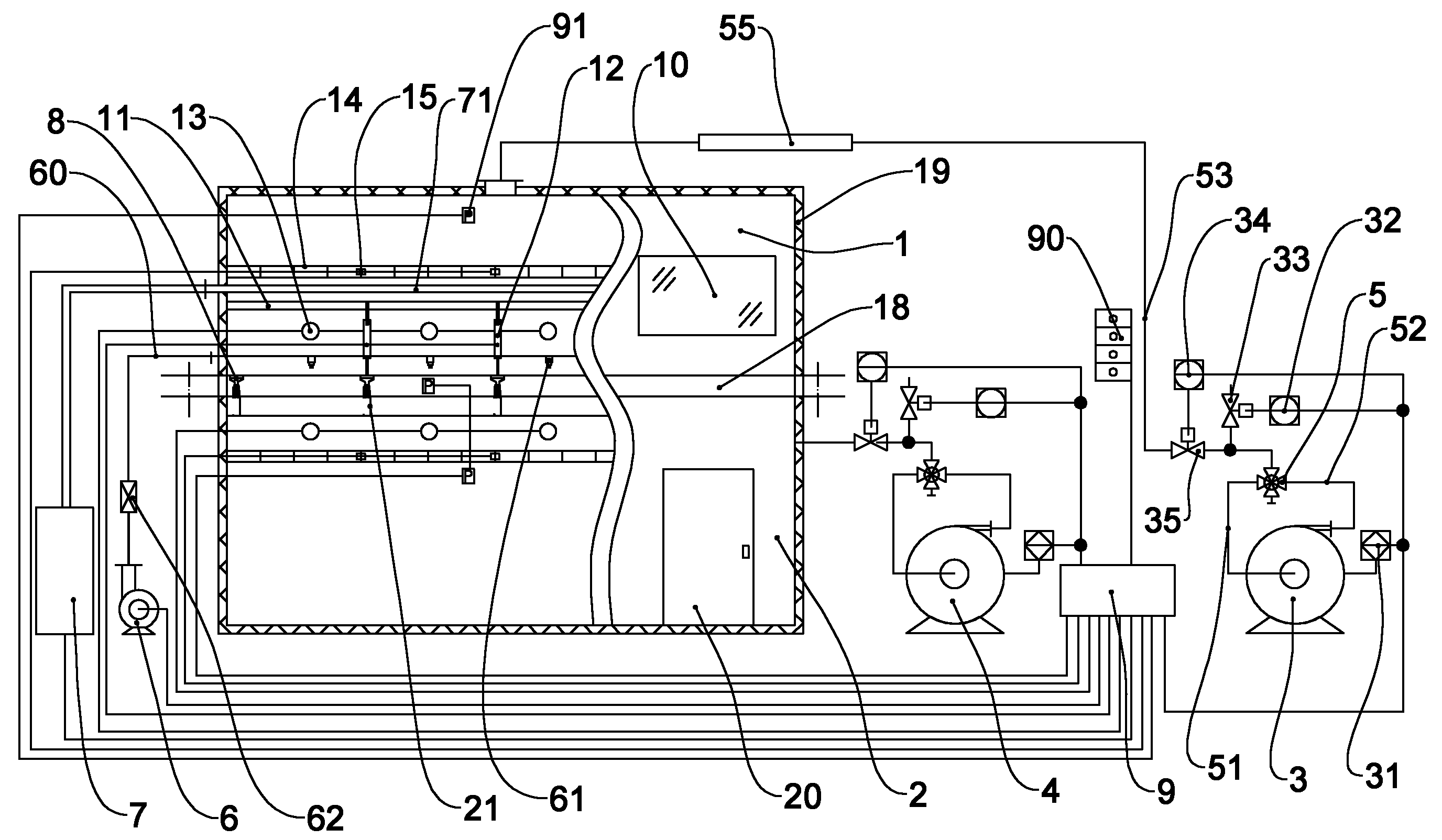

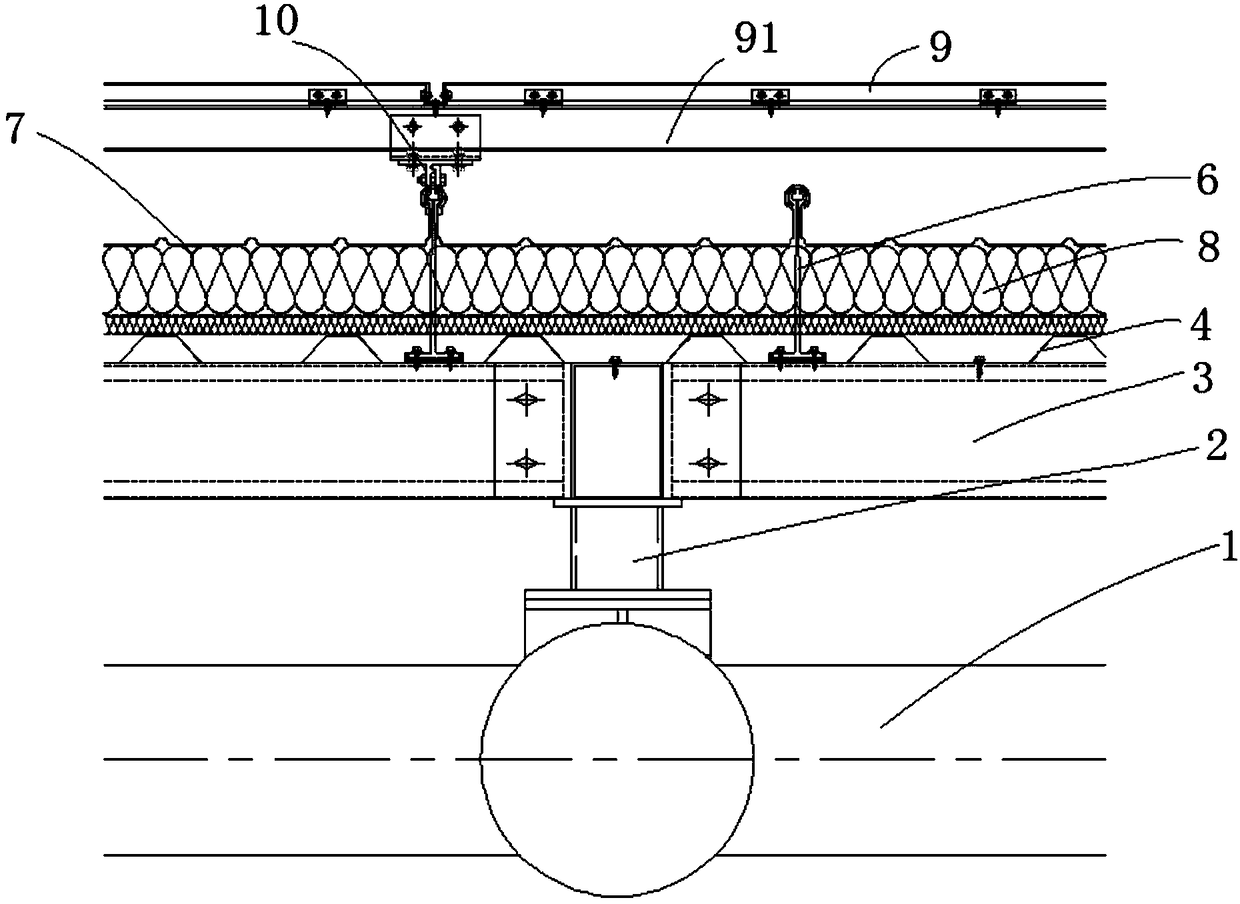

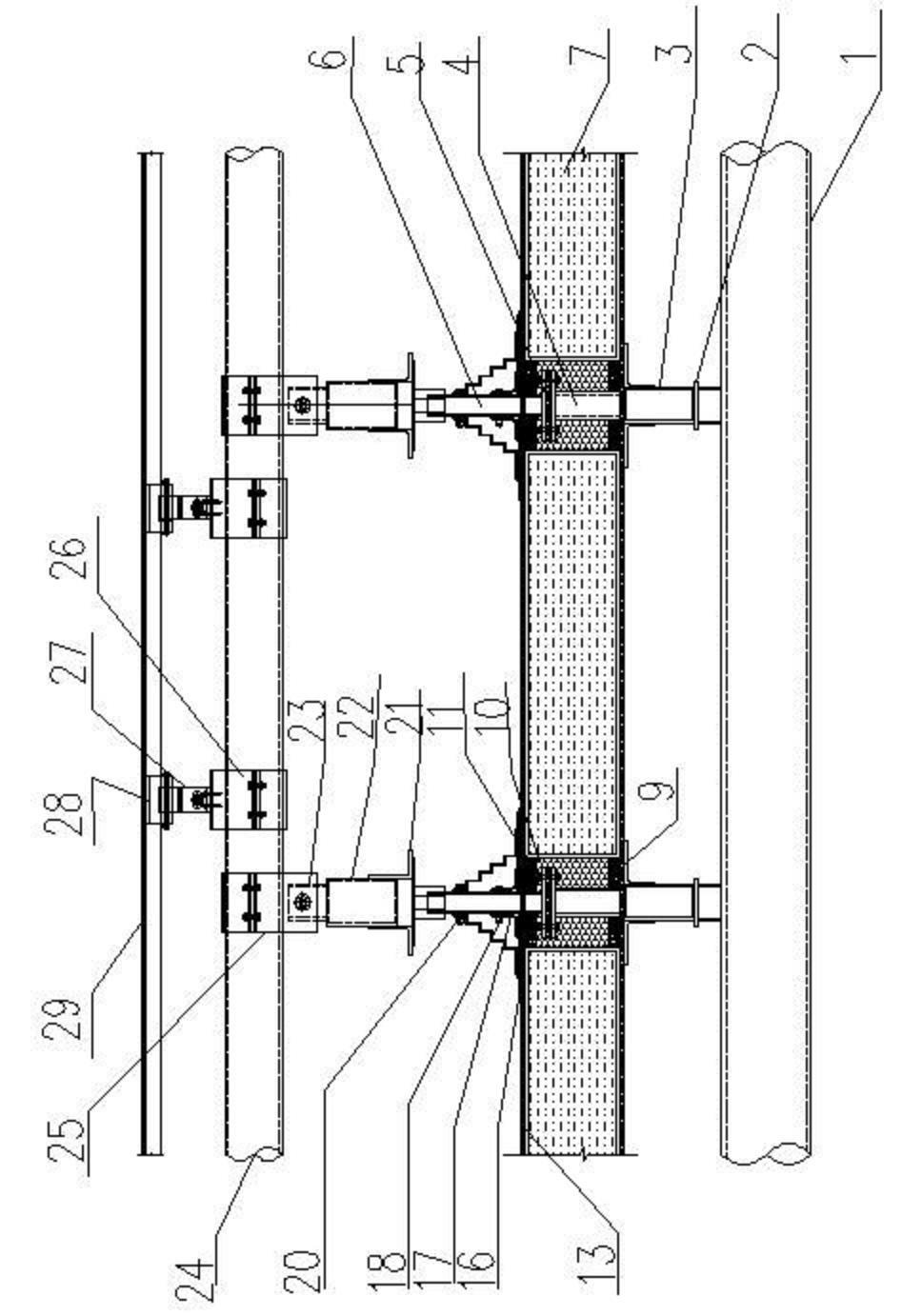

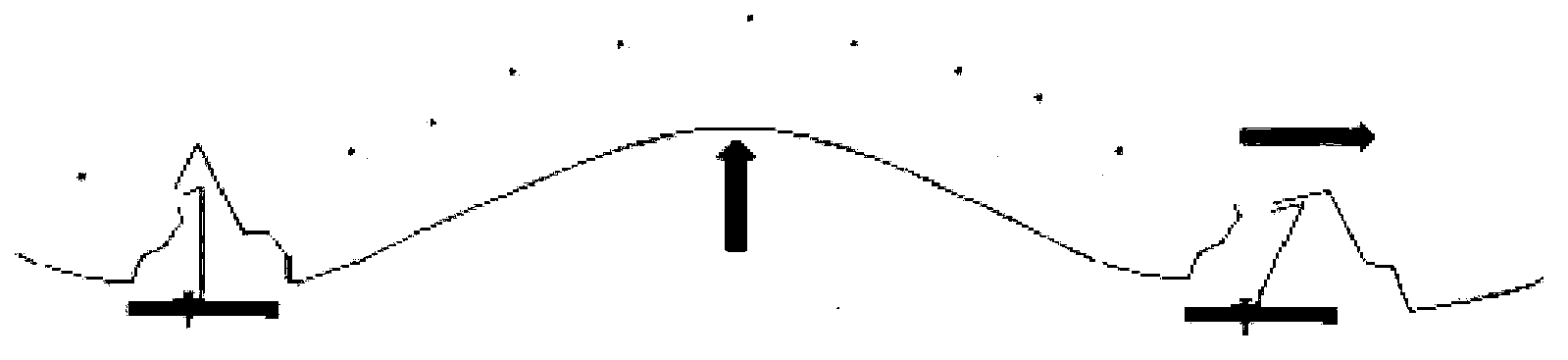

System for testing comprehensive performance of metal roof

InactiveCN102183380ADetectable watertightnessDetectable cold and heat expansion performance indicatorsFluid-tightness measurement using fluid/vacuumEngineeringElectric control

The invention discloses a system for testing comprehensive performance of a metal roof. The system comprises an upper tank body (1), a lower tank body (2), a sealing piece (18), a support (21), a first air supply / exhaust device, a pump (6), a shower pipe (60), a shower nozzle (61), a refrigerator (7), a refrigerating pipe (71), an electric control device (9), a hanging rod (11), a displacement sensor (12), an electric heater (13), a net rack (14), a temperature / humidity sensor (15), and a wind pressure sensor (91), wherein a closed space is formed by the upper tank body (1) and a metal roof testing piece (8); a closed space is formed by the lower tank body (2) and the metal roof testing piece (8); the first air supply / exhaust device comprises a first fan (3) and a reversing valve (5); a reversing device is arranged in the valve body of the reversing valve (5); when the reversing device is in a first reversing state, the first fan (3) exhausts air from the upper tank body (1); and when the reversing device is in a second reversing state, the first fan (3) supplies air to the upper tank body. The system for testing the comprehensive performance of the metal roof can be widely applied to the field of test of metal roofs.

