Patents

Literature

246results about How to "Avoid uneven wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wear leveling techniques for flash EEPROM systems

InactiveUS6850443B2Avoid uneven wearExtended service lifeMemory architecture accessing/allocationRead-only memoriesElectricityProgrammable read-only memory

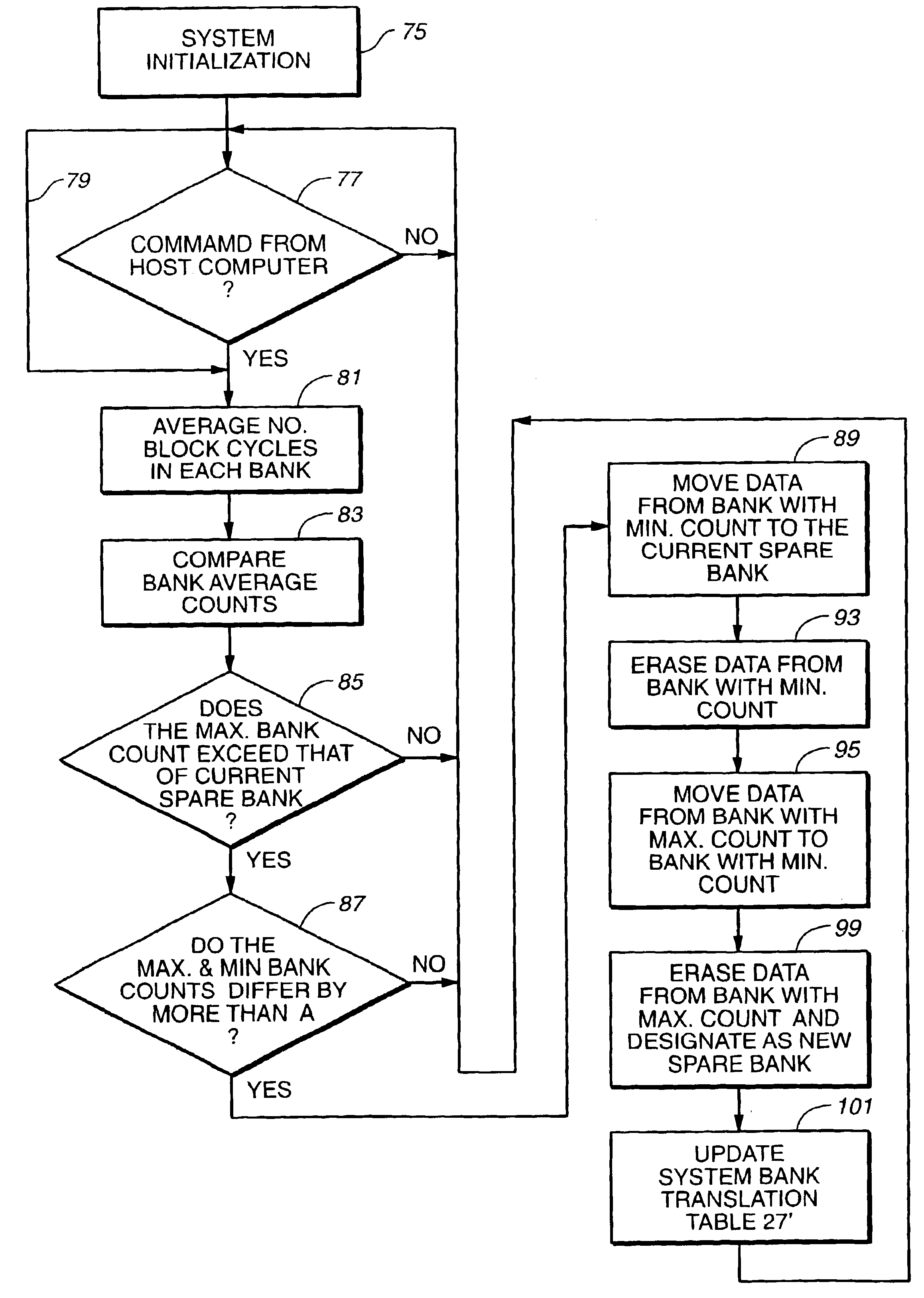

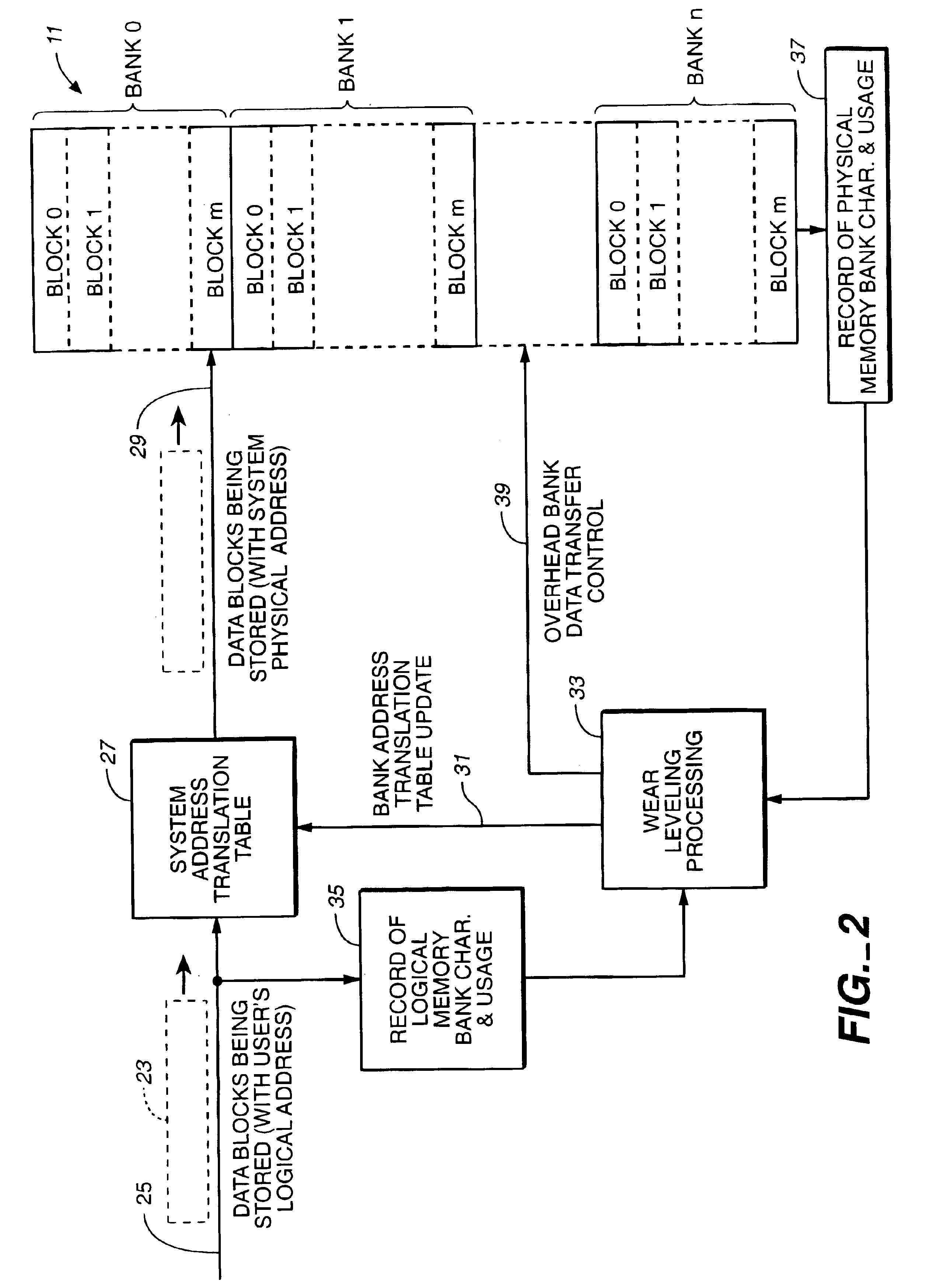

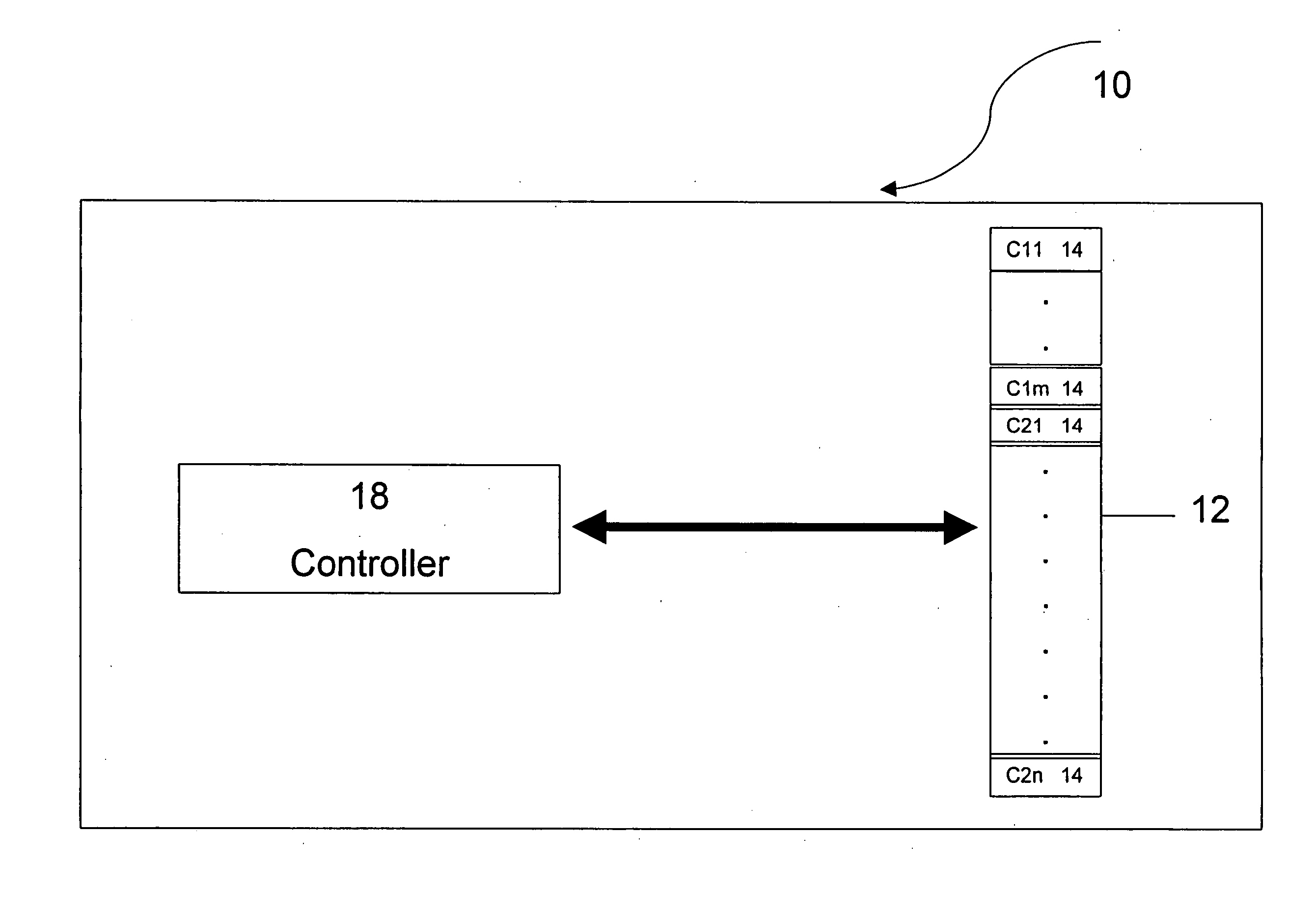

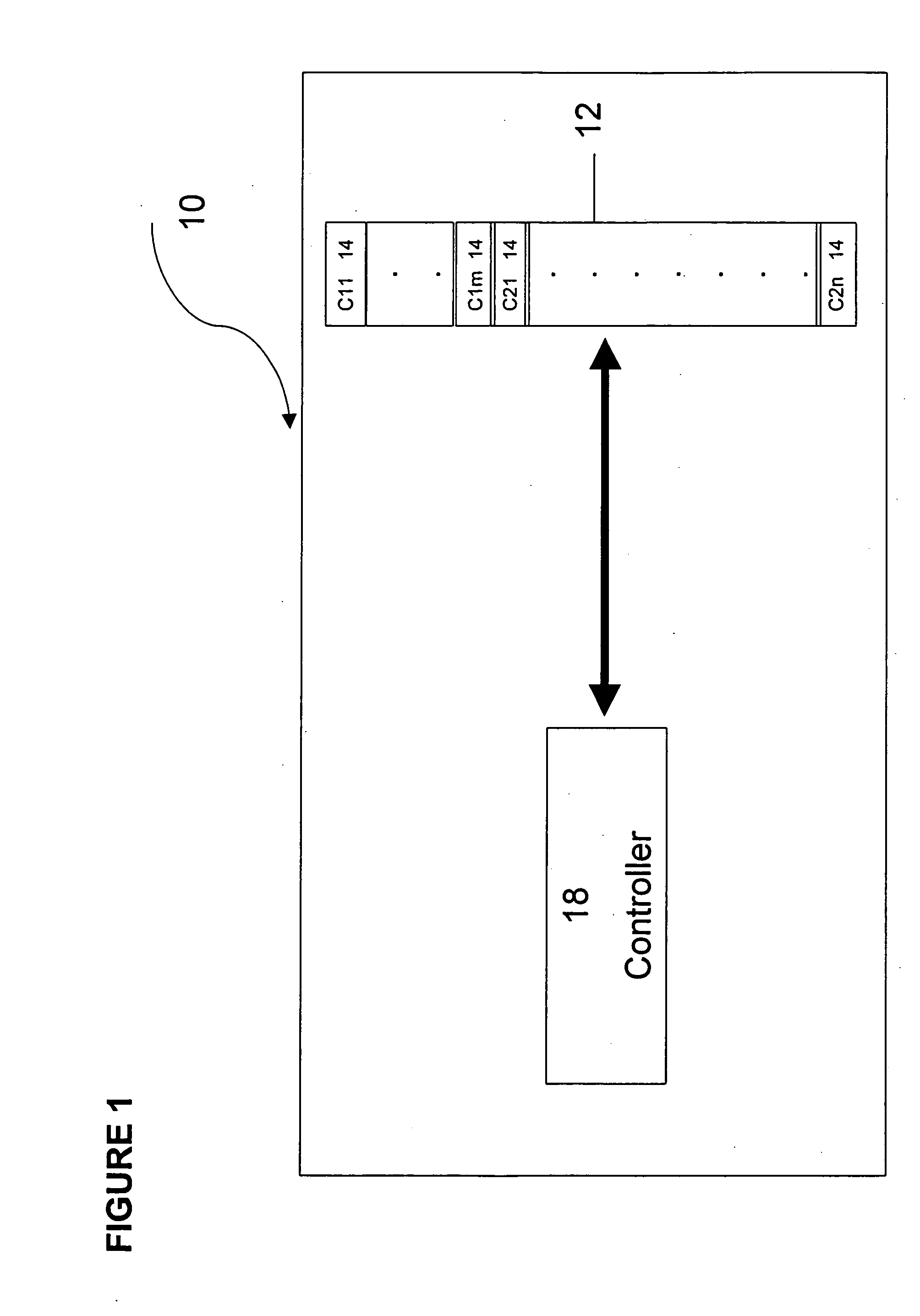

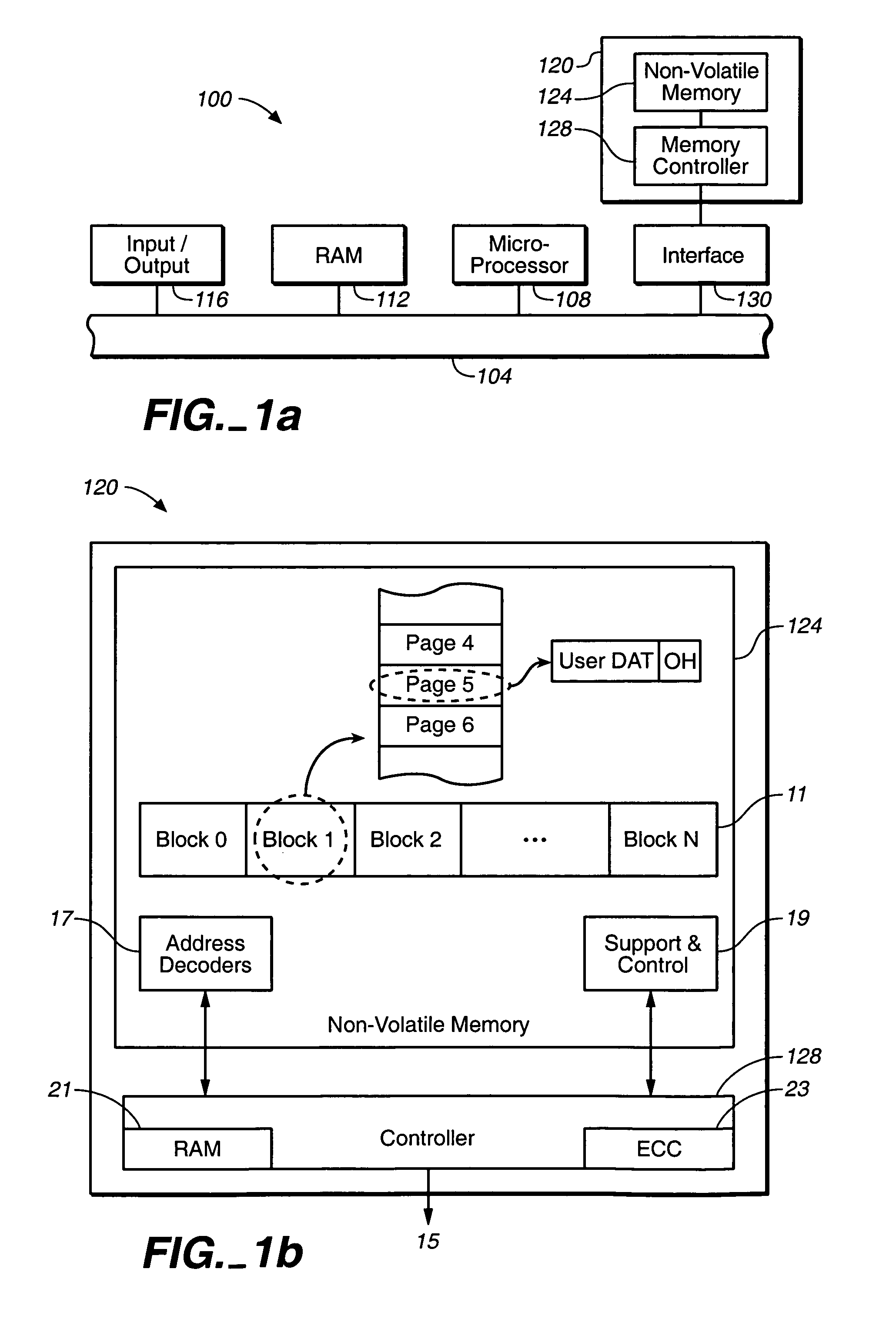

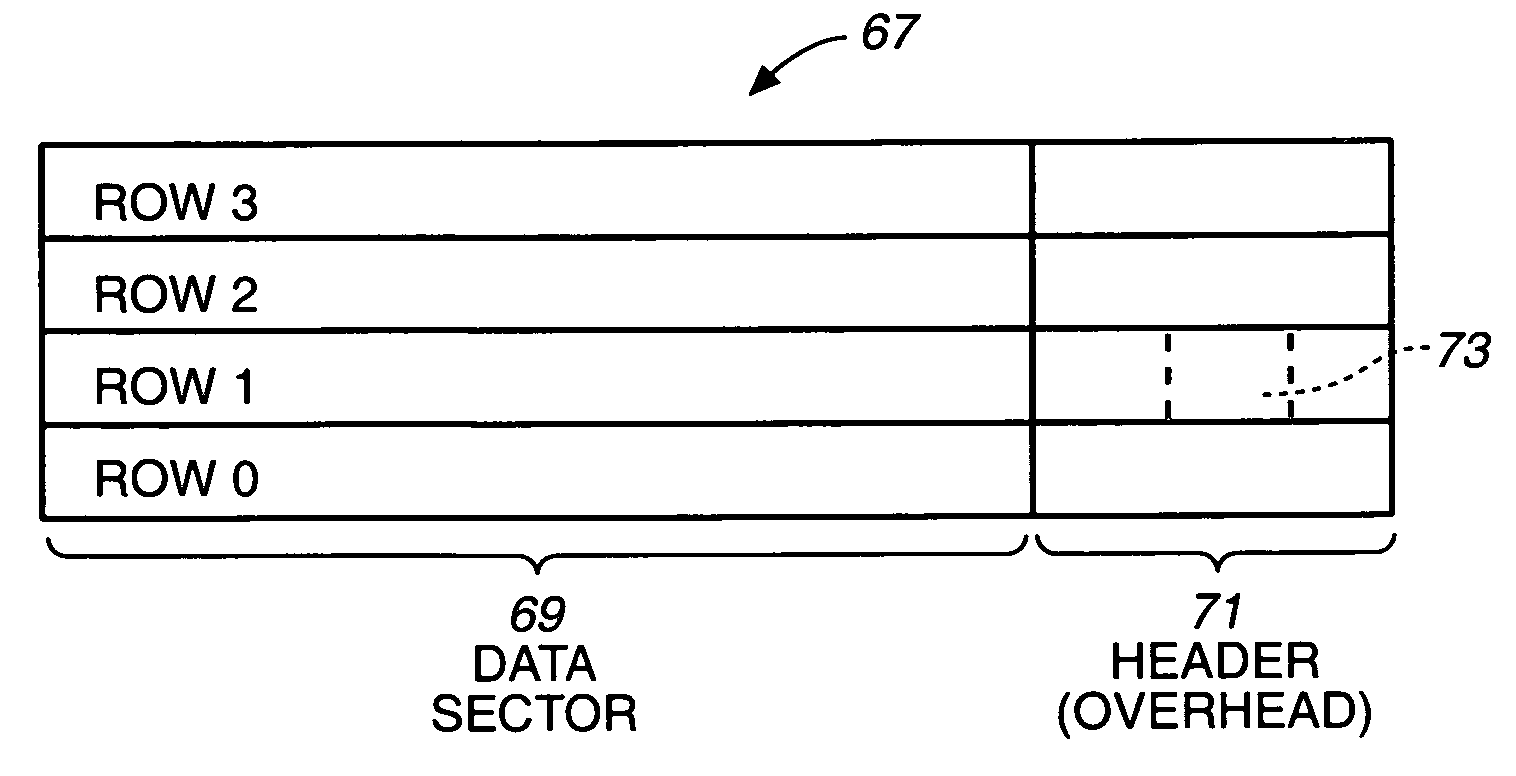

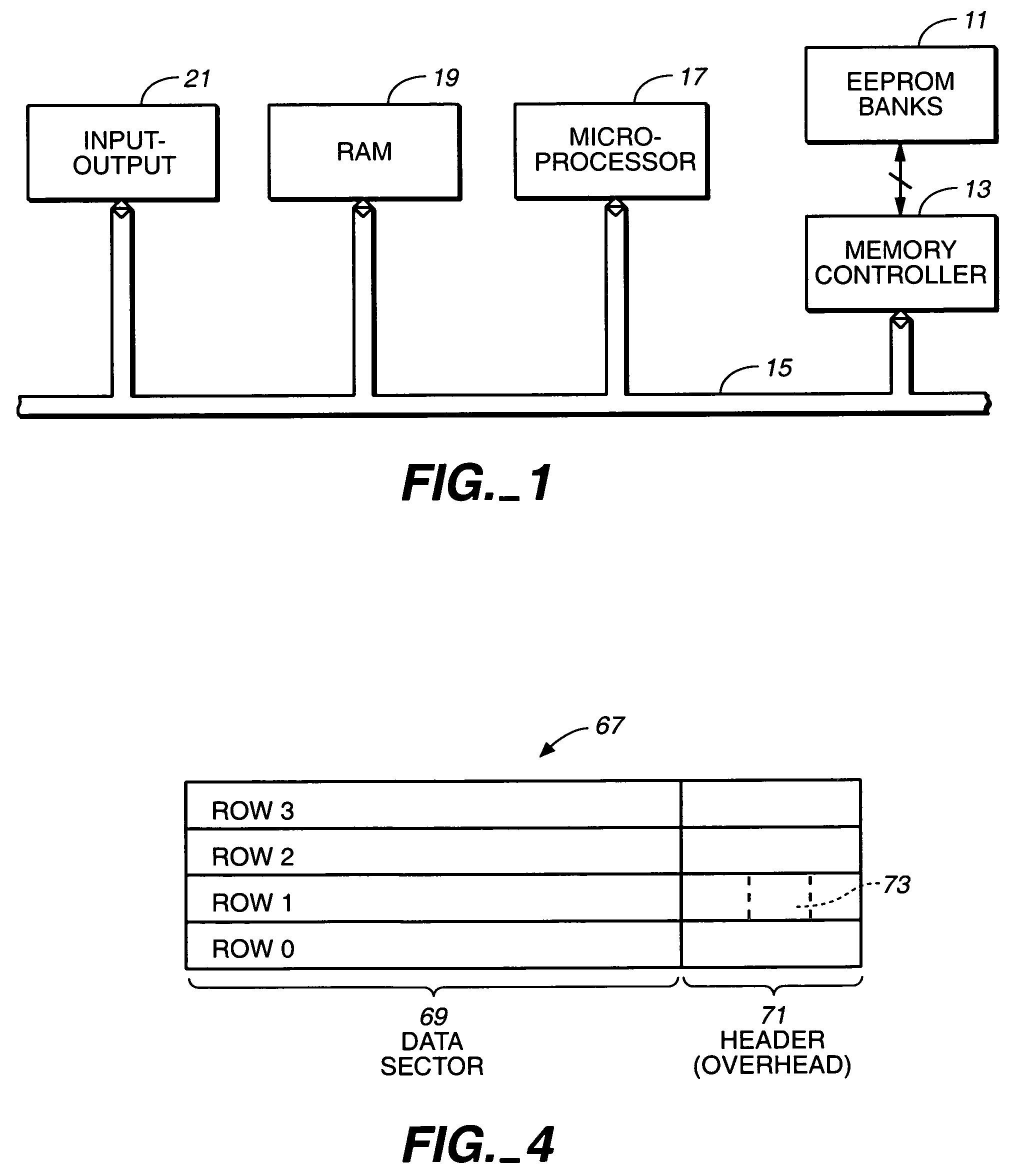

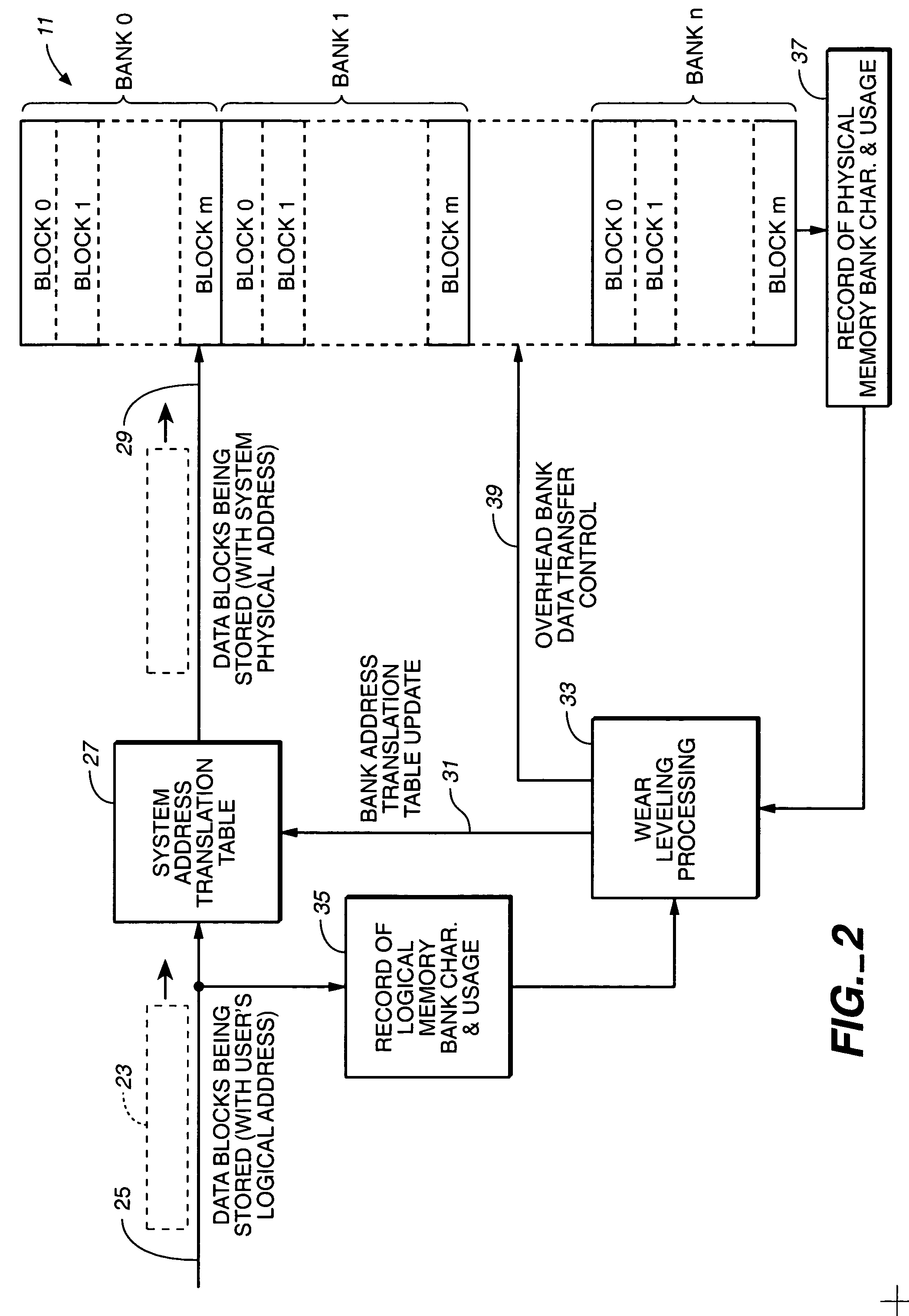

A mass storage system made of flash electrically erasable and programmable read only memory (“EEPROM”) cells organized into blocks, the blocks in turn being grouped into memory banks, is managed to even out the numbers of erase and rewrite cycles experienced by the memory banks in order to extend the service lifetime of the memory system. Since this type of memory cell becomes unusable after a finite number of erase and rewrite cycles, although in the tens of thousands of cycles, uneven use of the memory banks is avoided so that the entire memory does not become inoperative because one of its banks has reached its end of life while others of the banks are little used. Relative use of the memory banks is monitored and, in response to detection of uneven use, have their physical addresses periodically swapped for each other in order to even out their use over the lifetime of the memory.

Owner:SANDISK TECH LLC

Flash memory storage system and method

ActiveUS20070061502A1Overcome disadvantagesEqually distributedMemory architecture accessing/allocationRead-only memoriesParallel computingStorage cell

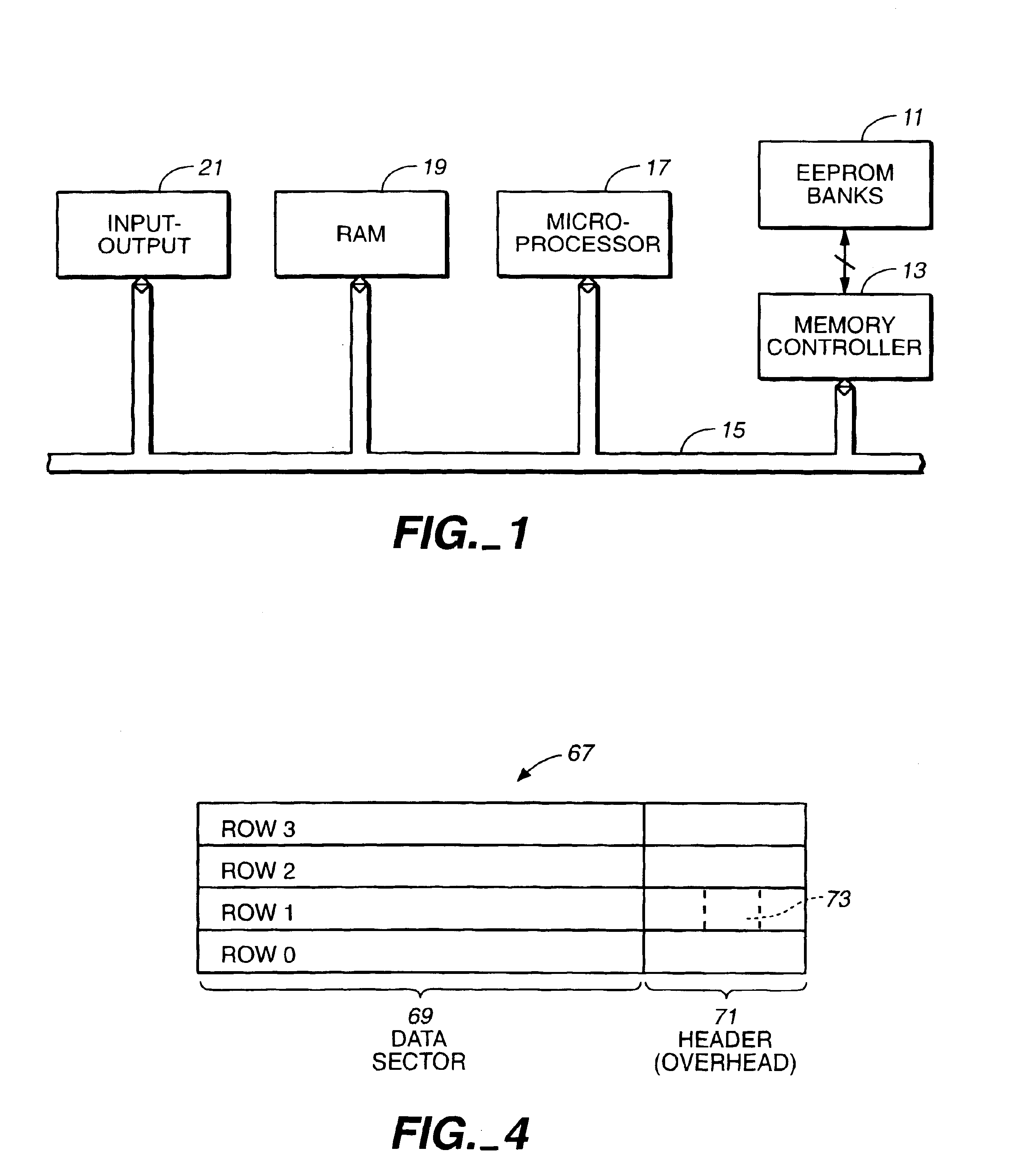

A flash memory storage system includes a memory array containing a plurality of memory cells and a controller for controlling the flash memory array. The controller dedicates a first group of memory cells to operate with a first number of bits per cell and a second, separate group of memory cells to operate with a second number of bits per cell. A mechanism is provided to apply wear leveling techniques separately to the two groups of cells to evenly wear out the memory cells.

Owner:WESTERN DIGITAL ISRAEL LTD

Automated wear leveling in non-volatile storage systems

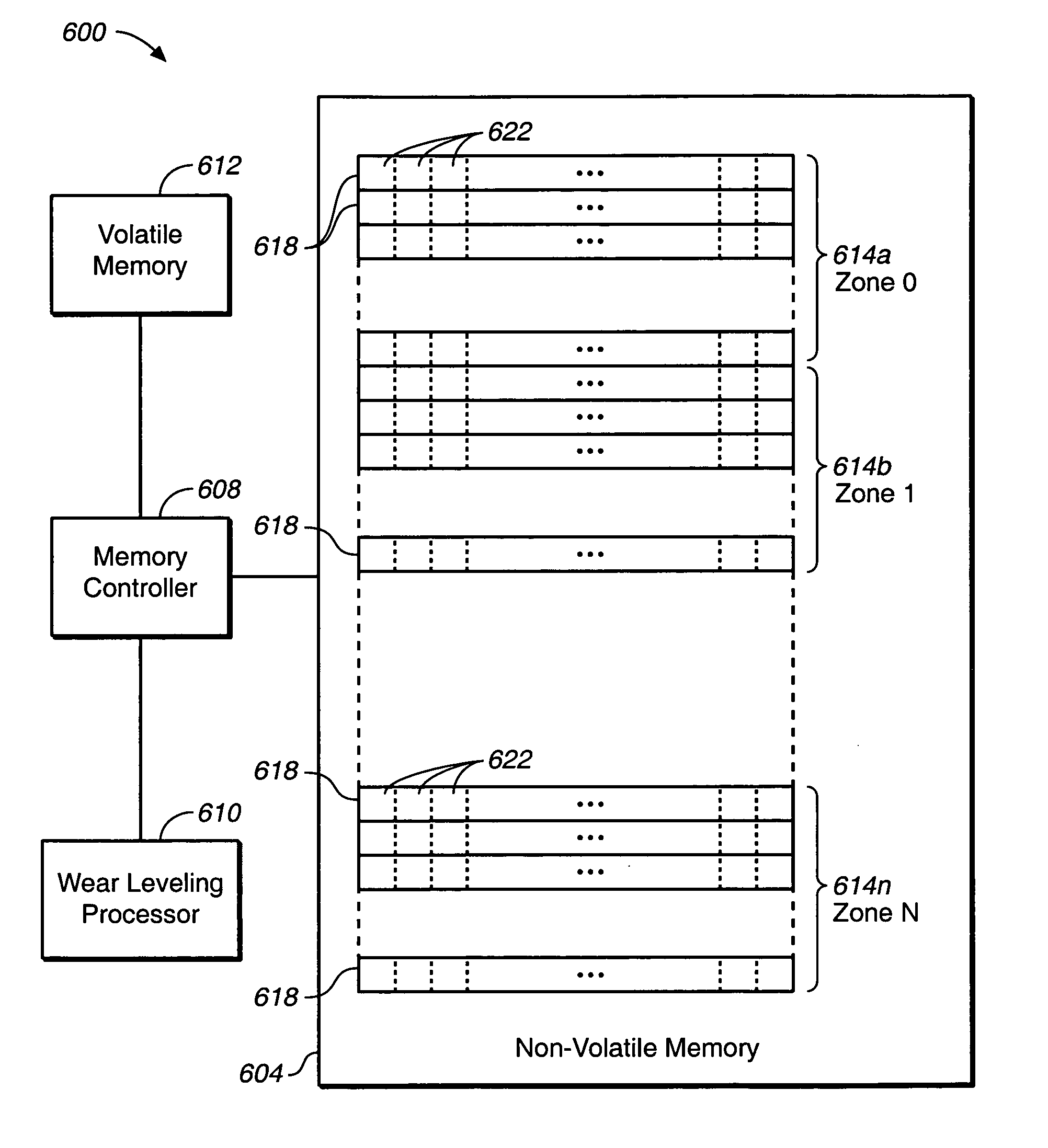

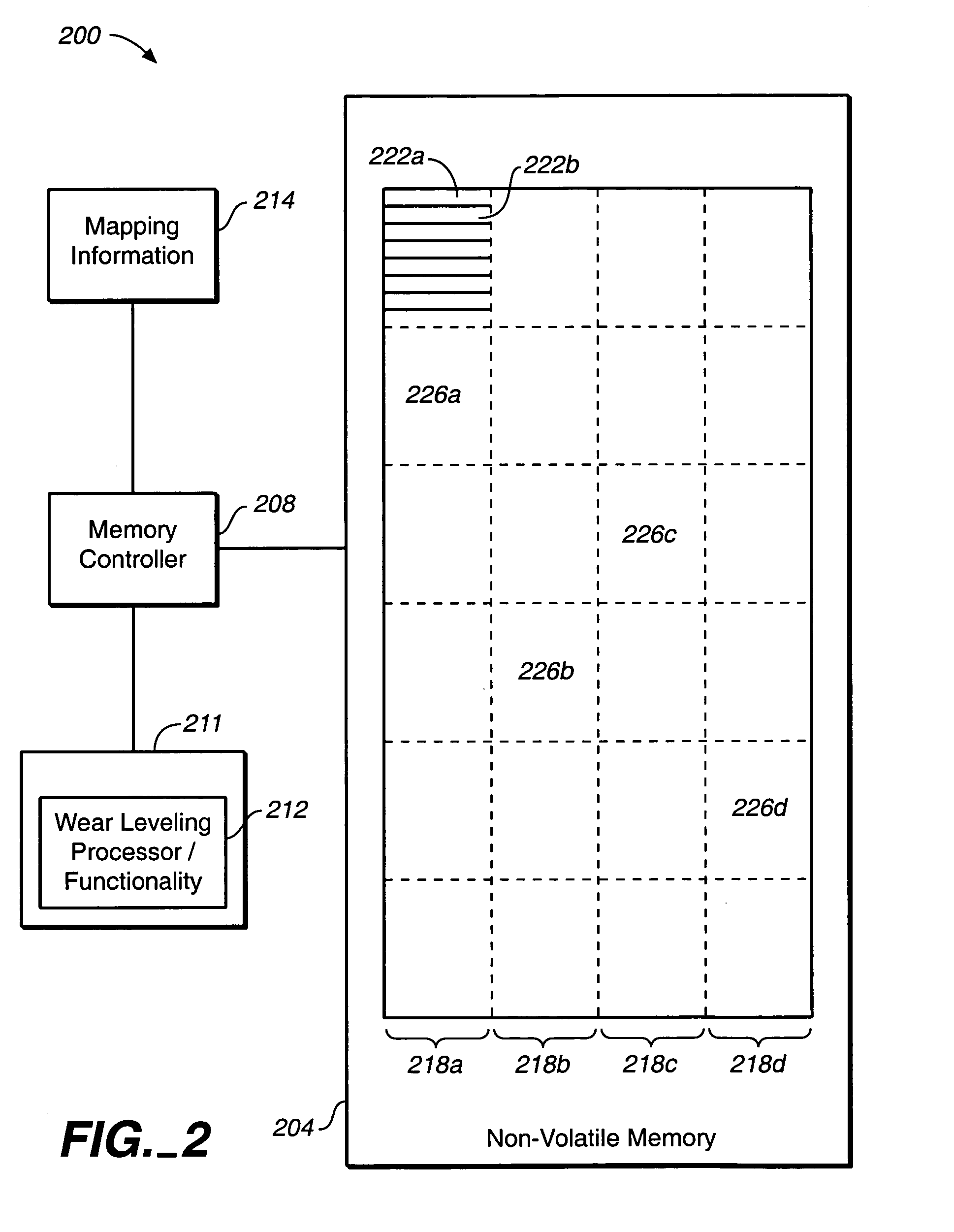

ActiveUS7120729B2Lower Level RequirementsAvoid uneven wearMemory architecture accessing/allocationMemory adressing/allocation/relocationParallel computingMemory systems

Methods and apparatus for performing wear leveling in a non-volatile memory system are disclosed. Included is a method for performing wear leveling in a memory system that includes a first zone, which has a first memory element that includes contents, and a second zone includes identifying the first memory element and associating the contents of the first memory element with the second zone while disassociating the contents of the first memory element from the first zone. In one embodiment, associating the contents of the first memory element with the second involves moving contents of a second memory element into a third memory element, then copying the contents of the first memory element into the second memory element.

