Patents

Literature

216 results about "Edge segment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

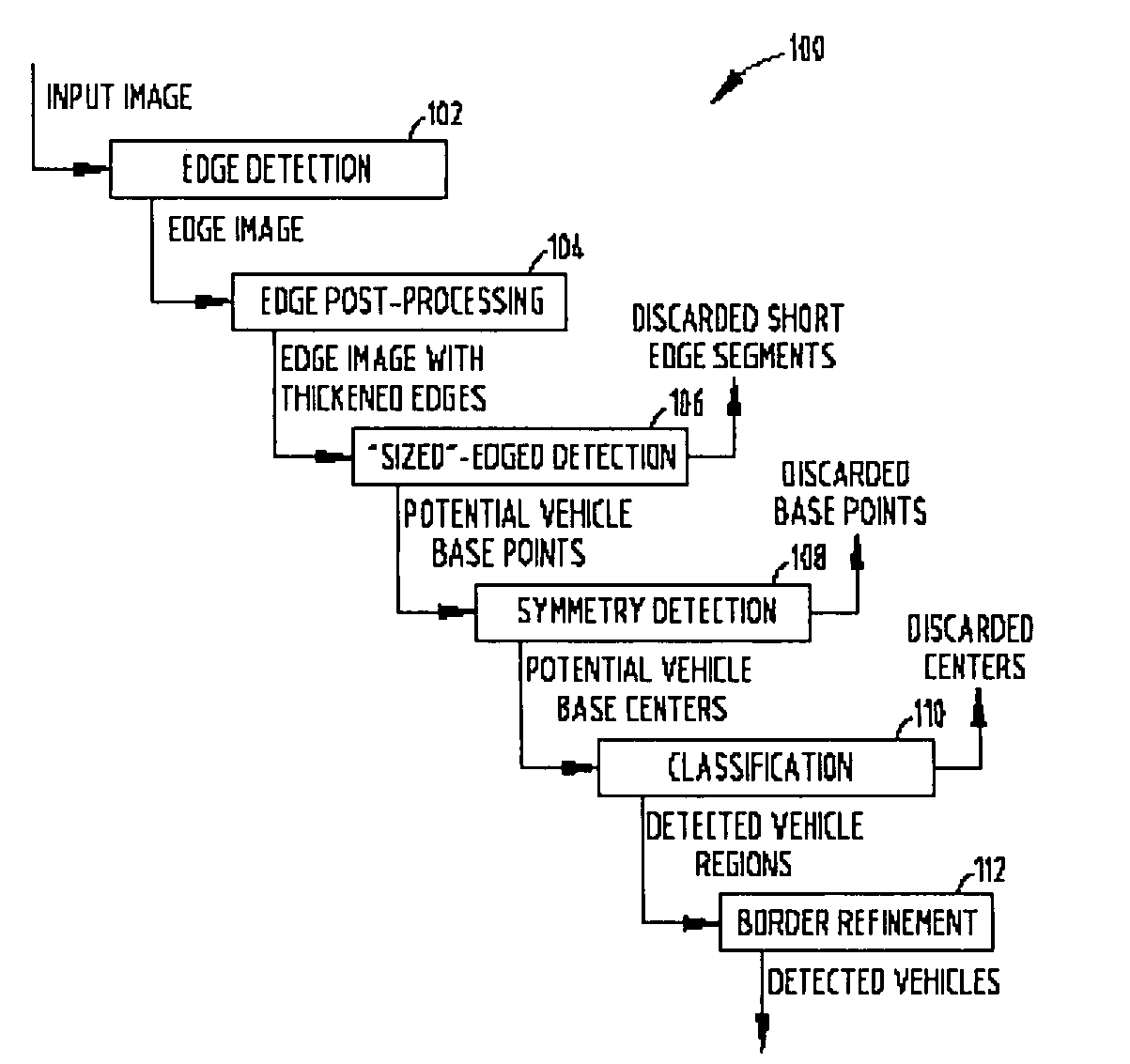

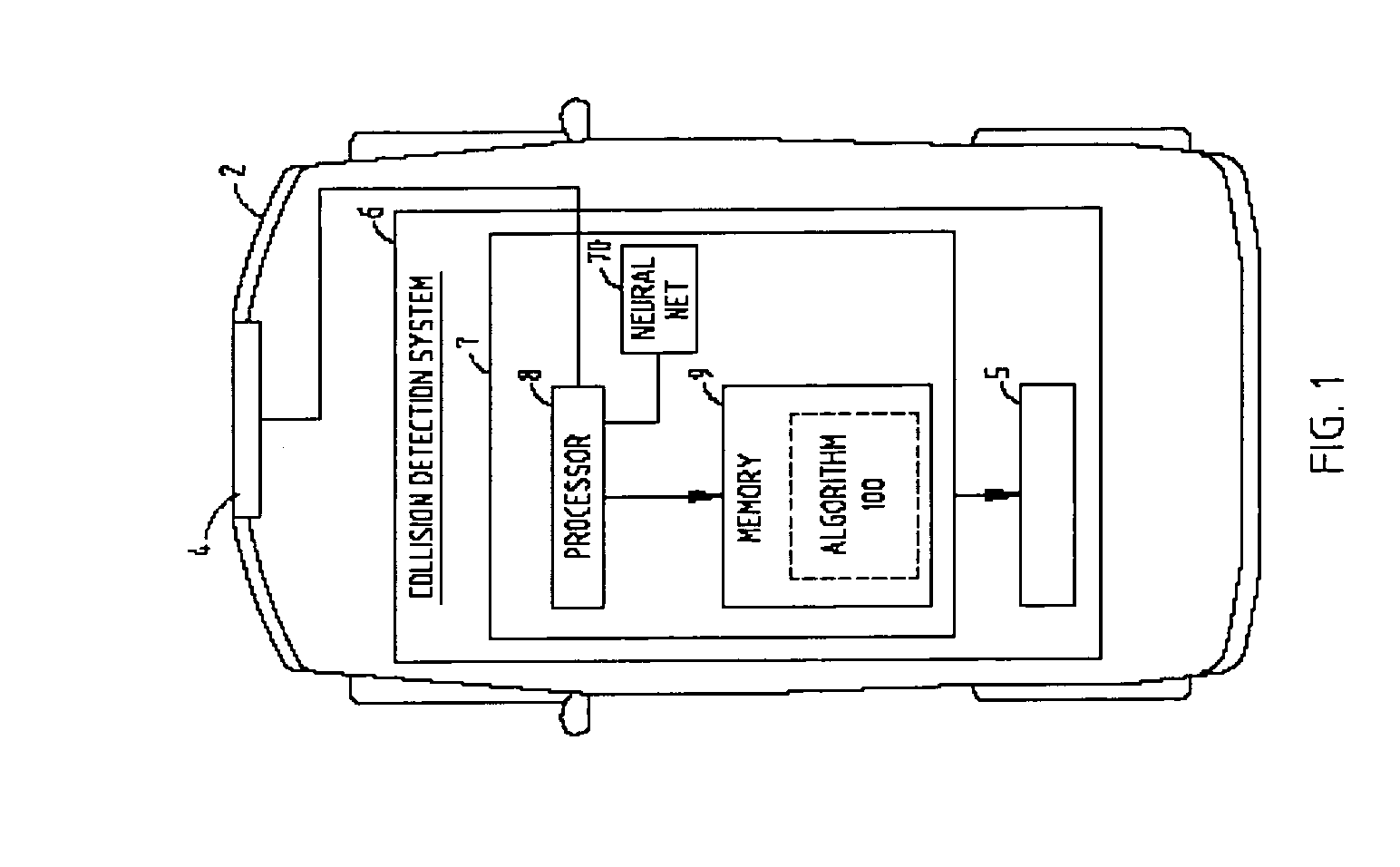

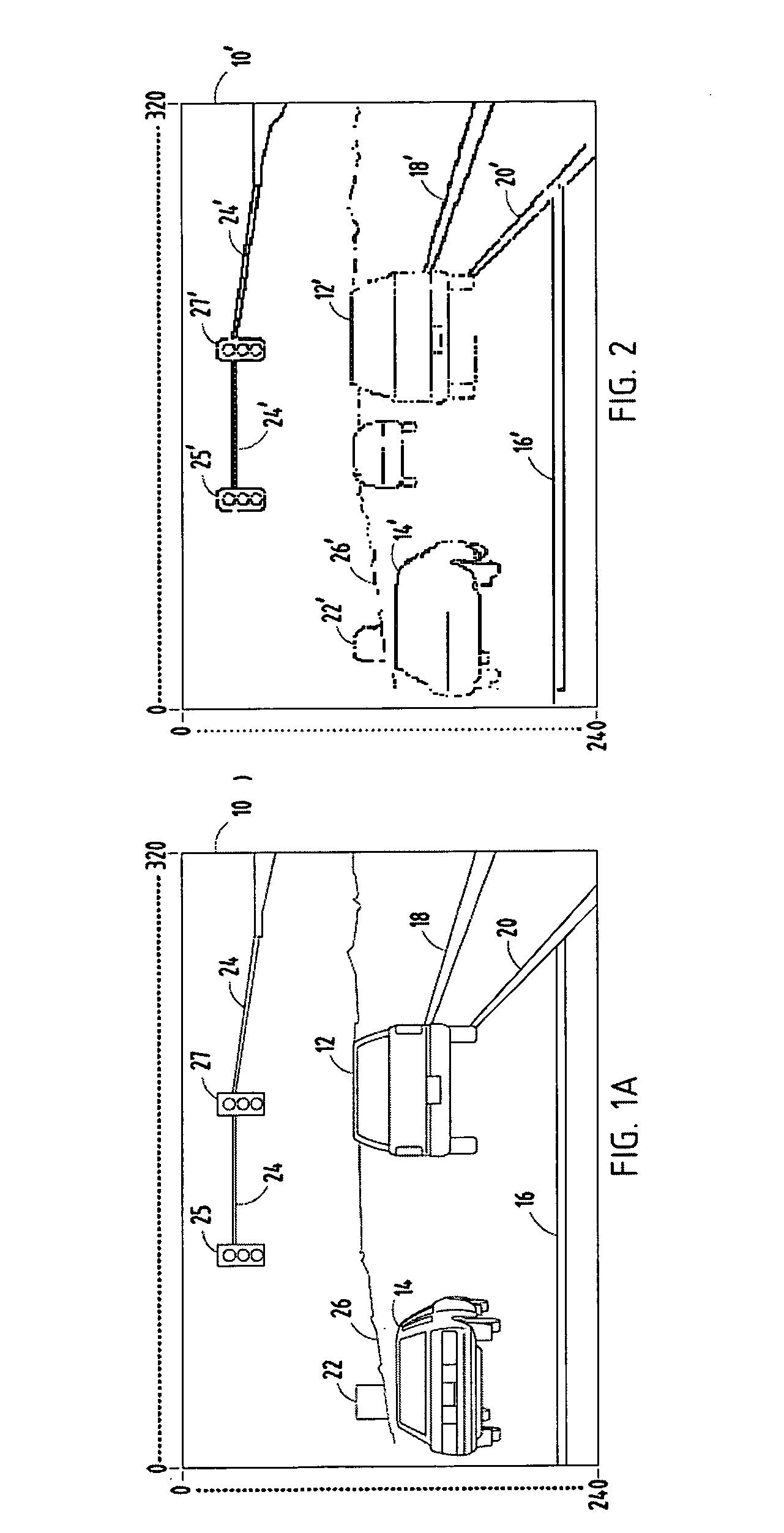

Method for identifying vehicles in electronic images

A method for identifying objects in an electronic image is provided. The method includes the steps of providing an electronic source image and processing the electronic source image to identify edge pixels. The method further includes the steps of providing an electronic representation of the edge pixels and processing the electronic representation of the edge pixels to identify valid edge center pixels. The method still further includes the step of proving an electronic representation of the valid edge center pixels. Each valid edge center pixel represents the approximate center of a horizontal edge segment of a target width. The horizontal edge segment is made up of essentially contiguous edge pixels. The method also includes the steps of determining symmetry values of test regions associated with valid edge center pixels, and classifying the test regions based on factors including symmetry.

Owner:APTIV TECH LTD

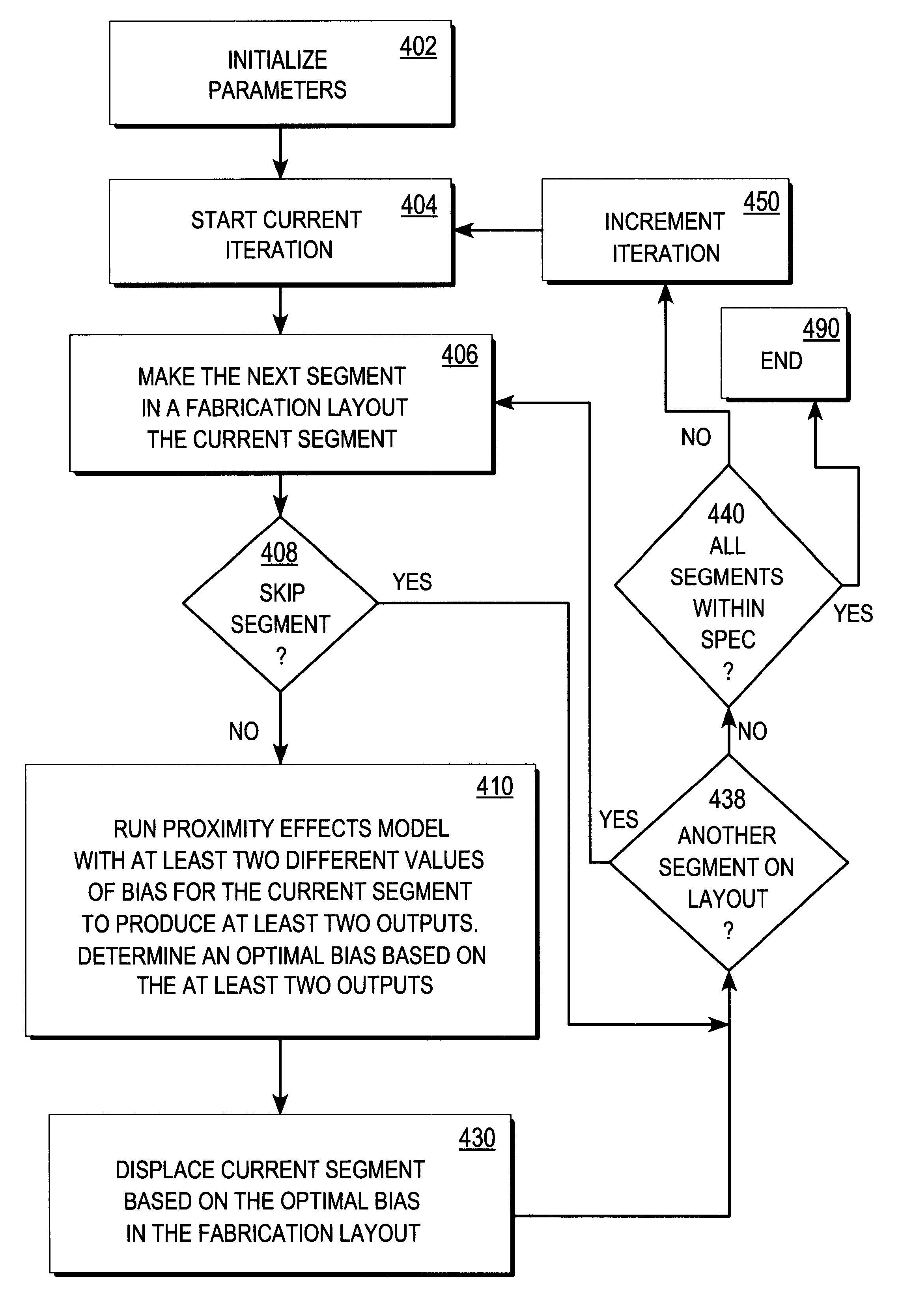

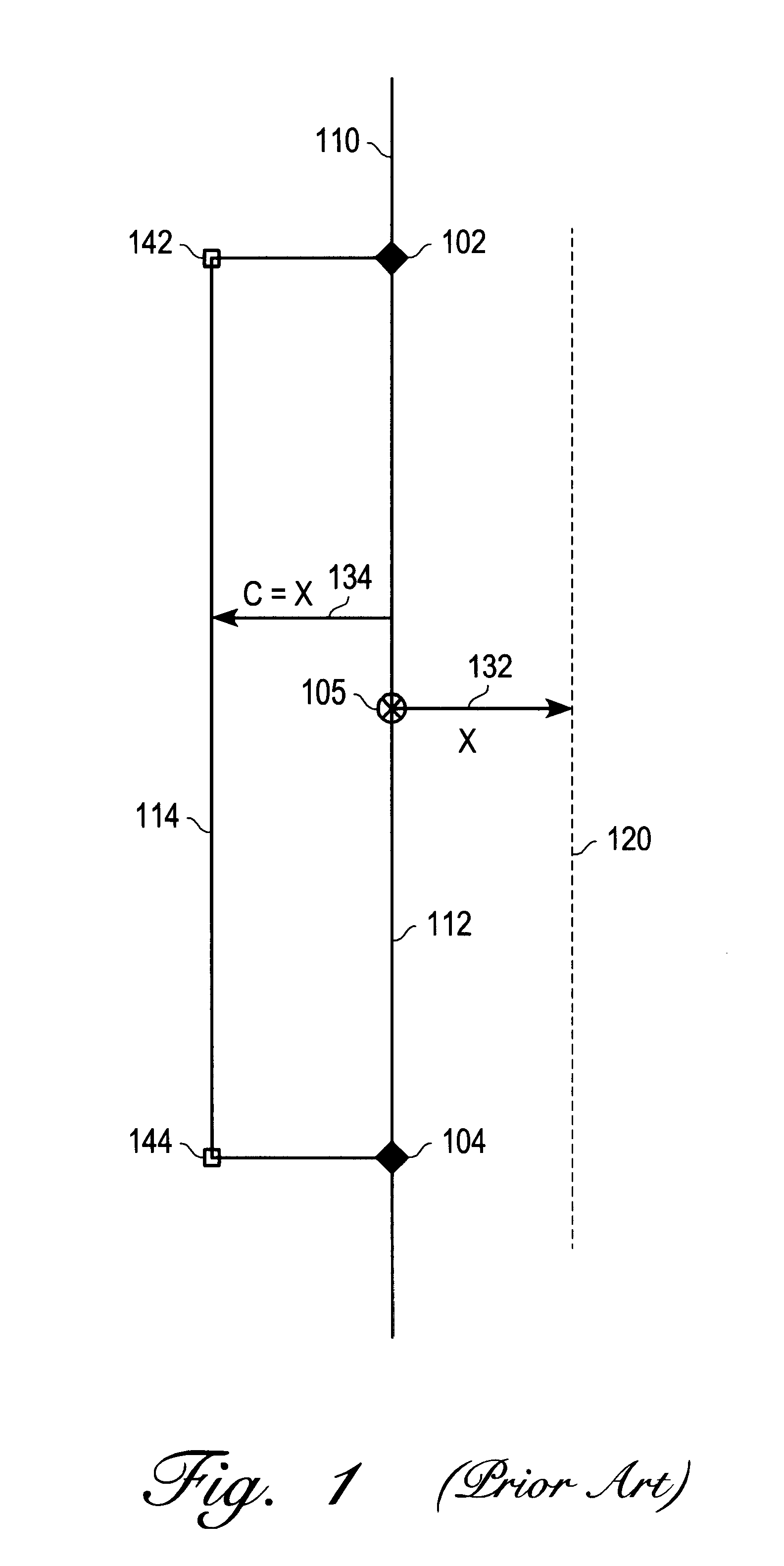

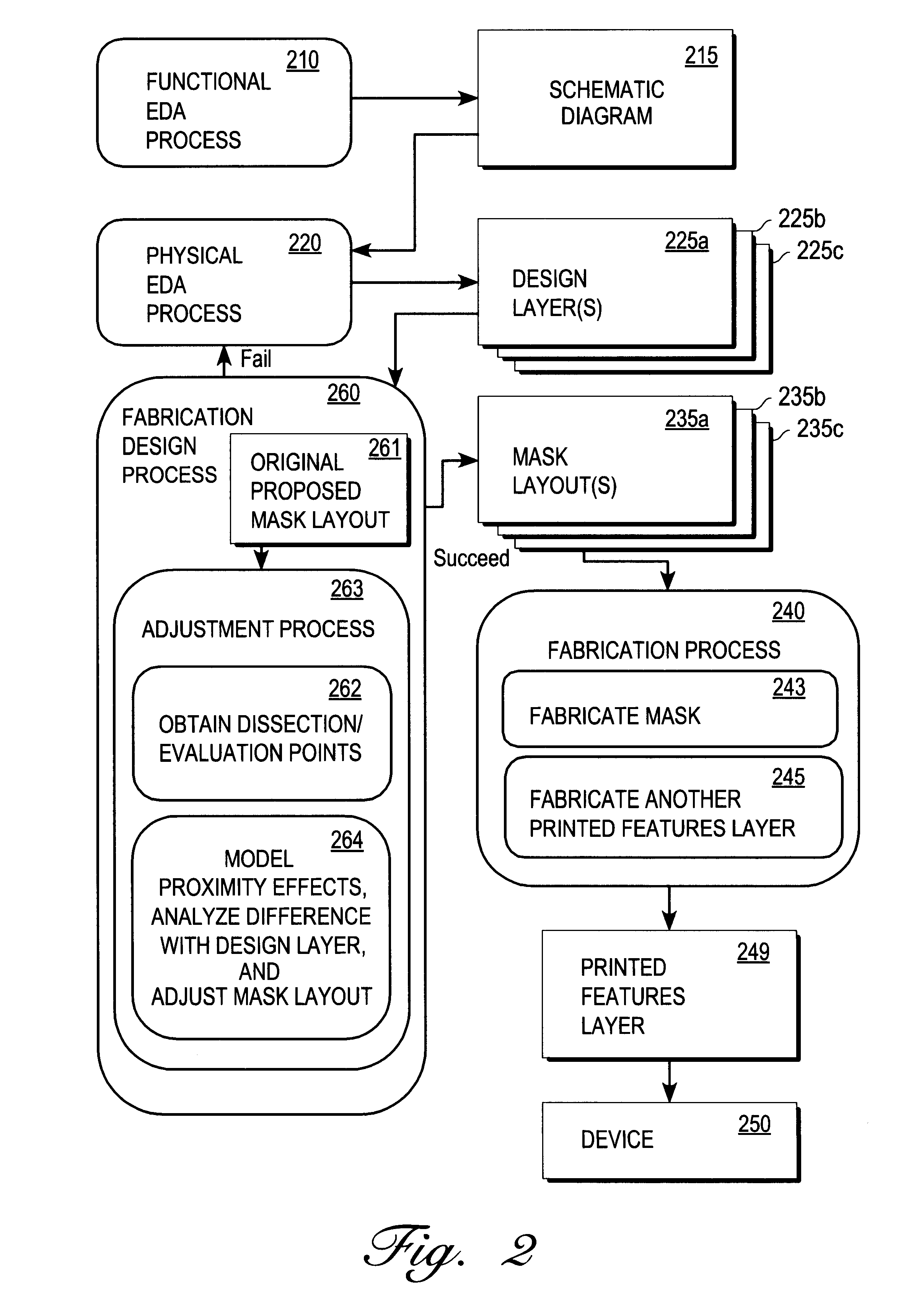

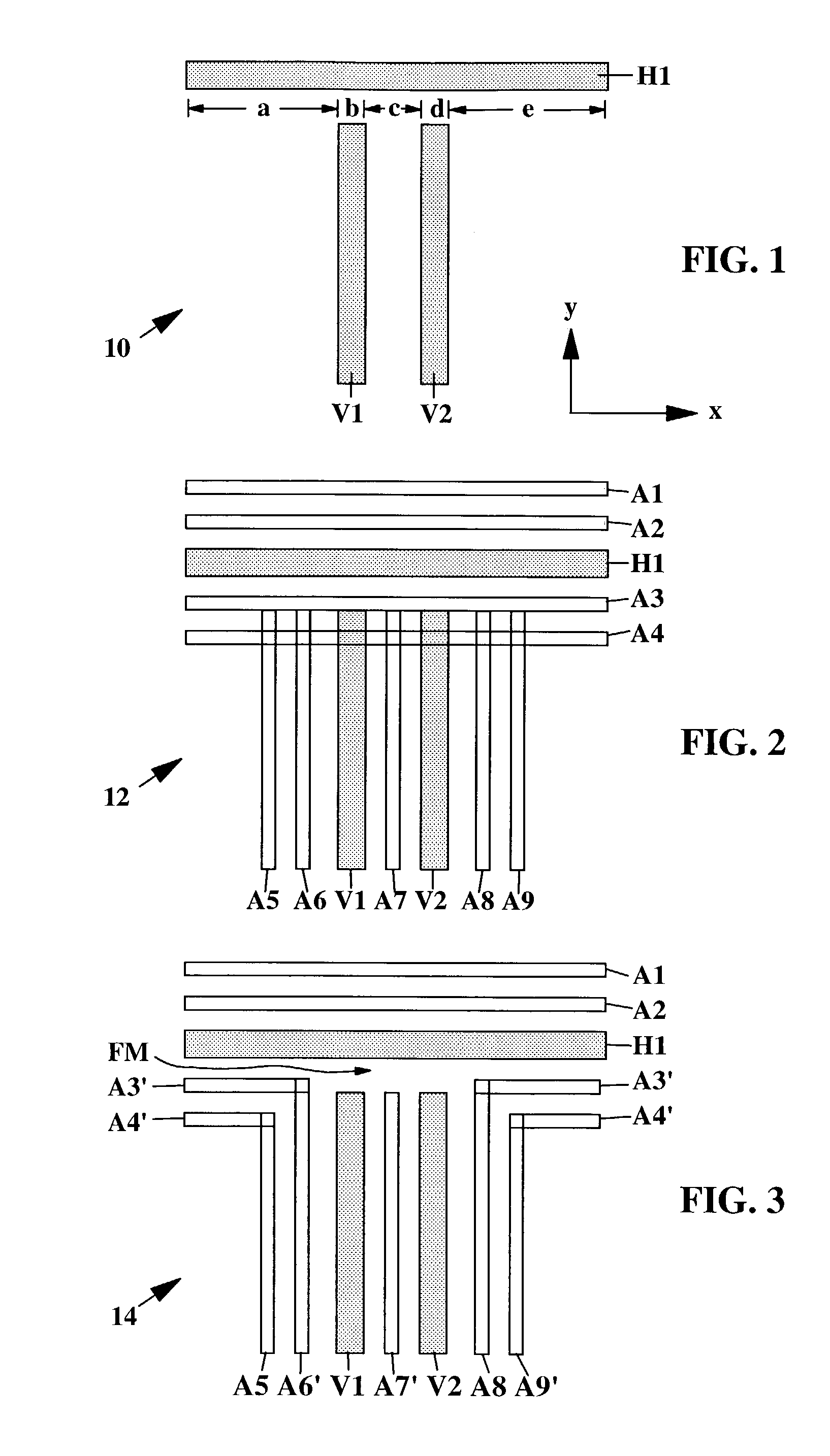

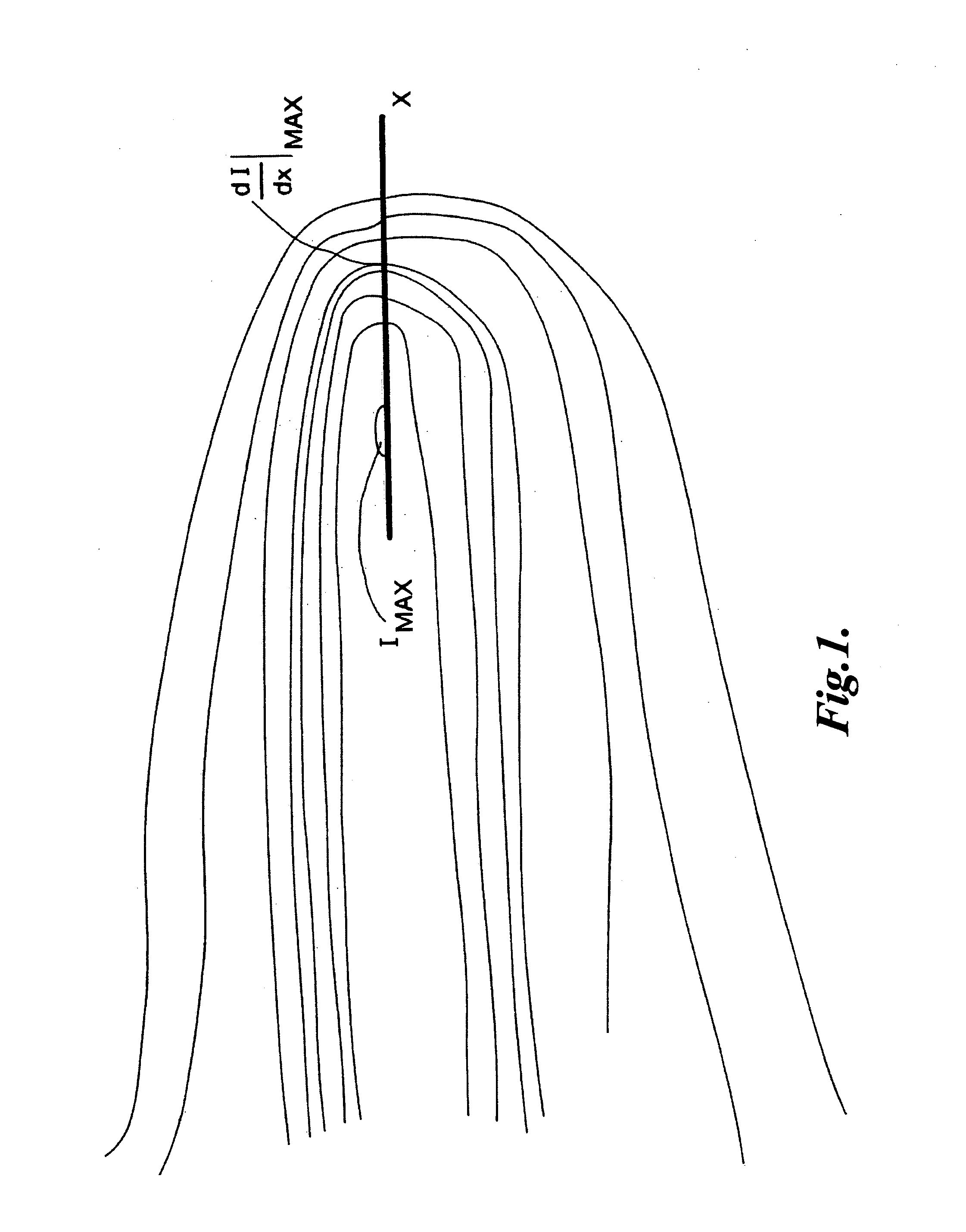

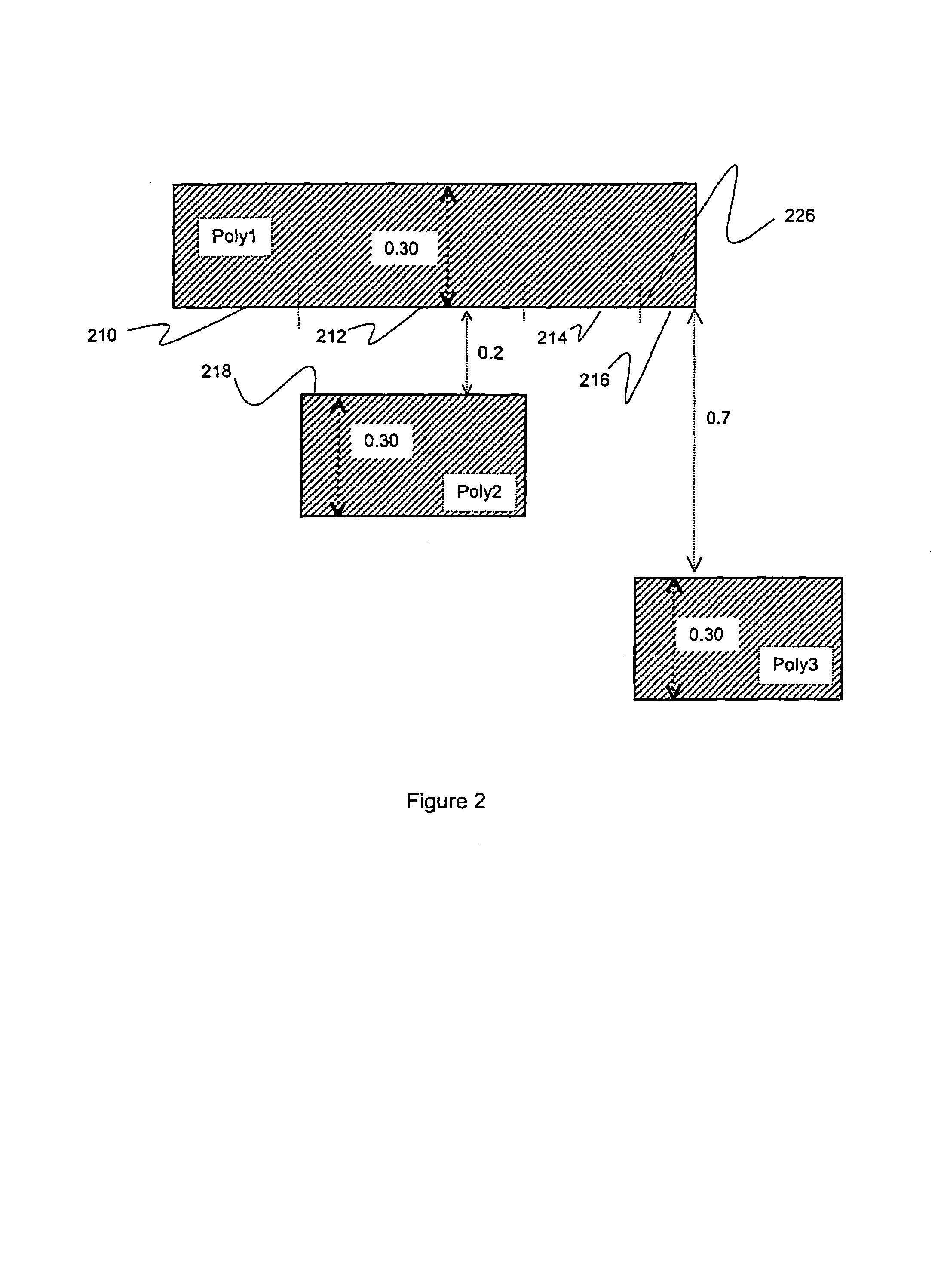

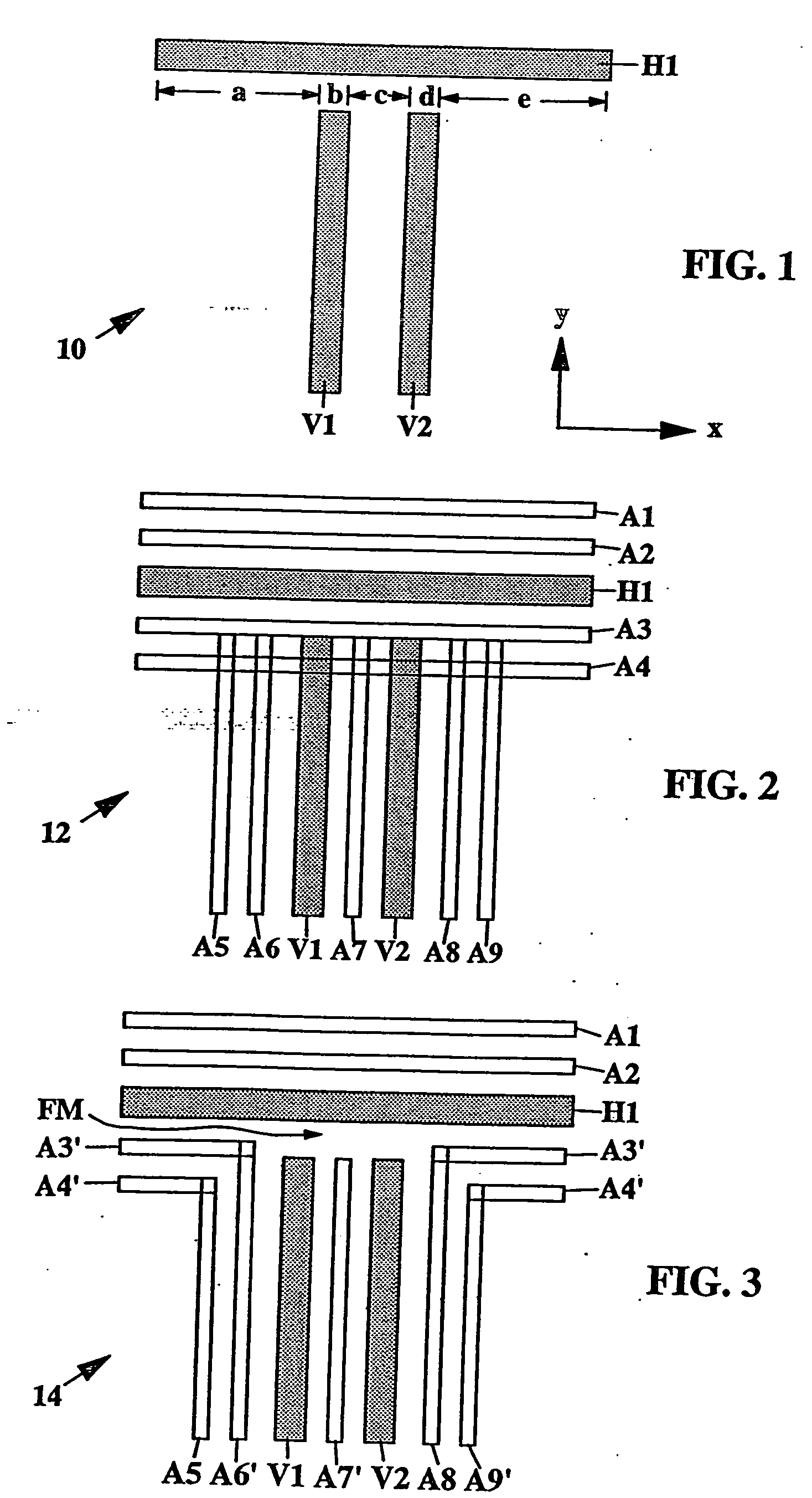

Displacing edge segments on a fabrication layout based on proximity effects model amplitudes for correcting proximity effects

InactiveUS6665856B1Photomechanical exposure apparatusMicrolithography exposure apparatusEdge segmentEdge based

Techniques for forming a fabrication layout, such as a mask, for a physical design layout, such as a layout for an integrated circuit, include correcting the fabrication layout for proximity effects using a proximity effects model. A proximity effects model is executed to produce an initial output. The initial output is based on a first position for a segment in a fabrication layout. The first position is displaced from a corresponding original edge in the original fabrication layout by a distance equal to an initial bias. The model is also executed to produce a second output based on a second position for the segment. The second position is displaced from the corresponding original edge by a distance equal to a second bias. An optimal bias for the segment is determined based on the initial output and the second output. The segment is displaced in the fabrication layout from the corresponding edge based on the optimal bias.

