Patents

Literature

91results about How to "Improve on-snow performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pneumatic tire

ActiveCN101804773AHigh shear forceWithout sacrificing drivabilityTyre tread bands/patternsRoad surfaceGradual increase

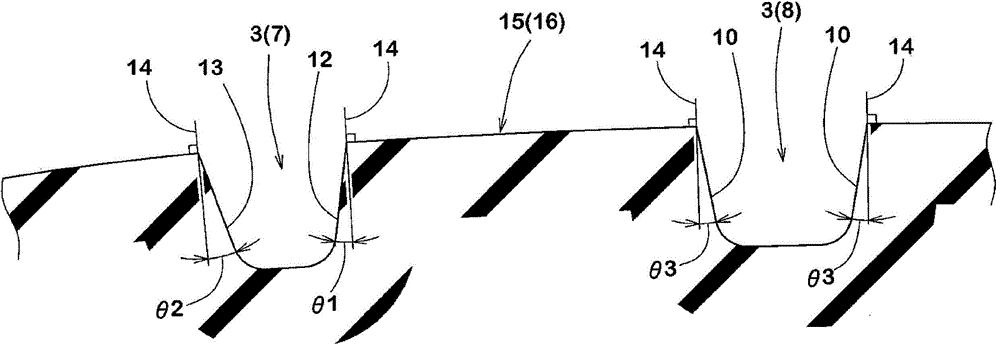

Provided is a pneumatic tire having snow performances which are capable of being enhanced without sacrificing its running performance on dry road surfaces. A pneumatic tire of the invention includes two first main grooves, a plurality lateral grooves and a plurality of sipes in a tread part. In the pneumatic tire, a groove wall surface, of each first main groove, closer to a tire equatorial line is formed so as to cyclically repeat, in the tire circumferential direction, a change in an inclination angle of the groove wall surface to a direction normal to a tread, the change being a gradual increase from a minimum value of 0 DEG to 15 DEG to a maximum value of 15 DEG to 45 DEG. In places where the inclination angel of the groove wall surface, of the first main groove, closer to the tire equatorial line, is at its maximum, no lateral grooves communicate with the first main groove, and in the places, the other groove wall surface, of the first main groove, closer to a corresponding contact end extends uninterruptedly.

