Patents

Literature

1576results about How to "Simple and compact structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

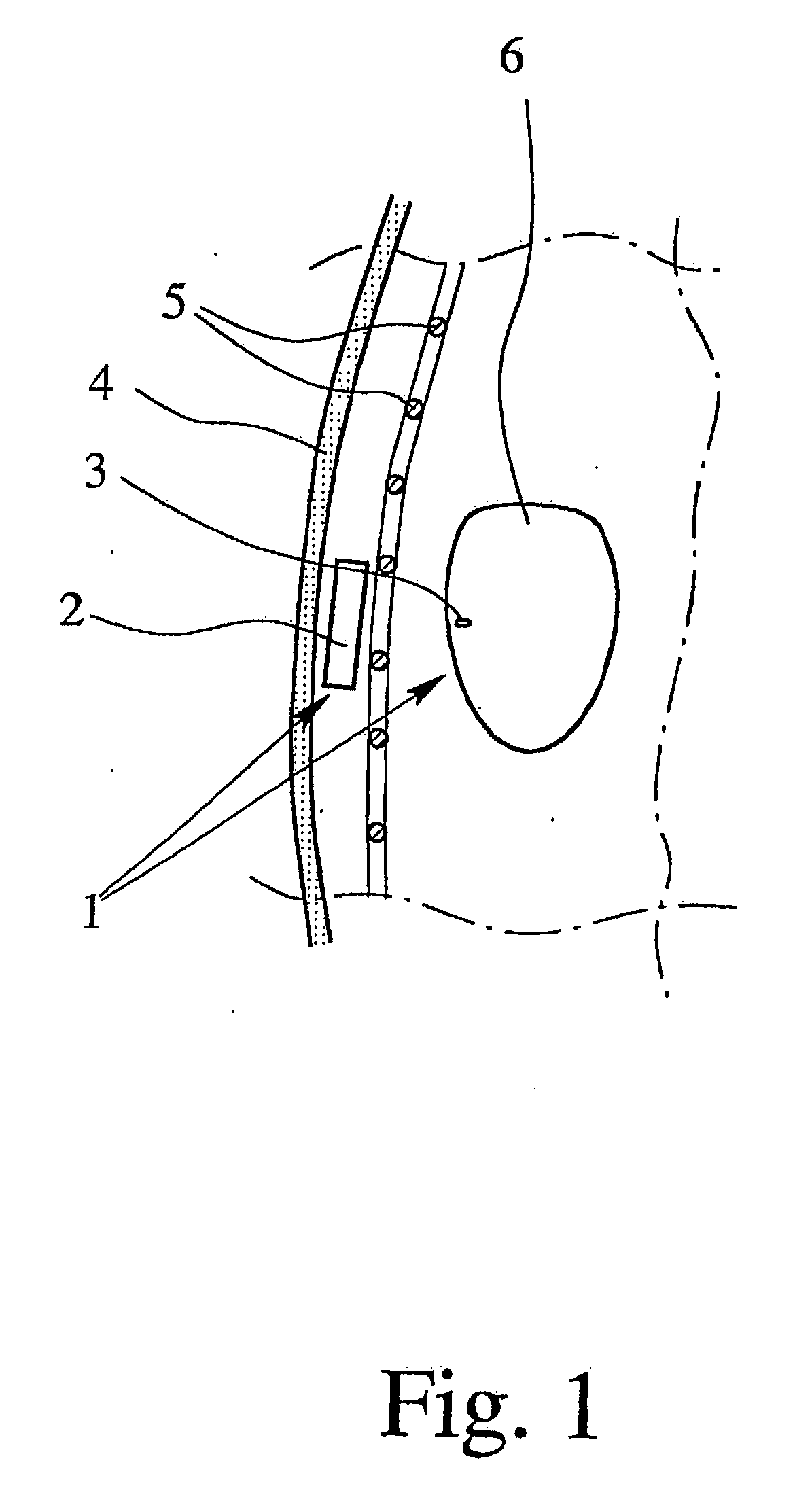

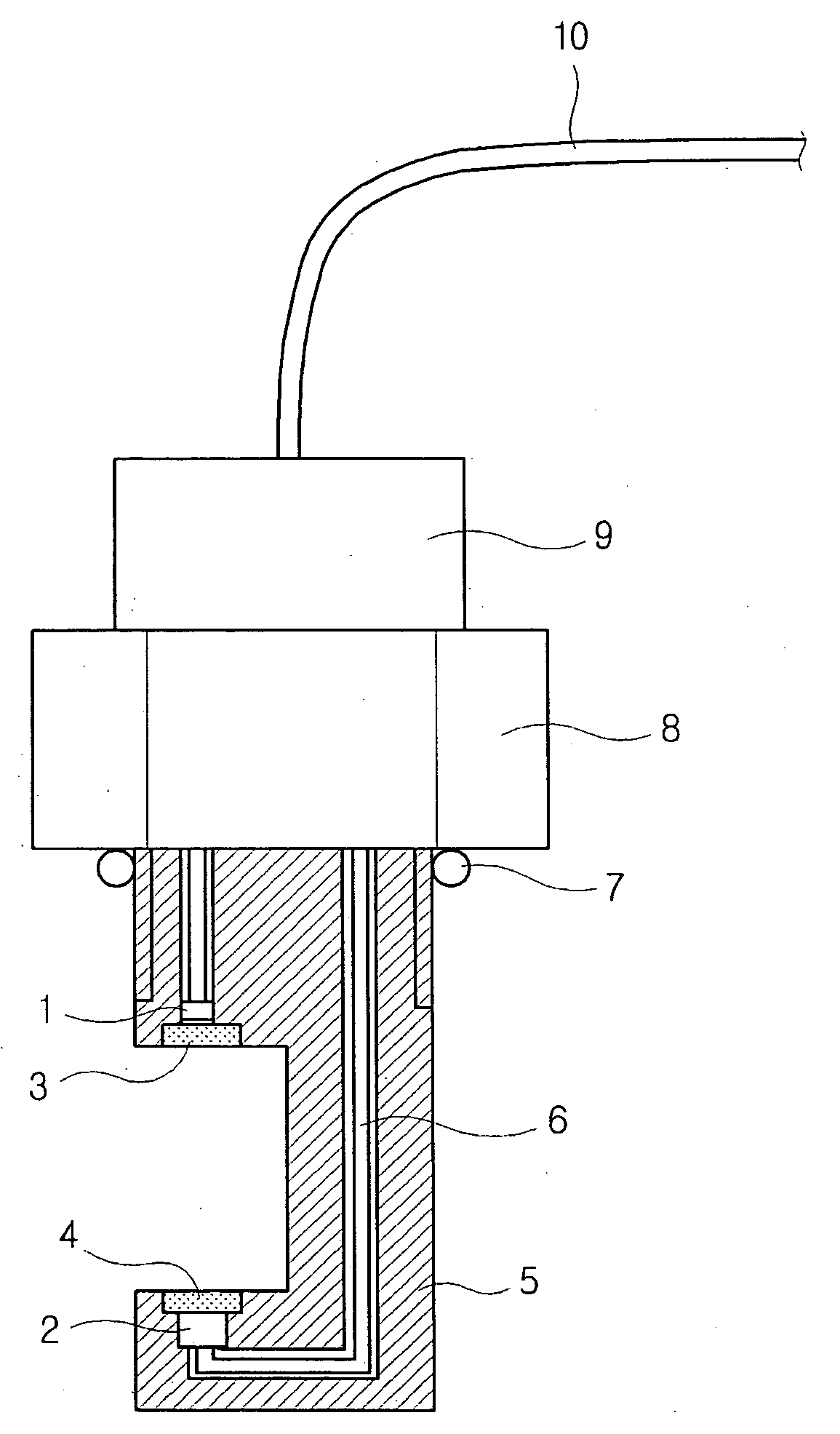

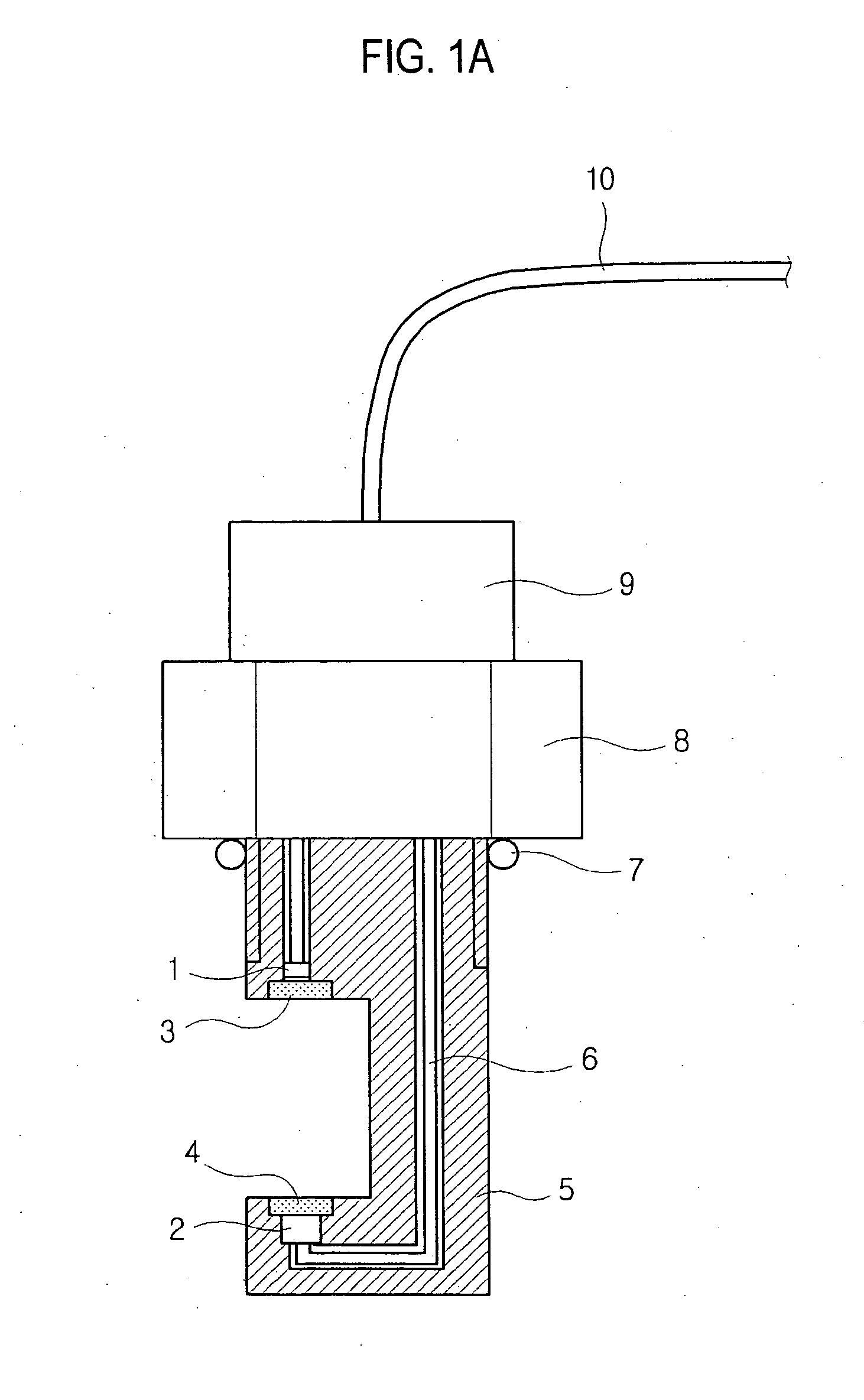

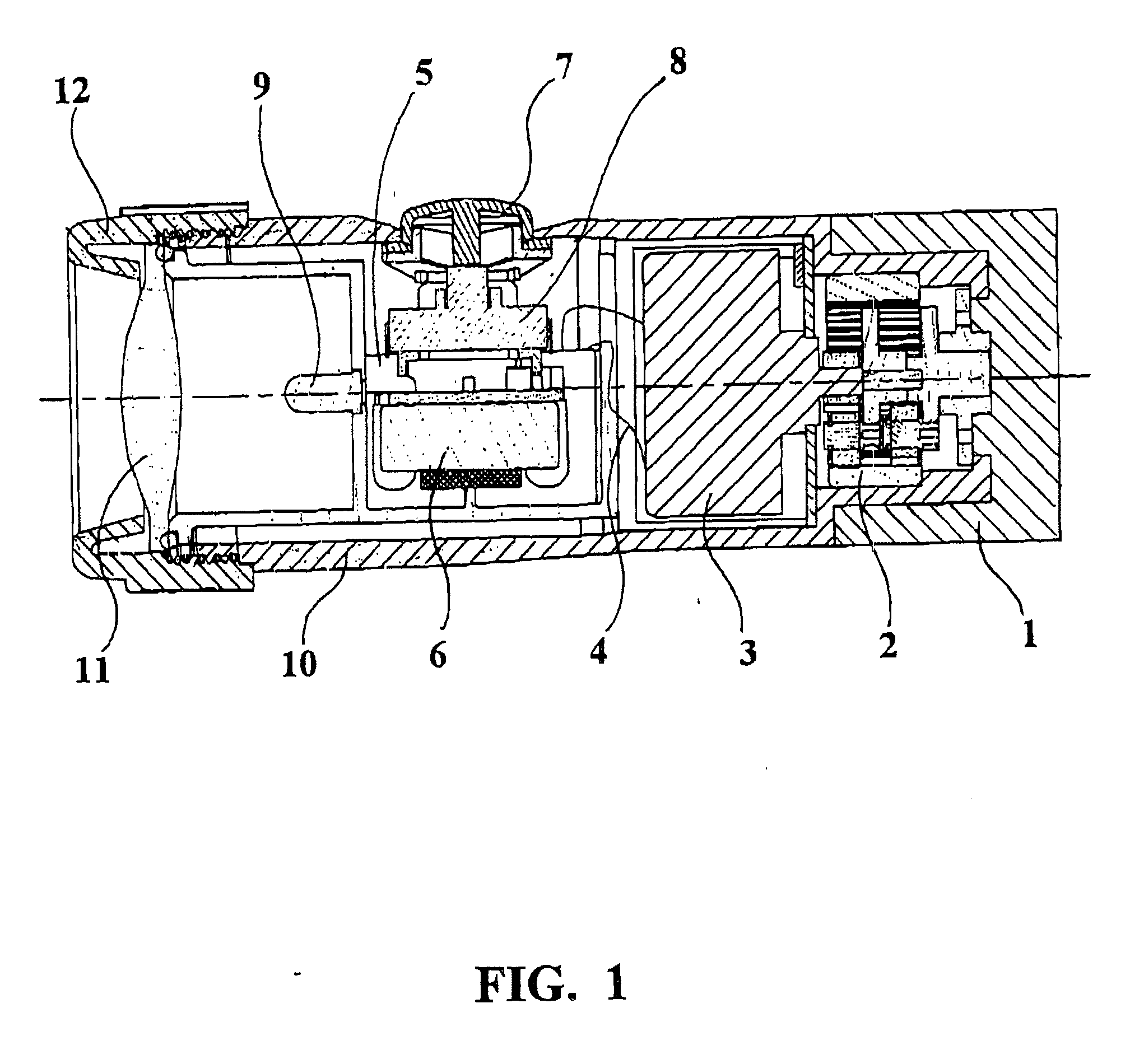

Device for detecting three-dimensional shapes of elongated flexible body

InactiveUS6868195B2Simple and compact structureEndoscopesMaterial analysis by optical meansFiberRefractive index

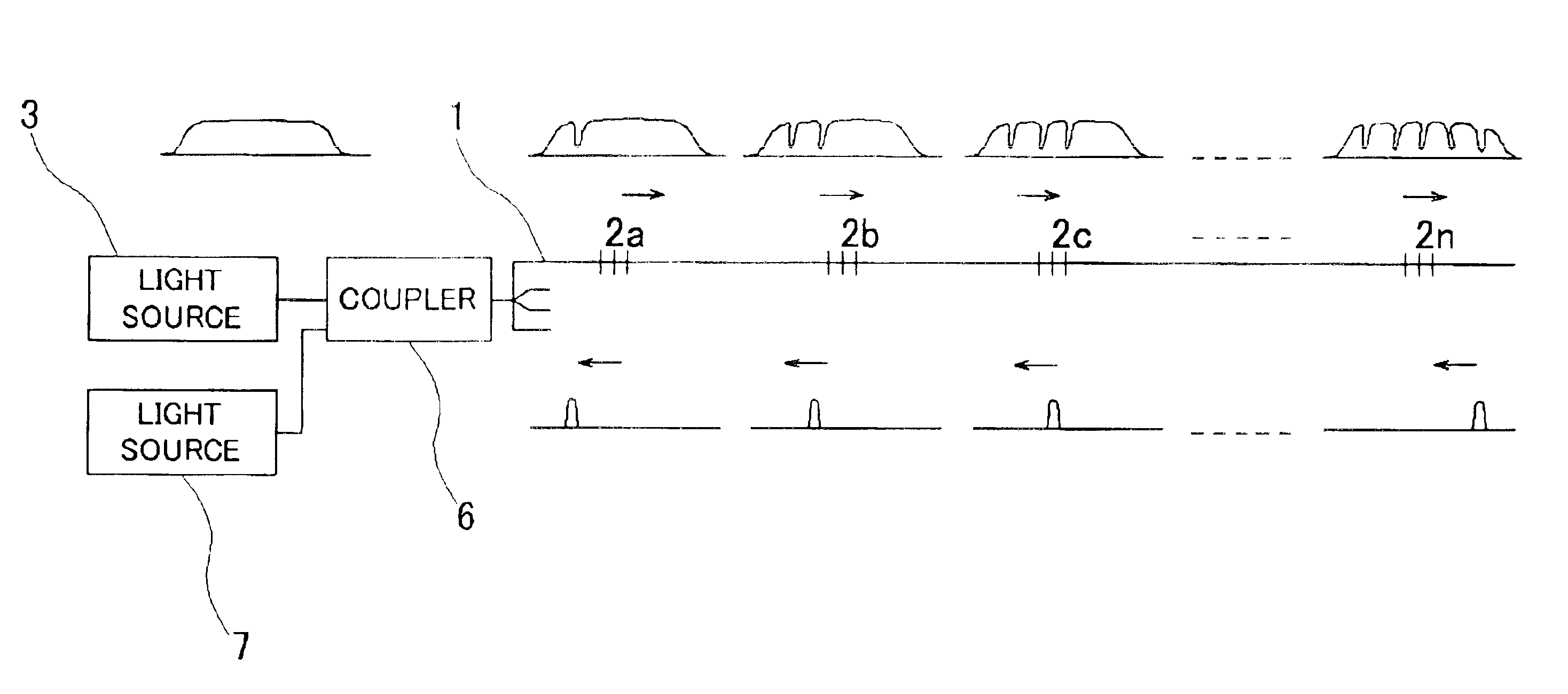

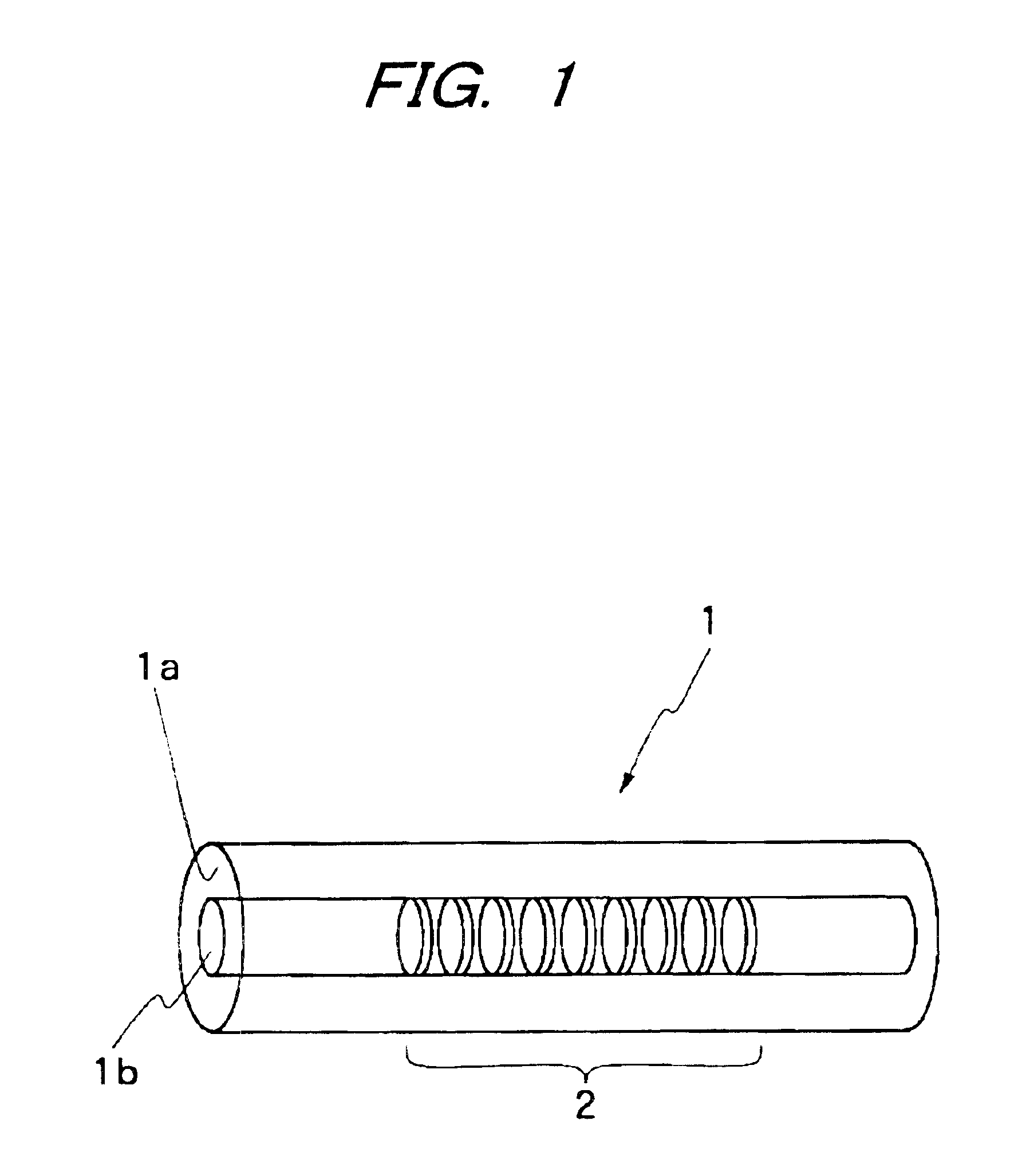

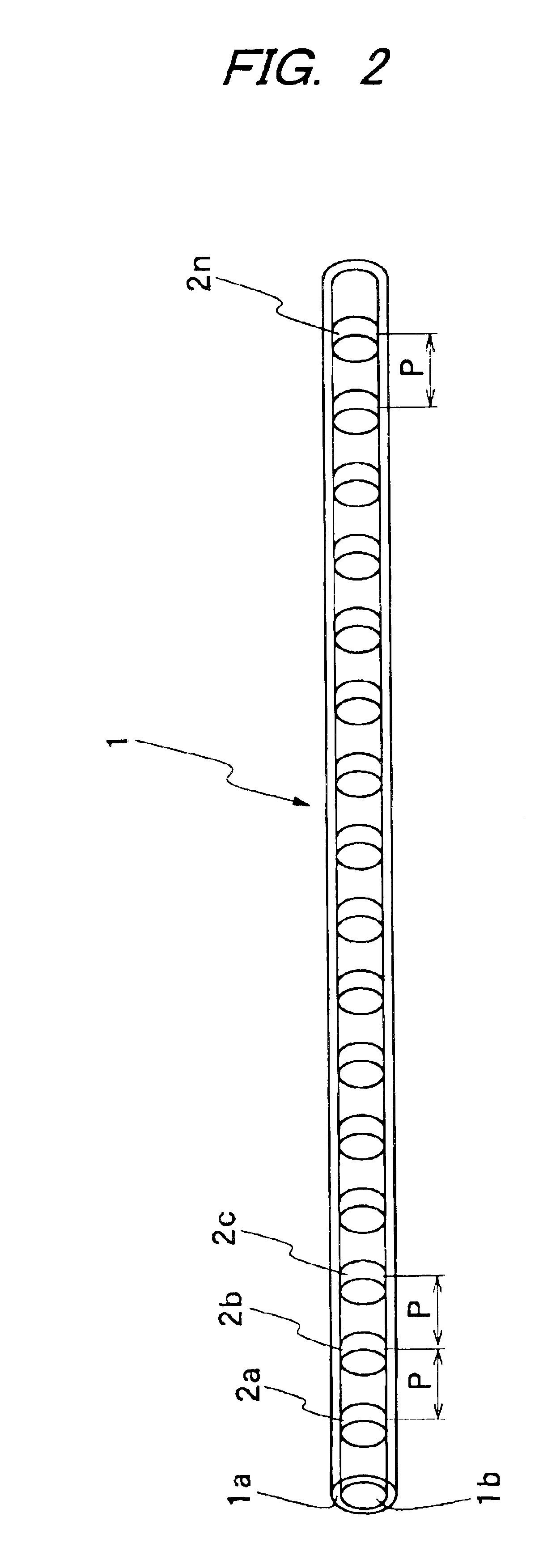

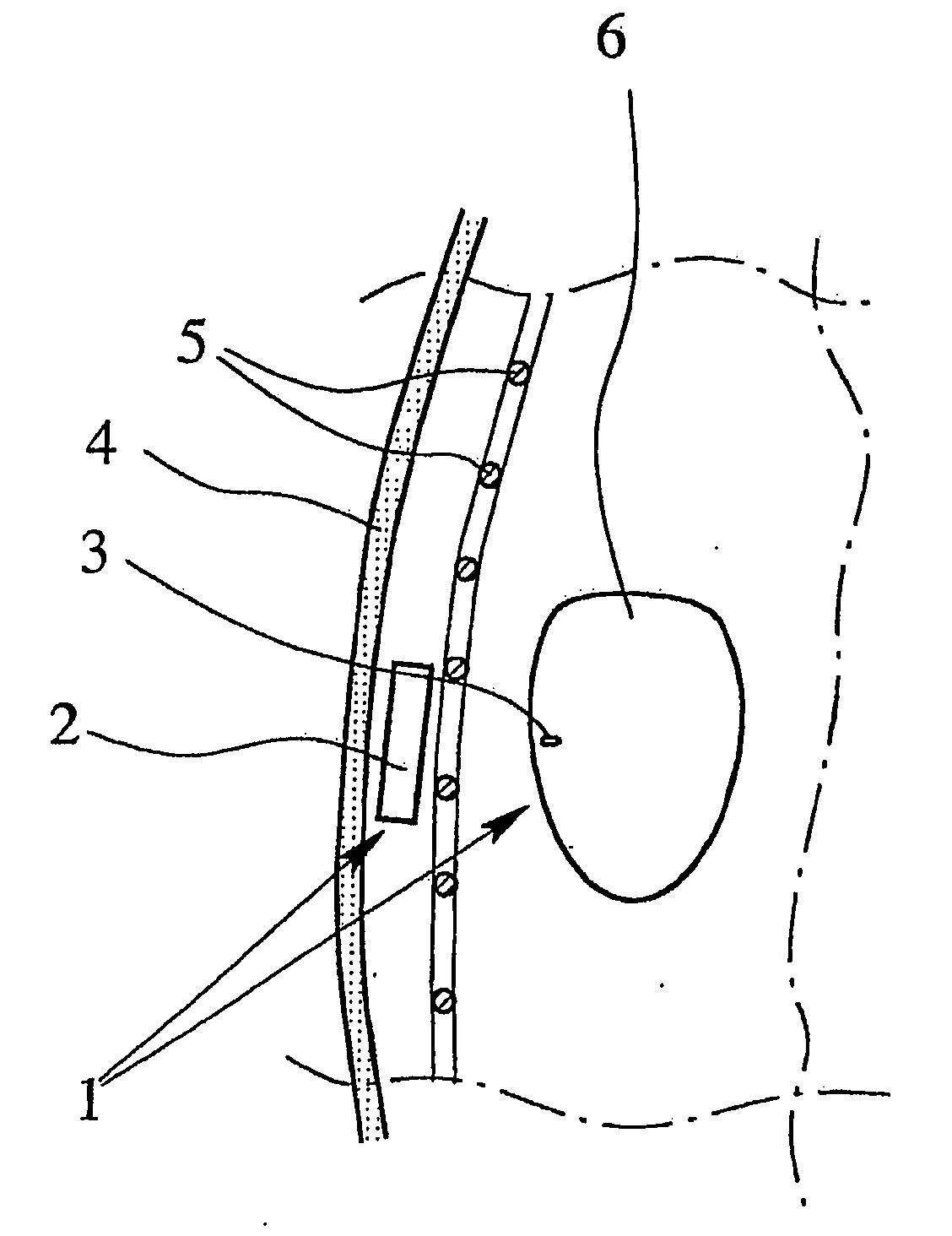

For detecting three-dimensional shapes of an elongated flexible body, a sensor cable to be placed in a passage or channel which is formed axially and coextensively within the elongated flexible body. The sensor cable has two pairs of fiber Bragg grating strands within a tubular carrier casing. A signal light beam containing Bragg wavelength bands is projected from a light source to input same to refractive index change portions in the fiber Bragg grating strands. Reflection diffraction light signals from the refractive index change portions are received by a signal processor to measure the degree of strain at each one of the respective refractive index change portions by comparing wavelengths of the reflection diffraction light signals with reference wavelength.

Owner:FUJI PHOTO OPTICAL CO LTD

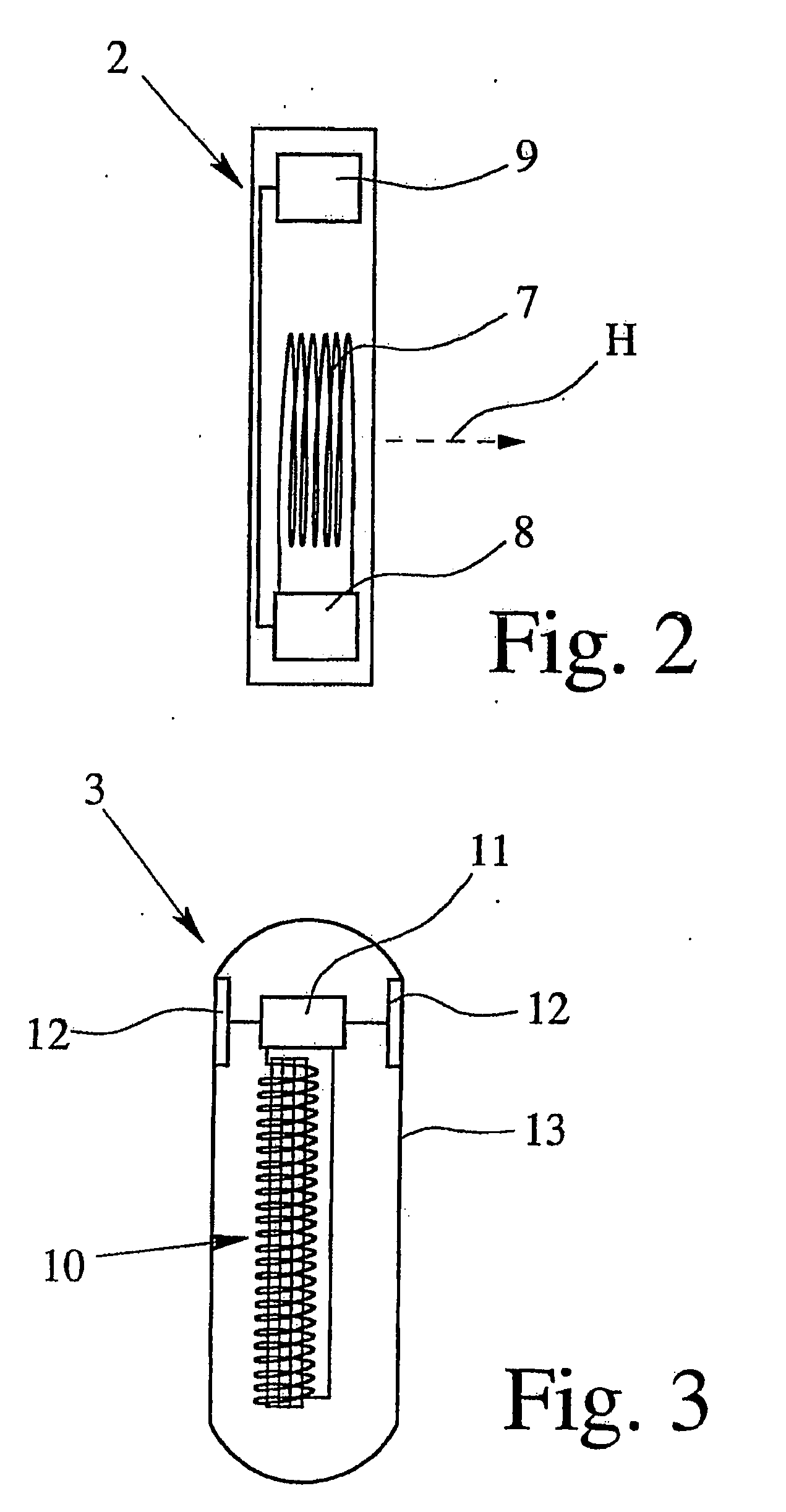

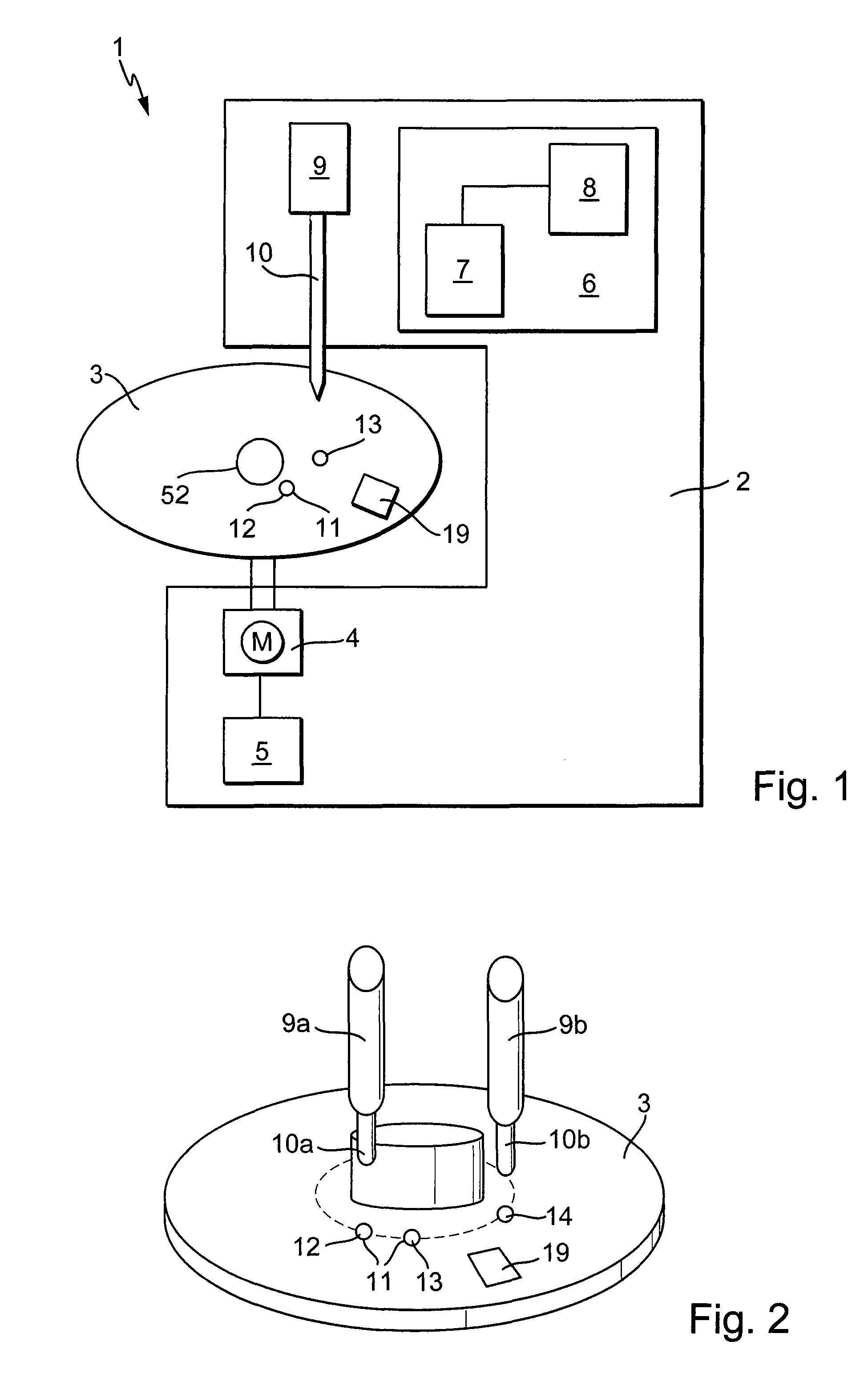

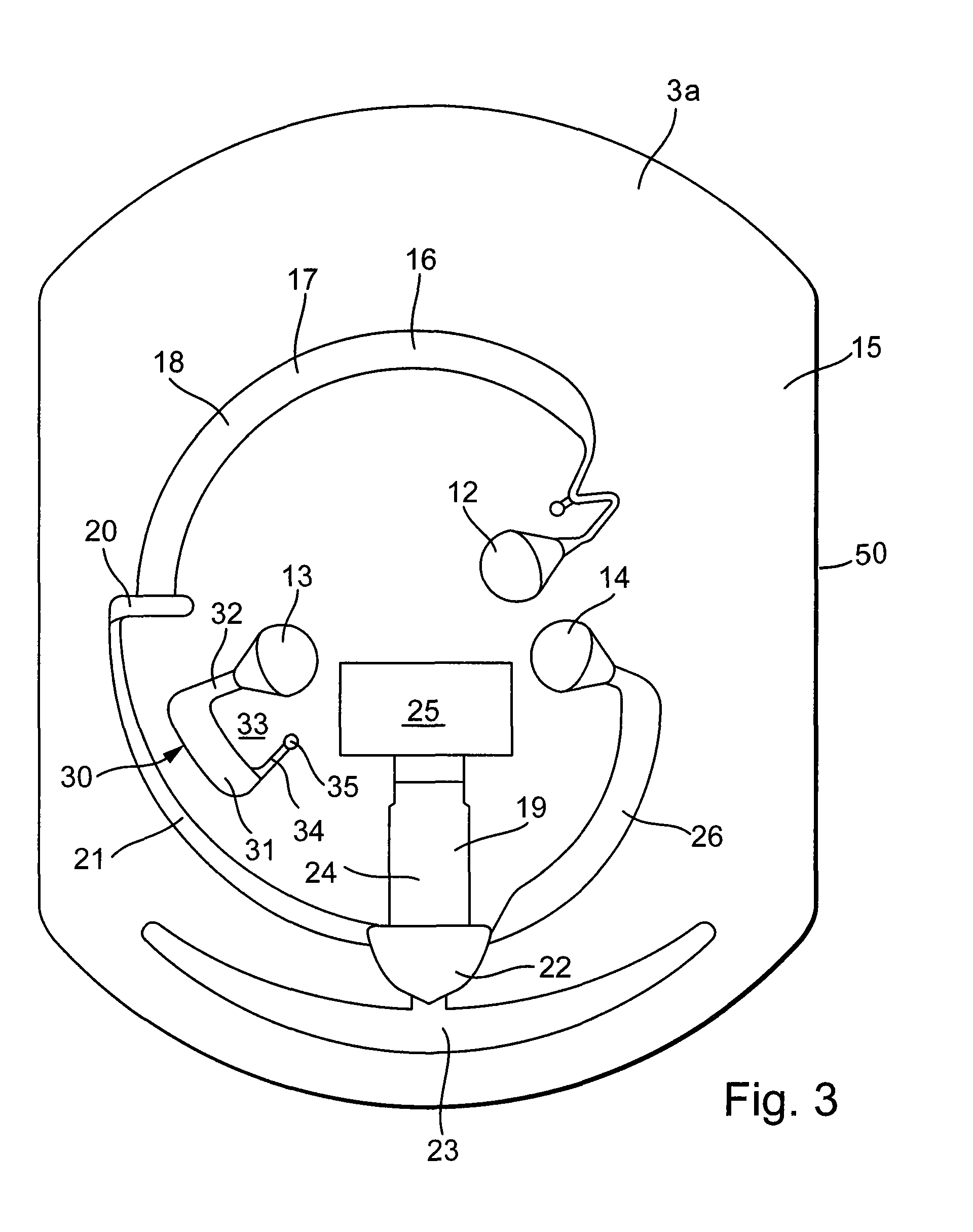

Stimulation system, in particular a cardiac pacemaker

InactiveUS20090024180A1Reliable defined controlCompact structure of electrodeHeart stimulatorsImplantable ElectrodesCardiac pacemaker electrode

A stimulation system, an implantable electrode device and a method for operating an implantable electrode device are proposed. A simplified implantation, a simple construction and reliable control are made possible by the electrode device being supplied with energy, and controlled, in an exclusively wireless manner via a time-variable magnetic field. The magnetic field is generated by an implanted control device.