Owner:SYNOPSYS INC

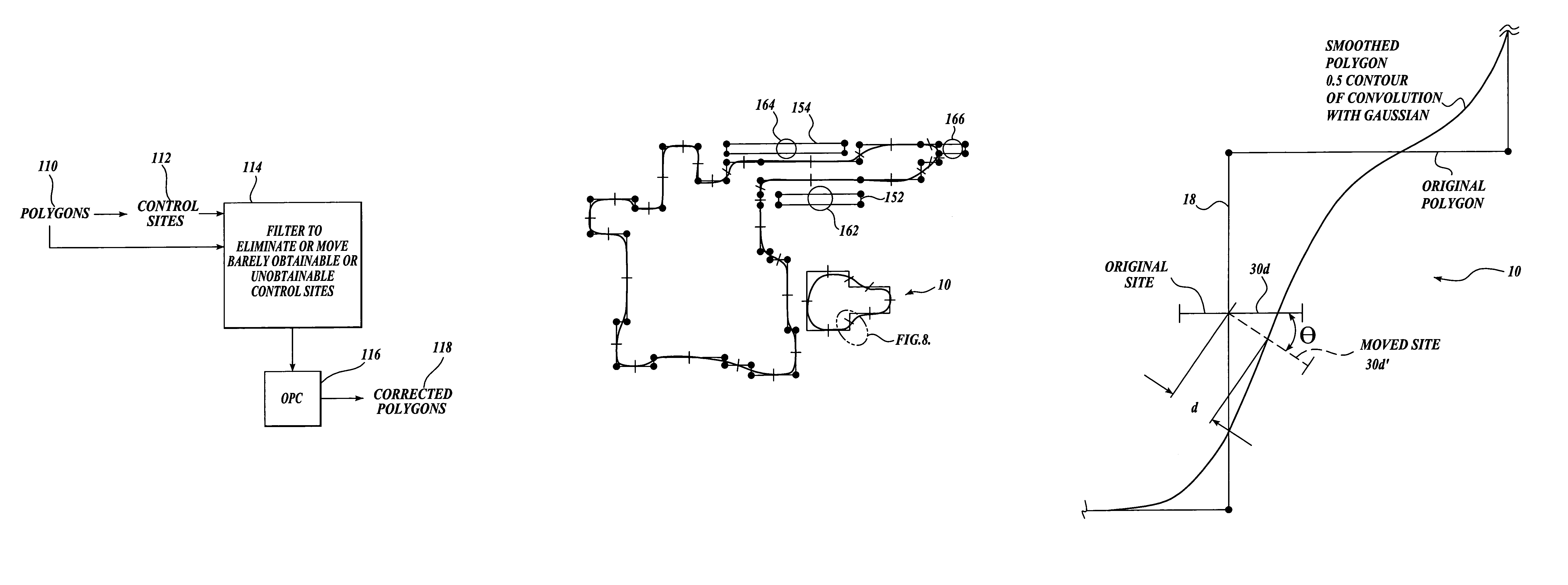

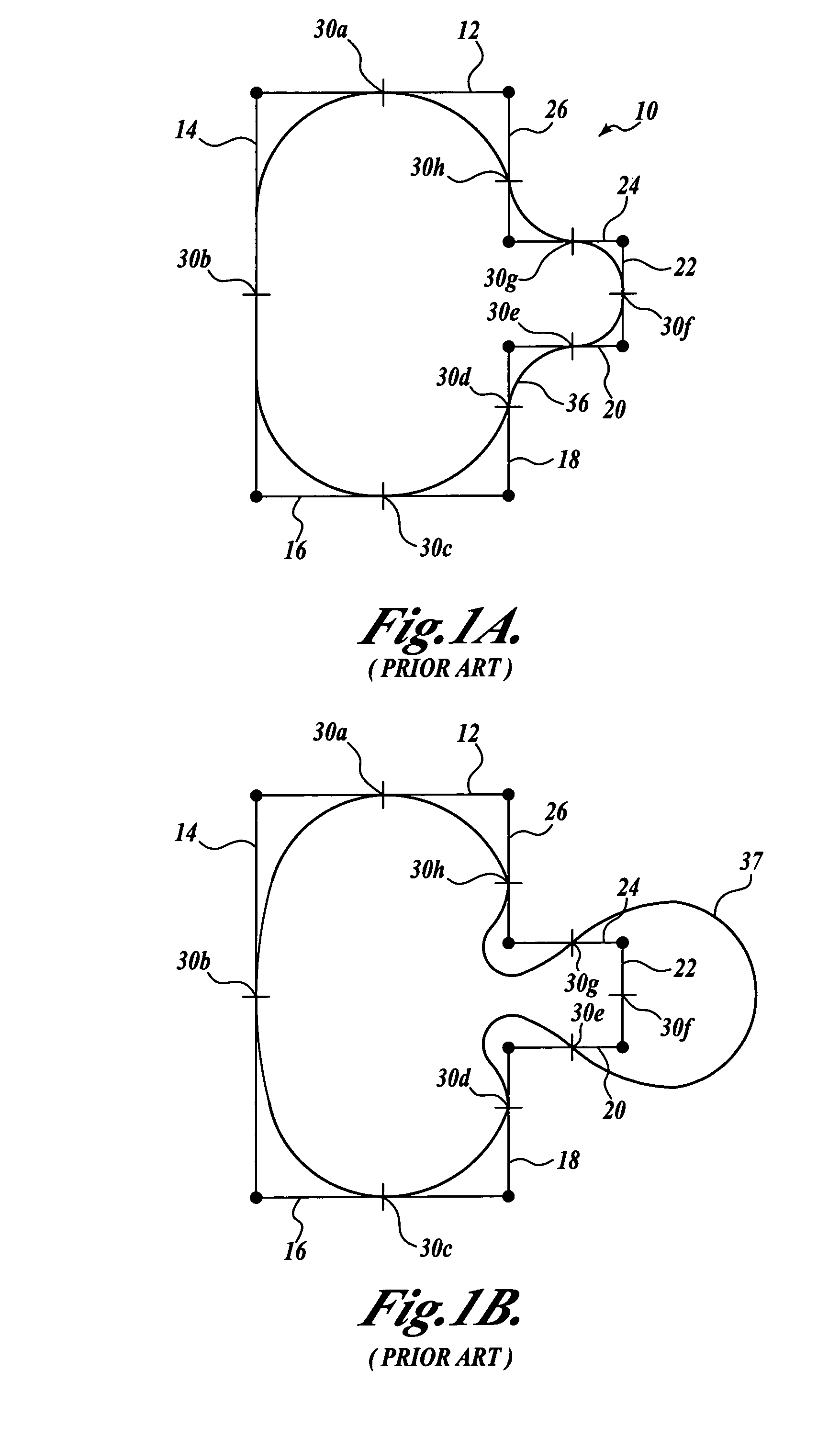

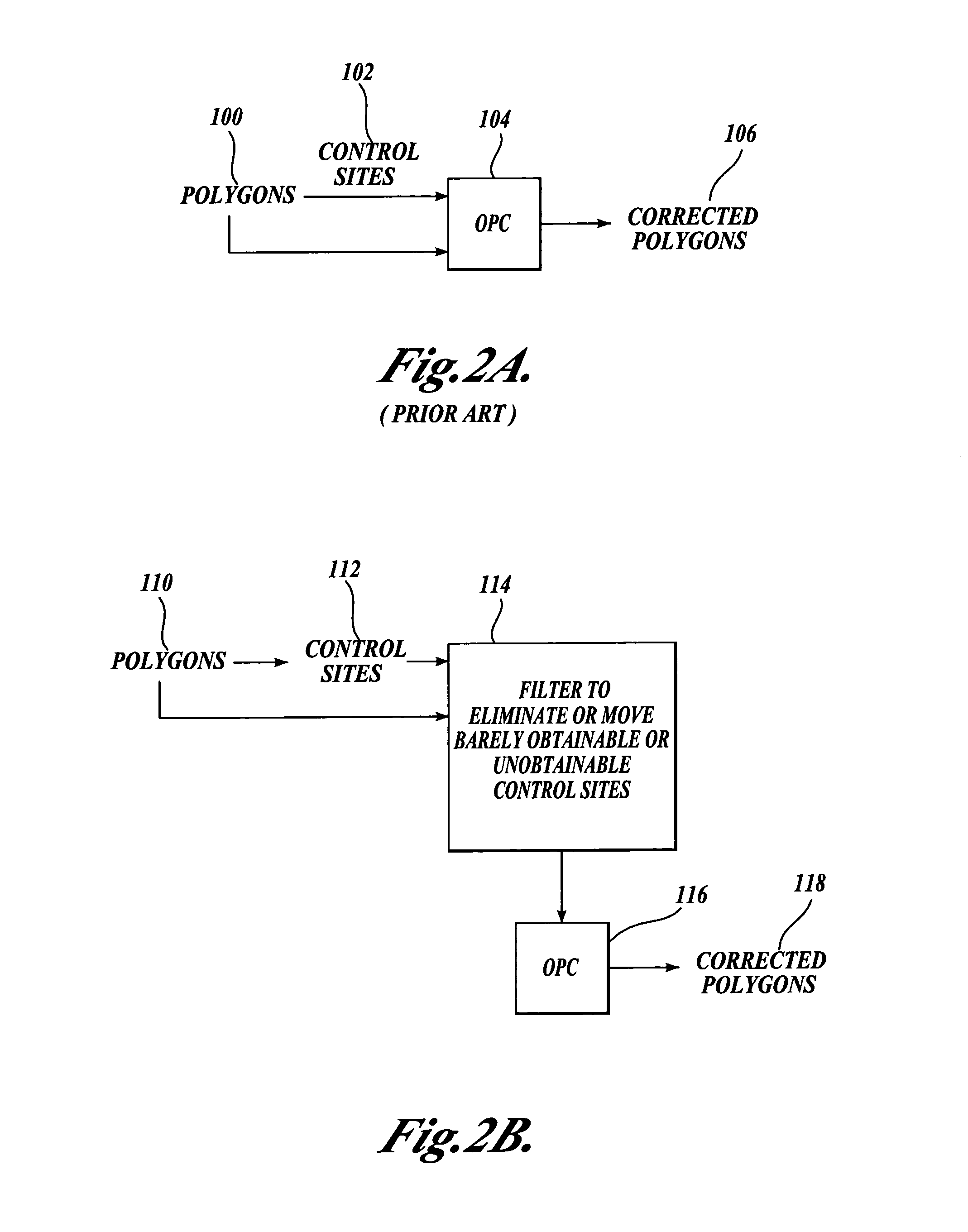

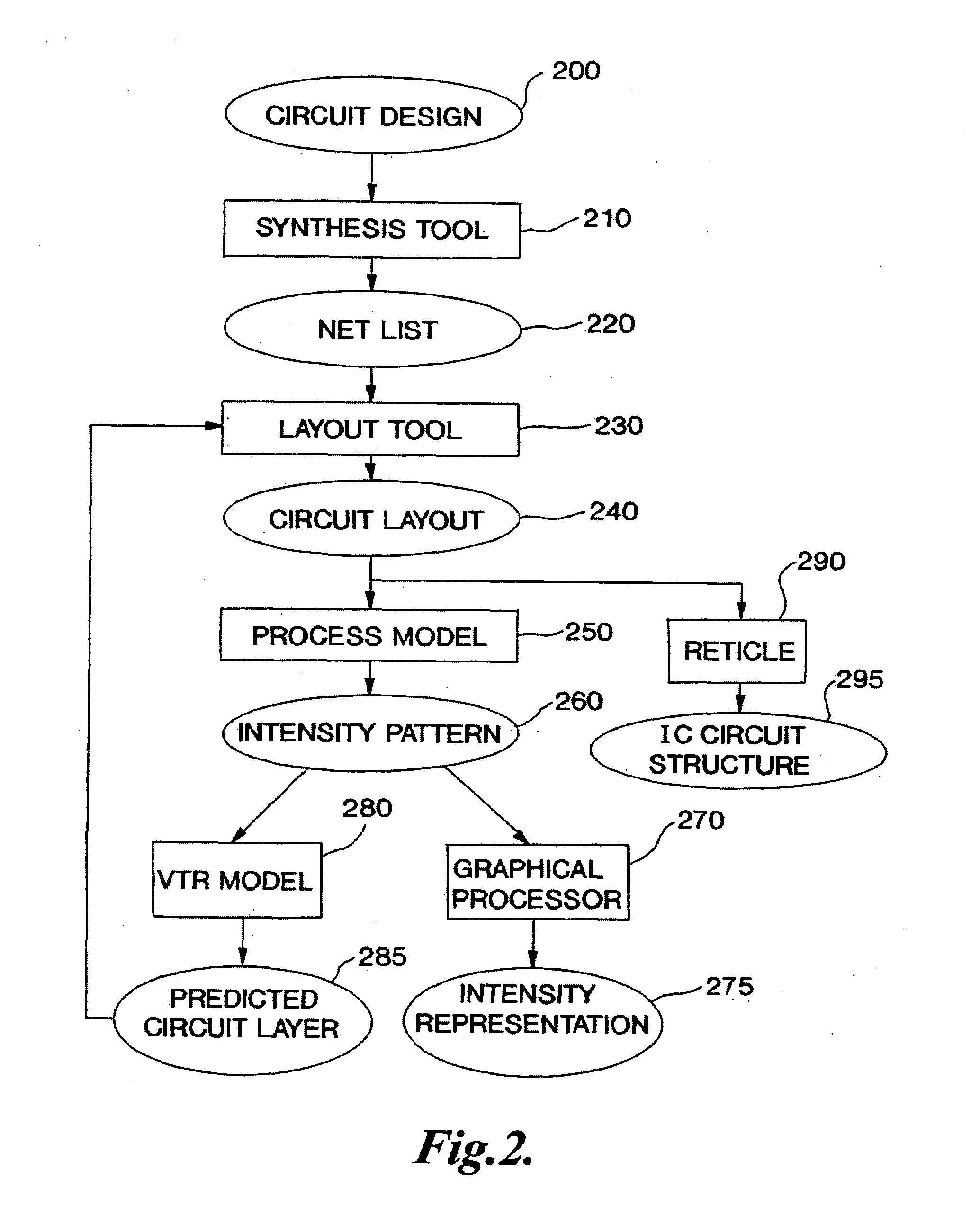

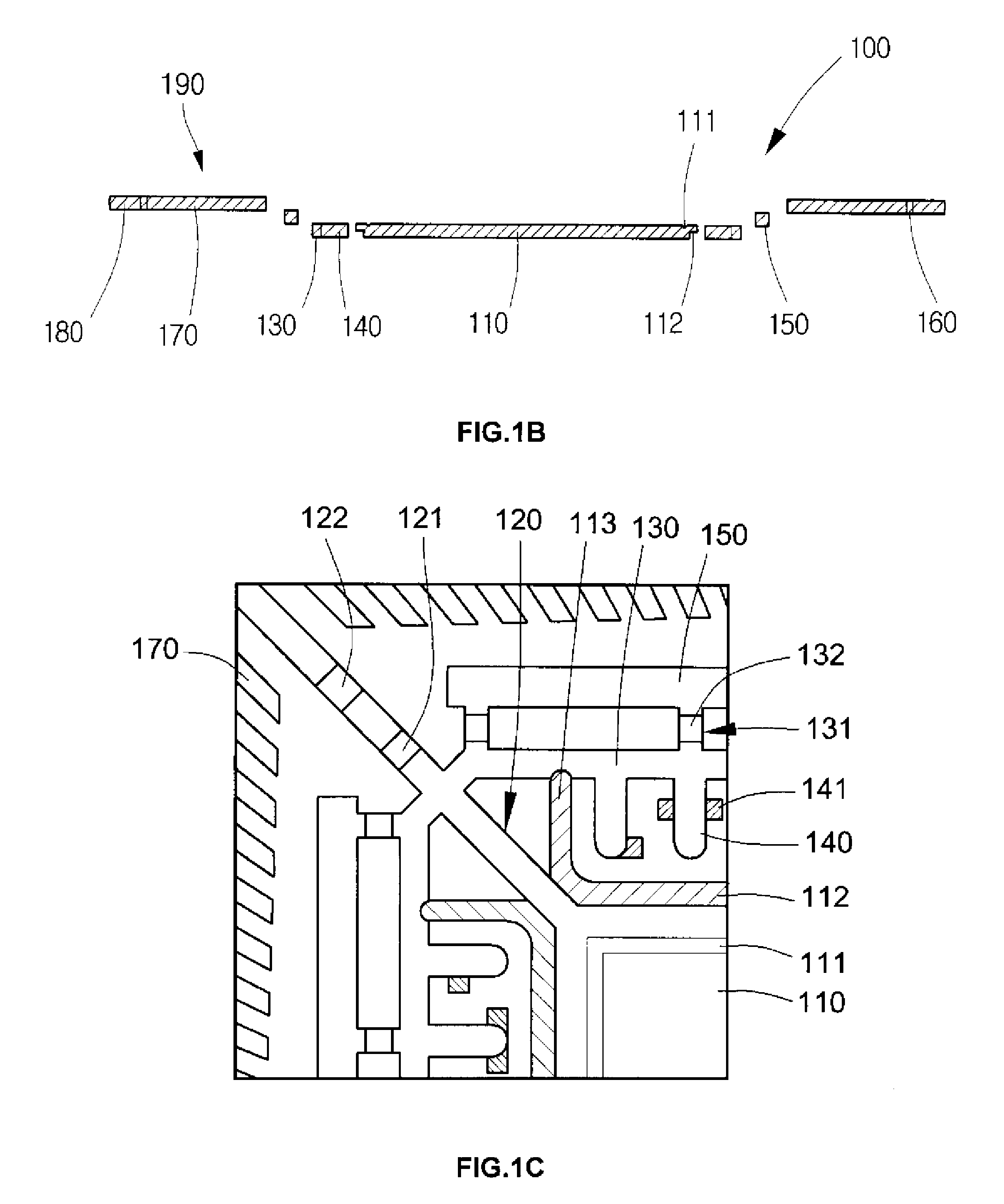

Site control for OPC

ActiveUS7073162B2Electric discharge tubesOriginals for photomechanical treatmentEdge segmentPhotolithography

A method for processing objects to be created via photolithography. Each object to be created is defined as a polygon that is fragmented into a number of edge segments that extend around the perimeter of the polygon. At least some of the edge segments have an associated control site where the edge placement error for the edge segment is to be minimal. A smoothing filter is applied to the polygon to identify those control sites that may cause an OPC tool to produce erroneous results. The identified control sites are moved and / or eliminated from the polygon, and polygon and the adjusted control sites are supplied to an OPC tool.

Owner:SIEMENS PROD LIFECYCLE MANAGEMENT SOFTWARE INC

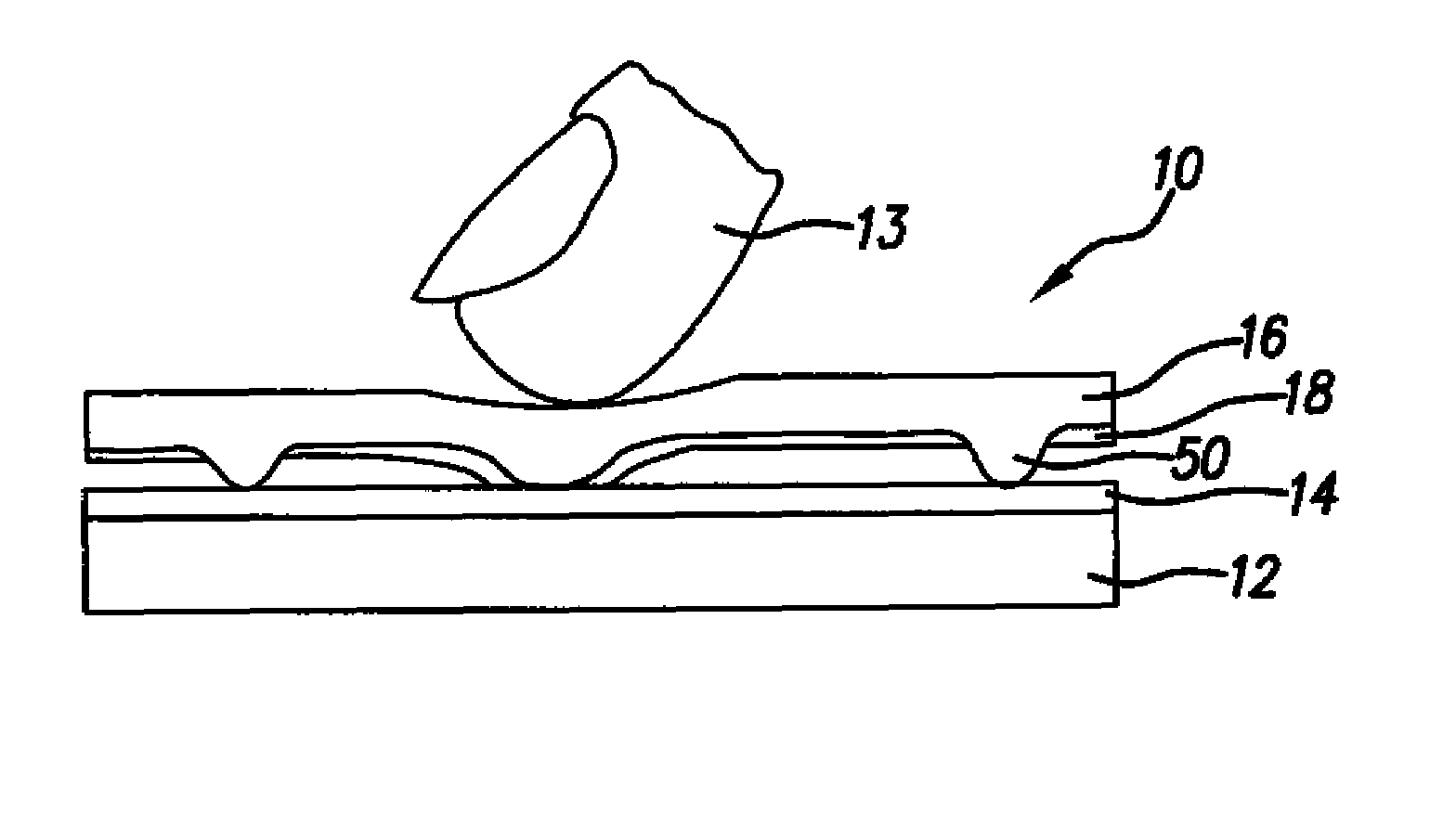

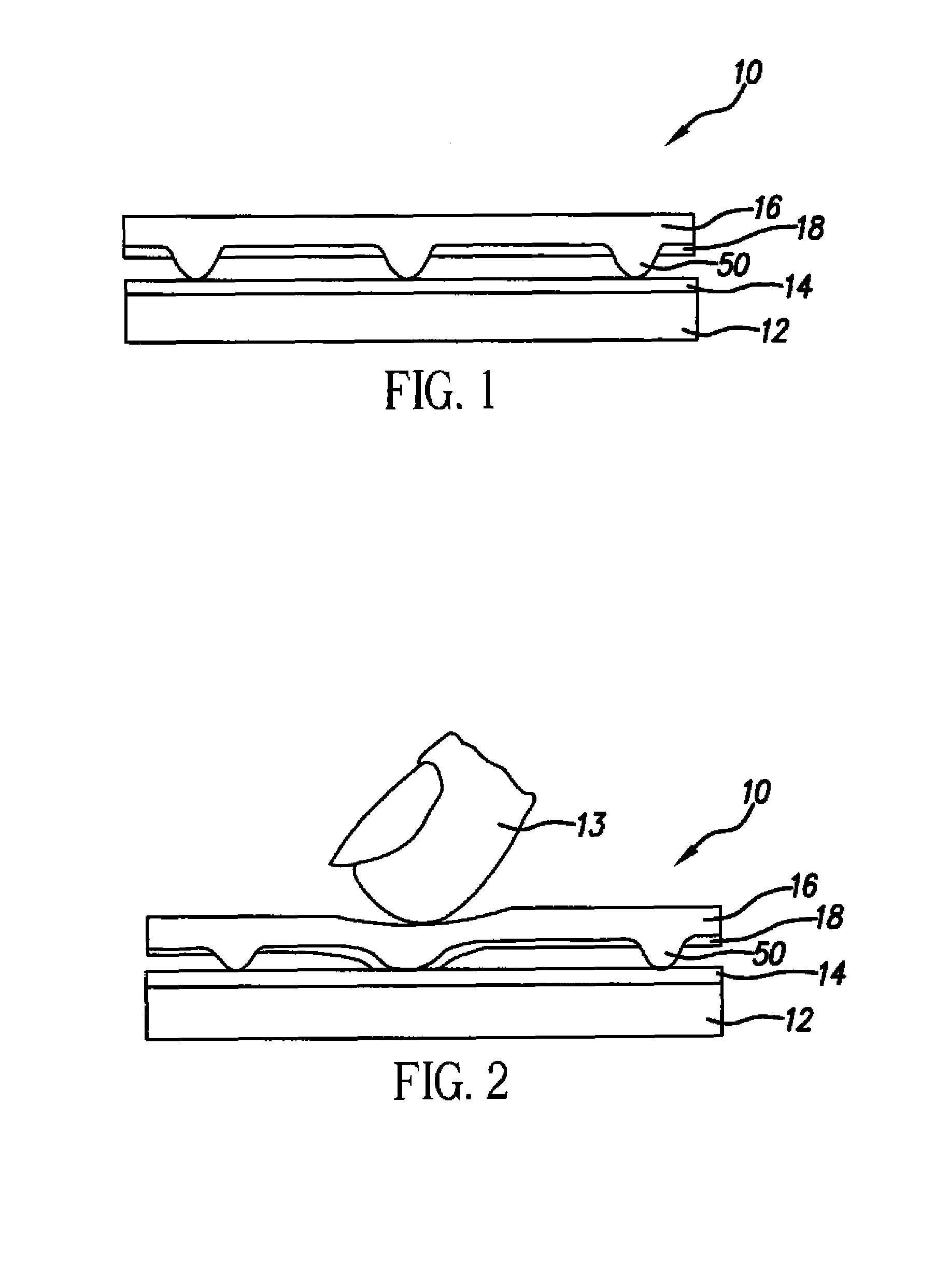

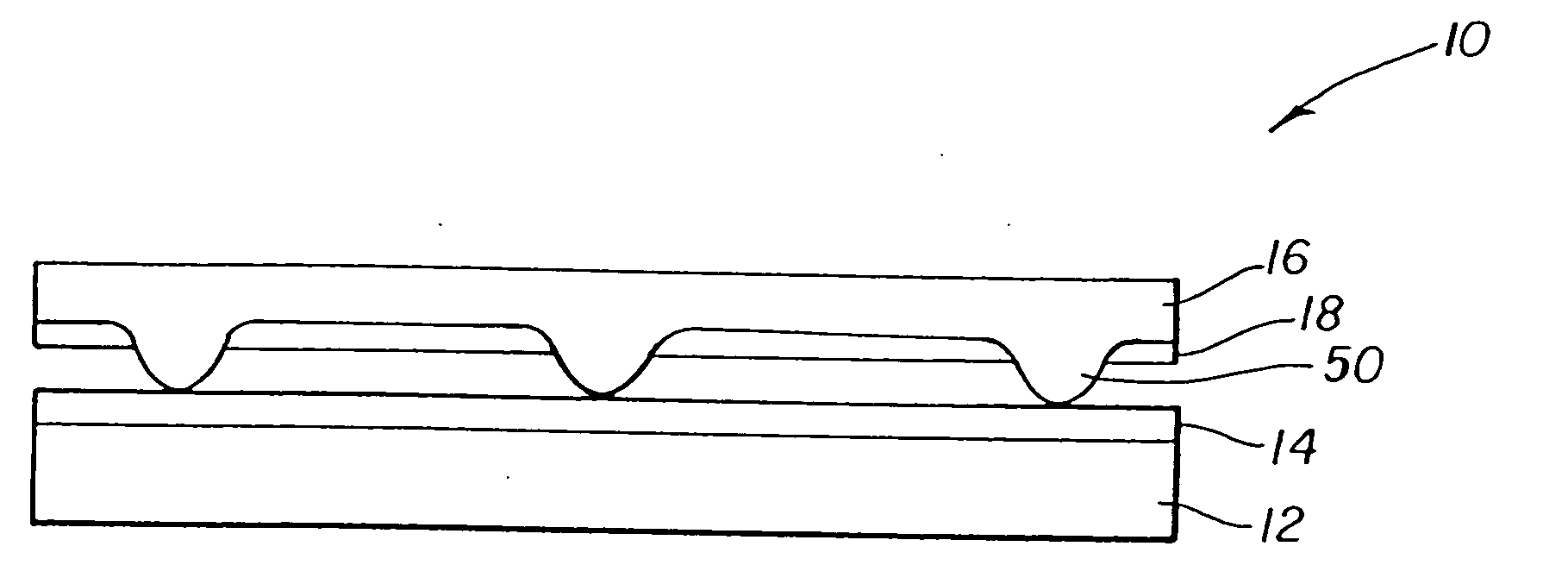

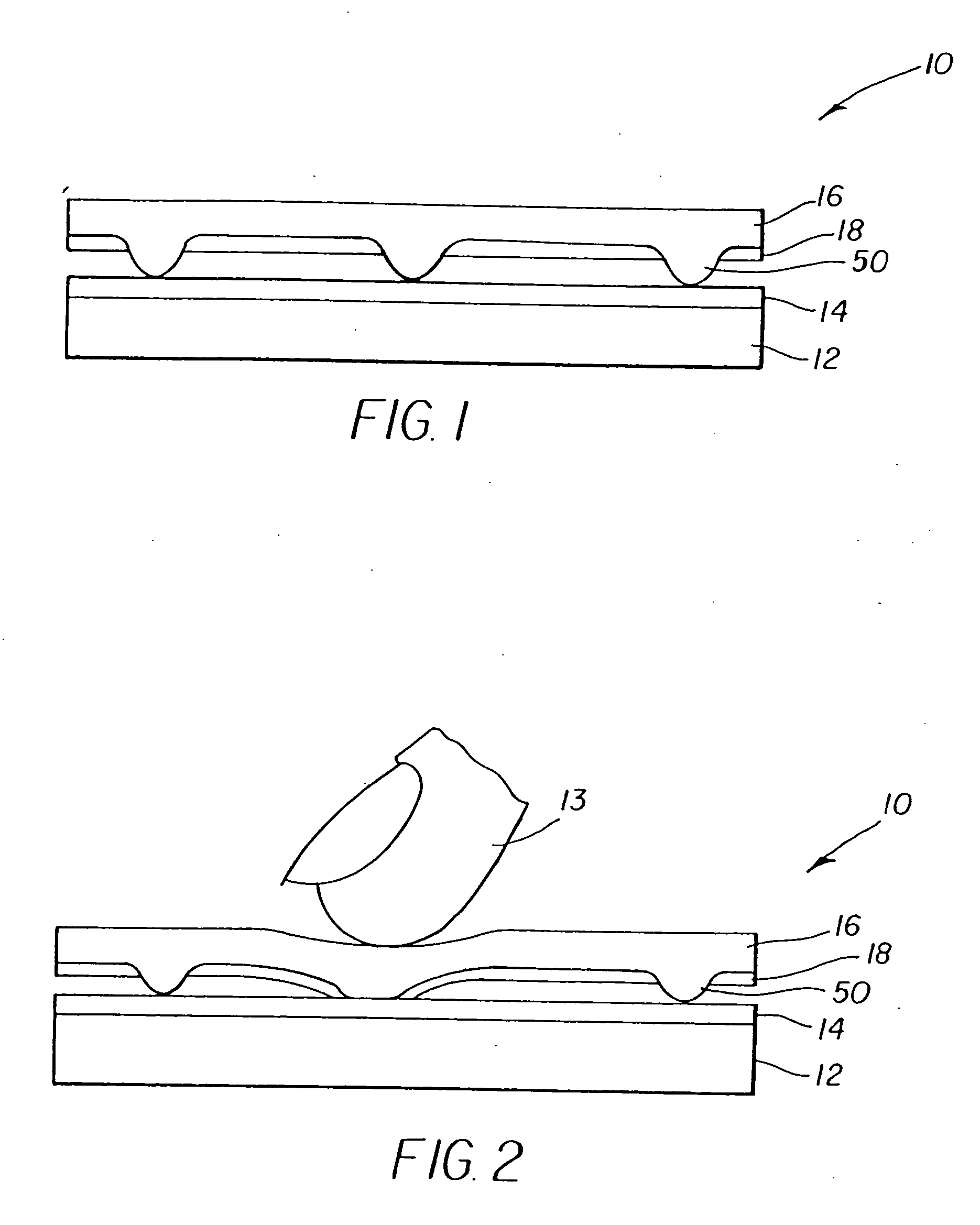

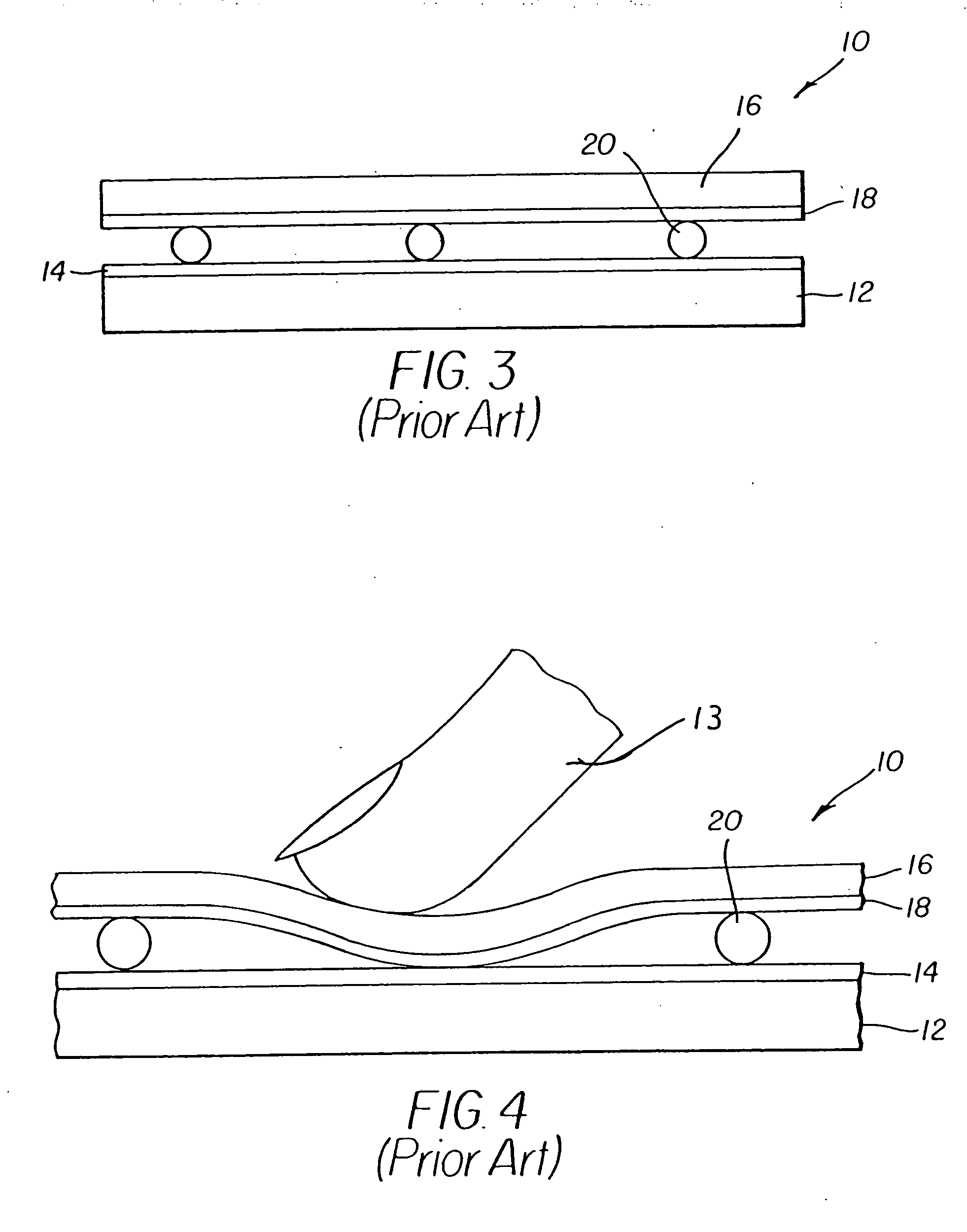

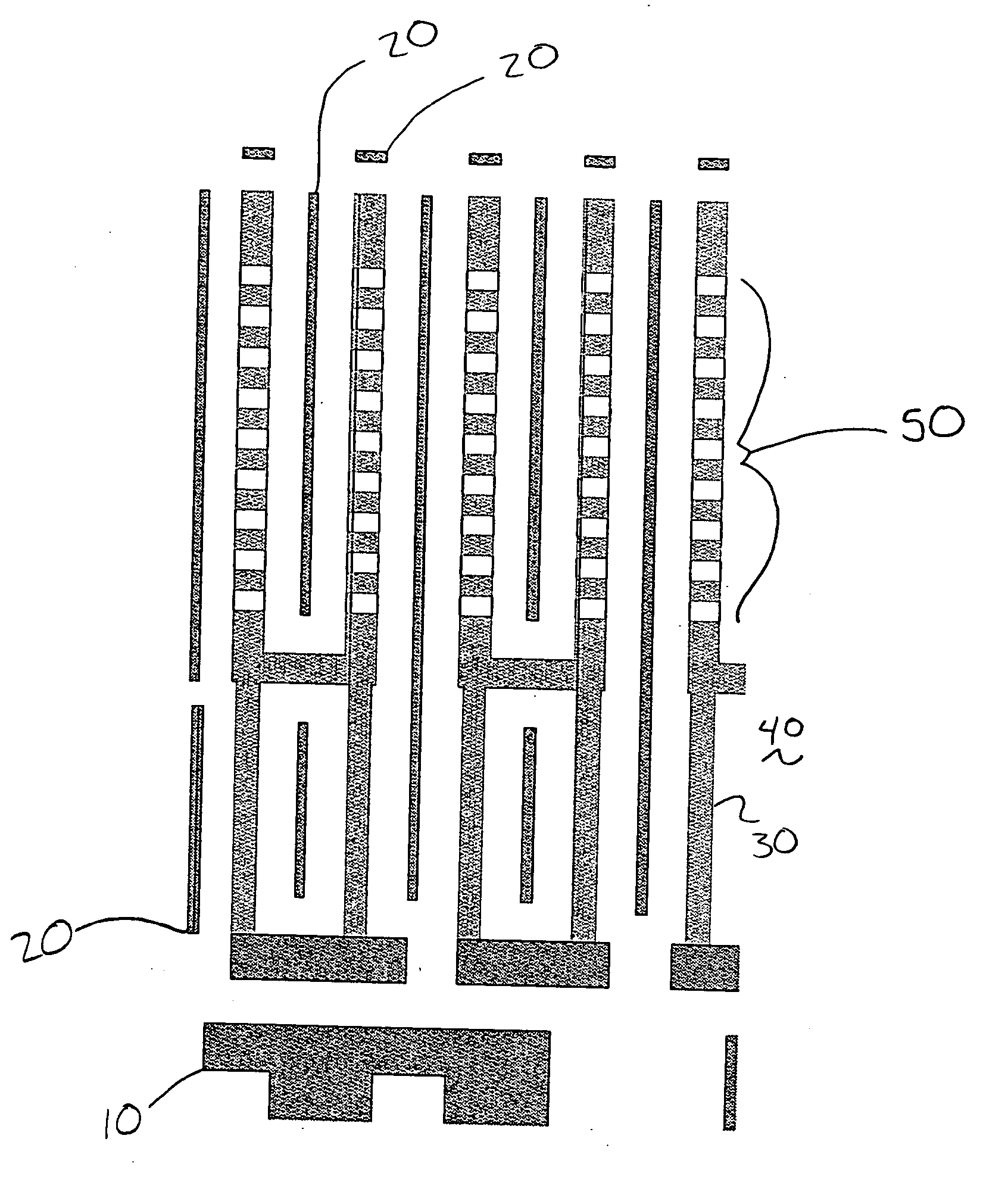

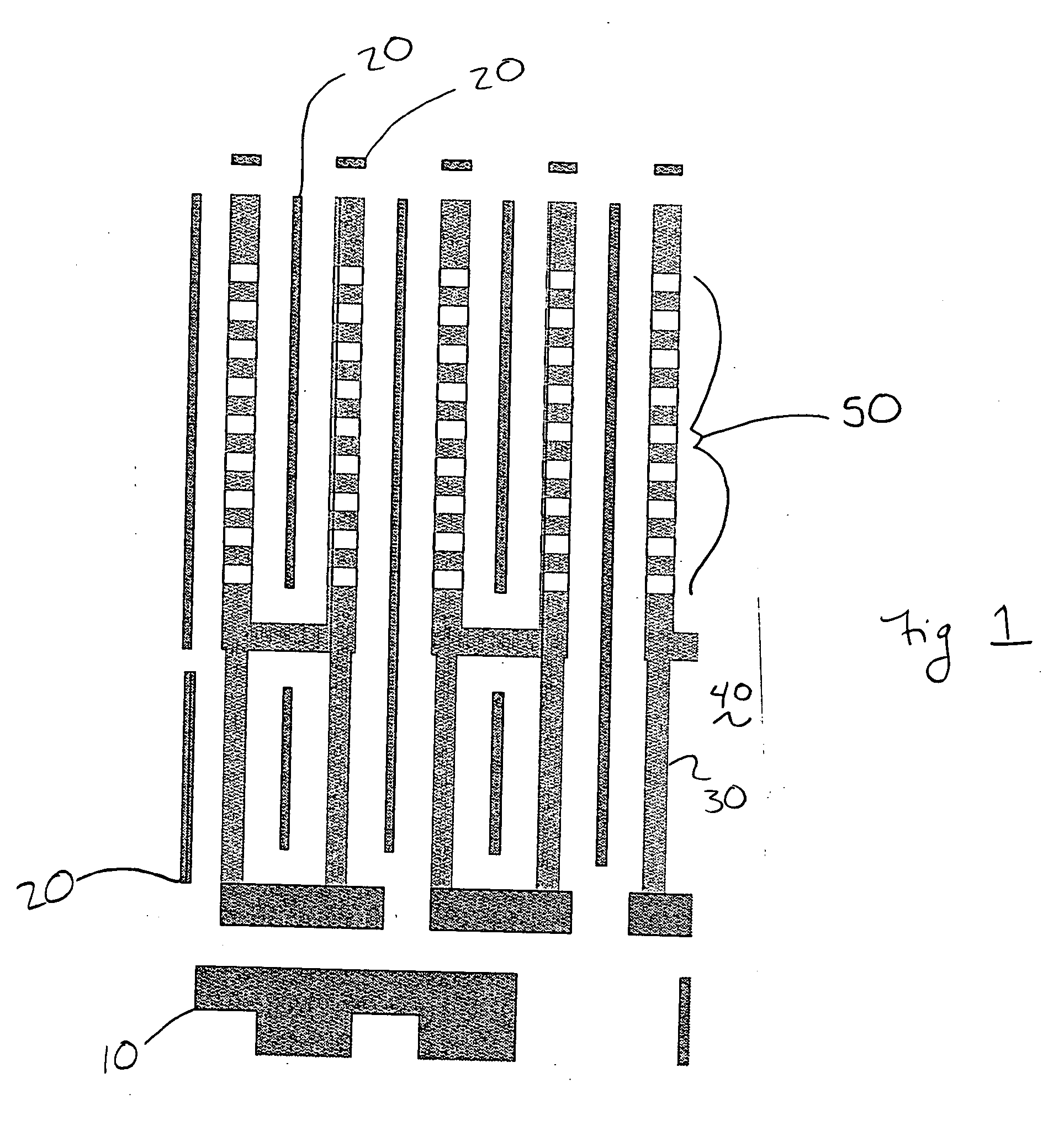

Integral spacer dots for touch screen

ActiveUS7397466B2Easy to manufactureGreat accuracy and robustness and clarityContact surface shape/structureTransmission systemsEdge segmentEngineering