Owner:THE YOKOHAMA RUBBER CO LTD

Pneumatic tire

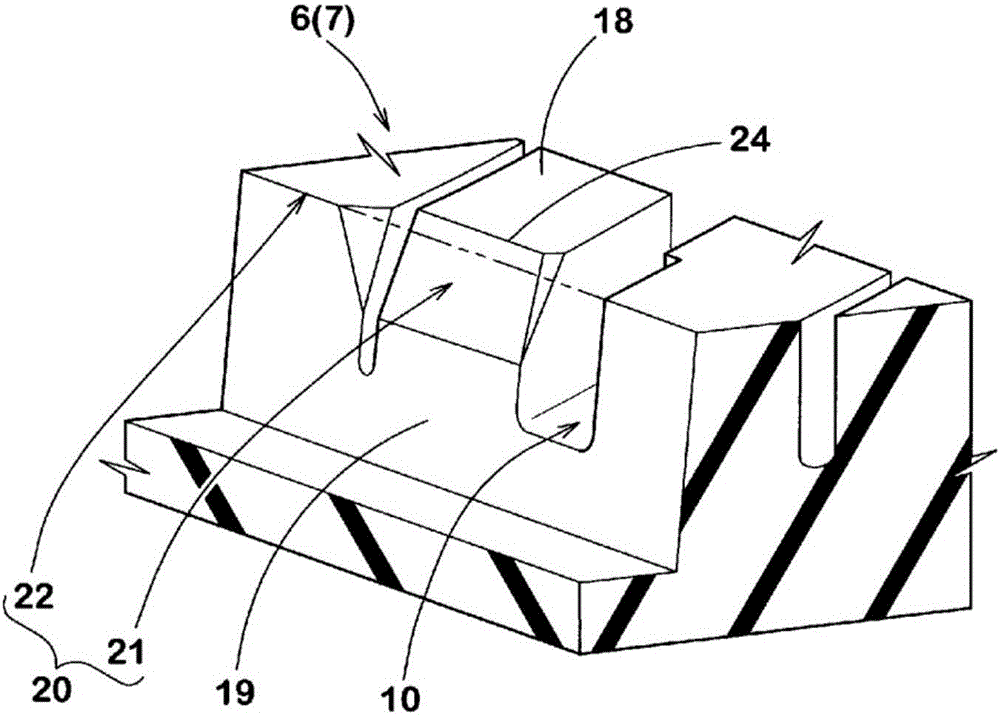

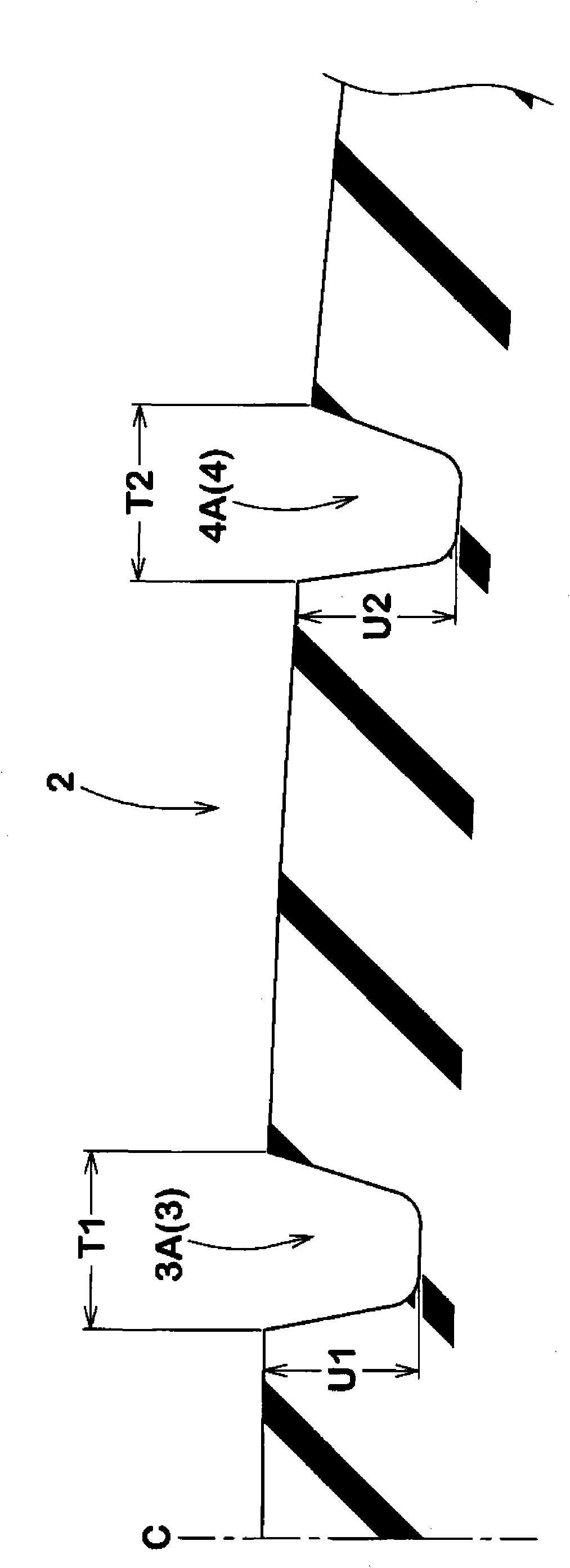

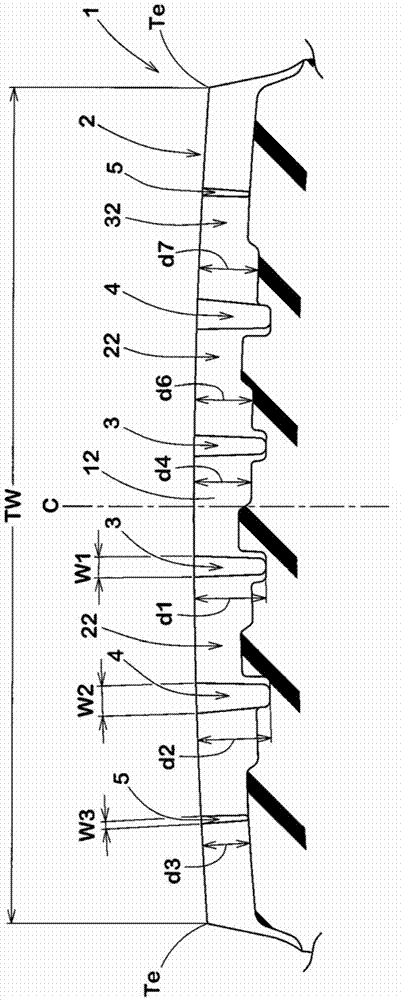

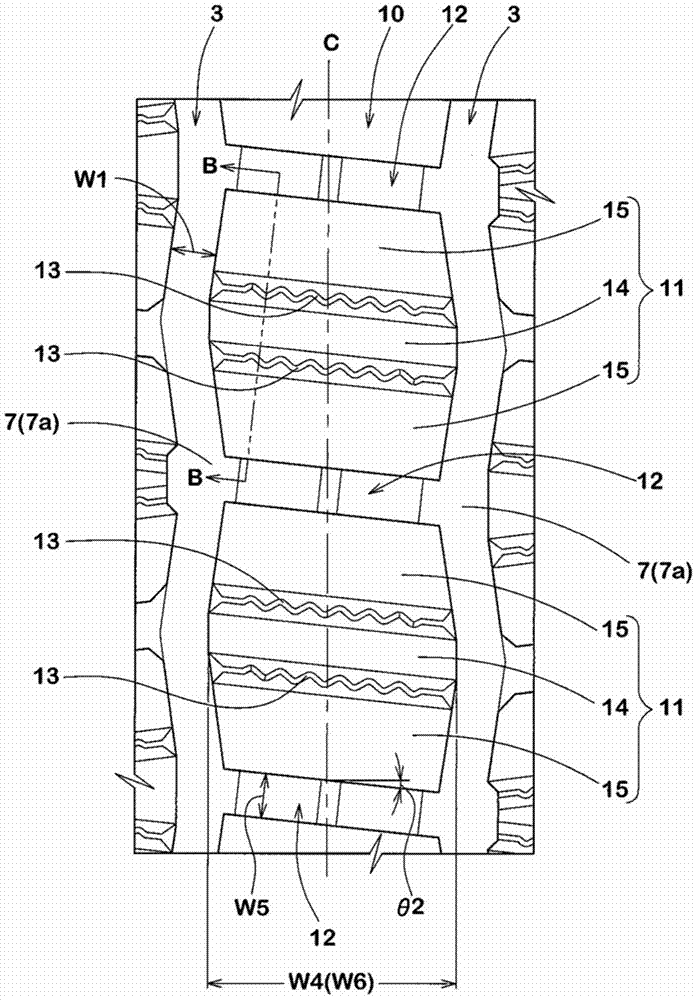

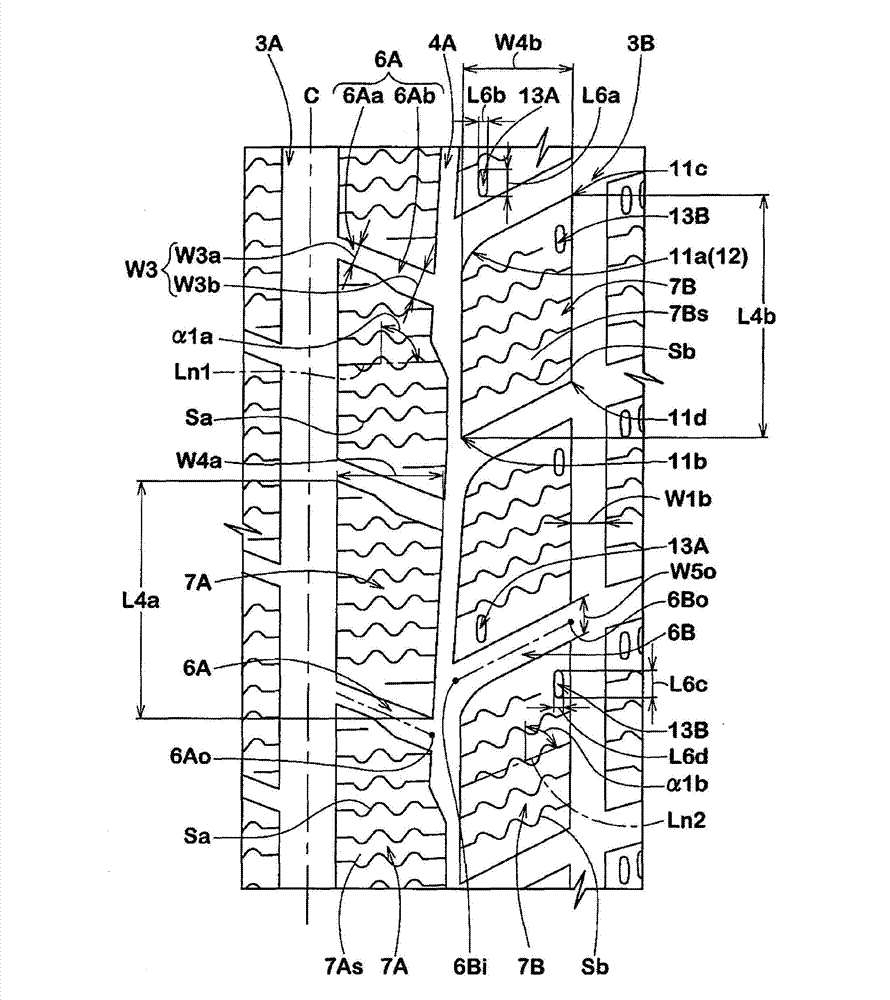

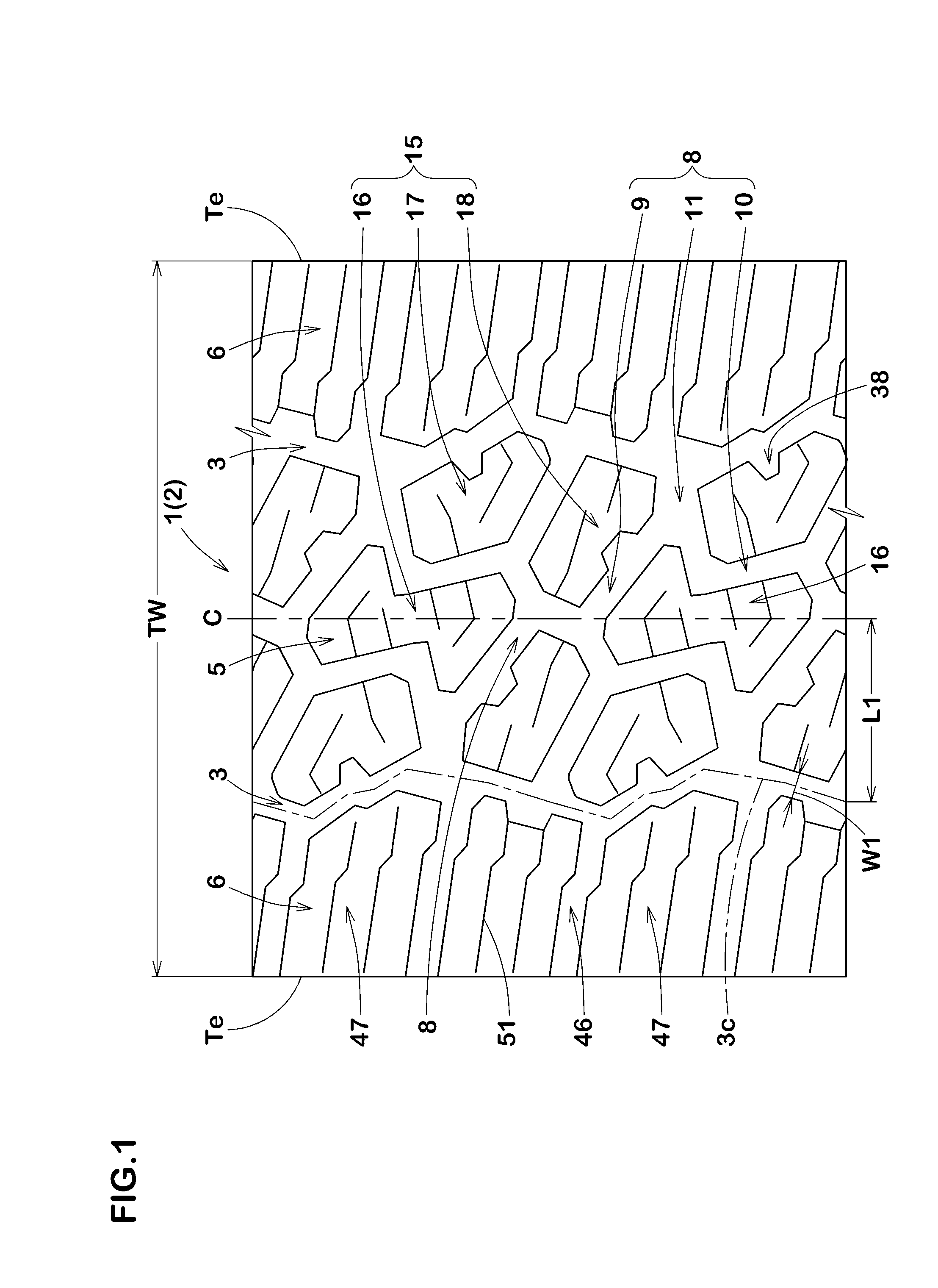

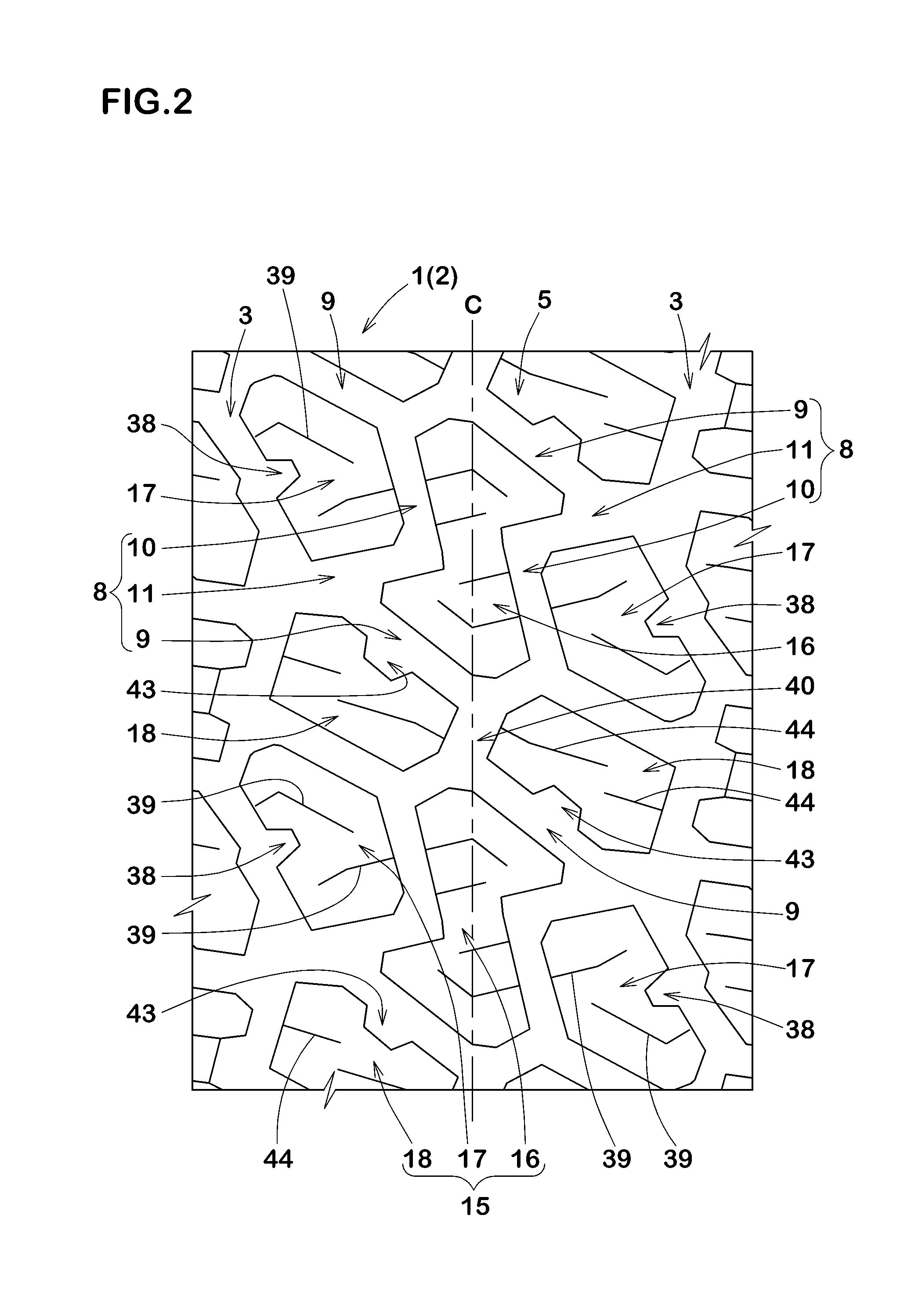

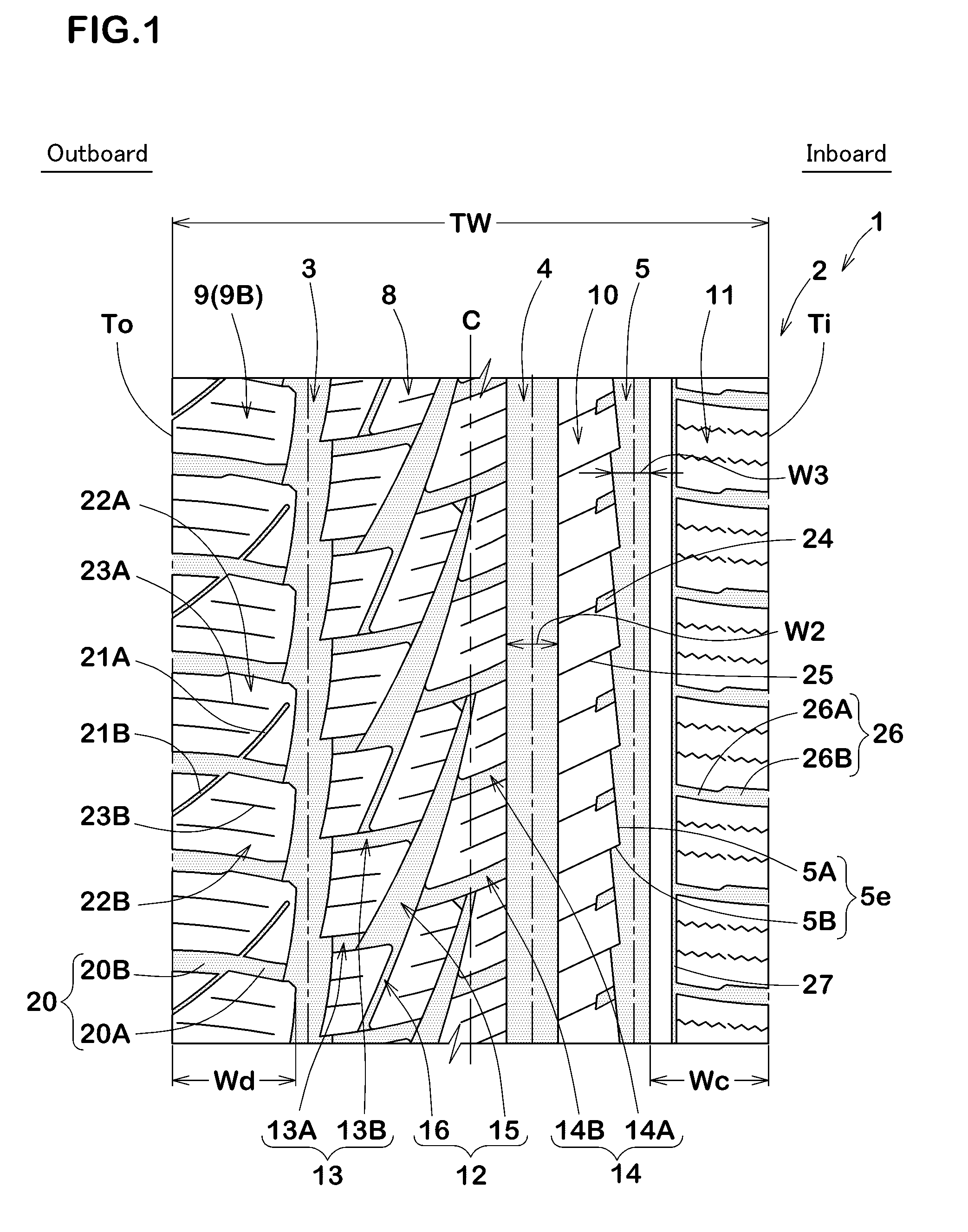

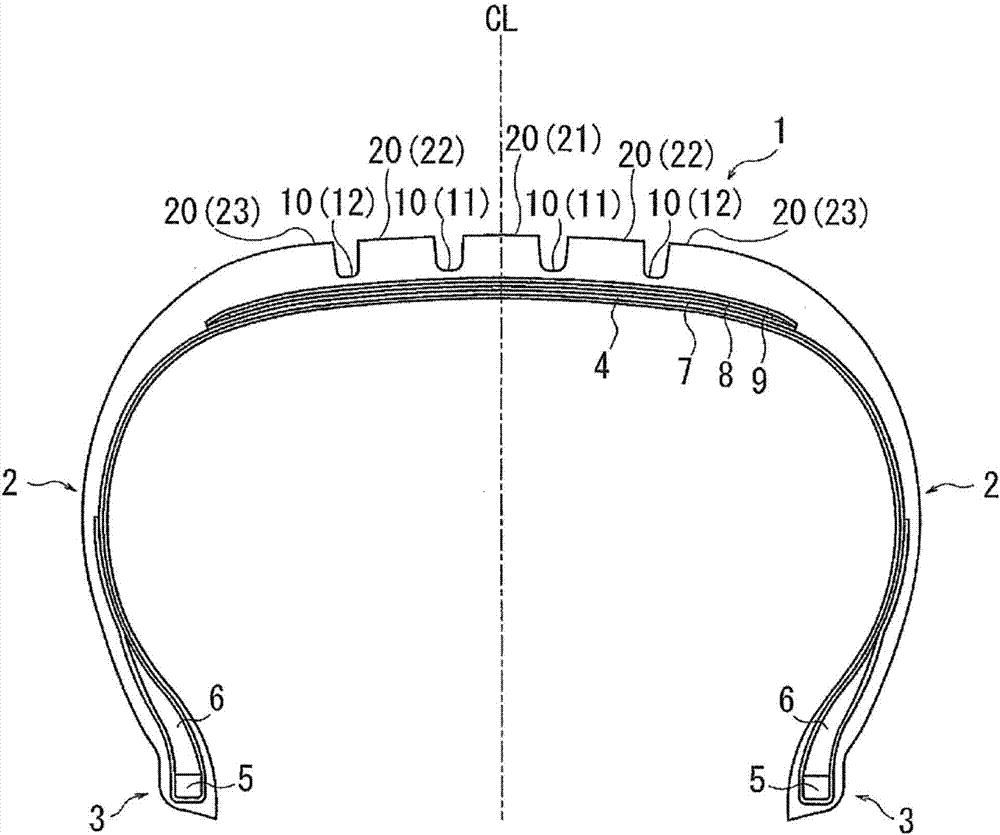

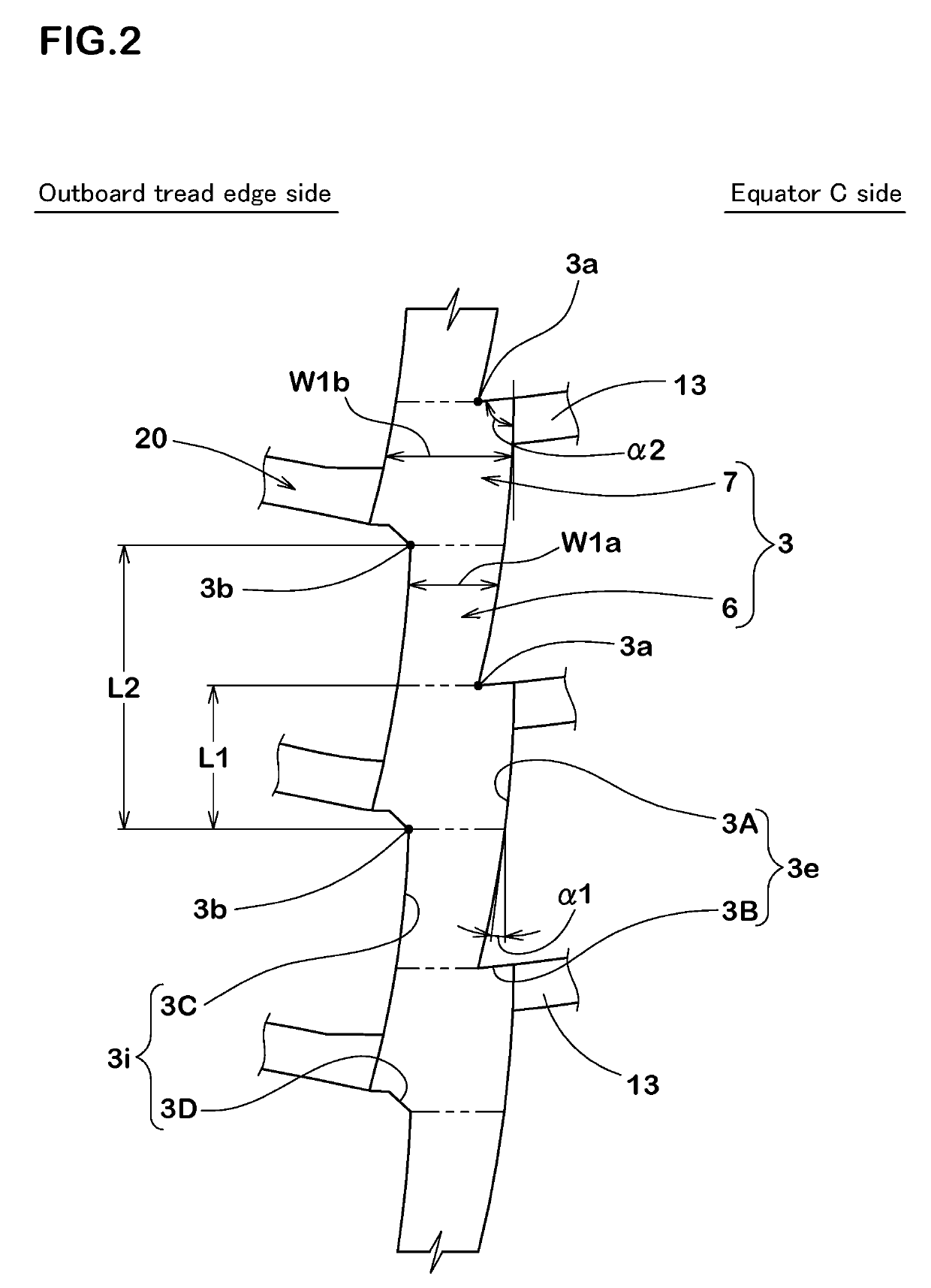

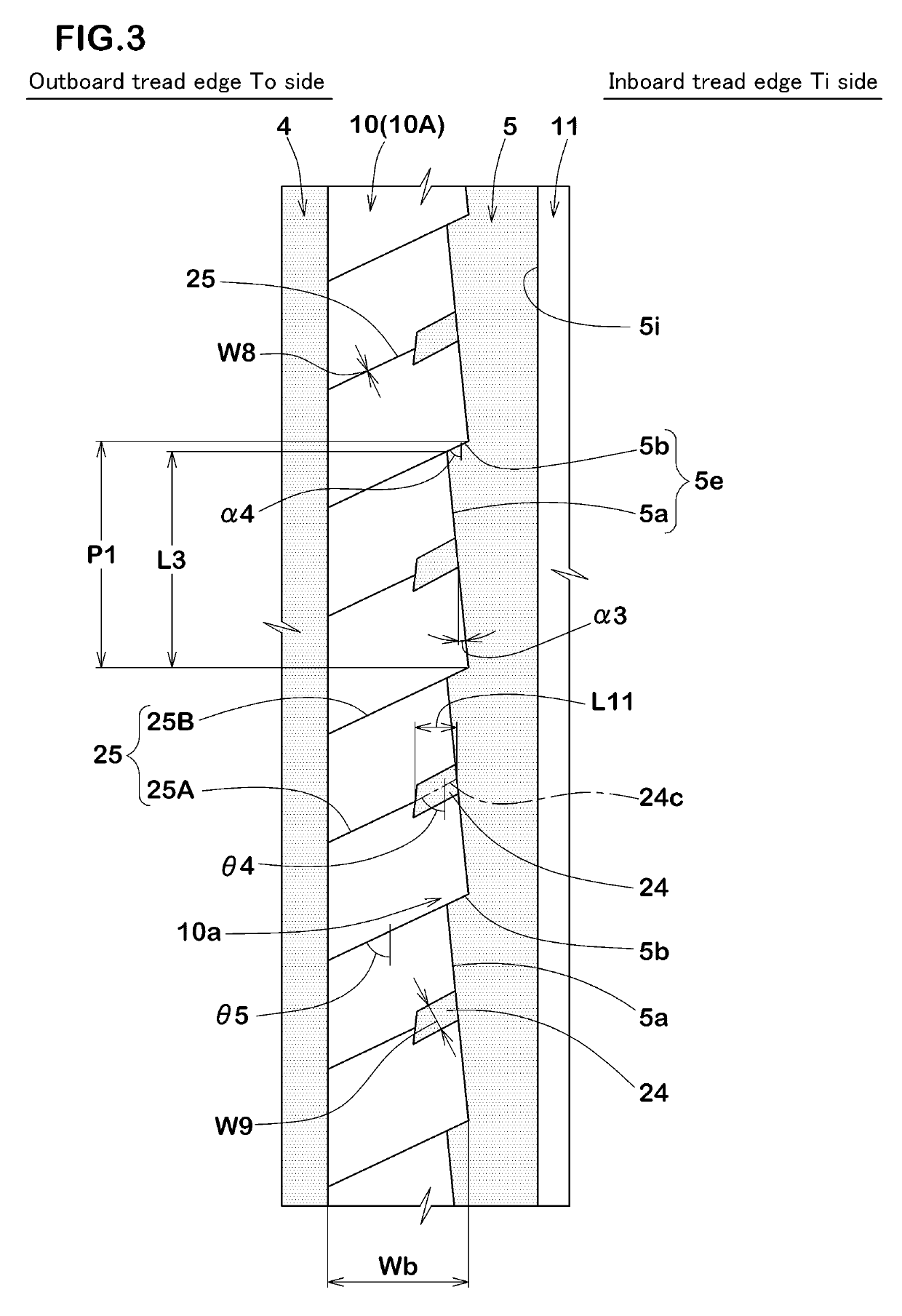

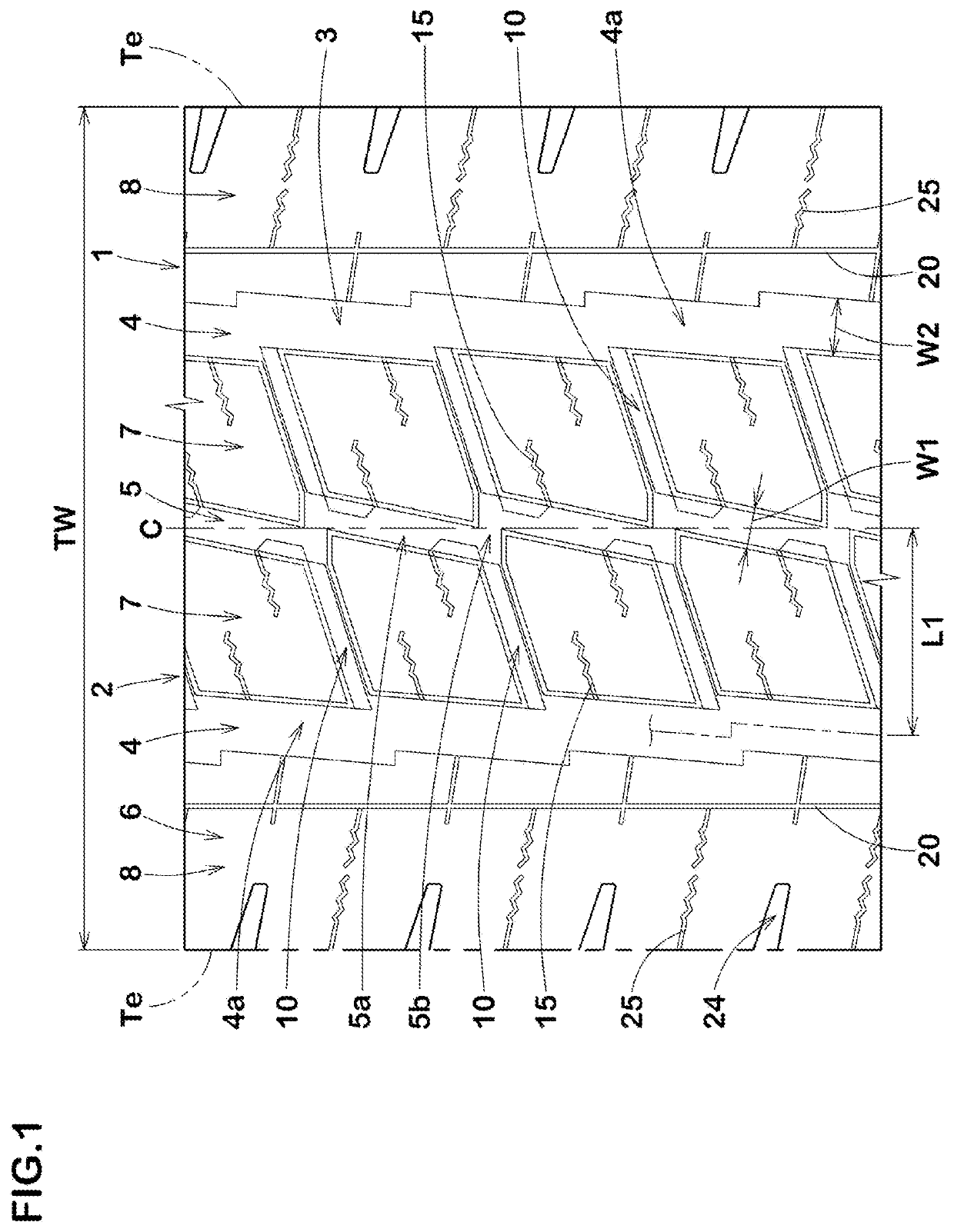

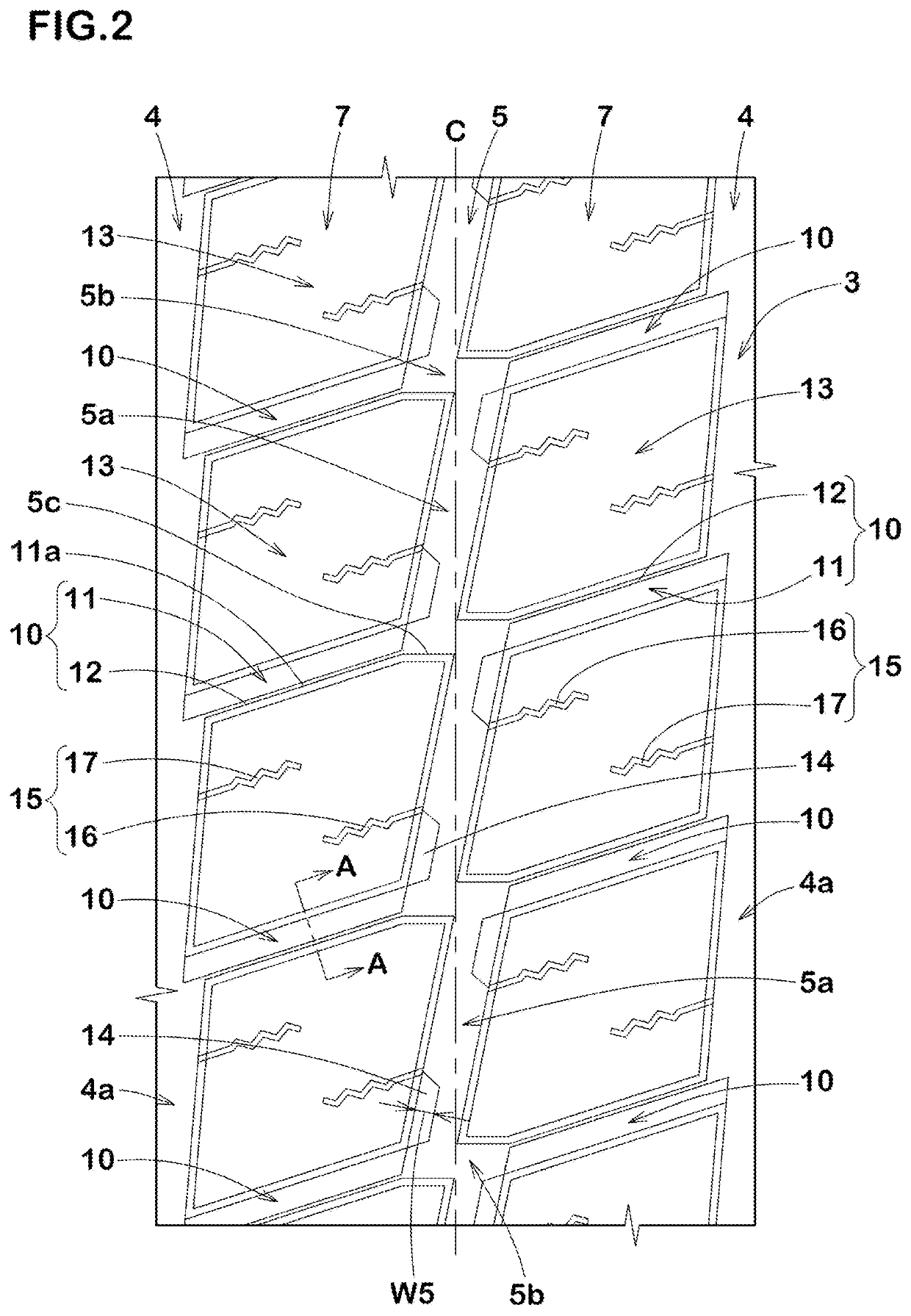

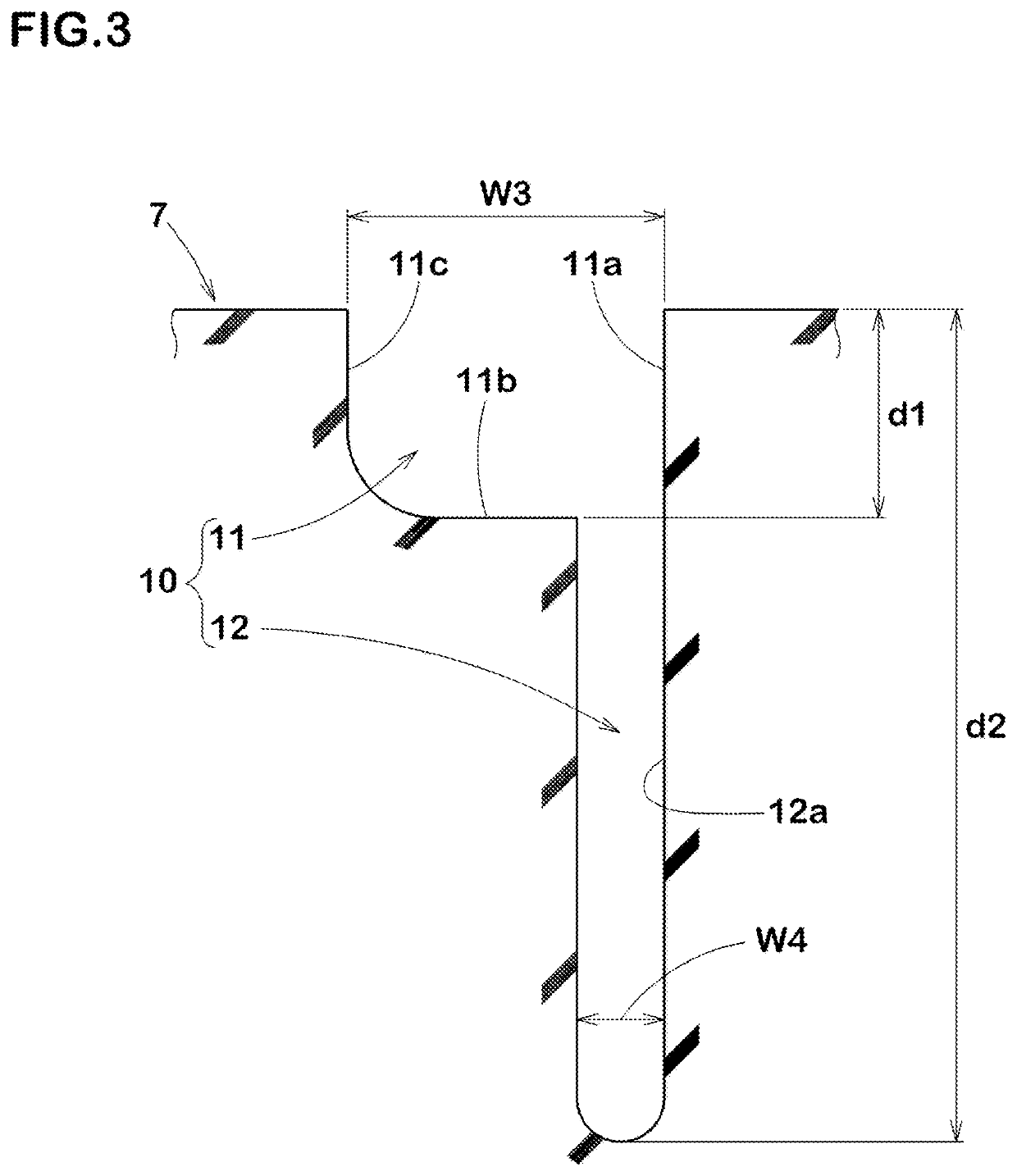

ActiveCN105270101AImprove on-snow performanceIncrease frictionTyre tread bands/patternsMain channelEngineering

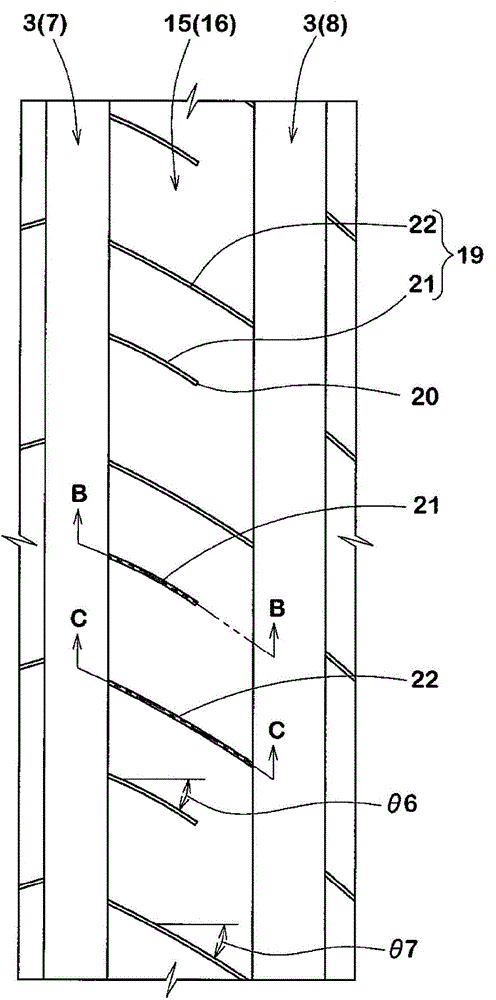

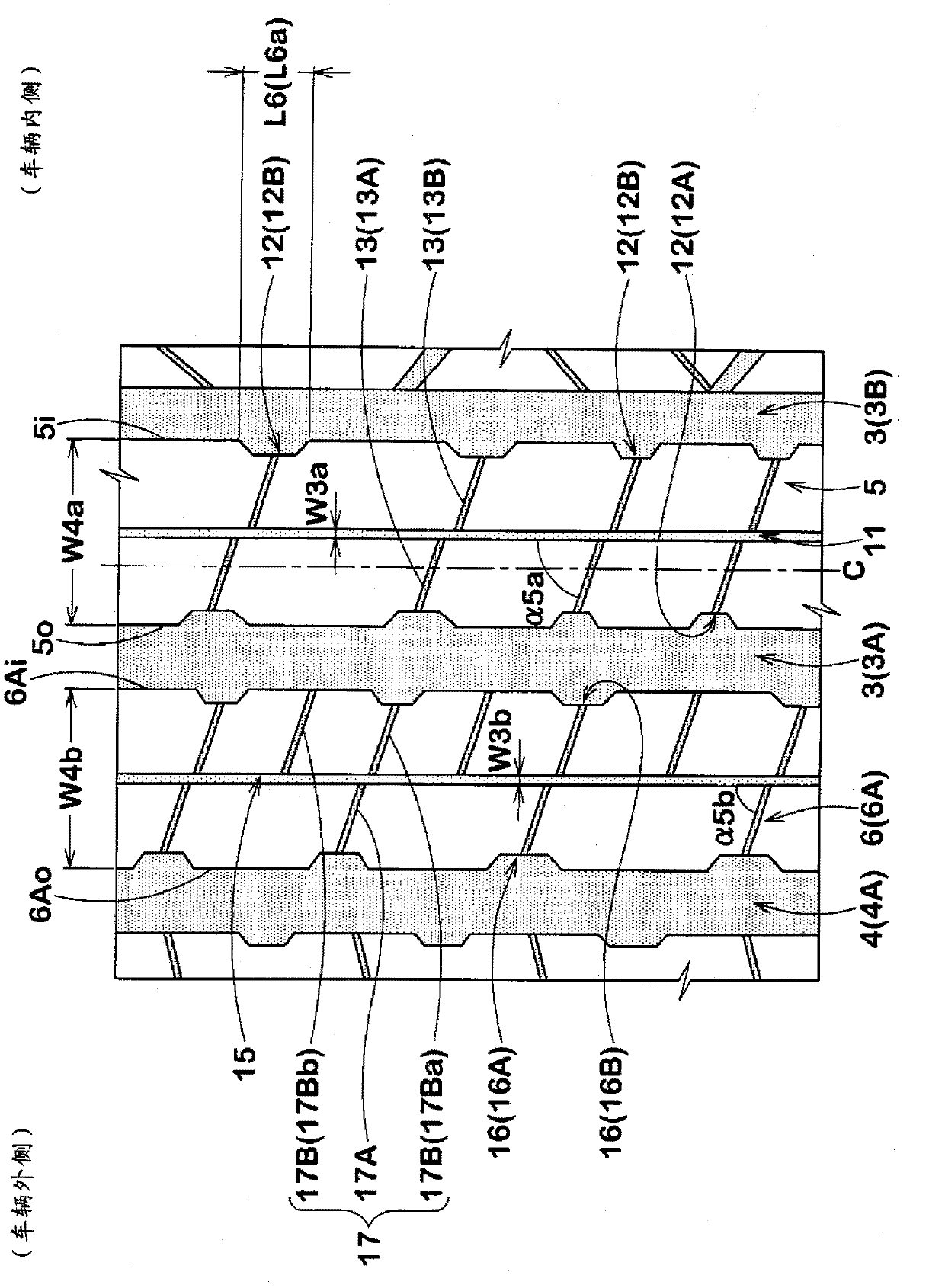

The present invention provides a pneumatic tire capable of maintaining the properties of a trunk road and a wet road while improving the performance of the pneumatic tire on the snow. The tread (2) of the pneumatic tire (1) comprises a main channel (3) and a land part (5). The main channel (3) is composed of an inner trench wall (12) on the side of a tire equatorial (C), and an outer trench wall (13) on the side of a tread end (Te). The tilt angle of the outer trench wall (13) is larger than that of the inner trench wall (12). The land part (5) is composed of an inner land part (15) adjacent to the tire equatorial (C) of the main channel (3). The inner land part (15) is provided with a siping (19) in communication with the main channel (3). The siping (19) is composed of a bottom surface (24) and a shallow bottom part (25) that is raised at the end portion of the main channel (3).

Owner:SUMITOMO RUBBER IND LTD

Pneumatic tire

ActiveCN106042785AGuaranteed rigidityImprove on-snow performanceTyre tread bands/patternsGround contactRoad surface

Owner:SUMITOMO RUBBER IND LTD

Pneumatic tire

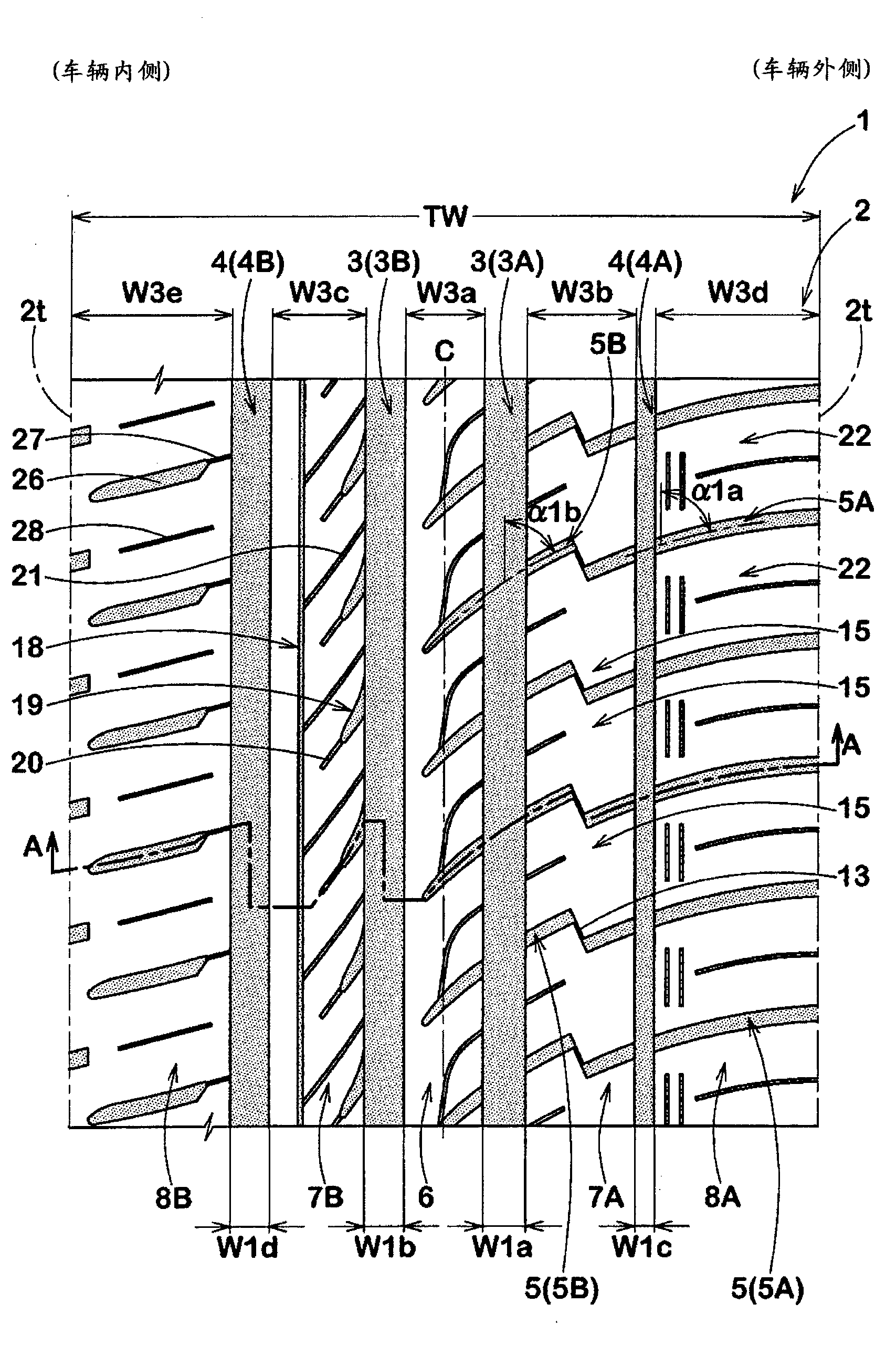

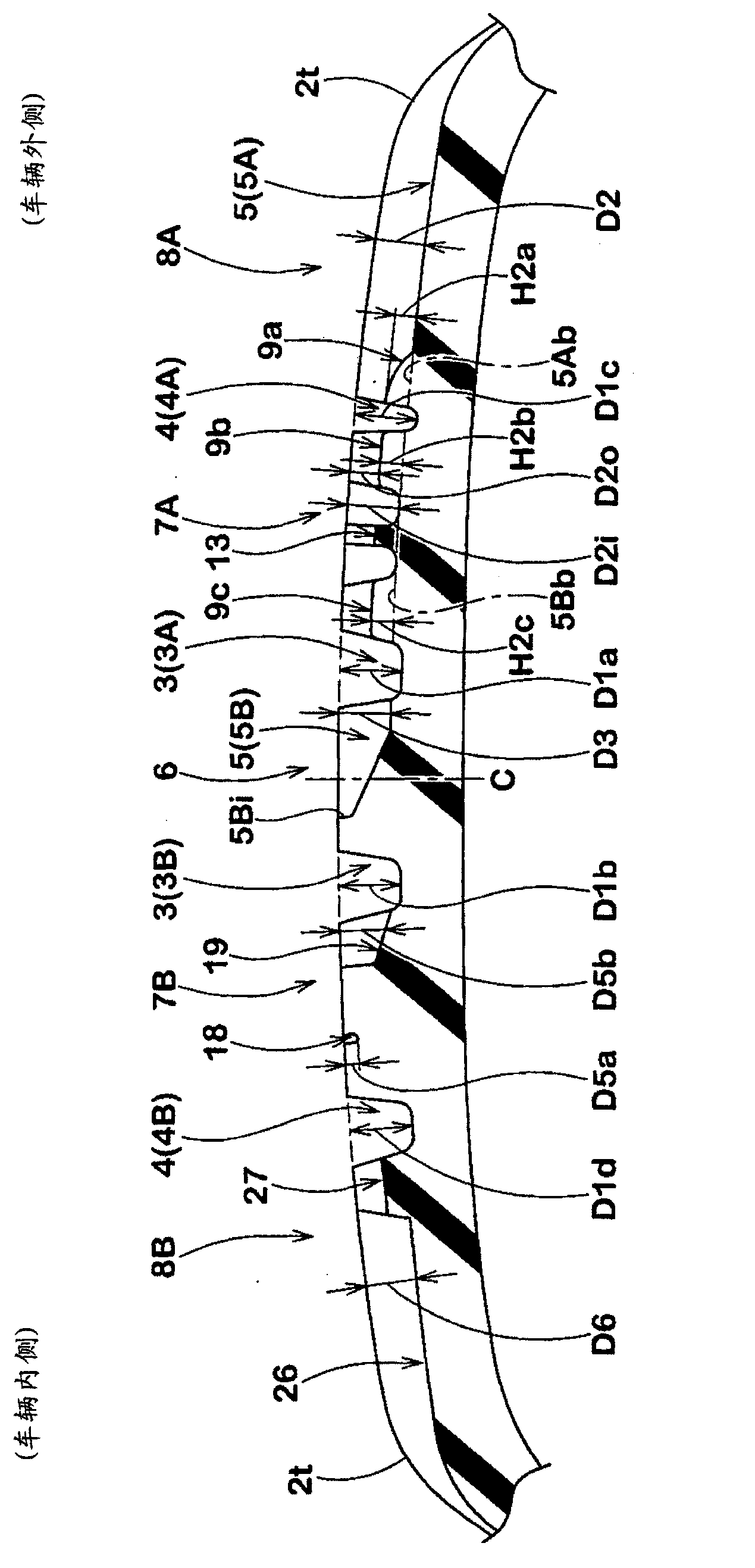

ActiveCN103182902ASmooth dischargeImprove drainage capacityTyre tread bands/patternsEngineeringRoad surface