Owner:SANDISK TECH LLC

Wear leveling techniques for flash EEPROM systems

InactiveUS20050114589A1Avoid uneven wearExtended service lifeMemory architecture accessing/allocationRead-only memoriesElectricityProgrammable read-only memory

A mass storage system made of flash electrically erasable and programmable read only memory (“EEPROM”) cells organized into blocks, the blocks in turn being grouped into memory banks, is managed to even out the numbers of erase and rewrite cycles experienced by the memory banks in order to extend the service lifetime of the memory system. Since this type of memory cell becomes unusable after a finite number of erase and rewrite cycles, although in the tens of thousands of cycles, uneven use of the memory banks is avoided so that the entire memory does not become inoperative because one of its banks has reached its end of life while others of the banks are little used. Relative use of the memory banks is monitored and, in response to detection of uneven use, have their physical addresses periodically swapped for each other in order to even out their use over the lifetime of the memory.

Owner:SANDISK TECH LLC

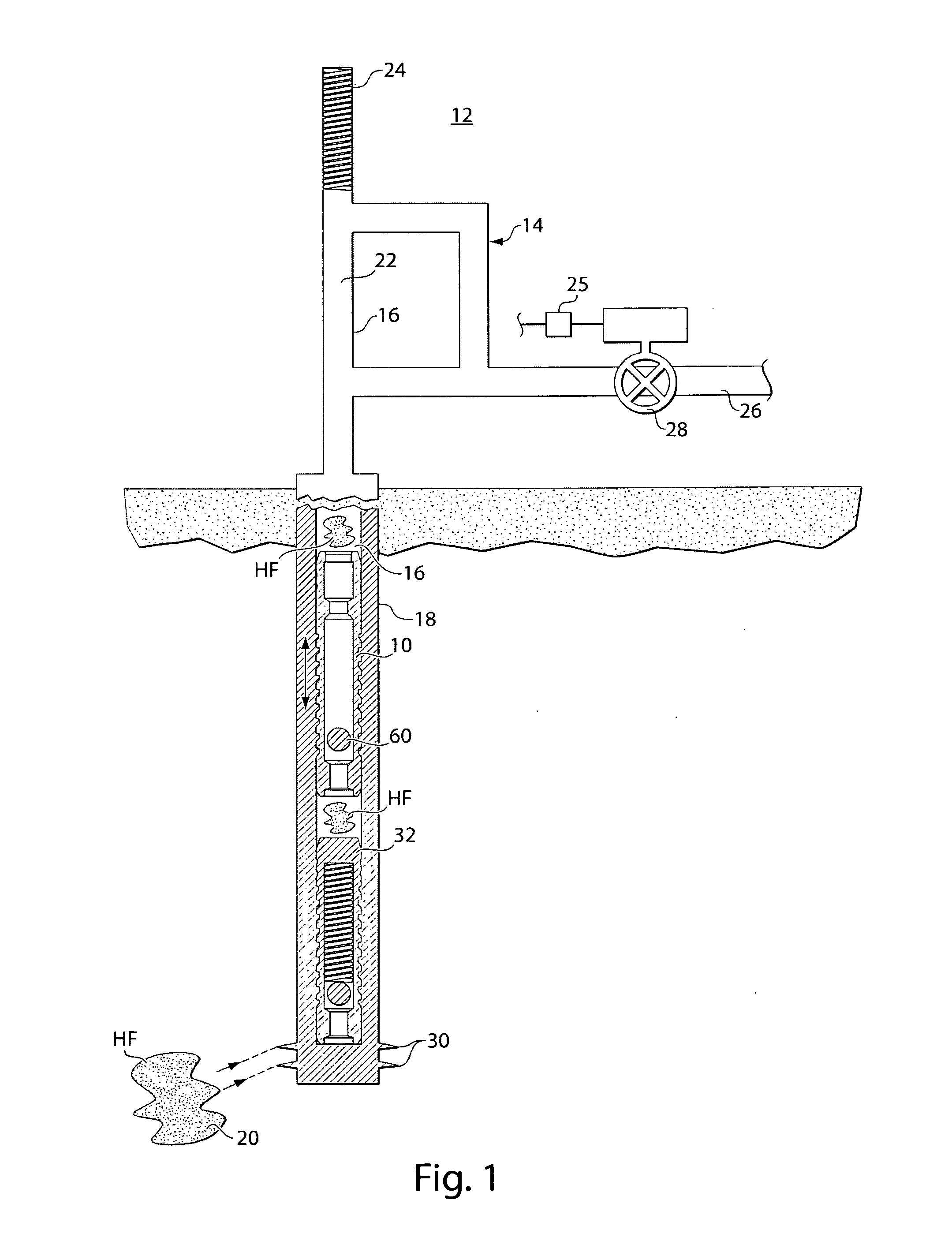

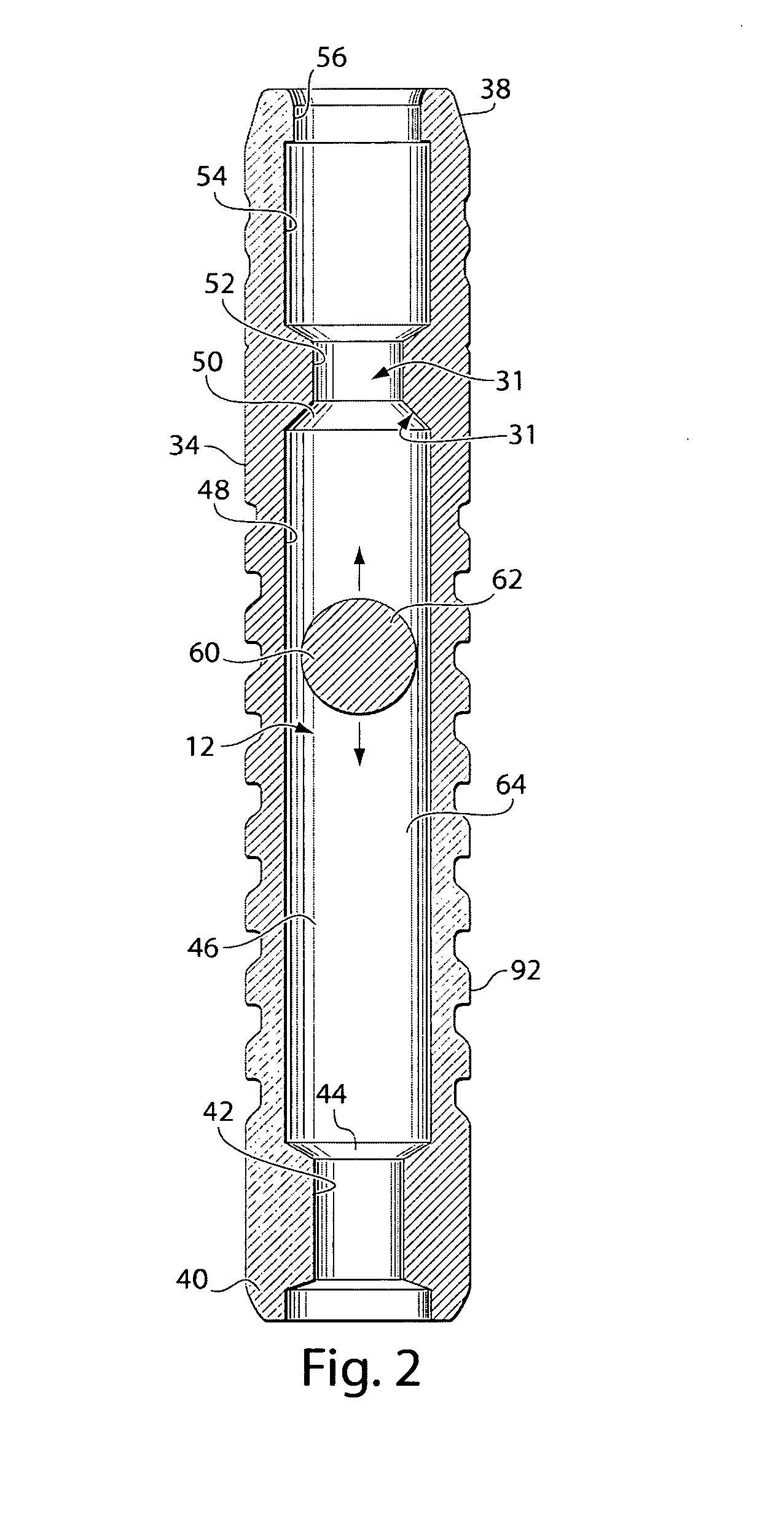

Plunger lift arrangement

ActiveUS20160108710A1Flow on effectEfficient use ofConstructionsFluid removalPlungerWaste management

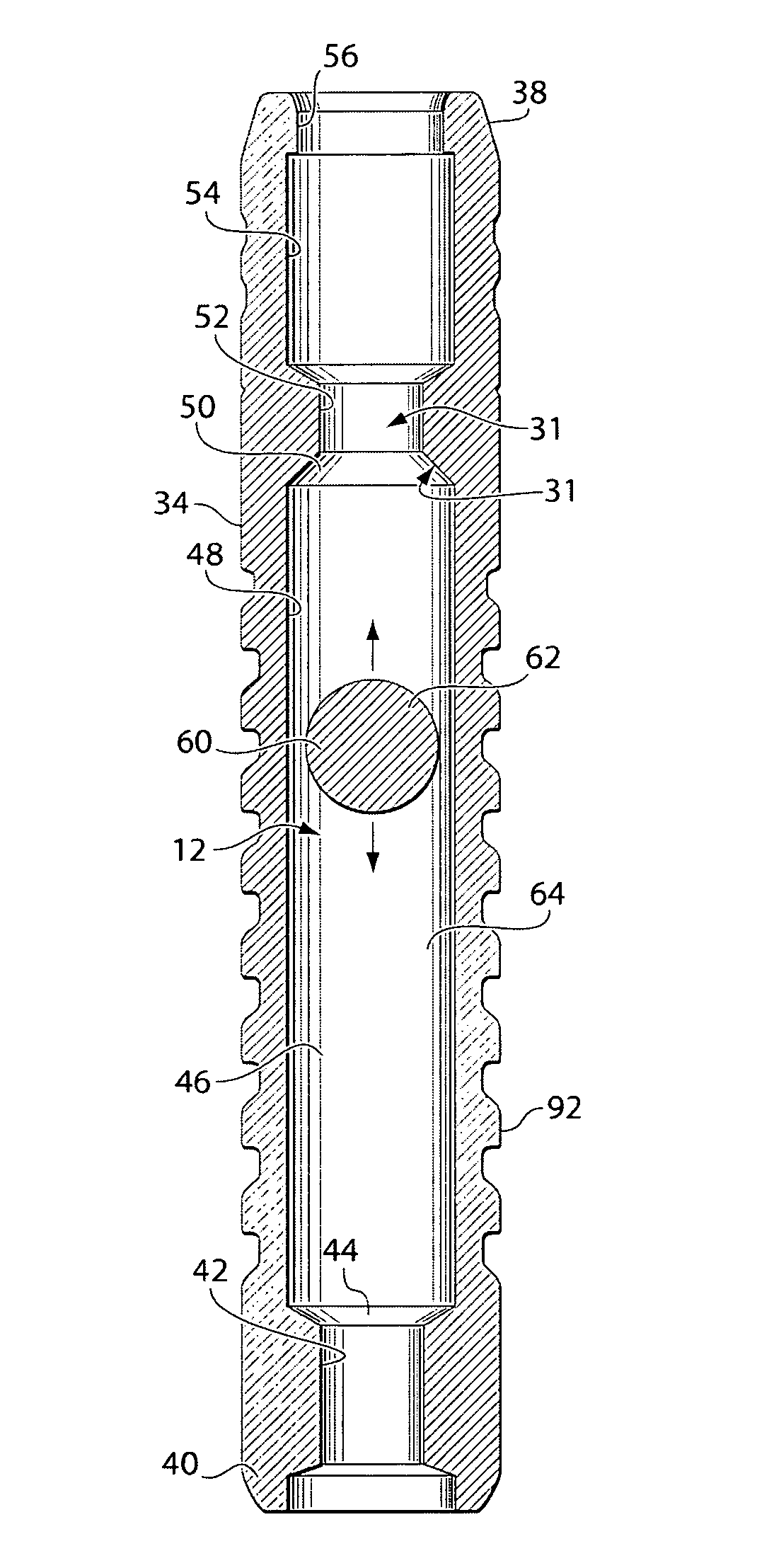

A plunger for extraction of hydrocarbon fluids from a gas well system wherein the plunger is arranged to move upwardly and downwardly in an arrangement of inner tubing within the gas well system. The plunger comprises an elongated housing sleeve having a longitudinally directed bore, an elongated central chamber within the longitudinally directed bore, the central chamber having a plug nestable seat at each end thereof; and a plug displacably arranged within the central chamber so as to seal the bore during travel of the plug in a first direction in the inner tubing, and to permit flow of fluid through the plunger as the plunger travels in a second direction in the inner tubing.

Owner:WELL MASTER CORP

Pneumatic tire

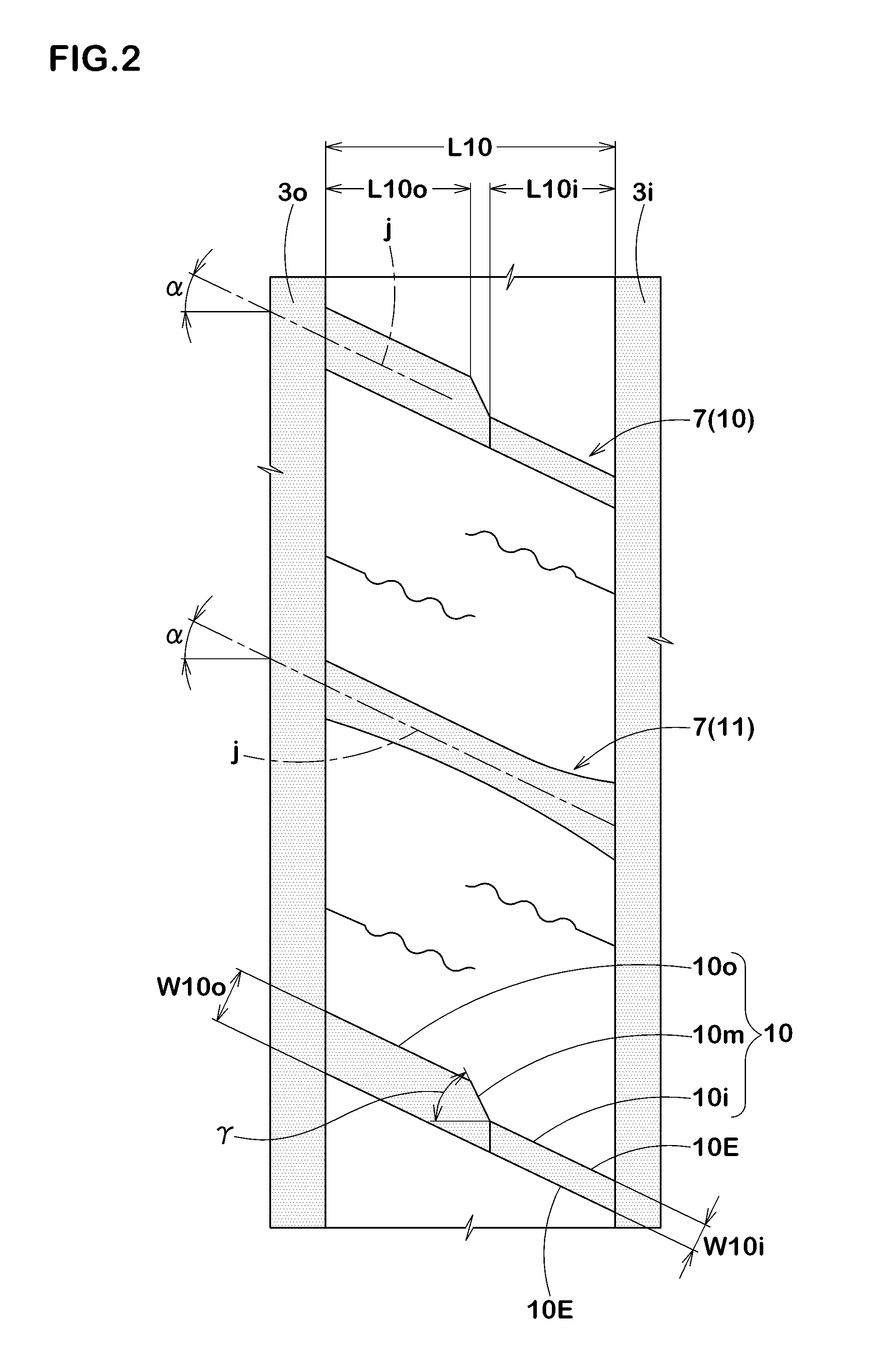

ActiveUS20130192731A1Improve rigidityAvoid uneven wearTyre tread bands/patternsNon-skid devicesGround contactMarine engineering

A tread portion of a pneumatic ti re includes inner land portions between outer circumferential main grooves disposed most on tread ground-contact end sides and at least one inner circumferential main groove on the inner side thereof. The inner land portions are divided into inner blocks by inner lateral grooves inclined at an angle α of 10 to 40°. The inner lateral grooves consist of first inner lateral grooves and second inner lateral grooves which are alternately arranged in a circumferential direction. The first inner lateral grooves include a wide-width part connecting to the outer circumferential main groove and a narrow-width part connecting to the inner circumferential main groove.

Owner:SUMITOMO RUBBER IND LTD

Pneumatic tire

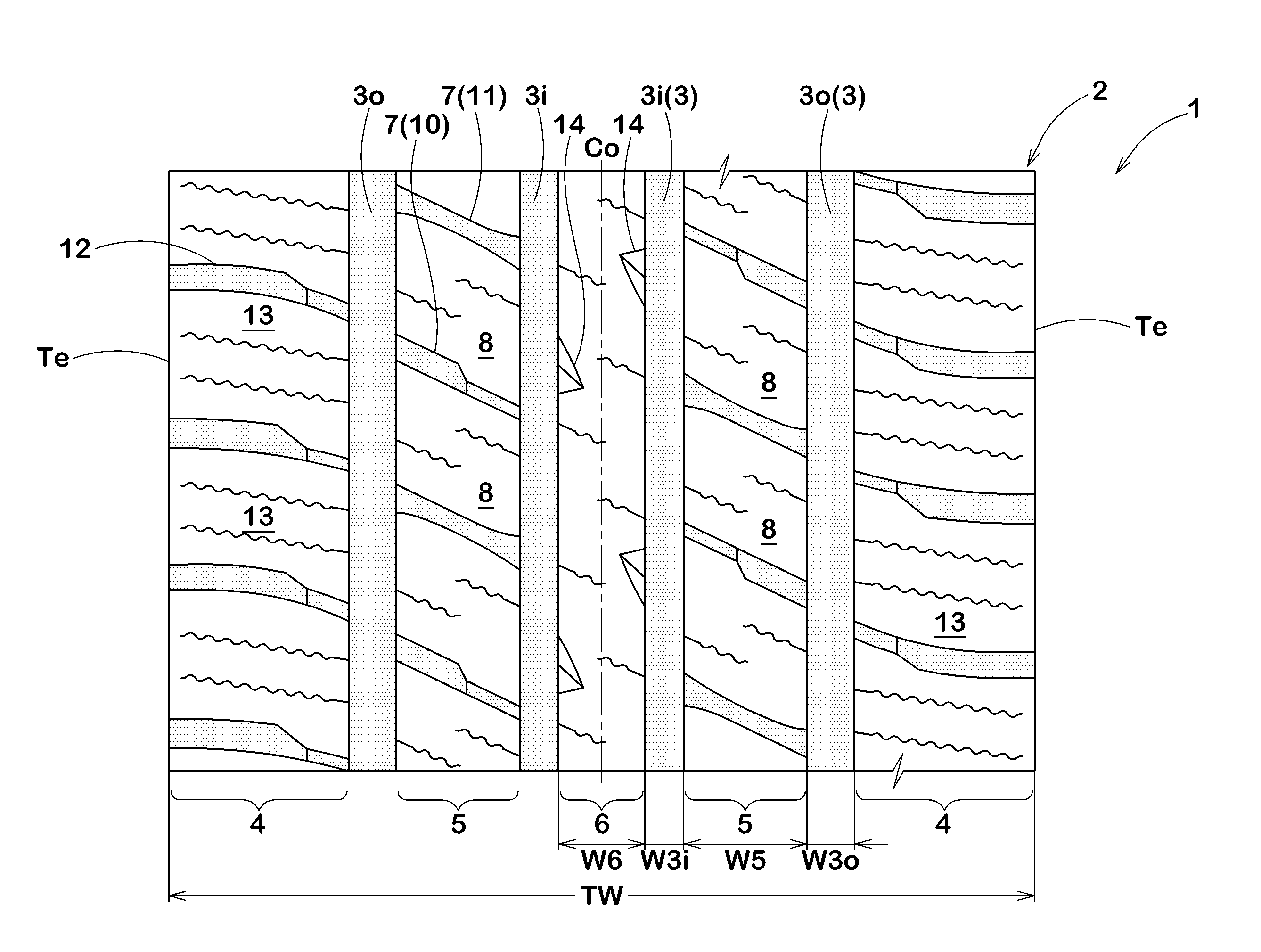

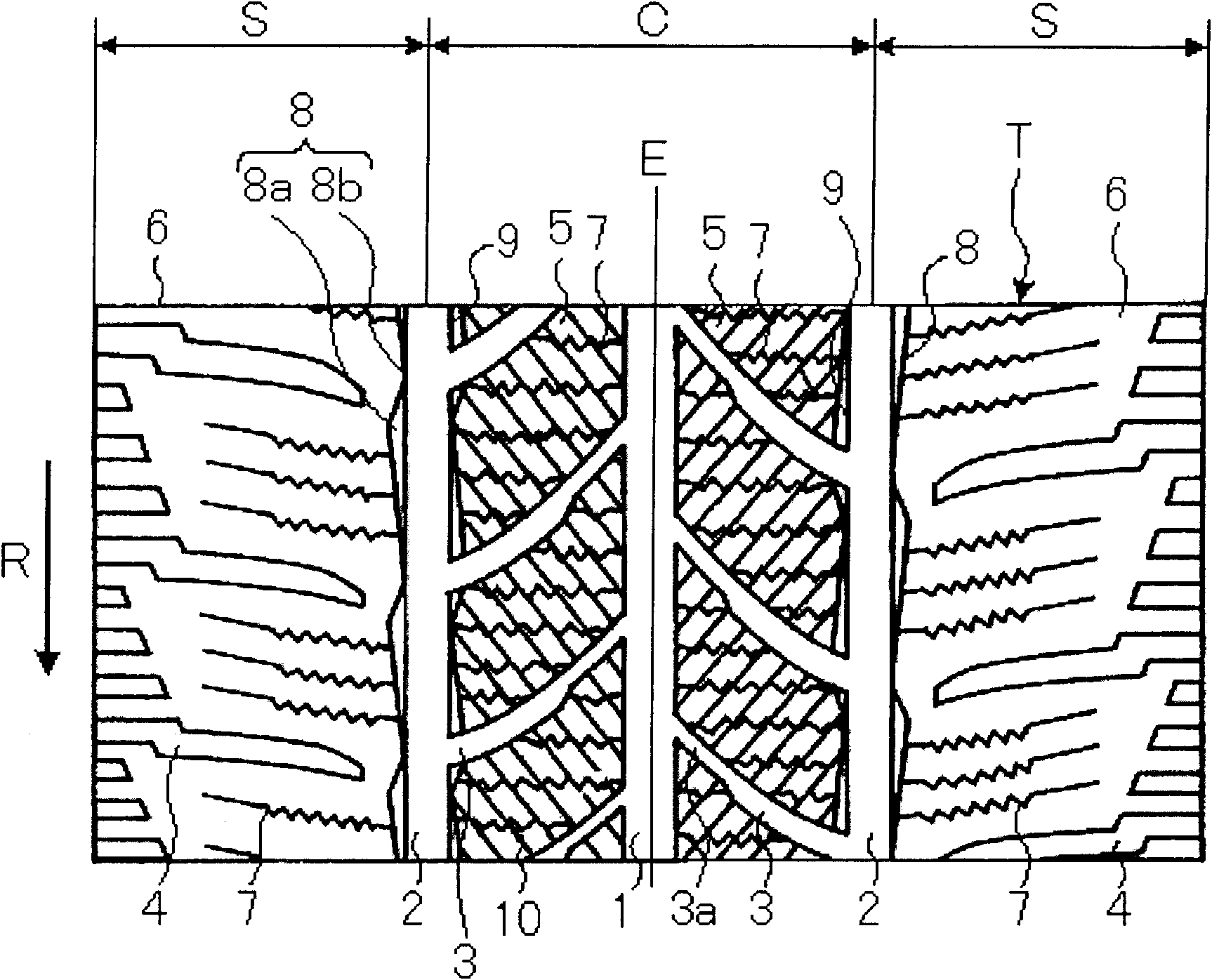

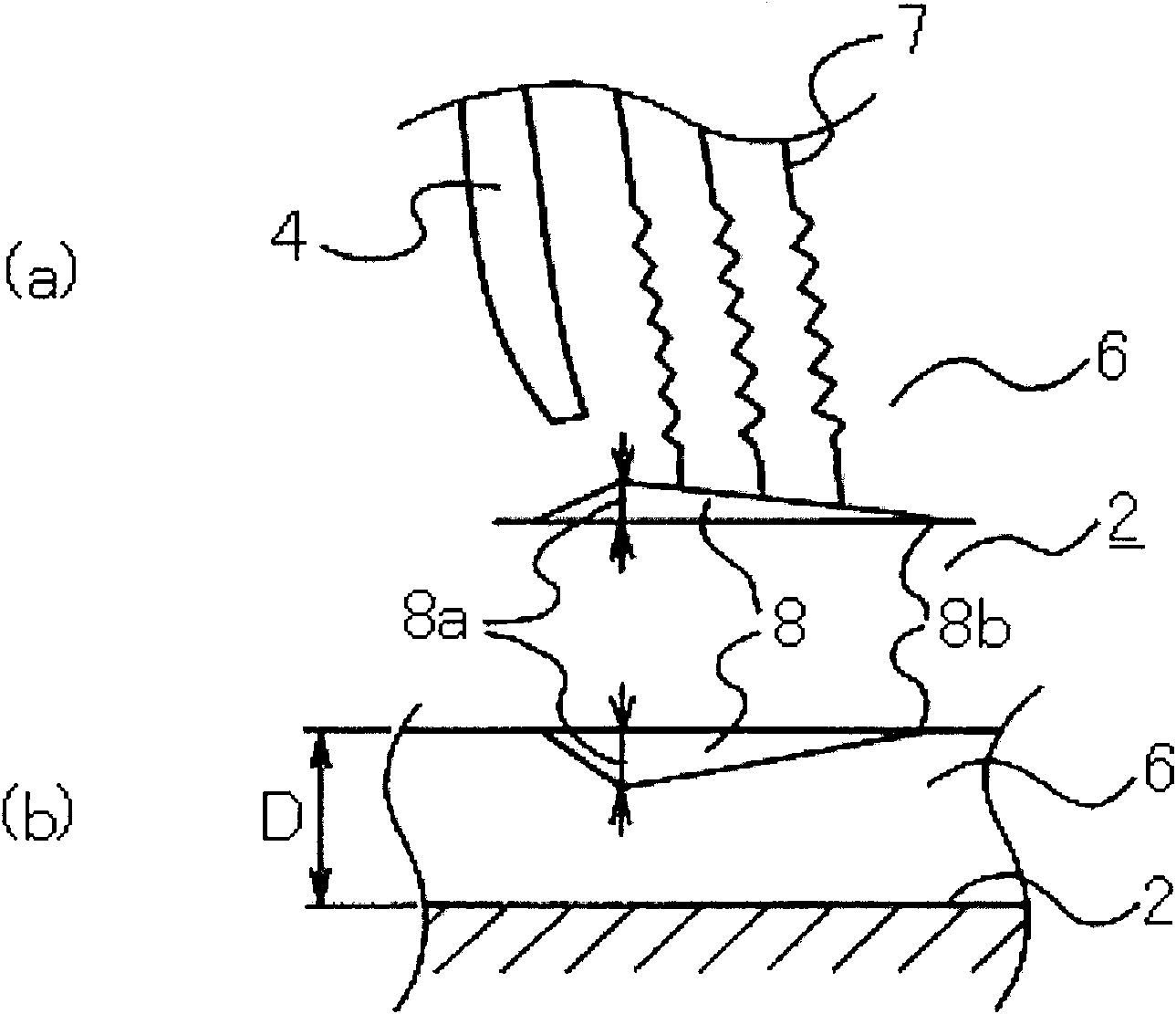

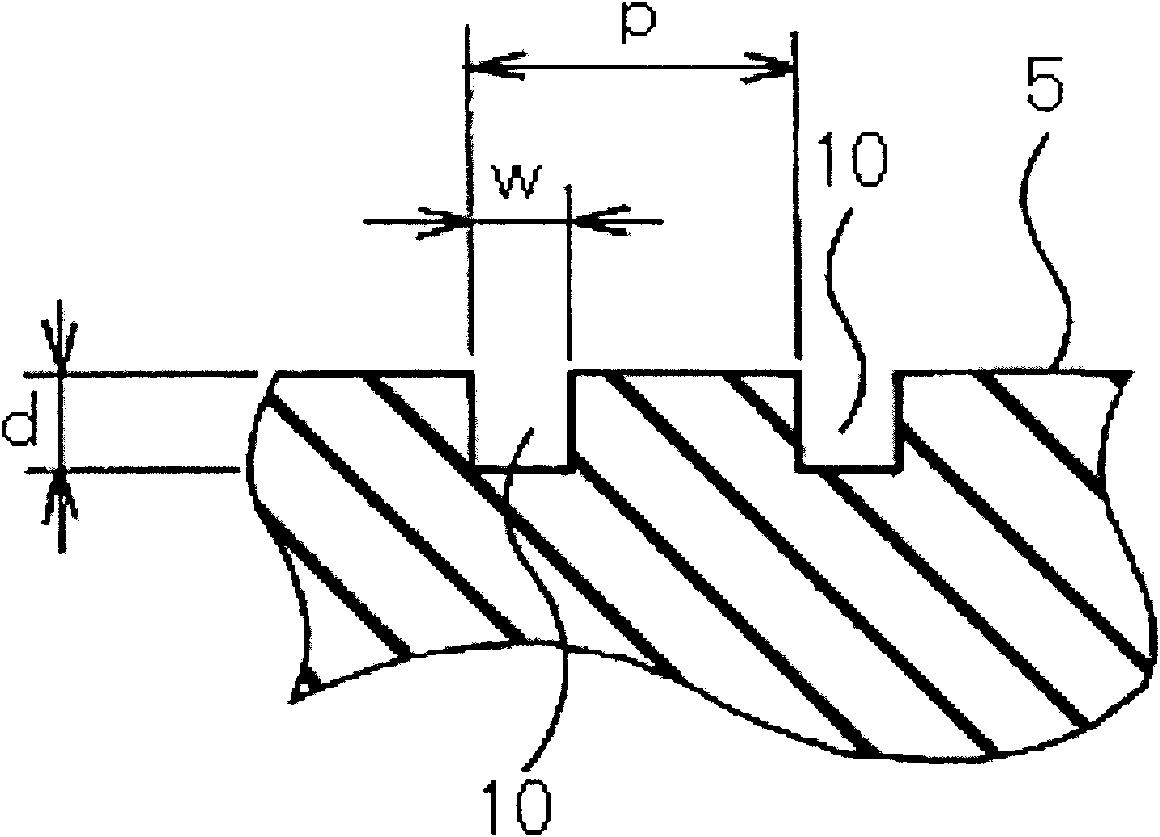

ActiveCN101811420AIncreased edge lengthEnhance the edge effectTyre tread bands/patternsEngineeringOperational stability

This invention provides a pneumatic tire with directional tread pattern which can improve the anti-irregular wear performance without reducing the snow operational stability. Said tire form a tread pattern array through the multiple main grooves (1,2) extending along the circumferential direction of the tire and the tread pattern groves(3) that slantingly communicates with the main grooves insidethe external main grooves (2). There arranged multiple cut pattern (7) in these pattern blocks (5), therefore, forming directional tread patterns which is characterized in that there formed half-closing tire pattern (4) and strip patterns(6) that are arranged with cut pattern (7) in the tire shoulder S outside the external main grooves (2), and there intermittently and continuously formed multiple chamfer section (8) in the inner edge of the strip patterns(6) along the tire width direction. Said chamfer section (8) has a shape, of which the chamfering valve is periodically changed along the circumferential direction of the tire.