Owner:UNIV DUISBURG ESSEN

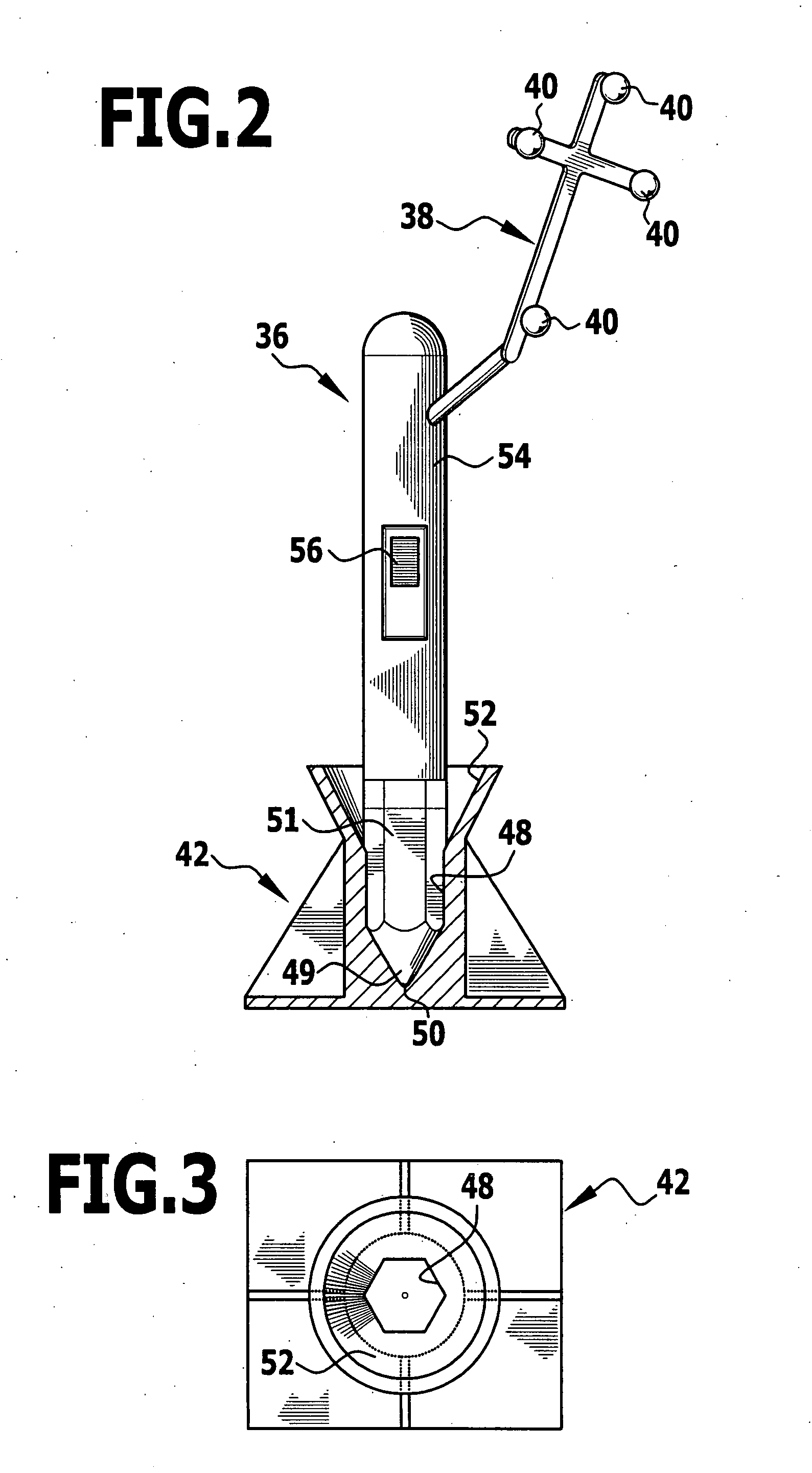

Calibration method and calibration device for a surgical referencing unit

InactiveUS7702477B2Easy to operateQuick and simple calibration and referencingDiagnosticsSurgical navigation systemsNavigation systemOptics

A calibration method and also a calibration device are proposed to enable a spatial position and / or orientation of a surgical referencing unit of a surgical navigation system fitted with at least one inertial sensor to be specified in relation to a spatial coordinate system.

Owner:AESCULAP AG

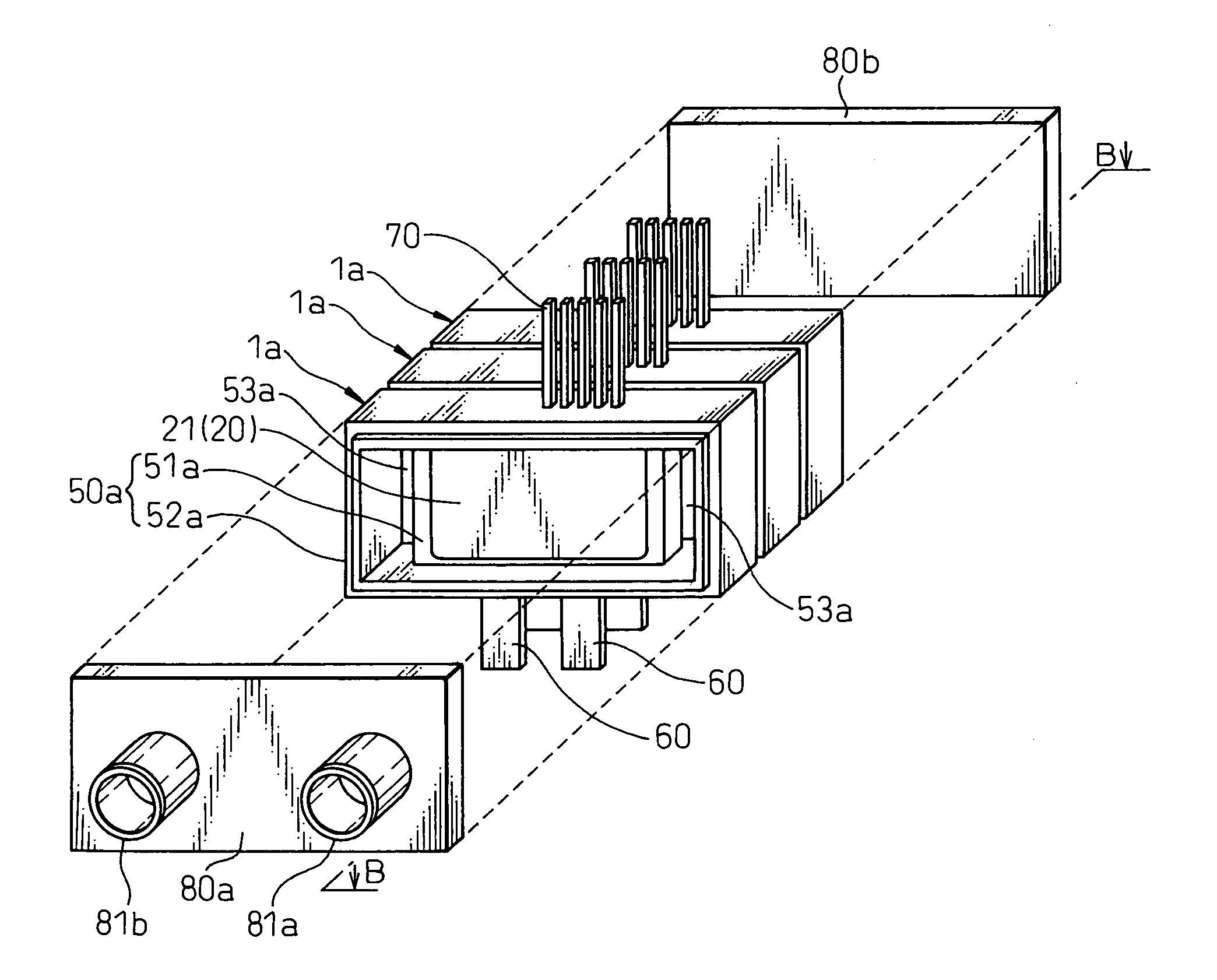

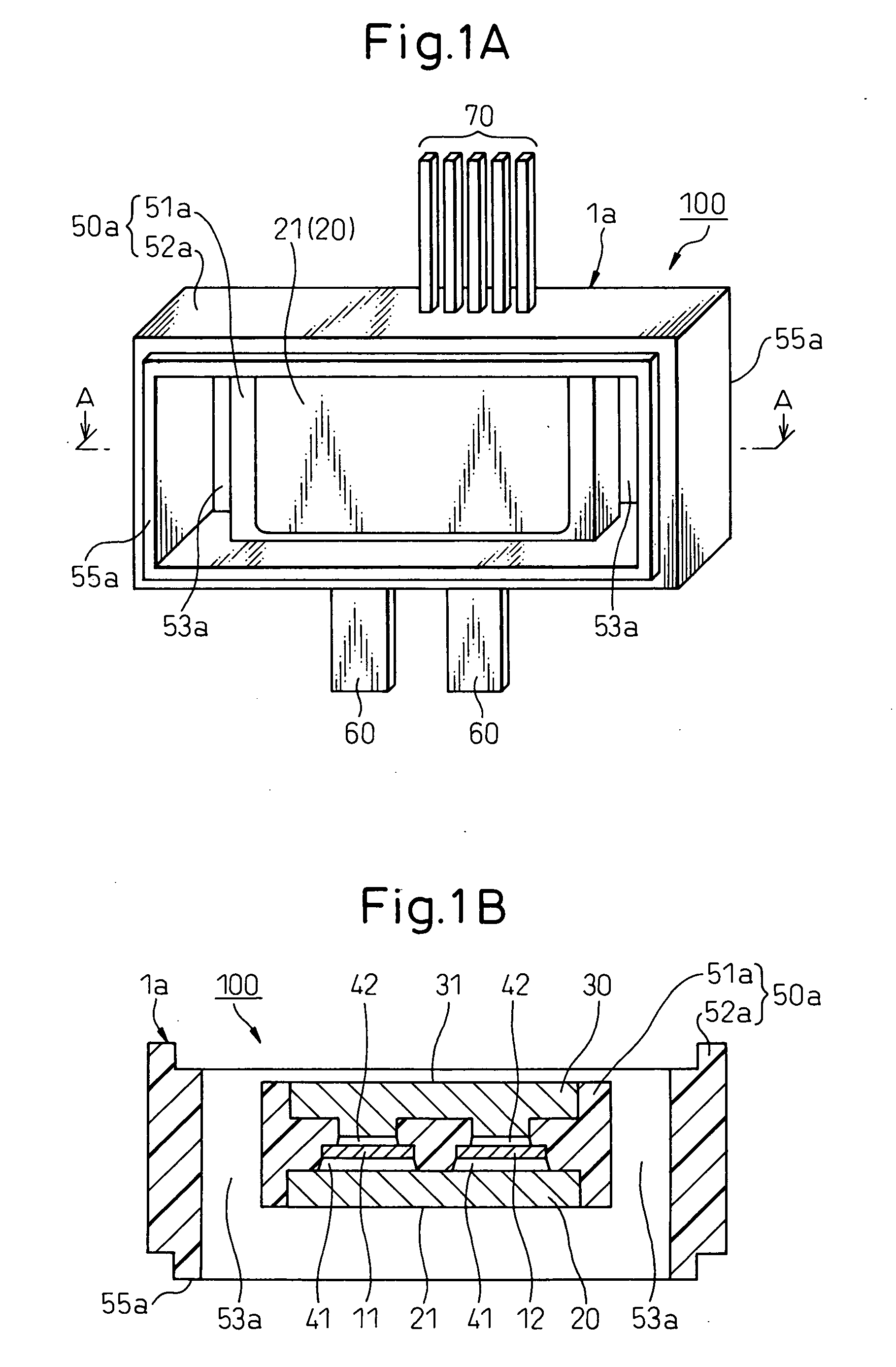

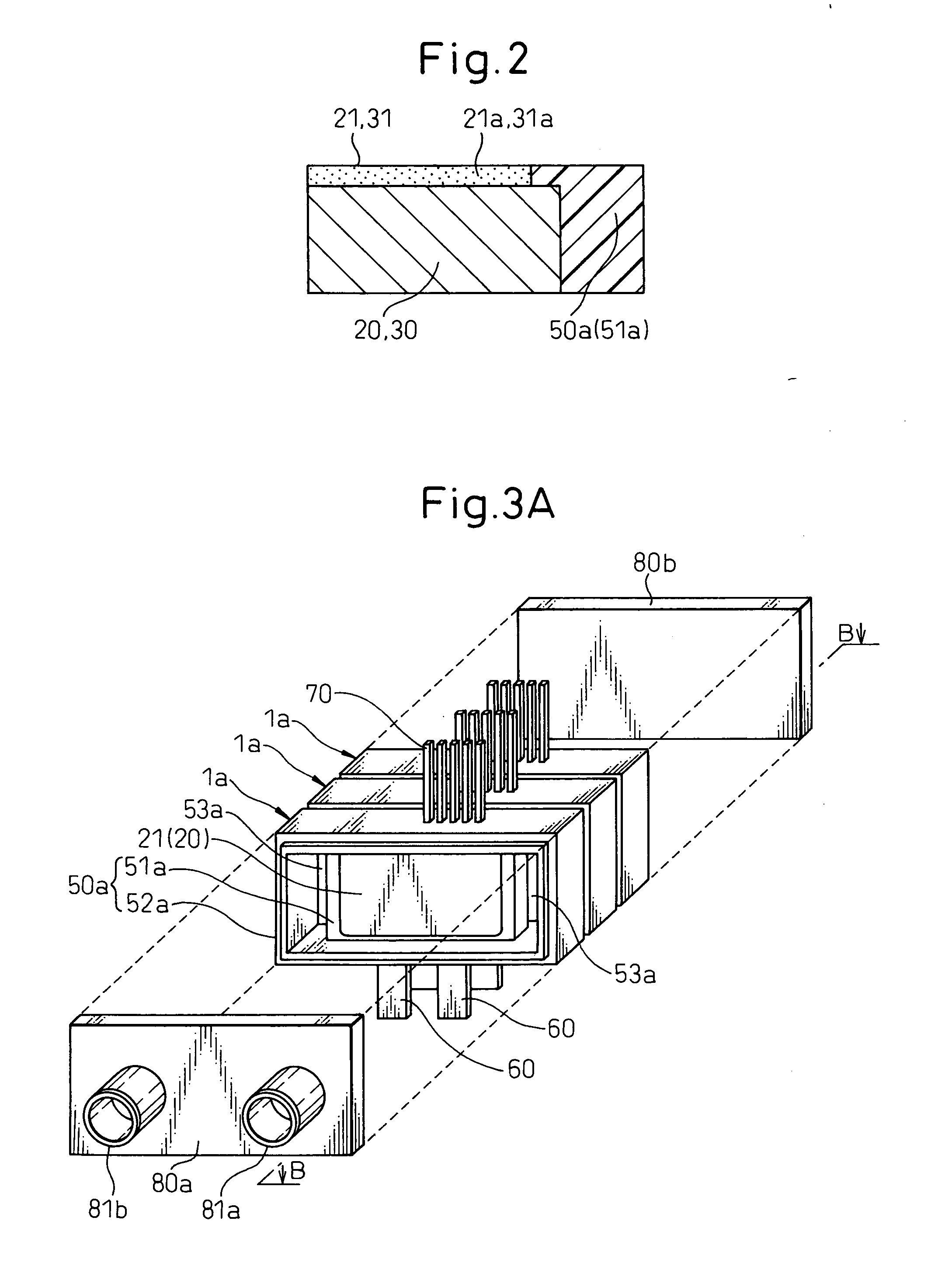

Semiconductor device

ActiveUS20060096299A1Simple cooling structureSimple and compact structureThermoelectric device with peltier/seeback effectSemiconductor/solid-state device detailsDevice materialSemiconductor chip

A semiconductor device comprises at least a semiconductor module including a semiconductor chip, a heat sink thermally connected to the semiconductor chip and a seal member for covering and sealing the semiconductor chip and the heat sink in such a manner as to expose the heat radiation surface of the heat sink. The radiation surface is cooled by a refrigerant. An opening is formed in a part of the seal member as a refrigerant path through which the refrigerant flows.

Owner:DENSO CORP

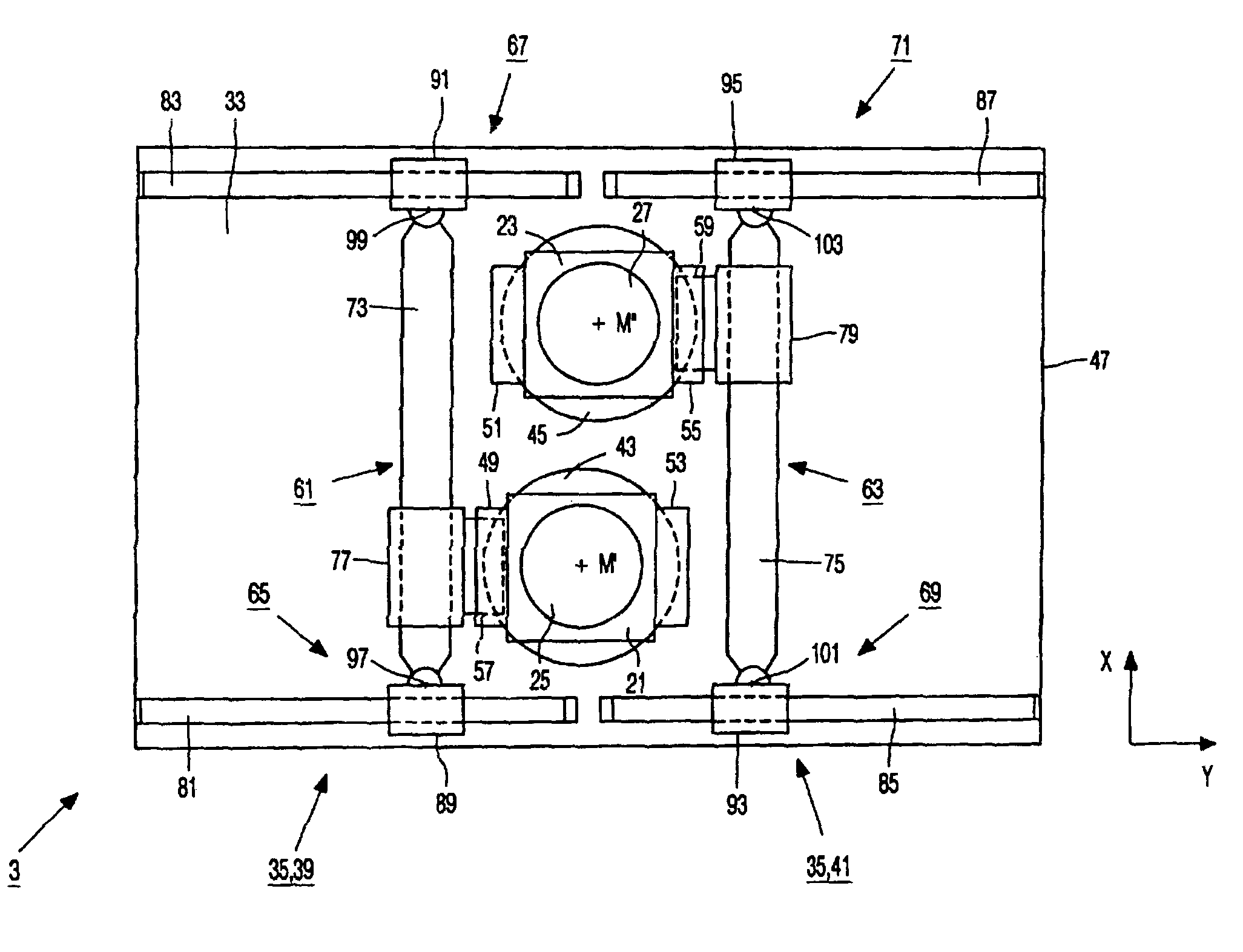

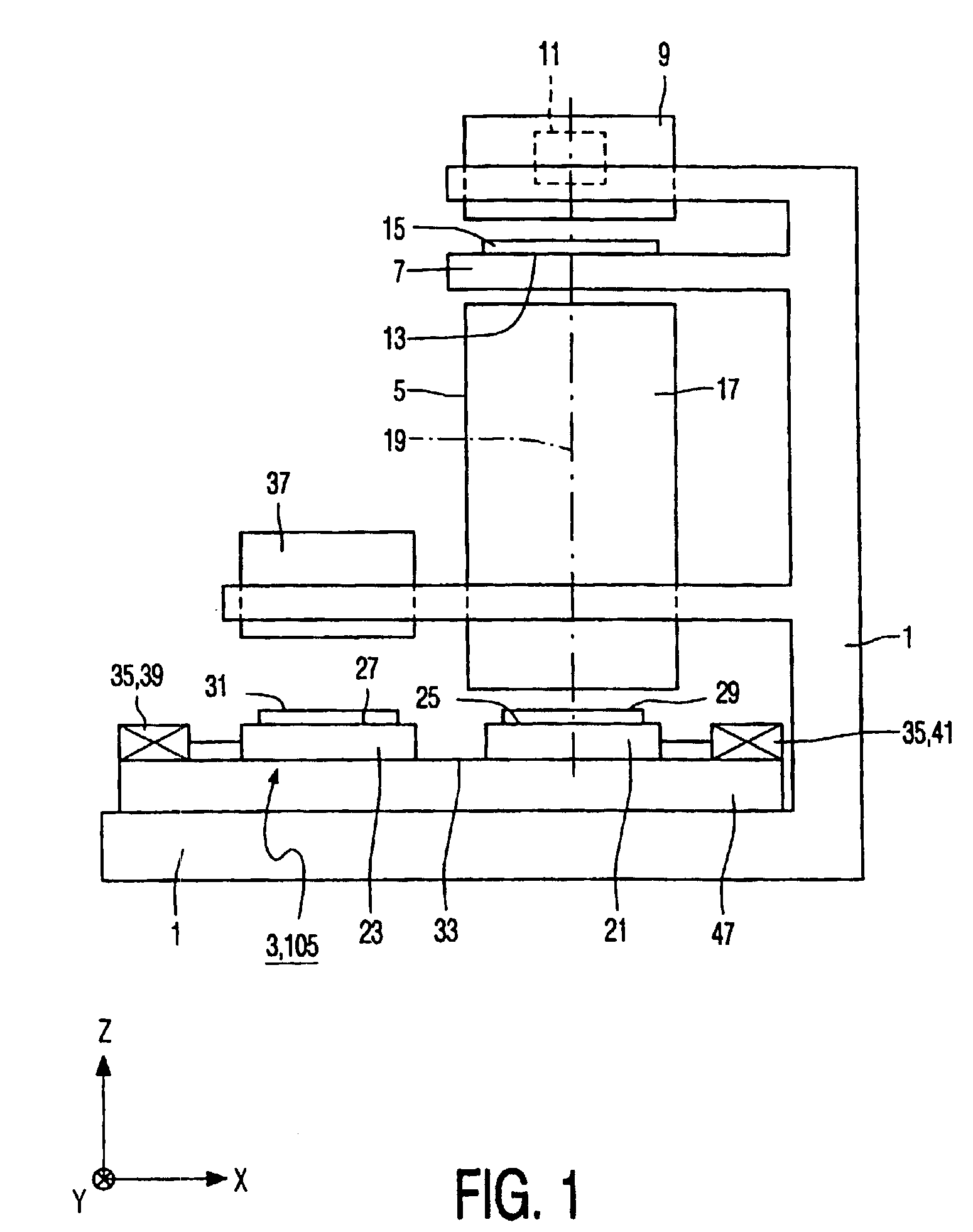

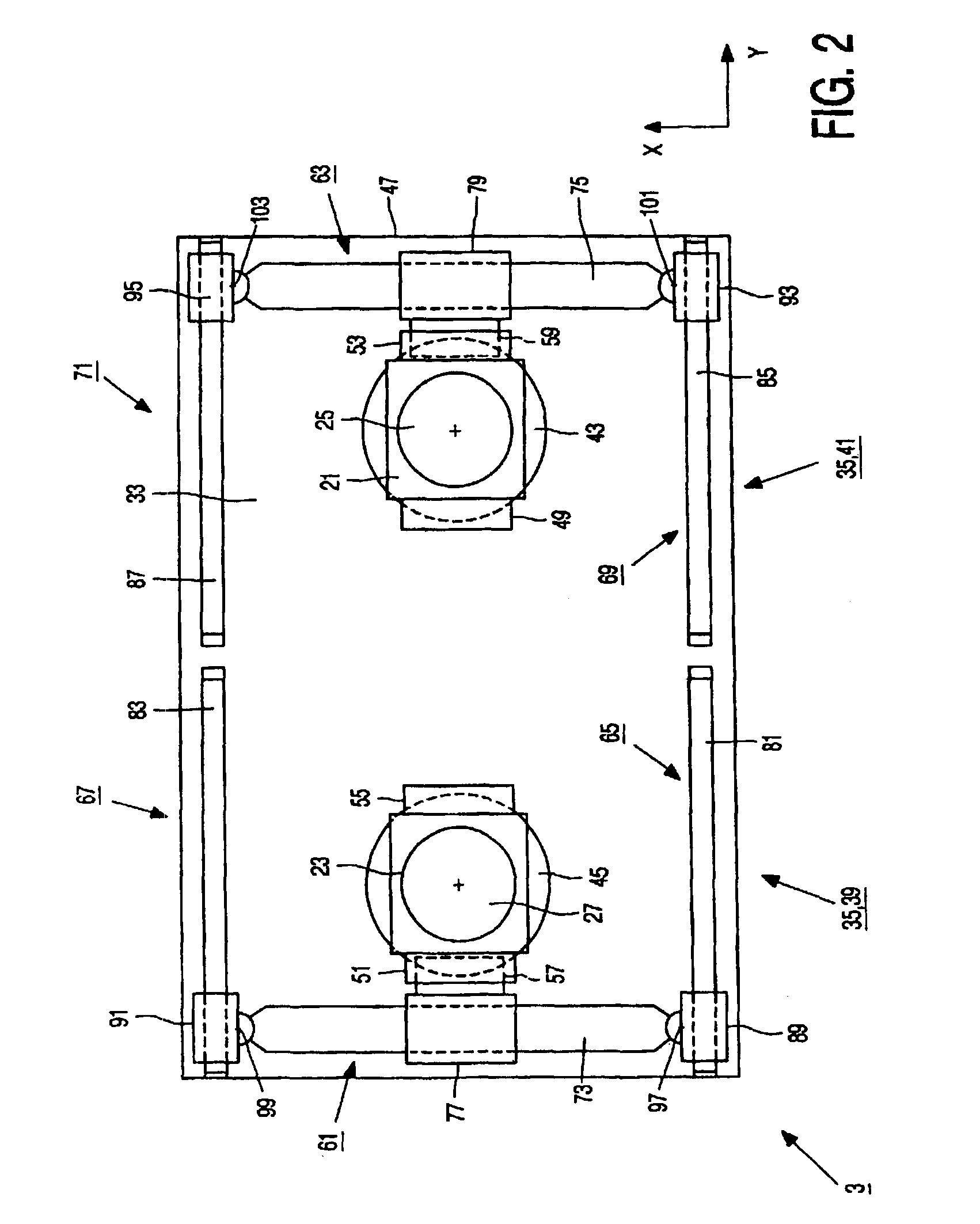

Positioning device having two object holders

InactiveUSRE40043E1Easy to adjustEasy constructionSemiconductor/solid-state device manufacturingInstrumental componentsEngineeringSemiconductor

A positioning device has first and second object holders that are guided over a guiding surface extending parallel to an X-direction and parallel to a Y-direction perpendicular to the X-direction and which are displaceable over the guiding surface from a first position into a second position by means of a displacement system. The displacement system includes a first displacement unit and a second displacement unit to which the object holders can be alternately coupled. The first displacement unit is suitable for carrying out a first series of positioning steps of the first object holder in the first position and for displacing the first object holder from the first position into an intermediate position between the first and second positions. The second displacement unit is suitable for carrying out a second series of positioning steps of the second object holder in the second position, simultaneously with and independently of the first displacement unit, and for displacing the second object holder from the second position into the intermediate position. In the intermediate position, the object holders are exchanged, after which the first series of positioning steps can be carried out by the first displacement unit with the second object holder in the first position and the second series of positioning steps can be carried out by the second displacement unit with the first object holder in the second position. The positioning device is suitable for use in a lithographic device to carry out an exposure process with a first semiconductor substrate in an exposure position and, simultaneously therewith and independently thereof, a characterization process with a second semiconductor substrate in a characterization position.

Owner:ASML NETHERLANDS BV

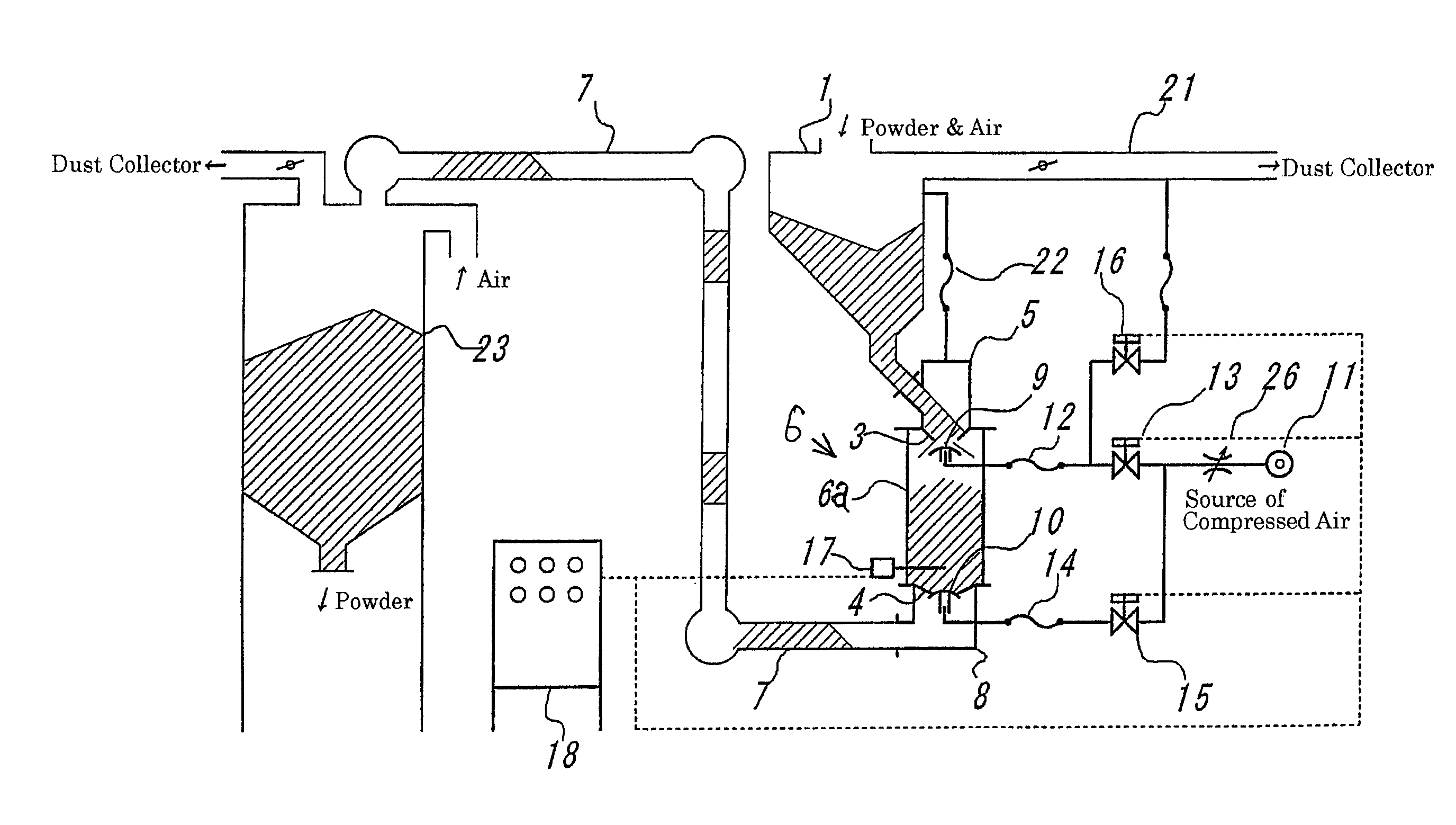

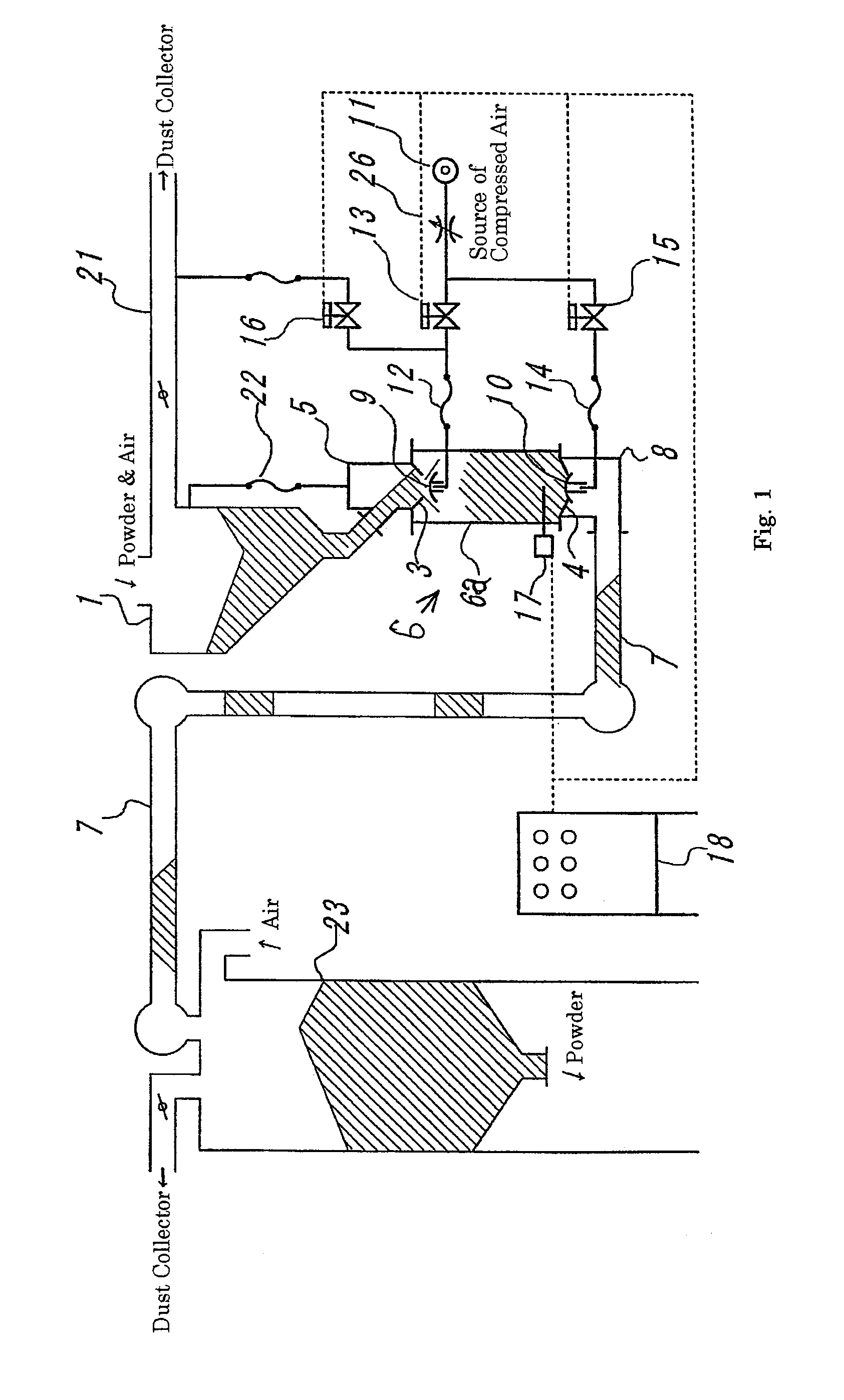

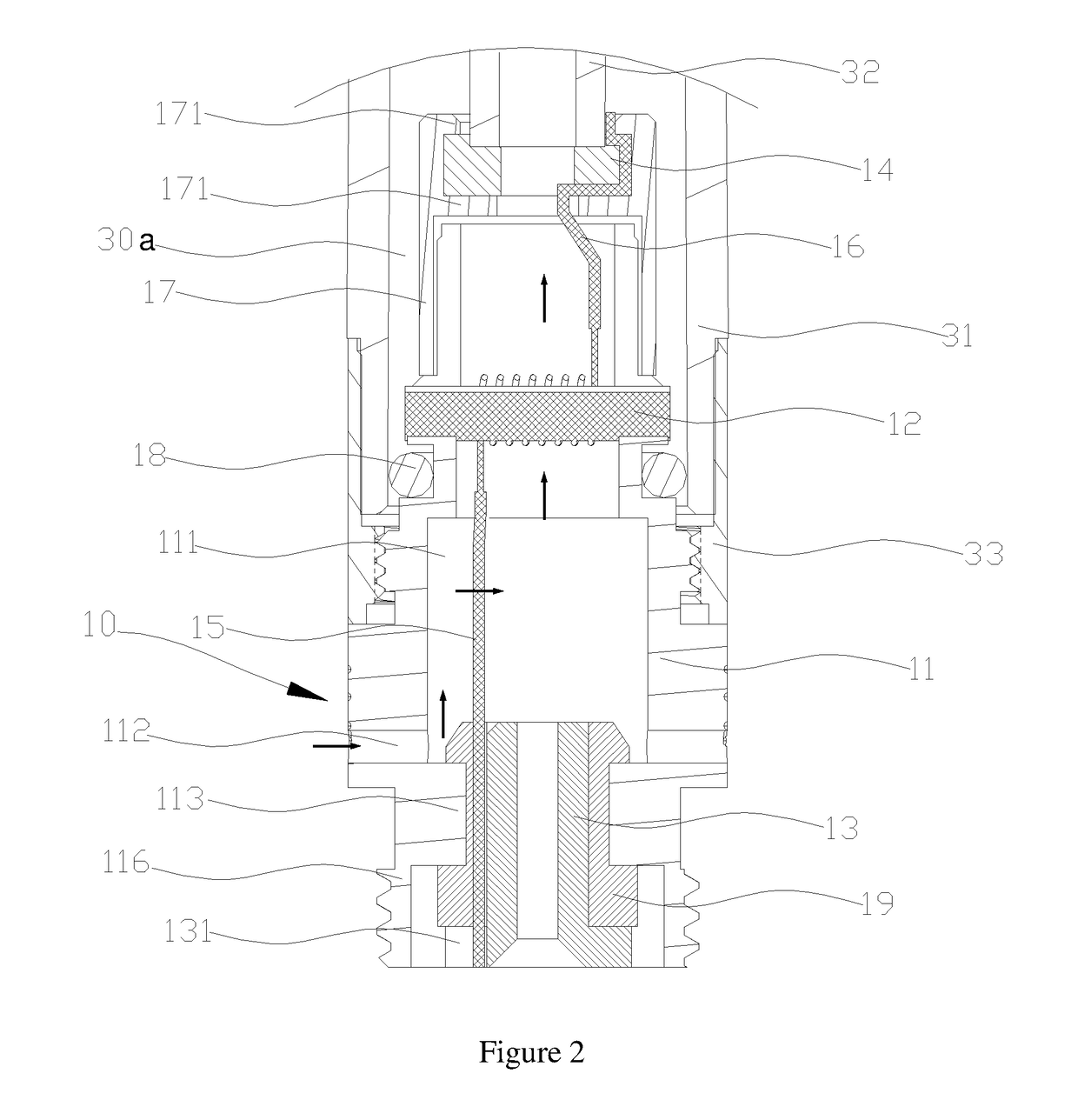

Pressure tank, an device for feeding powder to a conveying pipe, and its feeding method, and method for determining feeding intervals of powder to the conveying pipe

A pressure tank having a simple structure to intermittently feed powder to a conveying pipe, and a method for determining the intervals for feeding the powder to the conveying pipe. The pressure tank includes a tank body used as a structure of a pressure vessel having a receiving port at its upper portion and a discharging port at its lower portion, a first check valve disposed just under the receiving port so that it can freely move up and down, and so that it can close the receiving port by its upward movement that is caused by means of compressed air, and a second check valve disposed just under the discharging port so that it can freely move up and down, and so that it can close the discharging port by its upward movement that is caused by means of compressed air. To determine the intervals for feeding the powder to the conveying pipe, the apparatus is controlled based on measurements of the pressure loss or of the time that is required for feeding the powder to the conveying pipe, so that the pressure loss of the compressed air in the conveying pipe corresponds to the pressure of the compressed air supplied to the conveying pipe.