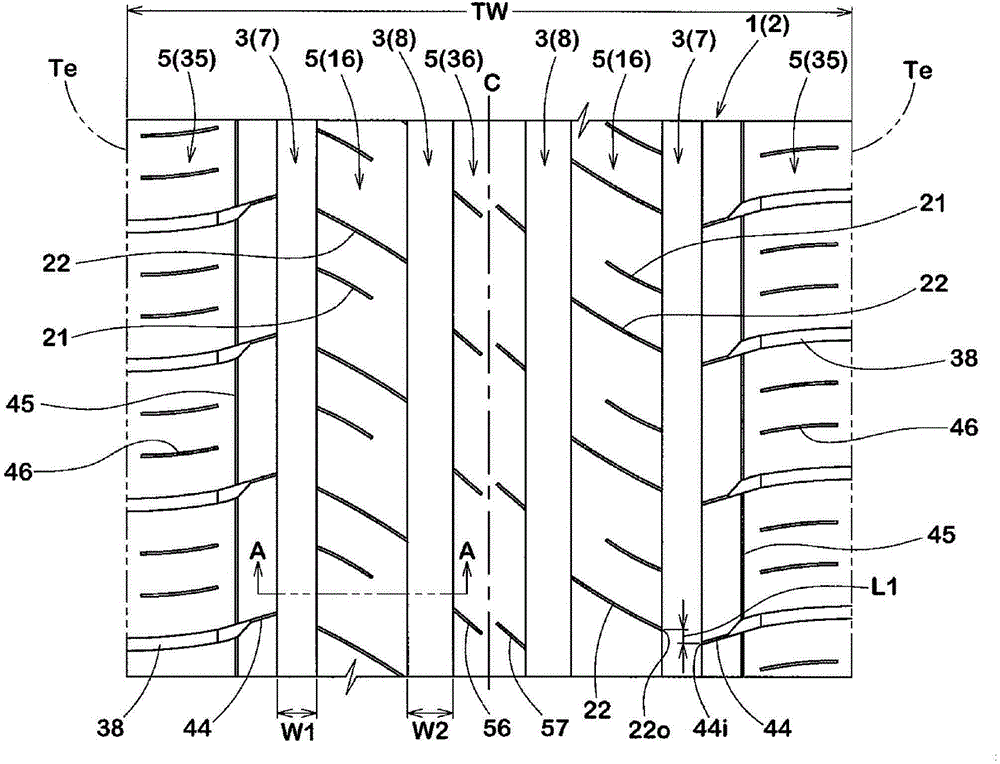

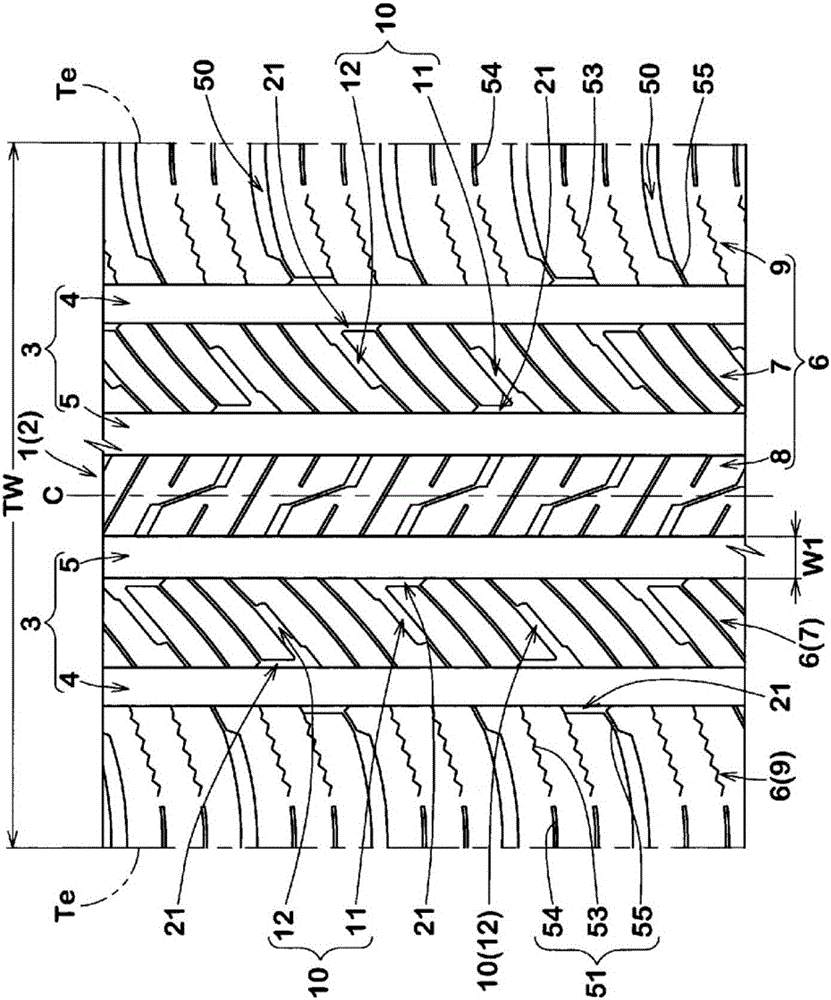

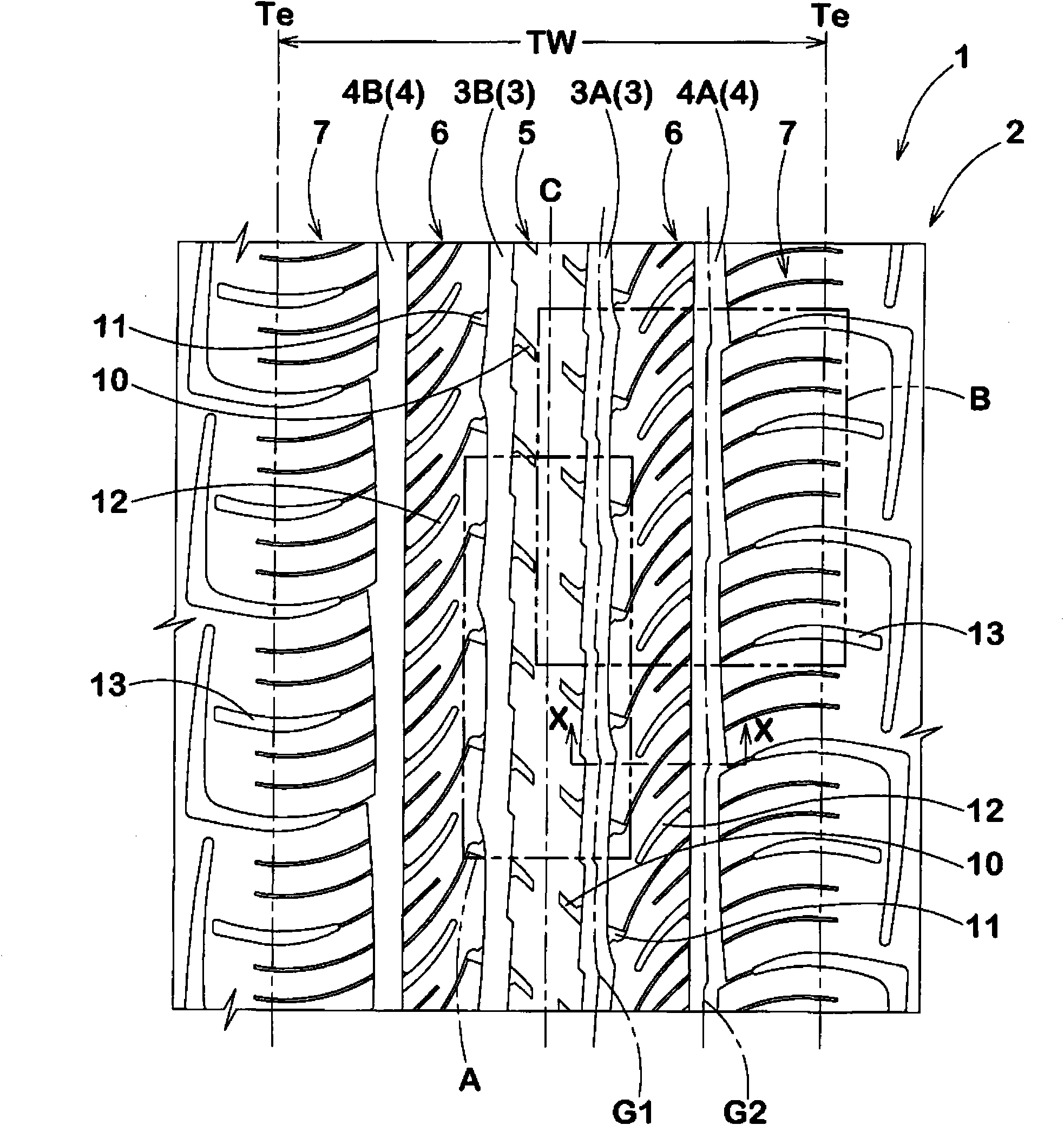

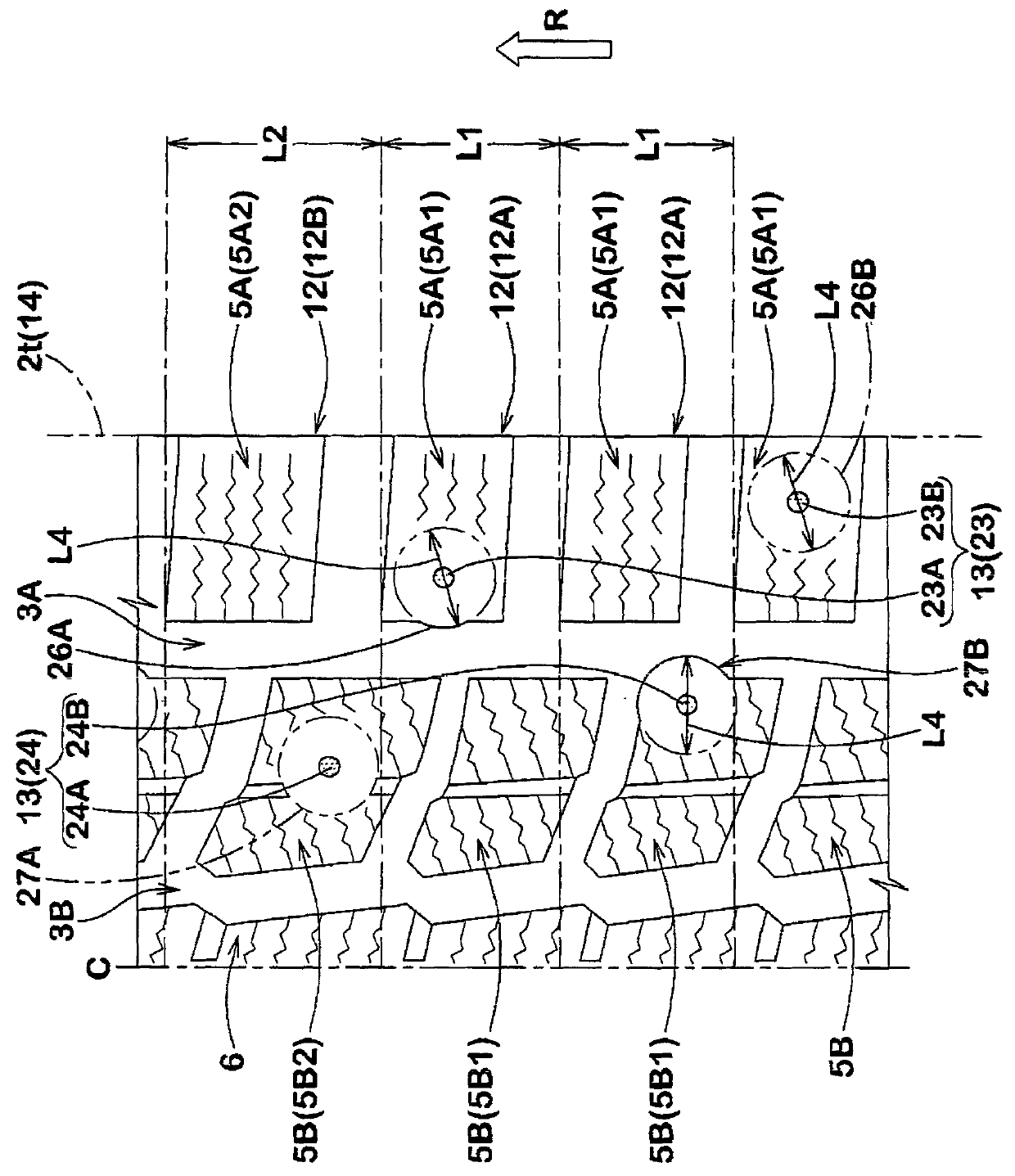

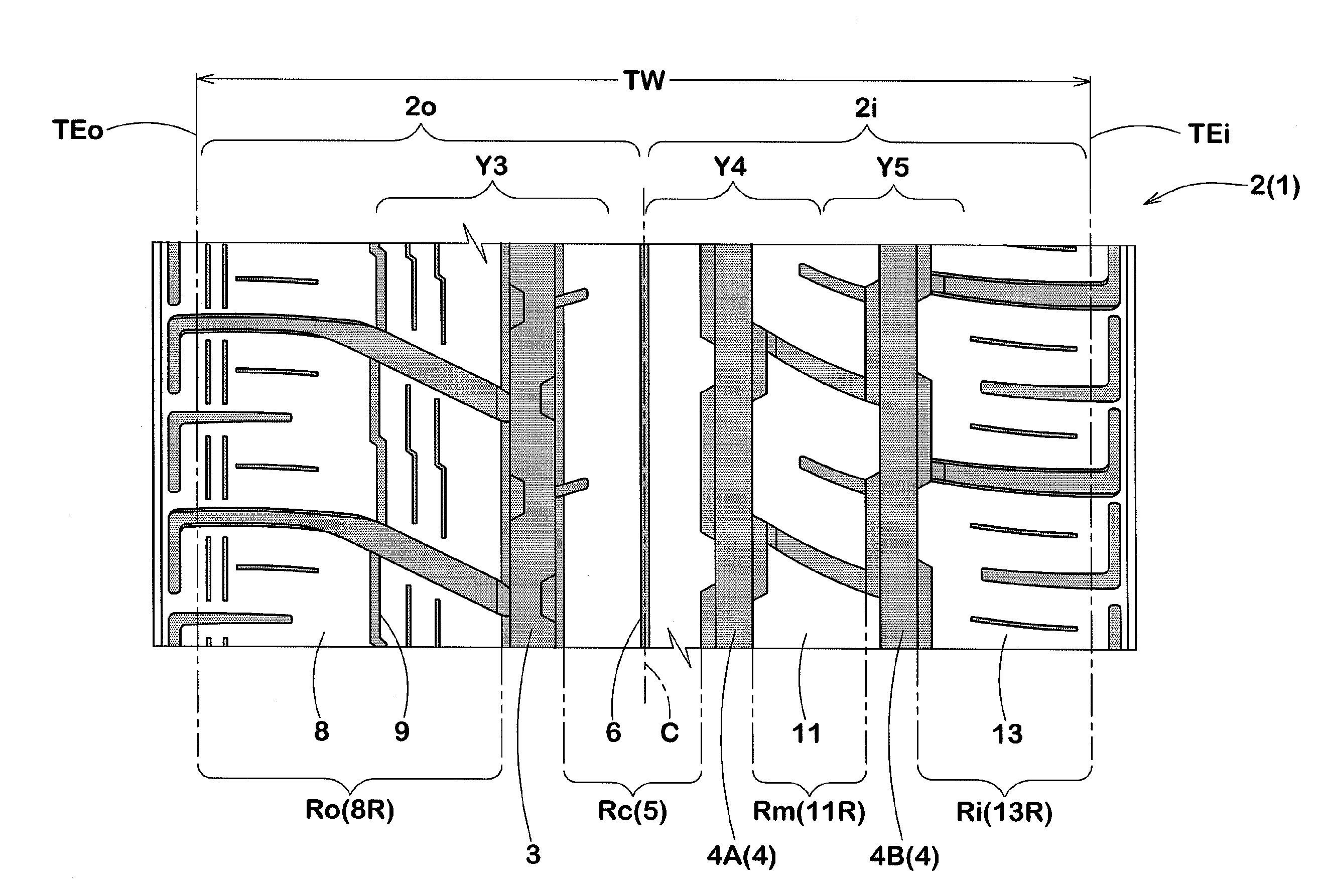

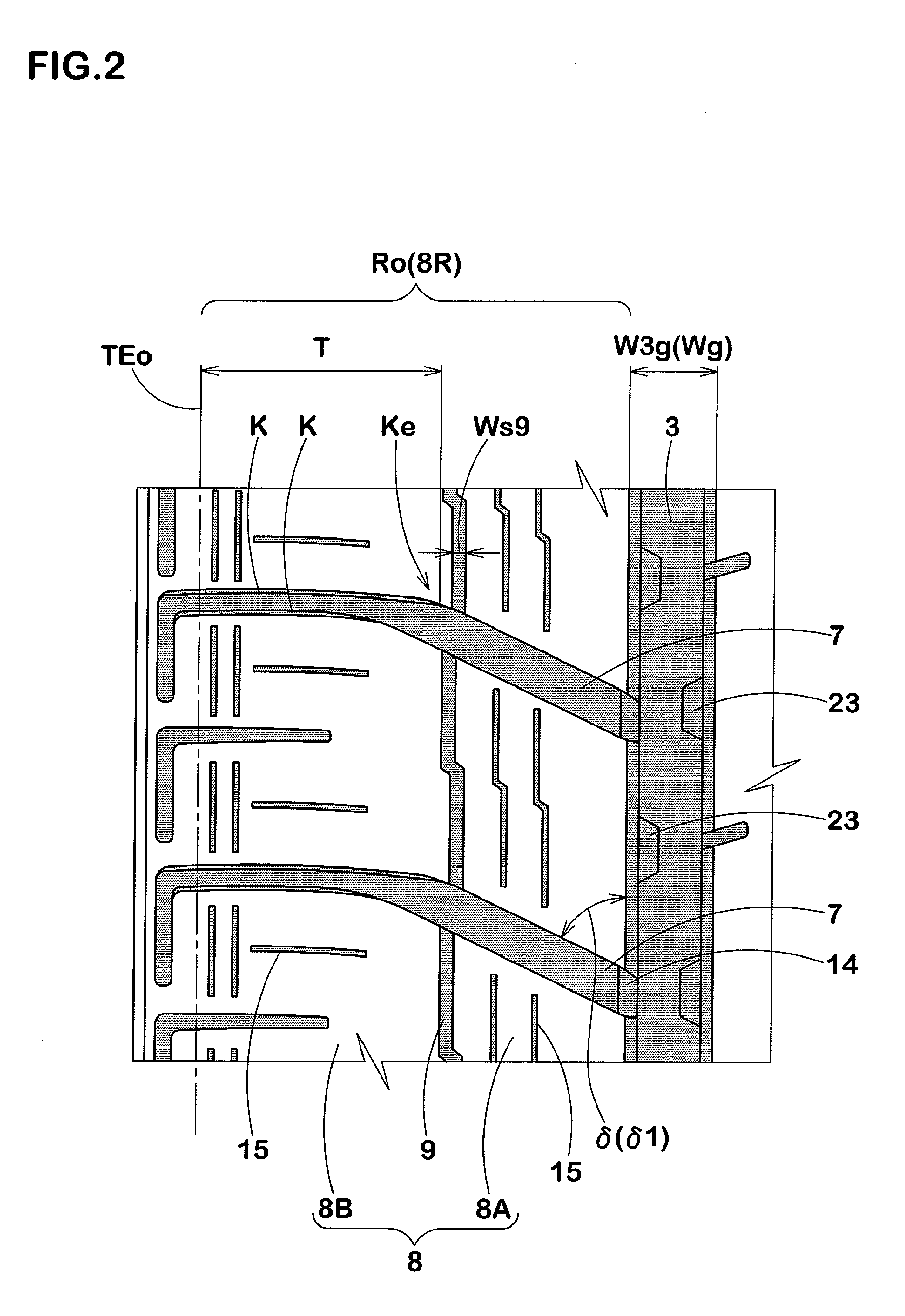

The present invention provides a pneumatic tire capable of improving the drainage performance, on-snow performance, and on-ice performance while maintaining the steering stability on a dry road surface. The pneumatic tire (1) has a designated mounting orientation with respect to a vehicle. A tread portion (2) divided into a center land portion (6), an outer middle land portion (7A), an inner middle land portion (7B), an outer shoulder land portion (8A), and an inner shoulder land portion (8B); the outer shoulder land portion (8A) enables outer shoulder blocks (22) which are sectioned by outer shoulder lateral grooves (5A) to be arranged circumferentially on the tire in a space manner; the inner shoulder land portion includes inner shoulder lateral grooves (26) having outer ends which are on the outside of the vehicle and form terminals in the land portion (8B), and inner shoulder auxiliary grooves (28); the inner middle land portion includes an inner middle sub-groove (18) which continuously extends in a circumferential direction and inner middle sipes (21) which extend between the inner middle sub-groove and the inner center longitudinal groove (3B).

Owner:SUMITOMO RUBBER IND LTD

Pneumatic tire

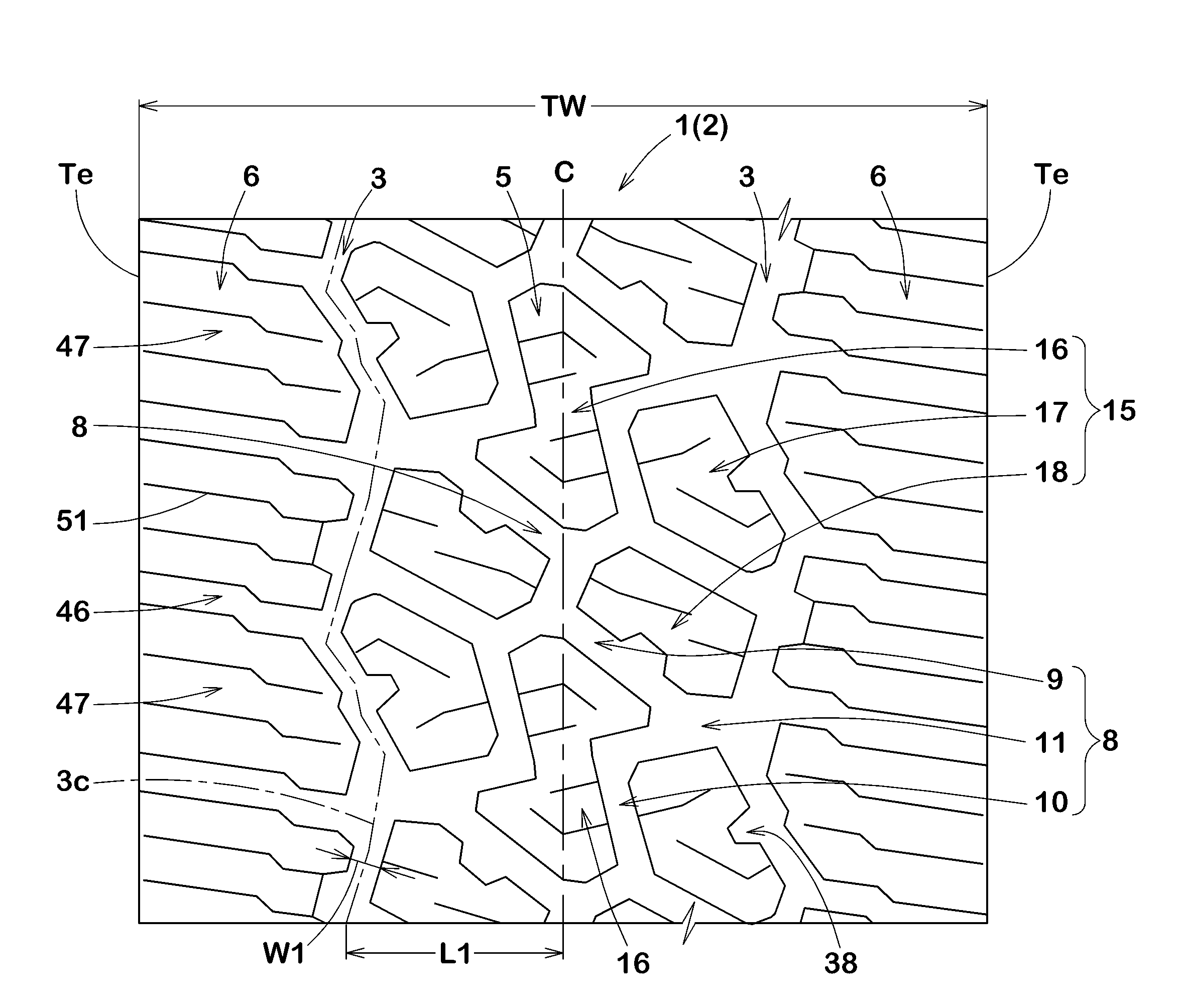

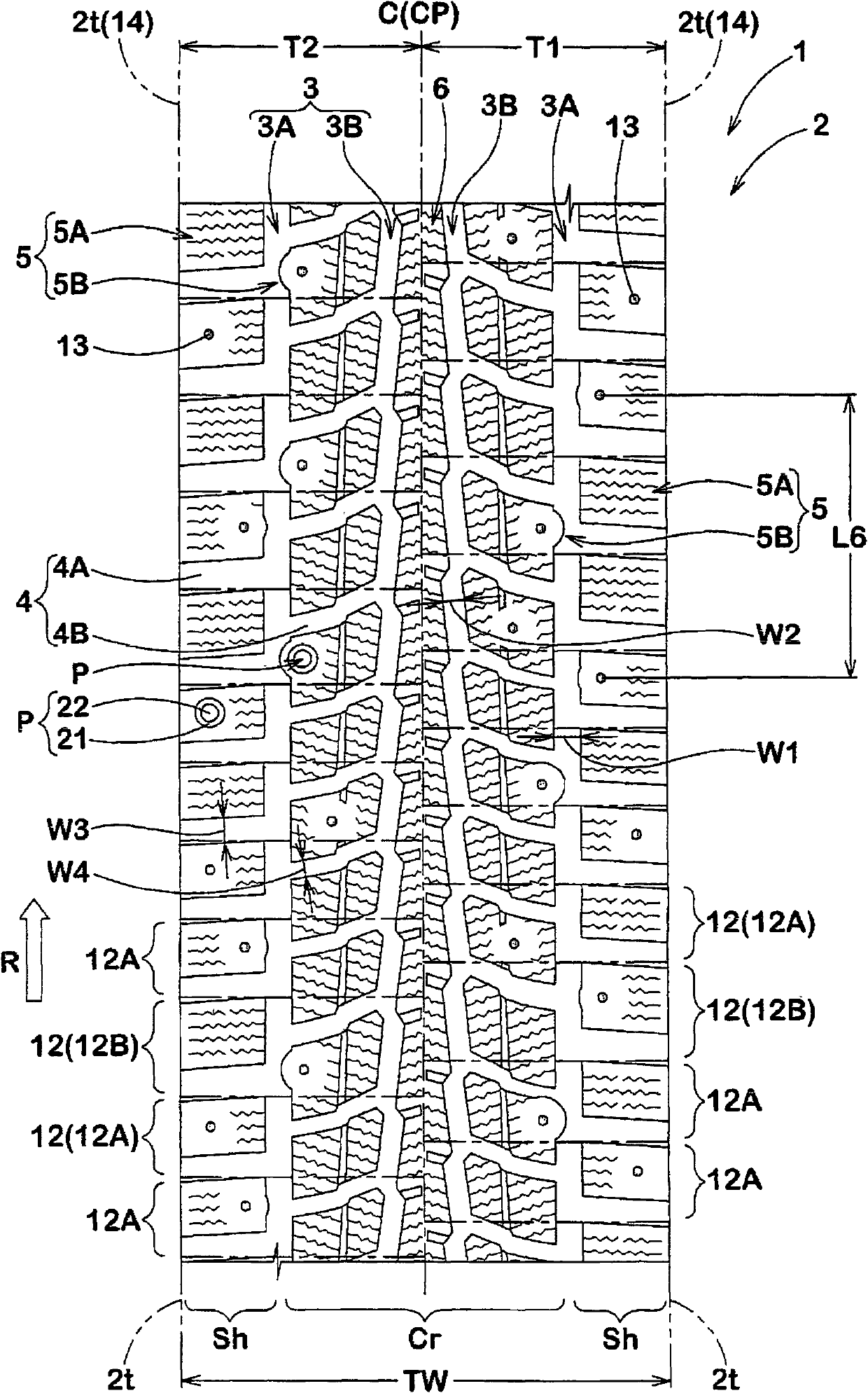

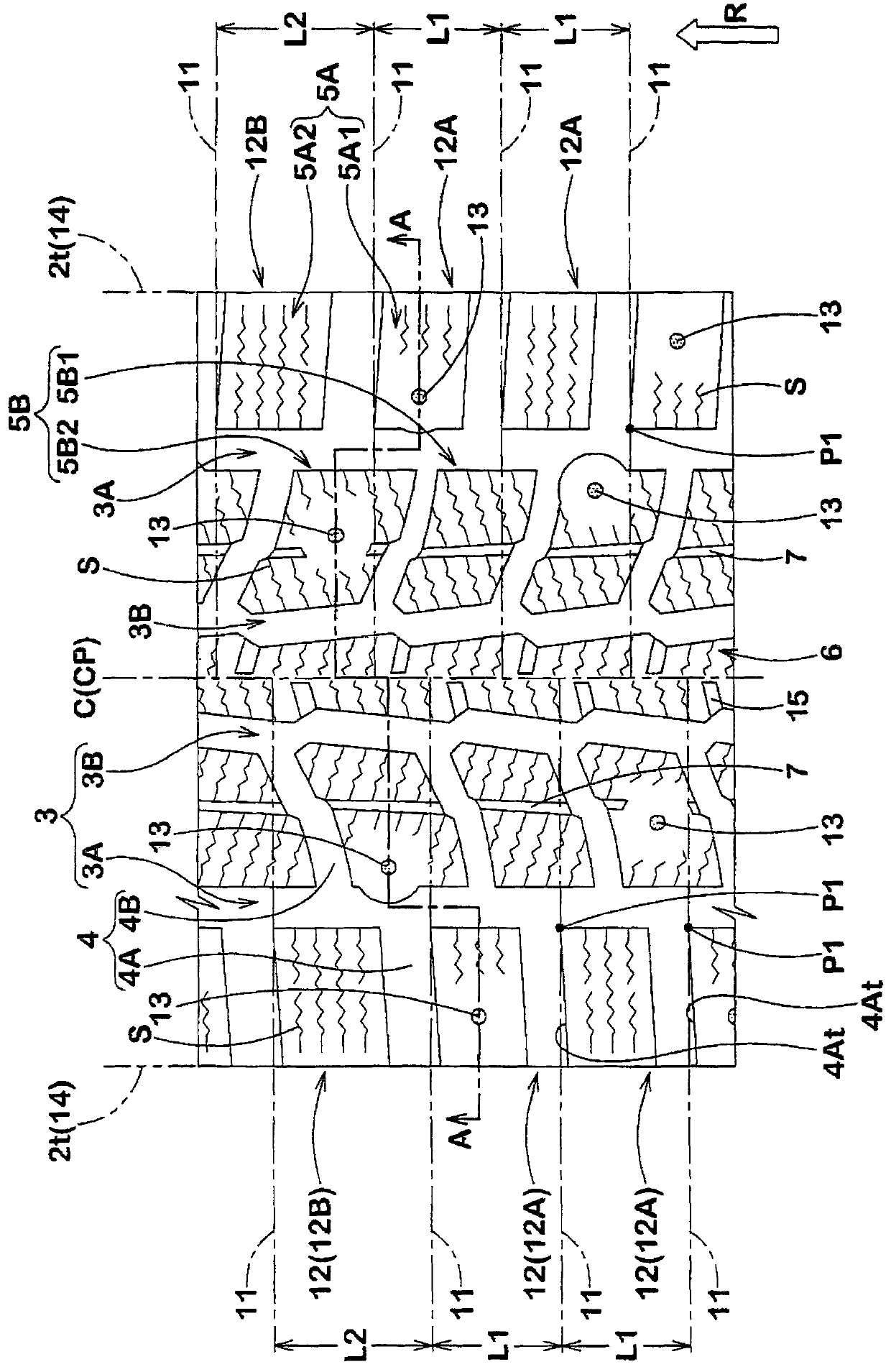

ActiveCN101920636AGuaranteed rigidityImprove snow removal performanceTyre tread bands/patternsEdge segmentEngineering

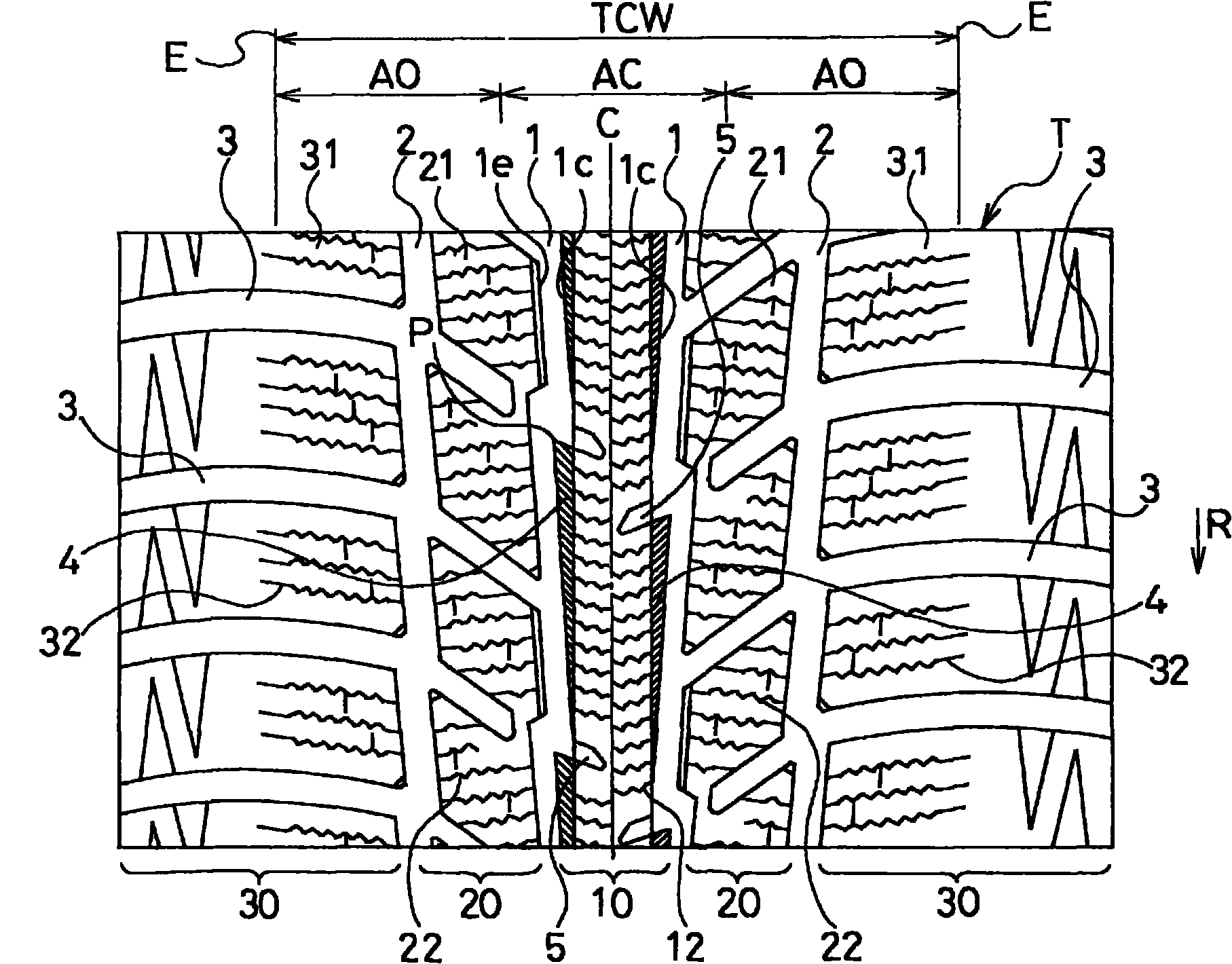

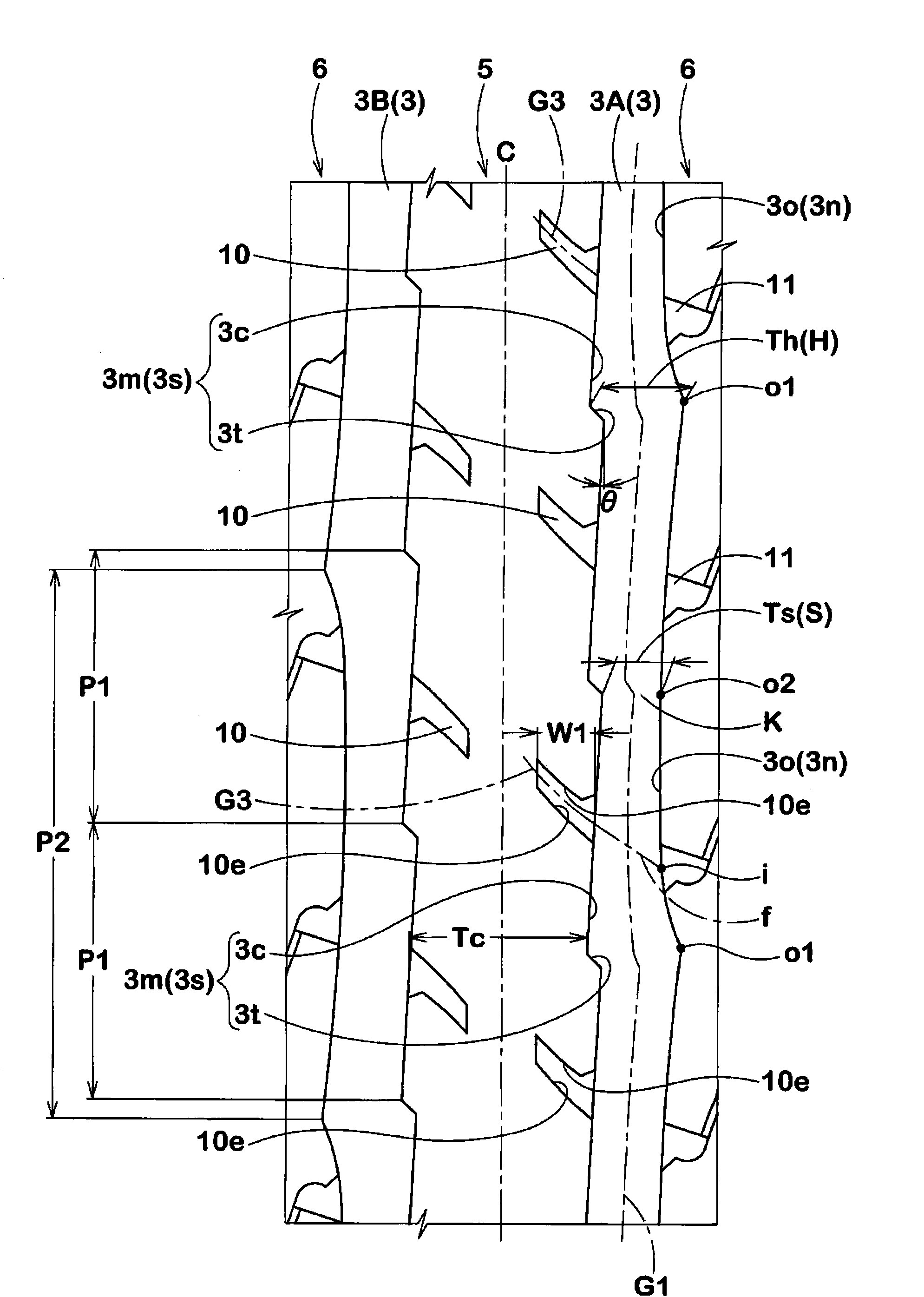

A pneumatic tire 1 having excellent on-snow performances improved with maintaining steering stability and uneven wear resistance and including tread portion 2 having a pair of crown circumferential grooves 3 which extend continuously in the tire circumferential direction on both sides of tire equator C and have groove edges, one edge 3m extending in such a zigzag form that italic L-shaped groove edge segments 3s are continuously connected to each other in the circumferential direction, and the other edge 3n extending in such a wavy form that circular arc groove edge segments 3o each having a circular arc shape convex toward a groove center are continuously connected to each other in the circumferential direction, wherein each of the italic L-shaped groove edge segments 3s comprises long side part 3c inclined at an angle of 1 to 20 DEG with respect to the circumferential direction, and short side part 3t having a circumferential length smaller than that of the long side part 3c and inclined in the opposite direction to the long side part 3c with respect to the circumferential direction.

Owner:SUMITOMO RUBBER IND LTD

Pneumatic tire

ActiveCN104275988AImprove on-snow performanceImprove performance on iceTyre tread bands/patternsEngineering

Owner:SUMITOMO RUBBER IND LTD

Pneumatic tire

ActiveCN102700366AImprove on-snow performanceRealize white noiseTyre tread bands/patternsLanding zoneEngineering