Owner:THE YOKOHAMA RUBBER CO LTD

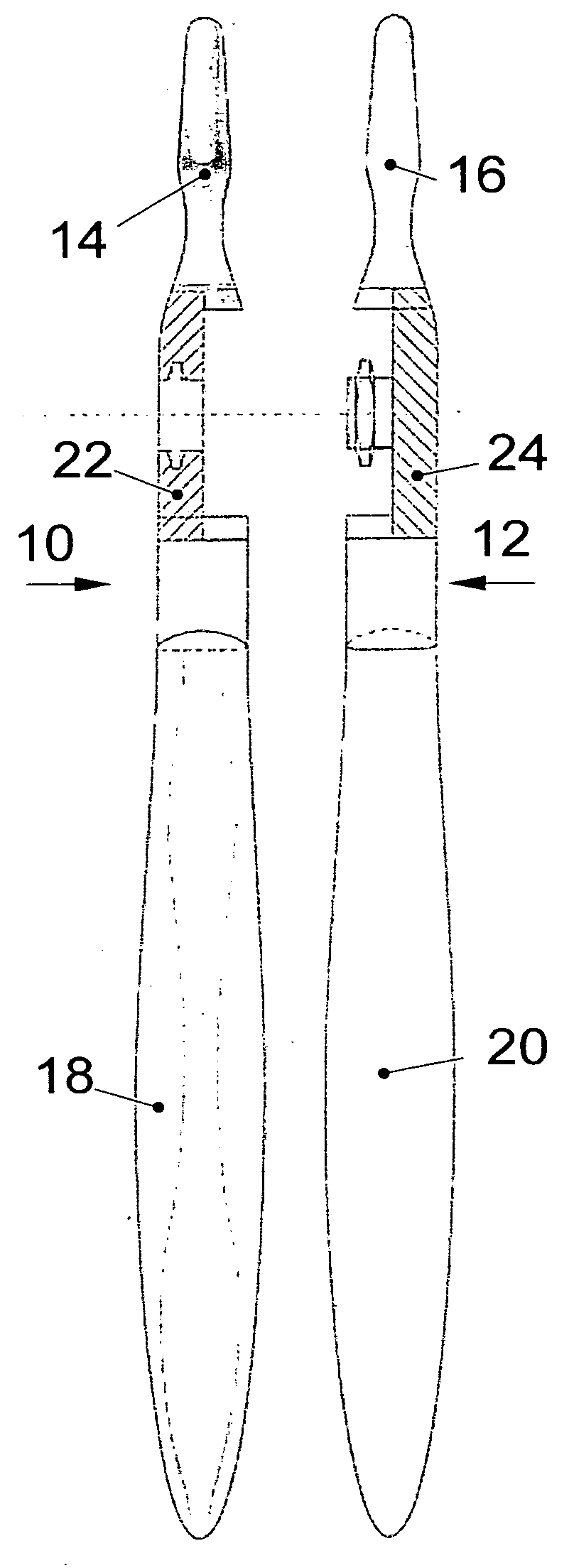

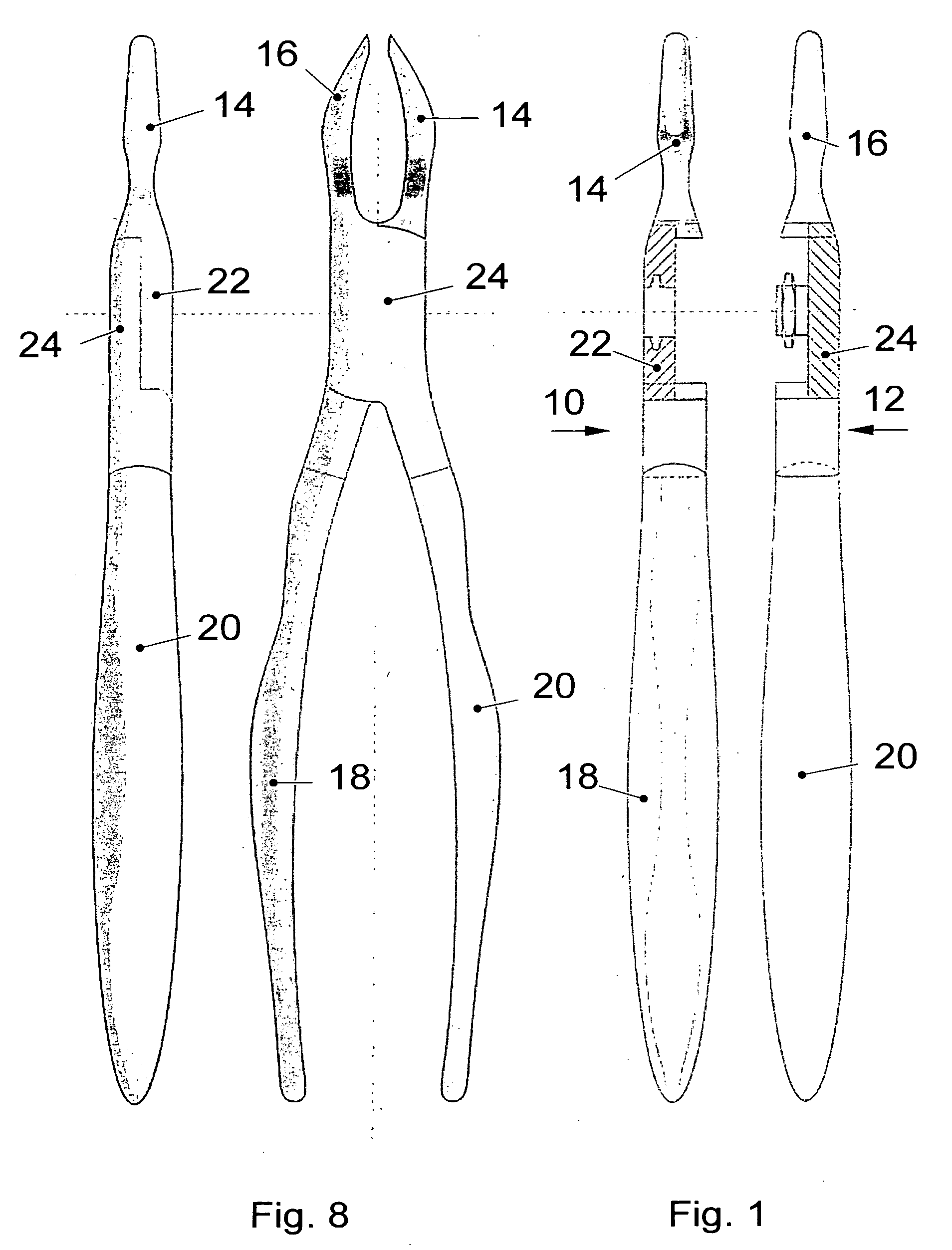

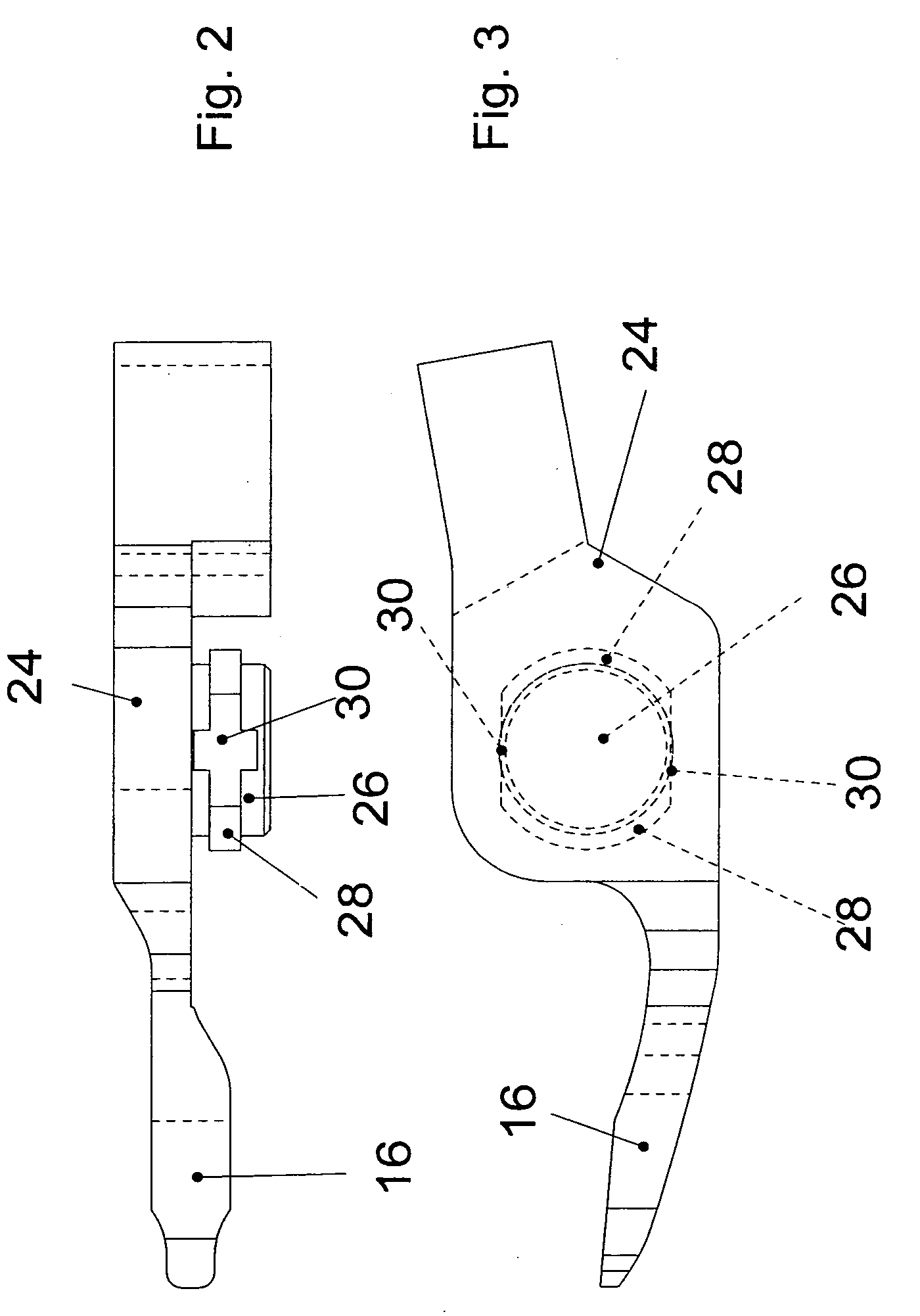

Dental pliers

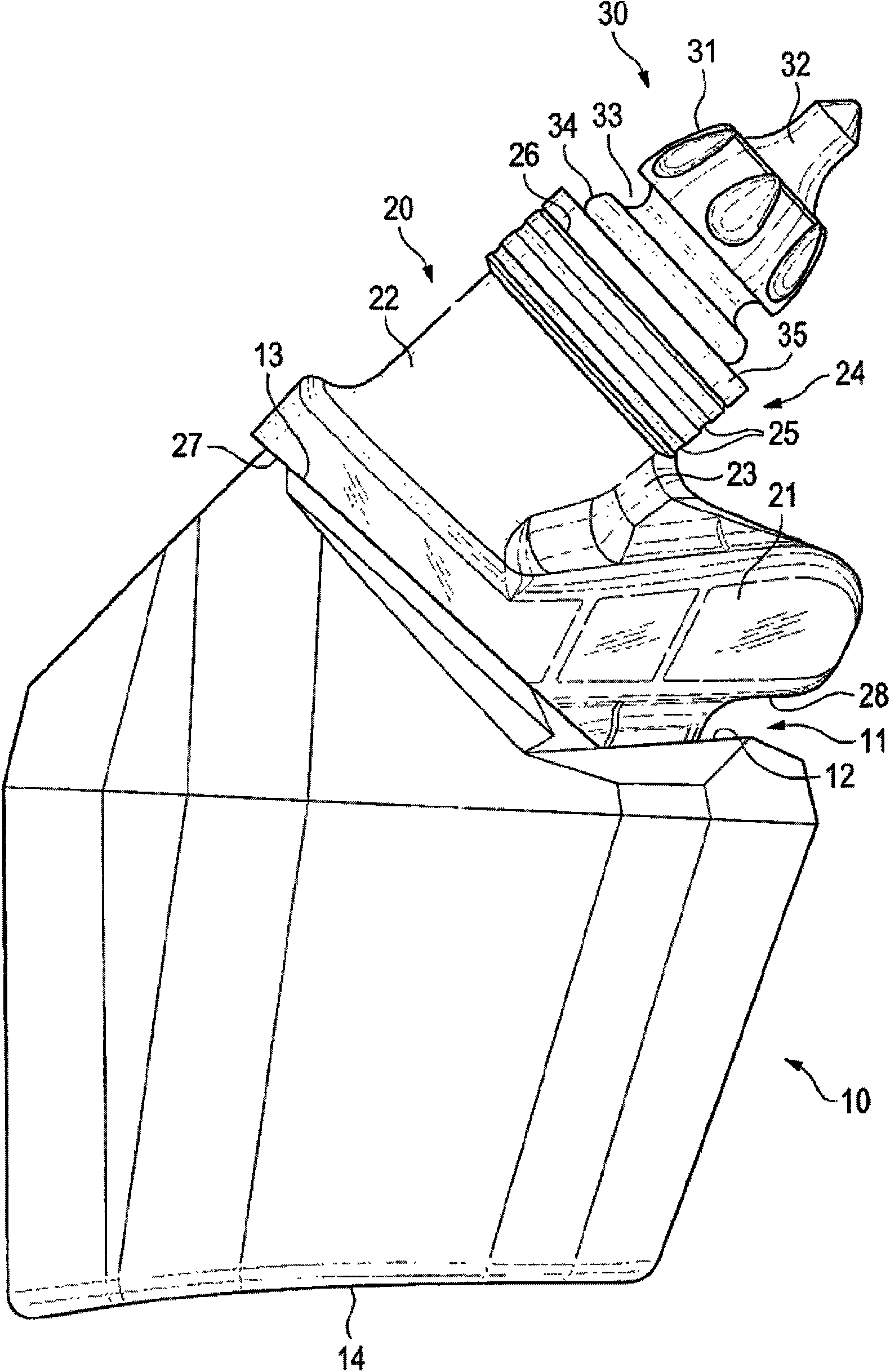

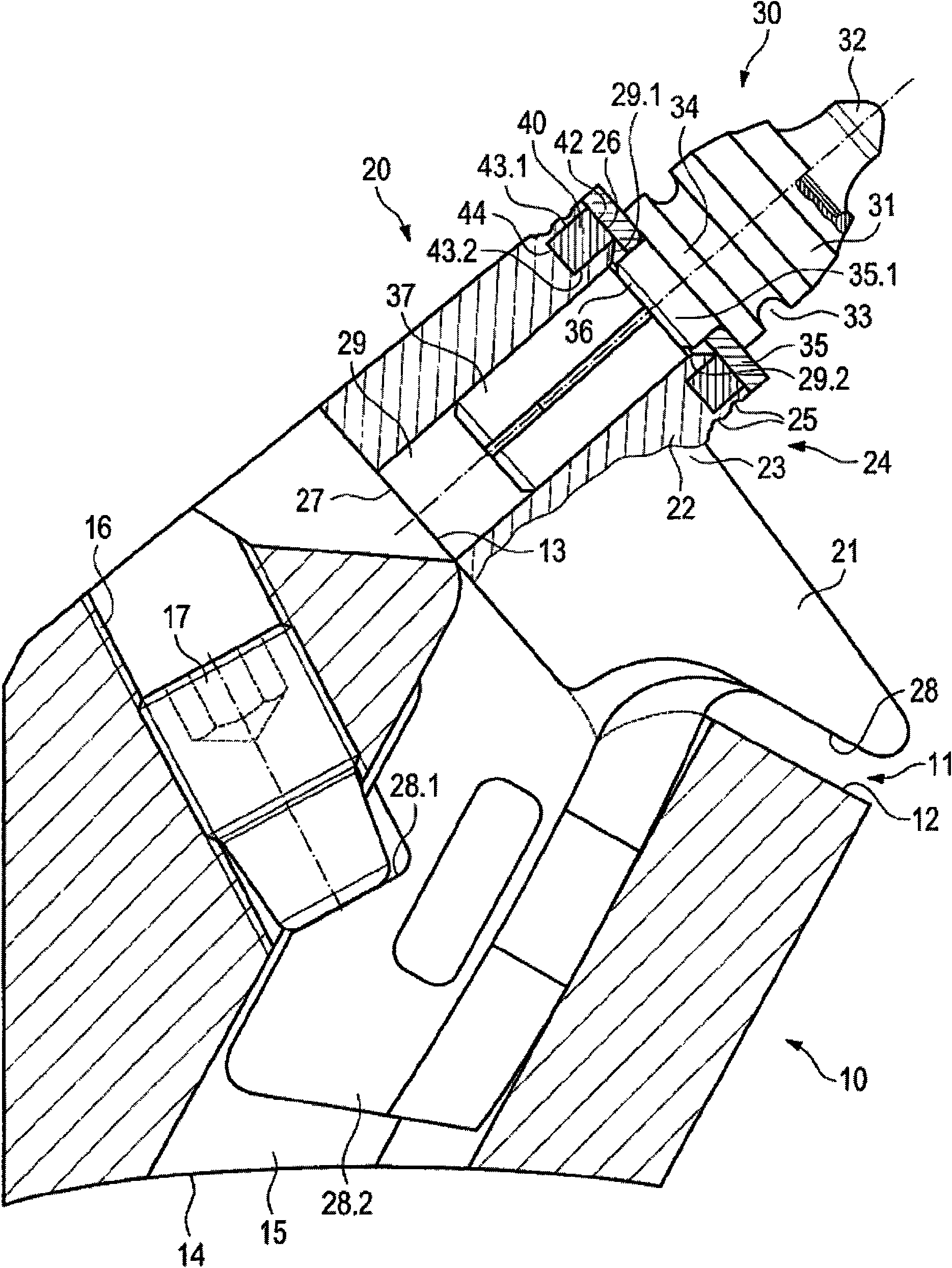

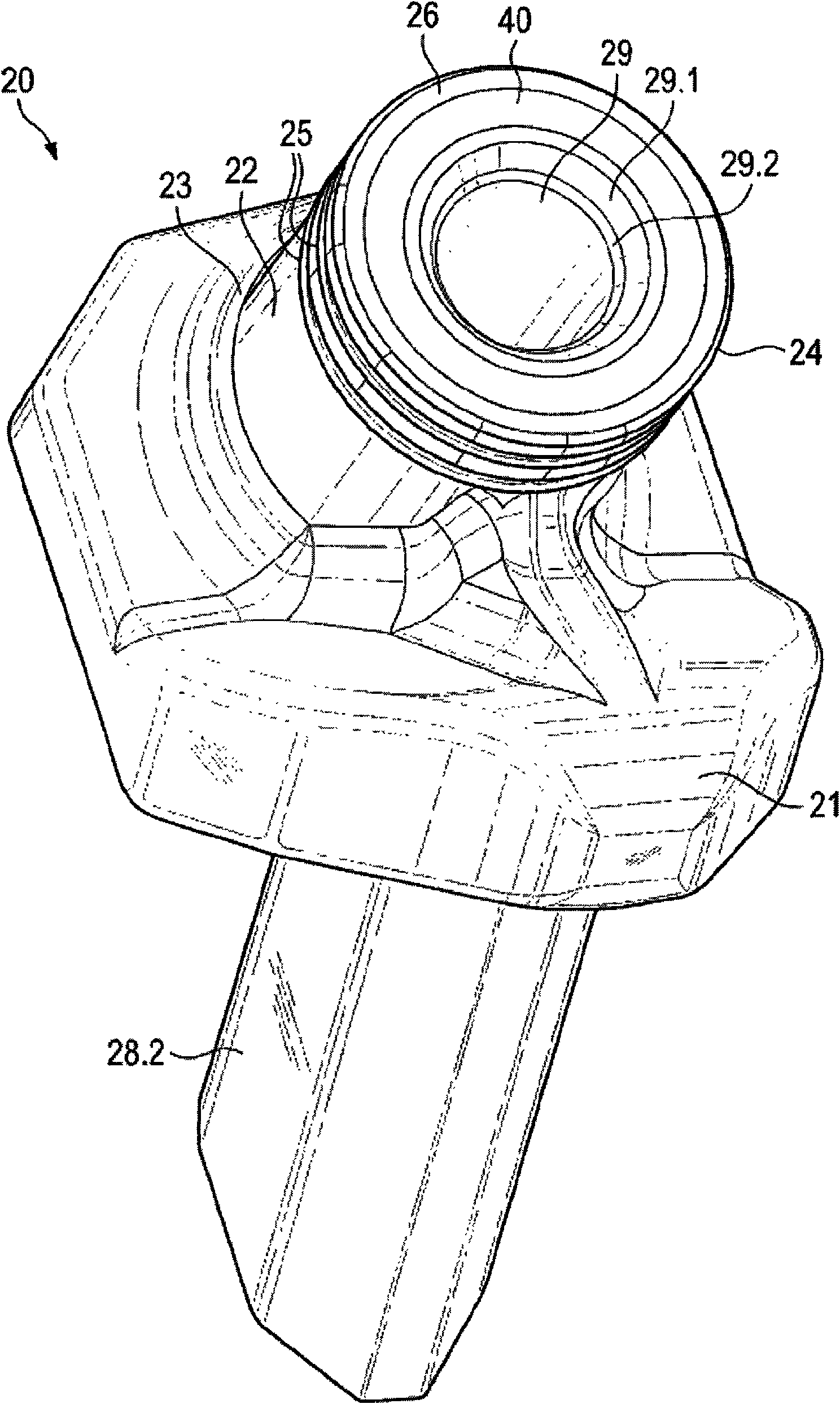

InactiveUS20050186536A1Reduce manufacturing costReduce material costsDentist forcepsDiagnosticsEngineeringLinkage concept

Dental pliers with two pliers parts, each respectively comprising one jaw of a pliers mouth and one lever arm of a pliers grip, the pliers parts pivotably connected with each other via a linkage. The linkage includes a cylindrical journal (26) on the first pliers part (12) coaxial to the pivot axis, which engages in a cylindrical bore (32) on the other pliers part (10) coaxial to the pivot axis having the same diameter, and is rotatable in this bore (32) about the pivot axis. The journal (26) and the bore (32) are axially located form-fittingly via at least one circumferential tab (28) and one circumferential groove (34). The at least one circumferential tab (28) extends only over a partial angular area of the circumference. At least one entry segment (36) corresponding to the cross-sectional shape of the circumferential tab (28) leads axially to the circumferential groove (34). The at least one circumferential tab (28) and the at least one entry segment (36) are so oriented in their angular orientation in the respective linkage area (22) or as the case may be (24), that these come into registry with each other in the open or spread position of the pliers parts (10, 12), and the at least one circumferential tab (28) can be introduced into the circumferential groove (34) through the entry segment (36) or as the case may be removed therefrom, while in the other spread positions of the pliers parts (10, 12) the at least one circumferential tab (28) engages in the circumferential groove (34) and is held form-fittingly axially therein.

Owner:INTEGRA YORK PA

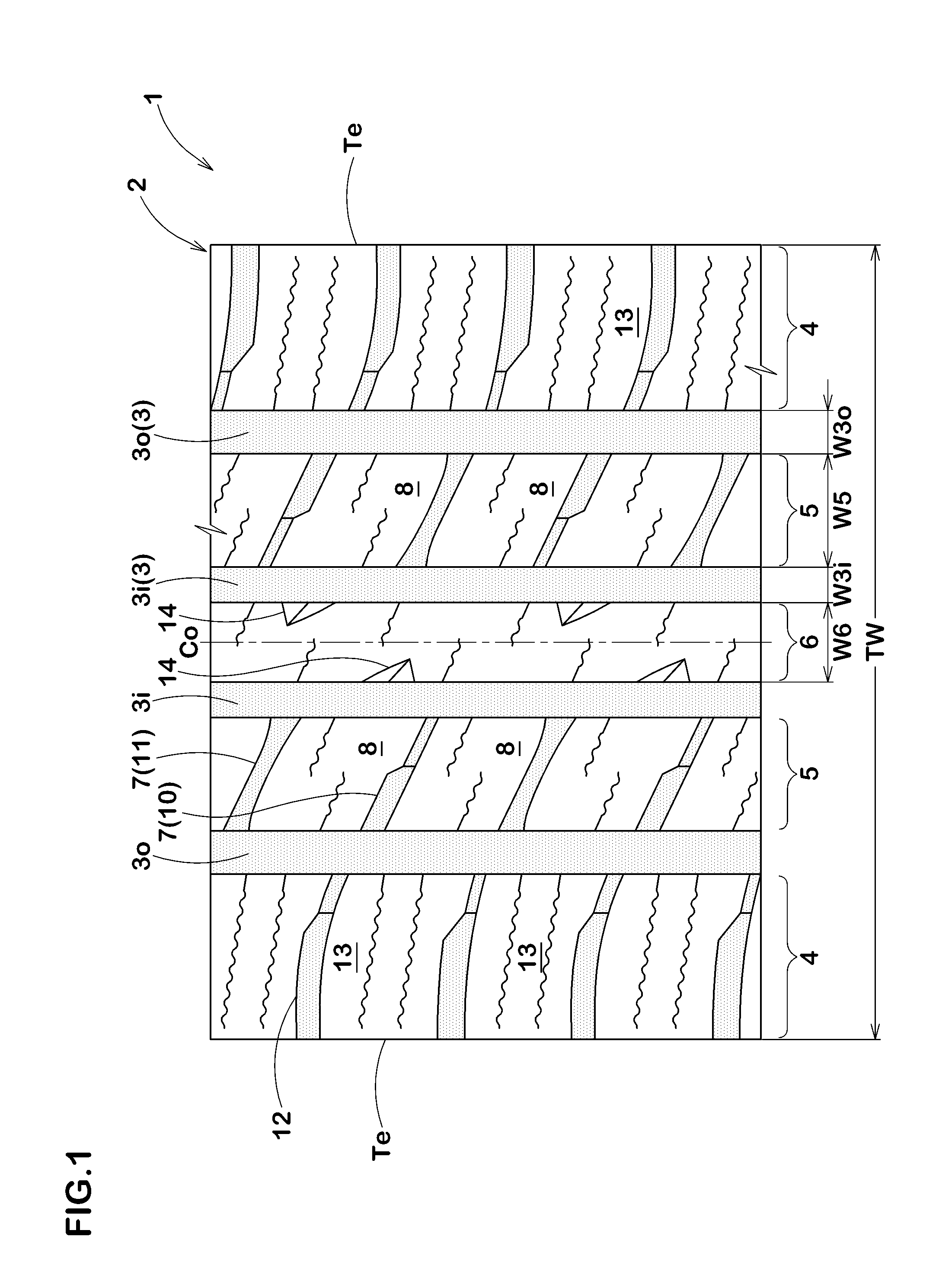

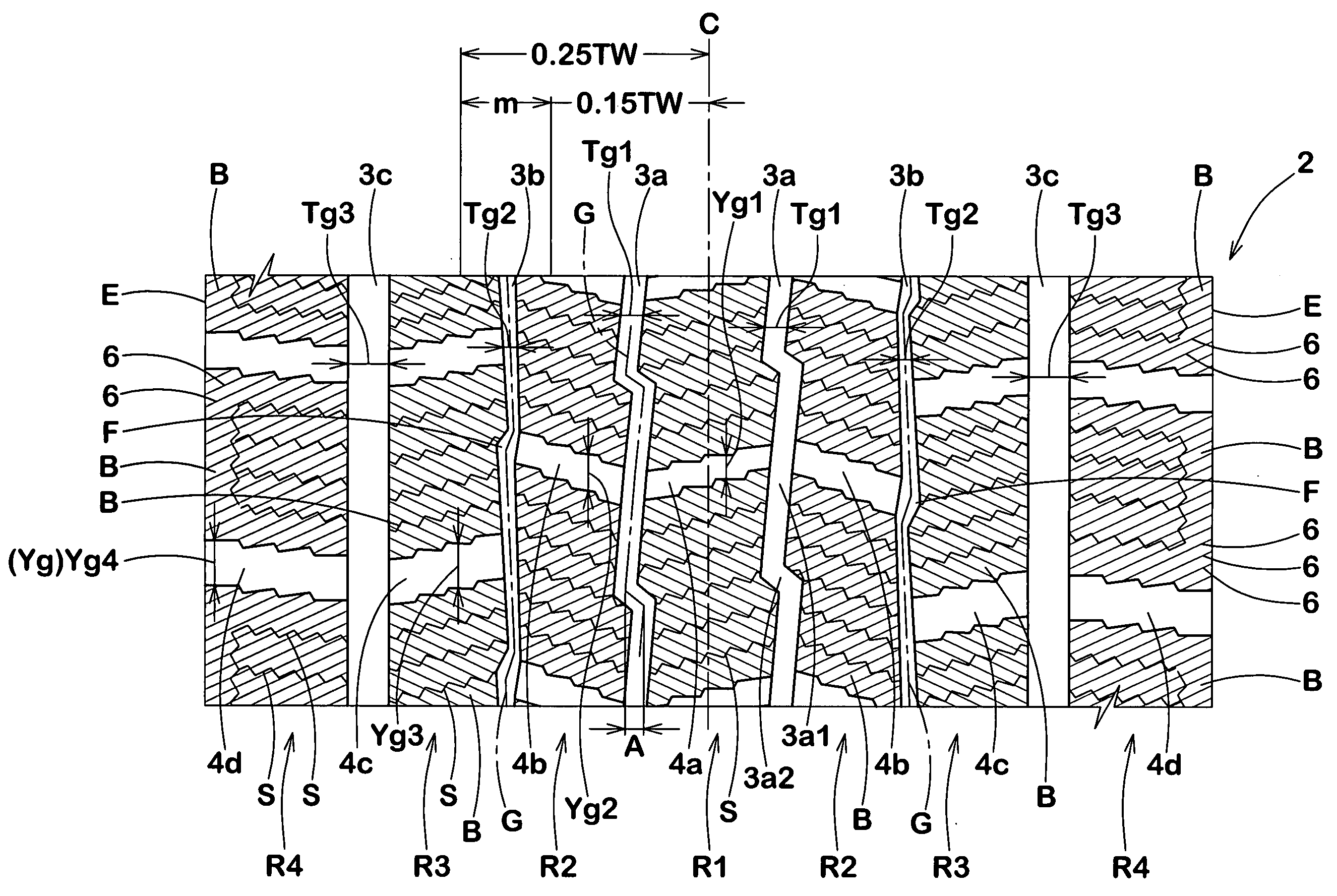

Studless tire

InactiveUS20080202658A1Reduce coefficient of frictionIncrease friction forceTyre tread bands/patternsNon-skid devicesGround contactShoulder region

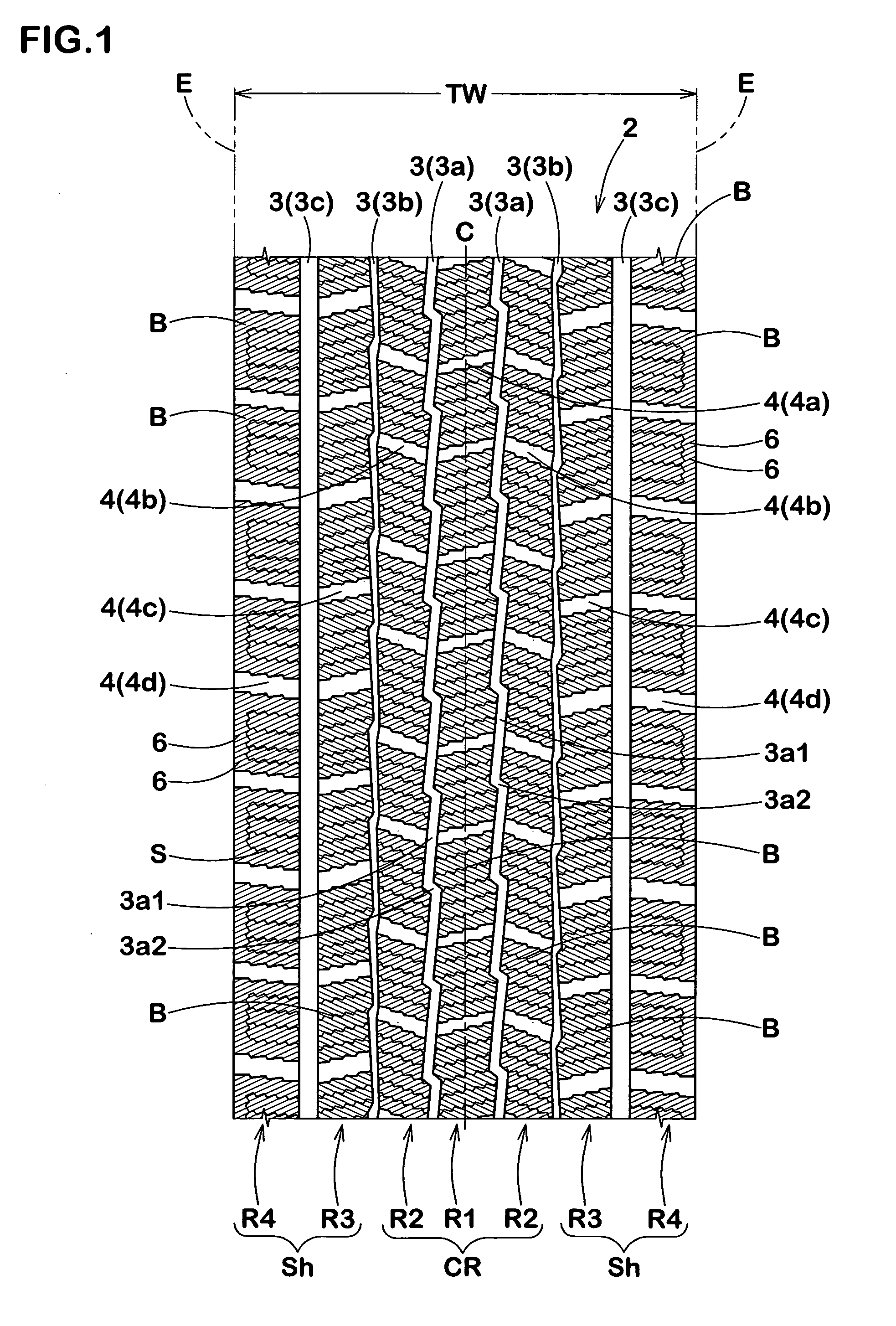

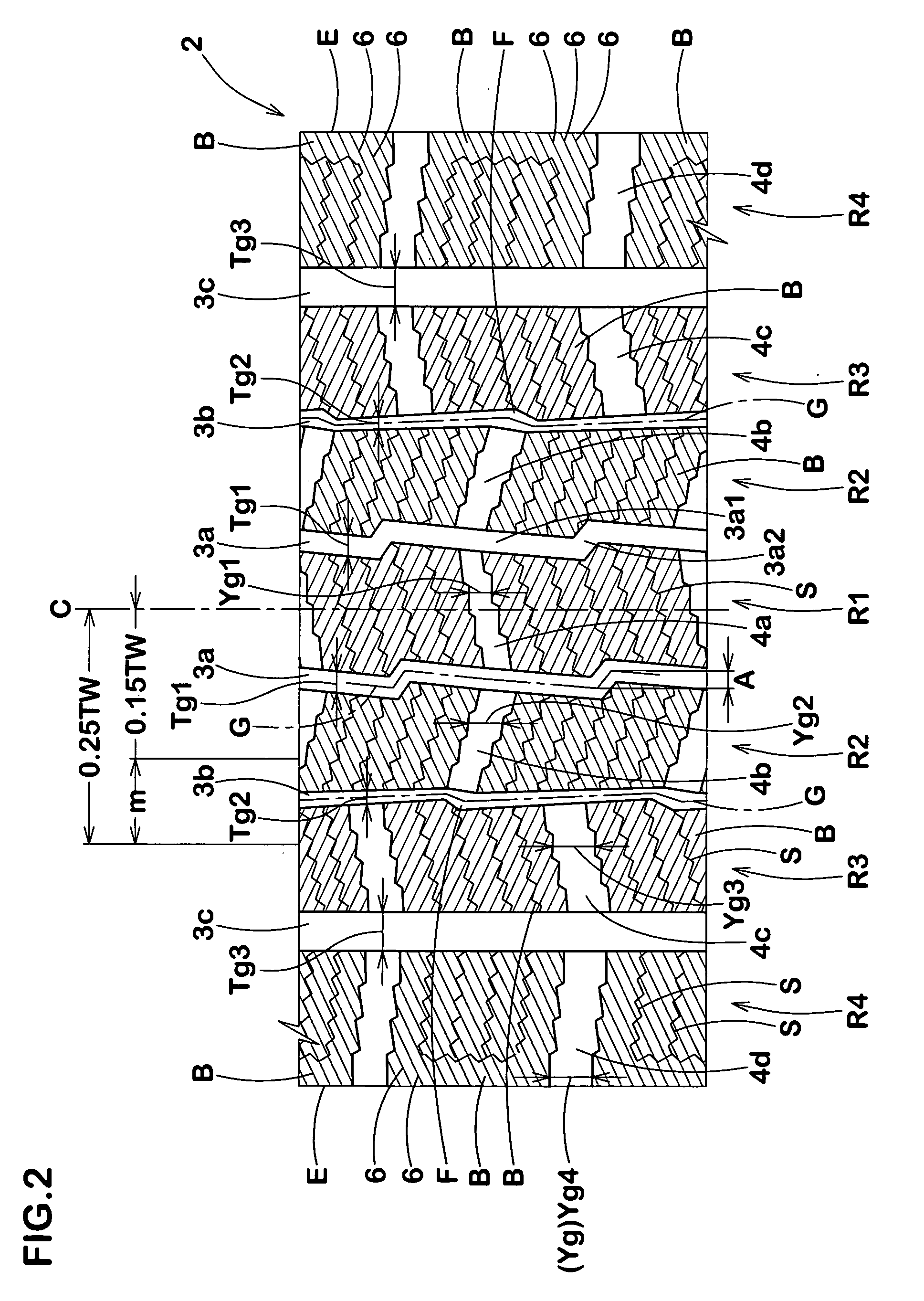

A studless tire capable of exhibiting excellent performances on both icy road and snow-covered road, including tread portion 2 having a pair of middle circumferential grooves 3b each extending in a region between 15% and 25% of tread width TW from tire equator C to provide crown region CR between the middle grooves 3b and a pair of shoulder regions Sh between the middle groove 3b and ground contact edge E, wherein the crown region CR includes rows R1, R2 of blocks B having sipes S and defined by zigzag inner circumferential grooves 3a and crown lateral grooves 4a, 4b, each shoulder region Sh includes rows R3, R4 of blocks B having sipes S and defined by linear outer circumferential grooves 3c and shoulder lateral grooves 4c, 4d, and groove area rate Gs (%) of shoulder regions Sh is larger than groove area rate Gc (%) of crown region CR so that the difference (Gs−Gc) is from 3 to 7%.

Owner:SUMITOMO RUBBER IND LTD

Brake disk producing method and brake disk

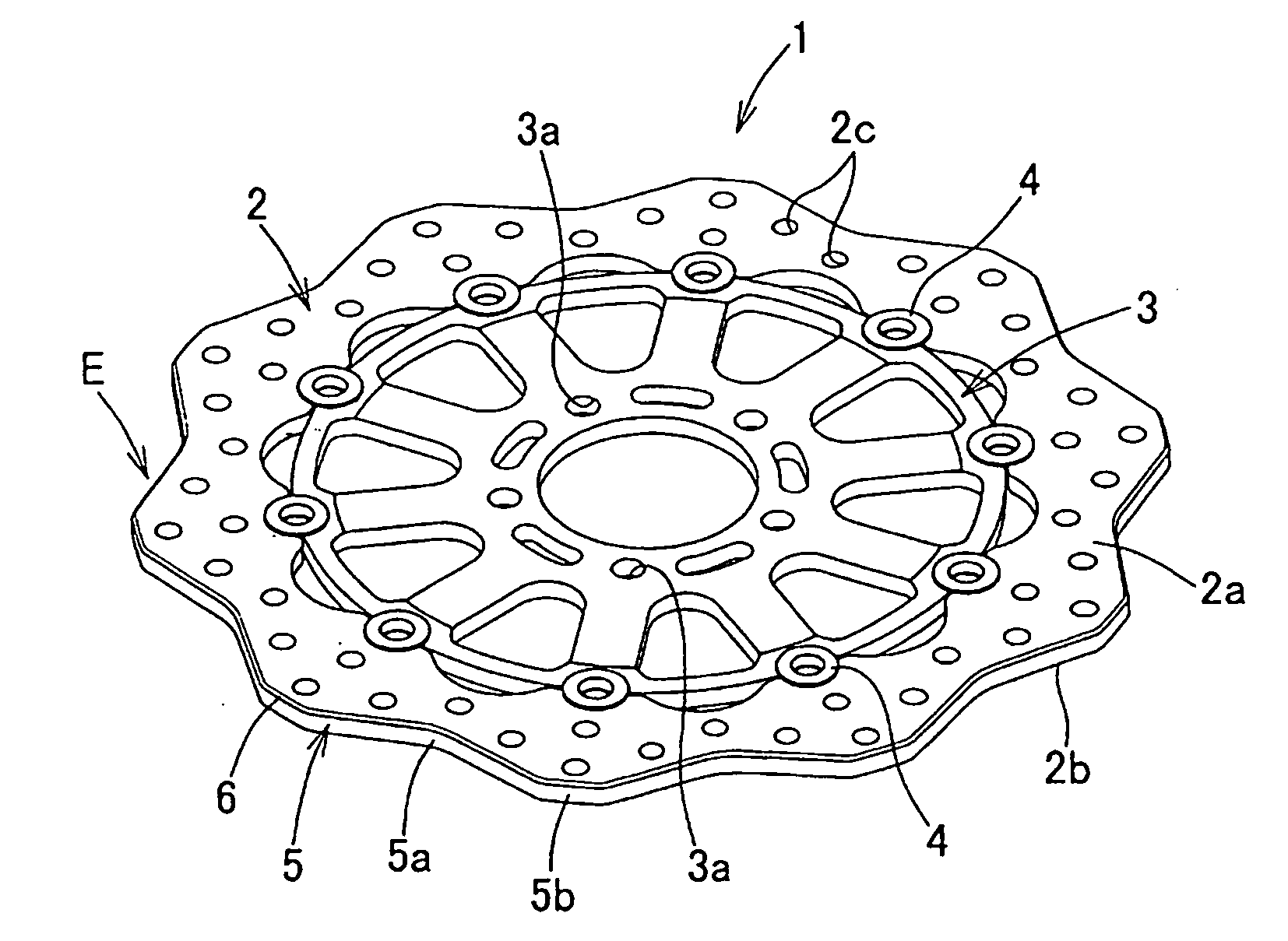

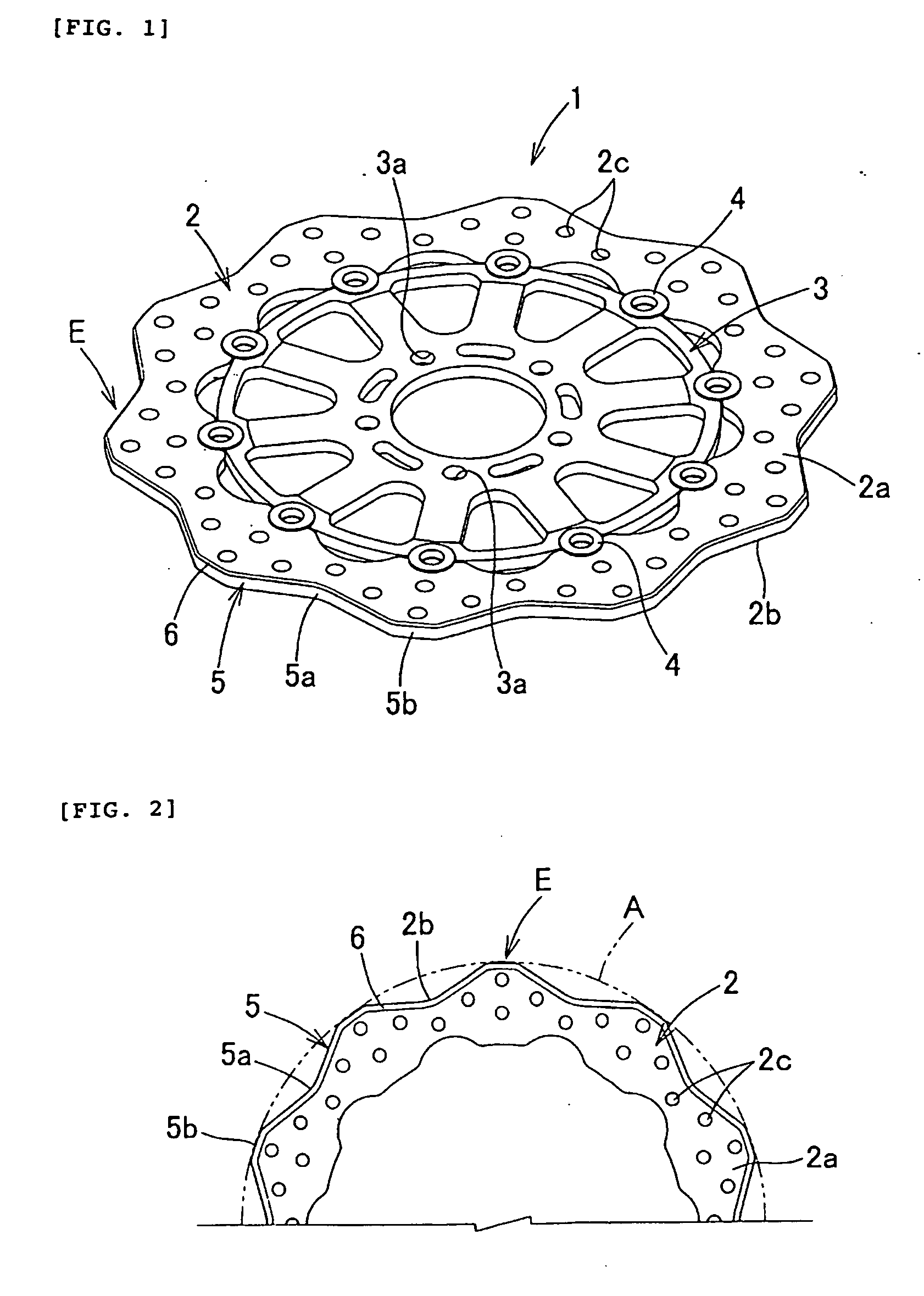

InactiveUS20070102247A1Avoid uneven wearReduce wearBraking discsFriction liningMoment of inertiaEngineering

A brake disk producing method, comprising a periphery pressing step for forming an outer peripheral shape (5) of a rotor plate (2) into a peripheral shape having recesses and ridges (5a, 5b) repeated in a radial direction, and a chamfering step for forming a chamfered surface (6) by pressing, against a corner portion (2d) on an outer peripheral edge of the rotor plate (2), a die (7), and a brake disk made by the method. Accordingly, it is possible to improve heat radiation capability, reduce the weight and moment of inertia, improve safety in handling, and suppress increase in production costs. Furthermore, by forming the chamfered surface (6), the amount of wear of a brake pad pressed by the brake disk (1) can be reduced, and durability of braking performance can be maintained or improved.