Owner:SINTOKOGIO LTD

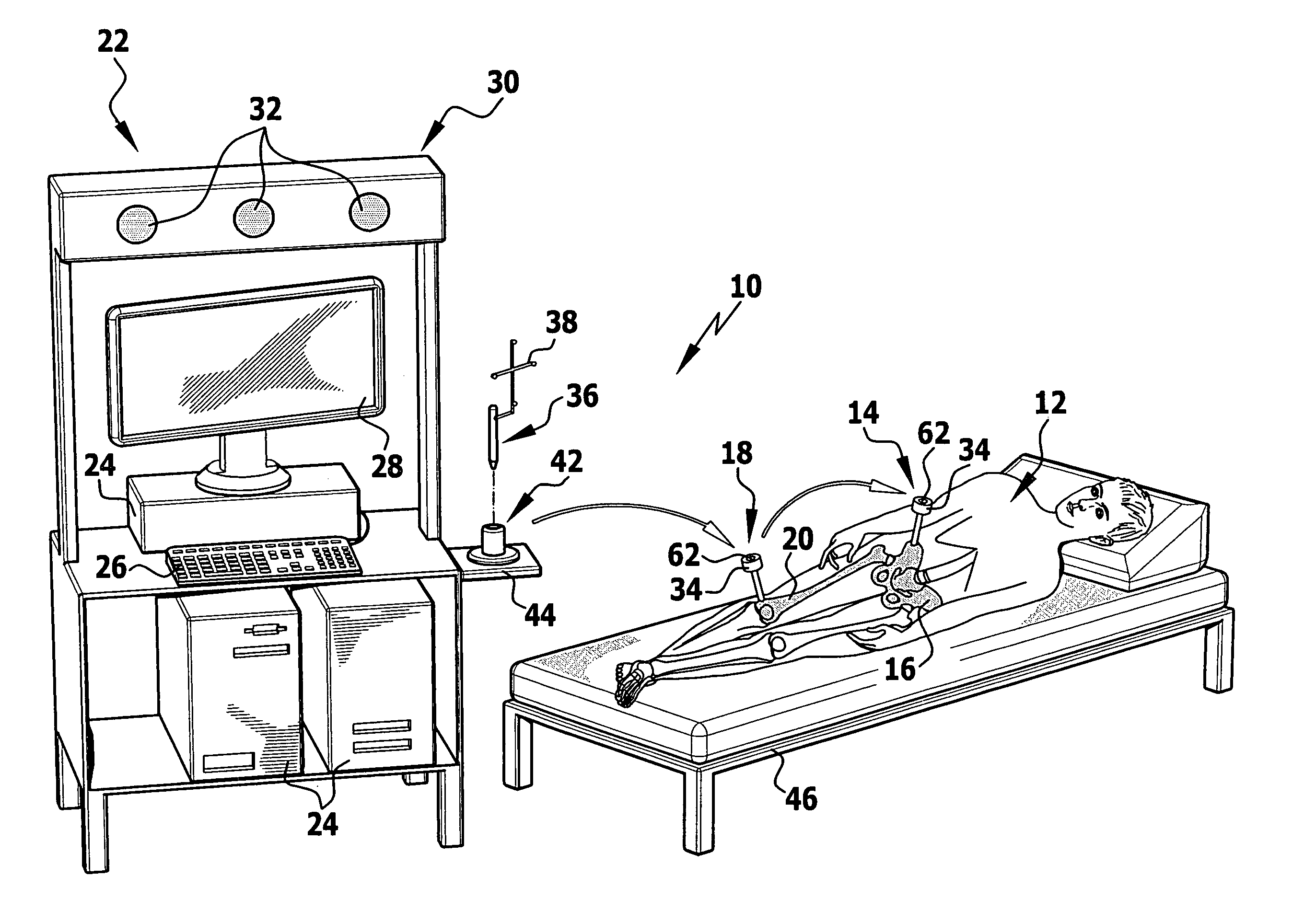

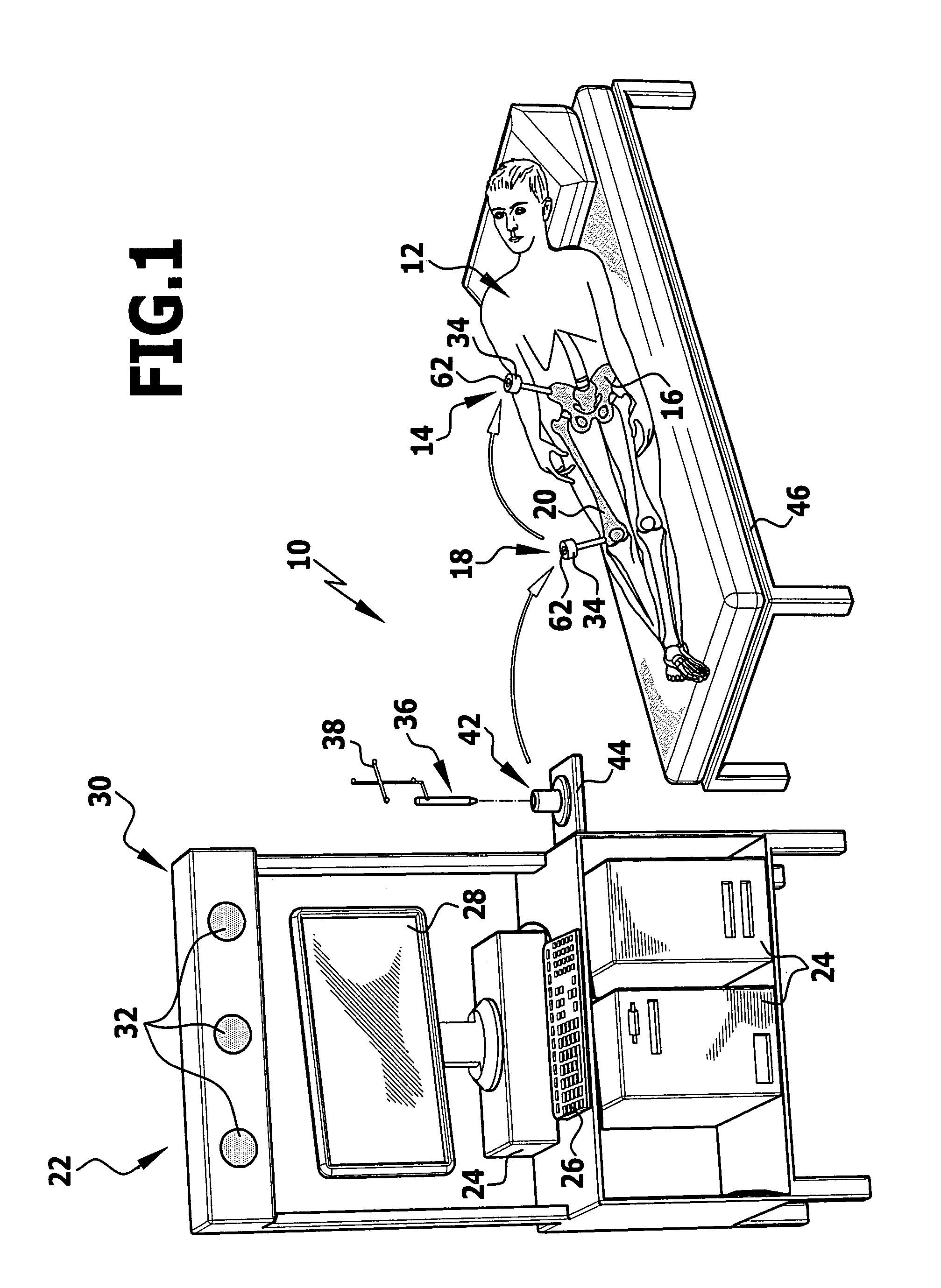

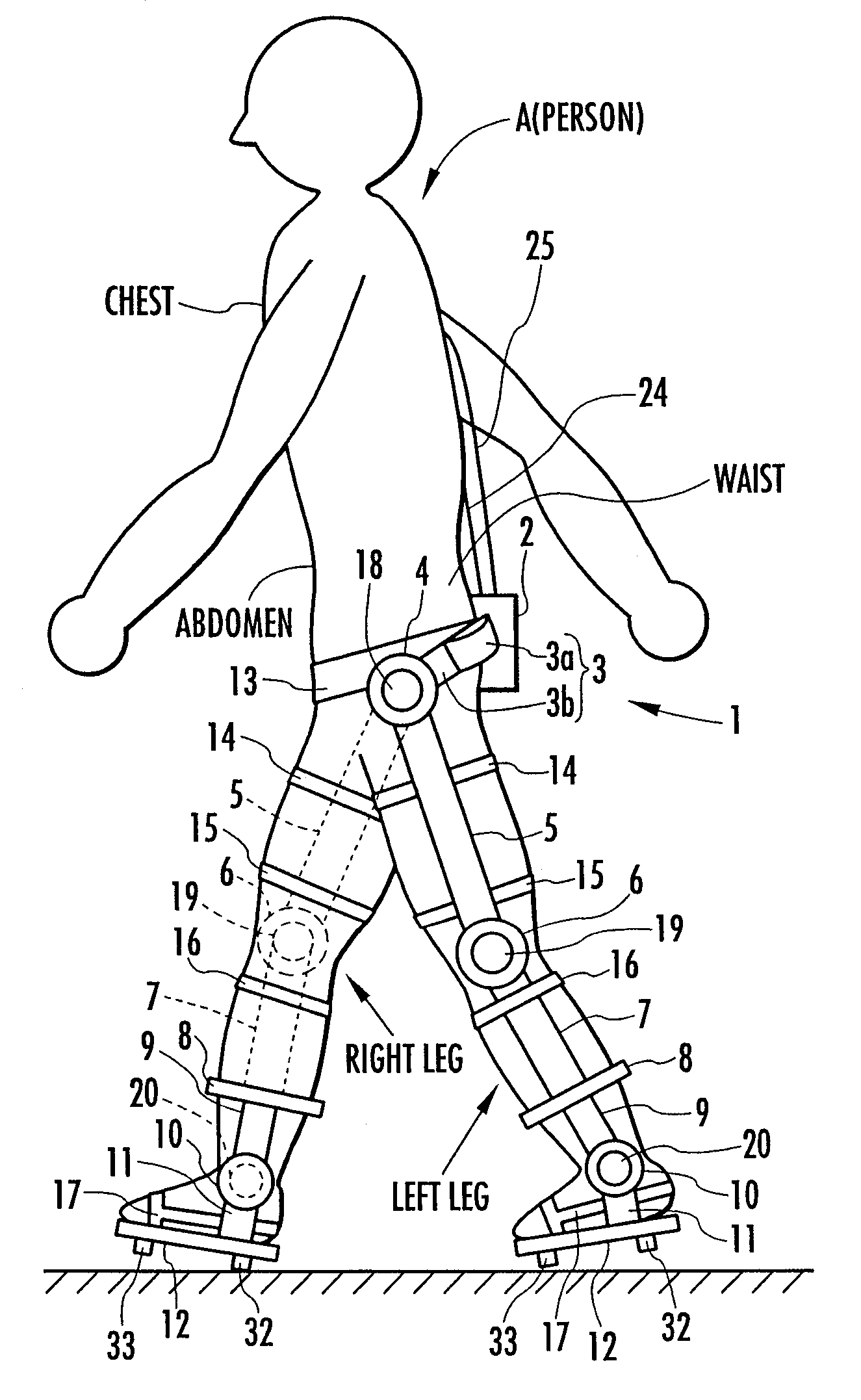

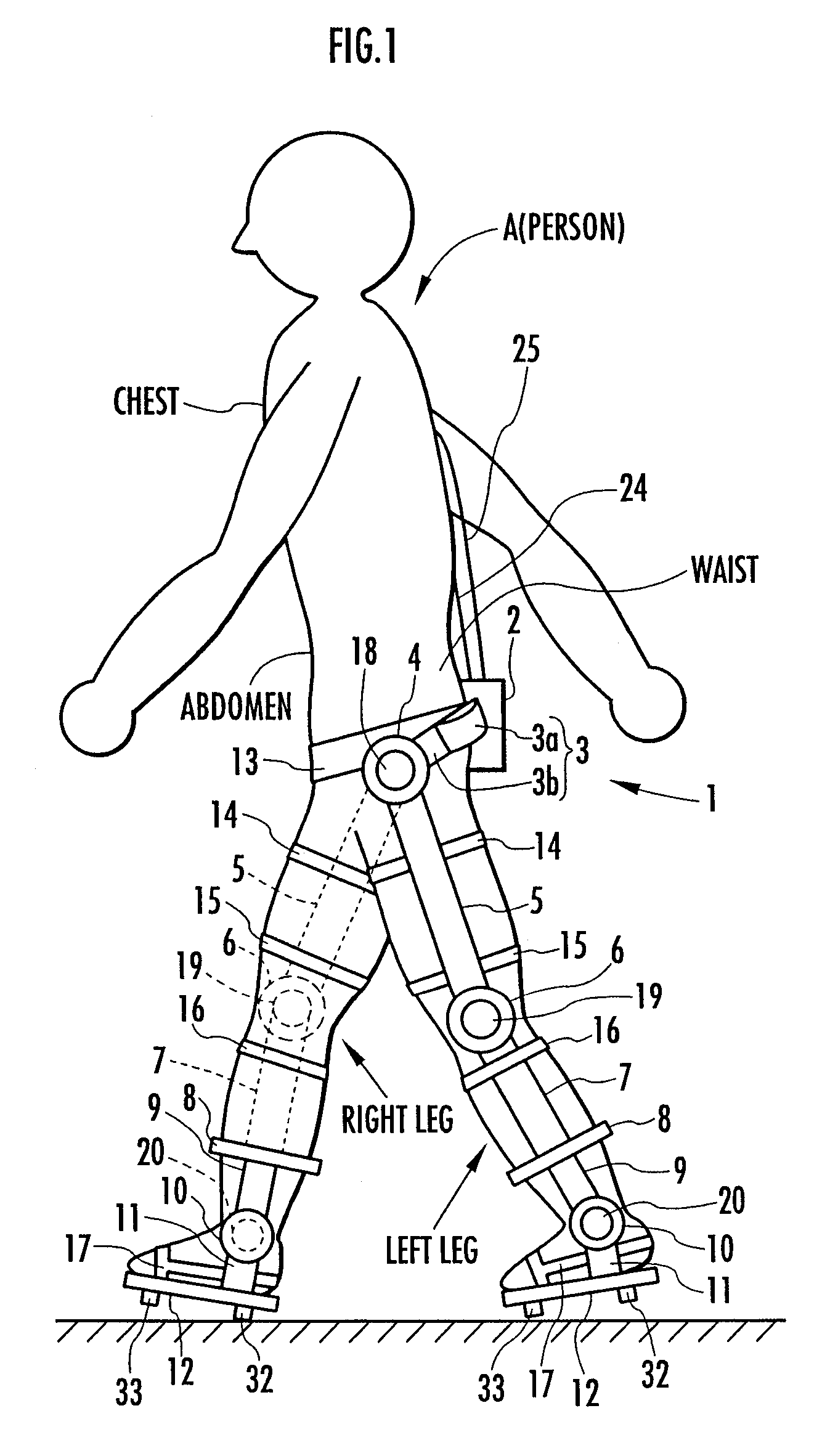

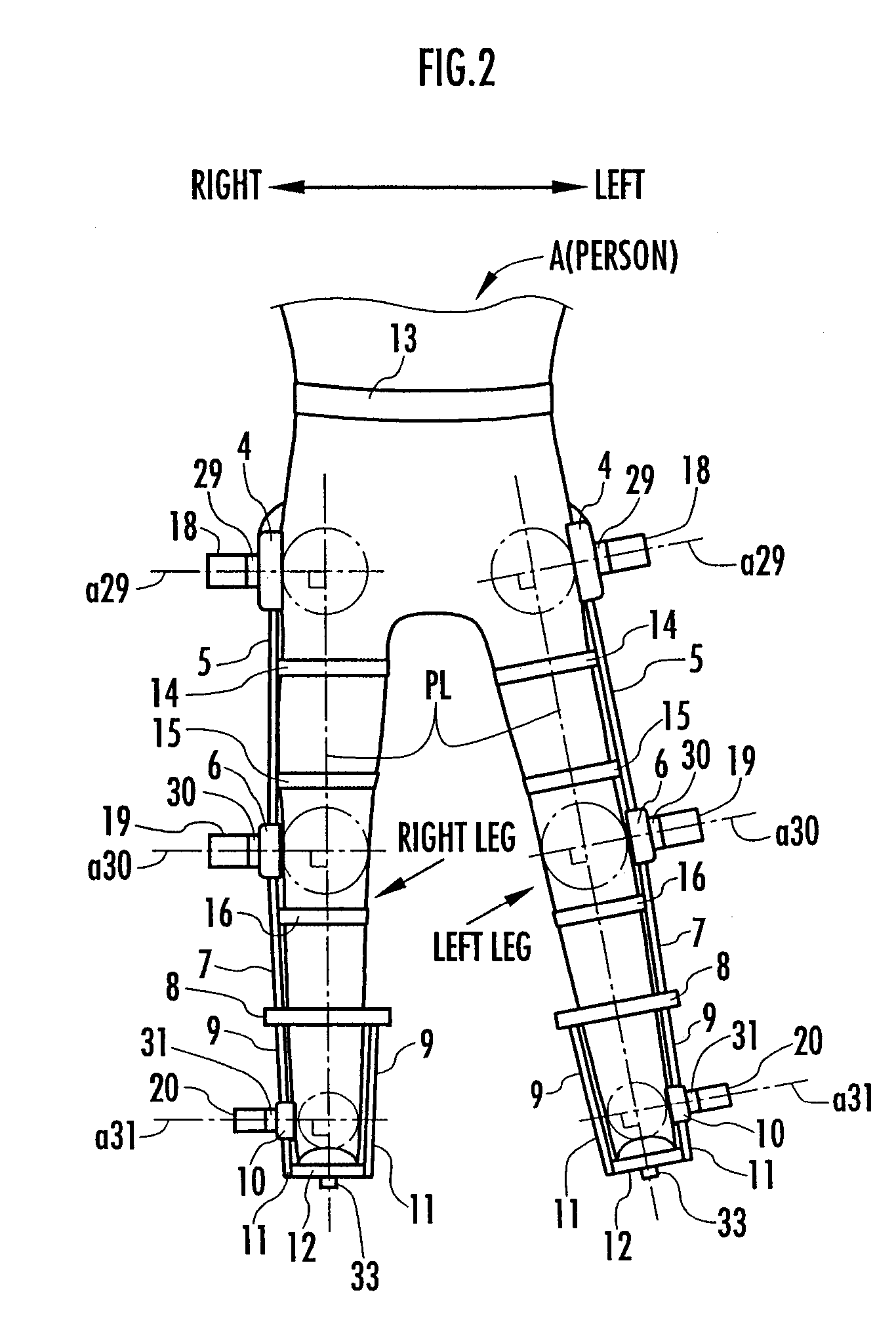

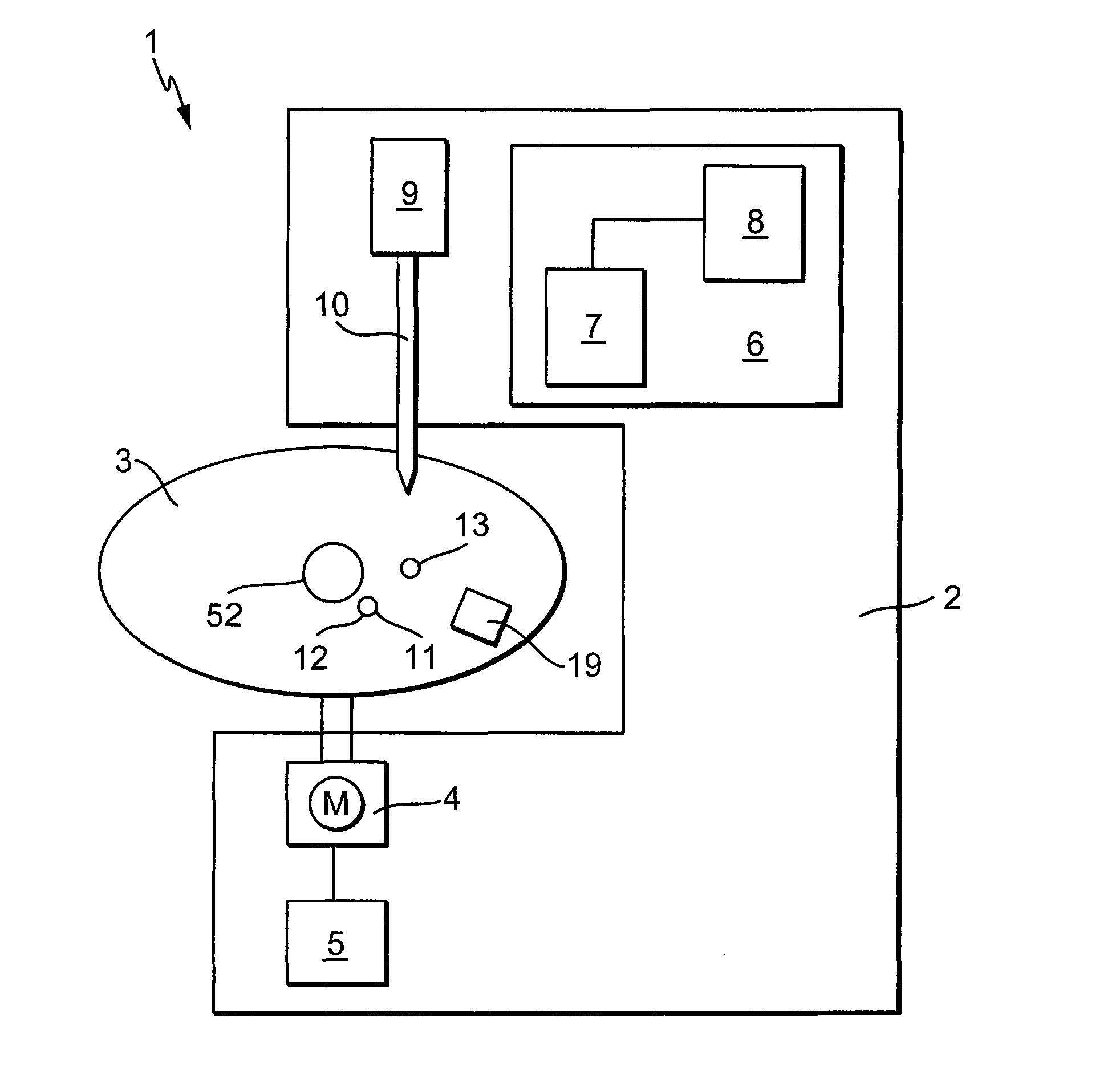

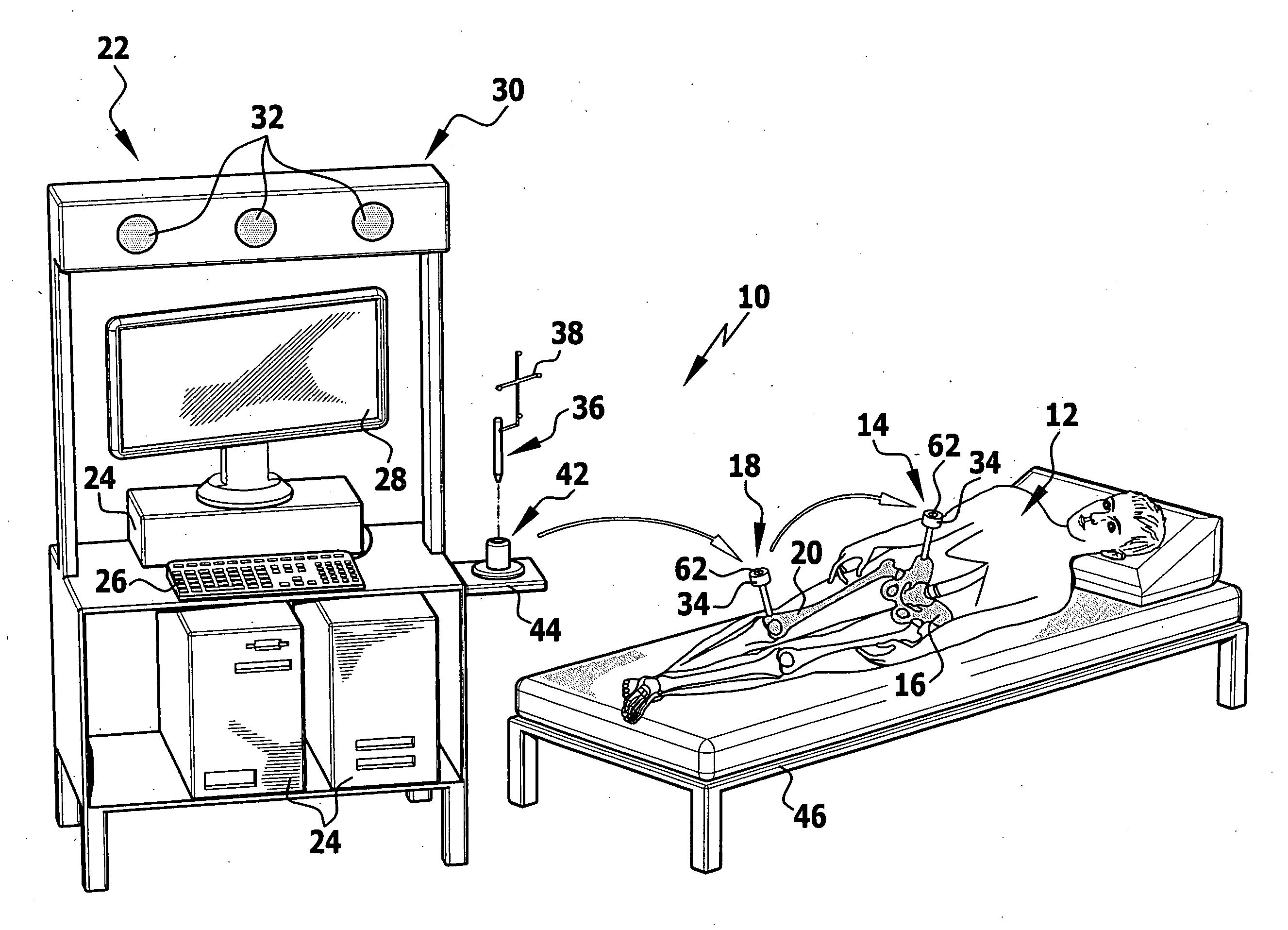

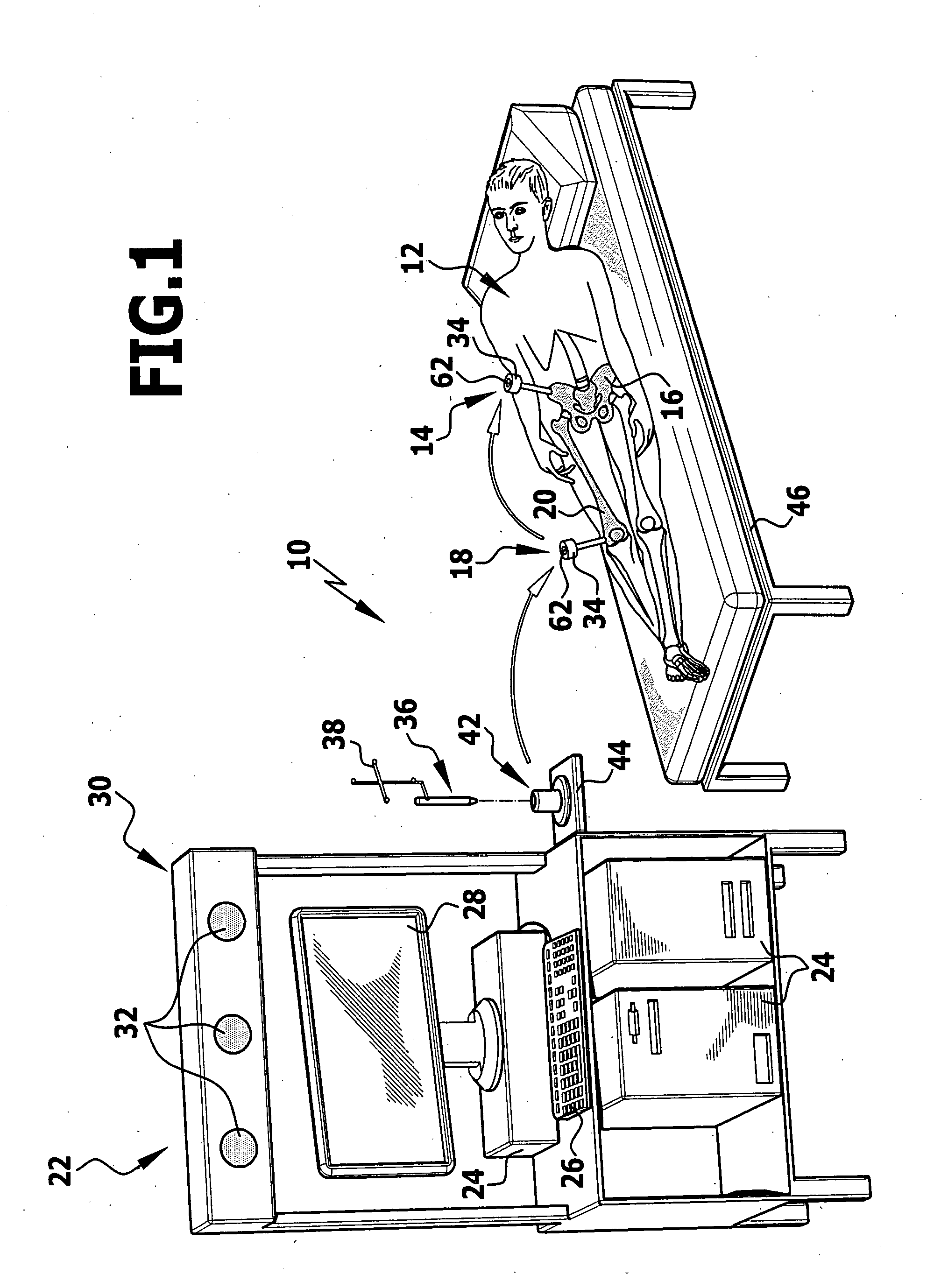

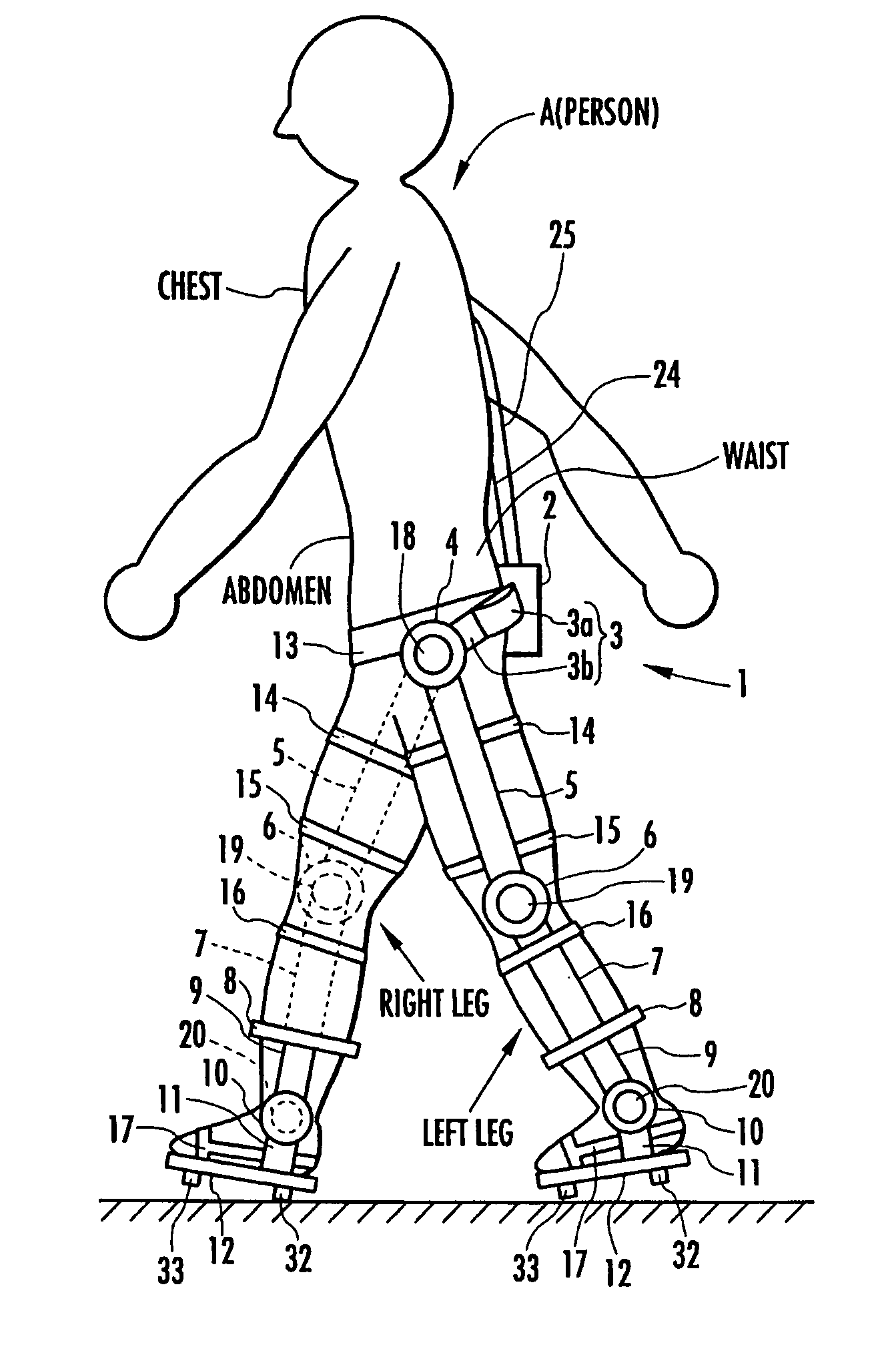

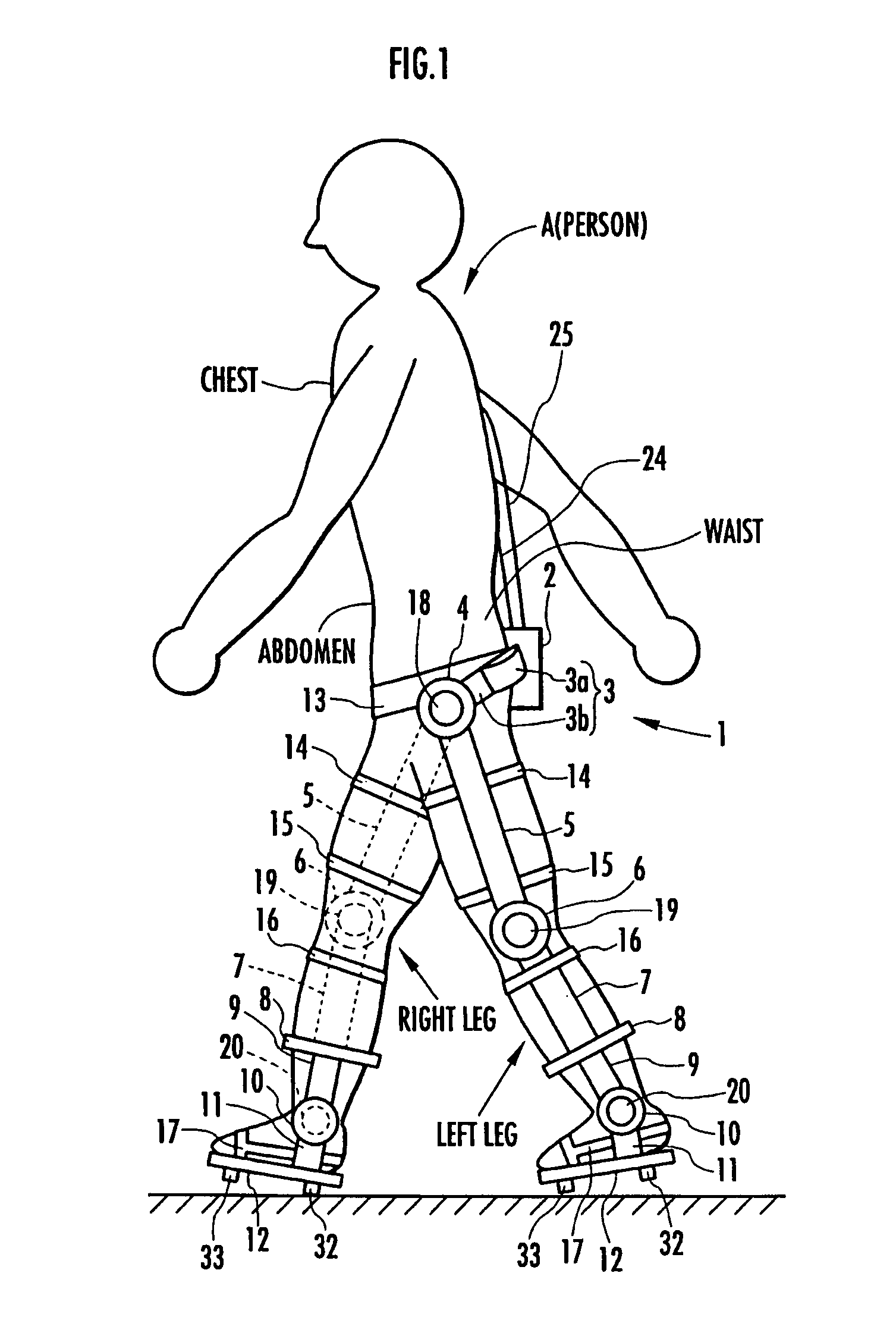

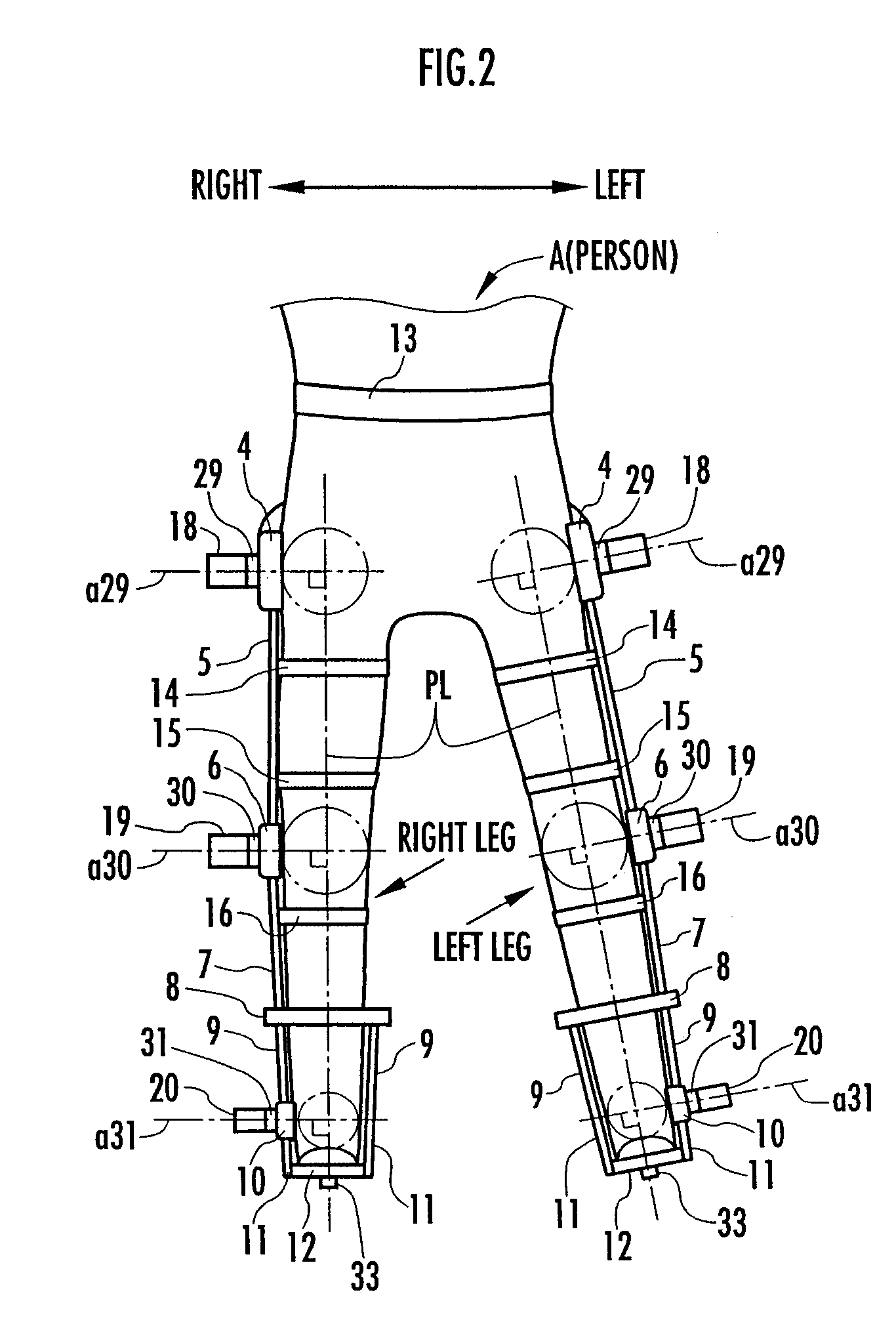

Generated torque control method for leg body exercise assistive apparatus

InactiveUS20070054777A1High degree of freedomPrevent be attachProgramme-controlled manipulatorChiropractic devicesSacroiliac jointEngineering

A generated torque control method for a leg body exercise assistive apparatus enabling a person to make a leg motion in such a feeling that the person is not wearing the leg body exercise assistive apparatus as much as possible by reducing the weight of the leg body exercise assistive apparatus attached to the person acting on the person. On the assumption that a person (A) not wearing the assistive apparatus (1) is making the same motion as a leg motion of the person (A) wearing the leg body exercise assistive apparatus (1) during the leg motion of the person (A), an estimation is made for a person-side joint moment to be generated in each joint of the leg of the person (A), and on the assumption that the assistive apparatus (1) is independently making the same motion as the leg motion, an estimation is made for an apparatus-side joint moment to be generated in the joint regions (4), (6), and (10) of the leg sections of the assistive apparatus (1). The estimated value of the apparatus-side joint moment is considered as a reference torque for torque generation means (18), (19), and (20), and a torque formed by adding a torque according to the estimated value of the person-side joint moment to the reference torque is generated in the torque generation means (18), (19), and (20).