Owner:BAIANLI STEEL STRUCTURE APPL SCI TECH

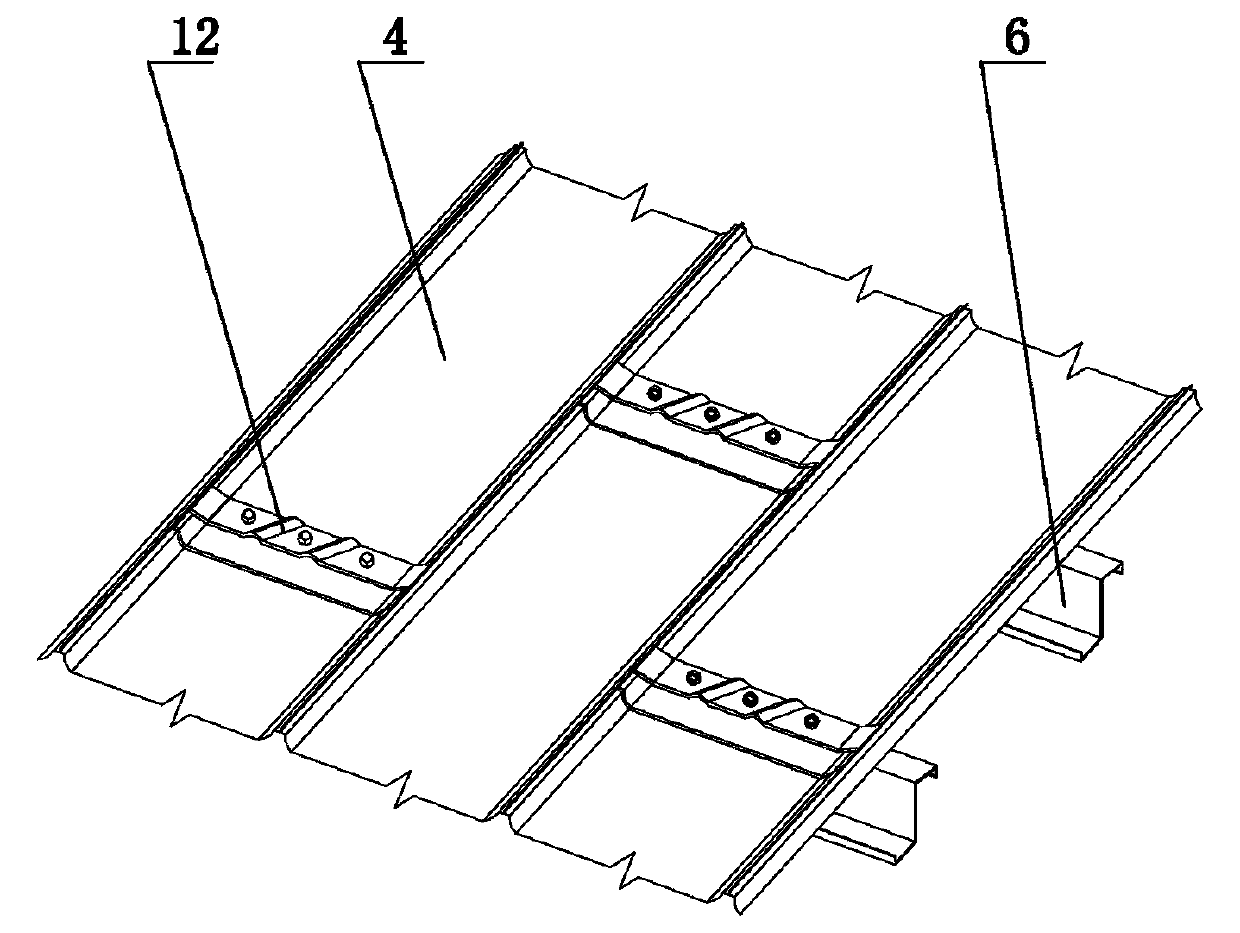

Metal roof system

InactiveCN103469971AImprove water tightnessFasten the connectionRoof covering using slabs/sheetsRoof drainageLap jointEngineering

The invention relates to metal roof system structural modification and provides a metal roof system. The metal roof system comprises color steel roof panels disposed on purlines. A gutter is correspondingly disposed at the end of each color steel roof panel. The side of each color steel roof panel is connected with a gable closing edge of a wall face outer board. The metal roof system is characterized in that the color steel roof panels are mutually connected through lap joint fasteners. Each lap joint fastener comprises a support plate disposed below a color steel roof panel lap joint part and a pressing strip disposed above the color steel roof panel lap joint part, the support plate is provided with riveting screws, the pressing strip is fixed with the riveting screws penetrating the color steel roof panel lap joint part, and an arc-shaped water hole is formed in the pressing strip. The metal roof system is good in wind pressure resistance and waterproofing and reasonable in connecting structure.

