Chisel holder

A tool holder and tool technology, used in cutting machinery, earth-moving drilling, slitting machinery, etc., can solve problems such as unevenness, influence of tool rotation performance, and the central longitudinal axis of the tool holding device cannot be vertical, etc., and achieves easy manufacturing. The effect of stable and reliable arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

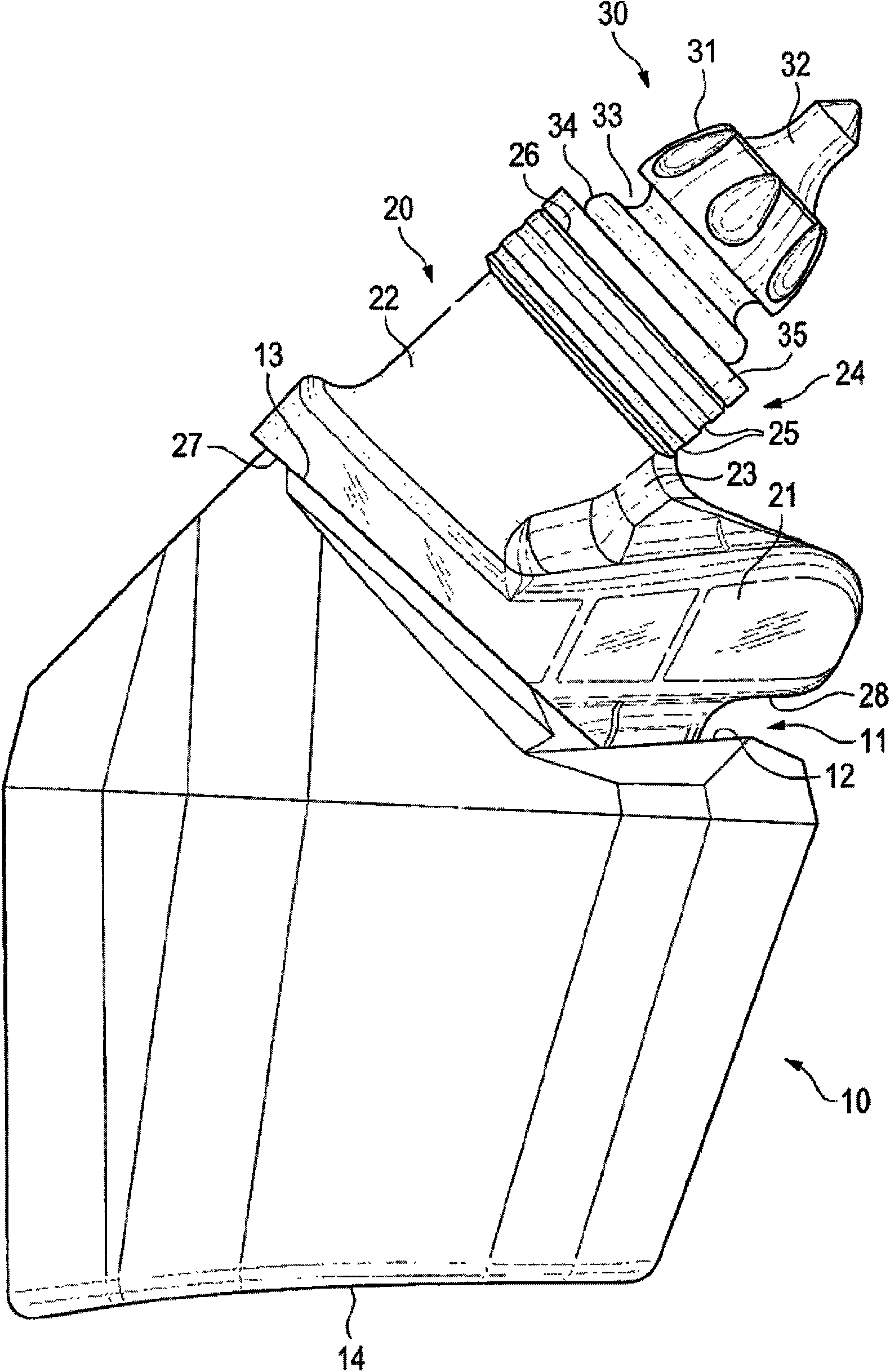

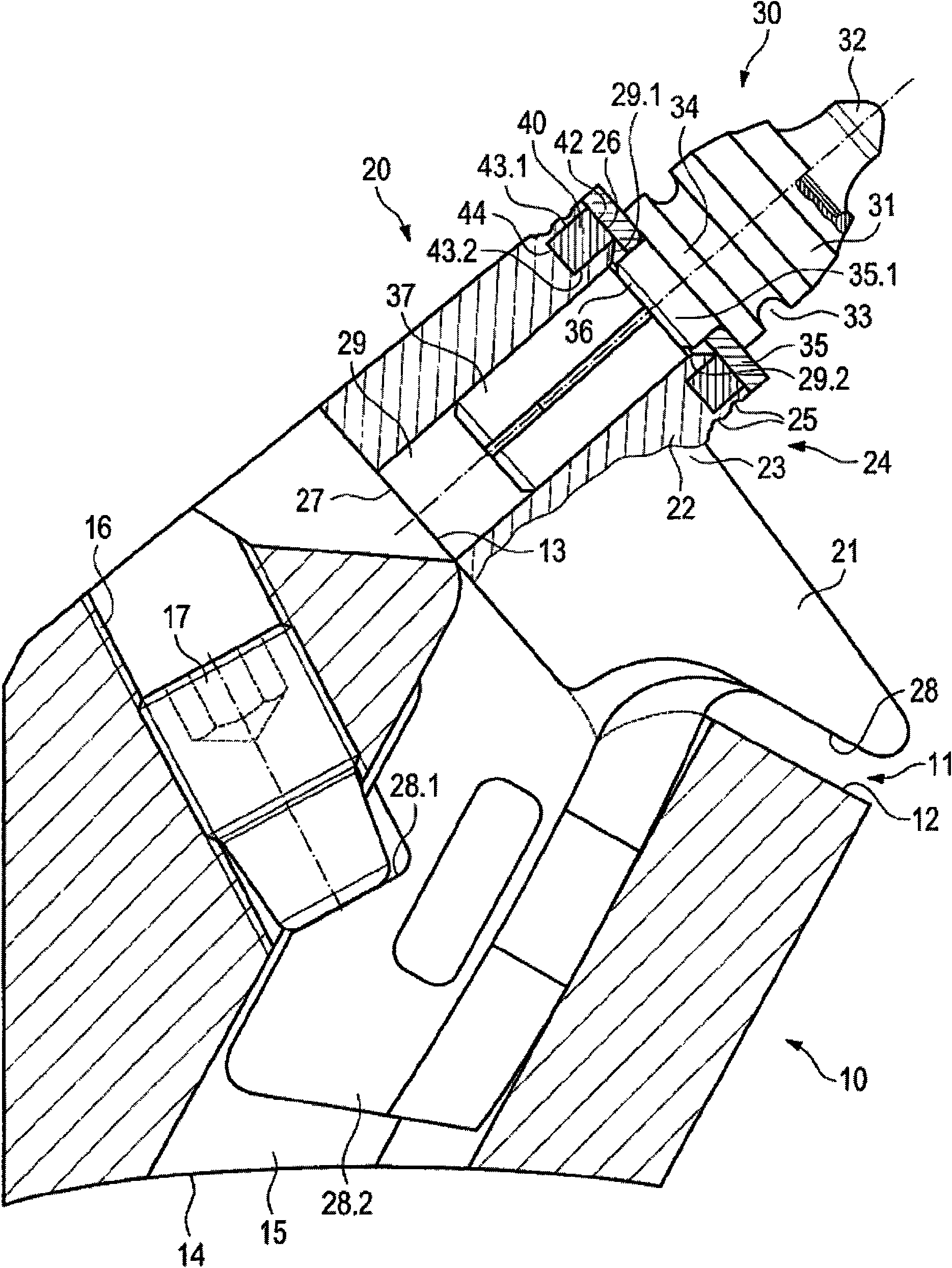

[0028] figure 1 and figure 2 A tool holder changing system is described which has a base 10 , a tool holder 20 and a tool 30 .

[0029] Such as figure 2 As shown, the base 10 has a shank holder 15 which is formed in the base 10 in the form of a through-hole starting from the shoulder 12 or the base 14 .