Owner:SUNSTAR GIKEN KK

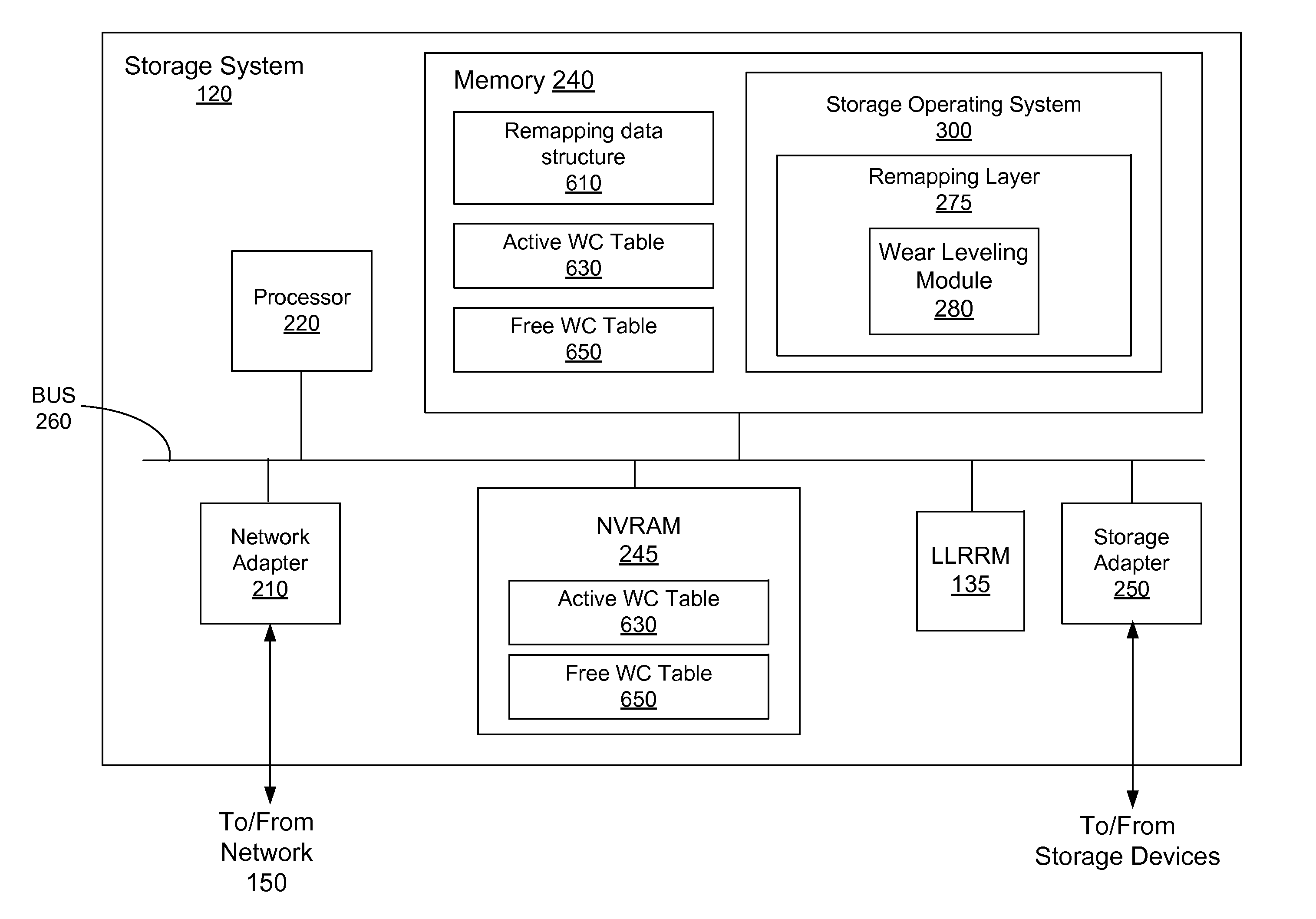

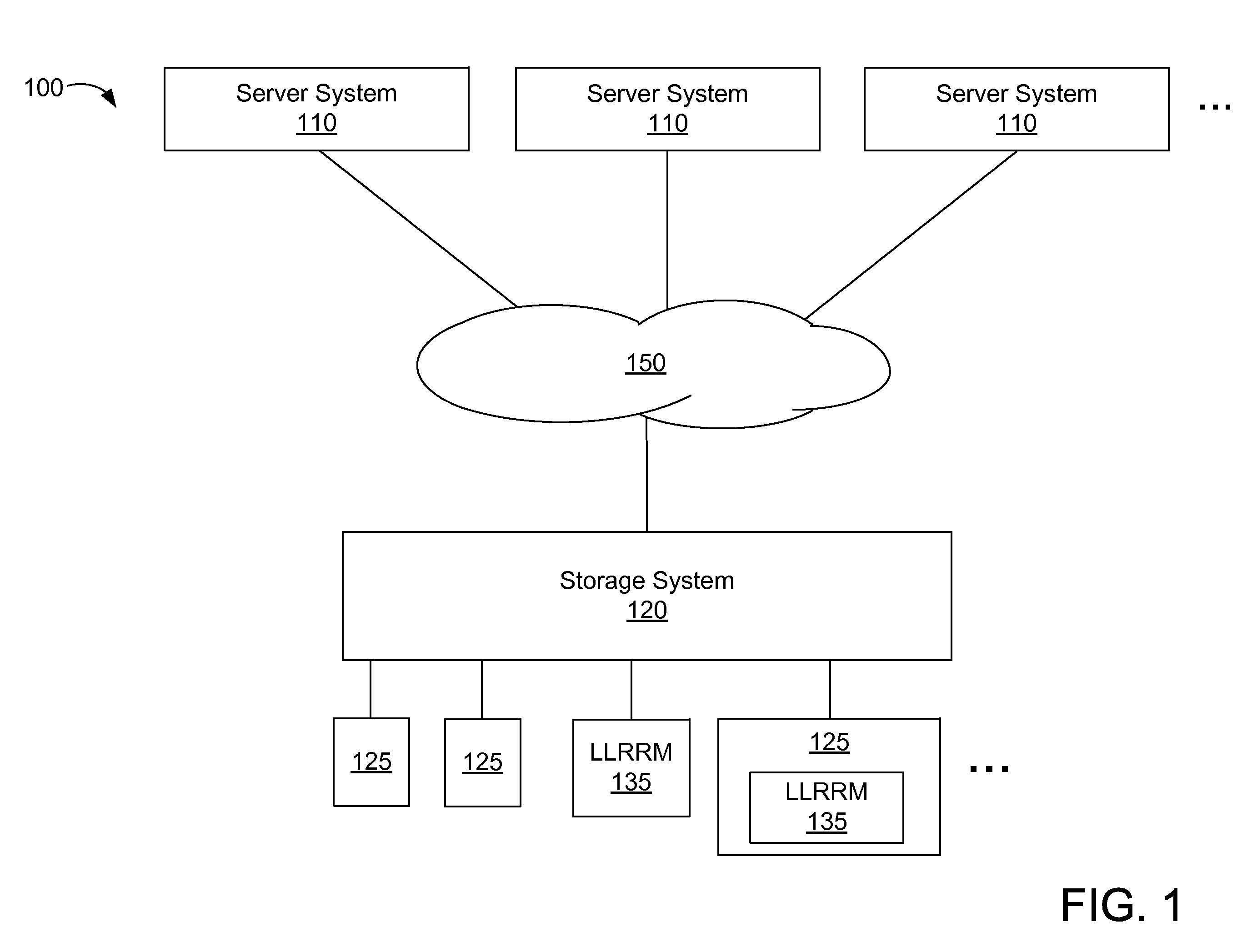

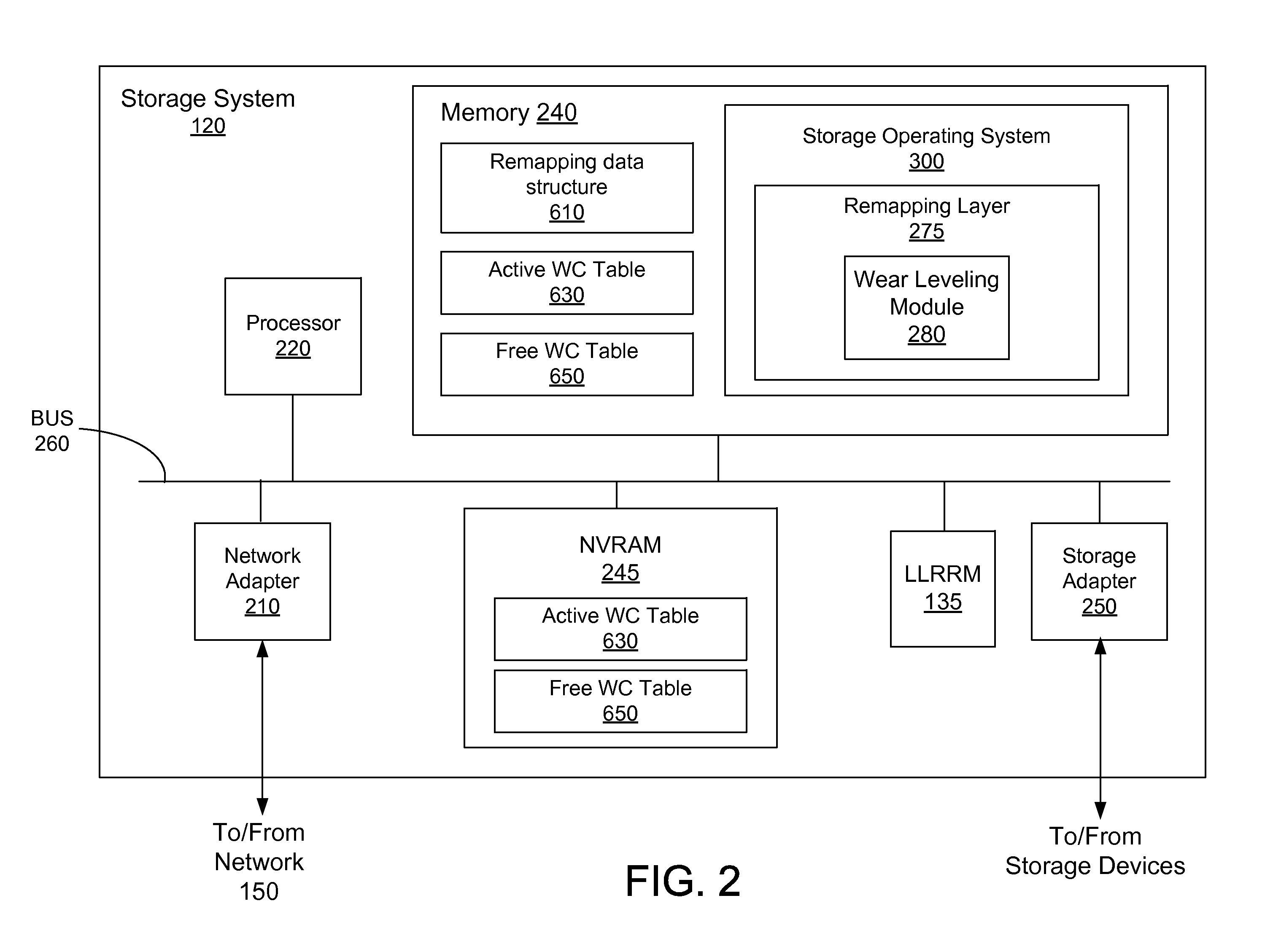

Wear leveling for low-wear areas of low-latency random read memory

ActiveUS20110271046A1Low wear countReduce current rate of wearMemory architecture accessing/allocationError detection/correctionLatency (engineering)Data content

Described herein are method and apparatus for performing wear leveling of erase-units of an LLRRM device that considers all active erase-units. Wear counts of all active erase-units (containing client data) and free erase-units (not containing client data) are tracked. Wear counts are used to determine low-wear active erase-units having relatively low wear counts and high-wear free erase-units having relatively high wear counts. In some embodiments, data contents of low-wear active erase-units are transferred to high-wear free erase-units, whereby the low-wear active erase-units are converted to free erase-units and may later store different client data which may increase the current rate of wear for the erase-unit. The high-wear free erase-units are converted to active erase-units that store client data that is infrequently erased / written, which may reduce the current rate of wear for the erase-unit. As such, wear is spread more evenly among erase-units of the LLRRM device.

Owner:NETWORK APPLIANCE INC

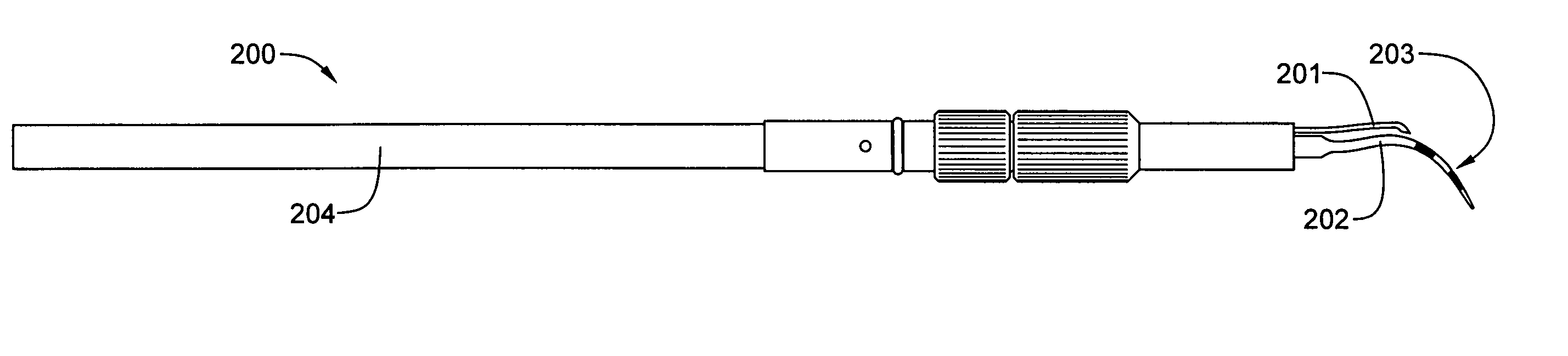

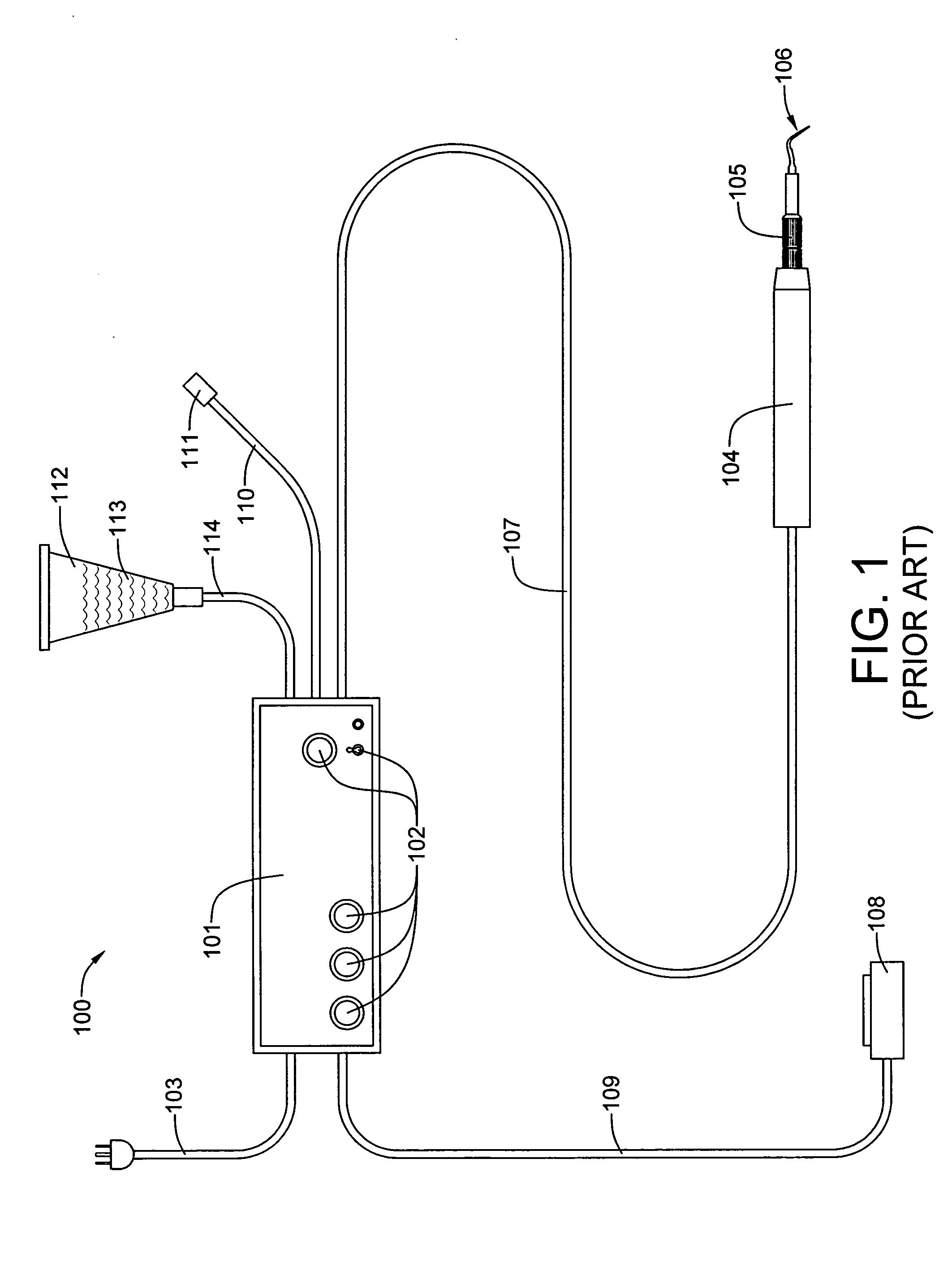

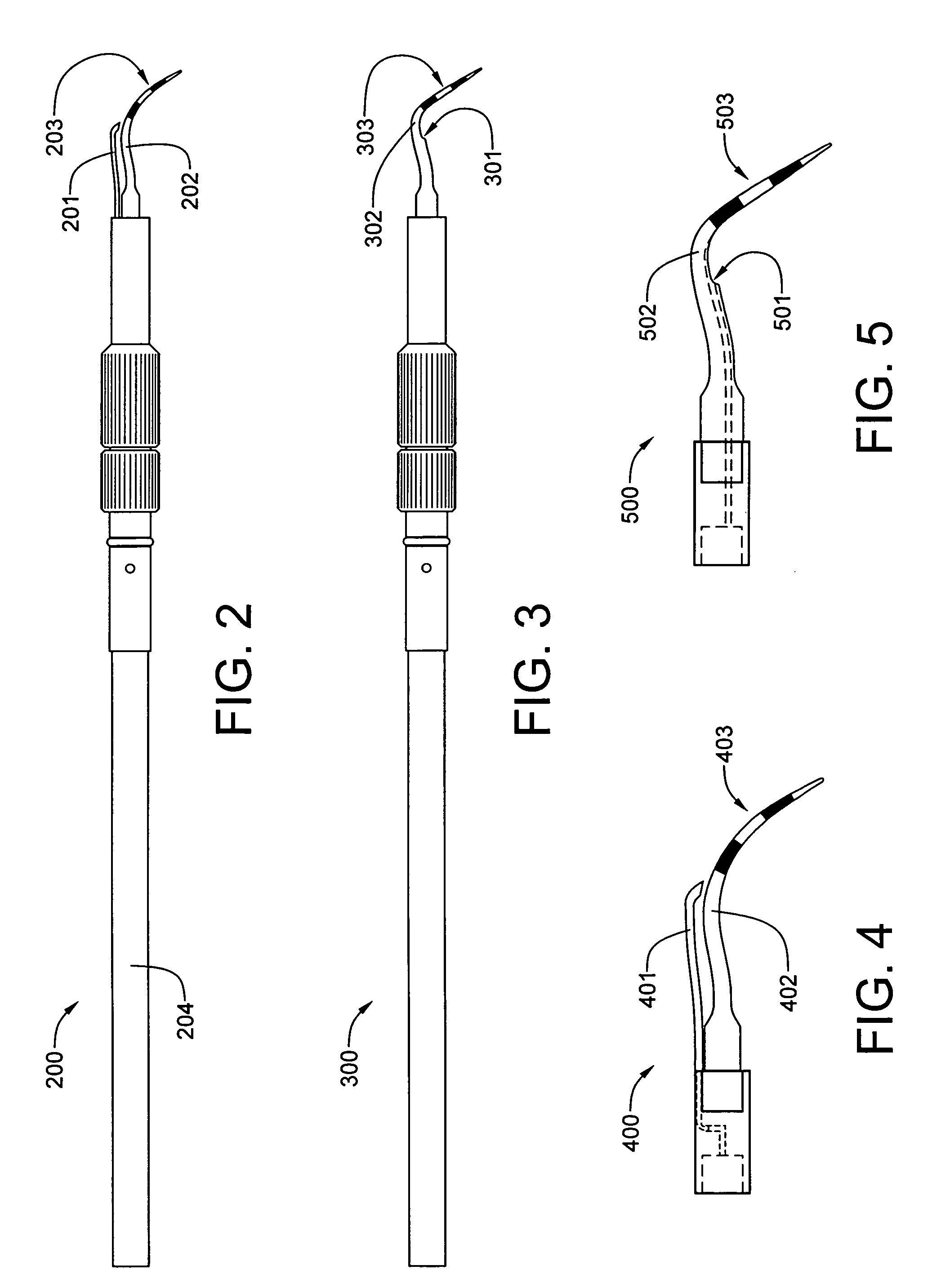

Ultrasonic scaler tip incorporating a depth gauge

InactiveUS20050181328A1Accurate judgmentAvoid damageTooth pluggers/hammersCleaning using liquidsMulti bandUltrasonic scaler

An ultrasonic scaler tip incorporating a multi-banded depth gauge allows a dental professional to more accurately judge the position of the tip with respect to the location of live tissue and alveolar bone. A typical cleaning operation would involve a two step process, with the depths of pockets being measured with a dental probe tip, the depths noted, and subsequently referred to during a cleaning of the teeth. The depth gauge is fabricated of durable coatings so as to be able to withstand the harsh conditions to which it will be repeatedly subjected. The banded scaler tip of the present invention may be fabricated in various ways. For a preferred embodiment, very thin bands of a dark-colored cylindrical bands are created on the tip. The entire tip is then covered by a transparent wear-resistant coating.

Owner:MILNE STEPHANIE C

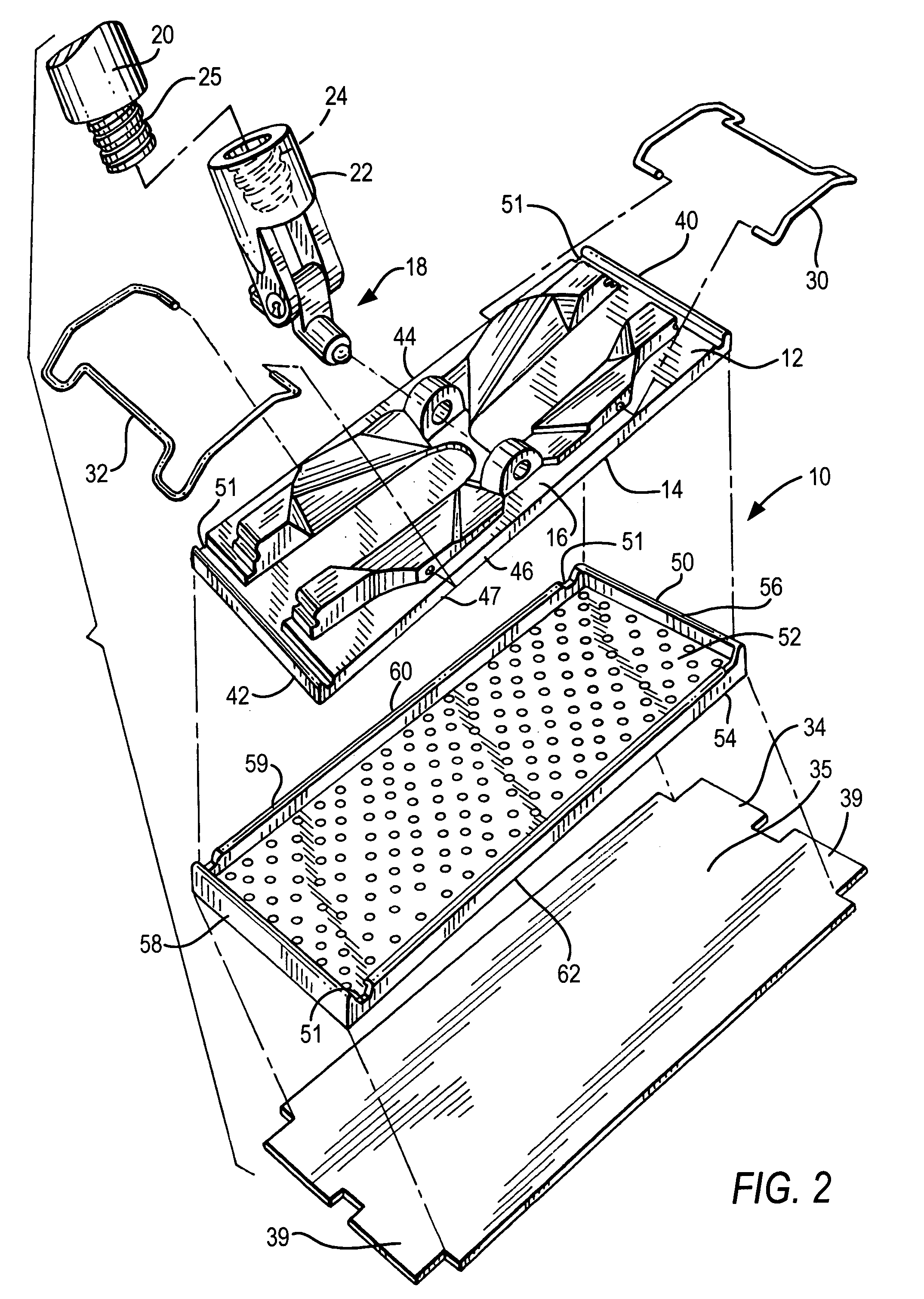

Sanding apparatus with molded elastomeric pad

ActiveUS7488242B2Avoid problemsThicker and wider and more secureAbrasion apparatusPortable grinding machinesSanderThermoplastic elastomer

A sander comprises a body member molded of polypropylene to which a soft pad member is integrally molded or directly bonded thereto. Preferably, the material comprising the pad member is of a thermoplastic elastomer material, such as Santoprene®. Significantly, when the pad member is molded directly to the body member, the pad has internal dimensions only slightly larger than the external dimensions of the body member so that, when the body member is located within the confines of the pad member, a secure fit is formed between these two members, without any space between them. Further, the respective dimensions of the body member and pad member give the sander a thick, one-piece appearance in side and end views. The pad member may also include a plurality of openings which help provide a “spongy” effect to the user, smoothing the peaks and reaching the valleys of an uneven surface upon which the sander is utilized.

Owner:ALLWAY TOOLS

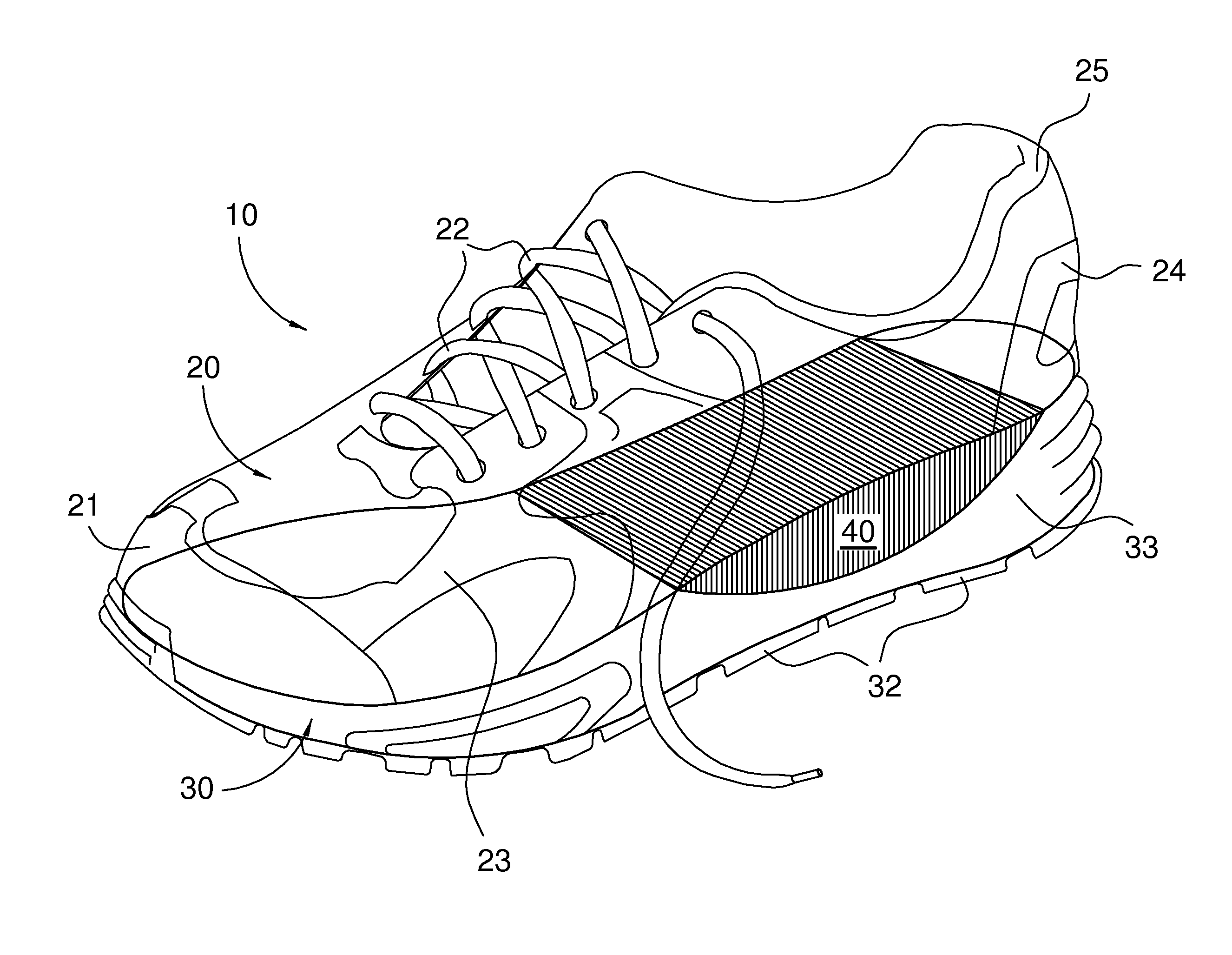

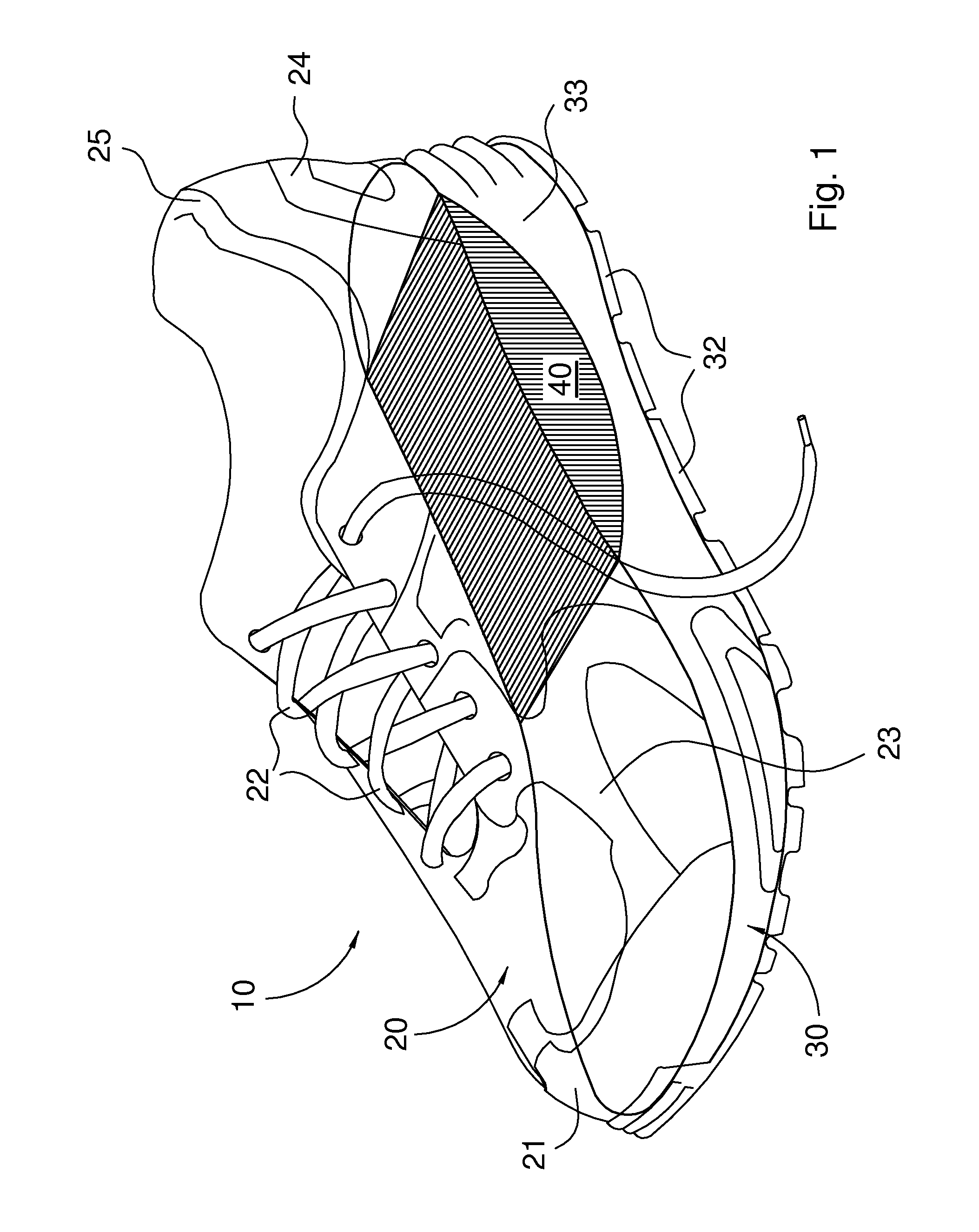

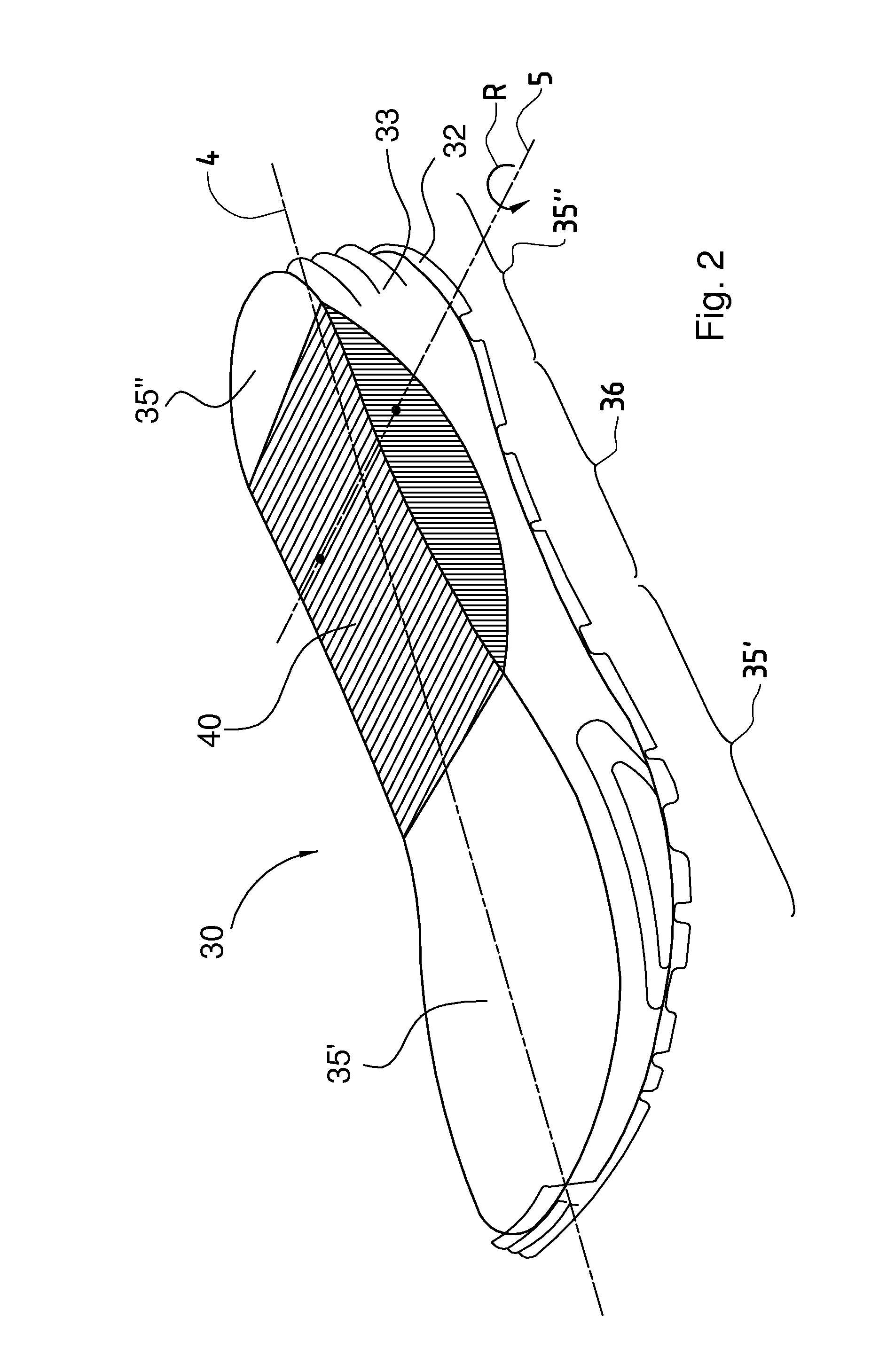

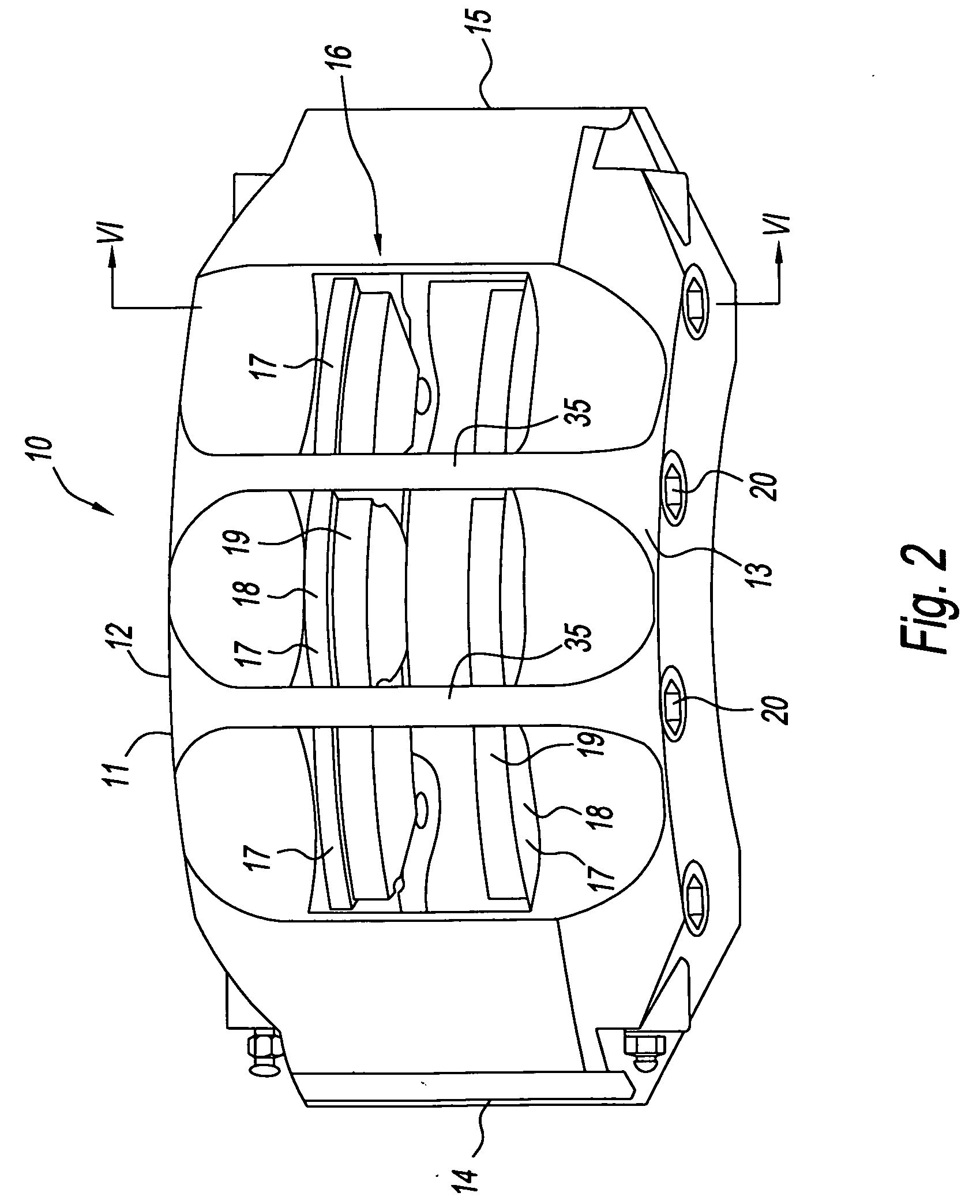

Footwear for walking or running with rolling action

A footwear sole assembly (10) for walking with a rolling action is described. An elastically compressible midsole element (33) is provided with a rolling element (40) situated in and extending over a portion of the length and over at least a portion of the width of the midsole element (33). The rolling element (40) consists at least partially of a resilient material and is disposed at least in that region of the midsole (33) which is opposite to the arch of the wearer's foot. This shoe offers the rolling gait advantages of the well known MBT shoe, but has a different construction which enables it to retain the outward appearance of conventional shoes such as trainers.