Owner:LIAONING HUAXIA STEEL STRUCTURE

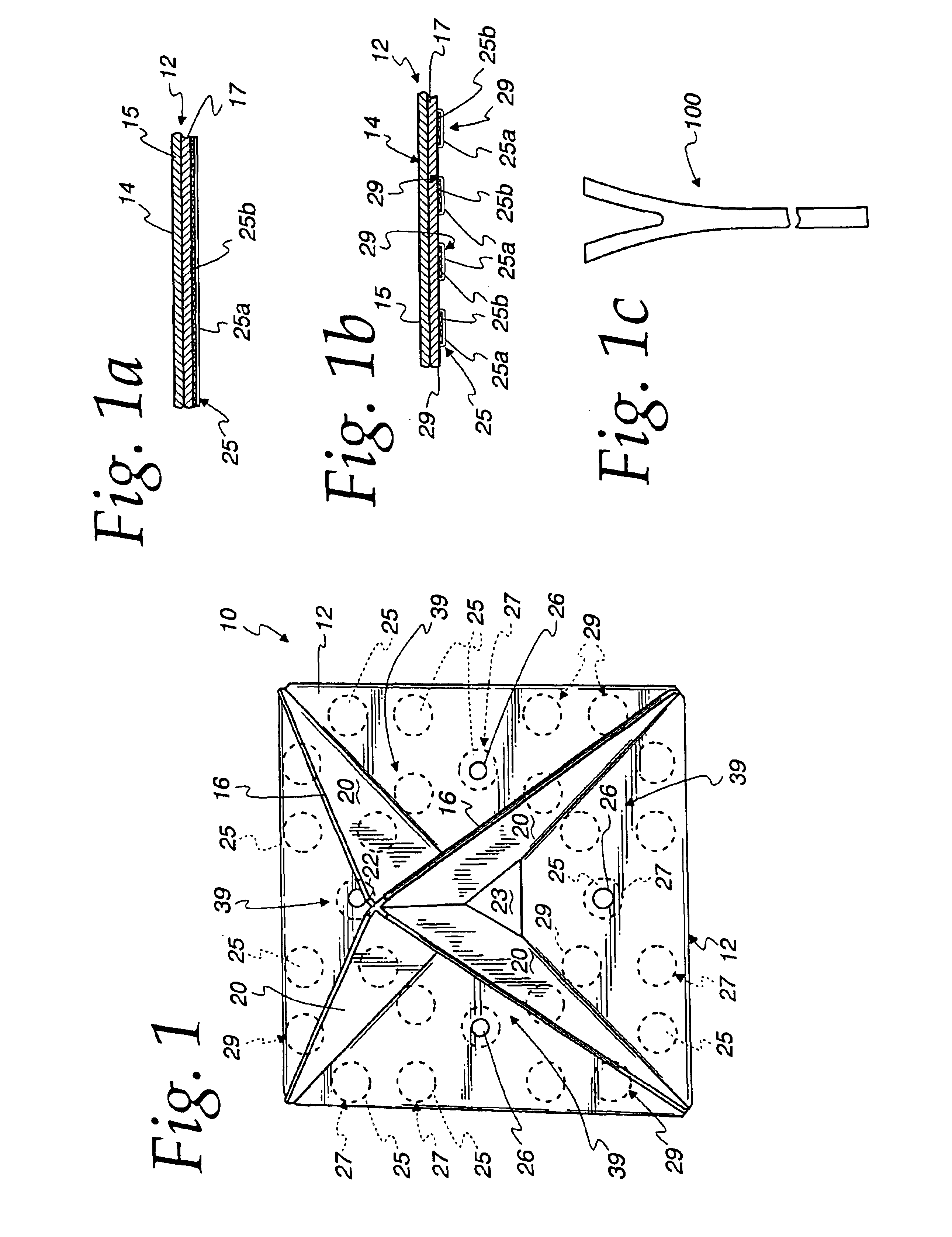

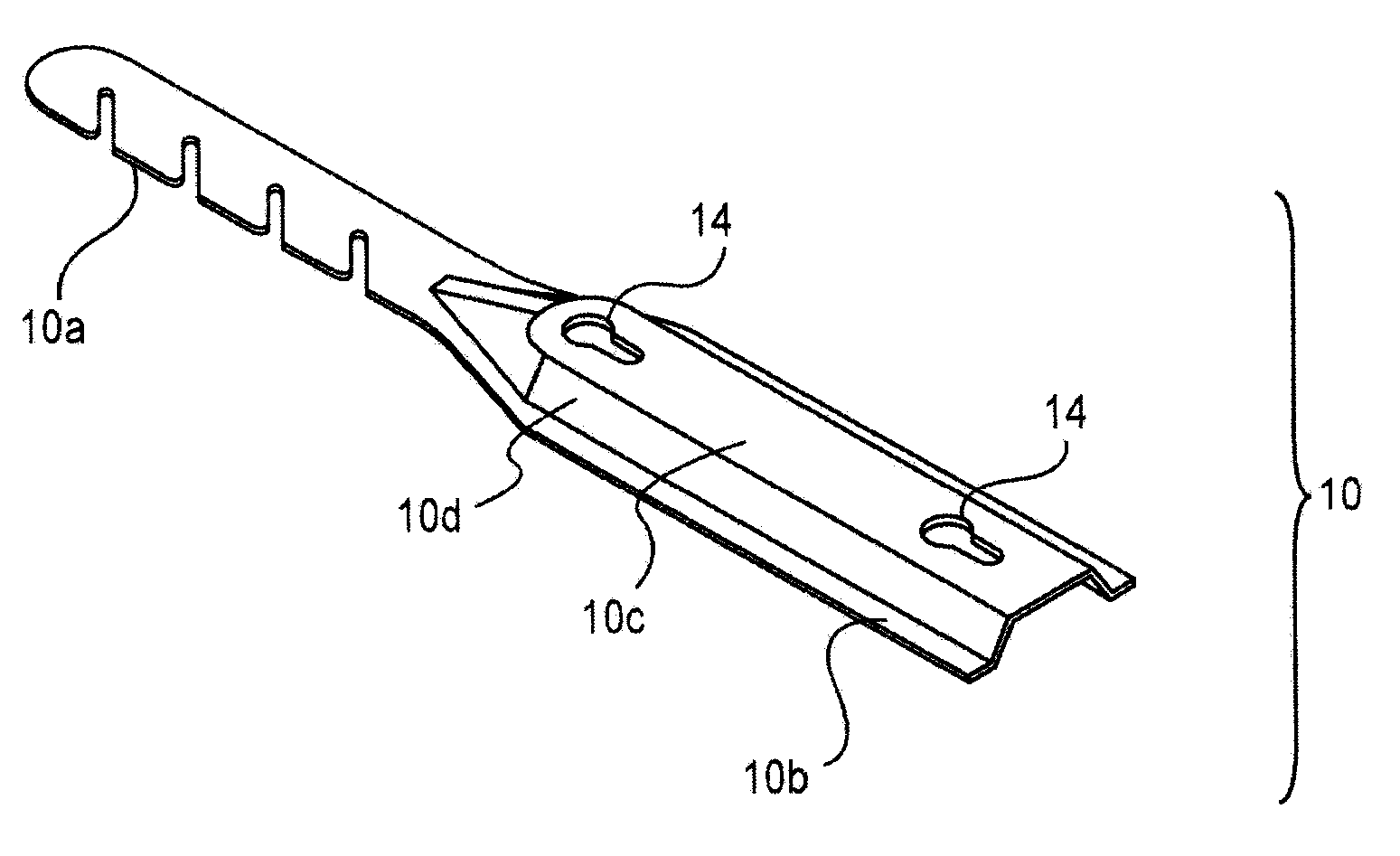

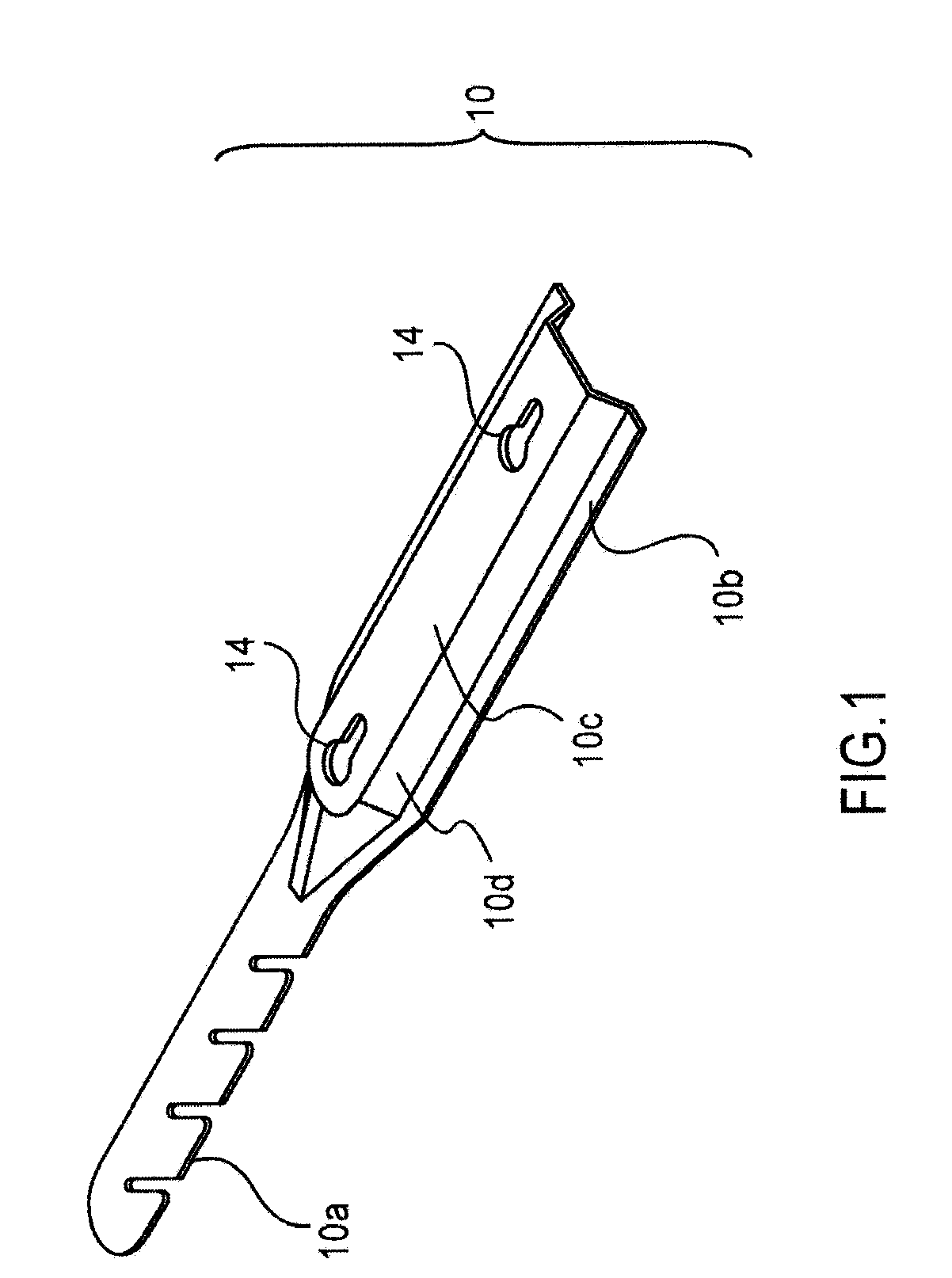

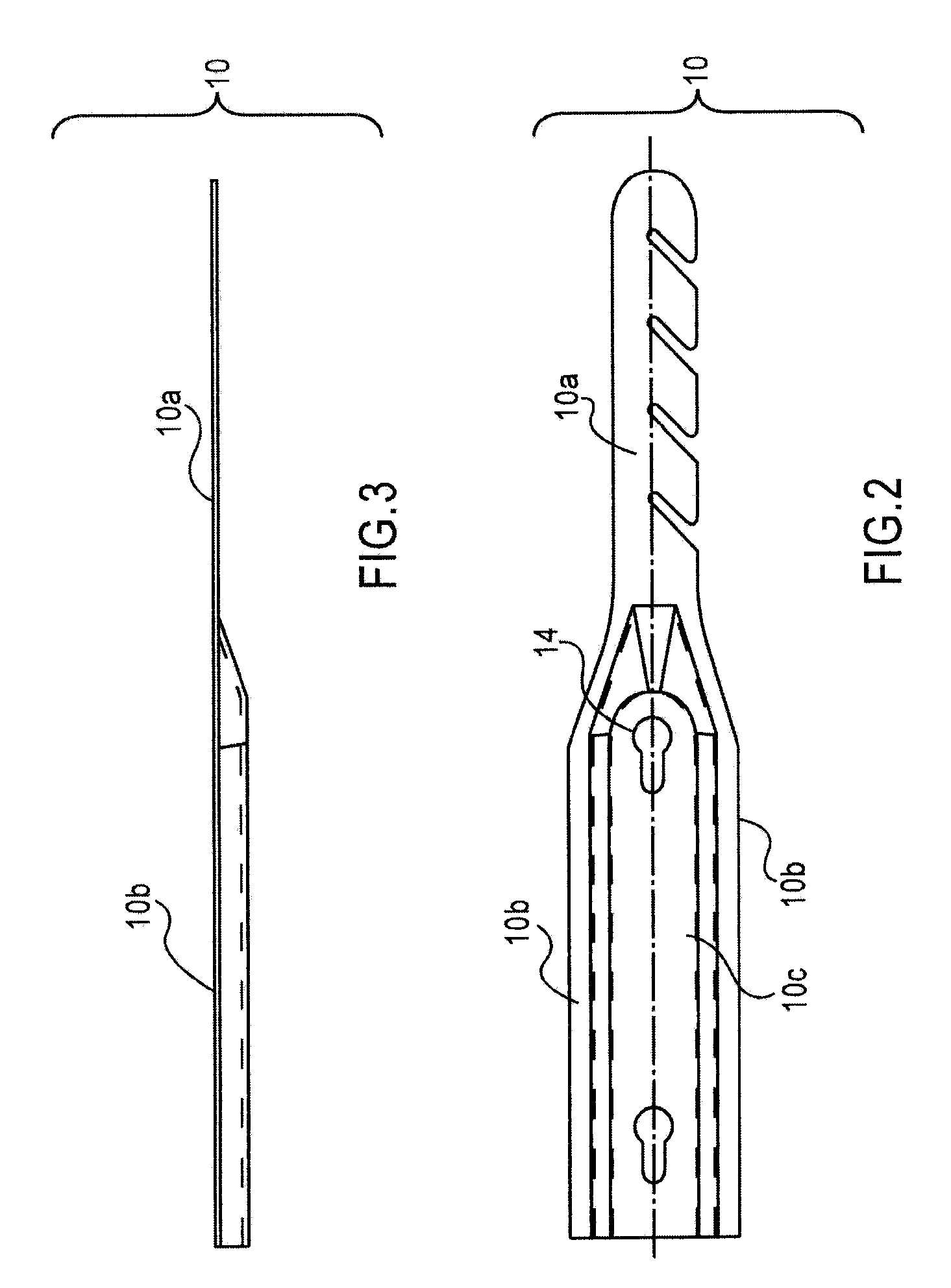

Metal roofing shingle, metal roofing shingle system, and method of installing

InactiveUS20100186334A1Suitable for installationAvoid damageRailway roofsCovering/liningsEdge segmentEngineering

The present invention is directed to a metal roofing shingle system comprising universal flashing installed as either a ridge cap, hip flashing, or valley flashing and including non-visible double-flanged interlock joints that extend beneath the underside surface of the flashing, the interlock joints are adapted to couple with metal shingles; each metal shingle having a planar segment, a first longitudinal edge segment opposite a second longitudinal edge segment that includes a non-visible double-flanged interlock joint that extends beneath the bottom surface of the shingle, and a first transverse edge segment opposite a second transverse edge segment that includes a non-visible double-flanged compression joint that extends beneath the bottom surface of the shingle; and shingle shaping tools.

Owner:SEEM CHARLES T

Metal roofing light transmitting panel

InactiveUS20020026756A1Lower requirementRoof covering using slabs/sheetsBuilding roofsEngineeringUltimate tensile strength

A light transmitting panel of the type for connecting within a metal roofing system is provided. The light transmitting panel includes a translucent panel, a metal panel and a linear coefficient buffer therebetween to allow the respective panels to expand and contract with respect to the other without loss of containment or seal. The light transmitting panel is formed so as to substantially match the configuration and the strength characteristics of the roofing system into which it is installed.

Owner:GUMPERT LARRY +1

Roofing bracket for supporting a platform

A base element for assembly of a roofing bracket comprises a fastening means for temporarily or attaching the base element to a metal or non-metal roof and an upper surface. The upper surface comprises a means for engagement of an underside of an upper member of the roofing bracket. The upper member can be selectively attached to the base element in a first or second position.