Owner:SUMITOMO RUBBER IND LTD

Pneumatic tire

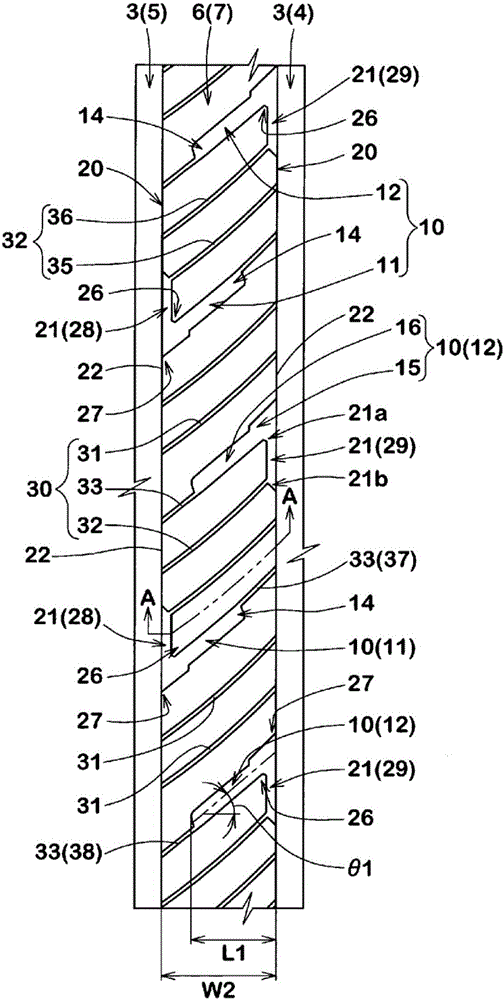

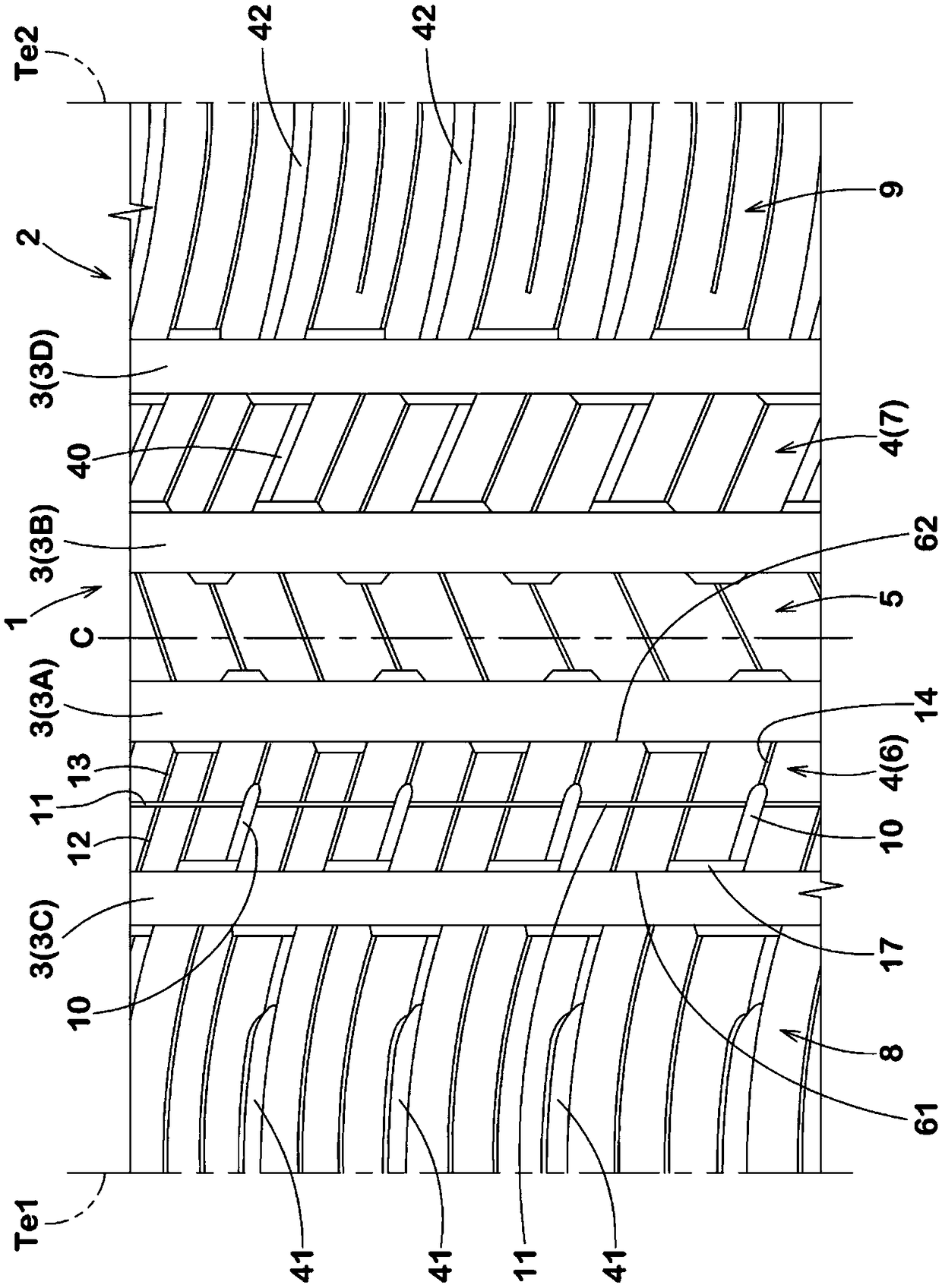

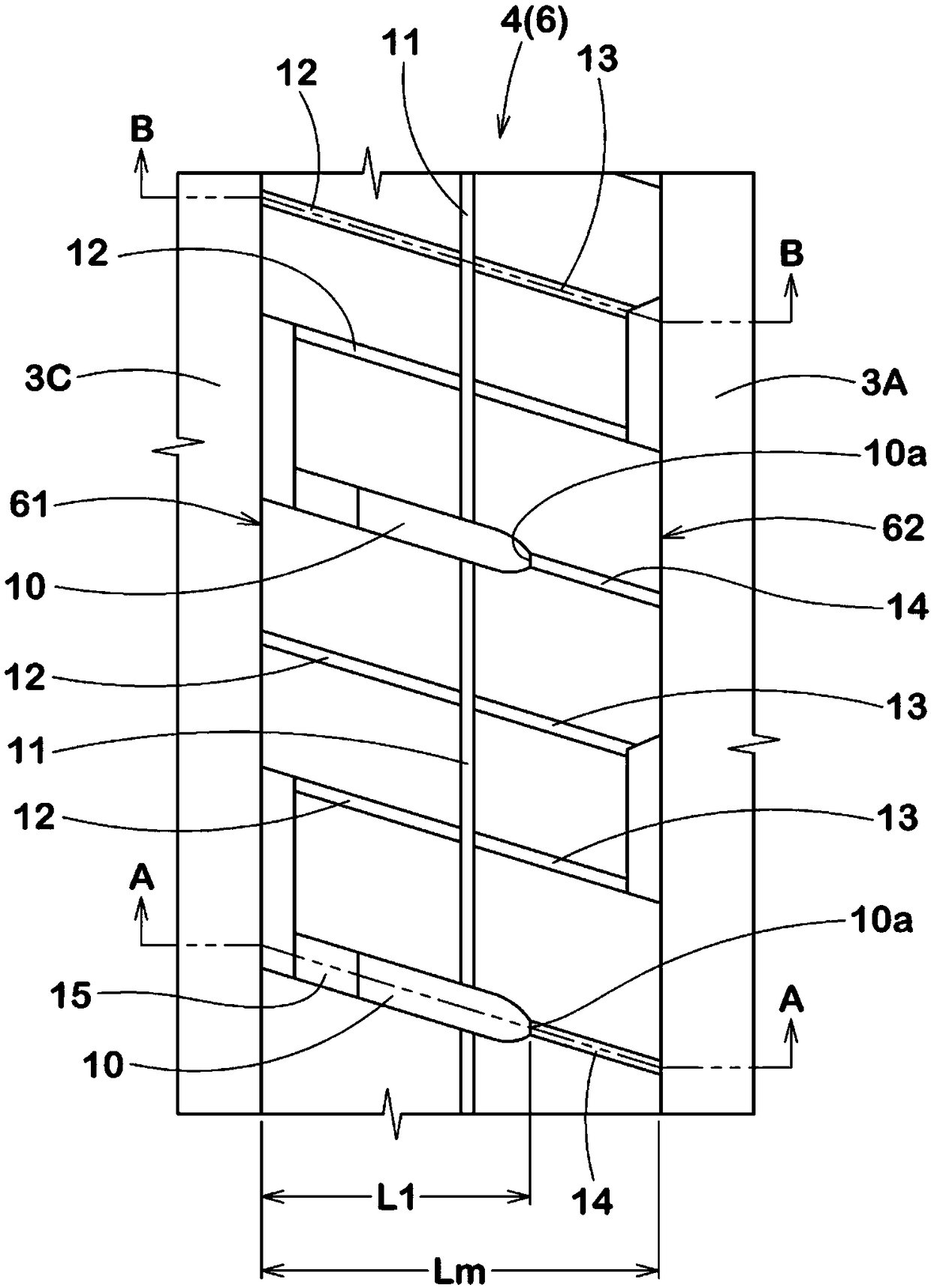

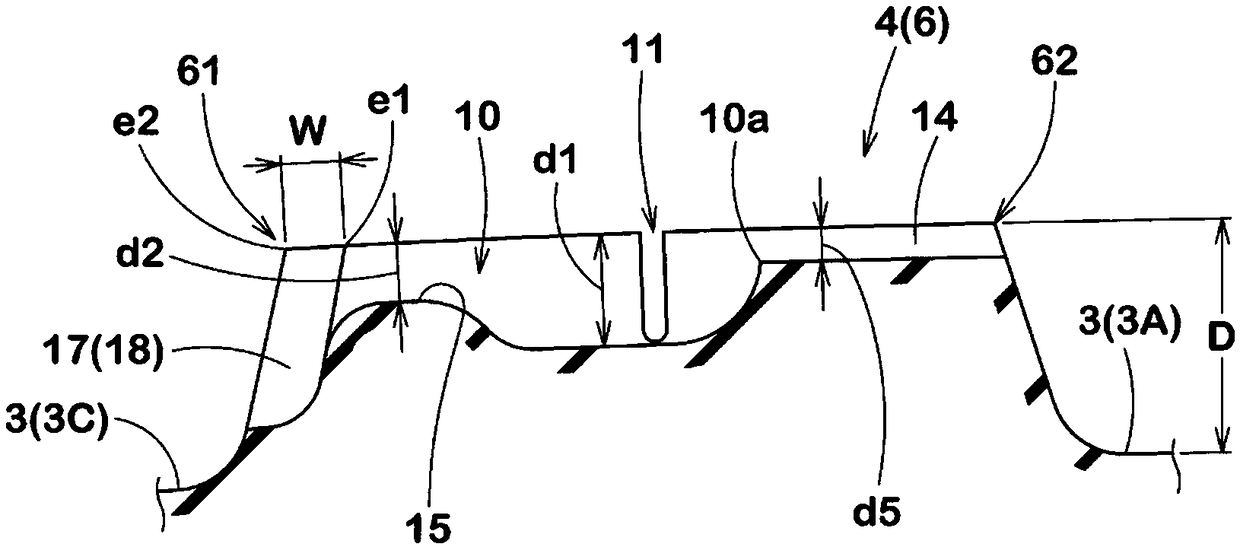

ActiveUS20160144668A1Reduce the angleReduce rigidityTyre tread bands/patternsNon-skid devicesRoad surfaceEngineering

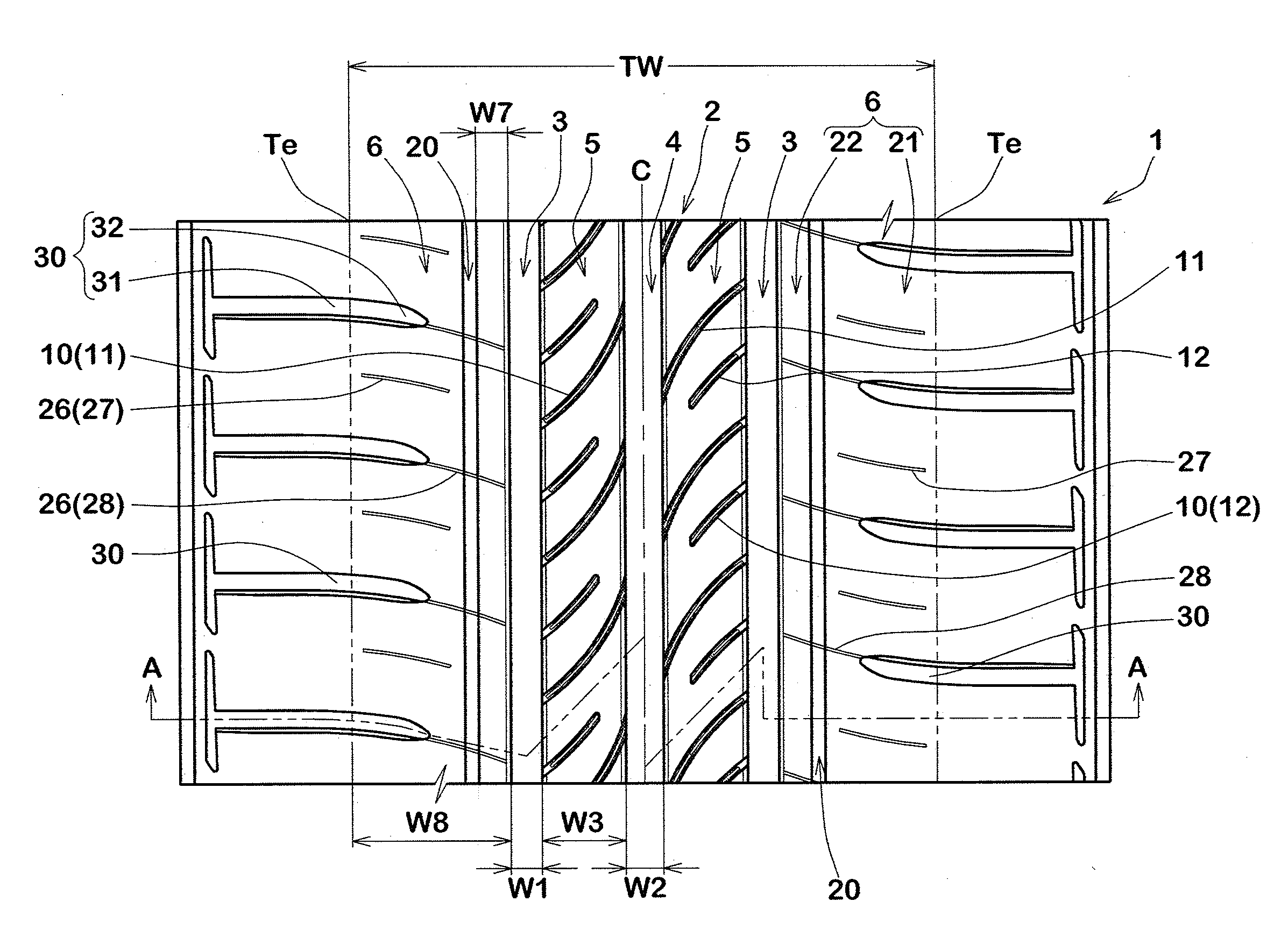

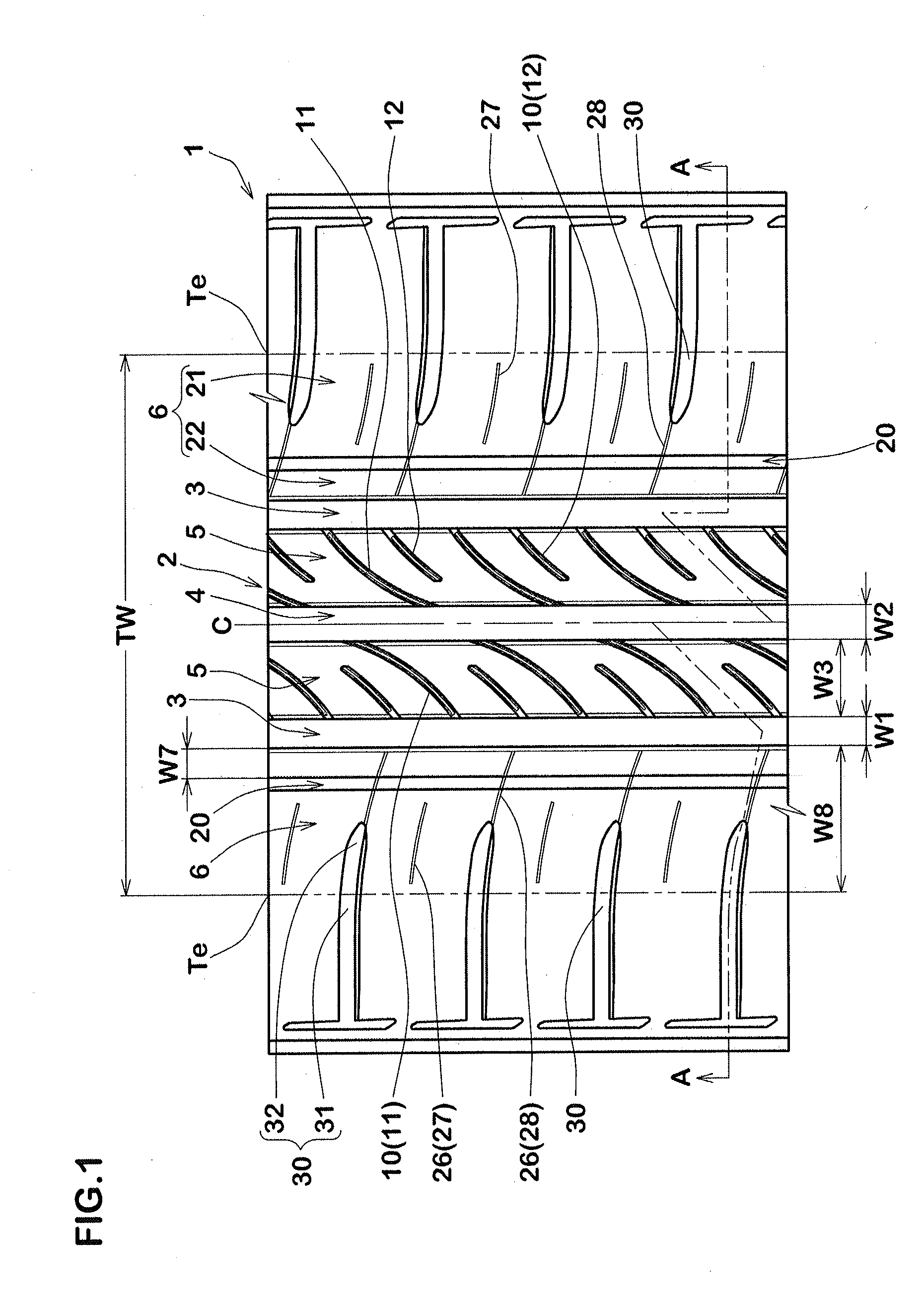

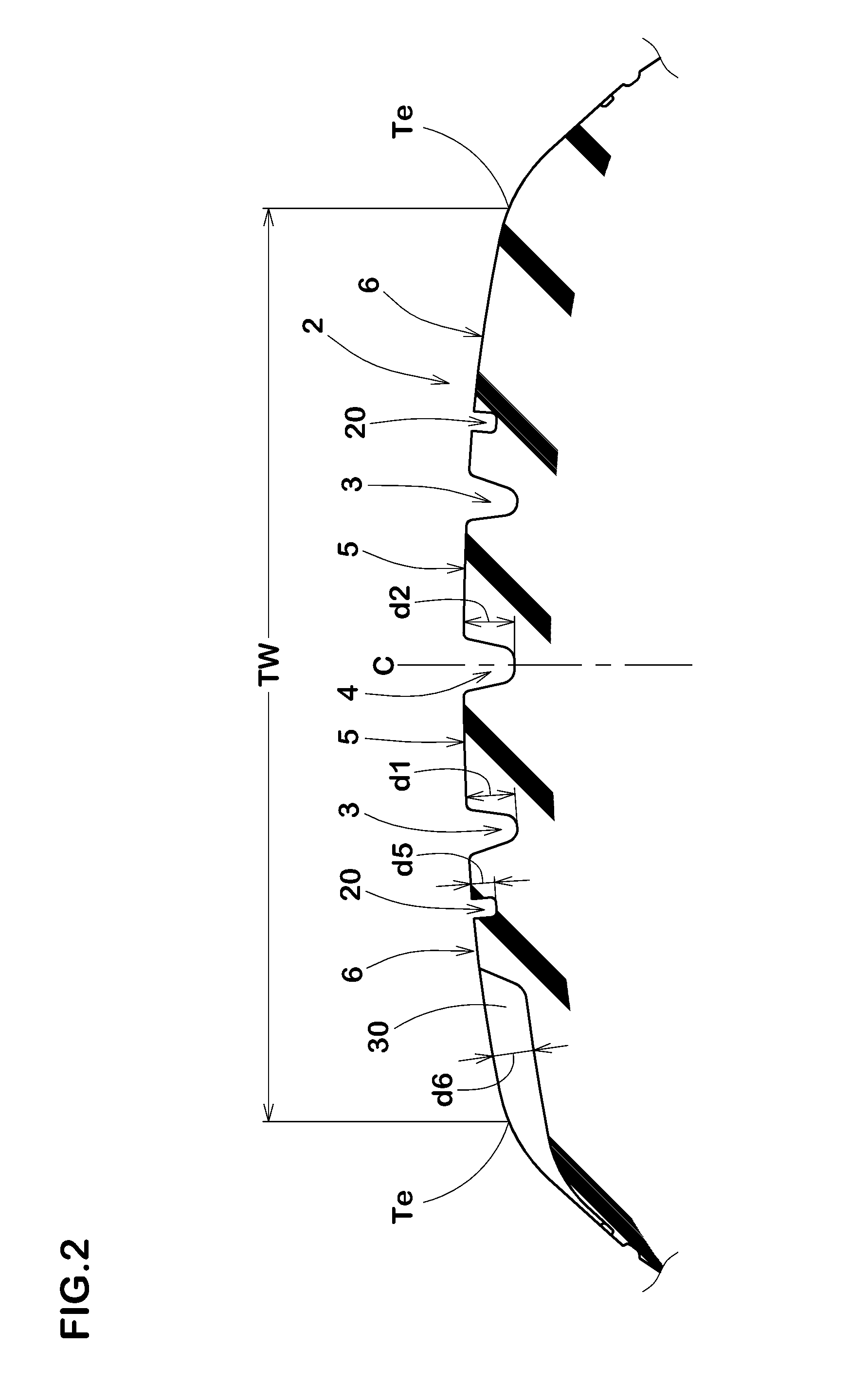

To provide a pneumatic tire which is improved in on-snow performance, while maintaining steering stability on dry road surface. The pneumatic tire is provided in a tread portion 2 with a pair of shoulder main grooves 3, a center main groove 4, shoulder land portions 6, and middle land portions 5. The middle land portions 5 are provided with middle lateral grooves 10 extending from the shoulder main grooves 3 toward the inside in the tire axial direction, while gradually decreasing the angle with respect to tire circumferential direction. The middle lateral groove 10 is provided with a groove bottom sipe 15 opened in the groove bottom.

Owner:SUMITOMO RUBBER IND LTD

Pneumatic tire

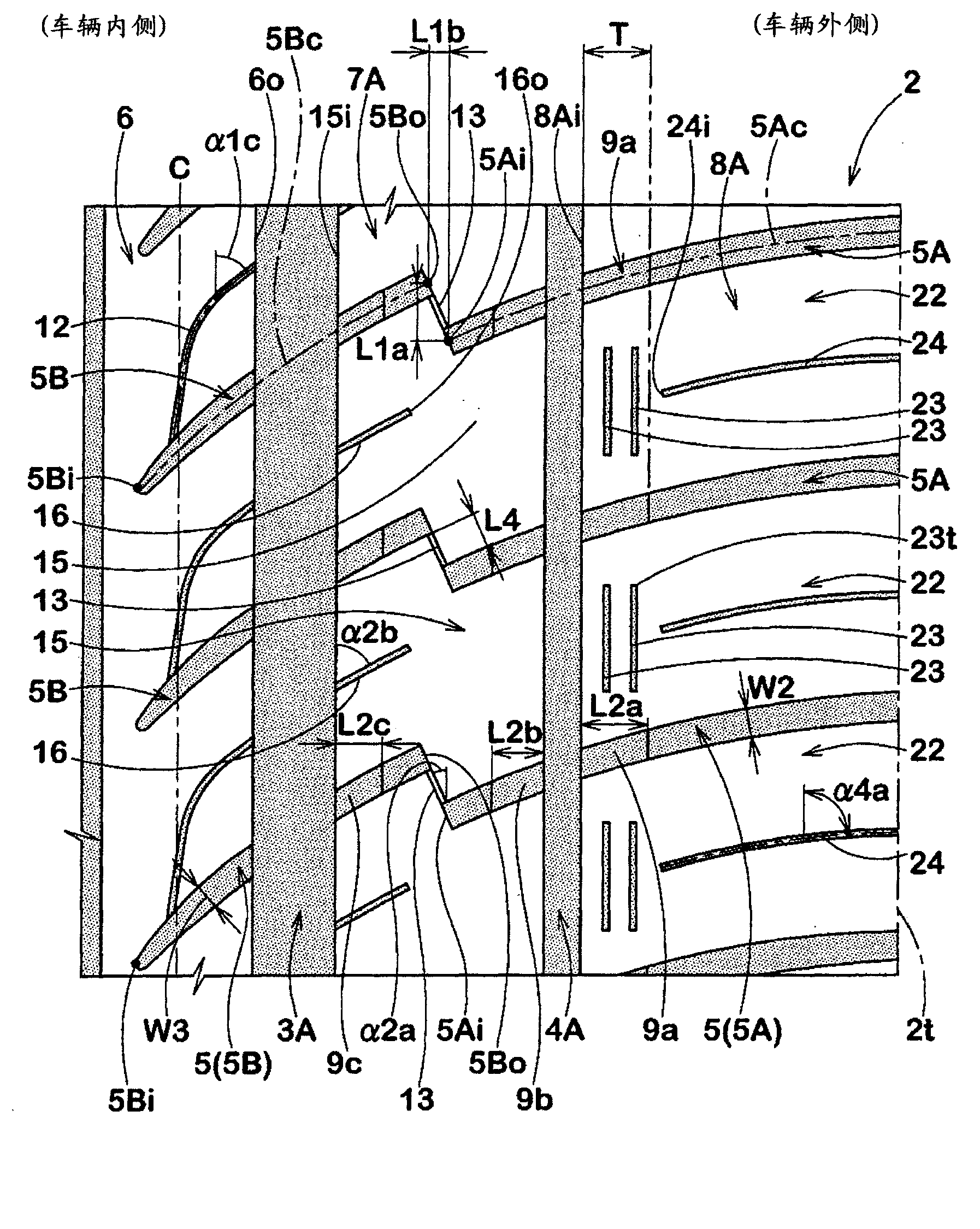

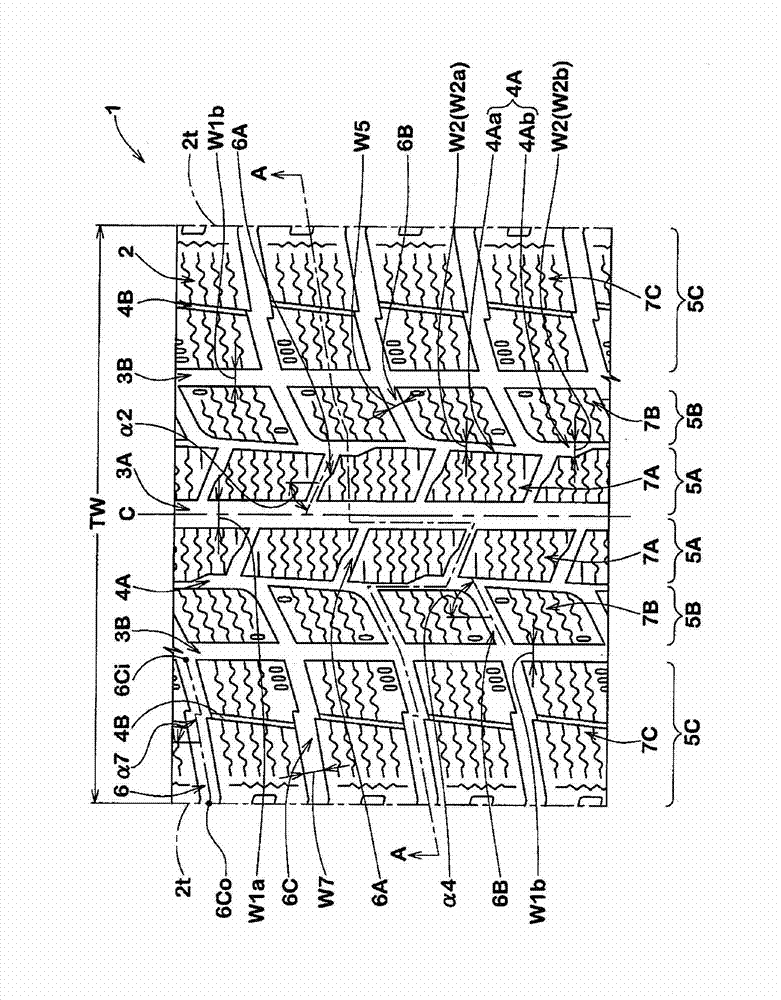

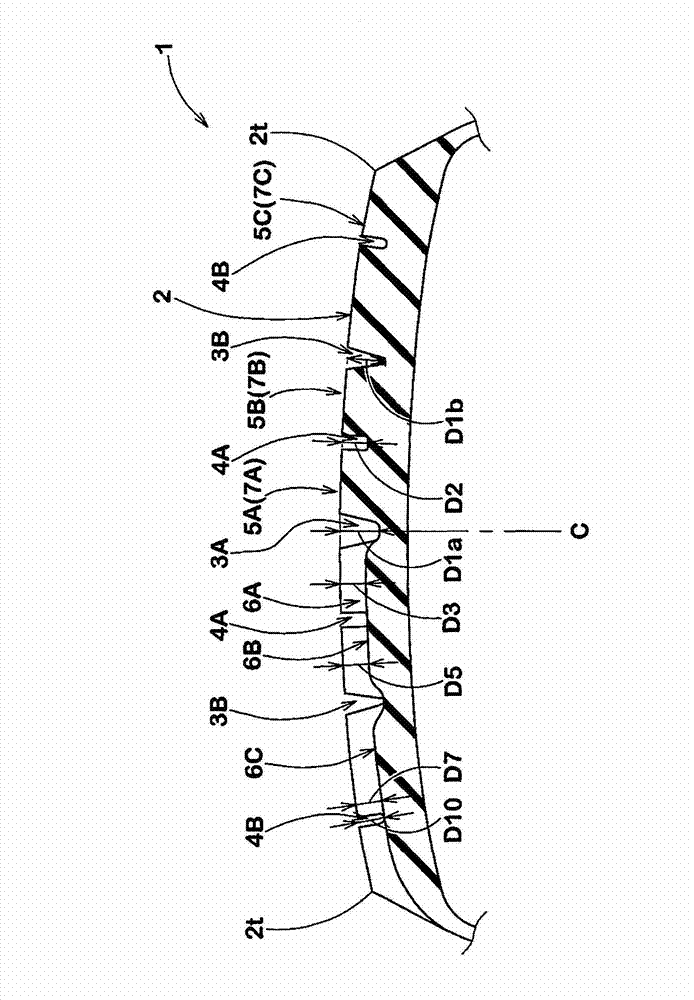

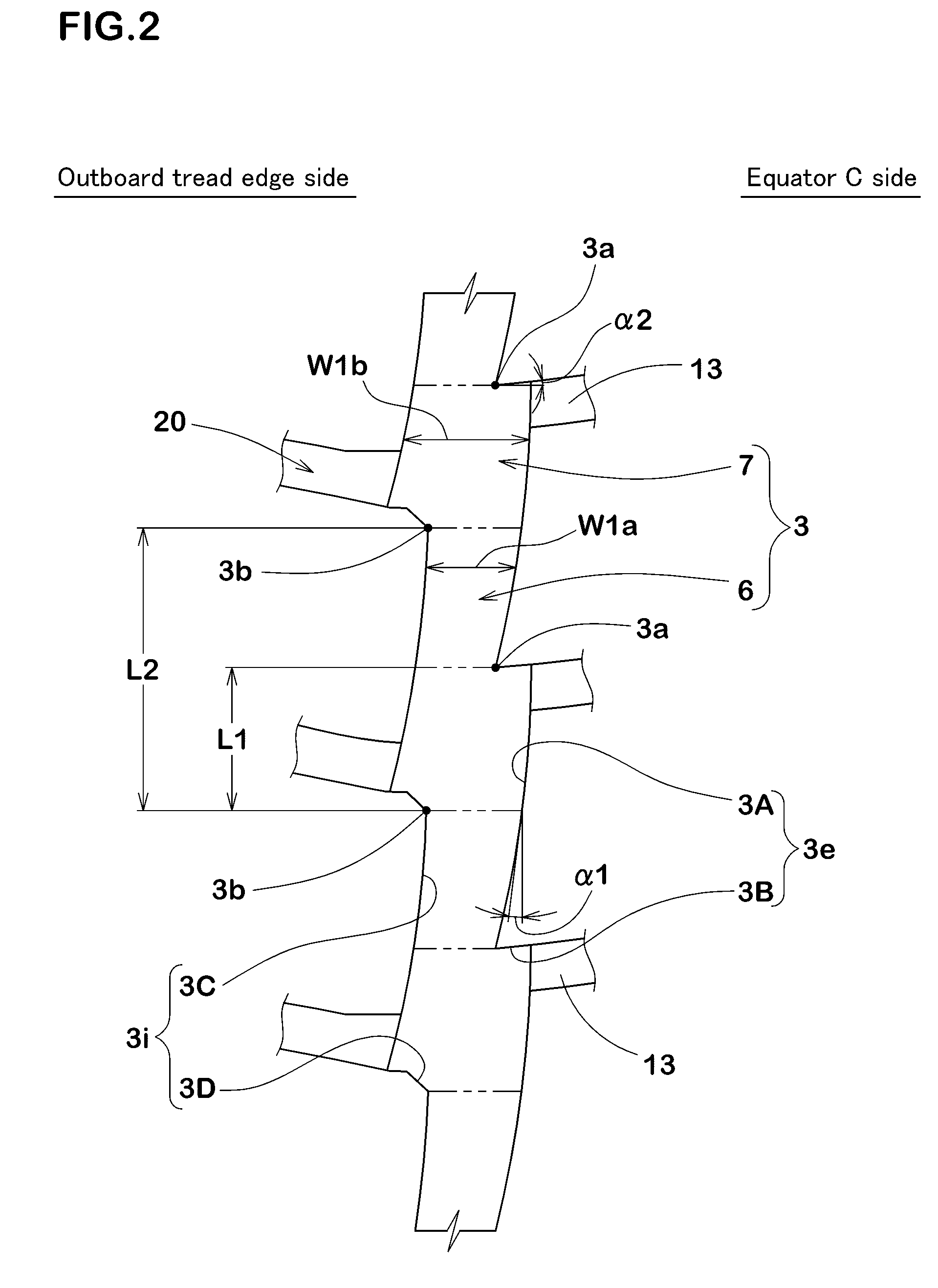

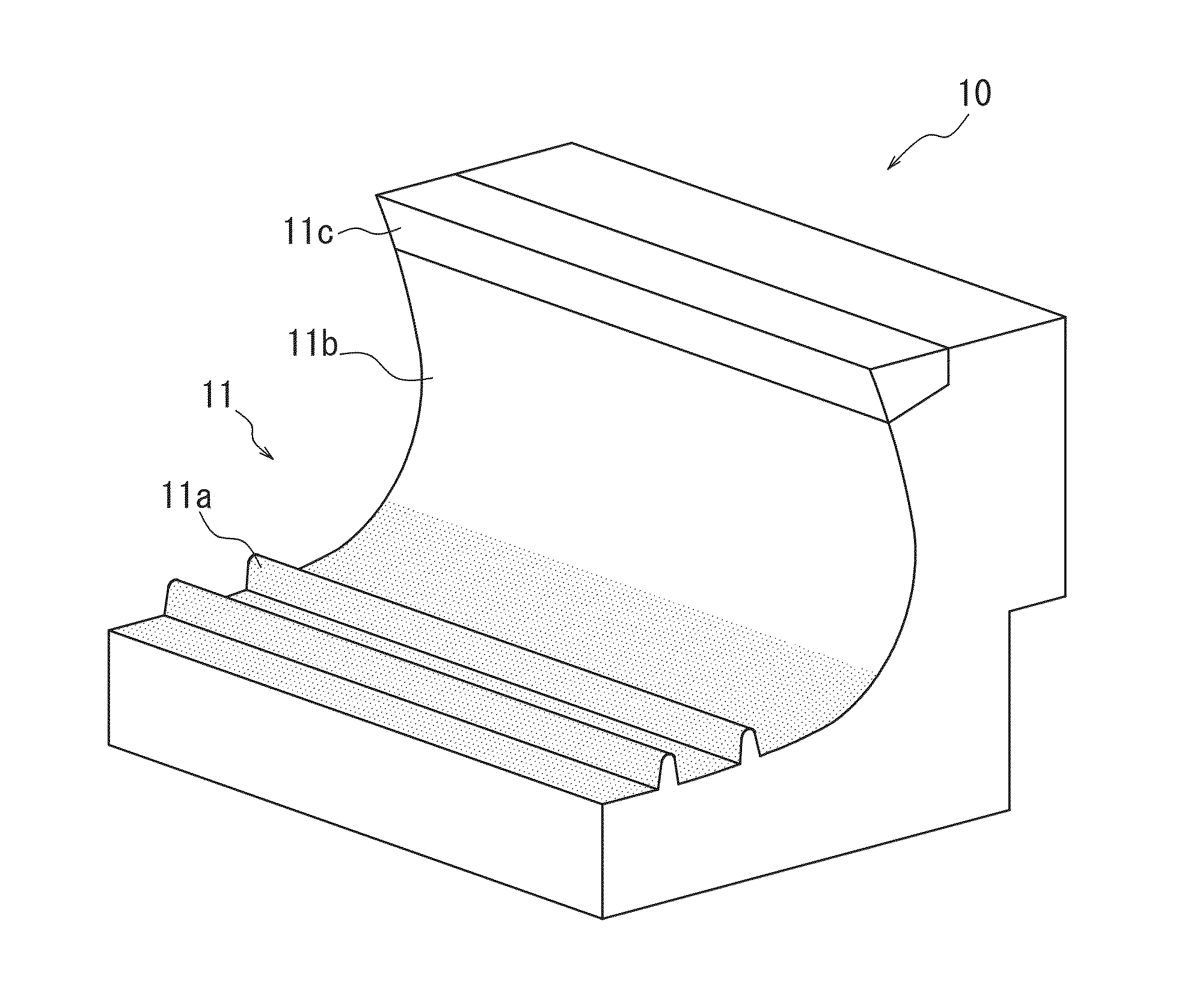

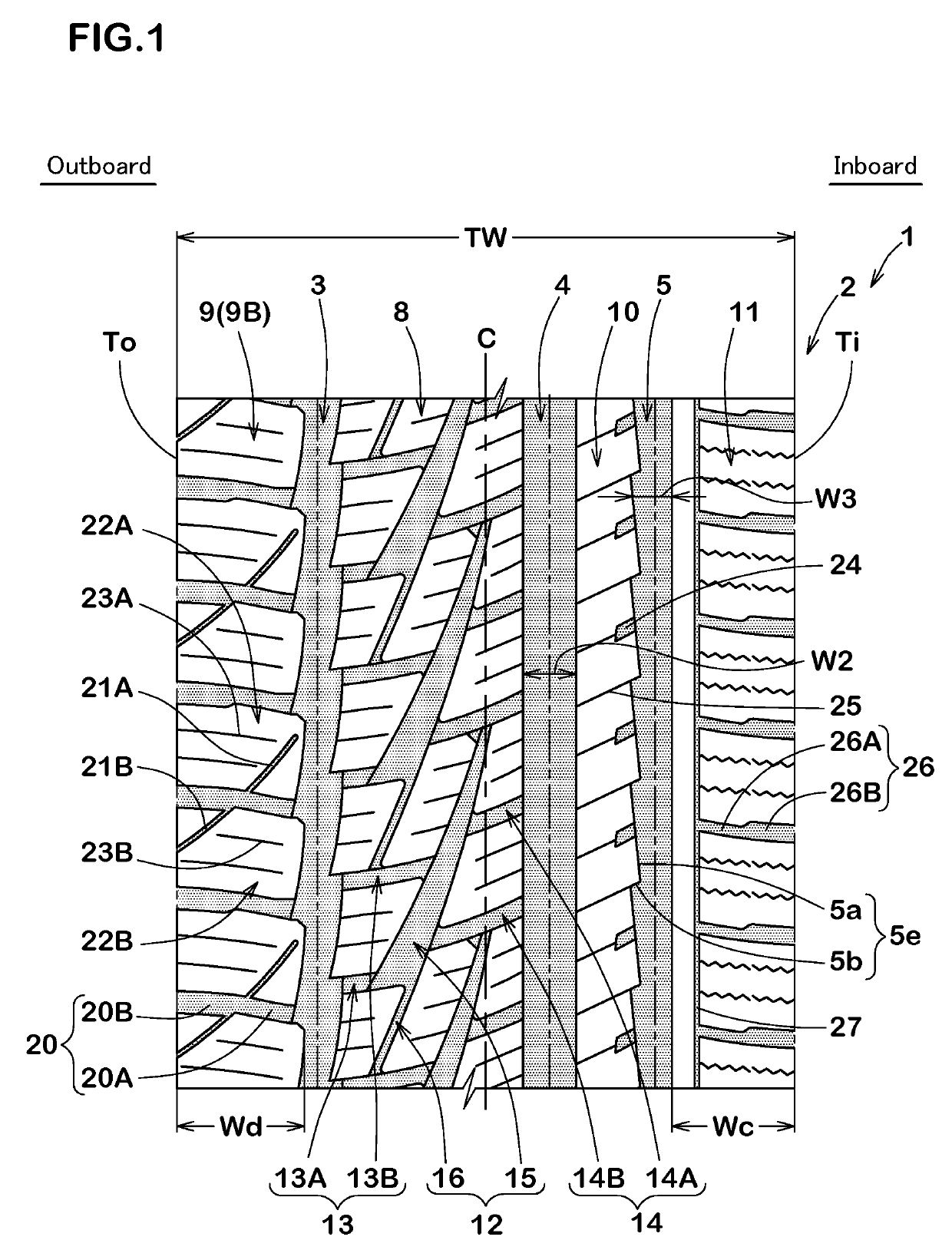

ActiveCN103303068ASmooth dischargeImprove on-snow performanceTyre tread bands/patternsMain channelChannel width

The invention provides a pneumatic tire, which can greatly improve performance on snow and draining performance. A tire face part (2) of the pneumatic tire (10) is provided with a central main channel (3A), a pair of tire shoulder main channels (3B), and a pair of central auxiliary channels (4A), and thereby an external side central land part (5B) and a tire shoulder land part (5C) are formed. The channel width (W1a) of the central main channel (3A) is larger than the channel width (W1b) of the tire shoulder main channels (3B). A tire shoulder transverse channel (6C) is disposed at the tire shoulder land part (5C). The angle (Alpha 7) of the tire shoulder transverse channel (6C) is larger than the angle (Alpha 4) of an outer side central transverse channel (6B). An outer end (6Bo) by which the outer side central transverse channel (6B) is communicated with the tire shoulder main channels (3B) and an inner end (6Ci) by which the tire shoulder transverse channel (6C) is communicated with the tire shoulder main channels (3B) are oppositely disposed with the tire shoulder main channel (3B) being arranged therebetween.