Owner:XELERO TECH

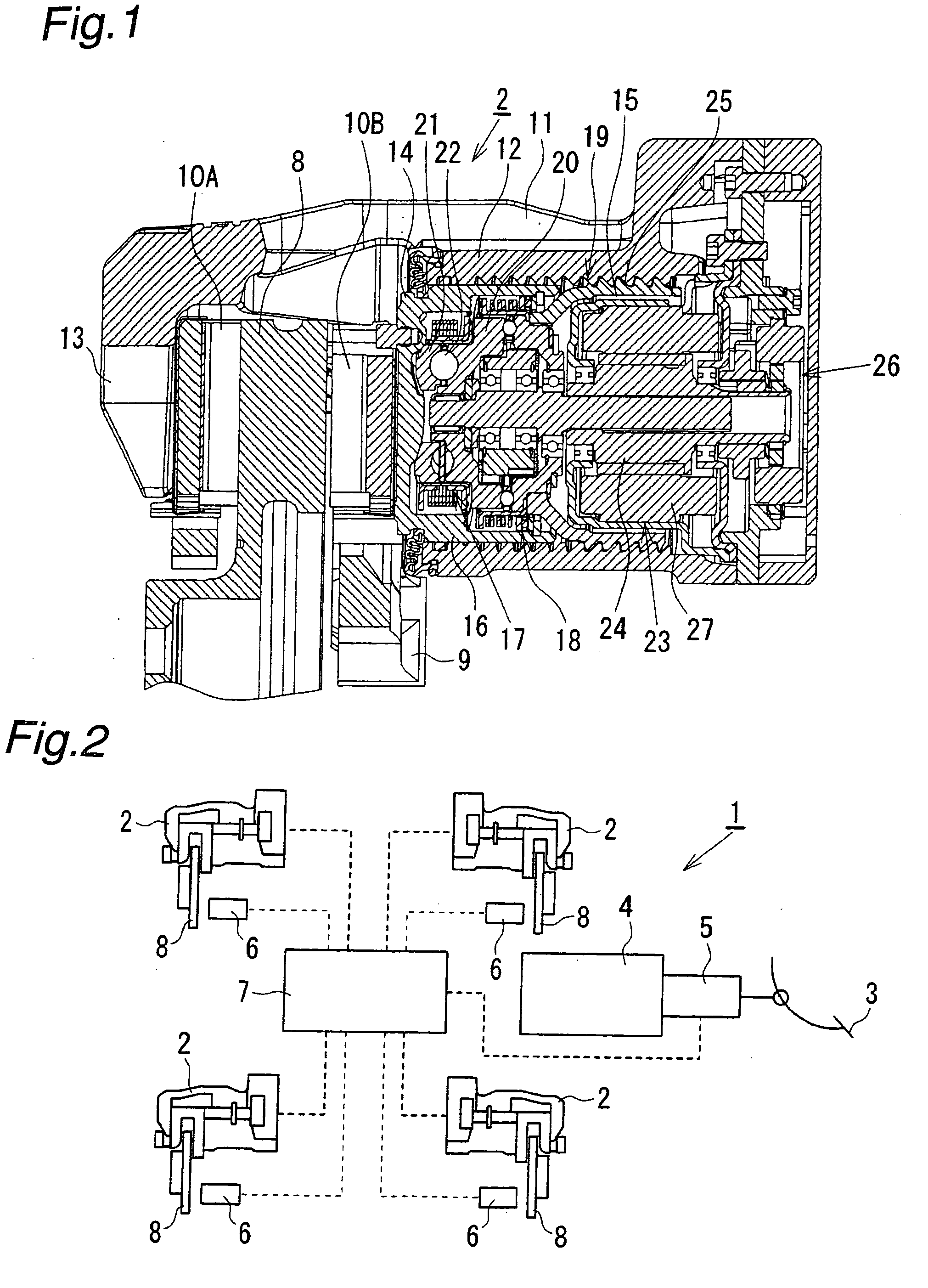

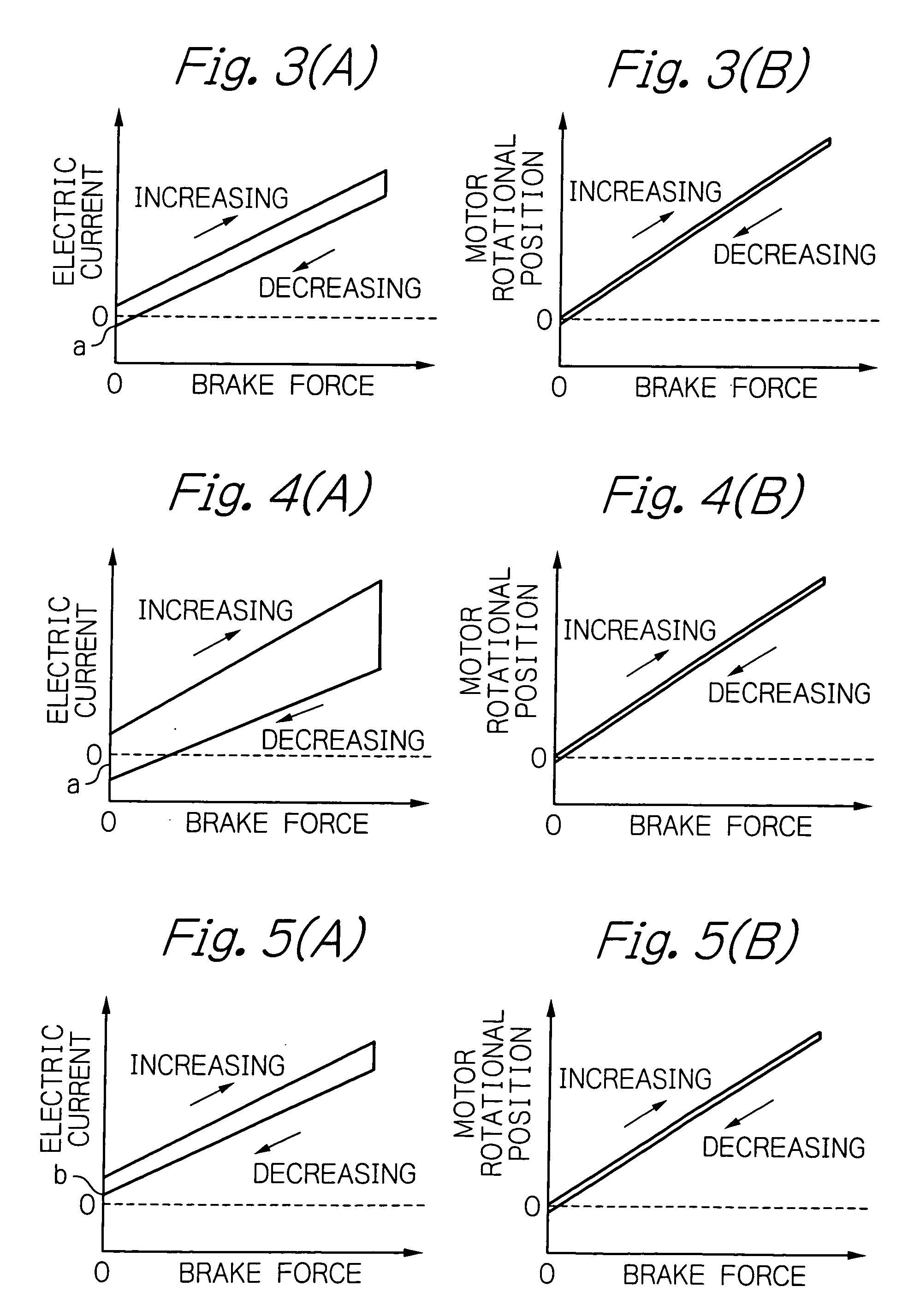

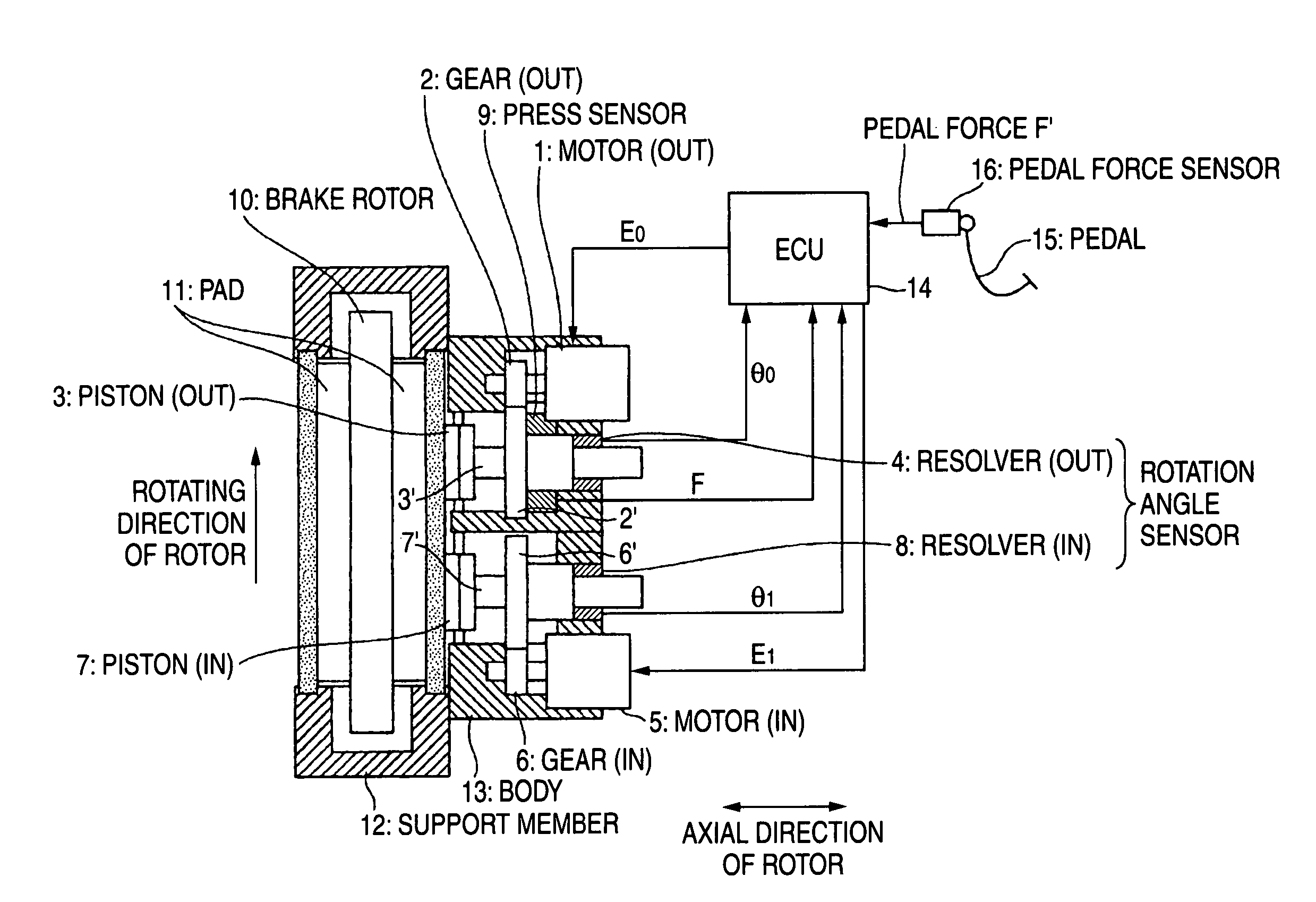

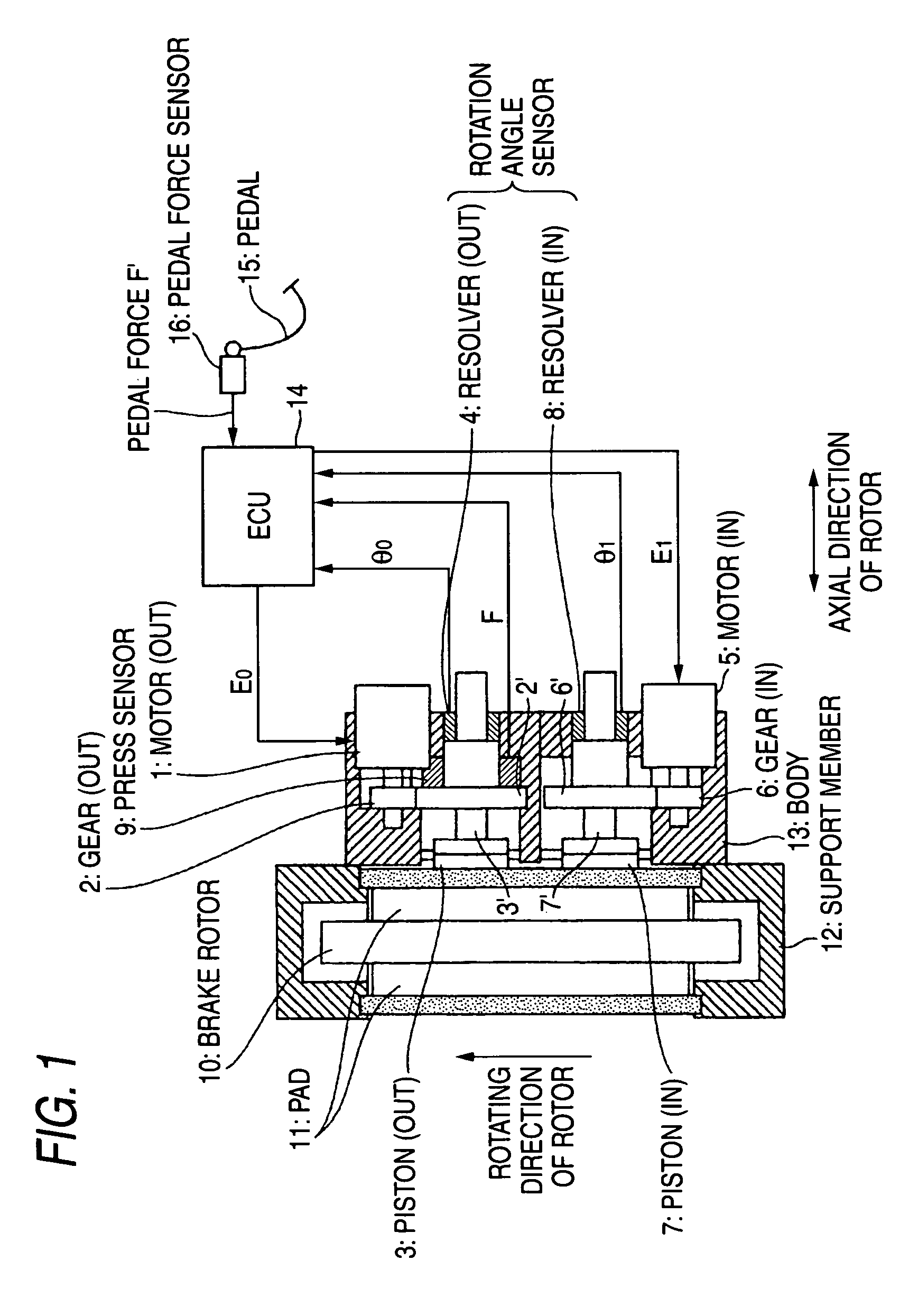

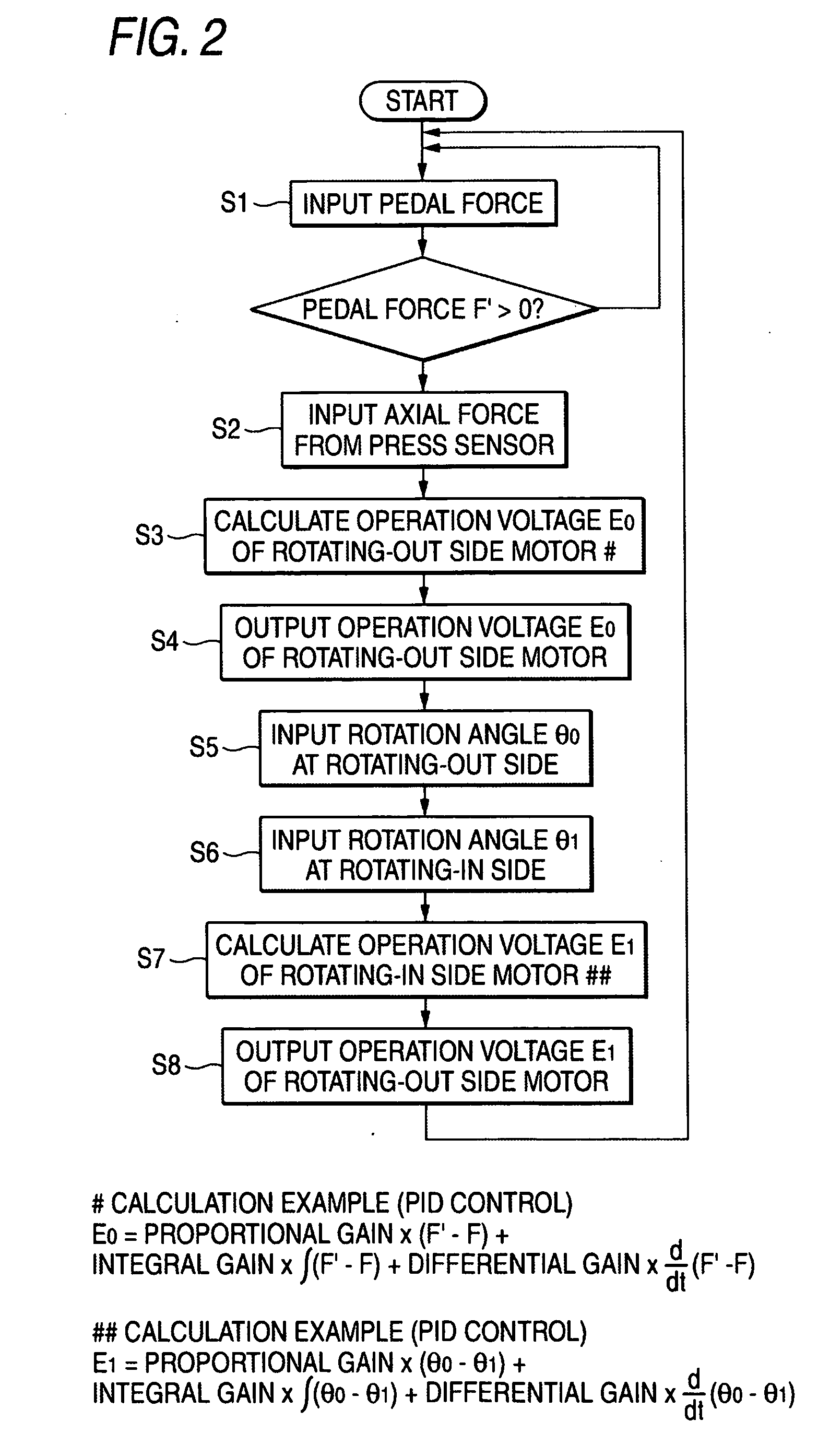

Electric disk brake

ActiveUS20090032342A1Avoid uneven wearMechanically actuated brakesBrake actuating mechanismsLinear motionControl theory

An object of the present invention is to, in an electric disk brake, prevent uneven abrasion of a disk rotor due to contact of the disk rotor to a brake pad when brake is not in operation. In the present invention, a rotation of an electric motor is slowed down by a differential speed reducing mechanism, and is converted to a linear motion of a piston by a ball ramp mechanism. Brake pads are pressed against a disk rotor by the piston to generate a brake force. When brake is not in operation, the piton is retracted by a reverse rotation of the electric motor so that a predetermined pad clearance is maintained. When brake is not in operation, a pad-retracting-control electric current is supplied to the electric motor so that the piston is biased backward while being maintained in one position. When brake is not in operation, contact of the disk rotor to the brake pads due to runout of the disk rotor triggers smooth retracting of the piston, whereby uneven abrasion of the disk rotor can be prevented.

Owner:HITACHI ASTEMO LTD

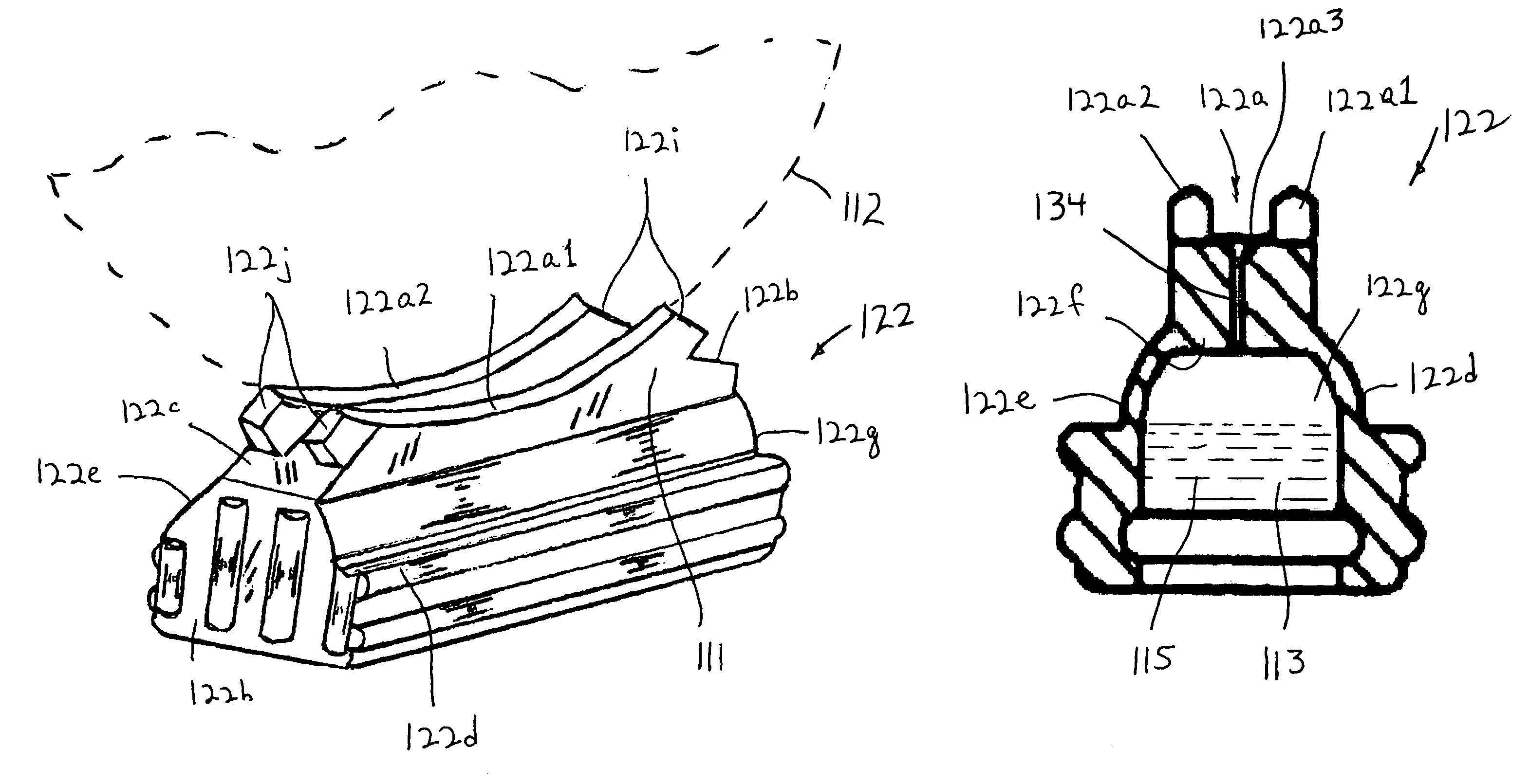

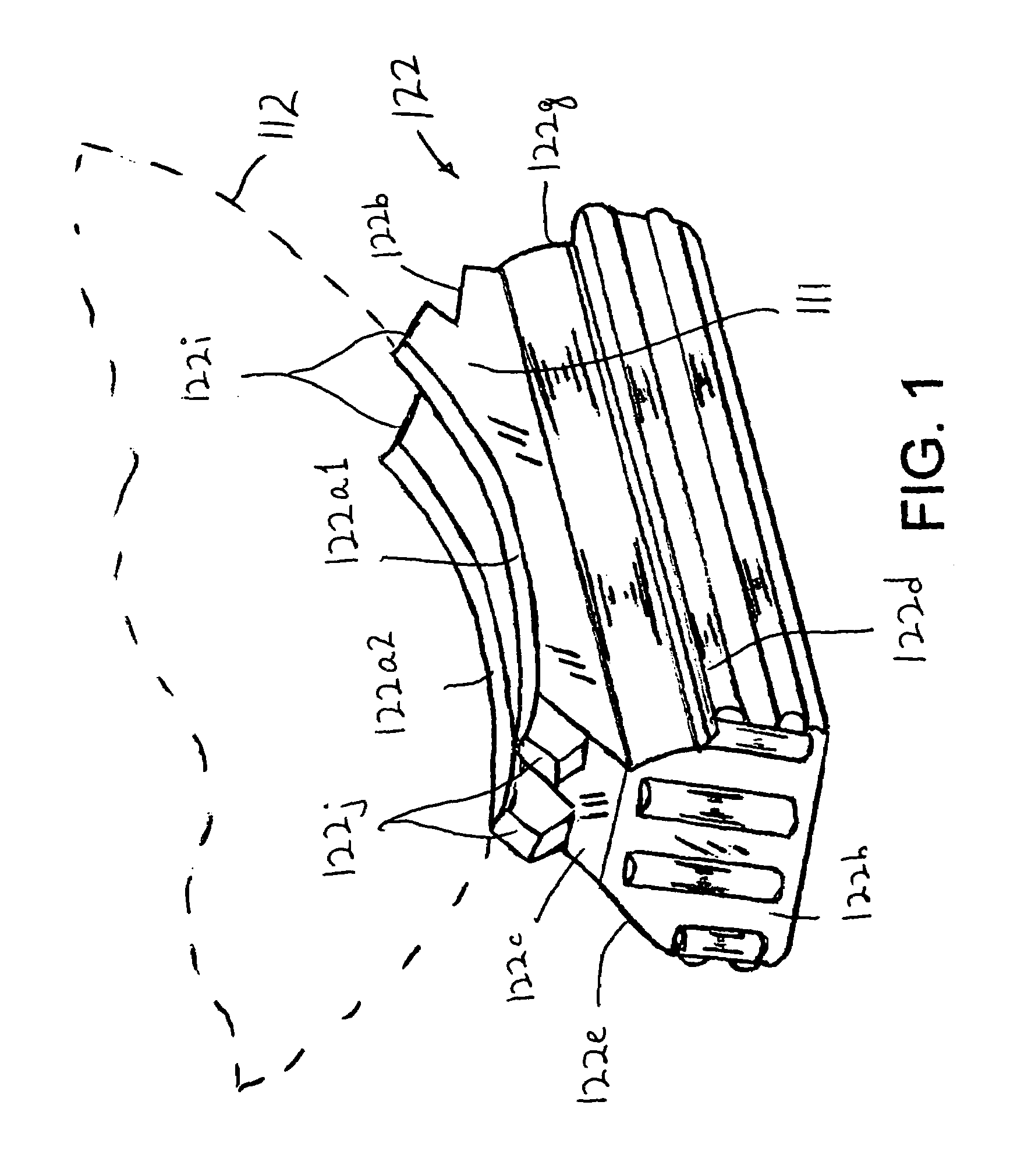

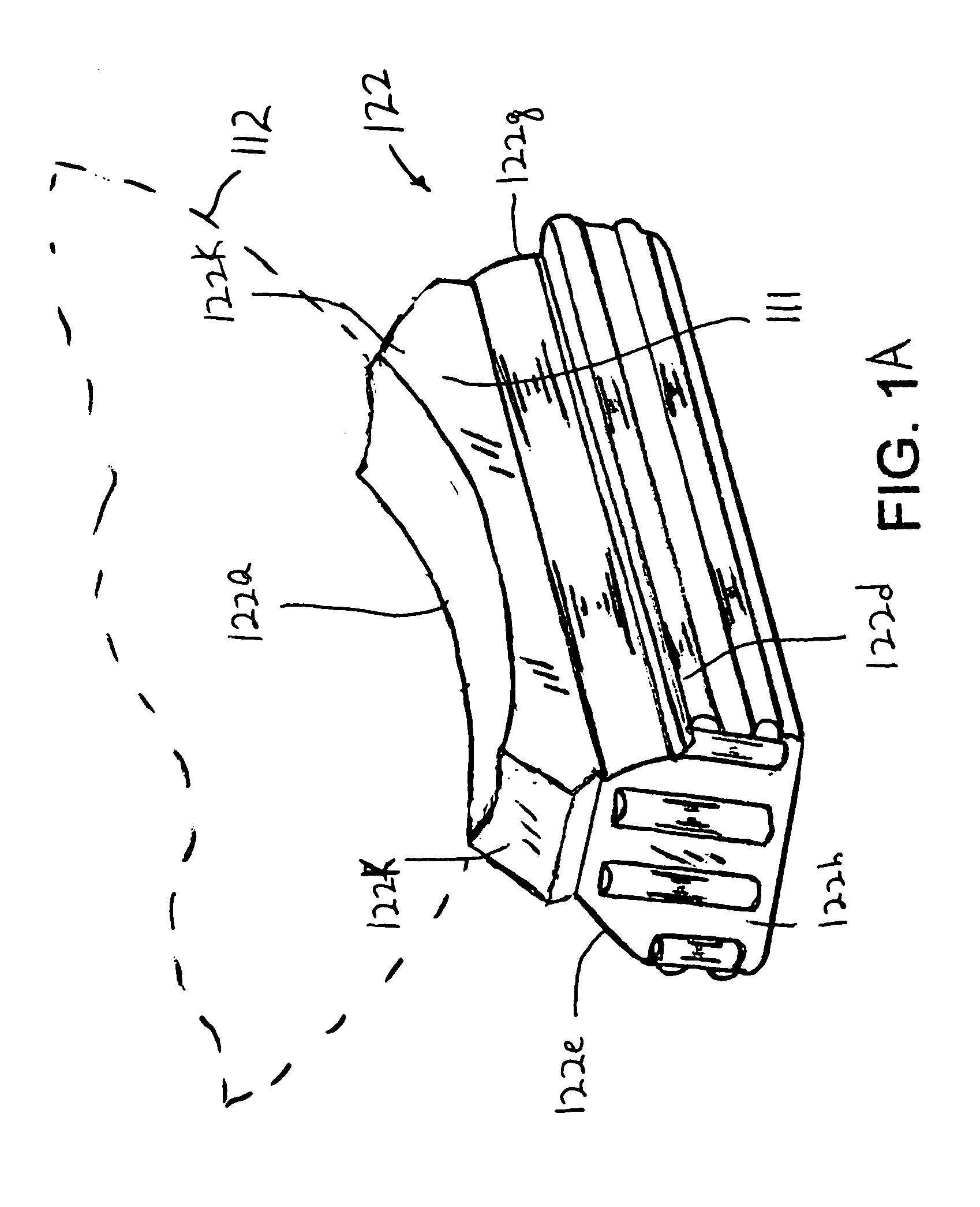

Chisel holder

ActiveCN101666229AConstant wear resistanceReliable arrangementSlitting machinesCutting machinesChiselSupport surface

The invention relates to a chisel holder for a cutting machine, road milling machine, surface miner, or the like, having a chisel receptacle, which comprises an insertion opening, and having a chiselsupporting surface, wherein at least one wear protection element is arranged in an area associated with the chisel supporting surface. In order to bring about effective wear protection in such a chisel holder at low cost, it is provided that the at least one wear protection element is designed as a weld and is arranged at least in areas in at least one opening.

Owner:WIRTGEN GMBH

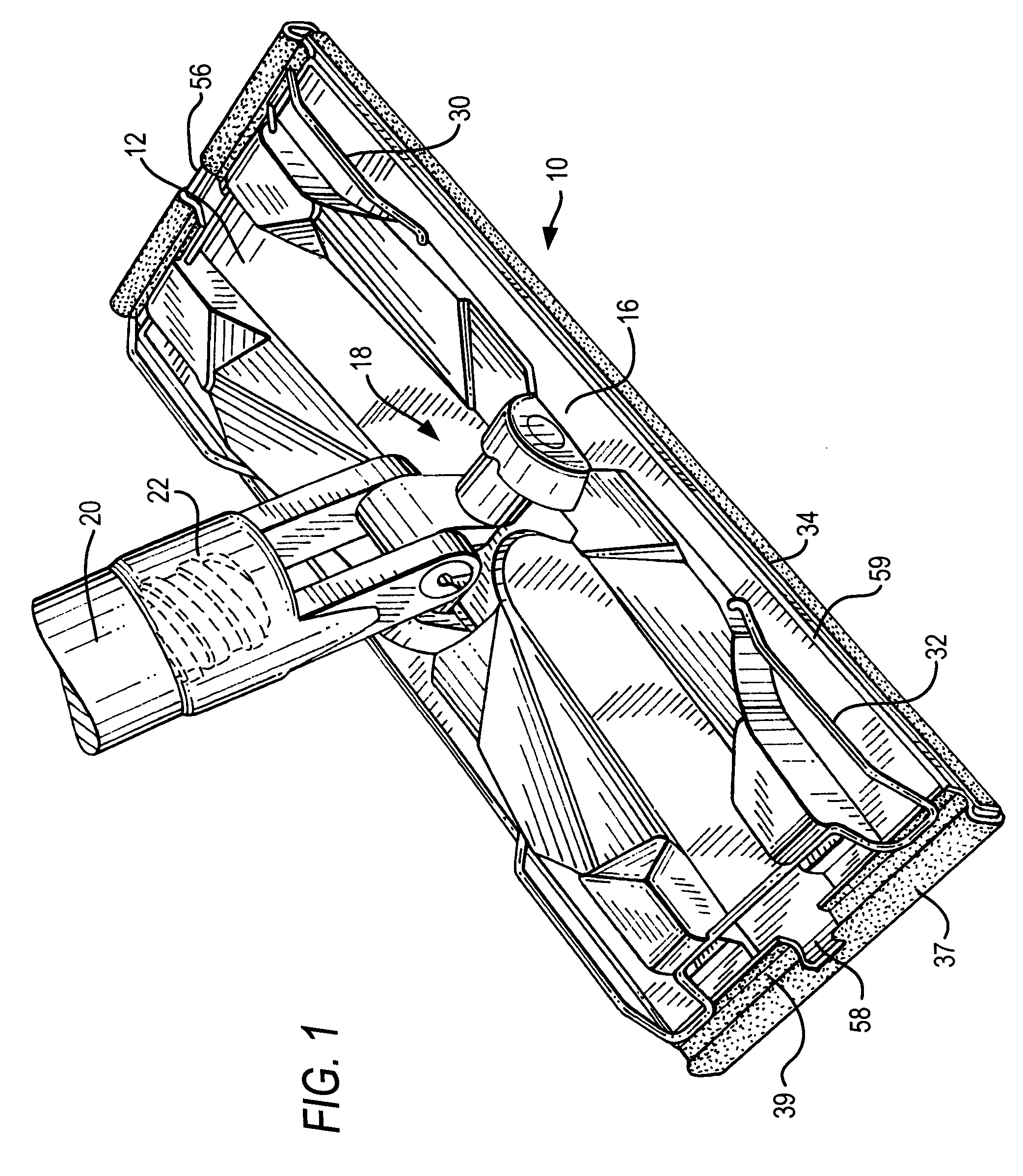

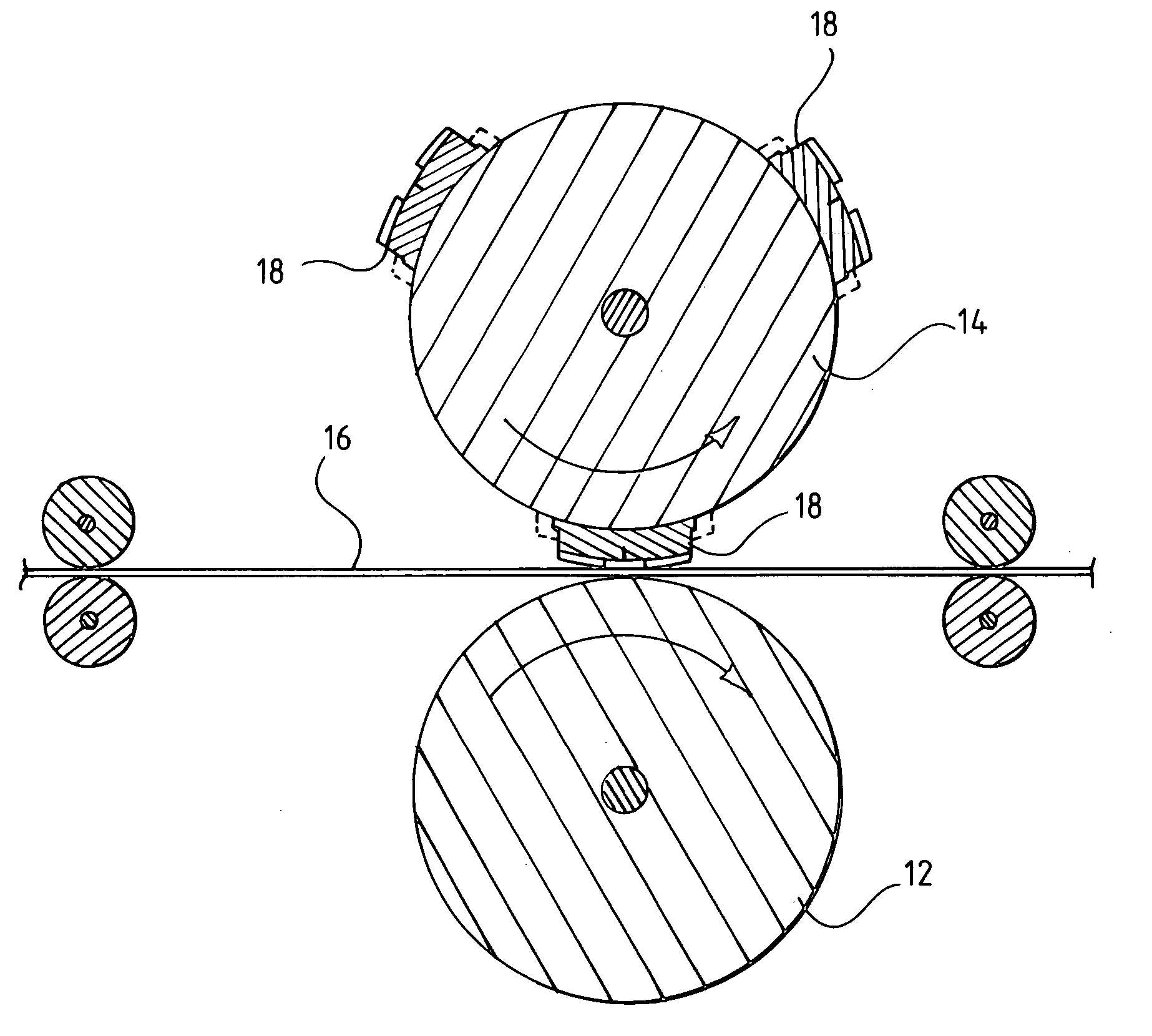

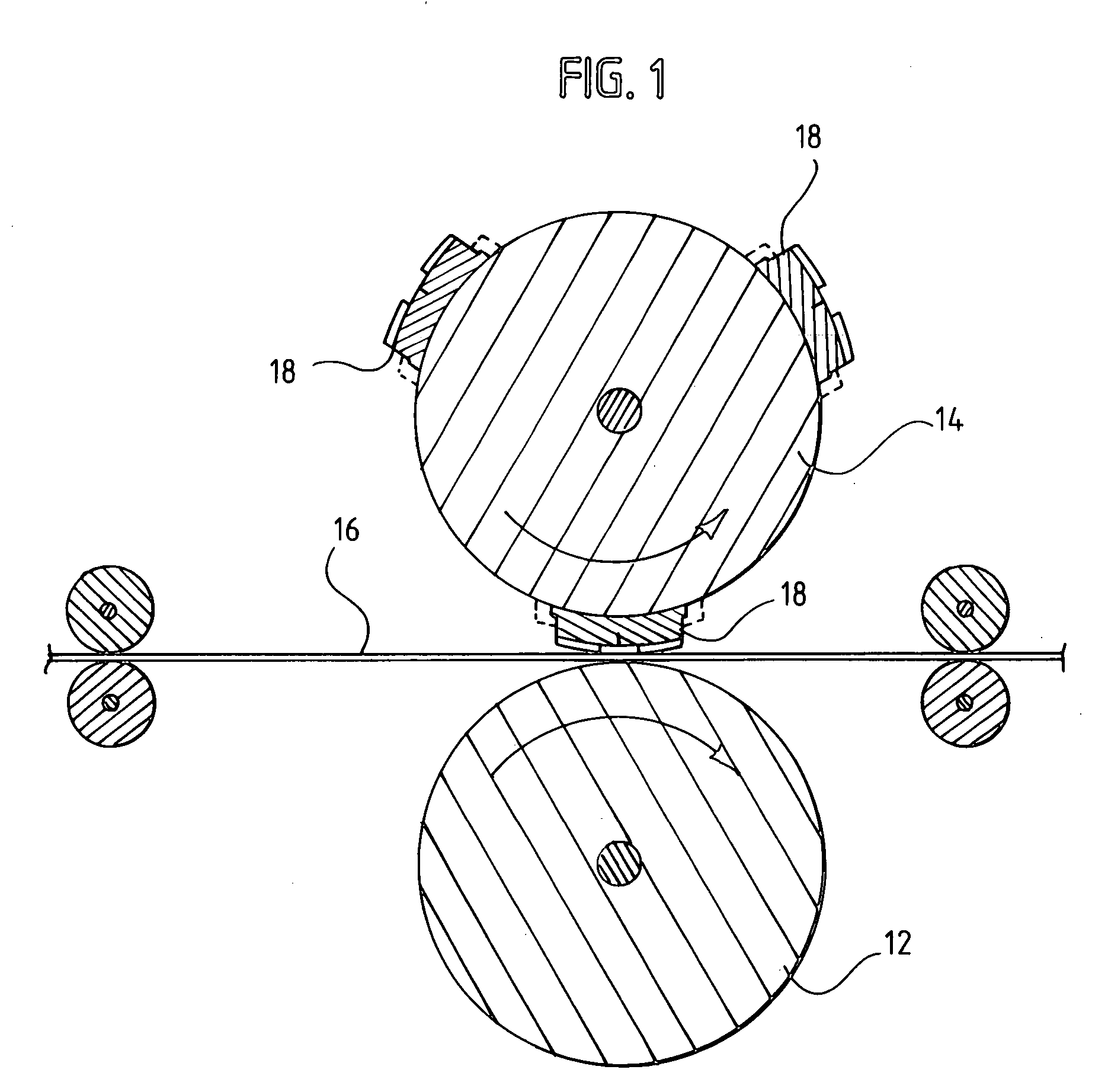

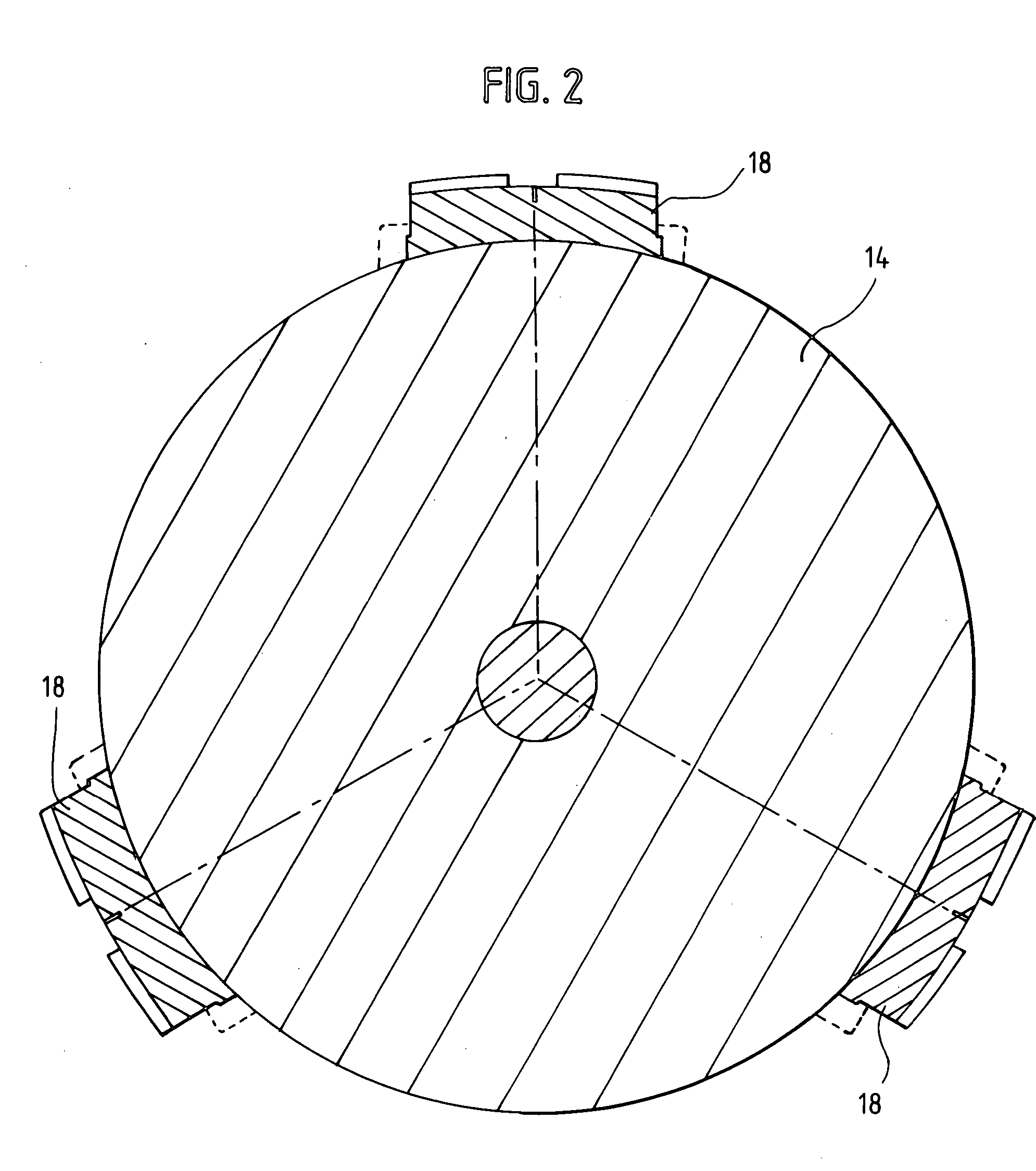

Rotary web cutting system with resilient mounting assembly for shaped knife blades

InactiveUS20050166733A1Avoid uneven wearAvoid deformationStock shearing machinesMetal working apparatusElastomerEngineering

A knife holder mounted on the periphery of a knife roller in an apparatus for cutting lengths of webs such as paper is disclosed. The knife holder in the system disclosed is formed of an elastomeric material. The knife blades have shaped configurations in order to cut contours, angles, curves, or geometric shapes into the web. The knife blades are held in place principally by friction in slots cut into the knife holder and seat themselves in the elastomer during set-up and changing. Additionally, flexibility in milling shapes and contours, reduced and even wear of knife blades, and prevention of deformation or displacement of cutting blades is achieved.