Owner:EASTMAN KODAK CO

Image processing apparatus and method

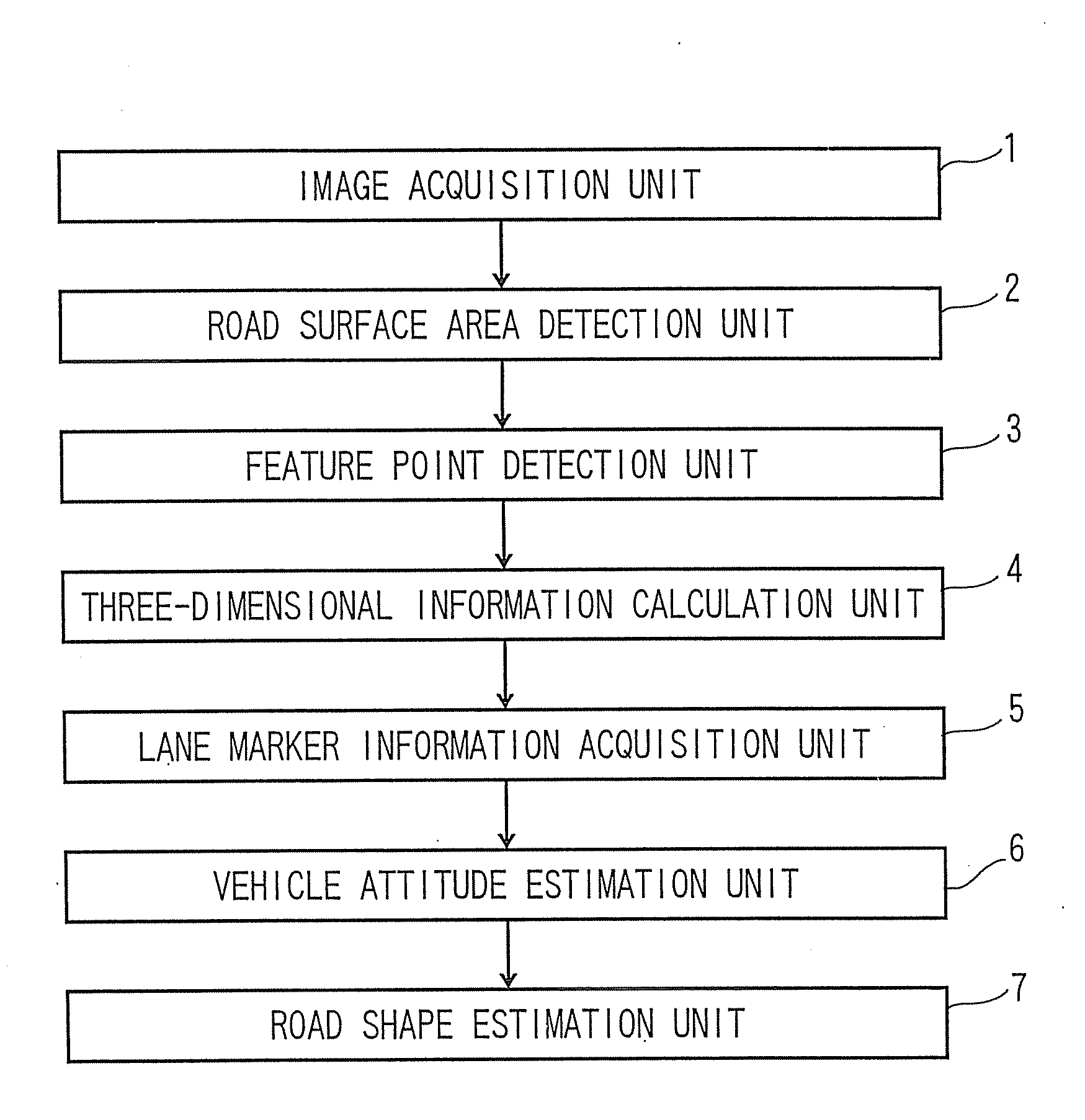

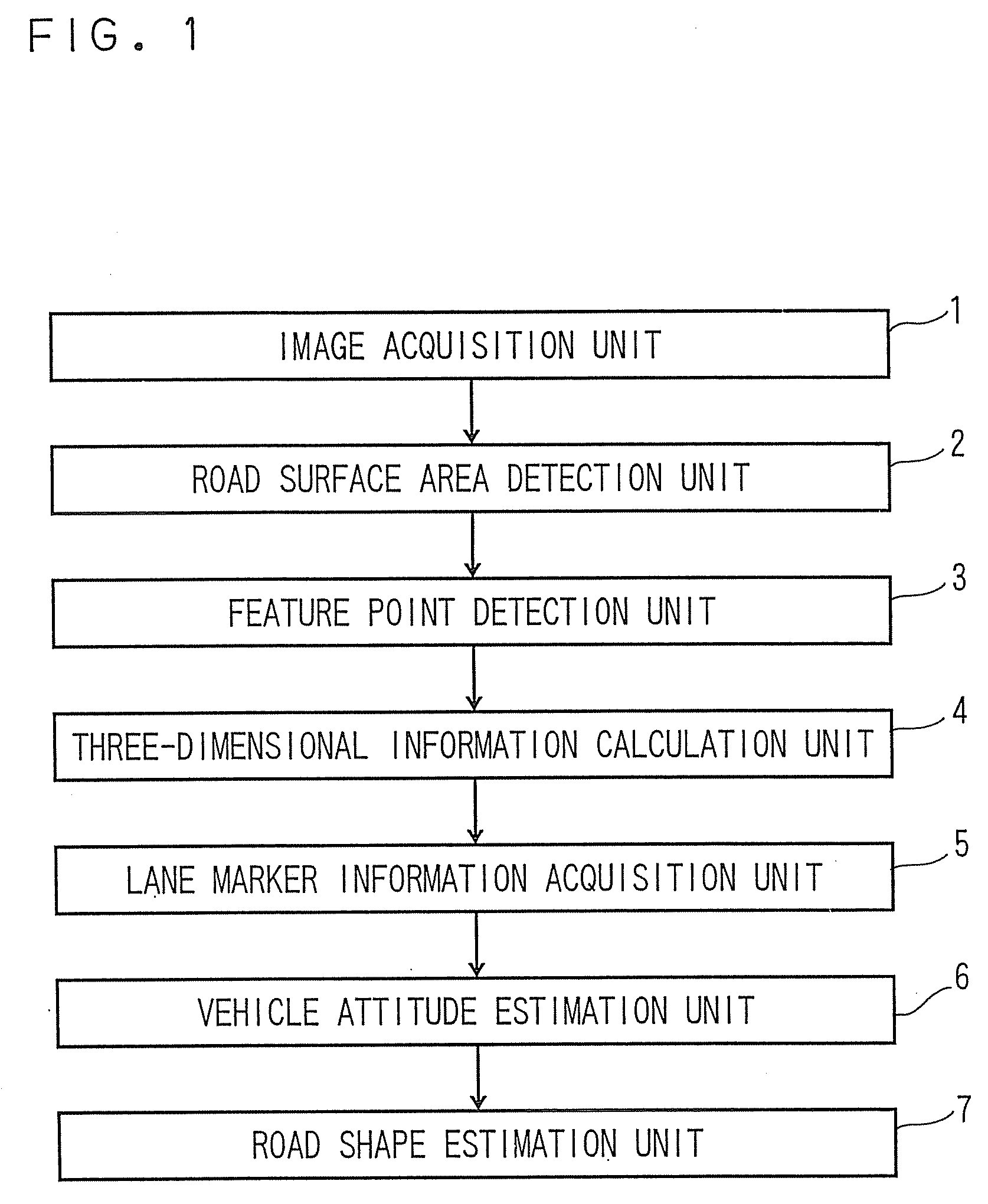

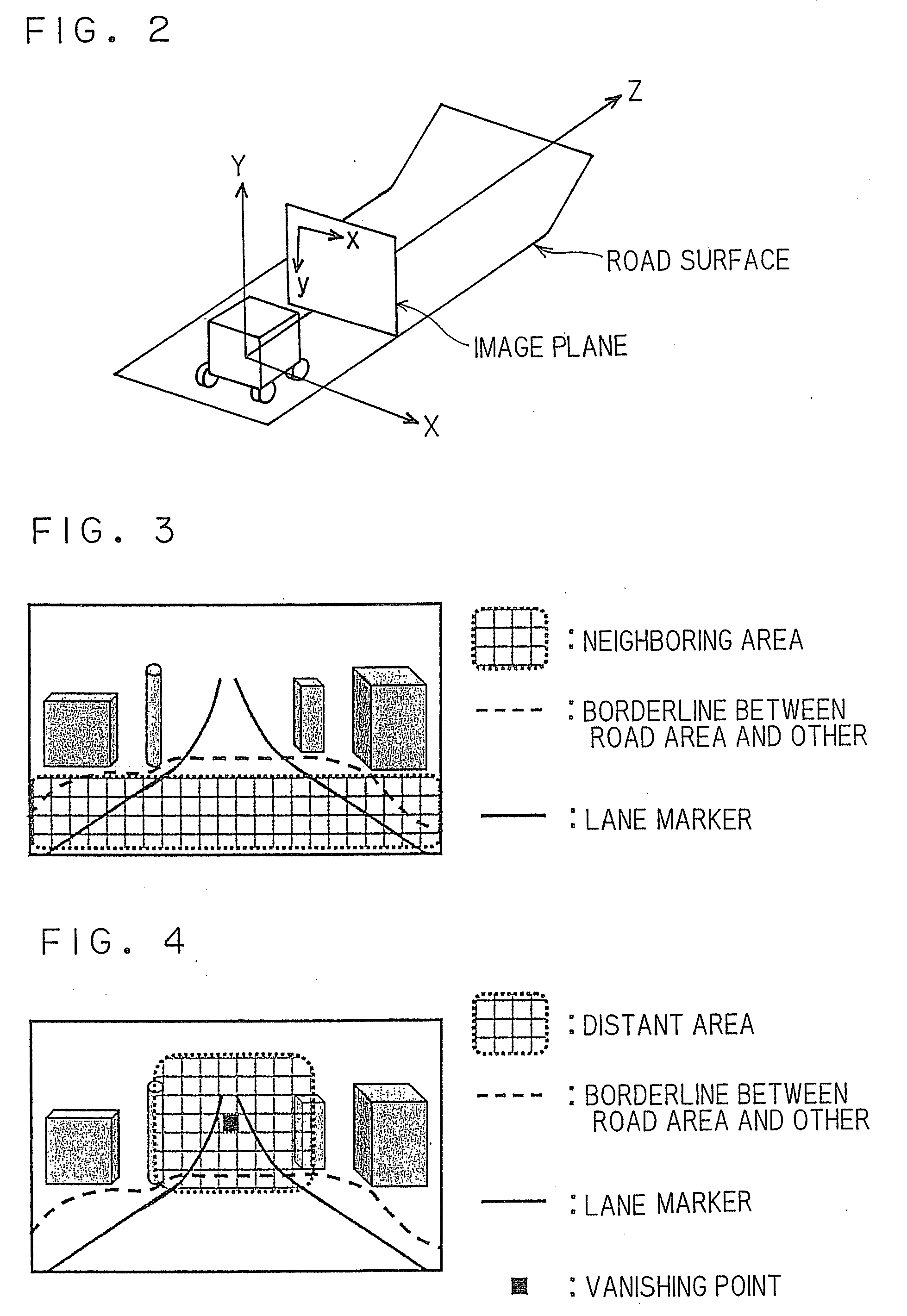

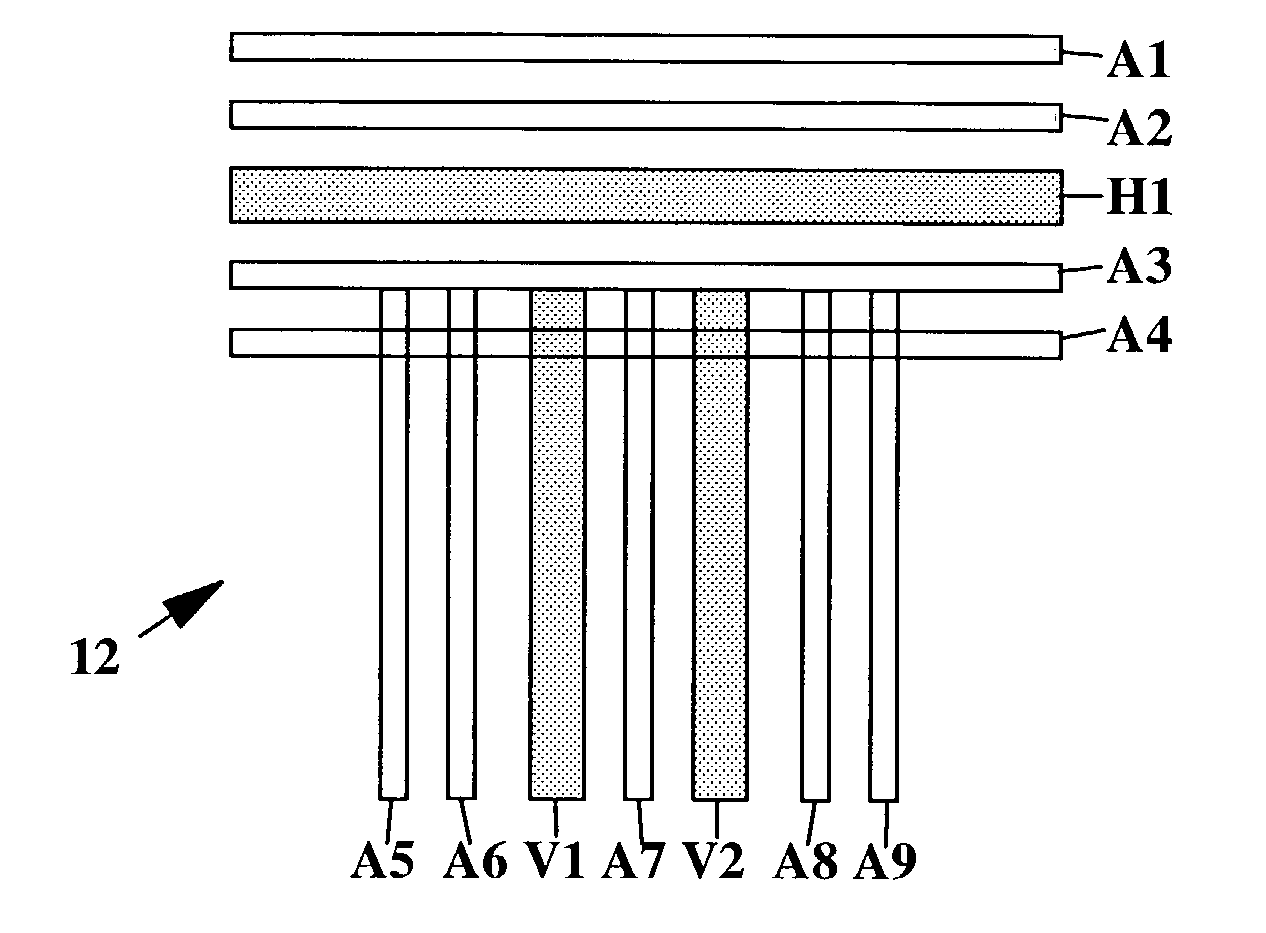

InactiveUS20090041337A1Character and pattern recognitionColor television detailsParallaxImaging processing

Three-dimensional position information of each of feature points in a left and a right image is calculated based on a disparity between the left and right images; a lane marker existing on a road surface is detected from each of the left and right images; based on three-dimensional position information of a lane marker in a neighboring road surface area, by extending the lane marker to a distant area, a lateral direction position, and a depth direction position, of the extended lane marker in the distant area are estimated; an edge segment of a certain length or more is detected from feature points in the distant area in each of a plurality of images; three-dimensional position information of the edge segment is calculated; and, based on the three-dimensional position information of the edge segment, and on the extended lane marker information, a road incline in the distant area is estimated.

Owner:KK TOSHIBA

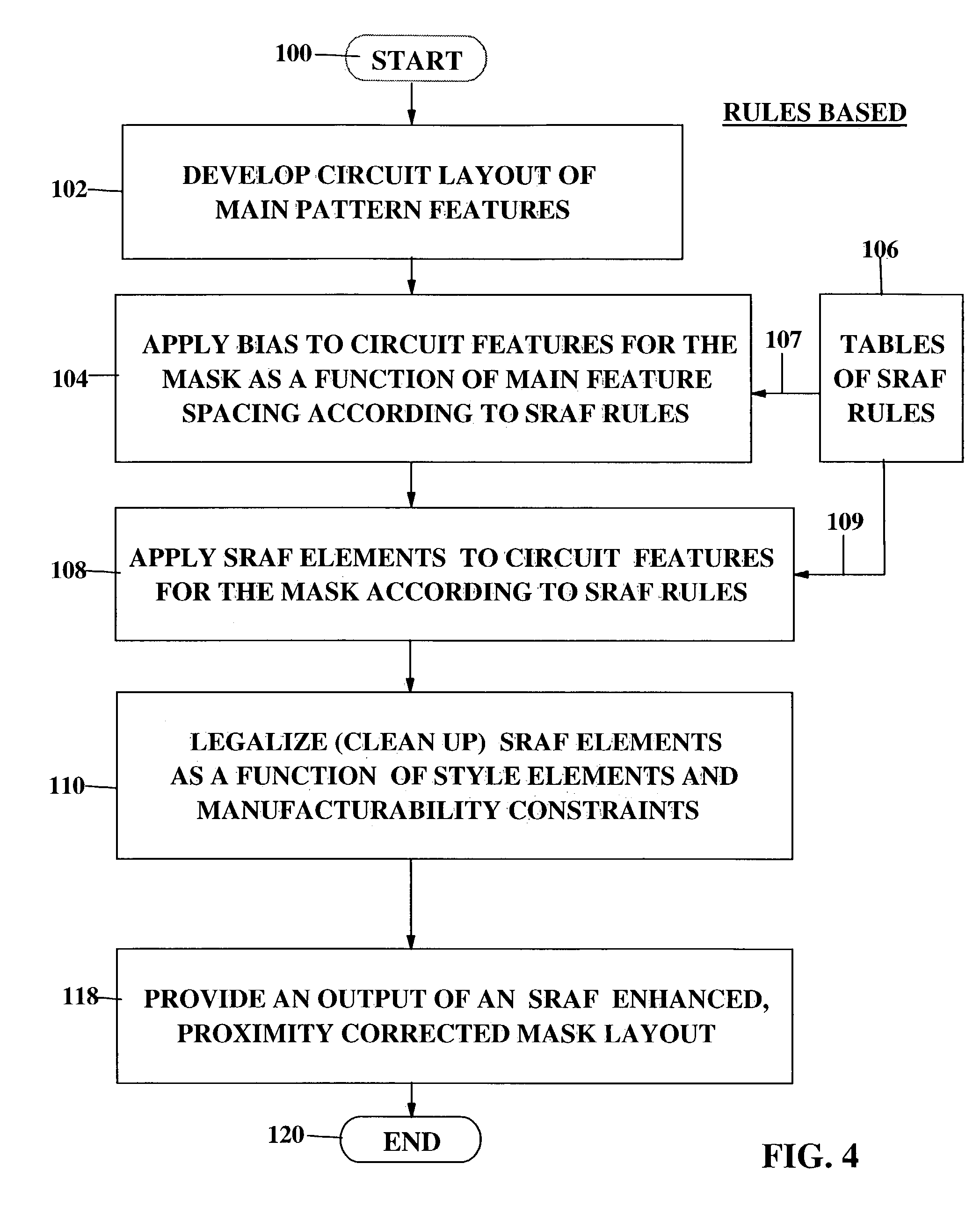

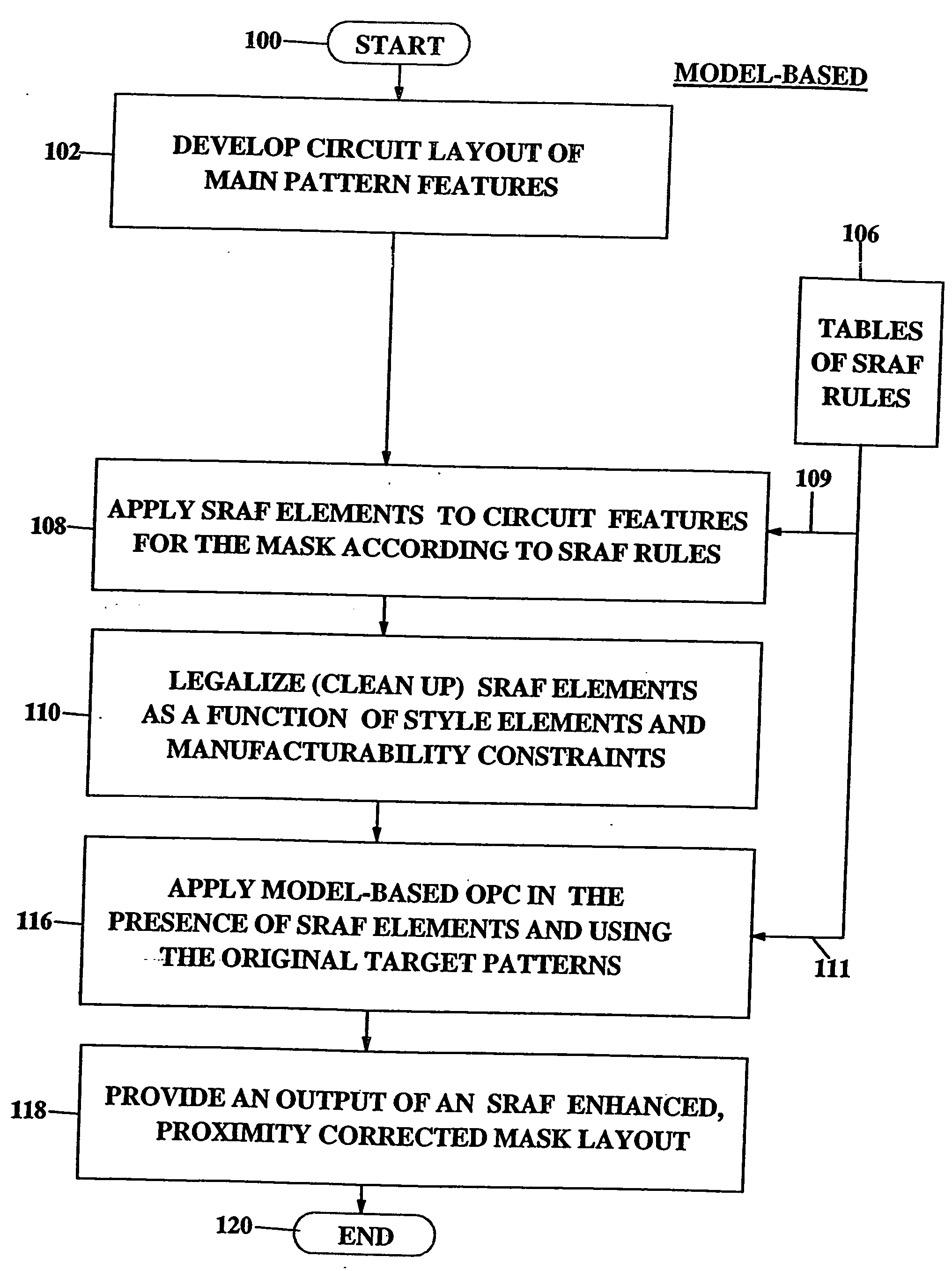

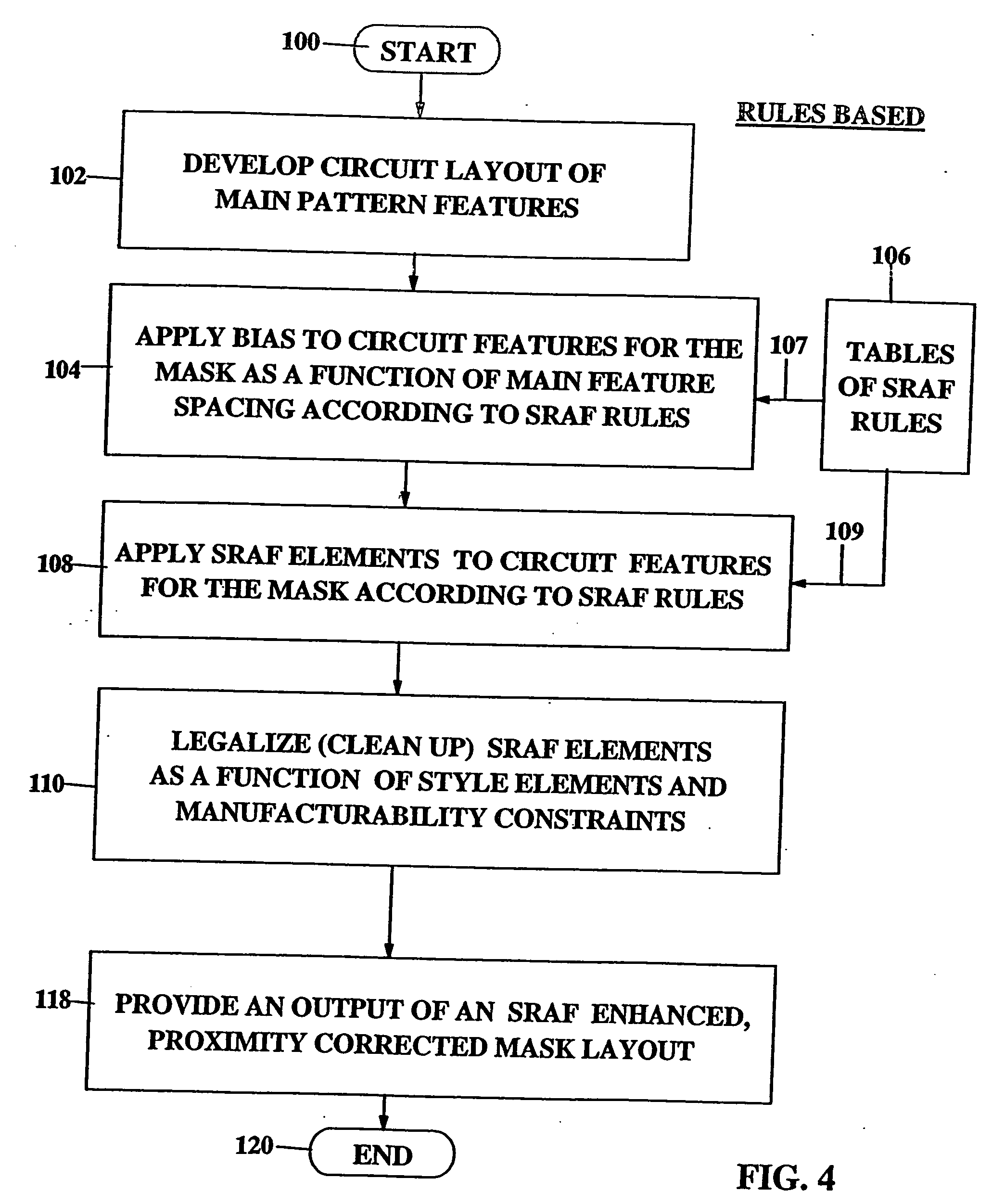

Binary OPC for assist feature layout optimization

InactiveUS7001693B2Avoid catastrophic failureSuitable for processingOriginals for photomechanical treatmentSpecial data processing applicationsEdge segmentIdentifying problems

A method of forming a photolithographic mask layout with Sub-Resolution Assist Feature (SRAF) elements on a mask for correcting for proximity effects for a pattern imaged comprising the steps of developing a layout of mask features for printing main pattern features. Provide a table of SRAF element data including spacing of main pattern features and SRAF elements, applying SRAF elements to the mask layout as a function of spacing of main pattern features and SRAF elements, legalizing the SRAF elements as a function of style options, and providing a target pattern comprising a modified layout for the mask, identifying problem edge segments of an SRAF element of the target pattern at risk of causing a printing defect, applying a selected bias to the problem edge segments to modify the pattern where there are areas of SRAF element loss, and providing an output of a modified pattern with modified SRAF elements removing the areas of SRAF element loss. The system can provide SRAF elements to the mask layout as a function of spacing of main pattern features and SRAF elements may be based on data from the SRAF table; or the system can applying model based OPC for exposure dose values based on data from the SRAF table.