Owner:NELSON ROBIN +2

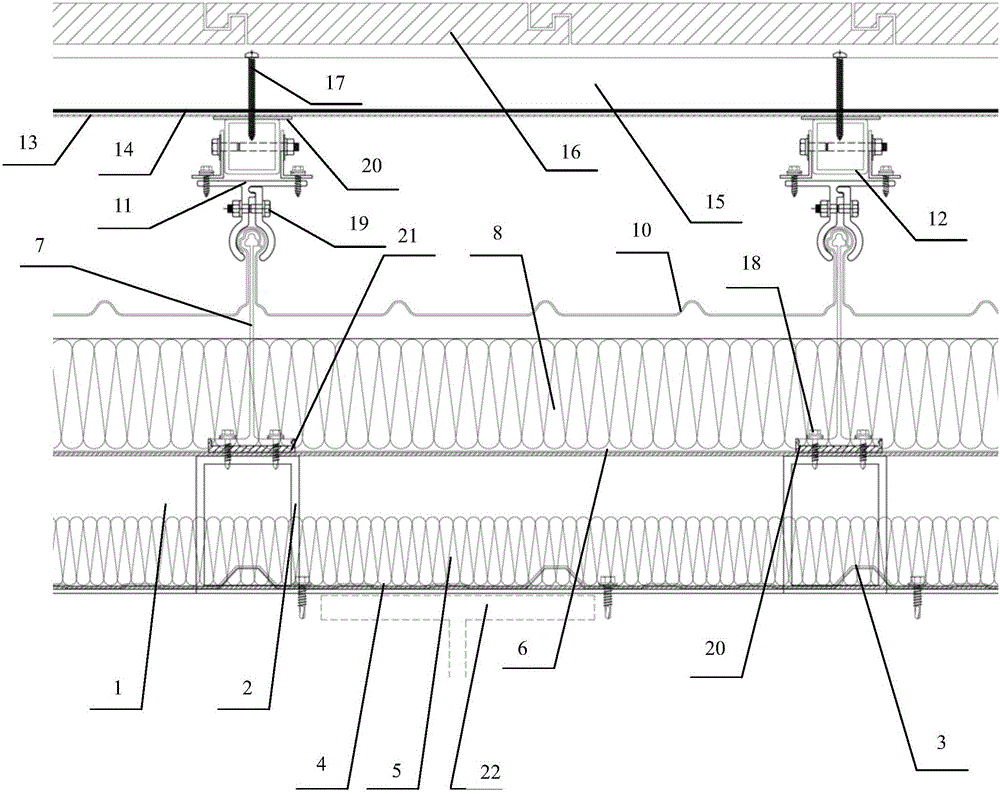

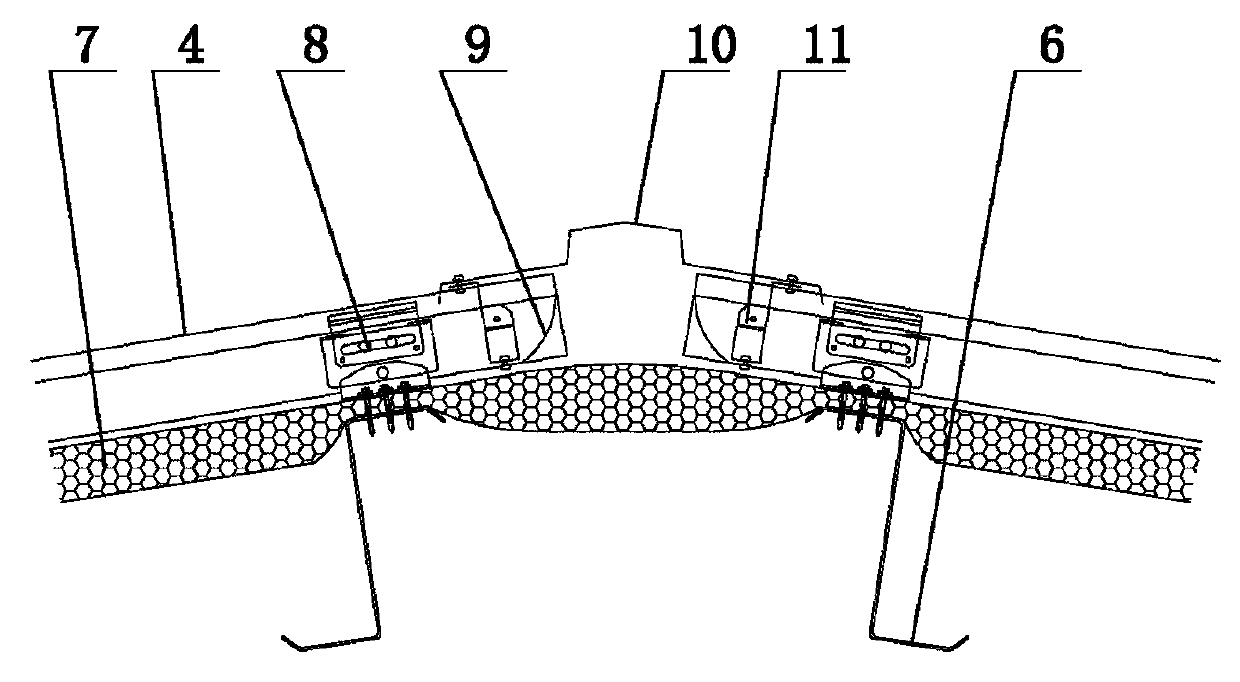

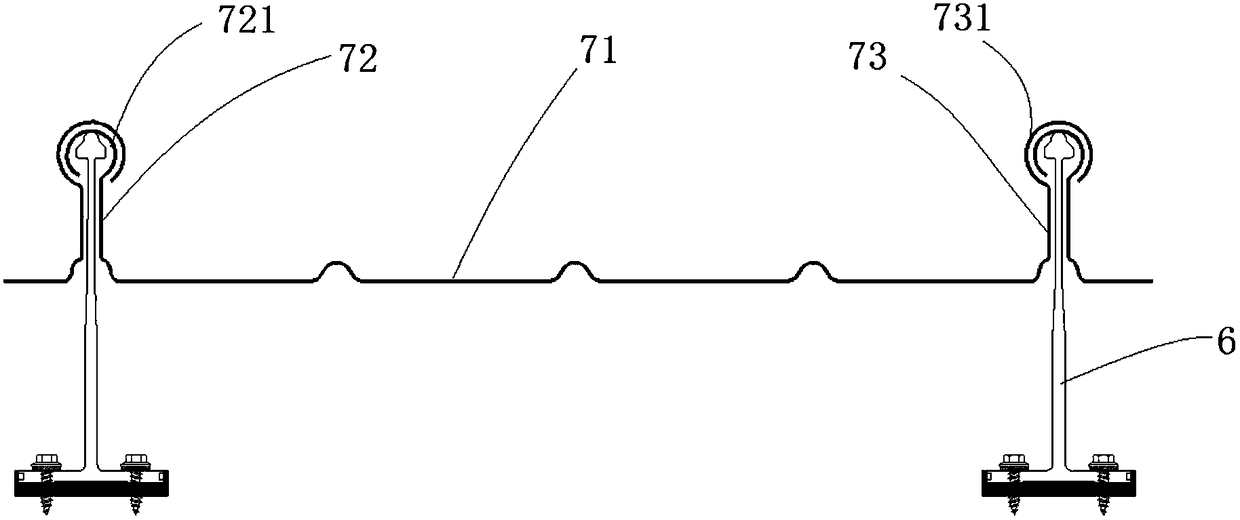

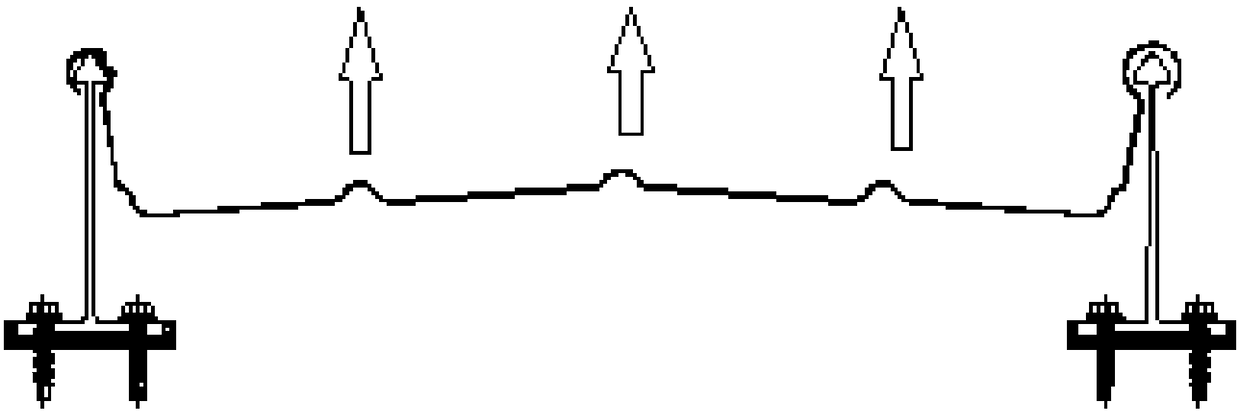

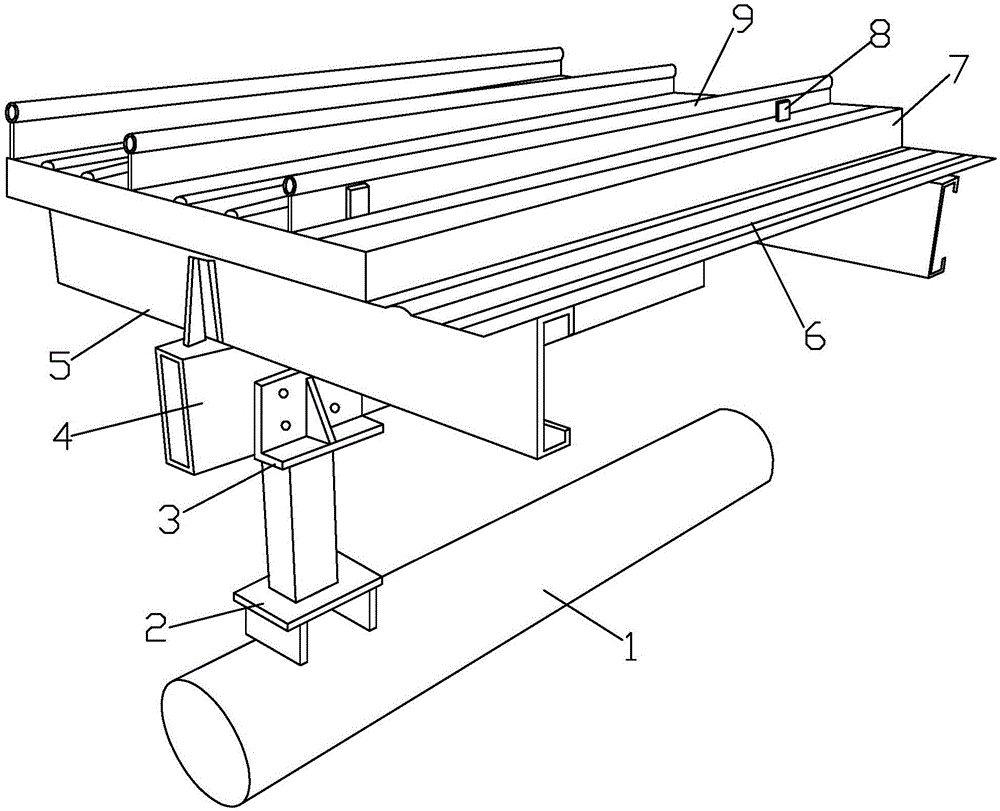

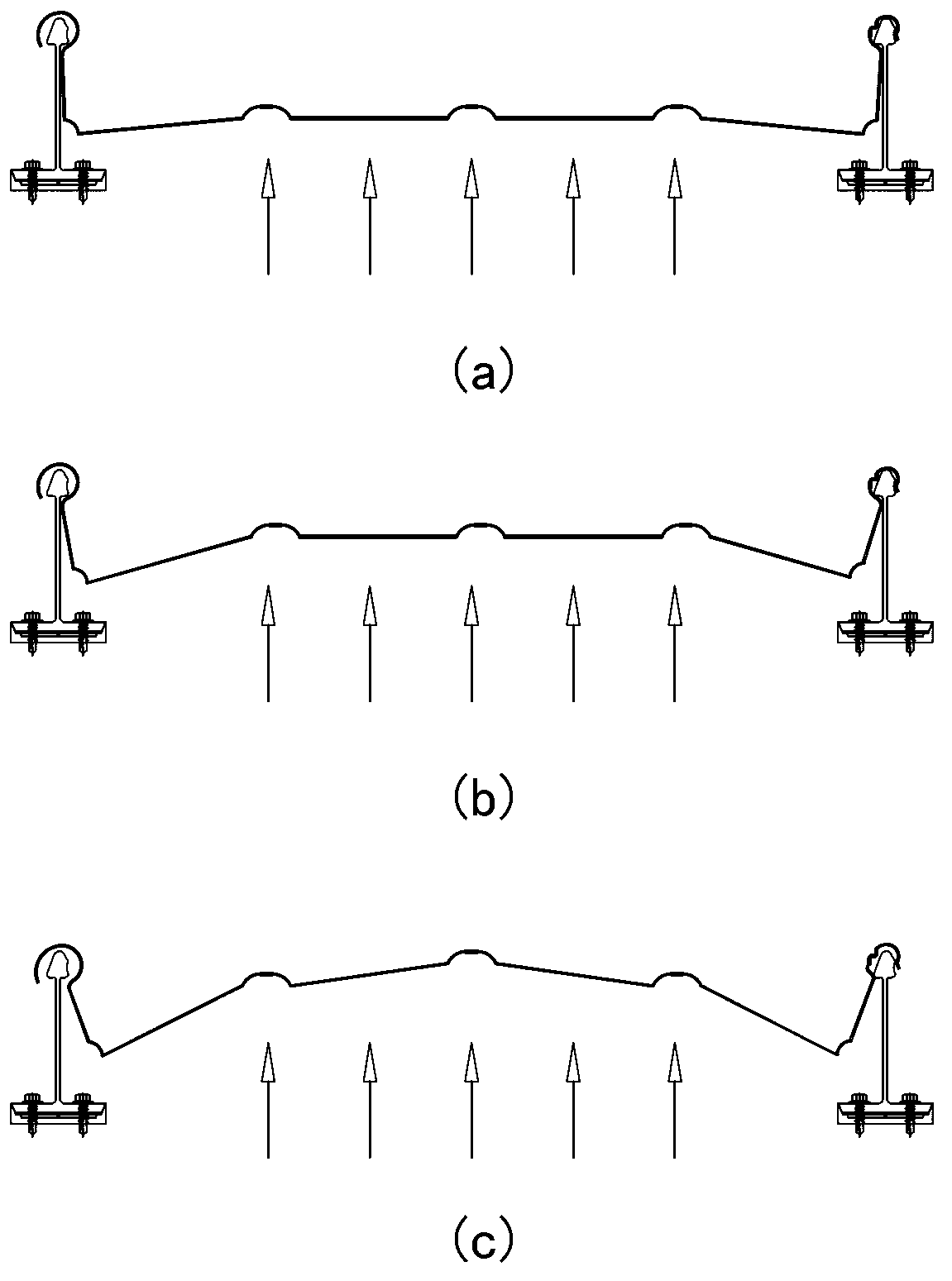

Anti-typhoon and anti-leakage metal roof system

PendingCN108590007AAvoid fatigue damageNo stress concentration problemsBuilding roofsRoof covering insulationsThermal insulationEngineering

The invention discloses an anti-typhoon and anti-leakage metal roof system. The metal roof system sequentially comprises a main steel structure, main roof purline, secondary roof purline, pressed steel bottom plates and purline laid on the pressed steel bottom plates from top to bottom. A plurality of fixed seats are fixed to the purline at intervals, concave roof plates which are engaged with thefixed seats are arranged between the fixed seats, and multiple layers of sound-insulation and vapor-proof thermal insulation materials are laid on the pressed steel bottom plates. The fixed seats include fixed supporting seats and panel engaging plates, wherein the purline is fixedly connected with the lower ends of the fixed supporting seats; the panel engaging plates are fixedly connected withthe fixed supporting seats, and small angles are formed between the panel engaging plates and the fixed supporting seats in the length direction of the roof plates so that the panel engaging plates and the fixed supporting seats can rotate relatively; and panel engaging parts are formed in the upper parts of the panel engaging plates, and the panel engaging parts and both side edges of the roof plates form engaging connection. The anti-typhoon and anti-leakage metal roof system solves the problems that a traditional metal roof system with vertical lockrands has low wind resistance, and is prone to leaking and prone to producing expansion deformation damage, and the safety of upper supporting facilities is affected.

Owner:CENT INT GROUP +1

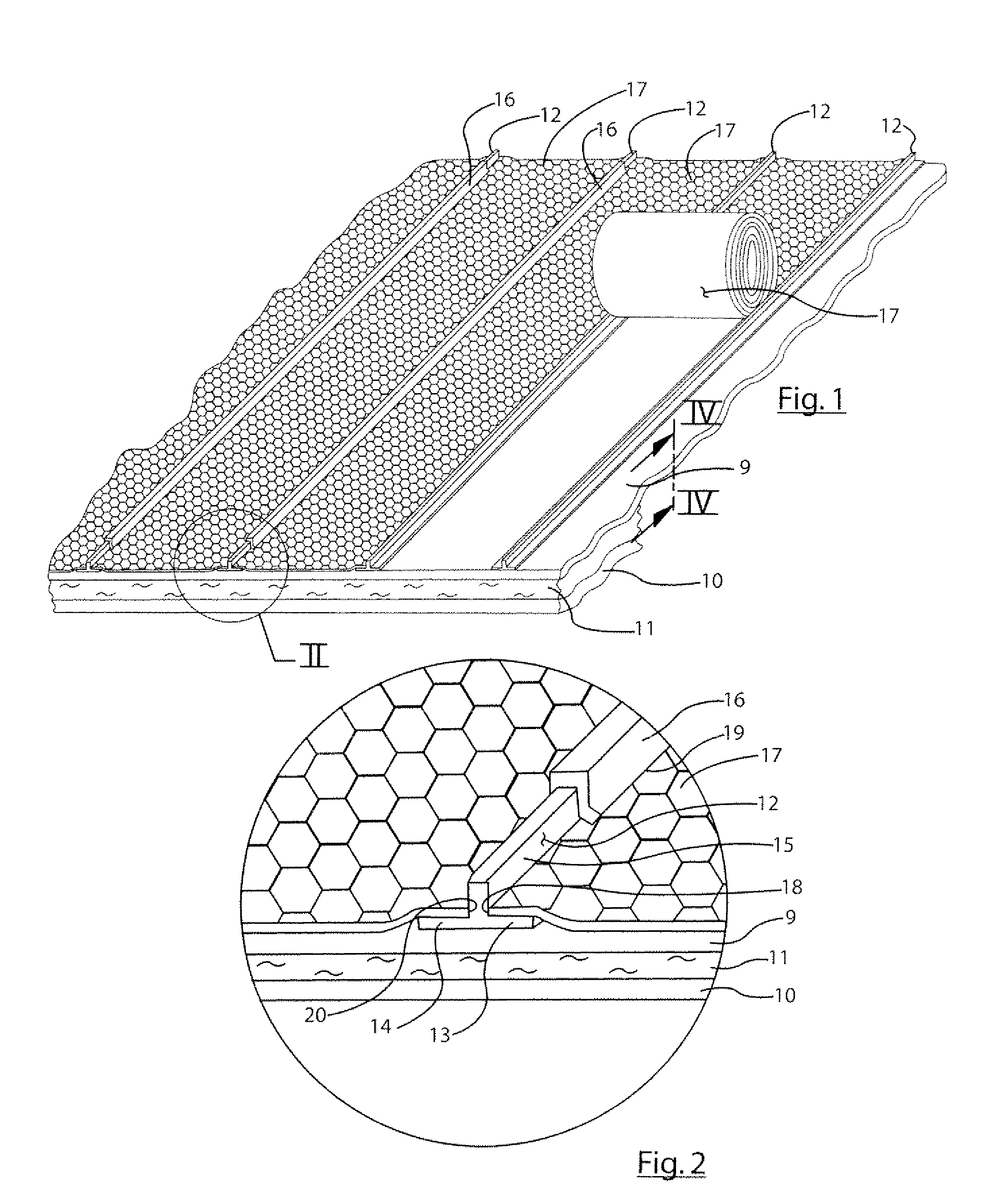

Self-adhering modified bitumen underlayment for metal roofs

InactiveUS7115313B2High tear strengthReduce intensityTreadsRecord information storageMembrane surfaceMechanical engineering

A self-adhering modified bituminous underlayment for metal roof assemblies that comprises an APP modified bitumen compound on the front side, and a factory-applied self-adhesive compound on the back side of a reinforcement carrier sheet, and a fabric at least partially embedded in the APP modified bitumen compound to provide a non-skid surface. A method of manufacturing such composite comprising coating an APP compound on the top surface and affixing a self-adhesive compound to the bottom surface of a reinforcement carrier support sheet, and applying a release liner to the tacky self-adhesive layer during manufacture, stripping the release liner, selvage release film and end lap film from the membrane immediately prior to use, subsequently placing the surface of the membrane directly on to the upper surface of the roof deck, base sheet or underlayment, and applying force directly to the sheet to enhance the bond between the composite and the underlying surface that is created by the tacky self-adhesive compound. The present invention relates generally to residential roofing assemblies using metal as the surface.

Owner:POLYGLASS

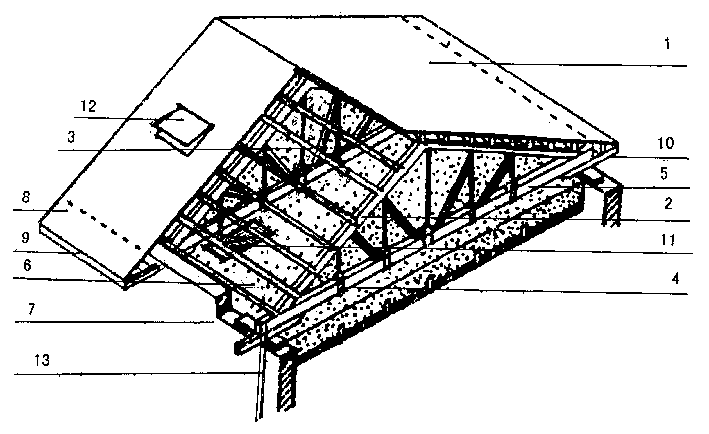

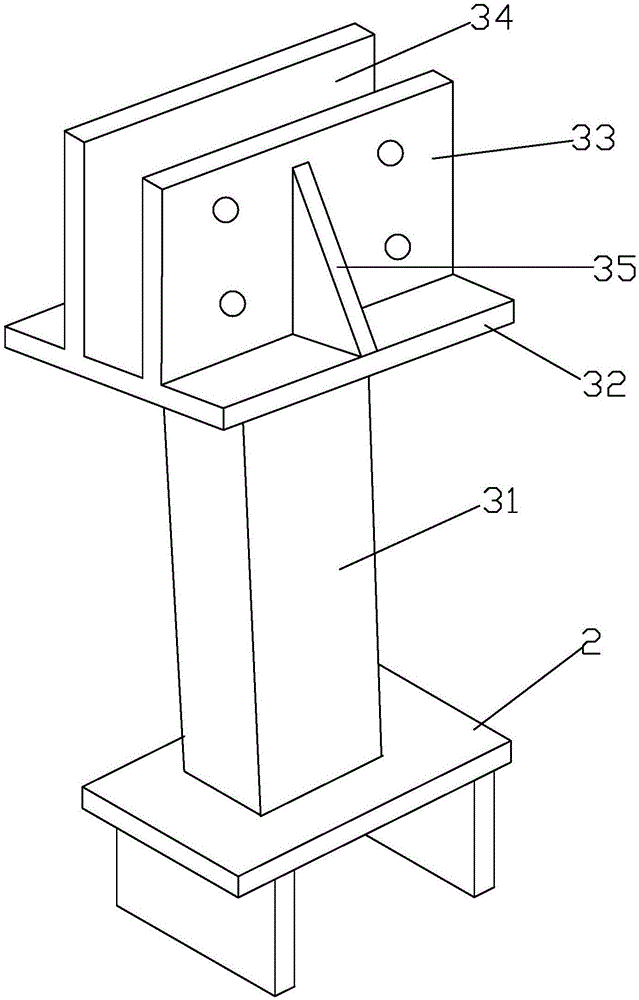

Hidden button type super-long metal roof standing seam and construction method thereof

InactiveCN106677439AAdvanced technologyStrong wind resistanceRoof covering using slabs/sheetsArchitectural engineeringMetal roof

The invention discloses a hidden button type super-long metal roof standing seam. The hidden button type super-long metal roof standing seam comprises a main steel structure, an gradient adjusting bracket is installed on the main steel structure, and a main wingceltis bracket is installed on the gradient adjusting bracket; and a main wingceltis strip is installed on the main wingceltis bracket, a vice wingceltis strip is installed on the main wingceltis strip, a base plate is installed on the vice wingceltis strip, a heat preservation layer is installed on the base plate, and roof outer plates are fixed to the heat preservation layer through metal fixing seats. According to the hidden button type super-long metal roof standing seam, short stand edges of the roof outer plates adopt hidden button type occlusion airtight connection, operation of a technique is easy on spot, the hidden button type super-long metal roof standing seam can be used for construction of various irregular multi-hook-surface roofs, different style models of building roofs can be met, and the attractive construction effect is reflected.