Owner:ILF TECH

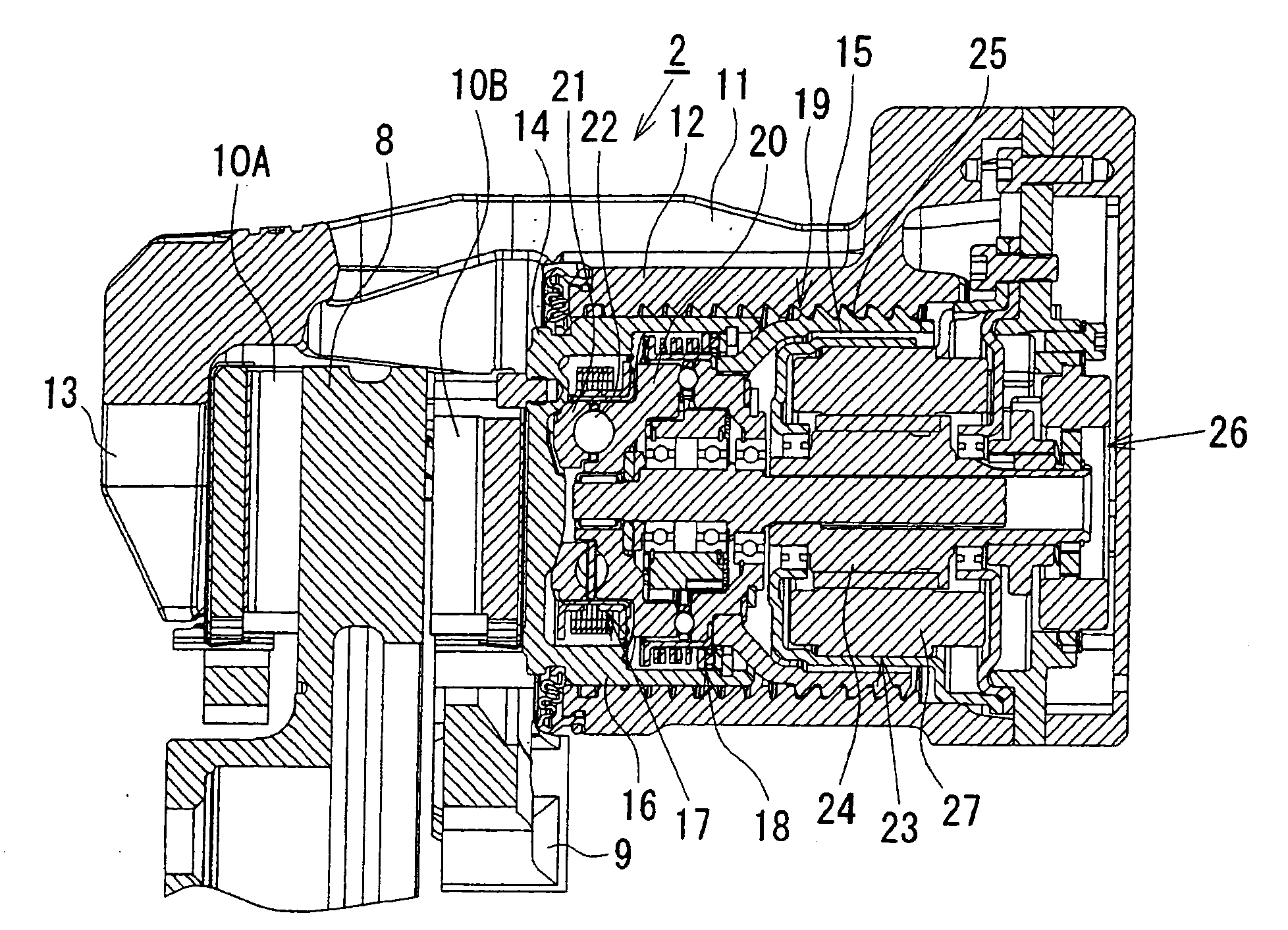

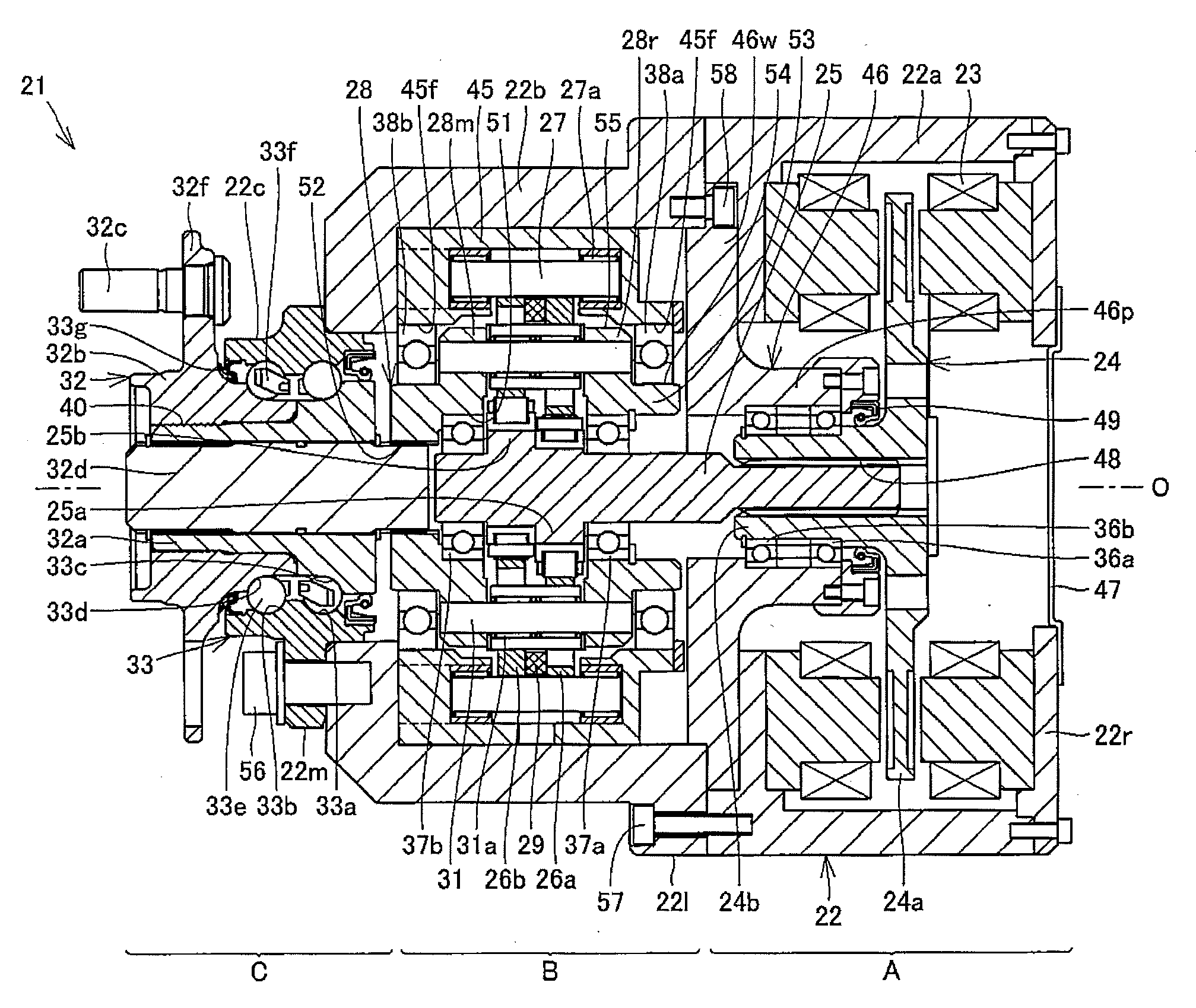

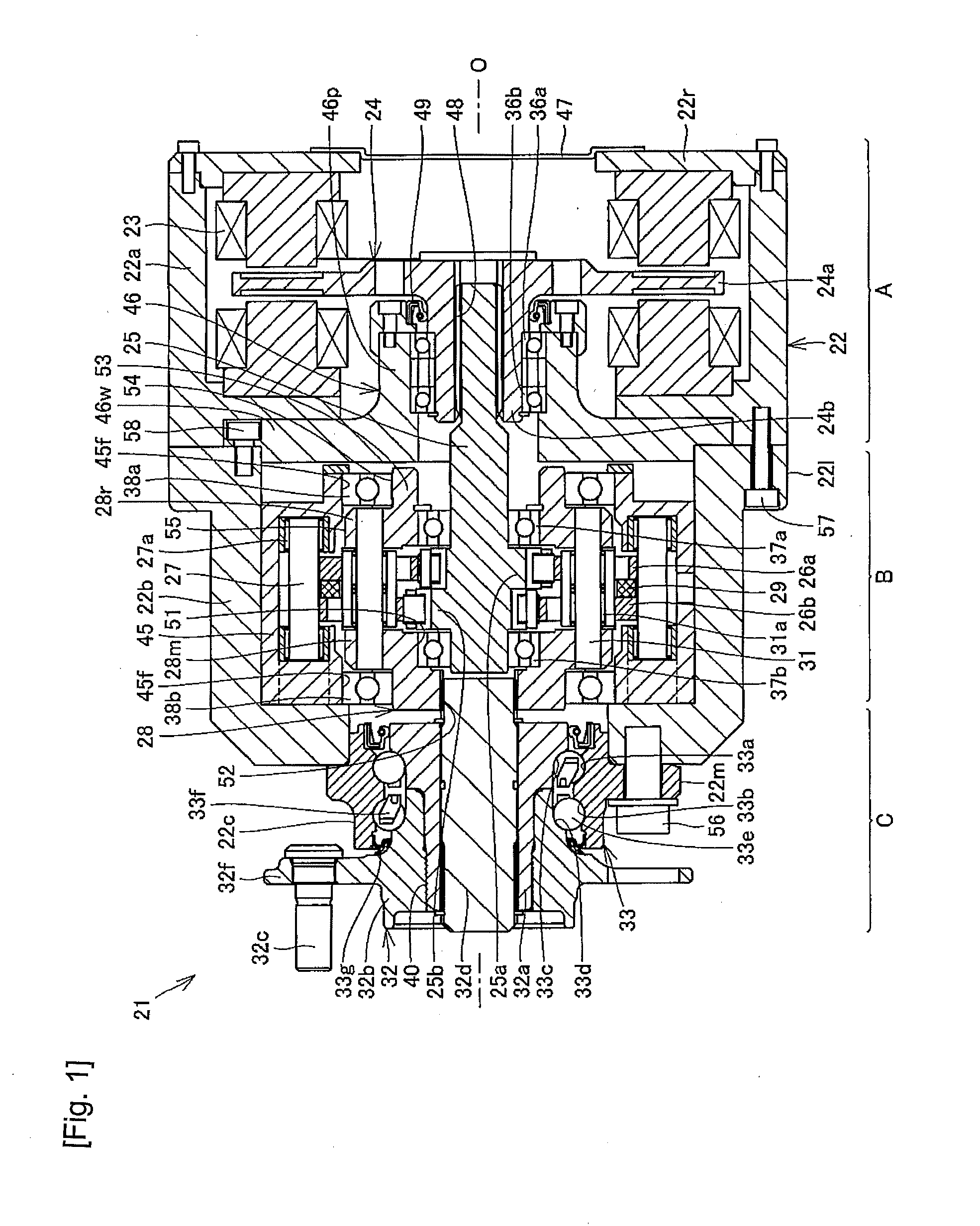

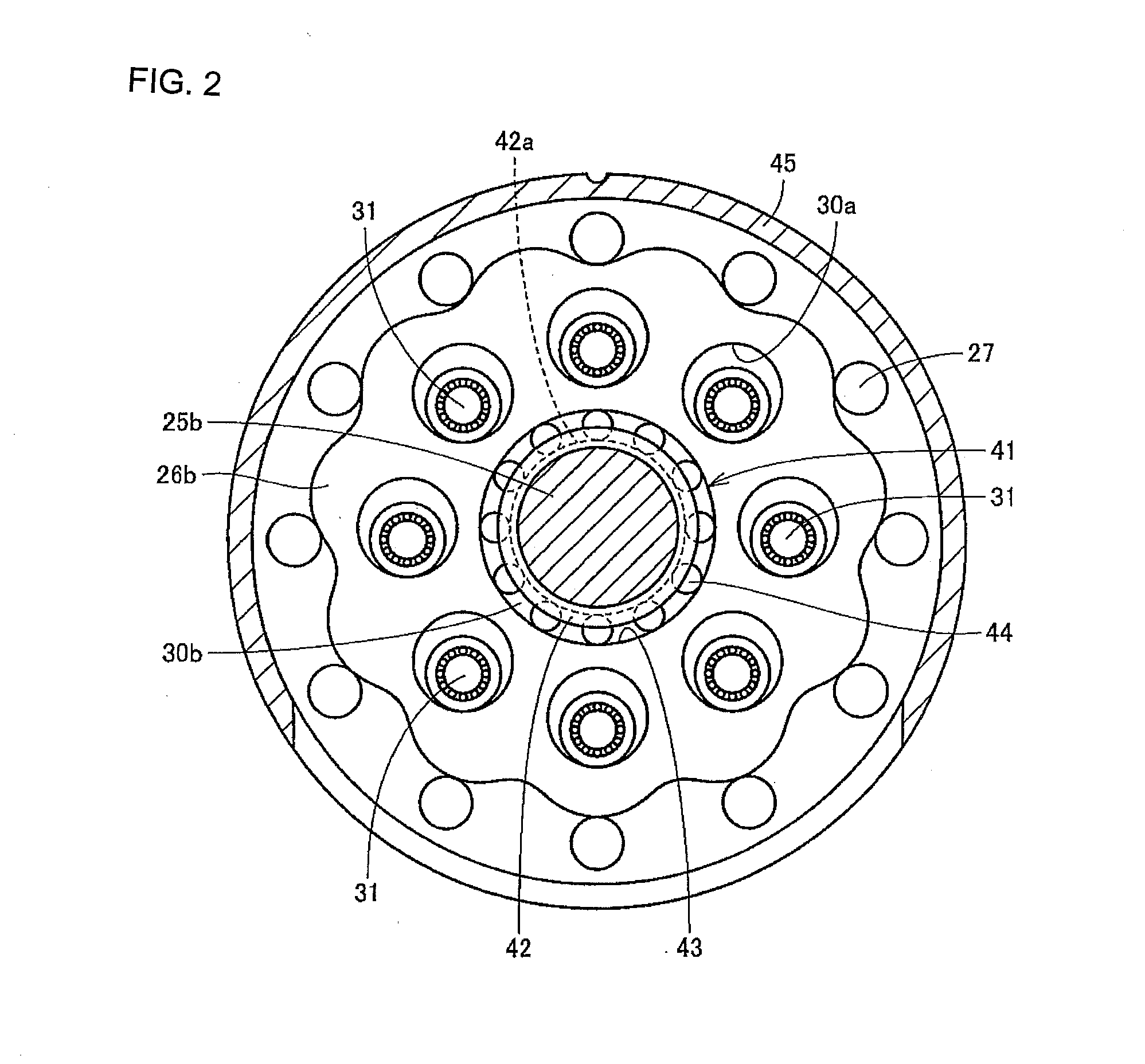

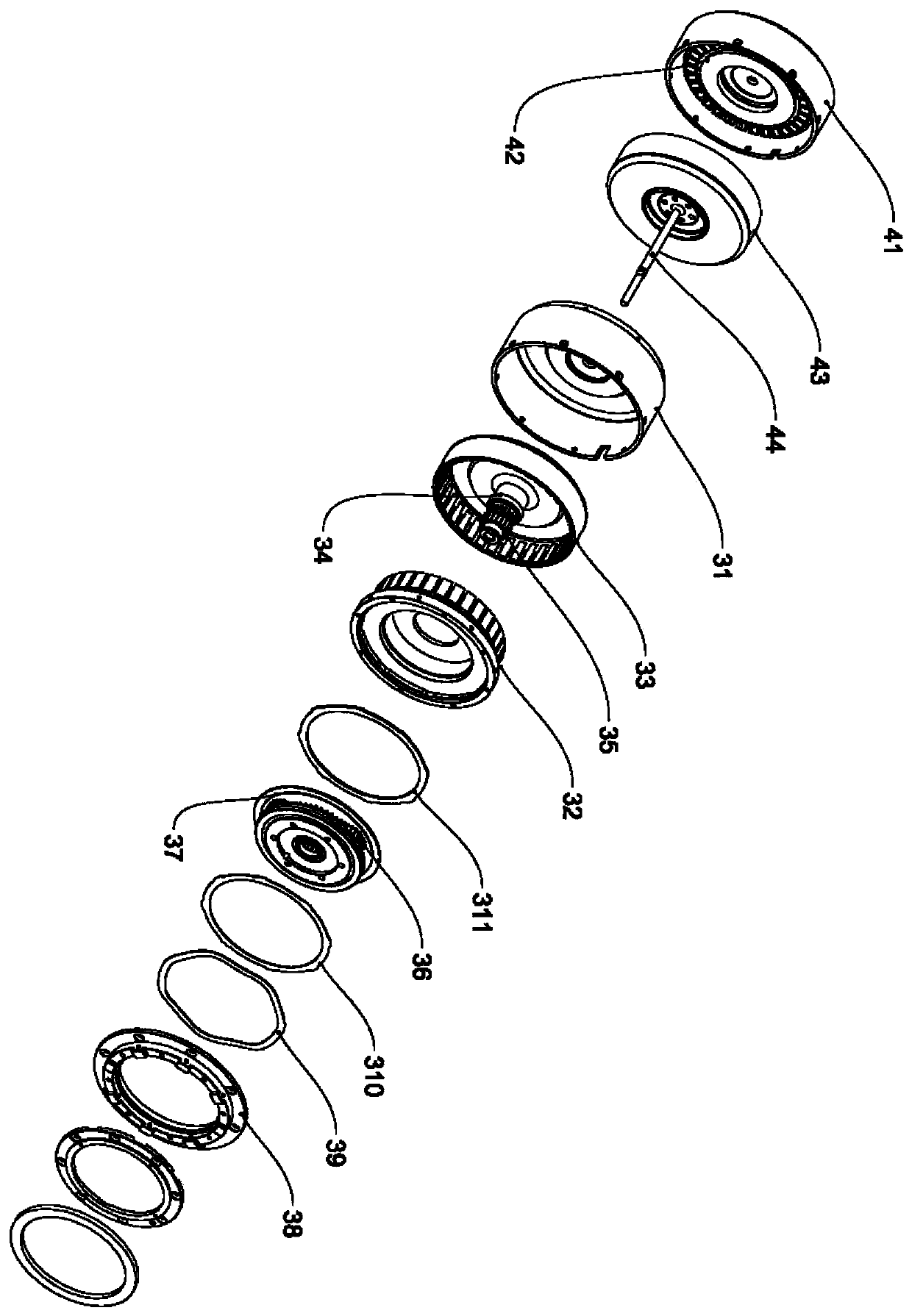

In-wheel motor drive device

InactiveUS20120241233A1Avoid uneven wearIncreased durabilityElectric propulsion mountingToothed gearingsMotor driveControl theory

An in-wheel motor drive device 21 includes: a motor portion A; a speed reduction portion B that reduces the speed of rotation of the motor portion A to output the rotation having the reduced speed to an output shaft 28; and a wheel hub 32 coupled to the output shaft 28. The speed reduction portion B has a cylindrical casing-side member 45 that extends from one axial end to the other axial end of the speed reduction portion and that has both one end and the other end formed integrally, the output shaft 28 that is inserted through an inner space region of the casing-side member, and two output-shaft bearings 38a, 38b that are respectively provided on an inner periphery at both ends 45f of the casing-side member to rotatably support the output shaft 28.

Owner:NTN CORP

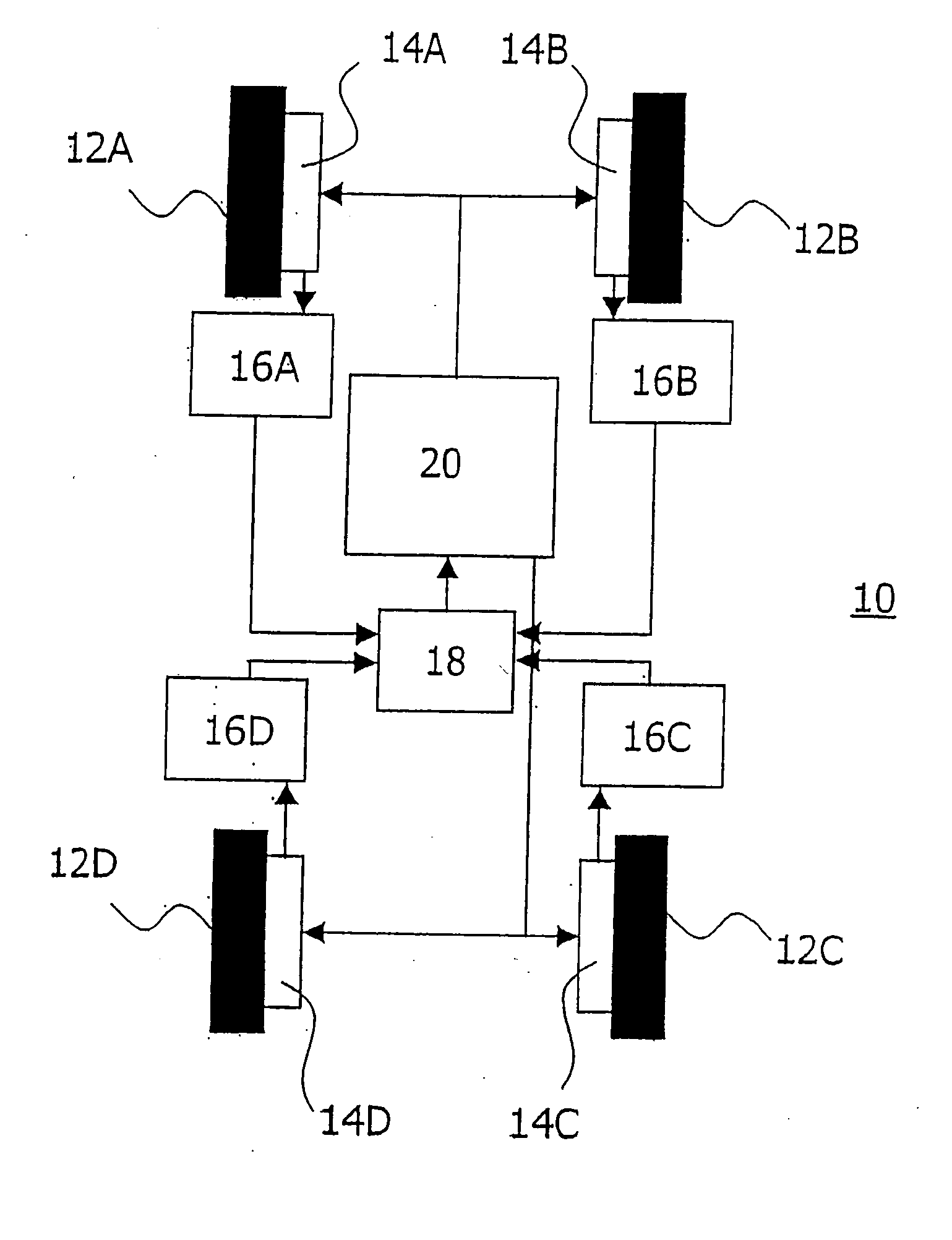

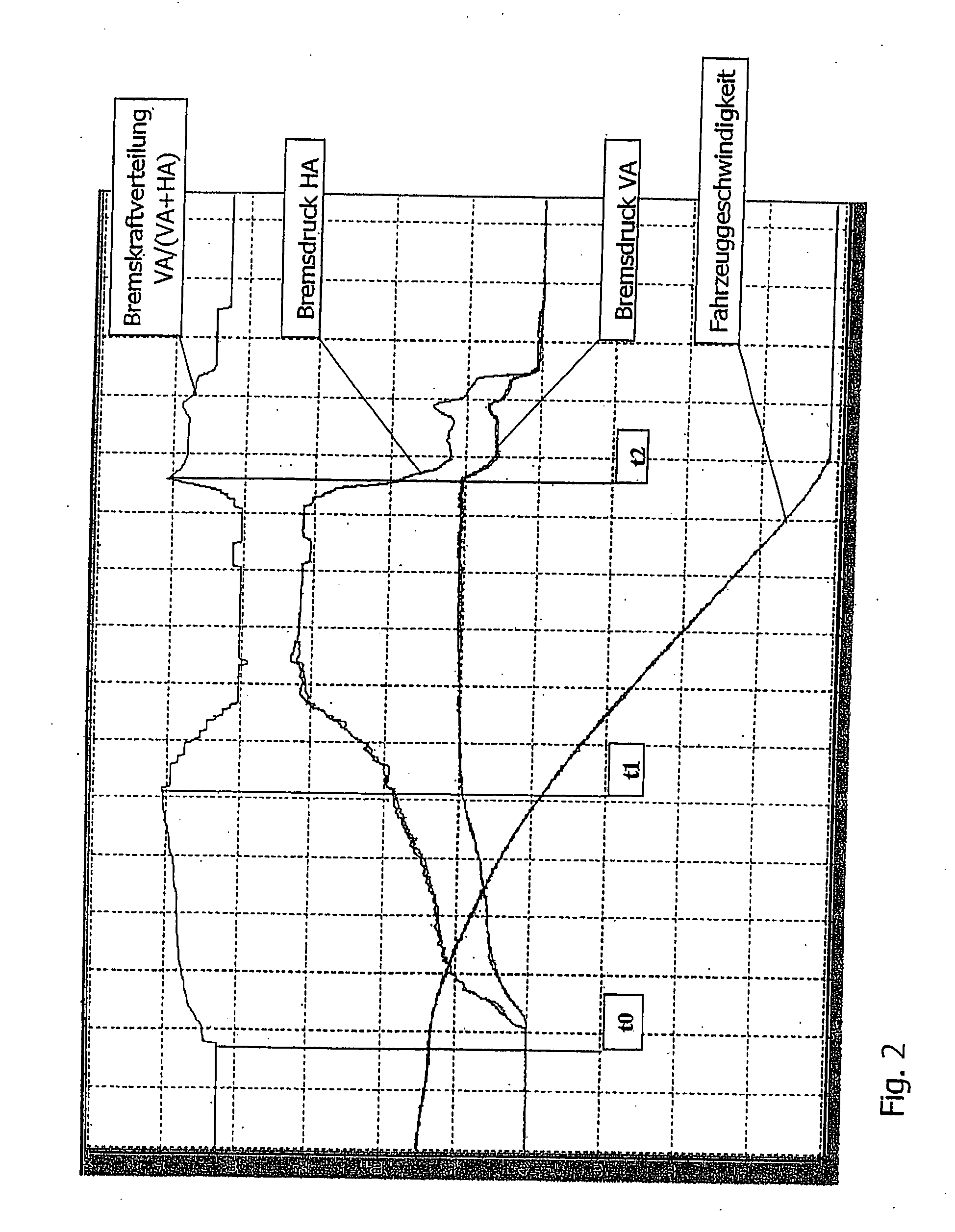

Noise-reduced vehicle brake system

InactiveUS20060202555A1Avoid uneven wearIncrease and reduce brake forceNoise/vibration controlBraking systemsNoise generationVehicle brake

A method of automatically suppressing or preventing noise generation during the actuation of a vehicle brake system comprising two or more wheel brakes is described. For this purpose, a parameter that allows a conclusion to be drawn about noise generation is acquired and evaluated to detect the occurrence or imminent occurrence of noises. Should the evaluation reveal the occurrence and imminent occurrence of noises, the brake force distribution between the wheel brakes is changed. This change of the brake force distribution is effected while simultaneously retaining a desired and / or set vehicle deceleration.