Owner:IBM CORP

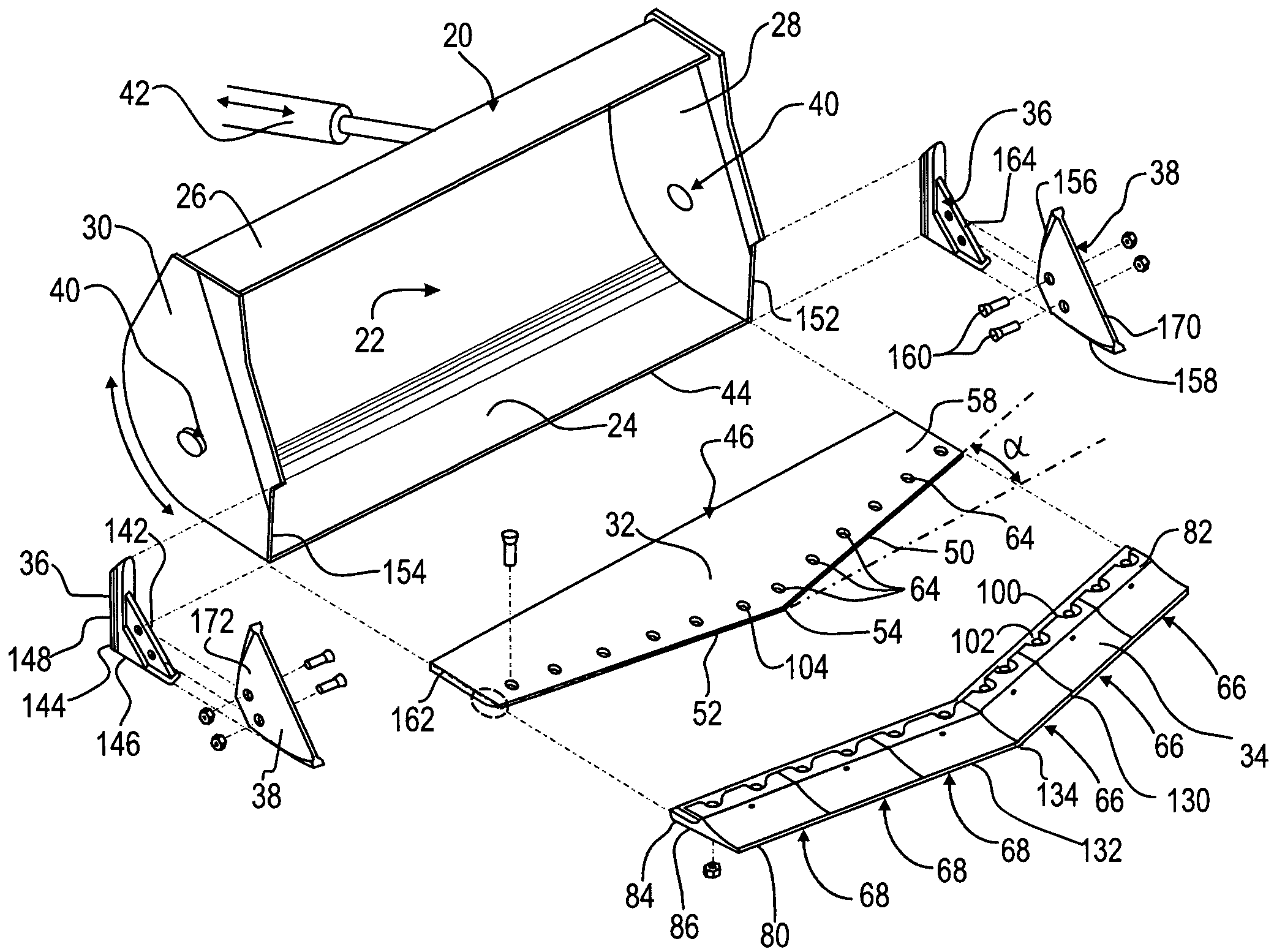

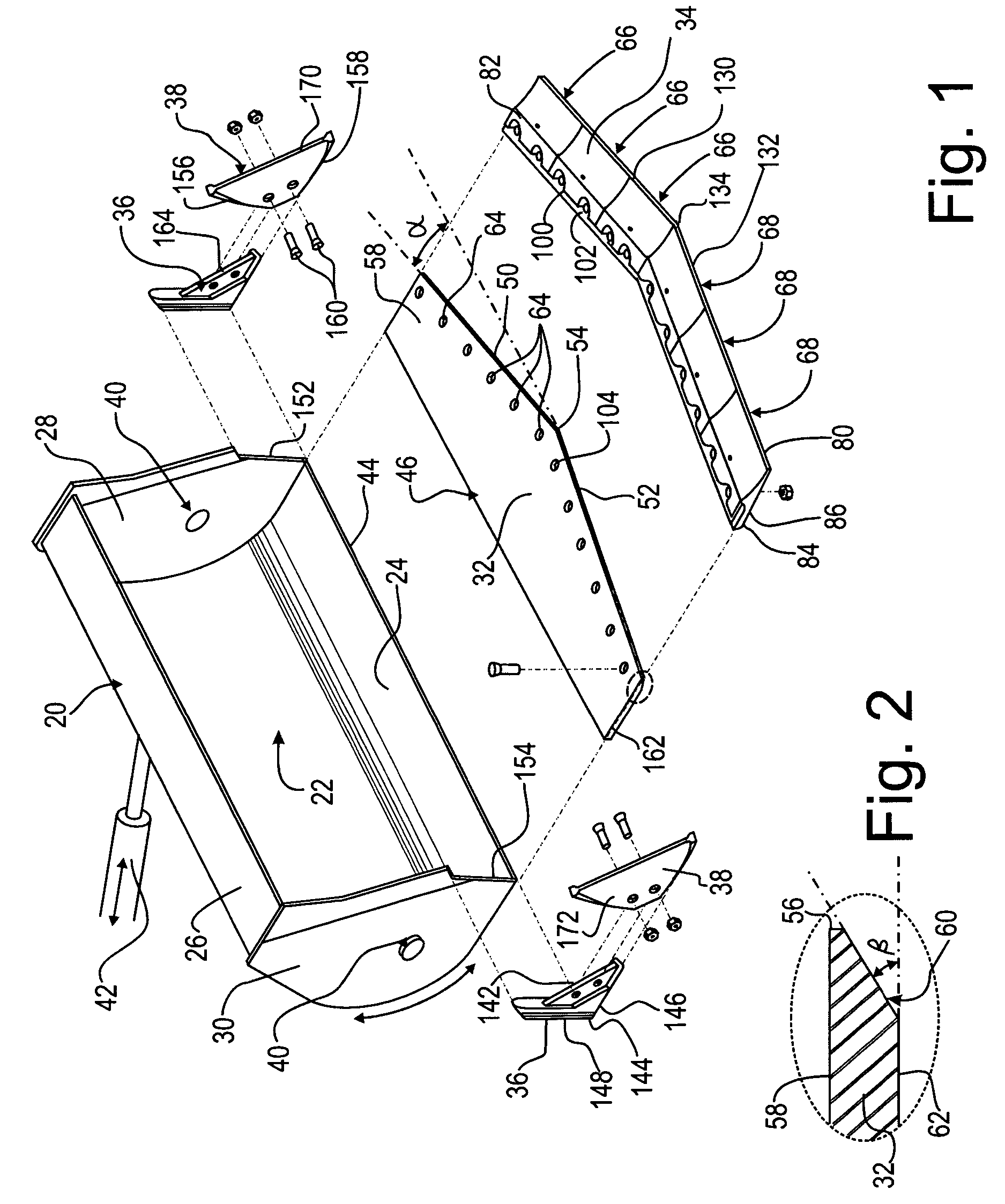

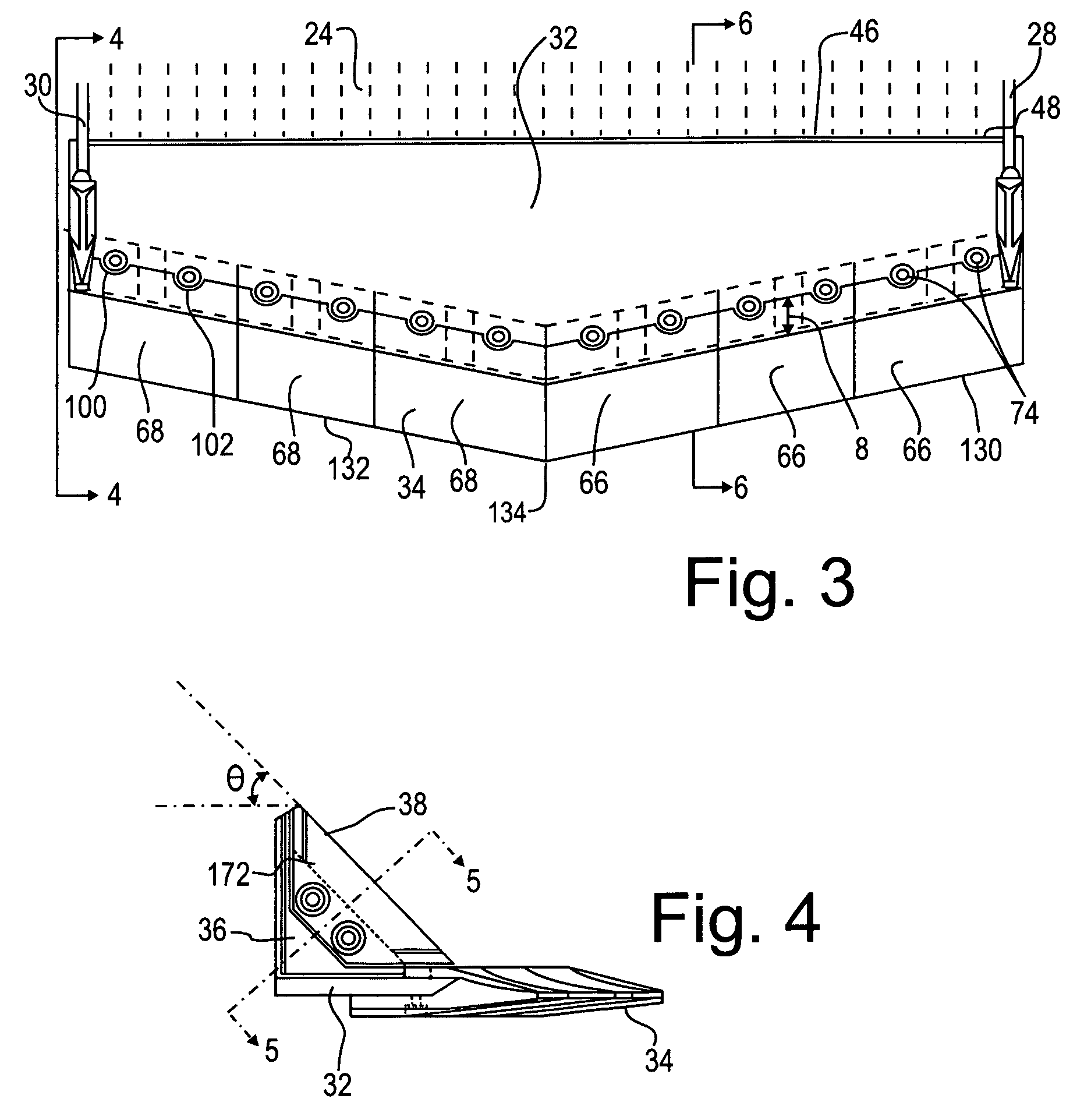

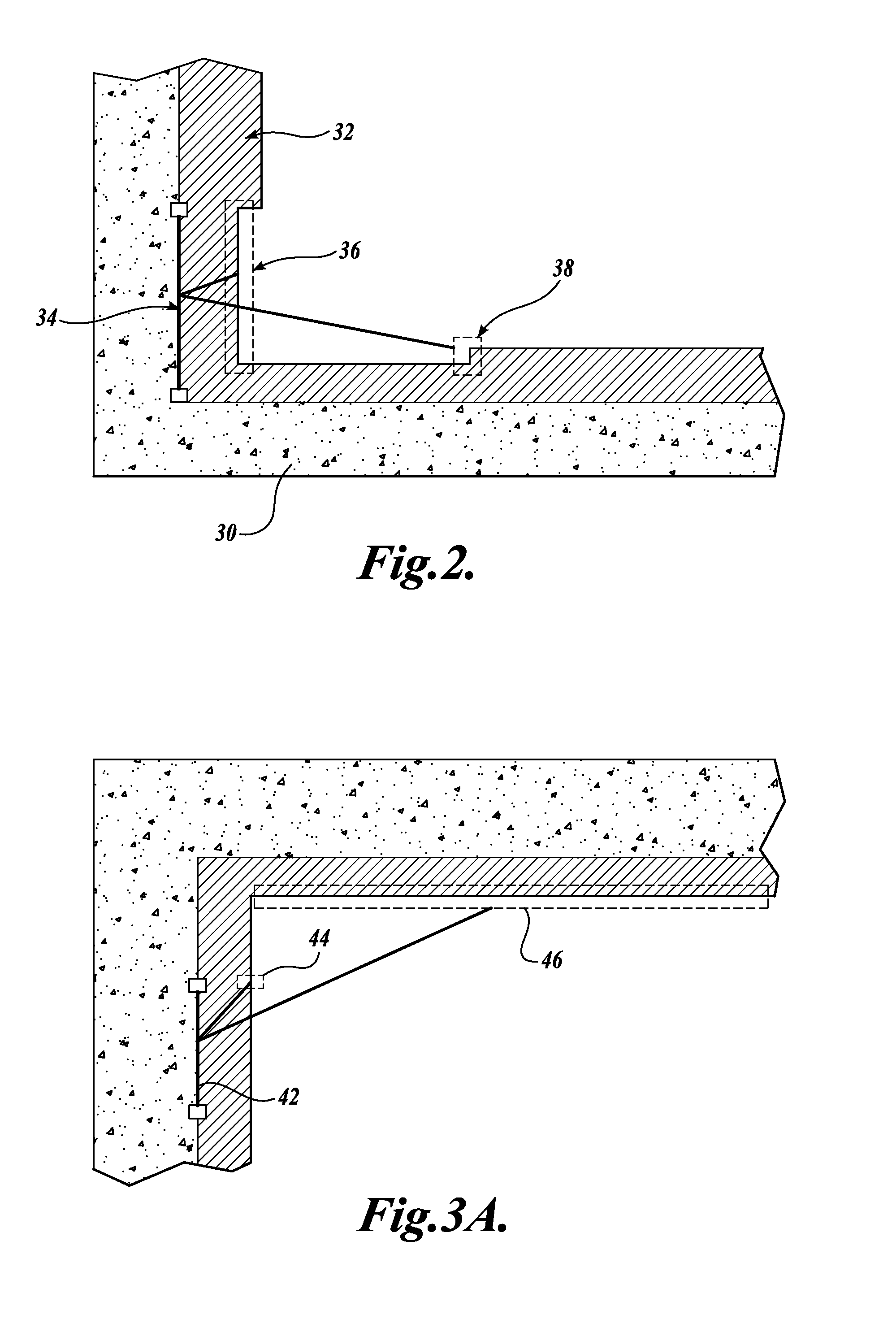

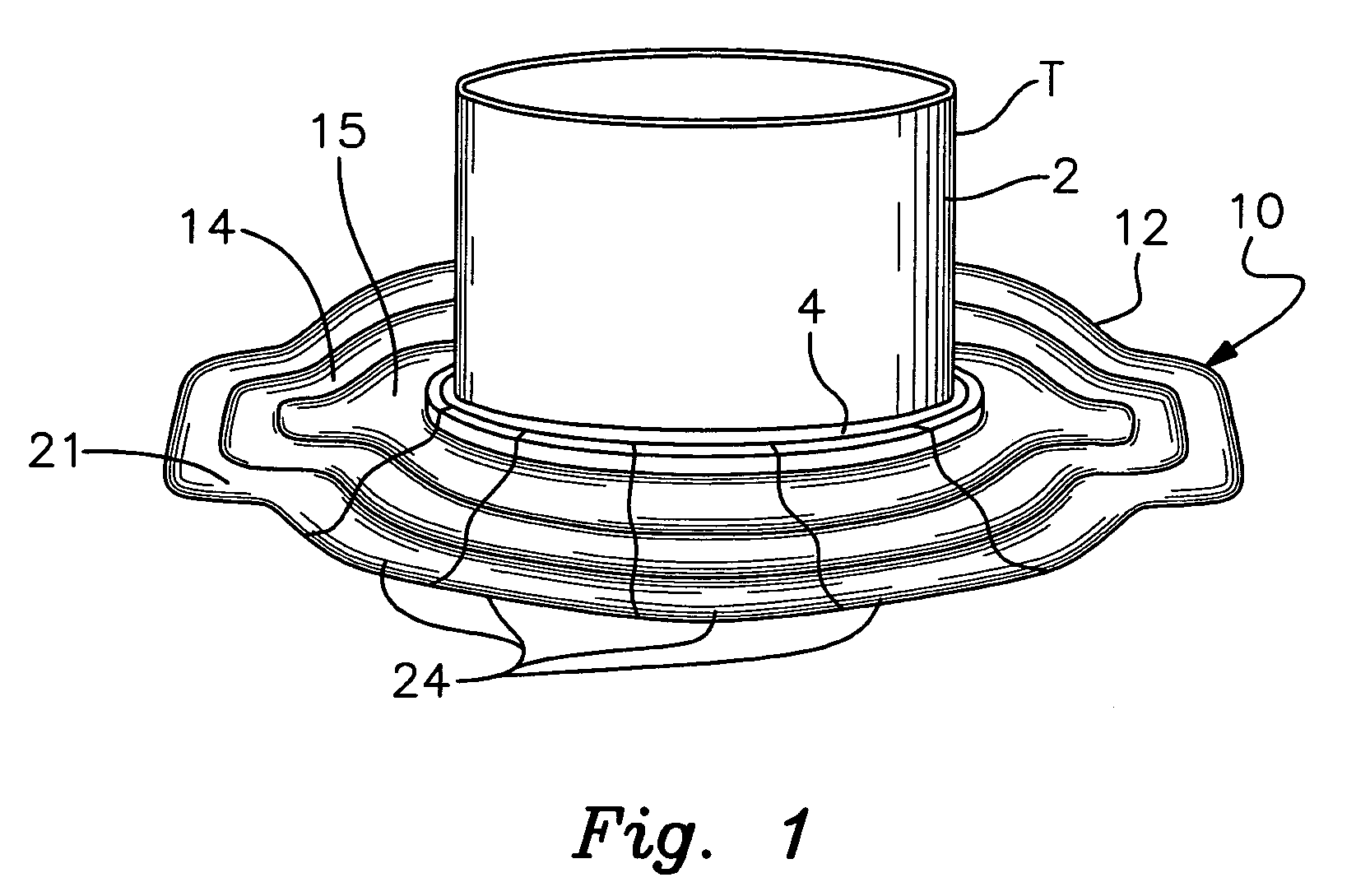

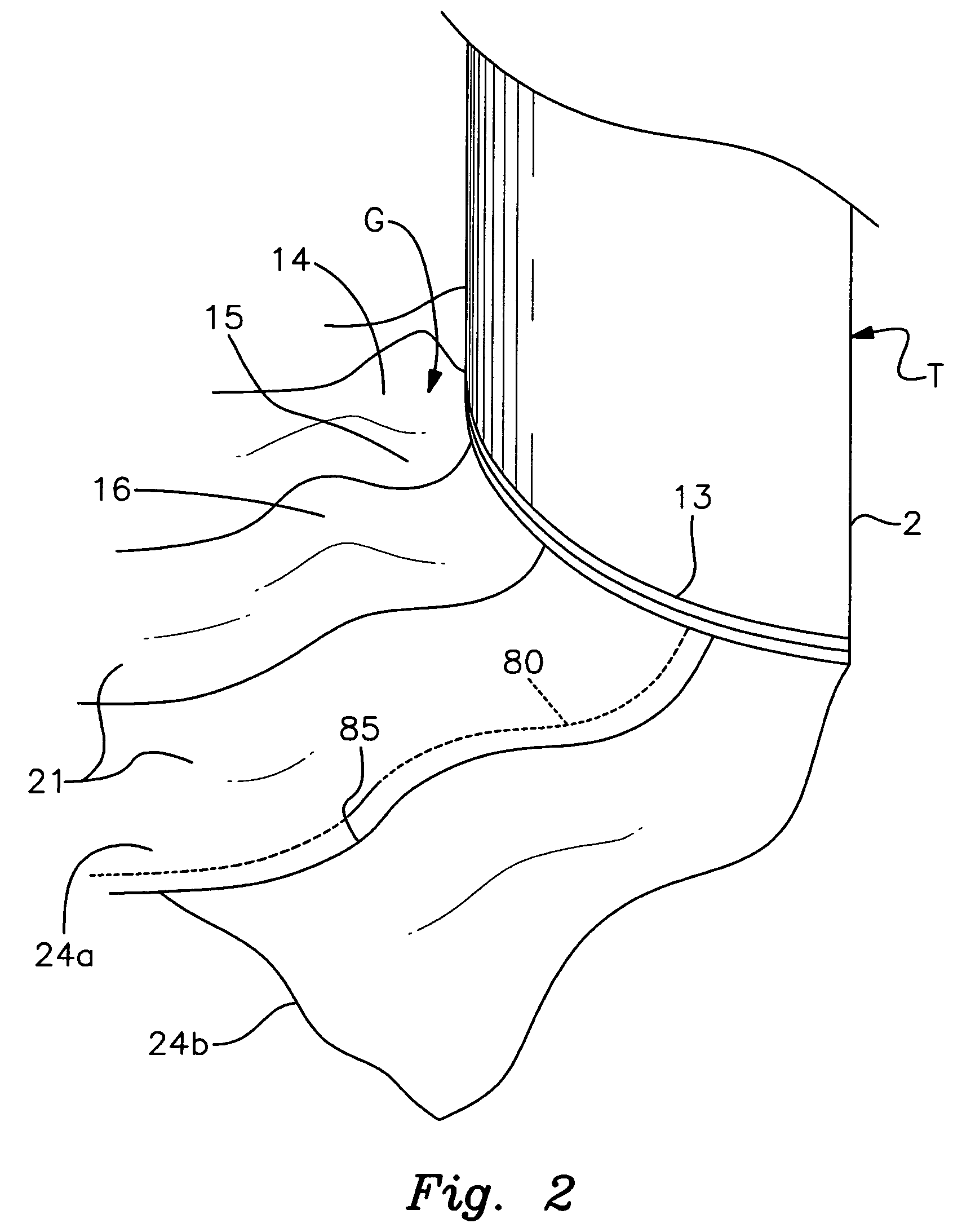

Wear plate assembly

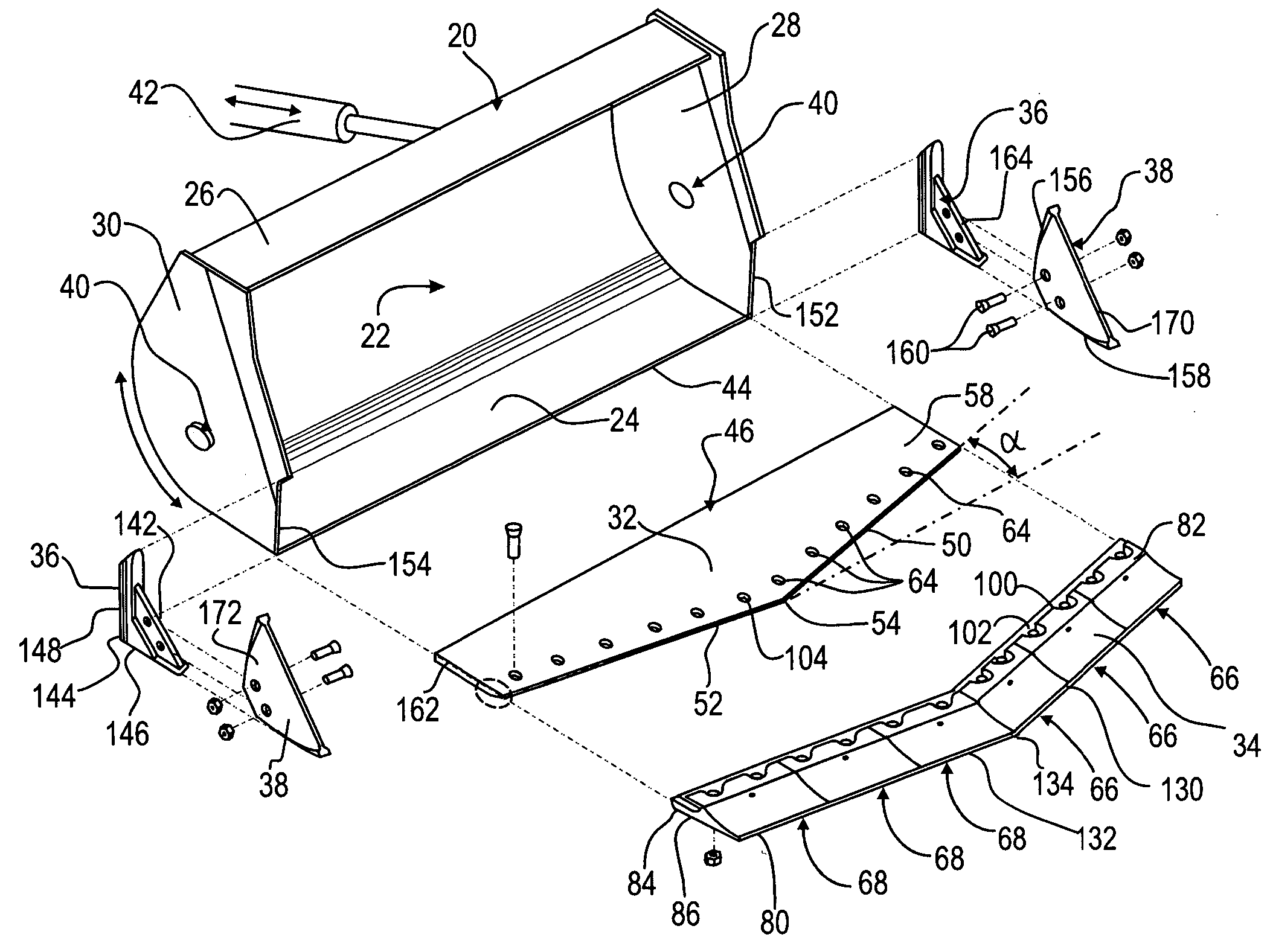

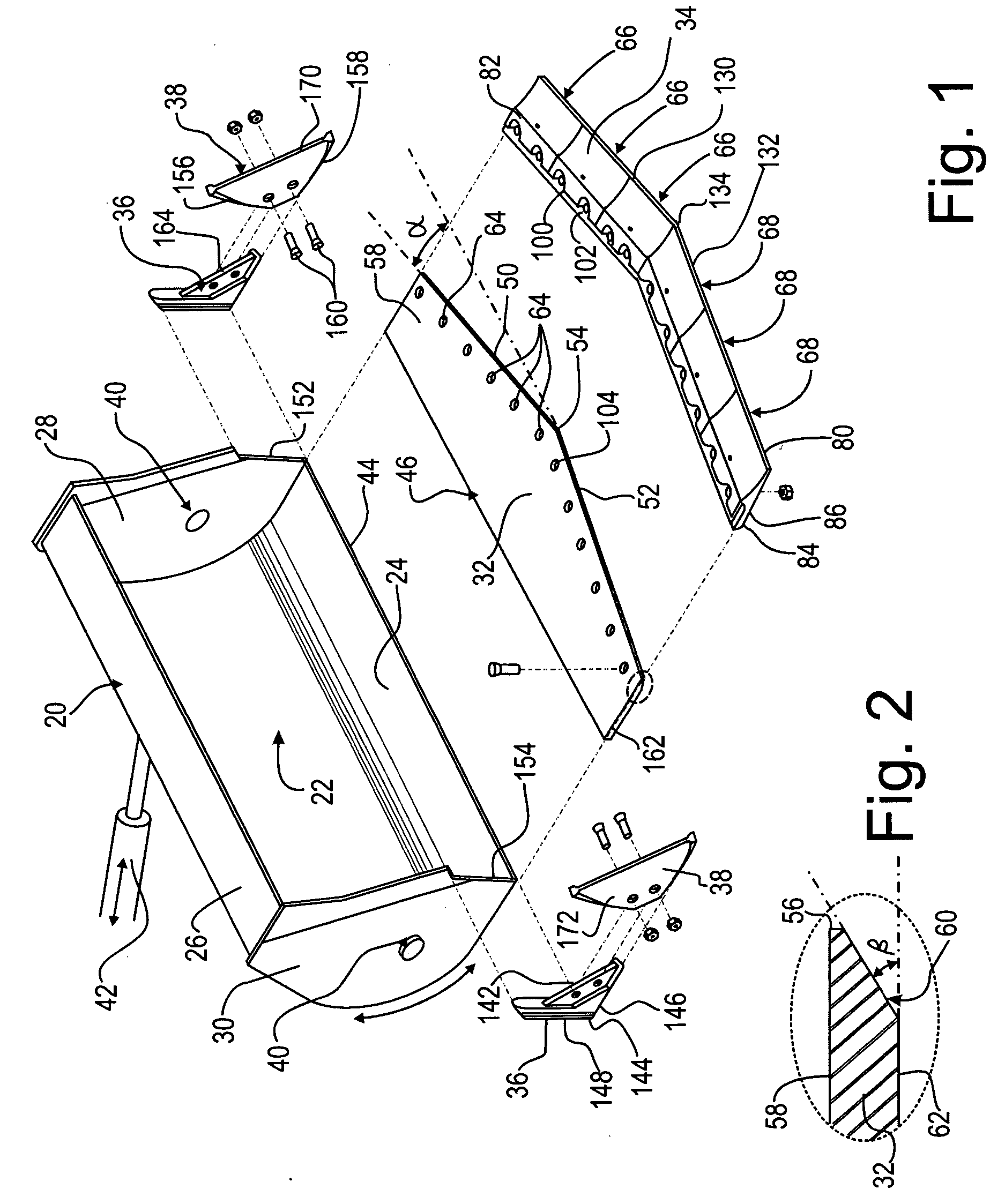

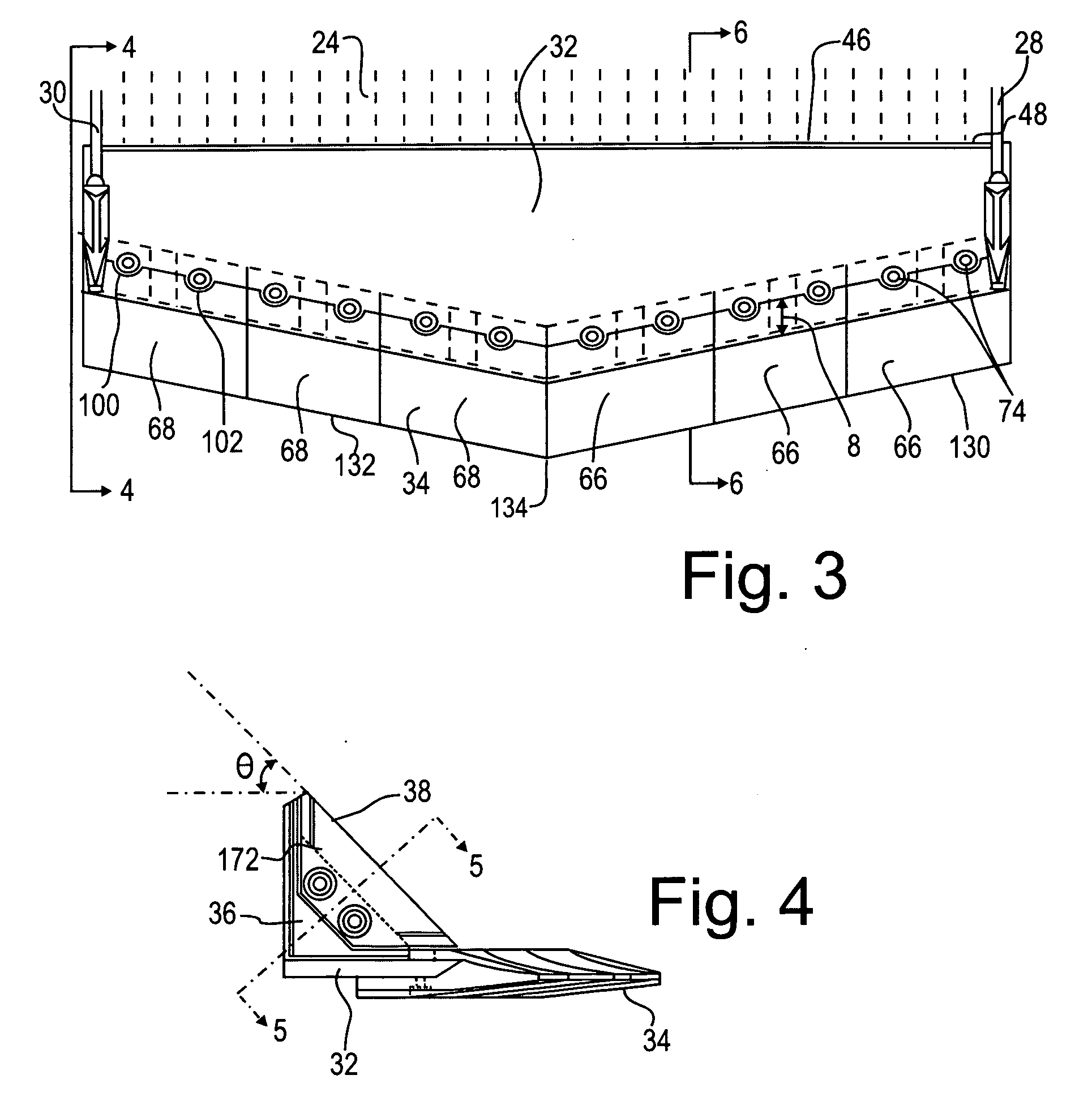

InactiveUS7266914B2Thicker wear lip sectionEliminate and reduce movementMechanical machines/dredgersLeading edgeEdge segment

A bucket assembly is provided with a kit that includes a base plate for permanent connection to a lower part of the bucket, and sacrificial, impermanent replaceable wear edge segments for the forward lip and corner leading edges of an excavator or loader bucket. These segments form a set of “bolt on” cast wear members and wing wear segments. The base plate and wear plates are drilled and machined to accommodate the precision fitting bolting on of the replaceable lips and cast wing segments. The cast lip segments are of both left and right hand configurations and come in a variety of widths that, in combination, may tend to fit a large number of different commercially available bucket sizes. The lip top and bottom faces are shaped in a profile that may tend to result in relatively uniform wear and a reduction in friction when digging into various materials.

Owner:PENINSULA ALLOY +1

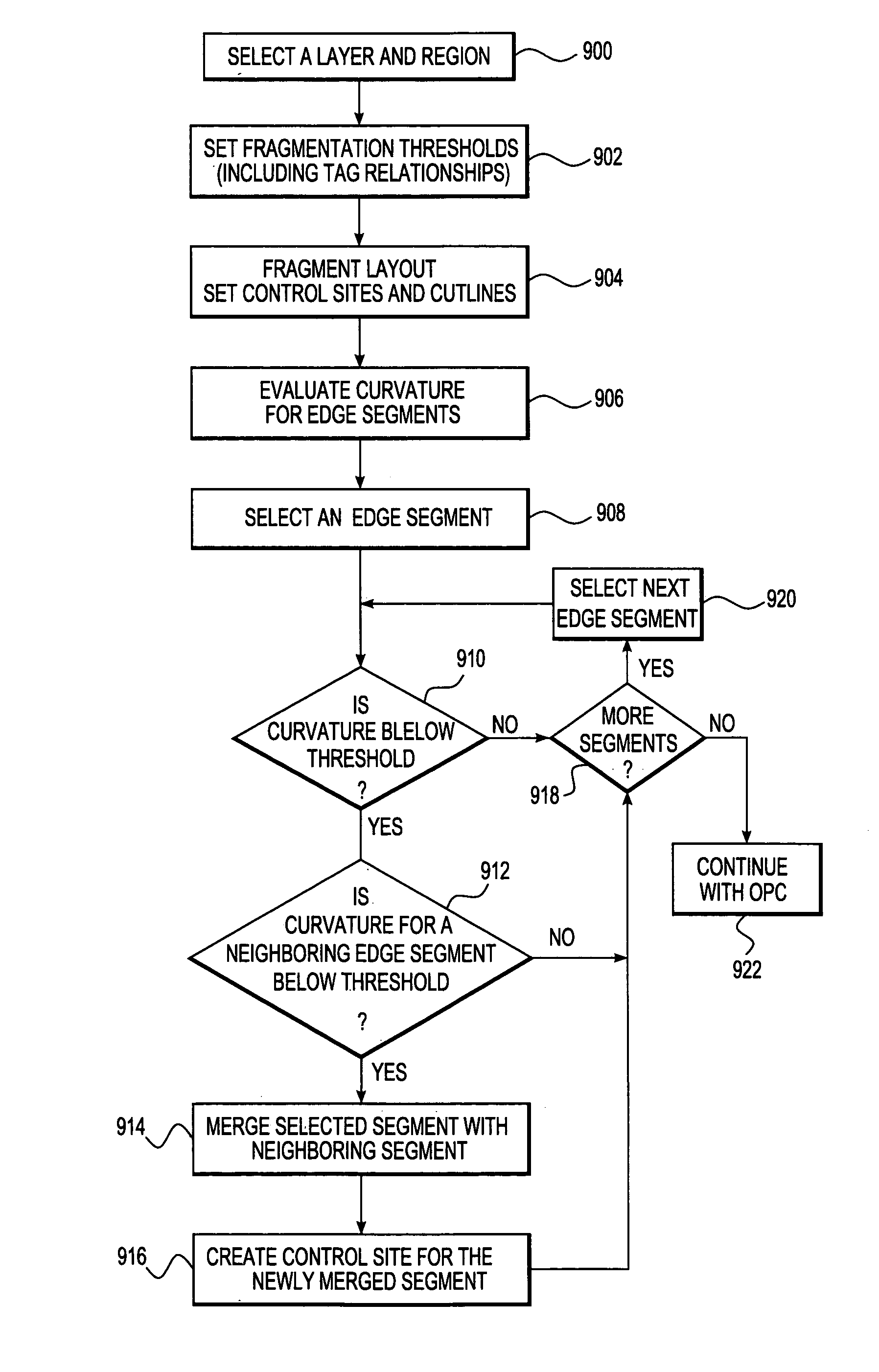

Method and apparatus for performing OPC using model curvature

InactiveUS7324930B2Analogue computers for electric apparatusComputation using non-denominational number representationEdge segmentProcess conditions

A method of preparing a file that stores layout of devices to be created with photolithography for optical and process correction (OPC). Polygons that define structures to be created are initially fragmented into edge segments and a simulation of how the edge segments will be printed under process conditions is performed. The results of the simulation are used to adjust / refragment the edge segments. In one embodiment, the curvature of light intensity at the edge segments is used to adjust the fragmentation of the polygons.

Owner:SIEMENS PROD LIFECYCLE MANAGEMENT SOFTWARE INC

Wear plate assembly

InactiveUS20050172524A1Reduce and eliminate lip movementThicker wear lip sectionMechanical machines/dredgersLeading edgeEdge segment

A bucket assembly is provided with a kit that includes a base plate for permanent connection to a lower part of the bucket, and sacrificial, impermanent replaceable wear edge segments for the forward lip and corner leading edges of an excavator or loader bucket. These segments form a set of “bolt on” cast wear members and wing wear segments. The base plate and wear plates are drilled and machined to accommodate the precision fitting bolting on of the replaceable lips and cast wing segments. The cast lip segments are of both left and right hand configurations and come in a variety of widths that, in combination, may tend to fit a large number of different commercially available bucket sizes. The lip top and bottom faces are shaped in a profile that may tend to result in relatively uniform wear and a reduction in friction when digging into various materials.

Owner:PENINSULA ALLOY +1

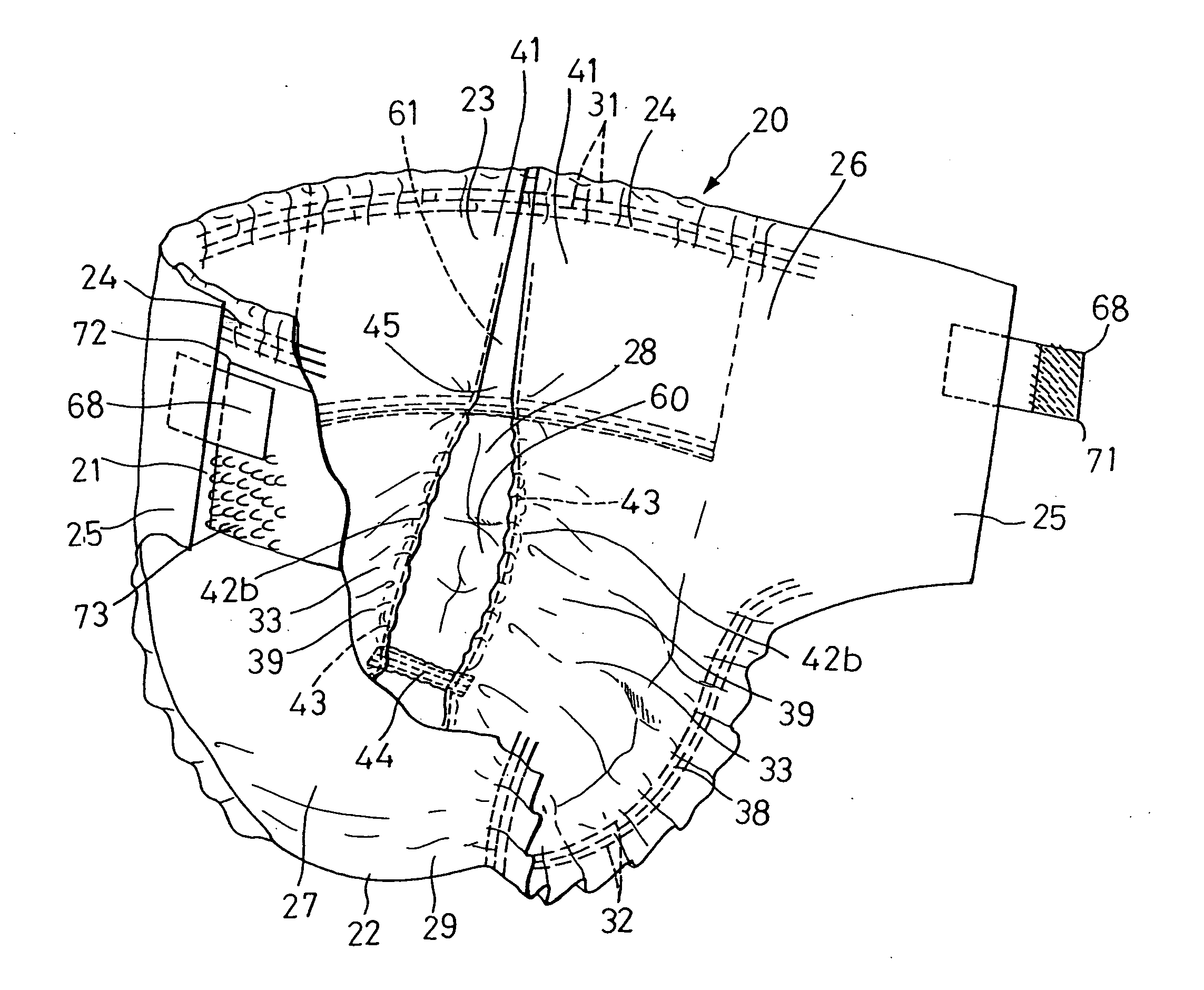

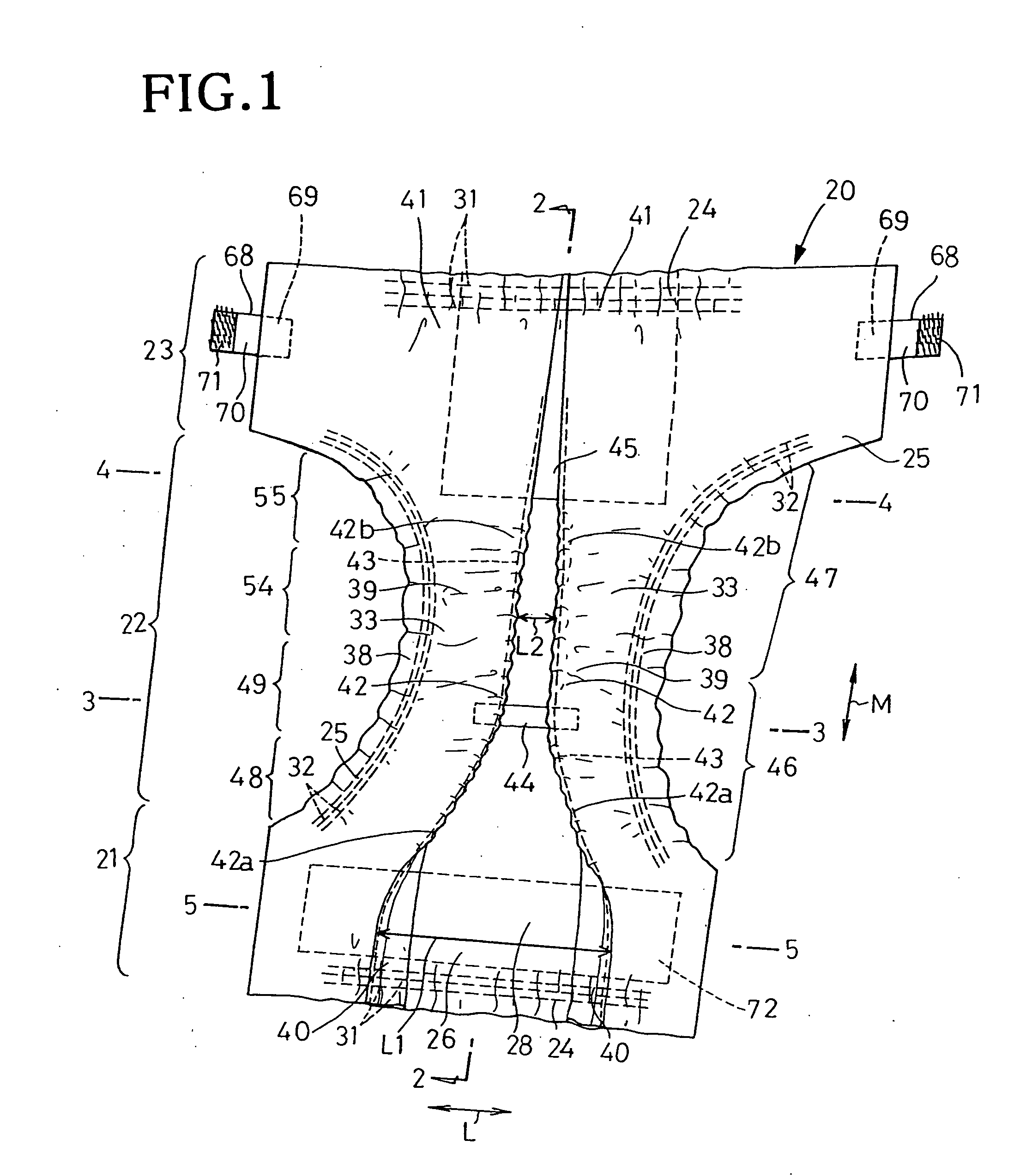

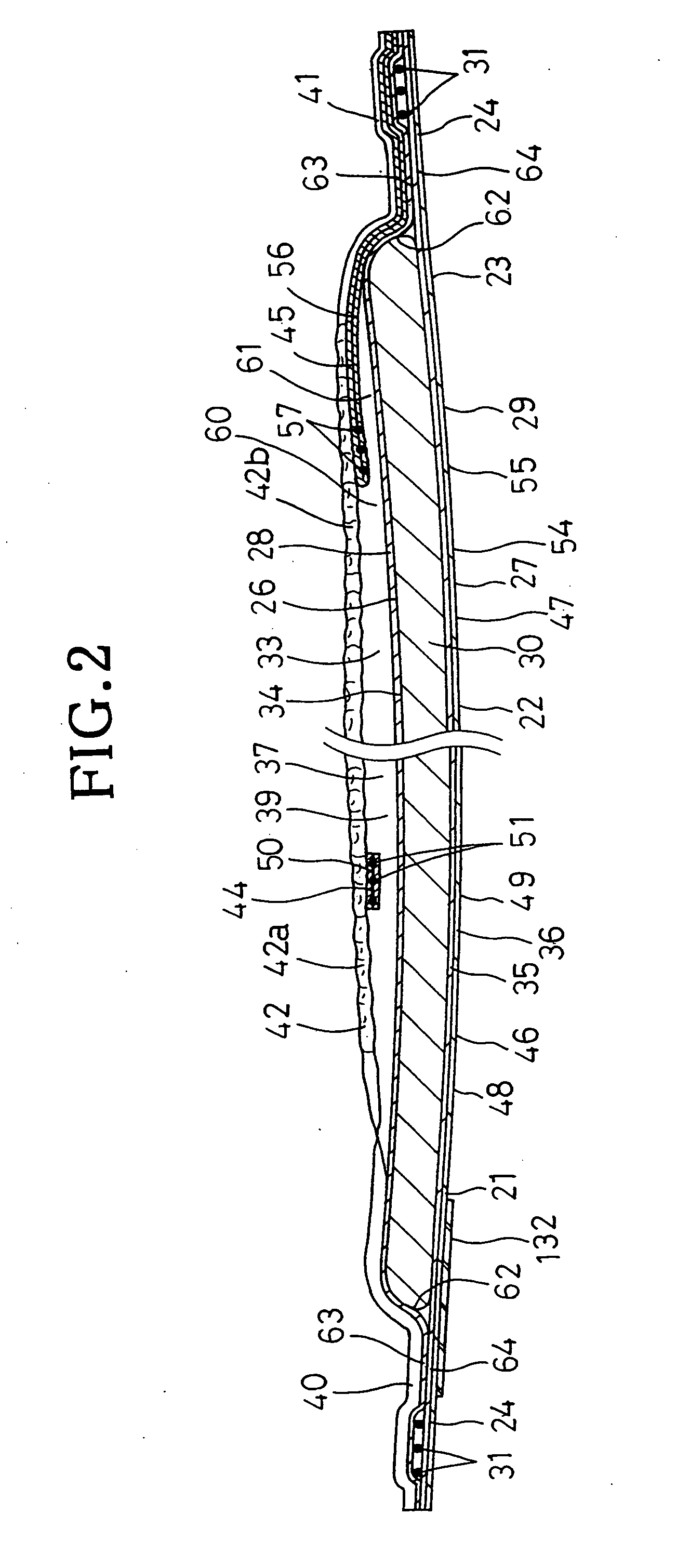

Disposable wearing article

A disposable wearing article has an elasticized first band lying in a front half of a crotch region and attached to distal zones of a pair of leak-barrier sheets provided on a body side of the article and an elasticized second band lying in a rear half of the crotch region and attached to the distal zones. A dimension by which distal edge segments of the distal zones extending forward from the first band in a longitudinal direction are spaced from each other is gradually enlarged from the side of the first band toward the side of the a front waist region.