Owner:HONDA MOTOR CO LTD

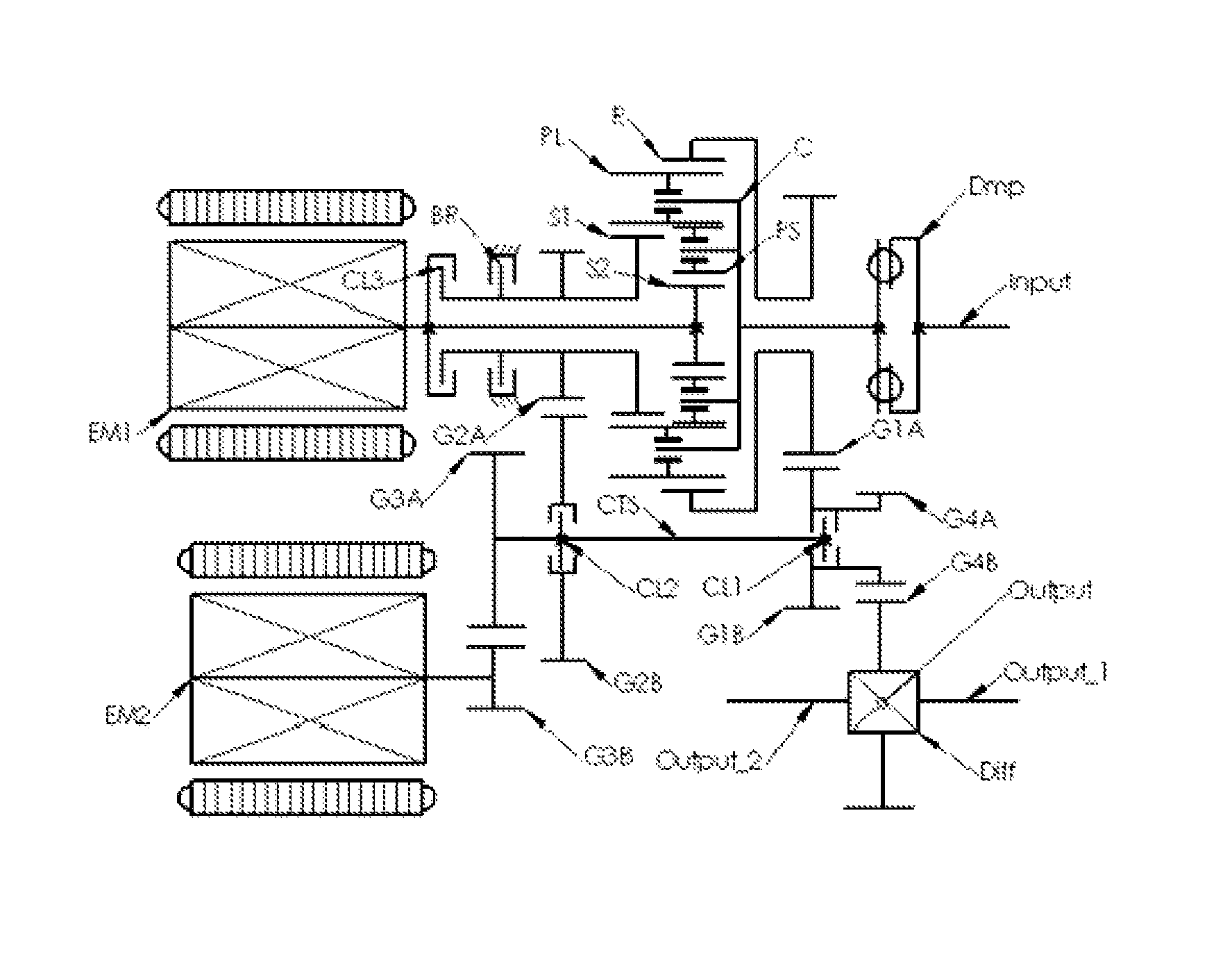

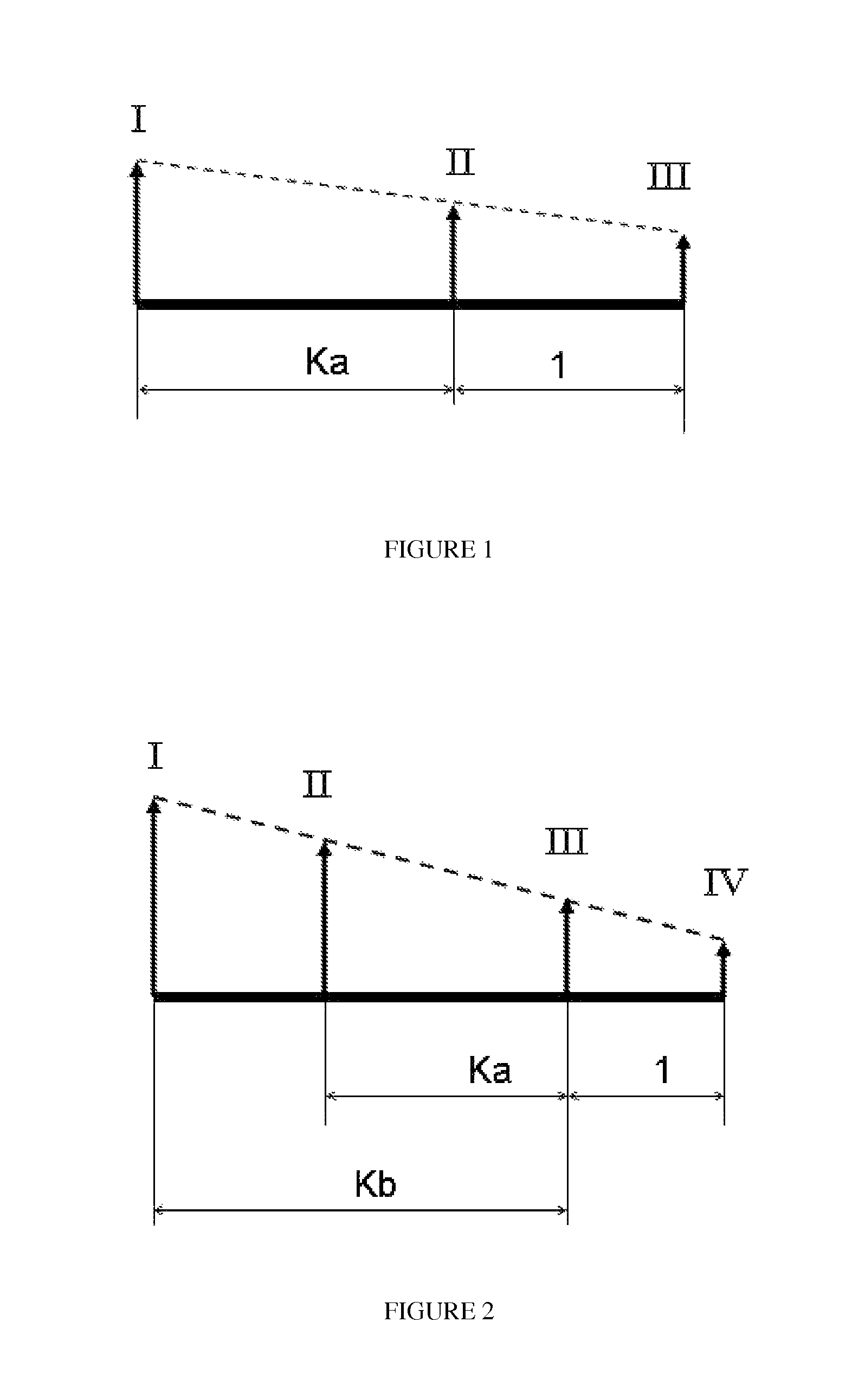

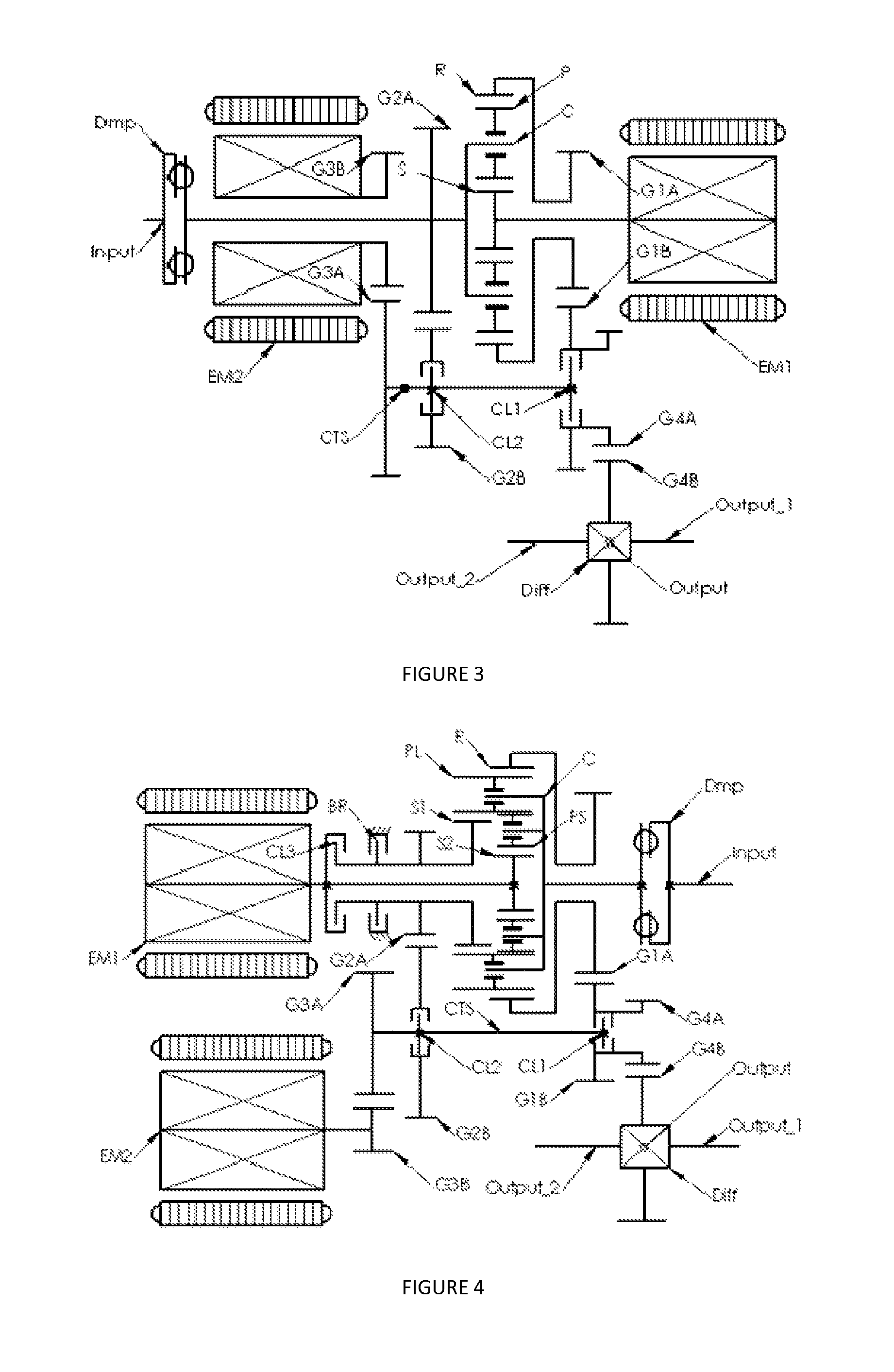

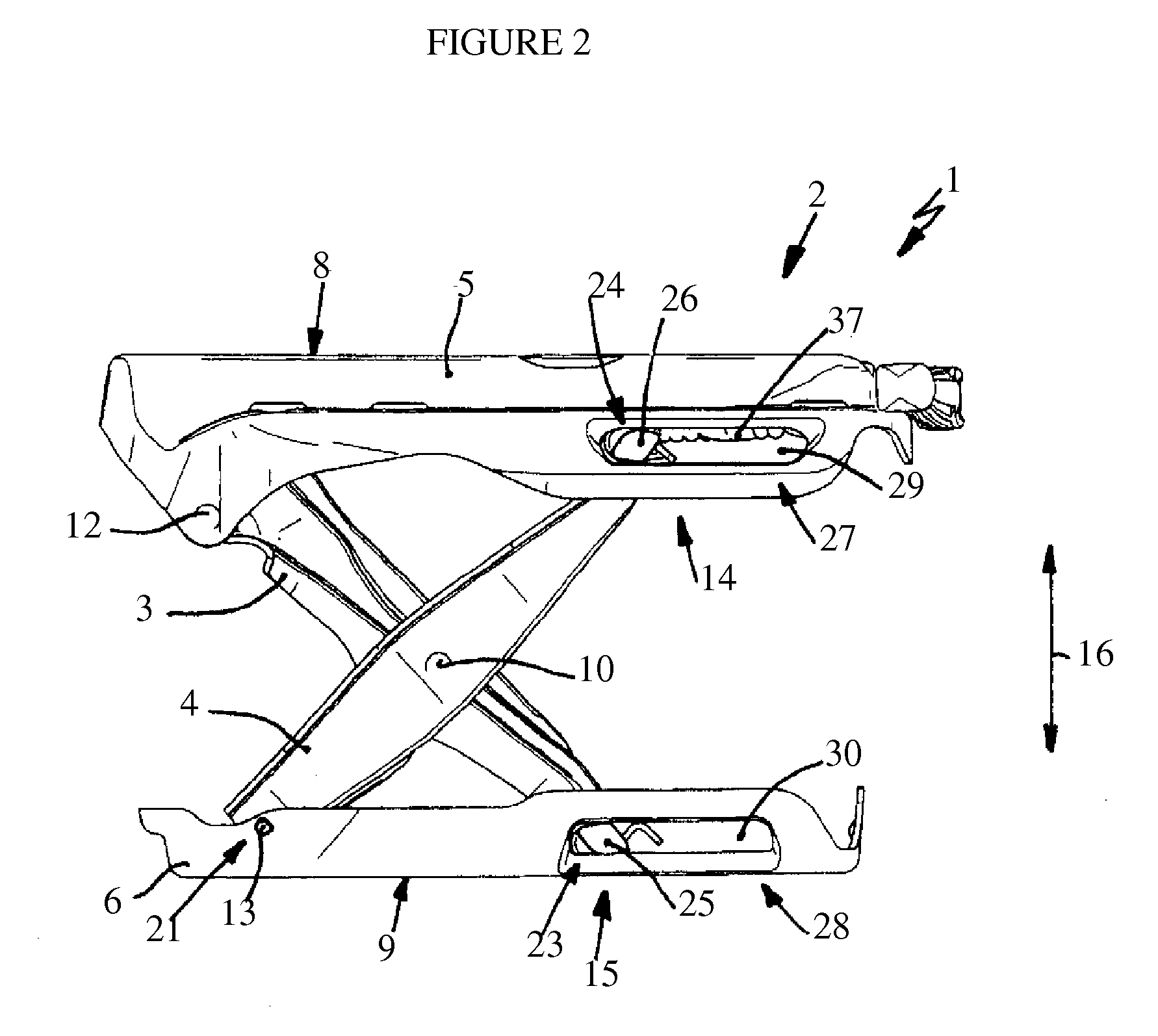

Dual-mode electromechanical variable speed transmission apparatus and method of control

InactiveUS8734281B2Improve transmission efficiencyAvoid powerHybrid vehiclesElectric propulsion mountingElectric machineDual mode

A dual-mode electro-mechanical variable speed transmission includes an input shaft, an output shaft system, a gear system having at least three branches, two electric machines, and at least a clutch. The first electric machine couples to a branch of the gear system, the output shaft system couples to another branch of the gear system, the input shaft couples to the remaining branch or one of the remaining branches of the gear system, and the second electric machine selectively couples either to the same branch that is coupled to the output shaft system with a speed ratio or to one of the remaining branches that that is not coupled to the first electric machine with a different speed ratio. The transmission provides at least two power splitting modes to cover different speed ratio regimes. The transmission can also provide at least a fixed output shaft to input shaft speed ratio.

Owner:SHANDONG LIANCHENG GREENMAX TECH

Analysis system and method for the analysis of a body fluid sample for an analyte contained therein

ActiveUS8114351B2Improve user friendlinessSimple and compact structureMaterial analysis by optical meansBurettes/pipettesAnalyteVariable Characteristic

Analysis system and method for the analysis of a body fluid sample for an analyte contained therein are disclosed. The analysis system has a dosing station for dosing a liquid into a test element through a sample supply opening, which reacts with a reagent system present in a sample analysis channel of the test element. The analysis system also has a measurement station for measuring a measurement variable characteristic of the reaction at the measuring zone of a test element for the analytical result. The test element also includes a separate flushing liquid supply opening and a flushing liquid collection chamber which are in fluid communication to one another via a flushing liquid channel. The flushing liquid channel and the sample analysis channel differ from one another in such a manner that a liquid flowing through the flushing liquid channel does not reach the measuring zone.

Owner:ROCHE DIAGNOSTICS OPERATIONS INC

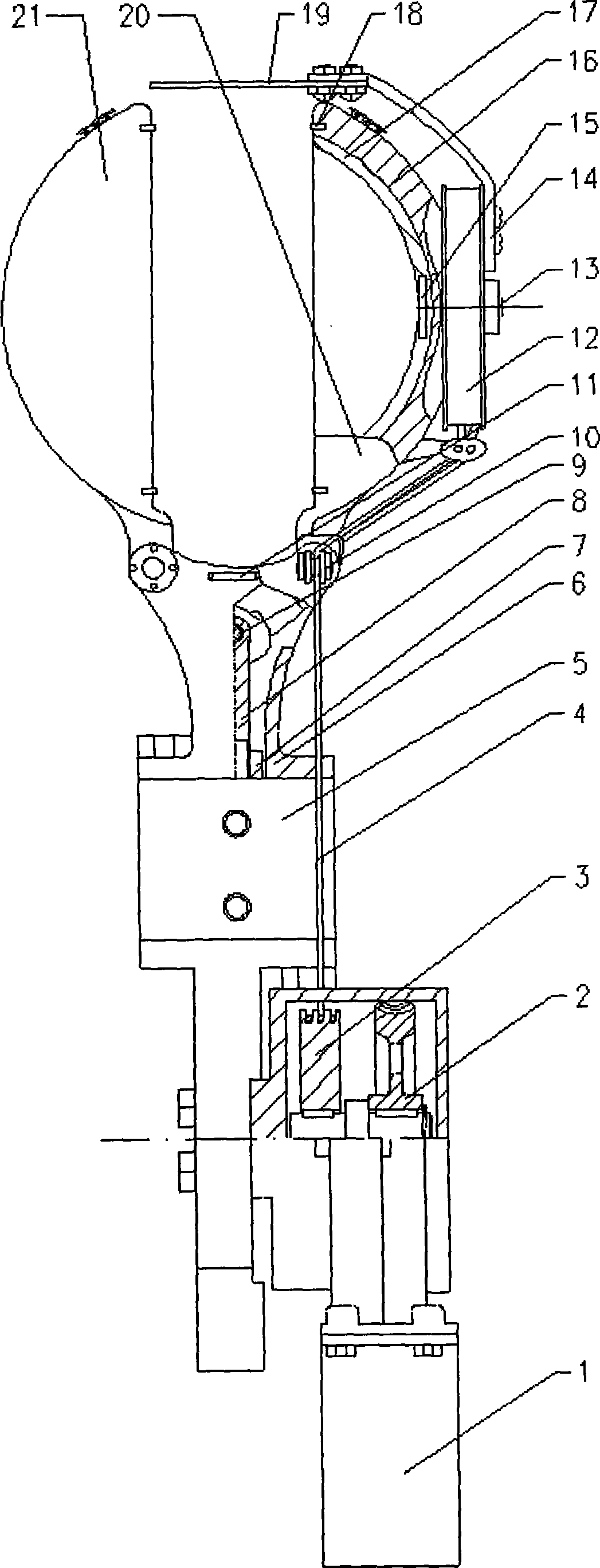

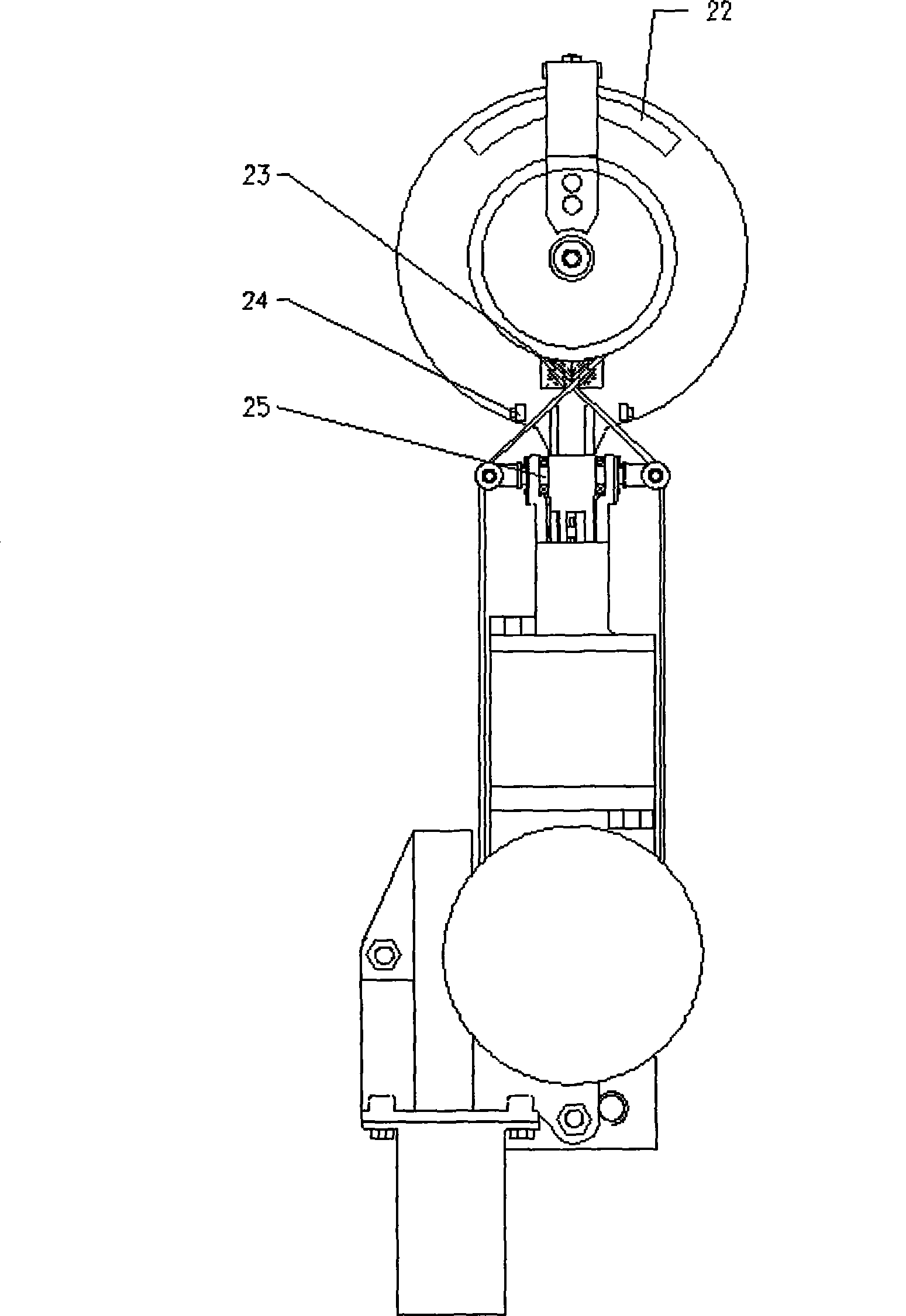

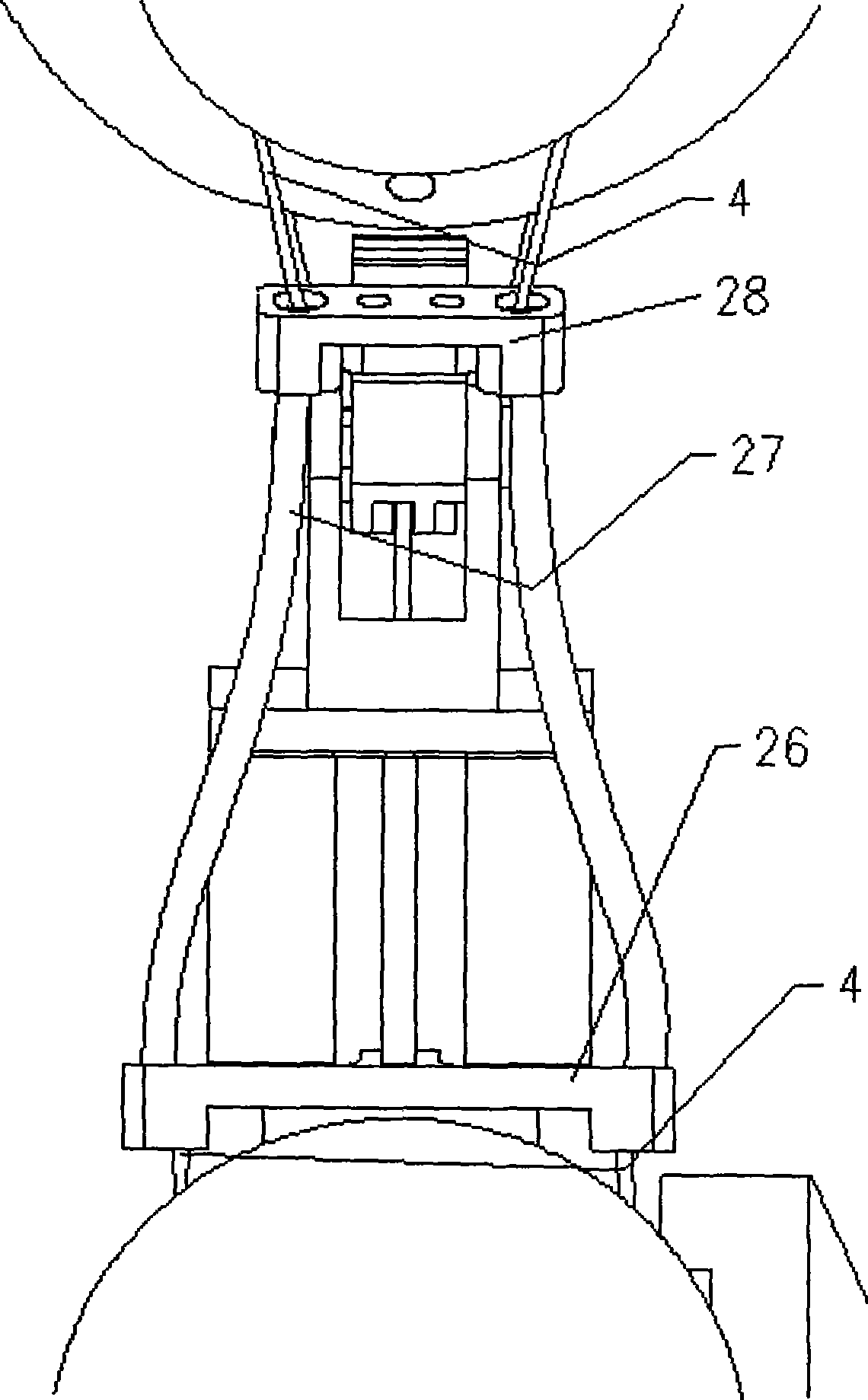

End effector of apple picking robot

InactiveCN101395989ASave the complicated processImprove versatilityProgramme-controlled manipulatorPicking devicesRobot end effectorActuator

The invention relates to an end effector of a fruit and vegetable picking robot. The end effector mainly consists of a clamping system, a cutting system and a sensor system. The clamping system mainly adopts a mechanism formed by cylinder sliding chutes to drive two fingers to open and close, thus realizing the action of grasping apples; the cutting system adopts a DC motor with 12V as the power source to drive blades to rotate nearly a circle around the fingers by the transmission of steel wires or the transmission of steel wire trolley wheels, thus cutting apple stems at any position along the circumferential direction of the fingers; the sensor system consists of an opto-electrical position switch, a pressure sensor, a micro-vision sensor, a touch sensor and a limit switch and plays a role of connecting motions and controlling the process during the process of clamping and cutting the apple stems. The end effector has a simple and reliable picking way, good commonality, low control difficulty, low cost, which ensures an intelligentized picking, thus meeting the demands of a football-like fruit picking robot and being conducive to realizing the practical utilization and commercialization of fruit picking robots.

Owner:JIANGSU UNIV

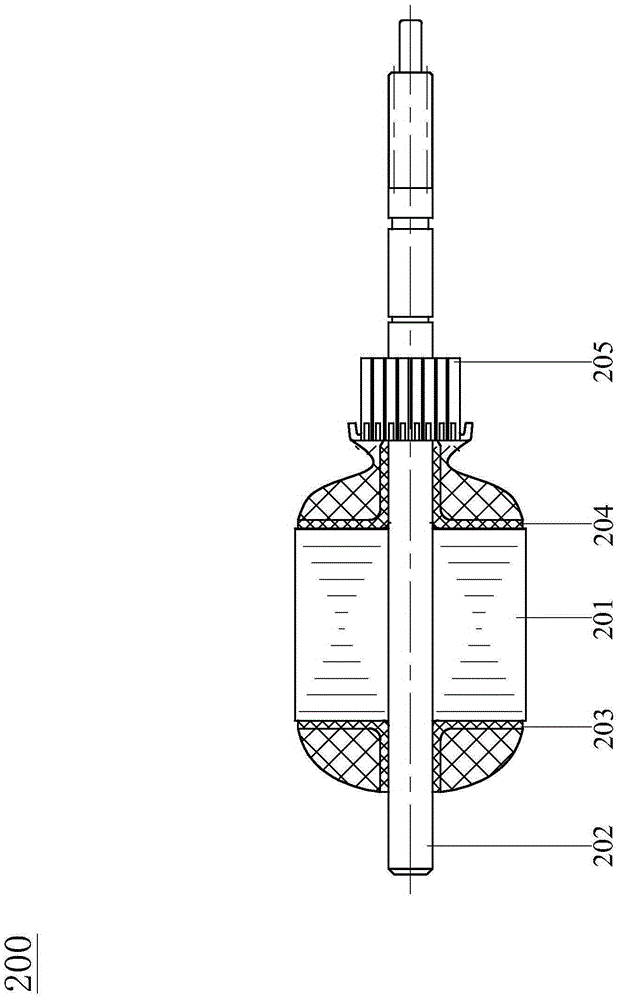

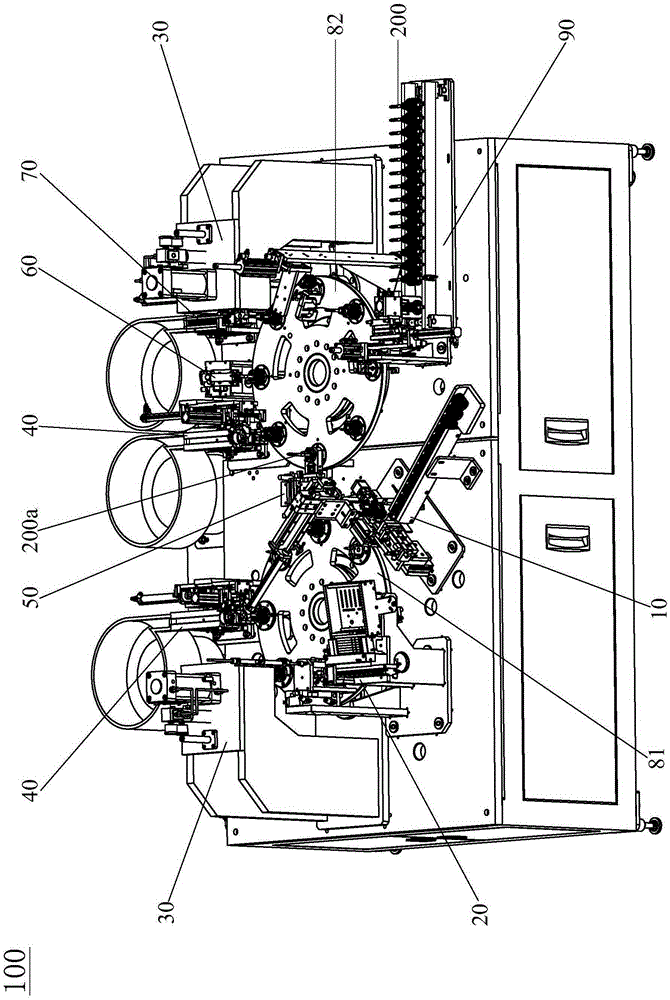

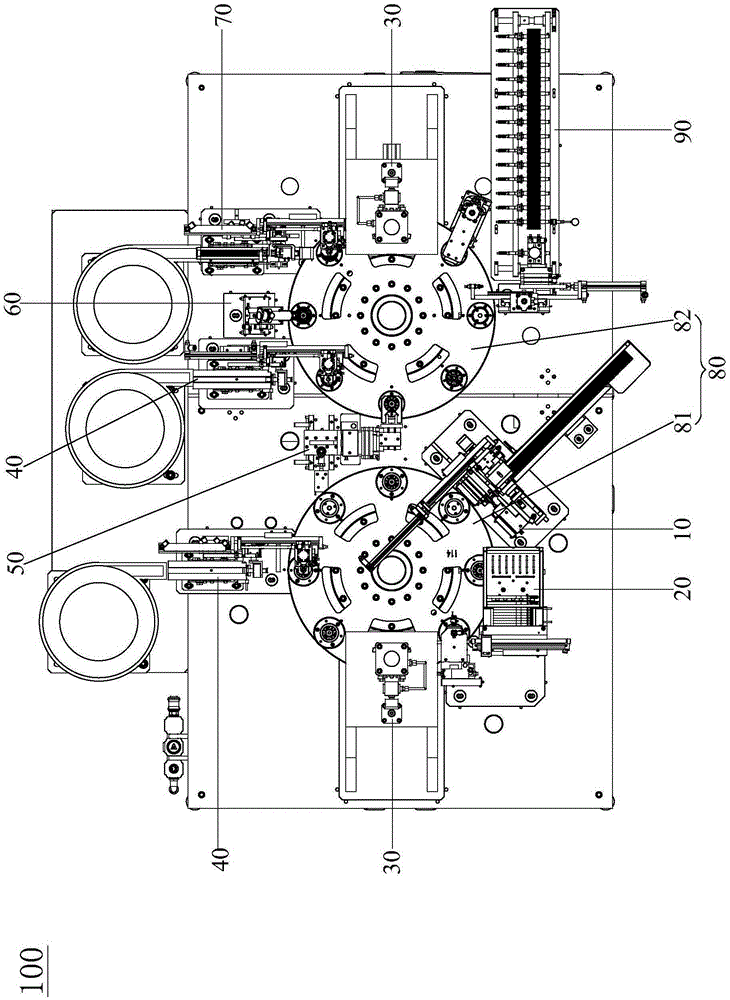

Motor rotor automatic assembling machine

ActiveCN105406664ASimple and compact structureSmall footprintAssembly machinesManufacturing stator/rotor bodiesWork in processEngineering

The invention discloses a motor rotor automatic assembling machine including an iron core feeding device, a main shaft feeding device, a press-fit device, an insulating sheet feeding device, a turning device, a dispensing device, a commutator feeding device, a rotary disc conveyer, and a discharging device. The rotary disc conveyer includes a first rotating disc and a second rotating disc, the iron core feeding device, the main shaft feeding device, the press-fit device, and the insulating sheet feeding device are cooperated on the first rotating disc to assemble an iron core, a main shaft, and an insulation sheet into a half-finished rotor, the turning device conveys the half-finished rotor to the second rotating disc, the insulating sheet feeding device, the dispensing device, the commutator feeding device, and the press-fit device are cooperated on the second rotating disc to assemble the half-finished rotor, a lower insulation sheet, and a commutator into a finished rotor, and the discharging device takes the finished rotor off the second rotating disc and rotates for discharging. The whole machine is compact and reasonable in structure, high in efficiency, low in cost, and high in automation degree.

Owner:DONGGUAN WORLD PRECISION MACHINERY

Calibration method and calibration device for a surgical referencing unit

InactiveUS20080039868A1Easy to operateQuick and simple calibration and referencingDiagnosticsSurgical navigation systemsNavigation systemOptics

A calibration method and also a calibration device are proposed to enable a spatial position and / or orientation of a surgical referencing unit of a surgical navigation system fitted with at least one inertial sensor to be specified in relation to a spatial coordinate system.

Owner:AESCULAP AG

Method and apparatus for monitoring oil deterioration in real time

InactiveUS20080024761A1Simple and compact structureInvestigating moving fluids/granular solidsOptically investigating flaws/contaminationLength waveWavelength range

There is provided a method and apparatus for monitoring oil deterioration in real time. The method includes the steps of radiating light into an oil medium and measuring light intensities at red, green and blue wavelength ranges of the light after passing through a certain thickness of the oil. A ratio of the light intensity at the red wavelength range to the light intensity at the green wavelength range is computed by using the measured light intensities. These steps are repeated to monitor a change in the above ratio value in real time of oil use. The apparatus includes a light source means for radiating light into an oil medium, a color sensing means for measuring light intensities at red, green and blue wavelength ranges of the light that has passed through a certain thickness of the oil, and a control means for computing and monitoring a ratio of the light intensity at the red wavelength range to the light intensity at the green wavelength range, using the light intensities measured by the color sensing means.

