Checkered steel plate and production method thereof

The technology of a patterned steel plate and a production method, which is applied in the field of steel rolling, can solve the problem that the thin-sized patterned steel plate cannot be produced stably in batches, etc., and achieve the effects of alleviating the uneven distribution of contact pressure between rolls, reducing damage, and ensuring the cooling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

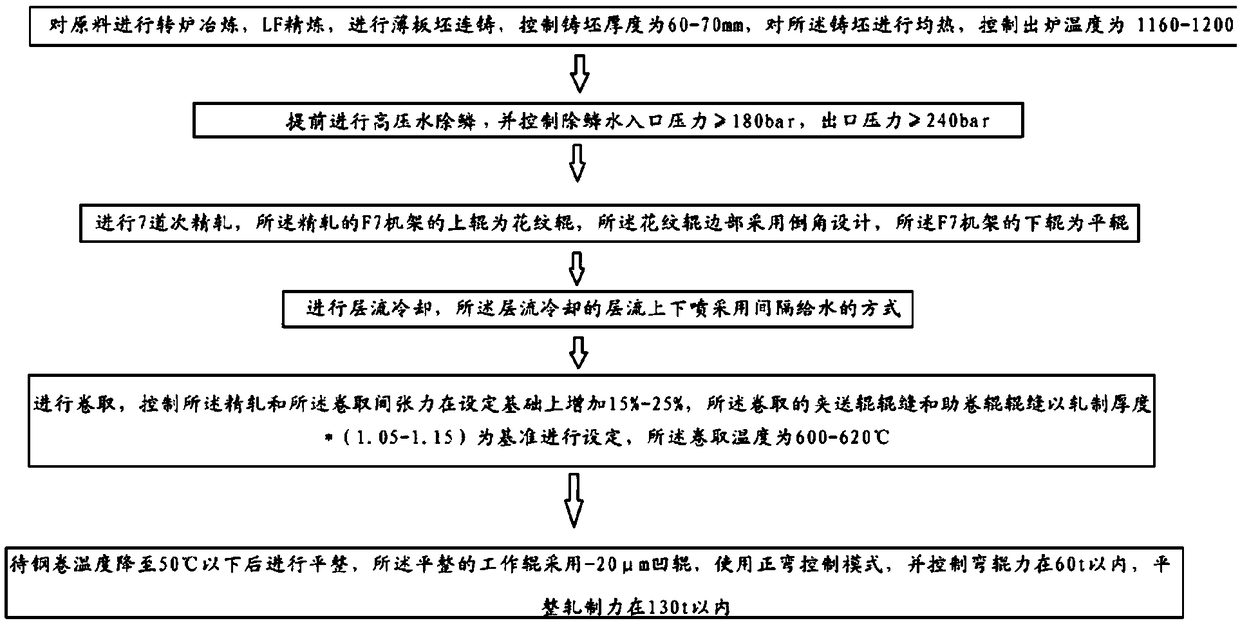

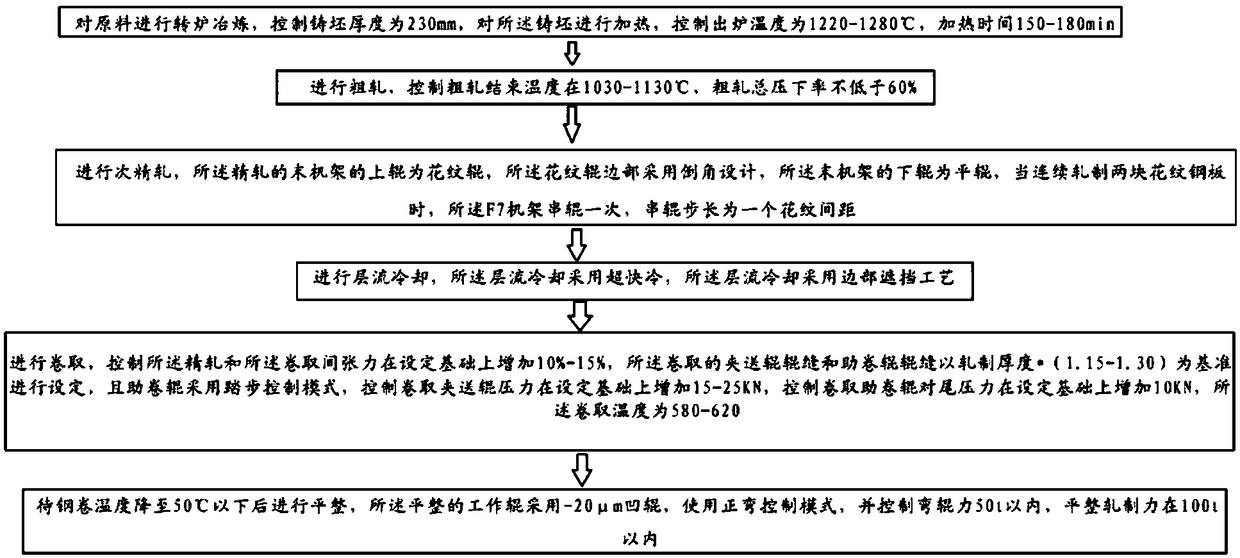

Method used

Image

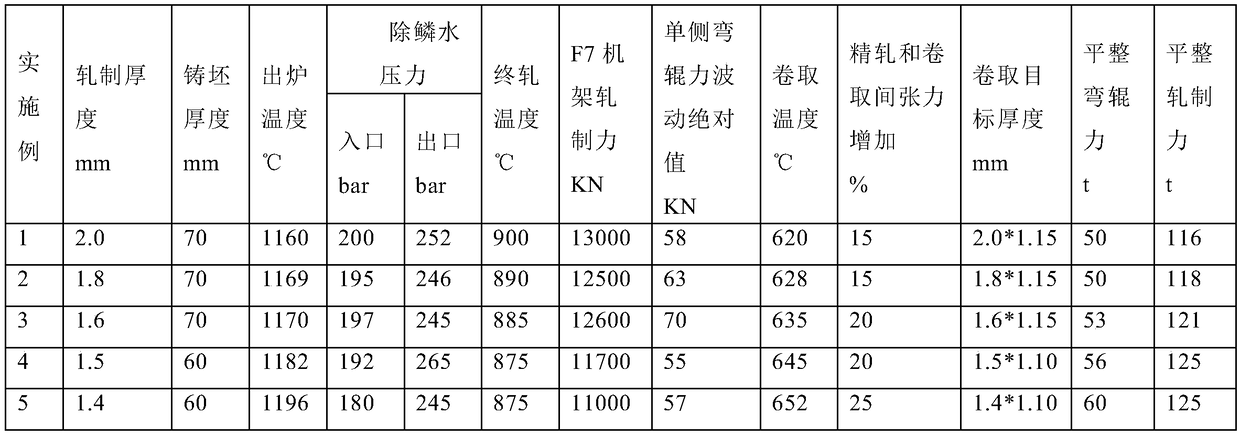

Examples

Embodiment Construction

[0021] see figure 1 , the composition of a patterned steel plate provided by the embodiment of the present invention is by weight percentage: C: 0.020-0.065%, Si≤0.40%, Mn: 0.20-0.70%, P≤0.025%, S≤0.015%, Als: 0.02 ~0.06%, N≤0.010%, the rest is iron and unavoidable impurities.

[0022] Description of the main alloy elements of the present invention:

[0023]C is the most economical and effective element for improving steel strength, but excessive C content will deteriorate the weldability of the steel. The weather-resistant patterned steel plate of the present invention must have good weldability, and the C content of the present invention is designed to be 0.040-0.075%.

[0024] Si is beneficial to improve the strength and yield point of steel, and is also an important element affecting the surface quality of hot-rolled strip steel. In order to ensure the good surface quality of the steel plate, the Si content of the present invention is designed to be 0.25-0.45%.

[0025] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com