Owner:UNI CHARM CORP

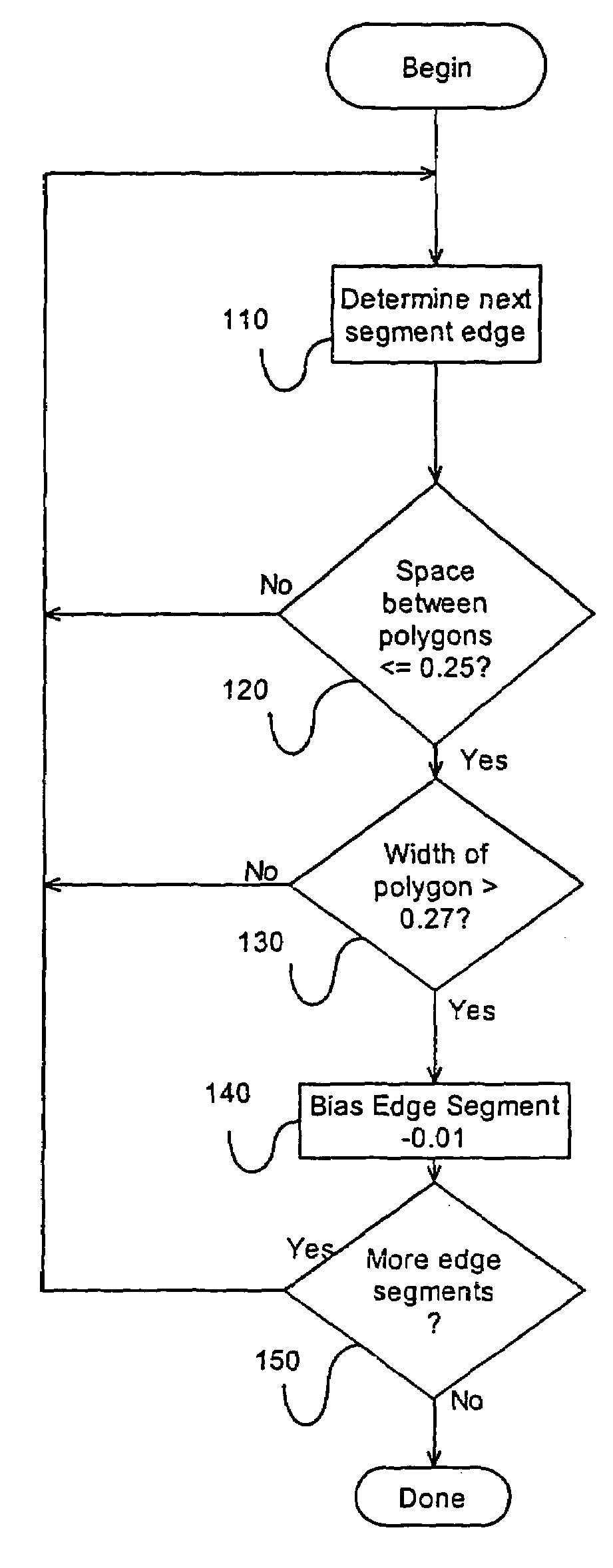

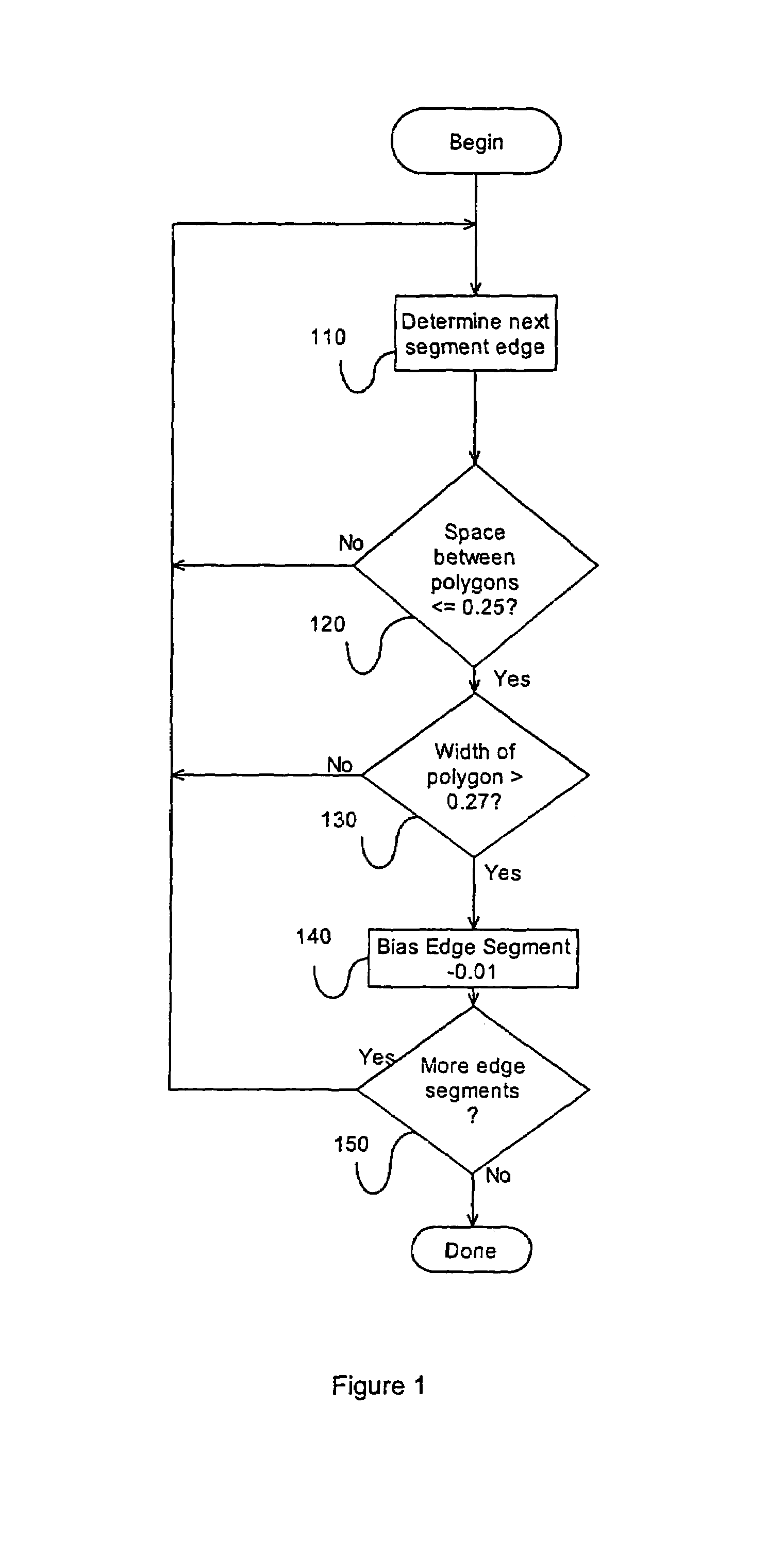

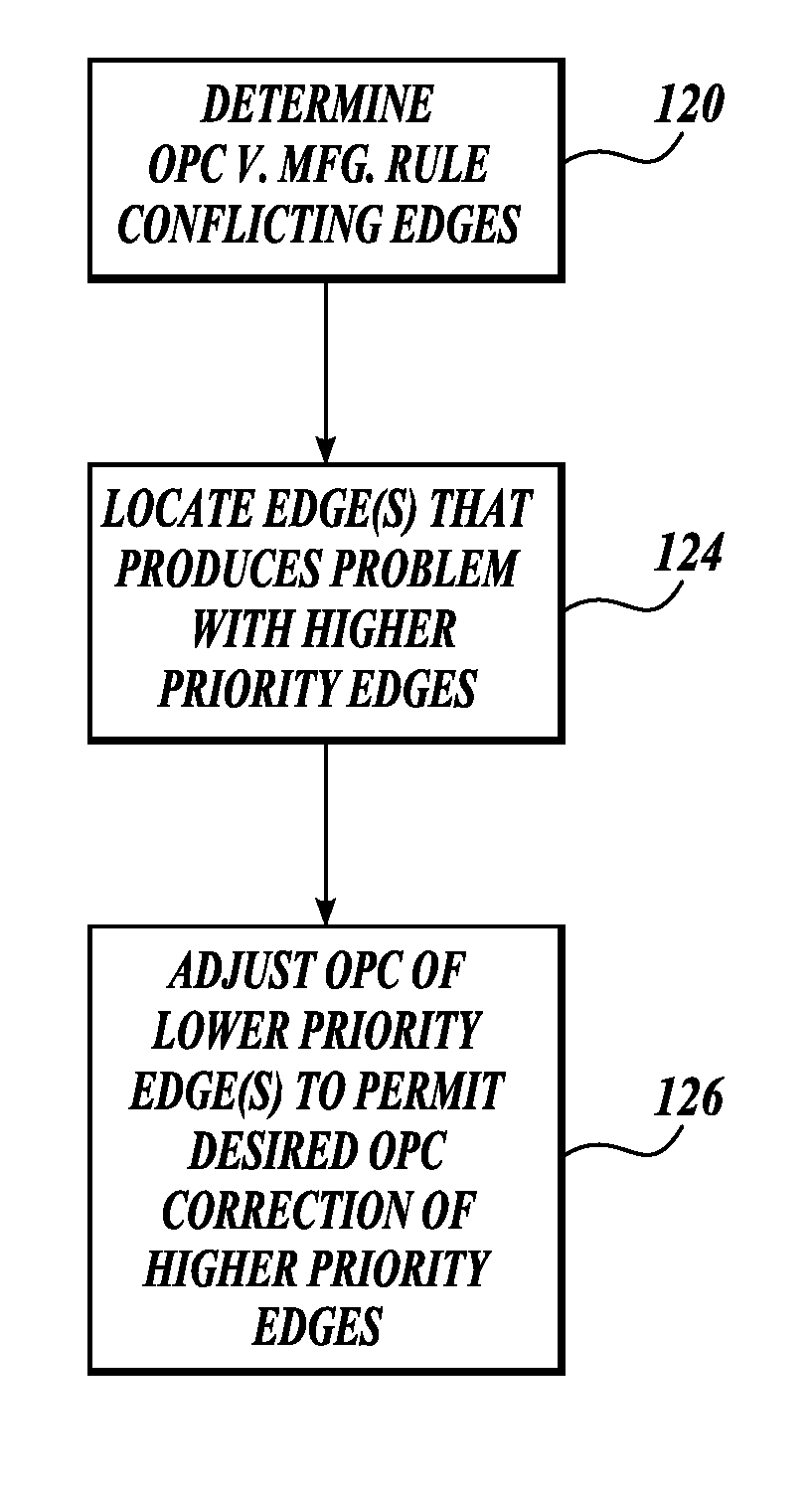

Short edge management in rule based OPC

Owner:MENTOR GRAPHICS CORP

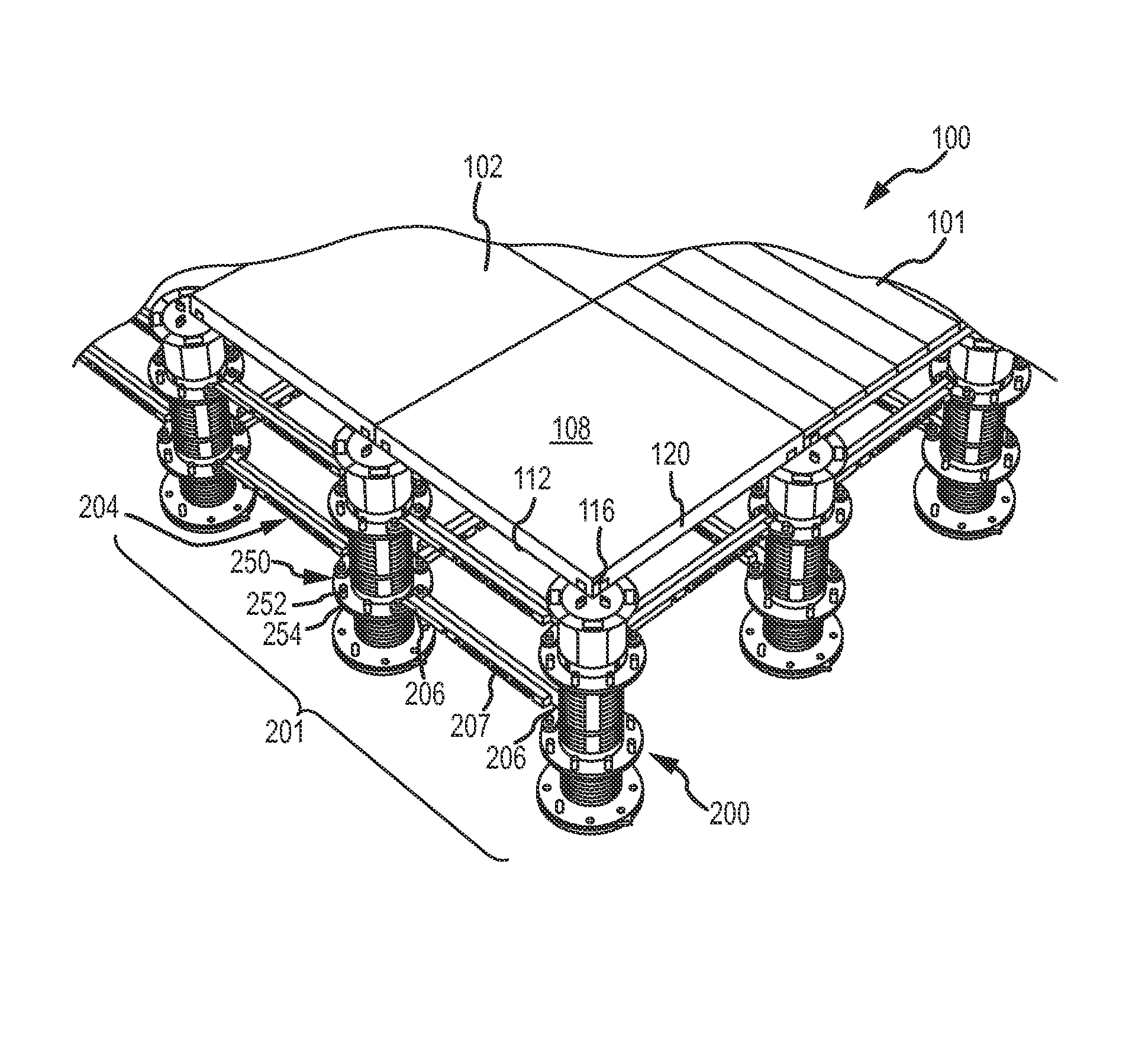

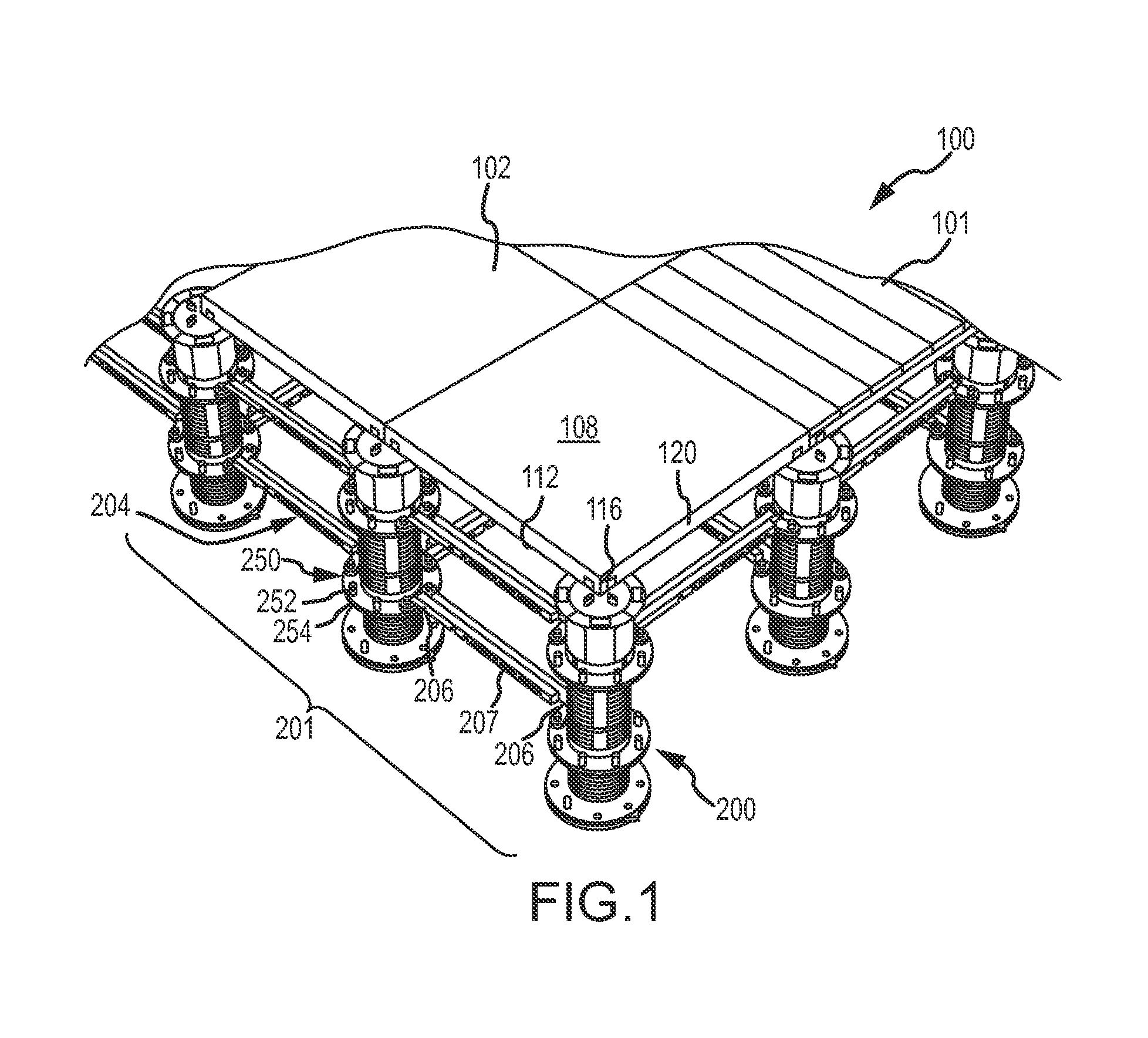

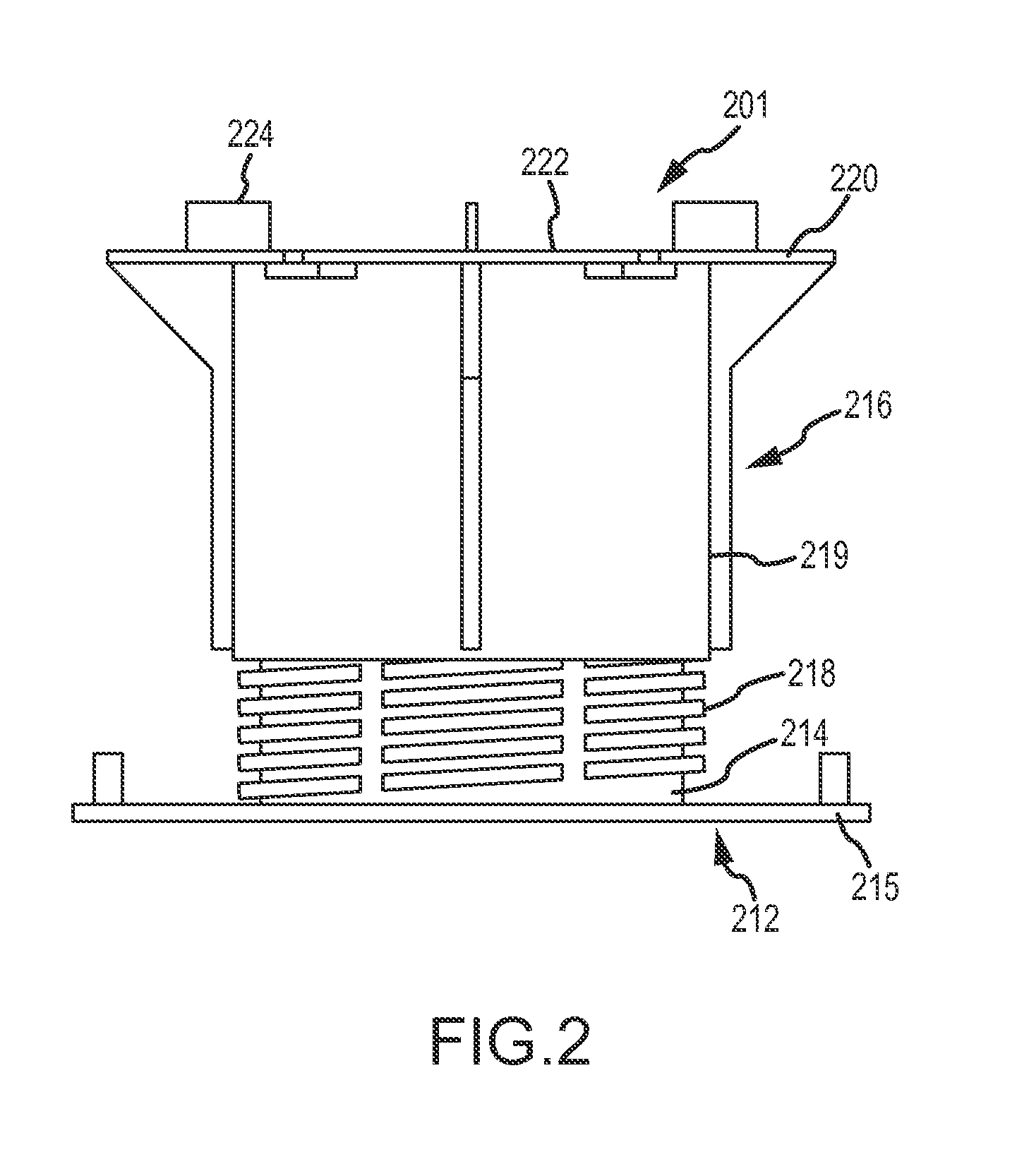

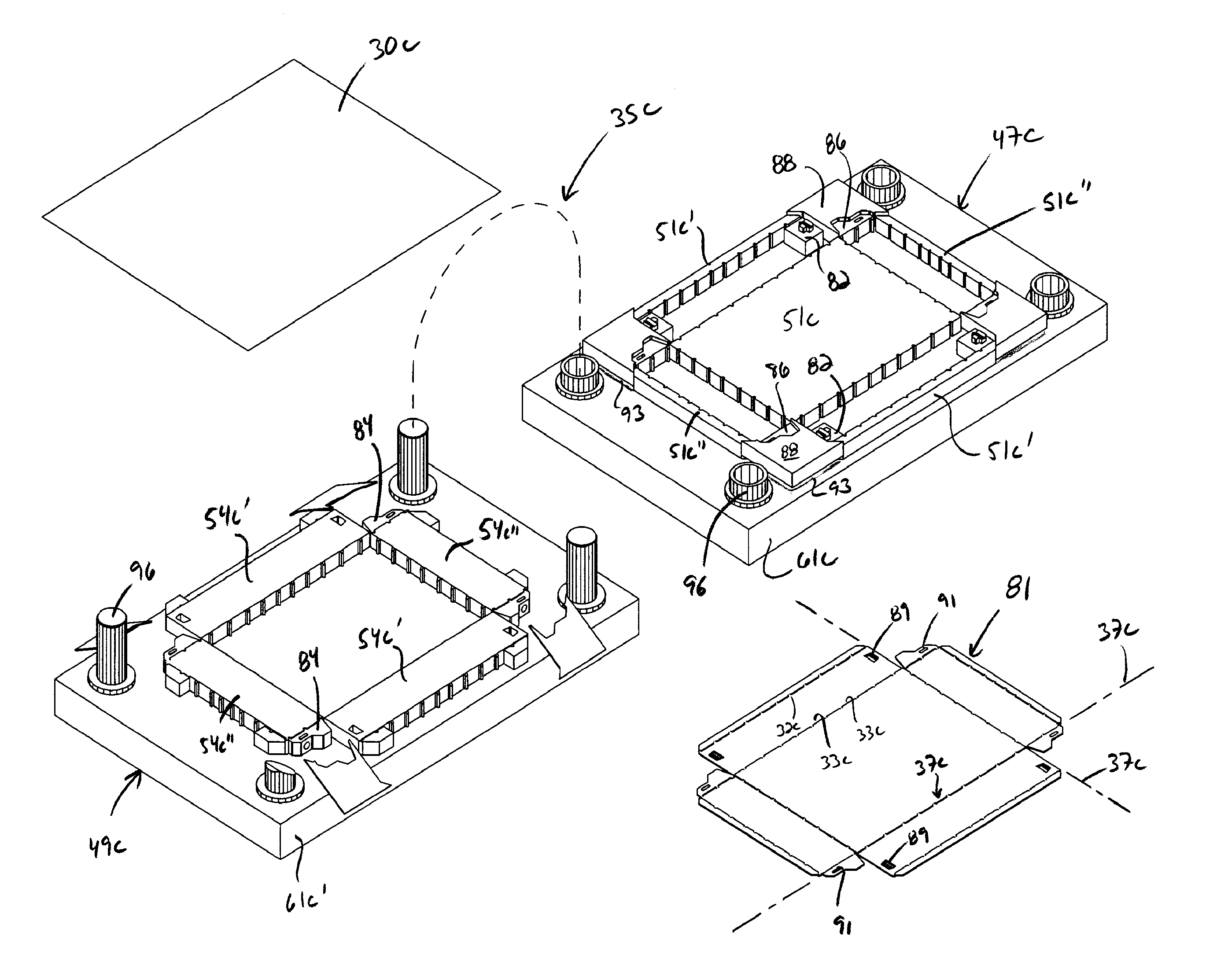

Restraint system for elevated surface tiles

ActiveUS8898999B1Improve structural stabilityPlace safeBuilding roofsCeilingsEdge segmentEngineering

Owner:UNITED CONSTR PROD LLC

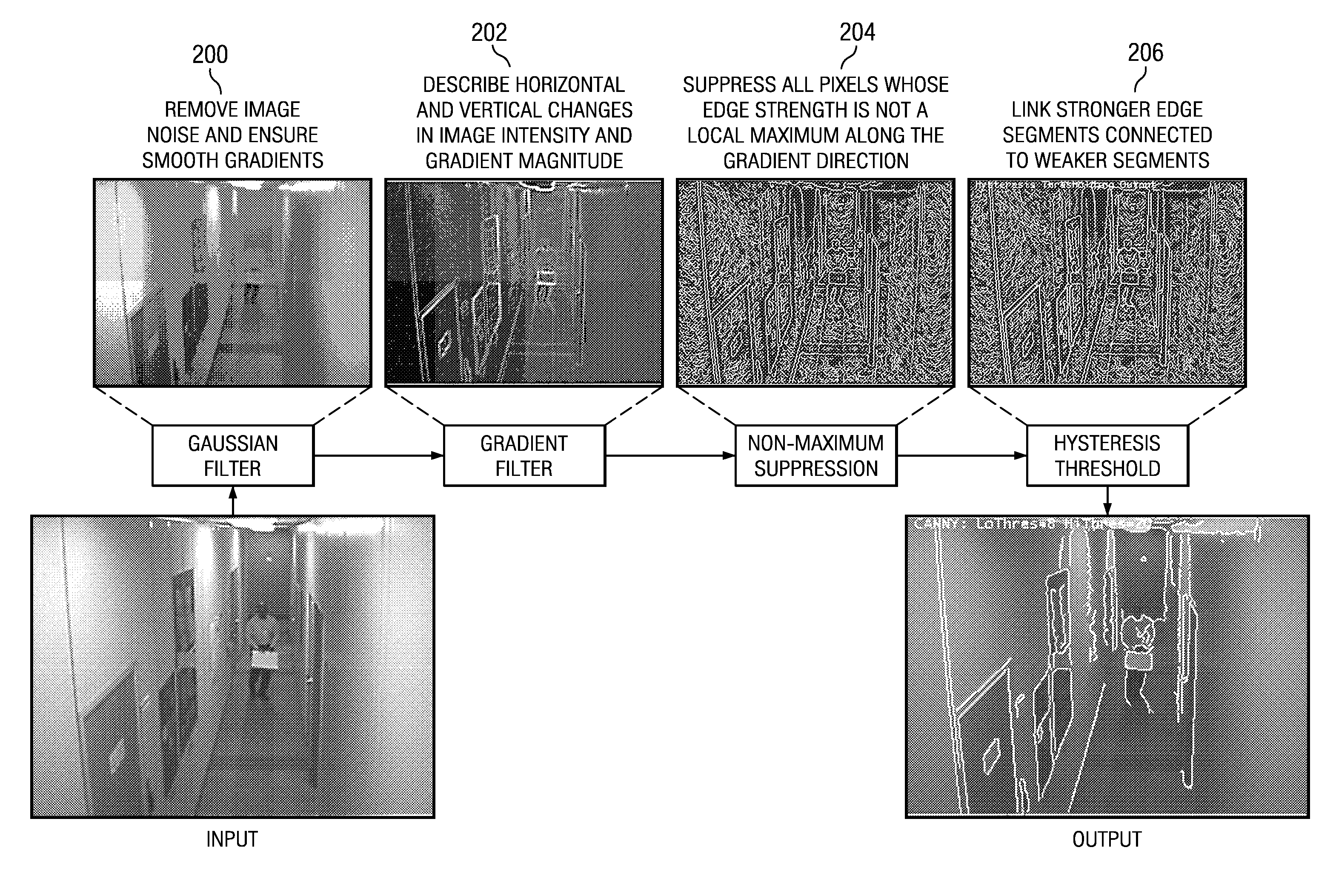

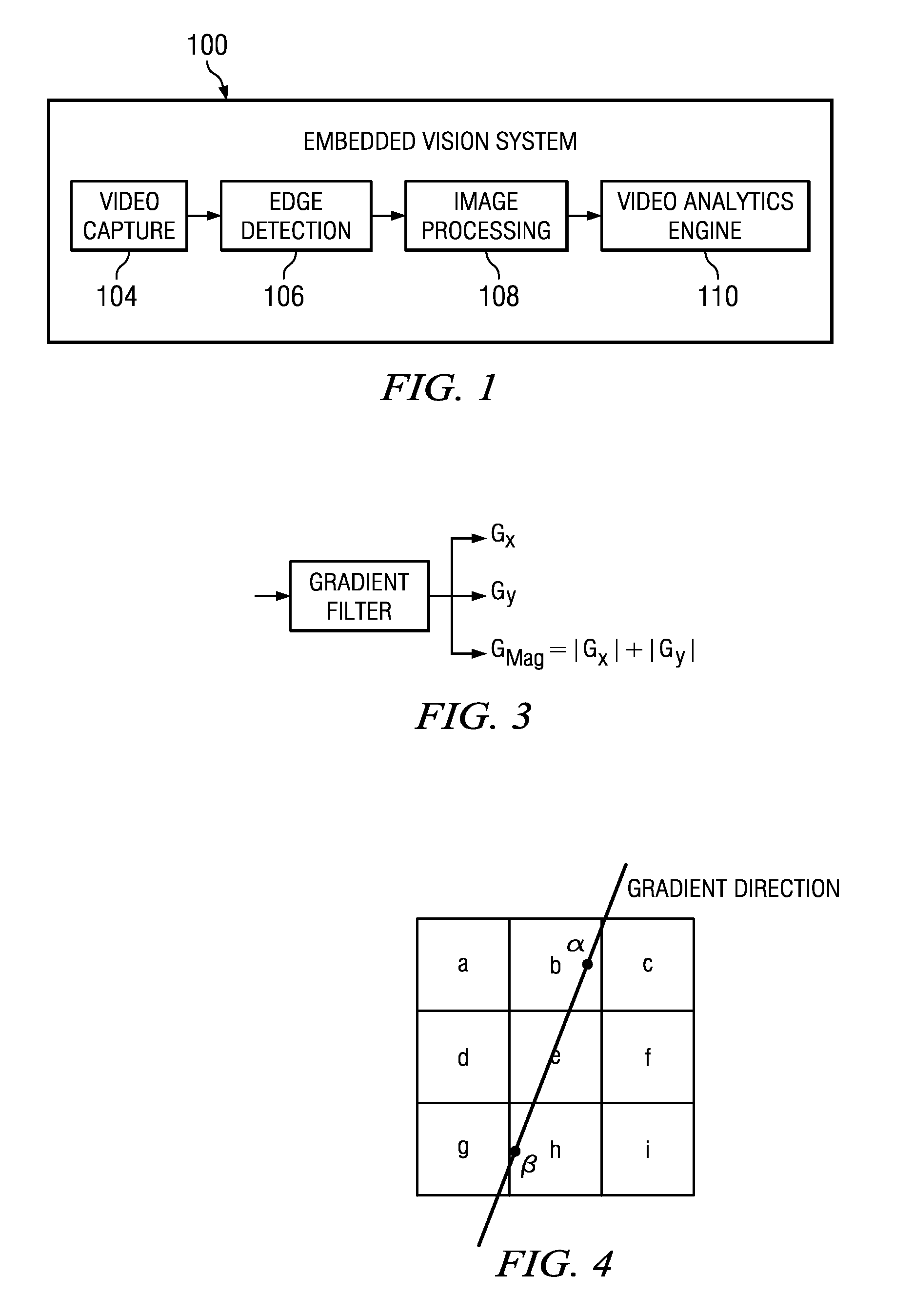

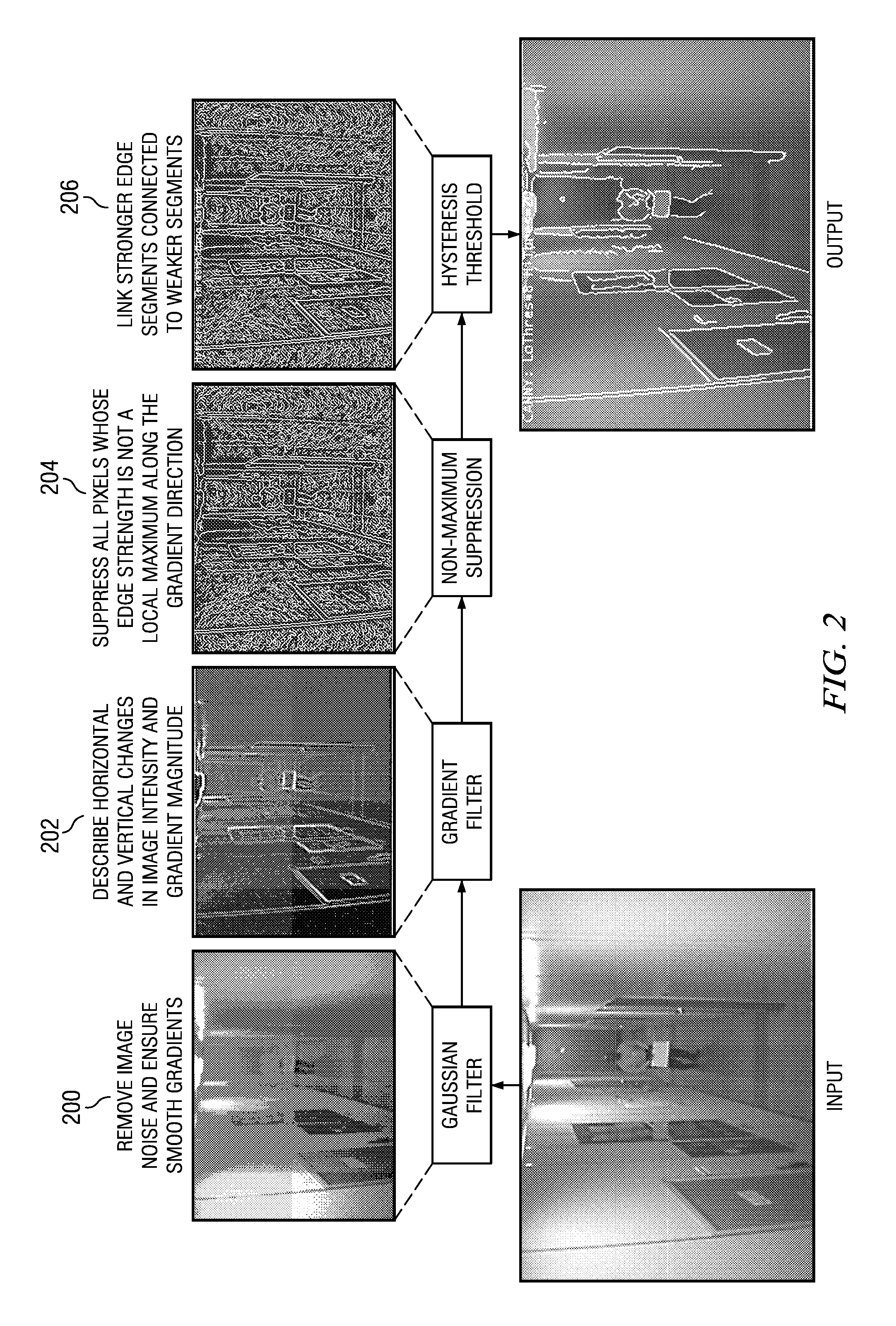

Fast Hysteresis Thresholding in Canny Edge Detection

A method of image processing is provided which includes non-recursive hysteresis thresholding in Canny edge detection. The non-recursive hysteresis thresholding reduces computational complexity and eliminates the potential for call stack overflow. More specifically, hysteresis thresholding is performed in a raster-scan order pass over the image data to connect edge segments to form continuous edges.

Owner:TEXAS INSTR INC

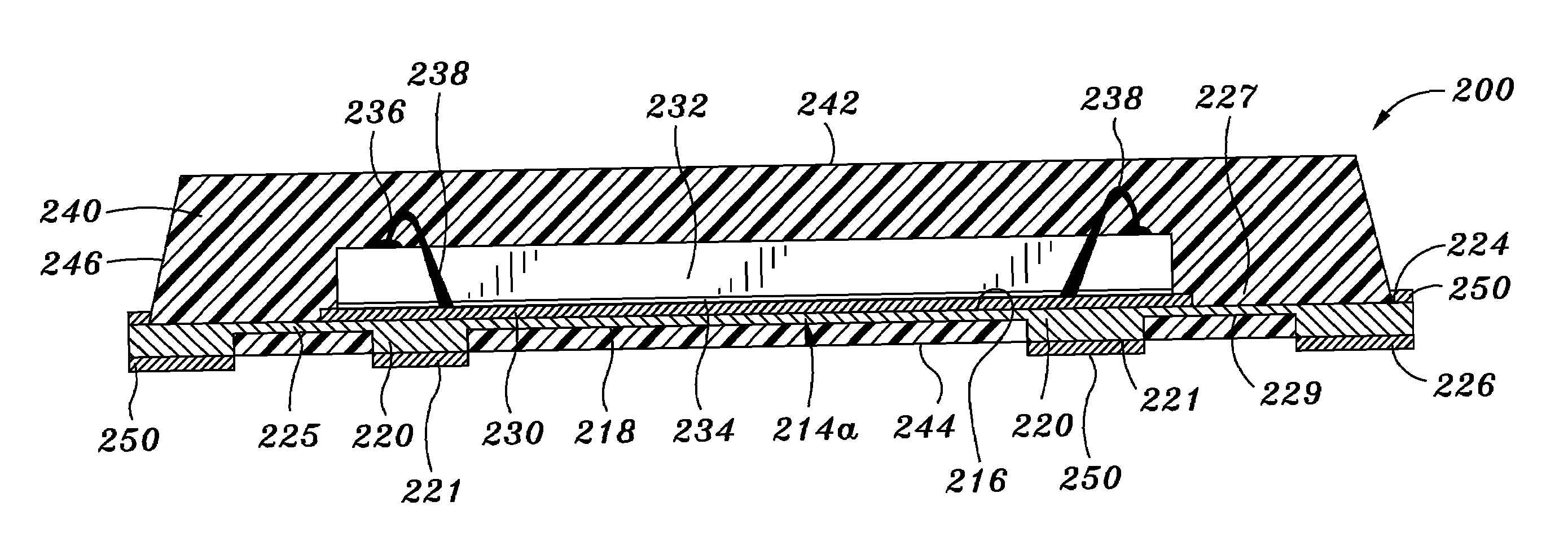

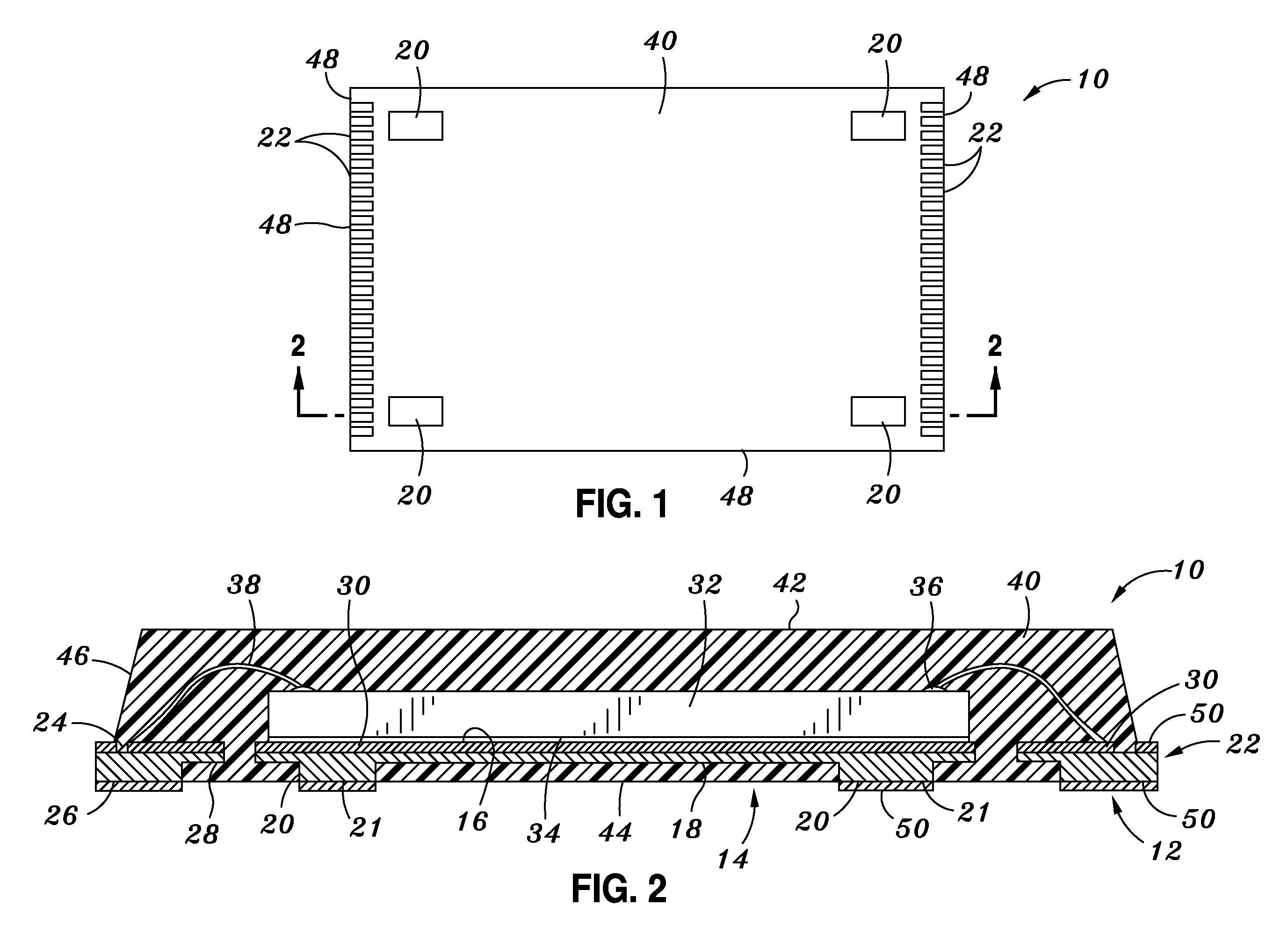

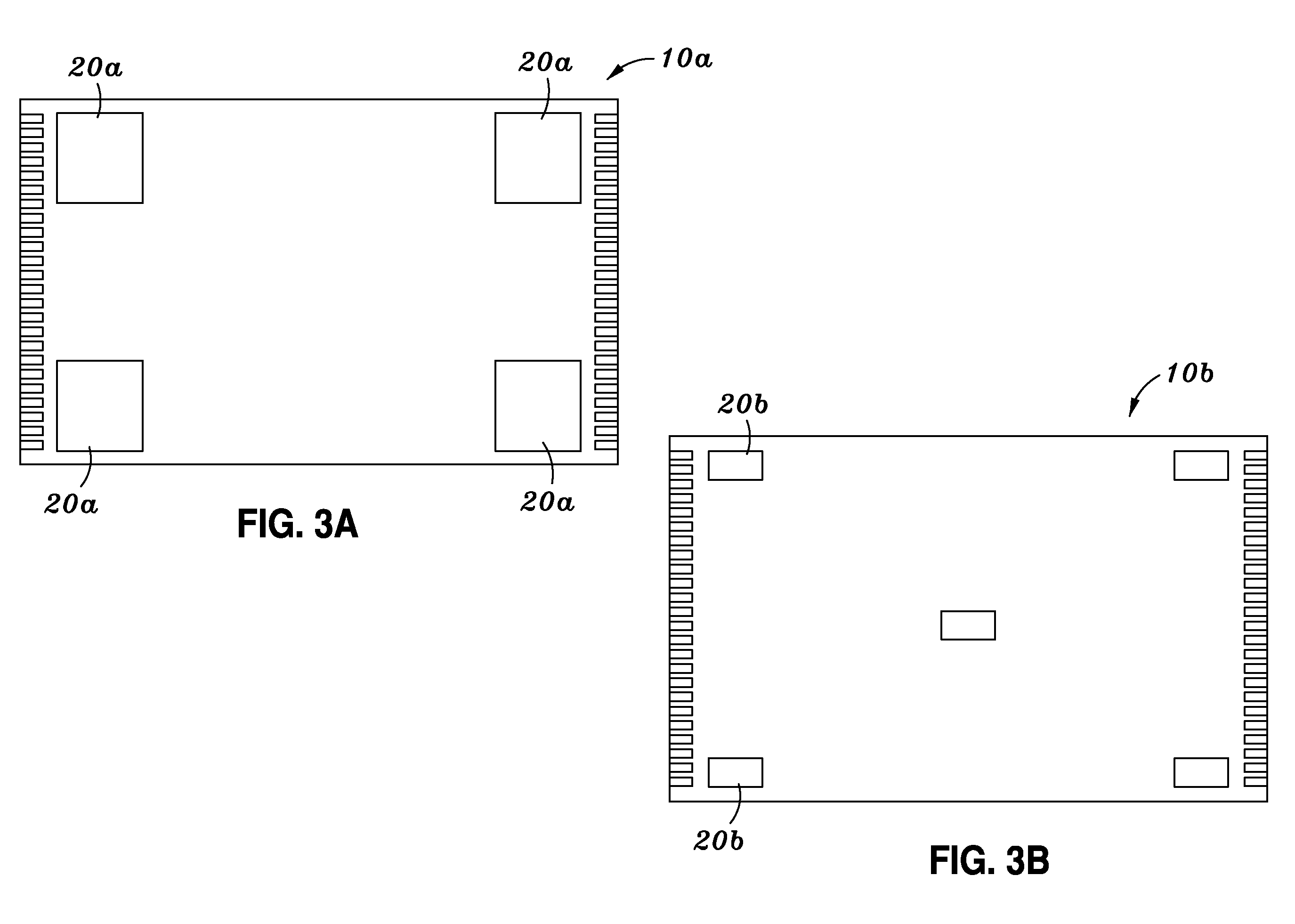

Integral spacer dots for touch screen

ActiveUS20060103632A1Easy to manufactureImprove accuracyContact surface shape/structureCathode-ray tube indicatorsEdge segmentEngineering

A touch screen comprising a flexible sheet comprising a substantially planar surface and integral compressible spacer dots formed thereon, where each spacer dot comprises a base cross section in the substantially planar surface of the flexible sheet defined by a first point or set of connected points intersecting an axis in the substantially planar surface, a second opposed point or set of connected points intersecting the axis, and first and second continuous edge segments connecting the first and second points or end points of the first and second sets of points on opposite sides of the axis, wherein the spacer dot has a variable height perpendicular to the substantially planar surface along the axis, and wherein the surface of the spacer dot extending above the base cross section is not equidistant from the mid-point of the axis between the intersections of the first and second points or sets of connected points and the axis.