Owner:ZHEJIANG QINYE COUNSTRUCTION GRP CO LTD

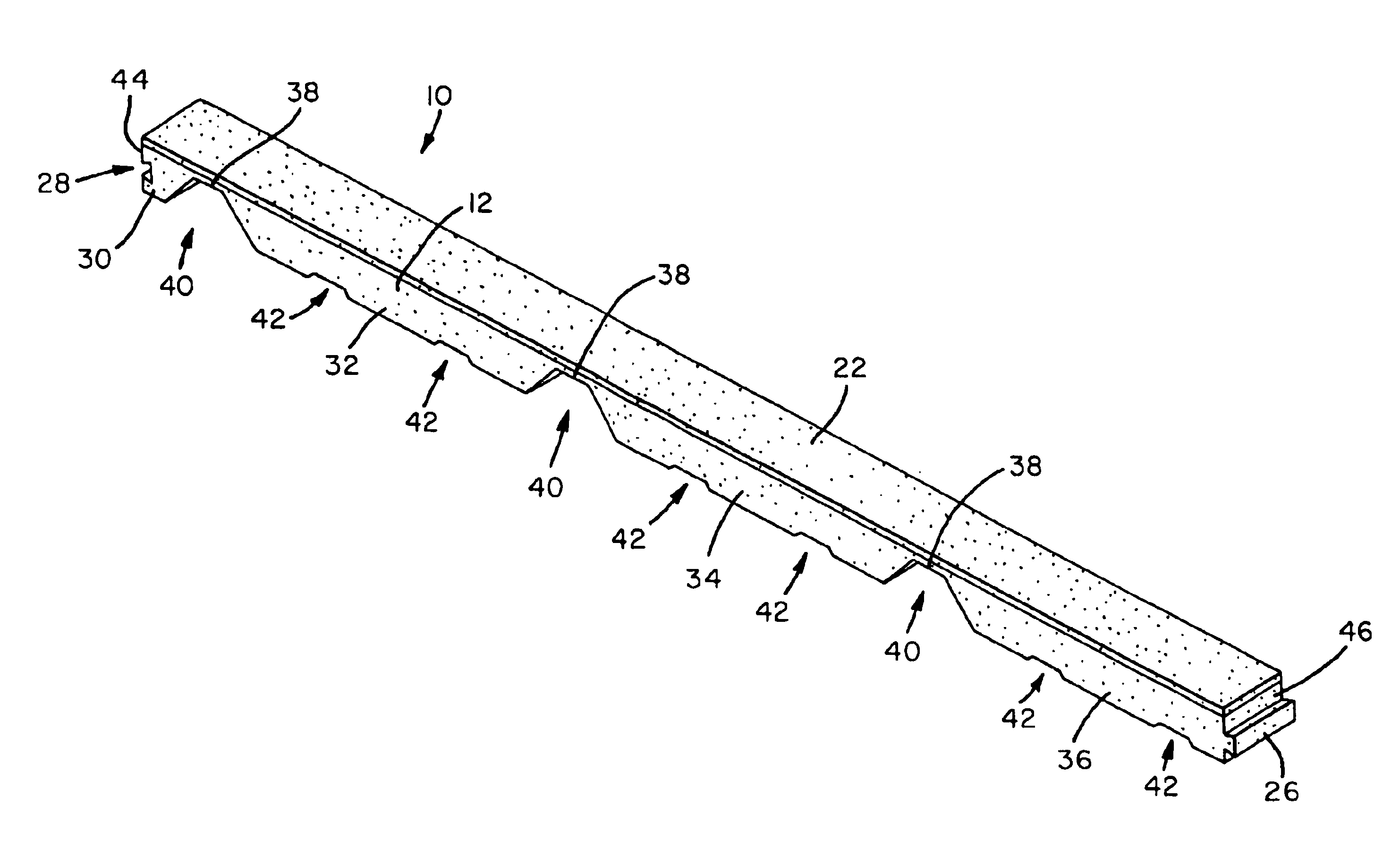

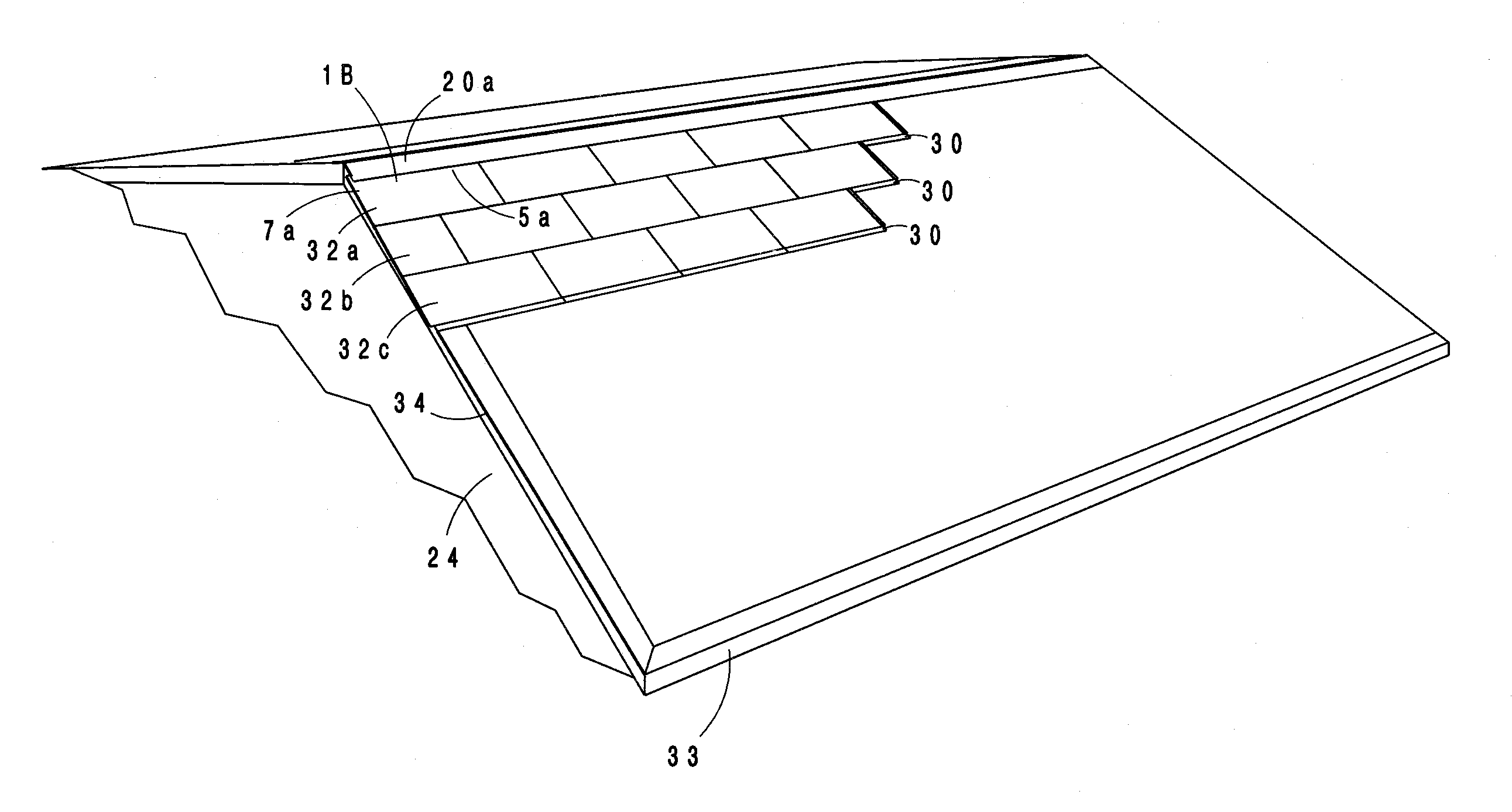

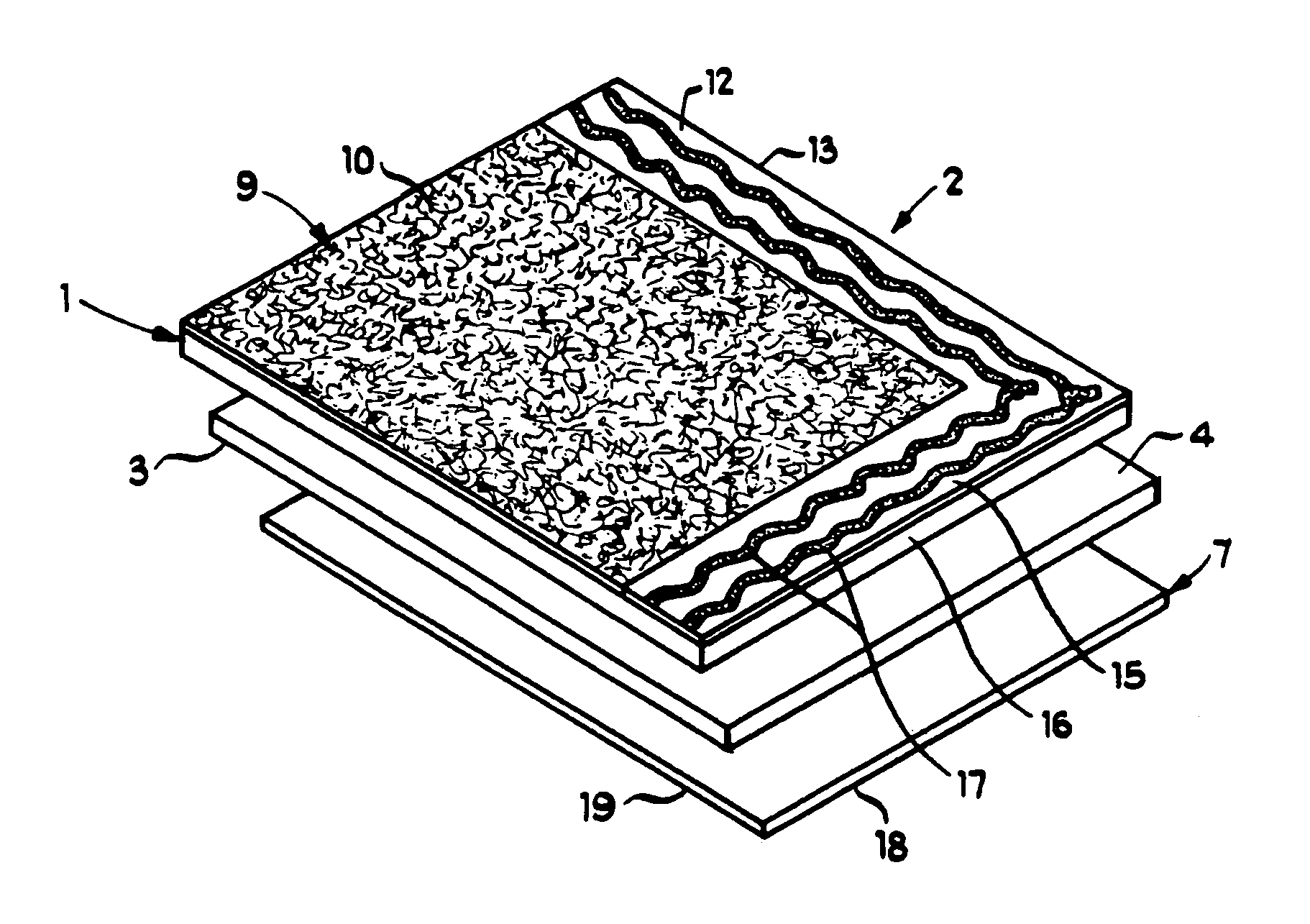

Roof membrane and roof system using the membrane to simulate a standing seam metal roof

A roof membrane is disclosed, for use in simulating a standing seam metal roof when applied to a roof surface and a roof system is also provided, that employs the roof membrane, disposed between longitudinal, but spaced-apart, generally parallel roof battens. Underlayments of various constructions are also provided, beneath the membrane, as an option. Caps are provided for upstanding legs of the roof battens.

Owner:CERTAINTEED CORP

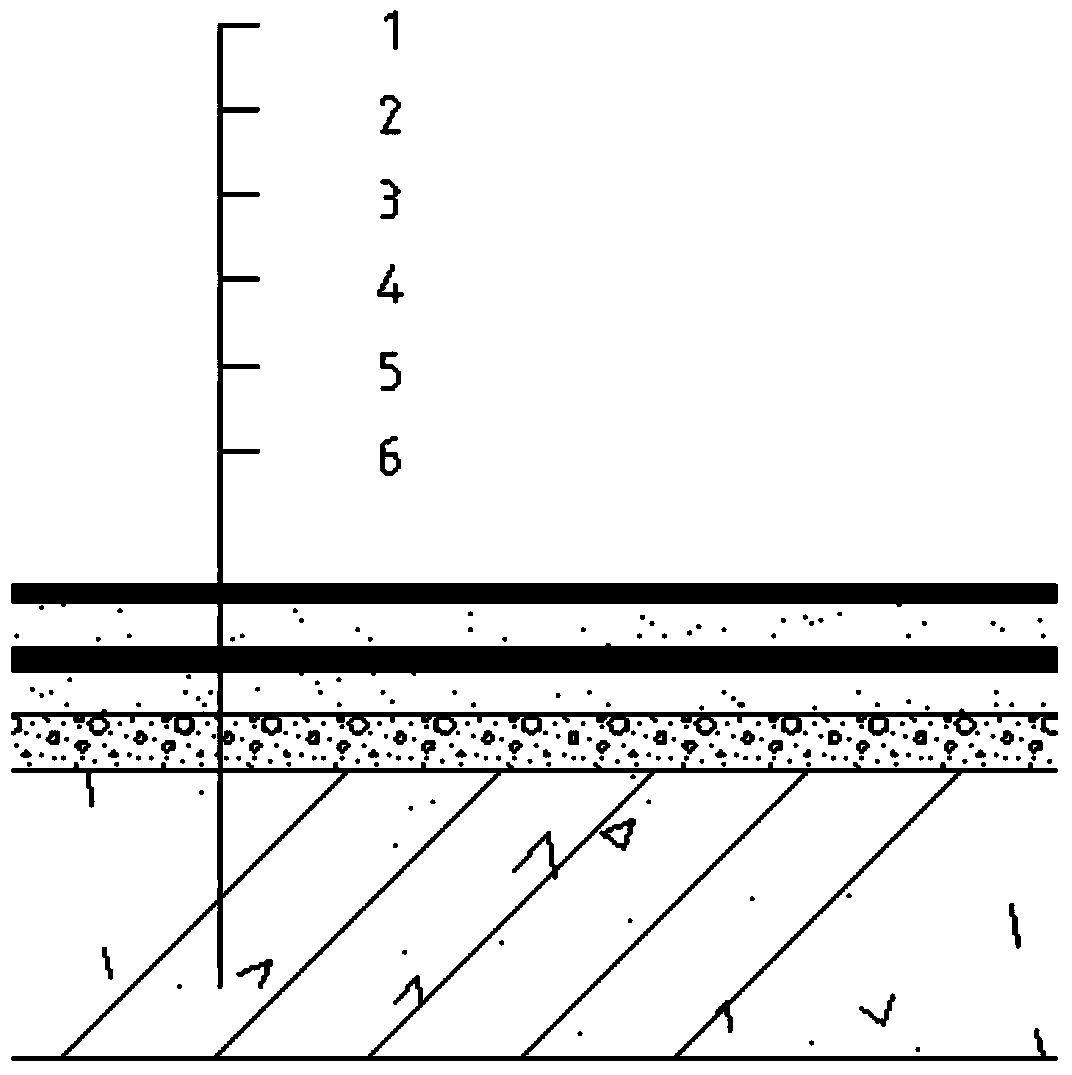

Process for constructing metal roof of building with super-large space

InactiveCN103291011AMeet waterproofMeet the requirements of sound absorption performanceRoof covering insulationsManganeseEngineering

The invention discloses a process for constructing a metal roof of a building with super-large space. The process includes steps of 1), laying a steel lining plate on the lowermost layer of a roof structure; 2), laying a non-woven dustproof layer on the lining plate; 3), laying a glass wool sound absorbing layer on the non-woven dustproof layer and compacting the glass wool sound absorbing layer; 4), laying a vapor barrier on the glass wool sound absorbing layer; 5), laying lower-layer glass wool on the vapor barrier and compacting the lower-layer glass wool; 6), laying upper-layer heat-insulation rock wool on the lower-layer glass wool and compacting the upper-layer heat-insulation rock wool; 7), mounting support purline; 8), laying supporting steel plates; 9), laying a gypsum fiber board; 10), laying a waterproof vapor-permeable layer on the gypsum fiber board; 11), laying an ultrafine glass cotton anti-noise layer on the waterproof vapor-permeable layer; 12), mounting an aluminum-magnesium-manganese alloy roof panel on the uppermost layer of the roof structure. The process for constructing the metal roof has the advantages that a waterproof effect of the metal roof is improved, water seepage at pierced positions is prevented, outdoor noise is prevented from being transmitted into a room, and heat-insulation, damp-proof and vapor-permeable effects of the metal roof are improved.