Owner:SUMITOMO RUBBER IND LTD

Pneumatic tire

ActiveUS20140224394A1Good friction propertiesImprove scratching effectTyre tread bands/patternsNon-skid devicesGroove widthEngineering

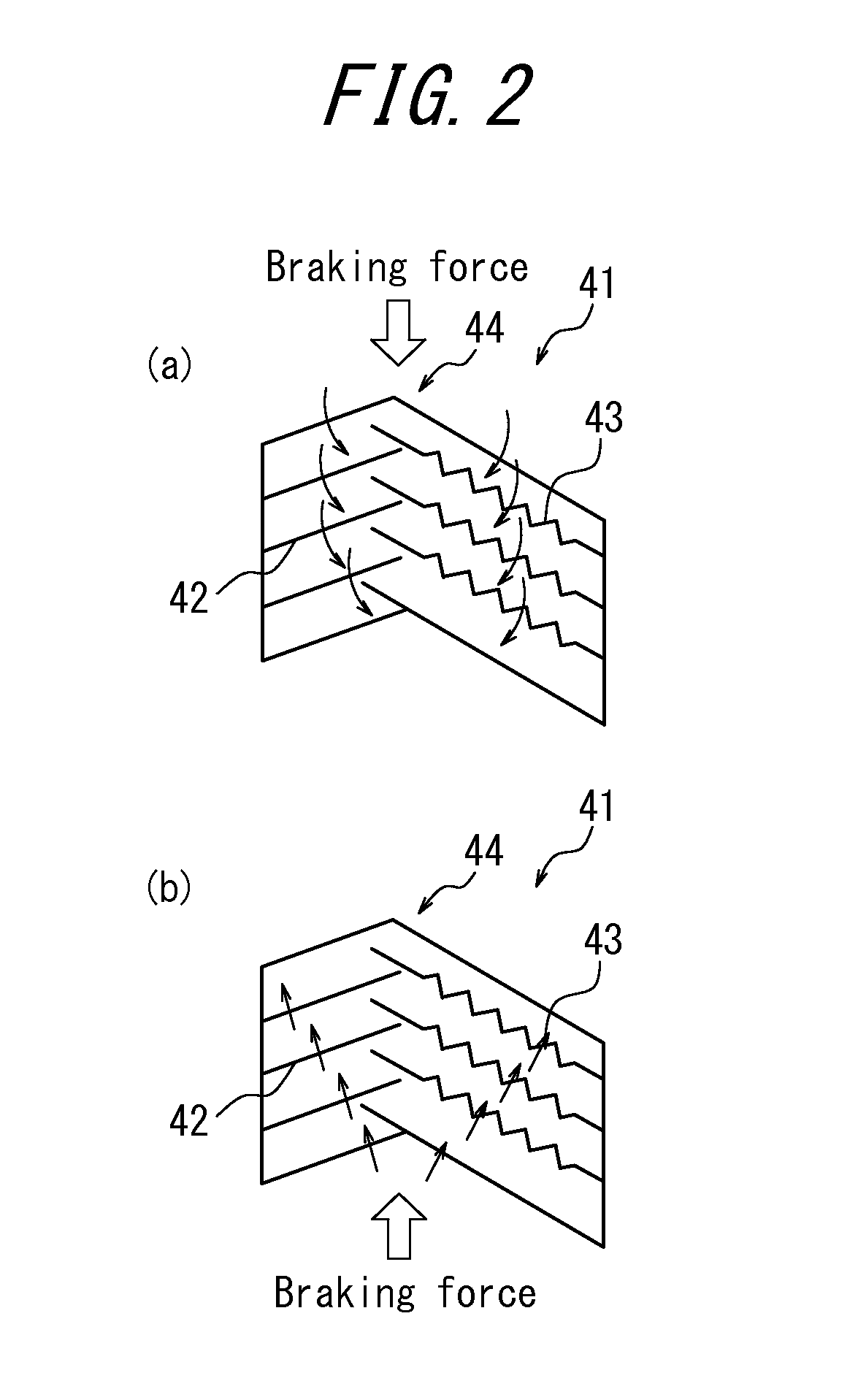

A pneumatic tire according to the present invention includes, one or more main grooves extending in the tire circumferential direction, and a plurality of lateral grooves extending in the tire width direction, the main grooves and the lateral grooves defining a block row formed by a plurality of blocks, at least one sipe being disposed in each block. Each block has a first cutaway groove with one end opening into a lateral groove located on one side of the block and the other end terminating within the block, a second cutaway groove with one end opening into a lateral groove located on the other side of the block and the other end terminating within the block, and a connecting narrow groove having a groove width narrower than that of the first and the second cutaway groove and connecting the first and the second cutaway groove.

Owner:BRIDGESTONE CORP

Pneumatic tire

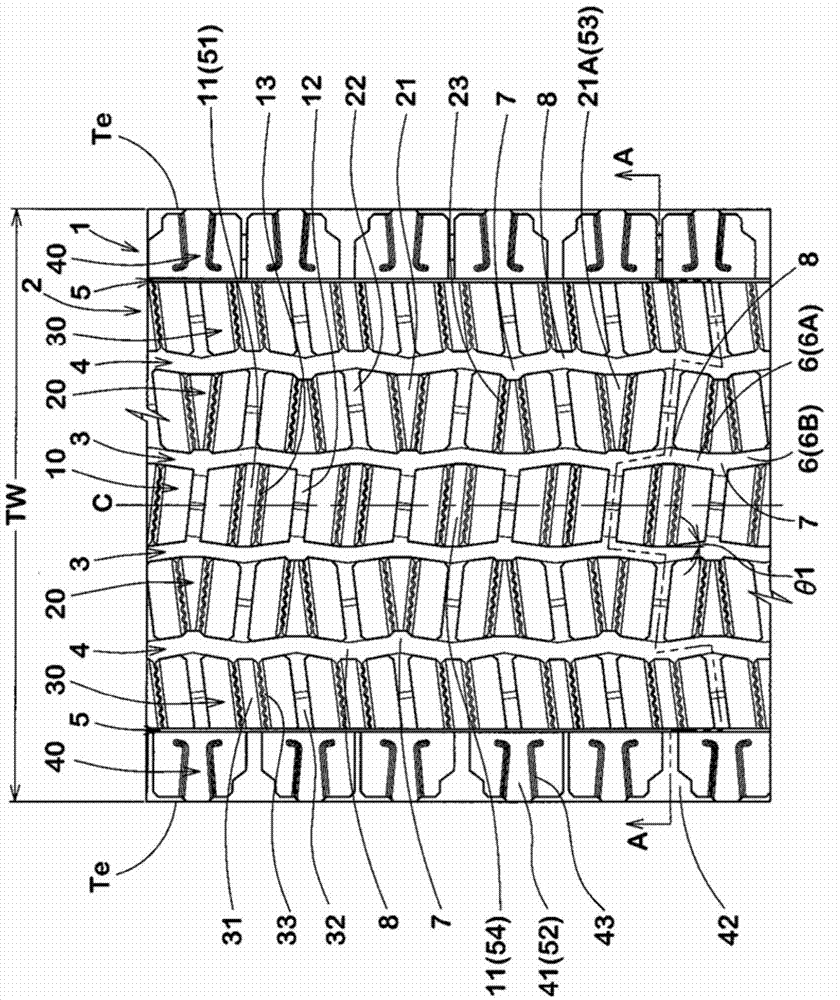

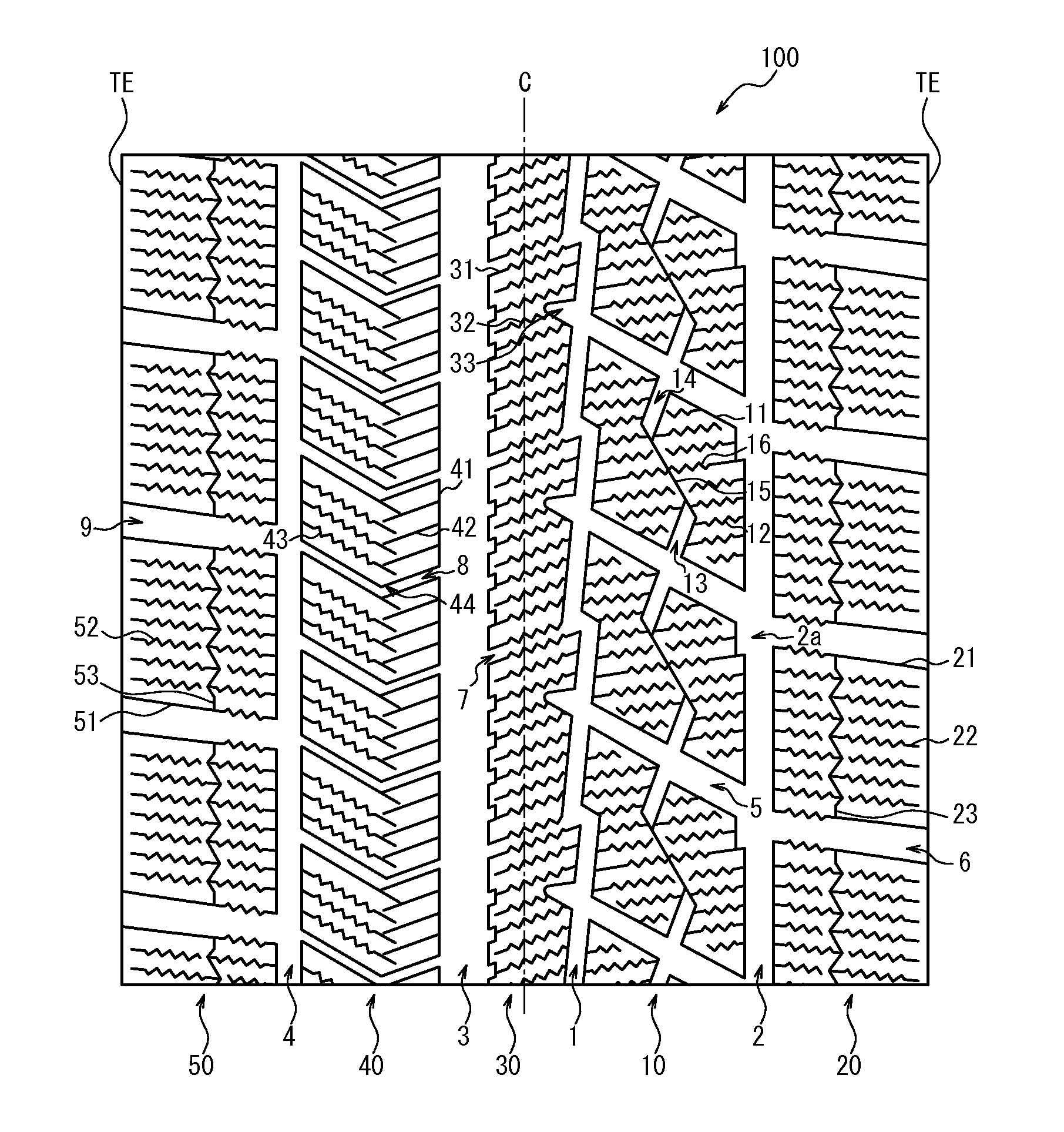

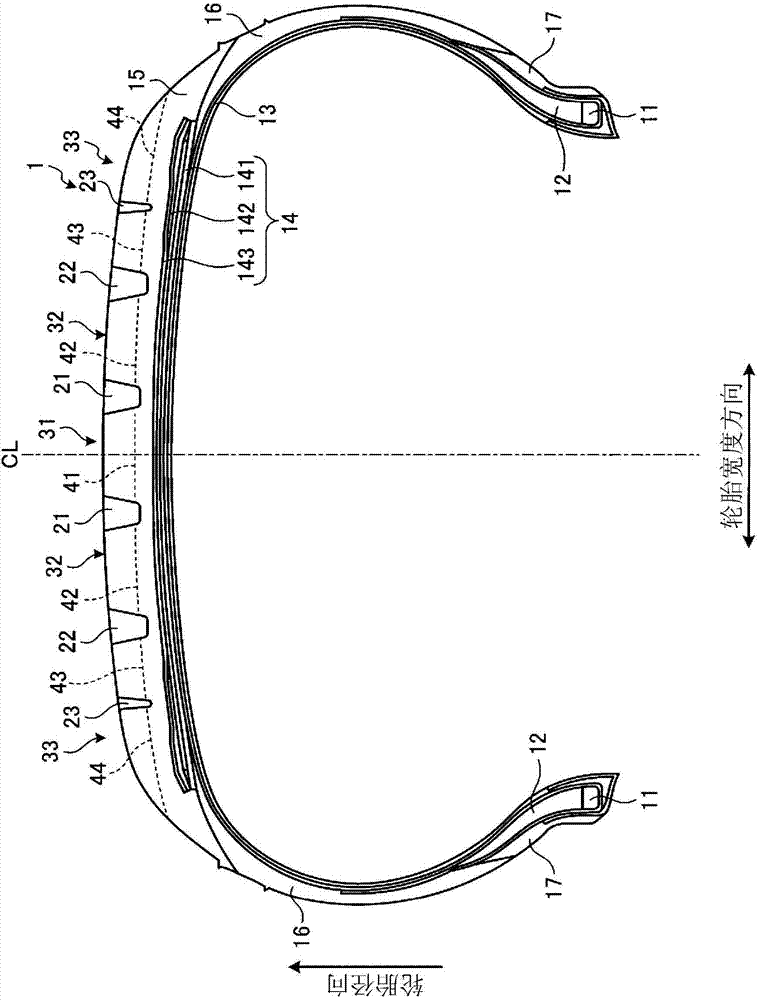

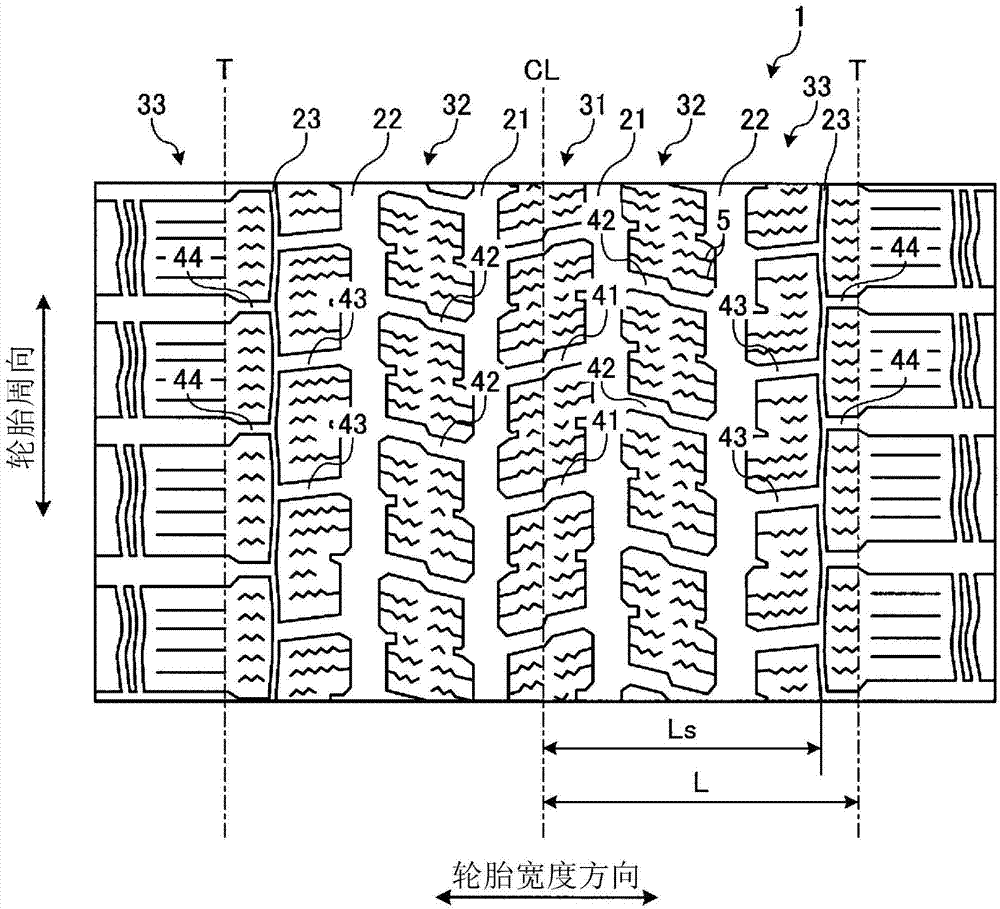

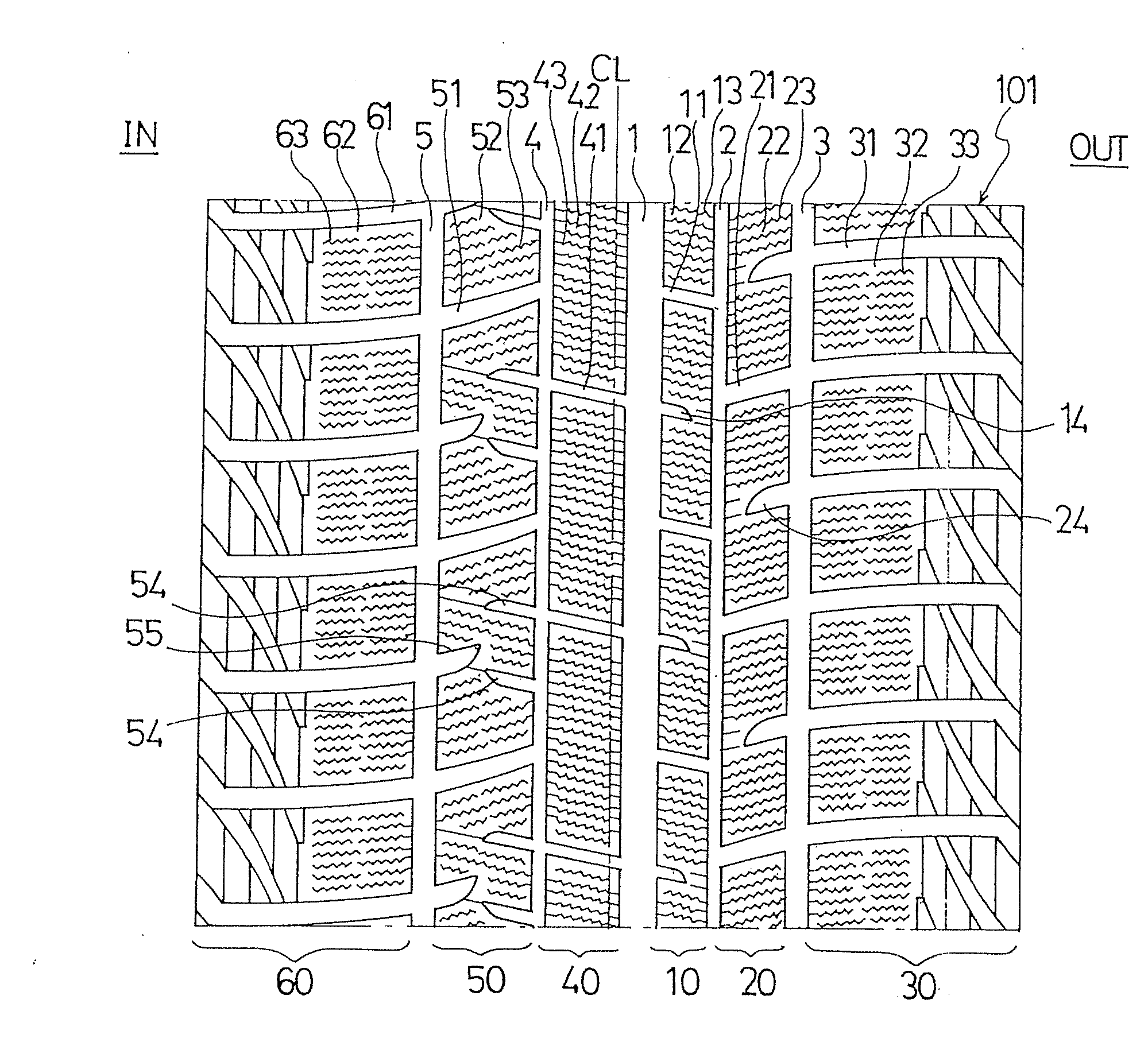

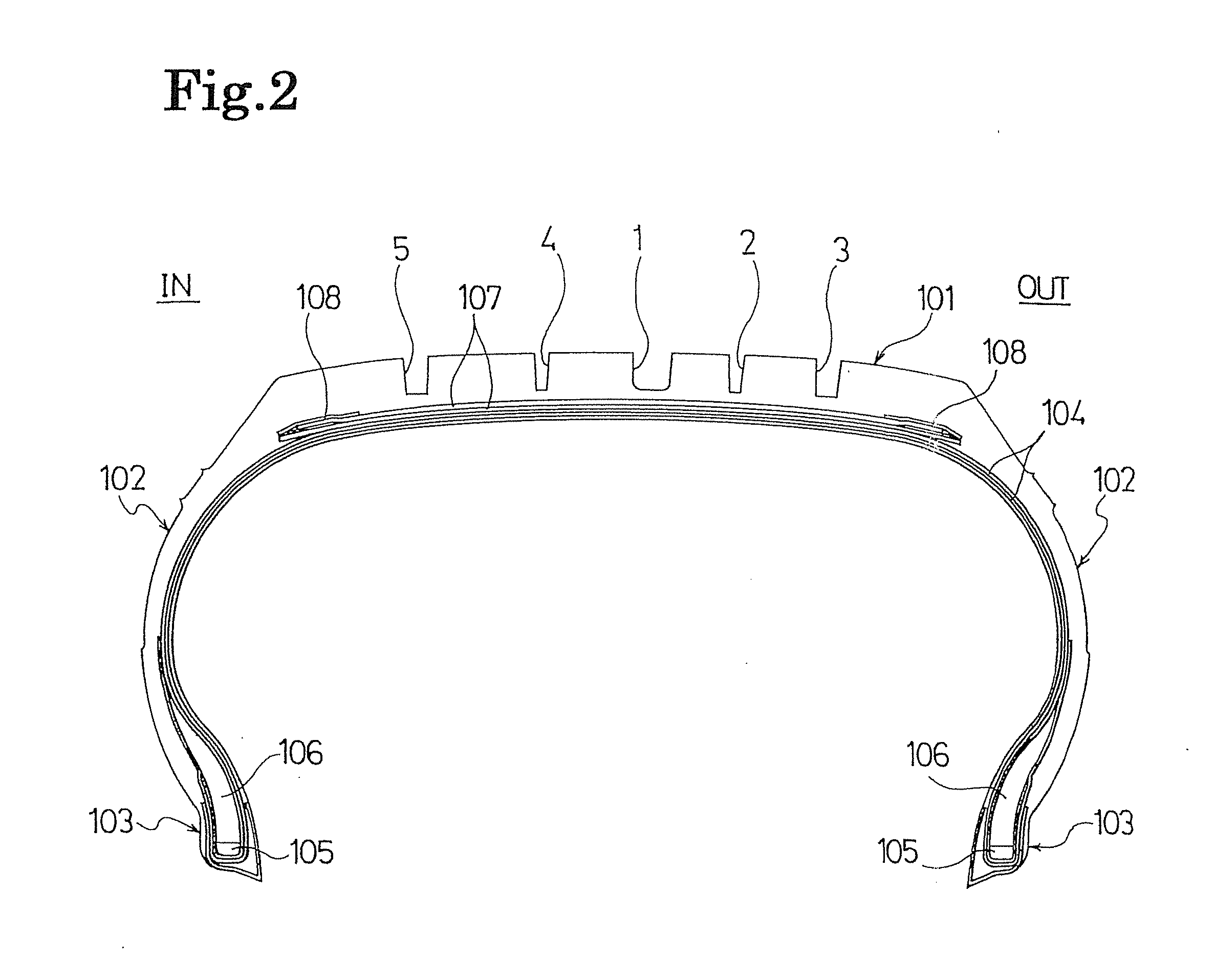

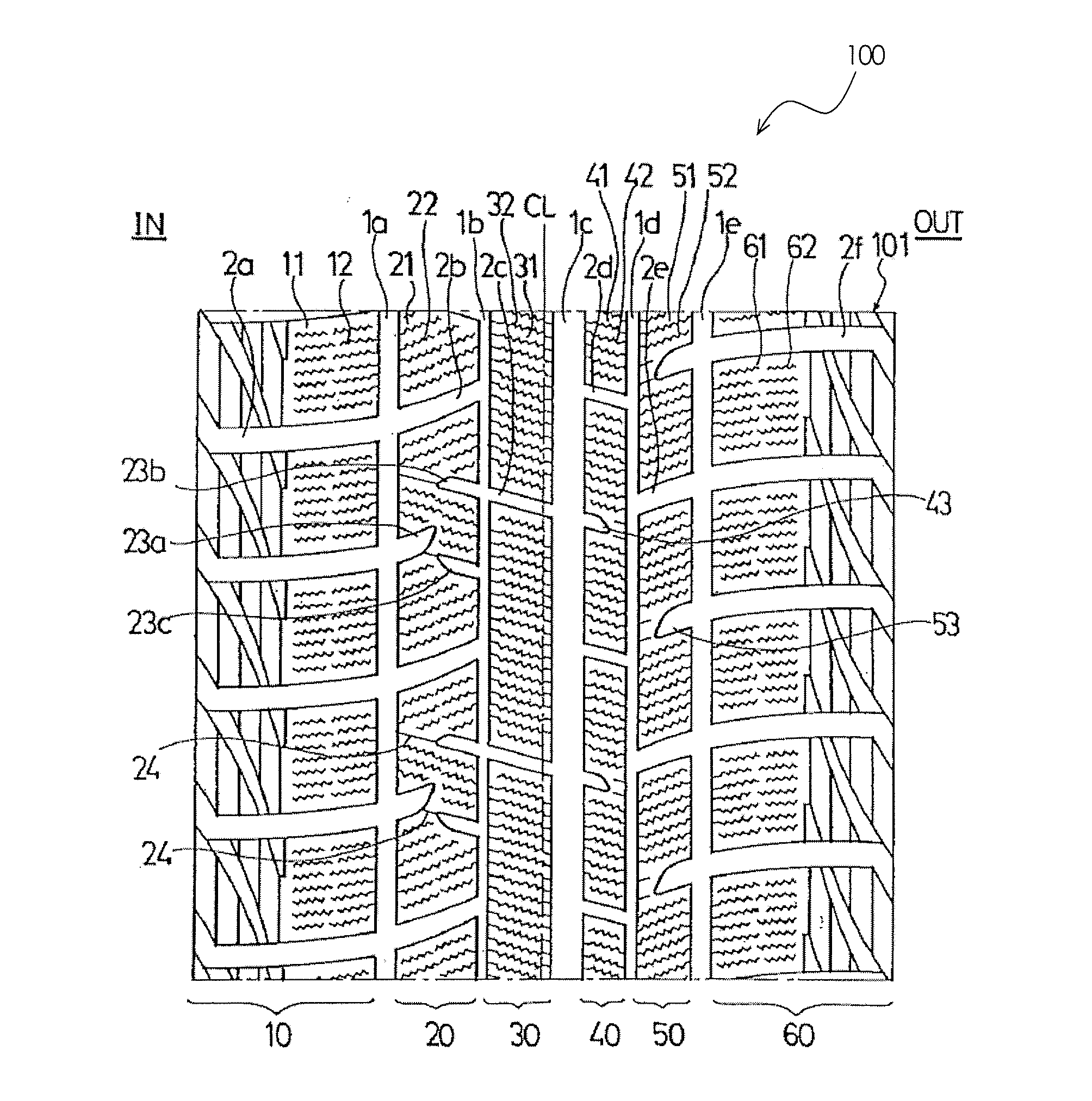

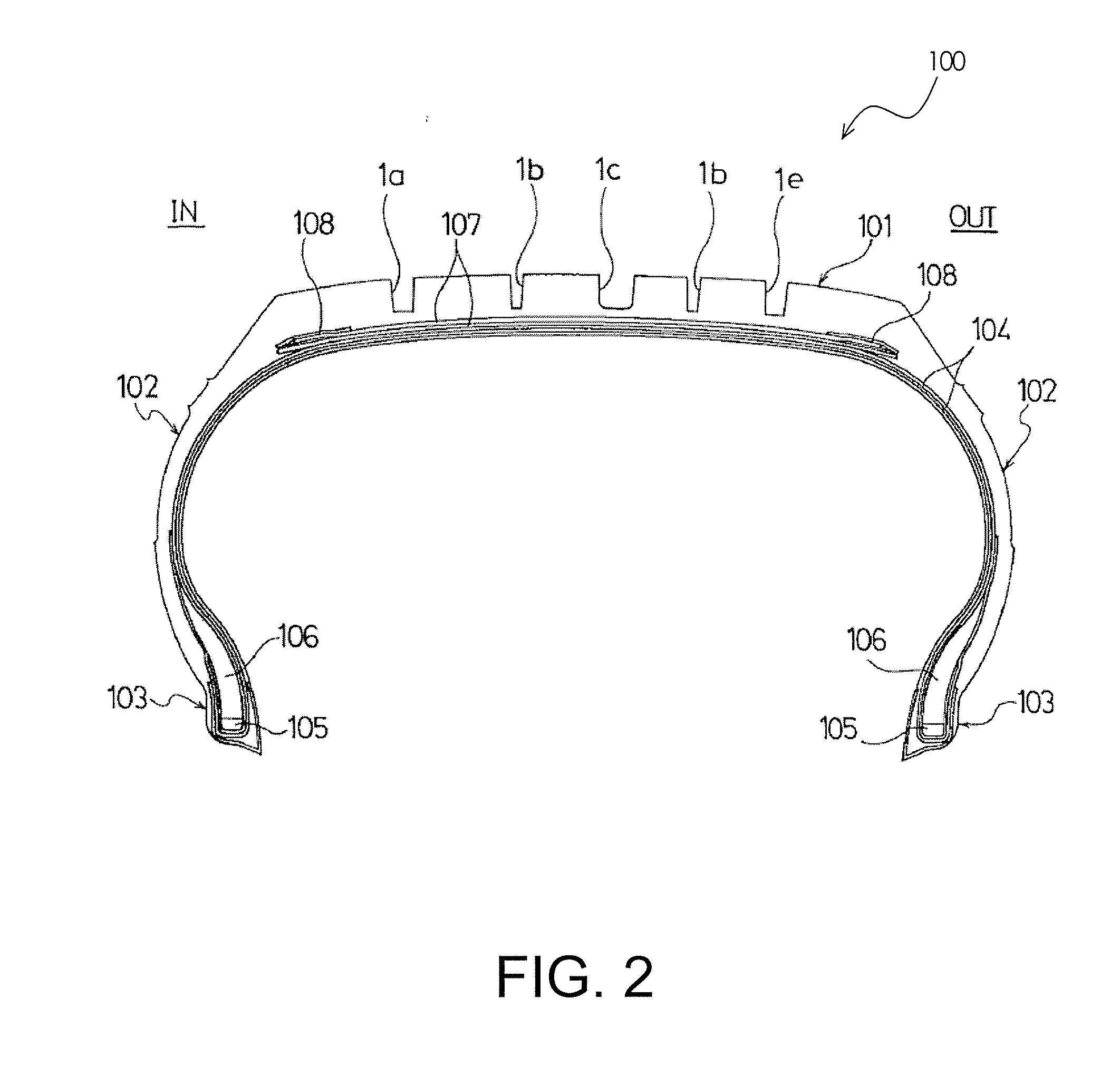

InactiveCN104768774AImprove performance on iceImprove on-snow performanceTyre tread bands/patternsEngineeringTread

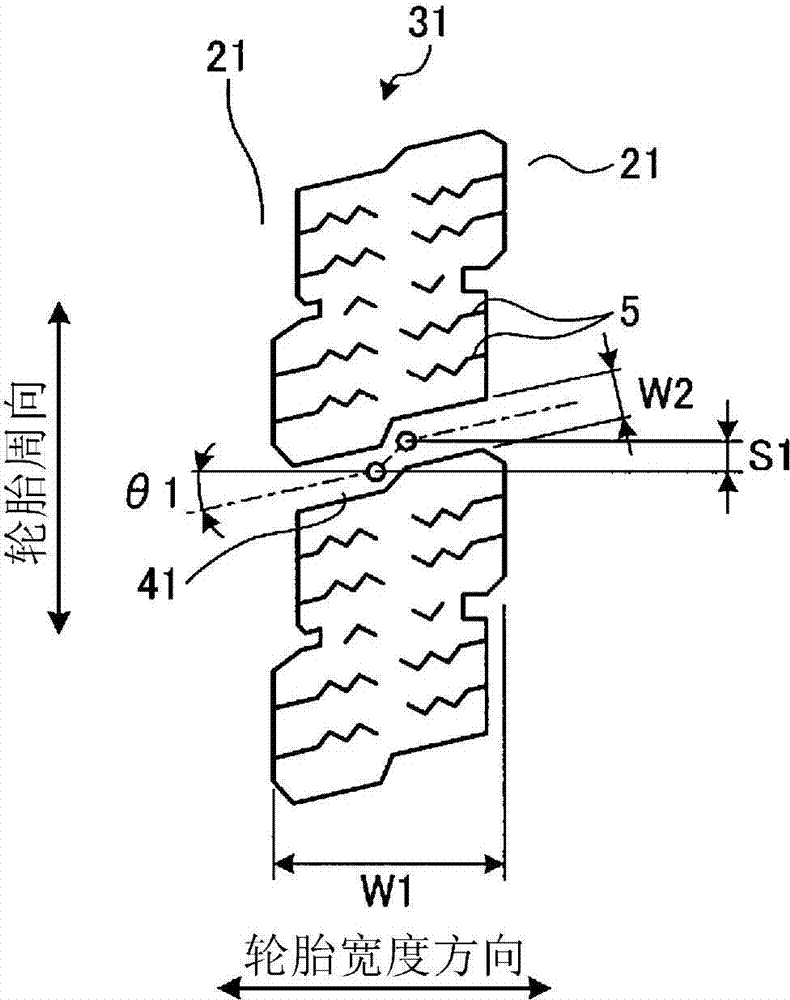

This pneumatic tire (1) is provided with at least four circumferential main grooves (21, 22) extending in a tire circumferential direction, and a plurality of land portions (31-33) formed by being demarcated by the circumferential main grooves (21, 22). The pneumatic tire is further provided with a first lug groove (41) penetrating the center land portion (31) in a tire width direction, a circumferential narrow groove (23) disposed in the shoulder land portion (33) and extending in the tire circumferential direction, a second lug groove (43) extending inward from the circumferential narrow groove (23) in the tire width direction and open to the outermost circumferential main groove (22), and a third lug groove (44) extending outward from the circumferential narrow groove (23) in the tire width direction, open to a tread end, and disposed to be positionally displaced from the second lug groove (43) in the tire circumferential direction. The first lug groove (41) has a bent shape and is open with a see-through structure to the right and left circumferential main grooves (21, 22) that demarcate the center land portion (31).