Owner:EASTMAN KODAK CO

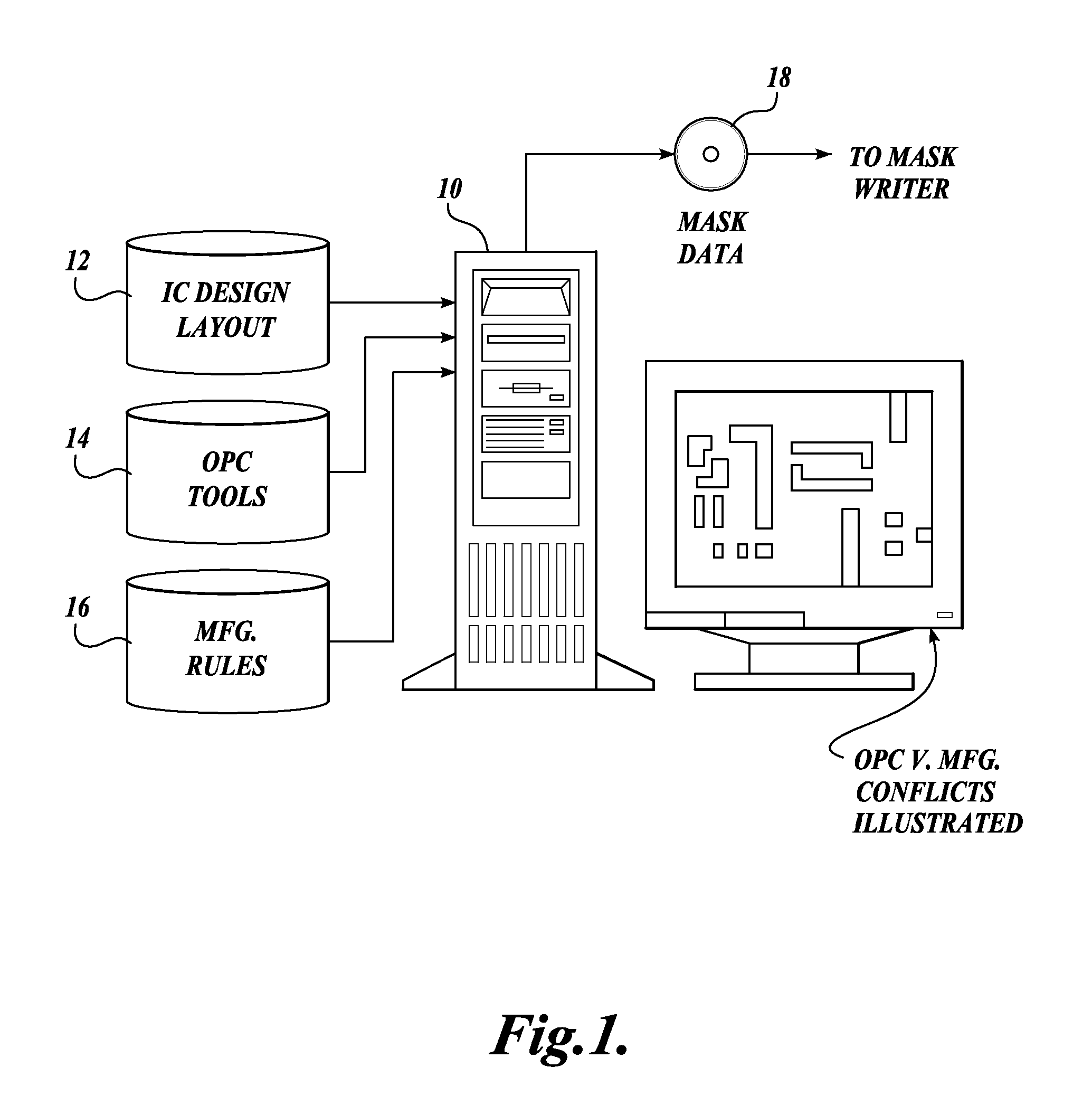

OPC conflict identification and edge priority system

ActiveUS20070118826A1Preventing a better OPC correctionAvoid poor resultsOriginals for photomechanical treatmentSoftware simulation/interpretation/emulationEdge segmentVerification system

An integrated circuit verification system provides an indication of conflicts between an OPC suggested correction and a manufacturing rule. The indication specifies which edge segments are in conflict so that a user may remove the conflict to achieve a better OPC result. In another embodiment of the invention, edge segments are assigned a priority such that the correction of a lower priority edge does not hinder a desired OPC correction of a higher priority edge.

Owner:SIEMENS PROD LIFECYCLE MANAGEMENT SOFTWARE INC

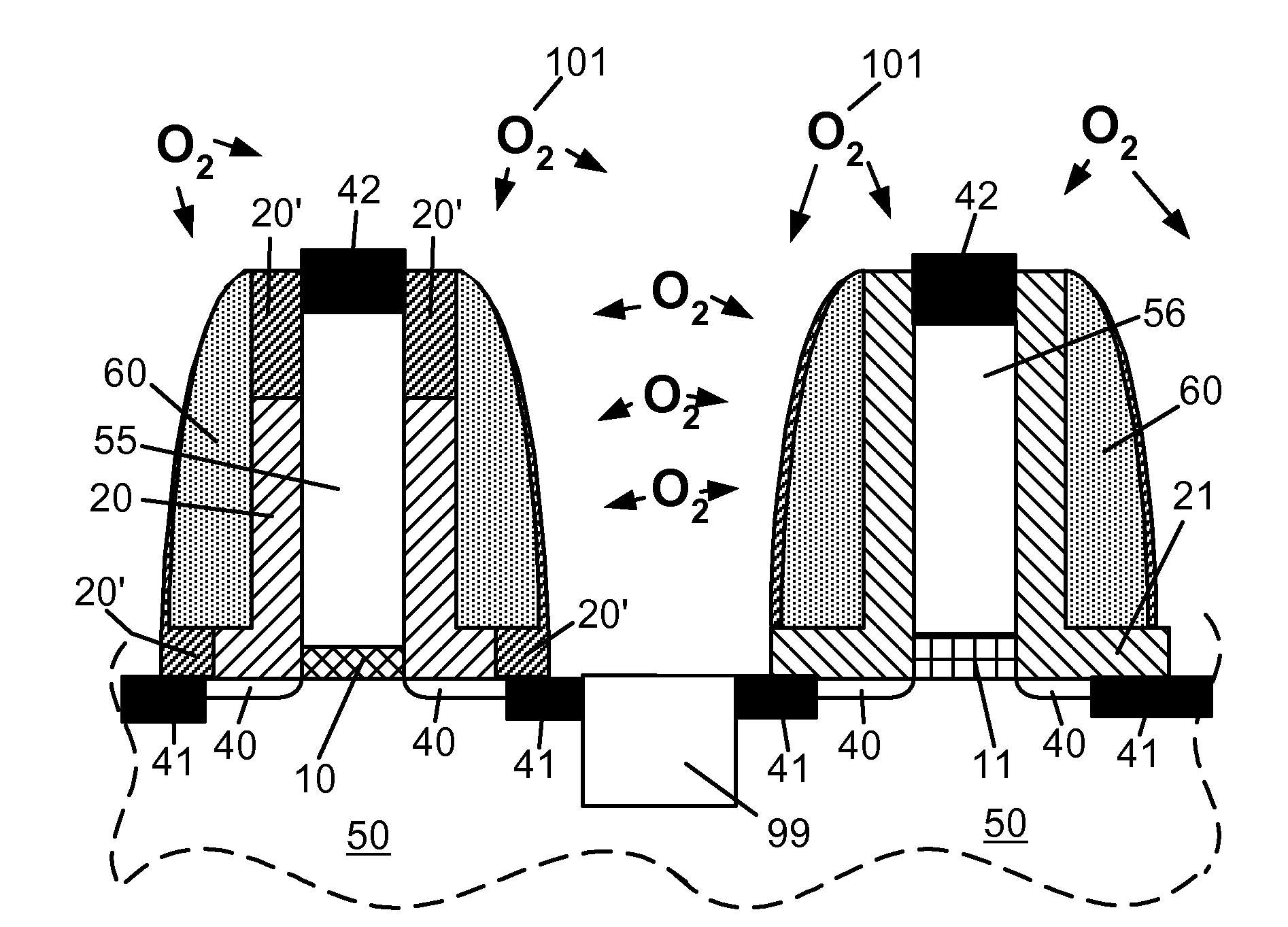

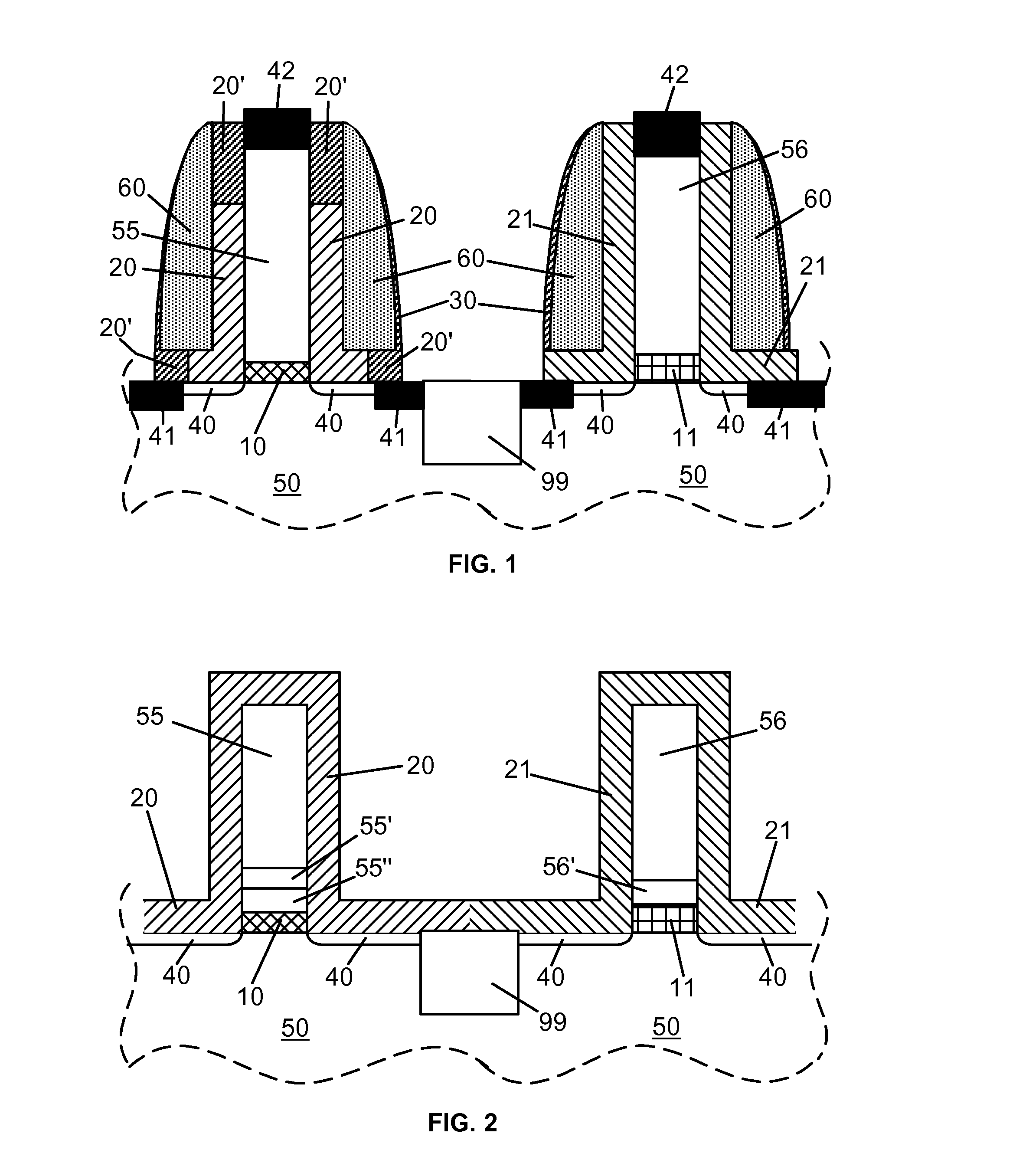

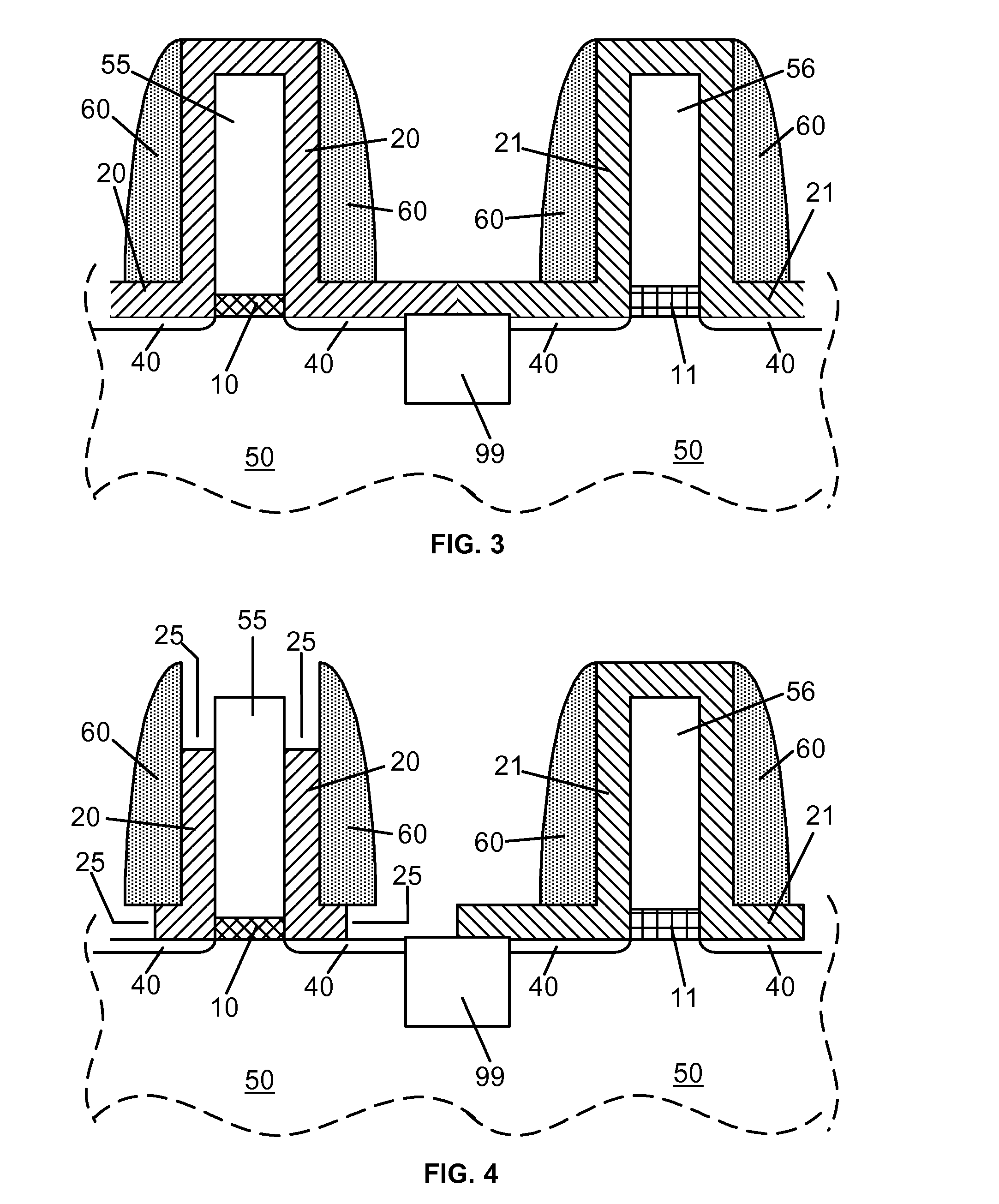

CMOS Circuits with High-K Gate Dielectric

InactiveUS20080272438A1Threshold voltage shiftTransistorSemiconductor/solid-state device manufacturingDielectricCMOS

A CMOS structure is disclosed in which a first type FET contains a liner, which liner has oxide and nitride portions. The nitride portions are forming the edge segments of the liner. These nitride portions are capable of preventing oxygen from reaching the high-k dielectric gate insulator of the first type FET. A second type FET device of the CMOS structure has a liner without nitride portions. As a result, an oxygen exposure is capable to shift the threshold voltage of the second type of FET, without affecting the threshold value of the first type FET. The disclosure also teaches methods for producing the CMOS structure in which differing type of FET devices have their threshold values set independently from one another.

Owner:IBM CORP

Performing OPC on structures with virtual edges

ActiveUS20060188796A1Improve fidelityImprove positionOriginals for photomechanical treatmentPhotographic processesResolution enhancement technologiesEdge segment

A method for compensating for optical distortions occurring in regions associated with non-phase-shifting regions in a mask or reticle. OPC or other resolution enhancement techniques are performed on one or more edge segments associated with adjacent phase-shifting regions in order to compensate for edge position errors occurring in areas corresponding to non-phase-shifting regions.

Owner:SIEMENS PROD LIFECYCLE MANAGEMENT SOFTWARE INC

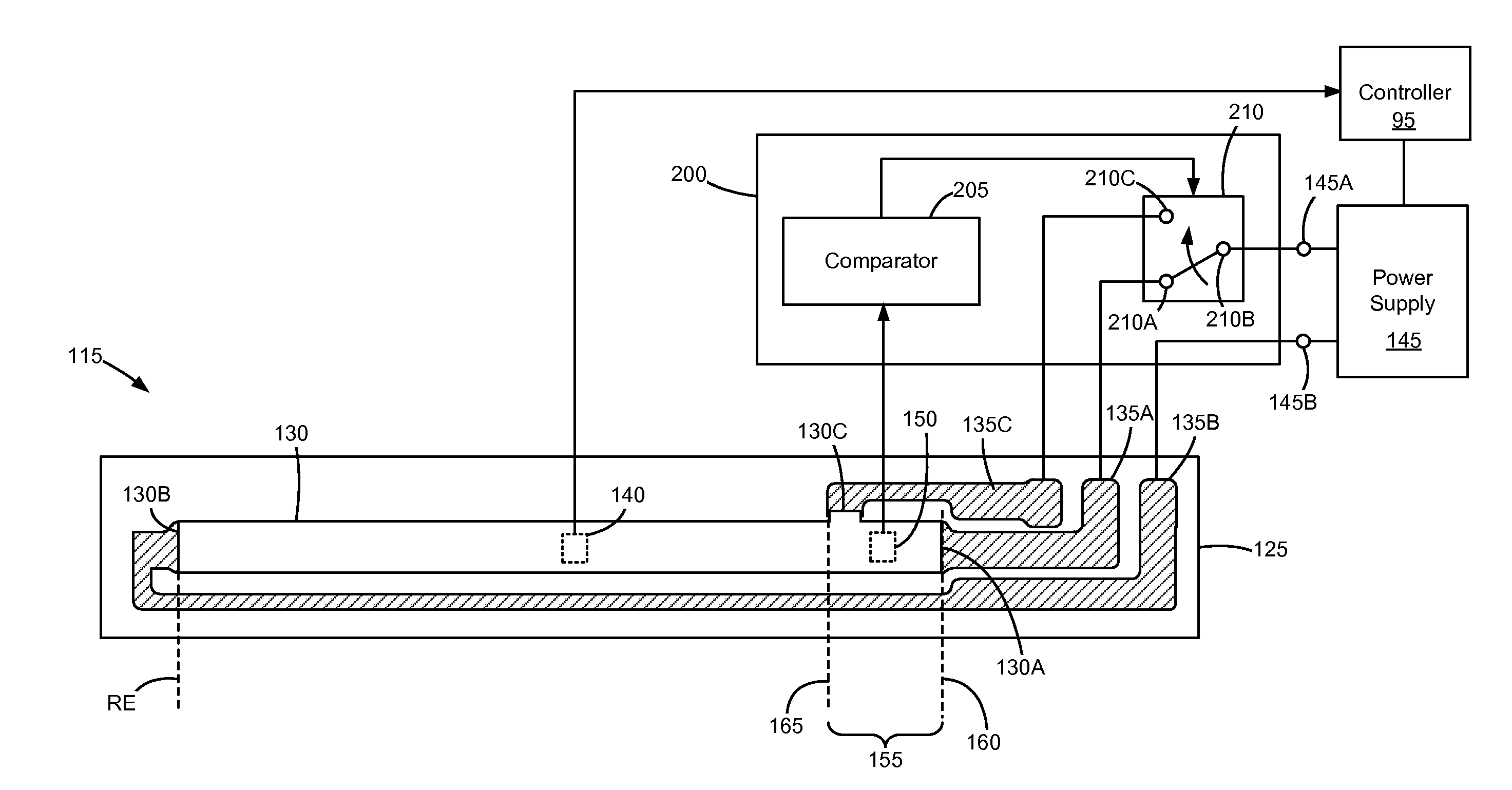

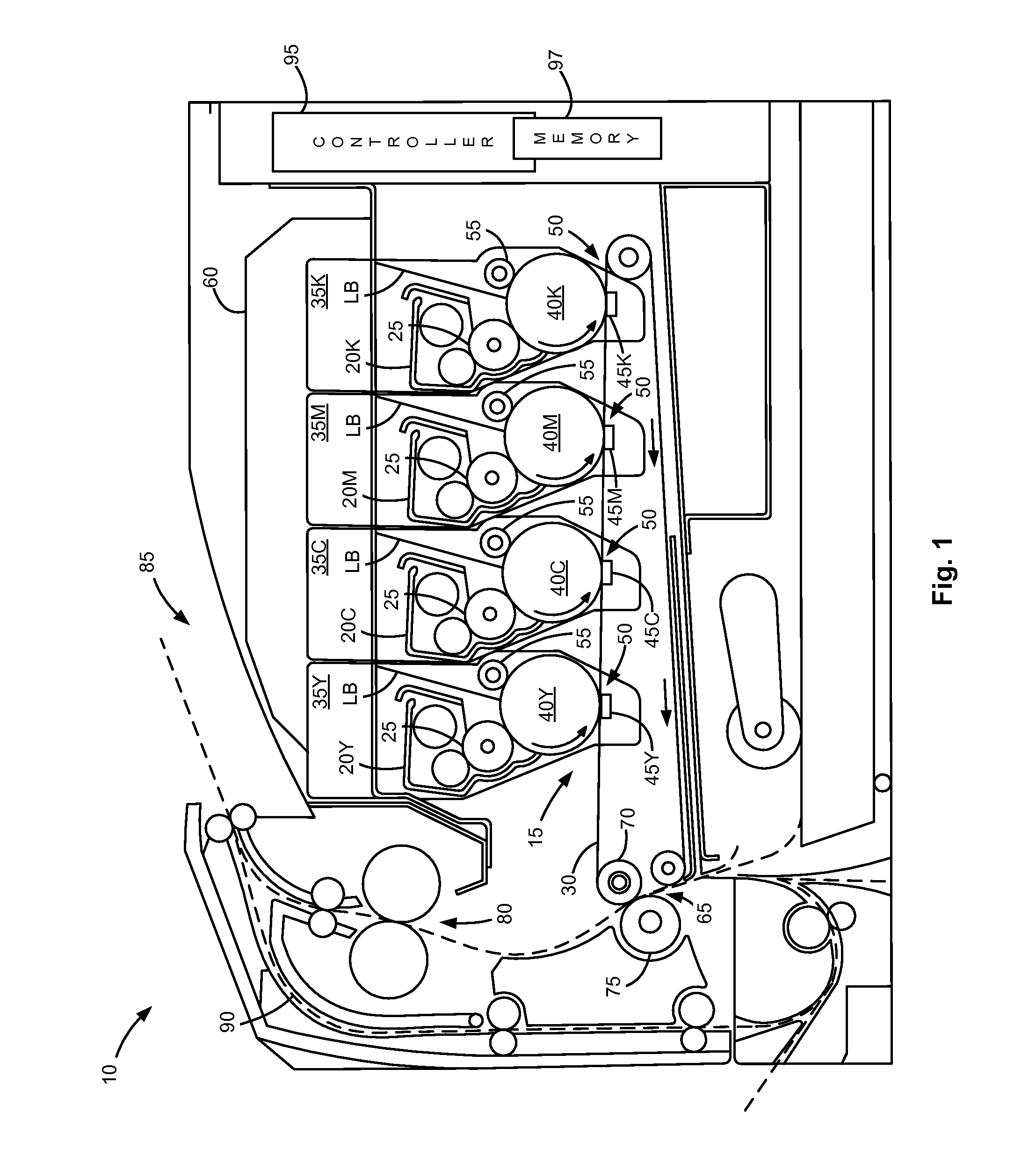

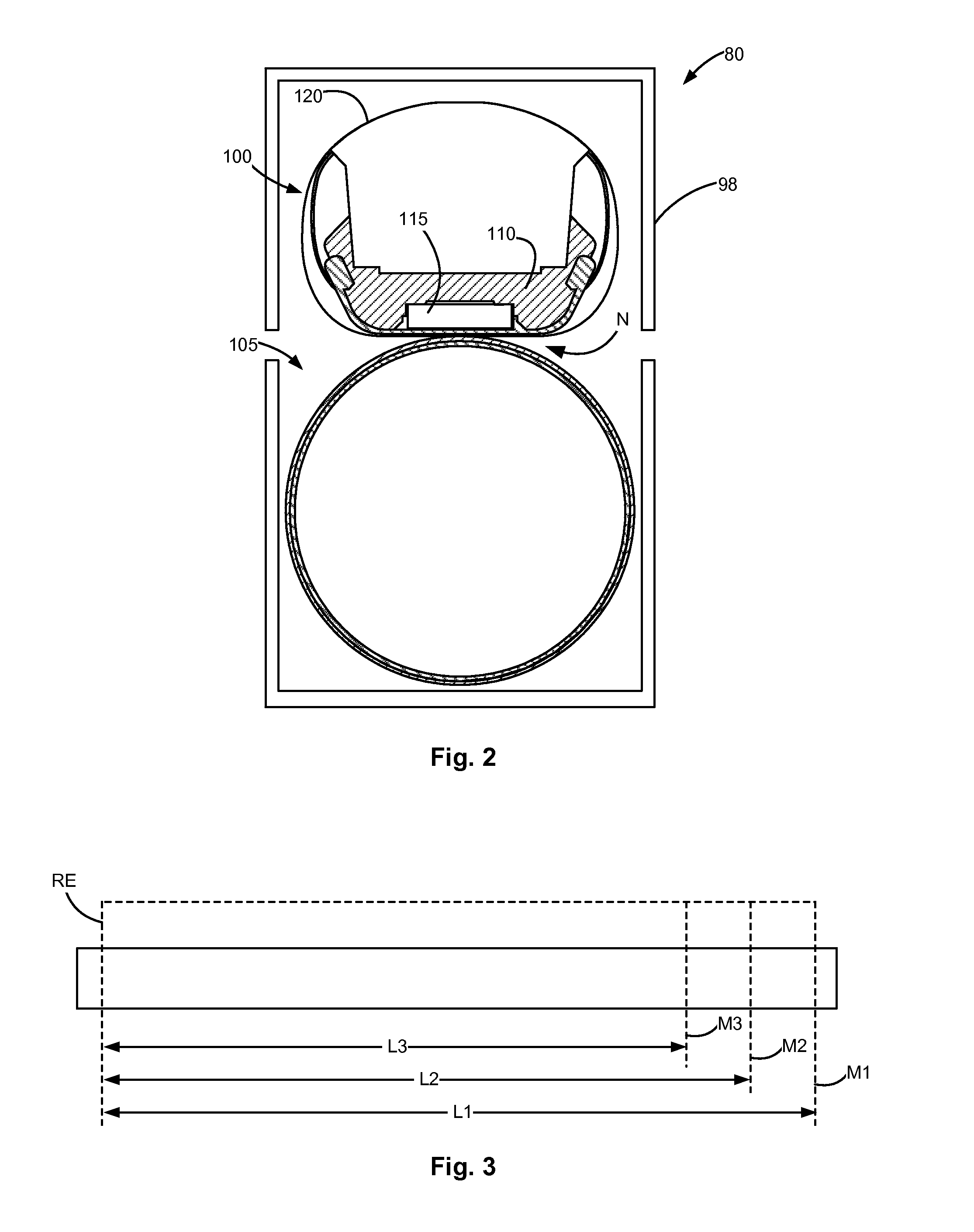

Fuser Assembly with Automatic Media Width Sensing and Thermal Compensation

InactiveUS20150086231A1Electrographic process apparatusElectrical resistance and conductanceElectrical conductor

A fuser assembly for an electrophotographic imaging device includes a heater including a substrate, a resistive trace disposed and running along a length of the substrate for generating heat for fusing toner to a sheet of media when a current is passed therethrough, and at least three conductors for passing current through the resistive trace. The at least three conductors include a first conductor connected to a first end portion of the resistive trace, a second conductor connected to a second end portion of the resistive trace, and a third conductor connected to the resistive trace at a location between the first end portion and the second end portion thereof. A temperature sensor senses a temperature of an edge segment of the substrate. Based upon the temperature sensed, circuitry selects between the first conductor and the third conductor for passing current through the resistive trace.