[0030] The stop surface 13 is connected at an angle to the shoulder 12 . The base 10 can be mounted via a bottom surface 14 on the outer circumference of a road milling machine milling drum (not depicted in the figures). The base 10 is welded to the milling drum. A threaded hole 16 leads into the tool shank holding device 15 in the opposite direction of tool feed, into which a set screw 17 is screwed.

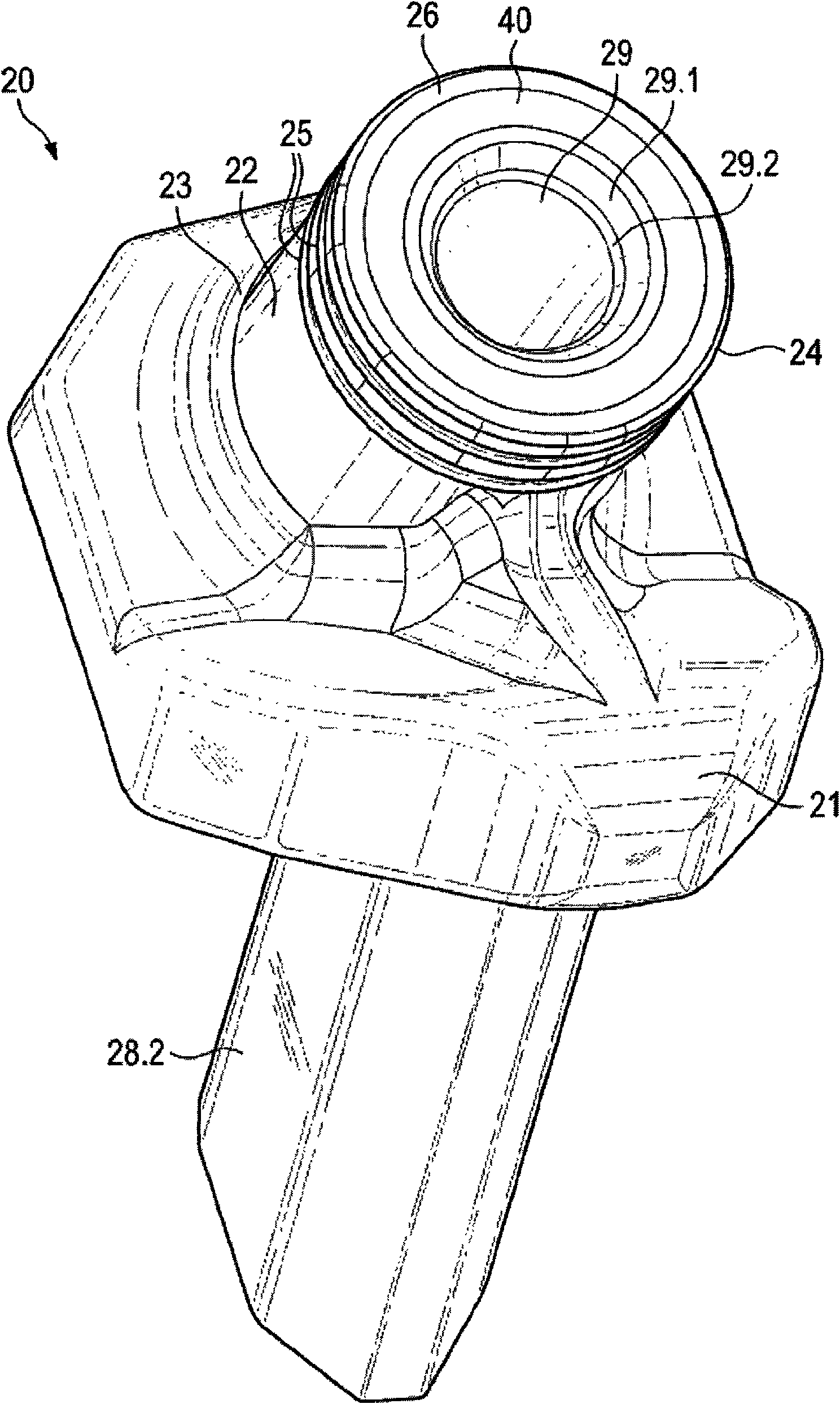

[0031] The fixing screw 17 is used to fix the knife seat 20. The knife holder 20 has a baffle 21 which is connected with a connecting section 23 . The connecting section 23 supports an additional part 22 which has a cylindrical section 24 extending beyond the stop 23 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com