Owner:LUCAS AUTOMOTIVE GMBH

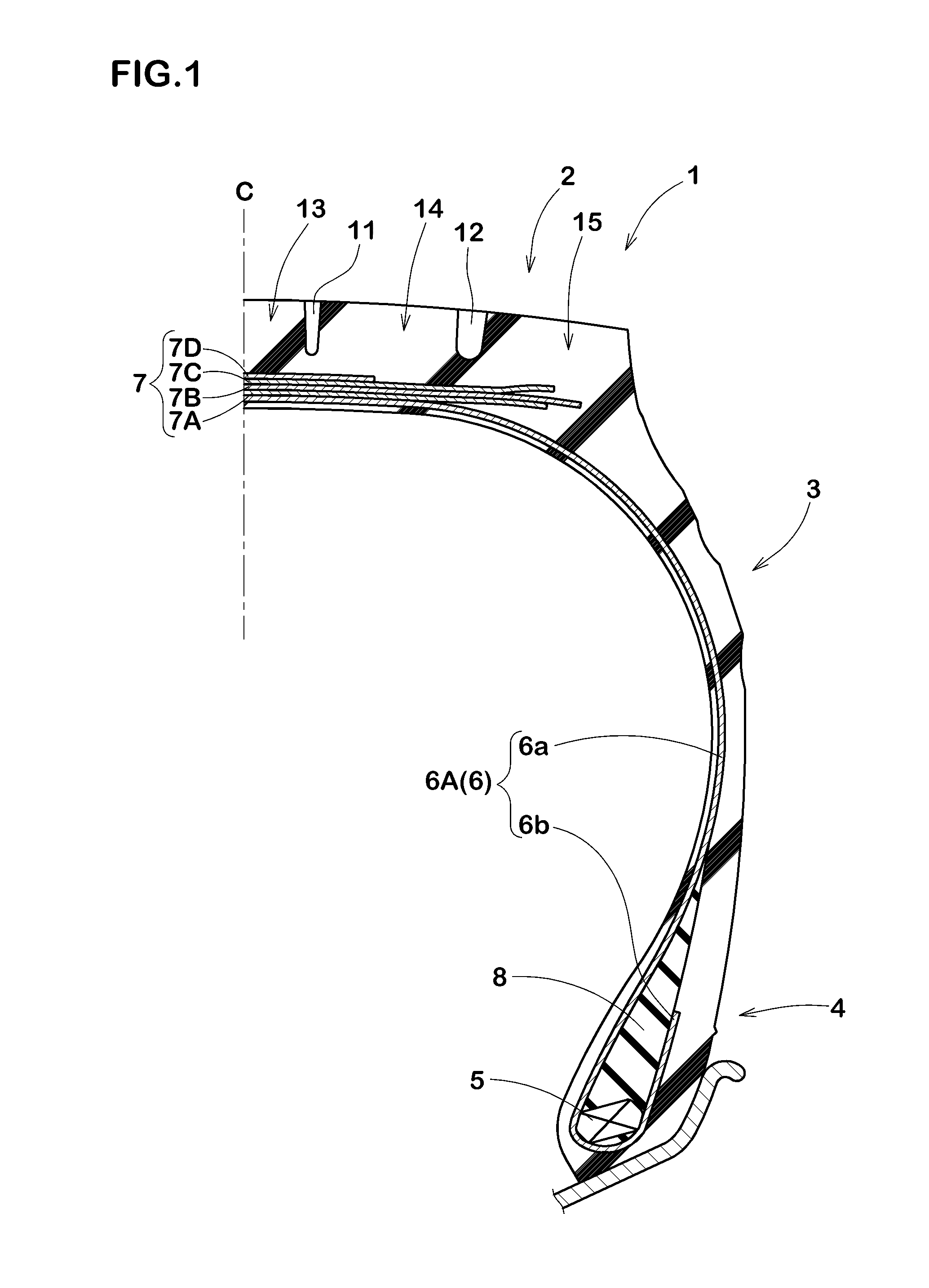

Pneumatic tire

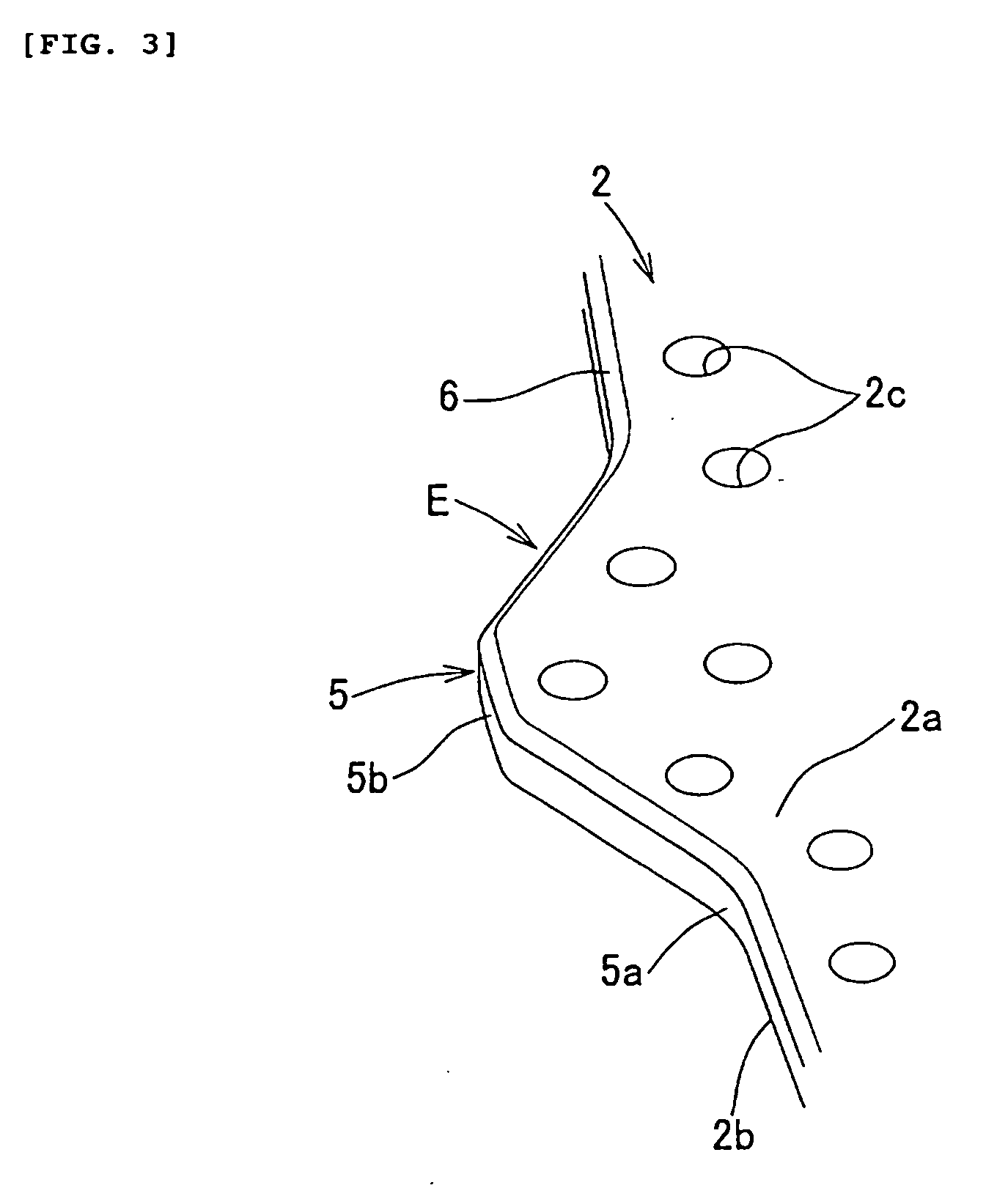

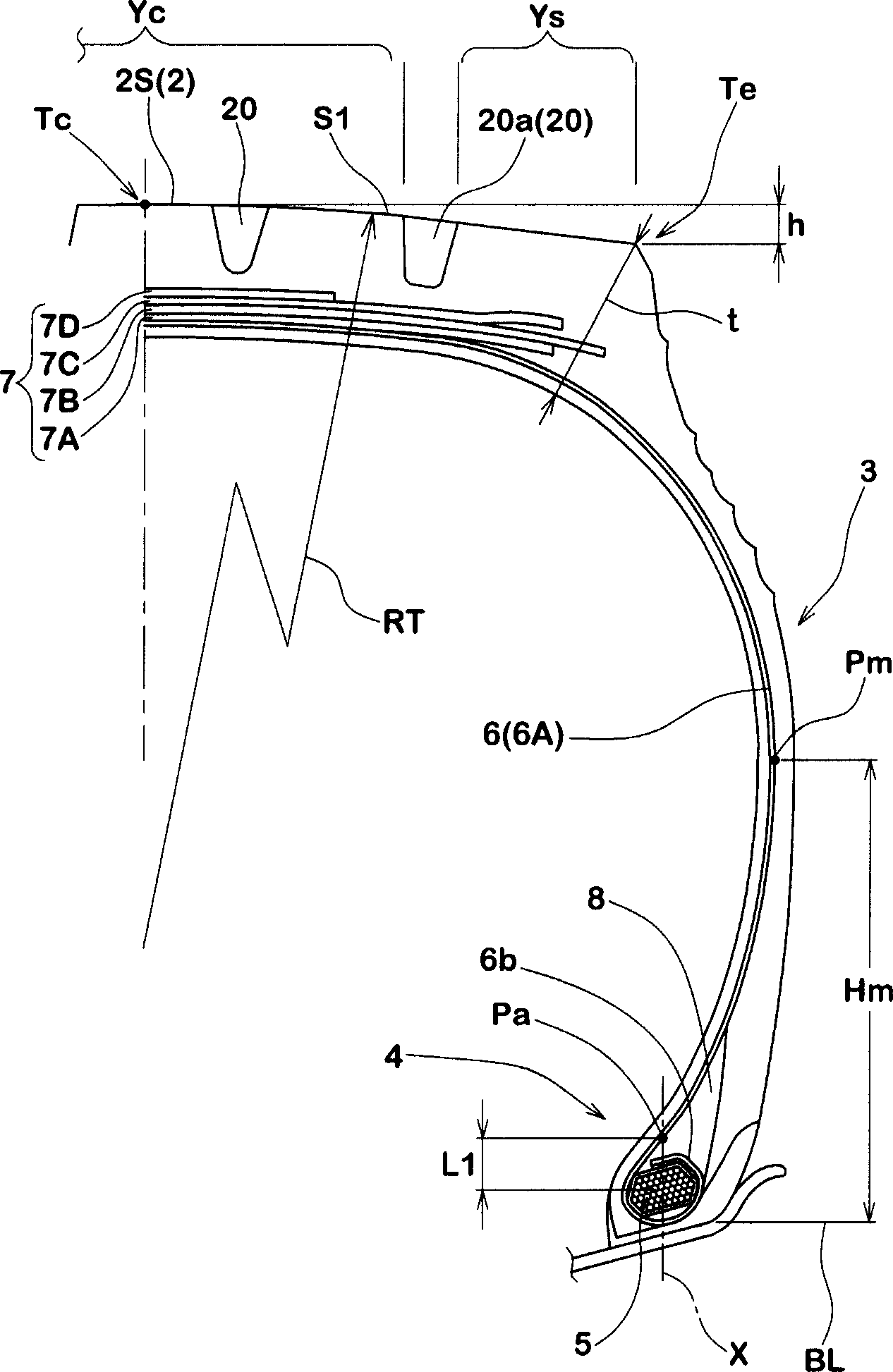

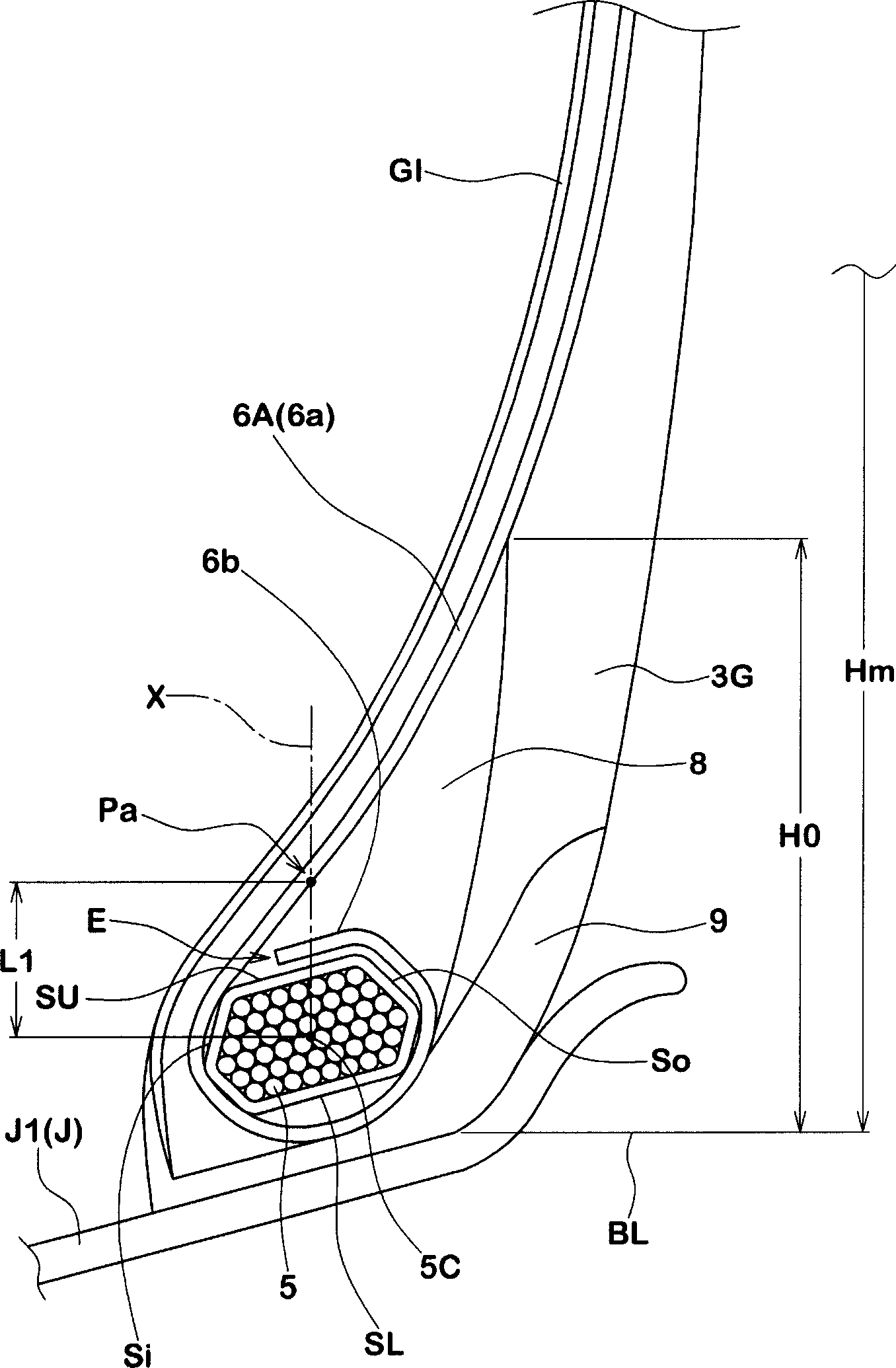

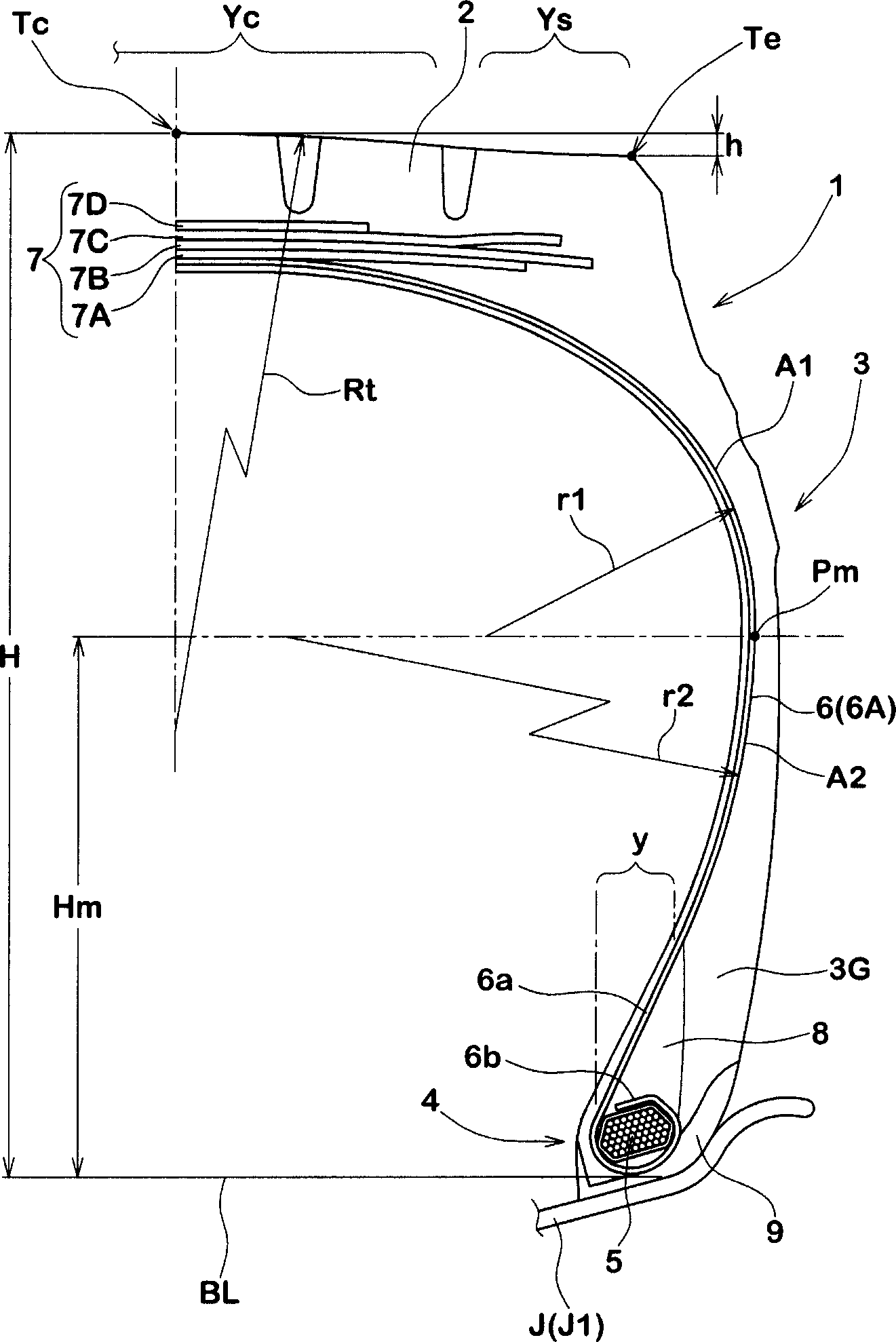

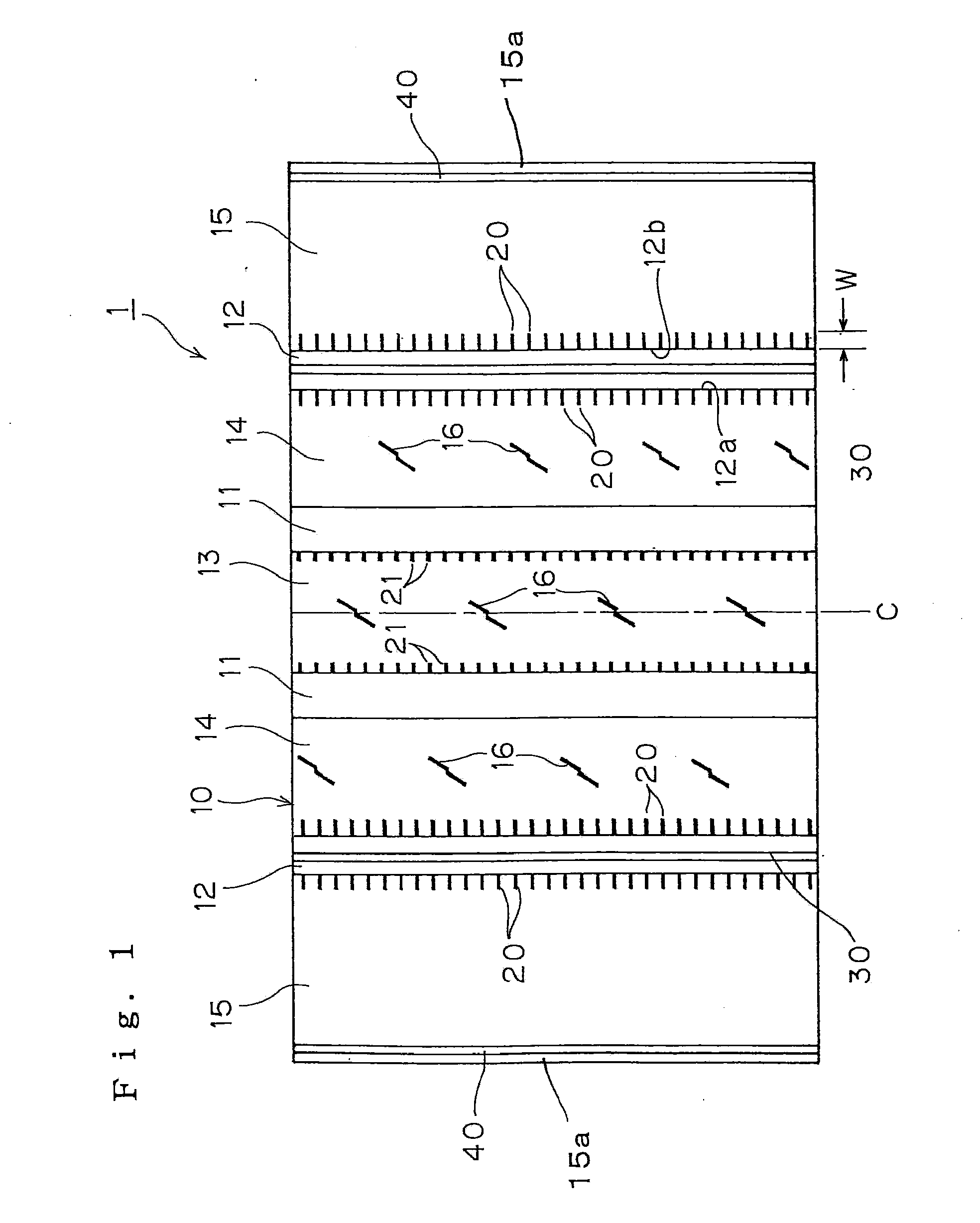

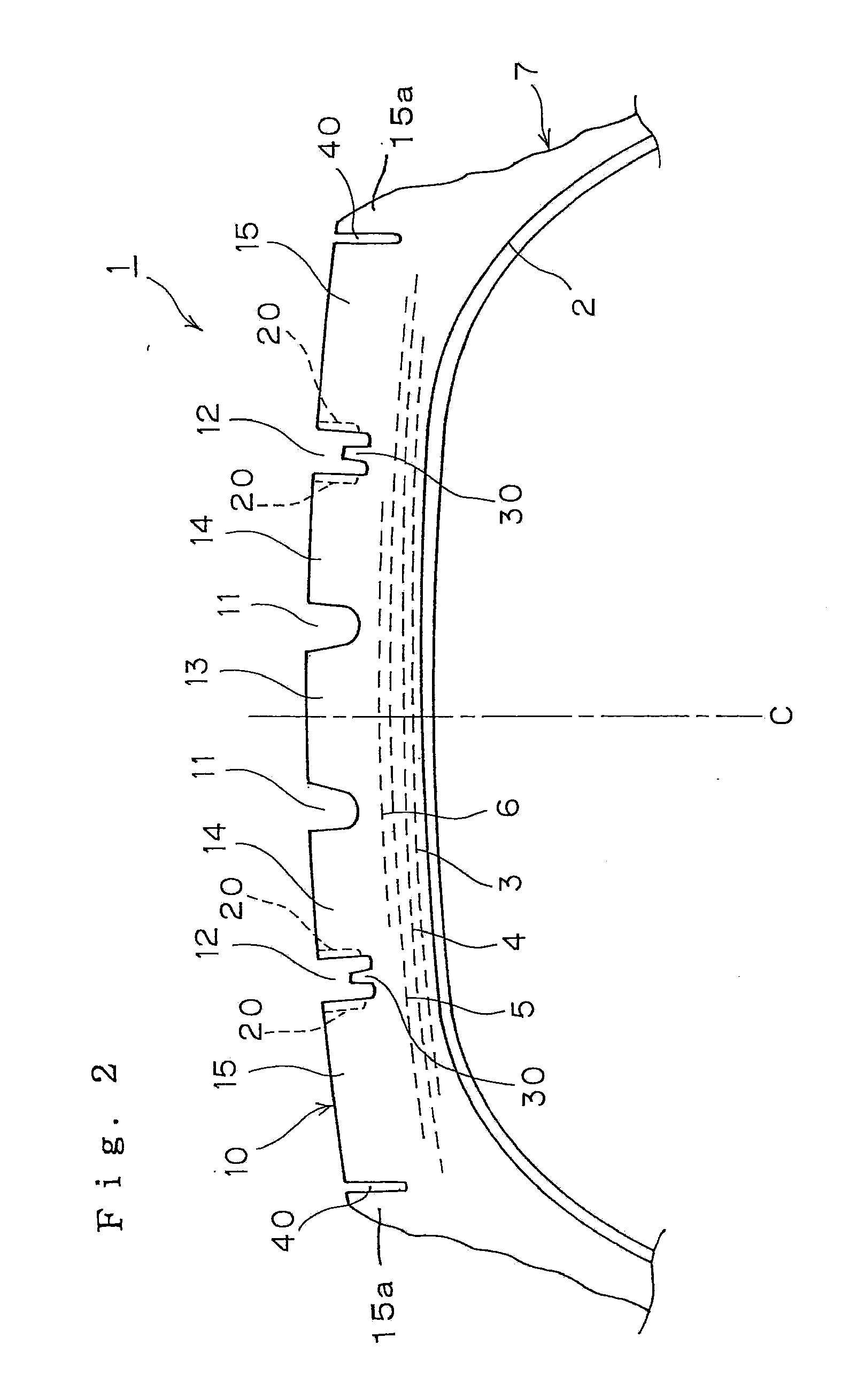

InactiveCN1550360AAchieve thinningAvoid uneven wearSpecial tyresPneumatic tyre reinforcementsMechanical engineeringTread

A pneumatic tire comprises a tread portion (2) with tread edges (Te), a pair of sidewall portions (3), a pair of bead portions (4) each with a bead core (5) therein, and a carcass ply (6) of cords comprising a main portion (6a) extending between the bead cores through the tread portion and sidewall portions and a wound portion (6b) wound around the bead core (5) in each said bead portion (4) from the inside to the outside of the tire, and an edge (E) of the wound portion (6b) is disposed between the bead core (5) and a bead apex rubber (8) disposed radially outside the bead core (5) to be secured therebetween.

Owner:SUMITOMO RUBBER IND LTD

Pneumatic Tire

InactiveUS20080128063A1Improve wear resistanceImprove rigidityTyre tread bands/patternsNon-skid devicesGround contactEngineering

A pneumatic tire is provided which can realize an increase in stone-catching resistance while suppressing uneven wear such as river wear in a tread portion. In a pneumatic tire in which a center rib and intermediate ribs which are defined by four straight-line main grooves, which extend continuously in a circumferential direction of the tire and shoulder ribs which are defined by the main grooves which are situated closer to shoulders of the tire and straight-line thin grooves which extend continuously in the circumferential direction of the tire in the vicinity of tread ground-contacting edges are formed on the surface of a tread of the tire, inclination angles of a shoulder side groove wall of the main groove which defines the shoulder rib and a tire's equator line side groove wall of the thin groove are both such an angle that the shoulder side groove wall and the tire's equator line side groove wall are inclined at an angle of not more than five degrees in a direction in which the width of a proximal portion of the rib is expanded relative to normal lines to the tread.

Owner:TOYO TIRE & RUBBER CO LTD

Coagulants made in situ from sulfate-containing water and uses therewith

InactiveUS20100187130A1Promote flocculationFacilitates oxidationWaste water treatment from quariesWater contaminantsSulfate radicalsSoil science

Acid mine drainage and surface waters containing sulfate are processed by an electrocoagulator to make aluminum or other polyvalent metal sulfate, which acts as a coagulant for solids suspended in the waters. The process thus removes and puts to good use highly undesirable sulfate anions, obviating combinations with barium and other scale forming metals when the fluids are used in well drilling for other purposes associated with hydrocarbon recovery. Well fluids may be treated with the acid mine drainage including the sulfate coagulant made in it. Efficiency of the process may be enhanced by the addition of an oxidizing agent and / or by passing the fluid through a cavitation device or other mechanism to improve mixing, enabling the process to handle large quantities of acid mine drainage and fluids handled in hydrocarbon recovery, particularly from shale formations.

Owner:TOTAL SEPARATION SOLUTIONS

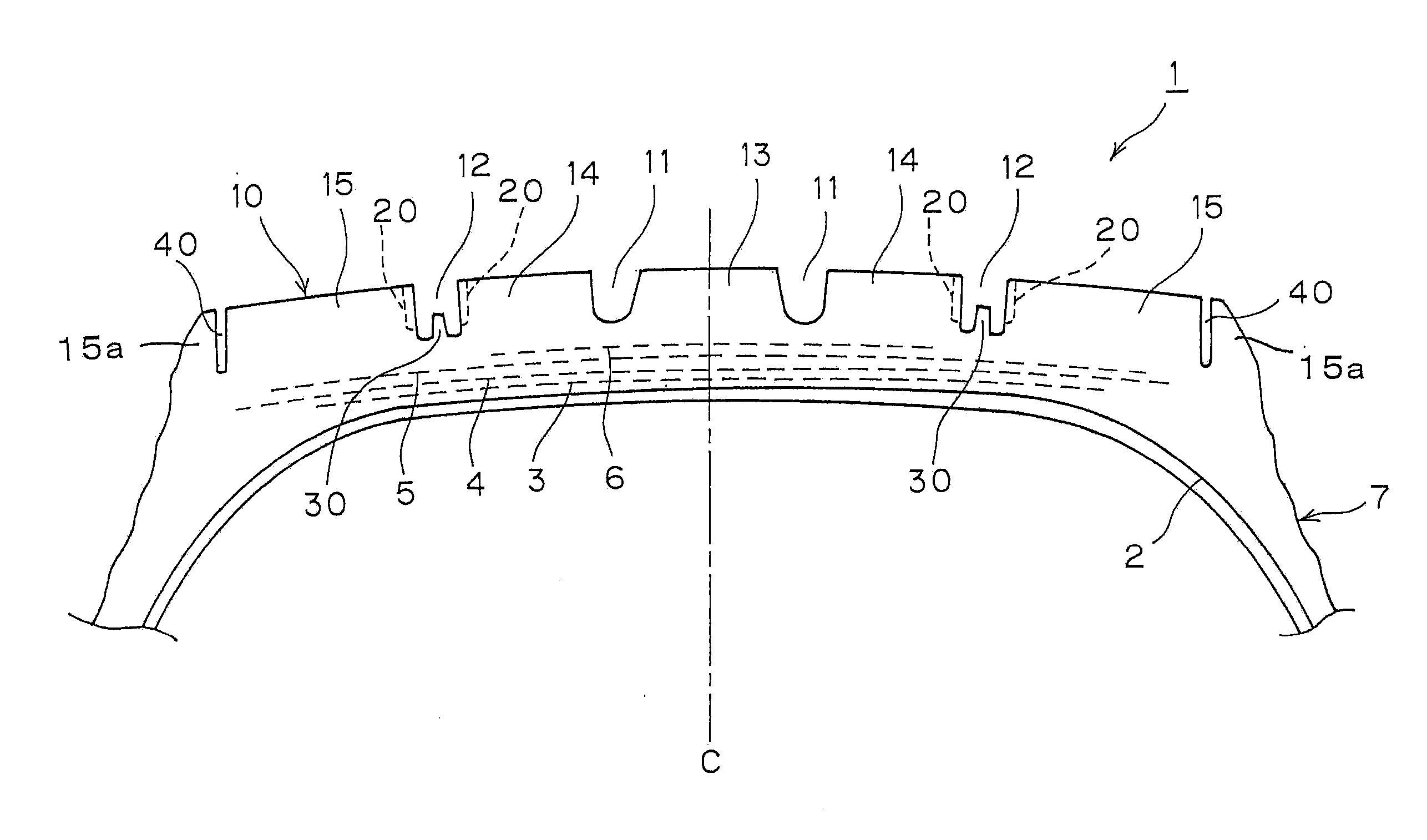

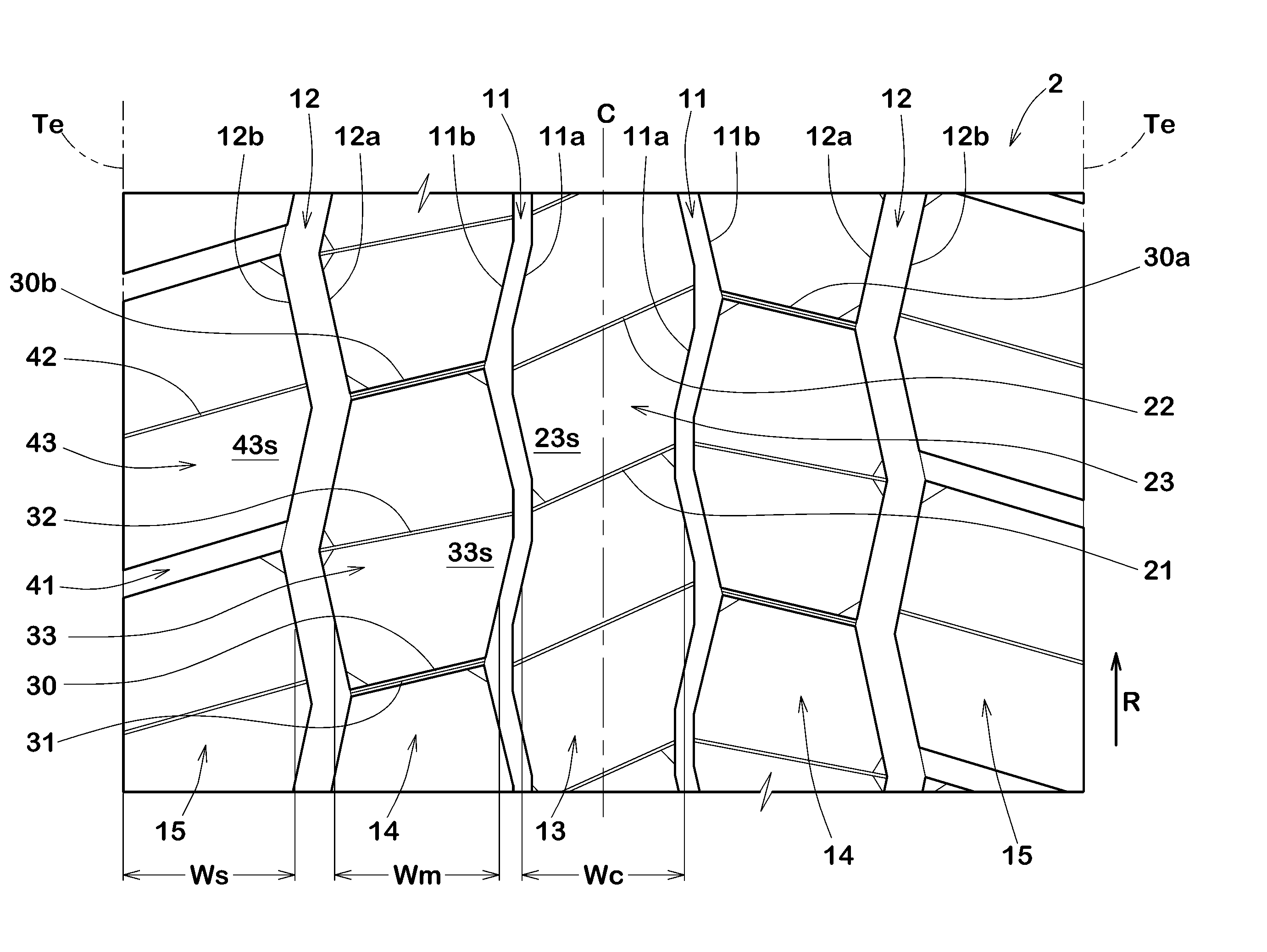

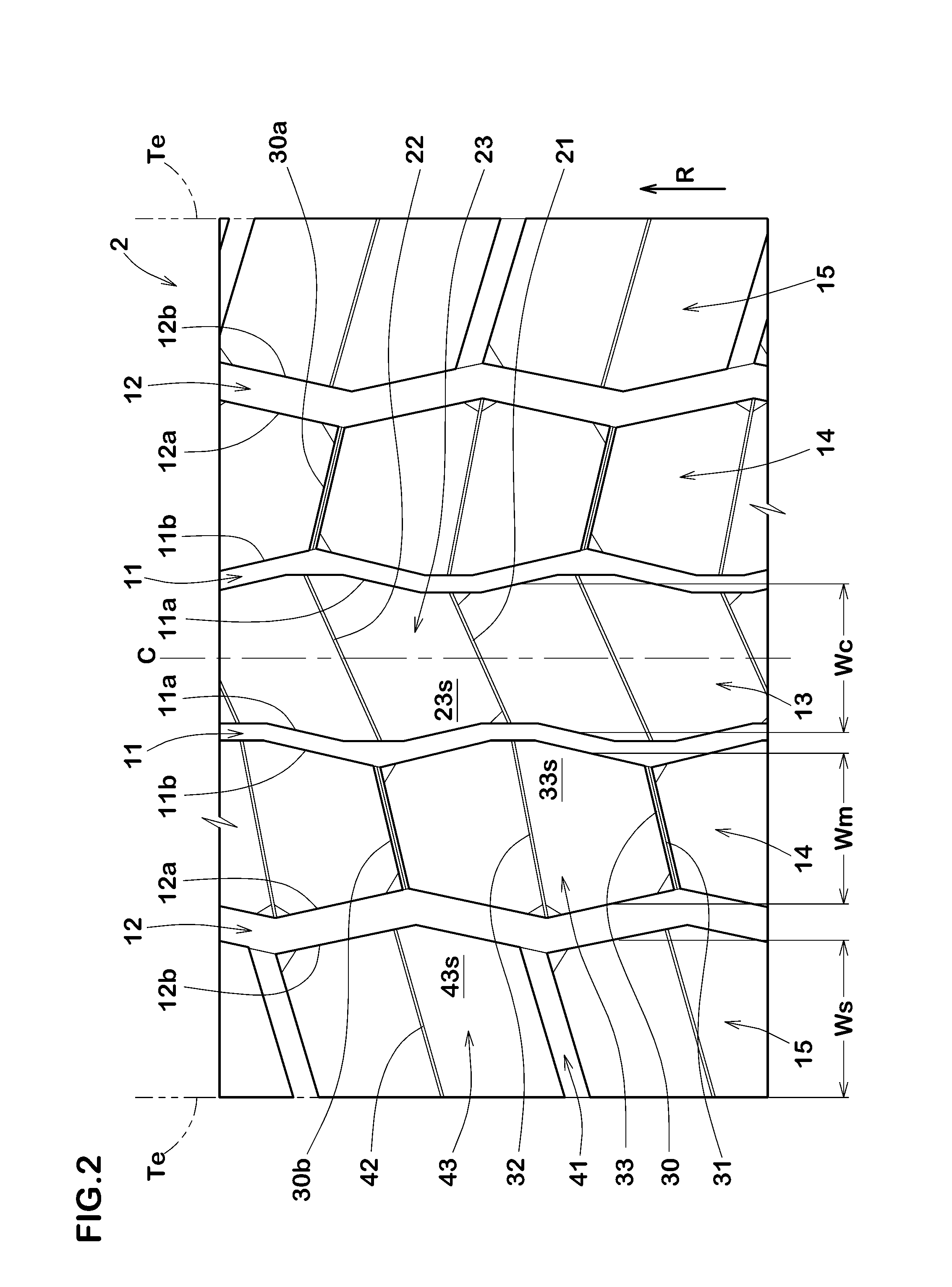

Heavy-duty tire

ActiveUS20160159158A1Improve rigiditySmall rolling resistanceHeavy duty tyresHeavy duty vehicleEngineeringHeavy duty

A tread portion (2) has a pair of center main grooves (11) extending zigzag and continuously in a tire circumference direction, a pair of shoulder main grooves (12), a center land portion (13), a pair of middle land portions (14), and a pair of shoulder land portions (15). The center main groove (11) has a first groove edge (11a) on the tire equator side and a second groove edge (11b) on the tread edge side. The shoulder main groove (12) has a third groove edge (12a) on the tire equator side and a fourth groove edge (12b) on the tread edge side. The middle land portion (14) is provided with a plurality of middle lateral shallow grooves (30) connecting between apex portions (11h) on the most tread edge side of the second groove edge (11b) and apex portions (12c) on the most tire equator side of the third groove edge (12a); and a plurality of first middle lateral sipes (31) extending along the middle lateral shallow grooves (30) at the groove bottoms of the middle lateral shallow grooves (30) and connecting between the center main groove (11) and the shoulder main groove (12).

Owner:SUMITOMO RUBBER IND LTD

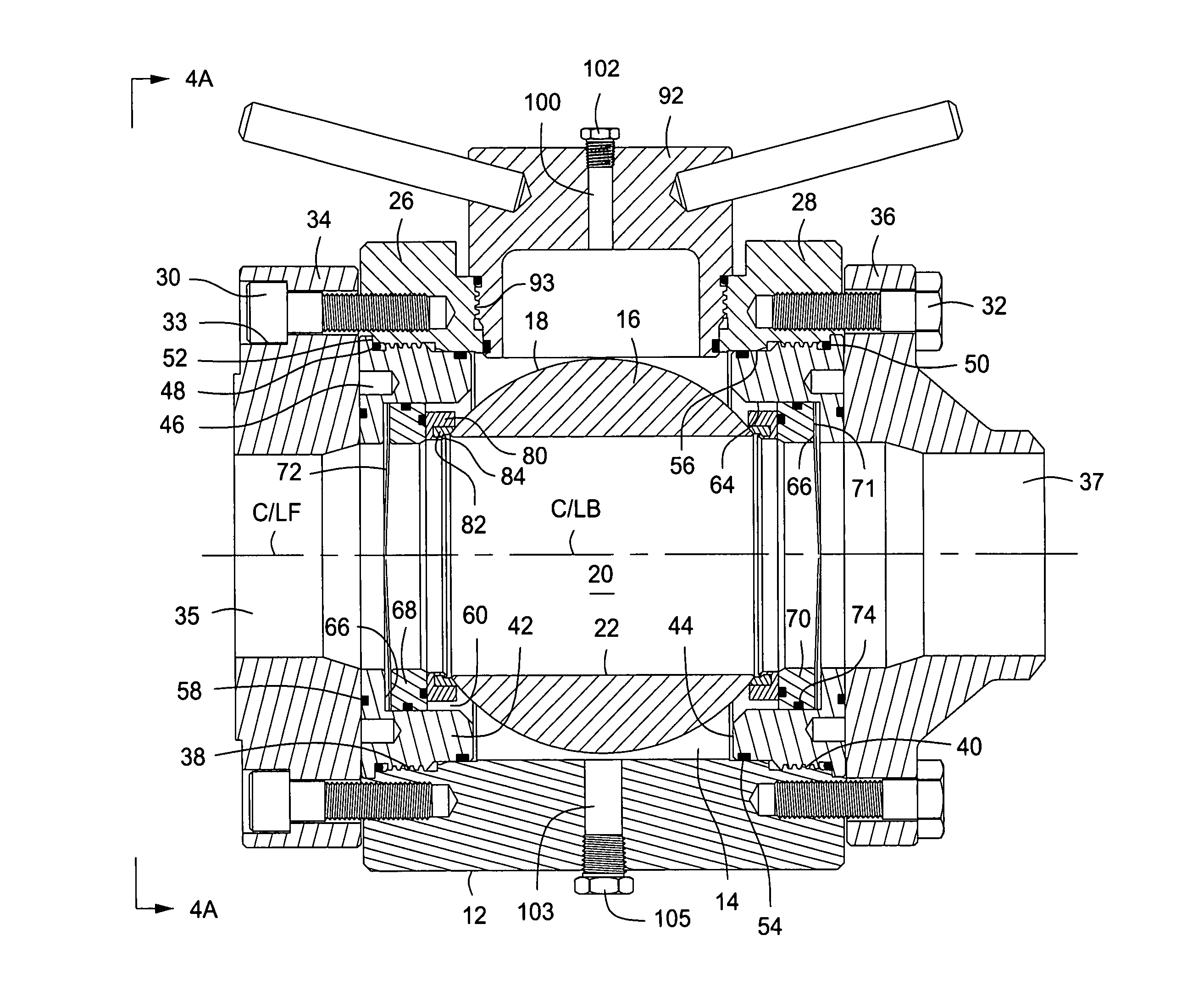

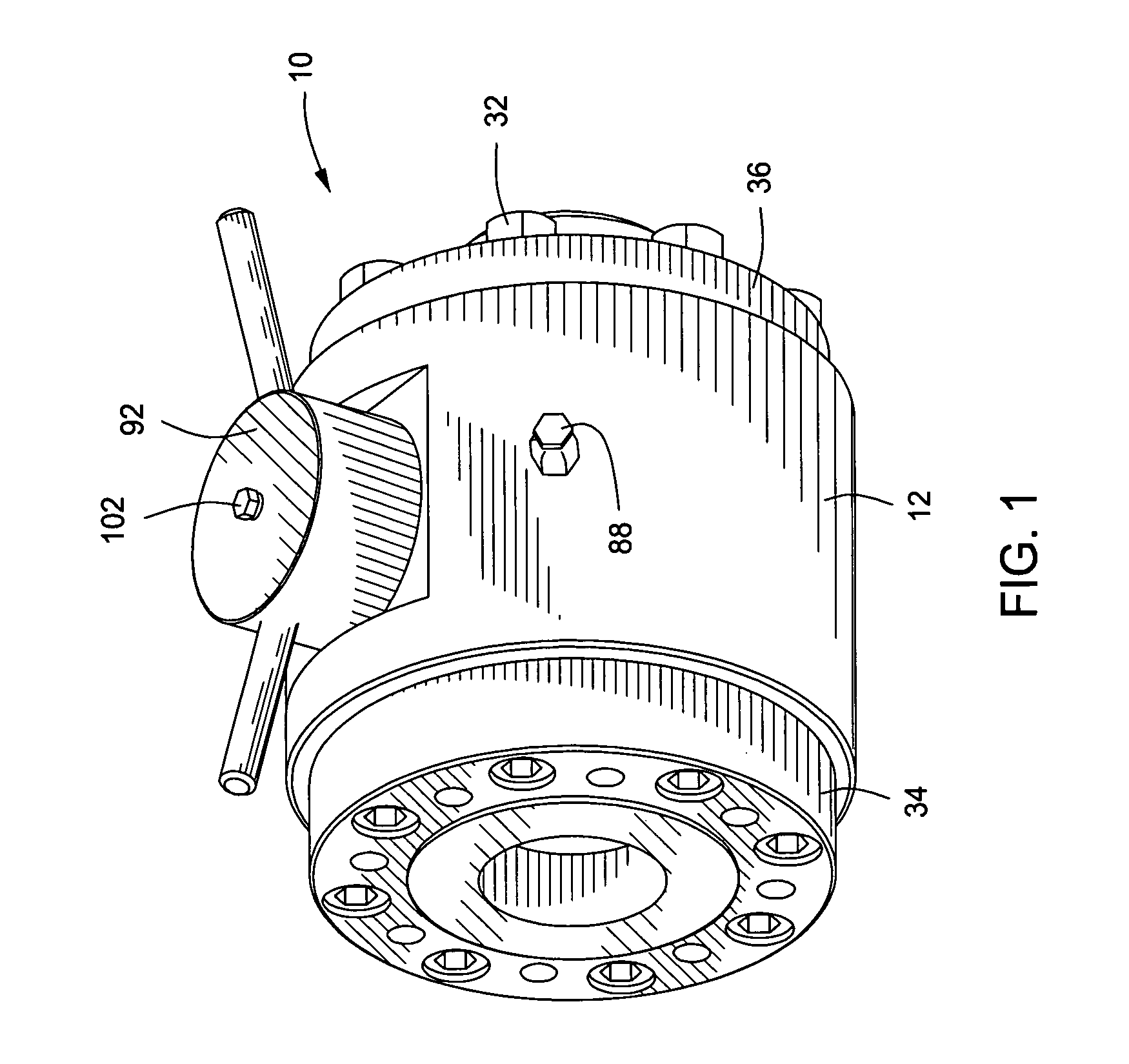

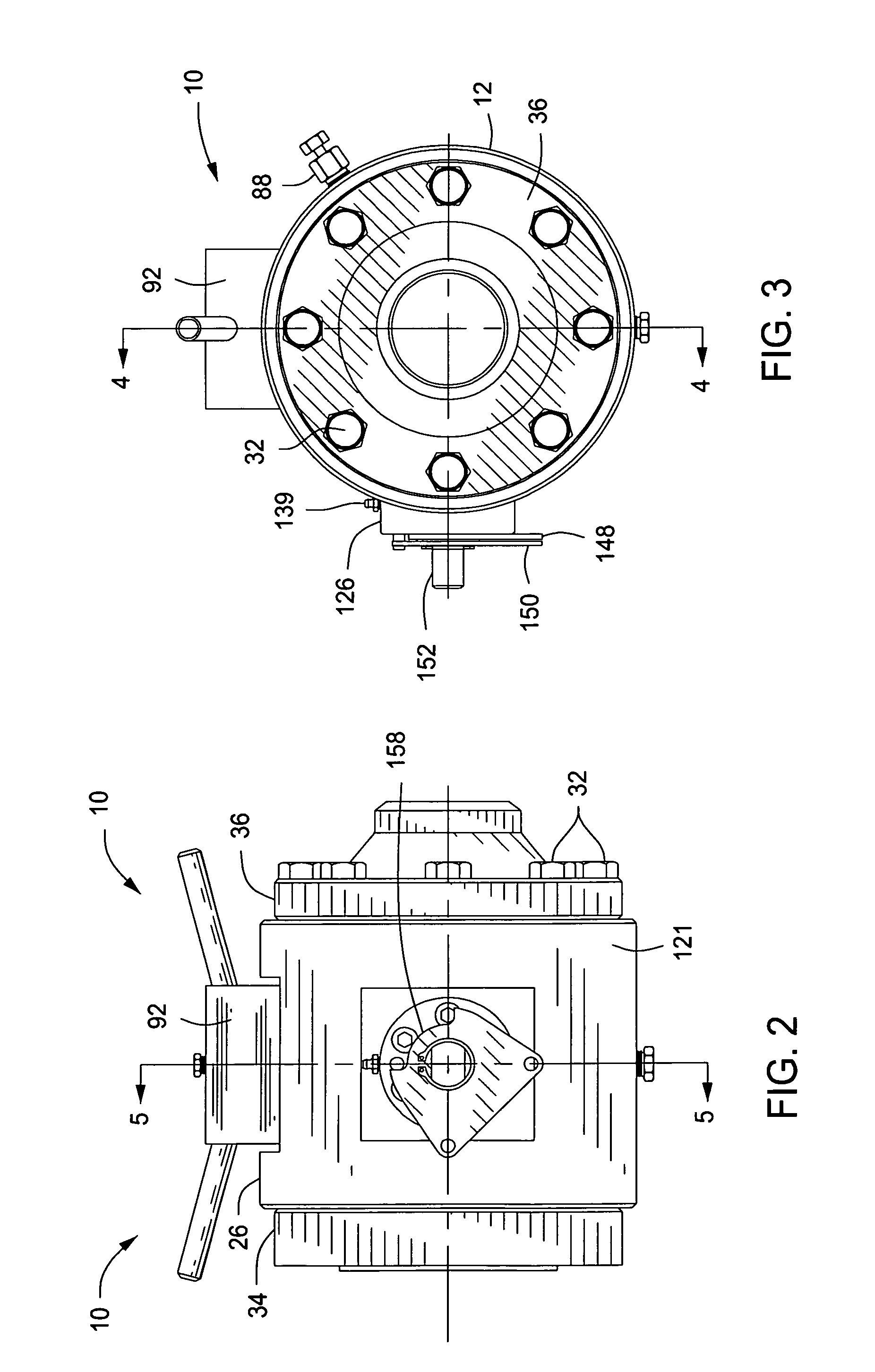

Pig valve having trunnion supported ball, self-centering seats and universal type mounting flanges

A pig launching and retrieval valve, which is adapted to be mounted within a pipeline for fluid flow control and for inserting and retrieving pig devices, such as round nosed cylinders, balls, scrapers and the like, for pipeline cleaning, for separation of fluids within the pipeline and for other pipeline inspection and servicing activities. The pig valve is of universal nature, having sub flanges for adaptation of special flange mounting and / or API standard flange mounting. The pig valve has a trunnion supported valve ball and pressure energized seat members that are enabled to shift laterally within respective seat recesses and thus establish self-centering with the valve ball.