Owner:KOREA INST OF SCI & TECH

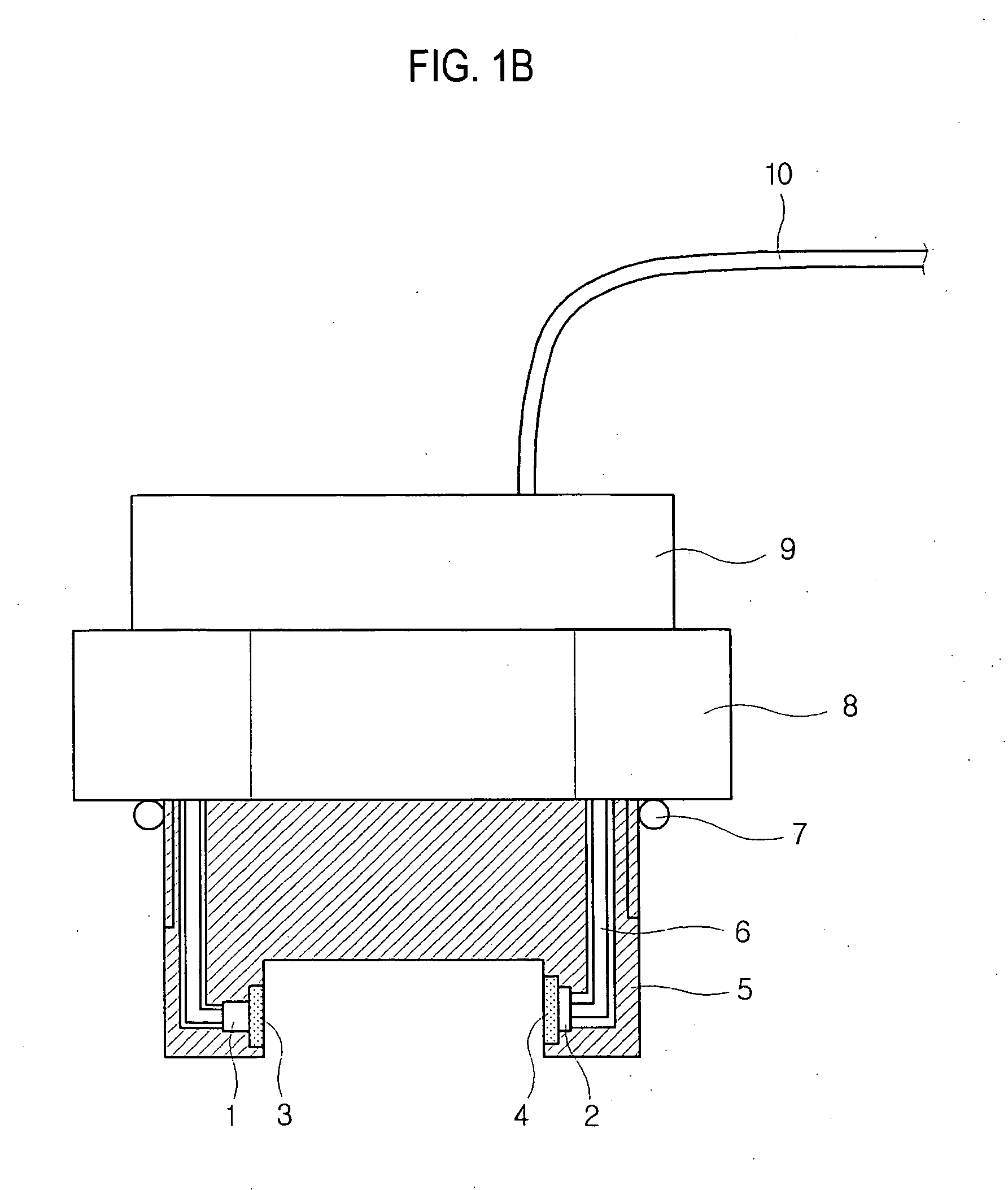

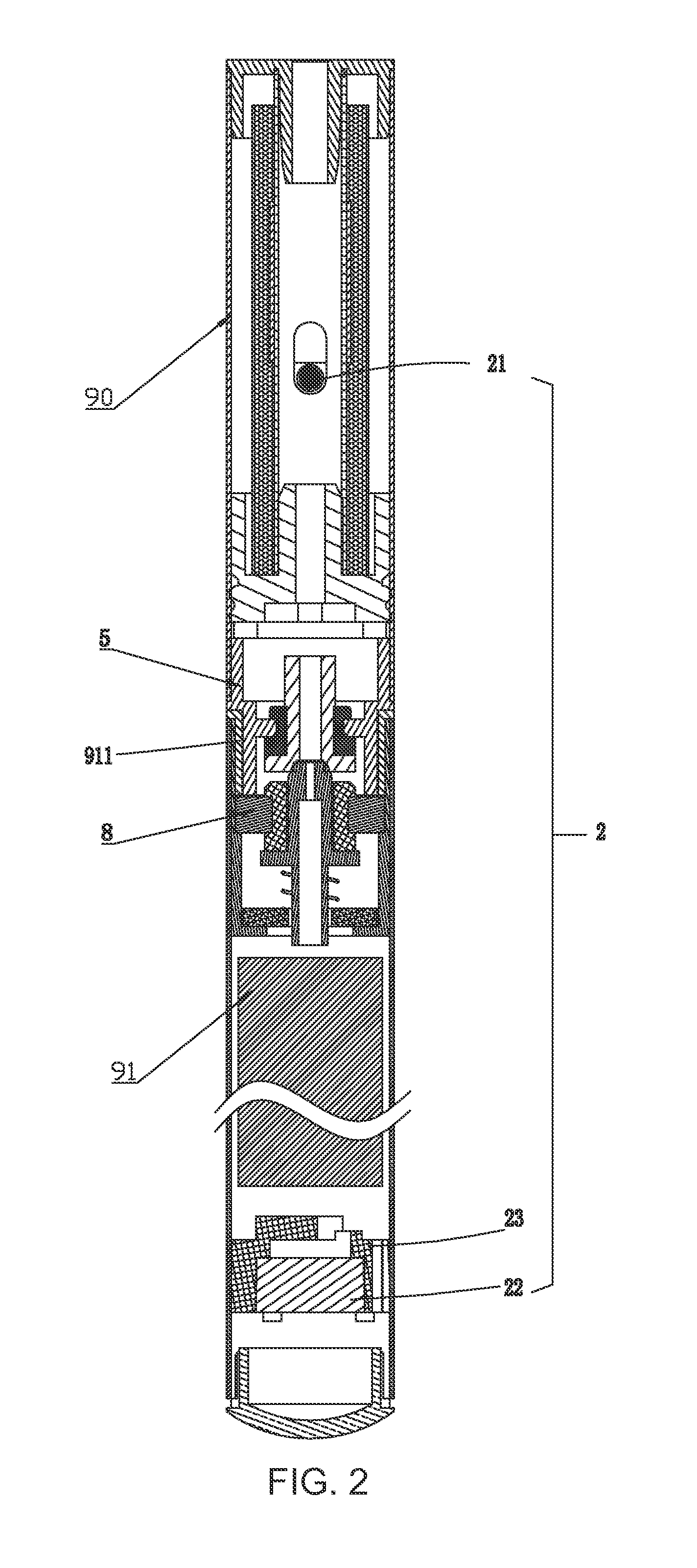

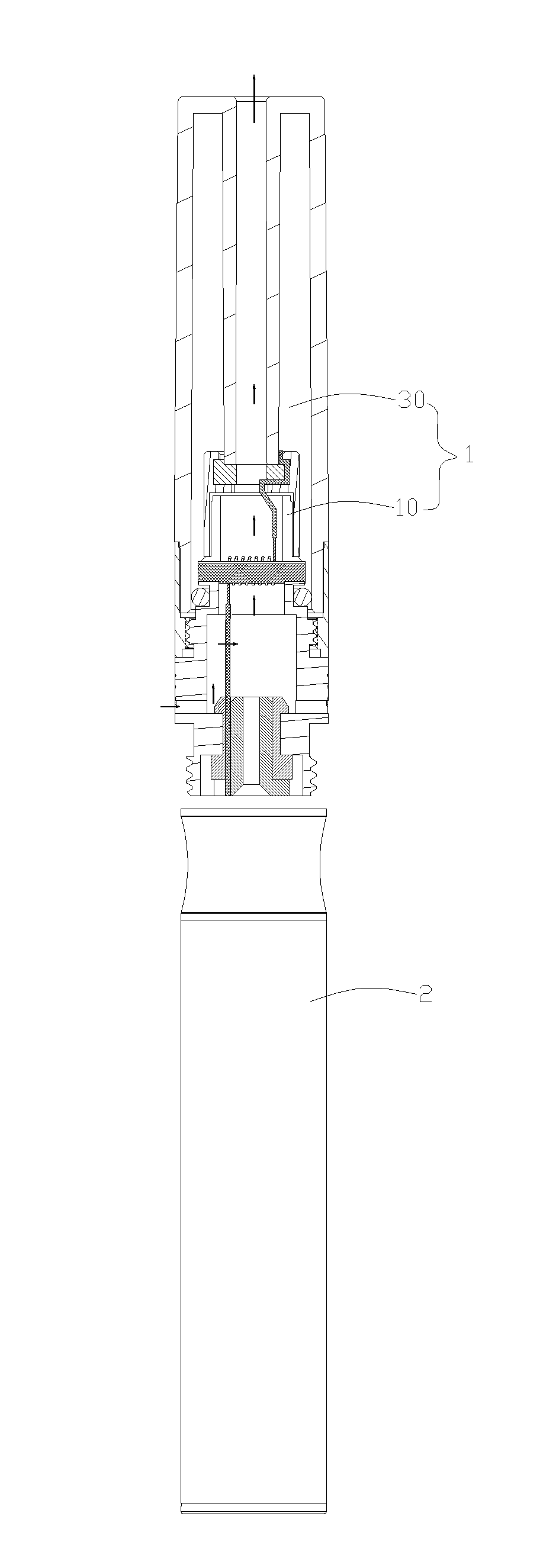

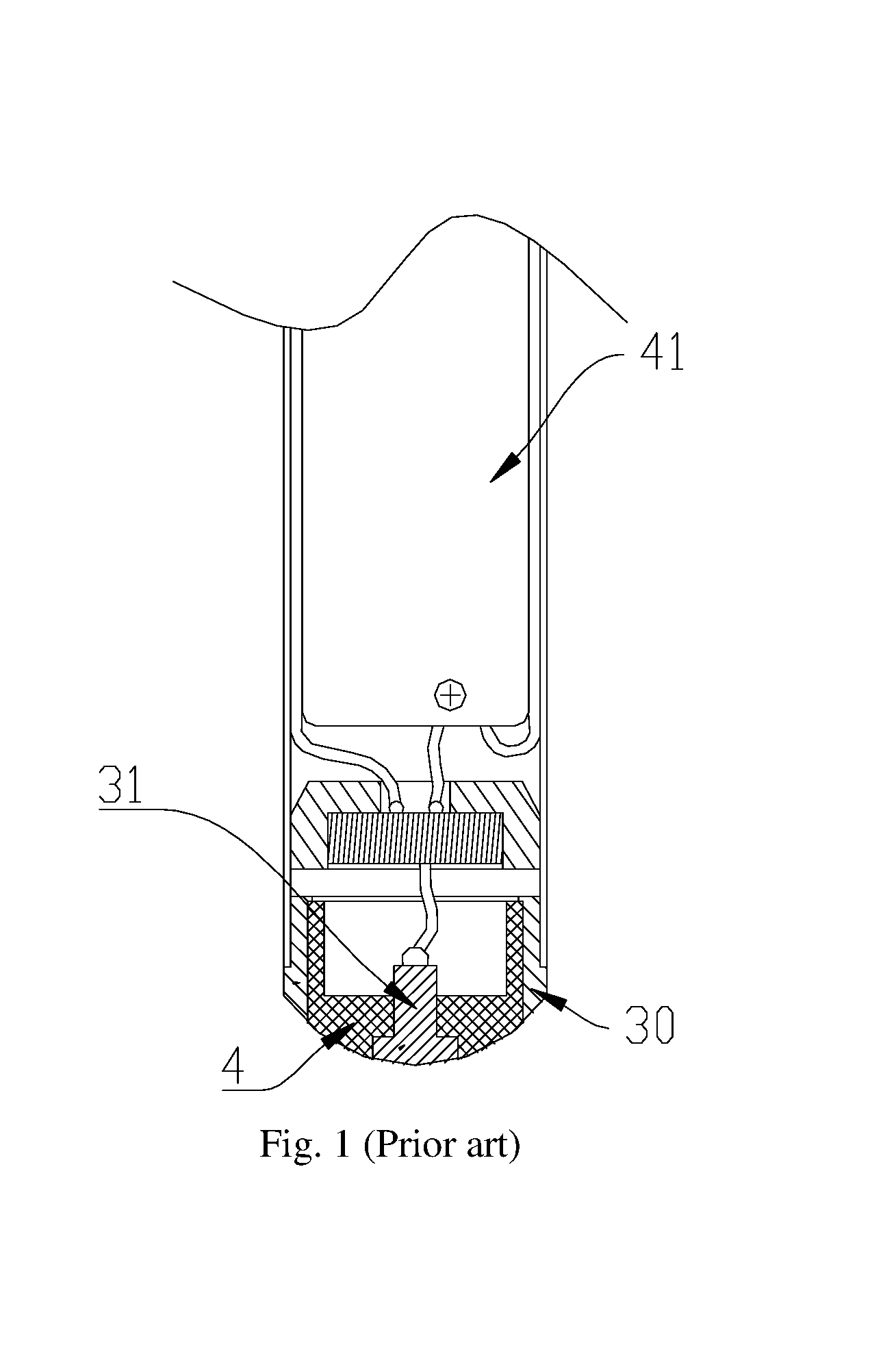

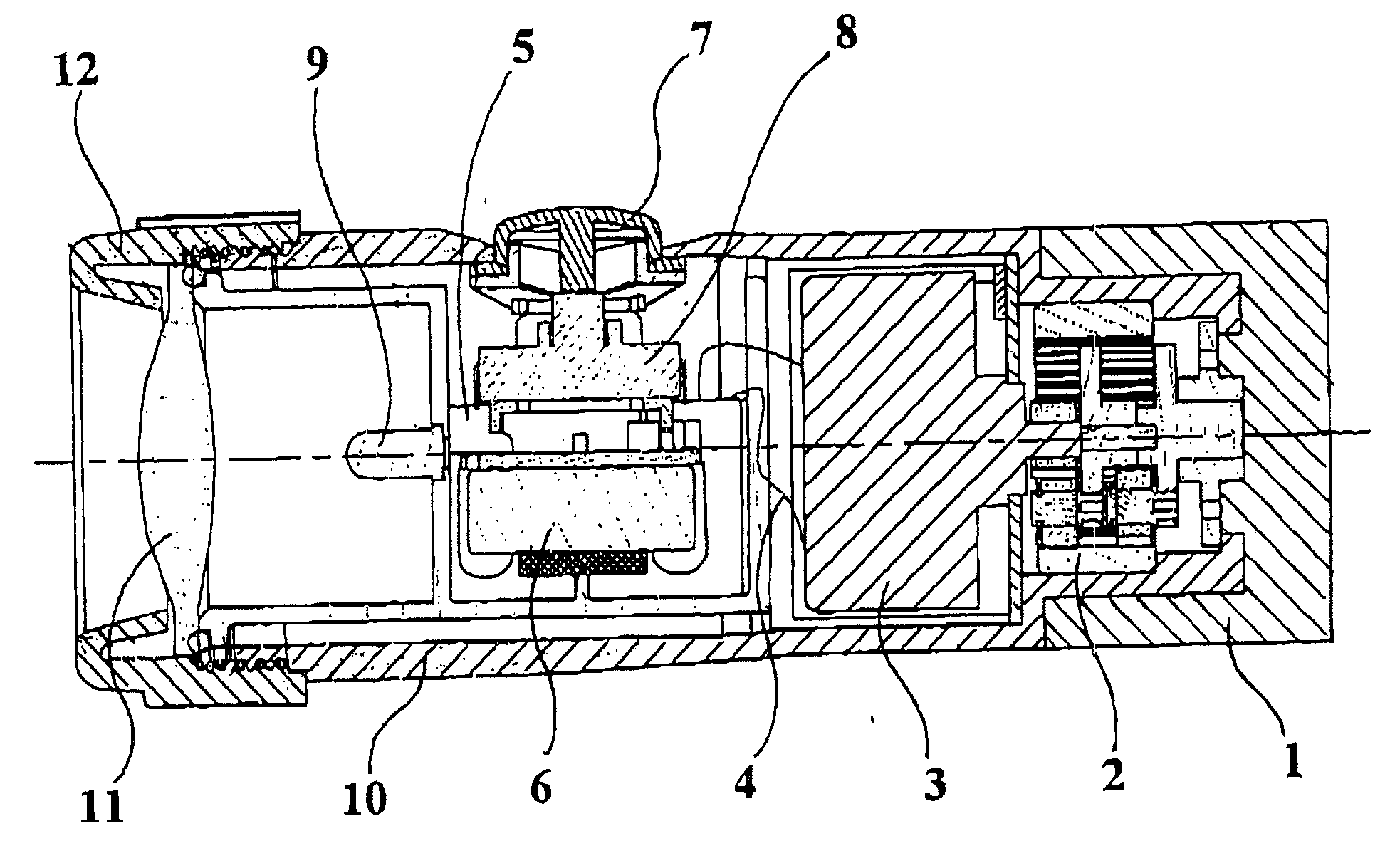

Electronic Cigarette

InactiveUS20140020696A1Easy to disassembleEasy maintenanceTobacco treatmentTobacco pipesElectronic cigaretteEngineering

An electronic cigarette comprises a smoking unit and a power unit. The smoking unit attachably connects with the power unit as a unitary member by magnetism. A connecting end of the smoking unit and a corresponding connecting end of the power unit respectively comprise a connecting element which is made of iron material. A permanent magnet is disposed in at least one of the connecting end of the smoking unit and the corresponding end of the power unit. The connecting element of the connecting end of the smoking unit and the connecting element of the corresponding connecting end of the power unit are removably and insertedly connected to each other, and engaged with each other via an attractive force of the permanent magnet. The electronic cigarette can be assembled and disassembled conveniently and efficiently, and is easy for maintenance and replacement.

Owner:HUIZHOU KIMREE TECH

Generated torque control method for leg body exercise assistive apparatus

InactiveUS7278954B2Reduce weightReduce empty weightProgramme-controlled manipulatorChiropractic devicesEngineeringAssistive equipment

A generated torque control method for a leg body exercise assistive apparatus enabling a person to make a leg motion in such a feeling that the person is not wearing the leg body exercise assistive apparatus as much as possible by reducing the weight of the leg body exercise assistive apparatus attached to the person acting on the person. On the assumption that a person (A) not wearing the assistive apparatus (1) is making the same motion as a leg motion of the person (A) wearing the leg body exercise assistive apparatus (1) during the leg motion of the person (A), an estimation is made for a person-side joint moment to be generated in each joint of the leg of the person (A), and on the assumption that the assistive apparatus (1) is independently making the same motion as the leg motion, an estimation is made for an apparatus-side joint moment to be generated in the joint regions (4), (6), and (10) of the leg sections of the assistive apparatus (1). The estimated value of the apparatus-side joint moment is considered as a reference torque for torque generation means (18), (19), and (20), and a torque formed by adding a torque according to the estimated value of the person-side joint moment to the reference torque is generated in the torque generation means (18), (19), and (20).

Owner:HONDA MOTOR CO LTD

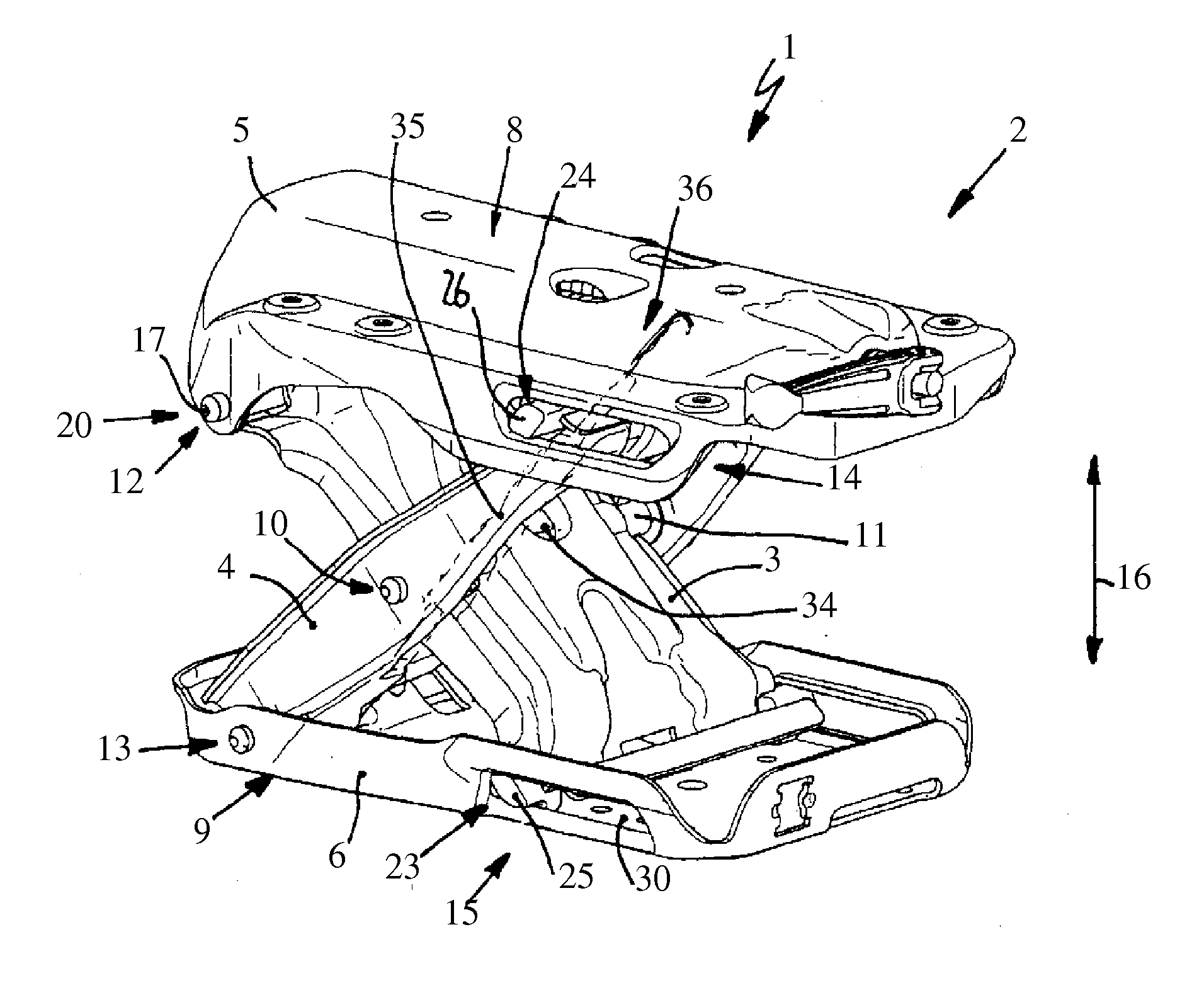

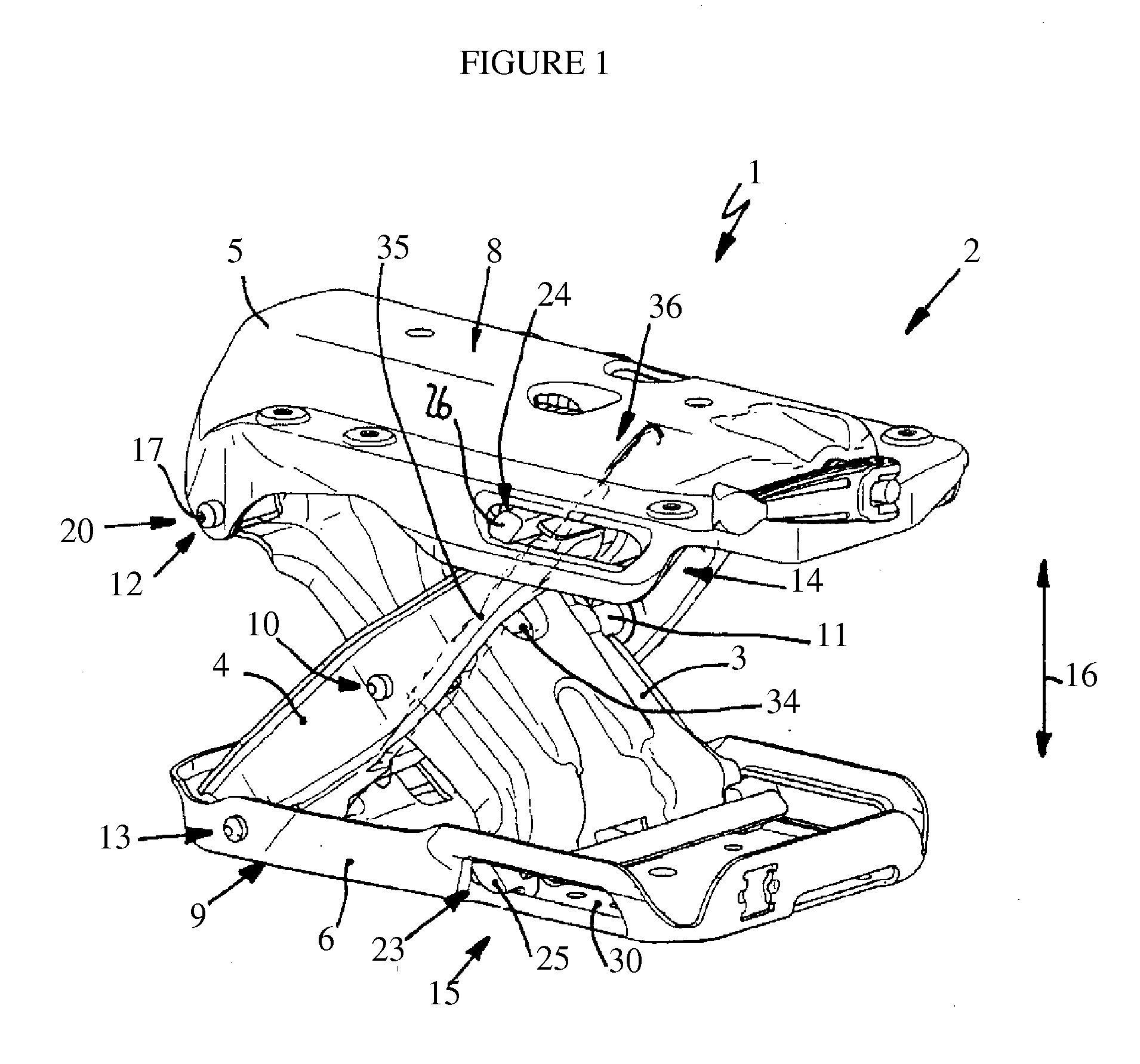

Scissors-type frame for a vehicle seat and method for producing a substructure of a vehicle seat

ActiveUS20100117428A1Speed up preparationEasily and quickly producedSeat framesStands/trestlesMobile vehicleEngineering

Owner:GRAMMER AG

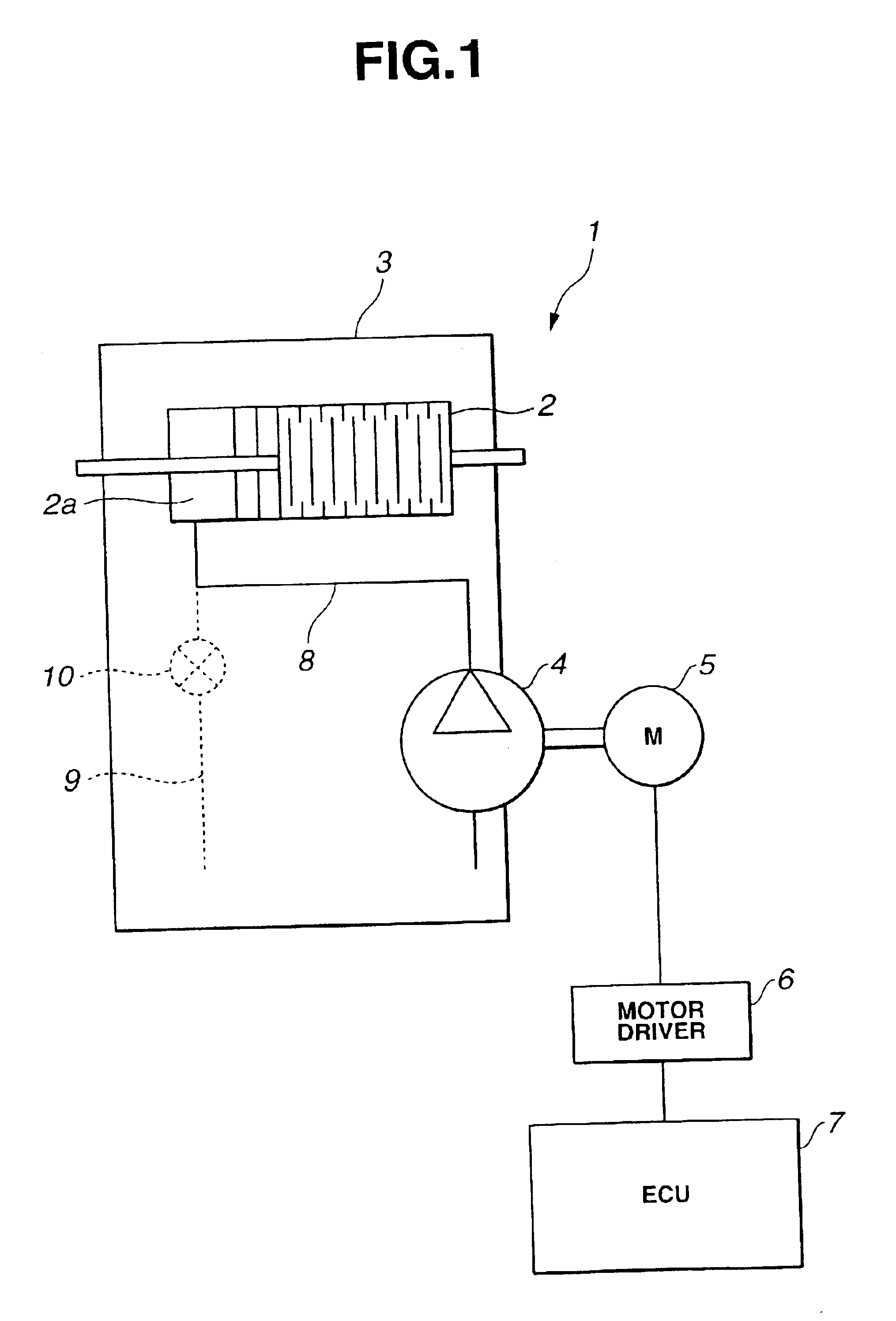

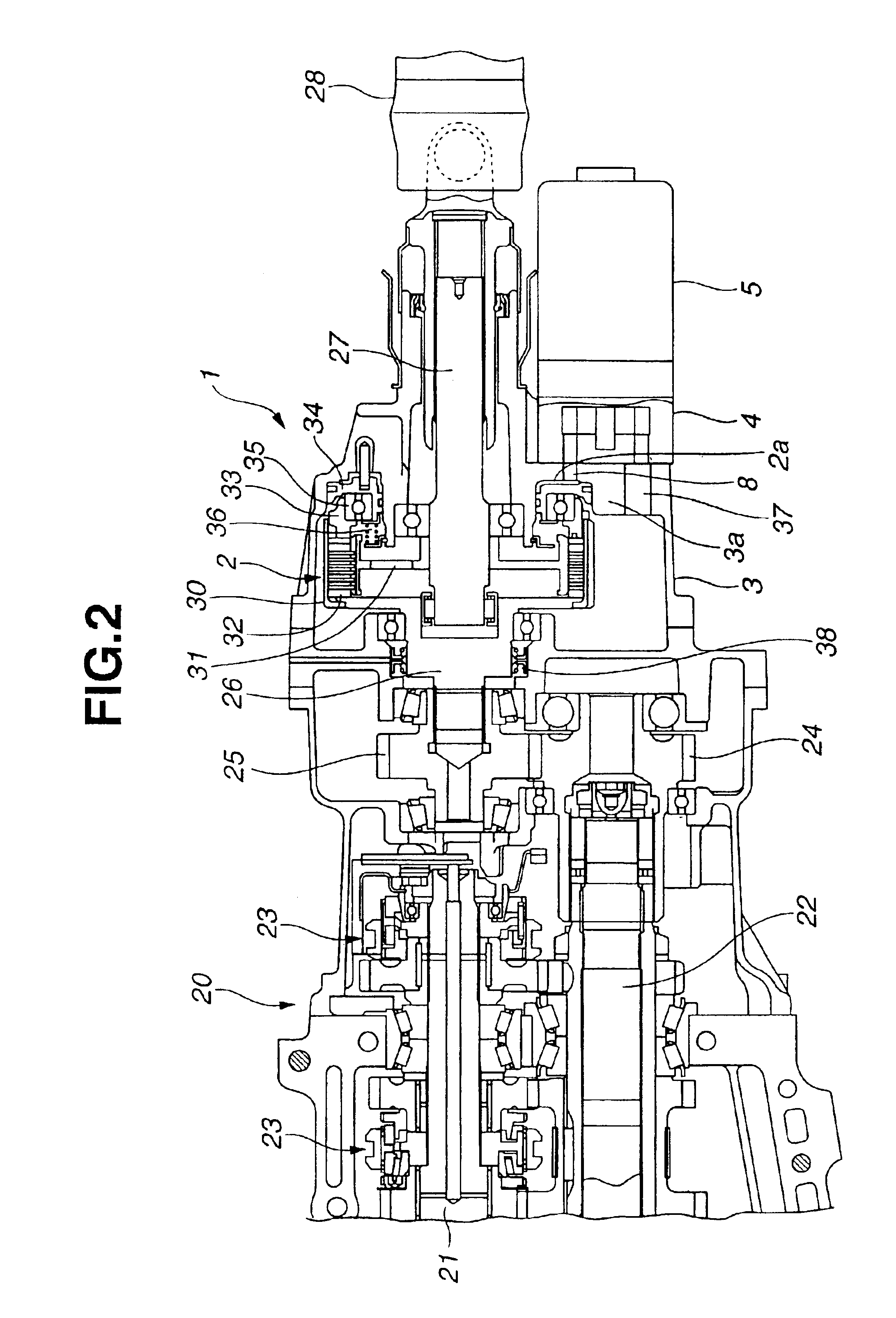

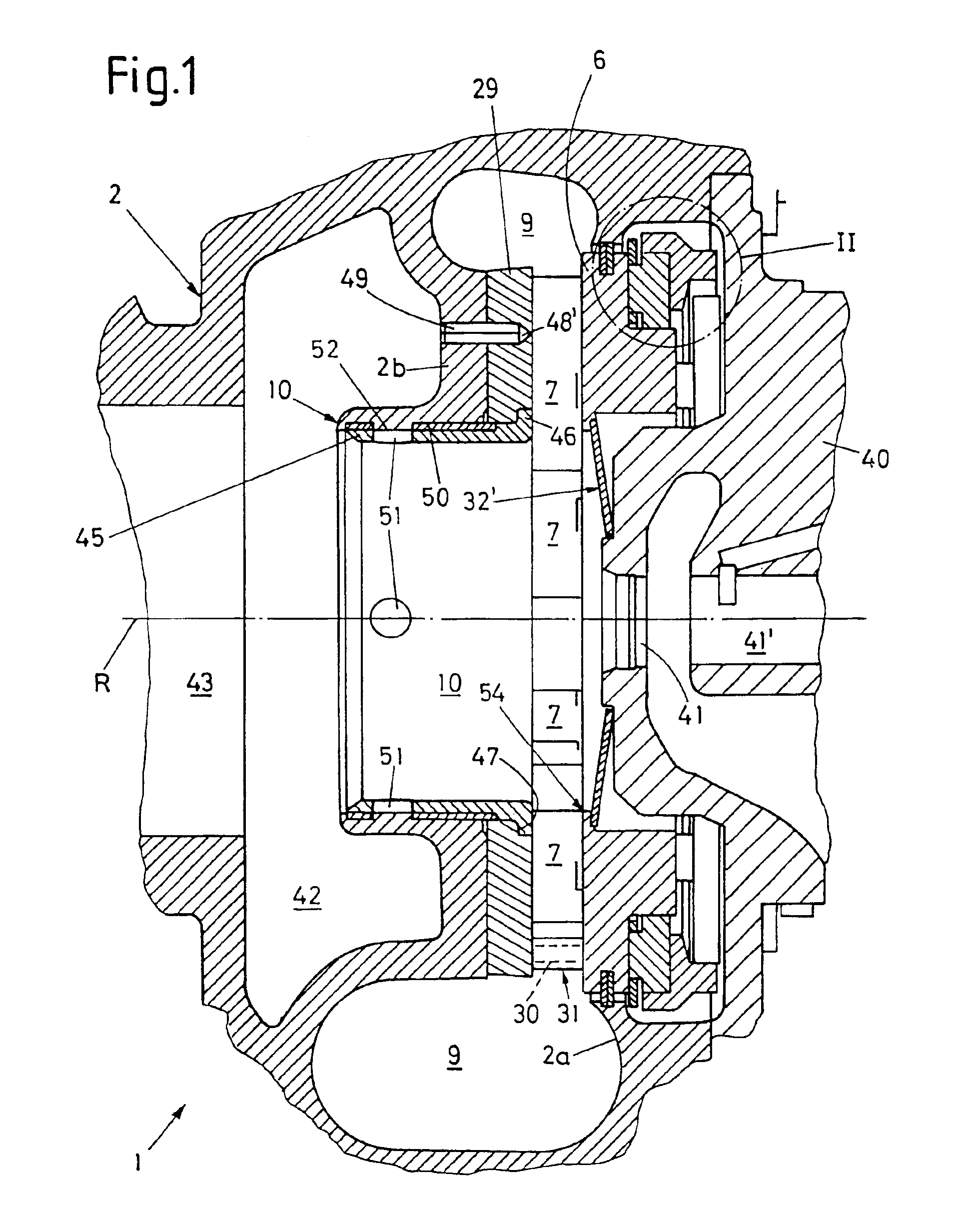

Electronic controlled coupling

InactiveUS6848555B2Increased durabilityIncrease flexibilityFluid actuated clutchesMagnetically actuated clutchesDischarge pressureClutch

An electronic controlled coupling including a wet-type multiple disc clutch, a coupling case, a hydraulic chamber, an oil pump, an electric motor, an electric control unit, and a supply passage for supplying hydraulic pressure. The coupling case accommodates the wet-type multiple disc clutch and contains oil. The oil pump driven by the electric motor is connected to the coupling case. The outlet of the oil pump is connected to the hydraulic chamber of the wet-type multiple disc clutch with the supply passage therebetween. The electric control unit controls the speed of rotation of the electric motor through a motor driver so that the pump discharge pressure is equal to an operating pressure required for the wet-type multiple disc clutch. The electronic controlled coupling performs a complete coupling mechanism increasing the durability as a coupling and a compact and simple structure enhancing the flexibility in designing.