Owner:ZHONGTIAN CONSTR GROUP

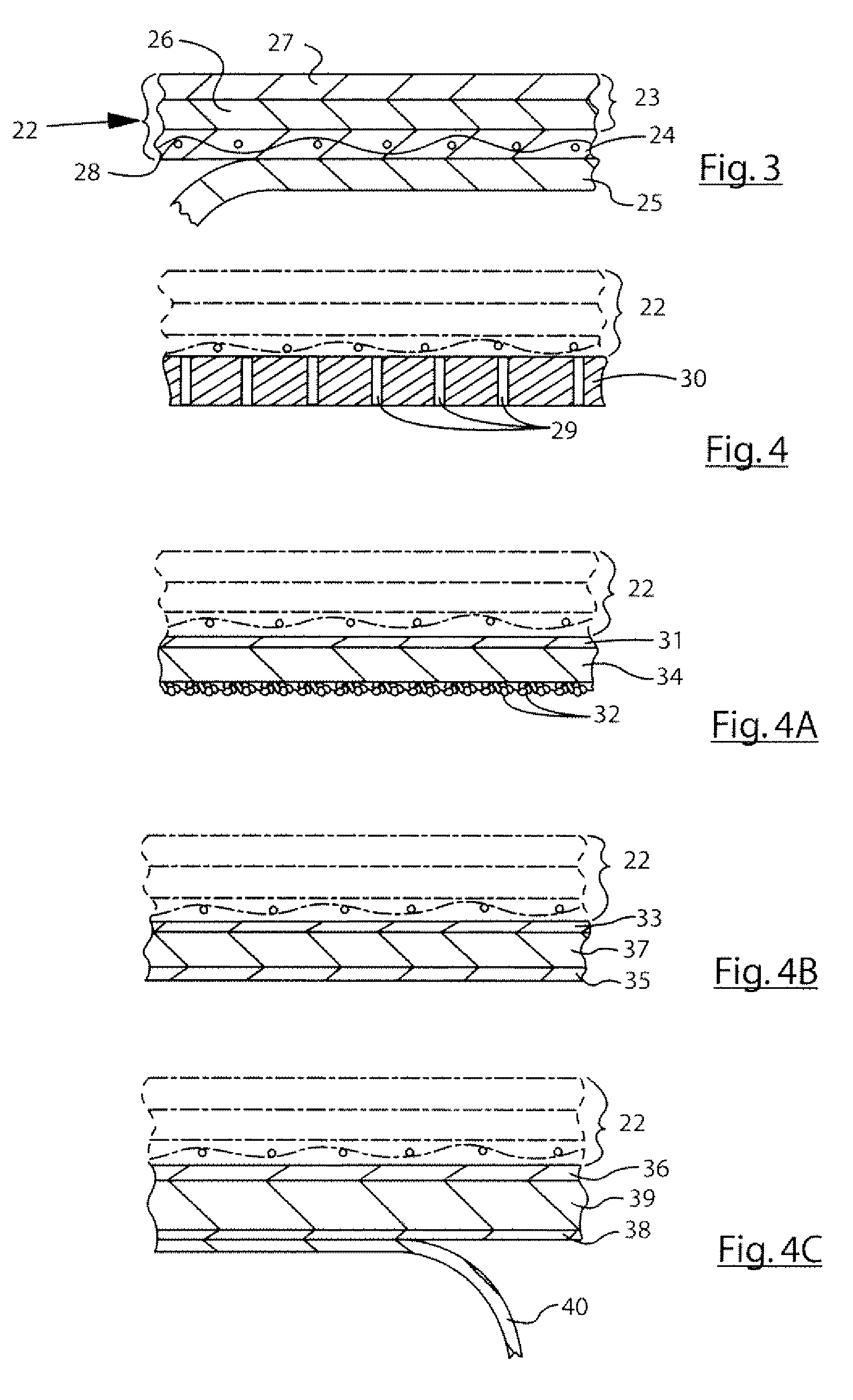

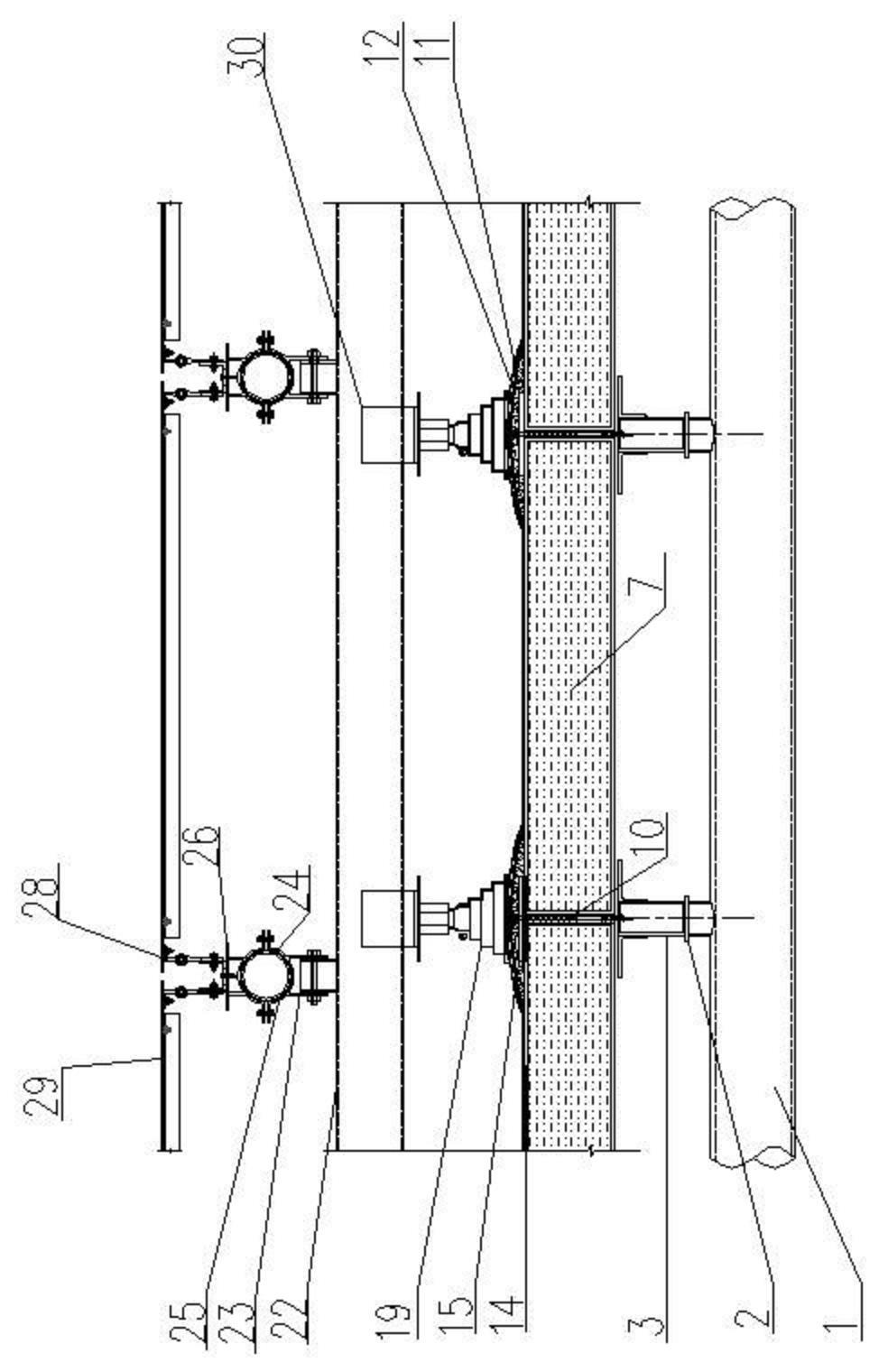

Waterproof heat-insulating fireproof metal roof system

InactiveCN102587590APrevent leakageAvoid condensationRoof covering using slabs/sheetsBuilding roofsVapor barrierPurlin

The invention relates to a waterproof heat-insulating fireproof metal roof system, aiming at solving the problems that in the construction and use process of an existing roof heat-insulating system, fire disaster frequently occurs and is difficult to control, and as the interior decoration and roof materials are not fire retardant, once a big fire occurs, the fire is difficult to control, and huge economic losses are brought. The roof system comprises a decorating plate (29), a primary keel (22) and a secondary keel (24) of the decorating plate, a pipe boot, a purline (3) and a lower-part main structure (1), wherein the decorating plate is arranged on the secondary keel through a finished aluminum hinge (28); the primary keel (22) of the decorating plate is fixed on the purline (3) through an adjustable support piece; an insulating layer (7) of a composite insulation board is arranged on the purline; a waterproof vapor barrier (13) is arranged on the insulating layer (7) of the composite insulation board; and the purline (3) is supported on the lower-part main structure (1) by a purlin support (2). The waterproof heat-insulating fireproof metal roof system is used for waterproof heat-insulating fireproof metal roofs.

Owner:哈尔滨工业大学空间钢结构幕墙有限公司

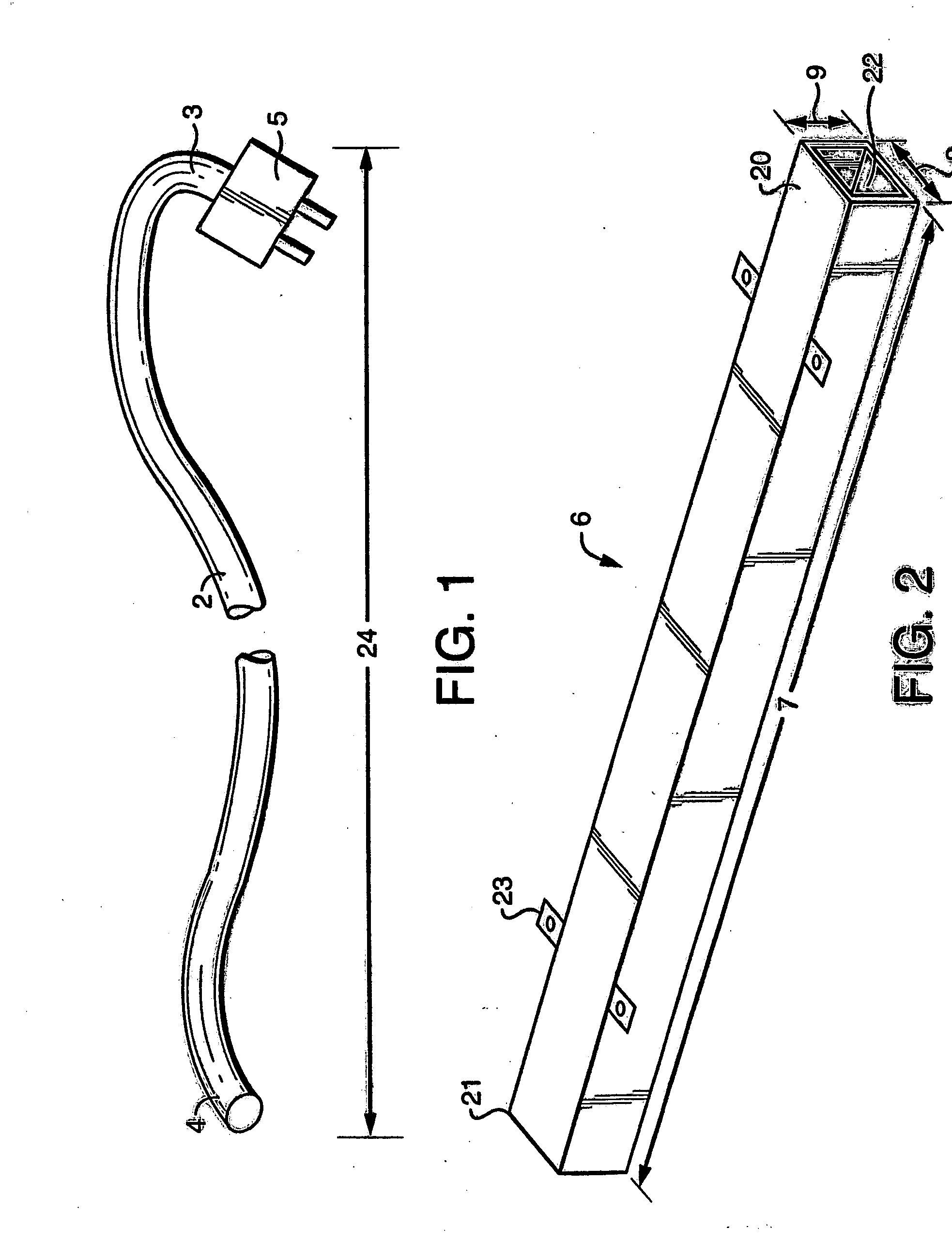

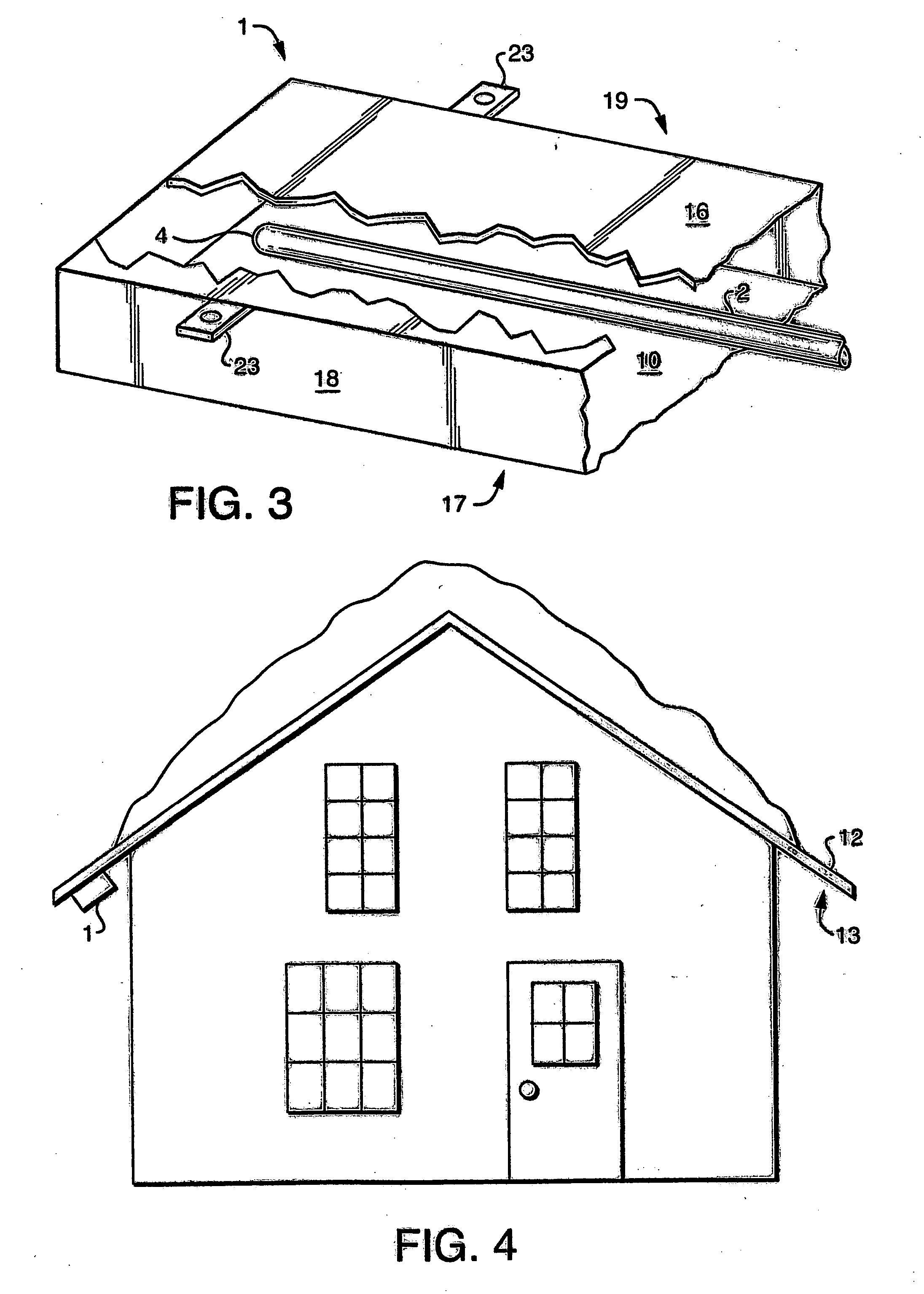

Building eaves heater for metal roof

A building eaves heater for metal roof comprising a hollow sheathe, a heating element located within the metal sheathe and tabs for attaching the metal sheathe to the metal roof.

