Antistatic flame-retardant thermoplastic polyurethane elastomer

A thermoplastic polyurethane and antistatic technology, applied in the field of antistatic flame retardant thermoplastic polyurethane elastomer, can solve the problems of easy water absorption, toughening and toughening of TPU without consideration, and achieve the effects of easy industrial production, good antistatic, and reduced water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

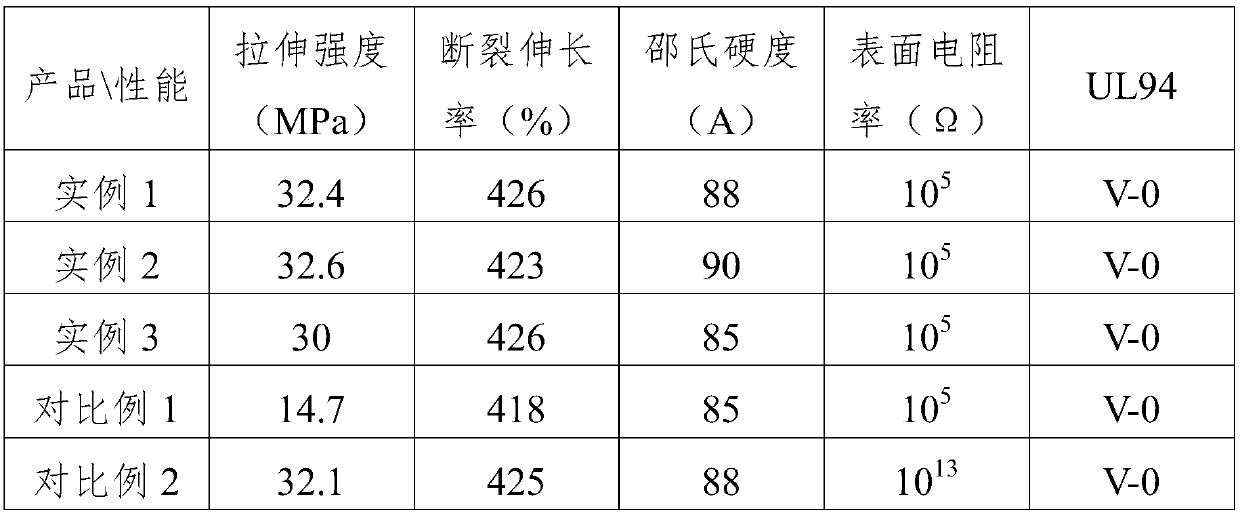

[0024] Weigh each component according to the following parts by weight: 80 parts of TPU, 20 parts of LLDPE, 8 parts of C nanomaterials, 12 parts of composite flame retardant, 4 parts of antimony trioxide, 5 parts of polyolefin elastomer grafted maleic anhydride, 0.35 parts of ethylene bis stearamide, 0.6 parts of polyethylene glycol, 0.3 parts of PE wax, 0.1 parts of 3-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate and 0.1 Tris(2,4-di-tert-butylphenyl)phosphite. First add the raw materials TPU, LLDPE and dispersant to an ordinary low-speed mixer and stir at room temperature for 5 minutes, then add other raw materials that have been weighed and stir for 10-15 minutes to disperse the components evenly; add them to a twin-screw extrusion granulator to melt and extrude Granulate. The melt extrusion temperature of the twin-screw granulator is from the feed port to the die head: 180°C, 190°C, 200°C, 210°C, 220°C, 220°C, 210°C. The relevant properties of the plastic alloy...

Embodiment 2

[0026] Weigh each component according to the following parts by weight: 80 parts of TPU, 30 parts of LLDPE, 8 parts of C nanomaterials, 12 parts of composite flame retardant, 4 parts of antimony trioxide, 5 parts of polyolefin elastomer grafted maleic anhydride, 0.35 parts of ethylene bis stearamide, 0.6 parts of polyethylene glycol, 0.3 parts of PE wax, 0.1 parts of 3-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate and 0.1 Tris(2,4-di-tert-butylphenyl)phosphite. Add the raw materials TPU, LLDPE and dispersant to an ordinary low-speed mixer and stir at room temperature for 5 minutes, then add other weighed raw materials and stir for 10-15 minutes to make the components evenly dispersed; add them to a twin-screw extrusion granulator for melt extrusion grain. The melt extrusion temperature of the twin-screw granulator is from the feed port to the die head: 180°C, 190°C, 200°C, 210°C, 220°C, 220°C, 210°C. The relevant properties of the plastic alloy are shown in Table ...

Embodiment 3

[0028] Weigh each component according to the following parts by weight: 80 parts of TPU, 10 parts of LLDPE, 8 parts of C nanomaterials, 12 parts of composite flame retardant, 4 parts of antimony trioxide, 5 parts of polyolefin elastomer grafted maleic anhydride, 0.35 parts of ethylene bis stearamide, 0.6 parts of polyethylene glycol, 0.3 parts of PE wax, 0.1 parts of 3-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate and 0.1 Tris(2,4-di-tert-butylphenyl)phosphite. Add the raw materials TPU, LLDPE and dispersant to an ordinary low-speed mixer and stir at room temperature for 5 minutes, then add other weighed raw materials and stir for 10-15 minutes to make the components evenly dispersed; add them to a twin-screw extrusion granulator for melt extrusion grain. The melt extrusion temperature of the twin-screw granulator is from the feed port to the die head: 180°C, 190°C, 200°C, 210°C, 220°C, 220°C, 210°C. The relevant properties of the plastic alloy are shown in Table ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com