Owner:THE YOKOHAMA RUBBER CO LTD

Pneumatic tyre

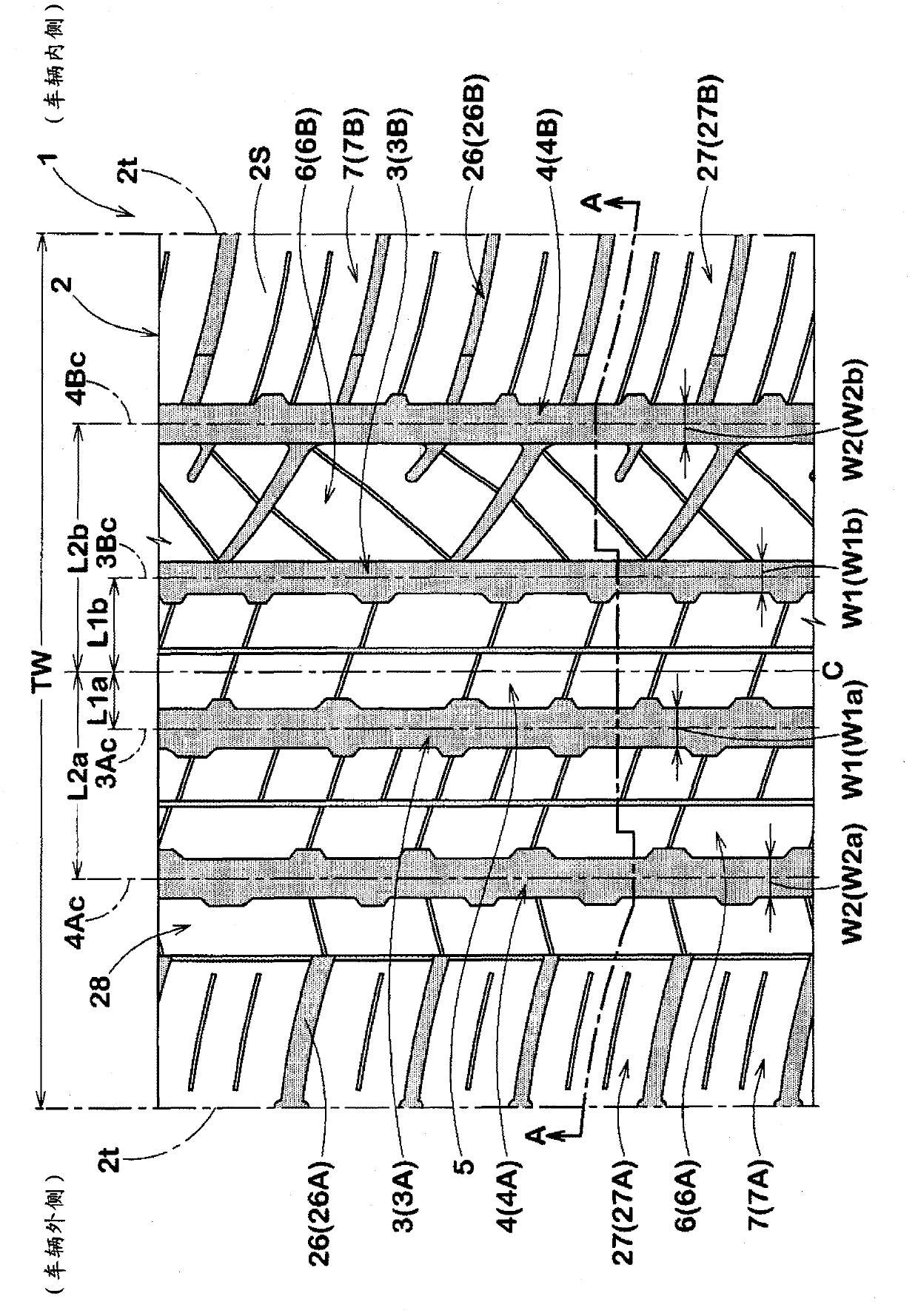

ActiveCN105415984AGuaranteed widthIncrease widthTyre tread bands/patternsControl theoryMechanical engineering

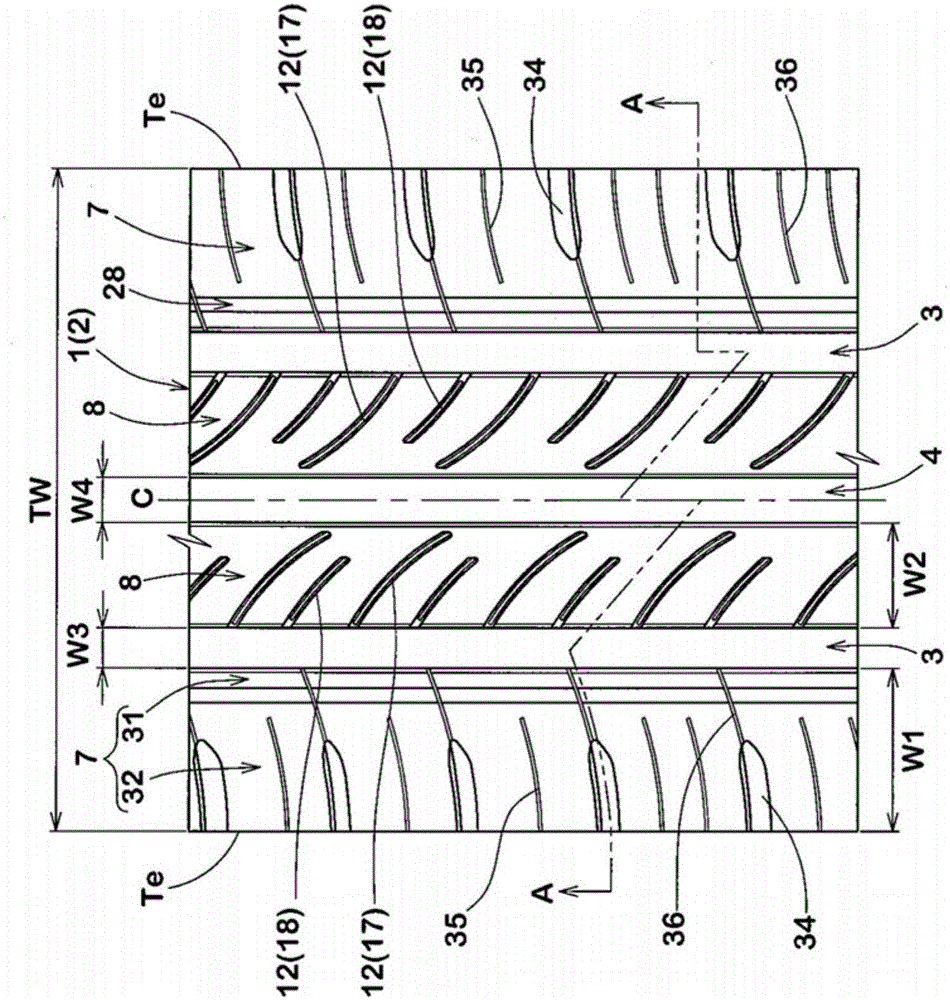

The present invention provides a pneumatic tyre capable of evenly improving steering stability on a dry roadway and performance on snow. The pneumatic tyre (1) is provided with a pair of tyre shoulder main channels (3) and a center main channel (4) at a tyre surface part (2), so as to obtain a pair of tyre shoulder land parts (7) and a pair of center land parts (8). The ratio W1 / W2 of the width W1 of the tyre shoulder land part (7) and the width W2 of the center land part (8) is 1.2-1.6. The center land parts (8) are provided with a plurality of center shallow channels (12) which extend obliquely relative to the axial direction of the tyre from the tyre shoulder main channels (3) and form terminals in the center land parts (8). The tyre shoulder land parts (7) are provided with, at the side of the tyre shoulder main channels (3), tyre shoulder accessory channels (28) which have the channel width less than the channel width of the tyre shoulder main channels (3) and extend continuously along the circumferential direction of the tyre.

Owner:SUMITOMO RUBBER IND LTD

Pneumatic tire with sipes

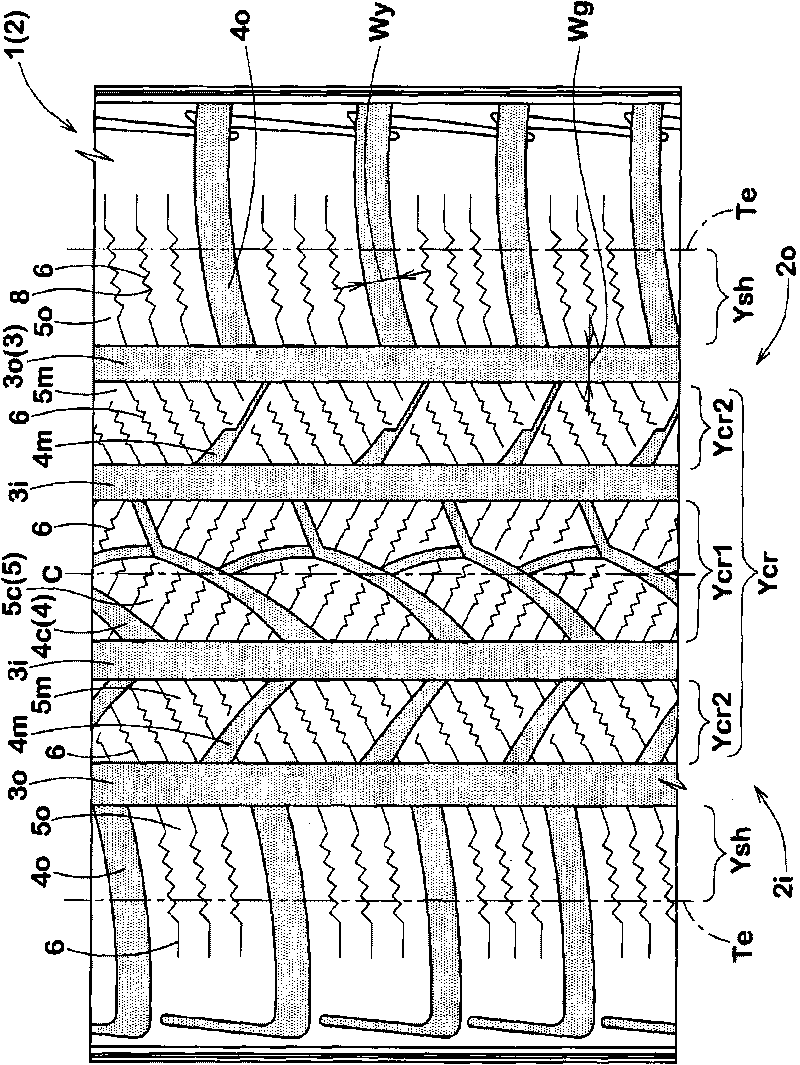

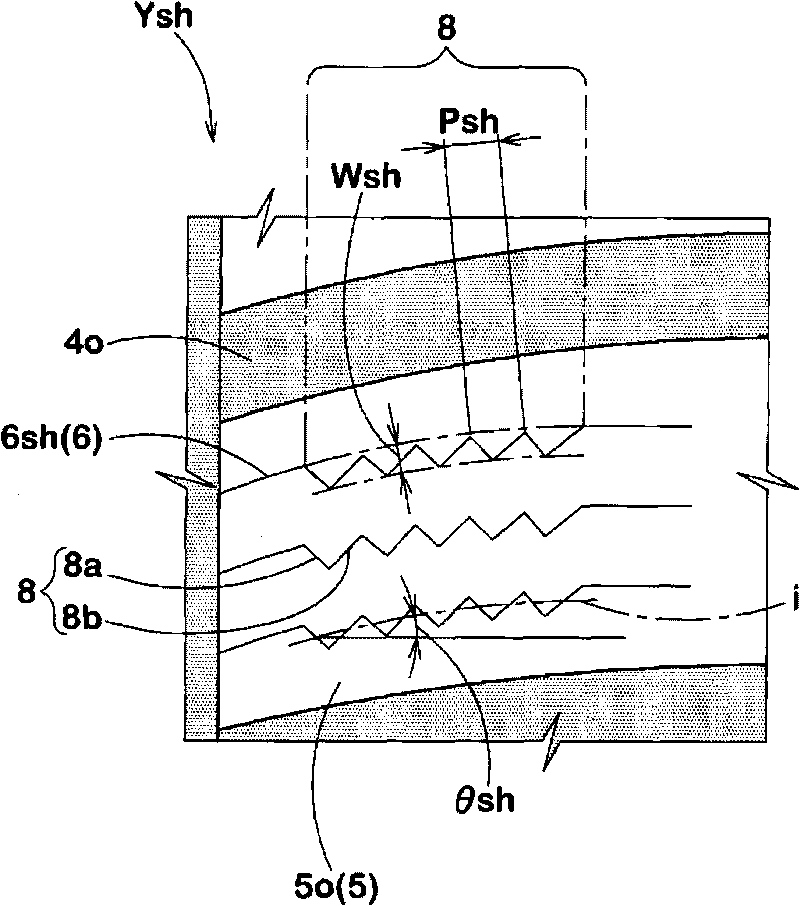

ActiveCN101758745AEasing rigidityImprove snow removal performanceInflatable tyresTyre tread bands/patternsShoulder regionRoad surface

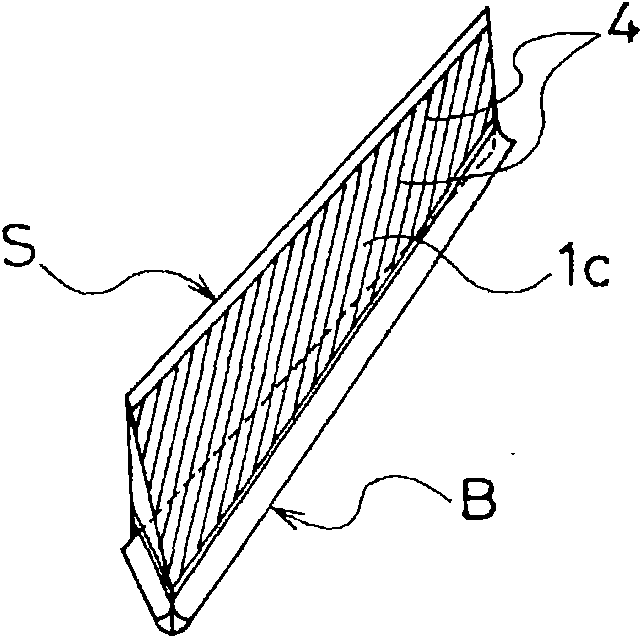

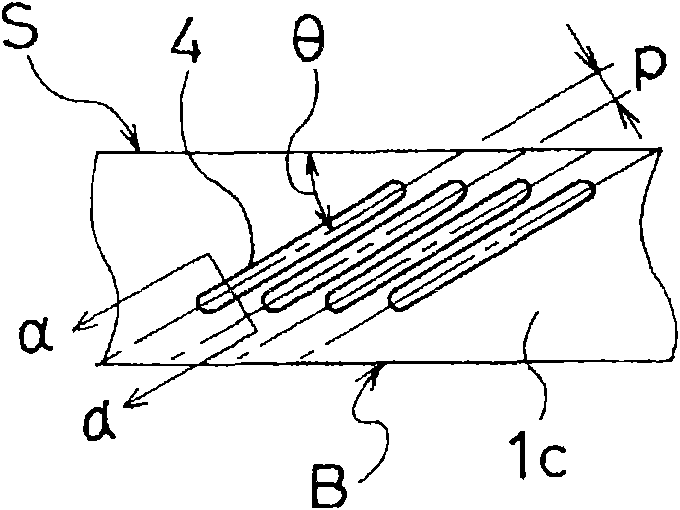

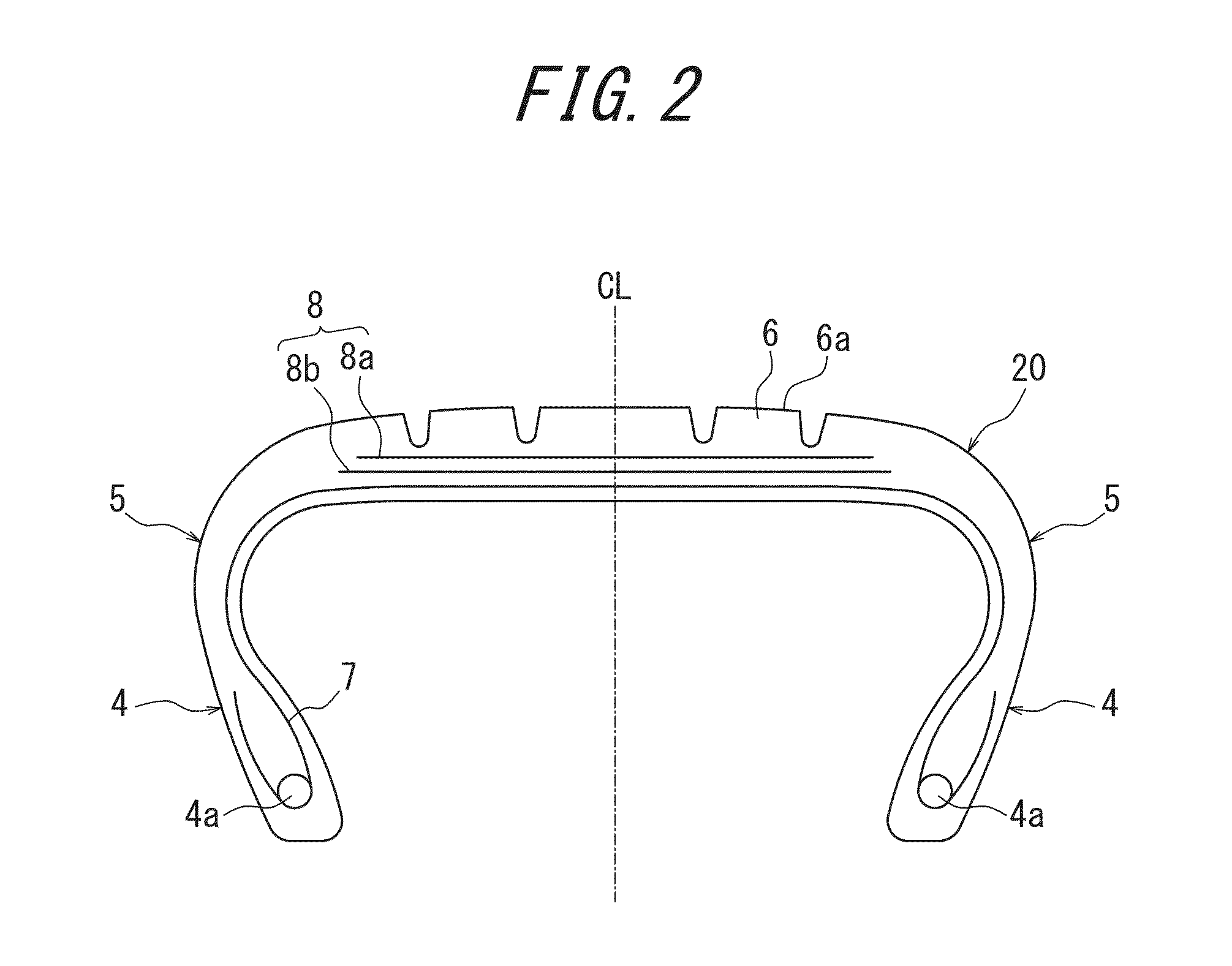

A pneumatic tire whose steering stability on dry roads is improved with minimizing lowering of on-snow performances and which has round shoulders and comprises tread portion (2) divided by circumferential main grooves (3) and lateral grooves (4) into blocks (5) provided with sipes (6) each having zigzag part (8), the circumferential grooves (3) including at least a pair of axially outermost circumferential grooves (3o) to divide the tread portion (2) into shoulder regions (Ysh) and crown region (Ycr), wherein the zigzag part (8) of sipes (6sh) disposed in the shoulder regions (Ysh) has a larger zigzag amplitude (Wsh) and a larger zigzag pitch (Psh) than zigzag amplitude (Wcr) and zigzag pitch (Pcr) of the zigzag part (8) of sipes (6cr) disposed in the crown region (Ycr), and angle ( sh) of the sipes (6sh) with respect to the axial direction is smaller than angle ( cr) of the sipes (6cr) with respect to the axial direction.

Owner:SUMITOMO RUBBER IND LTD

Pneumatic tire

ActiveUS20160193881A1Improve on-snow performanceTyre tread bands/patternsNon-skid devicesGround contactEngineering

A pneumatic tire includes a tread portion including a plurality of tread blocks including at least one constricted block with a first recess disposed on axially one side of the block and a second recess disposed on axially other side of the block so as to form a narrow portion between the first recess and the second recess. Each of the first recess and the second recess includes a V-shaped top edge on a ground contacting surface of the block. Each of the V-shaped top edges protrudes toward a center of the block in a planar view of the block.

Pneumatic tire

InactiveCN102310726AImprove on-snow performanceImprove performance on iceTyre tread bands/patternsAutomotive engineeringEngineering

The present invention relates to a pneumatic tire capable of improving snow and ice performances as well as noise performance. Shoulder pattern blocks are spacedly arranged on the tread portion of the pneumatic tire along the circumference of the tire. The shoulder pattern blocks are formed and divided by a pair of shoulder longitudinal grooves extending at the side closest to the tread ground end along the circumference of the tire, and by shoulder horizontal grooves extending between the tread ground end and the shoulder longitudinal grooves. Multiple reference space elements are configured and formed on the tread portion at two sides of the tire equator respectively along the circumference of the tire. The reference space element is formed by a space reference line, the tread ground end and the tire equator in a surrounding manner, wherein the space reference line runs through an intersection point between the shoulder longitudinal grooves and the shoulder horizontal grooves at one side edge portion of the circumference of the tire and is orthogonal to the tire equator surface. The reference space elements include at least two reference space elements with different tire circumferential lengths. In addition, each reference space element at least has a pin hole for mounting a pin.

Owner:SUMITOMO RUBBER IND LTD

Pneumatic tire

InactiveUS20120285591A1Improve balanceImprove on-ice performanceTyre tread bands/patternsNon-skid devicesTransverse grooveStructural engineering

A pneumatic tire has a good balance between on-ice and on-snow performances. The tire includes a tread portion having longitudinal and lateral grooves defining block rows. Each block in the block rows includes sipes. A length of each block in the first and second block rows is not less than 1.5 times and not more than 2.5 times a length of each third block row block. A width of each second block row block is larger than a width of each first block row block. The lateral grooves defining the first and second block row blocks are offset in the tire circumferential direction by not less than 0.2 times and not more than 0.8 times the length of each first block row block. The lateral grooves defining the second and third block row blocks communicate with each other while inclining in the same direction.

Owner:YOKOHAMA RUBBER CO LTD

Pneumatic tire

InactiveUS20120118454A1Improved on-ice performanceImprove on-snow performanceTyre tread bands/patternsNon-skid devicesEngineeringMechanical engineering

A pneumatic tire improved in on-ice performance and on-snow performance in good balance. The pneumatic tire includes a tread portion extending in a tire circumferential direction and forming a ring shape, a pair of sidewall portions on both sides of the tread portion, respectively, and a pair of bead portions on inner sides of the sidewall portions in a tire radial direction, respectively. The tread portion includes a plurality of longitudinal grooves extending in the tire circumferential direction and a plurality of lateral grooves extending in a tire width direction. The longitudinal and lateral grooves define a plurality of block rows each including a plurality of blocks. Each of the plurality of blocks included in at least one of the block rows includes at least three closed grooves including at least one first closed groove and at least one second closed groove.

Owner:THE YOKOHAMA RUBBER CO LTD

Pneumatic tire

ActiveUS20160297251A1Improve on-snow performanceImprove cornering performanceTyre tread bands/patternsEngineeringMechanical engineering

Owner:SUMITOMO RUBBER IND LTD

Inflation tyre

ActiveCN104890451AImprove rigidityEnsure handling stabilityTyre tread bands/patternsGroove widthTransverse groove

The invention provides an inflation tyre which can maintain the stability on a drying ground while improving the performance on the snow. The surface of the inflation tyre is provided with a pair of tyre shoulder main groove (3) and a central groove (4); a central landing part (10) is obtained through dividing the central groove (4) and the tyre shoulder main grooves on the two sides of the tyre equator; a plurality of middle transverse grooves (11) are positioned in the middle terrene (10); a plurality of middle transverse grooves (11) extending in the inclination manner relative to the tyre axial direction; the middle transverse groove (11) has an external end communicating with the tyre shoulder main groove, and an internal end formed in the middle part of the middle terran part. The groove width of the outer end (12) increases gradually towards the outward of the tyre axial direction; and a middle drawing rib with the bottom of the groove being raised is arranged on the external

Owner:SUMITOMO RUBBER IND LTD

Tire

ActiveUS20170368882A1Improve on-snow performanceMaintain relatively stableTyre tread bands/patternsEngineeringTread

A tire includes a tread portion being provided with a circumferentially and continuously extending outboard shoulder main groove, a circumferentially and continuously extending outboard crown main groove disposed between the outboard shoulder main groove and a tire equator, and an outboard middle land portion disposed between the outboard shoulder main groove and the outboard crown main groove. The outboard middle land portion is provided with a plurality of first outboard middle lug grooves extending from the outboard crown main groove and terminating within the outboard middle land portion, and a plurality of second outboard middle lug grooves extending from the outboard shoulder main groove and terminating within the outboard middle land portion, wherein the second outboard middle lug grooves are larger than the first outboard middle lug grooves in length in a tire axial direction.

Owner:SUMITOMO RUBBER IND LTD

Tire

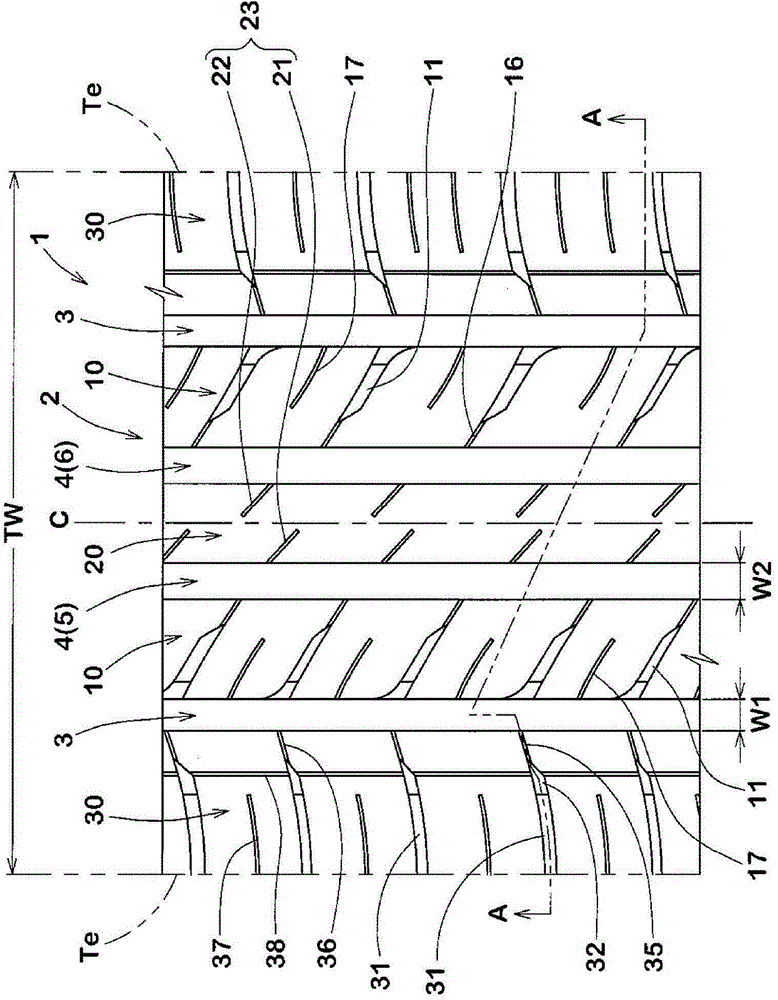

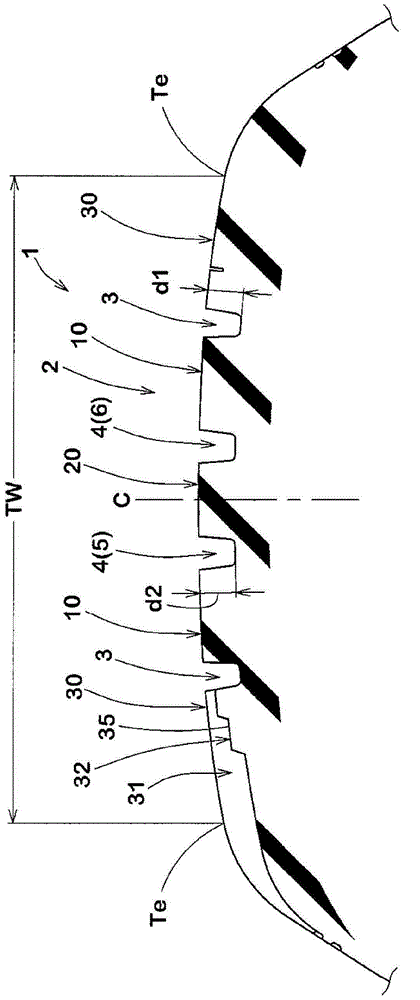

ActiveCN107539032AEnsure handling stabilityImprove on-snow performanceTyre tread bands/patternsMarine engineeringRoad surface

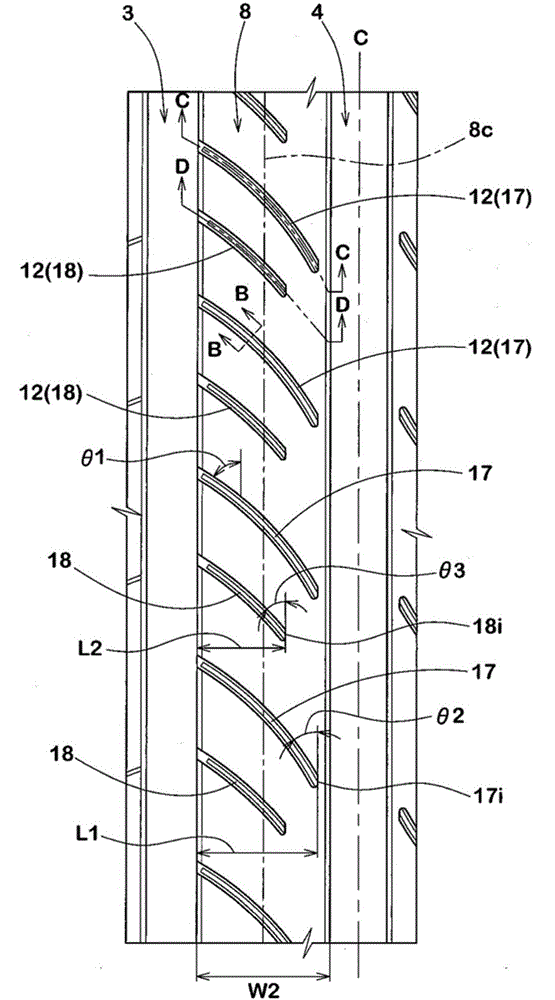

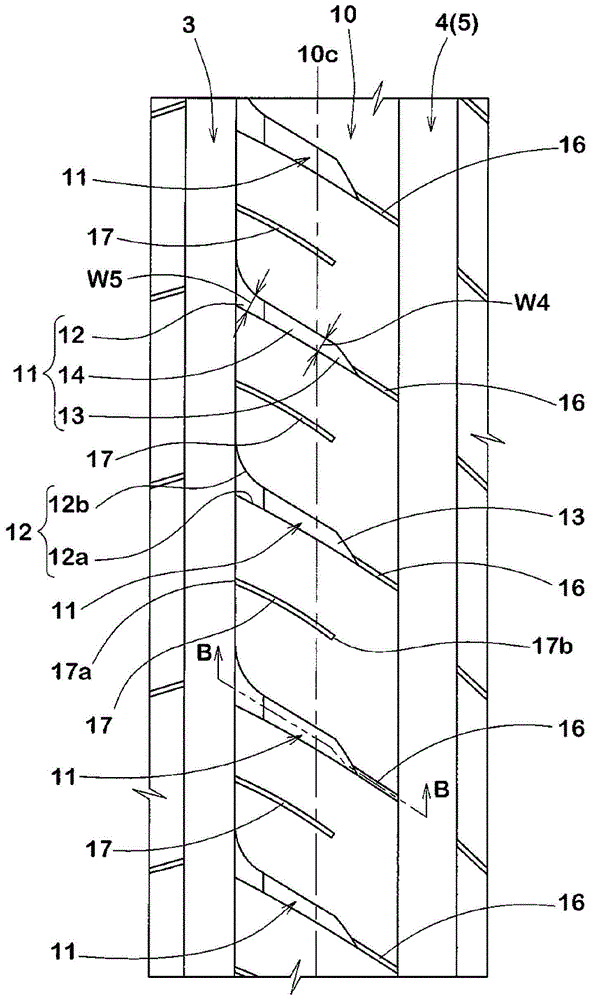

Provided is a tire. The aim of the invention is to maintain the operation stability of the tire on a dry pavement and to improve the performance of the tire in a snow environment. A tread portion (2)includes an outboard tread end (To) on the outer side of a vehicle when the vehicle with the tire is mounted and an inboard tread end (Ti) on the inner side of the vehicle when the vehicle is mounted.The tread portion (2) is provided with an outboard shoulder main groove (3), an outboard crown main groove (4) and an outboard middle land (10). The outboard middle land (10) is provided with first outboard middle lug grooves extending from the outboard crown main groove (4) and terminating within the outboard middle land (10), and second outboard middle lug grooves (17) extending from the outboard shoulder main groove (3) and terminating within the outboard middle land (10). The second outboard middle lug grooves (17) are larger than the first outboard middle lug grooves (16) in length in atire axial direction.