Owner:LEXMARK INT INC

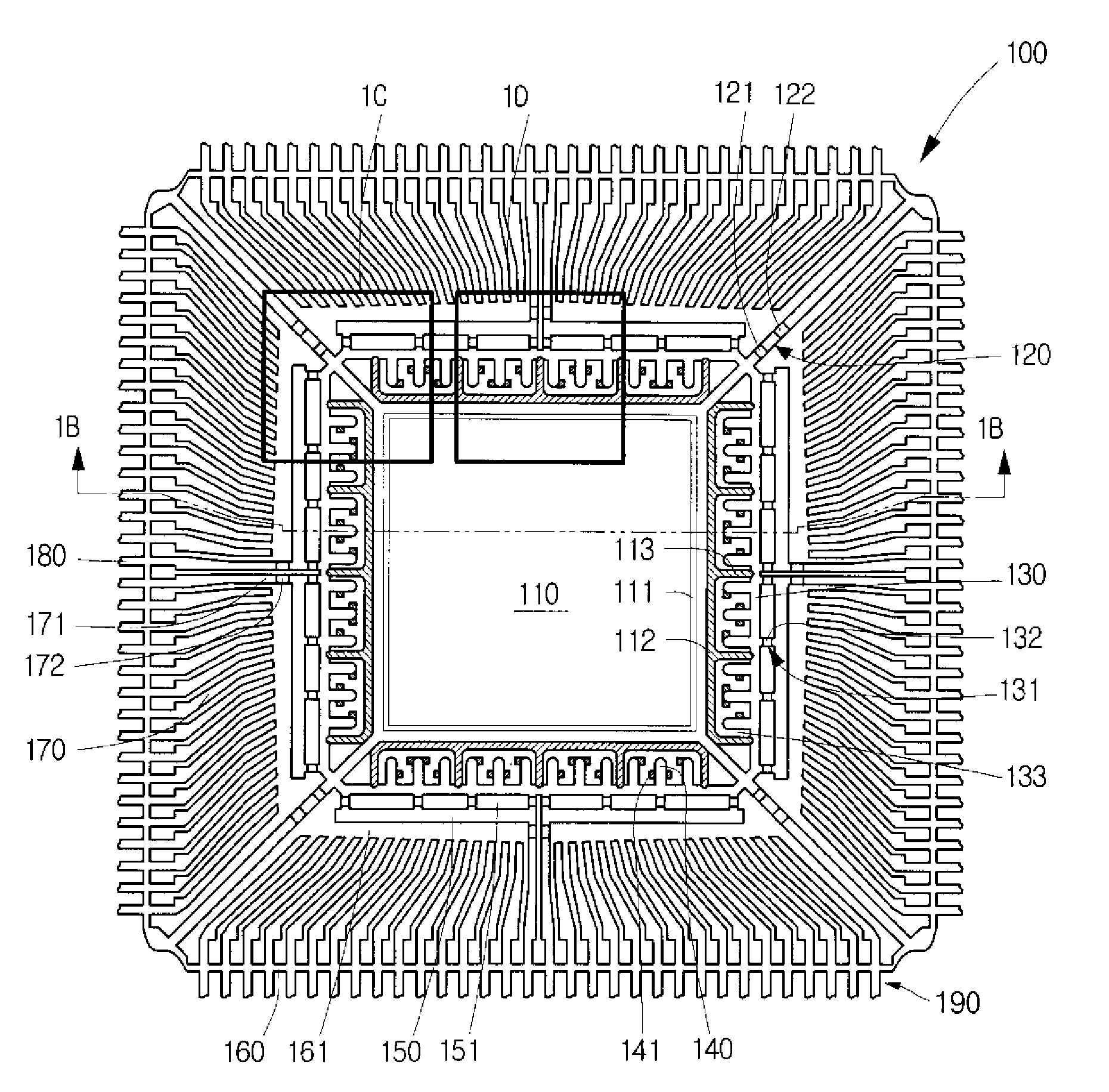

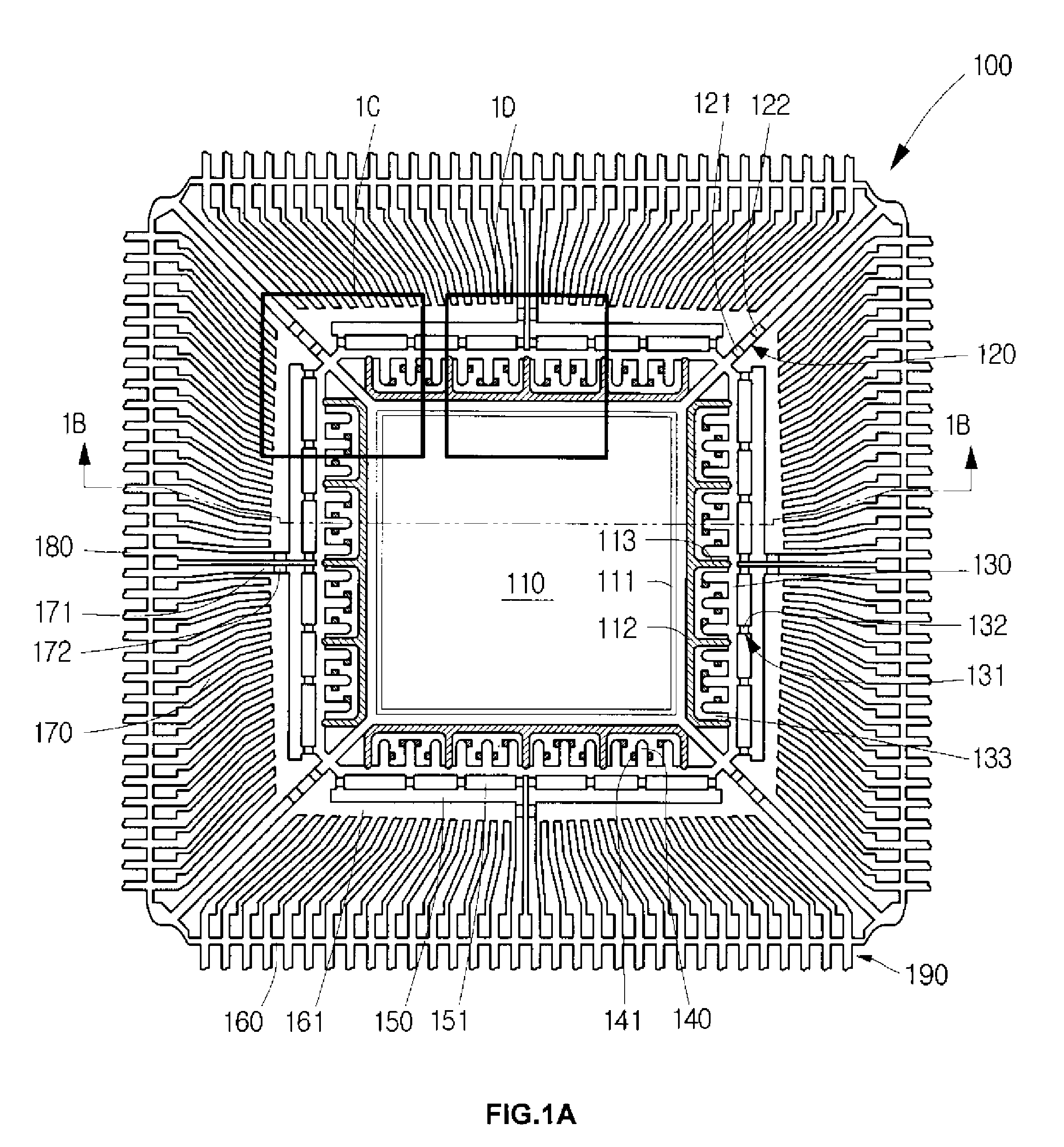

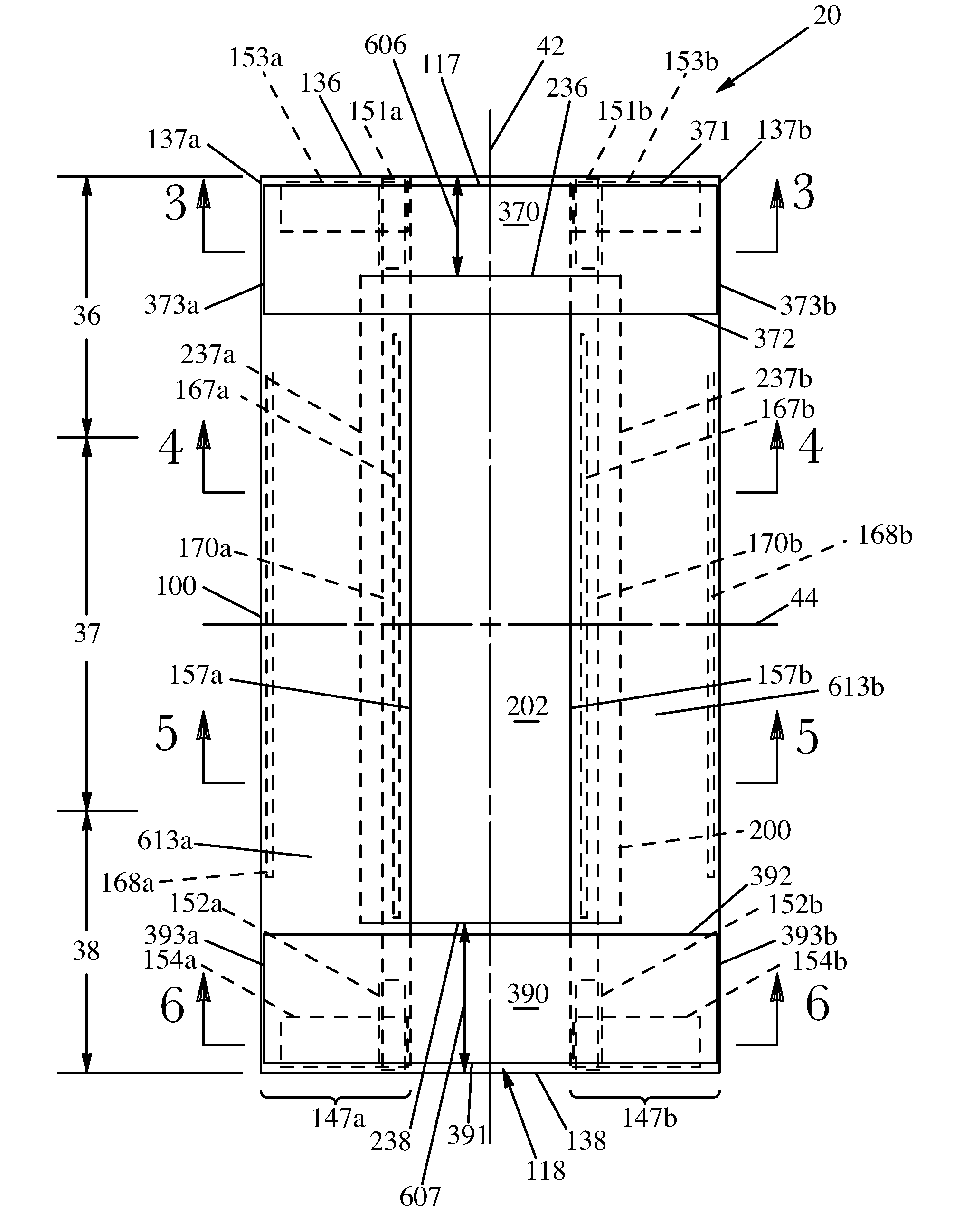

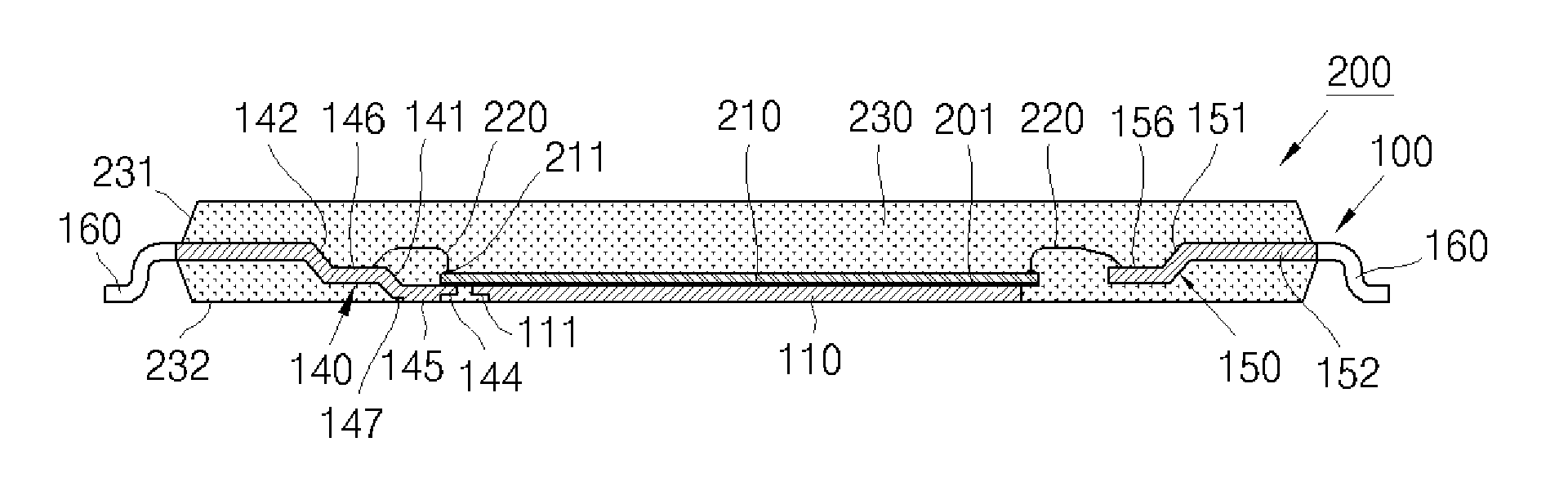

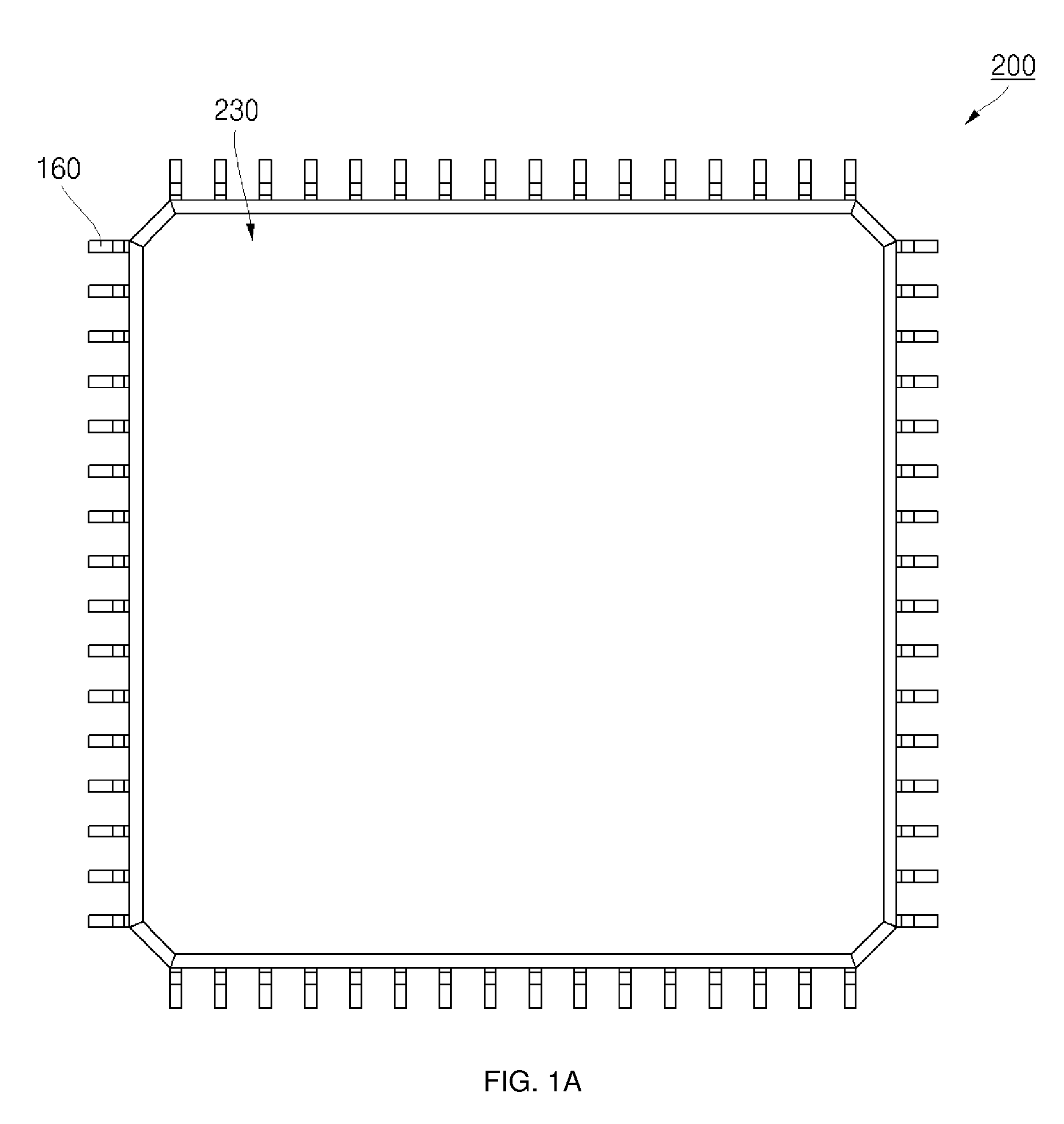

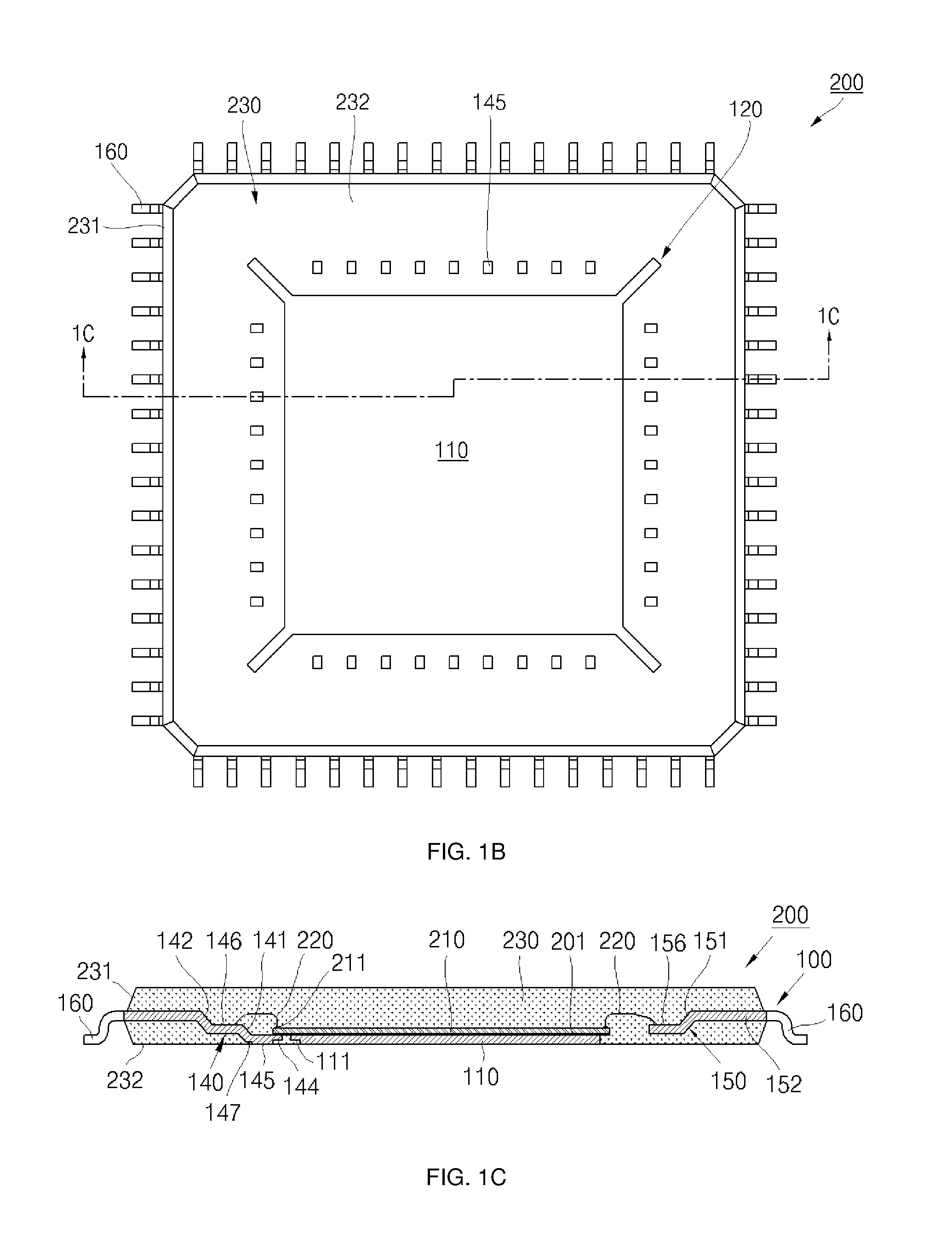

Semiconductor device including leadframe having power bars and increased I/O

ActiveUS7875963B1Maximize available numberEffectively electrically isolateSemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceEdge segment

In accordance with the present invention, there is provided a semiconductor package (e.g., a QFP package) including a uniquely configured leadframe sized and configured to maximize the available number of exposed leads in the semiconductor package. More particularly, the semiconductor package includes a generally planar die pad or die paddle defining multiple peripheral edge segments. In addition, the semiconductor package includes a plurality of leads. Some of these leads include bottom surface portions which, in the completed semiconductor package, are exposed and at least partially circumvent the die pad, with other leads including portions which protrude from respective side surfaces of a package body in the completed semiconductor package. The semiconductor package also includes one or more power bars and / or one or more ground rings which are integral portions of the original leadframe used to fabricate the same.

Owner:AMKOR TECH SINGAPORE HLDG PTE LTD

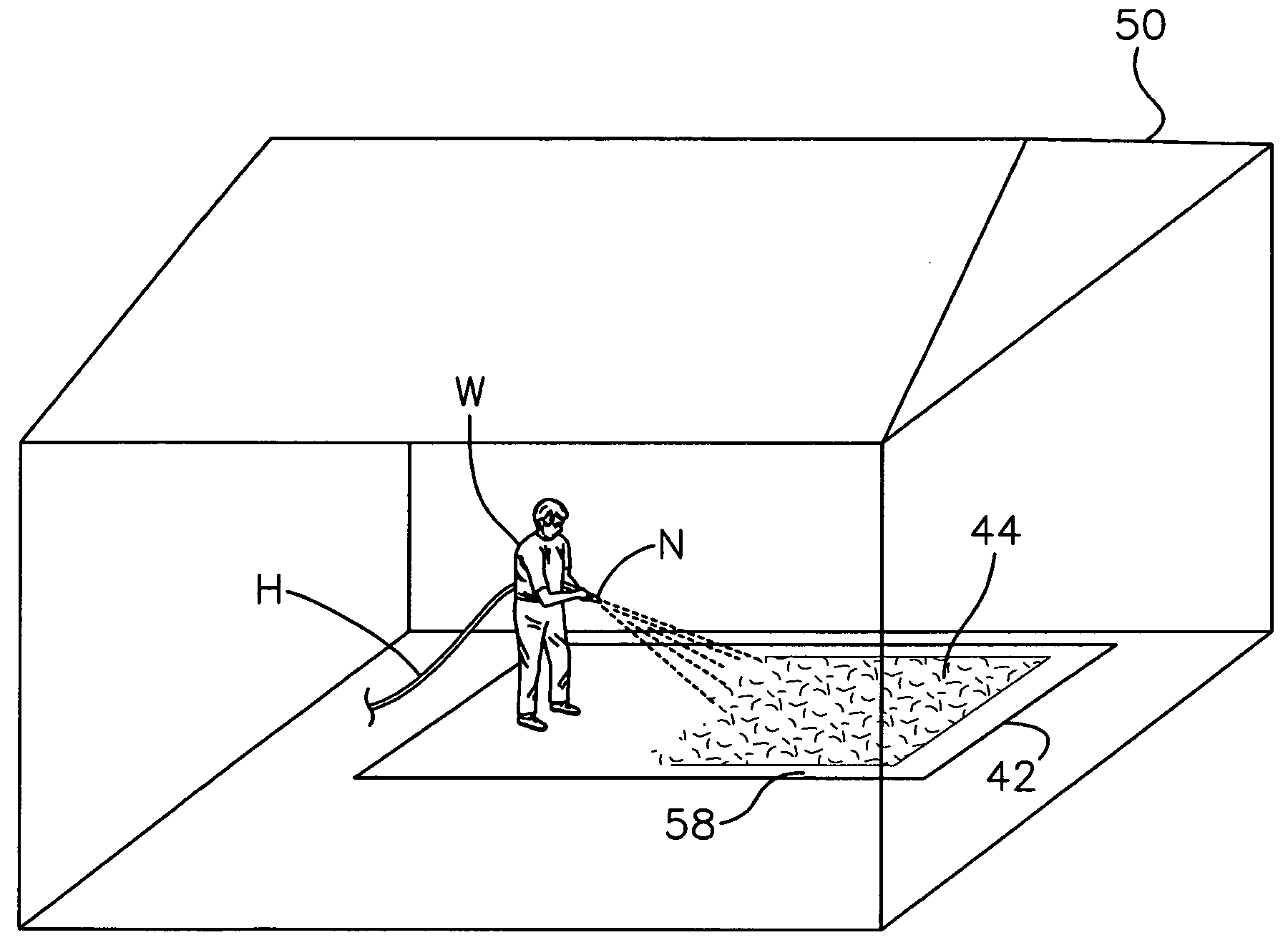

Secondary containment panels and process for making and installing same

InactiveUS20100140262A1Efficient and improved techniqueImproved and efficientSolid waste disposalLarge containersEdge segmentAbove ground

A method of manufacturing a plurality of secondary containment panels and assembling and installing the panels in a secondary containment system of an above-ground liquid storage tank or other retention facility includes forming a plurality of flexible substrate pieces. A liquid impermeable coating is applied to the upper surface of each piece such that an edge segment of the piece remains uncoated. The coating is applied to the substrate piece in an indoor enclosure. The coated pieces are delivered to the site of the tank and extended across the ground adjacent to the tank. At least a pair of the pieces are juxtaposed relative to one another such that a first one of the pieces overlaps the uncoated segment of the second piece to form a seam. An adhesive substance is then applied to the seam to fasten the first and second pieces together.

Owner:TITELINE LLC

Semiconductor package having leadframe with exposed anchor pads

ActiveUS7687893B2Semiconductor/solid-state device detailsSolid-state devicesEdge segmentHigh density

Owner:AMKOR TECH SINGAPORE HLDG PTE LTD

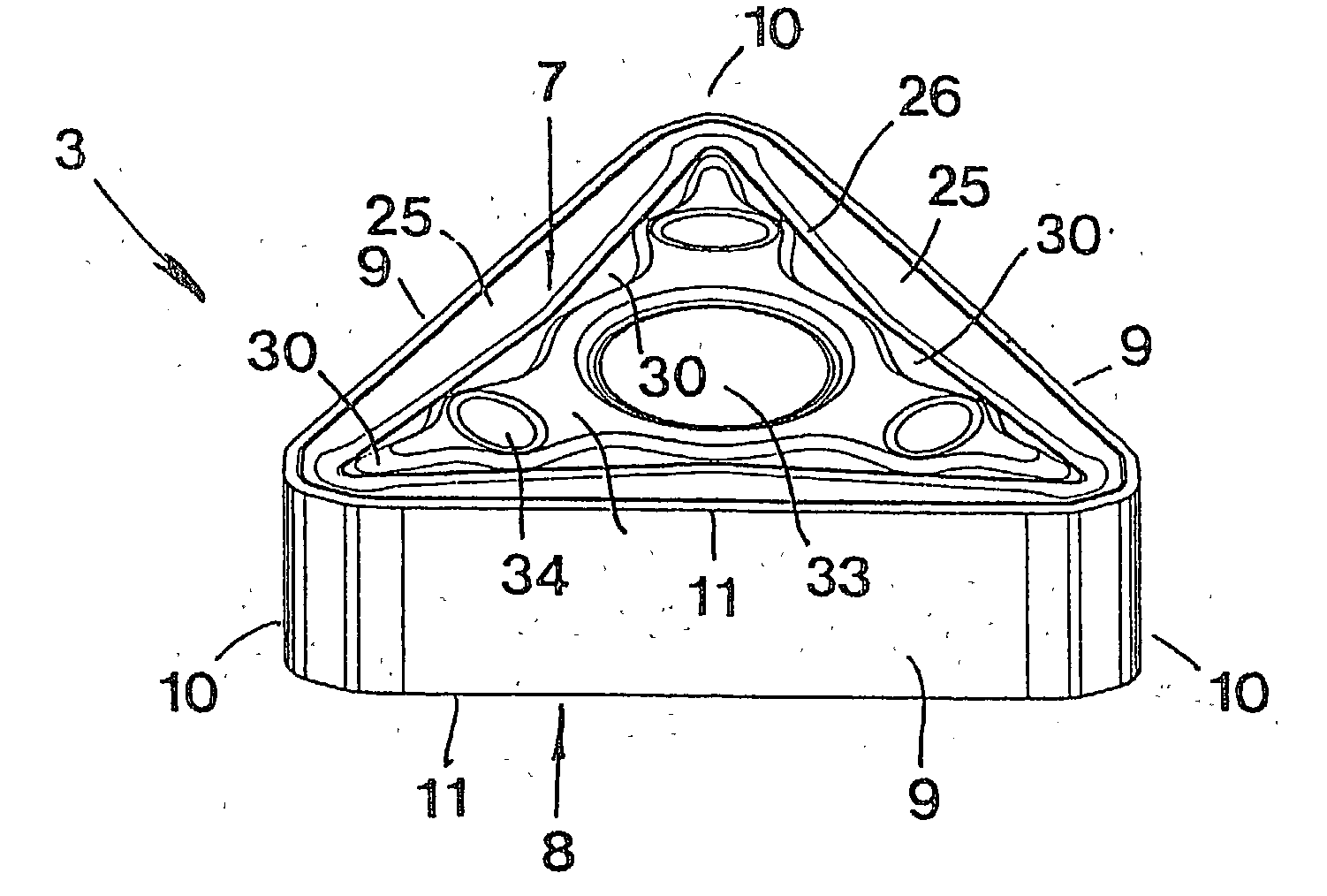

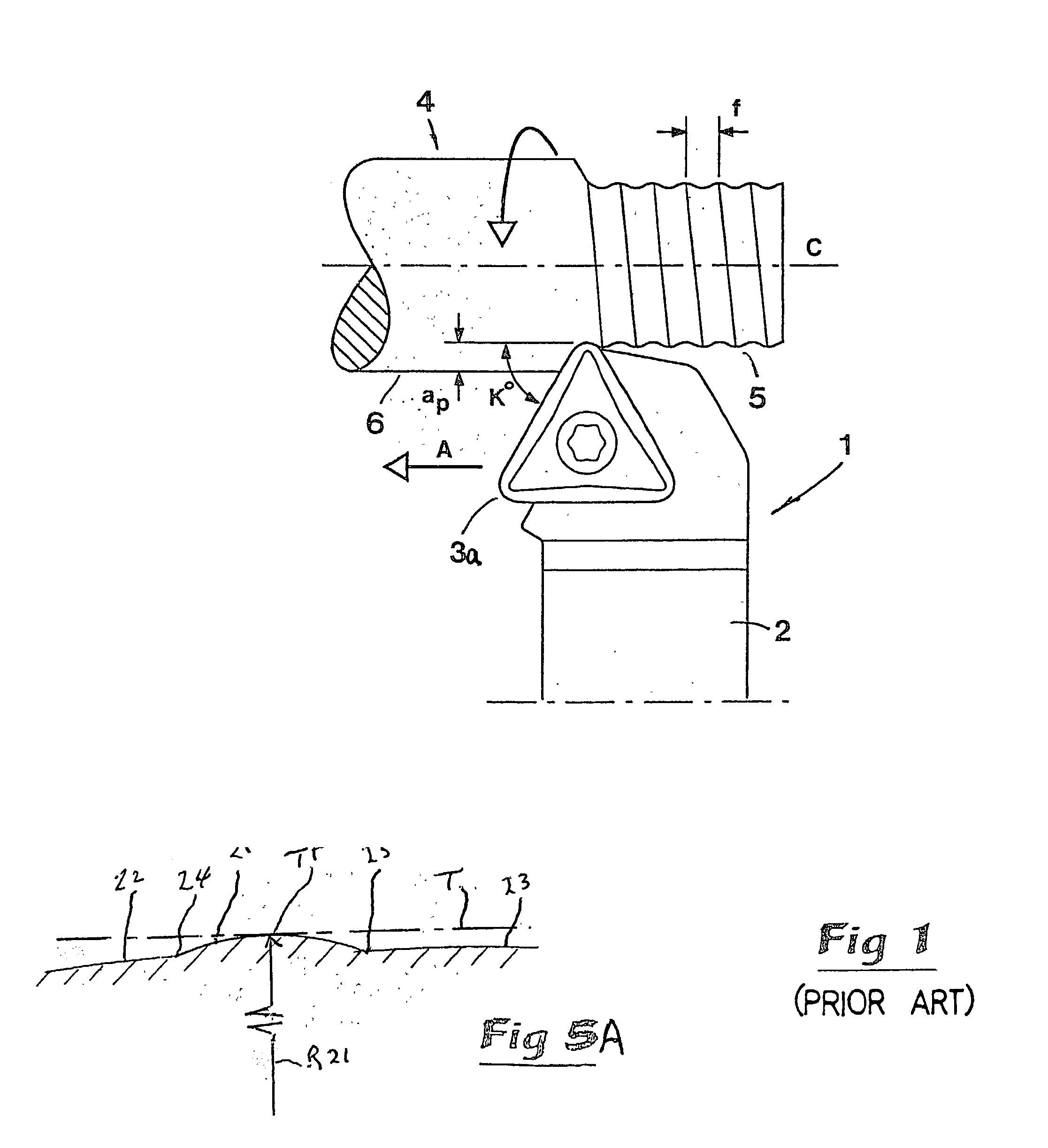

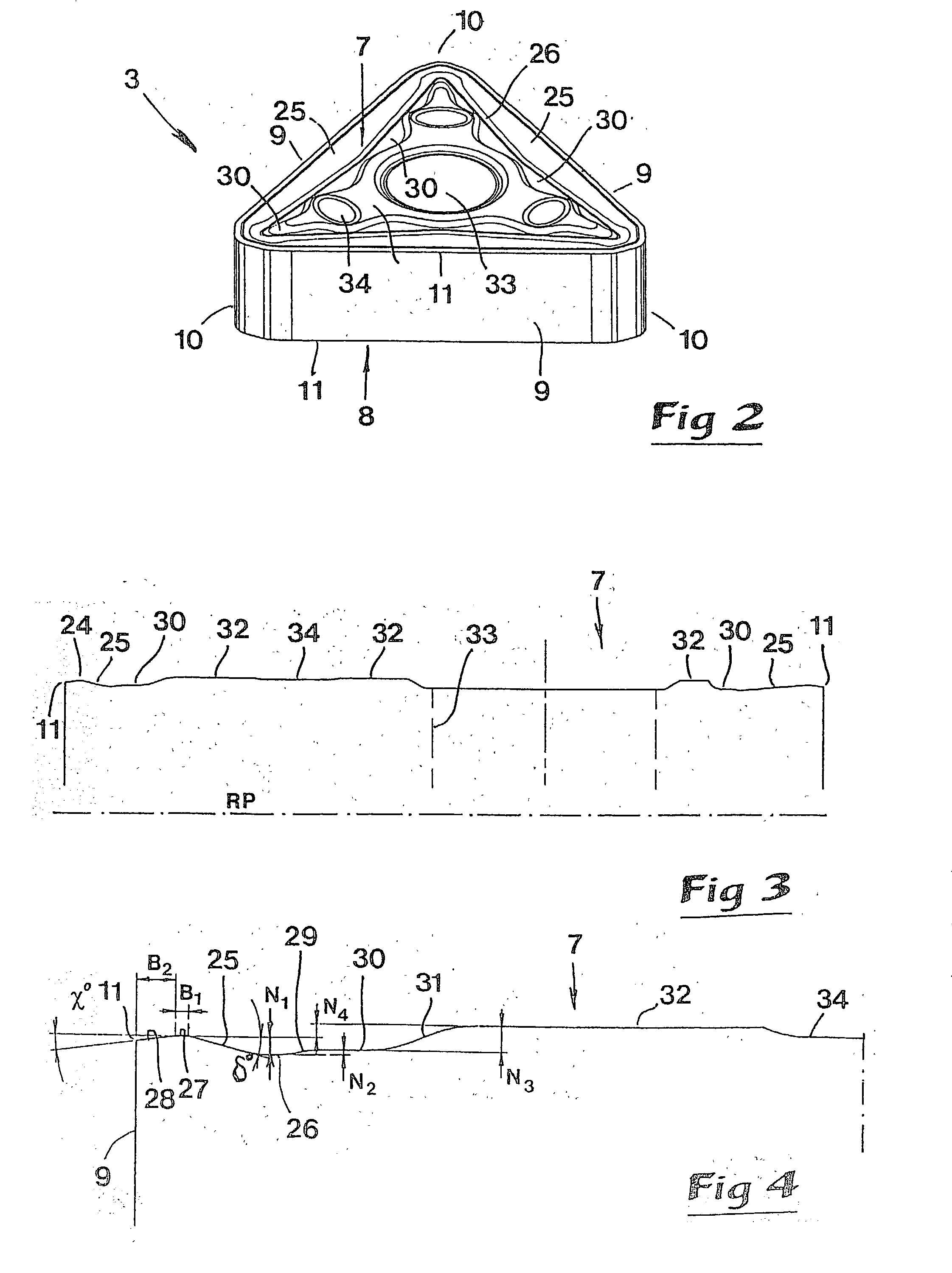

Cutting insert for chip removing machining

InactiveUS20030077131A1Improved cutting insertHigh surface finishCutting insertsTurning toolsEdge segmentMachined surface

A cutting insert, intended for chip removing machining, includes a body delimited by two opposite, first and second surfaces, which in the operative state of the cutting insert form an actively chip removing top surface and a bottom surface, respectively. The insert also includes at least one side surface, serving as a flank surface, which extends between the first and second surfaces. A cutting edge is formed between the flank surface and at least one of said first and second surfaces, in which a segment is included, which has the purpose of smoothening and facing the machined surface of the workpiece. The smoothening edge segment is divided into at least three different part edge segments, a first of which forms a tangent point and is surrounded by two part edge segments having longer radii (R22, R23) than the first edge part segment.

Owner:SANDVIK INTELLECTUAL PROPERTY AB +1

Binary OPC for assist feature layout optimization

InactiveUS20060057475A1Avoid catastrophic failureSuitable for processingPhotomechanical apparatusOriginals for photomechanical treatmentIdentifying problemsEdge segment

A method of forming a photolithographic mask layout with Sub-Resolution Assist Feature (SRAF) elements on a mask for correcting for proximity effects for a pattern imaged comprising the steps of developing a layout of mask features for printing main pattern features. Provide a table of SRAF element data including spacing of main pattern features and SRAF elements, applying SRAF elements to the mask layout as a function of spacing of main pattern features and SRAF elements, legalizing the SRAF elements as a function of style options, and providing a target pattern comprising a modified layout for the mask, identifying problem edge segments of an SRAF element of the target pattern at risk of causing a printing defect, applying a selected bias to the problem edge segments to modify the pattern where there are areas of SRAF element loss, and providing an output of a modified pattern with modified SRAF elements removing the areas of SRAF element loss. The system can provide SRAF elements to the mask layout as a function of spacing of main pattern features and SRAF elements may be based on data from the SRAF table; or the system can applying model based OPC for exposure dose values based on data from the SRAF table.

Owner:IBM CORP

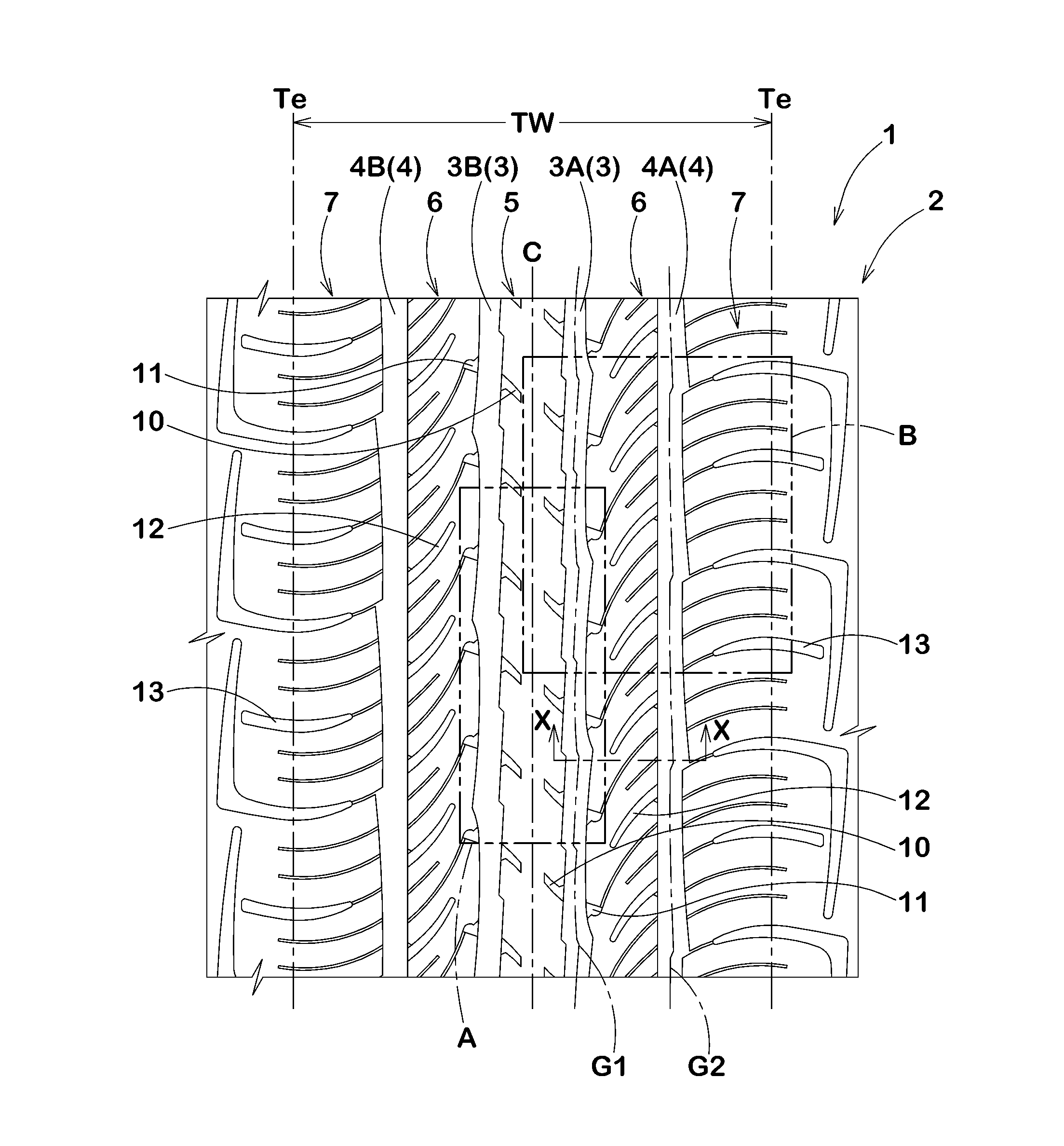

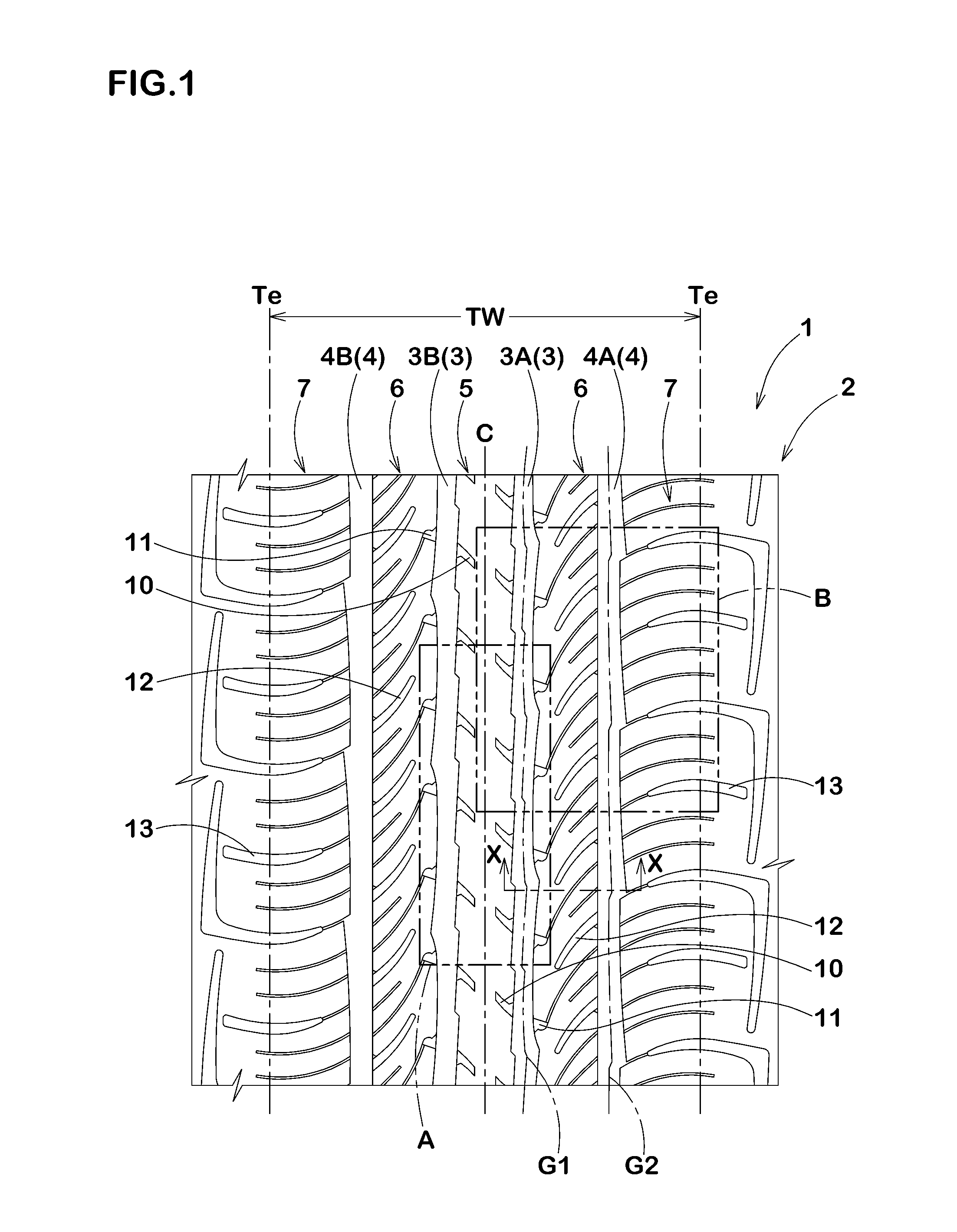

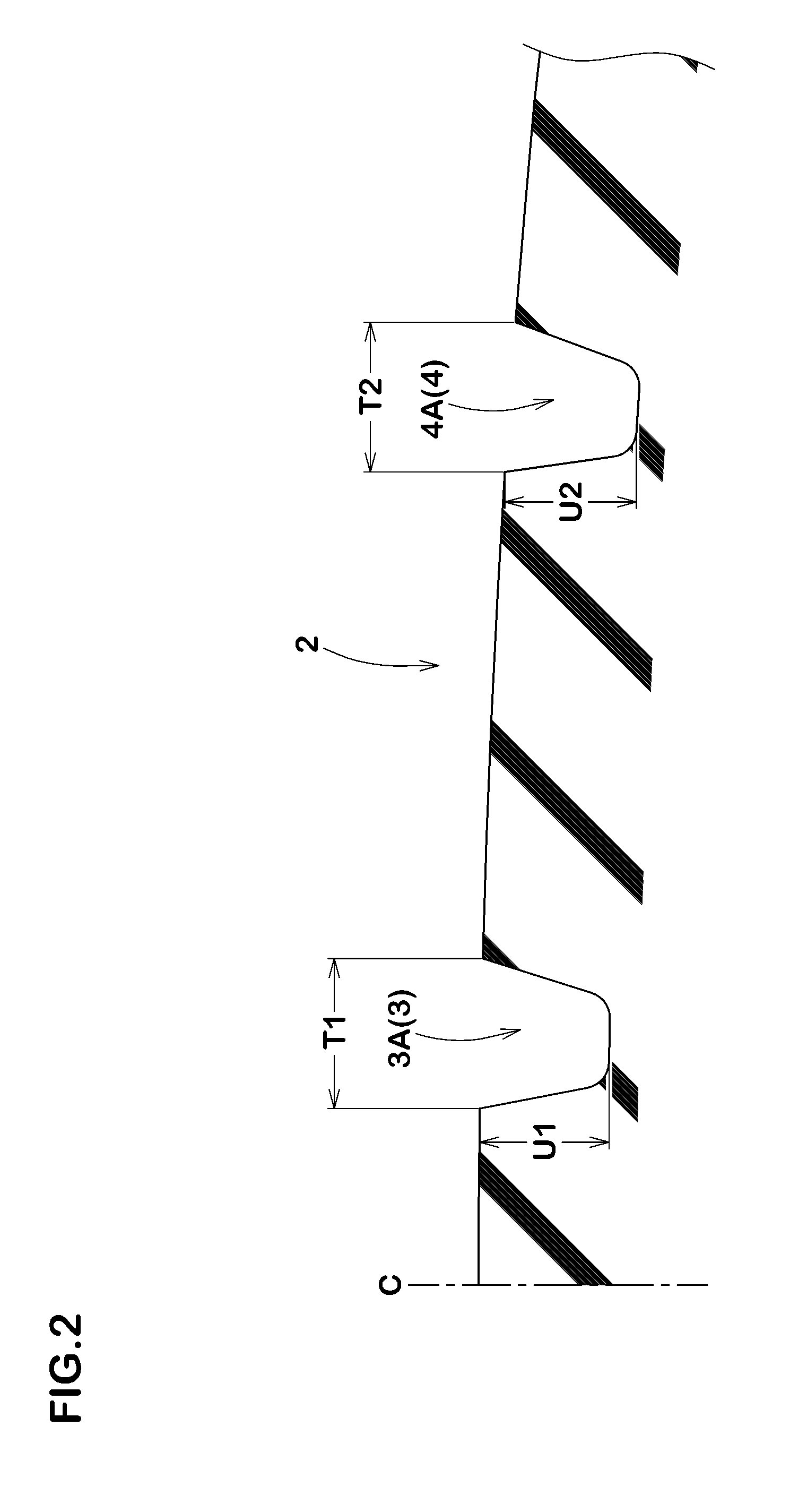

Pneumatic tire

InactiveUS20100314012A1Improve on-snow performanceImprove snow removal effectTyre tread bands/patternsNon-skid devicesEdge segmentWear resistance

A pneumatic tire 1 having excellent on-snow performances improved with maintaining steering stability and uneven wear resistance and including tread portion 2 having a pair of crown circumferential grooves 3 which extend continuously in the tire circumferential direction on both sides of tire equator C and have groove edges, one edge 3m extending in such a zigzag form that italic L-shaped groove edge segments 3s are continuously connected to each other in the circumferential direction, and the other edge 3n extending in such a wavy form that circular arc groove edge segments 3o each having a circular arc shape convex toward a groove center are continuously connected to each other in the circumferential direction, wherein each of the italic L-shaped groove edge segments 3s comprises long side part 3c inclined at an angle of 1 to 20° with respect to the circumferential direction, and short side part 3t having a circumferential length smaller than that of the long side part 3c and inclined in the opposite direction to the long side part 3c with respect to the circumferential direction.