Owner:KNAPPMILLER LEONARD V

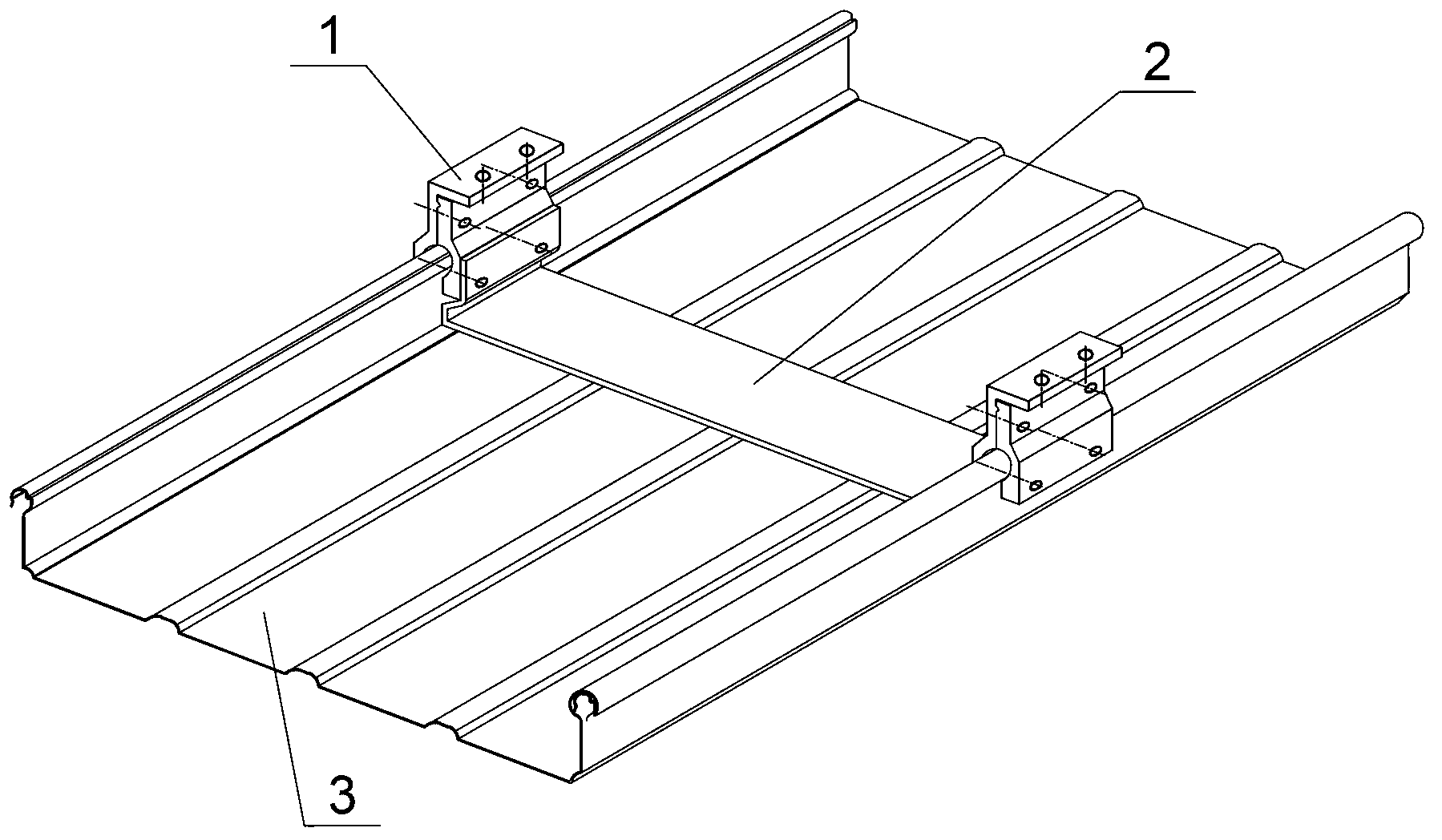

Windproof clamp for metal roof plates

InactiveCN103291008AStable structureOvercome the disadvantages of unstable structures that easily cause roof panels to rolloverRoof covering using slabs/sheetsEngineeringMechanical engineering

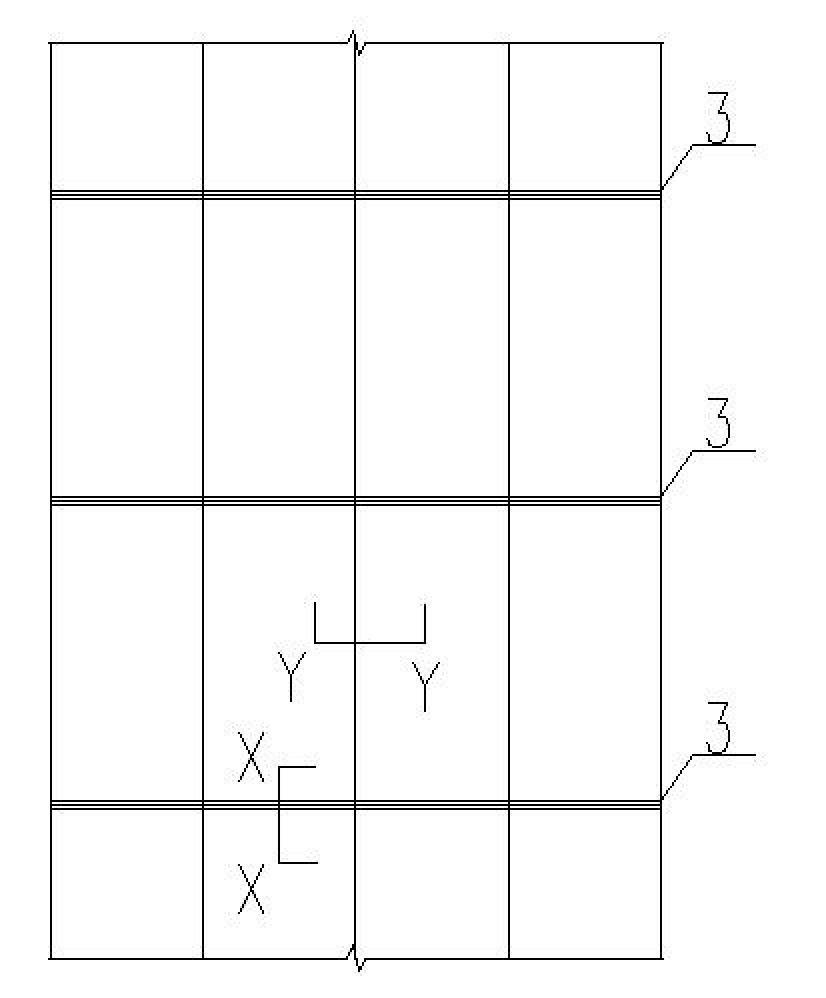

The invention discloses a windproof clamp for metal roof plates. The windproof clamp is stable in structure, convenient to construct and good in windproof effect and comprises fastening clamp components (1), a reinforcing member (2), the metal roof plate (3) and a roof plate fixing seat (4), the metal roof plate (3) comprises a baseplate (30), a first vertical ribbed plate (31) and a second vertical ribbed plate (32), a first buckling portion (32) and a second buckling portion (34) are arranged at the top of each of the first vertical ribbed plate (31) and the second vertical ribbed plate (33) respectively, adjacent metal roof plates (3) are in buckled connection through the first buckling portions (32) and the second buckling portions (34) and are in buckled fixing with the roof plate fixing seat (4), the fastening clamp components (1) are clamped and fixed on the first buckling portions (32) and the second buckling portions (34) to clamp and fix the adjacent metal roof plate (3), the reinforcing member (2) are positioned between the first vertical ribbed plate (31) and the second vertical ribbed plate (33) of the metal roof plate (3), and two ends of the reinforcing member (2) are respectively fixedly connected with the fastening clamp components (1) to form a frame-type reinforcing structure. The windproof clamp for the metal roof plates can be widely applied to the field of metal roofs.