Owner:KOYO SEIKO CO LTD +1

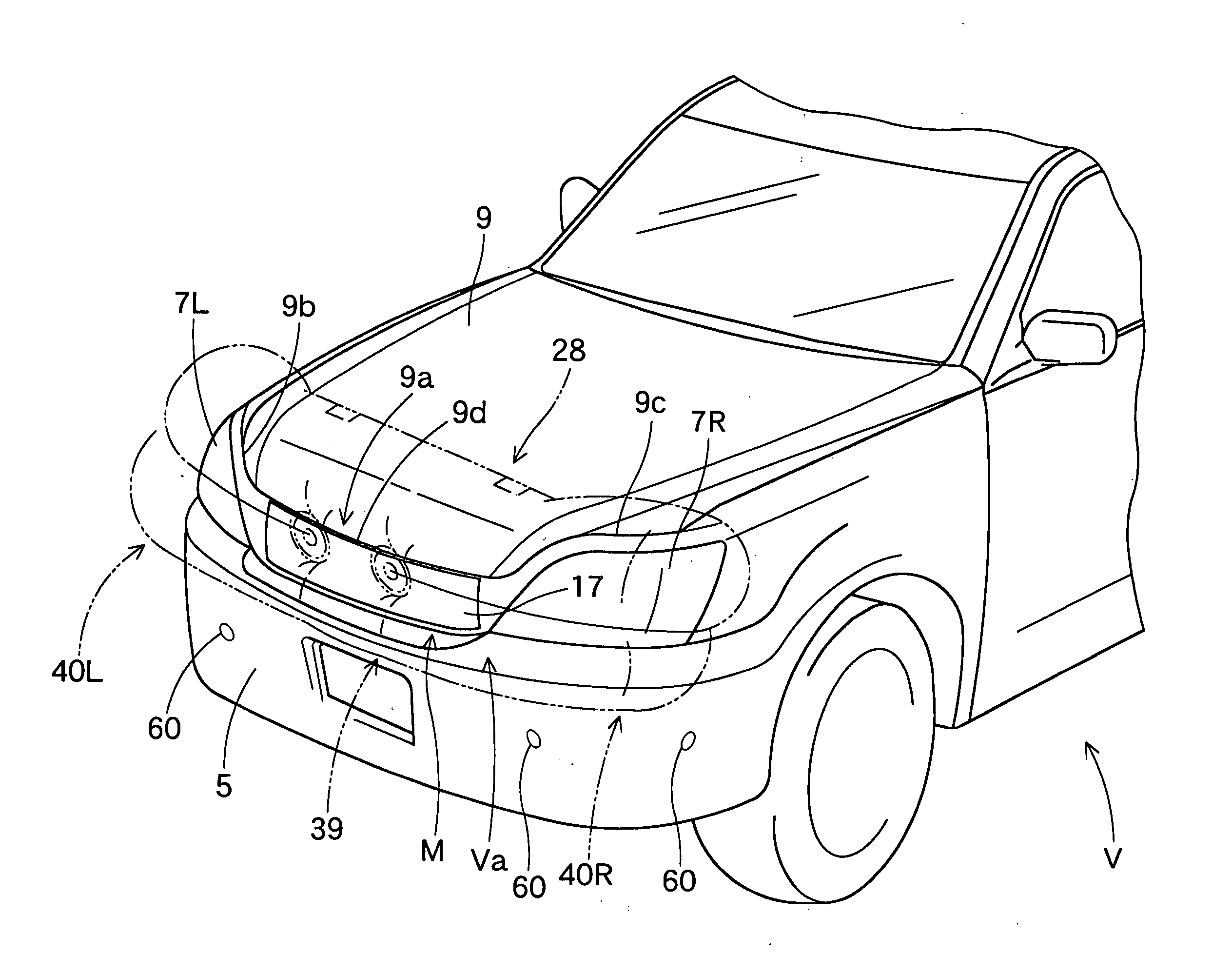

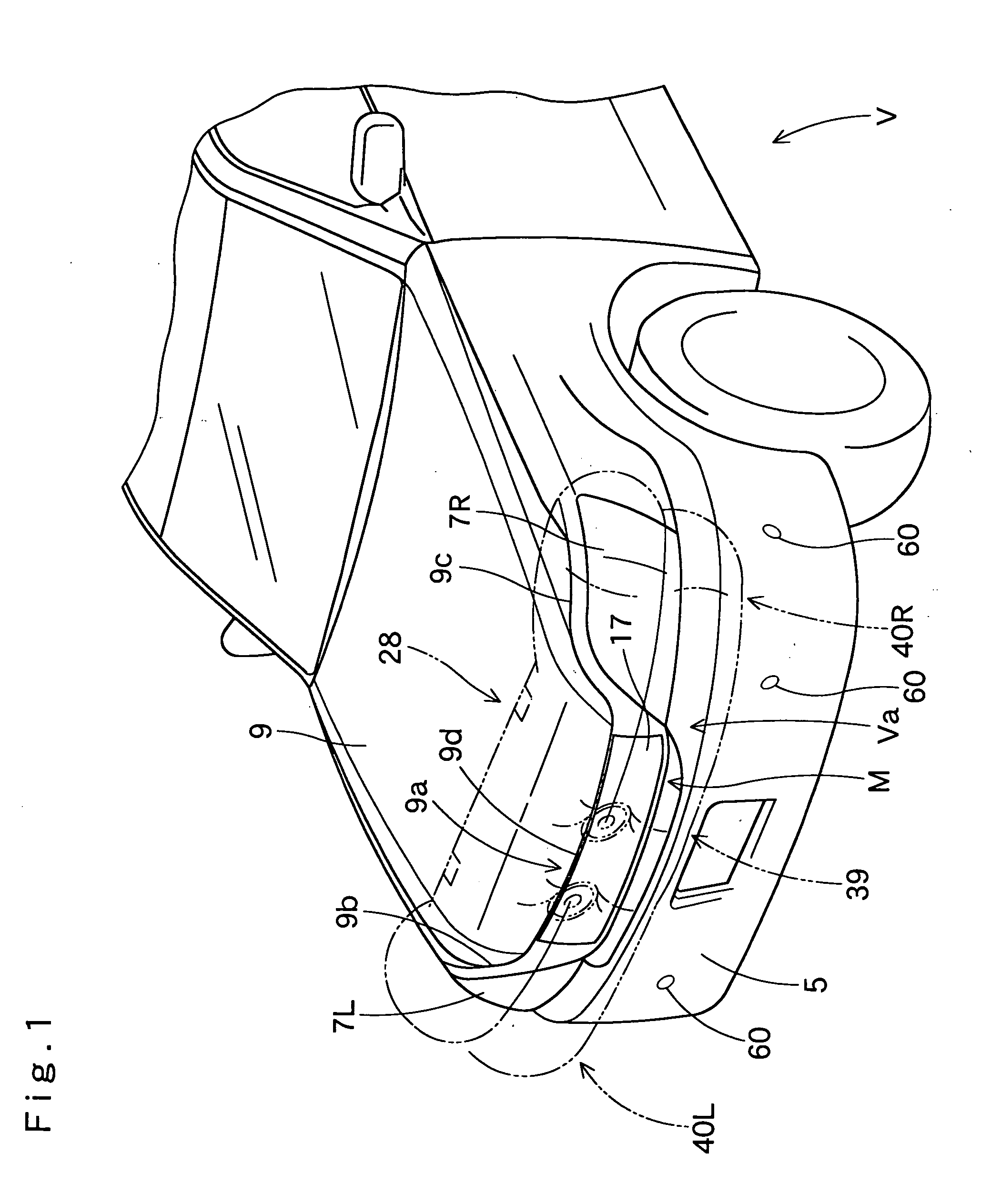

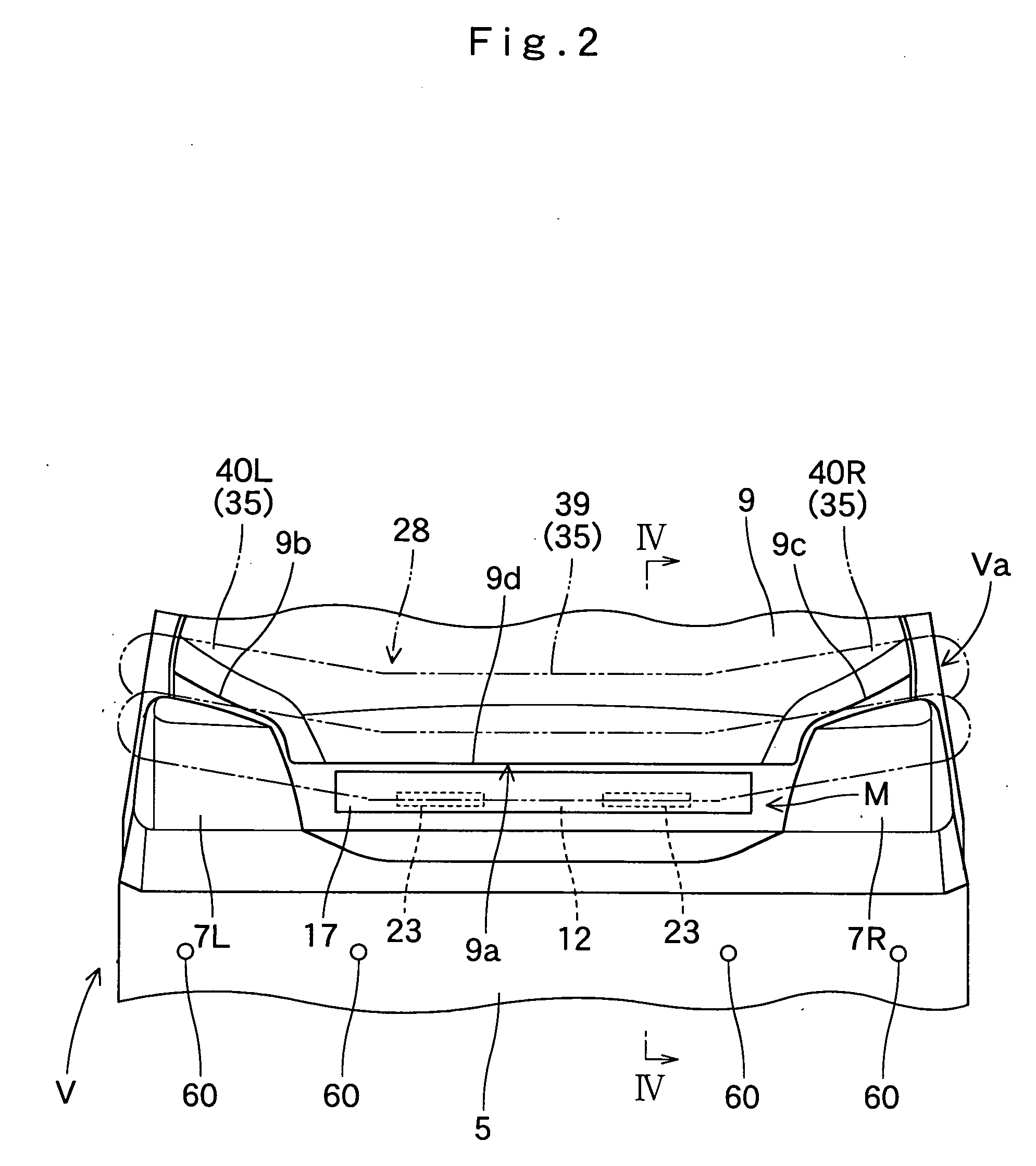

Airbage apparatus for pedestrian protection

InactiveUS20090102167A1Suppress its volumeSimple and compact structurePedestrian/occupant safety arrangementAirbagPedestrian

An airbag apparatus for pedestrian protection includes an airbag that emerges from an opening of a housing located below a front end of a hood panel and deploys upward and toward left and right. The airbag includes a protection portion that deploys along a foreface of a vehicle. The protection portion includes end regions for covering front faces of head lamps and the end regions are configured in a upward-bending manner from a central region. Contraction of the airbag at inflation is taken into account in order to configure a bending angle between each of the end regions and the central region as the airbag is flattened.

Owner:TOYODA GOSEI CO LTD

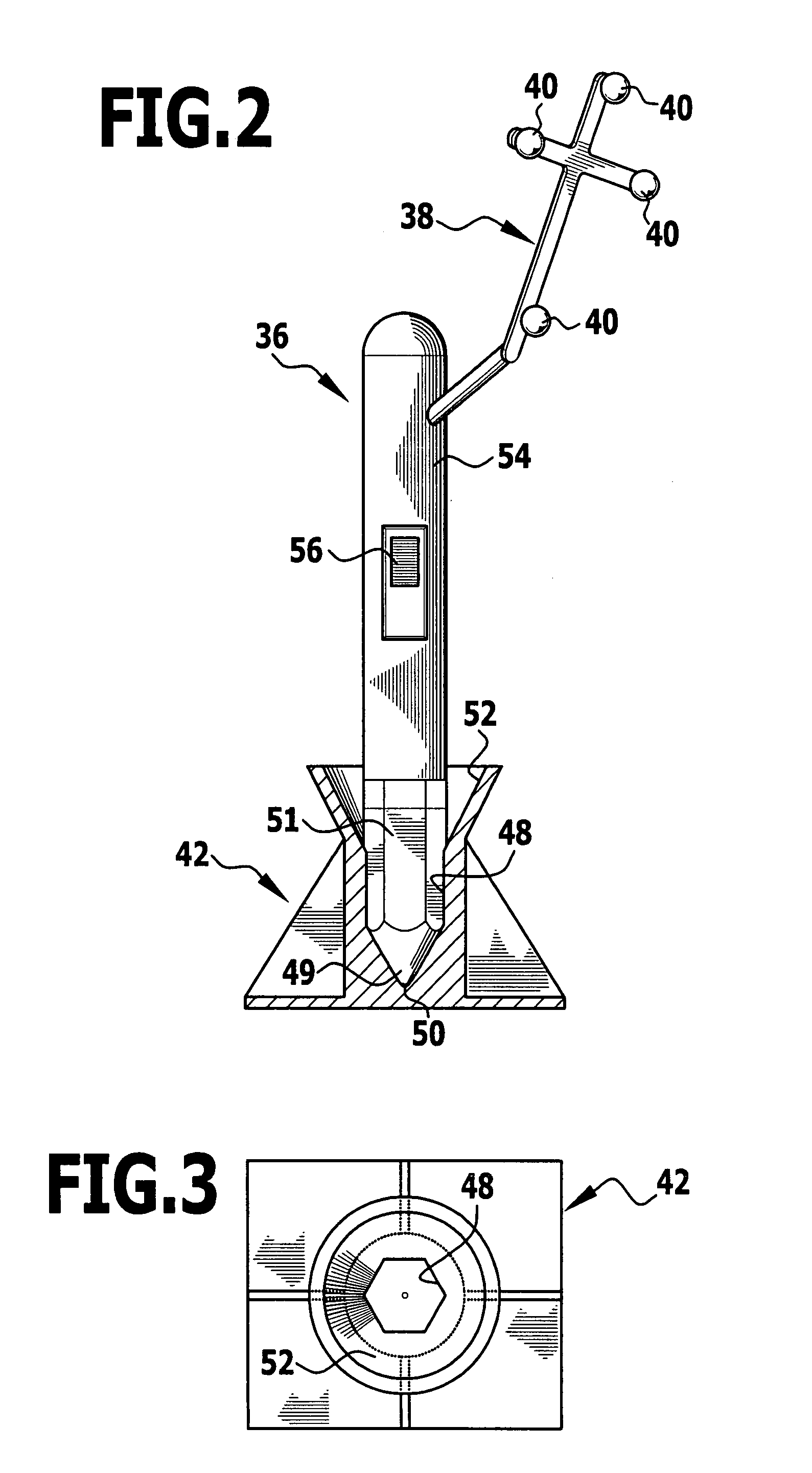

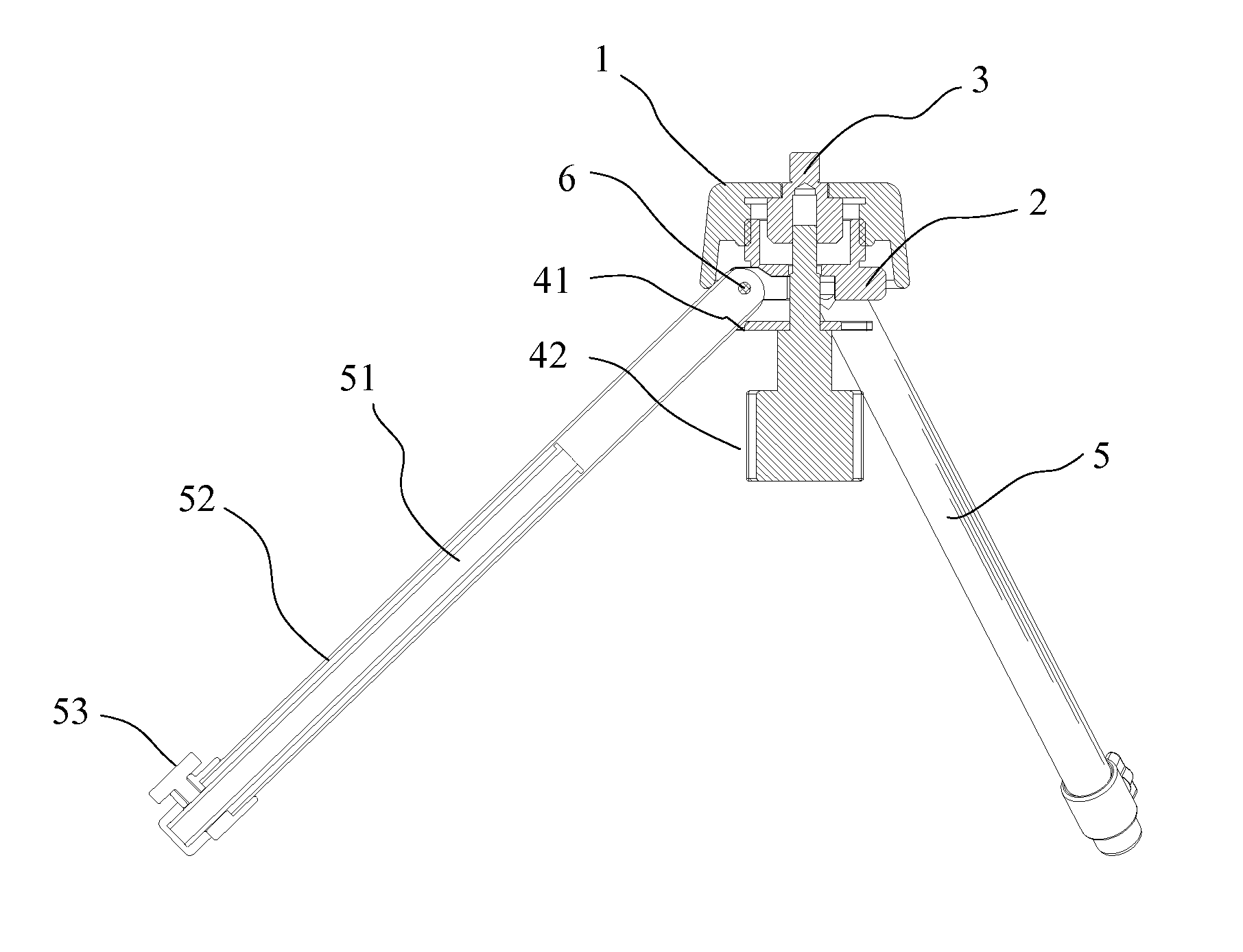

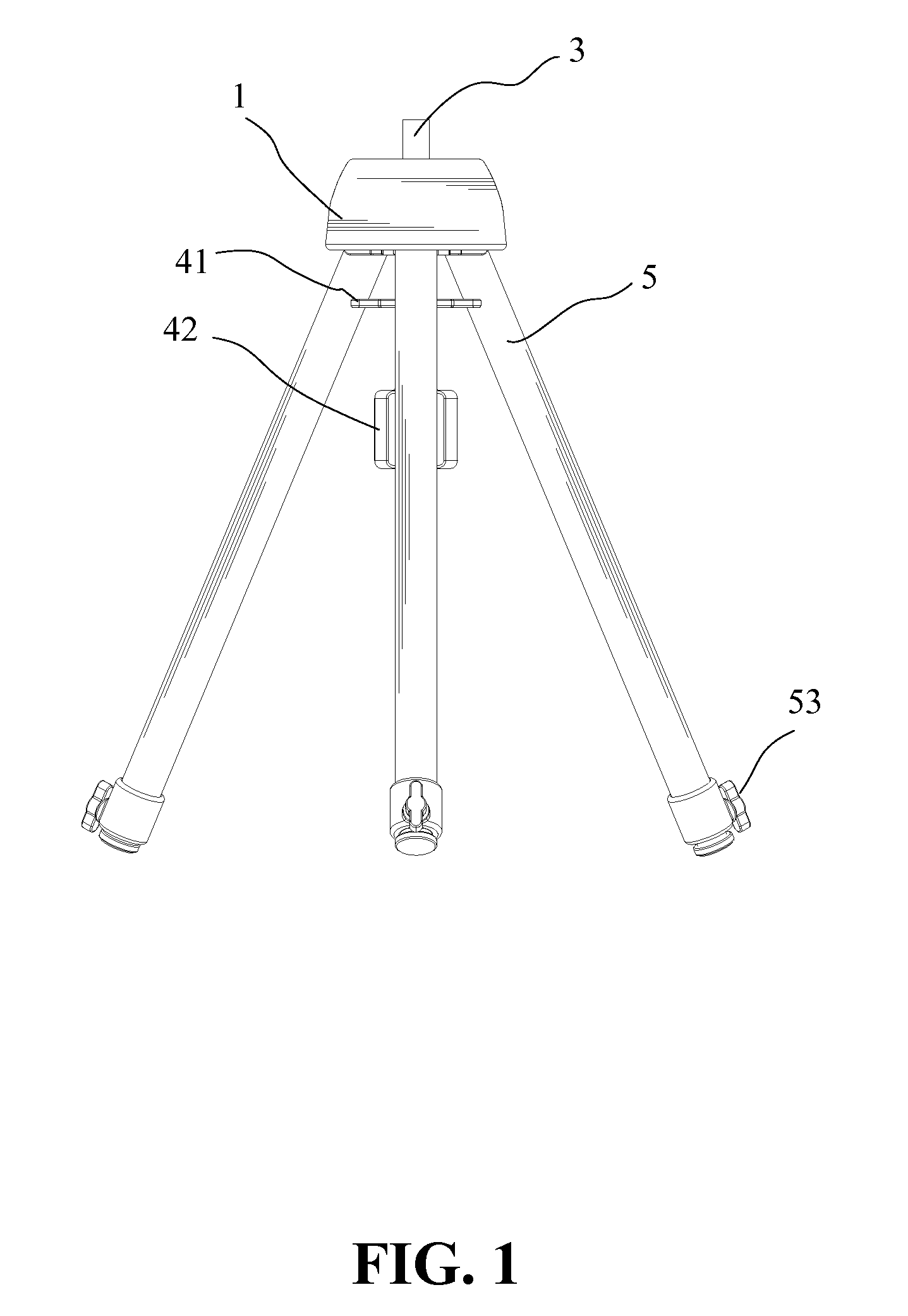

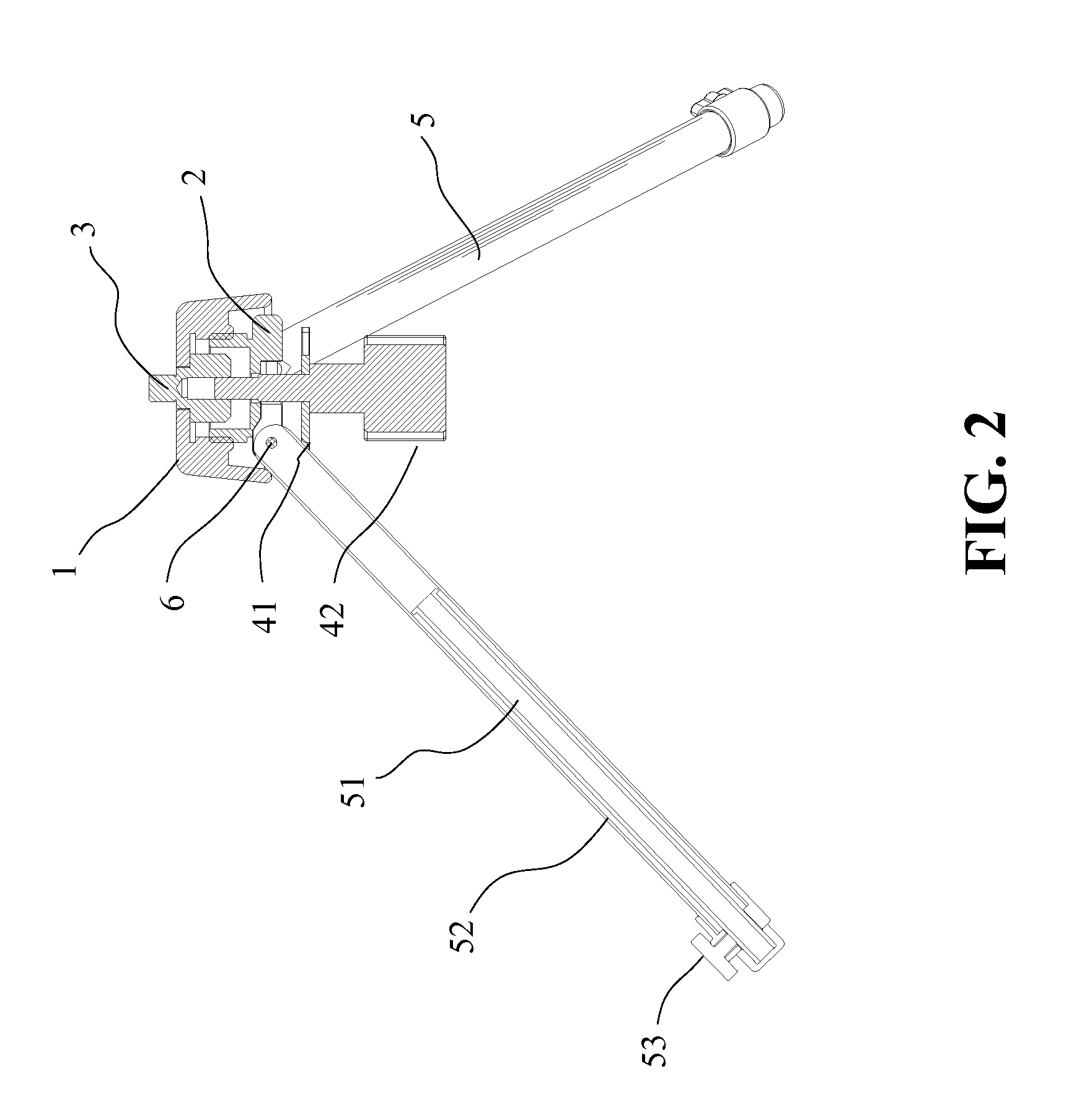

Continuously angle-adjustable multifunction tripod

InactiveUS8047481B2Simple and compact structureEasy to operateStands/trestlesKitchen equipmentAngular degreesEngineering

Owner:SUZHOU SYNTA OPTICAL TECH

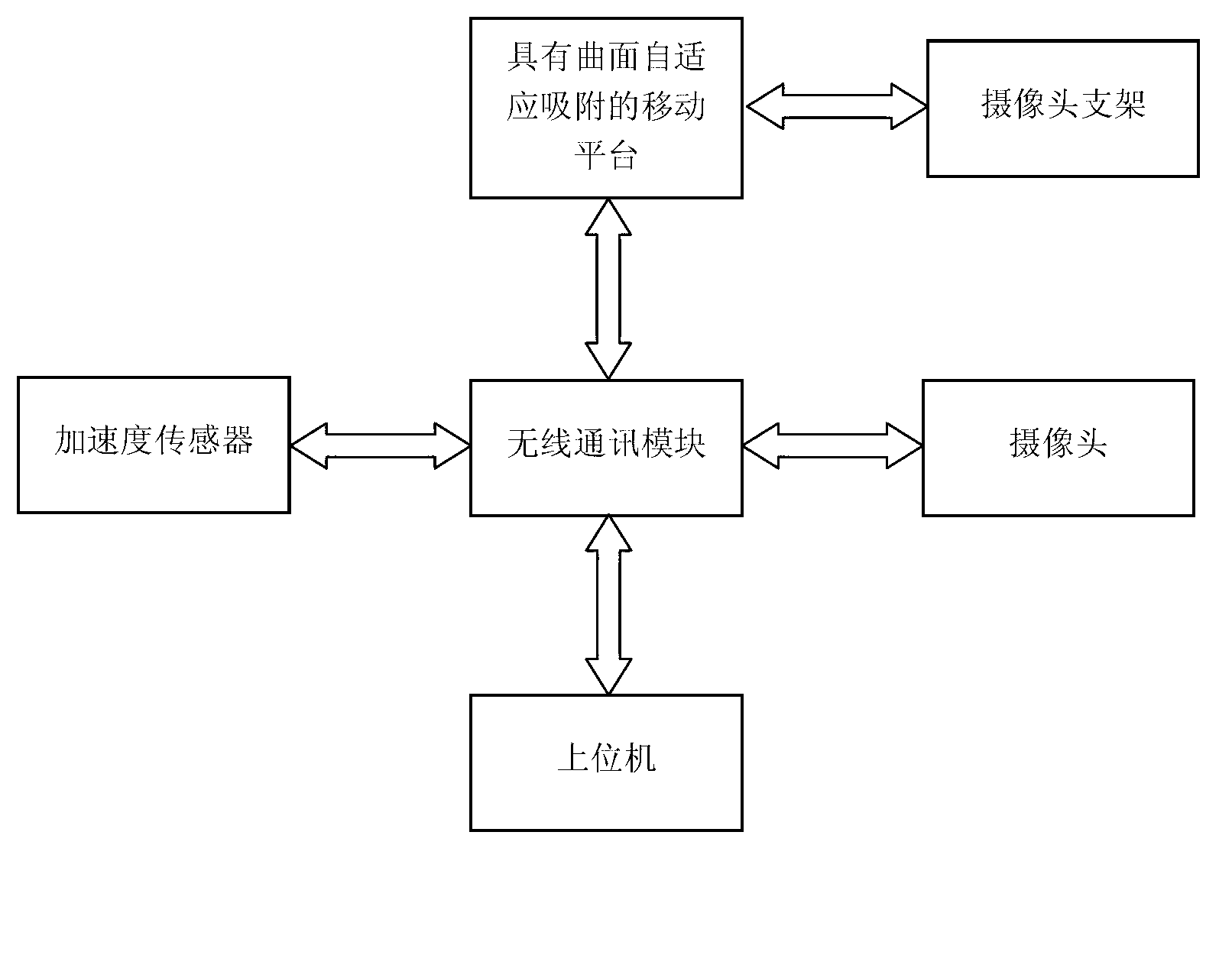

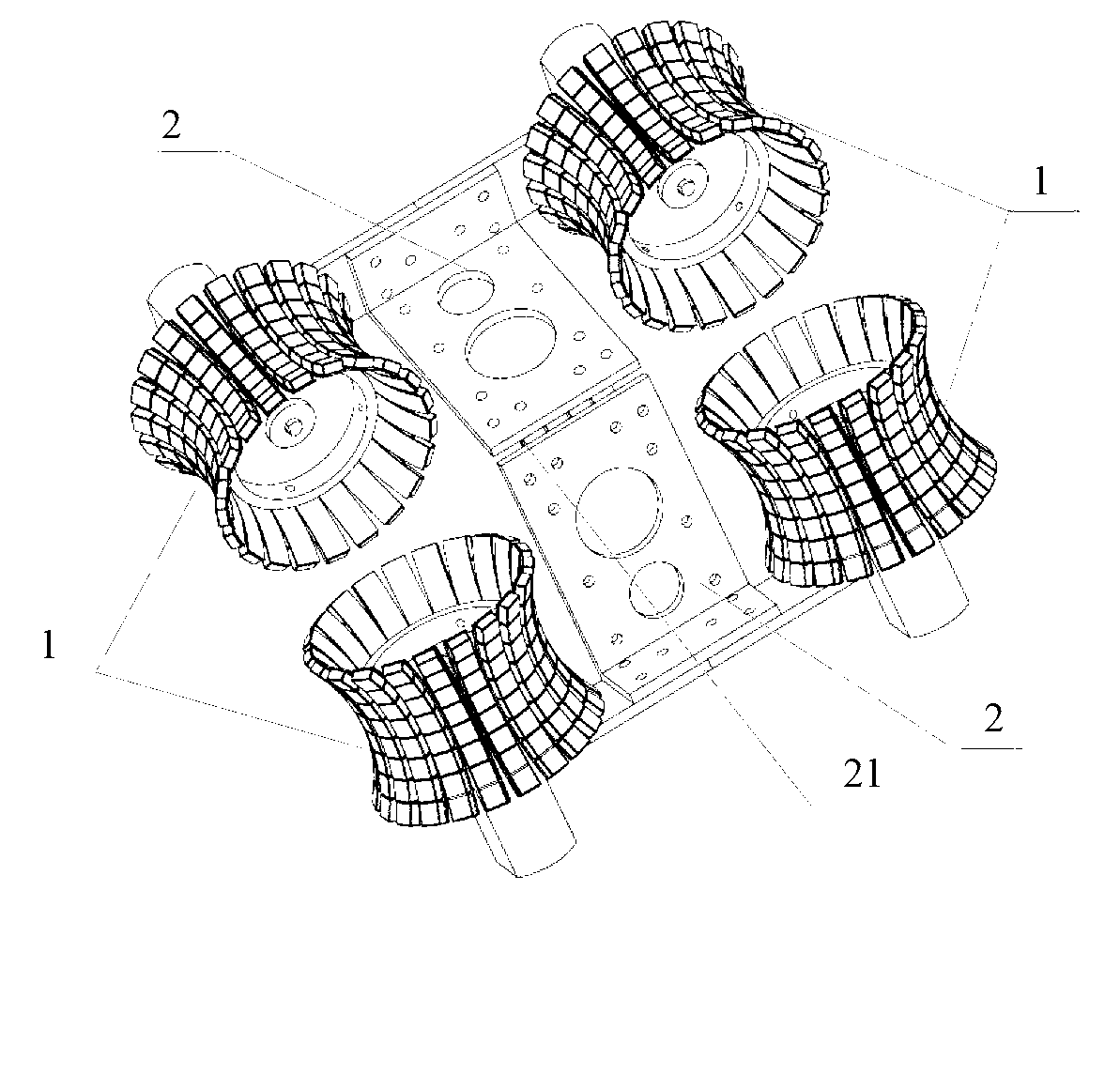

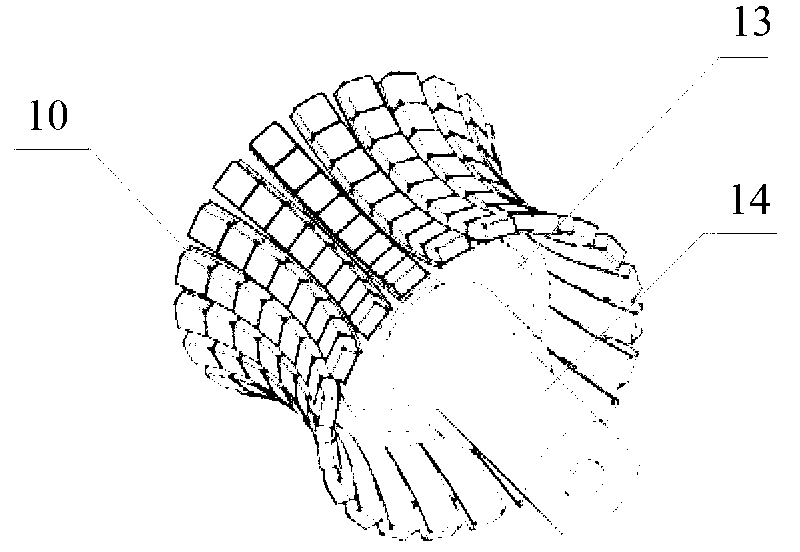

Magnetic wheel type wall climbing robot with curved face self-adaptation adsorption

InactiveCN103009373ACompact structureSimple and compactManipulatorVehiclesSelf adaptiveVehicle frame

The invention discloses a magnetic wheel type wall climbing robot with curved face self-adaptation adsorption. The magnetic wheel type wall climbing robot with the curved face self-adaptation adsorption comprises a mobile platform with the curved face self-adaptation adsorption, an acceleration sensor, a wireless communication module, a camera and an upper computer, wherein the mobile platform with the curved face self-adaptation adsorption consists of magnetic driving wheel units and curved face self-adaptation frames; and through the common deformation of an elastic permanent magnetic adsorption layer in each magnetic driving wheel and a loose-leaf hinge in each frame, the curved face self-adaptation adsorption is realized. The magnetic wheel type wall climbing robot with the curved face self-adaptation adsorption provided by the invention has a good curved face self-adaptation ability and a good obstacle climbing ability and can stably walk on a curved face with smaller curvature radius, thereby availably meeting the demands of engineering applications such as wireless health detection of a large-span space grid structure and the like.

Owner:ZHEJIANG UNIV

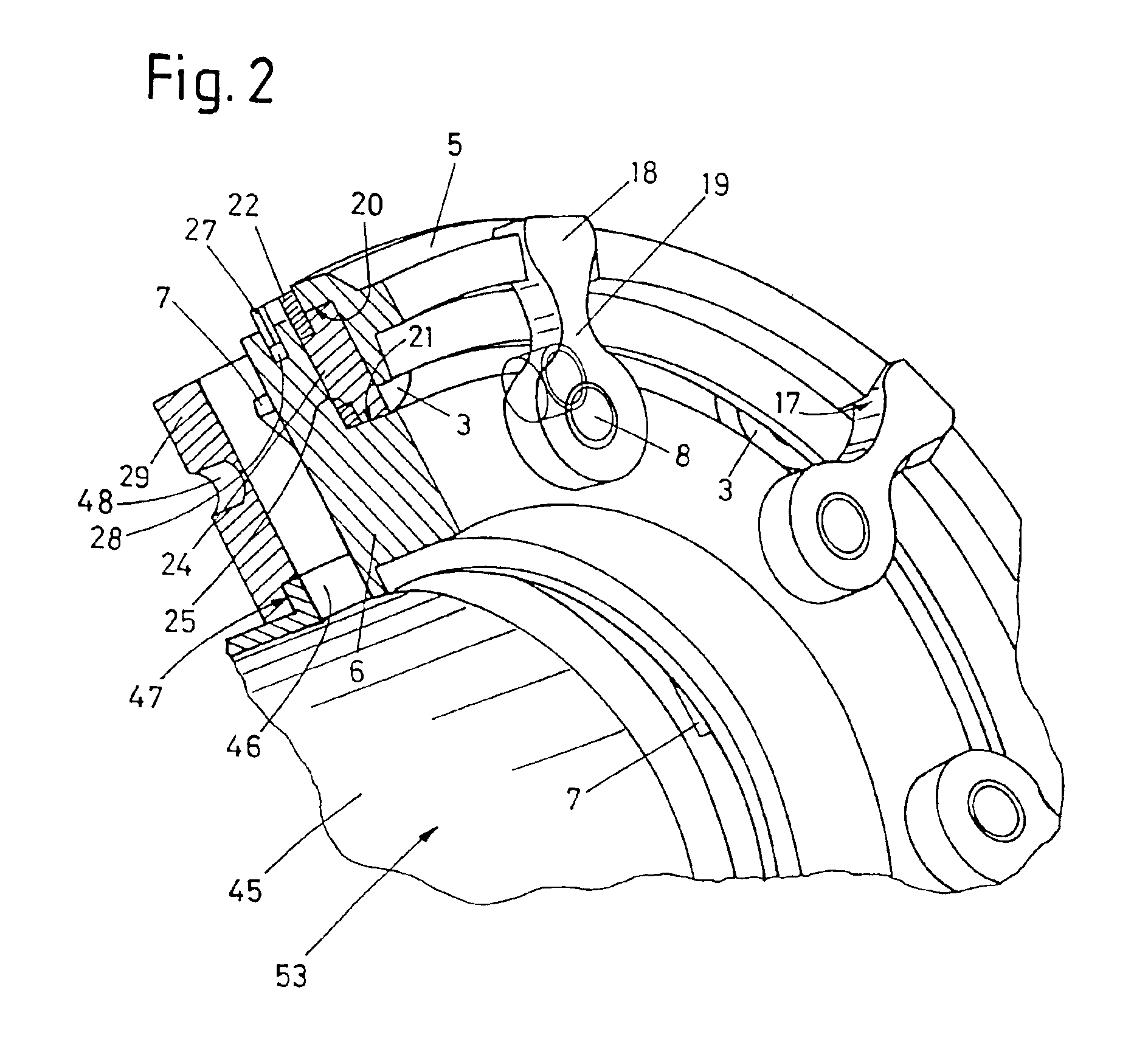

Guiding grid of variable geometry and turbocharger

ActiveUS6916153B2Prevent movementEasy to assemblePump componentsWind motor controlAngular distanceNozzle

A guiding grid of variable geometry comprises a plurality of guiding vanes in a housing in angular distances around a central axis in an axially extending vane space of a predetermined axial distance. Each vane is pivotal about an associated pivoting axis to assume different angles in relation to the central axis and, thus, to form a nozzle of variable cross-section between each pair of adjacent vanes. A nozzle ring supports the vanes around the central axis and forms a first axial limitation of the vane space. A unison ring is displaceable relative to the nozzle ring and is connected to the vanes to pivot them. An annular disk is fixed to the housing and faces the nozzle ring in an axial distance to form a second axial limitation of the vane space and a central opening. Into this opening, a sleeve may be inserted. A fixing arrangement determines the axial position of the annular disk with respect to the housing.