Owner:STUNKARD GERALD A

Electric brake

InactiveUS20070062764A1Avoid uneven wearInhibits uneven wearDynamo-electric brakes/clutchesElectrodynamic brake systemsPosition controlPiston

Pistons 3 and 7 are pressed to a friction member 11 at two points that are positioned at a rotating-in side and a rotating-out side in a rotating direction of a brake rotor 10. An axial force control is performed for the piston 3 on the rotating-out side, and a position control based on the position of the piston 3 on the rotating-out side is performed for the piston 7 on the rotating-in side.

Owner:AKEBONO BRAKE IND CO LTD

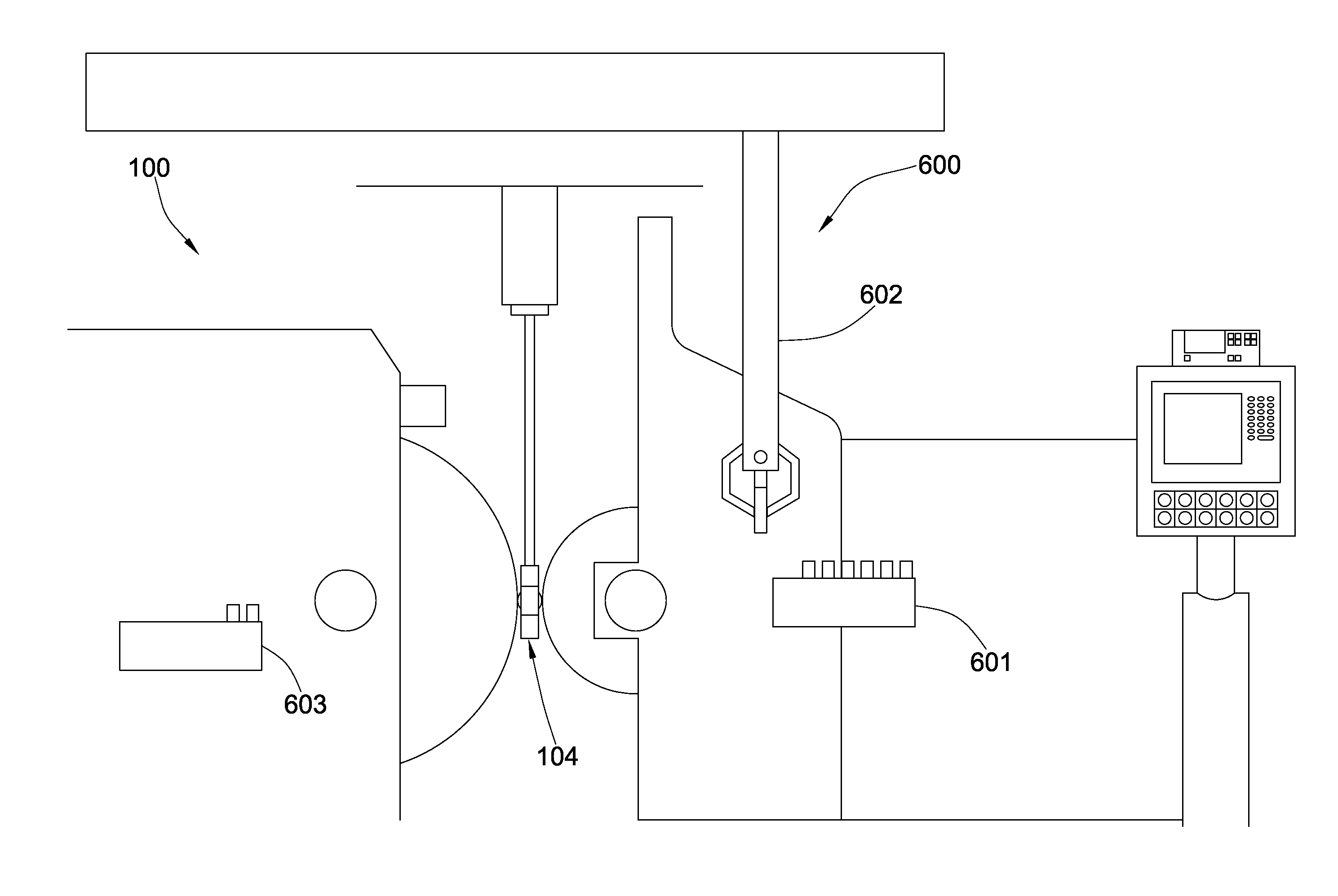

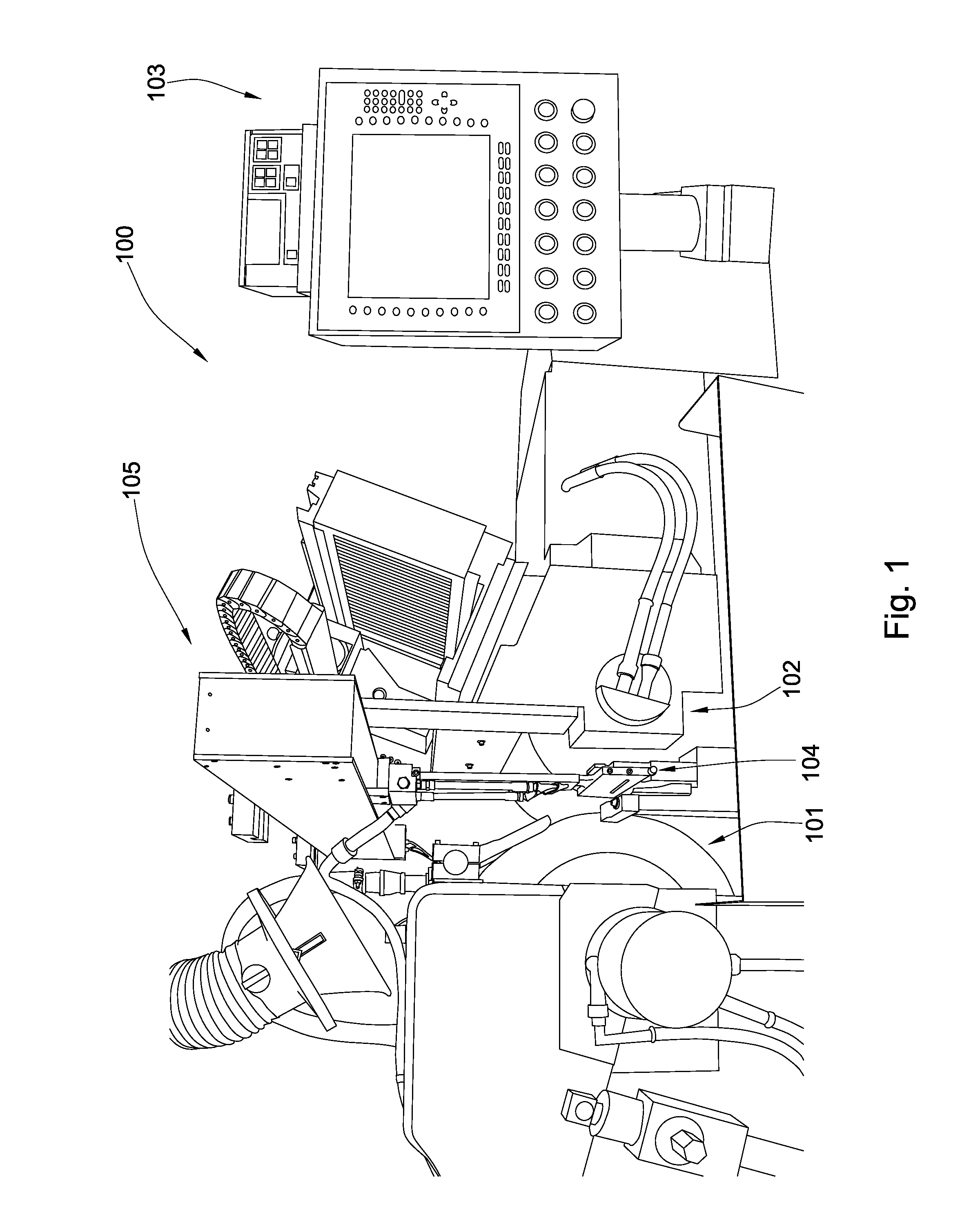

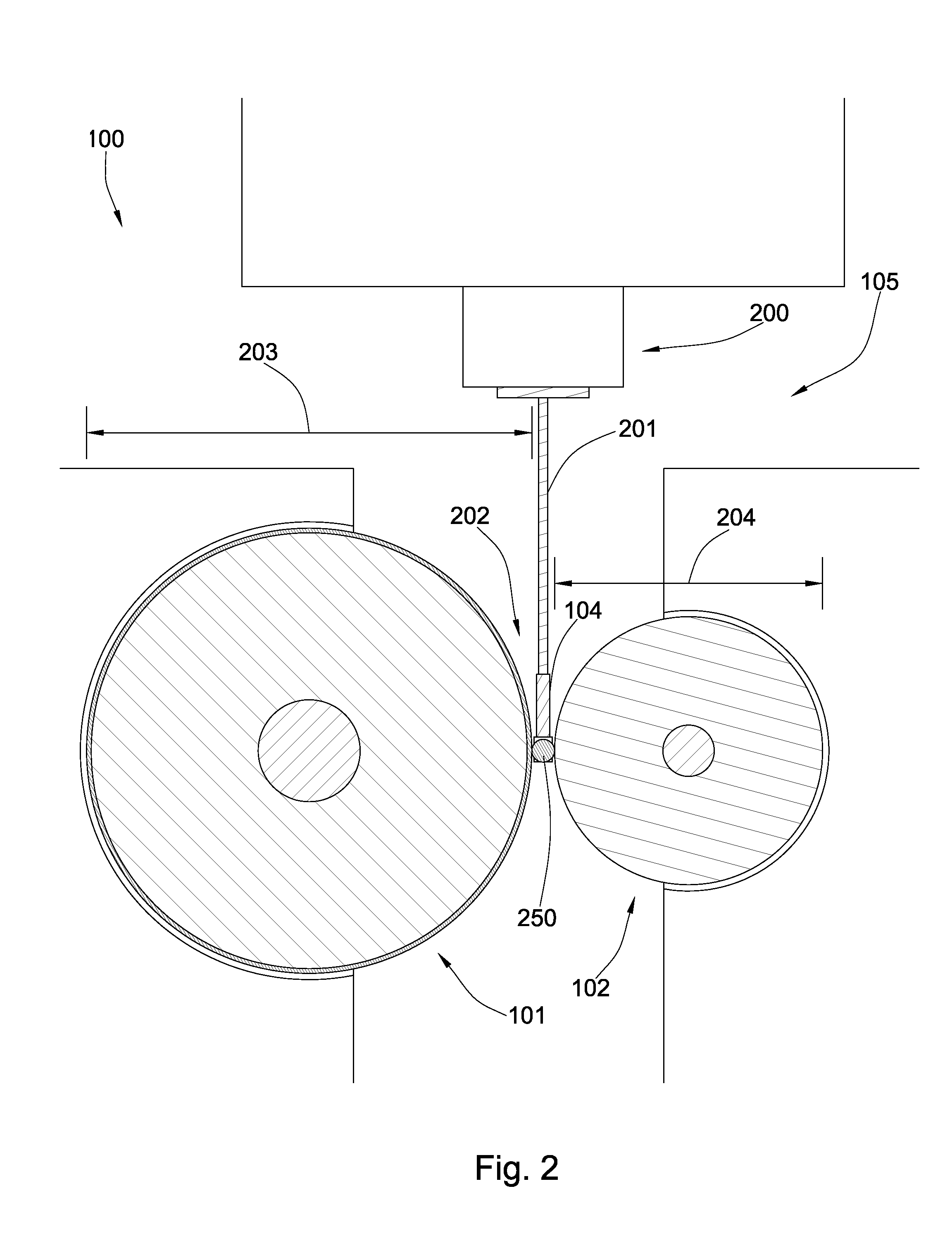

O.D. Centerless Grinding Machine

InactiveUS20080293328A1Avoid uneven wearEdge grinding machinesRevolution surface grinding machinesMechanical engineeringElectronic equipment

In one aspect of the present invention, an outer diameter (O.D.) centerless grinding machine for use in grinding a diamond workpiece has a grinding wheel positioned parallel to a regulating wheel which is adapted to press a cylindrical workpiece into the grinding wheel as the regulating wheel rotates. Electronic equipment may be adapted to adjust a pressure of the regulating wheel against the grinding wheel. Also, a carrier may be adapted to house the workpiece, the carrier being attached to a translation mechanism adapted to move the carrier between the wheels such that the workpiece is in contact with both wheels.

Owner:NOVATEK IP

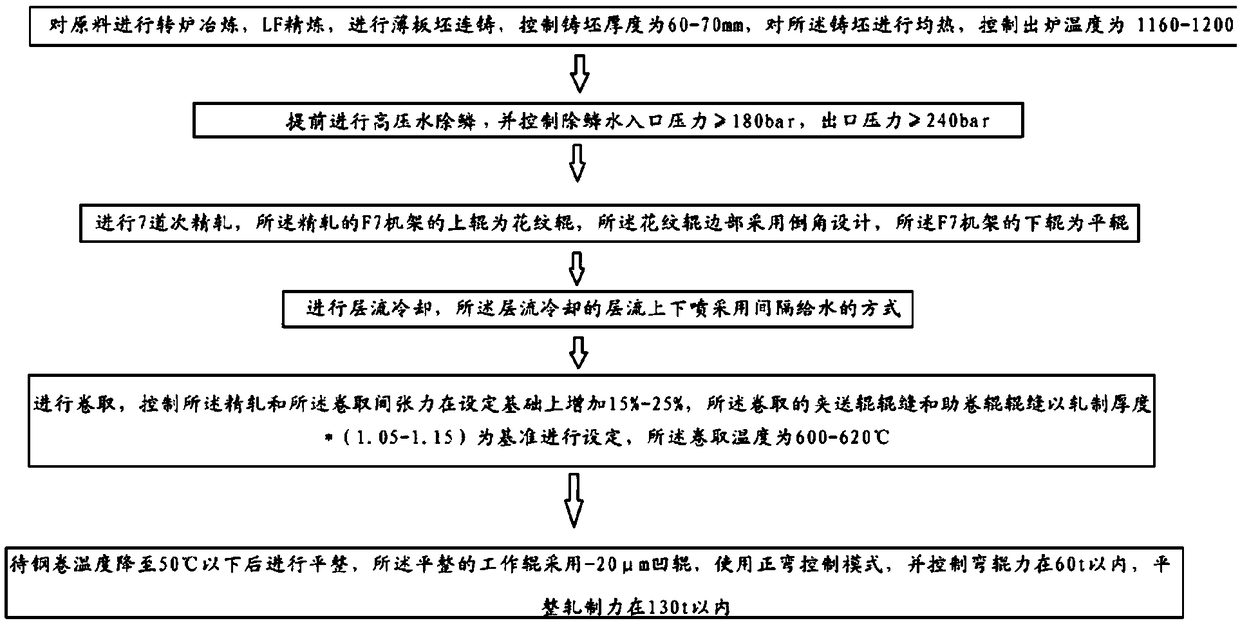

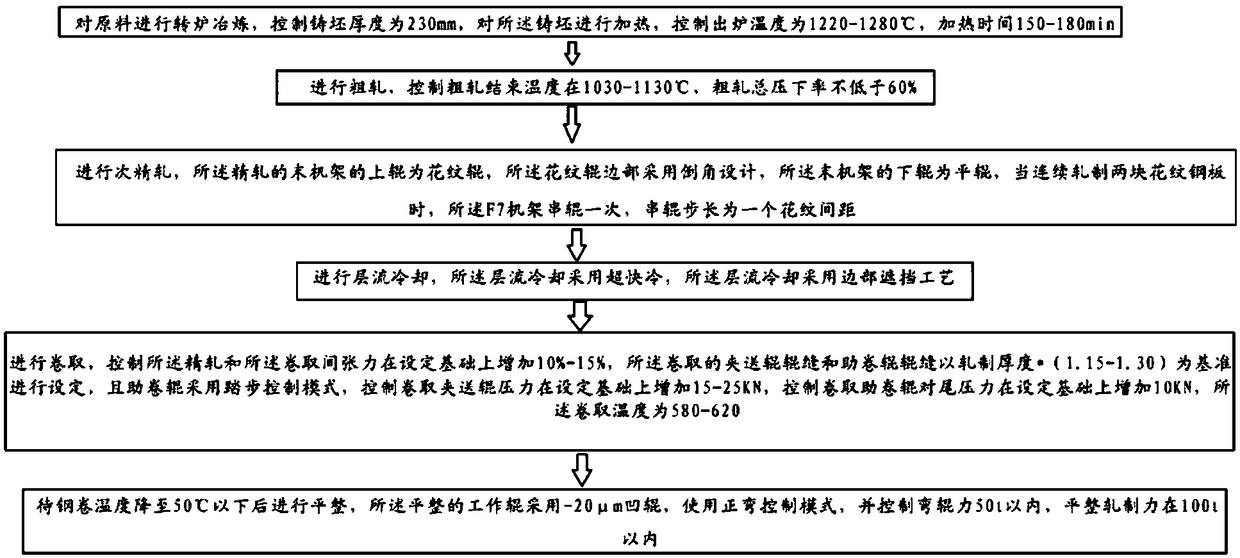

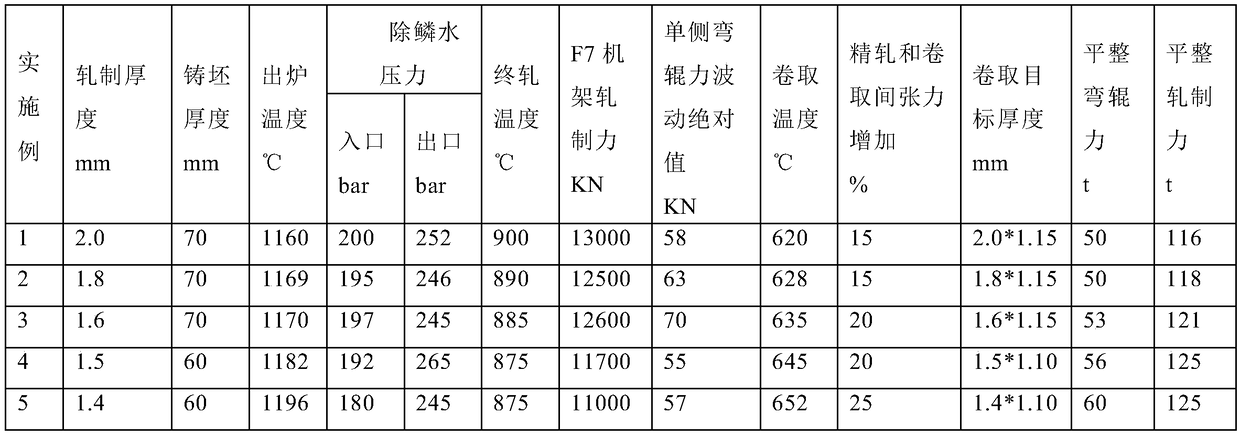

Checkered steel plate and production method thereof

ActiveCN108971224AReduce the temperatureUniform temperature throughoutRollsMetal rolling arrangementsSheet steelImpurity

The invention discloses a checkered steel plate and a production method thereof, and belongs to the technical field of steel rolling. The checkered steel plate is characterized in that the checkered steel plate comprises the components of, by weight, 0.020-0.065% of C, no more than 0.40% of Si, 0.20-0.70% of Mn, no more than 0.025% of P, no more than 0.015% of S, 0.02-0.06% of Als, no more than 0.010% of N, and the balance iron and unavoidable impurities. According to the checkered steel plate and the production method thereof, the demands of batched stable production of thin specification checkered steel plates can be met.

Owner:武汉钢铁有限公司

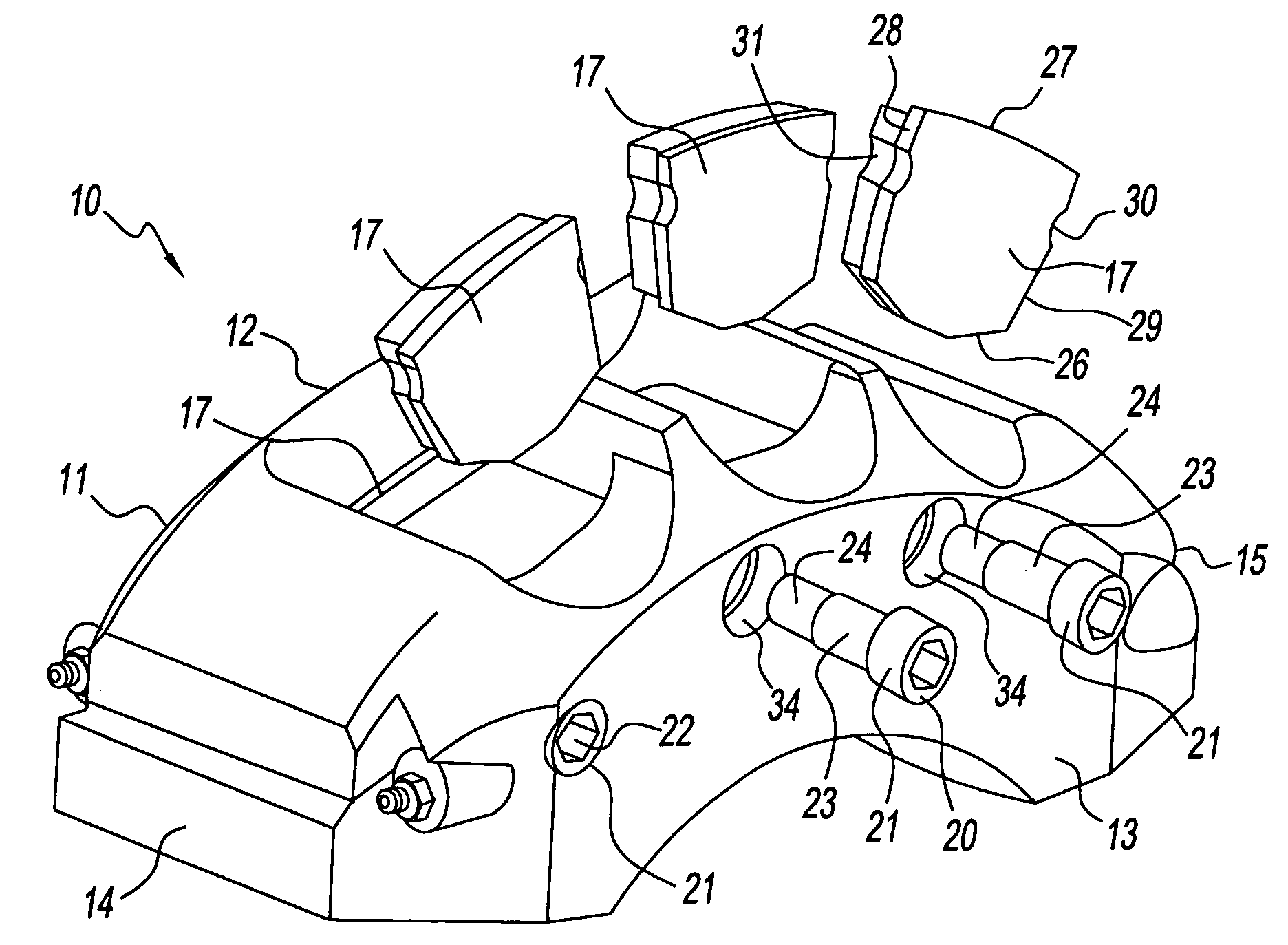

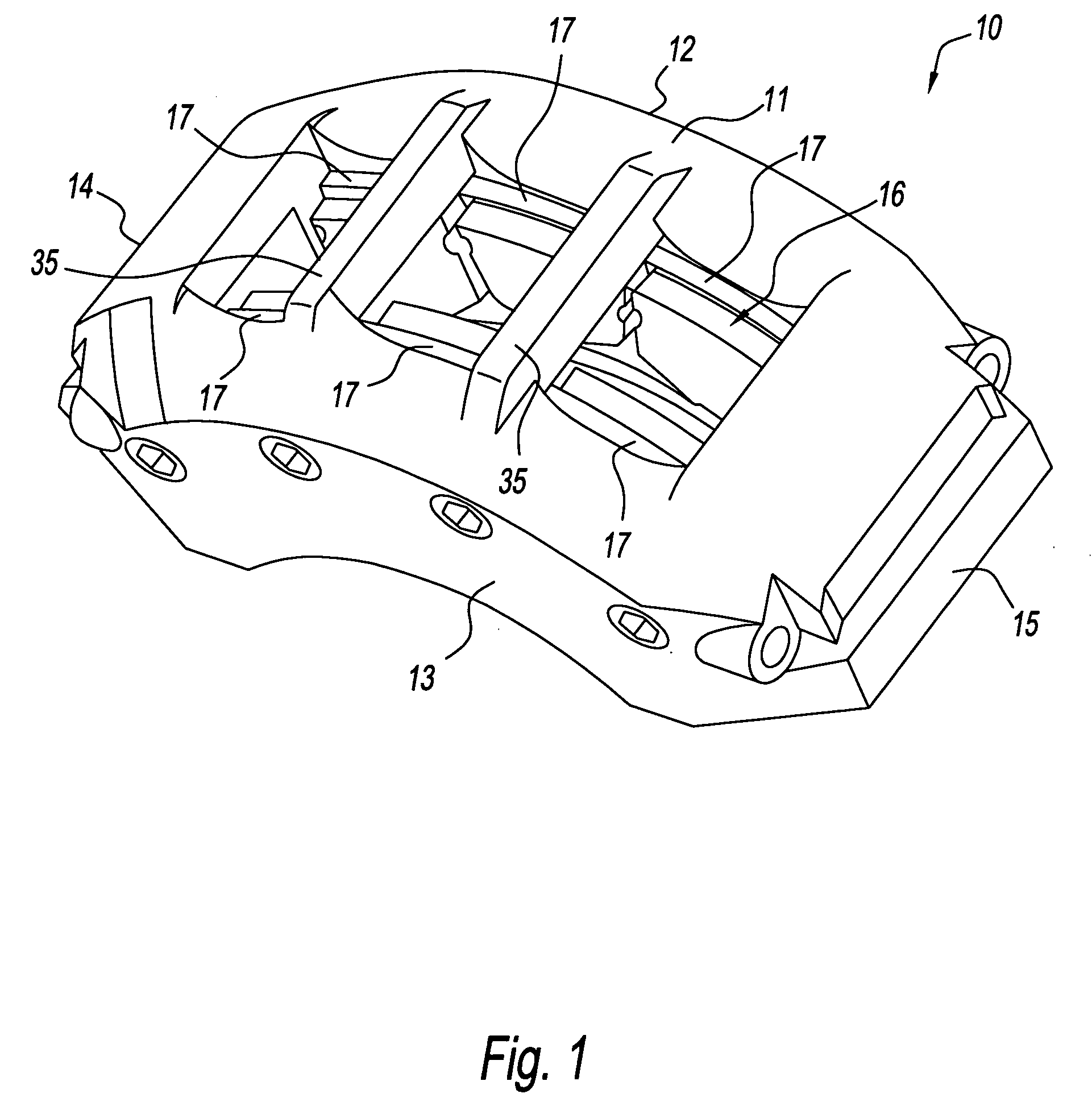

Disc brake caliper

InactiveUS20080264738A1Increase stiffnessLow costFluid actuated brakesMechanically actuated brakesEngineeringCalipers

An opposed piston disc brake caliper has a caliper housing arranged for mounting brake shoes on each of opposite sides of a rotor. The rotor in use is disposed between the brake shoes with each brake shoe having a backing plate and a friction lining applied to the backing plate. The caliper housing has side walls extending generally in a plane parallel to a plane of the rotor and on opposite sides of the plane of the rotor which accommodate a piston. The caliper housing has mounting members for engagement with each of the side edges of each backing plate between the radially inner edge and the radially outer edge of the friction lining. The engagement is such as to substantially limit movement of each brake shoe other than in a direction toward or away from the rotor with at least one of the mounting members being removable from the caliper housing to facilitate removal of the brake shoe from the caliper housing.

Owner:PBR AUSTRALIA PTY LTD

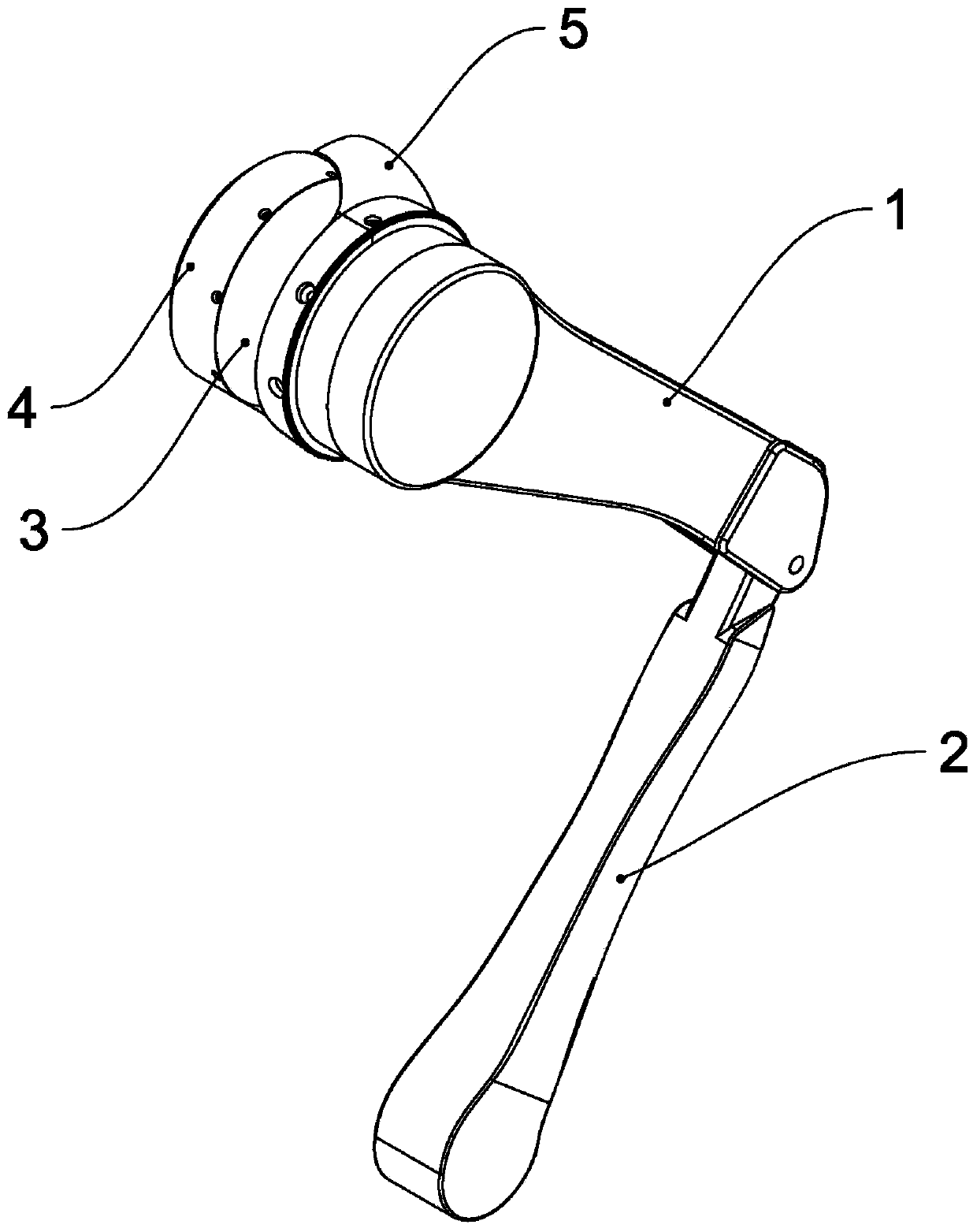

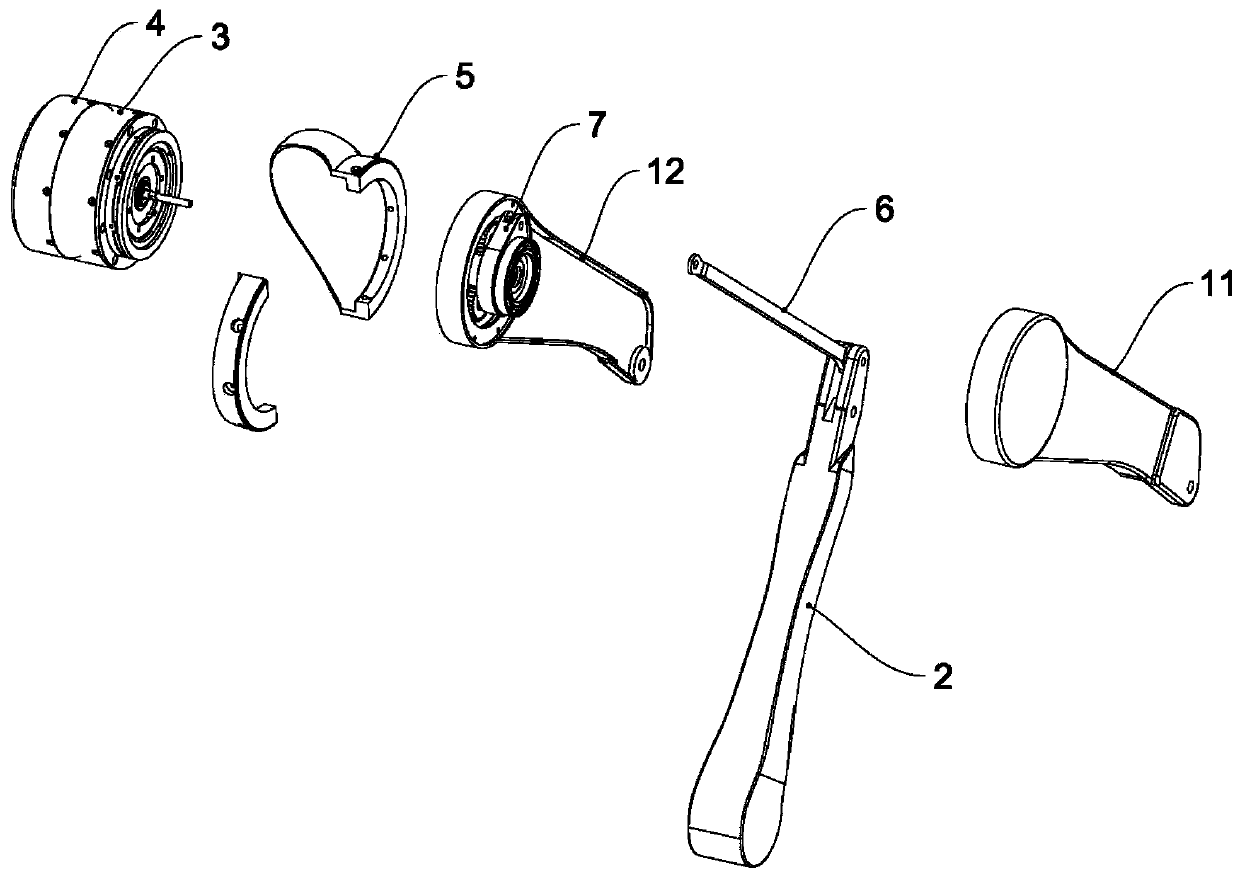

Robot integrated joint unit and foot type robot applying same

PendingCN109941369AAvoid crossing the jointReduce fatigue damageProgramme-controlled manipulatorJointsFatigue damageReduction drive

The invention discloses a robot integrated joint unit and a foot type robot applying the same, and belongs to the technical field of robot joints. An existing double-joint line arrangement mode influences structure safety and attractiveness of a robot, a wire is easily damaged, and the service life of the wire is influenced. The robot comprises a first motor, a speed reducer assembly, a second motor assembly, a second speed reducer assembly and a first output connecting rod. Double motors of double joints are located on the same side of the joints, and the situation that a motor power cable needs to pass through the joints is avoided so that the fatigue damage of the motor power cable can be effectively relieved, and the service life of the motor cable wire can be prolonged. The motor assembly and a joint connecting rod do not need to reserve a special threading hole and a cable arrangement mechanism, so that the structure is more reliable; the integration degree of the double-joint unit is further improved, the axial size of the joint unit is reduced, and the structure is more attractive.

Owner:HZ UNITREE TECHNOLOGY CO LTD

Sealing assembly for an ink chamber which includes self-lubricating anilox roll seal with improved blade/seal area

InactiveUS7597761B2Avoid uneven wearImprove sealingLiquid surface applicatorsRotary intaglio printing pressSupport surfaceLubricant

A sealing assembly for an ink chamber associated with an anilox roll, includes a doctor blade having a doctoring edge, with each end having a notch at the doctoring edge, and first and second seals adapted to seal ends of the ink chamber. Each seal includes a peripheral supporting wall, an upper wall thereon including an upper concave surface for engaging an outer surface of the anilox roll, a flat upper supporting surface at opposite ends of the upper wall on which ends of the doctor blade seat, and an extension above the flat upper supporting surface for engaging within the notch at the end of the doctor blade to permit the doctor blade to bend thereat. A lubricant chamber is defined therein and the upper wall includes an opening through which the lubricant is forced out of the lubricant chamber due to external pressure.

Owner:VALLEY HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com