Owner:SUMITOMO RUBBER IND LTD

Pneumatic tire

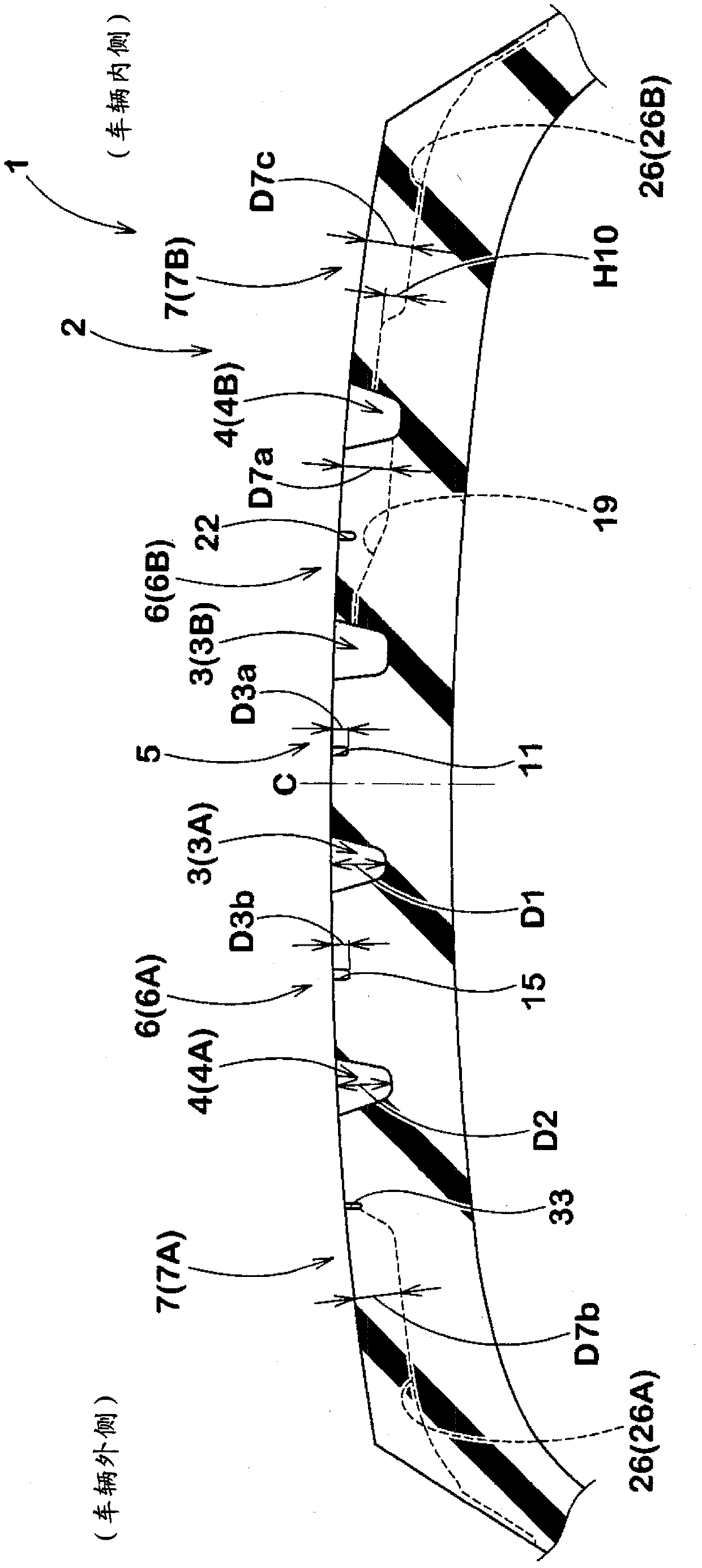

ActiveCN108688411AGood drainageSuppression of slippageTyre tread bands/patternsRoad surfaceEngineering

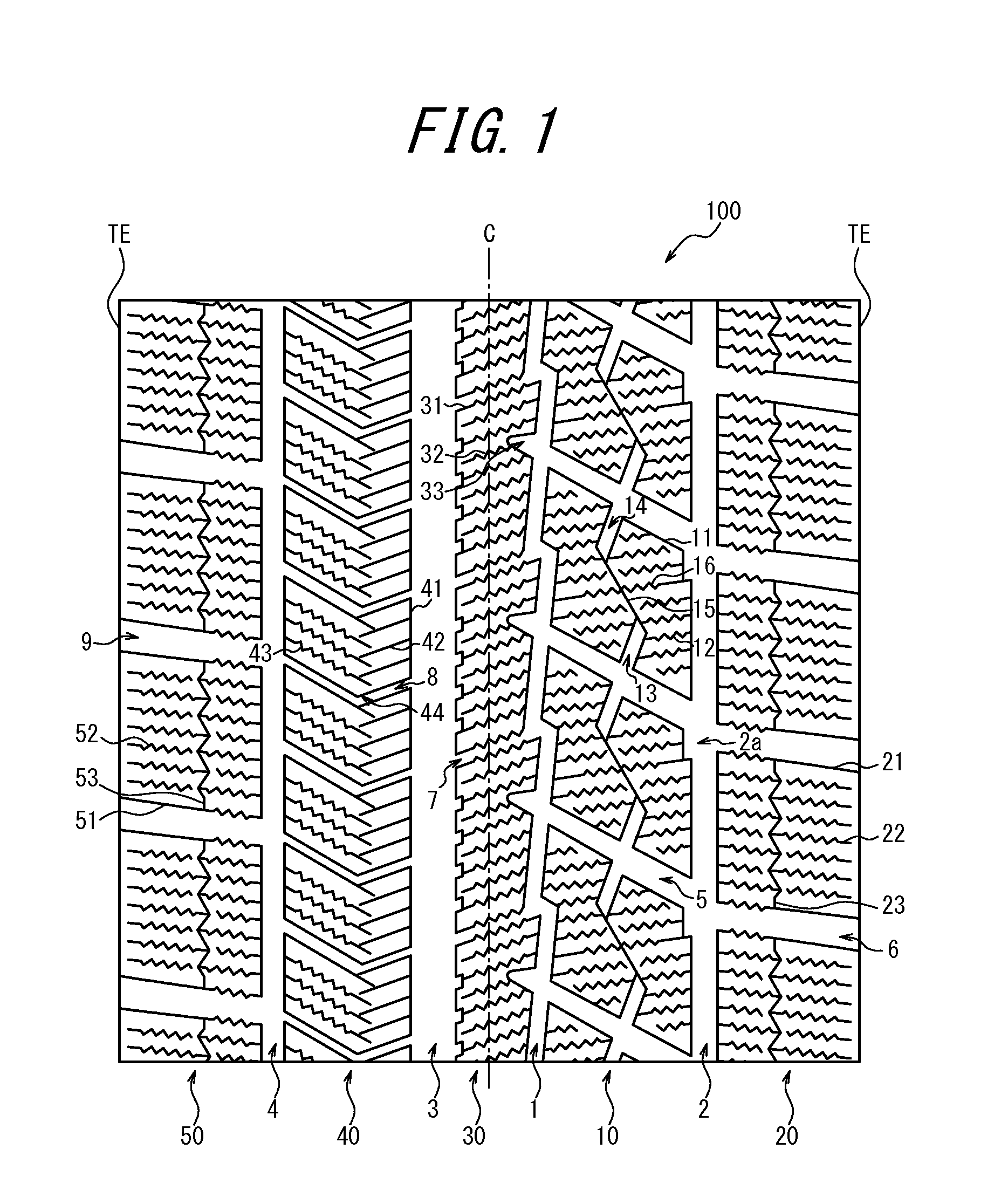

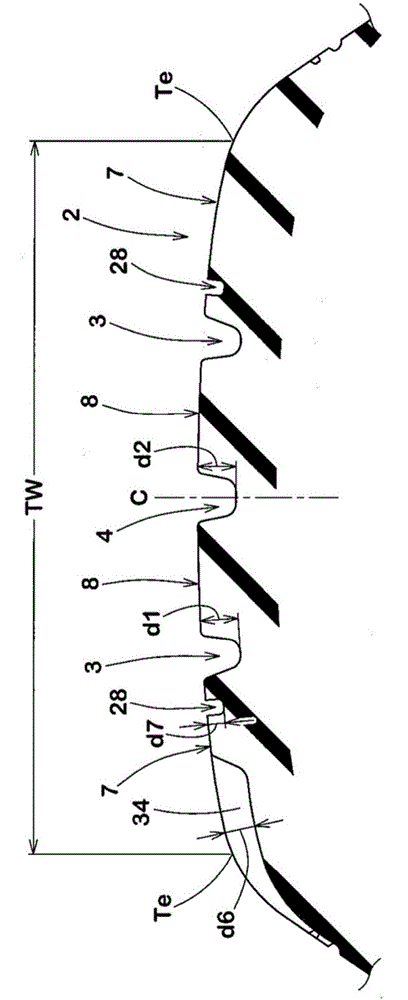

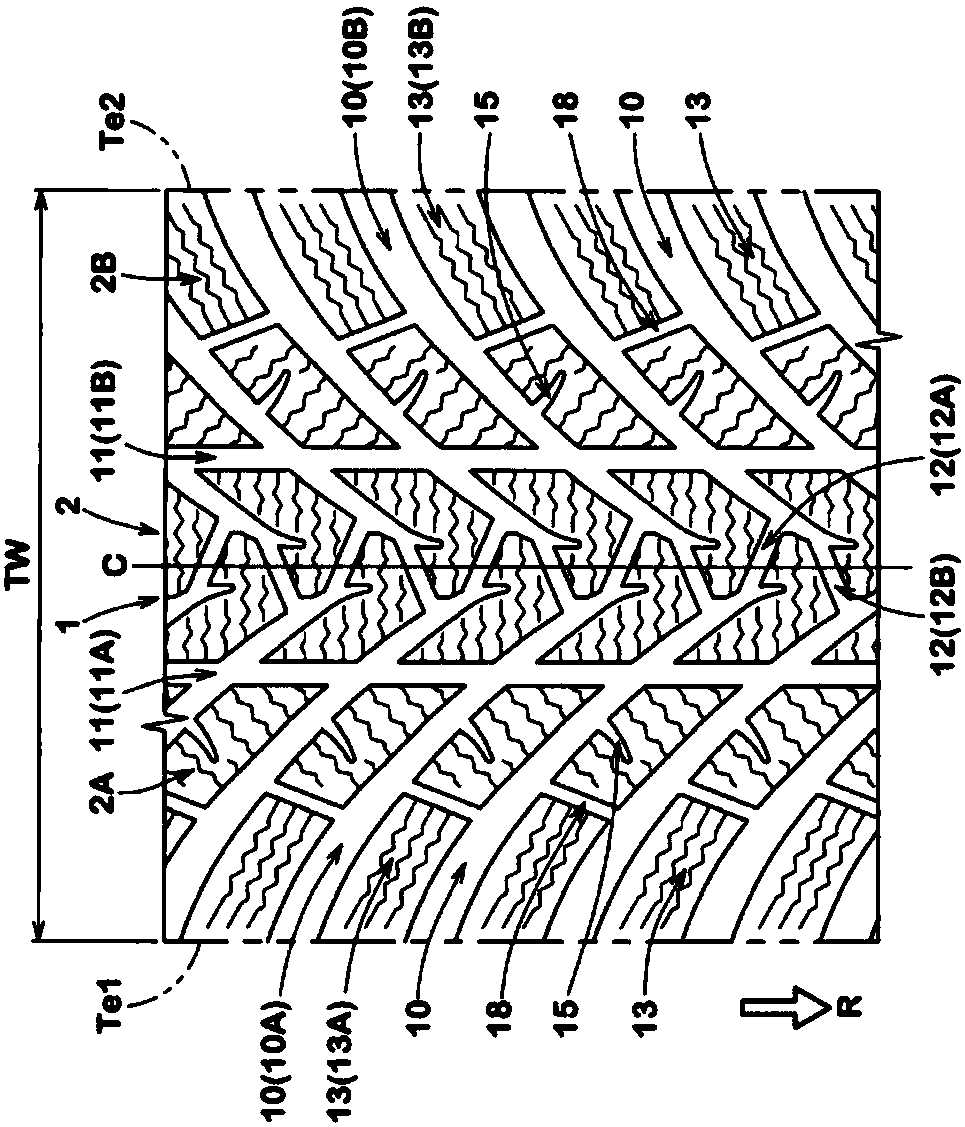

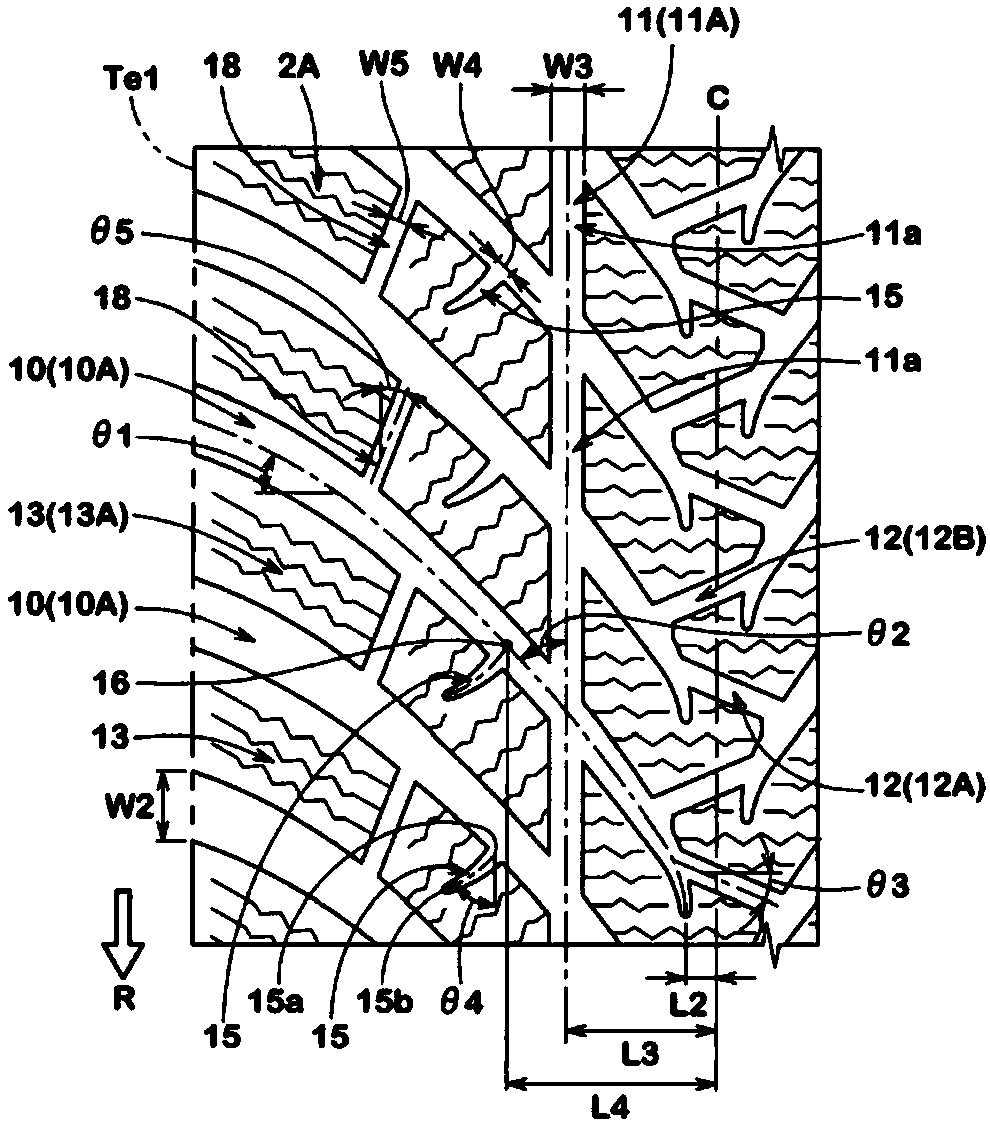

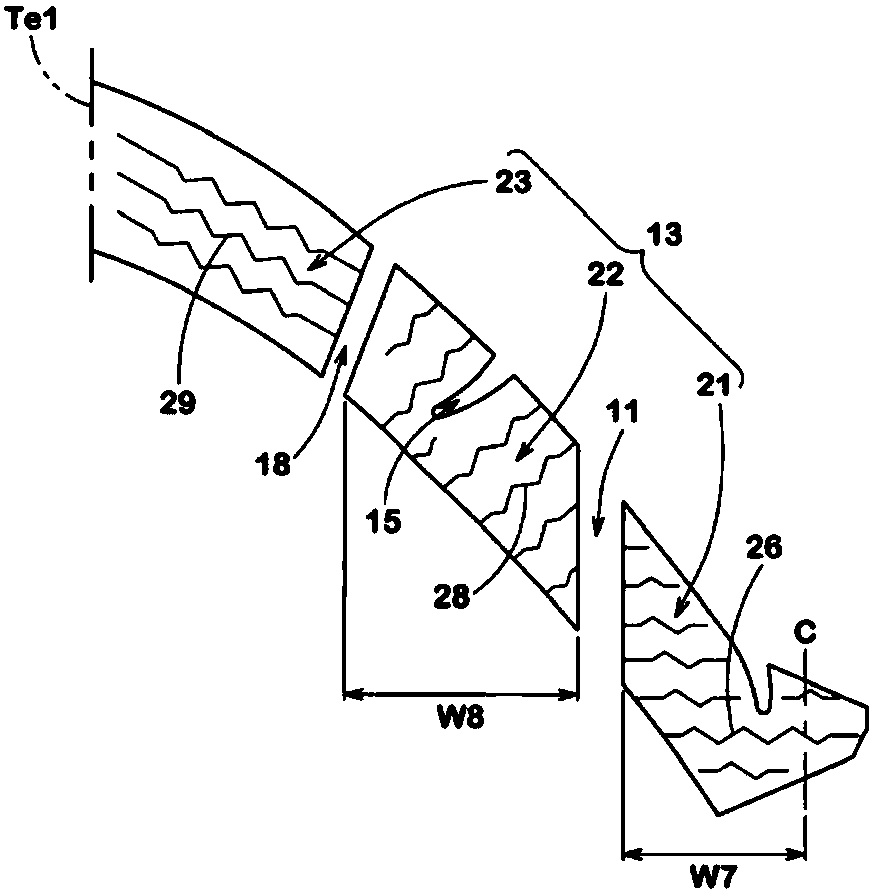

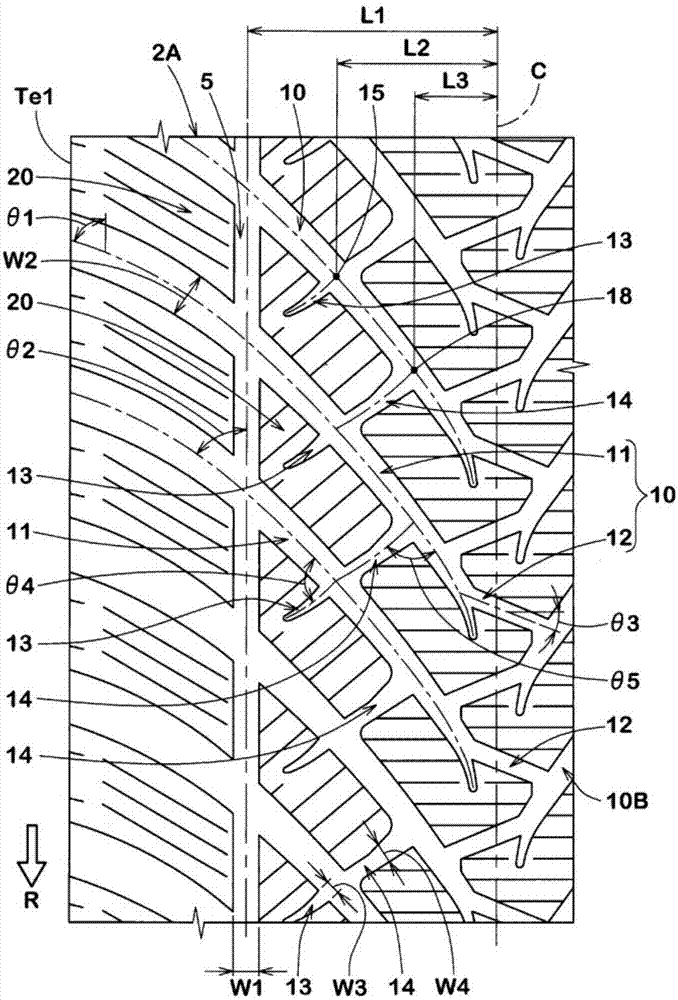

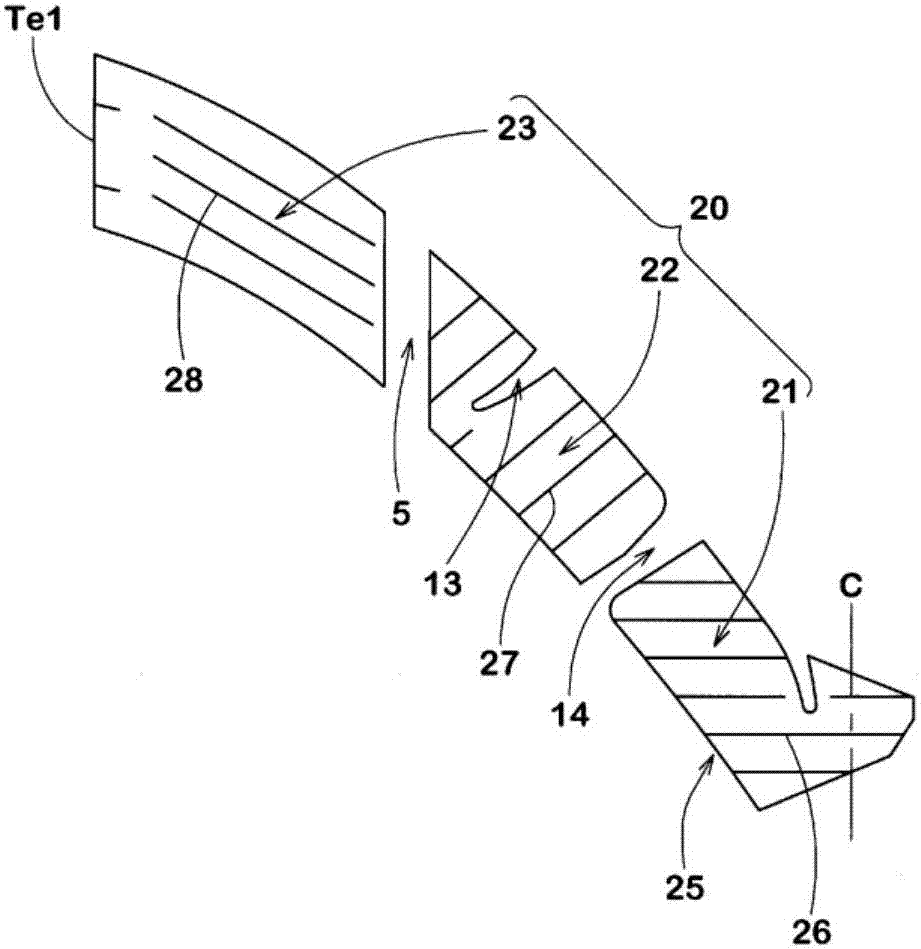

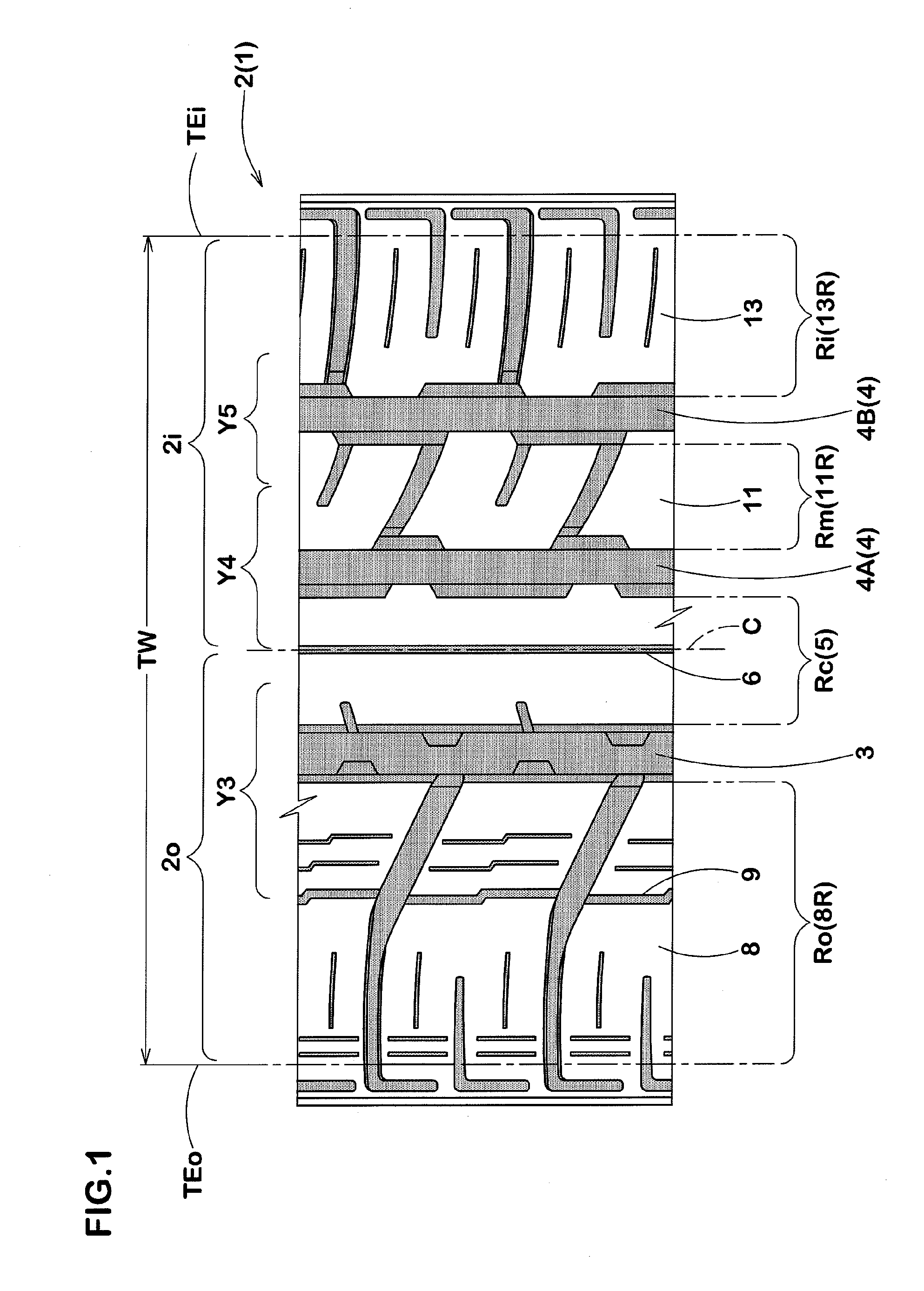

The pneumatic tire provided by the present invention is capable of maintaining steering stability and snow performance on a dry road surface and suppressing the slip phenomenon. A pneumatic tire having a tread portion (2); the tread portion (2) is provided with a main groove (11) extending continuously in the tire circumferential direction between the first tread end (Te1) on one side in the tireaxial direction and the tire equator (C), a plurality of inclined grooves (10) extending from the first tread end (Te1) toward the tire equator (C) side and forming a terminal end at a position crossing the main groove (11) toward the tire equator (C) side, and a plurality of inclined land portions (13) partitioned between the inclined grooves (10) adjacent in the tire circumferential direction. Alug groove (15) is provided in at least one of the inclined land portions (13) adjacent to the main groove (11). One end of the lug groove (15) is connected to the inclined groove (10), and the otherend is interrupted in the inclined land portion (13).