Owner:BORGWARNER INC

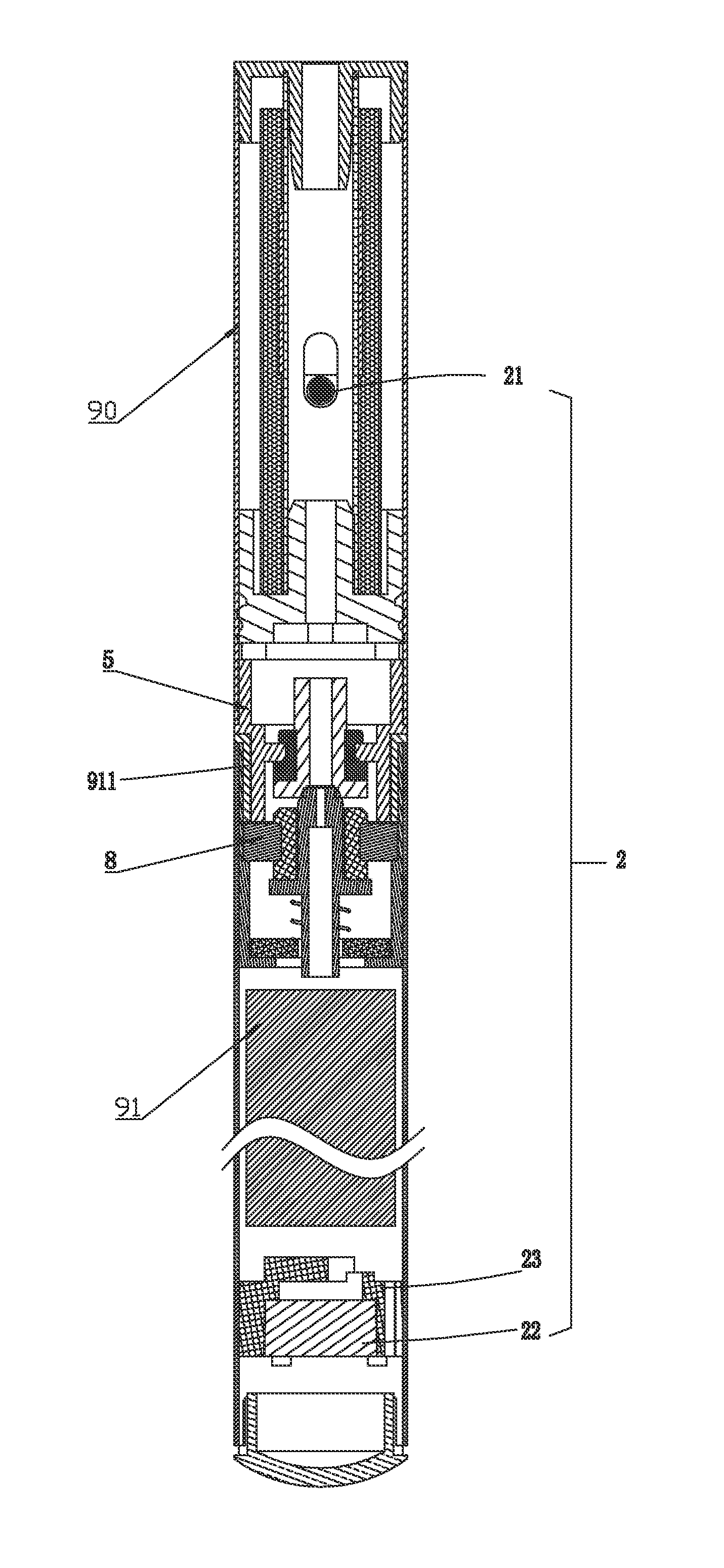

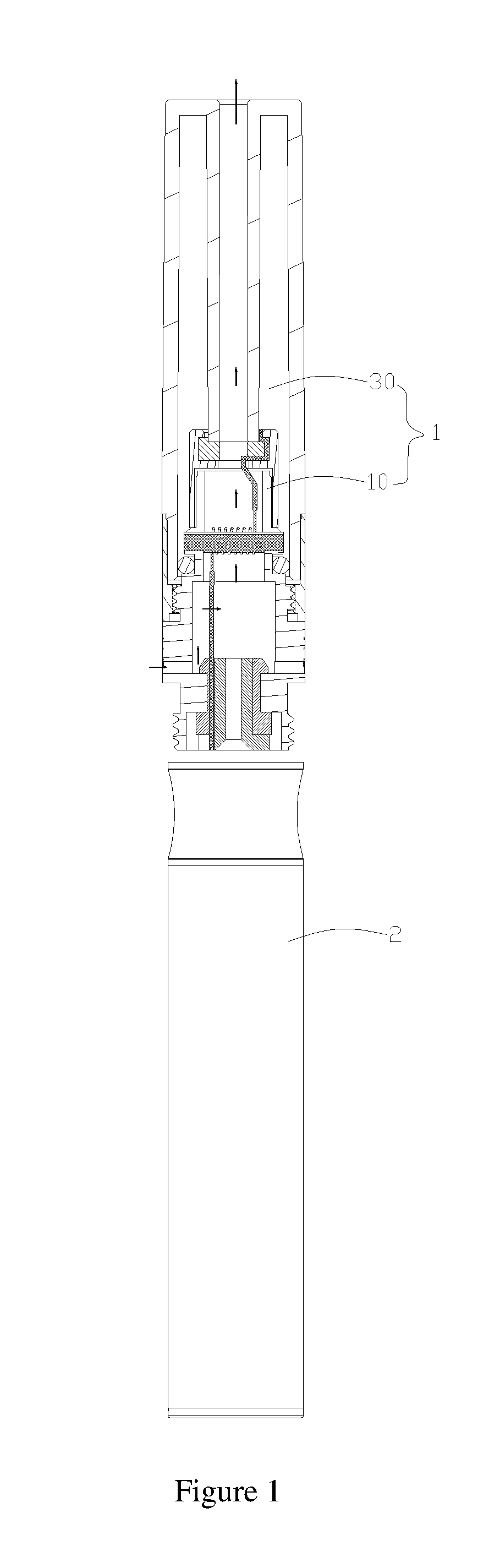

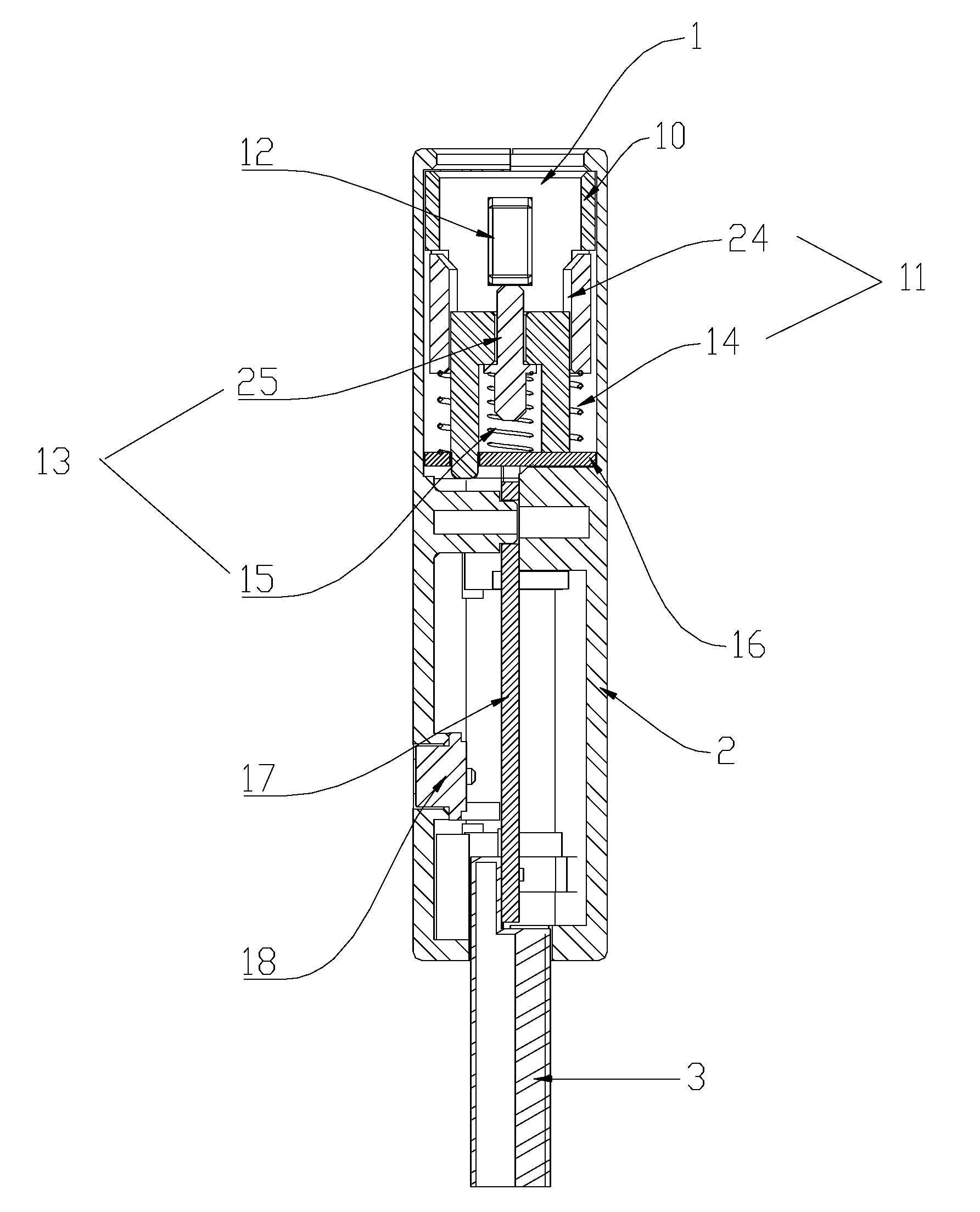

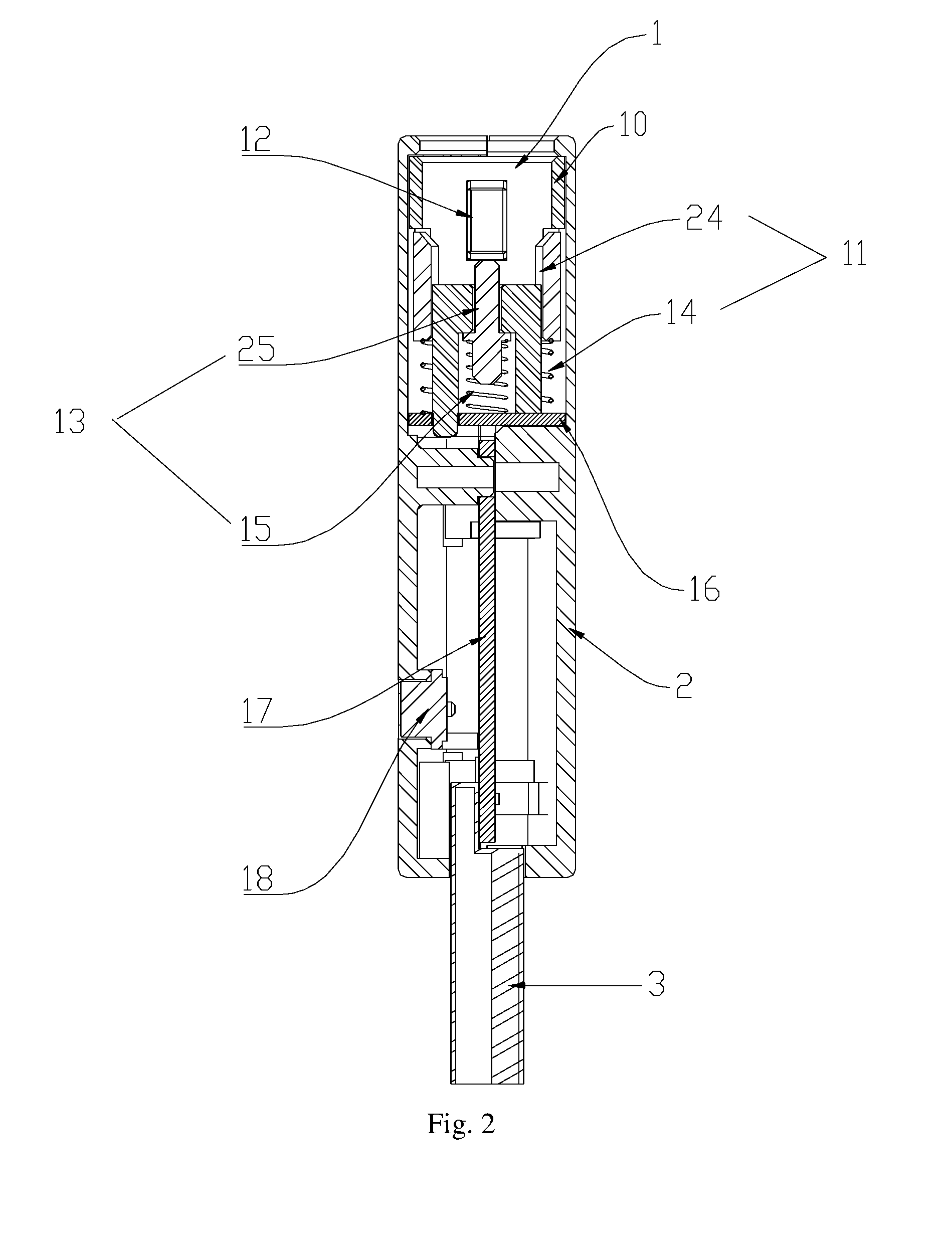

Electronic cigarette, and method for assembling electronic cigarette

InactiveUS20170202267A1Conveniently disassembledAvoid pollutionTobacco devicesStructural engineeringElectronic cigarette

An electronic cigarette comprises an atomization core comprising a connector, a heating wire assembly, an internal electrode, an elastic sleeve, an atomization cap, and a first electronic wire and second electronic wire; a receiving recess is arranged on the internal electrode; the first electronic wire is accommodated in the receiving recess and is electrically connected to the internal electrode; the elastic sleeve is retained on the inside wall of the atomization cap to hold the second electronic wire between the inside wall of the atomization cap and the outside wall of the flexible sleeve; the atomization cap is electrically connected to the other end of the battery assembly through the connector; one end of a vent pipe elastically abuts against one end of the elastic sleeve. The electronic cigarette has the advantages of easy replacement of the heating wire assembly, easy addition of smoke oil, and stable electrical connections.

Owner:LIU QIUMING

Charging device of electronic cigarette and charging method thereof

InactiveUS20160268824A1Avoid defectsSimple and compact structureIndicating/monitoring circuitsTobacco devicesElectronic cigaretteMechanical engineering

This present application relates to a charging device of an electronic cigarette and a charging method thereof. The charging device including a charging base, in which a first charging electrode assembly and a second charging electrode assembly are arranged separately for connecting with a first and a second electrode of the electronic cigarette, wherein in the charging base, a charging slot is defined in the charging base. The first charging electrode assembly, the second charging electrode assembly and the charging base are coaxially sheathed, and both the first charging electrode assembly and the second charging electrode assembly extend into the charging slot. By implementing this structure, the electronic cigarette has a simplified and compact structure and an easy assembly, also facilitates a steady electrical connection with the electronic cigarette. When charging, it is only needed to insert the electronic cigarette into the charging slot.

Owner:HUIZHOU KIMREE TECH

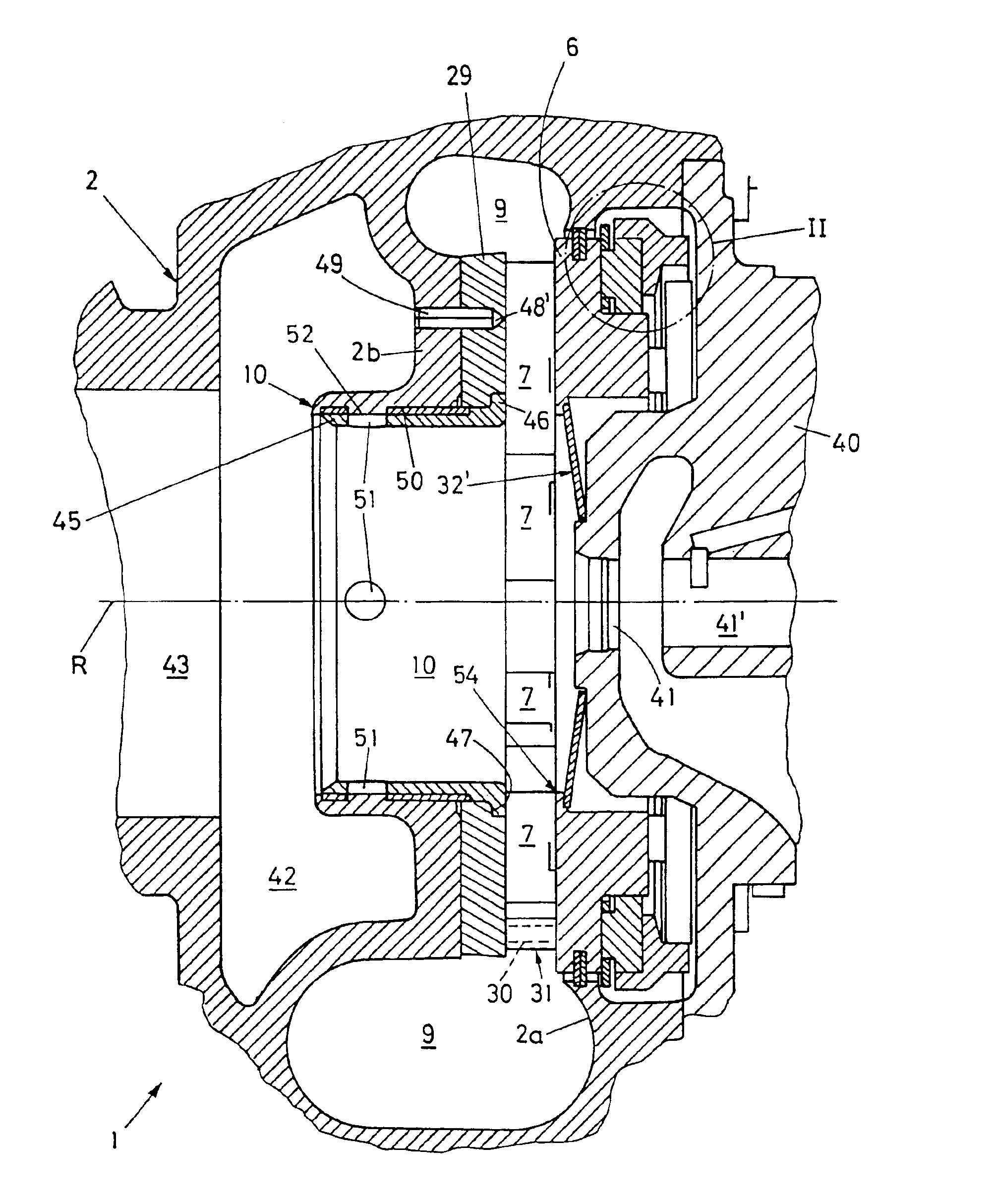

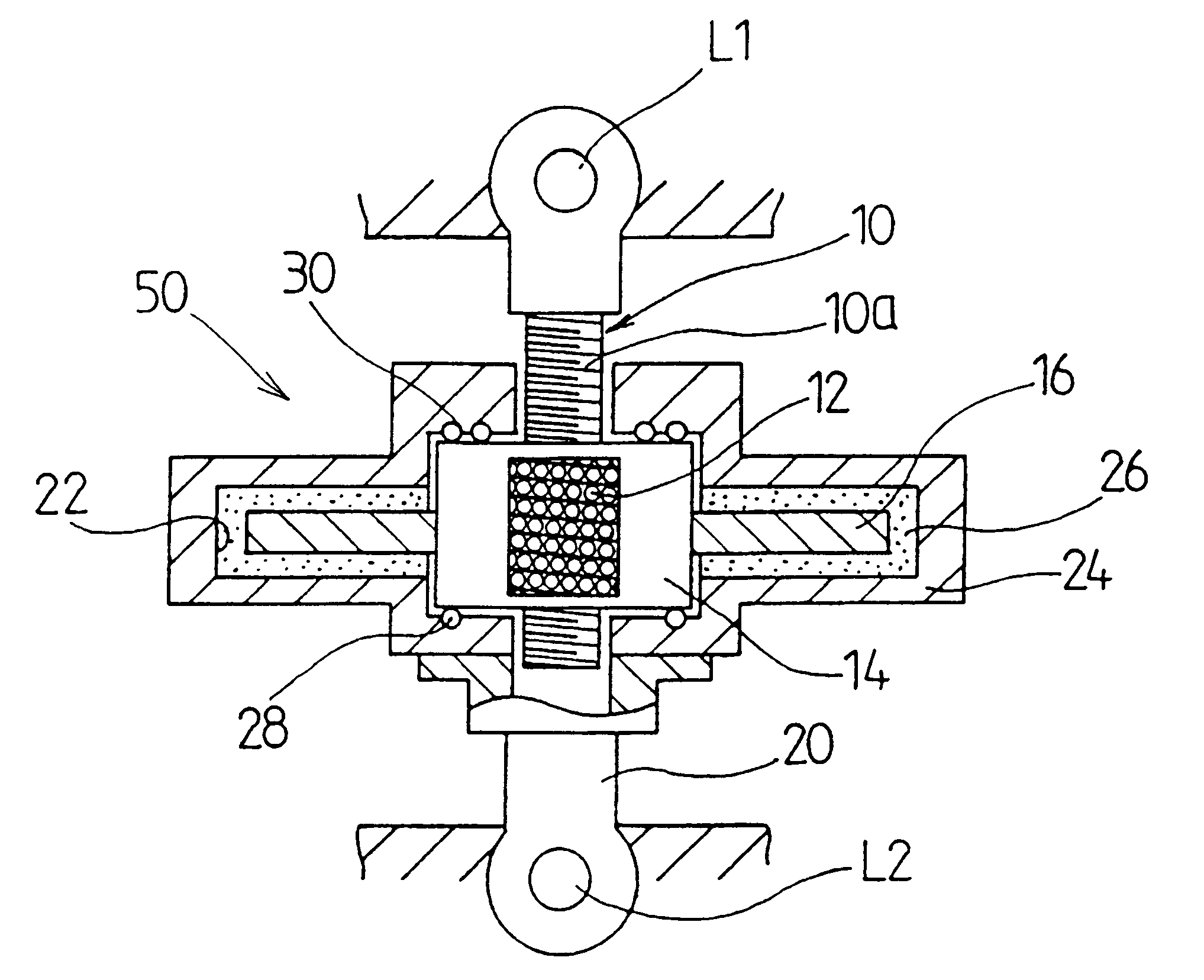

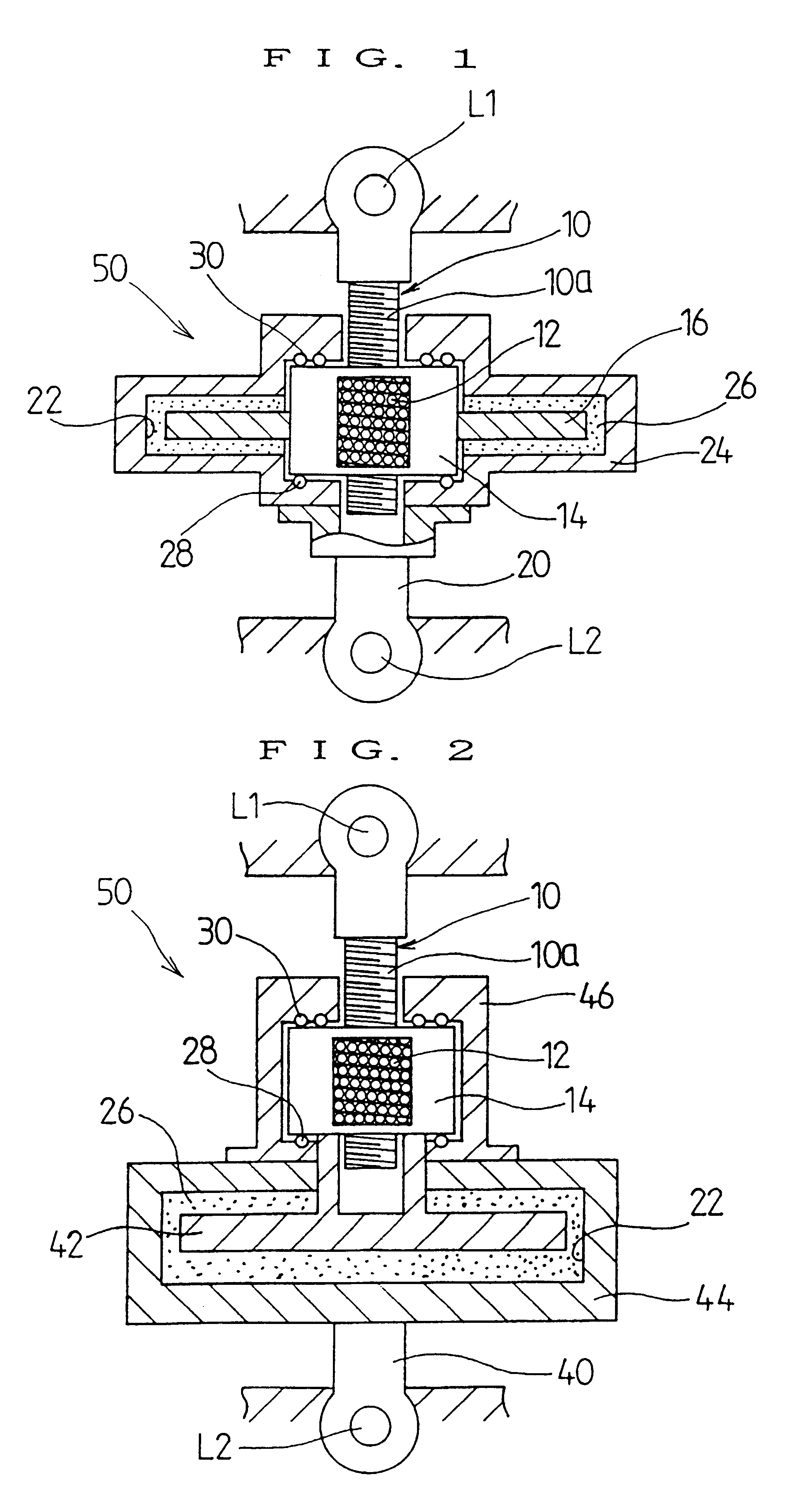

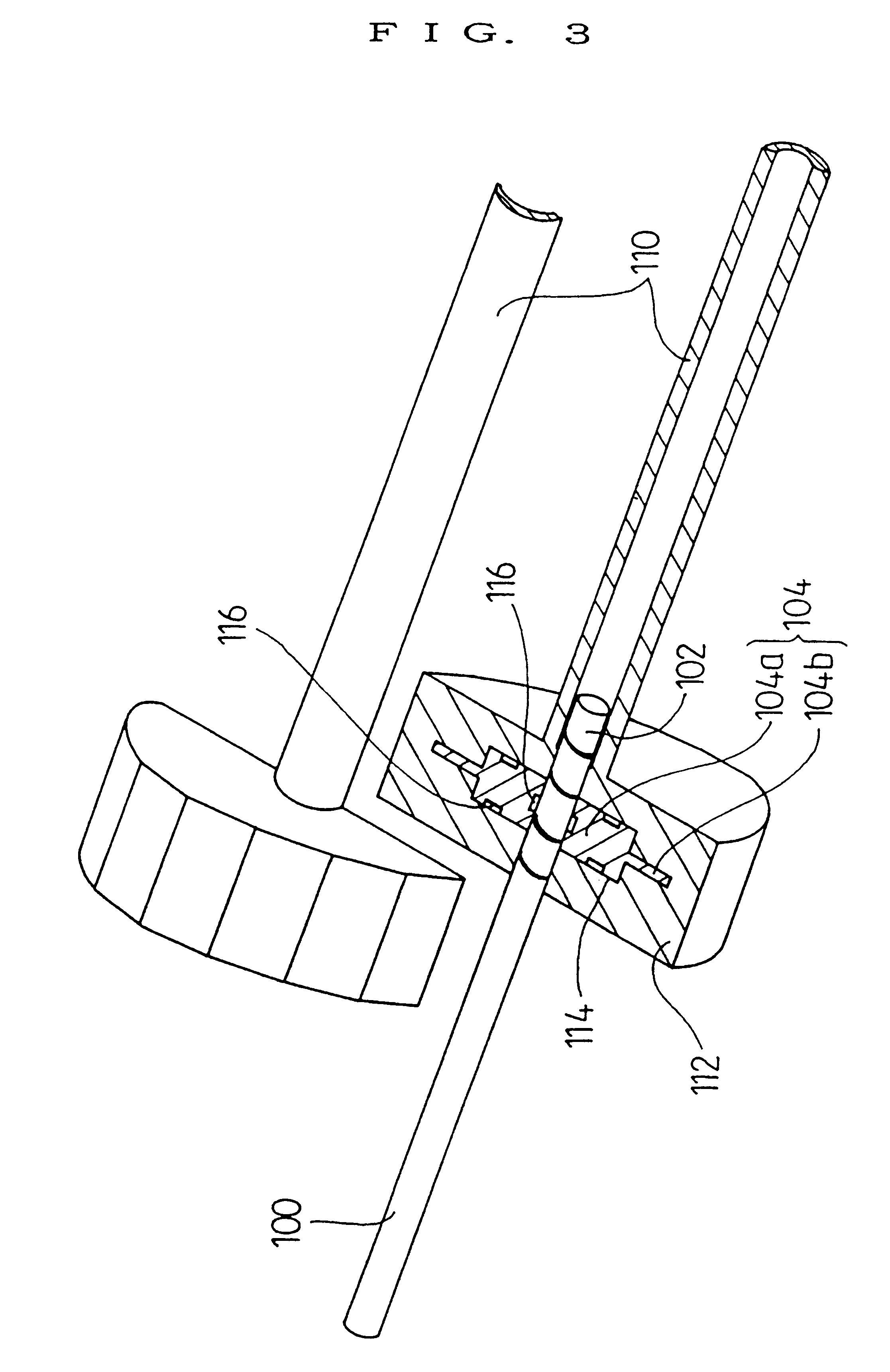

Damping top, damping rod, and damping device using same

InactiveUS6230450B1Improve featuresSimple and compact structureSpringsLiquid based dampersBall bearingEngineering

A damping top which comprises first and second L1 connection members (10, 20) connected to each other so as to connect two relatively displacing points (objects) (L1, L2) to each other, which connection members are fixed at one end thereof to the two points (L1, L2), respectively. The first connection member (10) is formed at its connection side with a guide screw portion (10a), on which is rotatably and slidably mounted a rotating top (integral rotating unit) (16) adapted to be driven by a guide nut (14) threaded onto the screw portion through a ball bearing (12). The second connection member (20) is formed at its connection side in a casing (24) for a chamber (22), which receives therein the rotating top (16), and a damping viscous body (26) is filled in the chamber (22). Thus it is possible to provide a damping device which is simple and small-sized, and provides great damping effects.

Owner:SUMITOMO MITSUI CONSTR CO LTD

A Spontaneous Electric Energy Storage Hand Tweak Torch

InactiveUS20070159823A1Simple and compact structureEasy to operateLighting device with mechanical drivePoint-like light sourceStored energyTorch

The present invention provides a spontaneous electric energy storage hand tweak torch, comprising a lamp cap and a cylindrical casing. The casing comprises a front casing and a rear casing capable of being bi-directionally tweaked about an axis. The lamp cap is fixed on the front casing. The interior of the front casing is provided with an electric generator, an energy storage element, a circuit board and a control switch. The exterior of the front casing is provided with a push button corresponding to the control switch. The output end of the electric generator is connected with the input end of the circuit board via a lead. The output end of the circuit board is connected with the energy storage element. The rotating shaft of the electric generator is connected with the rear casing via a gear set. The present invention has a simple and compact structure as well as a regular and uniform profile. Besides, it is convenient to operate and therefore saves labor. Consequently, it has a very prominent operation effect.

Owner:MINGLE DEV (SHENZHEN) CO LTD

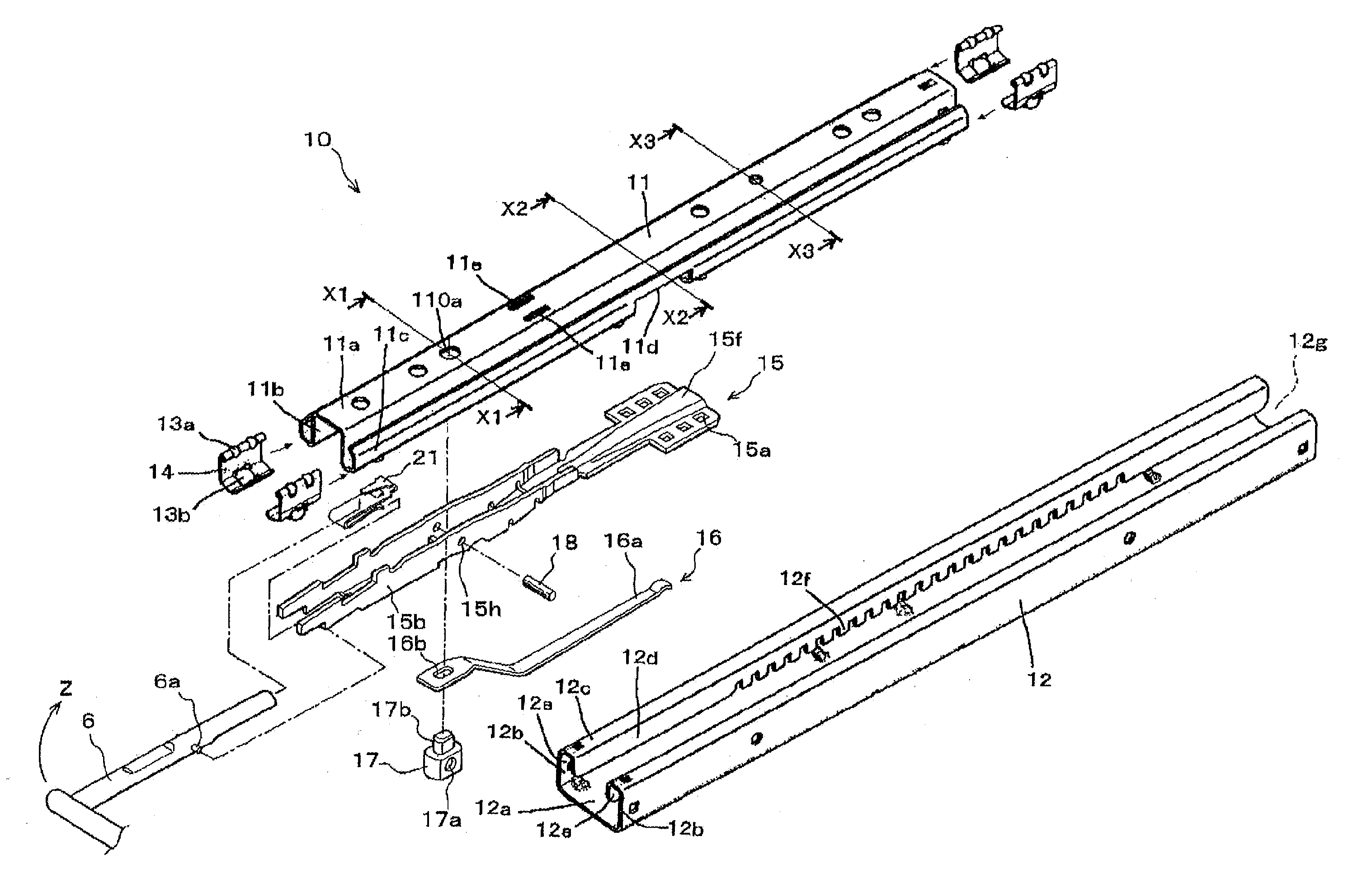

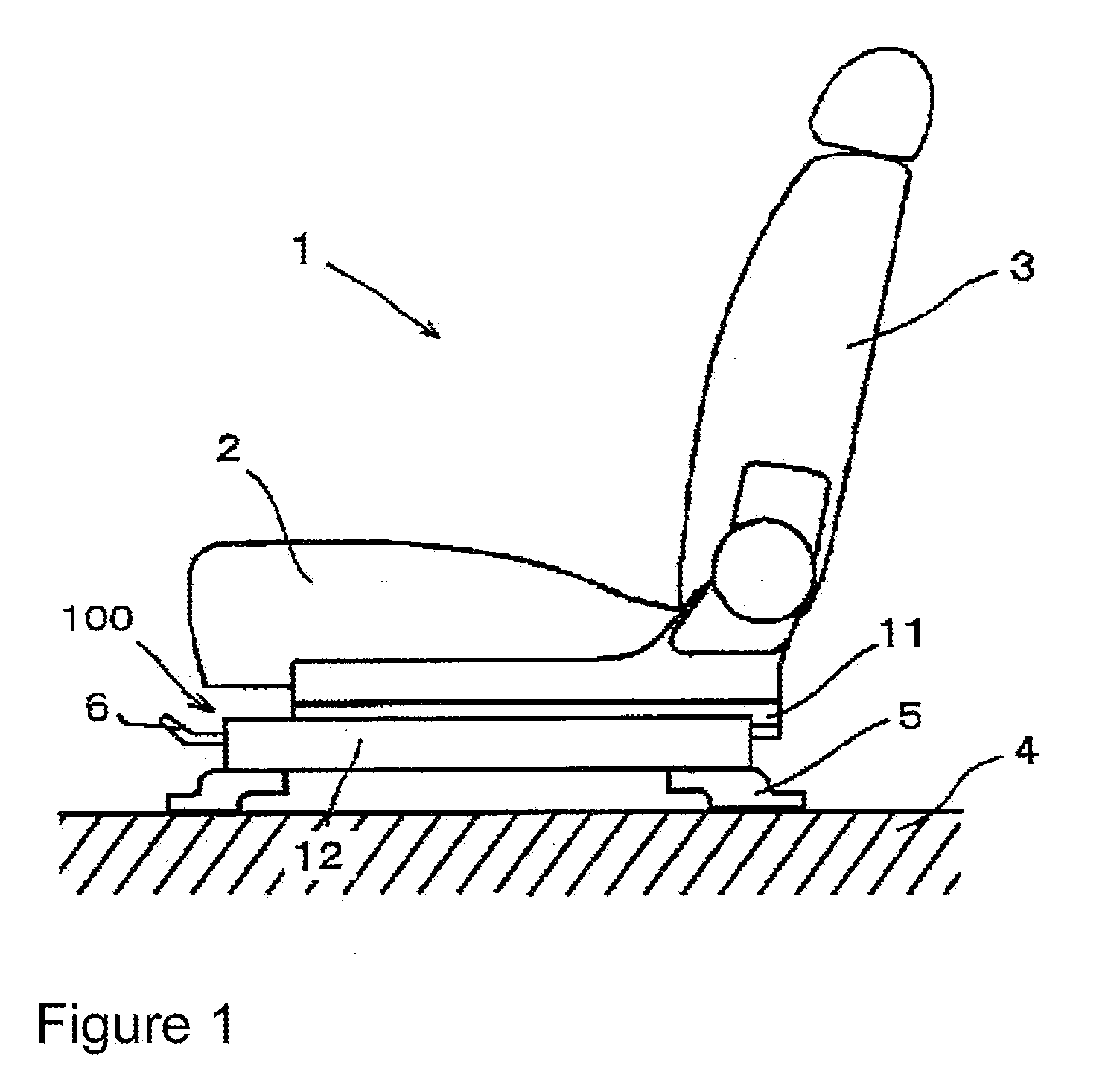

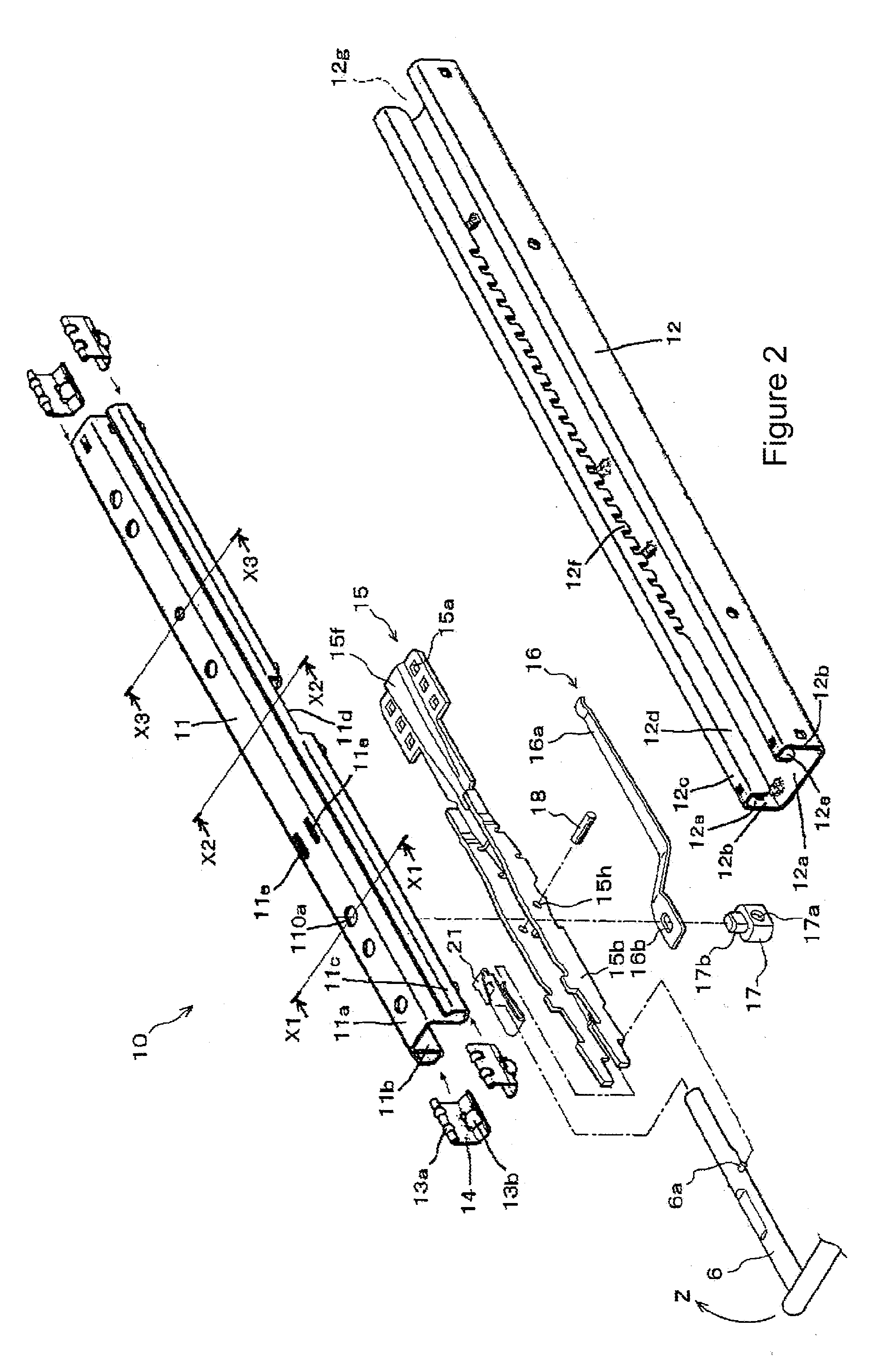

Slide rail unit

ActiveUS20080231101A1Prevent displacementReliably completeSafety beltsPedestrian/occupant safety arrangementLeaf springEngineering

A simple, compact and easy-to-assemble slide rail unit is provided. The slide rail unit reliably restrains right and left rails from sliding even when the right and left rails are installed onto the vehicle floor at an inclination angle different from each other in a longitudinal direction thereof. The slide rail unit includes a slide rail member having an upper rail member and an upper rail member slidably engaged with each other and a lock lever rotatably pivoted to the upper rail member so as to engage with / disengage from an engagement portion formed on the lower rail member. The slide rail unit also includes an operation lever connected to the lock lever within the slide rail member. Between the lock lever and the operation lever, a leaf spring member is disposed for connecting the lock lever and the operation lever therebetween.