Owner:BAIANLI STEEL STRUCTURE APPL SCI TECH

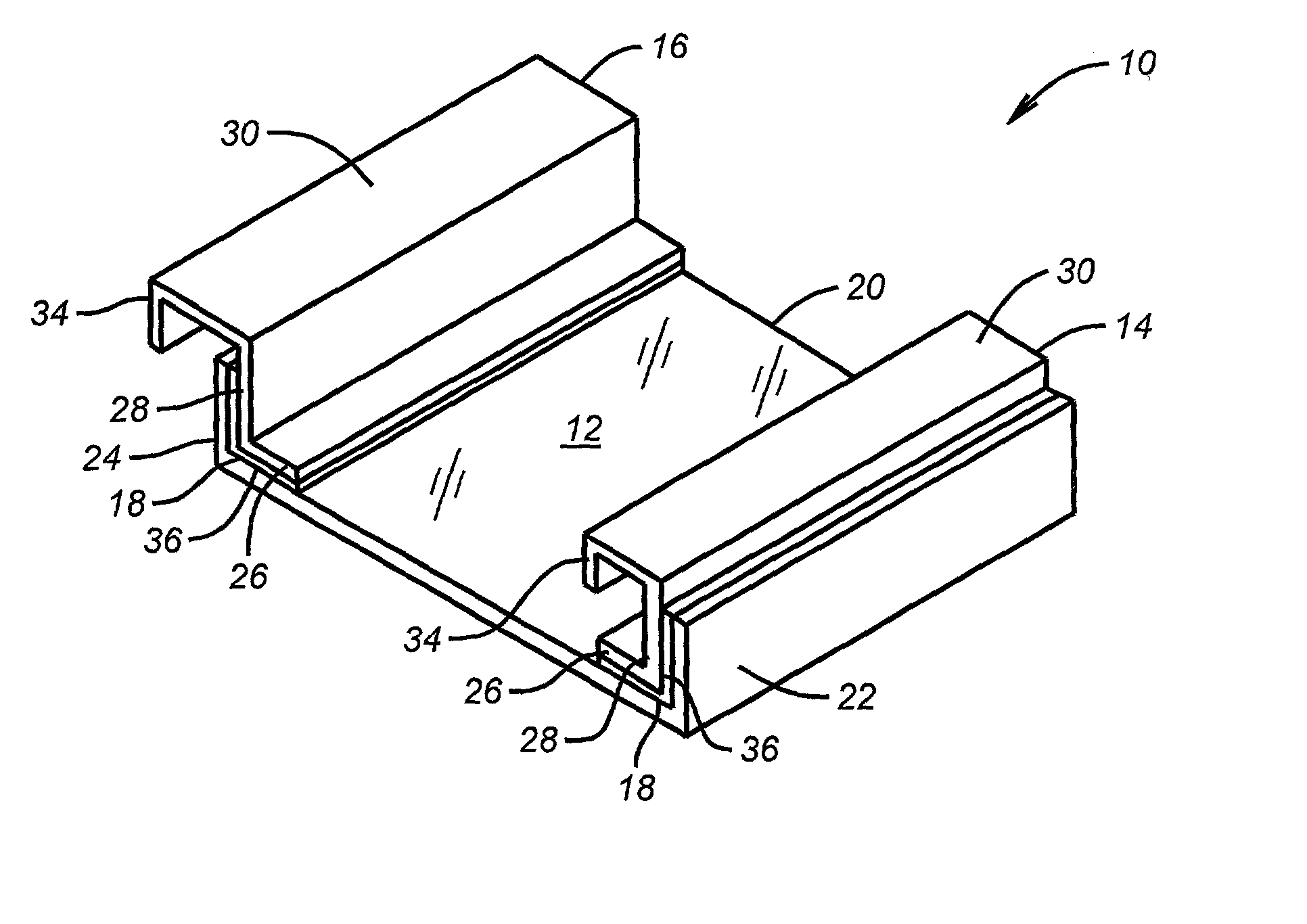

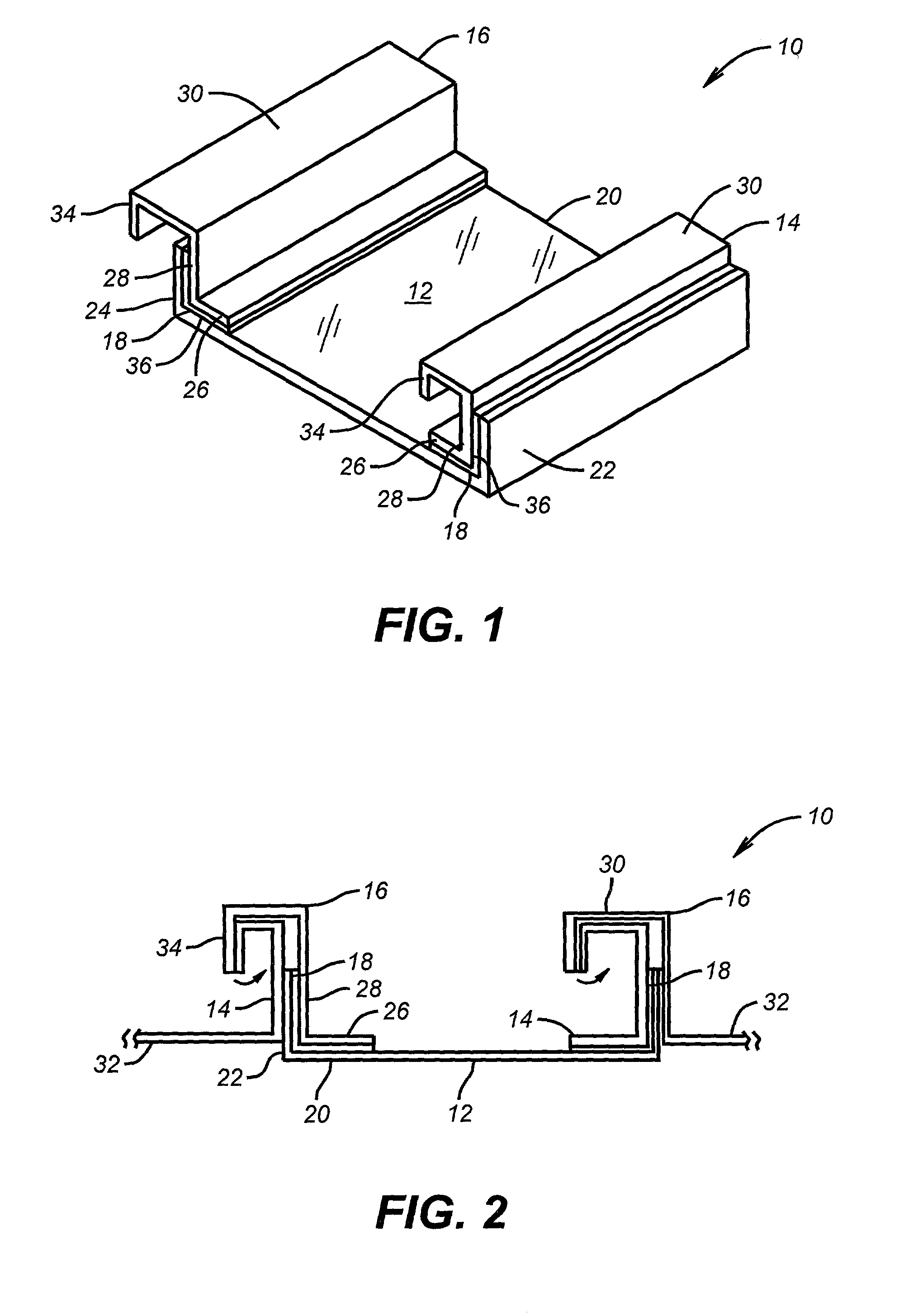

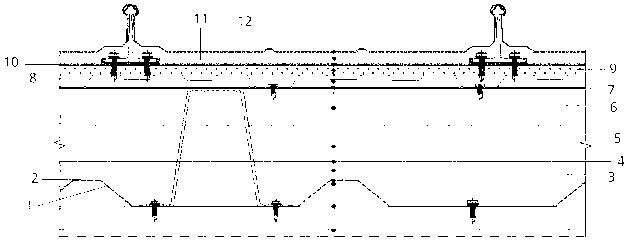

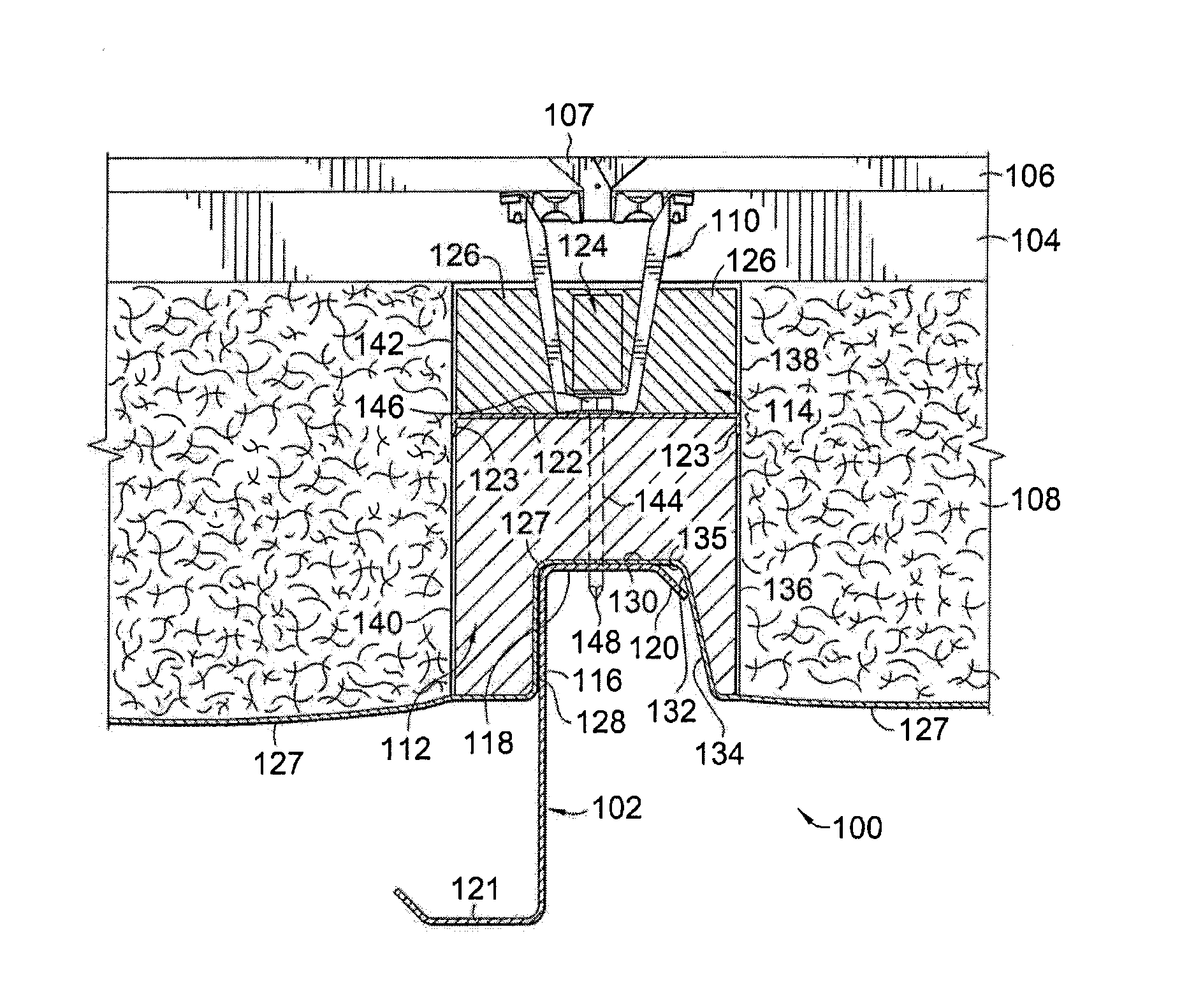

Over-purlin insulation system for a roof

A system and method for insulating a metal roof includes a thermal block arrangement disposed over each of a pair of purlins. A vapor-barrier sheet spans between and is secured over the opposing pair of purlins, the vapor-barrier sheet being secured underneath each thermal block arrangement. A batt insulation receiving cavity is defined by an upper surface of the vapor-barrier sheet and between opposing faces of each of the thermal block arrangements.

Owner:BLUESCOPE BUILDINGS NORTH AMERICA

Construction method for waterproofing of energy-saving self-protection roof

ActiveCN103469977ANo pollution in the processTo achieve airtight waterproof effectBuild-up roofsRoof toolsCement slurryProtection layer

The invention discloses a construction method for waterproofing of an energy-saving self-protection roof and belongs to the technical field of waterproofing of building. The construction method constructs by combining rigid and flexible waterproof materials and comprises the following steps of paving a hydrophobic sloped and heat-insulating layer, prepared from a waterproof agent, cement and heat-insulating light aggregates, on a structural layer of the roof; paving a leveling layer, prepared from the waterproof agent and cement slurry, on the sloped and heat-insulating layer; paving a flexible waterproof layer, prepared from a flexible self-adhesion waterproof roll, on the leveling layer; paving a protection layer, prepared from the waterproof agent and the cement slurry, on the flexible self-adhesion waterproof roll; paving a layer of metal roof acrylic acid high-elasticity waterproof paint on the protection layer, or leveling the protection layer by the waterproof agent and the cement slurry. According to the construction method for the waterproofing of the energy-saving self-protection roof, which is disclosed by the invention, the construction begins treatment of the leveling layer of a base layer, so that each layer is waterproof and is not subjected to water penetration, the waterproofing is permanent through once construction without hidden danger, the problem that leakage points are hard to be found out by the traditional waterproof construction is solved, and meanwhile, the functions of sloping, protection, heat insulation and heat preservation are achieved; the functions that the waterproof effect is permanent if the structure of the base layer is changeless and the likeare also achieved.

Owner:张寅秋

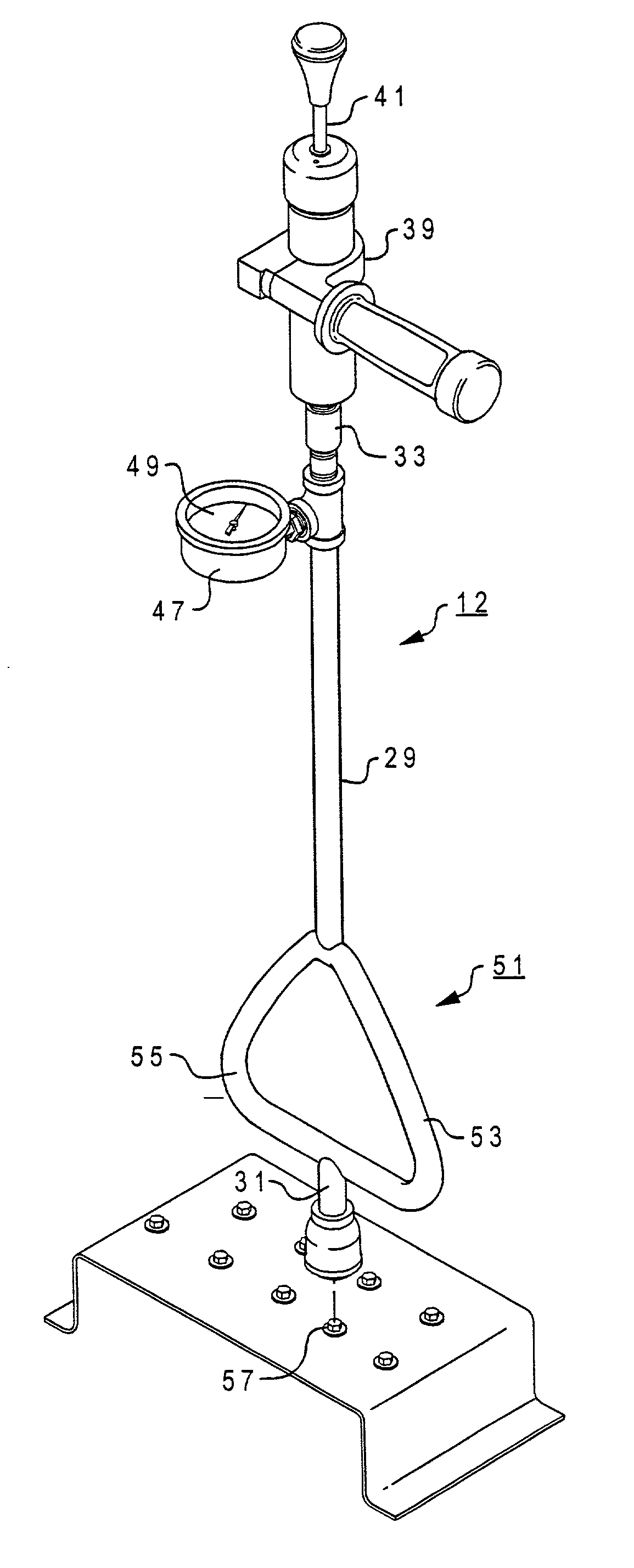

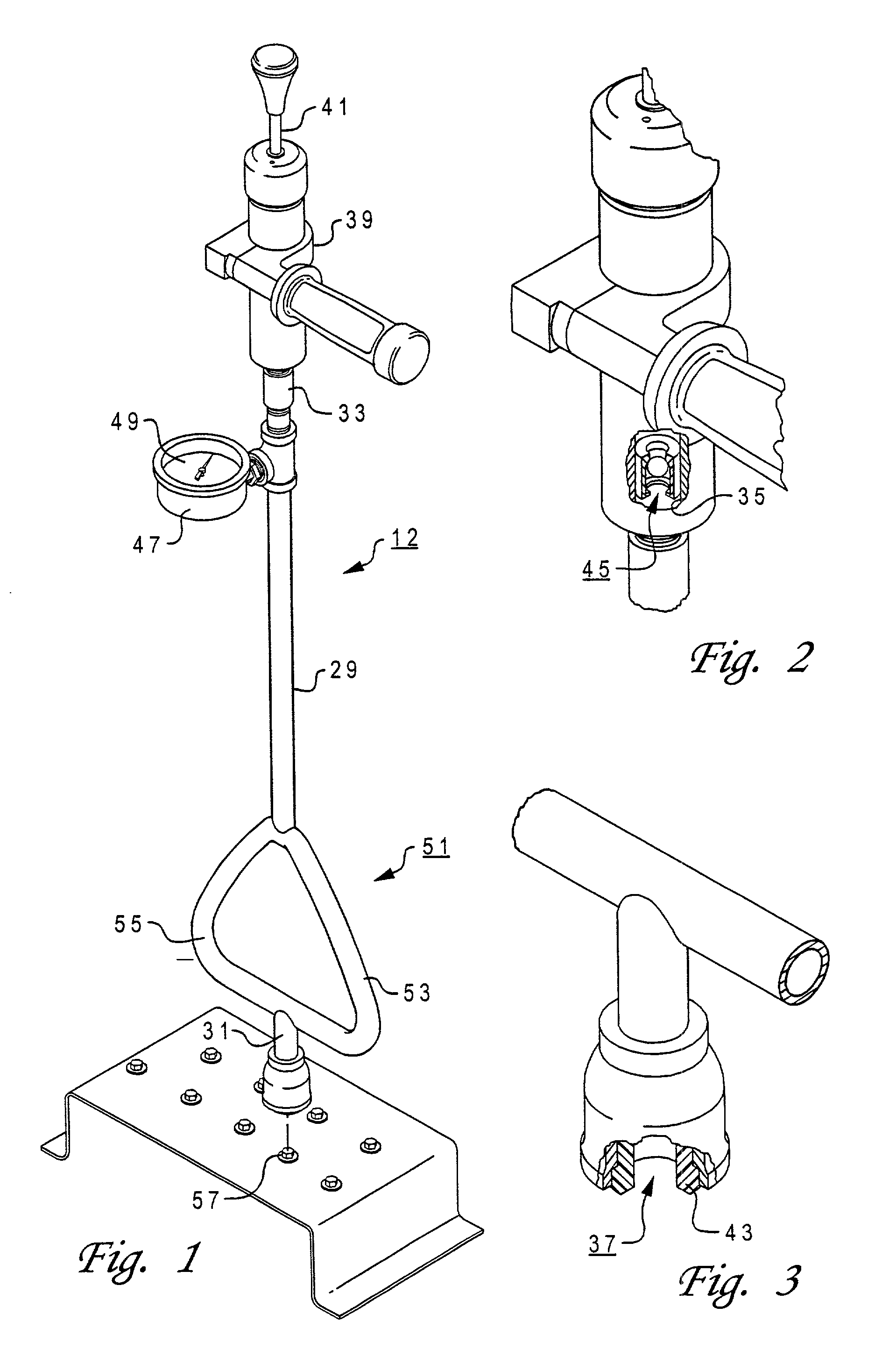

Apparatus and method for detecting leaks in metal roofs

InactiveUS20030167826A1Detection of fluid at leakage pointMeasurement of fluid loss/gain ratePositive pressureEngineering

An apparatus and method are shown for detecting leaks in metal roofs which are made up of metal roof panels secured in position to form a roof structure by metal screws. The apparatus includes an elongate tubular stand having a lower extent and an upper extent connected by an internal bore, the lower extent terminating in a bore end opening. A hand operated pump communicates with the internal bore for supplying positive pressure or drawing a vacuum on the internal bore. The bore end opening is sealed by an elastomeric seal which is used to form a pressure tight seal about one of the metal screw to be tested. A pressure gauge on the stand communicates with the internal bore for measuring a change in pressure within the internal bore, such pressure change being indicative of a leak present at the metal screw being tested.

Owner:HOLT JESSE E

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com