Owner:SUMITOMO RUBBER IND LTD

Tire

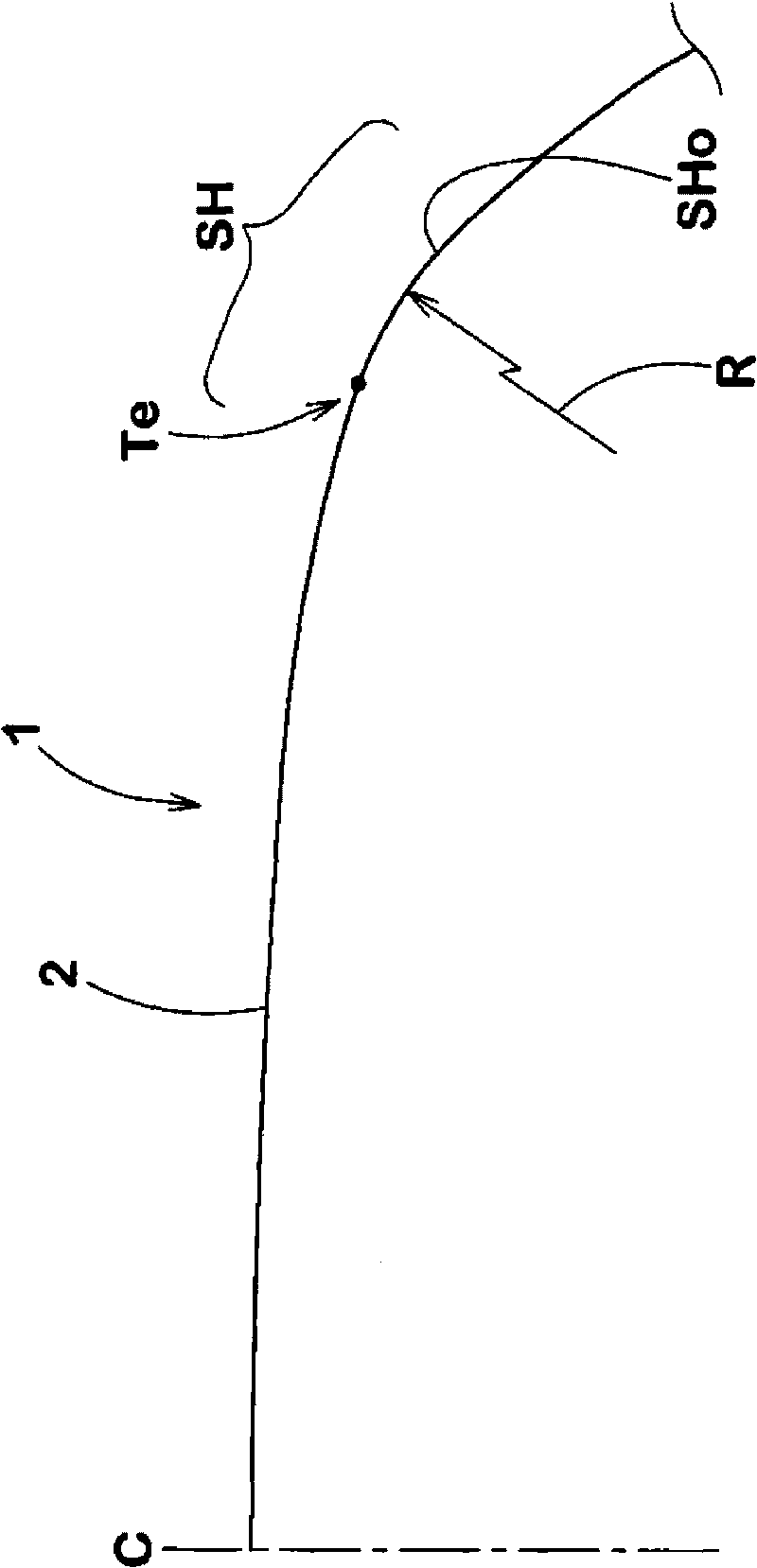

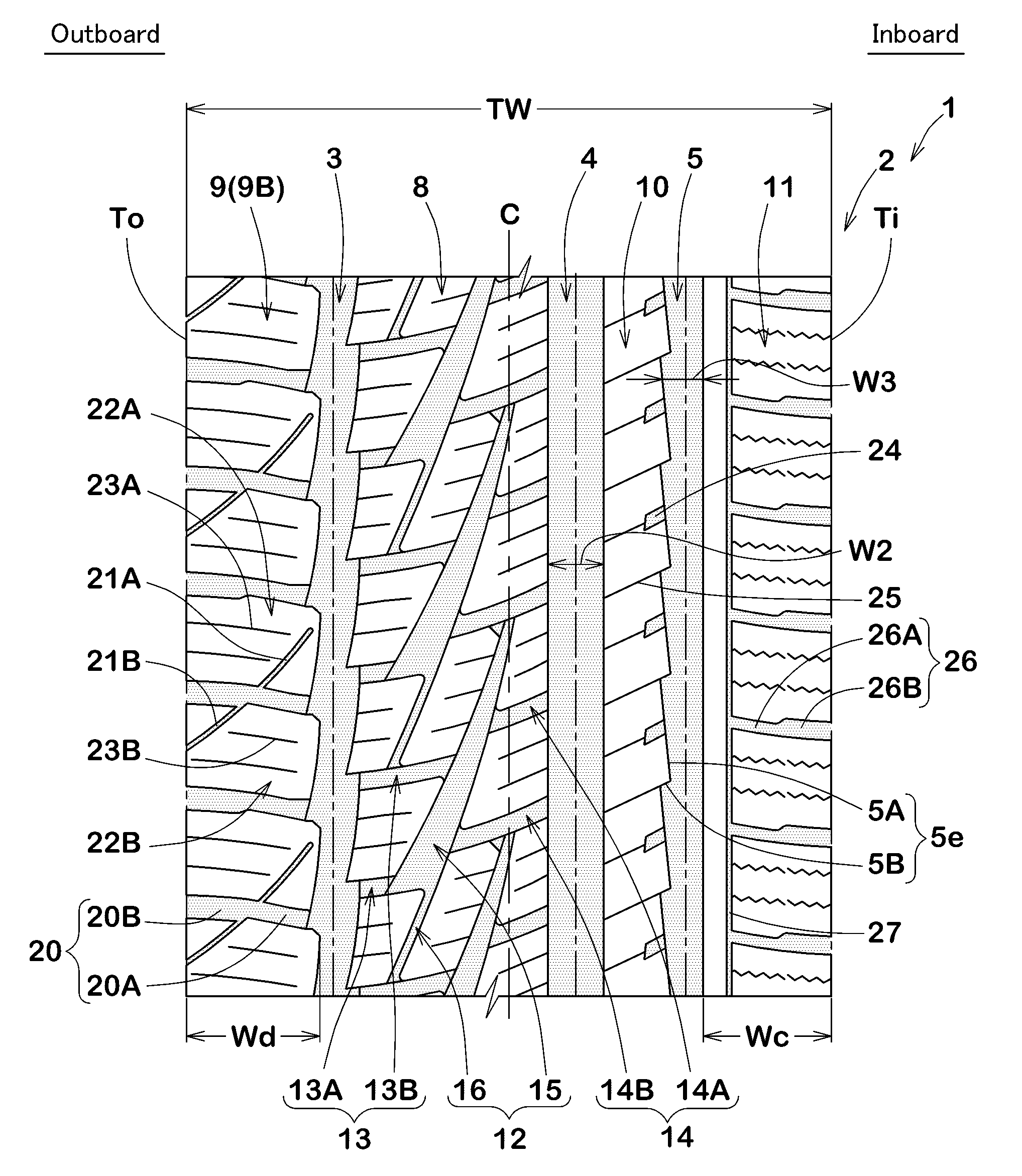

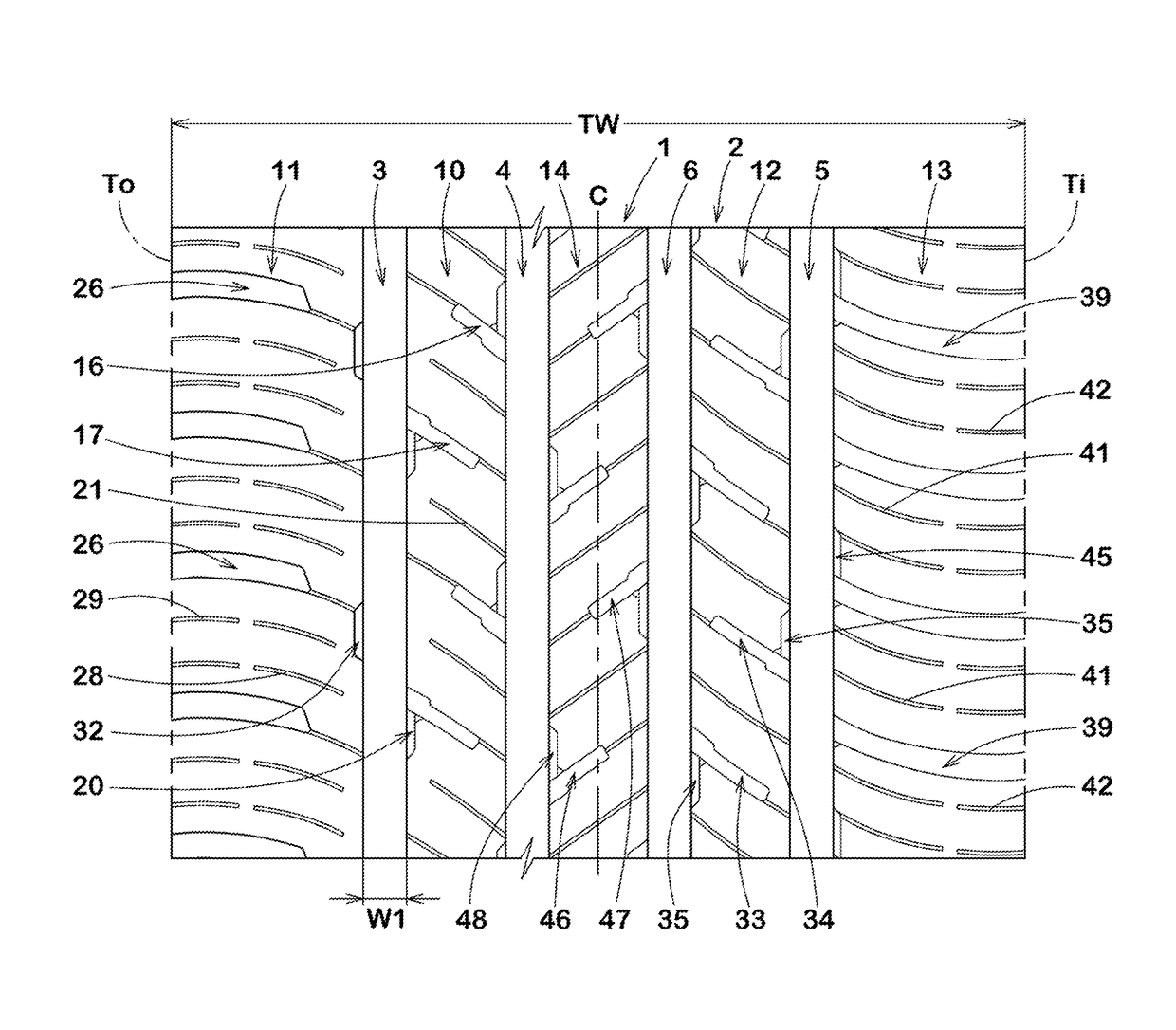

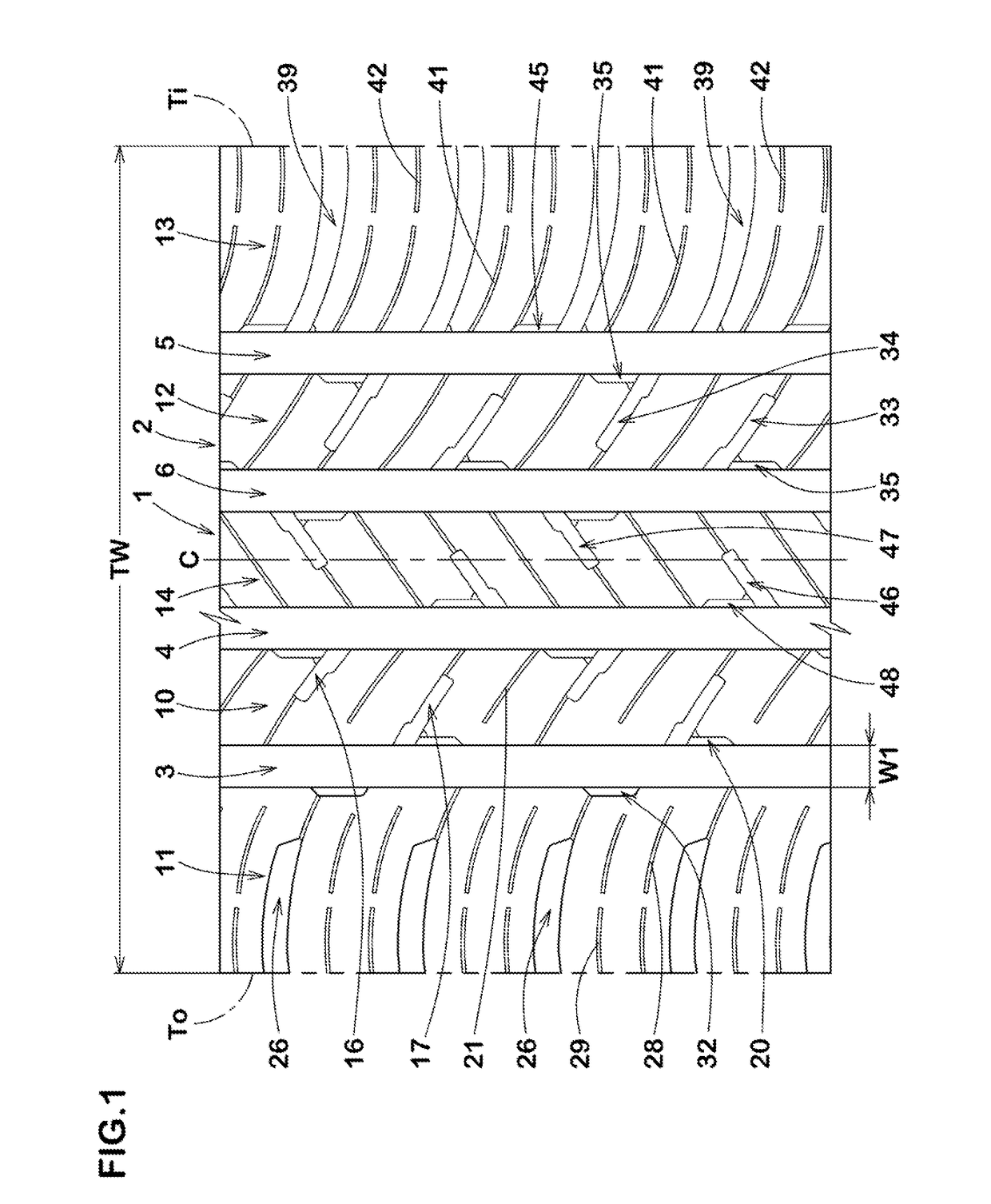

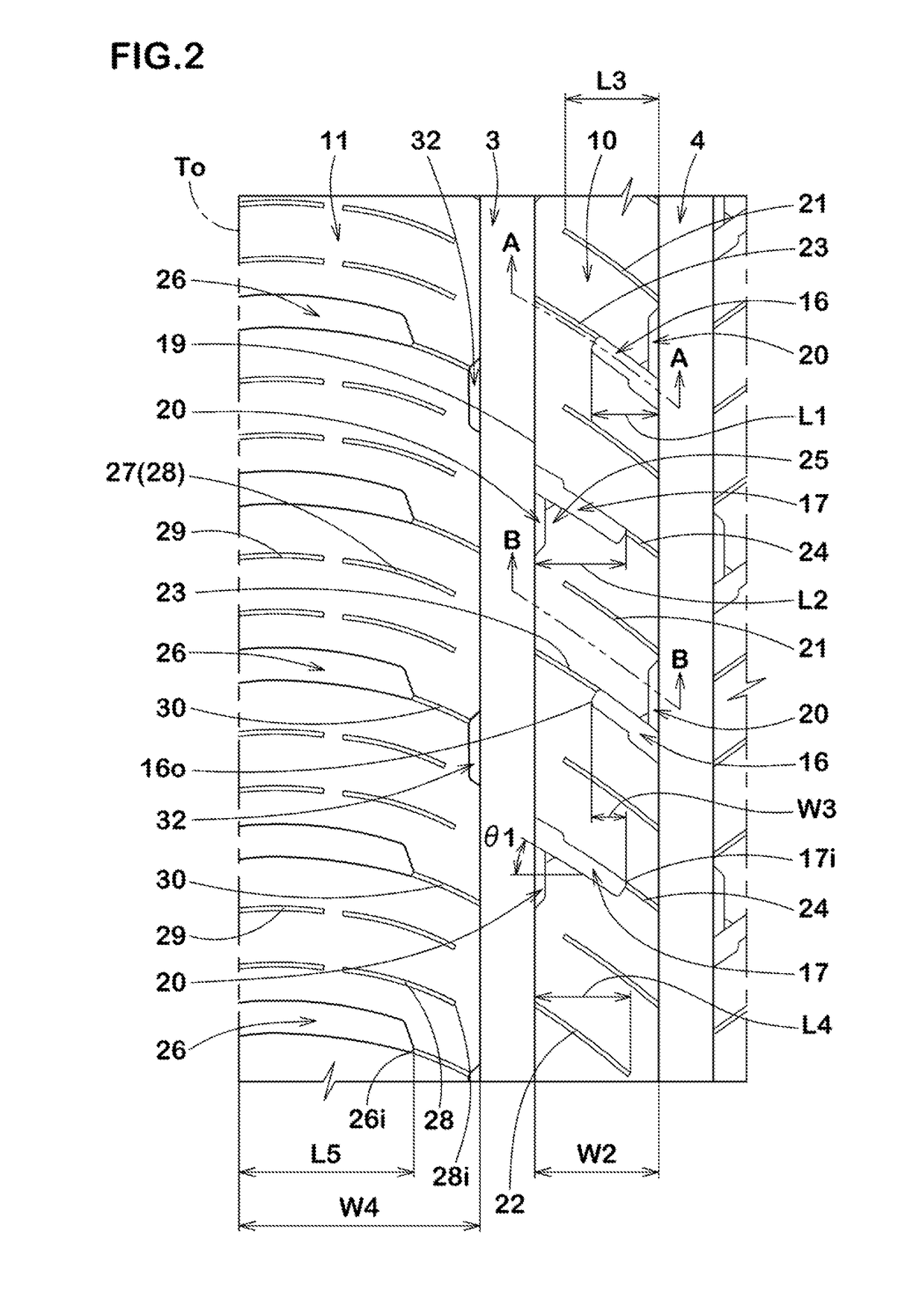

ActiveCN107984978ALarge shear forceGreat tractionTyre tread bands/patternsEngineeringMechanical engineering

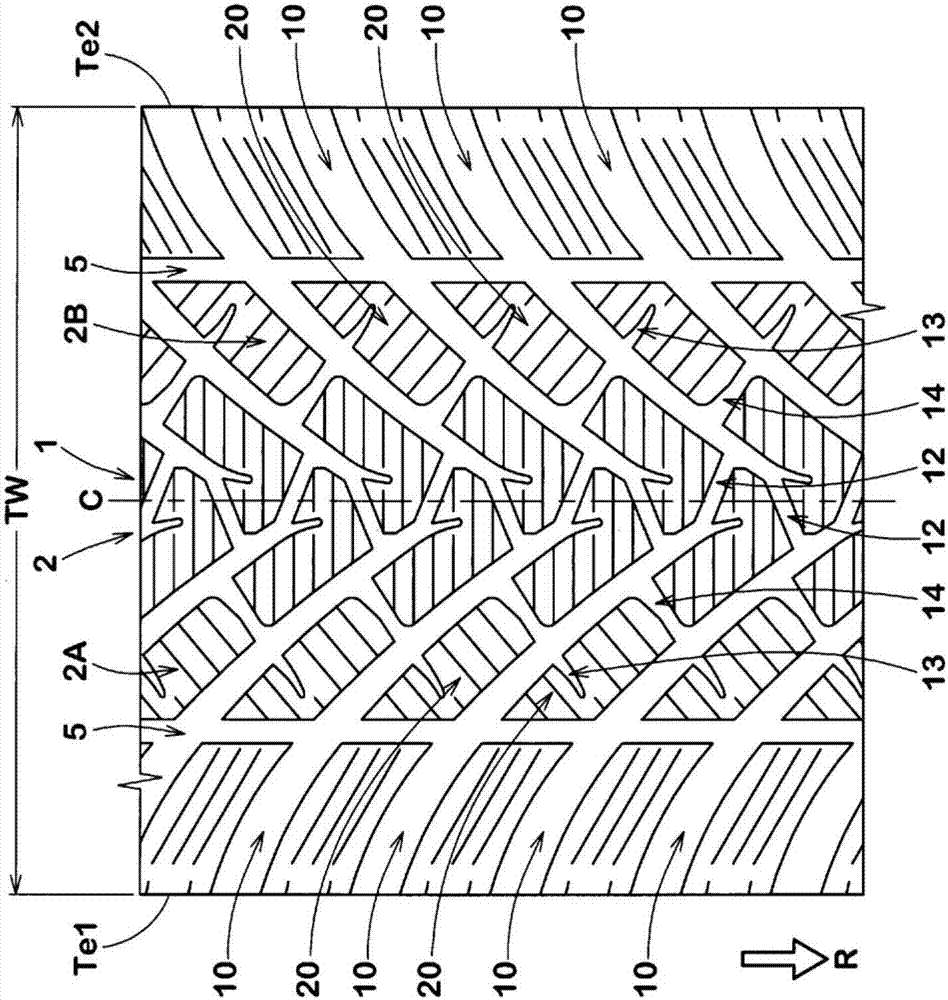

The invention provides a tire capable of exerting excellent on-snow performance. The tire comprises a tread portion (2) comprising a first tread portion (2A) defined between a tire equator (C) and a first tread edge (Tel). The first tread portion (2A) comprises a shoulder main groove (5) extending circumferentially, continuously, and straight, oblique main grooves (10) extending obliquely from thefirst tread edge (Te1) toward the tire equator (C) to intersect the shoulder main groove (5), and oblique land regions (20) each defined between circumferentially adjacent pair of the oblique main grooves (10). At least some of the oblique land regions each comprise an outer oblique sub-groove (13) extending axially inside the shoulder main groove (5) from one of the pair of the oblique main grooves (10) and terminating within the oblique land region (20) and an inner oblique sub-groove (14) extending axially inside the outer oblique sub-groove (13) to completely intersect the oblique land region (20).

Owner:SUMITOMO RUBBER IND LTD

Pneumatic tire

ActiveUS20150266345A1Improve drainage performanceImprove on-snow performanceTyre tread bands/patternsNon-skid devicesEngineeringMechanical engineering

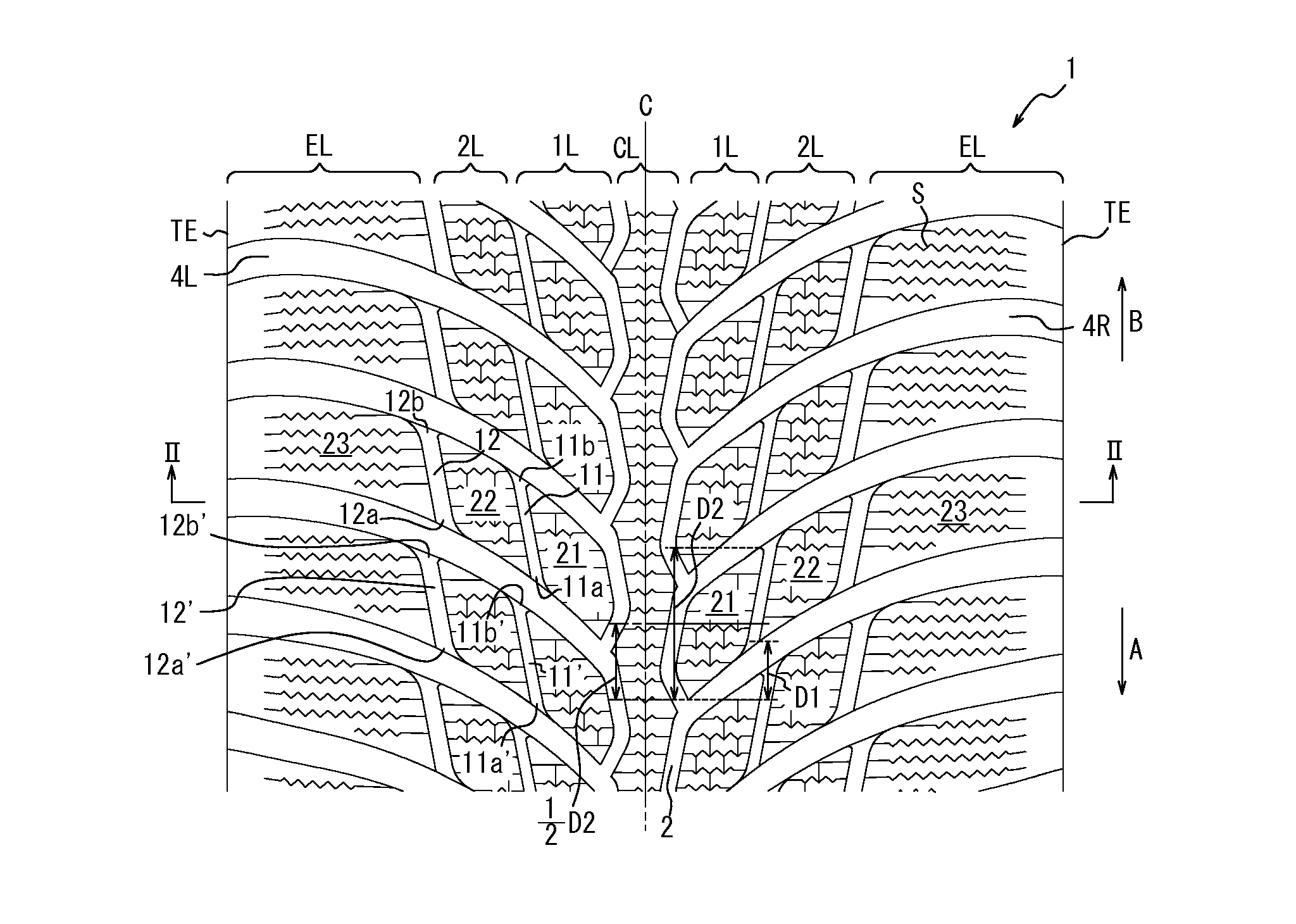

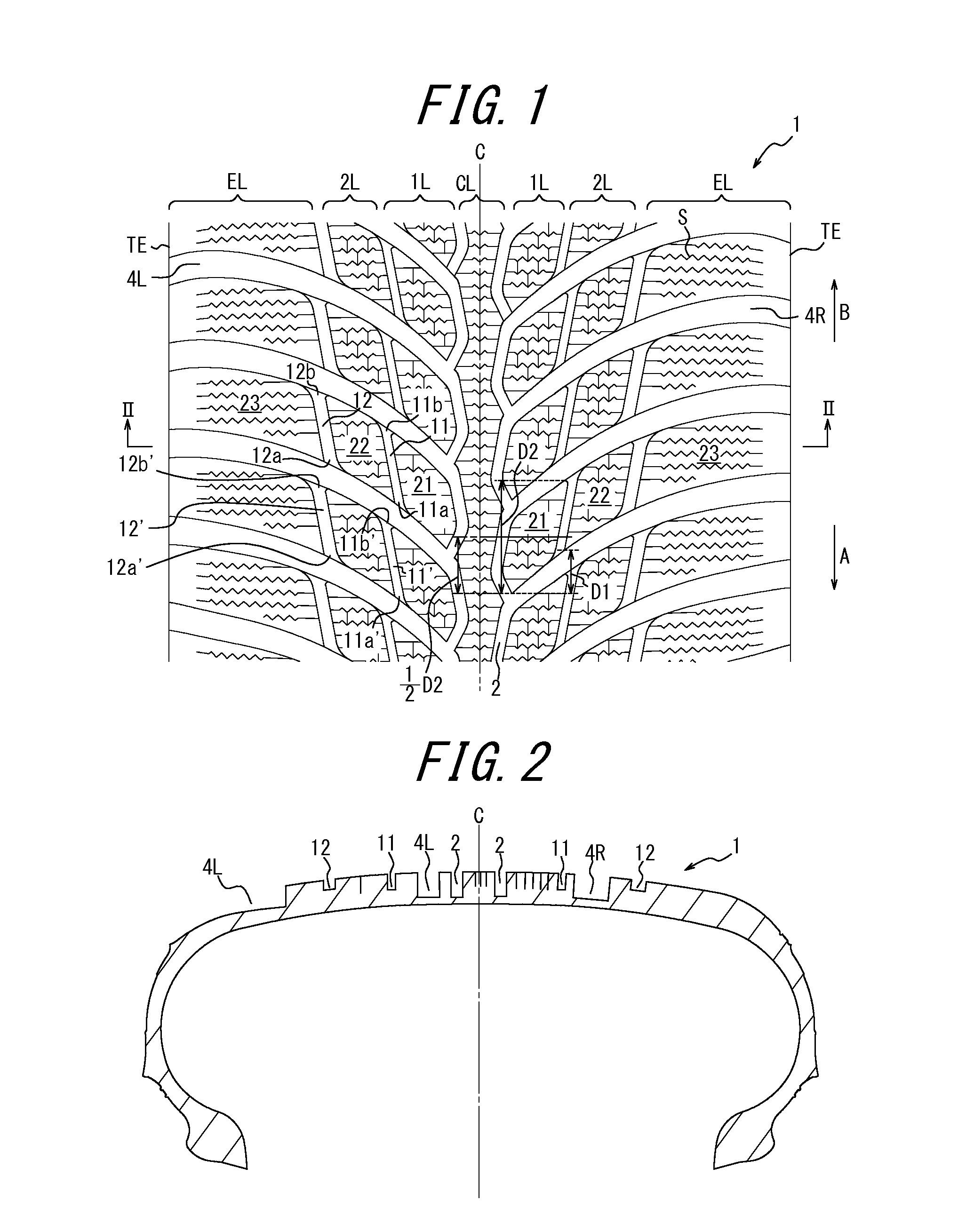

A pneumatic tire, having in a tread surface thereof a pair of circumferential grooves formed on respective sides of the tire equatorial plane in the middle, a rib-like central land portion row demarcated by the circumferential grooves, and a plurality of lateral grooves extending between the central land portion row and each tread end, comprises in each half region of the tread: a row of first intermediate blocks each having a circumferential length D2 and demarcated by the lateral grooves, the corresponding circumferential groove, and first longitudinal grooves; and a row of second intermediate blocks demarcated by the lateral grooves, the first longitudinal grooves, and second longitudinal grooves, wherein facing openings of the first / second longitudinal grooves adjacent in the tire circumferential direction are offset from each other, and provided that D1 represents a circumferential distance between adjacent ends of the adjacent first and second intermediate blocks, D1≦D2 / 2.

Owner:BRIDGESTONE CORP

Pneumatic tire

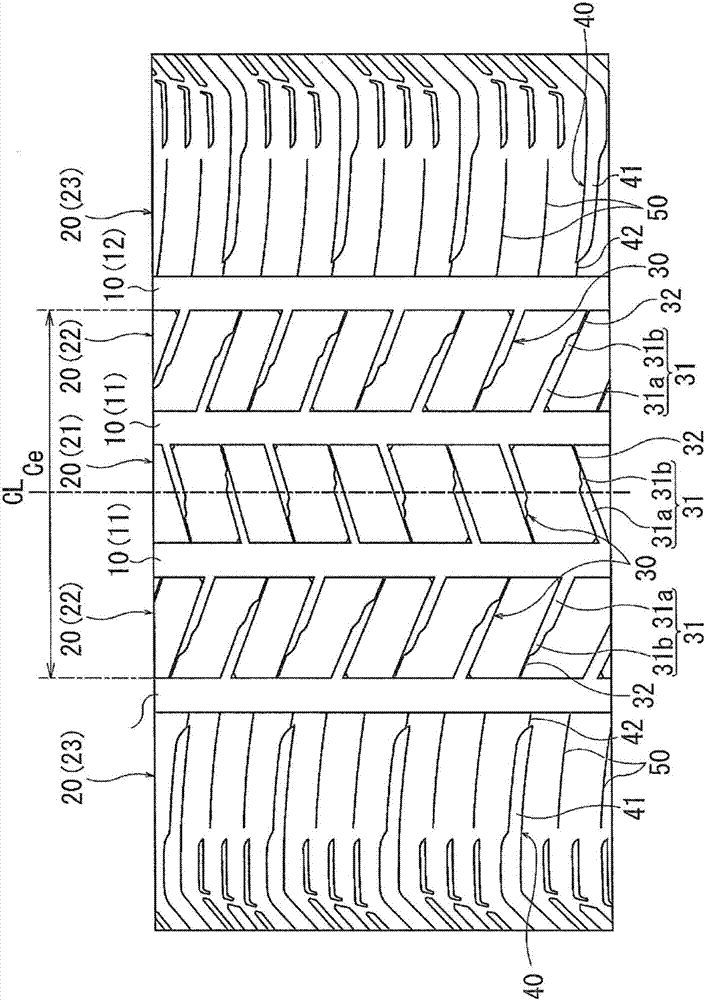

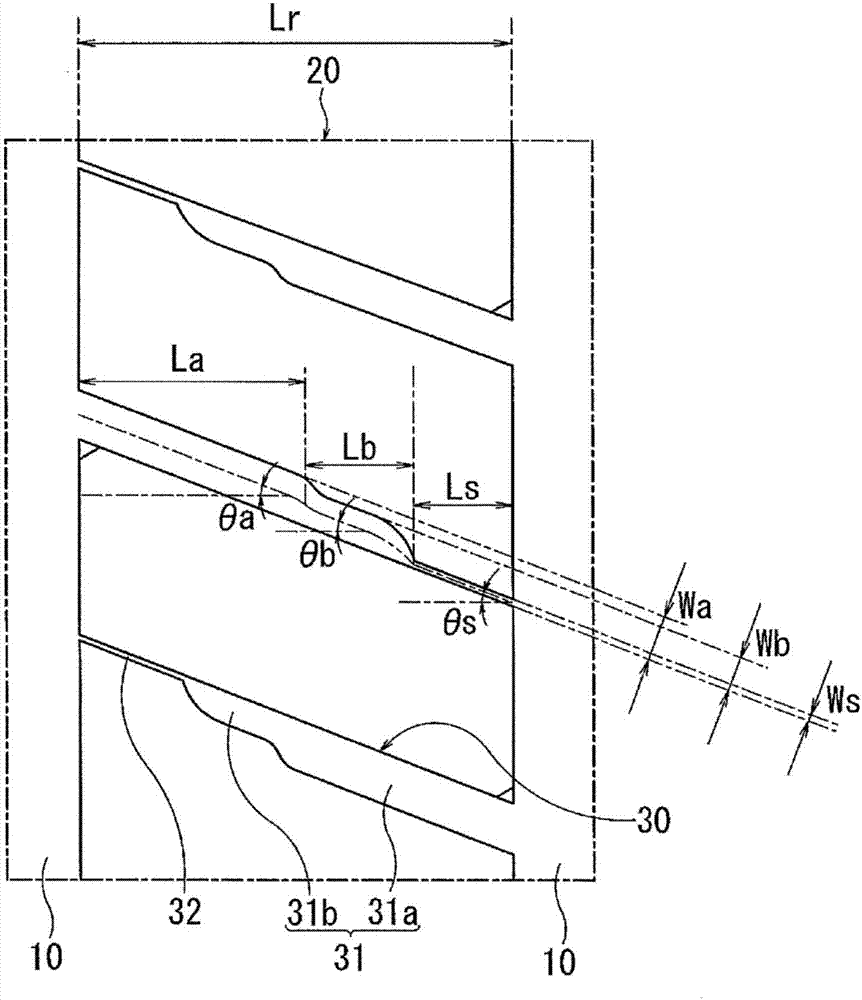

ActiveCN107000492AImprove on-snow performanceSufficiently maintain wear resistanceTyre tread bands/patternsGroove widthEngineering

Provided is a pneumatic tire capable of improving on-snow performance and anti-wear performance. A plurality of compound grooves 30 comprising horizontal grooves 31, one end of which connects to a principal groove 10 on one side thereof and the other end of which ends inside a rib 20, and further comprising sipes 32 extending from the other end of the horizontal grooves 31 to a principal groove 10 on the other side thereof, are formed at an interval from one another in the tire-circumferential direction in one or more rows of ribs 20 positioned inside a center region Ce. The compound grooves 30 are positioned in a manner such that the opening direction of the horizontal grooves 31 relative to the principal grooves 10 alternatingly reverses in the tire circumferential direction. A wide section 31a and a narrow section 31b are formed in each of the horizontal grooves 31. The ratio Wa / Wb of the groove width Wa of the wide section 31a to the groove width Wb of the narrow section 31b is in the range of 1.2-3.0, and the ratio Wb / Ws of the groove width Wb of the narrow section 31b to the groove width Ws of the sipes 32 is in the range of 1.2-5.0.

Owner:THE YOKOHAMA RUBBER CO LTD

Pneumatic tire with tread having circumferential grooves

ActiveUS8555940B2Uneven wearImprove on-snow performanceTyre tread bands/patternsNon-skid devicesRoad surfaceEngineering

Owner:SUMITOMO RUBBER IND LTD

Tire mold, tire, and tire manufacturing method

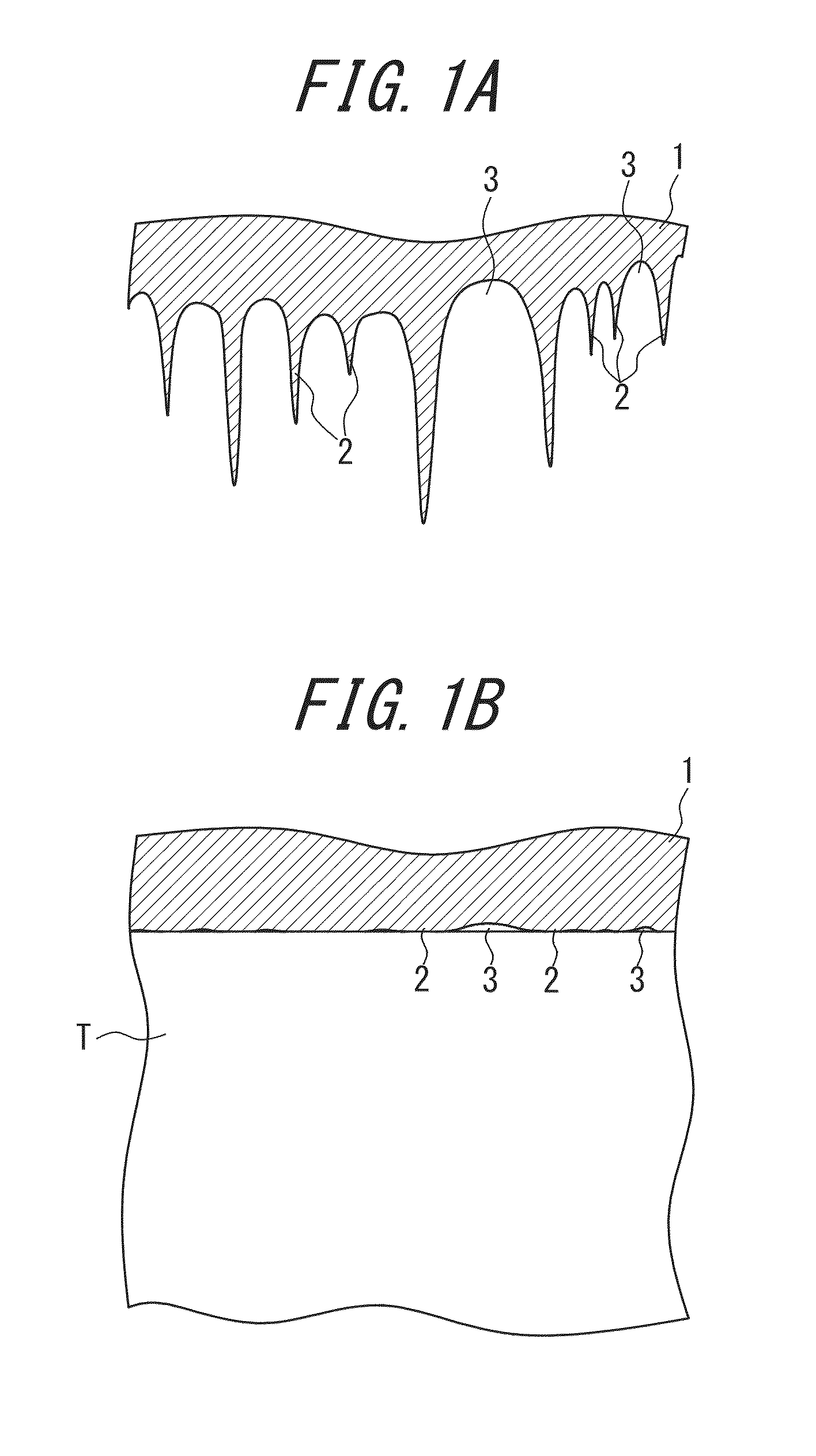

ActiveUS20140190608A1Excellent on-ice performanceImprove on-snow performanceTyresTyre tread bands/patternsSpherical formSphericity

The tread surface of a tire according to the present invention is molded with a tire mold having a tread molding surface, and at least a portion of the tread molding surface is formed by projecting spherical projection material having a predetermined sphericity and causing the spherical projection material to collide.

Owner:BRIDGESTONE CORP

Pneumatic tire

ActiveUS10272725B2Improve on-snow performanceImprove cornering abilityTyre tread bands/patternsMechanical engineeringEngineering

Owner:SUMITOMO RUBBER IND LTD

Tyre

ActiveUS20200361244A1Reduced wear resistance requirementsImprove on-snow performanceRoad vehicle tyresTyre tread bands/patternsGround contactTransverse groove

A tyre includes a tread portion including a crown land portion defined between two main grooves extending continuously in a tyre circumferential direction. The crown land portion is provided with crown lateral grooves traversing the crown land portion. Each of the crown lateral grooves, in a cross-sectional view perpendicular to its longitudinal direction, includes a sipe portion having a width equal to or less than 1.5 mm, and a main portion connected to the sipe portion and opening at a ground contact surface of the crown land portion. The main portion has a width enlarging from the sipe portion. The main portion has a depth smaller than depths of the main grooves. The sipe portion has a first wall extending in a tyre radial direction so as to be continuous with a first wall of the main portion to form a single groove wall together.

Owner:SUMITOMO RUBBER IND LTD

Tire

ActiveCN109130709AImprove traction performanceIncrease braking powerTyre tread bands/patternsMining engineeringMechanical engineering

Owner:SUMITOMO RUBBER IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com