Owner:IMASEN ELECTRIC IND

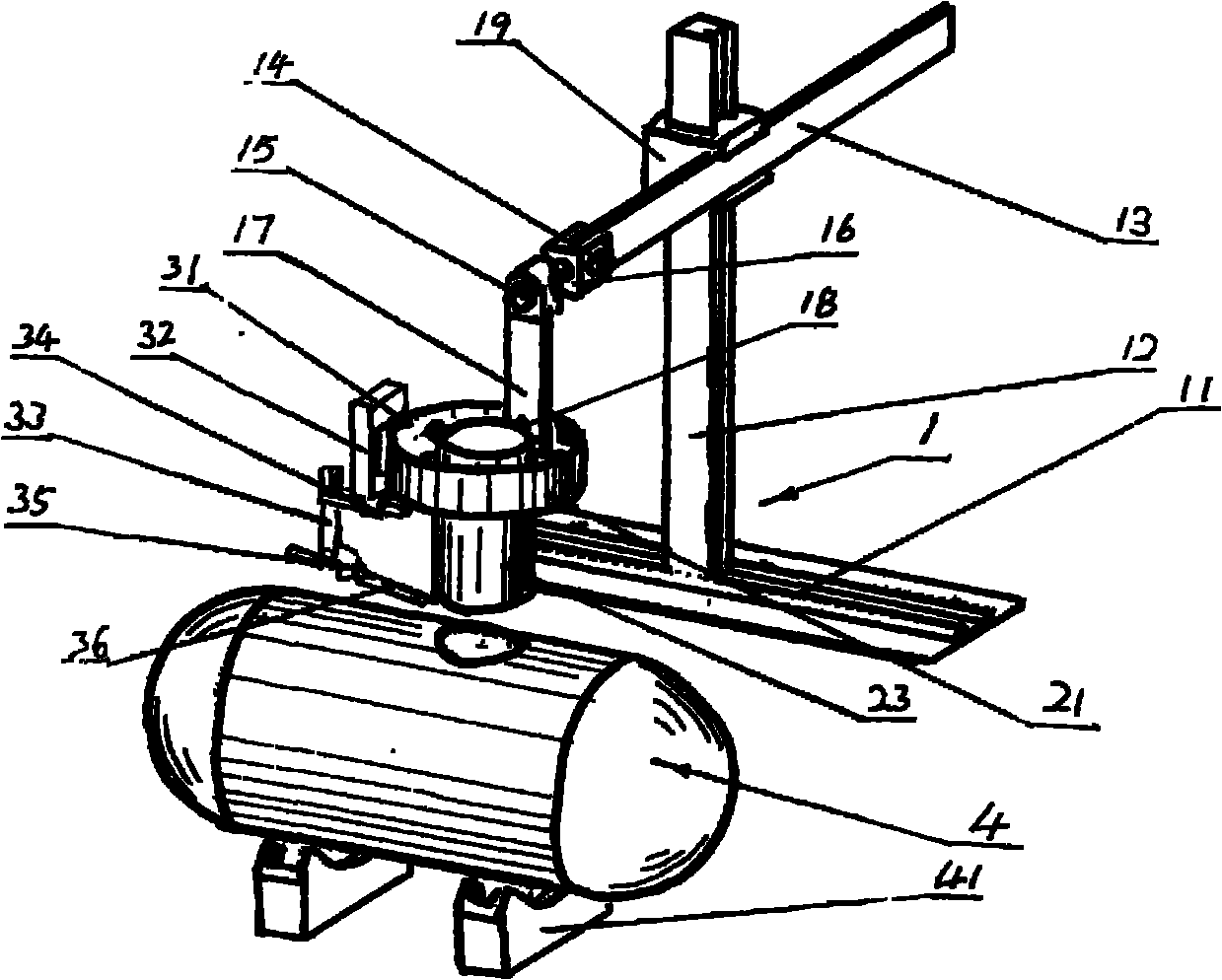

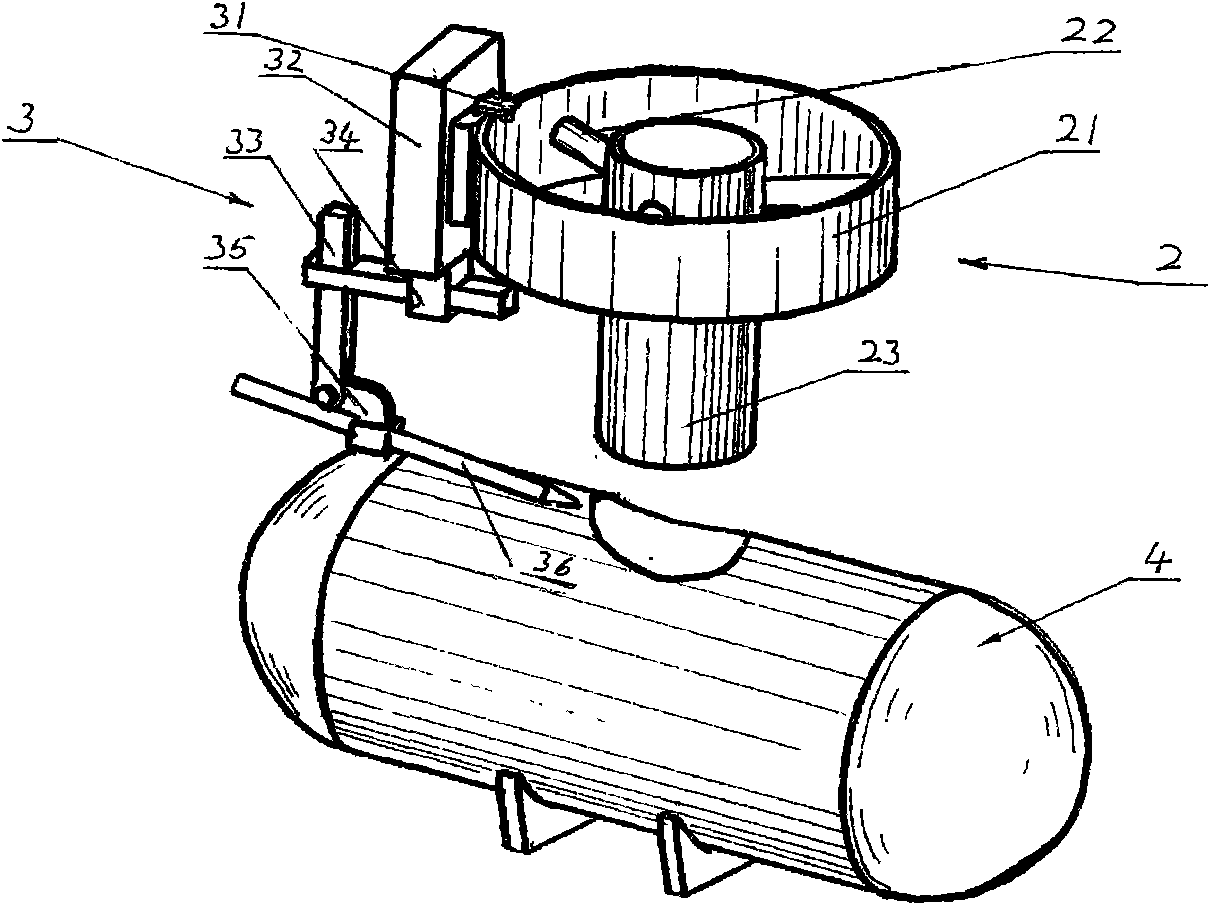

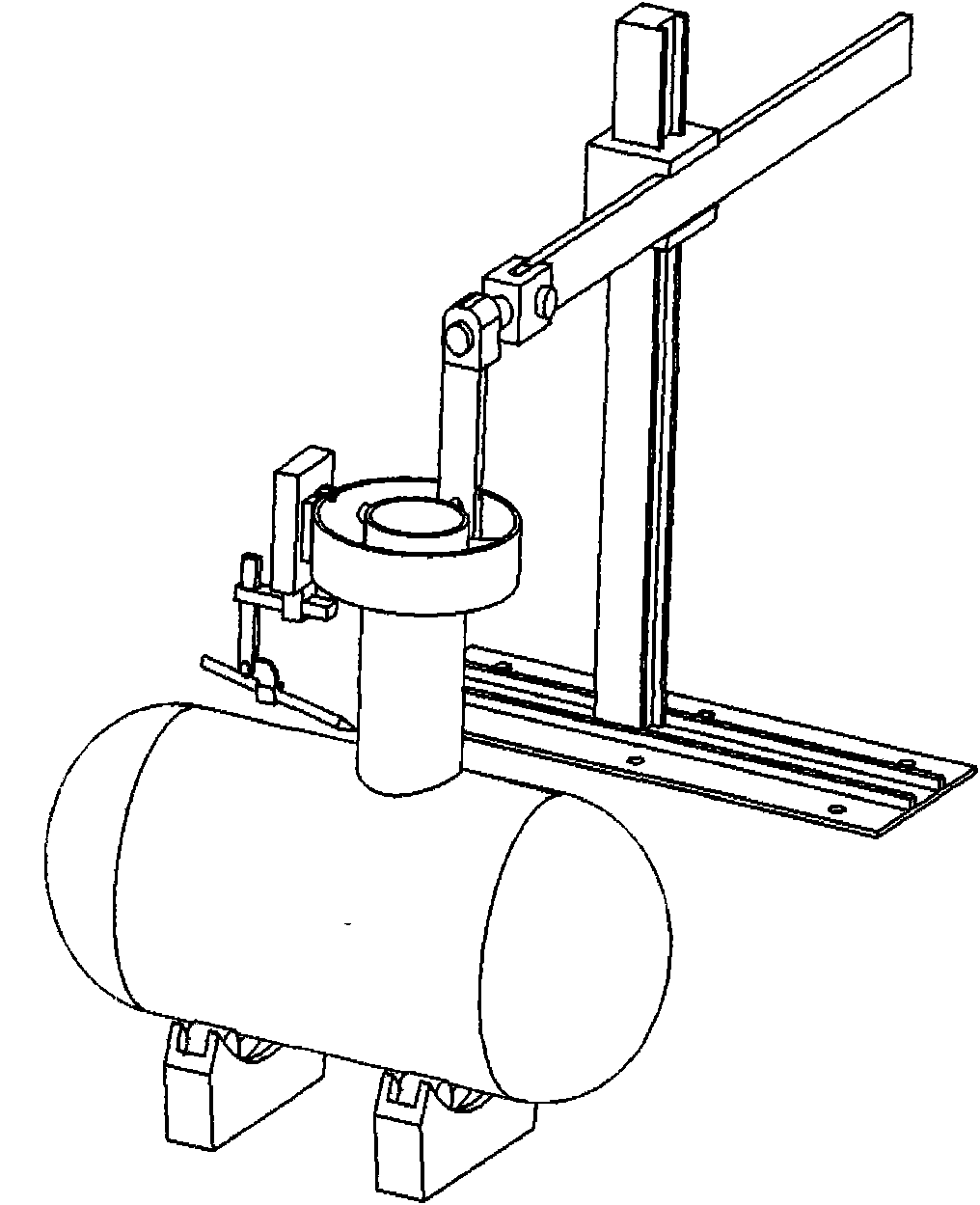

Opening-nozzle saddle-shaped seam welding equipment

ActiveCN101786210ASimple and compact structureRealize one machine with multiple functionsWelding/cutting auxillary devicesAuxillary welding devicesSeam weldingSaddle shape

The invention relates to opening-nozzle saddle-shaped seam welding equipment, which mainly comprises a cross-shaped automatic operation machine (1), a welding head track (2), a welding head (3) and a cylinder body workpiece (4). An axial moving device (11) of the cross-shaped automatic operation machine (1) is connected with a corresponding basic part; a vertical lifting arm (12) of the cross-shaped automatic operation machine (1) is assembled together with a transverse moving arm (13) by taking the axial moving device (11) as the base and is connected with the welding head track (2) through a suspension arm (17); and the welding head (3) is connected with the welding head track (2) through a locking mechanism (31) and can run along a ring-shaped track (21). The equipment achieves the function of multiple purposes, namely can perform gas cutting or plasma cutting on a saddle-shaped bevel pipe end and a pipe hole, and can perform high quality welding between the bevel pipe end and the pipe hole after an actuating mechanism is replaced; and in addition, the equipment has a compact and simple structure and is very suitable to be used on a construction site.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

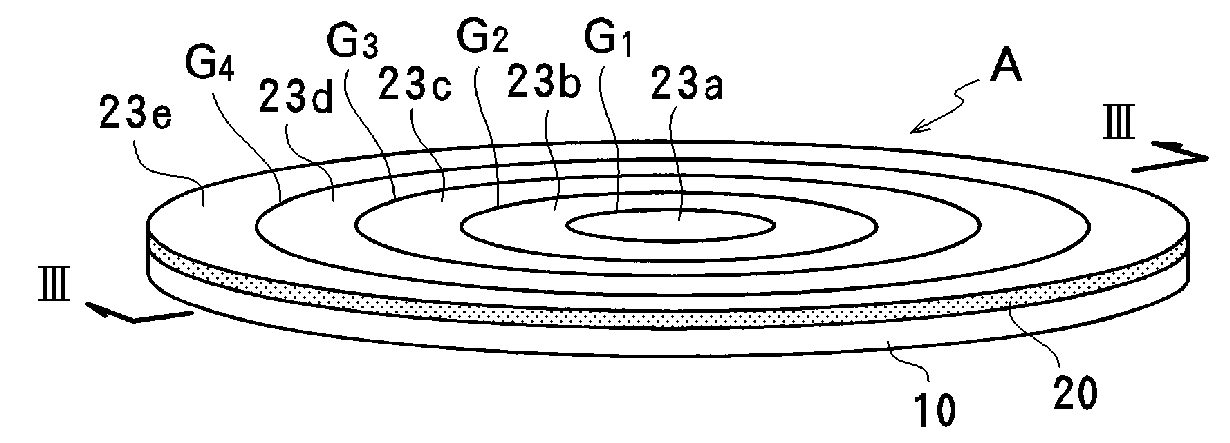

Fluid conveyance device

ActiveUS20090232685A1Simple and compact structureEfficientlyFlexible member pumpsPiezoelectric/electrostrictive/magnetostrictive devicesEngineeringMechanical engineering

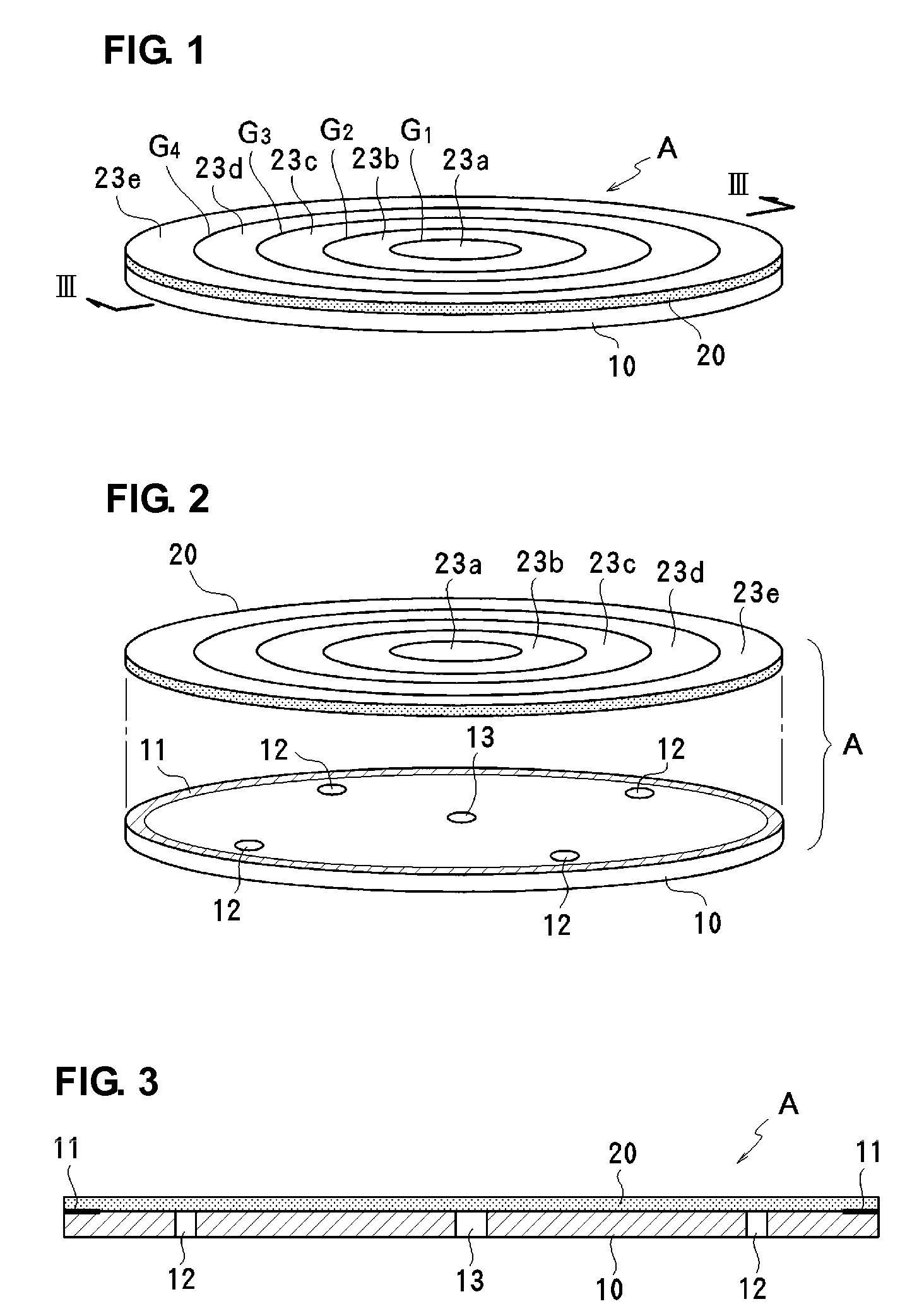

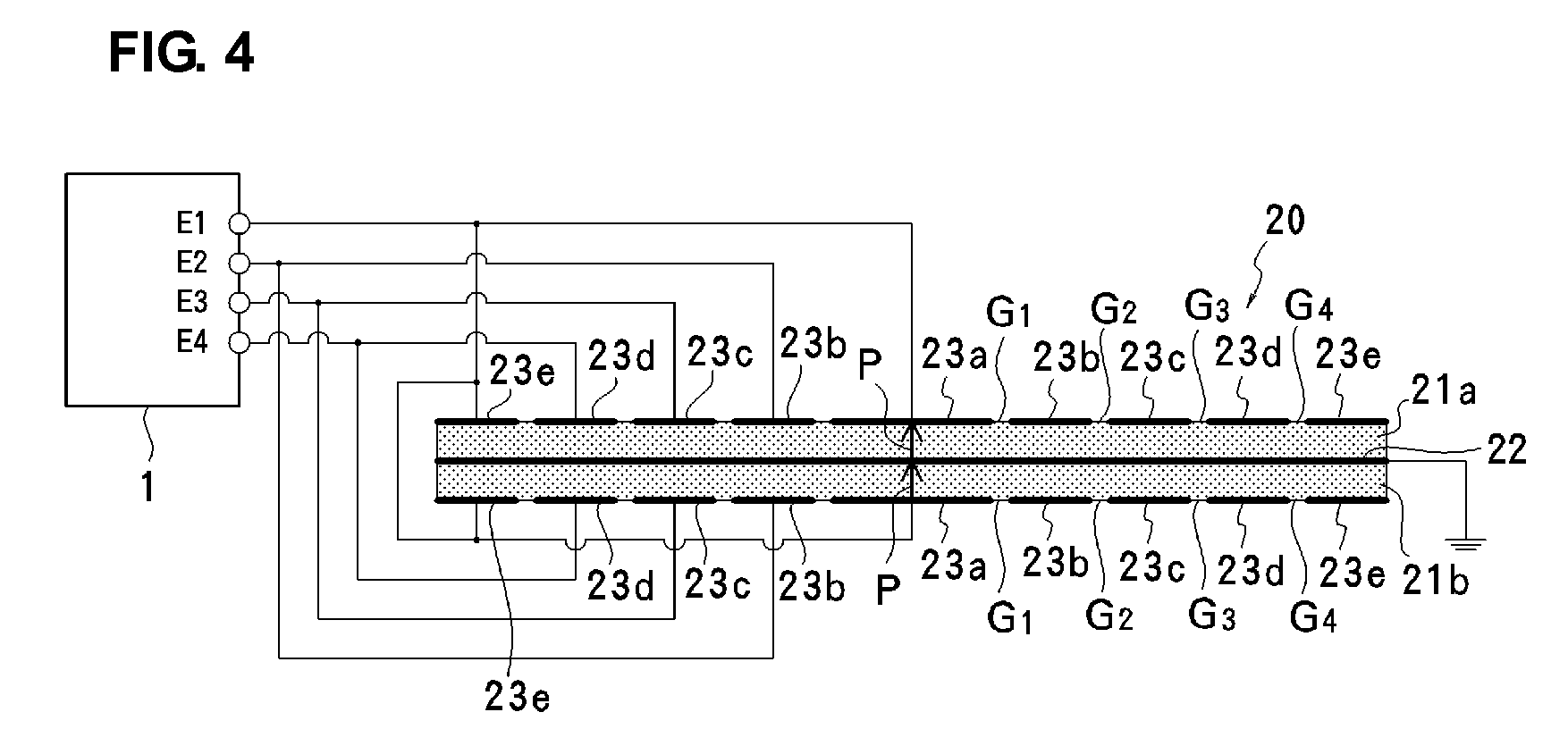

A fluid conveyance device includes a substrate, and a disk-shaped piezoelectric element arranged in a bendable manner on the substrate. A plurality of substantially circular concentric segment electrodes are provided on the piezoelectric element, and are provided with voltages with phases that are shifted. A wavy ring deformation is thus produced on the piezoelectric element. A pocket produced between the piezoelectric element and the substrate is moved in a radial direction so as to convey a fluid from an outer substantially circular portion to a central portion and to discharge the fluid from the central portion.

Owner:MURATA MFG CO LTD

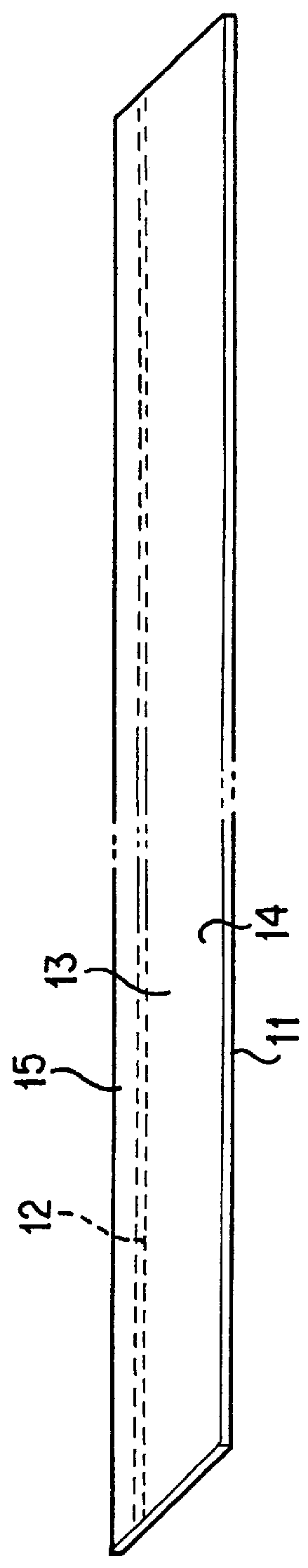

Printed wiring board and its manufacturing method, and electronic apparatus

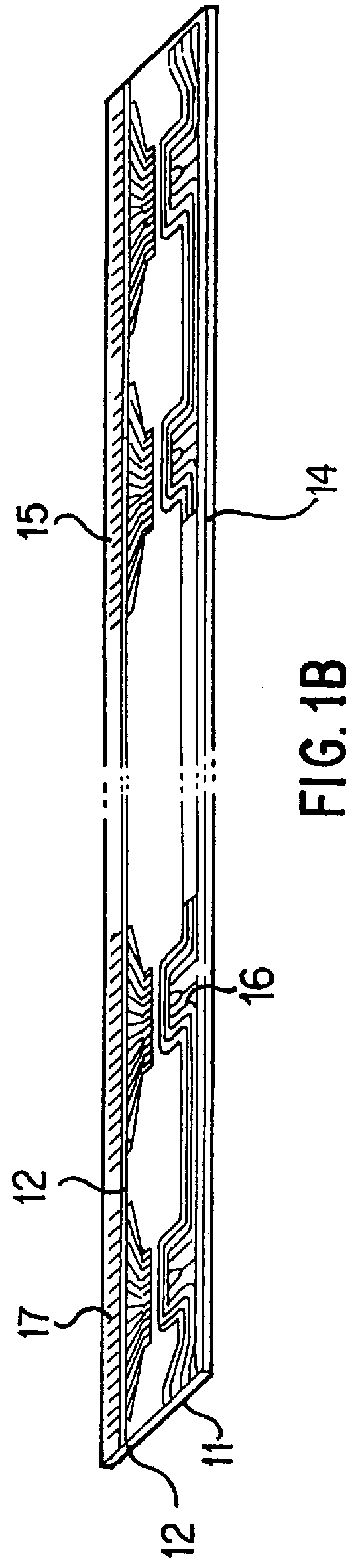

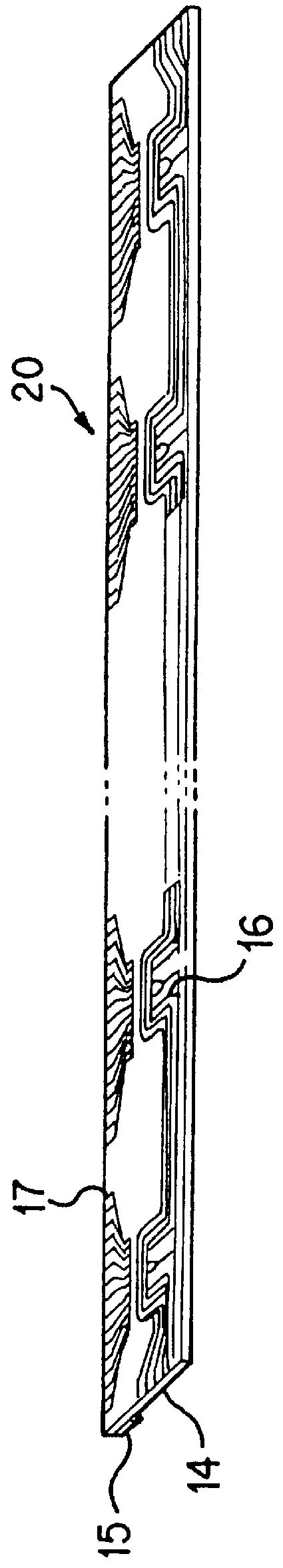

InactiveUS6121988AReduce manufacturing costSimple designPrinted circuit assemblingSemiconductor/solid-state device detailsLiquid-crystal displayElectrical conductor

PCT No. PCT / JP95 / 01941 Sec. 371 Date Mar. 27, 1997 Sec. 102(e) Date Mar. 27, 1997 PCT Filed Sep. 26, 1995 PCT Pub. No. WO96 / 10326 PCT Pub. Date Apr. 4, 1996A cutout portion 12 is formed by partially cutting out a board along a predetermined fold and a first portion 14 and a second portion 15 partitioned along the fold are folded and attached together into a unitary body by a bonding agent or thermal fusing. Formed on a surface of the printed wiring board 11 is a conductor pattern 17 that continuously runs across the fold at the cutout portion between the first portion and the second portion, and thus the conductor pattern assuring continuity between both sides of a printed wiring board 20 results without the need for providing through-holes. By employing such a printed wiring board, a compact and low-cost feature can be implemented into electronic apparatuses or portable information apparatuses, such as liquid crystal display devices or electronic printers, through a miniature, light-weight and flat design effort.

Owner:BOE TECH GRP CO LTD

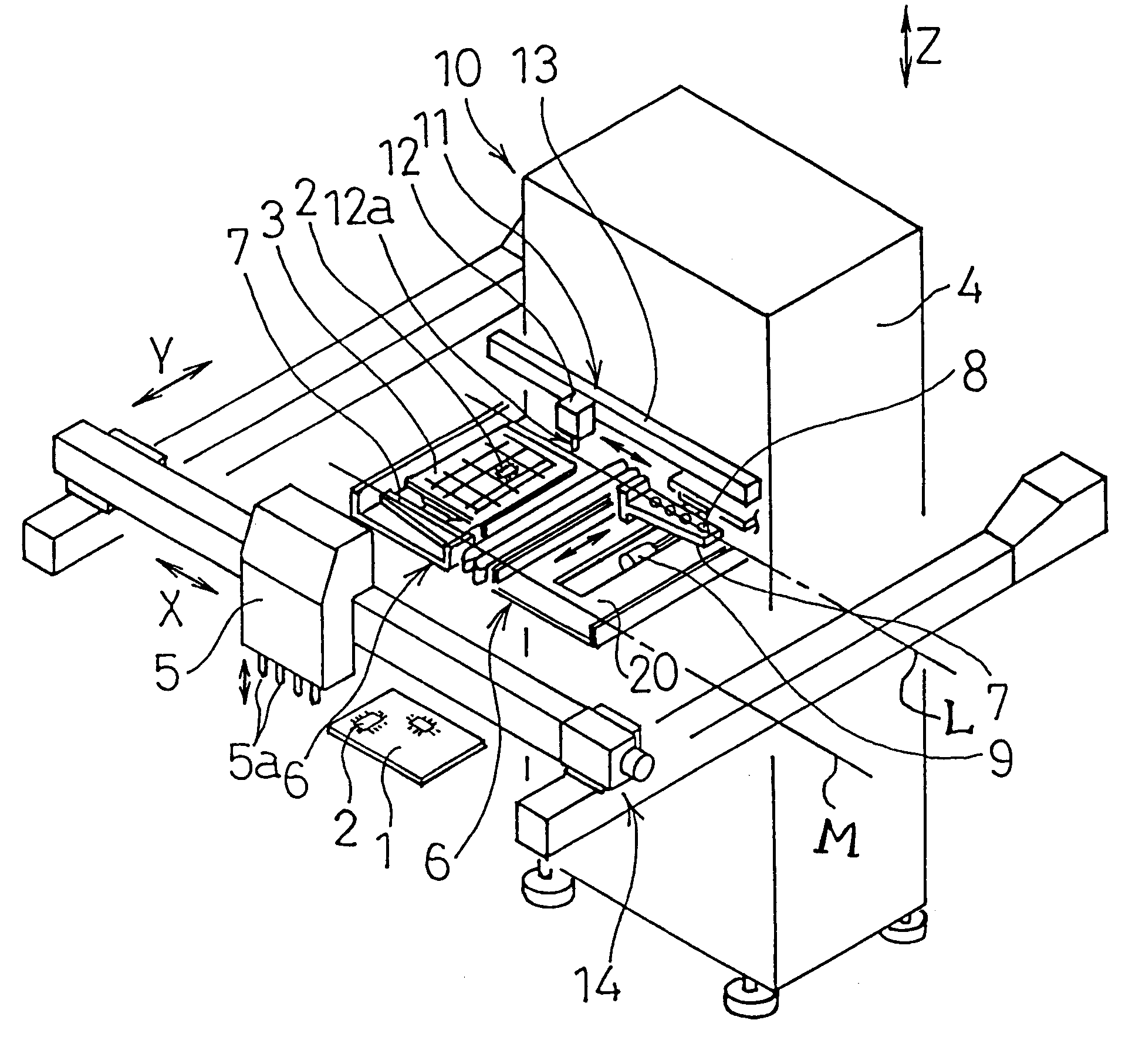

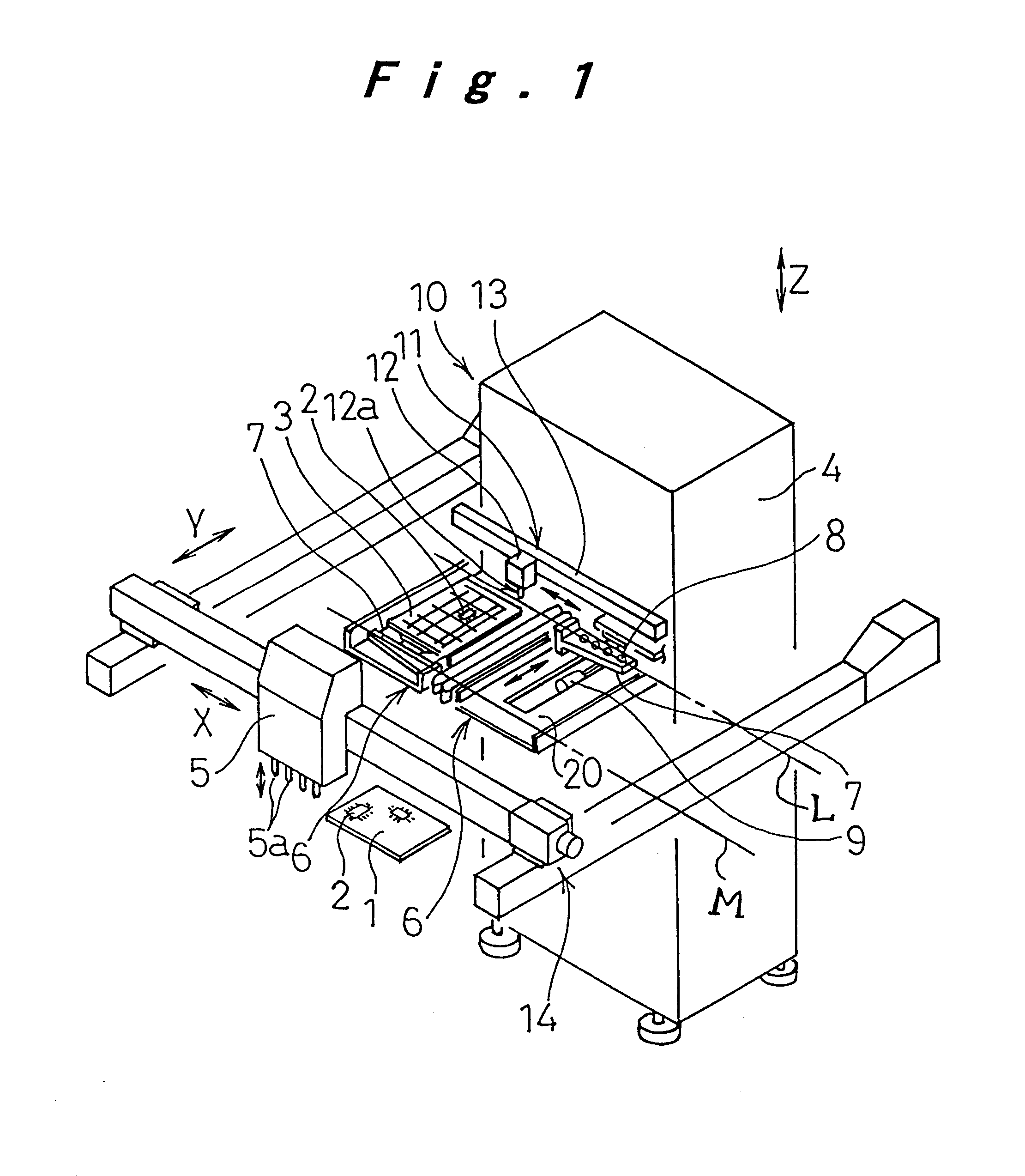

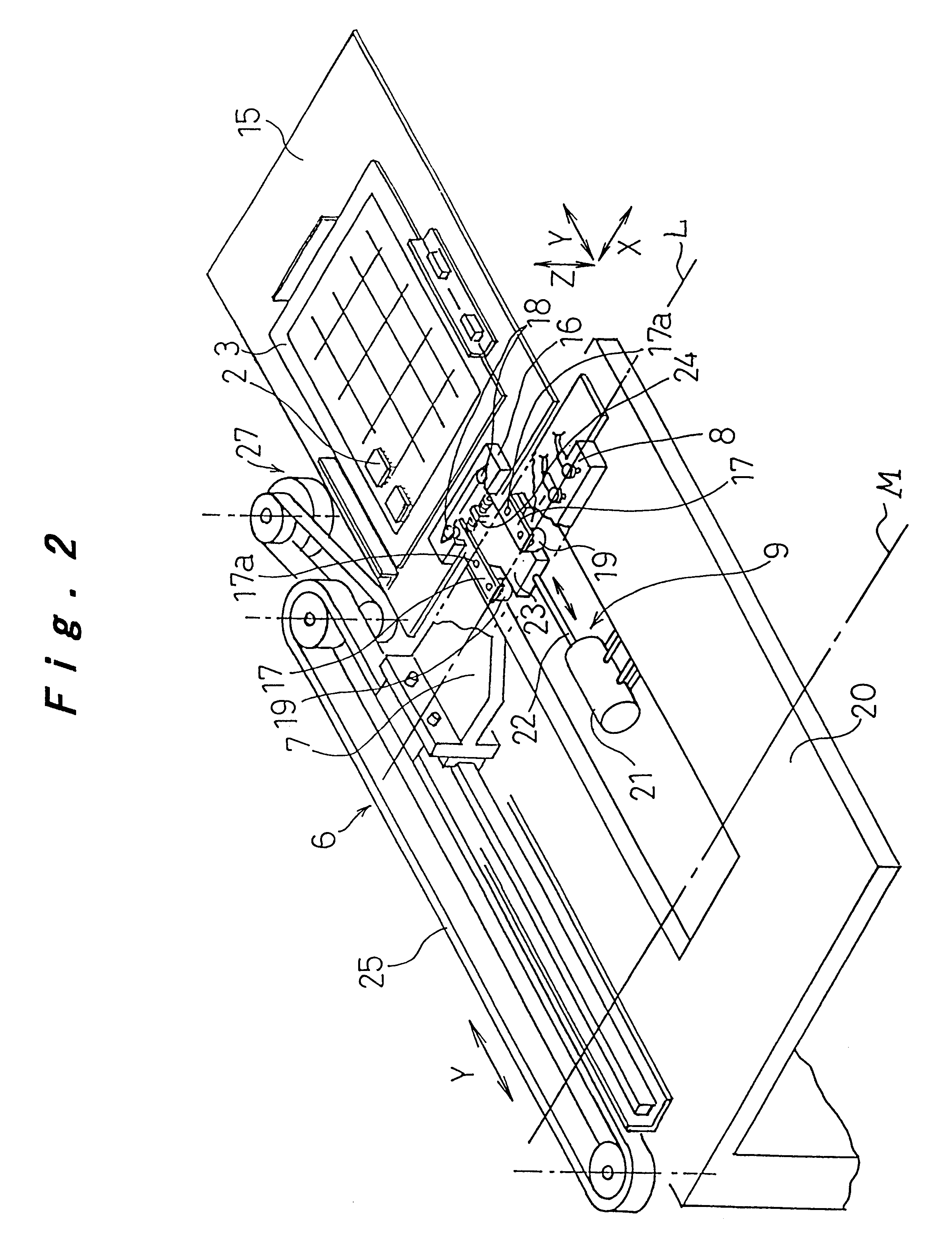

Method and apparatus for mounting electronic components

InactiveUS6266873B1Apparatus structure compact and simpleSimple and compact structurePrinted circuit assemblingArticle unpackingProduction rateEngineering

Method and apparatus for mounting electronic components in which components are efficiently fed and transferred for enhancing productivity is provided. Tray draw-out device (6) is disposed at a component feeding unit (4) for pulling out a tray (3) accommodating electronic components (2) from the component feeding unit (4) to a given pick-up position, where the electronic components (2) are transferred by the transfer mechanism (11) on to a temporary holder (8) disposed on a draw-out arm (7) of the tray draw-out device (6). Mounting head (5) has a plurality of mounting nozzles (5a), with which the mounting head (5) picks up several electronic components (2) aligned on the temporary holder (8) at a time and mount them on to a circuit board (1) which has been loaded and located at a prescribed position.

Owner:PANASONIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com