Owner:SUMITOMO RUBBER IND LTD

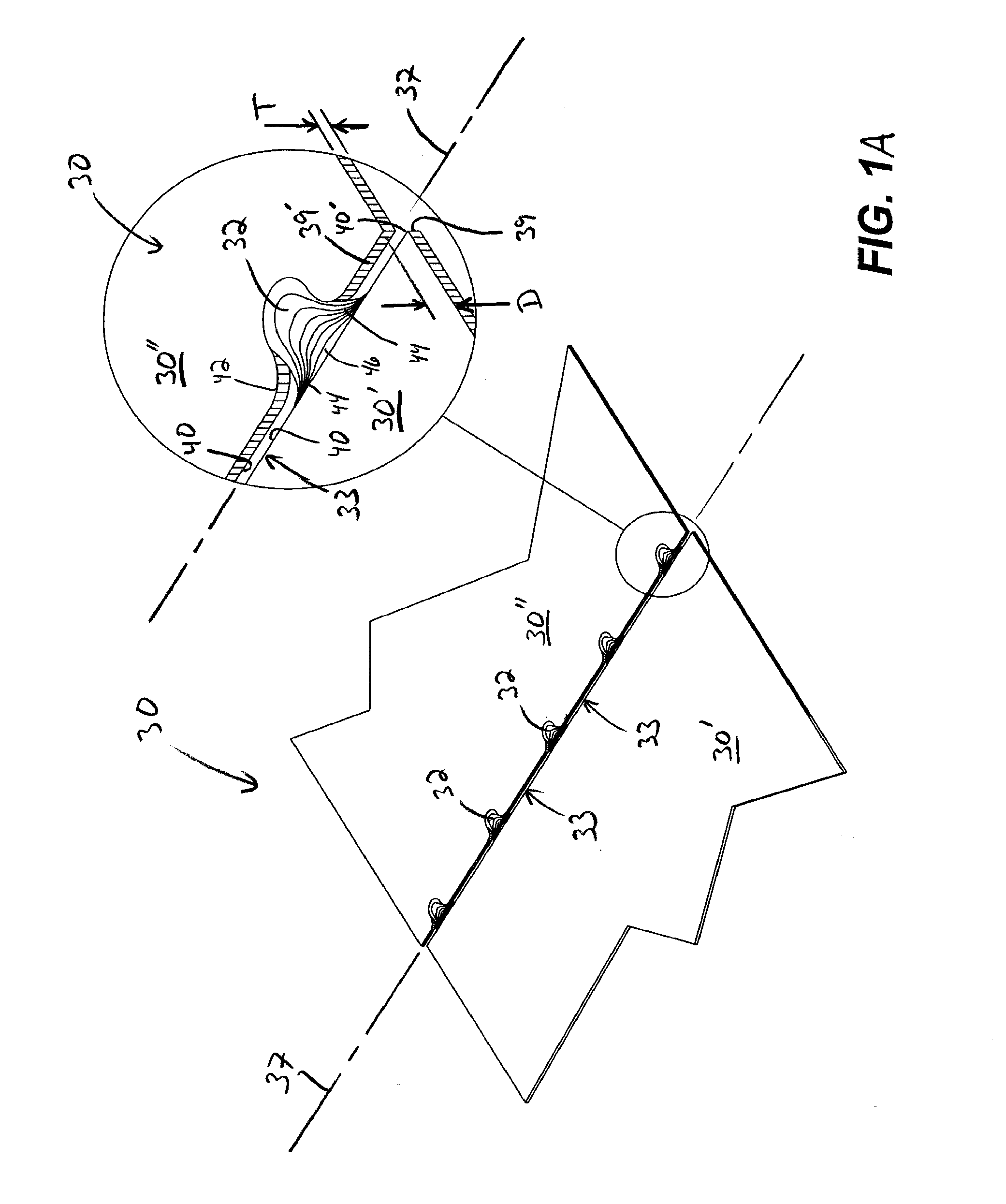

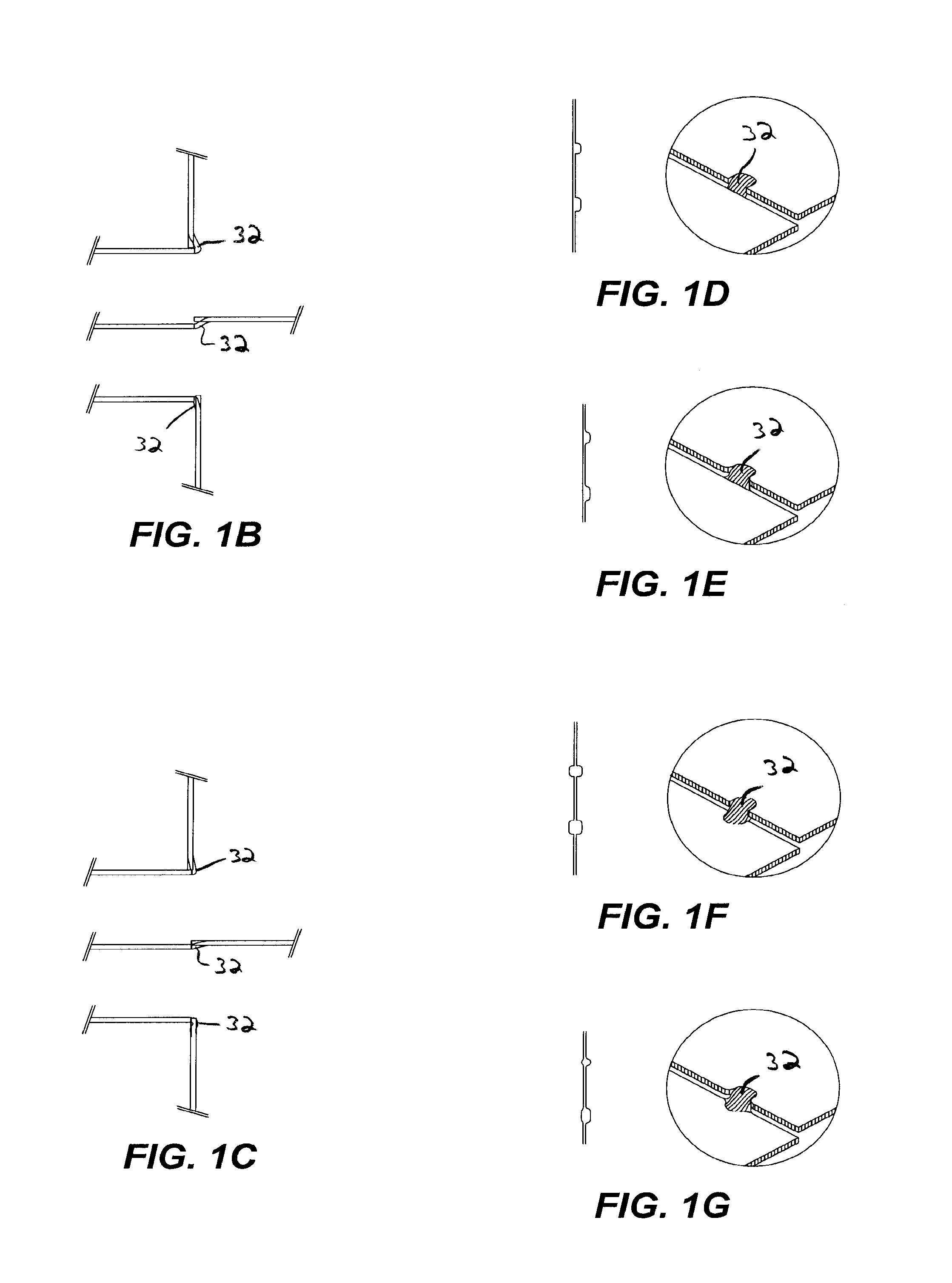

Method and apparatus for forming bend-controlling straps in sheet material

A substantially two-dimensional sheet material is configured for bending along a bend line to form a three-dimensional article. The sheet material includes a sheet of elastically and plastically deformable material, one portion of the sheet material located on one side of the bend line and another portion located on the opposing side of the bend line, one portion being displaced relative to the another portion in the direction of the thickness of the sheet material, and / or a plurality of shear lengths extending along the bend line separating the one and another portions of the sheet material. At least a pair of adjacent shear lengths define a strap interconnecting the one and another portions of the sheet material. A tooling assembly is configured for forming the bend-controlling straps and includes a punch assembly and a die assembly dimensioned and configured to move relative to one another, a punch block having a continuous shear edge, the punch block removably secured on the punch assembly, and / or a die block having an interrupted shear edge broken into shear edge segments by one or more recesses, the die block removably mounted on the die assembly, wherein moving one of the punch assembly and the die assembly toward the other, the continuous shear edge of the punch block cooperates with the shear edge segments for impart shear lengths upon the sheet material along the predetermined bend line. A method of using the tooling assembly and forming the sheet material is also described.

Owner:IND ORIGAMI INC CA US

Absorbent Article Comprising A Barrier Attachment Zone

A disposable absorbent article may comprise a chassis comprising side edges. The side edges of the chassis may comprise folded side edge segments disposed in the front and back waist regions and cut side edge segments disposed in the crotch region. The chassis may further comprise a barrier attachment zone disposed between a side edge of the absorbent assembly and the side edge of the chassis. The barrier attachment zone may extend continuously from the front waist region through the crotch region to the back waist region and may form an area of attachment between the side flaps and the backsheet. The chassis may also comprise an elastic gathering member disposed between the side barrier attachment zone and the side edge of the chassis.

Owner:THE PROCTER & GAMBLE COMPANY

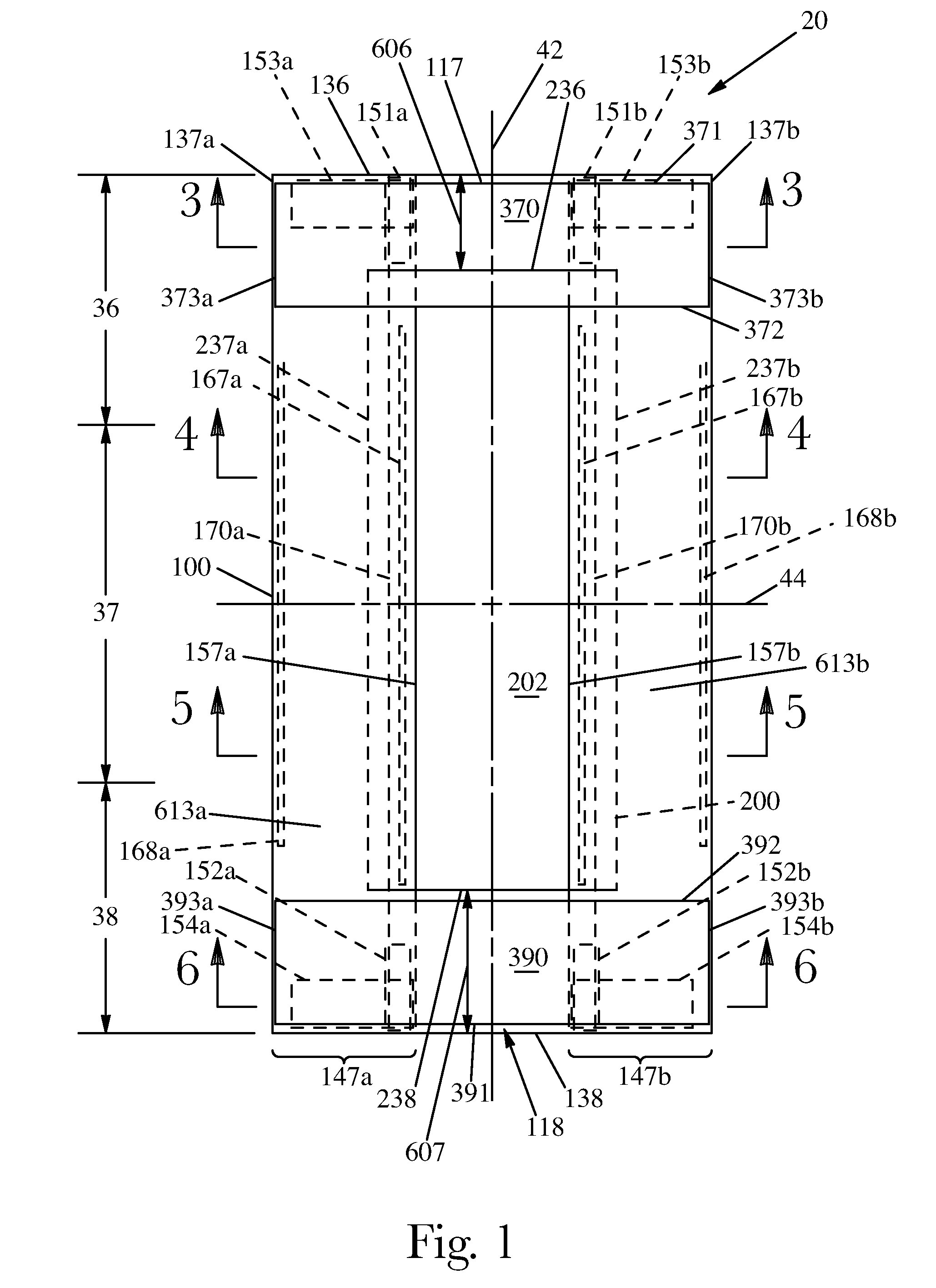

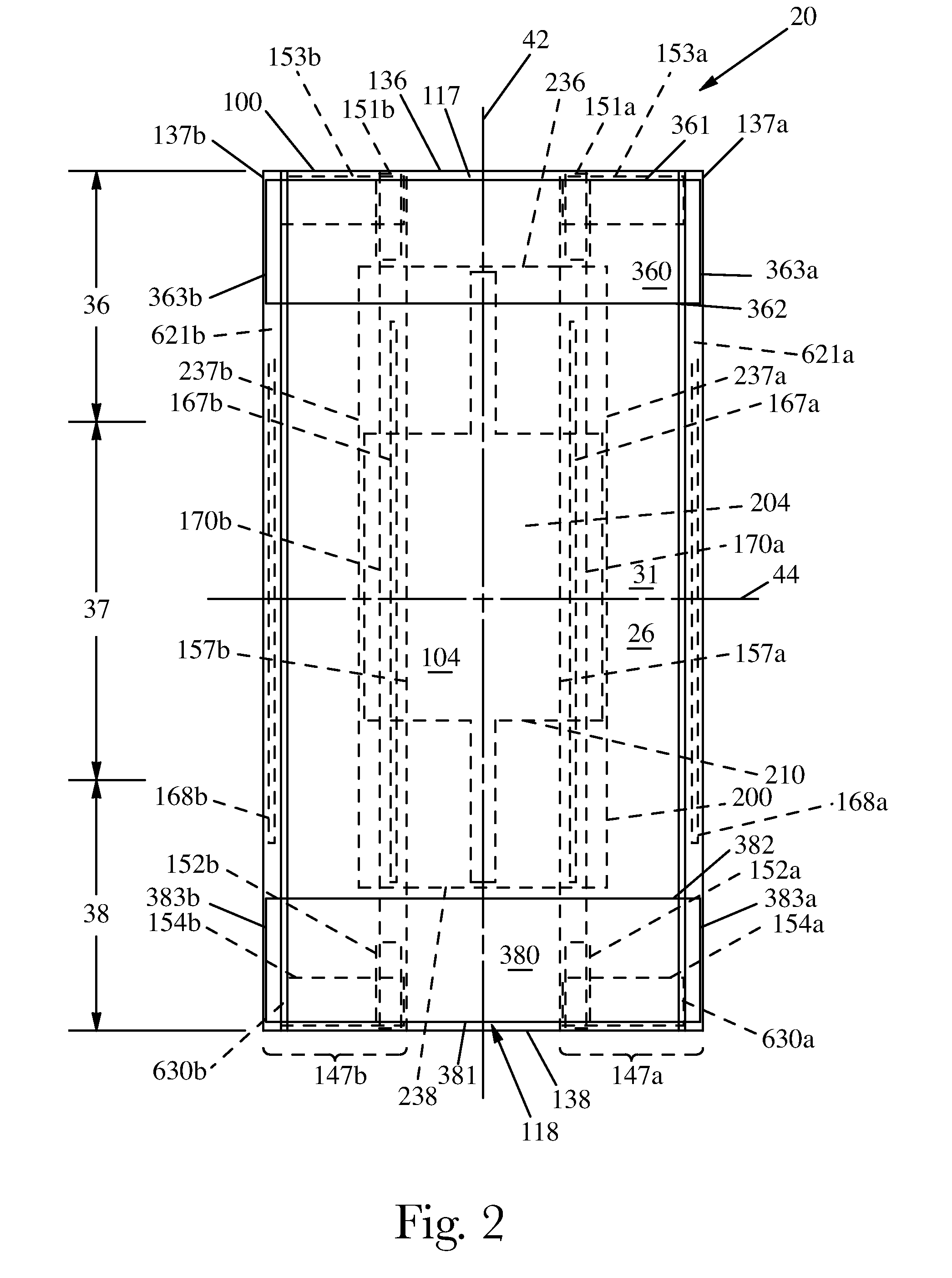

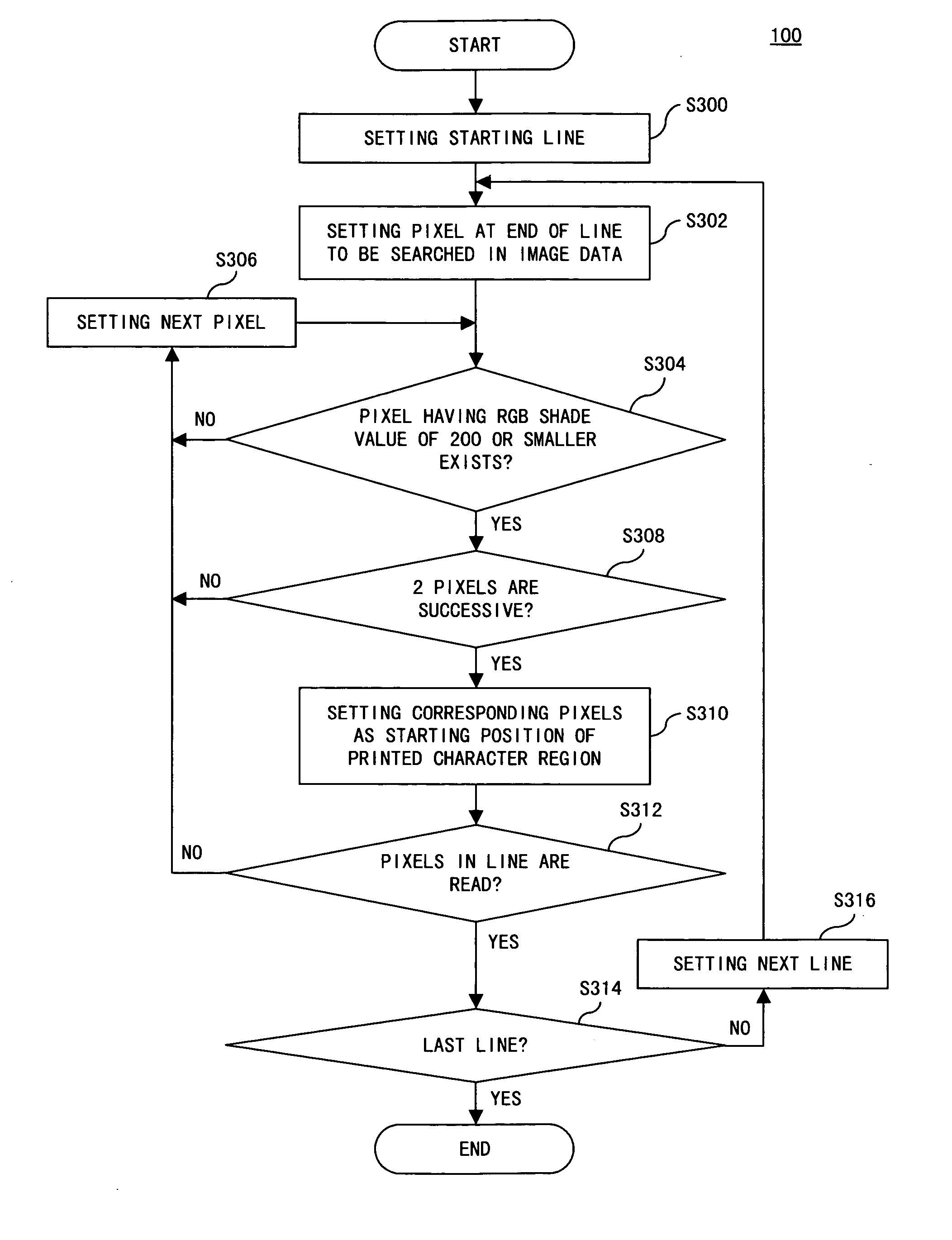

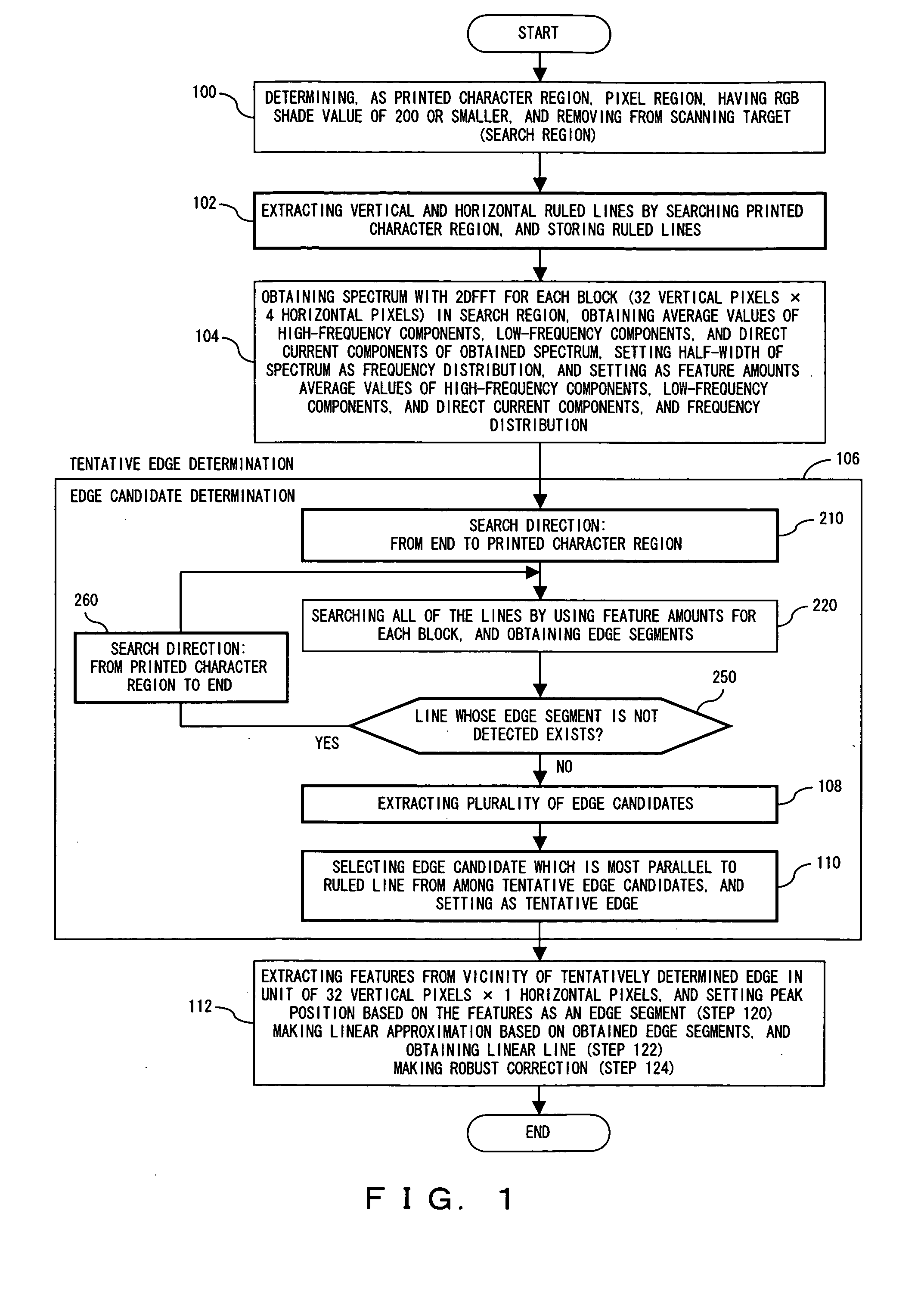

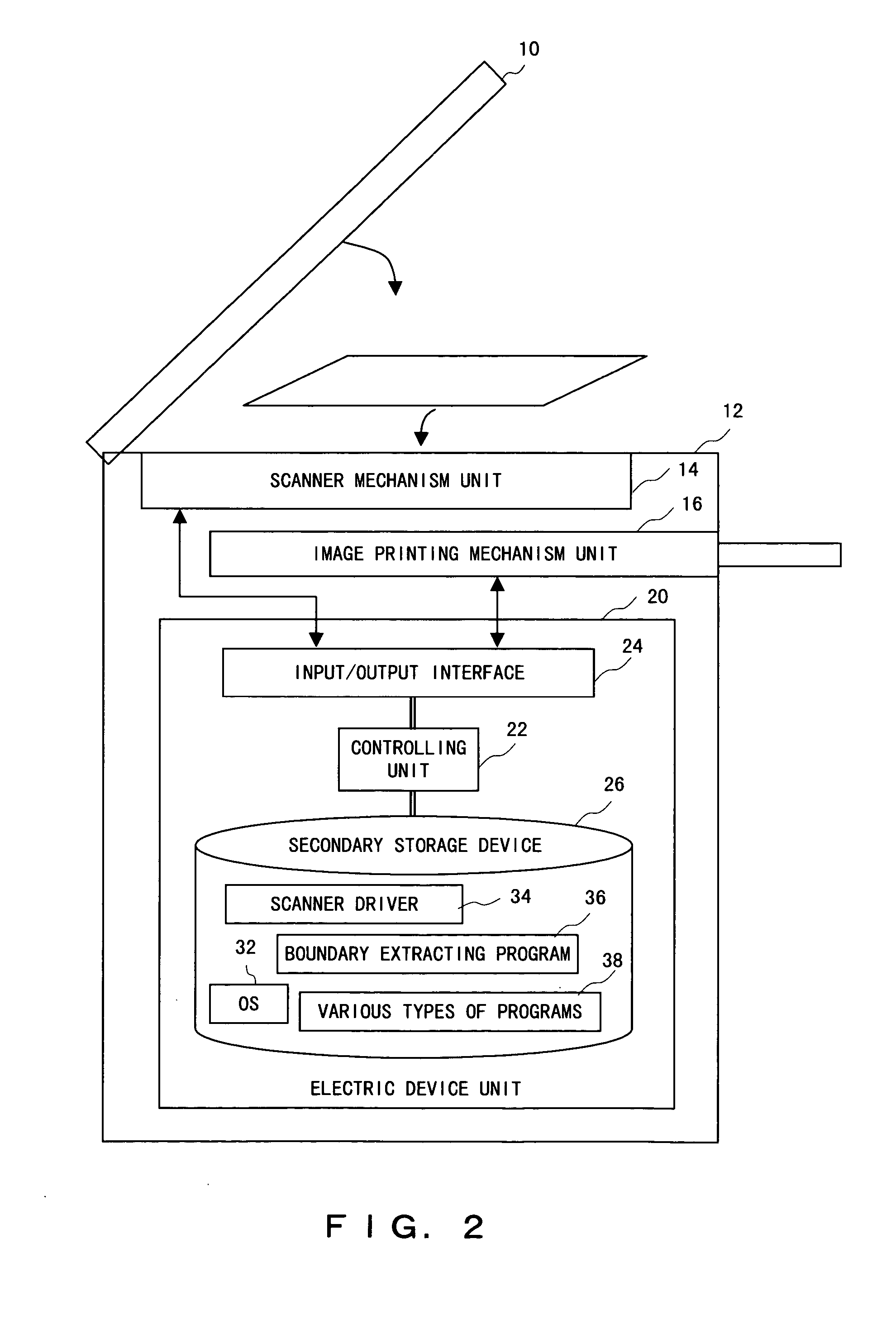

Boundary extracting method, program, and device using the same

InactiveUS20050226510A1Improve accuracyDigitally marking record carriersImage analysisEdge segmentLinearity

An edge detecting method detects edge segments by searching all of the search lines forming an image from an end of the image in a direction perpendicular to the edges. If a line whose edge segment cannot be detected exists, a search is made in all of the search lines from the vicinity of the center of the image toward the end of the image, whereby edge segments are detected. A linear edge is determined from edge segments. A plurality of edge candidates are obtained from the edge segments for all of the search lines, and an optimum candidate is selected from among the edge candidates. Ruled lines are extracted from the source document in the image, and an optimum candidate is selected based on a comparison with a ruled line. As a result, an edge of the source document can be detected with high accuracy even if an image on a background side is unstable, or if materials of the background and the source document are similar.

Owner:FUJITSU LTD +1

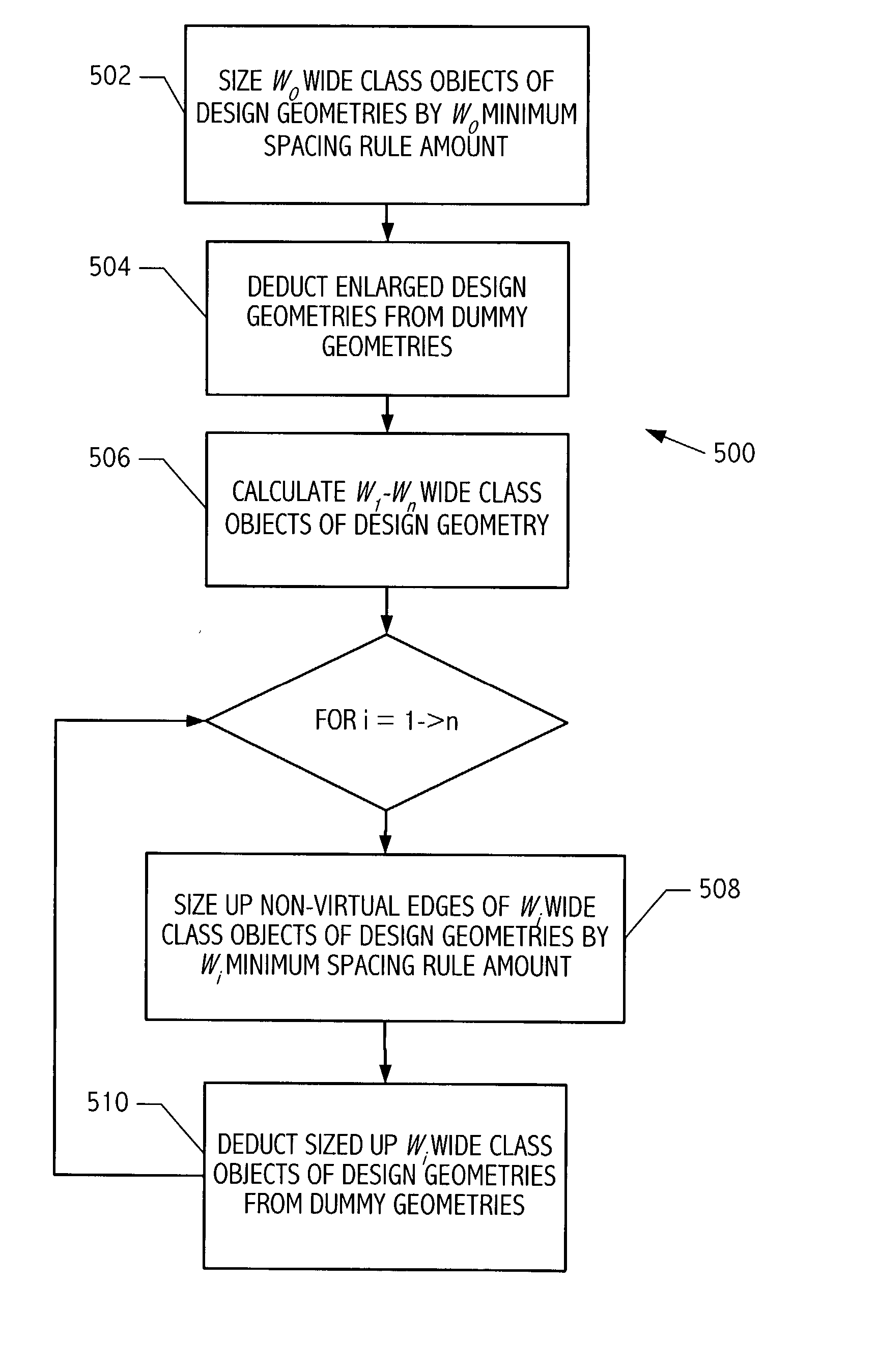

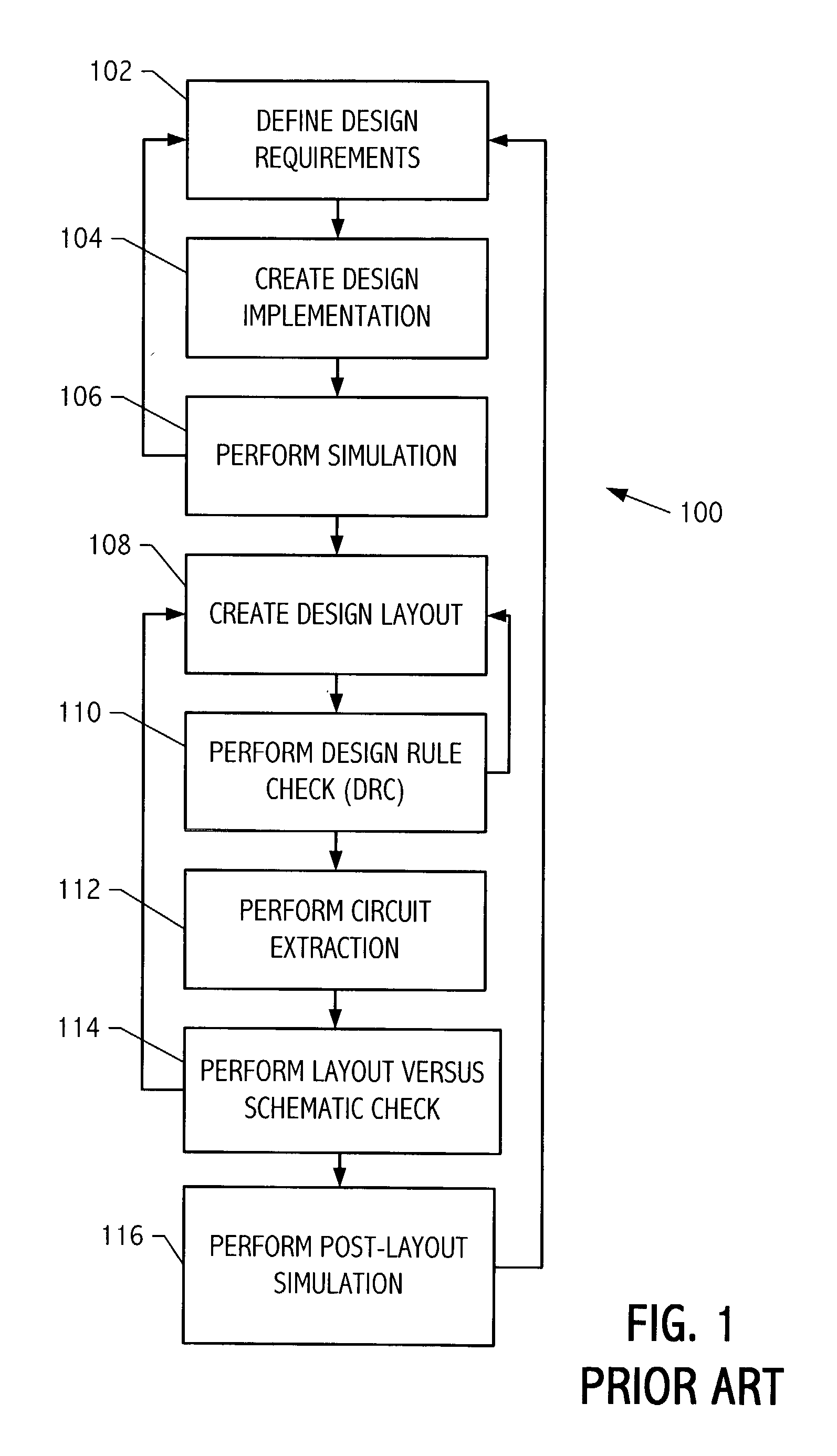

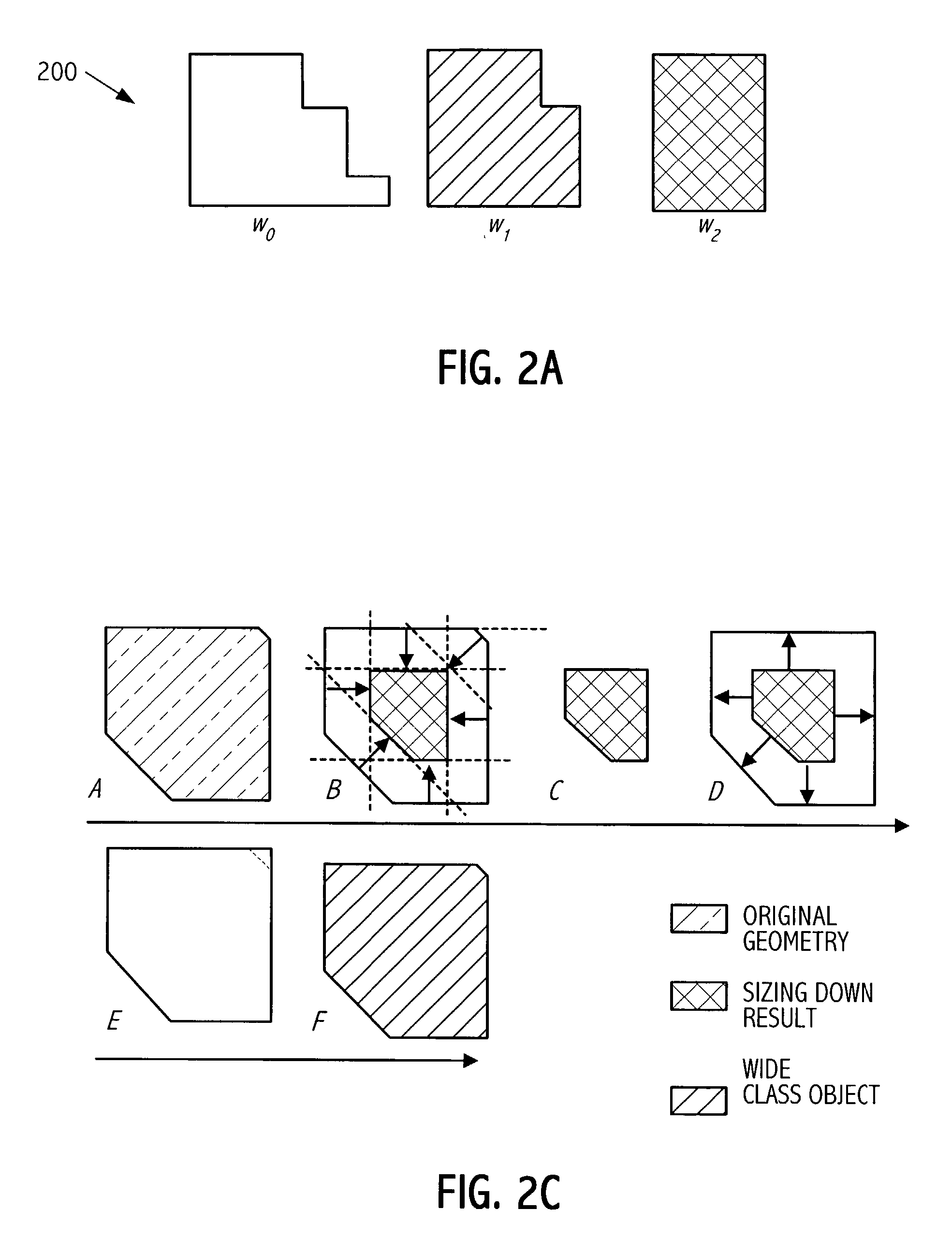

Correction of width violations of dummy geometries

Automated techniques to correct certain rule violations with respect to non-design geometries are used, simplifying and automating the design layout of an electronic circuit, whether embodied as a design encoding or as a fabricated electronic circuit. Correcting minimum width rule violations of non-design geometries is accomplished by forming one or more cutting areas adjoining one or more erroneous edges of a non-design geometry, and deducting the cutting areas form the non-design geometry, splitting the non-design geometry into two or more remaining non-design geometries. Any slivers of remaining non-design geometries, i.e., any pieces that are smaller than a minimum size amount, are removed. Cutting areas are formed by stretching ends of erroneous edge segments by a minimum width rule amount and sizing the stretched edge segments which are inside the non-design geometry outward by a minimum spacing rule amount.

Owner:ORACLE INT CORP

Semiconductor device with increased I/O leadframe

ActiveUS8008758B1Maximize available numberSemiconductor/solid-state device detailsSolid-state devicesEdge segmentSemiconductor package

In accordance with the present invention, there is provided a semiconductor package (e.g., a QFP package) including a uniquely configured leadframe sized and configured to maximize the available number of exposed leads in the semiconductor package. More particularly, the semiconductor package of the present invention includes a generally planar die pad or die paddle defining multiple peripheral edge segments. In addition, the semiconductor package includes a plurality of leads. Some of these leads include exposed bottom surface portions which are provided in at least one row or ring which at least partially circumvents the die pad, with other leads including portions which protrude from respective side surfaces of a package body of the semiconductor package. Connected to the top surface of the die pad is at least one semiconductor die which is electrically connected to at least some of the leads. At least portions of the die pad, the leads, and the semiconductor die are encapsulated by the package body, with at least portions of the bottom surfaces of the die paddle and some of the leads being exposed in a common exterior surface of the package body.

Owner:AMKOR TECH SINGAPORE HLDG PTE LTD

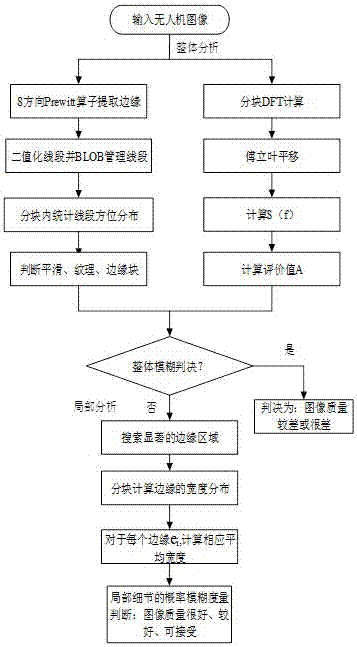

Method for evaluating quality of image shot by unmanned aerial vehicle

Owner:SHANGHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com